Patents

Literature

749 results about "Metal nitrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alkali metal nitrate. Alkali metal nitrates are chemical compounds consisting of an alkali metal ( lithium, sodium, potassium, rubidium and caesium) and the nitrate ion. Only two are of major commercial value, the sodium and potassium salts. They are white, water-soluble salts with relatively similar melting points.

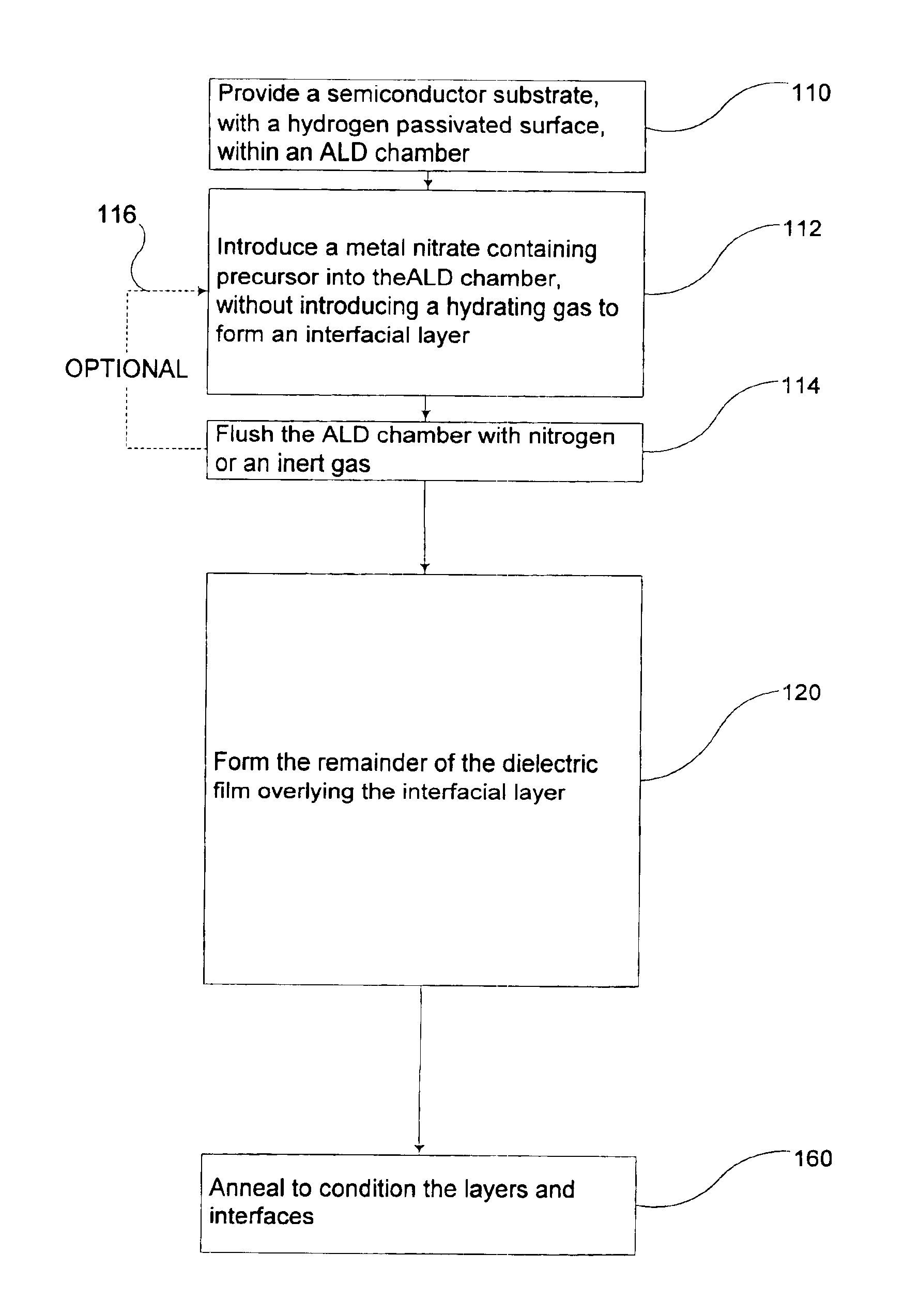

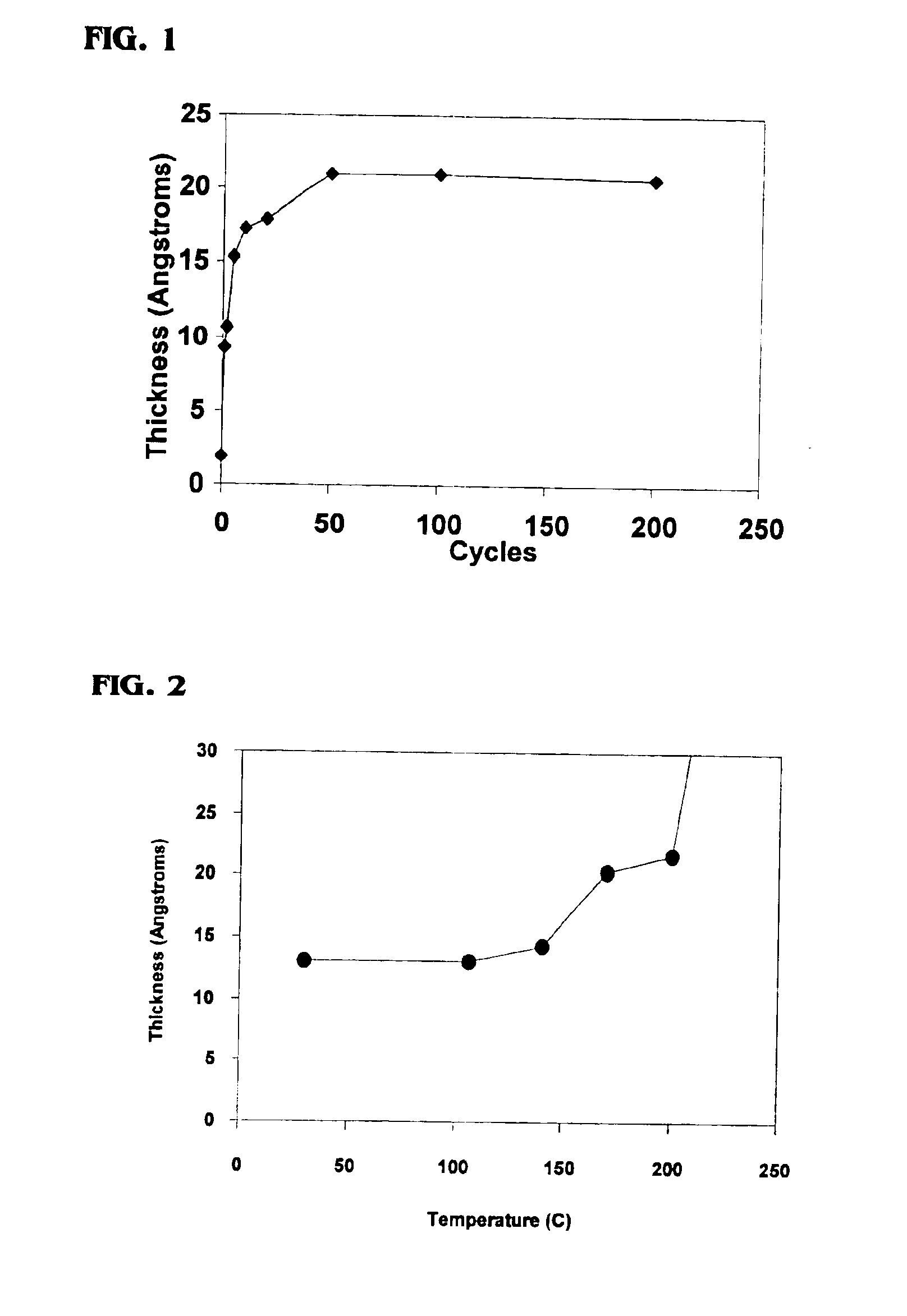

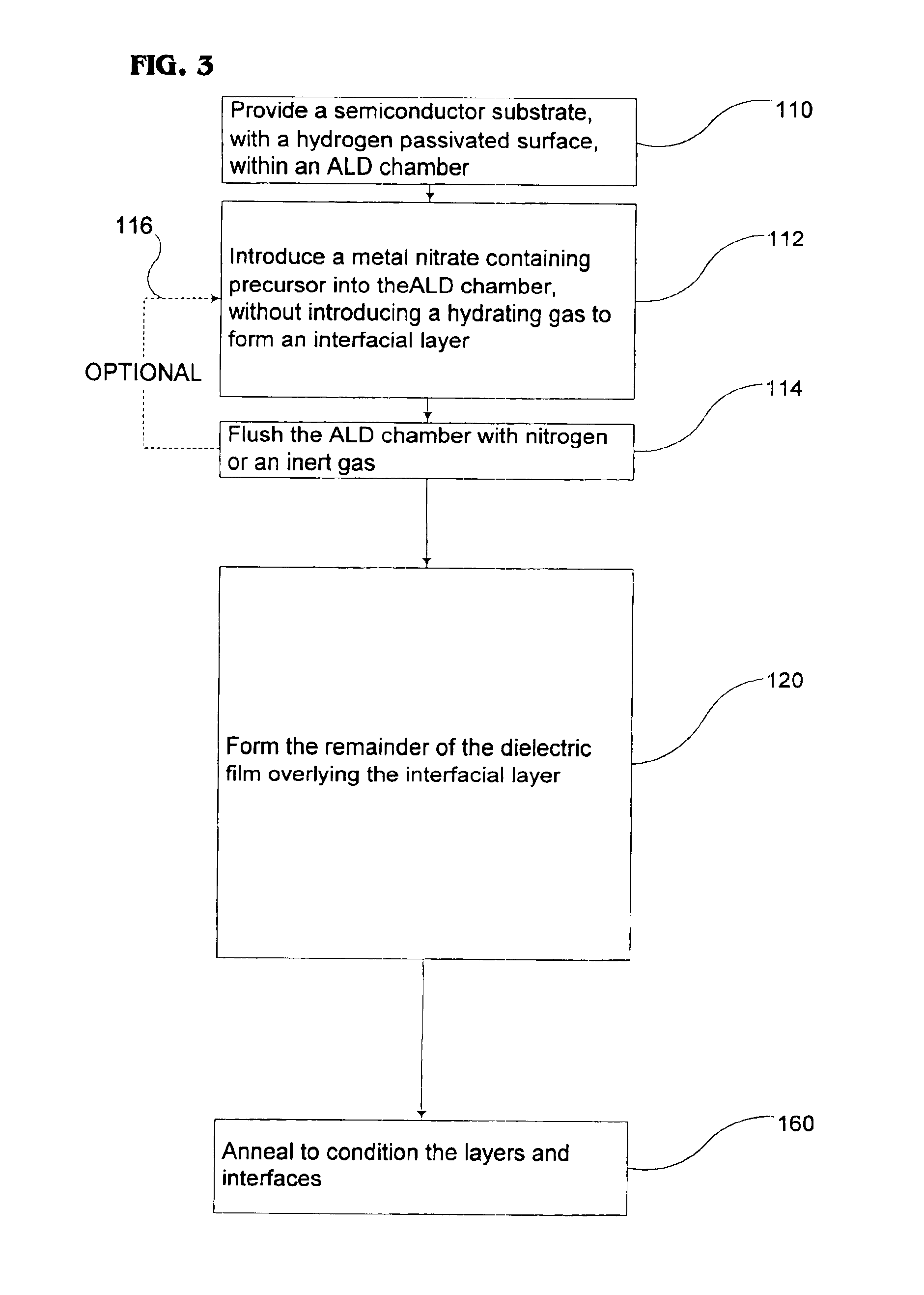

Method to control the interfacial layer for deposition of high dielectric constant films

Methods of forming an interfacial layer on a hydrogen-passivated substrate are provided. These methods utilize atomic layer deposition techniques incorporating metal nitrate-based precursors, such as hafnium nitrate or zirconium nitrate, without introducing a hydrating agent, or oxidizing agent, such as water, during the formation of the interfacial layer. Also provided are methods of forming high-k films, by first forming an interfacial layer on the surface of a hydrogen-passivated substrate, and then depositing one, or more, high-k dielectric films.

Owner:SHARP LAB OF AMERICA INC

Formaldehyde gas oxidation catalyst under room temperature

ActiveCN1714930ARaw materials are readily availableSimple conditions of useDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCatalytic oxidationSilicon dioxide

The present invention provides a kind of formaldehyde gas oxidizing catalyst for room temperature use. Metal oxide is first obtained with soluble metal nitrate, carbonate or other inorganic salt and through oxidation and precipitation; and then loaded with small amount of metal to form the catalyst with room temperature formaldehyde oxidizing activity. The catalyst has metal oxide as main body and supported noble metal as active component, and features that the metal oxide may be oxide of Al, Ni, Mn, Si or Fe, and the noble may be Pt, Ru, Au, Rh or Pd. The catalyst of the present invention has high catalytic activity, and long sustaining time. The catalyst has formaldehyde converting rate up to 100 %, and results in low power consumption.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

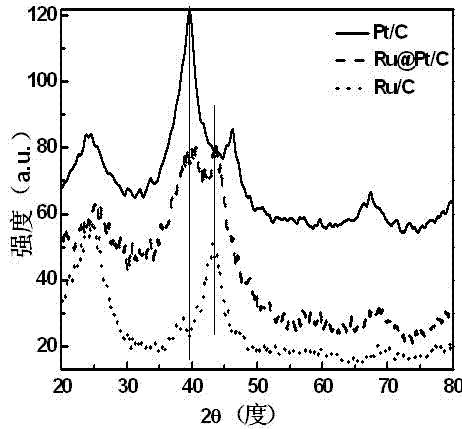

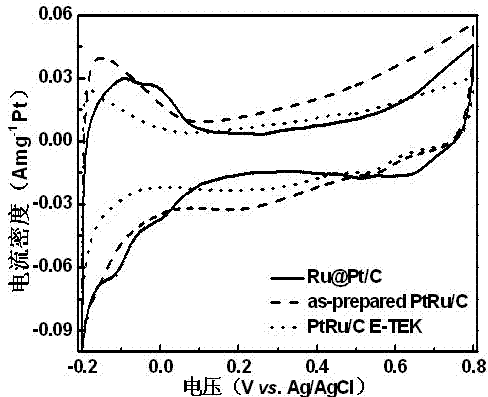

Preparation method of catalyst with core-shell structure for low-temperature fuel cell

InactiveCN102500365AHigh catalytic activitySolve the costCell electrodesCatalyst activation/preparationIridiumPtru catalyst

The invention discloses a preparation method of a catalyst with a core-shell structure for a low-temperature fuel cell, belonging to the technical field of fuel cells. In the catalyst with the core-shell structure prepared with the preparation method, platinum is taken as a shell, a metal alloy consisting of more than one of metals including ruthenium, platinum, iron, cobalt, nickel, copper, tin, iridium, gold and silver is taken as an inner core, and the shell and the inner core are loaded on a carbon carrier. The preparation method comprises the following preparation steps of: reducing a metal chloride or a metal nitrate with a reducing agent, and forming a core on the carbon carrier with a large specific surface area; stabilizing the core; and precipitating Pt on a core layer with a impregnation reduction method, a high-pressure organic sol method, a microwave method or an electrodeposition process to form the catalyst with the core-shell structure. Due to the adoption of the preparation method, the utilization ratio of noble metal platinum is increased, the cost of an electro-catalyst is reduced effectively, and the methanol oxidizing capability and oxygen reducing activity of the obtained catalyst are increased by 10.8 times and 8.7 times in maximum respectively in comparison to the mass ratio and activity of a commercial JM4100Pt / C catalyst.

Owner:SOUTH CHINA UNIV OF TECH

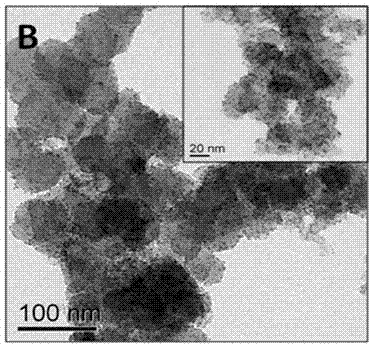

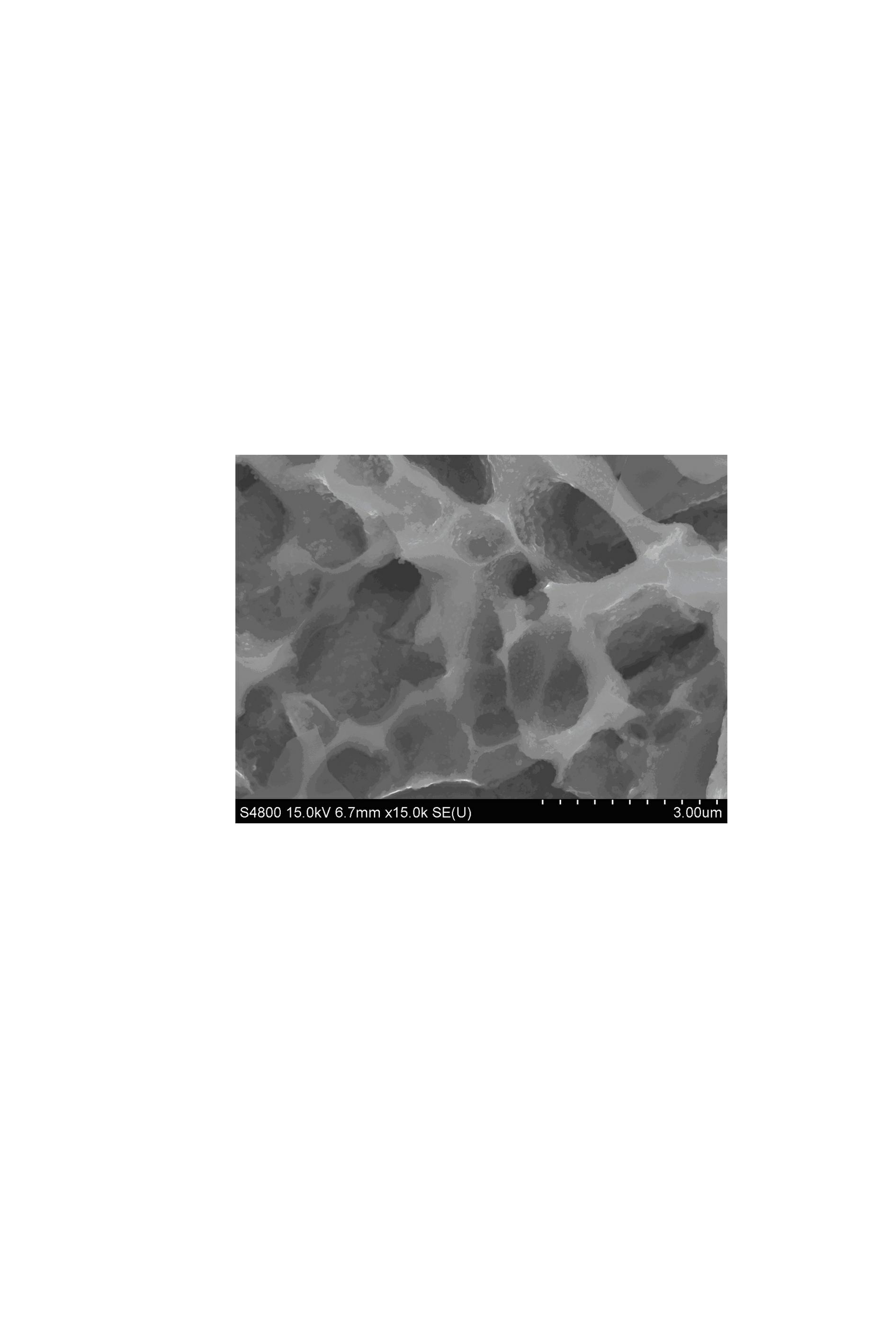

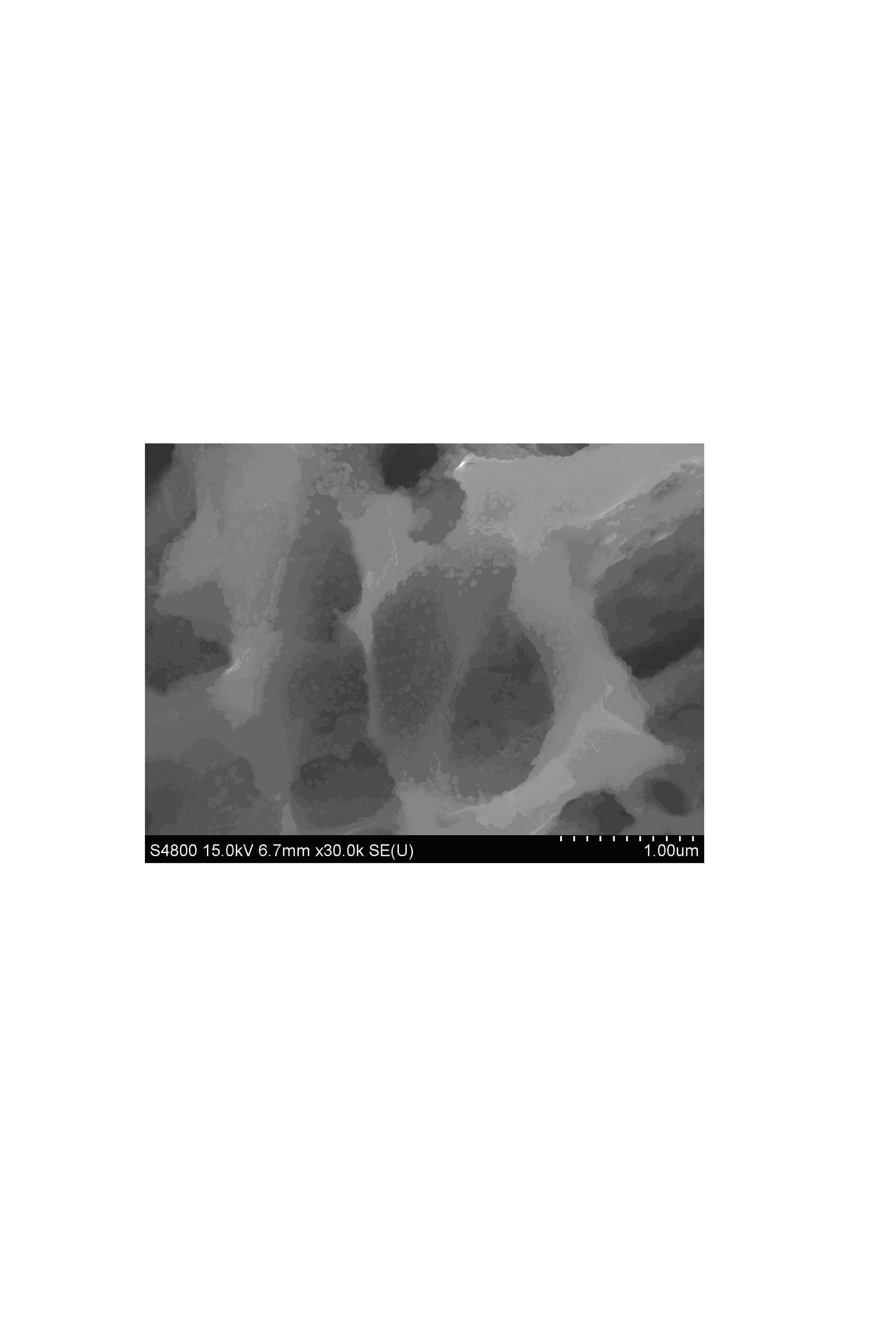

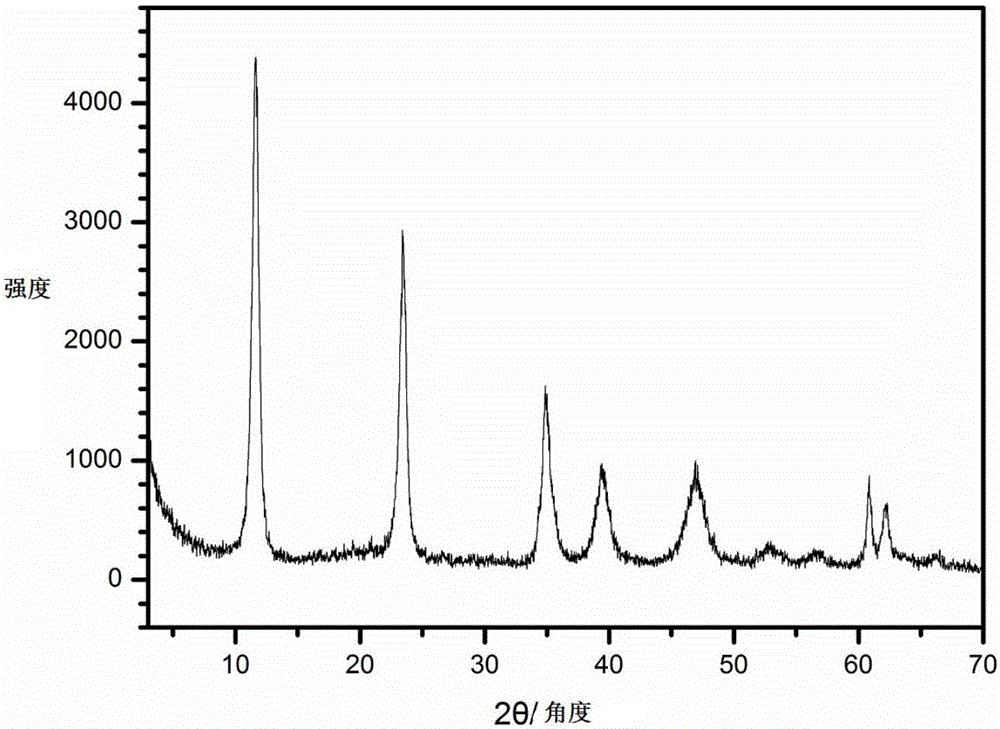

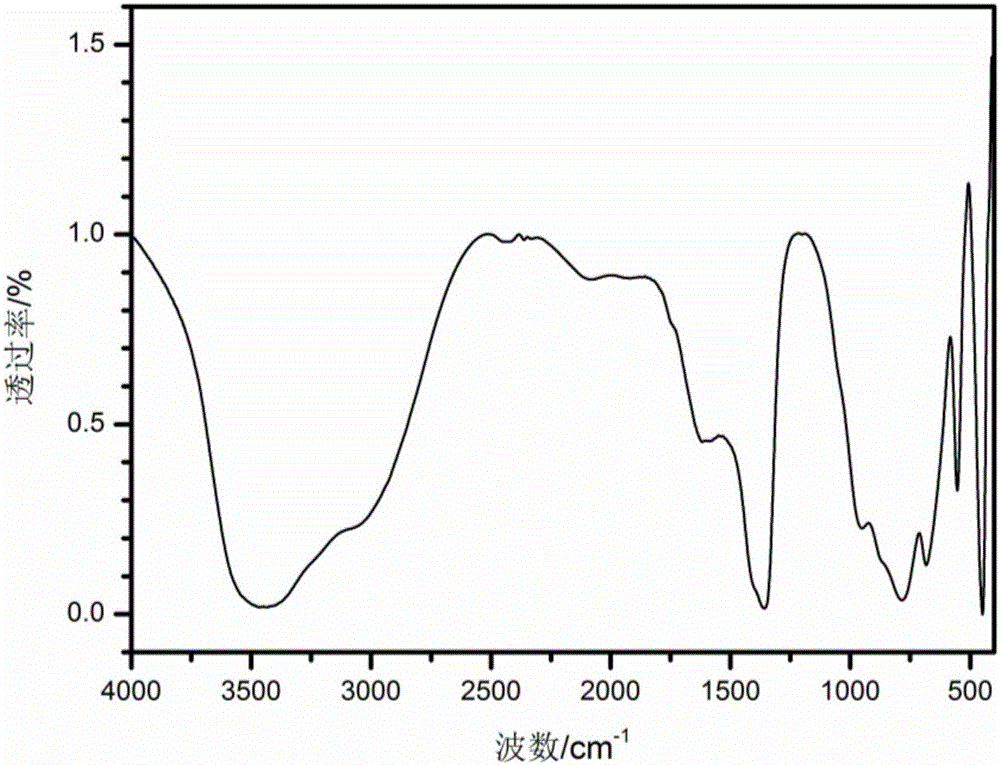

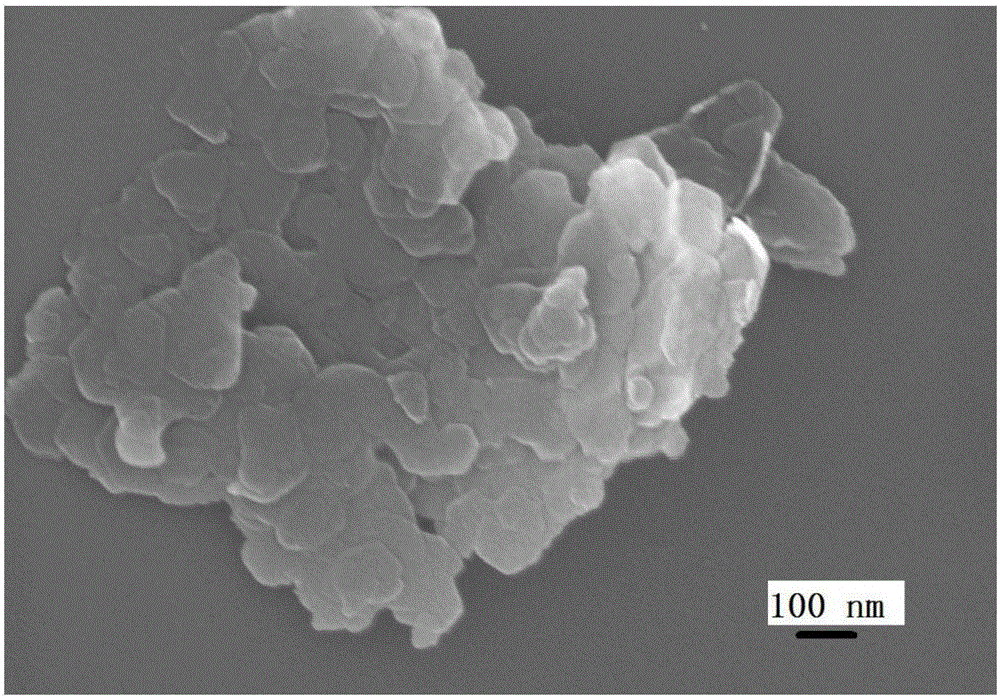

Nanometer perovskite/graphene composite material and preparation method thereof

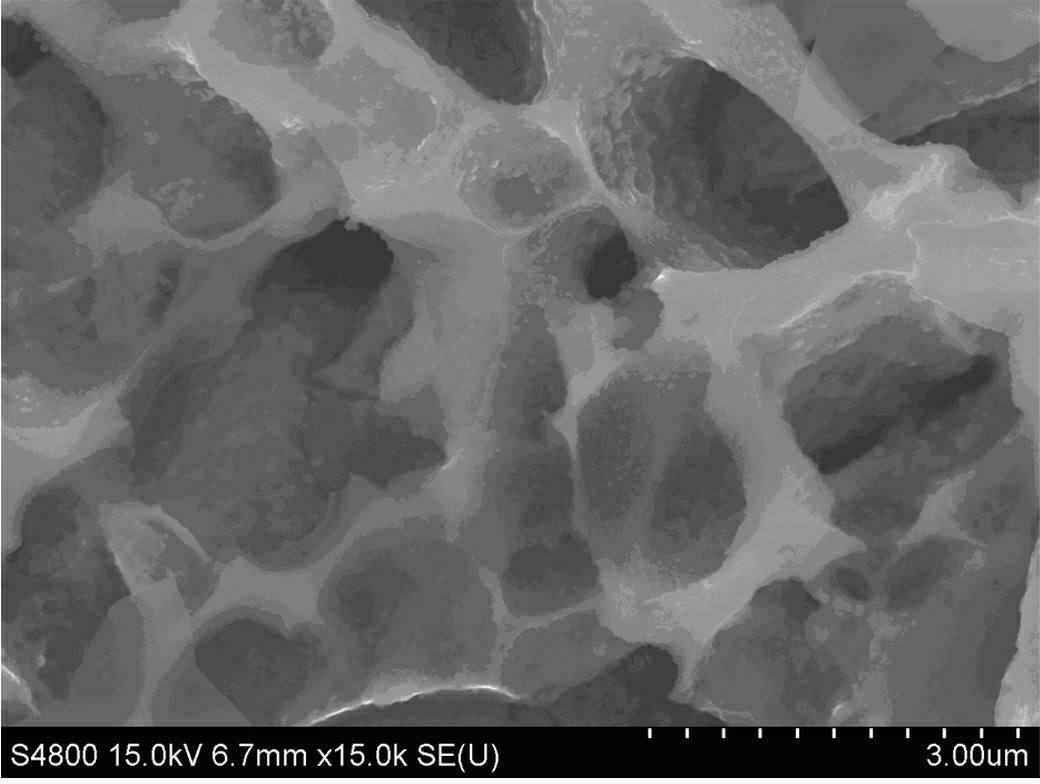

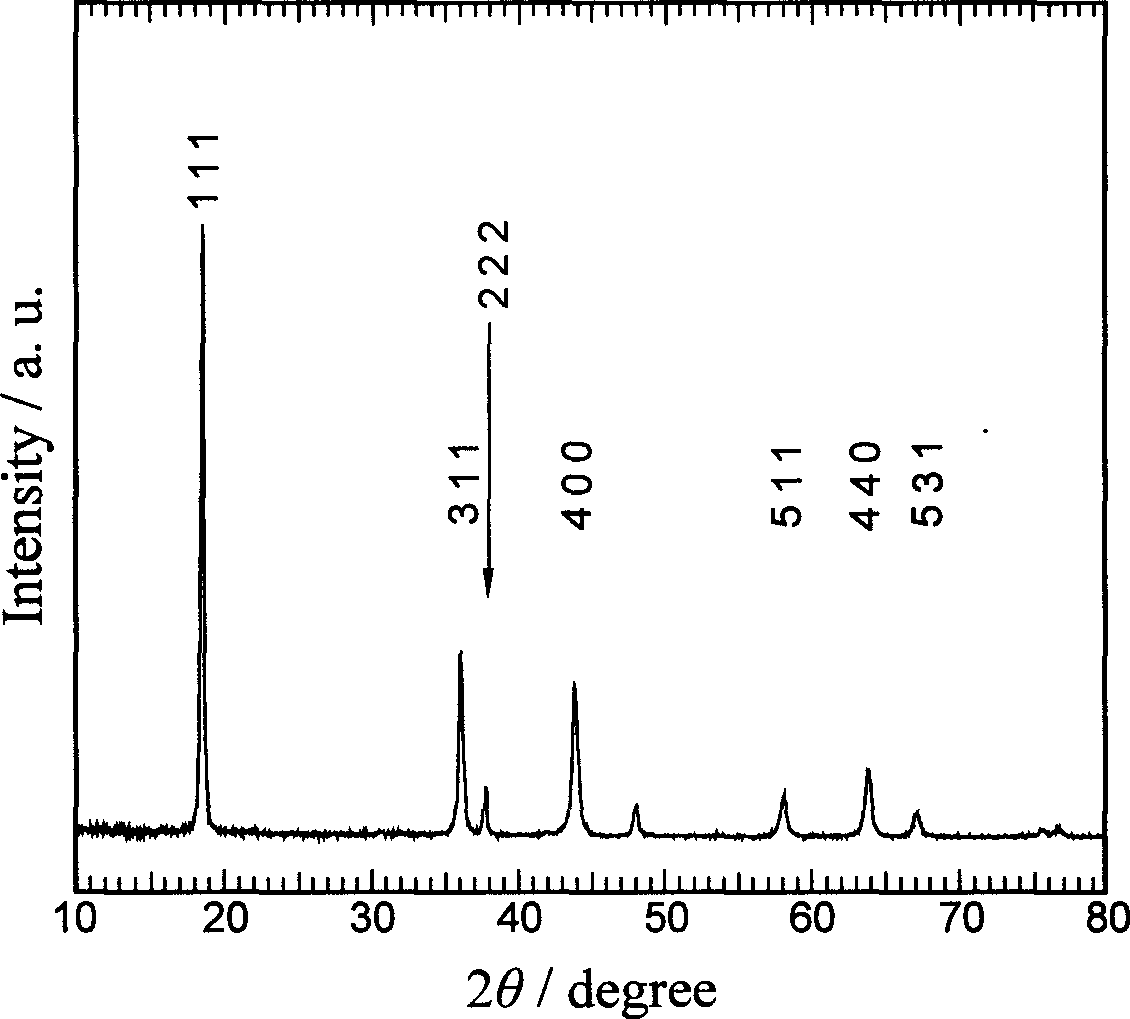

The invention relates to a nanometer perovskite / graphene composite material. The nanometer perovskite / graphene composite material is of a porous structure, the aperture of the nanometer perovskite / graphene composite material is about 0.5-1.5 microns, nanometer perovskite particles are distributed uniformly on a graphene film, and the average crystallite dimension of the composite material is about 10-20nm. A preparation method of the nanometer perovskite / graphene composite material comprises the following steps of: with graphite paper as an anode, a carbon rod as a cathode and concentrated sulfuric acid as an electrolyte, carrying out oxidation peeling to prepare a thin-layer graphene material, and then preparing graphene suspension from the thin-layer graphene material; adding nitrate and citric acid to the graphene suspension to enable the metal nitrate to be hydrolyzed to form sol, polymerizing the sol to form gel, finally drying and baking the gel to obtain the nanometer perovskite / graphene composite material. The preparation method disclosed by the invention has the advantages of simple process and low cost; and the nanometer perovskite / graphene composite material disclosed by the invention has good chemical uniformity; in addition, a reaction process is easy to control, and nanometer perovskite particles are more uniformly distributed on the graphene film and have smaller particle sizes, thus the nanometer perovskite / graphene composite material prepared by the method disclosed by the invention has excellent electro-catalysis performances and is suitable for being taken as an electro-catalysis material of a fuel cell.

Owner:YANSHAN UNIV

Rare-earth doped low-temperature denitration catalyst and preparation method thereof

ActiveCN103055848ALow running costLow retrofit costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRare earthSlurry

The present invention relates to a rare-earth doped low-temperature denitration catalyst and a preparation method thereof. The main active component of the catalyst is manganese oxide, the carrier is titanium oxide, and cerium oxide and iron oxide are used as cocatalysts. The preparation method includes the following steps: adding solutions of various metal nitrates into a metatitanic acid slurry, then adjusting the pH of the mixture to obtain complete precipitation by using concentrated ammonia, stirring for a while, and performing centrifugal filtration to the resulting suspension, and drying and calcining at a temperature to obtain the rare-earth doped low-temperature denitration catalyst; wherein the molar ratio of each element is as follows: Mn: Fe: Ce: Ti = 5: (0 ~ 2): 4:20. In the temperature range of 140-180 DEG C, the denitration activity of the metal oxide low temperature catalyst of the present invention can reach 80-98%, and the catalyst has a relatively excellent water and sulfur resistance performance.

Owner:ZHEJIANG HAILIANG ENVIRONMENTAL MATERIALS

Substituted basic metal nitrates in gas generation

A material for a pyrotechnic composition and related pyrotechnic compositions are provided in which the material includes a substituted basic metal nitrate including a reaction product of an acidic organic compound and a basic metal nitrate. A method for enhancing a burn rate of a gas generant composition and a burn rate enhanced gas generant composition including a reaction product of basic metal nitrate and tetrazoles, tetrazole derivatives, and combinations thereof, and a nitrogen-containing co-fuel such as guanidine nitrate are also disclosed. The burn rate enhance gas generant composition may optionally include an additional oxidizer such as basic copper nitrate.

Owner:AUTOLIV ASP INC

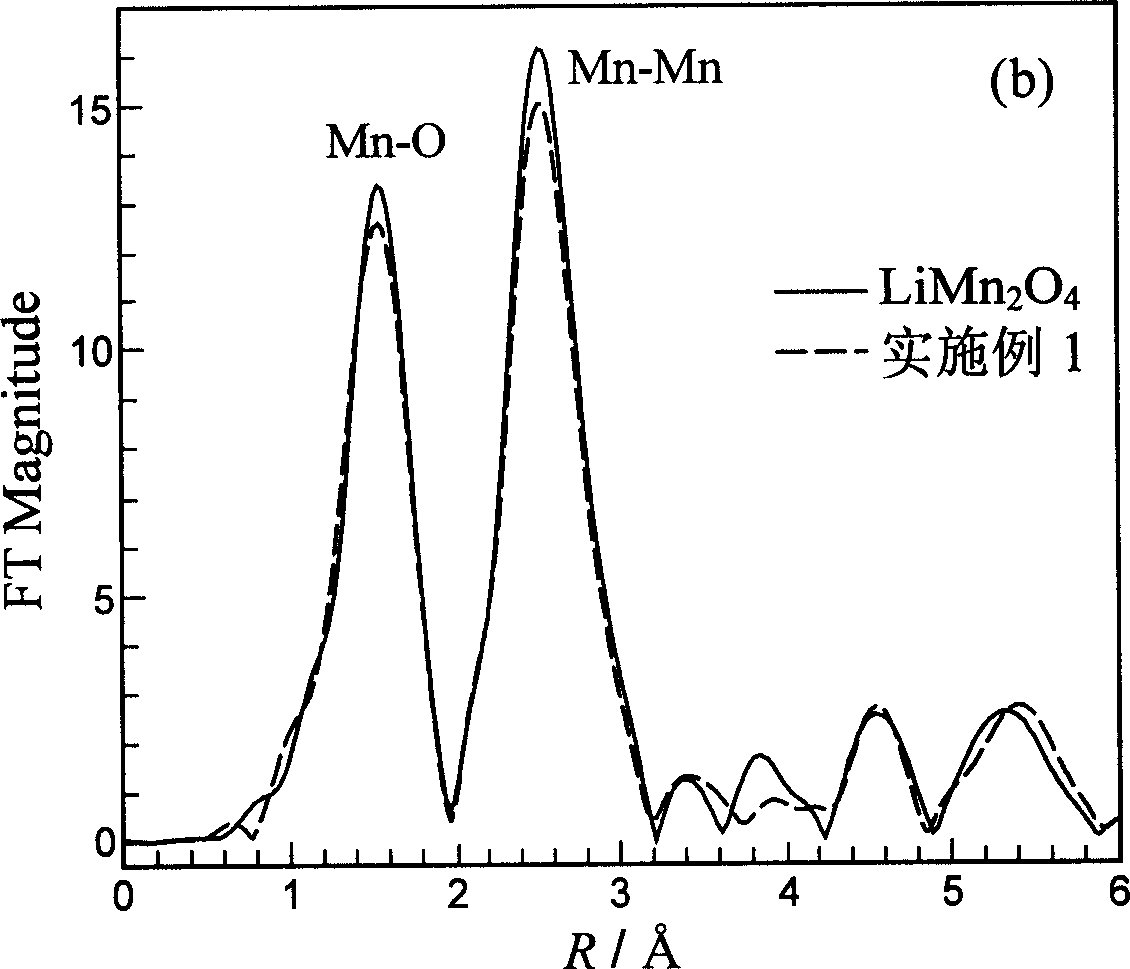

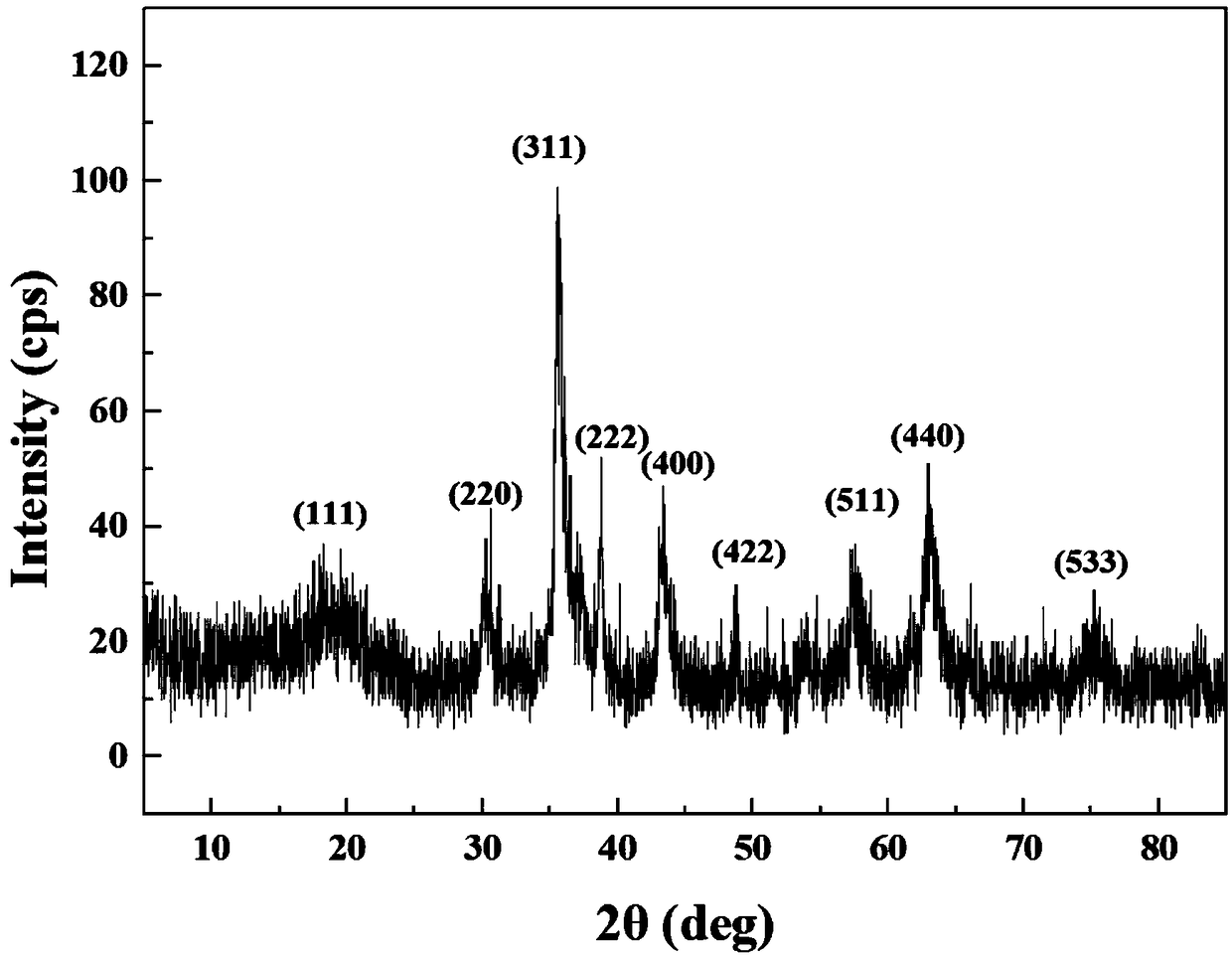

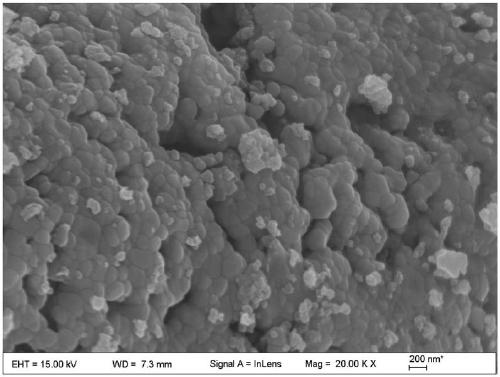

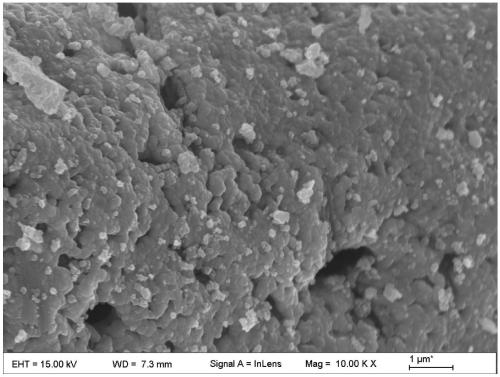

Surface modified positive pole material of lithium ion cell and preparation method thereof

InactiveCN1731605ALow costCoated evenlyElectrode manufacturing processesLithium compoundsMetal nitrateMolten salt

The invention relates to a lithium battery anode material and method for making same. The said anode comprises base material and surface modification layer or surface coating layer or both of them. The inventive method comprises steps of mixing metal nitrate or other low melting point molten salt with anode material base material; rising temperature 1 to melting the salt and forming perfect lubrication and coating on the surface of base particles; decomposing the salts into oxide in temperature 2 and coating on the base material surface, diffusing into the internal part of particles to form surface modification layer. The invention has the advantages of protecting anode material resolving and phase-change in electrolytic solution.

Owner:ZHEJIANG UNIV

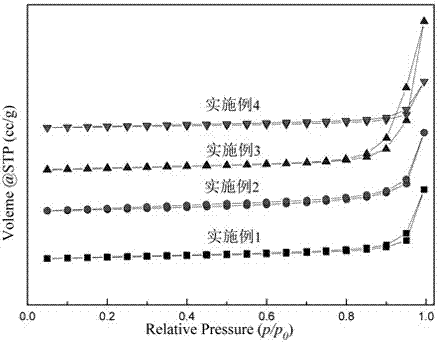

Preparation method of lithium ion battery negative electrode material spinel porous high-entropy oxide material

ActiveCN109052491AGood dispersionGood chemical uniformityChemical industryNegative electrodesAdditive ingredientSynthesis methods

The invention discloses a preparation method of a lithium ion battery negative electrode material spinel porous high-entropy oxide material, and belongs to the field of inorganic oxide powder materials. The method is a low-temperature combustion synthesis method, and specifically includes the steps that metal nitrate is adopted as a metal source, one or a mixture of several of tartaric acid, citric acid, glucose, hexamine and ethylenediaminetetraacetic acid is used as a fuel, and by controlling the concentration of the metal salt raw material, the kind and the amount of the fuel, the kind andthe amount of a combustion improver and an ignition mode, characteristics of the grain size, the shape and the like of spinel ransition metal high-entropy oxide nano-powder are adjusted and controlled. According to the preparation method of the lithium ion battery negative electrode material spinel porous high-entropy oxide material, liquid-phase ingredients are adopted, molecular-level even mixing of the raw materials is ensured, and a stoichiometric ratio of the product is achieved; meanwhile the preparation method of the lithium ion battery negative electrode material spinel porous high-entropy oxide material has the advantages of being energy-saving, high in production efficiency, environmentally friendly, free from complex post-treatment and the like, and the prepared high-entropy oxide powder is high in purity, small in grain size and even in distribution, and has high initial discharge capacity and good cycle performance.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

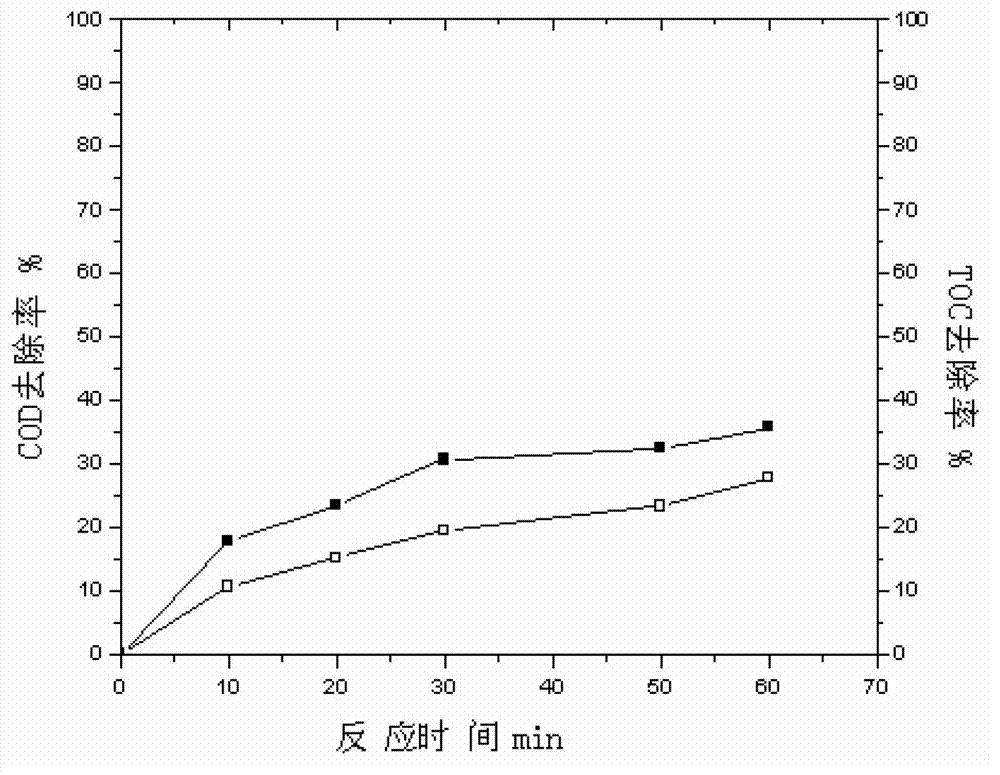

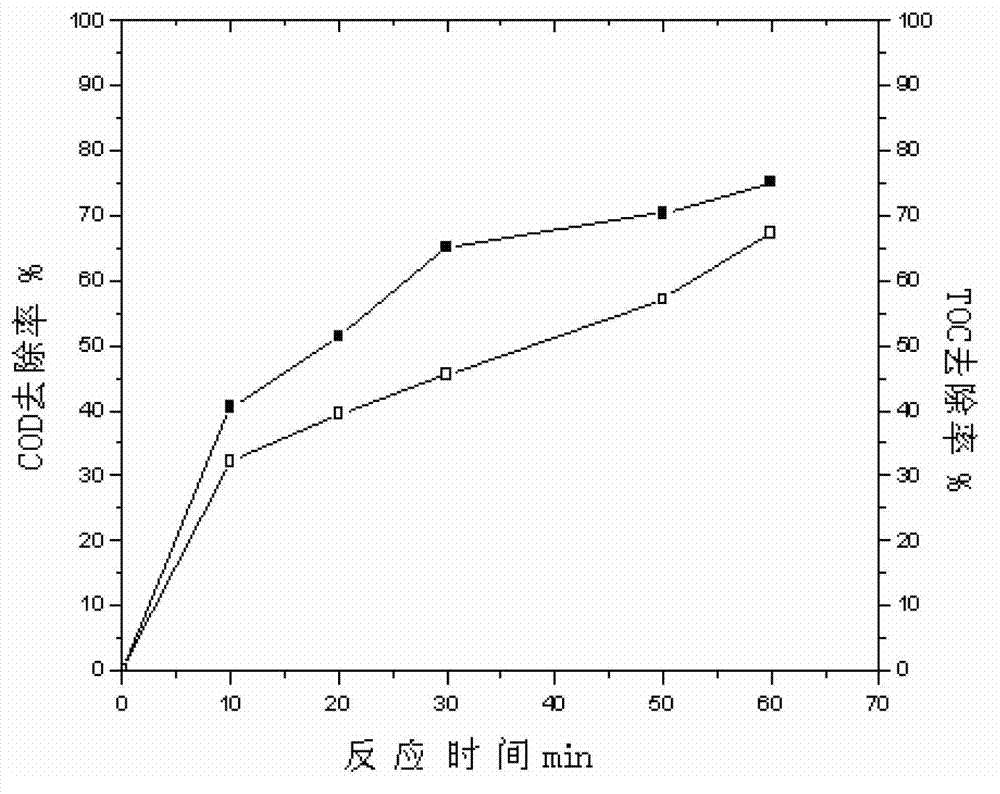

Preparation method of catalyst for catalyzing ozonation for advanced treatment of coal chemical wastewater

InactiveCN103111290AReduce pollution pressureLarge specific surface areaCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsSolubilityHazardous substance

The invention discloses a preparation method of a catalyst for catalyzing ozonation for advanced treatment of coal chemical wastewater and relates to a preparation method for the catalyst. The preparation method is used for solving the technical problems that the existing ozonation method is poor in ozone water solubility and low in degradation rate, successfully applied to the advanced treatment of the coal chemical wastewater, and capable of removing the degradation-resistant hazardous substances in water, improving the biodegradability of the wastewater and enabling the quality of the outlet water to reach the first-grade national emission standards. The preparation method comprises the following steps of: firstly, washing active carbon particles; secondly, soaking the active carbon in a metal nitrate solution, shaking for mixing and reacting, and taking out the active carbon 12 hours later; and thirdly, drying the active carbon and putting the dried active carbon to a muffle furnace, heating the muffle furnace to 200 DEG C by adopting nitrogen gas as the protective gas, roasting for one hour, continuing heating the muffle furnace to 600 DEG C and roasting for 3 hours at 600 DEG C to obtain the catalyst for treating the coal chemical wastewater. By using the catalyst prepared by the preparation method disclosed by the invention, the utilization rate of ozone is greatly improved, and the catalyst is very suitable for the field of coal chemical wastewater treatment.

Owner:HARBIN INST OF TECH

Preparation method of spinel-type porous high entropy oxide material

ActiveCN108821351AAchieving a stoichiometric ratioReduce energy consumptionMaterial nanotechnologyNickel compoundsHexamethylenetetramineSynthesis methods

Belonging to the field of inorganic oxide powder materials, the invention discloses a preparation method of a spinel-type porous high entropy oxide material. The method is low temperature combustion synthesis method. Specifically, a metal nitrate is adopted as the metal source, one of or a mixture of several of citric acid, ethylenediamine tetraacetic acid, hexamethylenetetramine and glucose is adopted as the fuel, by controlling the concentration of the metal salt raw materials, the fuel type and adding amount, the combustion improver type and adding amount, and the ignition way, the granularity, morphology and other characteristics of the spinel-type transition metal high entropy oxide (CoCrFeMnNi)3O4 nanopowder can be regulated. The preparation method adopts liquid phase compounding toensure molecular level uniform mixing of the raw materials, and the product achieves stoichiometric ratio. At the same time, the method has the advantages of energy saving, high production efficiency,green and environmental protection, no need for complicated post-treatment and the like. The high entropy oxide powder prepared by the method provided by the invention has high purity and uniform particle size distribution.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Catalyst used for alcoholysis of urea for synthesizing propylene carbonate and preparation and application methods thereof

InactiveCN101979142AHigh catalytic activityHigh PC yieldOrganic chemistryPhysical/chemical process catalystsReaction temperatureCarbonate

The invention discloses a catalyst used for alcoholysis of urea for synthesizing propylene carbonate and preparation and application methods thereof. The catalyst consists of mixed metal carbonate of Pb-Zn, Pb-Mg, Pb-Cr, Zn-Mg, Zn-Cr or Mg-Cr, and is prepared by performing coprecipitation reaction on corresponding metal nitrate mixed solution and excessive sodium carbonate solution. The application method of the catalyst is that: the reaction pressure is the natural pressure, the reaction temperature is between 140 and 180 DEG C, the reaction time is 2 to 8 h, a molar ratio of a reactant urea and 1,2-propylene glycol is 1:1-1:20, and the adding amount of the catalyst is 0.5 to 6 weight percent. The catalyst has the advantages of high catalytic activity, low cost, long service life, simple process in the application process, environmental friendliness, mild reaction condition, small using amount of the 1,2-propylene glycol, high yield of the propylene carbonate and cheap and readily available raw materials, is easy to prepare and reaction can be performed at normal temperature and the like.

Owner:SOUTHEAST UNIV

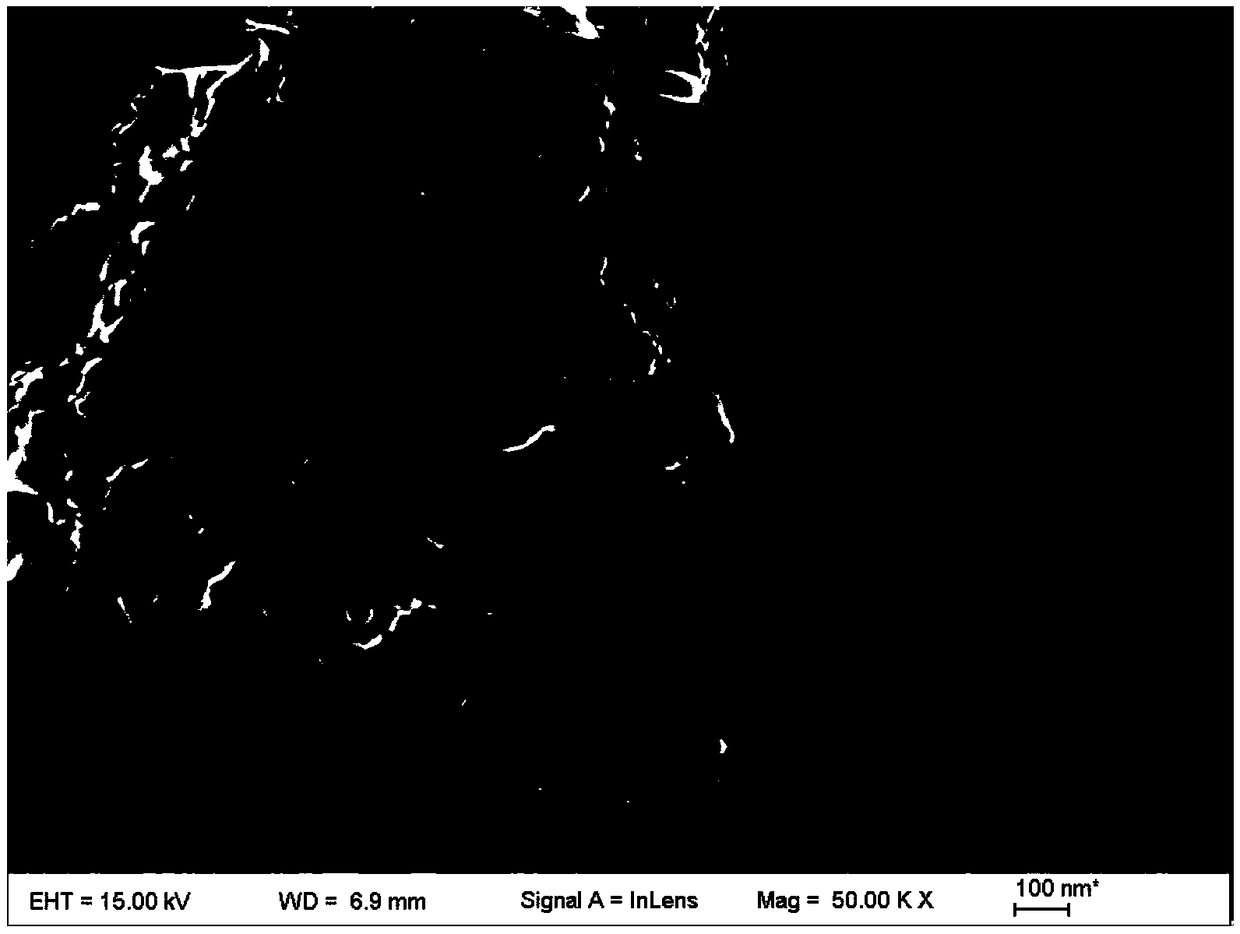

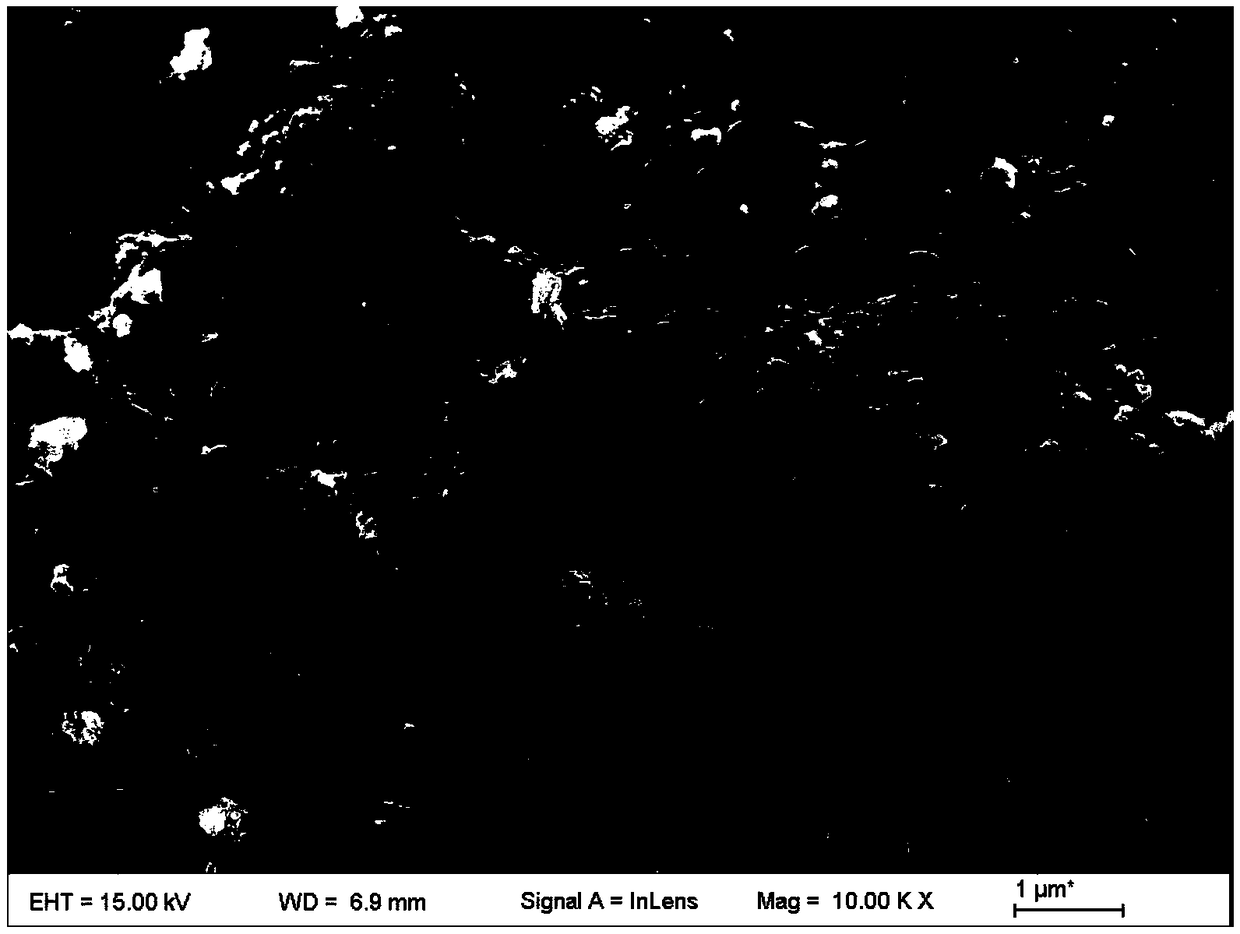

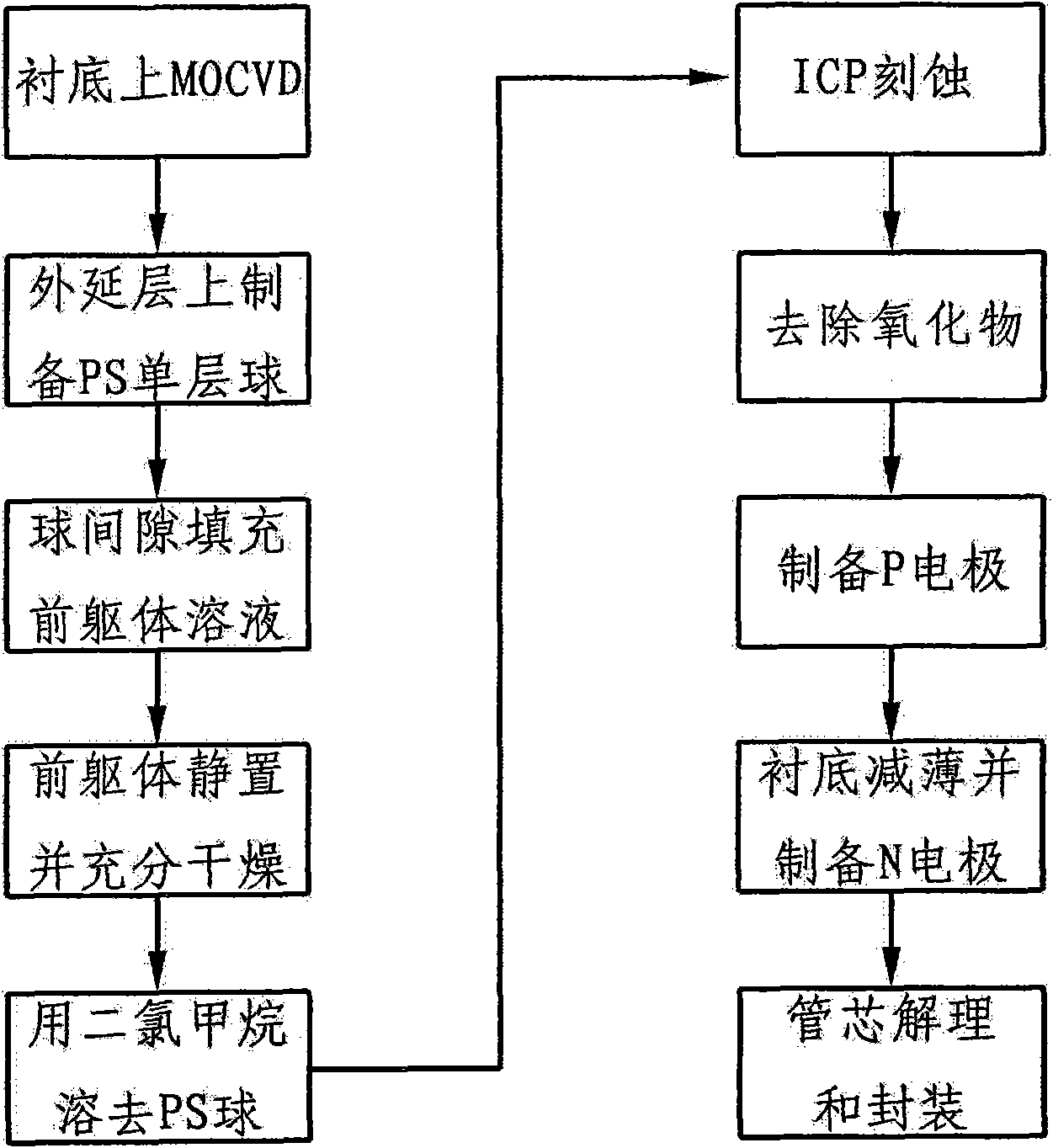

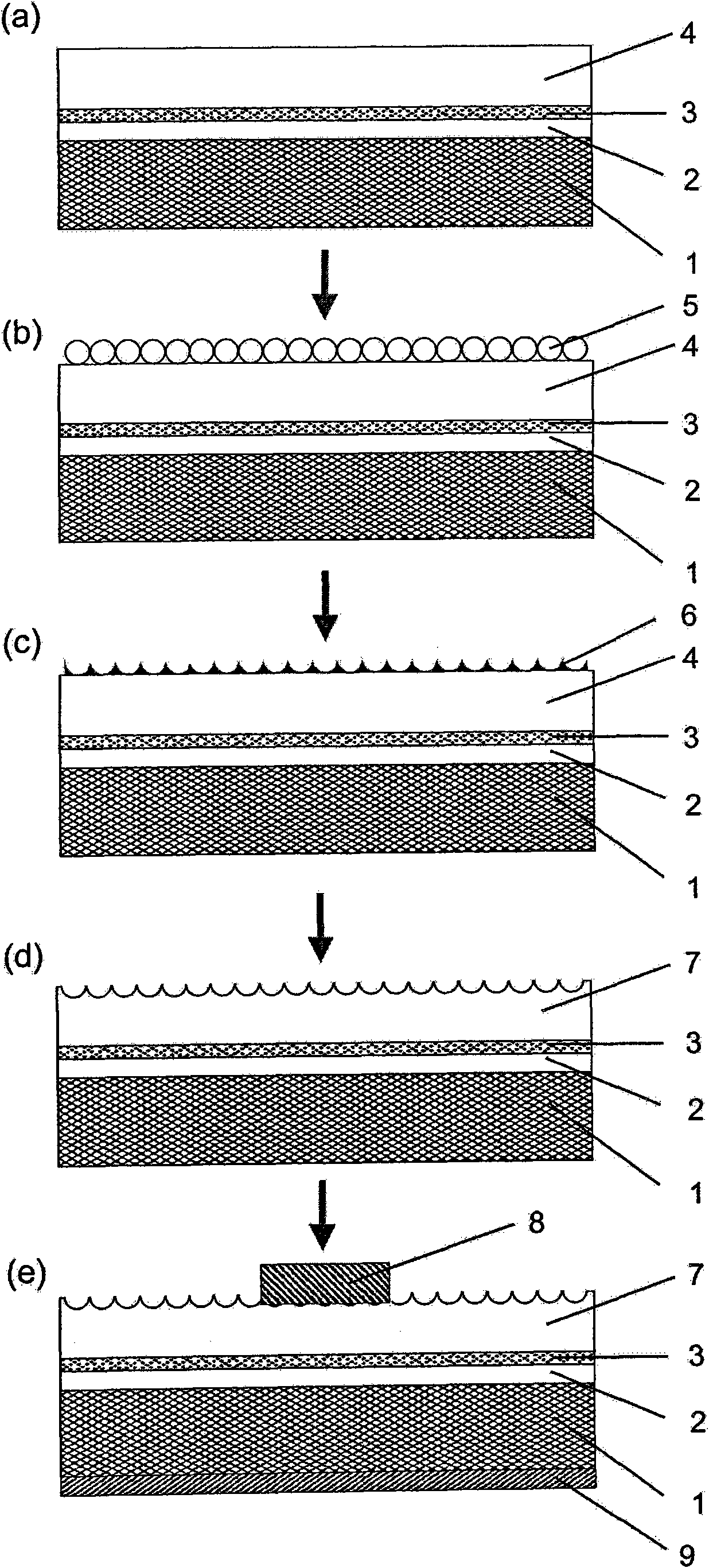

Method for preparing alligatored surface of light-emitting diode by using PS spheres as template

The invention provides a method for preparing an alligatored surface of a light-emitting diode by using PS spheres as template. The method comprises the following steps: (1) performing epitaxial growth according to the conventional method to prepare an epitaxial wafer; (2) paving a layer of one-layer film which comprises closely packed PS spheres on the P-type contact layer obtained through epitaxial growth; (3) mixing precursor which is tetraethyl silicate, metal chloride or metal nitrate with ethanol and water to fill in the gap of the PS spheres of the one-layer film and the P-type contactlayer, standing at room temperature, heating to decompose the mixture and obtain the related oxides; (4) placing the epitaxial wafer in dichloromethane to dissolve the PS spheres, preserving the formed oxides in the gap of the PS spheres and the P-type contact layer on the P-type contact layer according to bowl-shaped periodic arrangement structure; (5) using the formed oxides as mask to perform dry etching on the P-type contact layer and obtain the alligatored surface; and (6) corroding and removing the residual oxides. The invention can be used to prepare the alligatored surface of the light-emitting diode with controllable etching period and depth.

Owner:SHANDONG UNIV

Carrier style palladium amorphous alloy catalyst for hydrogenation of anthraquinone

InactiveCN1424145AHigh activityReduce loadMolecular sieve catalystsPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesRare-earth elementIce water

A carried non-crystal Pd alloy catalyst for hydrogenating anthraquinone to prepare H2O2 is prepared from the carrier which is one or two of gamma-Al2O3, alpha-Al2O3, MgO, activated carbon, molecular sieve and mullite, non-crystal PdB alloy and RE element through immersing the carrier in the solution of RE metal's nitrate under ultrasonic condition, calcining at 400-700 deg.C for 2-5 hr, immersing in PdCl2 solution, dropping KBH4 solution in ice water bath, and washing. Its advantages are high catalytic activity and low cost.

Owner:TIANJIN UNIV

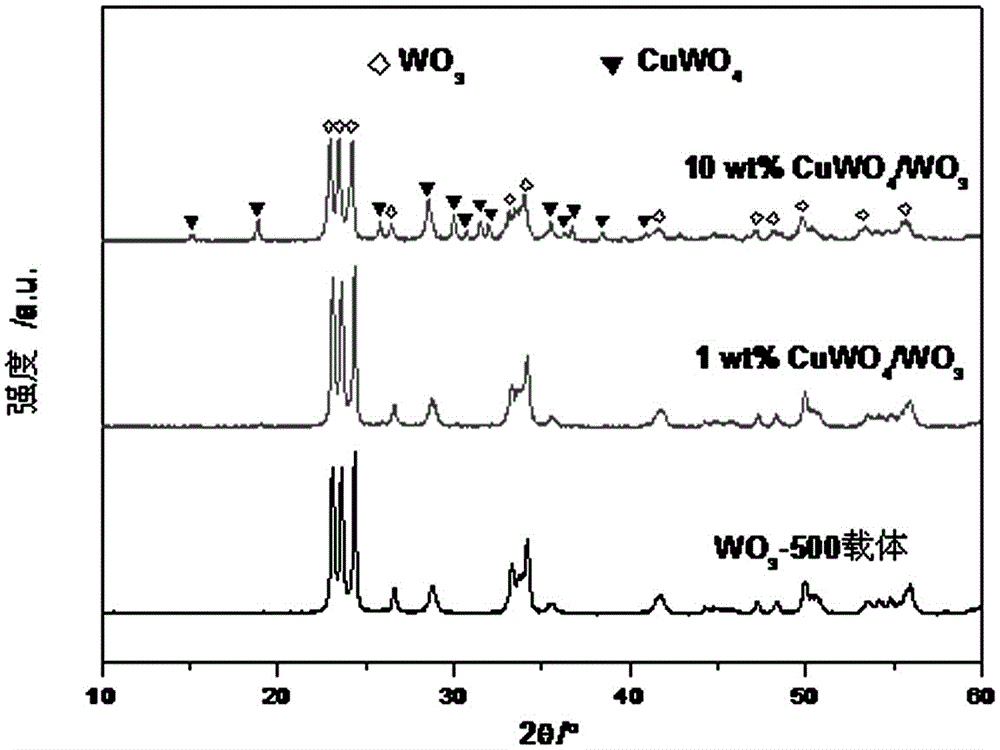

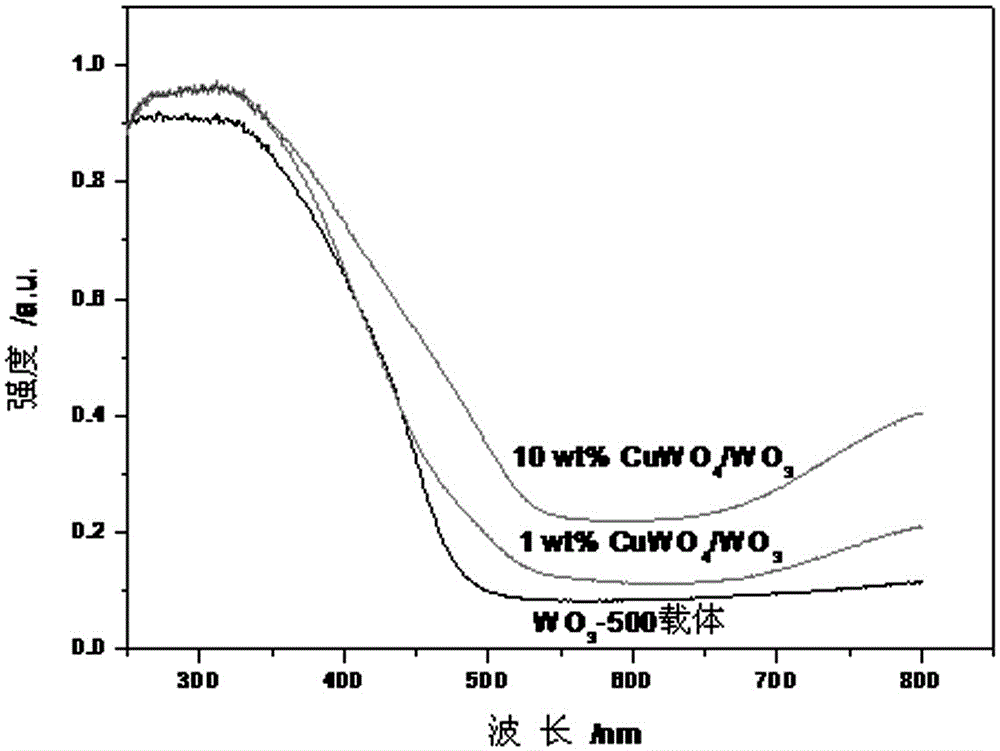

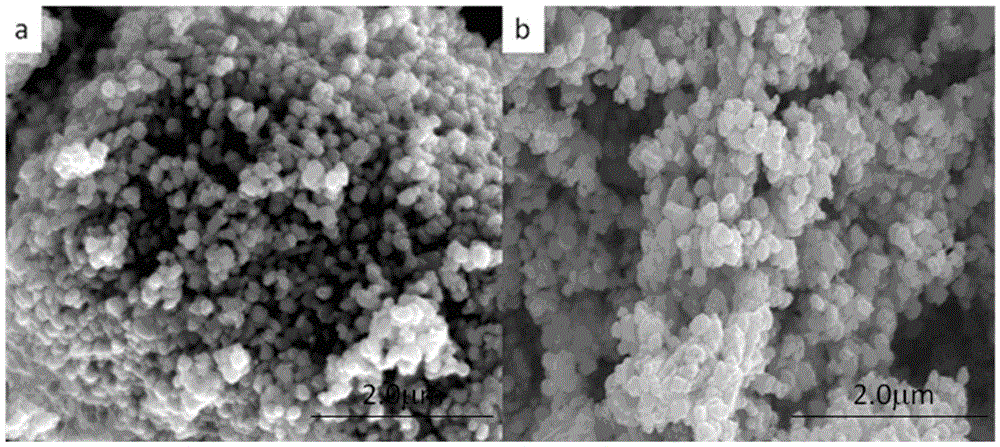

Method for synthetizing tungstate/tungsten oxide heterojunction photocatalyst in situ

InactiveCN105107519AEfficient separationTo overcome the shortcoming of high compounding efficiencyMetal/metal-oxides/metal-hydroxide catalystsHeterojunctionMetal nitrate

The invention relates to a method for synthetizing a tungstate / tungsten oxide heterojunction photocatalyst in situ. The method comprises the following steps that WO3 is prepared or externally purchased to serve as a carrier; 2, a metal nitrate solution is prepared; 3, the WO3 is dipped in the metal nitrate solution; 4, bath drying and roasting are performed on a mixture obtained in the step 3, metal nitrate is decomposed to obtain a metal oxide (MO) in the roasting process, the MO reacts with the WO3 to generate MWO4, the MWO4 is loaded on the WO3 carrier in situ, and the MWO4 / WO3 hetorojuncton photocatalyst is formed. According to the method, the MWO4 / WO3 hetorojuncton photocatalyst is synthetized in situ, the used raw materials are low in cost, the preparation process is easy to operate, the high pressure condition and special equipment are not needed, the technology is simple, and the preparation cost is low.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

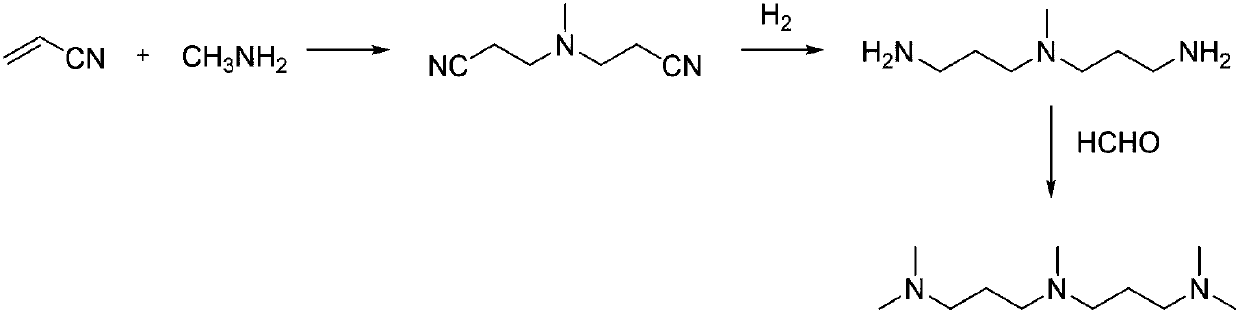

Metal supported MOFs catalyst as well as preparation method and application thereof to PMDPTA synthesis

ActiveCN107774331AEasy to prepareStable structureCarboxylic acid nitrile preparationOrganic compound preparationMetal chlorideMetal nitrate

The invention provides a metal supported MOFs catalyst as well as a preparation method and application thereof to PMDPTA synthesis and specifically relates to the technical field of catalysts. The catalyst comprises a carrier and an active component; the carrier is an MOFs material; and the active component is single metal or a composite metal particle. The catalyst is prepared by using an excessimpregnation method comprising the steps: stirring at least one solution in metal chloride or metal nitrate and the MOFs material at room temperature for 24h, and carrying out suction filtration to obtain a catalyst precursor; and making the catalyst precursor and a reducing agent generate an effect to obtain the metal supported MOFs catalyst. The preparation method of the catalyst has the advantages such as simple preparation process and stable structure. The catalyst is used for synthesizing PMDPTA and has the advantages such as low cost, high product yield, greenness and environment friendliness.

Owner:ZHENXING FINE CHEM CO LTD

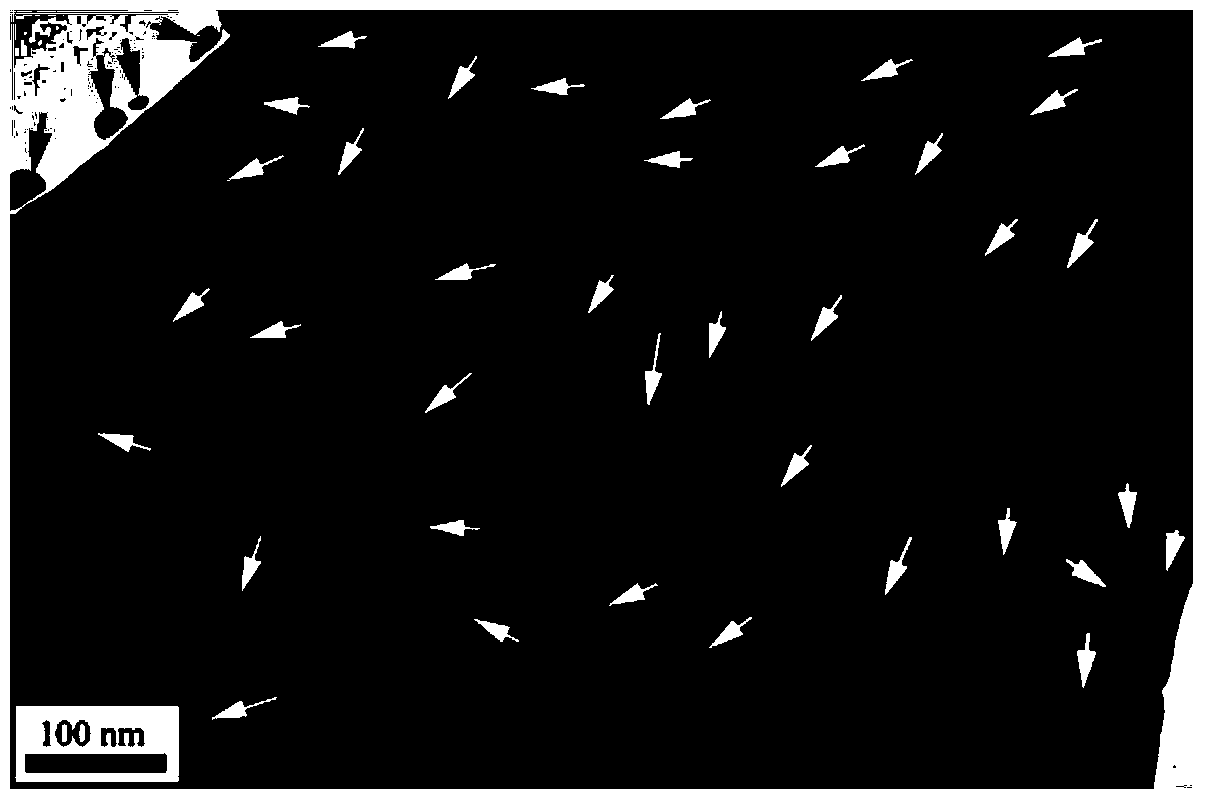

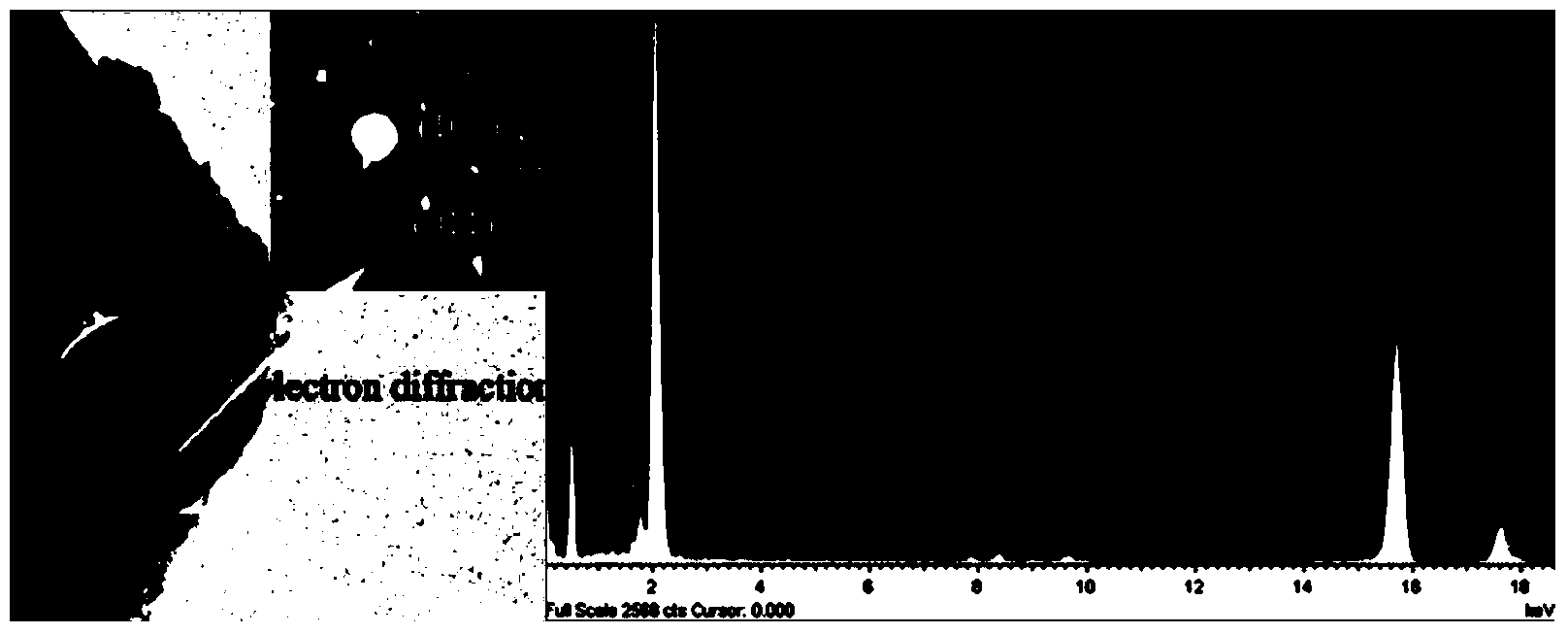

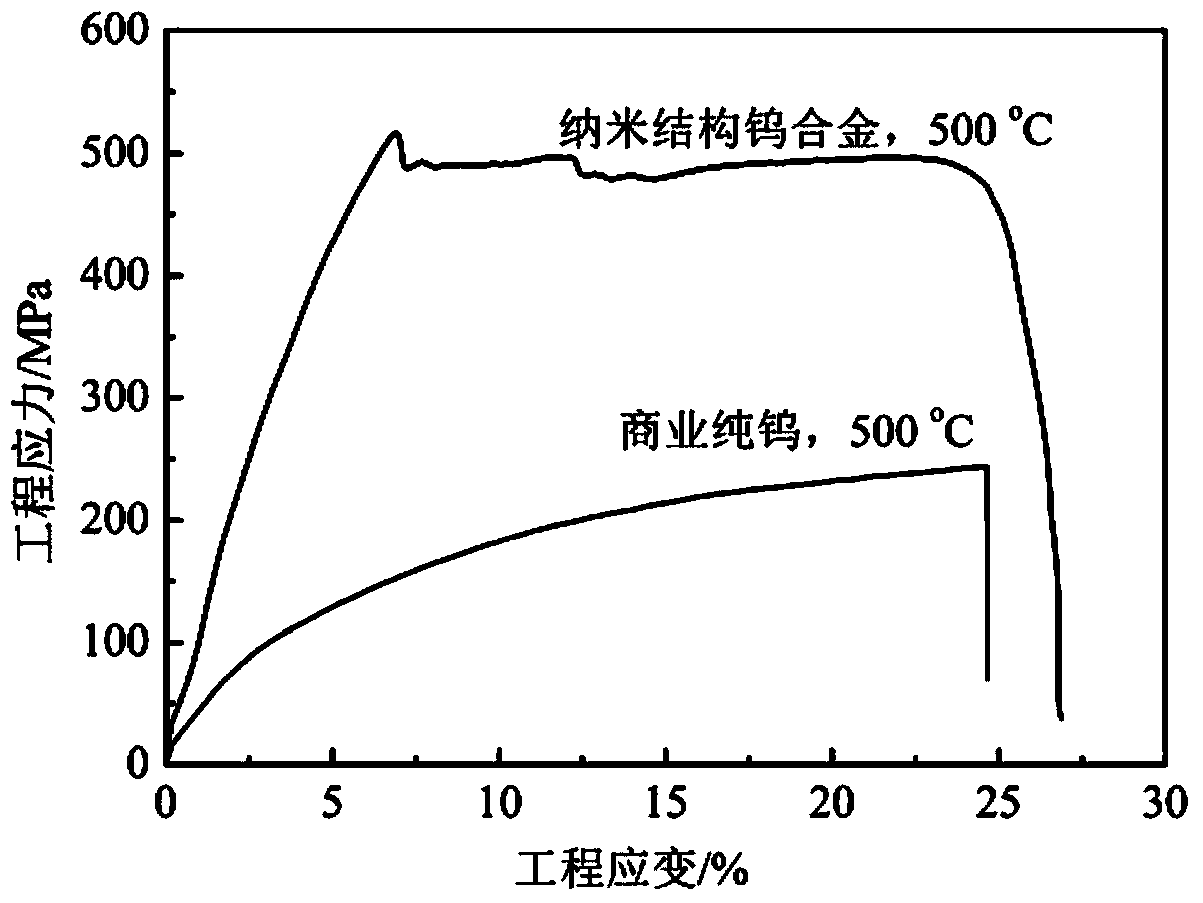

Nanostructure tungsten alloy and preparation method thereof

The invention discloses nanostructure tungsten alloy and a preparation method thereof. The alloy mainly comprises tungsten, and also comprises 0.05 to 1.0wt percent of zirconium and 0.2 to 2.0wt percent of rare-earth metal oxide particles, wherein the rare-earth metal oxide particle adopts yttrium oxide particles, lanthanum oxide particles or cerium oxide particles distributed in tungsten crystal particle. The method comprises the steps of firstly preparing ammonium paratungstate, rare-earth metal nitrate, citric acid and deionized water into transparent mixed liquor, stirring the transparent mixed liquor, obtaining gel after reaction, heating and drying the gel, then calcining the gel, so as to obtain a mixed powder of tungsten oxide and rare-earth metal oxide, putting the mixed powder into hydrogen atmosphere, so as to obtaining a mixed powder of tungsten and rare-earth metal oxide after reduction reaction, mixing the mixed powder with zirconium and zirconium hydride powder, so as to obtain a mixed powder of tungsten, zirconium, or zirconium hydride, and rare-earth metal oxide, and finally performing compaction and sintering to the mixed powder, so as to obtain the nanostructure tungsten alloy. The nanostructure tungsten alloy can be applied to fields of lighting, high-temperature components, aerospace devices, high temperature resistance containers and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Metal complexes for use as gas generants

InactiveUS20100084060A1Improve crush strength and other mechanical propertyEfficient combustionInorganic oxygen-halogen salt explosive compositionsNitrated metallo-organic explosive compositionsMetal nitrateHydrogen

Gas-generating compositions and methods for their use are provided. Metal complexes are used as gas-generating compositions. These complexes are comprised of a metal cation template, a neutral ligand containing hydrogen and nitrogen, and sufficient oxidizing anion to balance the charge of the complex. The complexes are formulated such that when the complex combusts, nitrogen gas and water vapor is produced. Specific examples of such complexes include metal nitrite amine, metal nitrate amine, and metal perchlorate amine complexes, as well as hydrazine complexes. A binder and co-oxidizer can be combined with the metal complexes to improve crush strength of the gas-generating compositions and to permit efficient combustion of the binder. Such gas-generating compositions are adaptable for use in gas-generating devices, such as automobile air bags.

Owner:NORTHROP GRUMMAN INNOVATION SYST INC

Composite rear earth pyrochlore-type oxide catalyst for catalyzing burning for removing soot of diesel vehicle and preparation method thereof

InactiveCN101879445AHigh selectivityThe synthesis process is simpleDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRare earthPyrochlore

The invention provides a composite rear earth pyrochlore-type oxide catalyst for catalyzing burning for removing soot of a diesel vehicle and a preparation method thereof, belonging to the technical field of a tail gas cleaning catalyst of the diesel vehicle. The expression formula of the composite metal oxide is A2B2-xMxO7, wherein A is La, B is Sn, M is Mn, Fe, Co, Ni or Cu. The invention adopts a coprecipitation method to prepare the catalyst, the preparation process is simple, and the cost is low. The preparation method comprises the following steps: mixing metal nitrate and tin tetrachloride solution; adjusting the pH value by ammonia solution; drying the obtained deposit; and roasting the deposit at the high temperature to obtain the composite rear earth pyrochlore-type oxide catalyst. Under the effect of the catalyst, a simulation diesel vehicle exhausts, the burning temperature of the soot particles is lowered to the exhaust range of the diesel vehicle, and the speed of the soot oxidation rate is improved. The catalyst is a useful catalyst for removing the pollution of soot particles of the diesel vehicle.

Owner:UNIV OF JINAN

Preparation method of LDHs (magnesium-based layered double hydroxides)

ActiveCN105753022ARich sourcesLow priceAluminium-carbonate compoundsZinc compoundsMagnesium saltCalcium magnesium

The invention provides a preparation method of LDHs (magnesium-based layered double hydroxides). According to the method, calcium oxides or calcium magnesium oxides are used as an alkali source, calcium oxides or calcium magnesium oxides and a magnesium salt are subjected to a precipitation reaction, magnesium hydroxide precipitates are produced, then the magnesium hydroxide precipitates and divalent and trivalent soluble metal nitrates or chlorides are used as raw materials, LDHs are prepared through a liquid-solid phase reaction, and byproducts, namely, magnesium chlorides or magnesium nitrates, can be used as raw materials. The method has the advantages that the raw materials are rich in source, the price is low, the preparation process is simple, reaction conditions are mild, industrial production is facilitated and the like, and prepared LDHs can be widely applied to fields of catalysis, adsorption, environmental protection, high-polymer plastic and the like.

Owner:BEIJING UNIV OF CHEM TECH

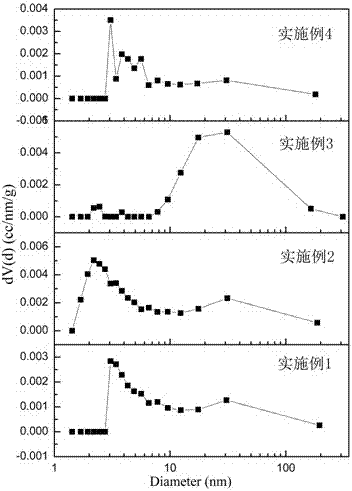

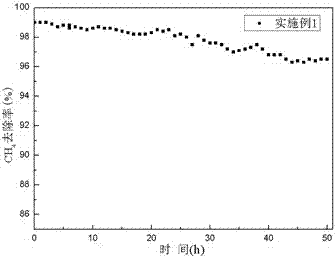

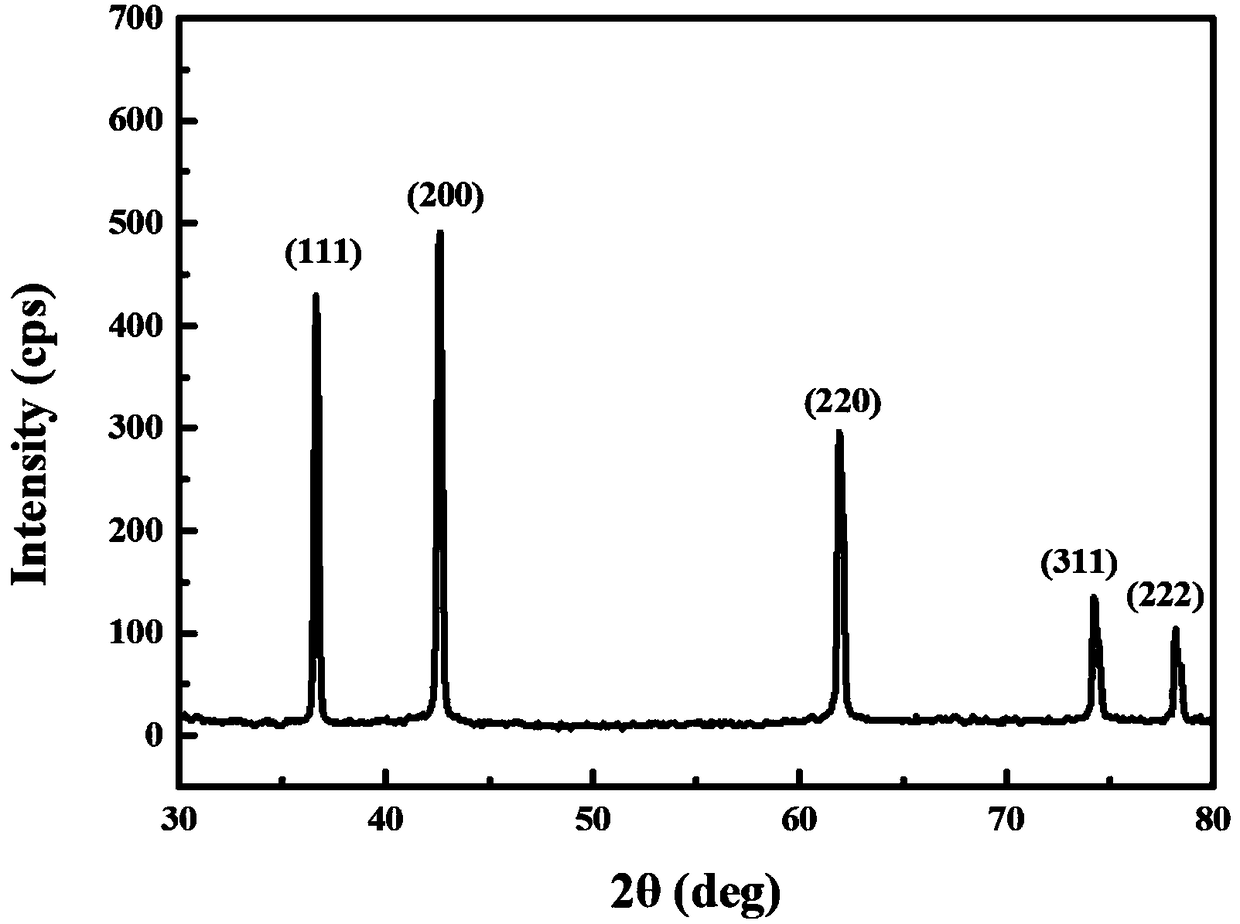

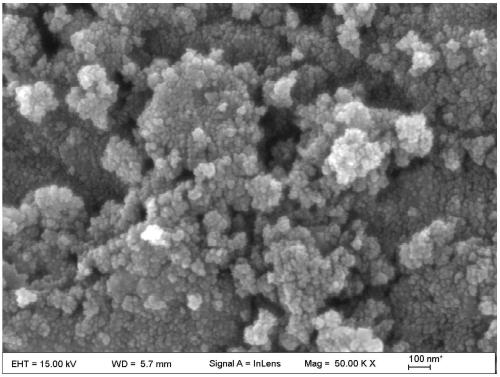

Preparation method for hierarchical pore perovskite catalyst

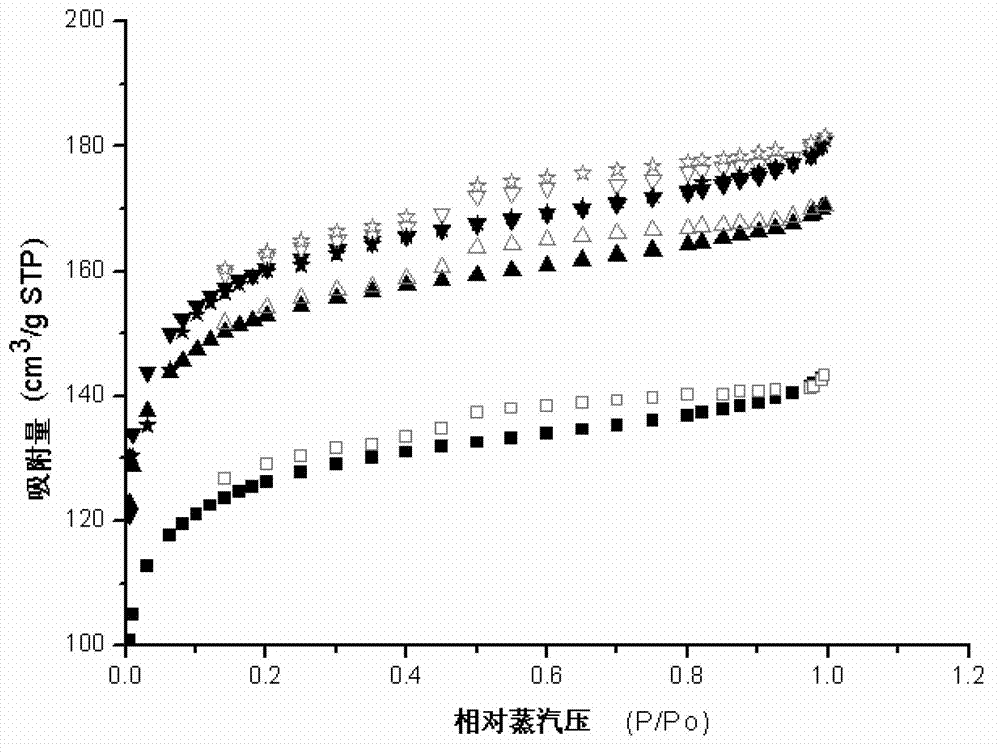

ActiveCN107376924AImprove adsorption capacityLarge specific surface areaGas treatmentMethane captureMetal nitrateNitrate

The invention relates to a preparation method for a hierarchical pore perovskite catalyst. The method comprises the following steps: 1) weighting metal nitrate mixture and complexing agent and mixing, wherein the mole number of the complexing agent is 1-2 times of the sum of the mole number of all the nitrate in the metal nitrate mixture; 2) adding the metal nitrate mixture and the complexing agent into deionized water and stirring under room temperature; 3) heating and stirring the acquired product at 60 DEG C-90 DEG C till forming a wet gel; 4) leaving the wet gel in a standby state, ageing, drying and grinding; 5) sintering for 5h at 800 DEG C; 6) reacting for 2-36h in a reaction kettle at 150-200 DEG C; 7) naturally cooling, filtering and drying; 8) sintering for 1-12h at 600 DEG C. The prepared catalyst has the advantages of excellent absorption property and large specific surface area.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Gas-generating agent composition comprising triazine derivative

InactiveUS20030024618A1Magnesium fertilisersPedestrian/occupant safety arrangementMetal nitrateCombustion

A gas generating composition for an air bag having a low toxicity, a high burning rate and a low combustion temperature is provided. It is a gas generating composition comprising (a) a triazine derivative, (b) a basic metal nitrate, and (c) a binder or (c) a binder and (d) an additive.

Owner:DAICEL CHEM IND LTD

Preparation method of rock salt type (MgCoCuNiZn)O high entropy oxide powder material

ActiveCN109019701AAchieving a stoichiometric ratioIncrease productivityCobalt compoundsSynthesis methodsMolecular level

Belonging to the field of high entropy oxide powder materials, the invention discloses a preparation method of a (MgCoCuNiZn)O high entropy oxide powder material with a rock salt type structure. The method is low-temperature combustion synthesis method, uses a metal nitrate as the metal source, and takes one or more of citric acid, tartaric acid and glucose with an appropriate carbon content as the fuel. The concentration of the metal salt raw material, the fuel variety and adding amount, the combustion improver variety and adding amount, and the ignition way are controlled to regulate the granularity, morphology and other characteristics of the high entropy oxide (MgCoCuNiZn)O nanopowder. According to the invention, the reactants exist in a solution, so that the raw materials in the solution can easily reach molecular level blending, and the product realizes a stoichiometric ratio. At the same time, the method provided by the invention has the advantages of energy saving, high production efficiency, simple and feasible process, green and environmental protection, no need for complex post-treatment, etc., and the prepared high entropy oxide powder has high purity and fine particlesize, and is uniformly distributed.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Preparation method of doped black titanium dioxide

ActiveCN107138161AFlexible Adjustment StructureFlexible adjustment of spectral responseMetal/metal-oxides/metal-hydroxide catalystsMetal nitrateFluoride

The invention provides a preparation method of novel doped black titanium dioxide. The method comprises the following steps: (1) a titanium oxide precursor is hydrolyzed, and after full washing, drying is carried out; (2) hydrolysate as well as metal nitrate, sulfide, fluoride, nitride and the like are fully mixed, and the materials are calcinated in an atmosphere furnace or a vacuum furnace at 300-800 DEG C for 2-15 hours. The products are fully washed and dried in order to obtain the doped black titanium dioxide. Doping with Fe, Mn, Sn, Ce and other metal cations as well as N, S, F and other anions are suitable for the method, the application range is wide, the process is simple, the cost is low, and the reaction conditions are simple.

Owner:上海友兰科技有限公司

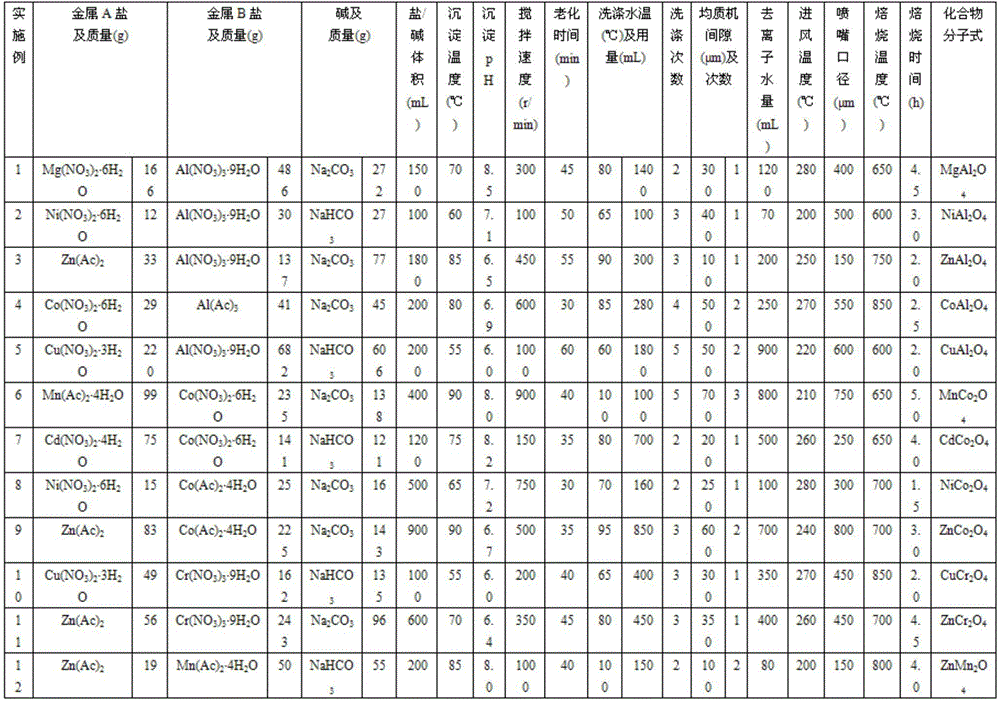

Method for preparing spinel-type complex oxide through co-precipitation, homogenization and spray drying

ActiveCN105417570AGuaranteed uniformityImprove purityZinc oxides/hydroxidesGallium/indium/thallium compoundsMetal nitrateNitrate

The invention belongs to the field of chemical engineering and relates to a preparation method of a spinel type material, in particular to a method for preparing a spinel-type complex oxide through co-precipitation, homogenization and spray drying. According to the method, a mixed solution of two metallic nitrates and an alkaline solution are combined and added to a precipitation tank for a reaction, an obtained material is washed by deionized water, filtered, subjected to beating and refined by a homogenizer and then is sent to a spray drying machine, the dried material is subjected to calcination, and the spinel-type complex oxide powder is obtained. The method has the advantages of low calcination temperature, short time and low energy consumption, and a product has low loss, high purity and small particle size.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Mesoporous metal oxide catalyst for photo-catalytic CO2 reduction and preparation method

InactiveCN104549412ALarge specific surface areaLarge pore volumeHydrocarbon from carbon oxidesMolecular sieve catalystsCerium nitratePtru catalyst

The invention discloses a mesoporous metal oxide catalyst for photo-catalytic CO2 reduction and a preparation method. The mesoporous metal oxide catalyst for the photo-catalytic CO2 reduction consists of an active component and a doping agent, wherein the active component is mesoporous CeO2, and the doping agent is transition metal ions. In the preparation process, transition metal nitrate and cerium nitrate are dissolved into acetone, mesoporous silica materials are added into an obtained metal nitrate acetone solution and are uniformly mixed, the mixture is naturally dried to obtain first powder, the first powder is calcined in a muffle furnace to obtain second powder, the second powder is etched by using a sodium hydroxide aqueous solution to remove the mesoporous silica materials, and the second powder is washed by using pure water and then is dried to obtain the mesoporous metal oxide catalyst for the photo-catalytic CO2 reduction, which has higher specific surface area, larger aperture and a regular pore structure. The mesoporous metal oxide catalyst is high in activity and selectivity in terms of photo-catalytic CO2 conversion, and the preparation method is relatively simple, and easy to expand.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Method for preparing perovskite type catalyst for methane or methanol recapitalization

InactiveCN101185885AEliminates sinterable propertiesHigh catalytic activityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsWater bathsMetal nitrate

The invention discloses a preparation method of a perovskite catalyst used for reforming methane or methanol, which comprises the following steps: the metal nitrates of A, A', B and B' are added with a complexing agent and heated to dissolute; ammonia regulation solution with pH=5-7 is added; gel is formed after dehydrating in a constant temperature water bath at the temperature of sixty to ninety DEG C; catalyst powders are obtained after the gel is dried and roasted; the general formula of the catalyst composition is A1-xA'XB1-yB'yO3, wherein x is more than or equal to 0 and less than or equal to1,y is more than or equal to 0 and less than or equal to 1, A or A' is La, Ce, Pr, Gd or Sm; B or B' is Cr, Zr, Zn, Ni, Co, Mn, Fe, Ru, Rh, Pt or Pd. The technique of the invention is simple; the cost is low; the catalyst has the high activity and the high stability; the sulfur tolerance is good; the conversion is high; the service life is long; at the same time, the invention has the advantages of being aseismatic, the small resistance and being easy to be replaced, etc. after being coated on a honeycomb structure and is suitable for mass production. The invention belongs to the field of the catalyst reforming the methane or methanol.

Owner:HANERGY TECH

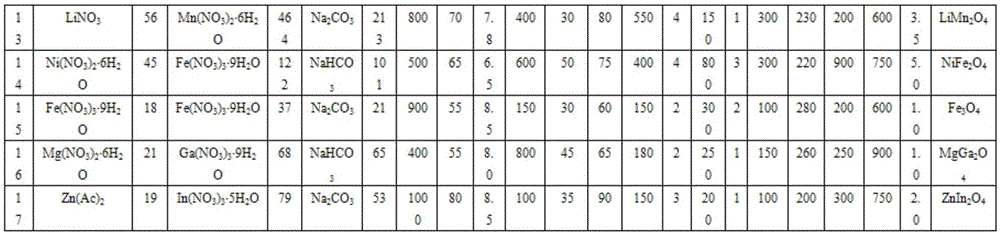

Preparation method for nano hydroxylapatite doped with metal ions

The invention relates to a preparation method of nano hydroxylapatite doped with metal ions, which comprises the following steps of: firstly, respectively preparing Ca(NO3)2 and (NH4)2HPO4 solution, mixing the Ca(NO3)2 and (NH4)2HPO4 solution, and obtaining clear and transparent solution A; adding metal nitrate into solution A and obtaining clear and transparent solution B; adding CO(NH2)2 into solution B, and obtaining solution C; finally heating and backflowing the solution C for 3 to 5 hours with the temperature of 100 DEG C under the magnetic force stirring; after the reaction is end, naturally cooling to room temperature; then vacuum-filtering, cleaning with water, drying for 24 hours under the temperature of 100 DEG C; and finally, obtaining nano hydroxylapatite crystal doped with metal ions. The preparation method adopts a metal salt solution heating even precipitation method, and takes inorganic salts containing calcium and phosphate group as raw materials; urea is acidity of a control reaction system of an additive; metal salts are added according to the doped proportion of 1 percent to 5 percent; reaction is carried out under the magnetic force stirring and heating conditions; and the backflowing of reaction liquid is adopted to synthesize nanoscale metal-doped nano hydroxylapatite crystal by one step. The method is obviously characterized by even doping and easy control for added amount.

Owner:SHAANXI UNIV OF SCI & TECH

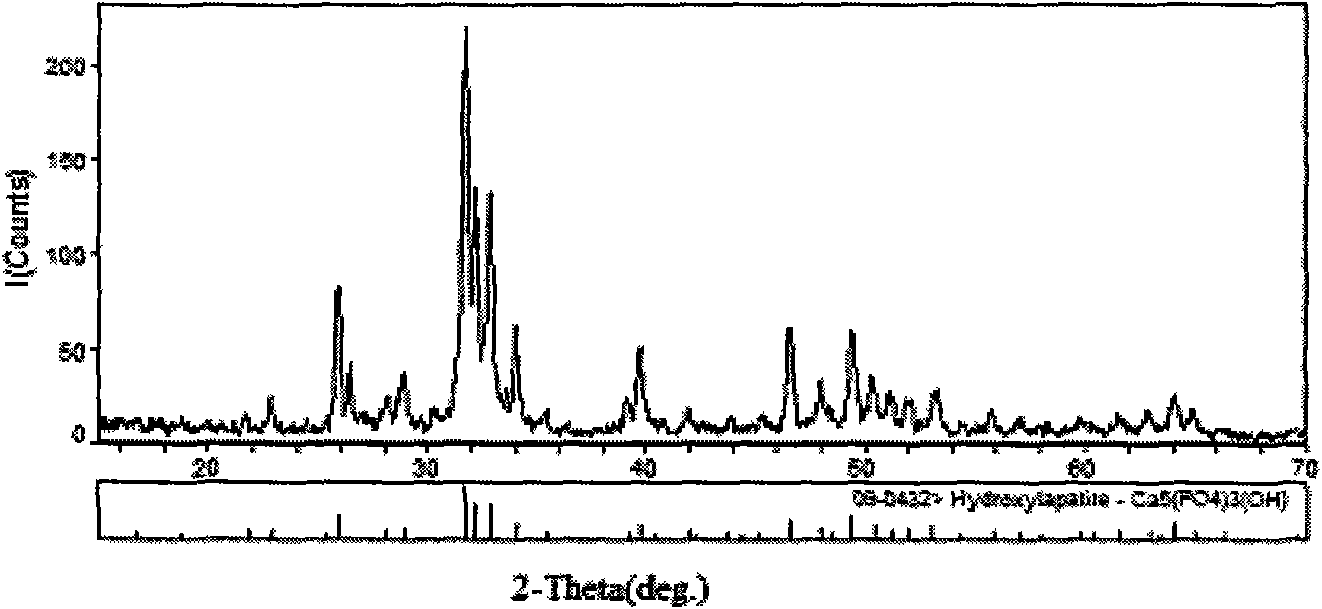

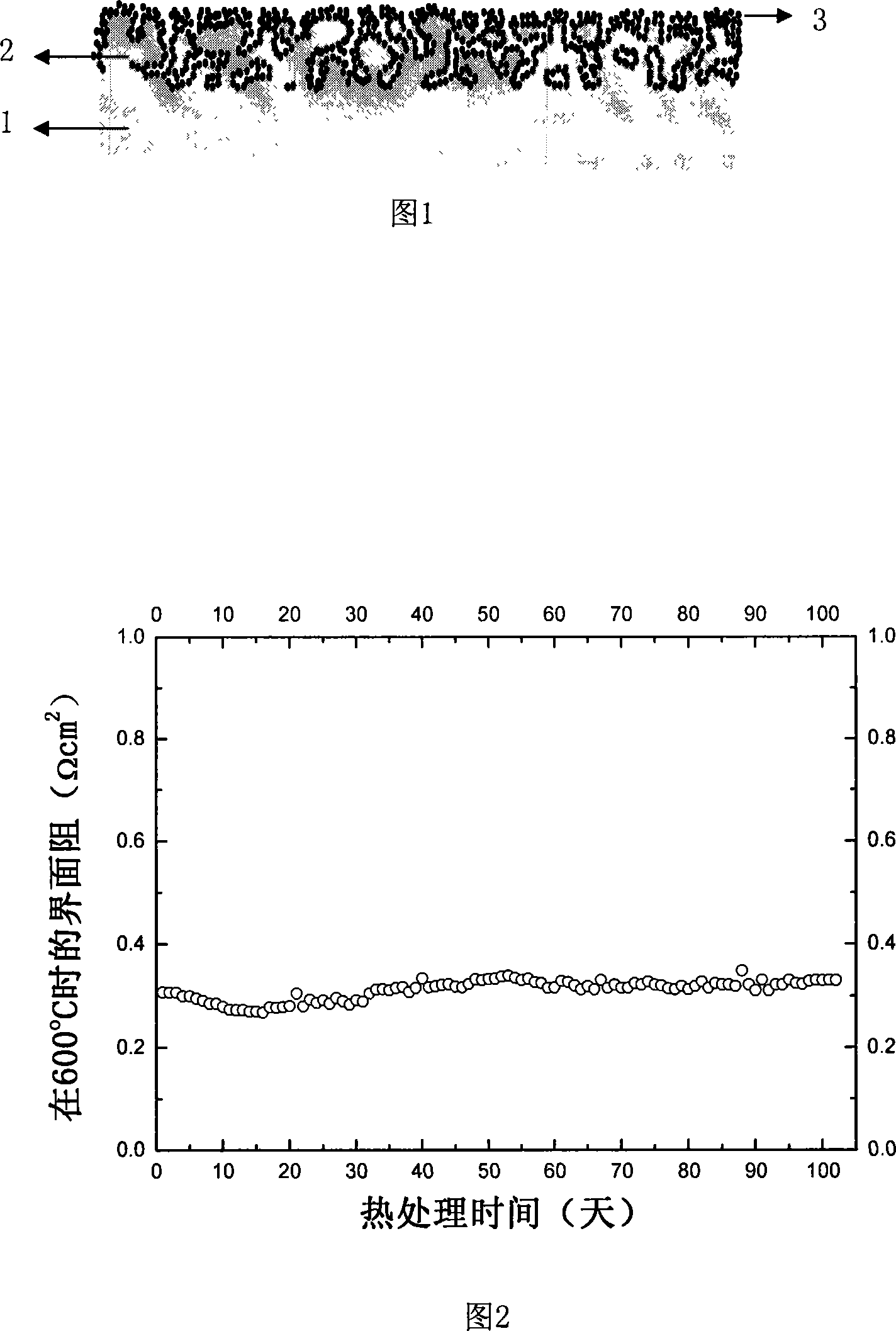

Solid-oxide fuel battery complex cathode and method for making same

InactiveCN101083324AImprove performanceHigh selectivityCell electrodesFuel cell detailsMetal nitrateFuel cells

The invention relates to the solid fuel battery technology area, specifically relates to a composit cathode of solid oxide compound fuel cell with high stable and its preparation method. The composit cathode includes the negative pole material thin film which is composed by nanometer level spheroidal particle whose diameter is the 50-100nm the and the electrolyte basis, electrolyte basis thickness is 0.7-1mm, the negative pole material thin film quality / ( the quality of negative pole material thin film + the quality of porous electrolyte skeleton) =50%-55%. The preparation method is that first prepares electrolyte powder body by the metal nitrate forerunner body, and forms the basis and the pulp, prints the pulp on the basis drtying, heating to obtain the porous three dimensional electrolyte skeleton, soaks the negative pole material forerunner body solution to the skeleton, puts heat treatment 2-3 hours under the 700-900deg.C , soaks the heat treatment cycle operation many times. The composit cathode has the very good electrochemistry performance.

Owner:UNIV OF SCI & TECH OF CHINA

Nano spinel type catalyst and preparation method thereof

InactiveCN106622241AWell mixedGuaranteed uniformityIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsMetal nitrateNitrate

The invention provides a nano spinel type catalyst and a preparation method thereof, and belongs to the field of volatile organic pollutant treatment and environment protection. By the preparation method, catalytic combustion activity of the nano spinel type catalyst can be improved effectively. The technical scheme includes that a sol precursor solution is obtained by a metal nitrate mixed solution, and xerogel is further obtained; the key point is to ignite the surface of the xerogel, a large quantity of gases are released through self-propagating combustion, fluffy tree-shaped powder is formed through combustion, and the nano spinel type catalyst is obtained finally. The nano spinel type catalyst can be applied to catalytic combustion of volatile organic pollutant gases.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

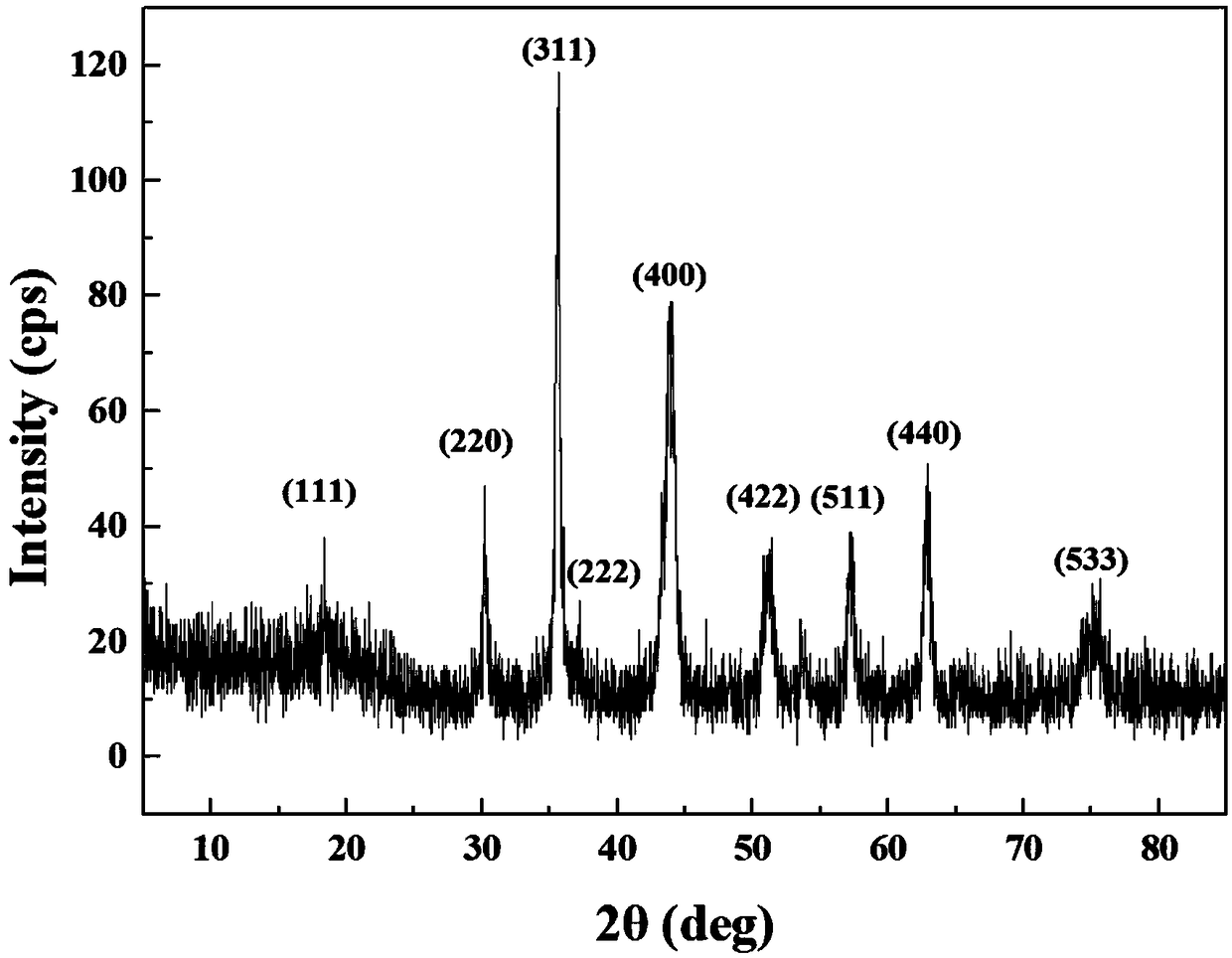

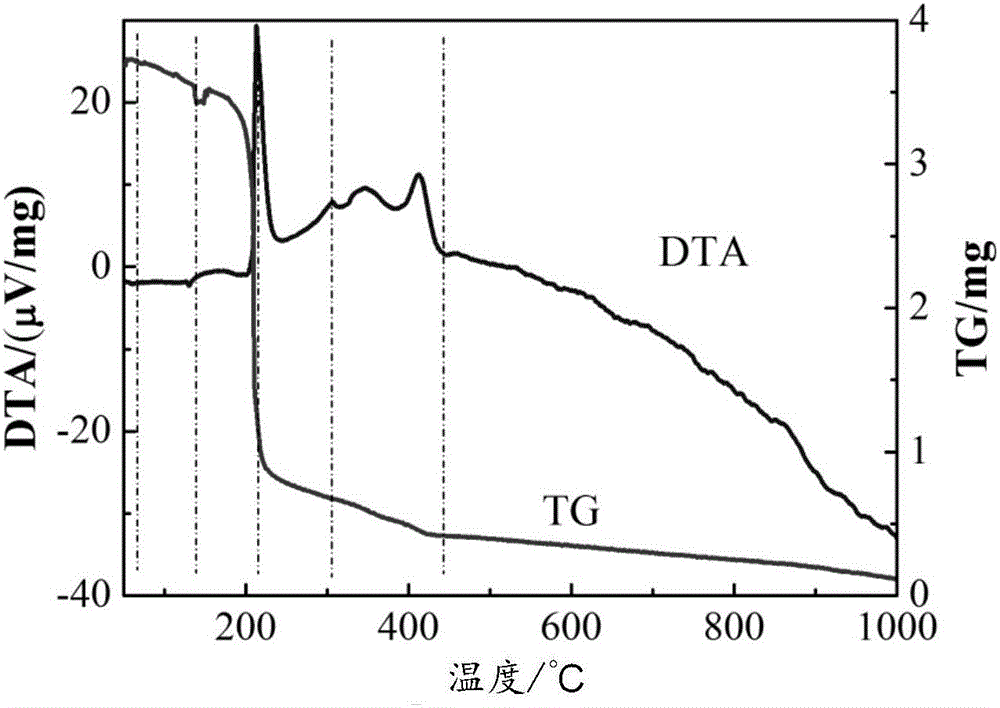

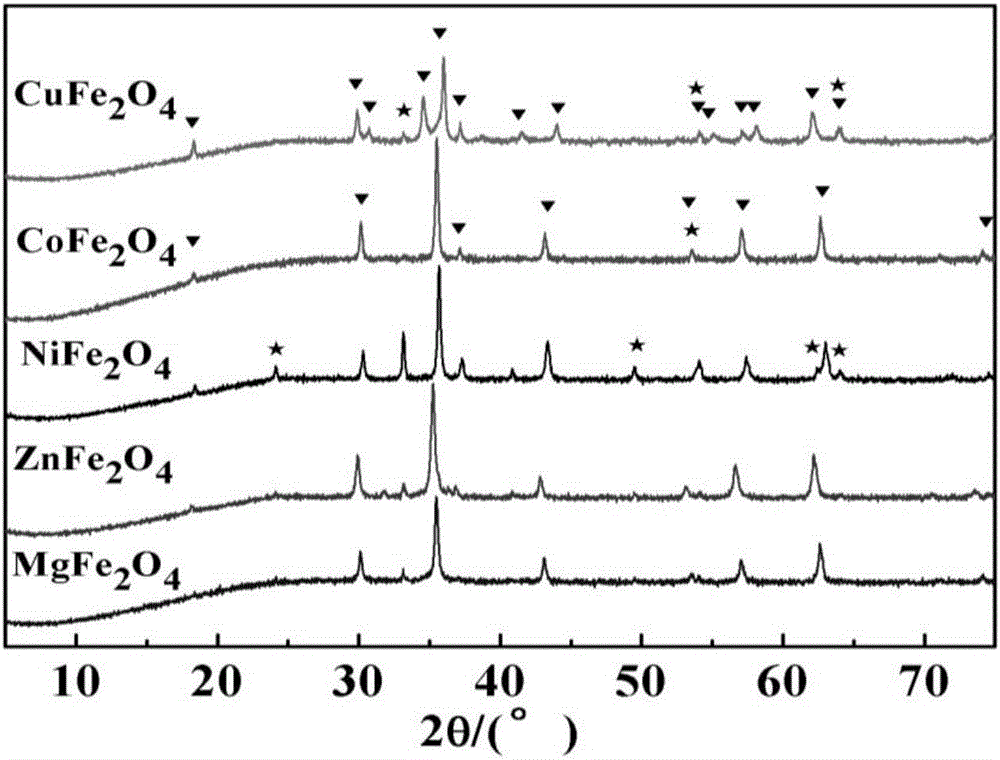

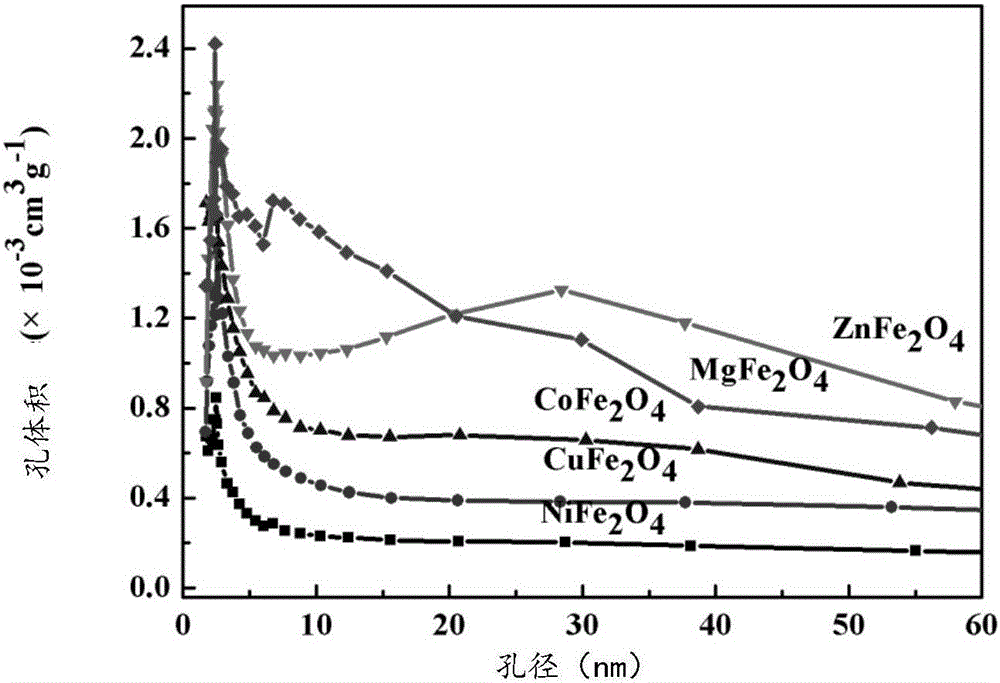

Prepn of doped magnetic ferrite material

InactiveCN1486958AEvenly dispersedSkip the ball milling processInorganic material magnetismMetal nitrateNitrate

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com