Patents

Literature

81 results about "Degree of order" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

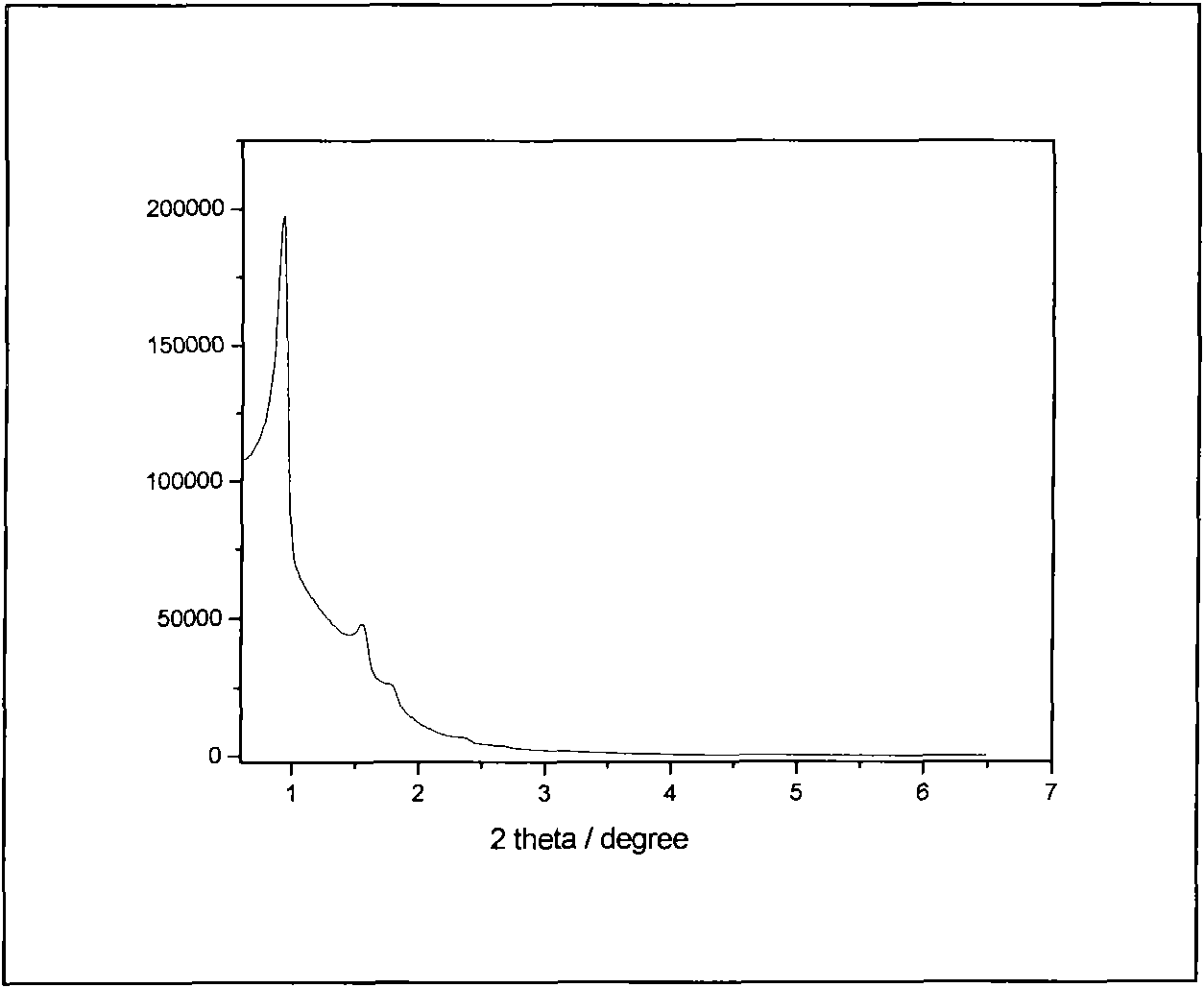

Preparation method of mesonic pore molecular sieve carrier material

The present invention belongs to the field of inorganic nanometer material technology, in particular, it relates to a method for preparing mesoporous molecular sieve carrier material by using diblockmacromolecular polymer. It is characterized by that under the acid condition it uses polyoxyethylene-polyoxybutylene diblock macromolecular surfactant as template agent and makes hydrothermal synthesis at 100 deg.C to prepare mesoporous silicon oxide material with two-dimensional hexagonal structure with high degree of order and large specific surface area and laminate silicon oxide material withhigh degree of order. These new material can be used as catalyst, catalyst carrier, adsorption film, organic-inorganic composite material, sensor and chromatographic packing, etc.

Owner:FUDAN UNIV

Porous carbon electrode with conductive polymer coating

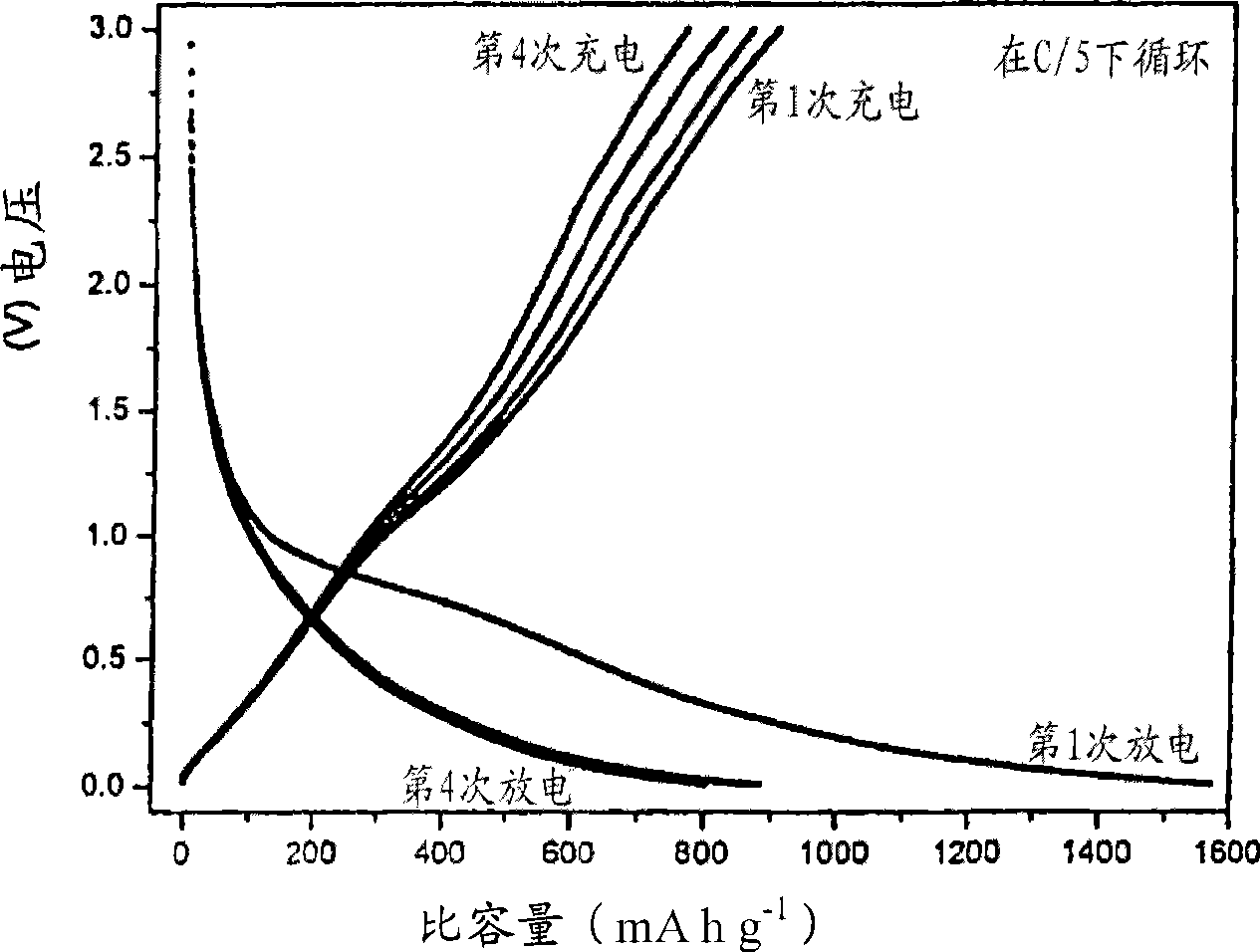

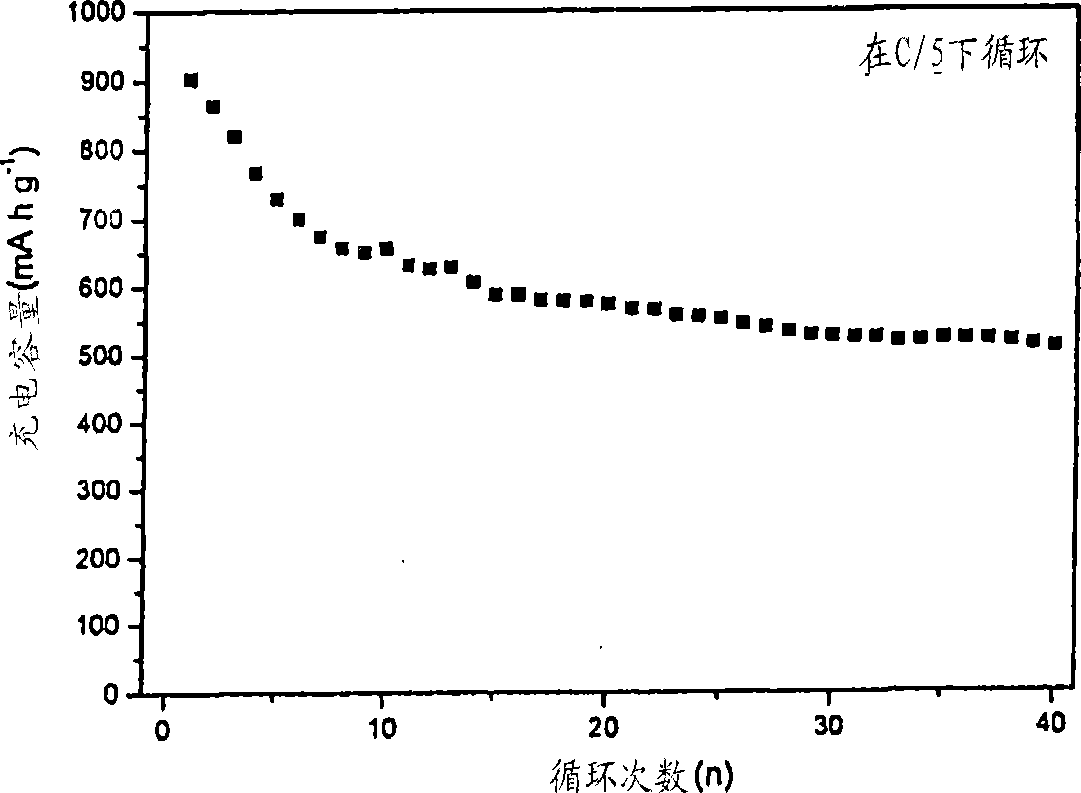

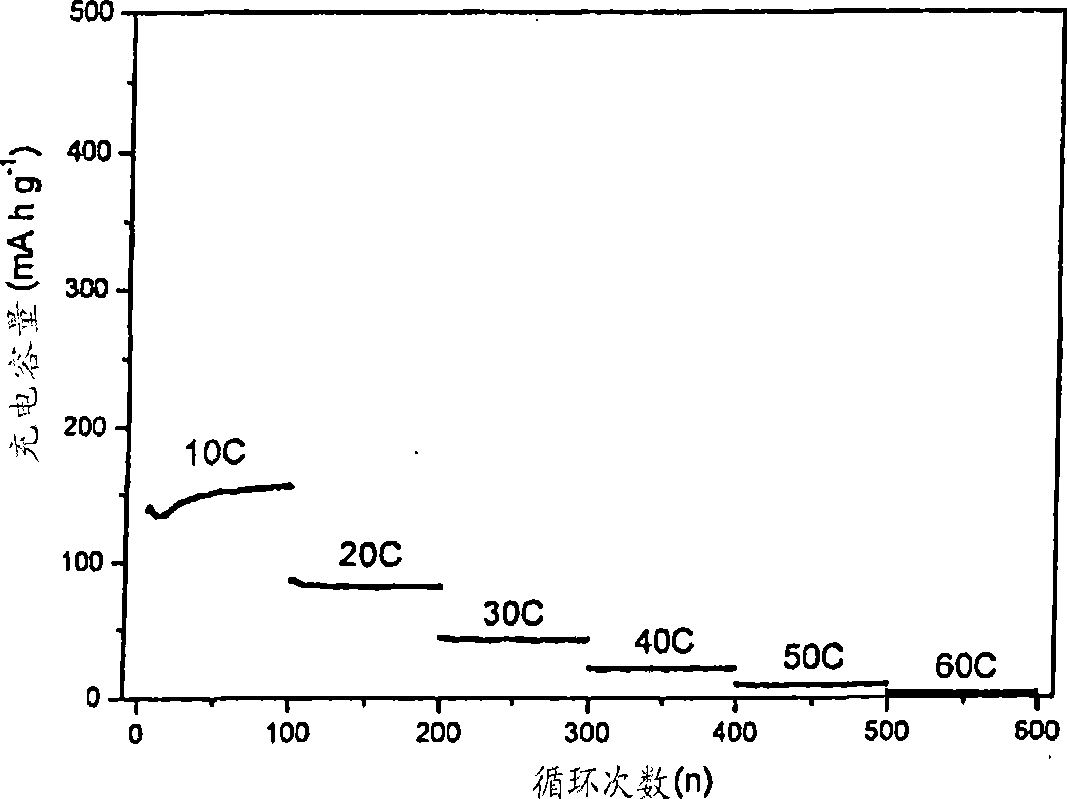

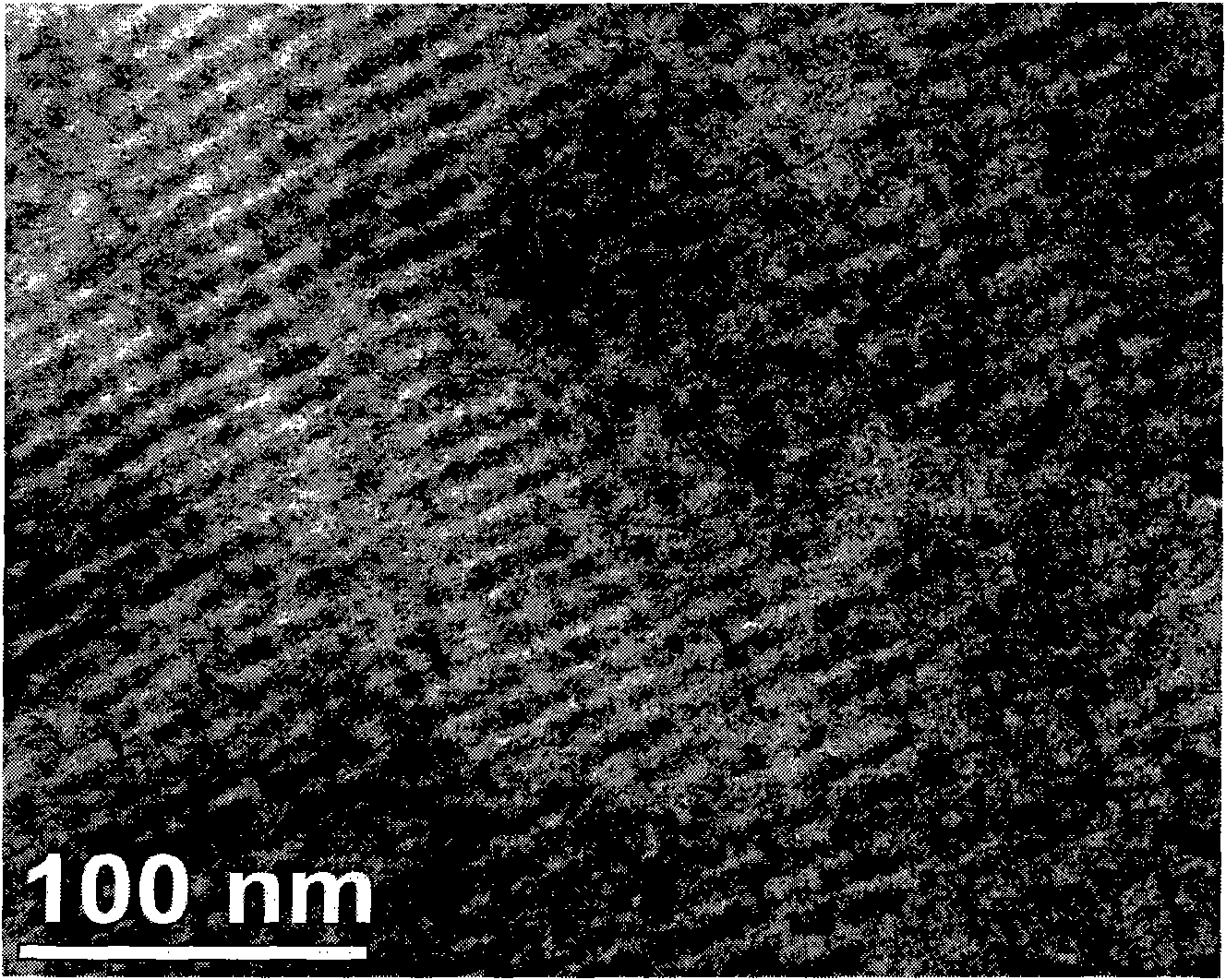

This disclosure relates to a porous electrically conductive carbon material having interconnected pores in first and second size ranges from 10[mu]m to 100nm and from less than 100nm to 3nm and a graphene structure and to diverse uses of the material such as an electrode in a lithium-ion battery and a catalyst support, e.g. for the oxidation of methanol in a fuel cell. The carbon material has been heat treated to effect conversion to non-graphitic carbon with the required degree of order at a temperature in the range from 600 DEG C to 1000 DEG C. A lithium-ion battery and an electrode for a lithium-ion battery are also claimed.

Owner:促进科学E.V.麦克斯-普朗克公司

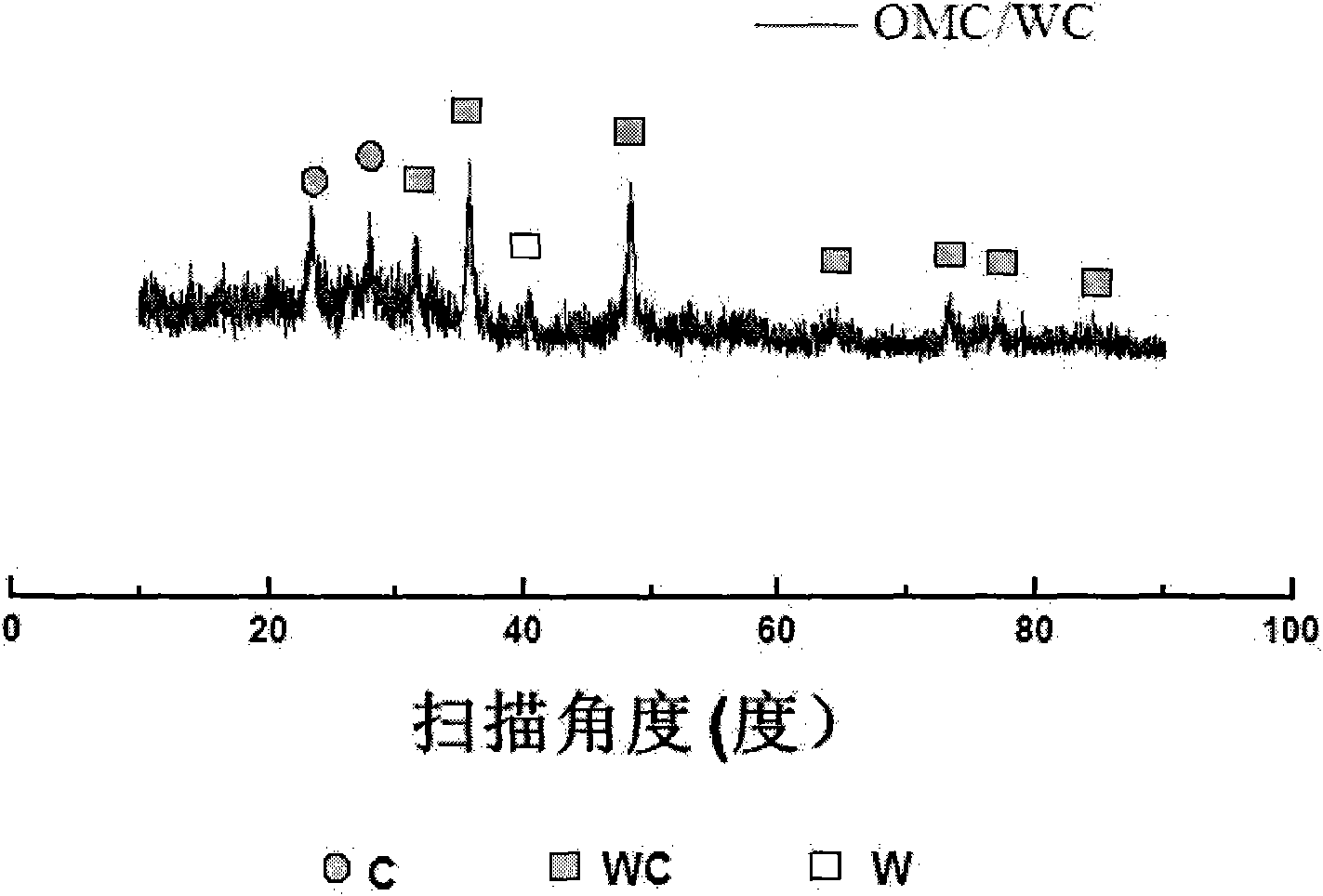

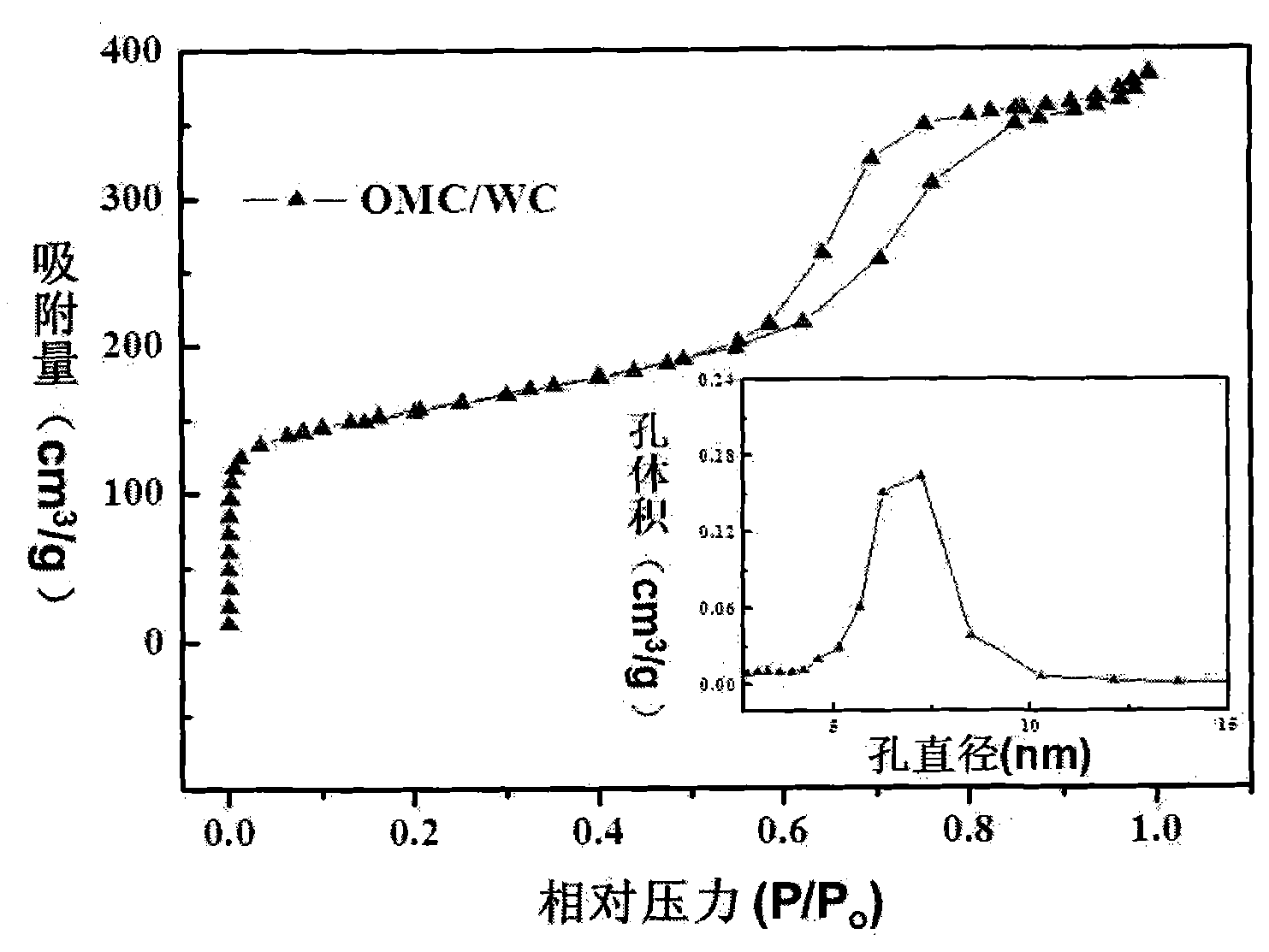

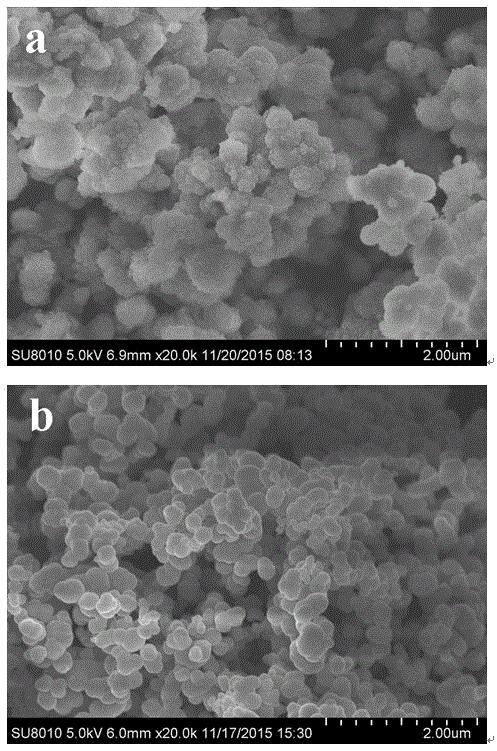

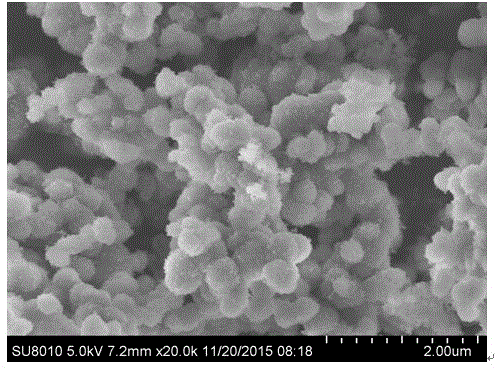

Ordered mesoporous carbon/tungsten carbide composite material and supported catalyst thereof and preparation method thereof

InactiveCN101869853AHigh degree of aperture orderNarrow pore size distributionCatalyst carriersCell electrodesSolventPt element

The invention discloses a preparation method for an ordered mesoporous carbon / tungsten carbide composite material and a supported catalyst thereof. In the method, an organic matter and a tungsten salt are separately used as a carbon source and a tungsten source, and the carbon source and the tungsten source are mixed with a surfactant; and a precursor of the ordered mesoporous carbon / tungsten carbide is synthesized by a solvent-evaporation induced self-assembly method, and then the precursor is subject to high-temperature treatment in the inert atmosphere to form the ordered mesoporous carbon / tungsten carbide composite material. The ordered mesoporous carbon / tungsten carbide composite material prepared by the method has the characteristics of high degree of order, narrow aperture distribution, large specific surface area (greater than 500 m<2> / g) and the like. The invention further comprises a supported catalyst prepared by supporting active components on the ordered mesoporous carbon / tungsten carbide composite material which is prepared by the method; and because of the synergistic effect and the structure effect of the ordered mesoporous carbon / tungsten carbide composite material, the catalyst has higher methanol electro-oxidation catalytic activity than a commercial carbon platinum-ruthenium catalyst.

Owner:SUN YAT SEN UNIV

Core-shell silicon carbon composite negative electrode material for high-capacity type lithium ion battery and preparation method therefor

ActiveCN105489855AImprove the first discharge capacityImprove cycle stabilityMaterial nanotechnologyCell electrodesCarbon layerCarbon composites

Owner:TIANJIN NORMAL UNIVERSITY

Preparation method for porous graphitized hard carbon for high-rate sodium ion battery cathode

InactiveCN108539197AImprove conductivityPlay a role in catalyzing graphitizationCell electrodesSecondary cellsCarbon compositesHigh rate

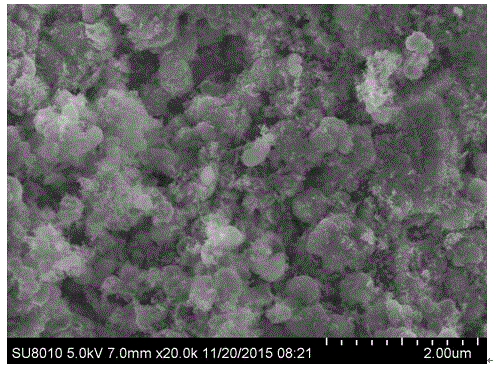

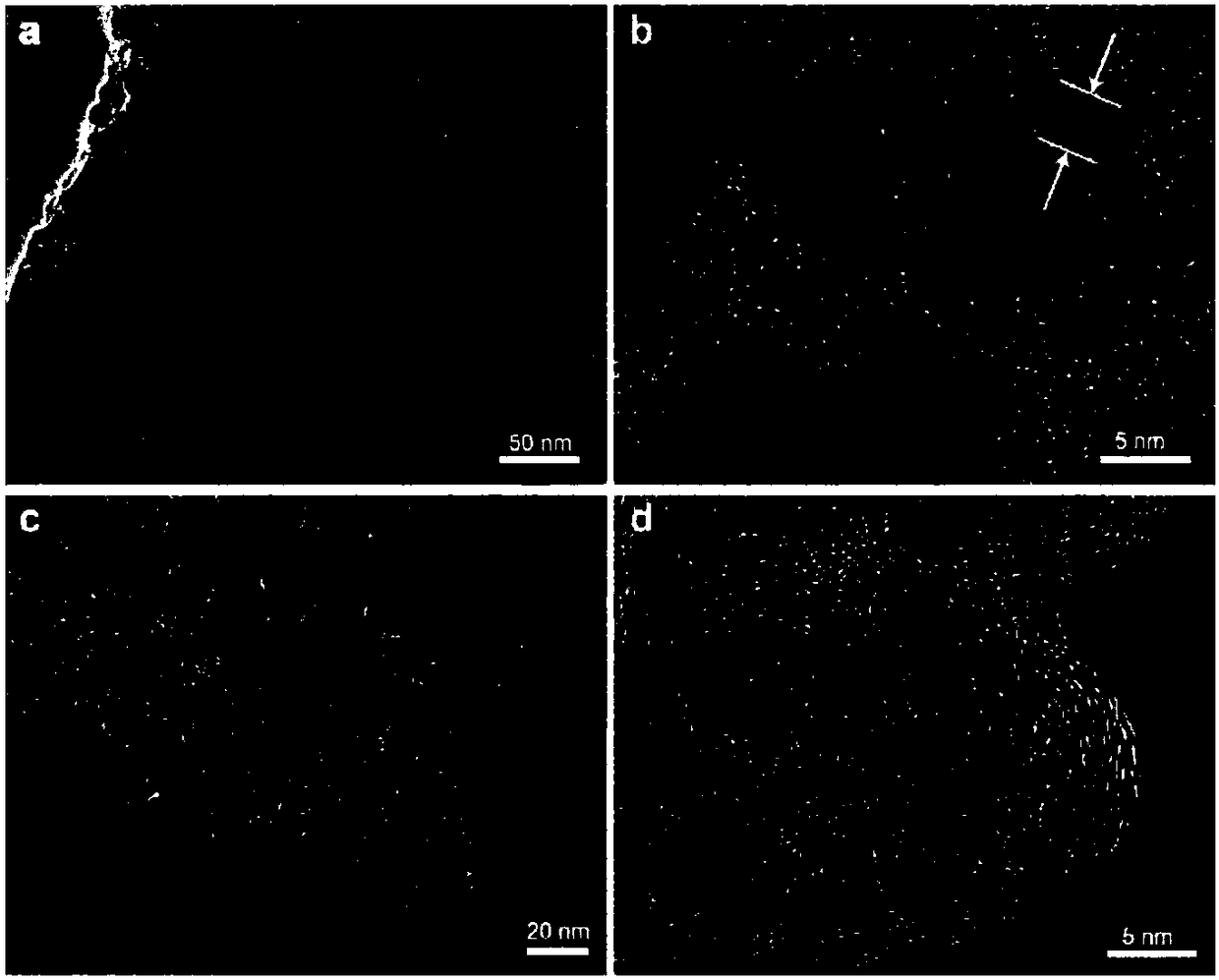

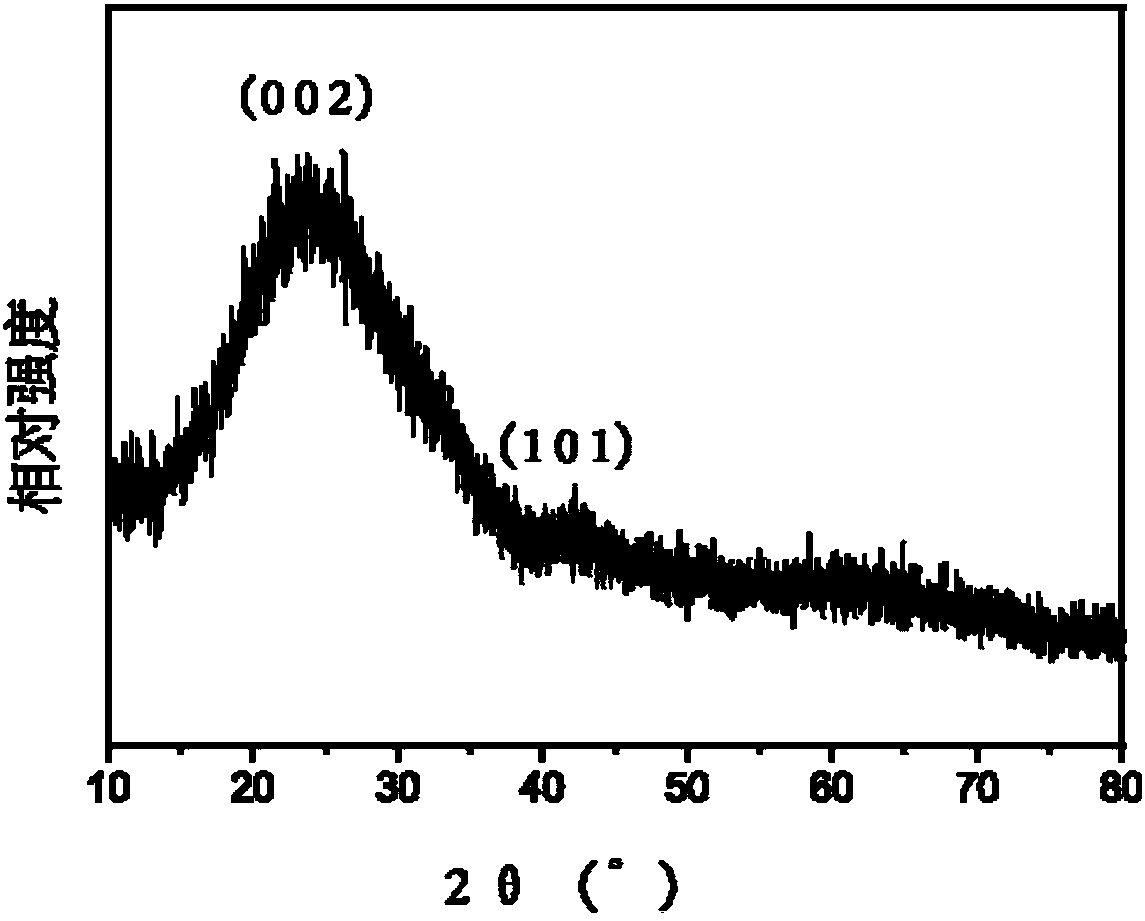

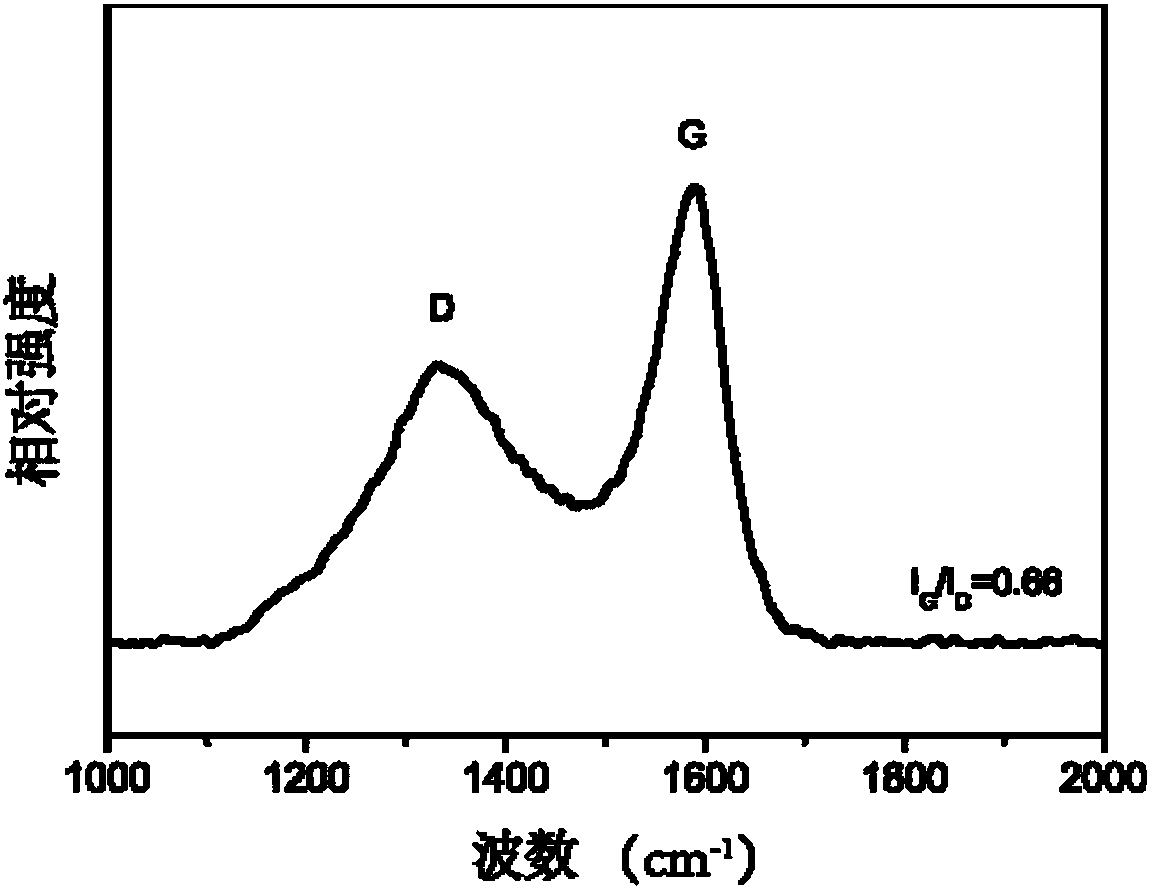

The invention discloses a preparation method for porous graphitized hard carbon for a high-rate sodium ion battery cathode. The preparation method mainly comprises the following steps: at first, performing interlinking reaction on sodium alginate and a cation of a polyvalent transition metal with a catalytic graphitization effect; then preparing a nanometal / carbon composite material by use of a carbonization catalytic graphitization method; finally removing nanometal catalyst particles by use of an acid washing process to obtain a graphitized hard carbon cathode material of a relatively ordered nano-mesoporous structure. According to the preparation method, uniform nanopores are introduced into the hard carbon by use of interlinking and acid washing methods, and the degree of order of a graphene layer of mesoporous surface carbon is improved by use of an in-situ catalytic graphitization method, so that the prepared porous graphitized hard carbon material is endowed with good pore channels, high electrical conductivity and high-capacity and high-rate sodium storage property and is more favorable for rapid introduction / removal of sodium ions and electrons.

Owner:SHANGHAI JIAO TONG UNIV

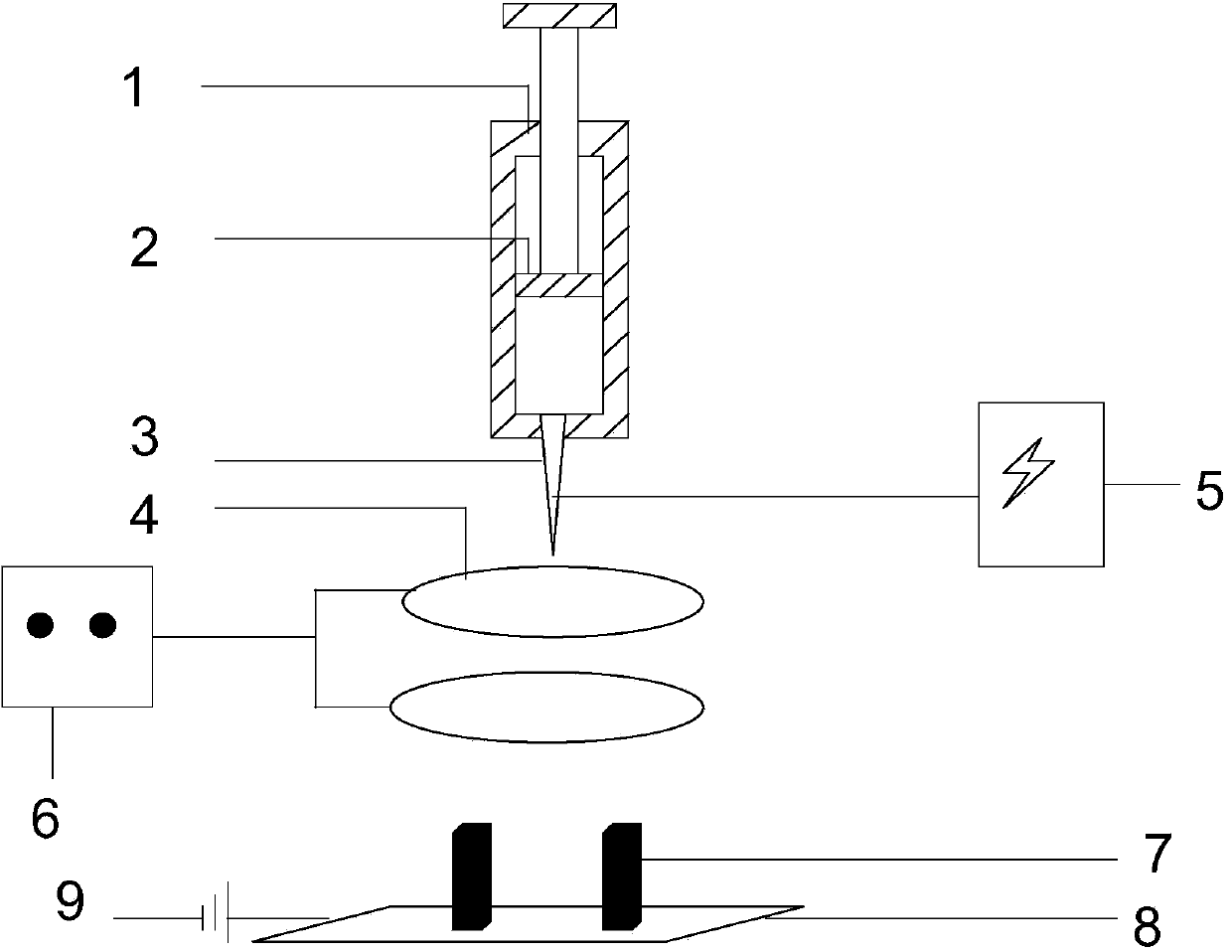

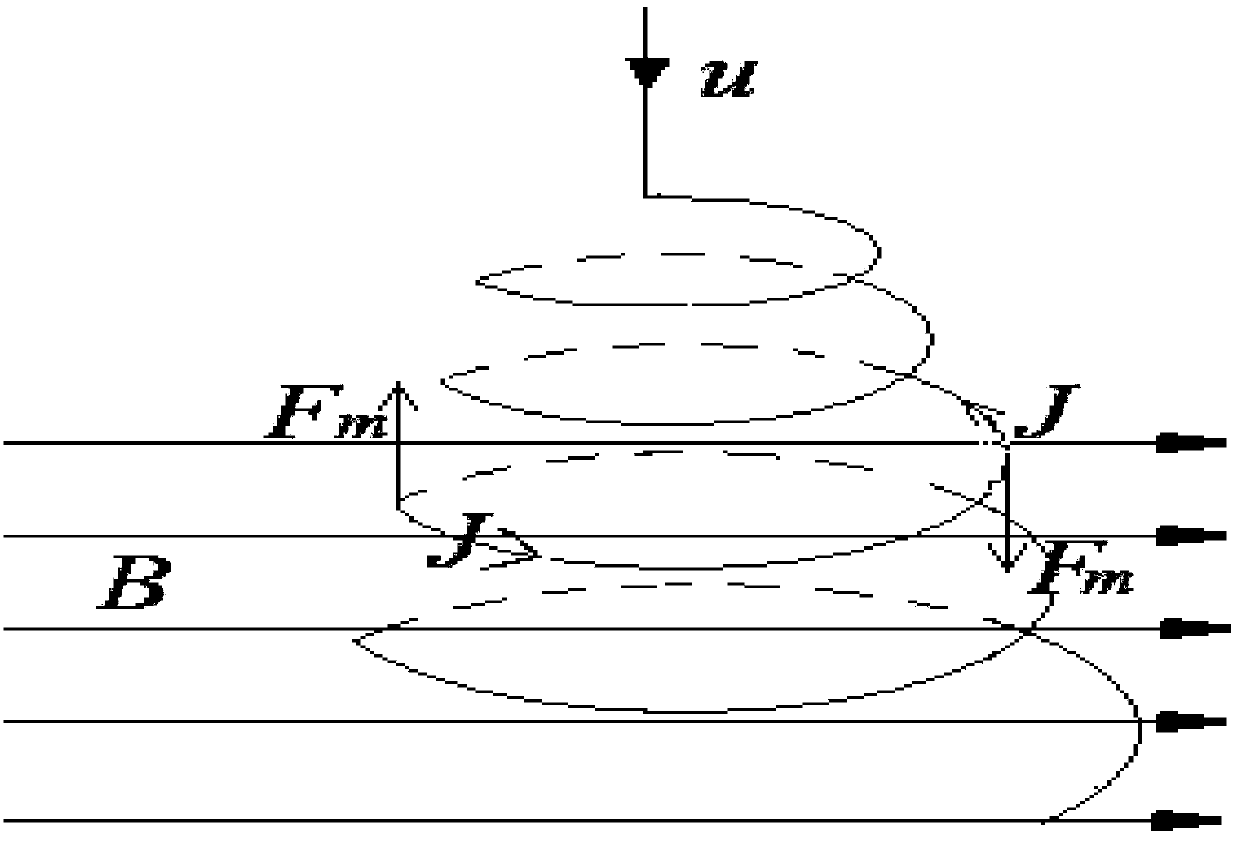

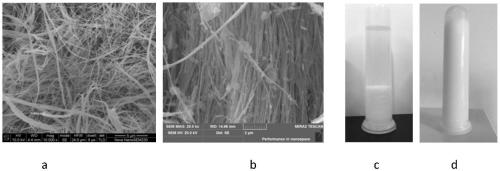

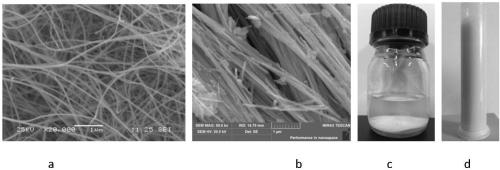

Electrostatic spinning device for manufacturing nano fibers in electromagnetic field with coupling method

InactiveCN103614791AGood orientationHigh degree of orderFilament/thread formingFiberElectromagnetic field coupling

The invention discloses an electrostatic spinning device for manufacturing nano fibers in an electromagnetic field with a coupling method. The electrostatic spinning device comprises a material basket, a piston, a spinning nozzle, a high-voltage power supply device, a receiving plate and a grounding power line. The electrostatic spinning device further comprises an electric conduction coil arranged between the spinning nozzle and the receiving board and right opposite to the spinning nozzle and the receiving board. Two electromagnets are arranged on the receiving board in parallel. The orientation of nano fibers collected by electrified polymer solutions is greatly improved under the action of the electromagnetic field which is large enough. Meanwhile, the positively charged coil is added in the flow jetting process of polymers, jet flow can be stabilized, the range of a Taylor cone is reduced, and the degree of order of the nano fibers is further improved. The electrostatic spinning device for manufacturing the nano fibers in the electromagnetic field with the coupling method is simple in structure, convenient to operate, easy to control and short in technological process.

Owner:SUZHOU UNIV

Mesoporous rare earth phosphate fluophor and preparation method thereof

InactiveCN101575514APorousHas luminous propertiesSolid-state devicesSemiconductor/solid-state device manufacturingPhosphatePhosphoric acid

The invention discloses a mesoporous rare earth phosphate fluophor and a preparation method thereof, belonging to the field of multifunctional rare earth luminescent material. The method, which takes mesoporous silicon dioxide with an ordered pore channel structure as a hard template agent, comprises the steps of adding homogeneous solution of soluble rare-earth salts / rare earth fluophor material / strong phosphoric acid / concentrated nitric acid in the silicon dioxide pore channel, removing the nitric acid solvent through direct volatilization, thus precipitating the phosphate fluophor in the pore channel; further leading the rare earth phosphate fluophor to be cured in the mesoporous pore channel through high-temperature roasting treatment, removing the silicon dioxide hard template agent, thus obtaining the mesoporous rare earth phosphate fluophor. The mesoporous rare earth phosphate fluophor material has the characteristics of high degree of order, adjustable pore diameter and mesoporous structure, large specific surface area, pore diameter and pore volume and the like, with the specific surface area being 100-500m / g, the pore diameter being 3-8nm, and the pore volume being 0.15-1.5cm / g; and can be used as a novel absorbing and embedding material of medicaments.

Owner:SHANGHAI INST OF TECH

High heat stability ordered mesoporous aluminum phosphate material and its preparing method

InactiveCN1749165AHigh degree of orderWell-preservedMolecular-sieve aluminophosphatesMolecular-sieve and base-exchange phosphatesMesoporous materialALUMINUM PHOSPHATE

The present invention is high heat stability ordered mesoporous aluminum phosphate material and its preparation process, and belongs to the field of inorganic chemistry and physical chemistry technology. The mesoporous aluminum phosphate material has composition of P2O5-Al2O3-MXOY, skeleton with primary and secondary zeolite structure units, 2D hexagonal structure, high heat stability and high degree of order. The preparation process includes synthesizing precursor solution containing the primary and secondary microporous aluminum phosphate zeolite structure units by using organic amine as template agent; and subsequent self-assembling process of the precursor and cationic surfactant to synthesize the ordered mesoporous aluminum phosphate material. The prepared mesoporous material has high specific surface area and atom connecting mode of microporous molecular sieve, may have several hetero atoms introduced, and may be used widely in chemical fields.

Owner:JILIN UNIV

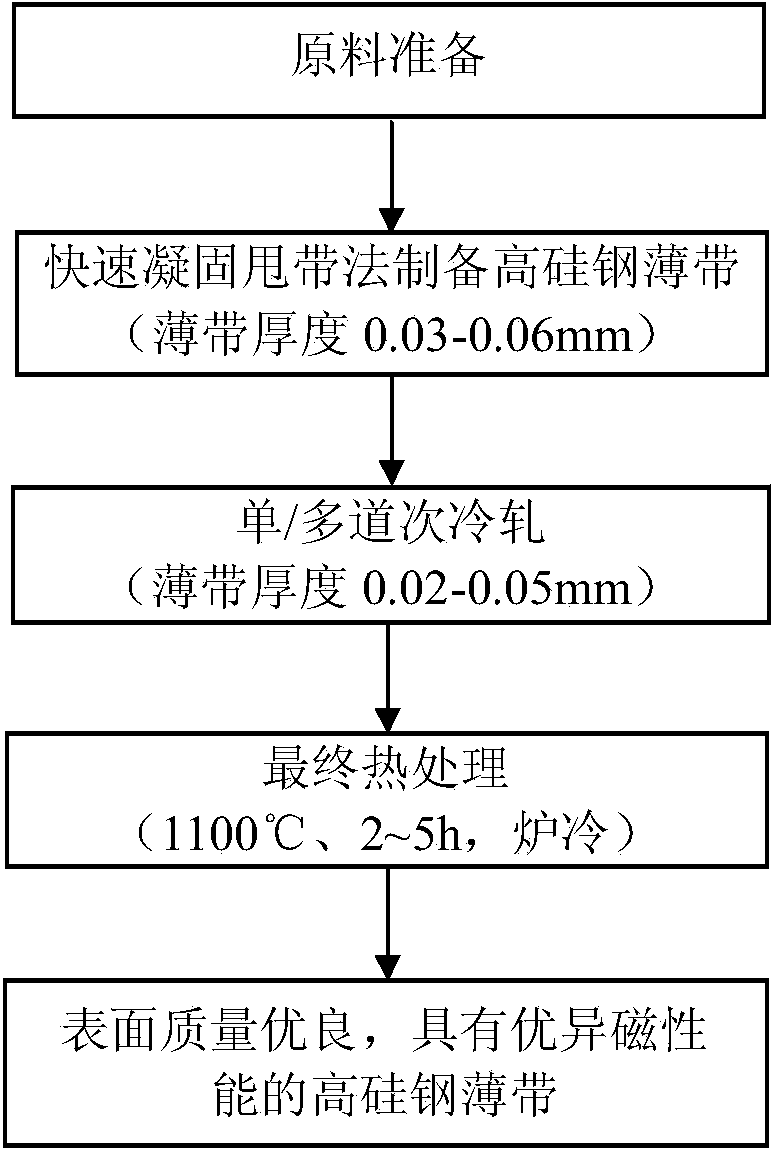

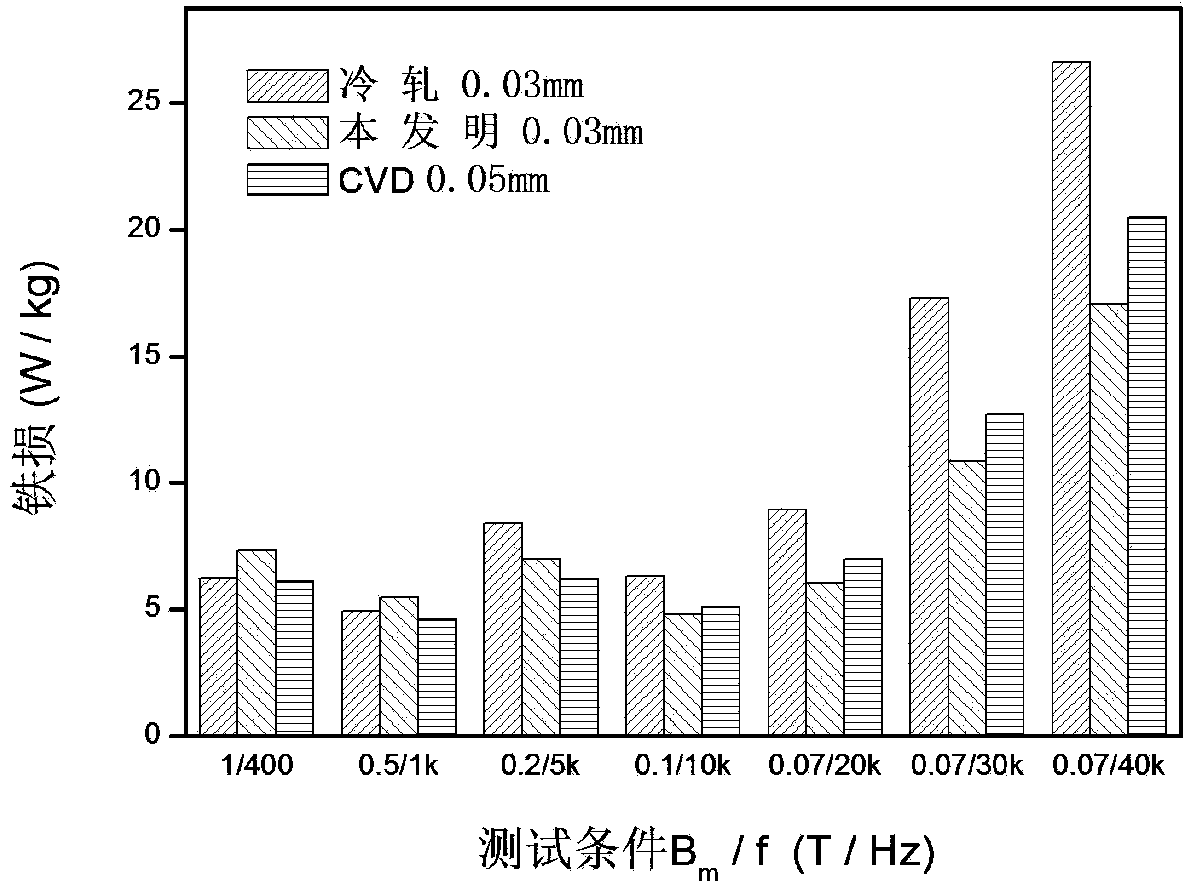

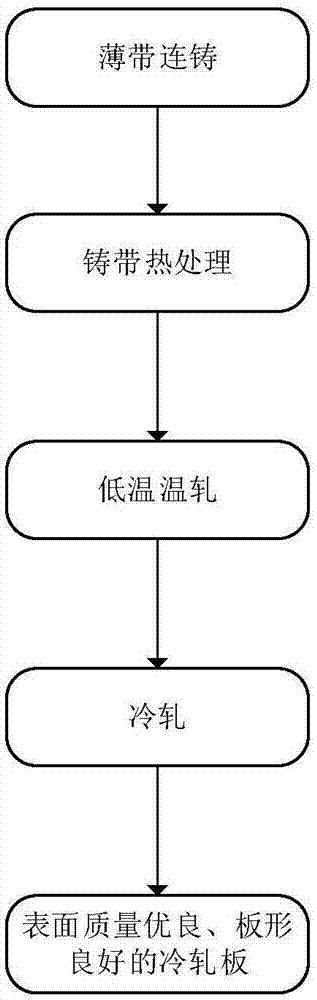

Short-process efficient cold-rolling preparation method of high-silicon steel thin strip

The invention aims at providing a short-process efficient cold-rolling preparation method of a high-silicon steel thin strip. The preparation method is characterized in that the high-silicon steel thin strip is prepared by using a rapid solidification method, and the thickness of the high-silicon steel thin strip is reduced by using a cold rolling method, the surface quality is improved, and the high-frequency magnetic performance is improved; due to rapid solidification, the plasticity of high-silicon steel can be improved, and the thin strip with certain plasticity is obtained and can be wound into a coil; then, cold rolling is carried out, so that the degree of order of the high-silicon steel is further lowered, the plasticity of the high-silicon steel is improved, and a high-silicon steel thin strip coil is obtained; the thin strip obtained through rapid solidification has the advantages that the crystal grain size is obviously reduced, the degree of order is obviously lowered, and the microhardness change is not great, so that next-step cold rolling is facilitated; during cold rolling, the rolling reduction of first-time rolling is controlled, and then, the plasticity is further improved, so that the thin strip with the thinnest thickness of 0.02mm can be obtained. According to the preparation method, the production efficiency of the prepared high-silicon steel thin strip is high, and the product quality of the prepared high-silicon steel thin strip is good, so that the method can be widely implemented industrially and accordingly has a broad application prospect.

Owner:UNIV OF SCI & TECH BEIJING

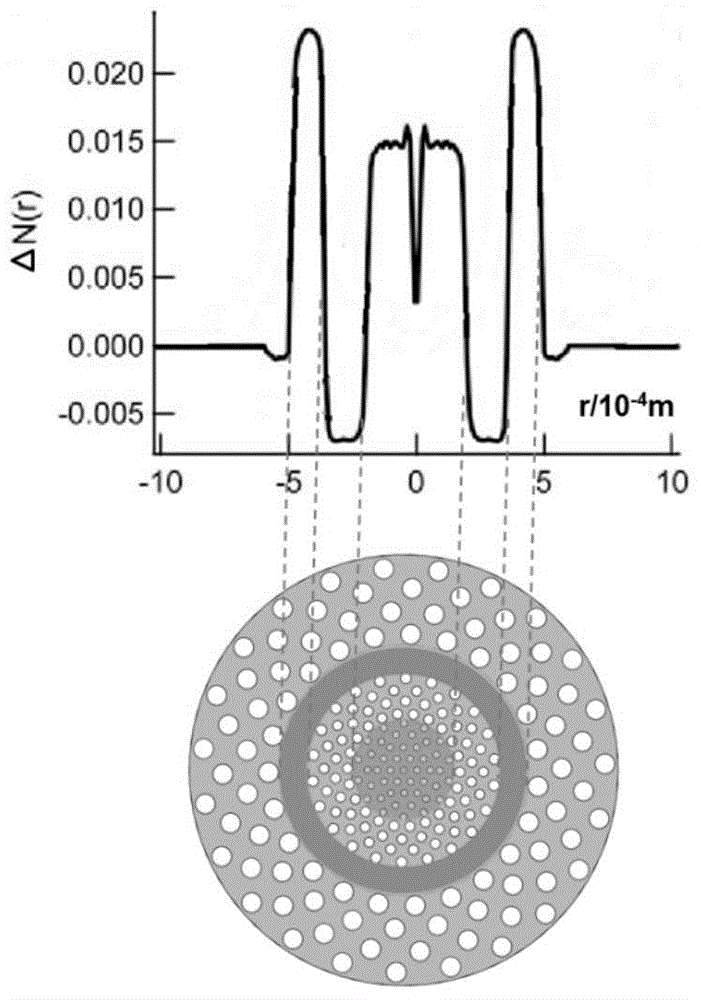

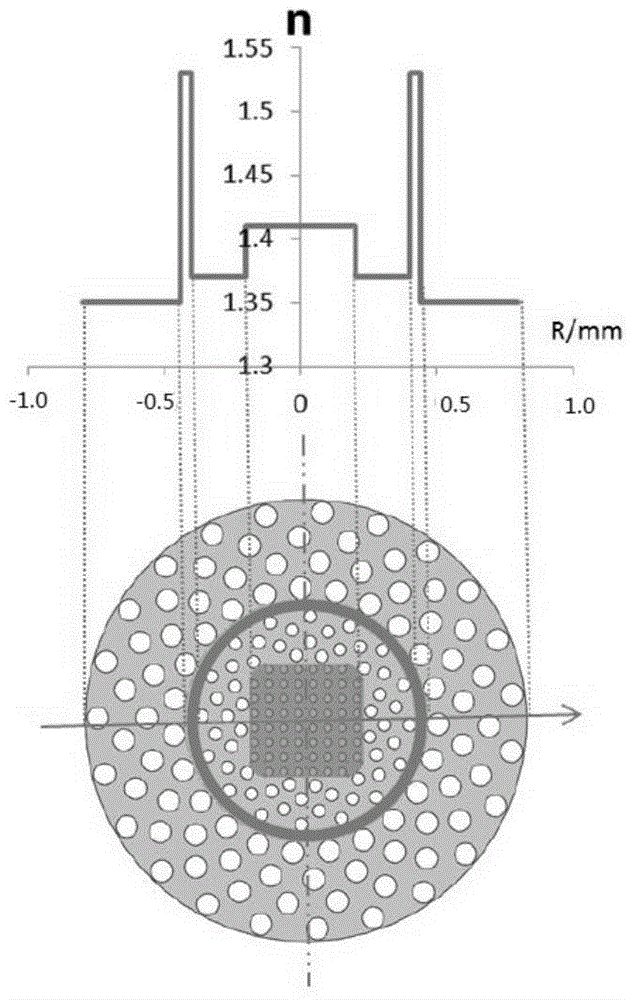

Micro-structured optical fiber for generating and transmitting vortex light beams

ActiveCN104062704AReduce manufacturing costReduce processing difficultyOptical fibre with multilayer core/claddingFiberLight beam

The invention provides a brand-new structure. By means of the brand-new structure, the micro-structured optical fiber for generating and transmitting vortex light beams does not need to be made into a circular lantern ring through as many as four kinds of materials with different refractive indexes, and the manufacturing cost and process difficulty of the optical fiber are reduced; meanwhile, the micro-structured optical fiber for generating and transmitting the vortex light beams is invariant in reflecting index outline in the long-term use process, and the degree of order and periodicity are controlled effectively. The micro-structured optical fiber for generating and transmitting the vortex light beams is provided with an inner fiber core, an inner cladding, an annular outer core and an outer cladding from inside to outside in sequence. A plurality of micro holes are evenly distributed in the inner fiber core, the inner cladding and the outer cladding. The reflecting index of each layer should meet the range of 1.510+ / -20.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

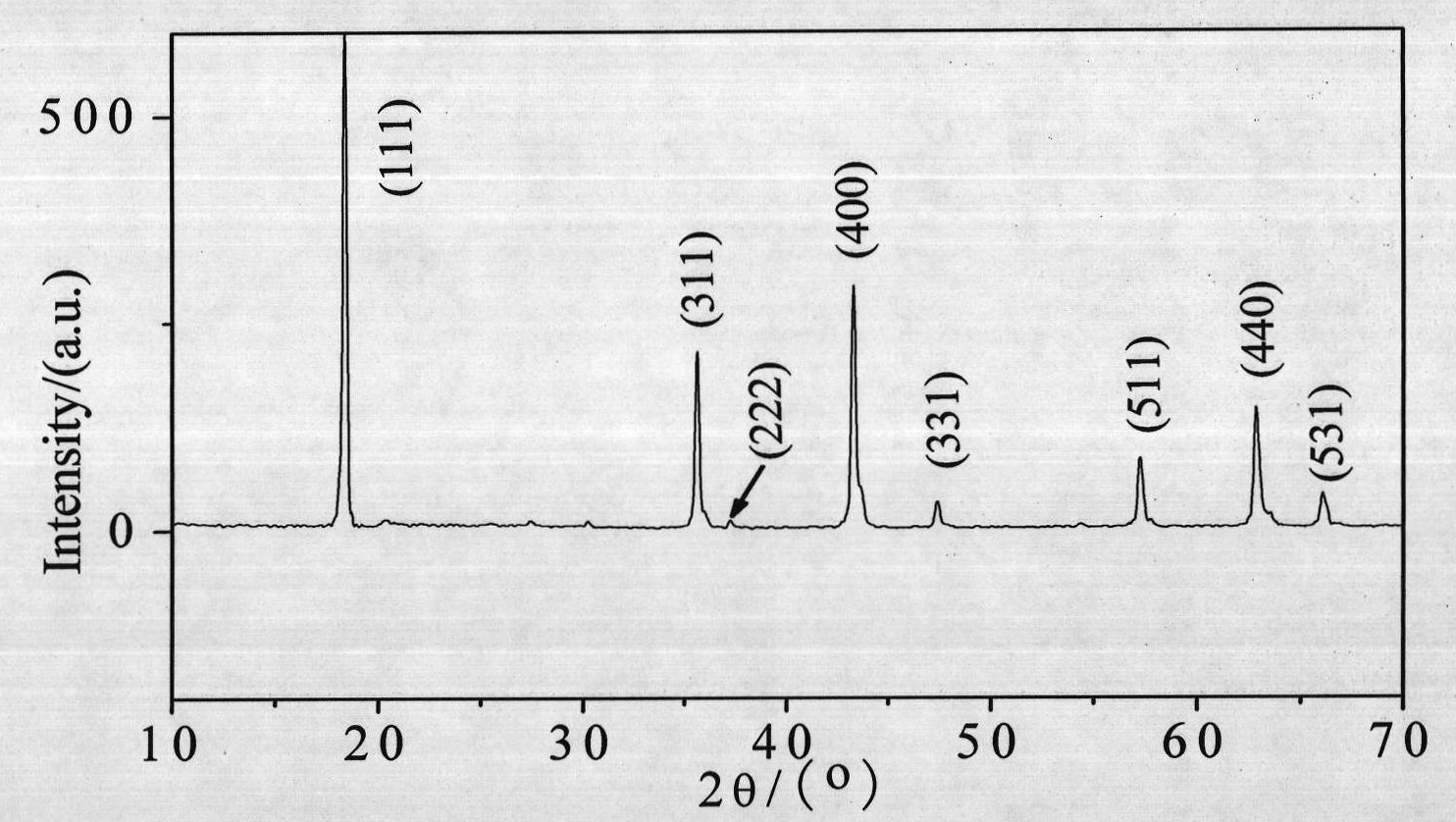

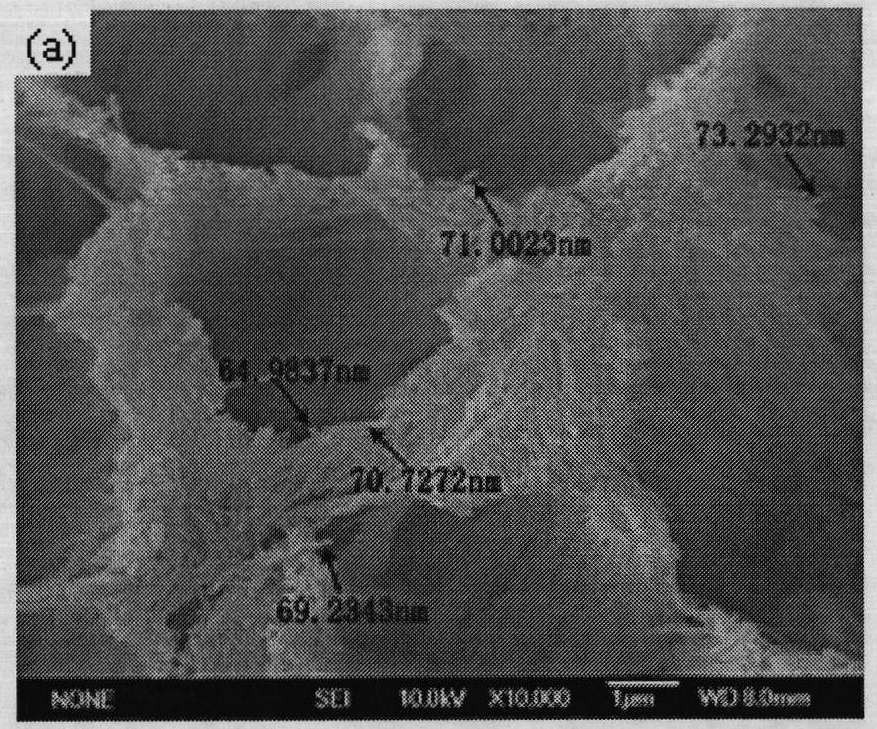

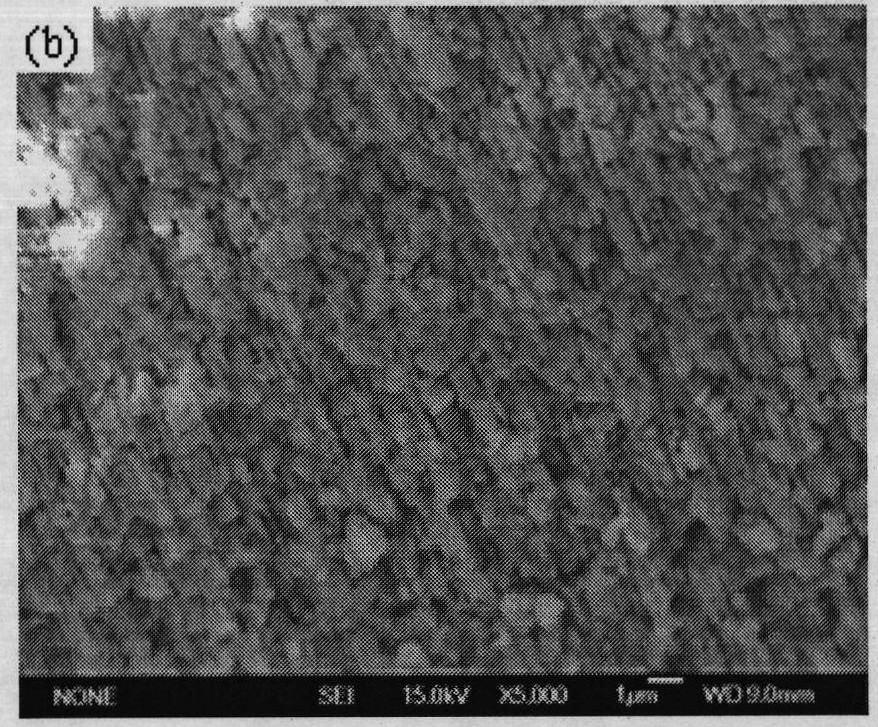

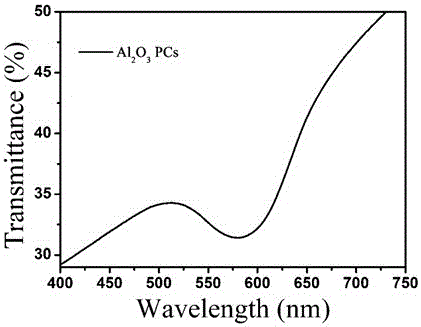

Method for preparing spinel type lithium titanate nanowire array

InactiveCN102044662AUniform pore sizeLarge specific surface areaCell electrodesSurface reaction electrolytic coatingRegular distributionSpinel

The invention discloses a method for preparing a spinel type lithium titanate nanowire array, in particular a method for preparing the spinel type lithium titanate nanowire array by using an aluminum oxide template. The method comprises the following steps of: preparing a porous aluminum oxide template; deoiling and annealing an aluminum plate, and performing electrochemical polishing, secondary anodic oxidation and hole expansion; synthesizing a lithium titanate sol precursor; adding butyl titanate, a complexing agent, ethylene glycol and lithium acetate dihydrate into absolute ethanol according to a proportion in turn and continuously stirring; preparing the lithium titanate nanowire array; dipping the porous aluminum oxide template into the lithium titanate sol precursor under vacuum; performing high-temperature roasting; and finally dissolving the template off with NaOH solution. Spinel type lithium titanate nanowires prepared by the method have the diameters of between 50 and 100nm; and the array has the advantages of uniform aperture size, large specific surface area, high degree of order, regular distribution, adjustable composition, controllable structure and the like.

Owner:TAIYUAN UNIV OF TECH

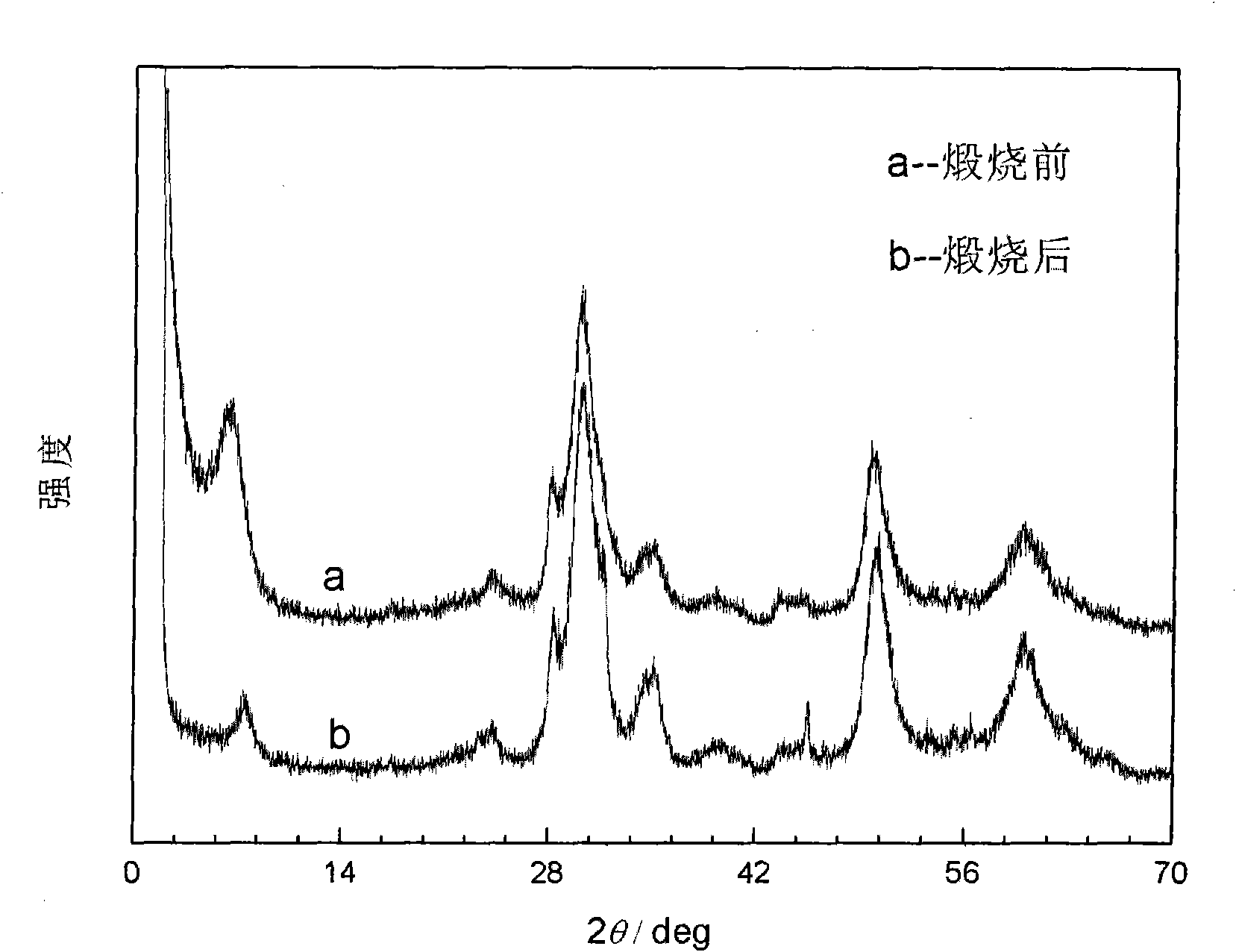

Method for preparing zirconium oxide polycrystalline powder with ordered laminar nanostructure/mesoporous structure by using surfactant as template

InactiveCN101913649AHigh degree of orderImprove thermal stabilityZirconium oxidesActive agentZirconium oxychloride

The invention discloses a method for preparing zirconium oxide polycrystalline powder with ordered laminar nanostructure / mesoporous structure by using a surfactant as a template. The method comprises the following steps of: (1) weighing 20 parts of mixed solution of zirconium oxychloride, water and alcohol; (2) weighing 20 parts of mixed solution of sodium dodecyl sulfate, water and alcohol; (3) weighing 10 parts of mixed solution of sodium hydroxide, water and alcohol; (4) adding the mixed solution prepared in the step (2) and the mixed solution prepared in the step (3) into a flask in the step (1) to reflux and react for 1 to 4 hours with stirring; (5) heating and performing hydrothermal reaction on the mixture for 12 to 36 hours under autogenous pressure; (6) standing the stock solution at the room temperature, washing the product, filtering or performing centrifugal separation on the product and drying the product; and (7) raising the temperature to 500 DEG C and calcining the product for 2 hours to obtain the zirconium oxide polycrystalline powder with ordered laminar nanostructure / mesoporous structure. By using a new method of combined reflux method and hydrothermal method and the surfactant as the template, the degree of order of the product is improved and high thermal stability of the product is ensured.

Owner:HEBEI UNIV OF TECH

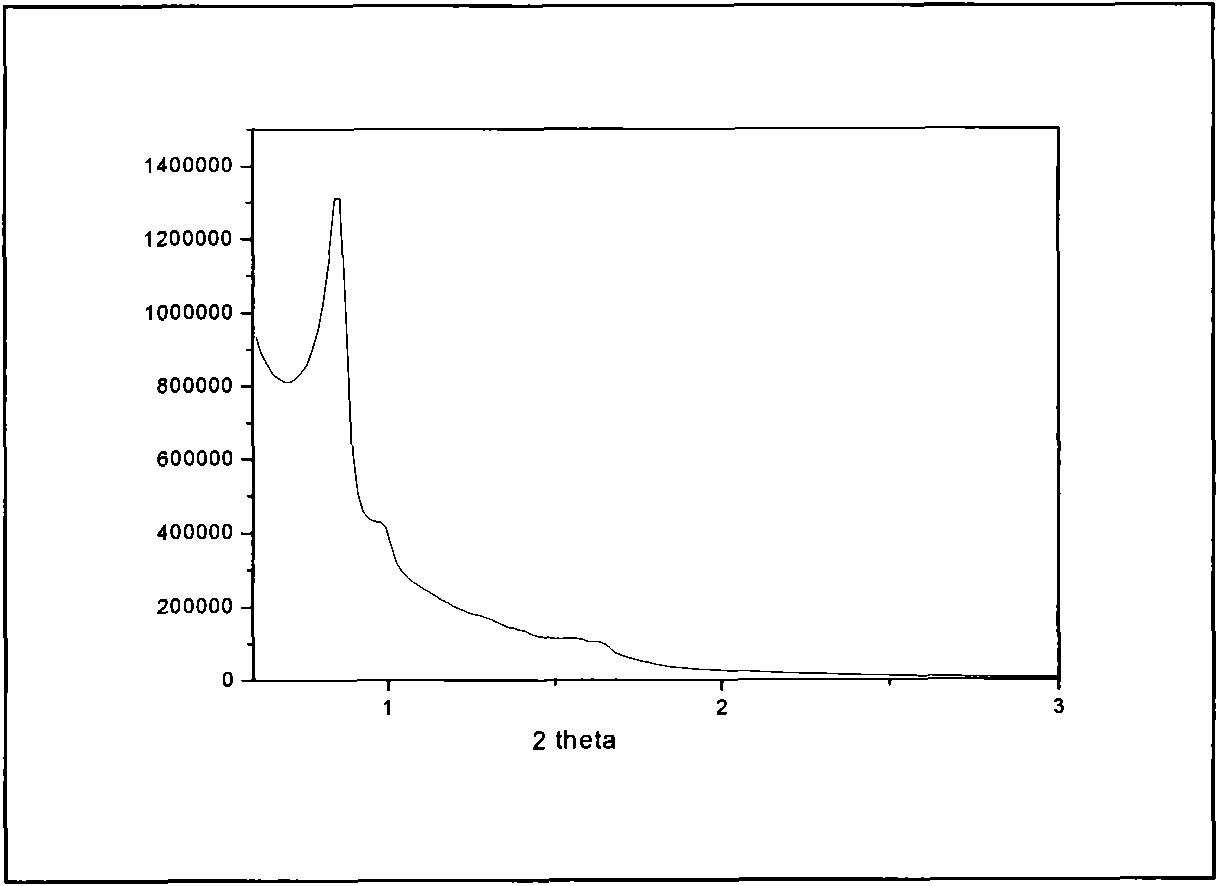

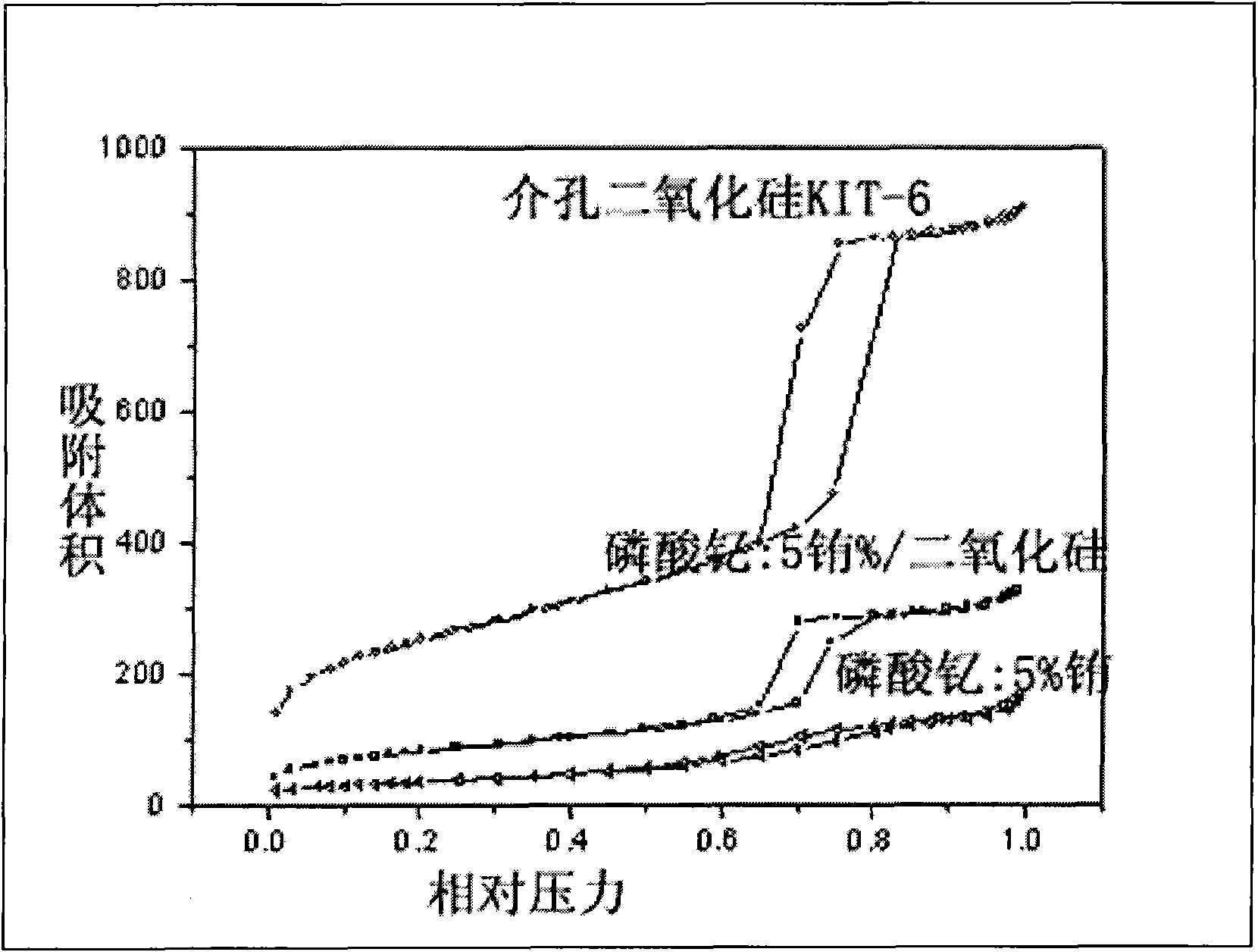

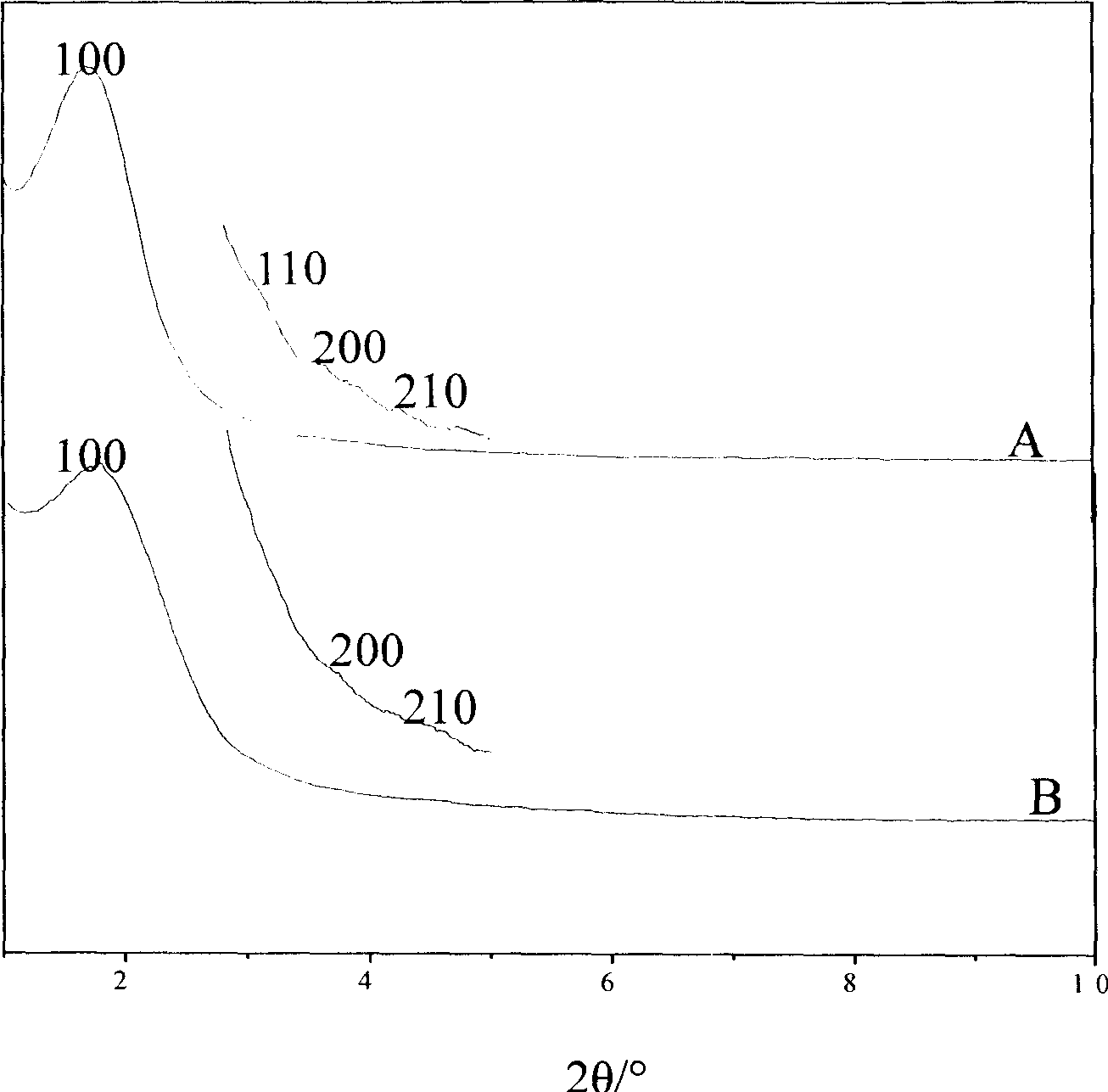

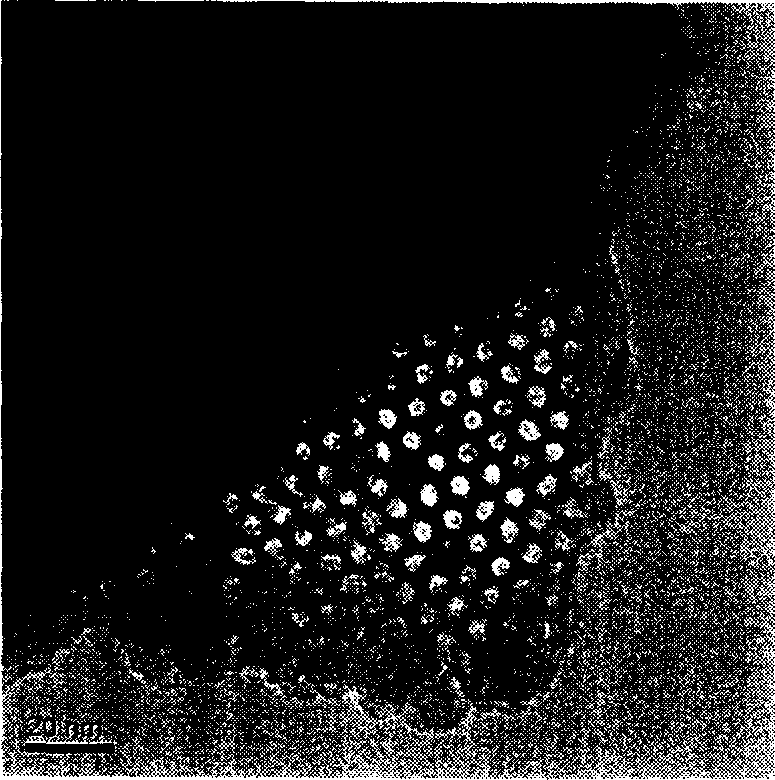

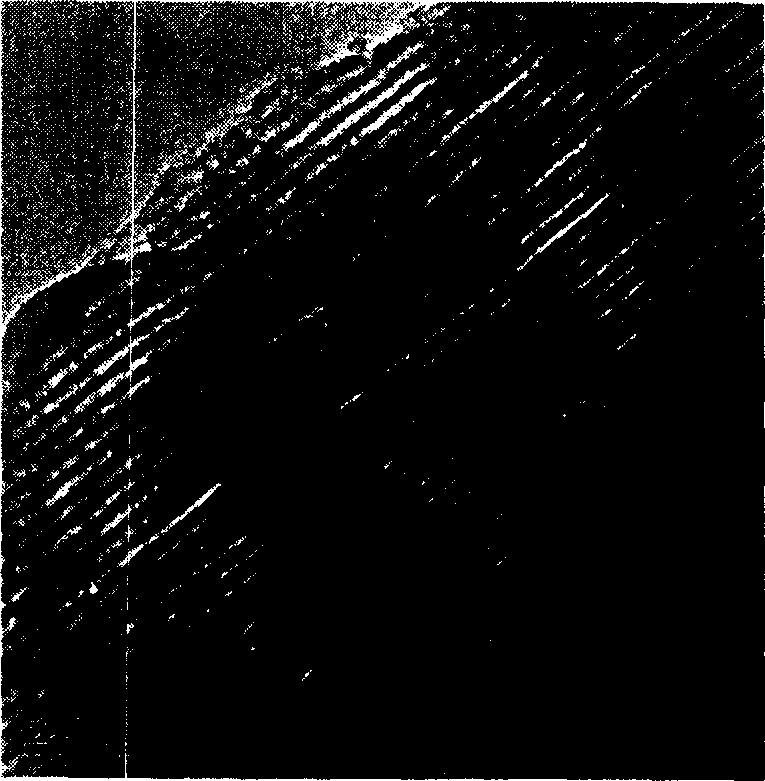

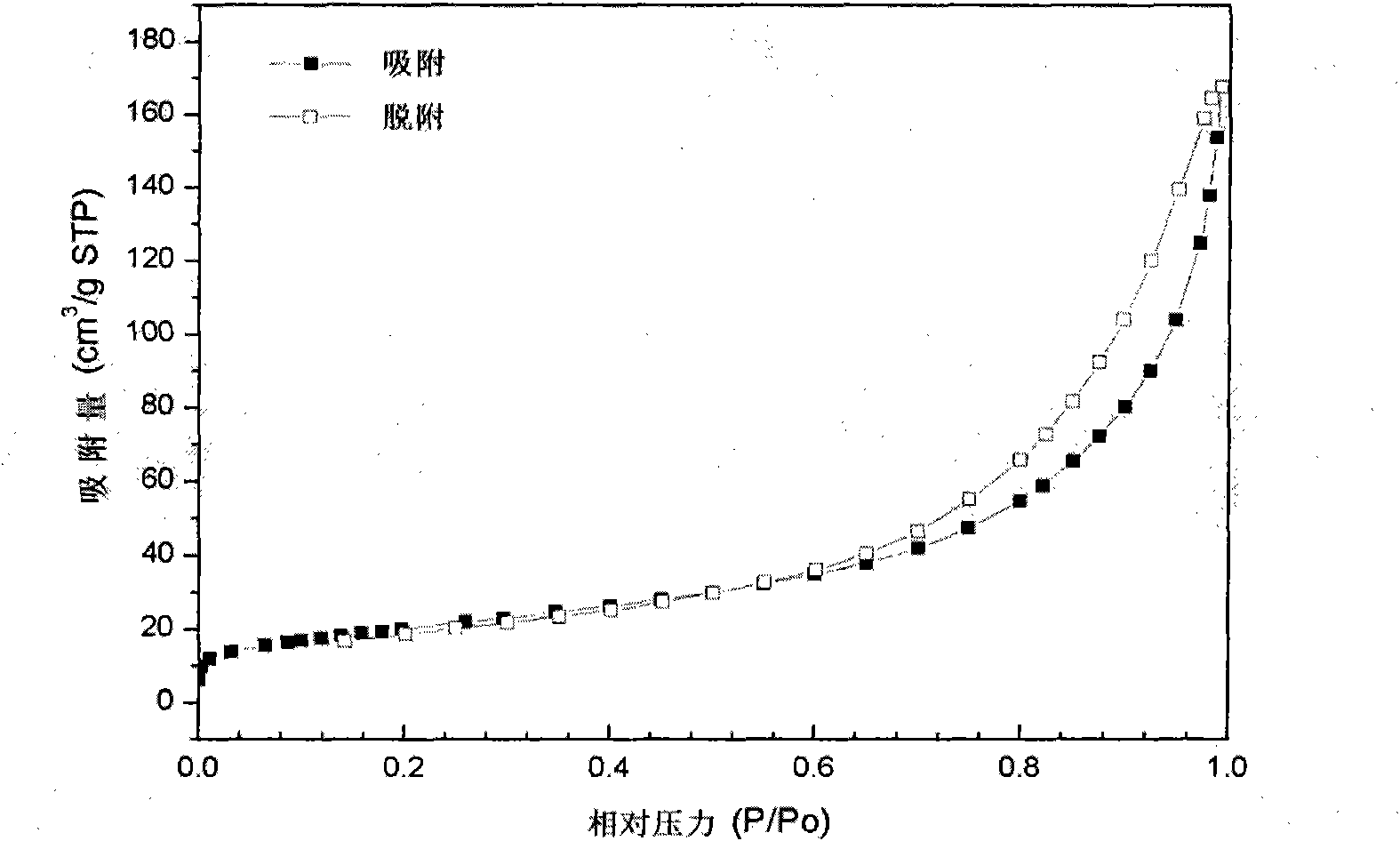

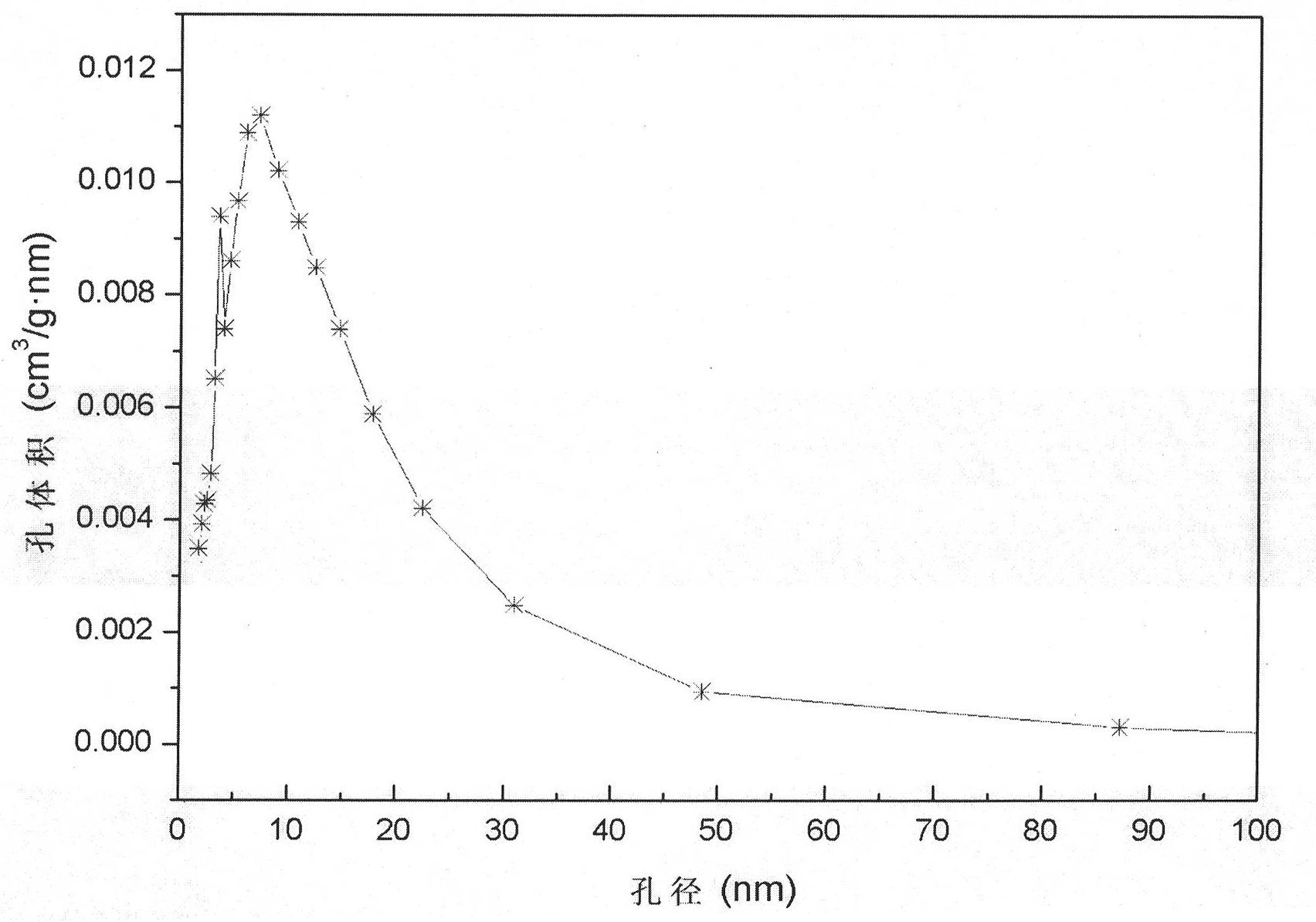

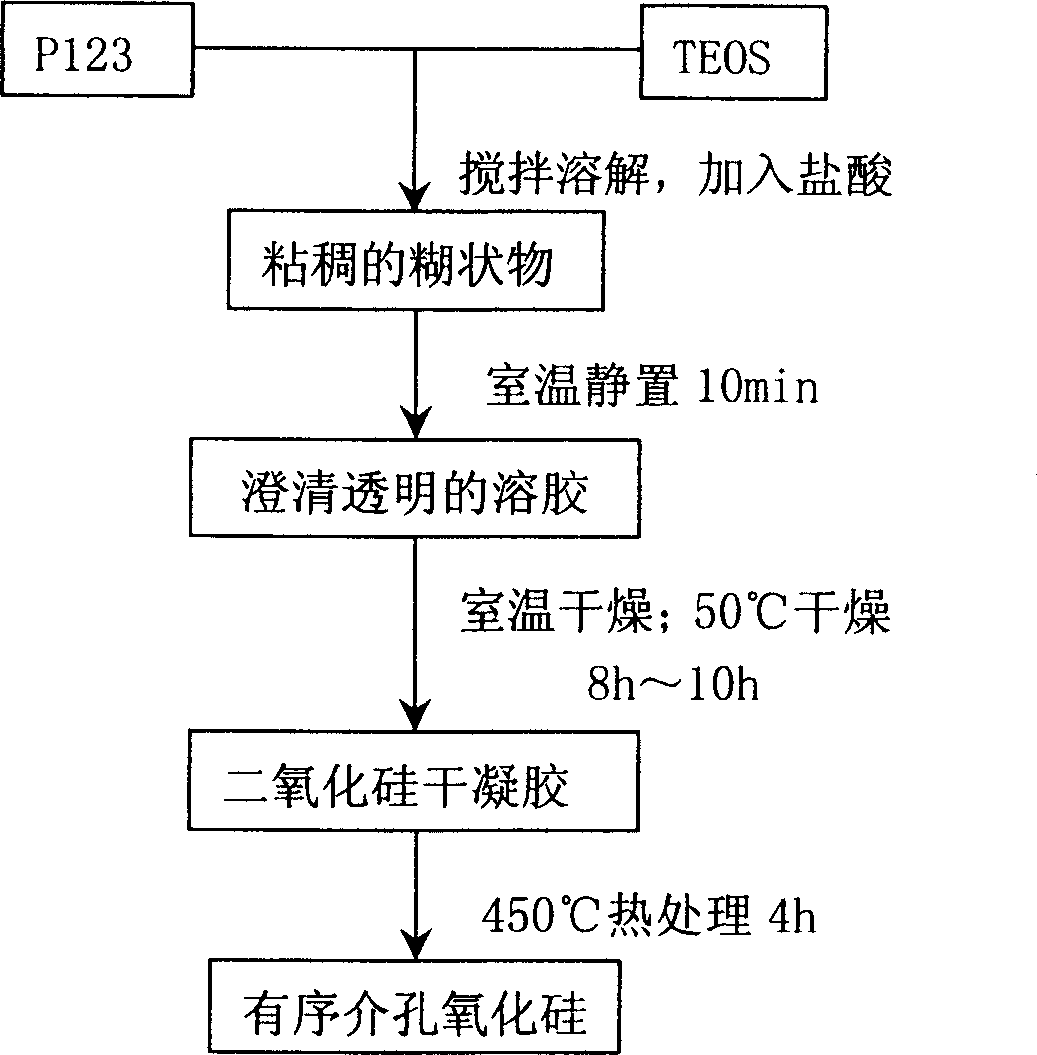

Ordered meso-porous silicon oxide and rapid preparation method thereof

The present invention discloses ordered mesoporous silica and its fast preparation process in an acid system with high concentration solution of three block copolymer P123 as the template agent and ethyl silicate (TEOS) as silicon source. The ordered mesoporous silica has the features of high degree of order, complete spatial group structure, great pore size, thick pore wall and high hydrothermal stability. Its preparation process is simple, fast, easy in operation, environment friendly and low in cost. It may be post-treated properly to prepare excellent adsorbent as one kind of environment protecting material or inorganic separating film with high flux, high selectivity and broad application range.

Owner:NANJING UNIV OF SCI & TECH

Prepn of silica with great specific surface area

The present invention relates to method of preparing silicon oxide material having high degree of order, large pore-mosopore dual pore and high specific surface area. Surfactant is used as structure guide agent combine with inorganic silicon material to assemble into ordered structure, and under the guide of new large pore template agent polystyrene ball, through sol-gel process to form into shape. Surfactant and polystyrene ball are rmoved under high temperature, thereby multigrade silicon oxide material with high degree of order and large pore mesopole is obtd. The invented multi grade porematerial can be extensively used in adsorption, separation, sensor, optical material etc.

Owner:FUDAN UNIV

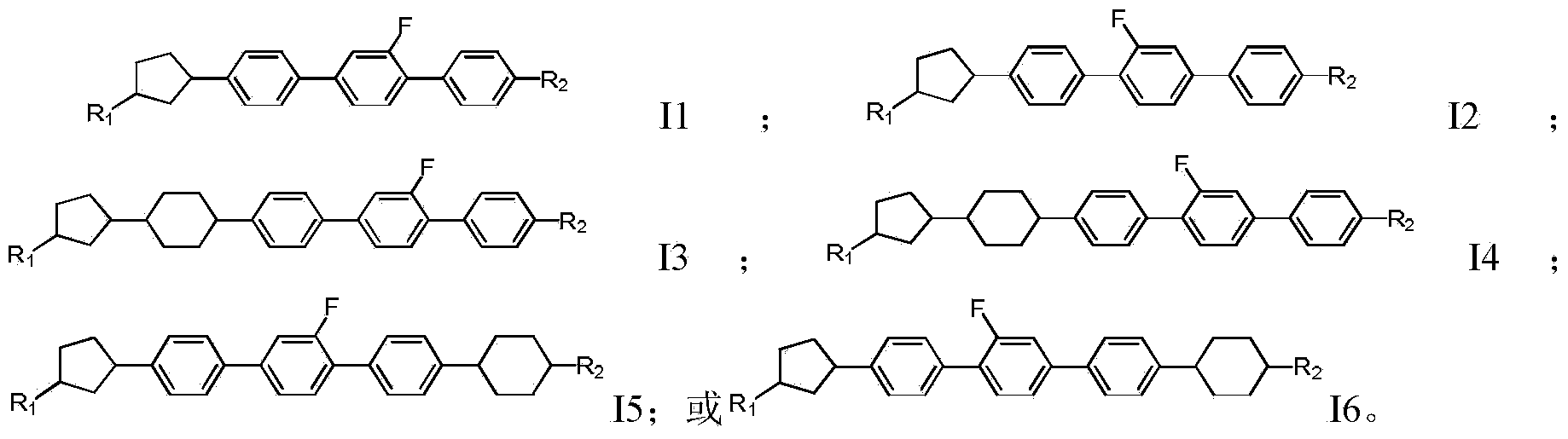

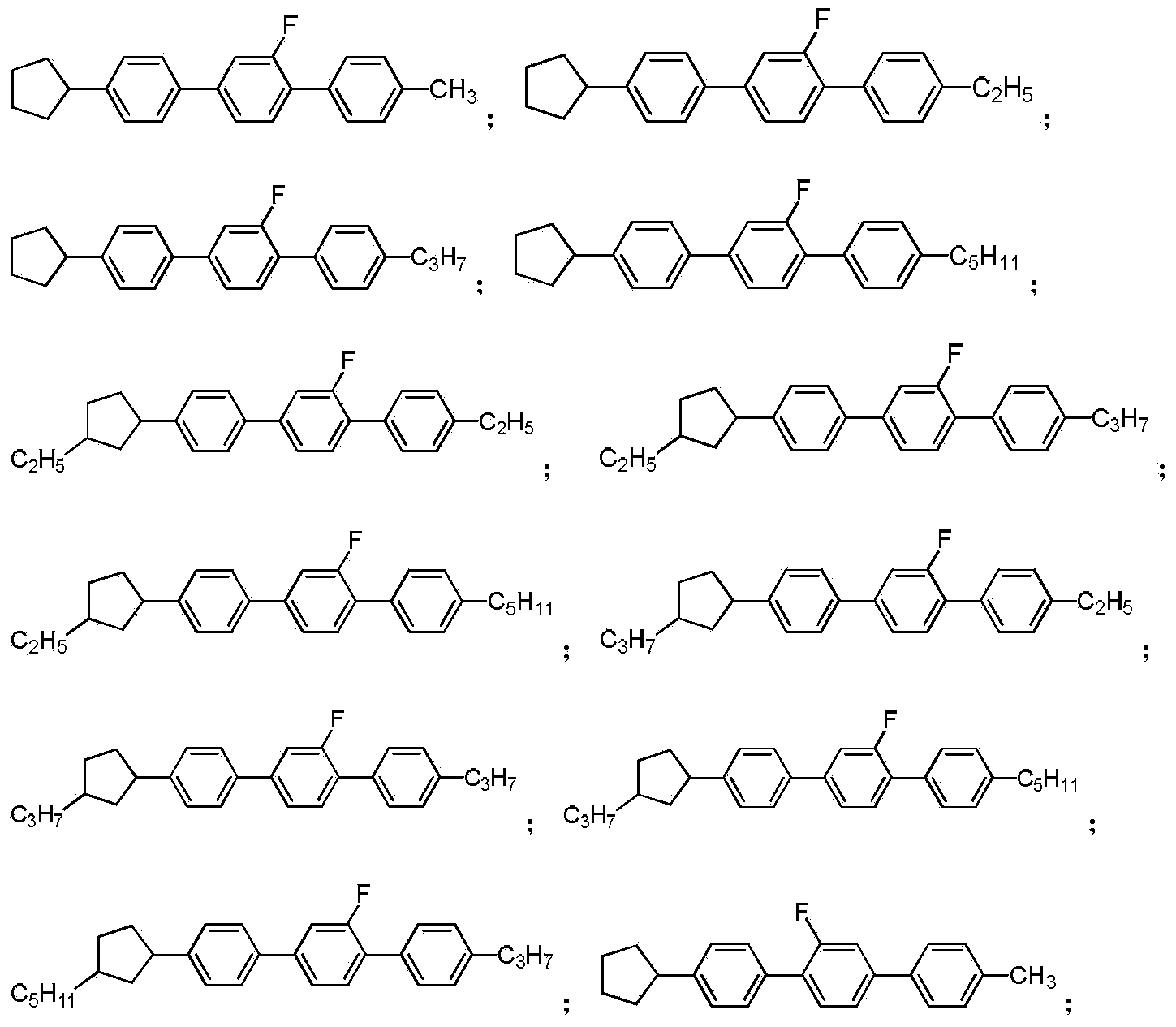

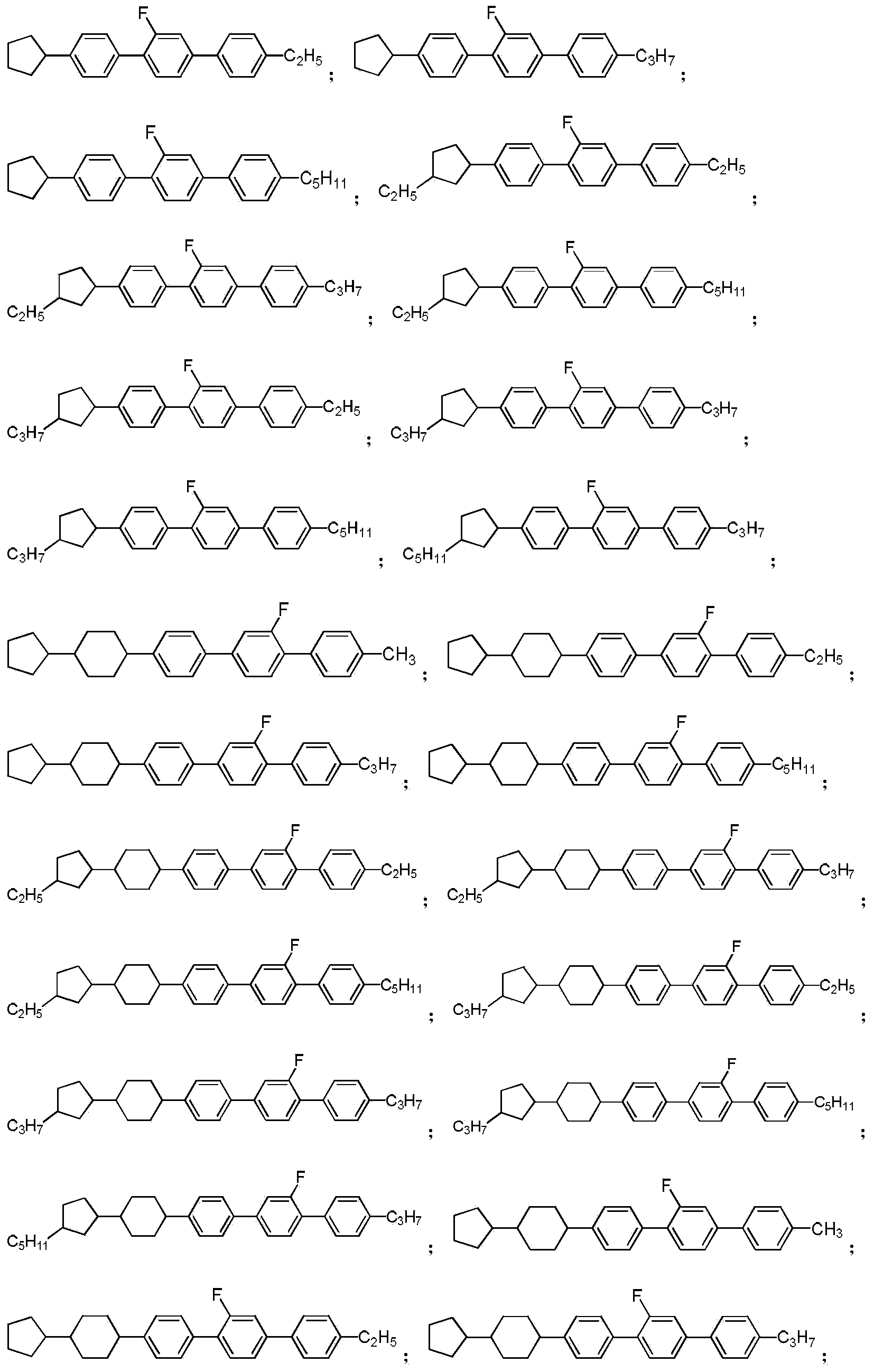

Liquid crystal compound and preparation method thereof as well as liquid crystal mixture containing liquid crystal compound and application of liquid crystal mixture

ActiveCN103525429AImprove long axisImproved Minor Axis RatioLiquid crystal compositionsHalogenated hydrocarbon preparationCrystallographyLiquid crystal

The invention provides a liquid crystal compound and a preparation method thereof as well as a liquid crystal mixture containing the liquid crystal compound and an application of the liquid crystal mixture. The liquid crystal compound has a general formula I as shown in the specification, wherein R1 and R2 are independently selected from one of H, alkyl with 1 to 15 carbon atoms, halogenated alkyl, alkoxy and alkenyl, one or more CH2 radicals in R1 and R2 can be independently substituted by -O-, -S- or -Cis equivalent toC-, and any adjacent two CH2 radicals can not be substituted by -O-O-; n1, n2, n3 and n4 are independently selected from 0 or 1, and at least one of n1 and n4 is 1; any one of X1, X2, X3 and X4 is F, and the others are H. The liquid crystal compound has good chemical, thermal and light stabilities; the addition of cyclopentyl can improve the ratio of a macroaxis to a brachyaxis of the liquid crystal compound and the value of degree of order S of the liquid crystal compound to ensure that the liquid crystal compound has a nematic phase with a wide temperature range and a high elasticity coefficient K.

Owner:JINGMEISHENG OPTOELECTRIC MATERIAL NANJING +1

Preparation method of graphene powder

ActiveCN106744894AImprove the recovery peeling degreeHigh degree of peelingCarbon compoundsLithiumReduction treatment

The invention relates to the technical field of preparation of nanophase materials, and in particular relates to a preparation method of graphene powder. The preparation method comprises the following steps: (1) preparing a graphene oxide solution; (2) adding organic small molecules to the graphene oxide solution, stirring and drying to obtain graphite oxide containing the organic small molecules; and (3) carrying out heat reduction treatment on the dried graphite oxide containing the organic small molecules to obtain graphene powder. The graphene powder prepared by the method provided by the invention has the characteristics of high degree of peeling, thin sheets, few structural defects, good degree of order and excellent electric conductivity, and has great application prospects in the fields of lithium-ion batteries, supercapacitors and the like.

Owner:BEIJING SINEVA MATERIAL TECH CO LTD +2

Method for preparing anodic alumina template by using plastic packaging process and application thereof

InactiveCN102358948AQuality improvementHigh success rate of preparationSurface reaction electrolytic coatingPlastic packagingEconomic benefits

The invention discloses a method for preparing an anodic alumina template by using a plastic packaging process and application thereof. The core point of the method is that the plastic packaging process is utilized for insulation blocking on one surface needing no reaction or treatment of an aluminum sheet, and the method comprises the following steps that: during electrochemical polishing of the aluminum sheet, one surface of the aluminum sheet is sealed by using the plastic packaging process, and the other surface of the aluminum sheet is exposed for polishing; during anodic oxidation of the aluminum sheet, only the surface exposed for polishing is subjected to anodic oxidation due to insulation blocking resulting from plastic packaging; during removal of an aluminum base, by utilizing sealing protection of plastic packaging to the alumina template, a surface of the aluminum base is exposed in a solution and removed so as to obtain the anodic alumina template. The anodic alumina template prepared by the method is colorless and transparent, has a high degree of order and is easy to preserve. According to the invention, high quality alumina templates can be prepared by using plastic package glue cover without any special equipment, and preparation of an alumina template with a large area is made to be simple and easy, thereby greatly improving a success rate of preparing templates, reducing preparation cost for the templates and having remarkable economic benefits.

Owner:JINAN UNIVERSITY

Method for preparing kaoline products for catalytic cracking catalyst

ActiveCN101392183AControl contentImprove performanceCatalytic crackingSilicon compoundsChemical industryHalloysite

Owner:中国高岭土有限公司

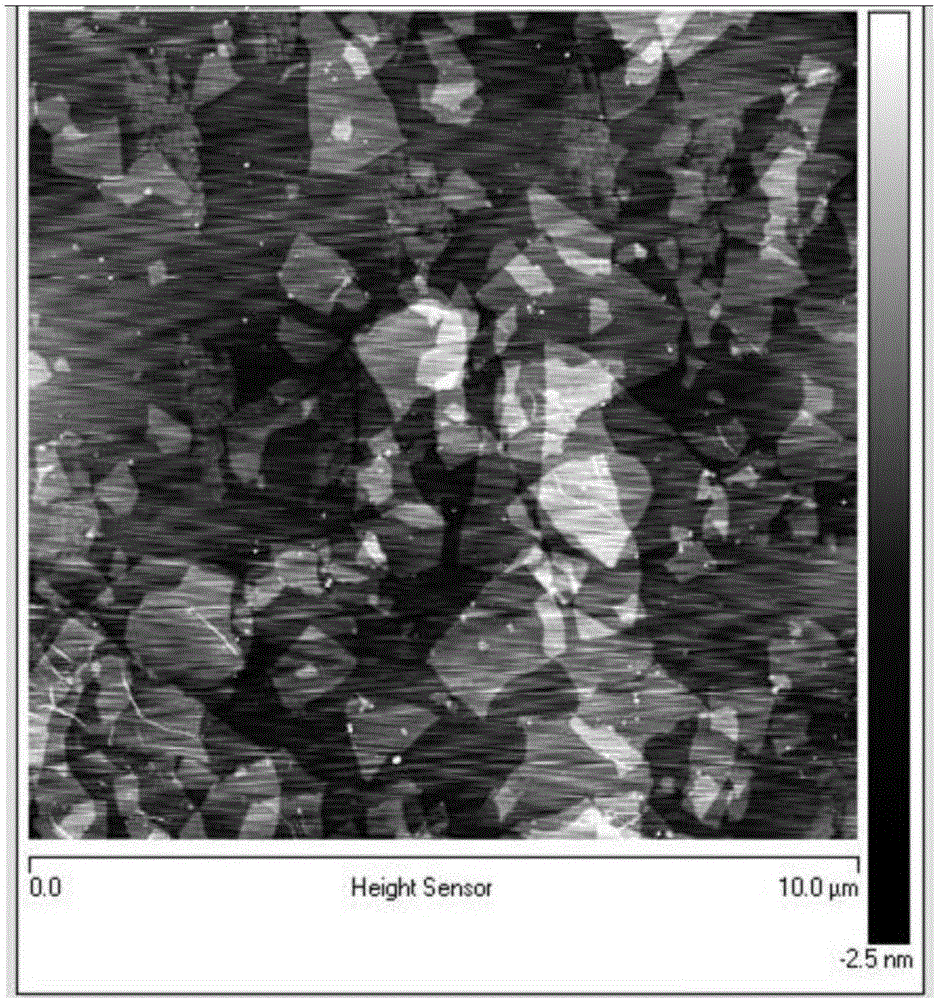

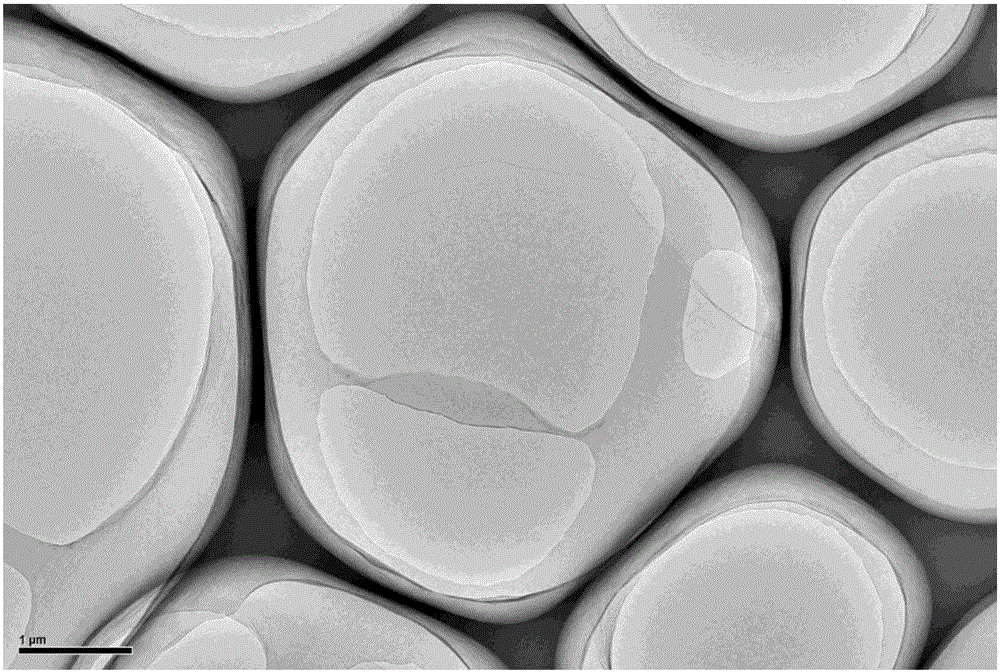

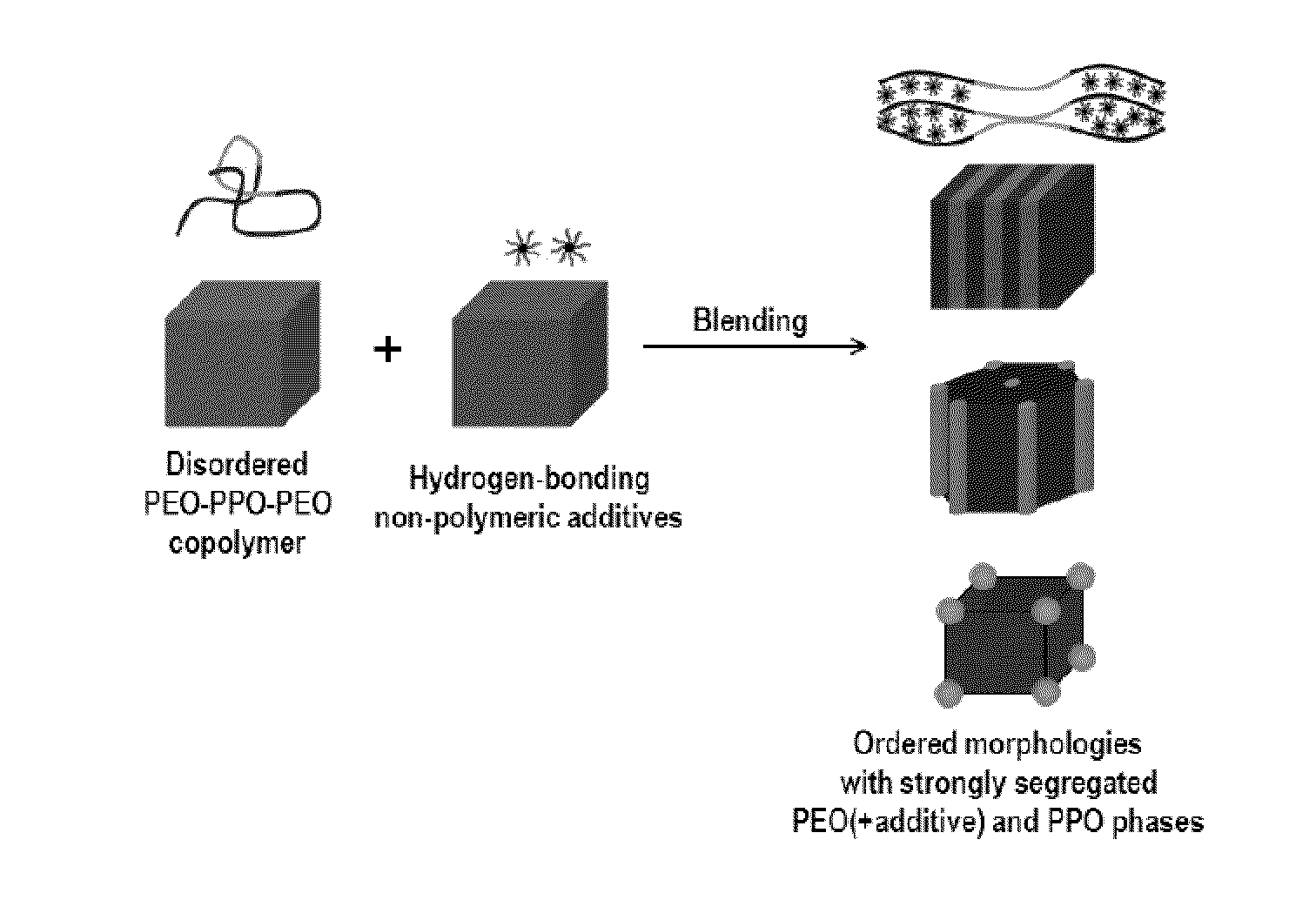

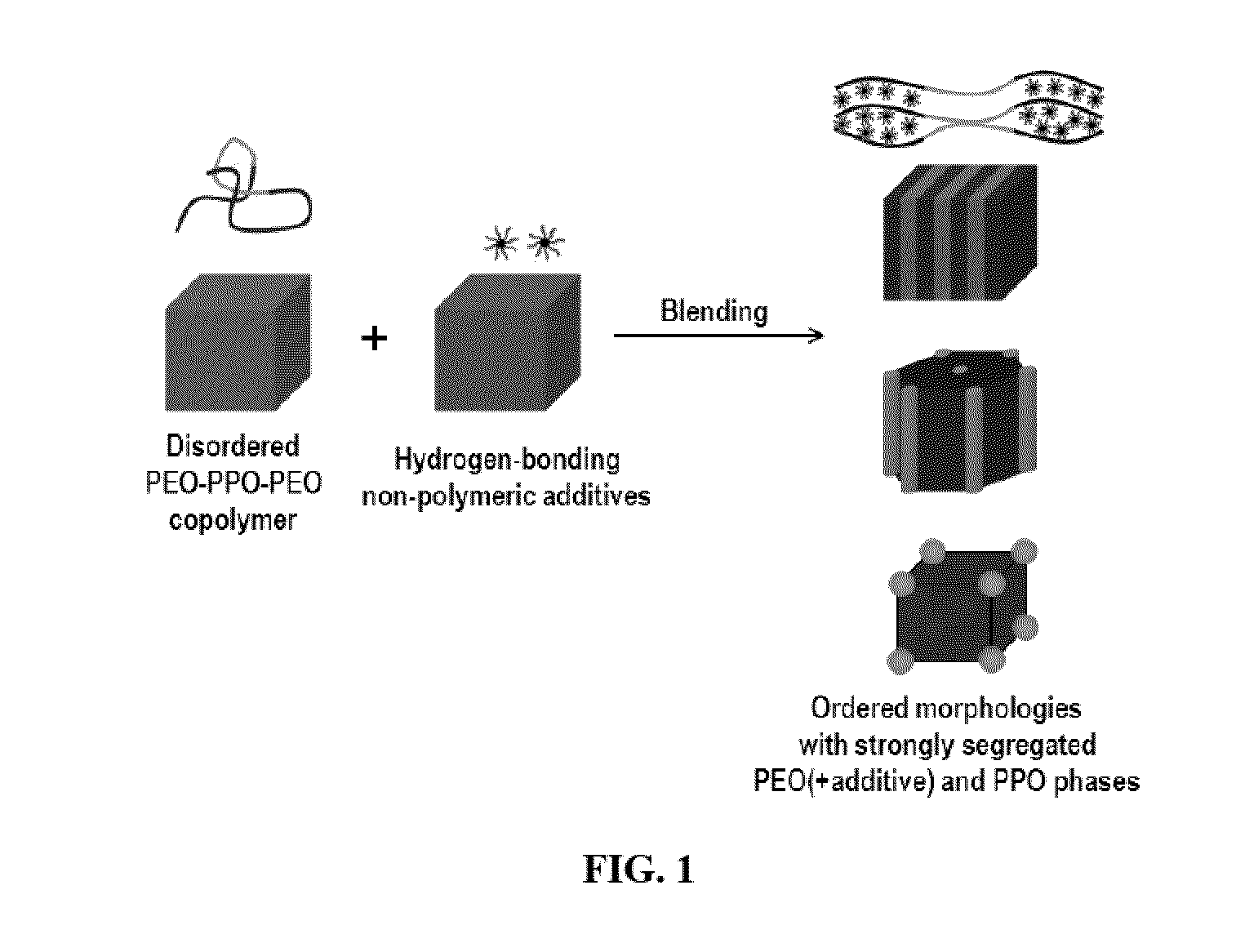

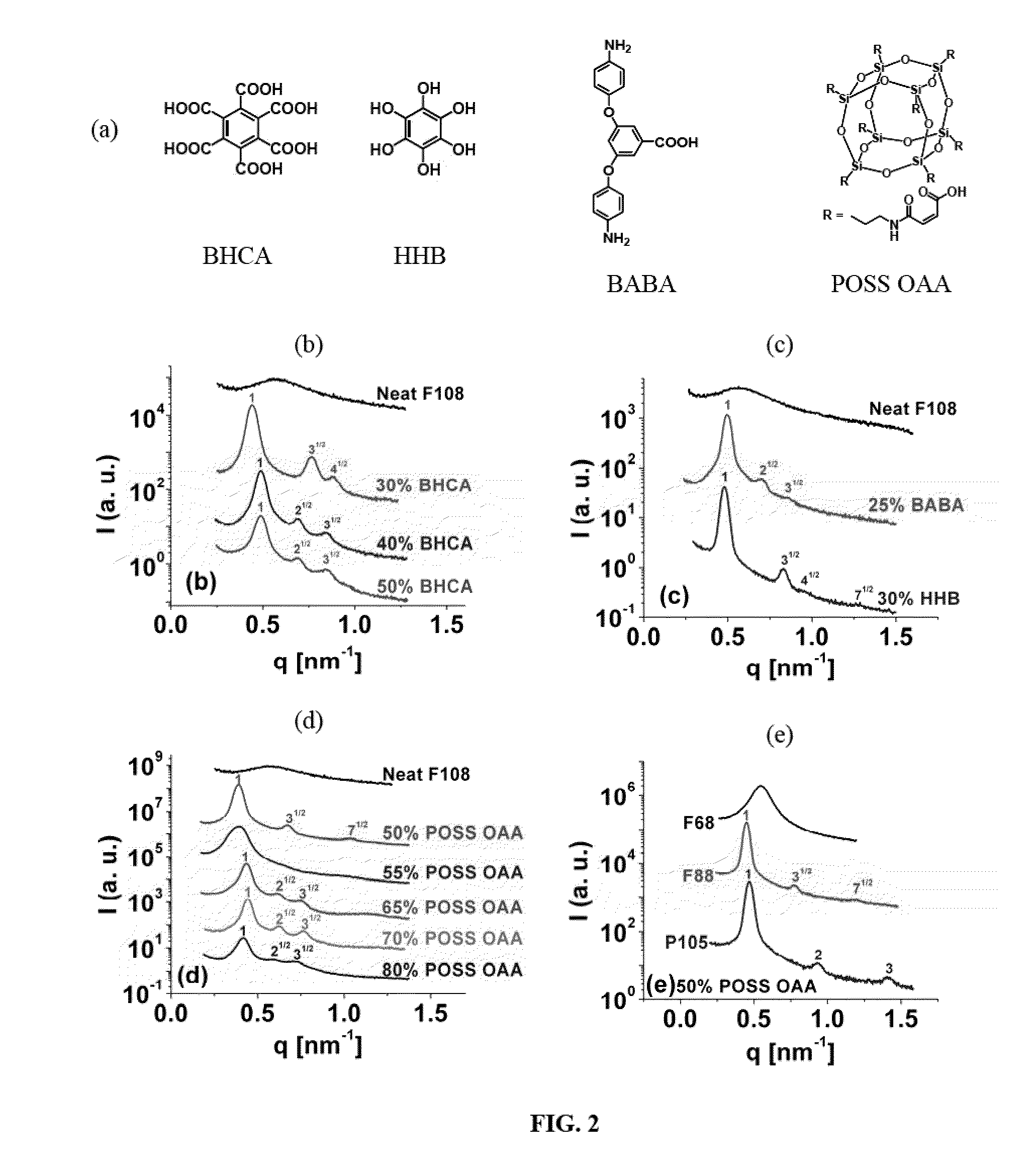

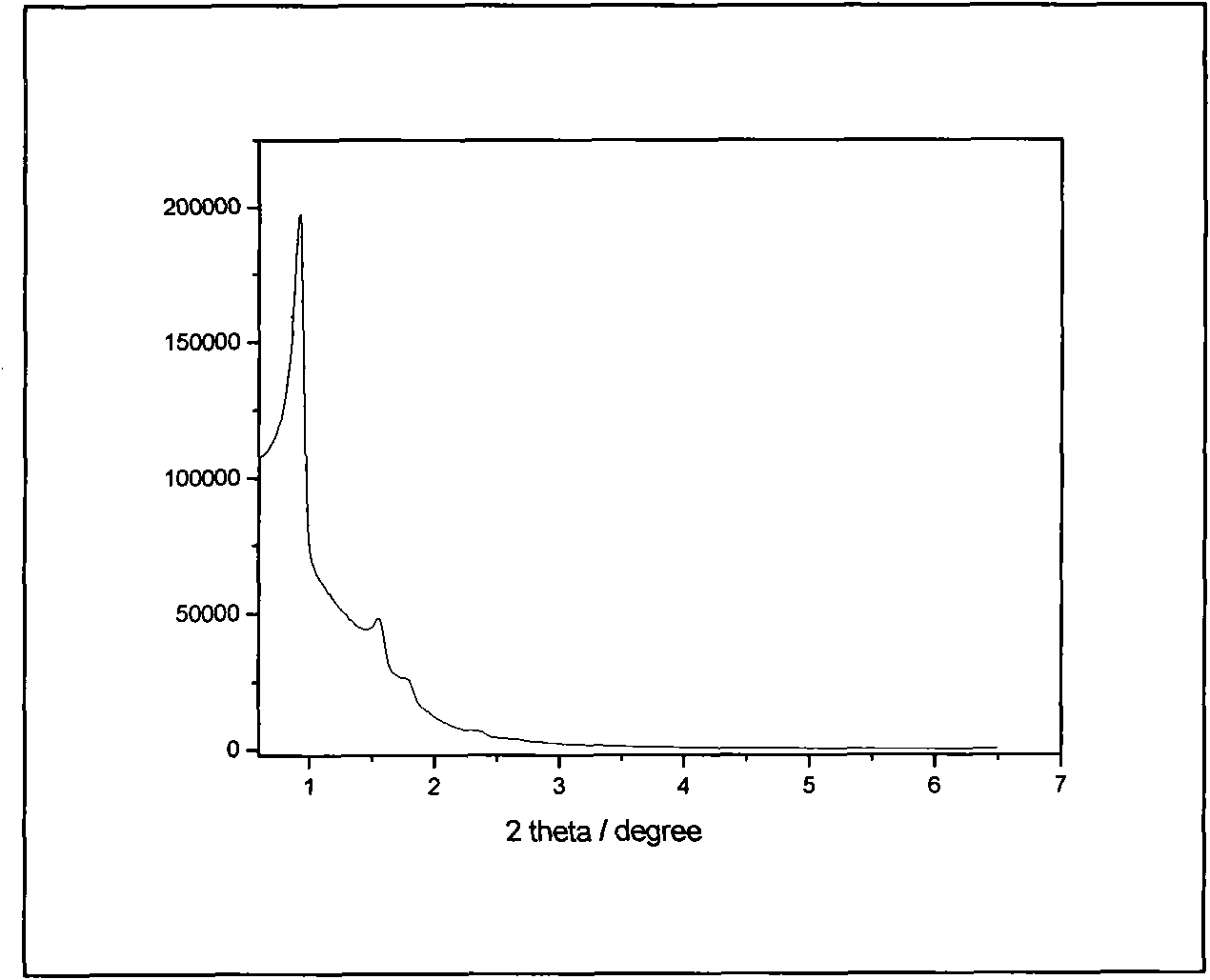

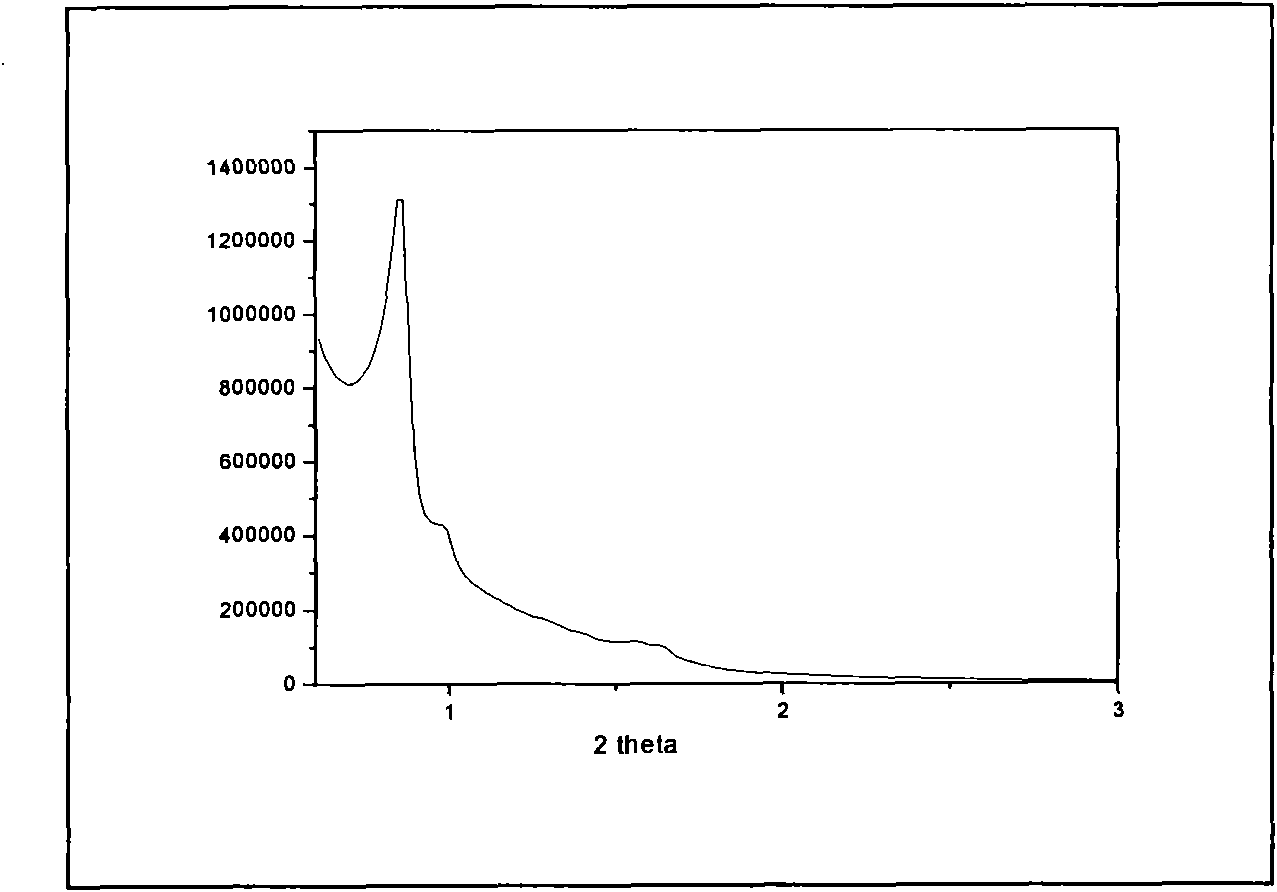

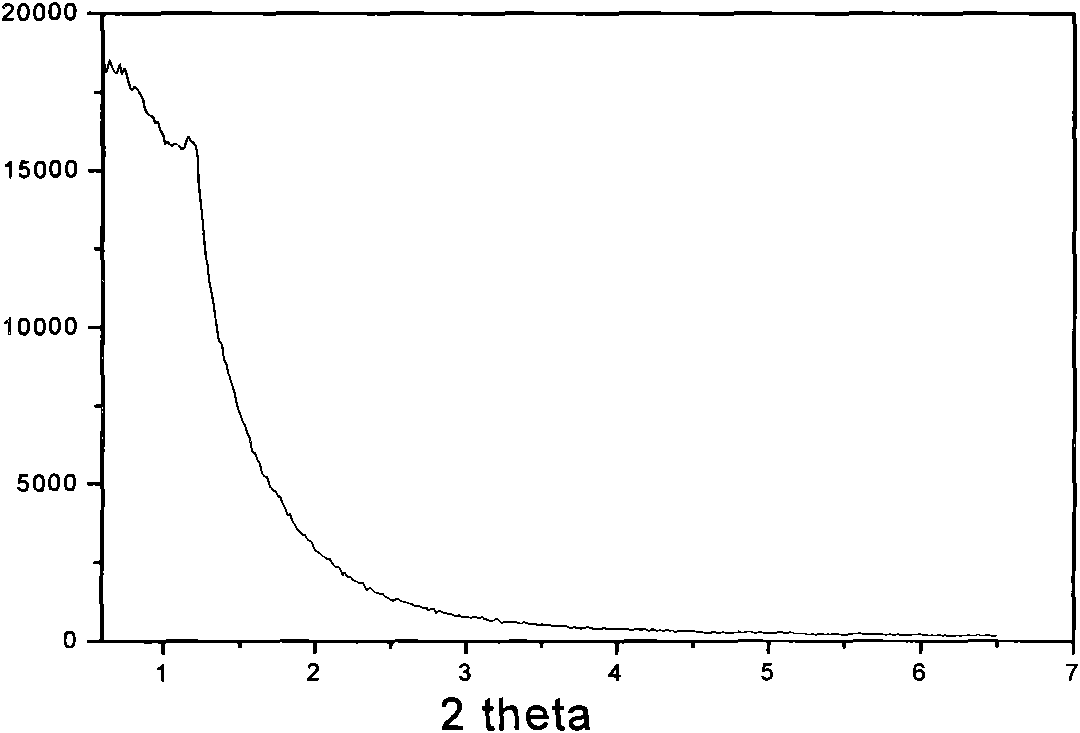

Induced polymer assemblies

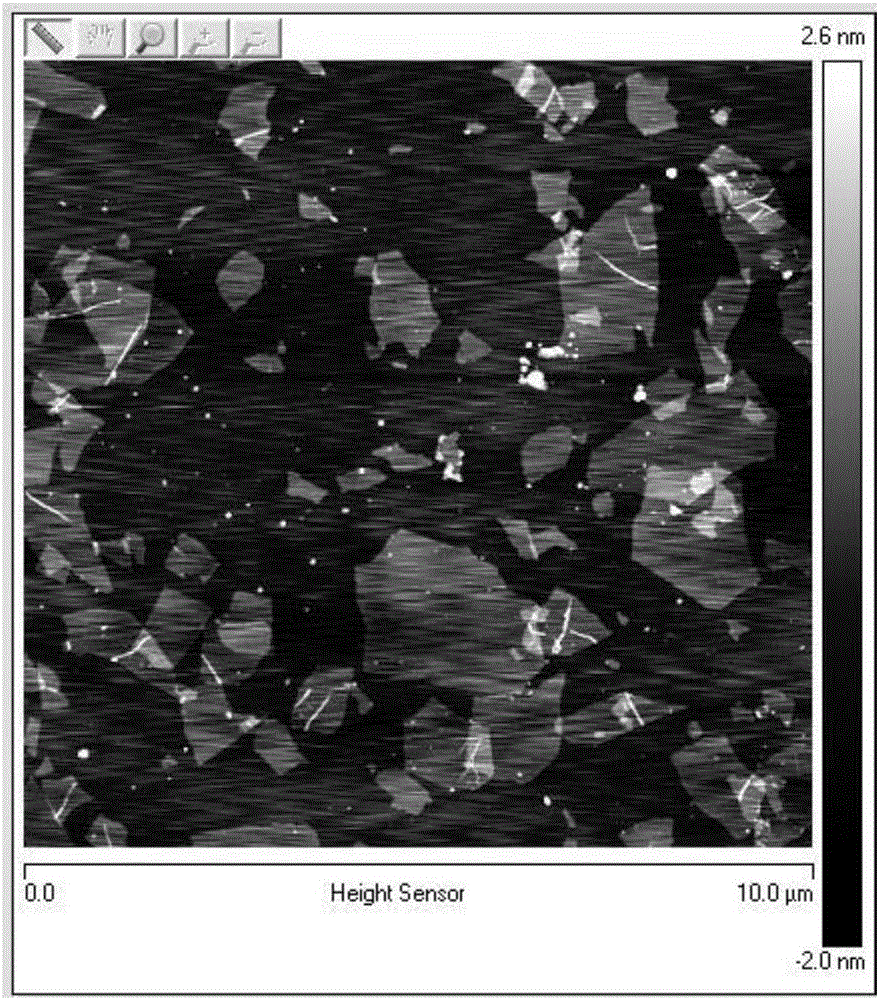

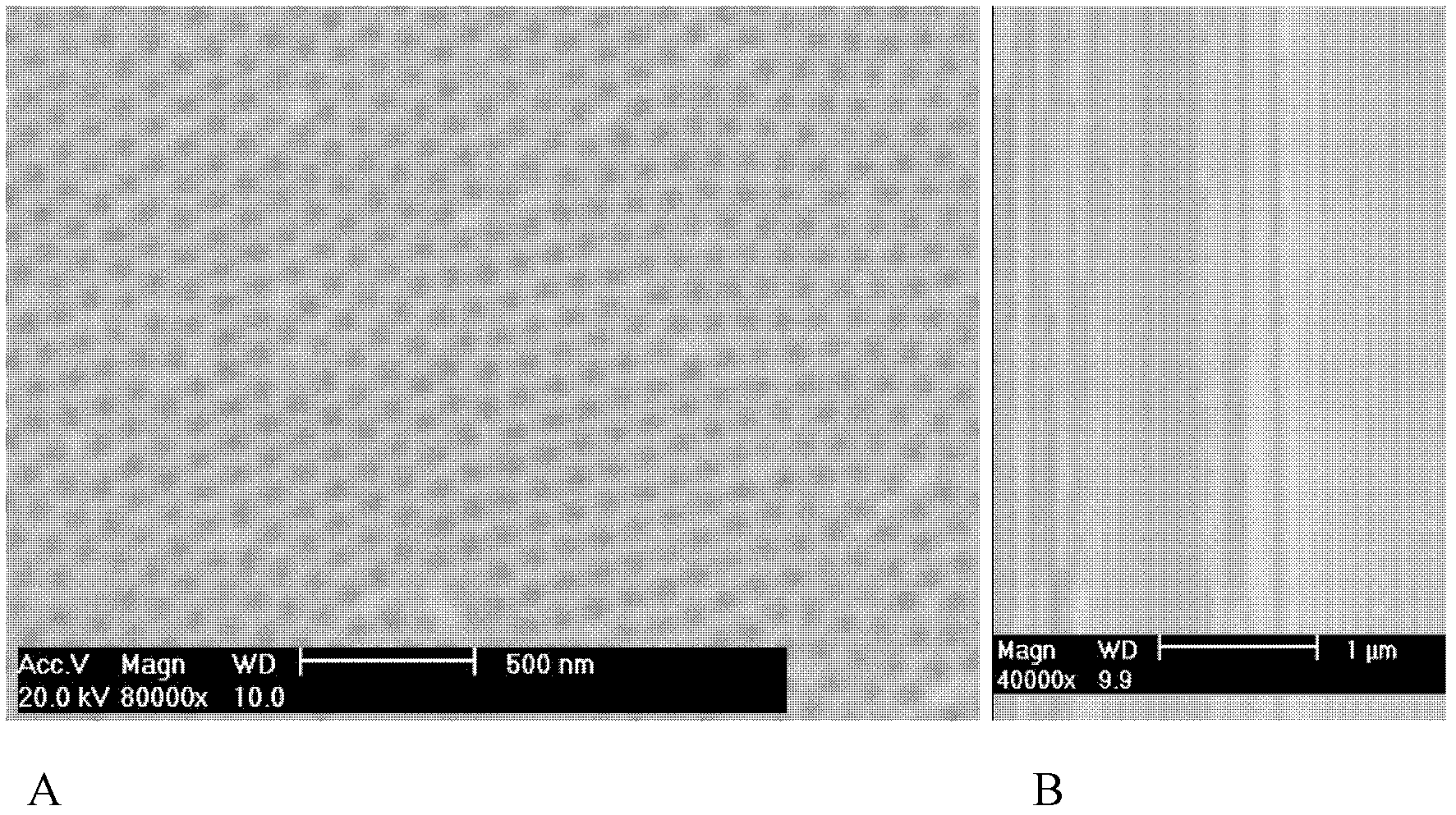

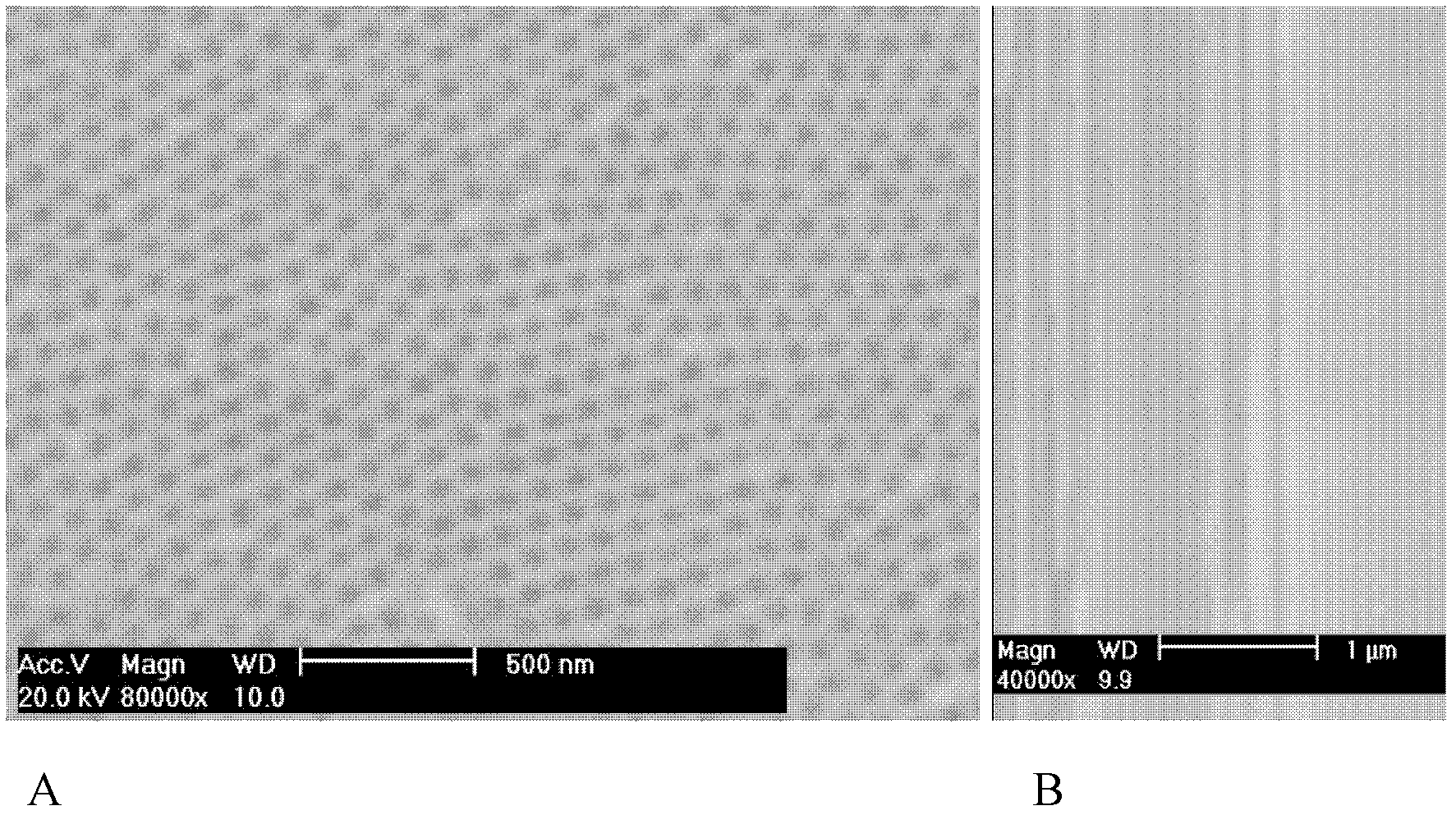

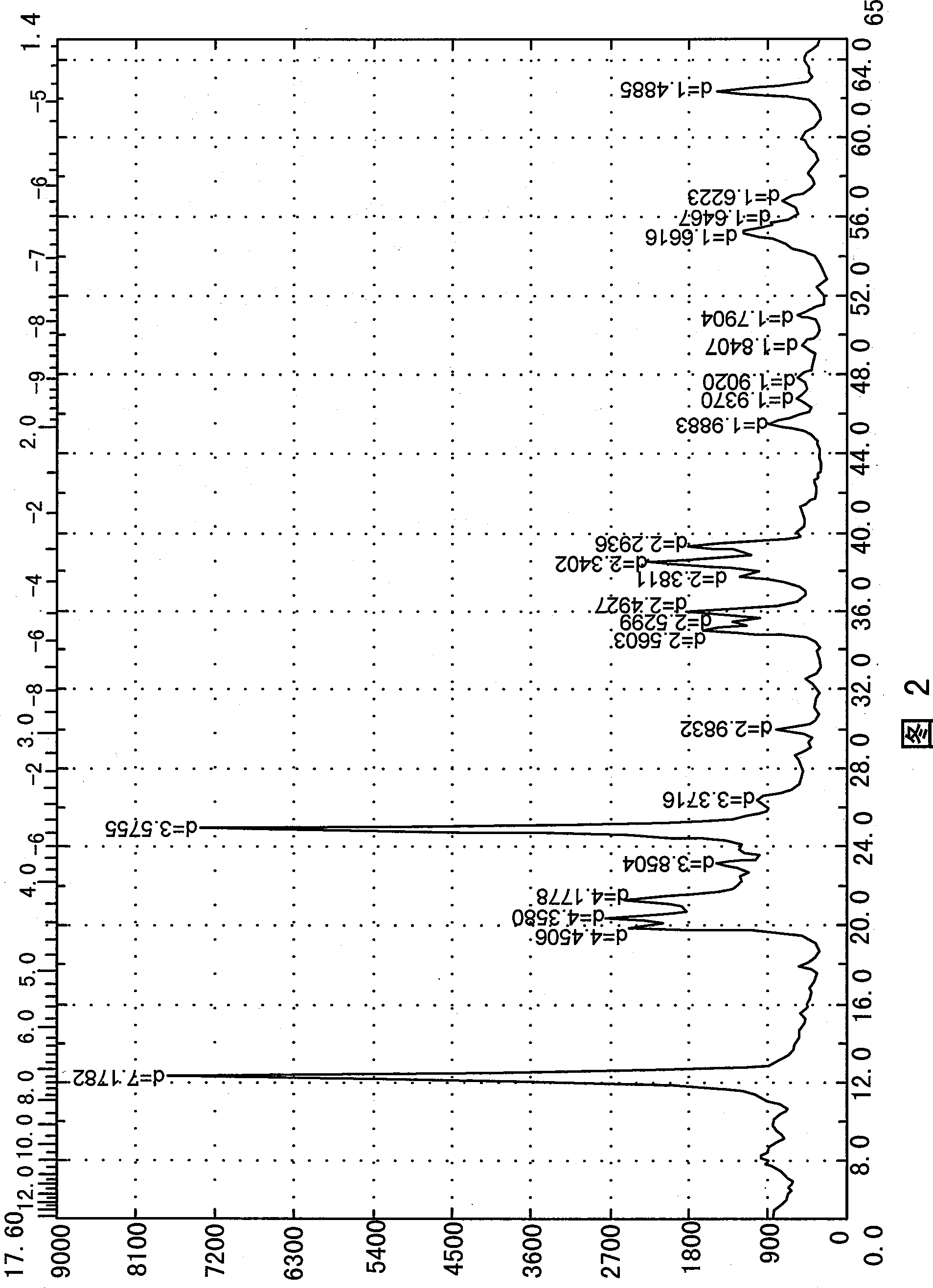

The invention provides compositions and methods for inducing and enhancing order and nanostructures in block copolymers and surfactants by certain nonpolymeric additives, such as nanoparticles having an inorganic core and organic functional groups capable of hydrogen bonding. Various compositions having lattice order and nanostructures have been made from a variety of copolymers or surfactants that are mixed with nonpolymeric additives. Particularly, a variety of nanoparticles with an inorganic core and organic functional groups have been discovered to be effective in introducing or enhancing the degree of orders and nanostructures in diverse block copolymers and surfactants.

Owner:UNIV OF MASSACHUSETTS

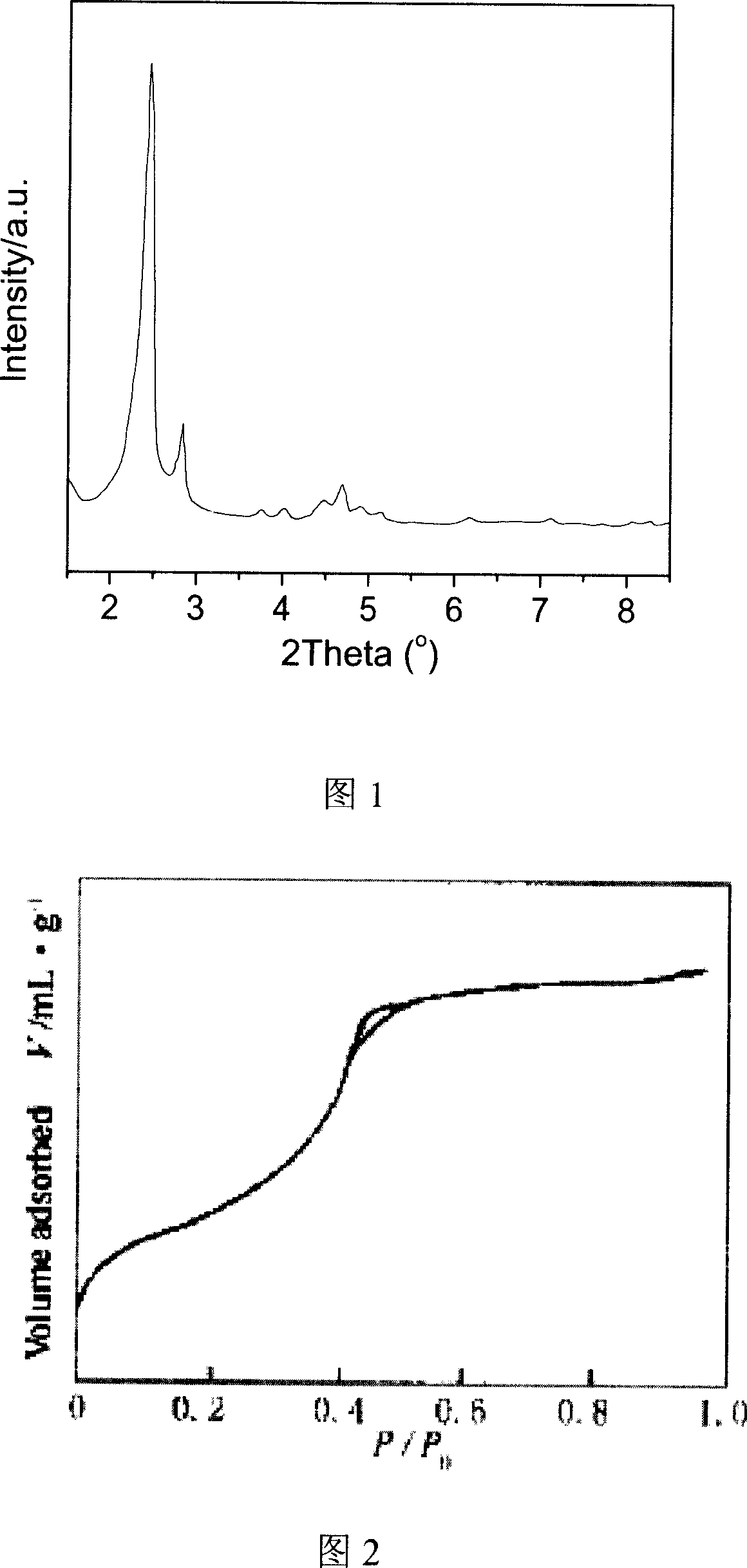

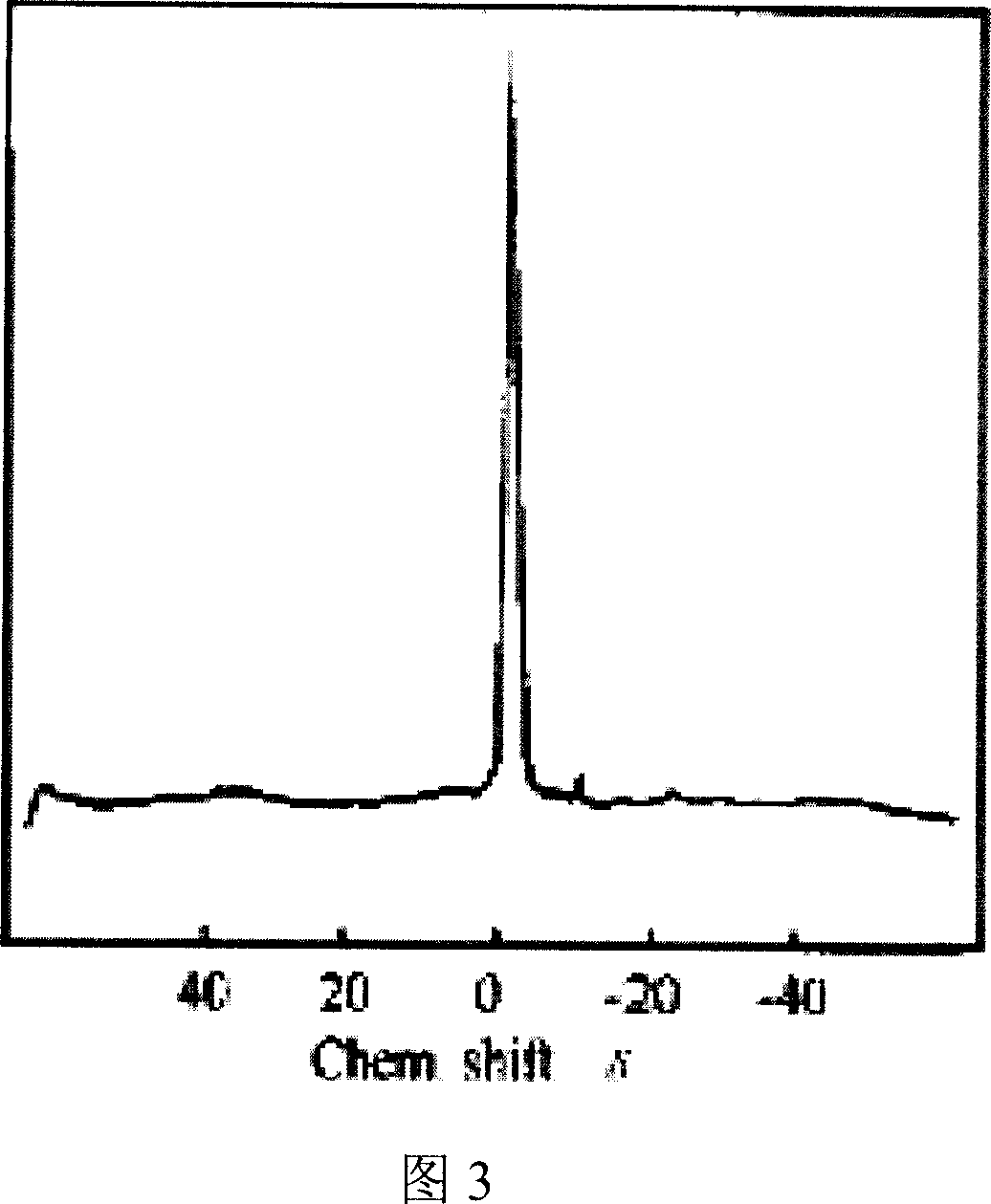

Method for preparing high degree of order and high stability molecular sieve MCM-41 medium pores

InactiveCN1626442AReduce dosageHigh degree of orderMolecular sieve catalystsCrystalline aluminosilicate zeolitesAlcoholColloid

A process for preparing high-ordering high-stability mesoporous molecular sieve MCM-41 by using the ammonium dodecyl (or tetradecyl or hexadecyl or hexadecyl or octadecyl) trimethyl chloride as template and the C1-C5 alcohol as organic disperser includes preparing microcrystalline solution and preparing colloid.

Owner:CHINA PETROLEUM & CHEM CORP

Mesoporous rare earth phosphate and preparation method thereof

The invention discloses a mesoporous rare earth phosphate and a preparation method thereof, belonging to the field of porous nano-material. The method, which takes mesoporous silicon dioxide with an ordered pore channel structure as a hard template agent, comprises the steps of adding homogeneous solution of soluble rare-earth salts / strong phosphoric acid / concentrated nitric acid in the silicon dioxide pore channel, removing the nitric acid solvent through direct volatilization, thus precipitating the phosphate in the pore channel; further leading the rare earth phosphate to be cured in the mesoporous pore channel through high-temperature roasting treatment, removing the silicon dioxide hard template agent, thus obtaining the mesoporous rare earth phosphate. The mesoporous rare earth phosphate has the characteristics of high degree of order, adjustable pore diameter and mesoporous structure, large specific surface area, pore diameter, pore volume and the like, with the specific surface area being 100-500m / g, the pore diameter being 3-8nm, and the pore volume being 0.15-1.5cm / g. The prepared mesoporous rare earth phosphate can be used for the embedding treatment of radioactive wastes.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

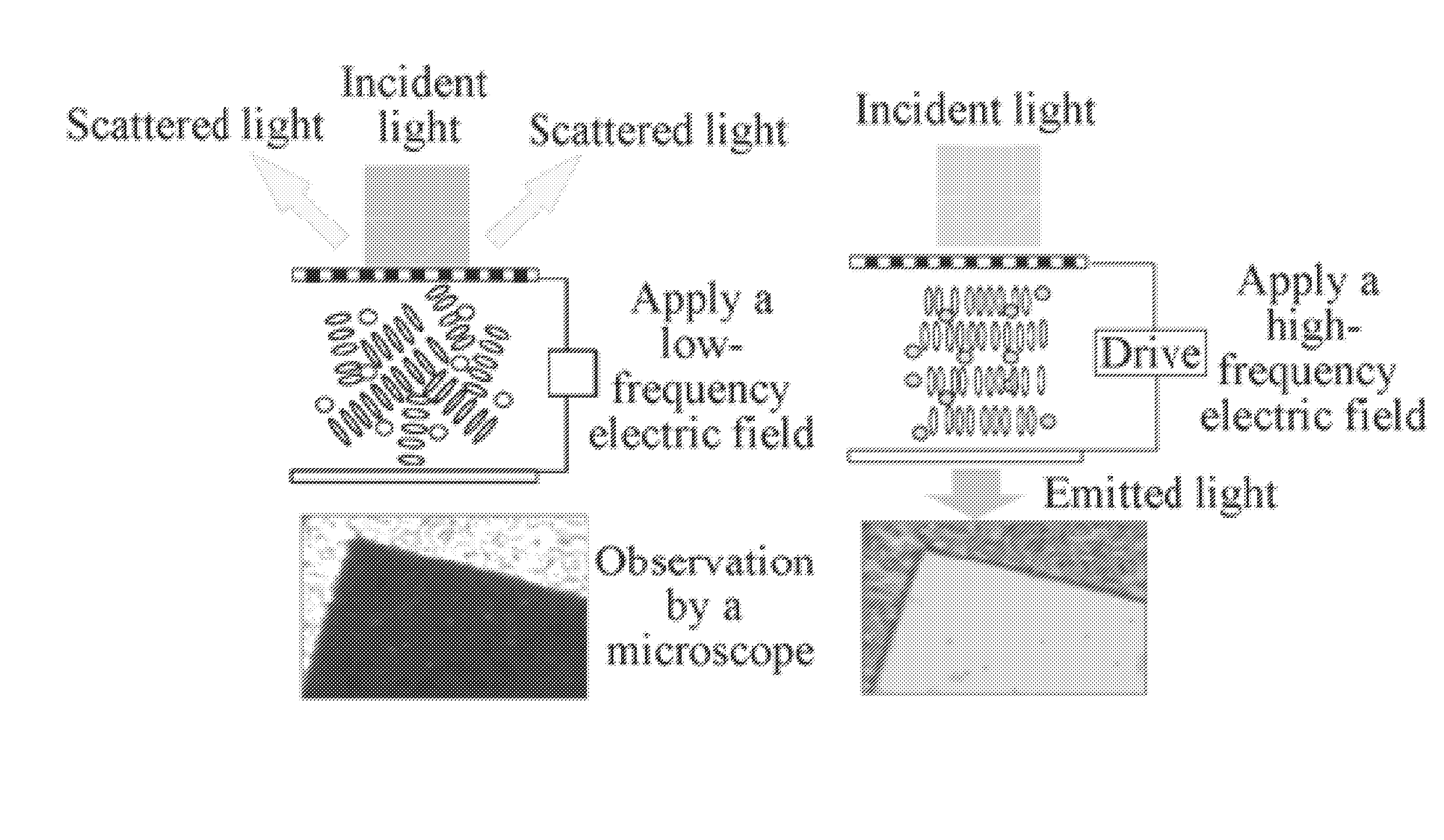

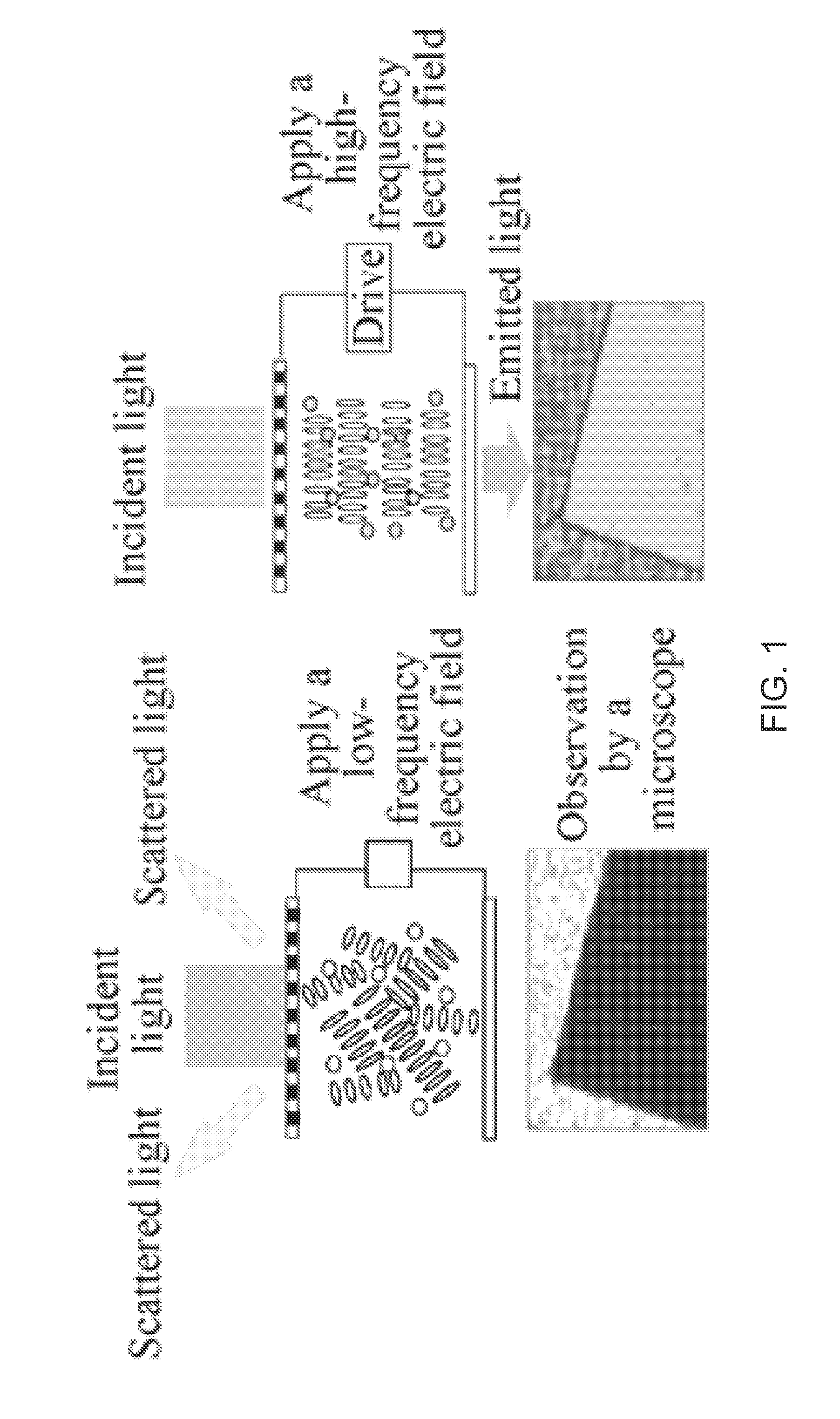

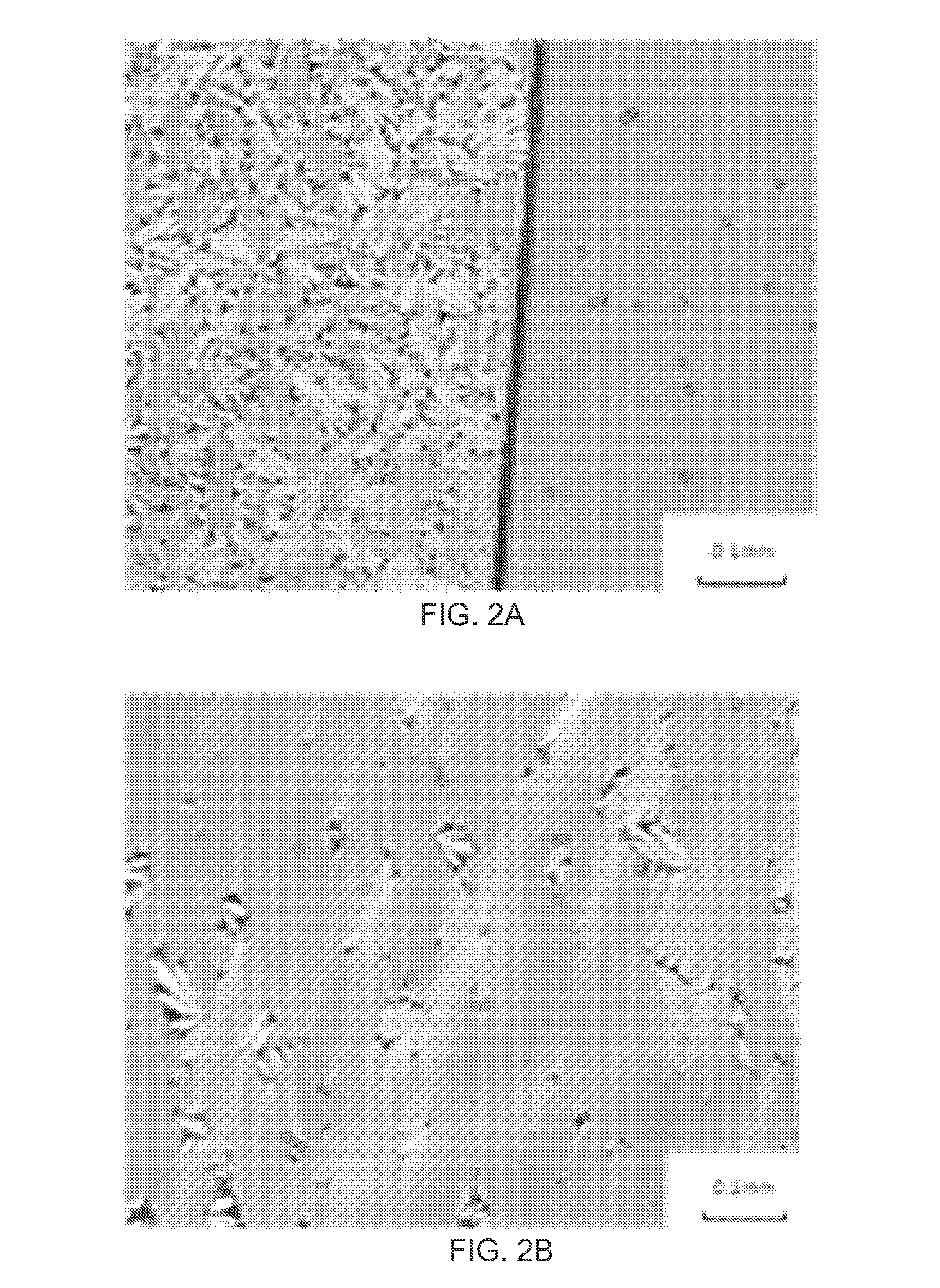

High scattering smectic liquid crystal material and display device using the same

ActiveUS20130342775A1Increase scatteringImprove display qualityLiquid crystal compositionsNon-linear opticsStable stateSimple Organic Compounds

The present invention relates to a high scattering smectic liquid crystal material and display device using the same. In the present invention, a series of smectic A phase liquid crystals having compact arrangement of crystal domains or a series of smectic liquid crystal mixed materials having a degree of order higher than that of the smectic A phase and an optical texture different from that of the smectic A phase are obtained by mixing a smectic liquid crystal with an organic compound having a high optical anisotropy (Δn) or mixing different types of smectic phases. When used in a smectic stable state liquid crystal display pattern, these materials have high scattering properties and can effectively improve the contrast of a smectic liquid crystal display device. The present invention also improves contrast when it used in a reflective smectic liquid crystal display device.

Owner:HALATION PHOTONICS CORP

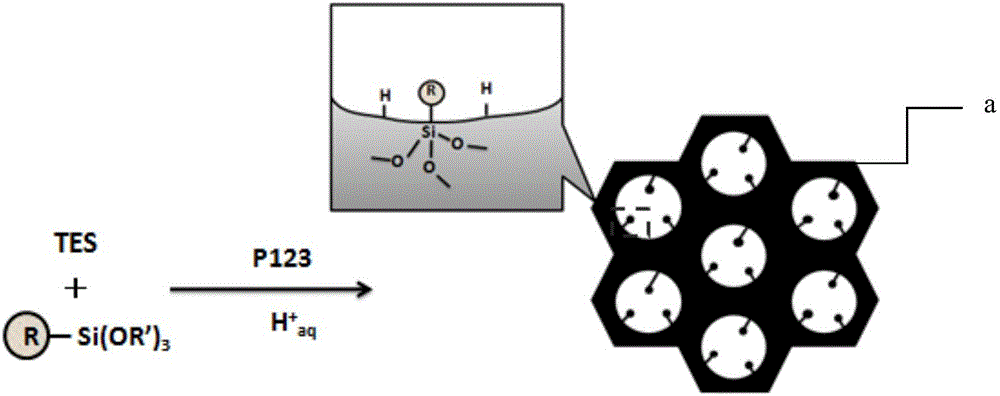

Synthetic method of organic functional mesoporous silicon oxide

ActiveCN106744991AEvenly distributedPore order is not destroyedSilicaPigment treatment with organosilicon compoundsPolyethylene oxideSilanes

The invention relates to a synthetic method of organic functional mesoporous silicon oxide. The method comprises the steps of coupling an organic functional group to ordered mesoporous silicon oxide through a copolymerization method in one step in an acidic condition to obtain the organic functional mesoporous silicon oxide, the functional degree of which is far greater than the grafting rate of a conventional copolymerization method, by taking triethoxy silane and tri alkoxy organic silane coupling agents as a silicon source and a polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123) as a surfactant. In a reaction process, by controlling the proportion of adding amount of the organic silane coupling agent and triethoxy silane, the functional degree of the mesoporous silicon oxide and the degree of order of ducts can be regulated.

Owner:SOUTHEAST UNIV

Preparation method of porous alumina template

InactiveCN104357887AHigh degree of orderPreparation conditions are easy to controlSurface reaction electrolytic coatingNanotechnologyOxalateElectrolysis

The invention discloses a preparation method of a porous alumina template and belongs to the technical field of nanoimprint. The preparation method comprises the following operation steps: (1) performing ultrasonic cleaning on the surface of an aluminum sheet; (2) annealing under the condition of a high temperature to eliminate the internal stress of the aluminum sheet; (3) performing electrochemical polishing in the mixed solution of perchloric acid and ethanol; (4) performing primary anodic oxidation in an oxalic acid solution; (5) performing secondary anodic oxidation in an oxalic acid solution; (6) finally, performing pore broadening on the aluminum sheet. The porous alumina template prepared by use of the preparation method has the advantages of high degree of order, stable preparation method and the like, and is suitable for industrial popularization and utilization.

Owner:WUXI IMPRINT NANO TECH

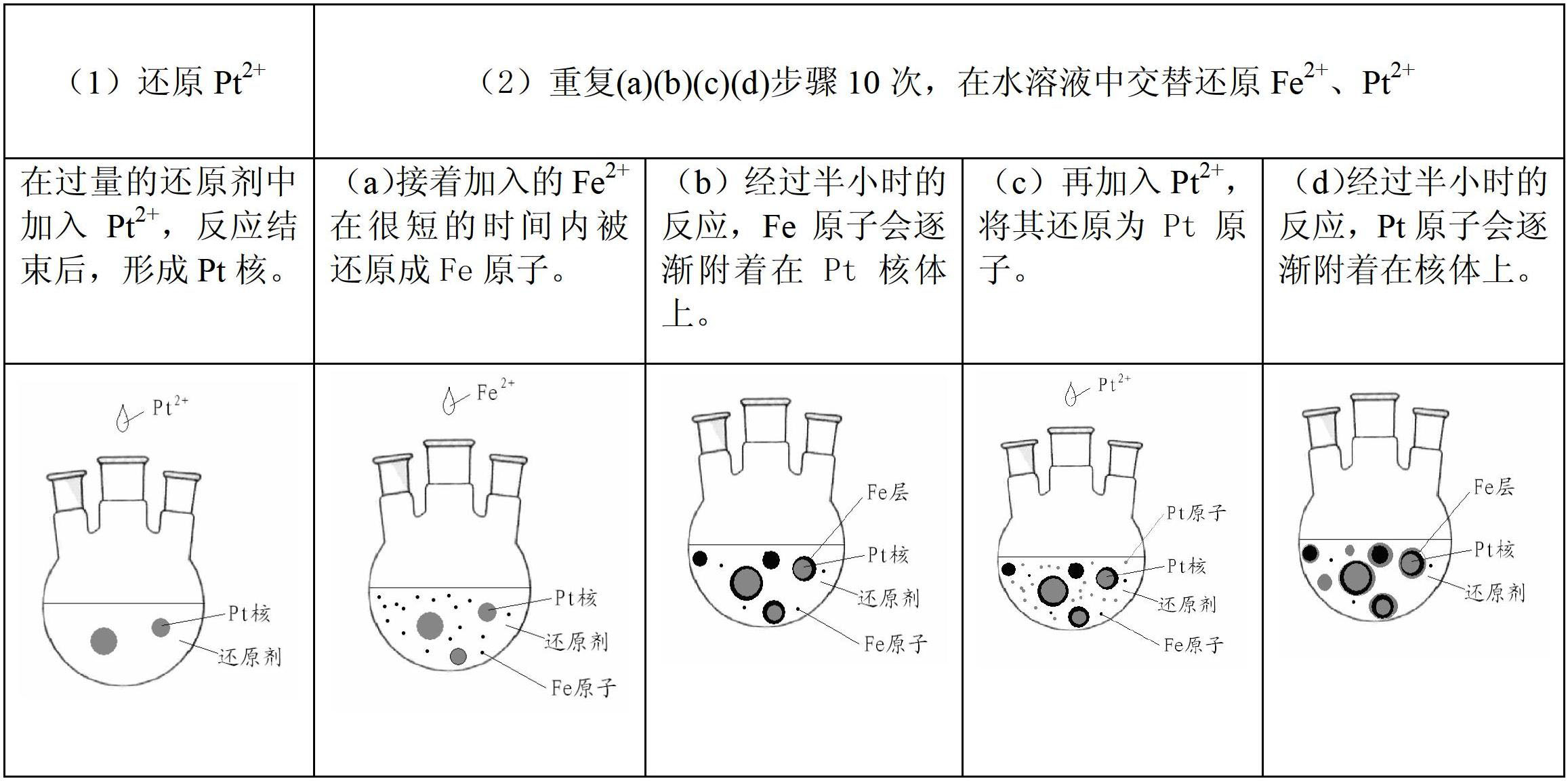

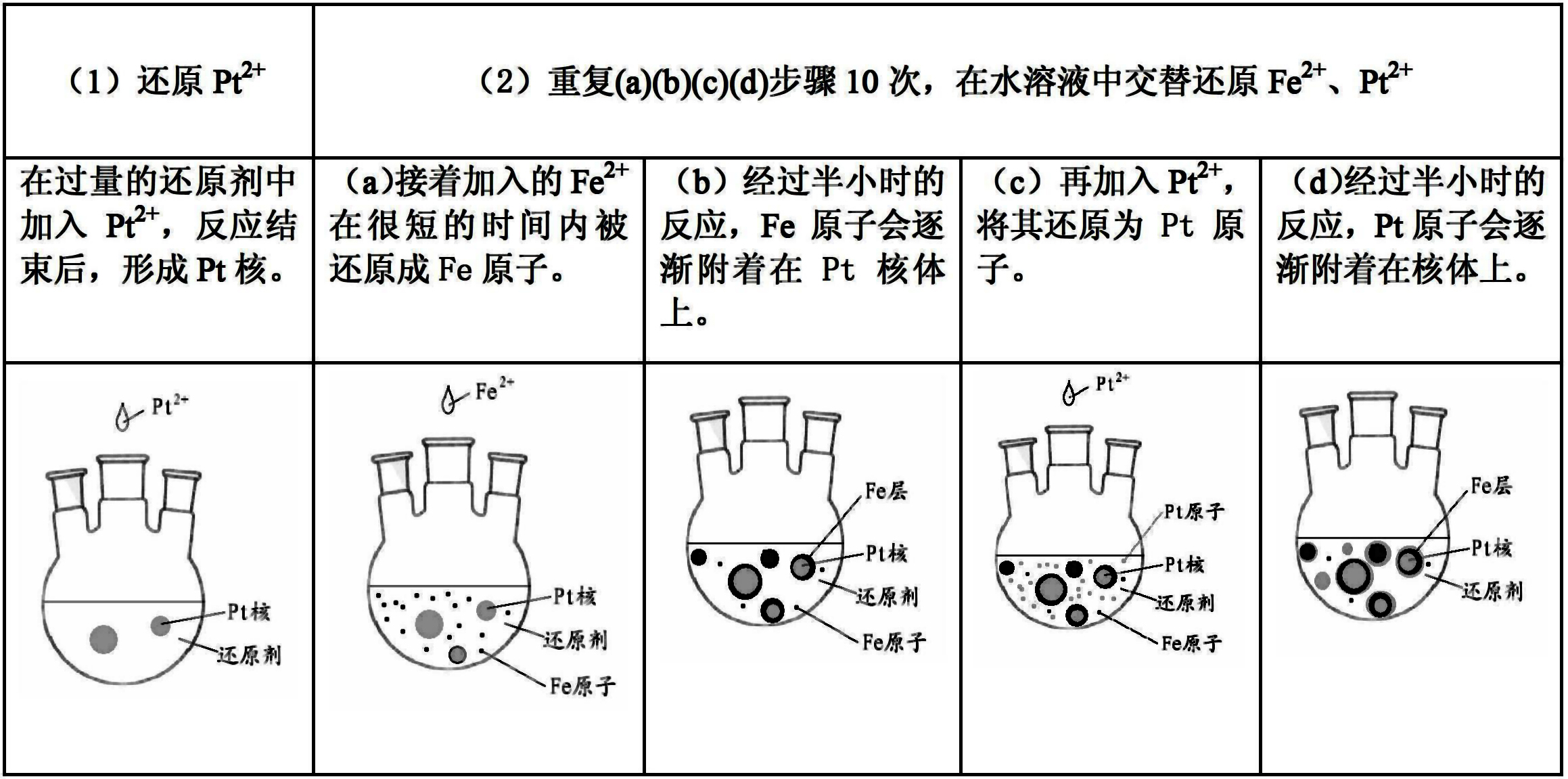

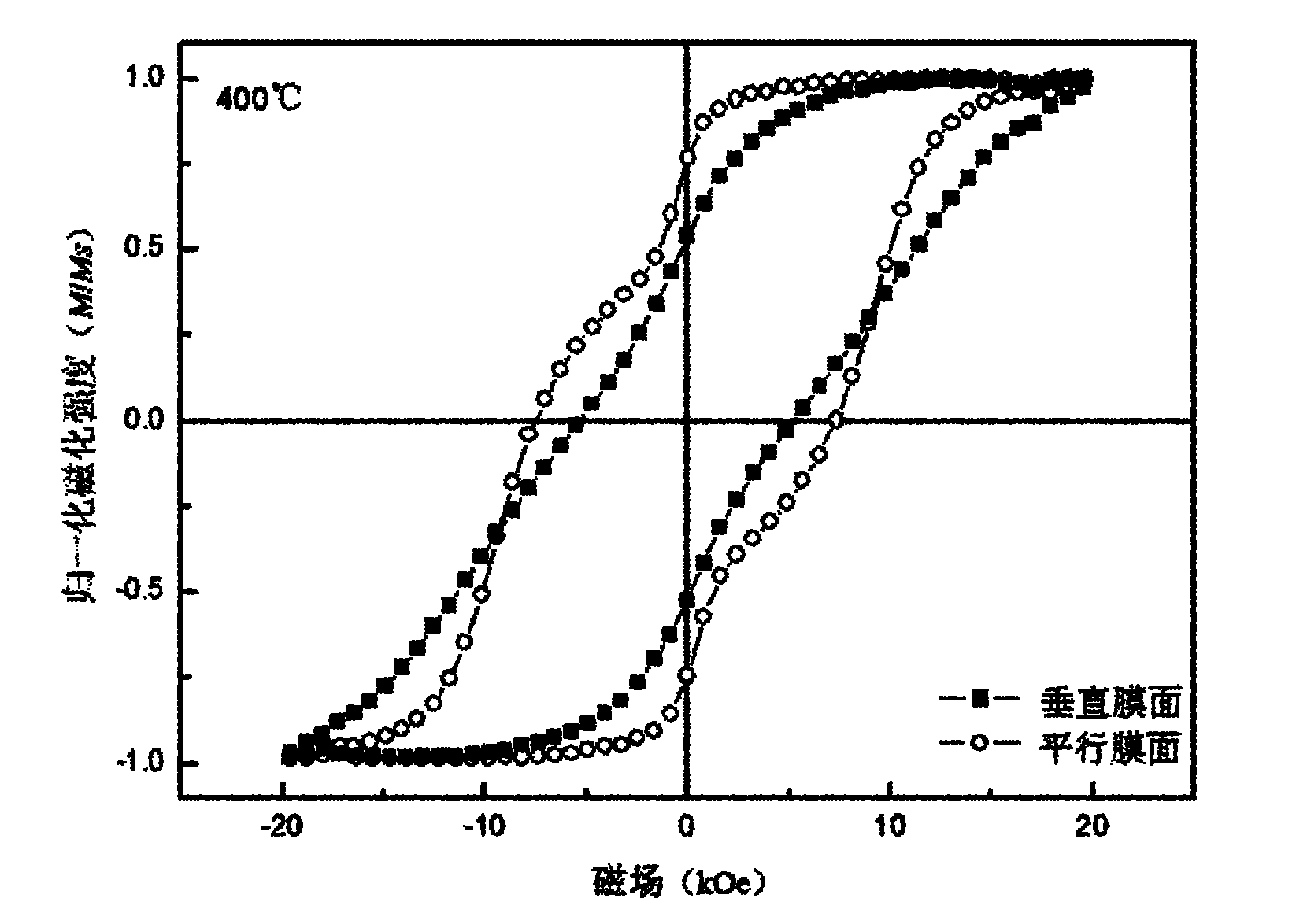

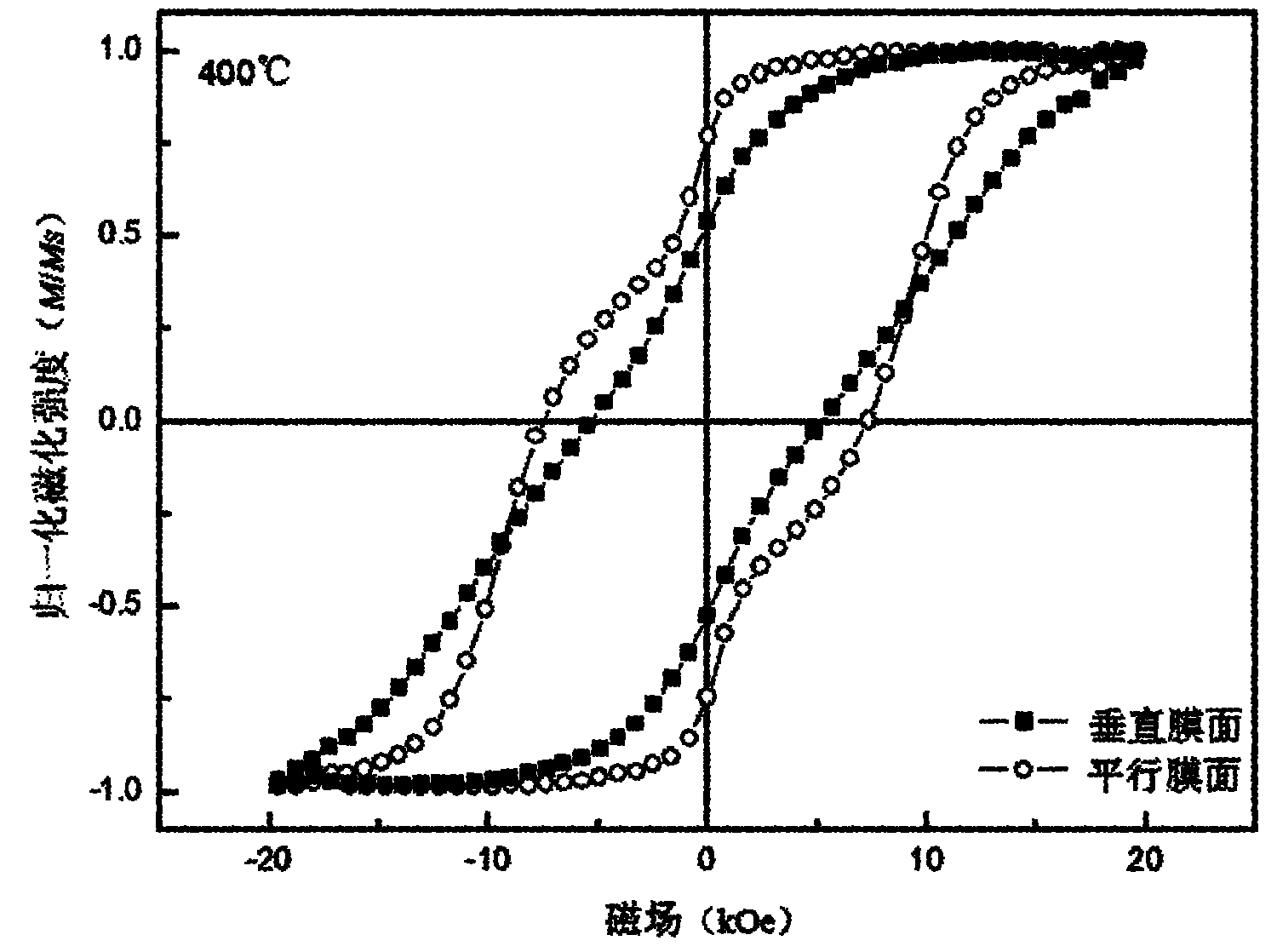

Method for preparing L10-FePt Nano-particles through water bath alternate reduction

InactiveCN102689019ALower phase transition temperatureLower ordering temperatureWater bathsNanoparticle

The invention relates to a method for preparing L10-FePt Nano-particles through water bath alternate reduction, and the method comprises the following steps of: controlling degree of order of Fe elements and Pt elements in particles; modulating chemical degree of order of the Nano-particles, thereby reducing phase transformation temperature of the Nano-particles; the phase transformation temperature of the L10-FePt Nano-particles is reduced, so that the L10-FePt Nano-particles are of important significance in application of ultrahigh density information storage field. In the method, FePt Nano-particles can be prepared at a lower temperature through a simple operation craft and a low-cost experiment method. The FePt Nano-particles prepared by the method disclosed by the invention is of a certain chemical order, therefore, ordering temperature of the L10-FePt Nano-particles can be effectively reduced, and the method disclosed by the invention belongs to a development field for ultrahigh density perpendicular magnetic recording materials...

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Novel method for synthesizing cubic phase interpose porus molecular sieve material

InactiveCN101108735AEvenly distributed mesoporesLarge specific surface areaCrystalline aluminosilicate zeolitesMolecular-sieve compoundsMolecular sieveMesoporous material

A novel method of synthesis of cubic mesoporous molecular sieve materials is provided, which relates to the synthetic method of the cubic (Ia3d) mesoporous molecular sieve materials. The invention aims to introduce the acidity and improve the stability. The quarternary ammonium cationics CmTMA+, the quarternary ammonium cationics Cn-3-1 with bipolar head, the boric acid, the water, the sodium hydroxide and the silicon source are mixed according to the mol ratio of 0.03 to 0.05 : 0.03 to 0.06 : 0.003 to 0.05 : 100 to 150 : 0 to 0.4 : 1; the silicon source is calculated based on the SiO2 volume and the pH value is adjusted to 9 to 10; then chemical regulators having mol ratio of 0.03 to 0.06 with the SiO2 volume of the silicon source are added into the mixture and is crystallized for 48 to 72 hours under 373K; the pH value is adjusted between 9 and 10 every 12 hours; the cubic mesoporous molecular sieve materials are gained through separation, washing and drying after completing the crystallization. The prepared mesoporous materials are characterized by high degree of order, uniform mesoporous arrangement, high specific area, strong acidity and high stability.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

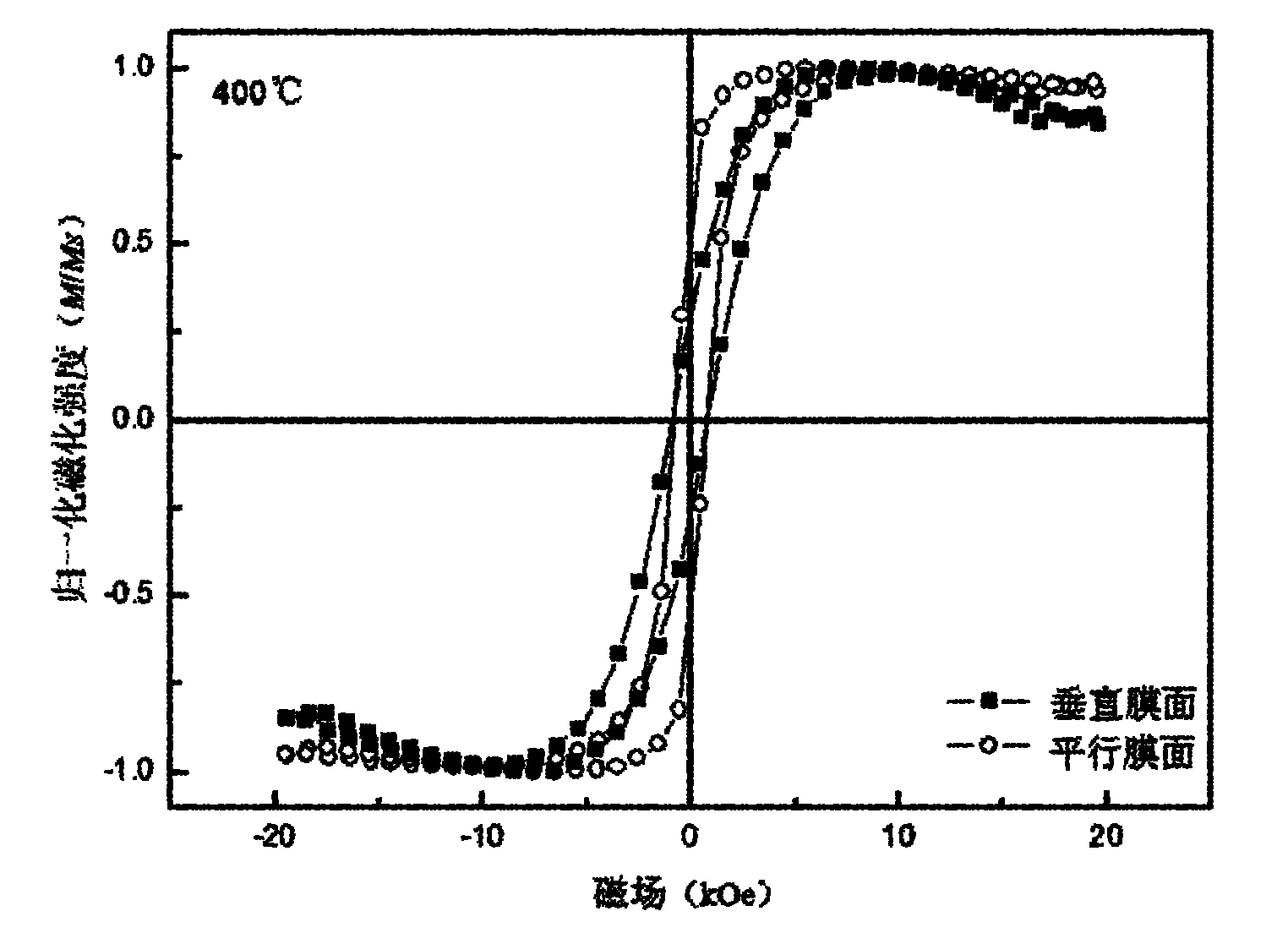

Preparation method of L10-FePt granular film

InactiveCN102061451ALower ordering temperatureSmall magnetic interactionVacuum evaporation coatingSputtering coatingSputteringRoom temperature

The invention discloses a preparation method of an L10-FePt granular film, relating to a method for preparing an L10-FePt granular film with high degree of order by preannealing in a magnetic field, which has the advantages of lowering the ordering temperature of a FePt granular film, promoting the growth of tissues of the L10-FePt granular film (001) and improving the magnetic property and comprises the following steps of: firstly, preparing a FeAg nano film on a substrate at room temperature by using a DC magnetic control sputtering method; secondly, placing the FeAg nano film prepared in the first step into the magnetic field and carrying out vacuum annealing to obtain an annealed FeAg nano film; and thirdly, depositing the annealed FeAg nano film obtained in the second step at room temperature by DC magnetic control sputtering to form a Pt layer, and then carrying out vacuum annealing without any magnetic field to obtain the L10-FePt / Ag film. With the method provided by the invention, the high-performance L10-FePt / Ag film with high degree of order, small crystallite size and small magnetic mutual effects among crystalline grains can be formed on any substrate.

Owner:JILIN NORMAL UNIV

Method for preparing high silicon steel cold-rolled strip steel based on thin-strip continuous casting

The invention belongs to the field of steel material preparation, and relates to a method for preparing high silicon steel cold-rolled strip steel based on thin-strip continuous casting. According to the method, molten steel is smelted according to set components, wherein the components comprise, by weight percentage, 0.002-0.005% of C, 4.0-7.0% of Si, 0.1-0.3% of Mn, 0.01-0.04% of Al, 0.02-0.03% of S, 0.008-0.020% of N, 0.02-0.05% of Nb, 0.01-0.04% of V, less than or equal to 0.002% of O, and the balance Fe and inevitable impurities; the Mn, the Al, the Nb, the V and other second phase forming elements are added into high silicon steel and are uniformly dispersed and separated out in the heat treatment process of a cast strip, and therefore normal growth of ferrite grains can be inhibited, occurrence of abnormal growth can be promoted, the texture of the cast strip can be optimized, and the machinability can be improved; and then low-temperature hot rolling is carried out on the cast strip, the degree of order of the high silicon steel can be further reduced, and the cold rolling process can be finally realized. The method for preparing the high silicon steel cold-rolled thin strip has the advantages of being short in process and high in efficiency, a final product is good in strip shape, and the method can be widely realized in the process and has a wide application prospect.

Owner:NORTHEASTERN UNIV

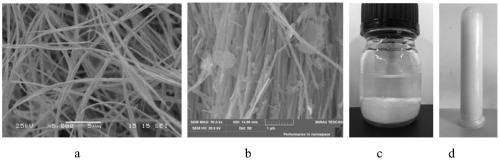

An inorganic fiber state bismuth compound and application thereof

ActiveCN109205670AUniform size distributionEasy to prepareMaterial nanotechnologyBismuth compoundsFiberBismuth compound

An inorganic fiber state bismuth compound and application thereof are disclosed. Bismuth oxide as a raw material is treated in a hydrothermal system, and varieties and dosages of additives and surfactants in the hydrothermal system are adjusted to control and regulate the degree of order and phase composition of a fiber product so as to obtain the nanometer ordered inorganic fiber state bismuth compound. The compound is used for preparing waterborne colloid with a simple preparation process and low reaction temperature, and the obtained waterborne colloid is uniform in composition and good instability.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL +1

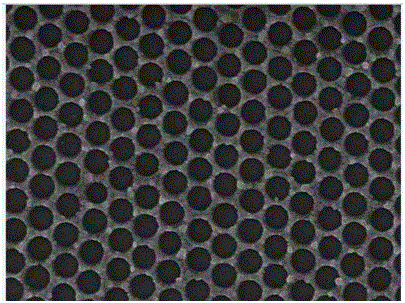

Preparing method for aluminum oxide two-dimensional photonic crystal

InactiveCN105887154AImprove controllabilityReduce breakageSurface reaction electrolytic coatingAnodizingPhotonic crystal

The invention discloses a preparing method for an aluminum oxide two-dimensional photonic crystal. The preparing method includes the following steps that an aluminum sheet is pretreated and subjected to anode electrochemical polishing; first-time anodizing is conducted; a first-time oxide film is removed; and second-time anodizing and chambering treatment are conducted. The requirements for high controllability, small fractures, a high degree of order and good crystallinity of a photonic crystal sample in the preparing process of the two-dimensional photonic crystal are met.

Owner:NANYANG NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com