Patents

Literature

61results about How to "Reduce acid strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Selective hydrodesulfurization catalyst and preparation method thereof

ActiveCN102335612AReduce acid strengthEnhance the interaction strengthMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsAlkaline earth metalHydrodesulfurization

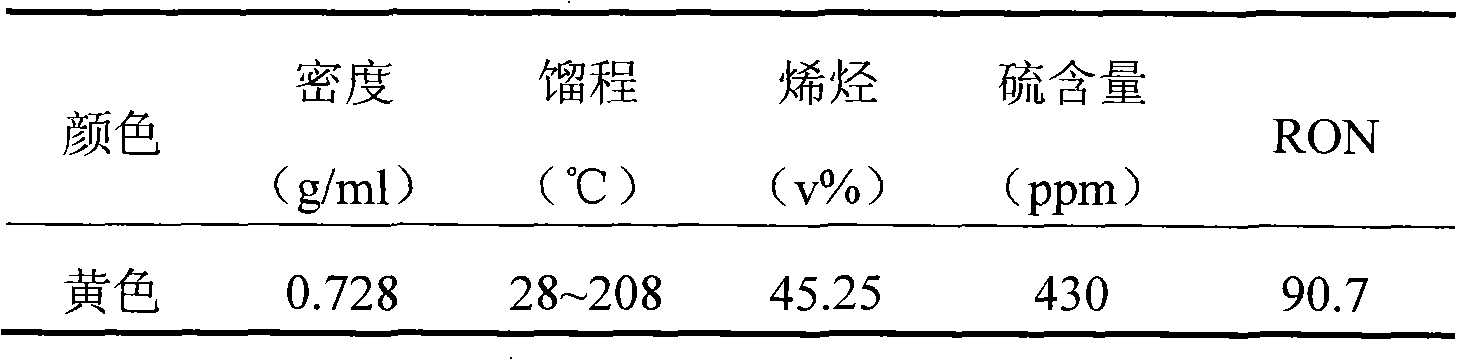

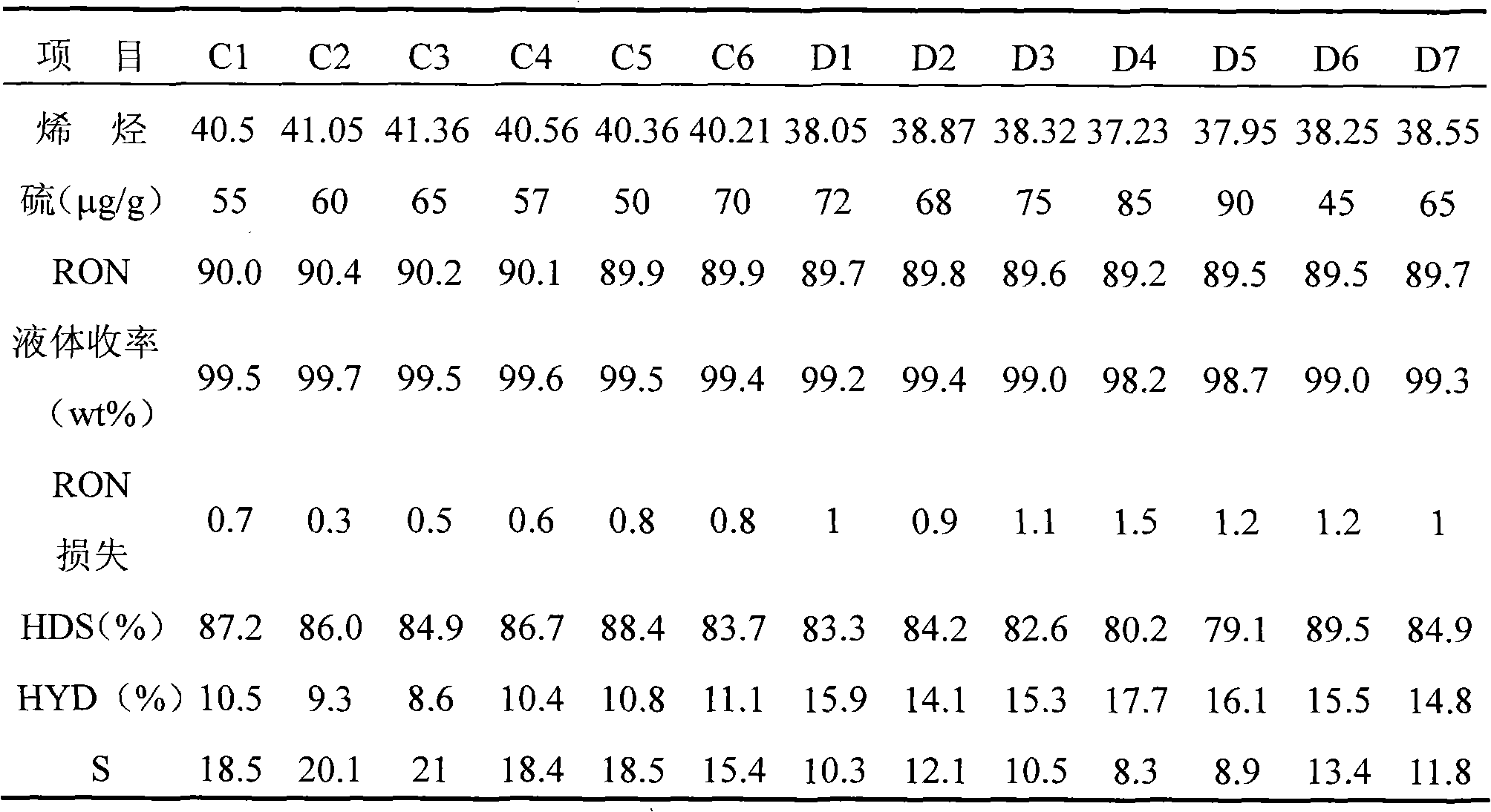

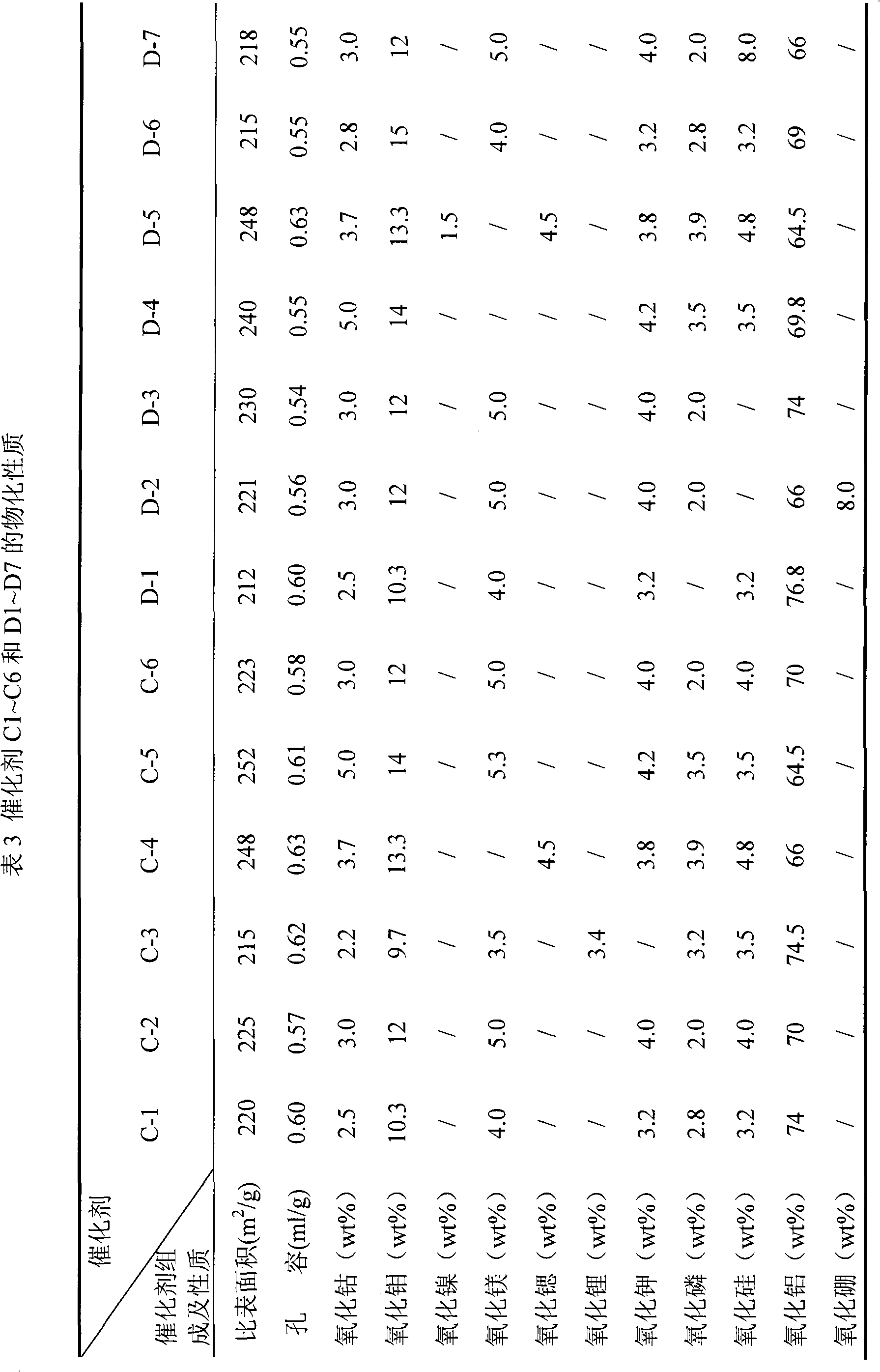

The invention relates to a selective hydrodesulfurization catalyst contains cobalt and molybdenum as active components. The selective hydrodesulfurization catalyst is characterized in that silicon oxide and aluminum oxide are used as carriers of the catalyst; based on the total weight of 100%, the catalyst comprises 2-6wt% of cobalt oxide, 9-15 wt% of molybdenum oxide, 2-8wt% of alkaline earth metal oxide, 2-6wt% of phosphorus oxide, 3-5wt% of alkali metal oxide, 2-6wt% of silicon oxide and 54-80 wt% of aluminum oxide; and the catalyst has the specific surface area of 200-300m<2> / g and the pore volume of 0.5-0.7mL / g. The catalyst has high hydrogenation activity and selectivity, good stability, low research octane number loss and high liquid yield. The catalyst is suitable for selective hydrodesulfrization of low-quality gasoline and is particularly suitable for selective hydrodesulfrization of low-quality FCC (Family Car China) gasoline.

Owner:PETROCHINA CO LTD

Dehydrogenation catalyst taking Sn-containing alumina as carrier and preparation method thereof

ActiveCN101898131ALarge specific surface areaHigh selectivityCatalyst activation/preparationHydrocarbonsFiberAdditive ingredient

The invention discloses a dehydrogenation catalyst taking Sn-containing alumina as a carrier and a preparation method thereof. The dehydrogenation catalyst takes the Sn-containing alumina as the carrier, nano fibers are carried on the pore surface of the carrier, and dehydrogenation active metal ingredients are carried by an immersion method. The preparation method for the catalyst comprises the following steps of: introducing the carrier to Sn when the alumina is gelled, carrying the carbon nano fibers to the Sn-containing alumina carrier in situ by ethylene cracking, then immersing the dehydrogenation active ingredients, and performing thermal treatment and water vapor treatment to obtain the final dehydrogenation catalyst. When the catalyst is used for a hydrocarbon dehydrogenation reaction process, in particular a propane dehydrogenation process, the catalyst has the advantages of high activity, high selectivity and the like, and particularly greatly improves the stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Dehydrogenation catalyst and preparation method and application thereof

ActiveCN103769156AReduce acid contentReduce acid strengthHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsManganeseDehydrogenation

The invention discloses a dehydrogenation catalyst and a preparation method and application thereof. The dehydrogenation catalyst uses ammonia processed alumina as a carrier, chrome as an active component, and one or a plurality of potassium, manganese, cobalt, iron, nickel, copper and zinc as an additive, the additive is loaded onto the carrier by a co-impregnation method, and taking oxide weight content in the final catalyst as a reference, the catalyst comprises 2%-6% of chromium oxide, and 0.1-5% of the additive. The preparation method of the hydrocarbon dehydrogenation catalyst comprises the following processes: using ammonia to preprocess an alumina carrier, using the co-impregnation method to load one or a plurality of potassium, manganese, cobalt, iron, nickel, copper and zinc, and loading the active component chrome. The dehydrogenation catalyst can be used in dehydrogenation of propane for preparation of propylene. The low carbon alkane dehydrogenation catalyst prepared by the preparation method has the advantages of low active component chromium oxide content, good propylene selectivity, high activity and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Application method of heteropoly acid type catalyst

InactiveCN1390643AImprove catalytic performancePrevent dehydrationPhysical/chemical process catalystsHeteropoly acidSolid acid

A process for improving the acid intensity stability of solid acid catalyst containing heteropoly acid or its salt (0.5-100 wt.%) features that said heteropoly acid or its salt has central atom (P or Si) and coordinating atom chosen from W, Mo and V, and there is water in reaction atmosphere.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

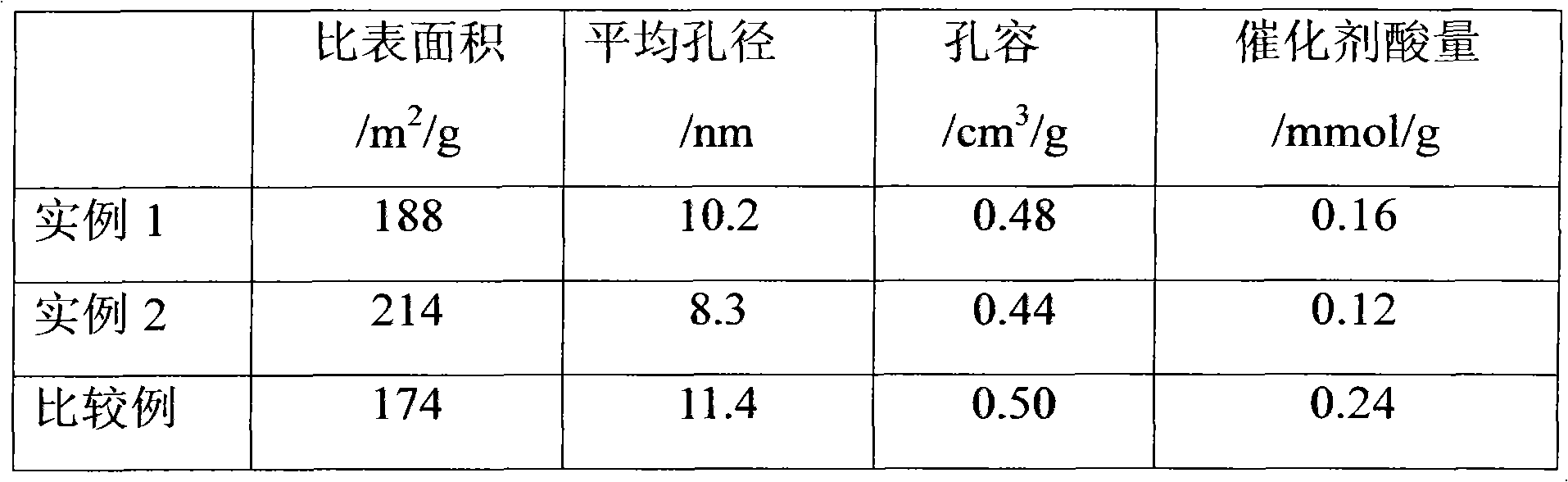

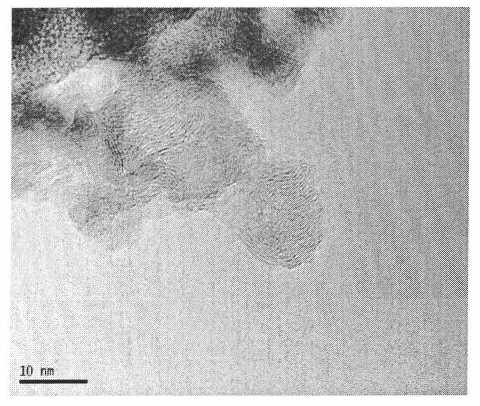

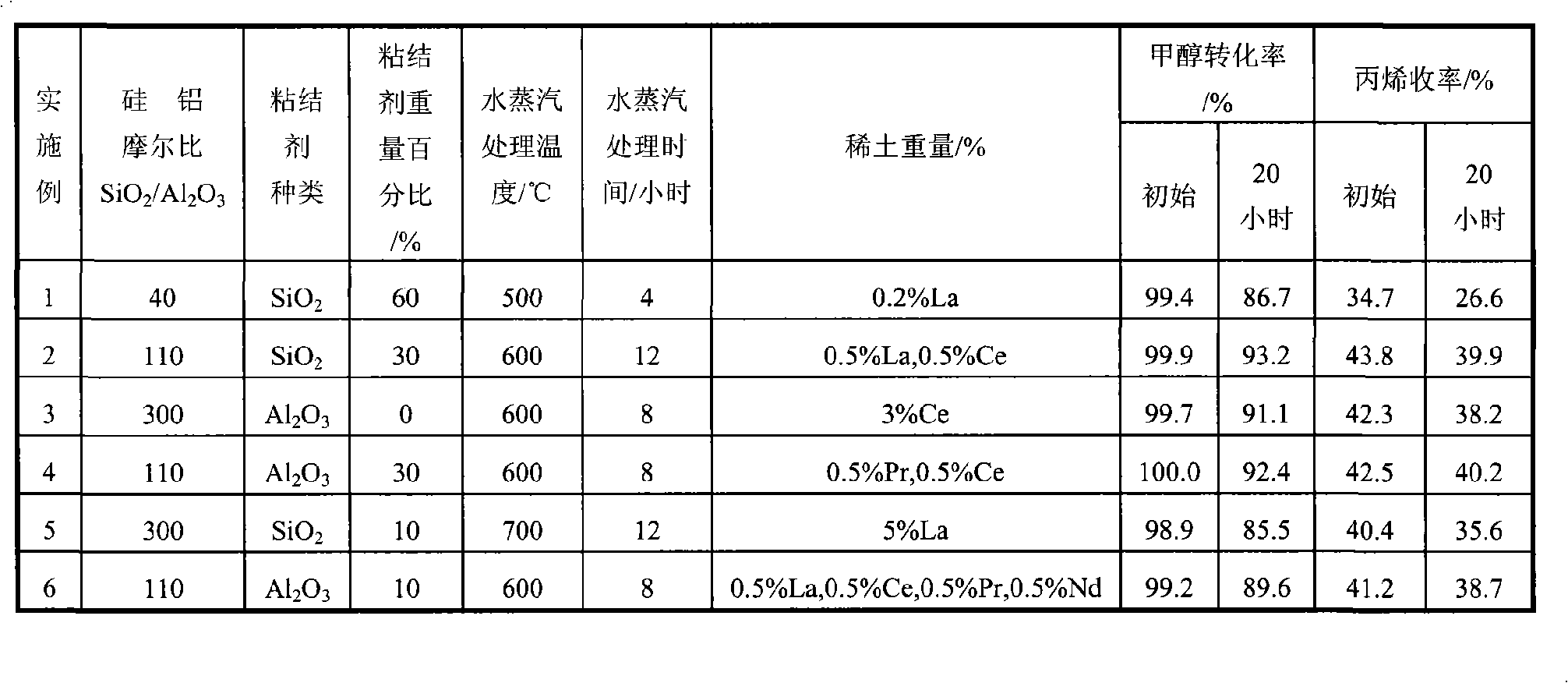

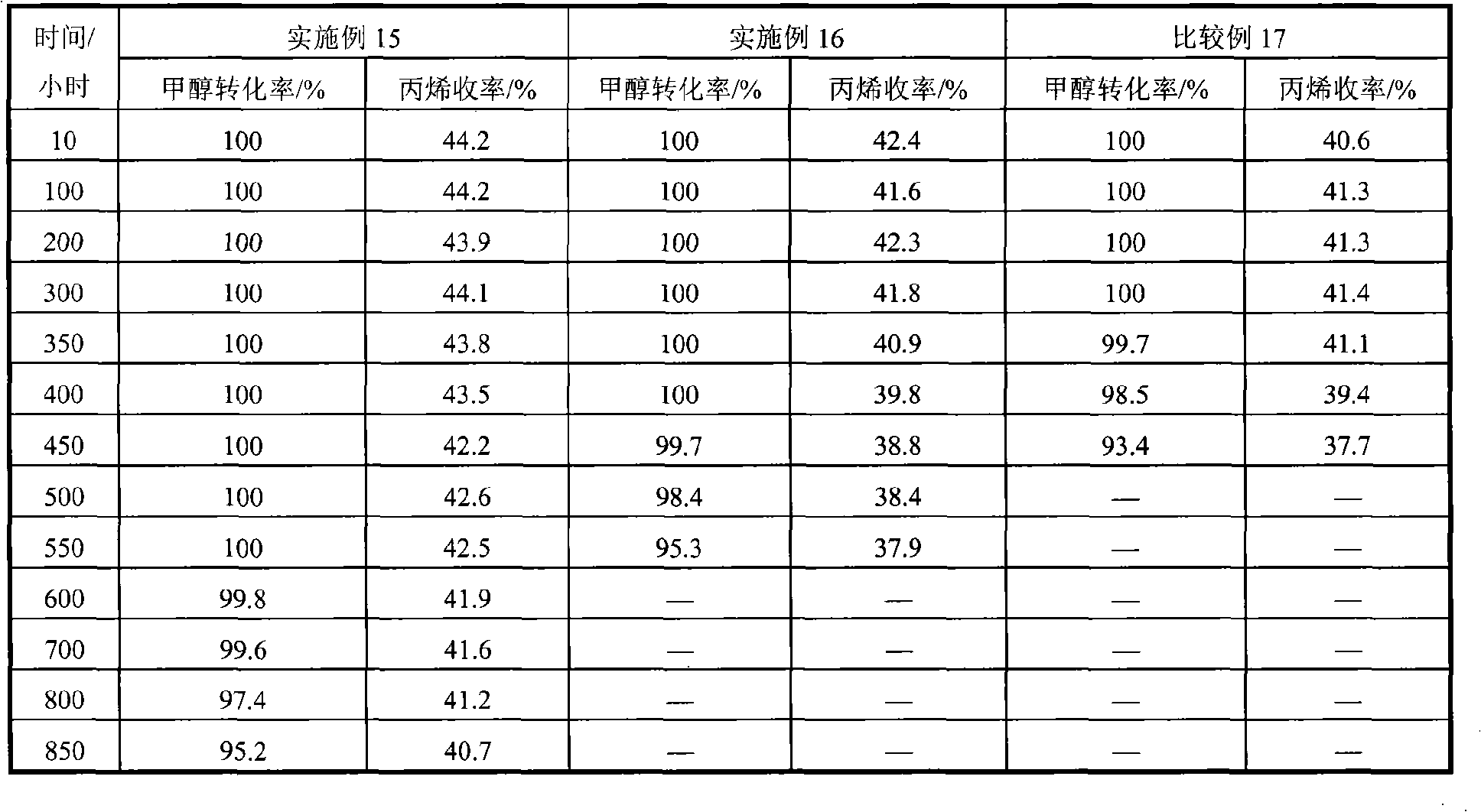

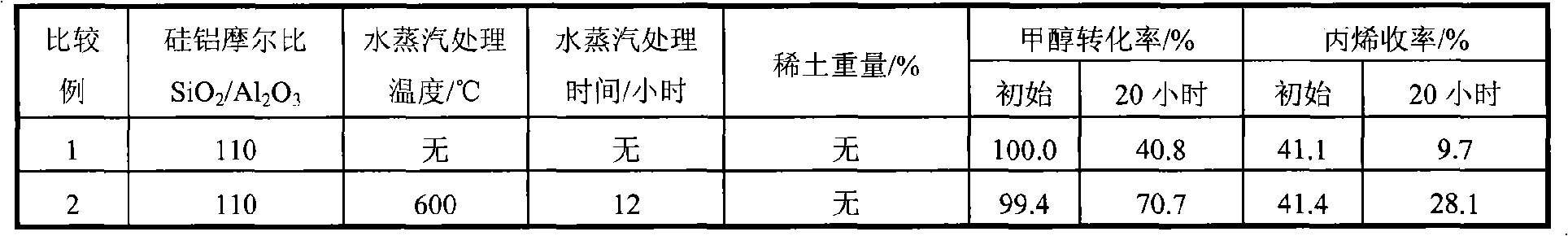

High stability molecular sieve catalyst for preparing propylene transformed from methanol and preparation thereof

ActiveCN101279281AStay acidicImprove anti-coking performanceMolecular sieve catalystsHydrocarbon from oxygen organic compoundsCerium nitratePhosphoric acid

The present invention relates to a high stability molecular sieve catalyst for preparing propylene by being converted from methanol and a preparation method thereof which mainly solve the problems of poor molecular sieve stability and water thermal stability as well as easy coking and deactivation in the prior art. The present invention adopts the technical proposal of adopting the molecular sieve raw powder with a silicon-aluminum mol ratio SiO2Al2O3 of 20 to 1000 and a weight percentage of 25 to 99.9 percent as well as at least one caking agent from SiO2, clay and Al2O3 to extrude, tablet or spray ball to shape; then treating for 1 to 8 hours by 0.1 to 3 mol / l of at least one ammonium liquor from ammonium nitrate, ammonium chloride or ammonium sulphate or 0.1 to 8.5 mol / l of at least one acid liquor from muriatic acid, nitric acid, vitriol, phosphoric acid or acetic acid under a temperature of 20 to 90 DEG C; then using 0.1 to 5 percent of at least one liquor selected from lanthanum, cerium nitrate or chloride calculated by weight percentage to treat for 4 to 8 hours under a temperature of 20 to 90 DEG C; then using steam to treat for 2 to 15 hours under the temperature condition of 400 to 700 DEG C; using a liquor of 0.1 to 3mol / l selected from at least one of oxalic acid, citric acid, phosphoric acid and maleic acid under a temperature condition of 20 to 90 DEG C to dip for 2 to 5 hours to obtain the modified molecular sieve catalyst, thus better solving the problems. The present invention can be used in the industrial production of propylene by being converted from methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Support for gas-phase oxidation catalyst and process for its production, gas-phase oxidation catalyst, and process for producing acrylic acid

ActiveUS7456129B2Easy to handleHigh yieldOrganic compound preparationOther chemical processesGas phaseCatalytic oxidation

A support for a gas-phase oxidation catalyst, the support including a solid acid, of which acid strength (H0) meets an inequality: −5.6≦H0≦1.5; a gas-phase oxidation catalyst including the above support and a complex oxide containing molybdenum and vanadium as essential components, the complex oxide being supported on the support; a process for producing acrylic acid by gas-phase catalytic oxidation of acrolein with molecular oxygen, the process including carrying out the gas-phase catalytic oxidation in a presence of the above gas-phase oxidation catalyst; and a process for producing the above support, the process including controlling an acid strength (H0) of a solid acid so as to meet an inequality: −5.6≦H0≦1.5 by adjusting a calcination temperature in a preparation of the solid acid contained in the support.

Owner:NIPPON SHOKUBAI CO LTD

Support for gas-phase oxidation catalyst and process for its production, gas-phase oxidation catalyst,and process for producing acrylic acid

ActiveUS20060234861A1Easily absorbHigh yieldOther chemical processesOrganic compound preparationAcroleinAcrylic acid

A support for a gas-phase oxidation catalyst, the support including a solid acid, of which acid strength (H0) meets an inequality: −5.6≦H0≦1.5; a gas-phase oxidation catalyst including the above support and a complex oxide containing molybdenum and vanadium as essential components, the complex oxide being supported on the support; a process for producing acrylic acid by gas-phase catalytic oxidation of acrolein with molecular oxygen, the process including carrying out the gas-phase catalytic oxidation in a presence of the above gas-phase oxidation catalyst; and a process for producing the above support, the process including controlling an acid strength (H0) of a solid acid so as to meet an inequality: −5.6≦H0≦1.5 by adjusting a calcination temperature in a preparation of the solid acid contained in the support.

Owner:NIPPON SHOKUBAI CO LTD

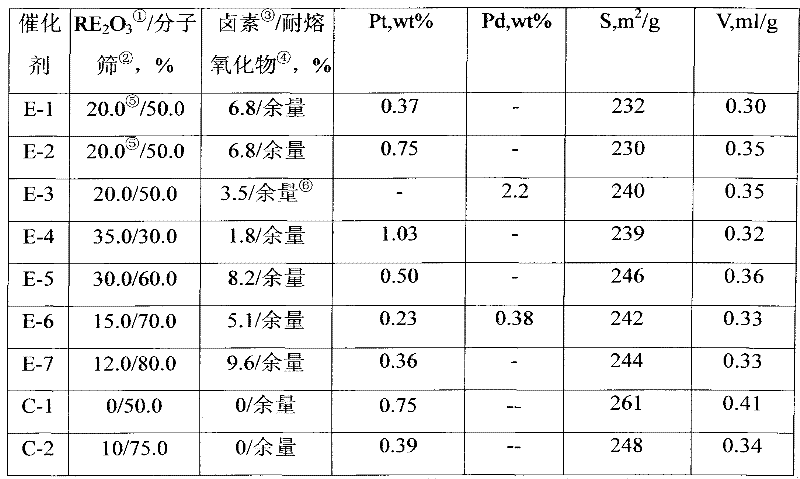

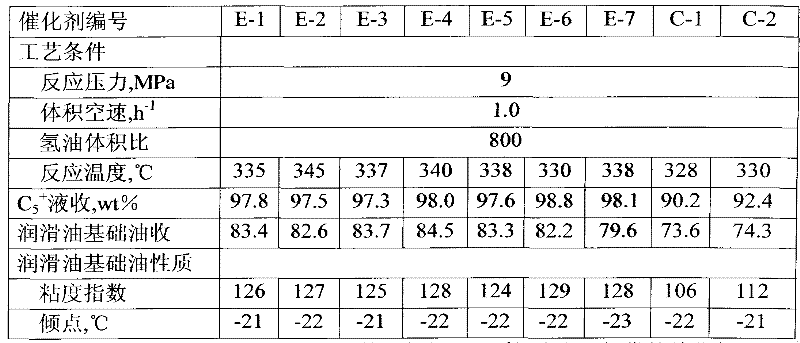

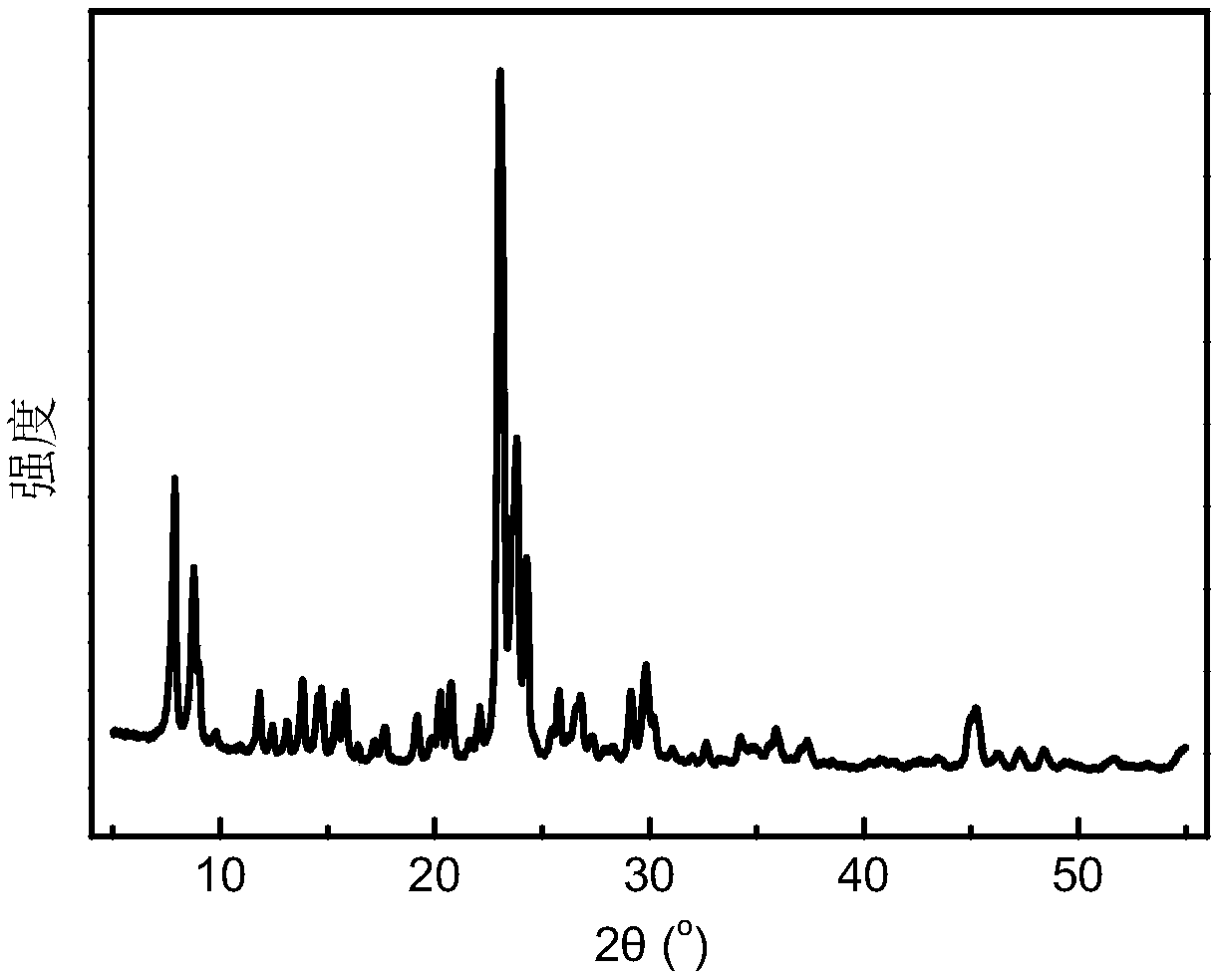

Paraffin hydrocarbon shape selective isomerization catalyst, preparation method and application thereof

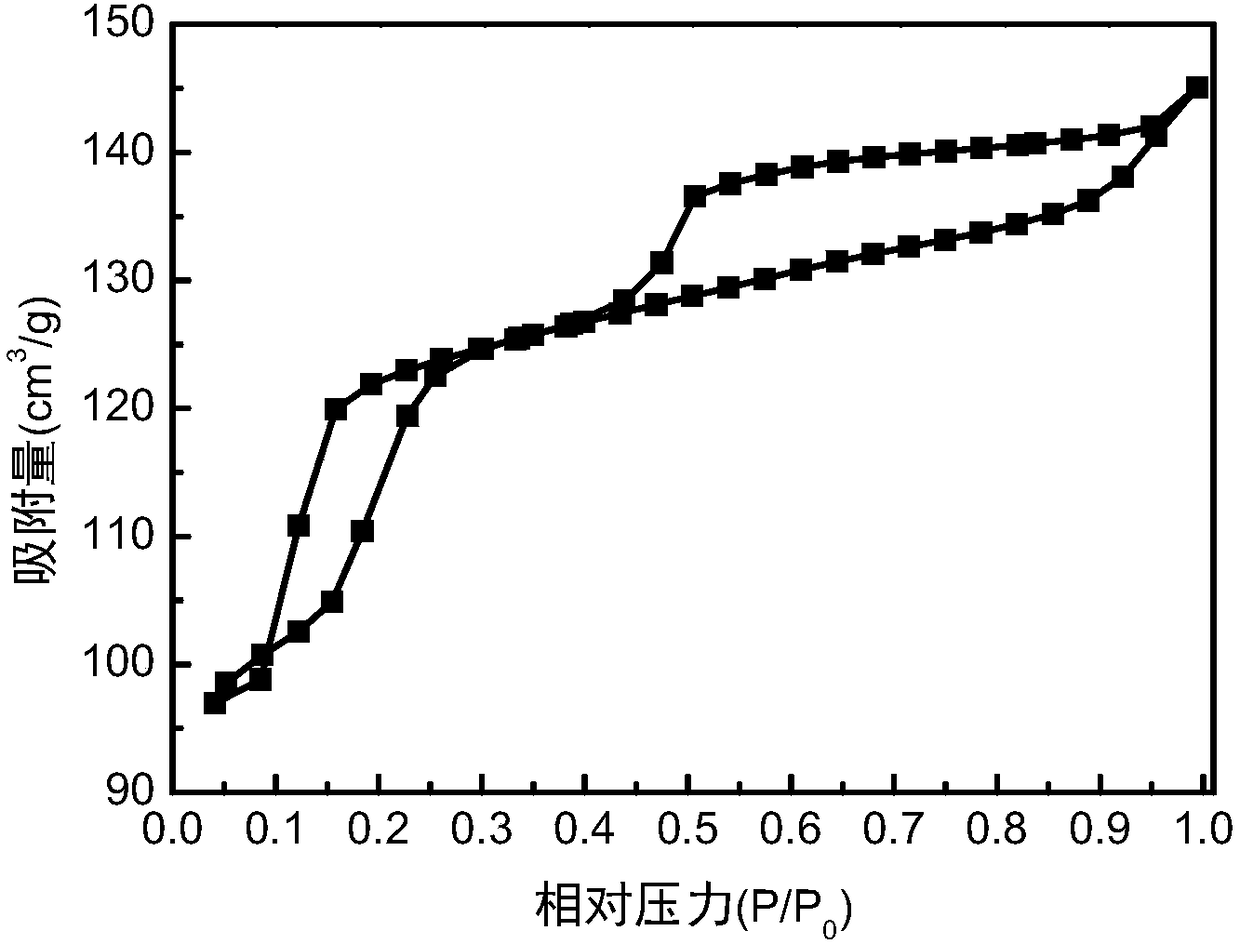

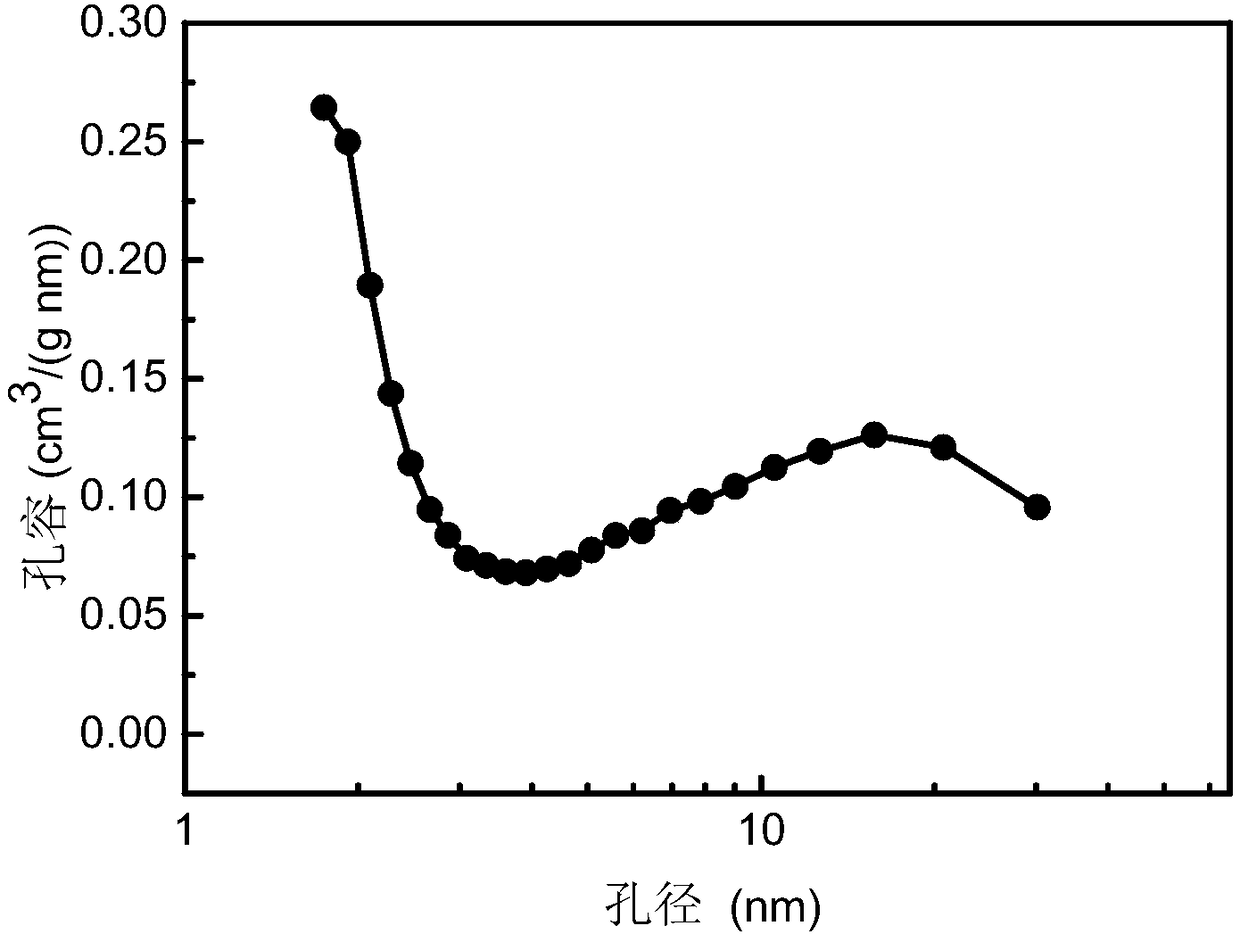

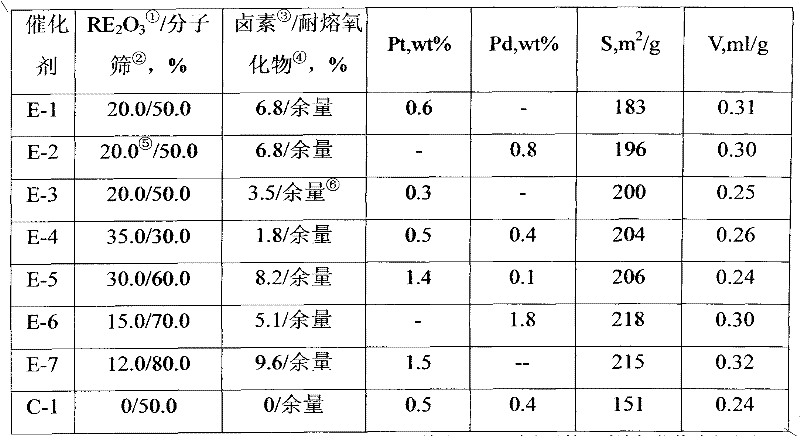

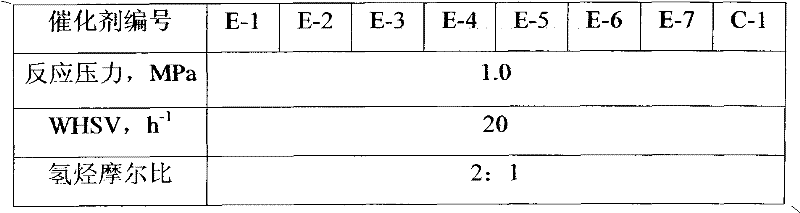

ActiveCN102441417AHigh yieldHigh viscosity indexMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveIsomerization

The invention discloses a paraffin hydrocarbon shape selective isomerization catalyst, a preparation method and application thereof. The catalyst comprises a rare earth-modified molecular sieve and a halogen-modified inorganic melting-resisting oxide and at least one VIII-family precious metal, wherein the molecular sieve is a TON type molecular sieve, the weight ratio of the rare earth-modified molecular sieve to the halogen-modified inorganic melting-resisting oxide is 10:90-90:10, in the catalyst, the content of the VIII-family precious metal is 0.1-10 percent by weight, in the rare earth-modified molecular sieve, the mass content of the rare earth oxide is 0.5-60.0 percent, and in the halogen-modified inorganic melting-resisting oxide, the mass content of the halogen is 0.1-20.0 percent. Compared with the prior art, the catalyst is especially suitable for a hydroprocessing process of lubricating oil distillate, and has the characteristics of high yield of a target product, low flow point and high viscosity index.

Owner:CHINA PETROLEUM & CHEM CORP +1

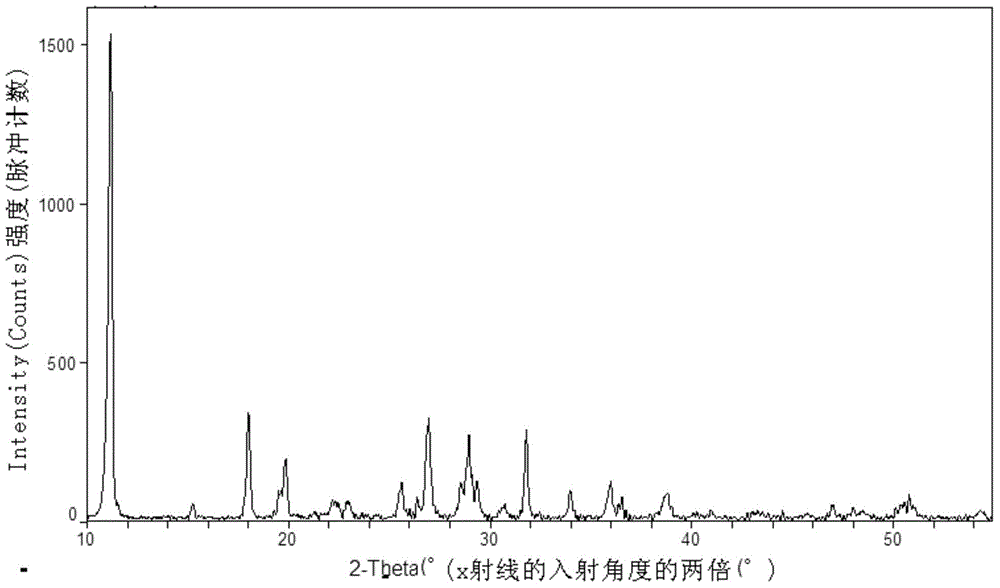

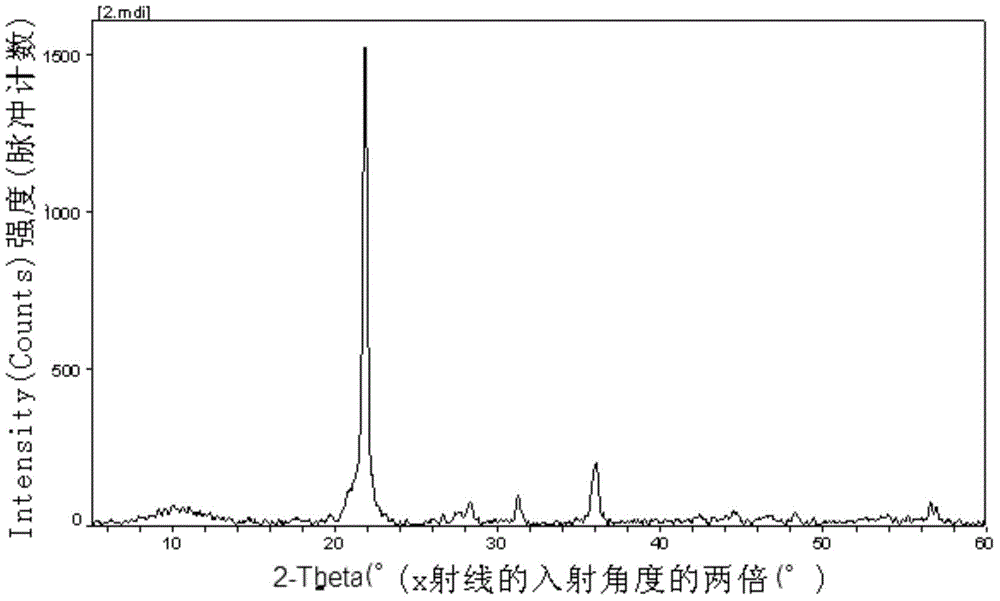

Mesoporous Zn-ZSM-5 molecular sieve and low-cost preparation method thereof

ActiveCN108435235AGood dispersionReduced Diffusion ResistanceMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveIsomerization

The invention relates to a mesoporous Zn-ZSM-5 molecular sieve and a low-cost preparation method thereof. The diameters of mesoporouss are centralized at 5-30nm, and the specific surface area is 300-600m<2> / g; and the content of zinc oxide is 0.1-10wt% of the total weight of the molecular sieve. The mesoporous Zn-ZSM-5 molecular sieve is low in acid strength, good in dispersity of Zn and strong inanti-carbon deposition performance and can be applied to the fields of hydrocracking, catalytic cracking, hydrocarbon isomerization and the like.

Owner:邵武绿闽环保科技有限公司

Isomerization catalyst and its application

ActiveCN103100413AHigh activityImprove stabilityHydrocarbon by isomerisationMolecular sieve catalystsAlkanePtru catalyst

The invention discloses an isomerization catalyst and its application. The catalyst comprises the following components by weight: 0.01%-5% of a group VIII noble metal element in the periodic table of elements, 10%-80% of rare earth modified mordenite, 0.1%-10% of an assistant, and the balance a binder with a halogen content of 0.5%-5%, as well as based on the weight of the rare earth modified mordenite, 5%-40% of a rare-earth oxide. The catalyst is used for an isomerization process of C4-C12 alkanes, has the characteristics of high catalytic activity and high iso-olefin selectivity, and can be used as a blending component for producing high octane gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Regeneration method of zeolite molecular sieve catalyst

InactiveCN102744103ASmall changes in mass transfer performanceImprove regeneration efficiencyMolecular sieve catalystsCatalyst regeneration/reactivationMolecular sieveAmmonia

The invention relates to a regeneration method of a zeolite molecular sieve catalyst to mainly solve technical problems of catalyst structure destroy and catalytic performance decrease caused by present zeolite catalyst regeneration technologies. The method, which allows the problems to be well solved through a technical scheme that the structure and catalytic performances of a regenerated catalyst are near to that of a fresh catalyst by contacting an ammonia-containing raw material with a deactivated catalyst at 100-300DEG C, can be applied to the regeneration of the zeolite catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

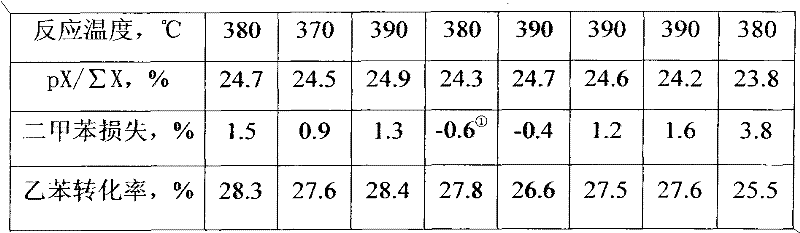

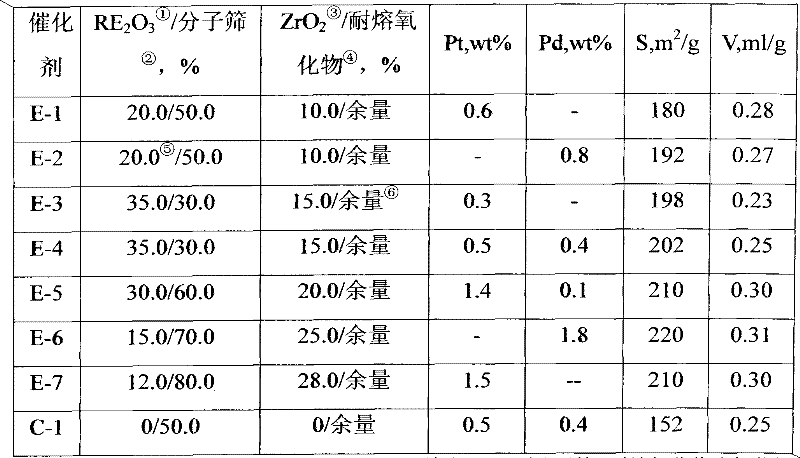

C8 aromatic hydrocarbon isomerization catalyst, preparation method and application thereof

ActiveCN102441420AHigh yieldReduce energy consumptionHydrocarbon by isomerisationMolecular sieve catalystsMolecular sieveIsomerization

The invention relates to a C8 aromatic hydrocarbon isomerization catalyst which comprises a rare earth-modified molecular sieve, a halogen-modified inorganic melting-resisting oxide and at least one VIII-family precious metal, wherein the molecular sieve is an EUO molecular sieve, the weight ratio of the rare earth-modified molecular sieve to the halogen-modified inorganic melting-resisting oxideis 10:90-90:10, in the catalyst, the content of the VIII-family precious metal is 0.1-10 percent by weight, in the rare earth-modified molecular sieve, the mass content of the rare earth oxide is 0.5-60.0 percent, and in the halogen-modified inorganic melting-resisting oxide, the mass content of the halogen is 0.5-20.0 percent. Compared with the prior art, the catalyst can ensure that the dimethylbenzene is isomerized and ethylbenzene is selectively transformed into paraxylene when used in C8 aromatic hydrocarbon isomerization and the concentration of the paraxylene in the catalyst in dimethylbenzene reaches or approaches a thermodynamic equilibrium value, and has high yield of the dimethylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

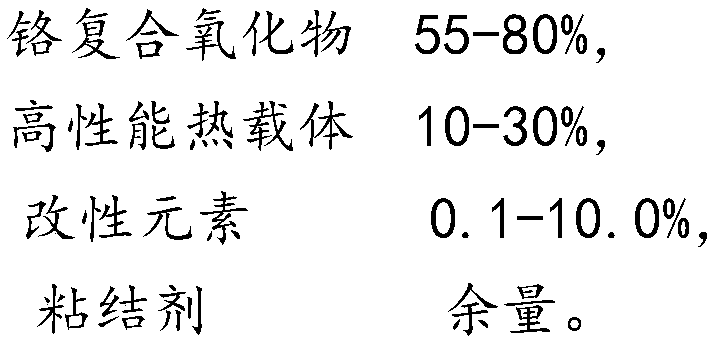

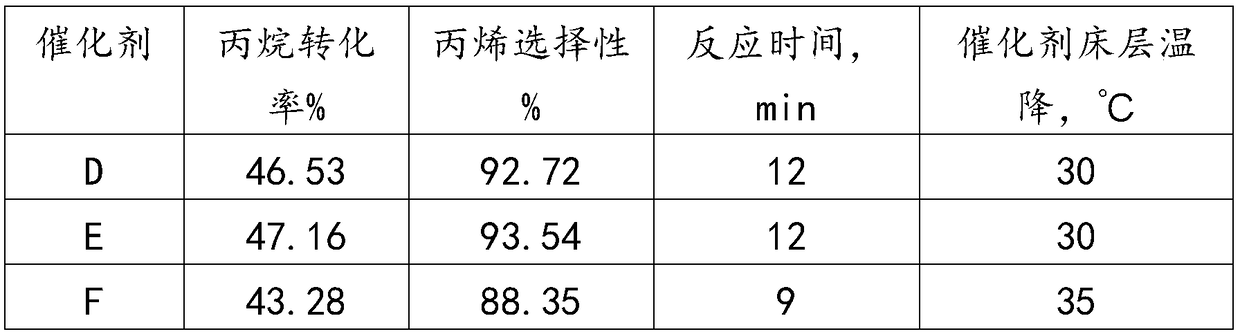

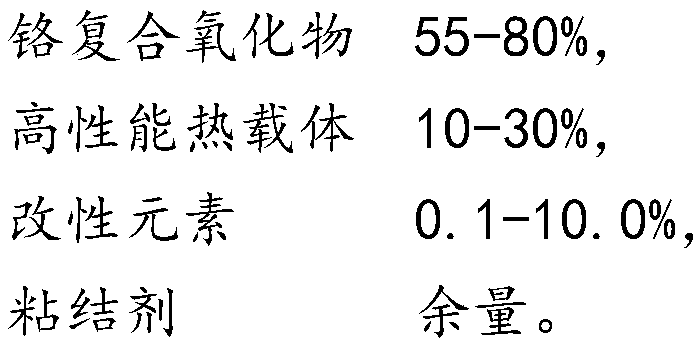

Propane dehydrogenation catalyst and preparation method thereof

ActiveCN108654596AGood dispersionImprove effective utilizationCatalystsHydrocarbon preparation catalystsDispersityChromium Compounds

The invention discloses a propane dehydrogenation catalyst and a preparation method thereof. Chromium compound oxide is used as an active component, is mixed with a high-performance thermal carrier, is added with an adhesive and a modifying element, and then is mixed and kneaded, subjected to band extrusion, dried and roasted to prepare the catalyst. The propane dehydrogenation catalyst comprisesthe following components in percentages by mass: 55-80% of the chromium compound oxide, 10-30% of the high-performance thermal carrier, 0.1-10.0% of a modifying element and the balance of the adhesive. The dispersity of chromium on the carrier is improved by synthesizing the chromium compound oxide, and the effective utilization rate of the active component and the conversion rate of the raw material propane are increased effectively; by metal modification treatment, the activity and selectivity of the catalyst are improved, and then, the yield of propylene is increased; by high-temperature water vapor treatment, the acid content and the acid strength of the surface of the carrier are greatly reduced, and the coking and olefin cracking reaction of the catalyst is relived effectively; and by addition of the high-performance thermal carrier, the catalyst utilization efficiency is improved effectively, and the production load of the device is increased.

Owner:洛阳市科创石化科技开发有限公司

C8 aromatic hydrocarbon isomerization catalyst and preparation method and application thereof

ActiveCN102441419AHigh activityImprove stabilityHydrocarbon by isomerisationMolecular sieve catalystsMolecular sieveIsomerization

The invention relates to a C8 aromatic hydrocarbon isomerization catalyst and a preparation method and application thereof. The catalyst consists of a rare earth-modified molecular sieve, zirconia-modified inorganic refractory oxide and at least one type of group VIII precious metal, the molecular sieve is an EUO molecular sieve, the weight ratio of the content of the rare earth-modified molecular sieve to the content of the zirconia-modified inorganic refractory oxide is 10:90 to 90:10, and the content of the group VIII precious metal is 0.1 to 10 percent by metal weight; in the rare earth-modified molecular sieve, the content of rare earth oxide is 0.5 to 60.0 percent by massweight; and in the zirconia-modified inorganic refractory oxide, the content of zirconia is 0.1 to 50.0 percent by massweight. Compared with the prior art, the catalyst can isomerize dimethylbenzene and selectively convert ethylbenzene into p-xylene when being used in C8 aromatic hydrocarbon isomerization, the concentration of the p-xylene in the dimethylbenzene in the product reaches or approximates a thermodynamic equilibrium value, and the yield of the dimethylbenzene is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

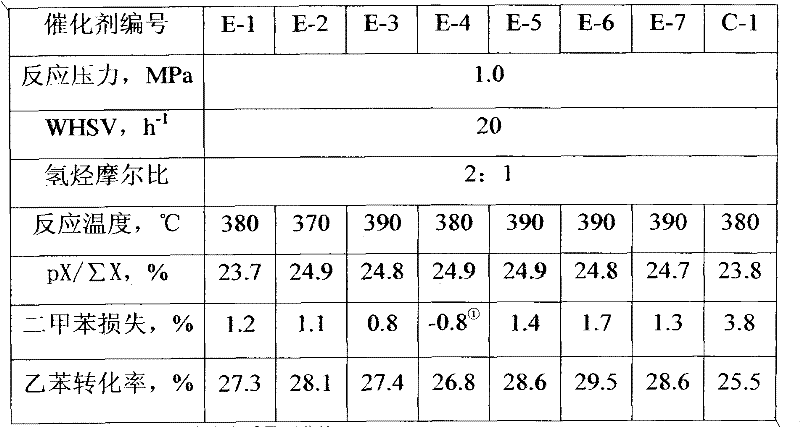

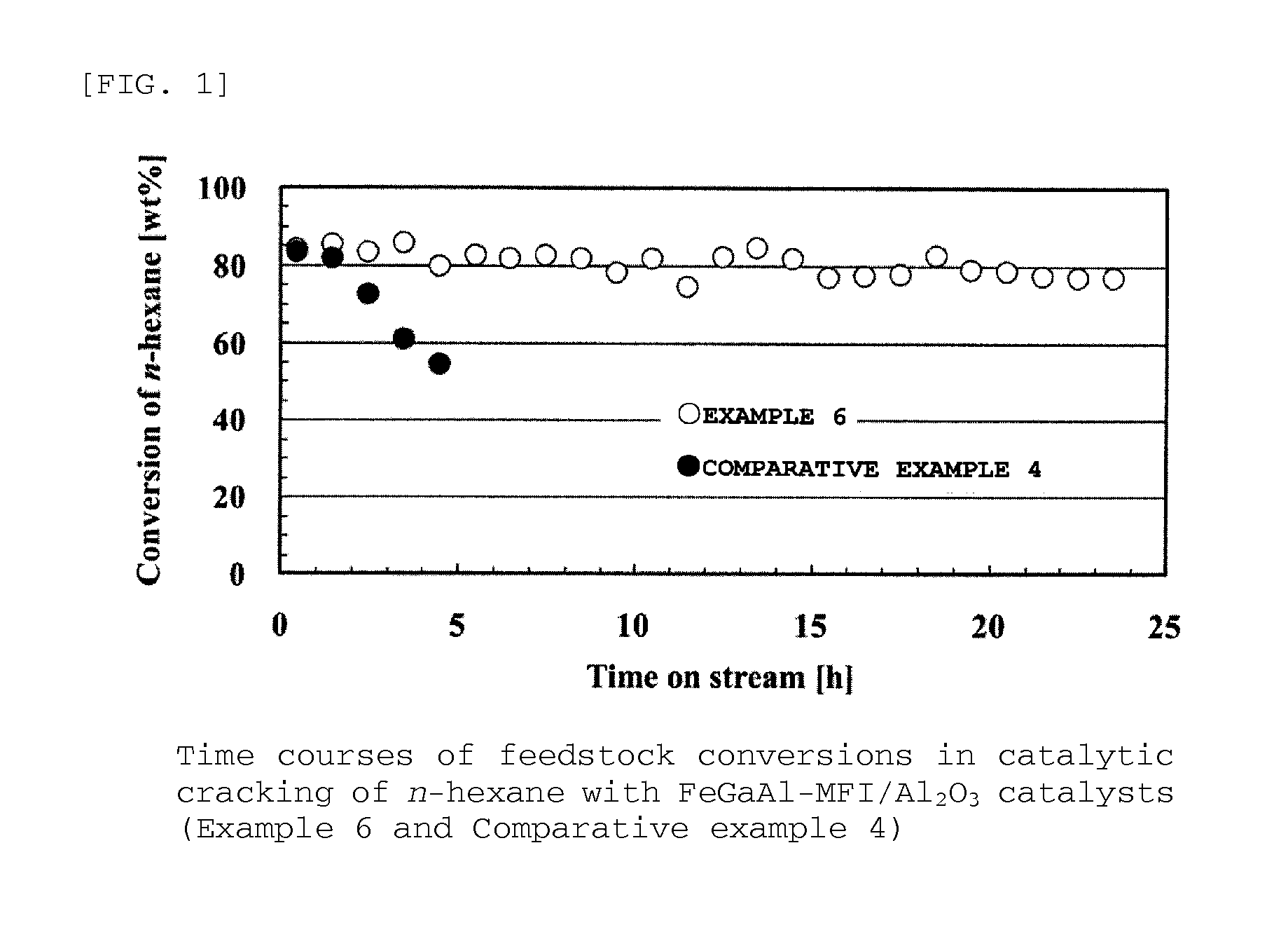

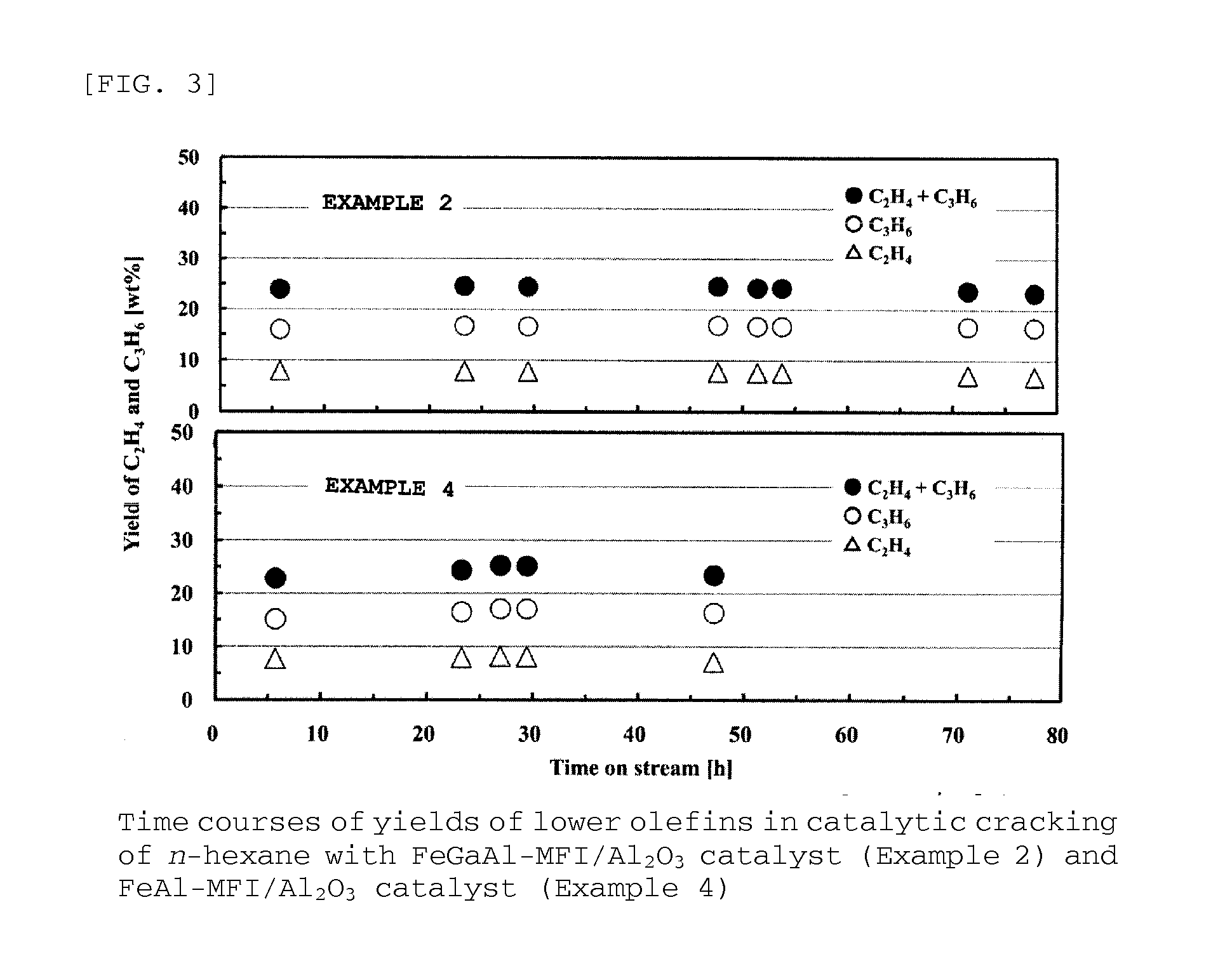

Zeolite catalysts, methods for producing zeolite catalysts, and methods for producing lower olefins

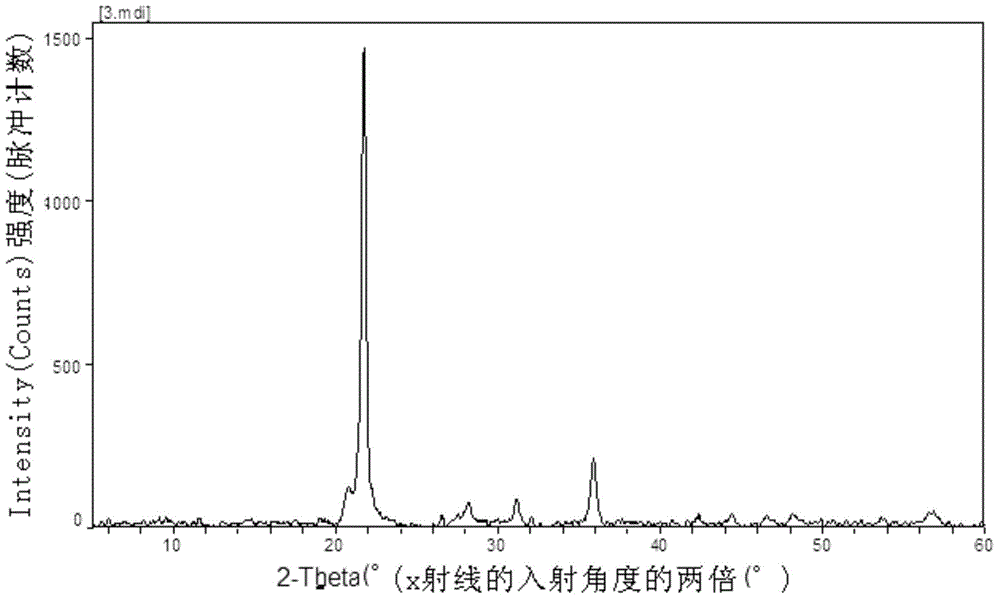

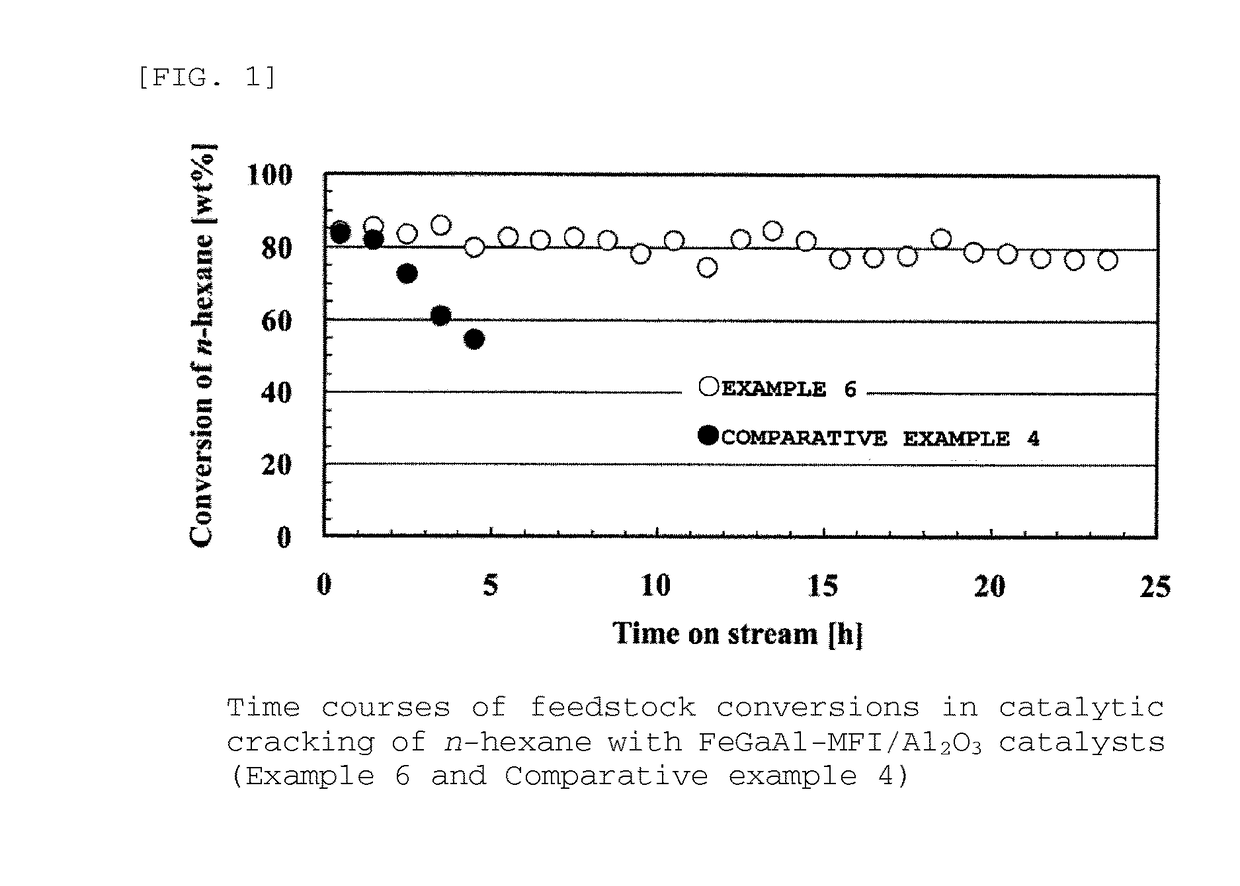

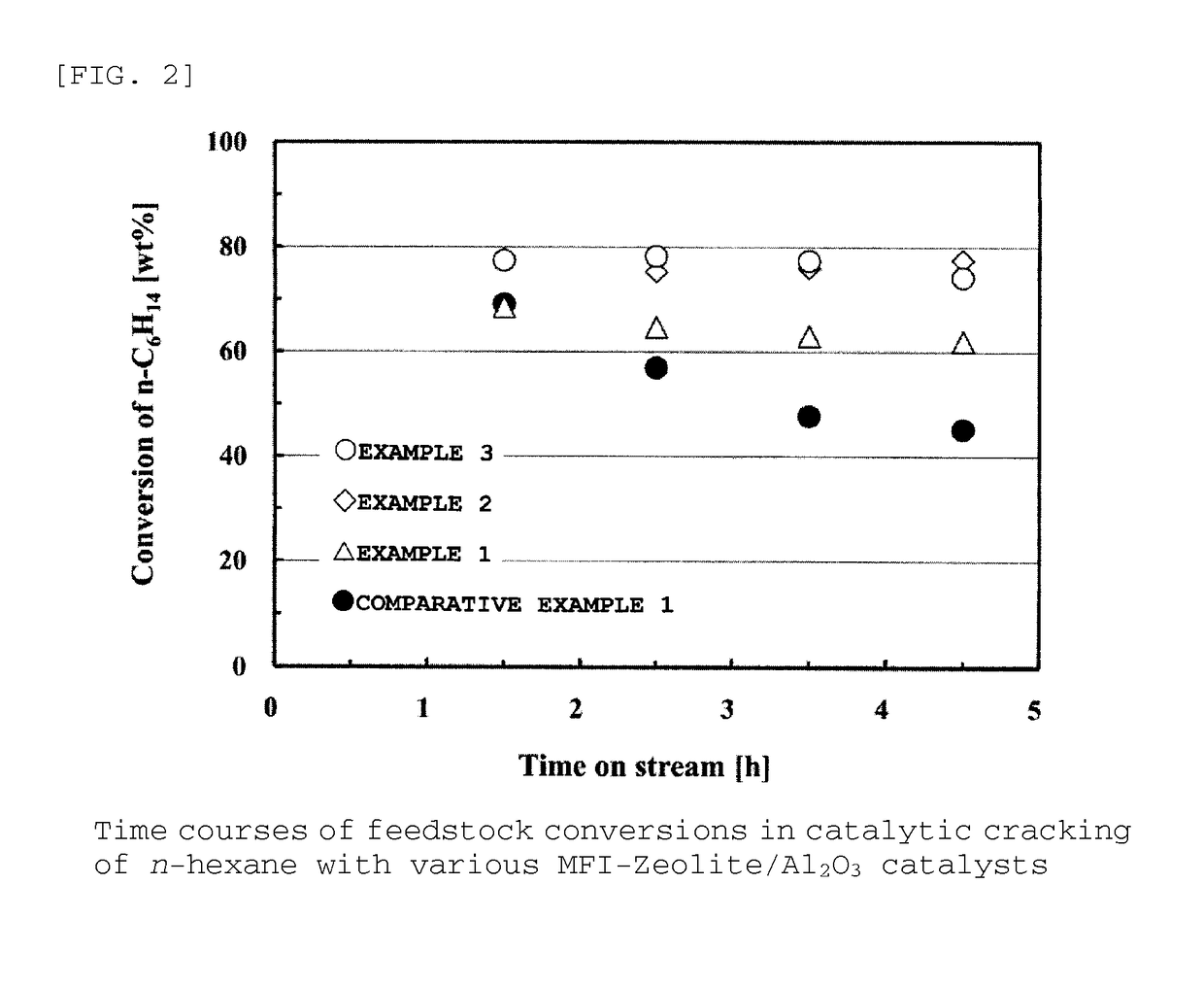

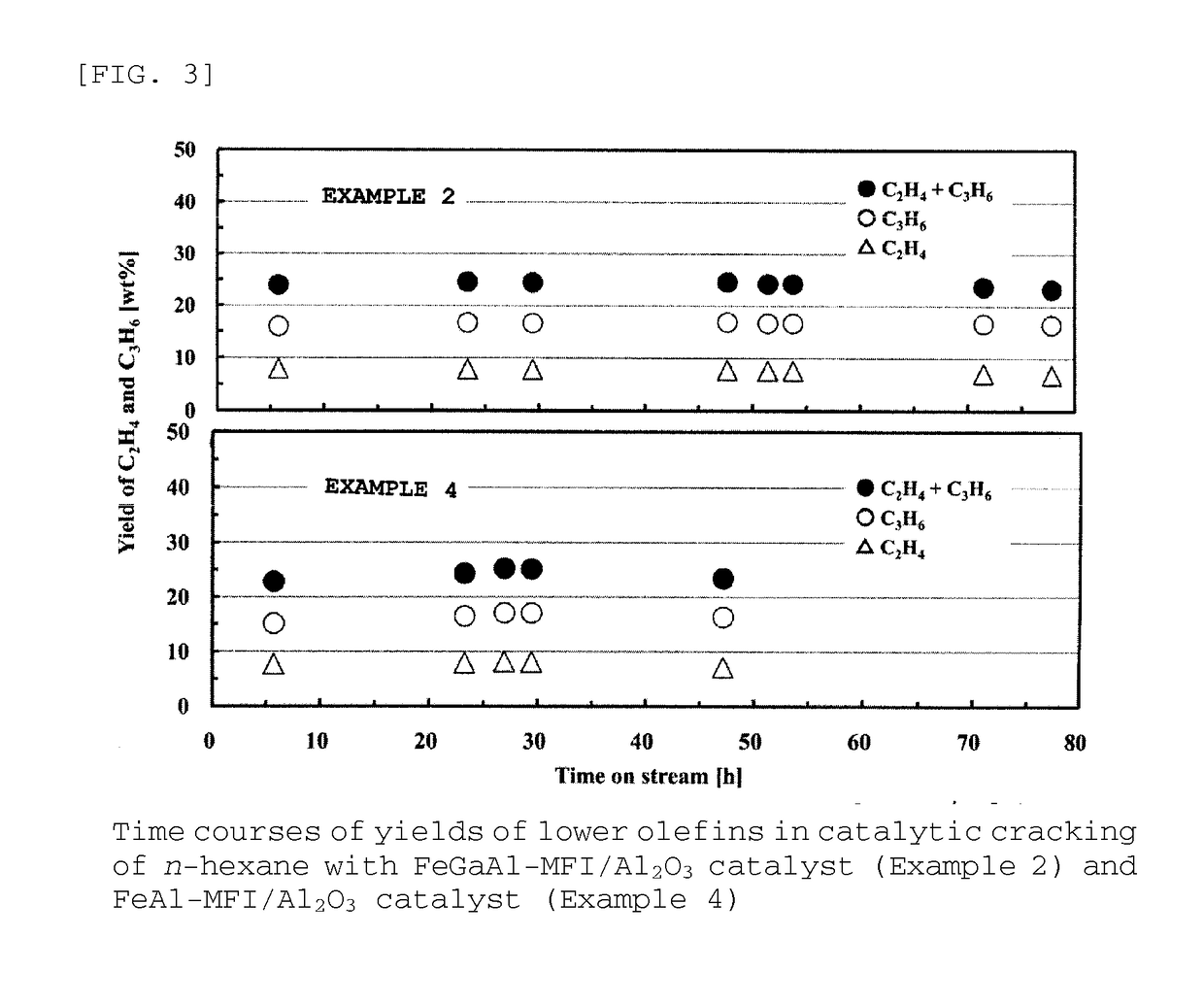

ActiveUS20150174565A1Increased formationReduce acid strengthAluminium compoundsCatalytic crackingNaphthaBoiling point

Provided are zeolite catalysts that allow reactions to proceed at temperatures as low as possible when lower olefins are produced from hydrocarbon feedstocks with low boiling points such as light naphtha, make it possible to make propylene yield higher than ethylene yield in the production of lower olefins, and have long lifetime.The zeolite catalysts are used in the production of lower olefins from hydrocarbon feedstocks with low boiling points such as light naphtha. The zeolite catalysts are MFI-type crystalline aluminosilicates containing iron atoms and have molar ratios of iron atoms to total moles of iron atoms and aluminum atoms in the range from 0.4 to 0.7. The use of the zeolite catalysts make it possible to increase propylene yield, to lower reaction temperatures, and to extend catalyst lifetime.

Owner:CHIYODA CORP

Catalyst for selective paraffin isomerization and preparation method and use thereof

ActiveUS20130248415A1High activityLow freezing pointMolecular sieve catalystsHydrocarbon oils refiningLiquid productAlkane

The present invention discloses a catalyst for paraffin isomerization, as well as a preparation method and use thereof. The catalyst comprises a TON molecular sieve modified by rare earth, an inorganic refractory oxide modified by zirconium oxide and a noble metal of group VIII. The weight ratio of the TON molecular sieve modified by rare earth to the inorganic refractory oxides modified by zirconium oxide is 10:90 to 90:10, and the content of the metal of group VIII is 0.1 to 10 wt % based on the metal. When used in the process of isomerization dewaxing of various raw materials containing paraffins, the catalyst can not only decrease the solidifying points of raw oil containing paraffins, but also increase the yield of liquid products. Particularly, when used in the process of isomerization dewaxing of lubricating oil distillates, the catalyst is advantageous in producing base oil for lubricating oil with a high a higher yield, a lower pour point (solidifying point) and a higher viscosity index.

Owner:CHINA PETROCHEMICAL CORP +1

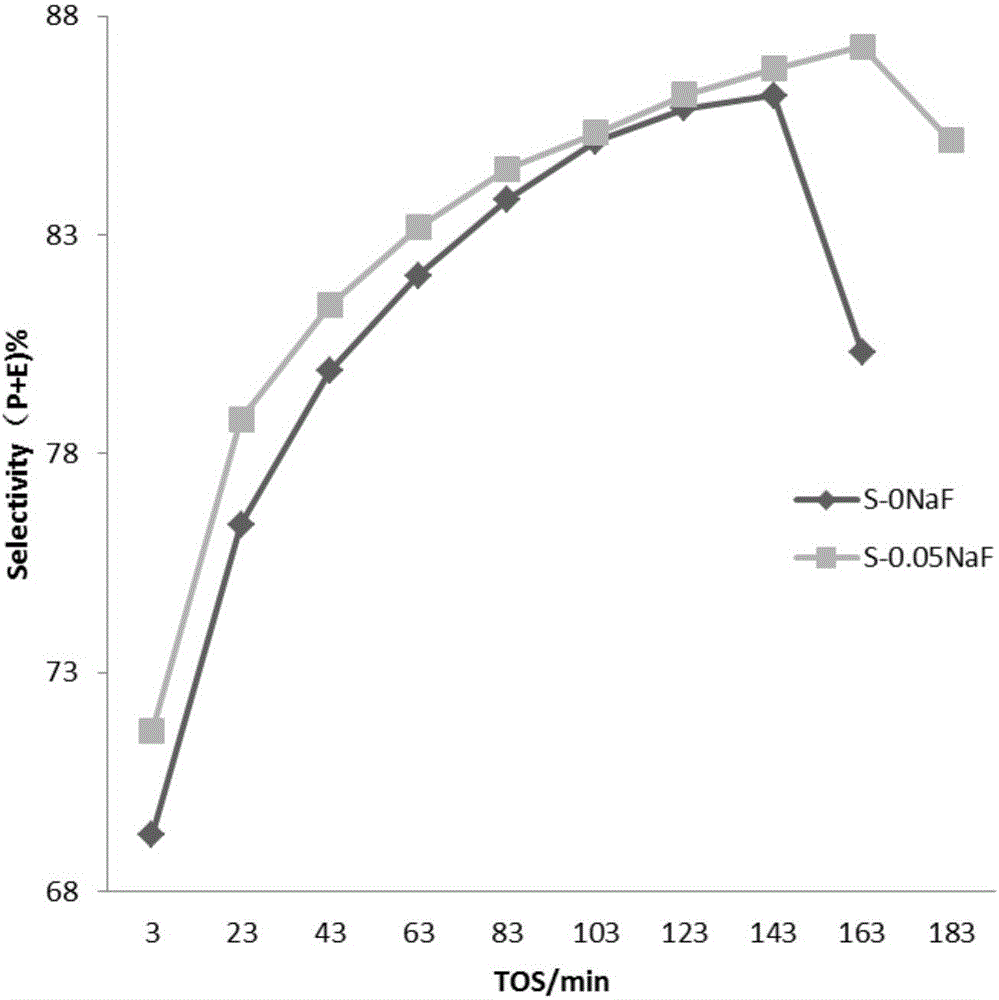

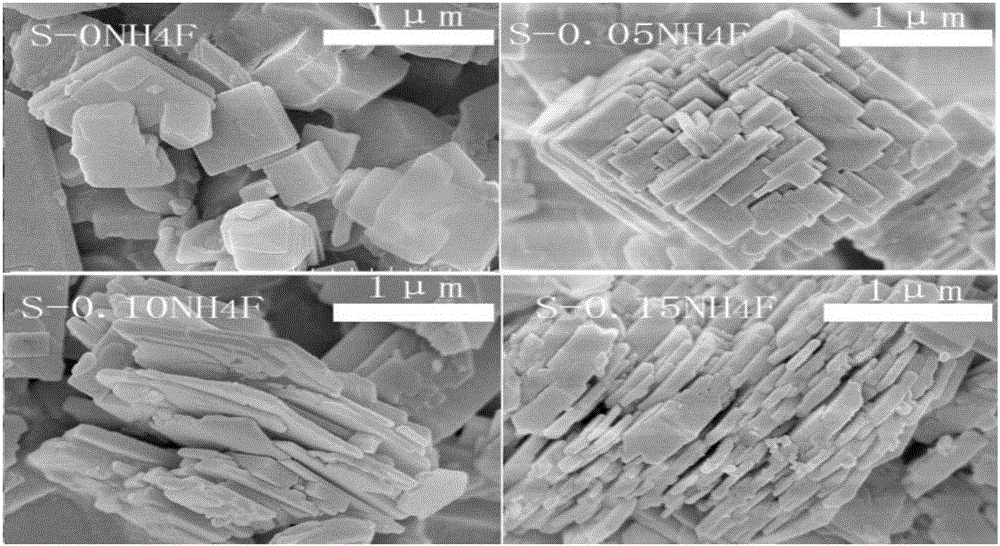

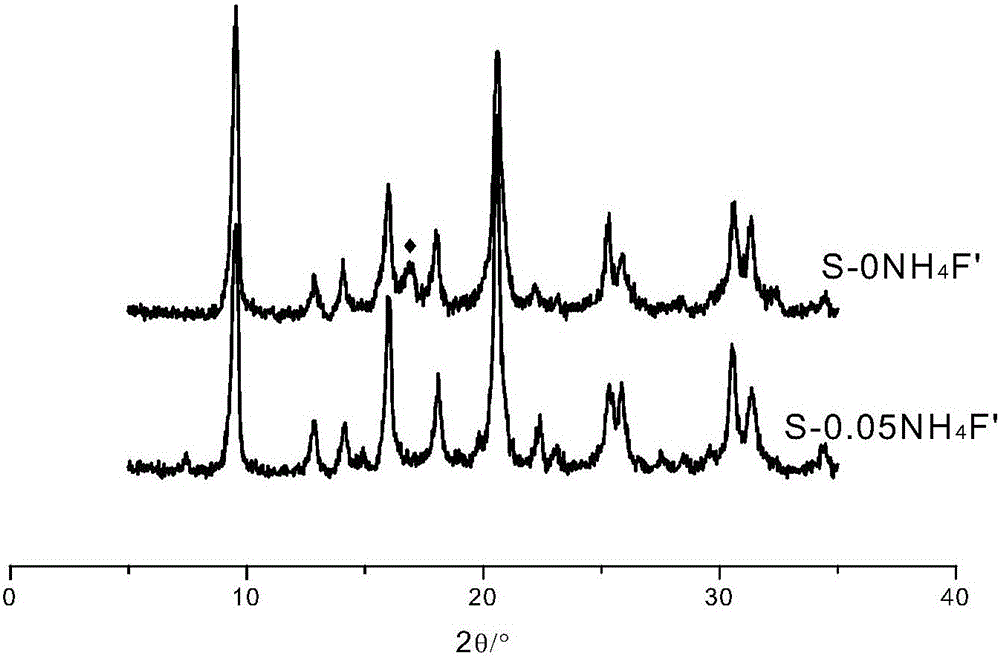

Solid-phase synthesizing method of flaky lamellar SAPO-34

ActiveCN106044791AHigh crystallinityRich pore structureMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveRoom temperature

The invention relates to a solid-phase synthesizing method of flaky lamellar SAPO-34. The synthesizing method includes: mixing deionized water, silicon source, aluminum source, phosphorus source, fluoride and template agent, and stirring for 5-8 hours under room temperature to obtain initial gel; aging the initial gel under room temperature for 8-12 hours, and drying the aged gel under 90-120 DEG C overnight to obtain dry gel; adding mixed liquid of water and triethylamine to the bottom of a reaction kettle, crushing the dry gel and placing into a teflon beaker, placing the beaker on the liquid in the kettle, and performing reaction under 170-200 DEG C for 2-3 days to obtain SAPO-34 molecular sieve. The flaky lamellar SAPO-34 is good in stability, high in crystallinity and good in selectivity.

Owner:CHIA TAI ENERGY MATERIALS DALIAN

Regeneration method of inactivated catalyst

ActiveCN106179489APrevent excessive heat release or concentrationAvoid overheatingMolecular sieve catalystsCatalyst regeneration/reactivationMolecular sieveOrganosolv

The invention discloses a regeneration method of an inactivated catalyst. The catalyst comprises a TON type molecular sieve and a group VIII precious metal component. The regeneration method comprises the following steps: processing the inactivated catalyst by using an organic solvent, loading nickel on the processed catalyst according to an atom ratio of nickel to platinum of 6:1-1:1, carrying out programmed carbon burning at a temperature being not higher than 450 DEG C under the action of an oxygen-containing gas, and reducing the processed catalyst in hydrogen atmosphere; and immersing the reduced catalyst in a chitosan-containing dilute acid solution in vacuum environment or inert atmosphere, drying the immersed catalyst, and roasting the dried catalyst to obtain the catalyst with recovered activity. The method has the advantages of effective removal of carbon deposit at a low temperature, guaranteeing of no destroy to the pore structure of the catalyst, good dispersion of precious metal, and realization of very good recovery of the performances of the regenerated catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

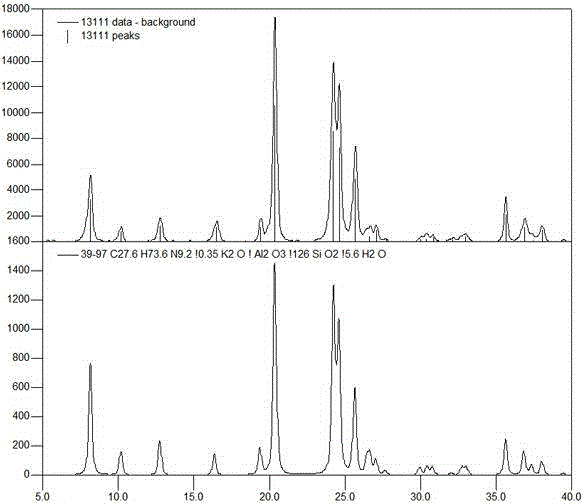

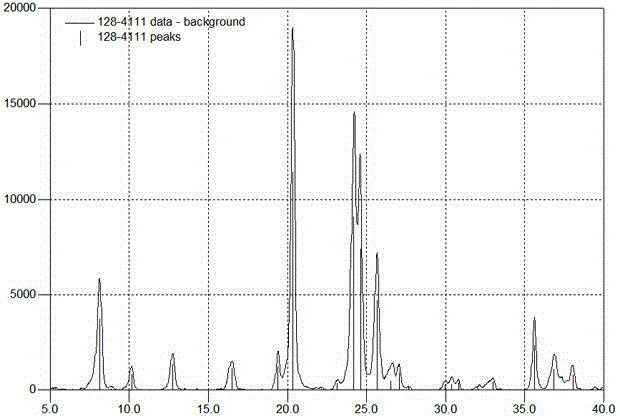

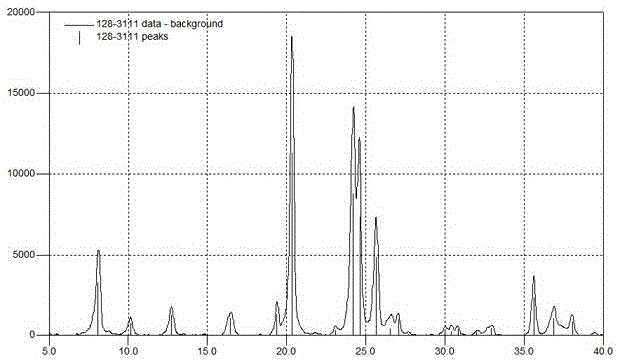

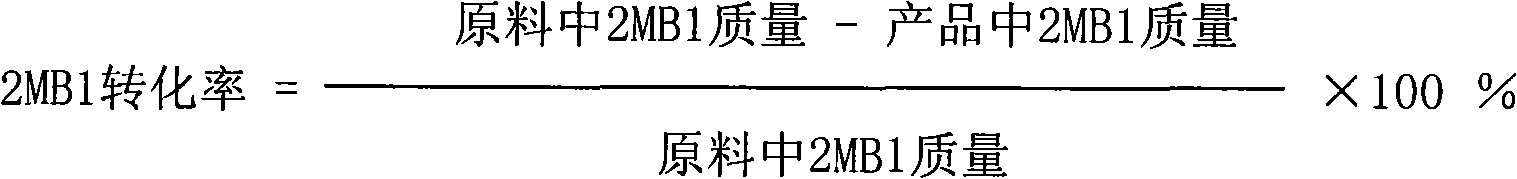

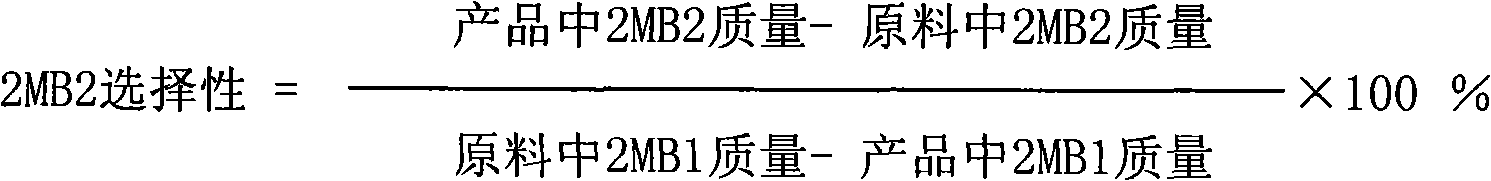

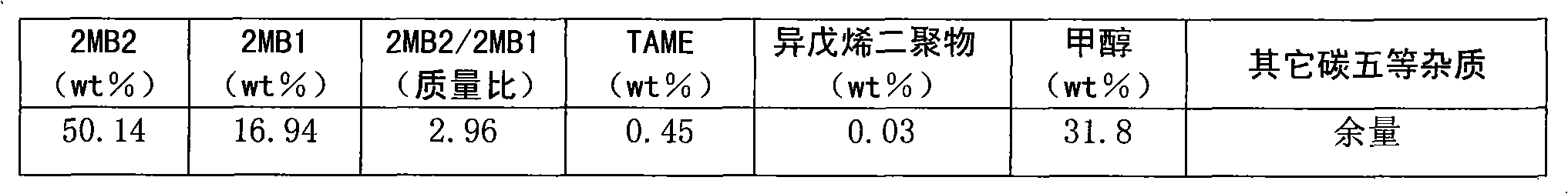

Method for preparing isoamylene by using tertiary amyl methyl ether

InactiveCN102040452ASlow reaction rateReduce acid strengthHydrocarbon by isomerisationIsomerizationBiopolymer

The invention relates to a method for preparing isoamylene by using tertiary amyl methyl ether, comprising: etherification reaction is carried out on the gas-phase tertiary amyl methyl ether by a catalyst bed layer; isomerization reaction is carried out on liquid-phase methanol-contained products in etherification reaction by means of the catalyst bed layer, so that 2-methyl-1-butylene in the etherification products is transformed into 2-methyl-2-butylene,wherein the quality air speed is 1-30hr<-1>, the reaction temperature is 20-47 DEG C, the reaction pressure is 0.3-1.0MPa, a catalyst is sulfonic cation exchange resin, and the quality exchange capacity is 3-5.5mmol / g; the methanol is removed from the products in the isomerization reaction, thus the isoamylene is obtained. By utilizing the method provided by the invention, the dimerization reaction during the isomerization reaction is effectively inhibited, thus the content of biopolymers in the product can be reduced to below 1%; only the sequence of the technical steps in the prior art is changed, other matters are not introduced into a reaction system, extra load can not be added for purifying or refining the product, and the defects in the prior art are effectively overcome.

Owner:CHINA PETROLEUM & CHEM CORP +1

A carried-type aluminium dihydrogen tripolyphosphate catalyst and a preparation method thereof

InactiveCN103331177AHigh surface areaImprove loading effectPhysical/chemical process catalystsOrganic compound preparationChemical treatmentChemical reaction

The invention discloses a carried-type aluminium dihydrogen tripolyphosphate catalyst and a preparation method thereof. Raw materials, for preparing the catalyst, comprise 0.5-20 g of a sulphur-containing substance; 20-400 g of a carrier, 23-46 g of phosphoric acid having a concentration of 85%, 8.0 g of aluminium hydroxide having a concentration of 98% or 5.2 g of active aluminum oxide, and 75-400 g of water. A sulfur-carried catalyst-carrier is prepared by gas-solid adsorption. Then after physical and chemical treatment under certain conditions, an aluminum phosphorus intermediate is reacted to produce aluminium dihydrogen tripolyphosphate, and the aluminium dihydrogen tripolyphosphate is carried by the sulfur-carried catalyst-carrier to produce the carried-type aluminium dihydrogen tripolyphosphate catalyst. The sulfur-carried catalyst-carrier after surface treatment has high specific surface and high carrying capacity, thereby increasing the specific surface and reducing acid strength of the aluminium dihydrogen tripolyphosphate, and improving the catalytic efficiency of the aluminium dihydrogen tripolyphosphate in organic reactions. The catalyst provided by the invention has advantages of low preparation reaction condition requirements, simple technology, easy operation, easy industrial production, low production cost, and good economic benefit and social benefit.

Owner:GUANGXI UNIV FOR NATITIES

Zeolite catalysts, methods for producing zeolite catalysts, and methods for producing lower olefins

InactiveUS20170282165A1Formation can be suppressedIncreased formationCatalytic crackingMolecular sieve catalystsNaphthaBoiling point

Provided are zeolite catalysts that allow reactions to proceed at temperatures as low as possible when lower olefins are produced from hydrocarbon feedstocks with low boiling points such as light naphtha, make it possible to make propylene yield higher than ethylene yield in the production of lower olefins, and have long lifetime. The zeolite catalysts are used in the production of lower olefins from hydrocarbon feedstocks with low boiling points such as light naphtha. The zeolite catalysts are MFI-type crystalline aluminosilicates containing iron atoms and have molar ratios of iron atoms to total moles of iron atoms and aluminum atoms in the range from 0.4 to 0.7. The use of the zeolite catalysts make it possible to increase propylene yield, to lower reaction temperatures, and to extend catalyst lifetime.

Owner:CHIYODA CORP

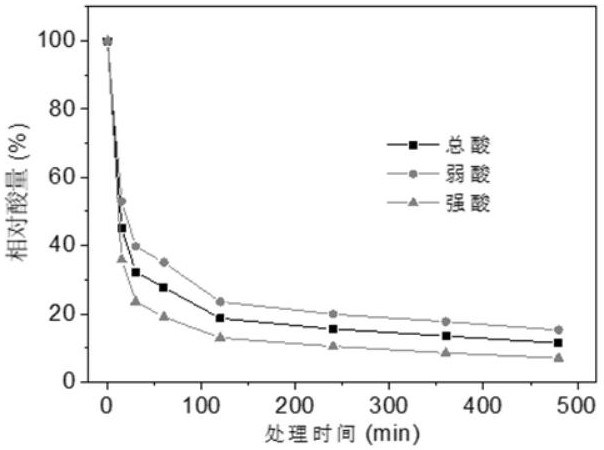

Catalyst modification method for improving yield of hydrocarbons produced by catalytic pyrolysis of biomass

ActiveCN112007687AFacilitated DiffusionImprove carbon deposition resistanceMolecular sieve catalystsCatalyst activation/preparationMolecular sieveCatalytic pyrolysis

The invention discloses a catalyst modification method for improving a yield of hydrocarbons produced by catalytic pyrolysis of biomass, and belongs to the field of biomass resource conversion and utilization. The method comprises the following steps: 1, tabletting and molding a powdery HZSM-5 molecular sieve, then crushing and screening particles, 2, placing the HZSM-5 molded particles in a carrier gas atmosphere containing water vapor, and carrying out constant temperature treatment, and 3, calcining the HZSM-5 molded particles subjected to water vapor treatment in air at a constant temperature, and cooling to obtain the modified HZSM-5 catalyst. By adopting the technical scheme provided by the invention, the skeleton structure and acidity of the HZSM-5 catalyst can be adjusted, the catalytic performance of the HZSM-5 catalyst in biomass pyrolysis steam catalytic conversion reaction is improved, and compared with an unmodified HZSM-5 catalyst, the yield of hydrocarbon target productsin biomass catalytic pyrolysis reaction is effectively improved.

Owner:SOUTHEAST UNIV

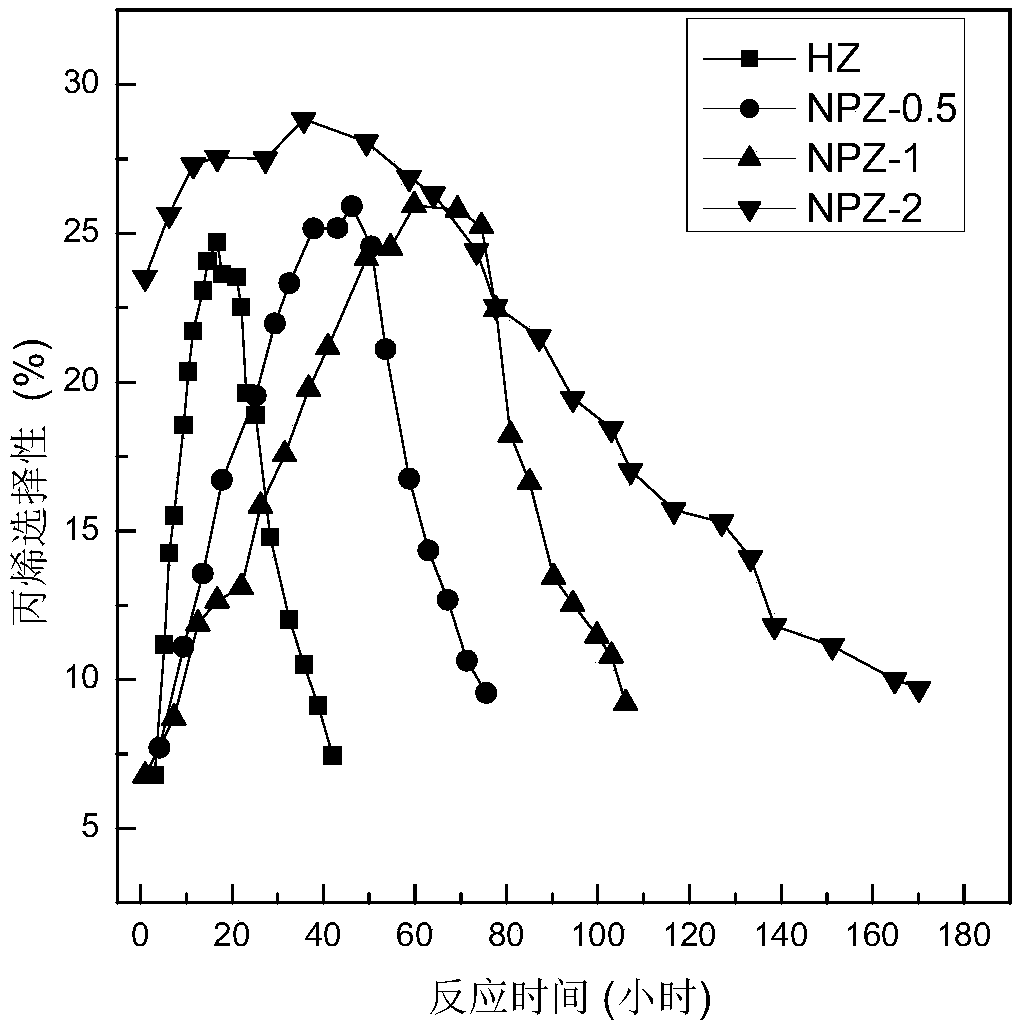

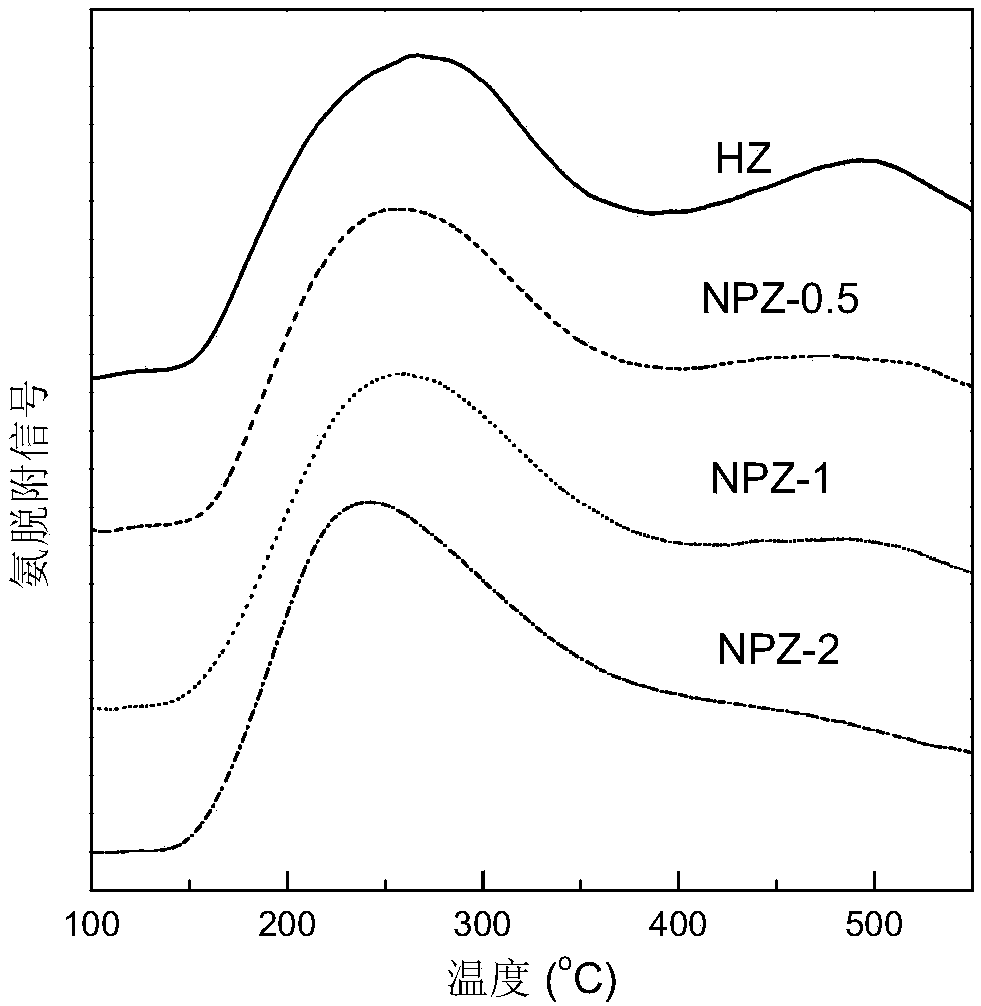

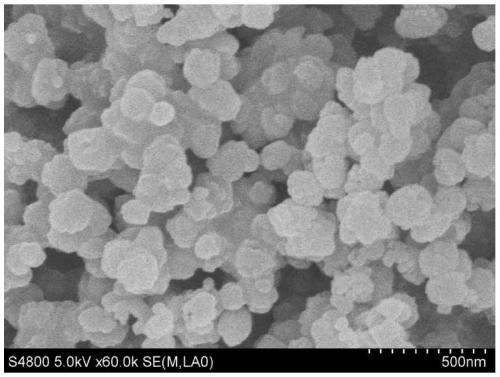

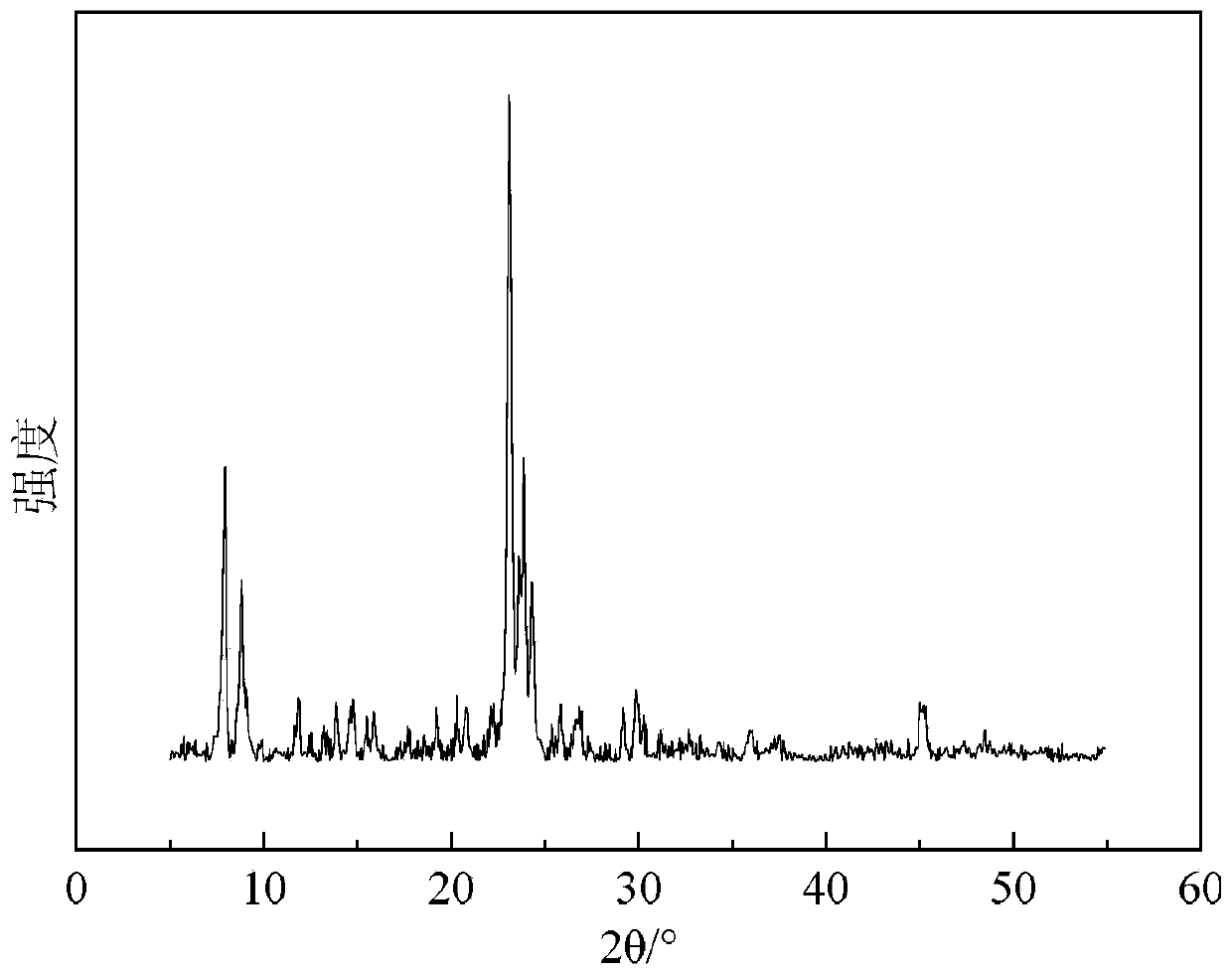

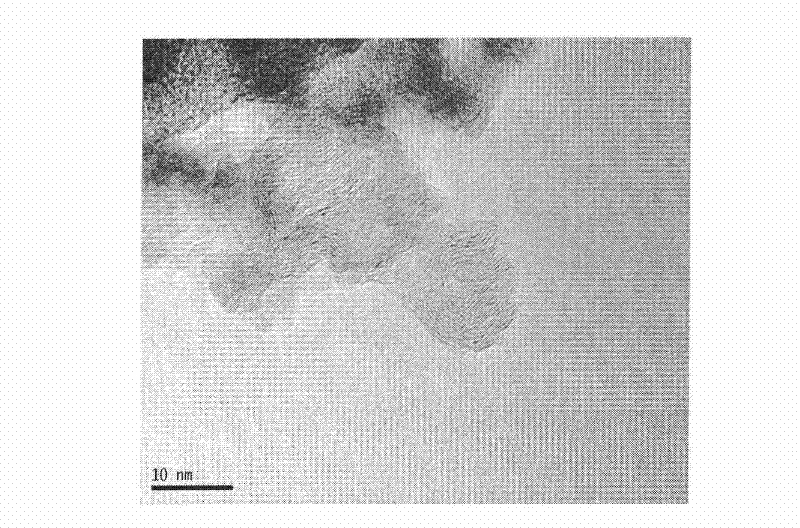

Nanometer HZSM-5 molecular sieve catalyst modified by phosphorus and preparation method of such nanometer HZSM-5 molecular sieve catalyst modified by phosphorus

InactiveCN107649173AReduce acid strengthHigh selectivityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsPhosphoric acidMolecular sieve

The invention discloses a nanometer HZSM-5 molecular sieve catalyst modified by phosphorus and a preparation method of such nanometer HZSM-5 molecular sieve catalyst modified by the phosphorus. By thepreparation method, a nanometer HZSM-5 molecular sieve and a phosphorous compound (phosphoric acid or ammonium phosphate) serve as raw materials, and the nanometer HZSM-5 molecular sieve is modifiedby equivalent-volume impregnation. The preparation method is simple, environment friendly, less in energy consumption, low in production cost, remarkable in effect and convenient to implement, popularize and apply. The nanometer HZSM-5 molecular sieve catalyst modified by the phosphorus is used for catalyzing bioethanol(the content of ethyl alcohol ranges from 50% to 90%)for propylene reaction andhas the advantages of high propylene selectivity, long service life and remarkable water-resistant thermal stability.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

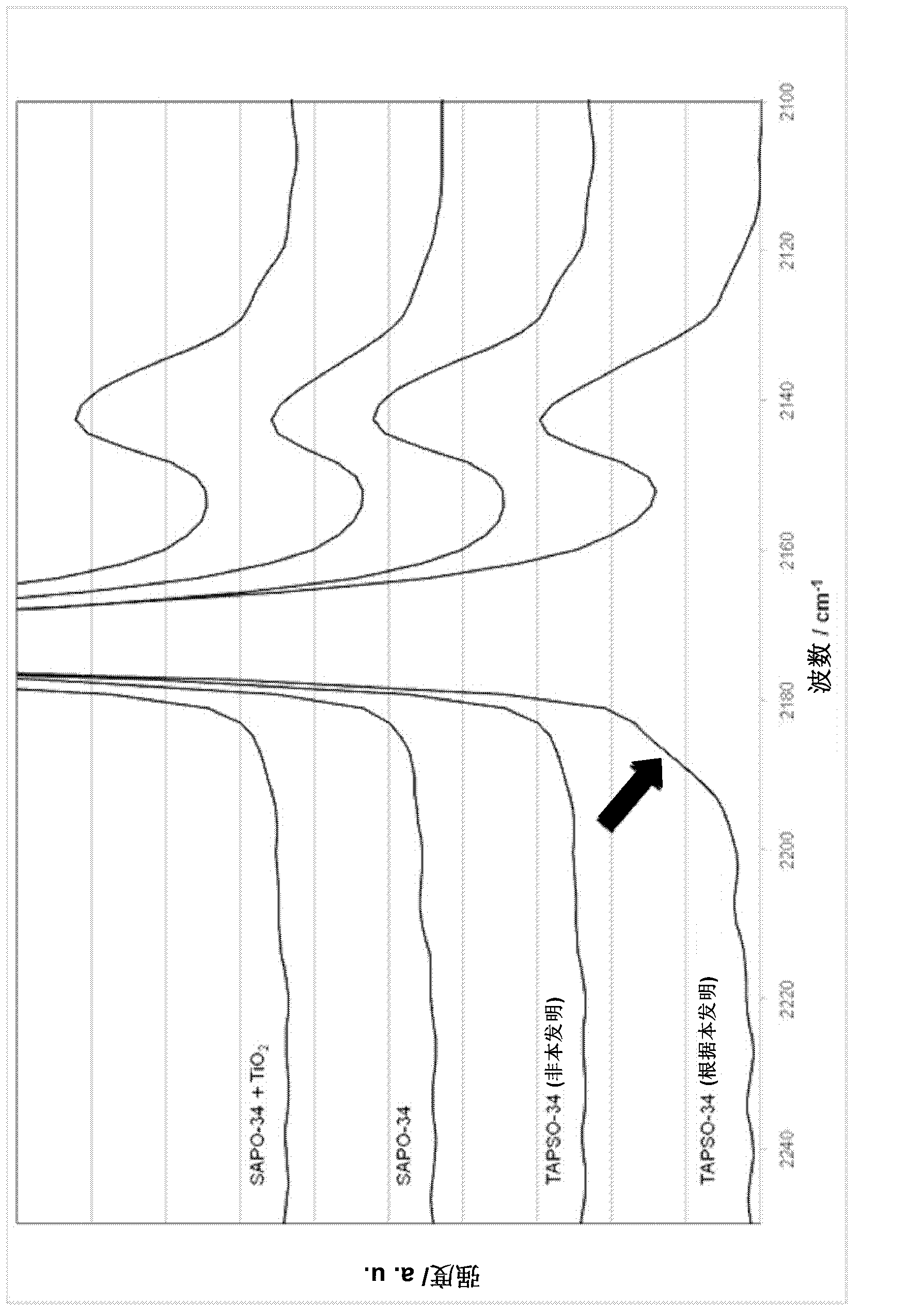

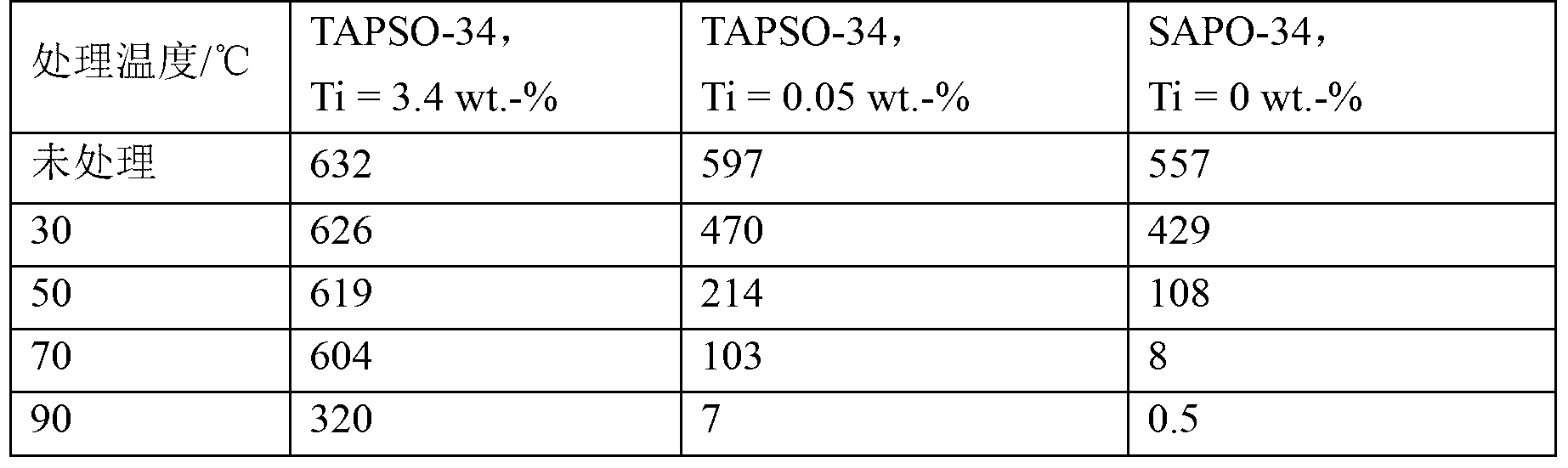

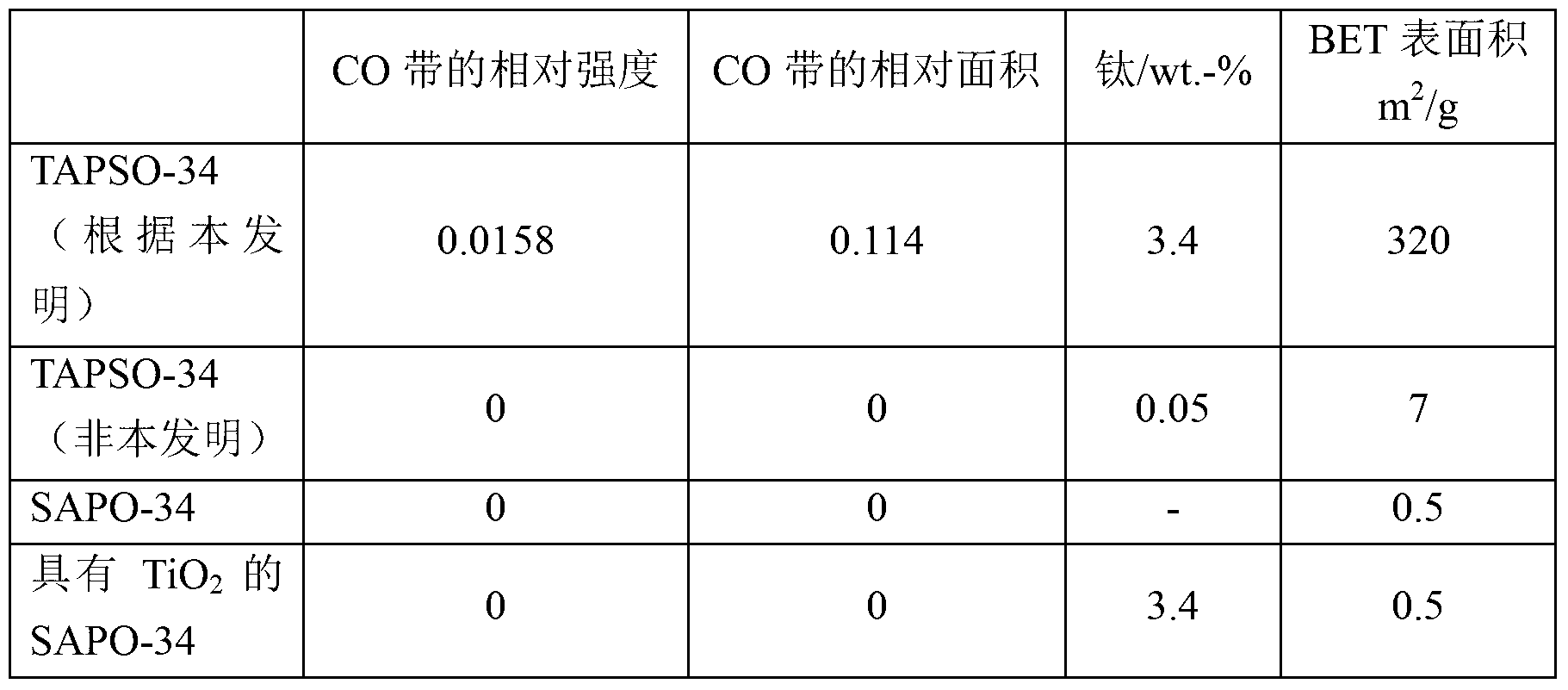

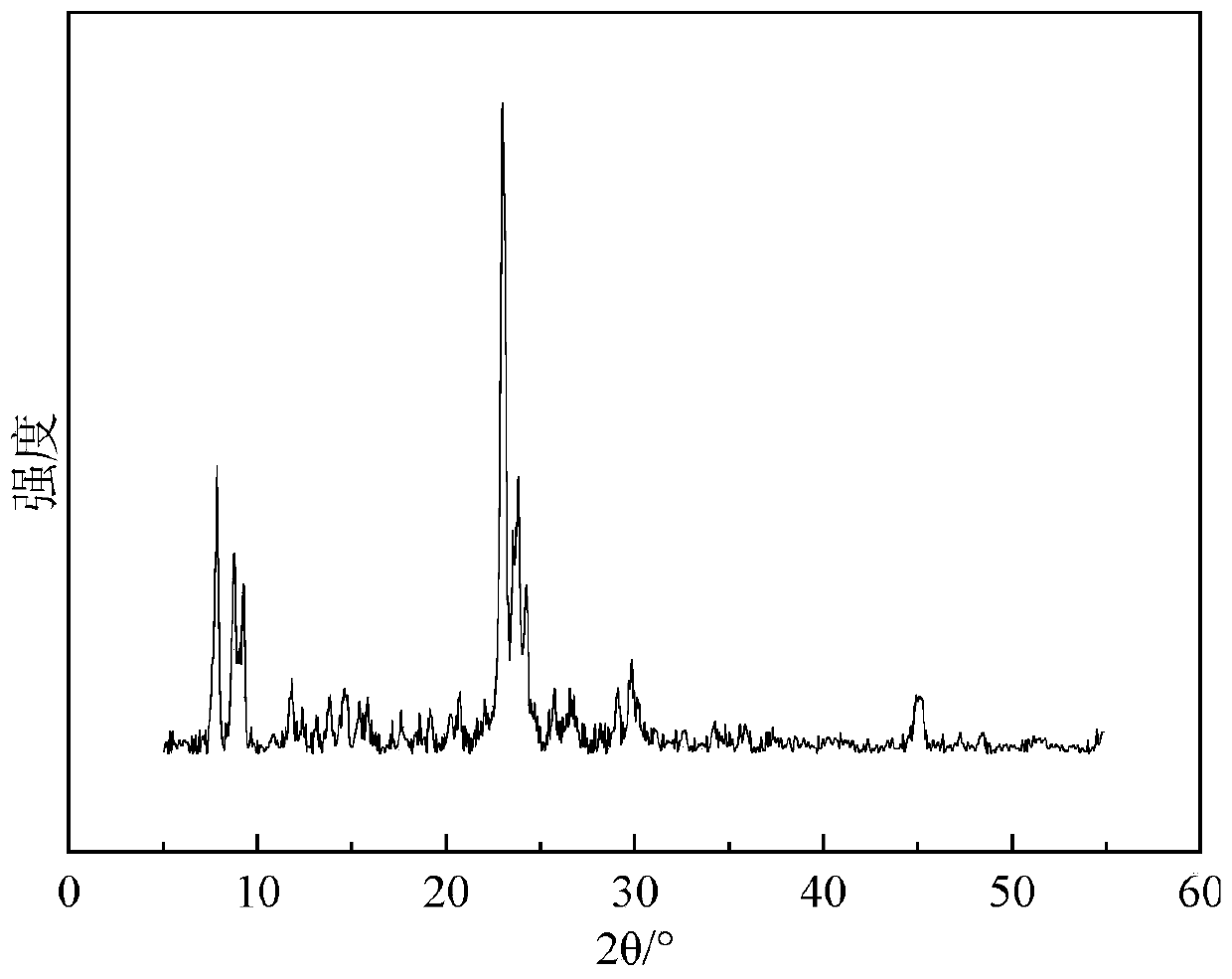

Titano-silico-alumo-phosphate

InactiveCN103269977AHigh acid strengthReduce acid strengthMolecular sieve catalystsMolecular-sieve aluminophosphatesPhosphorPhosphate

Owner:CLARIANT PROD DEUT GMBH

Method for in-situ synthesis of nano Zn/Al-ZSM-5 molecular sieve with steam-assisted dry glue conversion method

PendingCN110304637AReduce acid strengthAvoid structural defectsMolecular sieve catalystsPentasil aluminosilicate zeoliteIonChemistry

The invention discloses a method for in-situ synthesis of a nano Zn / Al-ZSM-5 molecular sieve with a steam-assisted dry glue conversion method. The invention belongs to the field of preparation of zeolite molecular sieve catalysts and aims to solve the problems that a conventional method for synthesizing a nano Zn / Al-ZSM-5 molecular sieve is long in crystallization time, large in energy consumption, large in molecular sieve crystal granule size and large in product waste liquid amount. The method comprises the following steps: I, weighing raw materials; II, mixing aluminum isopropoxide, a tetrapropylammonium hydroxide solution, tetraethoxysilane, zinc nitrate hexahydrate and deionized water, and carrying out vacuum drying so as to obtain a dry glue; and III, grinding the dry glue, putting the dry glue into a vessel at the upper part of a crystallization kettle, supporting the vessel by using a bracket, feeding deionized water into the bottom of the crystallization kettle, and carrying out crystallization at 160-190 DEG C, so as to obtain the nano Zn / Al-ZSM-5 molecular sieve. By adopting the method disclosed by the invention, the problem that a product is hard to separate from a mother liquid in the hydrothermal crystallization process is effectively avoided, the yield of the molecular sieve can be greatly increased, and a waste liquid with organic matters and alkalis are not generated after crystallization.

Owner:HEILONGJIANG UNIV

Method for improving stability of ZSM-5 zeolite catalyst for preparation of phenylacetaldehyde by styrene oxide rearrangement

ActiveCN110508316AImprove stabilityImprove production efficiencyMolecular sieve catalystsCatalyst activation/preparationStyrene oxideSolution treatment

Belonging to the catalytic field of fine chemicals, the invention relates to a method for improving the stability of a ZSM-5 zeolite catalyst for preparation of phenylacetaldehyde by styrene oxide rearrangement. The method includes: firstly subjecting a ZSM-5 zeolite catalyst to alkaline solution treatment, then loading a certain amount of phosphorus or boron through impregnation, and adjusting the pore structure and acidity of zeolite respectively. Specifically, alkali treatment can introduce a mesoporous structure into the zeolite structure, the loaded phosphorus or boron can reduce the acidstrength of zeolite strong acid site, the diffusion rate of molecules is increased in the catalytic reaction process, the probability of side reaction and the formation of carbon deposit are reduced,the catalyst stability is improved by 8-10 times, and no obvious deactivation occurs to the catalyst after 100h of continuous operation.

Owner:HENAN UNIV OF SCI & TECH

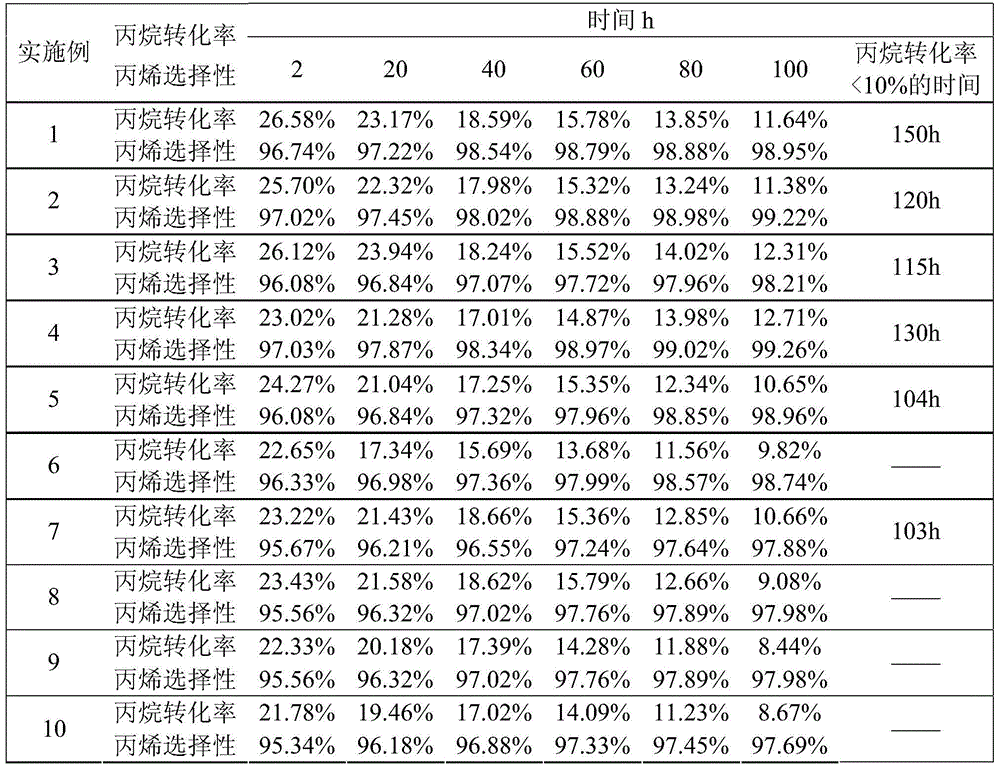

Quaternary platinum-based catalyst for propane dehydrogenation to propylene, preparation method and application thereof

ActiveCN104148069BReduce acid contentReduce acid strengthHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsActive componentDehydrogenation

The invention discloses a quaternary platinum-based catalyst used for production of propylene through propane dehydrogenation, and a preparation method and an application thereof. The catalyst treats alumina processed by an alkaline gas as a carrier, precious metal Pt and metal Sn as active components, and M1 and M2 as assistants, M1 is one selected from Na, K, Rb, Mg, Ca and Sr, and M2 is one selected from La, Ce, Pm, Sm, Ti, Ga, In, Zn and Fe. The finally obtained catalyst comprises 0.2-0.3wt% of Pt, 0.1-2wt% of Sn, 0.5-2wt% of M1 and 0.5-2wt% of M2. The preparation method of the catalyst comprises the following steps: preprocessing the alumina carrier by the alkaline gas, and loading Pt, Sn, M1 and M2 through an impregnation process. The catalyst prepared through the method has the advantages of low price, simple operation, high reaction activity, good propylene selectivity, long single-use life and the like when the catalyst is used to catalyze a production reaction of propylene through propane dehydrogenation.

Owner:HUALU ENG & TECH

Dehydrogenation catalyst taking Sn-containing alumina as carrier and preparation method thereof

ActiveCN101898131BLarge specific surface areaHigh selectivityCatalyst activation/preparationHydrocarbonsFiberWater vapor

The invention discloses a dehydrogenation catalyst taking Sn-containing alumina as a carrier and a preparation method thereof. The dehydrogenation catalyst takes the Sn-containing alumina as the carrier, nano fibers are carried on the pore surface of the carrier, and dehydrogenation active metal ingredients are carried by an immersion method. The preparation method for the catalyst comprises the following steps of: introducing the carrier to Sn when the alumina is gelled, carrying the carbon nano fibers to the Sn-containing alumina carrier in situ by ethylene cracking, then immersing the dehydrogenation active ingredients, and performing thermal treatment and water vapor treatment to obtain the final dehydrogenation catalyst. When the catalyst is used for a hydrocarbon dehydrogenation reaction process, in particular a propane dehydrogenation process, the catalyst has the advantages of high activity, high selectivity and the like, and particularly greatly improves the stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

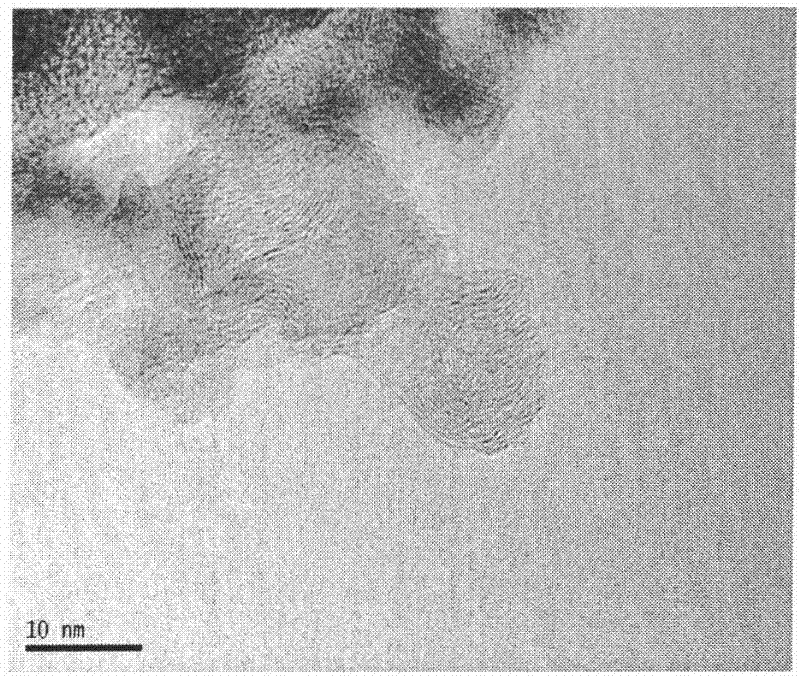

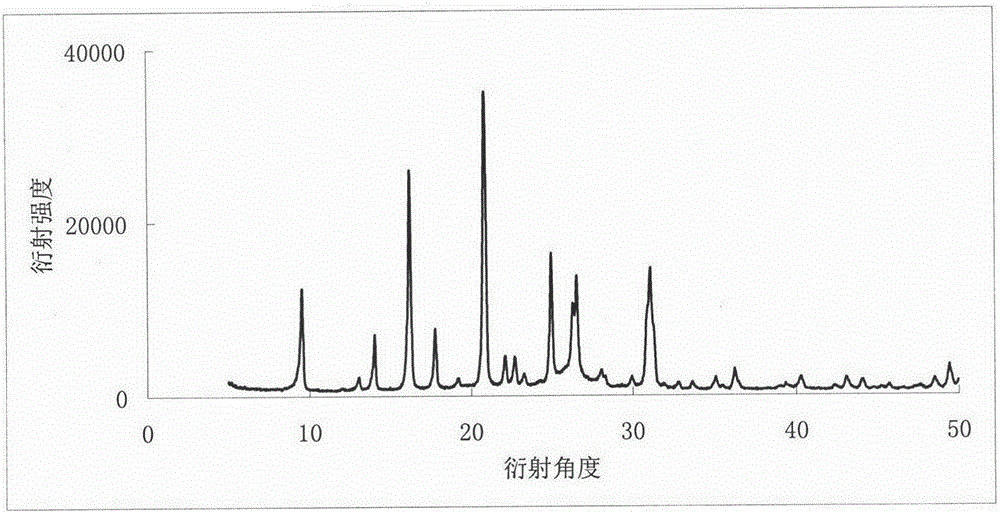

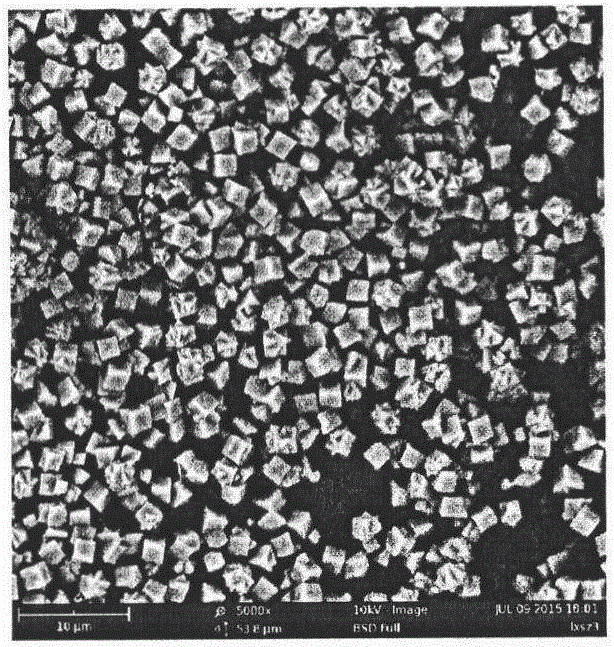

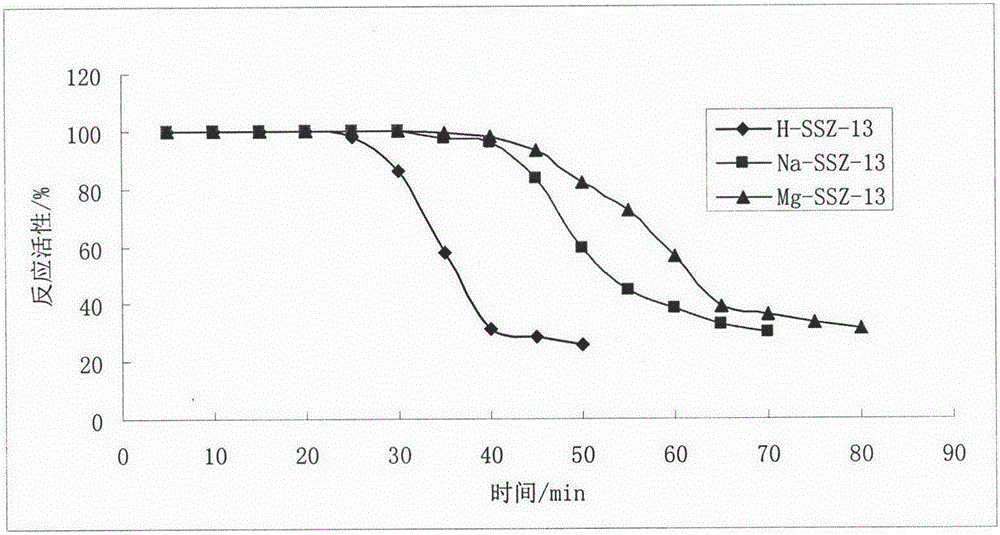

Preparation of magnesium metal modified low-silicon SSZ-13 molecular sieve and MTO reaction performance thereof

InactiveCN106554026AReduce acid strengthExcellent MTO reaction performanceMolecular sieve catalystsHydrocarbon from oxygen organic compoundsAluminium saltsOxide

The invention provides a preparation method of a magnesium metal modified low-silicon molecular sieve material. The magnesium metal modified low-silicon molecular sieve material comprises 0.1-6% of magnesium (calculated by magnesium oxide), 5.36-20% of aluminum (calculated by aluminum oxide), 69-94.5% of silicon (calculated by silicon oxide) and 0.01-5% of alkali metal (calculated by oxide), and has a CHA type topological structure, and the specific surface (through the BET method) of the magnesium metal modified low-silicon molecular sieve material is no smaller than 565 m2 / g after the magnesium metal modified low-silicon molecular sieve material is calcinated at 630 DEG C for 4 h. The preparation method of the magnesium metal modified low-silicon molecular sieve material comprises the steps that a template agent and a sodium hydroxide aqueous solution are added into an alkaline silica sol to be uniformly stirred, aluminum sulfate is added to be uniformly stirred, and chabasite crystalline phase seed crystal is added to be stirred at room temperature for 4 h to obtain uniform gel; and a product is obtained through crystallization, calcination and magnesium ion exchange, wherein magnesium ions can also be led in the molecular sieve synthesization process by one step. The molecular sieve material prepared through the preparation method has the advantages that the molecular sieve material is low in silicon-aluminum ratio, adjustable in acid center concentration, low in acid strength and high in MTO diolefin selectivity, and a large amount of ammonium chloride waste liquid does not exist in the preparation process.

Owner:TIANJIN POLYTECHNIC UNIV

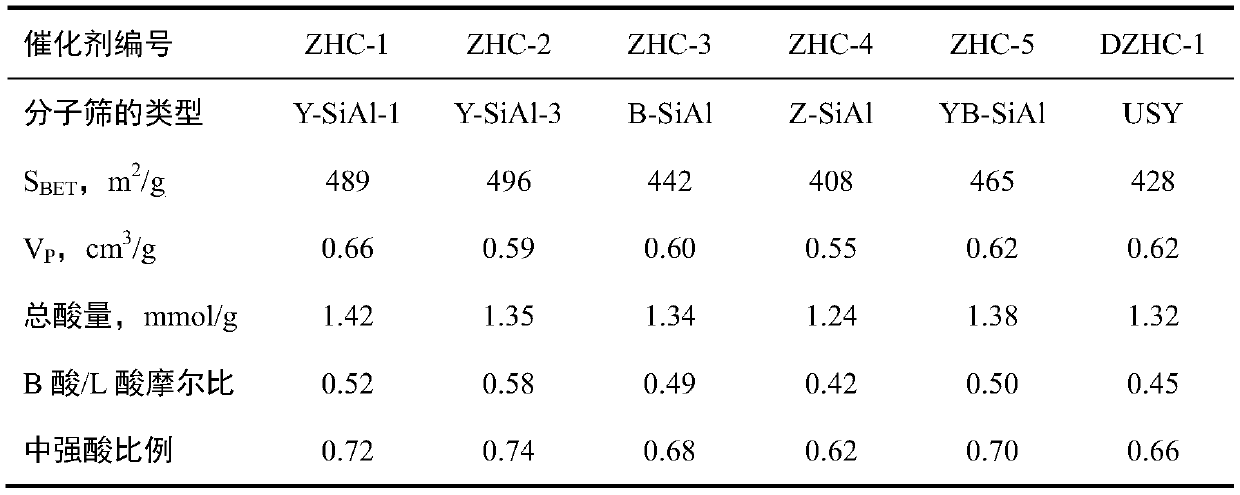

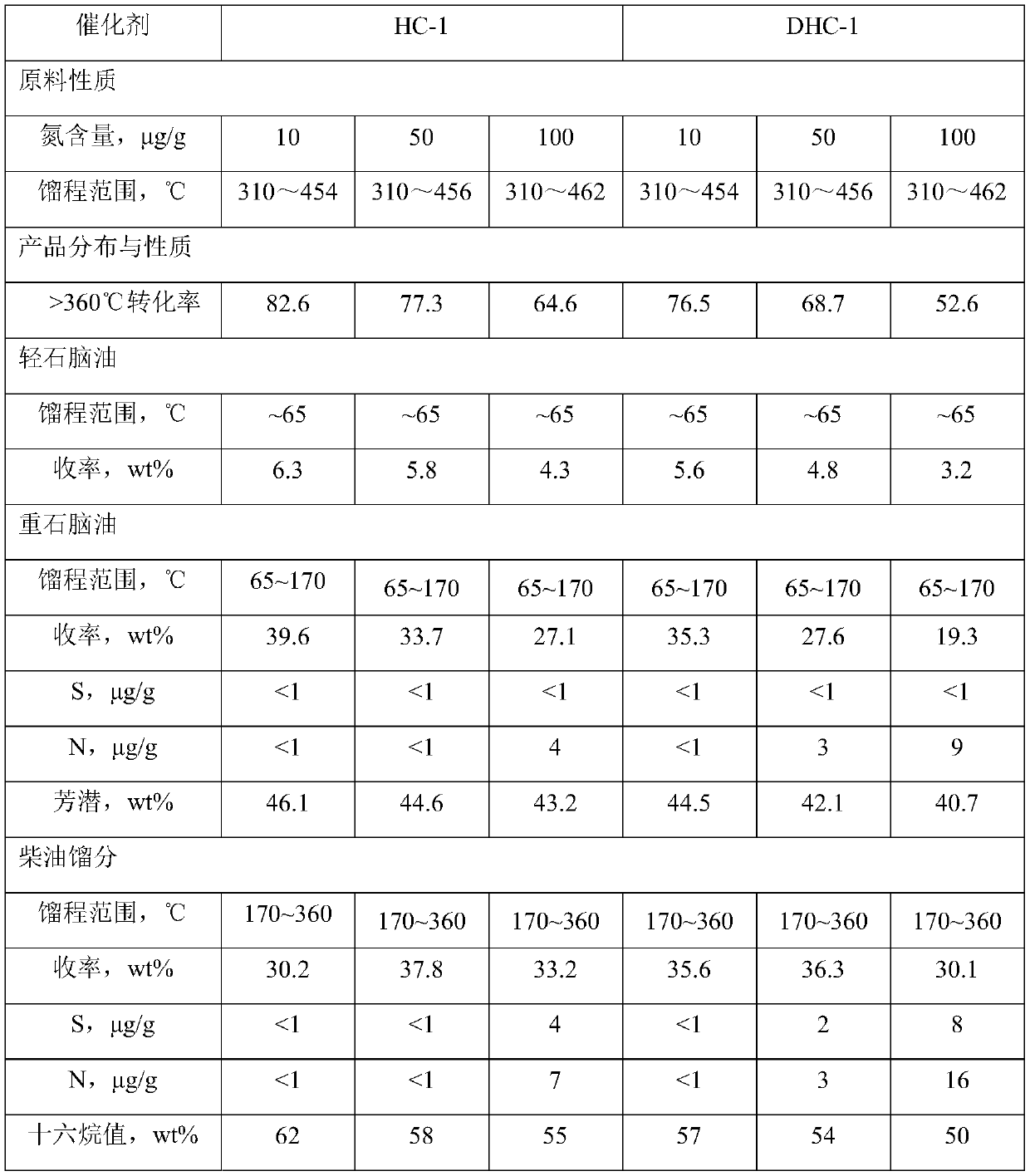

Nitrogen-resistant type hydrocracking catalyst carrier and preparation method thereof

InactiveCN109759124AImprove nitrogen resistanceAvoid inactivationMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The invention provides a nitrogen-resistant type hydrocracking catalyst carrier and a preparation method thereof. The nitrogen-resistant type hydrocracking catalyst carrier is jointly prepared from asilicon-aluminum molecular sieve / amorphous silicon-aluminum composite material, macroporous aluminum oxide and SB powder. the silicon aluminum molecular sieve / amorphous silicon aluminum composite material is a composite material synthesized by taking the silicon aluminum molecular sieve as a core and wrapping the modified molecular sieve with amorphous silicon aluminum, and the composite materialhas the cascade-distributed acid strength and of a cascade-distributed hole structure, the specific surface area of the carrier is 400-650 m<2> / g, the pore volume is 0.55-0.70 cm<3> / g, the total acidcontent of fourier infrared absorption spectroscopy is 1.1-1.5 mmol / g, the B acid / L acid molar ratio is 0.38-0.58, and the medium strong acid proportion is 50-80%. The carrier is loaded with VI B group metal oxide and VIII group metal oxide to prepare a hydrocracking catalyst, and adapts to a high-nitrogen distillate hydrocracking reaction.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com