Patents

Literature

245results about How to "High degree of order" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

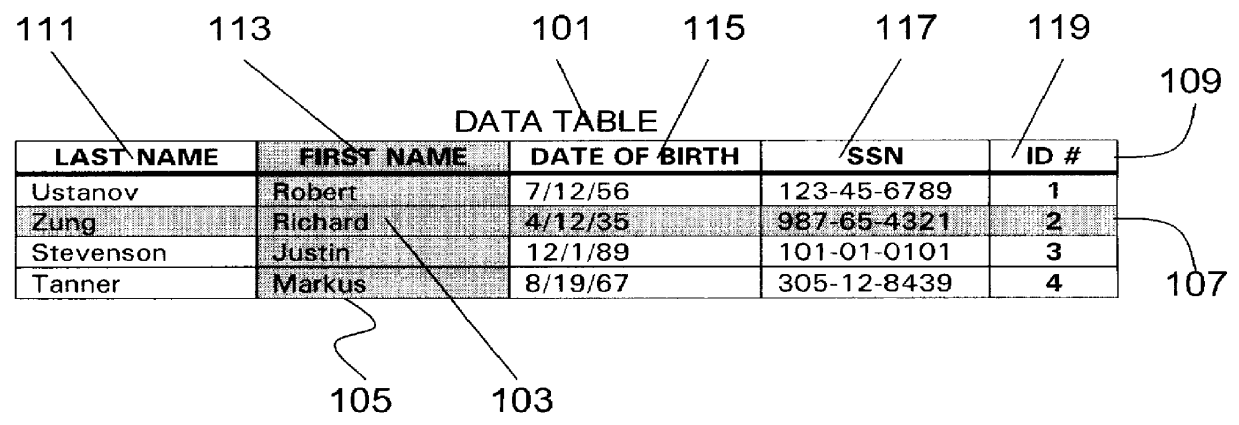

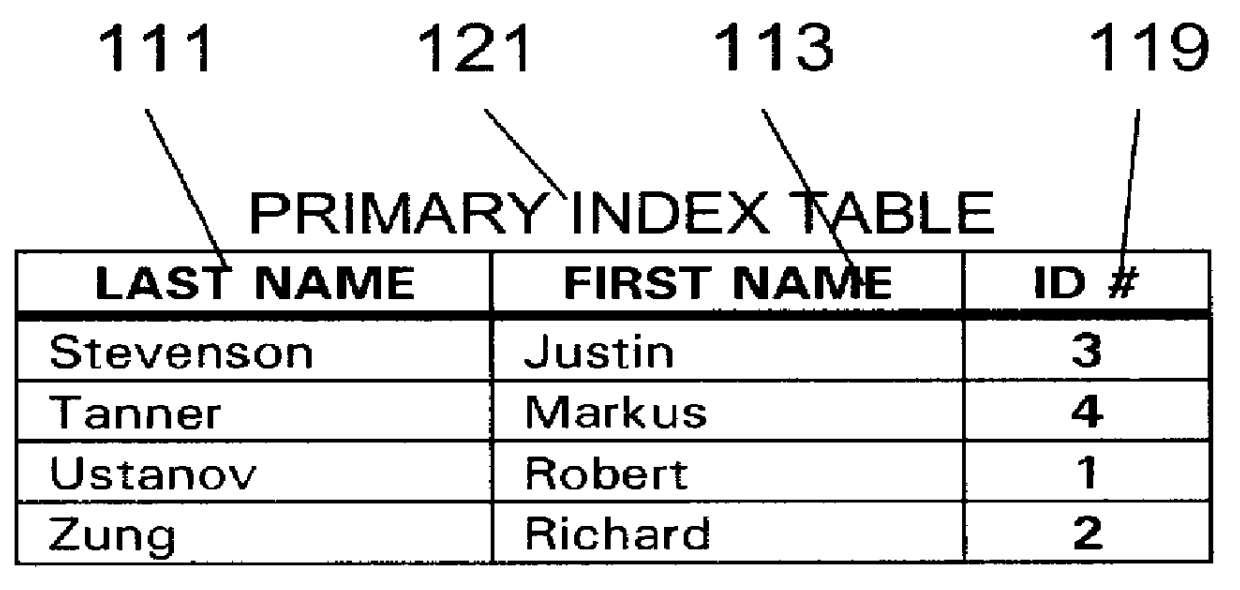

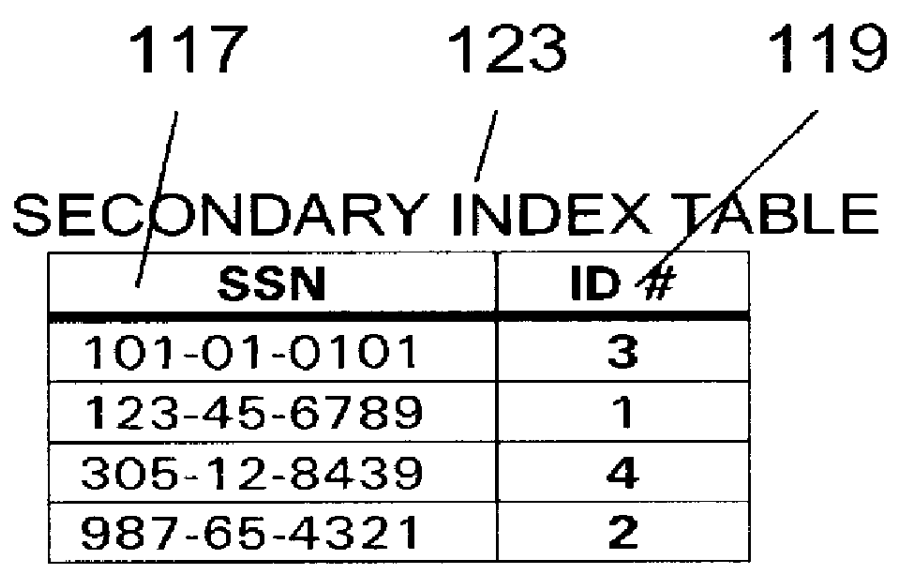

Associative database model for electronic-based informational assemblies

InactiveUS6112209AHigh degree of orderData processing applicationsRelational databasesData setData field

An indexing system and linking method for an assembly of electronic-based informational items stored in and ordered by a plurality of records uniquely identified over a plurality of relational data tables making up a data set wherein each table is assigned a unique domain of unique alphanumeric indicia for assignment and storage in the records. The records are ordered by the alphanumeric indicia whereby each data table acts as its own primary key. The records are bi-directionally linked to each other via a plurality of separate, central linking table indexes wherein each index record is structured with a plurality of linking fields defined to store sets of two or more alphanumeric indicia belonging to a plurality of records in the data set. Each record is further structured to include an internal set of unique indicum for each data field whereby the combination of the unique record indicum and the unique field indicum uniquely identify each record-field over the plurality of relational data tables making up the data set such that each record field may be linked to a plurality of other record-fields or records via the plurality of separate, central linking table indexes. Each central linking table indexes is further generalized to provide multiple arrays of linking indicia in a plurality of indexing fields such that a plurality of the records from a plurality of the data tables may be linked together as a data cluster. The linking values stored in the central linking table indexes may be predefined to automatically structure and link a plurality of unspecified data and changes in the data may alter the linking structure to provide further capabilities.

Owner:GUSACK MARK DAVID

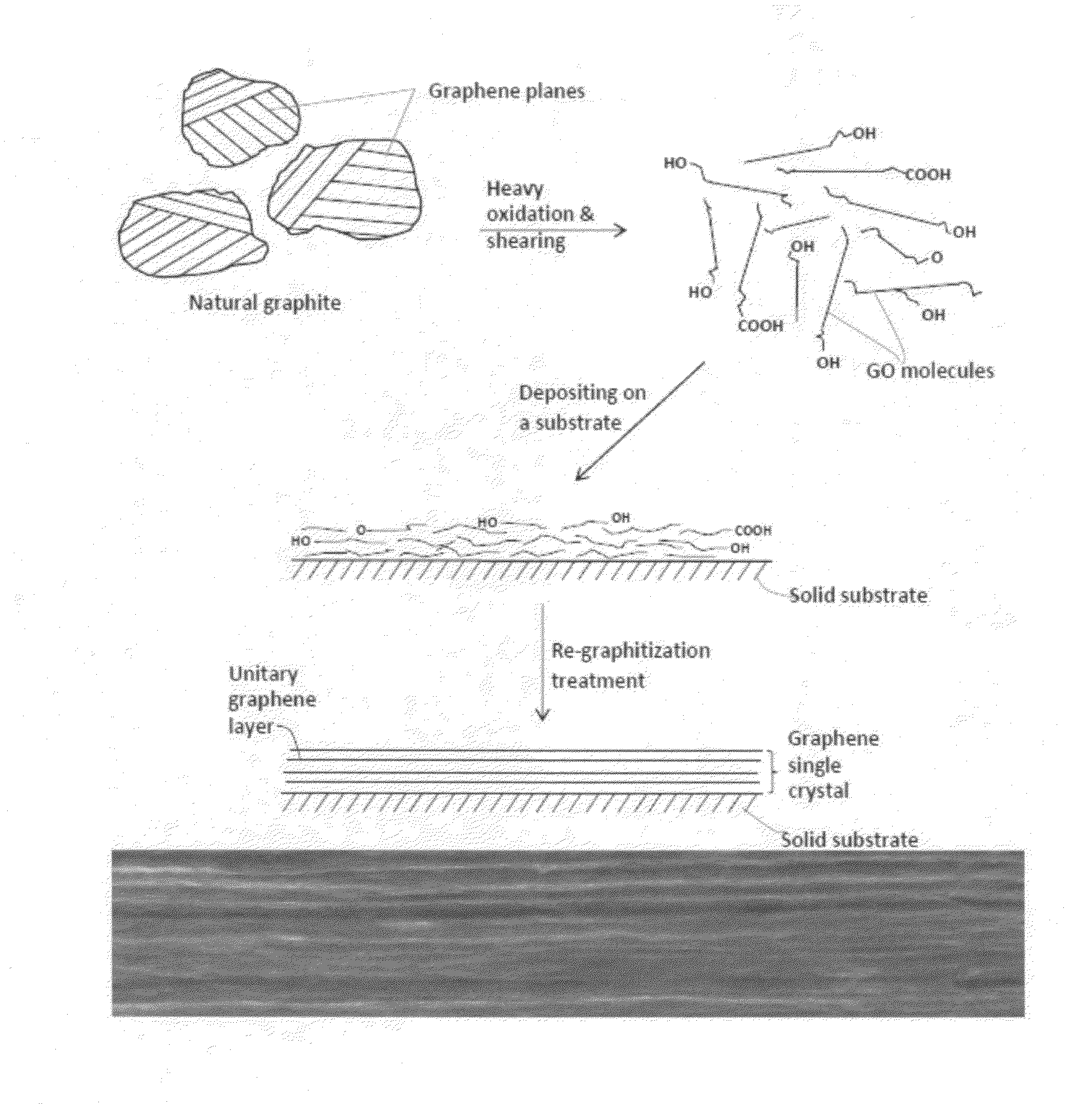

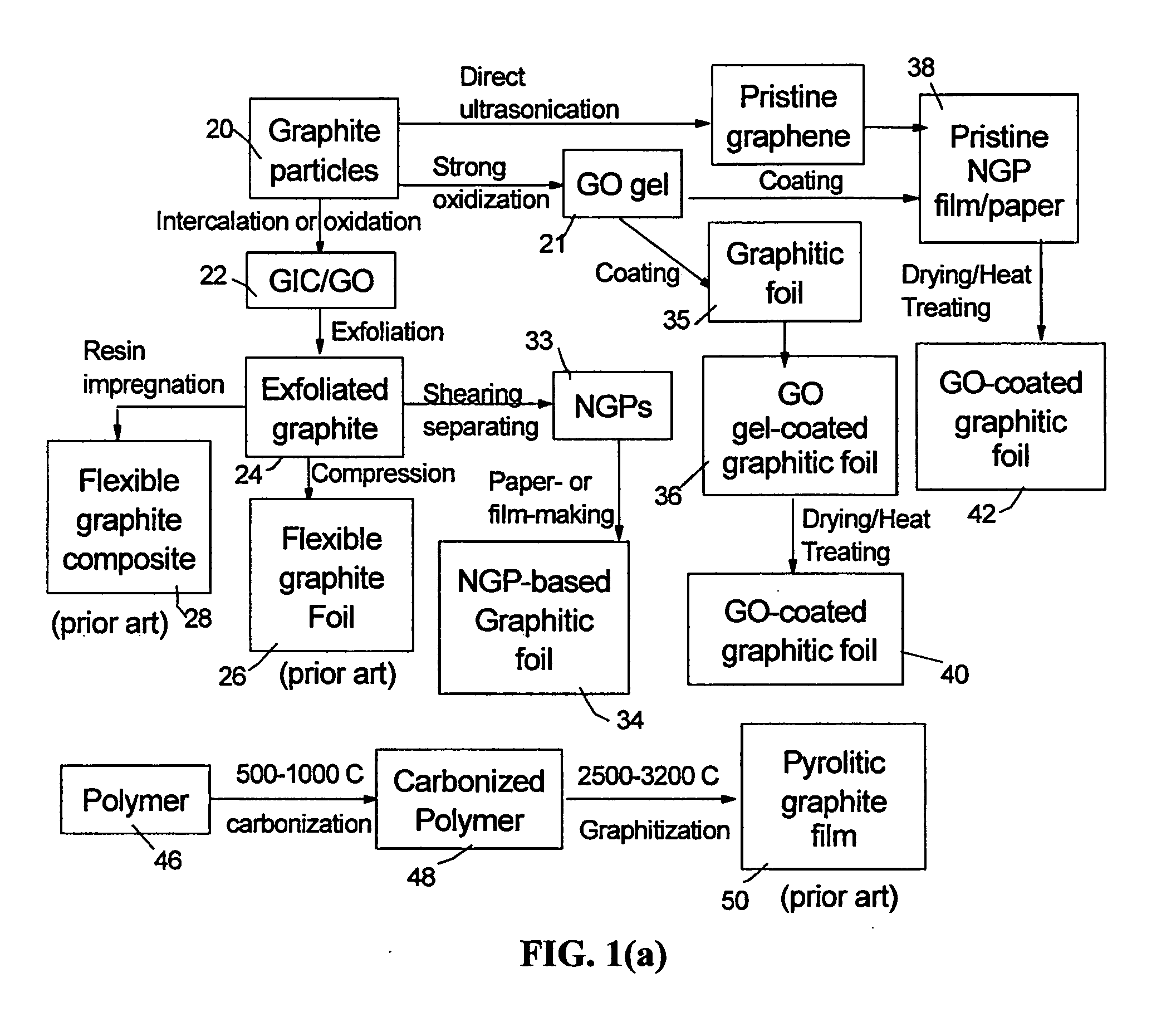

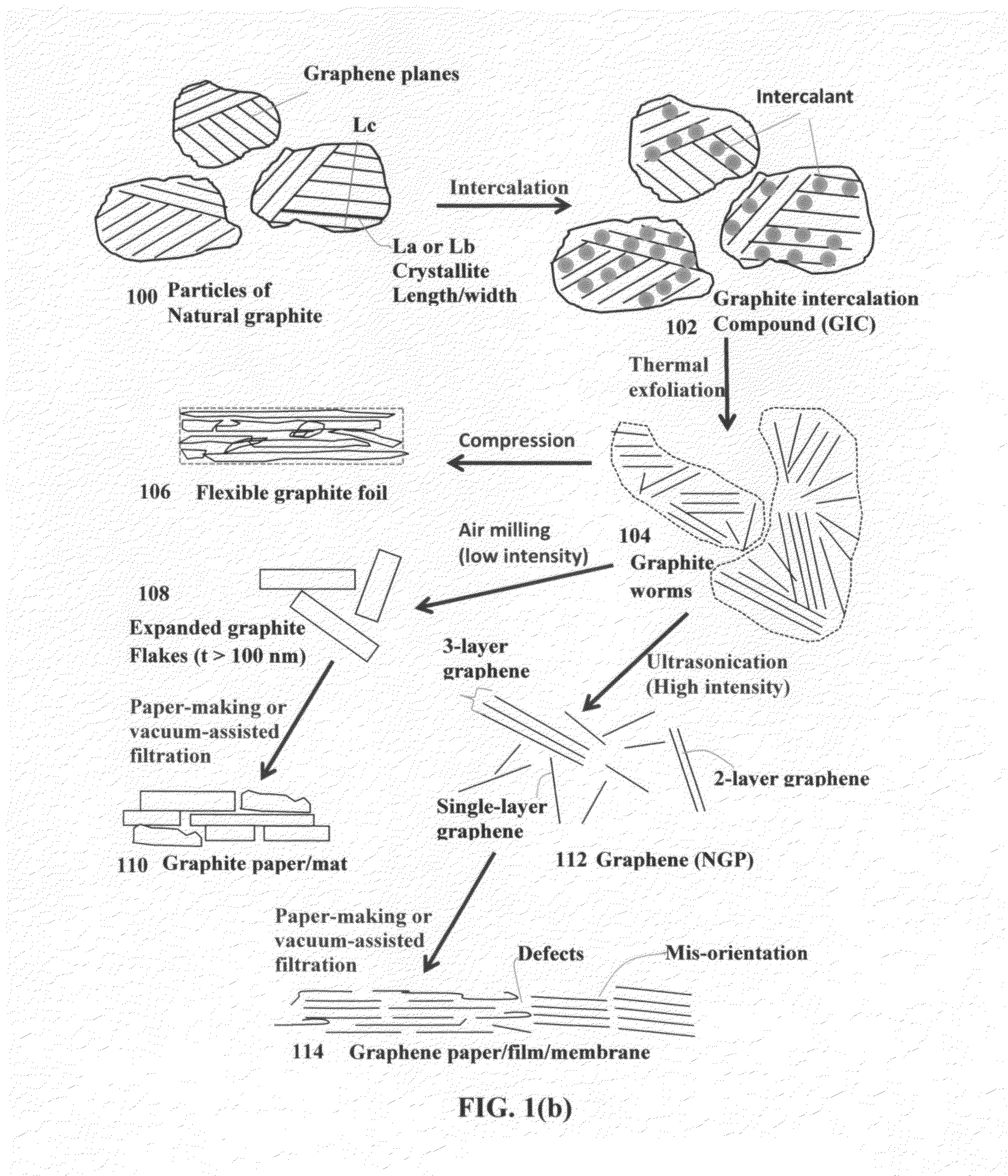

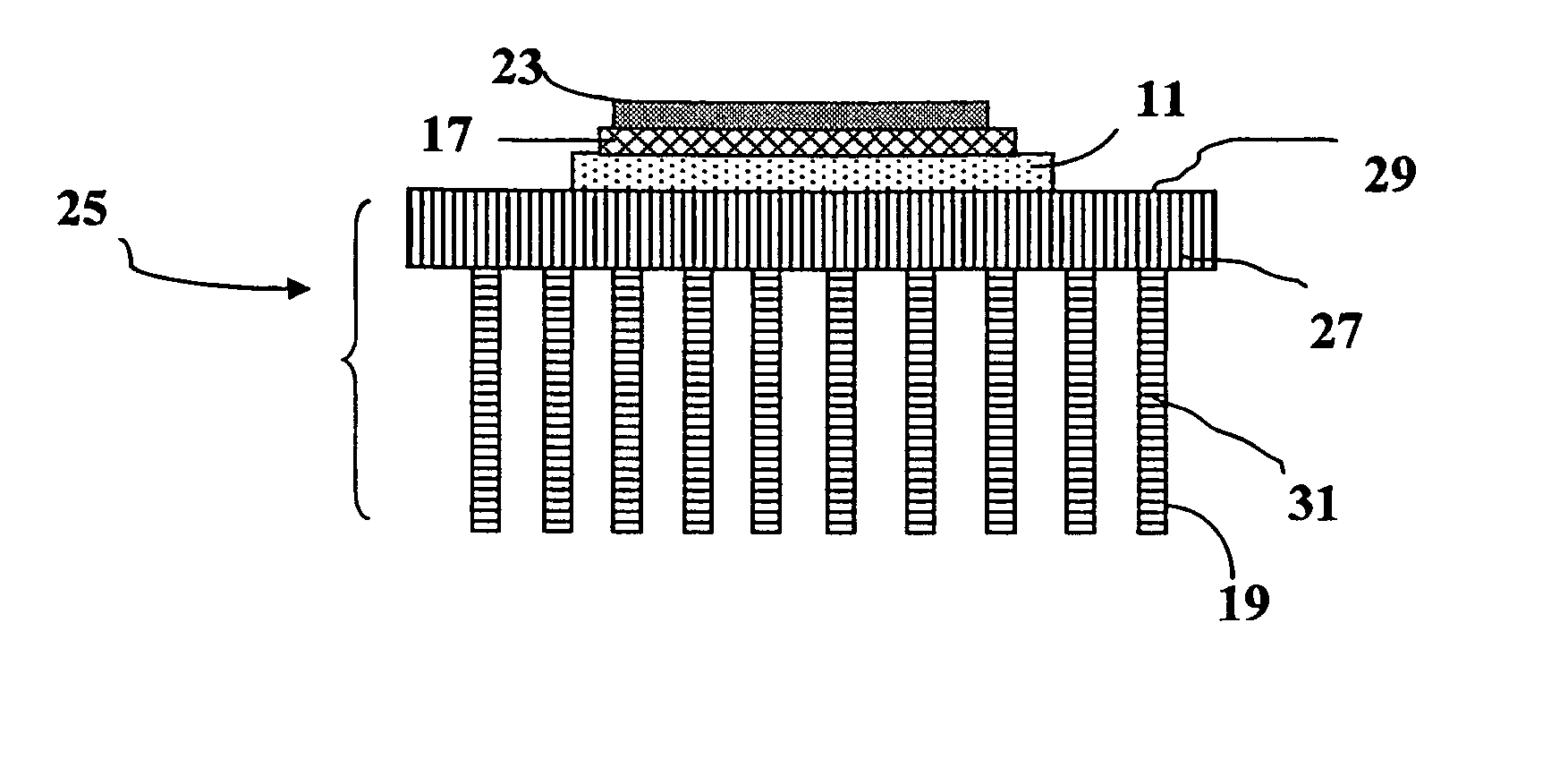

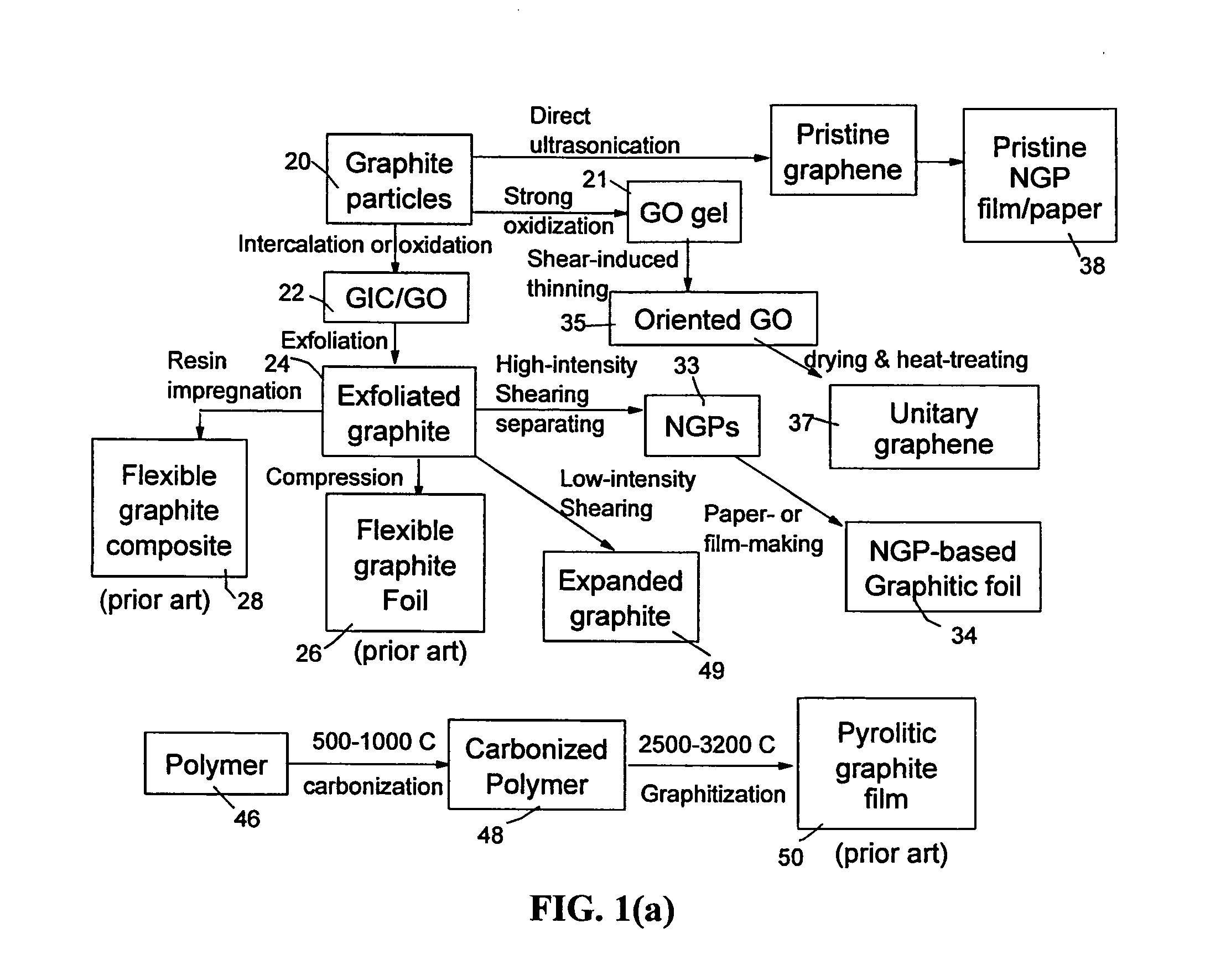

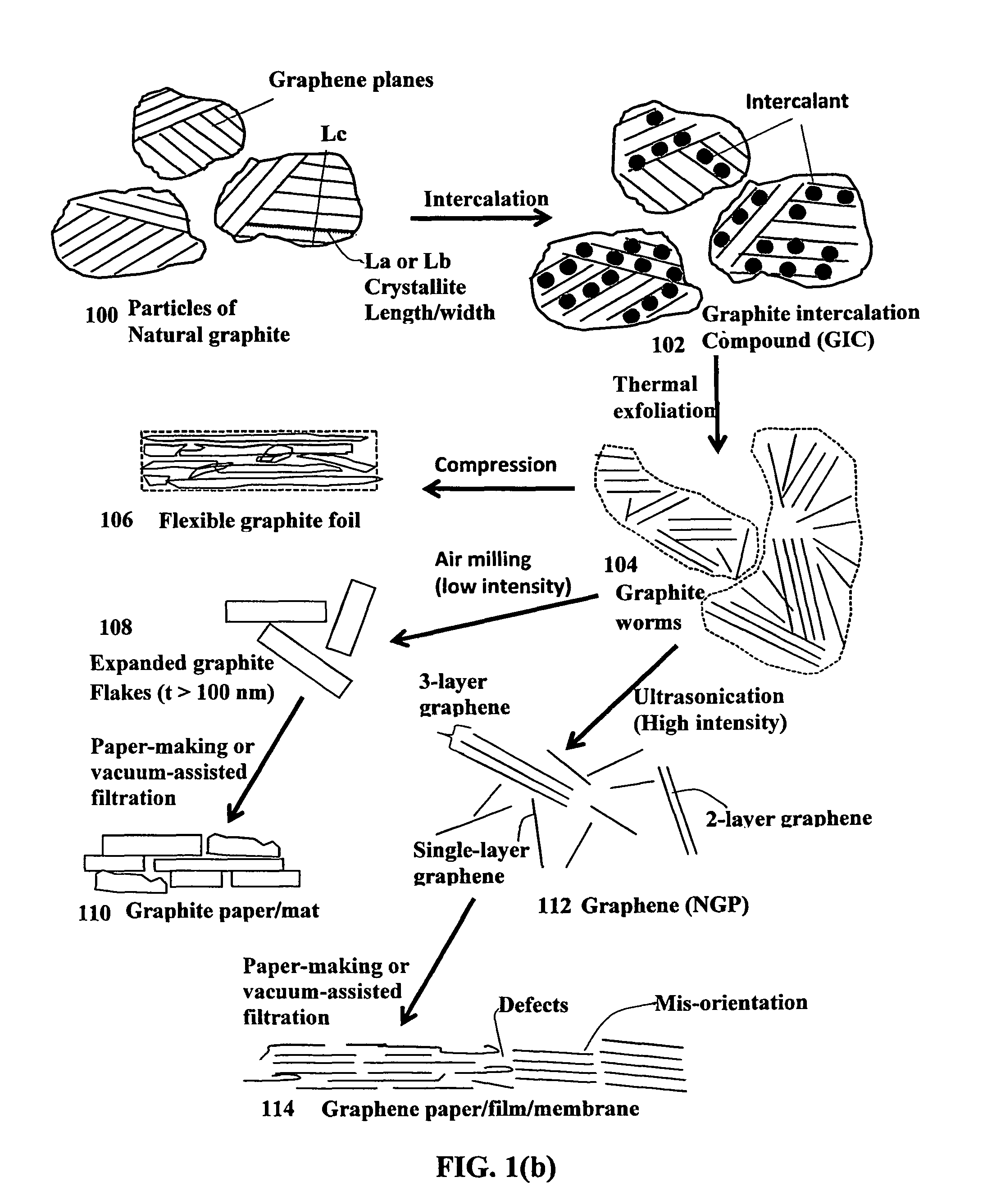

Unitary graphene material-based integrated finned heat sink

ActiveUS20140190676A1Outstanding mechanical strengthOutstanding scratch resistanceIndirect heat exchangersHeat-exchange elementsSingle crystalGraphene

A unitary graphene-based integrated heat sink comprising a heat collection member (base) and at least one heat dissipation member (e.g. fins) integral to the baser, wherein the base is configured to be in thermal contact with a heat source, collects heat therefrom, and dissipates heat through the fins. The unitary graphene material is obtained from heat-treating a graphene oxide gel at a temperature higher than 100° C., 500° C., 1,250° C., or 2,000° C., and contains chemically bonded graphene molecules having inter-graphene distance of 0.3354-0.4 nm (preferably <0.337 nm). The unitary graphene material is a graphene single crystal, a poly-crystal with incomplete grain boundaries, or a poly-crystal having large grain sizes (e.g. >mm or cm), exhibiting a degree of graphitization preferably from 1% to 100% and a Mosaic spread value less than 0.7 (preferably no greater than 0.4). The finned heat sink may also be made from a filler-reinforced graphene matrix composite.

Owner:GLOBAL GRAPHENE GRP INC

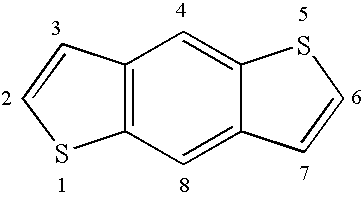

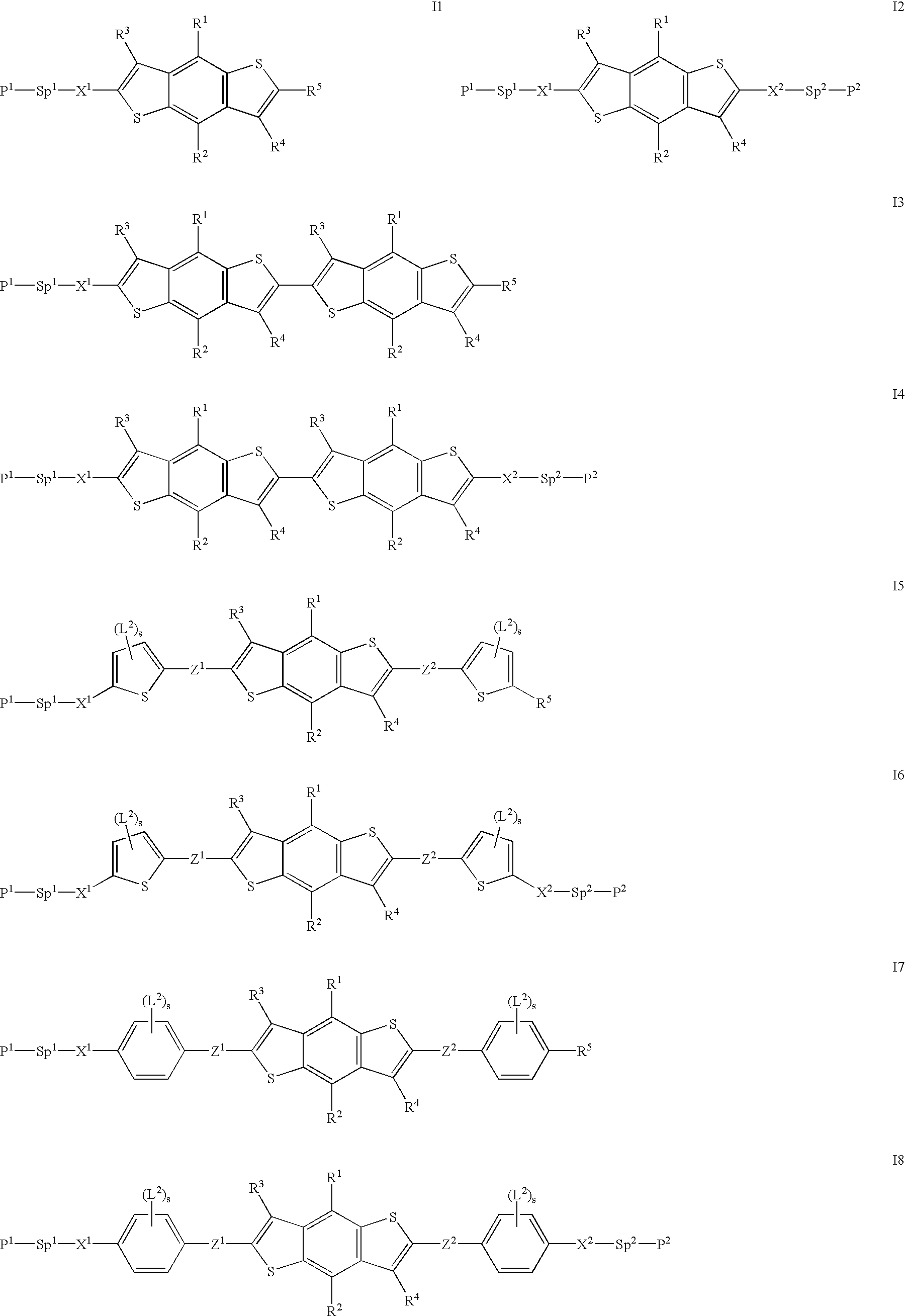

Reactive mesogenic benzodithiophenes

InactiveUS6913710B2High carrier mobilitySimple materialLiquid crystal compositionsOrganic chemistryOrganic field-effect transistorDisplay device

The invention relates to new reactive mesogenic benzodithiophene derivatives, their use as semiconductors or charge transport materials, in optical, electro-optical or electronic devices like for example liquid crystal displays, optical films, organic field effect transistors (FET or OFET) for thin film transistor liquid crystal displays and integrated circuit devices such as RFID tags, electroluminescent devices in flat panel displays, and in photovoltaic and sensor devices, and to a field effect transistor, light emitting device or ID tag comprising the reactive mesogenic benzodithiophenes.

Owner:MERCK PATENT GMBH

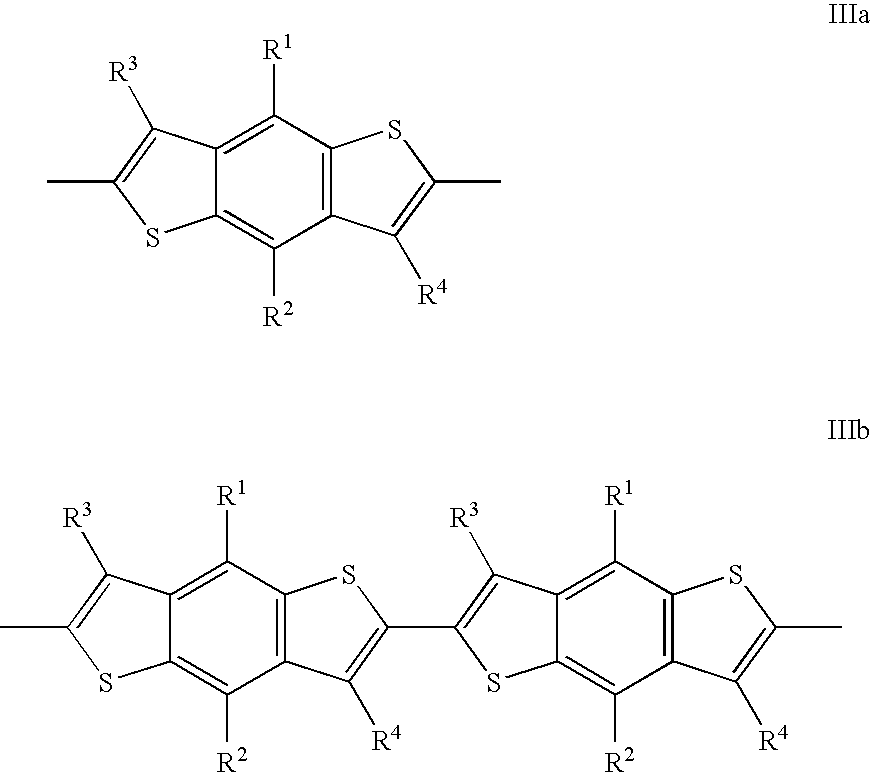

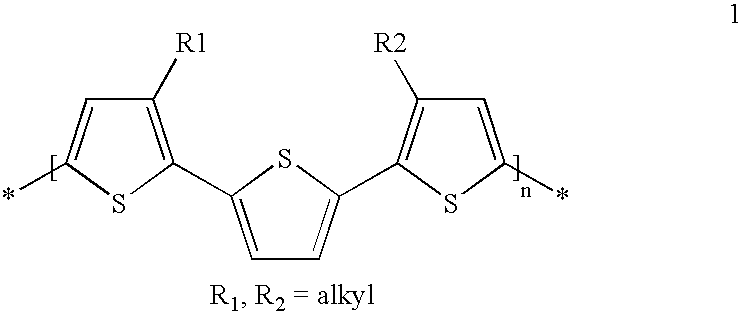

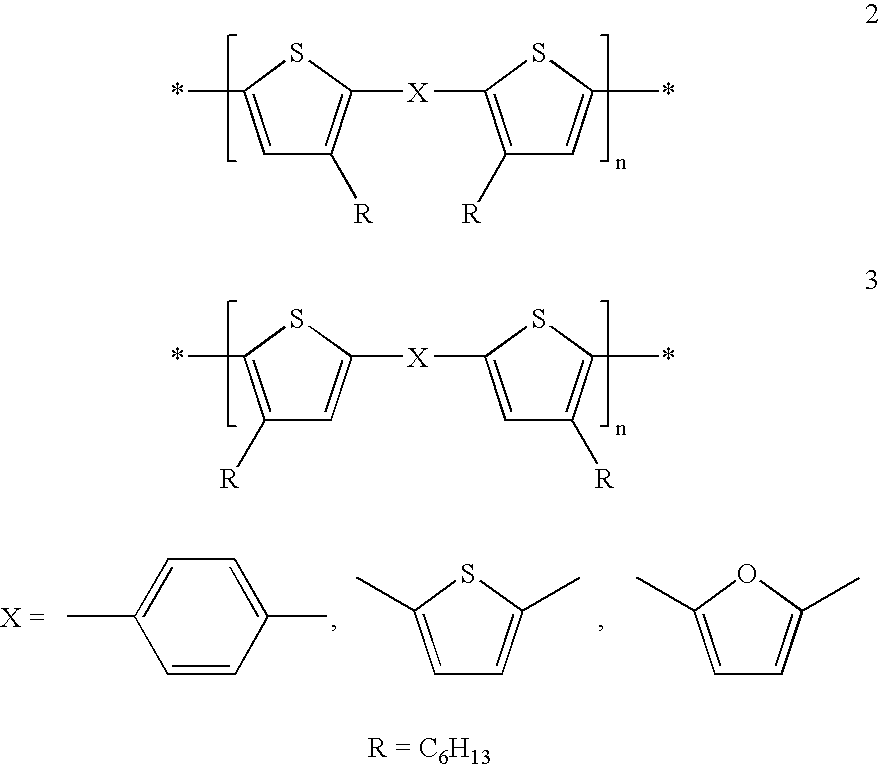

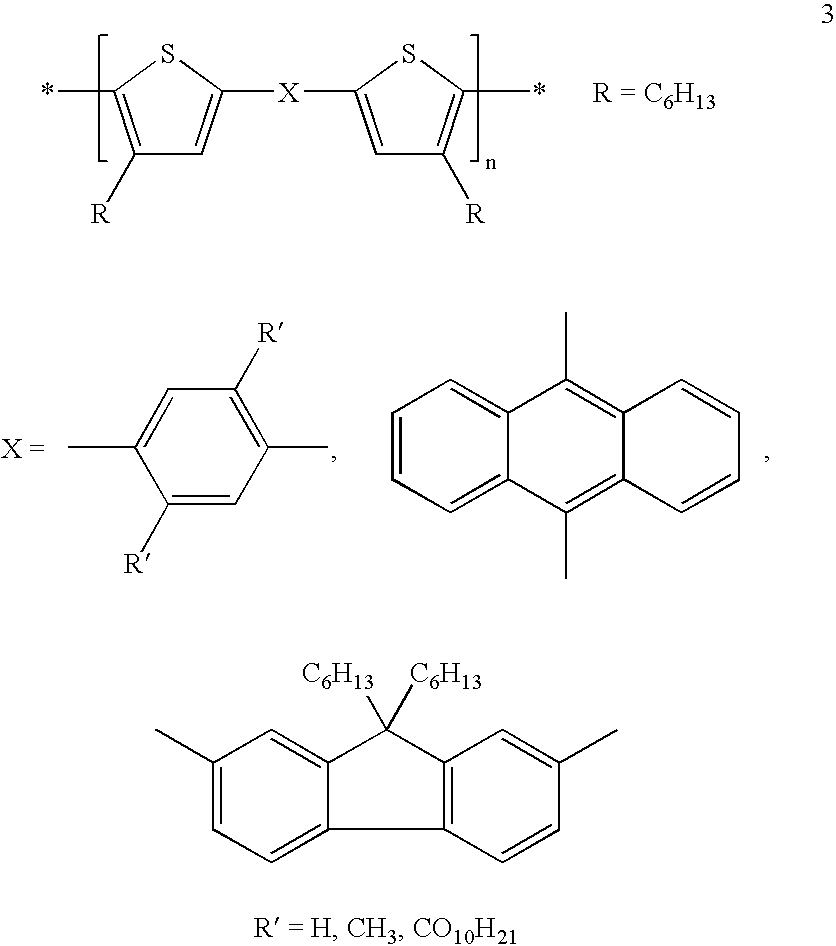

Mono-, oligo- and poly-bis(thienyl) arylenes and their use as charge transport materials

InactiveUS20040119049A1Improve mobilityHigh degree of orderLiquid crystal compositionsTransistorSemiconductor materialsEngineering

Mono-, oligo- and poly-bis(thienyl) arylenes are suitable as as charge transport materials or semiconductors in electrooptical, electronic and electroluminescent devices, to charge transport and semiconductor materials, components and devices comprising mono-, oligo- and poly-bis(thienyl) arylenes.

Owner:MERCK PATENT GMBH

Inorganic coating-protected unitary graphene material for concentrated photovoltaic applications

ActiveUS20140209168A1Outstanding mechanical strengthOutstanding scratch resistanceLayered productsThin material handlingConductive coatingCvd graphene

This invention provides an inorganic coating-protected unitary graphene material article for concentrated photovoltaic cell heat dissipation. The article comprises at least a layer of unitary graphene material having two primary surfaces and an electrically non-conducting layer of inorganic coating deposited on at least one of the primary surfaces, wherein the unitary graphene material is obtained from heat-treating a graphene oxide gel at a heat treatment temperature higher than 100° C. and contains chemically bonded graphene molecules or chemically merged graphene planes having an inter-graphene spacing no greater than 0.40 nm, preferably less than 0.337 nm, and most preferably less than 0.3346 nm.

Owner:GLOBAL GRAPHENE GRP INC

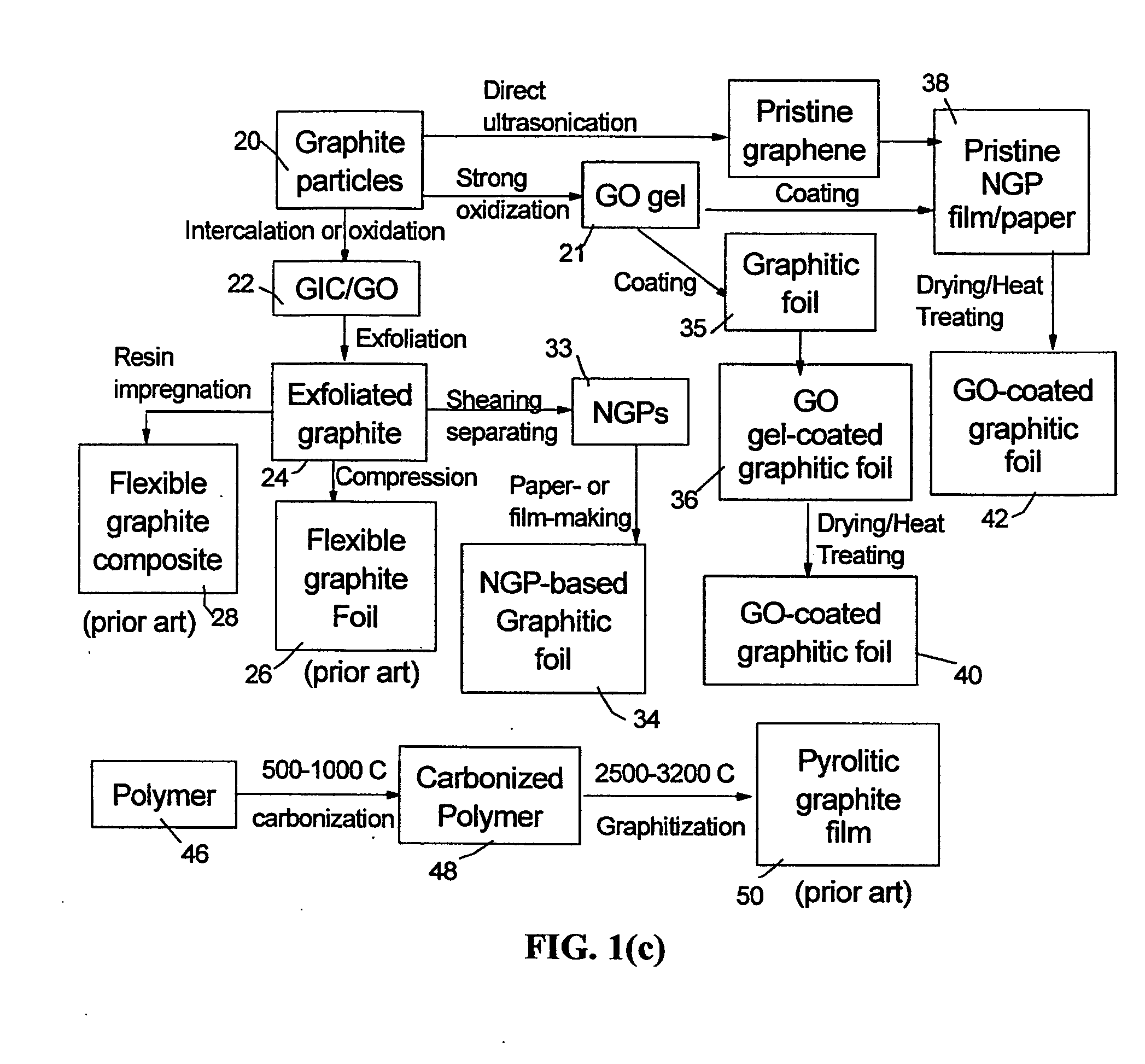

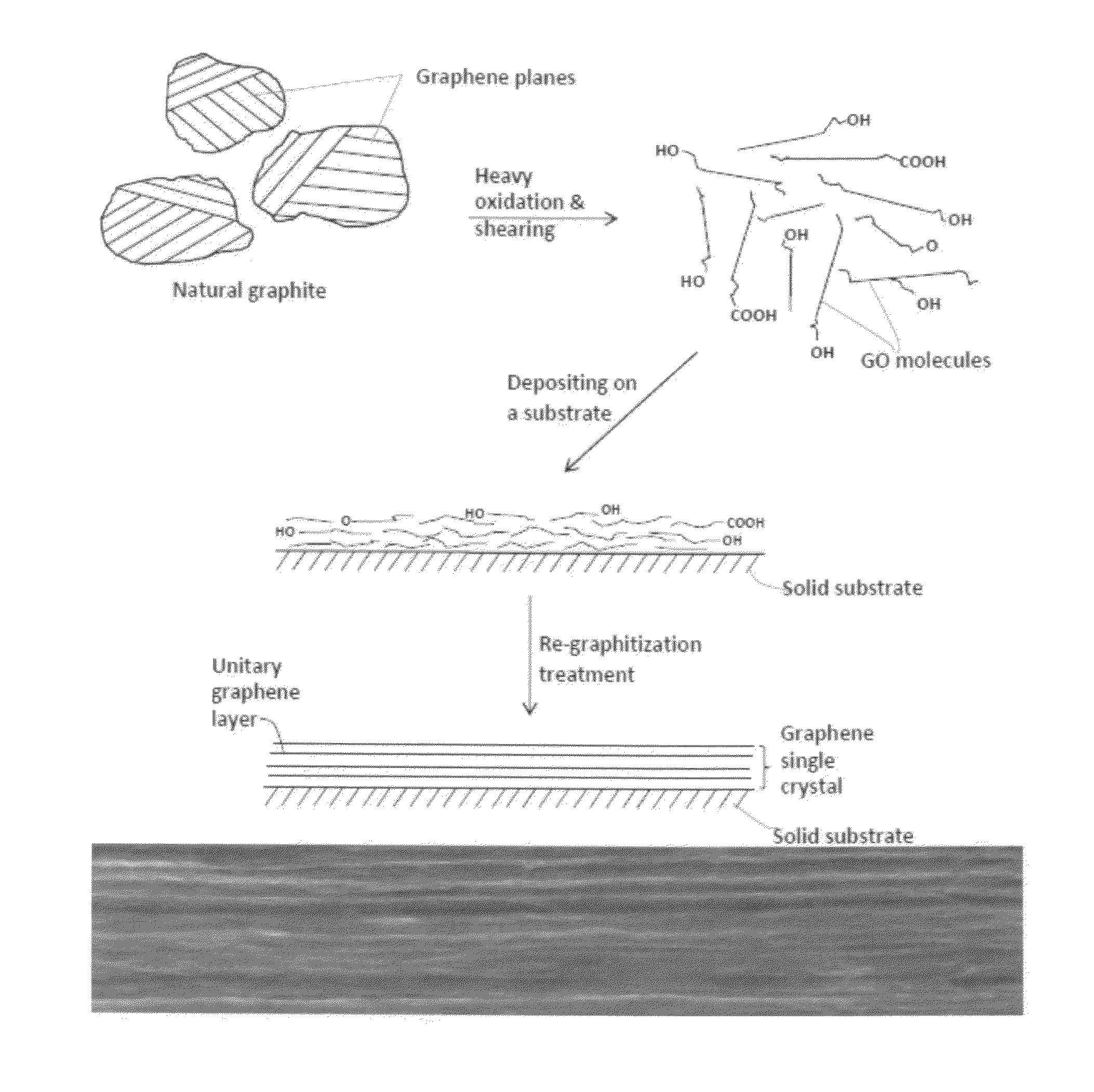

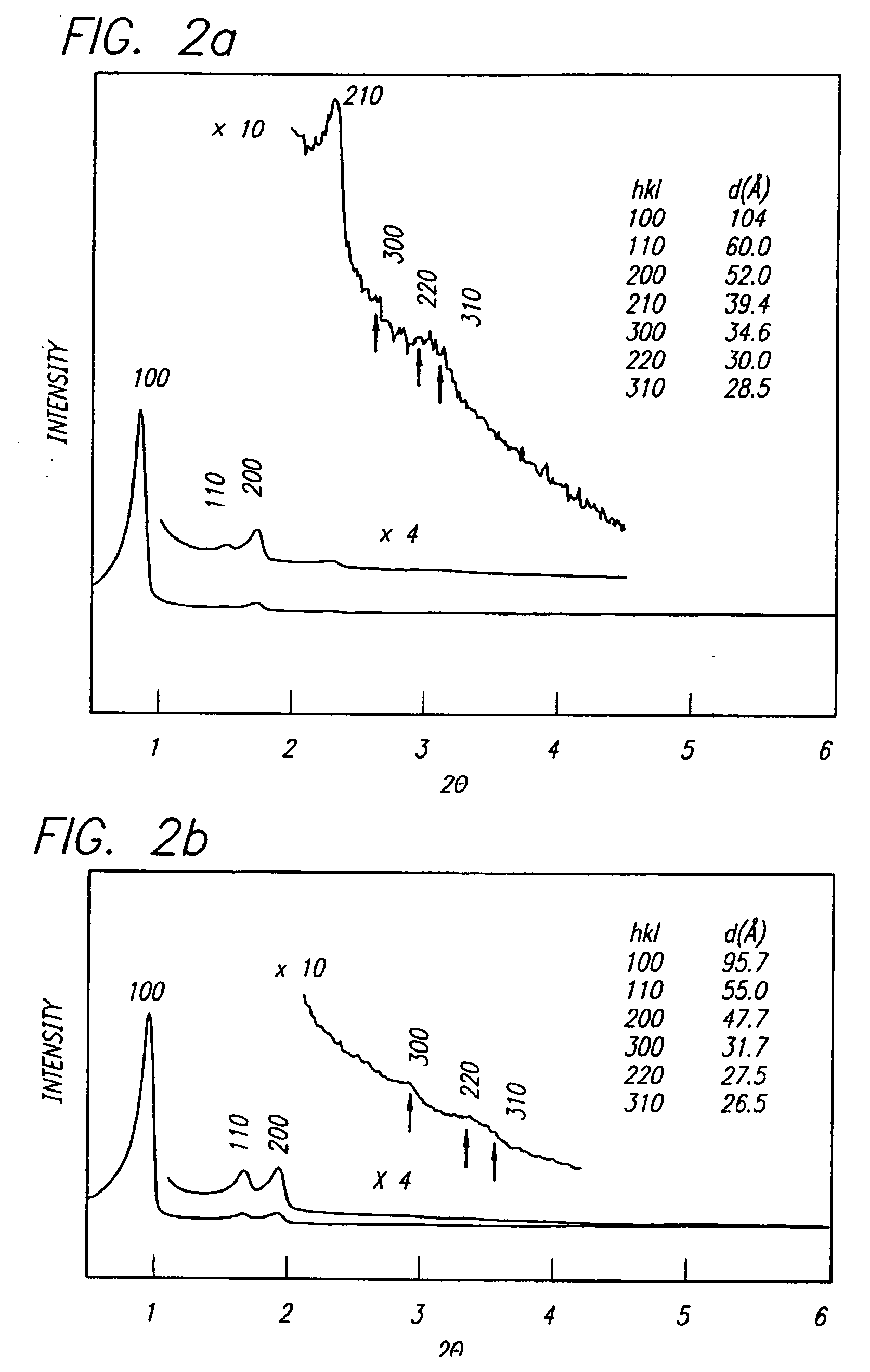

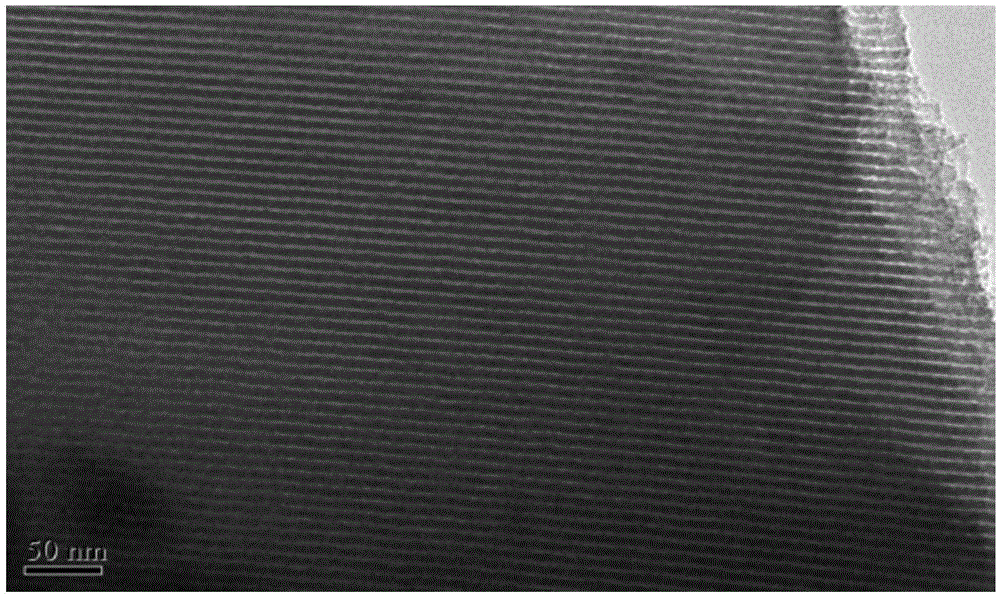

Process for producing unitary graphene materials

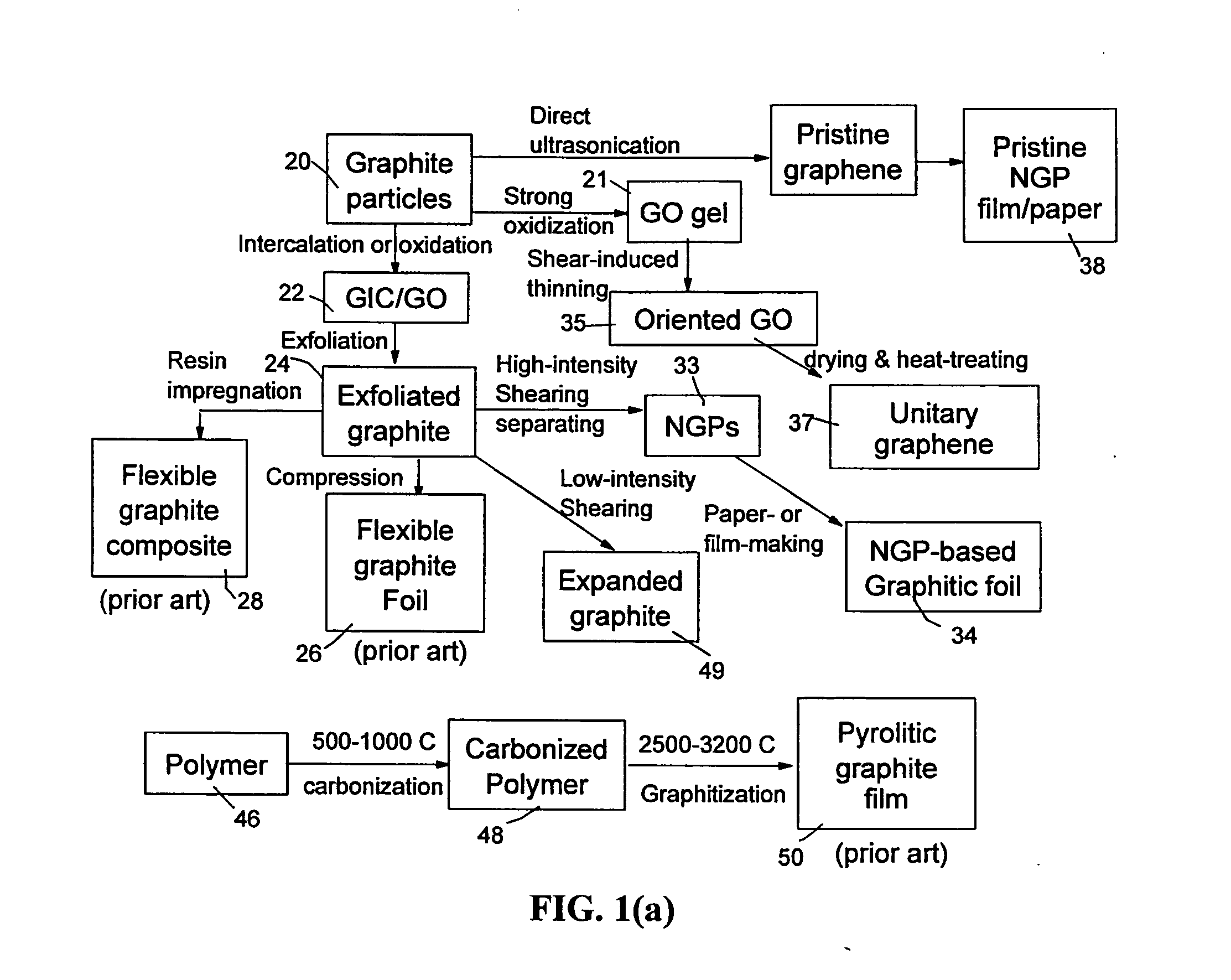

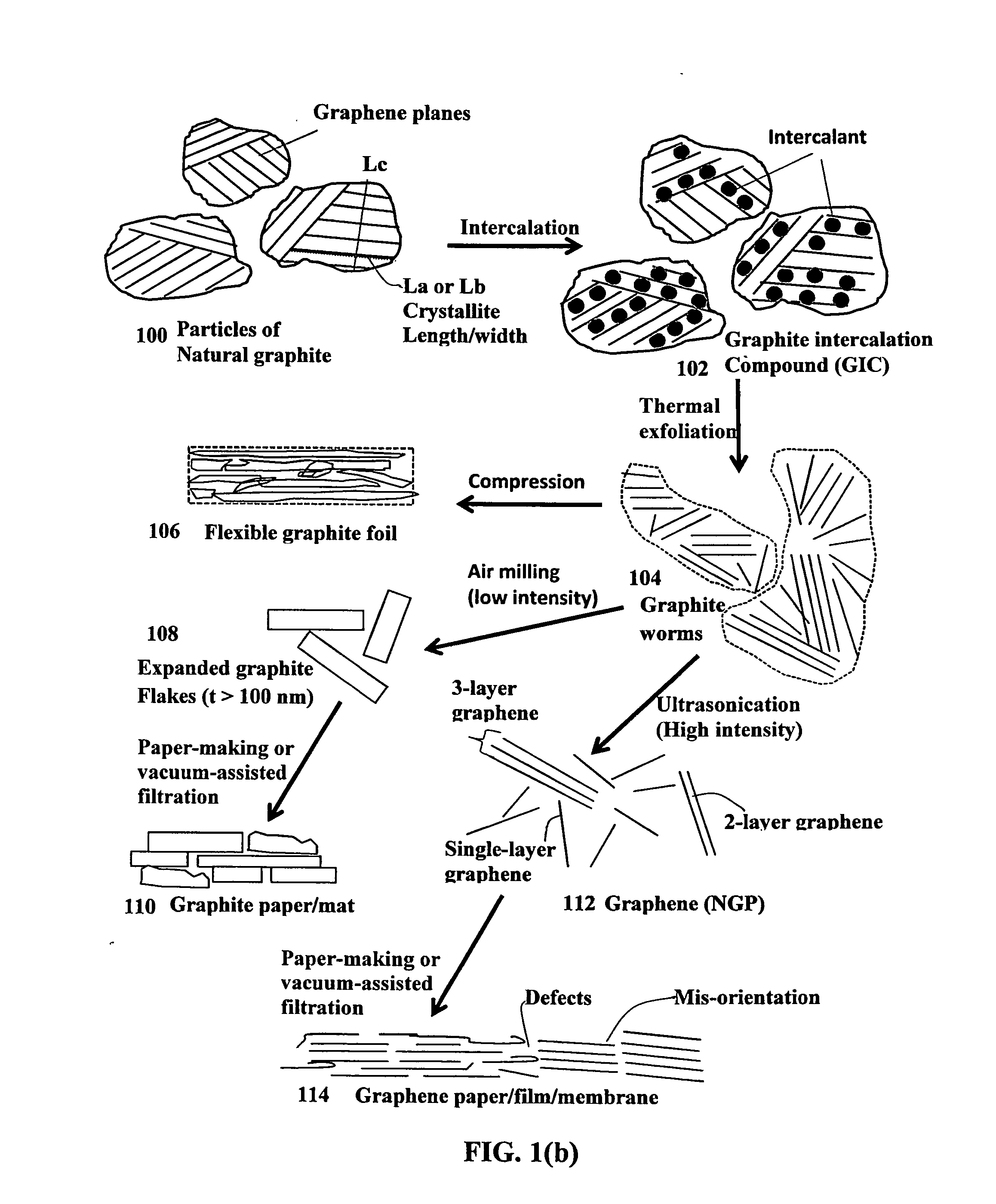

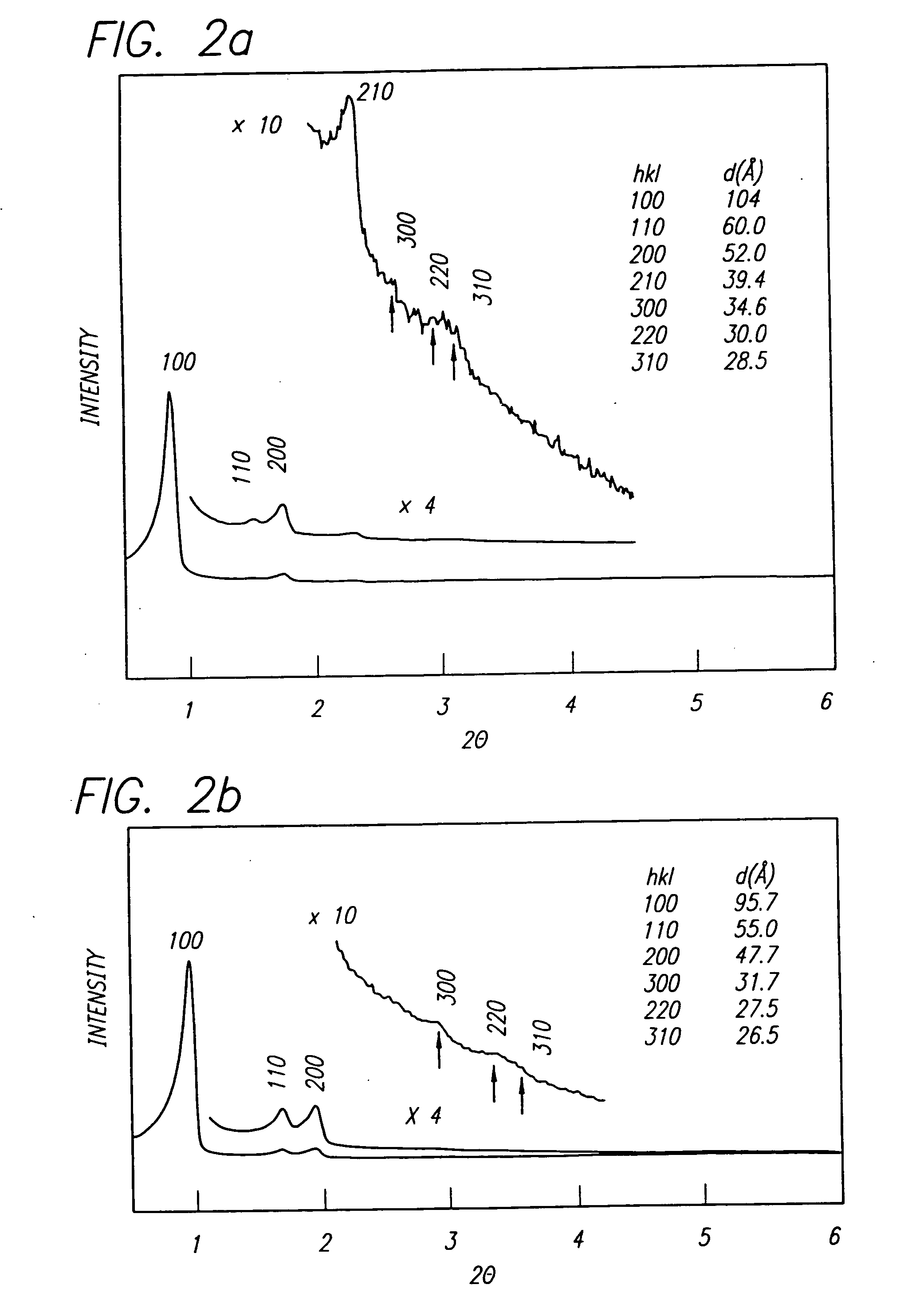

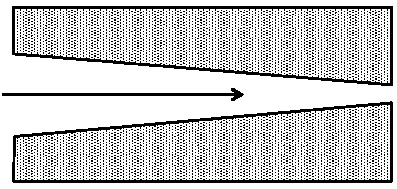

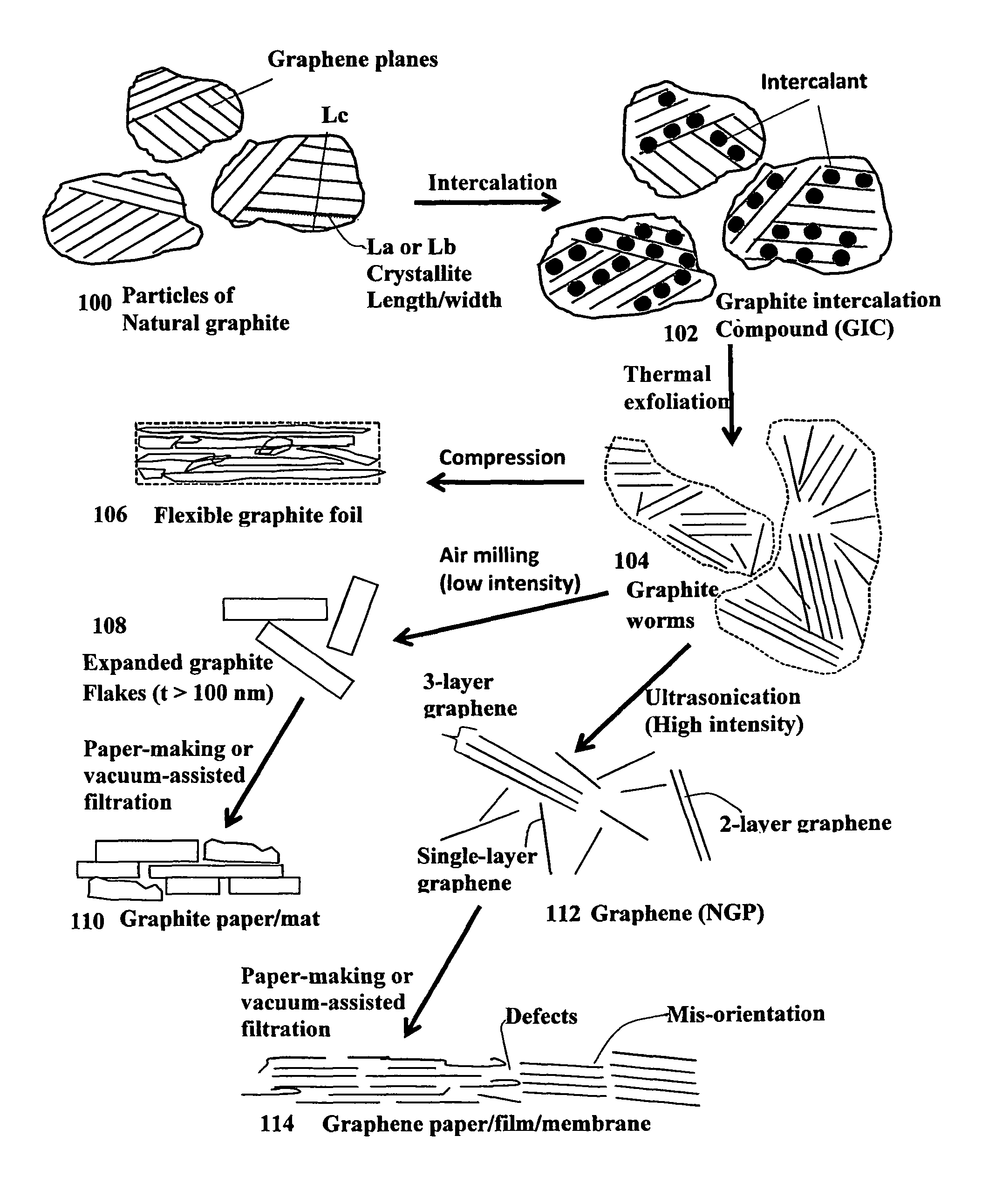

ActiveUS20140242275A1Increase in in-plane thermal conductivityHigh degree of orderPretreated surfacesGrapheneX-rayThinning

A process for producing a unitary graphene material, comprising: (a) preparing a graphene oxide (GO) gel having GO molecules dissolved in a fluid medium wherein the GO molecules contain higher than 20% by weight of oxygen; (b) dispensing and depositing a layer of GO gel onto a surface of a substrate to form a layer of deposited GO gel thereon, wherein the dispensing and depositing procedure includes shear-induced thinning; (c) removing the fluid medium from the deposited GO gel to form a GO layer having an inter-plane spacing d002 of 0.4 nm to 1.2 nm as determined by X-ray diffraction; and (d) heat treating the GO layer to form the unitary graphene material at a heat treatment temperature higher than 100° C. to an extent that d002 is decreased to a value of 0.3354 nm to 0.4 nm and the oxygen content is decreased to less than 5% by weight.

Owner:GLOBAL GRAPHENE GRP INC

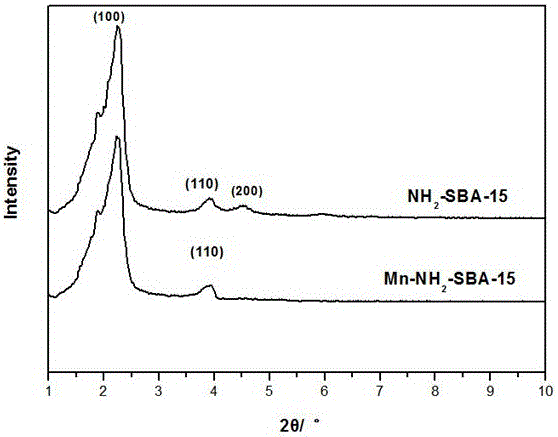

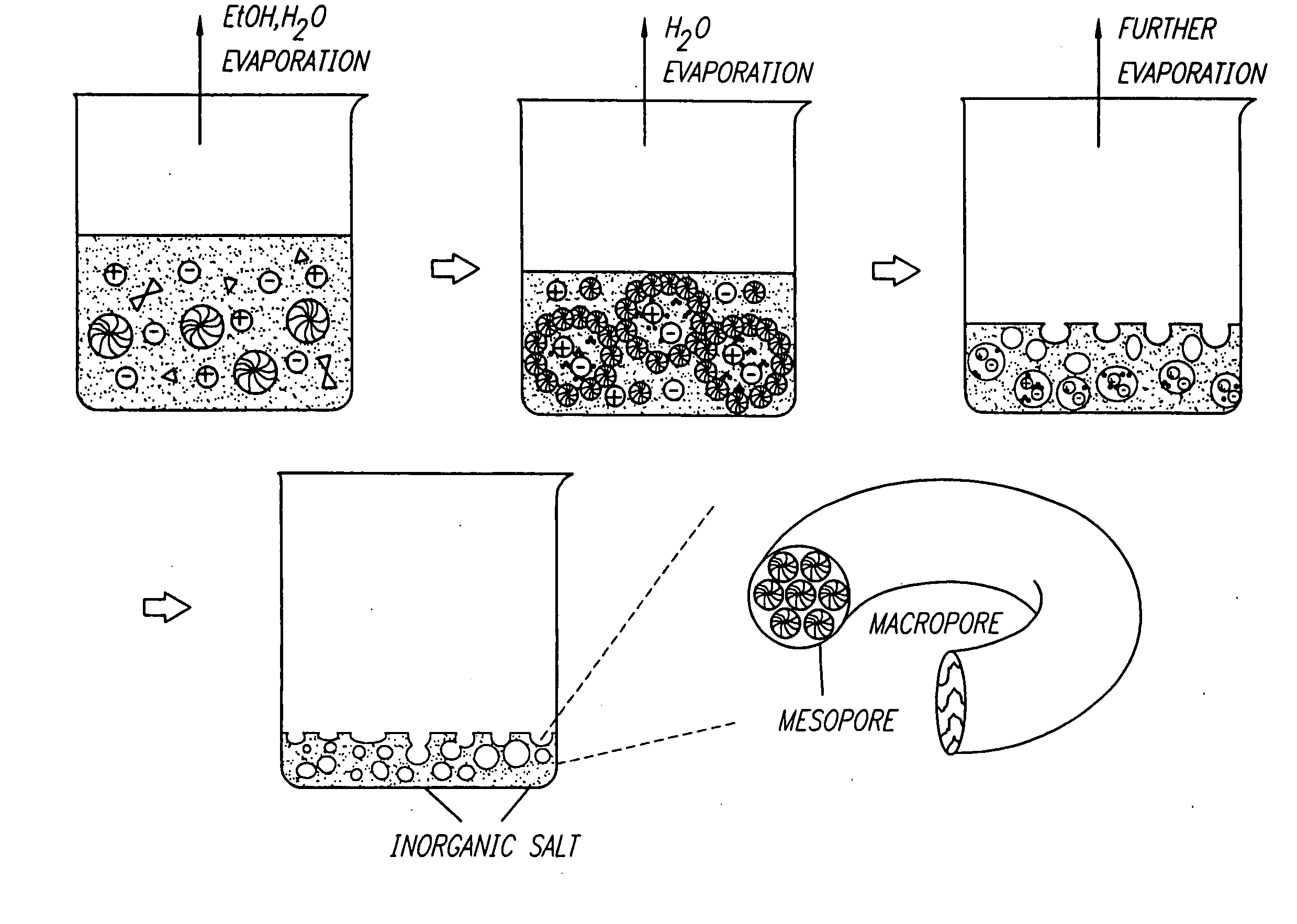

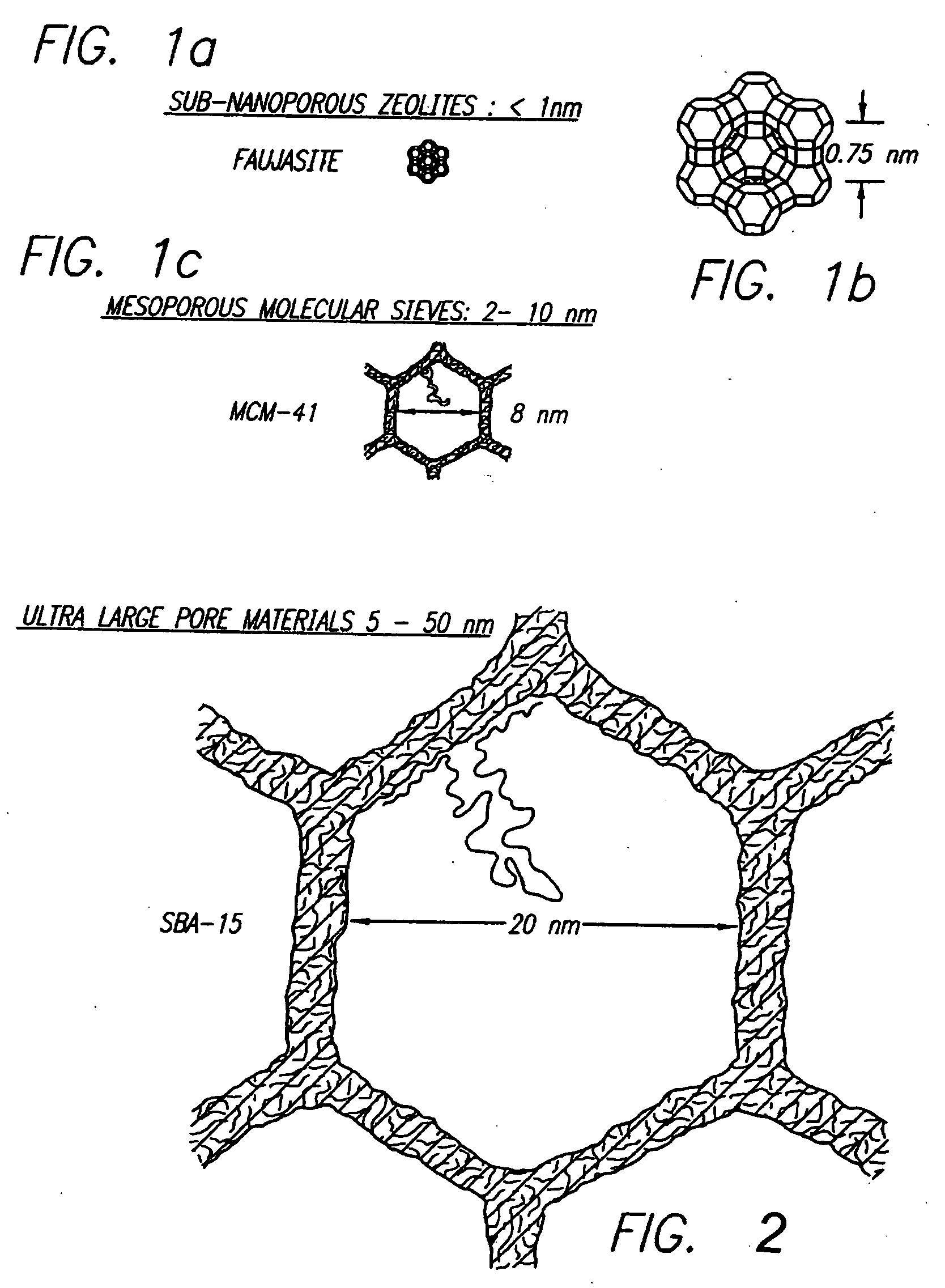

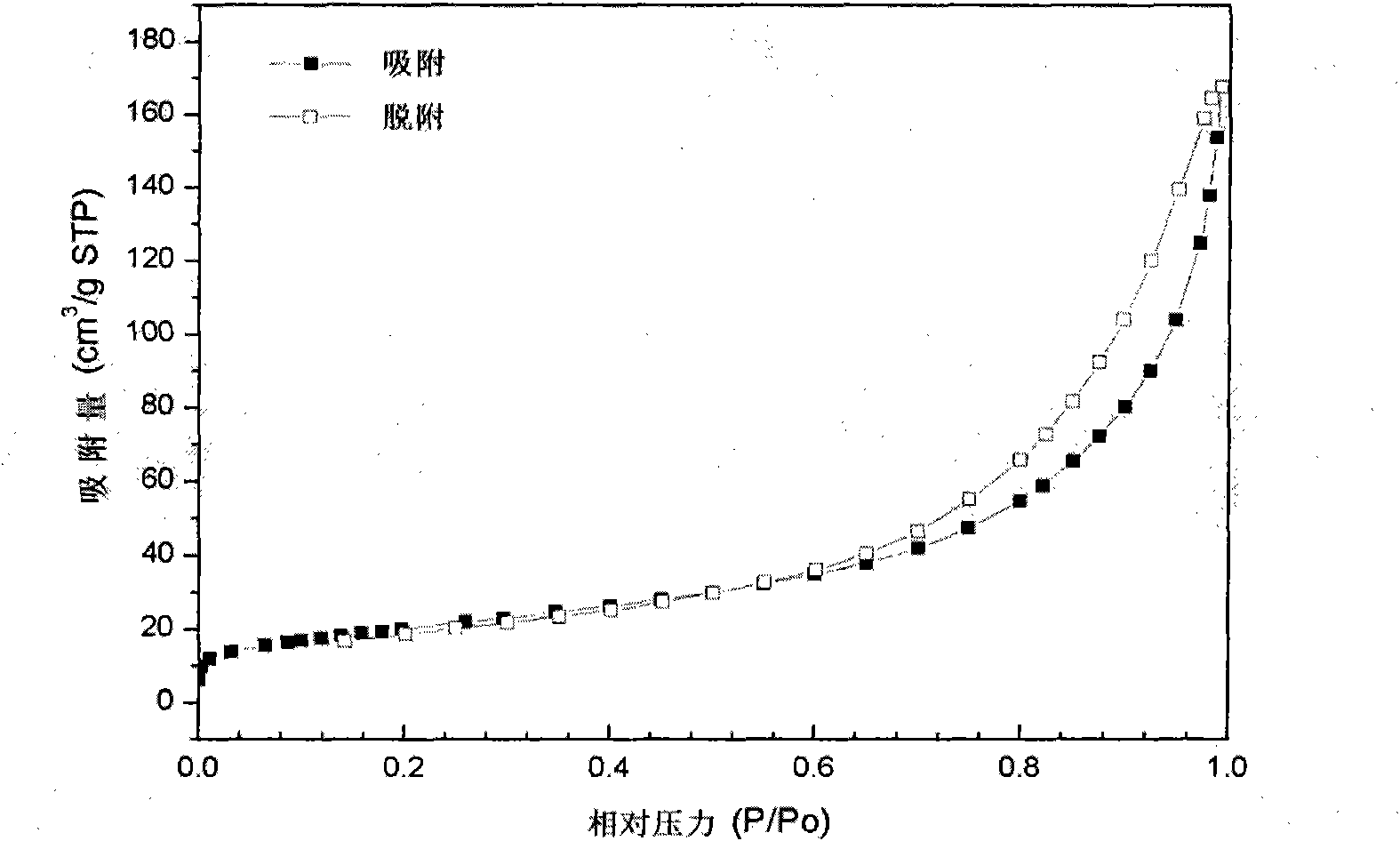

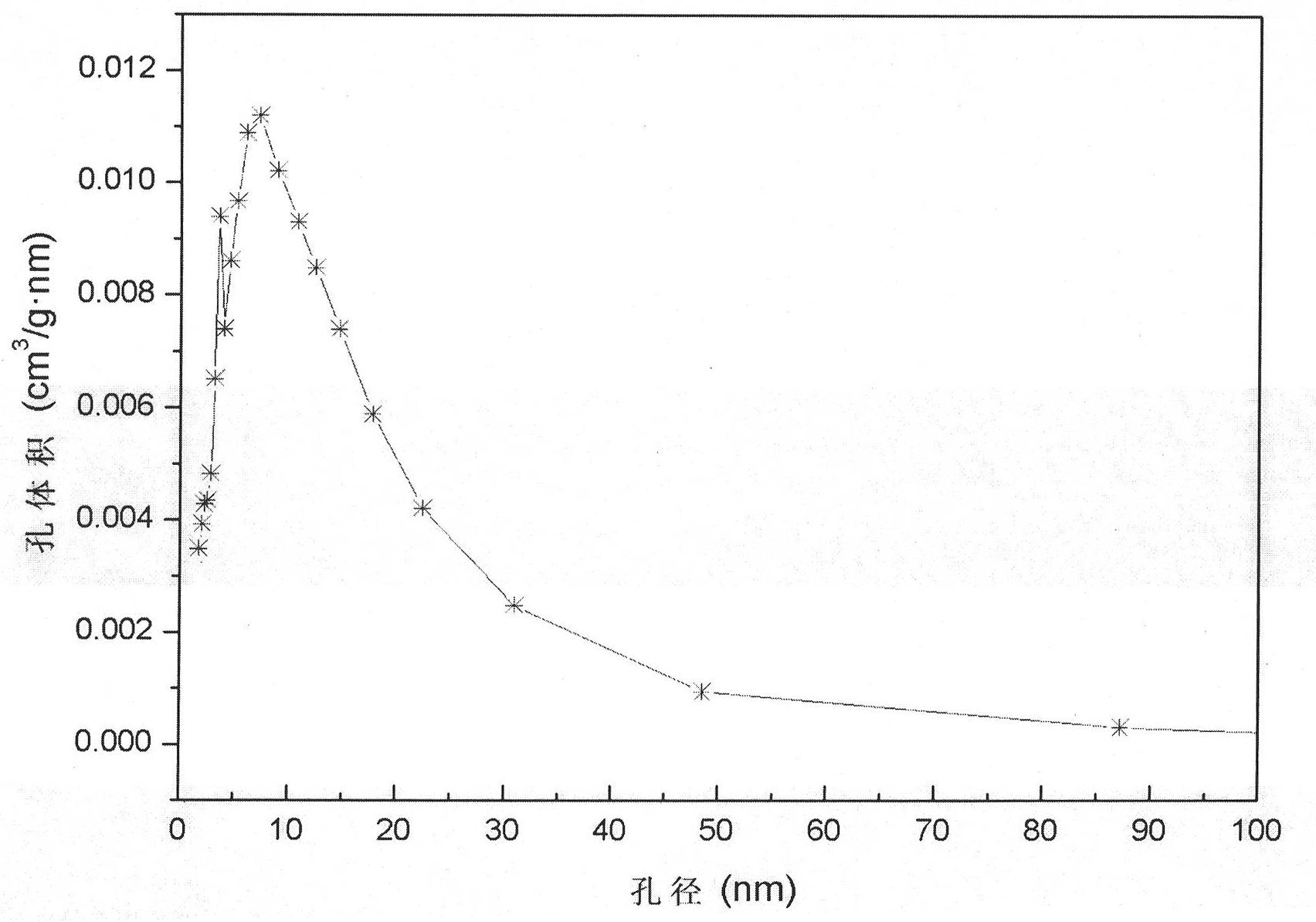

Organic-inorganic hybrid mesoporous catalyst for purifying VOCs (volatile organic compounds) and method for preparing organic-inorganic hybrid mesoporous catalyst

ActiveCN106215978ATo achieve the purpose of doping modificationImprove adsorption capacityGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsAlkaline earth metalLow temperature plasma

The invention discloses an organic-inorganic hybrid mesoporous catalyst for purifying VOCs (volatile organic compounds) and a method for preparing the organic-inorganic hybrid mesoporous catalyst. SBA-15 mesoporous molecular sieves are used as carriers of the organic-inorganic hybrid mesoporous catalyst, organic groups (phenyl groups, amino groups and sulfhydryl groups) and transition metal oxide (oxide of Mn, Fe and Co) are used as active components of the organic-inorganic hybrid mesoporous catalyst, and chloride of alkali metal or alkaline-earth metal is used as an auxiliary of the organic-inorganic hybrid mesoporous catalyst. The specific surface area of the organic-inorganic hybrid mesoporous catalyst ranges from 700 m<2> / g to 900 m<2> / g, and the average pore diameter of pore passages in the organic-inorganic hybrid mesoporous catalyst ranges from 8 nm to 15 nm. The method includes supporting the organic groups on the SBA-15 molecular sieves by the aid of an in-situ solvent thermal synthesis process; modifying the SBA-15 mesoporous molecular sieves by the transition metal oxide by the aid of an impregnation process to obtain the organic-inorganic hybrid mesoporous catalyst. The organic-inorganic hybrid mesoporous catalyst and the method have the advantages that the organic-inorganic hybrid mesoporous catalyst has large mesoporous pore diameters and the large specific surface area and is high in catalytic activity, catalytic active constituents are good in dispersibility, acid centers can be reinforced, and the method is simple and feasible and is low in cost; the VOCs can be converted into harmless carbon dioxide and water under synergy of the organic-inorganic hybrid mesoporous catalyst and low-temperature plasma technologies at the normal temperature, and the organic-inorganic hybrid mesoporous catalyst has few byproducts and is difficult to inactivate.

Owner:WUHAN UNIV

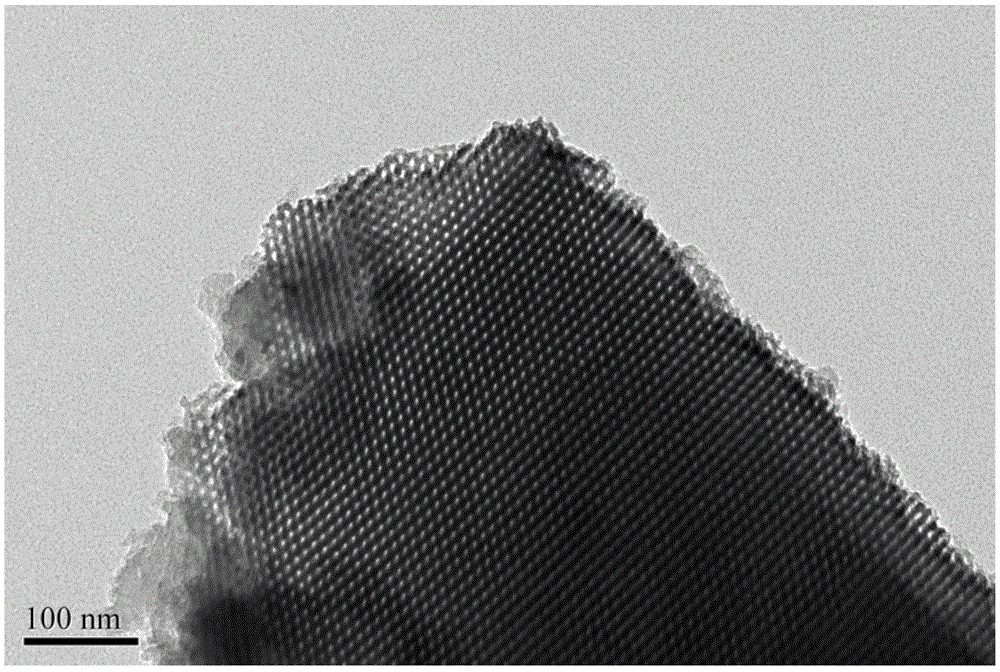

Preparation method of ordered macroporous materials with titanium dioxide inverse opal structures

InactiveCN102336434AHigh degree of orderImprove uniformityTitanium dioxideEmulsion polymerizationRoom temperature

The invention discloses a preparation method of ordered macroporous materials with titanium dioxide inverse opal structures, which comprises the following steps of: step 1, adopting an emulsifier-free emulsion polymerization method, preparing PS micro-balloons by taking a PS monomer as raw materials and dispersing the micro-balloons into ethanol solution to form PS micro-balloon dispersion liquid; step 2, utilizing the PS micro-balloon dispersion liquid in the step 1 to deposit and prepare a PS template with an opal structure by adopting a vertical deposition method under the conditions of constant temperature and constant humidity; step 3, preparing titanium tetrachloride hydrochloric acid solution, vertically immersing the PS template prepared in the step 2 into the titanium tetrachloride hydrochloric acid solution and heating to 70-90 DEG C, slowly filling hydrated titanium oxide on the PS temperate in a constant-temperature state and then taking out after 3-5 hours; and step 4, placing the PS template treated by the step 3 at a room temperature for drying, treating for 30 minutes at a high temperature and obtaining the ordered macroporous materials with the TiO2 inverse opal structures. Compared with the prior art, the prepared materials are uniform, have high order degree, less impurity and simple preparation process and are beneficial to popularization and implementation.

Owner:SOUTHWEAT UNIV OF SCI & TECH

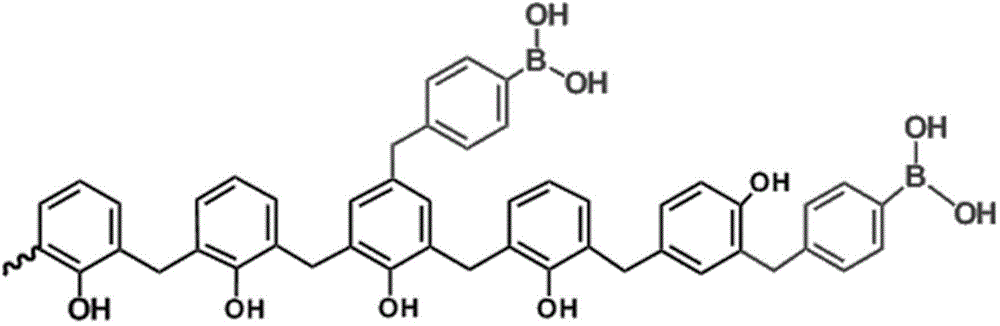

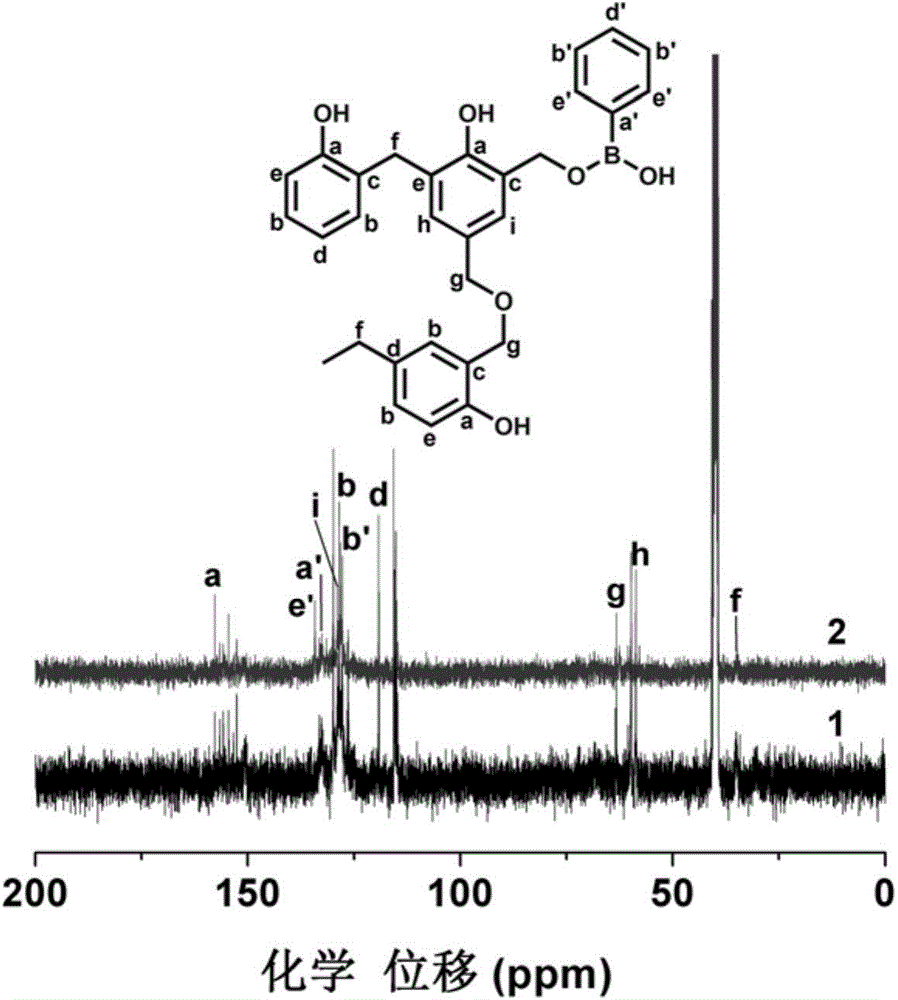

Preparation method of aryl-containing boron thermoplastic phenolic resin

A preparation method of an aryl-containing boron thermoplastic phenolic resin. The method is as below: adding a phenolic compound and a divalent metal salt catalyst into a reaction kettle, adding an aldehyde compound by two times, wherein after the first addition, reacting at 50-70 DEG C for 0.5-2 h, and after the second addition, adding an acidic catalyst, heating to a reflux reaction state for reaction, then removing generated water and unreacted phenolic compounds to obtain the thermoplastic phenolic resin; and adding a boronic acid-containing compound into the thermoplastic phenolic resin, then heating to 100-120 DEG C, removing generated water to obtain the aryl-containing boron thermoplastic phenolic resin; or directly mixing the thermoplastic phenolic resin with the boric acid-containing compound in a solvent evenly and drying to obtain the aryl-containing boron thermoplastic phenolic resin. As the added boronic acid-containing compound contains aryl boric acid, the prepared aryl-containing boron thermoplastic phenolic resin has low water absorption rate and low curing temperature, not only has excellent thermal properties but also shows superior processing and mechanical properties.

Owner:XI AN JIAOTONG UNIV +1

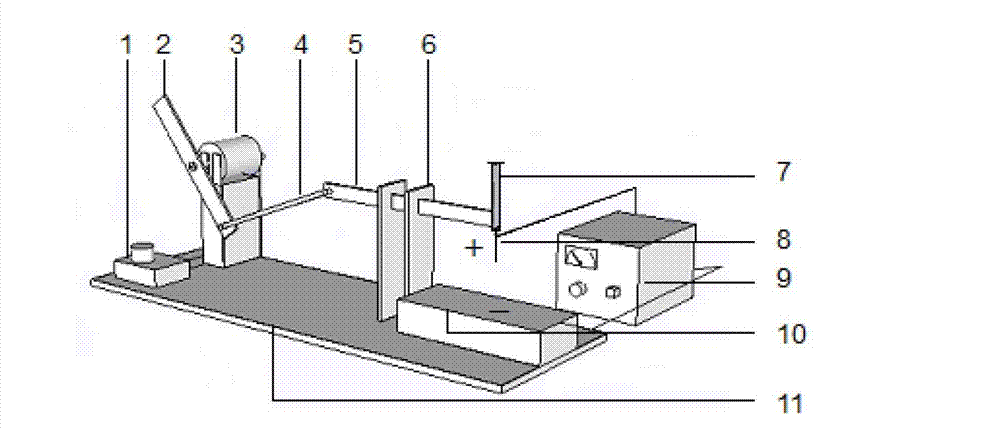

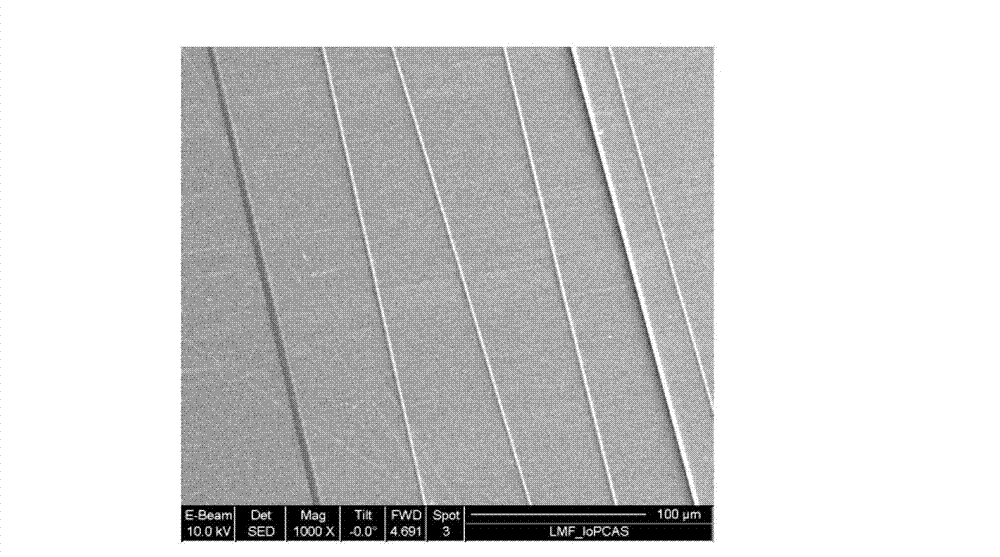

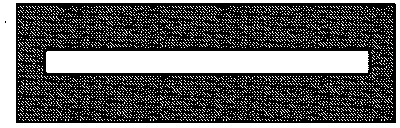

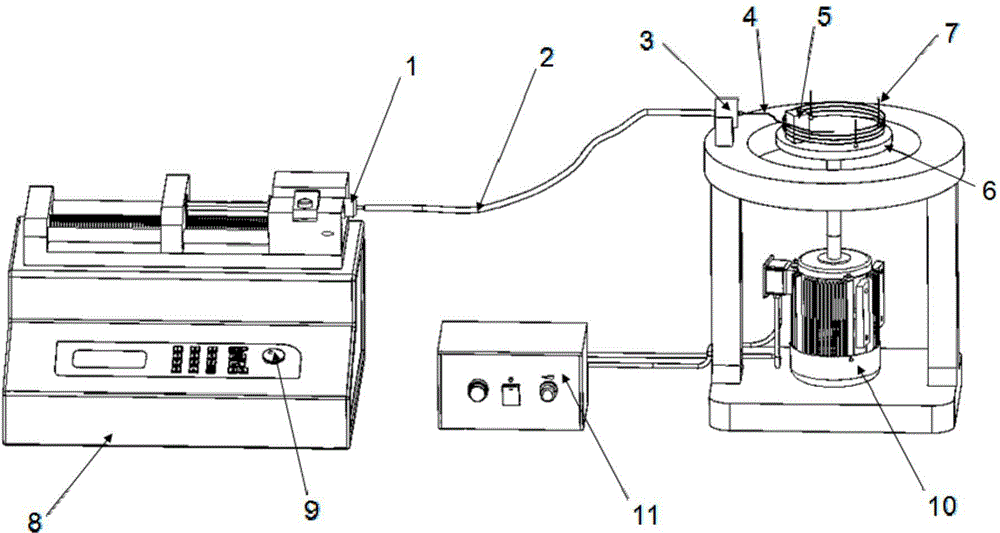

Electrostatic spinning device with spinning nozzle capable of doing linear reciprocating motion

InactiveCN102817089AVersatileConcentration and orderliness of textile distributionNew-spun product collectionFilament/thread formingElectrospinningInjector

The invention belongs to the technical field of preparation of micro-nano fibers and relates to an electrostatic spinning device with a spinning nozzle capable of doing a linear reciprocatingmotion; a stainless steel needle head is fixed on an injector needle tube and is connected with the anode of a high-voltage direct-current power supply; the cathode of the high-voltage direct-current power supply is connected with an aluminum foil collector; the aluminum foil collector is fixed on a base of the device; the injector needle tube is fixed on one end of a linear motion rod; the linear motion rod runs through two parallel brackets and is capable of doing harmonic linear motion on the brackets; and the other end of the linear motion rod is connected with an organic glass plate by a crankshaft connection rod. The electrostatic spinning device has the advantages of multiple functions, concentrated spinning distribution and good ordering, small spinning distance, high yield, low working voltage, and the like.

Owner:QINGDAO UNIV

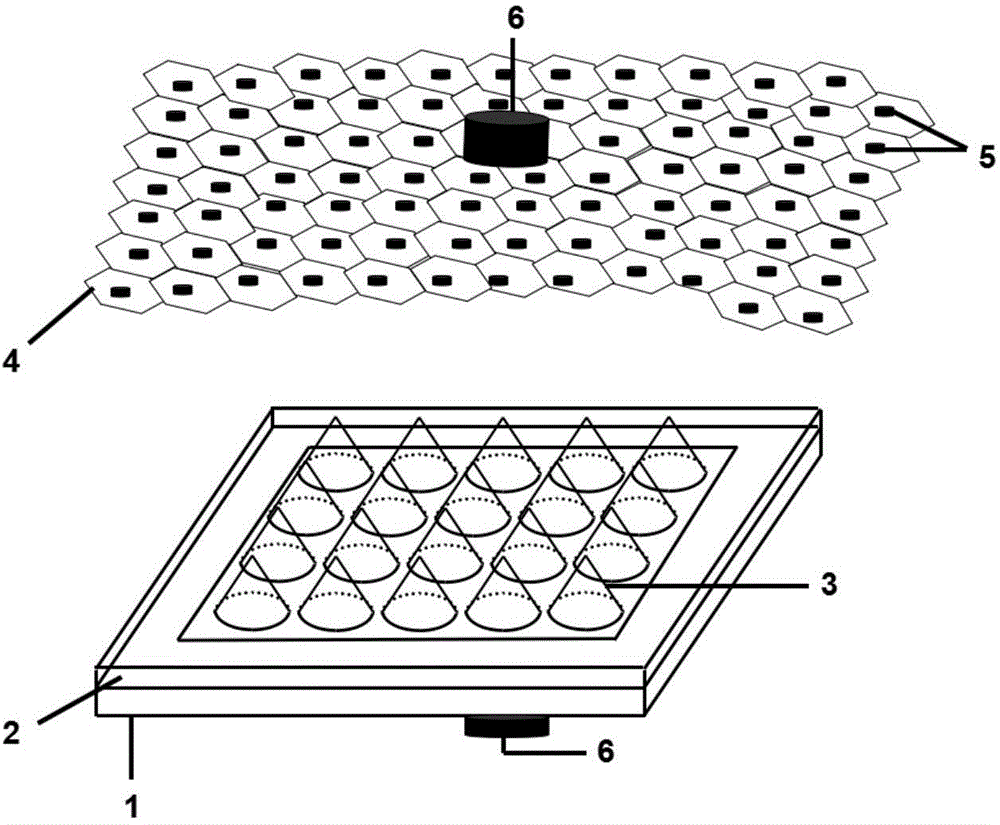

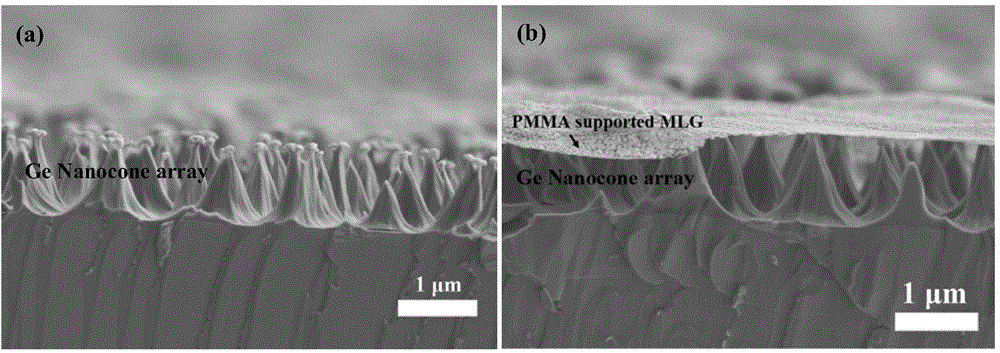

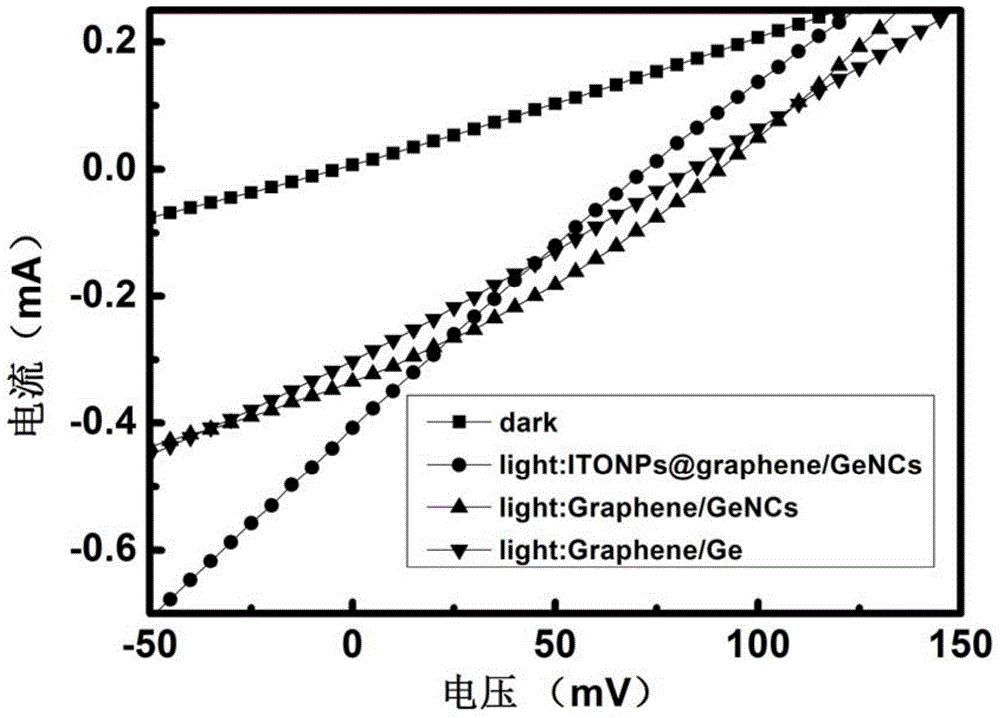

P-type graphene/N-type germanium nanocone array schottky junction infrared photoelectric detector and preparation method thereof

InactiveCN104638049AImprove performanceHigh conductancePhotovoltaic energy generationSemiconductor devicesPhotovoltaic detectorsEvaporation

The invention discloses a P-type graphene / N-type germanium nanocone array schottky junction infrared photoelectric detector and a preparation method thereof. The preparation method is characterized by comprising the following steps of forming an insulating layer on the front face of an N-type germanium basal layer in an evaporation manner by taking the N-type germanium basal layer as a base region of the photoelectric detector; arranging an N-type germanium nanocone array on the upper surface of the N-type germanium basal layer; transferring P-type graphene to the N-type germanium nanocone array covered with the insulating layer; coating the P-type graphene with indium tin oxide (ITO) nano-particles in a spin manner to realize a P-type graphene / N-type germanium nanocone array schottky junction-based photodiode. According to the infrared photoelectric detector disclosed by the invention, by utilizing the structure of the germanium nanocone array and the characteristic of the surface plasma resonance of the ITO nano-particles, the ability of absorbing light is enhanced, and the ability of responding to light is improved; the preparation method disclosed by the invention is simple, is suitable for mass production, and can be used for preparing the infrared photoelectric detector which has high light absorption ability and is high in photoelectric conversion efficiency, and a foundation is laid for applying the germanium nanocone array structure to the photoelectric detector.

Owner:HEFEI UNIV OF TECH

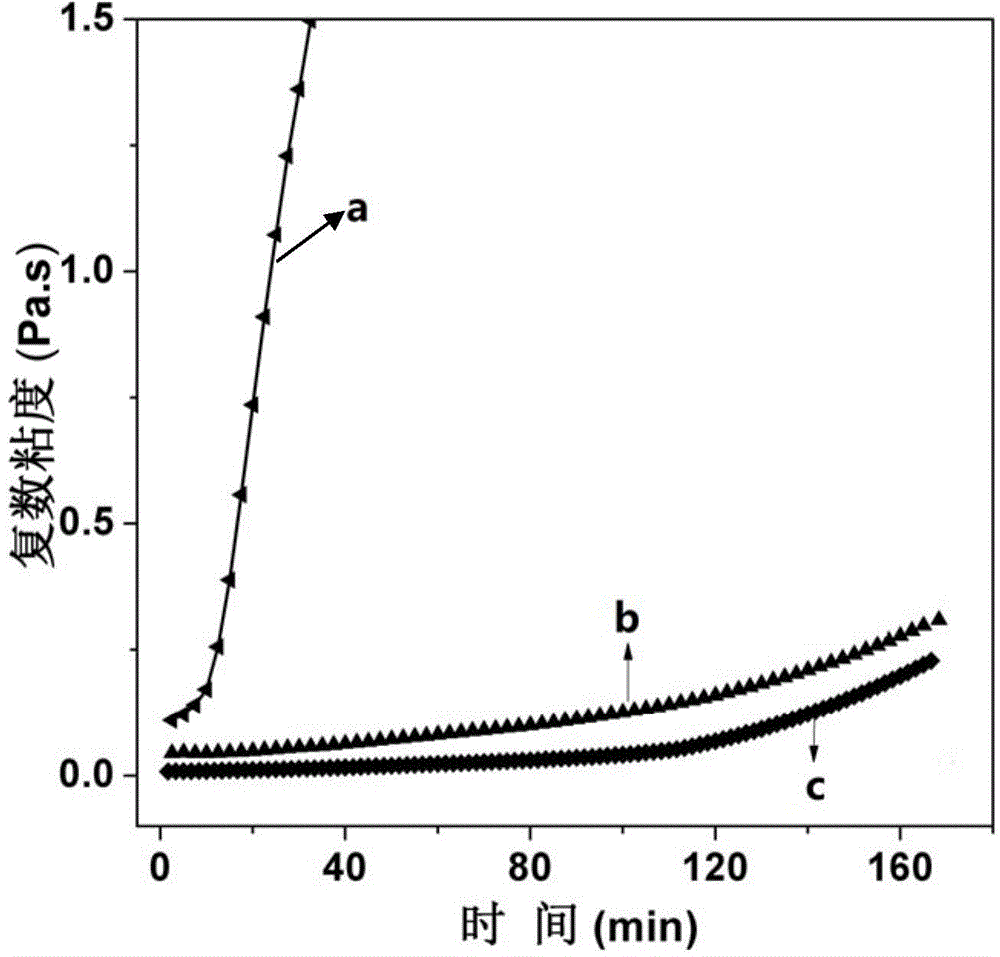

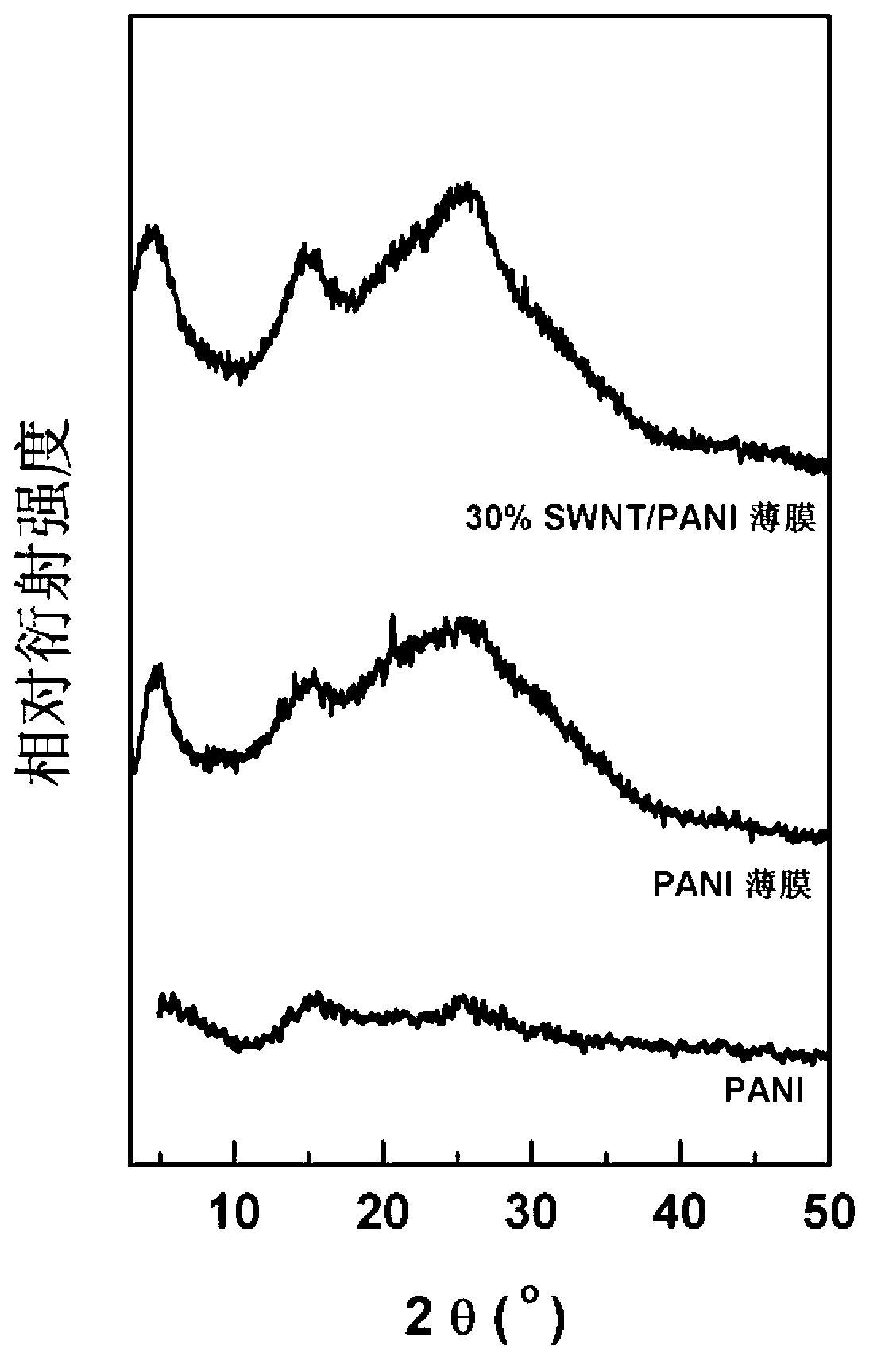

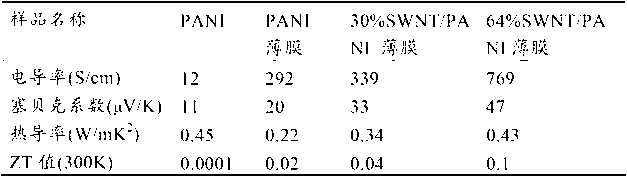

Method for obtaining high-performance polyaniline base thermoelectric materials

ActiveCN103137848AHigh degree of orderDefects to reduce π-π conjugation effectsThermoelectric device junction materialsThermoelectric materialsSolid reaction

The invention discloses a method for obtaining high-performance polyaniline base thermoelectric materials. The method comprises the following steps: (1) mixing polyaniline powder with ammonia water solution, carrying out stir, filter and drying, and obtaining eigen-state polyaniline, (2) mixing the polyaniline with sulfonic acid, carrying out grind, and obtaining polyaniline doped with the sulfonic acid, (3) dissolving the polyaniline doped with the sulfonic acid in phenol solvent, carrying out stirr, and obtaining polyaniline solution, and (4) adding nanocarbon materials in the polyaniline solution, carrying out stir in a full mode, removing the phenol solvent, and obtaining the high-performance polyaniline base thermoelectric materials. According to the method for obtaining the high-performance polyaniline base thermoelectric materials, the order degree of polyaniline molecular chain arrangement is firstly improved through interaction of the phenol solvent and polyaniline molecules, then through composition with the nano carbon composite materials, the order degree of the polyaniline molecular chain arrangement is further enhanced, and the high-performance polyaniline base thermoelectric materials are obtained. Therefore, ZT values of the polyaniline base thermoelectric materials and ZT values of block-shaped materials can be respectively improved by 0.5 and 0.05.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

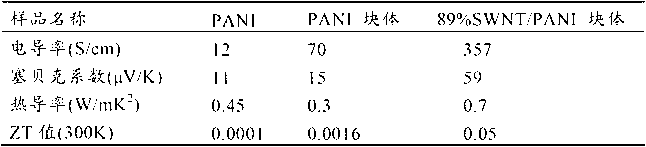

Block polymer processing for mesostructured inorganic oxide materials

InactiveUS20070256978A1High BET surface areaIncrease surface areaTantalum compoundsMolecular-sieve and base-exchange compoundsMesoporous materialCopolymer

Owner:RGT UNIV OF CALIFORNIA +1

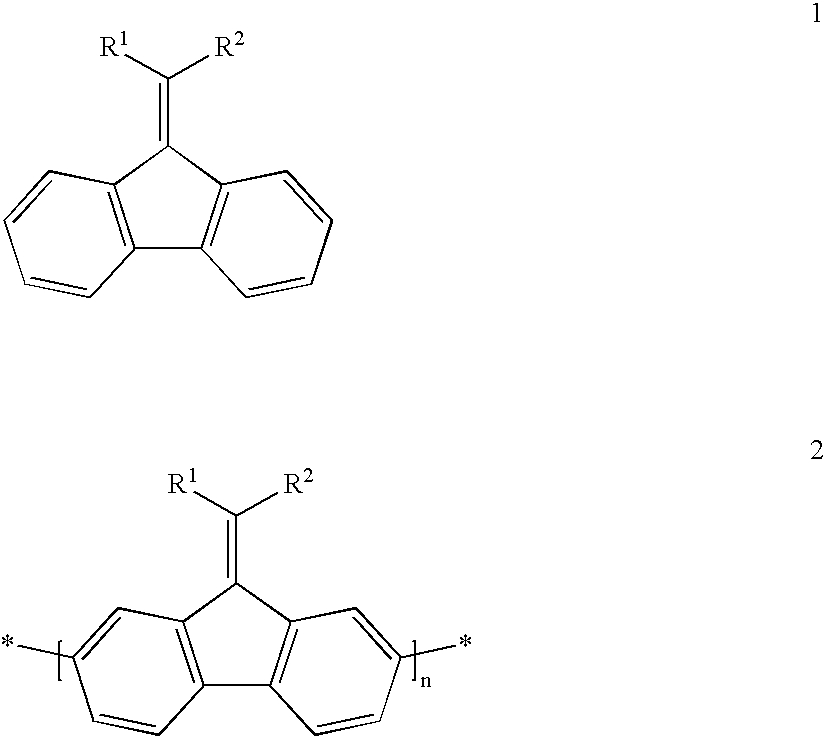

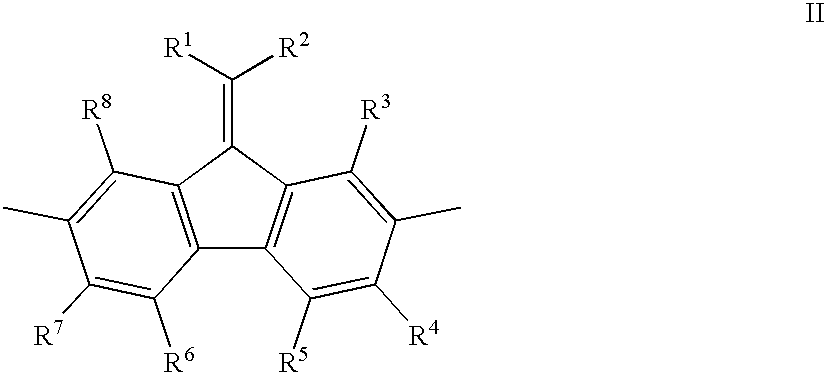

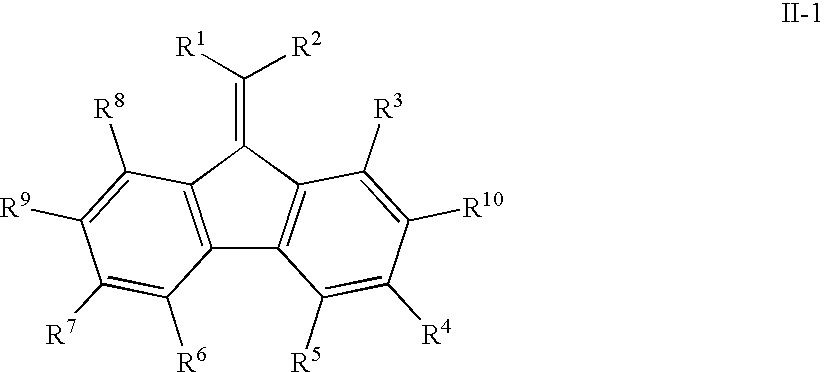

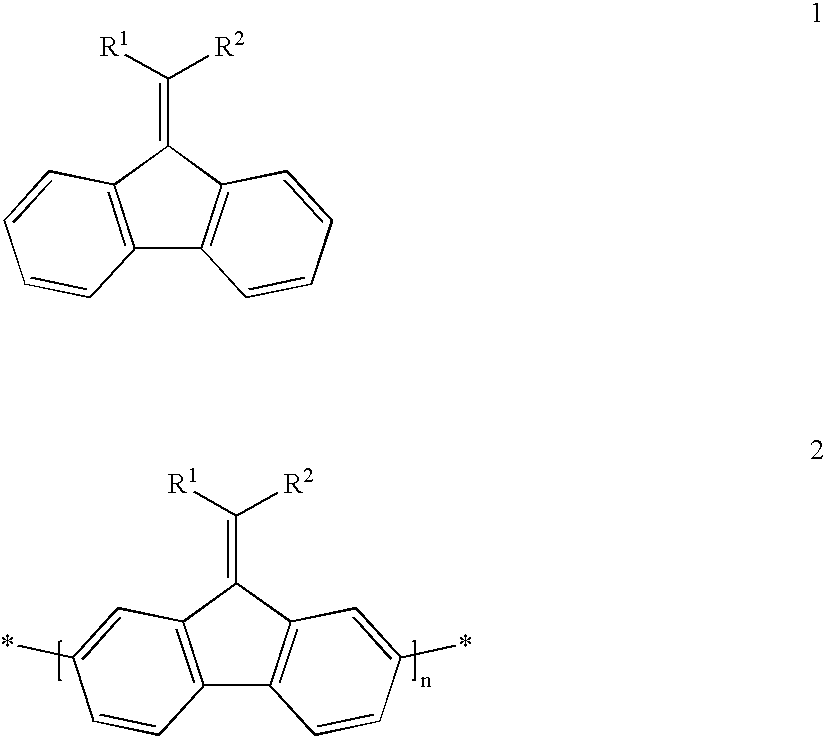

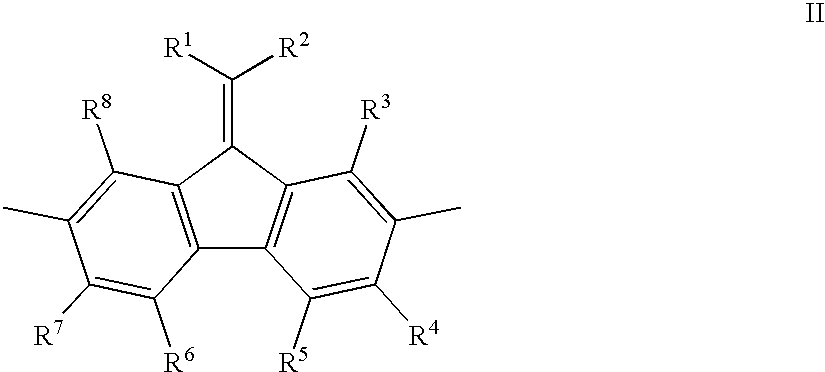

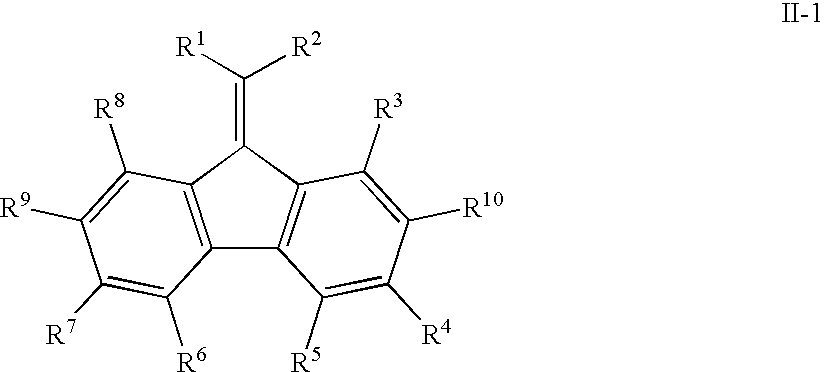

Mono-, oligo-and polyalkylidenefluorenes and their use as charge transport materials

InactiveUS6805922B2Improve resonance stabilityImprove solubilityLiquid crystal compositionsOrganic chemistryEngineeringField-effect transistor

Conjugated mono-, oligo- and polyalkylidenefluorenes are suitable for use as semiconductors or charge transport materials in optical, electrooptical or electronic devices including field effect transistors, electroluminescent, photovoltaic and sensor devices.

Owner:MERCK PATENT GMBH

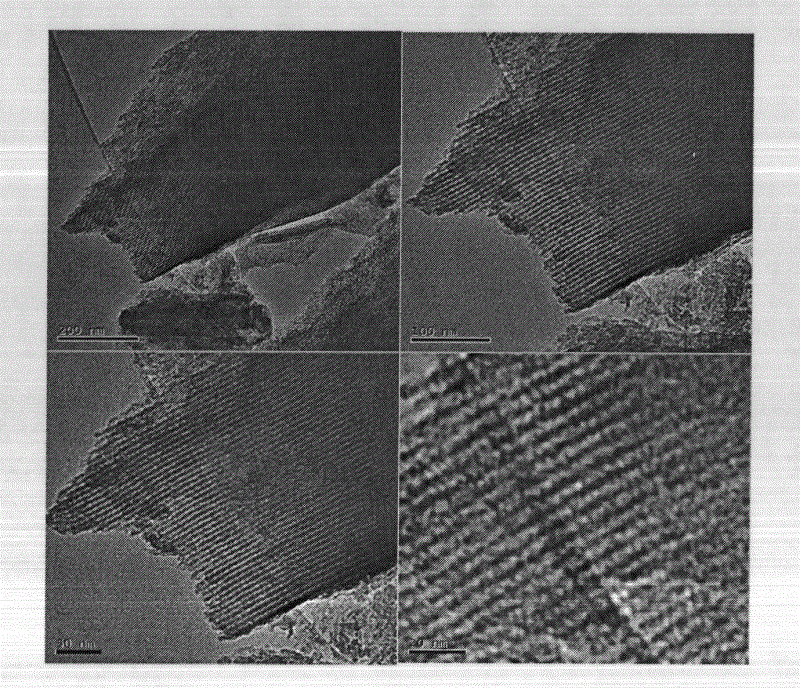

Preparation method of ordered graphene porous membrane

ActiveCN104229782AWide variety of sourcesConvenient sourceHybrid/EDL manufactureSupercritical dryingPtru catalyst

The invention discloses a preparation method of an ordered graphene porous membrane. The preparation method comprises the following steps: mixing 1 part by weight of graphene or graphene oxide with 10-1000 parts by weight of water to obtain a mixture; then, squeezing the mixture in a preparation device with a straight outlet, freezing the mixture in liquid nitrogen, performing freeze-drying or supercritical drying on the frozen mixture to obtain the ordered graphene porous membrane. The obtained graphene porous membrane has low density, high porosity, a controllable pore size, excellent mechanical performances and good toughness, and can be used for a plurality of different fields such as energy devices, water treatment, loading of various catalysts and electrochemical sensors.

Owner:ZHEJIANG TANGUSHANGXI MATERIAL SCI & TECH

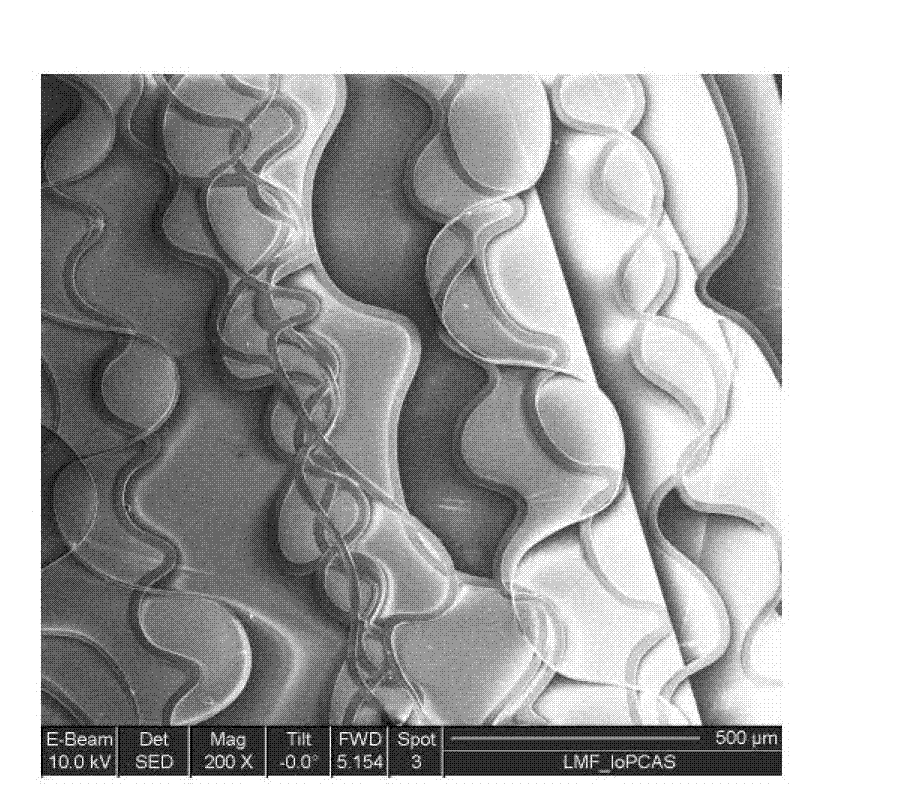

Method for preparing conducting polymer micro-nanofibers in magnetic spinning mode

ActiveCN104911719AArranged in an orderly mannerIncrease productionElectroconductive/antistatic filament manufactureFilament/thread formingMicro nanoFiber

The invention discloses a method for preparing conducting polymer micro-nanofibers in a magnetic spinning mode. The method comprises the steps that 1, a magnetic spinning device is built, wherein the magnetic spinning device comprises a rotary collection disc with a permanent magnet; 2, a spinning precursor solution is prepared, wherein magnetic nano particles, high-molecular polymer and conducting polymer are mixed and dissolved in an organic solvent solution; 3, the magnetic spinning device is utilized for preparing conducting polymer micro-nano complex fibers, wherein the spinning precursor solution is injected into a feeding device, the feeding device is started, liquid drops on an opening of a spinning nozzle forms a jet flow under the effect of magnetic field force to be connected with the permanent magnet to be a bridge, a brushless direct-current motor is started to drive the collection disc to rotate, the ferrofluid jet flow is continuously pulled out under the effect of magnetic field force, and conducting polymer micro-nanofibers are wound and formed among vertical supporting columns of the collection disc. The method does not need the high voltage effect, reduces the production cost and potential safety hazards, is suitable for large-scale production and has the good application prospect, and the fibers are distributed in order.

Owner:QINGDAO UNIV

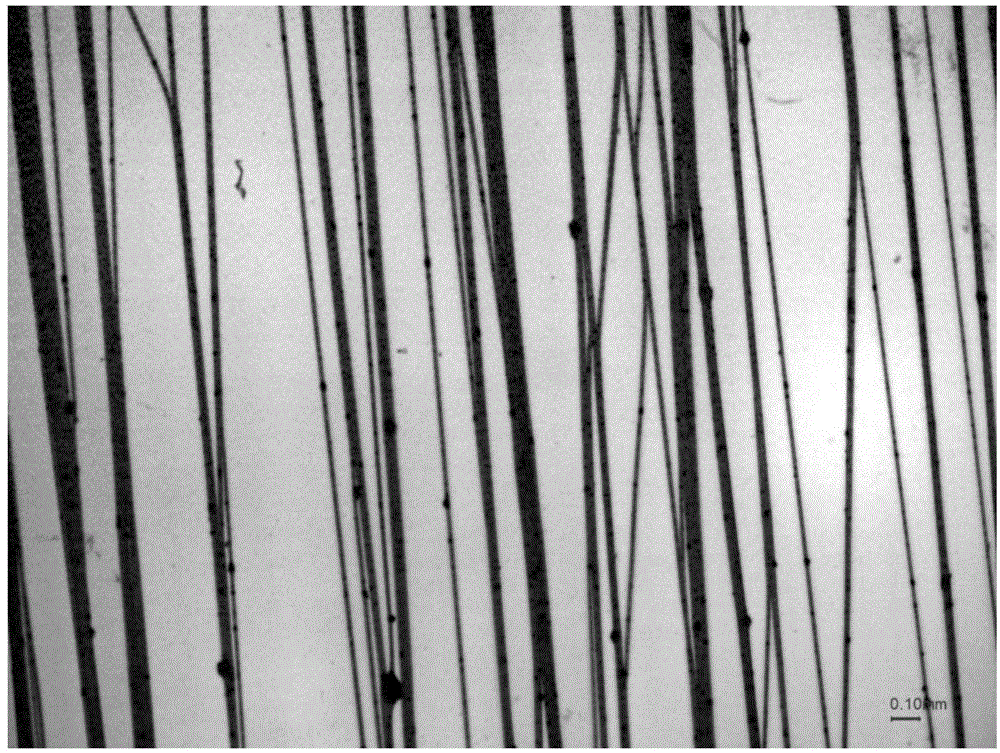

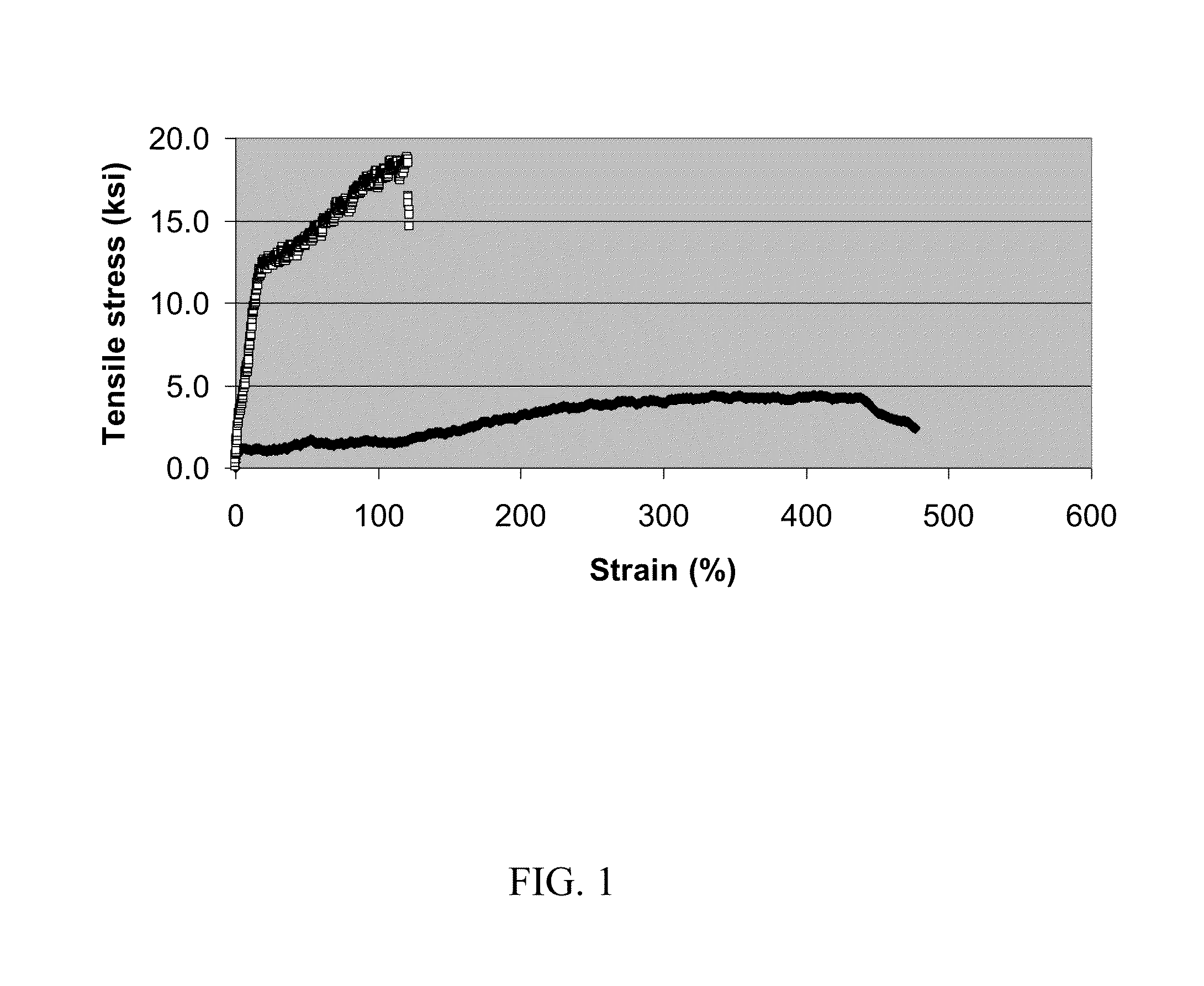

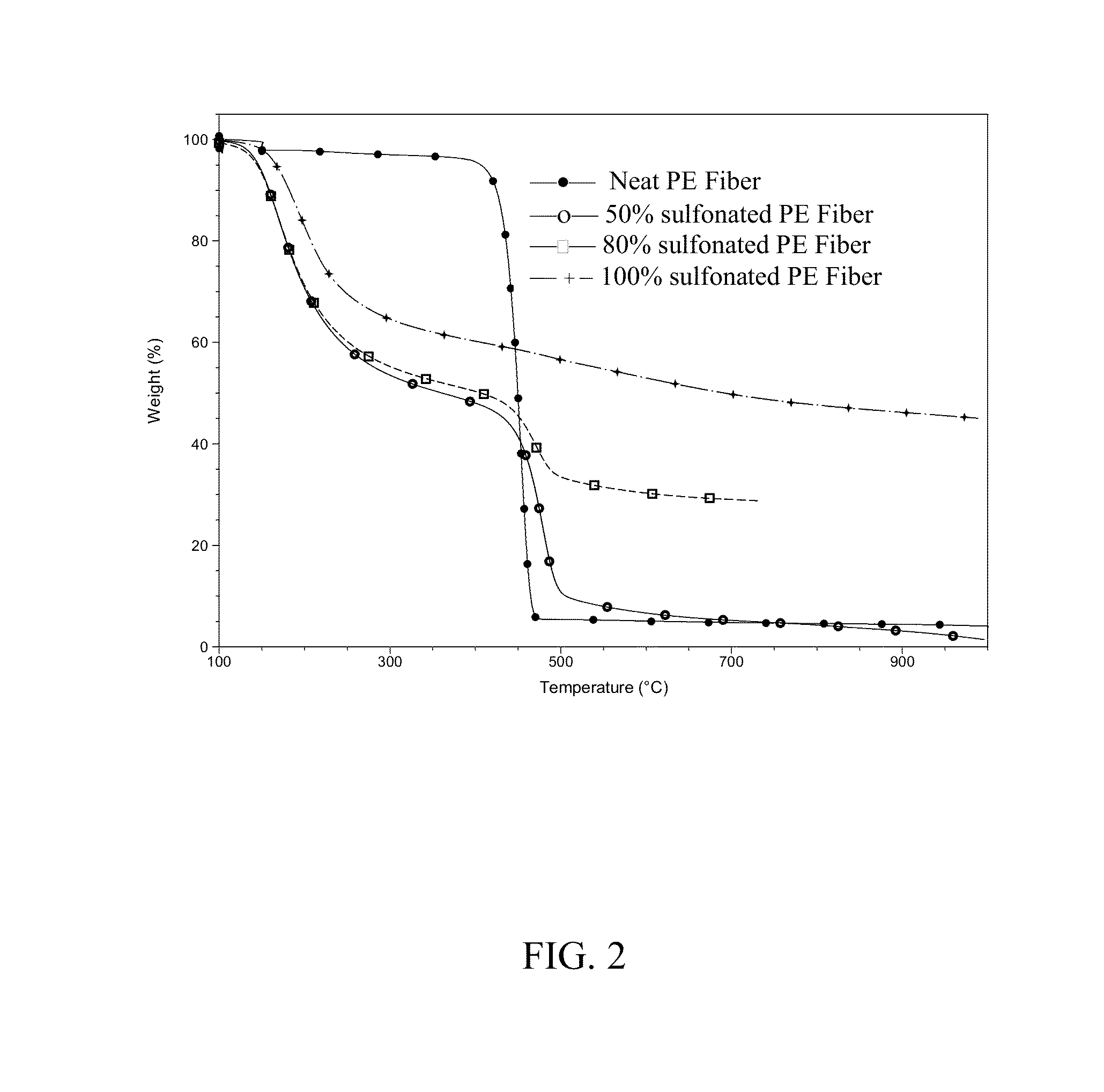

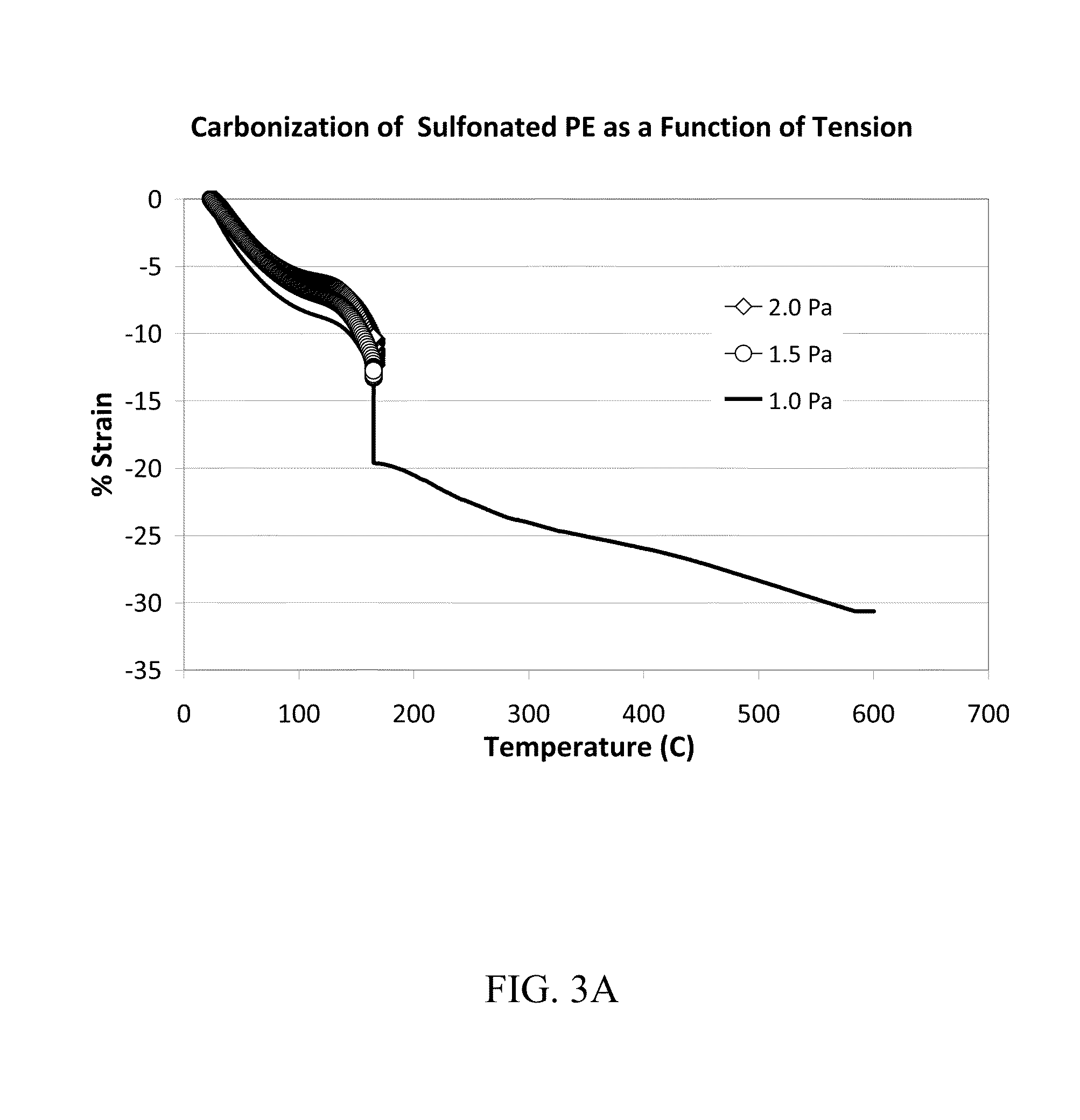

Controlled chemical stabilization of polyvinyl precursor fiber, and high strength carbon fiber produced therefrom

ActiveUS20140306364A1Improved strength and modulusHigh degree of orderFibre chemical featuresCarbonsing ragsFiberPolymer science

Method for the preparation of carbon fiber, which comprises: (i) immersing functionalized polyvinyl precursor fiber into a liquid solution having a boiling point of at least 60° C.; (ii) heating the liquid solution to a first temperature of at least 25° C. at which the functionalized precursor fiber engages in an elimination-addition equilibrium while a tension of at least 0.1 MPa is applied to the fiber; (iii) gradually raising the first temperature to a final temperature that is at least 20° C. above the first temperature and up to the boiling point of the liquid solution for sufficient time to convert the functionalized precursor fiber to a pre-carbonized fiber; and (iv) subjecting the pre-carbonized fiber produced according to step (iii) to high temperature carbonization conditions to produce the final carbon fiber. Articles and devices containing the fibers, including woven and non-woven mats or paper forms of the fibers, are also described.

Owner:UT BATTELLE LLC

Process for producing unitary graphene materials

A process for producing a unitary graphene material, comprising: (a) preparing a graphene oxide (GO) gel having GO molecules dissolved in a fluid medium wherein the GO molecules contain higher than 20% by weight of oxygen; (b) dispensing and depositing a layer of GO gel onto a surface of a substrate to form a layer of deposited GO gel thereon, wherein the dispensing and depositing procedure includes shear-induced thinning; (c) removing the fluid medium from the deposited GO gel to form a GO layer having an inter-plane spacing d002 of 0.4 nm to 1.2 nm as determined by X-ray diffraction; and (d) heat treating the GO layer to form the unitary graphene material at a heat treatment temperature higher than 100° C. to an extent that d002 is decreased to a value of 0.3354 nm to 0.4 nm and the oxygen content is decreased to less than 5% by weight.

Owner:GLOBAL GRAPHENE GRP INC

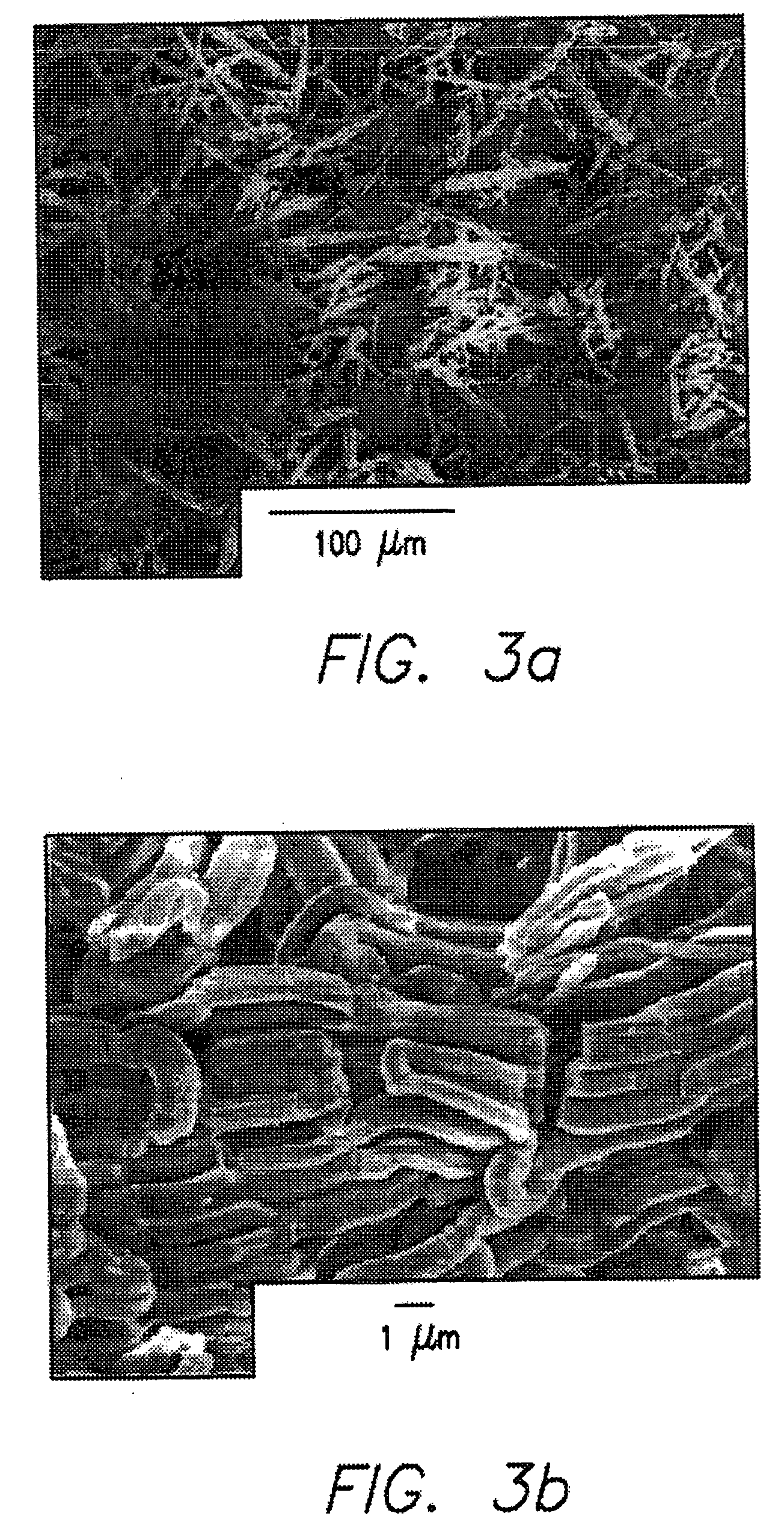

Preparation method of columnar monocrystal nano-TiO2 array film

InactiveCN101698937ALow raw material costExperimental temperature is lowPolycrystalline material growthFrom normal temperature solutionsPhotocatalytic degradationIon

The invention discloses a preparation method of columnar monocrystal nano-TiO2 array film. In the method, firstly, hydrochloric acid and alcohol substances (methyl alcohol, ethanol, butanol and glycol) are dipped into tetrabutyl titanate under the condition of stirring, and mixture is dripped into deionized water to form even solution; the solution is poured into a hydrothermal reaction kettle; the conductive surface of conductive glass cleaned by deionized water, alcohol and acetone solution faces downwards to lean against the inner wall of the reaction kettle; after the reaction kettle is put in a constant-temperature oven for hydro-thermal treatment for a period, conductive glass after reaction is washed with deionized water and naturally dried to obtain columnar monocrystal nano-TiO2. The invention has the advantages of low cost of raw materials, low experiment temperature, simple technology, convenient operation and the like. The prepared columnar monocrystal nano-TiO2 array film has adjustable density, thickness, orientation and degree of crystallinity and is suitable for industrial production. The invention can be used for solar cell film material and photocatalytic degradation organic matter material.

Owner:HUBEI UNIV

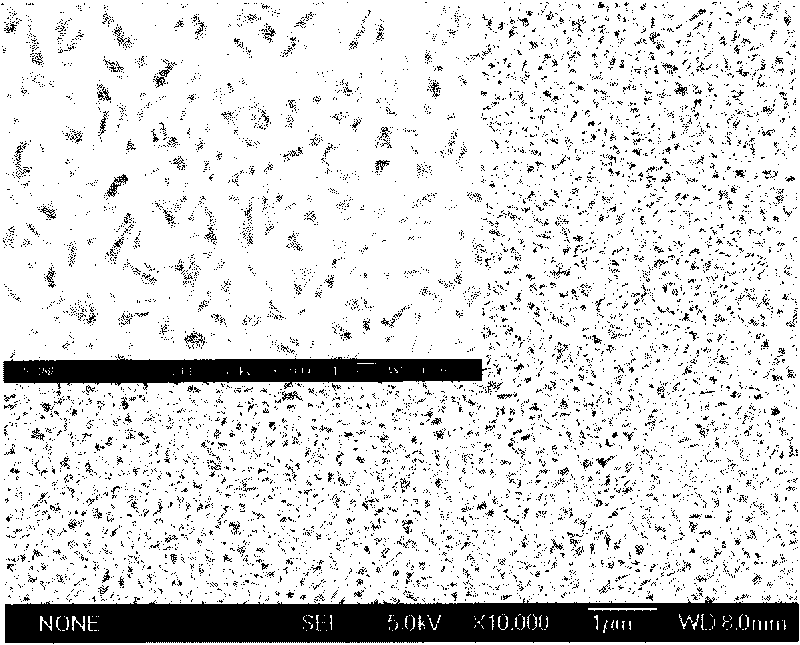

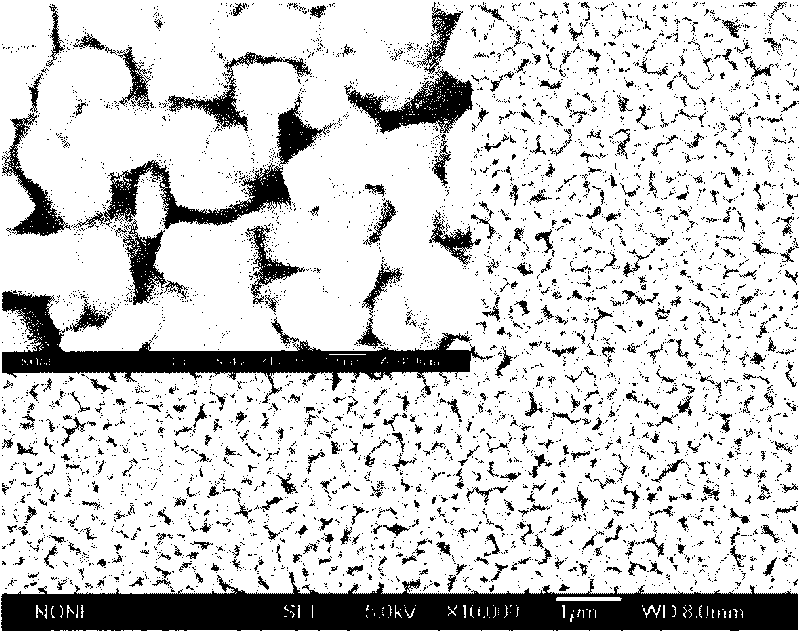

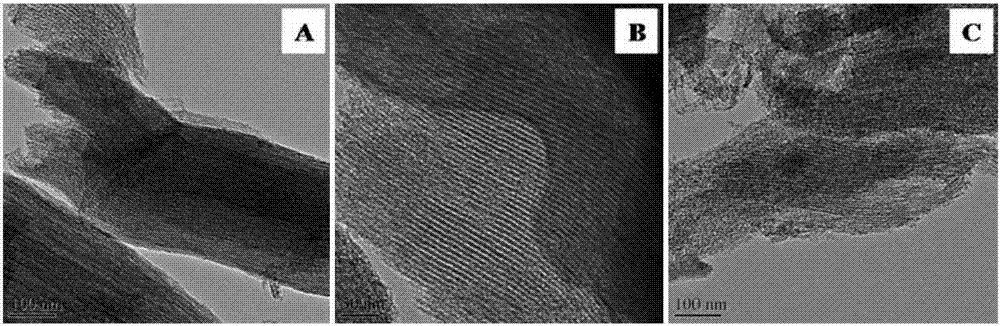

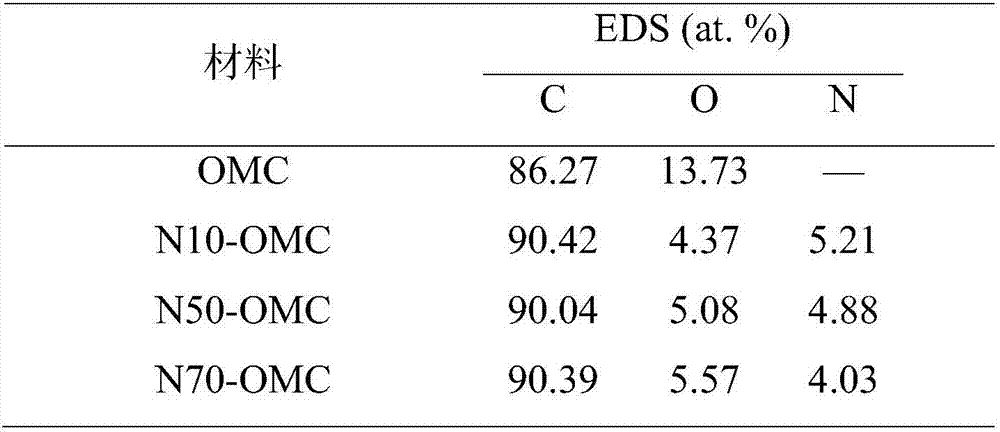

Nitrogen-doped ordered mesoporous carbon material and preparation method thereof

The invention belongs to the field of mesoporous materials and discloses a nitrogen-doped ordered mesoporous carbon material and a preparation method thereof. The preparation method comprises the following steps: after uniformly mixing concentrated sulfuric acid, saccharose and deionized water, adding a silicon-based mesoporous material SBA-15 to obtain a milk white suspended liquid A; drying A at 90-100 DEG C, and then raising the temperature to 150-170 DEG C to be carbonized to obtain a solid B; grinding the solid B into powder and then adding concentrated sulfuric acid, saccharose and deionized water to be uniformly mixed, repeating the drying and carbonizing processes, and then roasting the mixture at 900-1000 DEG C to obtain a solid C; and removing a SBA-15 template from the solid C to obtain ordered mesoporous carbon, and then uniformly grinding and mixing the carbon with a nitrogen source, and roasting the mixture for 3-6 hours at 900-1000 DEG C to obtain a product. The method provided by the invention not only can avoid roasting in a vacuum condition, but also can effectively simplify the operating process and greatly lower the preparation cost of the material.

Owner:SOUTH CHINA UNIV OF TECH

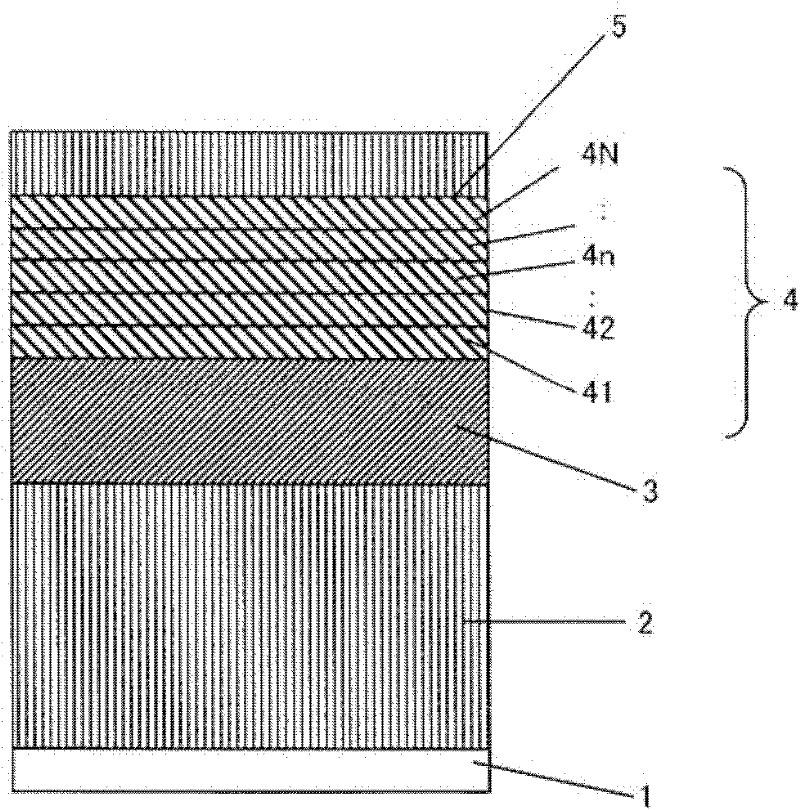

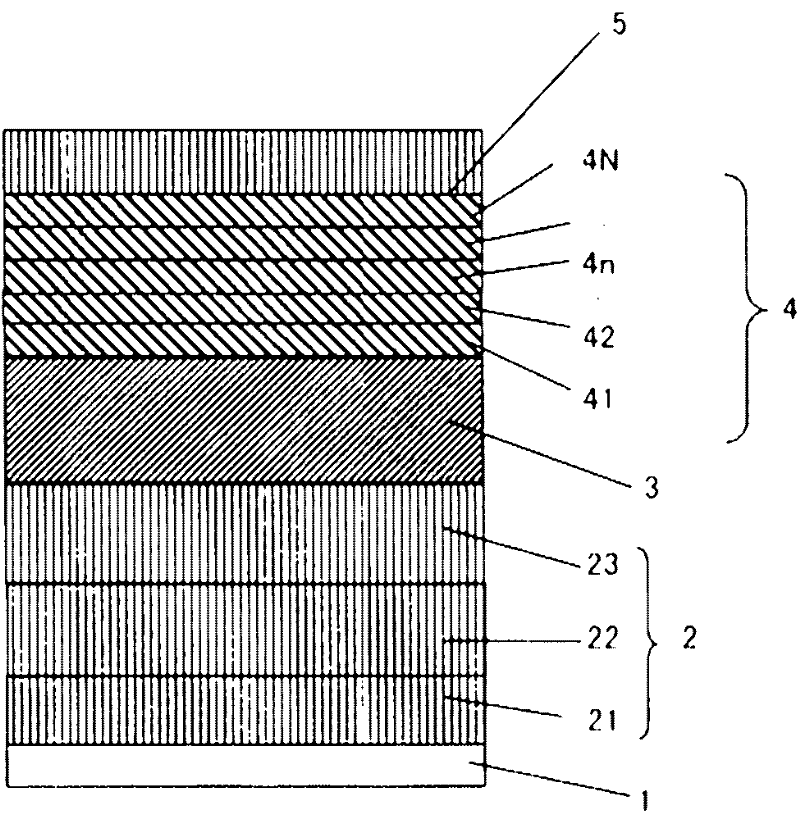

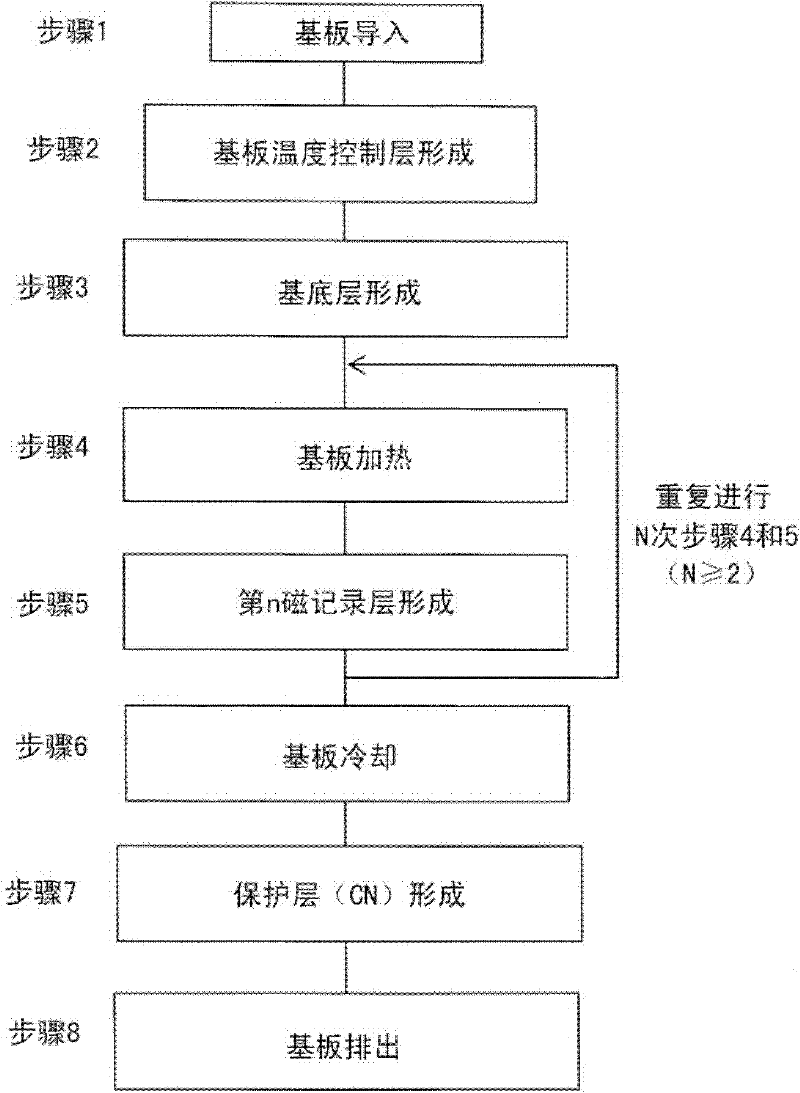

Perpendicular magnetic recording medium and manufacturing method of the same

InactiveCN102385871AHigh degree of orderSmall crystal particle sizeRecord information storageRecord carriers manufactureAlloyNon magnetic

A perpendicular magnetic recording medium having sufficient perpendicular uniaxial magnetic anisotropy energy and a crystal grain size for realizing an areal recording density of one terabit or more per one square centimeter, and excellent in mass productivity, and a manufacturing method of the same are provided. On a substrate, a substrate-temperature control layer, an underlayer and a magnetic recording layer are sequentially formed. The magnetic recording layer is formed by repeating a magnetic layer stacking step N times (N>=2), which includes a first step of heating the substrate in a heat process chamber, and a second step of depositing, in a deposition process chamber, the magnetic recording layer constituted of an alloy mainly composed of FePt to which at least one kind of non-magnetic material selected from a group constituted of C and an Si oxide is added.

Owner:HITACHI LTD

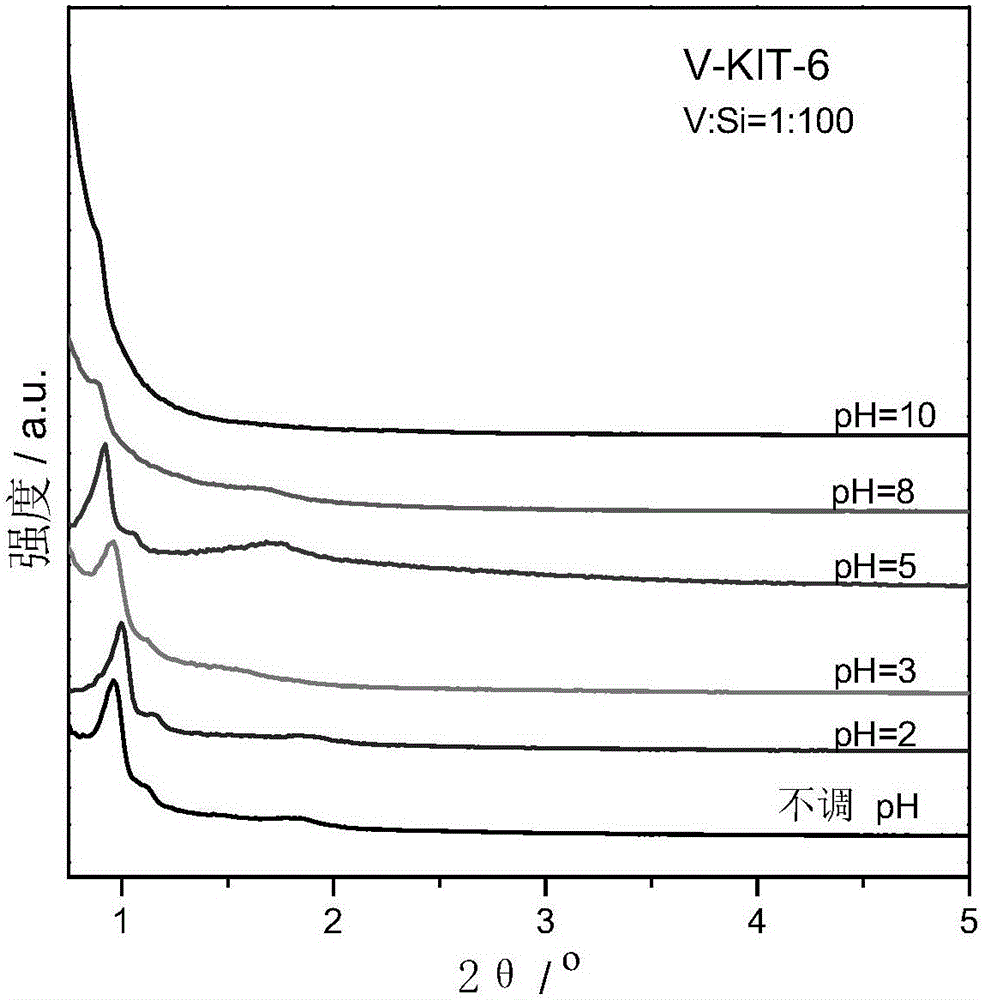

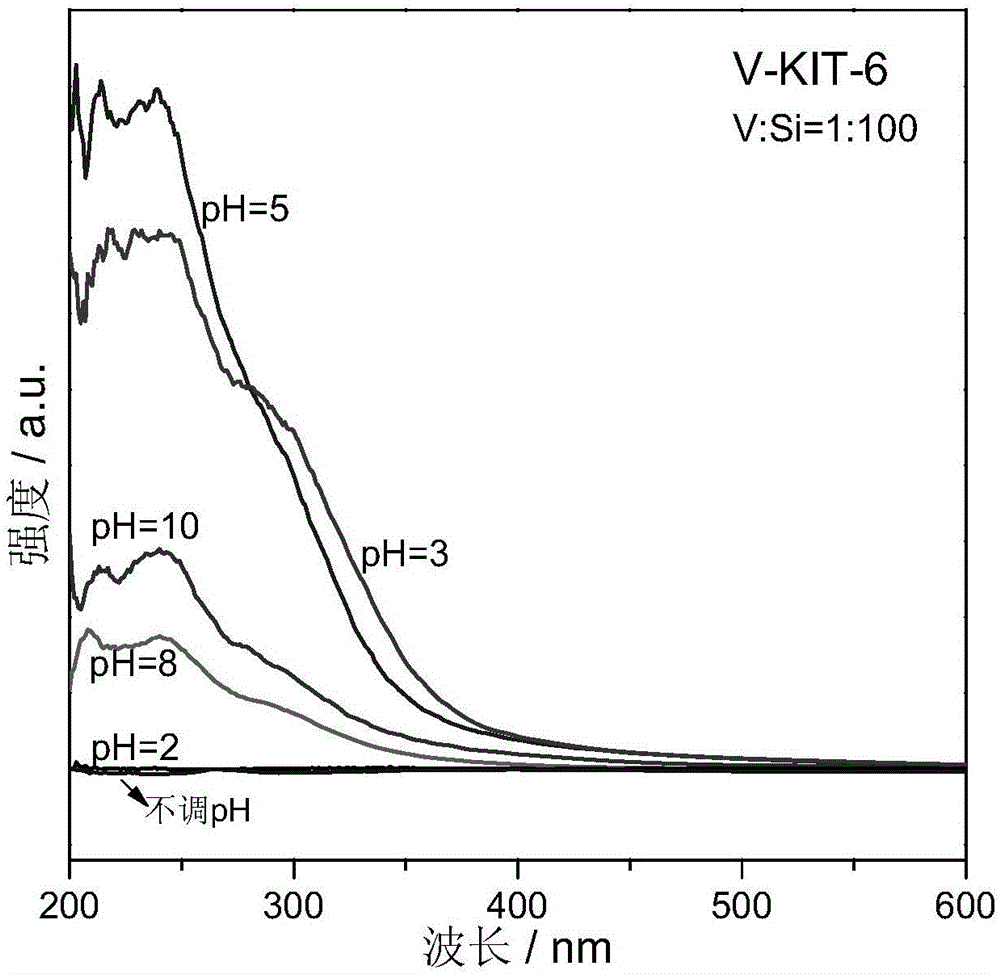

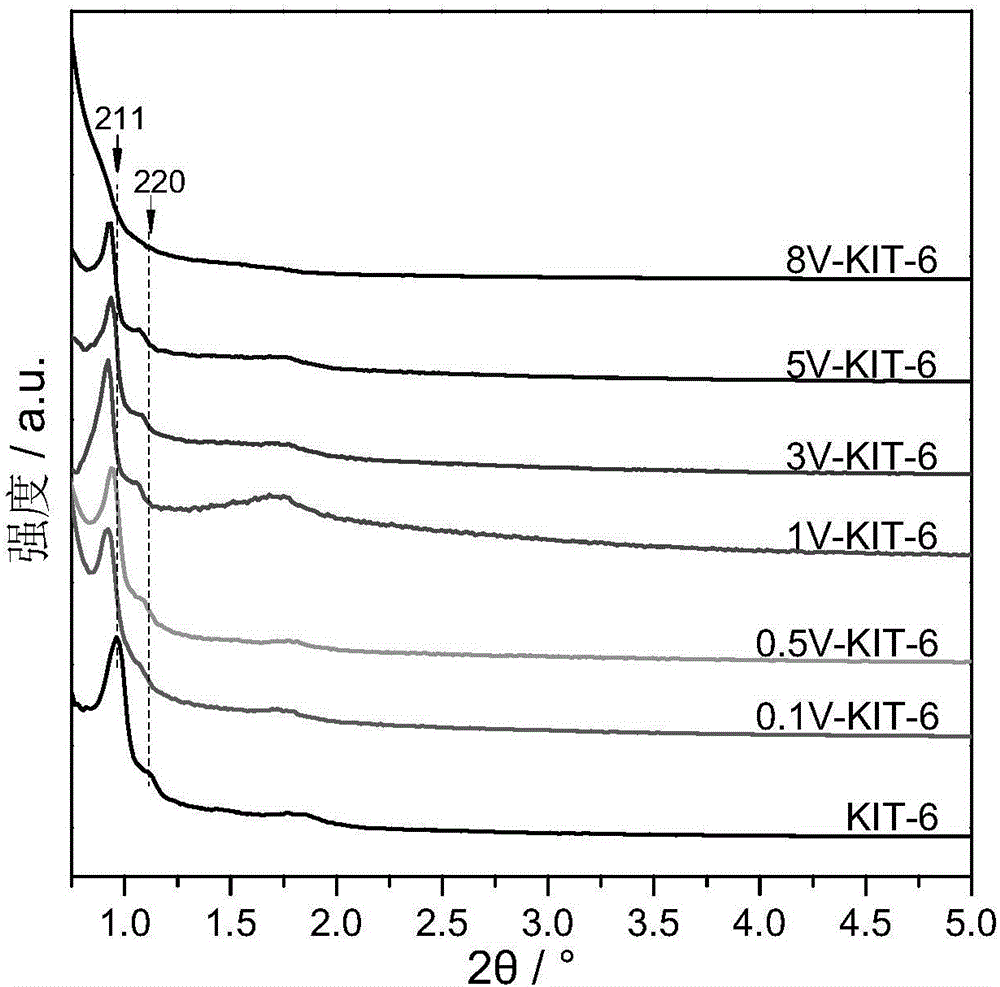

Vanadium-doped silicon oxide-based mesoporous molecular sieve catalyst, as well as preparation method and application thereof

ActiveCN105728013APore structure maintenanceNo change in ratioMolecular sieve catalystsHydrocarbonsDispersityMolecular sieve

The invention provides a vanadium-doped silicon oxide-based mesoporous molecular sieve catalyst, as well as a preparation method and application thereof. According to the catalyst, a pure silicon mesoporous molecular sieve KIT-6 is taken as a carrier, vanadium oxide is taken as an active ingredient, and is doped into a framework of the pure silicon mesoporous molecular sieve KIT-6, and the molar ratio of V to Si is 0.1:100 to 8:100. The invention further provides the preparation method for the catalyst and the application of the catalyst to selective oxidative dehydrogenation of propane for production of olefin. According to the vanadium-doped silicon oxide-based mesoporous molecular sieve catalyst, the dispersity of the active ingredient vanadium is higher, the concentration of an active site is higher, and the stability of the active site is higher, so that the catalytic activity of the catalyst is higher. When the catalyst is applied to reaction of selective oxidative dehydrogenation of the propane for production of the olefin, the molar recovery rates of products propene and olefin of selective oxidation reaction of the propane can reach 35.6 percent and 38.6 percent respectively.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Mono-, oligo-and polyalkylidenefluorenes and their use as charge transport materials

InactiveUS20030067267A1Improve resonance stabilityImprove solubilityLiquid crystal compositionsOrganic chemistryEngineeringField-effect transistor

Conjugated mono-, oligo- and polyalkylidenefluorenes are suitable for use as semiconductors or charge transport materials in optical, electrooptical or electronic devices including field effect transistors, electroluminescent, photovoltaic and sensor devices.

Owner:MERCK PATENT GMBH

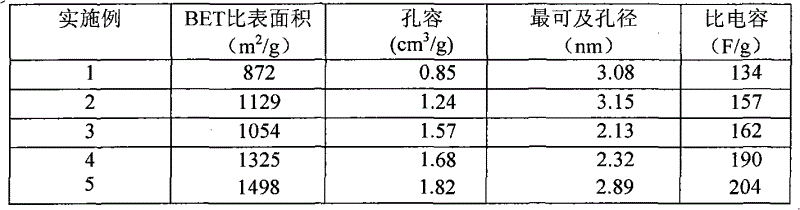

Preparation method for heteratom-containing ordered mesoporous carbon with high specific capacitance

InactiveCN102616766AThe preparation method has a short cycle timeEasy to operateElectrolytic capacitorsCarbon preparation/purificationSolventCapacitance

The invention relates to a preparation method for heteratom-containing ordered mesoporous carbon with high specific capacitance. The method comprises: melting phenol; adding a catalyst; uniformly stirring, and adding an aqueous solution of formaldehyde; carrying out a reaction for 10-60 minutes at a temperature of 65-90 DEG C; adding a heteroatom compound; continuously carrying out the reaction for 10-60 minutes, and stopping the stirring; adjusting the pH value of the solution to more than or equal to 7.0; carrying out decompression dehydration to obtain a resin; dissolving the resulting resin in an organic solvent to obtain a uniformly heteratom-containing phenol formaldehyde resin solution; dissolving a block copolymer in a solvent to form a uniform solution; adding an oligomer of silicon to the resulting uniform solution, and stirring for 0.5-4 hours; then adding the resulting solution to the heteratom-containing phenol formaldehyde resin solution; uniformly stirring, and volatilizing the solvent for 6-18 hours; curing for 6-48 hours; carrying out carbonization for 0.1-3 hours at a temperature of 600-1200 DEG C under inert atmosphere; adopting hydrofluoric acid or a concentrated alkali solution to treat the carbonized sample, removing the silicon, washing and drying to obtain the heteratom-containing ordered mesoporous carbon. The method of the present invention has advantages of simple process and low cost, and the produced carbon has high specific capacitance.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

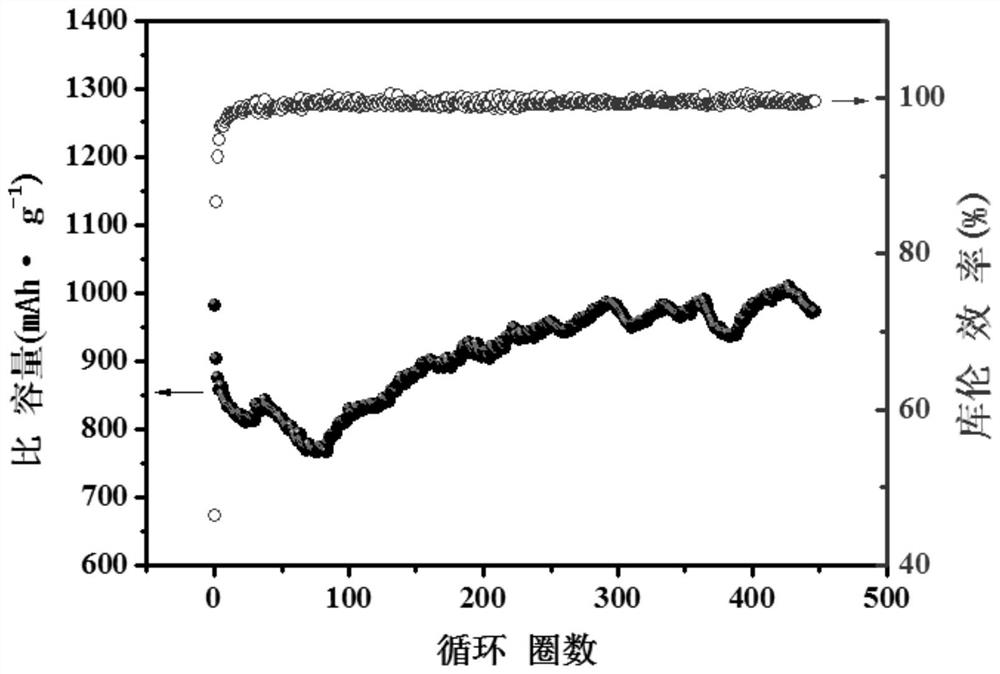

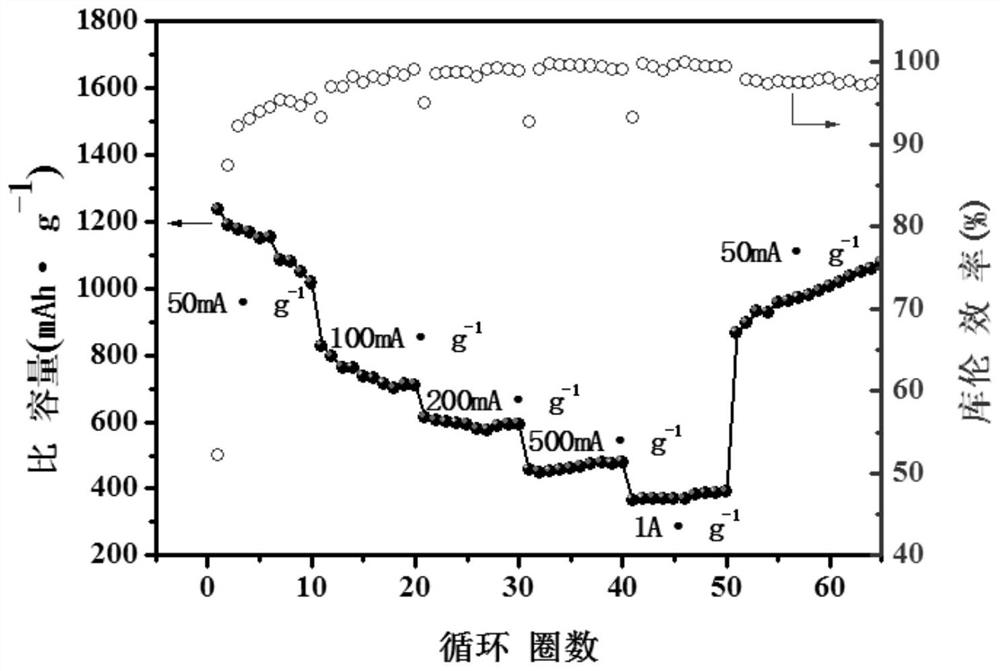

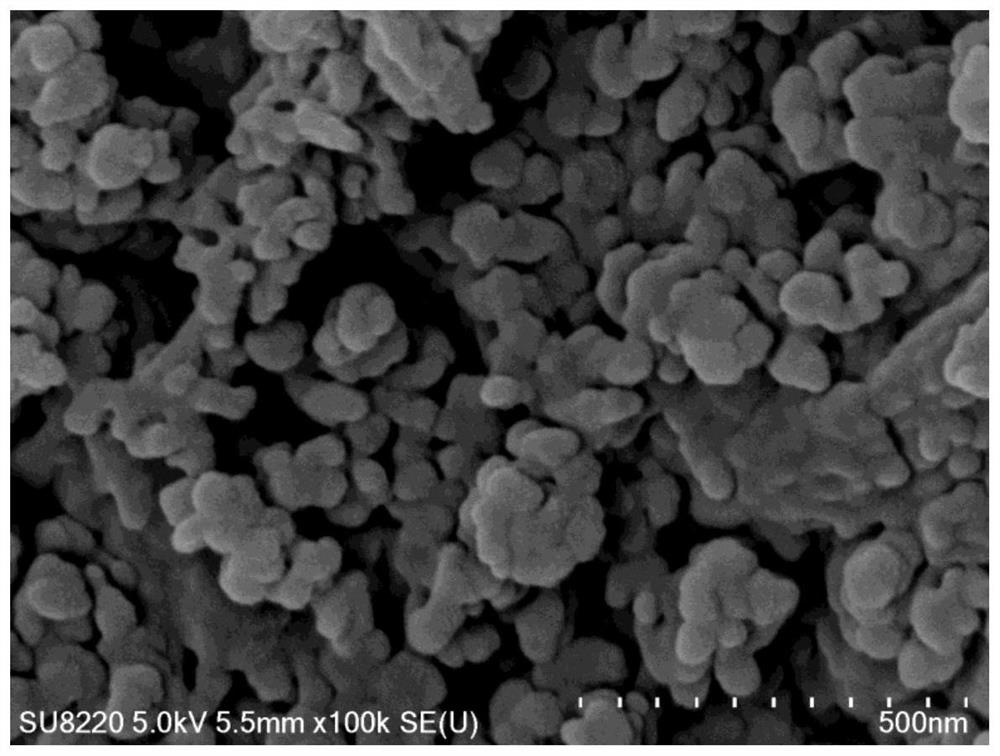

Nanometer lignin carbon-zinc oxidecomposite material as well as preparation method and application thereof

ActiveCN112072085AInhibition of volume expansionImprove conductivityMaterial nanotechnologyHybrid capacitor electrodesCarbon layerLithium-ion battery

The invention discloses a nanometer lignin carbon-zinc oxidecomposite material as well as a preparation method and application thereof. The method comprises the following steps: (1) dissolving ligninin an alkaline solution, carrying out hydrothermal pretreatment, conducting cooling, and adjusting a pH value to 3-5 to obtain an acid-soluble lignin solution; (2) adding a mixed solution of soluble zinc salt and soluble carbonate into the acid-soluble lignin solution, conducting a hydrothermal reaction, then adding aldehydes, and continuing the hydrothermal reaction to obtain a ploycondensed lignin / zinc oxide compound; and (3) carbonizing the polycondensed lignin / zinc oxide compound to obtain the nanometer lignin carbon-zinc oxidecomposite material. In the obtained nanometer lignin carbon-zinc oxidecomposite material, lignin carbon uniformly coats the surfaces of zinc oxide particles to form a uniform carbon layer with a continuous structure, so the problems of serious volume expansion and poor conductivity of zinc oxide serving as a lithium ion negative electrode material are solved, and the specific capacity, the initial coulombic efficiency and the rate capability of a lithium ionbattery are improved.

Owner:SOUTH CHINA UNIV OF TECH +1

Block polymer processing for mesostructured inorganic oxide materials

InactiveUS20060118493A9High BET surface areaIncrease surface areaMolecular sieve catalystsOther chemical processesMesoporous materialCopolymer

Owner:BOTTOMS WILMER

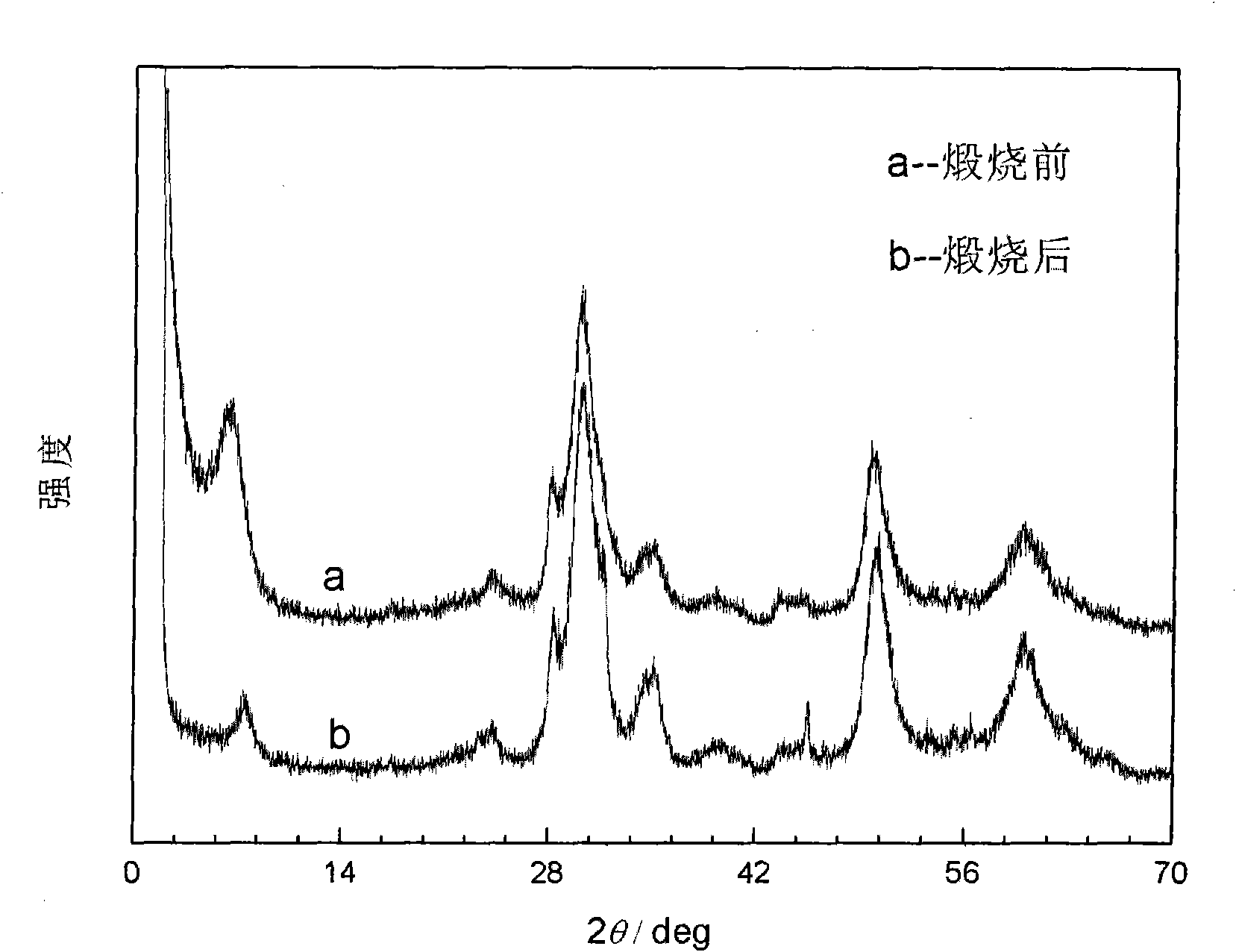

Method for preparing zirconium oxide polycrystalline powder with ordered laminar nanostructure/mesoporous structure by using surfactant as template

InactiveCN101913649AHigh degree of orderImprove thermal stabilityZirconium oxidesActive agentZirconium oxychloride

The invention discloses a method for preparing zirconium oxide polycrystalline powder with ordered laminar nanostructure / mesoporous structure by using a surfactant as a template. The method comprises the following steps of: (1) weighing 20 parts of mixed solution of zirconium oxychloride, water and alcohol; (2) weighing 20 parts of mixed solution of sodium dodecyl sulfate, water and alcohol; (3) weighing 10 parts of mixed solution of sodium hydroxide, water and alcohol; (4) adding the mixed solution prepared in the step (2) and the mixed solution prepared in the step (3) into a flask in the step (1) to reflux and react for 1 to 4 hours with stirring; (5) heating and performing hydrothermal reaction on the mixture for 12 to 36 hours under autogenous pressure; (6) standing the stock solution at the room temperature, washing the product, filtering or performing centrifugal separation on the product and drying the product; and (7) raising the temperature to 500 DEG C and calcining the product for 2 hours to obtain the zirconium oxide polycrystalline powder with ordered laminar nanostructure / mesoporous structure. By using a new method of combined reflux method and hydrothermal method and the surfactant as the template, the degree of order of the product is improved and high thermal stability of the product is ensured.

Owner:HEBEI UNIV OF TECH

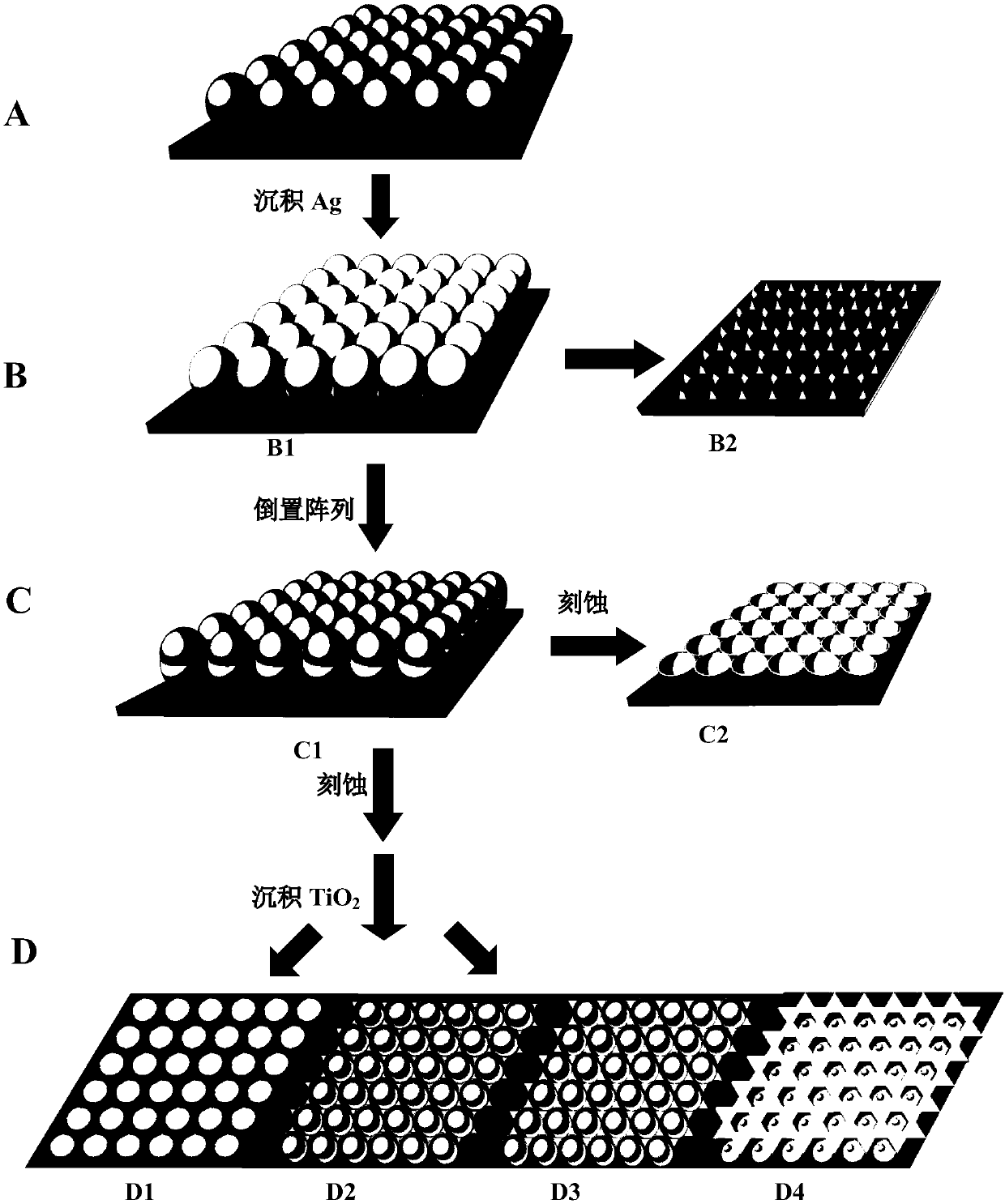

Method for controllably preparing composite nano pattern array

ActiveCN109592635AImprove uniformityHigh degree of orderDecorative surface effectsCoupling light guidesSputteringMaterial synthesis

The invention belongs to the technical field of nano composite material synthesis, and particularly relates to a method for controllably preparing a composite nano pattern array. The method comprisesthe steps: sputtering an Ag film on the surface of an ordered nano patterned structure template to form an Ag nano cap array and an Ag nano triangular array; inversely transferring the Ag nano cap array to another Si substrate to obtain a secondary template; completely etching PS spheres to obtain an Ag nano-bowl array; etching the PS spheres for different time periods, and sputtering and depositing a TiO2 film on the surface of each PS sphere to obtain an Ag-TiO2-FON array, an Ag-TiO2 nanocap-Star array and an Ag-TiO2 nanoring-particle array. According to the invention, the defects of tediousconstruction steps, low orderliness and density, long preparation period, high cost, rigorous test condition requirements and the like of the ordered nanostructure active substrate in the prior art are overcome, so that the method has the advantages of good uniformity, high orderliness, high repeatability, simple construction steps, short preparation period and low cost.

Owner:CHONGQING BIO NEWVISION MEDICAL EQUIP LTD

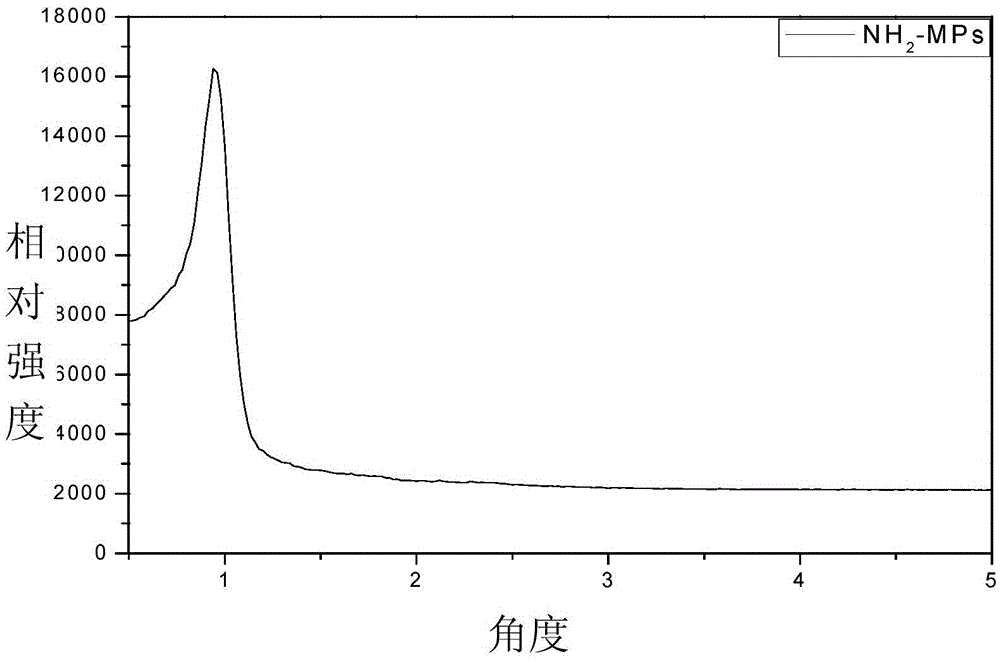

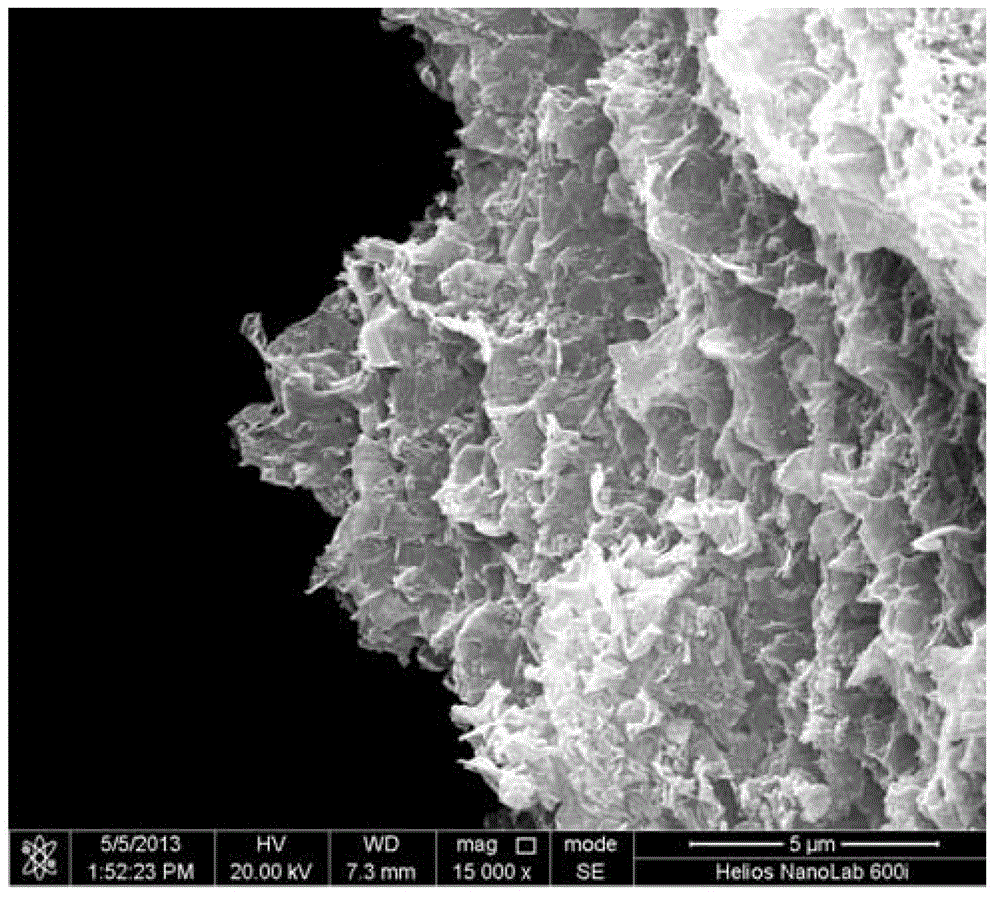

Amino-functionalization ordered mesopore phenolic resin material and preparing method thereof

The invention discloses an amino-functionalization ordered mesopore phenolic resin material and a preparing method thereof. The amino-functionalization ordered mesopore phenolic resin material comprises ordered mesopore phenolic resin and amino at least distributed on a pore path inner wall of the ordered mesopore phenolic resin, and the port path is regular and ordered and has an aperture of 3-5nm. The preparing process is simple, short in synthetic period, good in controllability, low in cost and suitable for large scale implementation, and accords with the requirements of green chemistry. The amino-functionalization ordered mesopore phenolic resin material has a two dimensional hexagonal ordered mesopore structure, is high in degree of order, large in specific area, rich in active amino sites, and has wide application prospect in fields of organic alkali catalytic reaction, CO2 adsorption and heavy metal ion adsorption, and the like.

Owner:SHANGHAI NORMAL UNIVERSITY

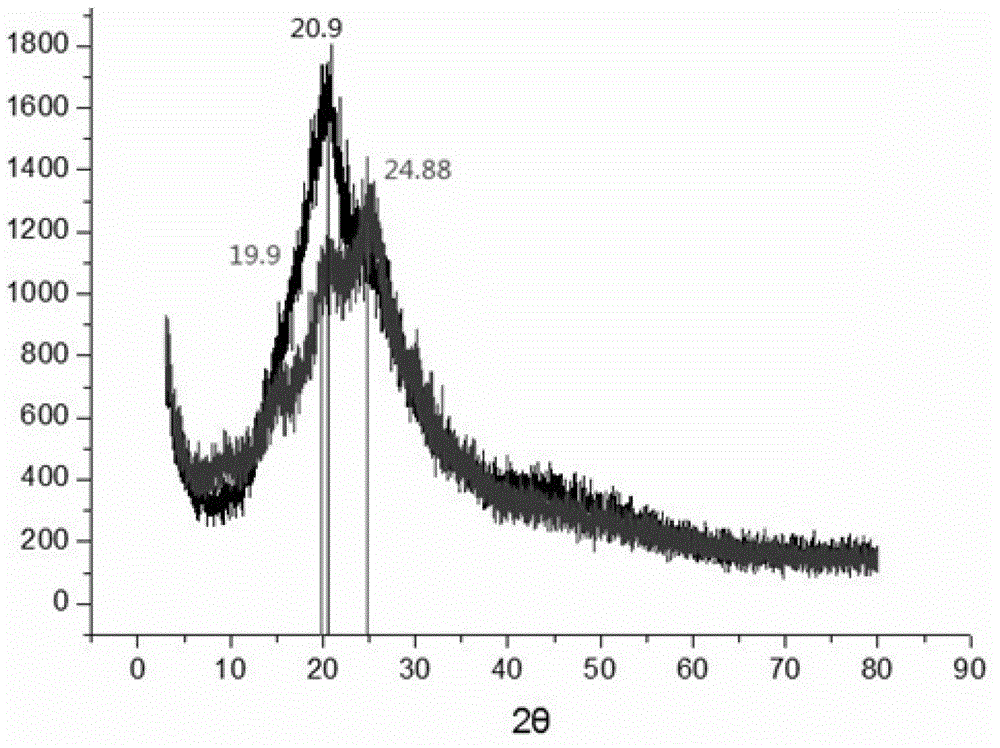

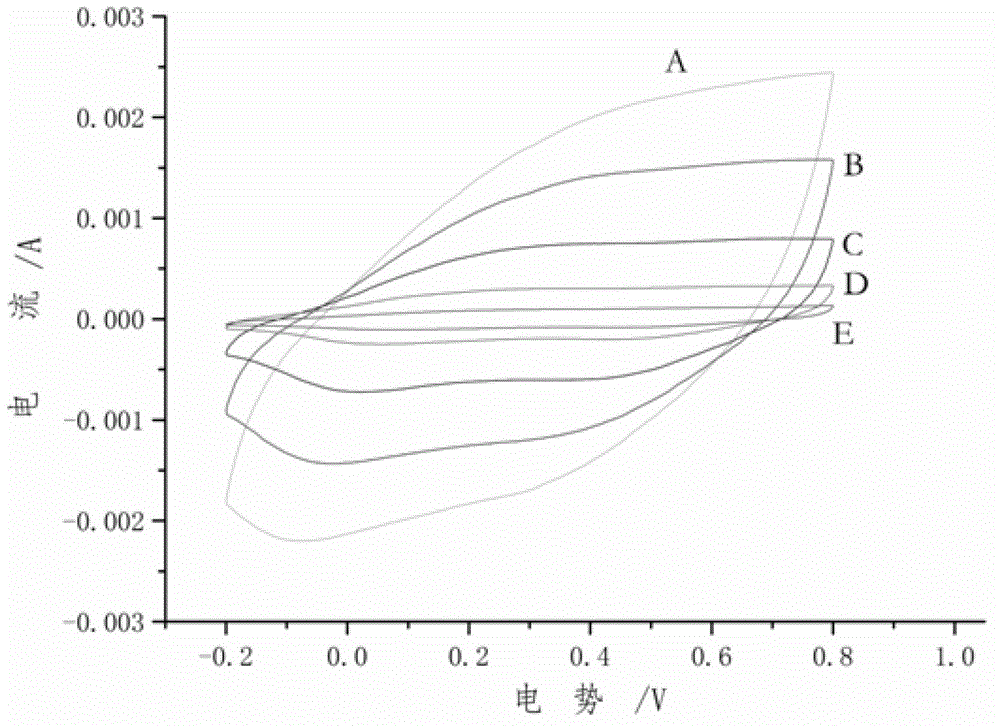

Preparation method for well-organized high-capacity self-supporting film based on epitaxial growth of polyaniline on graphene surface

ActiveCN103337377AGood size controlThickness is easy to controlHybrid capacitor electrodesHybrid/EDL manufactureFilm baseElectric capacity

The invention discloses a preparation method for a well-organized high- capacity self-supporting film based on epitaxial growth of polyaniline on a graphene surface and relates to the preparation method for the self-supporting film. The method that solves the problems that an oxidized graphene / polyaniline composite prepared by a conventional method is poor in stability and disordered in structure comprises the following steps: first, preparing the oxidized graphene; second, performing aniline acidation; third, preparing powder with the graphene / polyaniline micron-sized composite structure; and fourth, dissolving the powder obtained in the third step into the water, followed by sedimentation by utilizing an electrodeposition method, a vertical pulling method, a natural sedimentation method, a suction filtration sedimentation method or a spin-coating sedimentation method, thereby obtaining the film. According to the method, various directional sedimentation methods are adopted for film forming, the film with the layered ordered structure is obtained; the prepared film has favorable self-supporting performance from the aspect of macroscopic performance, and is proved to be high in electric capacity up to 323 F / g by a cyclic voltammetry, and be good in stability. The method belongs to the field of electrode material preparation.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com