Titano-silico-alumo-phosphate

A titanium-silicon-aluminum phosphate, coordination technology, applied in the direction of molecular sieve characteristic aluminum phosphate, molecular sieve characteristic silicoaluminophosphate, molecular sieve and alkali exchange phosphate, etc., to achieve lower process cost, high hydrothermal pressure resistance, high long-term stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example

[0088] For the synthesis example, bizoite (aluminum hydroxide SH10) from Aluminum Oxid Stade GmbH, Germany was used.

[0089] In addition, using from CWK Chemiewerk Bad Silica sol with 1030.30% silica from GmbH, Germany

[0090] Titanium dioxide TiO doped with silicon was obtained from Evonik, Germany 2 545S.

[0091] For the comparative example, SAPO-34 from Sud-Chemie AG was used.

Embodiment 1

[0093] According to TAPSO-34 preparation of the present invention

[0094] 100.15 parts by weight of deionized water were mixed with 88.6 parts by weight of biramite (aluminum hydroxide SH10). 132.03 parts by weight of phosphoric acid (85%) and 240.9 parts by weight of TEAOH (tetraethylammonium hydroxide) (in water, 35%), followed by 33.5 parts by weight of silica sol and 4.87 parts by weight of silicon-doped titanium dioxide Added to the resulting mixture, as a result, a synthetic mixture with the following composition is obtained:

[0095] Al 2 o 3 :P 2 o 5 :0.3SiO2 2 :0.1TiO 2 :1TEAOH:35H 2 o

[0096] The synthetic gel mixture with the above composition was transferred into a stainless steel autoclave. The autoclave was stirred and heated to 180°C, where this temperature was maintained for 68 hours. After cooling, the resulting product was filtered off, washed with deionized water and dried in a 100°C oven. X-ray diffraction of the resulting product showed that t...

Embodiment 2

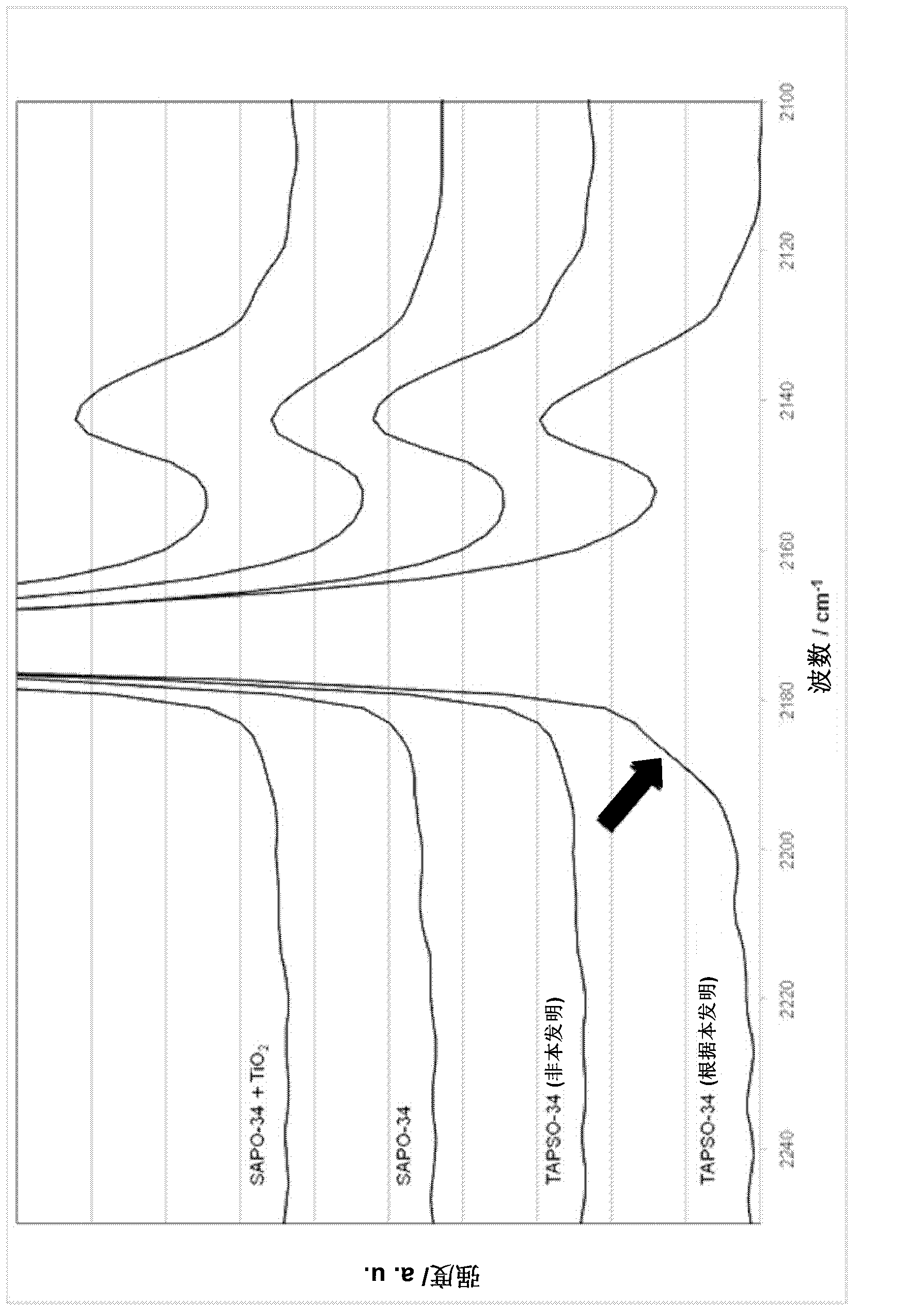

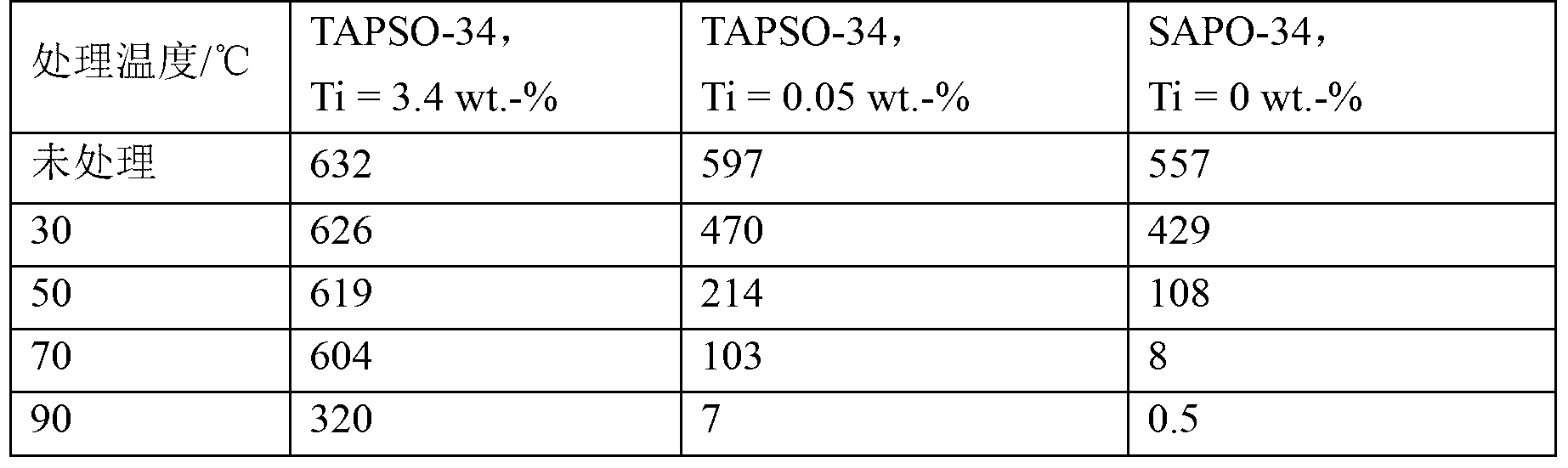

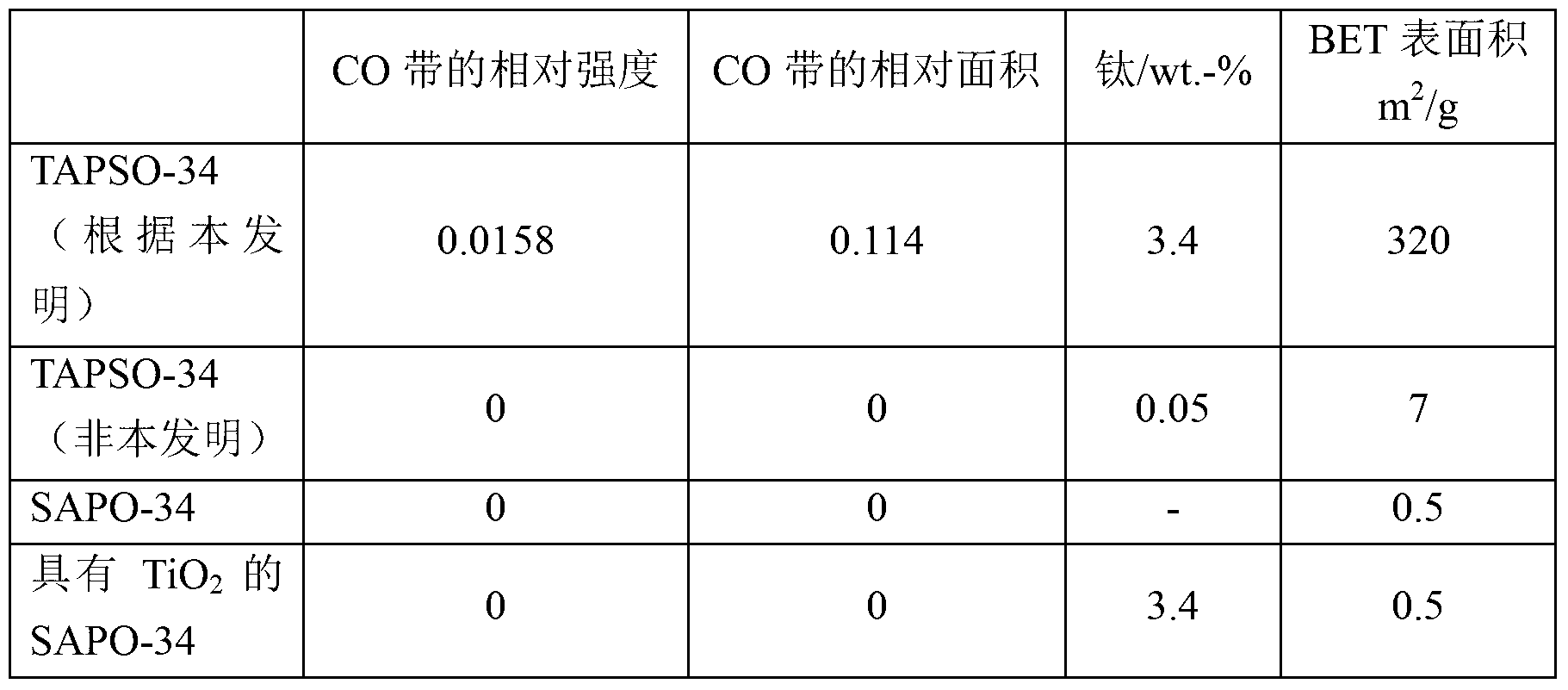

[0098] Long-term Hydrothermal Stress Test

[0099] The inventive titanosilicoaluminophosphate (TAPSO-34) with 3.4 wt.-% Ti (obtained as in Example 1 using a synthetic gel of correspondingly matched composition) with 0.5 wt.-% Ti Invention titano-silico-aluminophosphate (TAPSO-34) and titanium-free silico-aluminophosphate (SAPO-34) were treated with water to determine the long-term hydrothermal stability at different temperatures over an extended period of time.

[0100] Small-pore molecular sieves with a CHA structure have high adsorption capacity, but have different hydrothermal stability depending on the proportion of titanium in the structure. Therefore, in addition to titano-silico-aluminophosphate (TAPSO-34) according to the invention, non-invention titano-silico-aluminophosphate (TAPSO-34) with a low proportion of titanium and titanium-free titano-silico-aluminophosphate (SAPO-34) were selected , and tested it in the long-term hydrothermal stress test according to the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com