Copper-aluminum-iron-manganese high-temperature shape memory alloy and preparation method thereof

A memory alloy, high-temperature technology, applied in the field of copper-aluminum-iron-manganese (CuAlFeMn) high-temperature shape memory alloy and its preparation, can solve the problems of loss of memory performance, poor stability of shape memory effect, large phase transition lag, etc., and achieve high Martensitic Bulk phase transition temperature, excellent shape memory effect stability, effect of excellent shape memory stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

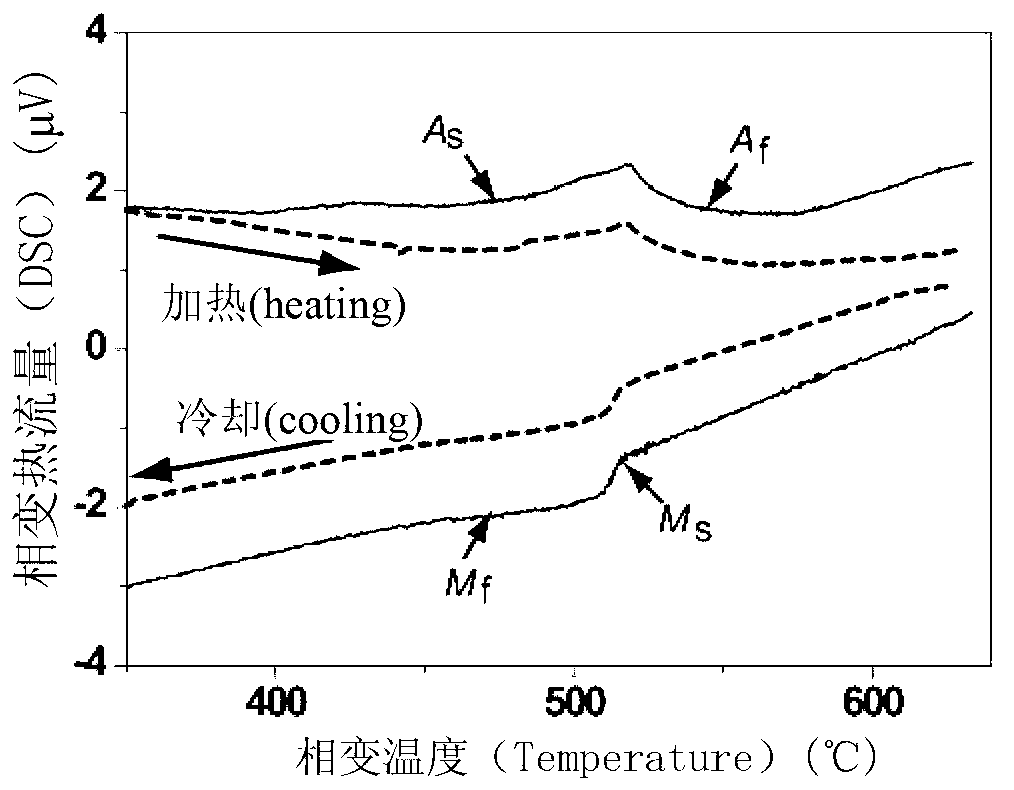

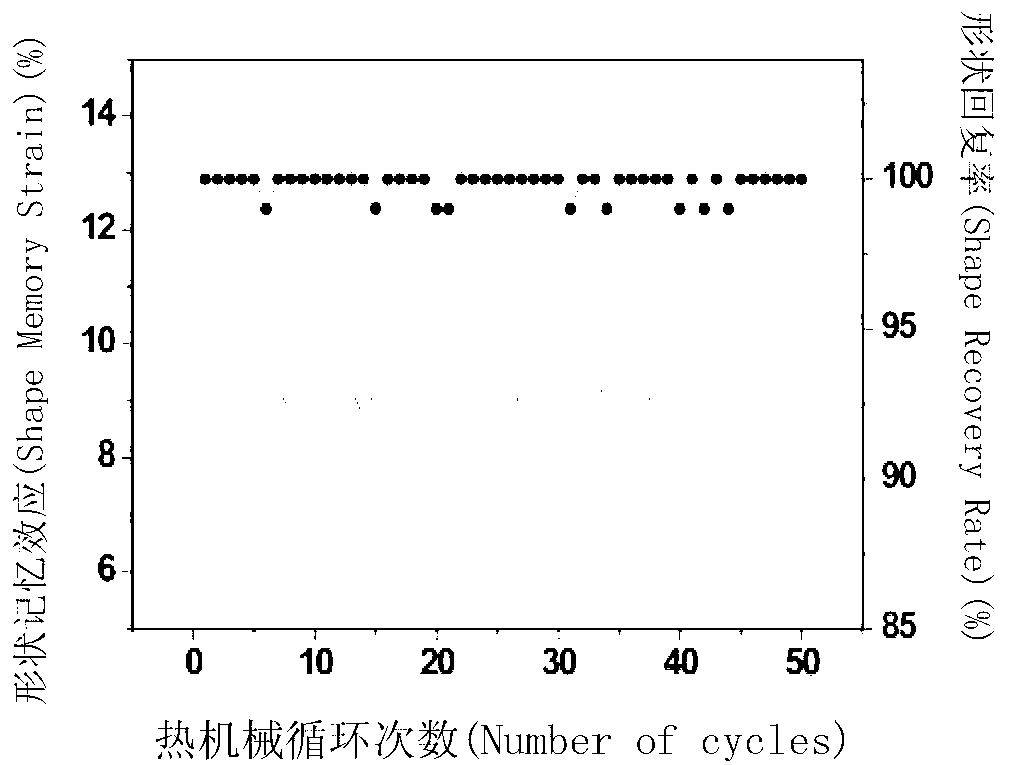

[0037] Embodiment 1: prepare Cu 78 Al 12 Fe 4 mn 6 High Temperature Shape Memory Alloy and Its Performance Test

[0038] Weigh 78% of copper with a purity of 99.9%, 12% of Al with a purity of 99.9%, 4% of iron with a purity of 99.9%, and 6% of manganese with a purity of 99.5%; put the above copper, aluminum, iron and manganese raw materials into In the vacuum melting furnace, vacuumize to 6.6×10 -3 Pa, filled with high-purity argon to 0.7×10 5 Pa, and then repeated smelting for 4 times to obtain copper aluminum iron manganese (CuAlFeMn) high temperature shape memory alloy ingots; the above prepared copper aluminum iron manganese (CuAlFeMn) high temperature shape memory alloy ingots were cut into cylindrical shapes by wire cutting Samples and sheet samples, the diameter of the cylindrical sample is 3mm, and the height is 5mm; the cylindrical sample and the sheet sample are put into a vacuum heat treatment furnace for heat treatment, the vacuum degree is 5Pa, and the heat t...

Embodiment 2

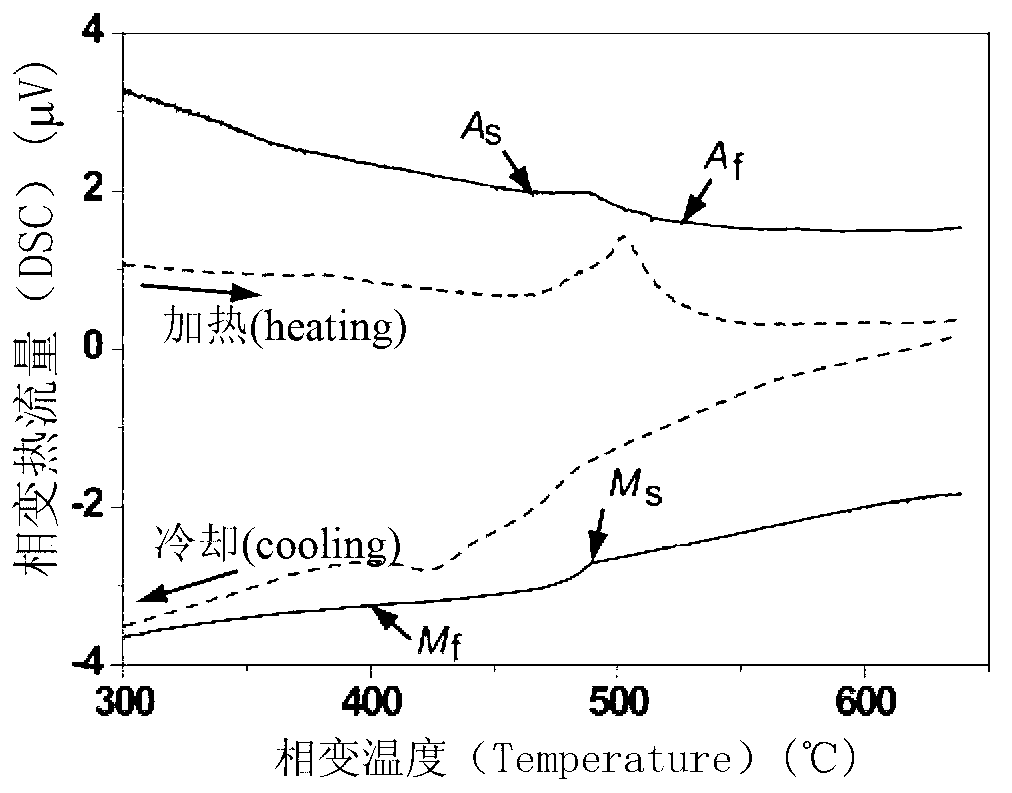

[0046] Embodiment 2: prepare Cu 77 Al 11 Fe 4 mn 8 High Temperature Shape Memory Alloy and Its Performance Test

[0047] Weigh 77% of copper with a purity of 99.9%, 11% of Al with a purity of 99.9%, 4% of iron with a purity of 99.9%, and 8% of manganese with a purity of 99.5%; put the above copper, aluminum, iron and manganese raw materials into In the vacuum melting furnace, vacuumize to 6.6×10 -3 Pa, filled with high-purity argon to 0.7×10 5 Pa, and then repeated smelting for 4 times to obtain copper aluminum iron manganese (CuAlFeMn) high temperature shape memory alloy ingots; the above prepared copper aluminum iron manganese (CuAlFeMn) high temperature shape memory alloy ingots were cut into cylindrical shapes by wire cutting Samples and sheet samples, the diameter of the cylindrical sample is 3mm, and the height is 5mm; the cylindrical sample and the sheet sample are put into a vacuum heat treatment furnace for heat treatment, the vacuum degree is 5Pa, and the heat t...

Embodiment 3

[0055] Embodiment 3: prepare Cu 82 Al 10 Fe 5 mn 3 High Temperature Shape Memory Alloy and Its Performance Test

[0056] Weigh 82% of copper with a purity of 99.9%, 10% of Al with a purity of 99.9%, 5% of iron with a purity of 99.9%, and 3% of manganese with a purity of 99.5%; put the above copper, aluminum, iron and manganese raw materials into In the vacuum melting furnace, vacuumize to 6.6×10 -3 Pa, filled with high-purity argon to 0.7×10 5 Pa, and then repeated smelting for 4 times to obtain copper aluminum iron manganese (CuAlFeMn) high temperature shape memory alloy ingots; the above prepared copper aluminum iron manganese (CuAlFeMn) high temperature shape memory alloy ingots were cut into cylindrical shapes by wire cutting Samples and sheet samples, the diameter of the cylindrical sample is 3mm, and the height is 5mm; the cylindrical sample and the sheet sample are put into a vacuum heat treatment furnace for heat treatment, the vacuum degree is 5Pa, and the heat t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Compressive fracture strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com