Patents

Literature

347results about "Hydrotalcite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium air secondary battery

ActiveUS20150024292A1Solve the blockageSolution to short lifeSolid electrolytesFuel and secondary cellsLithiumEngineering

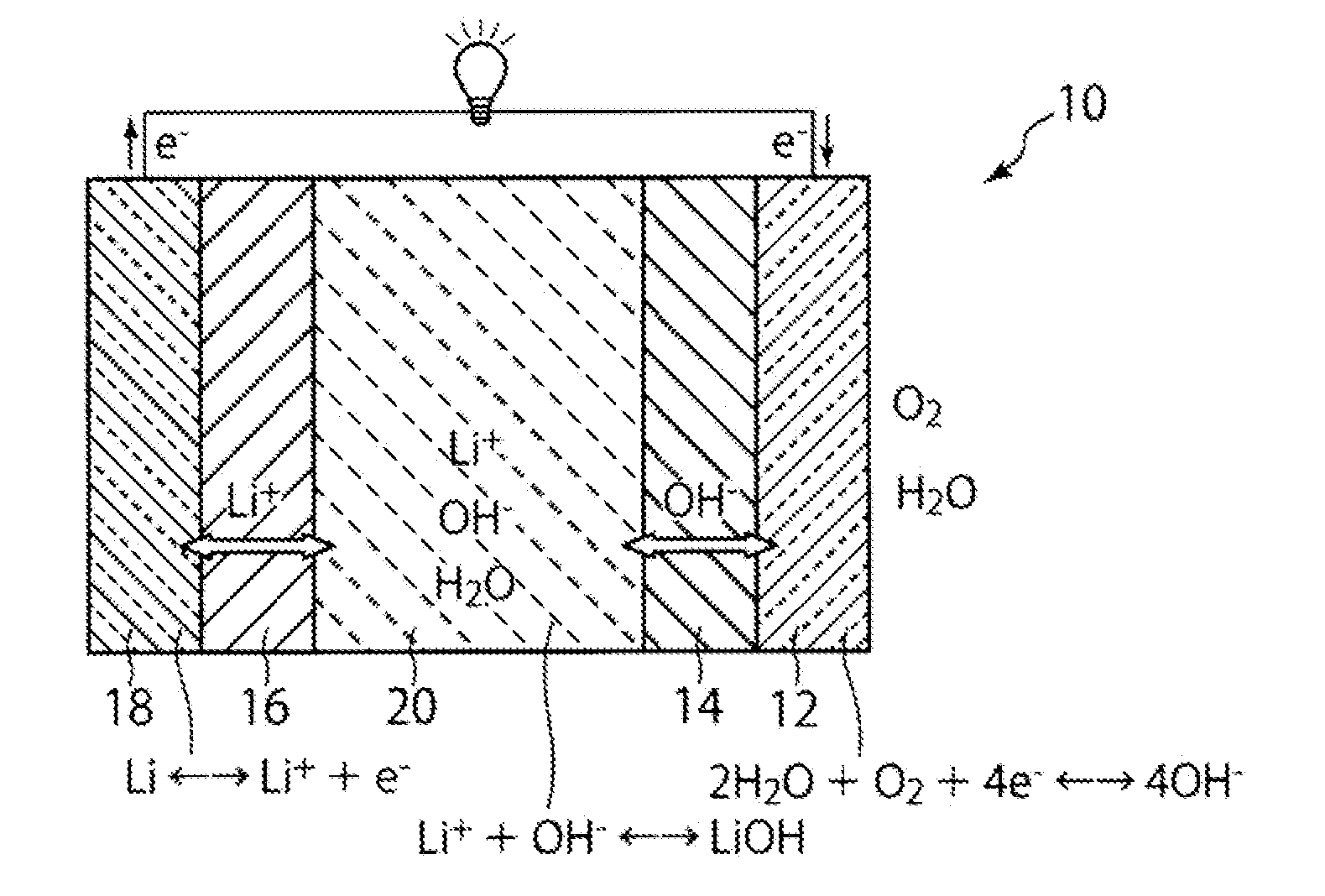

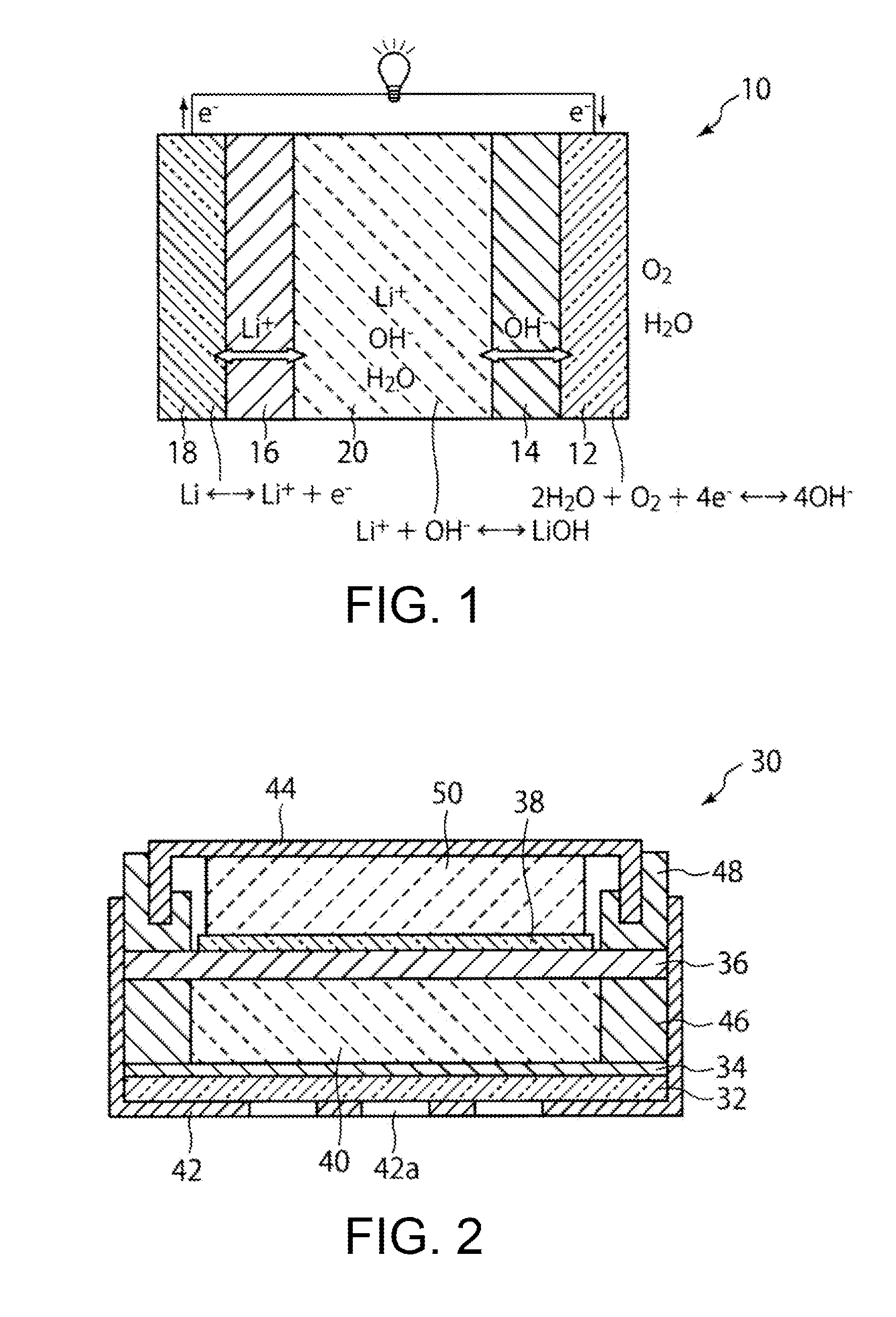

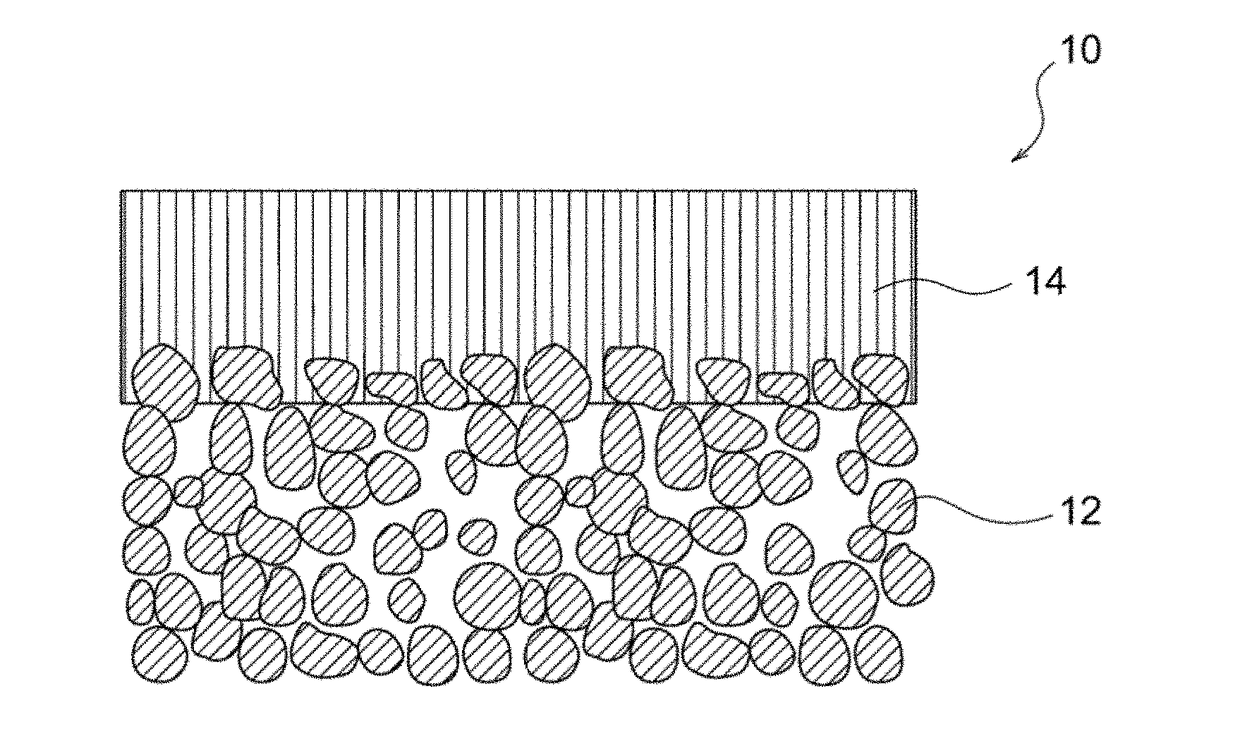

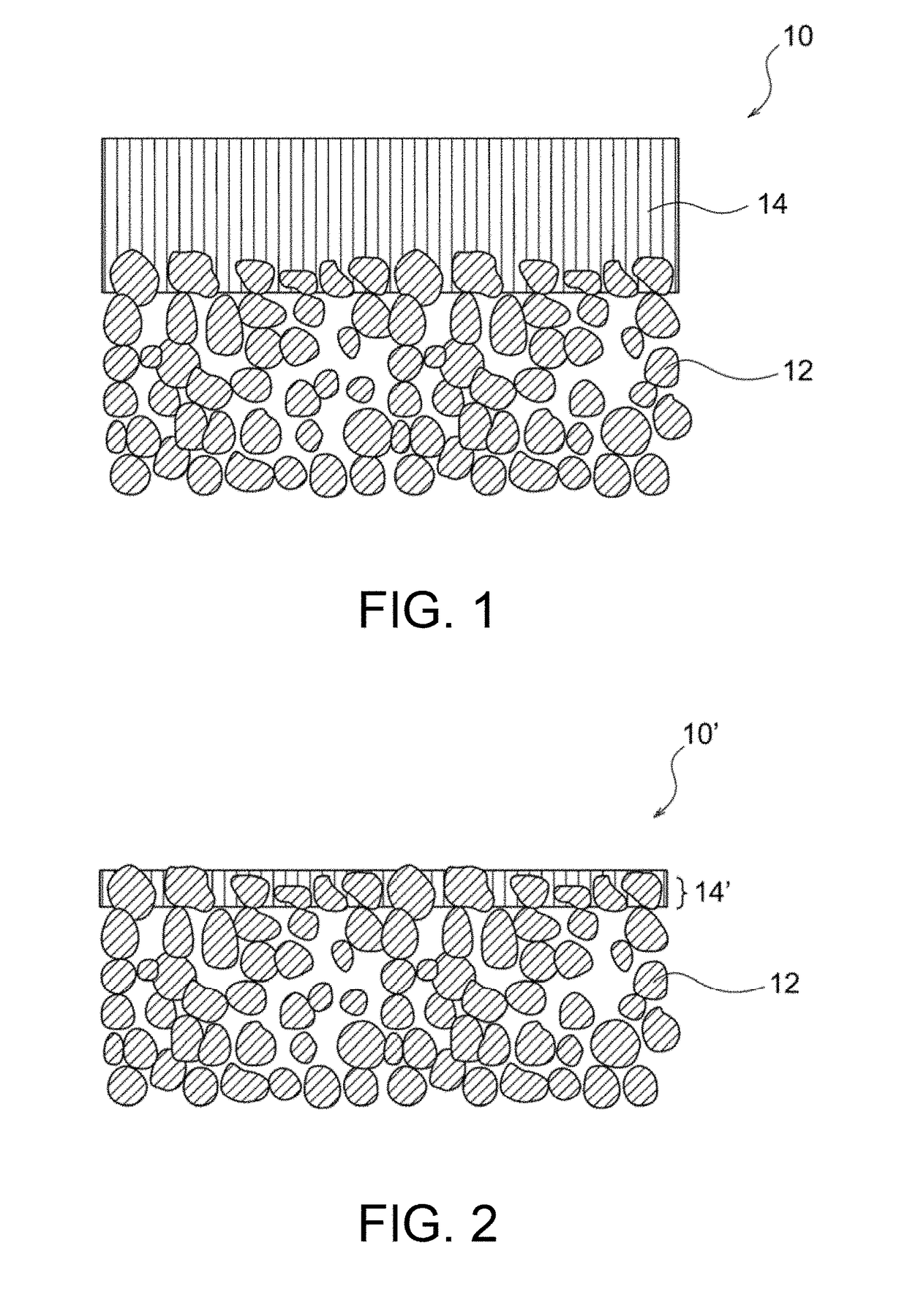

The present invention provides a lithium-air secondary battery that is capable of effectively preventing deterioration of an alkaline electrolytic solution, air electrode, and negative electrode and has a long life and high long-term reliability. The lithium-air secondary battery comprises an air electrode 12 functioning as a positive electrode, an anion exchanger 14 provided in close contact with one side of the air electrode and composed of a hydroxide-ion conductive inorganic solid electrolyte, a separator 16 provided away from the anion exchanger and composed of a lithium-ion conductive inorganic solid electrolyte, a negative electrode 18 provided so as to be capable of supplying and receiving lithium ions to and from the separator and comprising lithium, and an alkaline electrolytic solution 20 filled between the anion exchanger and the separator.

Owner:NGK INSULATORS LTD

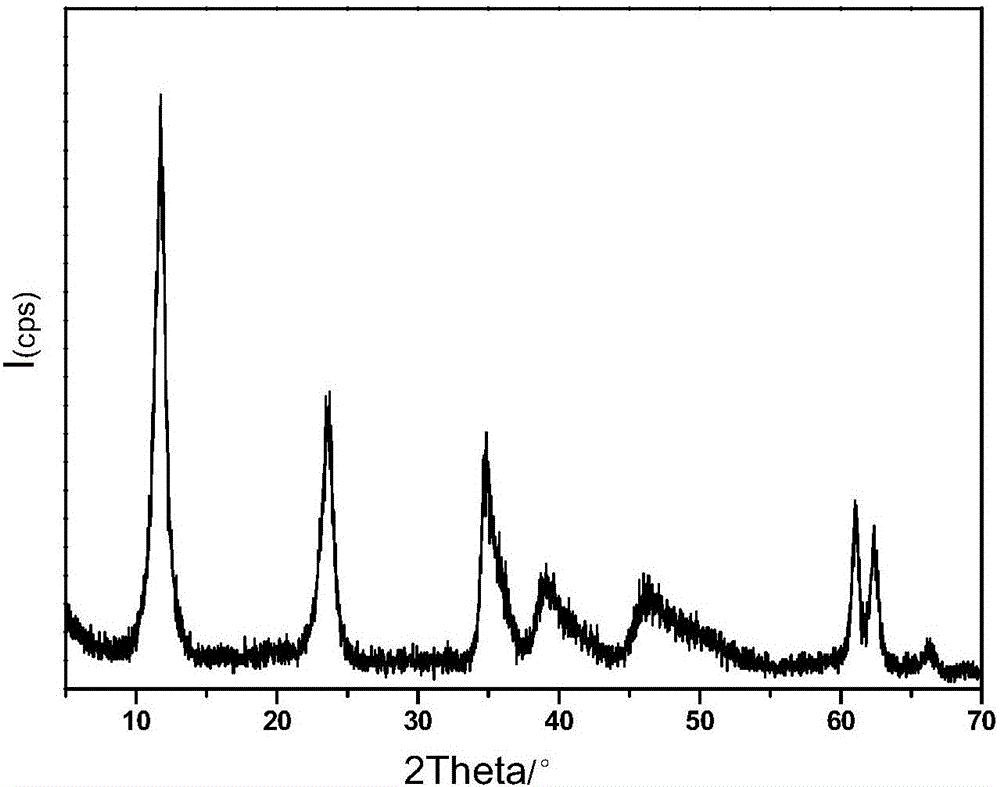

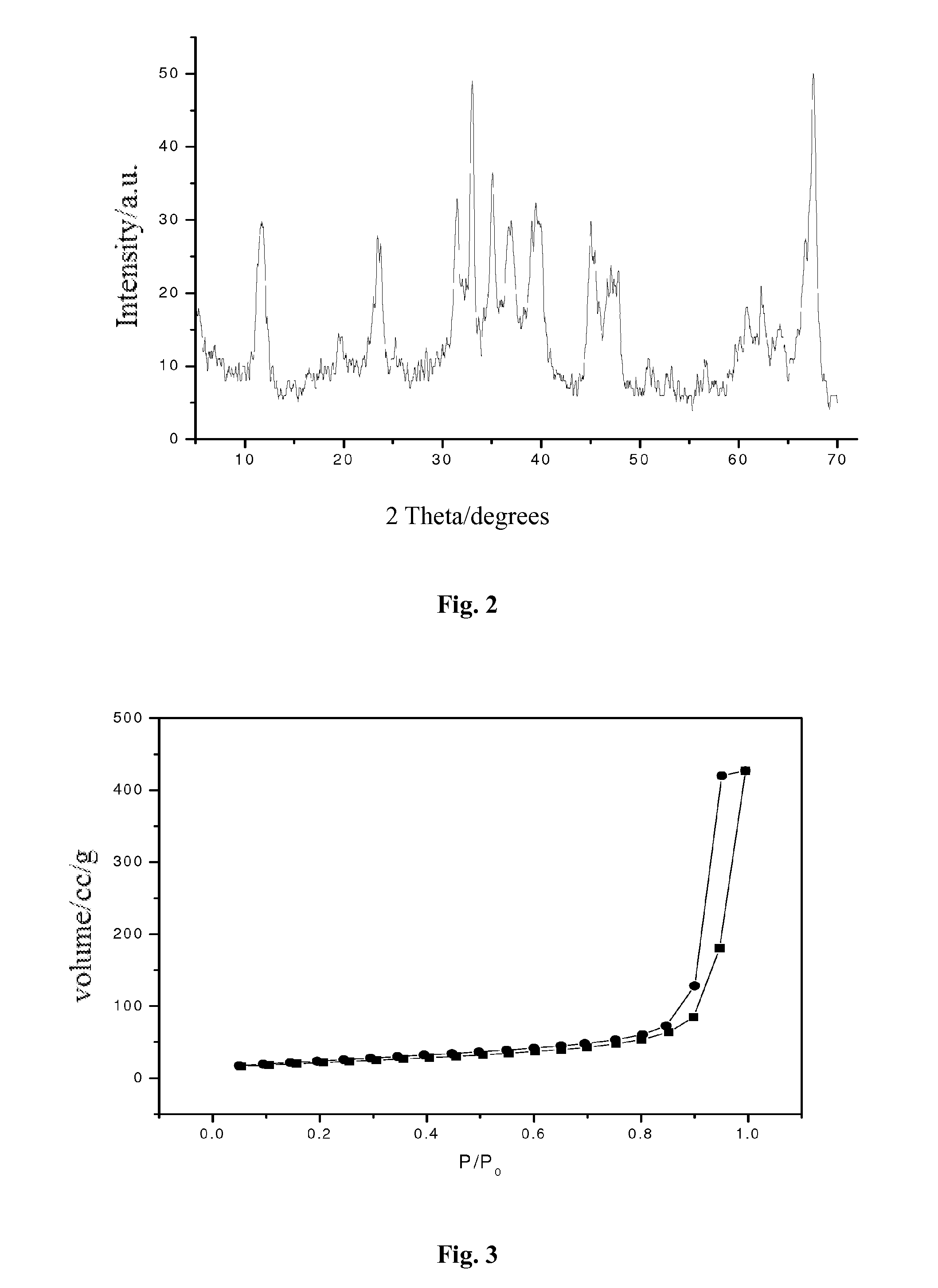

Mixed metal oxide sorbents

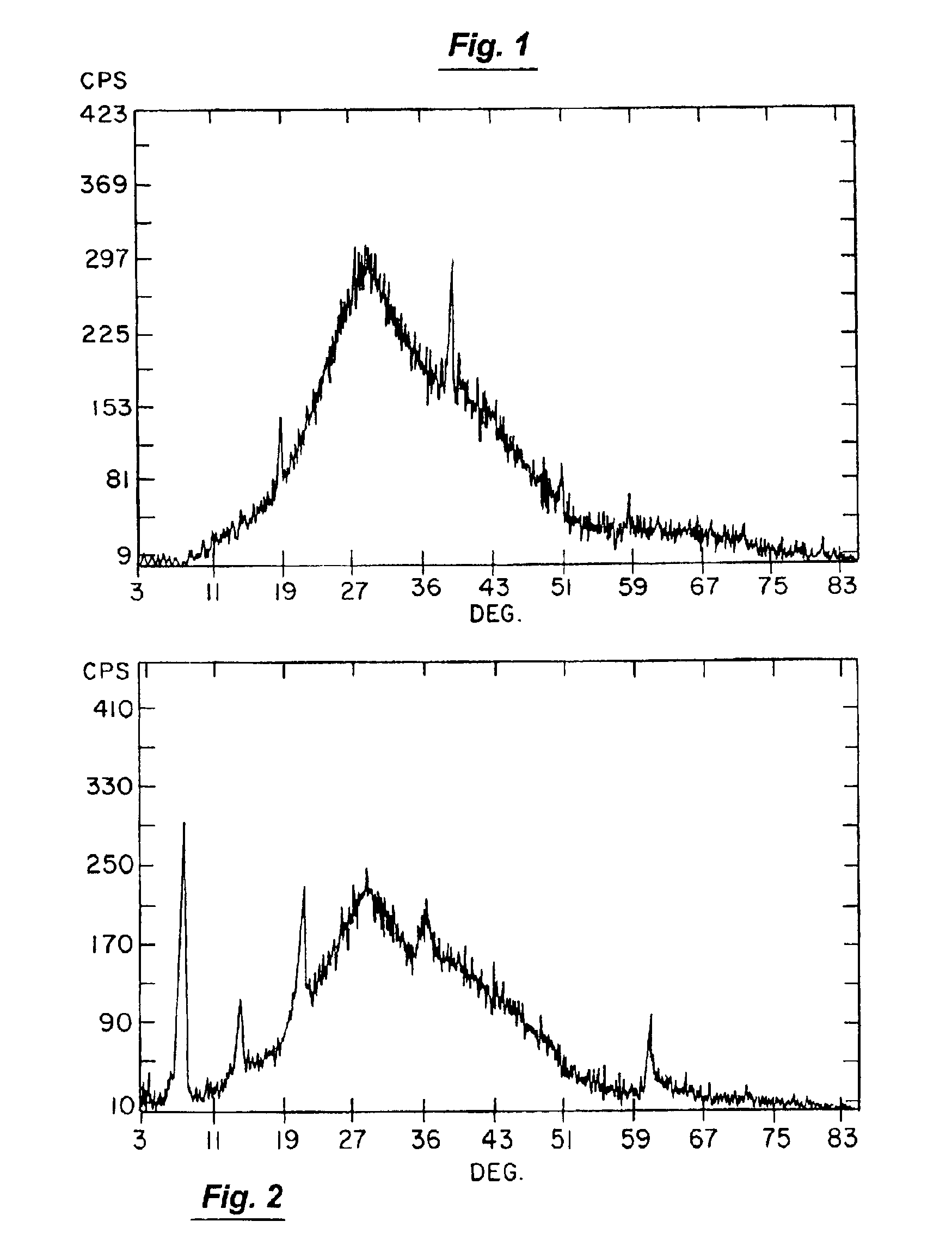

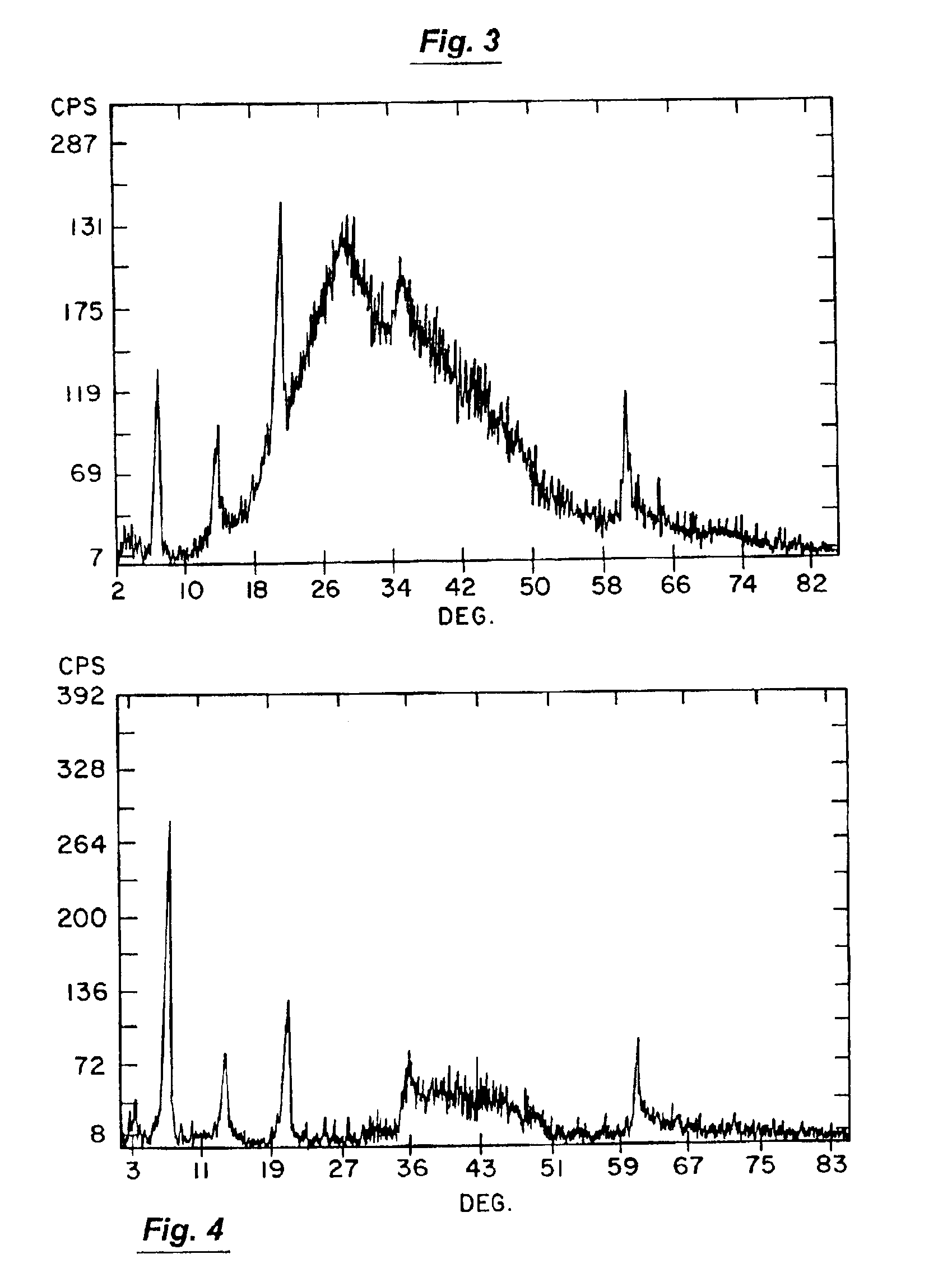

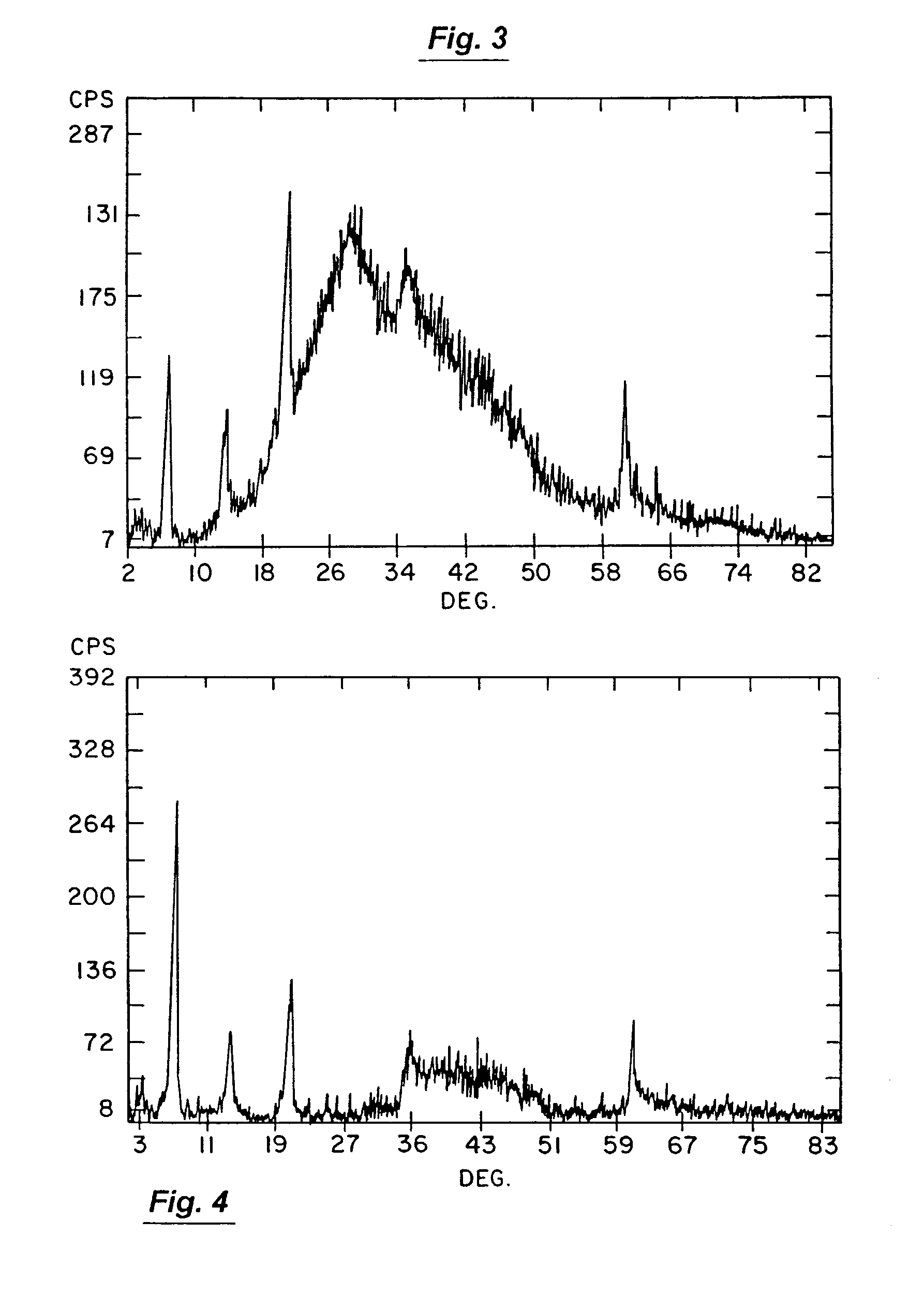

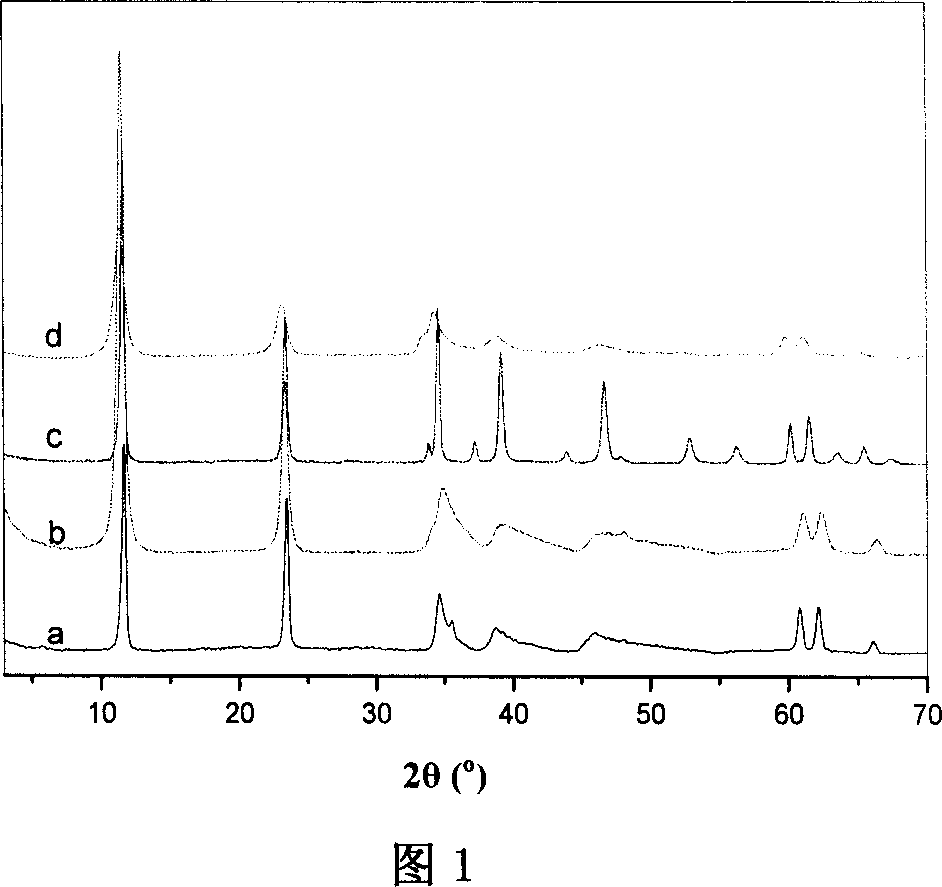

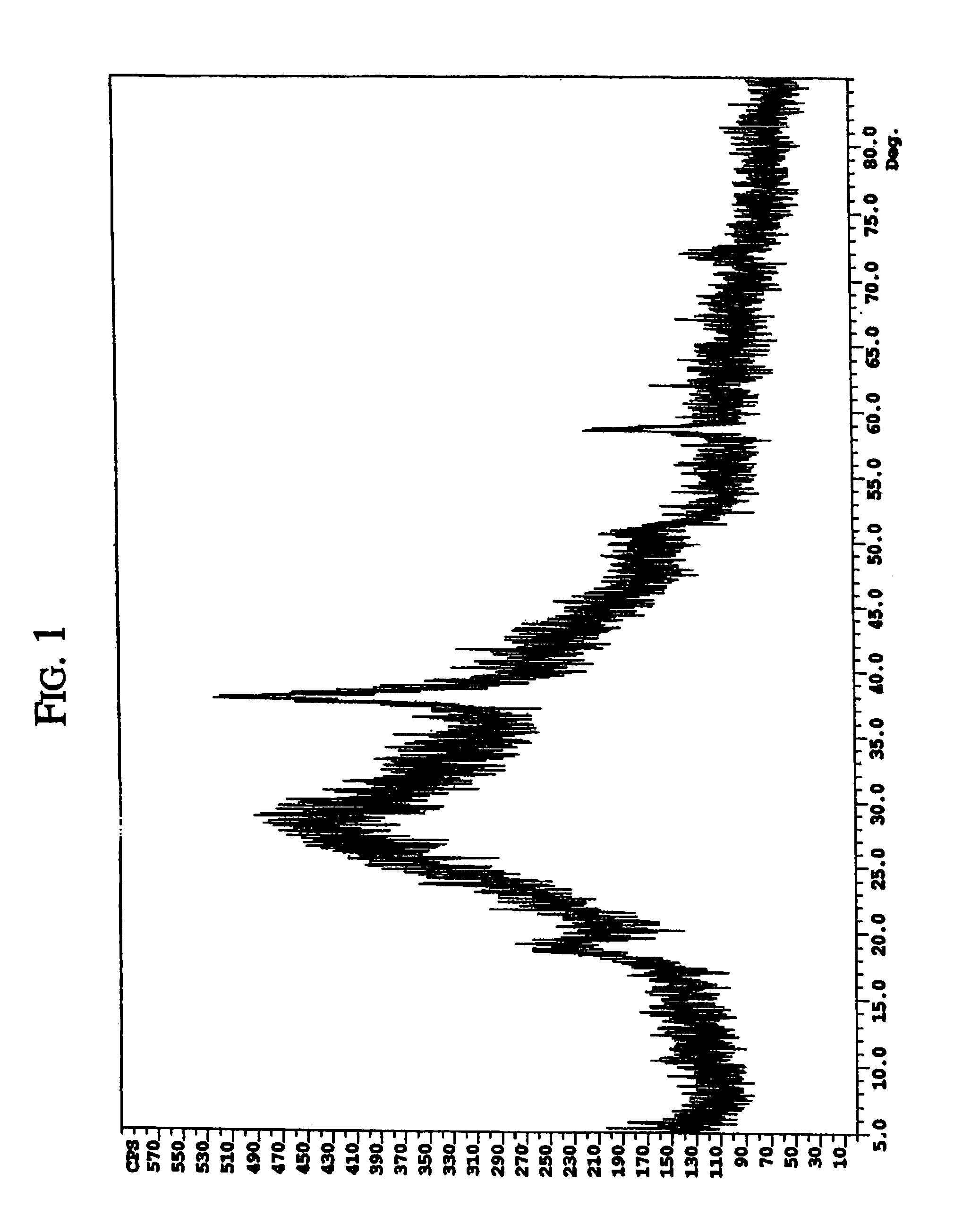

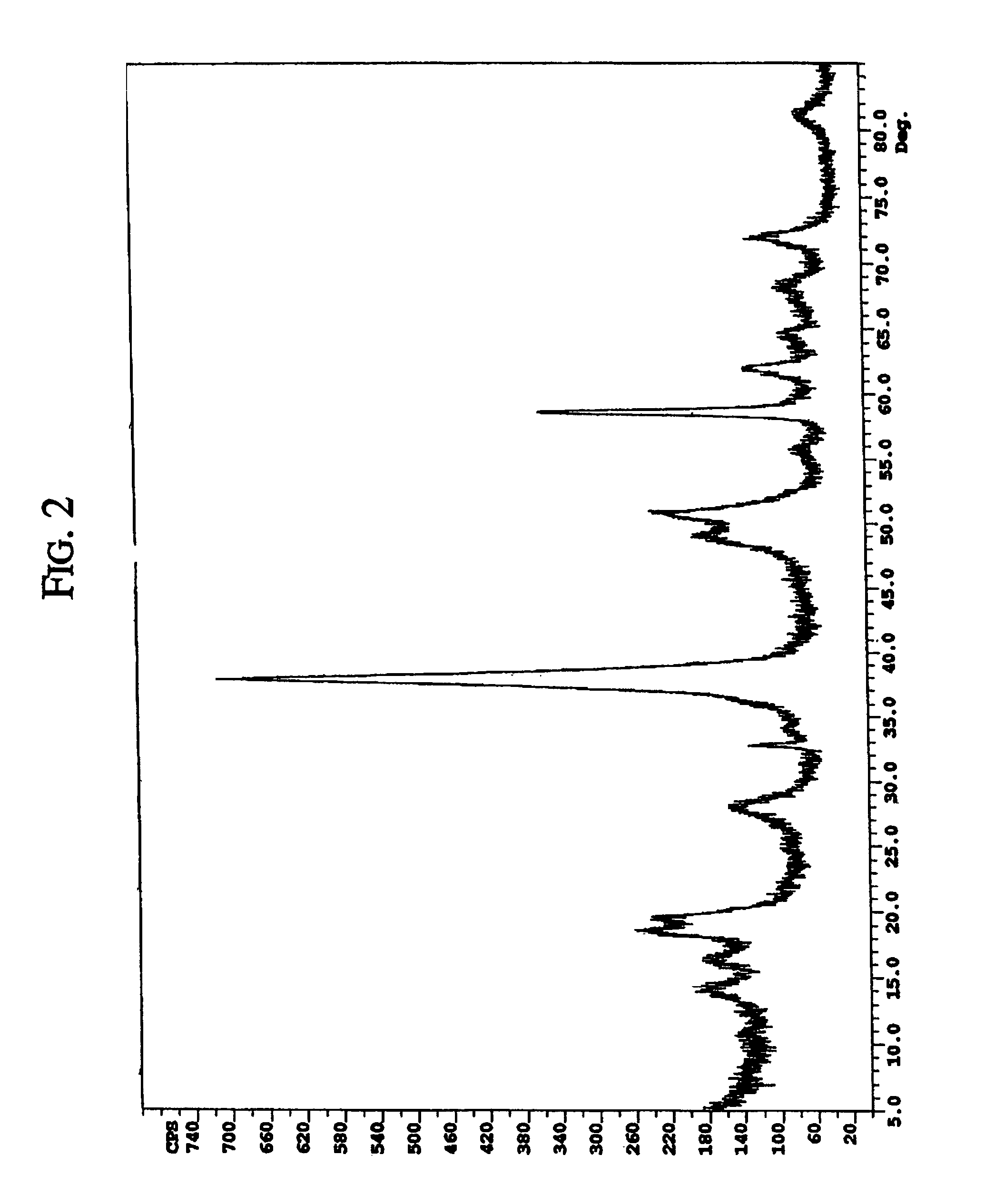

The present invention is directed to methods for reducing SOx, NOx, and CO emissions from a fluid stream comprising contacting said fluid stream with a compound comprising magnesium and aluminum and having an X-ray diffraction pattern displaying at least a reflection at a two theta peak position at about 43 degrees and about 62 degrees, wherein the ratio of magnesium to aluminum in the compound is from about 1:1 to about 10:1. In one embodiment, the ratio of magnesium to aluminum in the compound is from about 1:1 to about 6:1. In one embodiment, the ratio of magnesium to aluminum in the compound is from about 1.5:1 to about 10:1. In another embodiment, the invention is directed to methods wherein the ratio of magnesium to aluminum in the compound is from about 1.5:1 to about 6:1.

Owner:JOHNSON MATTHEY PROCESS TECH

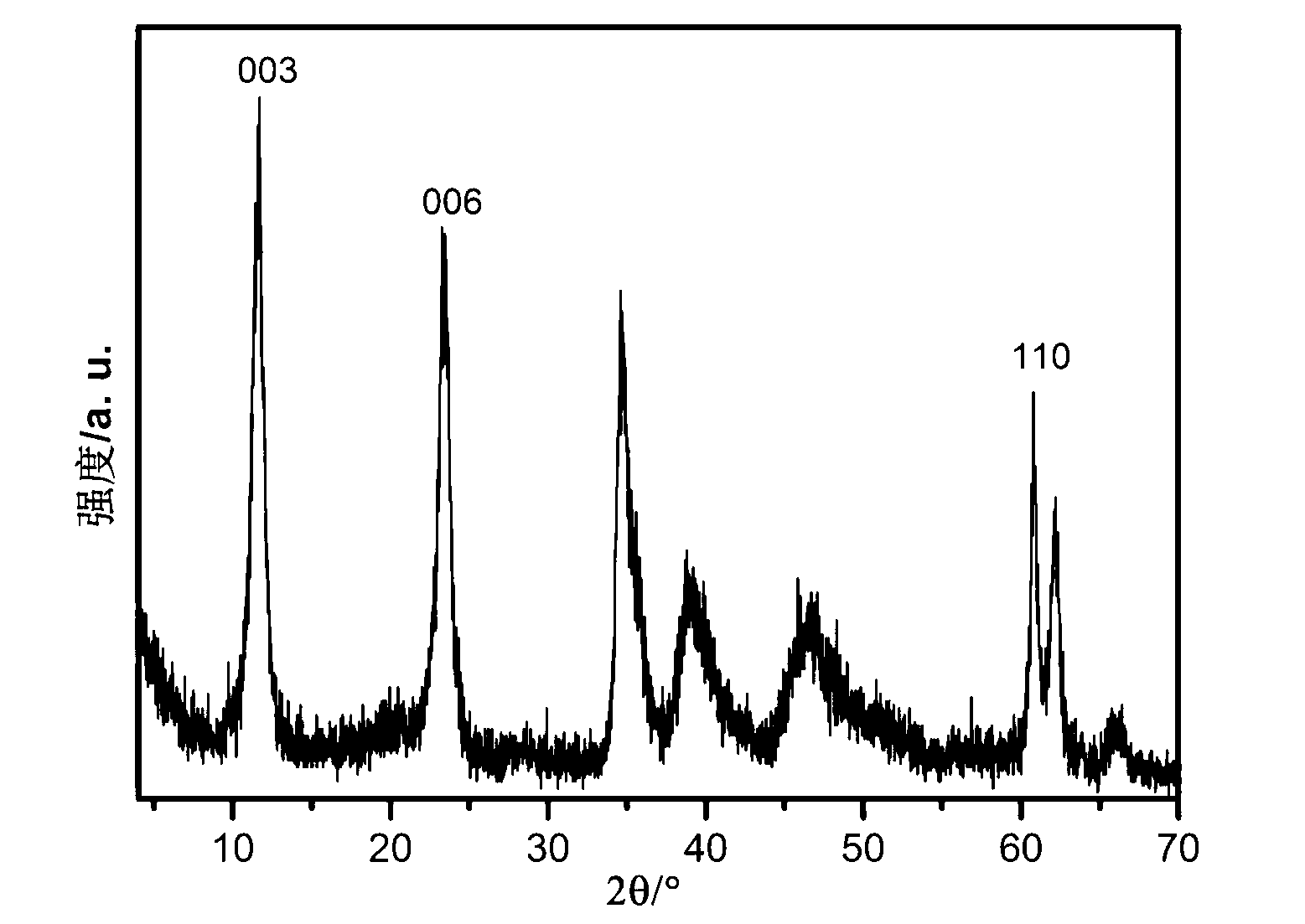

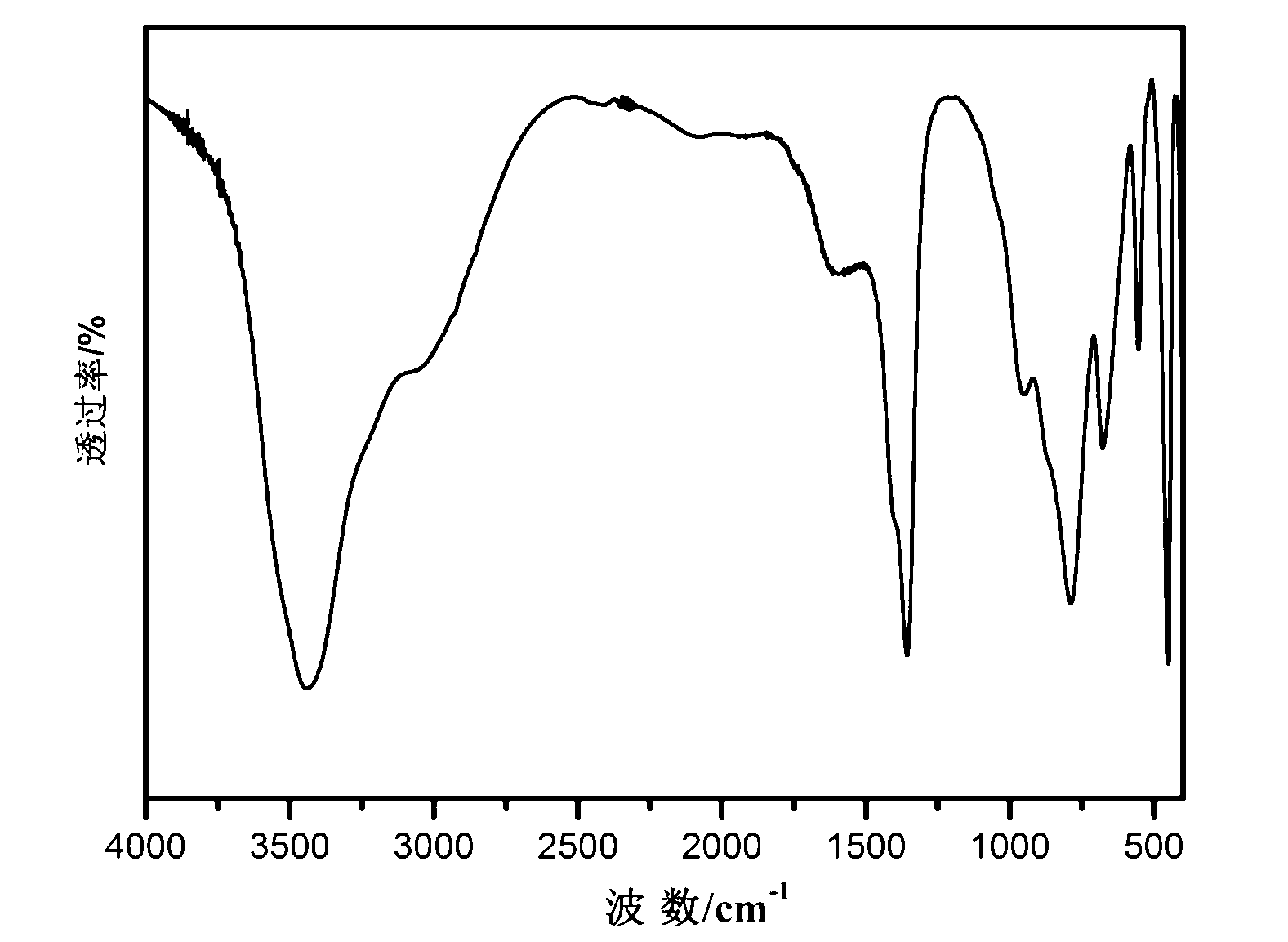

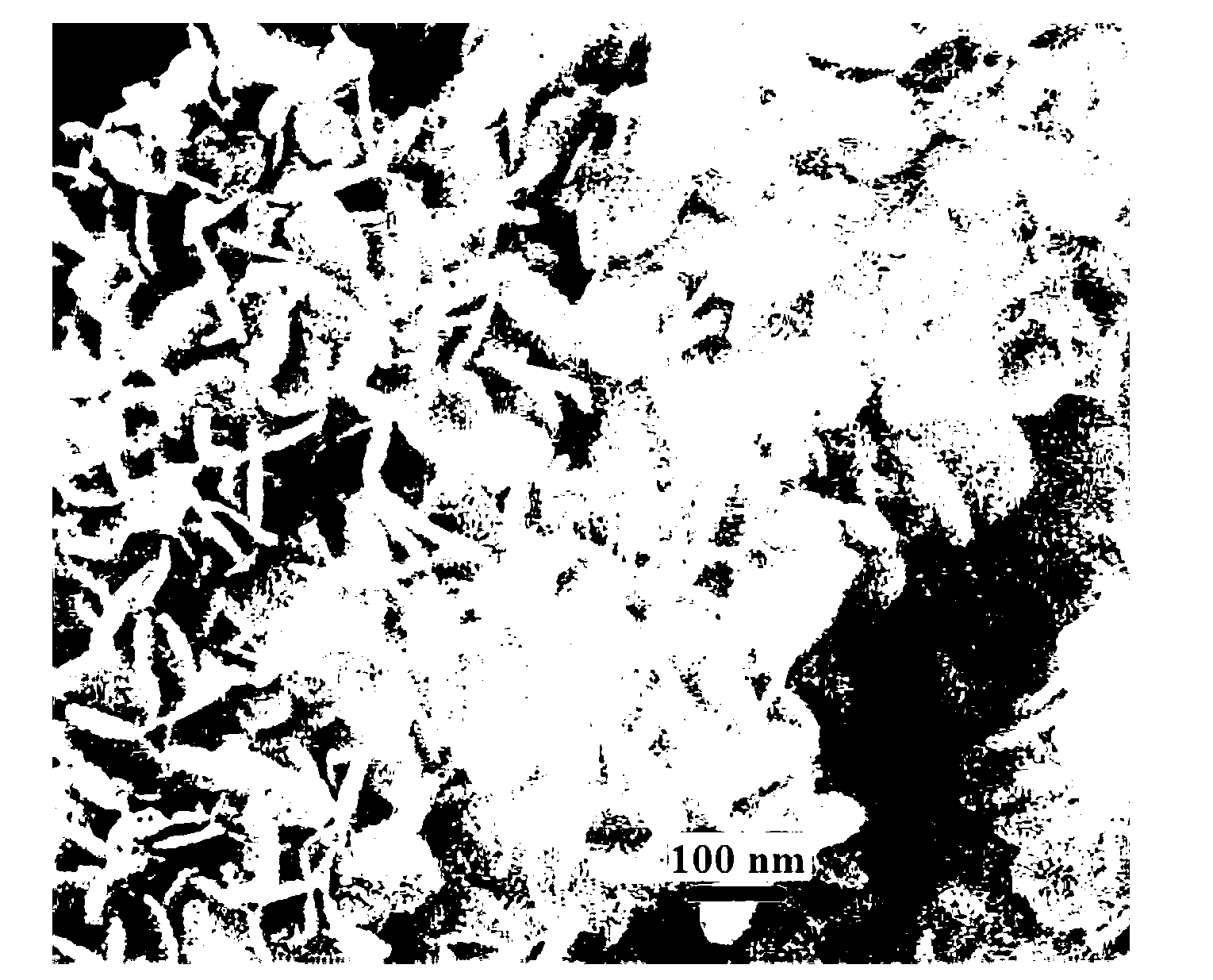

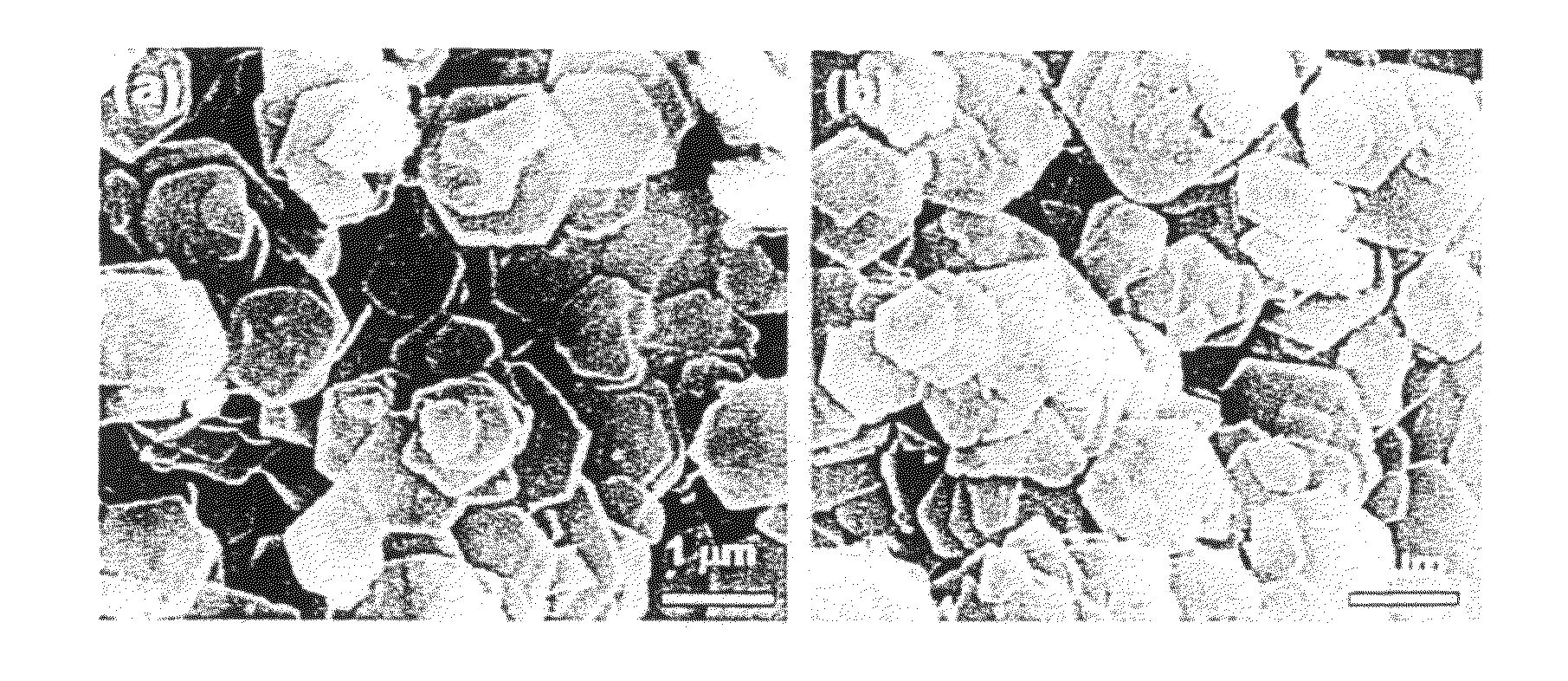

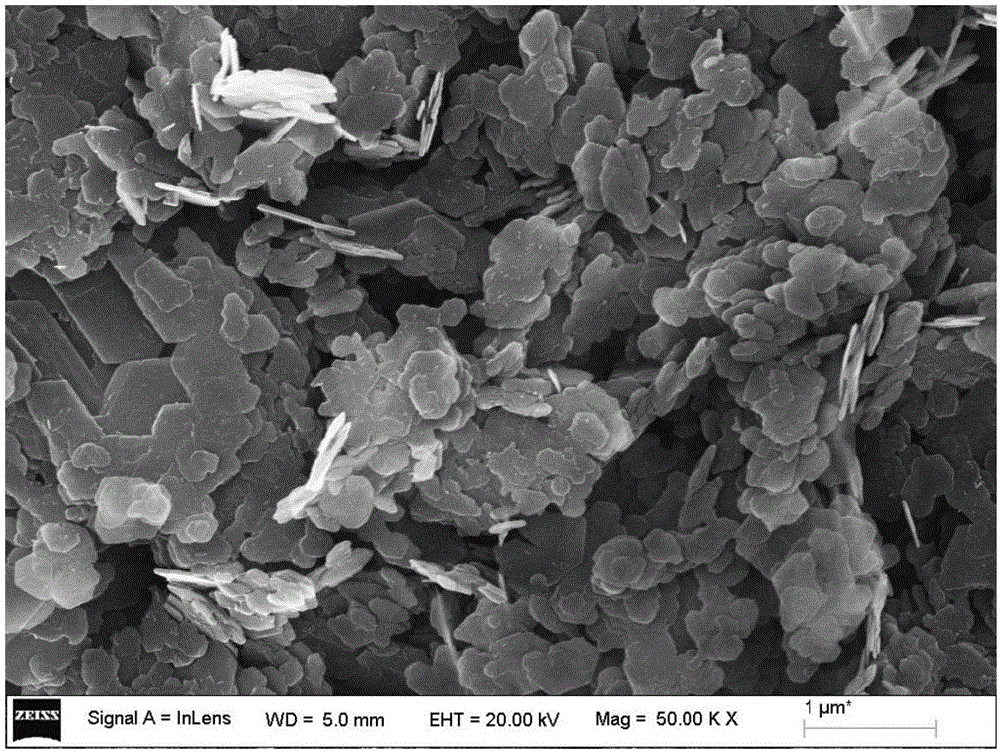

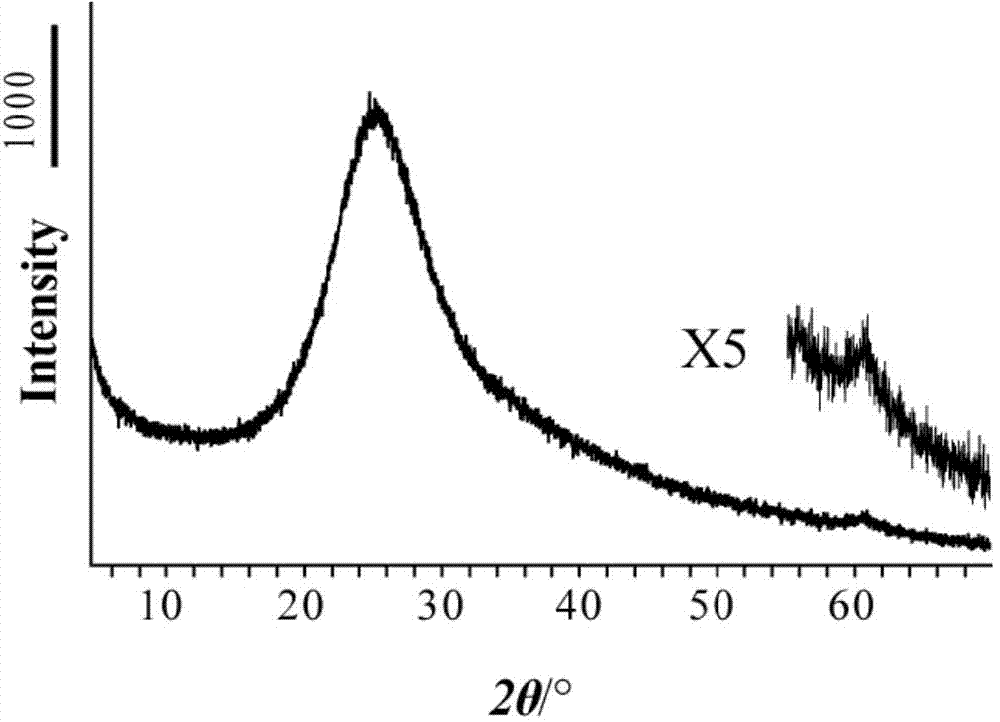

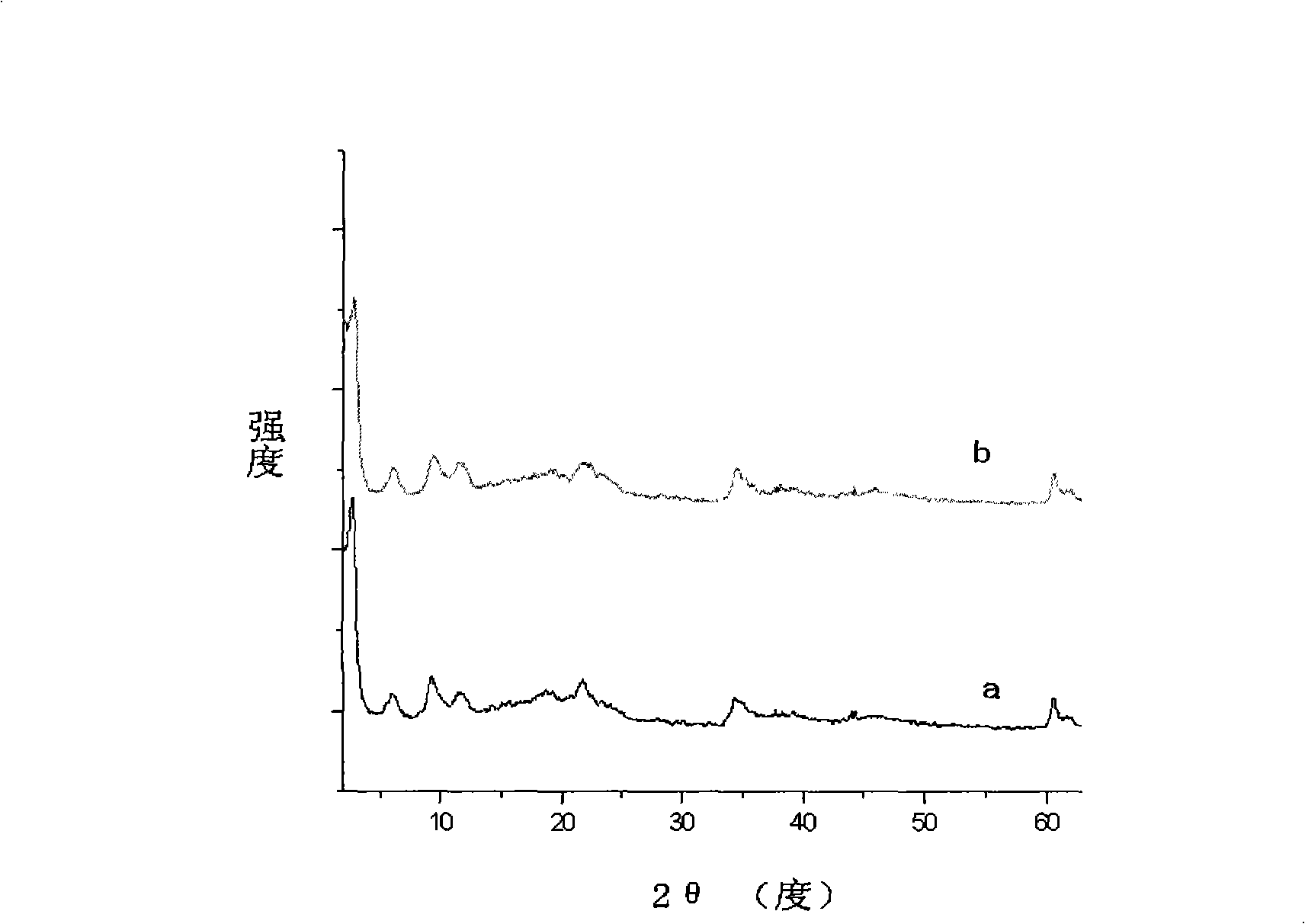

Nano-size layered double hydroxide and step-by-step precipitation preparation method thereof

InactiveCN103159238ARich sourcesLow costMaterial nanotechnologyTitanium compoundsPhysical chemistryAdsorption separation

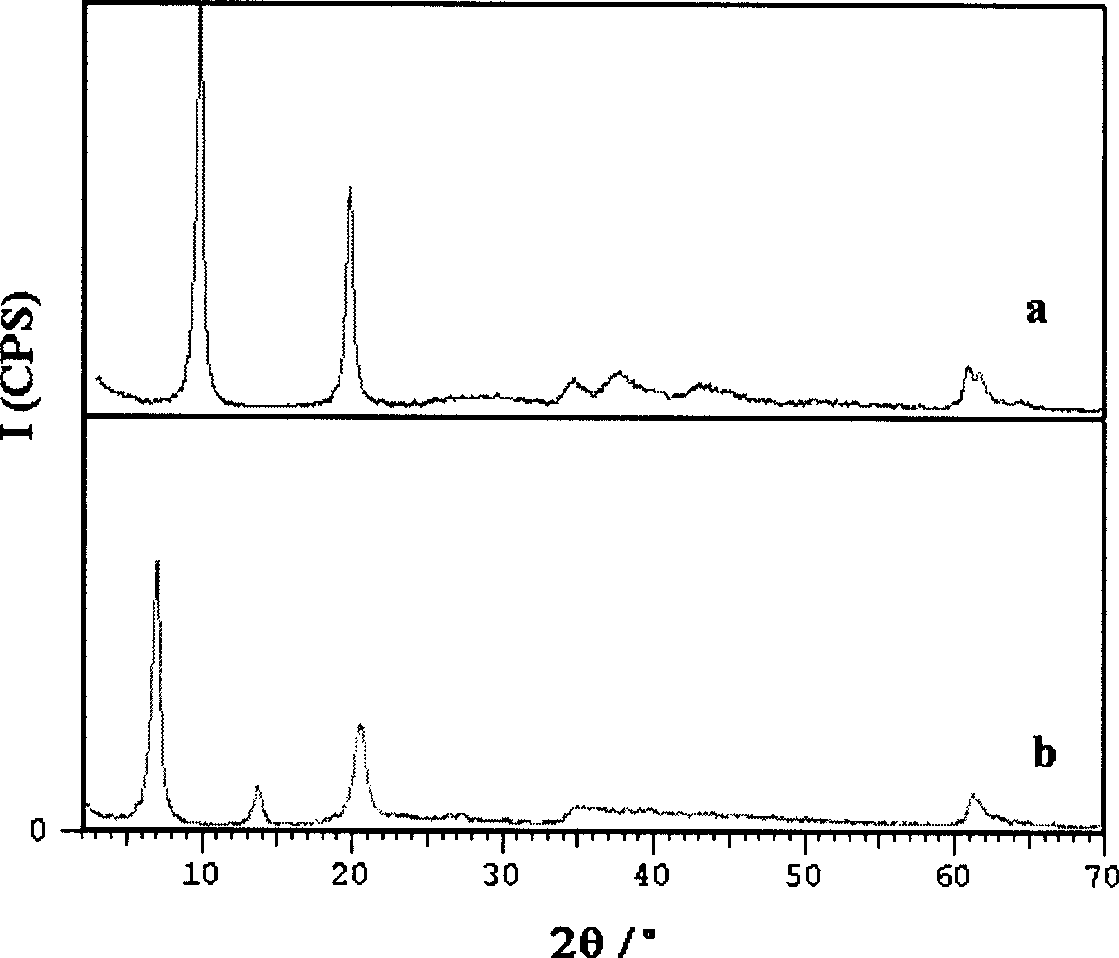

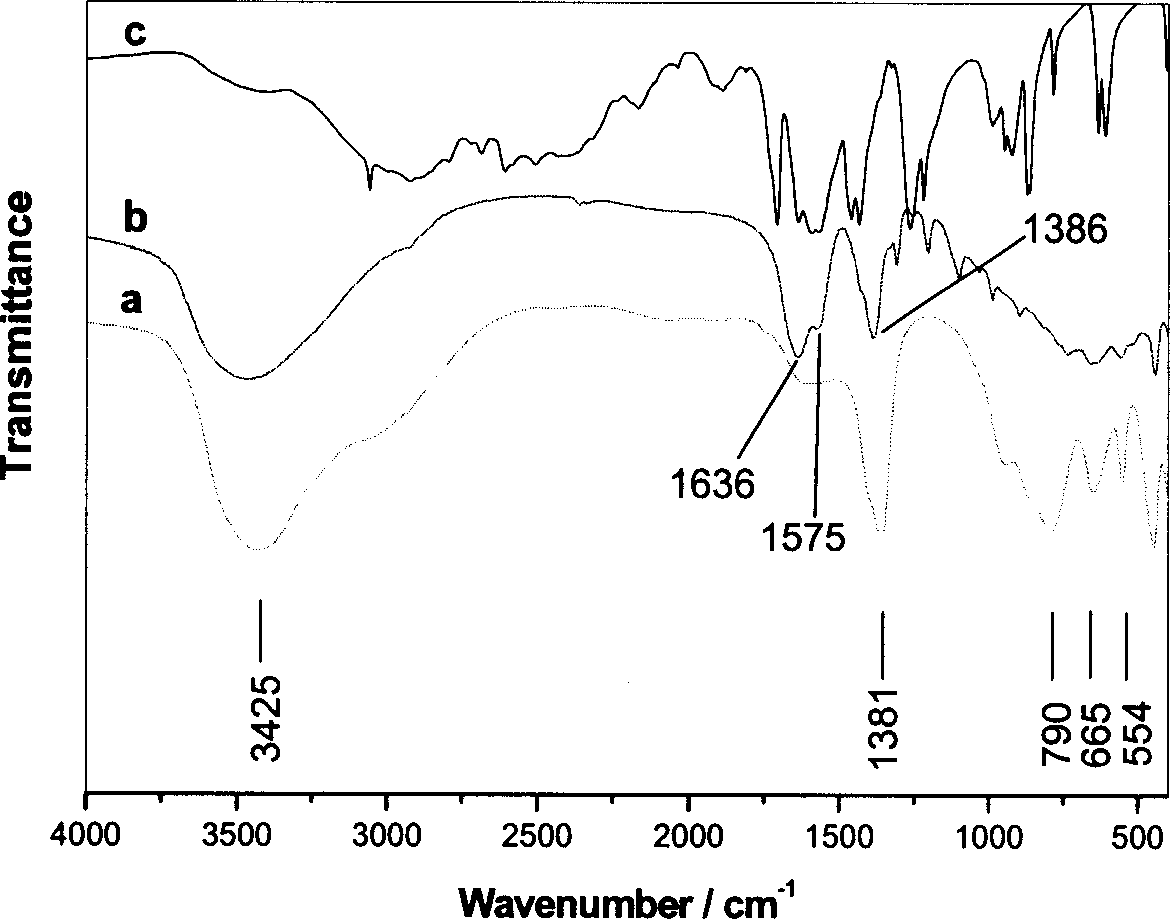

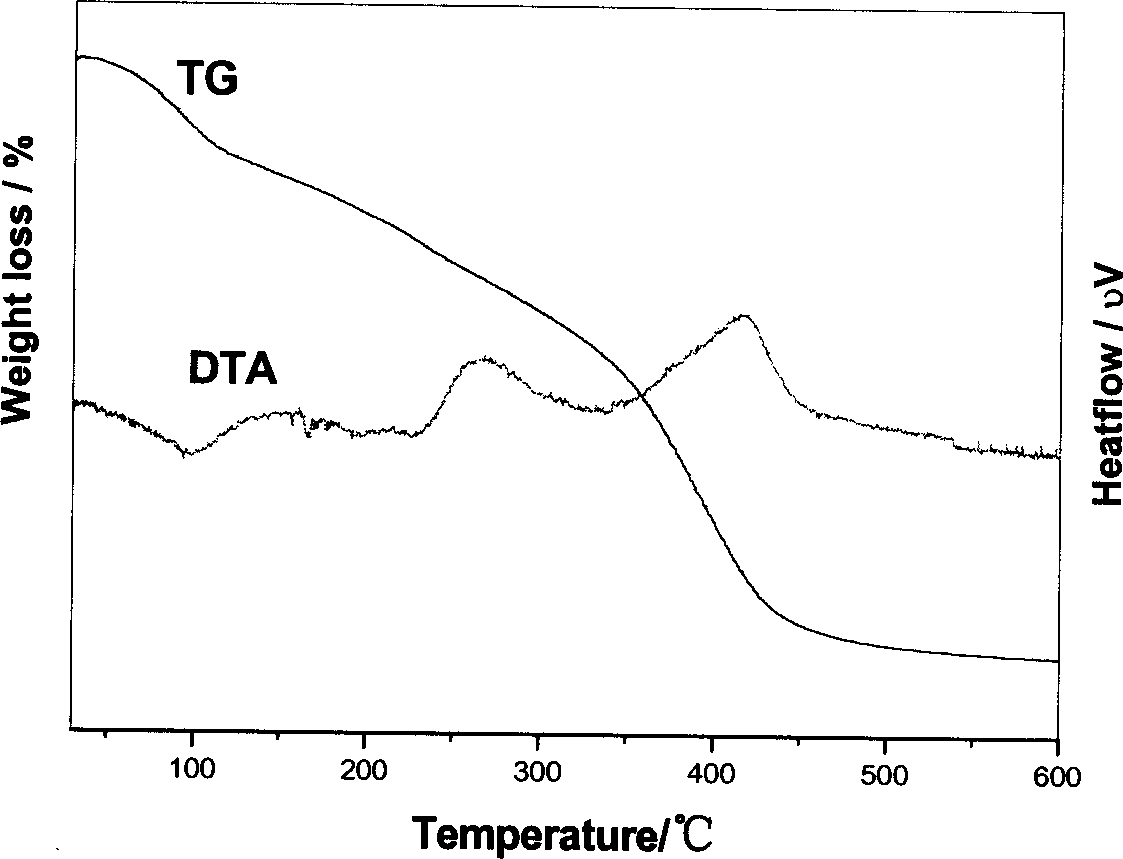

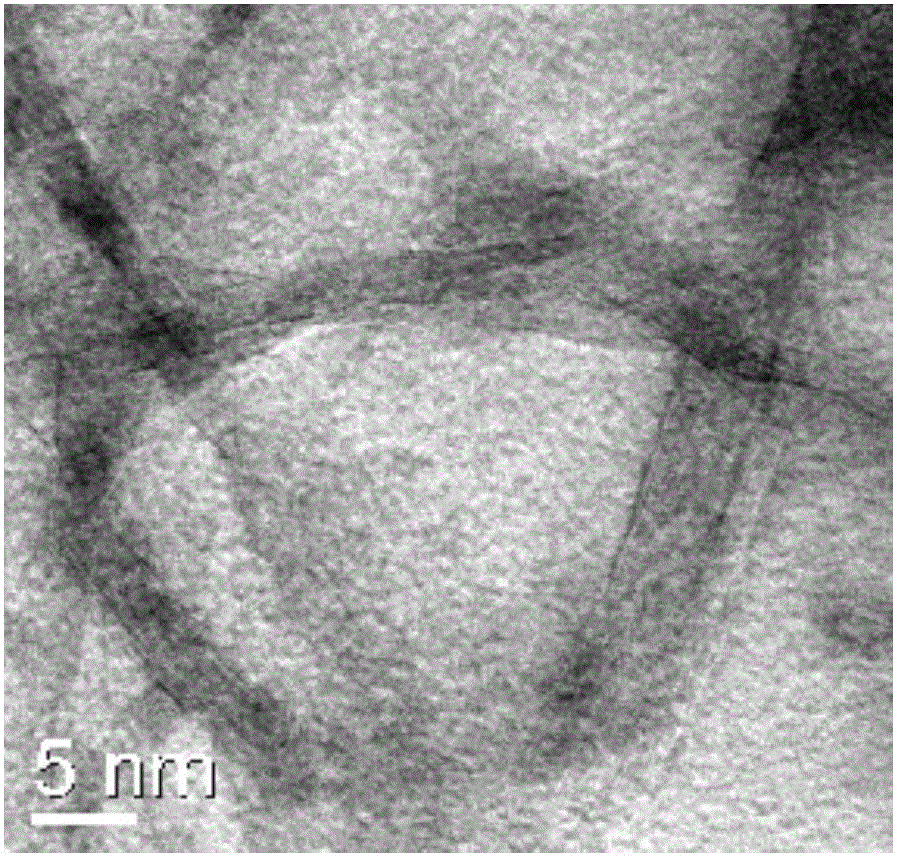

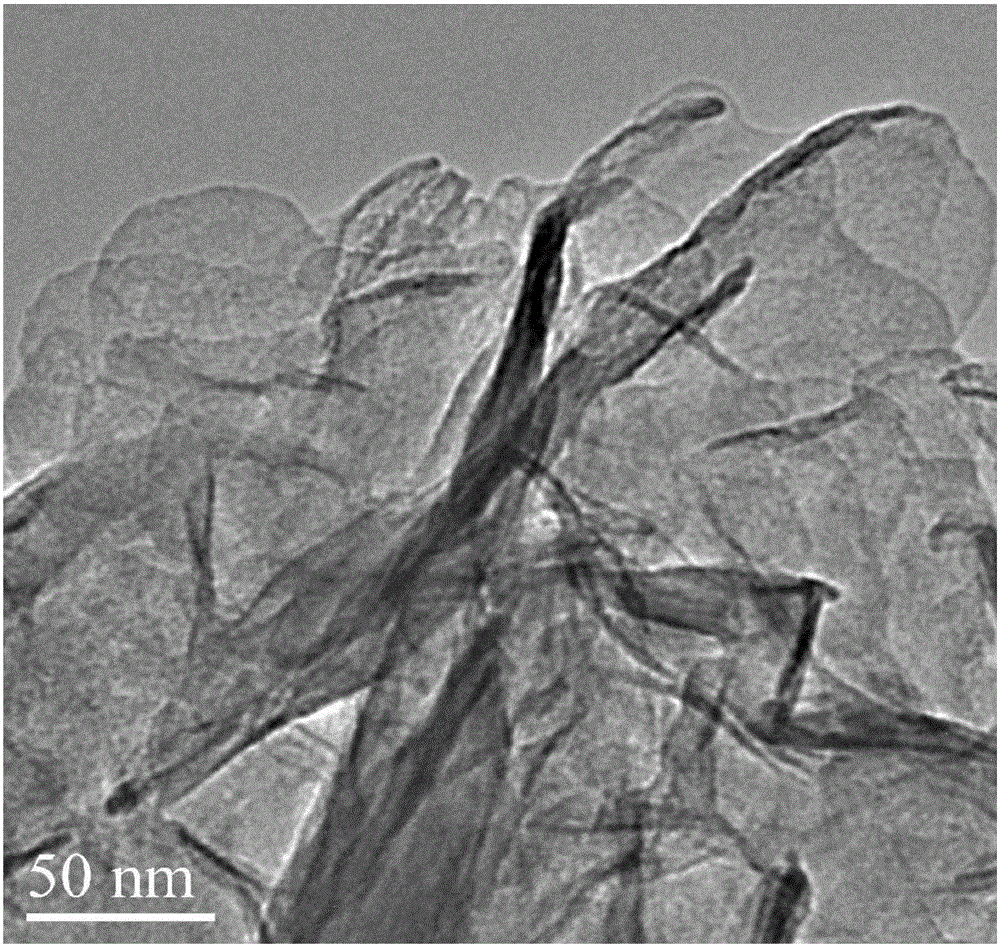

The invention provides a nano-size layered double hydroxide and a step-by-step precipitation preparation method thereof. The preparation method comprises the following steps: based on a soluble salt of a metal and an alkali as raw materials, respectively precipitating metal ions constituting an LDH (layered double hydroxide) layer plate through step-by-step precipitation reaction and generating the LDH during the second-step precipitation process. As the activity of the hydroxide prepared by the first-step precipitation reaction is high, the LDH can fast nucleate and grow during the second-step precipitation, an obtained LDH sheet is thinner, the thickness of the layer plate is 5-15nm, the length of the layer plate is 50-150nm, and the specific surface area of a BET (Brunauer-Emmett-Teller) is 140-280m<2> / g, which is much larger than the specific surface area of the common LDH. By adopting the method, the shortcoming of small specific surface area during the preparation of the LDH through a co-precipitation method can be overcome. The preparation method adopted by the invention is simple and convenient, high temperature and high pressure are not required, special equipment is not required, sources of the raw materials are rich, and the cost is low. The layered double hydroxide can be widely applied to the fields of adsorption separation, catalysis, high polymer materials and the like.

Owner:BEIJING UNIV OF CHEM TECH

Compounds, compositions and methods to reduce SOx emissions from FCC units

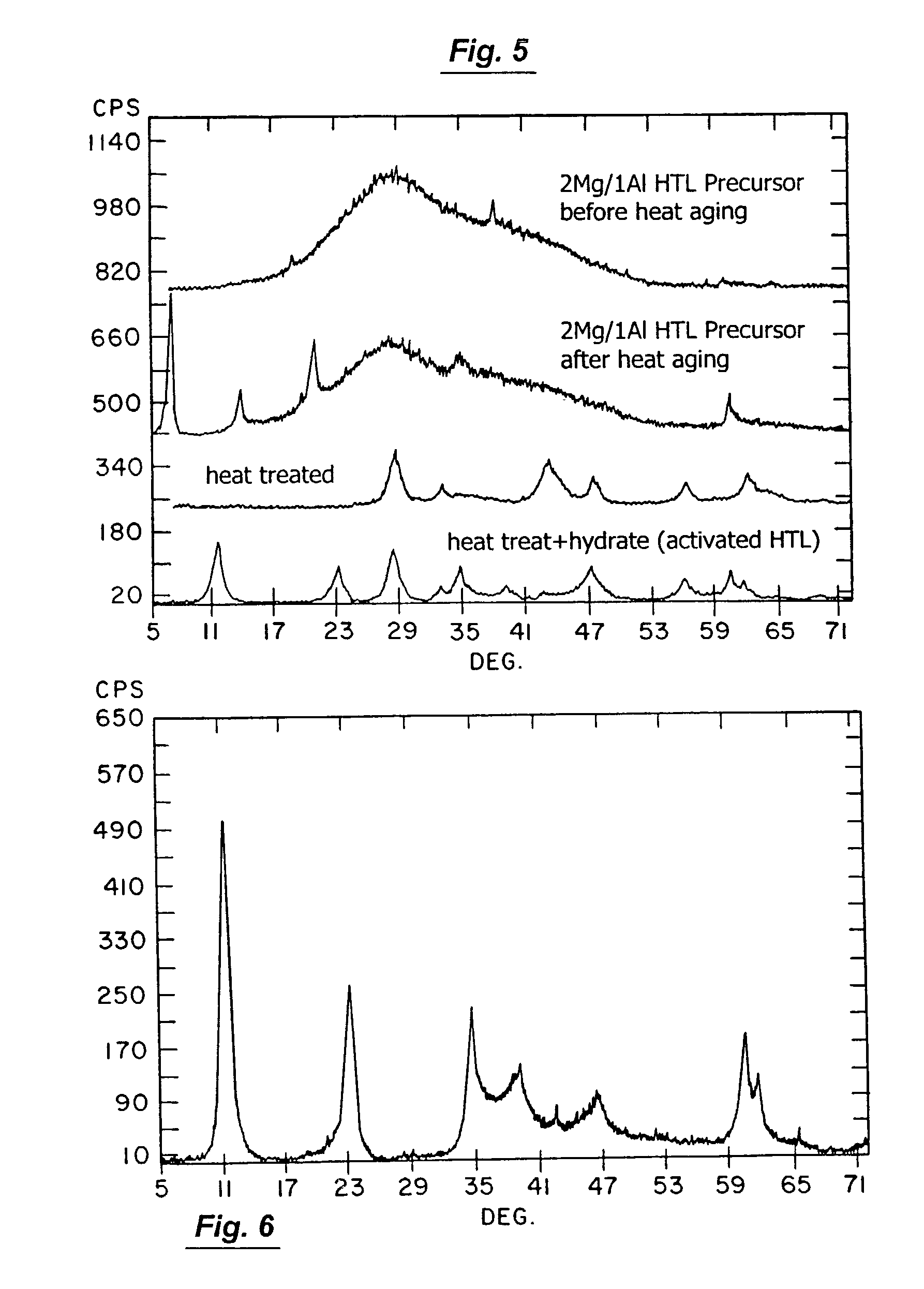

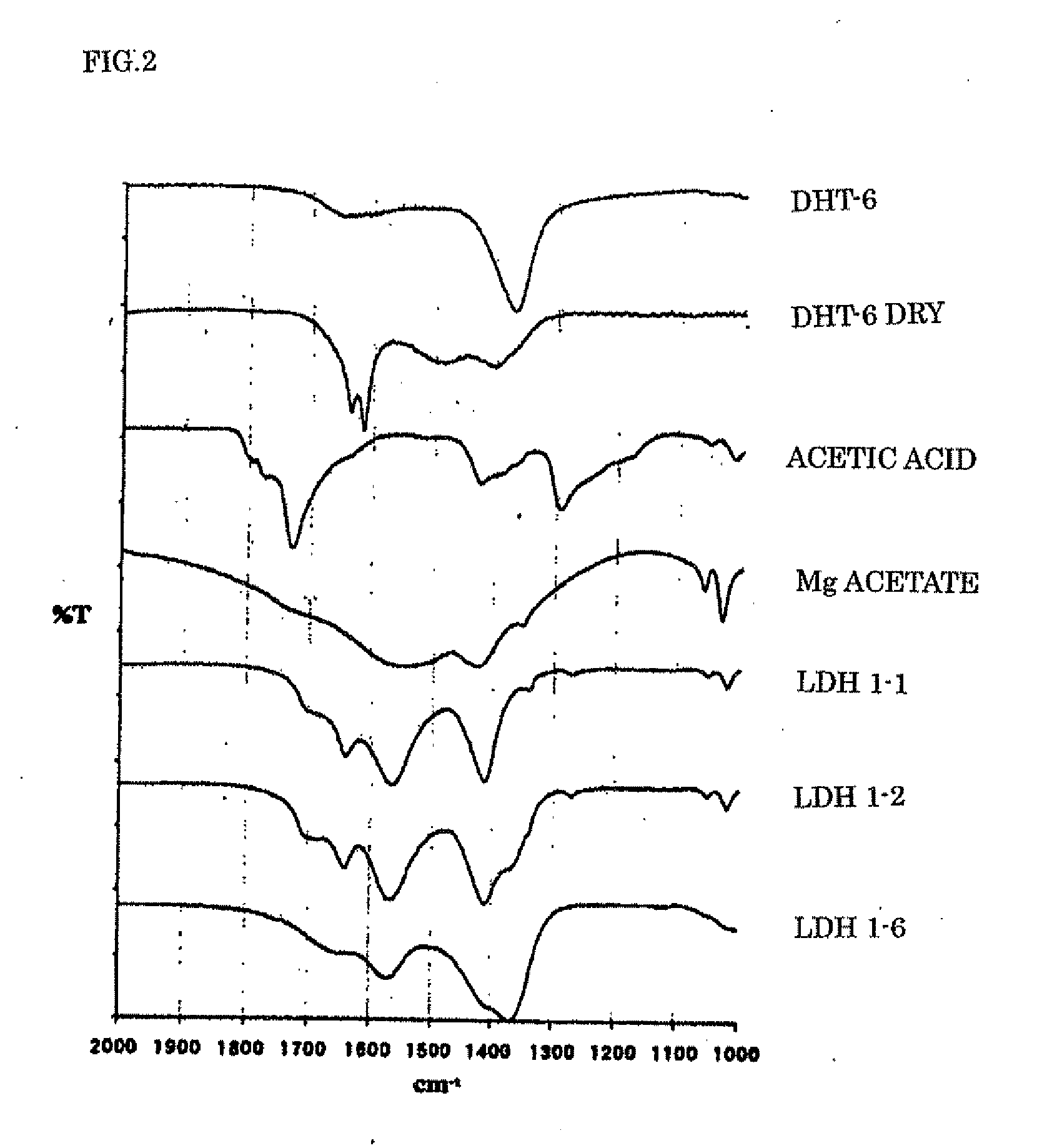

InactiveUS6929736B2Useful lifeExtended service lifeCatalytic crackingOxide/hydroxide preparationHydrotalciteHardness

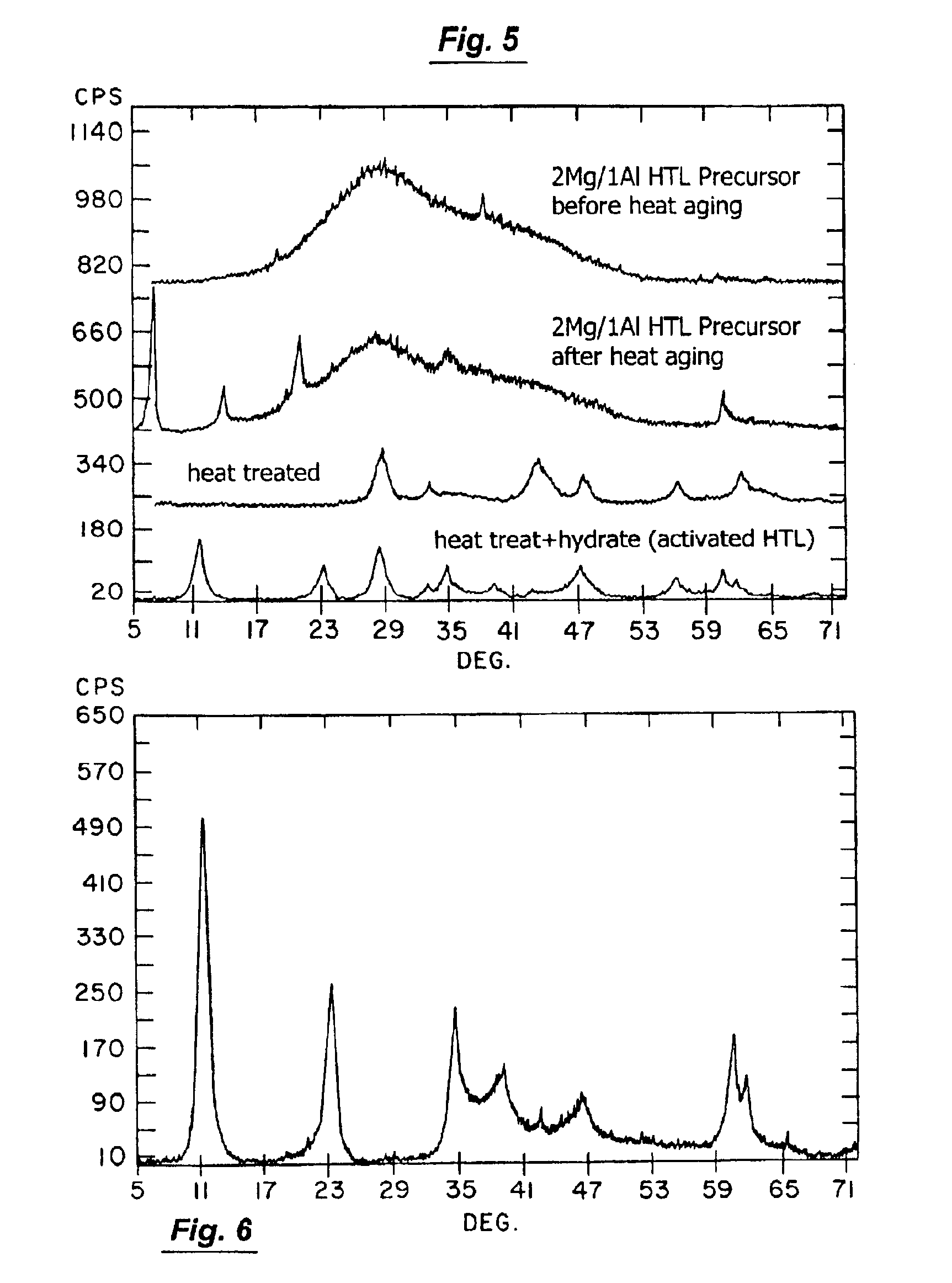

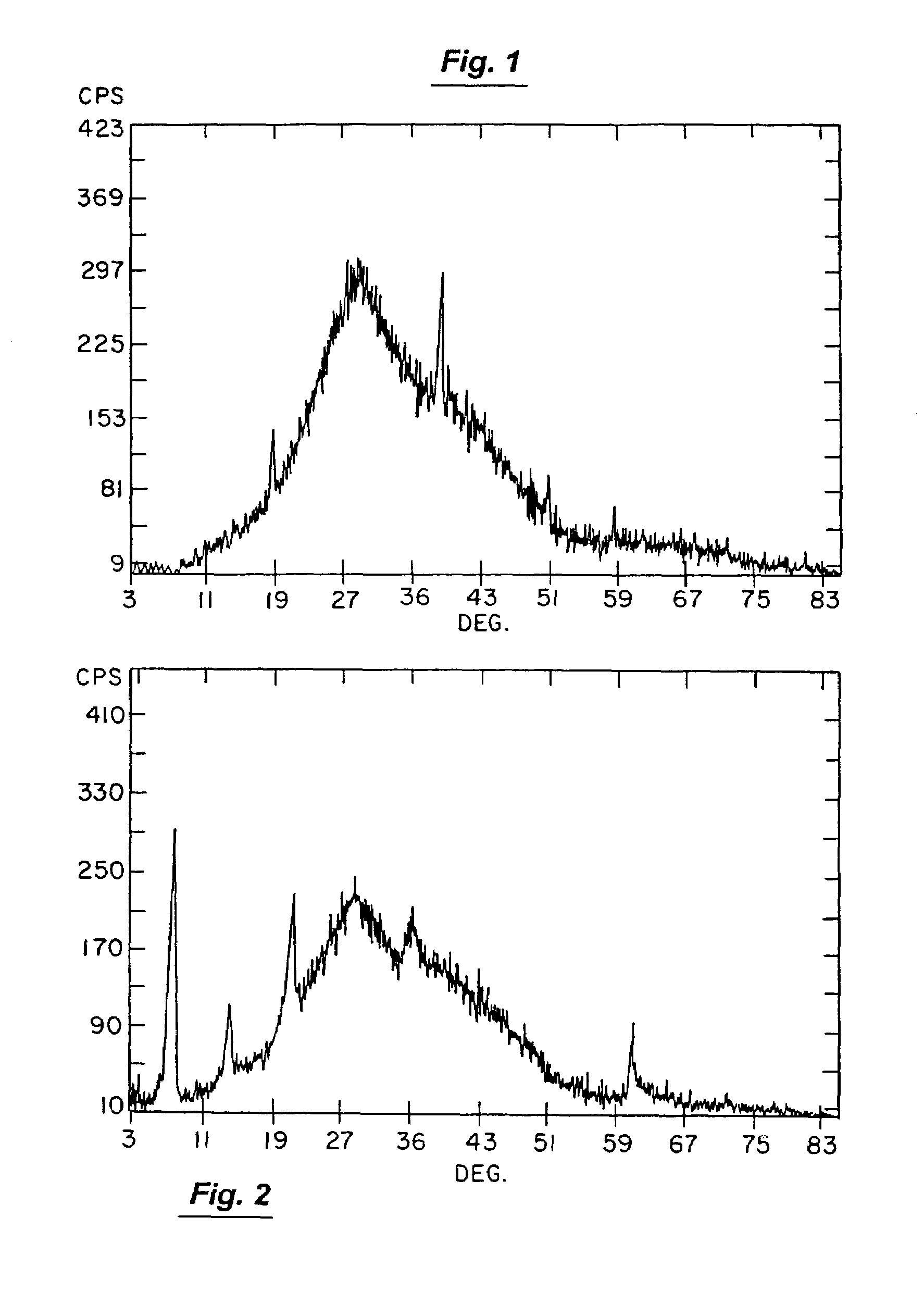

Anionic clay compounds such as hydrotalcite-like compounds can be made by a process wherein a non-hydrotalcite-like compound (or a hydrotalcite-like compound) are heat treated and then hydrated to form hydrotalcite-like compounds having properties (e.g., increased hardness and / or density) that differ from those of hydrotalcite-like compounds made by prior art methods wherein non-hydrotalcite-like compounds (or hydrotalcite-like compounds) are not similarly heat treated and hydrated to form such hydrotalcite-like compounds.

Owner:JOHNSON MATTHEY PROCESS TECH

Process for making, and use of, anionic clay materials

InactiveUS7112313B2Improved ability can be regeneratedHigh hardnessOxide/hydroxide preparationCatalytic crackingPhysical chemistryHydrotalcite

Anionic clay compounds such as hydrotalcite-like compounds can be made by a process wherein a non-hydrotalcite-like compound (or a hydrotalcite-like compound) are heat treated and then hydrated to form hydrotalcite-like compounds having properties (e.g., increased hardness and / or density) that differ from those of hydrotalcite-like compounds made by prior art methods wherein non-hydrotalcite-like compounds (or hydrotalcite-like compounds) are not similarly heat treated and hydrated to form such hydrotalcite-like compounds.

Owner:JOHNSON MATTHEY PROCESS TECH

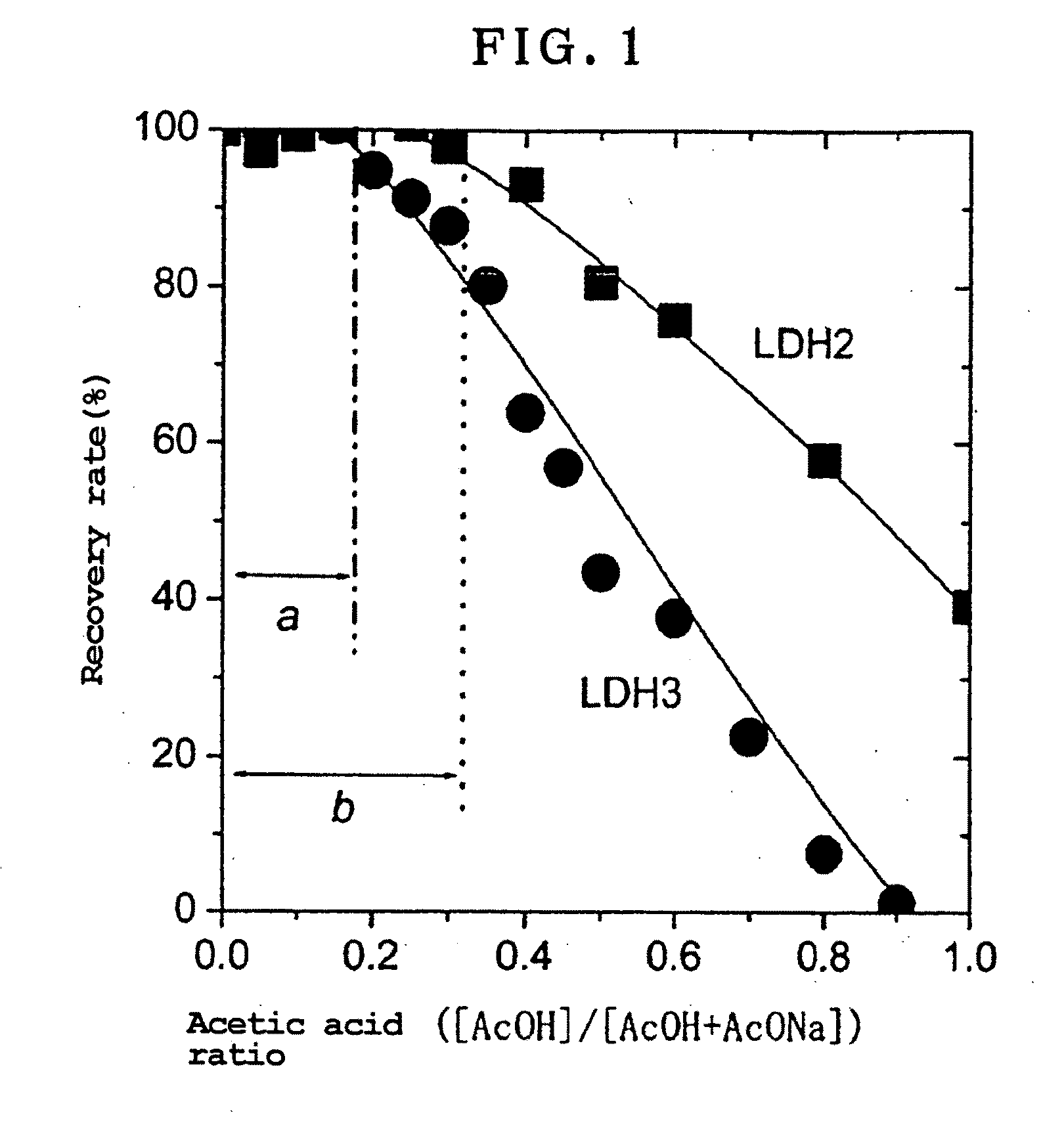

Preparation method for anion-exchangeable, layered double hydroxides

InactiveUS20100279848A1Overcome defectsSimple methodProductsGas treatmentIon exchangeDivalent metal ions

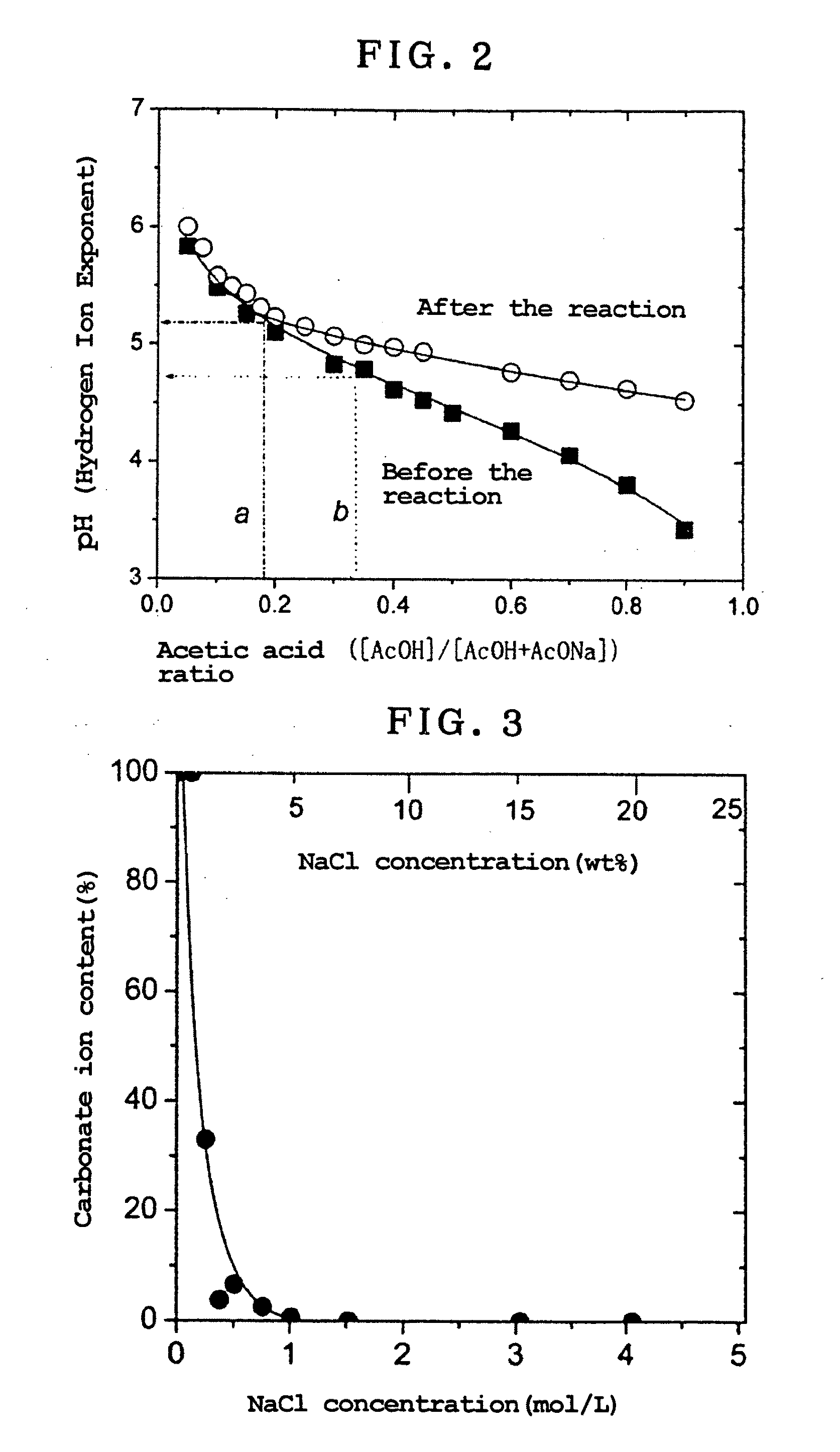

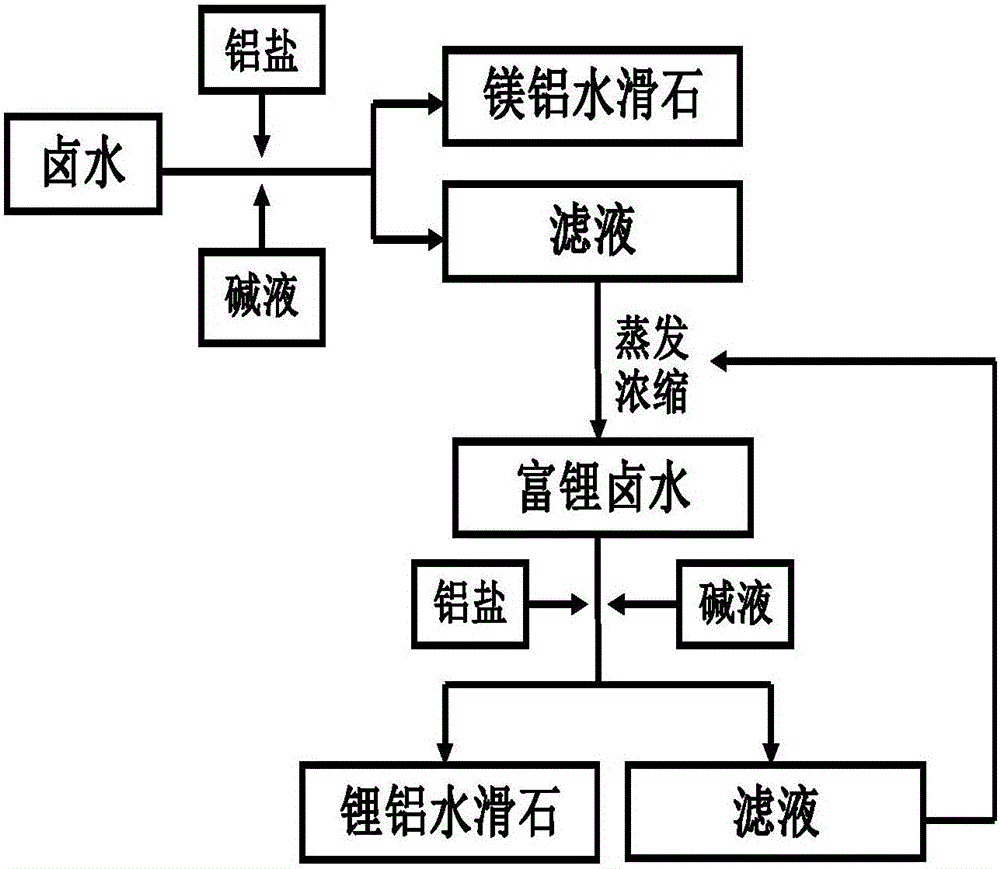

The invention has for its object to provide a preparation method for preparing an anion-exchangeable LDH by decarbonation of a carbonate ion type LDH, which makes sure de carbonation is implemented with safety in a continuous manner while crystal shape, crystal structure and crystallinity are kept intact.The invention provides a preparation method for preparing an anion-exchangeable, layered double hydroxide wherein a carbonate ion type layered double hydroxide (LDH) having a composition represented by a general formula: QxR(OH)z(CO32−)0.5-y / 2(X−)y.nH2O where x is indicative of a numeral range of 1.8≦x≦4.2; z is indicative of 2(x+1); y is indicative of a minimum value of at least 0 that increases to less than 1 when anions (X−) remain or a part of anions is introduced; Q is a divalent metal ion; R is a trivalent metal ion; and n is 2±2 is used as a starting material, and y in said general formula increases to a maximum of 1 by substitution of a minus monovalent anion (X−1) at a carbonate ion site thereby implementing substitution, characterized in that the starting material is dispersed in an aqueous solution mixed with a salt containing minus monovalent anions (X−) in an amount enough for substitution at the carbonate ion site while said aqueous solution is kept at a pH (hydrogen ion exponent) of greater than 4 to less than 7.

Owner:NAT INST FOR MATERIALS SCI

Treatment or remediation of natural or waste water

ActiveUS20120228229A1Protect the surfaceWater contaminantsSolid sorbent liquid separationAluminateAluminium hydroxide

A process for treating a natural or wastewater containing dissolved Mg or dissolved Al comprising the steps of adding at least one Mg-containing compound or at least one Al-containing compound to the natural or wastewater to thereby form a layered double hydroxide (LDH) containing Mg and Al as predominant metal species in a lattice of the LDH. The LDH may comprise hydrotalcite. The AL-containing compound may be aluminate or aluminium hydroxide derived from the Bayer process or from an alumina refinery.

Owner:COMMONWEALTH SCI & IND RES ORG

Process method for extracting Mg and Li from bittern and simultaneously producing hydrotalcite

ActiveCN105152193ARealize resource separationAchieve productionSemi-permeable membranesHydrotalciteLithiumEvaporation

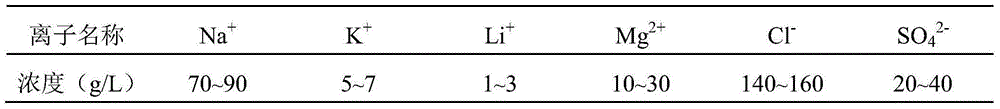

The invention provides a process method for separating Mg and Li from salt lake bittern and simultaneously producing magnesium-aluminum layered double hydroxide (MgAl-LDH) and lithium-aluminum layered double hydroxide (LiAl-LDH) by a reaction-separation combined technology. The process method comprises adding an Al salt in bittern, carrying out coprecipitation and crystallization on the bittern and alkali lye for coprecipitation to obtain an MgAl-LDH solid product and a filtrate, carrying out evaporation concentration on the filtrate to obtain Li-rich bittern, adding an Al salt into the Li-rich bittern, carrying out coprecipitation on the mixed Li-rich bittern and alkali lye, carrying out separation to obtain a LiAl-LDH solid product and a filtrate, carrying out evaporation concentration on the filtrate and recycling the concentrate. Mg in bittern can form MgAl-LDH and the MgAl-LDH is separated at first so that the traditional method for separating Mg and Li from a high Mg / Li ratio solution has high difficulty. Through the reaction-separation combined technology, Mg and Li resources in salt lake bittern are separated and simultaneously, MgAl-LDH and LiAl-LDH functional material production is realized. The process method realizes salt lake resource separation and produces a high added value functional material.

Owner:QINGHAI WESTERN MAGNESIUM NEW MATERIAL CO LTD

Preparation of new layered double hydroxides exchanged with osmate for asymmetric dihydroxylation of olefins to vicinal diols

InactiveUS6387033B1Facilitates oxygen transferHigh activityPreparation by oxidation reactionsCarboxylic acid esters preparationDiolAlkene

LDH-osmate of the formula [MII(1-x)MIIIx(OH)2][OsO42-]x / 2.zH2O wherein MII is a divalent cation selected from the group consisting of Mg2+, Mn2+, Fe2+, Co2+, Ni2+, Cu2+, Zn2+ and Ca2+ and MIII is a trivalent ion selected from the group consisting of Al3+, Cr3+, Mn3+, Fe3+ and Co3+, and x is the mole fraction having integral value ranging from 0.2 to 0.33, and z is the number of water molecules and ranges from 1 to 4, useful as, a catalyst, and a process for the preparation thereof and use thereof to manufacture vicinal diols.

Owner:COUNCIL OF SCI & IND RES

Microballons of laminar dual hydroxy composite metal oxide and preparation method

This invention relates to a method for preparing lamellar dihydroxyl composite metal oxide microspheres. The method comprises: preparing lamellar dihydroxyl composite metal oxide (hydrotalcite) nano- or submicro-particles by co-precipitation, nucleation / crystallization / isolation, nonequilibrium crystallization or hydrothermal synthesis, preparing into slurry with a certain solid content, adding bonding agent, spin-spraying for granulation, and drying to obtain microspheres with diameters of 5-100 mu.m. The bulk density, specific surface area, pore volume and most probable pore diameters of the microspheres are 0.4-0.8 g / cm3, 40-150 m2 / g, 0.1-0.8 cm3 / g and 2-40 nm, respectively. The microspheres can be directly used for catalysis or separation after activated, and the mass transfer resistance and carbon accumulation are minimized.

Owner:BEIJING UNIV OF CHEM TECH

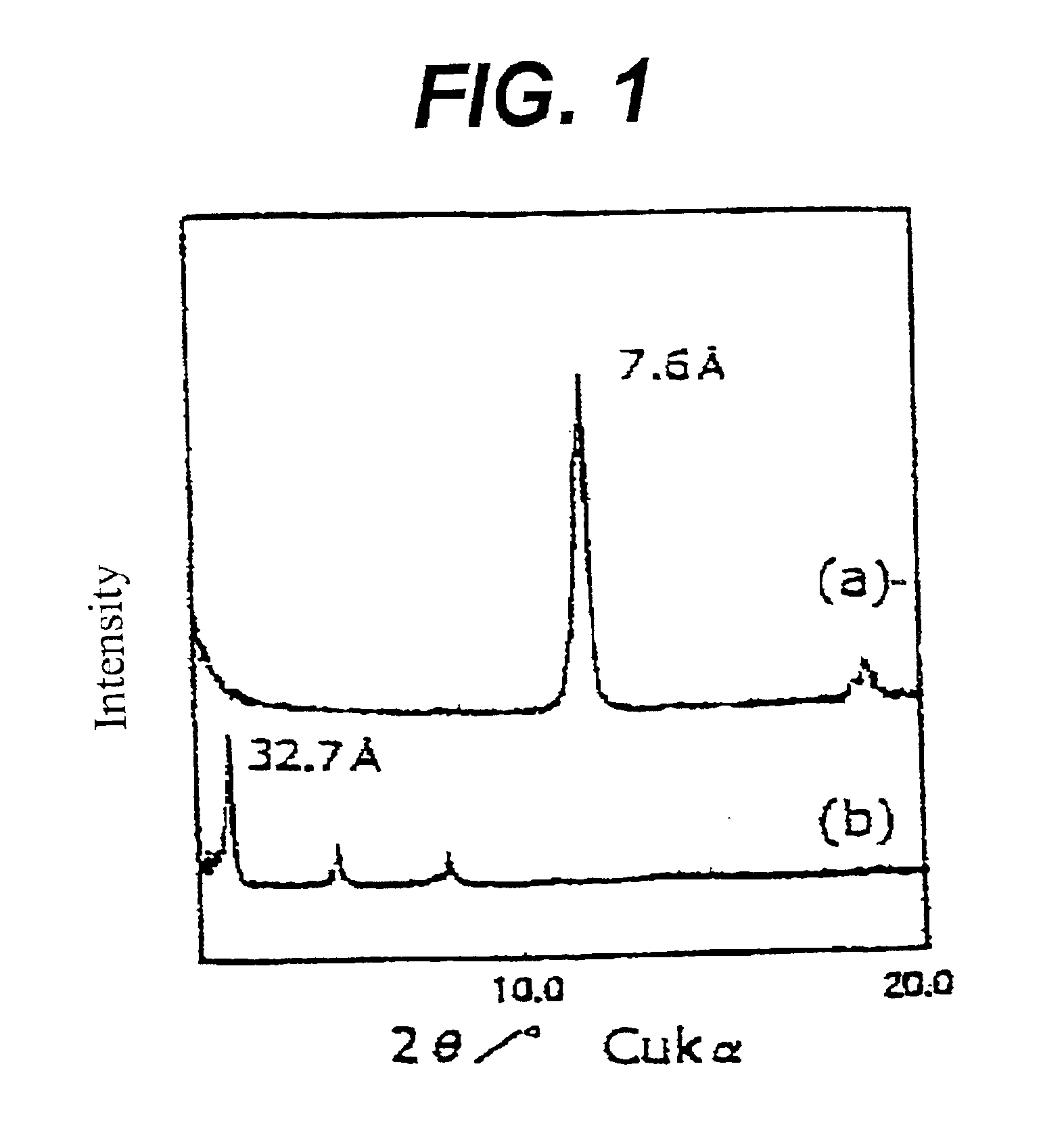

Layered Double Hydroxides That Delaminate In Water, Their Manufacturing Process And Use

ActiveUS20080021115A1High light transmittanceImprove corrosion resistanceBiocideCosmetic preparationsWater basedLotion

Disclosed is a layered double hydroxide capable of delamination in water comprising a plurality of basal layers of a double hydroxide of Formula: M(II)1-xM(III)x(OH)2 wherein M(II) is Mg, Zn or a combination thereof, M(III) is Al, and x is 0.2 to 0.33 and a plurality of intercalated layers between each adjacent basal layers of Mg acetate, Zn acetate or Ce acetate and water of intercalation. A process for producing the layered double hydroxide is also disclosed. The layered double hydroxide find use as an vehicle component or an anti-corrosive pigment of water-based protective coatings for metallic substrates, and as a humectant or a stabilizing agent for cosmetic preparations such as lotions, creams or foundations.

Owner:TAYCA CORP

Doped anionic clays

The present invention is directed to a process for the preparation of a doped anionic clay. In said process a trivalent metal source is reacted with a divalent metal source, at least one of the metal sources being either doped boehmite, doped MgO or doped brucite, to obtain a doped anionic clay. Suitable dopants are compounds containing elements selected from the group of alkaline earth metals (for instance Ca and Ba), alkaline metals, transition metals (for example Co, Mn, Fe, Ti, Zr, Cu, Ni, Zn, Mo, W, V, Sn), actinides, rare earth metals such as La, Ce, and Nd, noble metals such as Pt and Pd, silicon, gallium, boron, titanium, and phosphorus.

Owner:AKZO NOBEL NV +1

Magnesium aluminum hydrotalcite and method for preparing magnesium aluminum hydrotalcite

The present invention relates to the field of the hydrotalcite, discloses magnesium aluminum hydrotalcite and a method for preparing the magnesium aluminum hydrotalcite, the method comprises the following steps: (1) in the presence of water, performing ball-milling on a magnesium source and / or aluminum hydroxide to obtain a sol precursor; (2) diluting the sol precursor with water, mixing the diluted solution with the magnesium source and / or aluminum hydroxide, contacting the obtained mixture with an acid matter, and thermally insulating at 30-90 DEG C for 10-300min to obtain a magnesium aluminum composite sol; (3) under hydrothermal reaction conditions, contacting the magnesium aluminum composite sol with a crystal form control agent to obtain magnesium aluminum hydrotalcite paste; and (4) contacting the magnesium aluminum hydrotalcite paste with a surface modification agent for reaction. The method has the advantages of simple process and low cost, and can improve the crystallinity of the magnesium aluminum hydrotalcite.

Owner:LUOYANG ZHONGCHAO NEW MATERIAL SHARES CO LTD

Intercalated hydrotalcite containing double bond organic anion and its uses as heat stabilizer

InactiveCN1769355AImprove thermal stabilityHydrotalcitePigment treatment with non-polymer organic compoundsAnion intercalationHydrotalcite

The invention provides the organic anion intercalation hydrotalcite containing double bond, whose chemical formula is [M2+1-xM3+x(OH)2]An-x / níñmH2O. An is organic anion intercalation hydrotalcite containing double bond, such as maleic acid group, acroleic acid group, butenoic acid group, and so on. Because the double bond of organic anion intercalation hydrotalcite can react with the conjugate double bonds produced by PVC, the long-term thermal stability of PVC is improved markedly. The hydrotalcite can effectively improve the effectively of PVC.

Owner:BEIJING UNIV OF CHEM TECH

Nano magnesium-aluminum hydrotalcite and preparation method thereof

ActiveCN106379924AUniform particle sizeHigh purityMaterial nanotechnologyHydrotalciteMagnesium saltHydrotalcite

The present invention discloses a nano magnesium-aluminum hydrotalcite, wherein a soluble magnesium salt, a soluble aluminum salt, a soluble carbonate and an alkaline precipitant are adopted as main raw materials. A foaming assistant is added into the above raw materials. Firstly, a precursor filter cake is prepared through the reaction of a gas bubble liquid membrane. After that, the nano magnesium-aluminum hydrotalcite is prepared based on the hydrothermal reaction through the filtering, washing and drying process. According to the invention, the nano magnesium-aluminum hydrotalcite is prepared based on the combination of the gas bubble liquid membrane process and the hydrothermal reaction. The prepared nano magnesium-aluminum hydrotalcite is uniform in particle size, high in purity, good in dispersibility and good in repeatability. Meanwhile, the preparation process is simple and environment-friendly, and the large-scale production of the nano magnesium-aluminum hydrotalcite is realized. The reaction of the gas bubble liquid membrane can be conducted at a normal temperature and the energy consumption is reduced. The production cost is saved.

Owner:BELIKE CHEM

Process for preparing and self-assembling property of nanobinary and ternary oxy/hydroxides

InactiveUS20050238569A1Large specific surface areaSmall particle sizeMaterial nanotechnologyOxygen/ozone/oxide/hydroxideSupercritical dryingSolvent

A process is disclosed for preparing and self-assembly of nanobinary and ternary metal oxy / hydroxides with high surface area and 1-10 nm size by aerogel procedure, involving homogenization of metal organic precursors in solvent mixture, controlled hydrolysis, gelation, hydrothermal treatment and finally supercritical drying of solvent.

Owner:COUNCIL OF SCI & IND RES

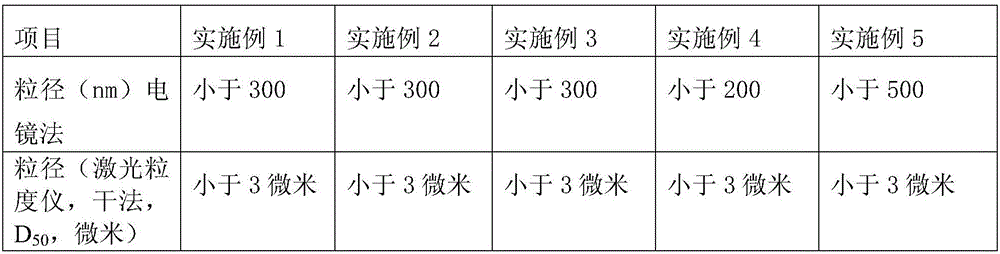

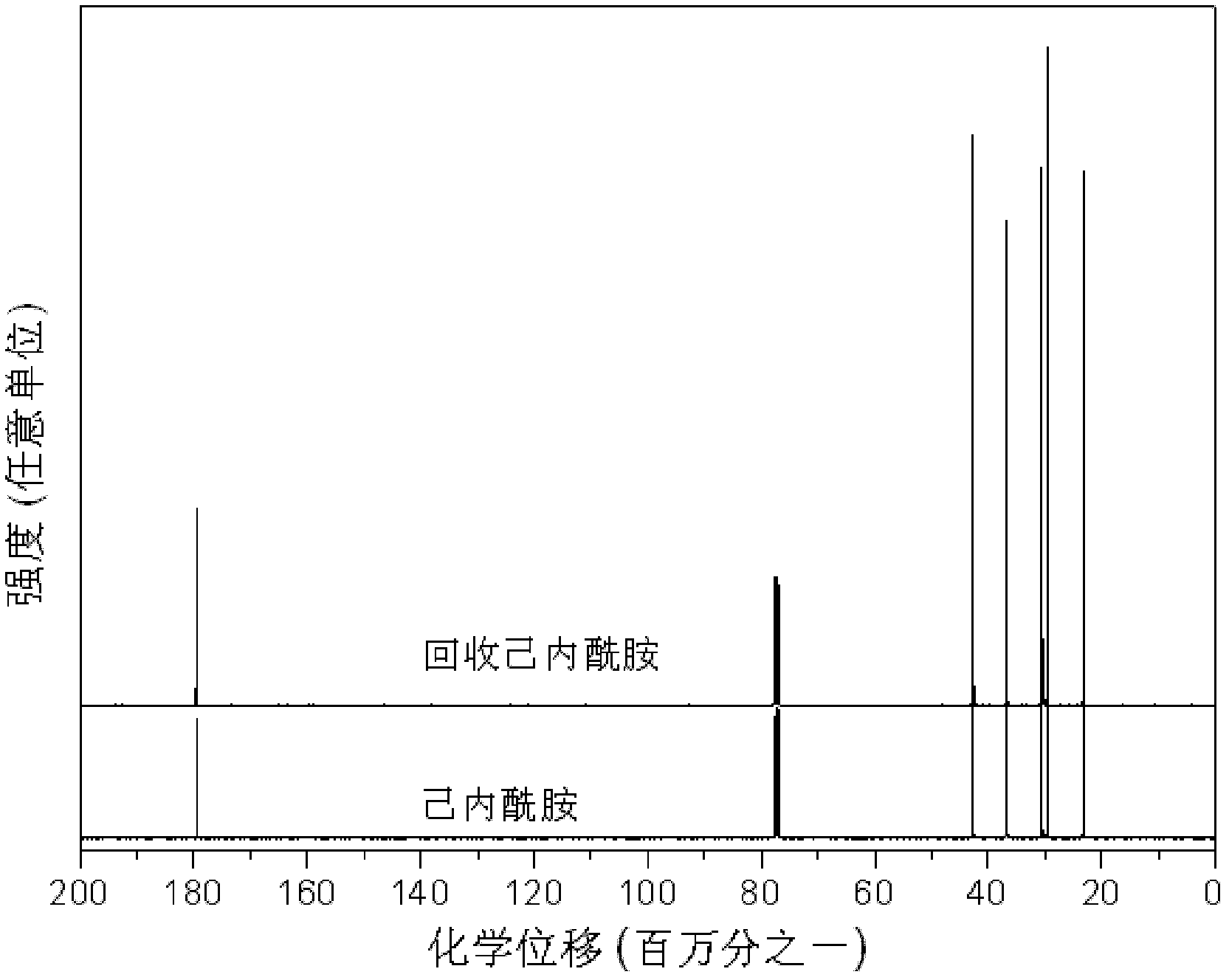

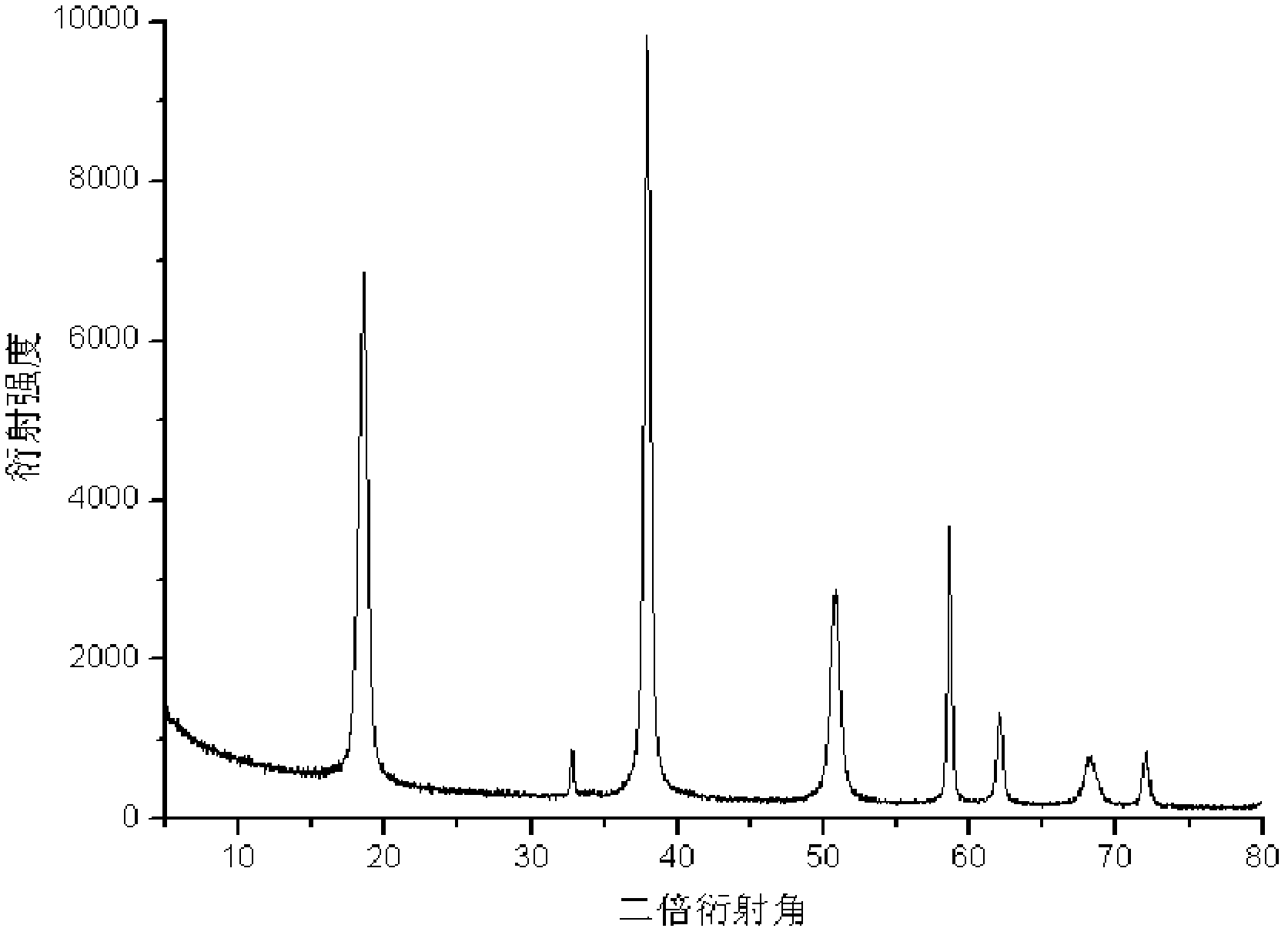

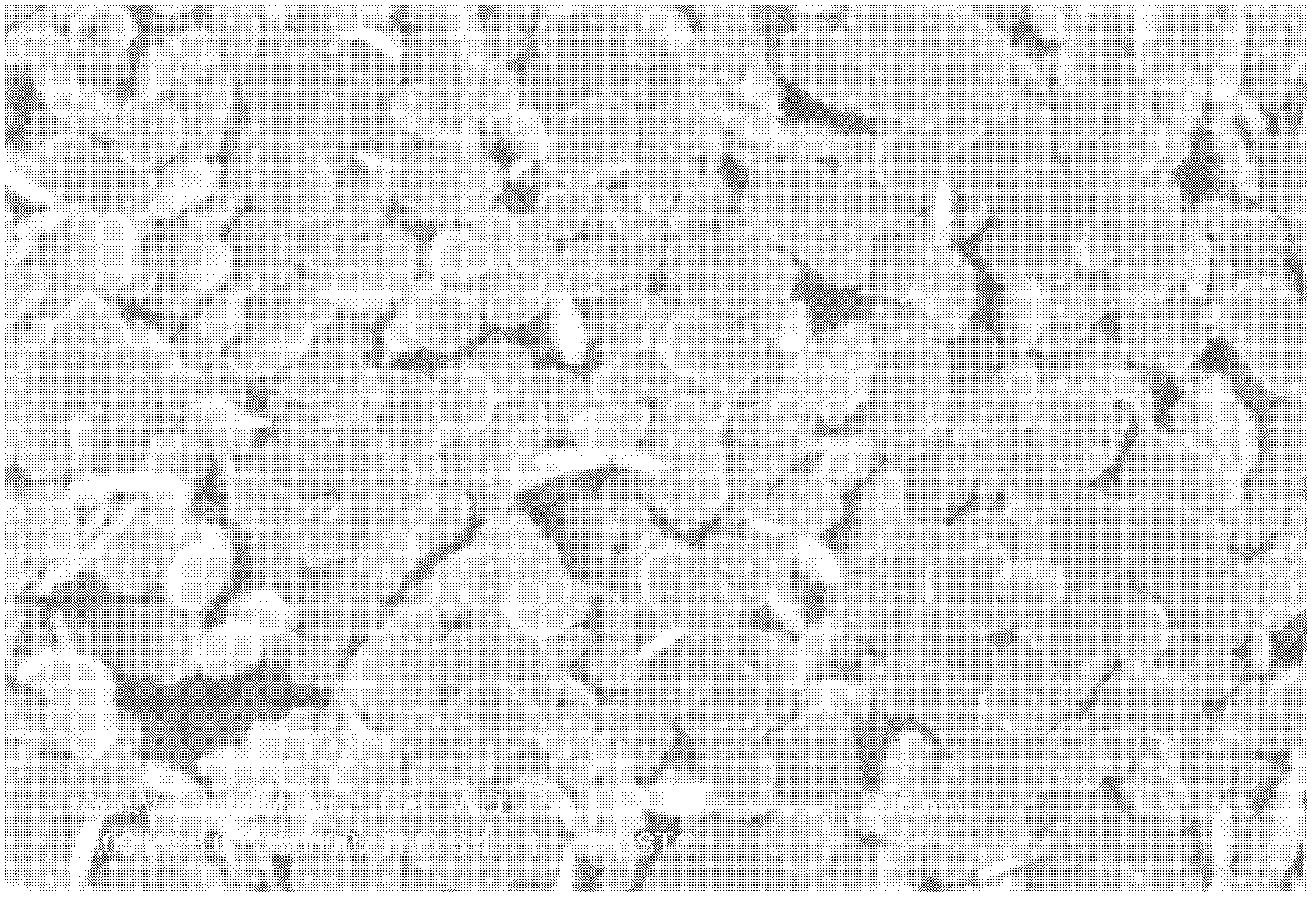

Application of lactam as solvent in nano-grade material preparation

ActiveCN103204525AIncrease added valueMeet the requirements of green environmental protectionMaterial nanotechnologySilicaSolventMacromolecule

Disclosed is an application of lactam as a solvent in nanomaterial preparation. The preparation method comprises a precipitation method, a sol-gel method or a high-temperature pyrolysis method. The method achieves recycling utilization of the lactam solvent, which meets the requirements of environmental protection.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

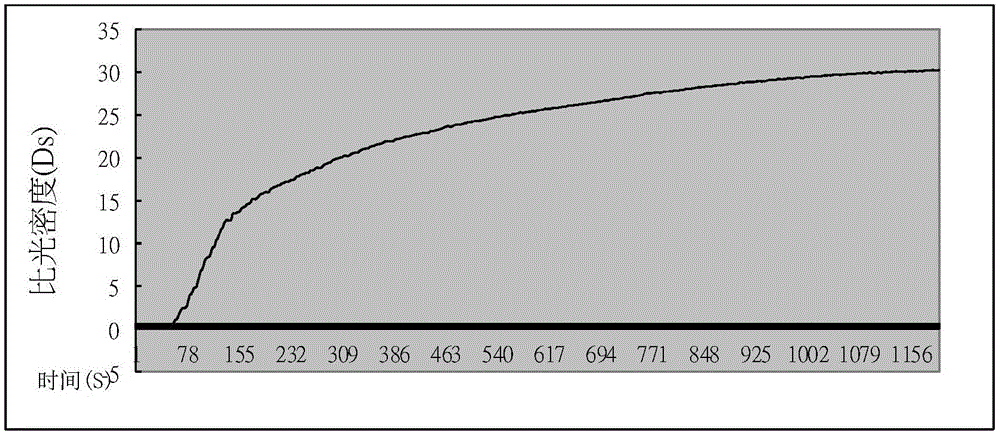

Intercalated layered double hydroxide smoke inhibitor and preparation method thereof

The invention discloses an intercalated layered double hydroxide smoke inhibitor and a preparation method thereof. The smoke inhibitor is a layered structural material formed by assembling a laminated sheet consisting of metal cations and interlayer anions, wherein a specific composition general formula of the smoke inhibitor is M<2+>1-xM<3+>x(OH)2(A<n->)n / 2.mH2O. According to the preparation method disclosed by the invention, the intercalated layered double hydroxide smoke inhibitor is prepared by adopting a one-step coprecipitation method or a clean hydrothermal reaction at one step; the preparation method is simple and practical; according to the obtained intercalated layered double hydroxide smoke inhibitor, smoke inhibiting groups such as molybdate anions, an octamolybdate radical, a cuprate radical and a stannate radical are arranged at an interlayer, and smoke inhibiting elements such as iron and copper are introduced into the laminated sheet, so that a good carbon forming effect is realized, the smoke generating amount can be reduced, and the smoke inhibiting effect is synergically enhanced; meanwhile, a layered double hydroxide laminated sheet forms an alkaline porous substance at high temperature; the alkaline porous substance has greater specific surface area and can effectively adsorb smog; the prepared intercalated layered double hydroxide smoke inhibitor is applied to an ordinary rubber-plastic product and a high-temperature rubber-plastic product; the maximum density (Ds, max) at low additive amount (1phr) can be reduced by 87.3 percent; the intercalated layered double hydroxide smoke inhibitor is remarkable in smoke inhibiting effect and is a smoke inhibitor material with excellent performance.

Owner:BEIJING UNIV OF CHEM TECH

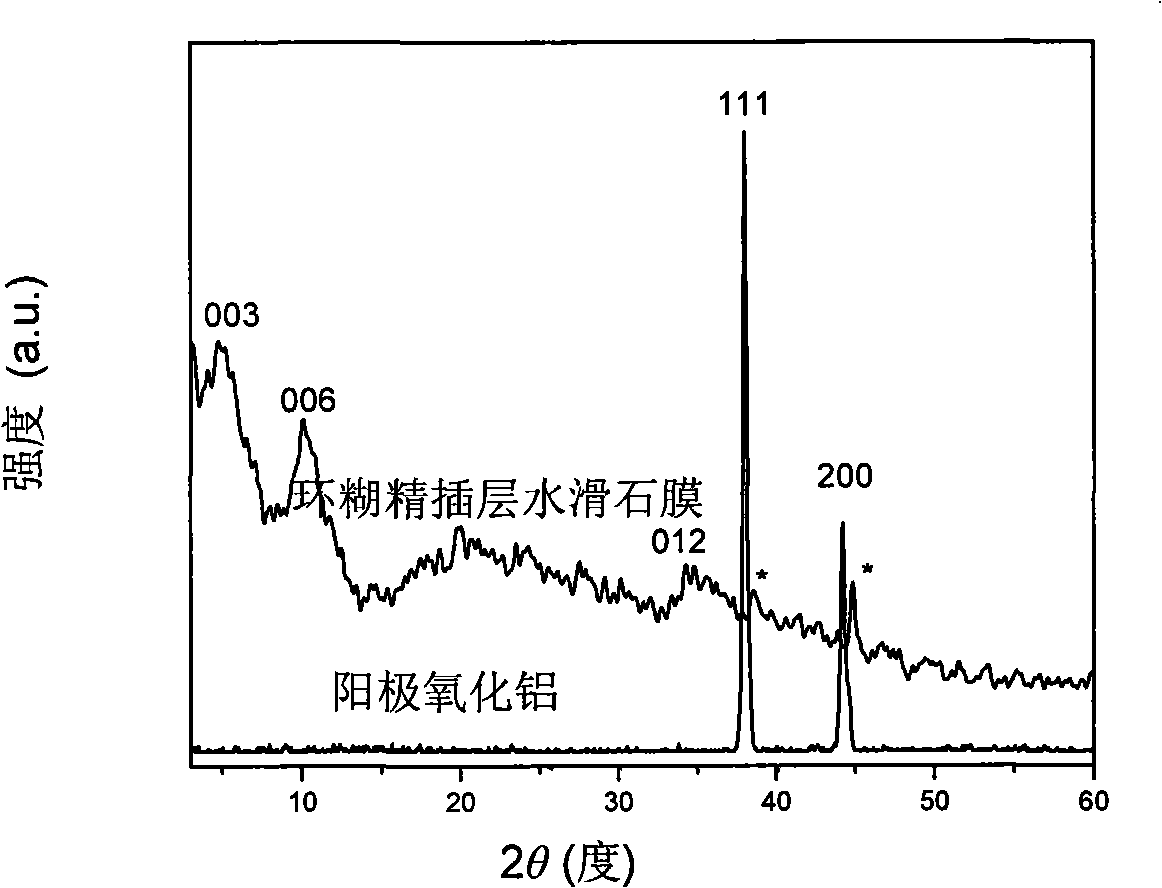

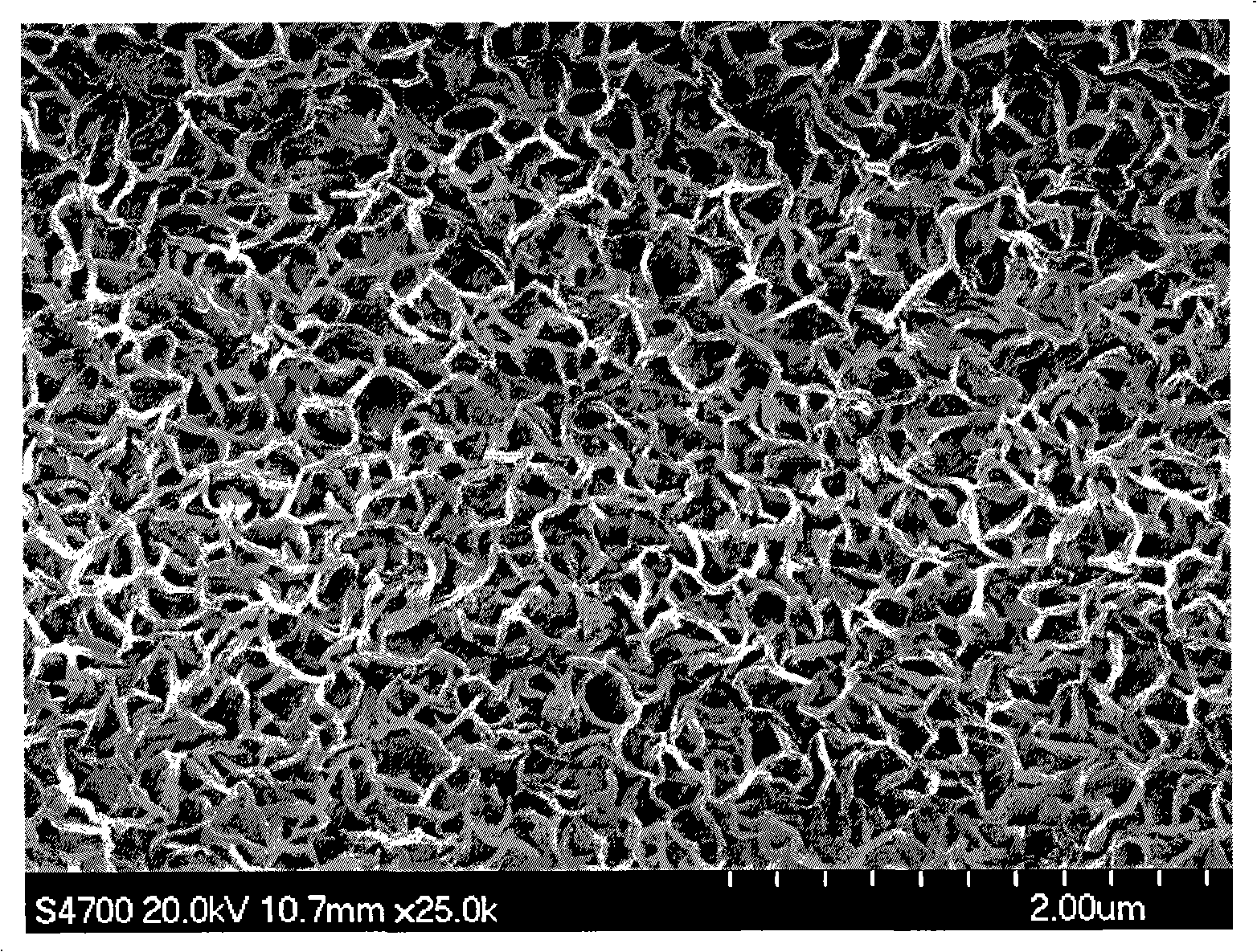

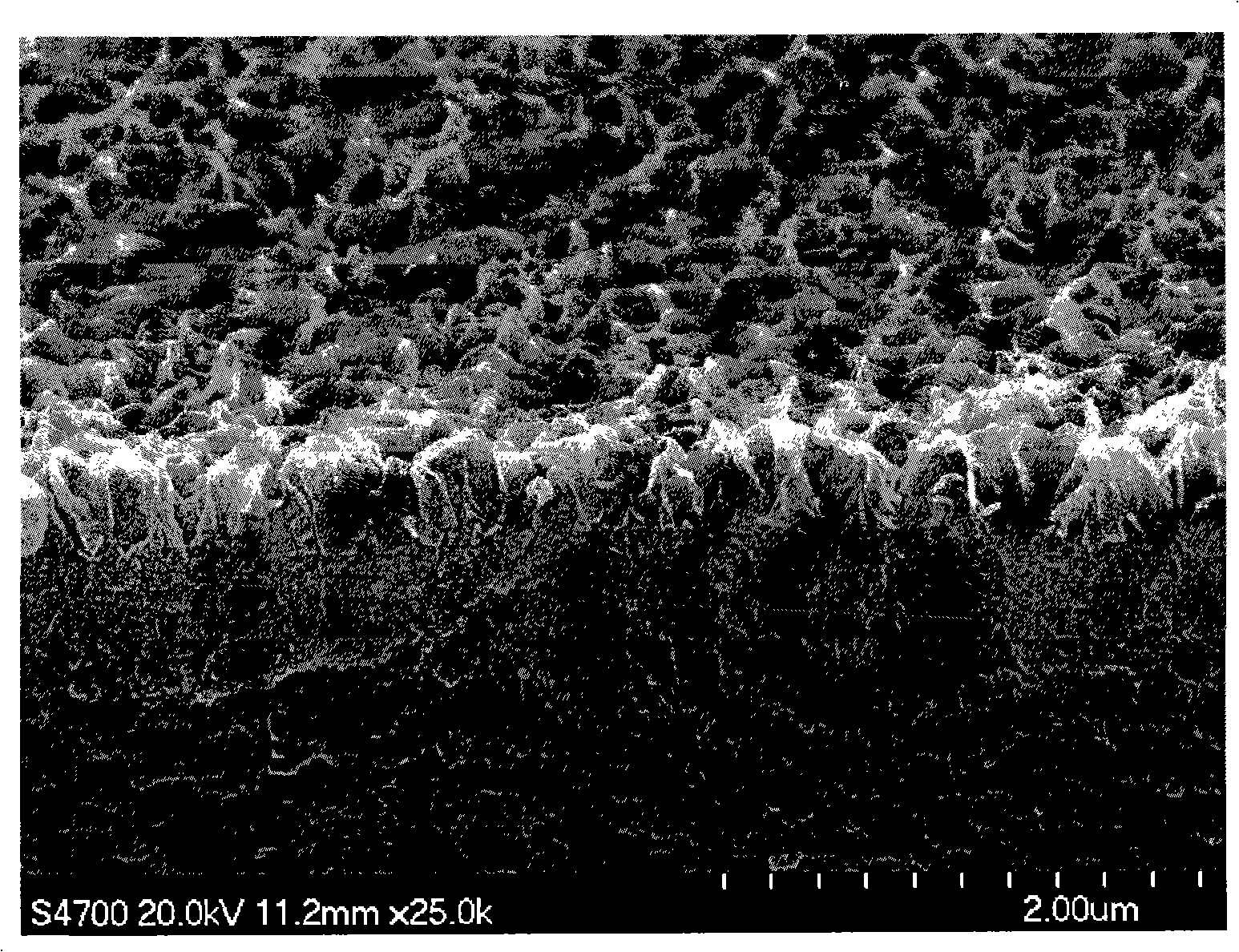

Vertical substrate grown cyclodextrin intercalation hydrotalcite film and preparation thereof

InactiveCN101323953AImmobilizationDeviceizationAnodisationCobalt compoundsCyclodextrinMaterials science

The invention relates to a cyclodextrin pillared hydrotalcite film which grows in a way of being perpendicular to a basis and a preparation method thereof, belonging to the technical field of organic-inorganic composite materials and preparation thereof. The chemical formula of pillared hydrotalcite is [(M<2+><1-x> (M<3+><x> (OH)2<x+> (CMCD <n->) x / n question mark mH2O. The preparation method comprises the steps as follows: aluminium flakes are firstly anodized under the condition of constant voltage; divalent metal salts are taken and weighed respectively, cyclodextrin decorated with negative ion and NH4NO3 are dissolved in de-ionized water to prepare into reaction synthetic solution, and then ammonia is used for adjusting the pH of the reaction synthetic solution to a value between 5.9 and 8.5. Anodized alumina / aluminium-base flakes are vertically hung in the reaction synthetic solution to carry out reaction at certain temperature for a certain time to prepare the cyclodextrin pillared hydrotalcite film. The invention has advantages that: the cyclodextrin pillared hydrotalcite film prepared by an in-situ growth technology is fixed on an aluminium basis, thus realizing the immobilization and unitization of the hydrotalcite; besides, the hydrotalcite prepared has certain mechanical strength, which provides great convenience to the application of cyclodextrin pillared hydrotalcite materials both in production and life.

Owner:BEIJING UNIV OF CHEM TECH

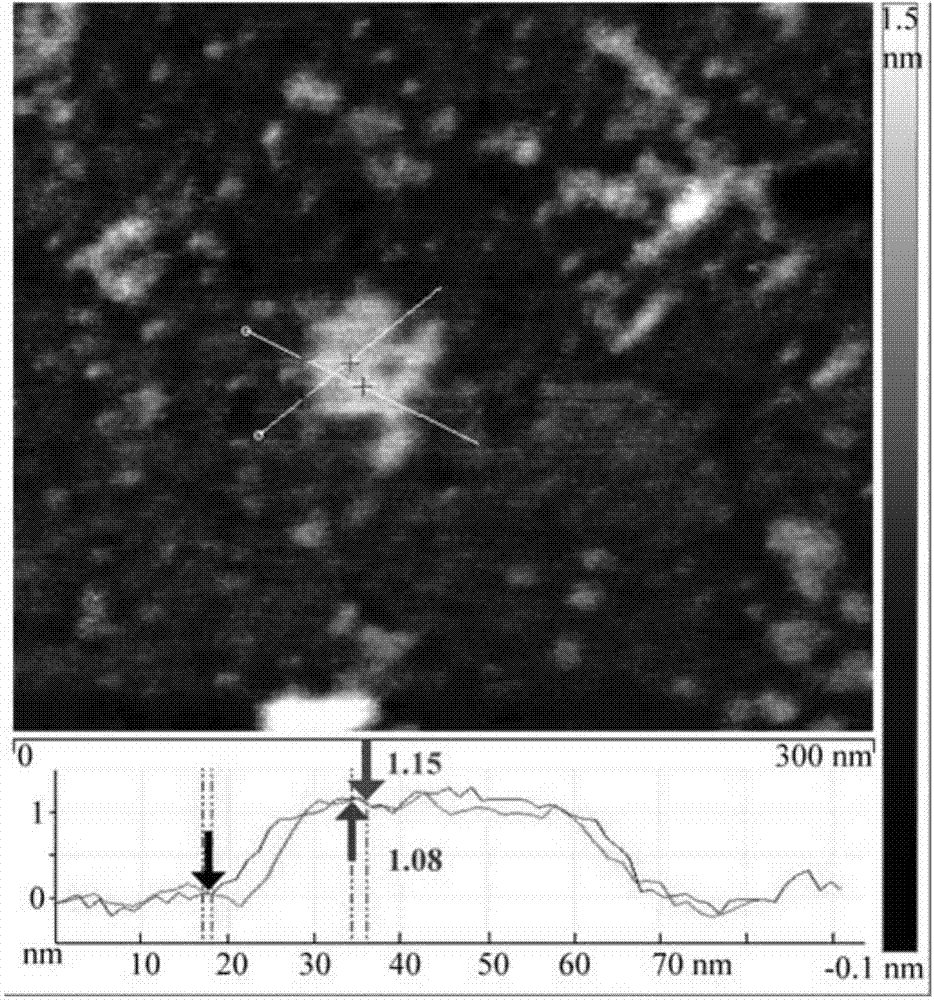

Method for preparing two-dimensional single-layer magnesium-aluminum layered double-metal hydroxide nanosheets

InactiveCN104291368AEvenly distributedLow costMaterial nanotechnologyHydrotalciteAluminum IonMagnesium salt

The invention discloses a method for preparing two-dimensional single-layer magnesium-aluminum layered double-metal hydroxide nanosheets. The method comprises the following steps: (a) dissolving a magnesium salt and an aluminum salt in formamide, thereby forming a liquid A, wherein a molar ratio of magnesium ions in the magnesium salt to aluminum ions in the aluminum salt is 2:1; (b) mixing a strong alkaline hydroxide with the liquid A, thereby obtaining a colloidal mixed liquid, wherein the molar ratio of the strong alkaline hydroxide to the aluminum ions in the aluminum salt is (9-15):1; and (c) carrying out a hydrothermal reaction on the colloidal mixed liquid obtained in the step (b), thereby obtaining the two-dimensional single-layer magnesium-aluminum layered double-metal hydroxide nanosheets, wherein the two-dimensional single-layer magnesium-aluminum layered double-metal hydroxide nanosheets are dispersed in the solvent formamide, and forming the dispersion of the two-dimensional single-layer magnesium-aluminum layered double-metal hydroxide nanosheets, wherein the temperature of the hydrothermal reaction is 20-70 DEG C, and the reaction time is 2-72 hours. The method is low in cost, simple in preparation process, short in production cycle and suitable for industrial production, and the solvent can be recycled.

Owner:BEIJING NORMAL UNIVERSITY +1

Method for manufacturing anion-layered double hydroxide intercalation compounds and compounds produced thereby

The present invention is a manufacturing method for an anion-layered double hydroxide intercalation compound that uses metal hydroxides as the stating material of the layered double hydroxides (LDH) which are the host material and allows sterically complicated and large-size anion compounds to be used as the guest material, and it has the characteristics such that a reaction mixture of the metal hydroxides and anion compound is heated and hydrothermally reacted in the absence of anion components other than the anion compound of the guest material. In addition, the present invention pertains to an anion-layered double hydroxide intercalation compound that uses bile acid as the anion compound of the guest material, which is effective as the carrier of medical drugs or as the absorbent of physiological active materials.

Owner:JAPAN SCI & TECH CORP

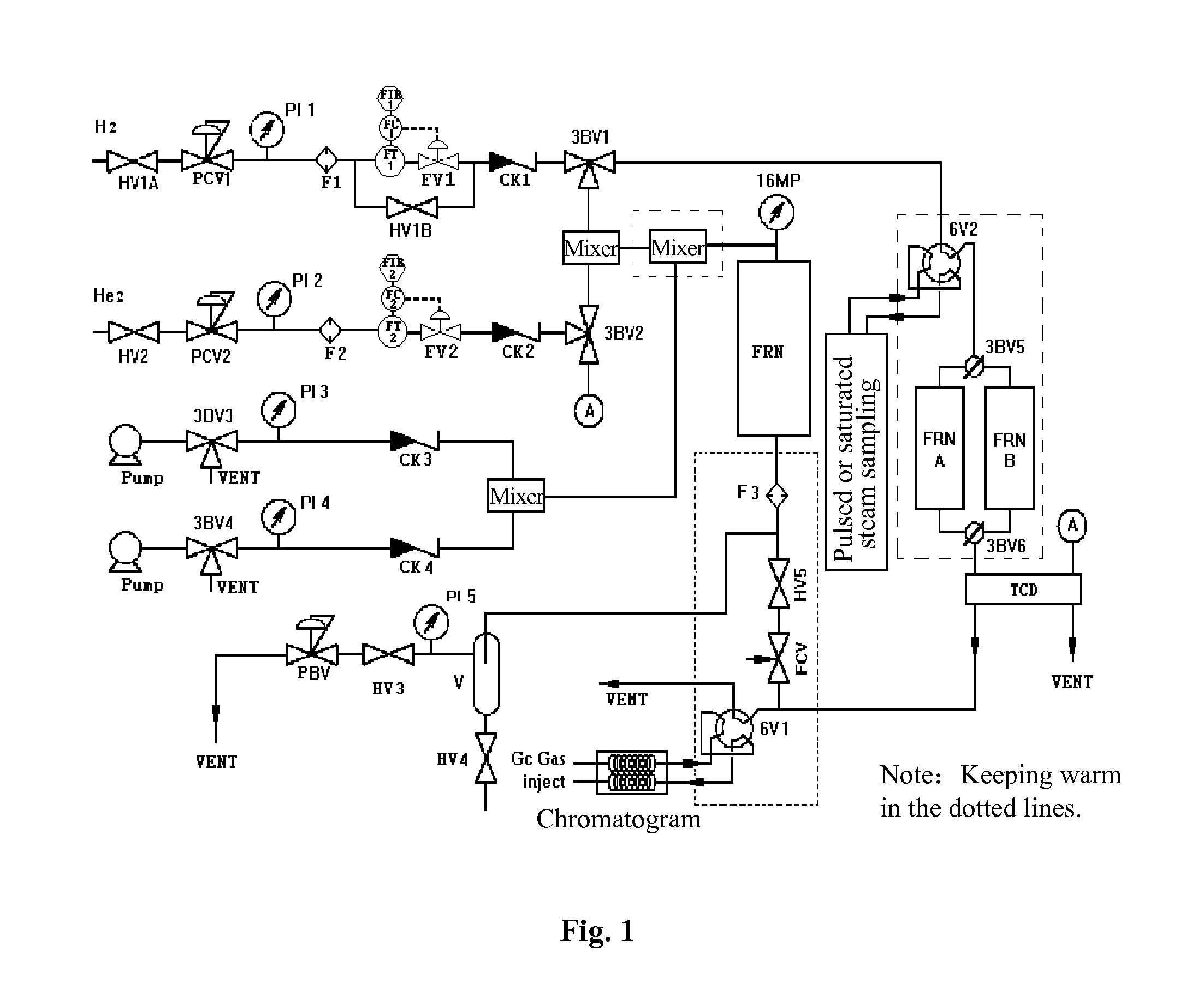

Process for preparing catalyst comprising palladium supported on carrier with high dispersion

InactiveUS20110237430A1Improve catalytic performanceImprove stabilityOrganic compound preparationCarboxylic acid esters preparationMicrospherePalladium catalyst

A process for preparing a catalyst comprising palladium supported on a carrier via a layered precursor, comprising the following steps: (1) synthesis of hydrotalcite layered precursor which comprises promoting metal element and aluminium on the surface of the carrier of Al2O3 microspheres, the atoms of the promoting metal and aluminium being highly dispersed by each other and bonded firmly to the carrier due to the crystal lattice positioning effect of the hydrotalcite crystal; (2) introduction of palladium into the carrier through impregnation; (3) drying; and (4) calcination and reduction with H2, the hydrotalcite layered precursor being converted into a composite oxide which consists of oxides of the promoting metal and aluminium, and the promoting metal element and aluminium being highly dispersed by each other and being able to separate and disperse the mainly active palladium element loaded later. The process has the advantages of improving the catalytic performance of the catalyst, enhancing the stability of the catalyst, and achieving the object of reducing the consumption of the precious metal-palladium.

Owner:BEIJING UNIV OF CHEM TECH

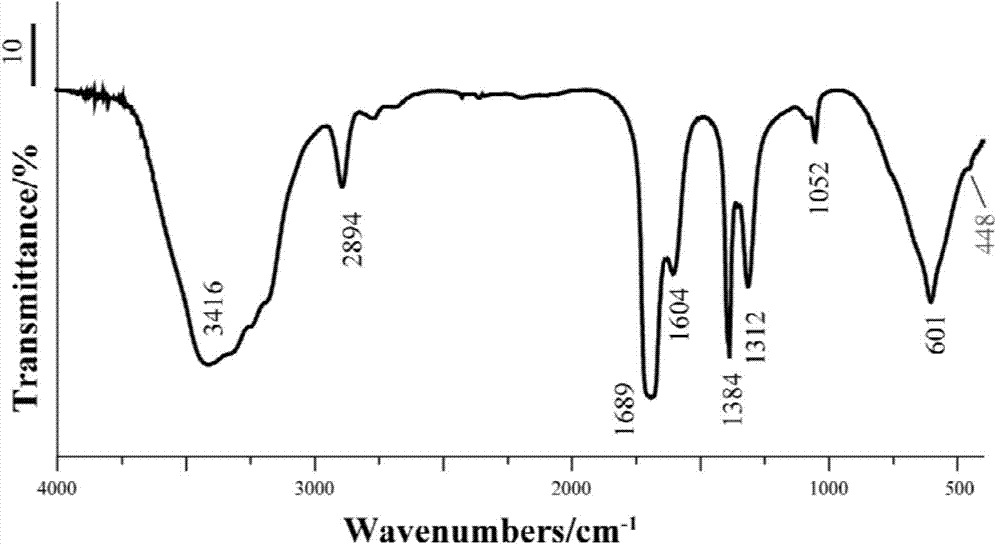

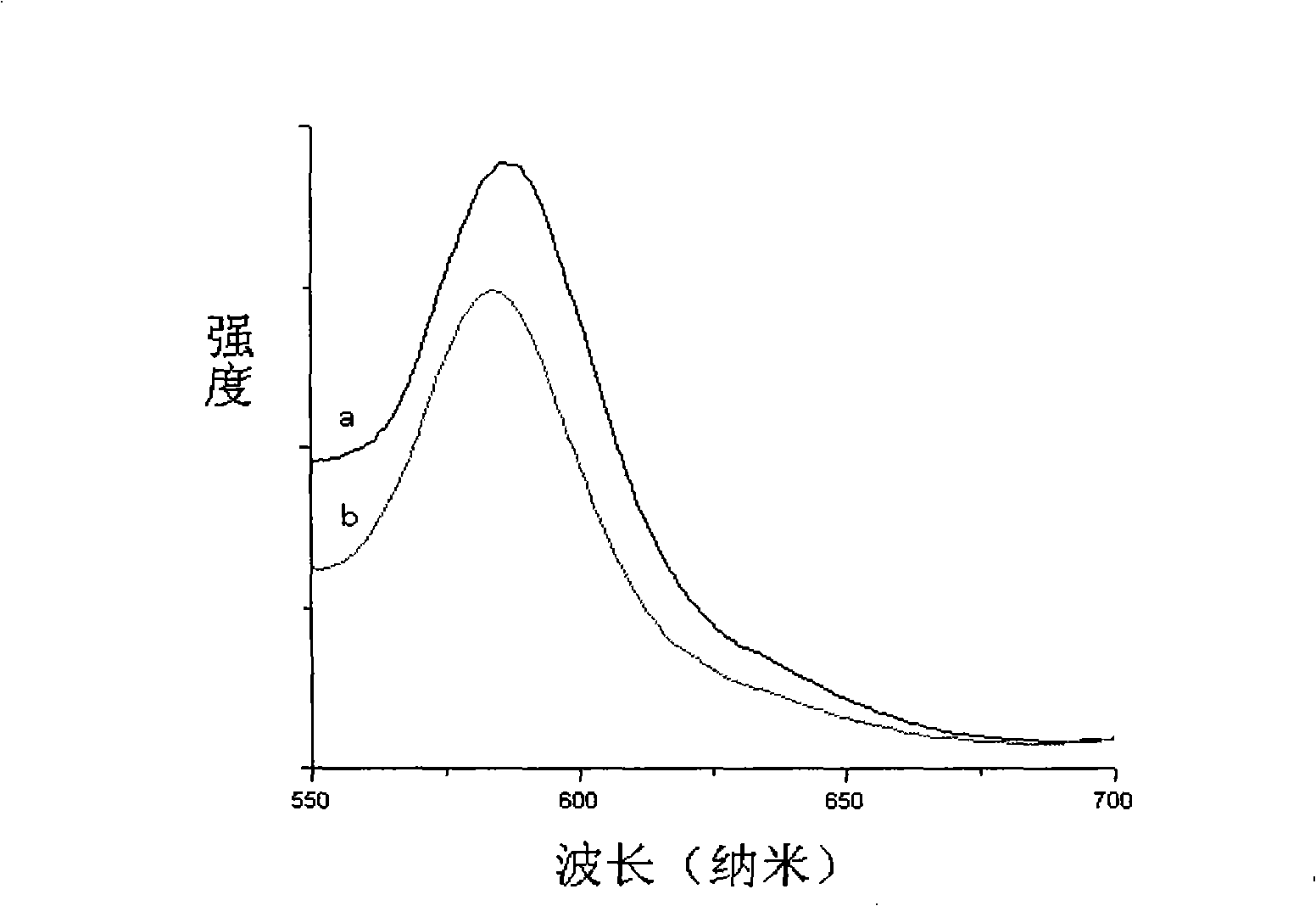

Method for preparing rhodamine intercalation hydrotalcite luminescent material

InactiveCN101255334AImmobilizationEvenly dispersedHydrotalciteSilicon compoundsSlurryMembrane reactor

A hydrotalcite composite luminescent material with rhodamine intercalation, which pertains to abio-organic composite luminescent material. The process is preparing solution A with mole ratio of bivalence and tervalence cation M2+ / M3+=2.0-4.0; adding laser dye sulphonated rhodamine and sodium salt of dodecylbenzene sulfonic acid into mixed solution of ethanol and water and fully dissolving to obtain solution of sulphonated rhodamine and dodecyl benzene sulfone acid group containing anion with negative charge B; mixing solution A, B into solution C, preparing NaOH solution; communicating solution C and NaOH solution into full-back-liquid mixing membrane reactor to react, mixing to obtain red slurry, introducing the red slurry into hydrothermal kettle, reacting, absterging by CO2, de-ionized water and absolute ethyl alcohol and centrifugally separating, vacuum drying. Then hydrotalcite system with co-intercalation of suphonated rhodamine and dodecyl sulfone acid group is obtained. Advantages of the invention are that dye molecular is immobilized, and fluorescence quenching caused by dye aggregation is reduced.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing hydrotalcite material adopting multi-shell hollow structure

The invention discloses a method for preparing a hydrotalcite material adopting a multi-shell hollow structure. The method comprises the following steps: firstly, preparing a metal organic framework material (MOF-1), epitaxially growing to obtain MOF-1@MOF-2, and then etching by a sacrificial template method to obtain single-layer hollow hydrotalcite (LDH); with MOF as a seed crystal, epitaxiallygrowing to obtain MOF-1@MOF-2@MOF-1@MOF-2, and then etching by the sacrificial template method to obtain double-layer hollow LDH; repeating the epitaxially growing step to obtain multi-shell MOF, andfinally etching to obtain the LDH adopting the multi-shell hollow structure. The method is simple, easy to implement, mild in condition and high in safety; by the method, the multi-shell hollow LDH can be obtained; the method has a wide application prospect.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of ultrathin modified hydrotalcite and application thereof to rubber gas barrier thin film material

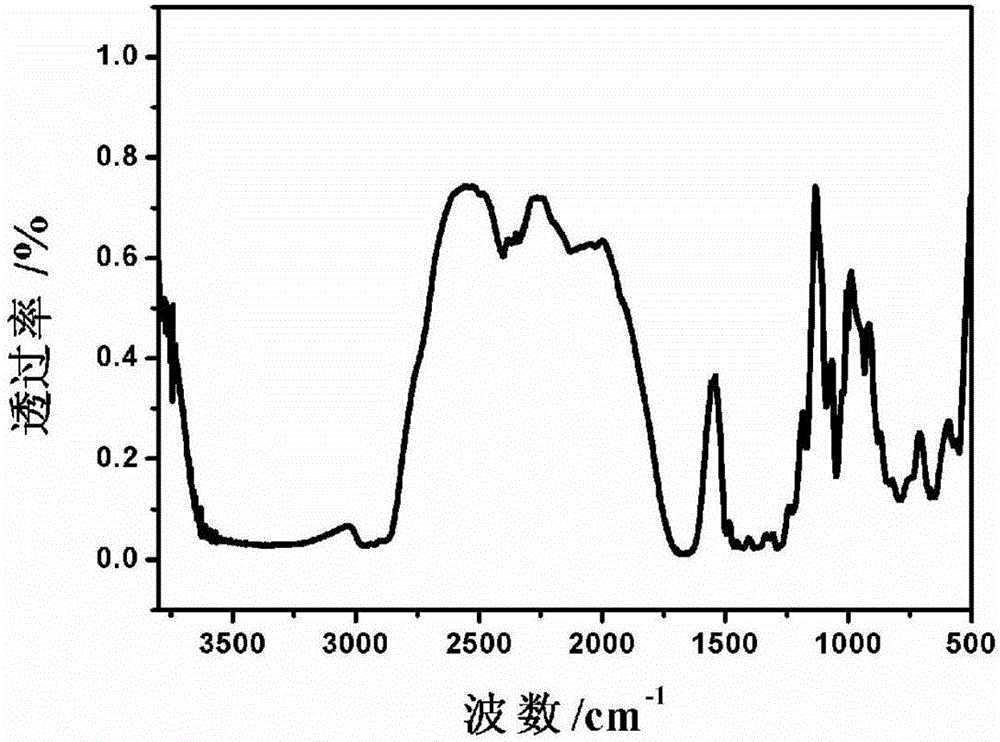

ActiveCN106674572AExtended Diffusion PathImprove interface compatibilityConjugated diene hydrocarbon coatingsHydrotalciteComposite filmHeat stability

The invention discloses a preparation method of ultrathin modified hydrotalcite and an application thereof to a rubber gas barrier thin film material. Firstly, coprecipitation is used for preparing ultrathin hydrotalcite with a high length diameter ratio, surface modification is carried out, spin coating method technology is used, the ultrathin modified hydrotalcite and rubber are compounded in order to form a film, and finally the gas barrier thin film material is prepared by compounding the ultrathin modified hydrotalcite and the rubber. The ultrathin hydrotalcite with a nanometer sheet shaped structure has high length diameter ratio, and can be used as a filler for substantially prolonging diffusion path of oxygen molecules in a thin film material; surface modification of hydrotalcite can improve interfacial compatibility between hydrotalcite and rubber, and reduce free volume, so that the composite thin film materials has excellent gas barrier performance, good heat stability and mechanical performance. The method has wide source, low cost, and simple preparation, and accords with environmental protection requirements; and the method has wide application prospects in the fields of automobile industry, outdoor packaging and aerospace industry.

Owner:BEIJING UNIV OF CHEM TECH

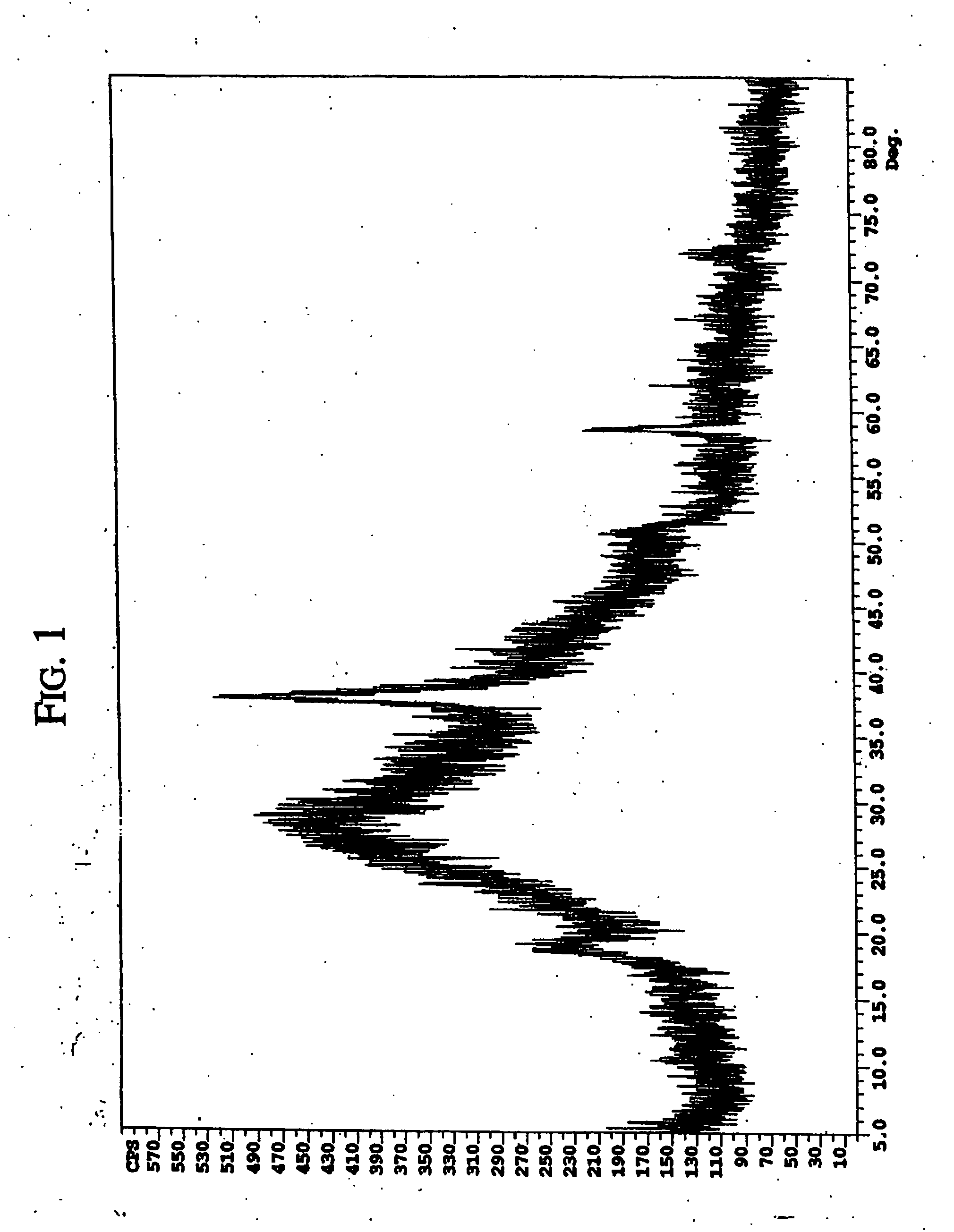

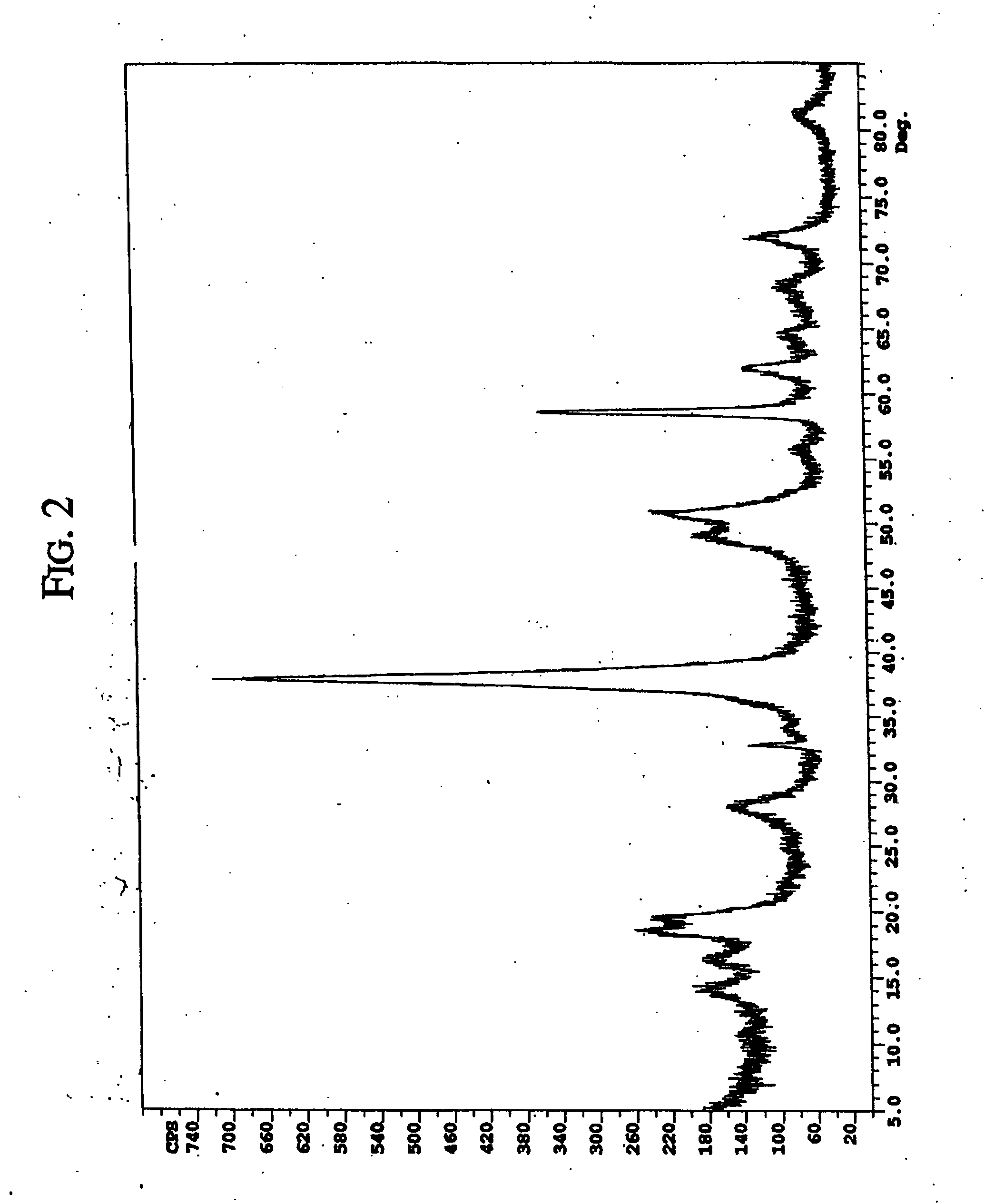

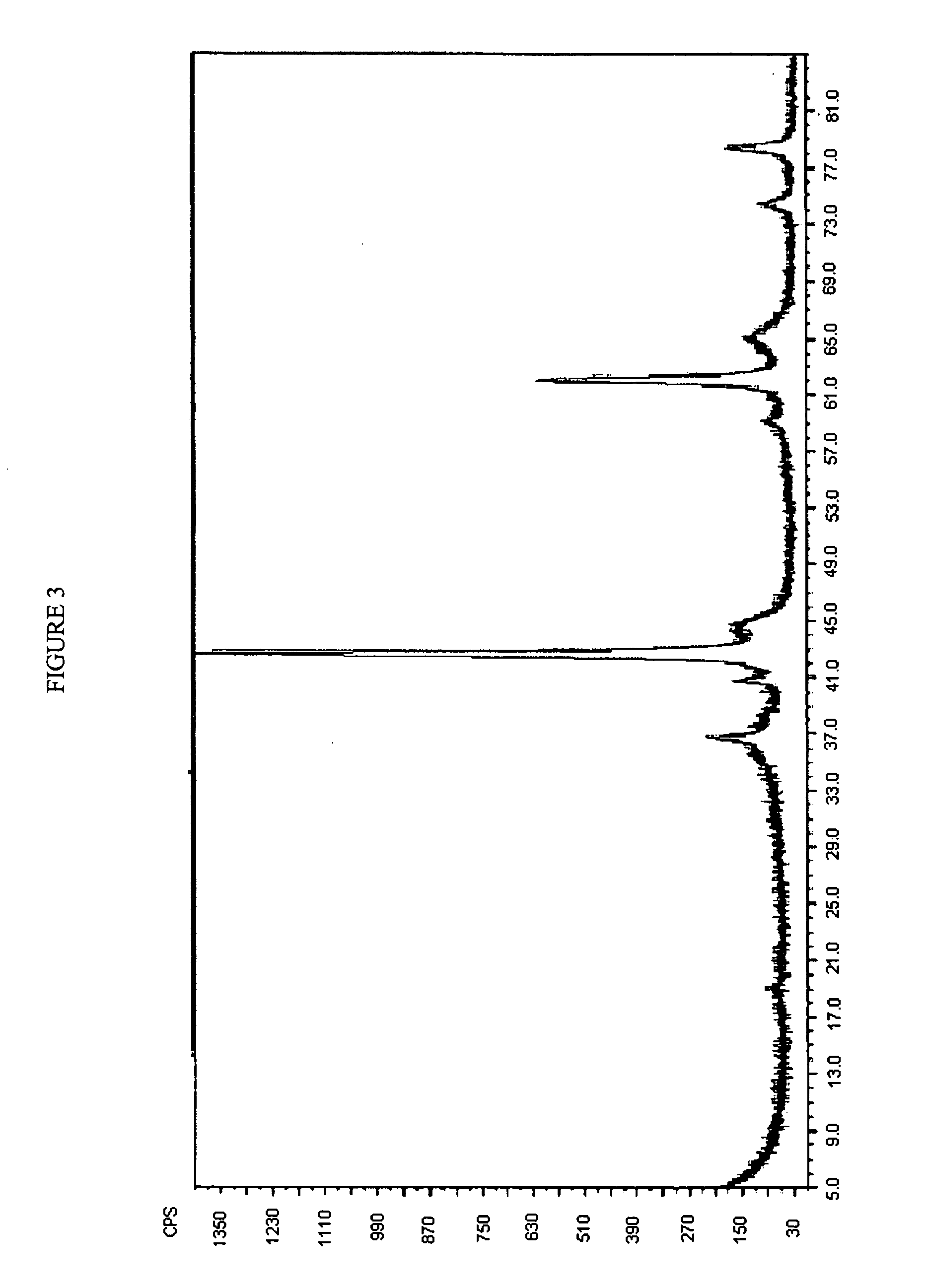

Mixed metal oxide sorbents

The present invention is directed to methods for reducing SOx, NOx, and CO emissions from a fluid stream comprising contacting said fluid stream with a compound comprising magnesium and aluminum and having an X-ray diffraction pattern displaying at least a reflection at a two theta peak position at about 43 degrees and about 62 degrees, wherein the ratio of magnesium to aluminum in the compound is from about 1:1 to about 10:1. In one embodiment, the ratio of magnesium to aluminum in the compound is from about 1:1 to about 6:1. In one embodiment, the ratio of magnesium to aluminum in the compound is from about 1.5:1 to about 10:1. In another embodiment, the invention is directed to methods wherein the ratio of magnesium to aluminum in the compound is from about 1.5:1 to about 6:1.

Owner:JOHNSON MATTHEY PROCESS TECH

Method for forming layered double hydroxide dense membrane

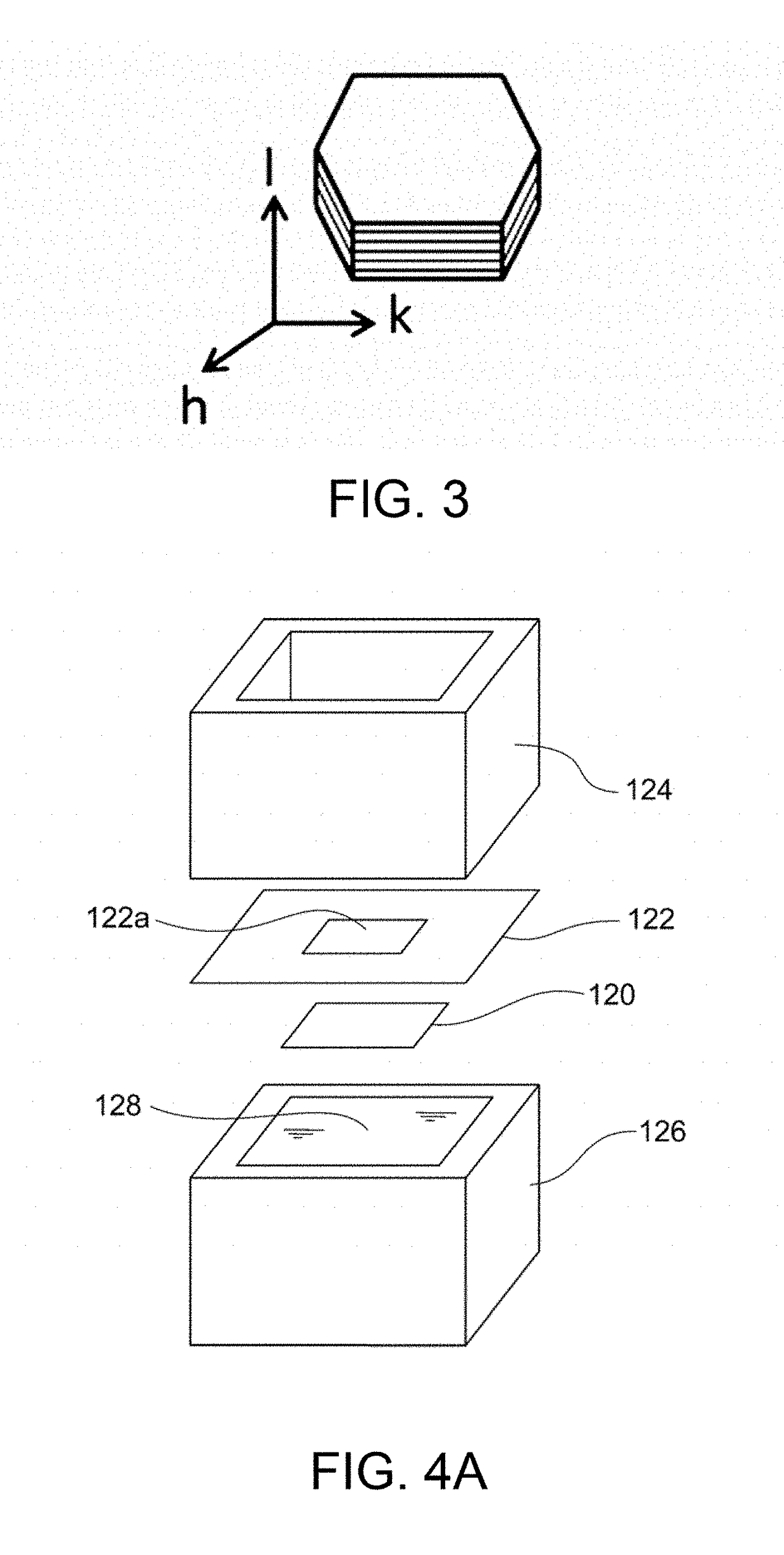

Provided is a method of forming a layered double hydroxide (LDH) dense membrane on the surface of a porous substrate. The LDH dense membrane is composed of an LDH represented by the formula: M2+1-xM3+x(OH)2An−x / n·mH2O where M2+ represents a divalent cation. M3+ represents a trivalent cation, An− represents an n-valent anion, n is an integer of 1 or more, and x is 0.1 to 0.4. This method includes (a) providing a porous substrate, (b) evenly depositing, on the porous substrate, a nucleation material capable of providing a nucleus from which the crystal growth of the LDH starts; and (c) hydrothermally treating the porous substrate in an aqueous stock solution containing a constituent element of the LDH to form the LDH dense membrane on the surface of the porous substrate. The method of the present invention can form a highly-densified LDH membrane evenly on the surface of a porous substrate.

Owner:NGK INSULATORS LTD

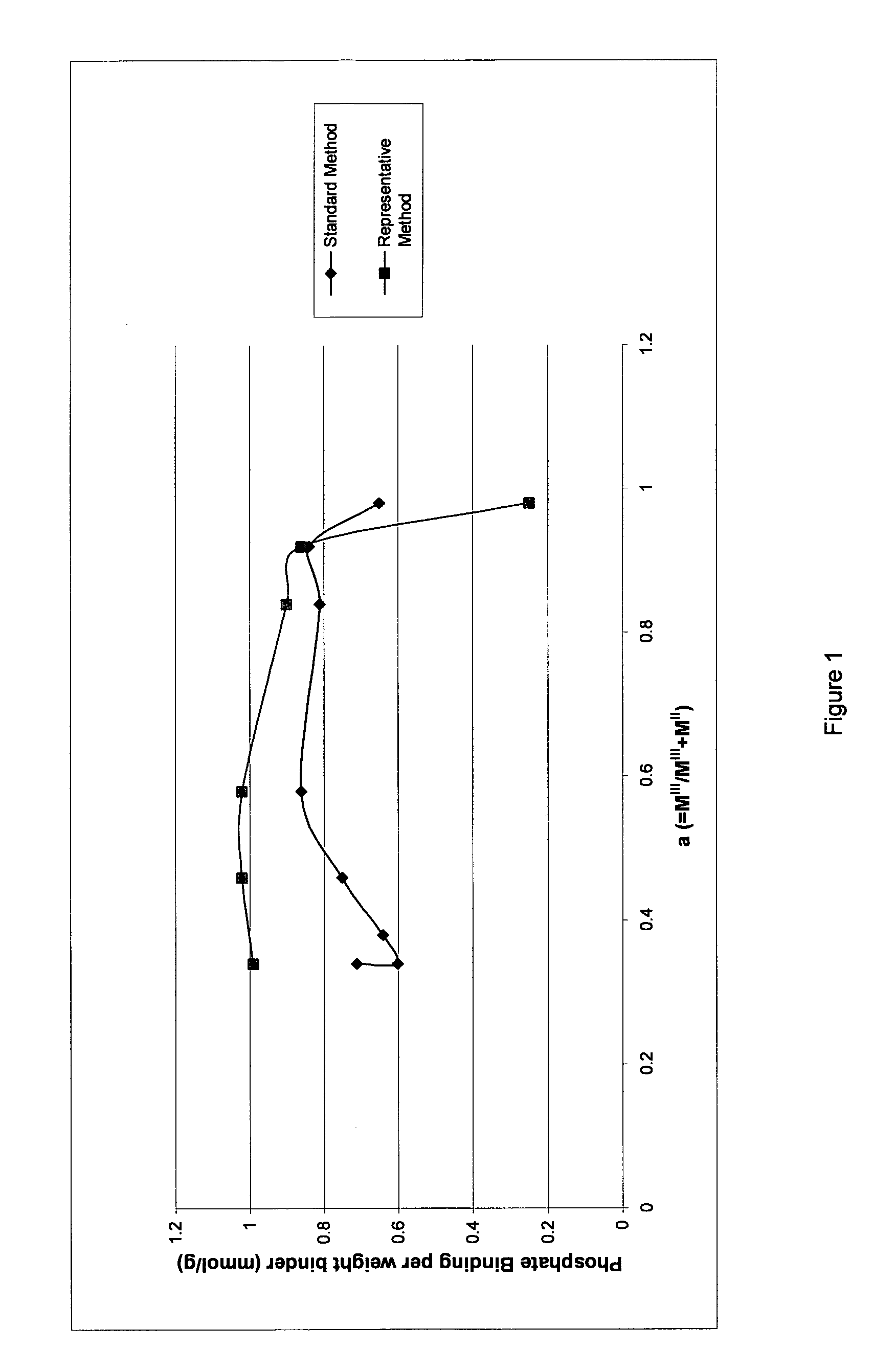

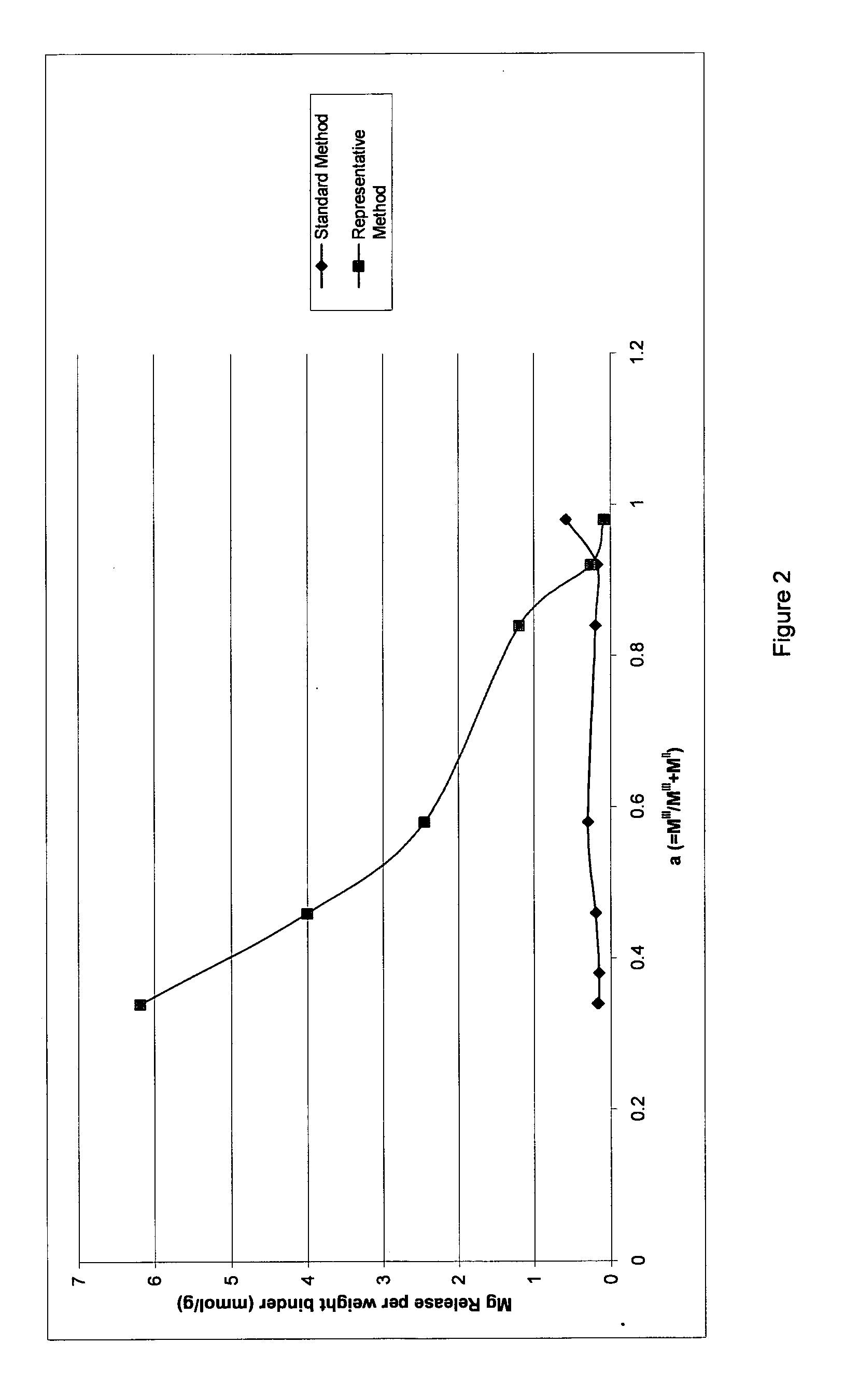

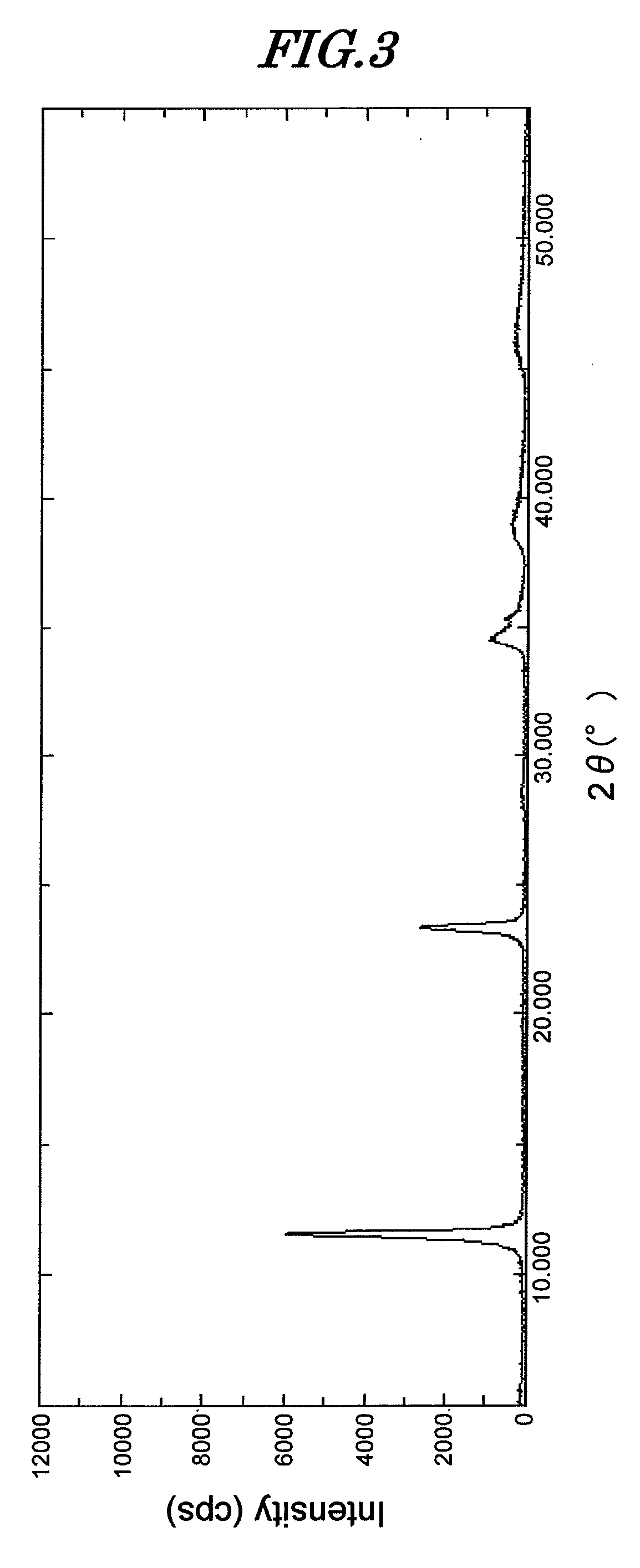

Mixed metal compounds for treatment of hyperphosphataemia

The present invention relates to mixed metal compounds having pharmaceutical activity, especially as phosphate binders. It also extends to methods of manufacture of those compounds, as well as to pharmaceutical compositions containing such compounds. It further relates to their pharmaceutical use. In particular, the present invention relates to use of compounds of Formula (I): MII1-aMIIIa wherein M is at least one bivalent metal (i.e. with two positive charges); M1 is at least one trivalent metal (i.e. with three positive charges); and 1>a>0.4.

Owner:OPKO IRELAND GLOBAL HLDG LTD

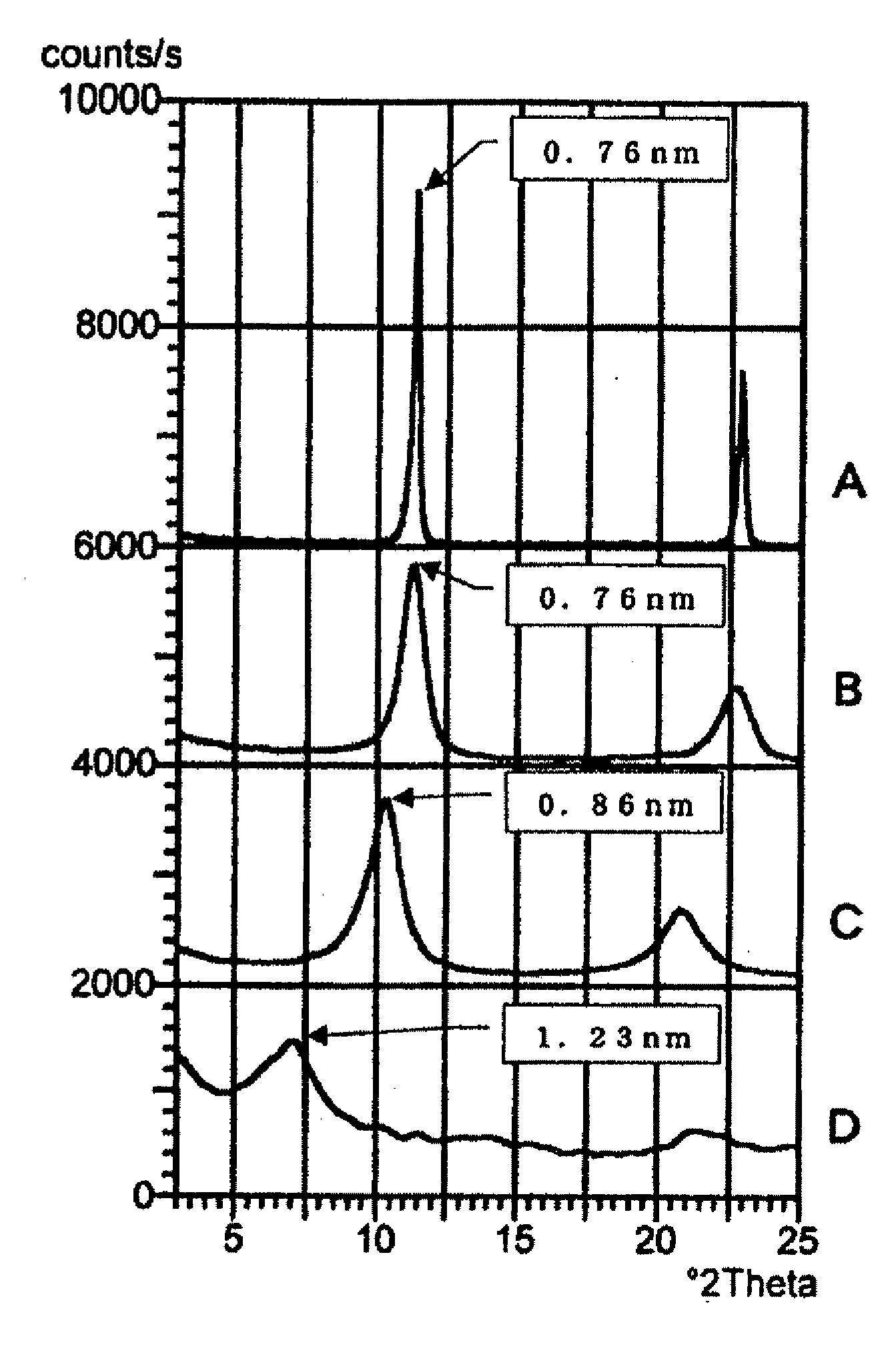

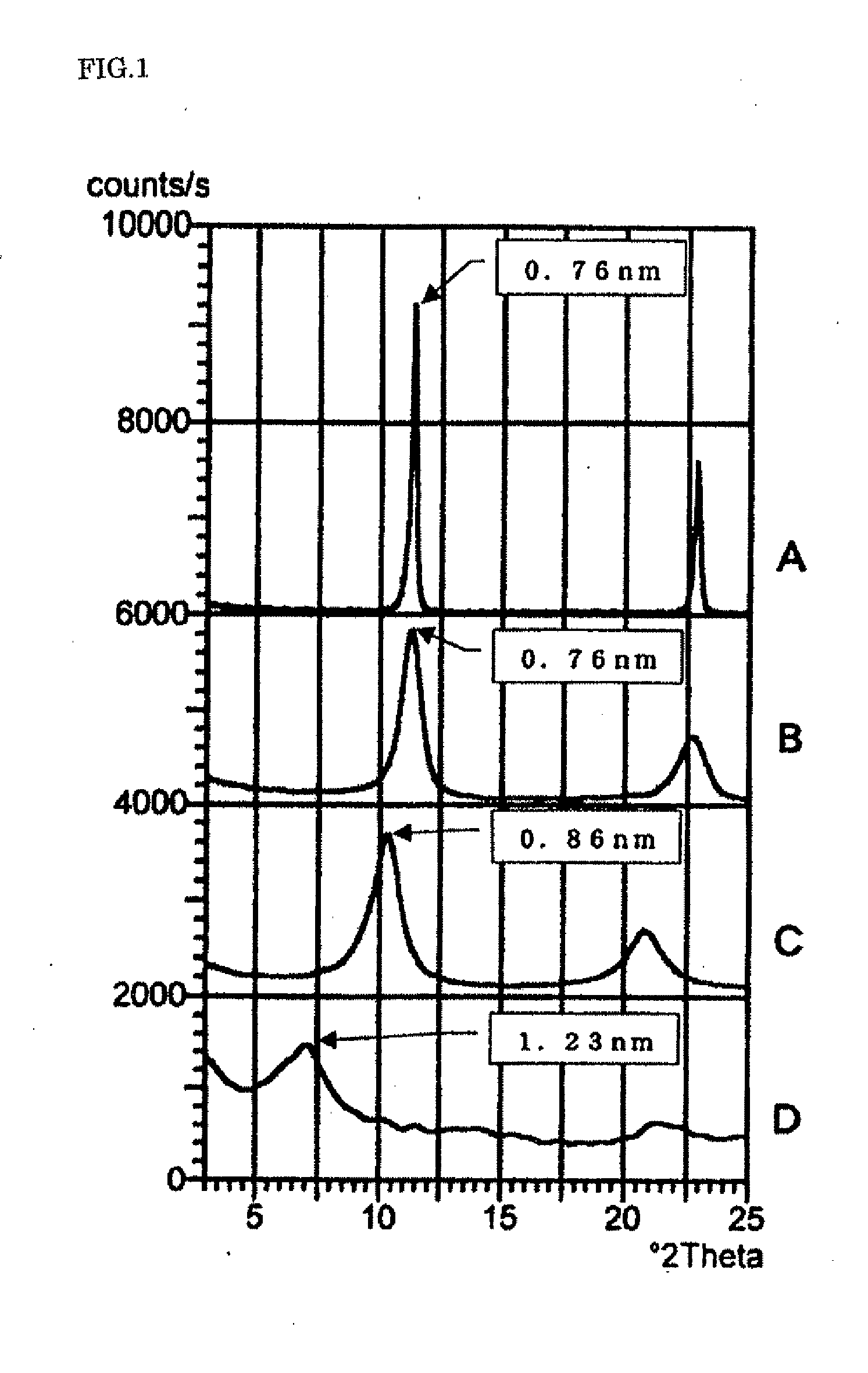

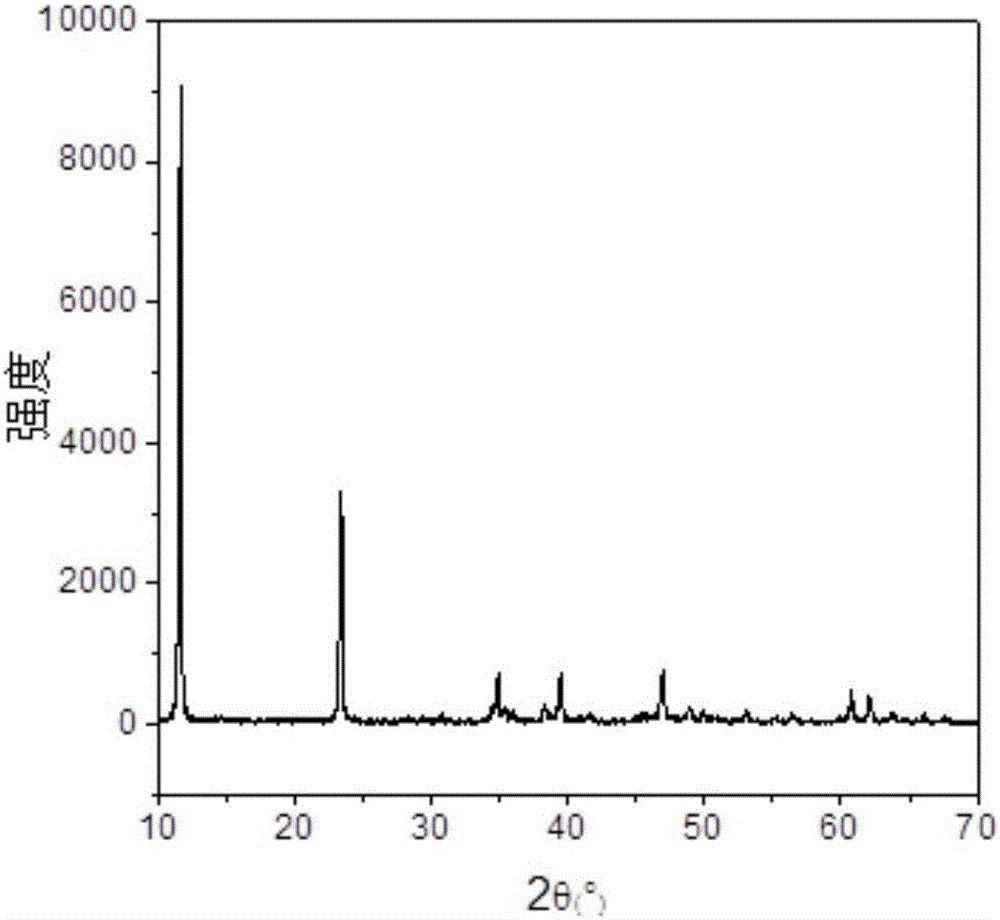

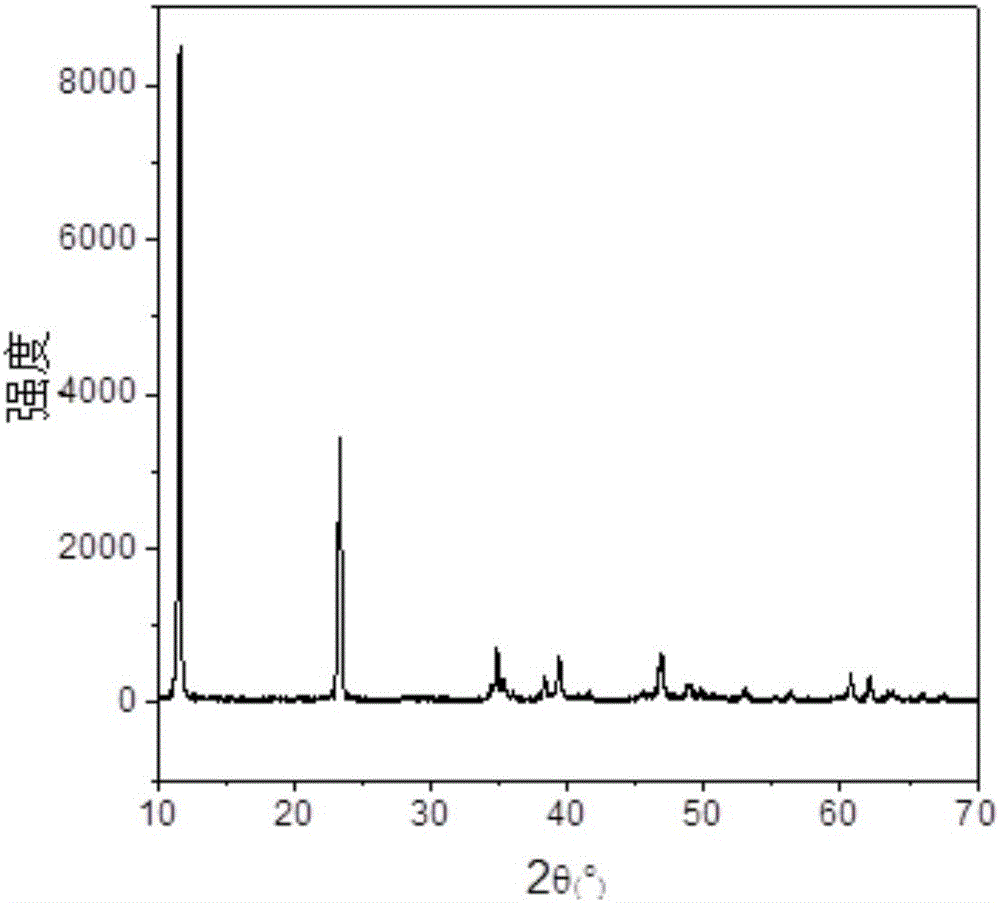

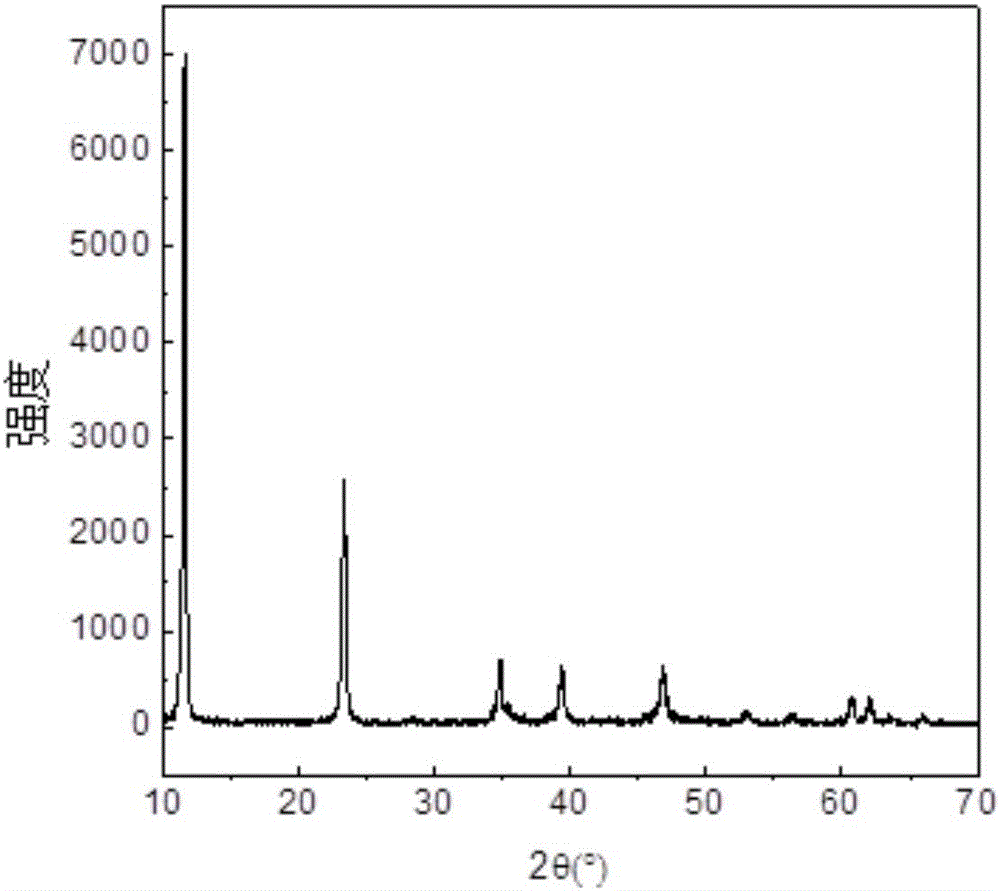

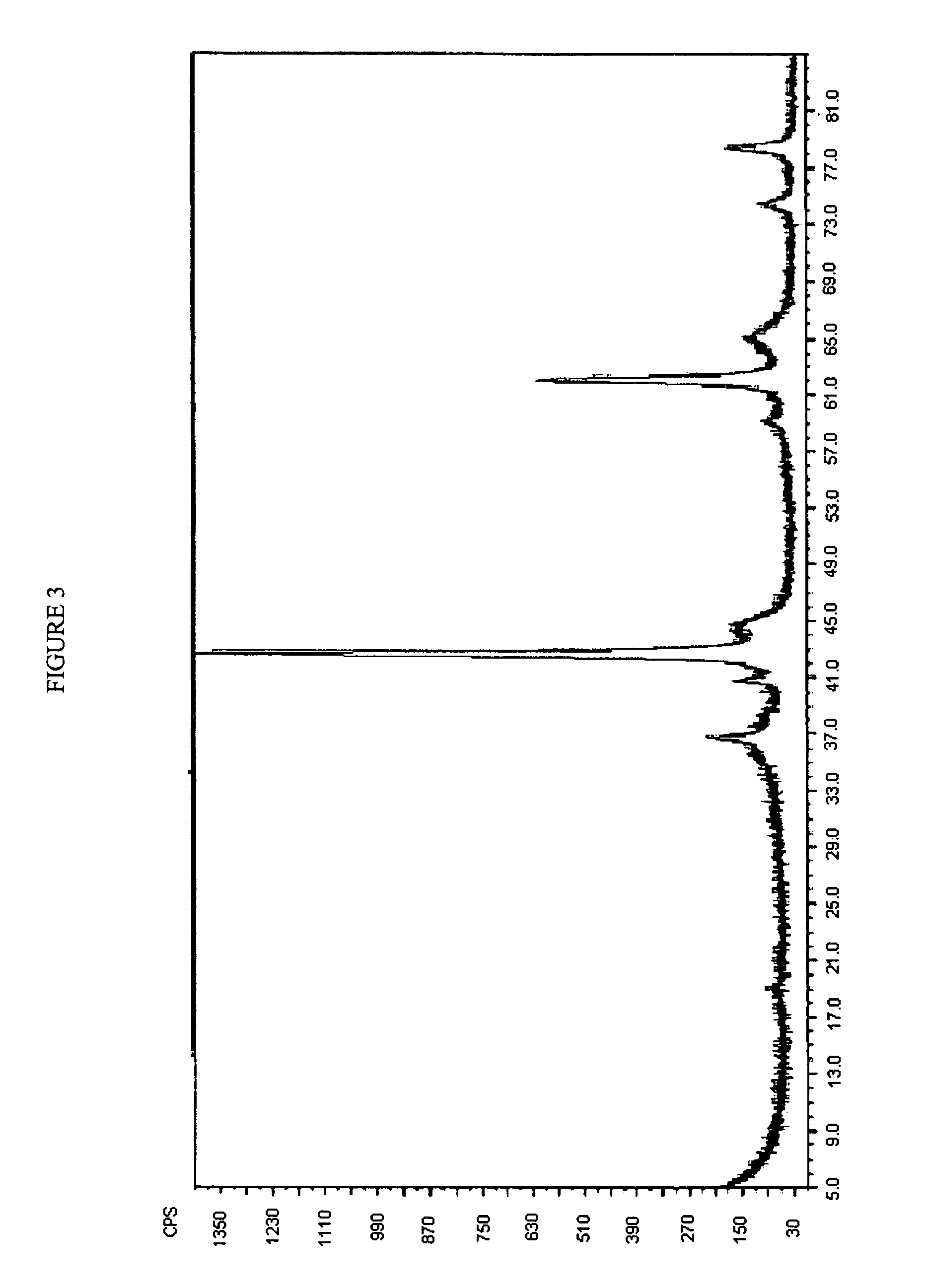

Hydrotalcite compound, process for producing same, inorganic ion scavenger, composition, and electronic component-sealing resin composition

InactiveUS20100123101A1Improve performanceExcellent metal corrosion inhibiting effectMaterial nanotechnologyOther chemical processesComposite numberScavenger

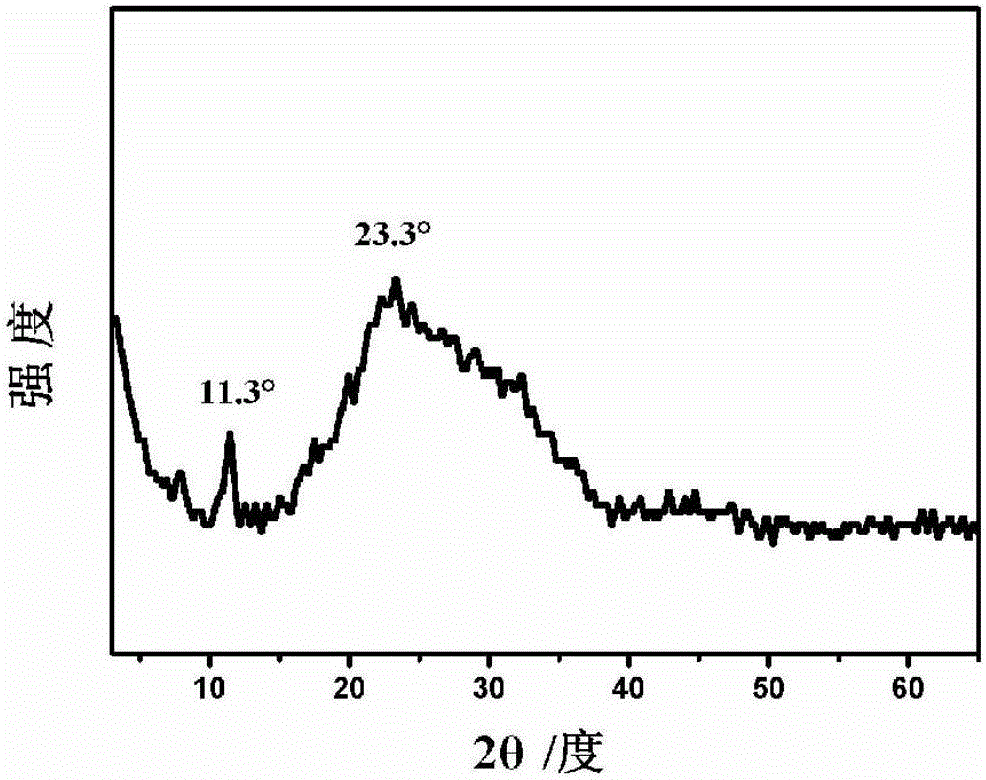

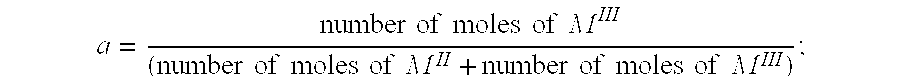

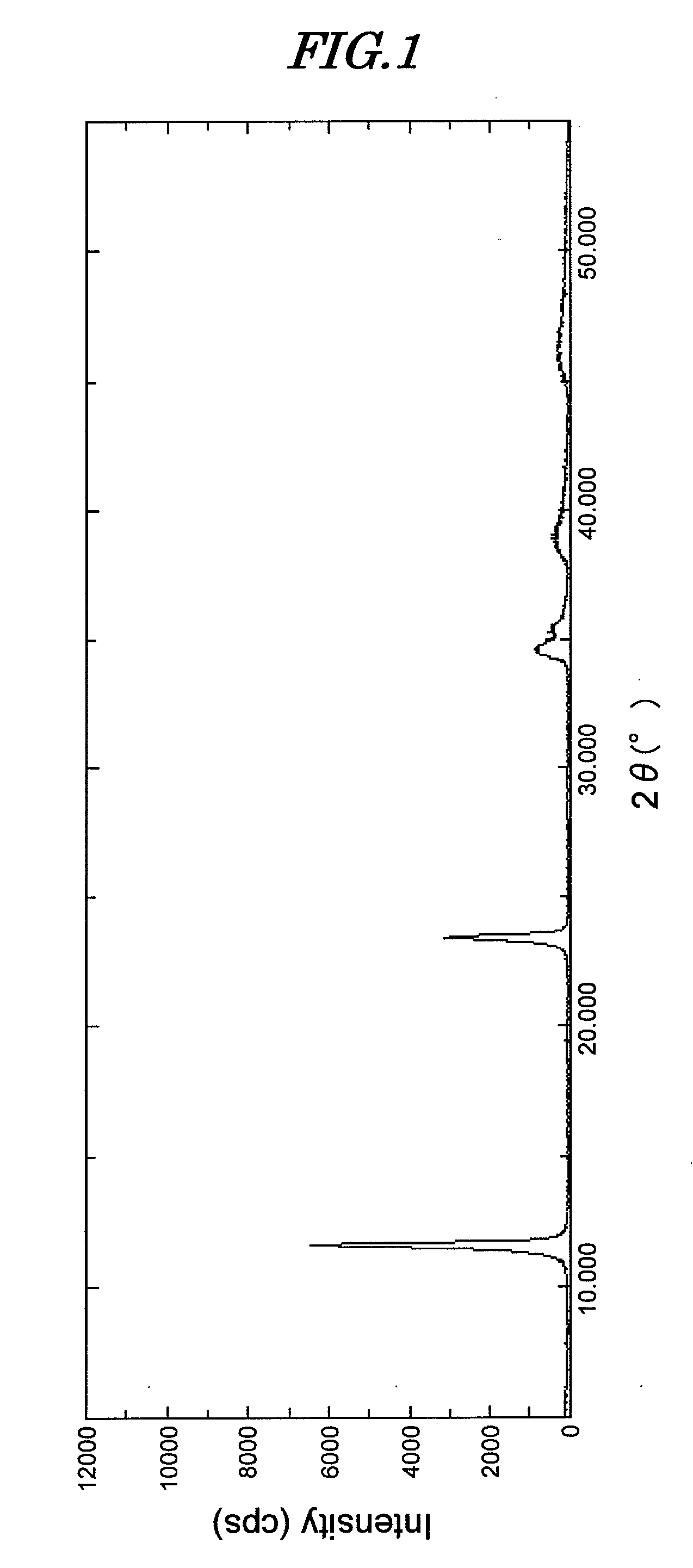

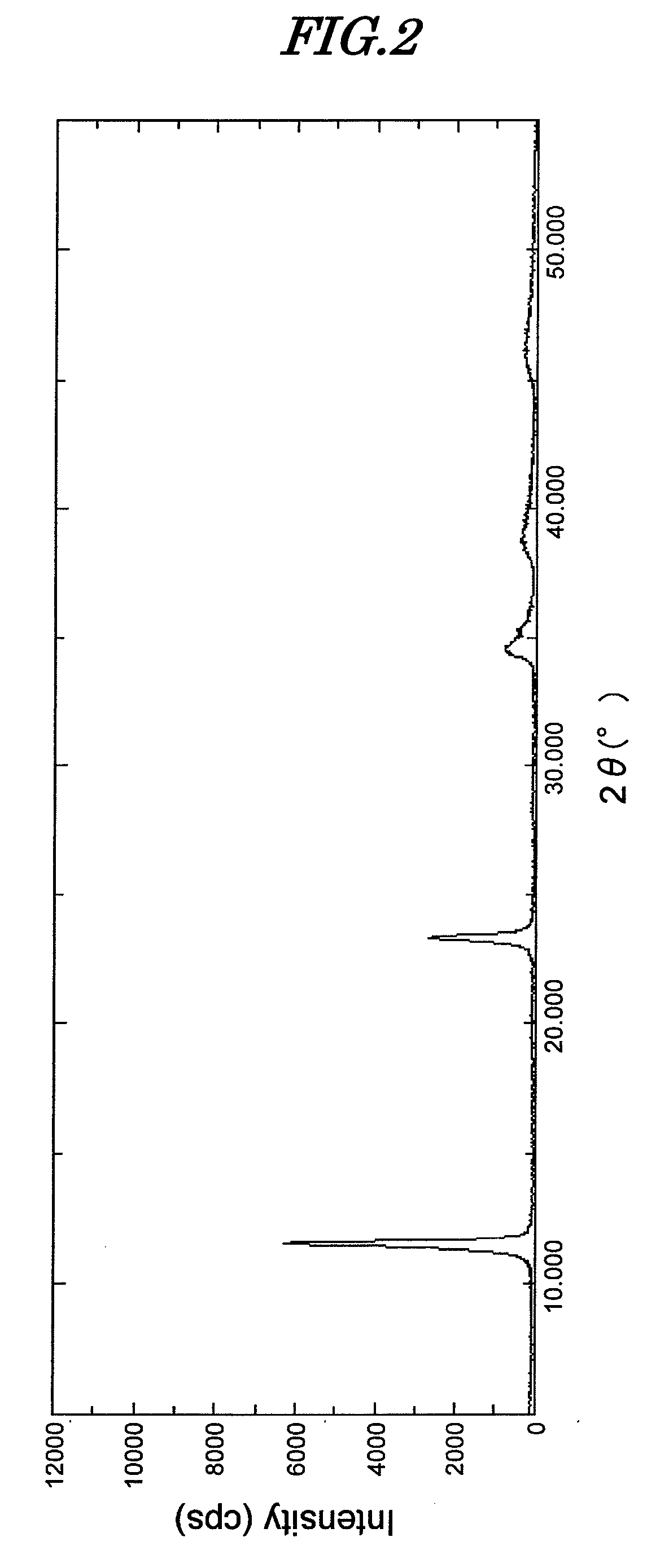

The present invention is a novel hydrotalcite compound that is environmentally friendly and exhibits an excellent metal corrosion inhibiting effect by the addition of a small amount thereof, and an inorganic ion scavenger employing same; the hydrotalcite compound is represented by Formula (1), has a hydrotalcite compound peak in the powder X-ray diffraction pattern, the peak intensity at 2θ=11.4° to 11.7° being at least 3,500 cps, and has a BET specific surface area of greater than 30 m2 / g.MgaAlb(OH)c(CO3)d·nH2O (1)In Formula (1), a, b, c, and d are positive numbers and satisfy 2a+3b−c−2d=0. Furthermore, n denotes hydration number and is 0 or a positive number.

Owner:TOAGOSEI CO LTD

Process for preparing hydrotalcite and brucite type posite charged layers

InactiveUS7022302B2Easy compoundImprove filtering effectPigmenting treatmentCalcium/strontium/barium compoundsHalogenPhysical chemistry

An improved process is described for the preparation of surface modified hydrotalcite. The process comprises reacting a precursor of magnesium and aluminium in the presence of suitable alkali carbonate at high temperature. The product has a BET surface area of ≦20 m2 / gm and average particle size of ≦0.5 μm and is useful as halogen scavenger and fire retardant.

Owner:COUNCIL OF SCI & IND RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com