Patents

Literature

1320 results about "Membrane reactor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

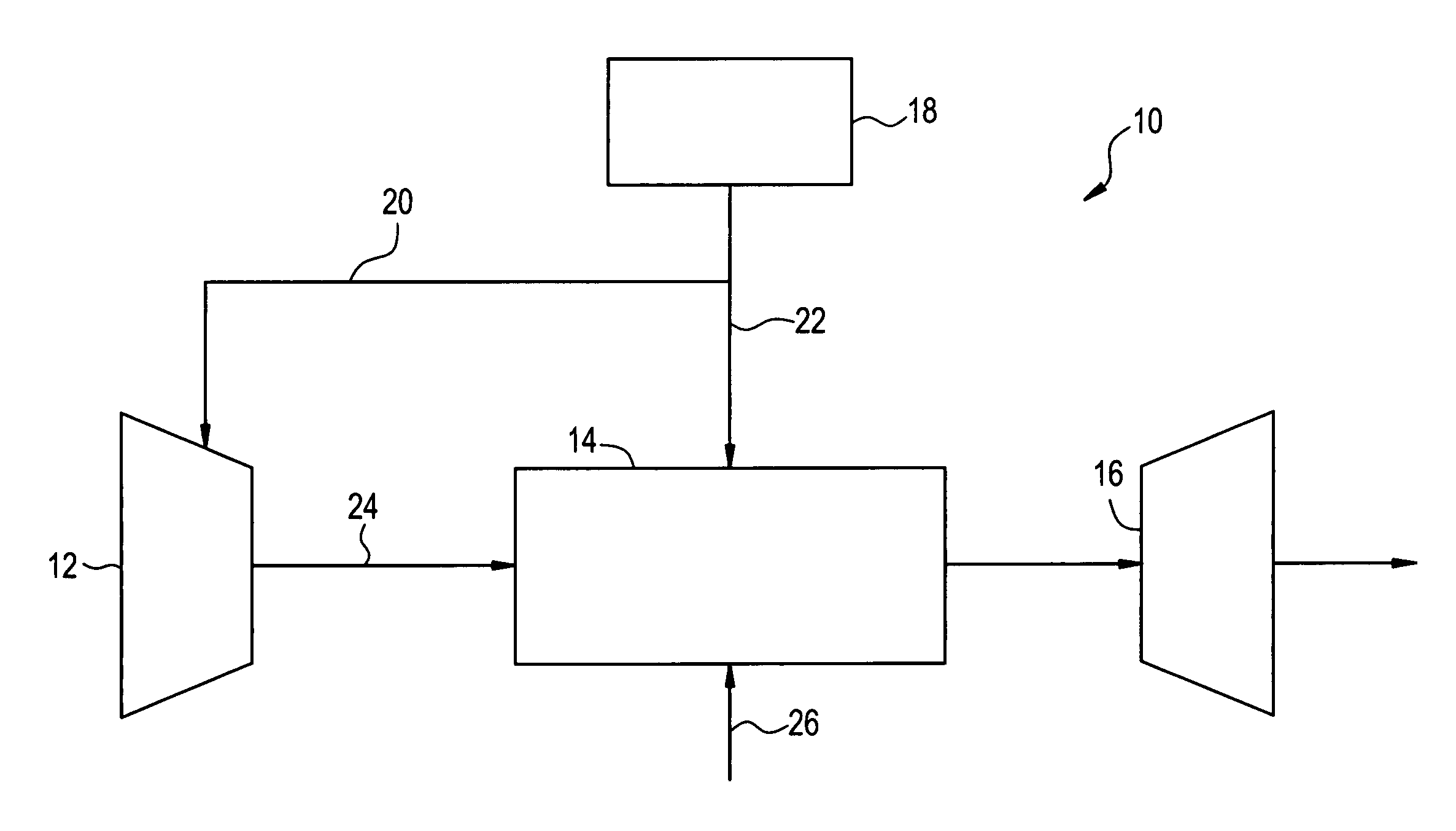

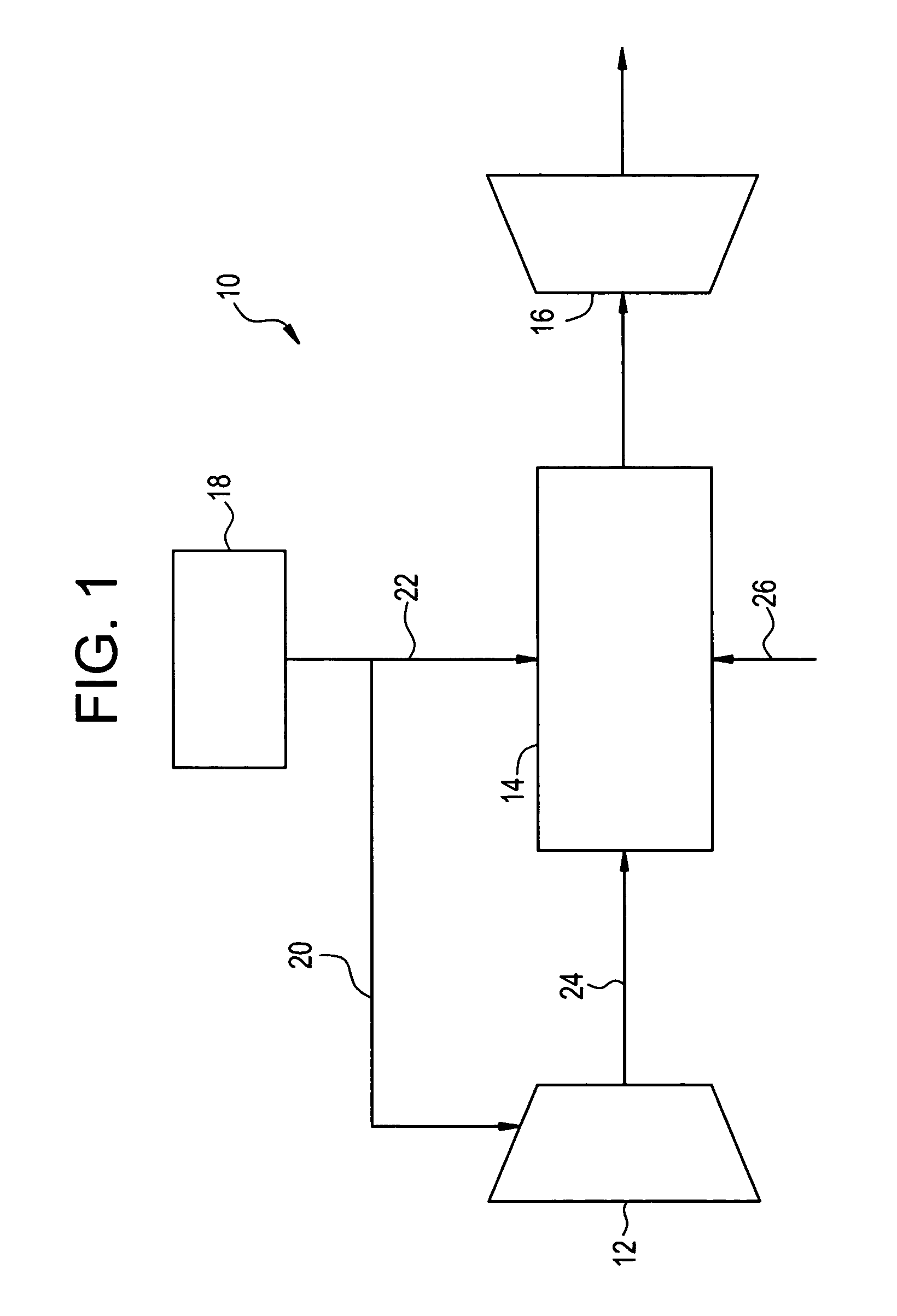

A membrane reactor is a physical device that combines a chemical conversion process with a membrane separation process to add reactants or remove products of the reaction. Chemical reactors making use of membranes are usually referred to as membrane reactors.

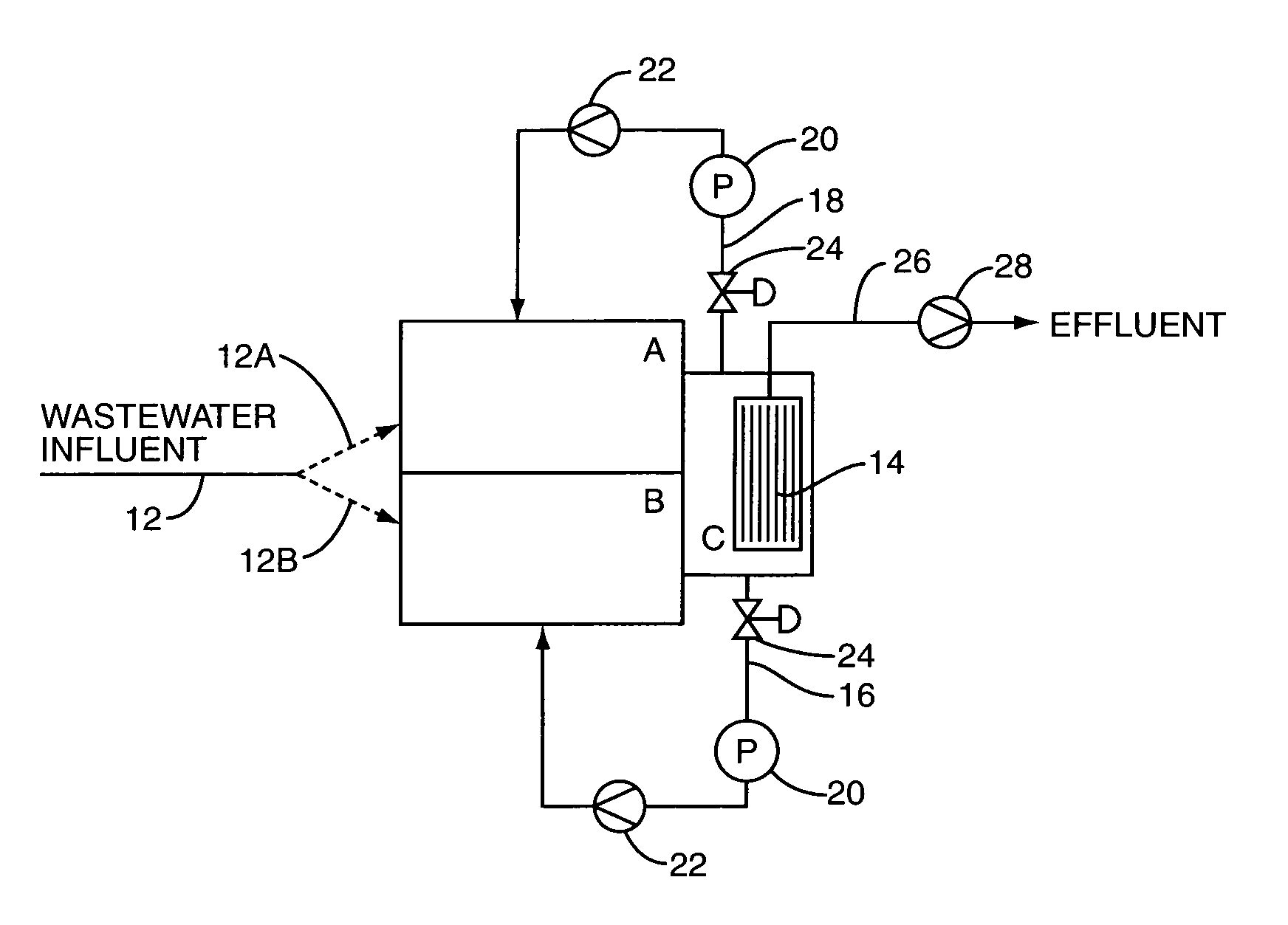

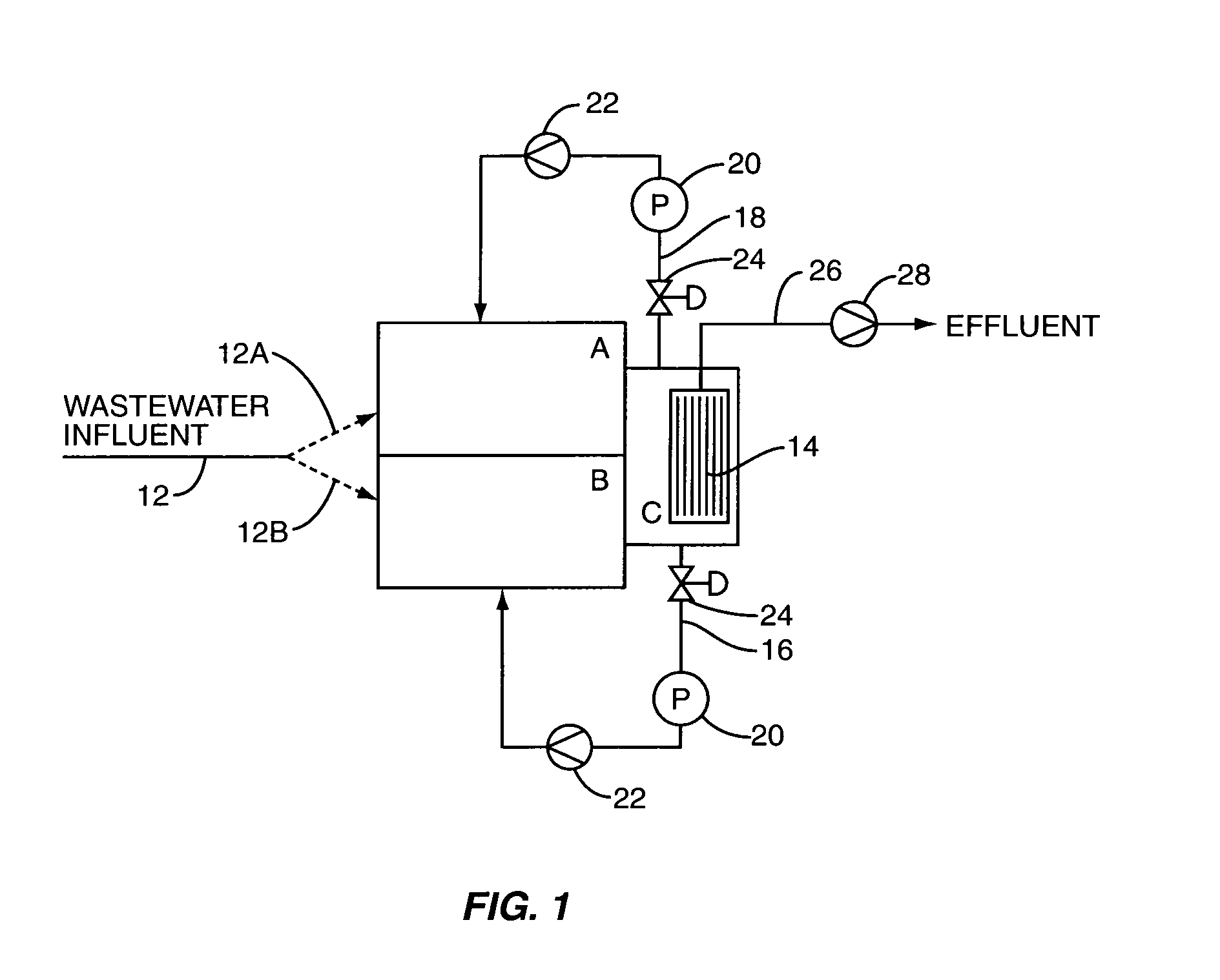

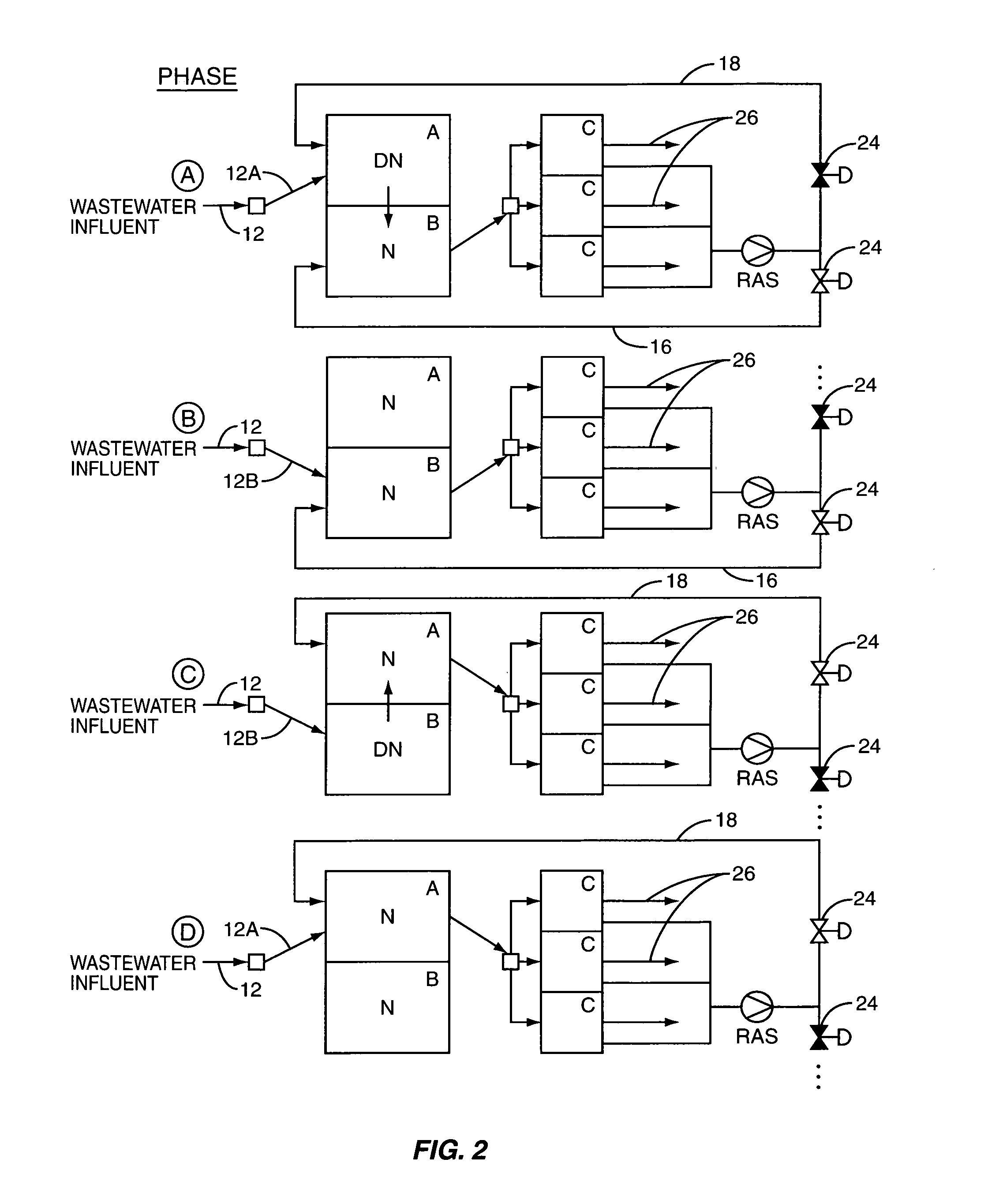

Method and system for nitrifying and denitrifying wastewater

ActiveUS7147778B1Reducing and minimizing dissolved oxygen concentrationReduces and minimizes dissolved oxygen concentrationTreatment using aerobic processesSeparation devicesActivated sludgeOxygen

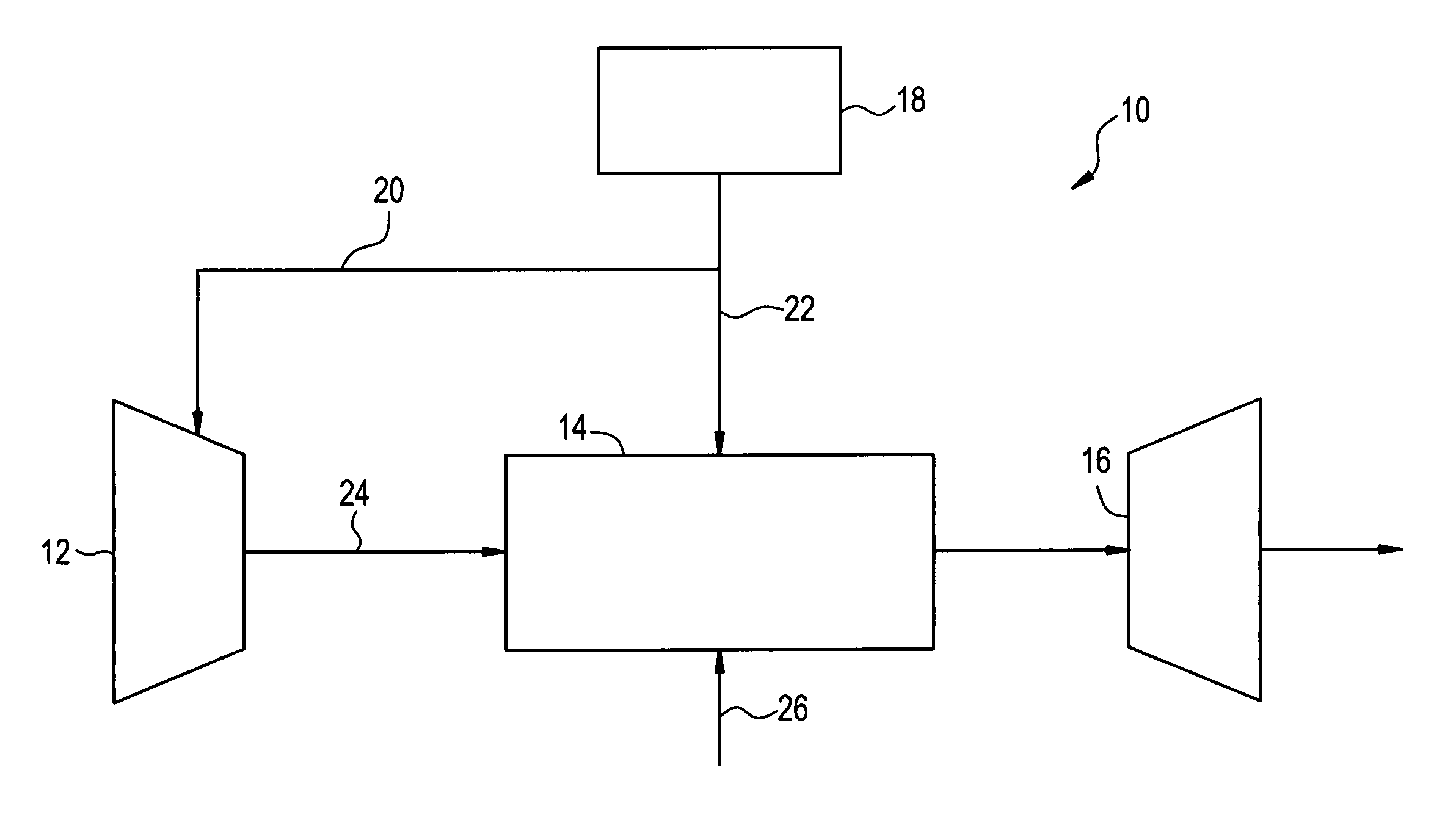

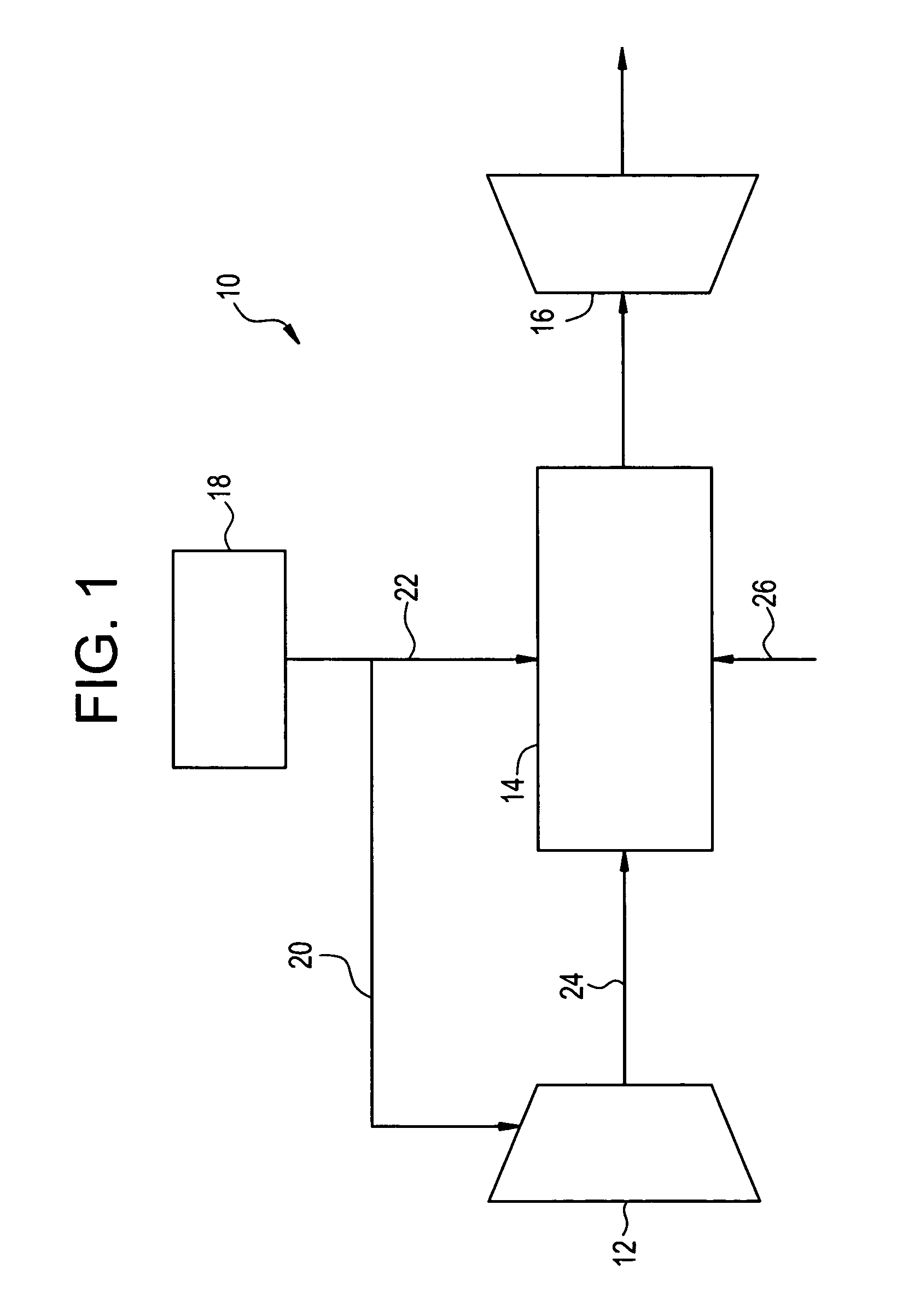

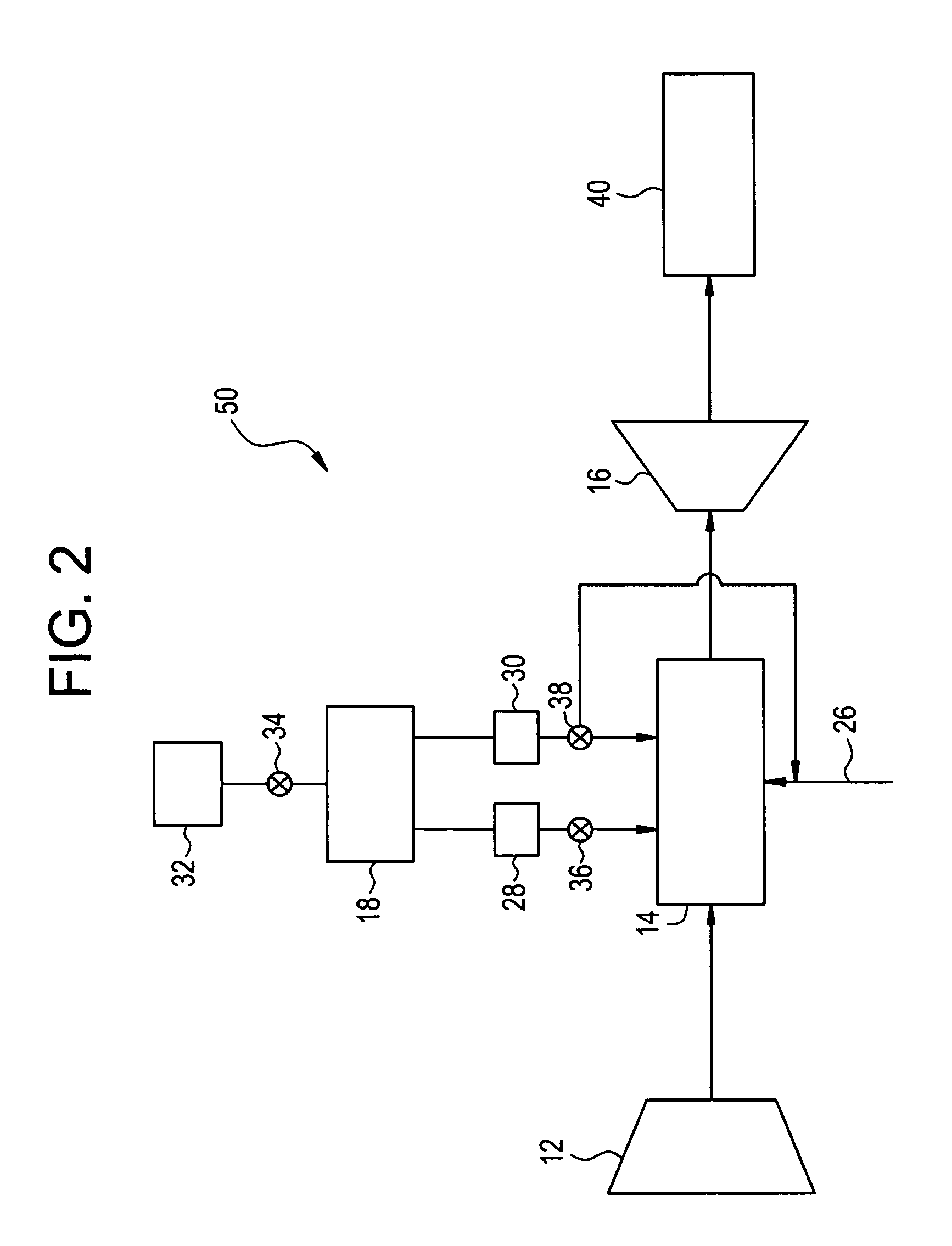

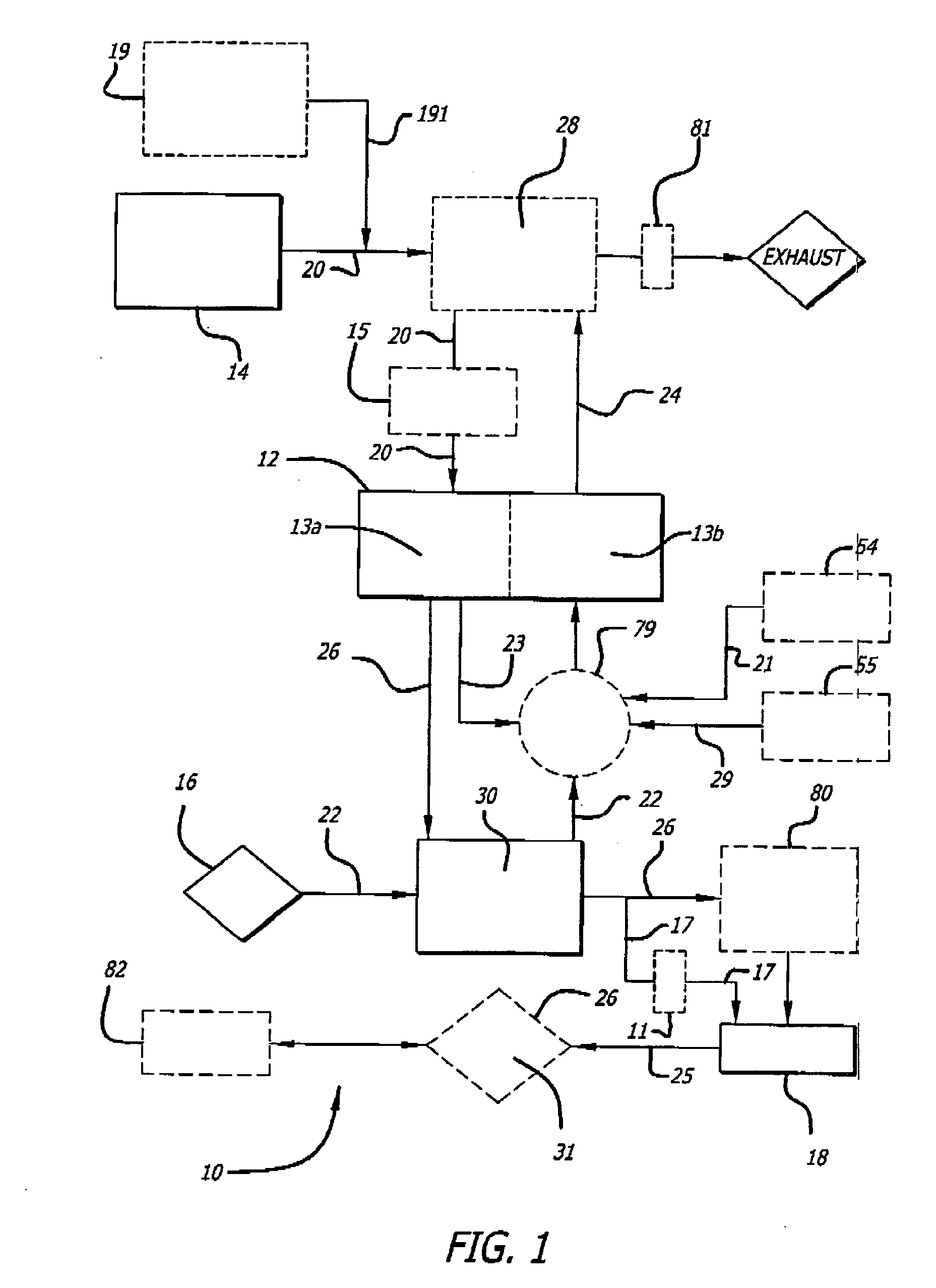

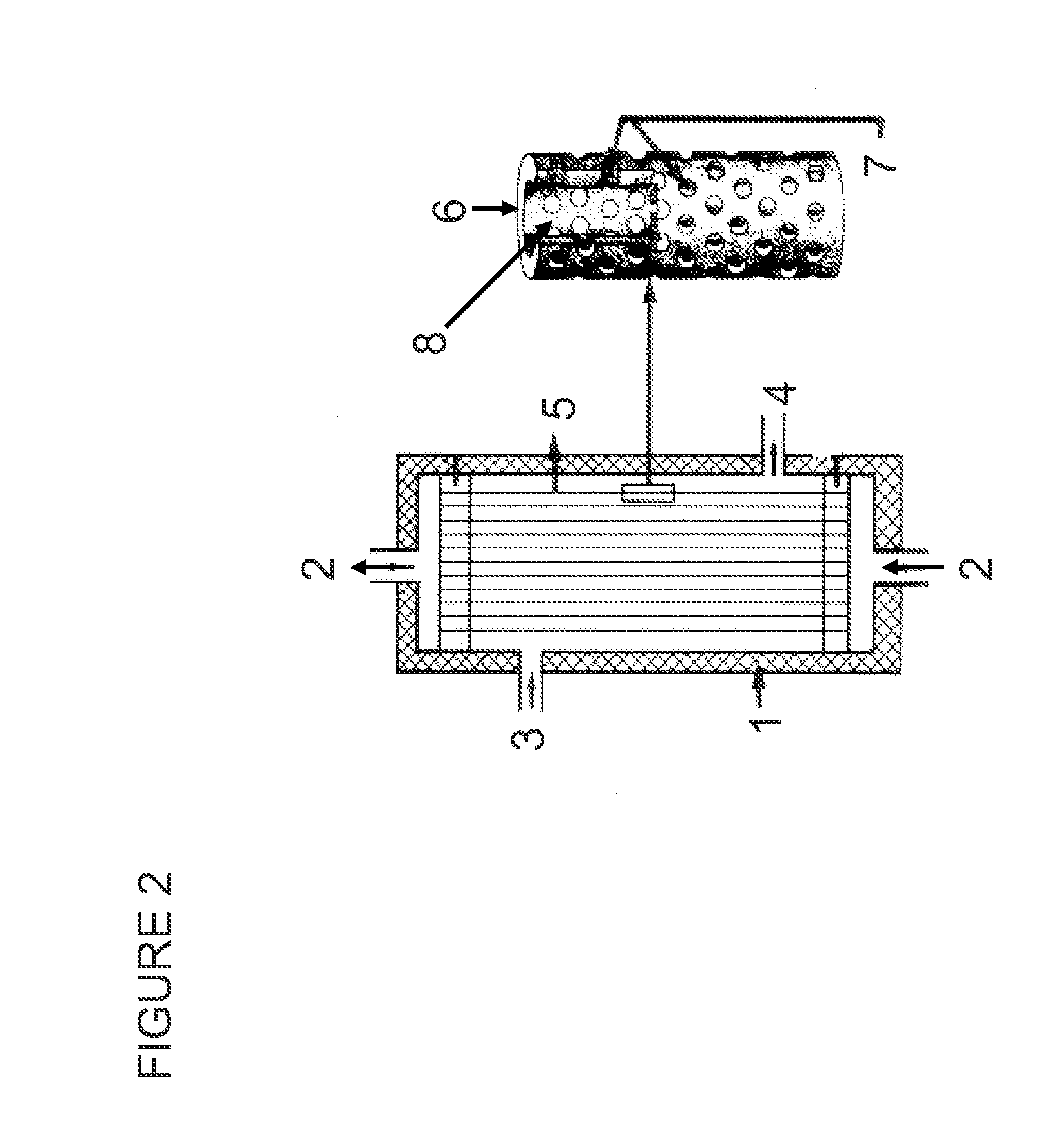

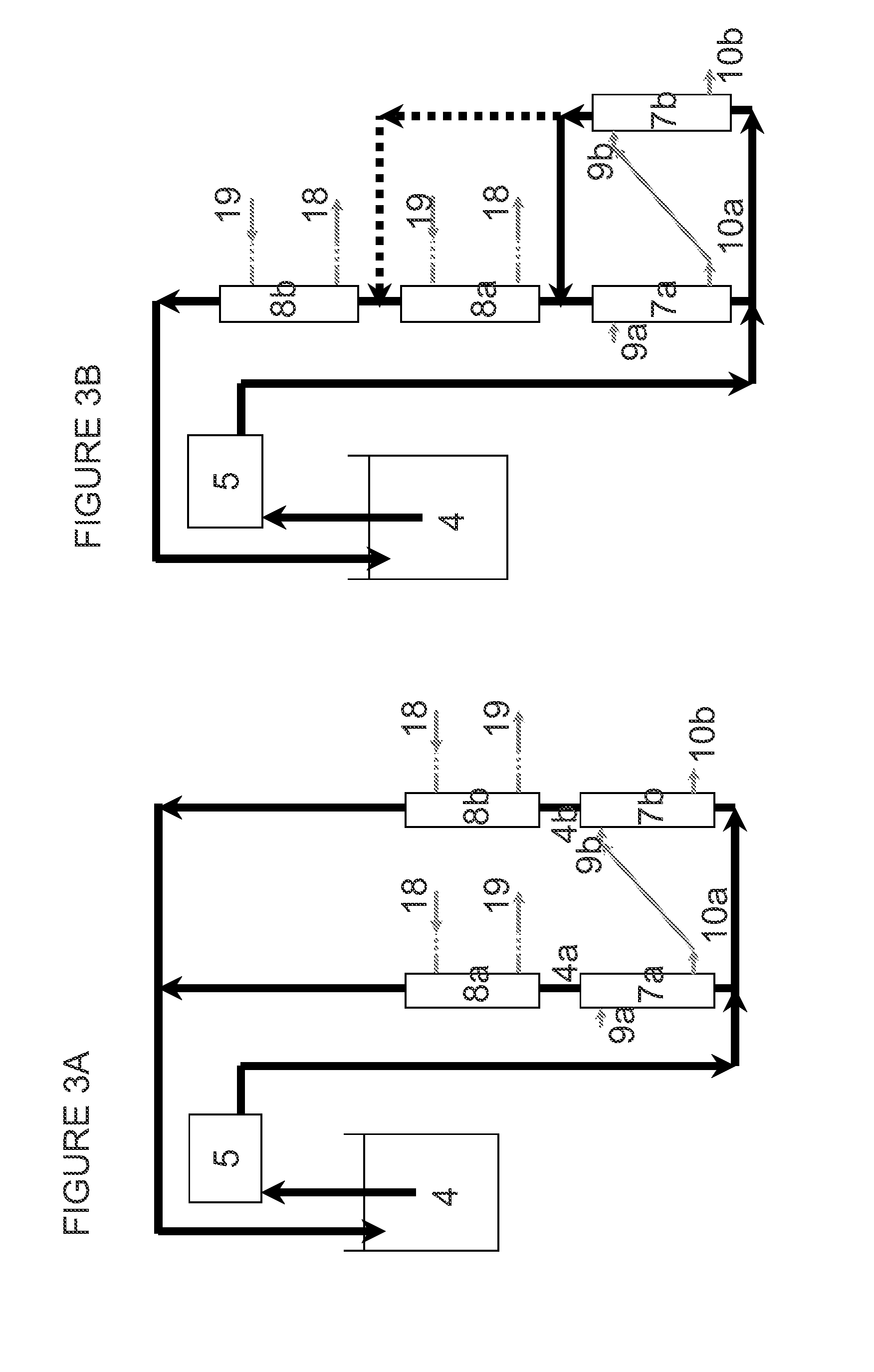

A wastewater treatment system is provided that includes first and second reactors, each operative to nitrify or denitrify wastewater contained therein. Downstream from the first and second reactors is a membrane reactor that operates under aerobic conditions and includes one or more submersed membranes for separating solids. Extending between the membrane reactor and each of the first and second reactors is a return activated sludge line with appropriate controls for permitting return activated sludge to be directed to one of the reactors at a time. To nitrify and denitrify wastewater, a wastewater influent stream is alternatively directed to the anoxic reactors which are alternatively operated under aerobic and anoxic conditions so as to nitrify or denitrify the wastewater contained therein. To reduce or minimize the dissolved oxygen return from the membrane reactor to the first and second reactors, the flow of return activated sludge is controlled such that generally return activated sludge is returned to the reactor operating under aerobic conditions.

Owner:KRUGER I INC

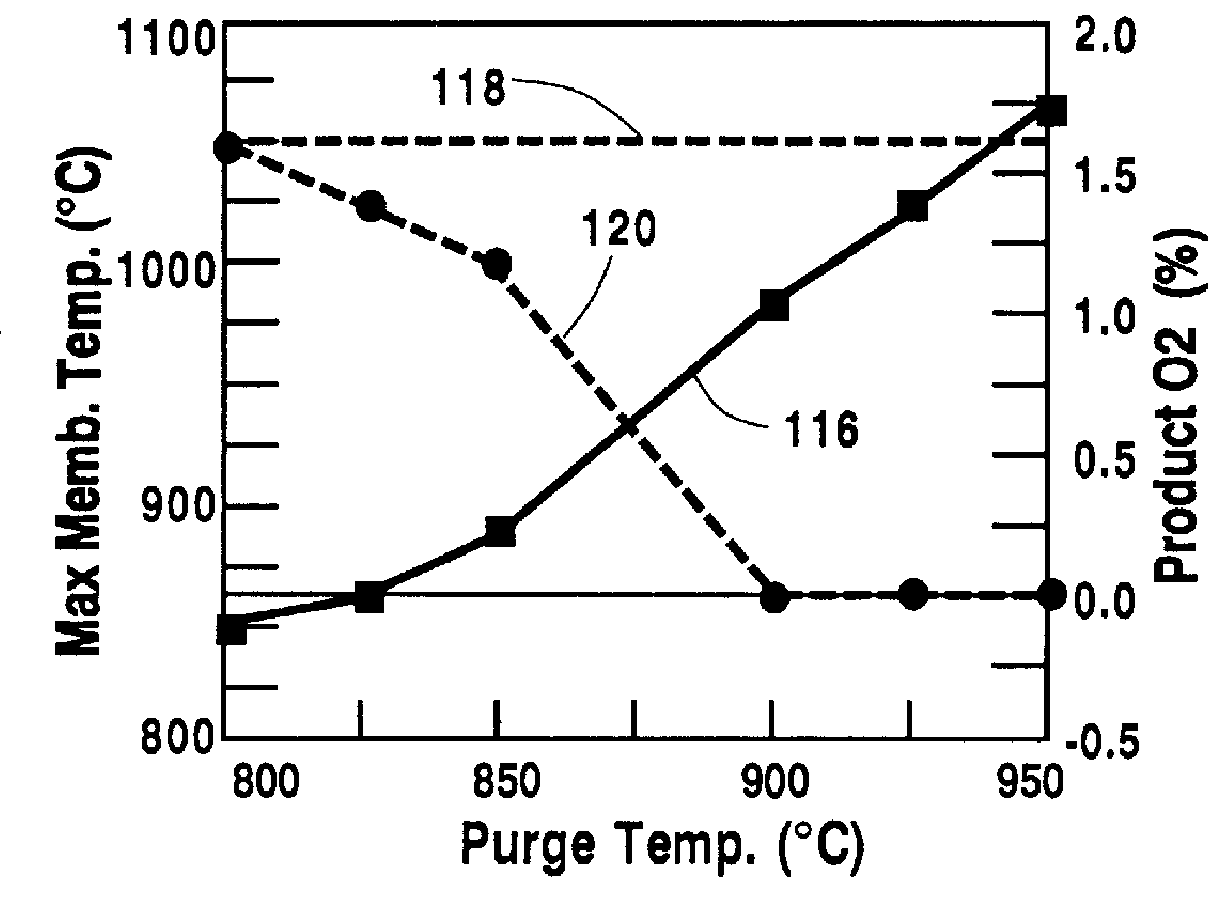

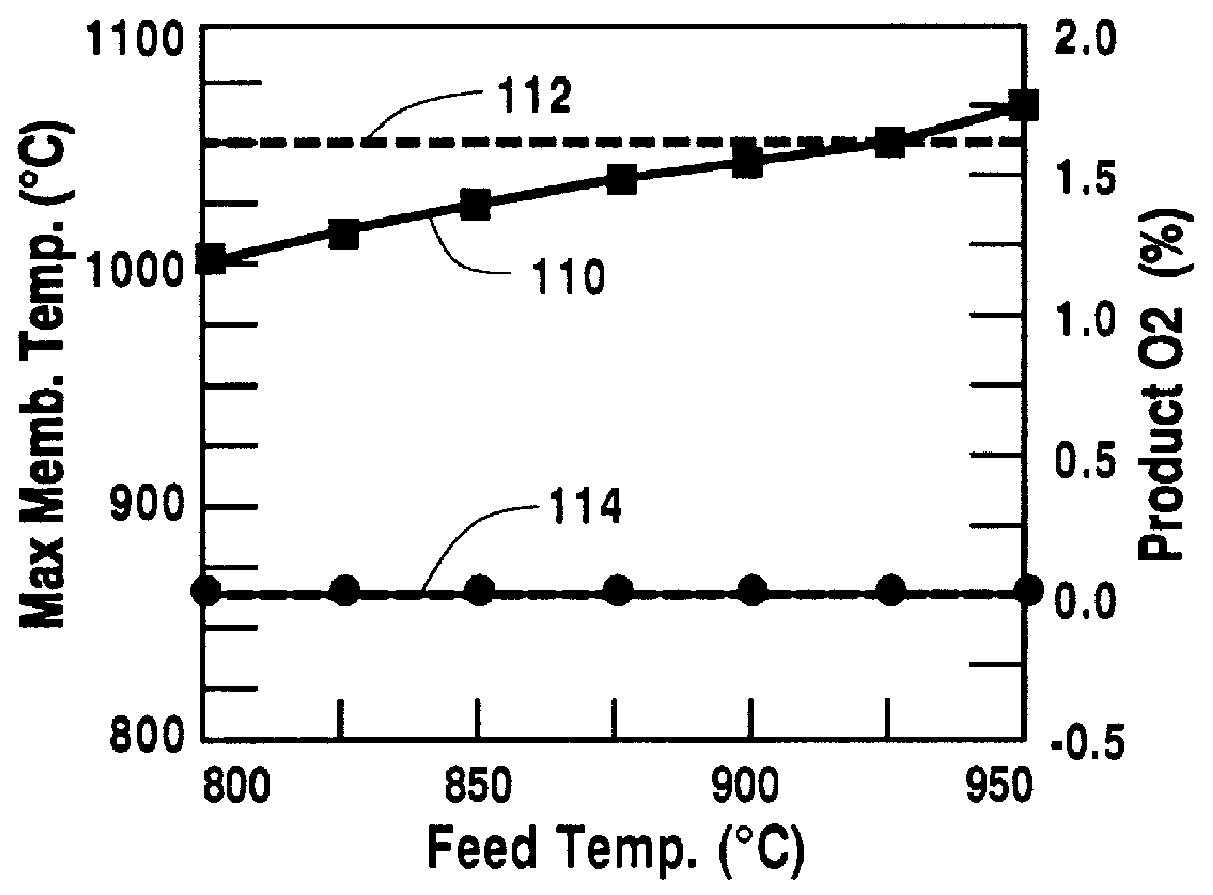

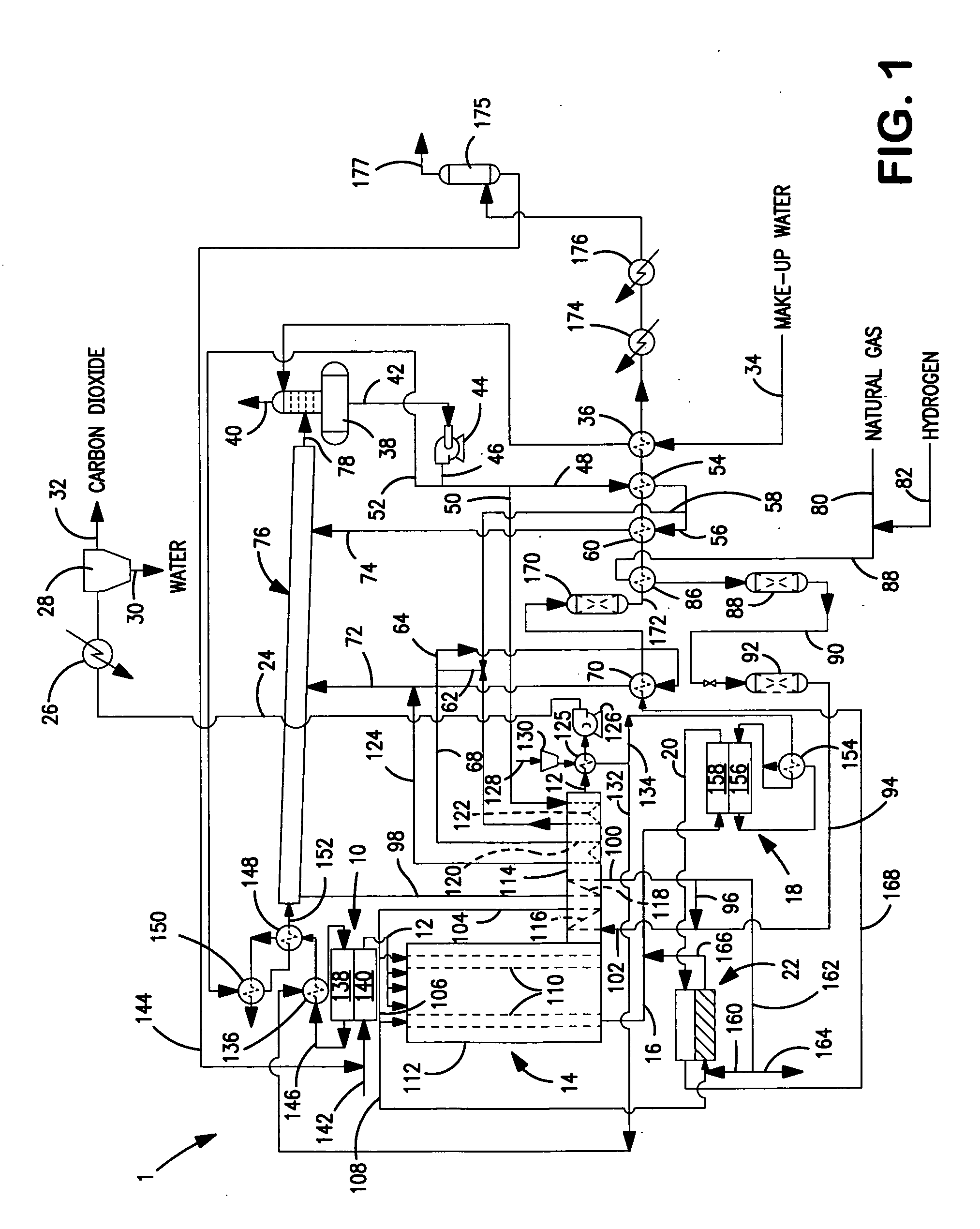

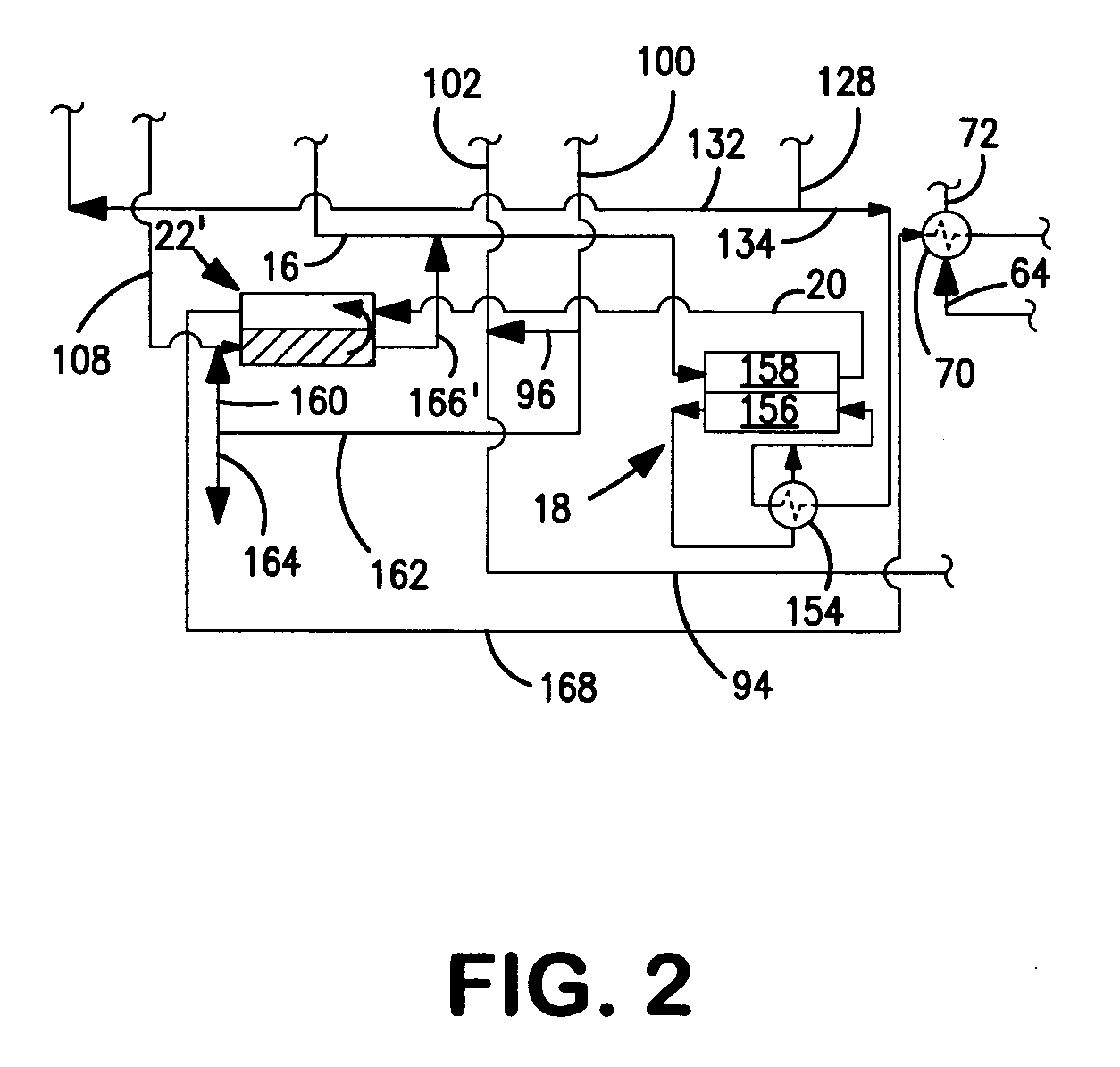

Temperature control in a ceramic membrane reactor

InactiveUS6010614AEnhance exchangeFine surfaceHydrogenLiquid separation by electricityTemperature controlOxygen ions

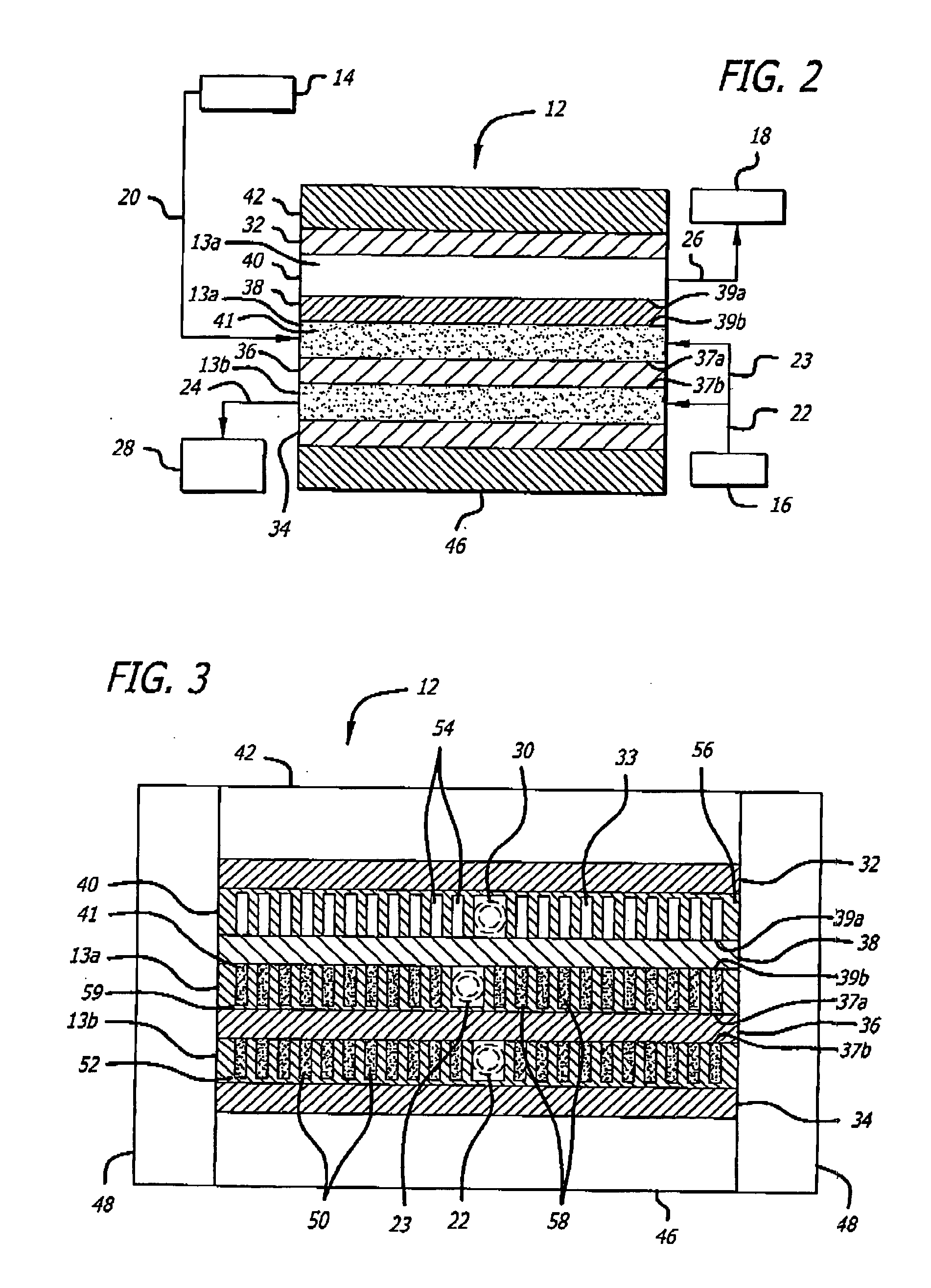

A method for maintaining the temperature of an oxygen-selective ion transport membrane within a desired temperature range includes providing an ion transport reactor with the oxygen-selective ion transport membrane. An oxygen-donating feed gas is delivered to a cathode side at a first temperature, at a first rate, and at a first oxygen partial pressure and a reactant gas is supplied to an anode side at a second temperature and a second rate. A physical condition is then established within the ion transport reactor that favors the transport of elemental oxygen through the oxygen selective ion transport membrane as oxygen ions. One or more process variables are then regulated to maintain the temperature of the oxygen selective ion transport membrane within the desired range.

Owner:PRAXAIR TECH INC

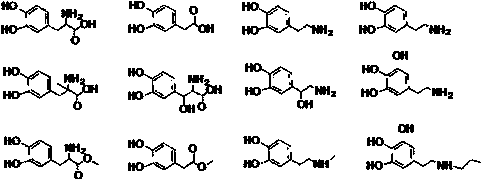

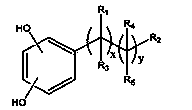

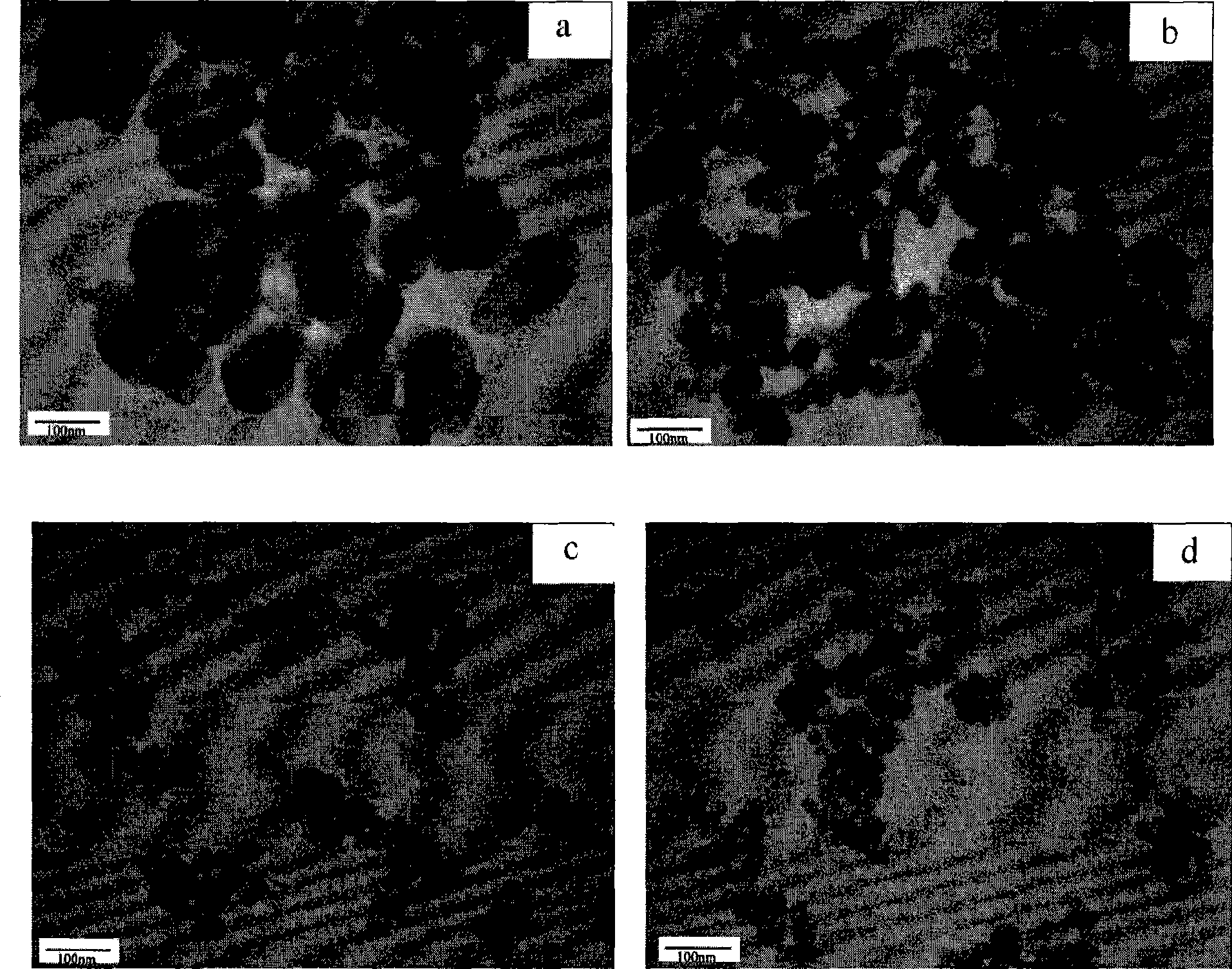

Preparation method and application of anti-pollution hydrophilic separating membrane

ActiveCN103480278AReduce dosageMeet the needs of hydrophilic immobilizationSemi-permeable membranesMembrane permeabilizationMicrofiltration membrane

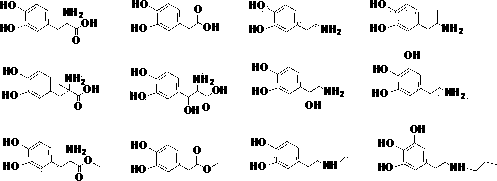

The invention discloses a preparation method and an application of an anti-pollution hydrophilic separating membrane. The preparation method is characterized in that a pyrocatechol derivative is used as an accelerant and a curing agent between a separating membrane material and a hydrophilic material, when blending casting film liquid of the separating membrane is prepared, the pyrocatechol derivative is added to blending liquid of the separating membrane material and the hydrophilic material, and the pyrocatechol derivative is subjected to polymerization cross-linking in a phase conversion process of the membrane preparation, so that the effect of fixing the hydrophilic material is achieved. The preparation method of the anti-pollution hydrophilic separating membrane has strong universality and is suitable for the blending of multiple hydrophilic materials and multiple membrane materials. The preparation method is simple, easy to operate, mild in conditions, economic, high-efficiency, environmentally-friendly, easy for industrialization and suitable for the preparation of multi-functional hydrophilic micro-filtration membranes, ultra-filtration membranes, nano-filtration membranes, reverse-osmosis membranes, positive-osmosis membranes, pressure-delay osmosis membranes, pervaporation membranes and the like which are used for liquid and gas separation and membrane reactors.

Owner:YANTAI LVSHUIFU MEMBRANE MATERIAL

Systems and methods of reducing NO.sub.x emissions in gas turbine systems and internal combustion engines

InactiveUS7650744B2Easy to operateAccelerate emissionsCombustion enginesGas turbine plantsCombustorOxygen

A gas turbine systems of reducing NOX emissions and enhancing operability comprises a compressor; a combustor disposed downstream of and in fluid communication with the compressor; a turbine assembly disposed down stream of and in fluid communication with the combustor; an oxygen-enriched gas source disposed in selective fluid communication with the compressor, the combustor, or a combination of the foregoing, wherein the oxygen-enriched gas source is a pressure swing absorption system, an electrolyzer, or a membrane reactor.

Owner:GENERAL ELECTRIC CO

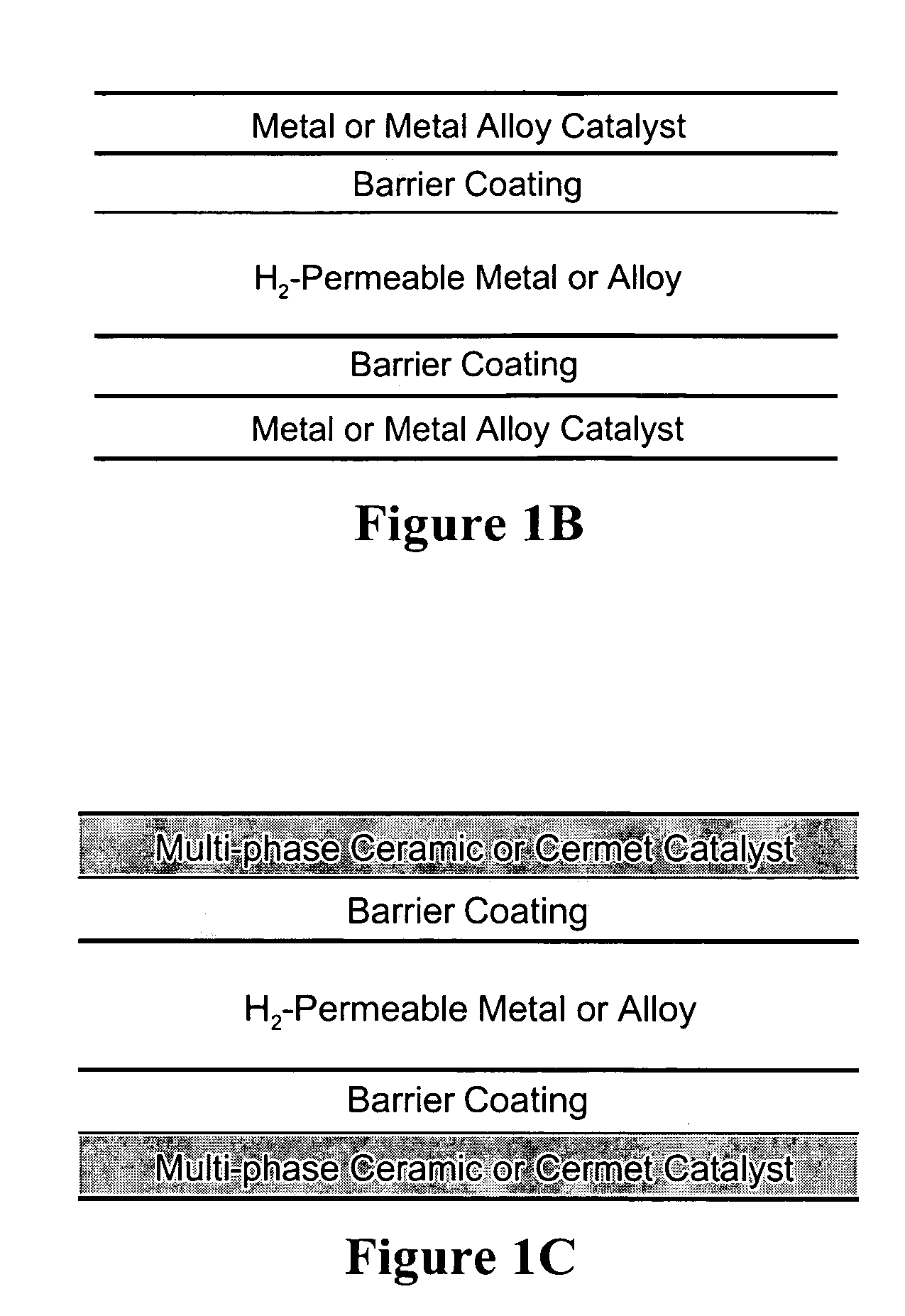

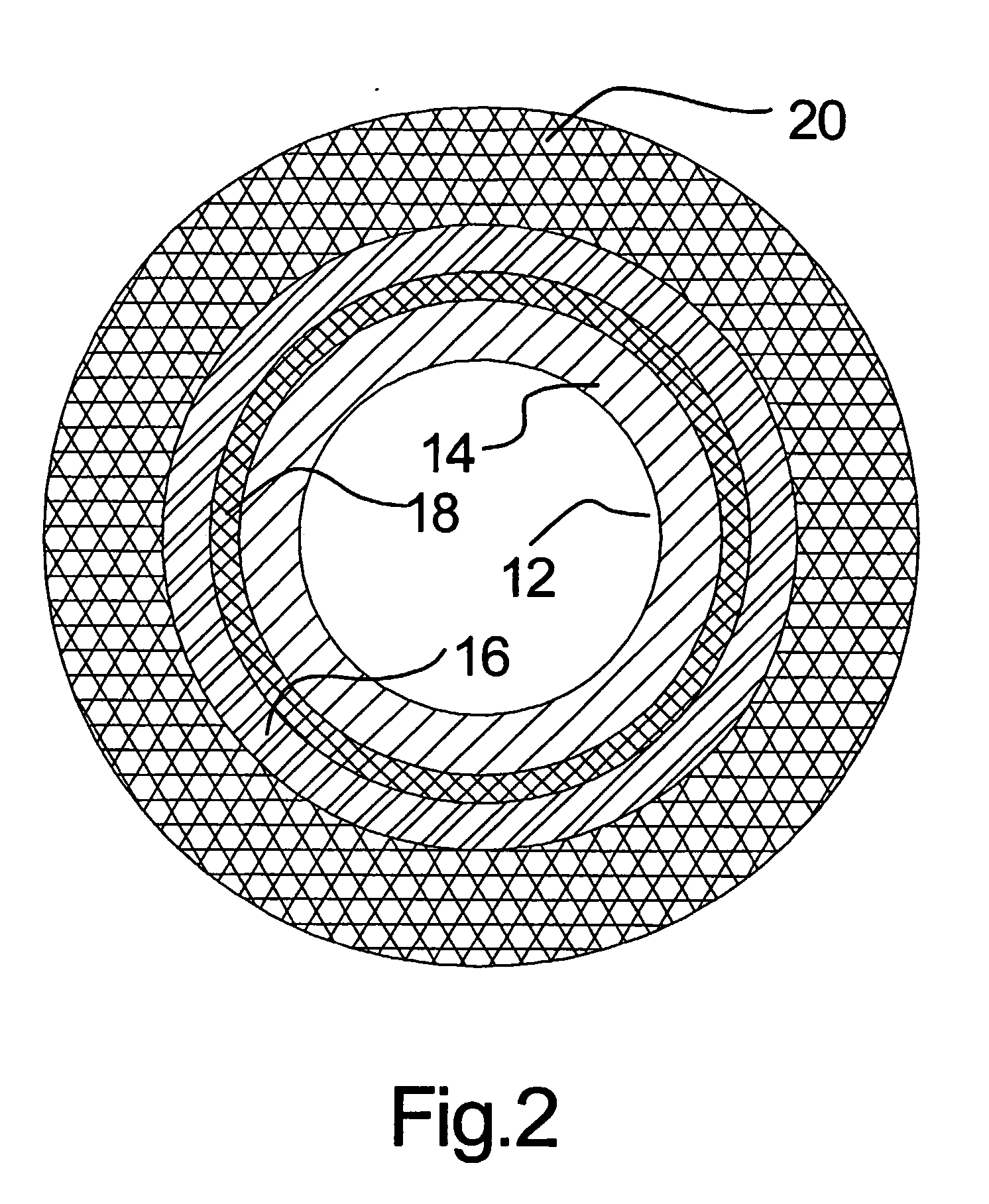

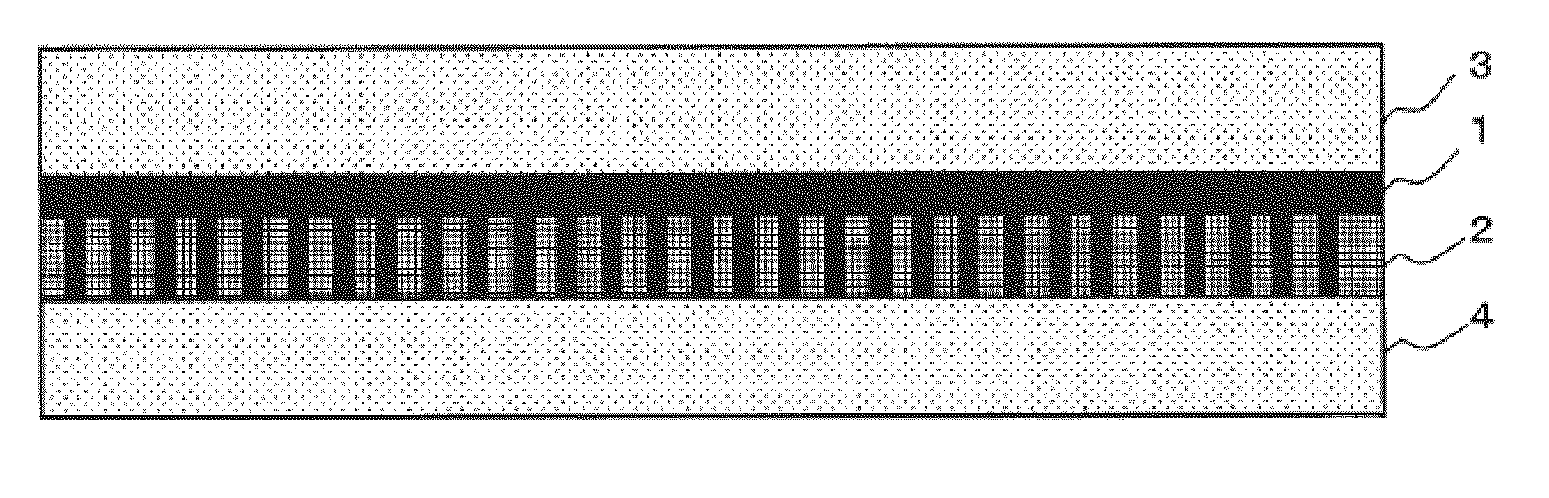

Dense, layered membranes for hydrogen separation

InactiveUS7001446B2Detrimental interdiffusionMinimize interdiffusionMembranesSemi-permeable membranesReactor systemProduct gas

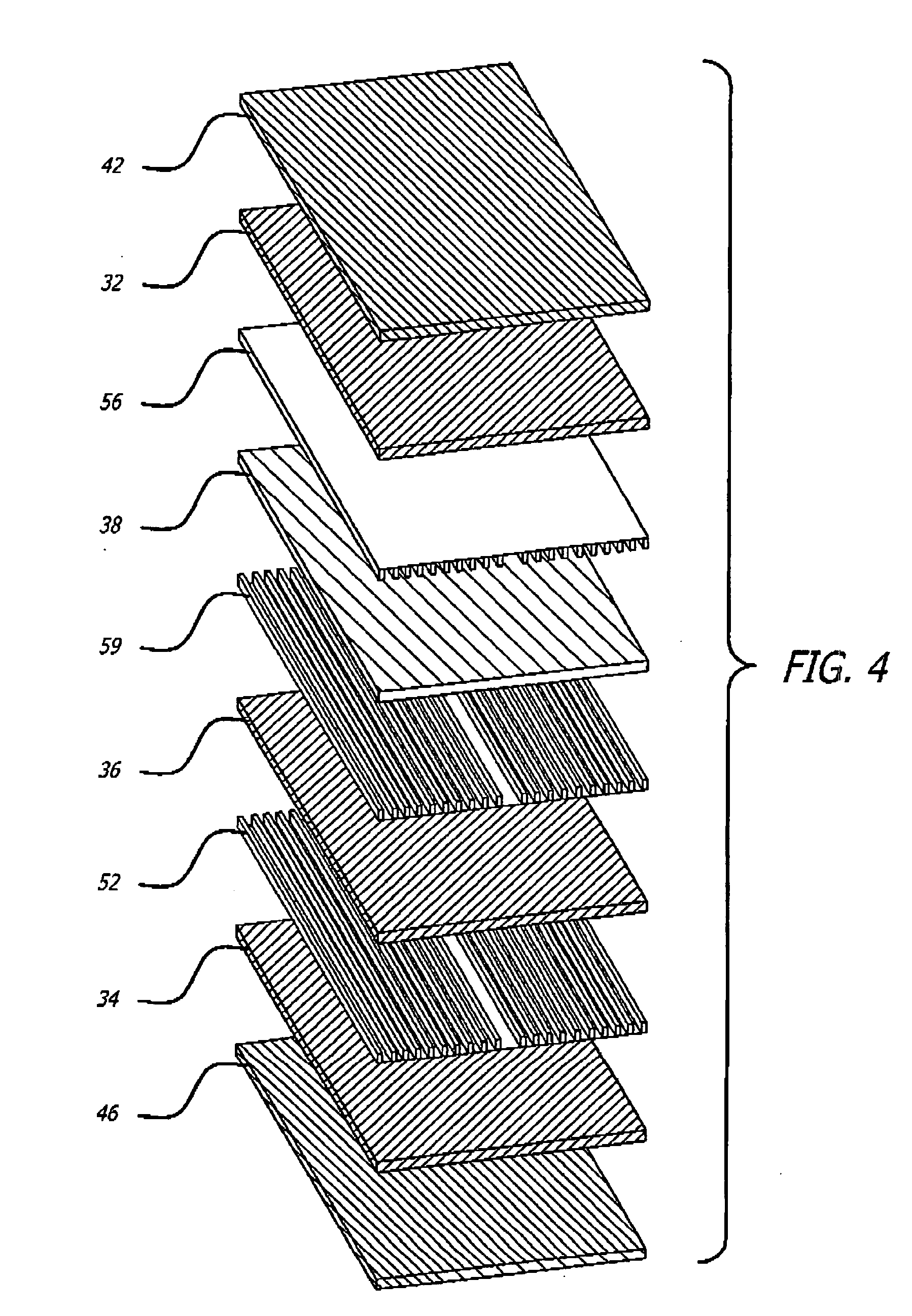

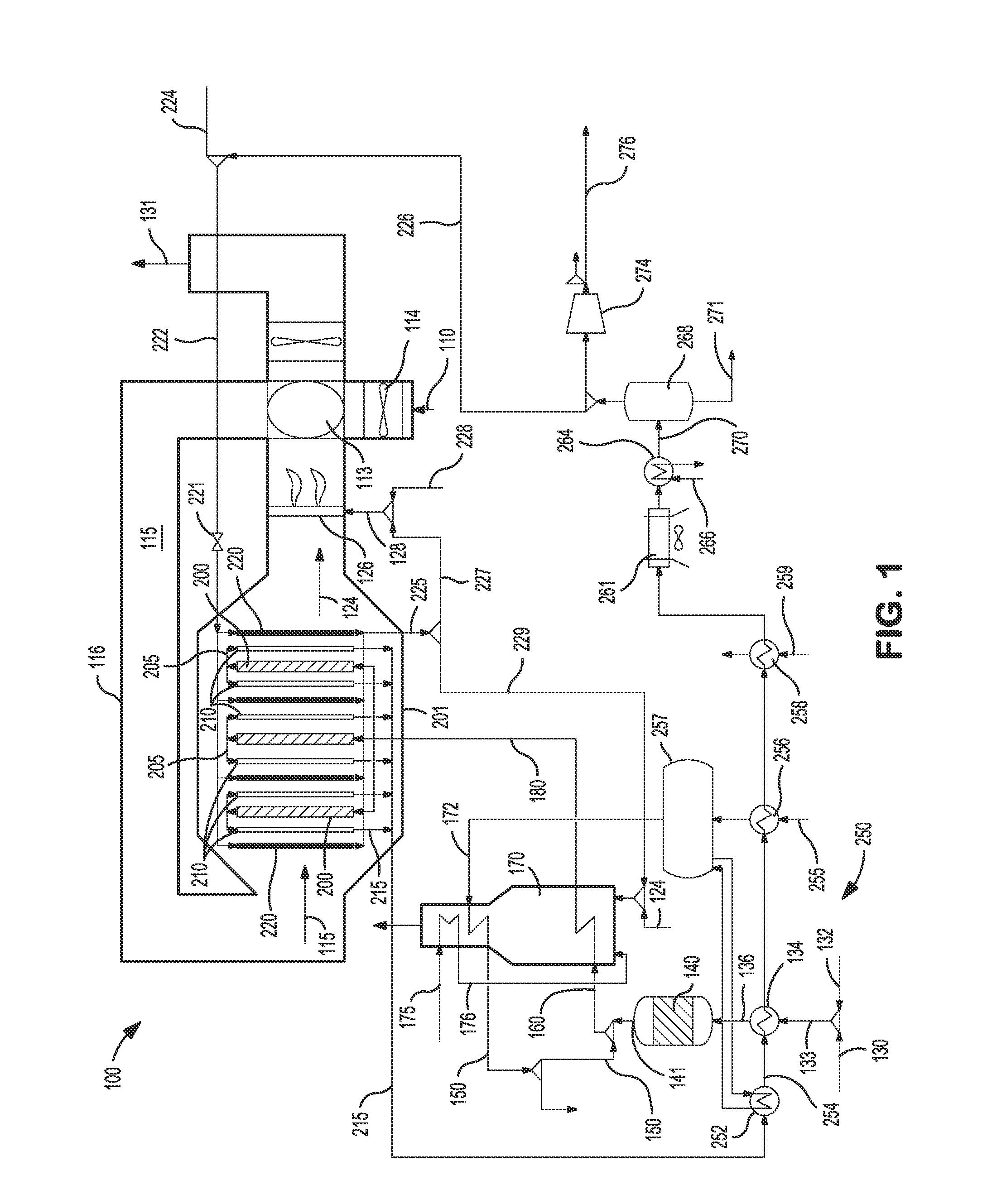

This invention provides hydrogen-permeable membranes for separation of hydrogen from hydrogen-containing gases. The membranes are multi-layer having a central hydrogen-permeable layer with one or more catalyst layers, barrier layers, and / or protective layers. The invention also relates to membrane reactors employing the hydrogen-permeable membranes of the invention and to methods for separation of hydrogen from a hydrogen-containing gas using the membranes and reactors. The reactors of this invention can be combined with additional reactor systems for direct use of the separated hydrogen.

Owner:ELTRON RES

Tubular solid oxide fuel cell stack

This invention relates to a stack comprising a continuous solid-phase matrix and tubular fuel cells embedded in the matrix. Each fuel cell comprises an inner electrode layer, an outer electrode layer, and an electrolyte layer sandwiched between the inner and outer electrode layers. The matrix is sufficiently porous to allow a first reactant to flow through the matrix and to the outer electrode of each fuel cell, and have sufficient mechanical strength to support the fuel cells in the stack. The fuel cells are embedded such that a second reactant may be flowed through the inside of each tubular fuel cell and to the inner electrode thereof. Alternatively, a stack of tubular separation membranes or a stack of tubular membrane reactors may be embedded in the matrix. The matrix material may comprise solid state foam, metal filament, or metal, cermet, or ceramic wool.

Owner:INNOTECH ALBERTA INC

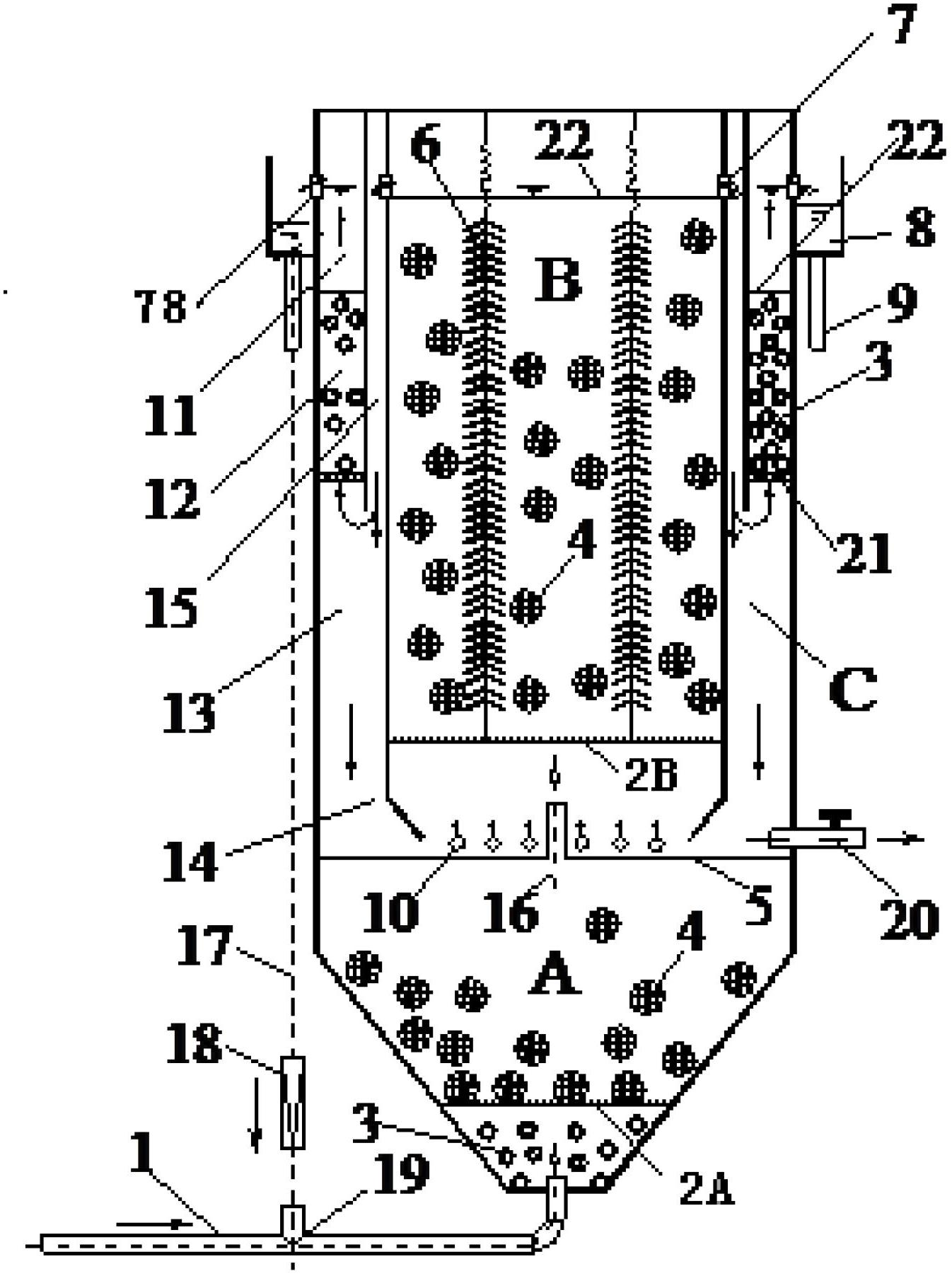

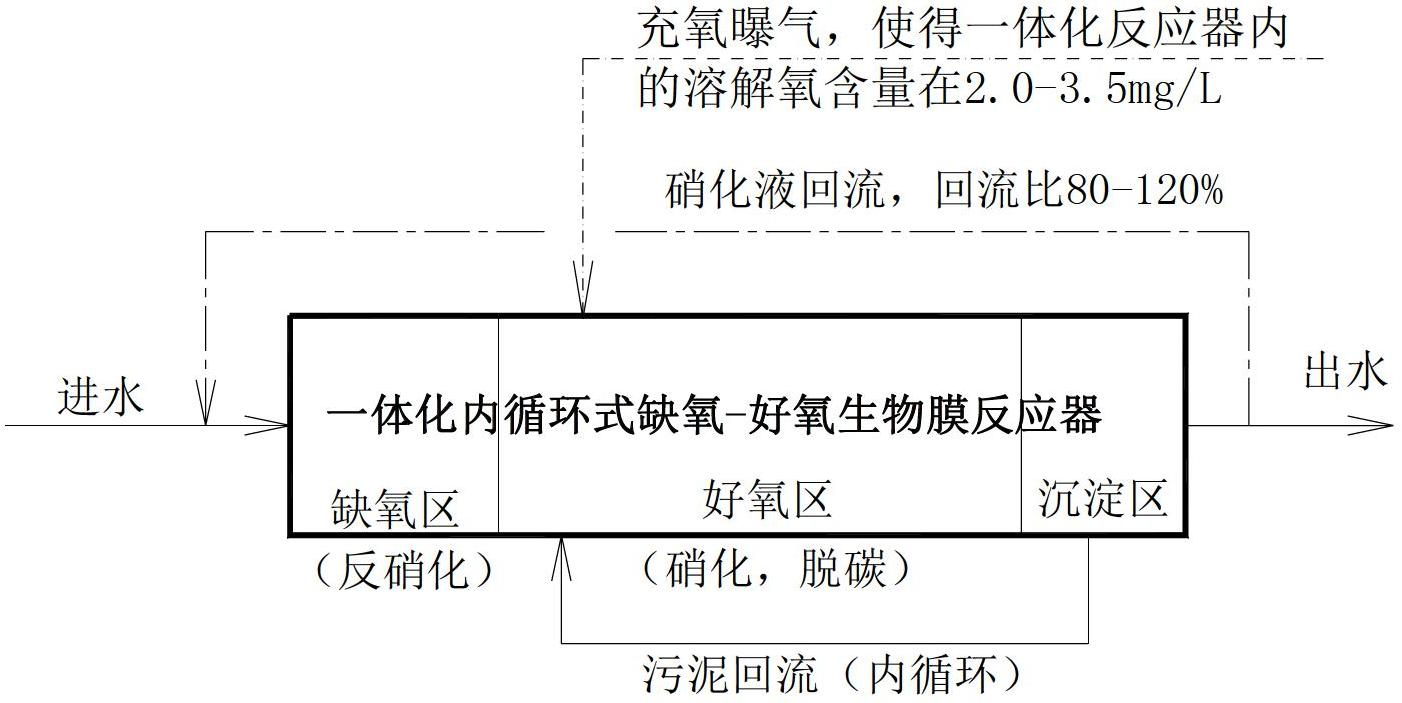

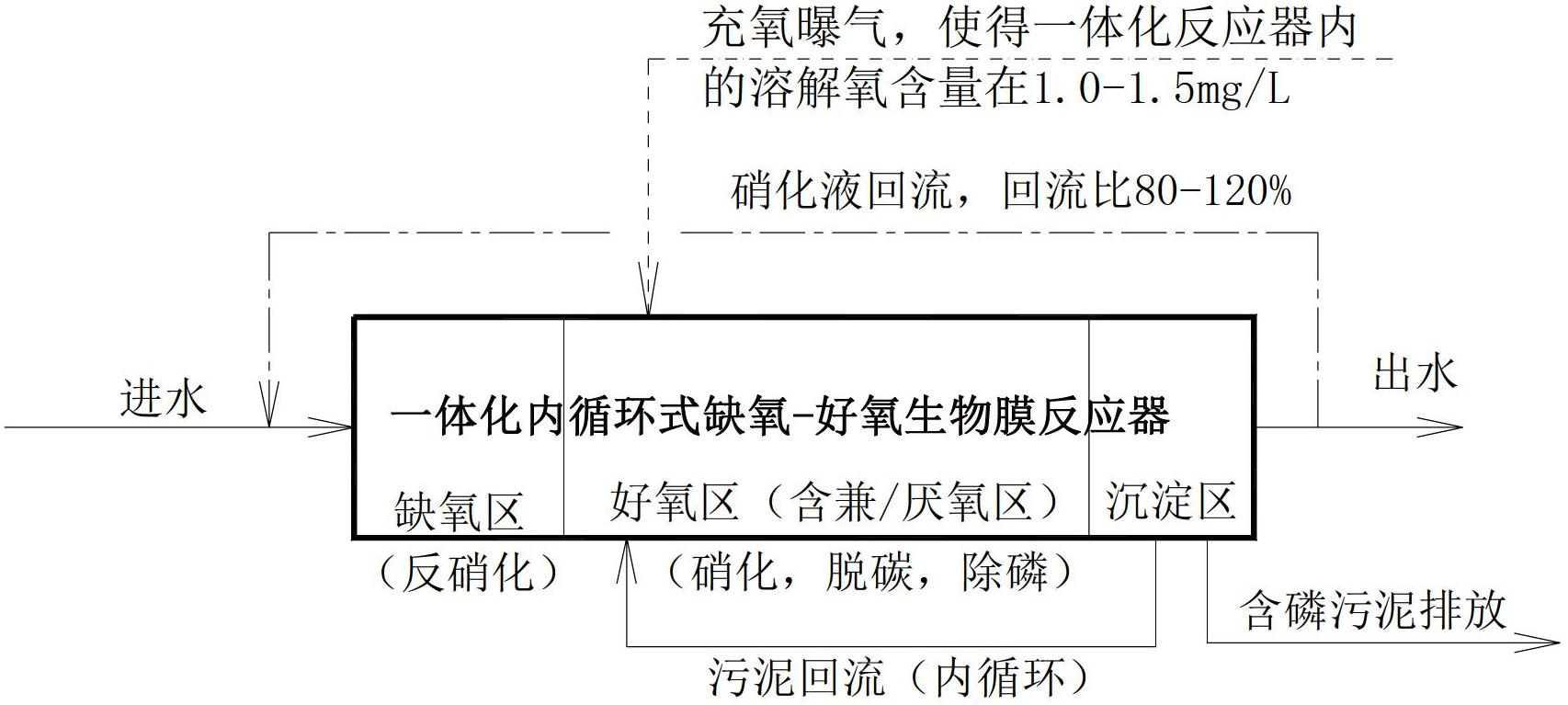

Integrated internal circulation type denitrification and decarburization bio-membrane reactor and operating method thereof

InactiveCN102659244AEfficient removalEfficient nitrogen and carbon removalTreatment with aerobic and anaerobic processesSludgeMembrane reactor

The invention provides an integrated internal circulation type denitrification and decarburization bio-membrane reactor and an operating method thereof. The main body of the reactor consists of an anoxic zone on the lower part, an aerobic zone on the upper part and a settling zone on the periphery of the aerobic zone; a composite filler is filled in the anoxic zone, and a water inlet pipe is communicated with the bottom of the anoxic zone; the aerobic zone is partitioned into a filler zone for adding a carrier on the upper part and a mud-water mixing zone on the lower part by adopting an orifice plate, the anoxic zone and the aerobic zone are partitioned through an impermeable partition plate, and a plurality of aeration pipes are arranged at the bottom of the aerobic zone and provided with air inlet pores; and the settling zone consists of three parts, namely a clean water zone, a contact settling zone and a sludge returning zone which are sequentially arranged from top to bottom, wherein the bottom of the sludge returning zone is provided with a sludge returning seam and communicated with the bottom of the aerobic zone. The reactor realizes zero power consumption in sludge returning, and is compact in structure; and a back flushing system is not required in the contact settling zone, and additional agents and carbon sources are not required, so that the reactor is low in running cost.

Owner:SUZHOU UNIV OF SCI & TECH

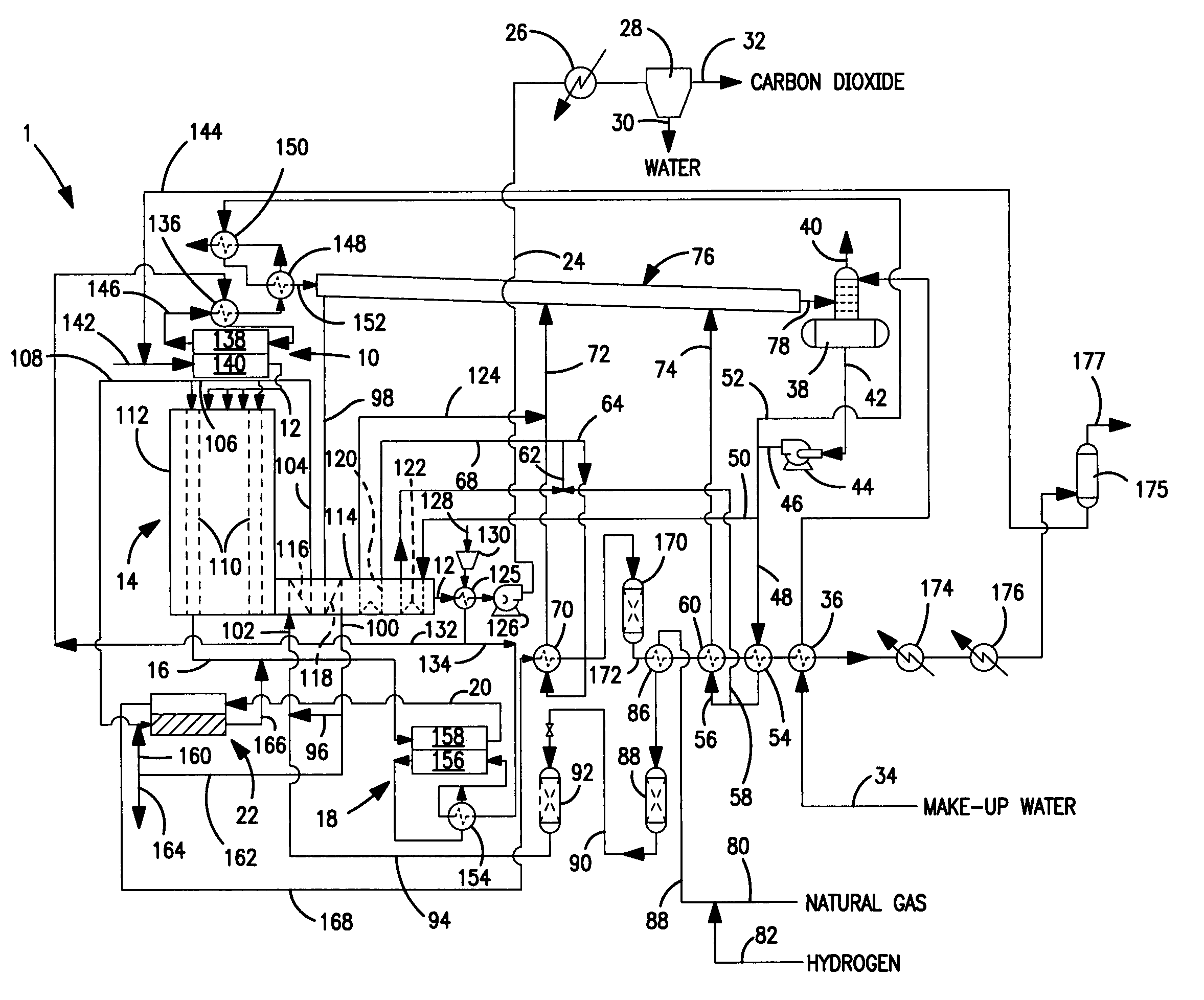

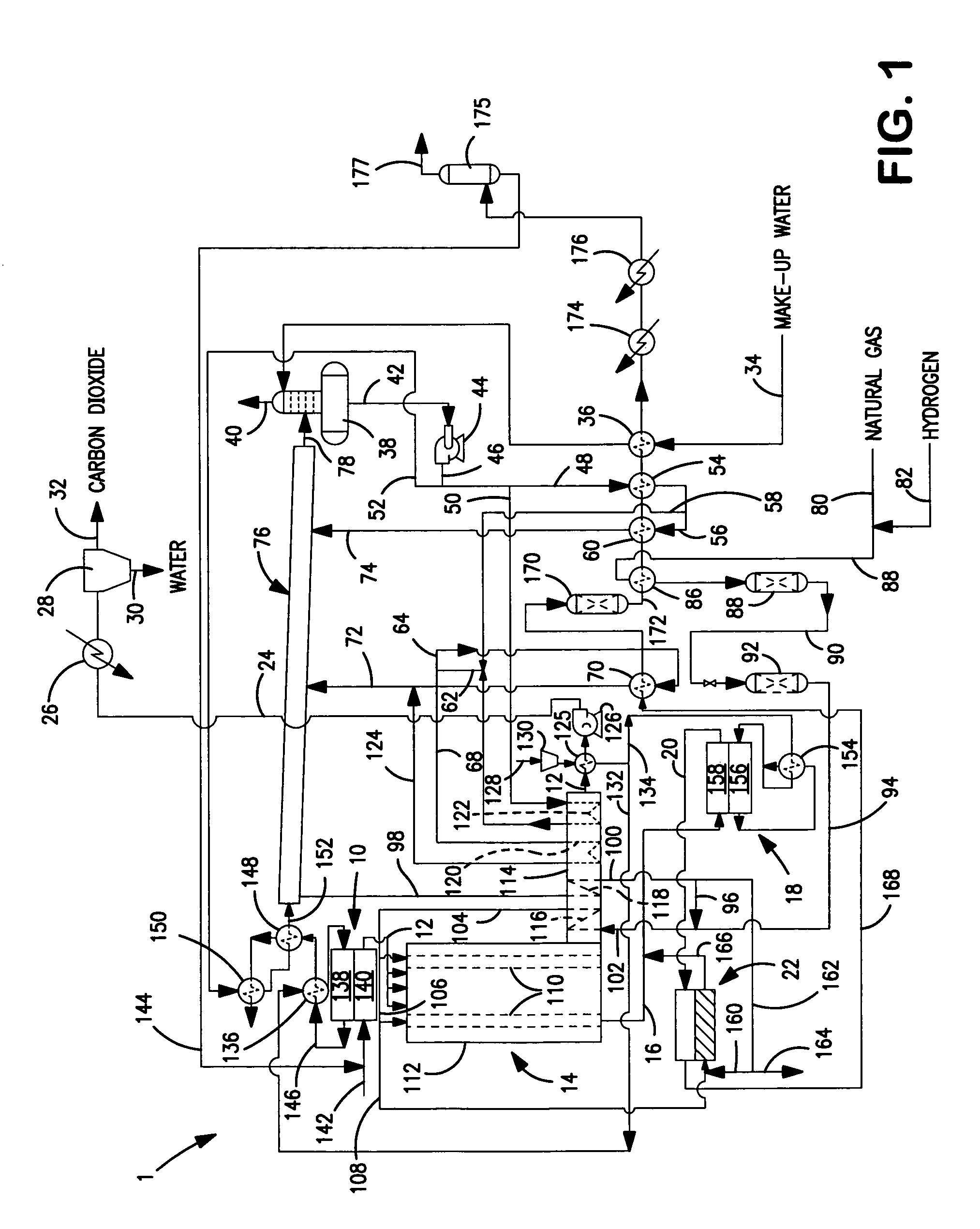

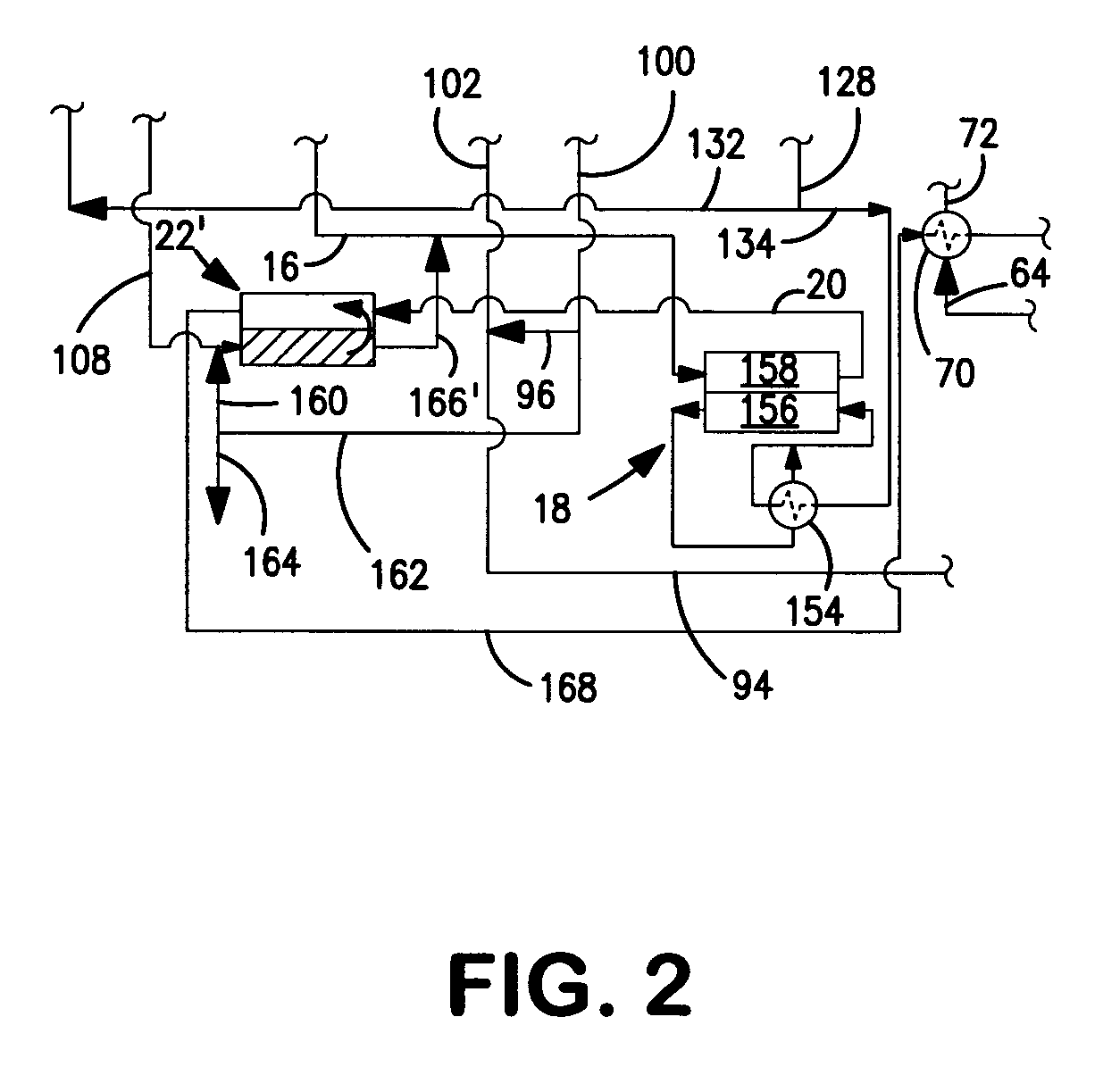

Synthesis gas and carbon dioxide generation method

A method of generating a synthesis gas product stream and carbon dioxide in which a fuel is combusted in an oxygen transport membrane combustor to produce a flue gas stream containing the carbon dioxide and water. Reforming duty is divided between a combined reforming process and a gas heated reformer to produce the product stream. The flue gas stream is used to supply heat to a primary, steam methane reforming stage of the combined reforming process. Residual methane, produced in the primary stage, is reacted in a secondary stage having an oxygen transport membrane reactor. Heat produced in the secondary stage is supplied to the gas heated reactor to support its operation. The flue gas stream is cooled and water is separated therefrom to produce the carbon dioxide at a concentration of at least 85 mol percent.

Owner:PRAXAIR TECH INC

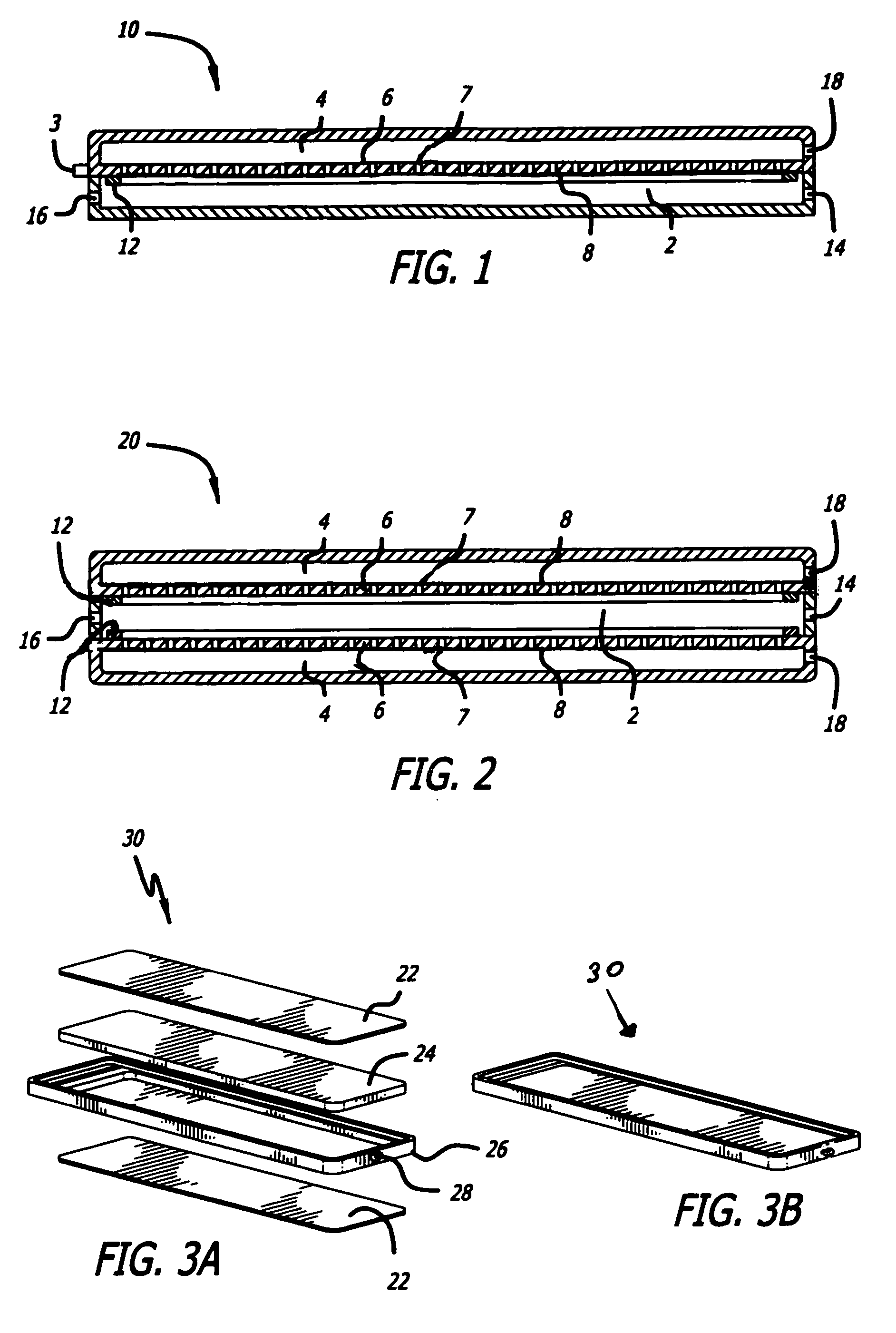

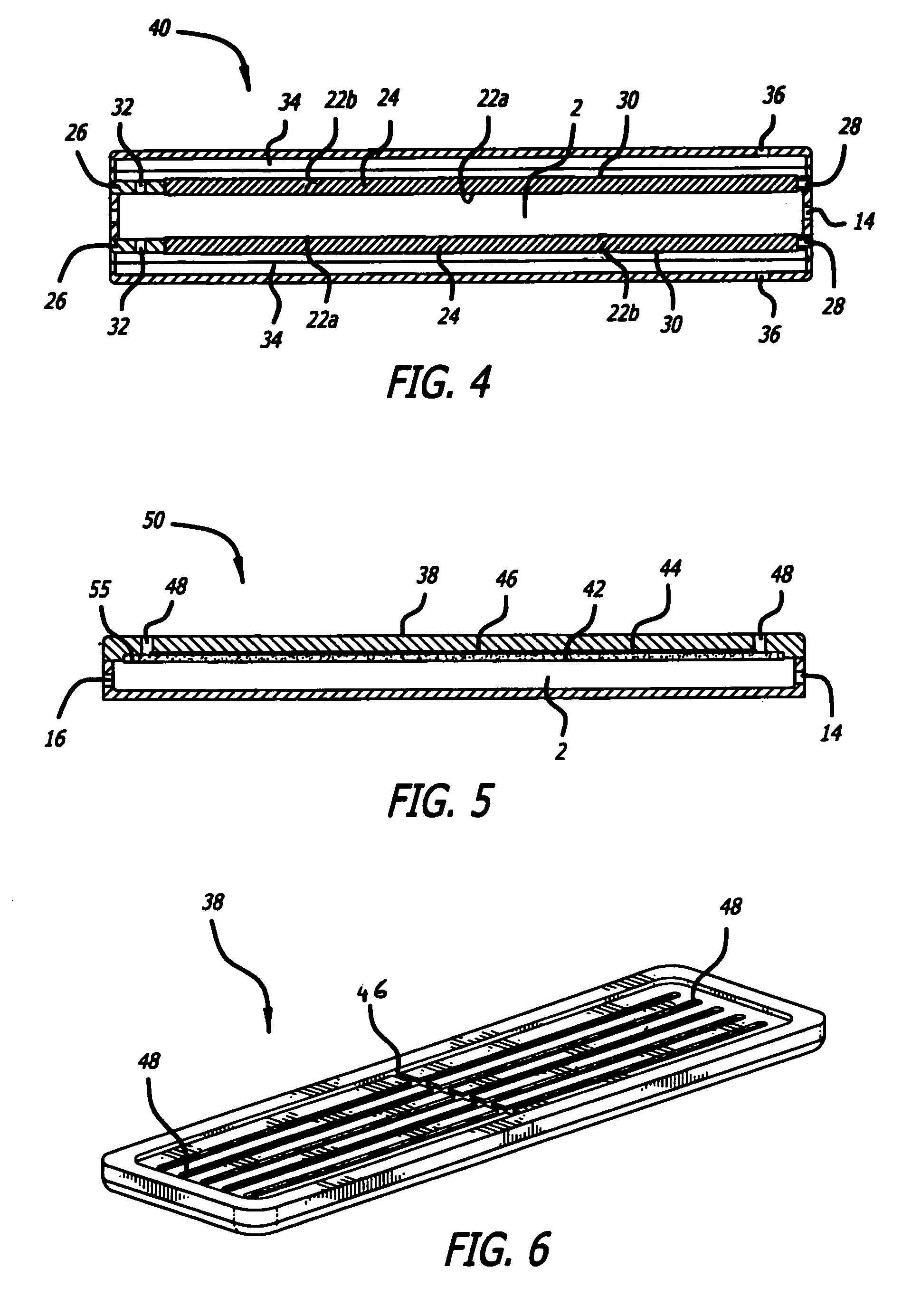

Co2-facilitated transport membrane and method for producing the same

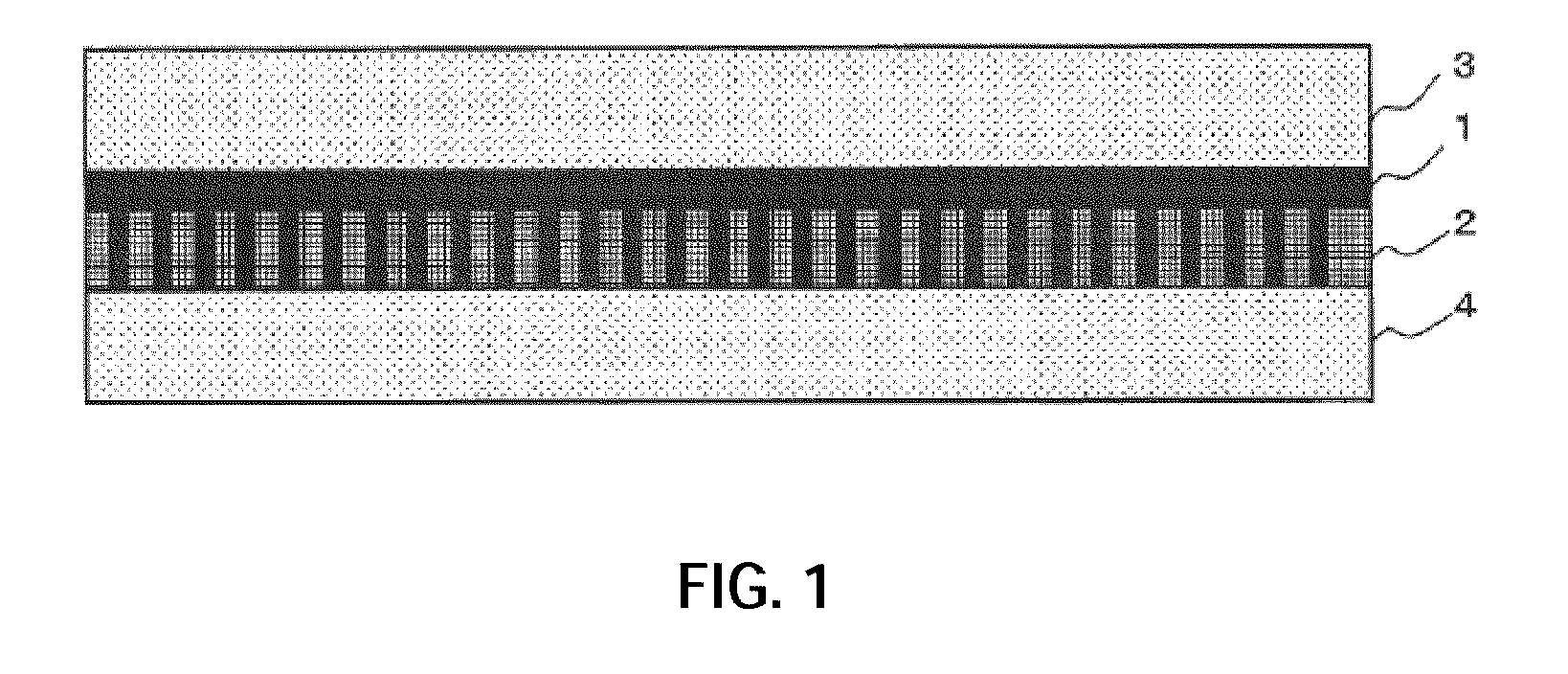

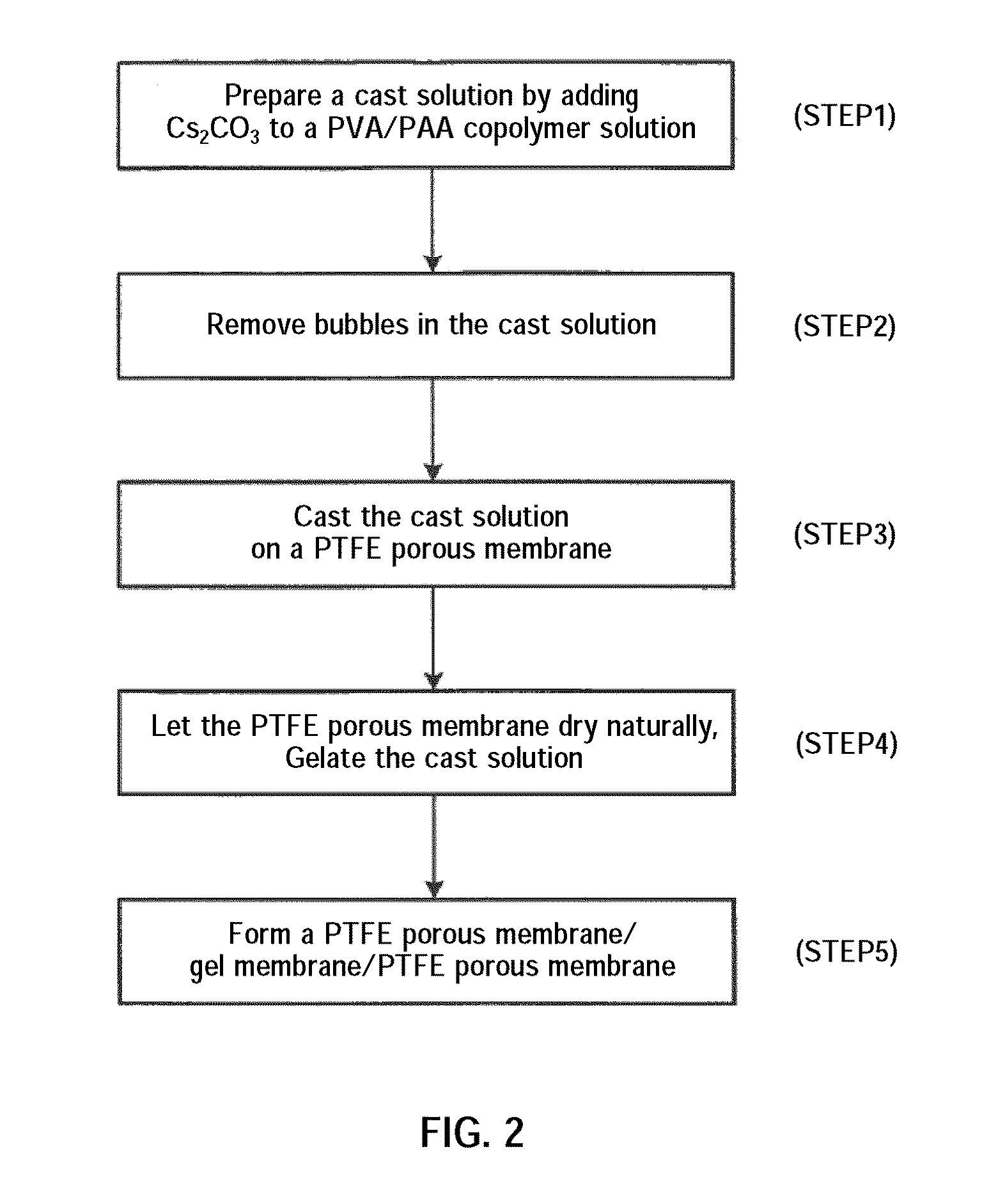

ActiveUS20110036237A1Good water solubilityImprove solubilityFinal product manufactureIsotope separationPolyvinyl alcoholPorous membrane

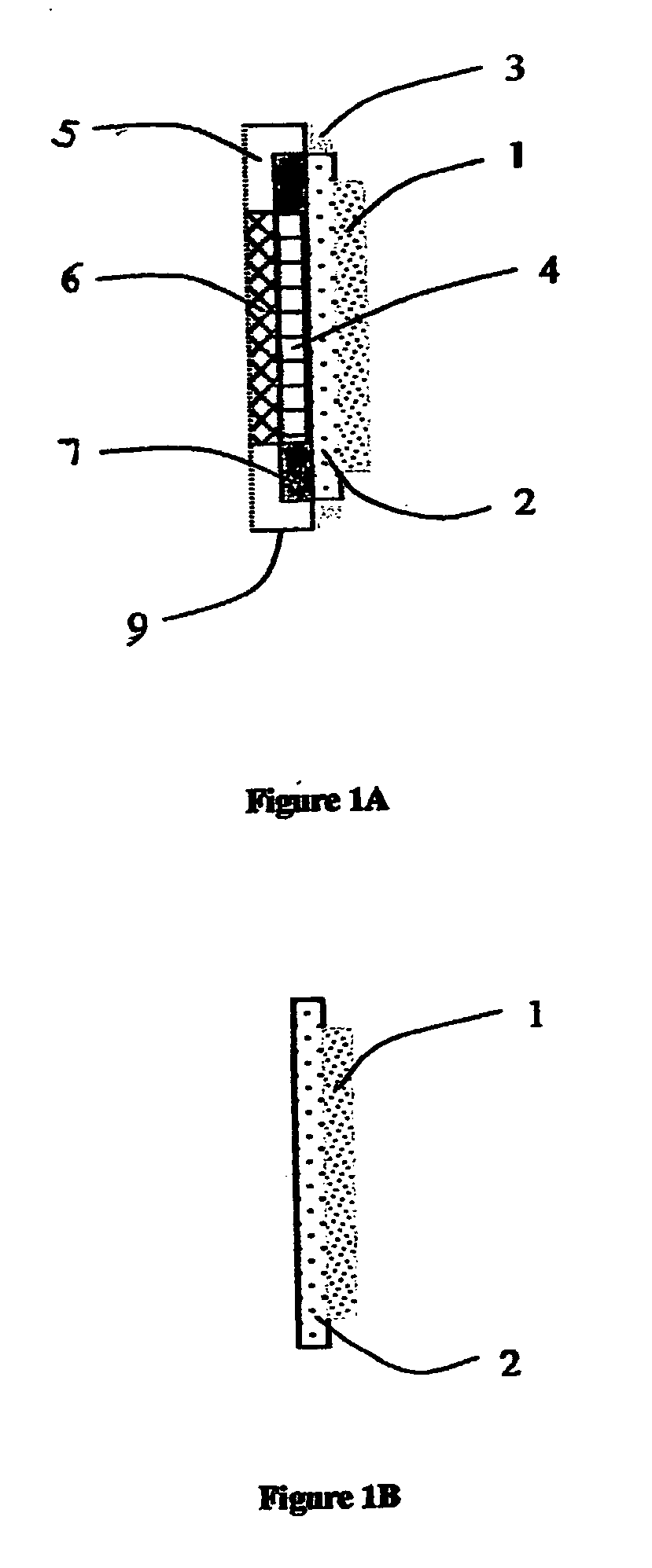

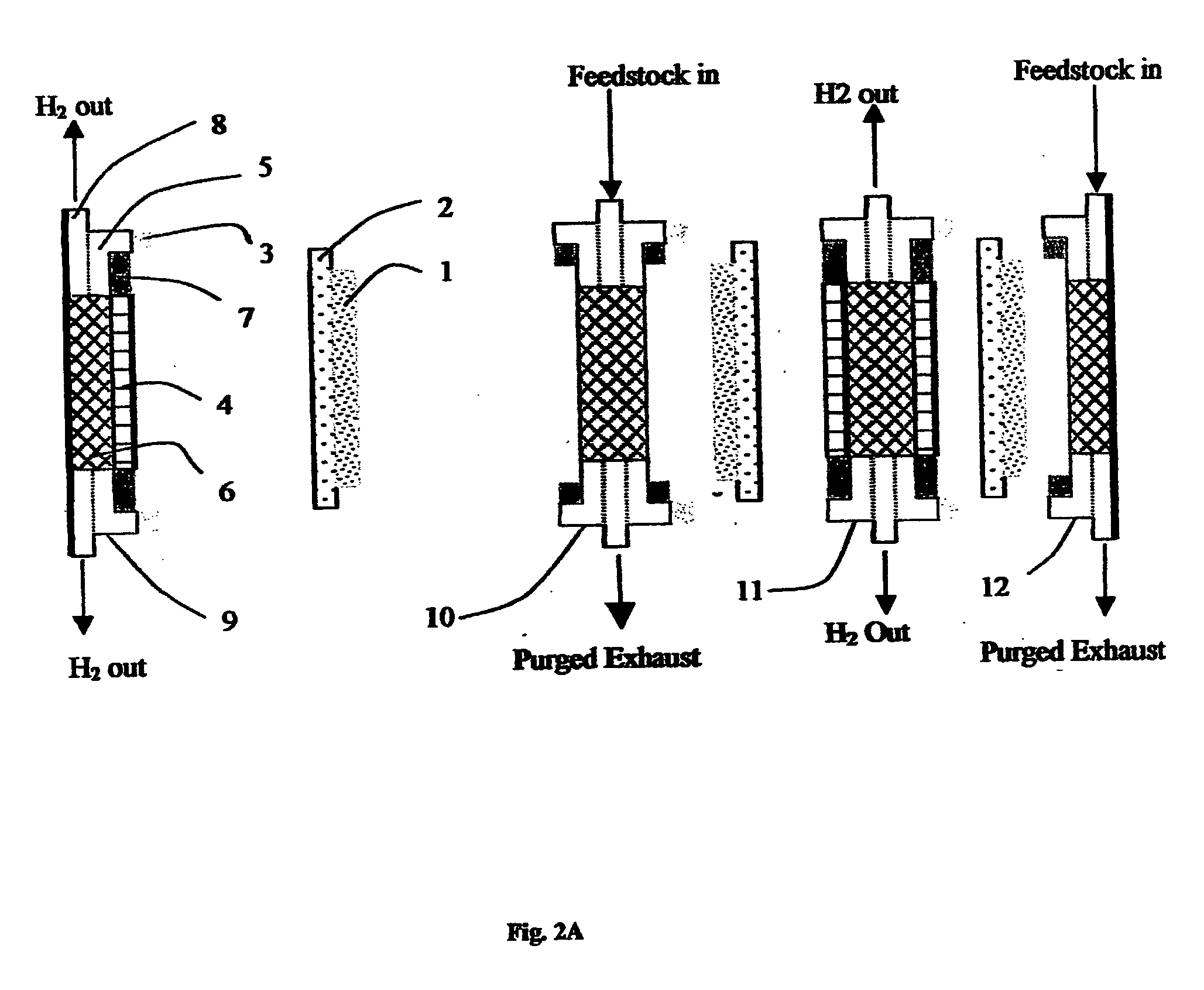

A CO2-facilitated transport membrane of excellent carbon dioxide permeability and CO2 / H2 selectivity, which can be applied to a CO2 permeable membrane reactor, is stably provided. The CO2-facilitated transport membrane is formed such that a gel layer 1 obtained by adding cesium carbonate to a polyvinyl alcohol-polyacrylic acid copolymer gel membrane is supported by a hydrophilic porous membrane 2. More preferably, a gel layer supported by a hydrophilic porous membrane 2 is coated with hydrophilic porous membranes 3 and 4.

Owner:RENAISSANCE ENERGY RES

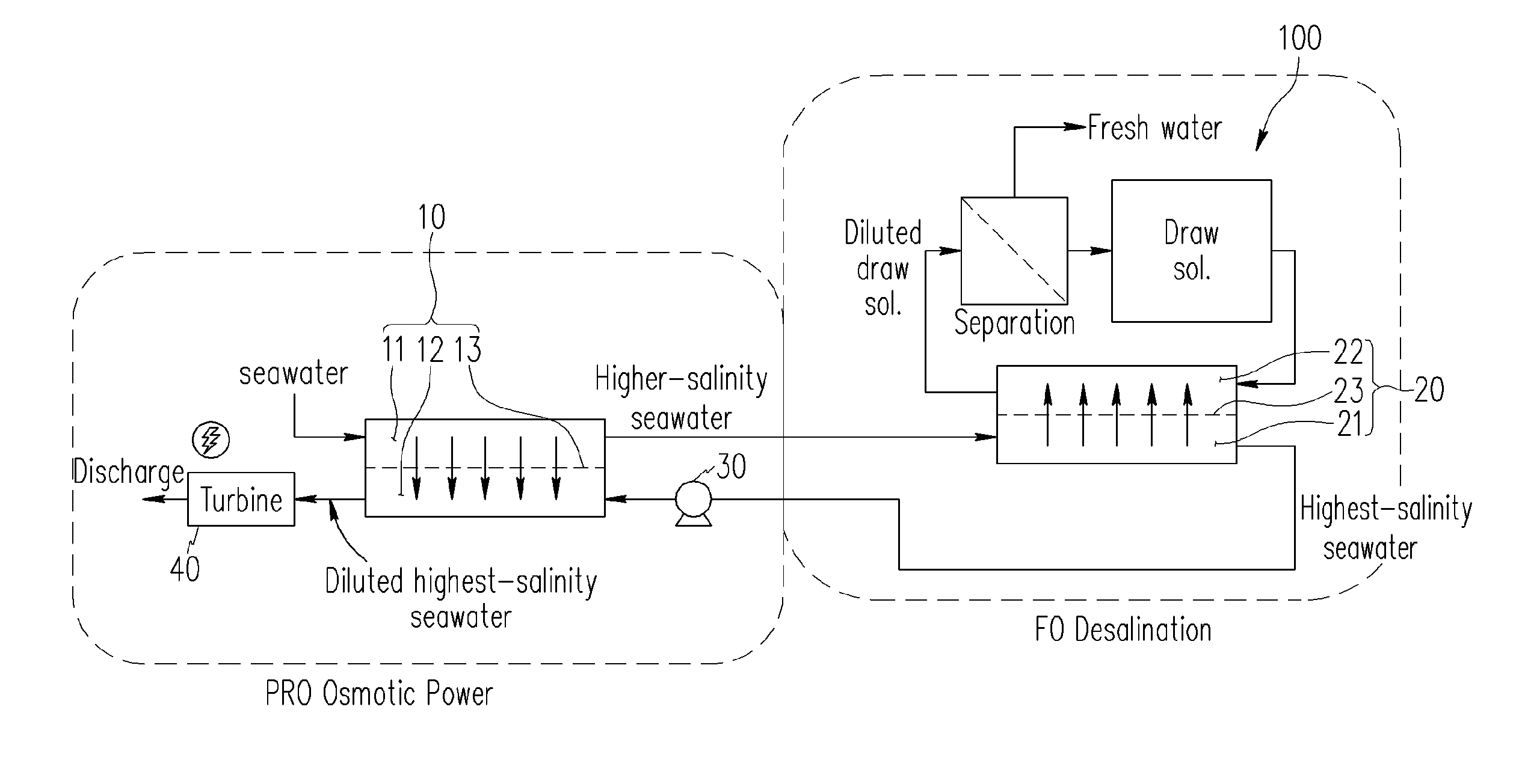

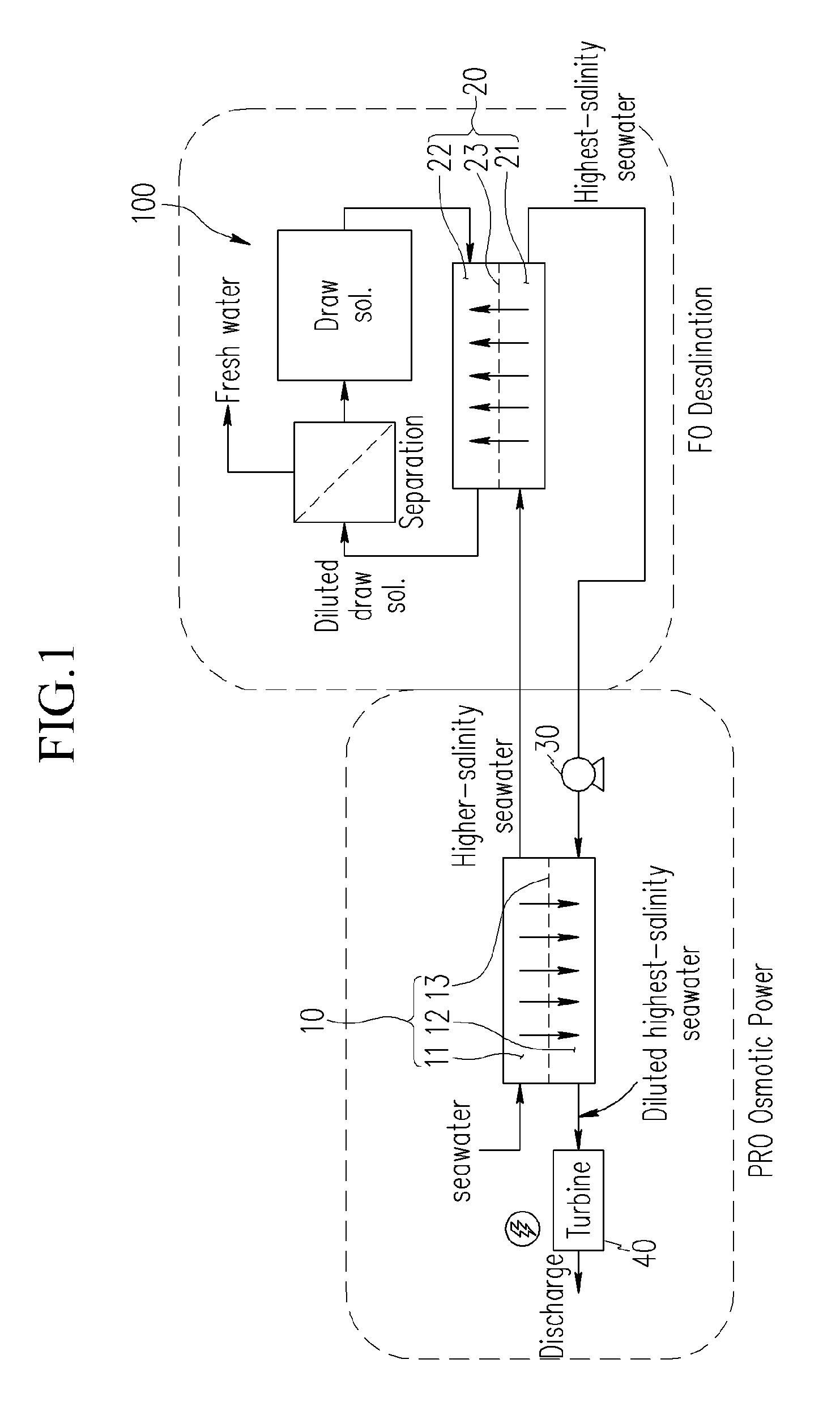

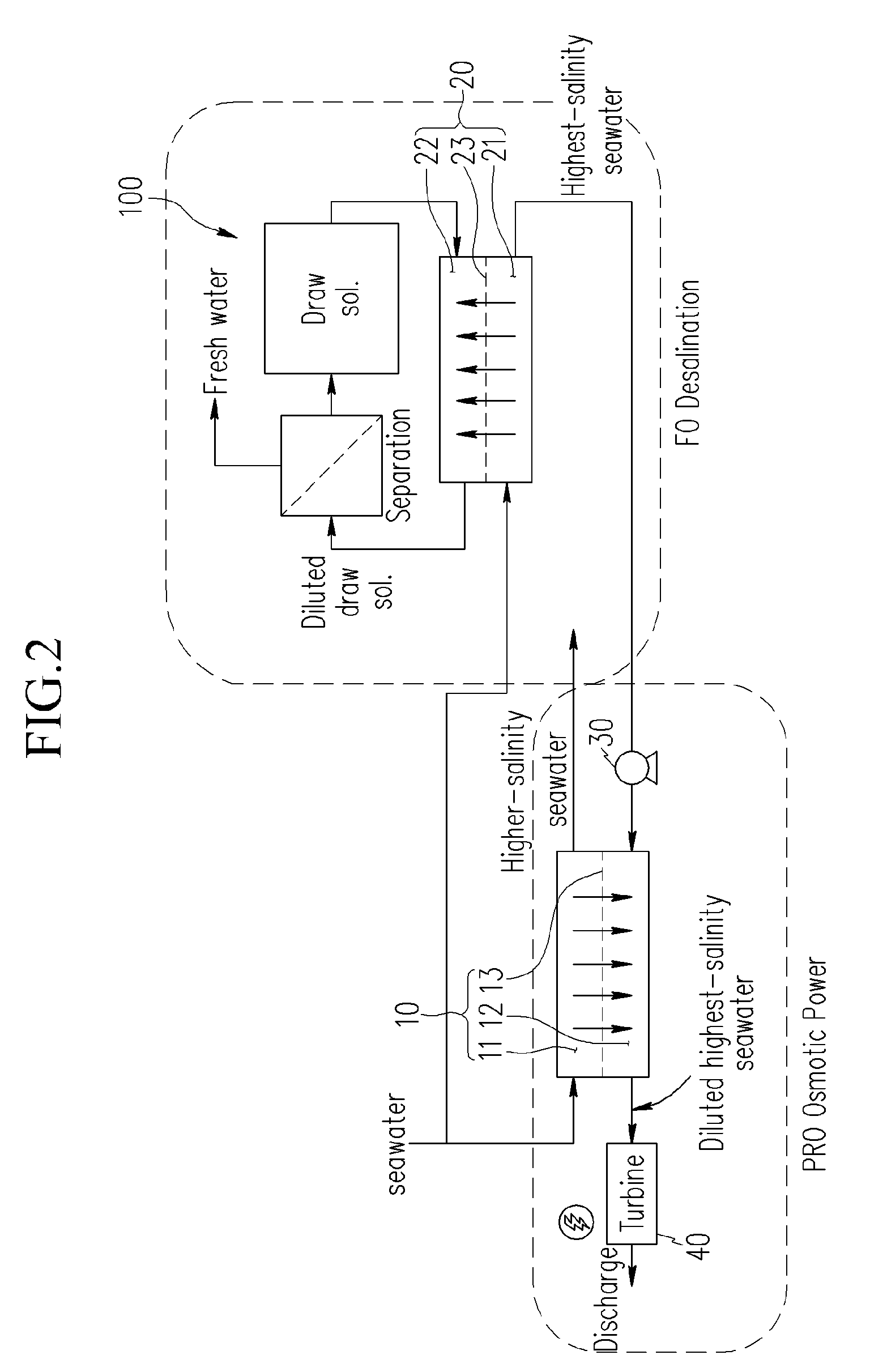

Apparatus for osmotic power generation and desalination using salinity difference

InactiveUS20120012511A1Reduce pressureGeneral water supply conservationSeawater treatmentSaline waterOsmotic power

An apparatus for osmotic power generation and desalination of seawater using a salinity difference is provided.The apparatus for osmotic power generation and desalination using a salinity difference includes: a first osmotic membrane reactor having a first salt water position space and a third salt water position space separated by a first forward osmotic membrane; a second osmotic membrane reactor having a second salt water position space and a draw solution position space separated by a second forward osmotic membrane; a high pressure pump connected between the second salt water position space and the third salt water position space and supplying salt water which has passed through the second salt water position space to the third salt water position space and pressurizing salt water, which has passed through the second salt water position space, to supply it to the third salt water position space such that pressure retarded osmosis can be made in the first osmotic membrane reactor; a desalination unit obtaining fresh water by separating a draw solute from a draw solution diluted through a transmission of water in salt water of the second salt water position space by way of the draw solution position space; and a turbine driven by flow force of salt water discharged from the third salt water position space to produce electric energy.

Owner:KOREA INST OF MACHINERY & MATERIALS

Synthesis gas and carbon dioxide generation method

A method of generating a synthesis gas product stream and carbon dioxide in which a fuel is combusted in an oxygen transport membrane combustor to produce a flue gas stream containing the carbon dioxide and water. Reforming duty is divided between a combined reforming process and a gas heated reformer to produce the product stream. The flue gas stream is used to supply heat to a primary, steam methane reforming stage of the combined reforming process. Residual methane, produced in the primary stage, is reacted in a secondary stage having an oxygen transport membrane reactor. Heat produced in the secondary stage is supplied to the gas heated reactor to support its operation. The flue gas stream is cooled and water is separated therefrom to produce the carbon dioxide at a concentration of at least 85 mol percent.

Owner:PRAXAIR TECH INC

Systems and methods of reducing NOx emissions in gas turbine systems and internal combustion engines

InactiveUS20070220896A1Reduce nitrogen oxide emissionsEasy to operateCombustion enginesEfficient propulsion technologiesCombustorEngineering

A gas turbine systems of reducing NOx emissions and enhancing operability comprises a compressor; a combustor disposed downstream of and in fluid communication with the compressor; a turbine assembly disposed down stream of and in fluid communication with the combustor; an oxygen-enriched gas source disposed in selective fluid communication with the compressor, the combustor, or a combination of the foregoing, wherein the oxygen-enriched gas source is a pressure swing absorption system, an electrolyzer, or a membrane reactor.

Owner:GENERAL ELECTRIC CO

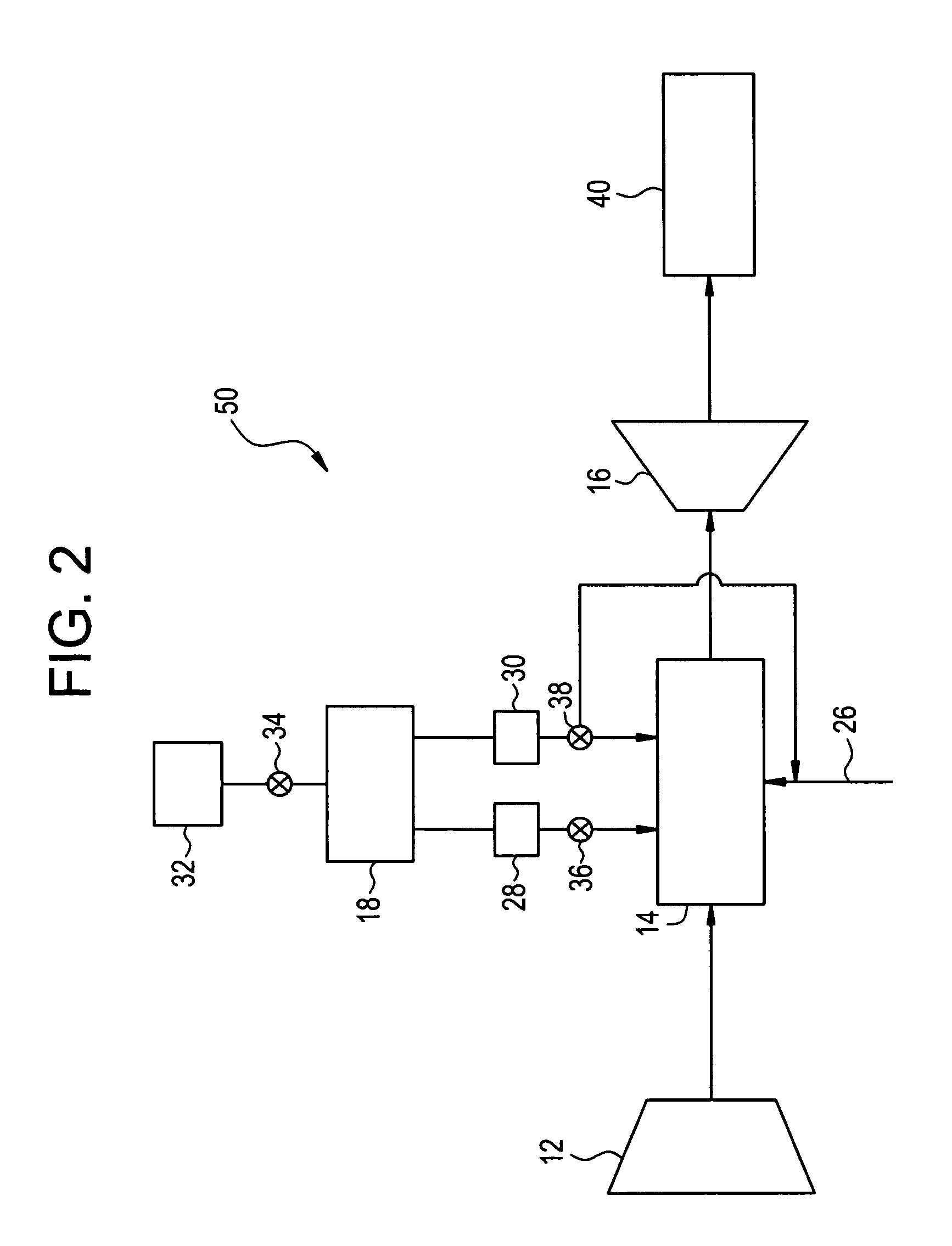

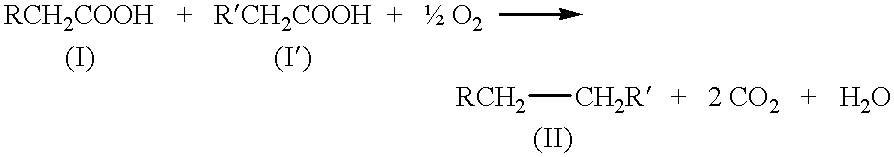

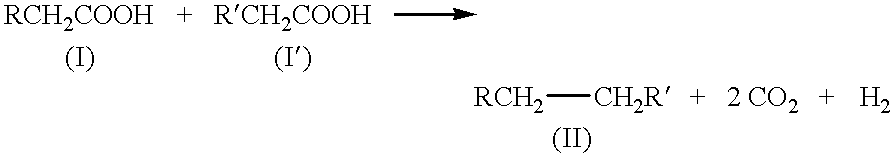

Kolbe electrolysis in a polymer electrolyte membrane reactor

InactiveUS6238543B1Electrolysis componentsElectrolytic organic coupling reactionsPlatinumPolymer electrolytes

Disclosed is a process, for the electrolytic coupling of carboxylic acids, carried out in a polymer electrolyte membrane reactor. The reactor design (1) discloses the use of gaseous or neat liquid reactants without the use of organic cosolvents, (2) prevents the loss of platinum, and (3) permits the use of oxygen reduction to water as the cathode reaction.

Owner:EI DU PONT DE NEMOURS & CO +1

Filter material, method for the production thereof, a filter and filtering method

ActiveUS20080164214A1High propertyLow hydrodynamic resistanceOther chemical processesLayered productsFiberRetention efficiency

The invention concerns the production of filter materials for the purification and disinfection of water, water solutions and other liquids, as well as for sterilizing filtration of injections and other solutions, for concentration of biomolecules in physiological liquids, concentration and extraction of viruses, preparation of apyrogenic water, in biocatalytic diaphragm reactors. The invention solves the problems of a new filter material production, characterized by high sorption properties, high retention efficiency of submicron electronegative particles, microorganisms, submicron non-polar particles and chemical contaminations, and, at the same time, characterized by low hydrodynamic resistance. A base of filter material is the nonwoven organic synthetic polymeric fabric, modified by the aluminum hydroxide particles, fixed to the surface of base fibers for improvement of its sorption properties and for making it positively charged. A method of filter material production comprises: applying the modifying composition onto the fibrous base in the form of organic nonwoven synthetic polymeric fabric, wherein said modifying composition comprises the particles of the aluminum-based material, hydrolysis thereof results to formation and fixation of the aluminum hydroxide particles to the base fibers. A method of fluid filtration is carried out using the filter material as a non-woven organic synthetic polymeric fabric, to the fibers of which the aluminum hydroxide particles are fixed.

Owner:INST OF STRENGTH PHYSICS & MATERIALS SCIENC

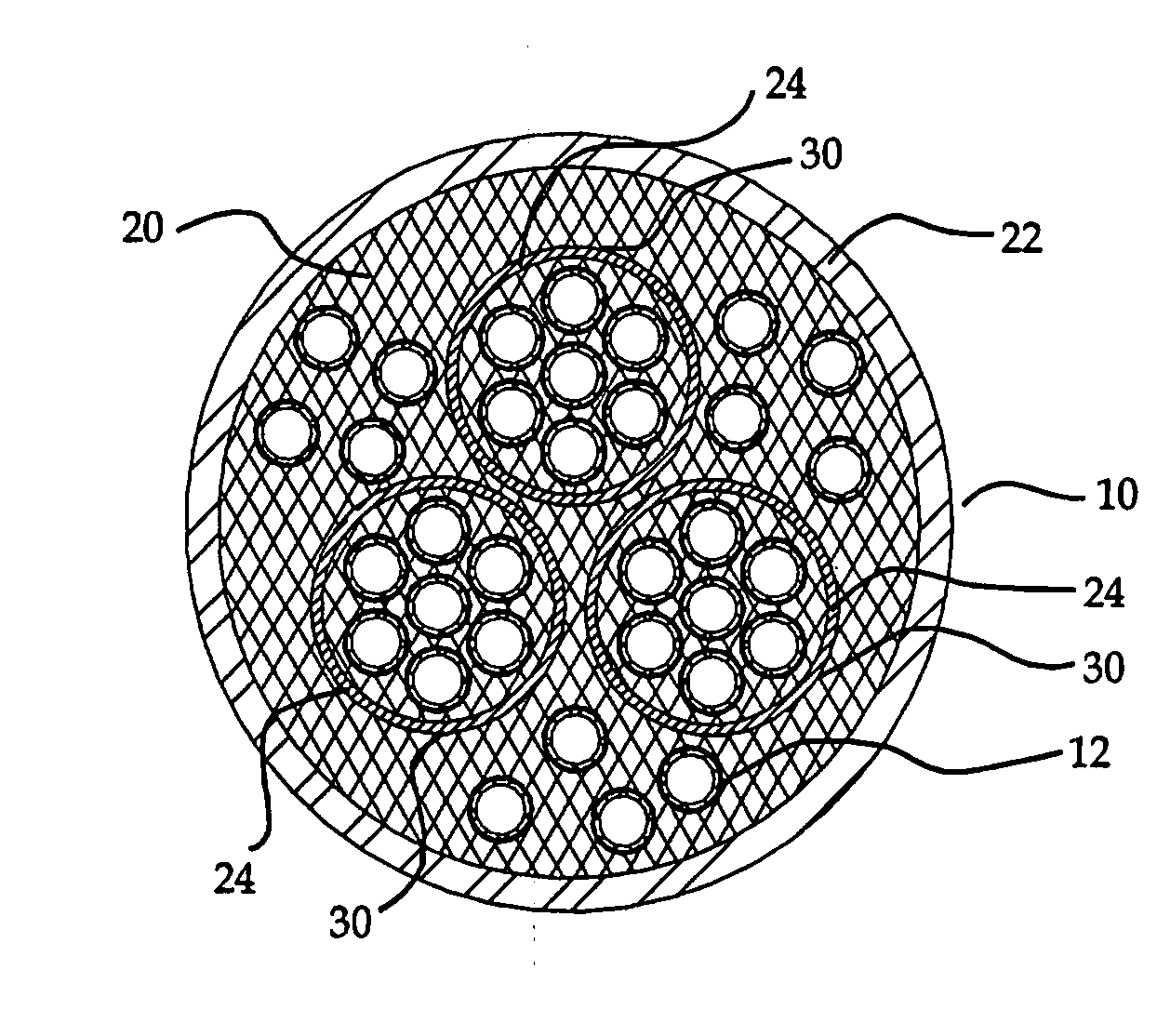

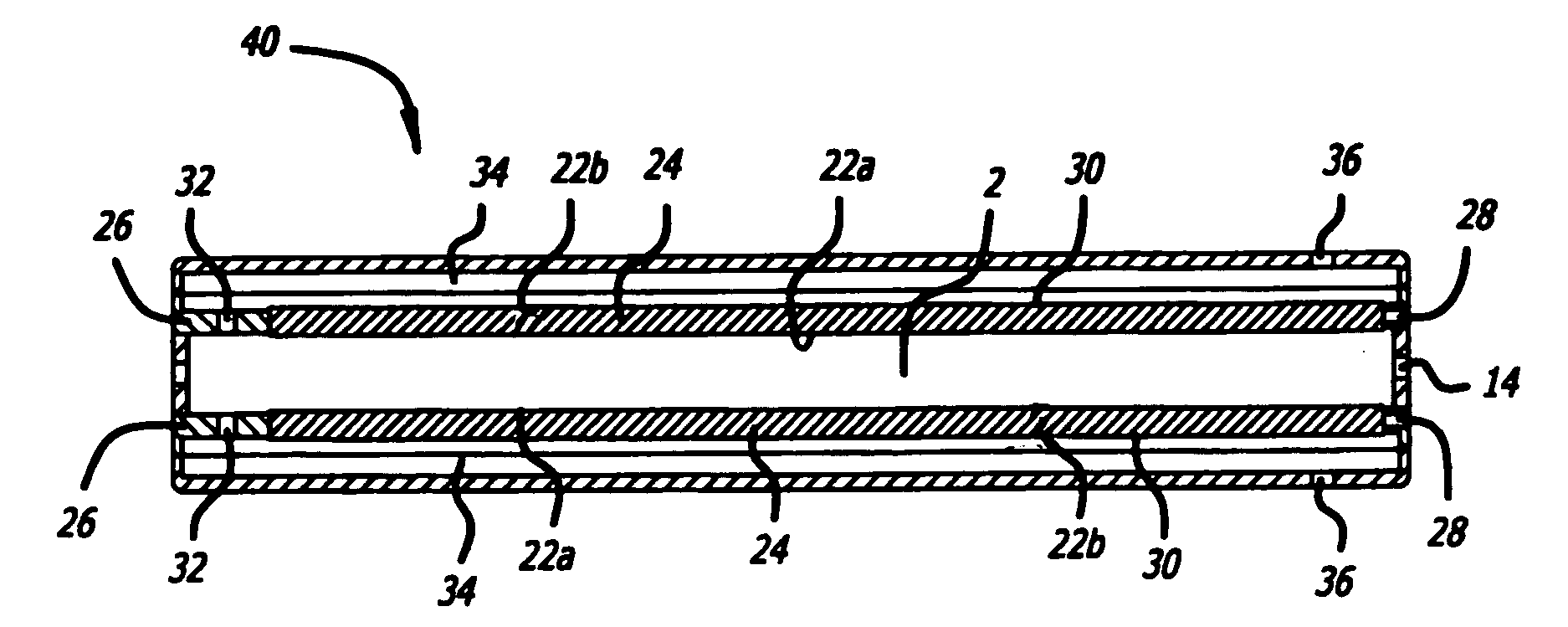

Single stage membrane reactor for high purity hydrogen production

InactiveUS20070157517A1Improve responseEasy to operateCatalytic gas-gas reactionMembranesSteam reformingMembrane reactor

Hydrogen generating method and apparatus. The apparatus comprises a mixed phase protonic-electron conducting cermet membrane (2), wherein said membrane is coated with porous metal or composite catalyst (1) effective to decompose hydro-carbon and water reactants into a hydrogen-rich syngas at elevated temperature and pressure. The hydrogen ions are continuously withdrawn in situ by diffusing them through the mixed phase conducting cermet membrane (2) to the second membrane side where the hydrogen ions can be reconstituted into molecular hydrogen with a supply of electrons. The method favorably shifts the equilibrium of steam reforming and water gas shift reaction by use a single stage, high efficiency and high purity membrane reactor.

Owner:TSAY DAVID +2

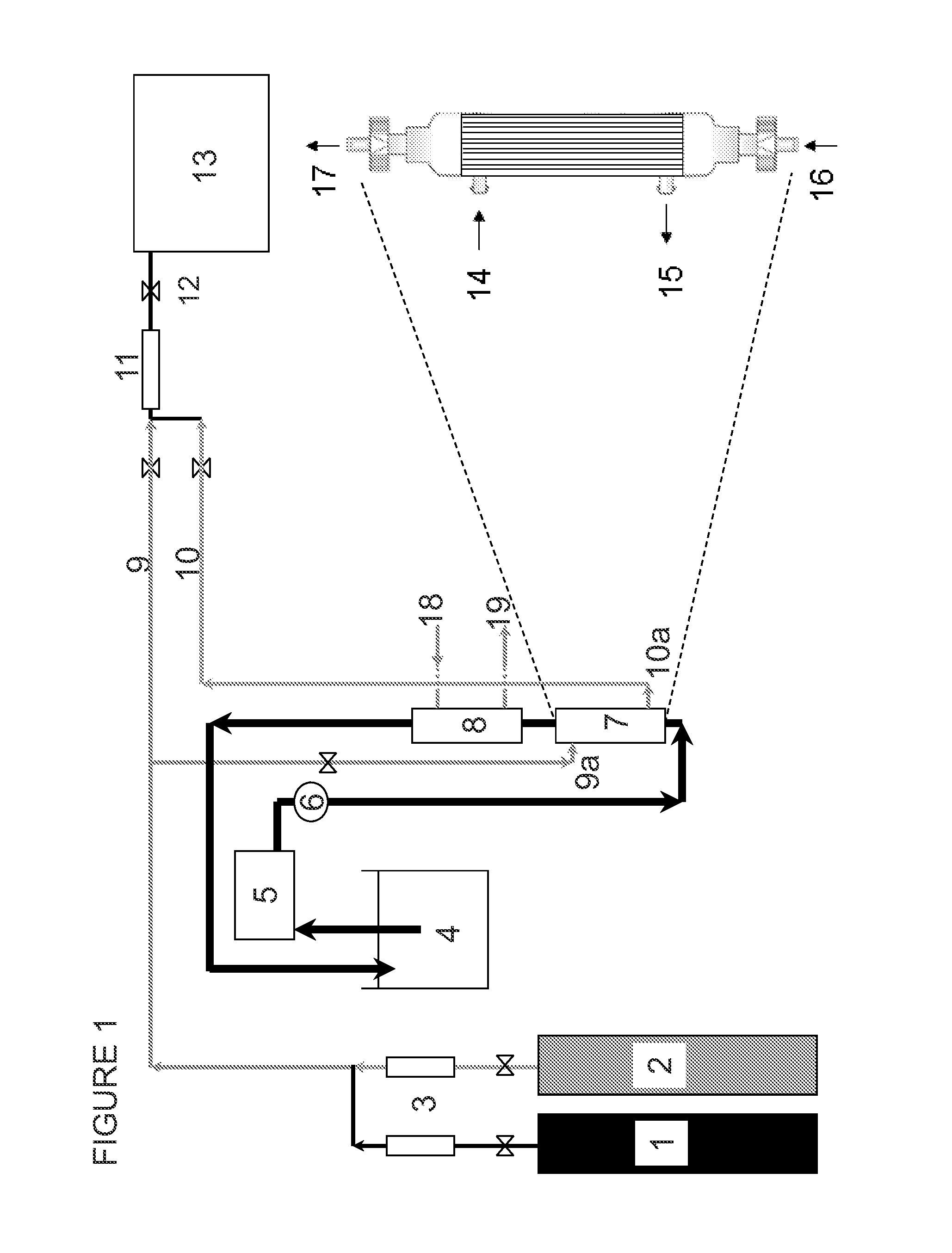

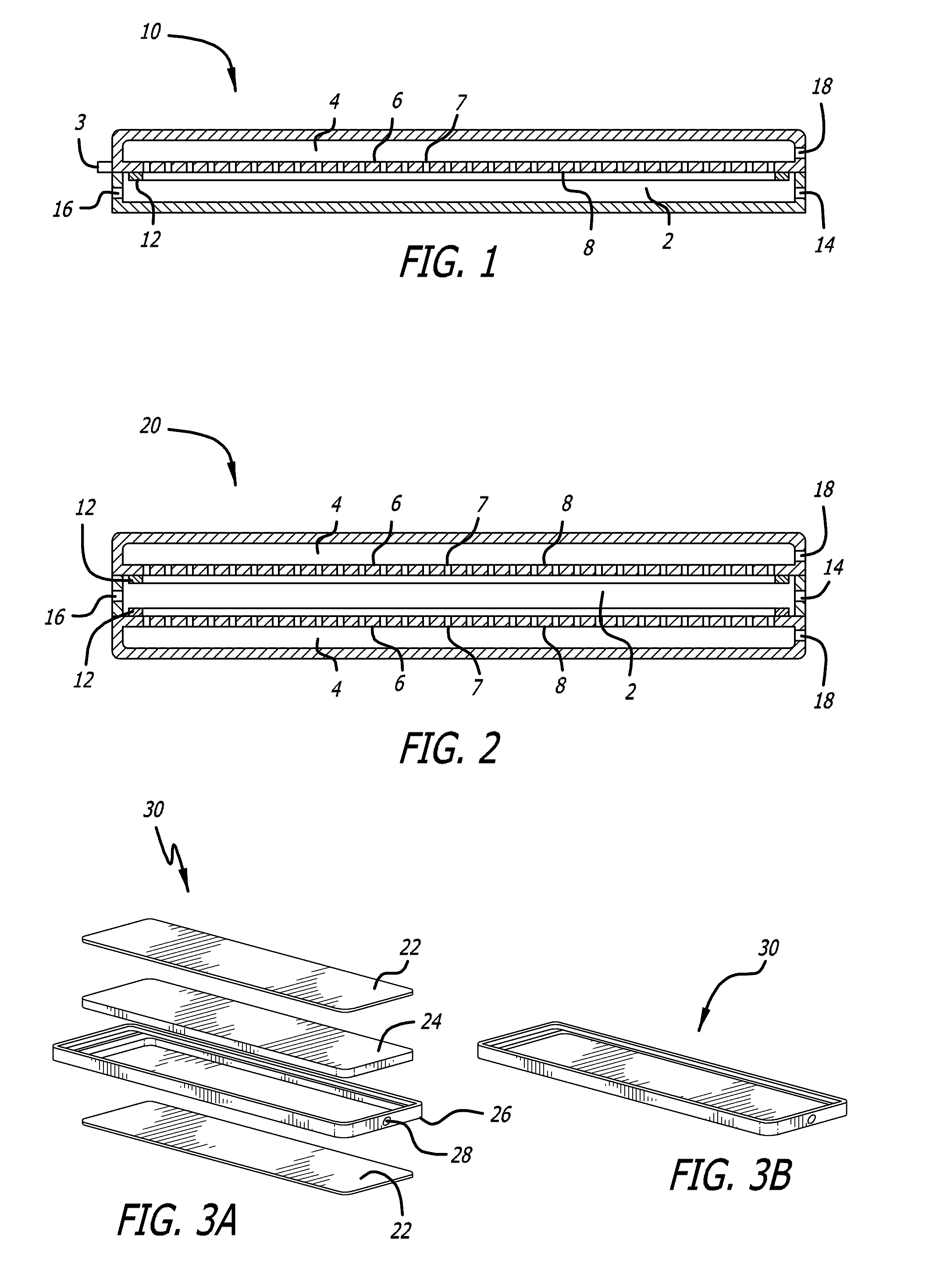

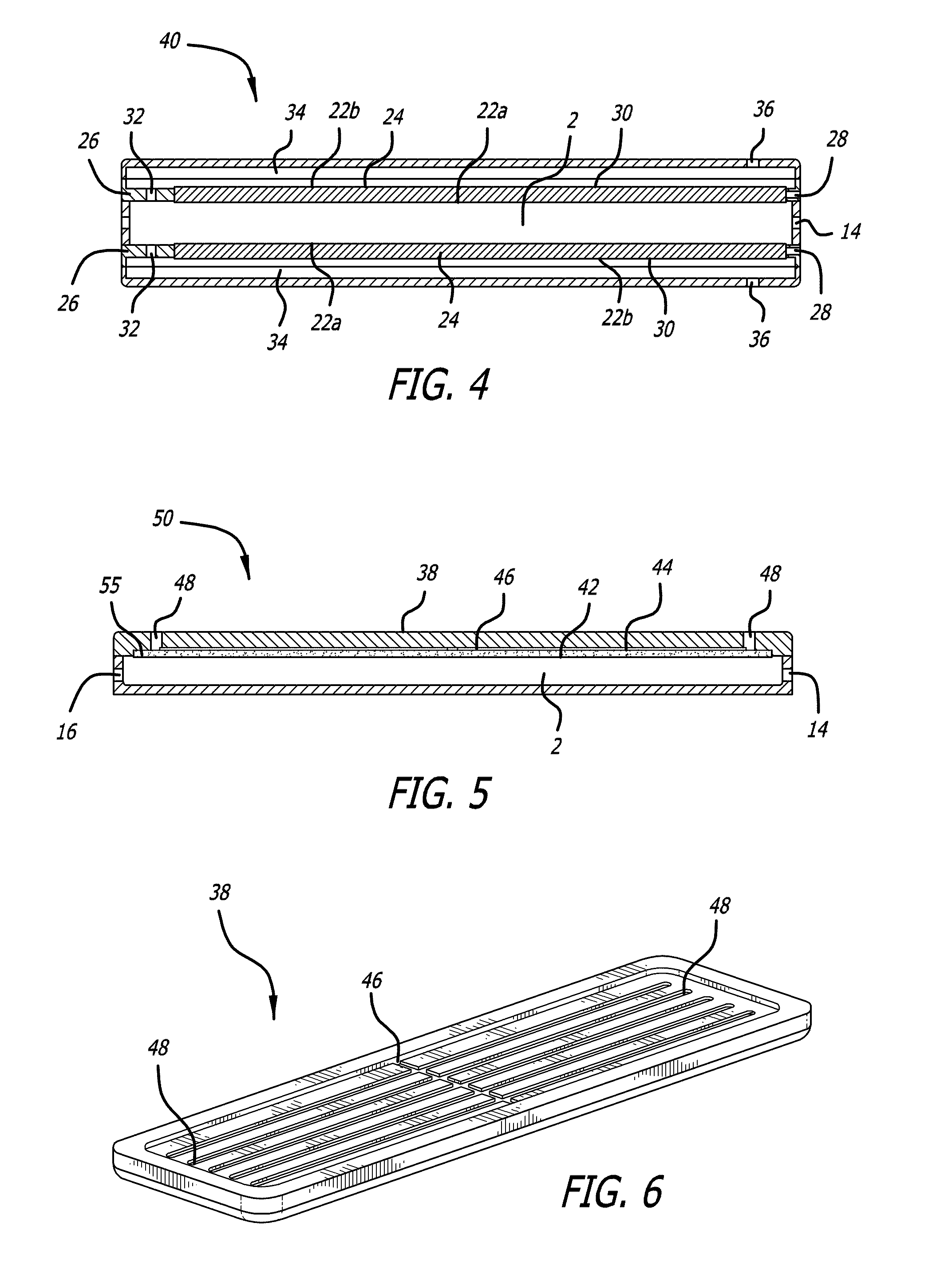

Compact devices for generating pure hydrogen

InactiveUS20060233700A1Chemical/physical/physico-chemical microreactorsCatalyst activation/preparationCombustion chamberProcess engineering

A hydrogen generator comprising a hydrogen membrane reactor, a fuel supply, a reaction fuel supply line, an air supply, an air supply line, a combustion fuel supply line, a tail gas supply line, a combustion by-product line for transporting combustion by-products from the combustion chamber, and a reaction product line. A membrane assembly to be joined to a reactor chamber of a hydrogen generator, which comprises a membrane; and a membrane support comprising a sintered porous metal. A reactor assembly comprising a reaction chamber containing a porous metal substrate, two membrane assemblies, a fuel supply, a reaction fuel supply line, and a tail gas supply line and a reaction product line. Methods associated with the hydrogen generator, membrane assembly and reactor assembly.

Owner:INTELLIGENT ENERGY INC

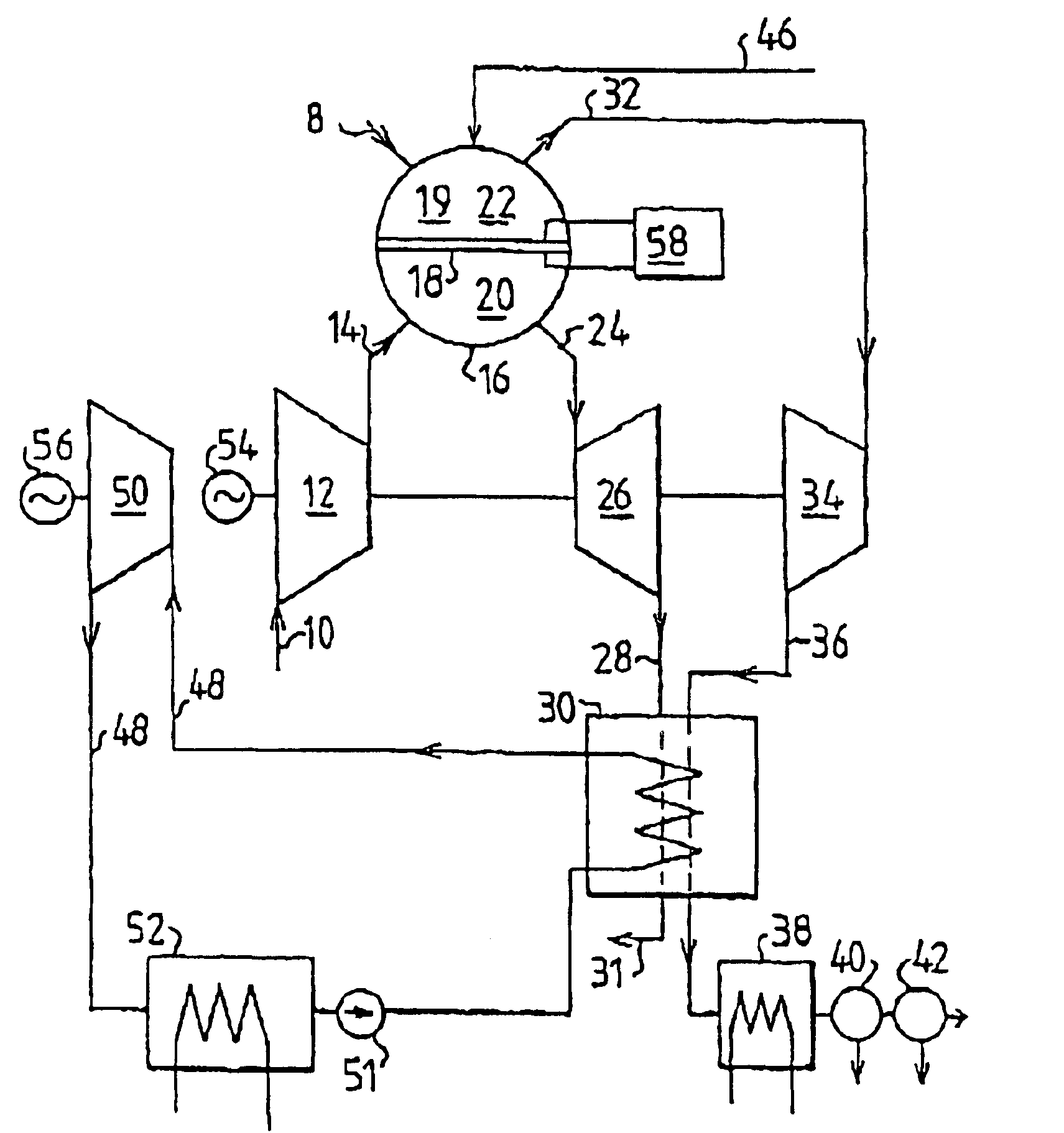

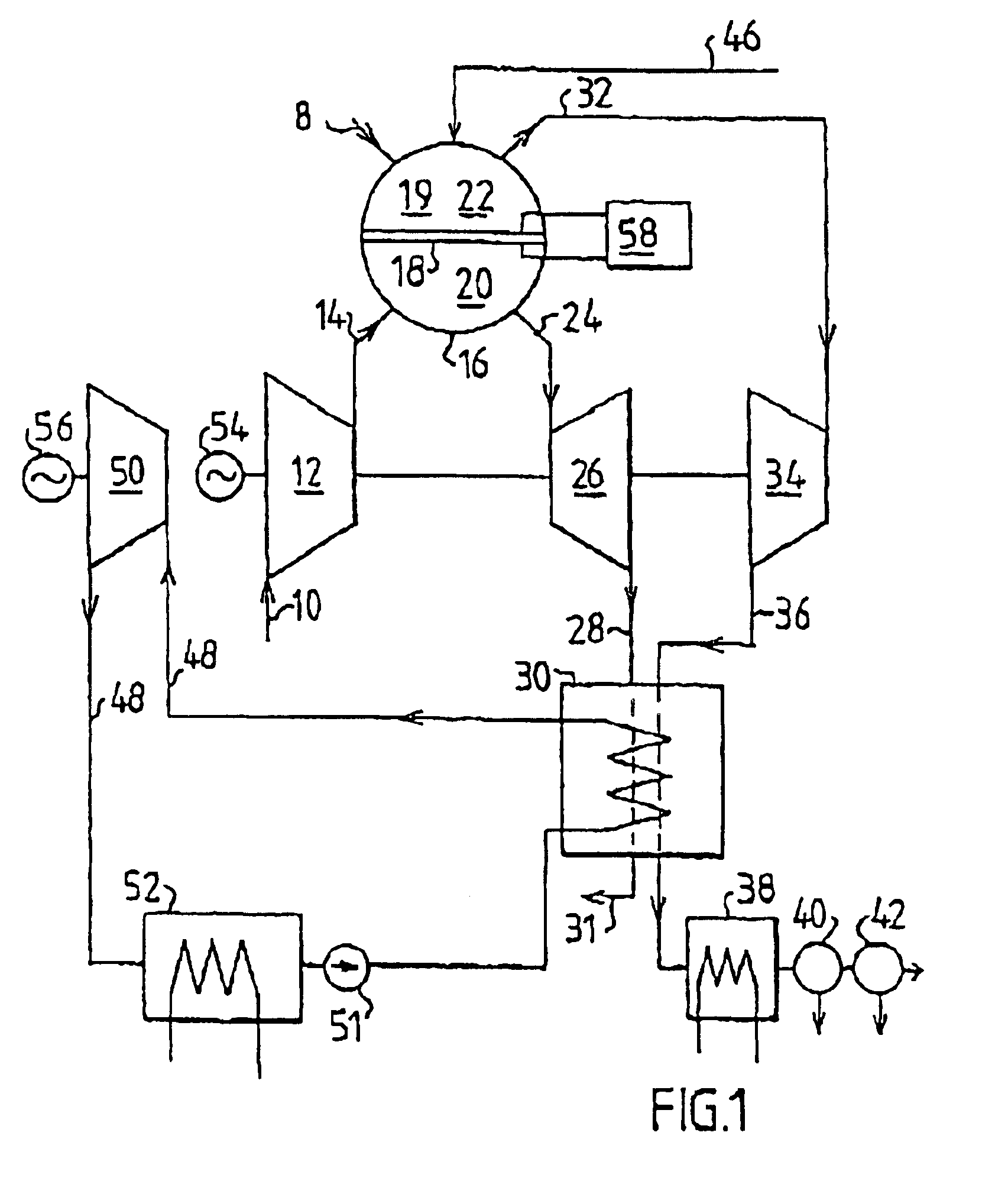

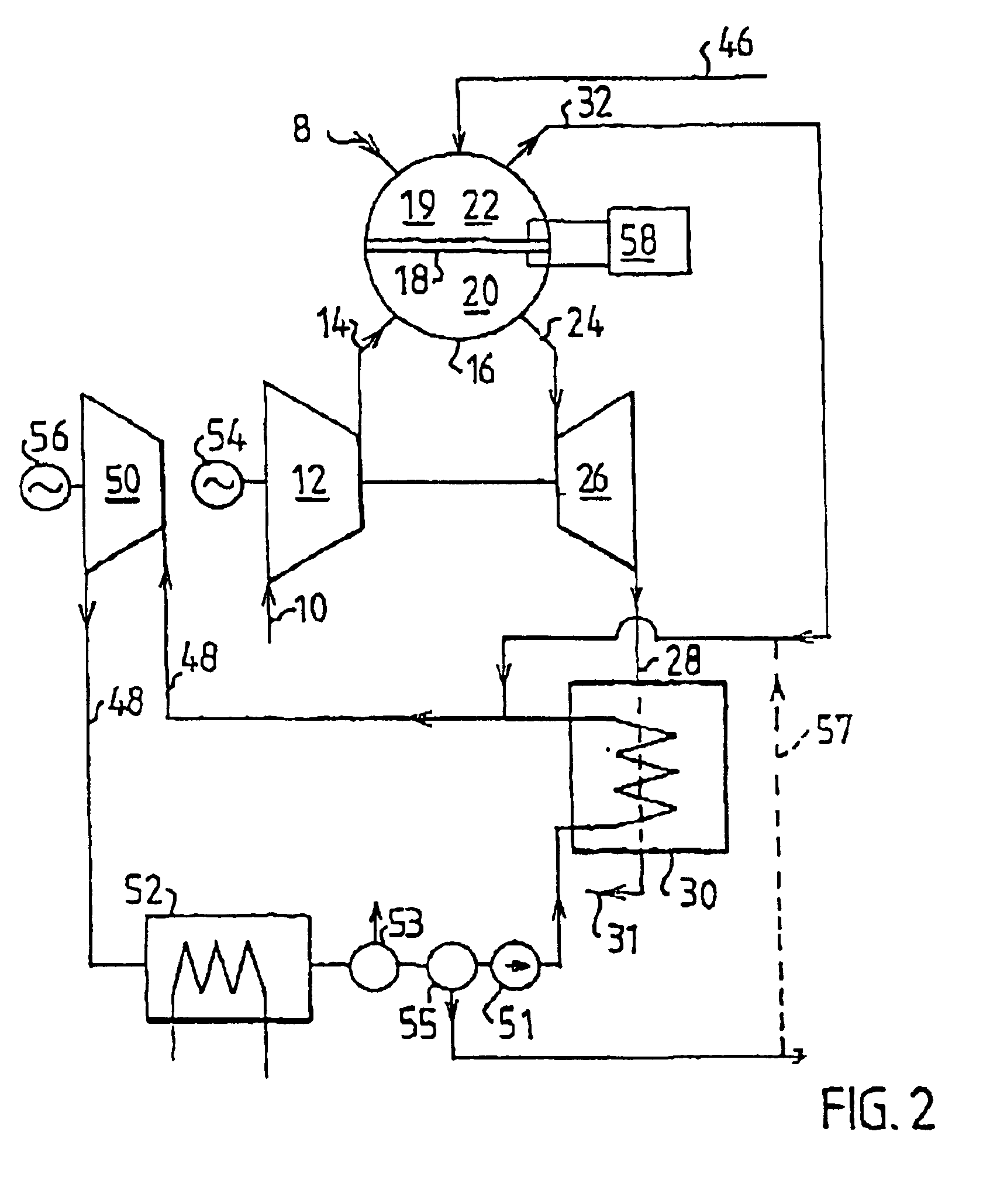

Method of operating a combustion plant and a combustion plant

InactiveUS6877319B2Improve efficiencyAvoid emissionsDispersed particle separationGas turbine plantsProduct gasProcess engineering

The invention concerns a method of operating a combustion plant comprising at least a first gas turbine (26), a second turbine (34, 50) and a membrane reactor device (16) which comprises a membrane filter device (18) for separating oxygen from a gas mixture and a combustion space (19). A gas mixture containing oxygen is supplied to the membrane reactor device (16). At least some oxygen is separated from the gas mixture with the help of the membrane filter device (18). The separated oxygen is used at the combustion in the combustion space (19). The oxygen-depleted gas that is obtained after the separation of oxygen and which has not gone through a combustion process is used to run the first gas turbine (26). Combustion gases run the second turbine (34, 50). The invention also concerns a combustion plant for carrying out the method.

Owner:NORSK HYDRO ASA +1

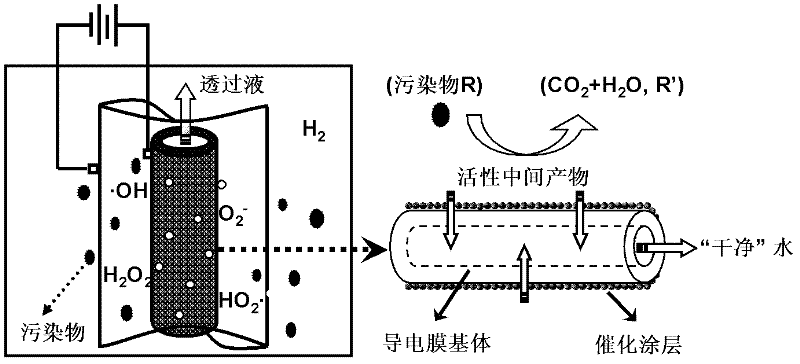

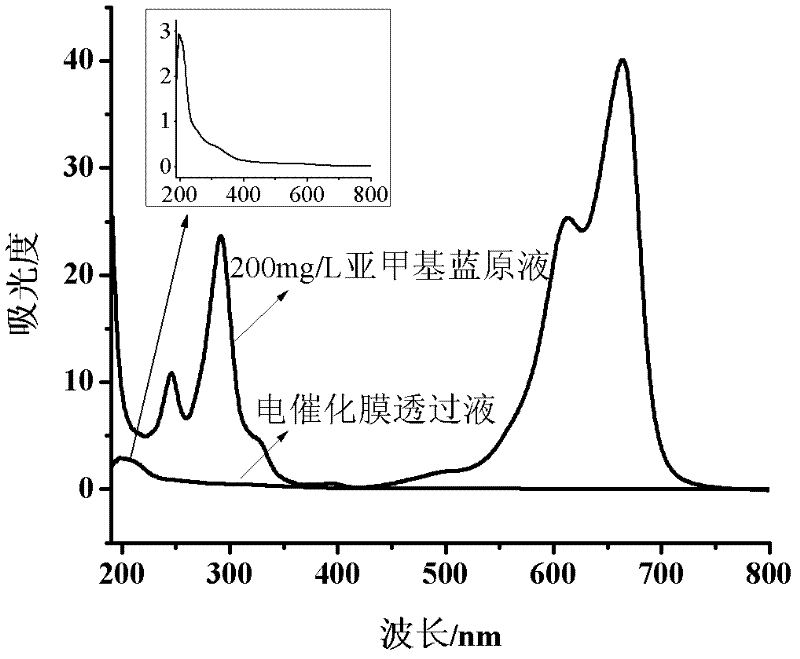

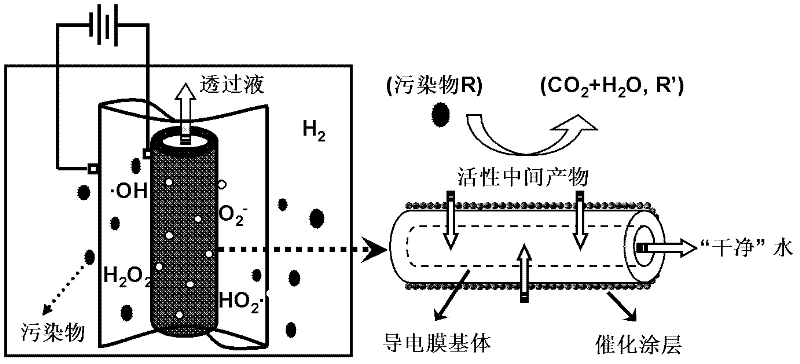

Nano loaded titanium-based electric catalytic film and preparation method thereof

InactiveCN102350228AImprove degradation efficiencyHigh electrode strengthSemi-permeable membranesDispersed particle separationAcid etchingCatalytic oxidation

The invention discloses a nano loaded titanium-based electric catalytic film comprising a conductive microporous separating titanium film matrix and a catalytic coating. Furthermore, the invention also discloses a preparation method of the nano loaded titanium-based electric catalytic film, which comprises the following steps of: (1) preprocessing the titanium film matrix by sand blasting, alkali washing, and acid etching: soaking the matrix after sand blasting in an NaOH solution for 0.5 to 2h, then processing for 1 to 2h in an oxalic acid solution with the mass percent concentration of 10 percent after washing to a neutral state, washing with water and drying at 100 to 120 DEG C; and (2) preparing and loading a catalytic coating: preparing the catalytic coating by adopting a sol-gel method, a thermal decomposition method, an electrodeposition method or a chemical vapor deposition method and loading at the surface of the titanium film matrix and in a hole. Furthermore, the invention also discloses a film reactor comprising the nano loaded titanium-based electric catalytic film. According to the nano loaded titanium-based electric catalytic film, the defects on material strength, range limitation of working voltage, catalytic oxidation efficacy and the like in the prior art are solved.

Owner:SHANGHAI CAS ADVANCED RES INST

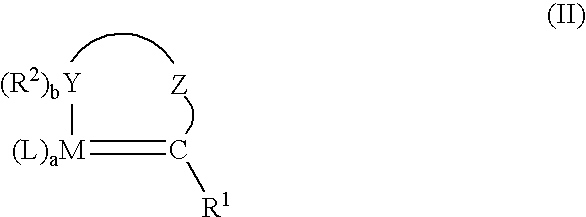

Membrane Separation Of A Metathesis Reaction Mixture

InactiveUS20080103346A1Reduces possibility of undesirableImprove efficiencySemi-permeable membranesCatalystsPolymer scienceCatalyst degradation

A process for separating a homogeneous metathesis catalyst and, optionally, one or more homogeneous metathesis catalyst degradation products from a metathesis reaction mixture containing in addition to said metathesis catalyst and said metathesis catalyst degradation product(s), one or more olefin metathesis products, one or more unconverted reactant olefins, and optionally, a solvent. The process involves contacting the metathesis reaction mixture with a nanofiltration membrane, such as a polyimide nanofiltration membrane, so as to recover a permeate containing a substantial portion of the olefin reaction products, the unconverted reactant olefins, and optional solvent, and a retentate containing the metathesis catalyst, and optionally, metathesis catalyst degradation product(s). In another aspect, this invention pertains to a continuous metathesis reaction-catalyst separation process, preferably, conducted in a nanofiltration membrane reactor.

Owner:DOW GLOBAL TECH LLC

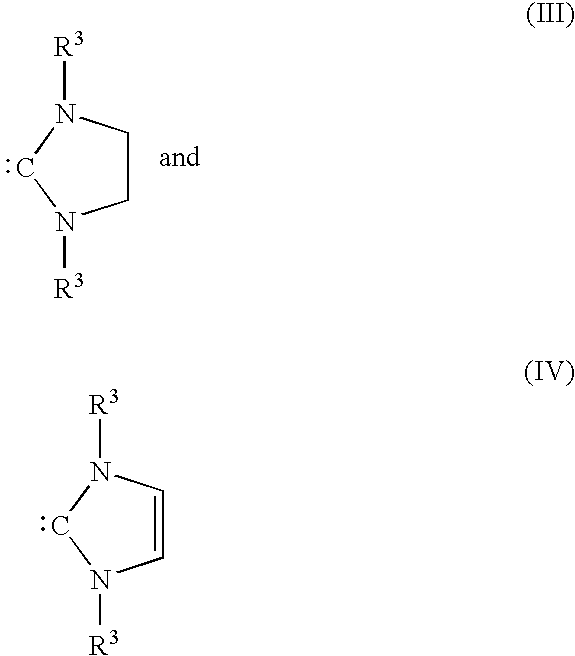

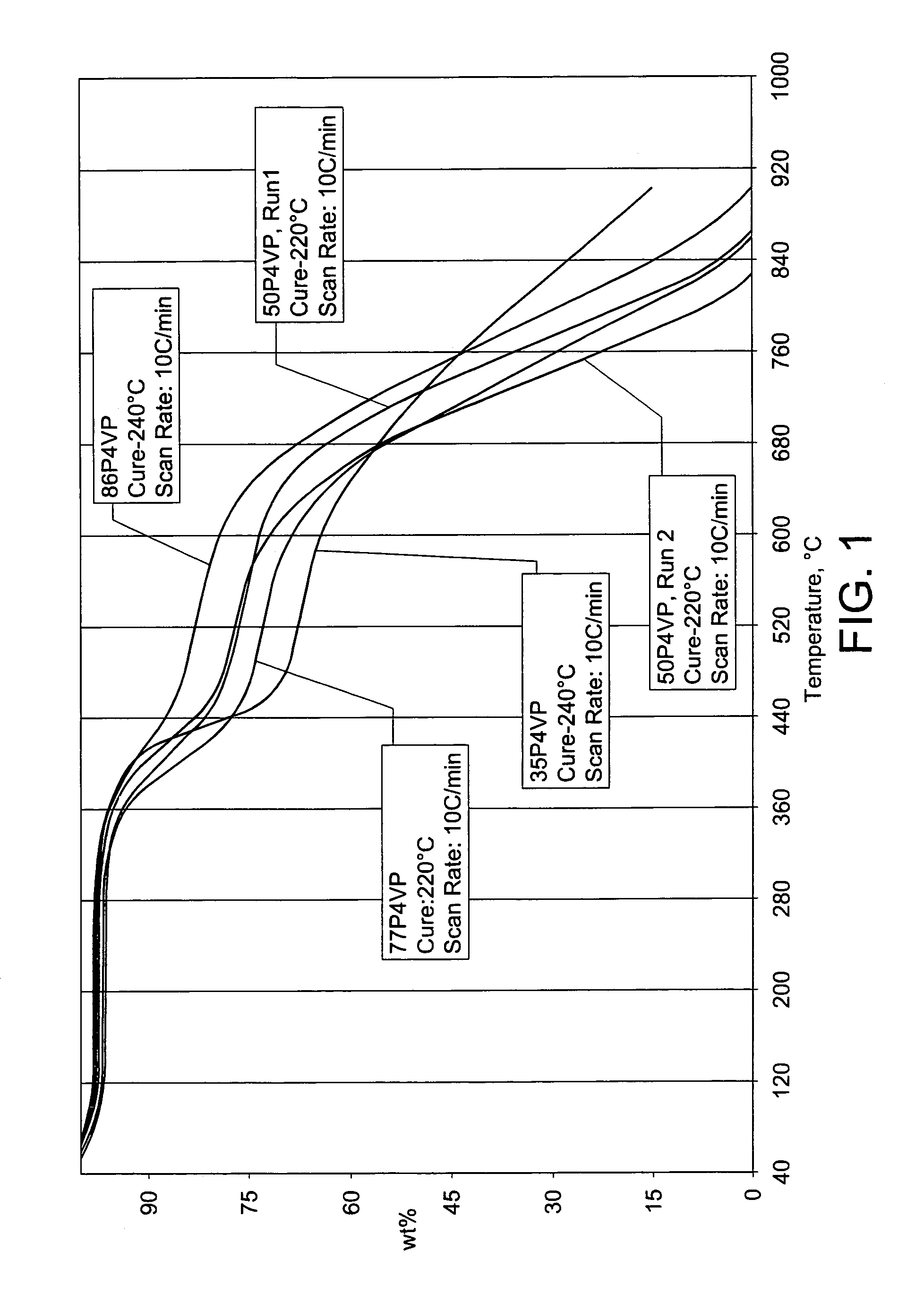

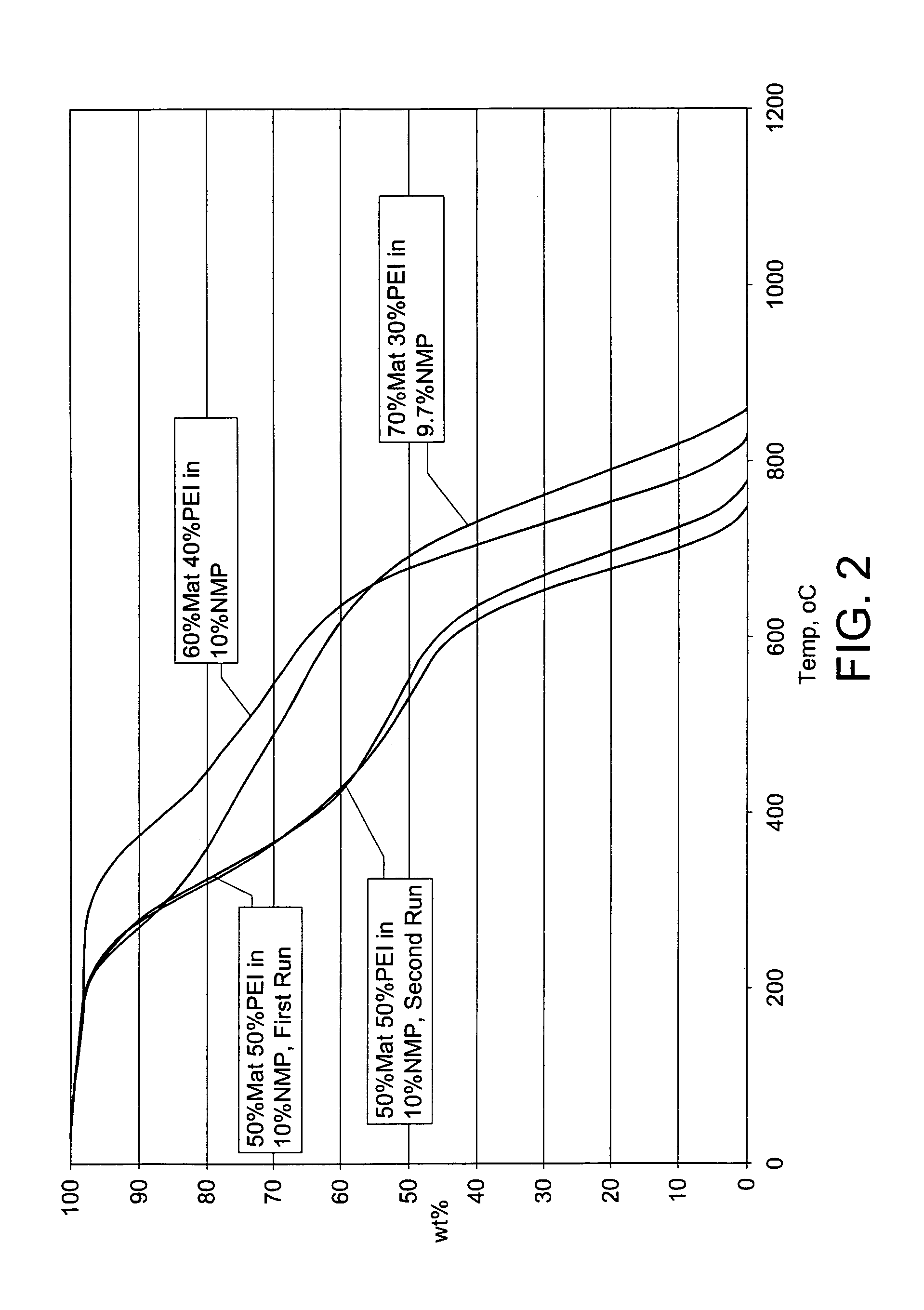

CO2-selective membranes containing amino groups

Novel compositions suitable for fabrication of CO2-selective membranes are disclosed. In one aspect, the present invention is directed to compositions comprising polyimide / polyamine blends and copolymers, and to compositions comprising interfacially polymerized polyamides. In another aspect this invention is directed to novel CO2-selective membranes comprising such polyimide / polyamine blends and copolymers, and to novel CO2-selective membranes comprising interfacially polymerized polyamides. In yet another aspect, the present invention is directed to a novel water-gas-shift (WGS) reactor comprising the novel CO2-selective membranes. Advantageously, the use of the novel CO2-selective membrane allows alteration of the normal WGS reaction equilibrium, shifting the reaction towards production of H2. Carbon dioxide on the high pressure, feed gas side of the membrane reactor reacts with the novel membranes of the present invention at the interface between the feed gas and the membrane. The reaction product permeates through the membrane to the interface between the feed gas and the low pressure side of the membrane, where the CO2 desorbs into the low pressure side and is removed.

Owner:UKRF +1

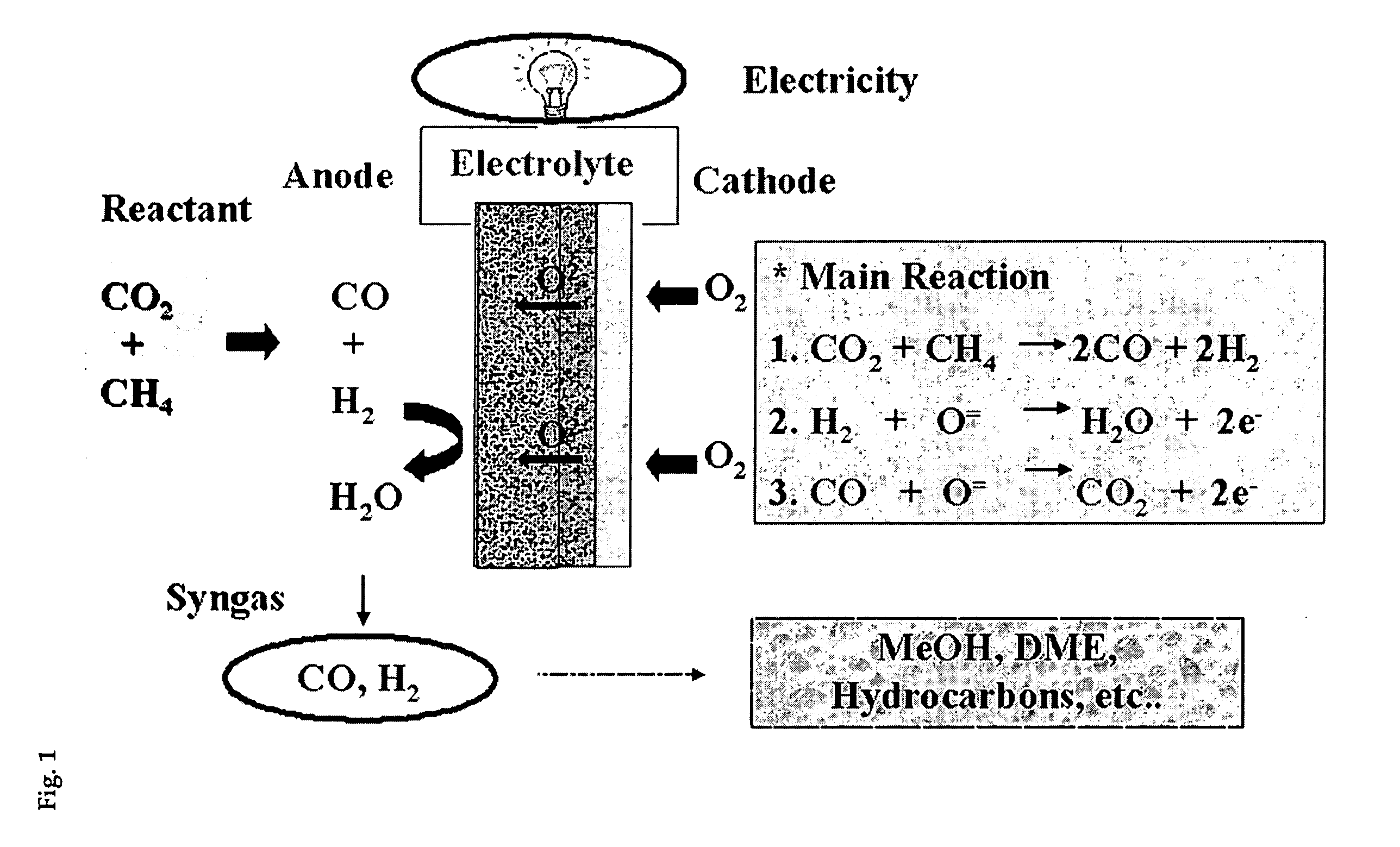

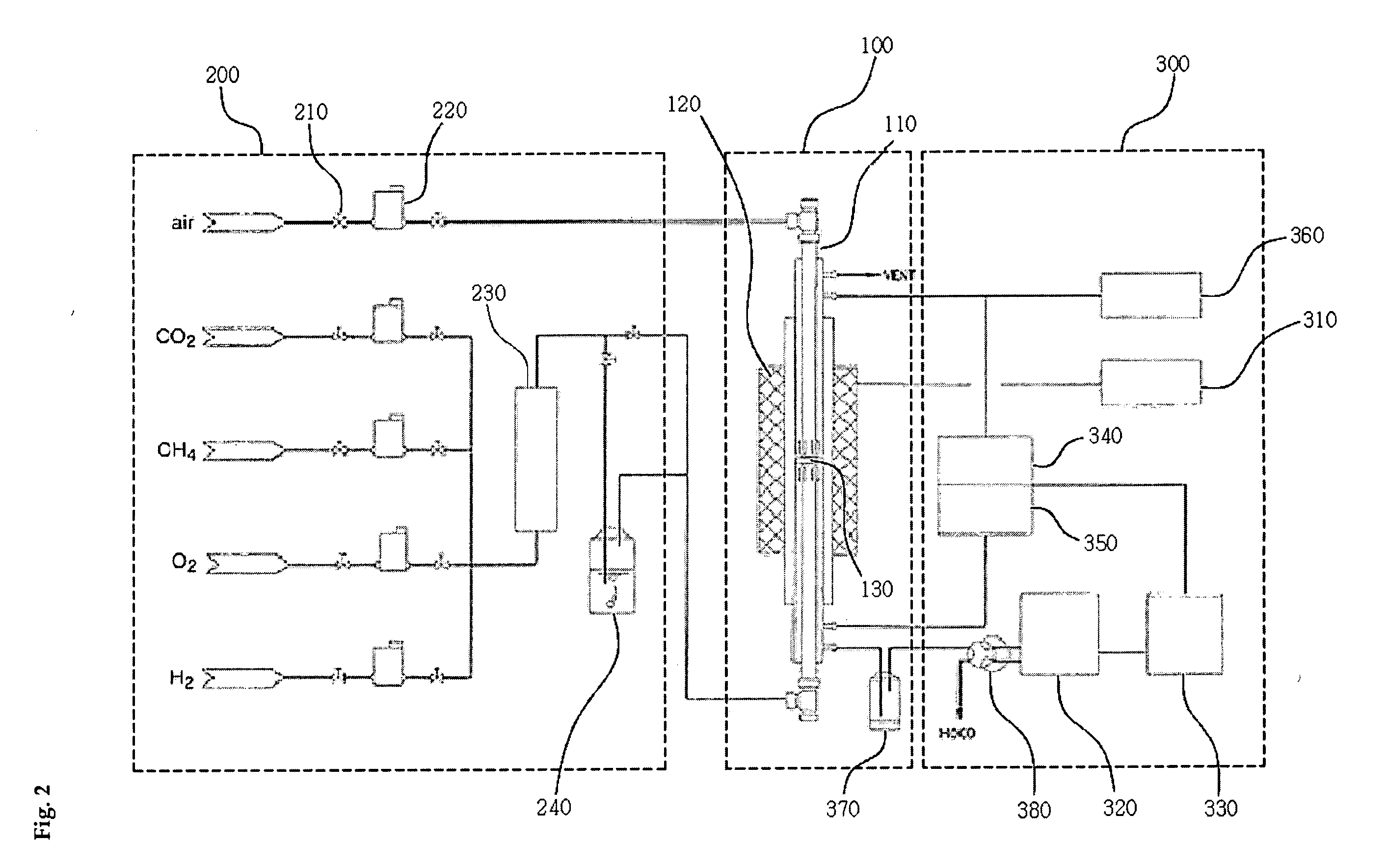

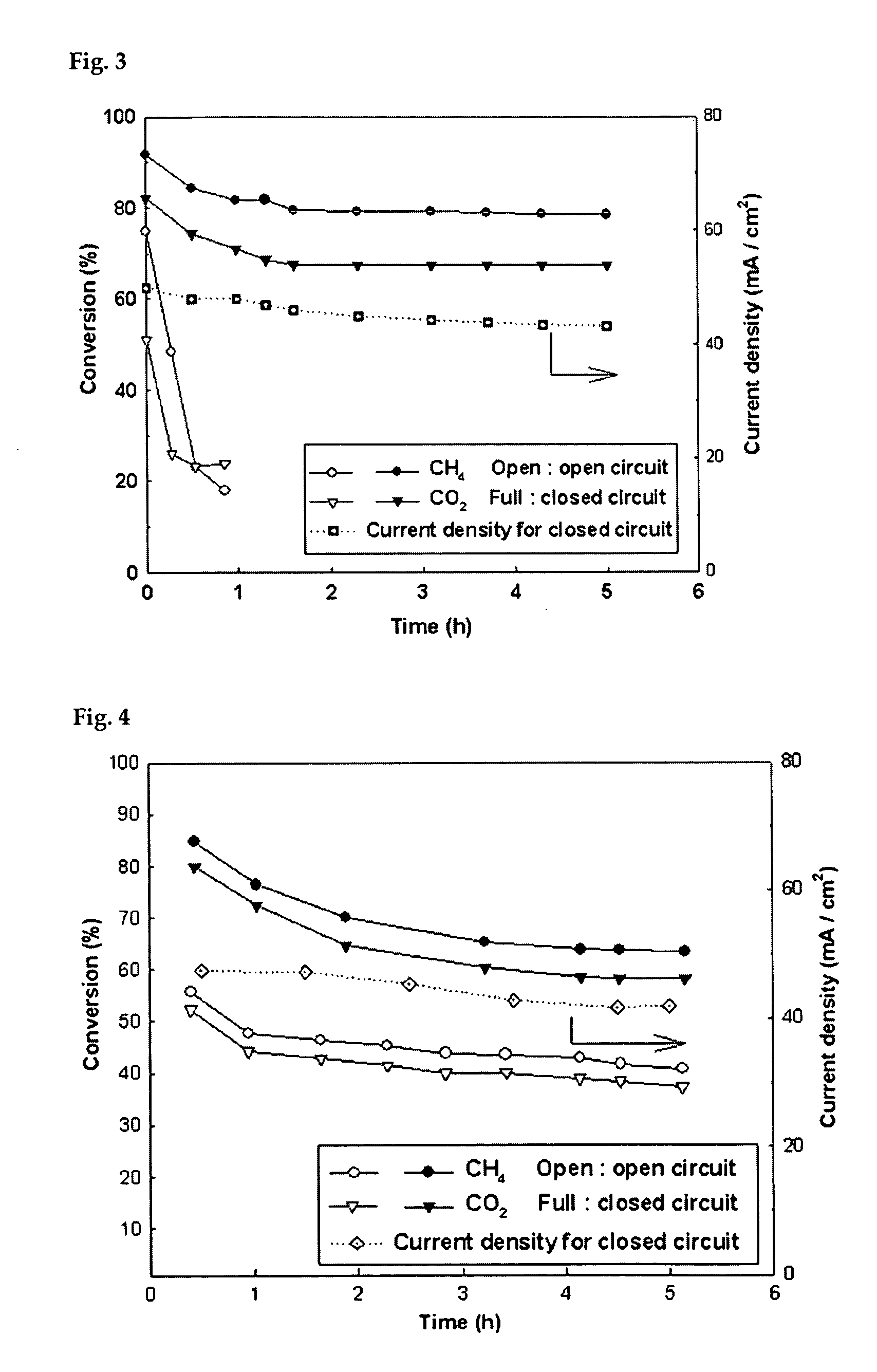

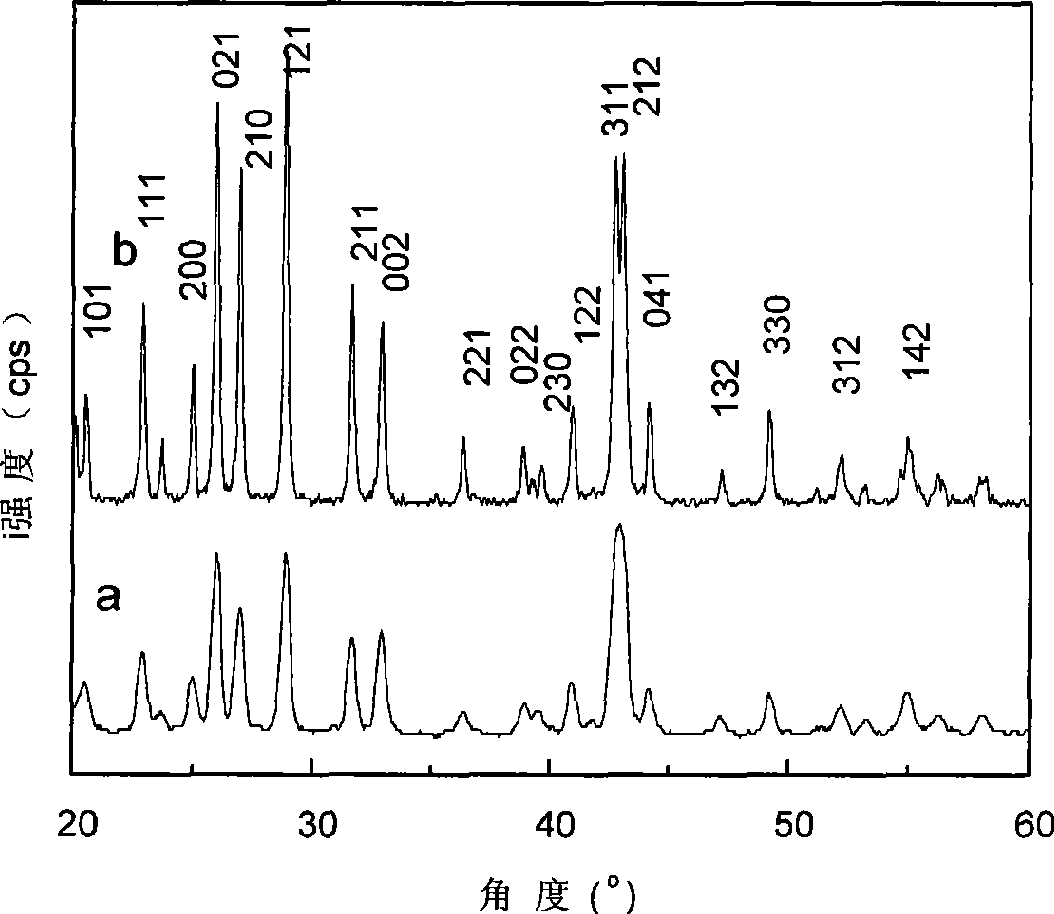

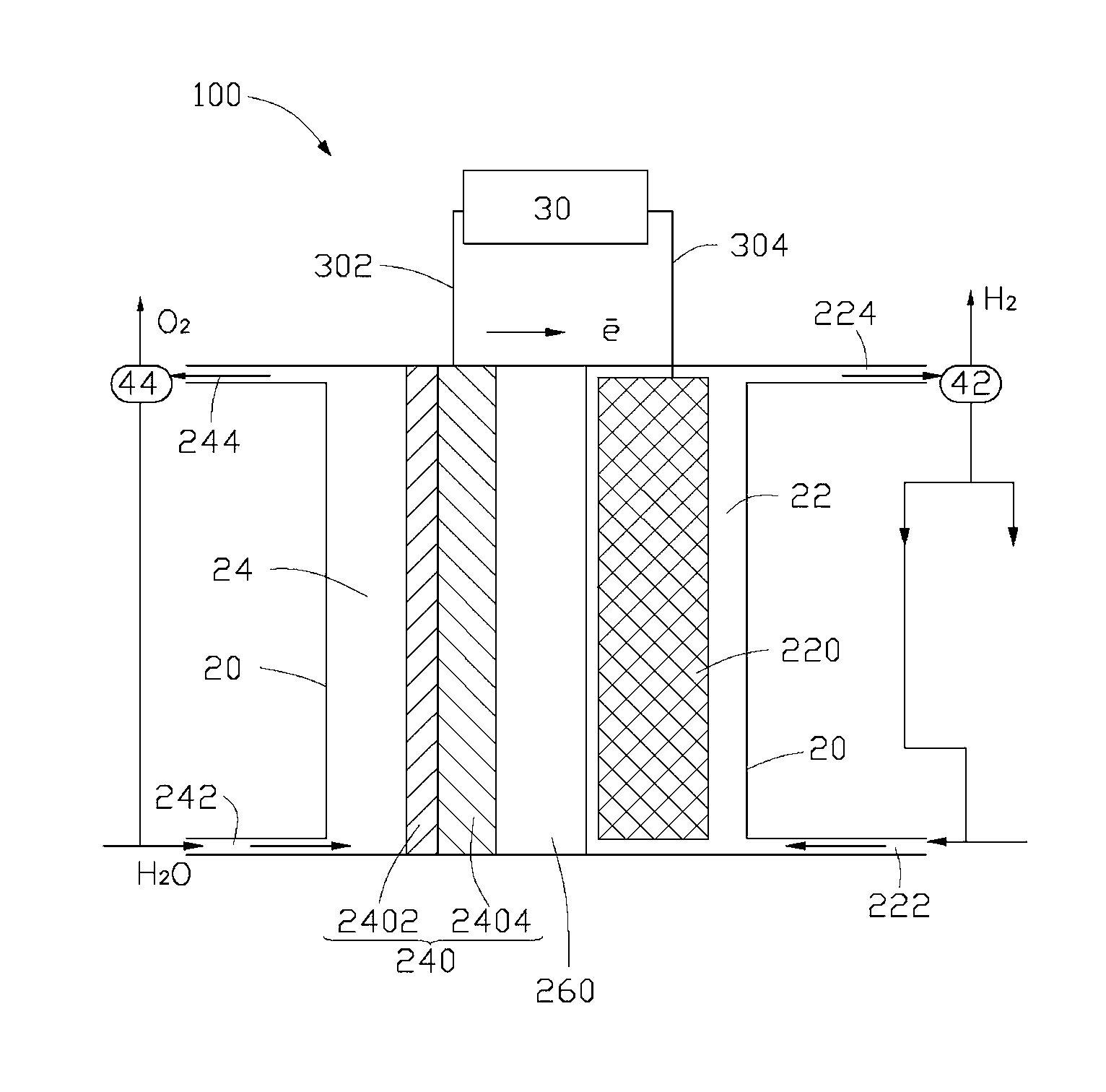

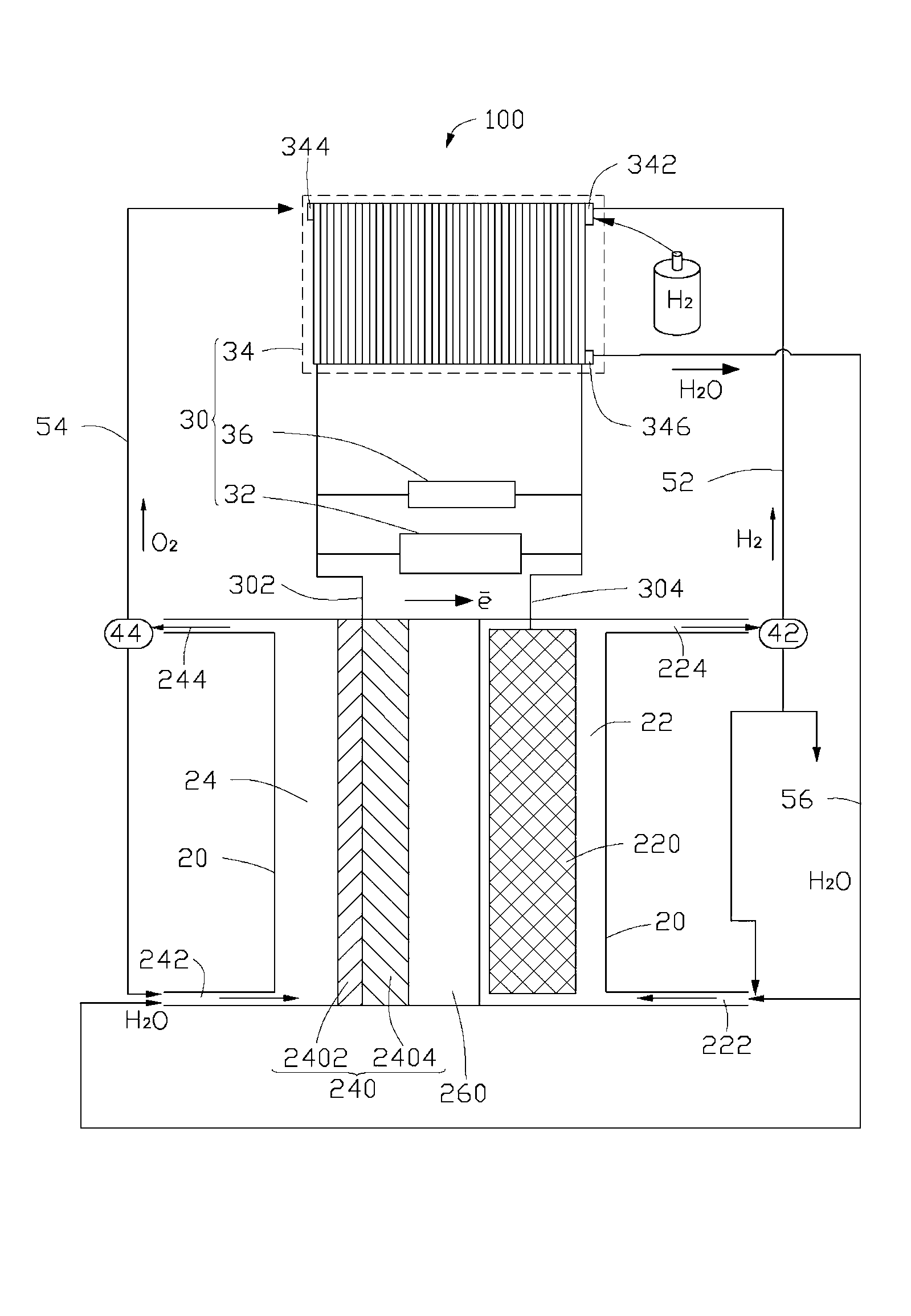

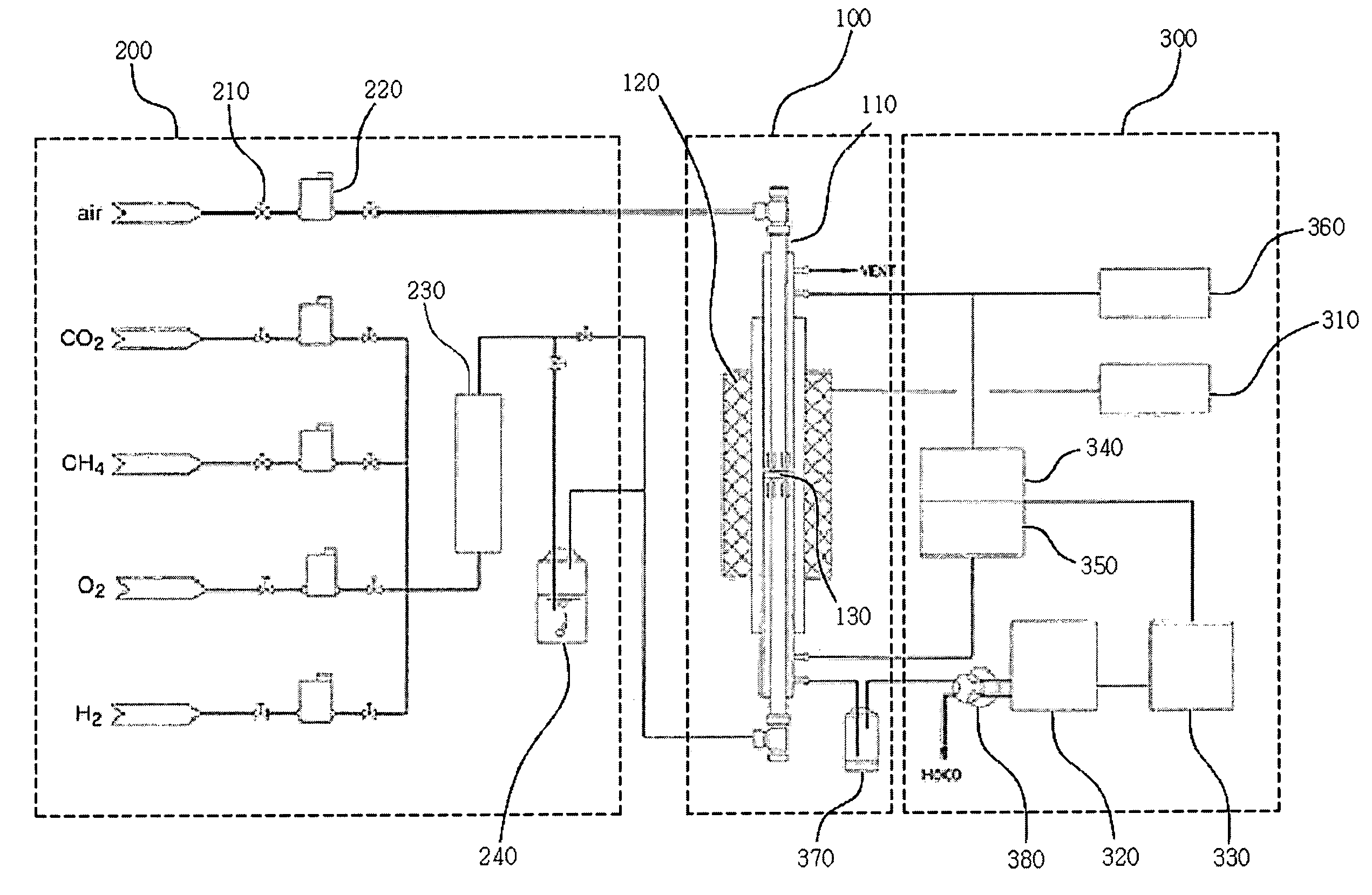

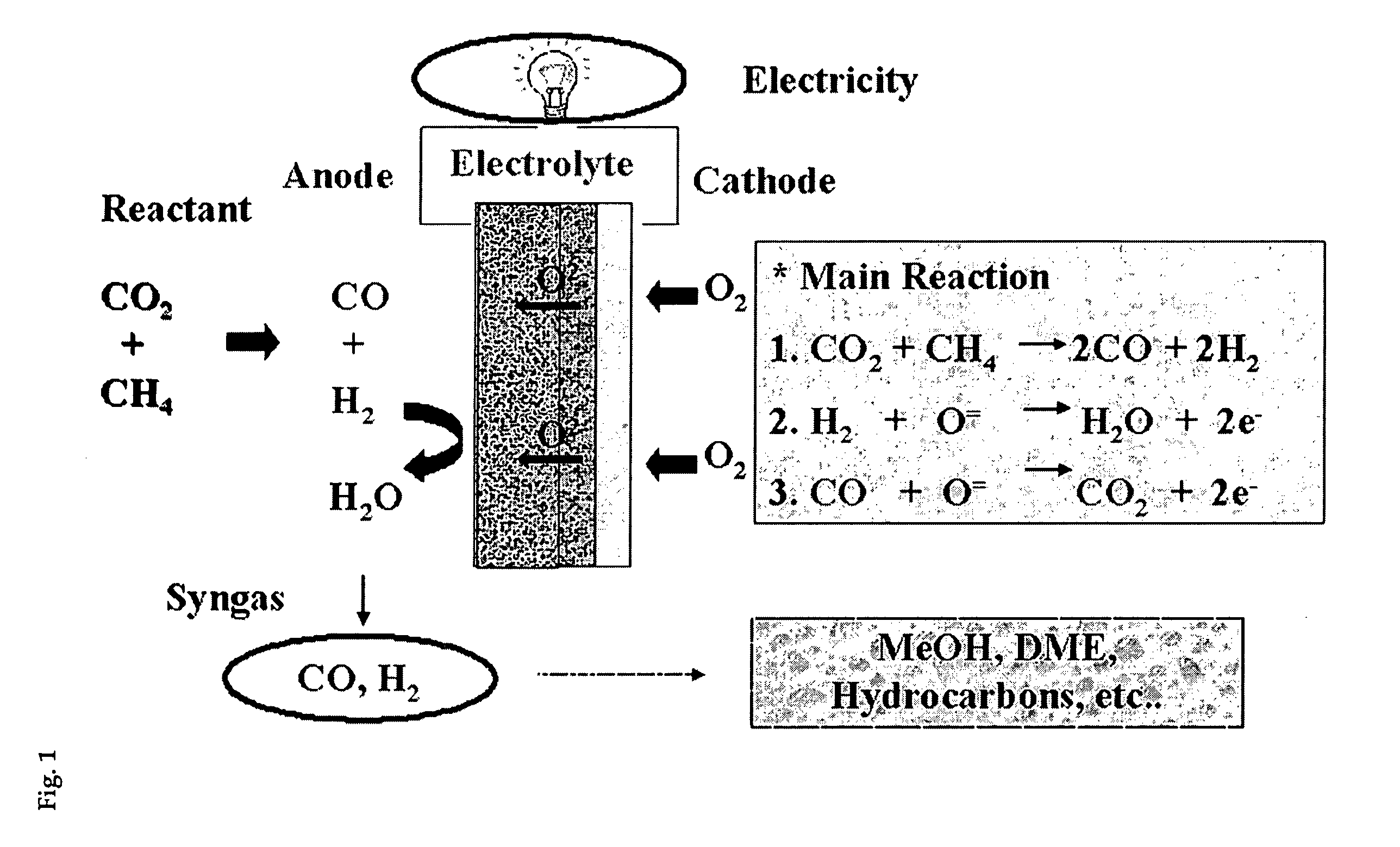

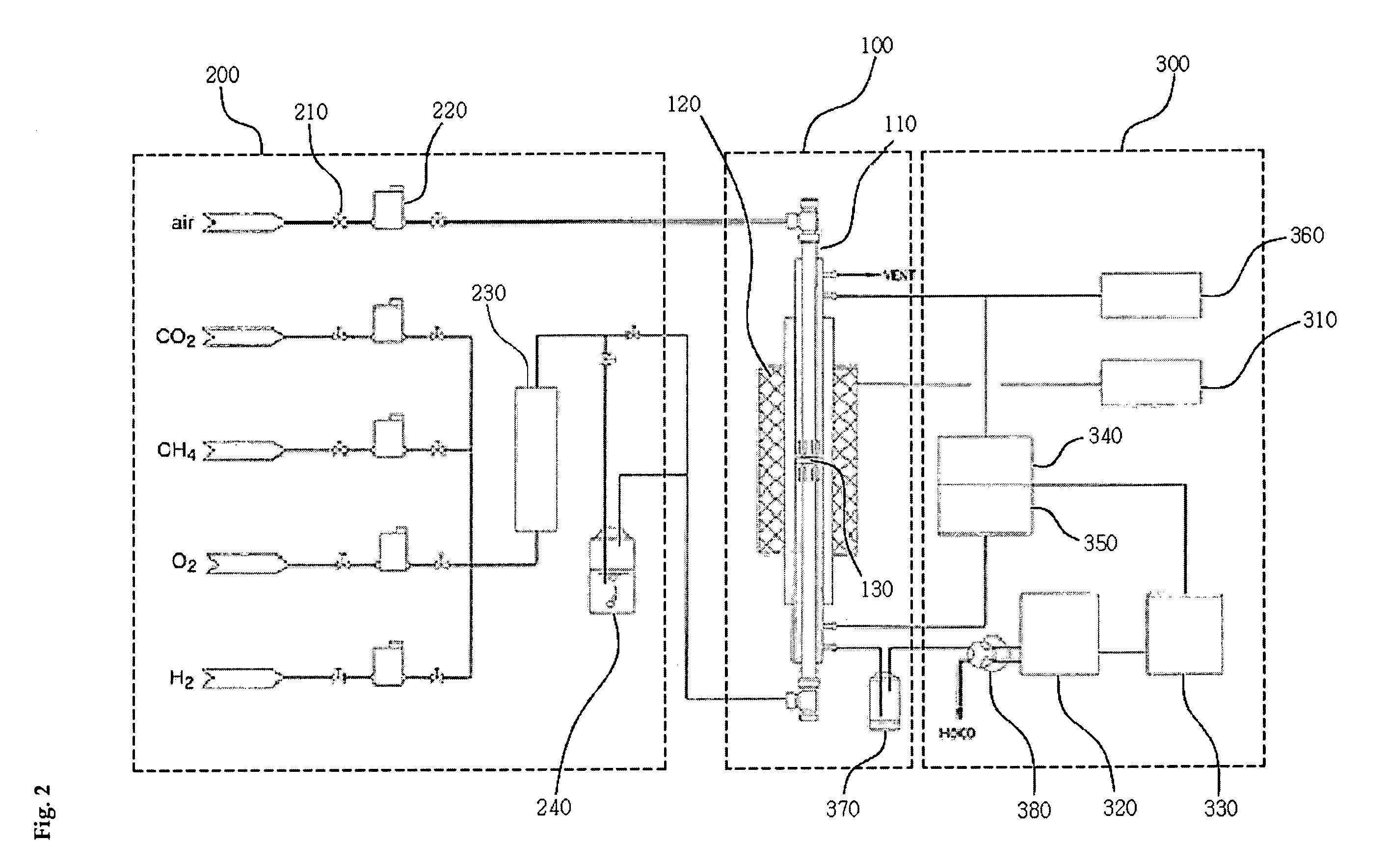

Solid oxide fuel cell (SOFC) for coproducing syngas and electricity by the internal reforming of carbon dioxide by hydrocarbons and electrochemical membrane reactor system

InactiveUS20050089740A1Maximize the effectImprove energy efficiencyCell electrodesSolid electrolyte fuel cellsHydrocotyle bowlesioidesManganese

The present invention relates to a solid oxide fuel cell for internal reforming of hydrocarbons and carbon dioxide, in particular, to a solid oxide fuel cell in which one side of solid oxide electrolyte (YSZ) is attached to an air electrode (La0.8Sr0.2MnO3) and its other side is attached to a catalyst electrode of Ni-YSZ type or perovskite type metal oxide. The electrochemical conversion system using the solid oxide fuel cell permits the occurrence of internal reforming of hydrocarbons and carbon dioxide concomitantly with the coproduction of a syngas and electricity, and overcomes the shortcomings associated with the catalytic deactivation due to carbon deposition and the high-energy consumption.

Owner:KOREA INST OF SCI & TECH

Method for preparing nano barium sulfate with controllable particle size distribution

InactiveCN101423239APrecise control of particle sizeInhibit growthCalcium/strontium/barium sulfatesEmulsionSlurry

The invention provides a preparation method of nano barium sulfate with the controllable particle size distribution. The preparation method takes BaCl2 and Na2SO4 as raw materials, respectively prepares two types of solution and then simultaneously adds the two types of solution into a rotary liquid membrane reactor with the high-speed rotation at the same flow rate for carrying out nucleation reaction, and centrifugal washing and drying are carried out to the obtained slurry to obtain the nano BaSO4 with the particle size of 30-120nm and the narrower particle size distribution. The purpose of precisely controlling the particle size of the product can be achieved by regulating and controlling the rotational speed, the gap and other operation parameters of the reactor, thereby being capable of preparing the BaSO4 with the particle size of 30-40nm. The method combines the advantages of a micro-reactor and a high gravity reactor and simultaneously avoids the shortcomings of the micro-emulsion method, the complex method and the like, thereby having small reaction space and high preparation speed and being capable of meeting the requirements on the industrial preparation of the nano BaSO4.

Owner:BEIJING UNIV OF CHEM TECH

Compact devices for generating pure hydrogen

InactiveUS7527661B2Chemical/physical/physico-chemical microreactorsHydrogen productionCombustion chamberProcess engineering

Owner:INTELLIGENT ENERGY INC

Hydrogen generation apparatus and method for using same

InactiveUS20050281735A1Increase temperatureHydrocarbon from carbon oxidesChemical industryCombustion chamberMembrane reactor

A compact hydrogen generator for use with fuel cells and other applications includes a hydrogen membrane reactor having a combustion chamber and a reaction chamber. The two chambers are have a fluid connection and a heat exchange relationship with one another. The hydrogen generation apparatus also includes a fuel supply, a fuel supply line for transporting fuel from the fuel supply to the reaction chamber, an oxygen supply, an oxygen supply line for transporting oxygen form the oxygen supply to the combustion chamber, as well as a tail gas supply line for transporting tail gas supply line for transporting tail gases form the reaction chamber, a combustion by-product line for transporting combustion by-products for the combustion chamber, and a reaction product line for transporting hydrogen from the reaction chamber.

Owner:INTELLIGENT ENERGY INC

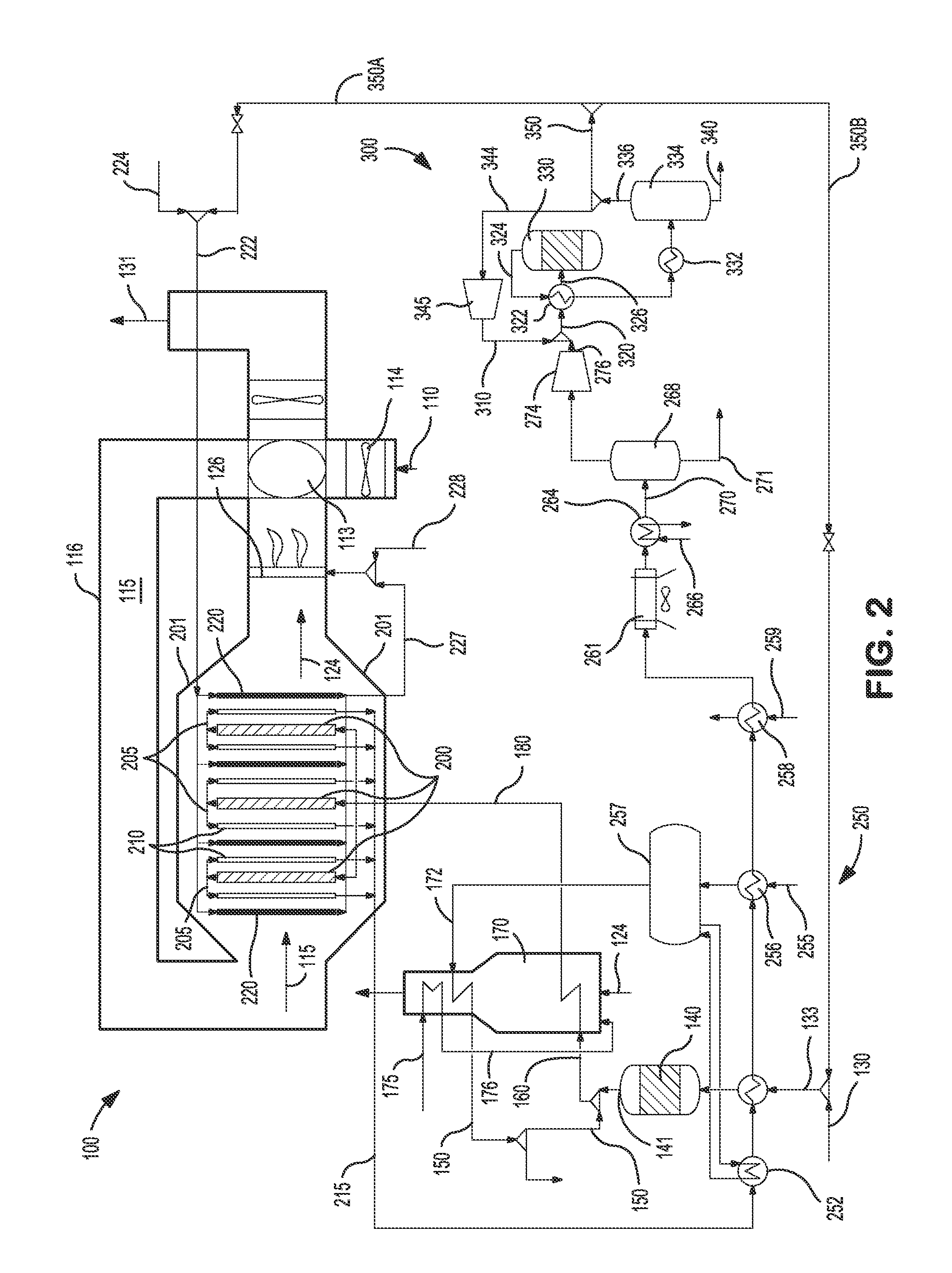

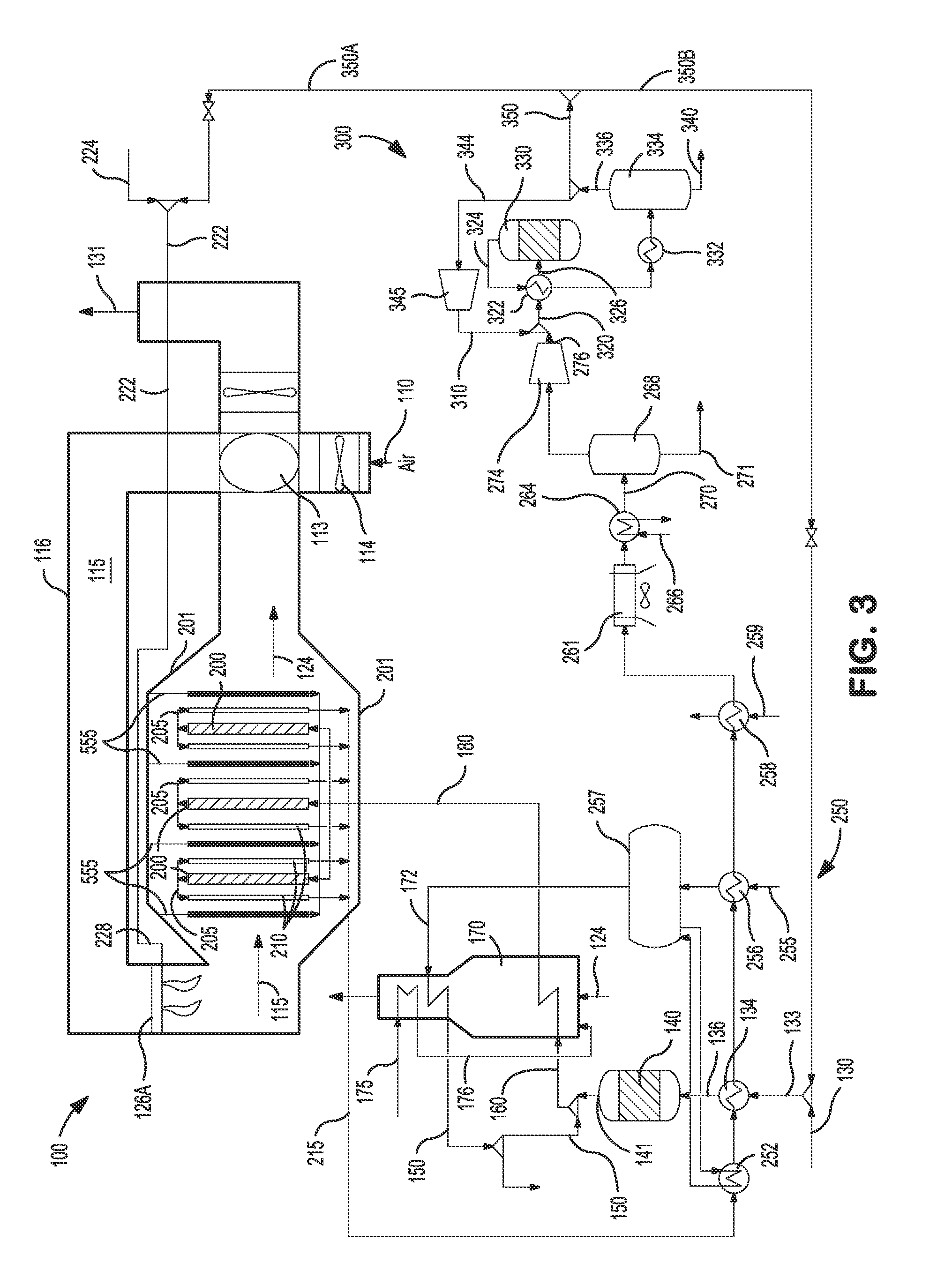

Method and system for producing a synthesis gas using an oxygen transport membrane based reforming system with secondary reforming and auxiliary heat source

A method and system for producing a synthesis gas in an oxygen transport membrane based reforming system is disclosed that carries out a primary reforming process within a reforming reactor, and a secondary reforming process within an oxygen transport membrane reactor and in the presence of heat generated from a oxygen transport membrane reactor and an auxiliary source of heat. The auxiliary source of heat is disposed within the reactor housing proximate the reforming reactors and may include an auxiliary reactively driven oxygen transport membrane reactor or a ceramic burner.

Owner:PRAXAIR TECH INC

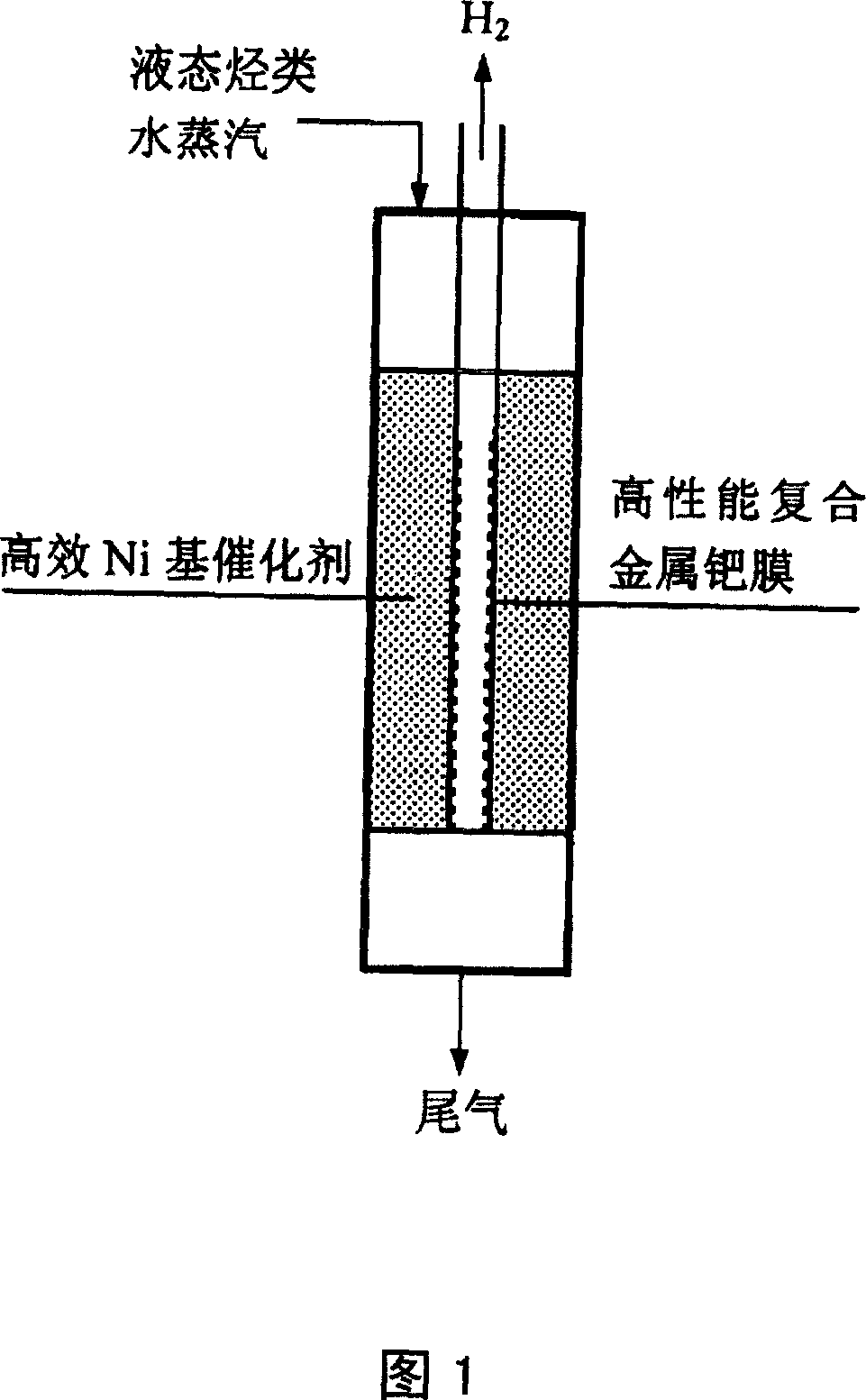

Process of preparing high purity hydrogen with liquid hydrocarbon in a palladium film reactor

The process of preparing high purity hydrogen with liquid hydrocarbon in a palladium film reactor adopts Ni base catalyst with high activity at low temperature to obtain liquid hydrocarbon converting rate near 100 % at the conditions of 450-550 deg.c temperature and carbon space velocity as high as 30,000 / hr, and uses high performance composite metal palladium film simultaneously at the conditions of 500-600 deg.c temperature and carbon space velocity as high as 2000 / hr for timely separating hydrogen generated through water vapor reformation of liquid hydrocarbon to avoid methanation reaction, so as to obtain methane selectivity lower than 3 % and hydrogen selectivity higher than 97 % and obtain high pure hydrogen in the permeation side of the palladium film. The present invention has low hydrogen producing cost and may be used widely in hydrogen refilling station and small dispersed power station.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Modular Membrane Reactor and Process for Carbon Dioxide Extraction

InactiveUS20110223650A1Bioreactor/fermenter combinationsBiological substance pretreatmentsDesorptionMembrane reactor

The present invention relates to a reactor and a process suitable for extracting carbon dioxide from carbon dioxide-containing gas stream. The reactor is based on a two module system where absorption occurs in one module and desorption occurs in the other module. The carbon dioxide extraction may be catalyzed by carbonic anhydrase.

Owner:NOVOZYMES AS

Carbon dioxide electrochemical reduction conversion utilization method

ActiveCN103160849AContinuous processingImprove recycling ratesCellsElectrochemical generatorsElectrolysisFuel cells

The invention relates to a carbon dioxide electrochemical reduction conversion utilization method comprising the steps that: a membrane reactor is provided, wherein the membrane reactor comprises a fuel cell and a cavity; an electrolyte separation membrane is arranged in the cavity, and divides the cavity into a cathode chamber and an anode chamber; an anode is arranged in the anode chamber, and a cathode is arranged in the cathode chamber; a cathode electrolyte and carbon dioxide are continuously and concurrently delivered into the cathode chamber of the membrane reactor, and an anode electrolyte and an anode active substance are continuously delivered into the anode chamber of the membrane reactor; electrolysis voltage is provided between the cathode and anode of the membrane reactor by using the fuel cell, such that carbon dioxide is decomposed, and expected products including hydrogen and oxygen are obtained; and hydrogen and oxygen are delivered into the fuel cell as fuels of the fuel cell, such that electric power can be obtained. The method provides good carbon dioxide conversion rate and energy circulation utilization rate.

Owner:TSINGHUA UNIV +1

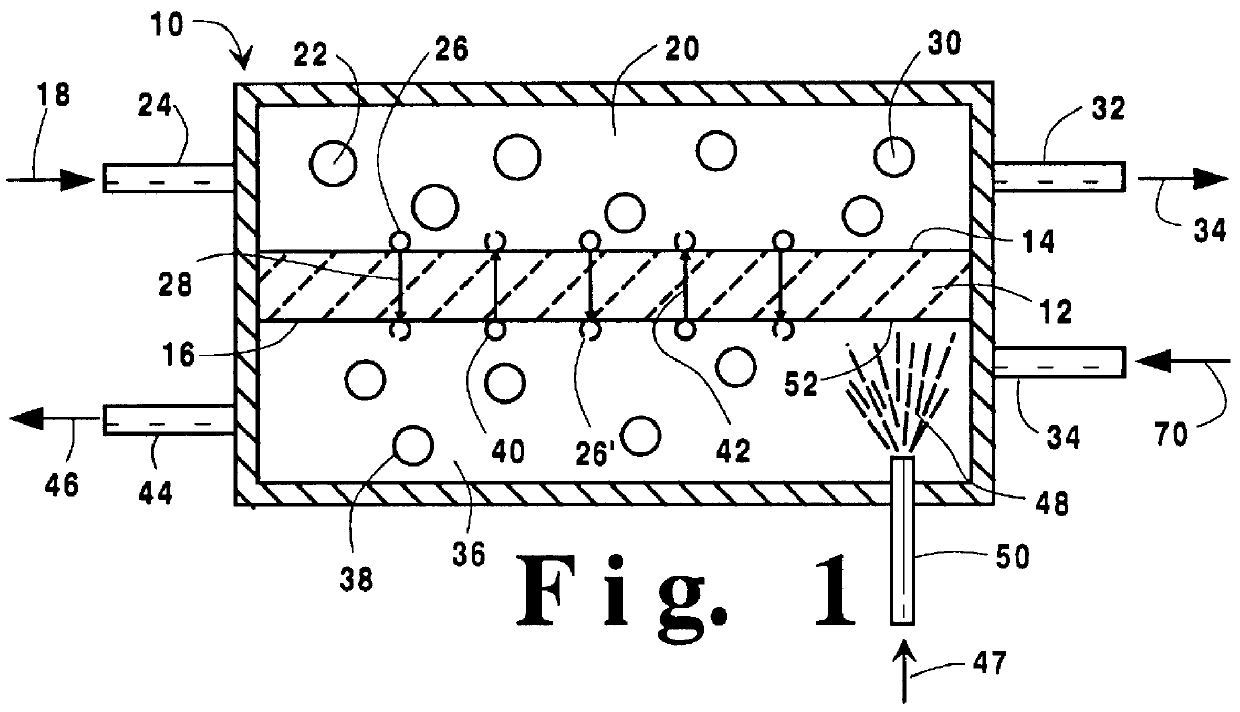

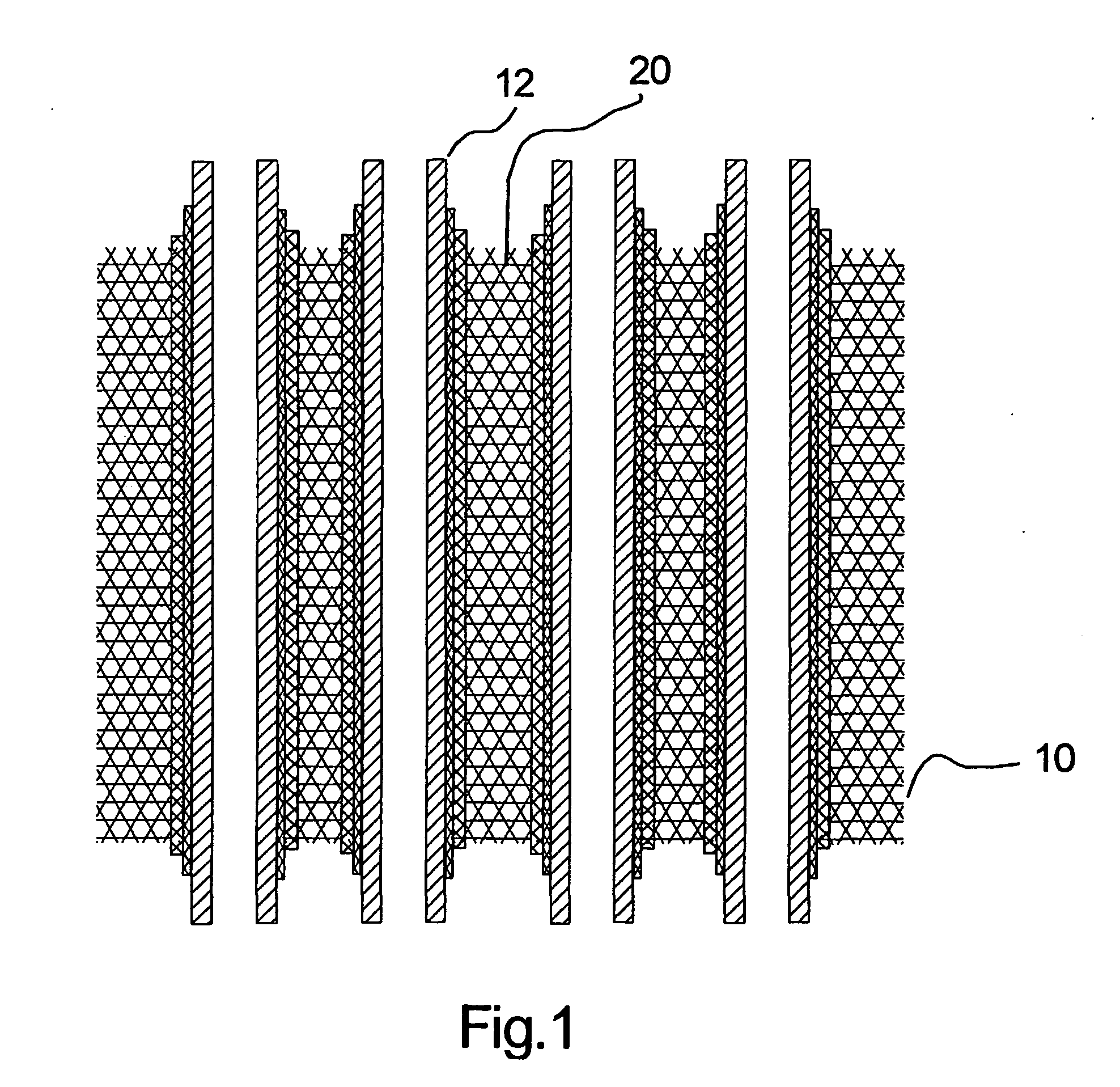

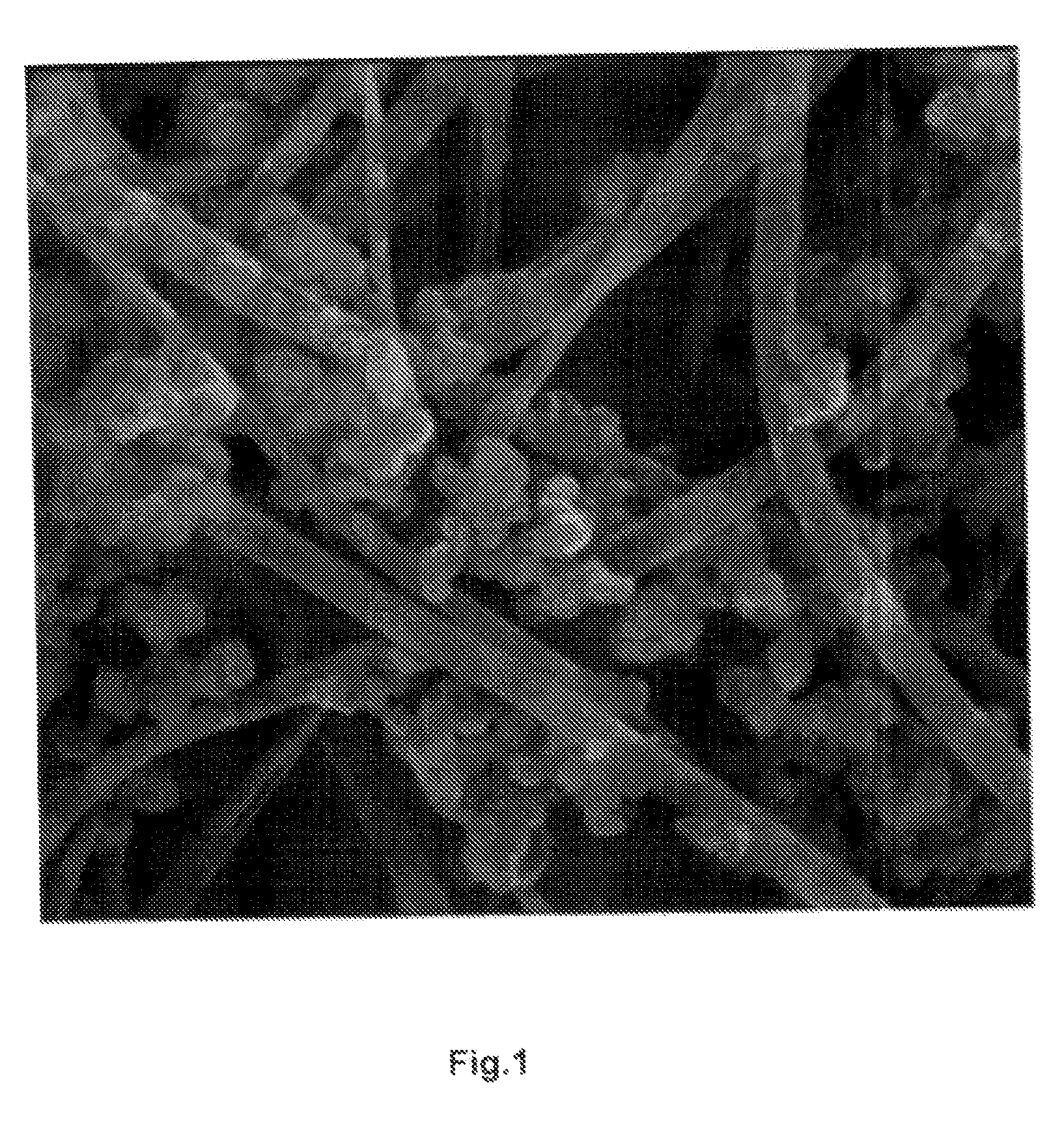

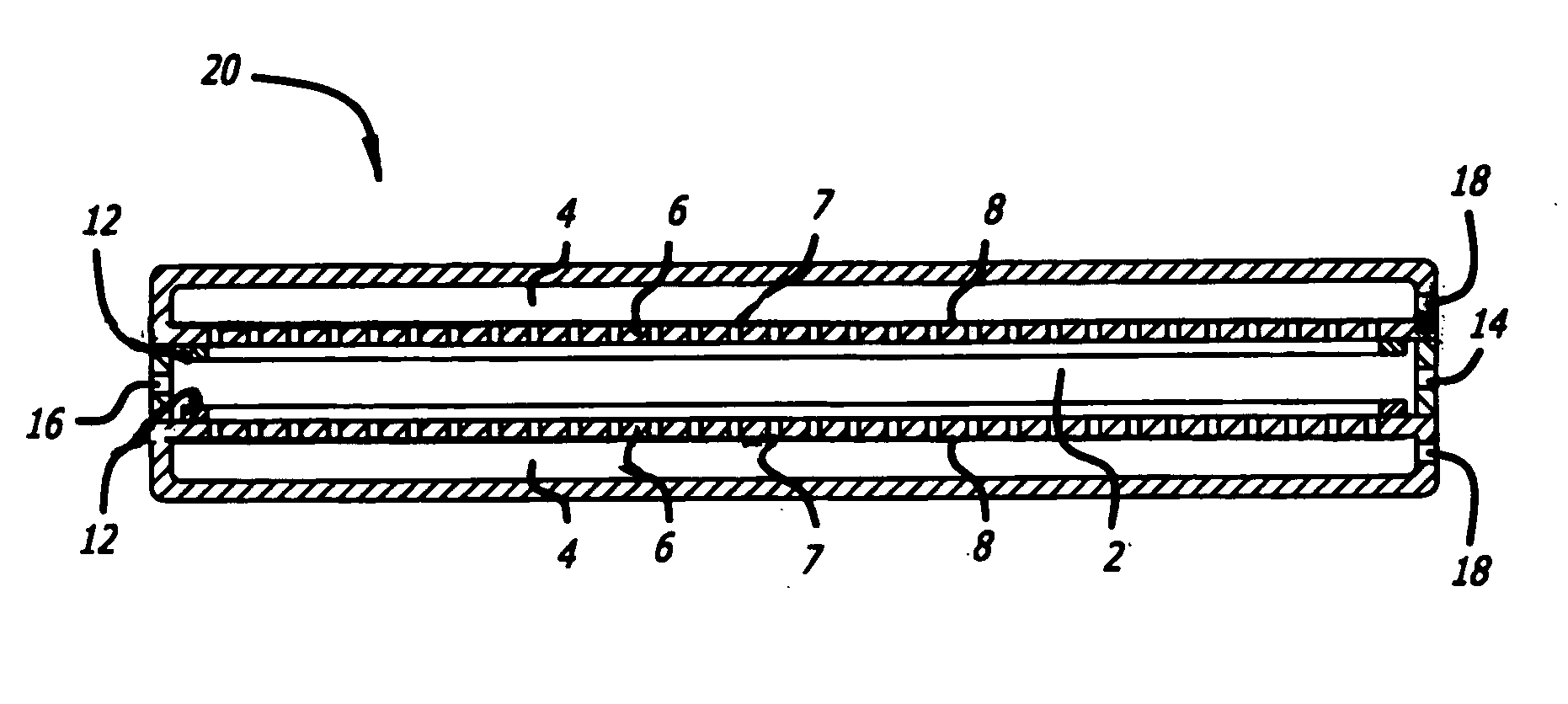

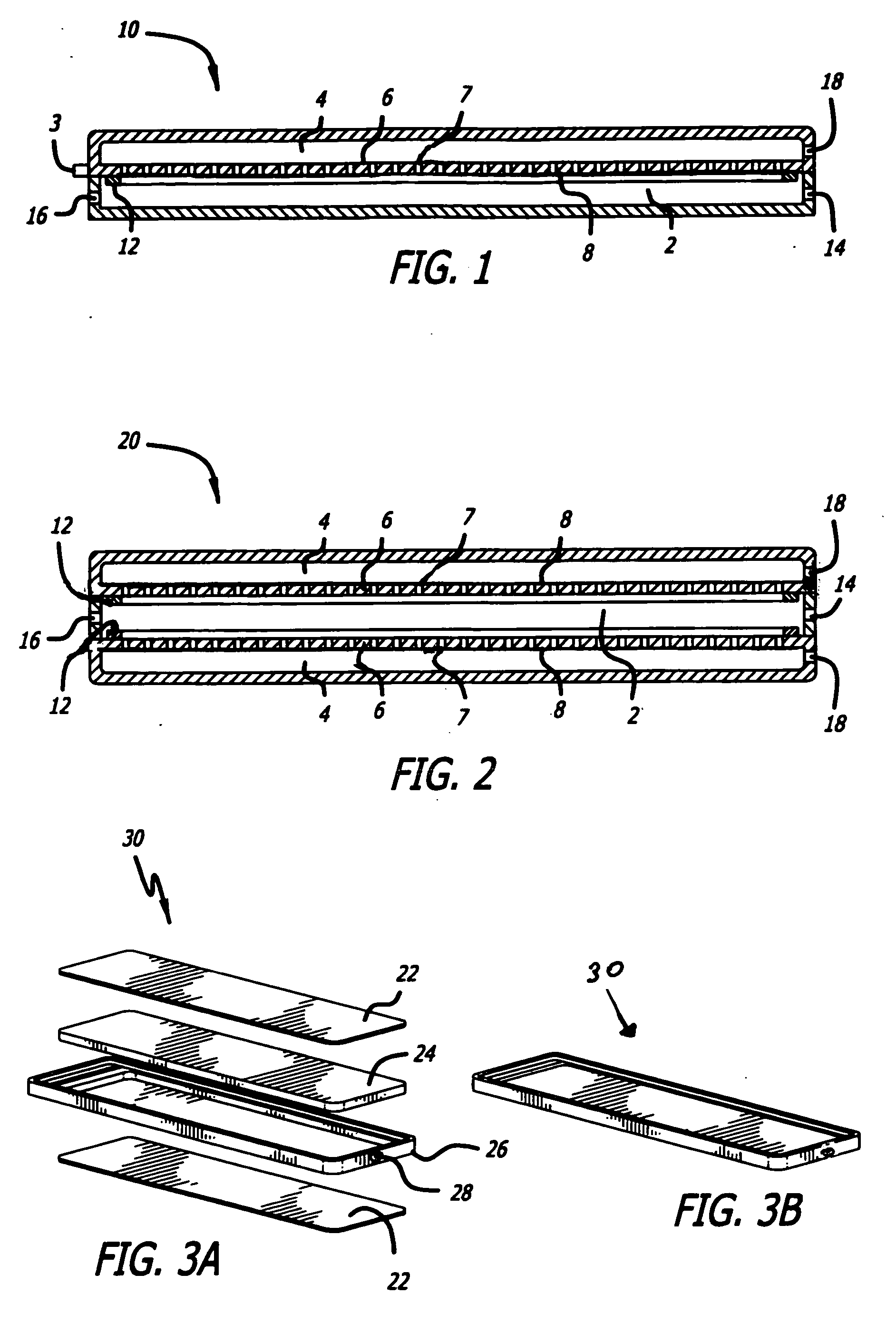

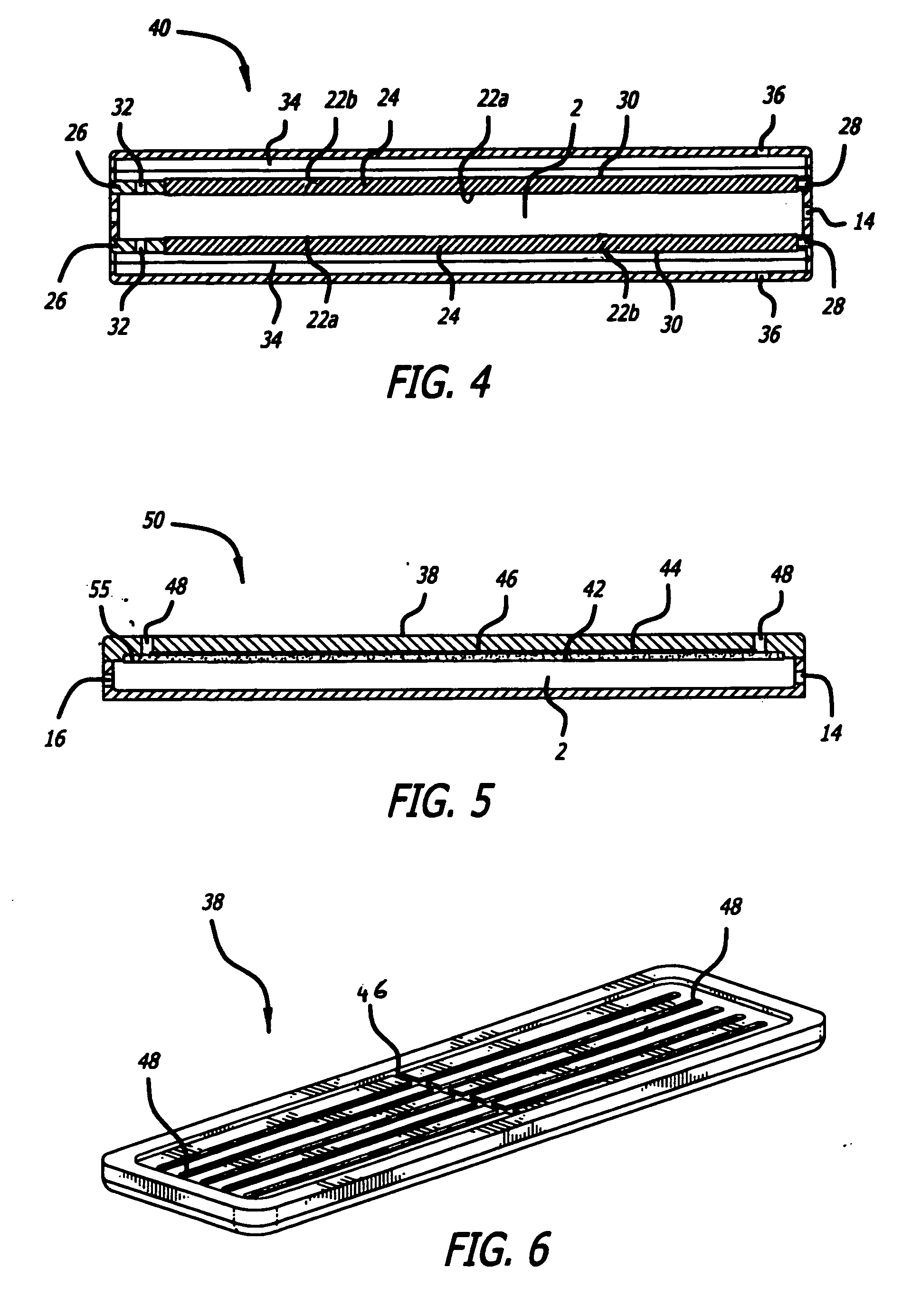

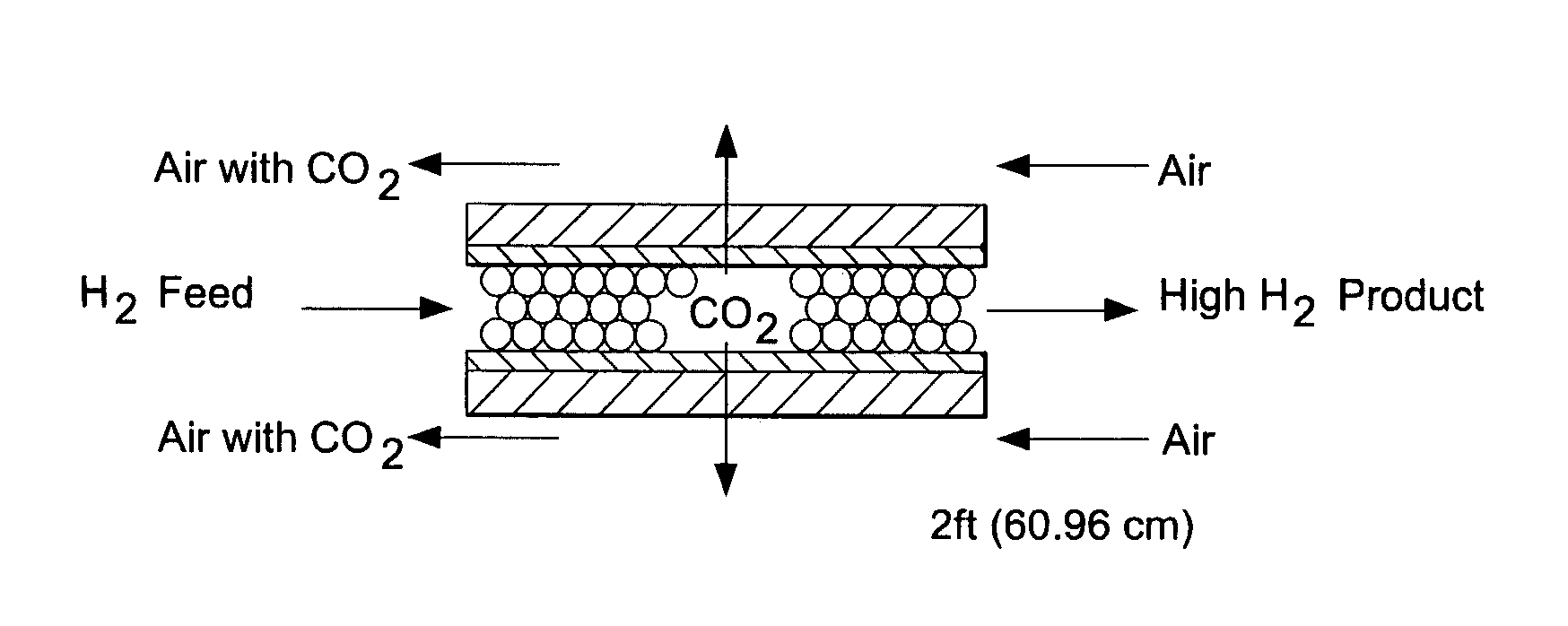

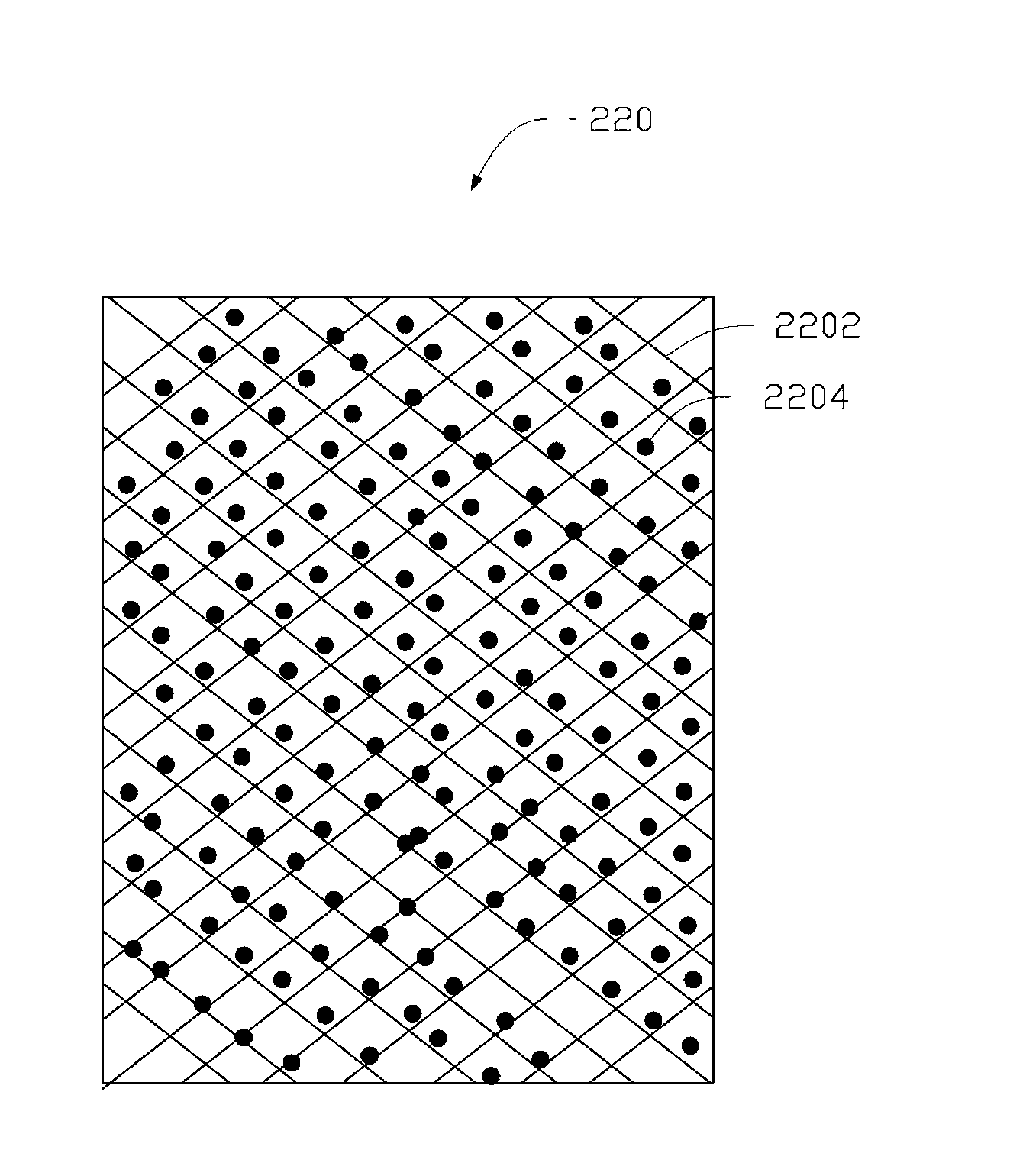

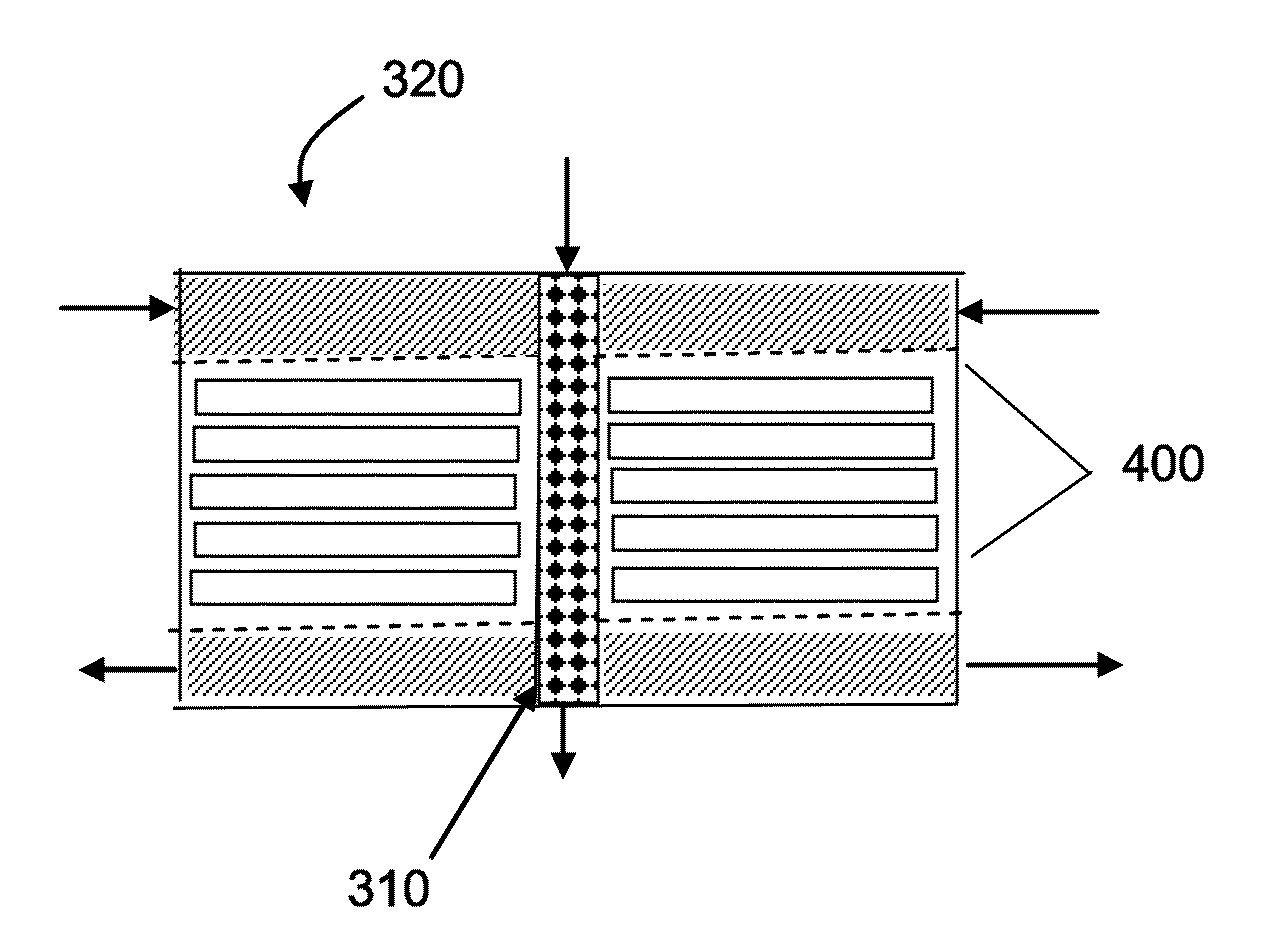

Array of planar membrane modules for producing hydrogen

InactiveUS20100068132A1High purityLow costChemical/physical/physico-chemical microreactorsIsotope separationMembrane reactorMembrane configuration

A shared or common environment membrane reactor containing a plurality of planar membrane modules with top and bottom thin foil membranes supported by both an intermediary porous support plate and a central base which has both solid extended members and hollow regions or a hollow region whereby the two sides of the base are in fluid communication. The membrane reactor operates at elevate temperatures for generating hydrogen from hydrogen rich feed fuels.

Owner:VENCILL THOMAS R +2

Solid oxide fuel cell (SOFC) for coproducing syngas and electricity by the internal reforming of carbon dioxide by hydrocarbons and electrochemical membrane reactor system

InactiveUS7410717B2Improve energy efficiencyImprove efficiencyCell electrodesFuel cell auxillariesElectrochemistryMembrane reactor

The present invention relates to a solid oxide fuel cell for internal reforming of hydrocarbons and carbon dioxide, in particular, to a solid oxide fuel cell in which one side of solid oxide electrolyte (YSZ) is attached to an air electrode (La0.8Sr0.2MnO3) and its other side is attached to a catalyst electrode of Ni-YSZ type or perovskite type metal oxide. The electrochemical conversion system using the solid oxide fuel cell permits the occurrence of internal reforming of hydrocarbons and carbon dioxide concomitantly with the coproduction of a syngas and electricity, and overcomes the shortcomings associated with the catalytic deactivation due to carbon deposition and the high-energy consumption.

Owner:KOREA INST OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com