Patents

Literature

102results about How to "Barrier erosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antiseptic wearable coat and coating method thereof

ActiveCN101191225ATo achieve the purpose of corrosion resistance and wear resistanceEasy to operateMetallic material coating processesRheniumThermal spraying

The invention discloses a corrosion and abrasion resistant coating and a coating method thereof, comprising: firstly, weight percentage of compositions of coating materials adopted is that: carbon: less than or equal to 0.5 percent; chromium: 16 to 26 percent; nickel: 3.5 to 9.5 percent; molybdenum: 1.0 to 4.0 percent; boron: 0.5 to 4.5 percent; silicon: 0.5 to 4.5 percent; copper: 1.0 to 4.0 percent; manganese: 0 to 2.0 percent; rare earth - rhenium: 0.01 to 1.5 percent; the residual is ferrum and inevitable impurities; secondly, pretreatment of the surface of a metallic matrix reaches technological demand; thirdly, thermal spraying is adopted on the matrix surface; a plurality of air cooling nozzles surrounding a spray gun which are in parallel with spraying flame velocity are arranged on the spray gun; travel rate of the spray gun is 150 to 400 millimeters per second; surface temperature of workpieces is controlled to be less than 150 DEG C; an amorphous stainless steel protective coating is formed on the matrix surface finally; fourthly, sundries on the coating surface are cleaned, and the coating is performed sealing treatment. The invention solves the protective problem of erosion-corrosion under the condition of acid humid environment and that Cl<-> ions and dust particles exist.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for manufacturing integral heater for carbon/carbon polycrystalline silicon ingot furnace

InactiveCN101905977AReduce consumptionMeet production requirementsSilicon compoundsCarbon compositesCarbonization

The invention discloses a method for manufacturing an integral heater for a carbon / carbon polycrystalline silicon ingot furnace. The method comprises the following steps of: winding carbon cloth or needled carbon felts on which resin is painted on a steel mold core layer after layer to obtain a prefabricated body; performing pressurized curing, carbonization and chemical vapor deposition densification treatment until the density of a heater product is more than or equal to 1.50 g / cm<3>; performing machining to achieve a shape and a size required by a customer; and performing high temperature purification treatment through a chemical vapor deposition (CVD) silicon carbide protective layer to obtain the integral heater for the carbon / carbon composite polycrystalline silicon ingot furnace. Compared with the conventional carbon material heater, the raw material consumption of the integral heater is lowered by over 90 percent; and a CVD surface deposition silicon carbide protective layer is formed on the surface of the product, so that corrosion of silicon steam, oxygen and the like on the product is blocked and service life is prolonged by at least more than one time.

Owner:HUNAN NANFANG BOYUN NOVEL MATERIAL

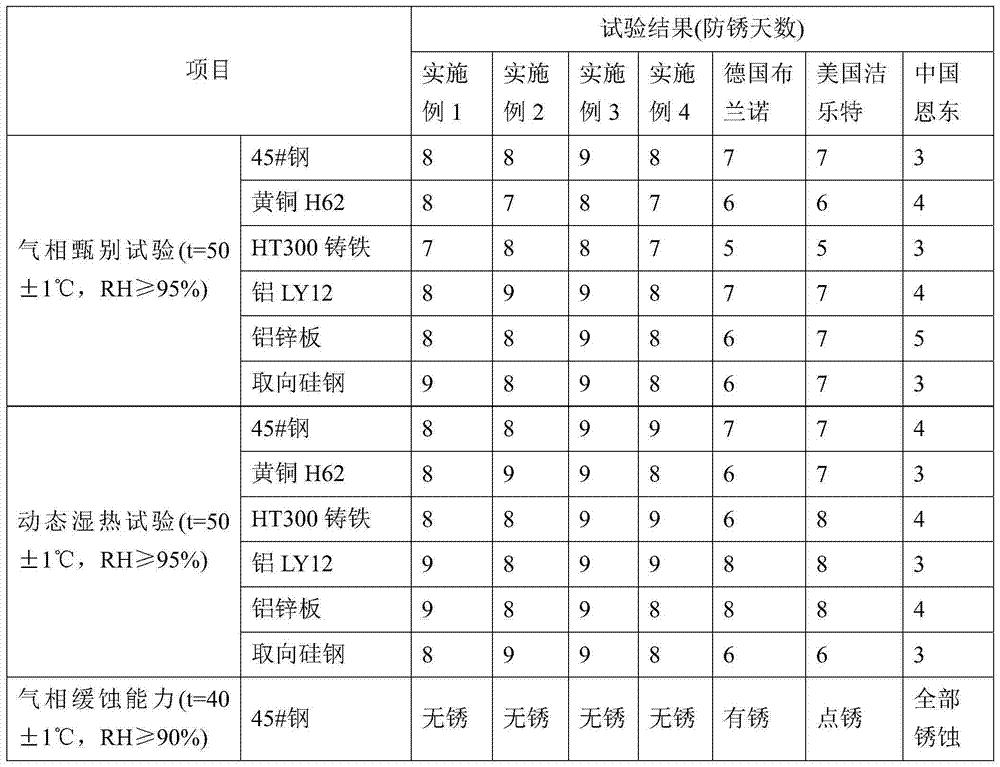

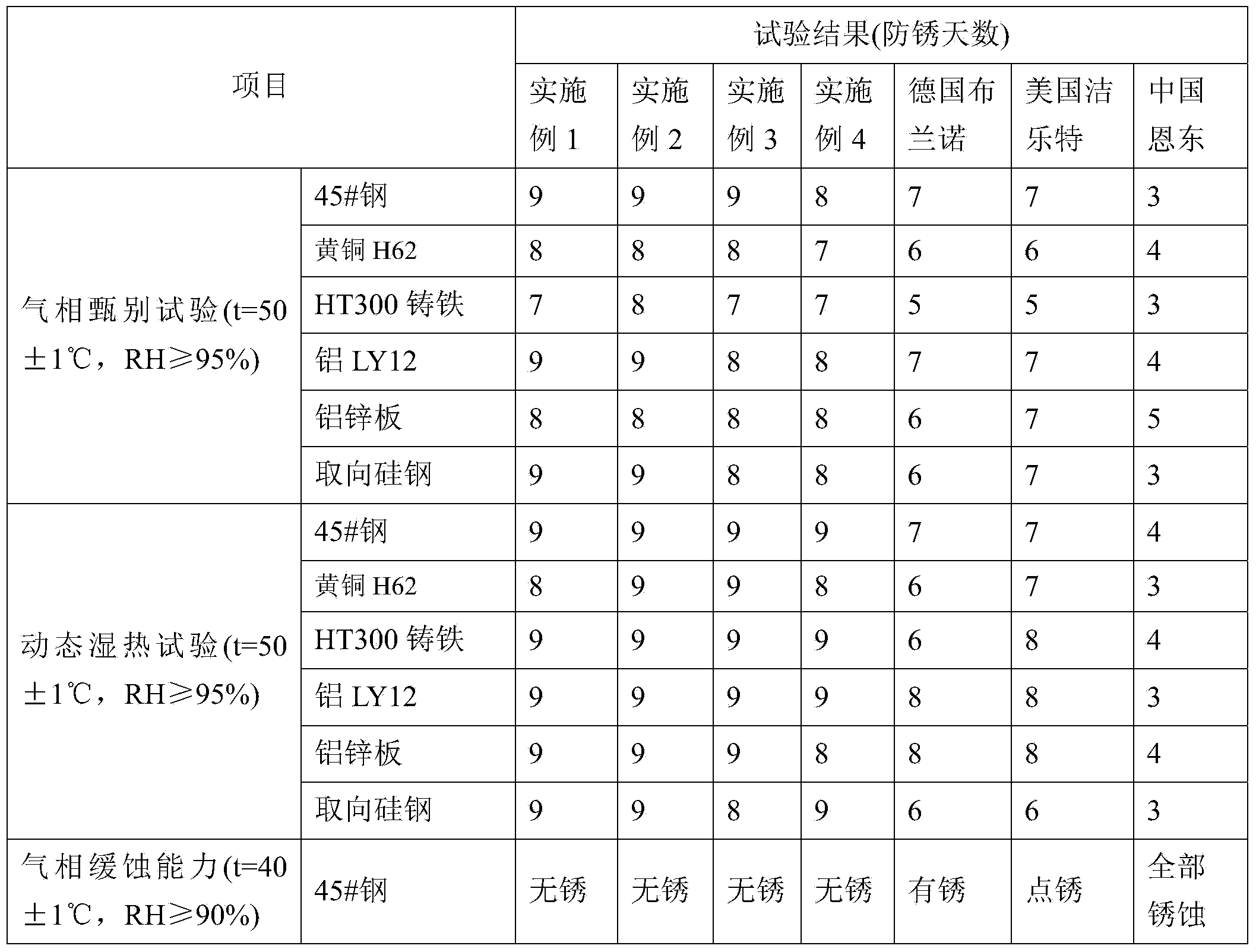

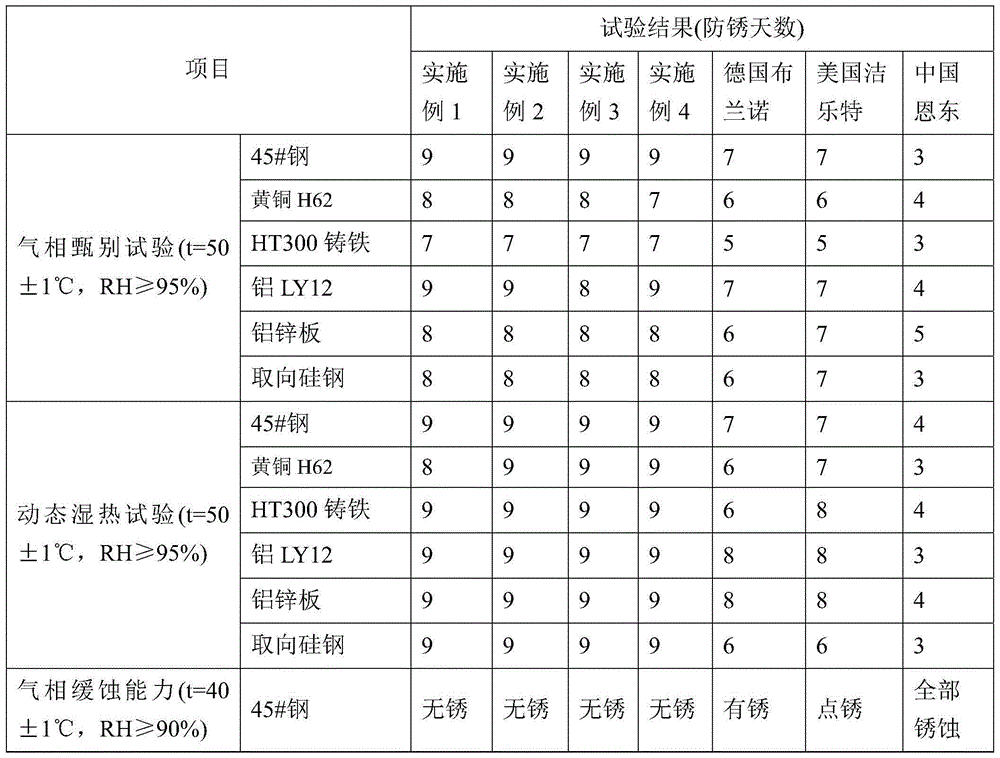

Phytic-acid type gas-phase antirust masterbatch, and preparation method and application thereof

The invention discloses a phytic-acid type gas-phase antirust masterbatch, and a preparation method and application thereof. The antirust masterbatch comprises the following components by weight: 30 to 50% a compound antirust agent, 40 to 60% parts of carrier plastic and 10 to 20% parts of an additive, wherein the compound antirust agent is prepared by mixing sodium benzoate, phytic acid, triethanolamine borate and monoethaneamine benzoate according to a mass ratio of 1.0-1.5: 2.5-3.2: 2.0-3.0: 1.0-1.3, and the additive is prepared by mixing sodium silicate, silicon dioxide, octadecanamide and an antioxidant 1076 according to a mass ratio of 1.0-1.3: 5.0-6.5: 2.5-3.3: 0.8-1.1. According to the invention, a strong chelating agent--alkaline phytic acid is used as a gas-phase corrosion inhibitor; triethanolamine borate is used as the additive; and the compound antirust agent has good dispersion and antirust effects and certain polarity, can penetrate the carrier plastic and volatilize to the surface of wrapped metal so as to form a protective film to block erosion by external corrosion substances, and is also exempt from frost precipitation due to incompatibility with a carrier caused by excessively-strong polarity of the compound antirust agent.

Owner:广州市科迩曼塑料科技有限公司

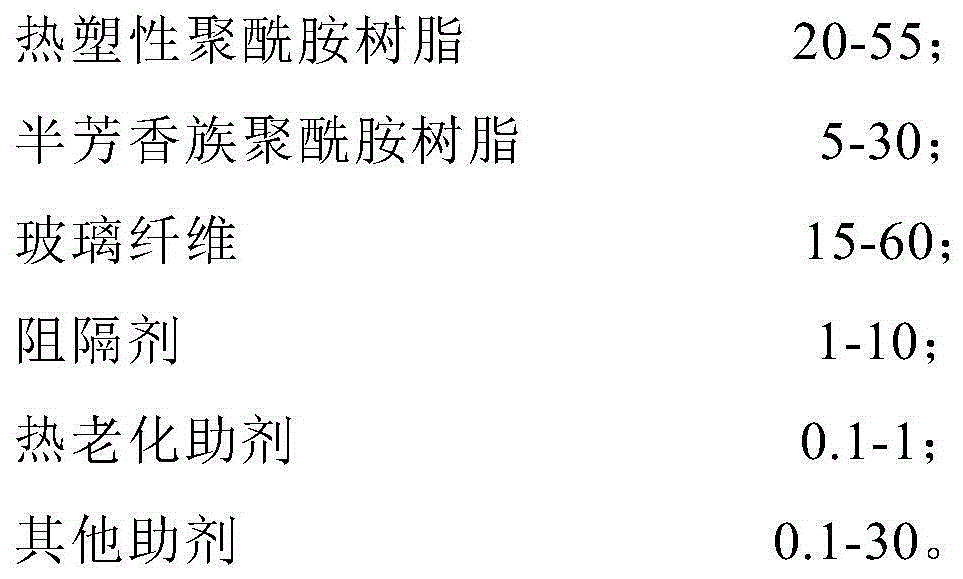

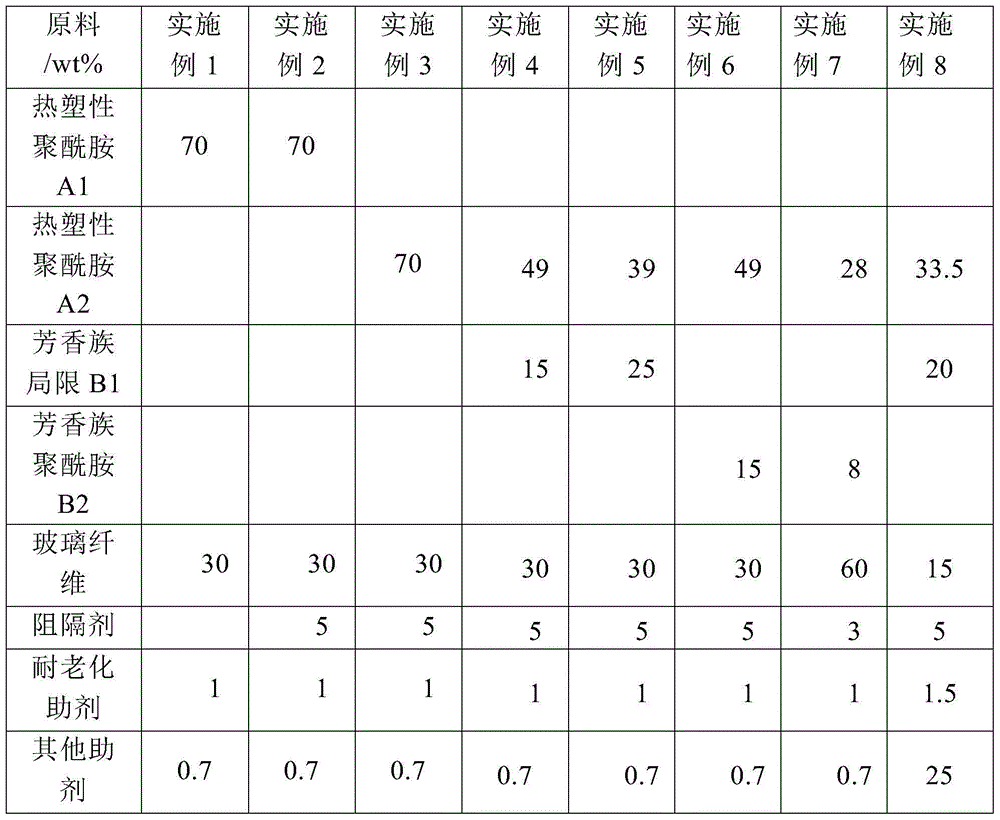

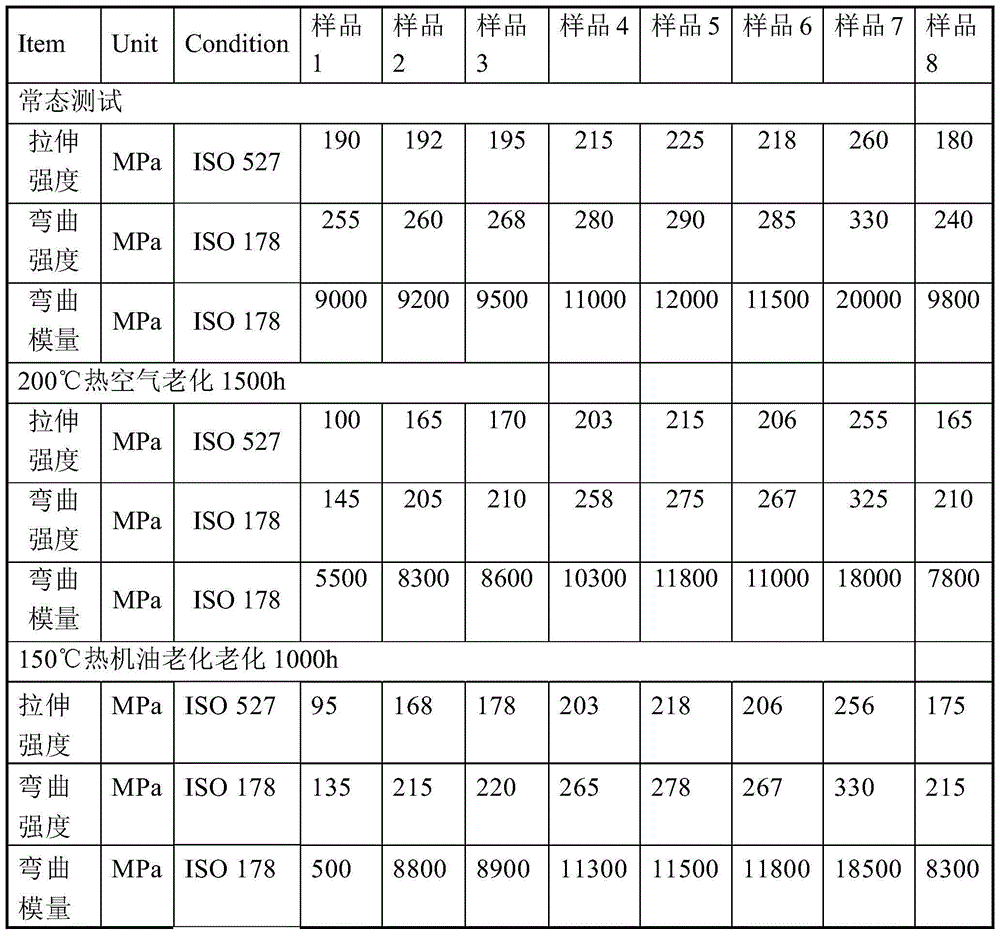

Low-moisture-absorption long-term heat-resistant aging-resistant polyamide composition and preparation method thereof

The invention relates to a low-moisture-absorption long-term heat-resistant aging-resistant polyamide composition and a preparation method thereof. The polyamide composition is prepared from the following raw materials in percentages by weight: 20-55% of thermoplastic polyamide resin, 5-30% of semi-aromatic polyamide resin, 15-60% of glass fiber, 1-10% of a blocker, 0.1-1% of a thermal aging additive and 0.1-30% of other additives. Compared with the prior art, the semi-aromatic polymer is added into the composite system, the moisture-absorption property of a matrix can be significantly decreased due to the high steric-hindrance effect of the composite system; in addition, because of the presence of benzene rings, characteristics of good barrier property and heat resistance and retention are achieved and the polyamide composition also has the advantages of low moisture absorption, very excellent mechanical strength, heat resistance, aging resistance and the like.

Owner:SHANGHAI SUNNY

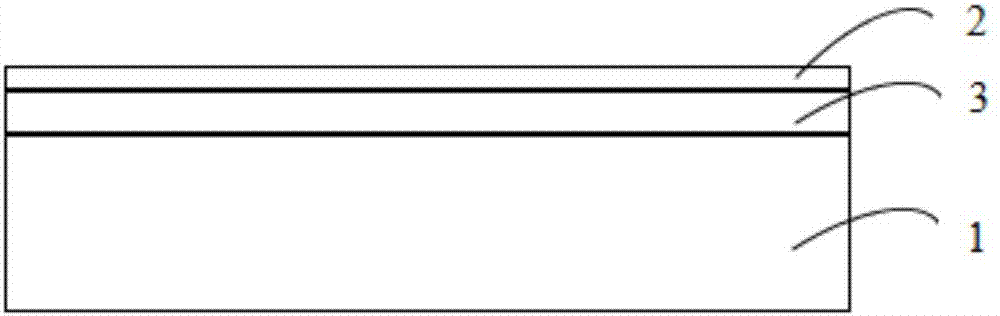

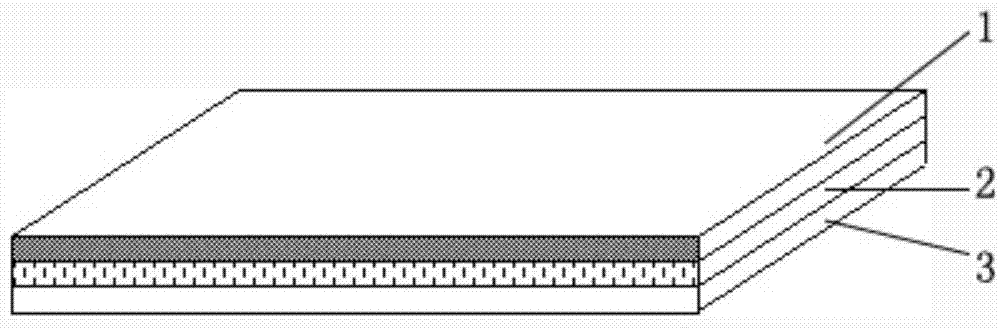

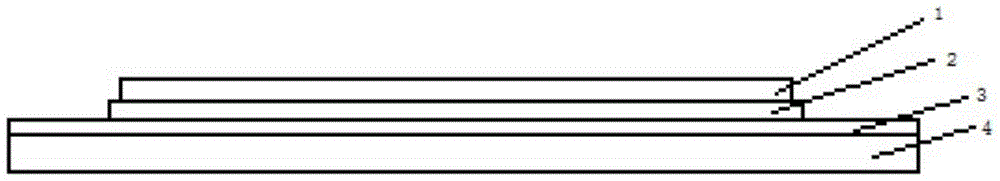

A flexible substrate and a preparation method thereof

InactiveCN109037460AExtended service lifeEffective absorptionFinal product manufactureSolid-state devicesTitanium oxideOxide

The invention provides a flexible substrate, comprising a first film layer, a second film layer and a third film layer which are laminated in sequence, wherein the first film layer and the third filmlayer are organic polymer films doped with nano particles selected from at least one substance of titanium oxide, zinc oxide or silicon oxide; and the second film layer is an inorganic film. The invention also provides a preparation method of the flexible substrate and a flexible display device including the flexible substrate. By doping nanoparticles in the first film layer and the third film layer of the flexible substrate, ultraviolet rays during laser peeling can be effectively absorbed or reflected, thereby preventing laser from causing damage to the thin film transistor and the OLED module on the other side of the flexible substrate.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

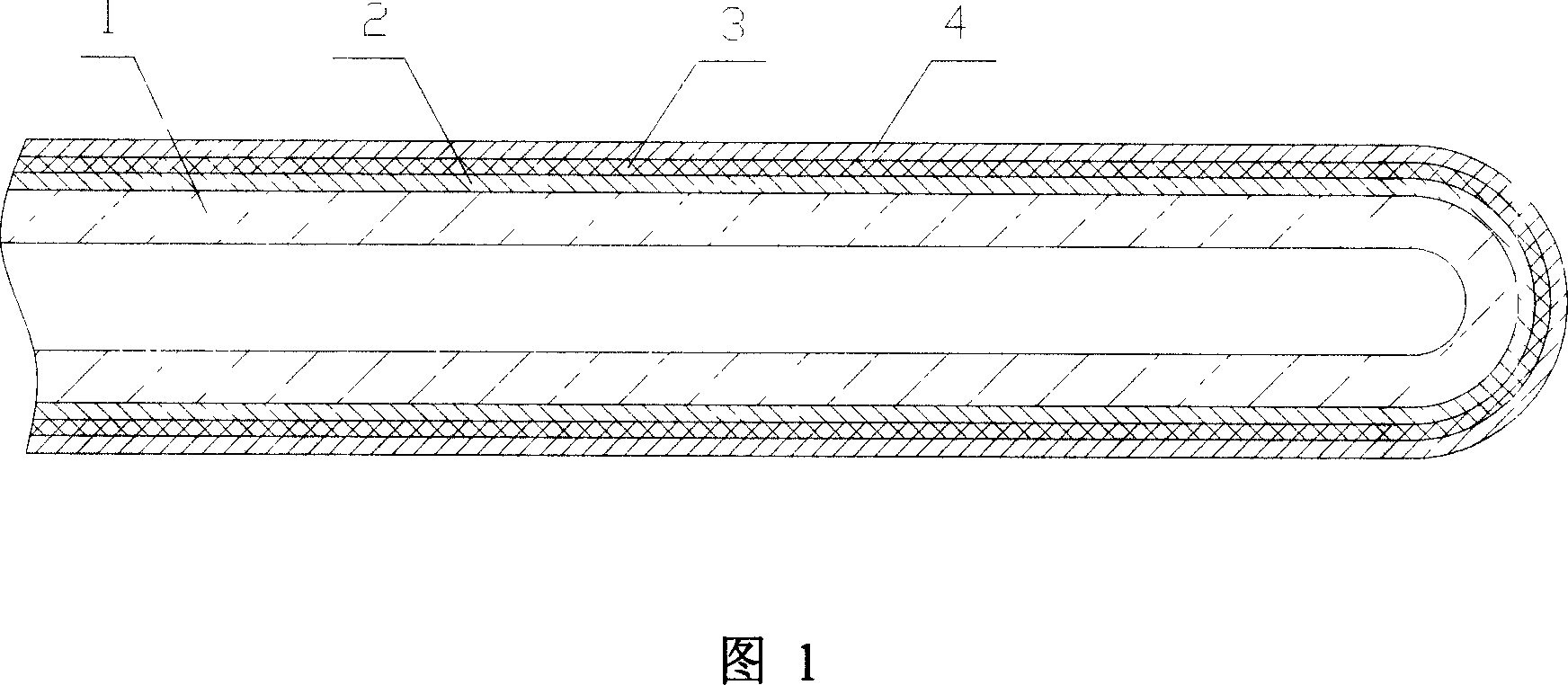

Thermo-couple composite protective sleeve and making method thereof

InactiveCN1924532AImprove thermal conductivitySensitiveThermometers using electric/magnetic elementsUsing electrical meansAlloyLiquid metal

This invention relates to heat couple protection tube and its process method. The heat couple compound protection tube comprises basic tube cylinder and coating, which is characterized by processing the end of the cylinder into arc surface, wherein, the basic cylinder is made of metal and the coating layer is composed of metal combination layer, middle transmission layer and surface work layer; the metal combination layer is of metal ceramics materials or alloy materials similar to the basic cylinder metal property; the surface coating is of oxidation ceramics materials and the middle coating is of metal ceramics materials and oxidation mixture.

Owner:BAOSHAN IRON & STEEL CO LTD

Multi-metal anti-rusting master batch as well as preparation method and application thereof

The invention discloses multi-metal anti-rusting master batch as well as a preparation method and application thereof. The anti-rusting master batch comprises the following components in percentage by mass: 30-50% of a compounded anti-rusting agent, 40-60% of carrier plastic and 10-20% of an additive, wherein the compounded anti-rusting agent is prepared by mixing sodium benzoate, sebacic acid, triethanolamine boric acid ester and benzotriazole in a mass ratio of (1-1.3):(1.1-1.5):(2.2-3.2):(0.8-1.2); the additive is prepared by mixing stearic acid amino, coarse whiting, sucrose fatty acid ester and an antioxidant 1076 in a mass ratio of (0.9-1.3):(4.8-6.5):(2.5-3.3):(0.8-1.1). When being used as an additive, the triethanolamine boric acid ester has both a dispersion function and an anti-rusting function, the compounded anti-rusting agent has certain polarity and can penetrate the carrier plastic to be volatilized to the surface of packaged metal to form a protecting film, so that corrosion of external corrosive substances is prevented, and the phenomenon that frost separation is generated as the compounded anti-rusting agent is not compatible with the carrier plastic because of the too high polarity is avoided. The multi-metal anti-rusting master batch is free of harmful component, is environment-friendly and safe to use, and has the anti-rusting function on multiple metals.

Owner:青岛鑫盈鑫包装材料有限公司 +1

Insulation processing method of MgB2 wire strip

ActiveCN102664086AHigh mechanical strengthImprove thermal conductivitySuperconductors/hyperconductorsSuperconductor devicesGlass fiberThermal expansion

The invention discloses an insulation processing method of an MgB2 wire strip. The insulation processing method of the MgB2 wire strip includes: firstly, weaving glass fiber on the surface of the MgB2 wire strip to obtain the MgB2 wire strip coated with woven fabric on the surface; secondly, processing the MgB2 wire strip coated with woven fabric on the surface by going through a paint box provided with insulating paint to obtain the MgB2 wire strip dipped with the insulating paint; thirdly, drying the MgB2 wire strip dipped with the insulating paint to obtain the MgB2 wire strip coated with the insulating paint; fourthly, winding the MgB2 wire strip coated with the insulating paint into a cake; or winding the MgB2 wire strip coated with the insulating paint into a magnet coil of requiredspecification; and fifthly, performing heat treatment for the cake or the magnet coil in a heat treating furnace. Mechanical strength and thermal conduction property of the MgB2 wire strip can be improved after the MgB2 wire strip is woven through the glass fiber and dipped by the insulating paint, and mutual bonding among sheathes caused by thermal expansion of the MgB2 wire strip in the thermaltreatment so as to influence engineering practical application is avoided.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

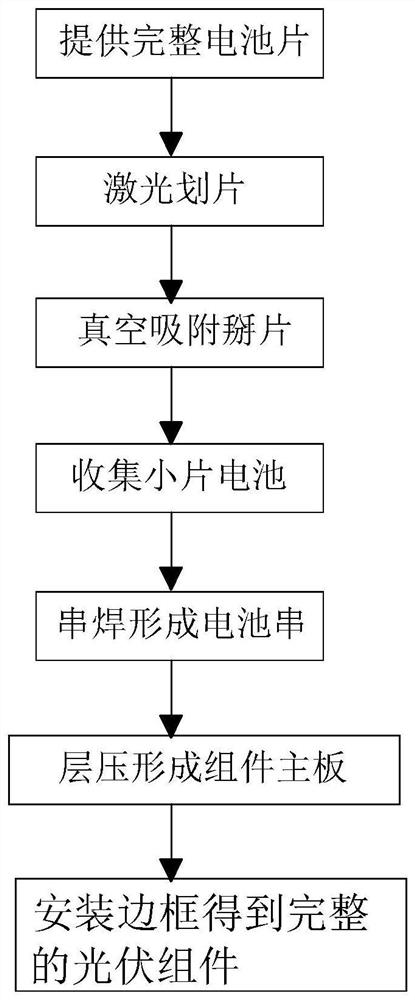

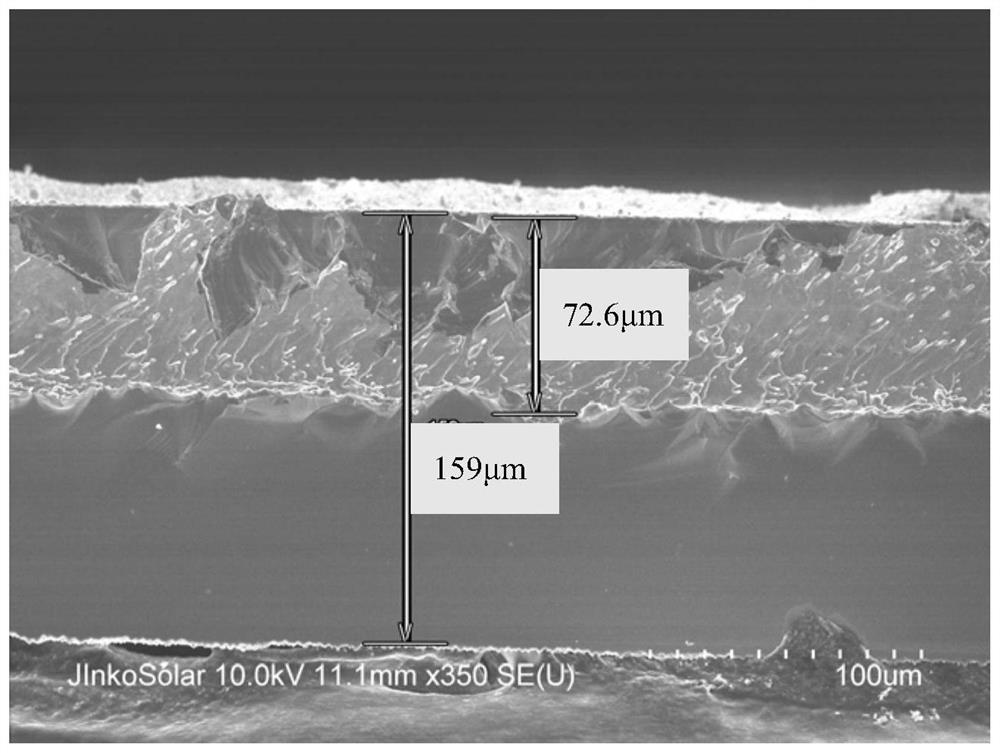

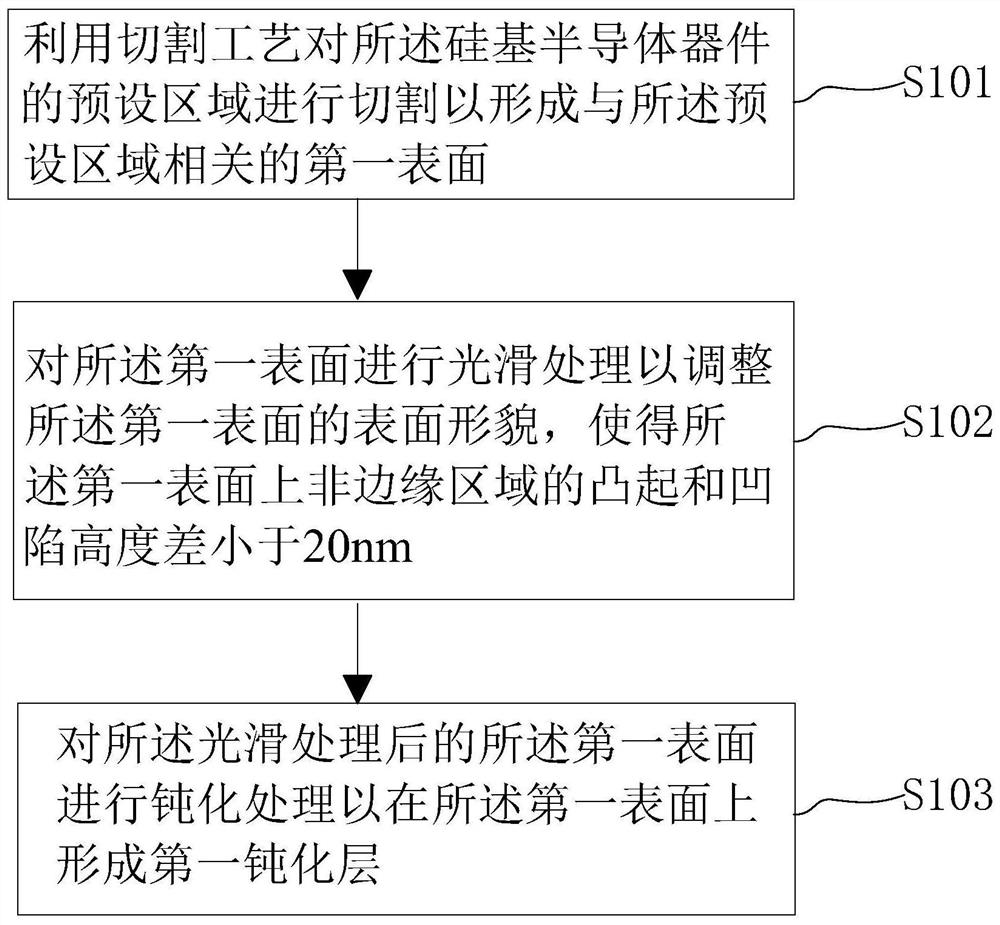

Post-cutting passivation method of silicon-based semiconductor device and silicon-based semiconductor device

ActiveCN111952414AImprove efficiencyBarrier erosionFinal product manufacturePhotovoltaic energy generationDevice materialEngineering

The invention provides a post-cutting passivation method of a silicon-based semiconductor device and the silicon-based semiconductor device, and relates to the technical field of semiconductor devices. The post-cutting passivation method of the silicon-based semiconductor device comprises the following steps: cutting a preset area of the silicon-based semiconductor device by using a cutting process to form a first surface related to the preset area; smoothing the first surface to adjust the surface morphology of the first surface, so that the height difference between bulges and recesses in anon-edge region on the first surface is less than 20nm; and the smoothed first surface is passivated so as to form a first passivation layer on the first surface. According to the invention, the problem of efficiency reduction caused by cutting of the silicon-based semiconductor device can be reduced or avoided, and the silicon-based semiconductor device with higher efficiency can be obtained.

Owner:JINKO GREEN ENERGY SHANGHAI MANAGEMENT CO LTD +1

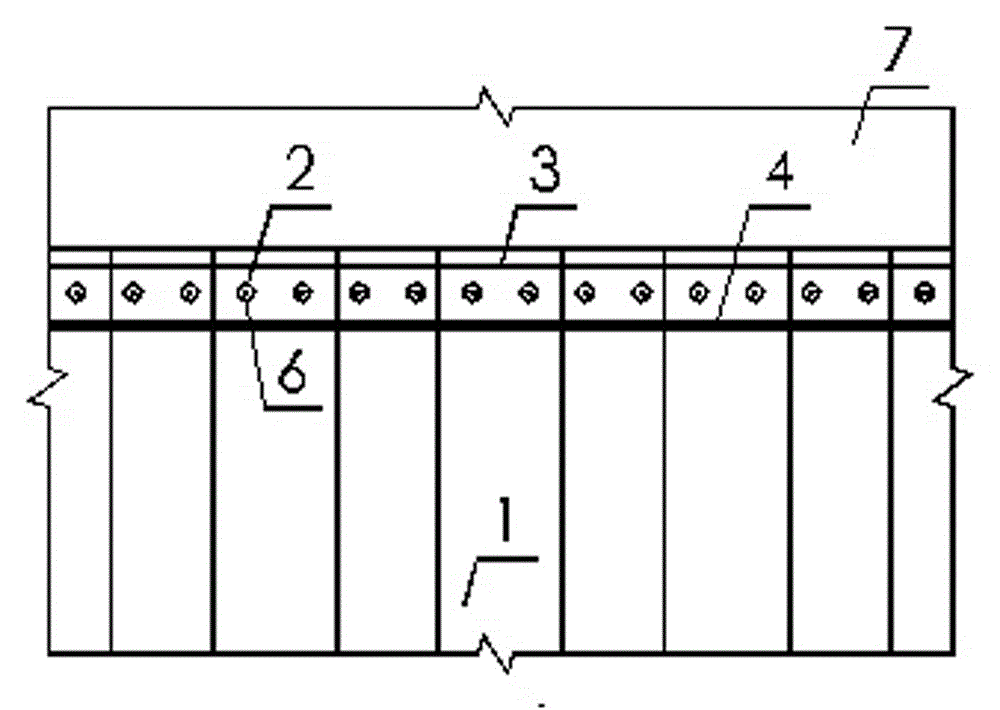

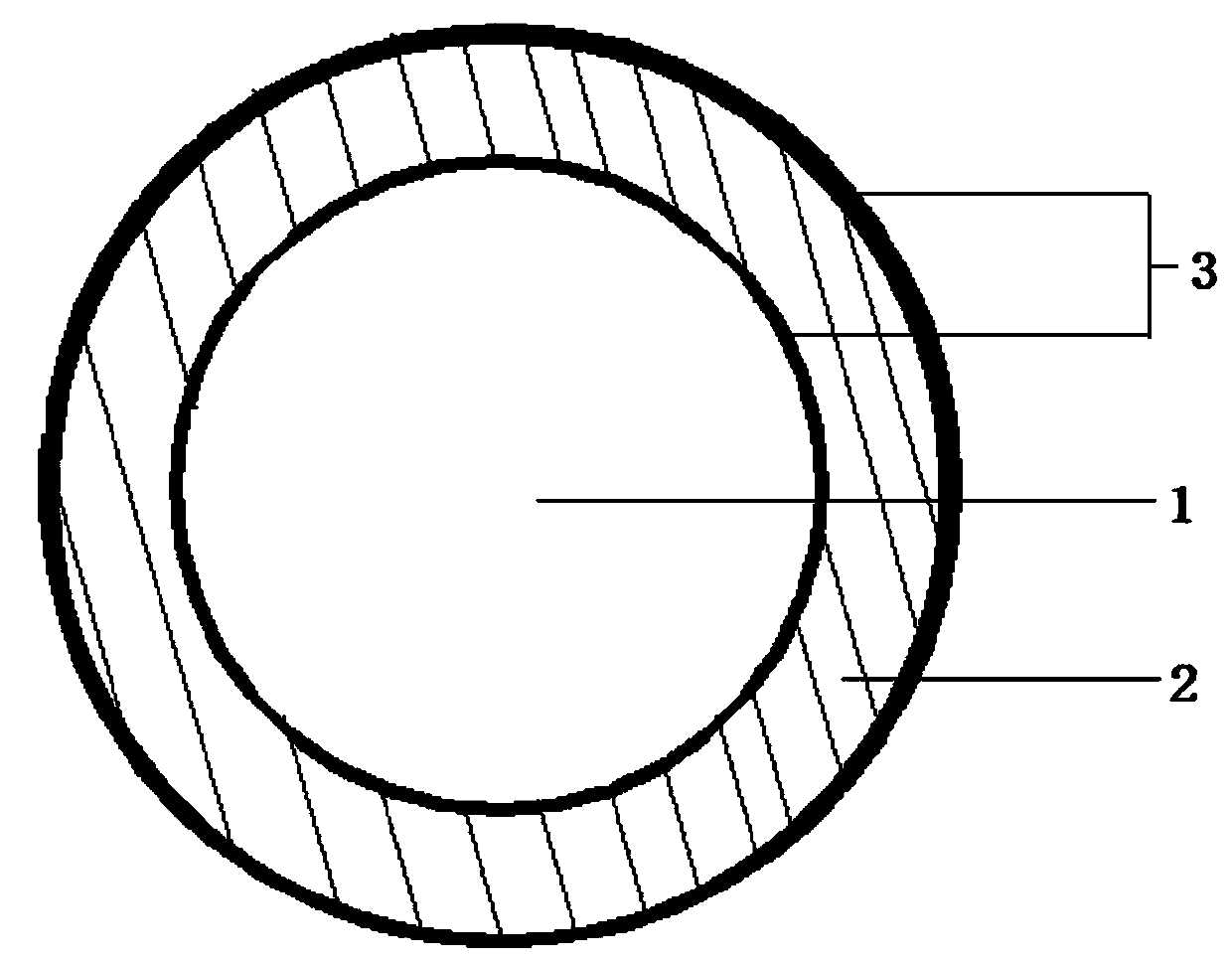

Flexible conductive film

InactiveCN107230514APermeation barrierBarrier erosionMaterial nanotechnologyConductive layers on insulating-supportsTransmittanceEngineering

The invention provides a flexible conductive film which comprises a flexible base layer, a flexible conductive layer and a flexible water vapor barrier layer. The flexible base layer, the flexible conductive layer and the flexible water vapor barrier layer are laminated to each other and are combined to form the flexible conductive film. The flexible conductive film is not easy to break, has the advantages of scrape resistance, scratch resistance, bending folding resistance, high light transmittance, low haze, water vapor resistance and the like, can be widely used in a variety of optoelectronic devices, and especially optoelectronic devices with flexible demand and waterproof demand.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

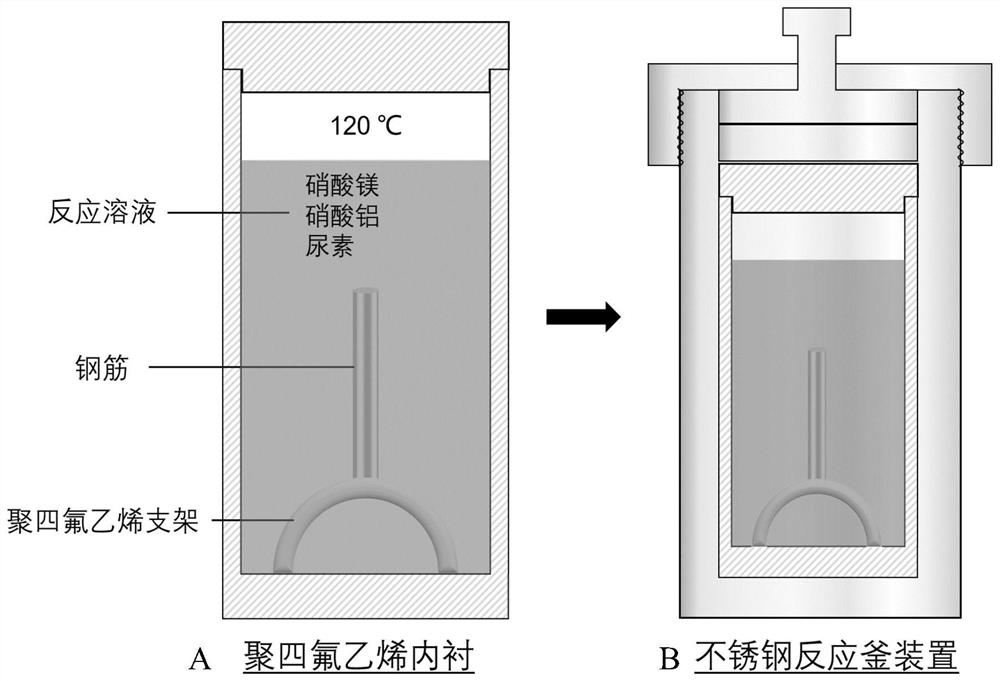

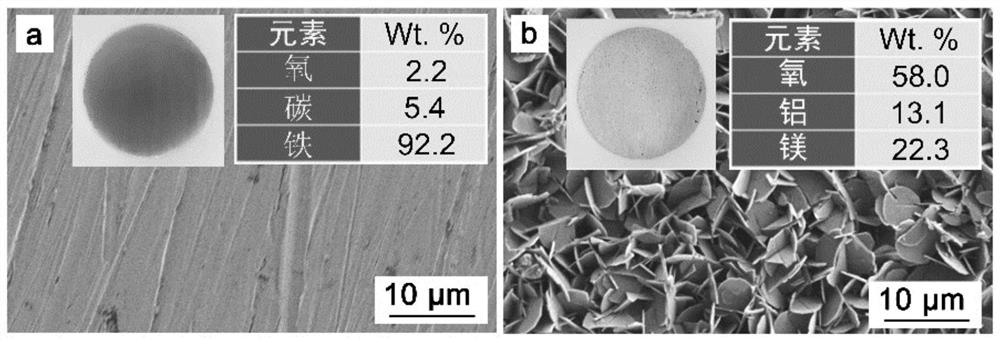

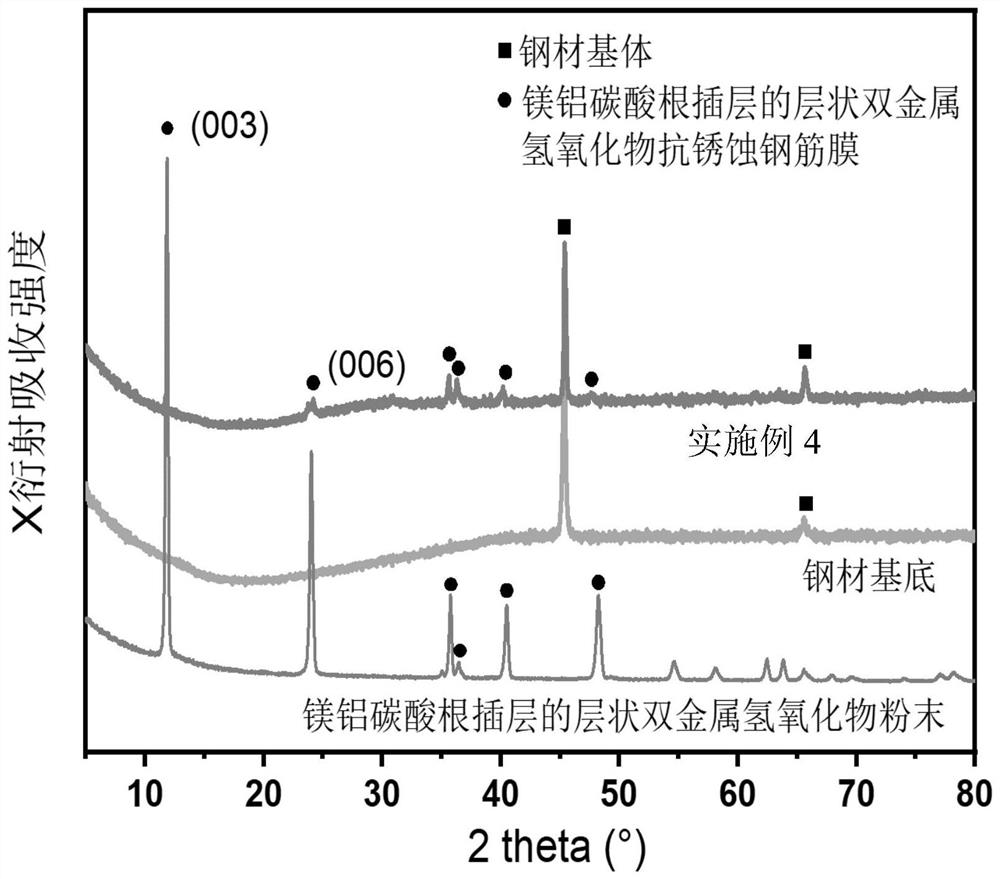

Method for preparing layered bimetallic hydroxide passivation film in situ

ActiveCN112301344ASimple processEasy to operateMaterial nanotechnologyMetallic material coating processesMetal nitrateDivalent metal

The application provides a method for preparing a layered bimetallic hydroxide passivation film in situ. According to the method, the layered bimetallic hydroxide passivation film grows on the surfaceof an iron-based substrate in situ in one step by utilizing a hydrothermal method and in combination with urea decomposition; a hydrothermal reaction is performed on the iron-based substrate obtainedby pretreatment and a reaction solution containing urea, a divalent metal nitrate, and a trivalent metal nitrate to grow the layered bimetallic hydroxide passivation film; the preparation method is simple in technology; further, the thickness of the passivation film can be controlled by controlling a reaction time and a reaction temperature; thus, the anti-corrosive protection of a reinforcing steel bar is achieved; the excessive pretreatment does not need to be performed on the reinforcing steel bar in a reaction process; the preparation of the layered bimetallic hydroxide passivation film can be easily realized by adopting a one-step in-situ synthesis urea decomposition hydrothermal method; and the method is simple, convenient, easy to operate, energy-saving, environment-friendly, further, low in cost, and suitable for wide industrial production.

Owner:SHENZHEN UNIV

Viscoelastic body anti-mildew and anticorrosion adhesive for buried pipelines, adhesive tape and preparation method thereof

ActiveCN104327756AAvoid erosionEnhanced inhibitory effectNon-macromolecular adhesive additivesFilm/foil adhesivesAdhesiveAntioxidant

The invention discloses a viscoelastic body anti-mildew and anticorrosion adhesive for buried pipelines, an adhesive tape and a preparation method thereof, and belongs to the technical field of pipeline anticorrosion. The viscoelastic body anti-mildew and anticorrosion adhesive is composed of the following components, by weight, 100-300 parts of a polymer viscous-elastic material, 1-10 parts of enhancing glue, 100-300 parts of a filling material, 1-10 parts of an antioxidant, 1-10 parts of a plasticizer, 1-5 parts of a mildew preventive and 0.1-0.5 part of a pigment. By adding the mildew preventive in the viscoelastic body anti-mildew and anticorrosion adhesive, erosion of mildew can effectively be prevented, and shear strength and volume resistivity of the adhesive layer can be enhanced by cooperation with other components in the formula. Thus, the adhesive's peel strength of a steel or PE material is raised, and mechanical property of the adhesive layer is improved. By the use of the adhesive, buried pipelines made of different materials can be glued well. The adhesive has a good effect of inhibiting common mildews such as aspergillus flavus, aspergillus niger, aspergillus sydowi, aspergillus terreus, aspergillus ustus, Penicilnum chysogenum, Cladosporium, cheatomium, trichoderma and the like.

Owner:ZHENGZHOU ZHONGYUAN SILANDE HIGH TECH CO LTD

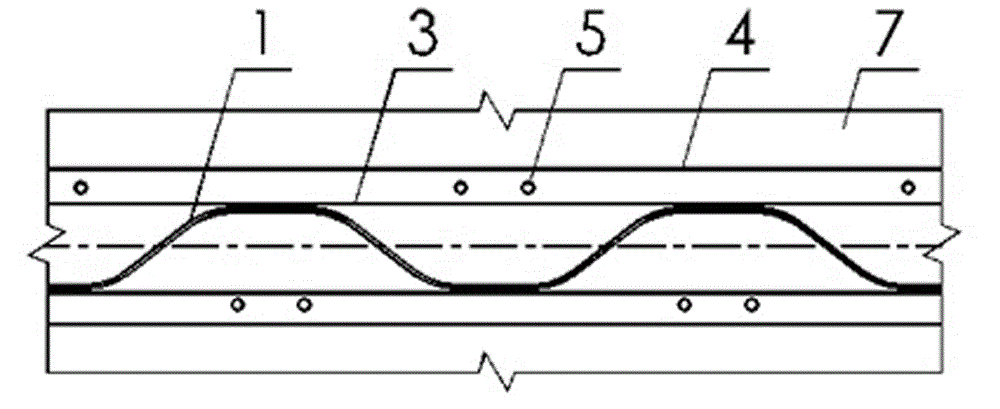

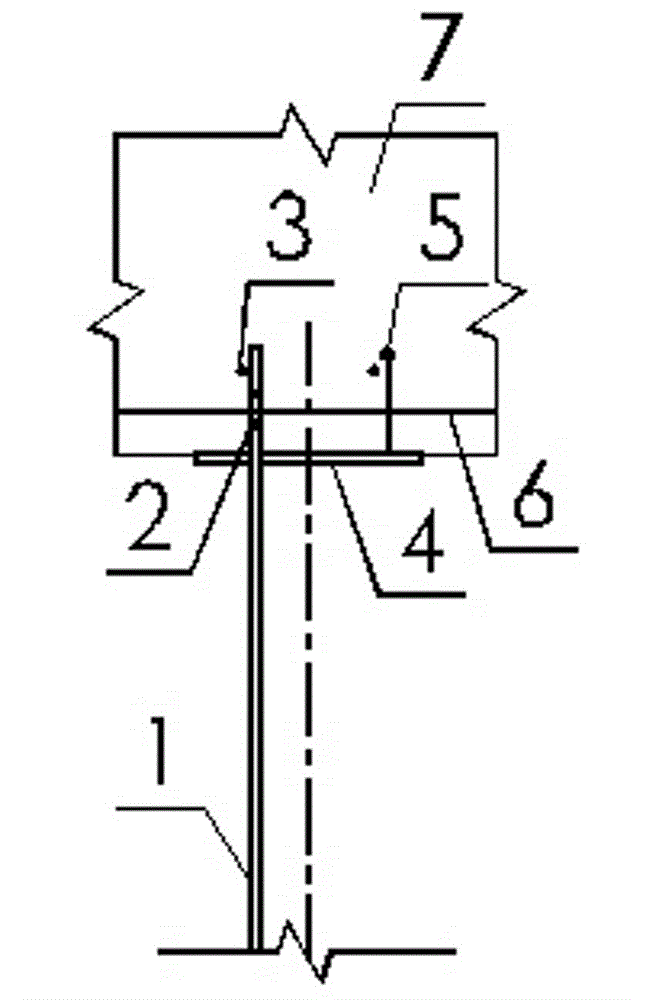

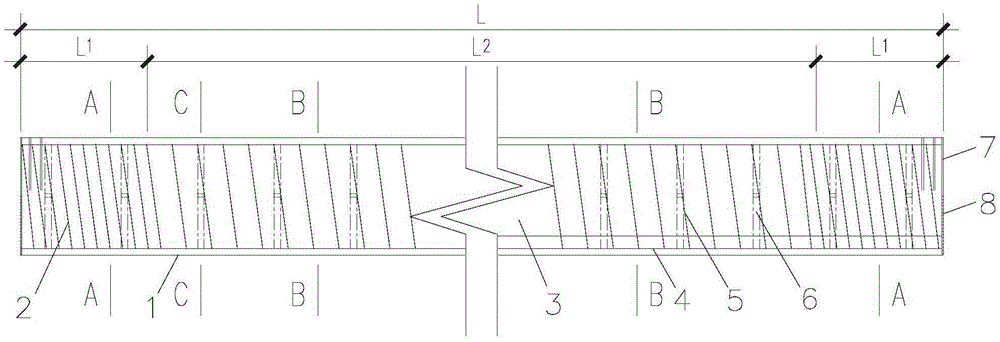

Steel-concrete mixing type anti-shearing connecting piece

InactiveCN102877550ASimple structureEasy constructionBuilding constructionsReinforced concreteWave shape

The invention provides a steel-concrete mixing type anti-shearing connecting piece which is applicable to connecting a wave-shaped steel web plate and a concrete top plate. The top of the wave-shaped steel web plate is provided with a hole; the upper part of the hole is respectively welded with one or more combined steel bars along the vertical direction of the two sides of the wave-shaped steel web plate; at the position of a combined face of the wave-shaped steel web plate and the concrete top plate, one horizontal frange plate which is in convex-concave complementation and tight adhesion with the wave-shaped steel web plate is respectively arranged at each one of the two sides of the wave-shaped steel web plate in the vertical direction; the frange plate is provided with a plurality of vertical welding nails; a connection structure above the frange plate stretches into the reinforced concrete top plate connected with the frange plate; and a transverse steel bar in the concrete top plate penetrates through the hole on the wave-shaped steel web plate, and the concrete of the wave-shaped steel web plate is poured. The steel-concrete mixing type anti-shearing connecting piece has the characteristics of an imbedded anti-shearing connecting piece and a frange type anti-shearing connecting piece; steel products are saved, the machining is convenient, the construction is convenient and the anti-shearing strength is high; the strength, the rigidity and the durability of a connecting part are better; and the integrity of the combined part is good, and the social and economic benefits are good.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

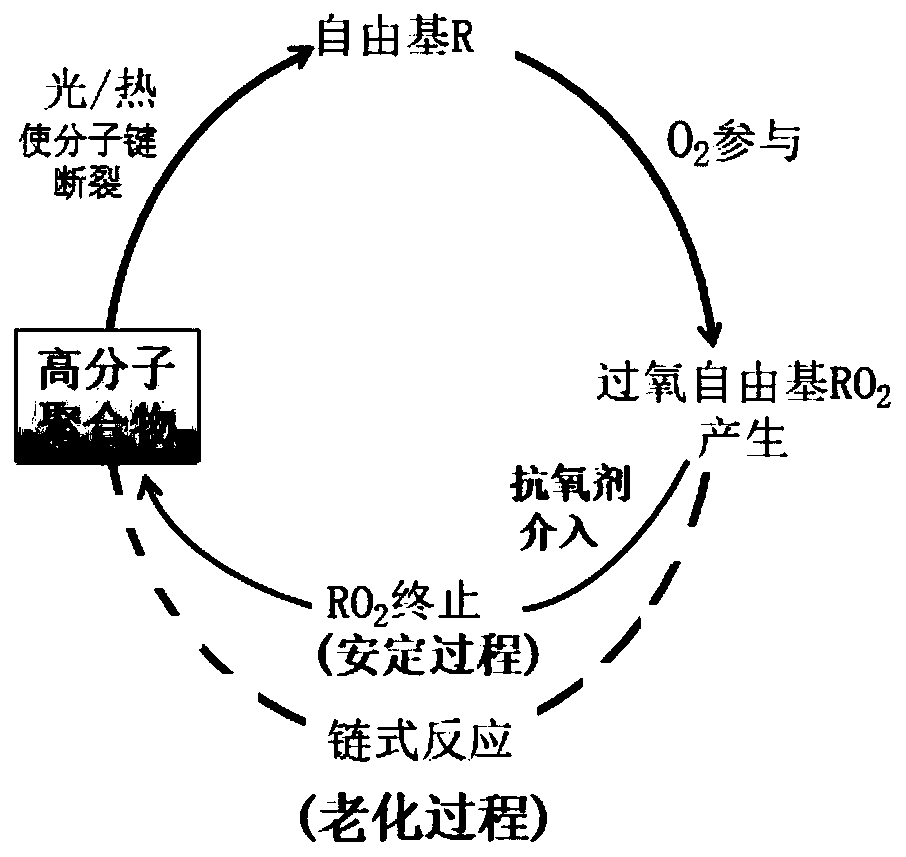

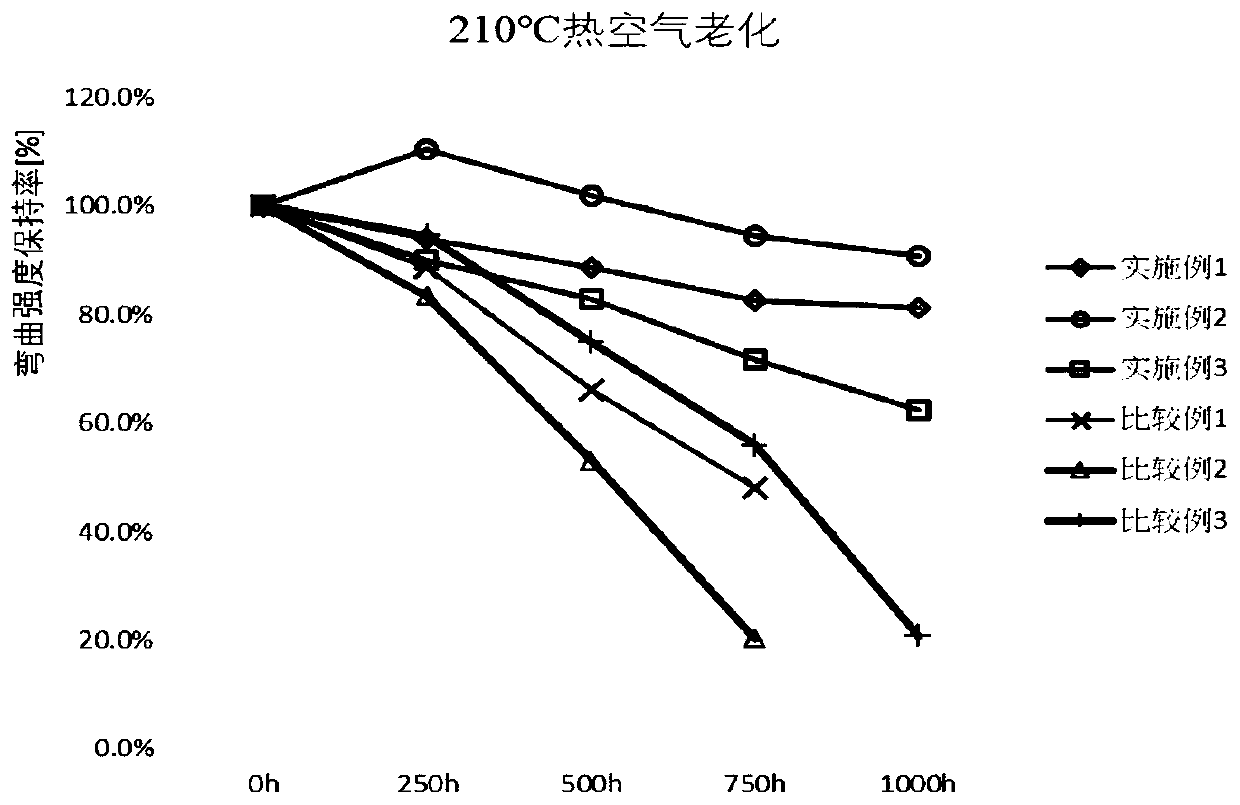

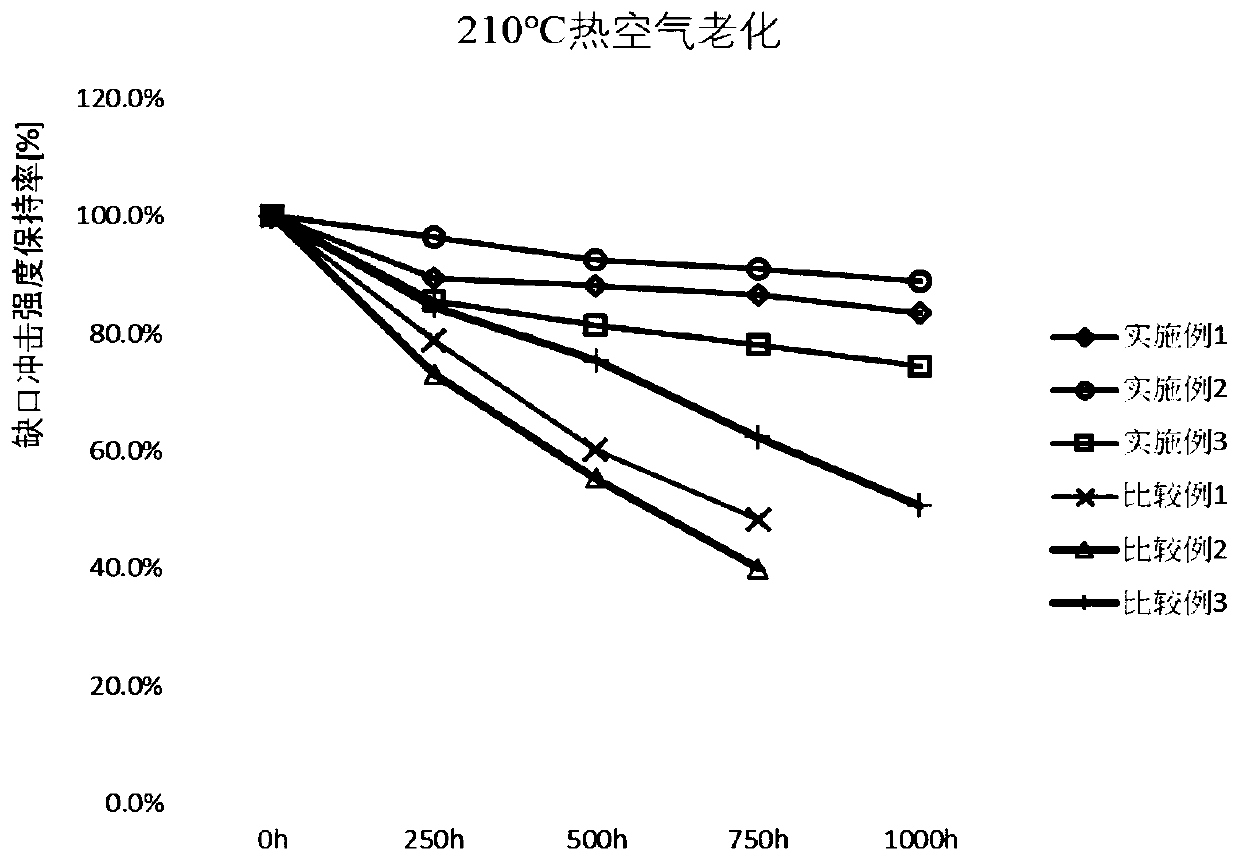

Highly-heatproof polyamide composition and preparation method thereof

The invention discloses a highly-heatproof polyamide composition and a preparation method thereof. The composition comprises 25.0-98.0 wt% of polyamide, 0.5-15.0 wt% of epoxy resin, 0.01-3.0 wt% of astabilizer and 0.01-60.0 wt% of a reinforcing agent, or further comprises 0.01-5.0 wt% of a functional assistant, and the sum of the mass percentages of all above raw materials is 100 wt%, the polyamide is semicrystalline polyamide having a melting point of 200 DEG C or above, and the epoxy equivalent of the epoxy resin is 100-2500 g / eq. The polyamide substrate with an amino group at the high endand a carboxyl group at the low end is selected to reduce the generation of free radicals, the high temperature aging resistance of the epoxy resin is used to block oxygen from corroding and thermo-oxidatively aging the polyamide resin, and the strong polarity of the epoxy group improves the compatibility of the polyamide with the reinforcing agent, so the problem that existing polyamide molding compositions have insufficient high-temperature thermal aging property and mechanical properties is solved.

Owner:江苏晋伦塑料科技有限公司

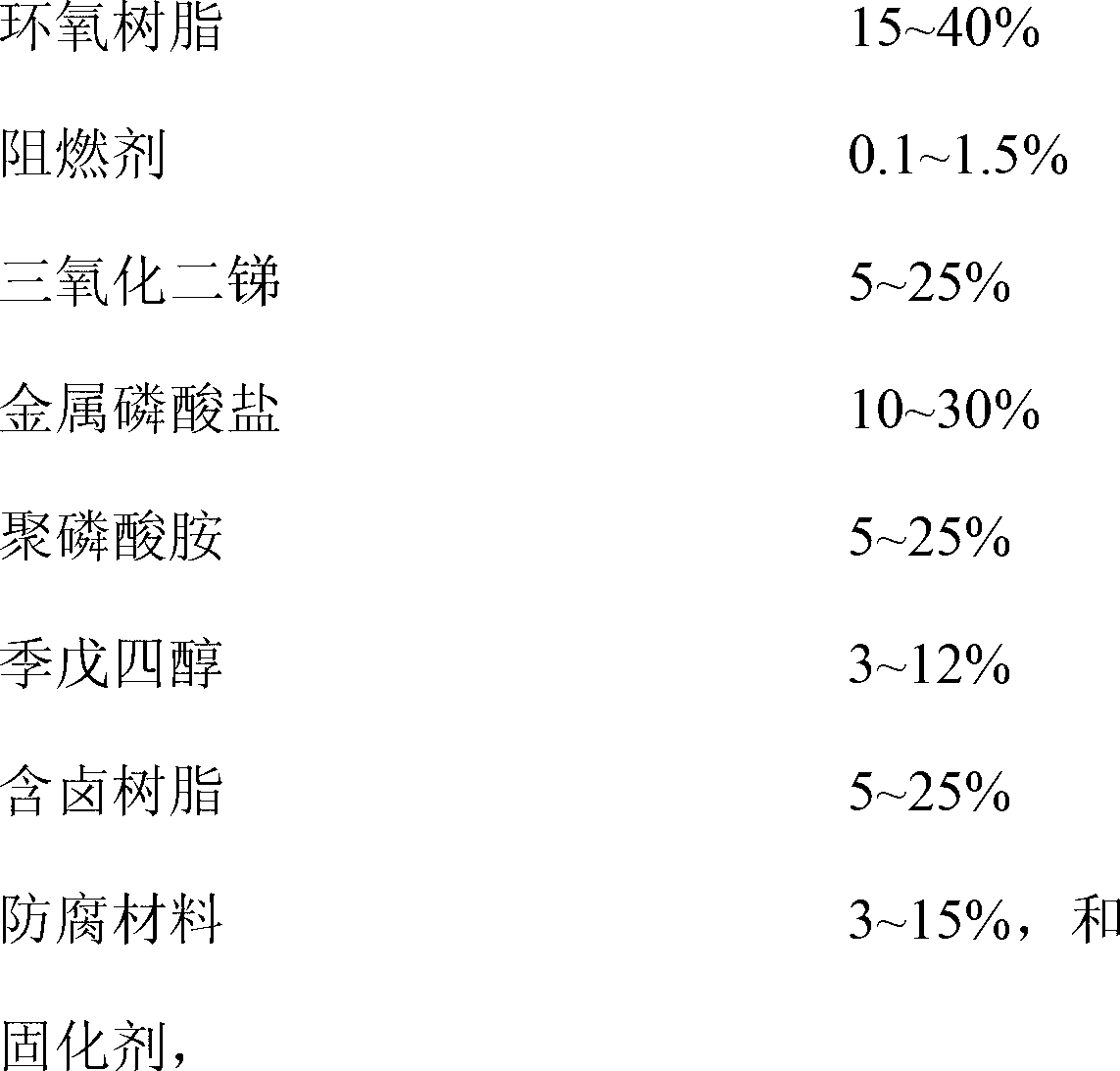

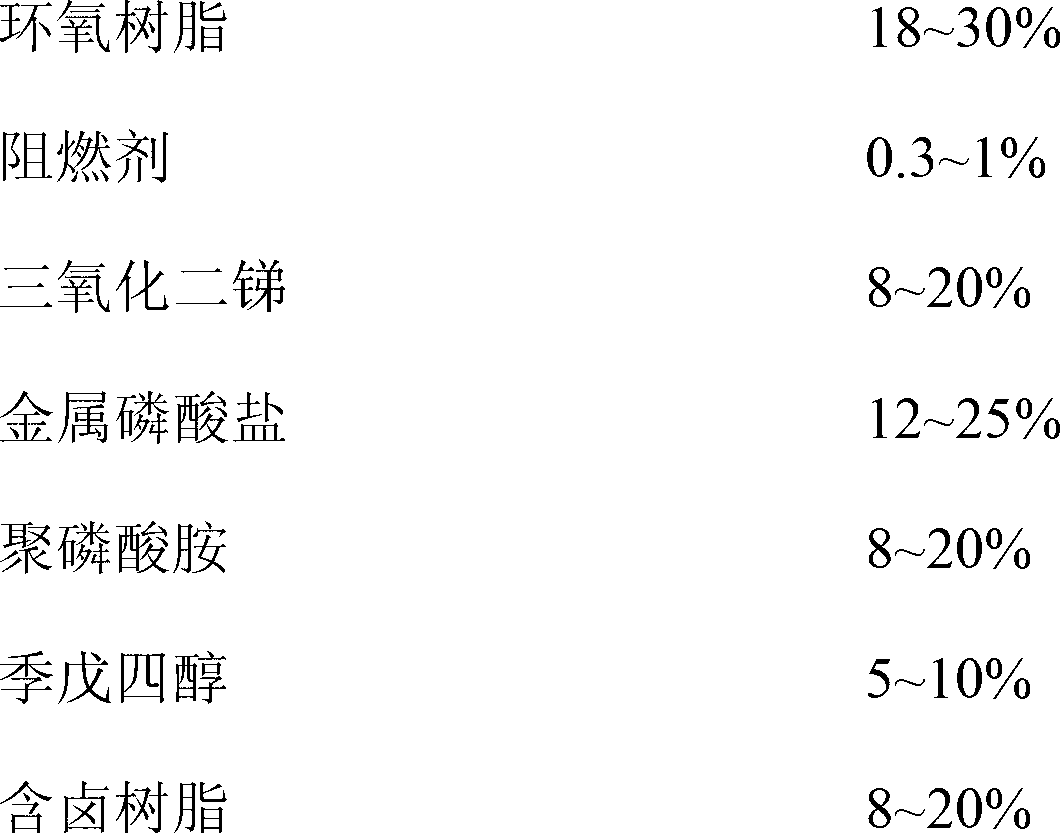

Fireproof, flame-resistant and anticorrosive paint

ActiveCN102993905AThe ether group is very polarStrong adhesionFireproof paintsAnti-corrosive paintsEpoxyPentaerythritol

The invention relates to a fireproof, flame-resistant and anticorrosive paint. The fireproof, flame-resistant and anticorrosive paint comprises the following components in percentage by weight: main agents consisting of 15-40% of epoxy resin, 0.1-1.5% of flame retardant, 5-25% of antimonous oxide, 10-30% of metal phosphate, 5-25% of polyamine phosphate, 3-12% of pentaerythritol, 5-25% of halogenous resin and 3-15% of an anticorrosive material; and a curing agent, wherein the mass ratio of the main agents to the curing agent is 3:1 to 8:1; and the anticorrosive material is silica powder and / or mica iron oxide ash. The fireproof, flame-resistant and anticorrosive paint provided by the invention is waterproof, can be used indoors and outdoors, and has fire resistance, good adhesive and excellent tensile strength.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

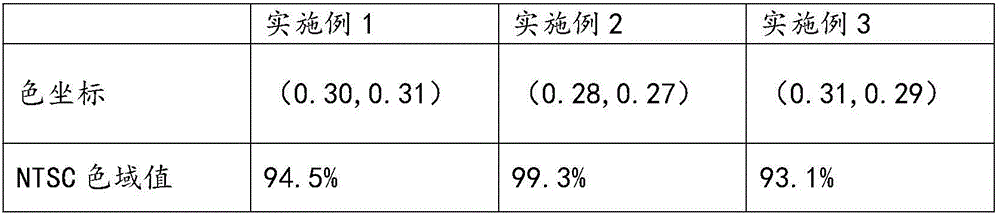

Cladding type quantum dot LED lamp bead packaging method

The invention belongs to the LED backlight processing field, and specifically relates to a cladding type quantum dot LED lamp bead packaging method; the half-wave width of the employed quantum dot material is relatively narrow, thus greatly improving LED lamp bead color gamut value, and the color gamut value of the obtained LED lamp bead can be above NTSC93%; epoxy resin is used to wrap the quantum dot material in an early stage, thus isolating external moisture and oxygen from eroding the quantum dot material, and improving the lamp bead reliability; quantum dot phosphor is employed to obtain the white light LED lamp bead; the quantum dot phosphor is high in excitation efficiency, and the phosphor concentration is low in a packaging working process, thus reducing the packaging work difficulty and product fraction defective; the cladding type quantum dot LED lamp bead packaging method is suitable for mass industrialization production, and can provide great market prospect and economic values.

Owner:HUIZHOU JUFEI OPTOELECTRONICS CO LTD

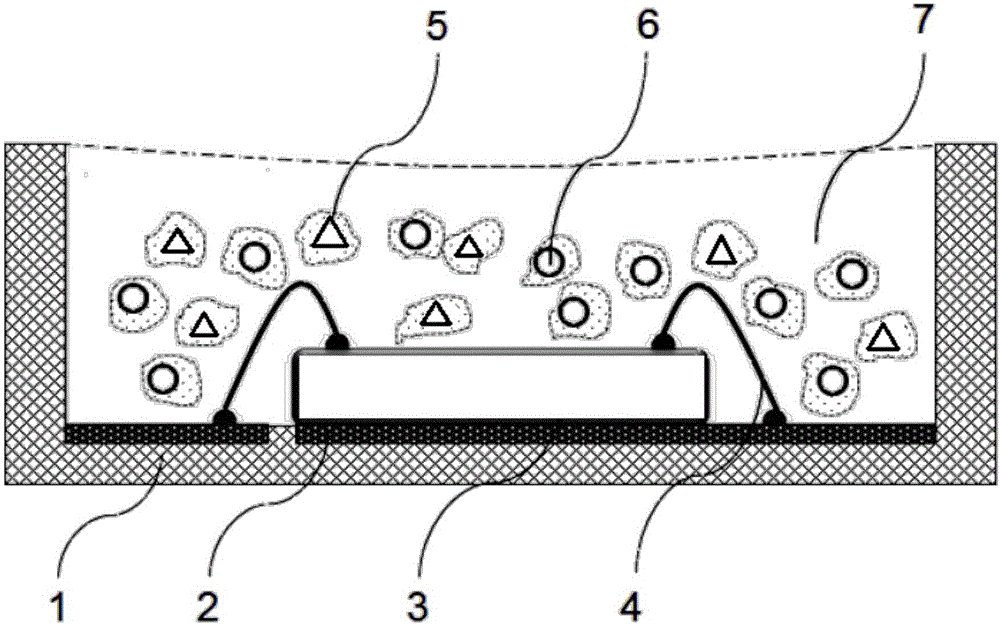

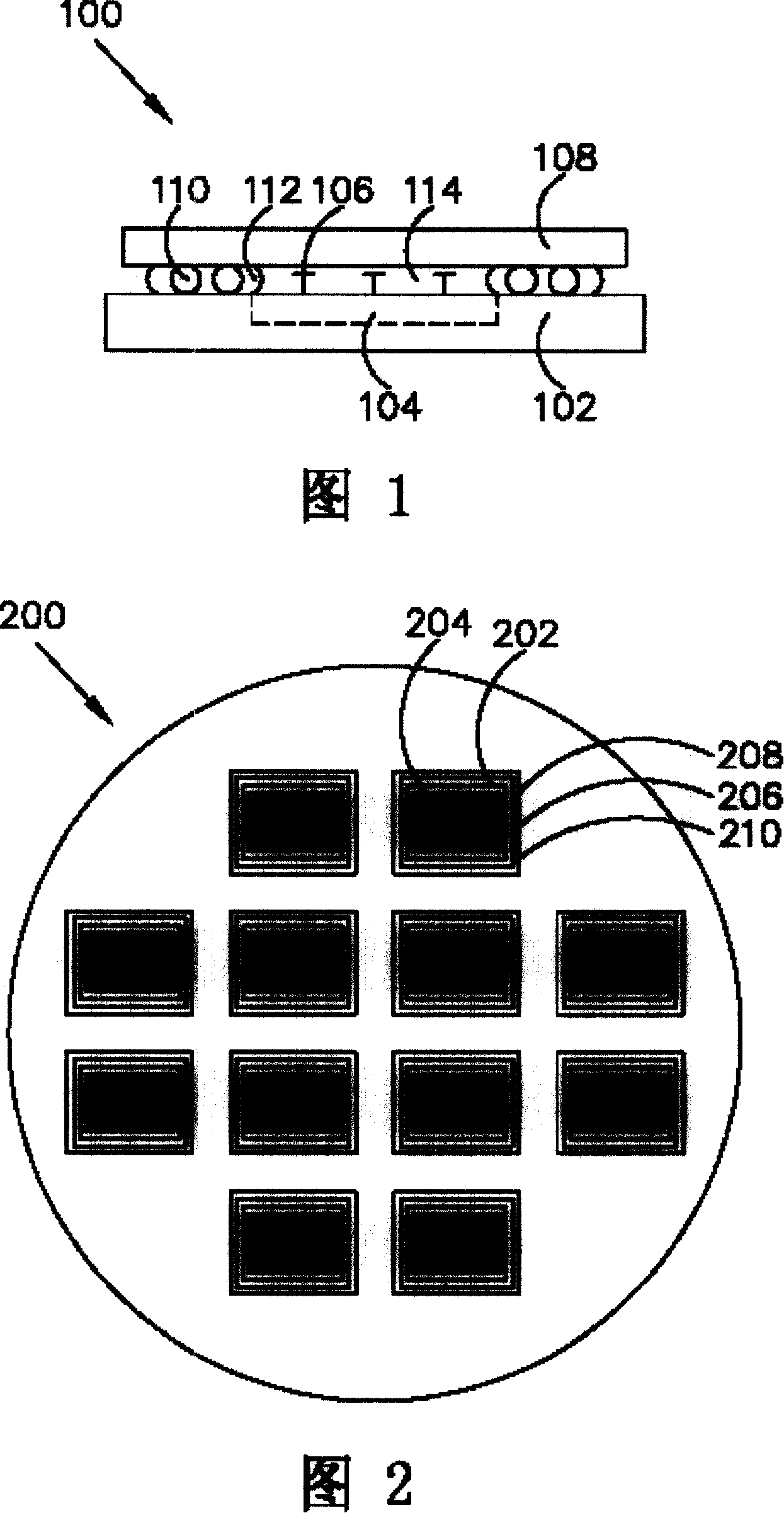

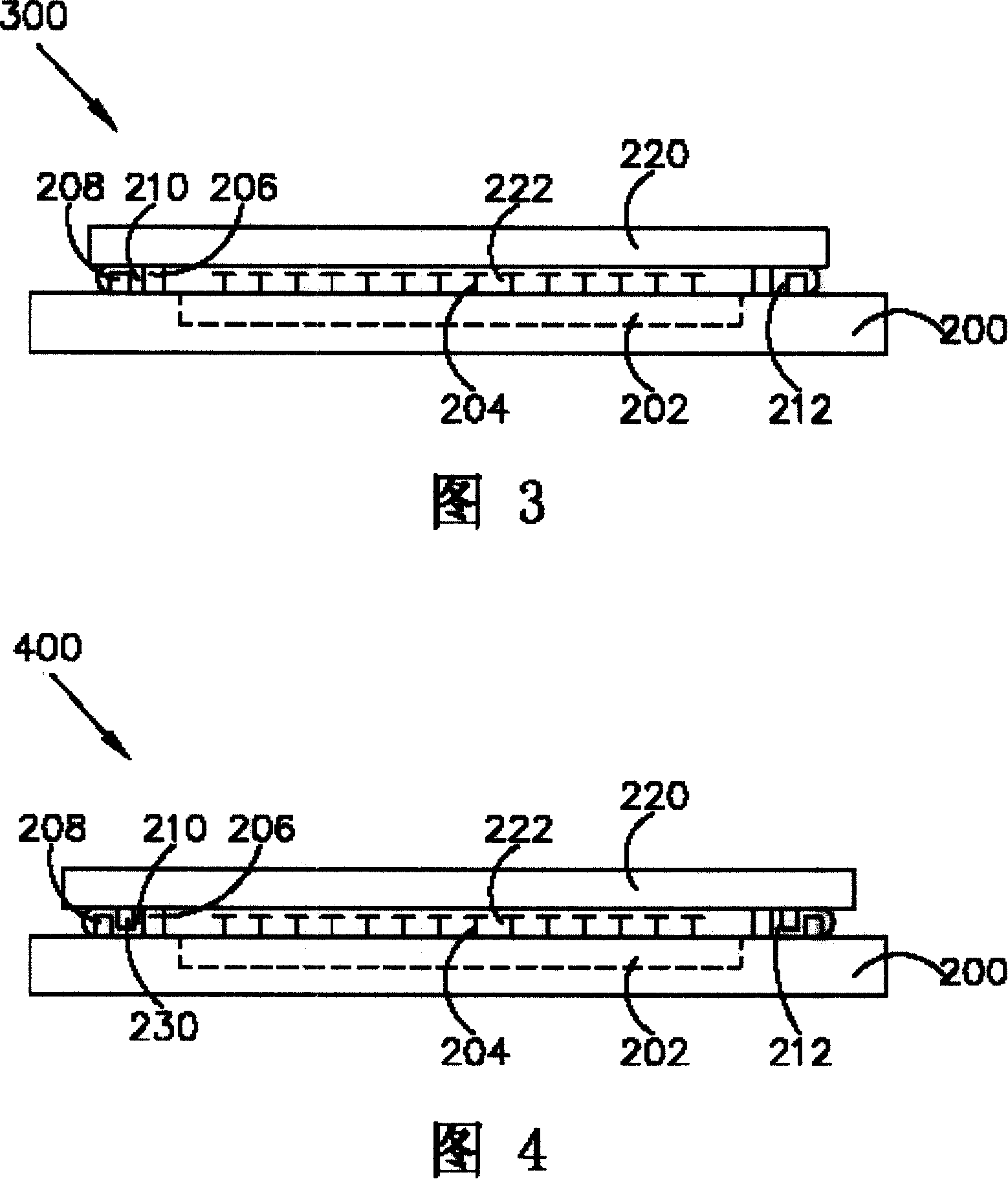

Packaging structure

ActiveCN101131972AReduce usageEffective control positionSemiconductor/solid-state device detailsSolid-state devicesEngineeringColloid

The present invention provides an embedding structure which includes a first and a second substrate. Upper surface of the first substrate has a certain region; a first sealing ring with a first height is located on the upper surface of the first substrate, and is set on peripheral part of the said certain region to connect lower surface of the second substrate; a second sealing ring with a second height which is smaller than the first height is located on the upper surface of the first substrate, and is set on peripheral part of the first sealing ring to form a trench with the first sealing ring together; a sealing colloid is set in the trench. The embedding structure of the present invention can effectively provide adhesion and air tightness, reduce used amount of the sealing colloid, and avoid polluting component region.

Owner:ADVANCED SEMICON ENG INC

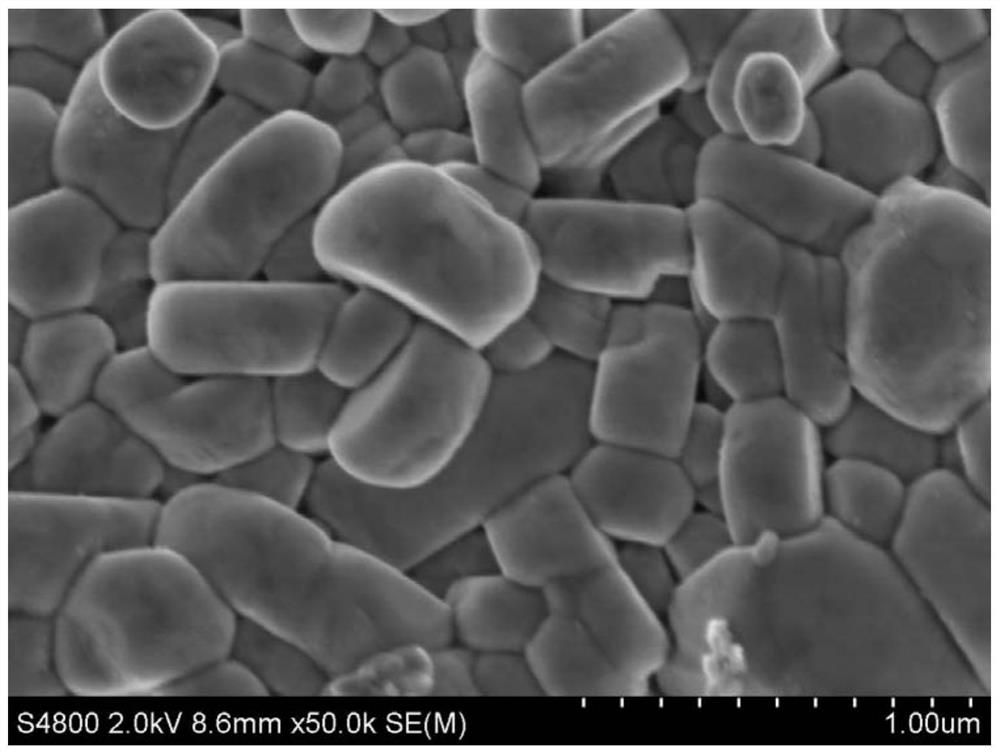

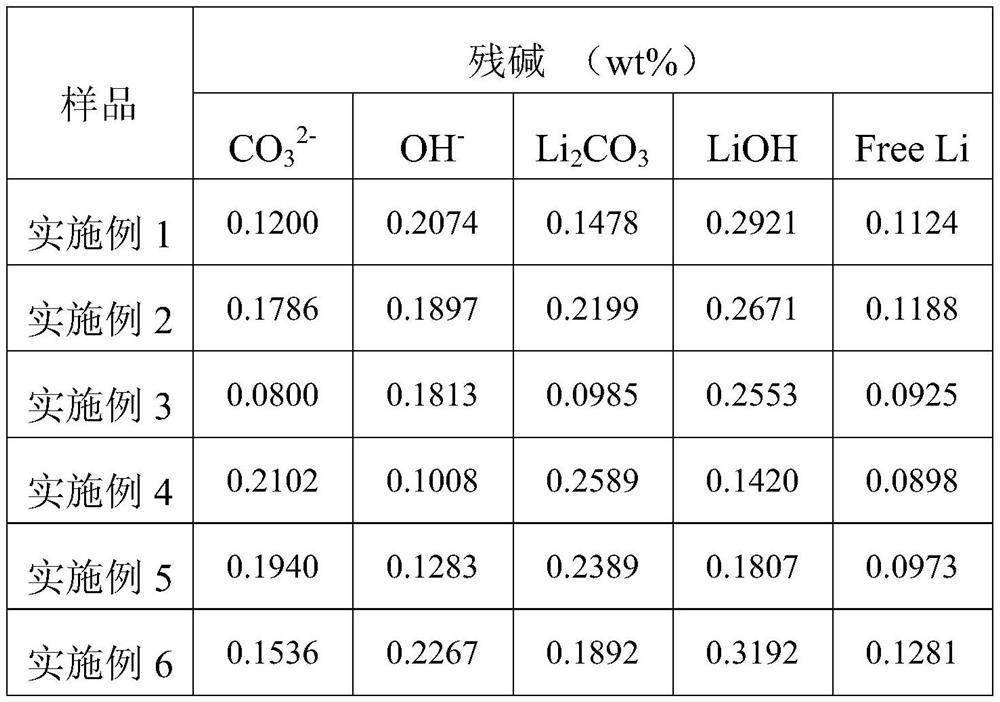

Reagent for wet coating of high-nickel ternary positive electrode material as well as preparation method and application of reagent

PendingCN112174221ABarrier erosionControl thicknessCell electrodesSecondary cellsFluid phasePower battery

The invention discloses a reagent for wet coating of a high-nickel ternary positive electrode material, and belongs to the technical field of lithium ion power batteries for new energy vehicles. The reagent for wet coating of the high-nickel ternary positive electrode material comprises the following raw materials: a metal source and / or a complexing agent and a solvent, wherein the metal source isat least one of a lithium source, an aluminum source, a magnesium source, a titanium source, a manganese source, a nickel source and a phosphorus source; the complexing agent is at least one of CTAB,citric acid and ammonium citrate; and the solvent is at least one of deionized water, ethanol, absolute ethyl alcohol and acetone. The reagent for wet coating coats the surface of a material througha liquid phase reaction, so that the surface of the material is uniformly coated, the circularity is good, and the residual alkali level is low.

Owner:ZHEJIANG MEIDU HITRANS LITHIUM BATTERY TECHNOLOGY CO LTD

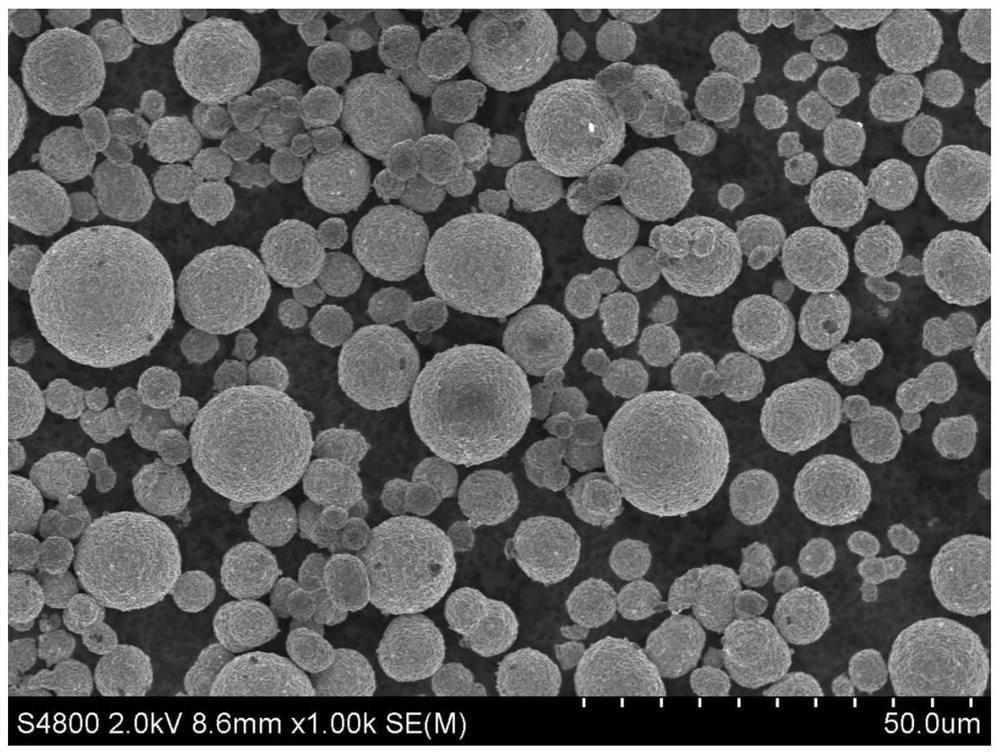

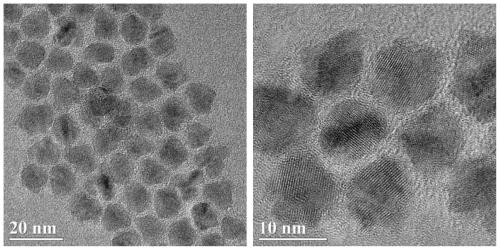

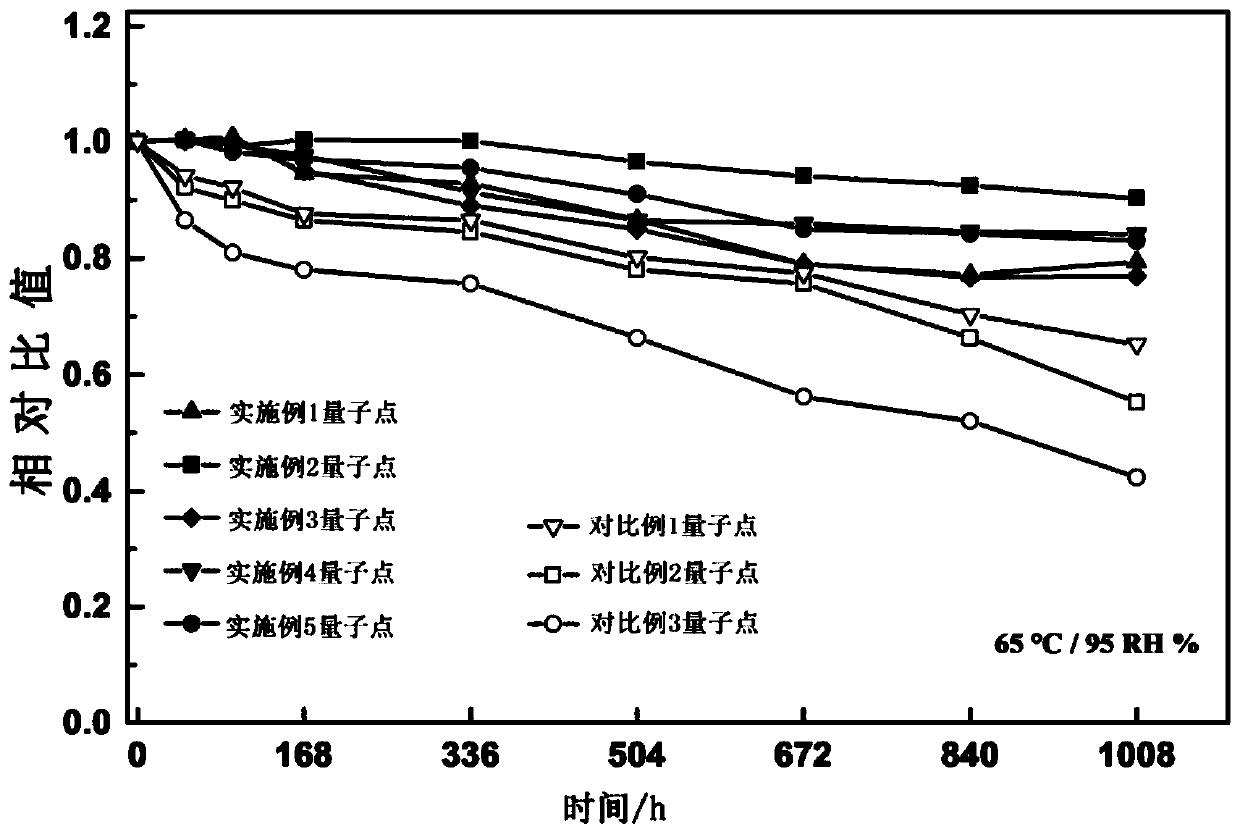

Quantum dots and preparation method thereof

ActiveCN109929559AImprove stabilityEffective protectionMaterial nanotechnologyNanoopticsHigh humidityQuantum dot

The invention discloses a quantum dot and a preparation method thereof. The quantum dot comprises a quantum dot core and a plurality of quantum dot shell layers wrapping the quantum dot core. A metaloxide layer is arranged between the quantum dot core and the adjacent quantum dot shell layer. A metal oxide layer is arranged between the adjacent quantum dot shell layers or on the outermost quantumdot shell layer. According to the invention, the metal oxide layers are generated on the surfaces of the core and the shell of the quantum dot by using the precursor with an oxidation effect, so thatthe core and the shell of the quantum dot are effectively protected, erosion of moisture, oxygen and the like to the core and the shell of the quantum dot is inhibited and the stability of the quantum dot is improved. When the quantum dot film is prepared by using the quantum dot, the quantum dot film still keeps good stability in a high-temperature and high-humidity environment under the condition that a water-blocking oxygen-isolating film is not used, so that the dependence on an expensive water-blocking oxygen-isolating film is weakened, and the cost is reduced. The method has important significance for the application of the quantum dots in the fields of display, illumination and the like.

Owner:魏县聚邦新材料科技有限公司

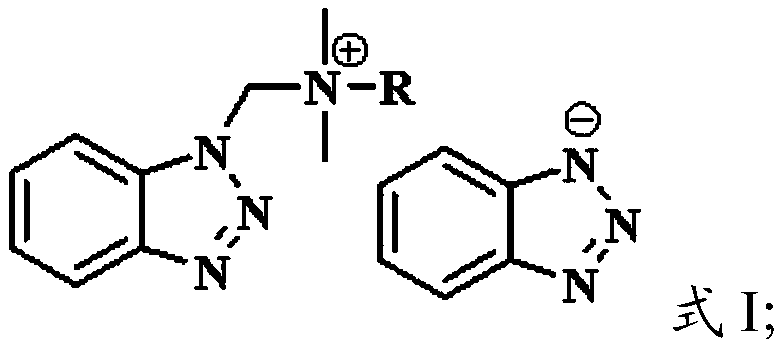

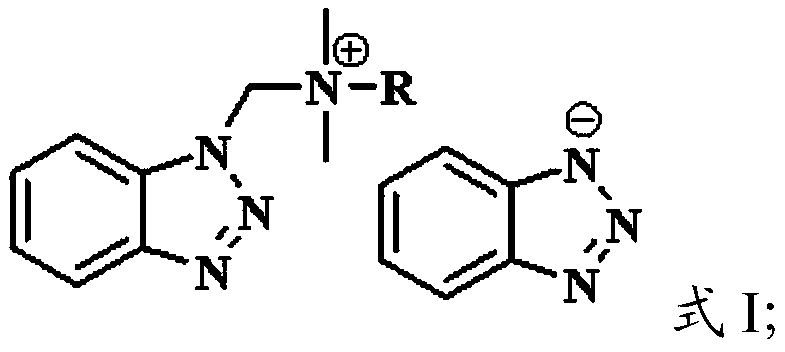

Benzotriazole functionalized quaternary ammonium salt as well as preparation method and application thereof

ActiveCN110845430AGood corrosion inhibitionImprove adsorption capacityOrganic chemistryAdditivesBenzotriazoleIonic liquid

The invention provides benzotriazole functionalized quaternary ammonium salt as well as a preparation method and application thereof, and belongs to the technical field of lubrication. The cation of the benzotriazole functionalized quaternary ammonium salt provided by the invention is benzotriazole functionalized quaternary ammonium salt with different alkyl chain lengths, and the anion of the benzotriazole functionalized quaternary ammonium salt is benzotriazole. According to the invention, a benzotriazole functional group is introduced into a quaternary ammonium salt structure, the obtainedbenzotriazole functionalized quaternary ammonium salt has excellent gelling performance and can be used as a gelator, and a stable gel material is formed by gelling a traditional ionic liquid lubricant through supramolecular self-assembly when the benzotriazole functionalized quaternary ammonium salt is used in the traditional ionic liquid lubricant. The gel material is good in thermal stability and excellent in tribological performance, and meanwhile creeping and leakage of the traditional ionic liquid lubricant in the using process are prevented; the benzotriazole functionalized quaternary ammonium salt also has excellent corrosion inhibition performance, and can be used as a corrosion inhibitor to effectively prevent an acidic medium from corroding a metal material substrate.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

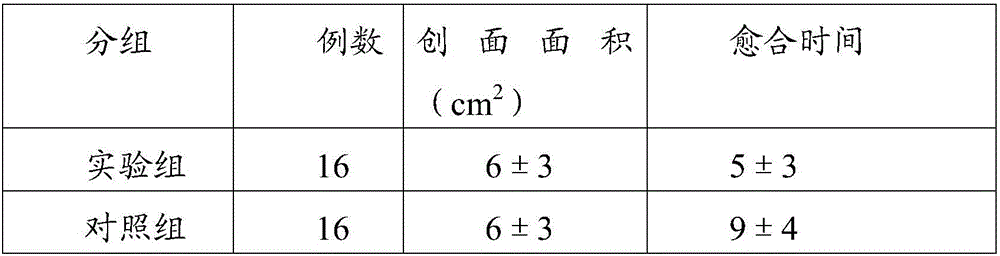

Medical dressing for treating large area wound and manufacturing method thereof

InactiveCN105662713APromote healingAnti-water intrusionPlastersAdhesive dressingsWound healingBurning Pain

The invention discloses a medical dressing for treating a large area wound and a manufacturing method thereof. The medical dressing is composed of from top to bottom: an isolation paper, a sodium alginate hydrogel, a non-woven fabric, a medical glue layer and a base cloth; or from top to bottom, an isolation paper, an alginate hydrogel, a medical glue layer and a base cloth. The sodium alginate hydrogel is a hydrogel mixed by 100 percent pure sodium alginate crystals and water. The alginate hydrogel is a hydrogel, which assumes a transparent gel shape formed by immersing a 100 percent pure calcium alginate non-woven fabric to a sodium alginate solution, automatically converts between a solid state and a liquid state based on changes of using state. The novelty of the invention lies in combining a material which promotes curing of the wound and a material which is secured to body surface. The medical dressing of the invention has the advantages of outside water resistance, extra-long adhering time, and simple operation and usage. The medical dressing of the invention faces towards the wound in humid environment, which promotes healing. The medical dressing can also reduce burning pain caused by the large area wound, prevent infection and wound adhesion, block bacteria from entering, and reduce times for changing medicine.

Owner:WUXI HENGCHENG MEDICAL TECH CO LTD

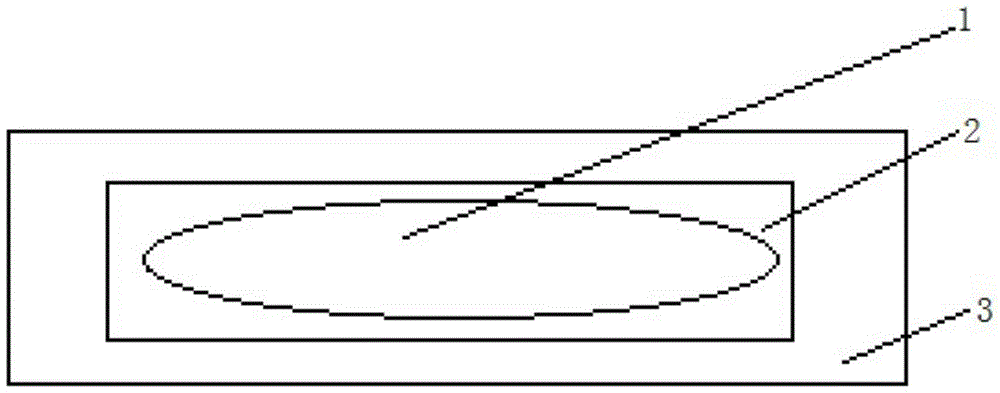

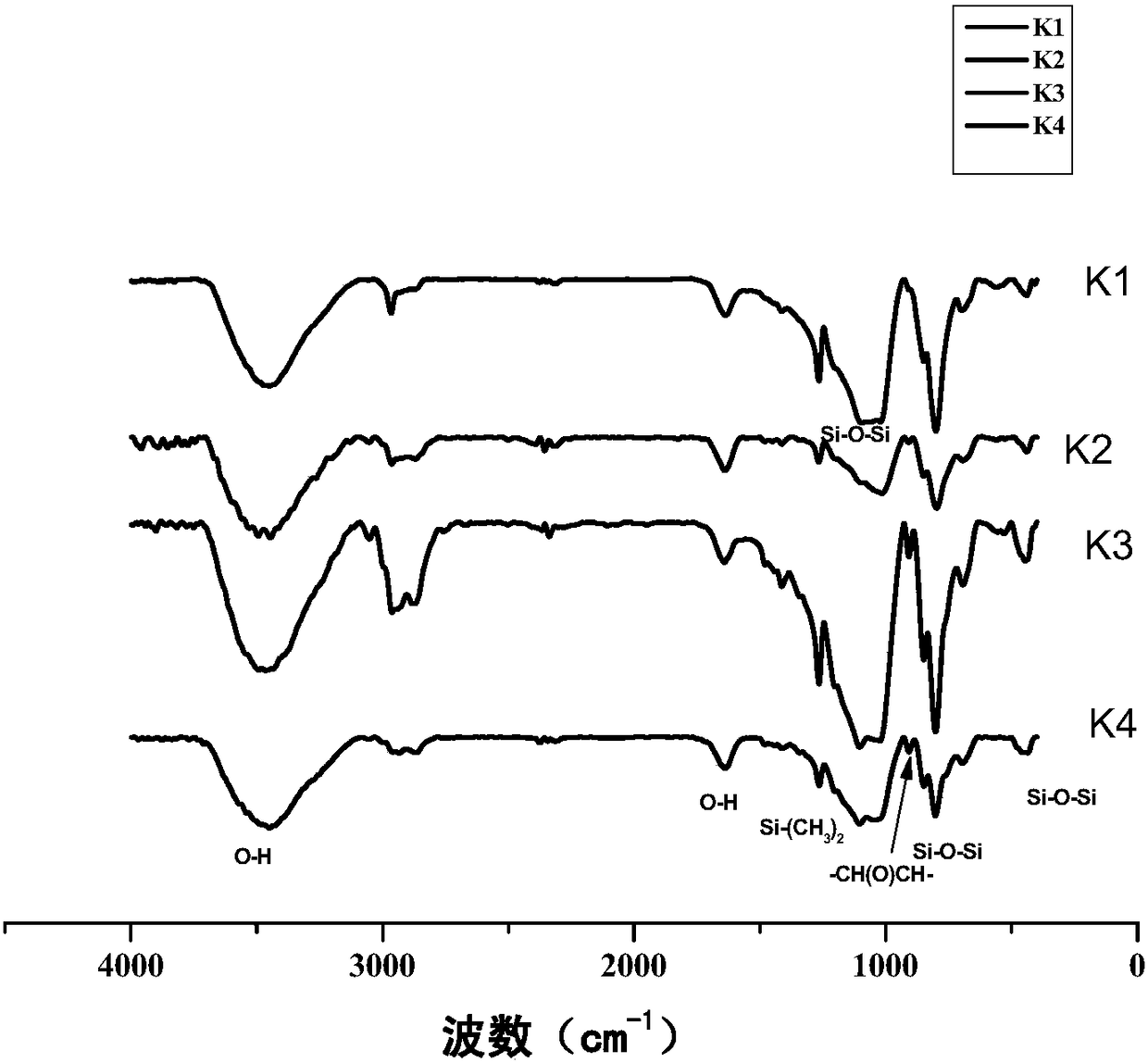

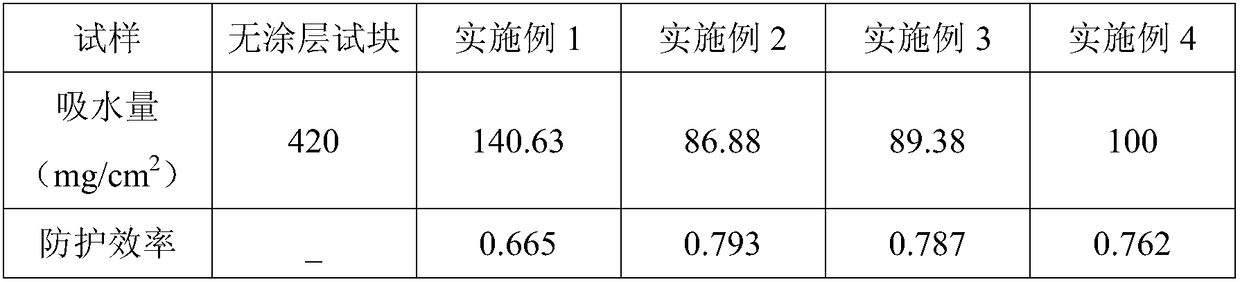

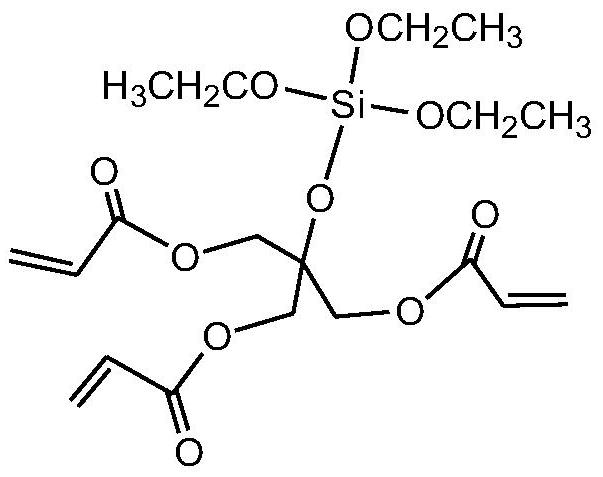

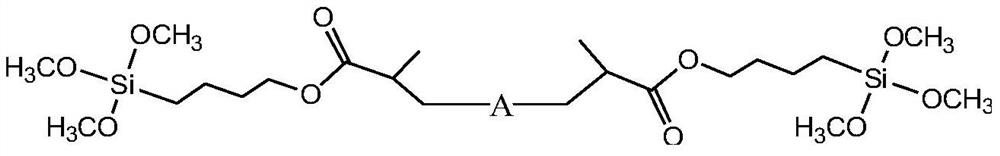

Organic and inorganic composite concrete protective coating modified by coupling agents, method for preparing organic and inorganic composite concrete protective coating and application thereof

InactiveCN108410218AImprove permeabilityImprove sealingAnti-corrosive paintsWeather resistanceAlcohol

The invention discloses a method for preparing an organic and inorganic composite concrete protective coating modified by coupling agents. The method includes steps of (1), preparing tetraethyl orthosilicate, deionized water and ethyl alcohol according to a molar ratio of 1:(3-6):(3-6) at the room temperature, gradually adding terminal hydroxyl polydimethylsiloxane into the tetraethyl orthosilicate, the deionized water and the ethyl alcohol under magnetic stirring conditions and stirring the terminal hydroxyl polydimethylsiloxane, the tetraethyl orthosilicate, the deionized water and the ethylalcohol for 15-25 min to obtain mixtures; (2), gradually adding the coupling agents into the mixtures at the temperature of 25 DEG C under magnetic stirring conditions, carrying out modification to prepare organic and inorganic composite protective coatings, stirring the organic and inorganic composite protective coatings until solution is uniform, then dropwise adding a catalyst n-octylamine into the solution and stirring the solution and the catalyst n-octylamine until transparent stable sol is obtained. The method has the advantages that protective coatings can be prepared by the aid of sol-gel processes, the method is simple, economical and practical and is low in cost, the organic and inorganic composite concrete protective coating is high in adhesion and corrosion resistance, outstanding in waterproof performance, good in weather resistance and applicable to civil waterproof engineering and waterproof engineering such as tunnel and ocean engineering, and the like.

Owner:SOUTH CHINA UNIV OF TECH

Environmentally-friendly water-based rusty antirust coating

The invention discloses an environmentally-friendly water-based rusty antirust coating, and belongs to the technical field of surface protection of metal products. The coating is prepared by the following steps: sequentially taking 20-30 parts by weight of a styrene-acrylic emulsion, 8-10 parts by weight of a polyvinyl alcohol liquid, 8-10 parts by weight of organic silicon resin, 8-10 parts by weight of modified starch, 8-10 parts by weight of calcium phosphite, 8-10 parts by weight of bamboo vinegar, 3-5 parts by weight of a defoaming agent, 3-5 parts by weight of a surfactant, 3-5 parts byweight of a thickening agent, 10-20 parts by weight of modified diatomaceous earth and 80-100 parts by weight of deionized water, putting the modified starch, the calcium phosphite, the bamboo vinegar, the defoaming agent, the surfactant, the thickening agent, the modified diatomaceous earth and the deionized water into a ball mill, performing ball milling mixing for 30-50 min, then adding the styrene-acrylic emulsion and the organic silicon resin into the ball mill, performing ball milling mixing for 40-60 min, and performing sieving by using a 80-mesh sieve to obtain the environmentally-friendly water-based rusty antirust coating. The environmentally-friendly water-based rusty antirust coating provided by the invention has good antirust performance.

Owner:常州五荣化工有限公司

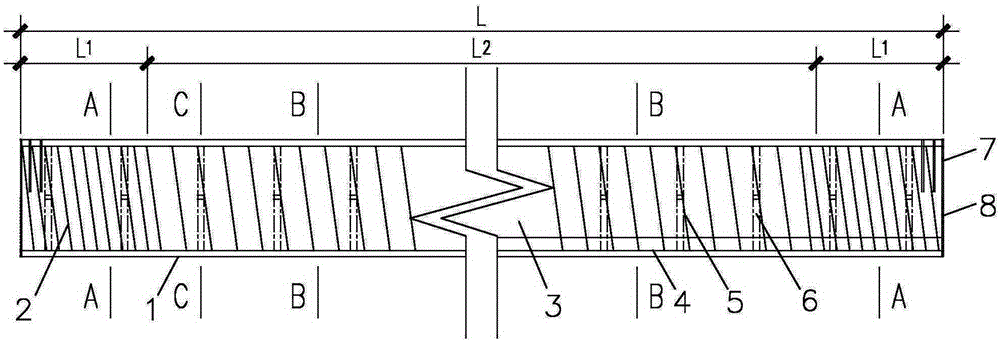

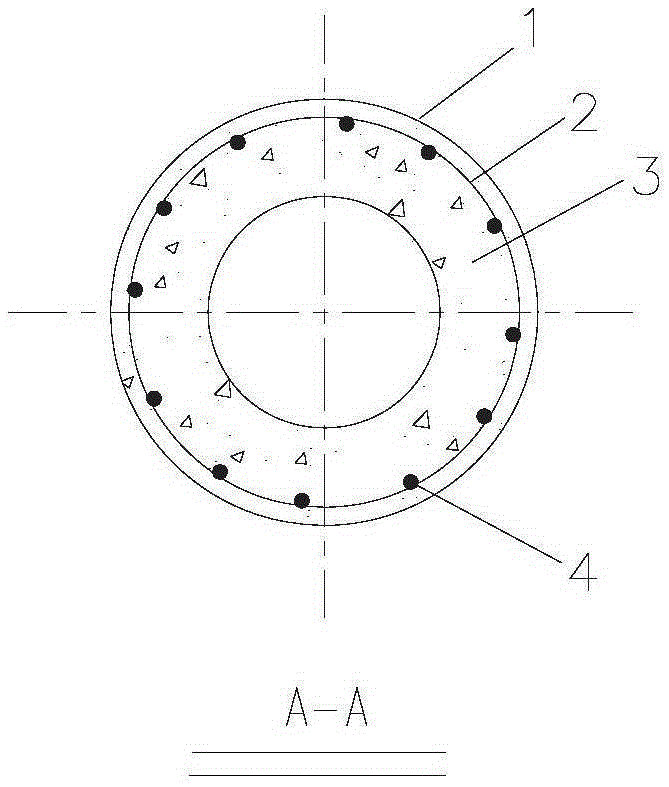

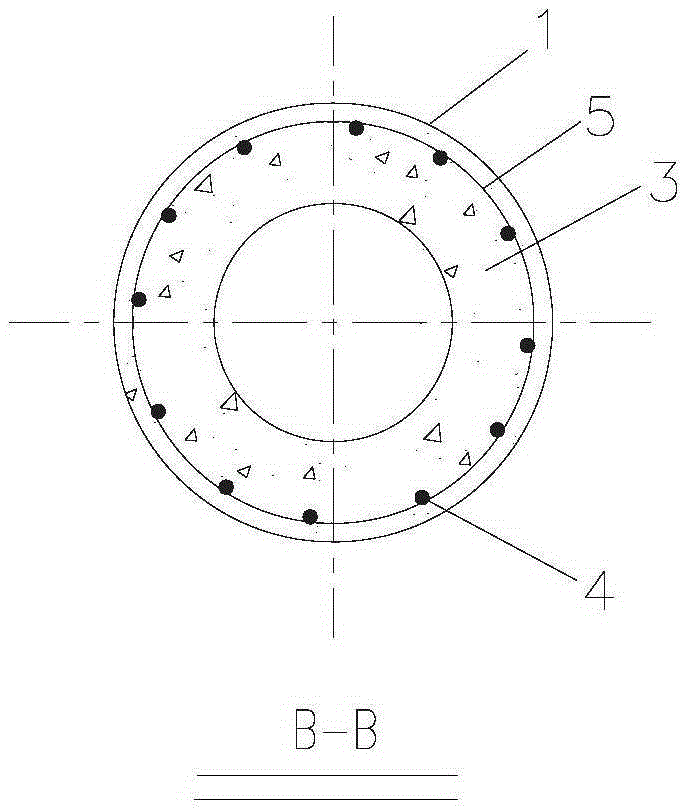

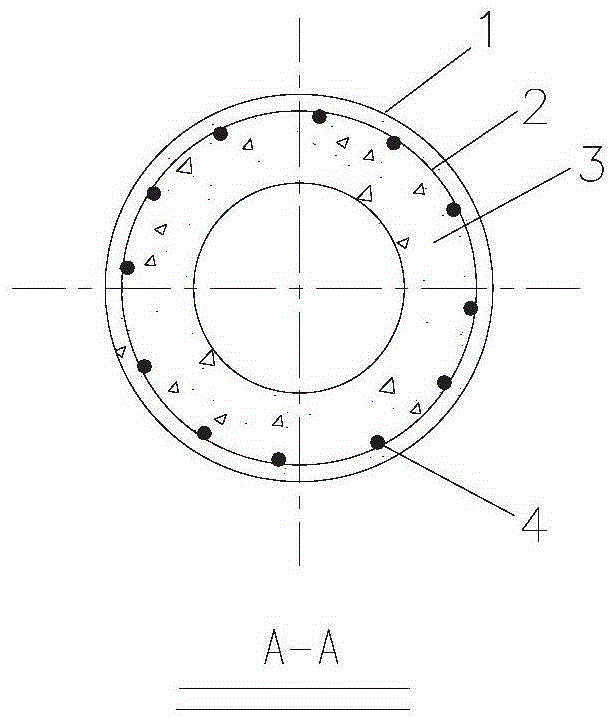

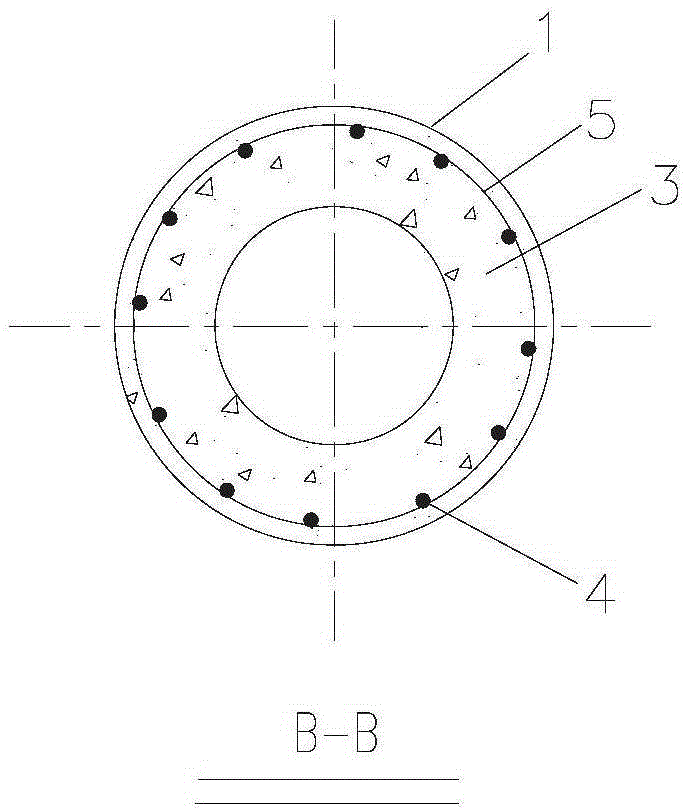

PVC pipe wrapped inner supporting cross prestress recycled concrete tubular pile

The invention discloses a PVC pipe wrapped inner supporting cross prestress recycled concrete tubular pile mainly formed by a PVC pipe, a round reinforcement cage framework, cross steel ribs and recycled concrete. The round reinforcement cage framework and the cross steel ribs are arranged in the PVC pipe, and a round inner cavity is formed in the PVC pipe by the recycled concrete. The round reinforcement cage framework is formed by welding longitudinal prestressed tendons and spiral stirrups. A PVC pipe wrapped pile body resistant to corrosion, light and high in strength can be effectively prevented from being corroded, the corrosion problem of the tubular pile is solved, and the durability of a pile foundation is improved. The inner supporting cross steel ribs can fully achieve the respective advantages of steel, prestressed reinforcement and concrete, the stress performance of the recycled concrete is improved, the bearing capacity and stability of the single pile are improved, the lateral rigidity of the pile body is increased, and transverse deformation is reduced. Waste concrete is fully utilized as recycled aggregate, and application and popularization of the recycled concrete in building foundation engineering are facilitated.

Owner:GUANGXI UNIV

Flame-retardant polyurethane material and preparation method thereof

The invention provides a flame-retardant polyurethane material and a preparation method thereof. The flame-retardant polyurethane material is prepared from the following raw materials in parts by weight: 22 parts of polyether polyol, 22 parts of isocyanate, 6 parts of expandable graphite and ammonium polyphosphate and 0.05-0.25 parts of modified graphene oxide. The modified graphene oxide is phytic acid modified graphene oxide, octadecylamine modified graphene oxide or isophorone diisocyanate (IPDI) modified graphene oxide. Graphene oxide is modified, the dispersity and compatibility of graphene oxide in a base material are improved, meanwhile, expandable graphite and ammonium polyphosphate cooperate to form a more compact and perfect carbon layer, and the flame retardance of the materialis improved.

Owner:NORTH CHINA INST OF SCI & TECH

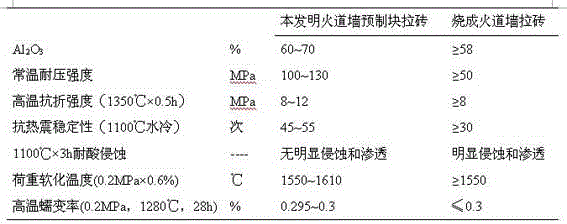

Carbon roaster flue wall guy brick precast block and production method thereof

The invention discloses a carbon roaster flue wall guy brick precast block and a production method thereof. The carbon roaster flue wall guy brick precast block is produced by subjecting a mixture and an additive to mixing, stirring with water, molding by casting, curing and roasting, wherein the mixture comprises, by weight, 60-80% of bauxite chamotte, 5-20% of silicon carbide, 3-10% of silica fume, 3-10% of alumina powder, 3-10% of fine kyanite powder, 3-10% of pure calcium aluminate cement and 3-10% of metallic silicon, and the mass ratio of the mixture to the additive is 100 to 0.2-2. The production method includes mixing the mixture with the additive with the water added, pouring a mixed material into a mould and casting for vibration molding; roasting for 24-48 hours at 110-300 DEG C after natural curing so as to obtain a finished product. The carbon roaster flue wall guy brick precast block is low in production cost and simple in technology, properties such as the high-temperature creep rate and refractoriness under load can reach the levels of fired guy bricks, and the strength, the thermal-shock-resistant stability and sulfide corrodibility are superior to those of the fired guy bricks.

Owner:河南鑫诚耐火材料股份有限公司

Liquid band-aid and preparation method thereof

The invention relates to the field of drug preparation, in particular to a liquid band-aid and a preparation method thereof. The liquid band-aid is obtained by mixing the following components: acrylic acid copolymer, polyvinyl alcohol and polyethylene glycol copolymer, polysorbate 80, glycerol, sodium bicarbonate / sodium hydroxide, and purified water. The invention has the beneficial effects: the liquid band-aid is convenient and simple to use, is not limited by any wound or location, and is a water-soluble liquid band-aid without organic solvent, so that the liquid band-aid doesn't cause any toxic or side effects, stimulation, anaphylaxes or drug resistance on wound surface tissue on the surface of skin, promotes muscular tissue repair and regeneration, protects and promotes wound healing, shortens healing time, effectively prevents wound infection and other problems, can rapidly form a film at the body temperature, has relatively good toughness, protects a wound, prevents infection, and promotes wound healing.

Owner:LANJIATANG BIOLOGICAL MEDICINE FUJIAN CO LTD

Antirust master batches for various metals as well as preparation method and application of antirust master batches

The invention discloses antirust master batches for various metals as well as a preparation method and application of the antirust master batches. The antirust master batches comprise the following components in percentage by mass: 30-50% of a compounded antirust agent, 40-60% of carrier plastic and 10-20% of an auxiliary agent, wherein the compounded antirust agent is prepared by mixing disodium sebacate, sodium molybdate and diglycolamide oleate borate according to a mass ratio of (1-1.3):(1.1-1.5):(2.2-3.2); and the auxiliary agent is prepared by mixing stearic acid amide, silicon dioxide, sucrose fatty acid ester and an antioxidant 1076 according to a mass ratio of (0.9-1.3):(4.8-6.5):(2.5-3.3):(0.8-1.1). The diglycolamide oleate borate is adopted as an additive and has a dispersion effect and an antirust effect, and the compounded antirust agent has certain polarity, can penetrate through the carrier plastic and volatilize to the surface of a packed metal to form a protective film so as to prevent corrosion of external corrosive substances, and cannot be incompatible with the carrier plastic to generate frost due to too strong polarity. The antirust master batches do not contain harmful ingredients, are environment-friendly and safe to use, and can achieve an antirust effect on various metals.

Owner:青岛鑫盈鑫包装材料有限公司 +1

FRP wrapped prestress recycled concrete tubular pile

The invention discloses an FRP wrapped prestress recycled concrete tubular pile mainly formed by an FRP pipe, a round reinforcement cage framework, cross steel ribs and recycled concrete. The round reinforcement cage framework and the cross steel ribs are arranged in the FRP pipe, and a round inner cavity is formed in the FRP pipe through the recycled concrete. The round reinforcement cage framework is formed by welding longitudinal prestressed tendons and spiral stirrups. An FRP pipe wrapped pile body resistant to corrosion, light and high in strength can be effectively prevented from being corroded, the corrosion problem of the tubular pile is solved, and the durability of a pile foundation is improved. The inner supporting cross steel ribs can fully achieve the respective advantages of steel, prestressed reinforcement and concrete, the stress performance of the recycled concrete is improved, the bearing capacity and stability of the single pile are improved, the lateral rigidity of the pile body is increased, and transverse deformation is reduced. Waste concrete is fully utilized as recycled aggregate, and application and popularization of the recycled concrete in building foundation engineering are facilitated.

Owner:GUANGXI UNIV

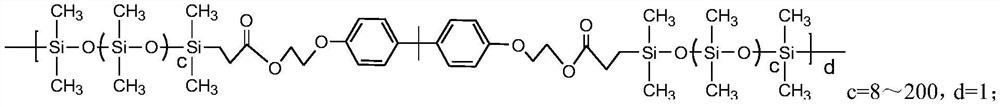

Oil-resistant, high-temperature-resistant and low-volatile organic silica gel

The invention relates to oil-resistant, high-temperature-resistant and low-volatile organic silica gel. Methyl vinyl MQ resin, methyl silicone oil, a silane coupling agent 1, a silane coupling agent 2, a silane coupling agent 3, hydrogen-containing silicone oil, white carbon black, a Pt catalyst, an inhibitor and black color paste are mixed in a weight ratio of (20-35) : (40-50) : (0.5-3) : (0.5-3) : (0.5-3) : (3-9) : (1-6) : (0.02-0.1) : (0.02-0.1) : (0.03-0.5). The silane coupling agent 1 adopted by the invention contains a plurality of ethoxy groups, so that the silane coupling agent 1 canplay a role of a water absorbent while playing a role of a coupling agent, the content of moisture in a system is reduced, and the storage stability of the product is improved; meanwhile, the silane coupling agent 2 contains two adjacent benzene rings, so that the cracking temperature of the glue at high temperature can be increased; besides, ether chain molecules contained in the silane couplingagent 3 fill among polysiloxane molecular chains, so that corrosion of oil molecules to colloid is effectively blocked.

Owner:YANTAI DARBOND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com