Patents

Literature

48results about "Aluminium-carbonate compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

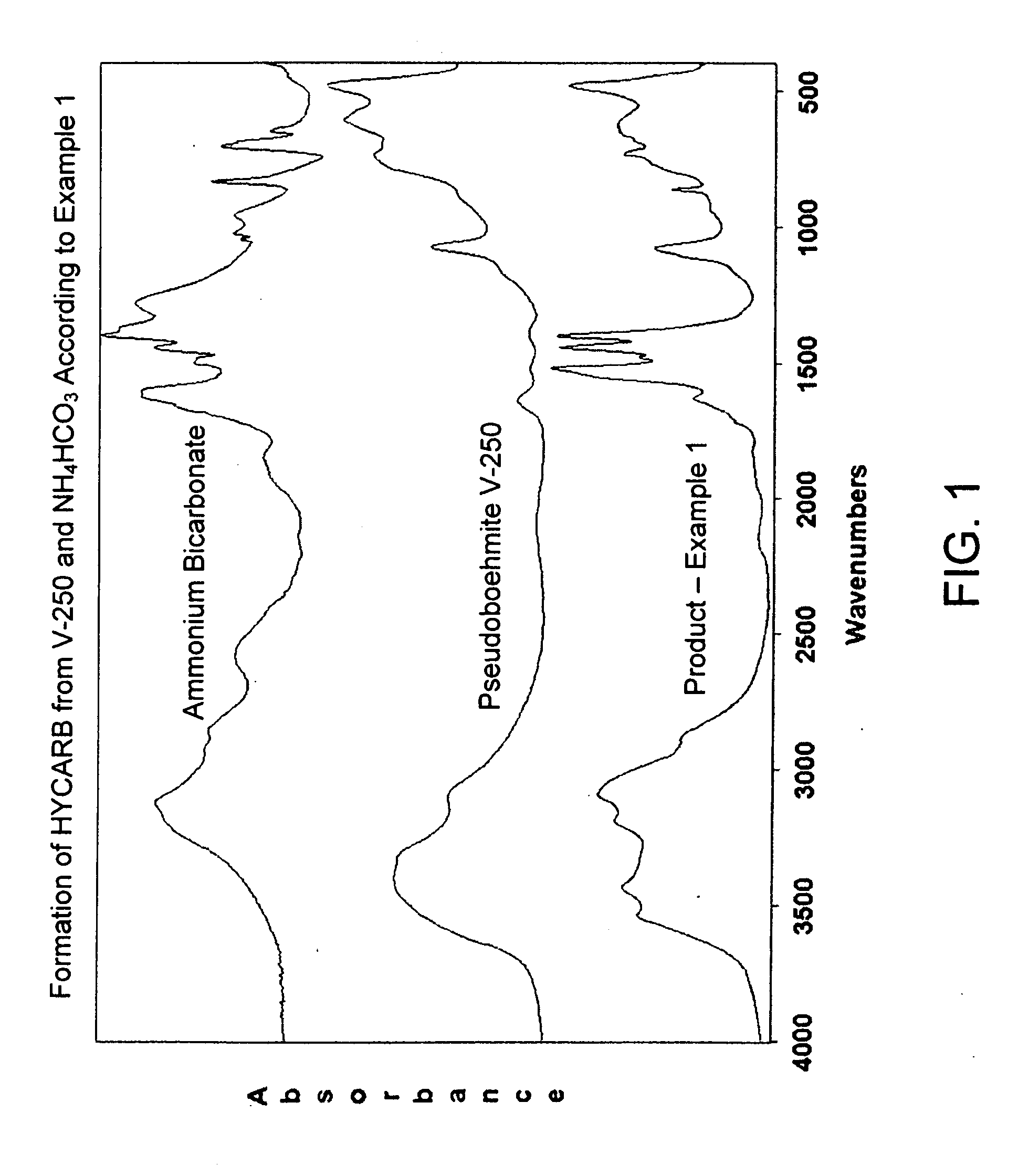

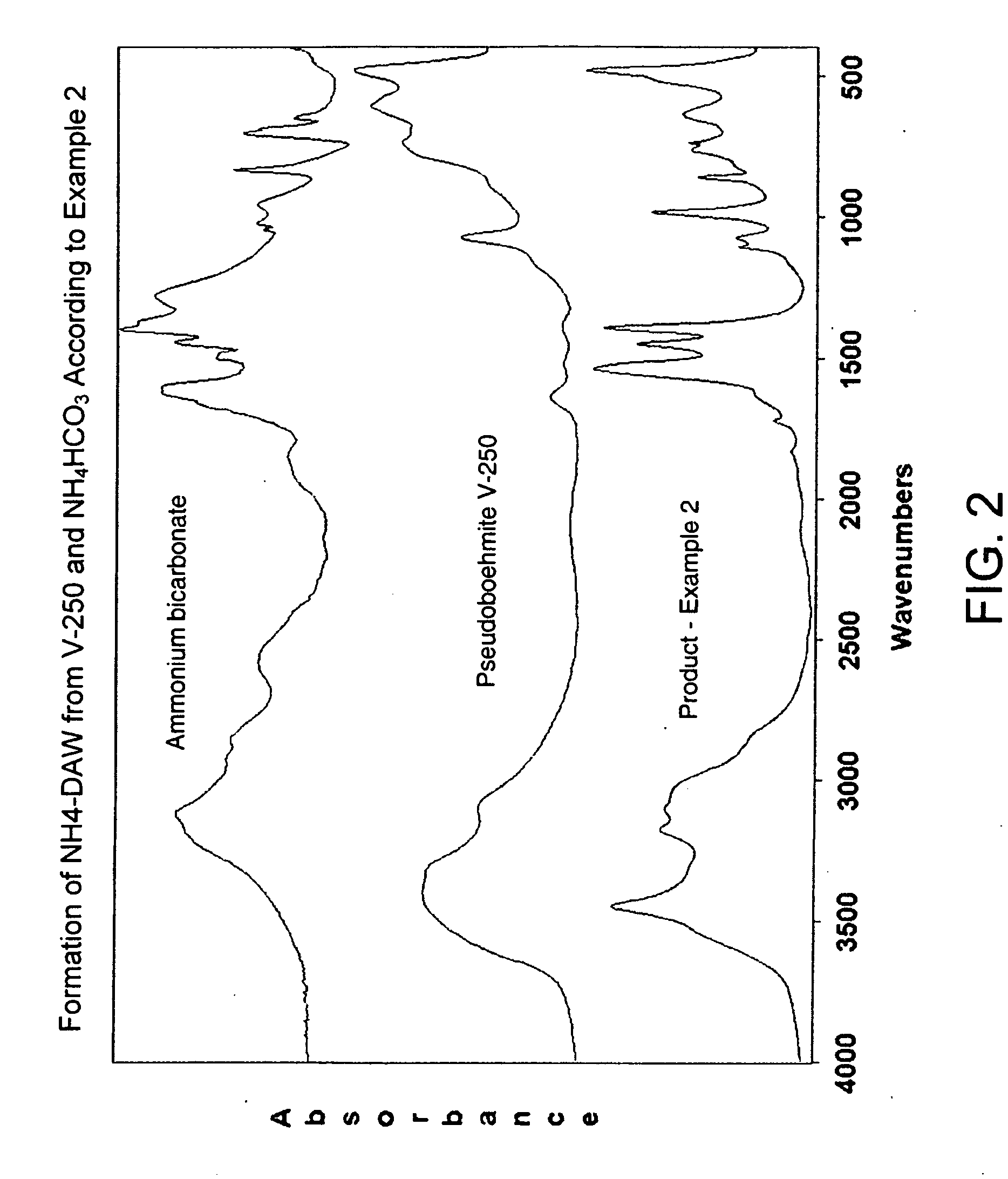

Scavengers for removal of acid gases from fluid streams

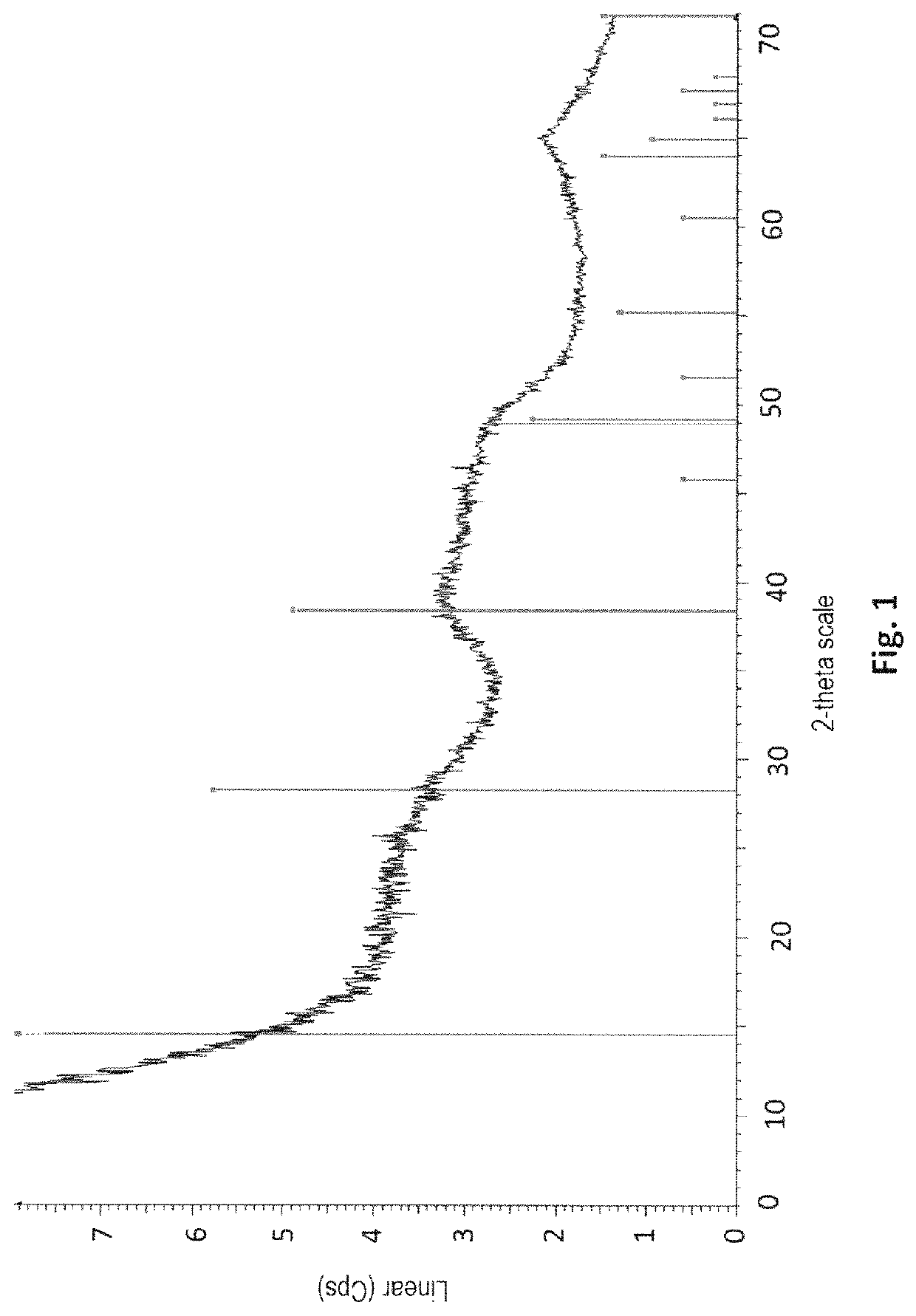

ActiveUS20060252642A1Low costHigh porosityGas treatmentOther chemical processesParticulatesScavenger

A composite sorbent is formed which is the reaction product of a solid alkali metal carbonate, rehydratable alumina and water or an aqueous solution of a metal salt. The reaction between the components occurs while forming particulates followed by curing and activation. In one embodiment, the composite contains an appreciable amount of a Dawsonite-type hydroxycarbonate as a final product or as an intermediate in at least one of the production stages. The alkali metal in the sorbent exhibits a highly reactive and accessible state that is very favorable for various sorption applications. The sorbent is especially useful for removal of HCl and other acid contaminants from gas and liquid hydrocarbon streams. It combines a high capacity for the contaminants with a low reactivity towards the hydrocarbon components of the main stream.

Owner:UOP LLC

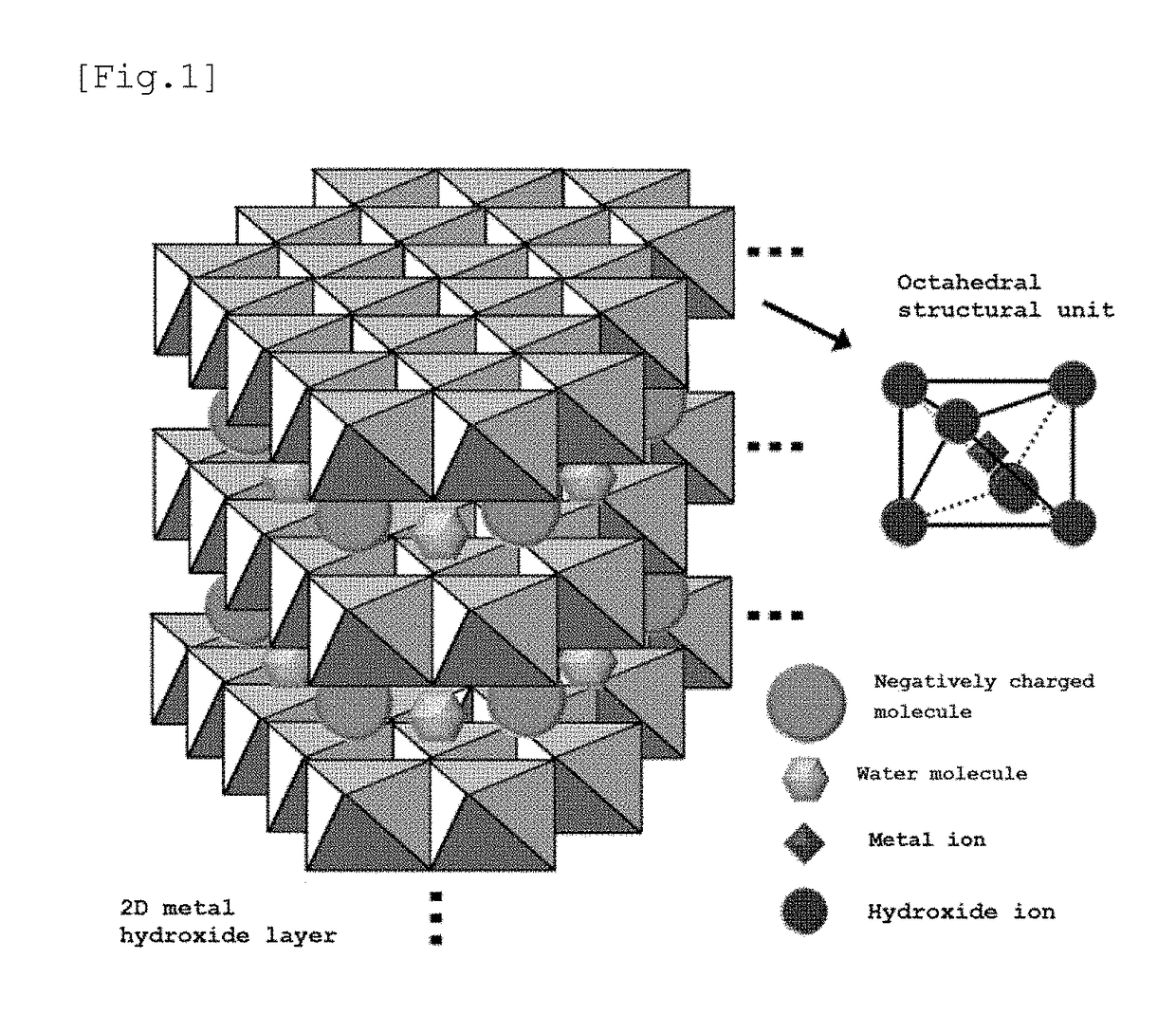

Preparation method of LDHs (magnesium-based layered double hydroxides)

ActiveCN105753022ARich sourcesLow priceAluminium-carbonate compoundsZinc compoundsMagnesium saltCalcium magnesium

The invention provides a preparation method of LDHs (magnesium-based layered double hydroxides). According to the method, calcium oxides or calcium magnesium oxides are used as an alkali source, calcium oxides or calcium magnesium oxides and a magnesium salt are subjected to a precipitation reaction, magnesium hydroxide precipitates are produced, then the magnesium hydroxide precipitates and divalent and trivalent soluble metal nitrates or chlorides are used as raw materials, LDHs are prepared through a liquid-solid phase reaction, and byproducts, namely, magnesium chlorides or magnesium nitrates, can be used as raw materials. The method has the advantages that the raw materials are rich in source, the price is low, the preparation process is simple, reaction conditions are mild, industrial production is facilitated and the like, and prepared LDHs can be widely applied to fields of catalysis, adsorption, environmental protection, high-polymer plastic and the like.

Owner:BEIJING UNIV OF CHEM TECH

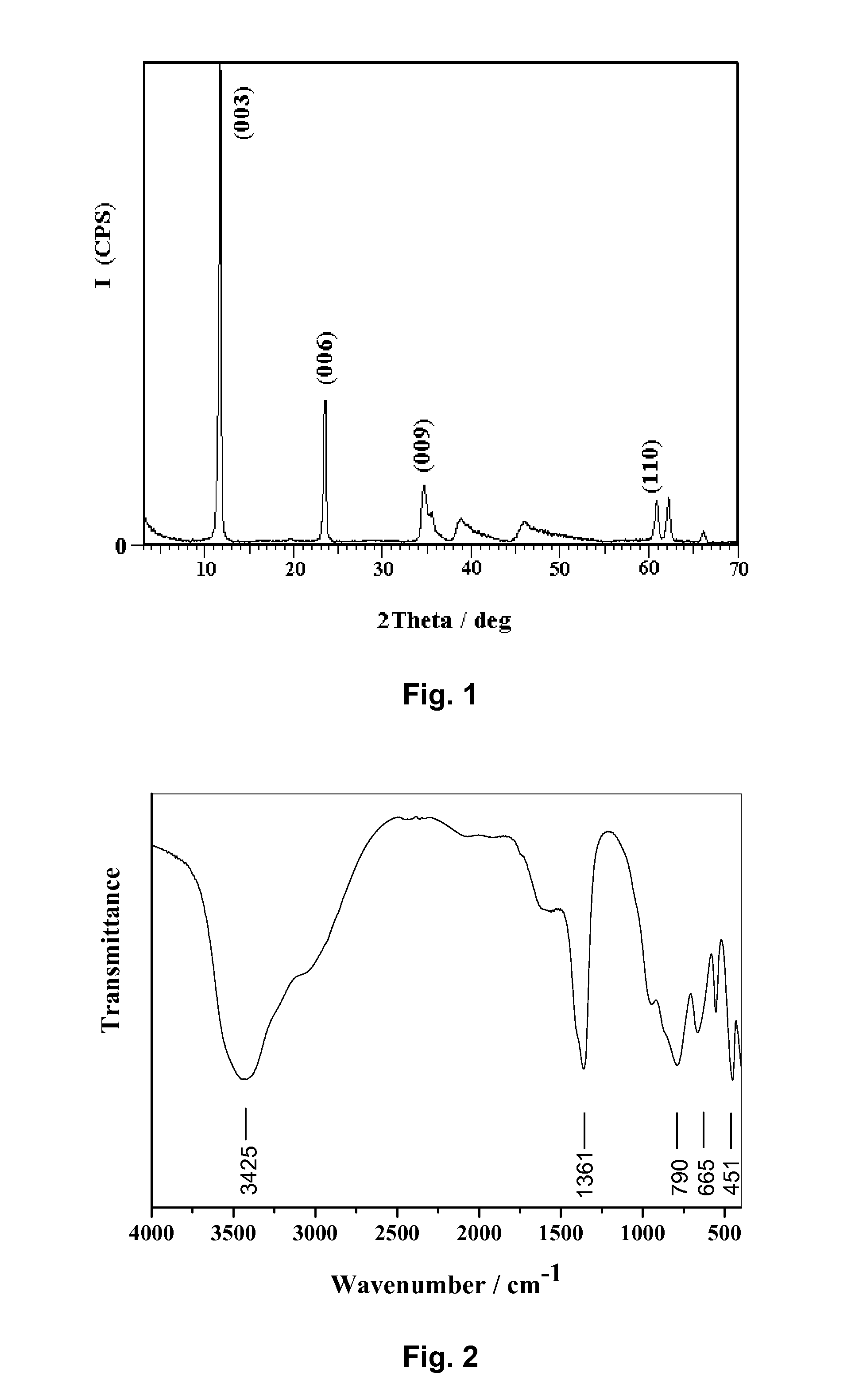

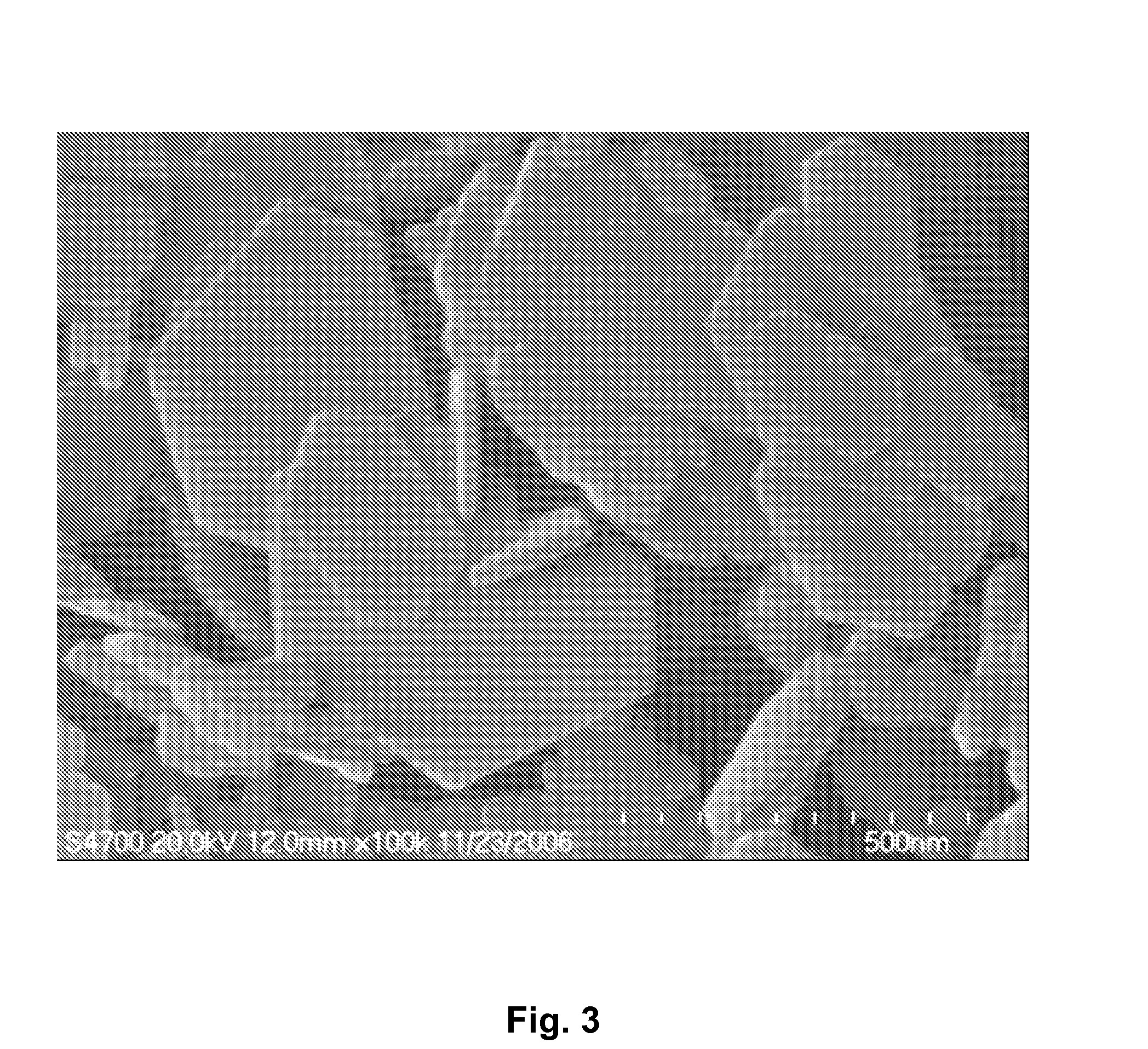

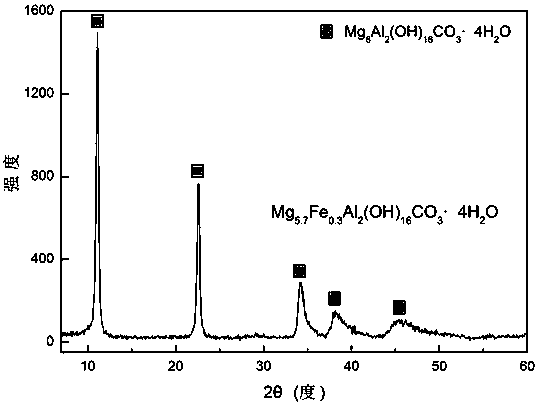

Clean method for preparing layered double hydroxides

ActiveUS20080170978A1Efficient responseProtect environmentLithium compoundsManganese oxides/hydroxidesFiltrationCleaning methods

Disclosed is a clean method for preparing layered double hydroxides (LDHs), in which hydroxides of different metals are used as starting materials for production of LDHs by atom-economical reactions. The atom efficiency of the reaction is 100% in each case because all the atoms of the reactants are converted into the target product since only M2+(OH)2, M3+(OH)3, and CO2 or HnAn− are used, without any NaOH or other materials. Since there is no by-product, filtration or washing process is unnecessary. The consequent reduction in water consumption is also beneficial to the environment.

Owner:BEIJING UNIV OF CHEM TECH

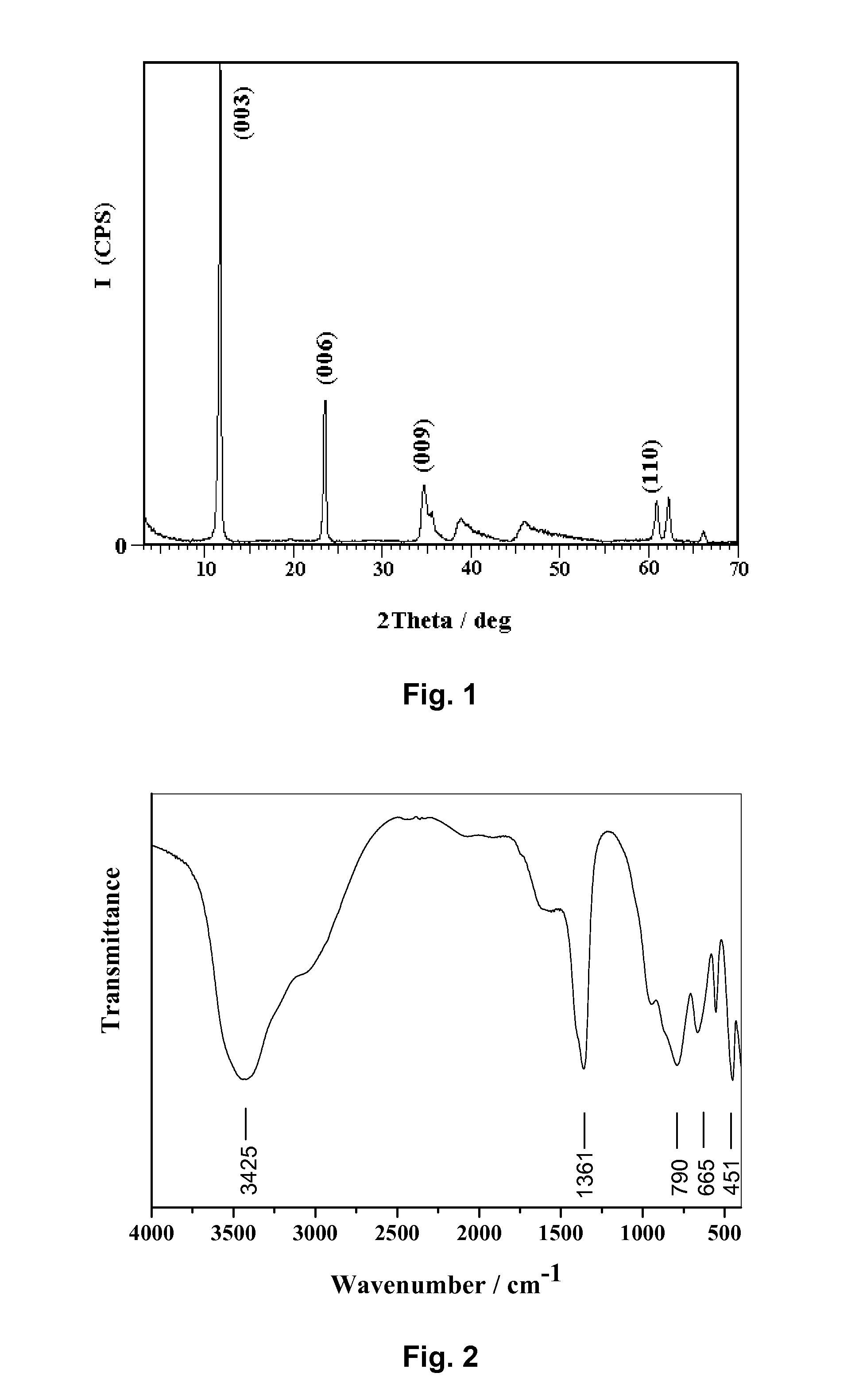

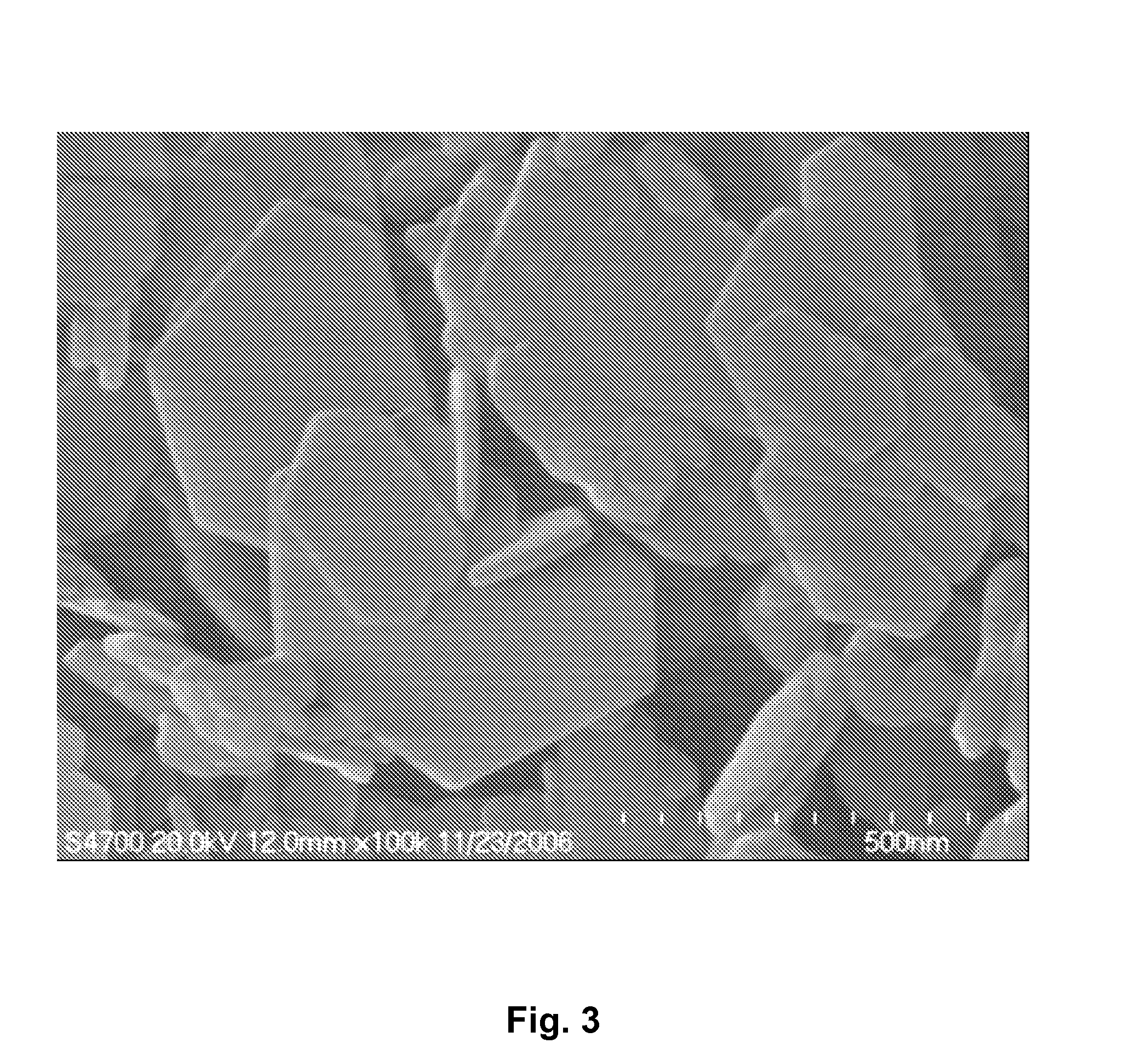

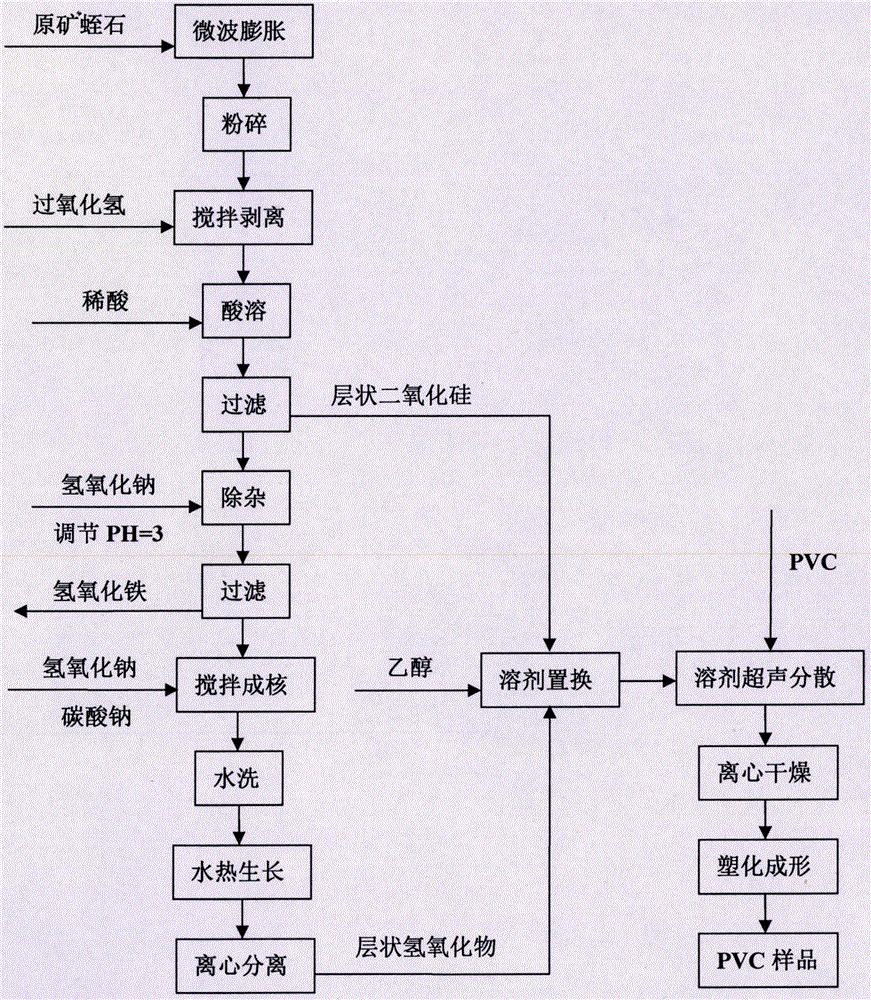

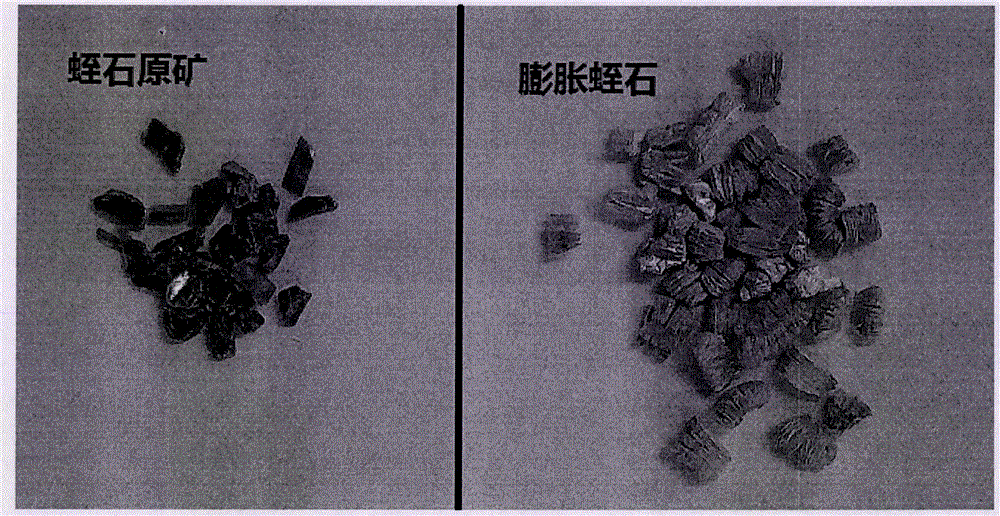

Method for preparing PVC heat stabilizer by taking vermiculite as raw material

The invention provides a method for preparing a PVC heat stabilizer through the steps that lamellar silica tetrahedrons and a refabricated lamellar alumina octahedron are obtained by taking ore as a raw material, utilizing the lamellar structure characteristic of vermiculite and removing an alumina octahedron layer between two silica tetrahedron layers, layer splitting of the vermiculite is achieved. Particularly, the method comprises the steps that the vermiculite ore is subjected to microwave expansion to obtain expanded vermiculite; a nano-scale vermiculite flake is obtained by means of ion stirring stripping; the solid lamellar silica (silica tetrahedrons) are obtained according to the characteristics that the silica tetrahedrons are insoluble in acid and the alumina octahedron is soluble in acid by splitting the vermiculite through acid dissolving; iron ions in an acid solution are removed through a graded precipitation method, impurities such as salt ions are removed through quick nucleation and water washing, crystal growth is controlled through a hydrothermal method, and the nano-scale lamellar hydroxide (alumina octahedron) is obtained; the obtained silica and hydroxide successfully achieve mixing of a heat stabilizer and PVC through a solvent replacement and dispersion method, and the agglomeration and redispersion problems of the nano-scale silica and hydroxide are solved. According to the method, the PVC heat stabilizer is prepared by selecting the advantageous mineral vermiculite in China as the raw material, and the advantages of being wide in raw material source, low in cost, simple in process, non-toxic, easy to apply and popularize and the like are achieved; in addition, the efficient heat stabilizer is prepared from the original ore vermiculite, the defects of existing toxic heat stabilizers which are high in price or contain lead are overcome.

Owner:TARIM UNIV

Scavengers for removal of acid gases from fluid streams

A composite sorbent is formed which is the reaction product of a solid alkali metal carbonate, rehydratable alumina and water or an aqueous solution of a metal salt. The reaction between the components occurs while forming particulates followed by curing and activation. In one embodiment, the composite contains an appreciable amount of a Dawsonite-type hydroxycarbonate as a final product or as an intermediate in at least one of the production stages. The alkali metal in the sorbent exhibits a highly reactive and accessible state that is very favorable for various sorption applications. The sorbent is especially useful for removal of HCl and other acid contaminants from gas and liquid hydrocarbon streams. It combines a high capacity for the contaminants with a low reactivity towards the hydrocarbon components of the main stream.

Owner:UOP LLC

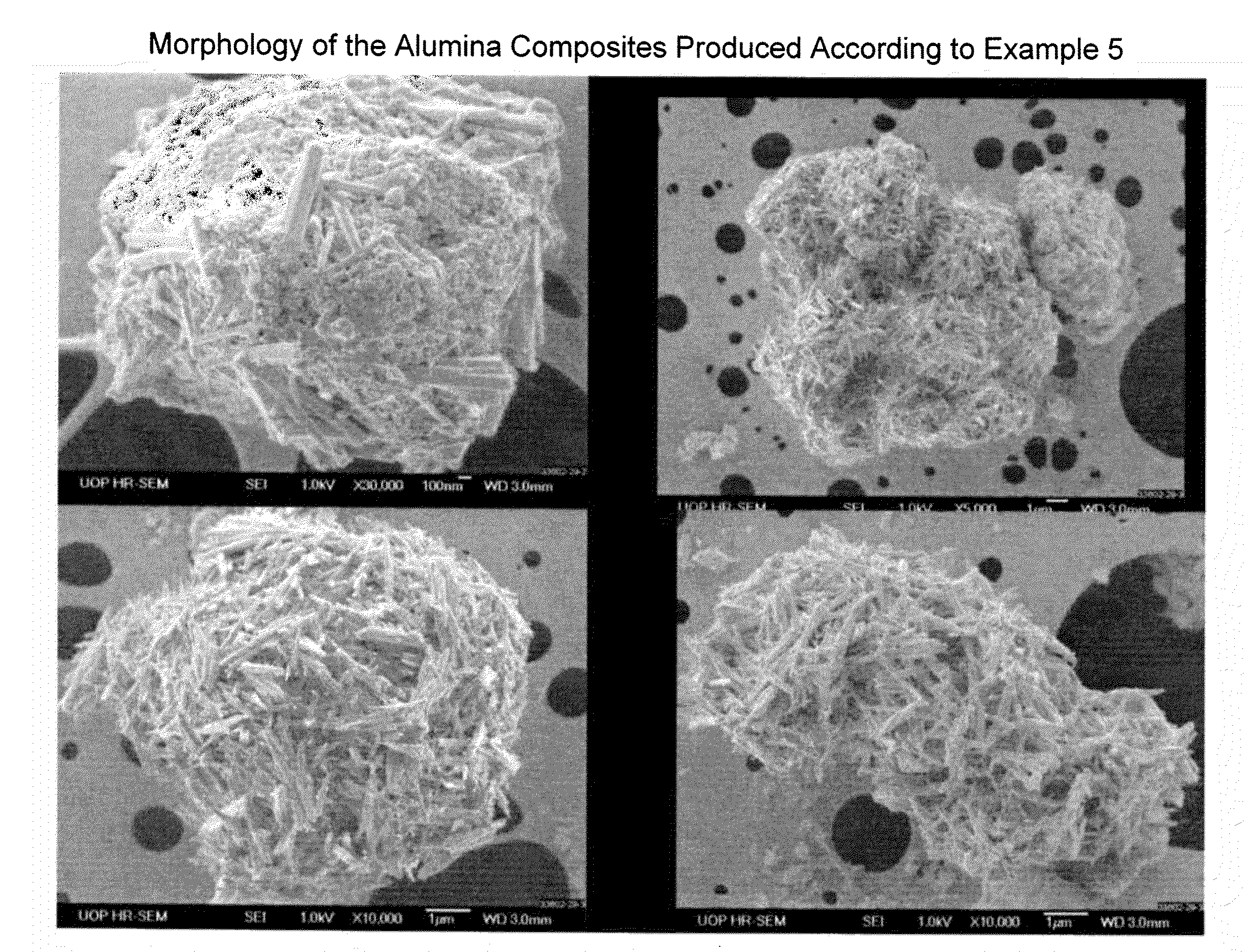

Wide mesoporous alumina composites having trimodal pore structure

ActiveUS7790130B2Improve performanceReduced responseMaterial nanotechnologyChlorine/hydrogen-chloride purificationParticulatesSorbent

Wide mesoporous alumina composites are produced by an “in situ reaction” route comprising agglomeration of an alumina powder that is capable of rehydration together with a second reactive powder such as carbonate. In one method of production, the powders are fed to a rotating forming device that is continuously sprayed with liquid under conditions to form particulates. The discharging beads are then subjected to curing and thermal activation to produce the final catalyst or adsorbent. The alumina participates in a pore altering process involving the carbonate component upon formation of hydroxycarbonate intermediates such as Dawsonite. Large fraction of the pore volume of the final product consists of wide mesopores in the 15-50 nanometers range. The alumina composites exhibit a characteristic trimodal pore structure that includes also small micro-meso pores and macropores larger than 200 nanometers.

Owner:UOP LLC

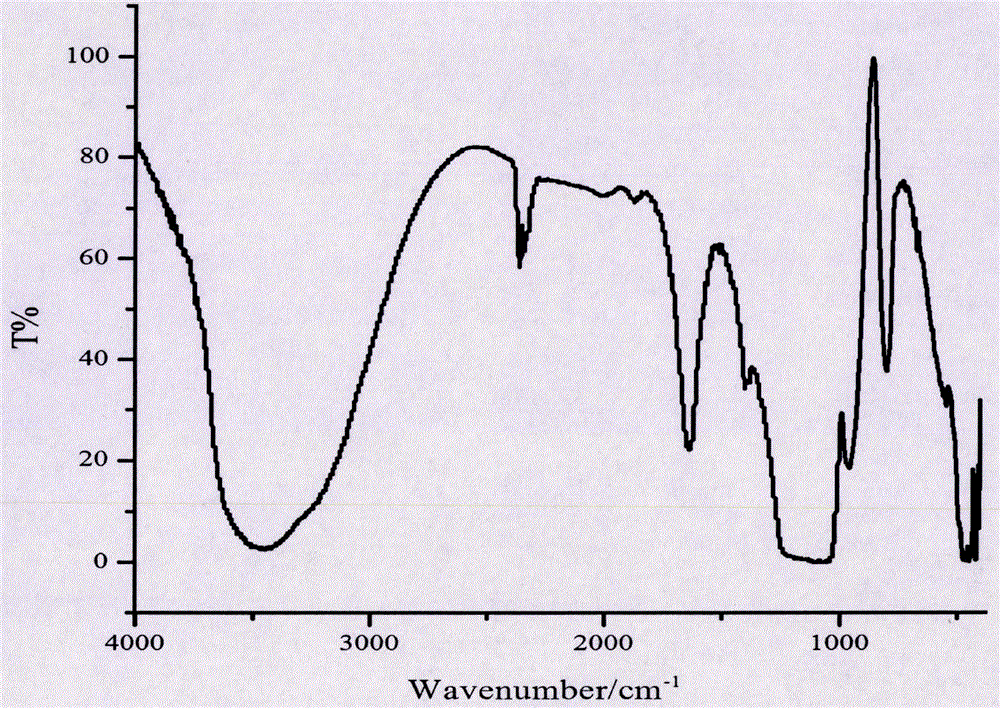

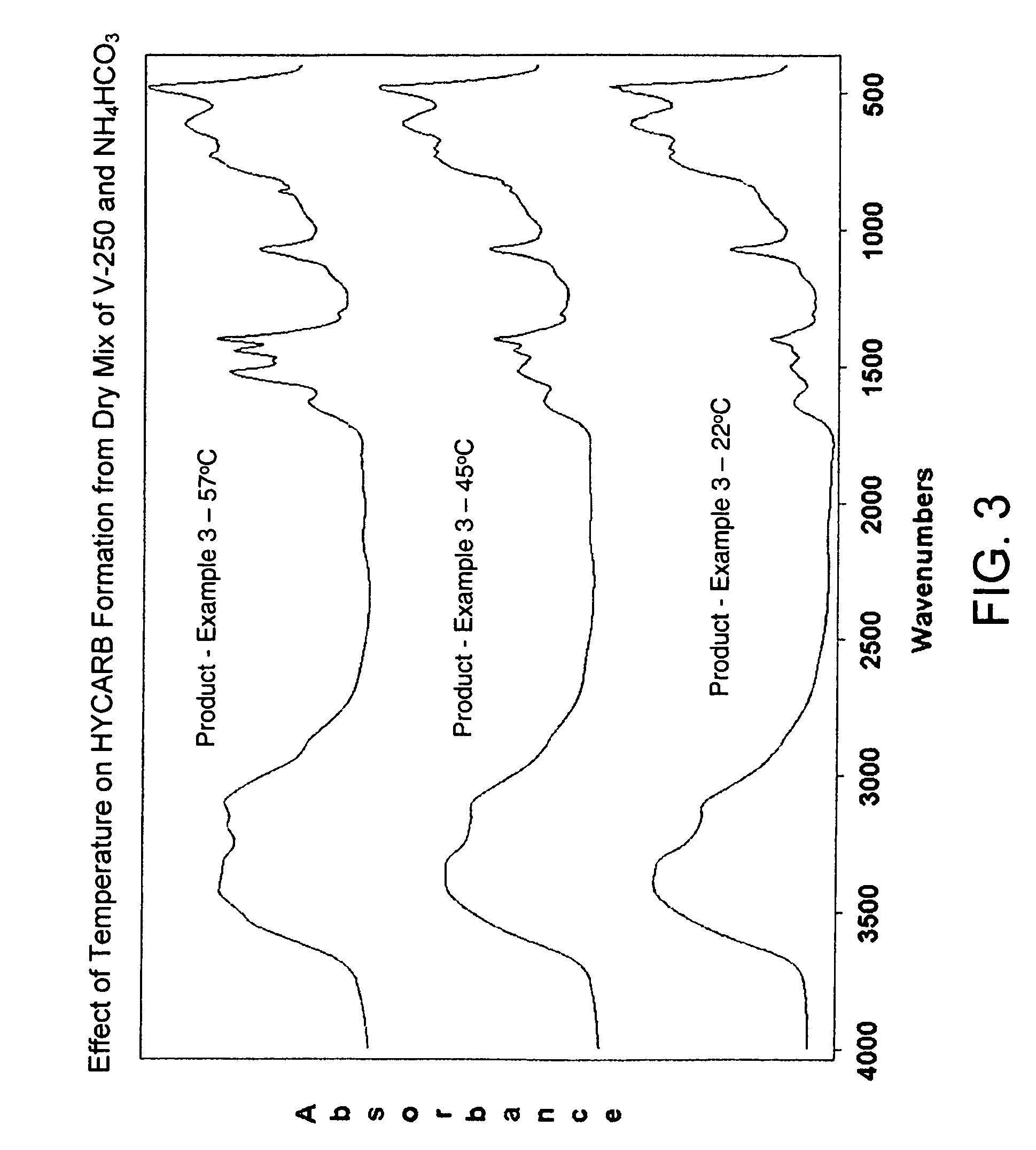

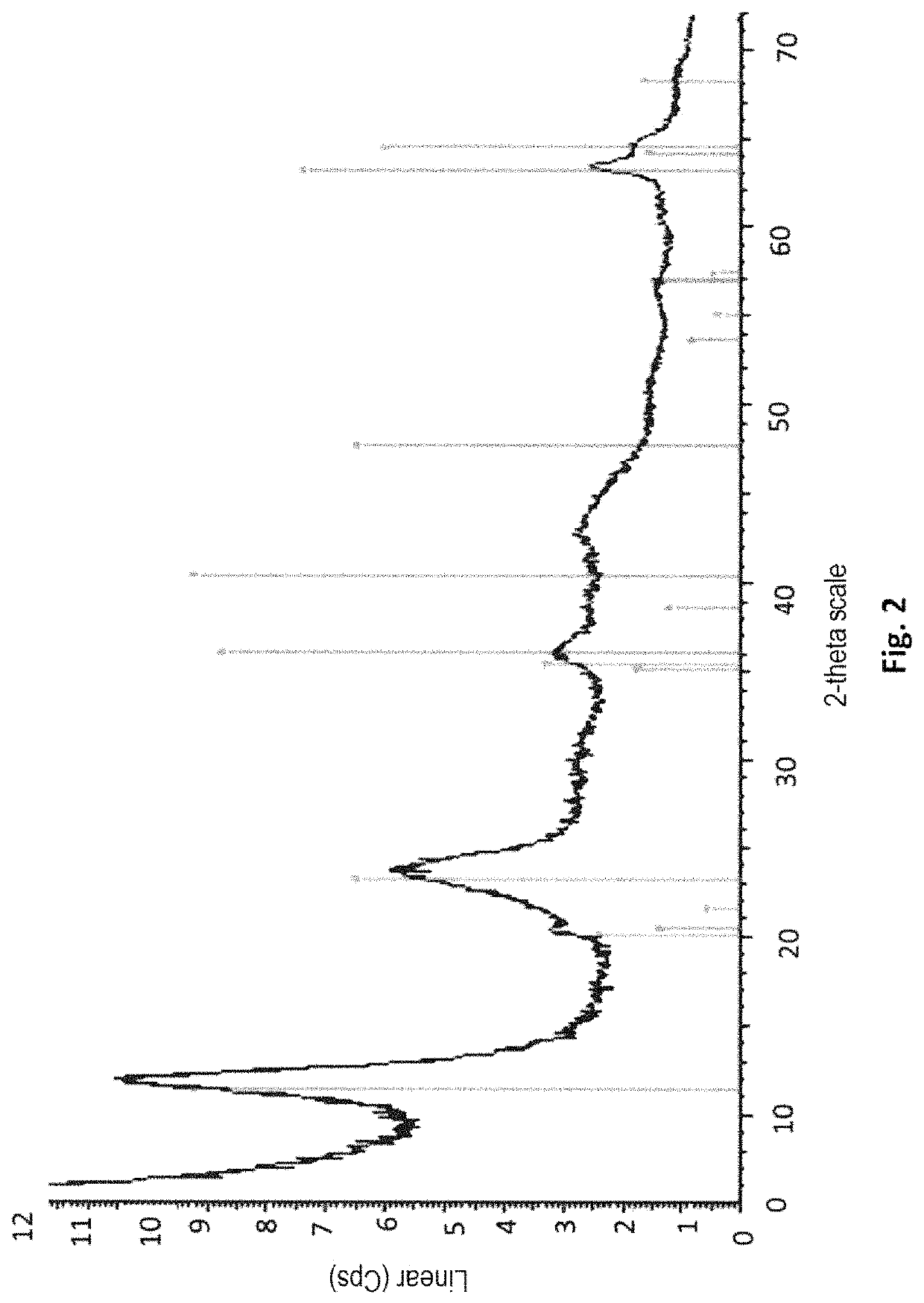

Process for Conversion of Aluminum Oxide Hydroxide

ActiveUS20100148116A1Other chemical processesAmmonium carbonates/bicarbonatesAluminium hydroxideAluminum oxide hydroxide

The present invention is a process for the conversion of aluminum oxide hydroxide (AlOOH) to aluminum oxide. About 30 to 70 wt-% of AlOOH, about 30 to 70 wt-% ammonium hydrogencarbonate NH4HCO3 and 0 to 20 wt-% water are combined to produce a mixture. This mixture is then cured at a temperature from about 30° to about 90° C. to convert at least 5% of the AlOOH to a ammonium hydroxycarbonate (dawsonite-type) intermediate and then the dawsonite-type intermediate is decomposed at a temperature from about 130° to 320° C. to produce aluminum oxide. The aluminum oxide can be further calcined at 500° to 800° C. to produce a gamma-theta phase alumina.

Owner:UOP LLC

Clean method for preparing layered double hydroxides

ActiveUS8088349B2Prevent materialAvoid prolonged useLithium compoundsManganese oxides/hydroxidesCleaning methodsLayered double hydroxides

Disclosed is a clean method for preparing layered double hydroxides (LDHs), in which hydroxides of different metals are used as starting materials for production of LDHs by atom-economical reactions. The atom efficiency of the reaction is 100% in each case because all the atoms of the reactants are converted into the target product since only M2+(OH)2, M3+(OH)3, and CO2 or HnAn− are used, without any NaOH or other materials. Since there is no by-product, filtration or washing process is unnecessary. The consequent reduction in water consumption is also beneficial to the environment.

Owner:BEIJING UNIV OF CHEM TECH

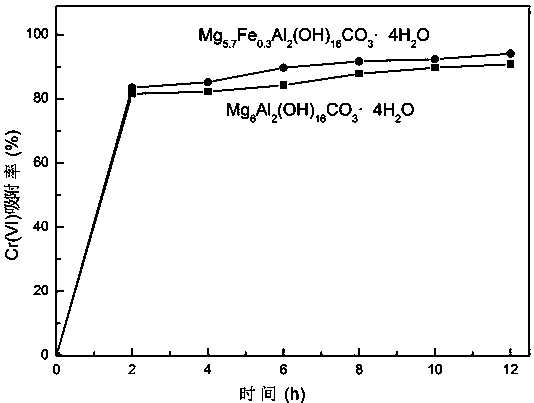

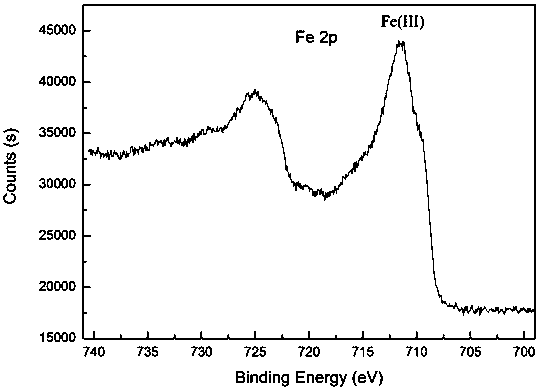

Method for adsorbing and reducing Cr (VI) based on iron magnesium aluminum hydrotalcite

InactiveCN108160026ARealize environmental protection cycle adsorptionSave raw materialsOther chemical processesWater contaminantsFiltrationPollution

The invention relates to a preparation method and an application of a hydrotalcite-like compound for adsorbing and reducing heavy metals. The preparation method concretely comprises the following steps: a) weighing all raw materials according to the stoichiometric ratio of an object having a general formula of Mg6-xFexAl2(OH)16CO3.4H2O (x = 0.3-1.2), adding deionized water into a magnesium raw material, an iron raw material and an aluminum raw material to form a solution A, and adding deionized water into alkali metal and carbonate raw materials to form a solution B; b) dropwise adding the solution A to the solution B, pouring the formed mixed suspension into an autoclave, heating the autoclave to 120-180 DEG C, performing heat treatment, and performing suction filtration, washing and drying to form a Mg6-xFexAl2(OH)16CO3.4H2O sample; and c) adding the sample into a potassium dichromate solution, taking the obtained supernatant and testing the adsorption rate of the supernatant every 2h, and detecting the Cr (VI)reduction degree of the material. Iron magnesium aluminum hydrotalcite prepared in the invention has good adsorption capability to heavy metals, and can be recycled through the reduction and separation of Fe<2+> on the heavy metals. The method has the advantages of simplicity in operation, high adsorption and reduction efficiency, low cost and no secondary pollution.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

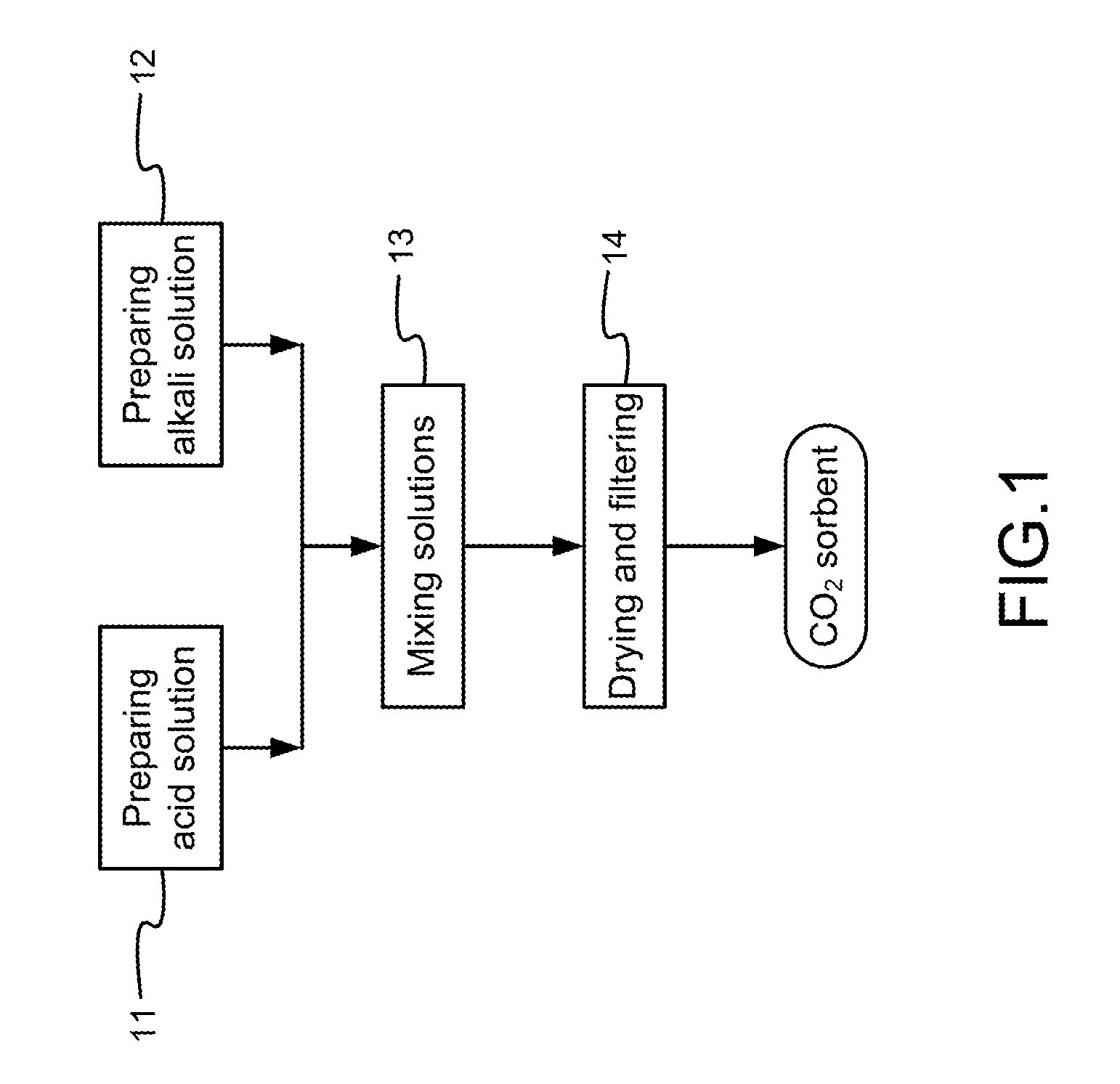

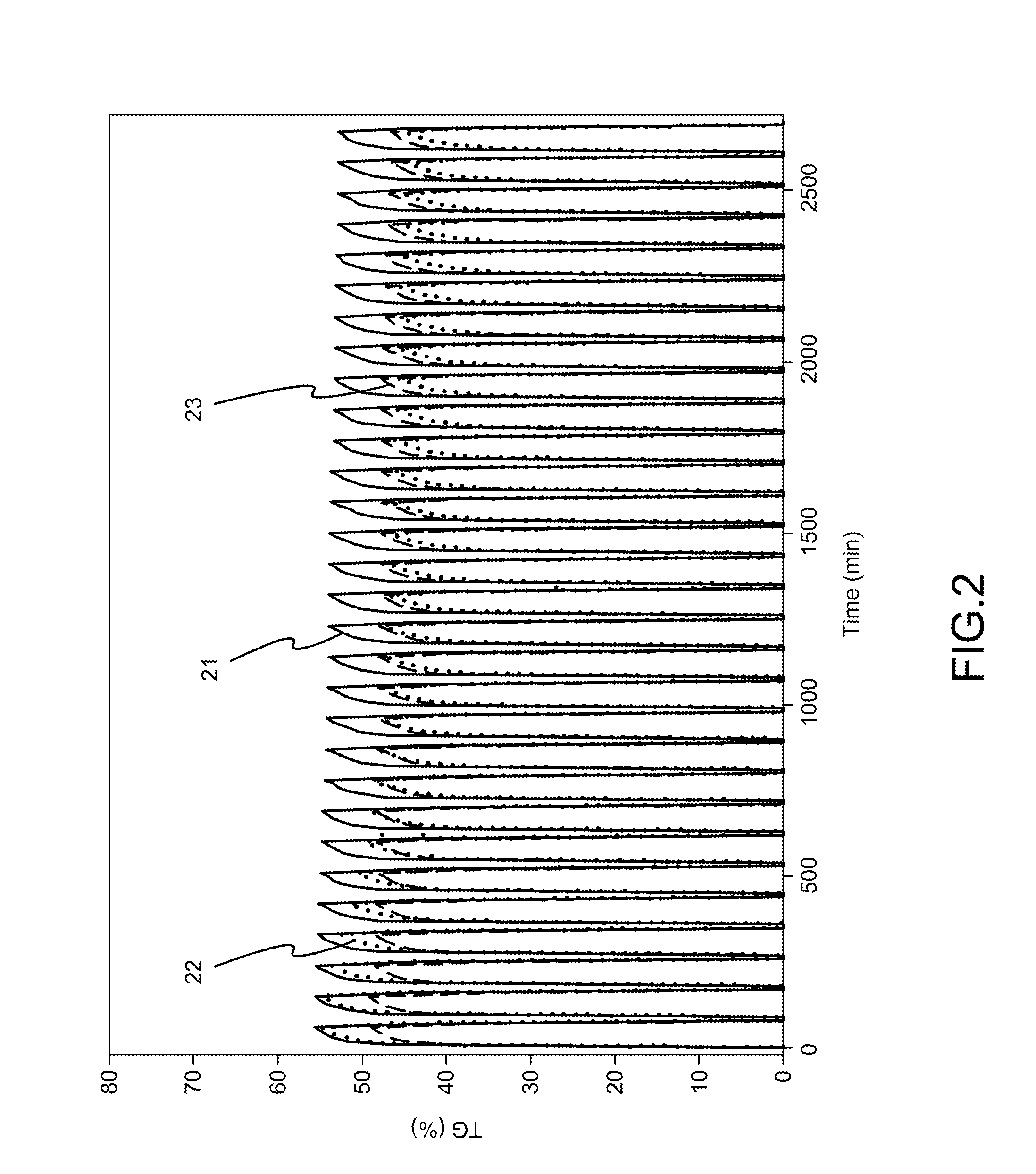

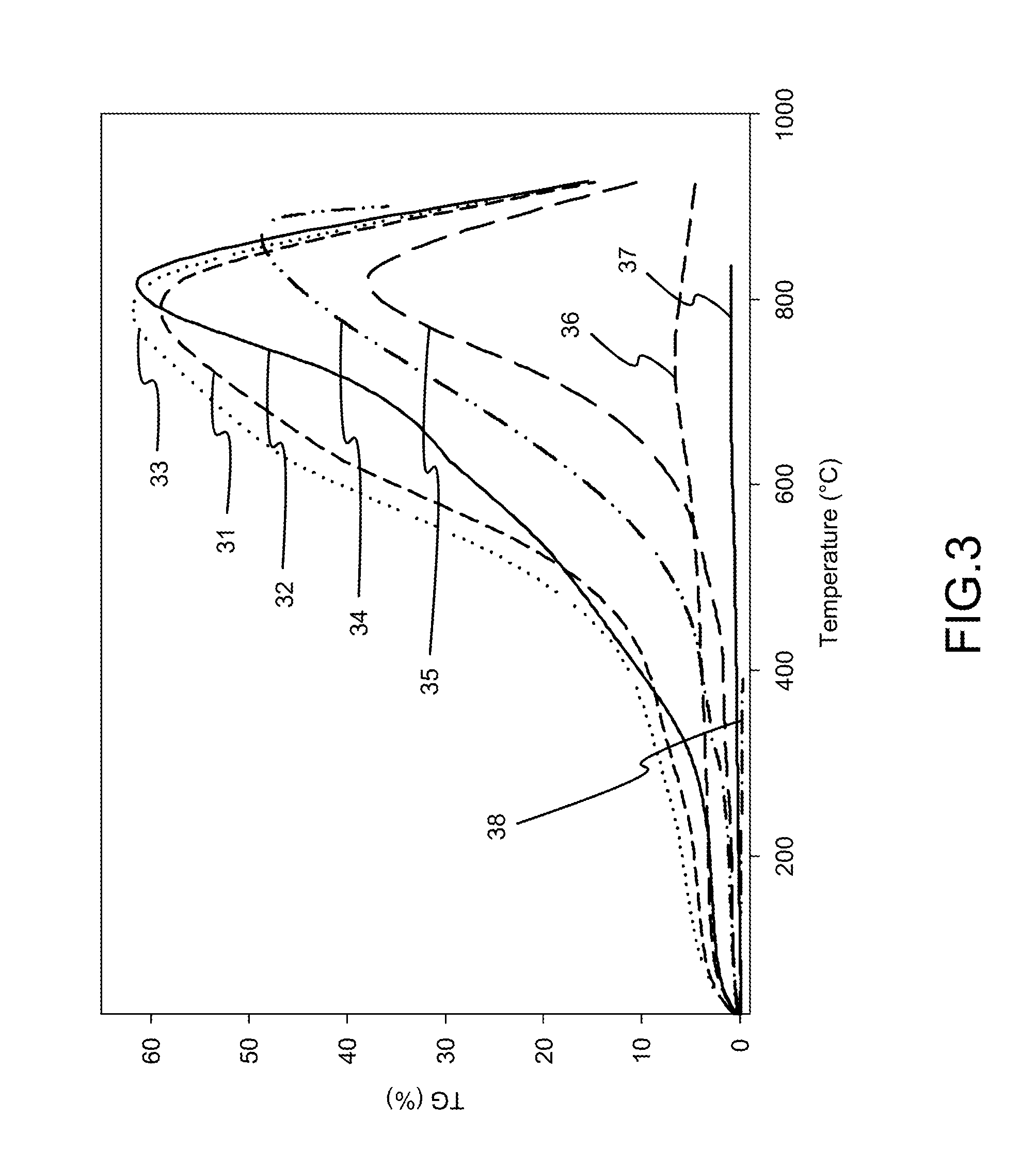

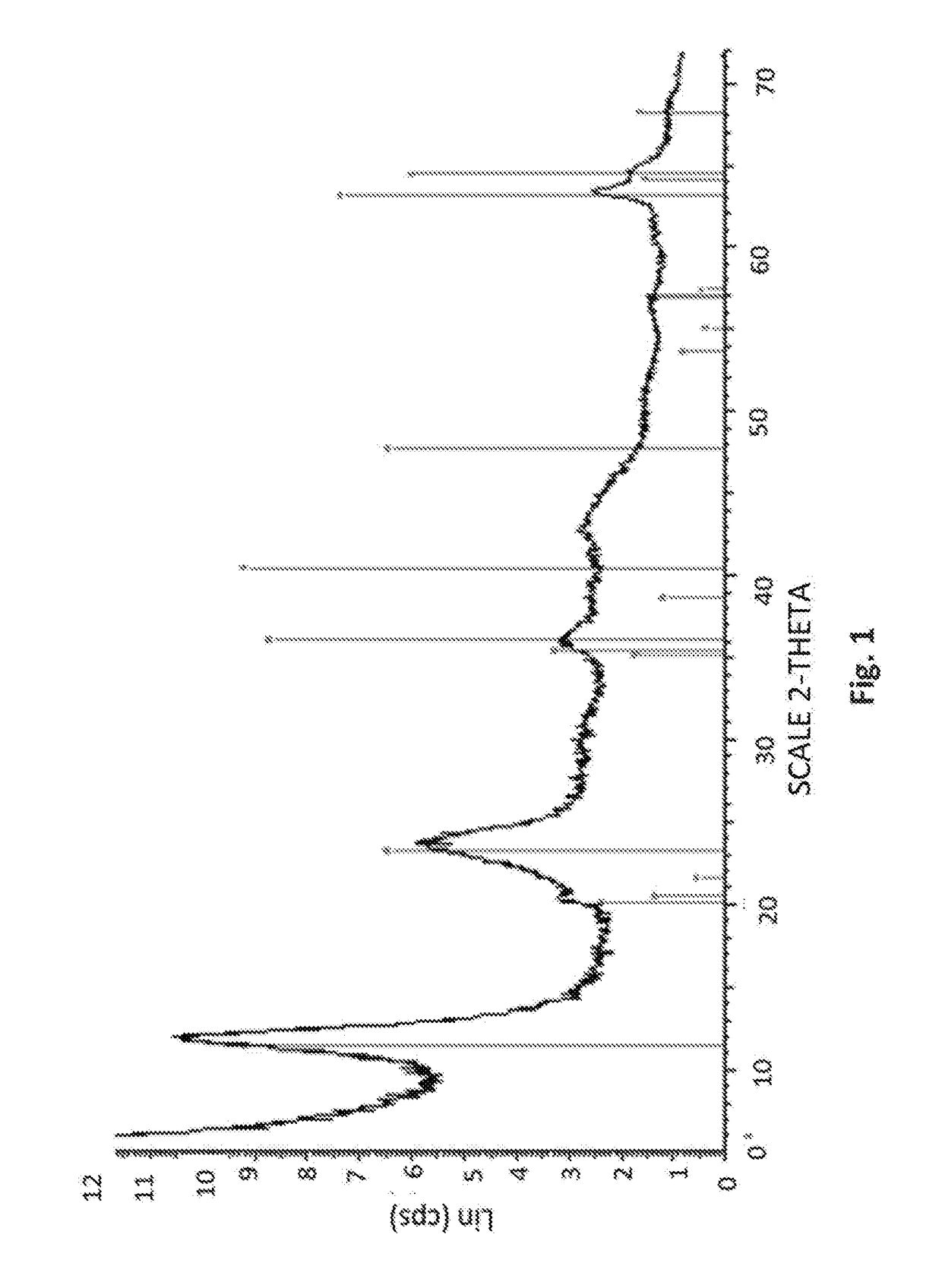

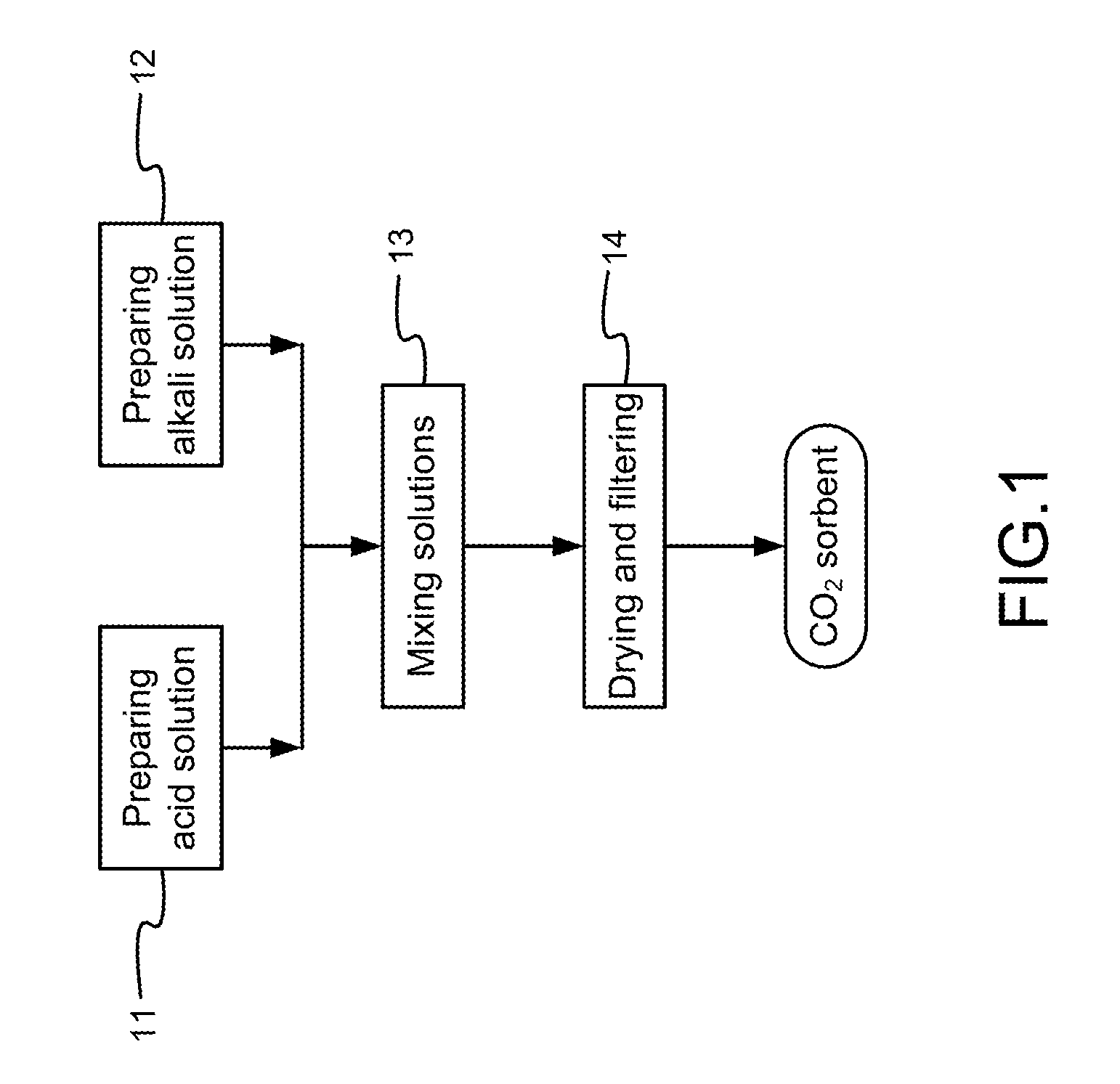

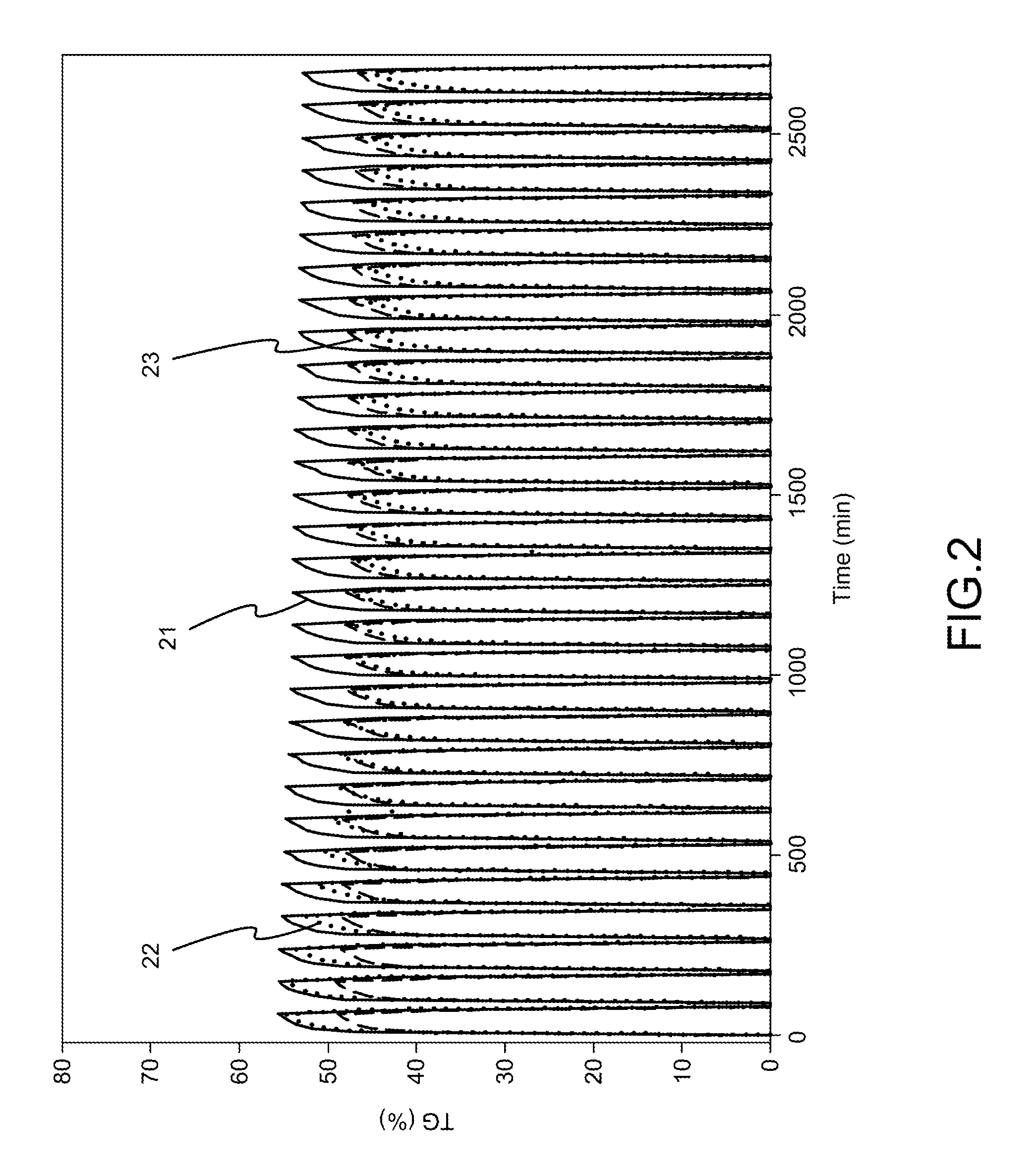

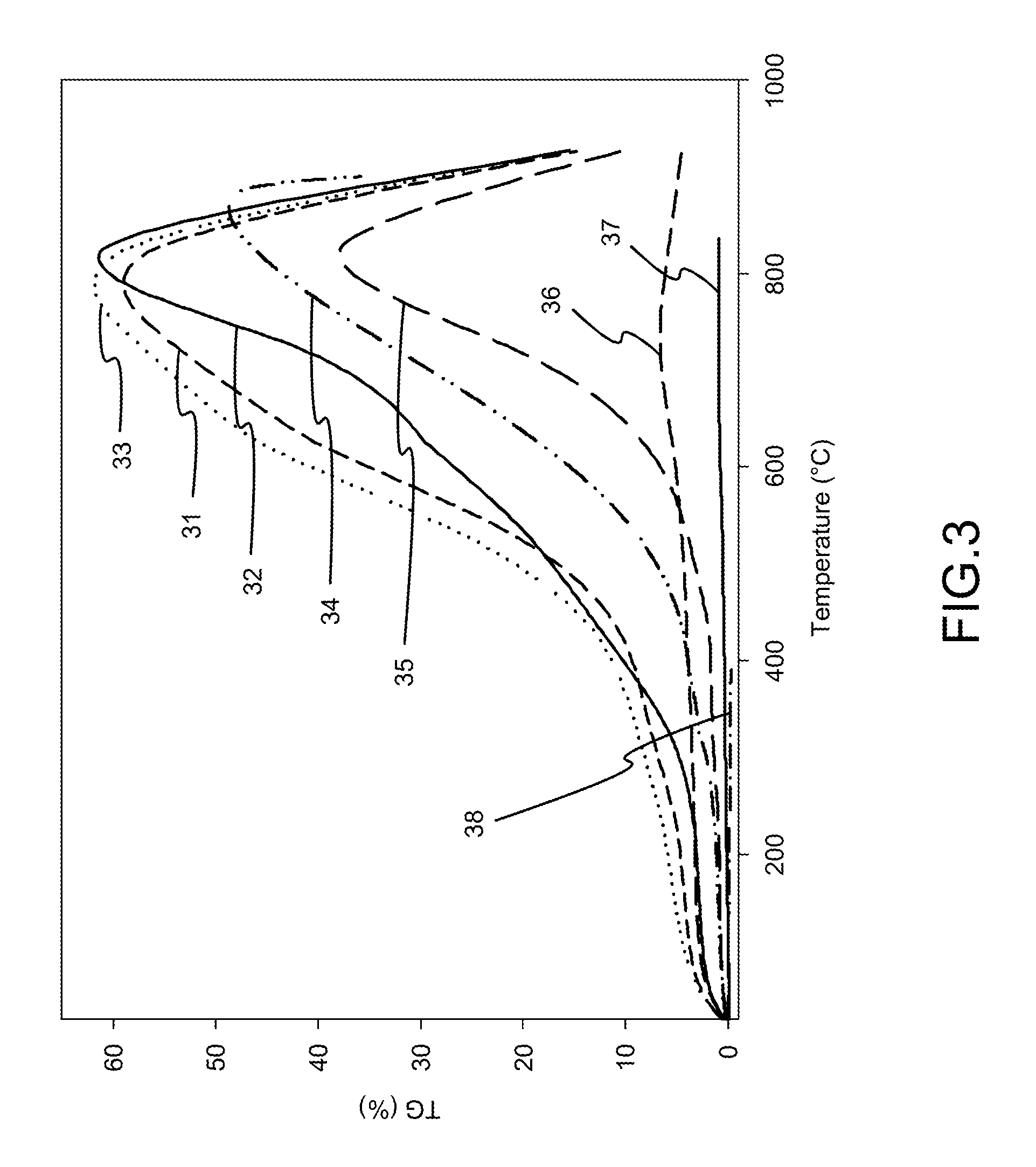

Method of Fabricating Medium-High Temperature CO2 Sorbents Made of Alkali Metal Promoted Calcium Aluminate Carbonates

InactiveUS20130015399A1Fast captureImprove stabilityCalcium/strontium/barium carbonatesProductsCelsius DegreeSorbent

A dry material is synthesized by alkali metal (Li, Na and K) promoted calcium aluminate carbonates to obtain a CO2 sorbent used at a temperature higher than 600 Celsius degrees (° C.). The key composition of the sorbents is 52˜69% of CaO, which is beneficial to capture CO2 at 400˜800° C. A breakthrough result is achieved by using this sintering-resistant sorbent, which includes the features of 50% initial carbonation capacity and 20 folds CO2 capturing performance maintained after 40˜60 hours. Besides, alkali bearing material provides good velocity in CO2 capturing / releasing cycles; for example, by using Li and K series sorbents, 40 hours is required for 40 cycles only.

Owner:INST NUCLEAR ENERGY RES ROCAEC

Wide Mesoporous Alumina Composites Having Trimodal Pore Structure

ActiveUS20090060811A1Improve performanceReduced responseMaterial nanotechnologyChlorine/hydrogen-chloride purificationParticulatesSorbent

Wide mesoporous alumina composites are produced by an “in situ reaction” route comprising agglomeration of an alumina powder that is capable of rehydration together with a second reactive powder such as carbonate. In one method of production, the powders are fed to a rotating forming device that is continuously sprayed with liquid under conditions to form particulates. The discharging beads are then subjected to curing and thermal activation to produce the final catalyst or adsorbent. The alumina participates in a pore altering process involving the carbonate component upon formation of hydroxycarbonate intermediates such as Dawsonite. Large fraction of the pore volume of the final product consists of wide mesopores in the 15-50 nanometers range. The alumina composites exhibit a characteristic trimodal pore structure that includes also small micro-meso pores and macropores larger than 200 nanometers.

Owner:UOP LLC

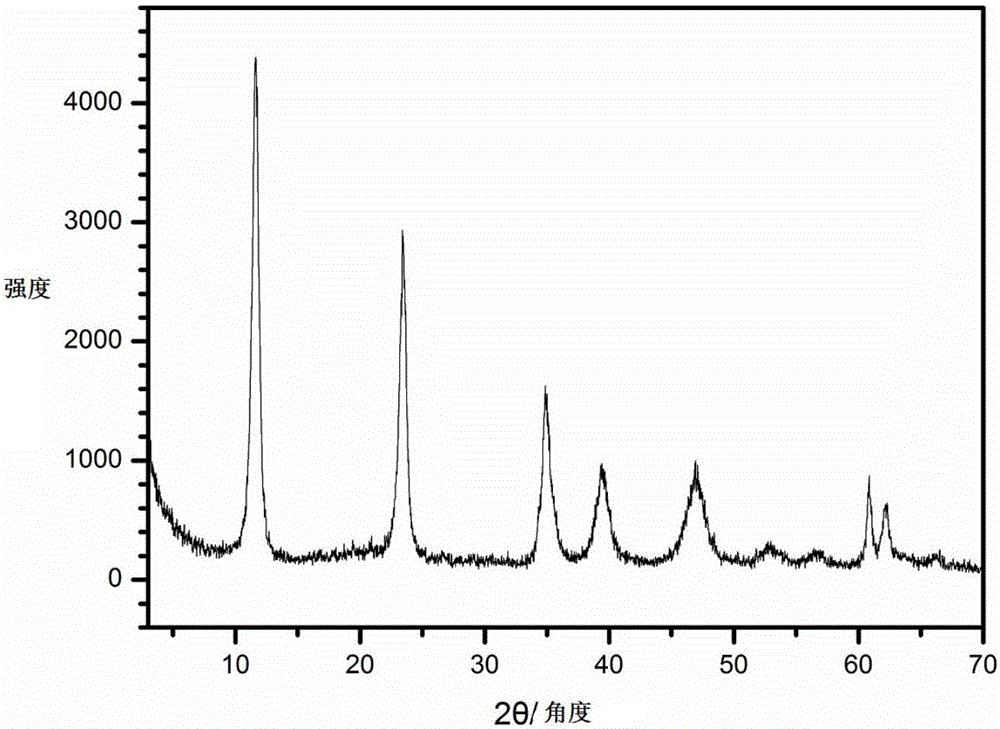

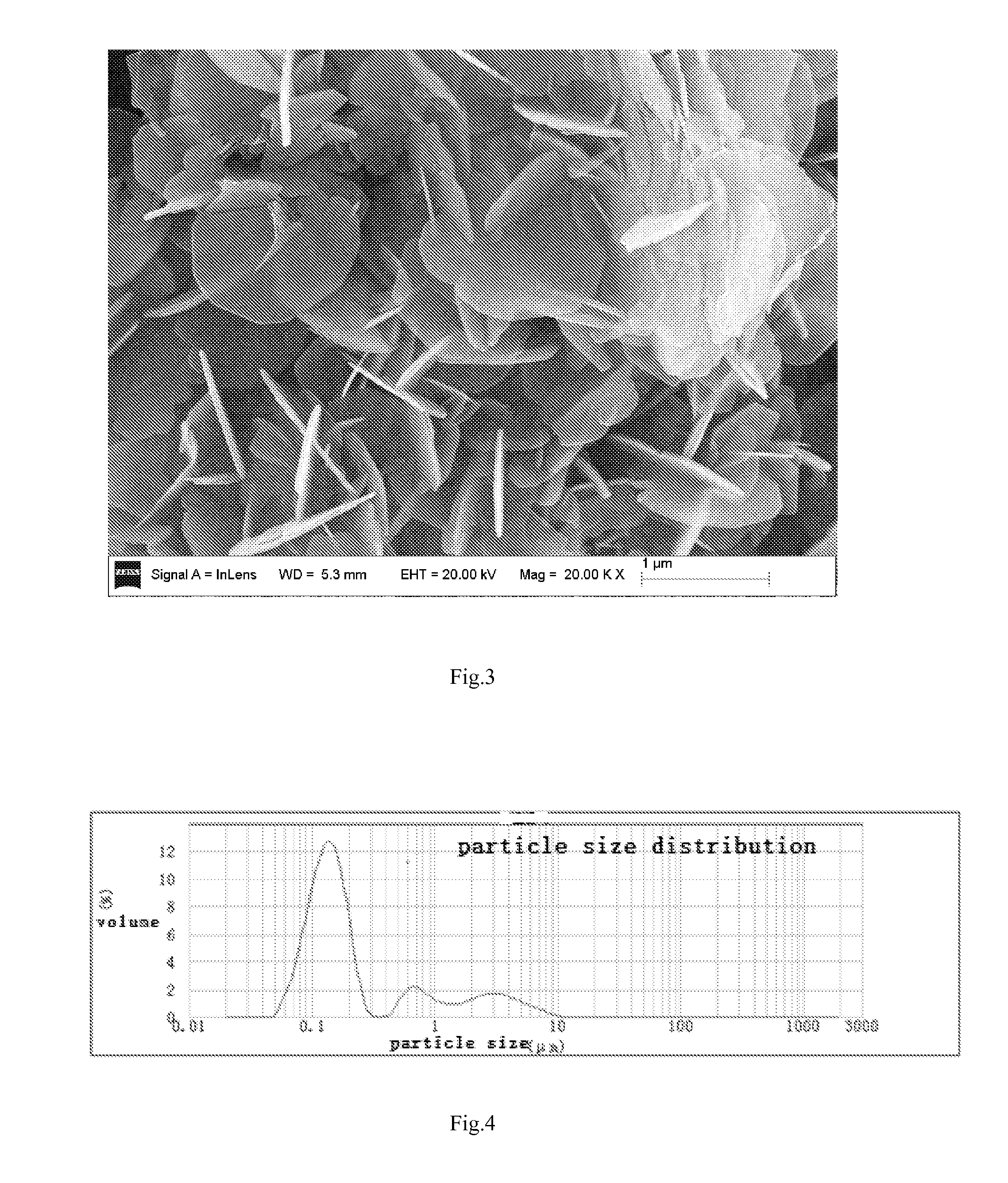

Preparation method for carbonate type hydrotalcite compound powder

InactiveCN108946773AControl particle size distributionHigh reactivityAluminium-carbonate compoundsCobalt compoundsUltrasonic assistedDivalent metal

The invention provides a preparation method for carbonate type hydrotalcite compound powder. The method comprises the following steps: taking divalent metal oxide or hydroxide and trivalent metal hydroxide as main raw materials; compounding with divalent metal carbonate (normal salt or subcarbonate) of the same metal of the divalent metal oxide or hydroxide, for supplying carbonate; directly compounding the hydrotalcite compound with regular structure and uniform grain size through one-step ultrasonic-assisted hydrothermal reaction. The preparation method belongs to atom economy reaction; thereaction speed is high; no waste is discharged during the process; the product can be directly dried without washing, so that water resource can be greatly saved; the method has the characteristics ofsimple technological process, environmental protection and easiness in industrial production.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI +1

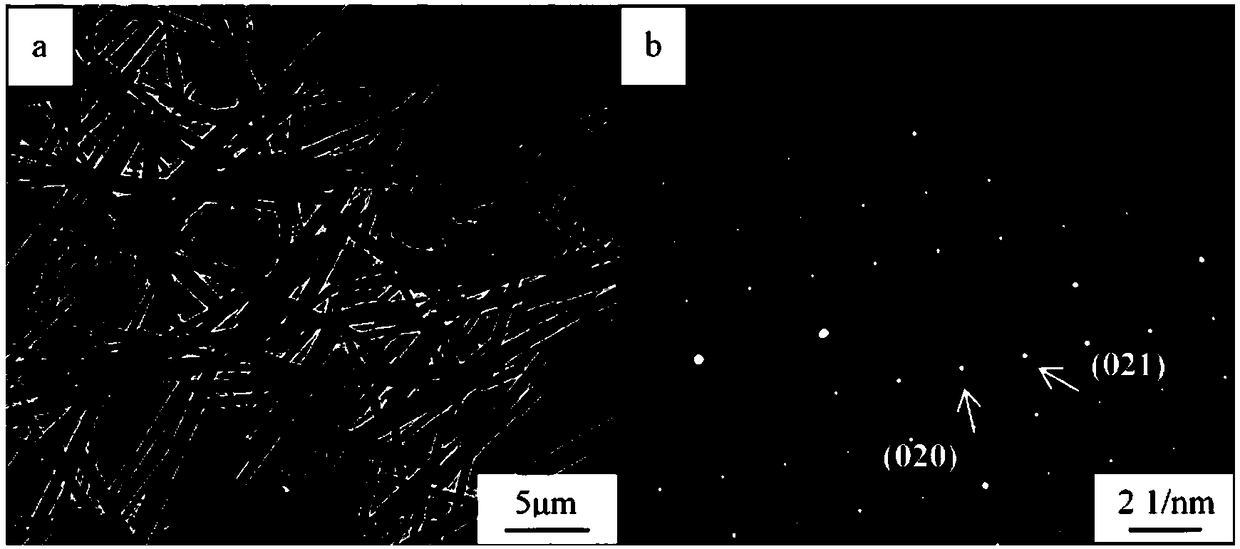

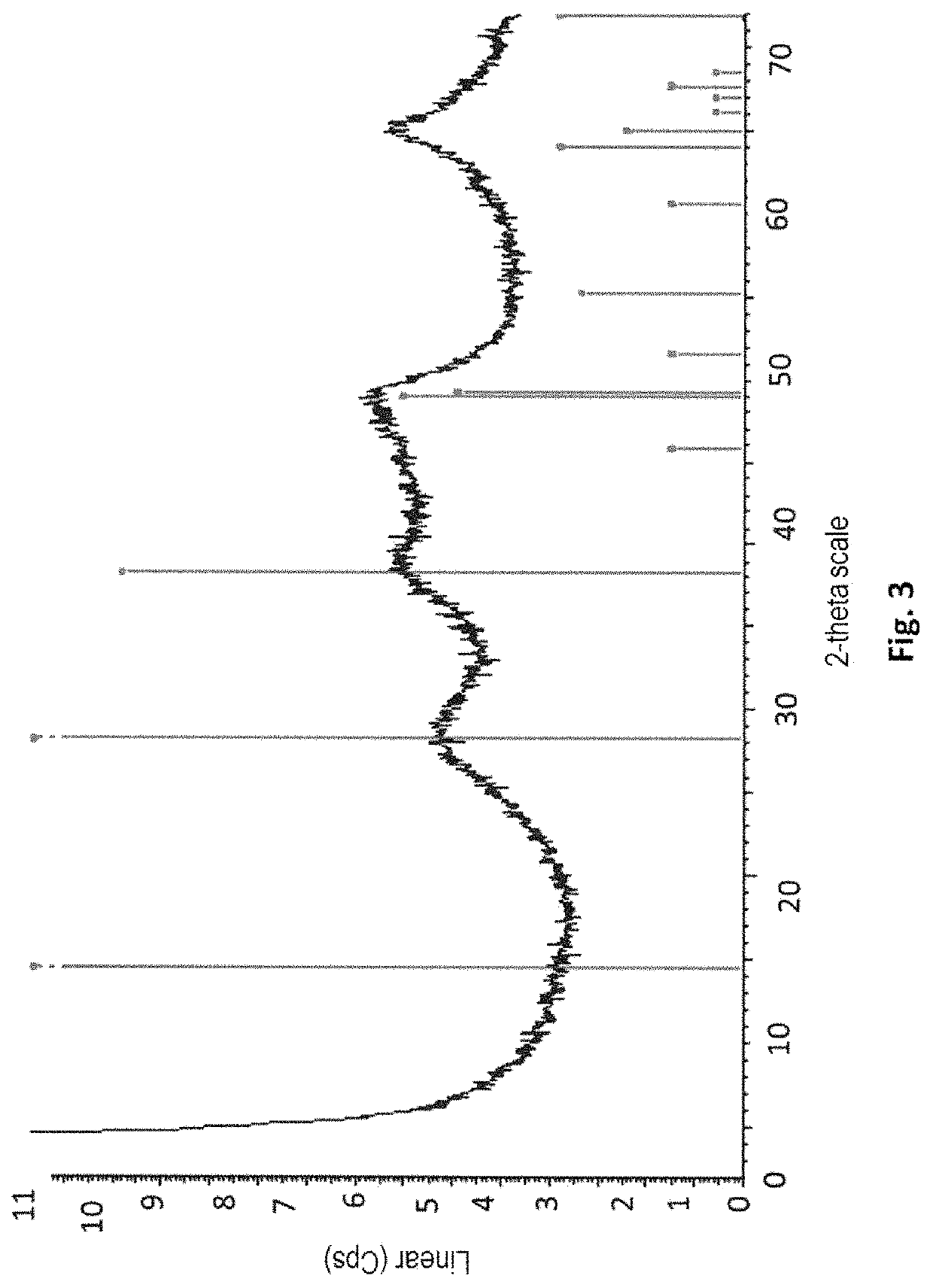

Calcium carbonate hydroxodialuminates comprising a hexagonal platelet-shaped crystal habit

InactiveUS7919066B2Improve water absorptionPigmenting treatmentOther chemical processesAluminum oxide hydroxideAluminium hydroxide

A process is provided for preparing calcium carbonate hydroxodialuminates which have a hexagonal platelet-shaped crystal habit and are of the formula (A):CamAl2(OH)6+2(m−1)An*nH2O (A)where m=3.5 to 4.5 and An=carbonate which may be partly replaced by perchlorate and / or trifluoromethanesulfonate (triflate) and n=0 to 6, comprising the steps of reacting calcium oxide or calcium hydroxide with optionally activated aluminum oxohydroxide or aluminum hydroxide and simultaneously or subsequently with a carbonate source consisting of carbon dioxide or alkali metal (bi)carbonate and optionally further reacting the product obtained in step (a) with perchloric acid and / or trifluoromethanesulfonic acid or optionally calcining the product obtained in step (a) at 200° C. to 900° C. and subsequently exchanging ions in the presence of a perchlorate and / or triflate salt, optionally in the presence of alkali metal (bi)carbonate, in water. The present invention further relates to the aluminates thus obtained in compositions and stabilizer systems and to the use thereof.

Owner:NABALTEC AG

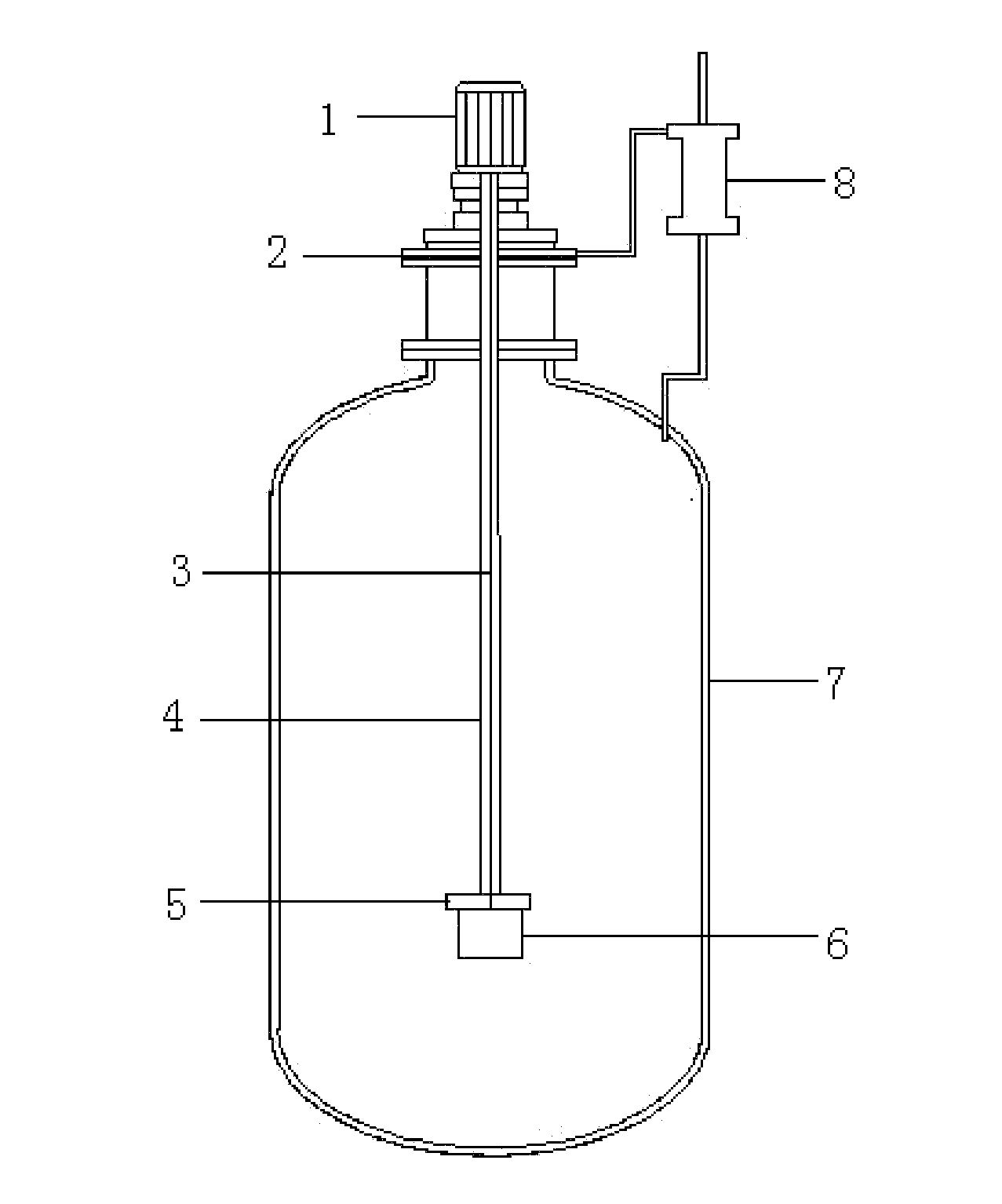

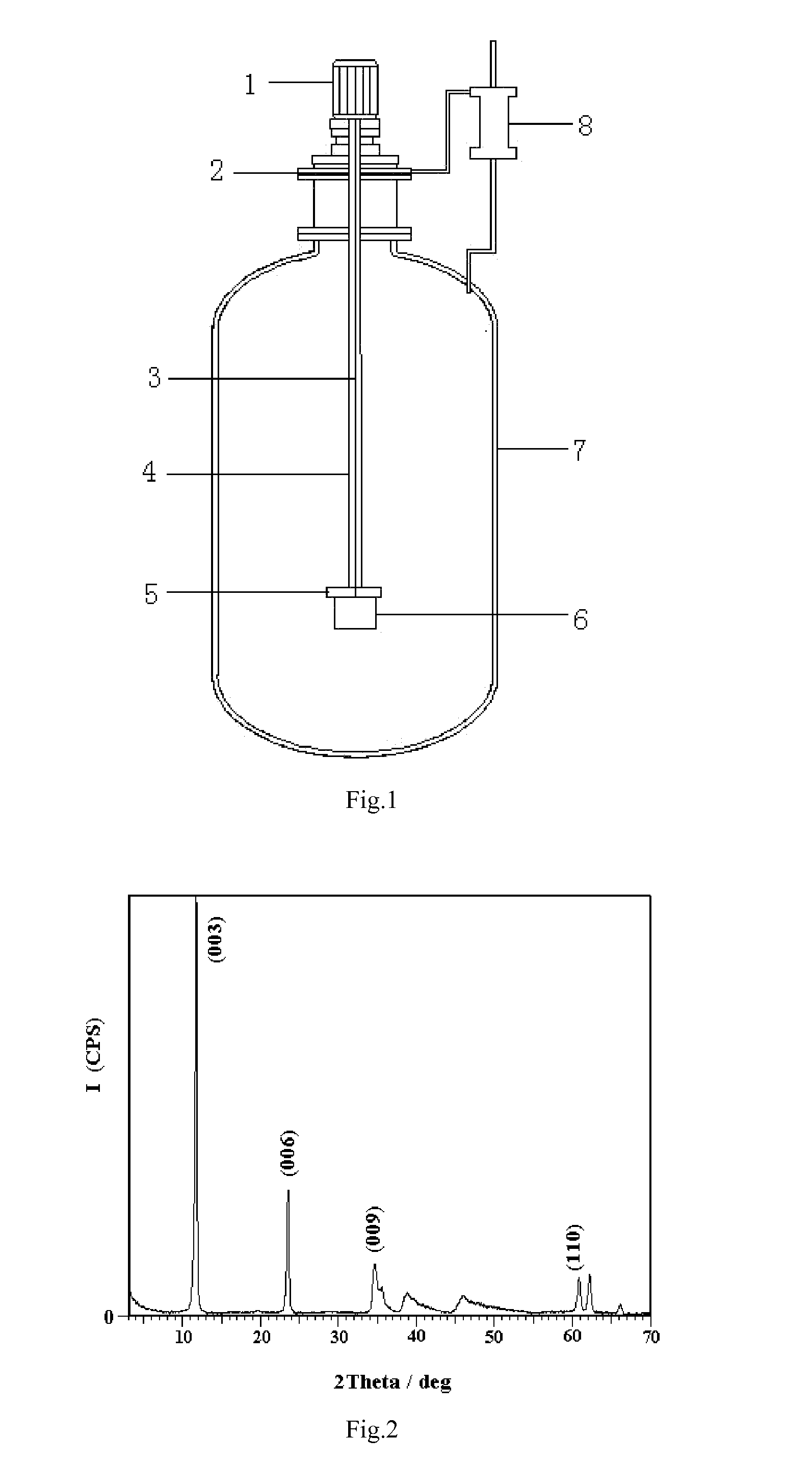

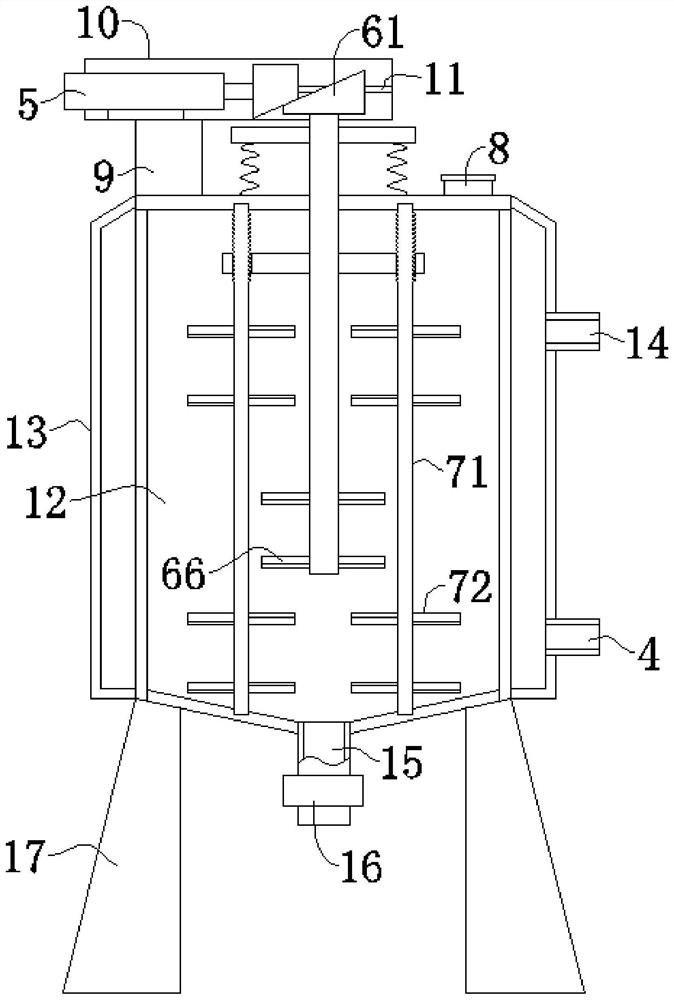

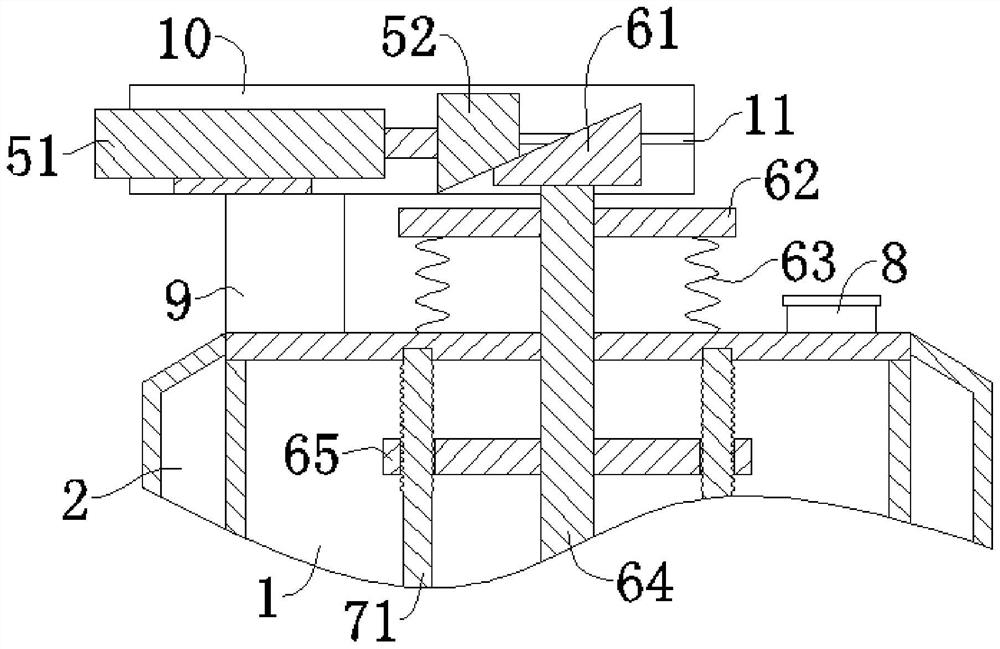

Self-balanced high-pressure and high-shear autoclave and the application in the preparation of layered double hydroxides

ActiveUS20160009566A1Alleviate volume effectStable pressureOxygen/ozone/oxide/hydroxideZinc oxides/hydroxidesMotor driveReaction temperature

The present invention belongs to the synthesis technology field of inorganic functional materials, and particularly provides a self-balanced high-pressure and high-shear autoclave and its application in the preparation of layered double hydroxides (LDHs). In this invention, by imbedding the handpiece of emulsification mill into the autoclave, and by taking the motor driving system outside of the autoclave, the pressure of the autoclave can be highly stable by the use of self-balanced seal gland. These characters solve the problem that the typical emulsification mill cannot be used in high-pressure system, and ensure the crystallization under the high-pressure and high-shear conditions. Such autoclave takes the advantages of additional equipment, and eliminates the volume effect in the amplification process. By the use of this new autoclave, the reaction time can be shorten from 24 hours to 2-6 hours, the reaction temperature can be reduced from 180° C. to 140° C. The LDHs products with small particle size and narrow size distribution are obtained. These results are better than those prepared at the laboratory level.

Owner:BEIJING UNIV OF CHEM TECH

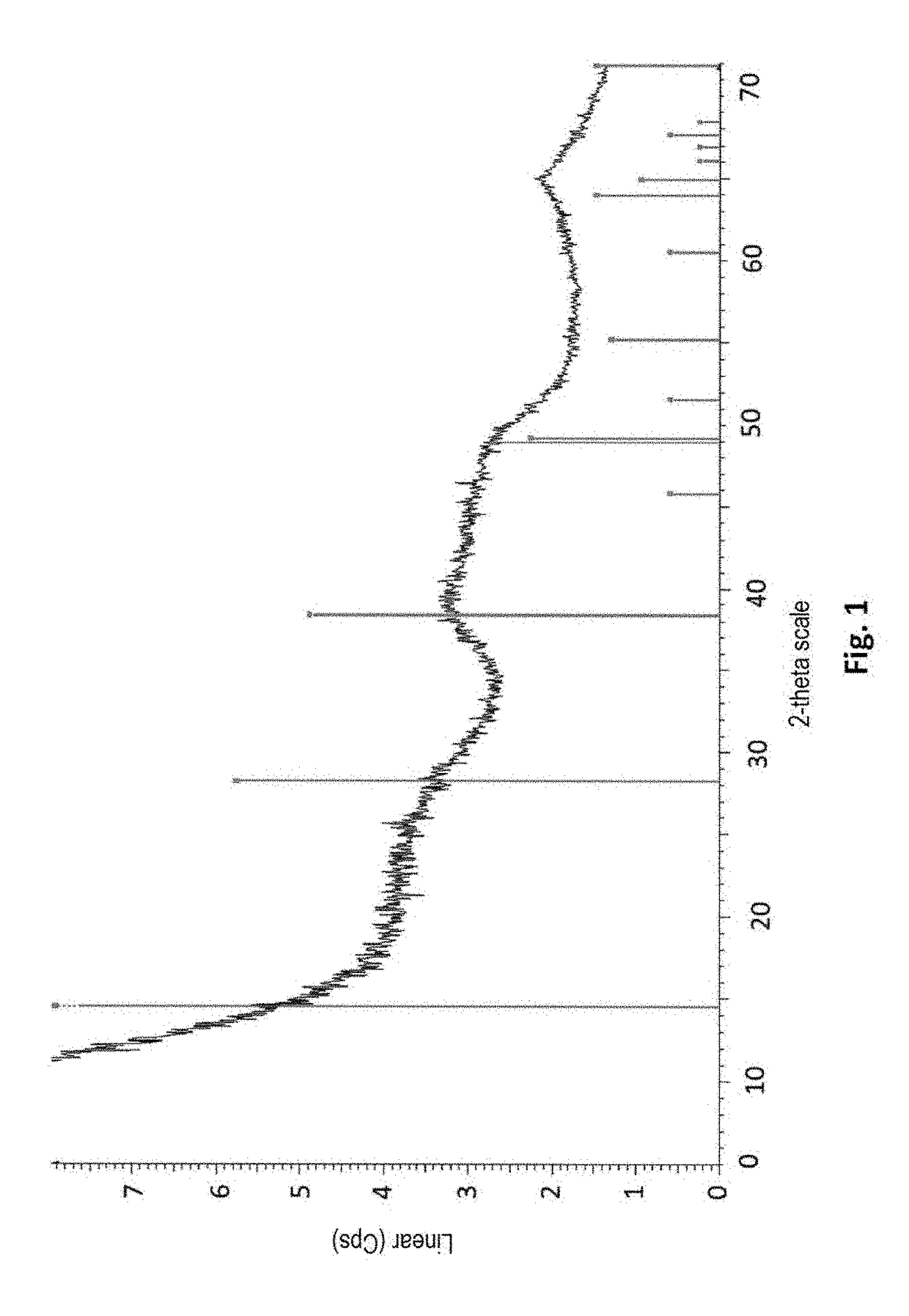

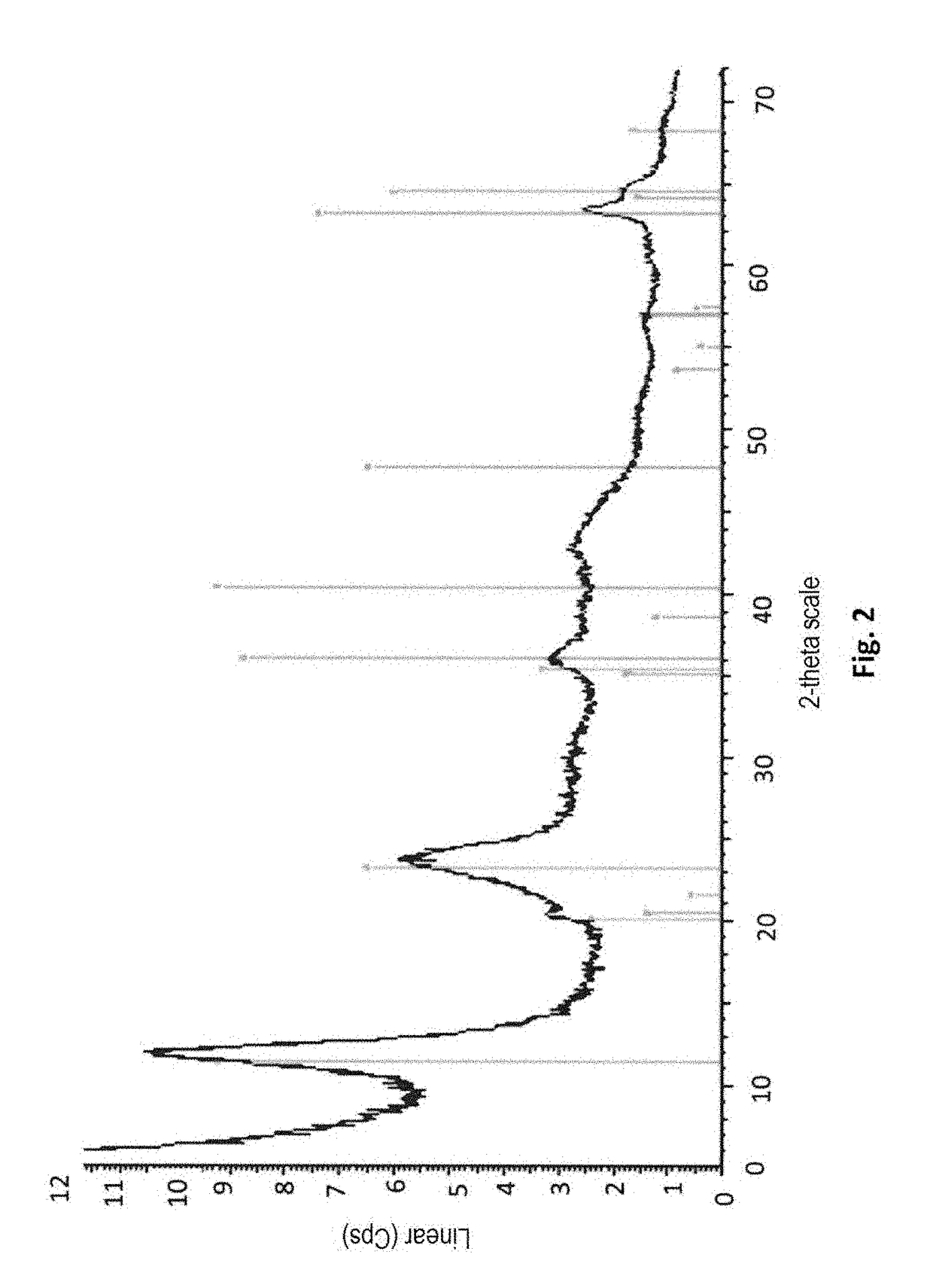

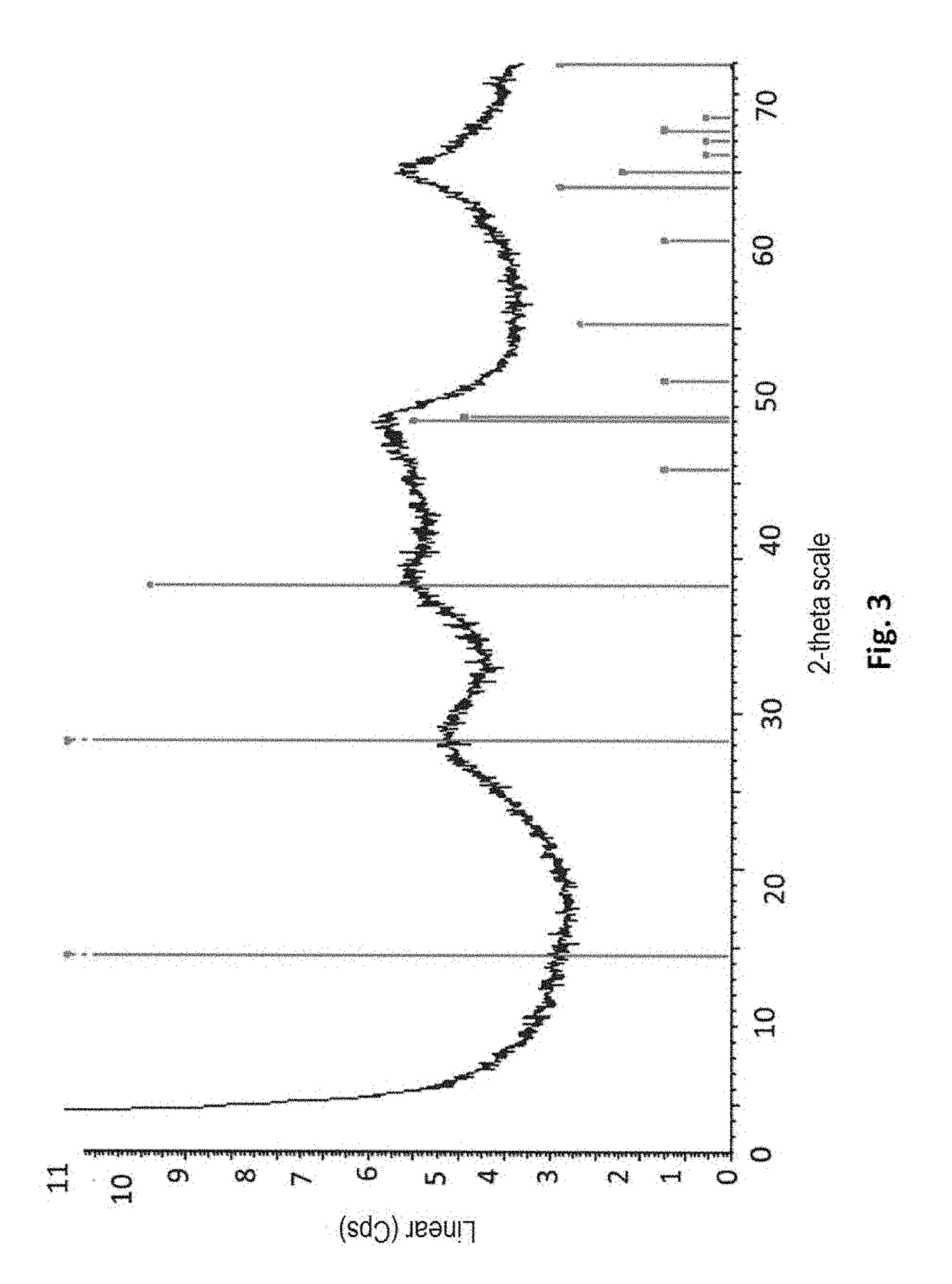

Process for conversion of aluminum oxide hydroxide

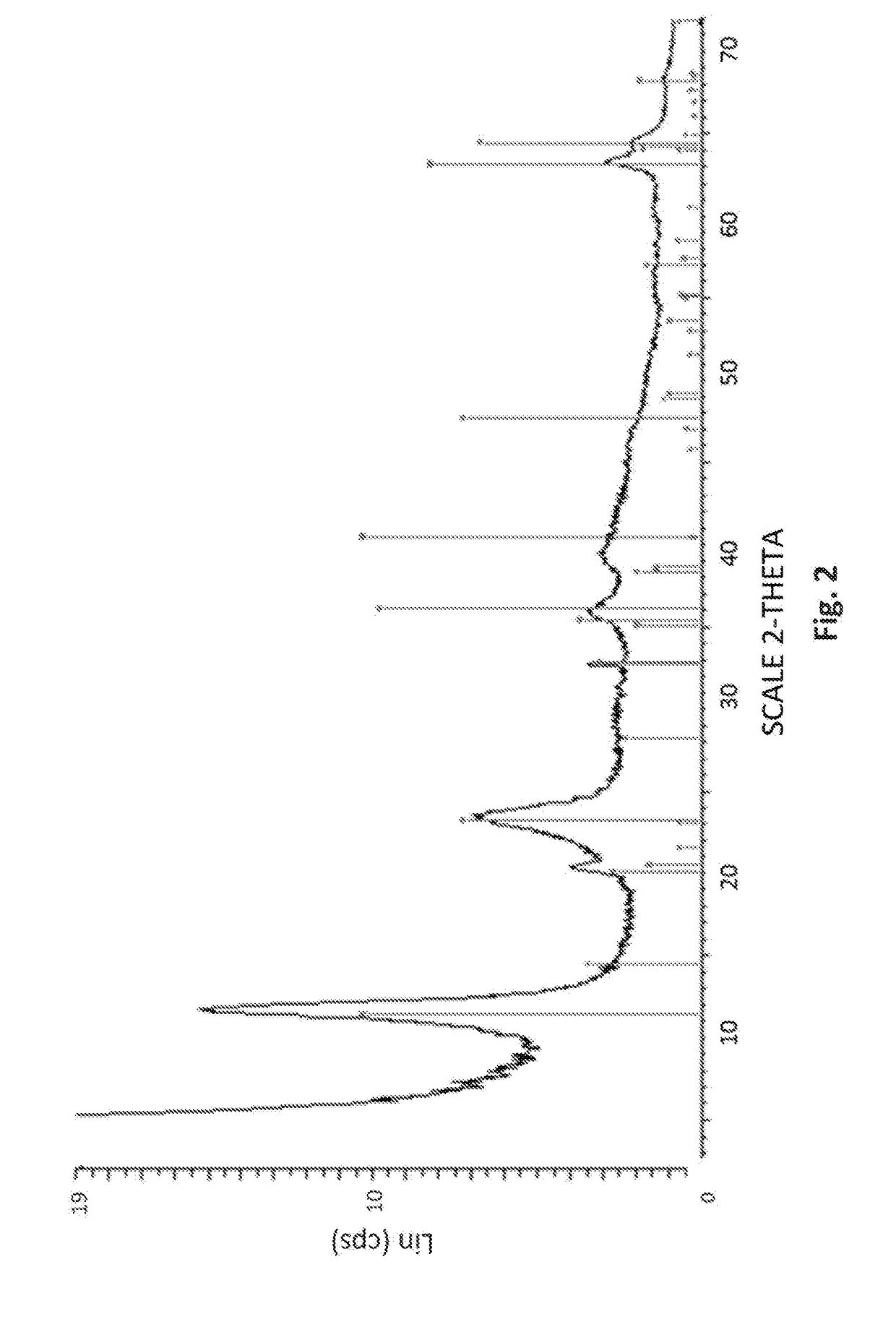

ActiveUS7947250B2Aluminium oxide/hydroxide preparationAluminium-carbonate compoundsAluminium hydroxideAluminum oxide hydroxide

The present invention is a process for the conversion of aluminum oxide hydroxide (AlOOH) to aluminum oxide. About 30 to 70 wt-% of AlOOH, about 30 to 70 wt-% ammonium hydrogencarbonate NH4HCO3 and 0 to 20 wt-% water are combined to produce a mixture. This mixture is then cured at a temperature from about 30° to about 90° C. to convert at least 5% of the AlOOH to a ammonium hydroxycarbonate (dawsonite-type) intermediate and then the dawsonite-type intermediate is decomposed at a temperature from about 130° to 320° C. to produce aluminum oxide. The aluminum oxide can be further calcined at 500° to 800° C. to produce a gamma-theta phase alumina.

Owner:UOP LLC

Calcium-aluminum hydrotalcite and preparation method thereof

PendingCN110078103AHigh purityImprove use valueAluminium-carbonate compoundsAluminum IonHydrotalcite

The invention belongs to the technical field of preparation of hydrotalcite-like compounds, and particularly relates to calcium-aluminum hydrotalcite and a preparation method thereof. The preparationmethod of calcium-aluminum hydrotalcite provided by the invention comprises the following steps: step (1) mixing a calcium source, an aluminum source, a stabilizer and water to obtain mixed liquid, and carrying out a reaction to obtain intermediate slurry, wherein anions in the mixed liquid contain OH<-> and complex anion; the complex anion contains one or more of Cl<->, F<->, SO4<2->, NO3-, PO4<3-> and HPO4<2->; and step (2) mixing and crystallizing the intermediate slurry and an alkaline salt solution to obtain the calcium-aluminum hydrotalcite. The preparation method provided by the invention follows a 'rapid nucleation mechanism'; and an intermediate is generated during preparation to avoid CaCO3 and other impurities generated by direct contact of calcium ions and aluminum ions and anions of an alkali solution, so that the prepared calcium-aluminum hydrotalcite has uniform crystal phase and high purity.

Owner:ZHAOQING UNIV +1

Calcium carbonate hydroxodialuminates comprising a hexagonal platelet-shaped crystal habit

InactiveUS20090292052A1Improve water absorptionPigmenting treatmentOther chemical processesAluminateAluminium hydroxide

A process is provided for preparing calcium carbonate hydroxodialuminates which have a hexagonal platelet-shaped crystal habit and are of the formula (A):CamAl2(OH)6+2(m−1)An*nH2O (A)where m=3.5 to 4.5 and An=carbonate which may be partly replaced by perchlorate and / or trifluoromethanesulfonate (triflate) and n=0 to 6, comprising the steps of reacting calcium oxide or calcium hydroxide with optionally activated aluminum oxohydroxide or aluminum hydroxide and simultaneously or subsequently with a carbonate source consisting of carbon dioxide or alkali metal (bi)carbonate and optionally further reacting the product obtained in step (a) with perchloric acid and / or trifluoromethanesulfonic acid or optionally calcining the product obtained in step (a) at 200° C. to 900° C. and subsequently exchanging ions in the presence of a perchlorate and / or triflate salt, optionally in the presence of alkali metal (bi)carbonate, in water. The present invention further relates to the aluminates thus obtained in compositions and stabilizer systems and to the use thereof.

Owner:NABALTEC AG

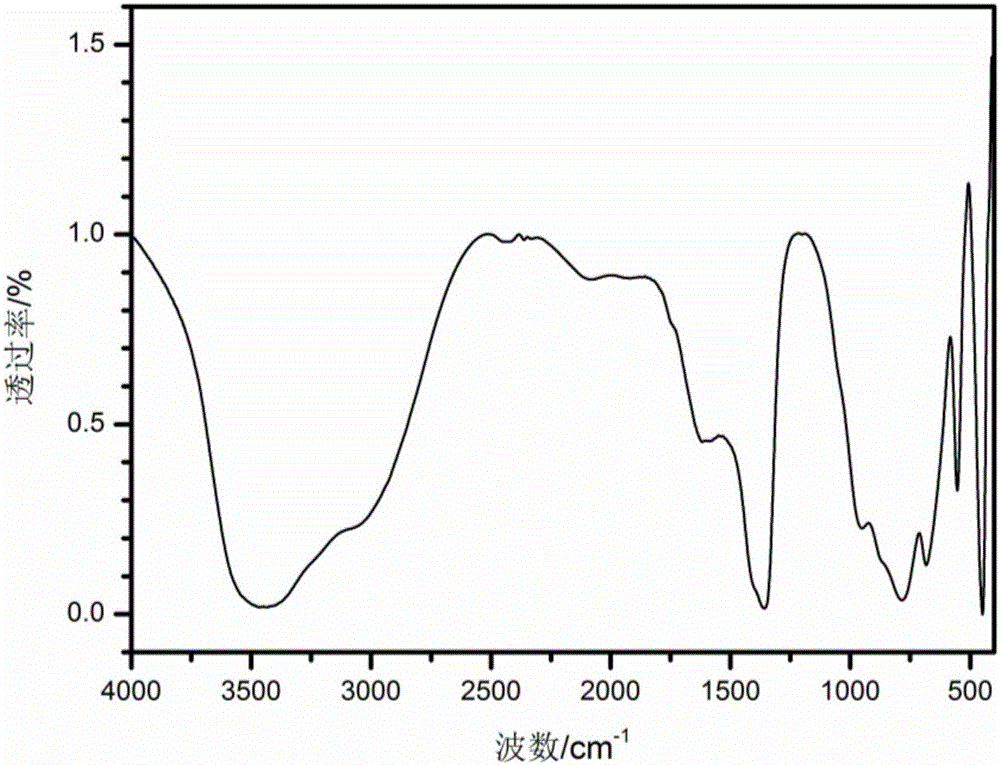

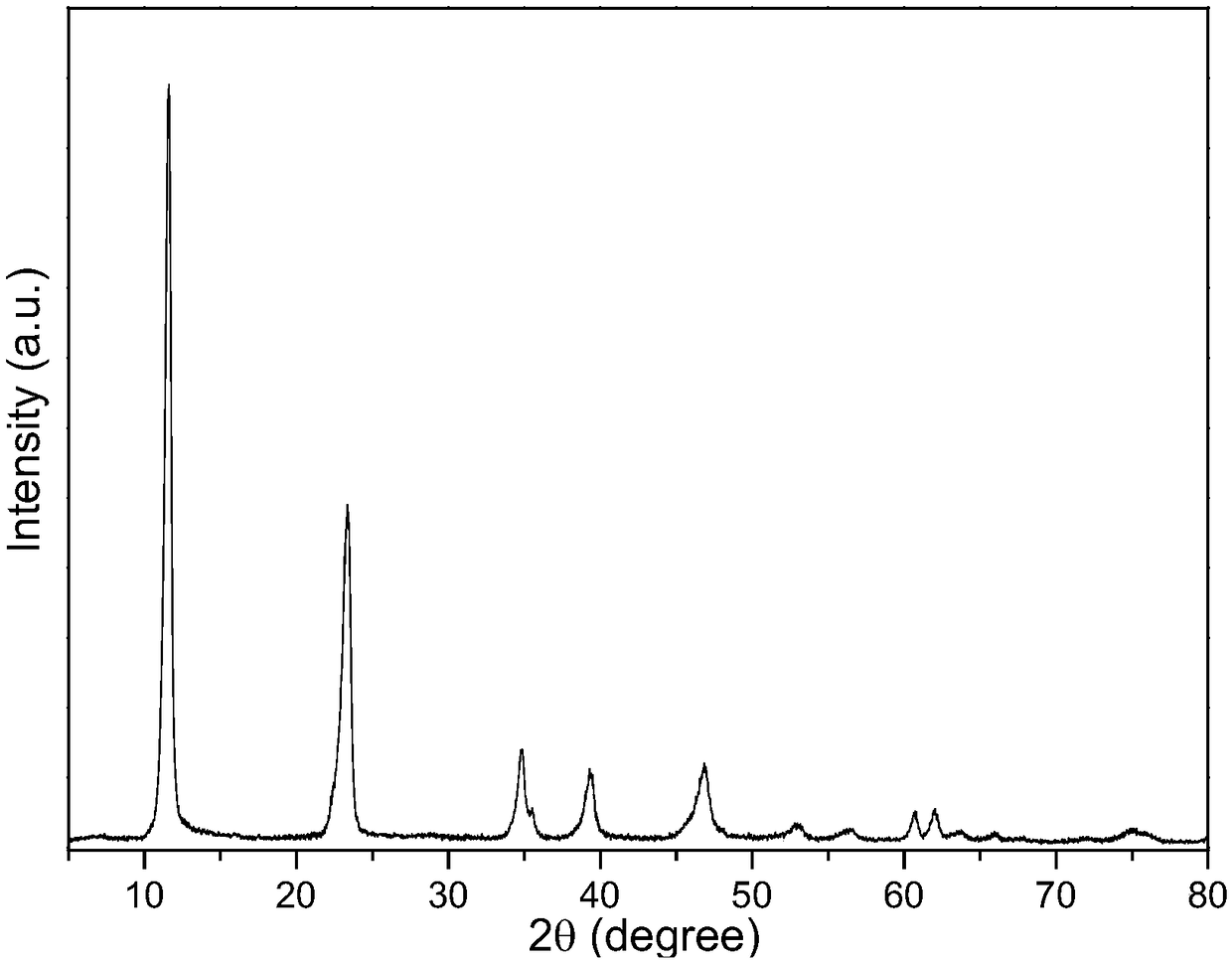

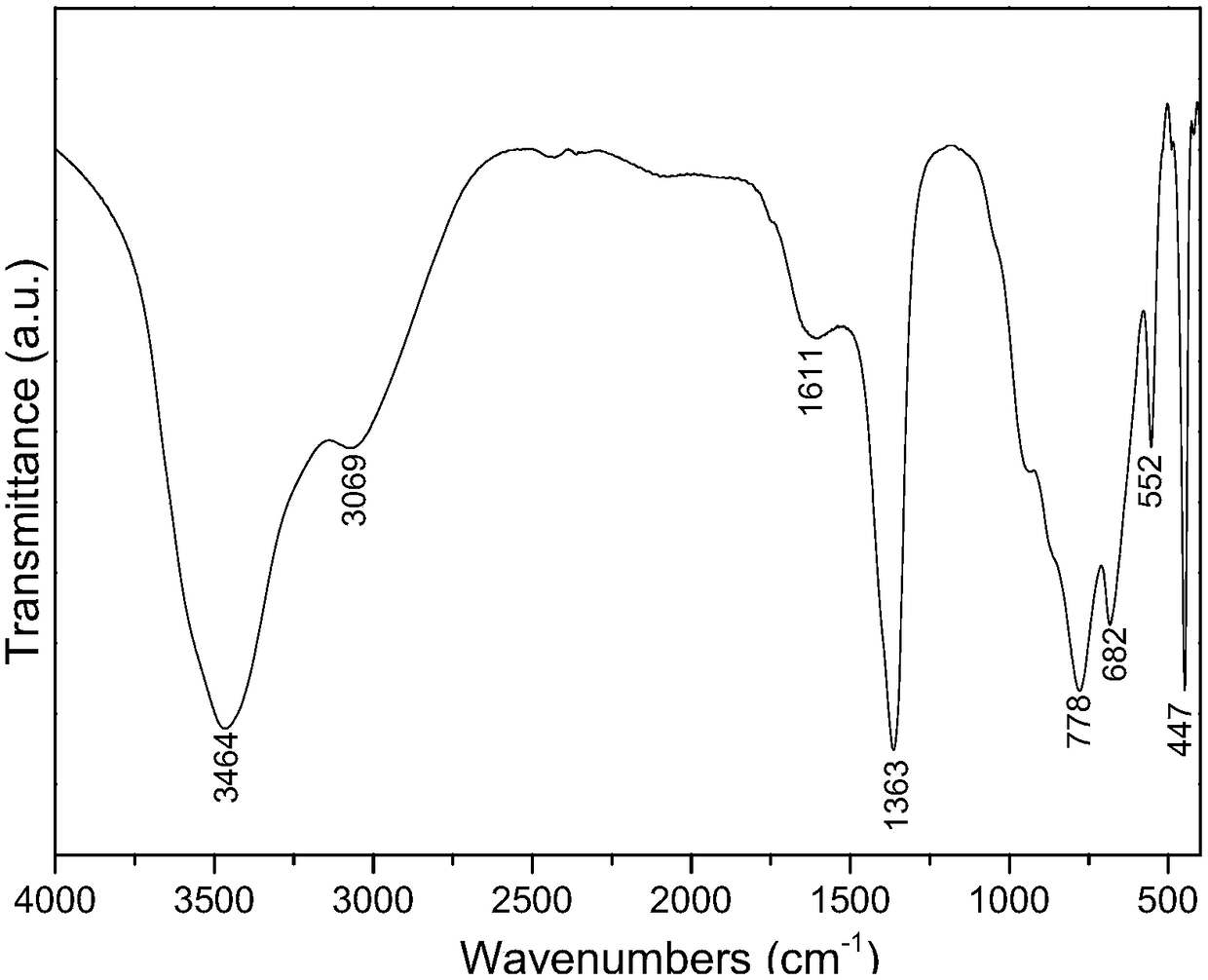

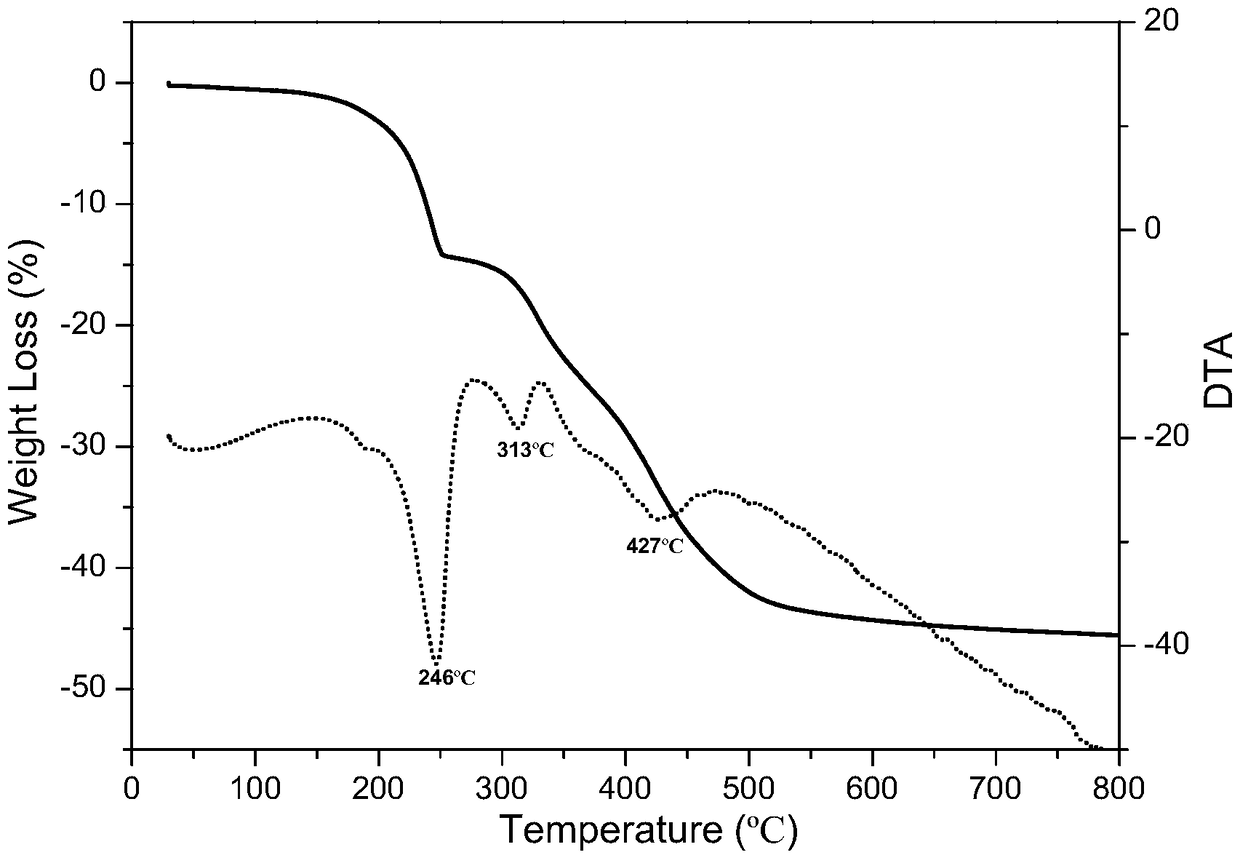

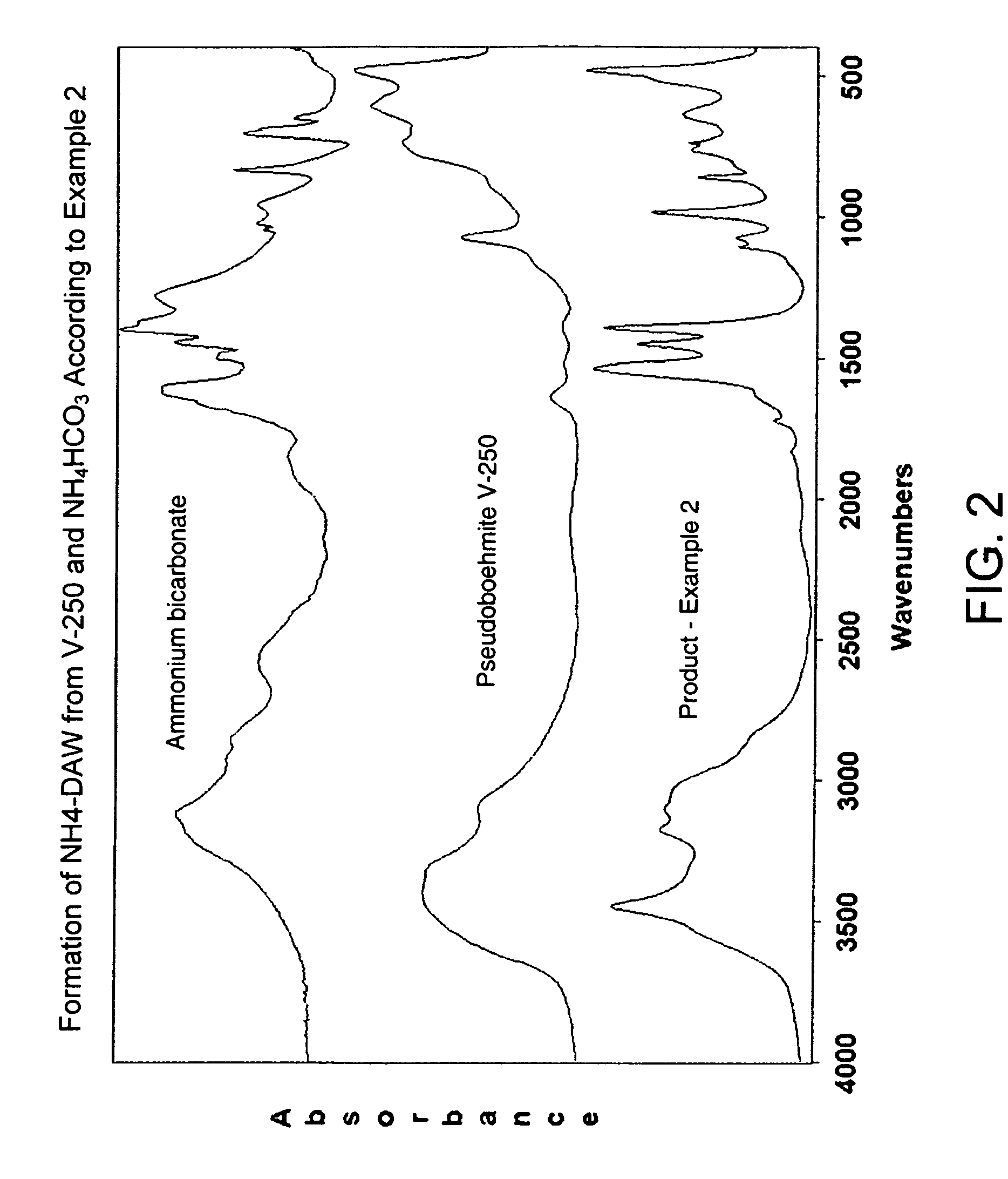

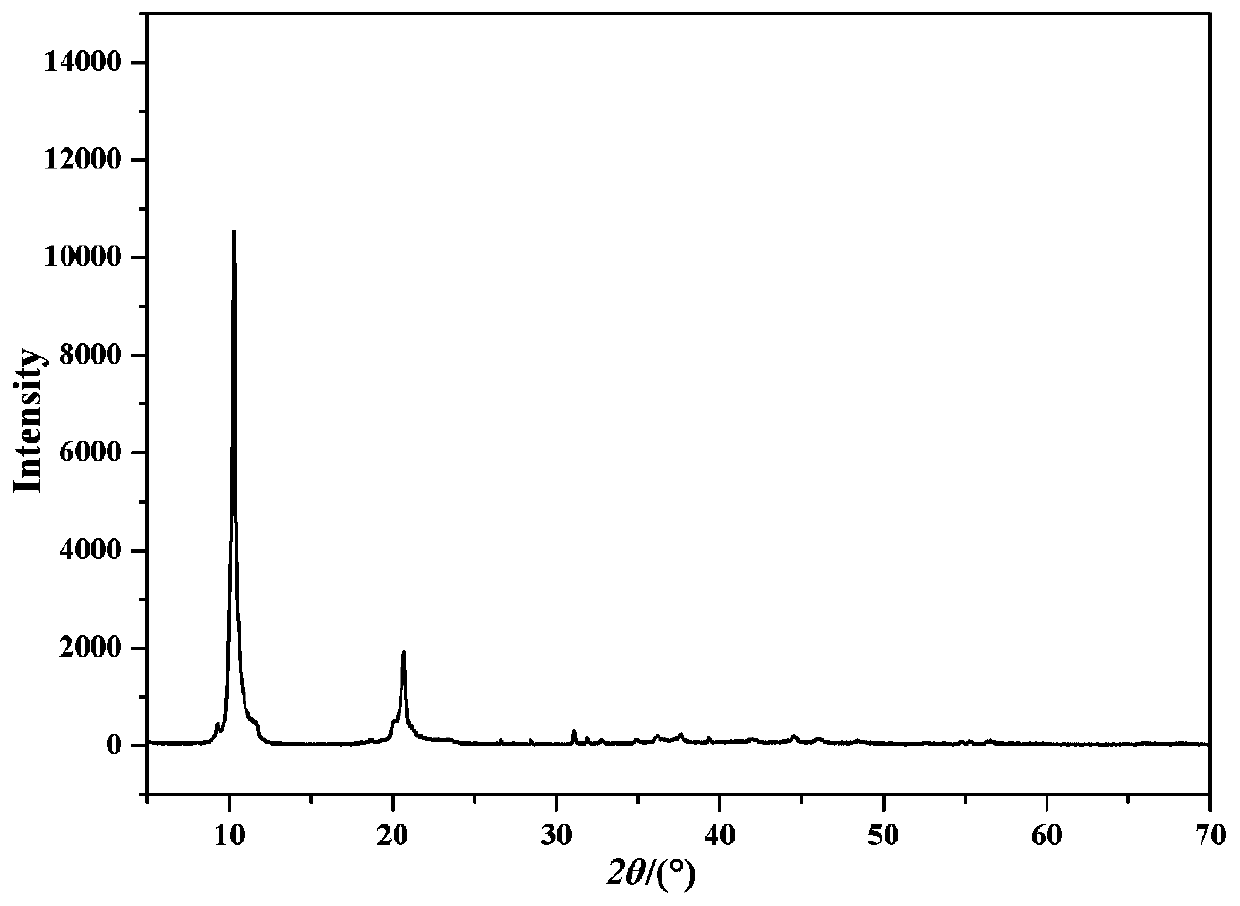

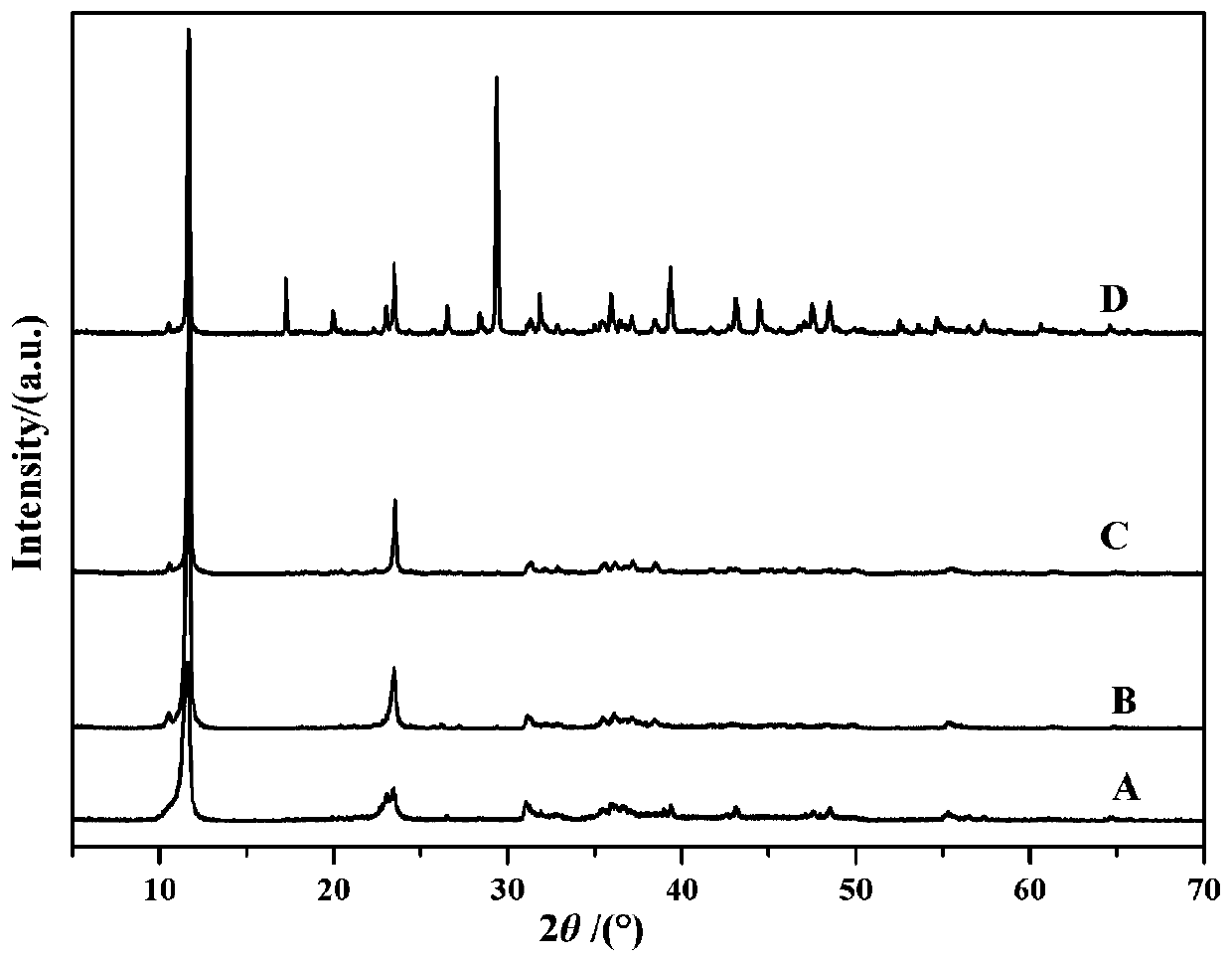

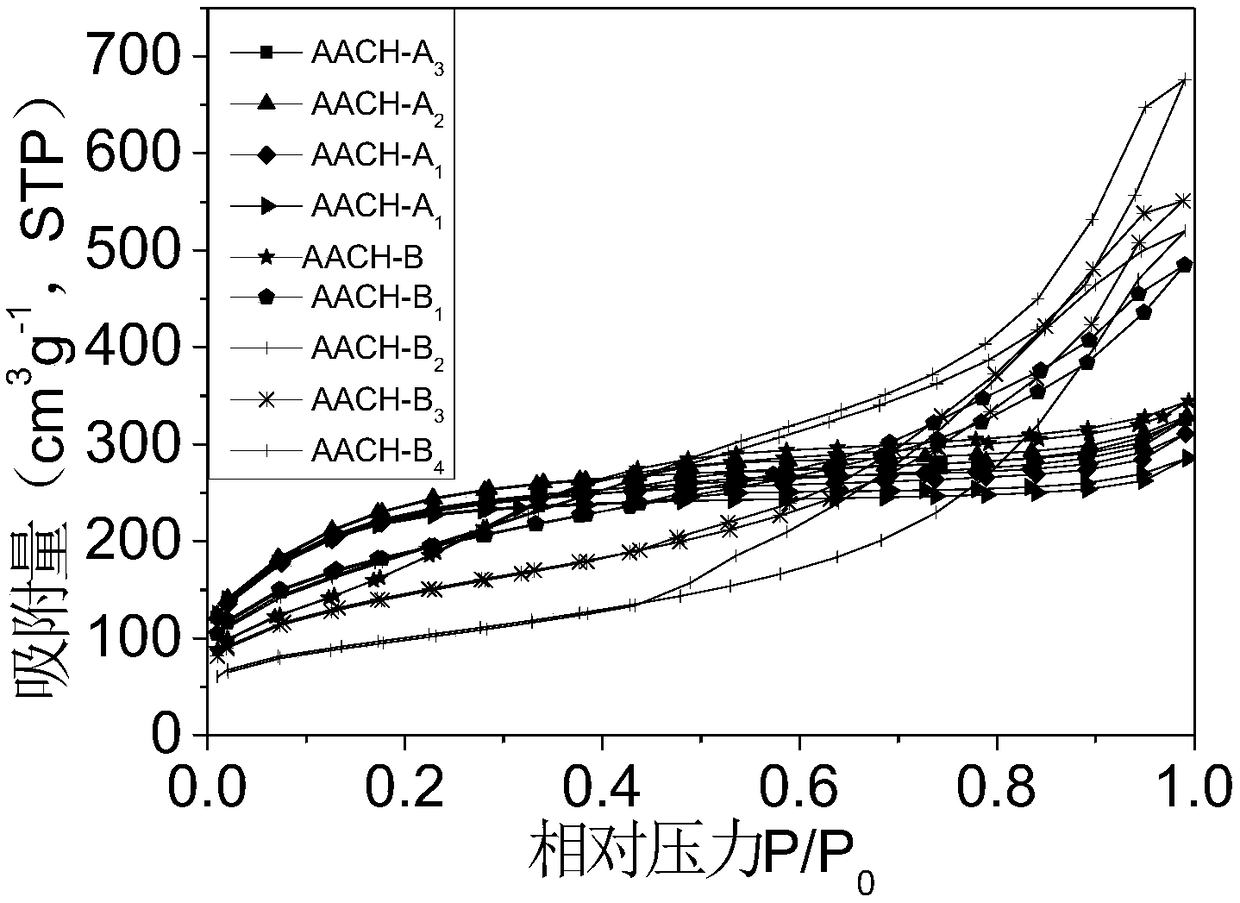

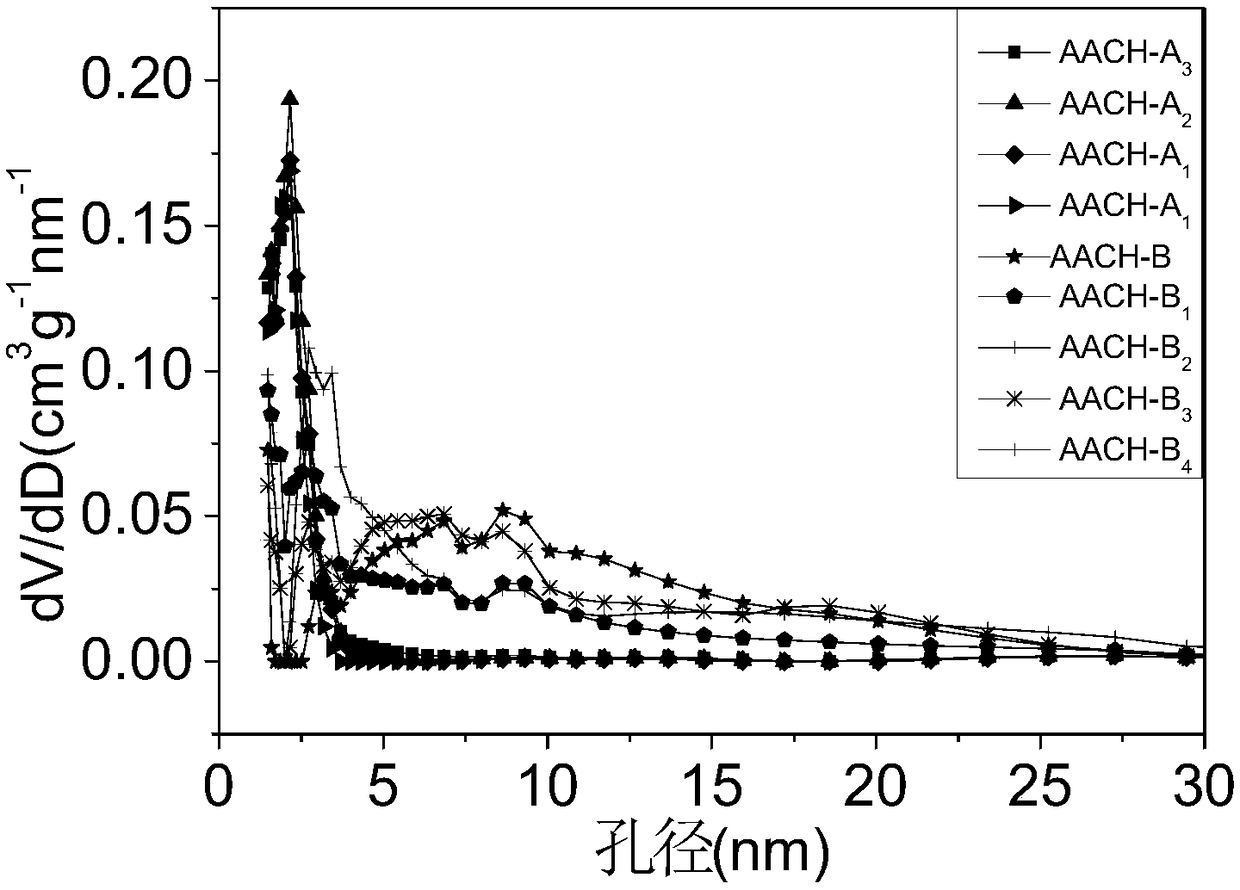

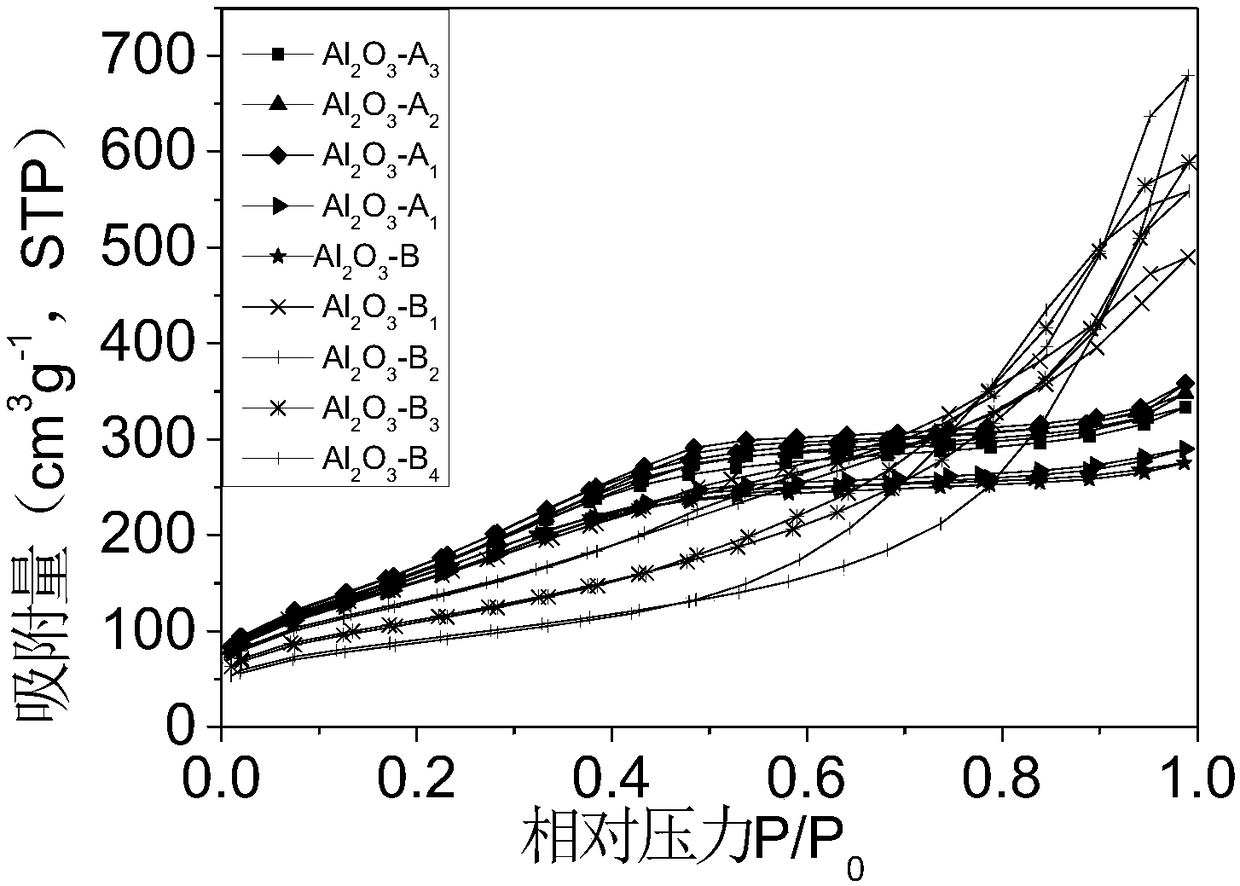

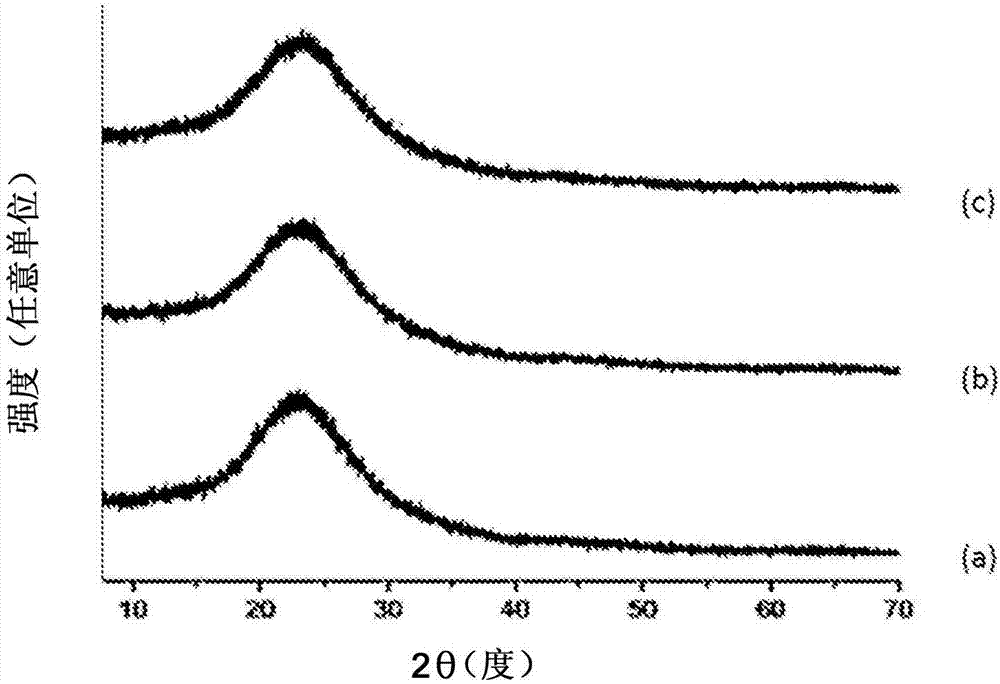

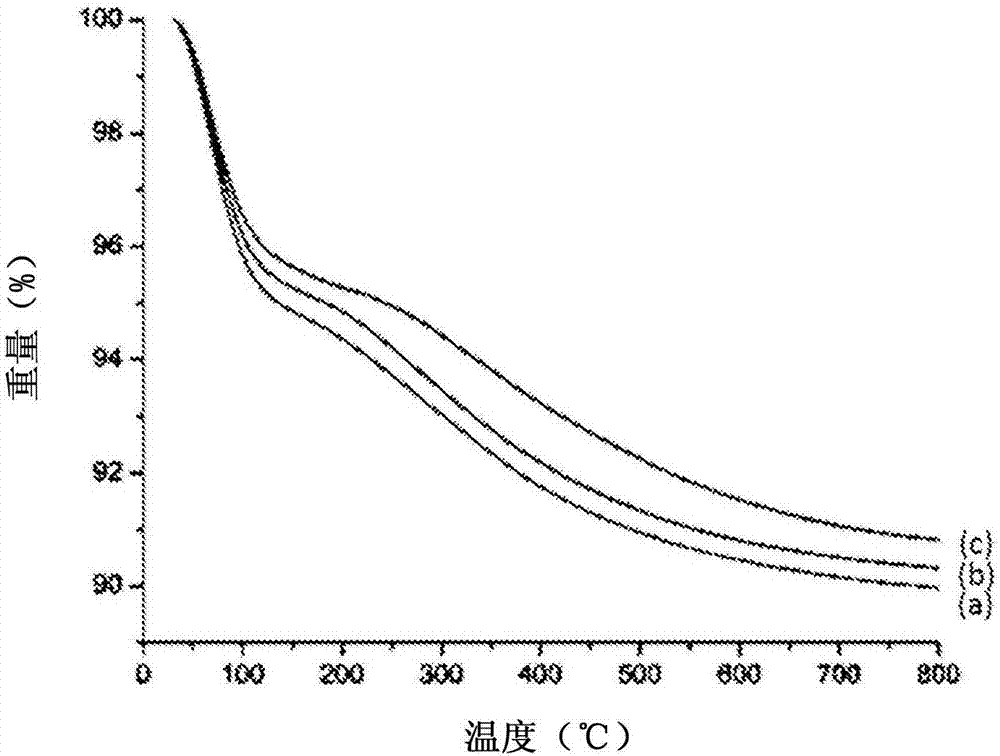

Green technology for synthesizing ammonium aluminum carbonate hydroxide and pyrolysis thereof to prepare high specific surface alumina

InactiveCN109292802AIncrease profitAchieve recyclingAluminium oxide/hydroxide preparationAluminium-carbonate compoundsAmmonium Hydrogen CarbonateCalcination

The present invention discloses a green technology for synthesizing ammonium aluminum carbonate hydroxide and a pyrolysis thereof to prepare high specific surface alumina. The green technology comprises the following steps: a, ammonium salts (ammonium carbonate and ammonium hydrogencarbonate) or amide compounds (formamide, acetamide, urea, etc.) are used as a modifier to prepare a clarified solution; b, pseudo-boehmite is added to the clarified solution in the step a at a certain molar ratio, the materials are stirred until the solution is uniform, then the solution is transferred to a crystallization kettle, crystallized solids are washed and dried to obtain the ammonium aluminum carbonate hydroxide (AACH), and obtained mother liquor is recycled for use; c, after the mother liquor obtained in step b is cooled, a certain amount of the modifier is supplemented for use, and the step b is repeated; and d, the ammonium aluminum carbonate hydroxide is pyrolyzed to obtain the high specific surface alumina. The AACH synthesized by the provided method for synthesizing the ammonium aluminum carbonate hydroxide has a specific surface as high as 812.5 m<2>g, after high temperature calcinations, the obtained alumina still has a relatively high specific surface (681.8 m<2> / g), and the green technology realizes the recycling of the mother liquor after reaction, and is free of waste liquid discharge, energy-saving and environmentally protective.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

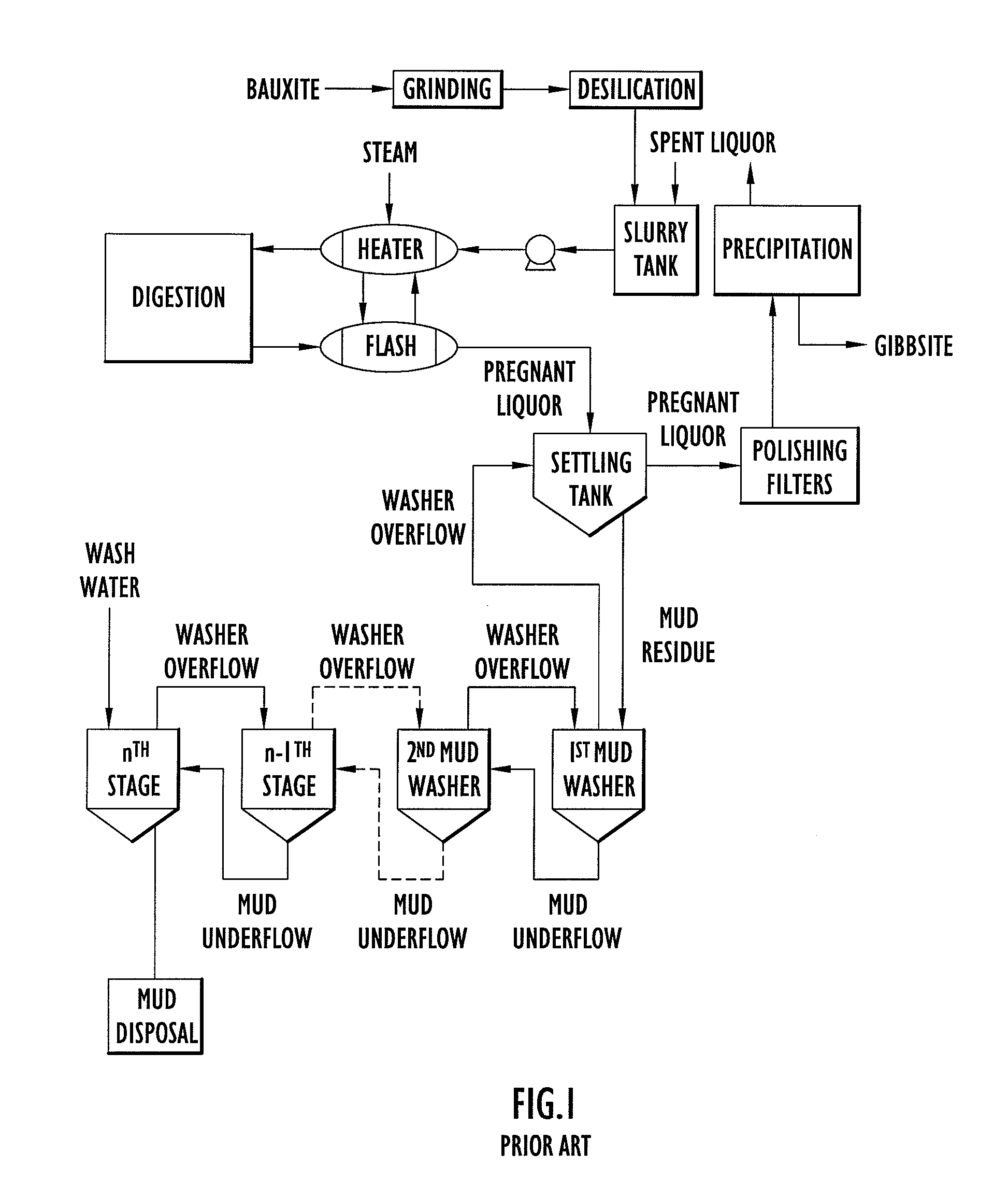

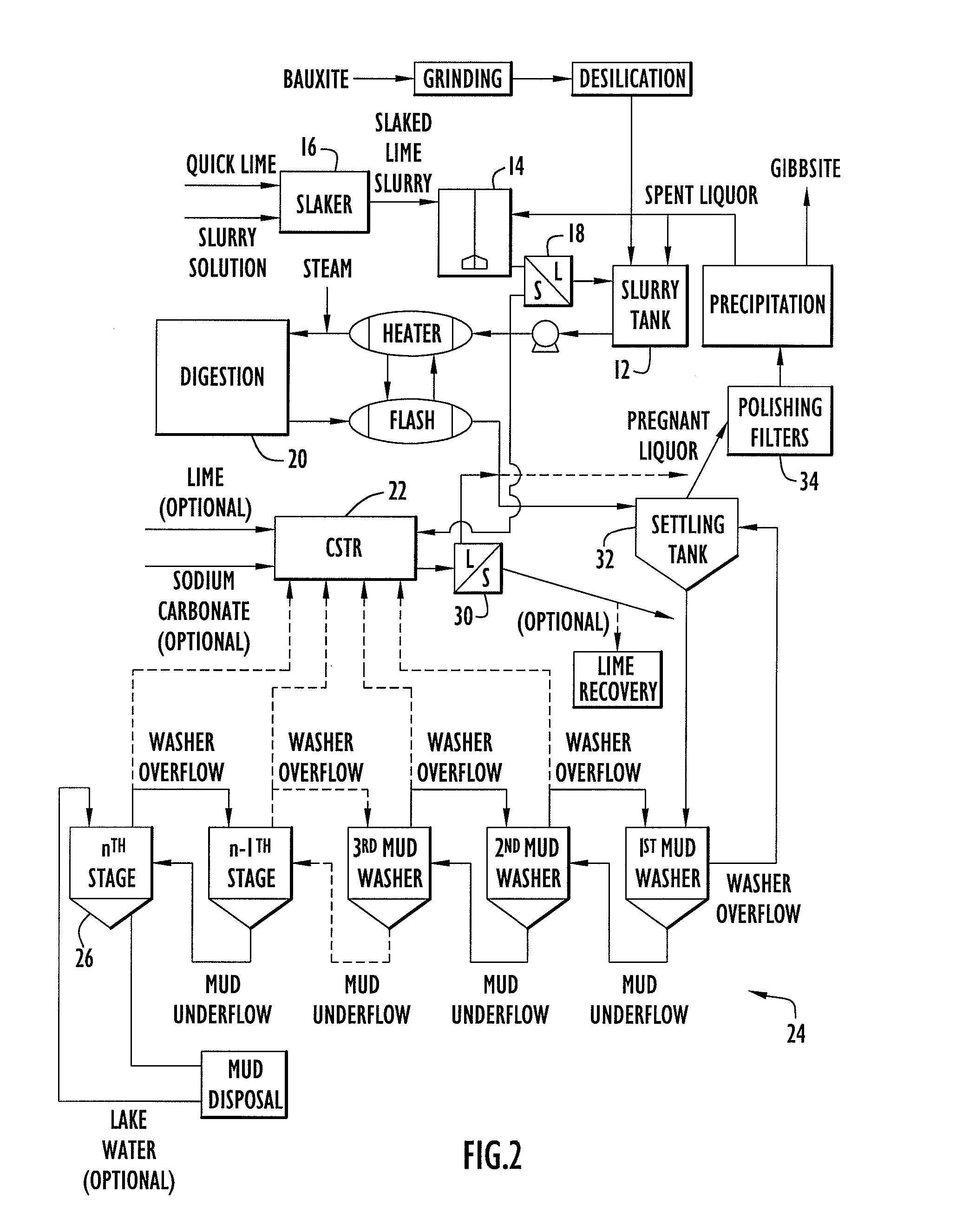

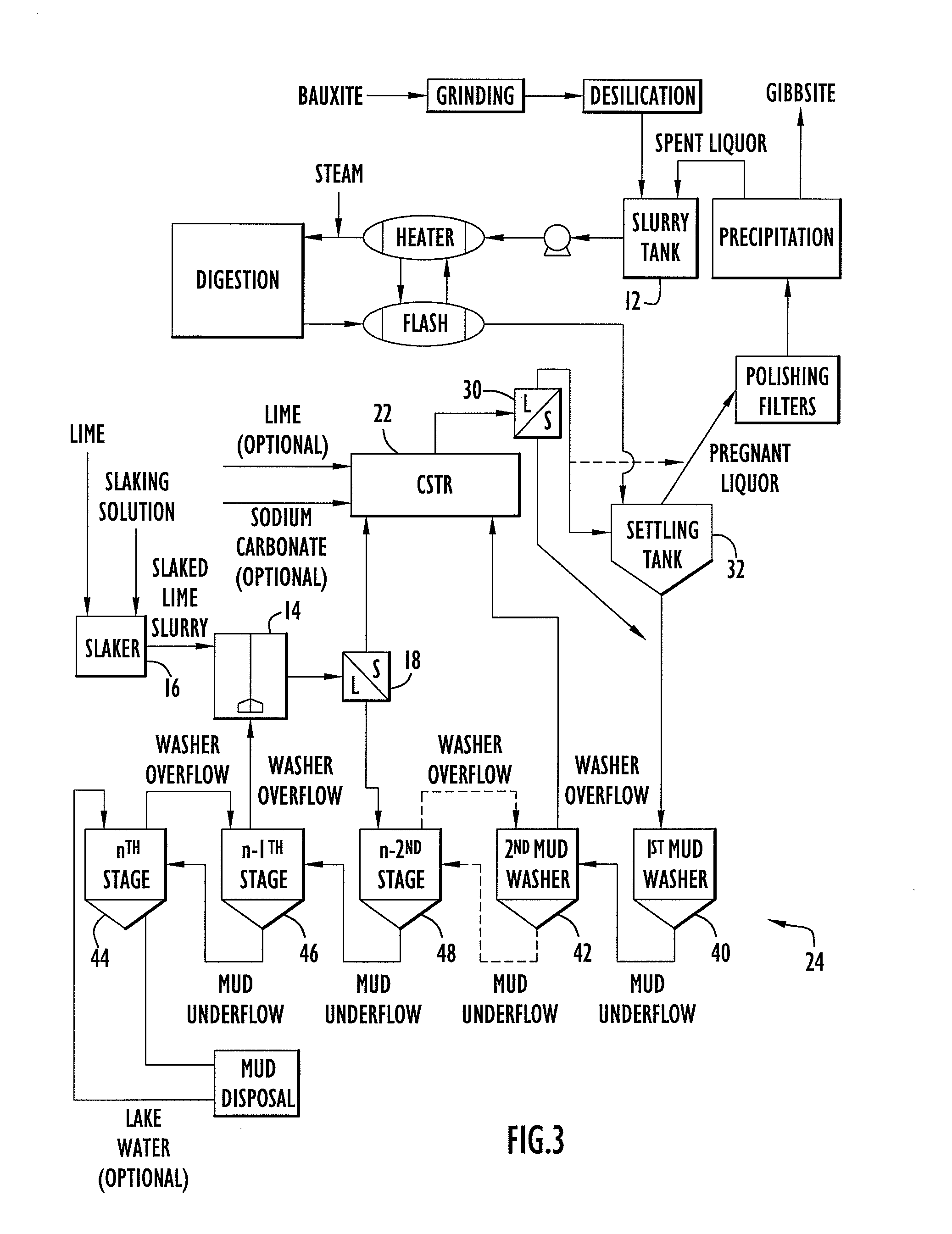

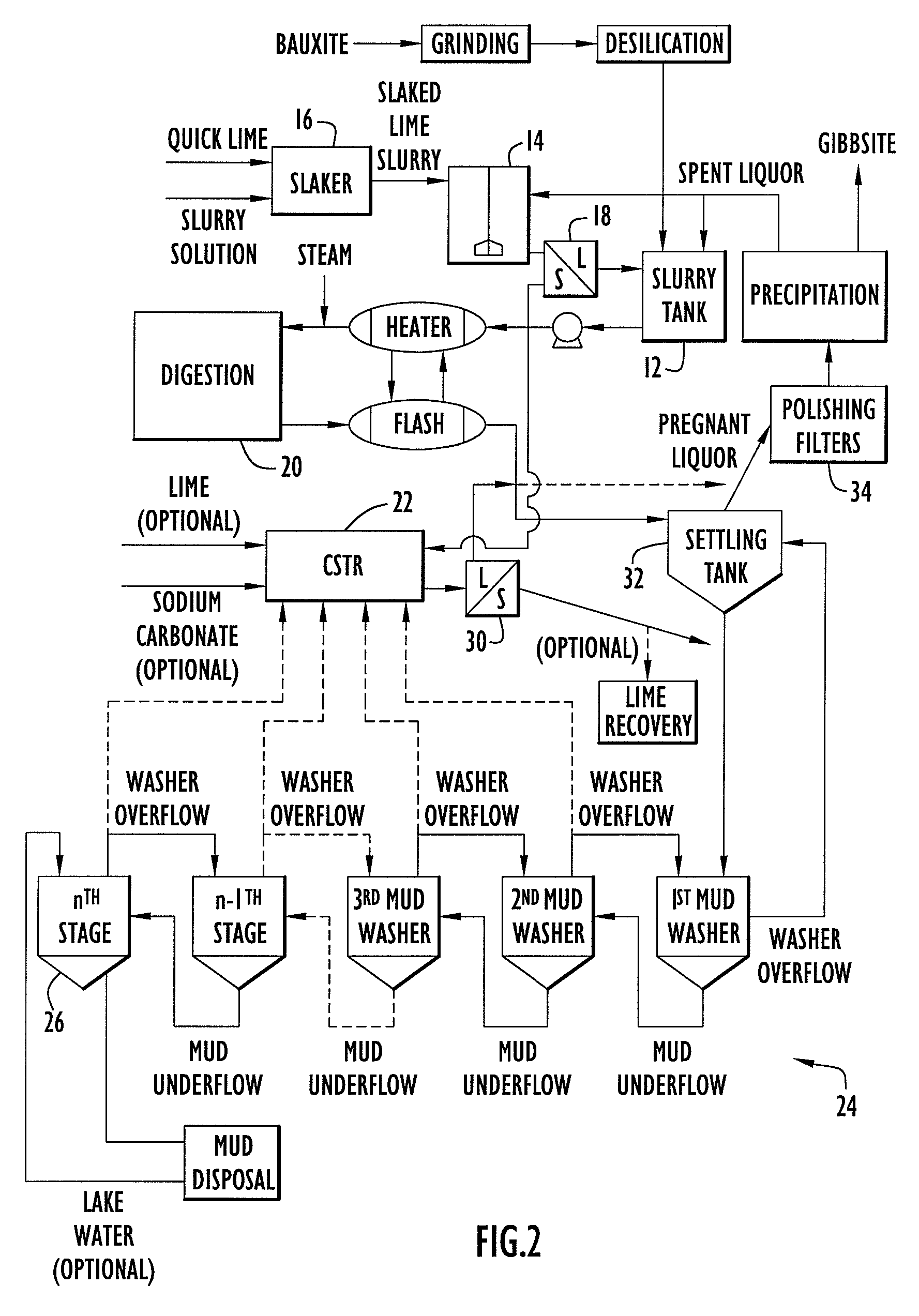

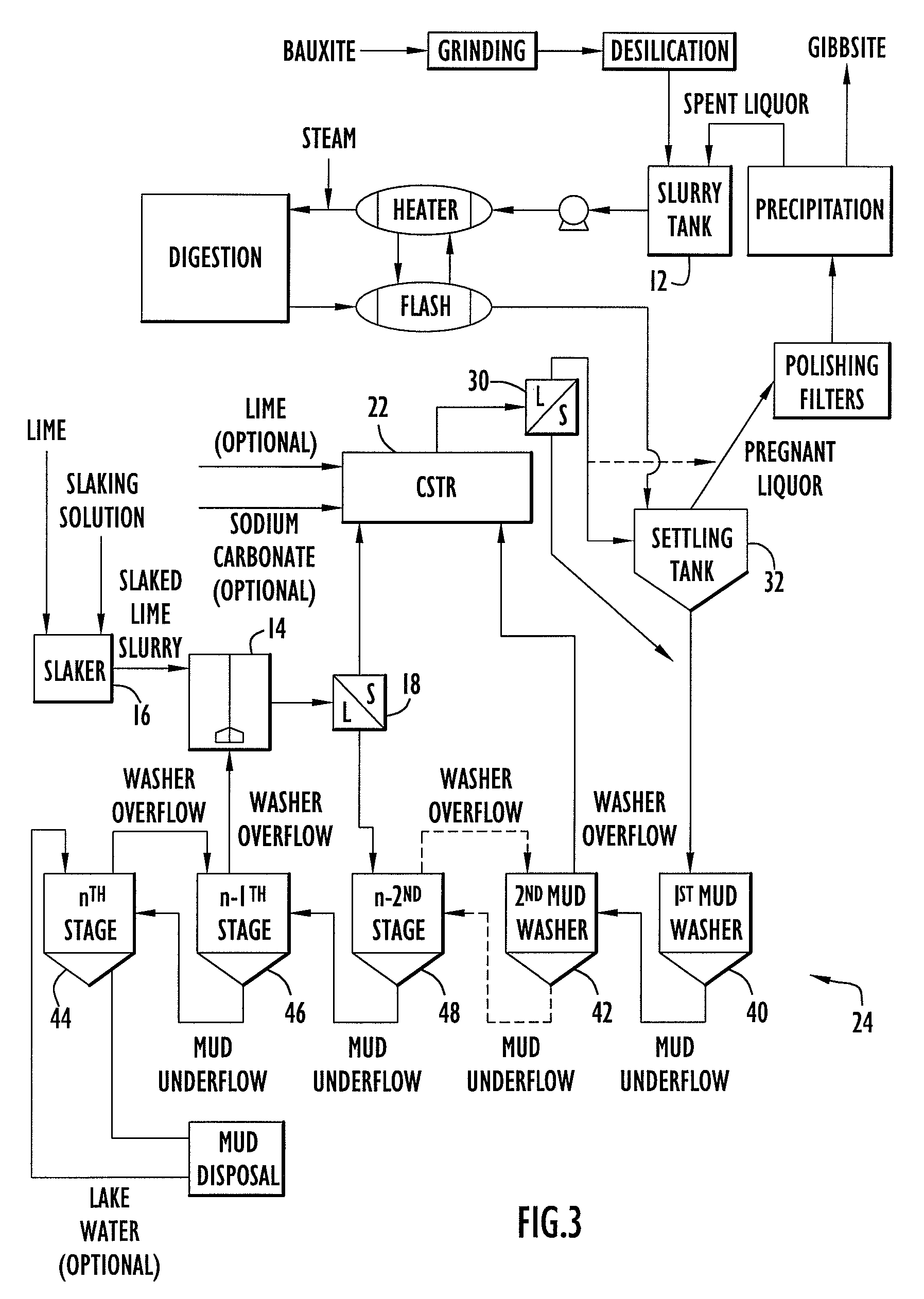

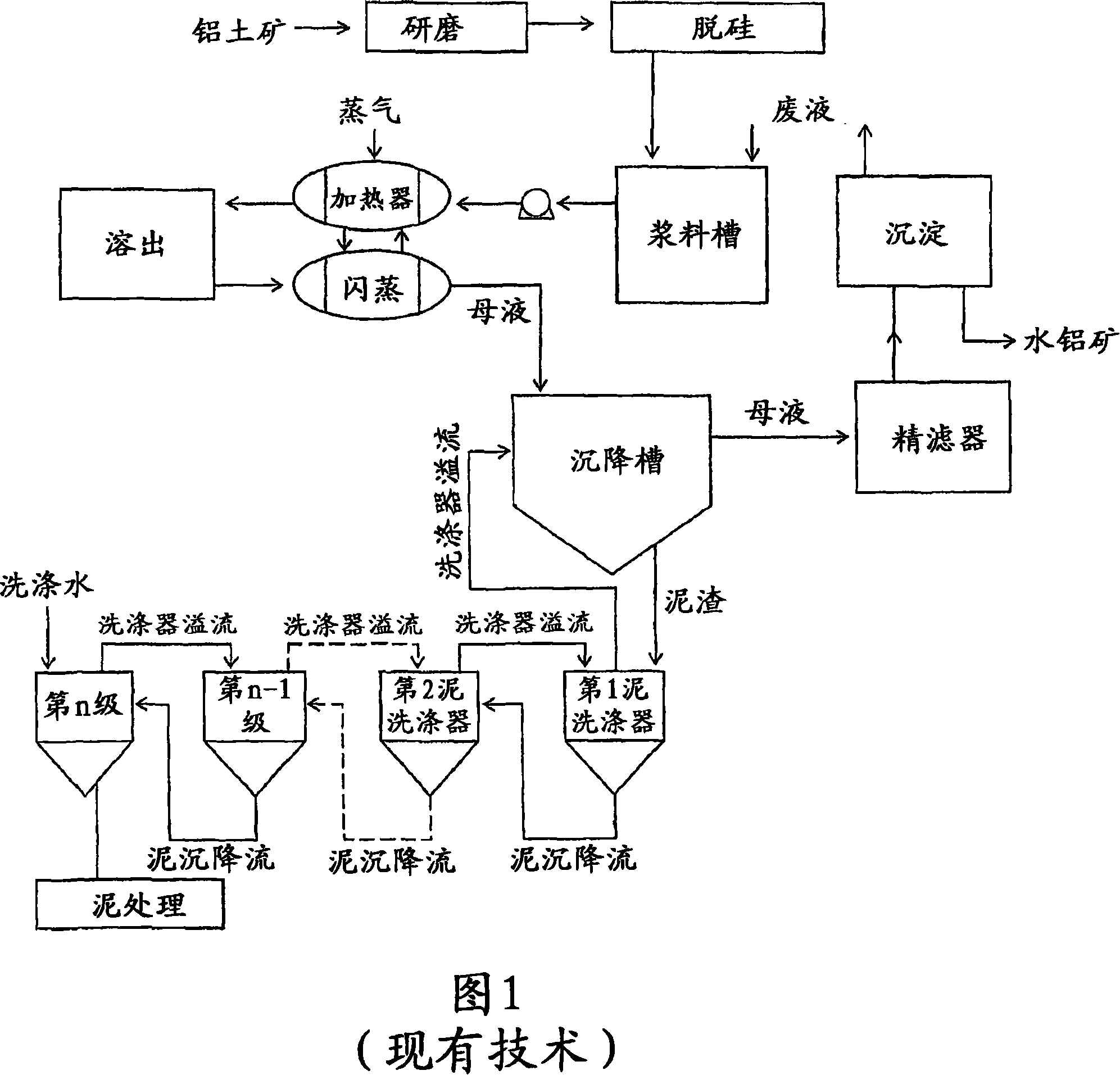

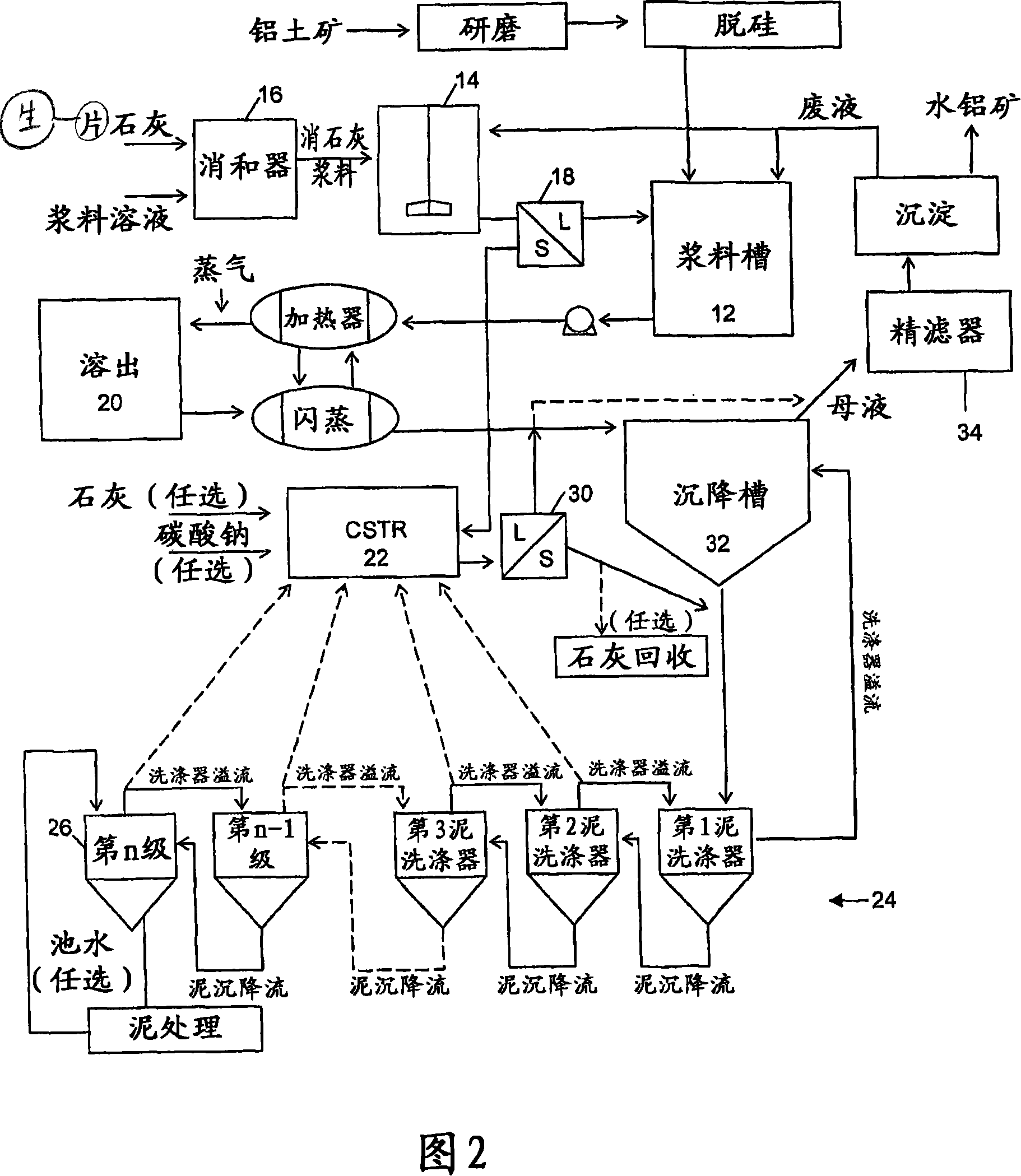

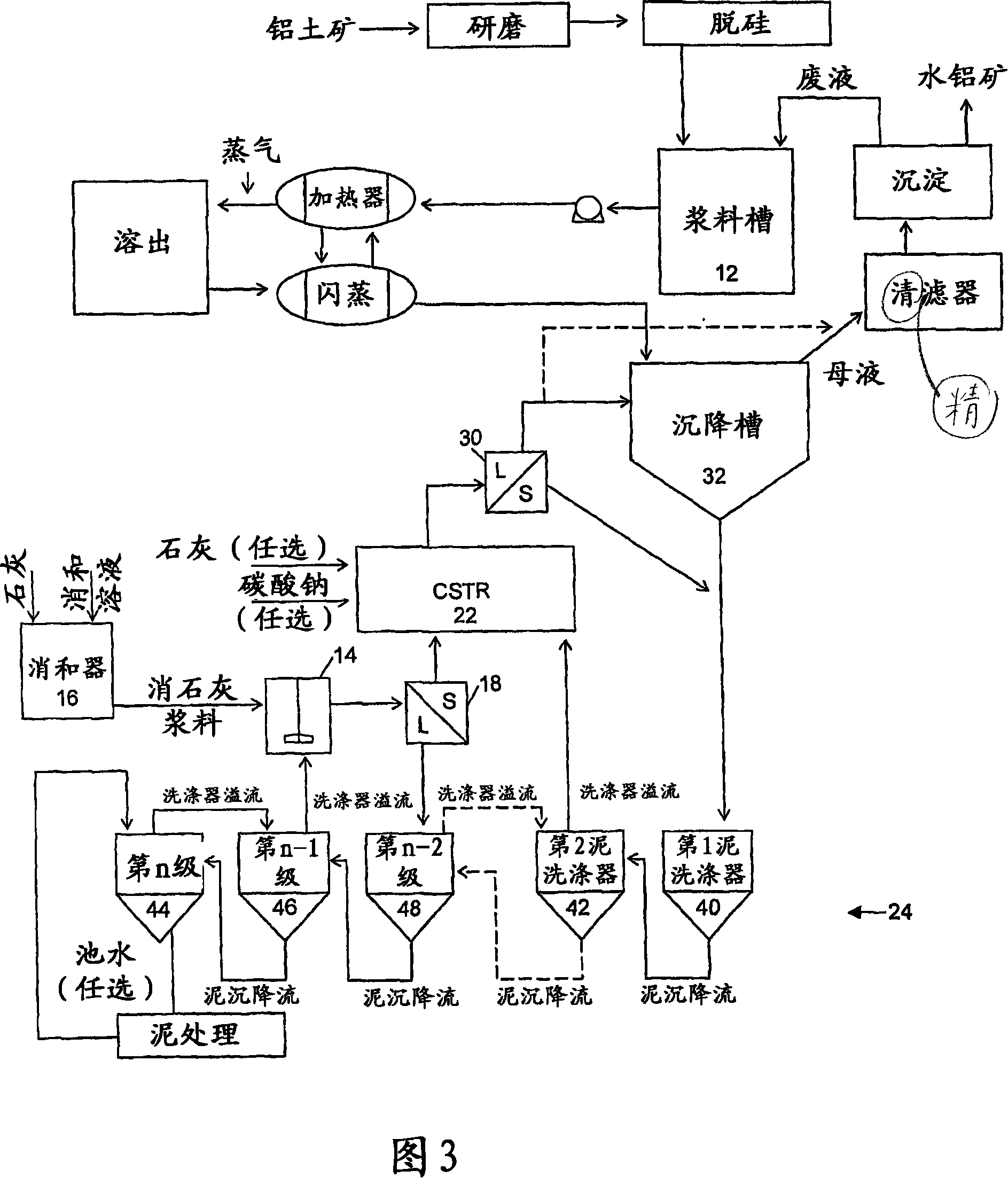

Alumina Recovery

InactiveUS20080025891A1Gallium/indium/thallium compoundsAluminium-carbonate compoundsSlurryIon release

A process for recovering alumina values from a first liquor having an initial concentration of aluminate ions and hydroxyl ions in solution is described. The first liquor is treated with a hydroxide of a metal other than aluminium to form an aluminium-bearing layered double hydroxide and produce a treated stream of first liquor, the treated stream of first liquor having a final concentration of aluminate ions less than the initial concentration of aluminate ions. The aluminium-bearing layered double hydroxide is separated from the treated stream of first liquor. Thereafter the clarified treated stream of first liquor is returned to a first location within an alumina refinery. The separated aluminium-bearing layered double hydroxide is contacted with a solution containing carbonate ions to form a slurry comprising an insoluble salt of the metal other than aluminium and a second liquor comprising aluminate ions released from the aluminium-bearing layered double hydroxide.

Owner:BHP BILLITON ALUMINUM AUSTRALIA

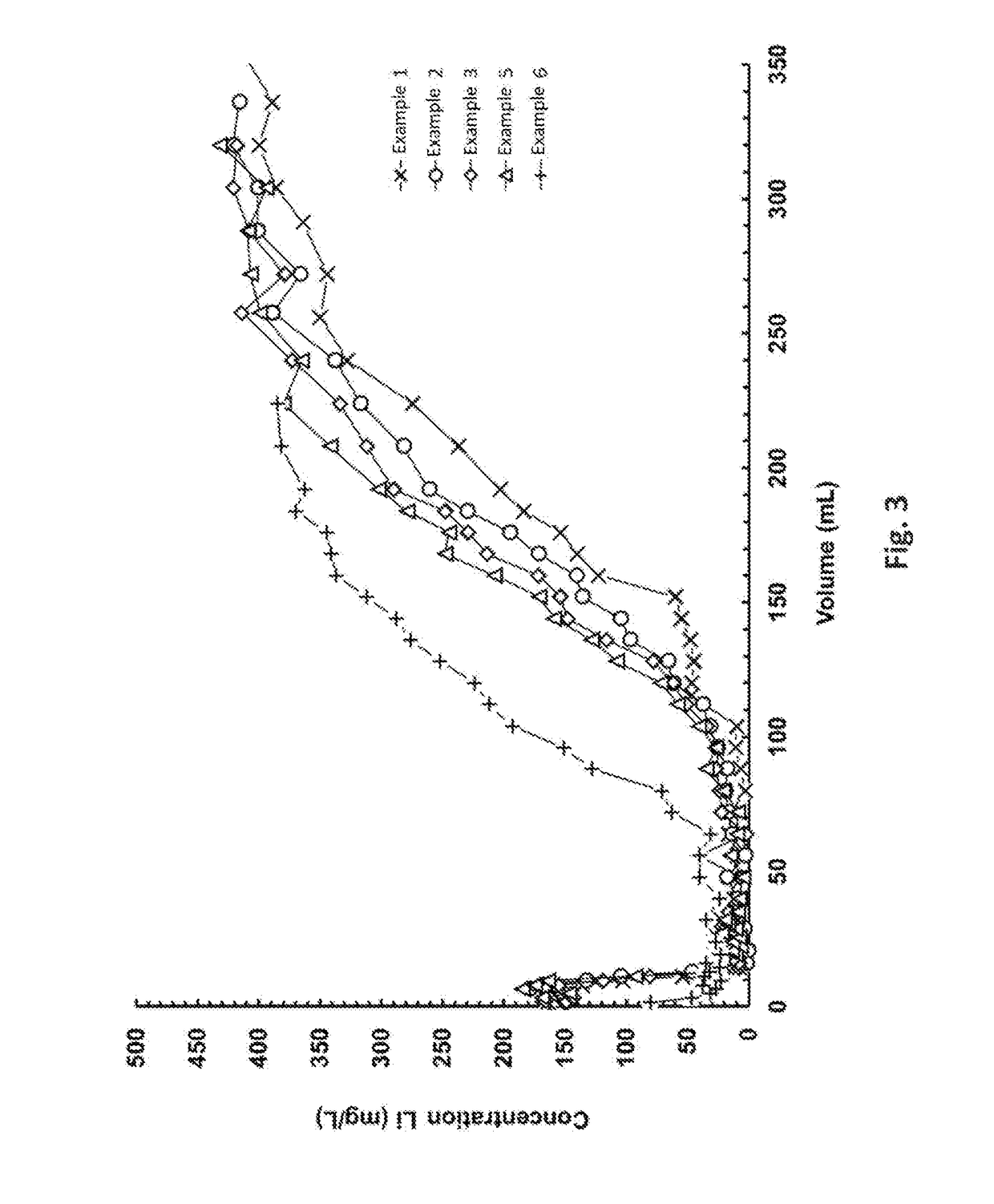

Process for preparing an adsorbing material comprising a precipitating step of boehmite according to specific conditions and process for extracting lithium from saline solutions using this material

ActiveUS20180353932A1Improve adsorption capacitySolve the lack of cohesionOther chemical processesAluminium hydroxide preparationNitrate anionPrecipitation

The present invention relates to the field of solid materials for adsorption of lithium. In particular, the present invention relates to a novel method for preparing a crystallized and shaped solid material, preferably as extrudates, of formula LiXx.2Al(OH)3, nH2O with n being comprised between 0.01 and 10, x being equal to 1 when X is an anion selected from among chloride, hydroxide and nitrate anions, and x being equal to 0.5 when X is an anion selected from among sulfate and carbonate anions, comprising a step a) for precipitation of boehmite under specific temperature and pH conditions, at least one shaping step, preferably by extrusion, said method also comprising a final hydrothermal treatment step, the whole giving the possibility of increasing the adsorption capacity for lithium as well as the adsorption kinetics of the materials obtained as compared with the materials of the prior art when the latter is used in a method for extracting the lithium from saline solutions.

Owner:ERAMET +1

Alumina recovery using aluminum containing layered double hydroxide

A process for recovering alumina values from a first liquor having an initial concentration of aluminate ions and hydroxyl ions in solution is described. The first liquor is treated with a hydroxide of a metal other than aluminium to form an aluminium-bearing layered double hydroxide and produce a treated stream of first liquor, the treated stream of first liquor having a final concentration of aluminate ions less than the initial concentration of aluminate ions. The aluminium-bearing layered double hydroxide is separated from the treated stream of first liquor. Thereafter the clarified treated stream of first liquor is returned to a first location within an alumina refinery. The separated aluminium-bearing layered double hydroxide is contacted with a solution containing carbonate ions to form a slurry comprising an insoluble salt of the metal other than aluminium and a second liquor comprising aluminate ions released from the aluminium-bearing layered double hydroxide.

Owner:BHP BILLITON ALUMINUM AUSTRALIA

Alumina recovery

InactiveCN101151212AAluminates/aluminium-oxide/aluminium-hydroxide purificationAluminium-carbonate compoundsSlurryIon release

Owner:SOUTH32 ALUMINUM RAA PTY LTD

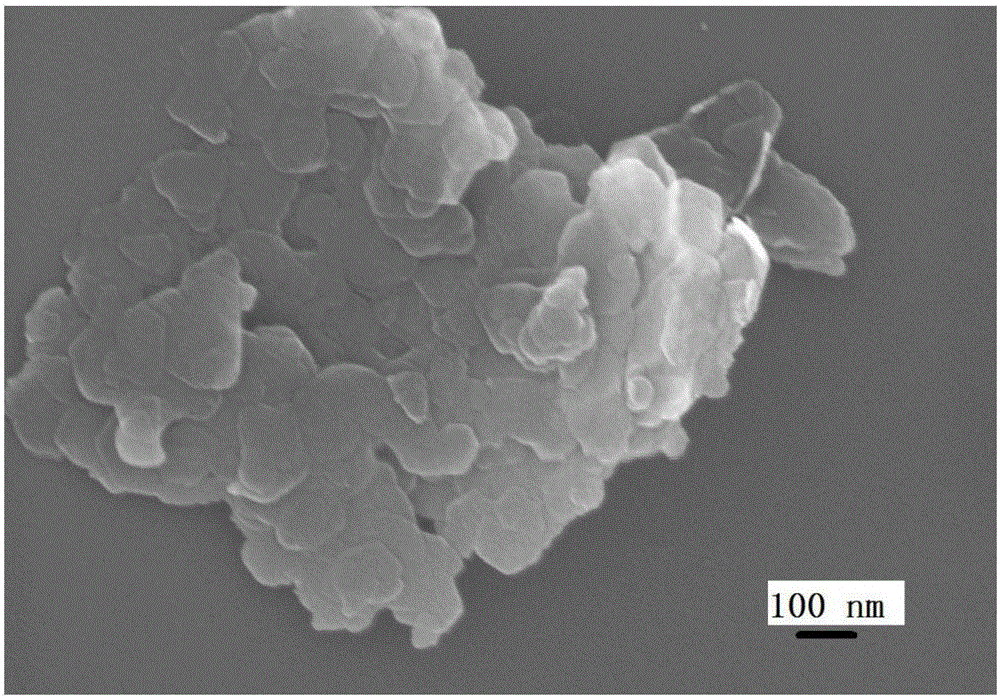

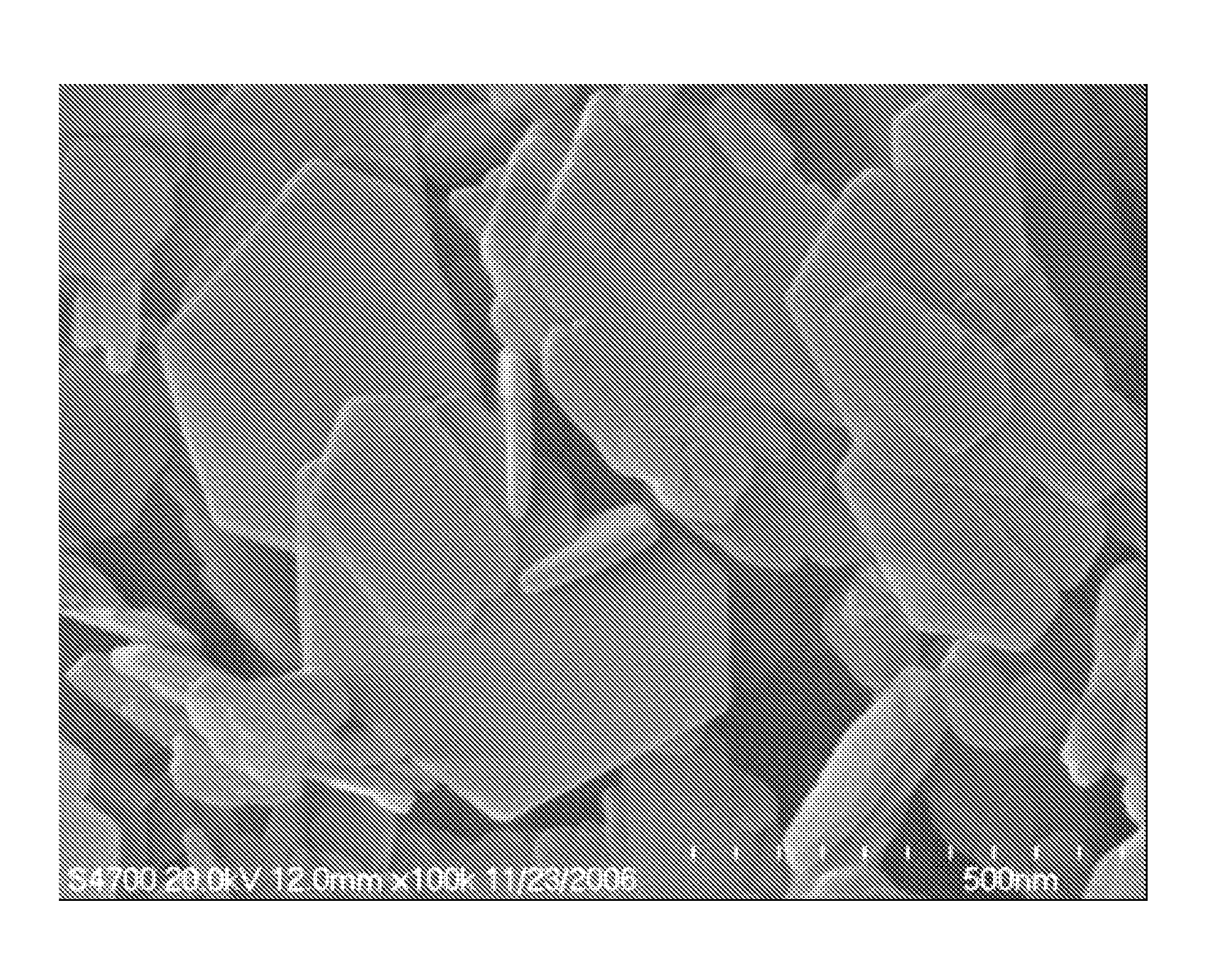

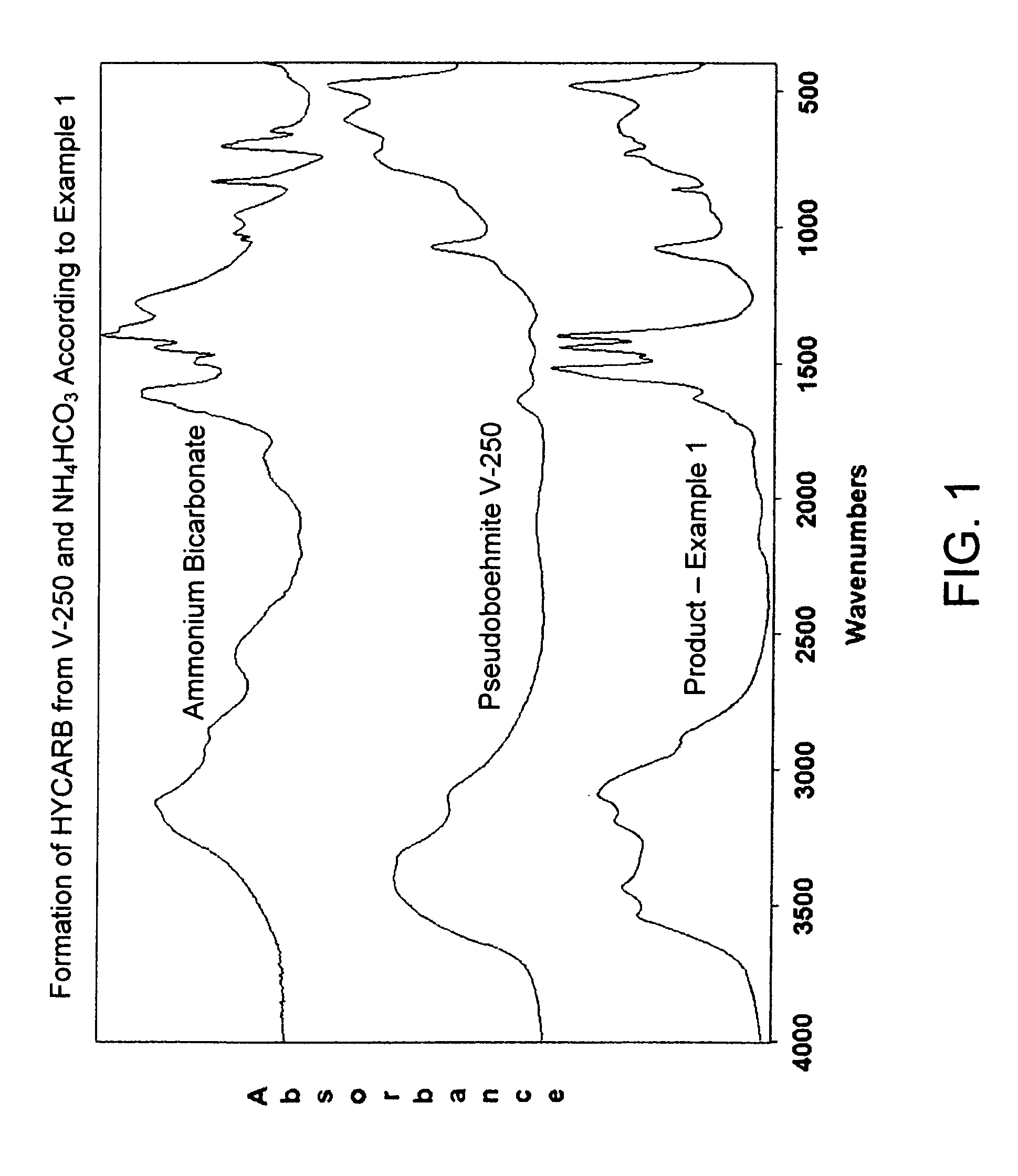

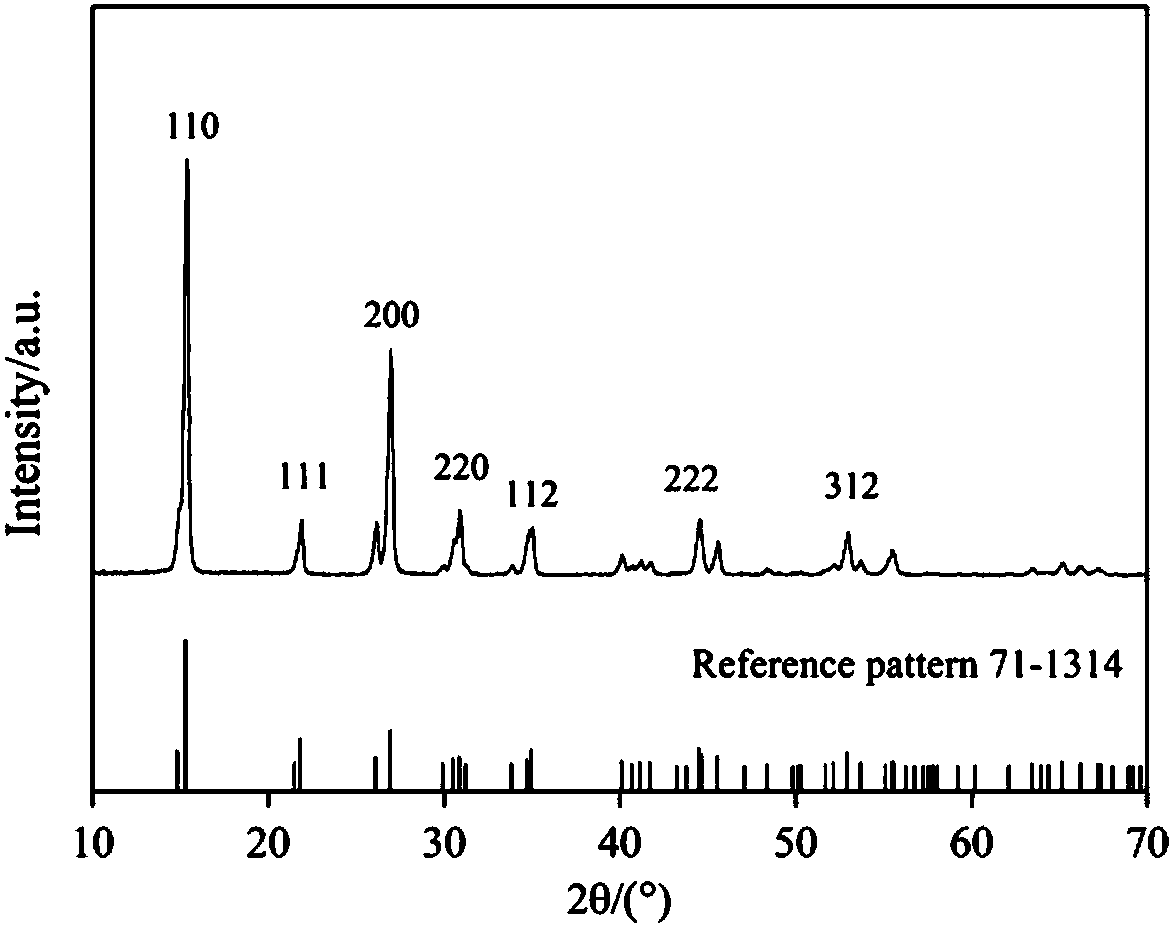

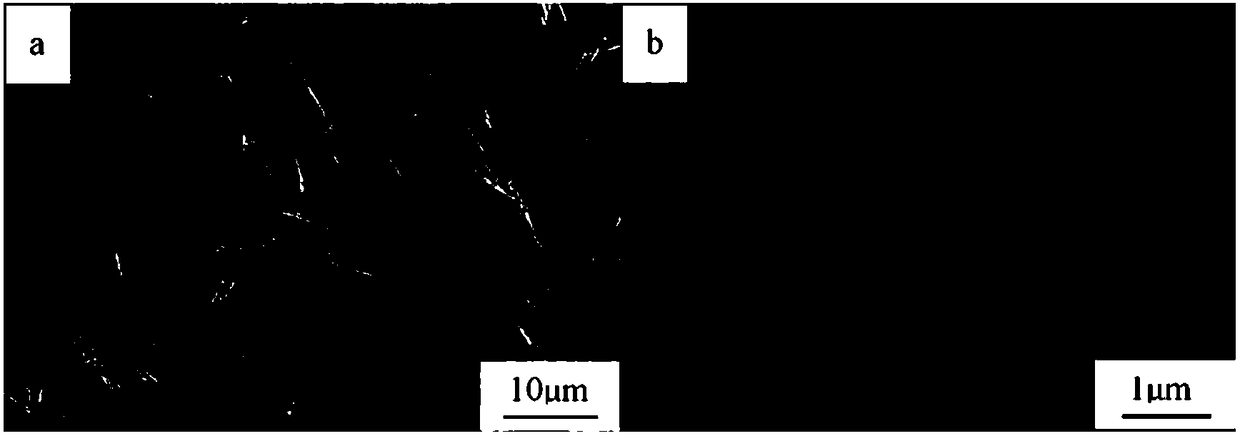

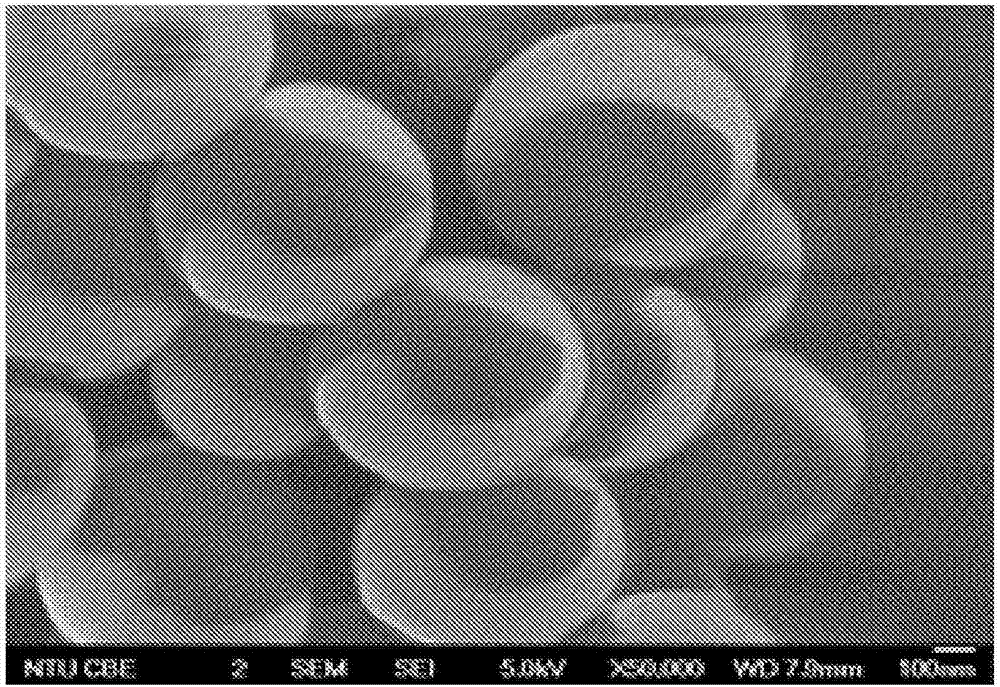

Method for preparing bar-shaped ammonium aluminum carbonate without template agent

InactiveCN108483470AHigh aspect ratioRegular shapeAluminium-carbonate compoundsAluminum CarbonateDiameter ratio

The invention discloses a method for preparing bar-shaped ammonium aluminum carbonate without a template agent. According to the method, an ammonium aluminum carbonate micron bar is hydrothermally synthesized without the template agent by taking Al(NO3)3 as an aluminum source and urea as a precipitator; and the ammonium aluminum carbonate micron bar prepared through hydrothermal reaction without the template agent is high in length-diameter ratio, regular in shape and good in crystallization performance. The bar-shaped micron bar prepared by virtue of the method is high in length-diameter ratio, the average length is about 15 microns, the average diameter is about 200nm, and the length-diameter ratio is about 75 to 1. The shape of the product is not controlled by virtue of a surfactant inthe preparation process, so that the preparation cost is lowered, the preparation process is simplified, a series of environmental pollution problems in the preparation process and the later-period cleaning process are avoided, the preparation process adopted in the method is an environment-friendly preparation process and is accordant with the environment-friendly development idea nowadays, and the preparation method is simple and convenient, the cost is low and the environmental friendliness is high.

Owner:SHAANXI XUEQIAN NORMAL UNIV

Sio2-layered double hydroxide microspheres and methods of making them

A method of making silica-layered double hydroxide microspheres having the formula I : (i) wherein, Mz+ and M'y+ are two different charged metal cations; z = 1 or 2; y = 3 or 4; 0 < x < 0.9; b is 0 to 10; c is 0 to 10; P > 0, q > 0, Xn- is an anion; with n > 0 a = z(1-x) + xy-2; and the AMO-solvent is an 100% aqueous miscible organic solvent; comprises the steps: (a) contacting silica microspheres and a metal ion containing solution containing metal ions Mz+ and M'y+ in the presence of a base and an anion solution; (b) collecting the product; and (c) optionally treating the product with AMO-solvent and recovering the solvent treated material to obtain the silica-layered double hydroxide microspheres. Preferably, M in the formula I is Li, Mg, Ni or Ca. Preferably, M' in formula I is Al. The invention further provides silica-layered double hydroxide microspheres having the formula I. The silica-layered double hydroxide microspheres may be used as catalysts and / or catalyst supports.

Owner:SCG CHEM CO LTD

Process for preparing an adsorbing material comprising a precipitating step of boehmite according to specific conditions and process for extracting lithium from saline solutions using this material

ActiveUS10786802B2Improve adsorption capacityImproved adsorption kineticsOther chemical processesCombustible gas purificationNitrate anionSulfate radicals

Owner:ERAMET +1

Method for preparing an adsorbent material comprising a step of basic mixing, and method for extracting lithium from saline solutions using said material

ActiveUS20180345244A1Increase capacityImprove adsorption capacityOther chemical processesLithium compoundsNitrate anionLithium

The present invention relates to the field of solid materials for the adsorption of lithium. In particular, the present invention relates to a new method for the preparation of a crystallized and shaped solid material, preferably in extruded form, of formula LiXx.2Al(OH)3,nH2O, wherein n is between 0.01 and 10, x is 1 when X is an anion selected from among chloride, hydroxide and nitrate anions, and x is 0.5 when X is an anion selected from among sulfate and carbonate anions, comprising a boehmite precipitation step a) under specific temperature and pH conditions, at least one basic mixing shaping step, wherein the method also comprises a final hydrothermal treatment step, all to increase the lithium adsorption capacity and the kinetics of adsorption of the materials obtained, compared with the materials of the prior art when it is used in a method for lithium extraction from saline solutions.

Owner:ERAMET +1

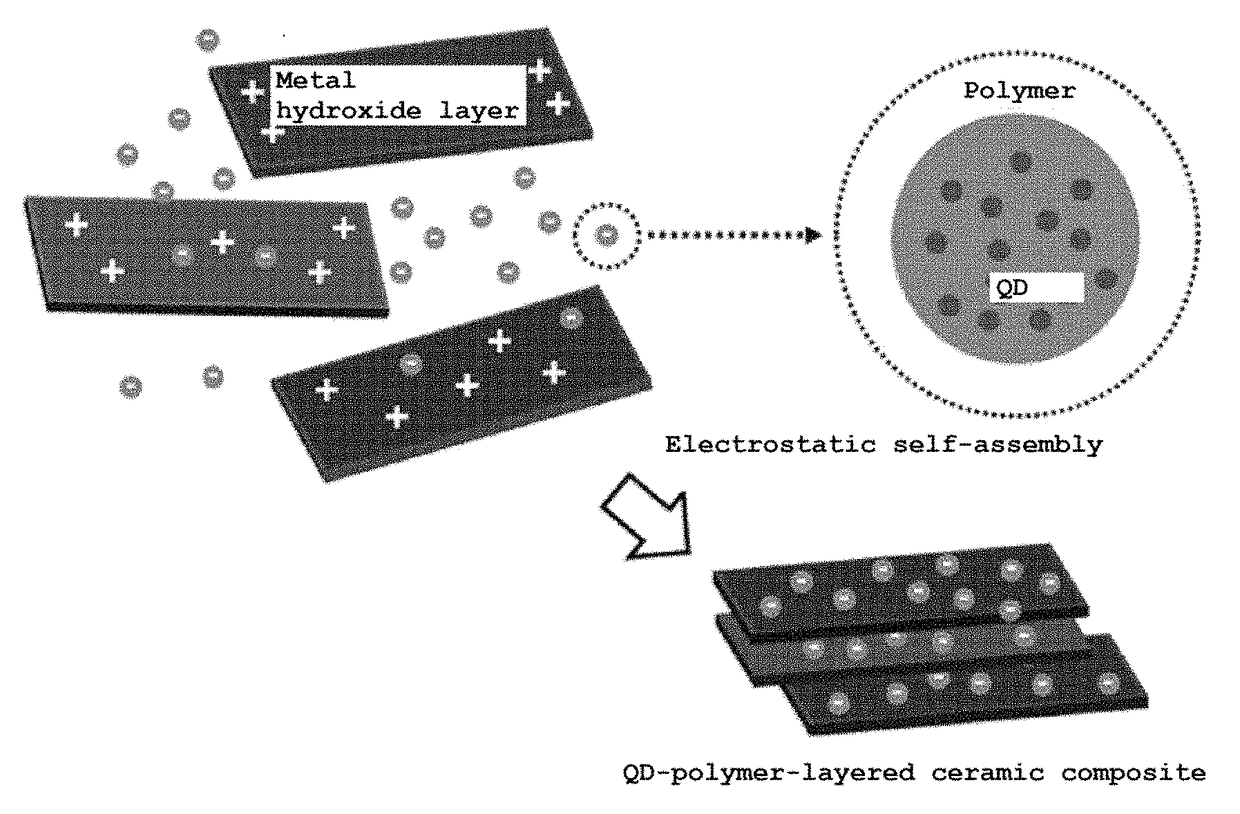

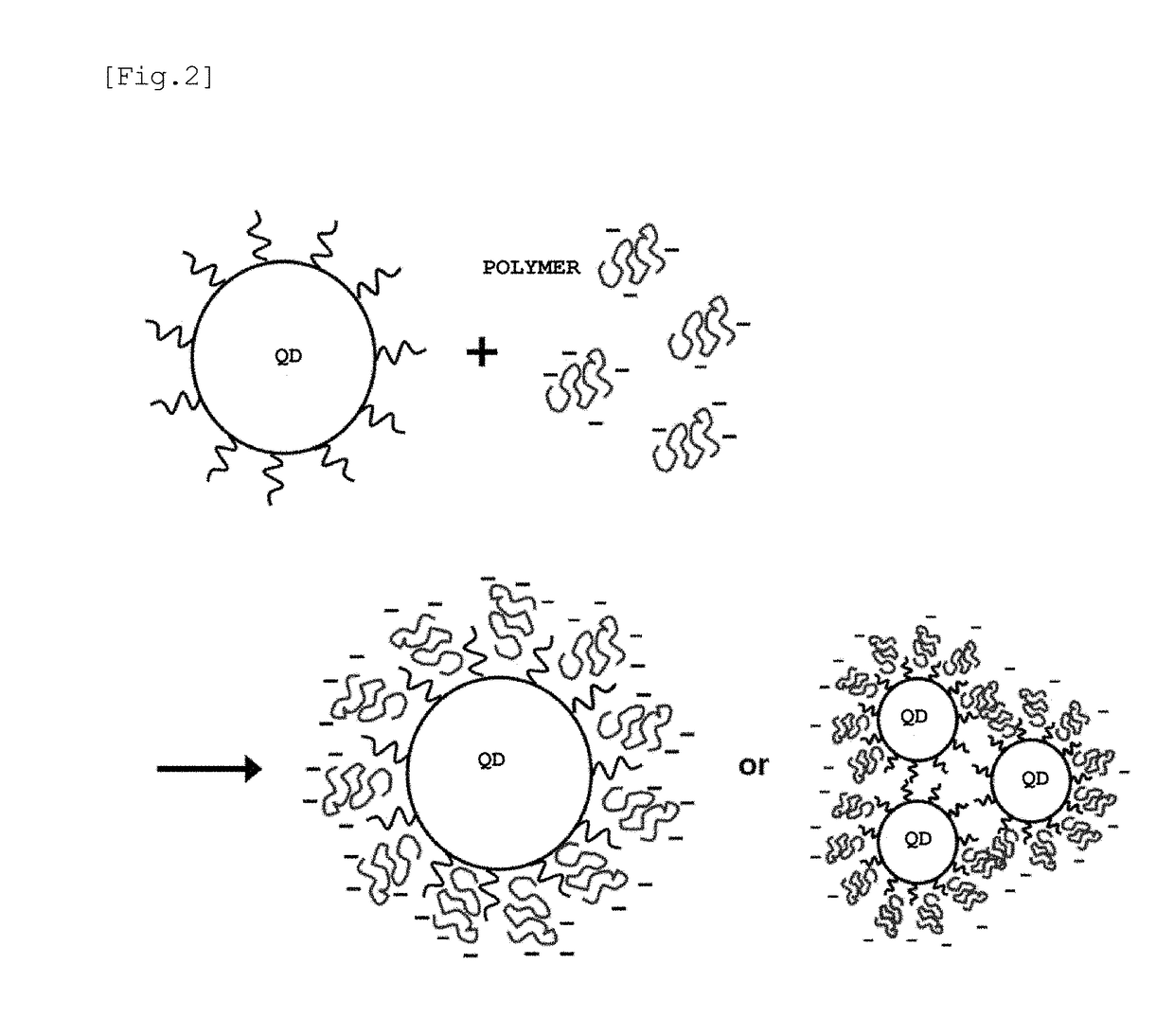

Synthesis of quantum dot/polymer/layered-structure ceramic composite

ActiveUS9802396B2Reduce penetrationImproved in chemical and thermal stability and optical stabilityMaterial nanotechnologySynthetic resin layered productsCeramic compositeQuantum dot

The present invention relates to a quantum dot and a preparation method therefor, and more specifically, to a novel quantum dot composite having high surface stability, and a preparation method therefor. The quantum dot composite according to the present invention constitutes a layered-structure ceramic composite in which the layered-structure ceramic comprises a polymer-quantum dot composite between the layers thereof.

Owner:POSTECH ACAD IND FOUND

Method of fabricating medium-high temperature CO2 sorbents made of alkali metal promoted calcium aluminate carbonates

InactiveUS8754002B2Velocity increasesImprove stabilityCalcium/strontium/barium carbonatesProductsSorbentDegree Celsius

Owner:INST NUCLEAR ENERGY RES ROCAEC

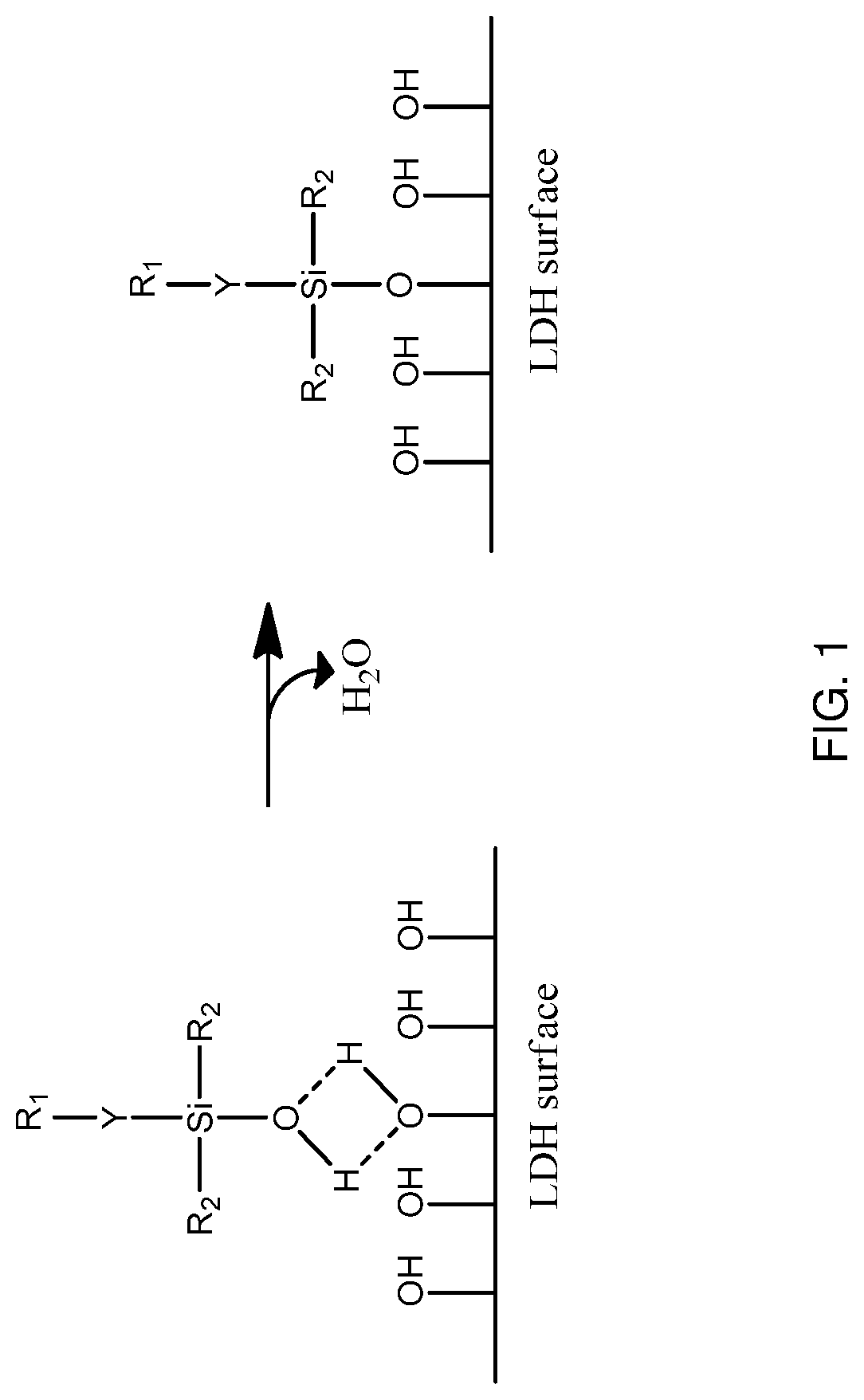

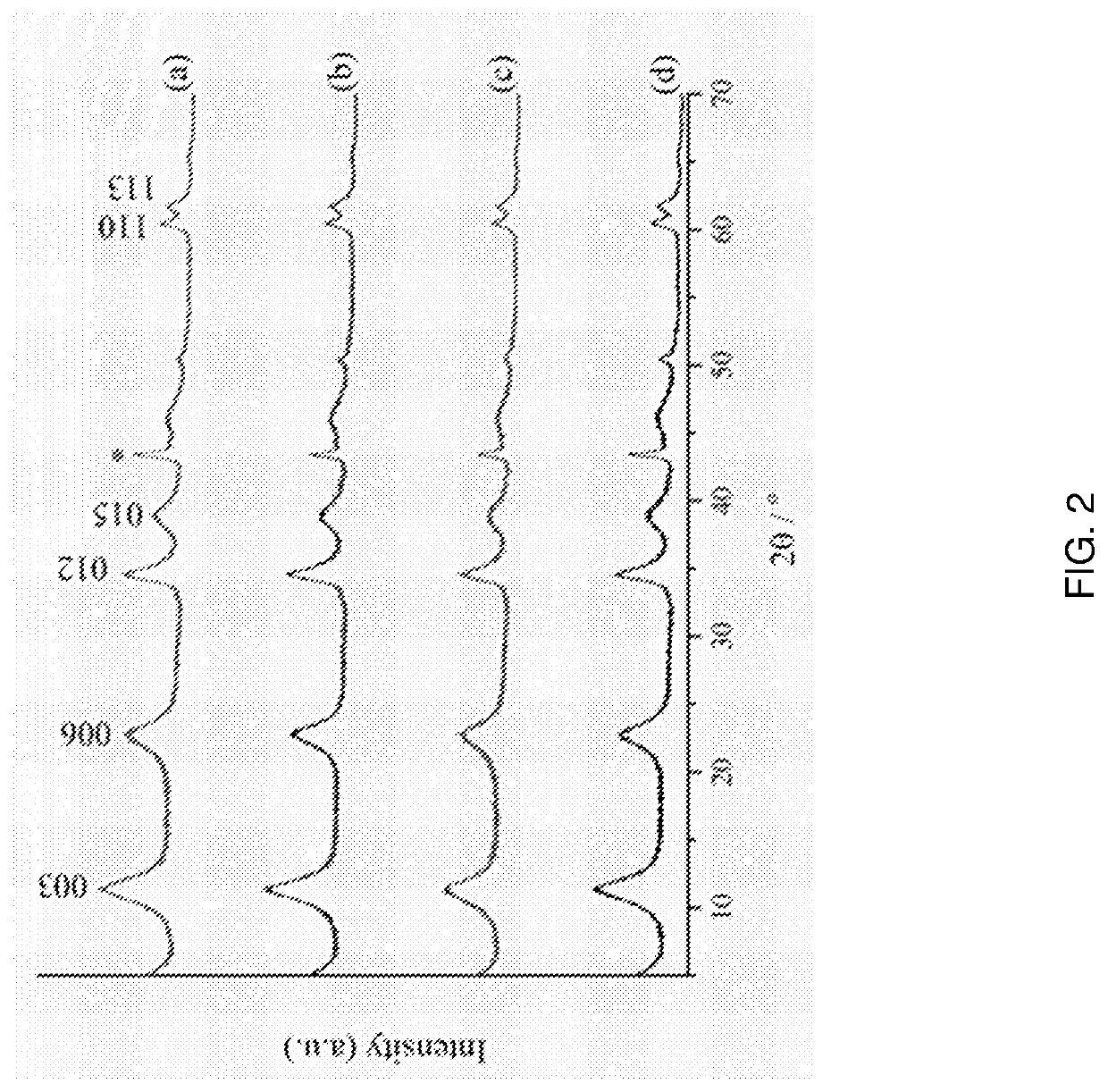

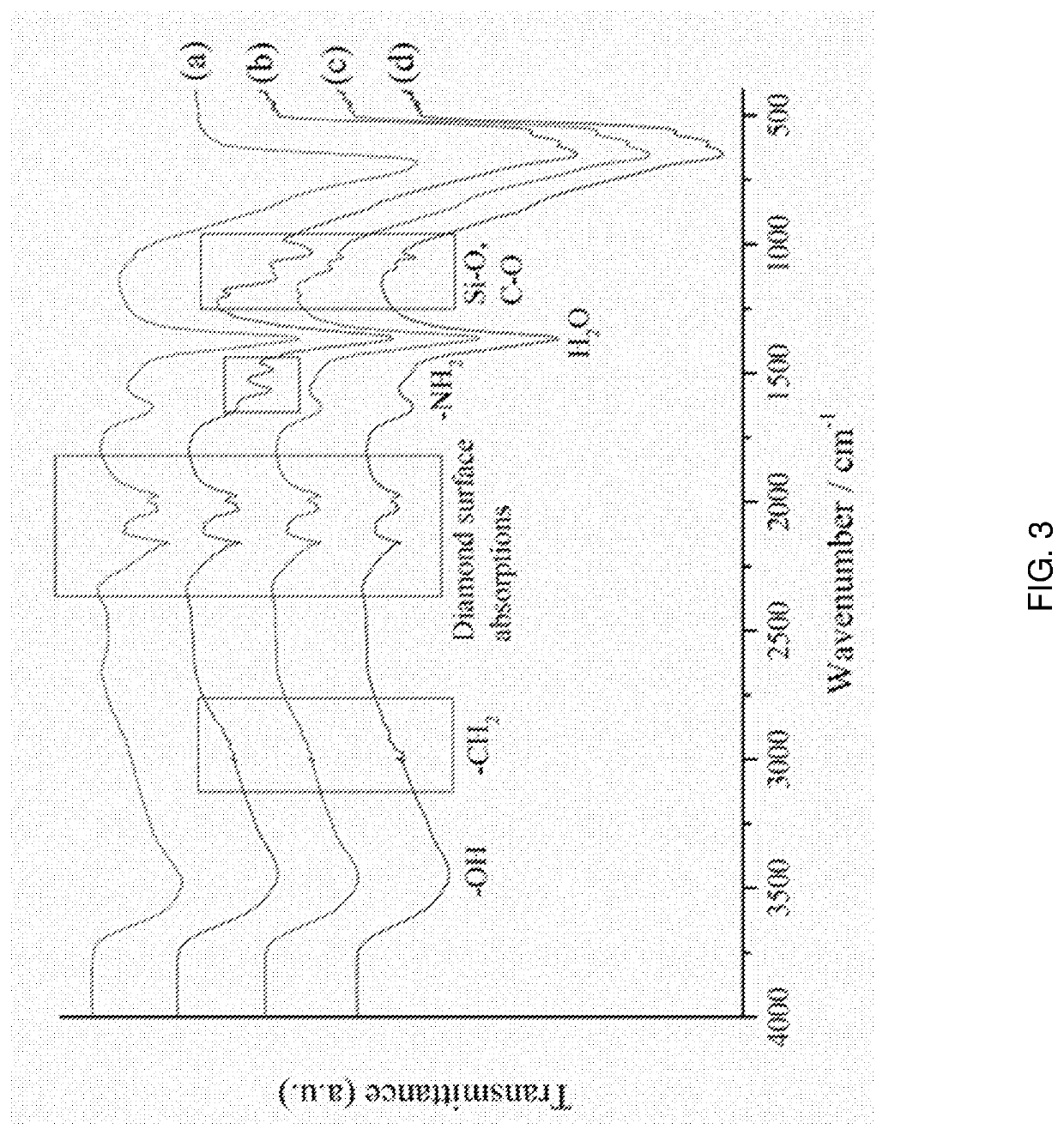

Surface modified layered double hydroxide

ActiveUS11242460B2Few available siteLow efficiencyOther chemical processesAluminium-carbonate compoundsMineralogyLayered double hydroxides

Surface-modified layered double hydroxides (LDHs) are disclosed, as well as processes by which they are made, and uses of the LDHs in composite materials. The surface-modified LDHs of the invention are more organophilic than their unmodified analogues, which allows the LDHs to be incorporated in a wide variety of materials, wherein the interesting functionality of LDHs may be exploited.

Owner:SCG CHEM CO LTD

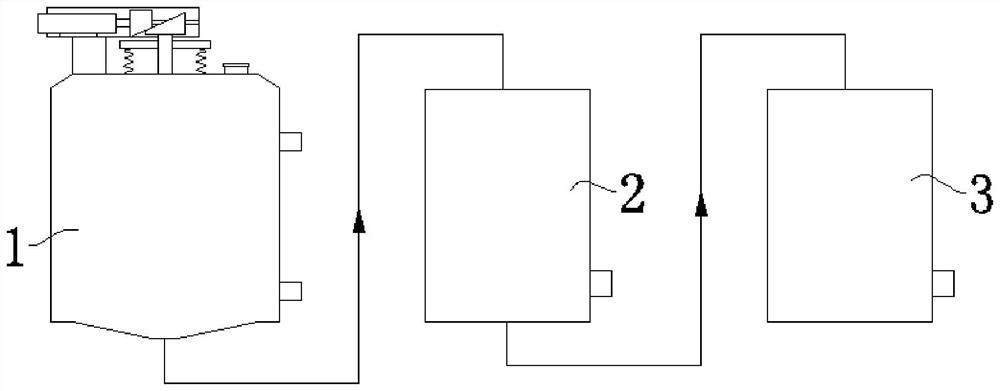

An intelligent aluminum magnesium carbonate crystallization system

PendingCN114700022AFull and fast responsePlay a mixing effectShaking/oscillating/vibrating mixersRotary stirring mixersPhysical chemistryMagnesium

The invention discloses an intelligent hydrotalcite crystallization system, and belongs to the technical field of hydrotalcite production.The hydrotalcite crystallization system comprises a reaction kettle, a filtering device and a drying device which are sequentially connected, the reaction kettle comprises a kettle body, a feeding port is formed in the top of the kettle body, and a jacket is arranged on the outer surface of the kettle body; the jacket is provided with a thermal medium inlet and a thermal medium outlet which are used for entering and exiting of a thermal medium; a discharging port is formed in the bottom of the kettle body, a driving mechanism, an up-down pushing mechanism and a stirring mechanism are arranged on the kettle body, the driving mechanism is located above the top of the kettle body and used for driving the up-down pushing mechanism and the stirring mechanism, and the stirring mechanism is used for stirring materials in the kettle body. And the up-down pushing mechanism is used for pushing materials in the kettle body up and down. According to the reaction kettle, materials can fully and quickly react in the reaction kettle.

Owner:GUANGXI NANNING BAIHUI PHARMA GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com