Patents

Literature

131results about How to "Good shape memory effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing shape memory polyurethane resin

InactiveCN101921382AObvious and excellent shape memory effectGood mechanical propertiesMonocomponent synthetic polymer artificial filamentPolyesterThermal insulation

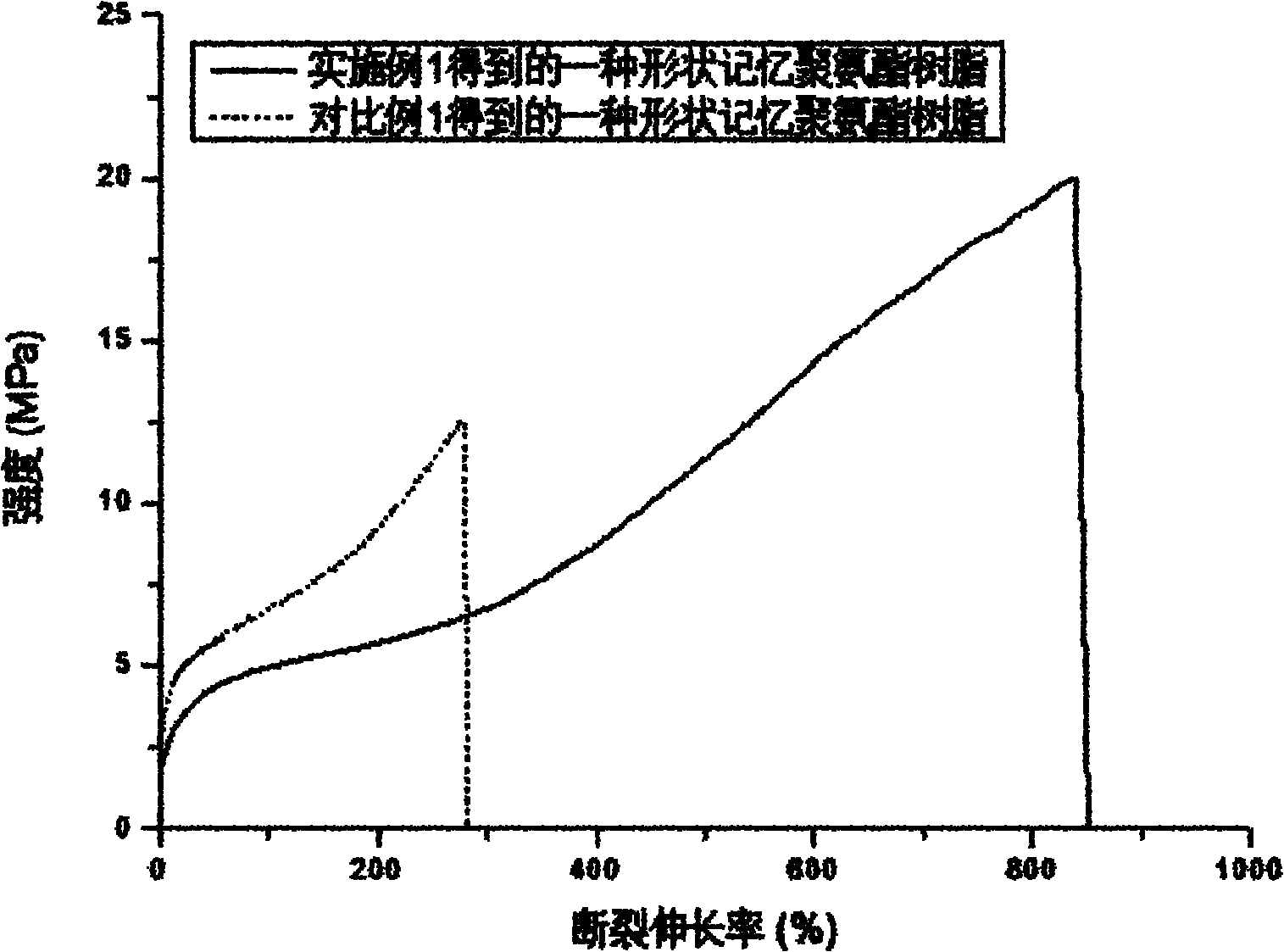

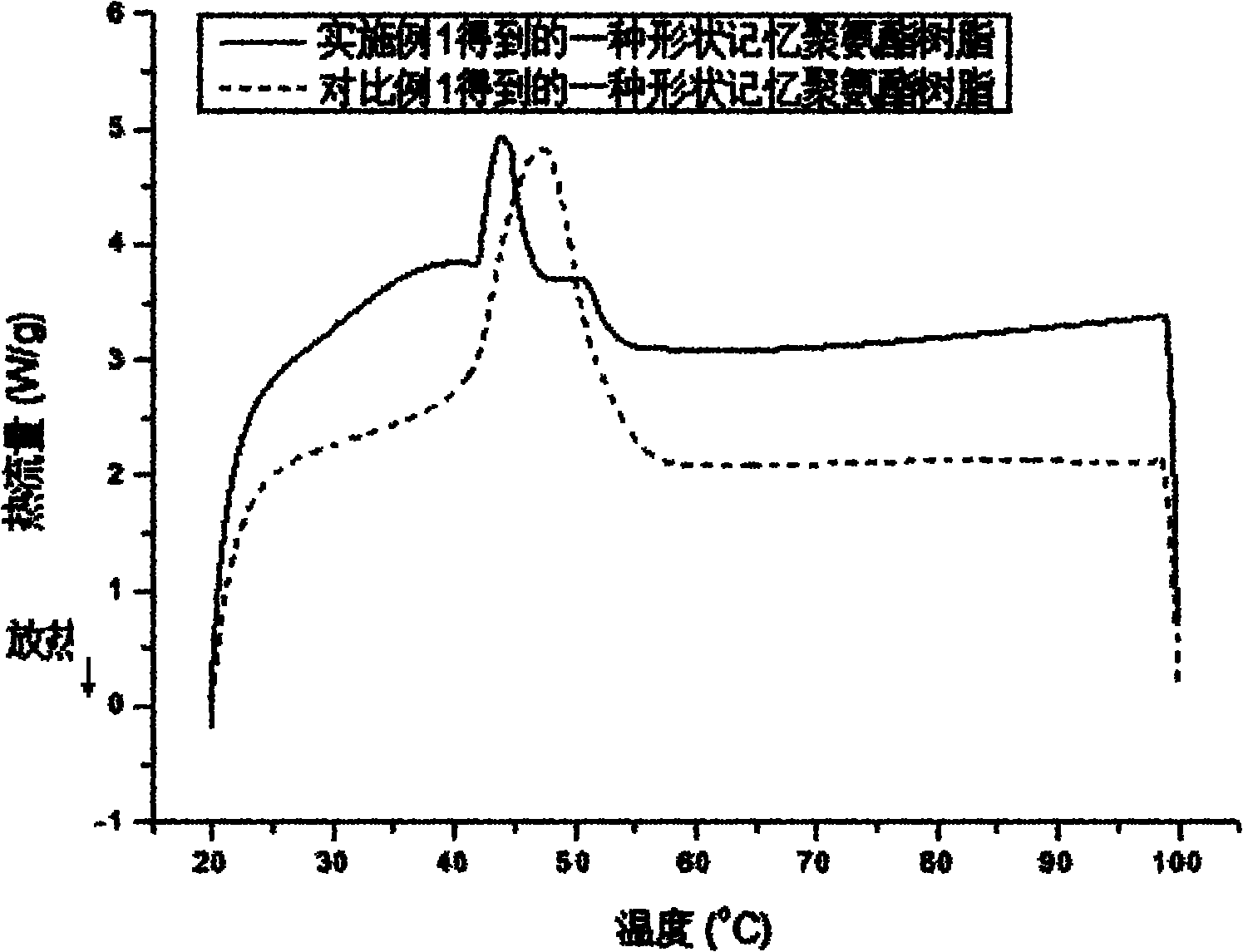

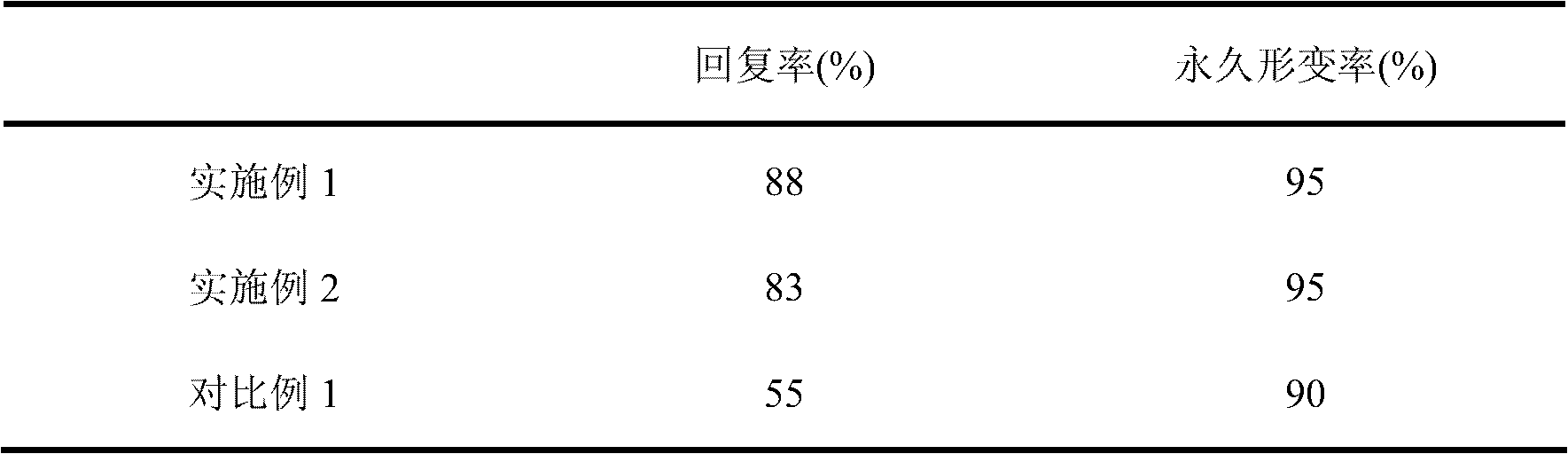

The invention discloses a method for preparing shape memory polyurethane resin. Polyethylene glycol is added during synthesis, and polyether diol or polyester diol is added as a soft segment; and the shape memory polyurethane resin is synthesized by a mass polymerization method. Compared with the shape memory polyurethane resin with single polyethylene glycol or polyether diol or polyester diol as the soft segment, the polyurethane resin prepared by the method has the characteristics of good shape memory effect, high phase change thermal insulation performance, high mechanical performance and the like; the shape memory recovery rate can reach 88%, the permanent deformation rate can reach 95%, the tensile strength at break can reach 20 MPa and the elongation at break can reach 75%; and meanwhile, a stable phase change enthalpy is kept, the requirements of spinning-level resin are met and the shape memory polyurethane resin can be directly spun and formed.

Owner:SHANGHAI JIAO TONG UNIV

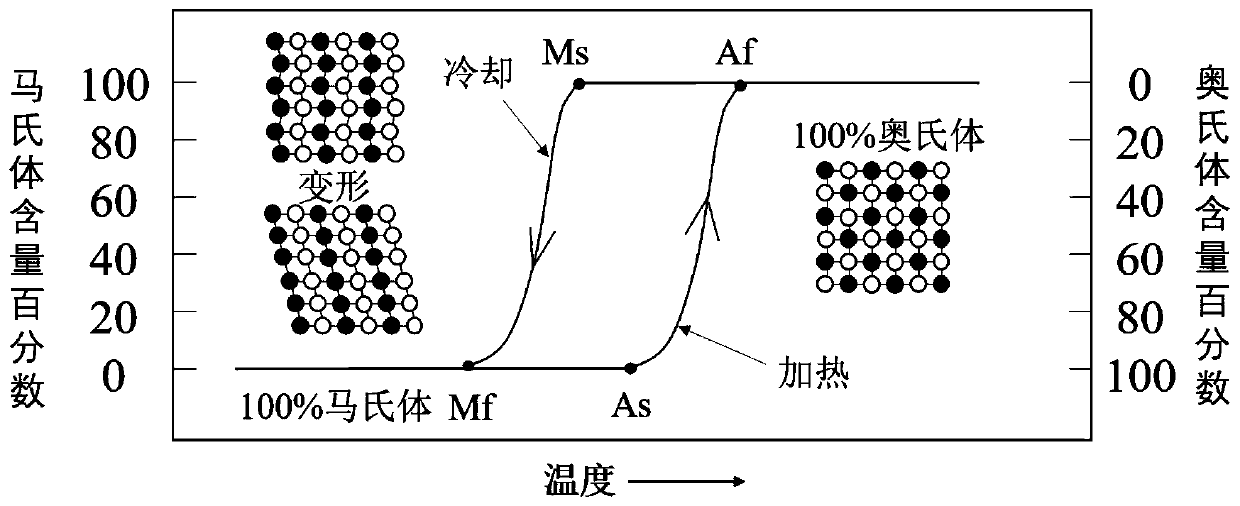

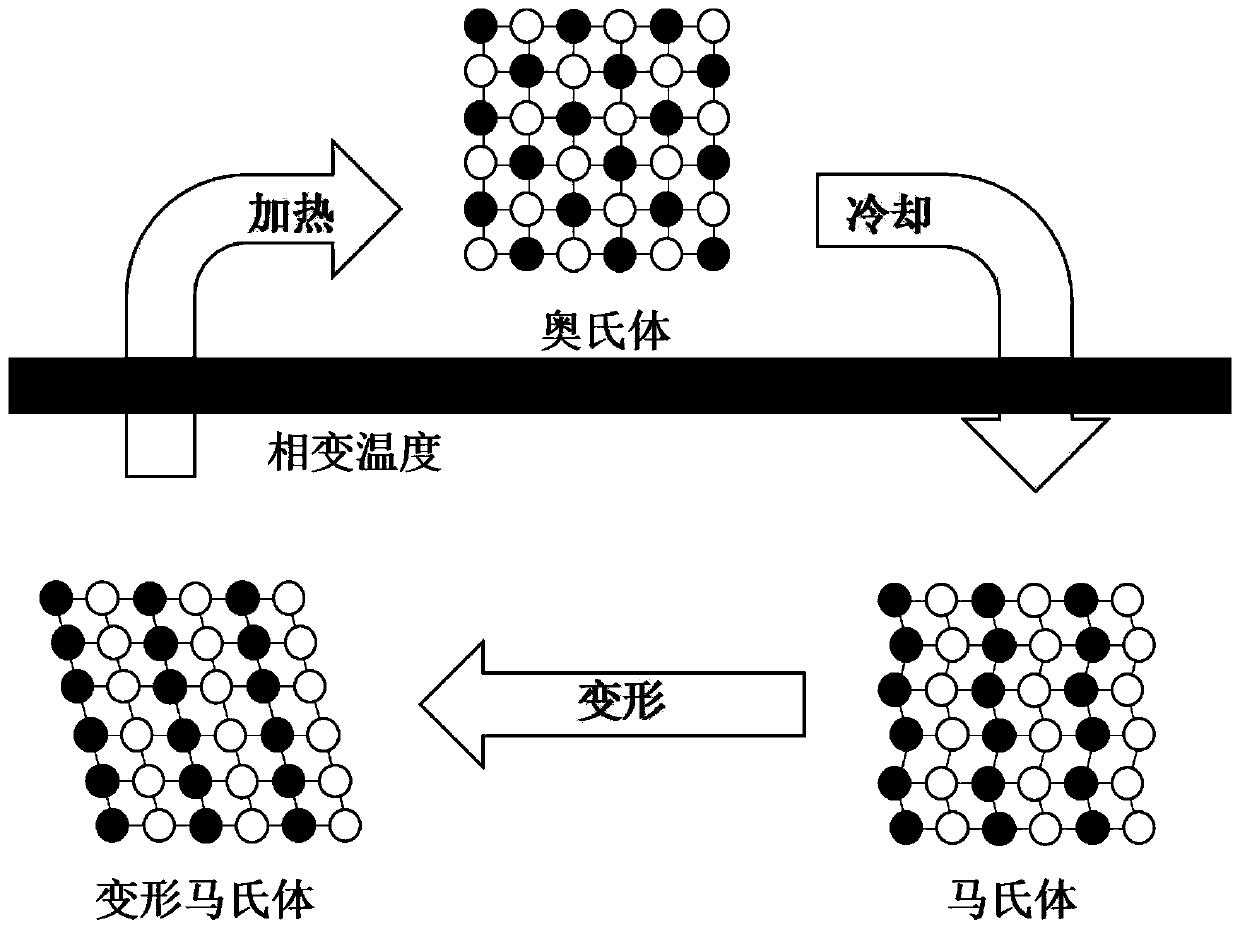

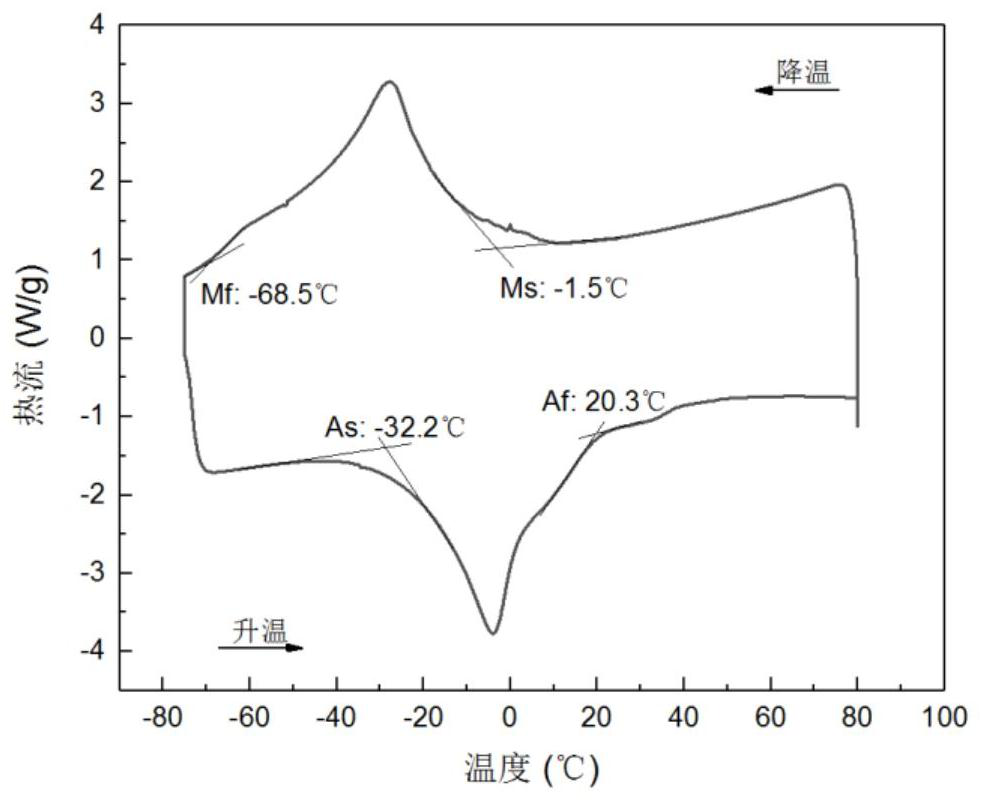

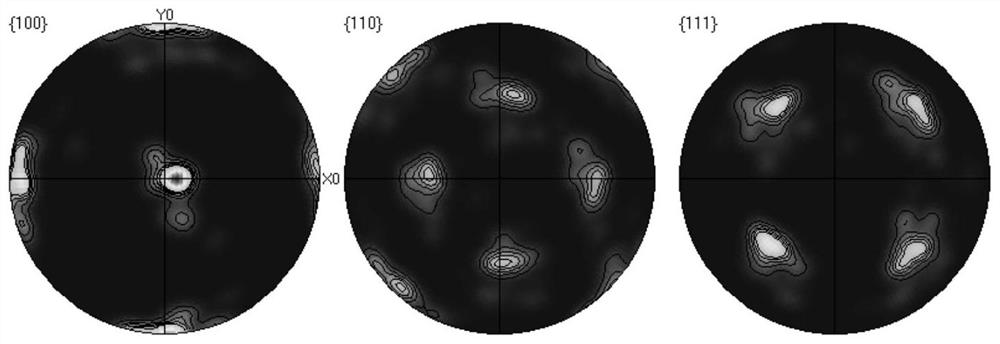

Processing method suitable for 4D printed nickel-titanium shape memory alloy

ActiveCN109746445AGood shape memory effectIncrease elasticityAdditive manufacturing apparatusIncreasing energy efficiencyRoom temperatureTitanium

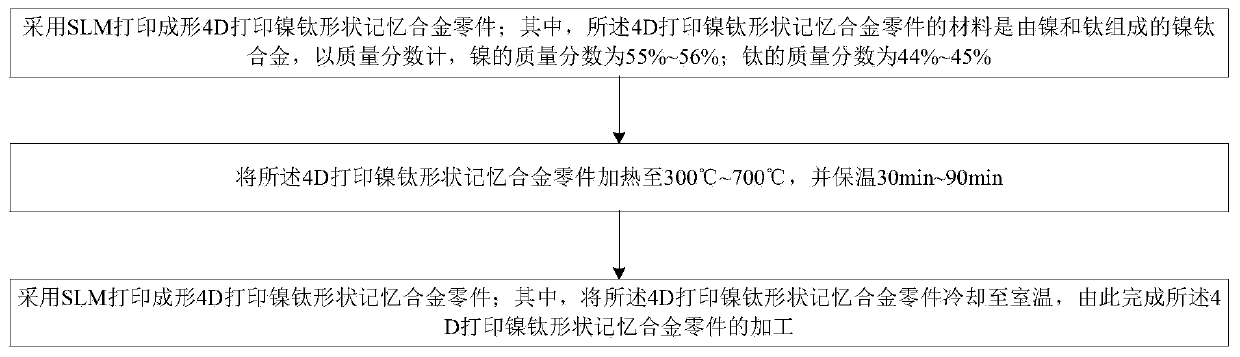

The invention belongs to the technical field of alloy molding and manufacturing, and discloses a processing method suitable for a 4D printed nickel-titanium shape memory alloy. The processing method includes the following steps that (1) 4D printed nickel-titanium shape memory alloy parts are printed and molded by using an SLM, the material of the 4D printed nickel-titanium shape memory alloy partsis the nickel-titanium alloy consisting of nickel and titanium, by the mass percentage, wherein the mass percentage of the nickel is 55-56%, and the mass percentage of titanium is 44-45%; (2) the 4Dprinted nickel-titanium shape memory alloy parts are heated to 300-700 DEG C, and heat insulation is conducted for 30-90min; and (3) the 4D printed nickel-titanium shape memory alloy parts are cooledto the room temperature, so that the processing of the 4D printed nickel-titanium shape memory alloy parts is completed. The processing method is simple in process, convenient to implement, higher inflexibility and higher in applicability.

Owner:HUAZHONG UNIV OF SCI & TECH

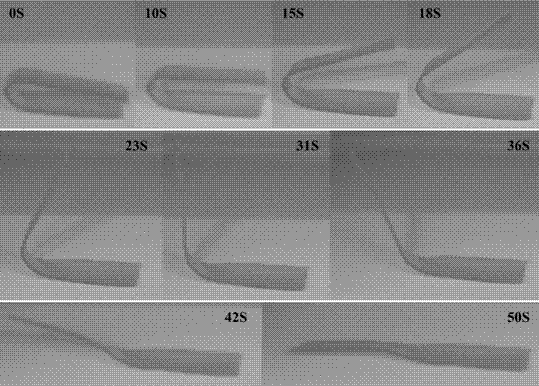

4D-printing shape-memory-polymer-composite-material tracheal stent and preparing method thereof

The invention discloses a 4D-printing shape-memory-polymer-composite-material tracheal stent and a preparing method thereof, and belongs to the technical field of 4D printing. As for the problem thata traditional tracheal stent is difficult to implant, and the secondary stricture problem caused by the overlarge hole diameter of the tracheal stent, and the problem that as the hole diameter of thetracheal stent is over small, swinging of airway cilia is blocked, a compound of a shape memory polymer and nanometer iron oxide serves as a material, a curve-edge rectangle serves as a basic unit, and a tracheal-stent three dimensional structure model is designed; the tracheal-stent three dimensional structure is printed and formed with the fused deposition or direct writing printing method, is subjected to electrostatic spinning medicine carrying covering, and then is subjected to in-vitro remote excitation so that the shape of the stent is recovered, and a formed tracheal stent is obtained.The 4D-printing shape-memory-polymer-composite-material tracheal stent and the preparing method thereof are suitable for production of the tracheal stent.

Owner:HARBIN INST OF TECH

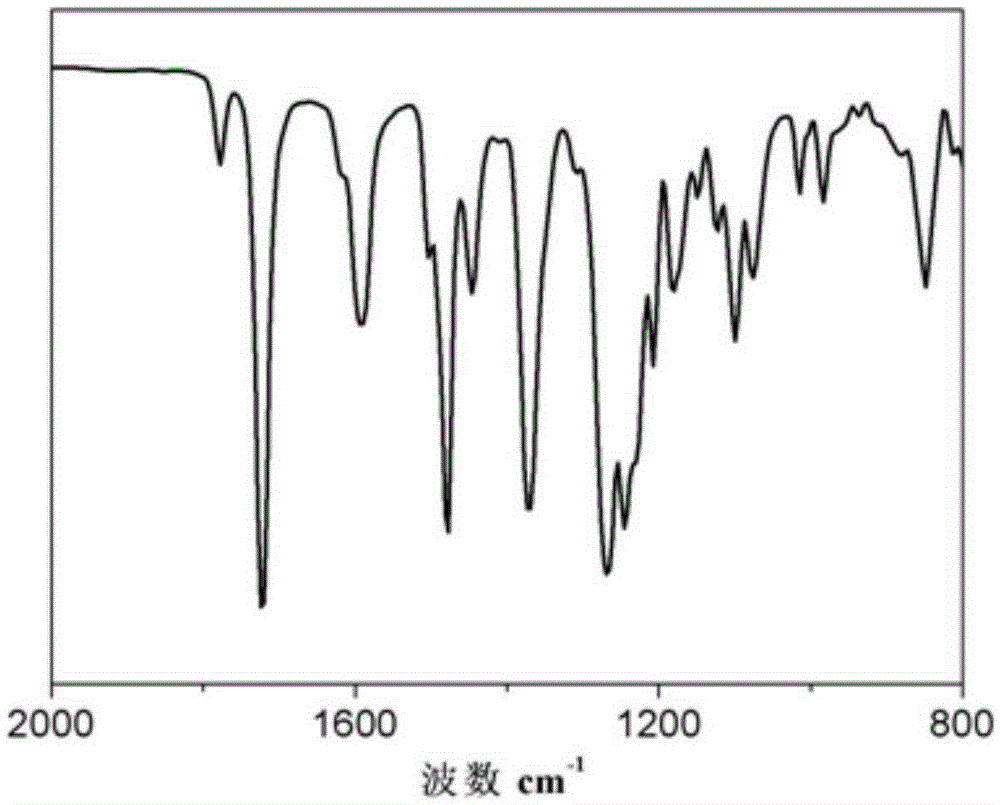

Liquid crystal epoxy resin with shape memory effect and preparation method and application thereof

InactiveCN102504202AEasy to adjustEasy to prepareLiquid crystal compositionsCollapsable antennas meansEpoxyMemory effect

The invention belongs to the field of material engineering and discloses a liquid crystal epoxy resin with a shape memory effect and a preparation method and application thereof. The preparation method of the liquid crystal epoxy resin with the shape memory effect comprises the following steps: heating to melt 100 parts of epoxy resin, adding 1.22-42.59 parts of unitary aliphatic amine, mixing uniformly, finally adding 10.57-26.20 parts of curing agent, and melting uniformly; pouring the obtained mixture into a preheating mould, heating to cure, and cooling to 20-30 DEG C to obtain the liquidcrystal epoxy shape memory material. The thermal response temperature of the liquid crystal epoxy resin with the shape memory effect can be adjusted conveniently, and the liquid crystal epoxy resin is short in thermal response time and high in shape recovery speed and still has the good shape memory effect after being subjected to repeated and circulatory shape memory.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +1

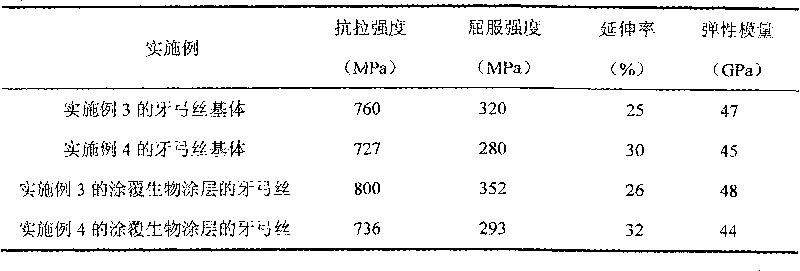

Biological coating and dental arch wire coated with same

InactiveCN101721742AReduce releaseHarm reductionArch wiresSurgeryBiocompatibility TestingMetallic materials

The invention discloses a biological coating and a dental arch wire coated with the same, and belongs to the technical fields of surface modification of biomedical metal materials and medical equipment. The biological coating comprises Ti and Nb serving as main components, and also comprises at least one of tin, aluminum, silicon, zirconium, tantalum, hafnium, palladium, gallium, nickel and oxygen. The invention provides the dental arch wire which uses a TiNbAl titanium alloy serving as a base material and is coated by the coating. Medical equipment products coated by the coating have good biocompatibility and good corrosion resistance and great improvement on superelasticity, shape memory effect, fatigue performance and other composite properties, and can be used in the field of medical treatment serving as functional coatings on surfaces of super-elastic stents, orthodontic dental arch wires, orthopedic implant equipment and the like. The dental arch wire has lower elastic modulus, excellent biocompatibility and mechanical compatibility; and the base material of the dental arch wire has excellent mechanical performance, corrosion resistance, and can be subjected to large deformation cold machining, such as cold rolling, cold wire drawing and the like.

Owner:GRIKIN ADVANCED MATERIALS

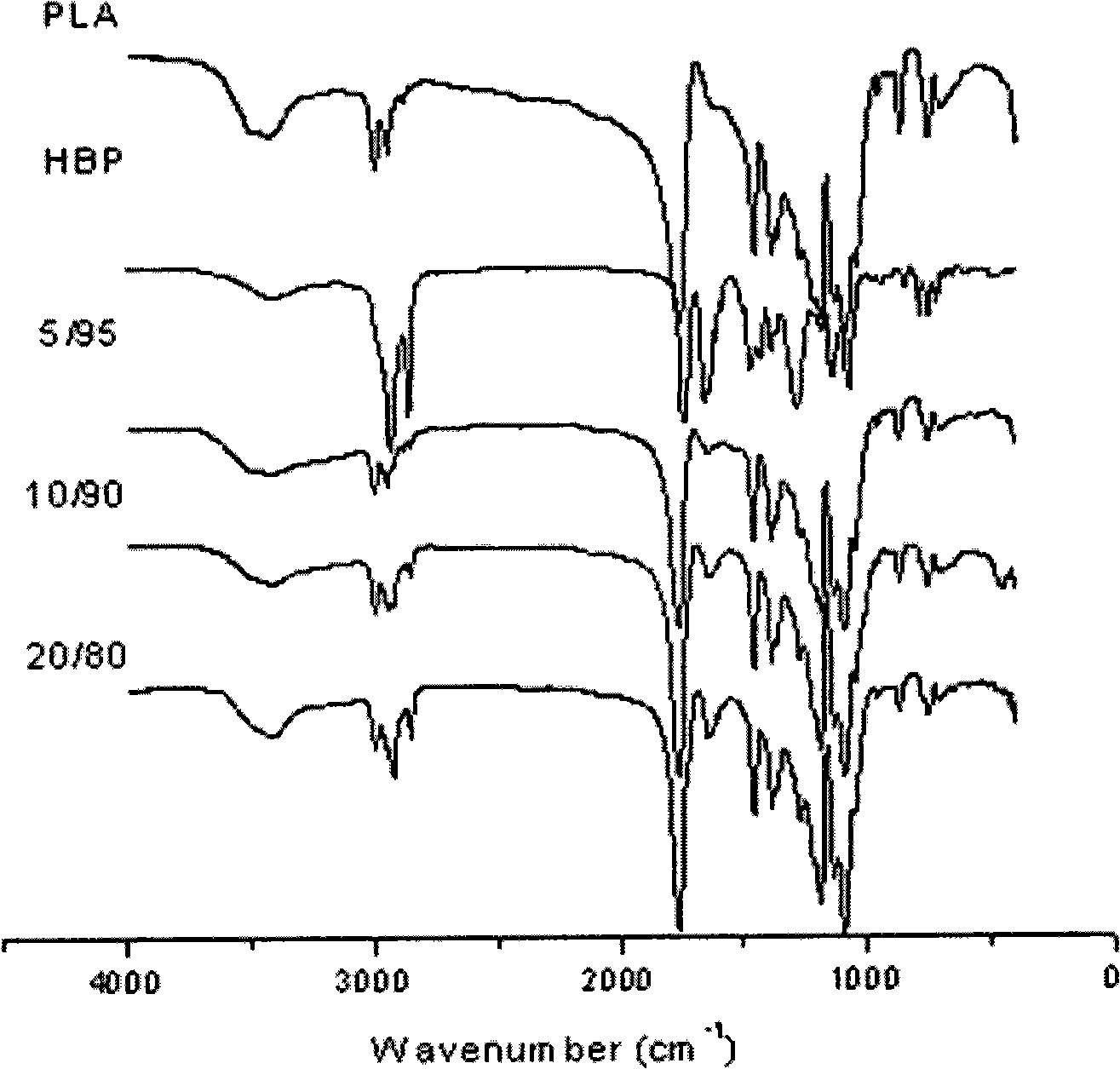

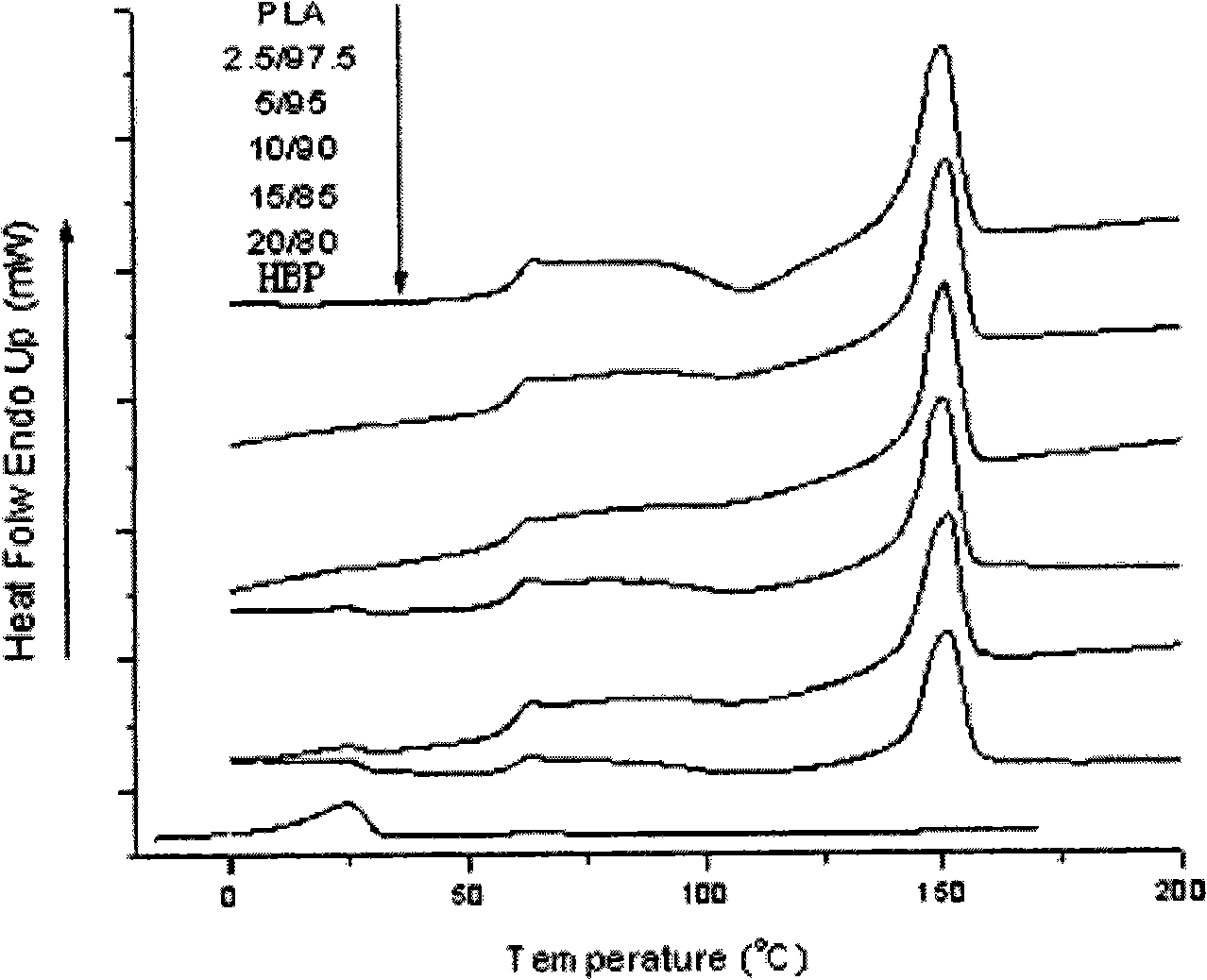

Shape memory material based on polylactic acid, manufacturing and using process thereof

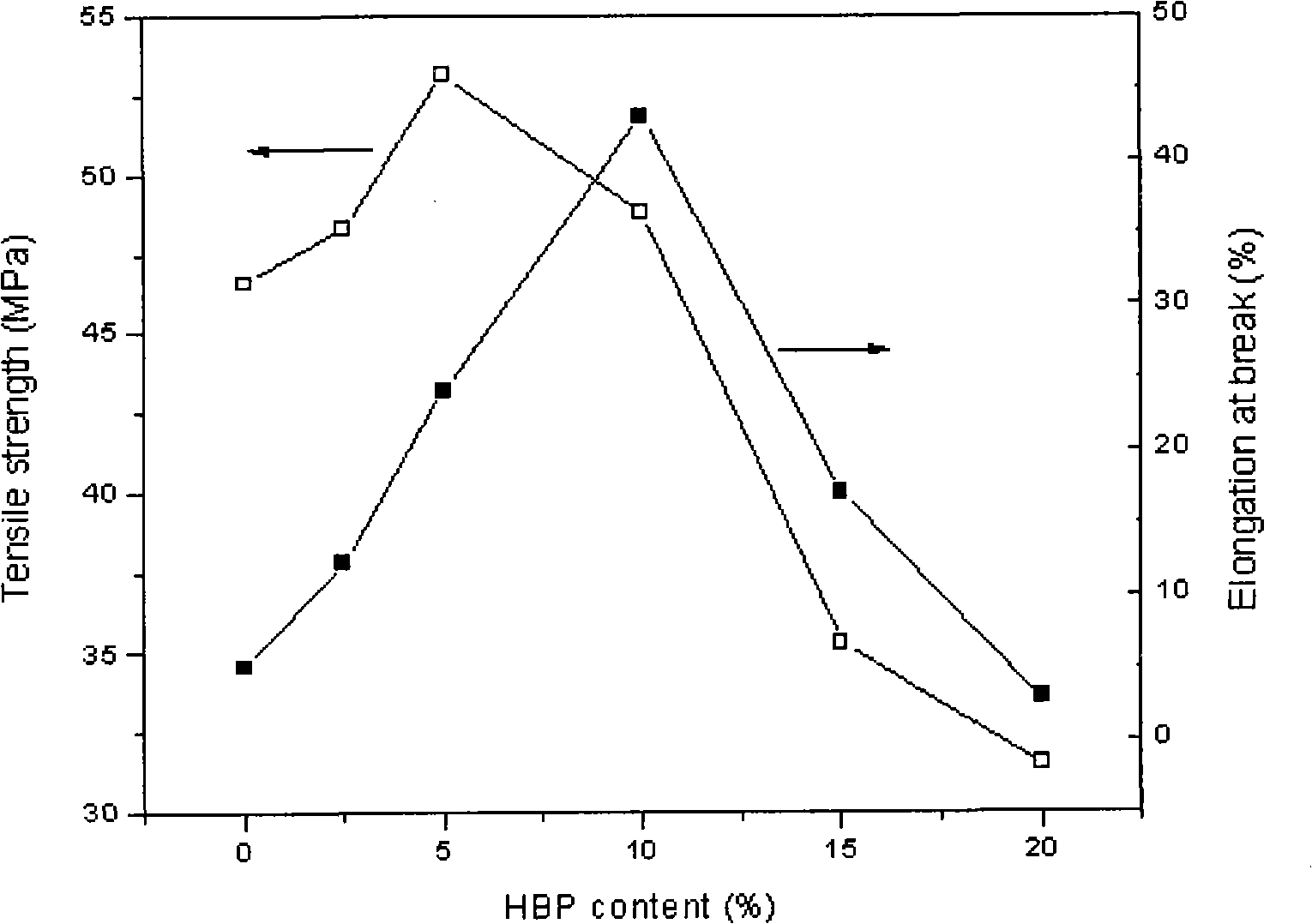

InactiveCN101319088AOvercome the disadvantage of brittlenessControl performanceCrystallinityDraw ratio

The invention provides a shape memory material on the basis of polylactic acid and a preparation method thereof. The shape memory material is characterized by consisting of the polylactic acid and hyper branched polyesteramide, wherein, the weight portion of the polylactic acid is between 80 and 98 portions and the weight portion of the hyper branched polyesteramide is between 2 and 20 portions. The shape memory material has the advantage that various performances of a product such as the mechanical intensity, the breaking elongation and the degree of crystallinity can be controlled by changing the ratio of the hyper branched polyesteramide to the polylactic acid and mixing the two. The general polylactic acid material is easy to rupture when subject to a stretching or bending stress. The polylactic acid material overcomes the shortcoming of brittleness of the pure polylactic acid and has high toughness and elongation at break. Therefore, the polylactic acid material does not break at a high draw ratio, can restore to the prior shape by being heated and has good shape memory effect.

Owner:DONGHUA UNIV

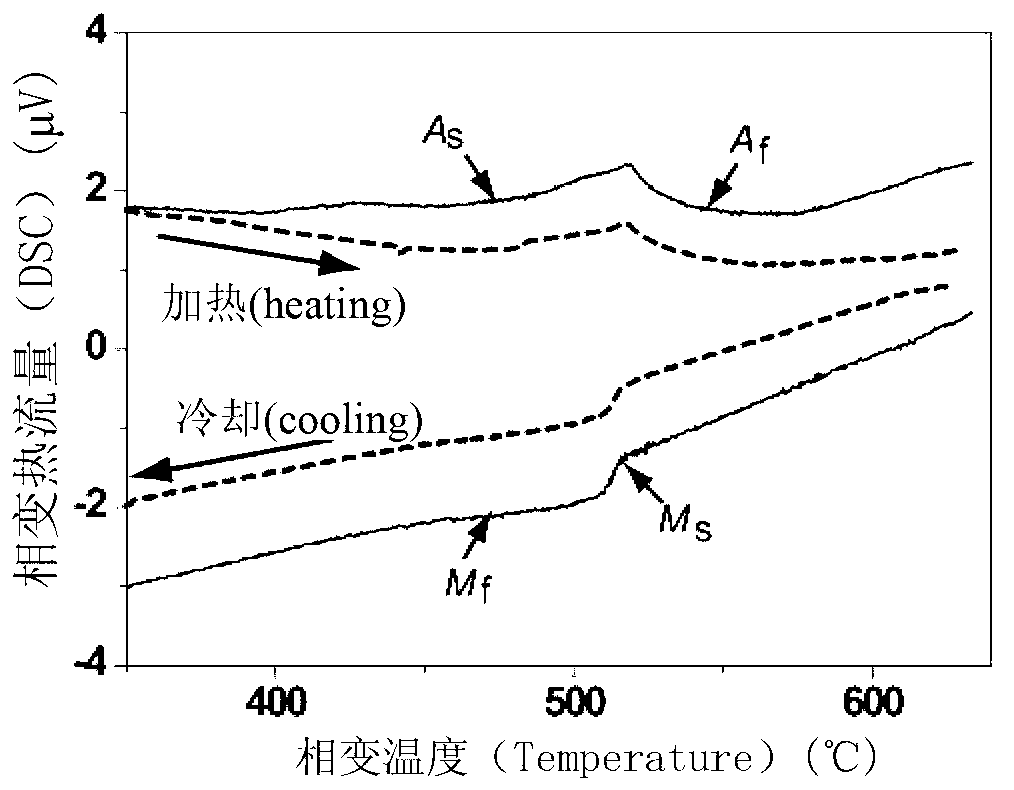

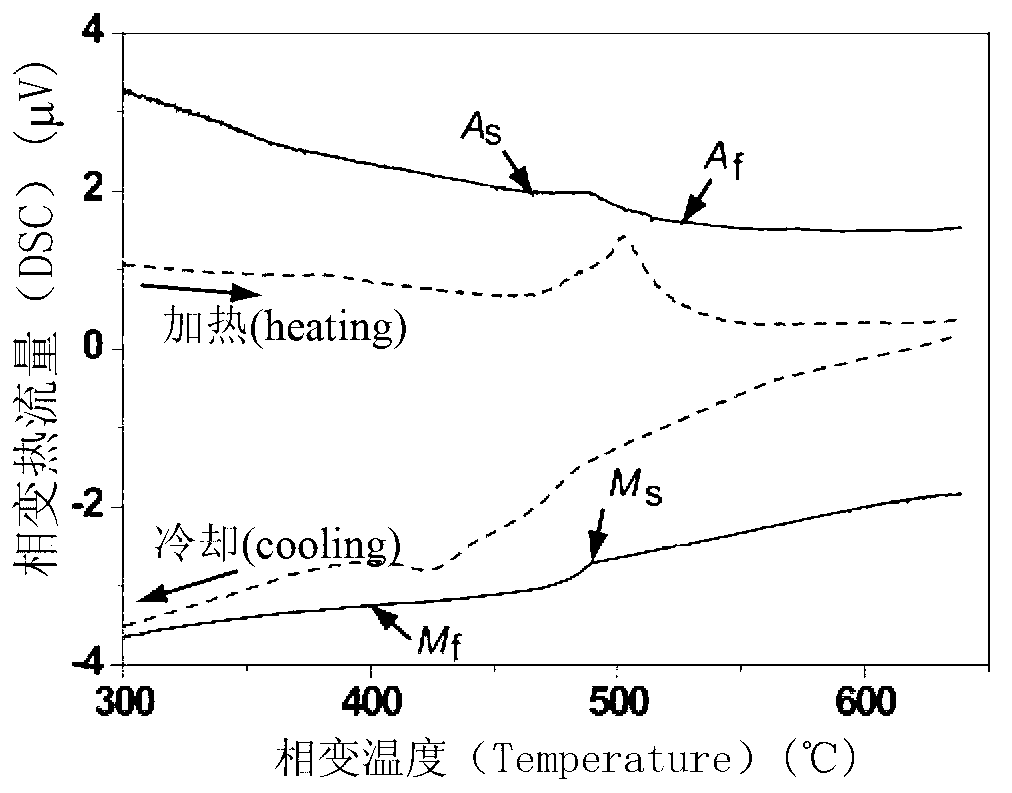

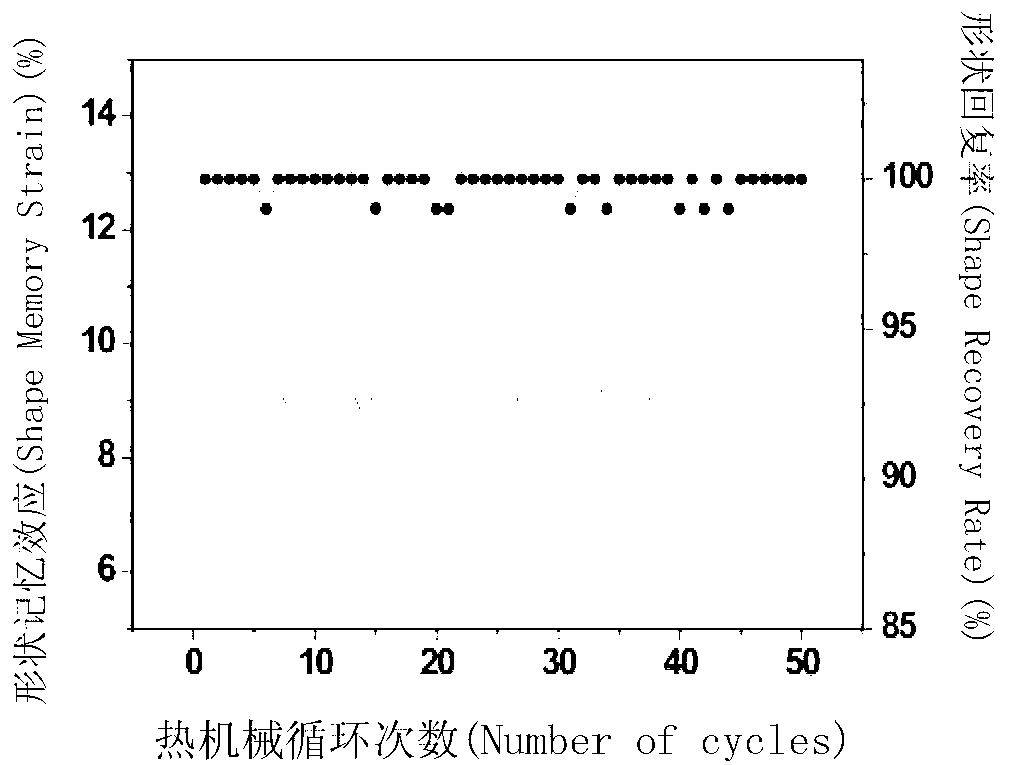

Copper-aluminum-iron-manganese high-temperature shape memory alloy and preparation method thereof

The invention relates to a copper-aluminum-iron-manganese high-temperature shape memory alloy and a preparation method thereof. The invention relates to a high-temperature shape memory alloy. The invention provides a copper-aluminum-iron-manganese high-temperature shape memory alloy with high martensitic phase-transformation temperature, stable extra-large shape memory effect and excellent stability thereof, good plasticity, and low cost. The invention also provides a preparation method thereof. The copper-aluminum-iron-manganese high-temperature shape memory alloy is composed of, by mass, 75- 83% of copper, 9-13% of aluminum, 3-6% of iron, and 2-9% of manganese. According to the invention, copper, aluminum, iron, and manganese raw materials are placed into a smelting furnace; the furnace is vacuumed, and argon is filled in; smelting is carried out under an argon atmosphere, such that a copper-aluminum-iron-manganese high-temperature shape memory ingot is obtained; the obtained copper-aluminum-iron-manganese high-temperature shape memory ingot cut into a sample; the obtained copper-aluminum-iron-manganese high-temperature shape memory ingot sample is subjected to a heat treatment, and is subjected to ice-water quenching, such that the copper-aluminum-iron-manganese high-temperature shape memory alloy is obtained.

Owner:XIAMEN UNIV

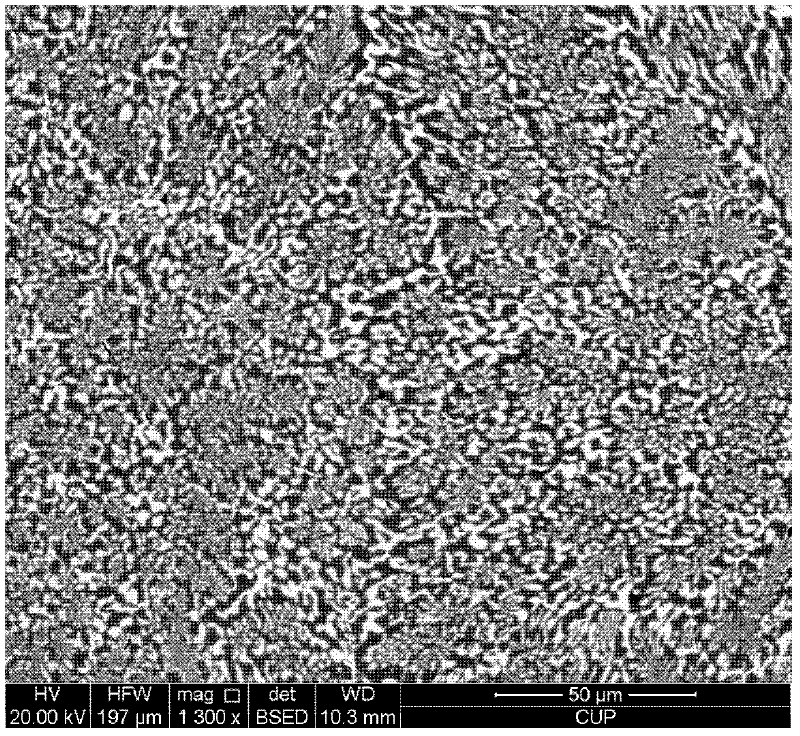

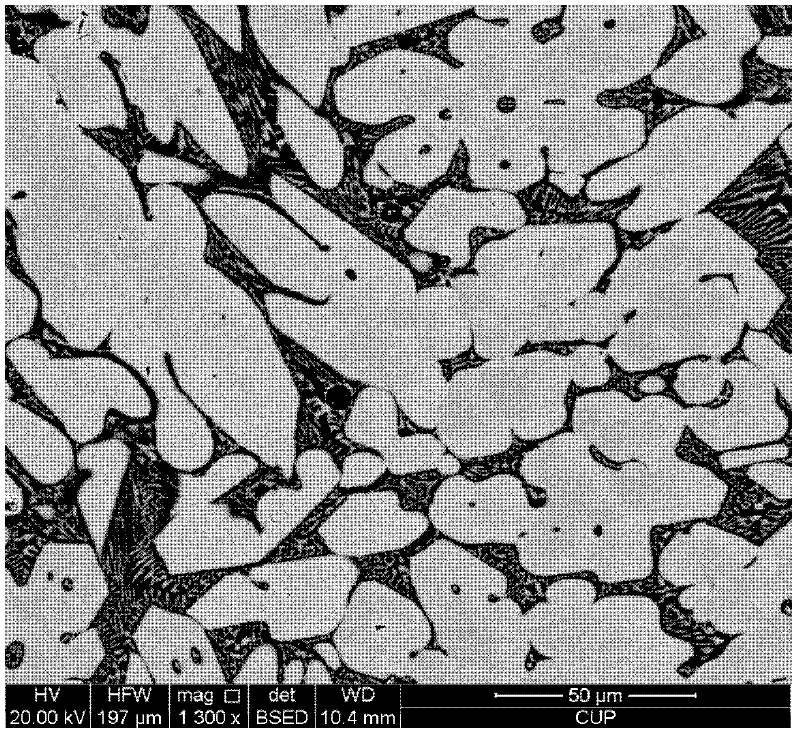

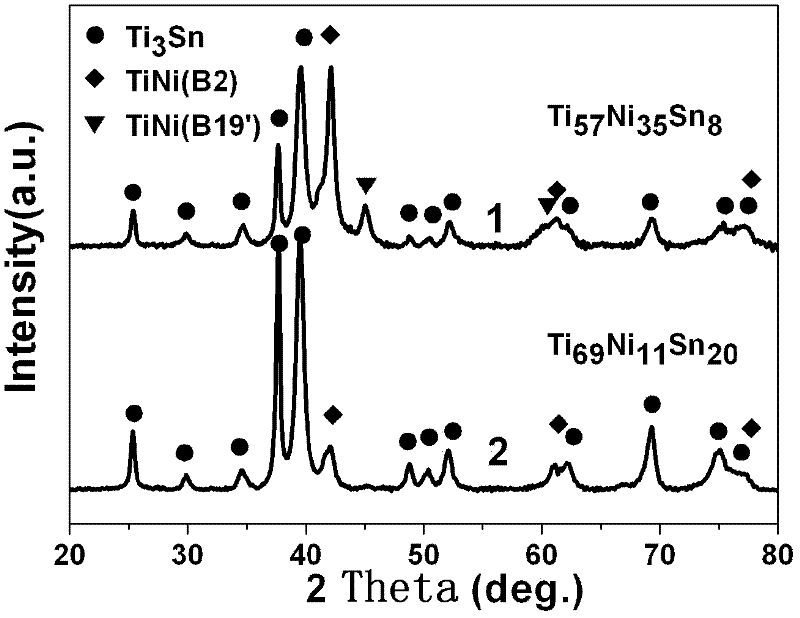

High-strength and high-damping Ti3Sn/TiNi memory alloy composite material

InactiveCN102358925AInterface is well integratedImprove the bonding strength of the interfaceHigh strainHigh intensity

The present invention relates to a novel high-strength and high-damping Ti3Sn / TiNi memory alloy composite material. The Ti3Sn / TiNi memory alloy composite material comprises a Ti element, a Sn element and a Ni element, wherein an atomic ratio of the three elements is (0.25x+y):0.25x:(100-y-0.5x), x comprises one selected from 16-84, y comprises one selected from 45.333-53.818. The memory alloy composite material of the present invention has unique functions of high strength, high plasticity, high strain strengthening, unobvious yielding, low frequency internal friction, high frequency acoustic attenuation and the like. The present invention further provides a preparation method for the Ti3Sn / TiNi memory alloy composite material. The preparation method comprises the following steps: selecting elementary substances of tin, titanium and nickel according to the component ratio of the Ti3Sn / TiNi memory alloy composite material, wherein the purities of the three elementary substances are more than 99 wt.%; placing the three elementary substances to a melting furnace with the vacuum degree more than 10<-1> Pa or under the protection of inert gas to carry out melting to obtain the Ti3Sn / TiNi memory alloy composite material.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

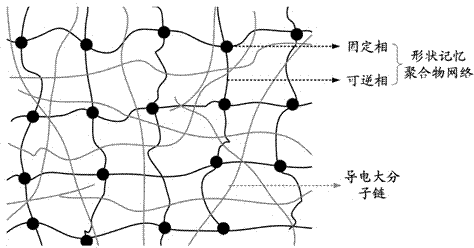

Intrinsic conduction shape memory polymer and preparation method thereof

The invention relates to a multifunctional polymer material, in particular to a shape memory epoxy polymer and an intrinsic conduction shape memory polymer of which the main component is conductive polyaniline. According to parts by weight, an aniline monomer or a derivative thereof and a doping agent are uniformly mixed; according to parts by weight, an oxidant is added into the mixture, and the materials are uniformly mixed and are subjected to ultrasonic treatment to obtain an emulsion; epoxy resin and a curing agent or the epoxy resin and the curing agent which is mixed with an accelerator are added into the emulsion at the same time, and the mixture is fully and uniformly mixed; the doping agent is continuously dropwise added, and the doping degree of the polyaniline is adjusted until the mixture is green or dark green; the mixture is filled into a die to be cured; the mixture is heated for 0.5 to 6 hours at the temperature of 50 to 80 DEG C, 0.5 to 6 hours at the temperature of 80 to 120 DEG C and then 0.5 to 6 hours at the temperature of 120 to 160 DEG C; and the product is cooled to room temperature and de-molded to obtain the intrinsic conduction shape memory polymer.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL

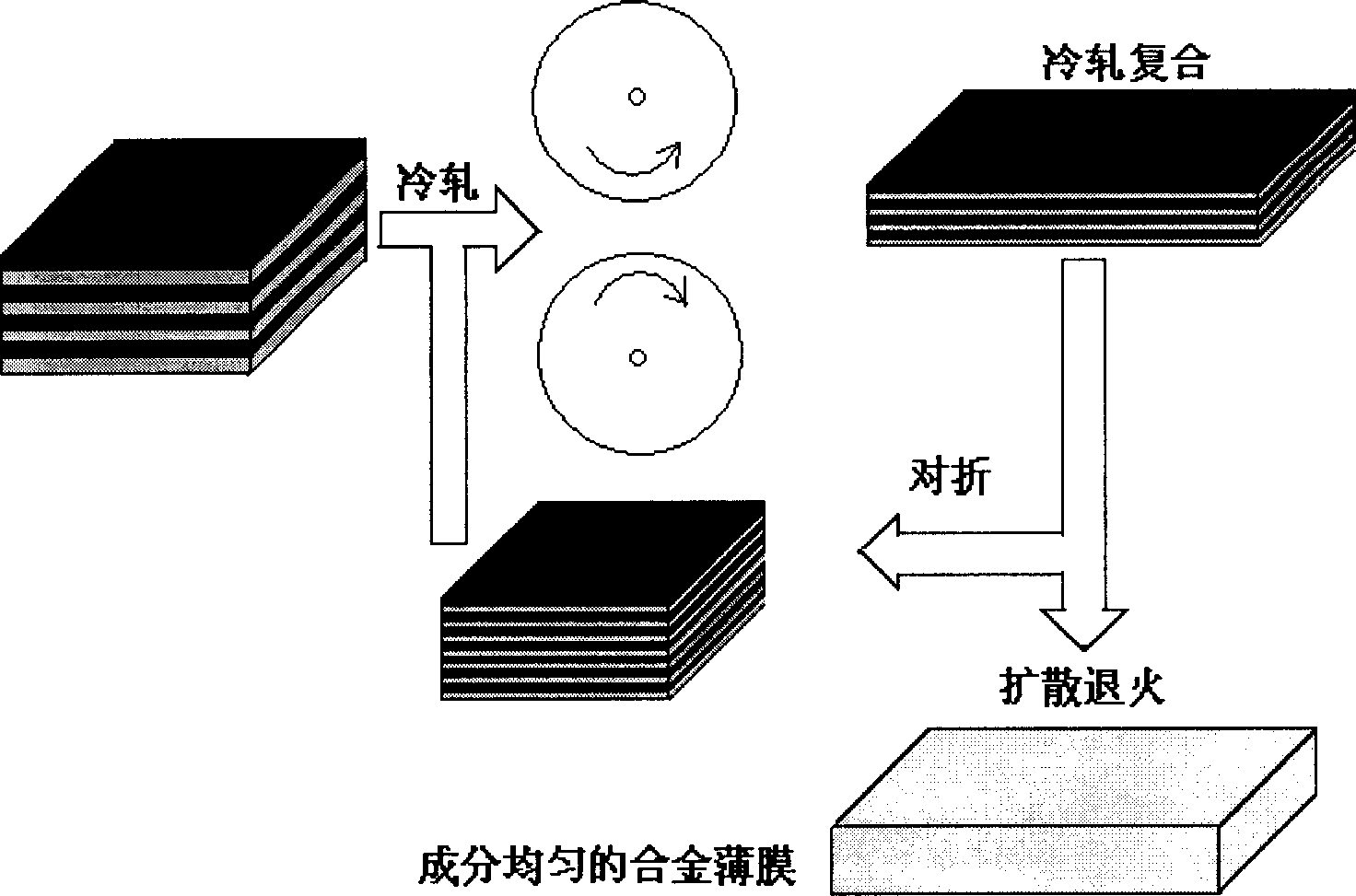

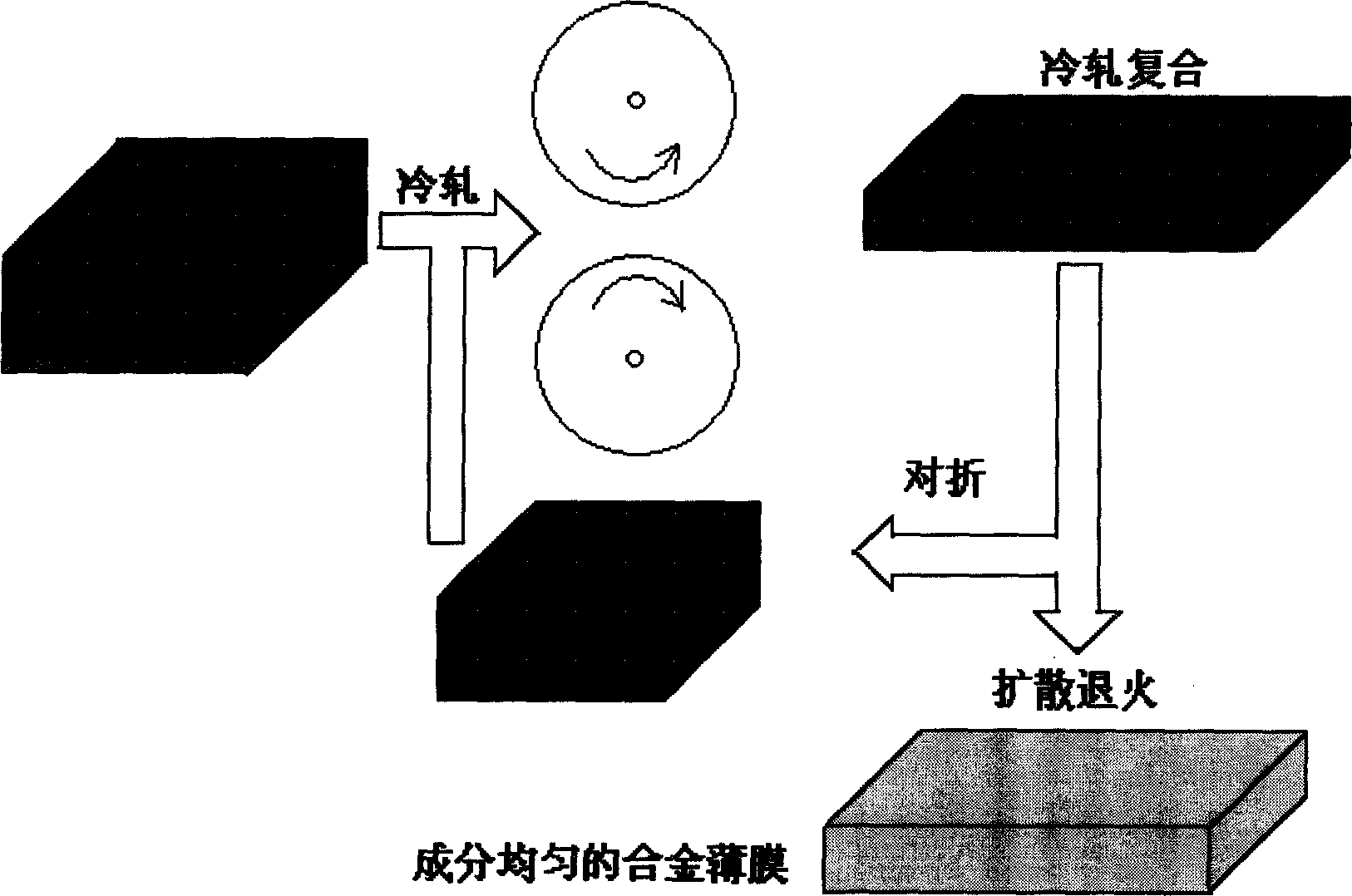

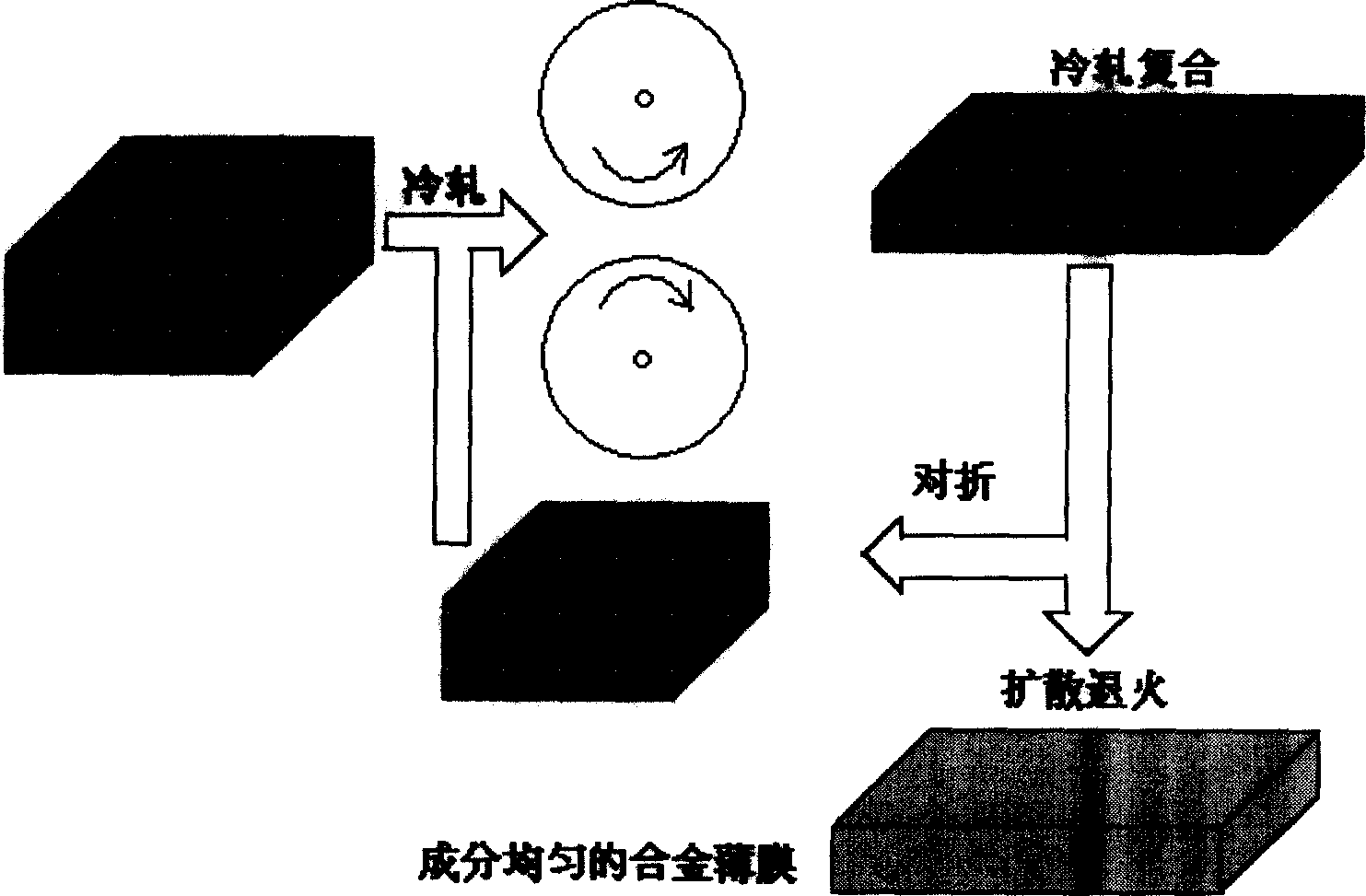

Method for preparing NiAl shape memory alloy film by cold rolling ultra-thin laminated alloy foil

InactiveCN1667144AGood shape memory effectImprove plasticityMetal rolling arrangementsMetal foilAlloy thin film

This invention discloses a method of preparing NiAl shape memory alloy thin film through cold rolling ultrathin lamination alloying. Good plasticity, easy deformed Al foil, Ni foils are materials, and foil thickness is defined according to atom constitution formula Ni1-XAlX. Metal foils are alternating laid, sandwich structure is got after big deformation cold rolling, it is repeated again and again, and finally components uniform alloy film is got after diffusion annealing alloying. The reactant ratio is 0.30íœxíœ0.40. The film components made by this method is easy control, crystal grain is small, fatigue life is high, area is large and cost is low.

Owner:SICHUAN UNIV

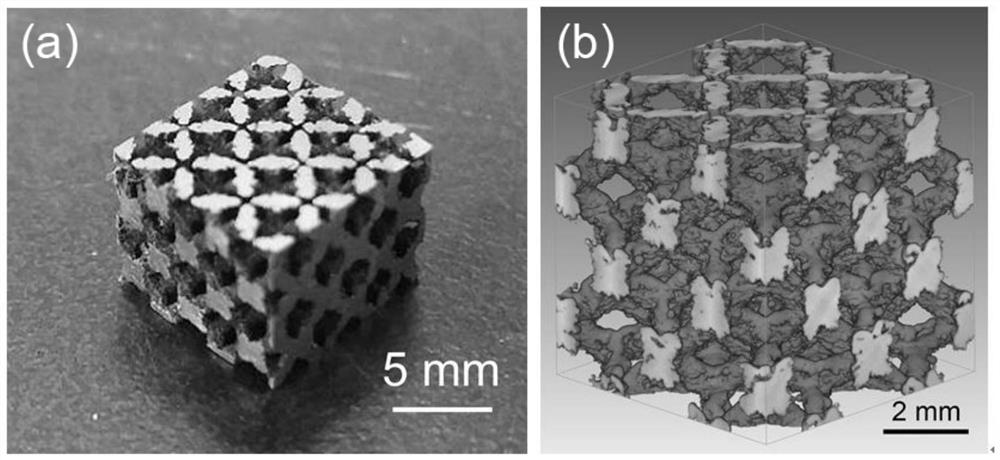

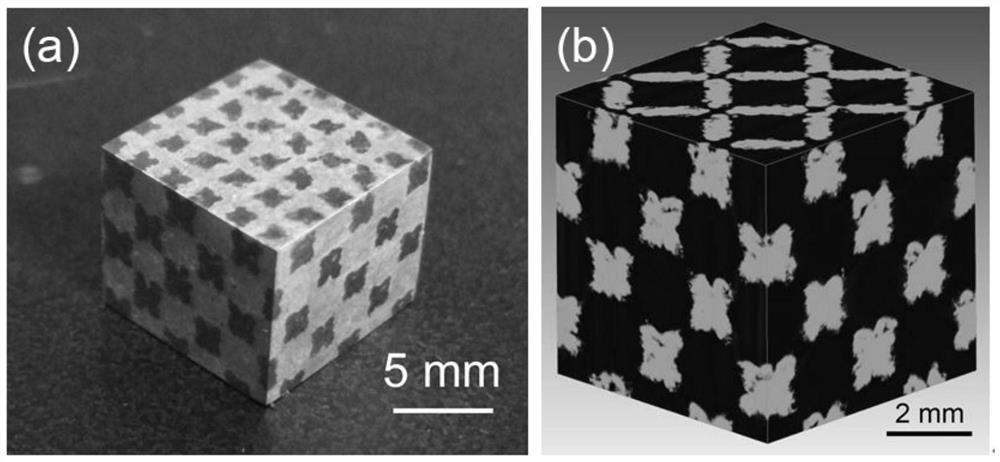

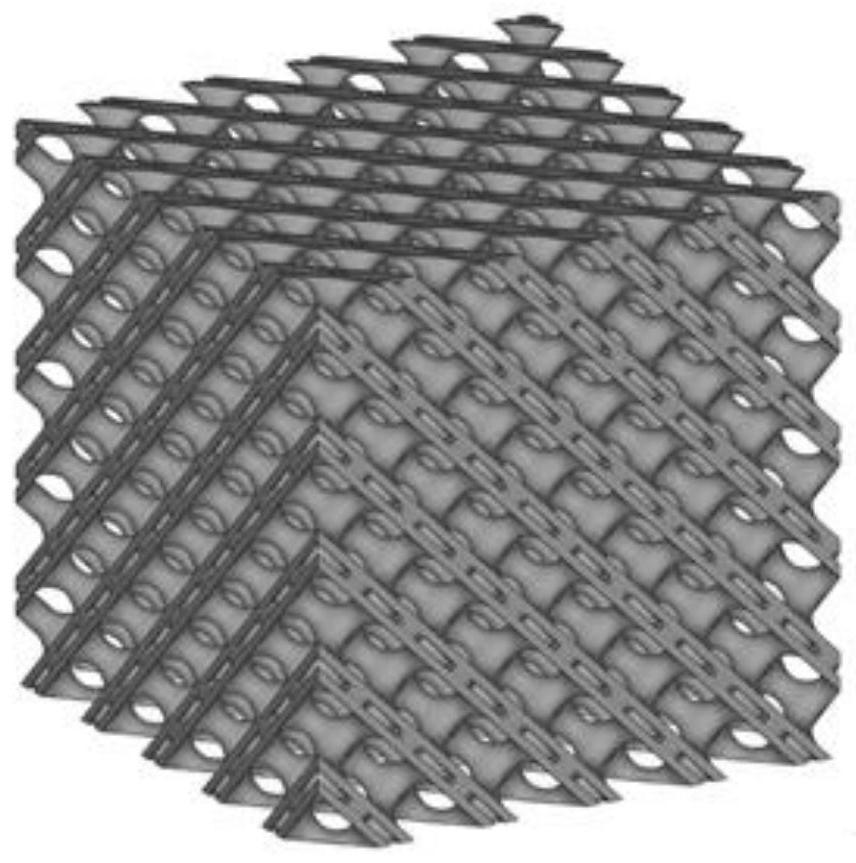

Shape memory alloy reinforced magnesium-based composite material with three-dimensional interpenetrating network structure and preparation method thereof

ActiveCN111745162AImprove interface strengthIdeal reinforcementAdditive manufacturing apparatusMagnesium matrix compositeShape-memory alloy

The invention relates to a magnesium-based composite material with a three-dimensional interpenetrating network structure and reinforced by a 3D-printed shape memory alloy reinforcement framework anda preparation method thereof. The composite material is composed of a shape memory alloy reinforcing body with the volume fraction of 10%-80% and a magnesium or magnesium alloy matrix, has the three-dimensional interpenetrating network structure and is characterized in that the reinforcing body and the matrix respectively have independent topological structures and are inserted and complementarilycombined in a three-dimensional space. The preparation method of the composite material comprises the following steps that the shape memory alloy reinforcement framework with the network topology structure is prepared by adopting a 3D printing technology, the framework is infiltrated by molten magnesium or magnesium alloy melt under a vacuum or protective atmosphere, and the composite material isobtained after solidification and cooling. The composite material is high in strength, large in plasticity, high in controllability of structure and mechanical property, has a certain shape memory effect, namely the room temperature deformation can be partially or completely recovered above the martensite transformation temperature and has considerable application prospect as a novel structural and functional integrated material.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

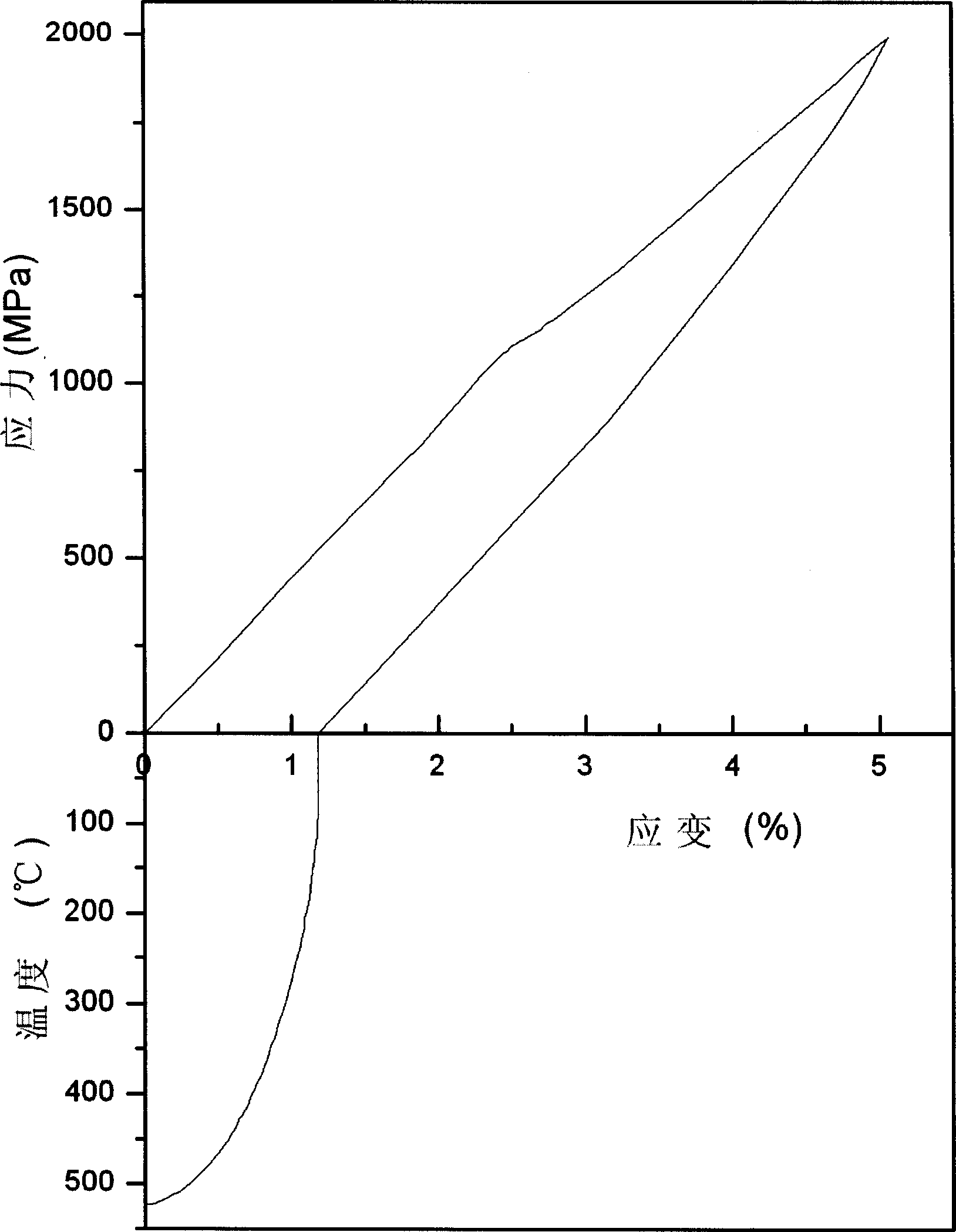

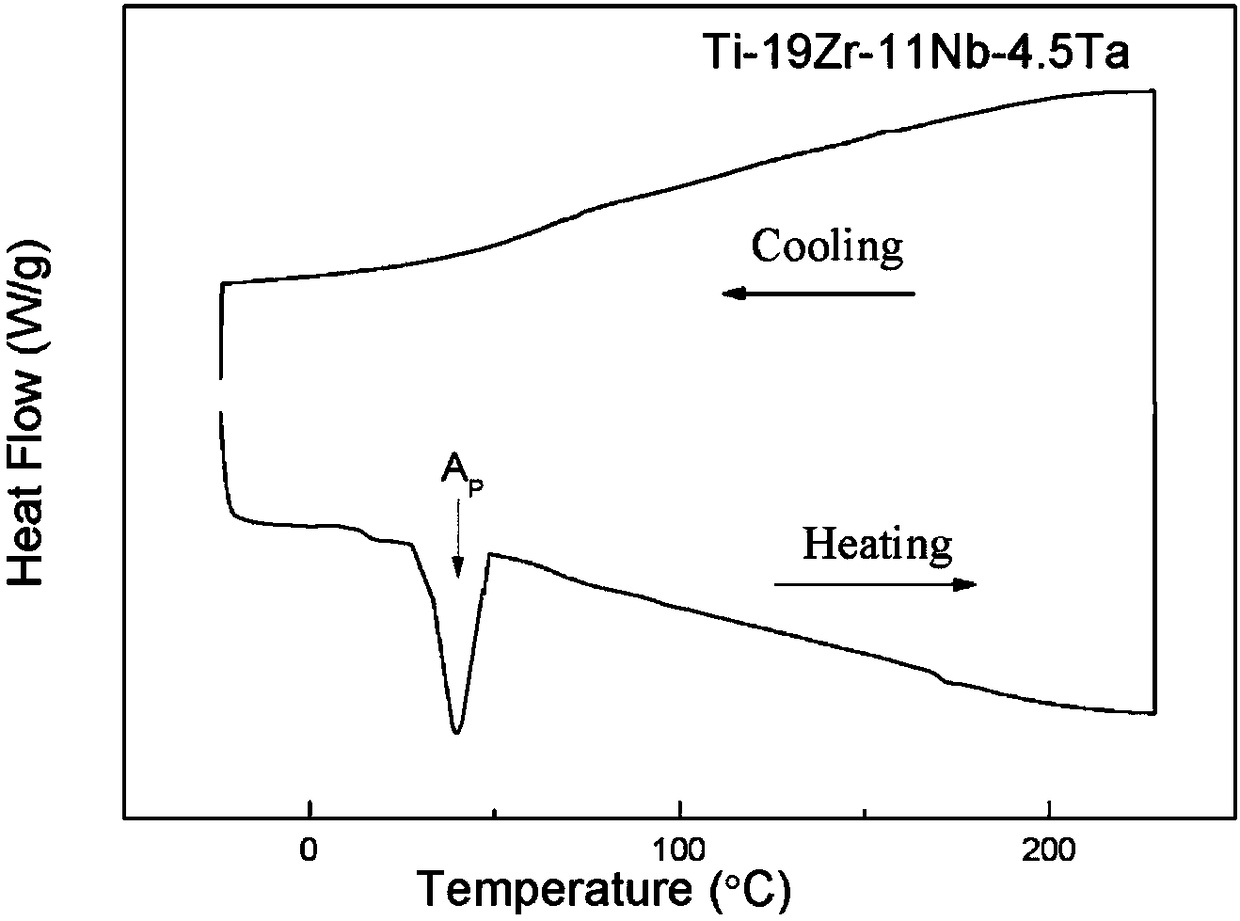

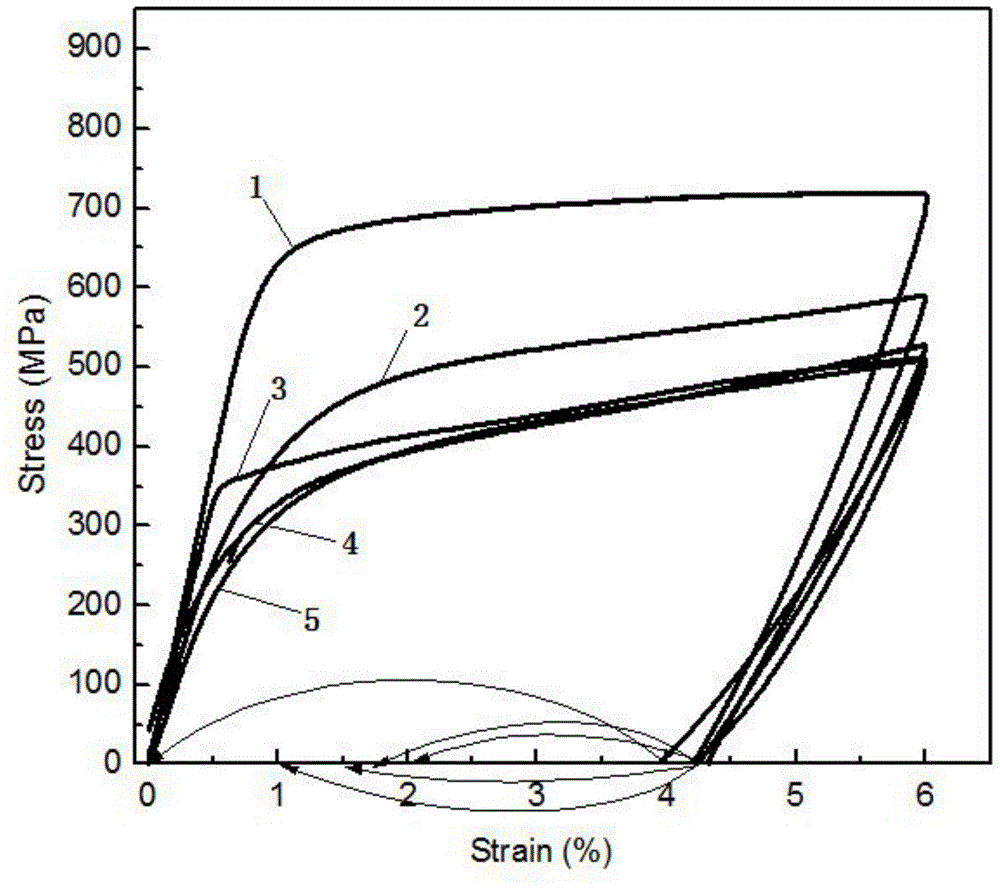

Wide-temperature-range hyperelastic titanium-zirconium-niobium-tantalum shape memory alloy and preparation method thereof

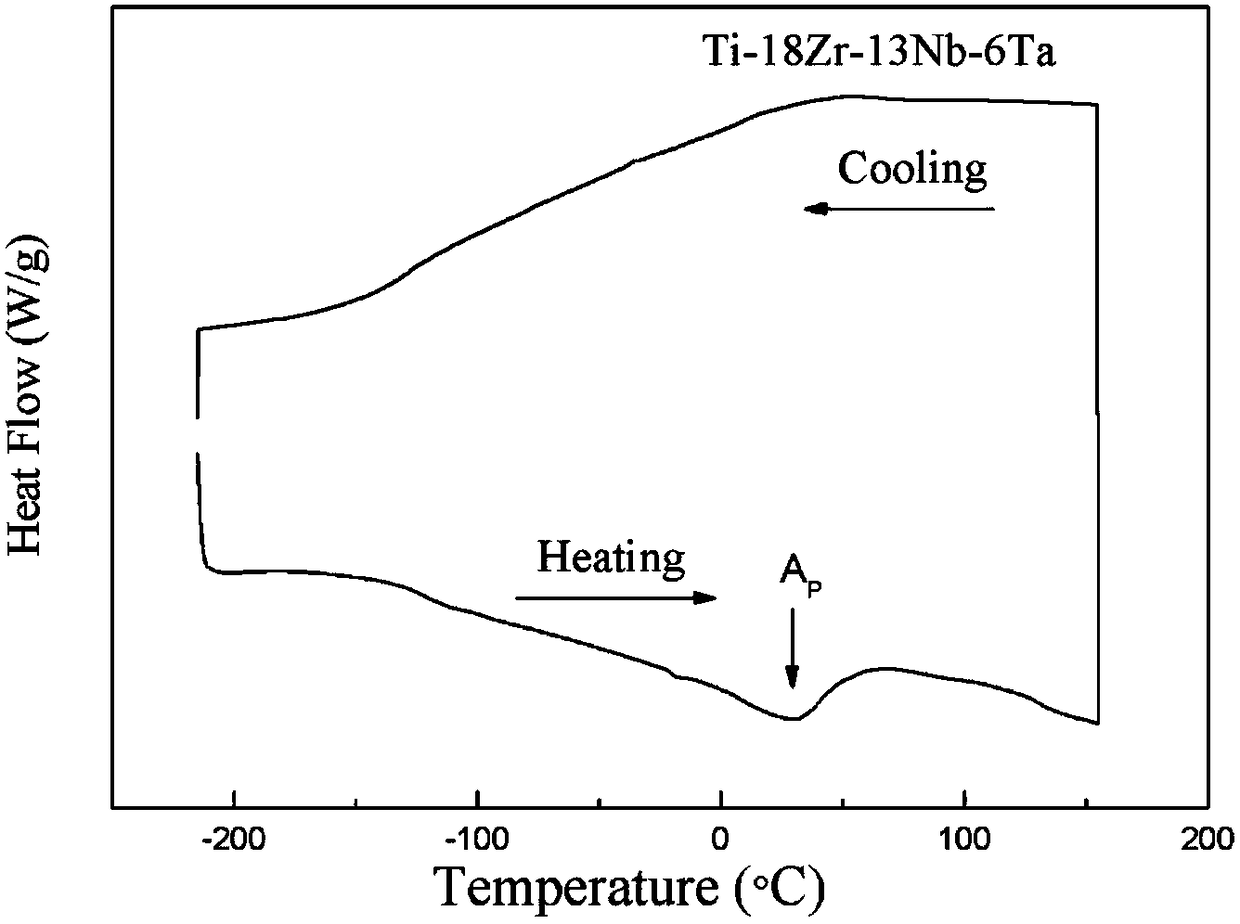

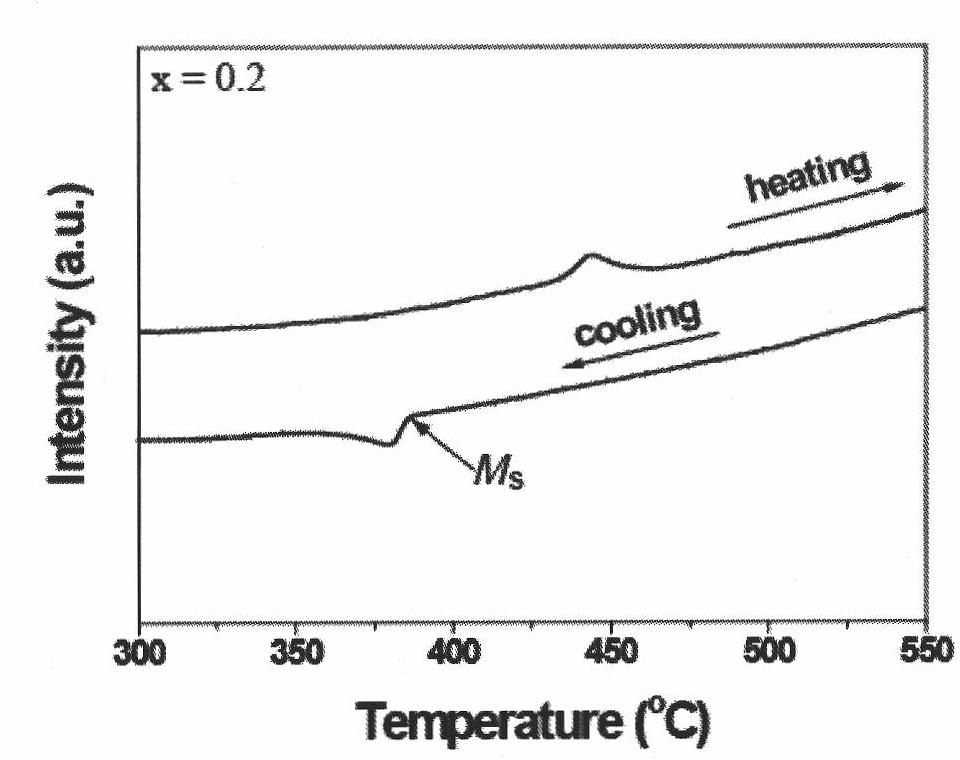

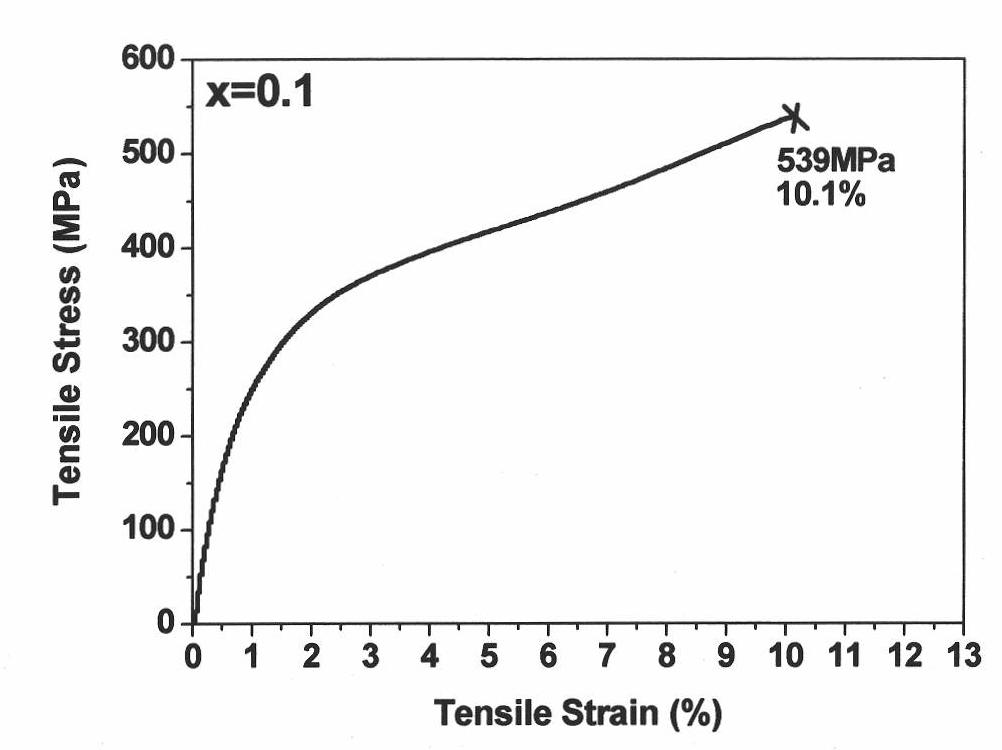

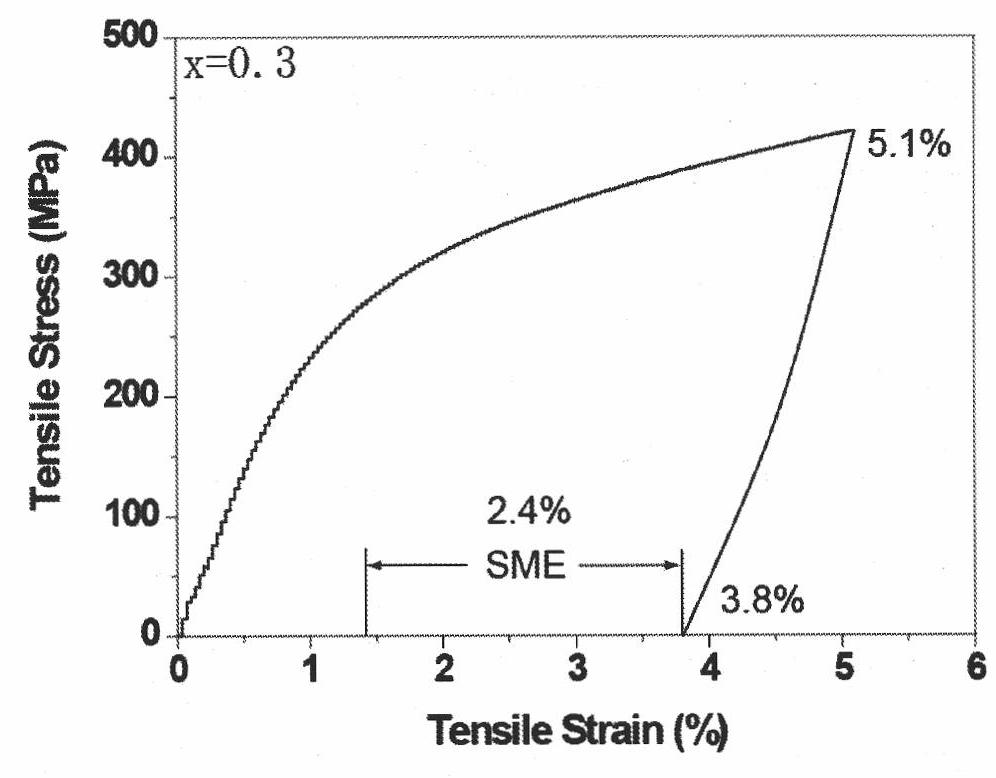

ActiveCN104032188ABreakthrough featureBreak through limitationsElemental compositionTitanium zirconium

The invention discloses a wide-temperature-range hyperelastic titanium-zirconium-niobium-tantalum shape memory alloy and a preparation method thereof. The wide-temperature-range hyperelastic titanium-zirconium-niobium-tantalum shape memory alloy consists of the following biosafety elements in percentage by atom: 20% of zirconium (Zr), 10% of niobium (Nb), 2-4% of tantalum (Ta) and the balance of titanium (Ti). Through different thermal treatment processes, the alloy has different functional characteristics of wide-temperature-range hyperelasticity and high-temperature shape memory effect, namely, the Ti-20Zr-10Nb-(2-4)Ta is of a beta phase at room temperature after annealing at 600 DEG C and air cooling and has a wide temperature range (from -196 DEG C to 135 DEG C) and hyperelasticity, and the maximum room-temperature hyperelasticity is 4.9%, and the highest hyperelasticity is obtained at 50 DEG C and reaches 5.0%; the Ti-20Zr-10Nb-(2-4)Ta is of an alpha phase at room temperature after annealing at 600 DEG C and quenching in water and has a high-temperature shape memory effect, the peak temperature of inverse martensite phase transformation is 97-130 DEG C, and the maximum shape memory effect is 3.34%.

Owner:BEIHANG UNIV +1

Production of TiNiCu shape memory alloy thin membrane by cold rolling superthin laminated alloy

InactiveCN1644740ASolve brittle, difficult-to-process problemsGood shape memory effectMetal rolling arrangementsAlloy thin filmShape-memory alloy

The invention was involved in the method to preparation of TiNiCu shaped memory alloy firm by cold roll ultrathin lamination alloying. Using Ti foil, Ni foil, Cu foil and NiCu foil as the rough material which has good plastic nature that easy to distortion. The thickness of foil determined according to Tix(Nil-yCuy)1-x. The foils were placed by mutual overlap, and the ultrathin sandwich structure formed by cool roll. The ultrathin structure was repeated cool rulled. The foil that has a homogeneous ingredient was gained after diffusion annealing. The ingredient has the quality of 0.45<=x<=0.55, 0<=y<=0.6. Its advantages: ingredients easy to be controlled and has a small crystal grain; has a long endurance life, a large area and a low cost.

Owner:SICHUAN UNIV

Shape memory ceramic and its prepn

The shape memory ceramic contains ZrO2 as base material, Ce and Y and consists of CeO2 7-10 mol%, preferably 7.5-8.5 mol%, Y2O3 0.2-0.8 mol%, preferably 0.45-0.55 mol%, and ZrO2 the rest. The preparation process includes the following steps: preparing superfine powder of the components via coprecipitation, sintering at 1500 deg.c for 4-6 hr, cooling gradually to obtain tetragonal crystal system of polycrystalline zirconia ceramic block with crystalline grain size 0.9-1.1 micron and density 5.9-6.1 g / cu cm. The shape memory ceramic has shape recovering rate of 95-100 % in strain up to 1.2 %,high action temperature and pseudo-elastic recovery of 3-4 %.

Owner:EMERSON ELECTRIC (CHINA) HLDG CO LTD

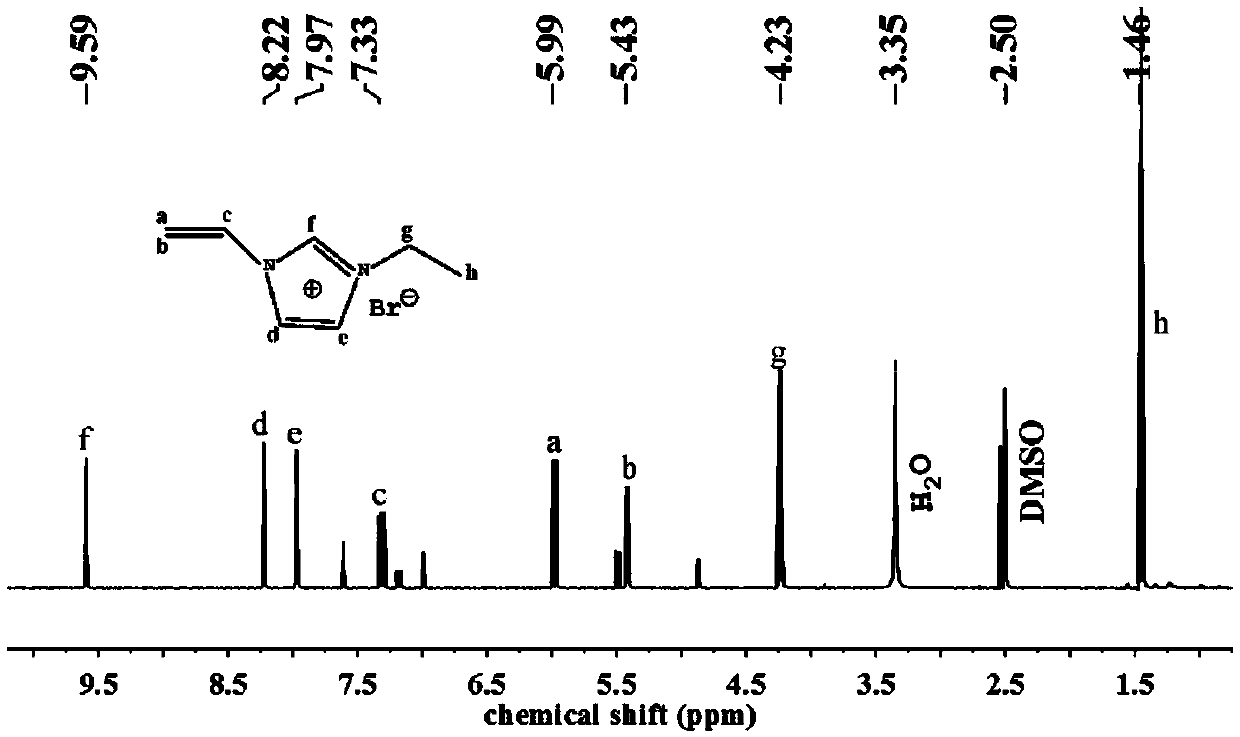

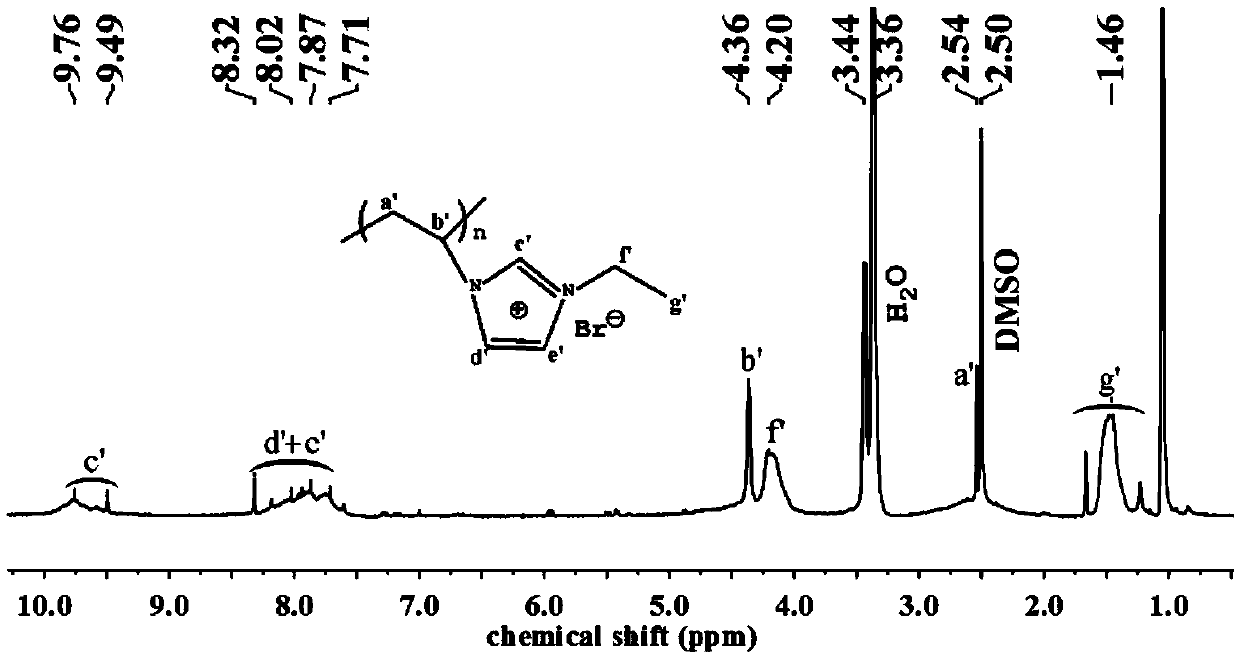

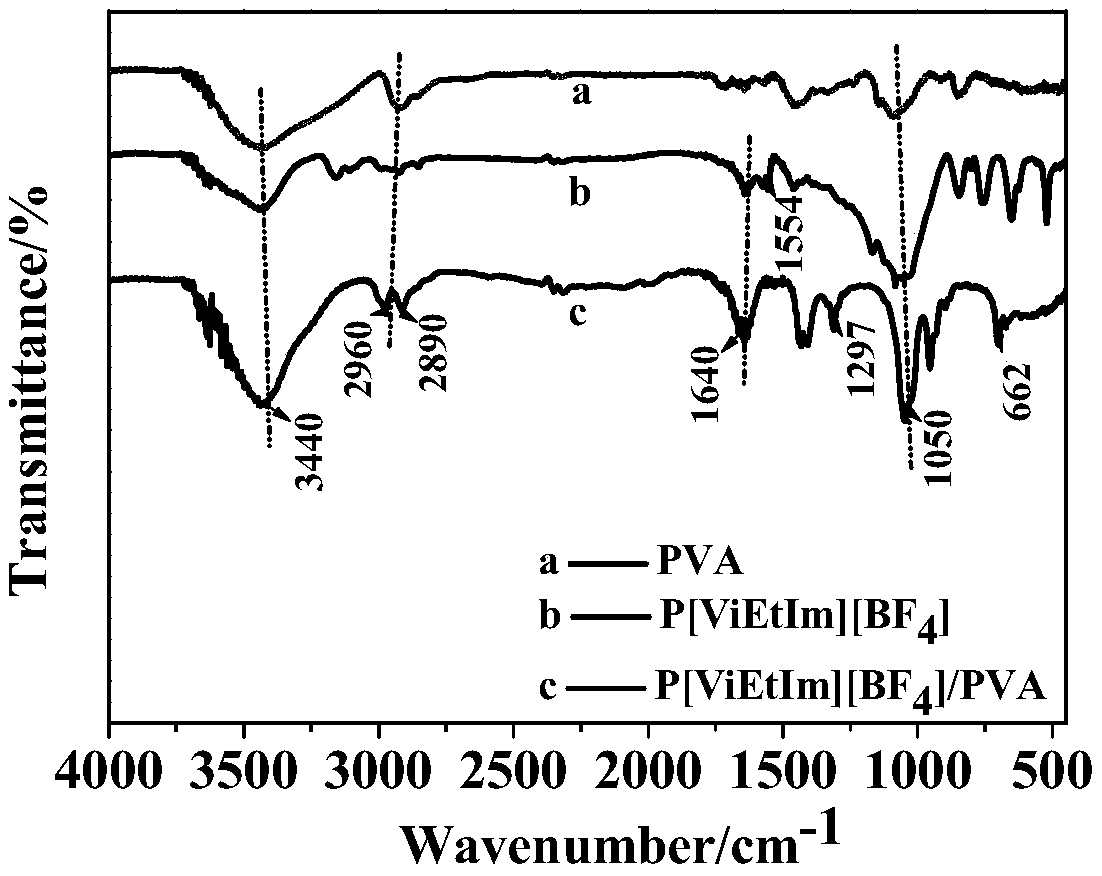

Method for preparing (1-vinyl-3-ethylimidazole borate)polyion liquid/polyvinyl alcohol polymer composite material

The invention provides a method for preparing a (1-vinyl-3-ethylimidazole borate)polyion liquid / polyvinyl alcohol polymer composite material. The method comprises the following steps: synthesizing an ethylimidazole functional ion liquid monomer; performing in situ polymerization on the ethylimidazole functional ion liquid monomer in a polyvinyl alcohol solution; introducing the polyion liquid into crosslinked polyvinyl alcohol in order to form a network-like composite material. Large anion-cation groups exist in the polyion liquid structure, have excellent polarization density and polarization rate, and serve as a very good microwave absorbing medium, so that the polymer composite material has a very good shape memory effect under the driving actions of microwaves. Compared with the convention shape memory polymer for realizing optical, electrical and magnetic remote responses by means of adding inorganic fillers under current research, the polymer composite material disclosed by the invention is totally based on a polymer, and is a non-directly-contact microwave-driven shape memory polymer, so that the problems of poor compatibility, non-uniform heating and the like caused by filling of the polymer with the inorganic fillers can be solved.

Owner:TAIYUAN UNIV OF TECH

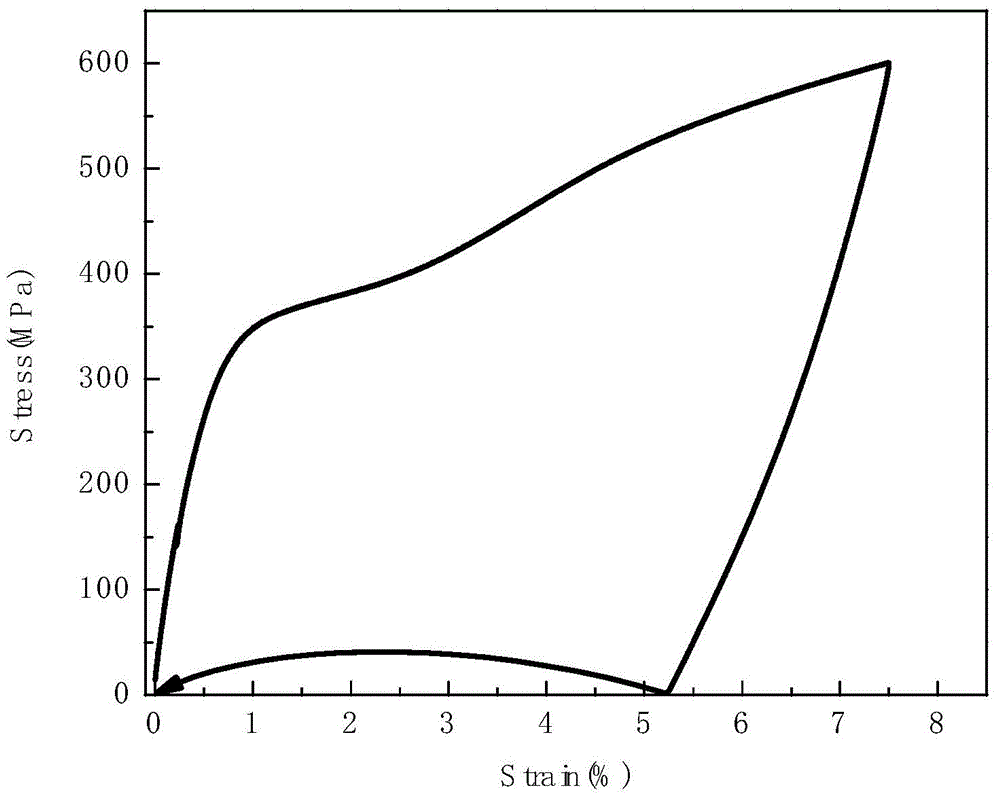

Low-phase-transformation-temperature titanium-zirconium-niobium-tantalum shape memory alloy, a preparation method and application thereof

The invention provides a novel titanium-zirconium-niobium-tantalum shape memory alloy with a low phase transformation temperature. Based on the total amount of 100 percent, the titanium-zirconium-niobium-tantalum shape memory alloy is prepared from the following components by atomic percent: 15 to 25 percent of zirconium, 11 to 15 percent of niobium, 4.5 to 10 percent of tantalum and the balance of titanium. The reverse martensitic phase transformation temperature is 0 to 45 DEG C, the maximum shape memory effect is 3.9 percent, and an alloy product with a great shape memory effect and good biocompatibility is obtained by certain thermomechanical treatment. According to the titanium-zirconium-niobium-tantalum shape memory alloy, a low-phase-transformation-temperature alloy material is provided to prepare a typical medical straddle nail product by use of an advanced machining technology for application to medical human body orthopaedic implantation, and preparation of connectors, vascular stents, straddle nails and various products in the field of human body implantation medical devices.

Owner:烟台浩忆生物科技有限公司

Rare earth Ni-Mg-Co-Ga-based high-temperature shape memory alloy

InactiveCN101876016AExcellent shape memory performanceHigh martensitic transformation temperatureMartensite transformationRare earth

The invention discloses a rare earth Ni-Mg-Co-Ga-based high-temperature shape memory alloy relating to a shape memory alloy. The invention provides a rare earth Ni-Mg-Co-Ga-based high-temperature shape memory alloy with high martensite phase-transition temperature and better plasticity and shape memory function, and a preparation method thereof. The chemical formula is (Ni53Mn22Co6Ga19)100-xAx, wherein A=Dy, Y and Gd, and the atom percent of x is 0-1. Ni, Mg, Co, Ga and rare earth raw material are put into a furnace, vacuumized, charged with argon and smelted to obtain the ingot material of the rare earth Ni-Mg-Co-Ga-based high-temperature shape memory alloy; the ingot material of the rare earth Ni-Mg-Co-Ga-based high-temperature shape memory alloy is processed by heating and is cooled along with the furnace; the ingot material of the rare earth Ni-Mg-Co-Ga-based high-temperature shape memory alloy, on which heat treatment is performed, is rolled into lamellar alloy; the obtained lamellar alloy is cut into test specimen; and after processed by heating, the test specimen is quenched by ice water to obtain the rare earth Ni-Mg-Co-Ga-based high-temperature shape memory alloy.

Owner:XIAMEN UNIV

A magnetic strap material having high strain shape memory effect and preparing method thereof

InactiveCN1501410ALow costEase of industrial mass productionInorganic material magnetismInductances/transformers/magnets manufactureElectrical resistance and conductanceMolten state

The invention relates to a magnetic material having high strain shape memory effect and process for making it, wherein the process for preparing comprises, melting the weighed material, preparing magnetic material using the conventional fast quench method with the preparation condition being, heating NiFeGa raw material to molten state, under the molten environment, ejecting argon of 1.0-1.50 barometric pressure to the copper wheel surface rotating at thread speed of 1-50 m / s, realizing 5-2000 m / s quick cooling down and acquiring fast quench thin belts. The starting temperature of the martensitic phase transformation of the material can be chosen to be in the range of between 120K-350K according to the need or the application. The material possesses better tenacity because of its iron content.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

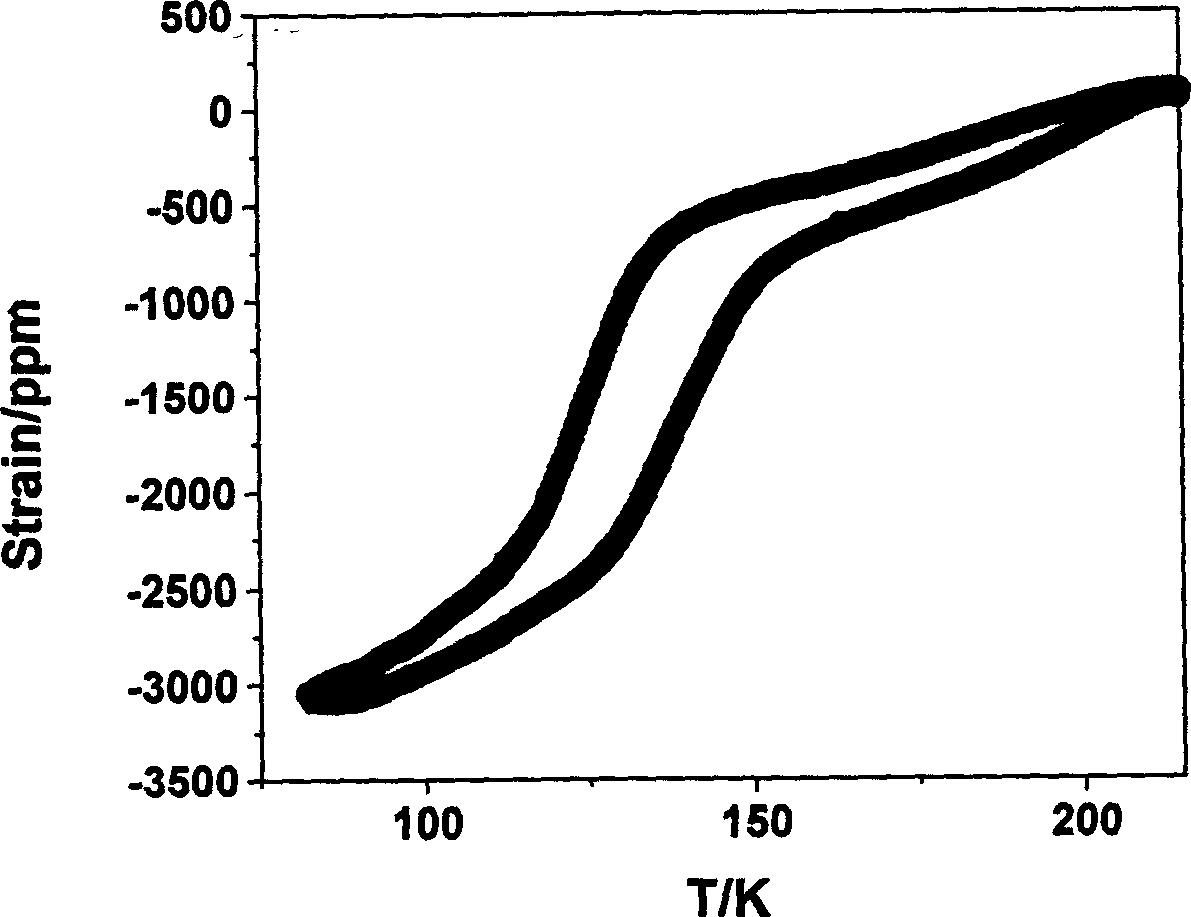

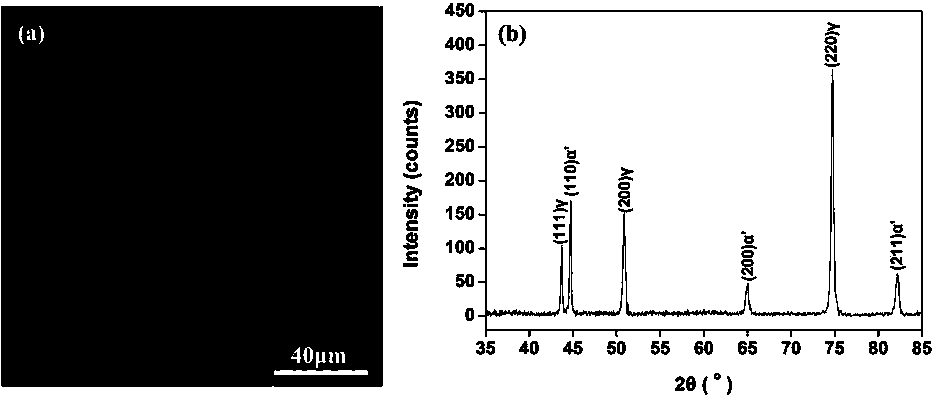

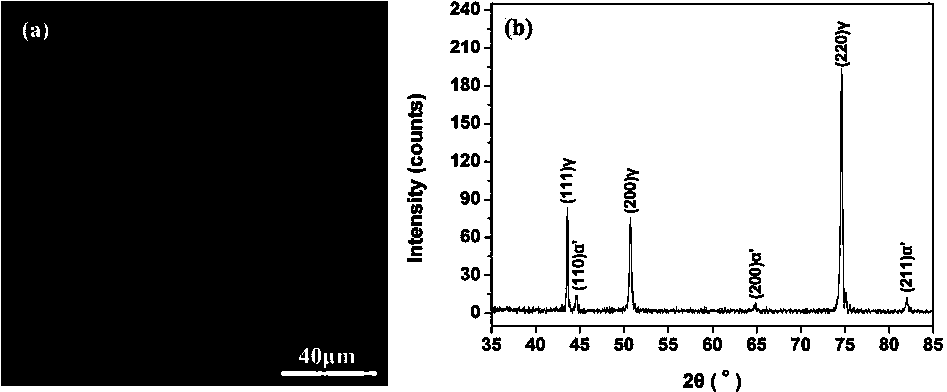

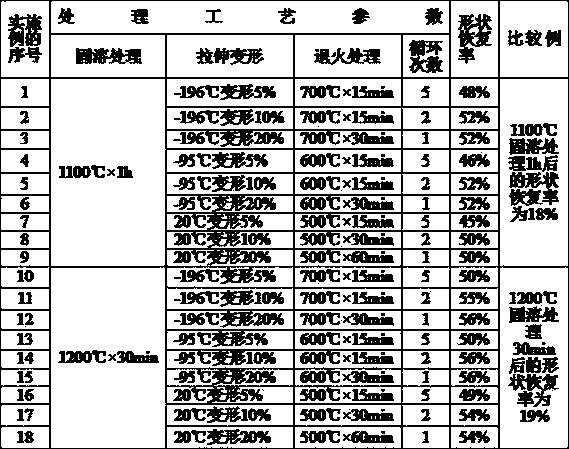

Method for improving shape memory effect of metastable austenitic stainless steel

InactiveCN103773933AImprove shape memory effectExpand the scope of applicationAustenitic stainless steelMemory effect

The invention discloses a method for improving a shape memory effect of metastable austenitic stainless steel and belongs to the field of austenitic stainless steel, aiming at an existing problem that the shape memory effect of the metastable austenitic stainless steel is poor. The method comprises the specific steps as follows: (1) carrying out solid solution treatment on the metastable austenitic stainless steel at 1,000-1,300 DEG C for 10 minutes to 2 hours; and (2) deforming the metastable austenitic stainless steel subjected to the solid solution treatment at -196 DEG C to induce alpha' martensite transformation, and performing stretching or rolling deformation for 5%-30% at a highest temperature Md; then carrying out annealing treatment at 400-800 DEG C for 5 minutes to 1 hour; and circulating the process of deforming and then carrying out the annealing treatment for 1-5 times, wherein an alpha' martensite exists in an austenitic base body of the metastable austenitic stainless steel treated by the method. The shape memory effect of the metastable austenitic stainless steel can be obviously improved.

Owner:SICHUAN UNIV

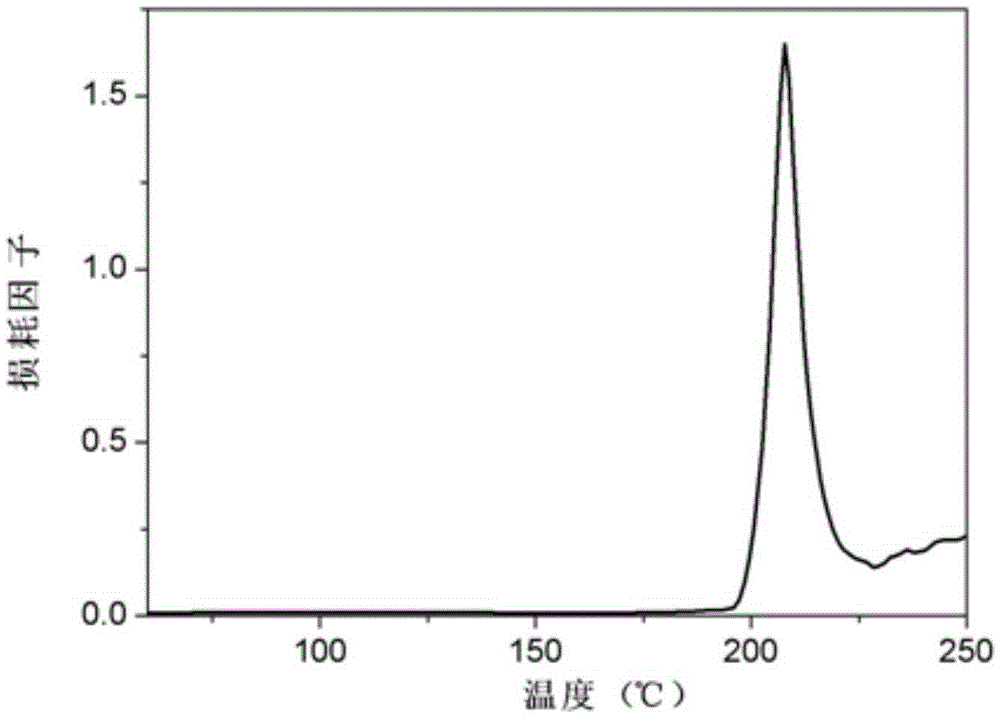

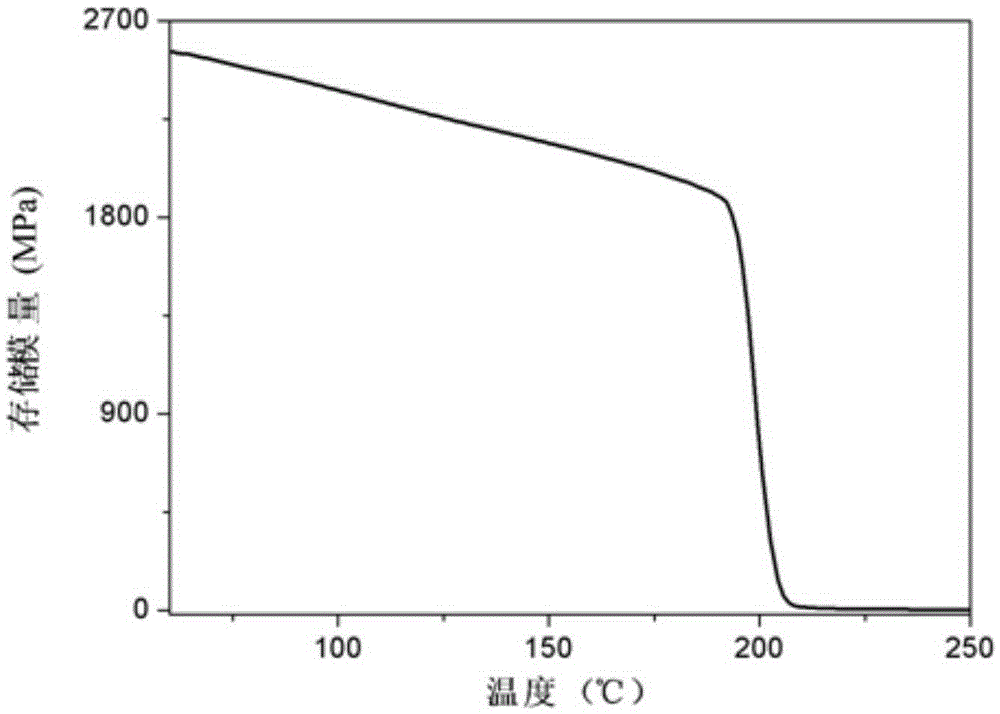

Shape memory random-copolymerized polyimide capable of being circularly used and preparation method thereof

The invention discloses a shape memory random-copolymerized polyimide capable of being circularly used and a preparation method thereof, relates to polyimide and a preparation method thereof, and aims to solve the problems that in the prior art, the preparation cost of shape memory polyimide is high, and the prepared shape memory polyimide cannot be repeatedly used. The provided polyimide is prepared from a mixture of 1,3-bis(3-aminophenoxyl)benzene, 4,4'-(4,4'-isopropylidenediphenoxy)bis(phthalic anhydride), and 4,4'-oxydiphthalic anhydride. The preparation method comprises the following steps: step one, preparing a diamine solution; step two, preparing a dianhydride solution; step three, preparing a polyamide acid solution; step four, carrying out thermal imidization to obtain a glass plate containing polyimide; step five, cleaning and drying to obtain the shape memory random-copolymerized polyimide capable of being circularly used. The provided method can obtain shape memory random-copolymerized polyimide capable of being circularly used.

Owner:HARBIN INST OF TECH

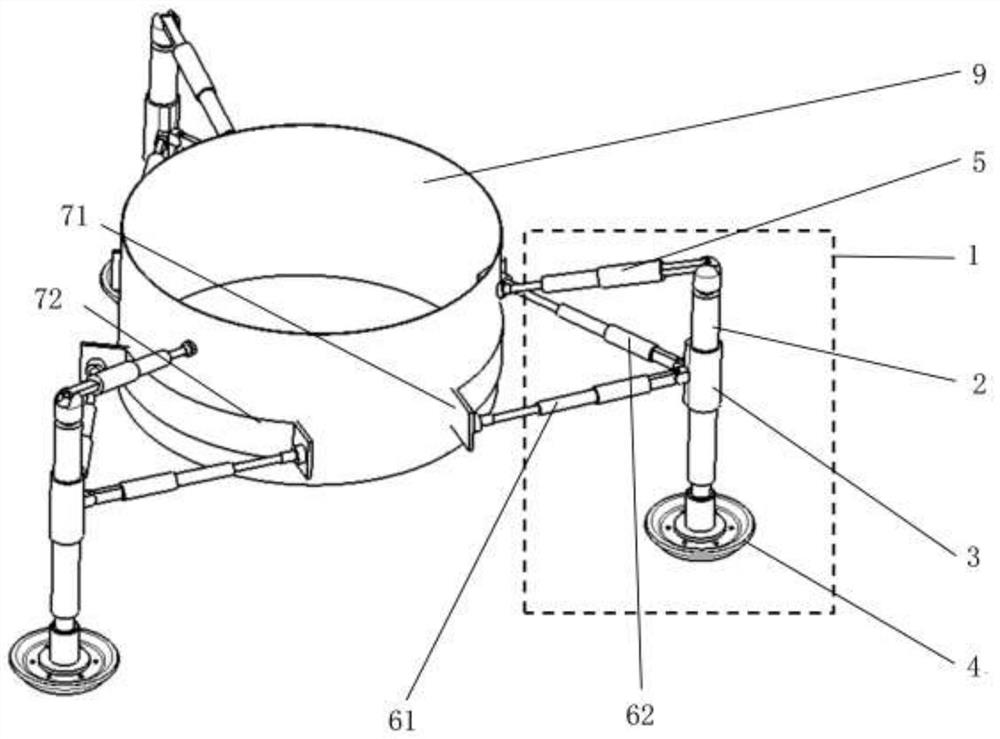

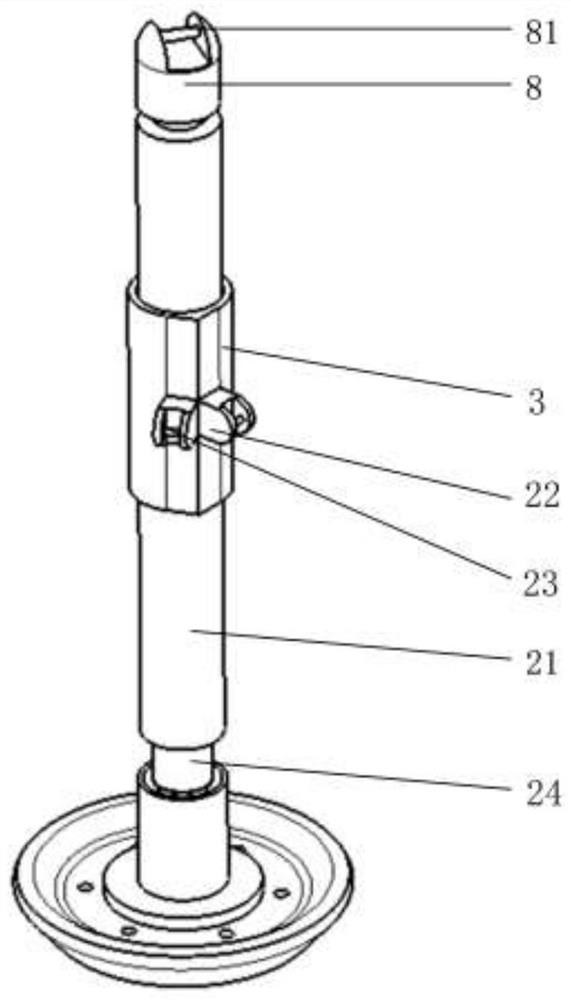

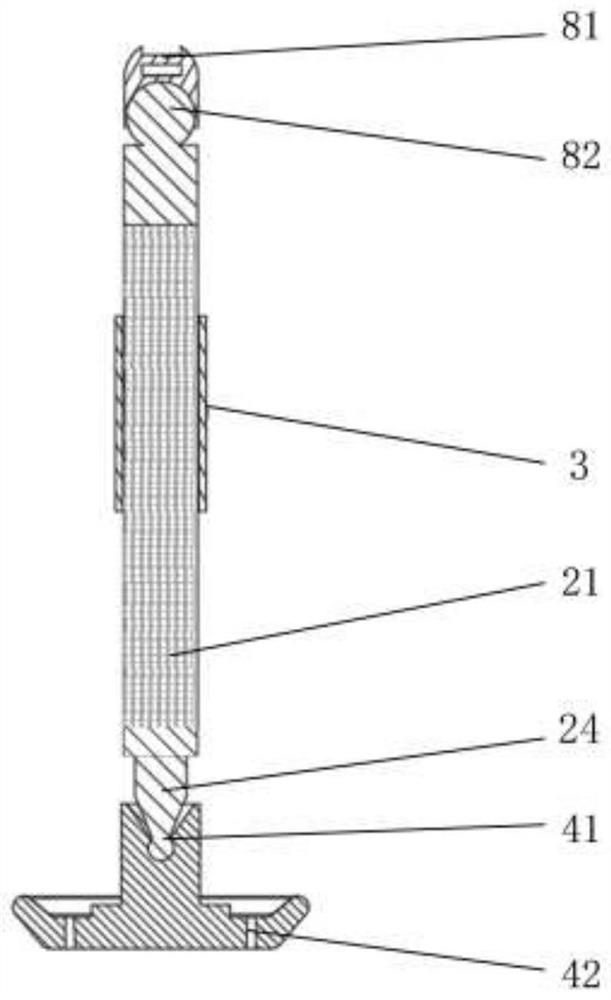

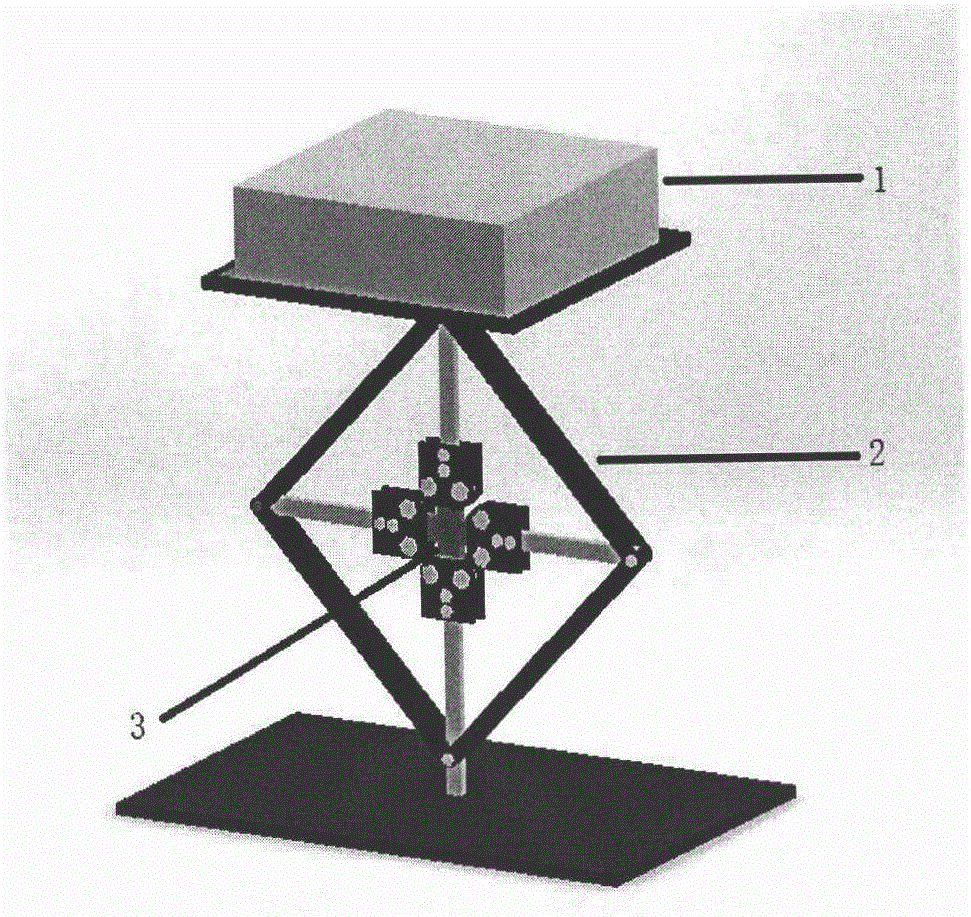

Memory alloy planet detection lander based on negative poisson ratio structure

ActiveCN111891410AStrong landing buffer performanceStrong attitude control abilitySystems for re-entry to earthCosmonautic landing devicesEngineeringHeavy load

The invention relates to a memory alloy planet detection lander based on a negative poisson ratio structure. The memory alloy planet detection lander comprises a lander body and a buffer structure. The lander body is used for containing effective loads, and the buffer structures are connected with the side wall of the lander body at equal intervals in the circumferential direction. The buffer structure comprises a mechanical leg assembly, a main shock absorber and a foot pad. The mechanical leg assembly comprises a landing leg which is made of memory alloy of a negative poisson ratio structure. One end of the main shock absorber is connected with the lander body, and the other end of the main shock absorber is hinged to the spherical hinge at the upper end of the landing leg to form a revolute pair of the main shock absorber relative to the mechanical leg assembly. The memory alloy planet detection lander has the beneficial effects that through the memory alloy landing supporting leg of the negative poisson ratio structure and the revolute pair of the main shock absorber relative to the mechanical leg assembly, the planet detection lander has high landing buffer performance, attitude control capacity and shape restorability, and after the buffer performance and attitude control capacity are enhanced, the lander can carry heavy loads.

Owner:JILIN UNIV

Production of CuALNiMn shape memory alloy thin membrane by cold rolling superthin laminated alloy

InactiveCN1644728AGood shape memory effectImprove plasticityMetal rolling arrangementsThin membraneAlloy thin film

The invention opened a method to make CuAlNiMn shape-memory alloy firm by the cold-roll ultrathin laminated alloy. The process use the Al foil, CuNiMn alloy foil as the material and decide the thickness according to the the composition. The foil is interactively overlapped and cold-rooled to form the ultrathin laminated alloy. The CuAlNiMn alloy firm is consists of Al11.5-14.5%, Ni 0-5%, Mn 0-3%, the remain is Cu. The alloy firm has the good features of fine crystal, long life, big area and low cost.

Owner:SICHUAN UNIV

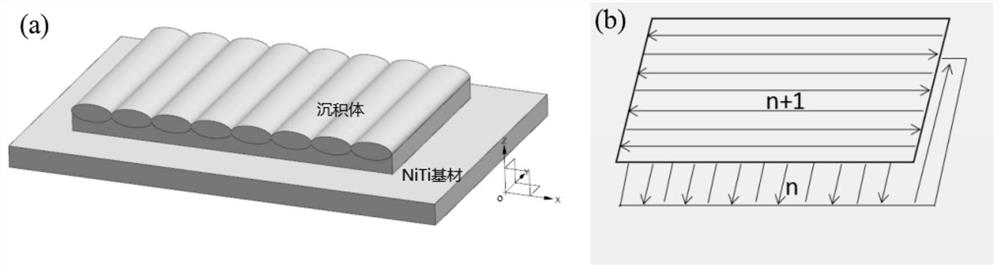

Laser additive manufacturing method of NiTi alloy with large recoverable strain

PendingCN112404454AExcellent superelastic recovery performance and shape memory effectLarge forming process windowAdditive manufacturing apparatusTransportation and packagingErbium lasersHigh energy

The invention relates to a laser additive manufacturing method of a NiTi alloy with large recoverable strain. The method includes the following steps that a NiTi alloy plate is used as a base material, two different energy sources, namely a CO2 laser and a semiconductor laser are adopted, high-purity argon is introduced to control the oxygen content of the atmosphere in a forming chamber to be within 100 ppm, and NiTi alloy powder with the granularity being 50-150 mu m is continuously fused and deposited on the base material in a coaxial powder feeding mode with a cross scanning strategy; in the deposition process, a relatively-large laser beam spot diameter and high laser power are selected, relatively-high energy input is obtained by controlling the laser power and the scanning rate under a certain powder feeding rate, then a formed compact NiTi alloy block is obtained, and it is guaranteed that the mechanical property of a formed sample is equal to or even superior to that of a homogeneously-cast and forged NiTi alloy sample. The NiTi alloy block prepared with the technology has relatively-strong preferred orientation (<001> / / deposition direction), and the excellent superelasticrecovery performance and shape memory effect of the formed sample are ensured.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

High-damping shape memory alloy

The invention discloses high-damping shape memory alloy. The high-damping shape memory alloy comprises the following main components in percentage by mass: 80 to 83 percent of Cu, 10 to 12 percent of Al and 5 to 8 percent of Mn, further comprises the following trace elements in percentage by mass: 0.15 to 0.25 percent of Ni, 0.2 to 0.3 percent of Ti and 0.05 to 0.1 percent of Co, and the following rare earth elements in percentage by mass: 0.05 to 0.1 percent of Ce, 0.02 to 0.05 percent of Gd and 0.05 to 0.1 percent of Y. Through the adoption of the components, the high-damping shape memory alloy can refine tissues and improve the mechanical properties, such as strength, stability, corrosion resistance and fatigue resistance, of the material, and also can improve the shape memory effect and the superelasticity of the material and enhance the plasticity.

Owner:常熟市东方特种金属材料厂

Functionalized treatment method of Ti-V-Al light memory alloy for structural connection of aerospace non-metal-matrix composites

The invention discloses a functionalized treatment method of Ti-V-Al light memory alloy for structural connection of aerospace non-metal-matrix composites, and belongs to the technical field of aerospace composites. According to the method, an arc-melted Ti-V-Al alloy ingot is subjected to hot rolling after being subjected to solution treatment; the arc-melted Ti-V-Al alloy ingot is subjected to solution treatment again and quenched after having a certain thickness; then, cold rolling is performed; and the cold-rolled sample is annealed, and then the Ti-V-Al light memory alloy with an excellent shape memory effect can be obtained. By means of the method, the shape memory effect of the Ti-V-Al alloy can be substantially improved, and the completely reversible strain of the Ti-V-Al alloy reaches 7.5%, which is the maximum value except for that of TiNi alloy. The Ti-V-Al alloy which is subjected to thermal mechanical treatment is potential light memory alloy for structural connection of the composites in the aerospace field.

Owner:HARBIN INST OF TECH

Shape memory alloy and preparation method thereof

InactiveCN101705440AGood shape memory effectInhibition of plastic deformationShape-memory alloyUltimate tensile strength

The invention provides a shape memory alloy and a preparation method thereof, belonging to the technical field of materials. The shape memory alloy comprises the following components in percent by weight: 14-15% of Mn, 6-7% of Si, 9-10% of Cr, 5-6% of Ni, 0.05-0.1% of C, and the balance of Fe. The preparation method of the shape memory alloy comprises the following steps: firstly, according to the weight percentages of all components of the shape memory alloy, respectively taking the following raw materials, such as ultra low carbon steel, Mn, Si, Cr and Ni, or respectively taking low carbon steel, Fe, Mn, Si, Cr and Ni; secondly, melting all raw materials except Mn by vacuum induction; and thirdly, adding Mn in the mixture and conducting melting in the inert gas and obtaining the shape memory alloy by natural cooling. The strength and recoverable strain of the shape memory alloy is obviously higher than those of the normal Fe-Mn-Si alloy, the corrosion resistance of the shape memory alloy is good, the recoverable strain of the shape memory alloy is 3% under a casting condition and is further increased after solution-quenching treatment; furthermore, the preparation process of the shape memory alloy is simple.

Owner:SHANGHAI JIAO TONG UNIV

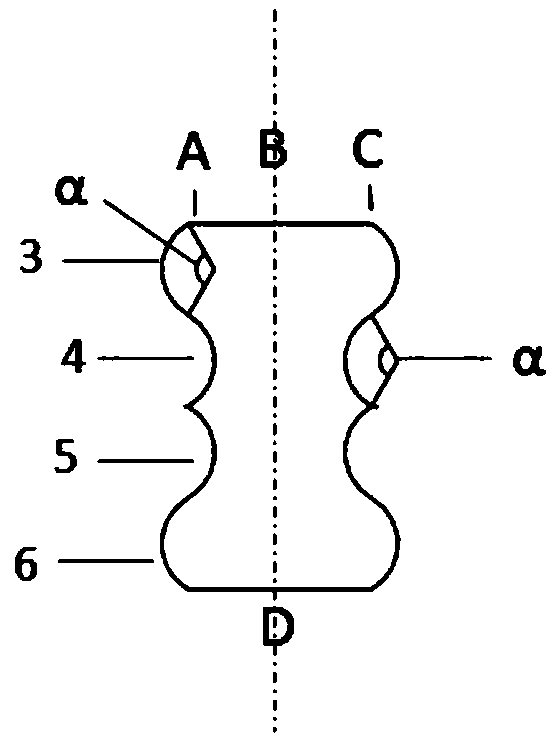

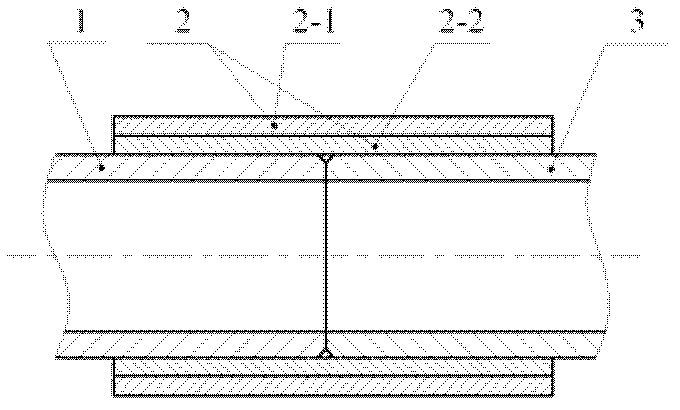

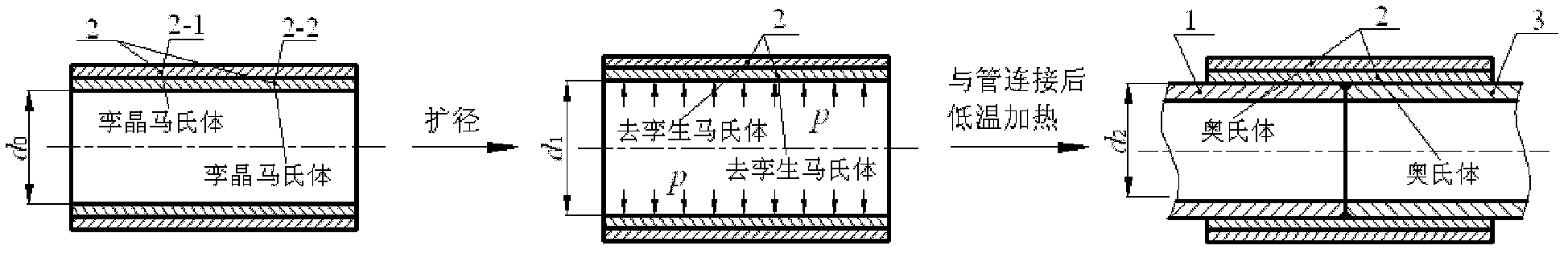

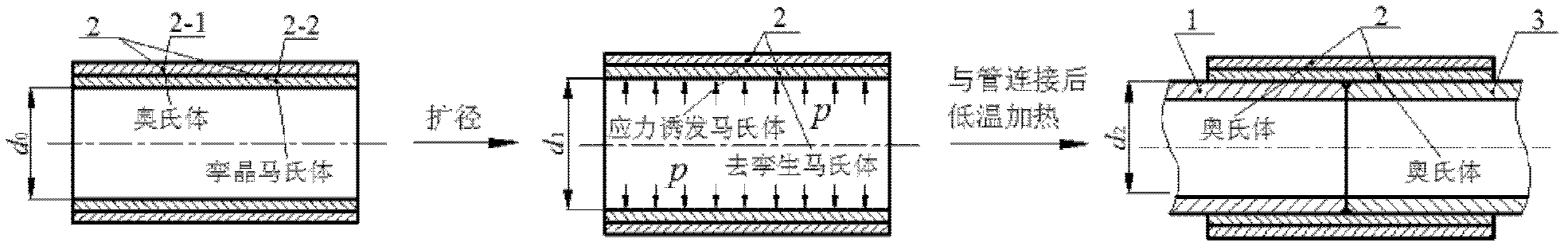

Nickel-titanium shape memory alloy composite pipe joint forming method

InactiveCN102632101AAvoiding Gradient Effect ProblemsHigh strengthRod connectionsNon-disconnectible pipe-jointsInterference fitDouble-walled pipe

The invention aims at providing a nickel-titanium shape memory alloy composite pipe joint forming method comprising the following steps of: assembling two layers of nickel-titanium shape memory pipes together in a way of clearance fit or interference fit to form a double-layer pipe, wherein the inner diameter d0 of the double-layer pipe is less than the outer diameter d2 of two pipes to be connected; performing expanding deformation on the double-layer pipe to enlarge the inner diameter of the double-layer pipe to d1 so as to compound and form the two layers of nickel-titanium shape memory pipes into a whole, wherein the d1 is more than the outer diameter d2 of the pipes to be connected; sheathing a pipe joint with the expanded diameter outside the two pipes to be connected; and recovering the shape of the pipe joint through low-temperature heating, and connecting the two pipes after the pipe joint is automatically contracted, thereby completing the forming of the pipe joint. The nickel-titanium shape memory alloy composite pipe joint forming method overcomes the defect that the wall of the conventional nickel-titanium shape memory alloy pipe joint is excessively thin or thick, and ensures the nickel-titanium shape memory alloy pipe joint to have enough fastening force and enough strength so as to enable the nickel-titanium shape memory alloy pipe joint to have excellent connection performance.

Owner:HARBIN ENG UNIV

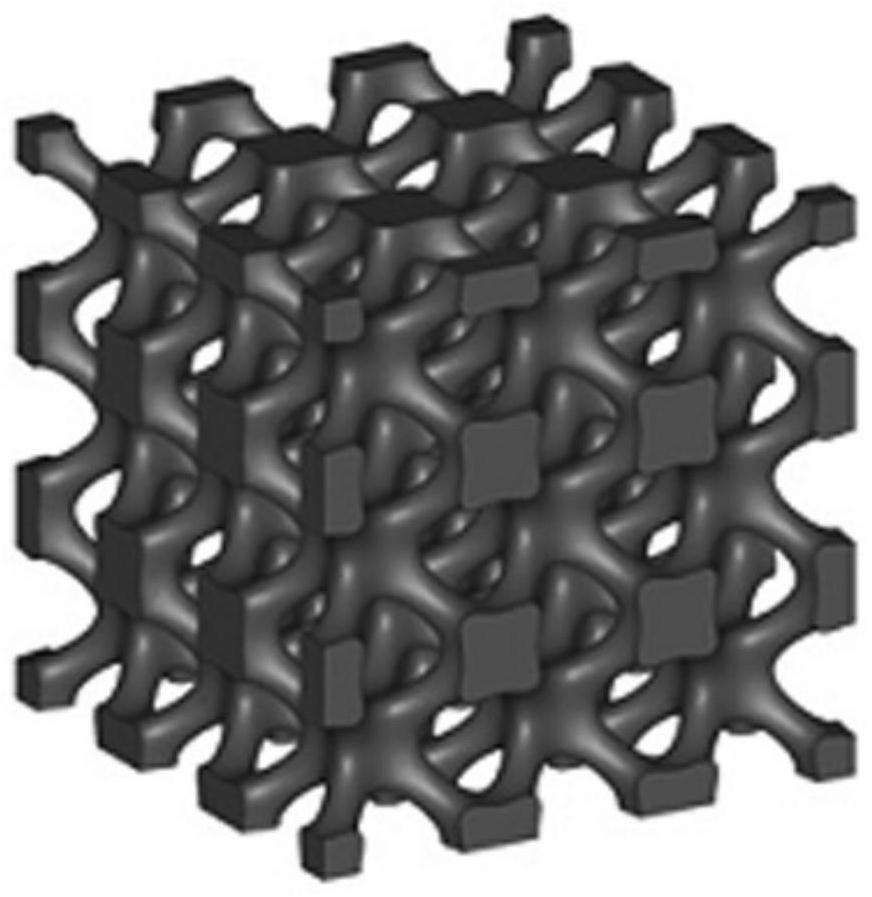

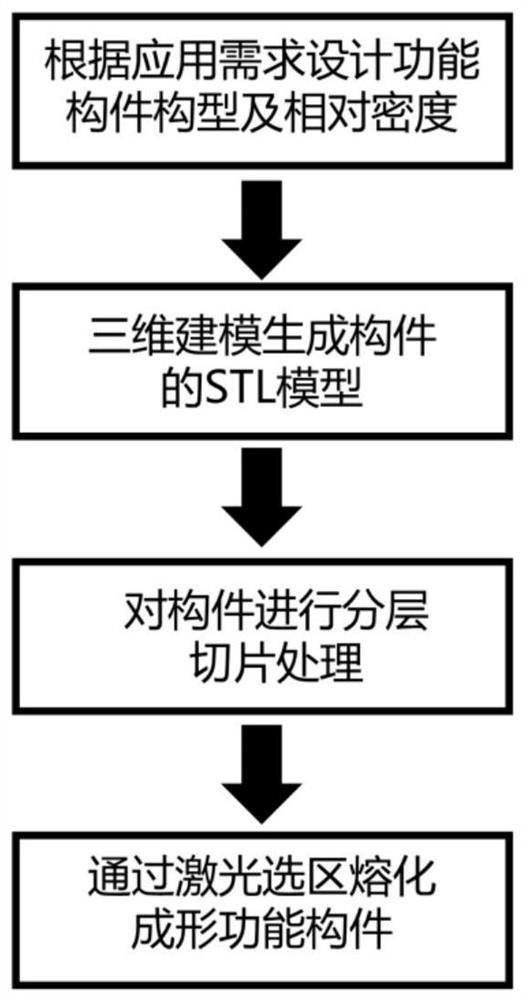

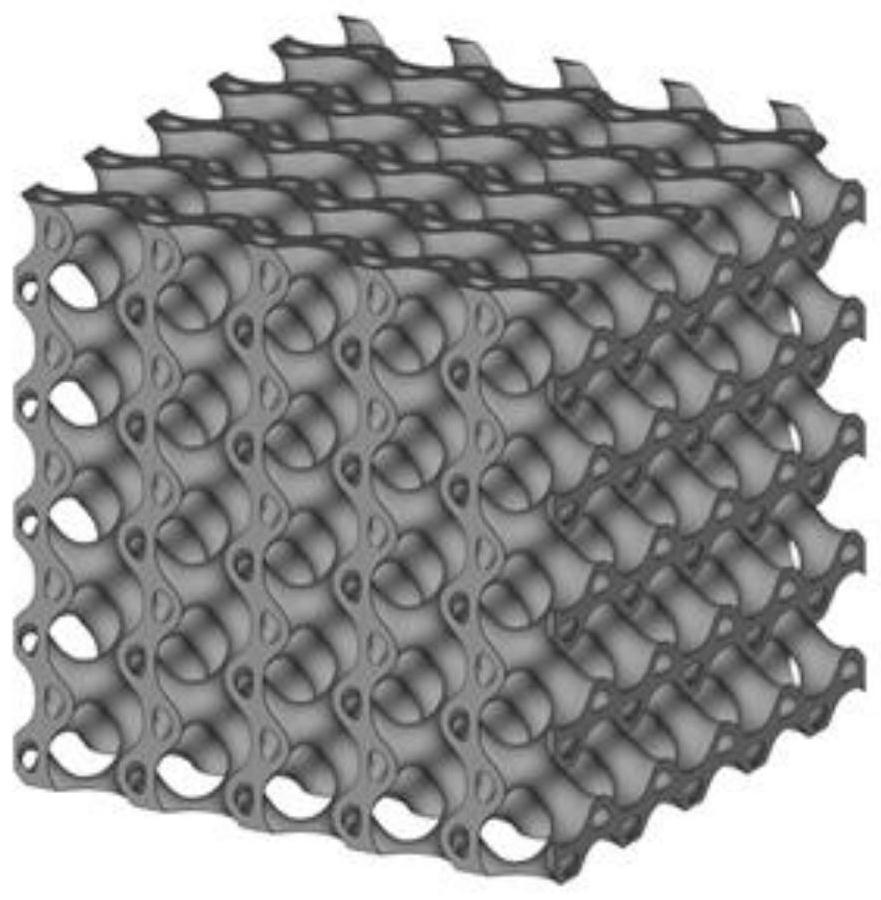

4D forming method for nickel-titanium alloy member with deformation recovery rapid response and product

ActiveCN112475319AIncrease surface areaHigh phase transition temperatureAdditive manufacturing apparatusSelective laser meltingLarge deformation

The invention belongs to the related technical field of metal additive manufacturing, and discloses a 4D forming method of a nickel-titanium alloy member with deformation recovery rapid response and aproduct. The 4D forming method of the nickel-titanium alloy member with deformation recovery rapid response comprises the following steps of S1, determining the deformation amount and deformation recovery speed requirements of the to-be-formed member, constructing a lattice structure SA and a lattice structure SB with different relative densities by adopting a three-period minimal curved surface,and performing Boolean differencing operation on the lattice structure SA and the lattice structure SB to remove the same parts in the lattice structures so as to obtain a shell lattice structure; S2, adjusting the parameters of the lattice structures SA and SB till the deformation amount and deformation recovery speed requirements of the to-be-formed member are met, and a three-dimensional modelis obtained; and S3, forming the three-dimensional model through selective laser melting so as to obtain the needed to-be-formed member. By means of the 4D forming method of the nickel-titanium alloymember with deformation recovery rapid response, the forming quality of the nickel-titanium alloy is effectively controlled, and the response speed of large deformation and deformation recovery of the obtained product is increased.

Owner:HUAZHONG UNIV OF SCI & TECH

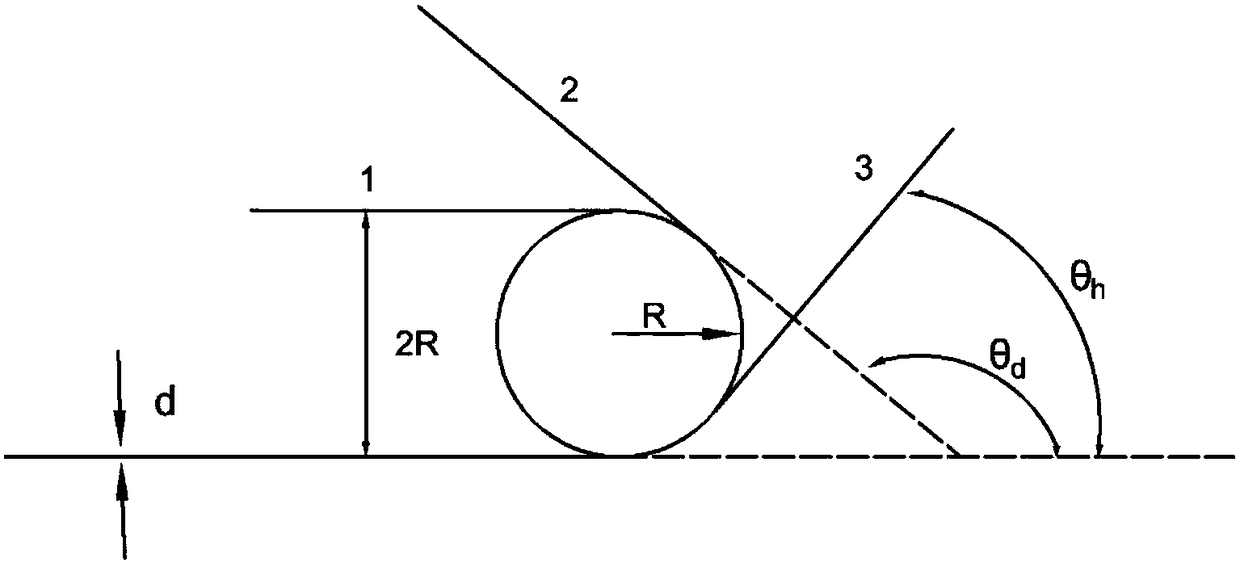

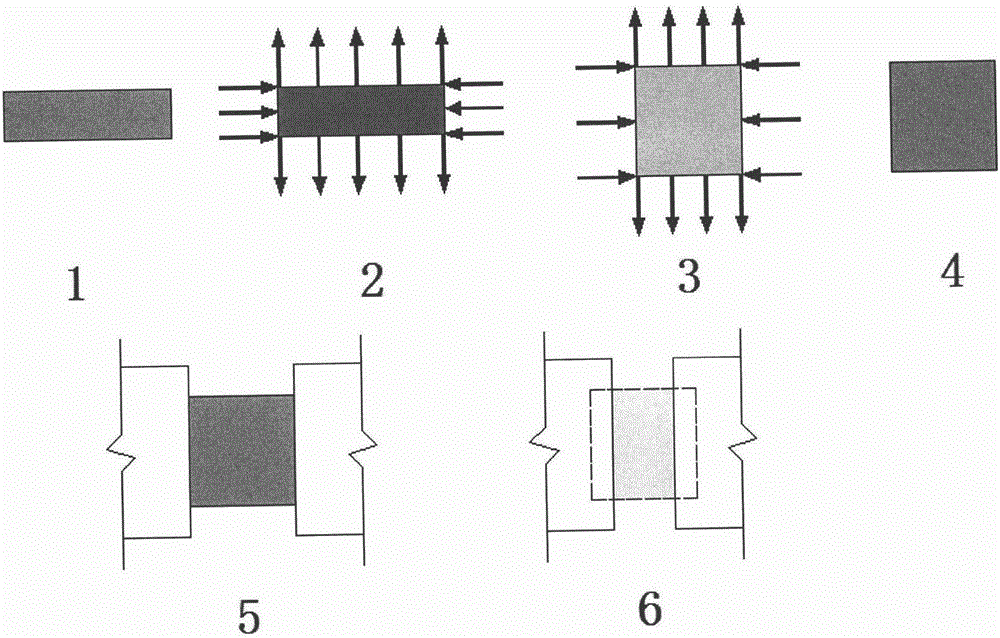

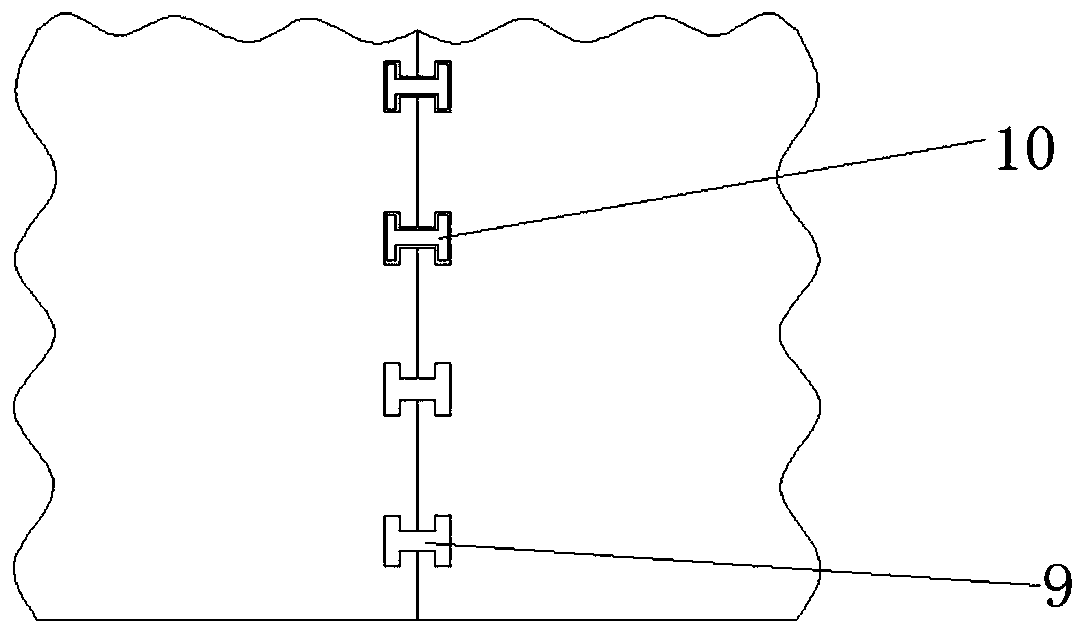

Single-stage double-shaft pre-deformation method for endowing pavement joint material with shape memory function

InactiveCN106638220AExtended service lifeImprove the quality of usePaving detailsSelf-healingPre strain

The invention provides a single-stage double-shaft pre-deformation method for endowing a pavement joint material with a shape memory function, belongs to the technical field of cement pavement, and solves the problem that existing single-stage single-shaft pre-deformation method can only endow the material with the shape memory function in one direction, and thus the material is poor in self-healing effect. A cruciform specimen of a shape memory polymer matrix composite is produced at first, pre-compaction deformation is performed along the vertical direction at the temperature higher than a glass-transition temperature, meanwhile prestretching deformation is performed along the horizontal direction, and thus the joint material is endowed with the shape memory function in both horizontal and vertical directions; then the shape memory effect of the joint material after pre-deformation is measured and further synthesized with other operational performance of the joint material to determine reasonable stretching and compression pre-strain values for endowing the joint material with the shape memory function. According to the pre-deformation method provided by the invention, the joint material actively adapt to cyclic change of the width of the cement pavement joint, usability and durability of the joint material are improved, and service life of the cement pavement is prolonged.

Owner:NANJING FORESTRY UNIV

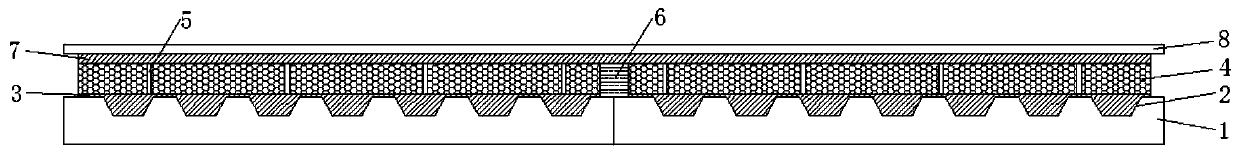

Modular self-snow-melting pavement based on graphene

ActiveCN110904774AExtended durability and performanceImprove conductivityPaving detailsElectrically conductiveExpansion joint

The invention discloses a modular self-snow-melting pavement based on graphene and relates to a conductive asphalt pavement. The invention aims to solve the problem that the modular conductive asphaltpavement joint sealing material cannot meet the requirement that the expansion joint is damaged due to the influence of pavement environment change. The problems of discontinuous conduction, energy waste and influence on the ice and snow melting effect due to incapability of adapting to pavement joint and crack width change and incapability of forming a conductive network of the assembled conductive asphalt pavement are solved; the problems that a conductive asphalt pavement is poor in high-temperature stability, low-temperature crack resistance, water stability and fatigue resistance and lowin conductivity are solved. In the modular self-snow-melting pavement, the graphene conductive asphalt layer plays a role in electric conduction and heating, and the conductive shape memory compositematerial is filled in the joint, can actively cater to the width change of the joint and the crack of the pavement, and can be better attached between unit asphalt pavements of the modular self-snow-melting pavement according to the environment change of the pavement so as to realize the joint connection and electric conduction continuity effect. The invention is applied to the field of self-snow-melting pavements.

Owner:HARBIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com