Method for preparing rhodamine intercalation hydrotalcite luminescent material

A technology of luminescent materials and hydrotalcites, which is applied in the direction of luminescent materials, hydrotalcites, chemical instruments and methods, etc., can solve the problems of high gain and low threshold, and achieve the effect of reducing fluorescence quenching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

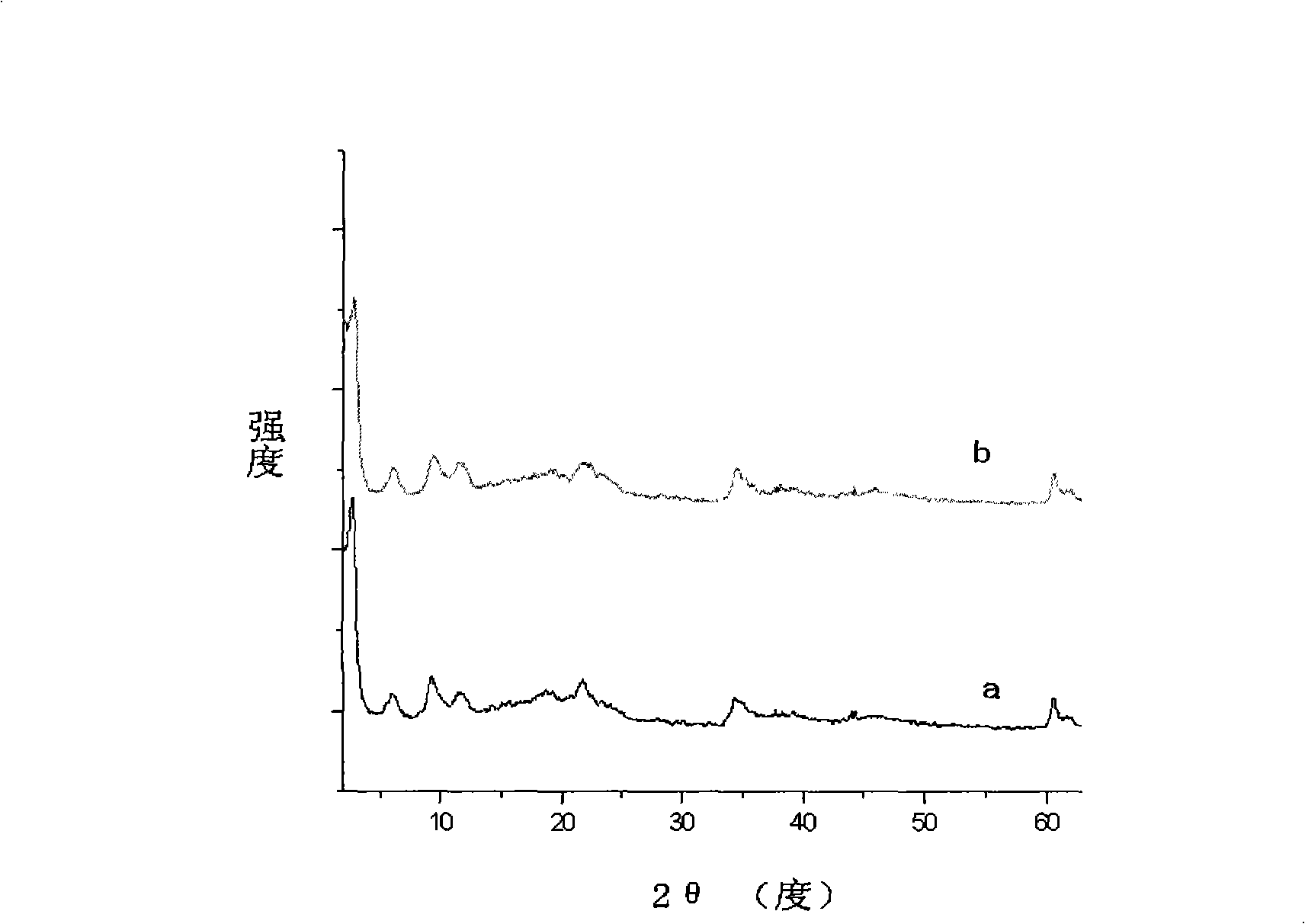

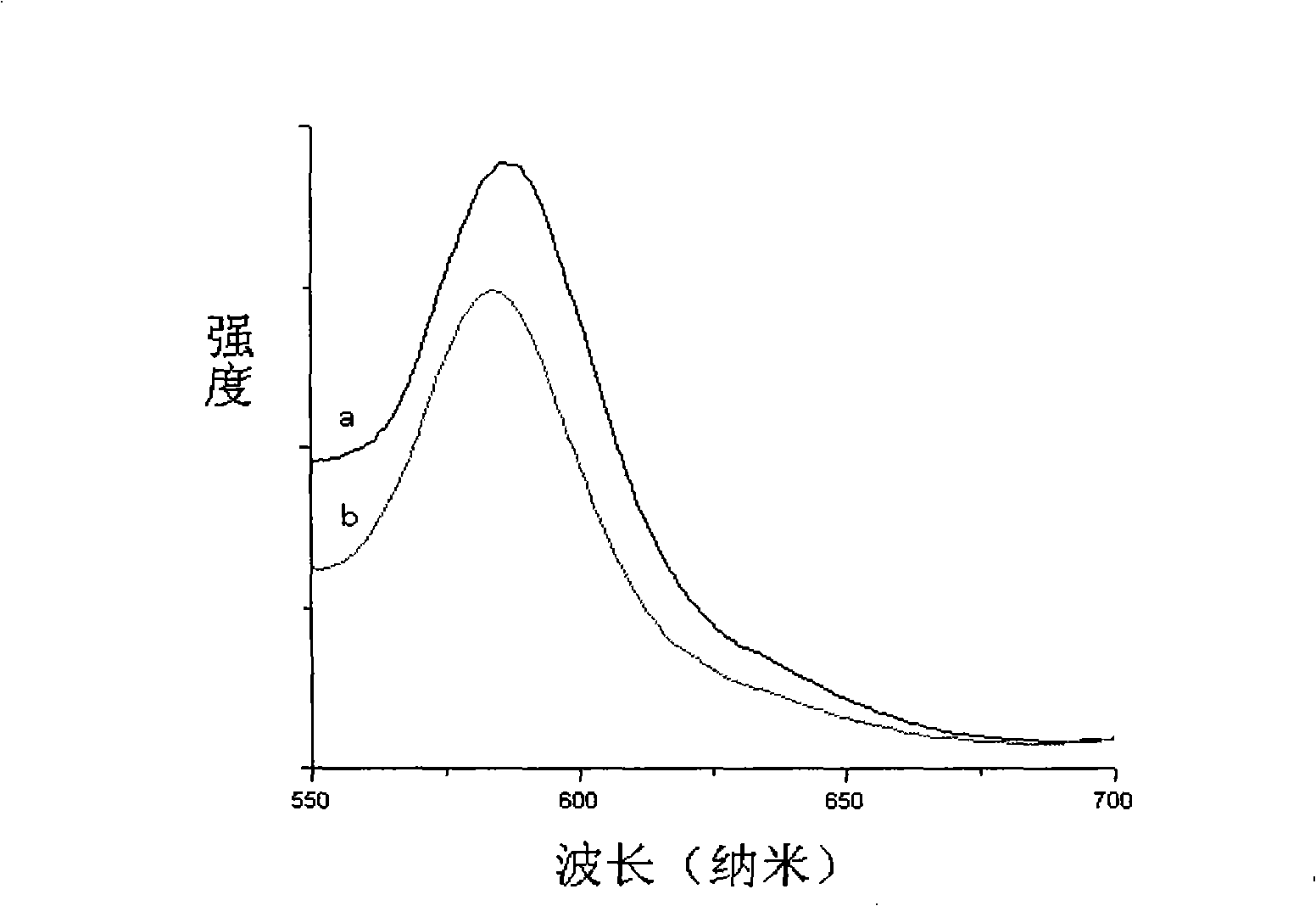

Embodiment 1

[0020] Step A: take by weighing 1.282g Mg(NO 3 ) 2 ·6H 2 O and 0.938g Al(NO 3 ) 3 9H 2 O, 0.828g of DBS and 0.026g of RB (that is, the initial molar ratio of DBS to RB at 100:5) were dissolved in 35ml to remove CO 2 , deionized water and 70ml of absolute ethanol to prepare mixed salt solution C, and another 0.6g NaOH was dissolved in 105ml to remove CO 2 , Deionized water is recorded as solution D.

[0021] Step B: Using the nucleation crystallization isolation method, the solutions C and D were fully reacted in a fully back-mixed liquid film reactor and mixed uniformly for 1 minute. Then the mixed slurry was poured into three 90ml polytetrafluoroethylene reaction containers and nitrogen gas was blown in for 5 minutes, then loaded into a pressure vessel, and reacted at 100°C for 24 hours under hydrothermal solvent thermal conditions.

[0022] Step C: Remove the product from the reactor, and use absolute ethanol and CO removal 2 1. Wash with deionized water for 3 times ...

Embodiment 2

[0025] Step A: take by weighing 1.282g Mg(NO 3 ) 2 ·6H 2 O and 0.938g Al(NO 3 ) 3 9H 2 O, 0.828g of DBS and 0.052g of RB (i.e. the initial molar ratio of DBS to RB is 100:10) were dissolved in 50ml to remove CO 2 , deionized water and 50ml of absolute ethanol to prepare mixed salt solution C, and another 0.6g of NaOH was dissolved in 100ml to remove CO 2 , Deionized water is recorded as solution D.

[0026] Step B: Same as Step B of Example 1, using the nucleation crystallization isolation method, fully reacting solutions C and D in a fully back-mixed liquid membrane reactor, and mixing uniformly for 1 minute. Then pour the mixed slurry into three 90ml polytetrafluoroethylene reaction containers and pass nitrogen gas for 5 minutes, then load the pressure bomb, and react for 24 hours under the condition of hydrothermal solvent heat at 100°C;

[0027] Step C: Same as Step C of Implementation Example 1, remove the product from the reactor, use absolute ethanol and remove C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com