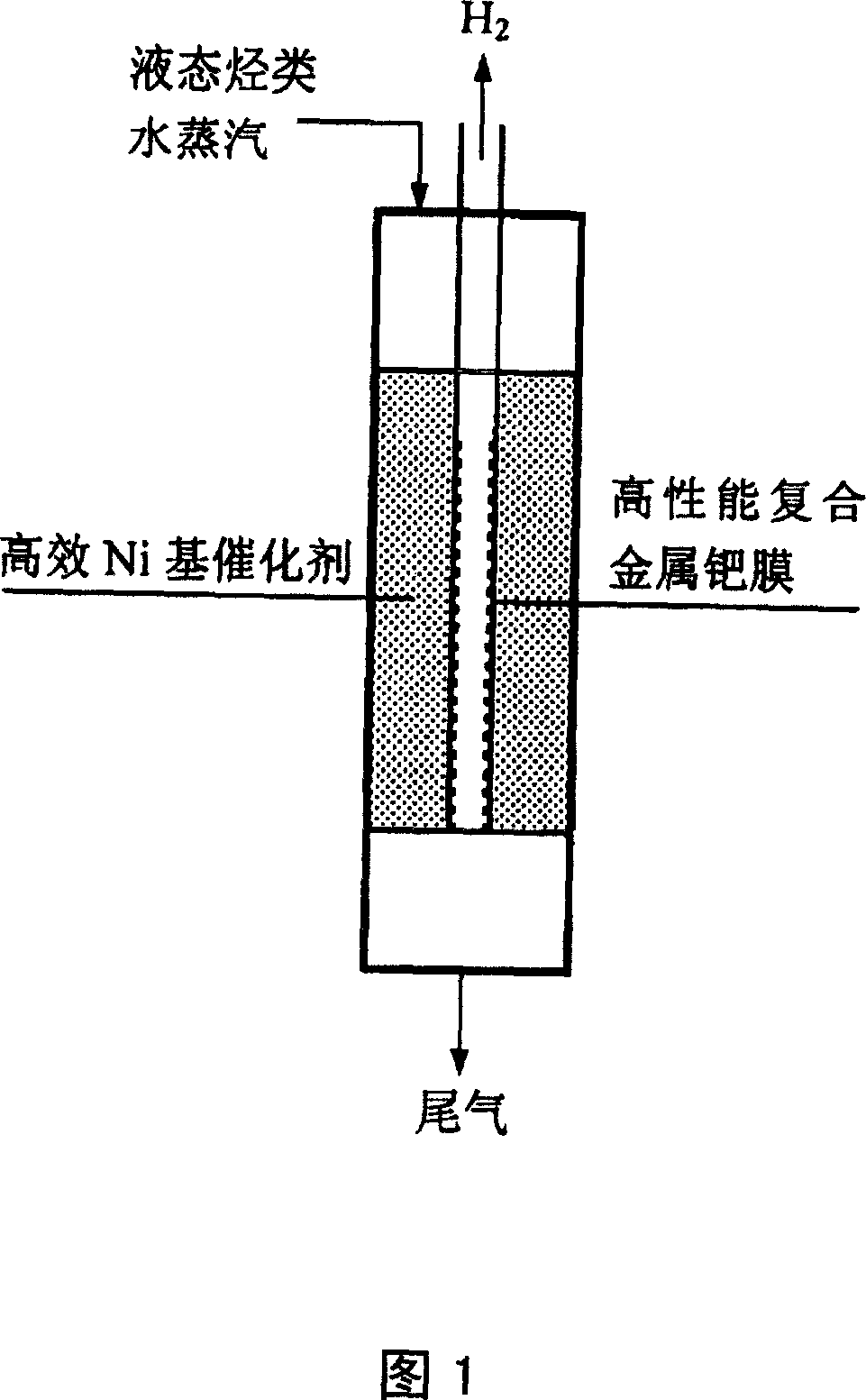

Process of preparing high purity hydrogen with liquid hydrocarbon in a palladium film reactor

A liquid hydrocarbon and reactor technology, which is applied in the field of producing high-purity hydrogen in a high-performance composite metal palladium membrane reactor, can solve the problems of high hydrogen selectivity and low methane selectivity, and achieve the effect of avoiding methanation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] With Ni(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O is the raw material, using (NH 4 ) 2 CO 3 As a precipitating agent, the temperature of the two solutions is controlled at room temperature for co-precipitation, and the pH is maintained at 8.0-8.5 during the precipitation process. After the precipitation is completed, it is aged for 2 hours, then washed, dried at 120 ° C, and roasted at 600 ° C for 4 hours. Control the NiO content in the catalyst at 40wt%, Al 2 o 3 is 60wt%. Take 5.5 g of the above catalyst, dilute it with quartz sand, and put it into a palladium membrane reactor with a bed height of 100 mm. The hydrogen permeation rate of the selected composite metal membrane is 52m 3 m -2 bar -1 h -1 , H 2 / N 2The separation factor is above 10,000. Using 6# solvent oil produced in Daqing as raw material, the fuel injection rate is 0.34ml / min, and the water injection rate is 0.80ml / min. The reaction was carried out at 550°C and 1.1 MPa, and the purge gas...

Embodiment 2

[0030] With Ni(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O and La(NO 3 ) 3 ·6H 2 Ni / La-Al prepared by co-precipitation method with O as raw material 2 o 3 Catalyst to NH 3 ·H 2 O is a precipitating agent, and the pH of the precipitation process is controlled to be about 8.0. After the precipitation process is completed, it is aged for 1 hour, washed by centrifugation, then dried at 120°C, and roasted at 600°C for 4 hours to prepare a composition of 50wt% NiO and 42wt% Al 2 o 3 , and 8 wt% La 2 o 3 catalyst. In a conventional fixed-bed reactor, using isooctane as a raw material, the performance of the catalyst was measured at 450°C, 500°C, and 550°C respectively. During the reaction, S / C=2.73 and pressure P=0.8MPa. The results in Table 1 show that the prepared catalyst has good low-temperature steam reforming activity, even if the carbon space velocity is as high as 30,000h -1 , at the temperature of 450°C, 500°C and 550°C, the conversion rate of liquid hydrocarbons ca...

Embodiment 3

[0034] With Ni(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O and Mg(NO 3 ) 2 ·6H 2 O is the raw material, using (NH 4 ) 2 CO 3 As a precipitant, control the temperature of the two solutions at room temperature for co-precipitation, maintain the pH at 8.0-8.5 during the precipitation process, age for 2 hours after the precipitation, then wash, dry at 120 ° C, and roast at 700 ° C for 4 hours. The composition of the catalyst is 36 wt% NiO, 12 wt% MgO and 52 wt% Al 2 o 3 , the prepared catalyst was crushed and sieved after being pressed into tablets, and Ni / MgO-Al with a particle size of 420-630 μm was taken 2 o 3 5.5g of the catalyst was diluted with quartz sand and loaded into a palladium membrane reactor with a bed height of 100mm. The hydrogen permeation rate of the selected composite metal membrane is 65m 3 m -2 bar -1 h -1 , H 2 / N 2 The separation factor is above 10,000. Using isooctane as a raw material, the carbon space velocity of the reaction in liquid hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com