Method for preparing (1-vinyl-3-ethylimidazole borate)polyion liquid/polyvinyl alcohol polymer composite material

A technology of ethyl imidazole borate and polyionic liquid, which is applied in the field of preparation of microwave-driven shape memory polymers, can solve the problems of uneven heating, poor compatibility between inorganic fillers and polymers, slow heating rate, etc. Good shape memory effect, avoid uneven heating, avoid the effect of poor compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

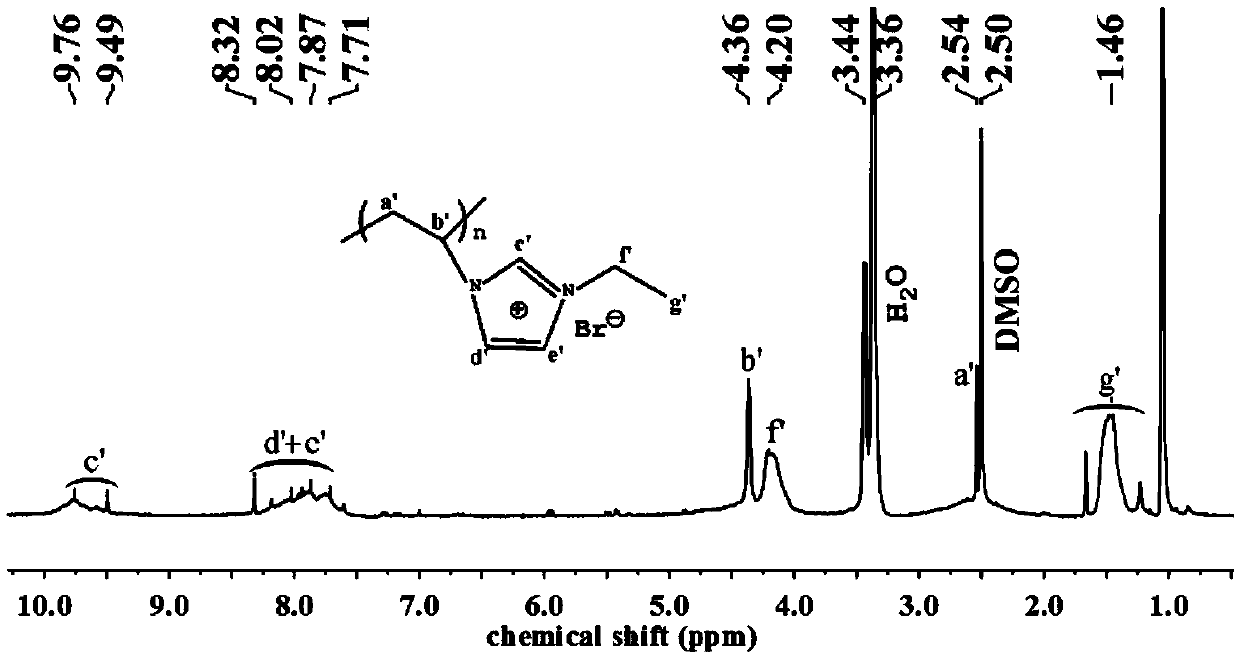

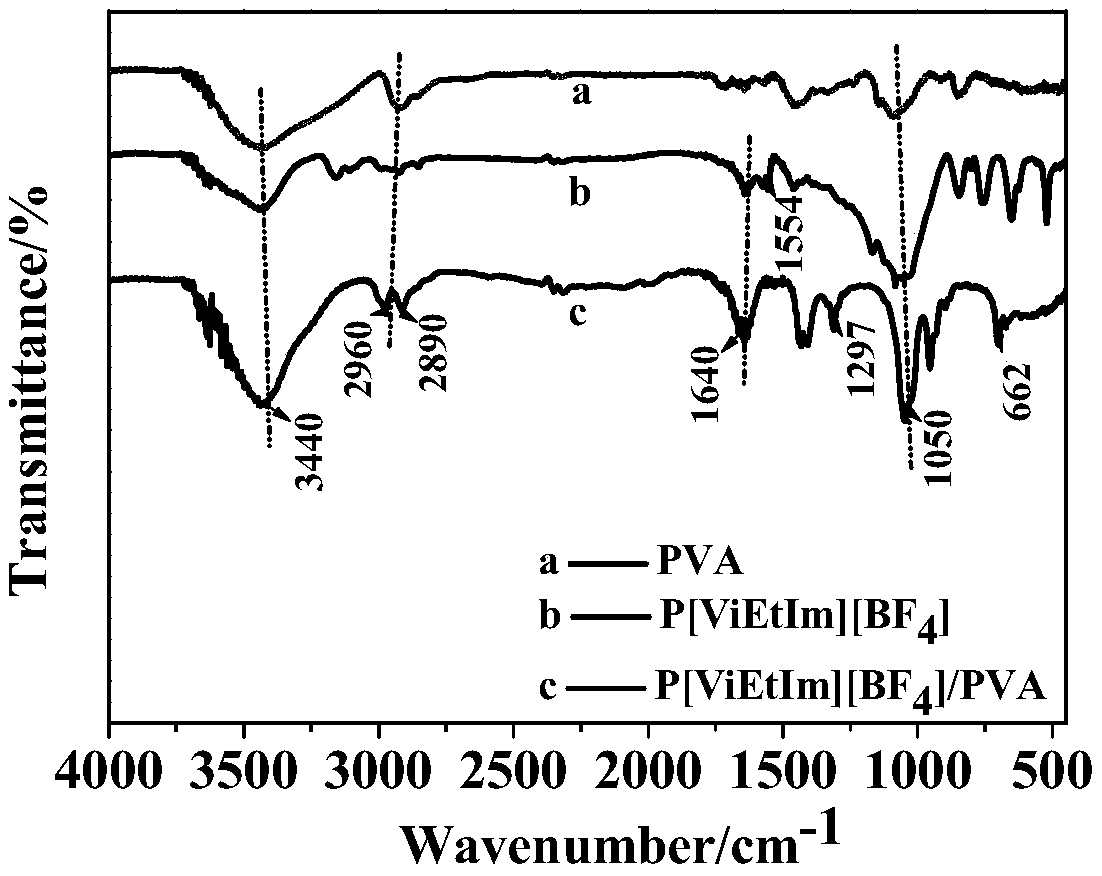

[0032] 1. 1-vinyl-3-ethylimidazolium borate ionic liquid monomer [ViEtIm][BF 4 ] synthesis and polymerization

[0033] P[ViEtIm][BF 4 ] The synthetic steps are as follows:

[0034]

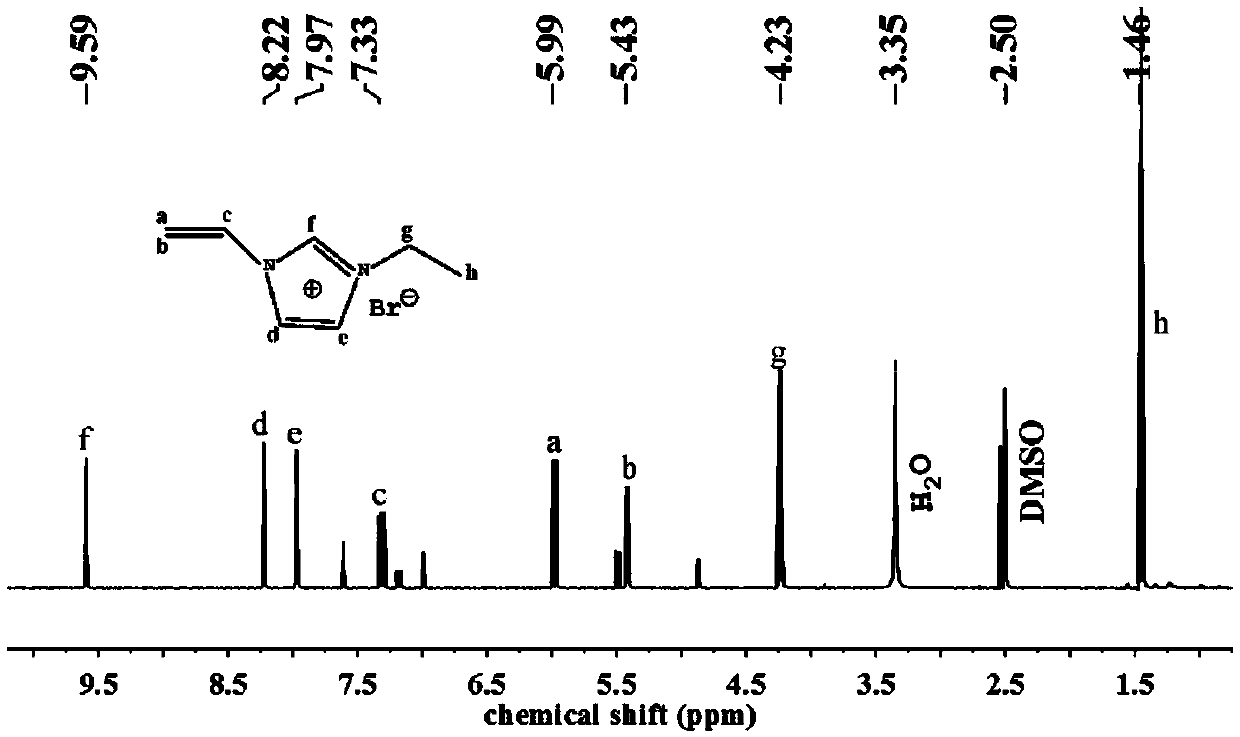

[0035] The first step: the synthesis of 1-vinyl-3-ethylimidazolium bromide [ViEtIm] [Br]:

[0036] Add 2g of N-vinylimidazole and 4g of ethyl bromide into a 50mL round-bottomed flask in turn, reflux in an oil bath at 80°C until white turbidity appears, keep the reaction until the white turbidity disappears until the reaction product becomes solid, and then continue the reflux reaction. When the reflux is not obvious, stop heating, wash with ether 2 to 3 times, and dry in vacuo to obtain a white-yellow solid [ViEtIm][Br];

[0037]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com