Nickel-titanium shape memory alloy composite pipe joint forming method

A memory alloy, composite pipe technology, applied in the direction of pipe/pipe joint/pipe fitting, non-removable pipe connection, rod connection, etc., can solve problems such as insufficient tightening force, recovery, and tightening force that does not meet the requirements of use. , to achieve the effect of improving service life, uniform force distribution and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

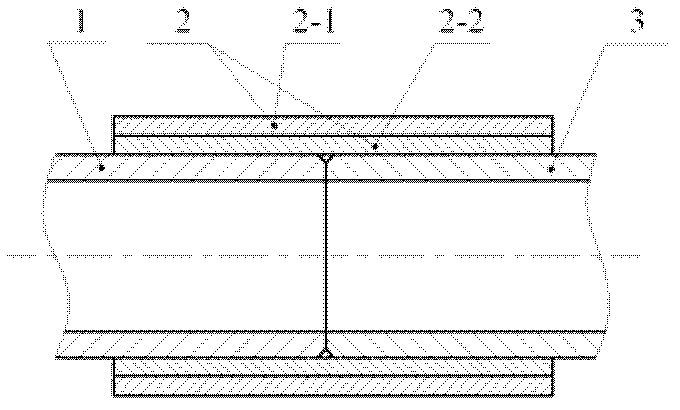

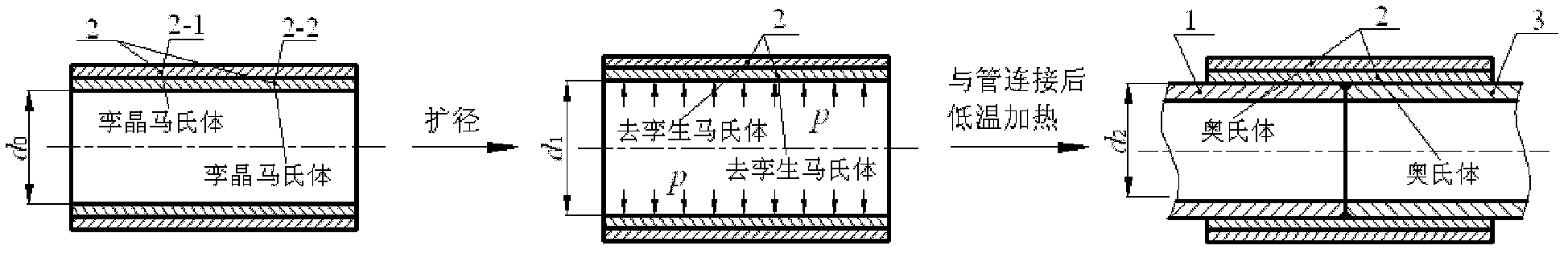

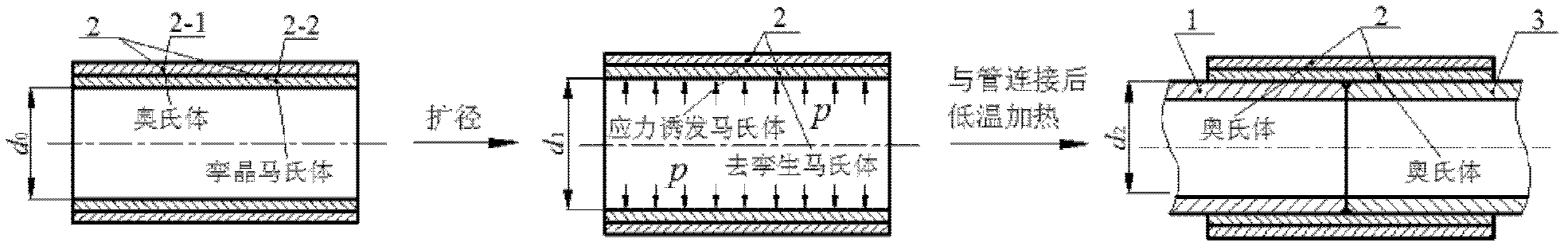

[0019] combine Figure 1~3 , NiTi shape memory alloy composite pipe joint structure such as figure 1 As shown, the forming method of the nickel-titanium shape memory alloy composite pipe joint proposed by the present invention mainly utilizes the shape memory effect and superelasticity of the nickel-titanium shape memory alloy, and its specific principle is shown in FIG. 2 . The nickel-titanium shape memory alloy composite pipe joint is composed of two layers of nickel-titanium shape memory alloy tubes 2-1 and 2-2. Different deformation and phase transition mechanisms realize the connection and fastening of the connected pipes 1 and 3 . First, two layers of nickel-titanium shape memory tubes 2-1 and 2-2 are assembled together by clearance fit or interference fit to form a double-layer tube 2, and the inner diameter d0 of the double-layer tube 2 is smaller than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com