Method for preparing L10-FePt Nano-particles through water bath alternate reduction

A technology of l10-fept and nanoparticles, applied in the field of alternate reduction of water bath to prepare L10-FePt nanoparticles, can solve the problems of carbonyl iron being highly toxic and unsuitable for large-scale use, and achieve the effect of reducing the ordering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0016] 1. With the sample: the H 2 PtCl 6 ·6H 2 O(n Pt mol) is soluble in water, the volume of water (liter) is related to n pt (mole) ratio is 25:1, dubbed into aqueous solution; FeCl 2 4H 2 O(n Fe mol) is soluble in water, the volume of water (liter) is related to n Fe (mole) ratio is 25:1, made into an aqueous solution, weighed CTAB n Fe +n Pt mol.

[0017] 2. Experimental steps

[0018] ①Put CTAB into a three-necked flask to make an aqueous solution. The ratio of the volume of water (liter) to the molar amount of CTAB is 25:1. Heat the three-neck flask to 70°C in a collector-type constant temperature heating magnetic stirrer, keep stirring and argon until the end of the experiment.

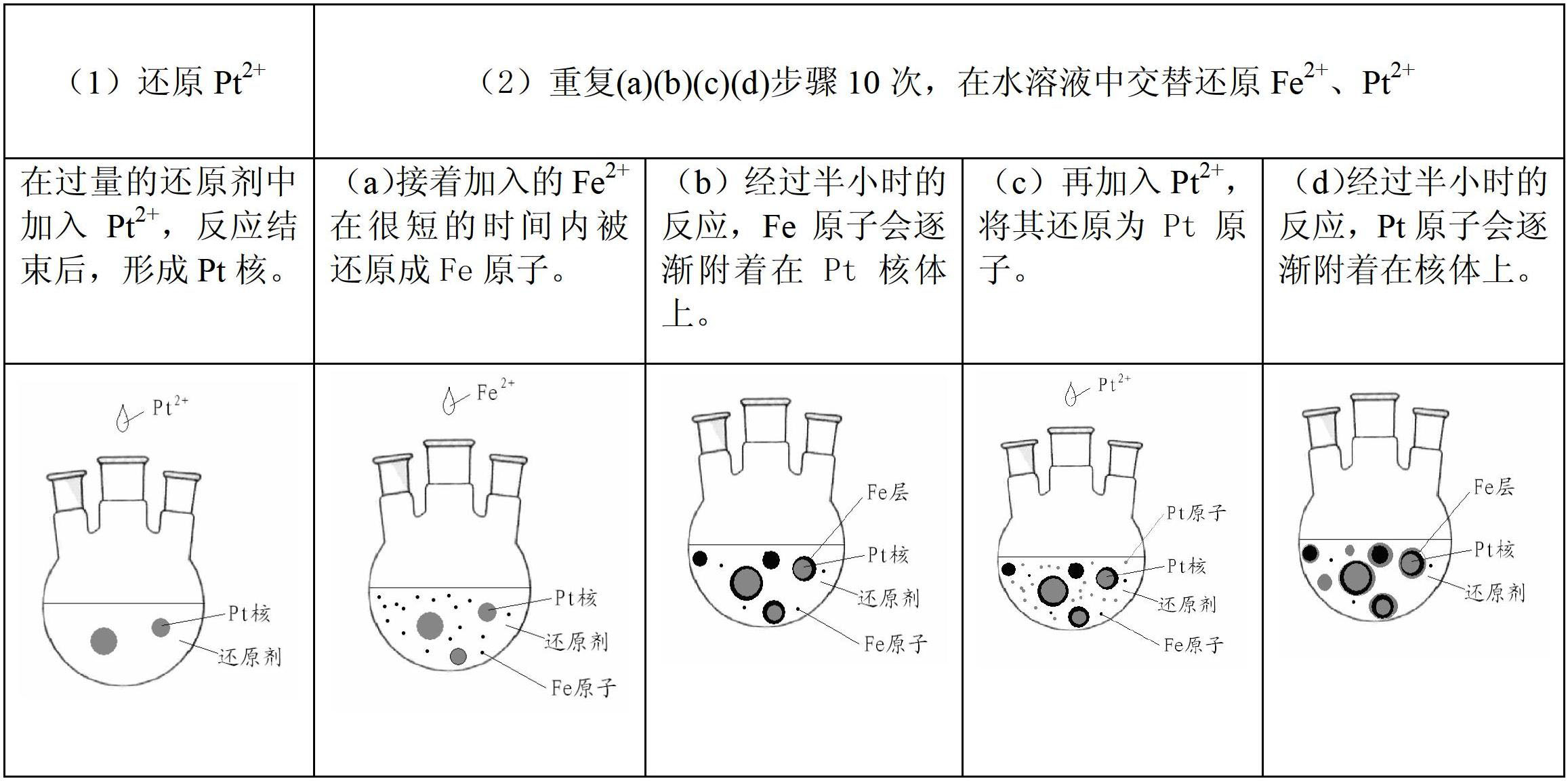

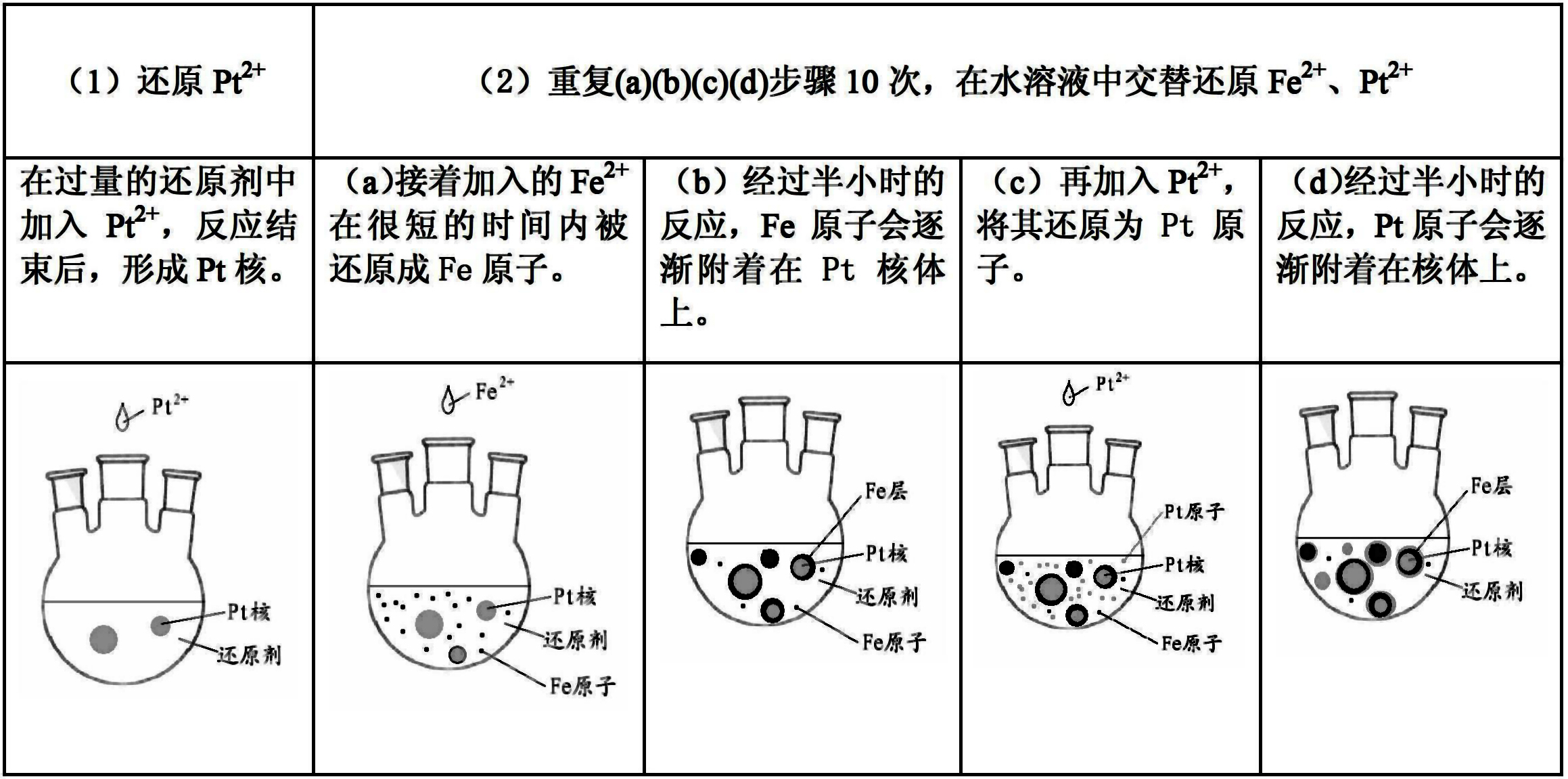

[0019] ② Set the molar weight as n Fe +n Pt The hydrazine hydrate was added to the three-necked flask, and then the Pt 2+ One-tenth of the solution was dripped into the three-neck flask very slowly (dropping time was 10 minutes) and evenly. After the dropwise addition was compl...

preparation example 2

[0025] 1. Sample preparation is the same as Example 1

[0026] 2. Experimental steps

[0027] ① Put CTAB(n Fe +n Pt mol) into a three-necked flask to form an aqueous solution, in which the ratio of the volume of water (liter) to the molar amount of CTAB is 25:1. Heat the three-neck flask to 70°C in a collector-type constant temperature heating magnetic stirrer, keep stirring and pass argon protection gas until the end of the experiment.

[0028] ② put n Fe +n Pt Moles of hydrazine hydrate were added to the three-necked flask, and then the Fe 2+ One-tenth of the solution was dripped into the three-necked flask very slowly (dropping time was 10 minutes) and evenly, and reacted for 30 minutes.

[0029] ③Inject Pt with an infusion set needle 2+ One-tenth of the solution was slowly and evenly dropped into the three-necked flask (dropping time was 10 minutes), and reacted for 30 minutes.

[0030] ④ Repeat steps ② and ③ 10 times, adding FeCl alternately 2 4H 2 O solution a...

preparation example 3

[0033] 1. Sample preparation is the same as Example 1

[0034] 2. Experimental steps

[0035]

x1

x2

x3

x4

x5

x6

x7

x8

x9

x10

Fe 2+

0.025V

0.042V

0.058V

0.072V

0.092V

0.108V

0.125V

0.142V

0.158V

0.175V

Pt 2+

0.025V

0.042V

0.058V

0.072V

0.092V

0.108V

0.125V

0.142V

0158V

0.175V

[0036] ① Put CTAB(n Fe +n Pt mol) into a three-necked flask to form an aqueous solution, wherein the ratio of the volume of water (liter) to the molar amount of CTAB is 25:1. Heat the three-neck flask to 70°C in a collector-type constant temperature heating magnetic stirrer, keep stirring and pass argon protection gas until the end of the experiment.

[0037] ② put n Fe +n Pt Mole of hydrazine hydrate was added to the three-necked flask, and then x1 ml FeCl 2 4H 2 O solution is dropped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com