Perpendicular magnetic recording medium and manufacturing method of the same

A technology of perpendicular magnetic recording and manufacturing method, which is applied in magnetic recording, data recording, disc carrier manufacturing, etc. It can solve the problems of poor vertical orientation, high order degree and high perpendicular magnetic anisotropy energy, etc., and achieve high effect of order

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

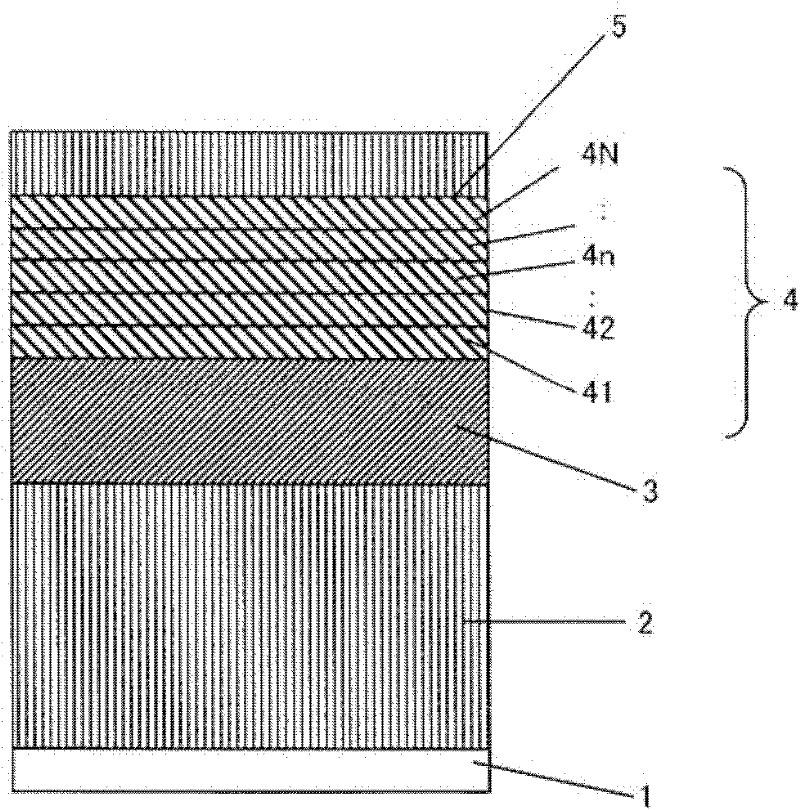

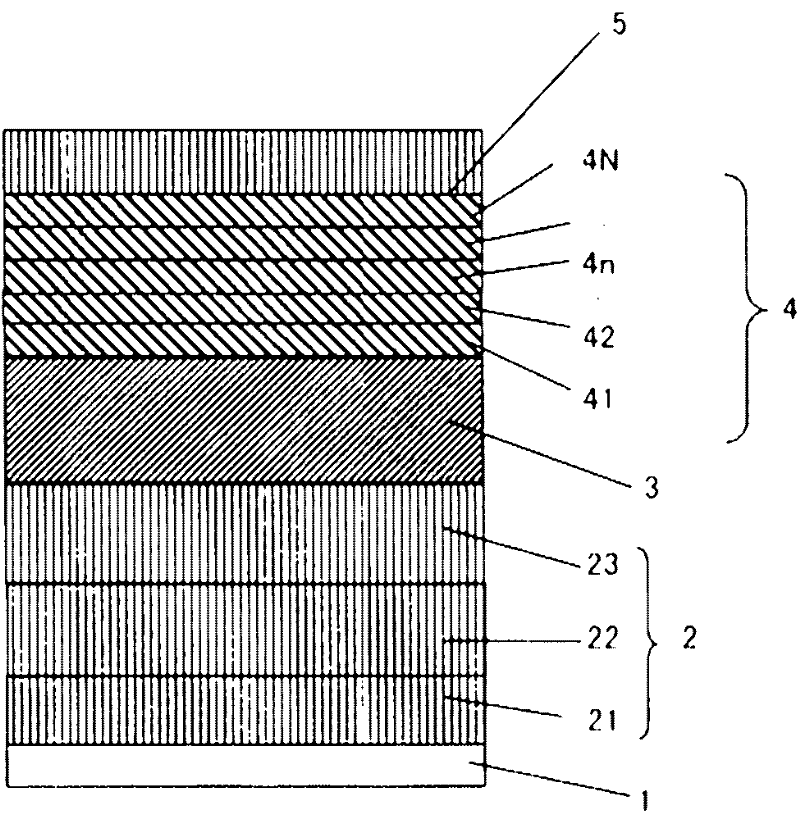

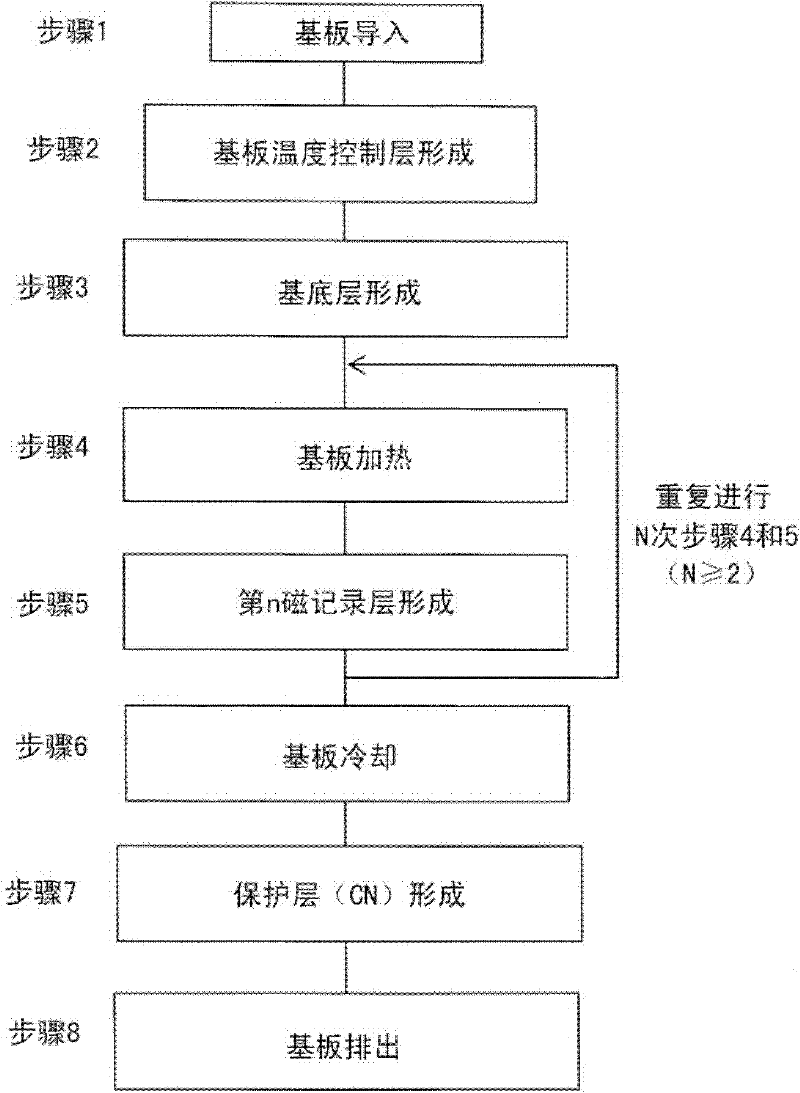

[0062] made with Figure 1A A schematic cross-sectional view of a perpendicular magnetic recording medium is shown in . The perpendicular magnetic recording medium of this example was produced using a continuous high-speed sputtering device (C3010) manufactured by Canon ANELVA. This equipment is composed of a plurality of process chambers for film formation, a dedicated heating chamber, and a substrate introduction / discharge chamber, and each chamber is independently exhausted. Before making the perpendicular magnetic recording medium of this embodiment, all chambers are exhausted until 8×10 -6 Vacuum degree below Pa. The process is performed sequentially by moving the carrier on which the substrate is mounted to each process chamber. In addition, the heating of the substrate was carried out in a dedicated heating chamber, and was carried out from both sides of the substrate using a PBN (Pyrolytic boron nitride: pyrolytic boron nitride) heater. The heating rate of the heate...

Embodiment 2

[0078] The perpendicular magnetic recording medium of this example was produced under the same film configuration and film formation conditions as in Example 1 except for the magnetic recording layer. In the present embodiment, through four-stage film-making ( figure 2 N=4 in the film forming method shown) The magnetic recording layer 4 was produced by changing the compositions of the first to fourth magnetic recording layers. All the thicknesses of the first to fourth magnetic recording layers were 1.5 nm. In addition, the samples were prepared under the condition that the heating temperature in the heating chamber was 500° C., and the heating time was 1 minute.

[0079] Table 2 shows the results of evaluating the composition, degree of order, crystal grain size, and vertical orientation of each magnetic recording layer of the prepared samples. In Table 2, for example, when expressed as (45 atomic % Fe-45 atomic % Pt-10 atomic % Ag)-30 atomic % C (22 volume % C), it means ...

Embodiment 3

[0084] The perpendicular magnetic recording medium of this example was produced under the same film configuration and film formation conditions as Samples 2-3 and 2-4 of Example 2 except for the film thickness of the first magnetic recording layer.

[0085] Sample series 3-1 of this example is a sample series in which the film thickness of the first magnetic recording layer of sample 2-3 of example 2 was changed. In addition, sample series 3-2 of this example is a sample series in which the film thickness of the first magnetic recording layer of sample 2-4 of example 2 was changed. The X-ray diffraction of the prepared sample series is measured, and the integrated intensity ratio I of the FePt(001) diffraction peak and the FePt(111) diffraction peak is (111) / I (001)Make an evaluation. In addition, the measurement of the crystal grain size was performed using TEM. Show the respective results in Figure 5A , Figure 5B .

[0086] From this, it can be seen that when the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com