Patents

Literature

246results about "Molecular-sieve aluminophosphates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synthesis of molecular sieves having the chabazite framework type and their use in the conversion of oxygenates to olefins

The synthesis of a crystalline aluminophosphate or silicoaluminophosphate molecular sieve having a chabazite-type framework type is conducted in the presence of an organic directing agent having the formula (I) [R1R2R3N—R4]+X− (I) wherein R1, R2 and R3 are independently selected from the group consisting of alkyl groups having from 1 to 3 carbon atoms and hydroxyalkyl groups having from 1 to 3 carbon atoms; R4 is selected from the group consisting of 4- to 8-membered cycloalkyl groups, optionally substituted by 1 to 3 alkyl groups having from 1 to 3 carbon atoms; 4- to 8-membered heterocyclic groups having from 1 to 3 heteroatoms, said heterocyclic groups being optionally substituted by 1 to 3 alkyl groups having from 1 to 3 carbon atoms and the heteroatoms in said heterocyclic groups being selected from the group consisting of O, N, and S; and aromatic groups optionally substituted by 1 to 3 alkyl groups, said alkyl groups having from 1 to 3 carbon atoms; and X− is an anion.

Owner:EXXONMOBIL CHEM PAT INC

Microporous Aluminophosphate Molecular Sieve Membranes for Highly Selective Separations

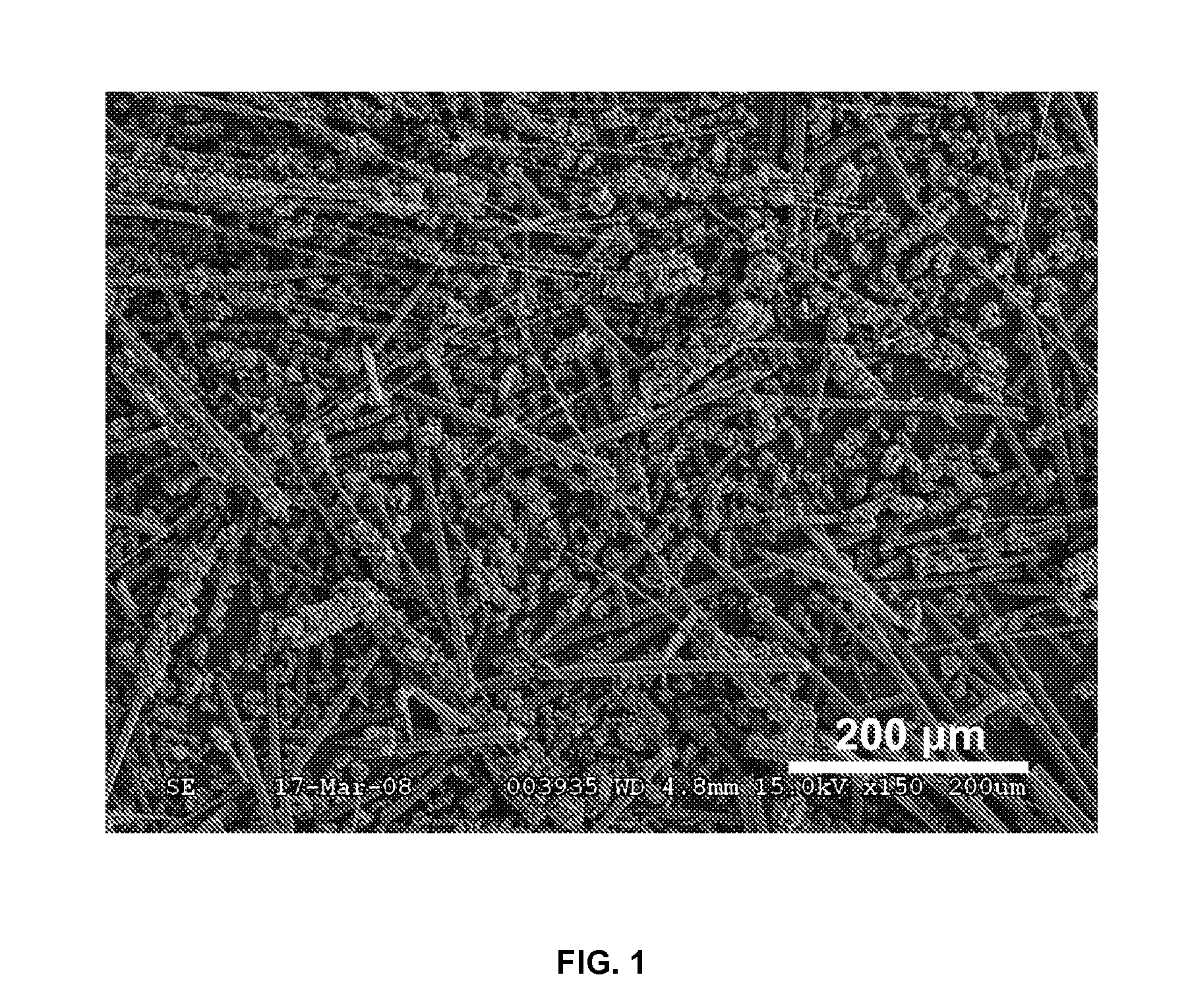

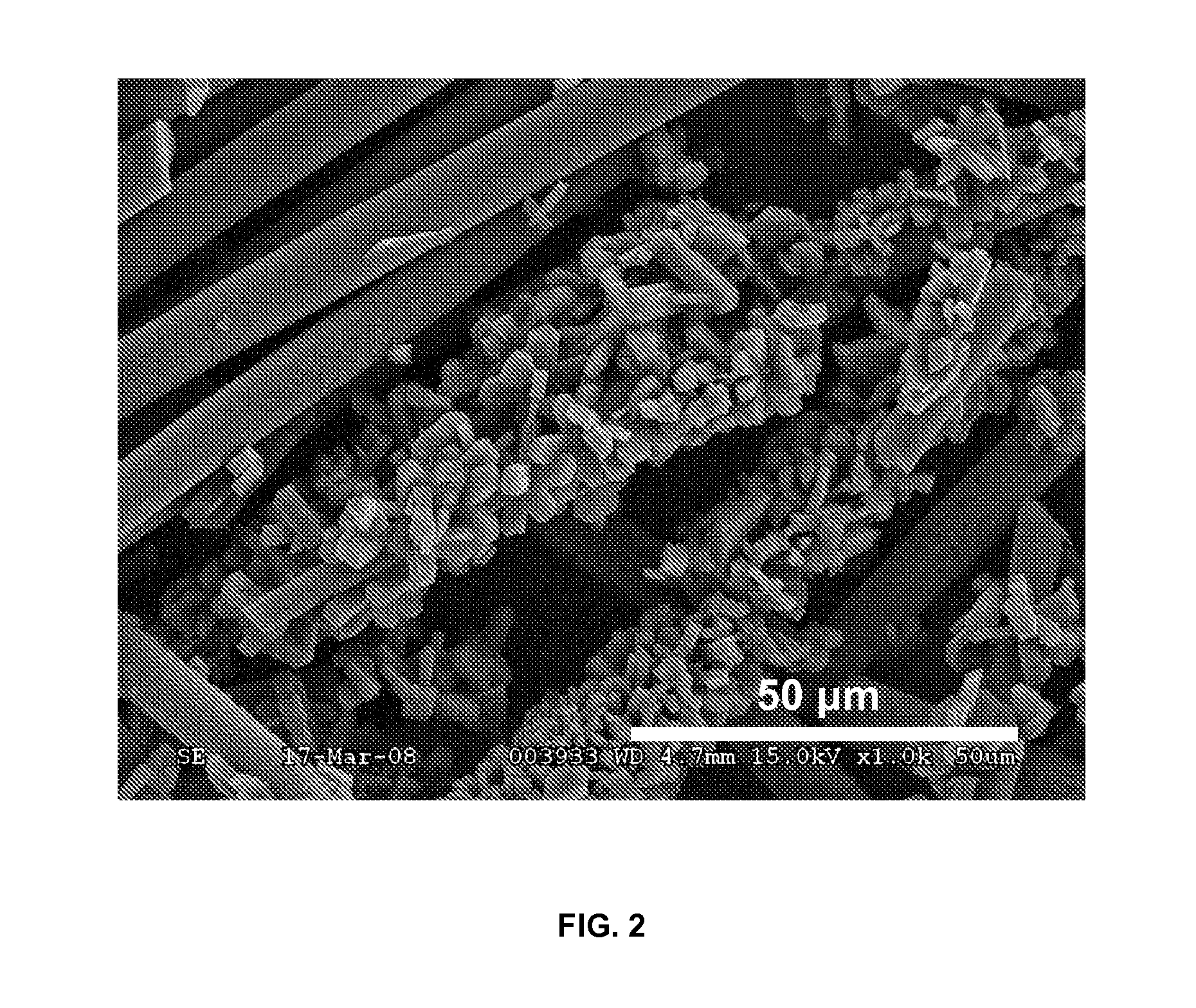

InactiveUS20090114089A1High selectivityGood chemical and thermal stabilityPhosphatesPretreated surfacesChemical stabilityPolymer

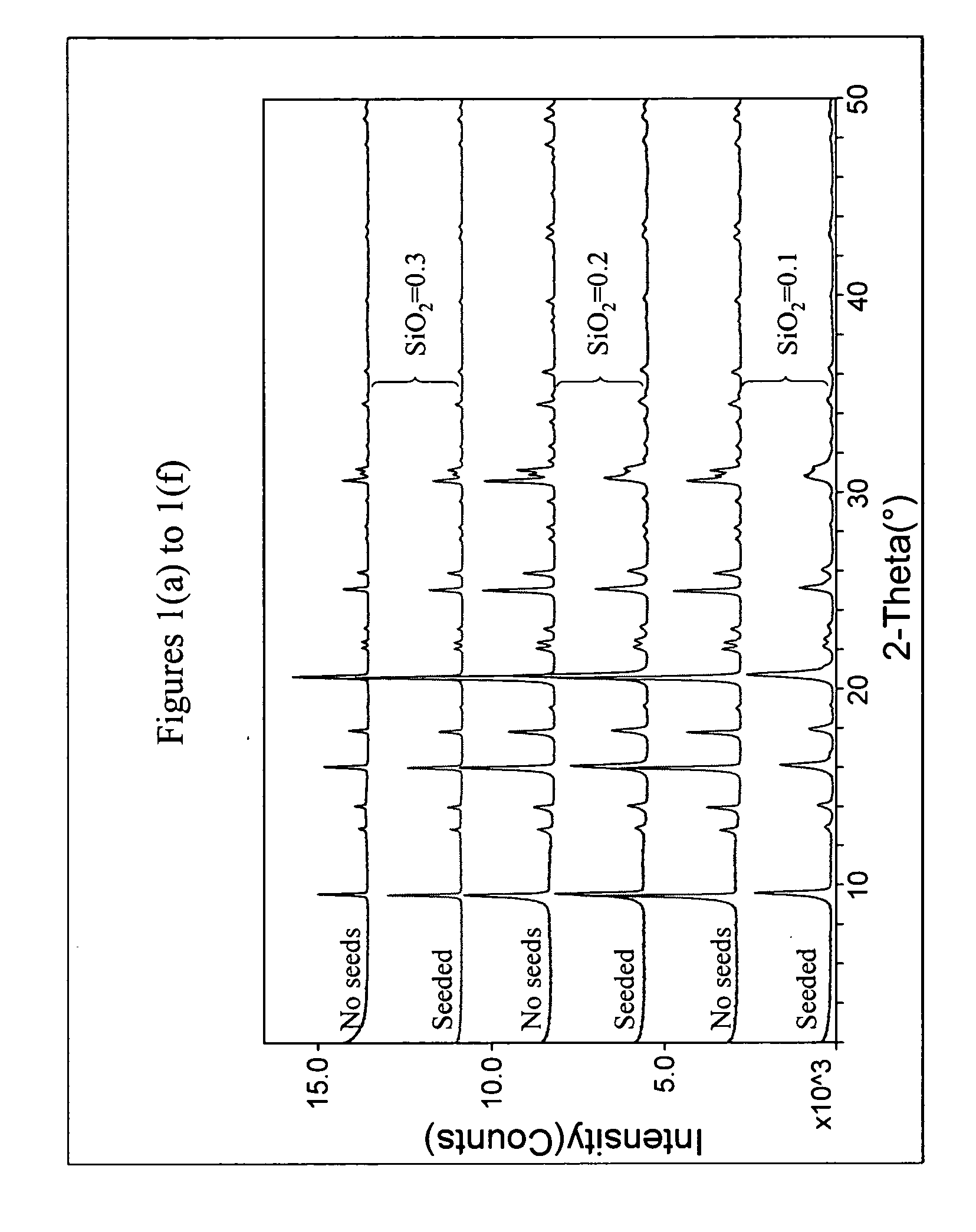

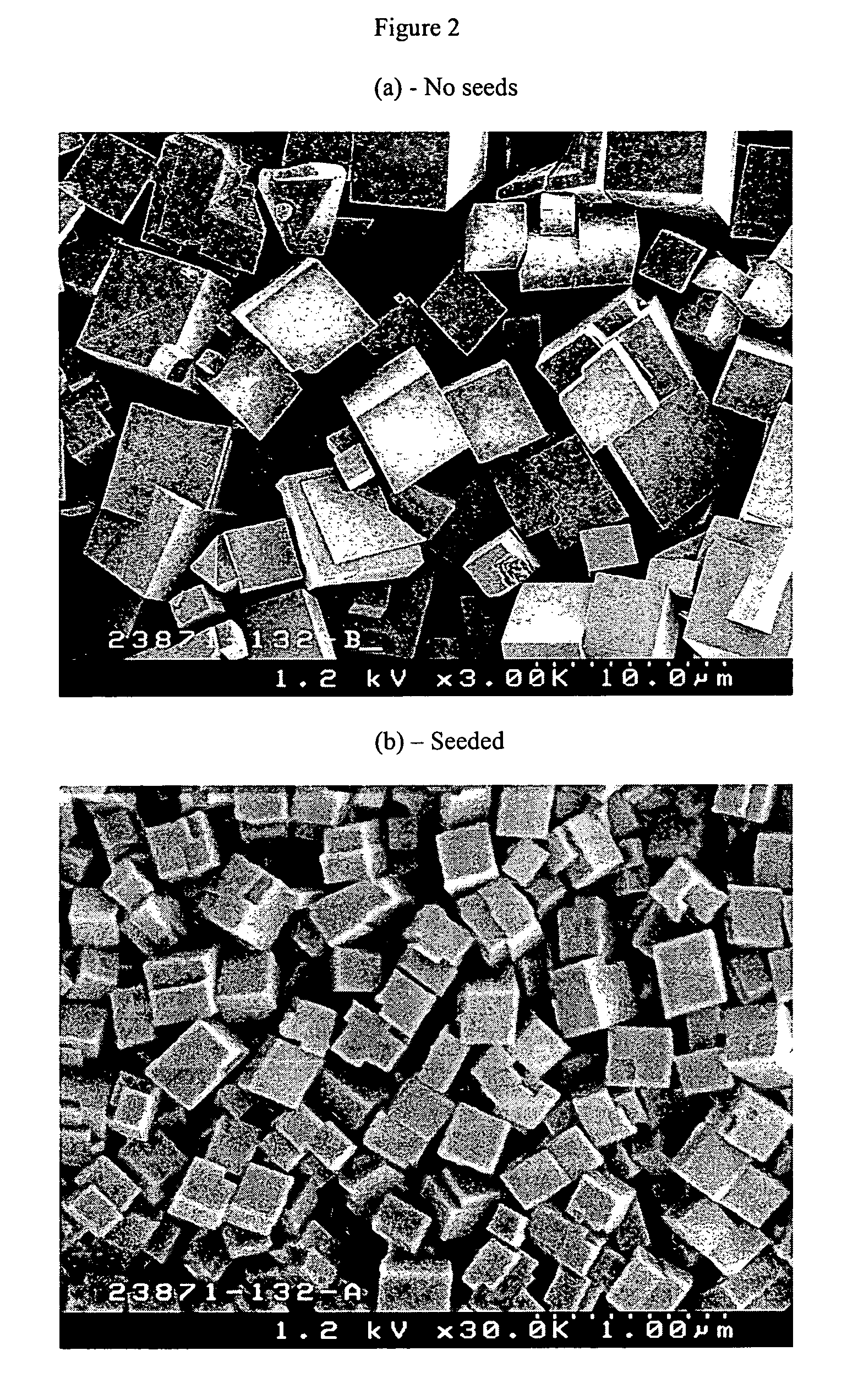

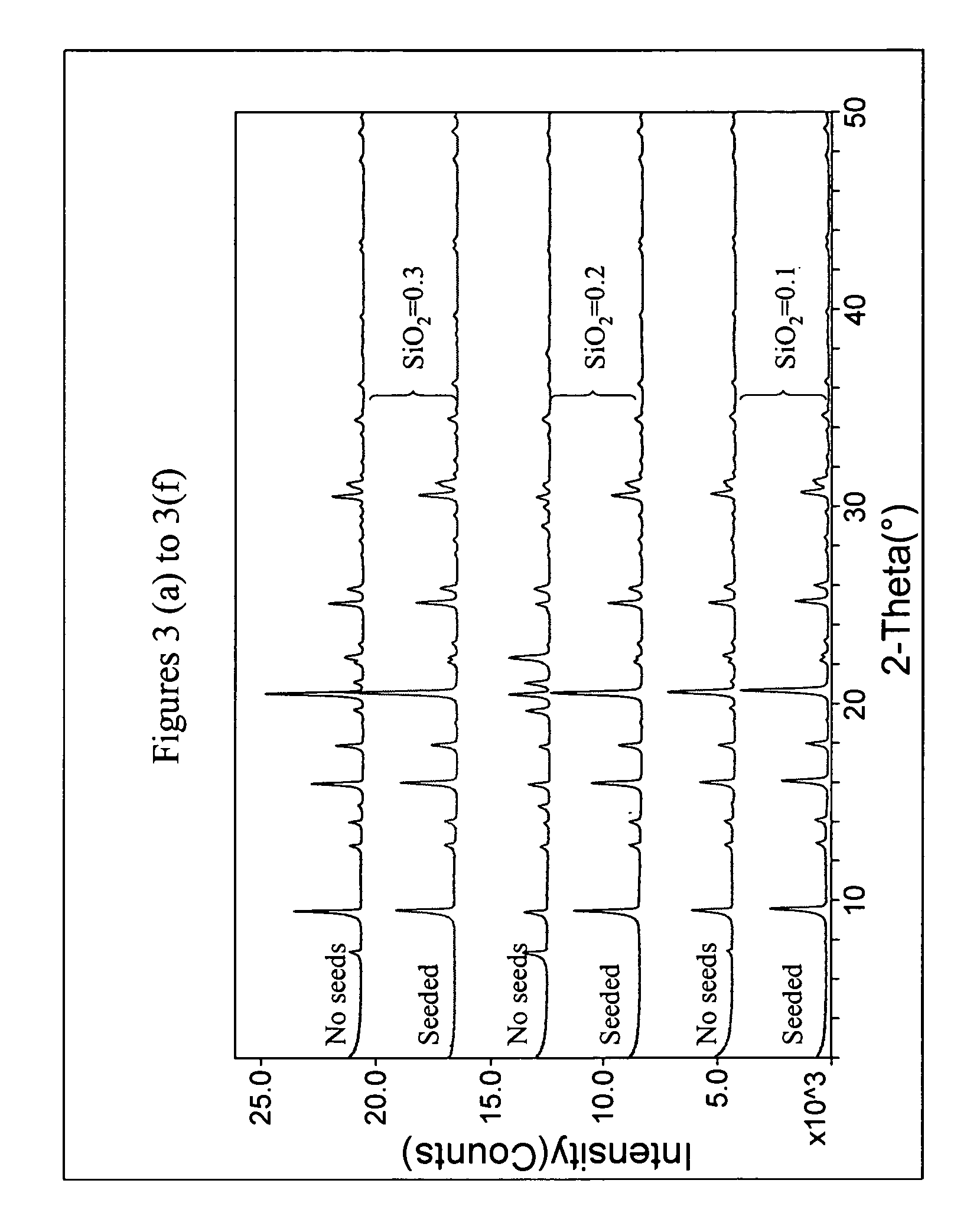

The present invention discloses microporous aluminophosphate (AlPO4) molecular sieve membranes and methods for making and using the same. The microporous AlPO4 molecular sieve membranes, particularly small pore microporous AlPO-14 and AlPO-18 molecular sieve membranes, are prepared by three different methods, including in-situ crystallization of a layer of AlPO4 molecular sieve crystals on a porous membrane support, coating a layer of polymer-bound AlPO4 molecular sieve crystals on a porous membrane support, and a seeding method by in-situ crystallization of a continuous second layer of AlPO4 molecular sieve crystals on a seed layer of AlPO4 molecular sieve crystals supported on a porous membrane support. The microporous AlPO4 molecular sieve membranes have superior thermal and chemical stability, good erosion resistance, high CO2 plasticization resistance, and significantly improved selectivity over polymer membranes for gas and liquid separations, including carbon dioxide / methane (CO2 / CH4), carbon dioxide / nitrogen (CO2 / N2), and hydrogen / methane (H2 / CH4) separations.

Owner:UOP LLC

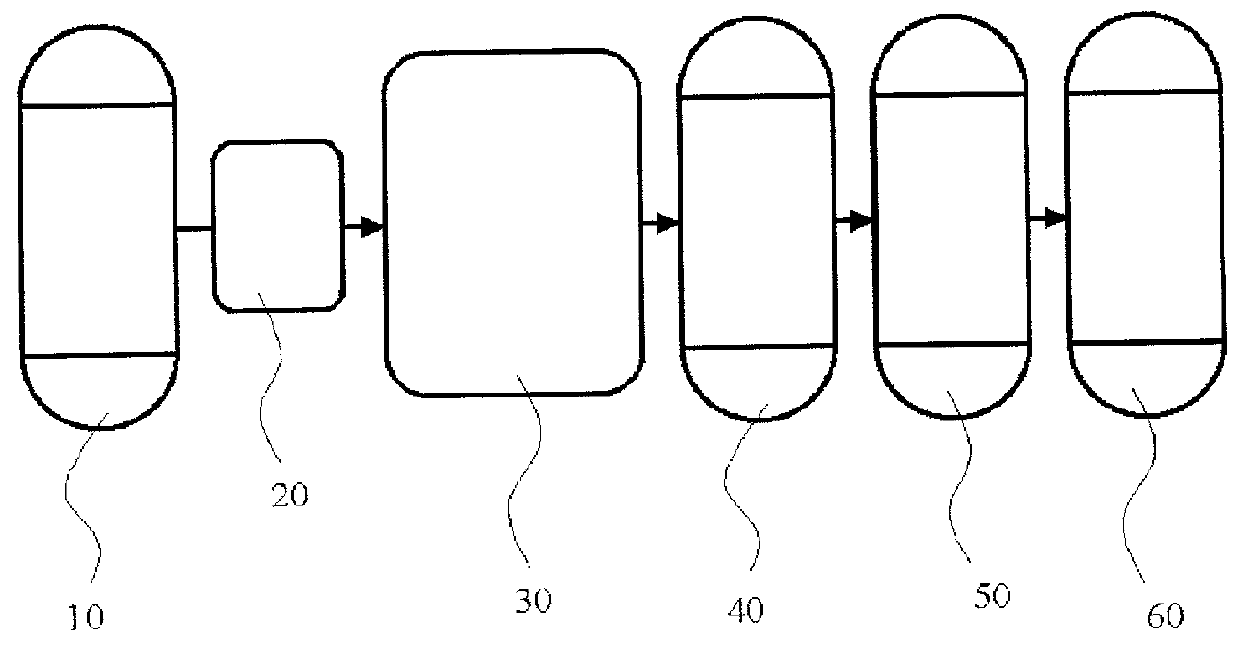

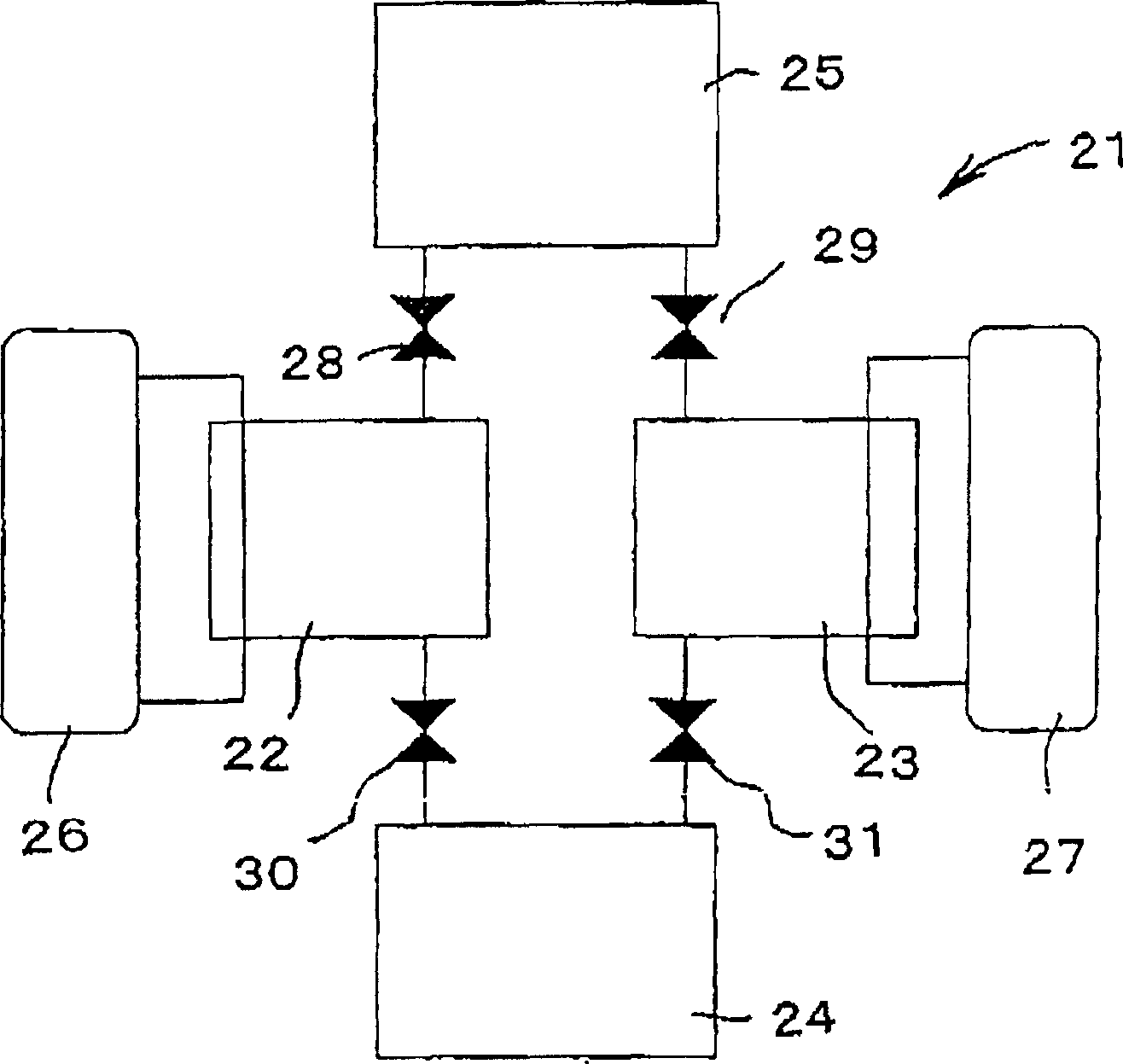

Continuous process and apparatus for preparing inorganic materials employing microwave

This invention relates to a continuous microwave synthesis process of inorganic materials and its apparatus and more particularly, to the process of synthesizing inorganic materials prepared in a manner such that after preparing a mixed solution of precursor materials for various inorganic materials such as porous molecular sieve, layered compounds and ceramics, this mixed solution is continuously added to a tube-type microwave reactor using a slurry pump for the synthesis and crystallization of inorganic materials. Thus the manufacturing process of this invention has the following advantages: (1) the reaction time is further shortened by several to tens of minutes for crystallization, compared to the conventional hydrothermal reaction requiring a prolonged time, (2) the continuous manufacturing and collection processes of this invention can give access to mass-scale production of inorganic materials with relatively small facility, compared to the conventional batch hydrothermal or microwave synthesis, and (3) less amount of organic templating agent can be required during the manufacture of porous molecular sieve.

Owner:KOREA RES INST OF CHEM TECH

Synthesis of silicoaluminophosphates

Disclosed is a method for the manufacture of silicoaluminophosphate (SAPO) and / or aluminophosphate (ALPO) molecular sieves. The method includes maintaining the slurry of the as crystallized molecular sieve under substantially static conditions when stored after substantially complete crystallization and prior to recovery of the product.

Owner:EXXONMOBIL CHEM PAT INC

Method for preparing AlPO4 or SAPO molecular sieve

InactiveCN1850606AHigh selectivityControls are responsiveMolecular-sieve aluminophosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveHydrofluoric acid

The invention is a method for preparing AlPO4 or SAPO molecular sieve, using ionic liquid as reaction medium, adding in amine as auxiliary template. And it can be used to synthesize molecular sieves of various structures, comprising the steps of: A) using halogen 1-alkyl-3- methylimidazole ionic liquid as reaction medium and amine as auxiliary template, blending at 70-100 deg.C for 1-30 min; B) adding in precursor compounds of P, Al and Si and hydrofluoric acid to prepare precursor mixture of molecular sieve, crystallizing at 150-300 deg.C for 0.5-3 h, where the molar ratio of Al2O3 to P2O5 to SiO2 to HF to amine to halogen 1-alkyl -3-methylimidazole ionic liquid = 1:(1.7-3.8):(0-1):(0.05-0.2):(0.5-3):(10-40); and C) cooling to room temperature, filtering, washing and drying, so as to obtain a solid-AlPO4 or SAPO molecular sieve.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Process for synthesising porous crystalline aluminophosphate molecular sieves

InactiveUS20060147364A1Easy to handlePhosphatesMolecular sieve catalystsMolecular sieveOrganic chemistry

Owner:COUNCIL OF SCI & IND RES

Process for synthesizing heteroatom substituted AEL cage construction aluminophosphates molecular sieve

InactiveCN101269822AMolecular-sieve aluminophosphatesMolecular-sieve and base-exchange phosphatesCeriumPropylamine

The invention relates to a synthetic method using hetero atoms to replace the AEL framework structure of a phosphoaluminate molecular sieve, and the method uses the hetero atoms of chlorine, titanium, cobalt, calcium, palladium, zinc, cerium, etc. as the materials of the hetero atoms to replace the AEL framework structure of the phosphoaluminate molecular sieve. In the synthesis process, aluminum isopropoxide or pseudo-boehmite is used as aluminum resources, and hexacosanoic propylamine and isopropylamine or the mixture of both are used as templates, thereby realizing the purposes of single feeding adoption, relatively mild crystallization condition, suitable water-solid ratio and great template dosage reduction. Once crystallization in the process can improve the crystallization efficiency, greatly improve the synthesis efficiency and control the formation of mixed crystal, having obvious advantages.

Owner:PETROCHINA CO LTD +1

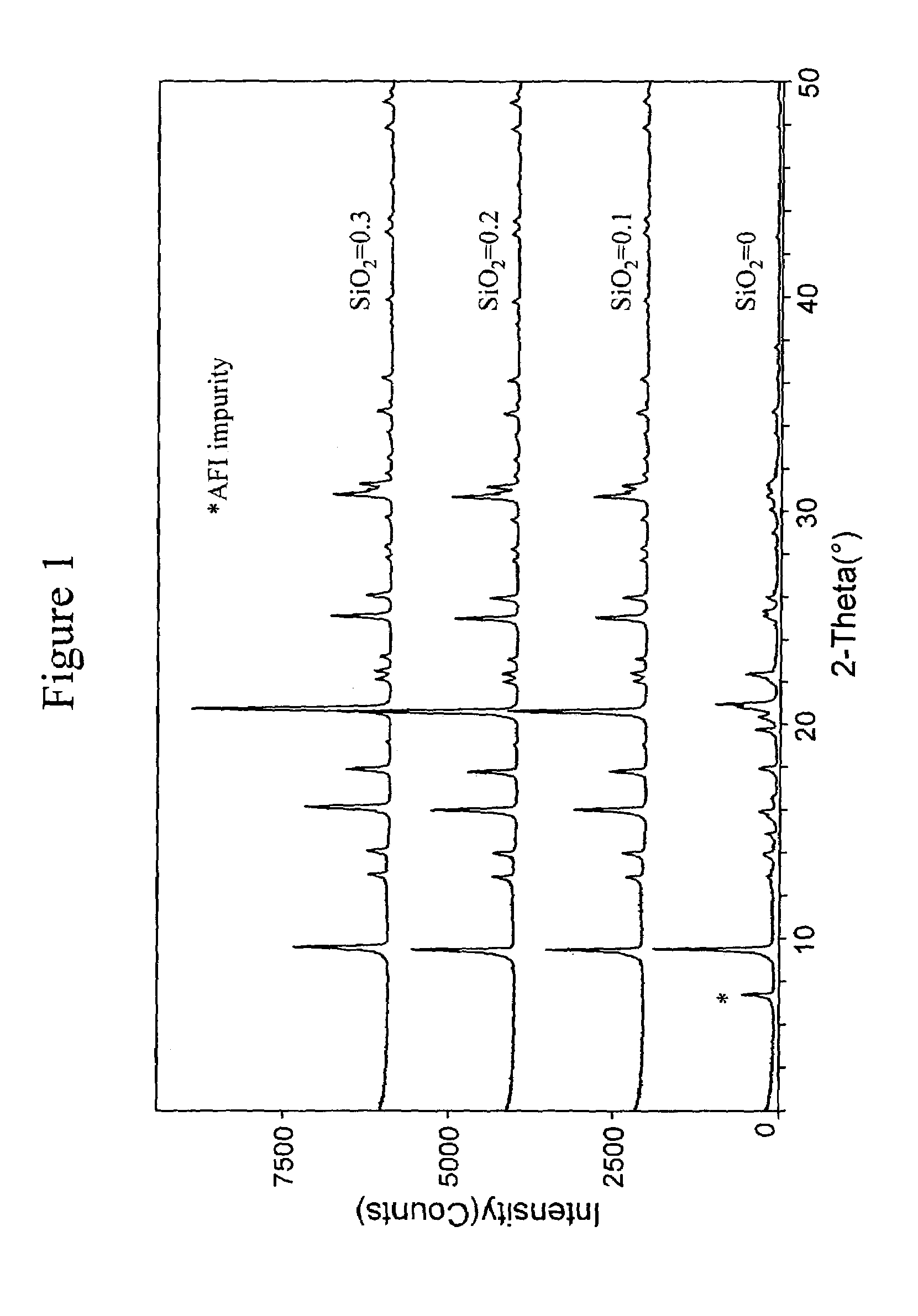

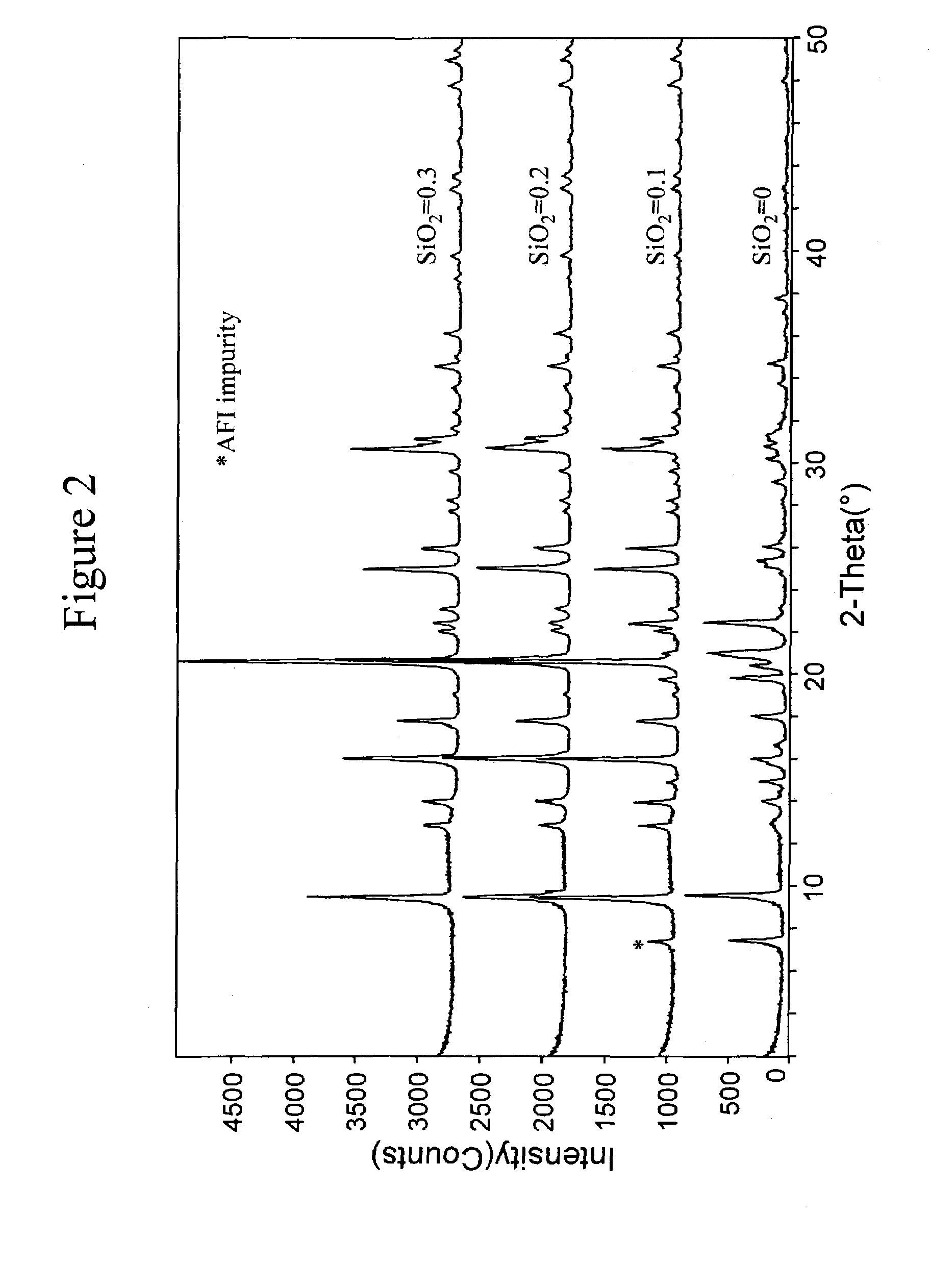

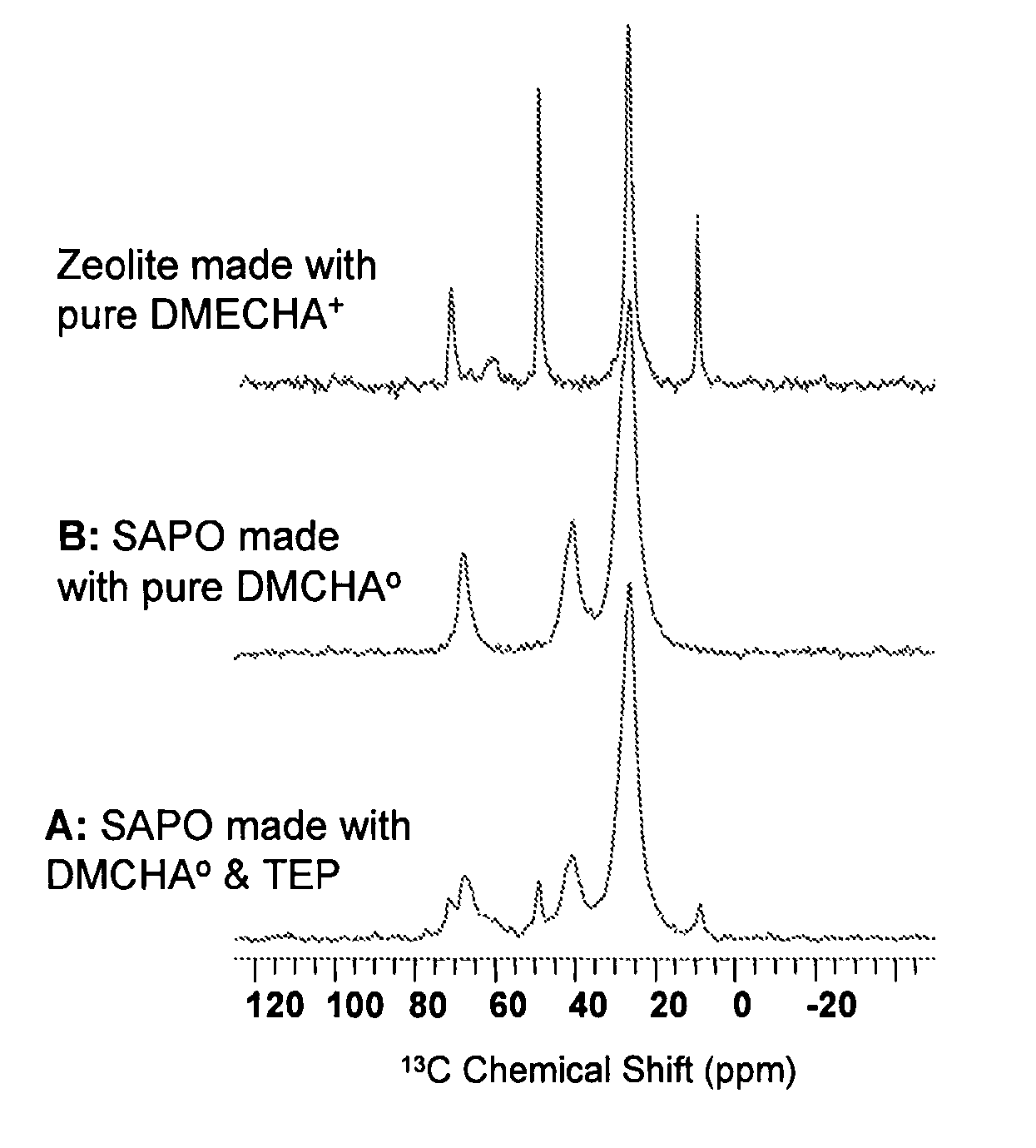

Synthesis of aluminophosphates and silicoaluminophosphates

The invention is directed to a method of synthesising silicoaluminophosphate and aluminophosphate molecular sieves using synthesis templates that contain at least one template of general formula R1R2N—R3, wherein R1 and R2 are independently selected from the group consisting of alkyl groups having from 1 to 3 carbon atoms and hydroxyalkyl groups having from 1 to 3 carbon atoms; R3 is selected from the group consisting of 4- to 8-membered cycloalkyl groups, optionally substituted by 1 to 3 alkyl groups having from 1 to 3 carbon atoms, and 4- to 8-membered heterocyclic groups having from 1 to 3 heteroatoms, said heterocyclic groups being optionally substituted by 1 to 3 alkyl groups having from 1 to 3 carbon atoms and the heteroatoms in said heterocyclic groups being selected from the group consisting of O, N, and S. In particular, the present invention relates to the synthesis of silicoaluminophosphate molecular sieves of the CHA framework type having a low silicon to aluminium atomic ratio.

Owner:EXXONMOBIL CHEM PAT INC

Method for making molecular sieves and novel molecular sieve compositions

Owner:ABB LUMMUS GLOBAL INC

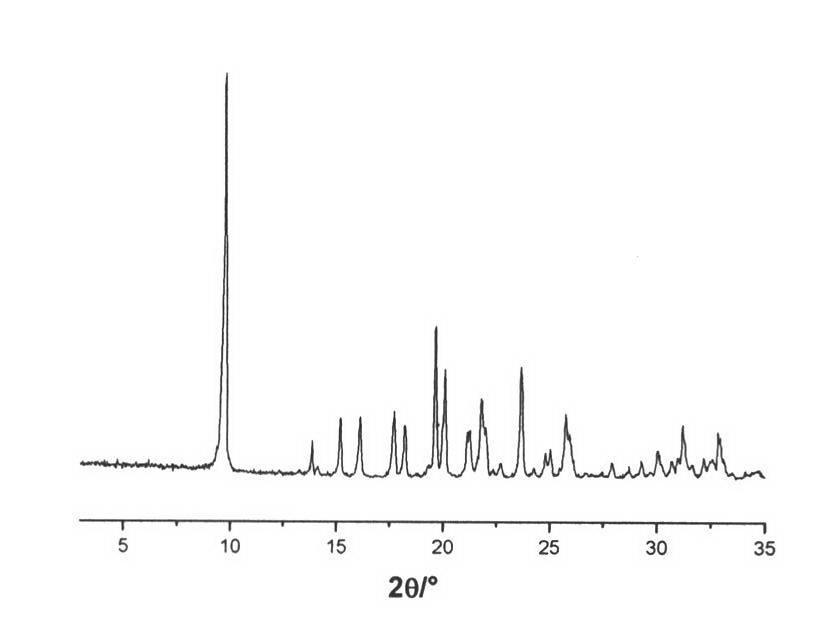

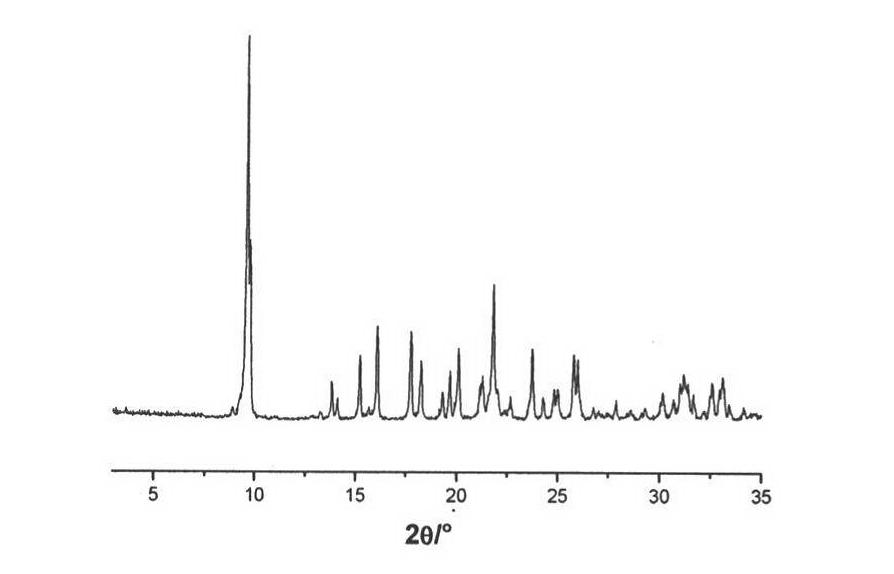

Zeolite, process for producing the same, adsorbent comprising the zeolite, heat utilization system, adsorption heat pump, cold/heat storage system, and air-conditioning apparatus for humidity regulation

InactiveUS20060245994A1Increased durabilityReduce adsorptionMaterial nanotechnologyPhosphatesSorbentNitrogen

Subjects for the invention are to provide a zeolite reduced in performance deterioration in repetitions of use or during long-term use and a process for producing the same and to provide an adsorbent comprising the zeolite and a heat utilization system or the like employing the adsorbent. The invention relates to a zeolite which has a framework density of from 10 T / nm3 to 16 T / nm3 and a carbon content of from 1% by weight to 6% by weight and satisfies the following (1) or (2): (1) the zeolite is an aluminophosphate which has a nitrogen content of from 0.5% by weight to 12% by weight and in which the aluminum may be partly replaced by Me; (2) the zeolite is a silicoaluminophosphate in which the aluminum may be partly replaced by Me and which, when burned to a carbon content lower than 0.3% by weight, retains the framework structure possessed by the silicoaluminophosphate before the burning: (provided that Me in (1) and (2) above is at least one element selected from the elements in Groups 2A, 7A, 8, 1B, and 2B of the periodic table).

Owner:MITSUBISHI PLASTICS INC

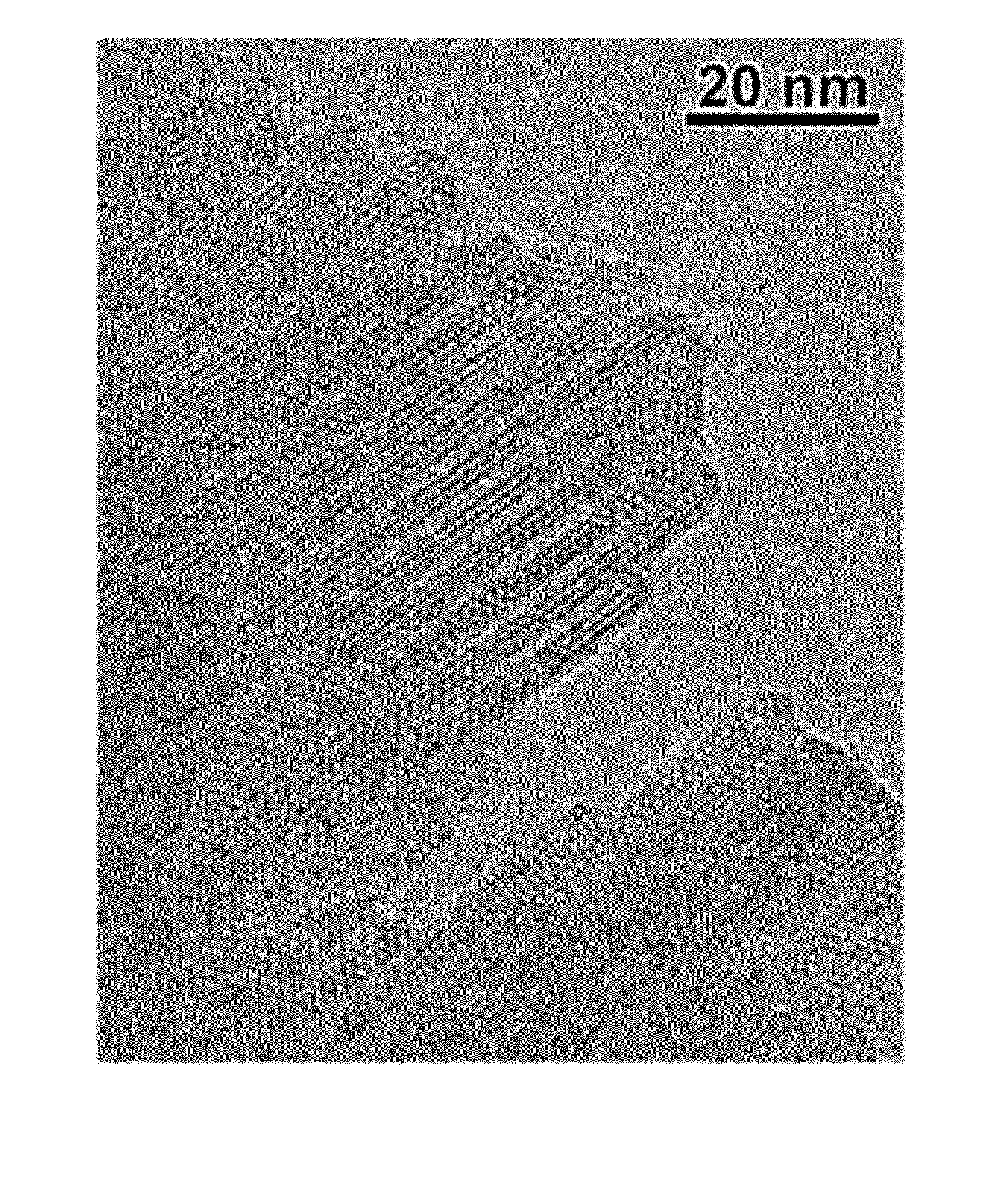

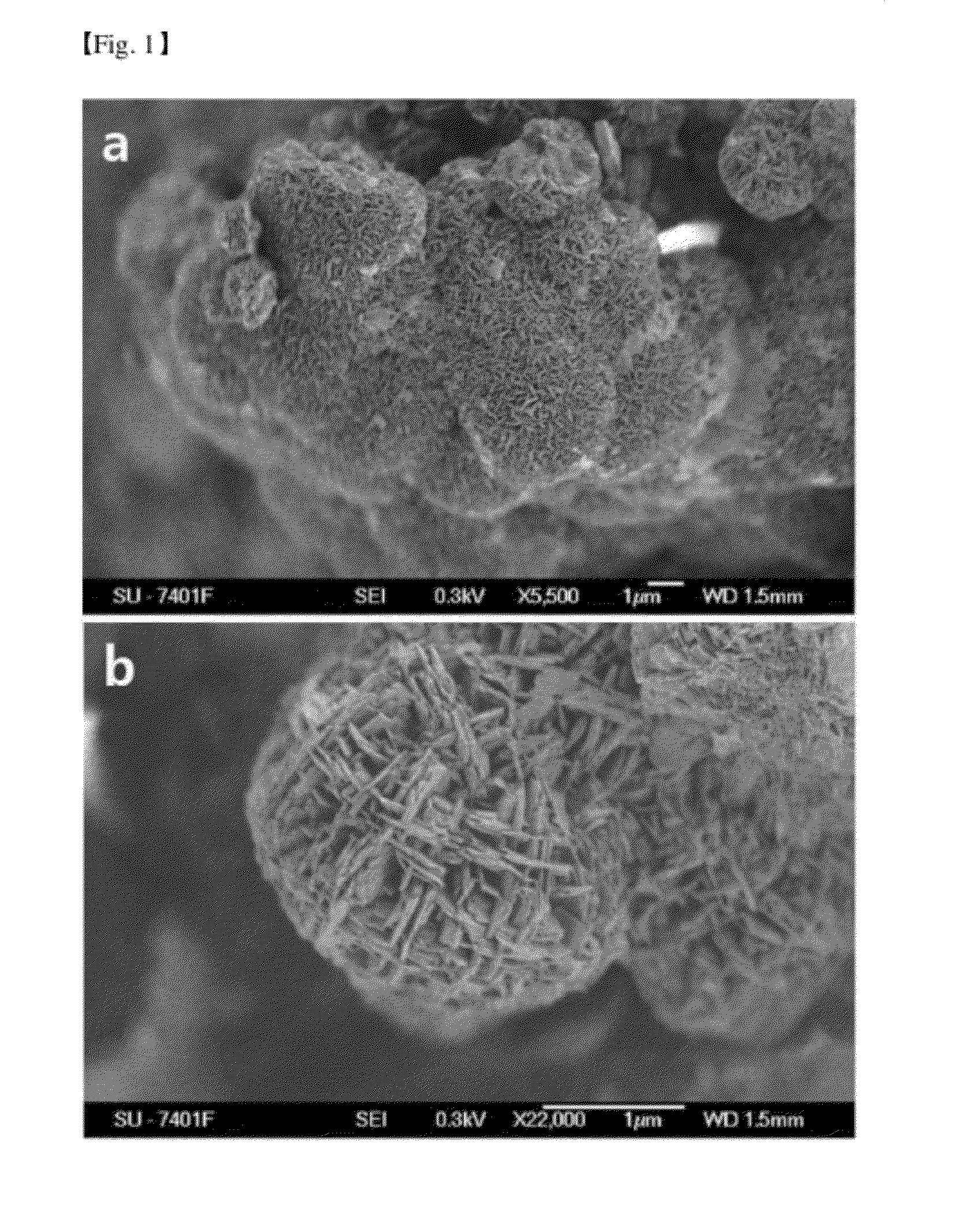

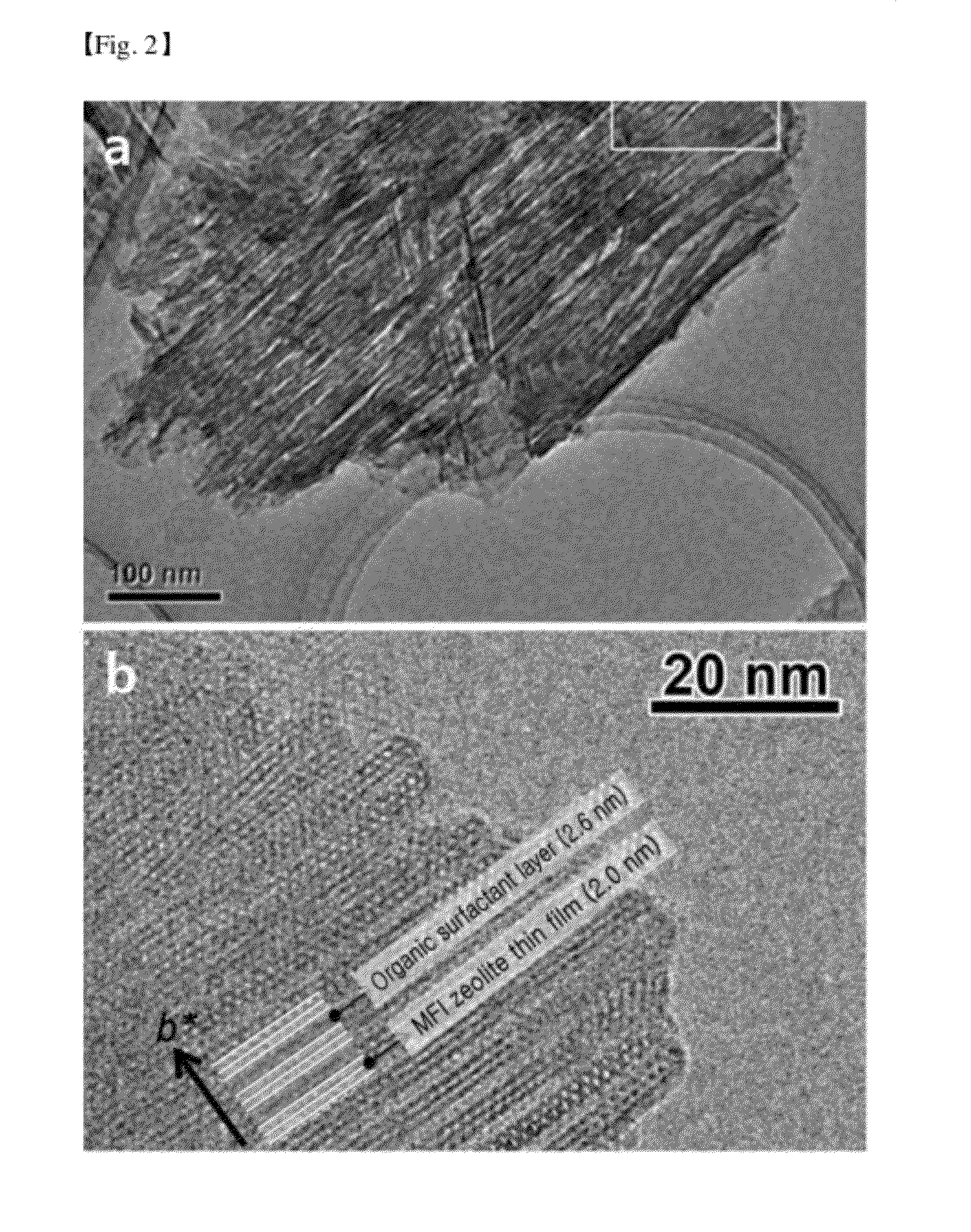

Regularly stacked multilamellar and randomly aligned unilamellar zeolite nanosheets, and their analogue materials whose framework thickness were corresponding to one unit cell size or less than 10 unit cell size

InactiveUS20120165558A1Increase surface areaHigh catalytic activityHydrogenAluminium compoundsIon exchangeOrganic reaction

The present invention relates to microporous molecular sieve materials and their analogue molecular sieve materials having a crystalline unilamellar or multilamellar framework with a single unit cell thickness in which layers are aligned regularly or randomly, the molecular sieve materials being synthesized by adding an organic surfactant to the synthesis composition of zeolite. In addition, the present invention relates to micro-mesoporous molecular sieve materials activated or functionalized by dealumination, ion exchange or other post treatments, and the use thereof as catalyst. These novel materials have dramatically increased external surface area by virtue of their framework with nano-scale thickness, and thus exhibit improved molecular diffusion, and thus have much higher activities as catalyst and ion exchange resin than conventional zeolites. In particular, the materials of the present invention exhibit high reactivity and dramatically increased catalyst life in various organic reactions such as carbon-carbon coupling, alkylation, acylation, etc. of organic molecules.

Owner:KOREA ADVANCED INST OF SCI & TECH

Zeolite, method for production thereof, adsorbent comprising said zeolite, heat utilization system, adsorption heat pump, heating and cooling storage system and humidity controlling air-conditioning a

The invention aims to provide a zeolite with less property degradation in repeated use or long period use and the preparation method, and also provide a sorbent containing the zeolite and a heat utilization system using the sorbent. The invention relates the zeolite with the frame density of 10T / nm<3> - 16T / nm<3> and carbon content of 1wt% - 6wt% and fulfilling two conditions that (1) the zeolite is al-phosphate with 1wt% - 6wt% carbon content and with part aluminum replaced by Me; (2) the zeolite is aluminosilicophosphate with part aluminum replaced by Me and keeping the frame structure before a baking course when baked until the carbon content is under 0.3wt%; (the condition is that the Me in the (1) and the (2) is selected from at least one of the elements from the 2A, 7A, 8, 1B and 2B families.).

Owner:MITSUBISHI PLASTICS INC

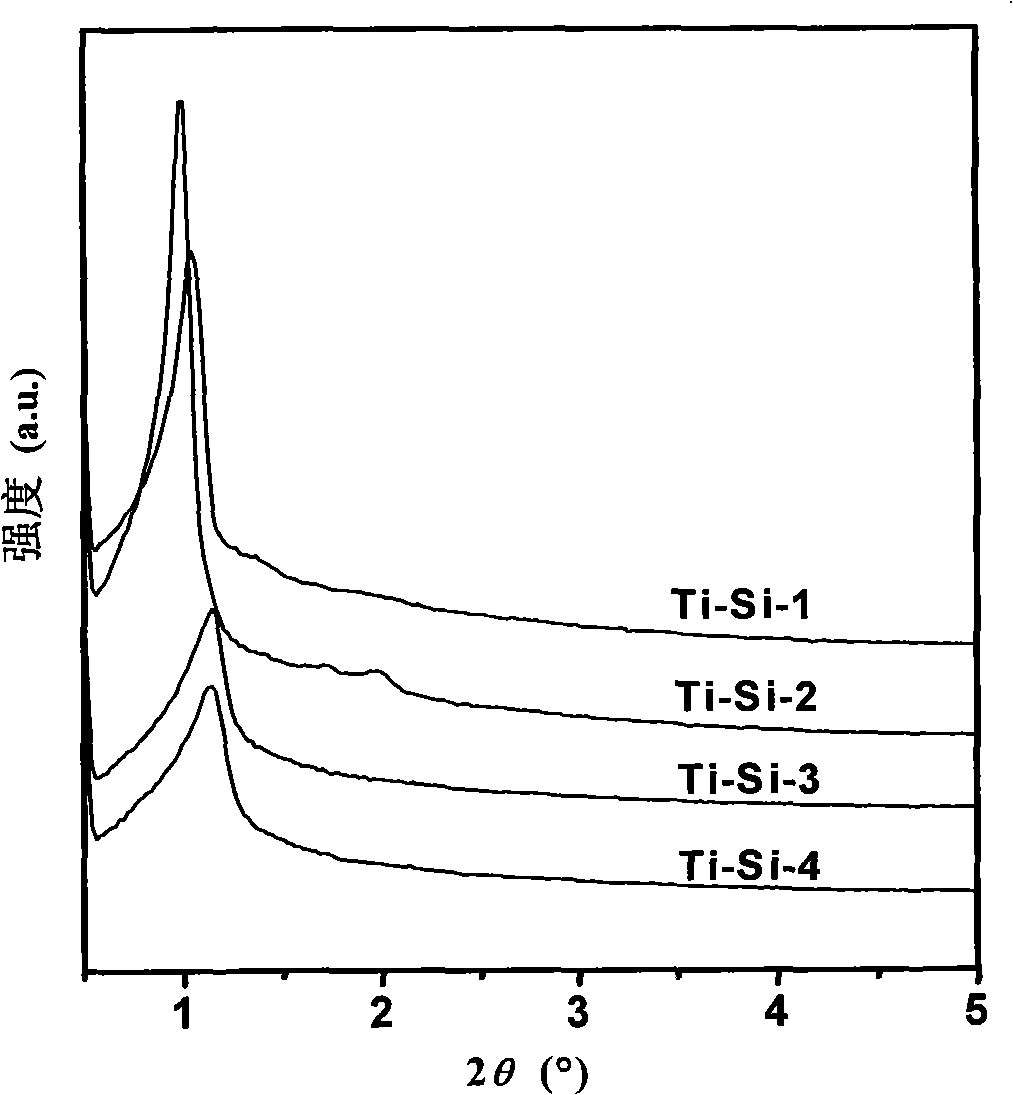

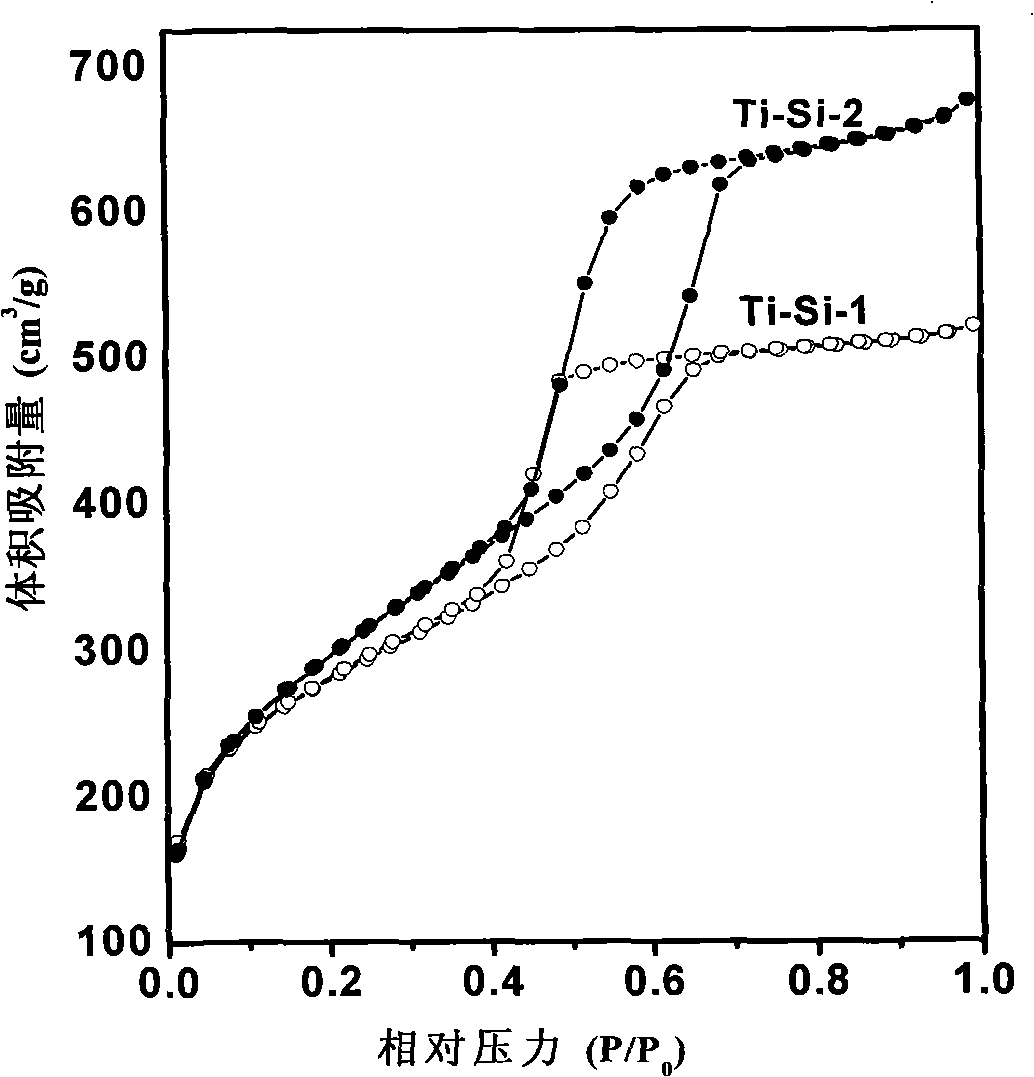

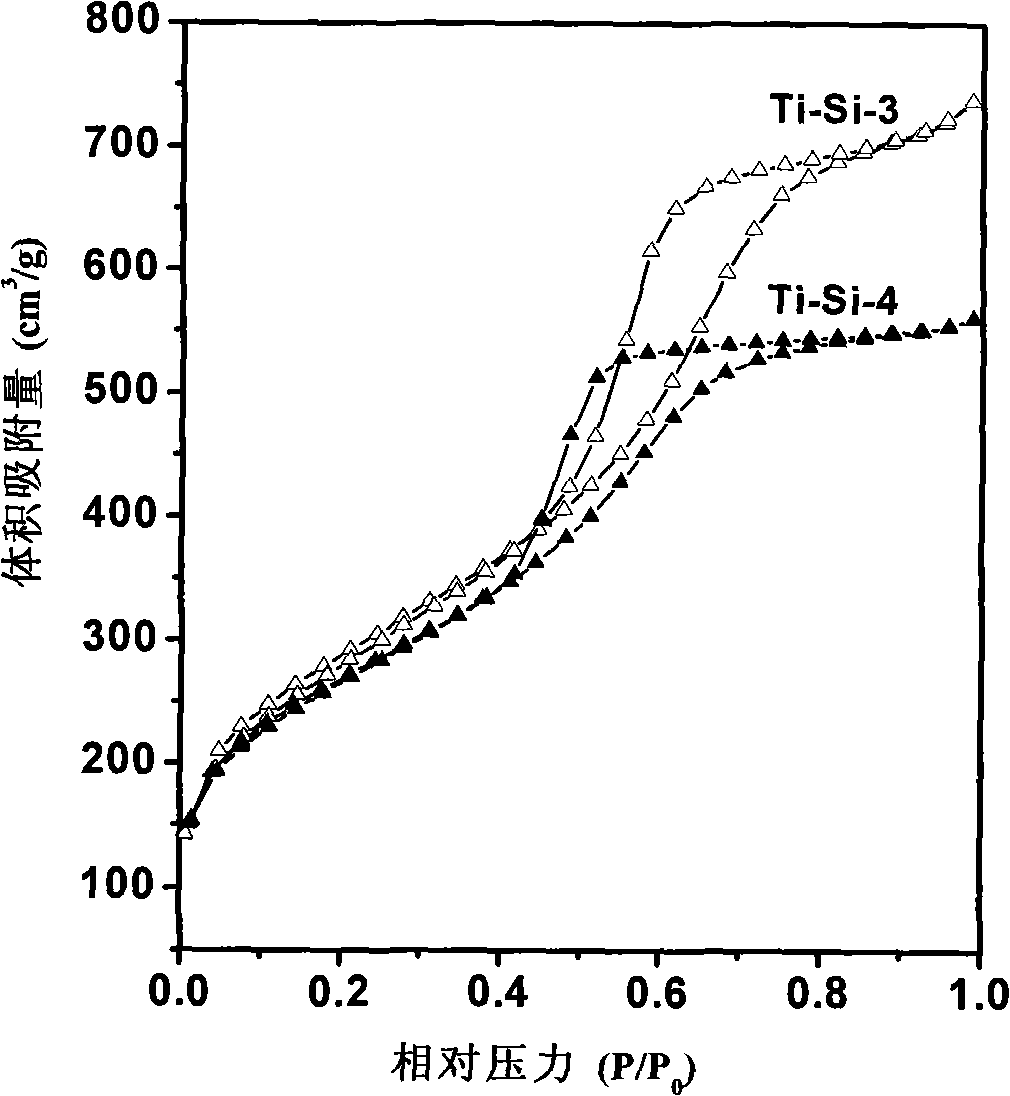

Method for synthesizing ordered mesoporous titanium oxide molecular sieve

InactiveCN101274766AMolecular-sieve aluminophosphatesCrystalline aluminosilicate zeolitesActive agentMesoporous material

The invention pertains to the technical filed of the preparation of mesoporous materials and more particularly relates to a method for synthesizing an ordered mesoporous titanium oxide-silicon molecular sieve. The synthesis method of the invention comprises the procedures that a mixed titanium source is pre-hydrolysed in an organic solvent to form the precursor of the titanium source; the precursor is then mixed with a silicon source and a nonionic surfactant for carrying out organic-inorganic self-assembly in an aqueous solution. The inorganic titanium source and the silicon source are treated with cross-bridging and polymerization around the surfactant so as to obtain the composite material of silicon oxide molecular sieves containing titanium and the nonionic surfactant; the surfactant is removed by counter-current extraction with solvent or roasting in air so as to obtain the ordered mesoporous titanium oxide-silicon molecular sieves. The prepared material has high specific area (700-1600m<2> / g), large pore volume (0.5-1.5cm<3> / g) and uniform pore diameter (4.0-8.0nm) and has a two-dimensional hexagonal mesoscopic structure or a three-dimensional cubic mesoscopic structure. Compared with the traditional method for preparing the titanium oxide-silicon molecular sieves, the synthesis method of the invention has the advantages of simple operation, low material cost and low requirement for facilities, etc.

Owner:FUDAN UNIV +1

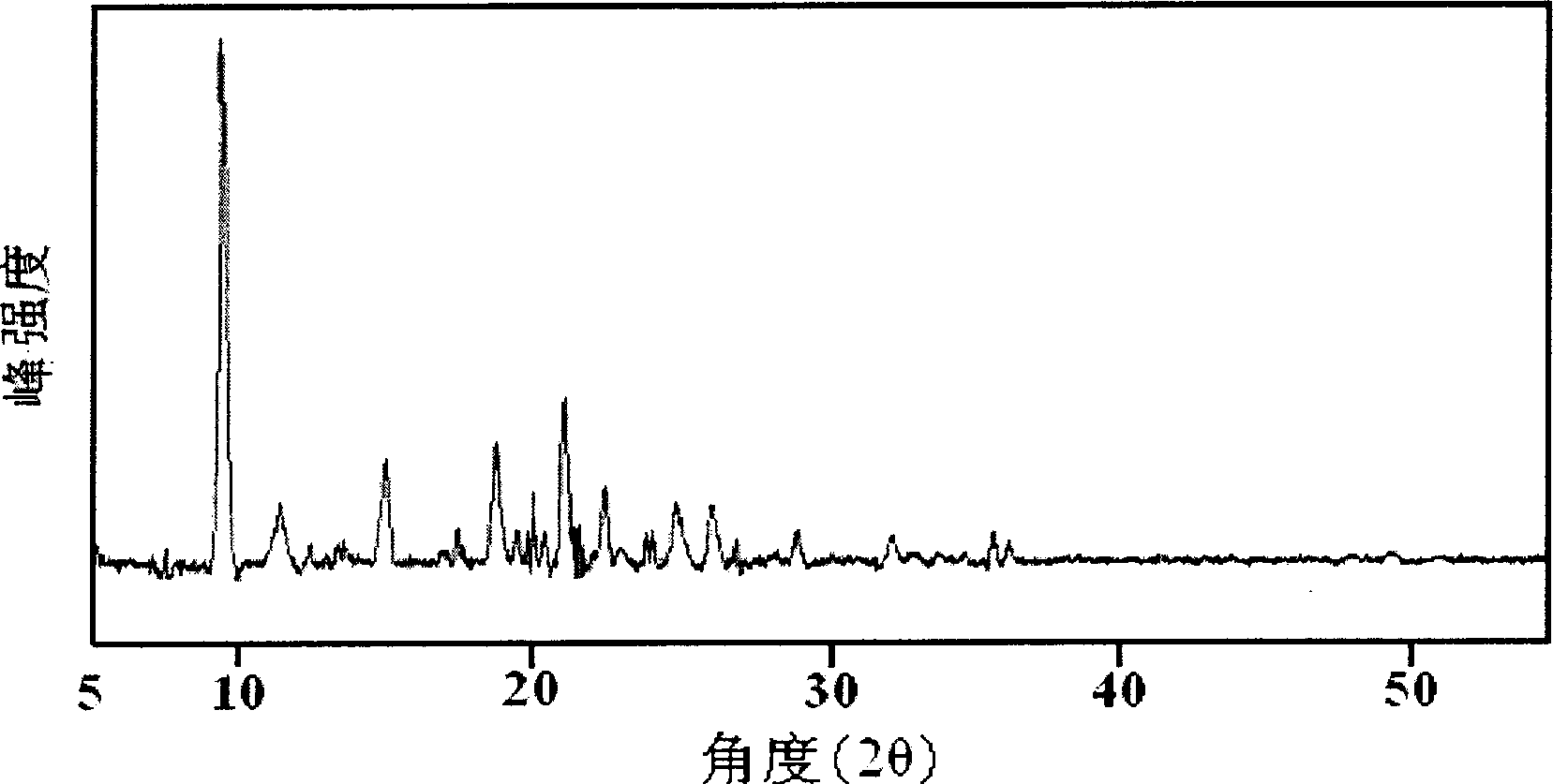

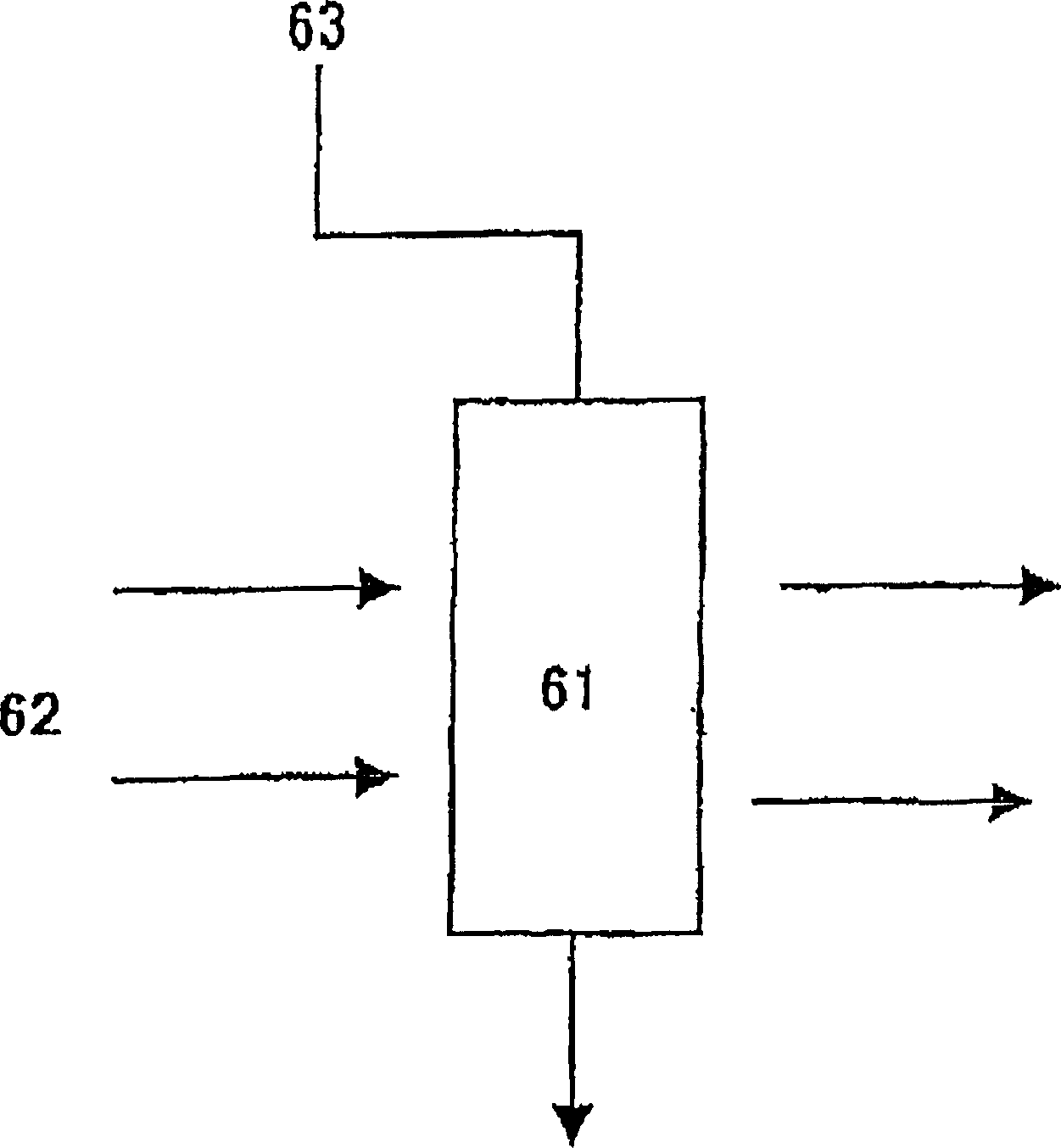

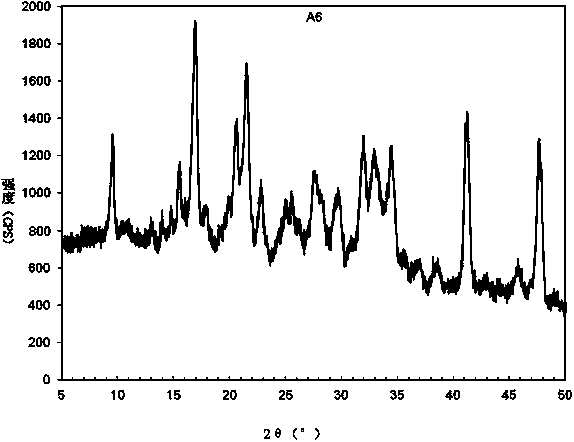

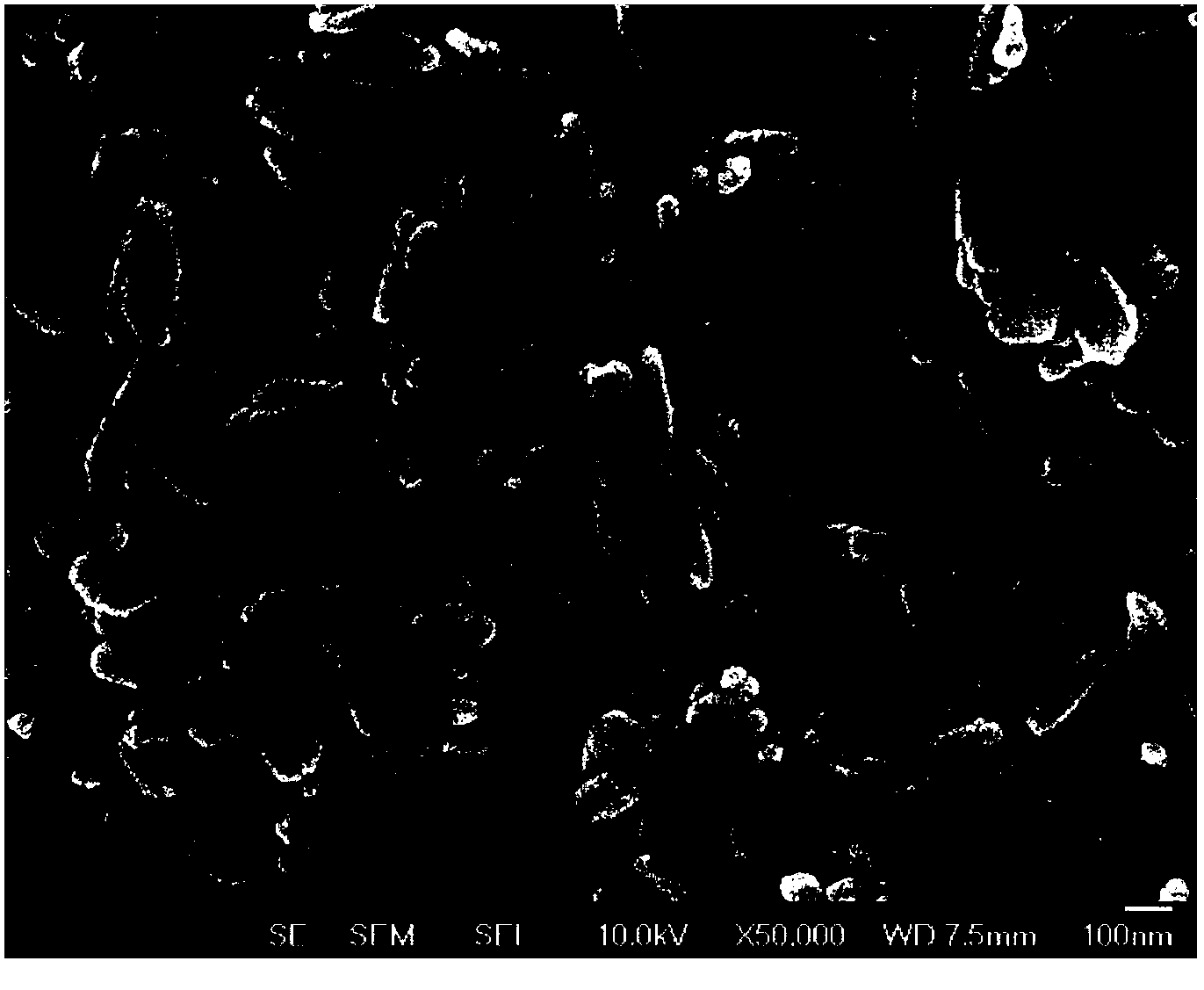

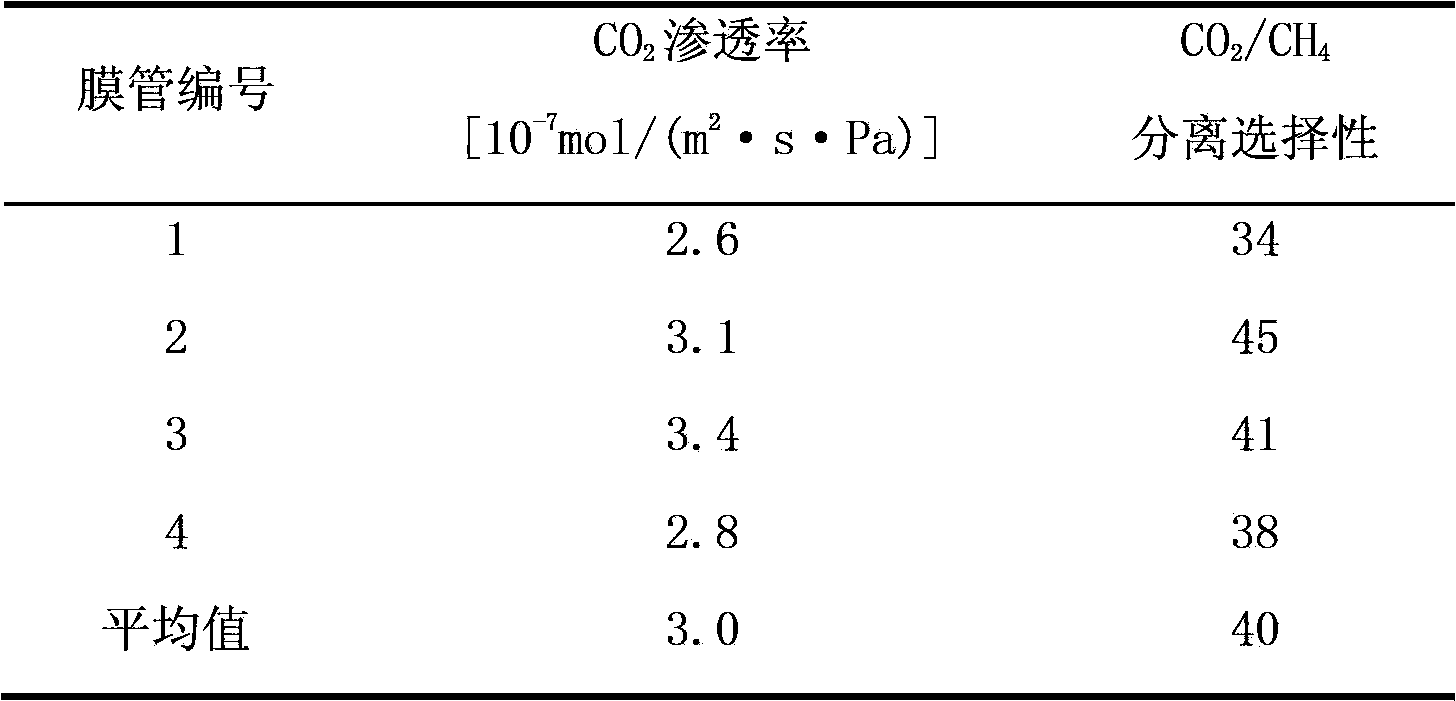

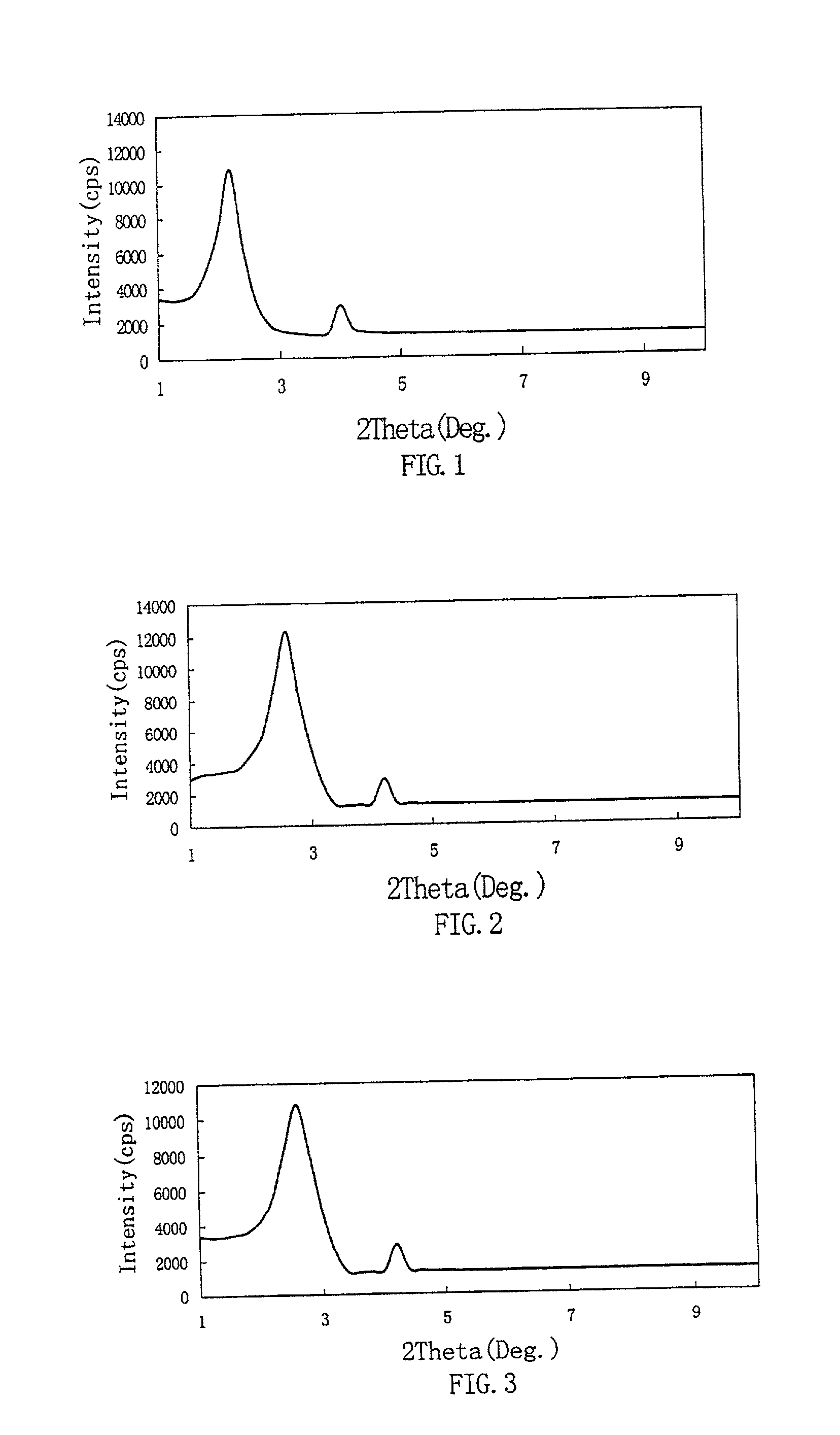

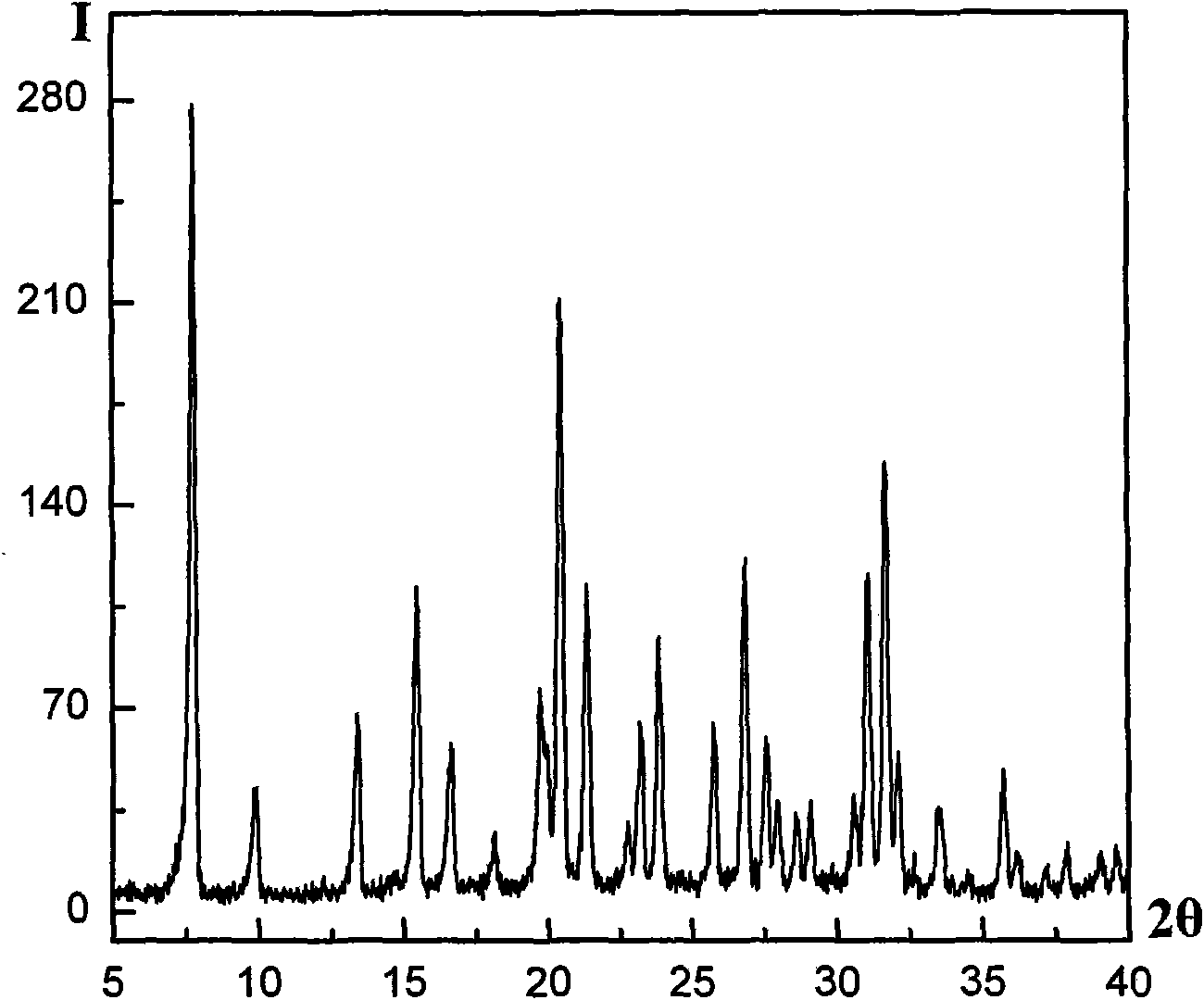

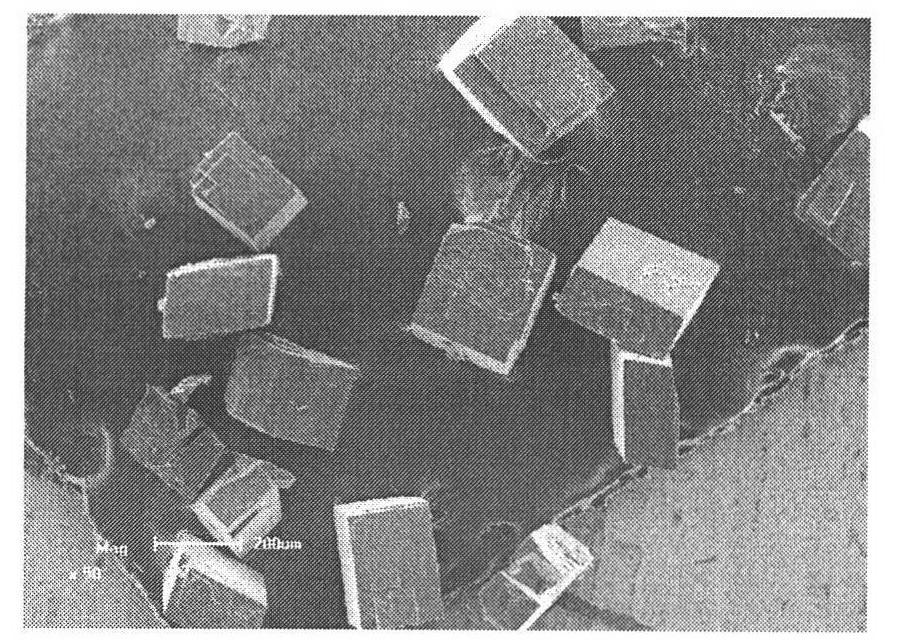

Preparation method of AlPO-18 molecular sieve membrane

InactiveCN103449475AHigh separation selectivityGood repeatabilityNanotechnologyMolecular-sieve aluminophosphatesPhosphoric acidMembrane synthesis

The invention discloses a preparation method of an AlPO-18 molecular sieve membrane. The preparation method comprises following steps: (1) mixing and dissolving aluminum source, tetraethylammonium hydroxide, and phosphoric acid in water, then carrying out hydro-thermal synthesis reactions to obtain AlPO-18 molecular sieve crystal seed; (2) coating the AlPO-18 molecular sieve crystal seed on the inner surface of a porous ceramic tube carrier; (3) mixing and dissolving aluminum source, tetraethylammonium hydroxide, and phosphoric acid in water to obtain molecular sieve membrane synthesis mother liquid, putting the ceramic tube, which has been coated with the AlPO-18 molecular sieve crystal seed, in a reactor, adding the molecular sieve membrane synthesis mother liquid, and then carrying out a hydrothermal crystallization treatment so as to obtain an AlPO-18 molecular sieve membrane after aging; (4) burning the membrane tube to remove the template agent so as to obtain an activated AlPO-18 molecular sieve membrane. The AlPO-18 molecular sieve membrane synthesized by the preparation method is capable of being applied to separations of CO2 / CH4 and CO2 / H2, and has a high selectivity and a high throughput of separations of CO2 / CH4 and CO2 / H2.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Mesoporous molecular sieve and a process for the preparation of the same

InactiveUS20020127164A1High hydrothermal stabilityHigh thermal and hydrothermal stabilityPhosphatesMolecular sieve catalystsMolecular sieveTitanium

The present invention relates to a mesoporous molecular sieve MPL-1 and its preparation process. The anhydrous composition of this molecular sieve contains at least three elements, i.e. aluminum, phosphorus and oxygen. The molecular sieve has larger pore diameters, generally 1.3 nm-10.0 nm, a larger specific surface area and adsorption capacity. It is synthesized under the hydrothermal process with an organic compound as template. Where necessary, silicon and / or titanium may be added to synthesize the aluminosilicophosphate, aluminotitanophosphate, or aluminosilicotitanophosphate molecular sieves having a mesoporous structure, and / or metal compounds may be added to synthesize derivatives of mesoporous aluminophosphate molecular sieves containing the corresponding hetero-atoms.

Owner:CHINA PETROLEUM & CHEM CORP +1

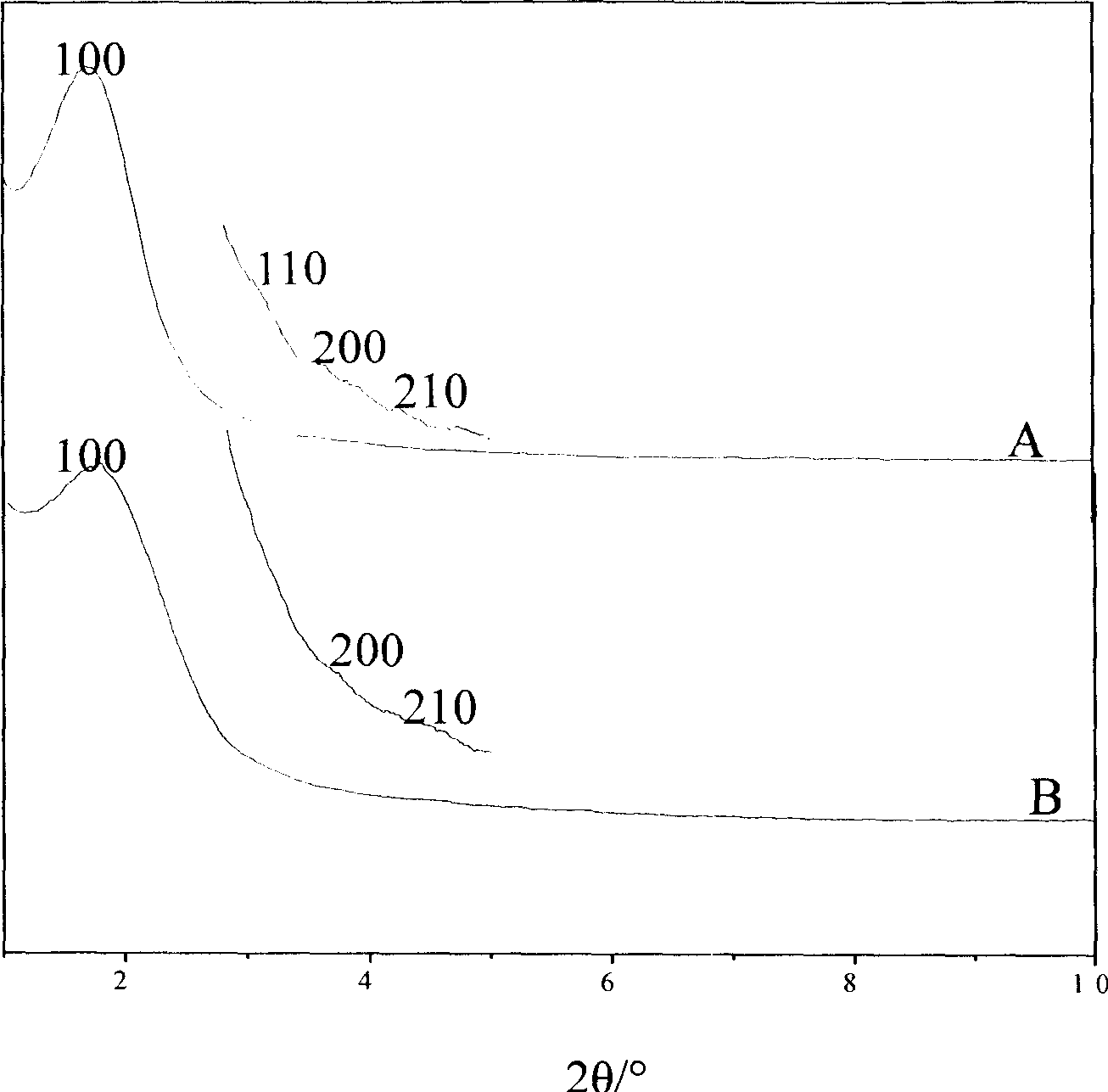

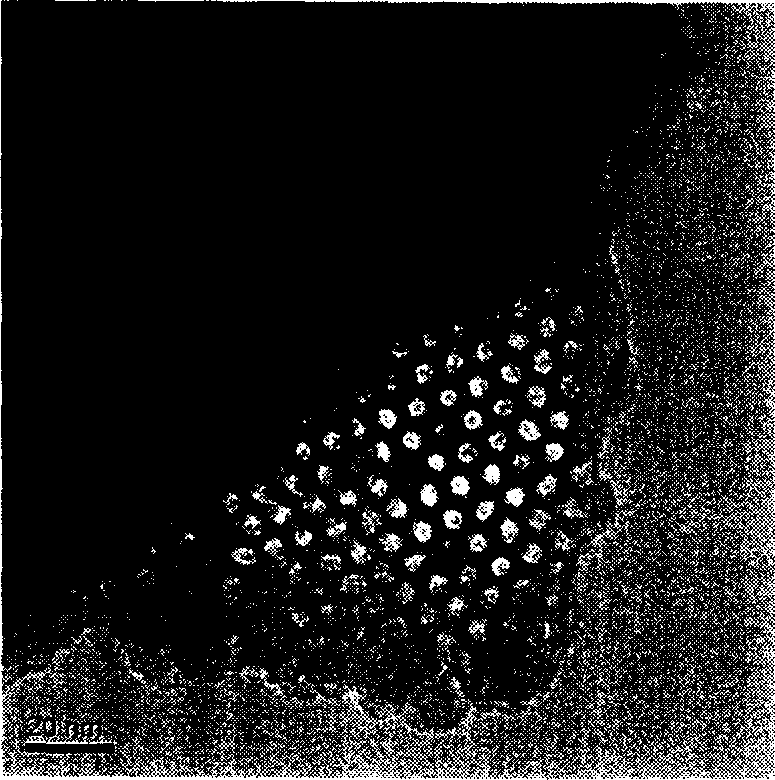

High heat stability ordered mesoporous aluminum phosphate material and its preparing method

InactiveCN1749165AHigh degree of orderWell-preservedMolecular-sieve aluminophosphatesMolecular-sieve and base-exchange phosphatesMesoporous materialALUMINUM PHOSPHATE

The present invention is high heat stability ordered mesoporous aluminum phosphate material and its preparation process, and belongs to the field of inorganic chemistry and physical chemistry technology. The mesoporous aluminum phosphate material has composition of P2O5-Al2O3-MXOY, skeleton with primary and secondary zeolite structure units, 2D hexagonal structure, high heat stability and high degree of order. The preparation process includes synthesizing precursor solution containing the primary and secondary microporous aluminum phosphate zeolite structure units by using organic amine as template agent; and subsequent self-assembling process of the precursor and cationic surfactant to synthesize the ordered mesoporous aluminum phosphate material. The prepared mesoporous material has high specific surface area and atom connecting mode of microporous molecular sieve, may have several hetero atoms introduced, and may be used widely in chemical fields.

Owner:JILIN UNIV

Method for preparing aluminum phosphate molecular screen in eutectic mixture

InactiveCN101602513AEasy to makeNot easy to deliquescenceMolecular-sieve aluminophosphatesMolecular-sieve and base-exchange phosphatesAlcoholInorganic Chemical

The invention provides a method for preparing an aluminum phosphate molecular screen in a eutectic mixture, and belongs to the field of inorganic chemical synthesis. In particular, the invention relates to a method for an aluminum phosphate molecular screen by the eutectic mixture as a reaction solvent and a template. The method is characterized by using the eutectic mixture prepared by combining alcohol and quaternary ammonium salt as the reaction solvent and the template to prepare the aluminum phosphate molecular screen. In the ion thermal reaction, the eutectic mixture has proper acidity and alkaline, the alcohol organic matters are not decomposed to release extra organic amine in the crystallization reaction process when being heated, and the quaternary ammonium salt in the system can fully complete the structure guide action. Compared with the imidazole ionic liquid, the used eutectic mixture material has the advantages of low price, easy purchase and preparation, hard deliquescence and convenient use.

Owner:TAIYUAN UNIV OF TECH

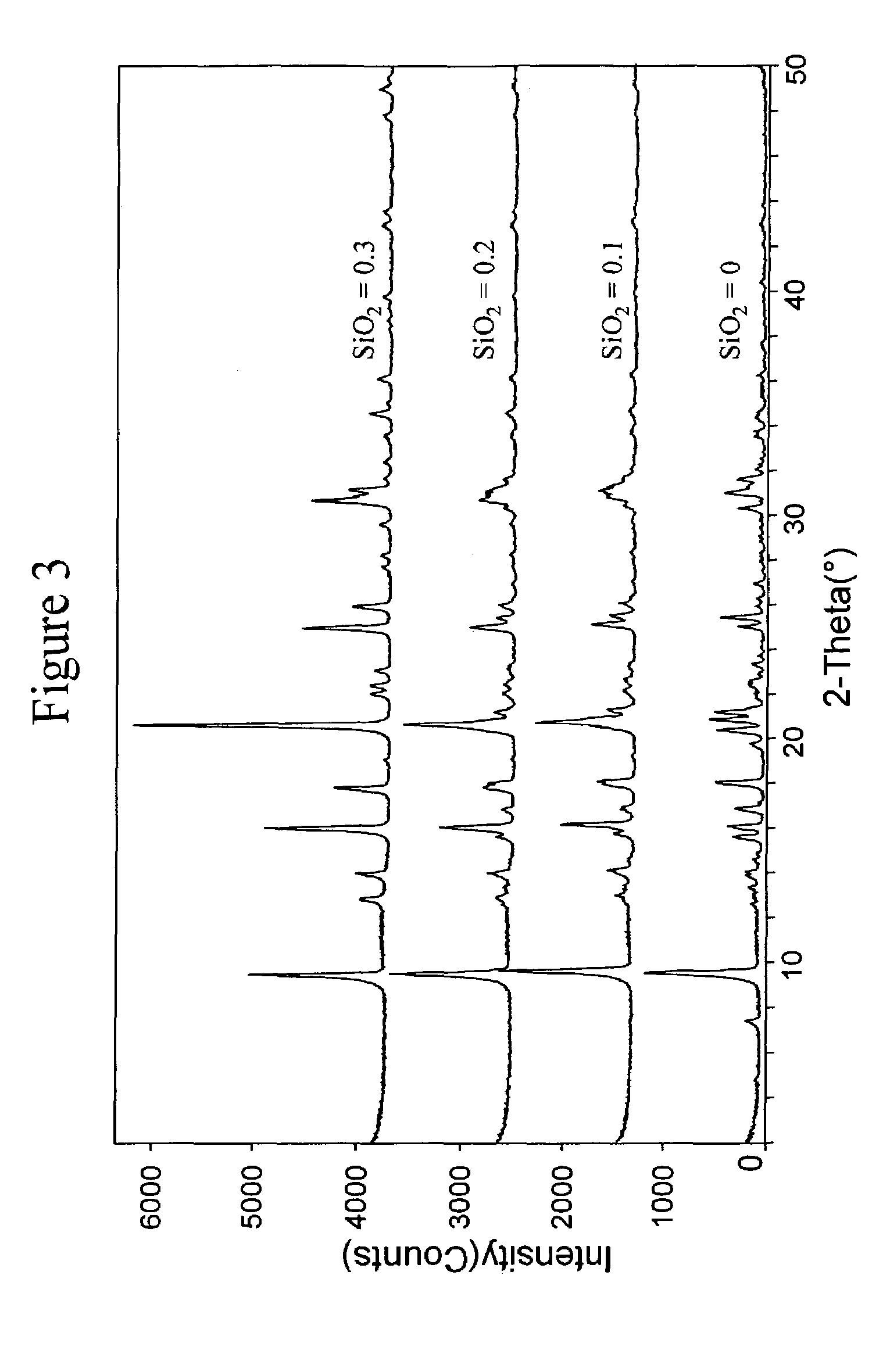

Microporous aluminophosphate molecular sieve membranes for highly selective separations

ActiveUS20100311565A1High selectivityGood chemical and thermal stabilitySolid sorbent liquid separationPretreated surfacesMolecular sieveIn situ crystallization

The present invention discloses microporous aluminophosphate (AlPO4) molecular sieve membranes and methods for making and using the same. The microporous AlPO4 molecular sieve membranes, particularly small pore microporous AlPO-14 and AlPO-18 molecular sieve membranes, are prepared by three different methods, including in-situ crystallization of a layer of AlPO4 molecular sieve crystals on a porous membrane support, coating a layer of polymer-bound AlPO4 molecular sieve crystals on a porous membrane support, and a seeding method by in-situ crystallization of a continuous second layer of AlPO4 molecular sieve crystals on a seed layer of AlPO4 molecular sieve crystals supported on a porous membrane support. The microporous AlPO4 molecular sieve membranes have superior thermal and chemical stability, good erosion resistance, high CO2 plasticization resistance, and significantly improved selectivity over polymer membranes for gas and liquid separations, including carbon dioxide / methane (CO2 / CH4), carbon dioxide / nitrogen (CO2 / N2), and hydrogen / methane (H2 / CH4) separations.

Owner:UOP LLC

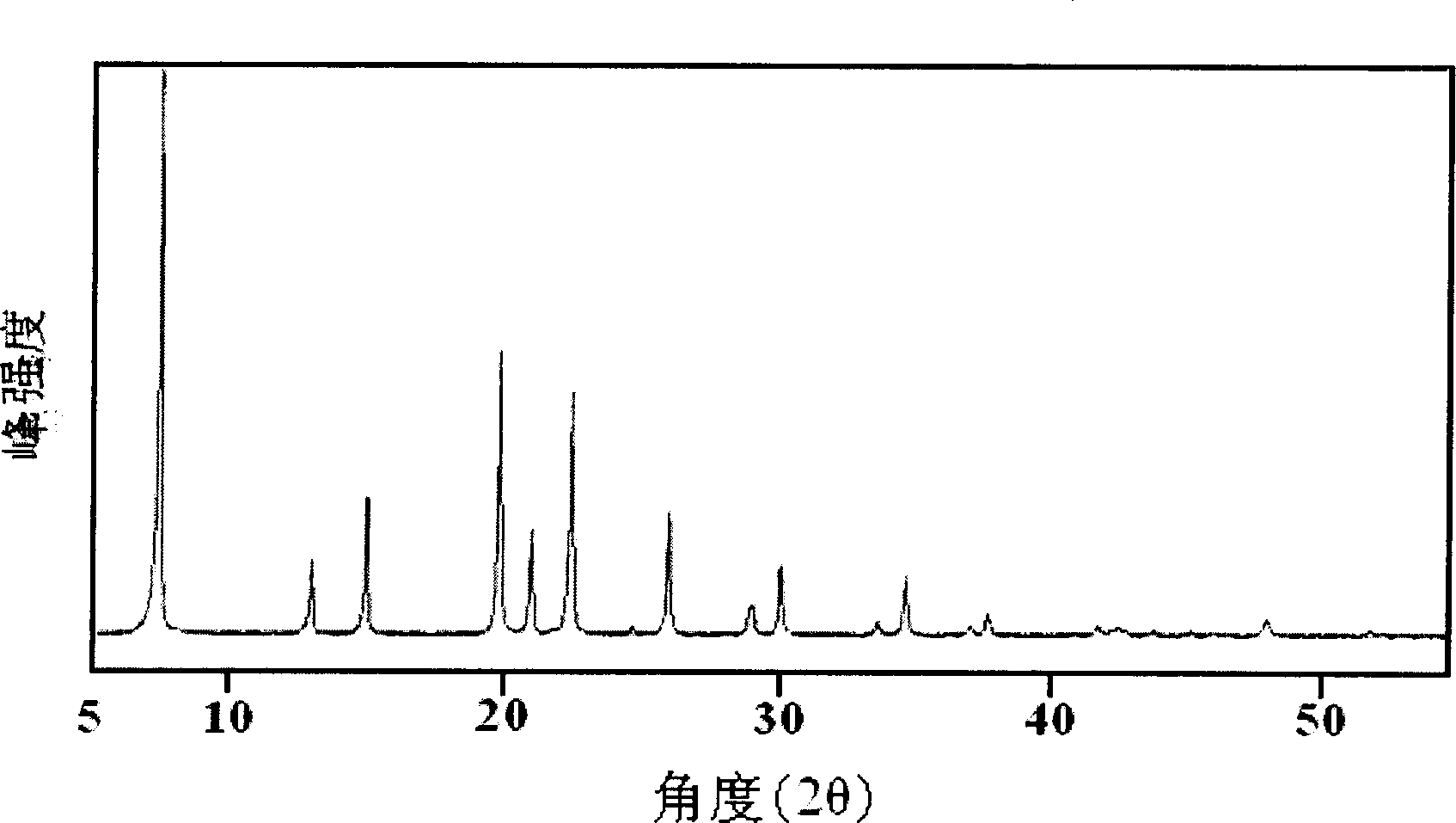

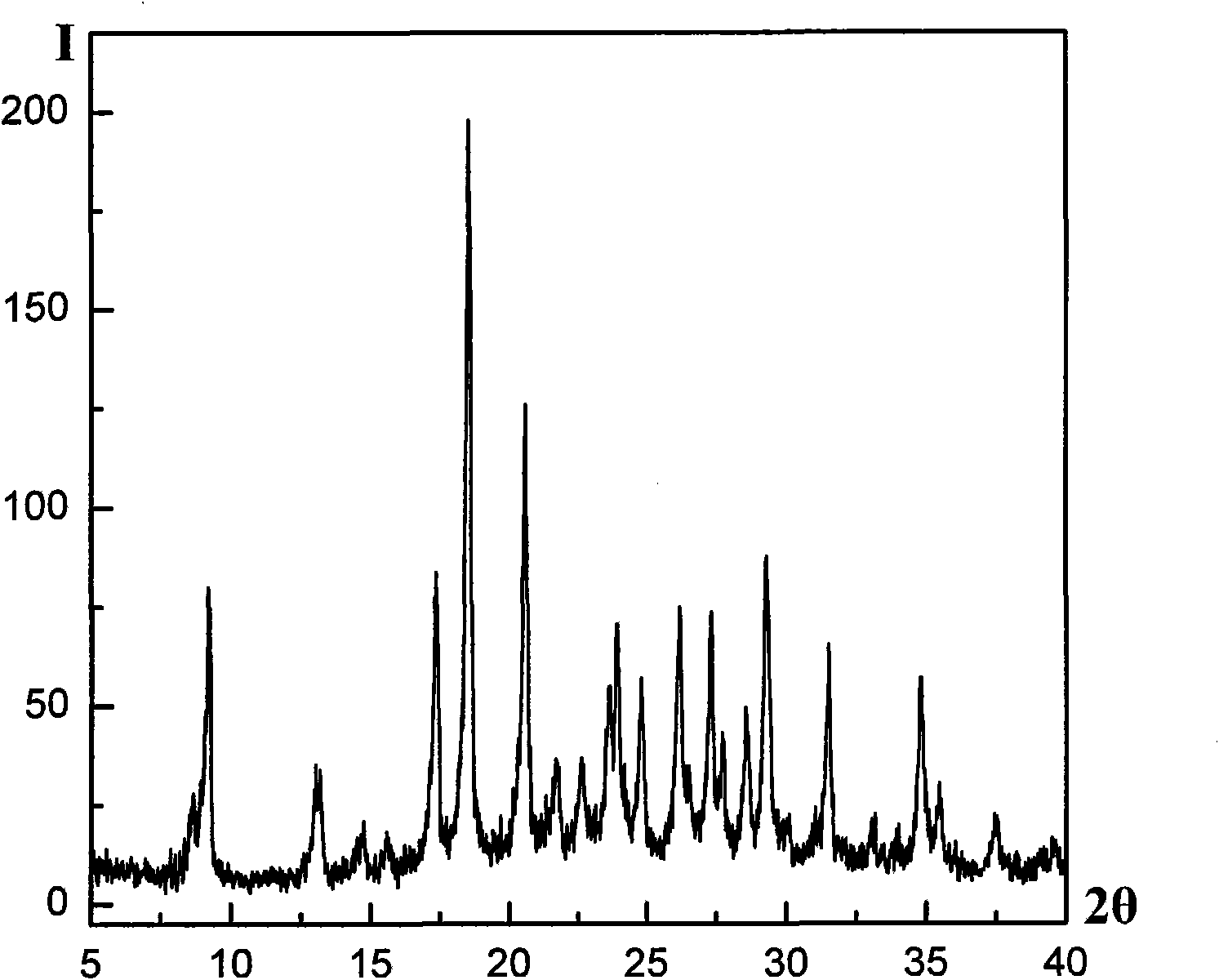

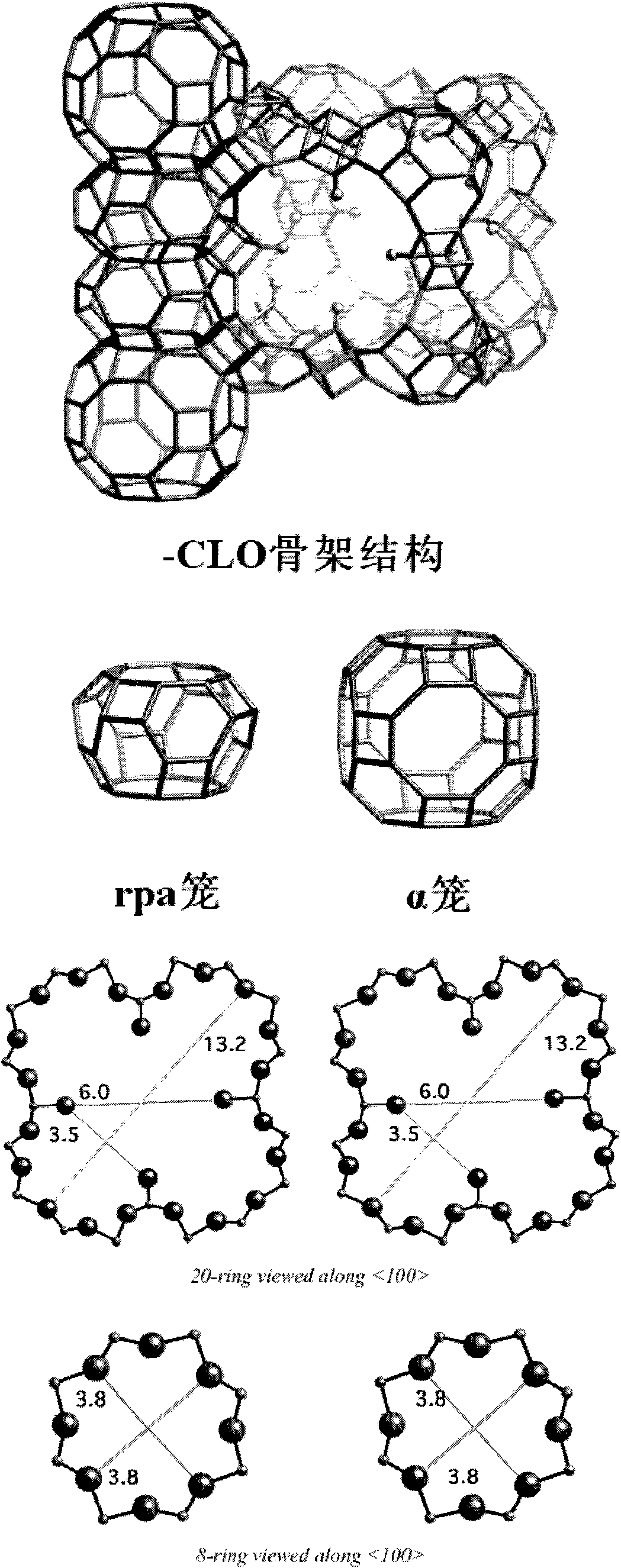

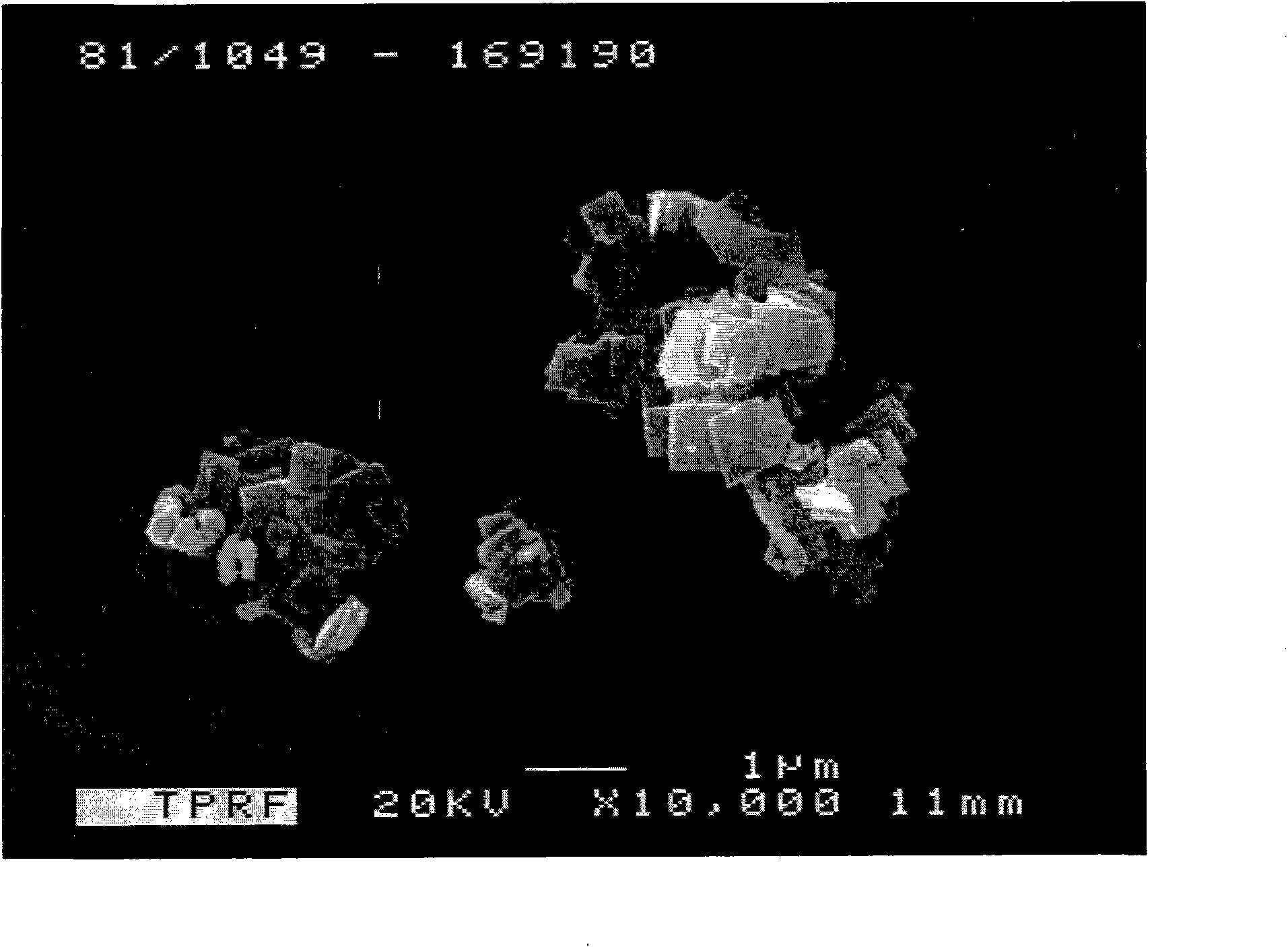

-CLO structural aluminum phosphate molecular sieve and preparation method thereof

InactiveCN102139885ALower synthesis costNo acid and alkali dischargeMolecular sieve catalystsMolecular-sieve aluminophosphatesMolecular sieveNational laboratory

The invention relates to a -cloverite (-CLO) structural aluminum phosphate molecular sieve Dalian national laboratory number 1 (DNL-1) and a preparation method thereof. The -CLO structural aluminum phosphate molecular sieve DNL-1 confirmed by International Zeolite Association is synthesized by an ionothermal method, wherein ionic liquid serves as a reaction medium. The molecular sieve has high stability, extremely low skeletal density and a wide application prospect in aspects of catalysis, gas adsorption and separation and the like. The preparation method is high in economy, is safe in operation, is convenient to operate and is environment-friendly.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

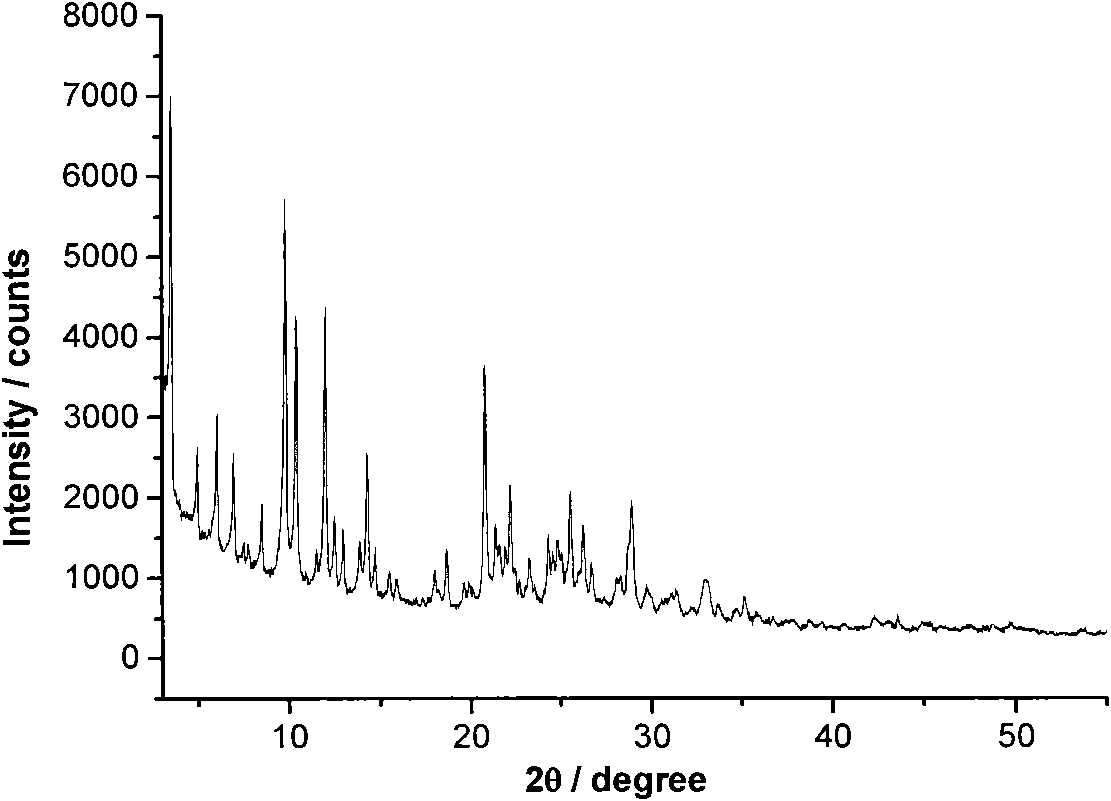

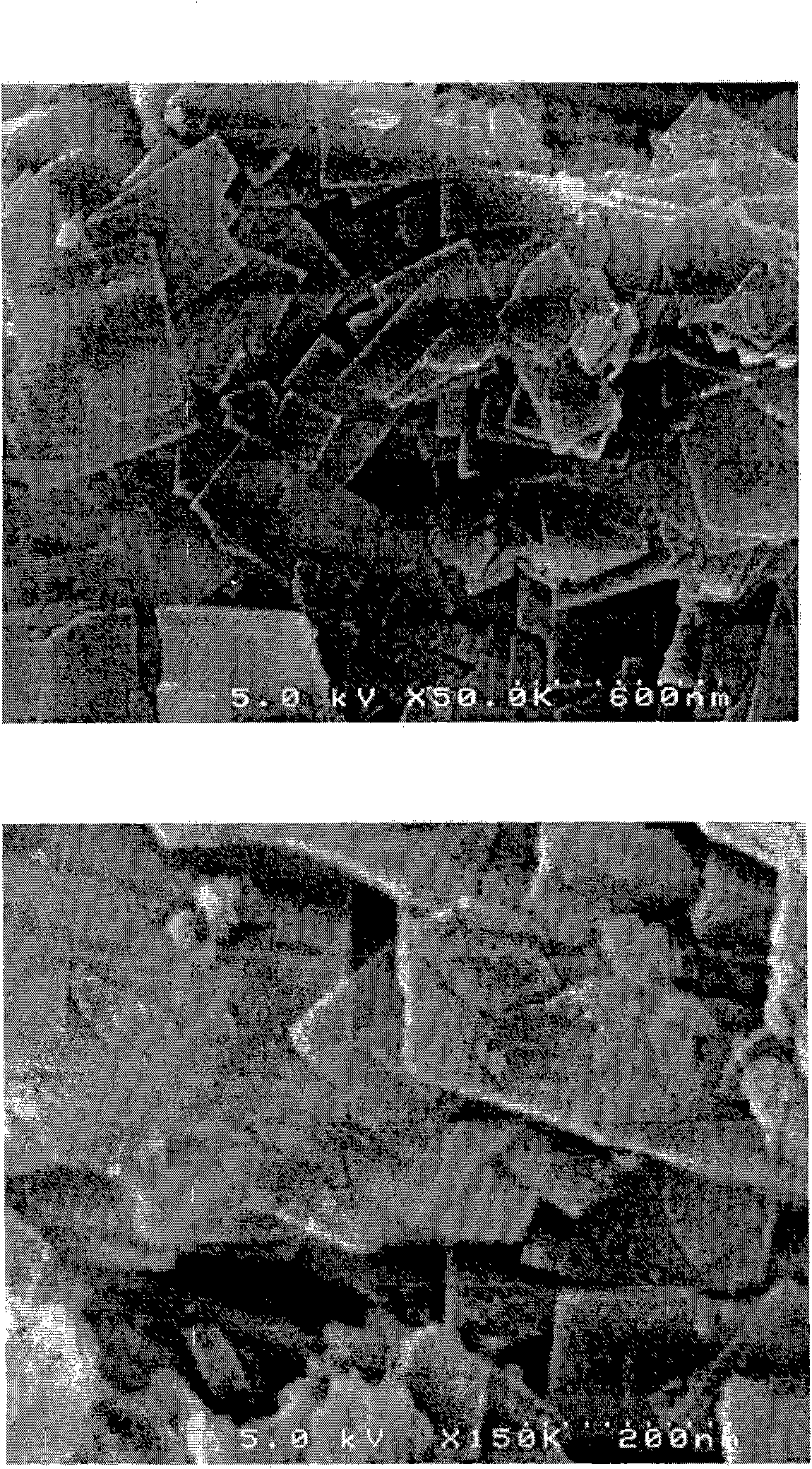

Method for preparing metalloaluminophosphate (MEAPO) molecular sieve

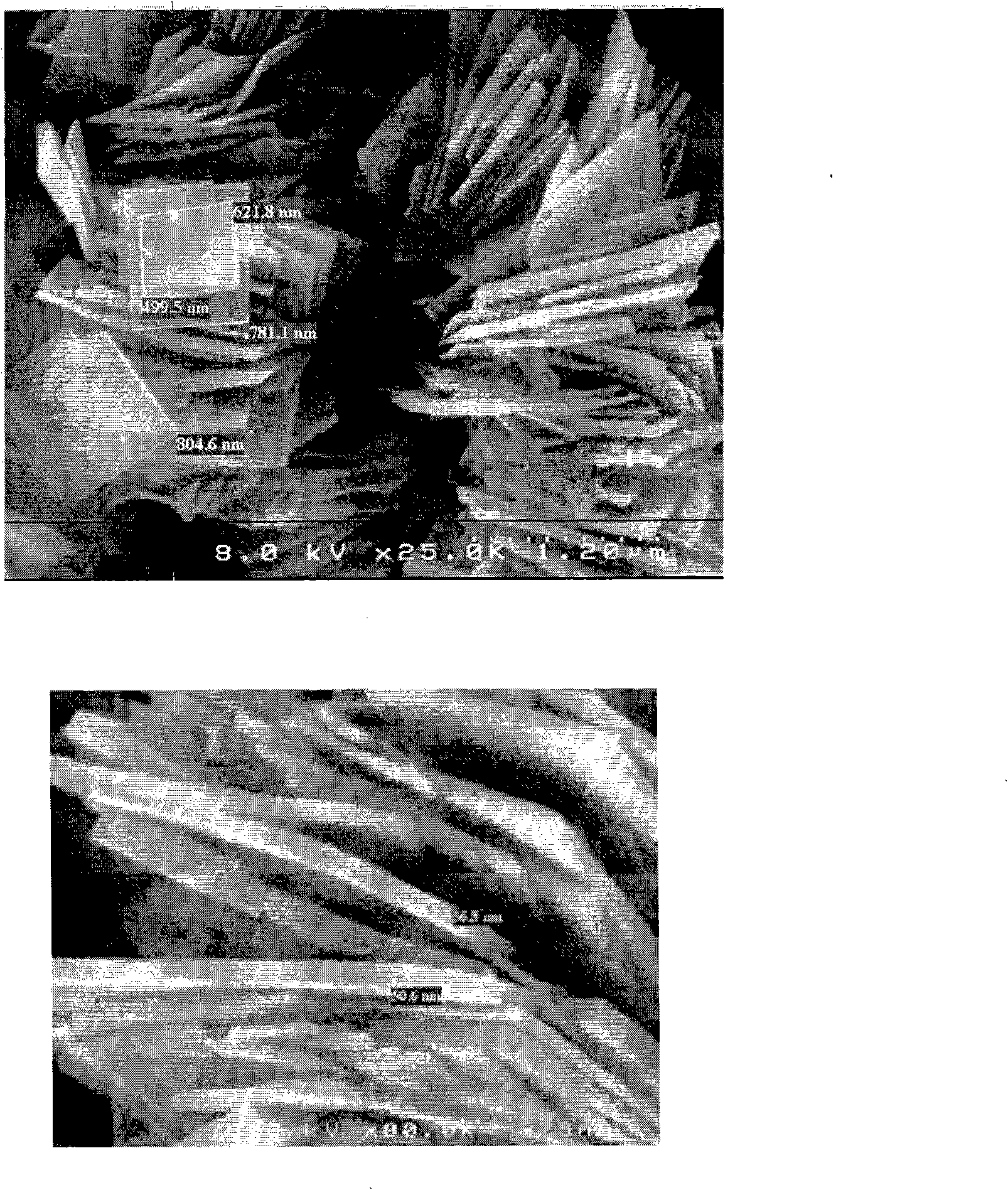

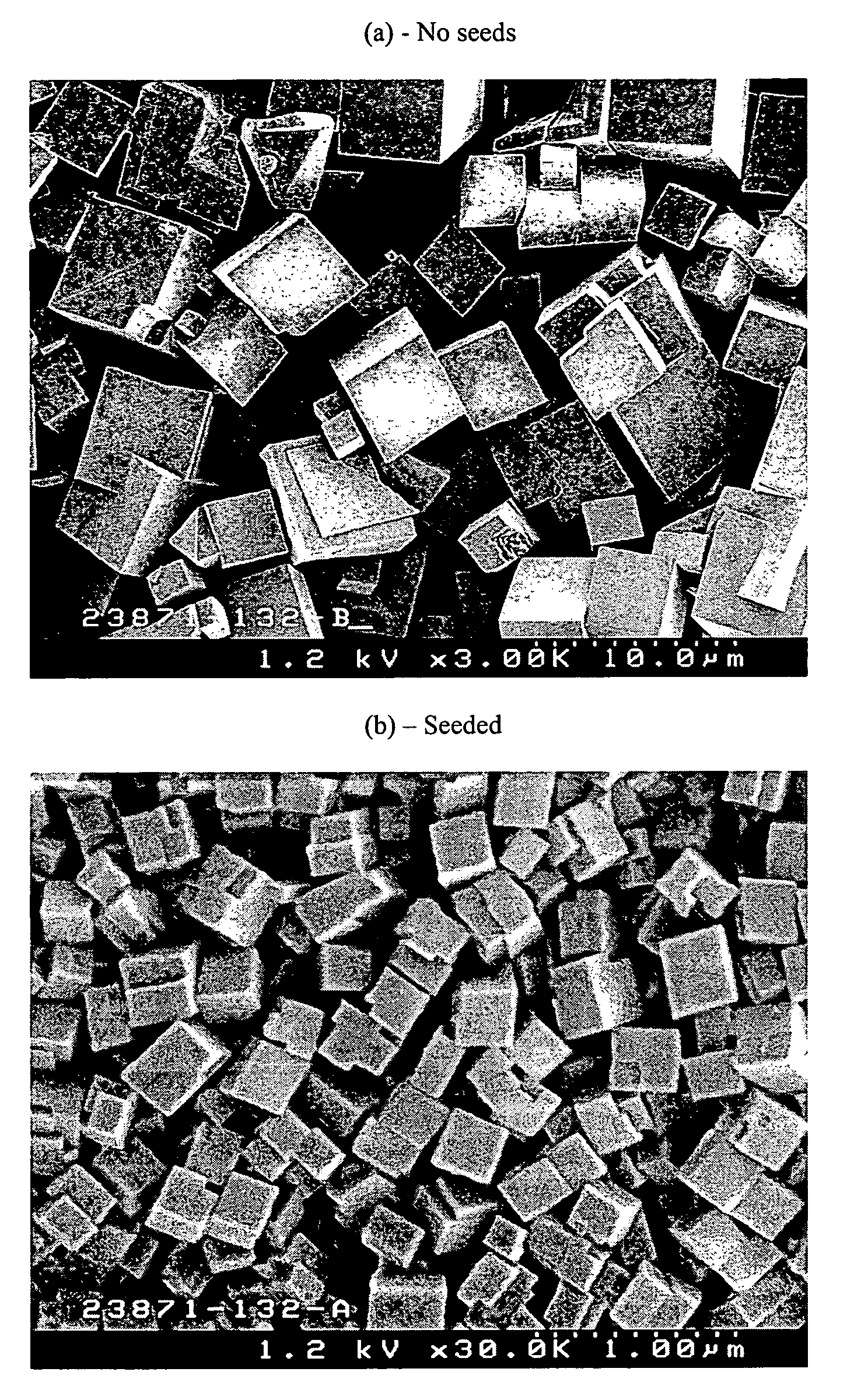

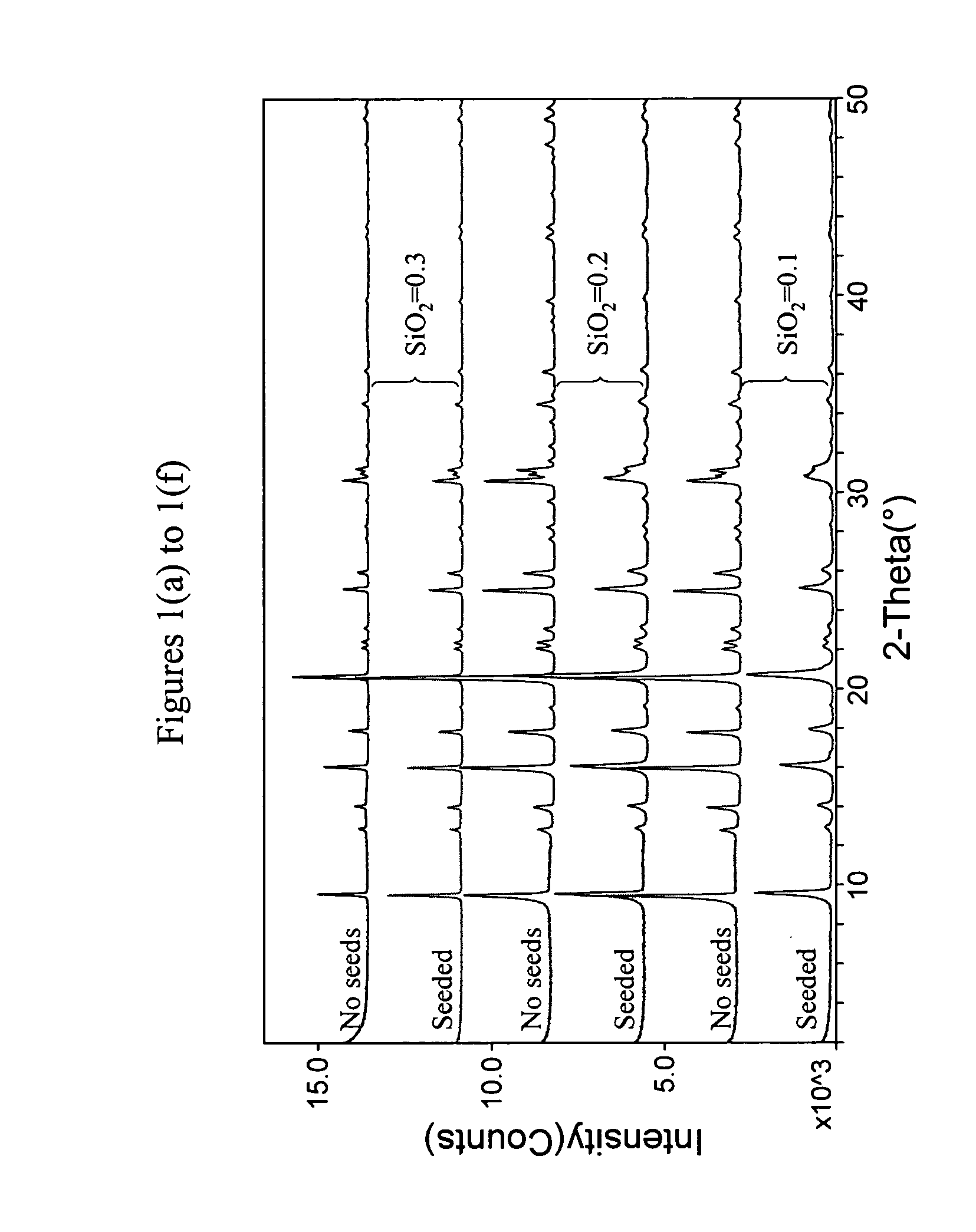

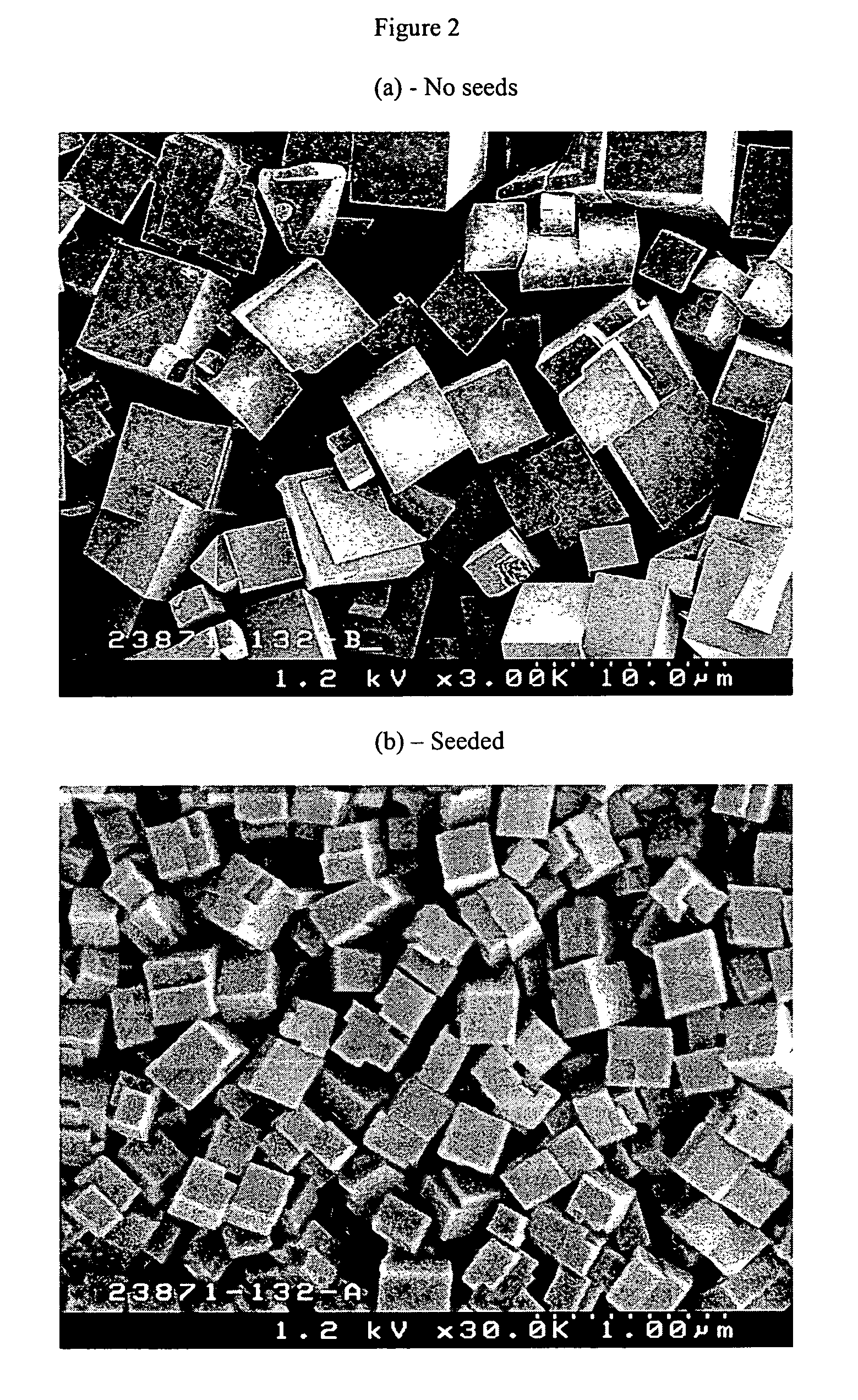

InactiveCN101679054AIncrease productionIncrease flexibilityMolecular sieve catalystsMolecular sieve catalystLamellar crystalsCrystal morphology

The present invention also relates to a method for preparing metalloaluminophosphate (MeAPO) molecular sieve said method comprising : a) forming a reaction mixture containing a texture influencing agent (TIA), an organic templating agent (TEMP), at least a reactive inorganic source of MeO2 insoluble in the TIA, reactive sources of Al2O 3 and P2O5, b) crystallizing the above reaction mixture thus formed until crystals of the metalloaluminophosphate are formed, c) recovering a solid reaction product, d) washing it with water to remove the TIA and e) calcinating it to remove the organic template.In a usual embodiment said reaction mixture has a composition expressed in terms of molar oxide ratios of: TEMP / Al2O3=0.3-5, more desirable 0.5-2 MeO2 / Al2O3= 0.005-2.0, more desirable 0.022-0.8 P2O5 / Al2O3=0.5-2, more desirable 0.8-1.2 TIA / Al2O3=3-30, more desirable 6-20. In a usual embodiment the metalloaluminophosphate (MeAPO) molecular sieves made with the above method have a lamellar crystal morphology having an empirical chemical composition on an anhydrous basis, after synthesis and calcination, expressed by the formula HxMeyAlzPkO2 wherein, y+z+k=1, x<=y, y has a value ranging from 0.0008 to 0.4 and more desirable from 0.005 to 0.18, z has a value ranging from 0.25 to 0.67 and more desirable from 0.38 to 0.55, k has a value ranging from 0.2 to 0.67 and more desirable from 0.36 to 0.54, said molecular sieve having predominantly a plate crystal morphology. In an advantageous embodiment the MeAPO made by the method of the invention have essentially a structure CHA or AEI or a mixture thereof. Preferably they have essentially the structure SAPO 18 or SAPO 34 or a mixture thereof. The present invention also relates to catalysts consisting of the above MeAPO molecular sieves madeby the method of the invention or comprising the above MeAPO molecular sieves made by the method of the invention.

Owner:TOTAL RES & TECH FELUY +1

Metal silicon-aluminum phosphate molecular sieve with AFO structure and synthesis method thereof

ActiveCN101367530AReduce dosageThe method flow is simpleMolecular sieve catalystsMolecular-sieve aluminophosphatesSynthesis methodsPhosphate

The invention relates to a metal aluminum-silicon phosphate molecular sieve MeAPSO-41; the water-free chemical formula of the molecular sieve is nMe(SixAlyPz)O2, wherein, n is the mole number of the metal corresponding to the (SixAlyPz)O2 per mole, and x, y and z respectively represent the molar fraction of silicon atom, aluminum atom and phosphorous atom, and n is equal to 0.001 to 0.60, x is equal to 0.001 to 0.60, y is equal to0.001 to 0.70, z is equal to 0.001 to 0.70, and x plus y plus z is equal to 1. The MeAPSO-41 molecular sieve has good water heating stability, and can be used as the ion exchanging agent and the absorption agent, and also can be used for catalyzing the transforming reaction of the hydrocarbon. The molecular sieve is synthesized in the method: aluminum source, silicon source, phosphorous source and the template agent are mixed to gel; AFO structural molecular sieve is adopted as the inoculating crystal; the mixture is heated in the water and crystallized more than one hour at the temperature of 110 to 250 DEG C; during the crystallization process, the mixture is added with metal oxide to produce the reaction compound with the mole compositions of aR2:Al2O3:bP2O5:cSiO2:dMeOx:eH2O, wherein, a is equal to 0.05 to 2.5, b is equal to 0.1 to 2.0, c is equal to 0.01 to 1.5, d is equal to 0.01 to 1.0 and e is equal to 5 to 150; after the crystallization is completed, the product is recycled. The method has simple flow procedures, consumes less template and has low cost.

Owner:CHINA PETROLEUM & CHEM CORP

Fibrous substrate-based hydroprocessing catalysts and associated methods

InactiveUS20120298554A1Improve physical surface areaSmall diameterMolecular sieve catalystsAluminium silicatesReaction zoneSilicon dioxide

Catalysts are disclosed comprising fibrous substrates having silica-containing fibers with diameters generally from about 1 to about 50 microns, which act effectively as “micro cylinders.” Such catalysts can dramatically improve physical surface area, for example per unit length of a reactor or reaction zone. At least a portion of the silica, originally present in the silica-containing fibers of a fibrous material used to form the fibrous substrate, is converted to a zeolite (e.g., having a SiO2 / Al2O3 ratio of at least about 150) that remains deposited on these fibers. The fibrous substrates possess important properties, for example in terms of acidity, which are useful in hydroprocessing (e.g., hydrotreating or hydrocracking) applications.

Owner:UOP LLC

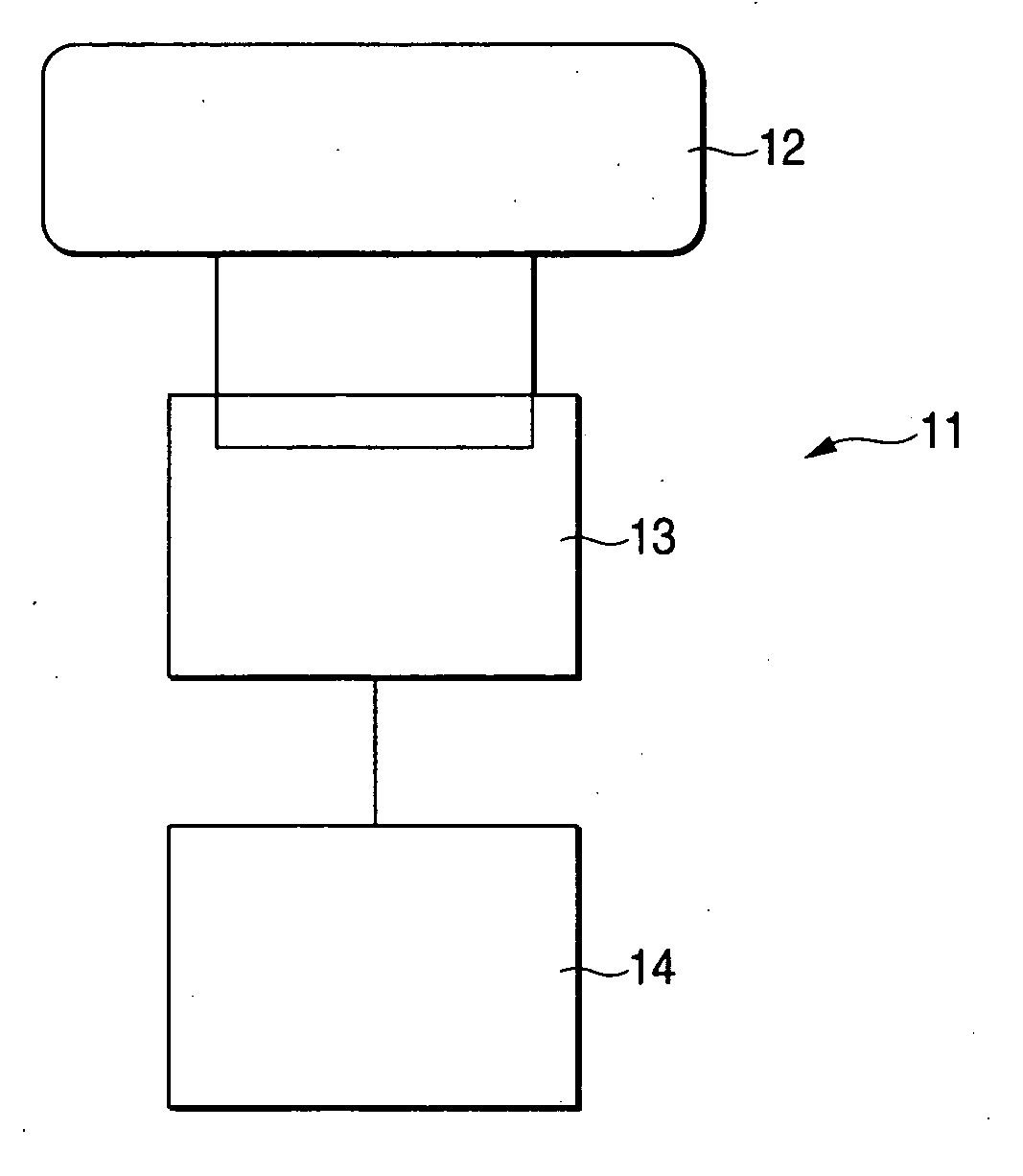

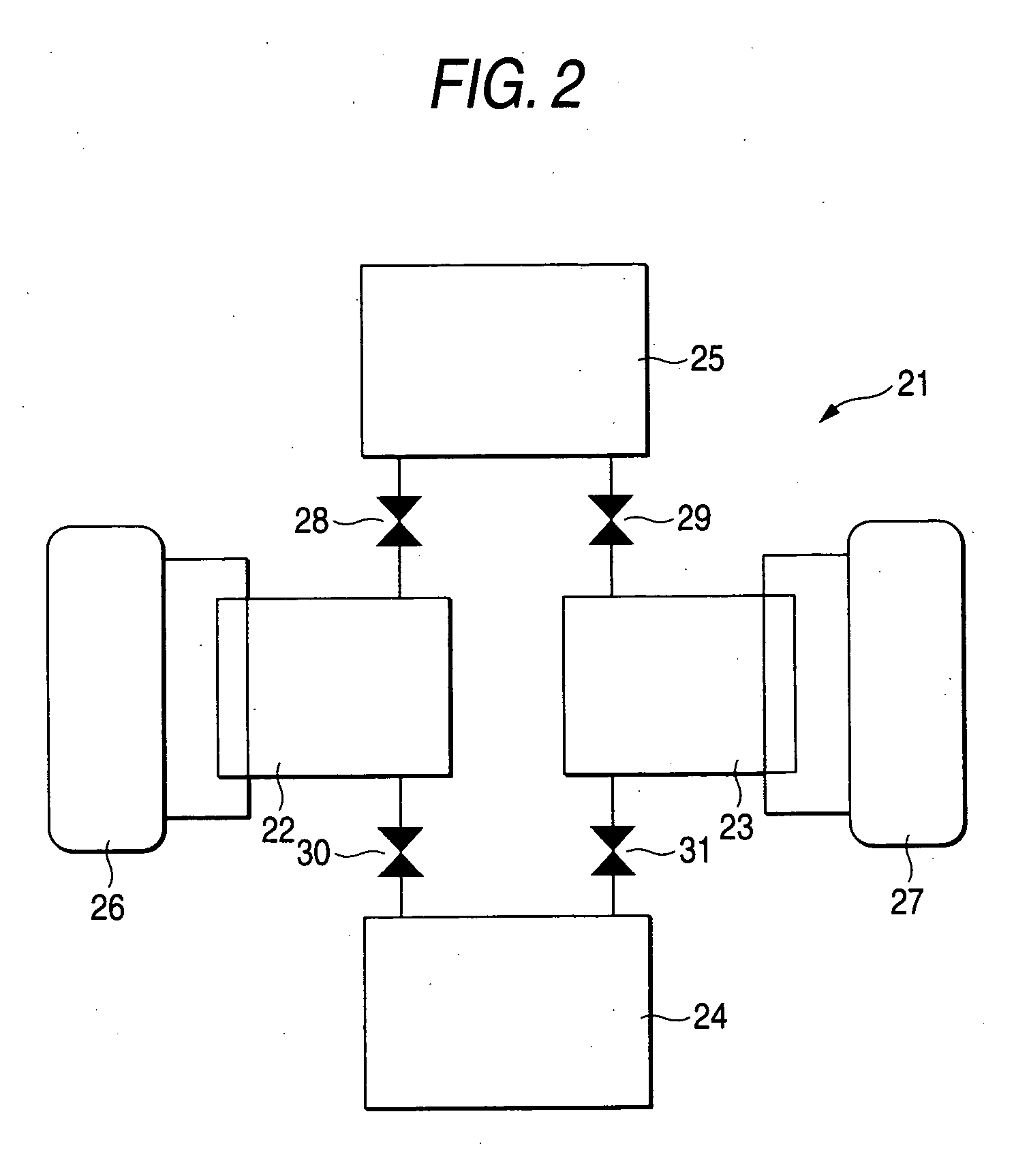

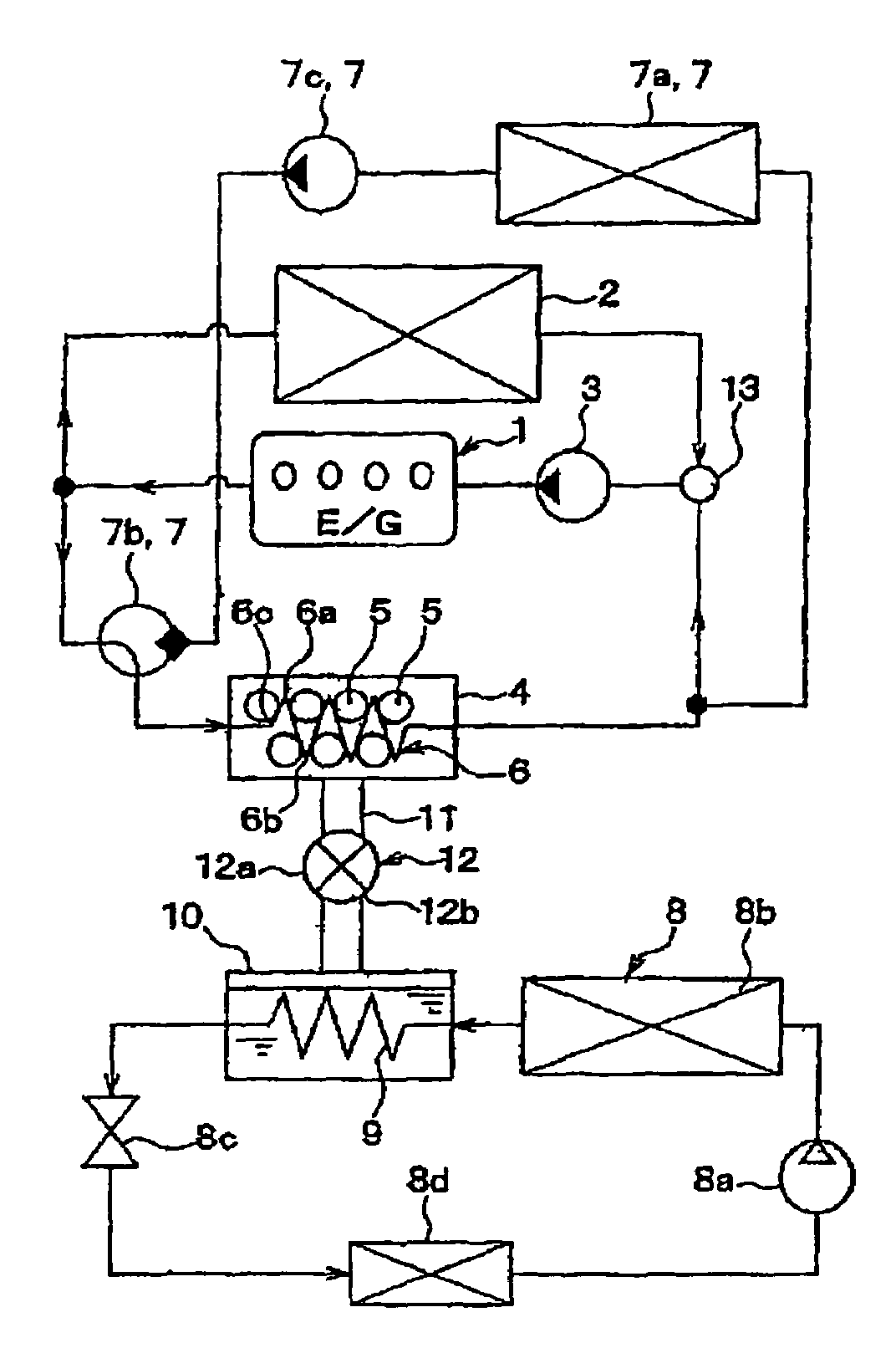

Adsorbent for heat utilization system, adsorbent for regenerator system, regenerator system comprising the adsorbent, ferroaluminophosphate and method for production thereof

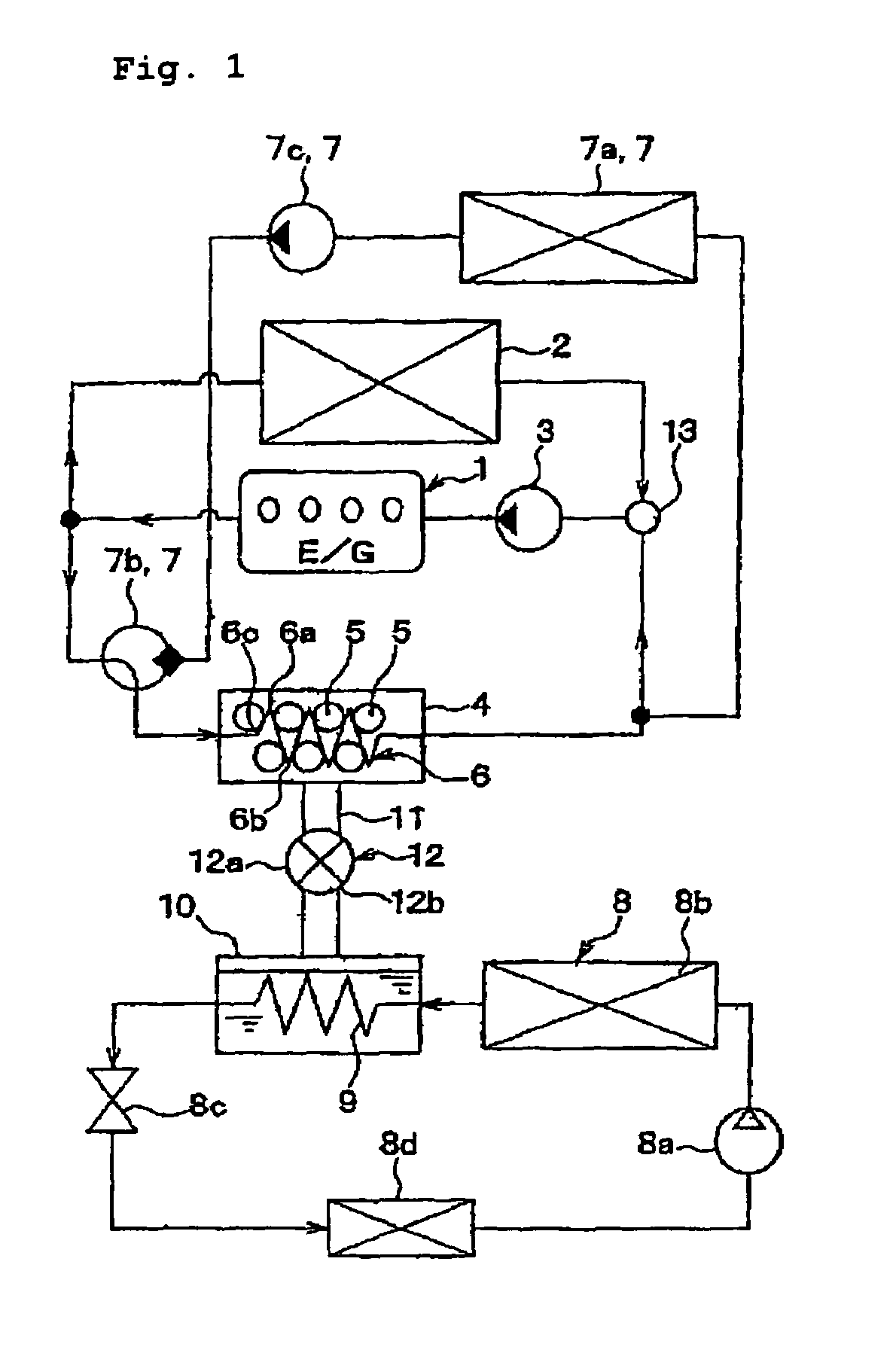

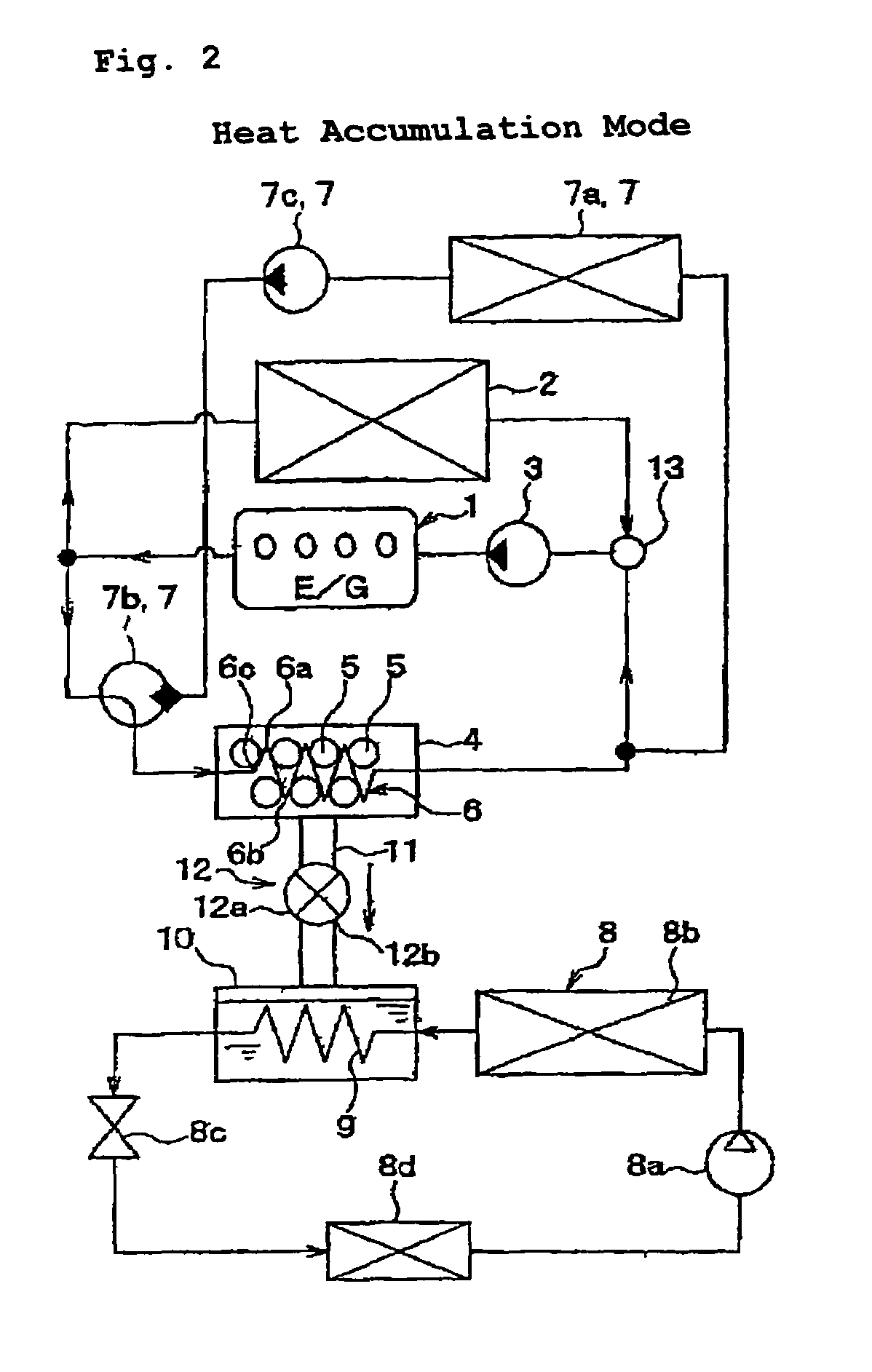

ActiveUS7037360B2Excellent adsorbentImprove the desorption effectCombination devicesInternal combustion piston enginesSorbentEngineering

An adsorbent for regenerator systems, to a heat utilization system and a regenerator system that comprise the adsorbent, and to a ferroaluminophosphate and a method for production thereof. More precisely, the invention relates to an adsorbent favorable for regenerator systems, which efficiently utilizes the heat source obtainable from cars and the like to thereby realize efficient regenerator systems, to a regenerator system that comprises the adsorbent, to a ferroaluminophosphate to be the adsorbent favorable for regenerator systems, and to a method for production thereof.

Owner:MITSUBISHI PLASTICS INC +2

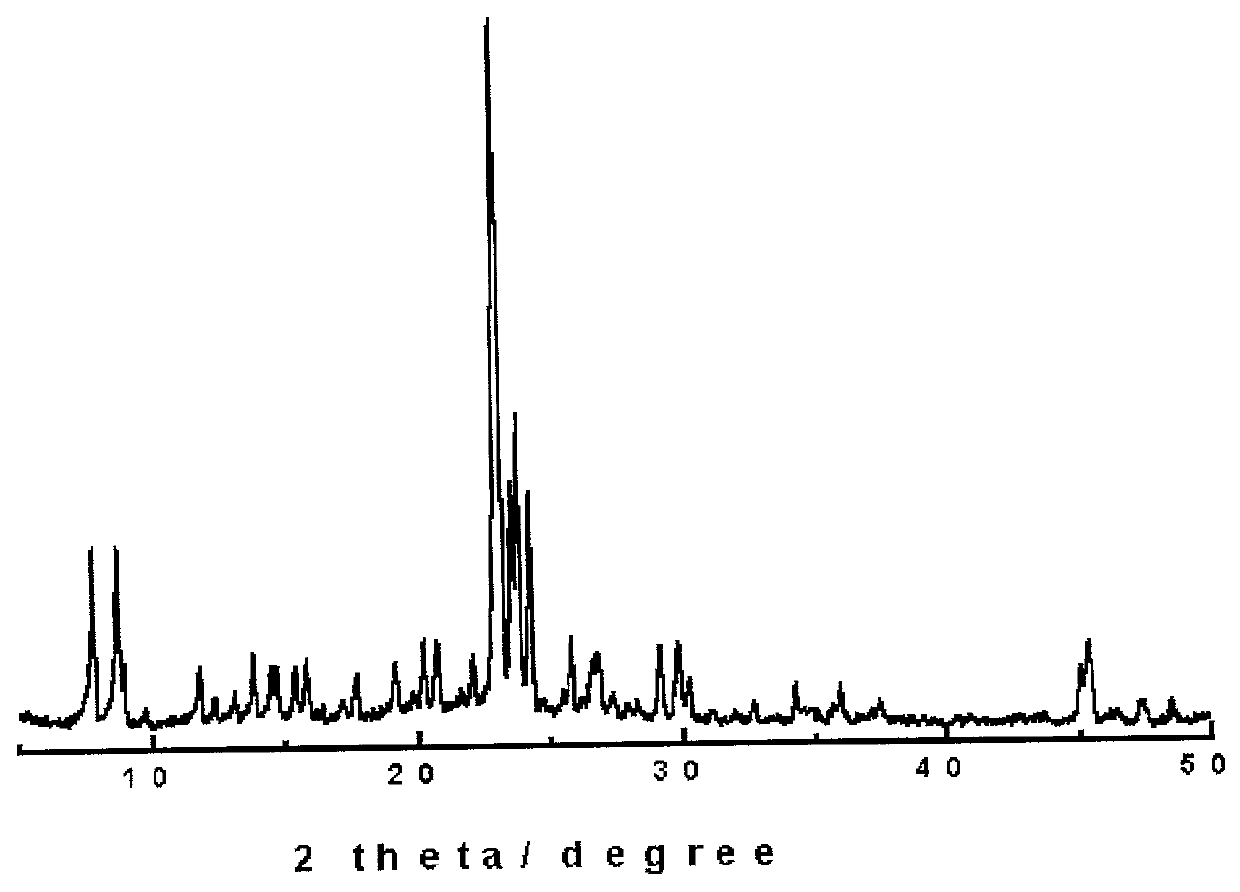

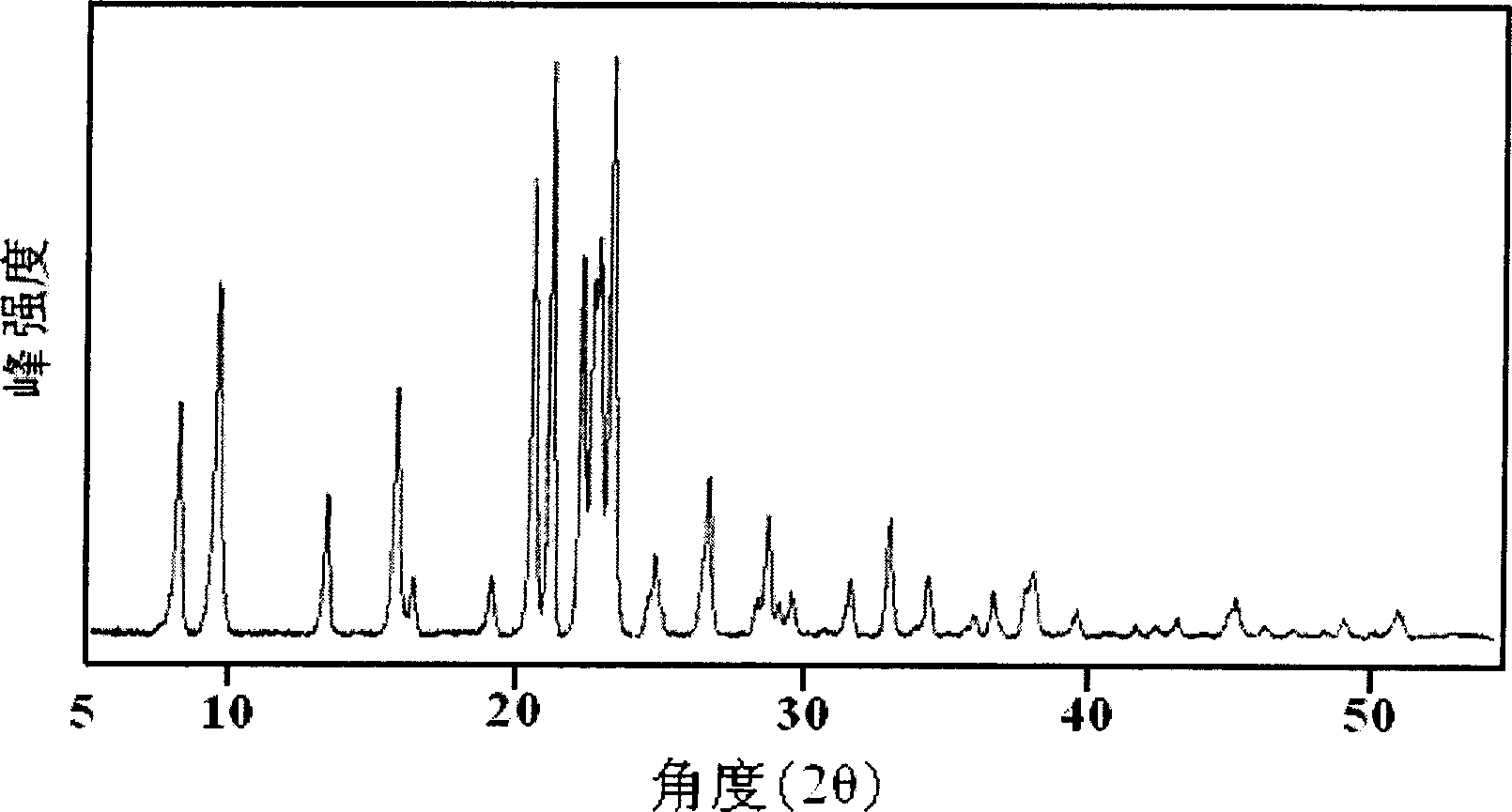

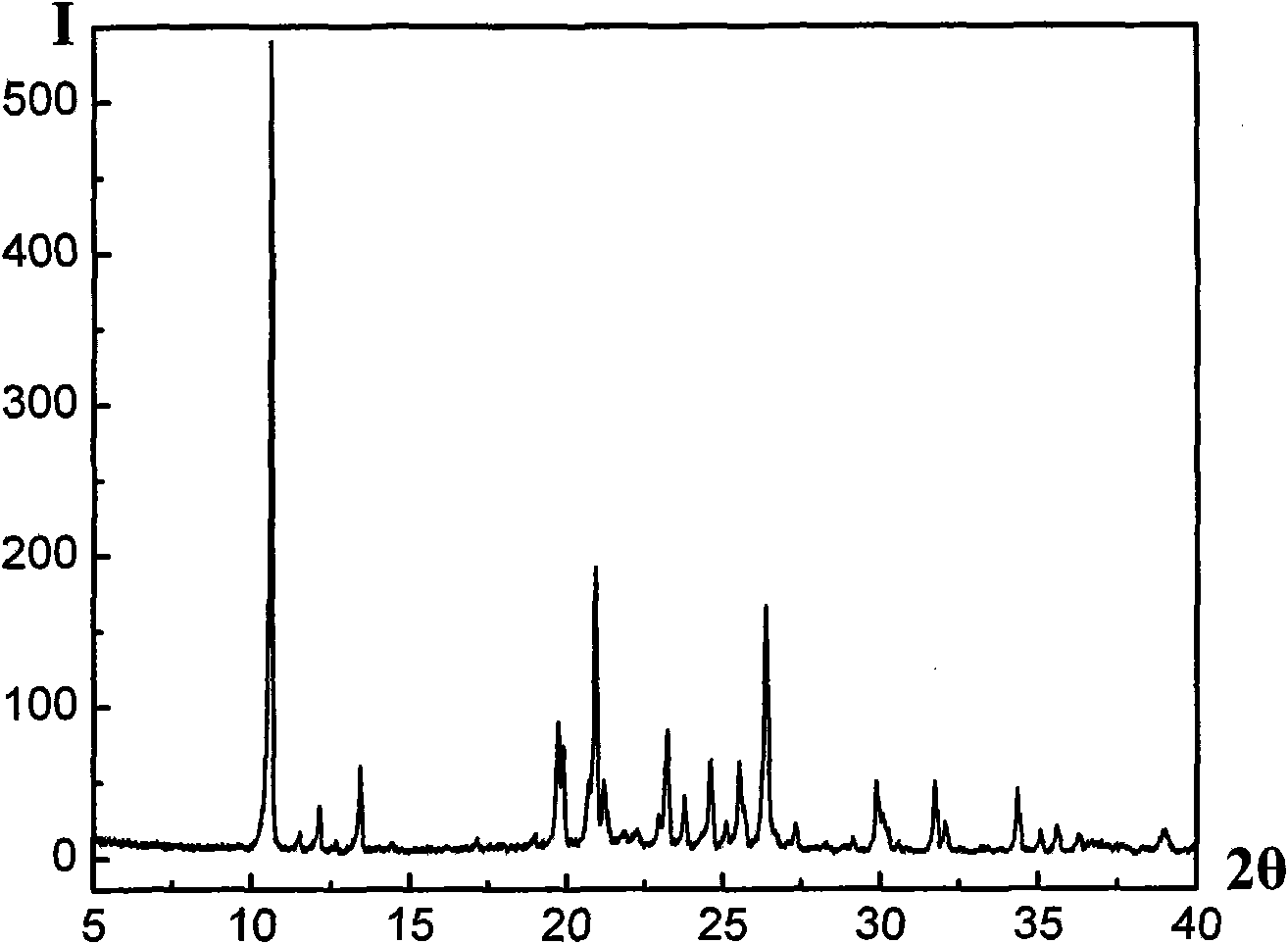

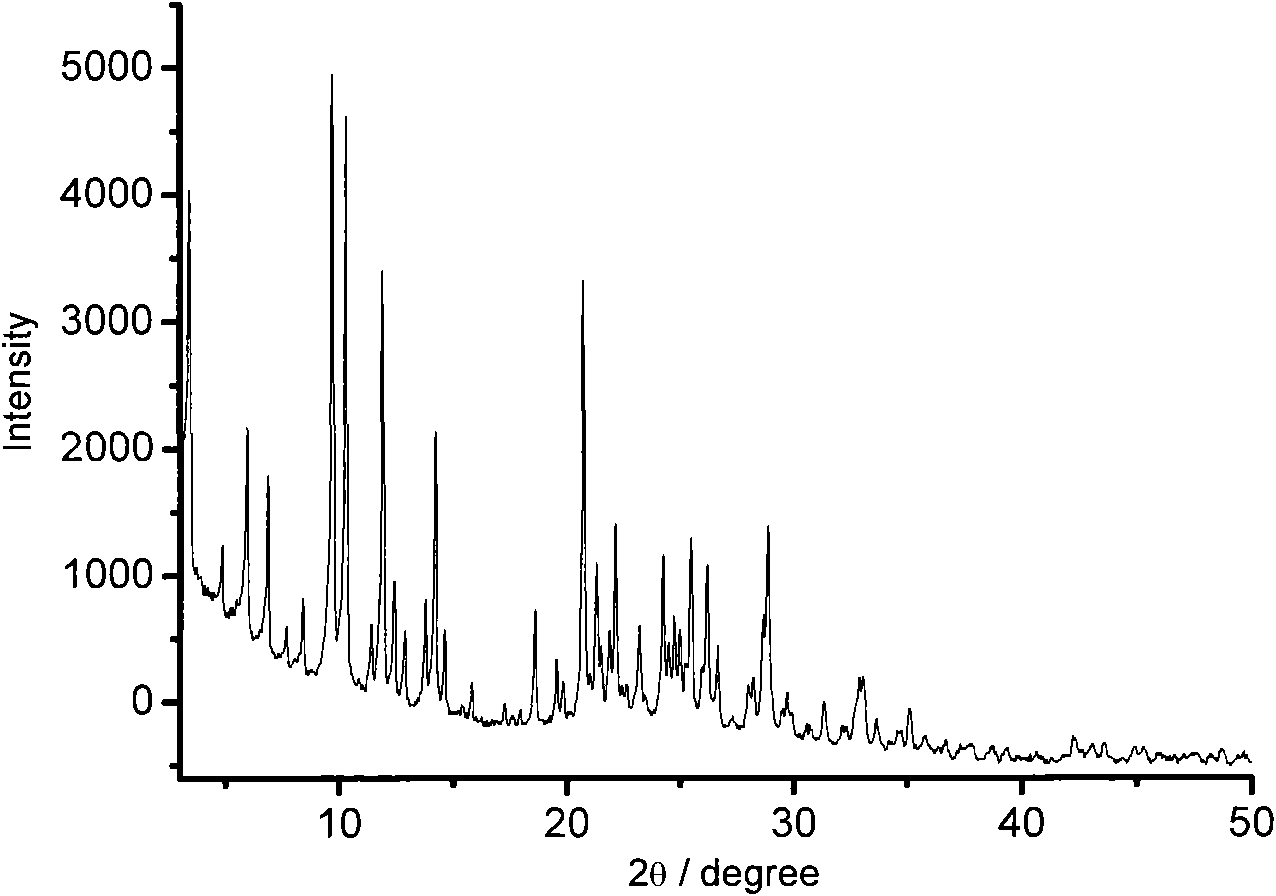

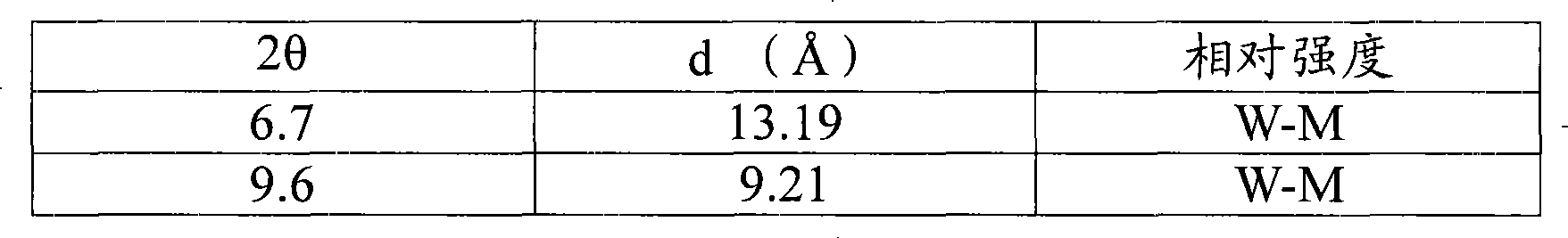

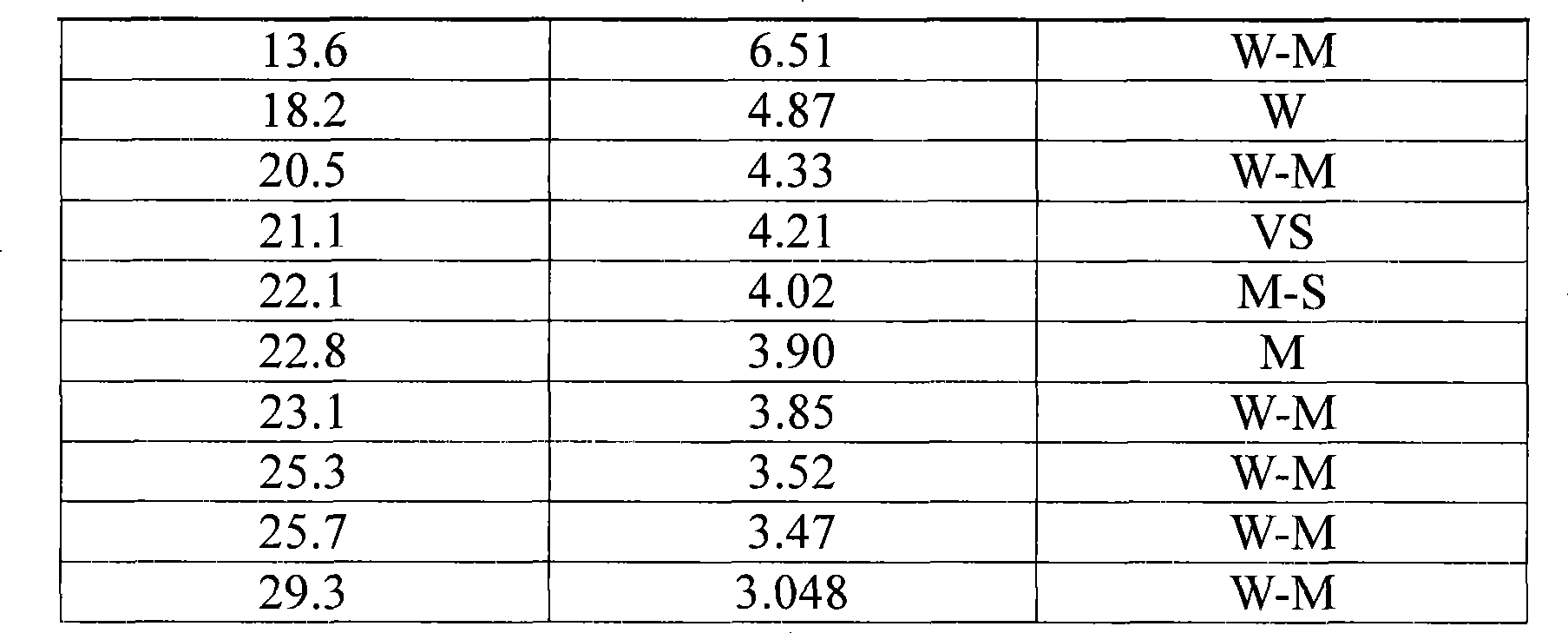

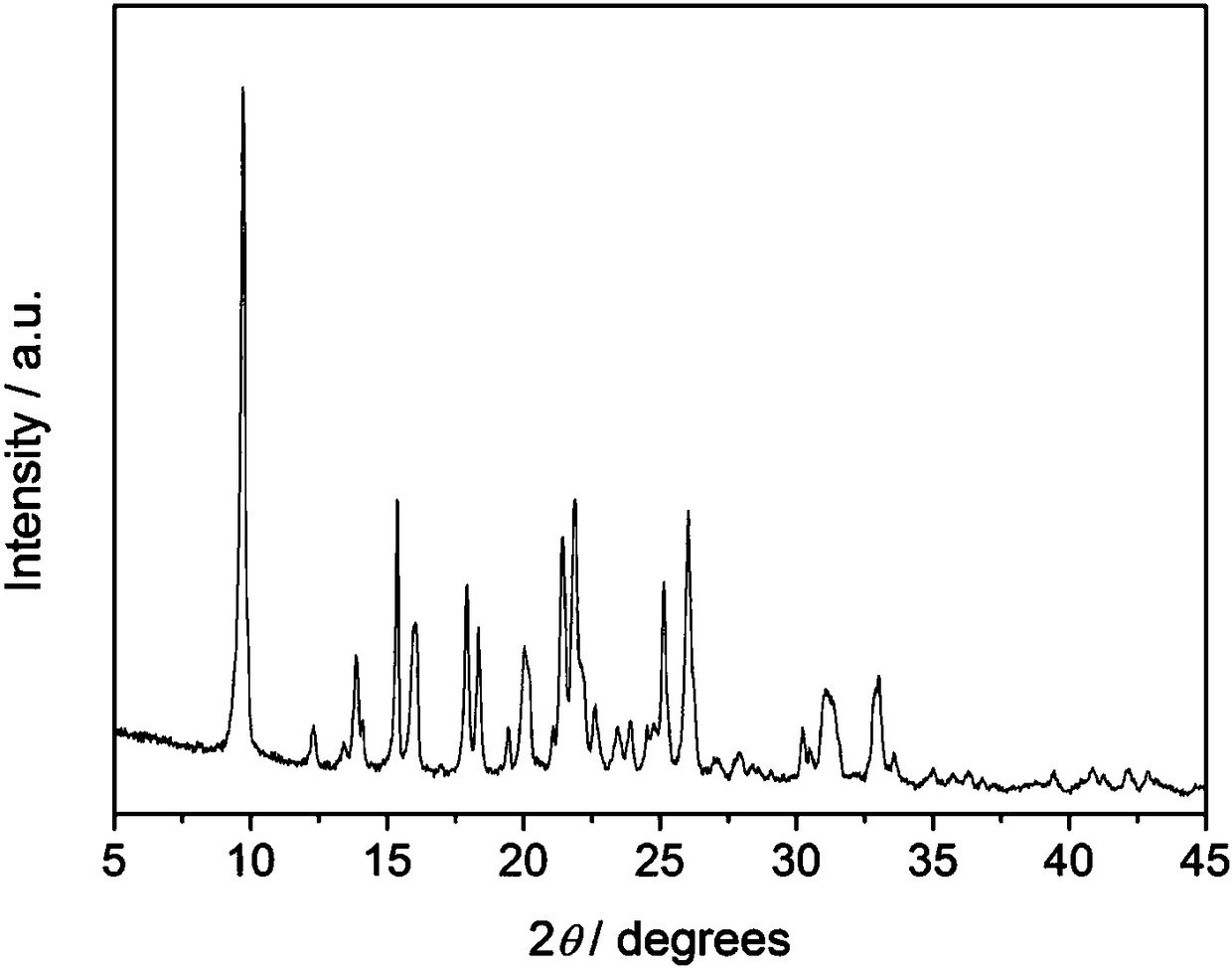

Hydrothermal fluorine-free synthesis method of AlPO4-34

InactiveCN102092738AHigh crystallinityThe implementation conditions are simpleMolecular-sieve aluminophosphatesMolecular-sieve and base-exchange phosphatesProper treatmentSynthesis methods

The invention mainly relates to a method for synthetizing fluorine-free AlPO4-34 crystals with higher crystallinity and large grain size in proper treatment conditions, wherein hydrofluoric acid is not added, common organic amine morpholine (C4H9NO) is used as template agent, the traditional hydrothermal synthesis method is adopted and a proper raw material ratio is adopted. The method comprises the following steps: mixing aluminium source, phosphorus source, water and organic template agent evenly according to a certain molar ratio in sequence, wherein the molar ratio of Al2O3 to P2O5, R(morpholine) and H2O is 1.0:0.8-1.2:2.0-4.0:40-100; stirring to age, transferring the mixture in a stainless steel reaction kettle, crystallizing at 160-190 DEG C for 3-15 days under the generated pressure; then performing shock cooling, collecting, filtering, washing, and airing naturally to obtain AlPO4-34 molecular sieve raw powder. The method of the invention is green, environmentally friendly and economical, and has simple implementing conditions and wide application prospect.

Owner:NANKAI UNIV

Synthesis of molecular sieves having the chabazite framework type and their use in the conversion of oxygenates to olefins

The synthesis of a crystalline aluminophosphate or silicoaluminophosphate molecular sieve having a chabazite-type framework type is conducted in the presence of an organic directing agent having the formula (I)[R1R2R3N—R4]+X− (I)wherein R1, R2 and R3 are independently selected from the group consisting of alkyl groups having from 1 to 3 carbon atoms and hydroxyalkyl groups having from 1 to 3 carbon atoms; R4 is selected from the group consisting of 4- to 8-membered cycloalkyl groups, optionally substituted by 1 to 3 alkyl groups having from 1 to 3 carbon atoms; 4- to 8-membered heterocyclic groups having from 1 to 3 heteroatoms, said heterocyclic groups being optionally substituted by 1 to 3 alkyl groups having from 1 to 3 carbon atoms and the heteroatoms in said heterocyclic groups being selected from the group consisting of O, N, and S; and aromatic groups optionally substituted by 1 to 3 alkyl groups, said alkyl groups having from 1 to 3 carbon atoms; and X− is an anion.

Owner:EXXONMOBIL CHEM PAT INC

Methods for making molecular sieves

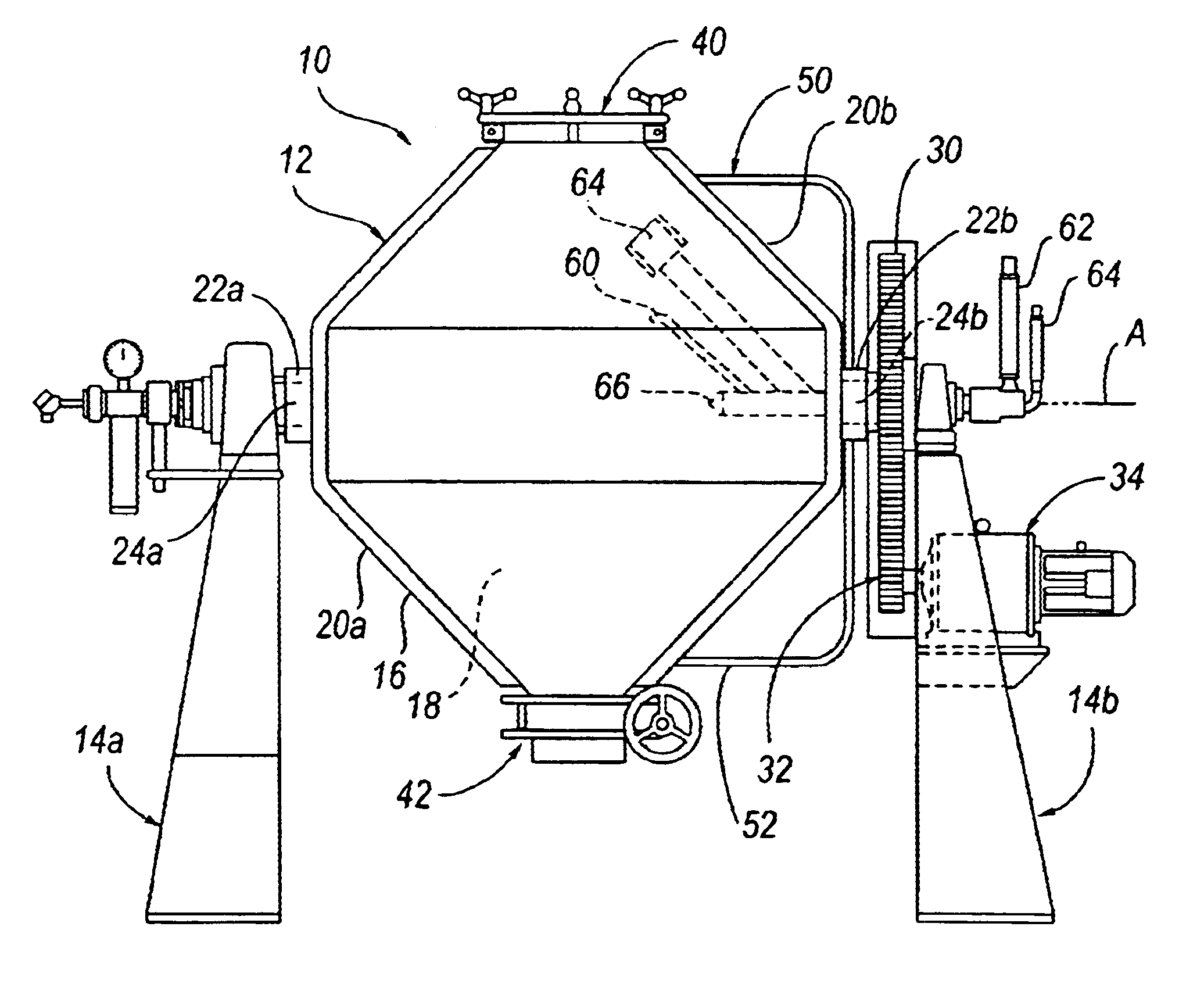

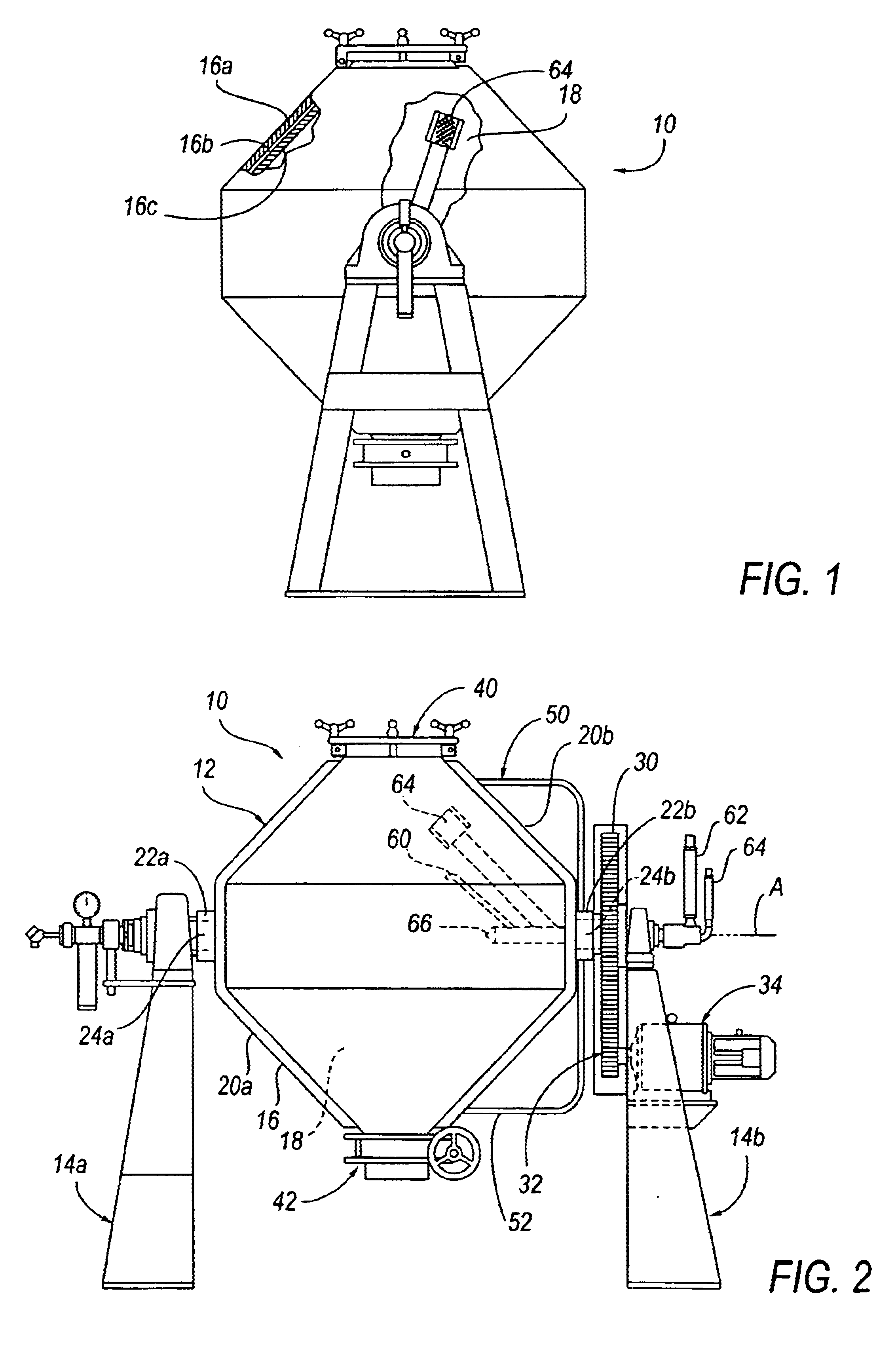

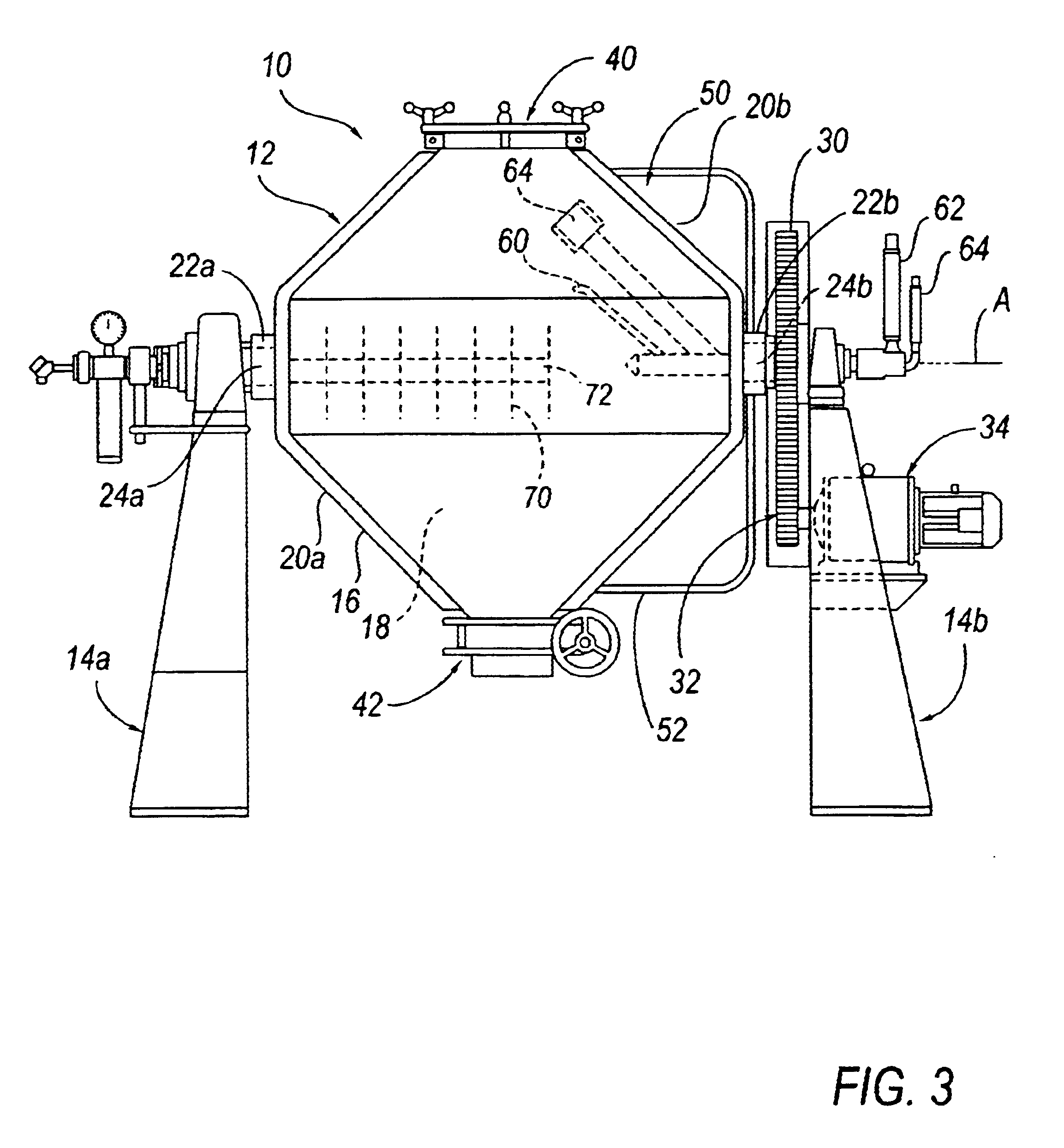

InactiveUS6632415B2Highly uniform and rapid distribution of heatReduce the amount of waterRotating receptacle mixersAluminium compoundsMolecular sieveLow speed

An in-extrudate reaction mixture to be effectively crystallized is effectively crystallized to produce zeolitic or non-zeolitic molecular sieves. The reaction mixture is heated within a slowly rotating, double-walled reactor vessel wherein a heated medium is conducted within a space formed between the double walls of the vessel. Thus, the reaction mixture is contacted by a uniformly heated wall while being gently tumbled at low speed. The tumbling action serves to uniformly distribute the heat within the reaction mixture without subjecting the mixture to such shearing that could damage shaped particles. A relatively high quantity of reaction mixture can be handled in that way to maximize the production volumes and reduce production costs.< / PTEXT>

Owner:CHEVROU USA INC

CHA type heteroatomic metal aluminum phosphate molecular sieve and premolding synthetic method

InactiveCN108147427AGuaranteed performanceReduce usageMolecular sieve catalystsMolecular-sieve aluminophosphatesMolecular sieveALUMINUM PHOSPHATE

The invention discloses a CHA type heteroatomic metal aluminum phosphate molecular sieve and a premolding synthetic method, and relates to the technical field of preparation of molecular sieves. The CHA type heteroatomic metal aluminum phosphate molecular sieve is mainly characterized by being prepared through the following steps: uniformly mixing an aluminum source, a phosphorus source, a metal source, a fluorine source, organic amine and water so as to prepare a gel, drying the gel, and carrying out molding; and subjecting the molded dry gel to crystallization at 80 to 300 DEG C for 10 min to 10 d so as to obtain a molded molecular sieve. According to the invention, an MeAPO-34 molecular sieve with a desired shape can be prepared through one step, and a preparation process for a catalystis simplified. The molded MeAPO-34 molecular sieve prepared by using the method provided by the invention can be directly used for an adsorbent or used as a catalyst carrier, and has high molecular sieve content. The method provided by the invention eliminates the molding step of the catalyst, is simple in process and has broad application prospects in the field of preparation of catalysts.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Microwave method for synthesizing nickel phosphates cobalt microporous material

InactiveCN101249969AOvercome timeOvercome uniformity issuesMolecular-sieve aluminophosphatesMolecular-sieve and base-exchange phosphatesNickel phosphateMicrowave method

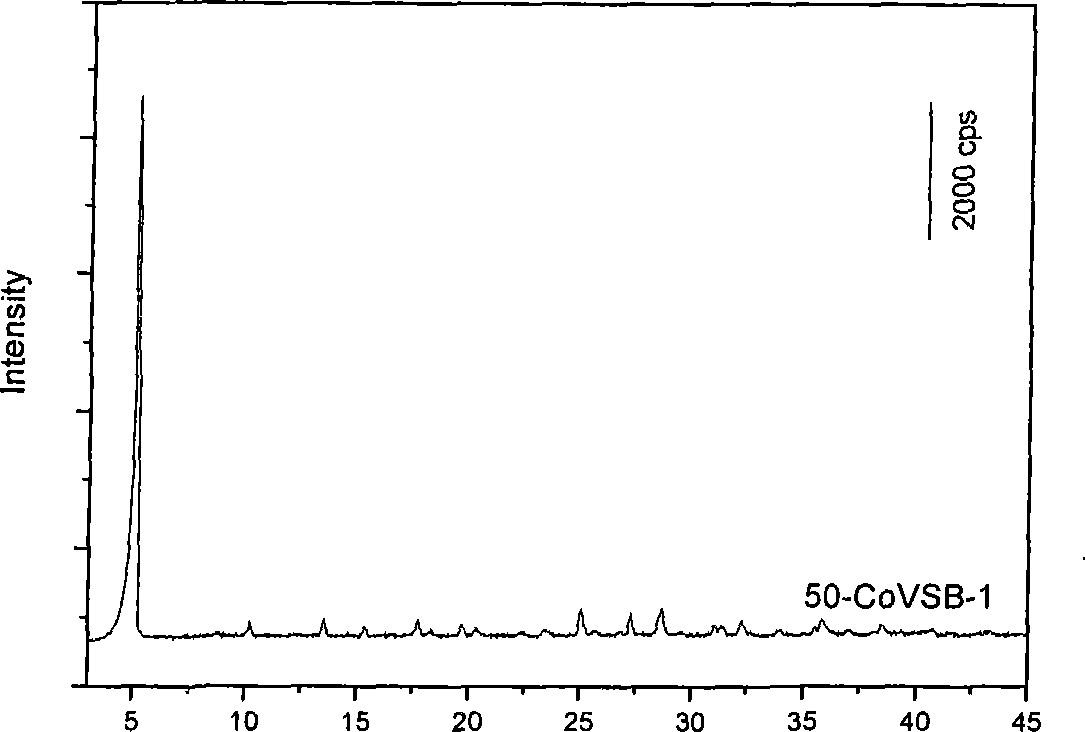

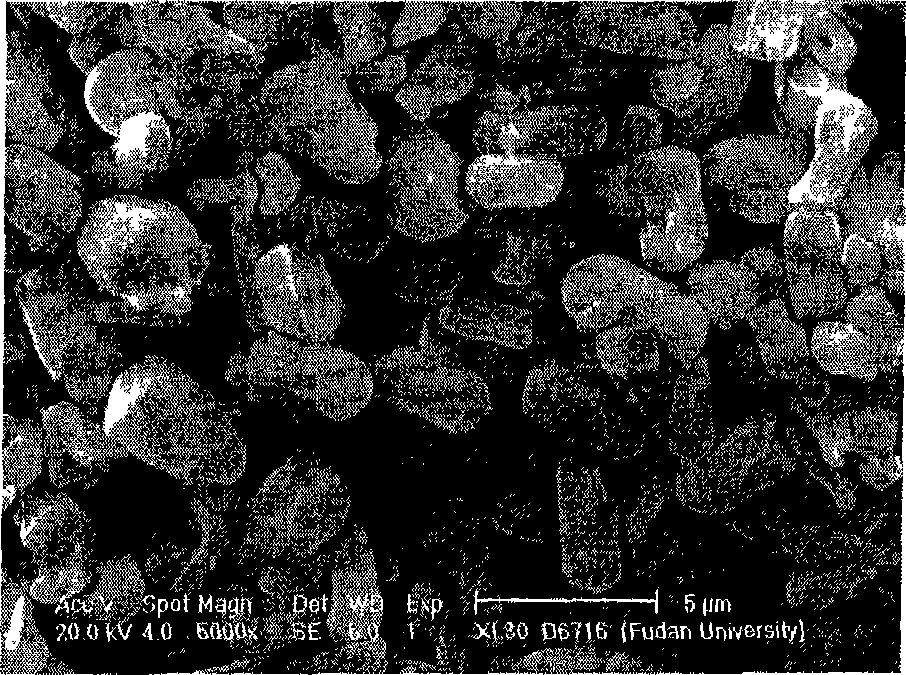

Disclosed is a microwave synthesis method of nickel phosphates cobalt cellular materials. The steps comprise preparing nickel source substance, cobalt source substance, phosphorus source substance, template, mineralizer and water according to oxide molecular ratio, initially dissolving the nickel source and the cobalt source in the water, adding with the phosphorus source when stirring, then adding with the template and the mineralizer and continuing to stir evenly, moving the reaction solution into a microwave synthesis reactor, irradiating for 3-360 minutes step by step under the temperature of 130-180 DEG C, then centrifugal separating, washing and freeze-drying, and thereby the nickel phosphates cobalt CoVSB-1 materials is obtained. The frequency of the microwave is 2450 megahertz, and the power is 400-1000 watt. A microwave is heated by employing the temperature controlling mode. Compared with the conventional hydro-thermal method, the synthesis time of the invention is shorter, the grain size distribution is more uniform, and the reducing of the size of crystal grain is in favor of the increasing of the catalytic performance of the product.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Nano grade titanium silicon molecular sieve and its synthesis technology

InactiveCN1426962AFine grainIncrease switching capacityMolecular sieve catalystsOther chemical processesRadioactive PollutantsSodium hydroxide

A nanometre-class TiSi molecular sieve for removing pollutants of heavy metals and radioactive substance from environment and purifying nuclein has a mole formular Na1+ / -xTi1.5+ / -ySi1+ / -zO5, where x=0.01-0.2, y=0.1-0.5 and z=0.1-0.2. It is prepared from tetrabutyl titanate or tetraisopropyl titanate, ethyl n-silicate, sodium hydroxide and water jointly by the sol-gel method and the hydrothermal synthesis method. Its advantages are fine crystal grain, high reaction activity, low cost, high exchange capacity with radioactive elements and heavy metals, and high thermal stability and radioactive resistance.

Owner:TSINGHUA UNIV

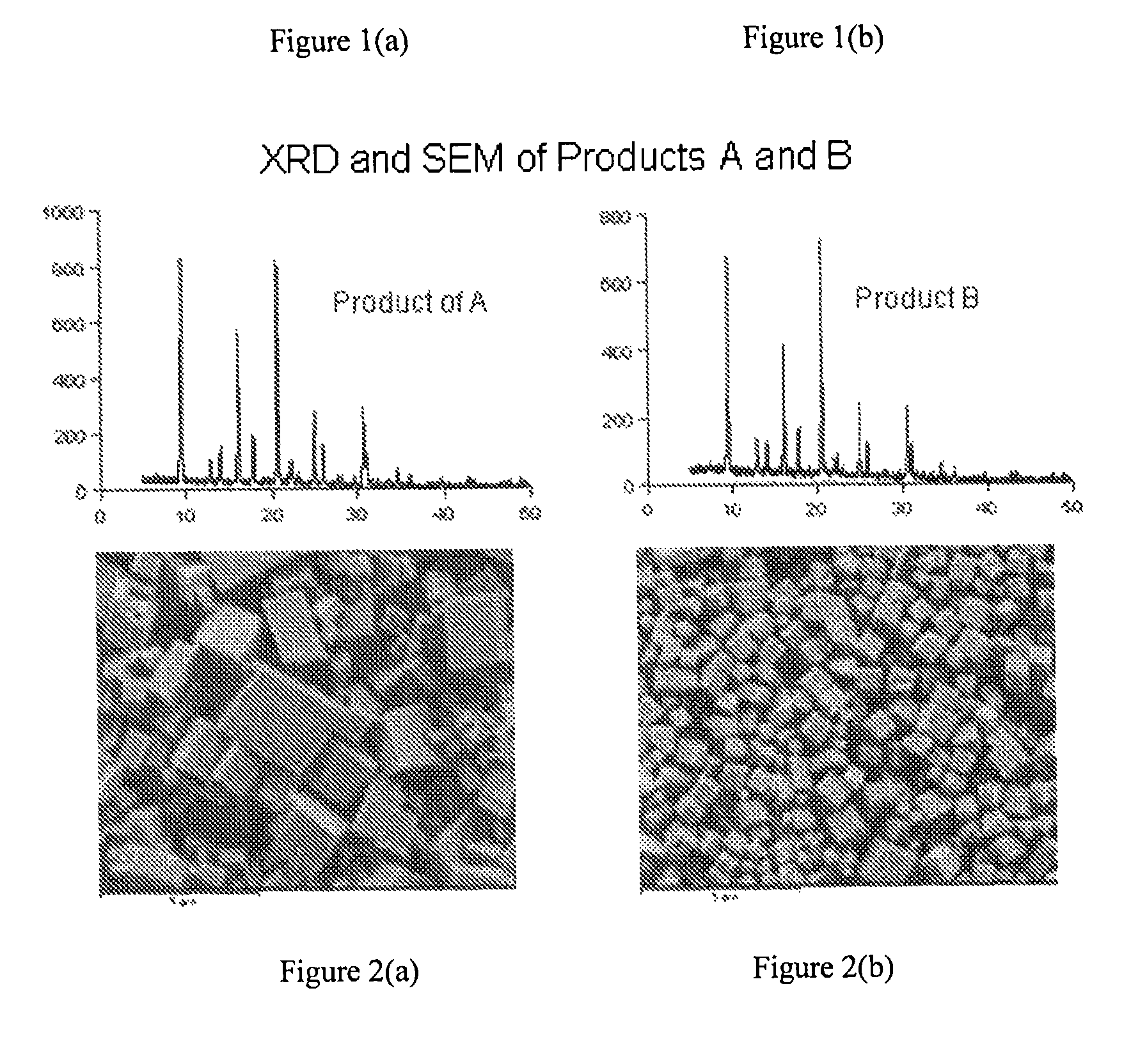

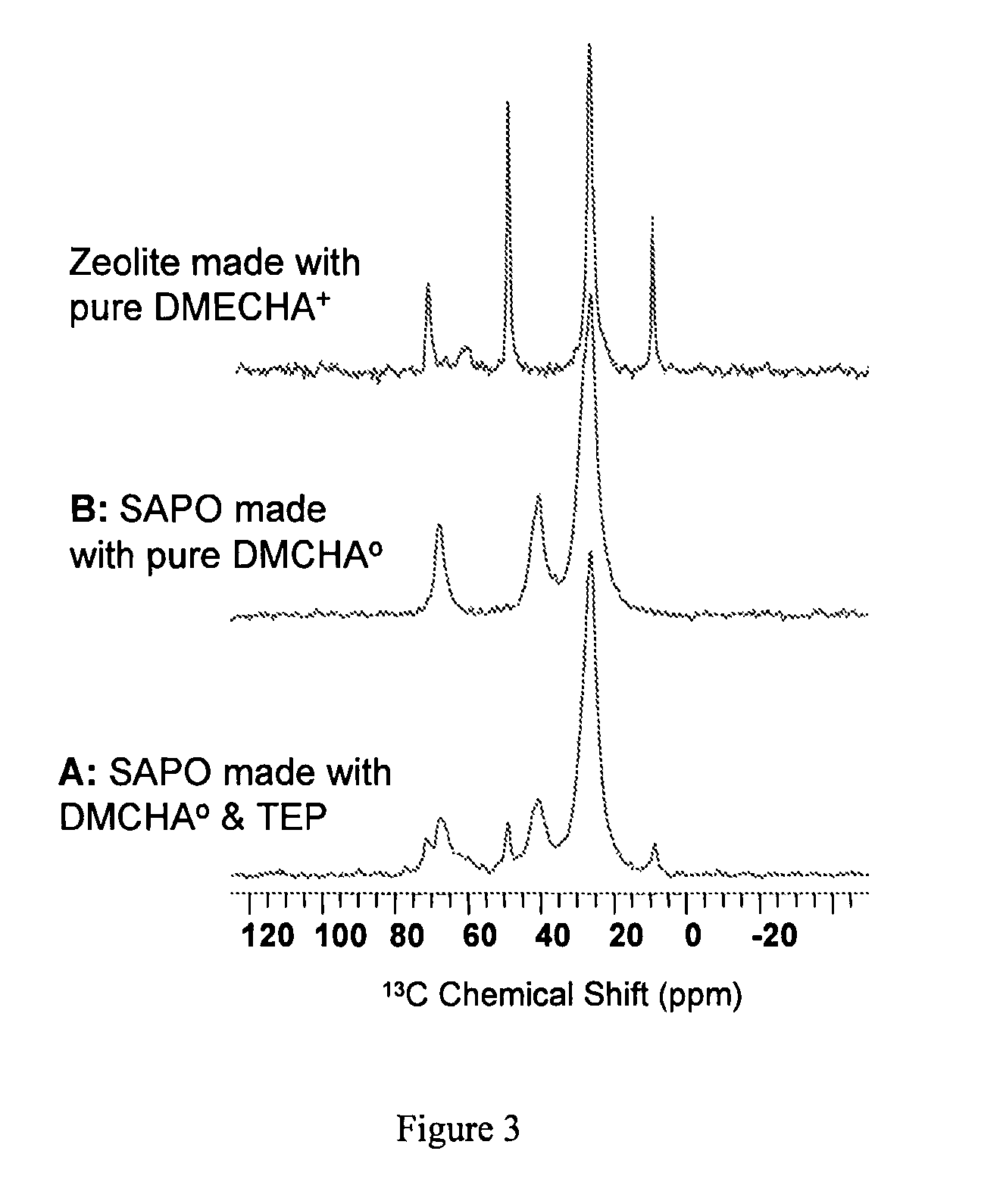

Synthesis of aluminophosphate and metalloaluminophosphate molecular sieves

In a method of synthesizing an aluminophosphate or metalloaluminophosphate molecular sieve, a synthesis mixture is provided comprising water, a source of aluminum, a source of phosphorus, optionally a source of a metal other than aluminum, a tertiary amine, and an alkylating agent capable of reacting with said tertiary amine to form a quaternary ammonium compound capable of directing the synthesis of said molecular sieve. The synthesis mixture is maintained under conditions sufficient to cause the alkylating agent to react with the tertiary amine to produce the quaternary ammonium compound and to induce crystallization of the molecular sieve.

Owner:EXXONMOBIL CHEM PAT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com