Sio2-layered double hydroxide microspheres and methods of making them

A hydroxide, layered double technology, applied in chemical instruments and methods, catalyst activation/preparation, silicon oxide, etc., can solve the problems of surface morphology LDH with small surface area, not allowing adjustment of LDH, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

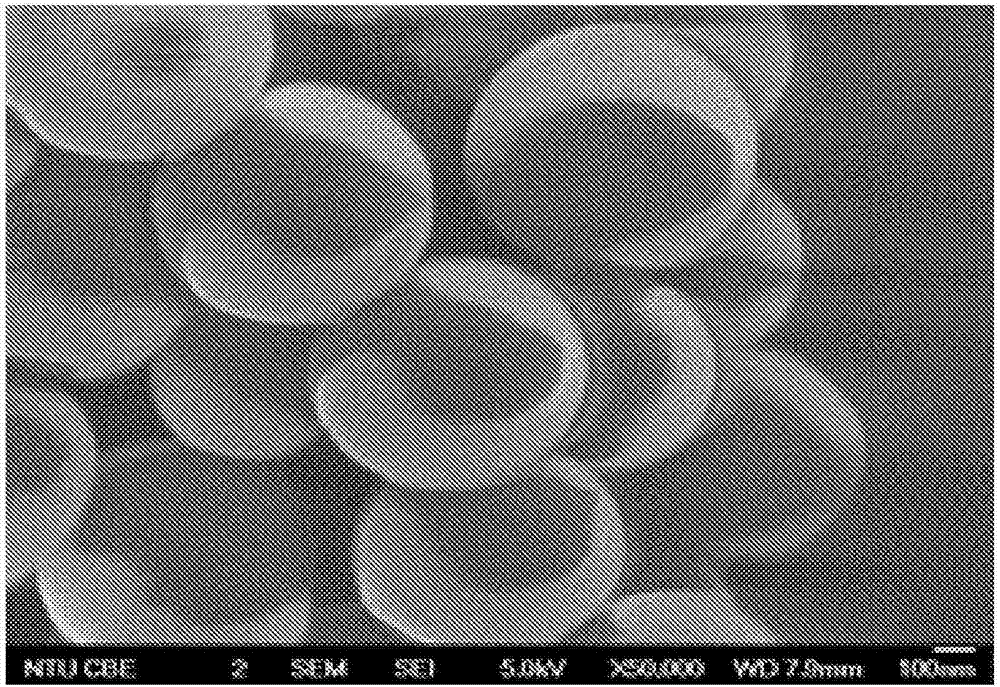

[0186] Silica spheres (100 mg, 550 nm) were dispersed in deionized water (20 mL) using sonication. After 30min, the Na 2 CO 3(0.96 mmol) was added to the solution and sonicated for an additional 5 min to form solution A. Next, the Mg(NO 3 ) 2 ·6H 2 O(0.96mmol) and Al(NO 3 ) 3 9H 2 A solution of O (0.48 mmol) in water (19.2 mL) was added to solution A. The pH of the reaction solution was controlled to 10 by adding 1M NaOH. The resulting solid was collected by centrifugation at 4000 rpm for 5 min, then redispersed in deionized water (40 mL) and stirred for 1 h. Repeat collection and redispersion two more times. Then, the solid was washed with acetone (40 mL), then redispersed in acetone (40 mL) and stirred overnight. The solid was then dried under vacuum.

[0187] Before treatment with acetone, the SiO obtained in this example 2 @LDH has the formula:

[0188] (SiO 2 ) 0.04 @{[Mg 0.75 Al 0.25 (OH) 2 ](CO 3 ) 0.125 1.34(H 2 O)} 0.05

[0189] SiO obtained af...

Embodiment 2

[0206] To obtain a 1:1 Mg:Al LDH, the procedure described above in Example 1 was repeated except that Mg(NO 3 ) 2 ·6H 2 O(0.72mmol) and Al(NO 3 ) 3 9H 2 A solution of O (0.72 mmol) in water (19.2 mL) was added to solution A.

Embodiment 3

[0208] To obtain a 3:1 Mg:Al LDH, the procedure described above in Example 1 was repeated except that Mg(NO 3 ) 2 ·6H 2 O(1.08mmol) and Al(NO 3 ) 3 9H 2 A solution of O (0.36 mmol) in water (19.2 mL) was added to solution A.

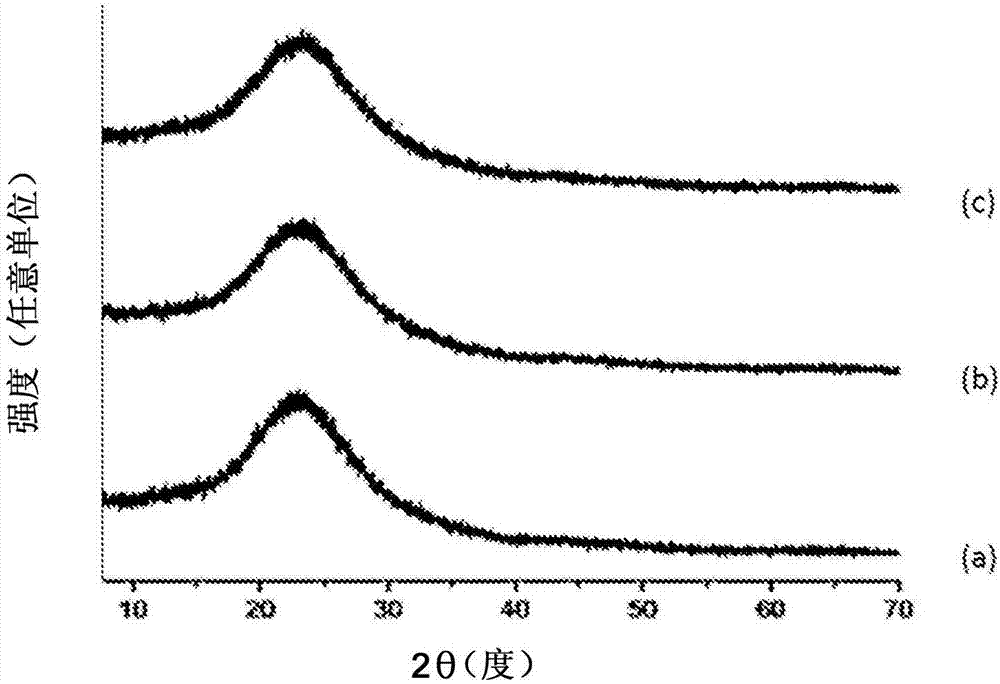

[0209] Figure 12 SiO prepared by Mg:Al ratios of 1:1 (Example 2) and 3:1 (Example 3) are shown 2 XRD patterns of @LDH samples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com