Patents

Literature

39results about How to "Inhibition of plastic deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

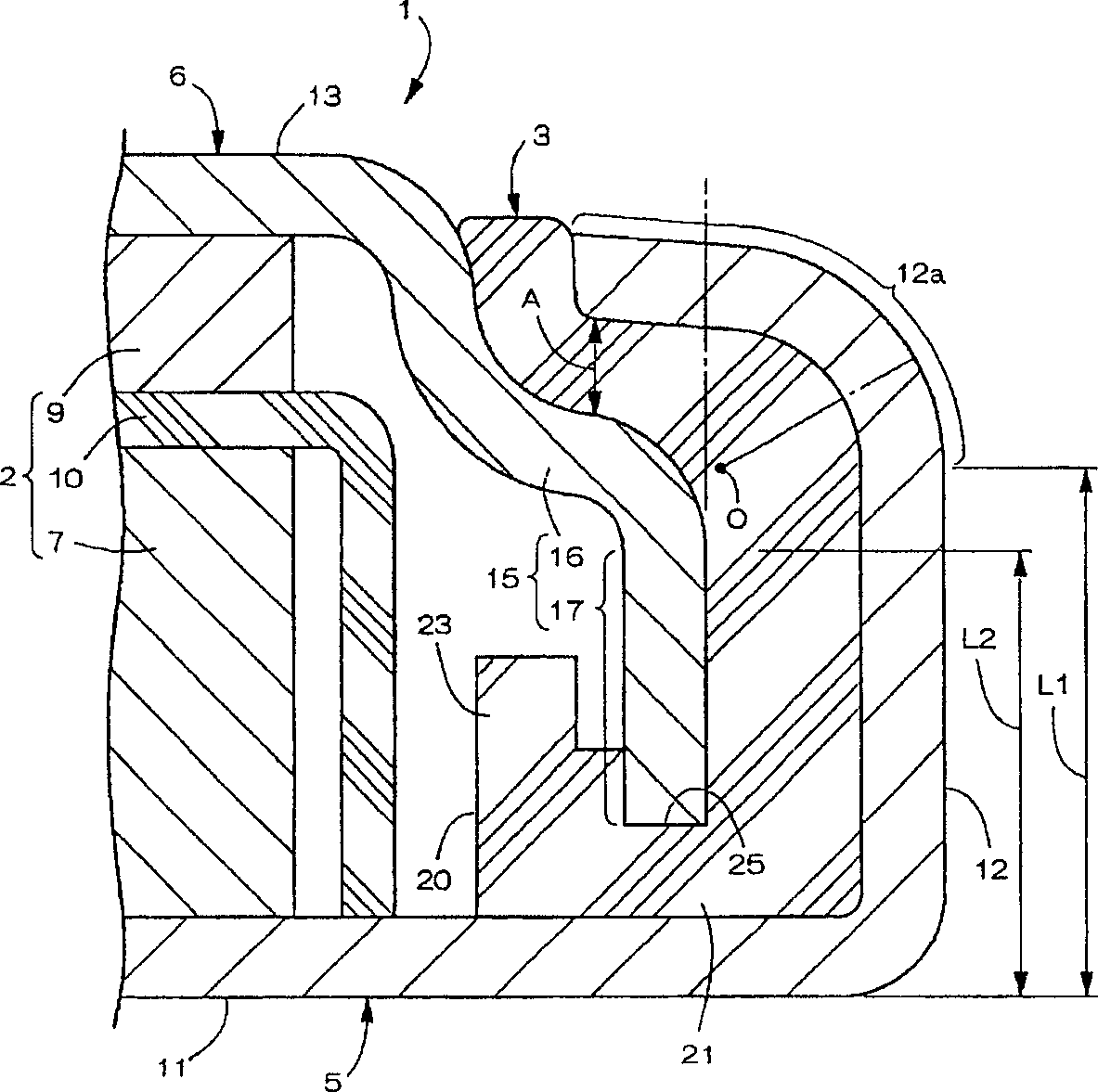

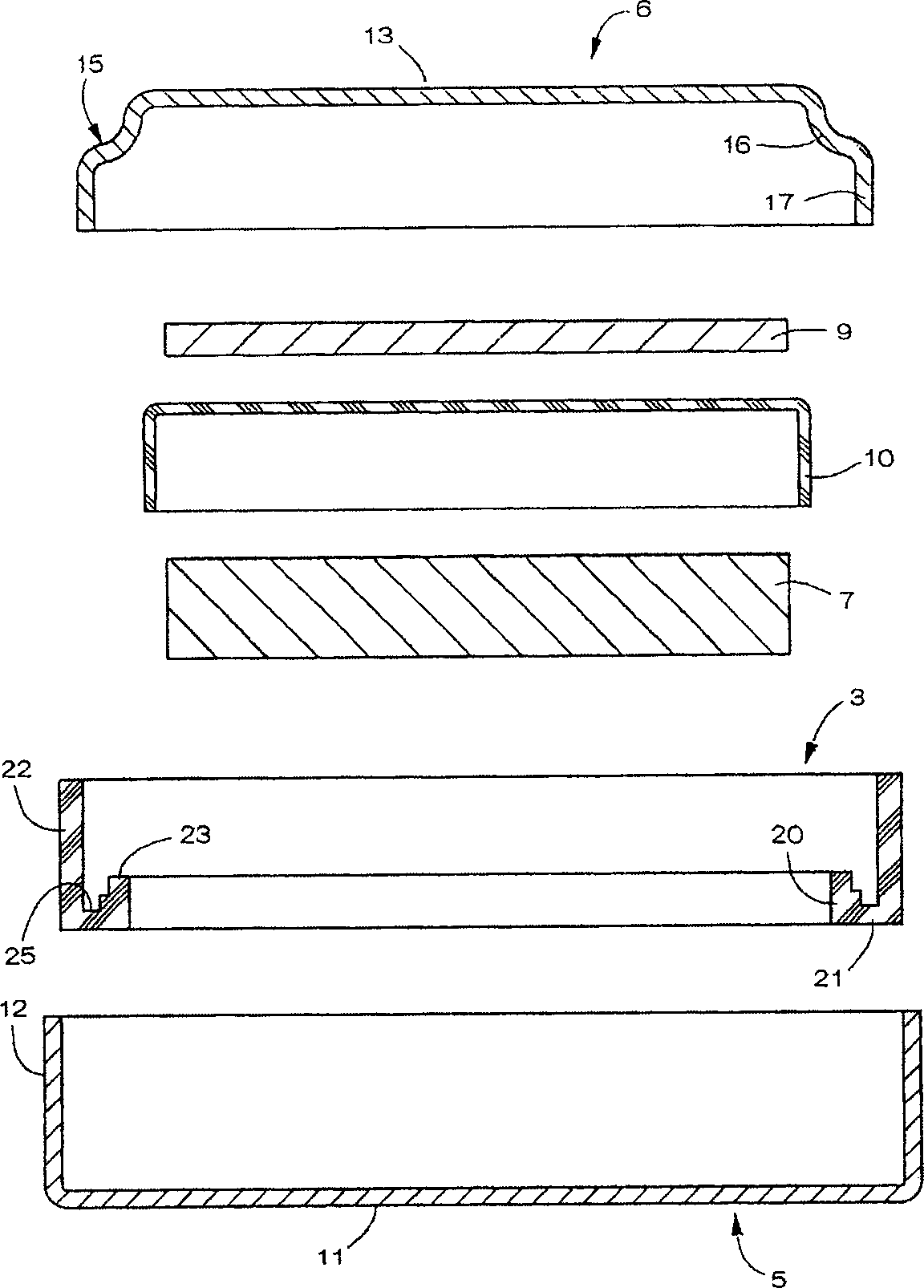

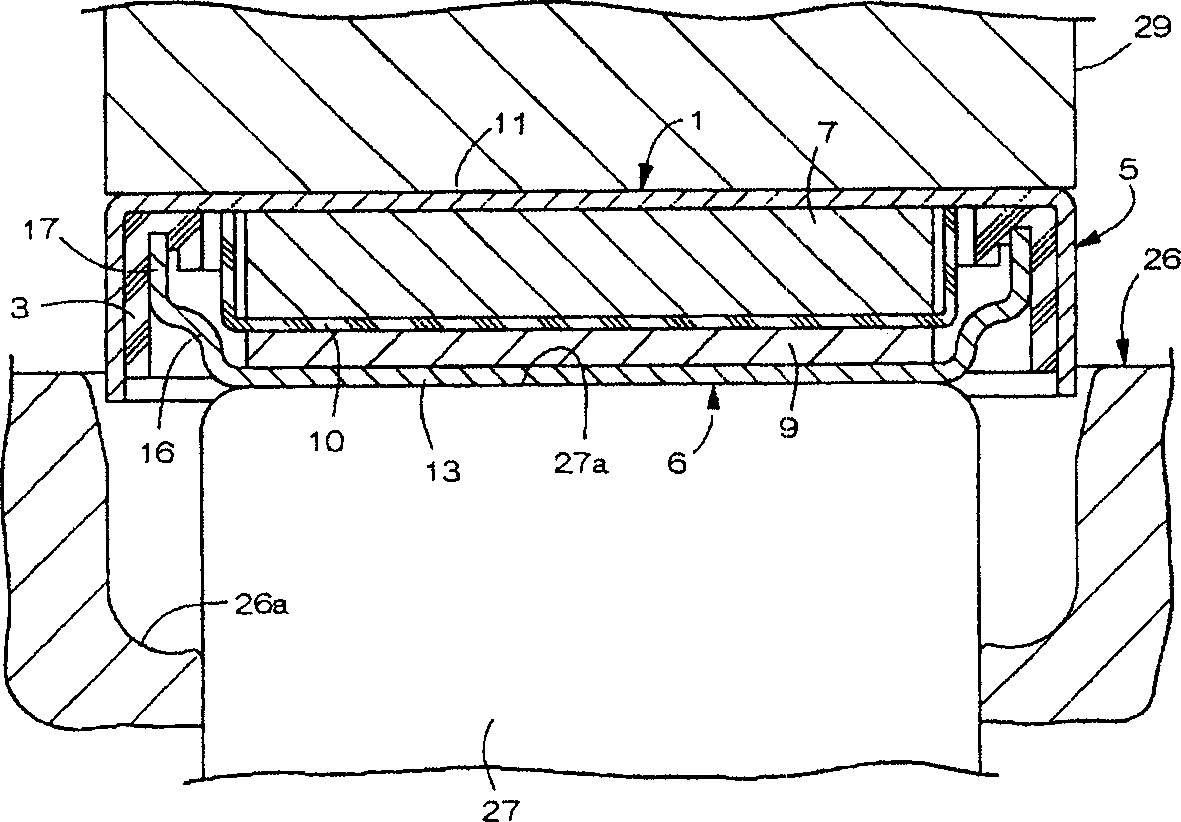

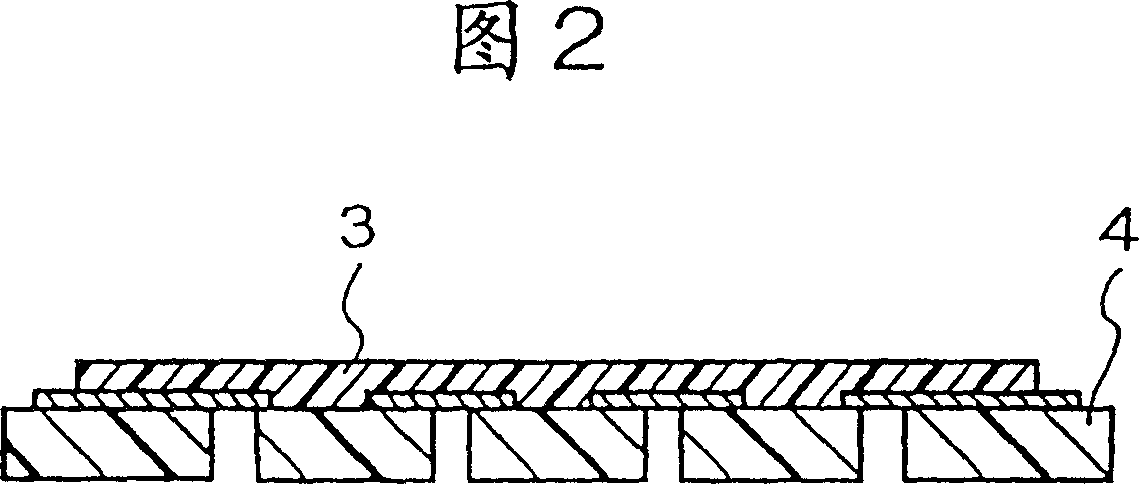

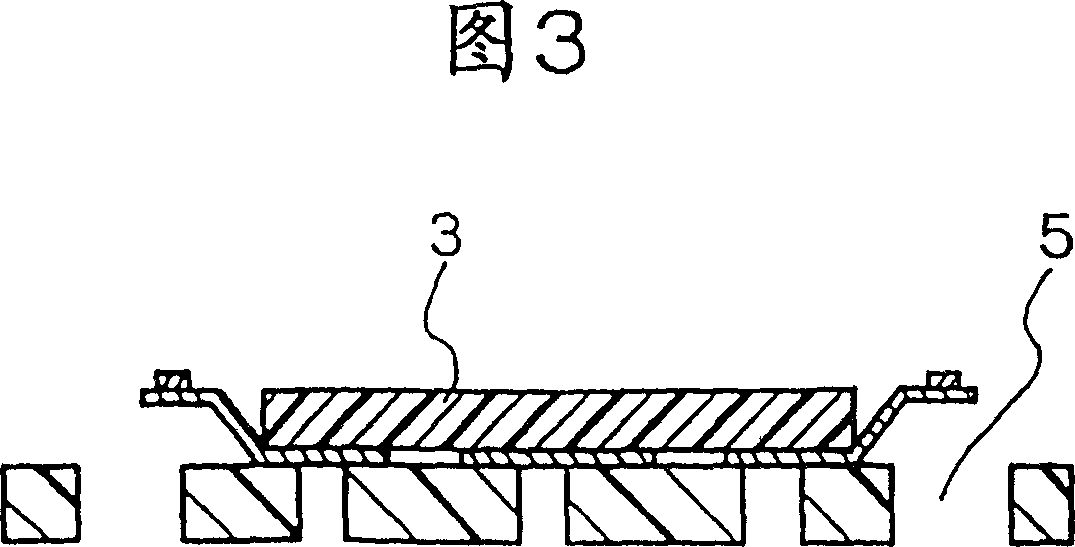

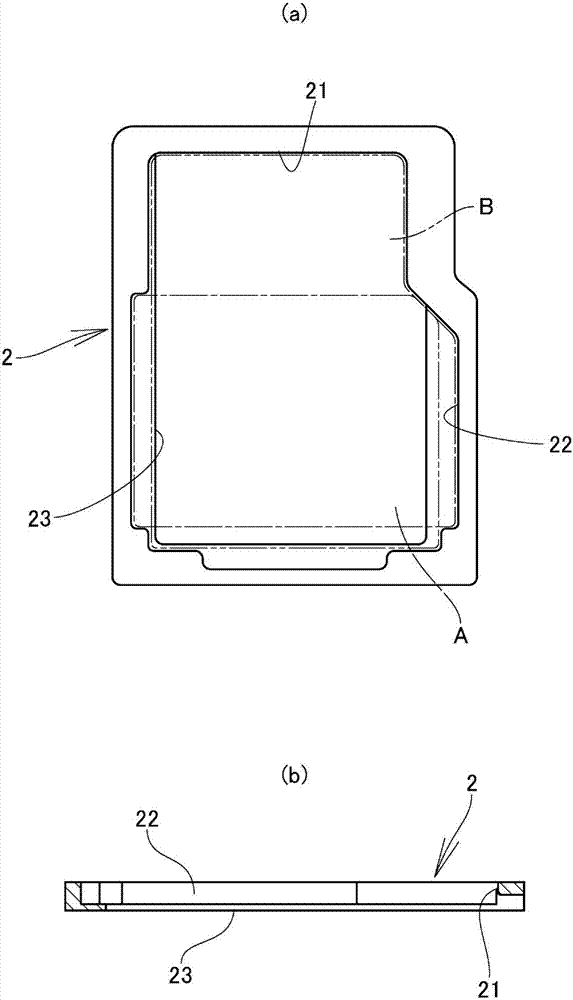

Button cell

To obtain a coin-shaped cell, in which liquid leakage from a sealed part can be prevented surely, while reduction of cell capacity is suppressed. A cell can for housing a power generation element includes a cathode can of which an outer peripheral cylindrical wall is bent upward from the outer peripheral brim of a bottom face wall, and an anode can of which an outer peripheral side wall is bent downward from the outer peripheral brim of an upper face wall. An upper end peripheral brim part of the peripheral cylindrical wall of the cathode can is calking worked inward via a gasket mounted on the outer peripheral side wall of the anode can. The outer peripheral side wall of the anode can includes an enlarged diameter part thrusting in a step form an an angle downward from the outer peripheral brim of the upper face wall, and a straight part linearly extending downward continually to the enlarged diameter part, so that the center of the curvature of a curving part of the outer peripheralcylindrical wall that is bent inward by the calking work of the outer peripheral cylindrical wall of the anode can is made to be positioned at further outside than the outer peripheral side wall of the anode can.

Owner:MAXELL HLDG LTD

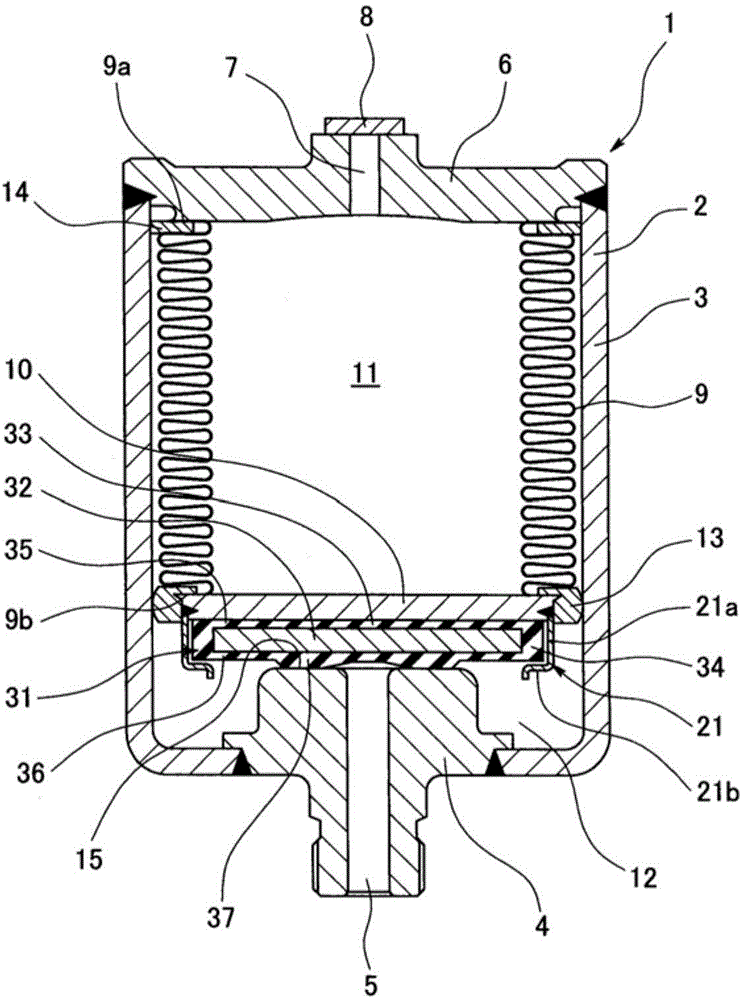

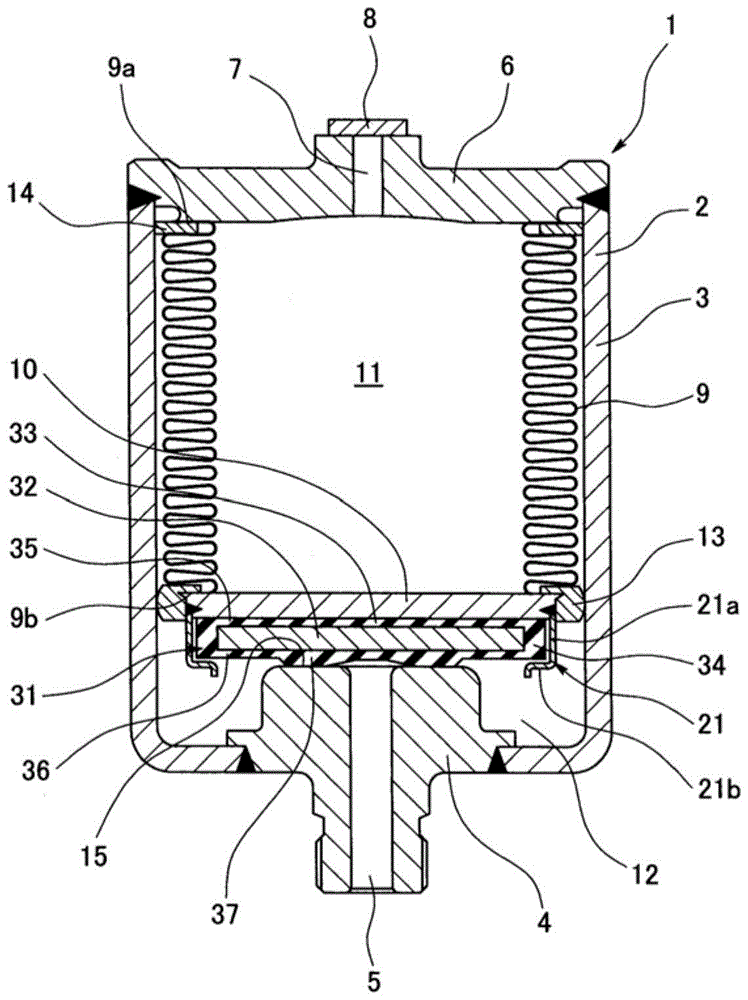

Accumulator

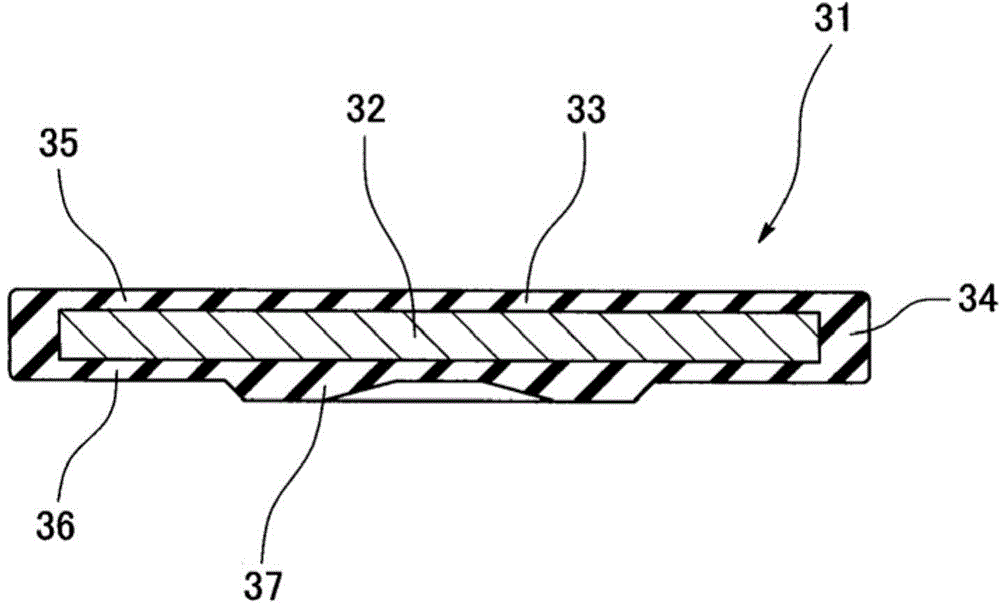

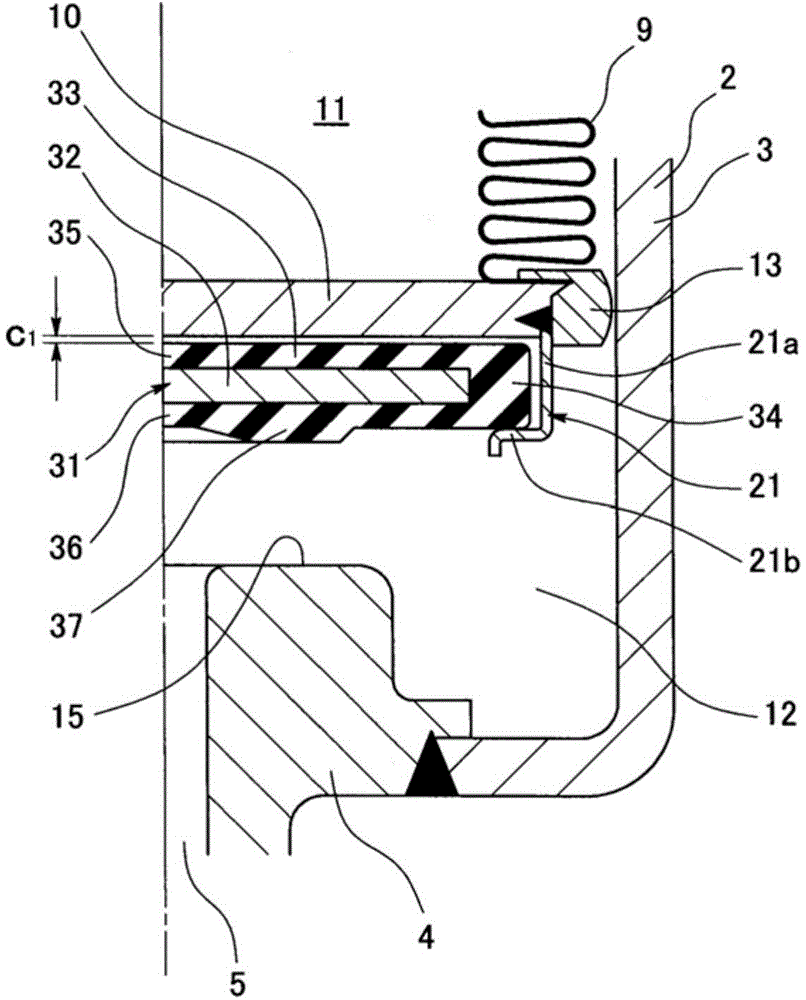

ActiveCN104583606AReduce length dimensionReduce in quantityFluid-pressure actuator safetyAccumulator installationsElastomerEngineering

Provided is an accumulator, which: is capable of reducing the pressure difference that is generated by differences in coefficients of thermal expansion when liquid trapped in the liquid chamber and a sealed gas undergo thermal expansion during zero-down, thereby limiting the occurrence of plastic deformation in the bellows; and has a structure in which the parts are small and few in number. To achieve said purpose, the accumulator has a sealing member held on the port hole-side of the bellows cap via a seal holder. When operation of the machine is stopped and the pressure inside the pressure piping decreases, the sealing member contacts the sealing section and closes the liquid chamber. If liquid trapped in the liquid chamber when the liquid chamber is closed undergoes thermal expansion, the bellows cap moves in the direction away from the sealing section while the sealing member is still in contact with the sealing section. Since the sealing member is a rigid plate, the outer circumferential surface of which is covered by a flexible section obtained from a rubber-like elastic body, the flexible section allows relative movement of the bellows cap by undergoing shear deformation as a result of engagement with the seal holder.

Owner:EAGLE INDS

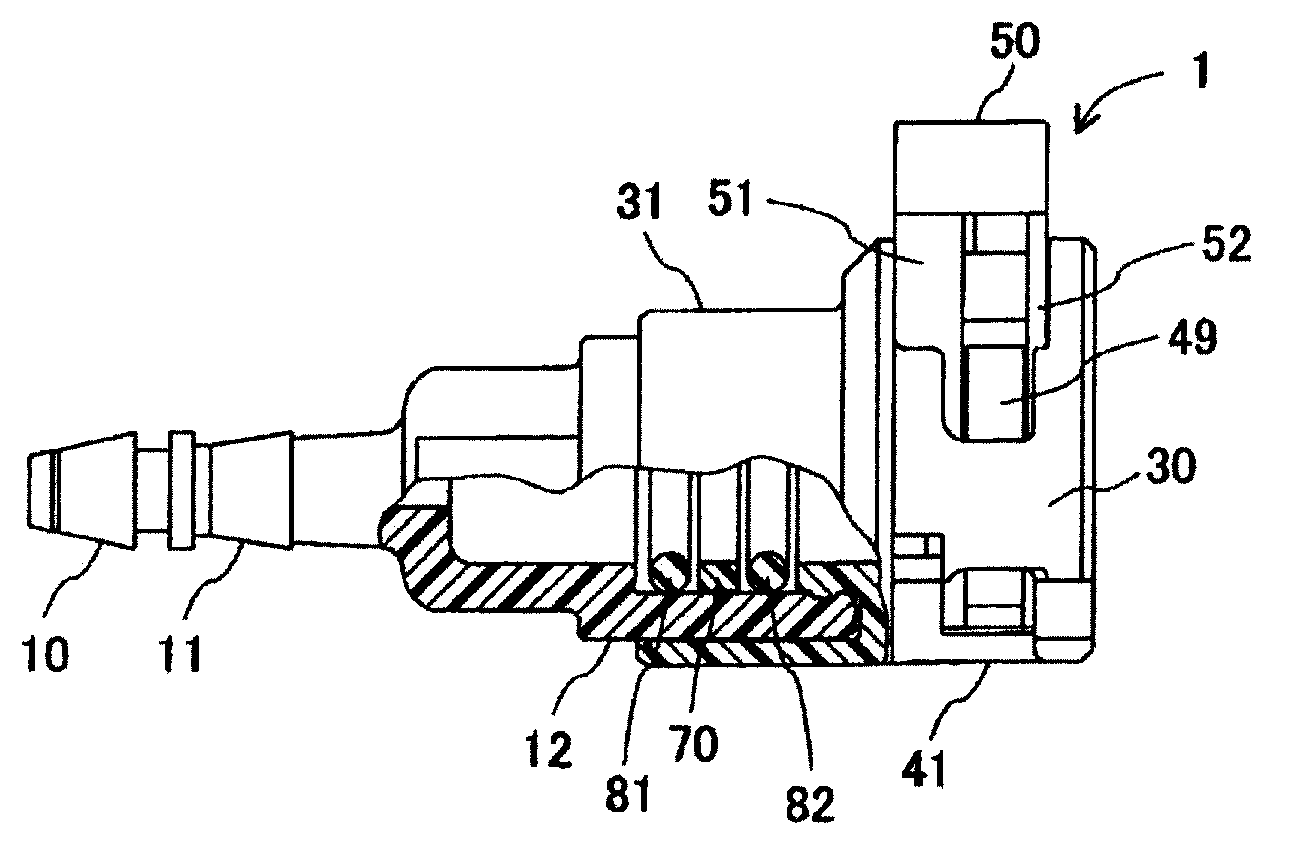

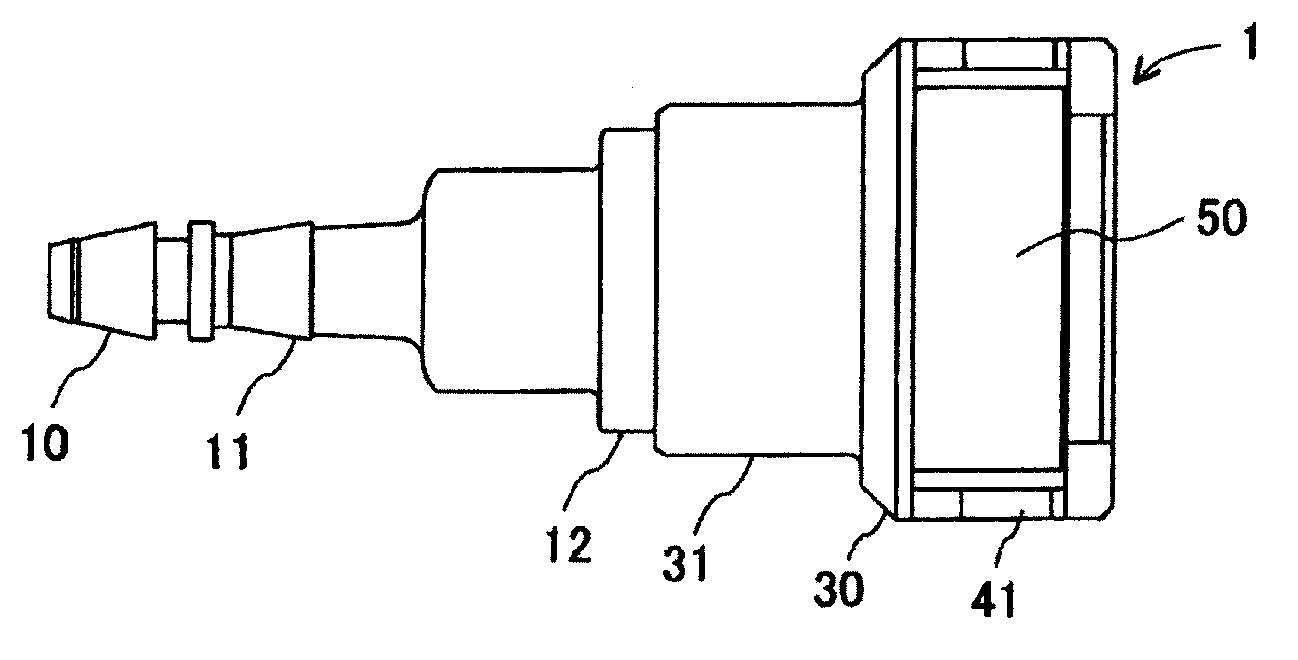

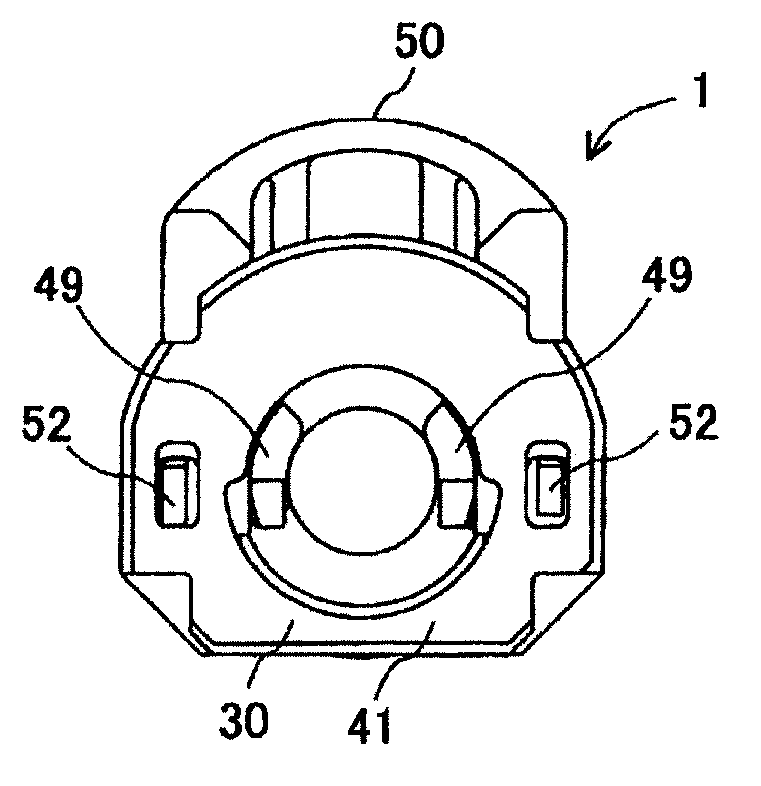

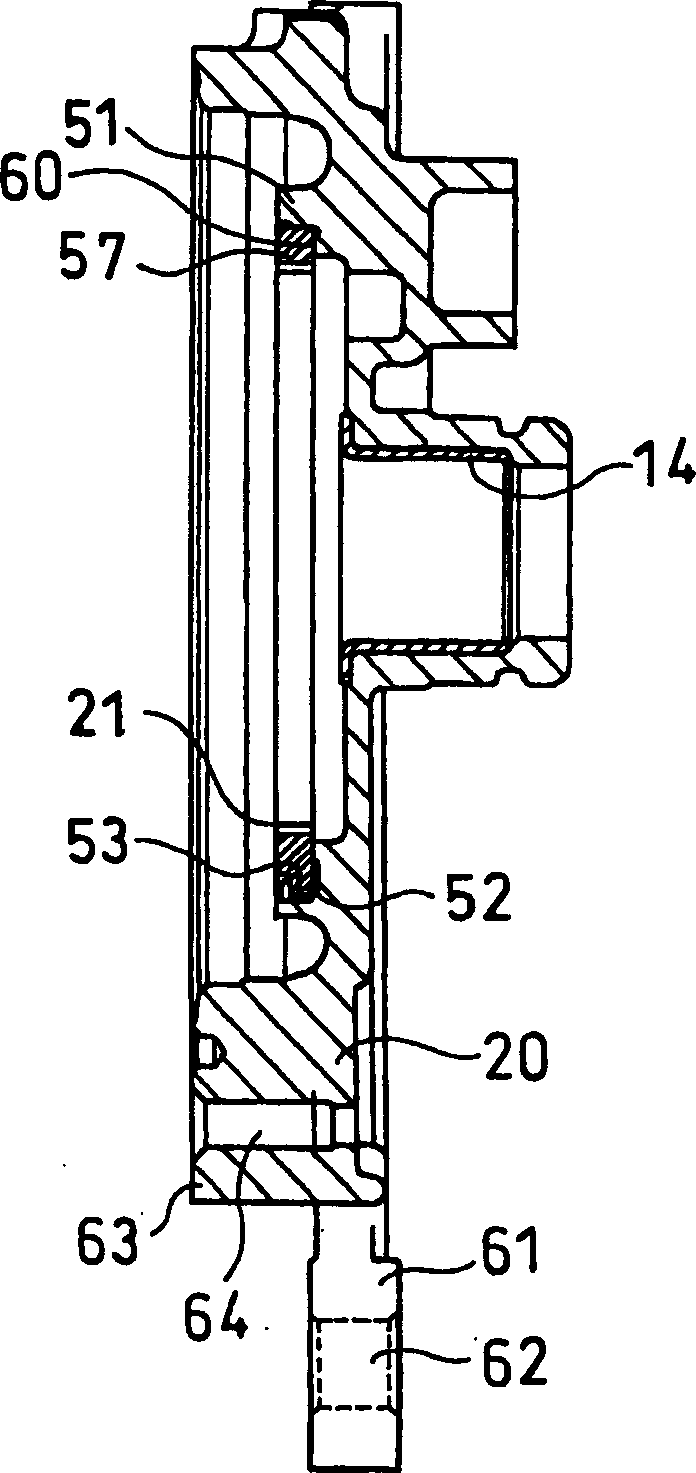

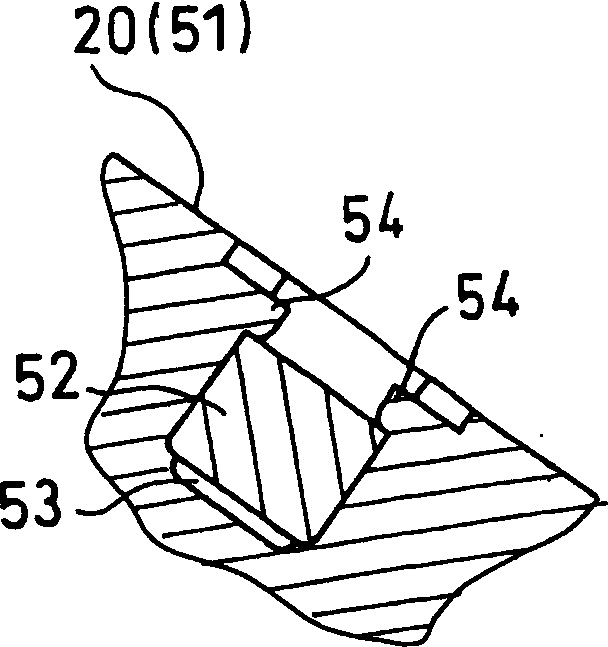

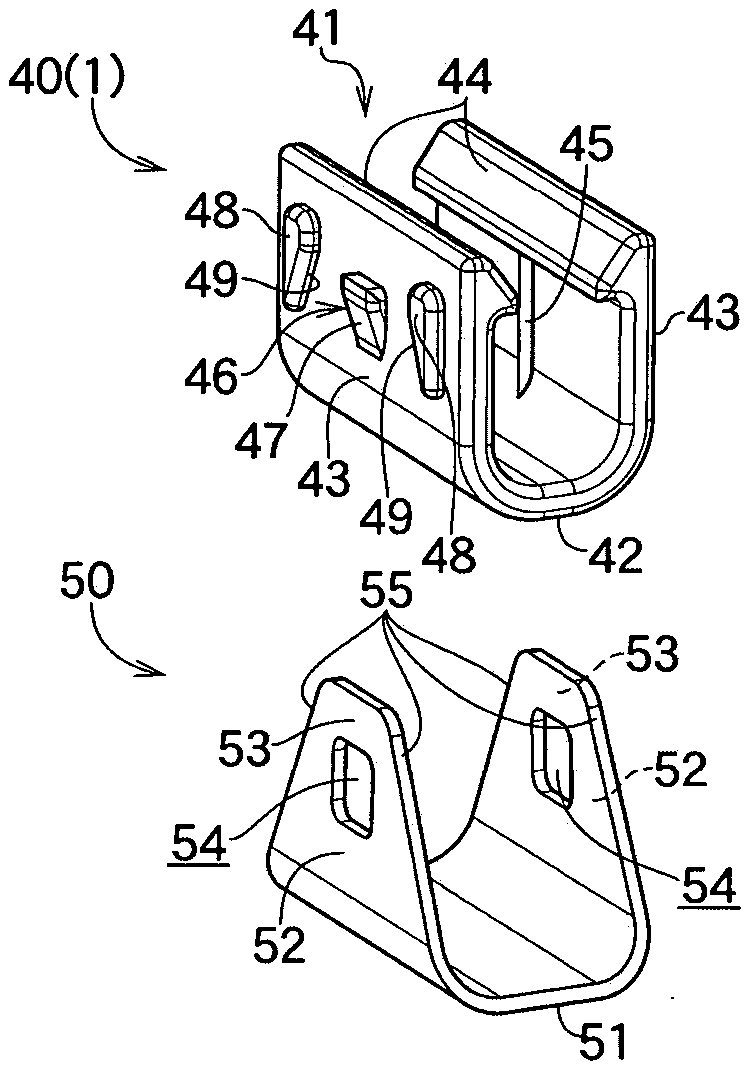

Quick connector

ActiveCN102918316AWell formedInhibition of plastic deformationPipe couplingsCouplingsBiomedical engineering

Provided is a quick connector which enables, when the elastically deformable claw of a retainer and the elastically deformable claw of a checker are disposed so as to be adjacent to each other in the axial direction, the engagement of a pipe body with the retainer to be reliably confirmed. Checker's axial elastically deformable claws (52, 52) are configured so that the front end side thereof can bend and deform in the axial direction. When the bending and deformation of the checker's axial elastically deformable claws (52, 52) are restricted by a retainer's elastically deformable claw (49), which can be expanded in diameter, while the claw (49) is expended in diameter, the claws (52, 52) are maintained engaged with second engagement sections (46) of the retainer body (42). When engaged with the second engagement sections (46) of the retainer body (42), the sliding motion of the checker's axial elastically deformable claws (52, 52) from a first position in a set radial direction relative to the retainer body (42) is restricted. The checker's axial elastically deformable claws (52, 52) can be disengaged from the second engagement sections (46) of the retainer body (42) when the shape of the retainer's elastically deformable claw (49) which can be expanded in diameter is restored, and this enables the claws (52, 52) to slide from the first position to a second position in the set radial direction relative to the retainer body (42).

Owner:TOKAI RUBBER IND LTD

Adhesive tape preventing adhesion by aquatic organisms

Provided is an adhesive tape for preventing adhesion by aquatic organisms which exhibits favorable adhesion underwater, has favorable mechanical properties, is easily detachable, can maintain an antifouling effect for the long term, has a light burden on people and the environment, is lightweight, can retain a stable quality, and can effectively prevent adhesion by aquatic organisms. Furthermore, it is preferable for the provided adhesive tape for preventing adhesion by aquatic organisms to require little labor to detach, to exhibit minimal plastic deformation of the substrate thereof when detaching, and to exhibit excellent reworkability when being applied. This adhesive tape for preventing adhesion by aquatic organisms is an adhesive tape including an antifouling layer, a substrate layer and an adhesive layer in this order, wherein the antifouling layer contains a silicone resin.

Owner:NITTO DENKO CORP

High-temperature-resistant alloy and production process thereof

ActiveCN103060652AImprove high temperature performanceImprove linear expansion coefficientRoom temperatureRare earth

The invention discloses a high-temperature-resistant alloy and a production process thereof. The high-temperature-resistant alloy comprises the following components in percentage by mass: 8 to 10 percent of Co, 4 to 6 percent of Ni, 1 to 2 percent of TaC, 0.5 to 1 percent of Cr3C2 and 80 to 85 percent of WC. A rare earth material of the high-temperature-resistant alloy can ensure that the linear expansibility of a hard alloy is significantly improved, so that the matching of the linear -expansibilities of the hard alloy and a mosaic matrix can be improved. Cr or Cr3C2 is added to strengthen a Ni binding phase, and the function is particularly effective. Thus, the mechanical properties and corrosion resistance of the alloy at room temperature can be obviously improved, the plastic deformation of the alloy at high temperature can be effectively inhibited, and the alloy is endowed with high oxidation resistance. Moreover, the corrosion resistance, the high temperature strength and the high temperature deformation resistance of the material are greatly improved to meet use requirements of clients.

Owner:中地装(无锡)钻探工具有限公司

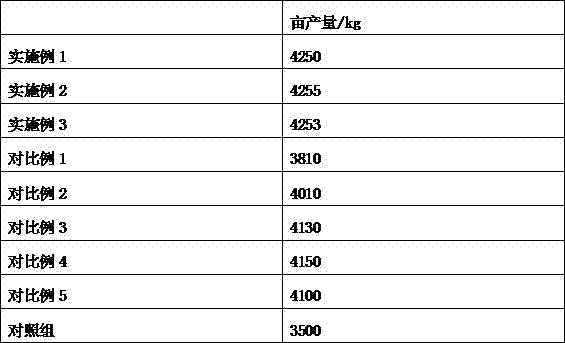

Biomass charcoal

InactiveCN107254324AHigh yieldIncrease productionBiofuelsSpecial form destructive distillationAgriculture cropsStipa capillata

The invention discloses biomass charcoal and relates to the technical field of straw application. The biomass charcoal is prepared from corn straw, wheat straw, cotton straw and stipa capillata in a mixing manner. The biomass charcoal disclosed by the invention is not only high in biomass charcoal yield and good in repairing effect on soil, but also capable of promoting absorption of fertilizer nutrients by crops, crop growth can be promoted, and the yield can be increased.

Owner:安徽省宗正农业科技开发股份有限公司

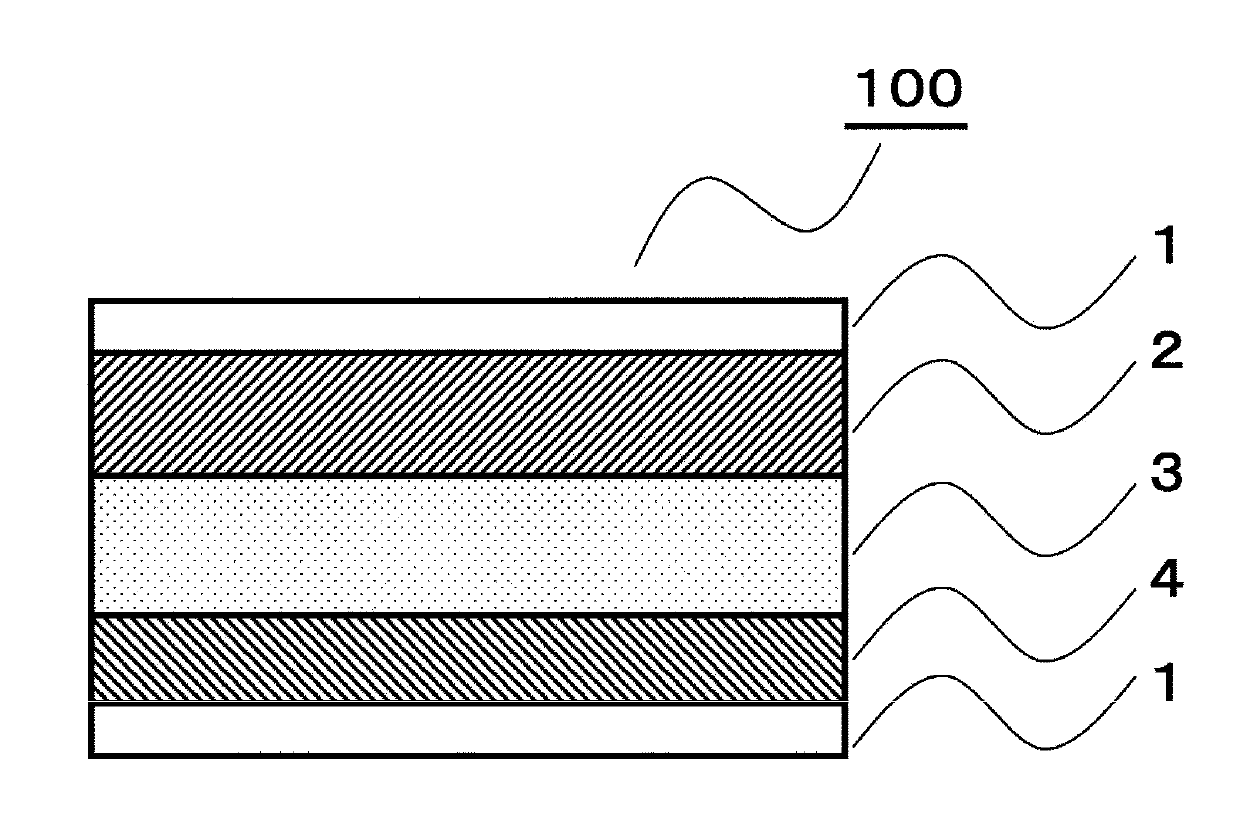

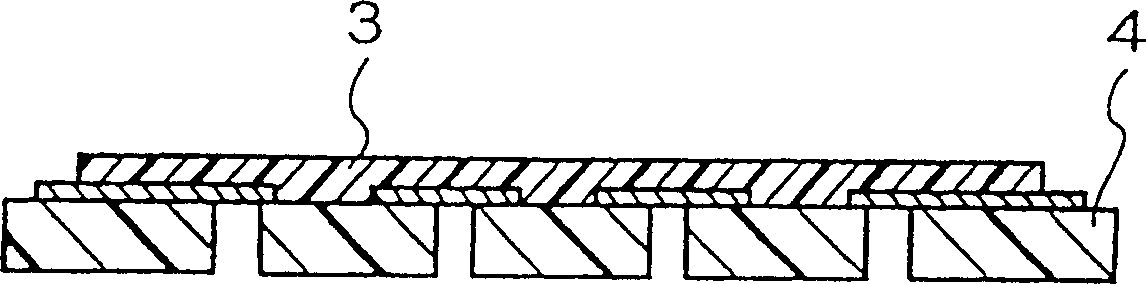

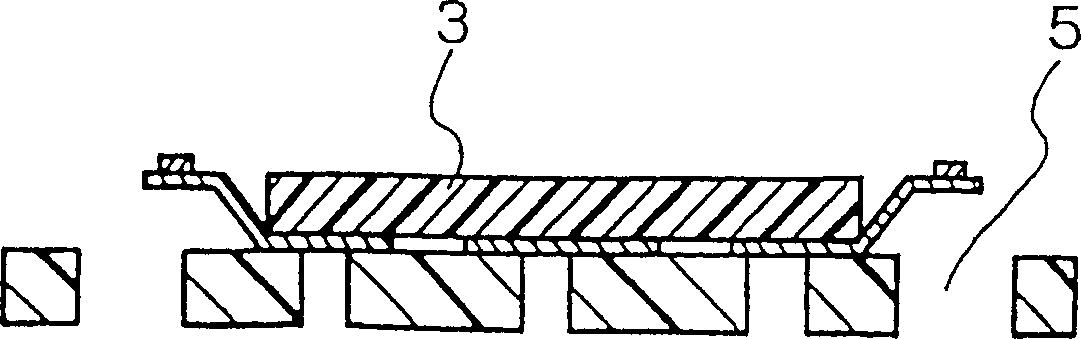

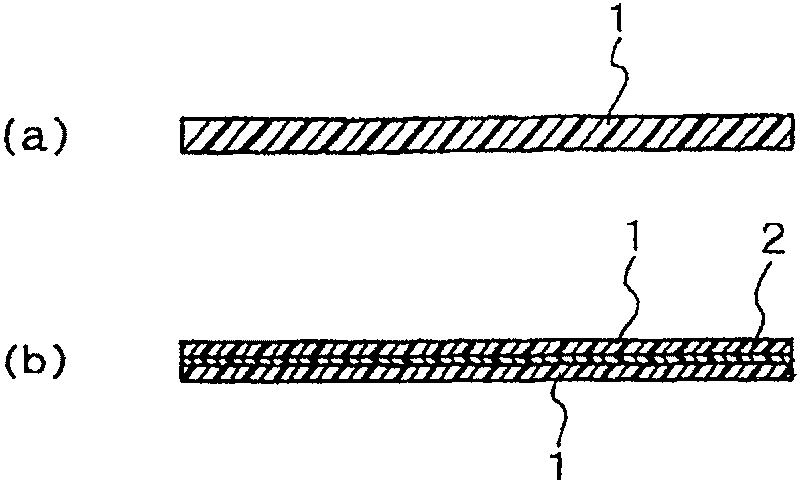

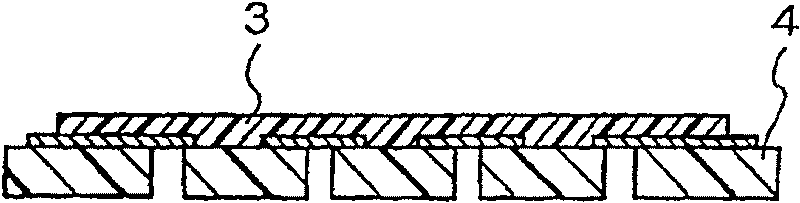

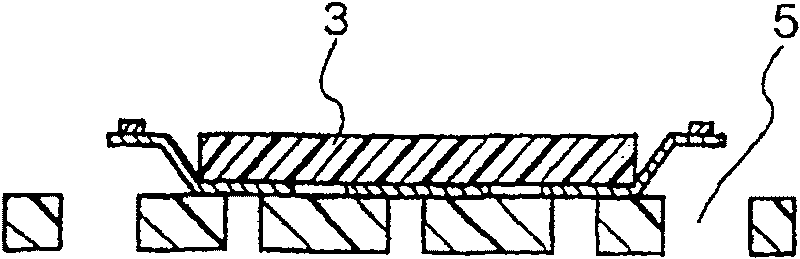

Semiconductor device, substrate for mounting semiconductor chip, processes for their production, adhesive, and double-sided adhesive film

InactiveCN1837317AInhibition of plastic deformationInhibition of mobilityFilm/foil adhesivesSemiconductor/solid-state device detailsDynamic viscoelasticityAdhesive

The invention aims at improving the temperature resisting cycle characteristics after mounting and moisture absorption resiting reflow characteristics of a chip-mounted semiconductor, and provides an adhesive which functions as a bonding member to be used when a semiconductor chip is mounted on an organic supporting substrate and which has storage moduli at 25 DEG C and at 260 DEG C as measured with a dynamic visco-elasticity measuring instrument of 10-2000 MPa and 3-50 MPa, respectively, a double-coated adhesive film produced therewith, a semiconductor device, an semiconductor chip mounting substrate, and methods of manufacturing these products.

Owner:HITACHI CHEM CO LTD

PPS (polyphenylene sulfide) and nano Al2O3 filled PTFE (polytetrafluoroethylene) composite material

InactiveCN108102261AEasing plastic deformationInhibit fibrosisPtfe compositeScanning electron microscope

The invention provides a PPS (polyphenylene sulfide) and nano Al2O3 filled PTFE (polytetrafluoroethylene) composite material. PPS and nano Al2O3 filled PTFE composite material samples are prepared with a method comprising steps of mechanical blending, cold press molding and sintering; frictional wear performance of the samples under the dry friction condition is tested by an MRH3 type ring-block tester; an SEM (scanning electron microscope) is adopted for observing and analyzing morphology of the wear surface and the transfer membrane surface of each sample. When the mass fraction of PPS is 5%, the friction coefficient and volume abrasion rate of the PPS / PTFE composite material both reach the minimum value; with addition of nano Al2O3, the tribological property of the PPS / PTFE composite material is further improved, when the mass fraction of nano Al2O3 is 5%, the volume abrasion rate of the nano Al2O3 / PPS / PTFE composite material is the minimum, and wear resistance is increased by 276 times as compared with that of pure PTFE. The main wear mechanism of PTFE / PPS / PTFE and the nano Al2O3 / PPS / PTFE composite material is adhesion wear at the room temperature, and the nano Al2O3 / PPS / PTFE composite material is accompanied with abrasive wear at 150 DEG C.

Owner:刘芳

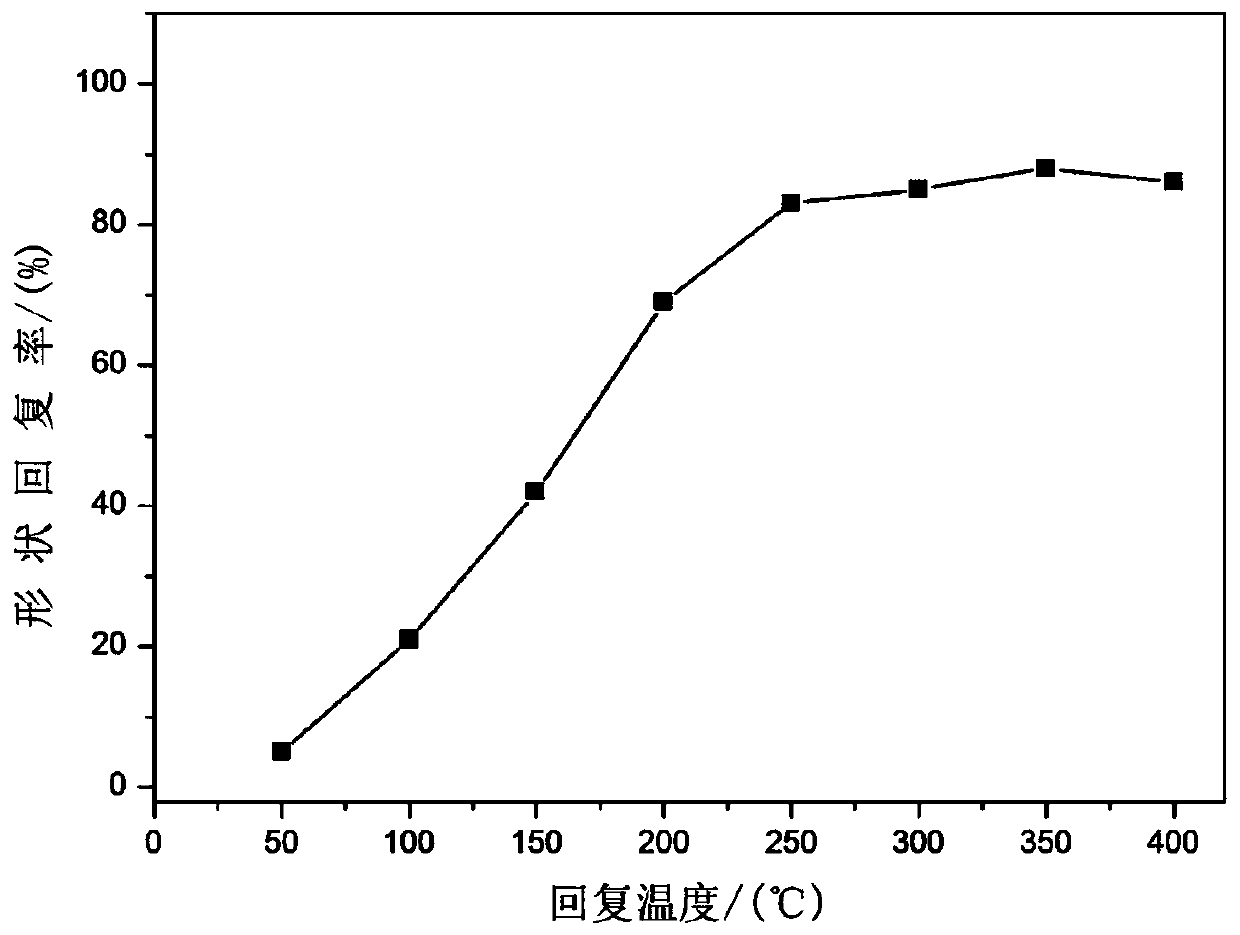

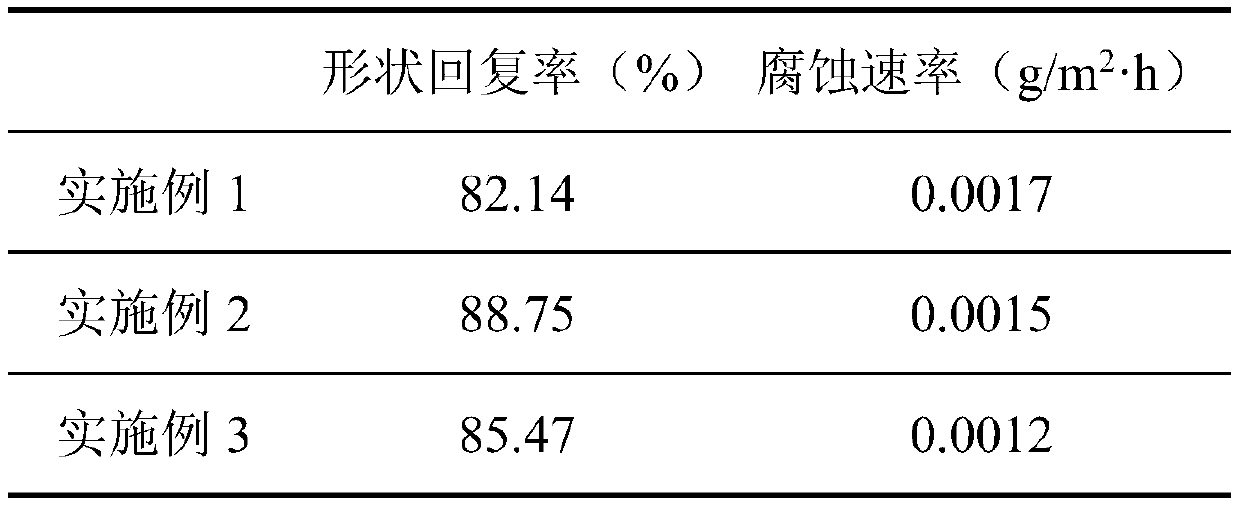

Shape memory alloy and preparation method thereof

InactiveCN101705440AGood shape memory effectInhibition of plastic deformationShape-memory alloyUltimate tensile strength

The invention provides a shape memory alloy and a preparation method thereof, belonging to the technical field of materials. The shape memory alloy comprises the following components in percent by weight: 14-15% of Mn, 6-7% of Si, 9-10% of Cr, 5-6% of Ni, 0.05-0.1% of C, and the balance of Fe. The preparation method of the shape memory alloy comprises the following steps: firstly, according to the weight percentages of all components of the shape memory alloy, respectively taking the following raw materials, such as ultra low carbon steel, Mn, Si, Cr and Ni, or respectively taking low carbon steel, Fe, Mn, Si, Cr and Ni; secondly, melting all raw materials except Mn by vacuum induction; and thirdly, adding Mn in the mixture and conducting melting in the inert gas and obtaining the shape memory alloy by natural cooling. The strength and recoverable strain of the shape memory alloy is obviously higher than those of the normal Fe-Mn-Si alloy, the corrosion resistance of the shape memory alloy is good, the recoverable strain of the shape memory alloy is 3% under a casting condition and is further increased after solution-quenching treatment; furthermore, the preparation process of the shape memory alloy is simple.

Owner:SHANGHAI JIAO TONG UNIV

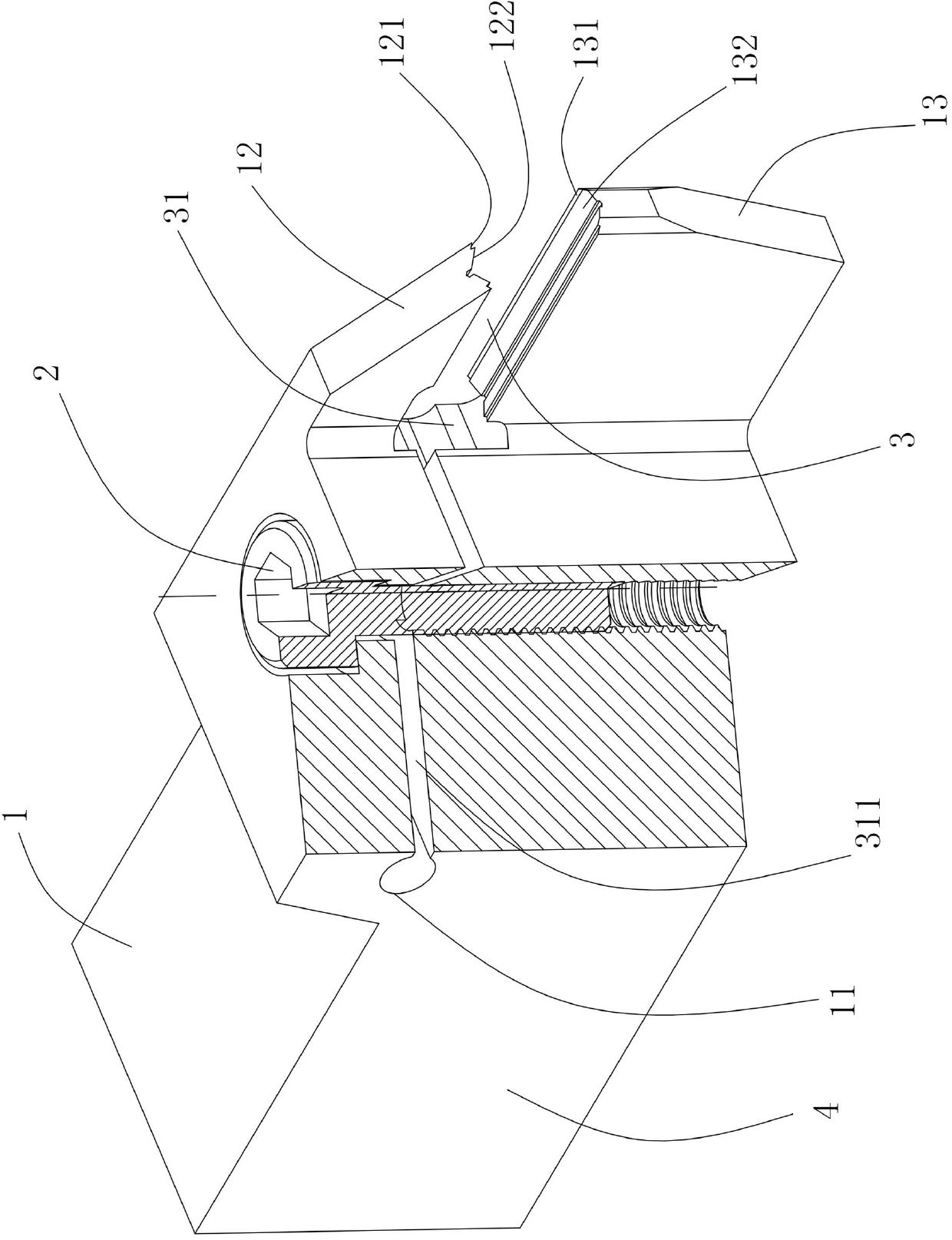

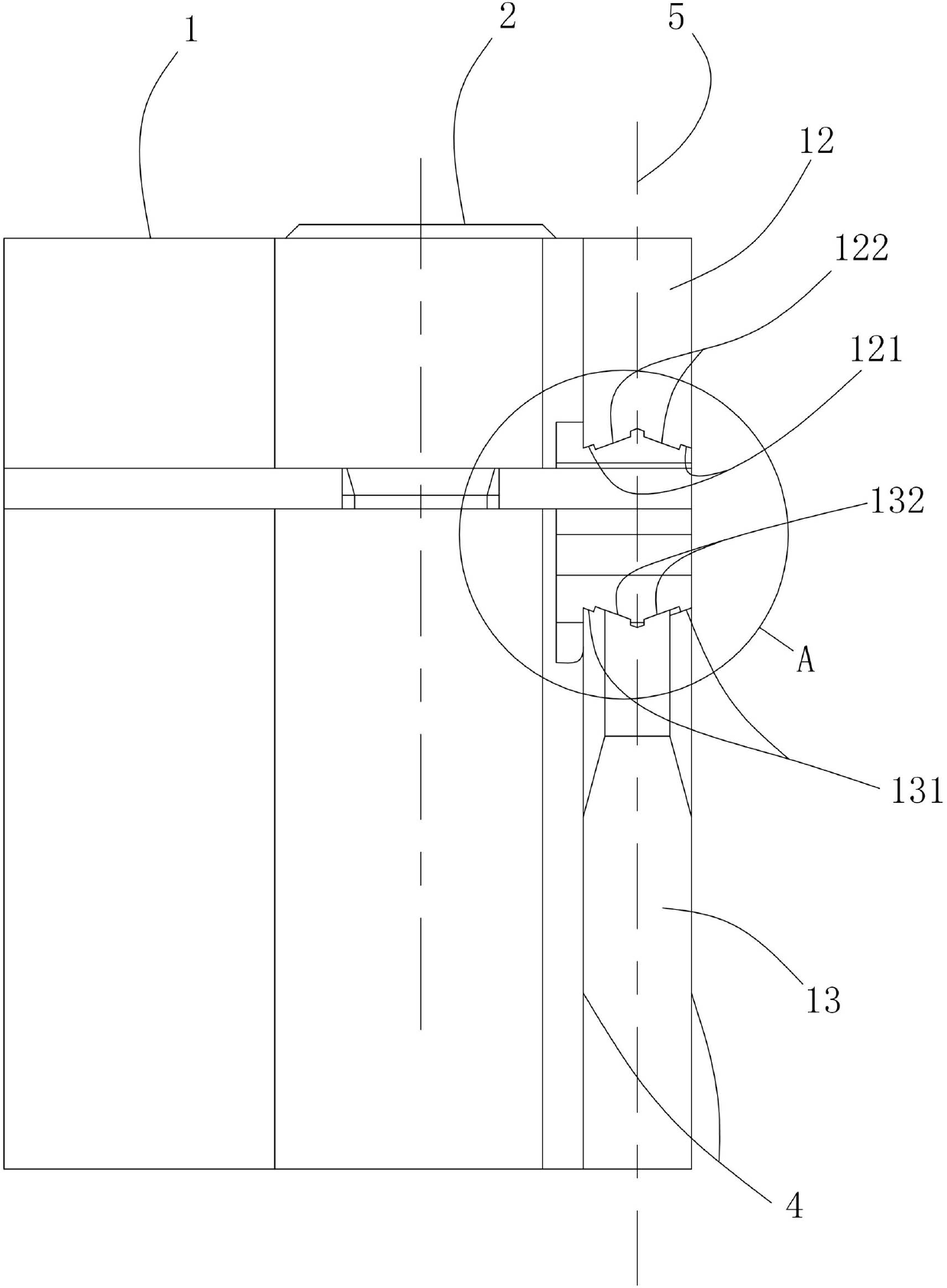

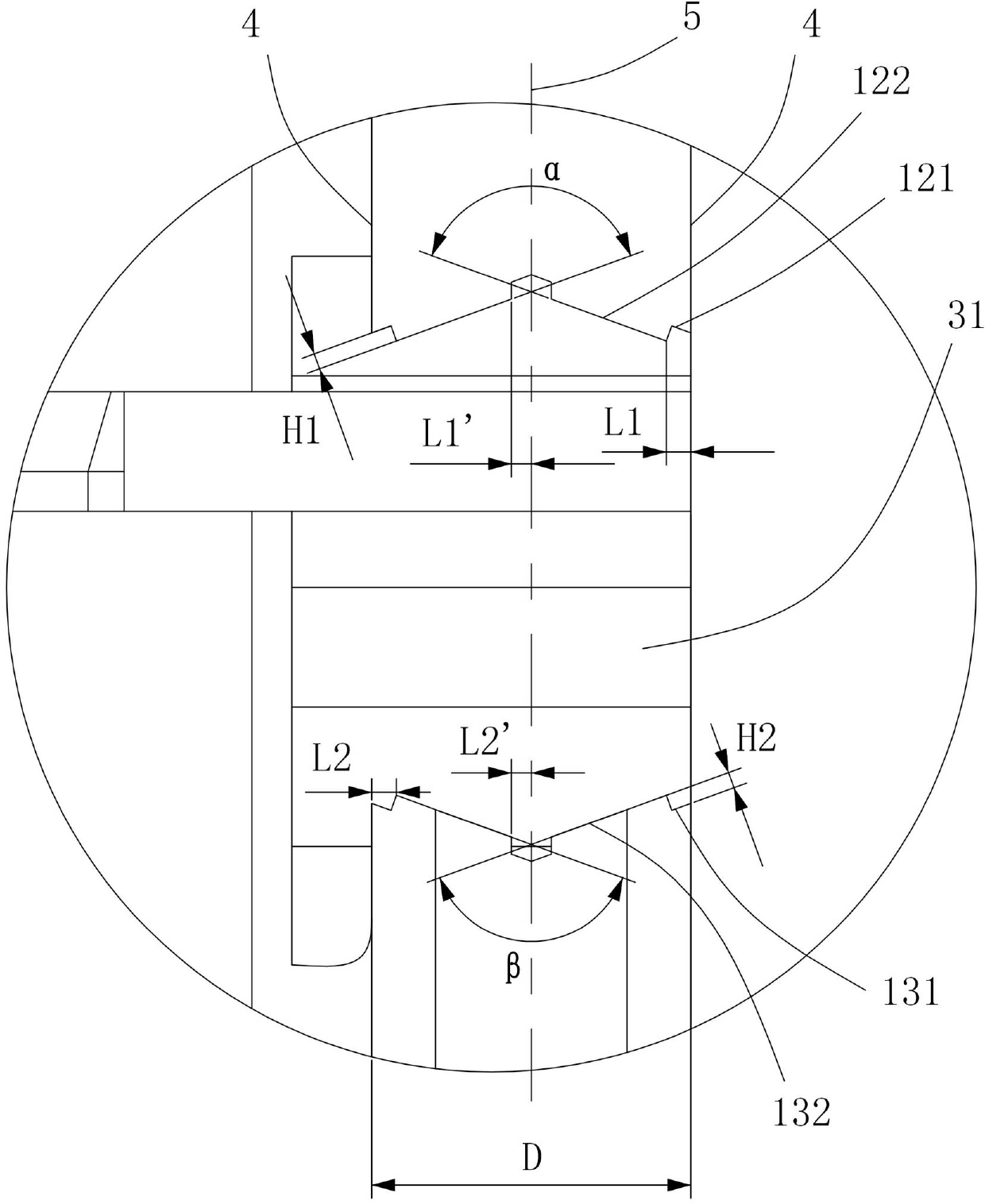

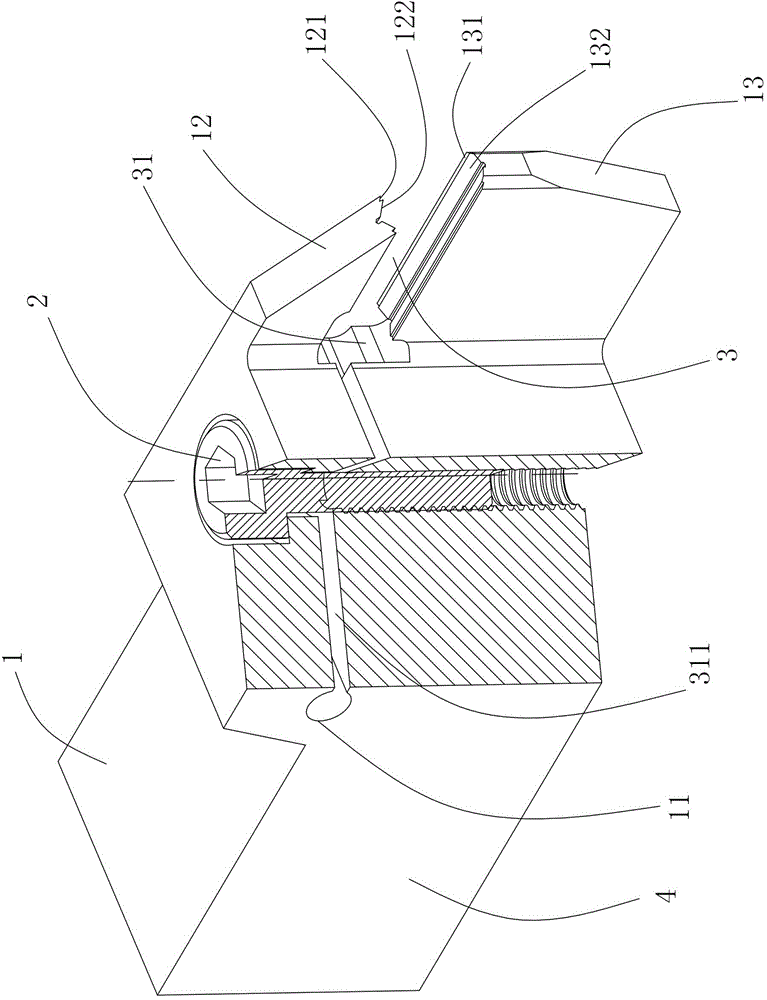

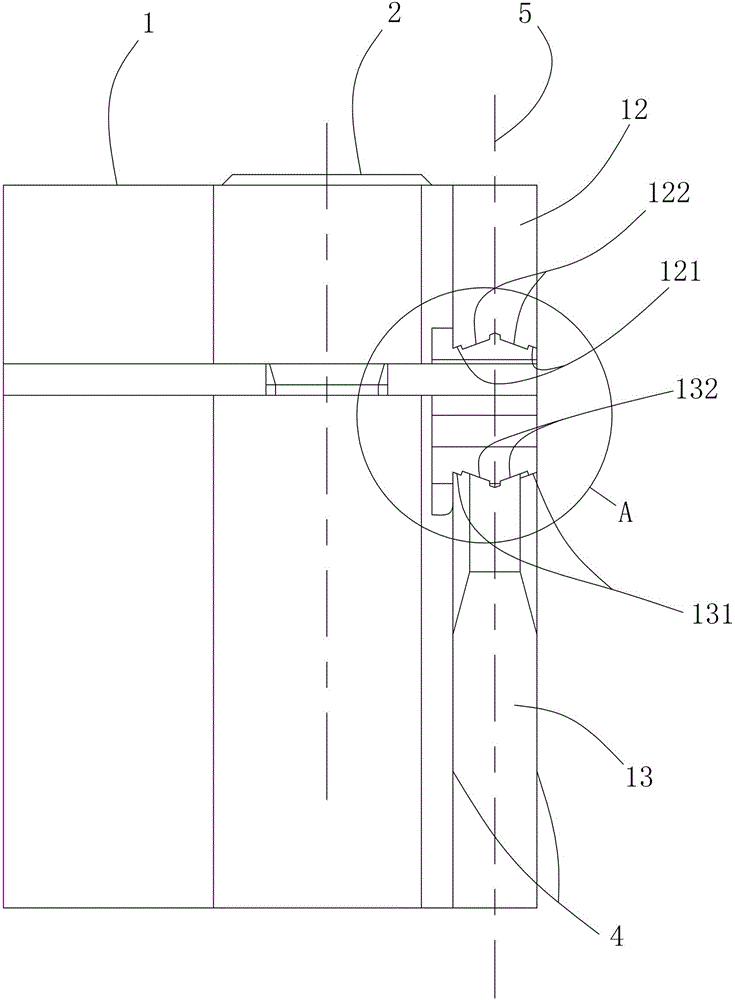

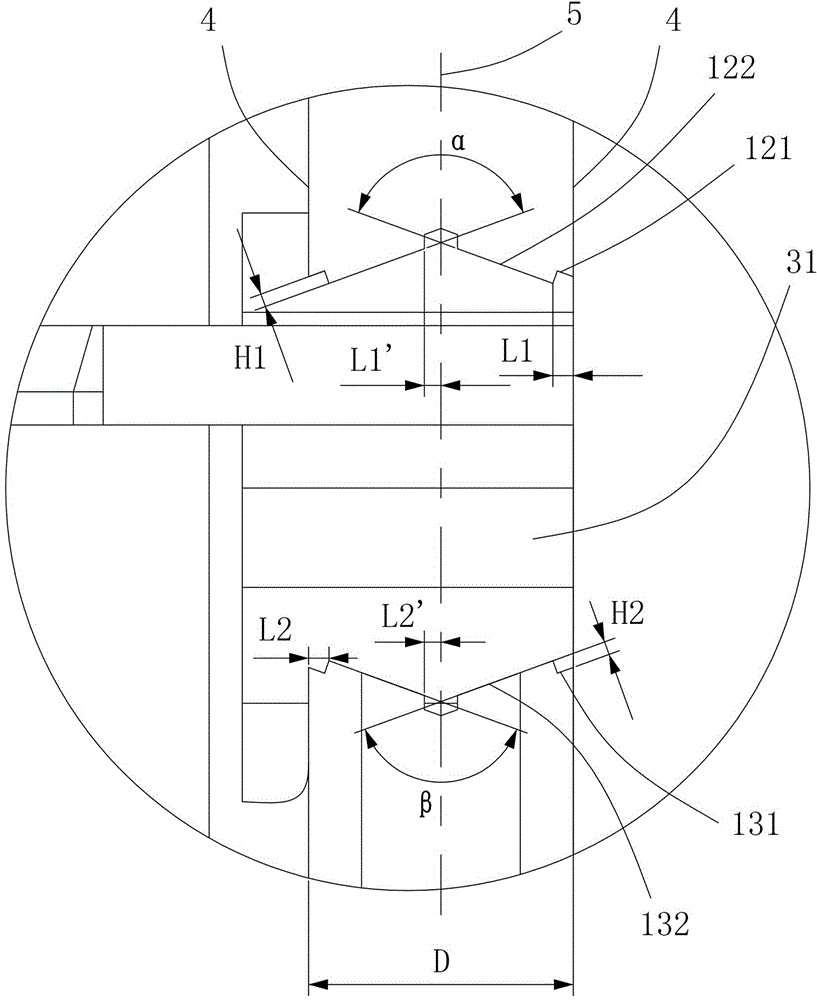

Tool holder for grooving cutting blade

ActiveCN102601403AAvoid deformationReduced positioning contact areaTurning toolsTool holdersEngineeringSupport surface

The invention discloses a tool holder for grooving a cutting blade. The tool holder comprises a tool holder body and a fastener, a clamping portion of the tool holder body consists of an upper clamping portion and a lower supporting portion, an upper positioning surface of the upper clamping portion and a lower positioning surface of the lower supporting portion enclose a blade clamping groove, a rear supporting surface and an elastic extending section are arranged at the rear end of the blade clamping groove, the elastic extending section extends backwards to the neck of the tool holder body, the fastener penetrates through the upper portion and the lower portion of the elastic extending section, M discontinuous upper positioning tables are arranged on the upper positioning surface, and N discontinuous lower positioning tables are arranged on the lower positioning surface, wherein 2<=M<=6, and 2<=N<=6. The tool holder for grooving the cutting blade has the advantages that positioning positions and angles can be automatically adjusted, plastic deformation of the tool body can be effectively suppressed, and the tool holder is stable in structure and long in service life.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Semiconductor device, adhesive, and adhesive film

InactiveCN1923939AInhibition of plastic deformationInhibition of mobilityFilm/foil adhesivesSemiconductor/solid-state device detailsDynamic viscoelasticityAdhesive

The invention aims at improving the temperature resisting cycle characteristics after mounting and moisture absorption resiting reflow characteristics of a chip-mounted semiconductor, and provides an adhesive which functions as a bonding member (3) to be used when a semiconductor chip (6) is mounted on an organic supporting substrate (4) and which has storage moduli at 25 DEG C and at 260 DEG C as measured with a dynamic visco-elasticity measuring instrument of 10-2000 MPa and 3-50 MPa, respectively, a double-coated adhesive film produced therewith, a semiconductor device, an semiconductor chip mounting substrate, and methods of manufacturing these products.

Owner:RESONAC CORPORATION

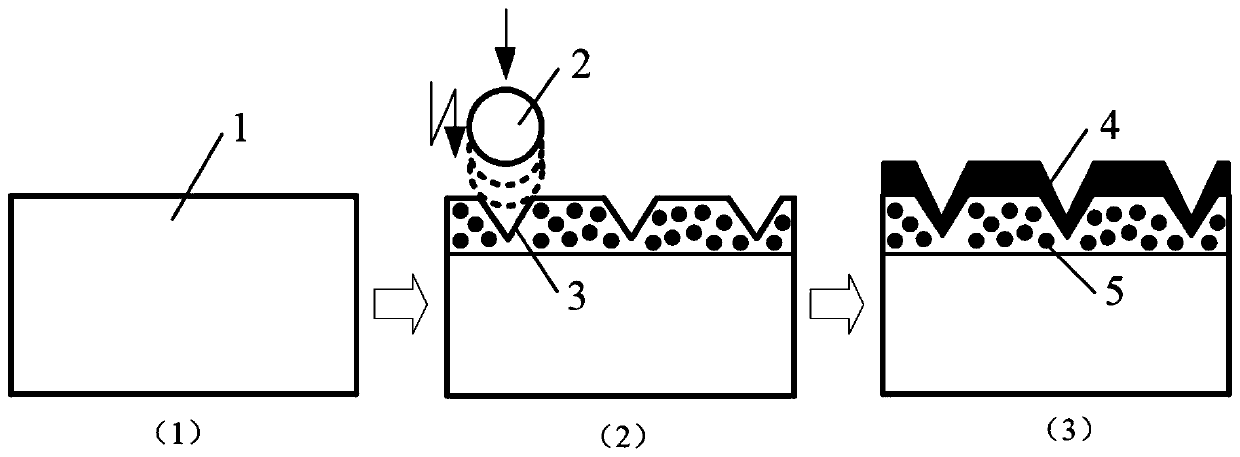

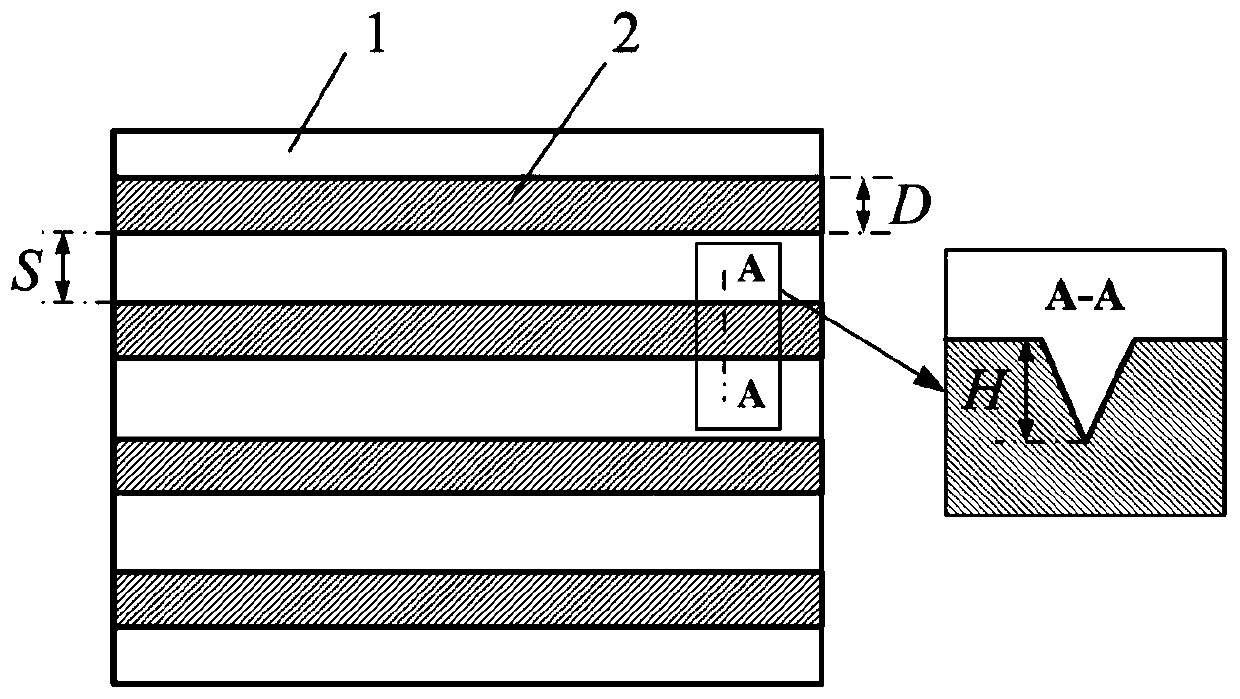

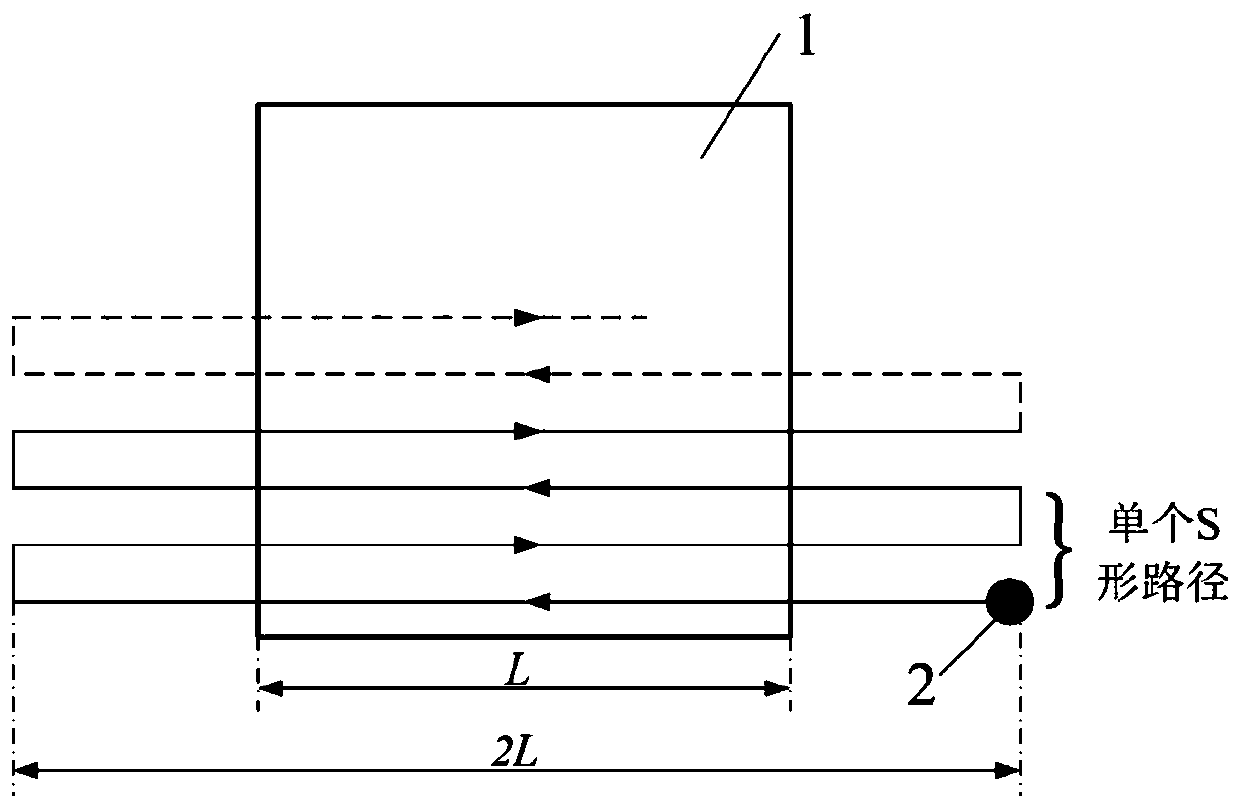

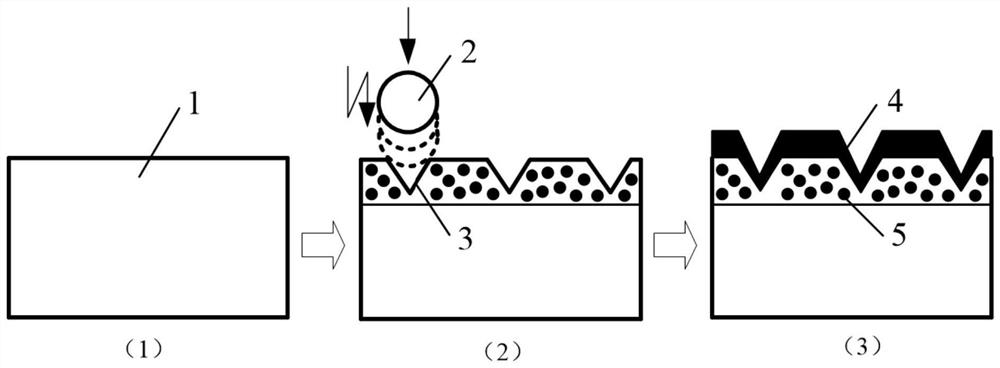

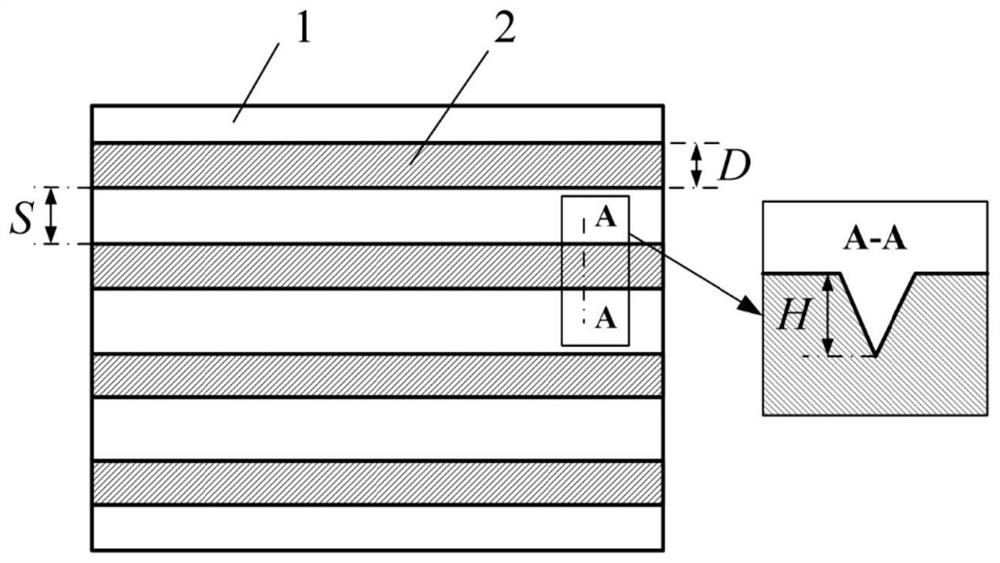

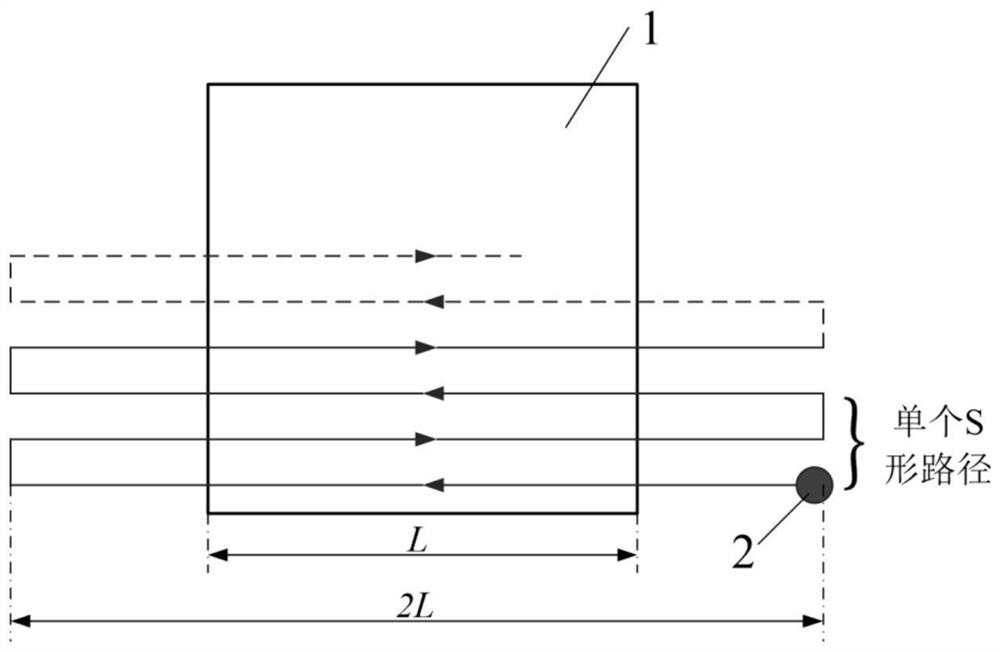

Ultrasonic rolling textured AlCrN coating on matrix surface and preparation process

ActiveCN111235520ADimensional parameters are controllableControllable shapeVacuum evaporation coatingSputtering coatingUltimate tensile strengthBonding strength

The invention discloses an ultrasonic rolling textured AlCrN coating on a matrix surface and a preparation process. The preparation process includes the steps that ultrasonic rolling texturing is first carried out on the matrix metal surface, and then the AlCrN coating is prepared on the textured matrix metal surface. The ultrasonic rolling texturing process includes the steps that during continuous ultrasonic rolling, matrix metal is moved by a set distance in the -X direction, moved by a set distance in the +Y direction and then moved by a set distance in the +X direction to form an S-shapedfeeding path, the single S-shaped feeding path is repeated by at least one time, and thus the surface of the matrix metal is textured. The bonding strength of coating-substrate of the matrix metal can be enhanced remarkably, and the tribology performance of the matrix metal is improved significantly.

Owner:SHANDONG UNIV

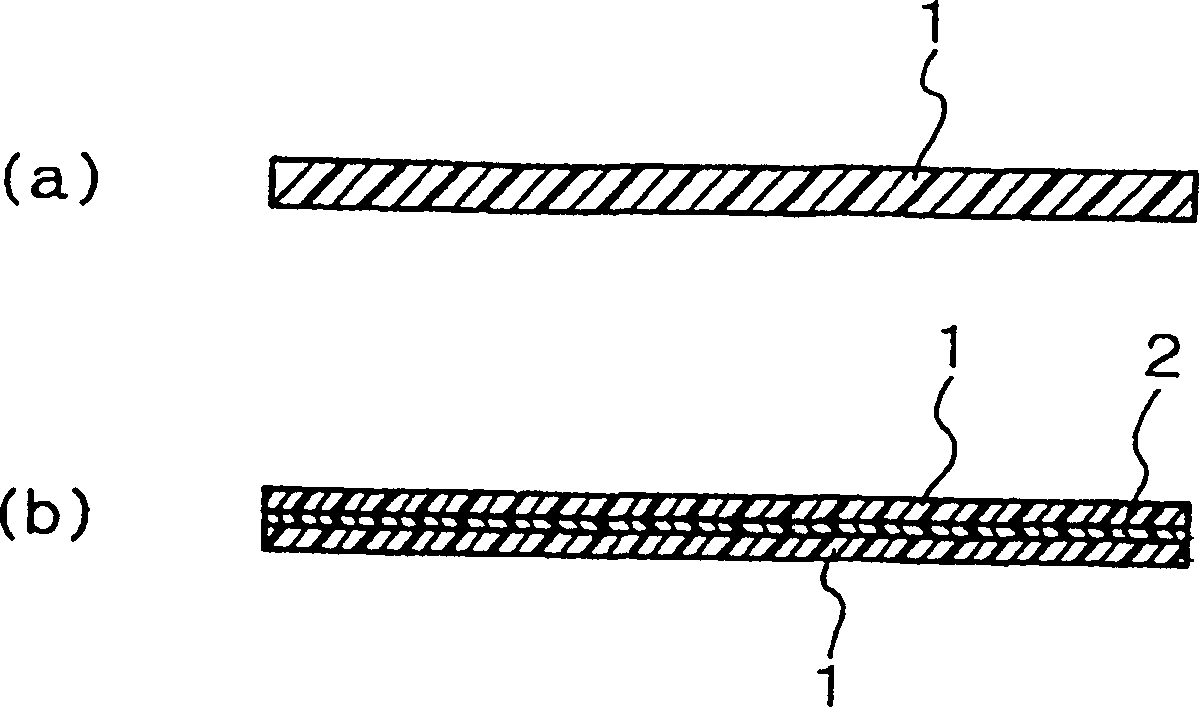

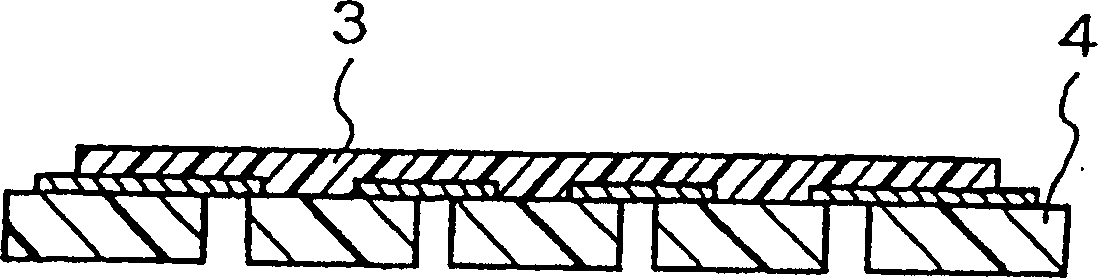

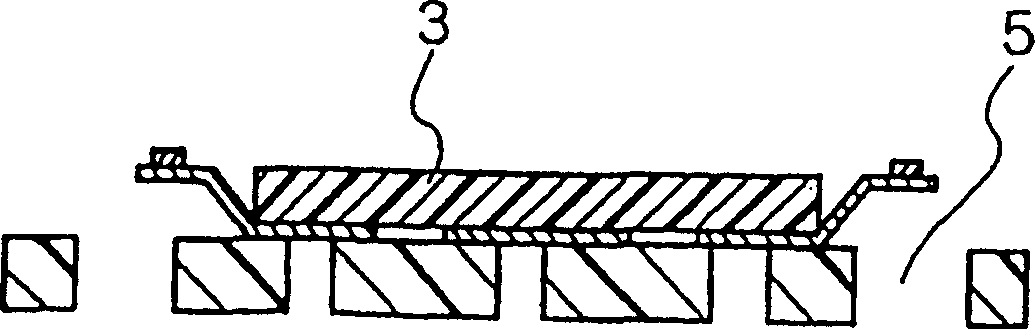

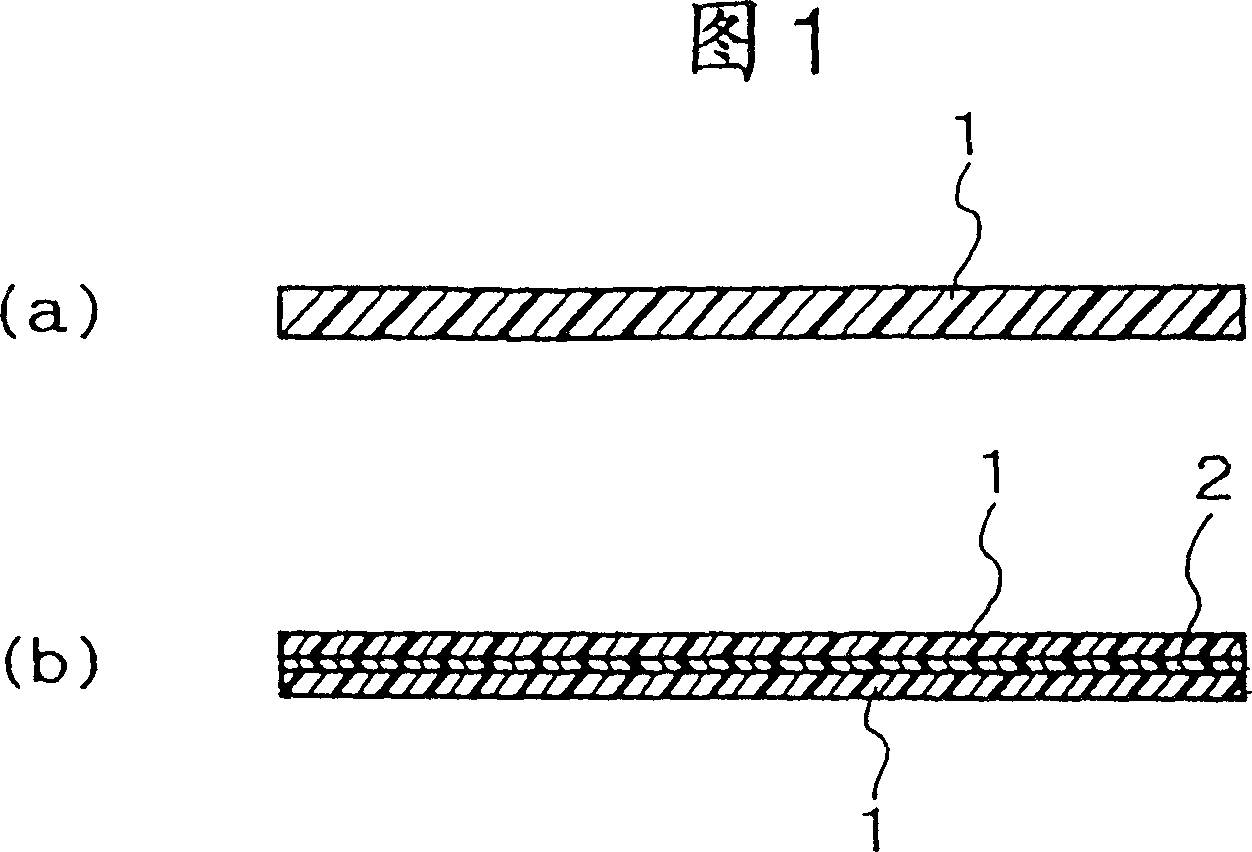

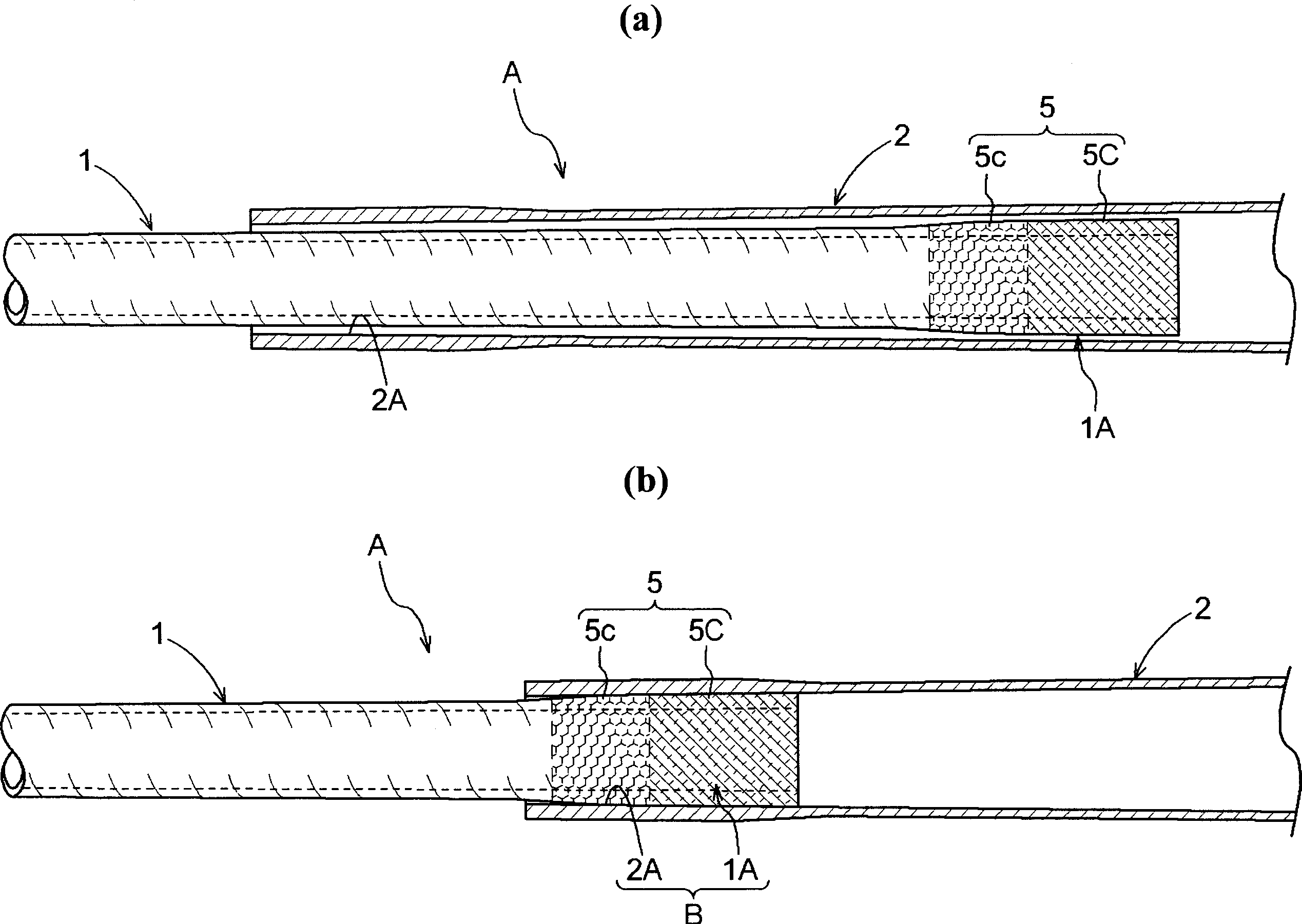

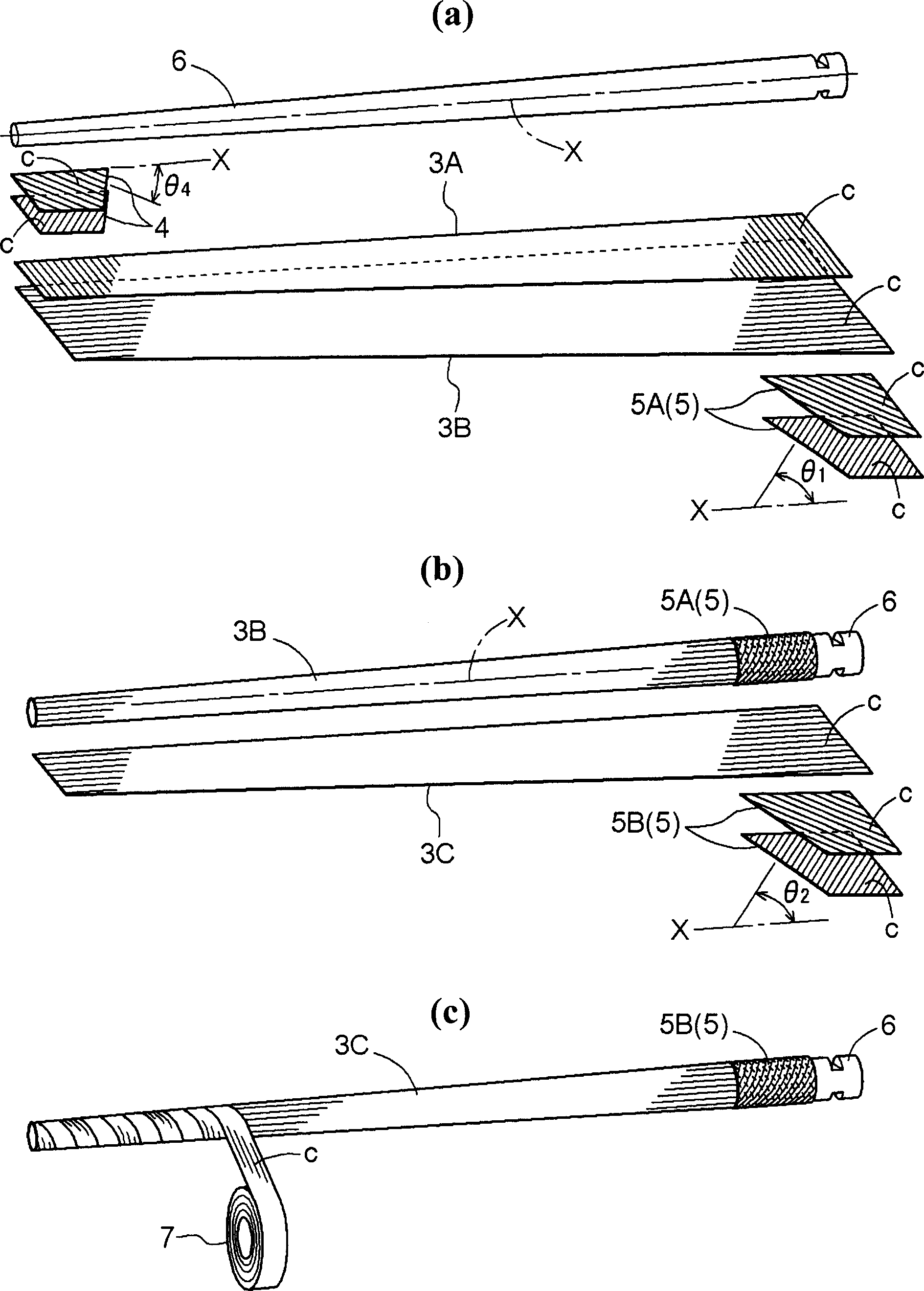

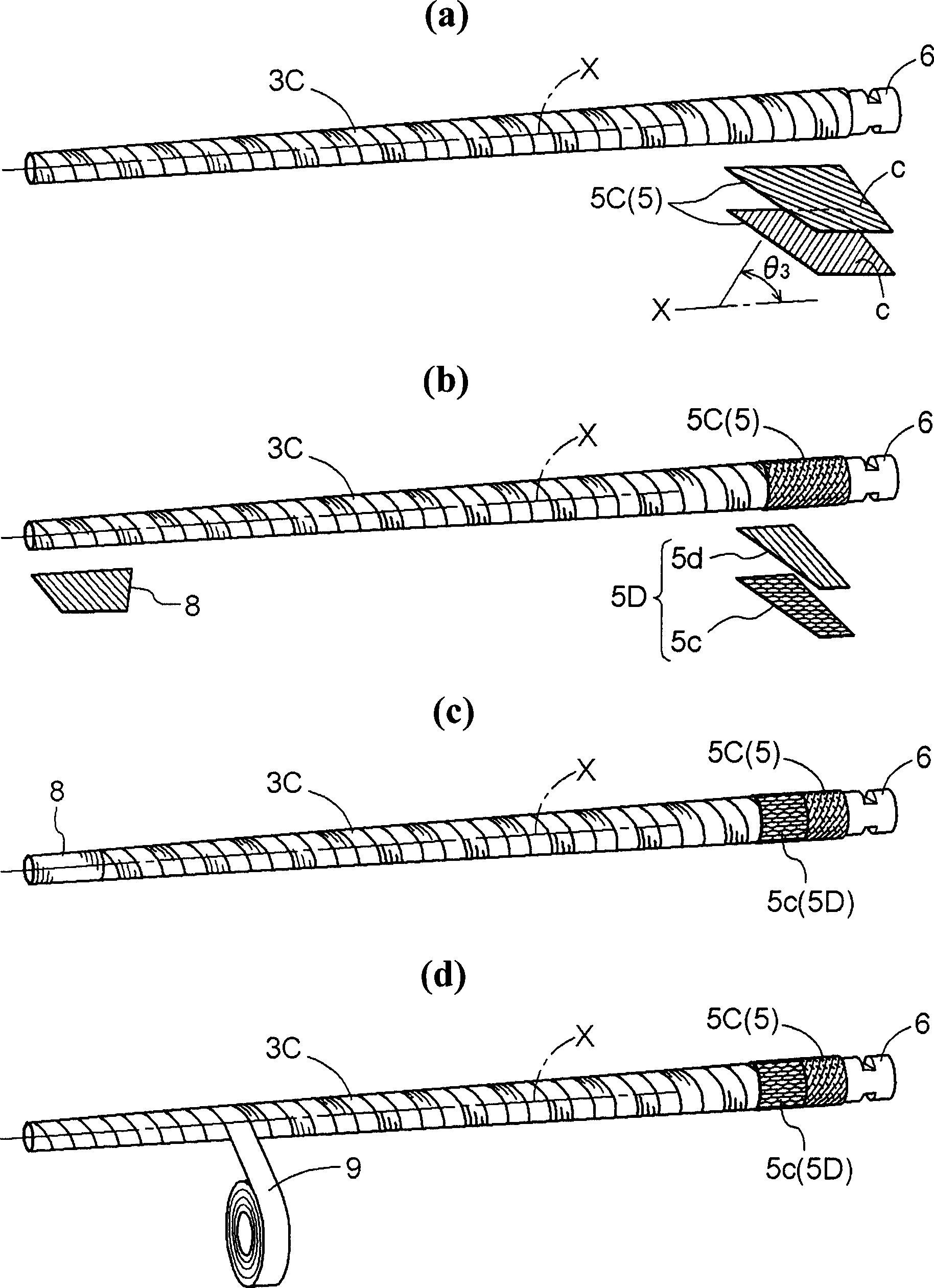

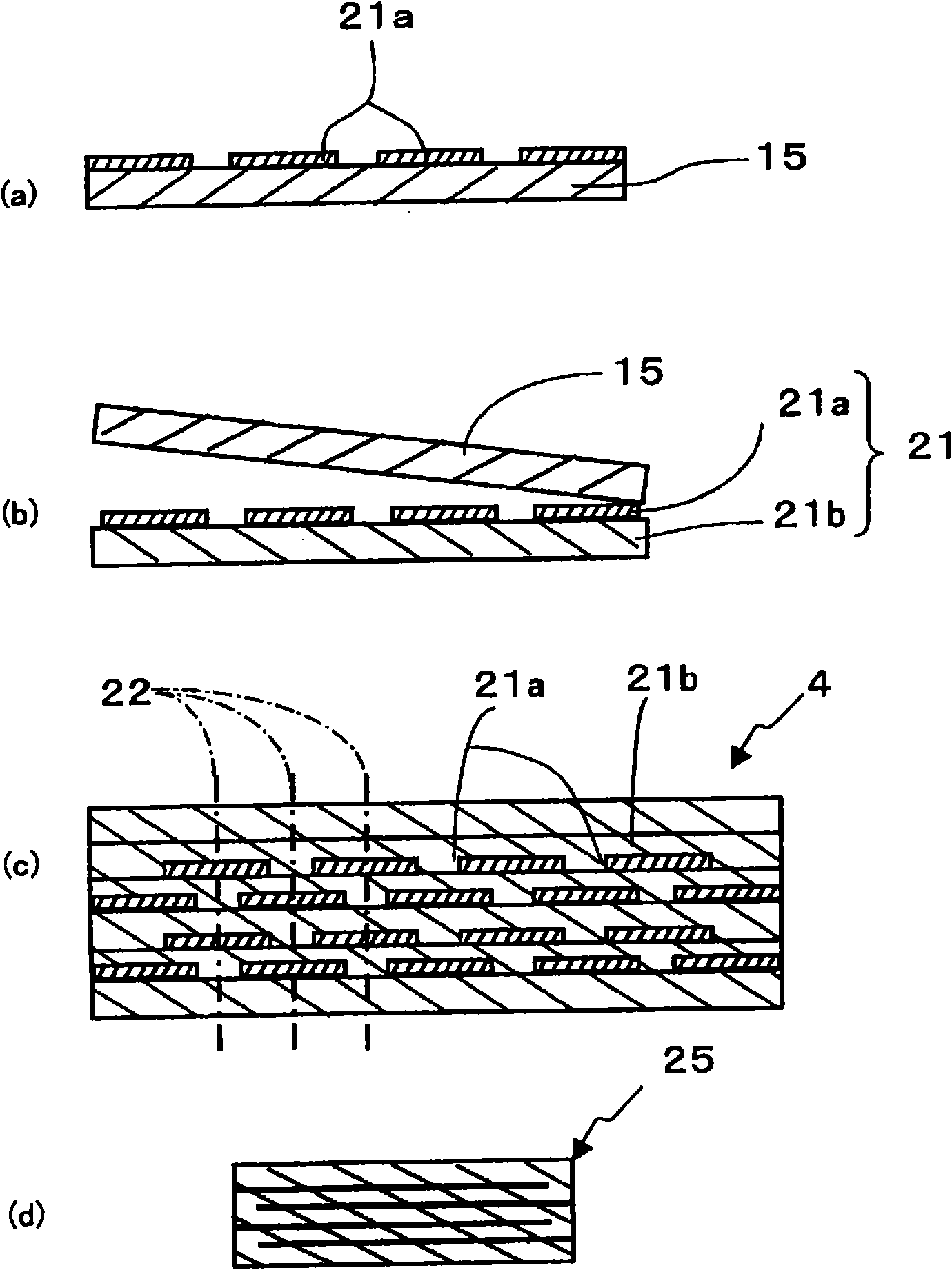

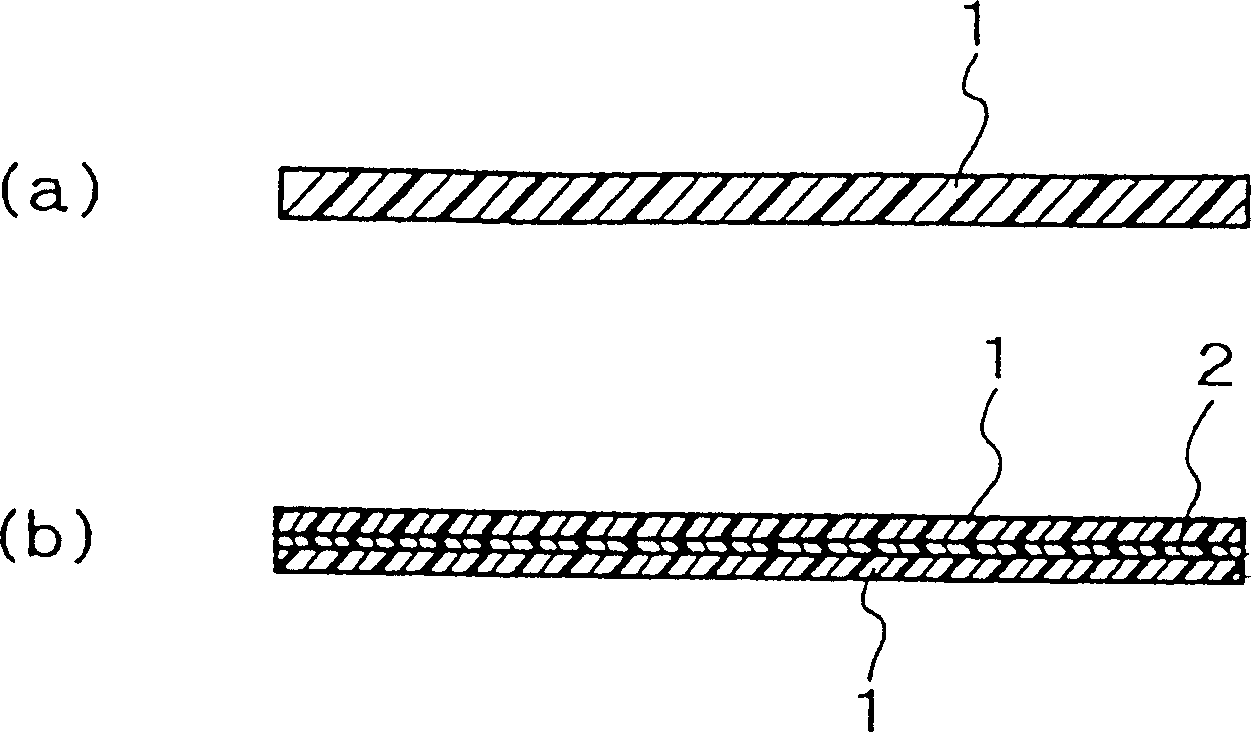

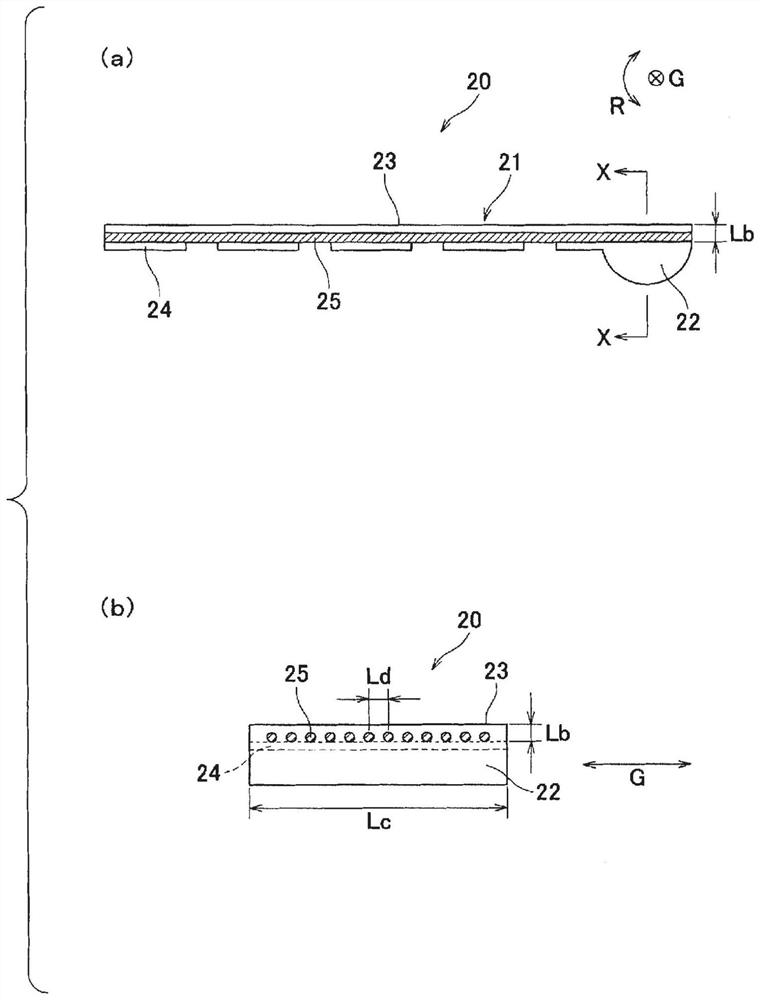

Rod of fishing pole and method for manufacturing same

ActiveCN1846483AAvoid separationInhibition of plastic deformationLamination ancillary operationsLaminationFiberFishing

The present invention provides a fishing rod body capable of suppressing plastic deformation, cracks, and the like at joints, and capable of smoothly bending when a fish bites on a hook, so as to gently withstand pulling of the fish. A reinforcing sheet (5) is disposed on the middle layer at the rod tail end of the rod body (1) on the rod side. The reinforcing sheet (5) is formed by overlapping two sheets of prepreg material, wherein one sheet of prepreg material has a group of reinforcing fibers (c) aligned along a direction forming a first inclination angle (θ1) with the rod axis (X), and the other sheet of prepreg material has a group of reinforcing fibers (c) aligned and arranged symmetrically with the group of reinforcing fibers (c) of the prepreg material relative to the rod axis.

Owner:SHIMANO INC

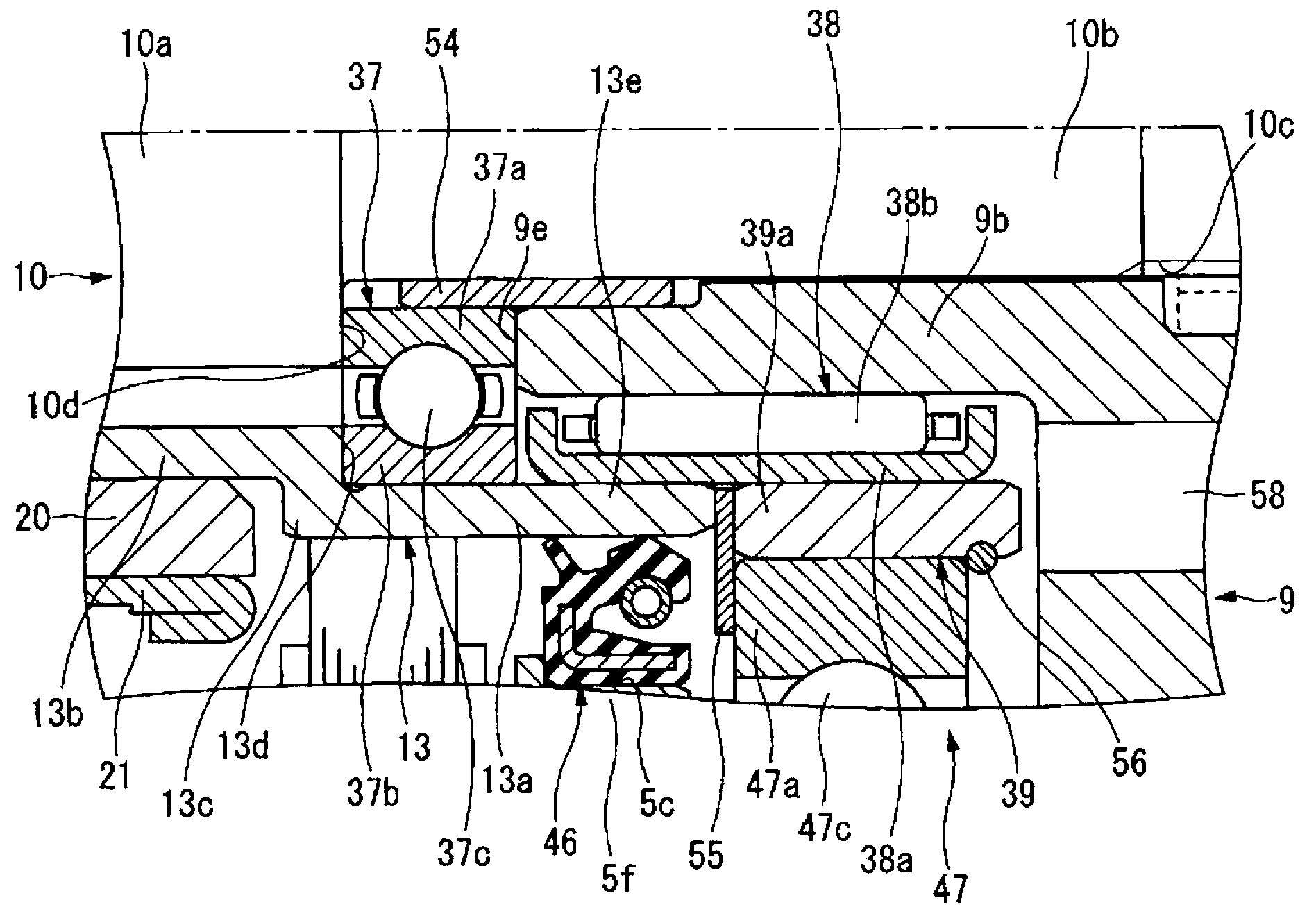

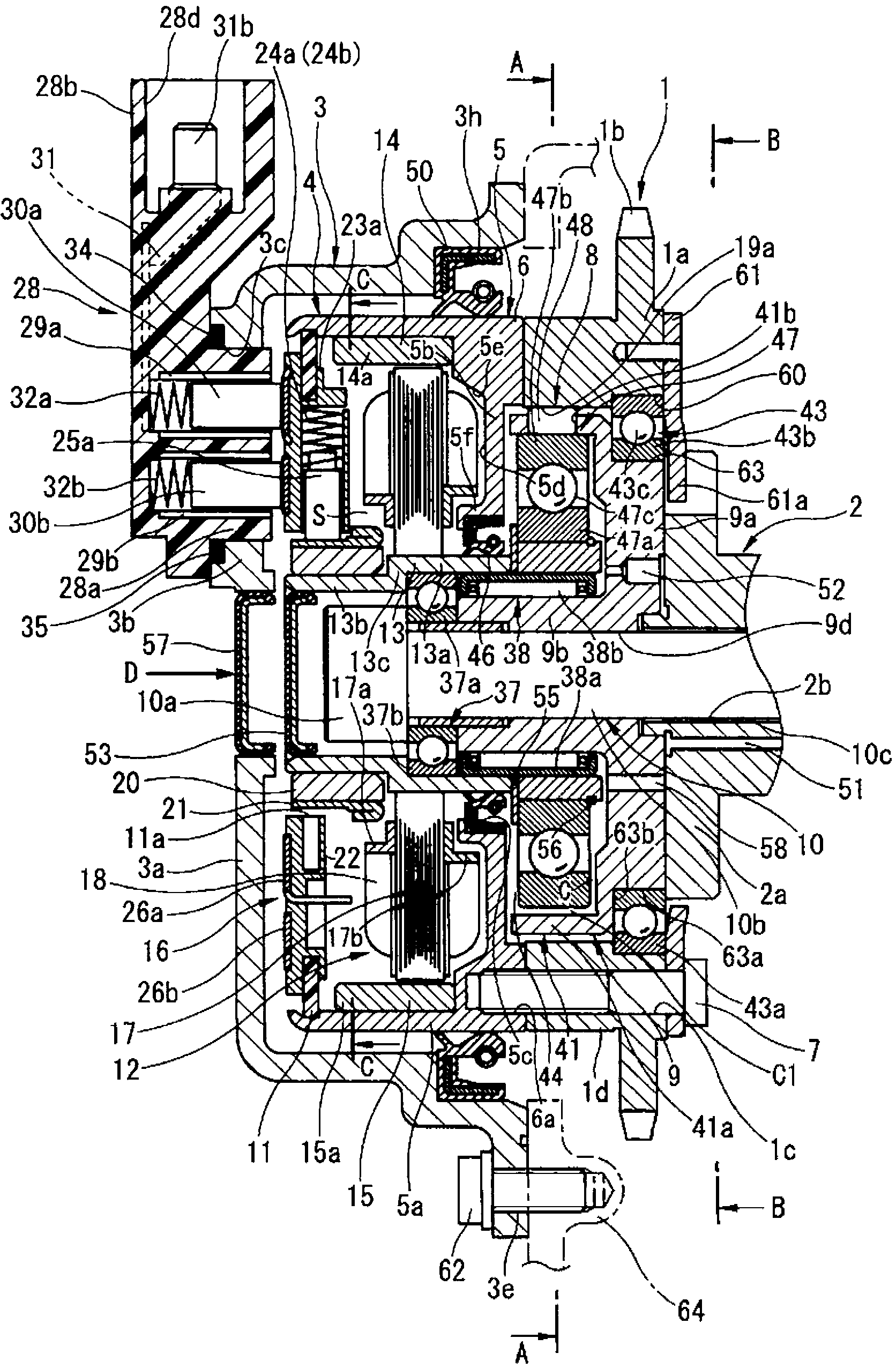

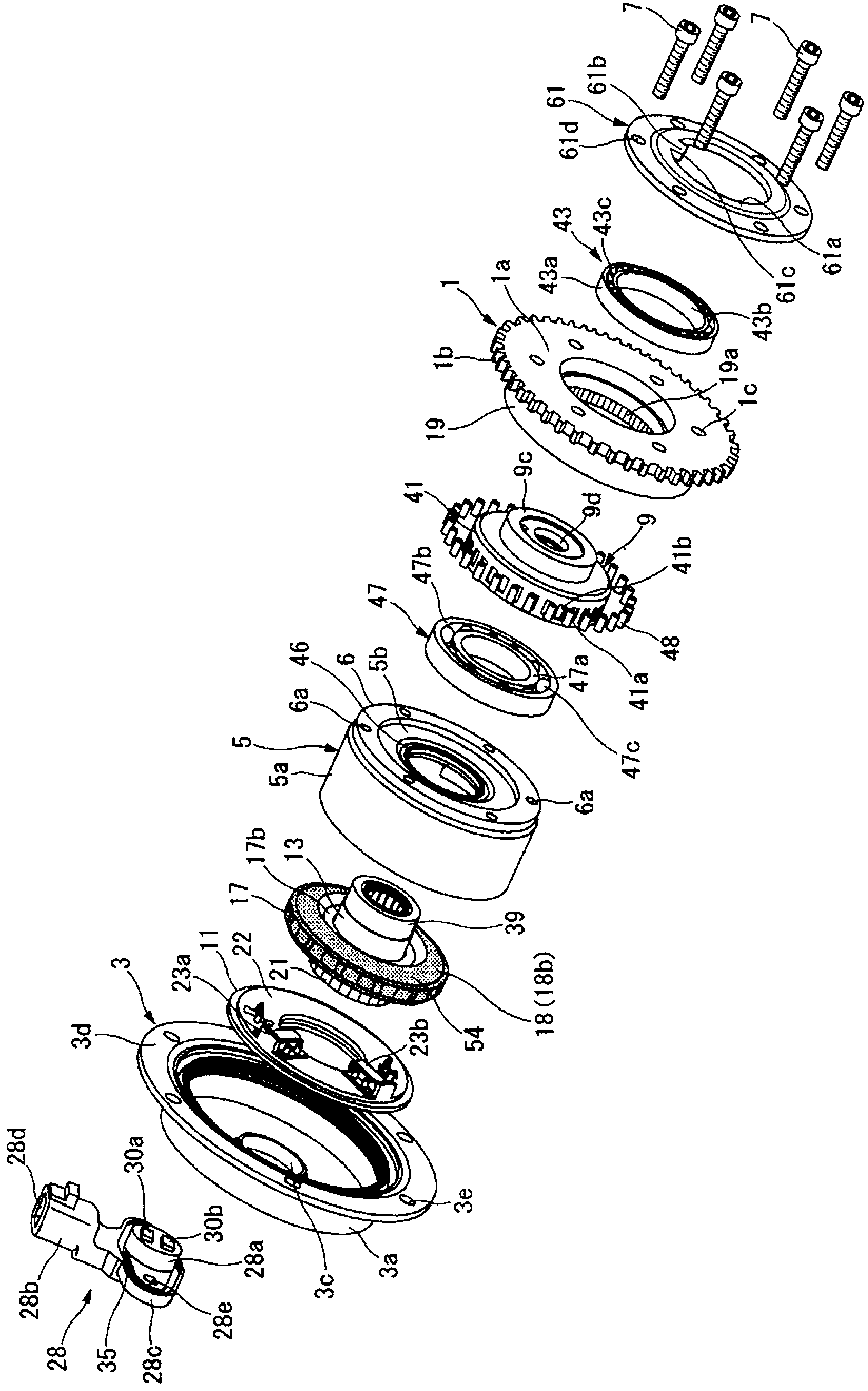

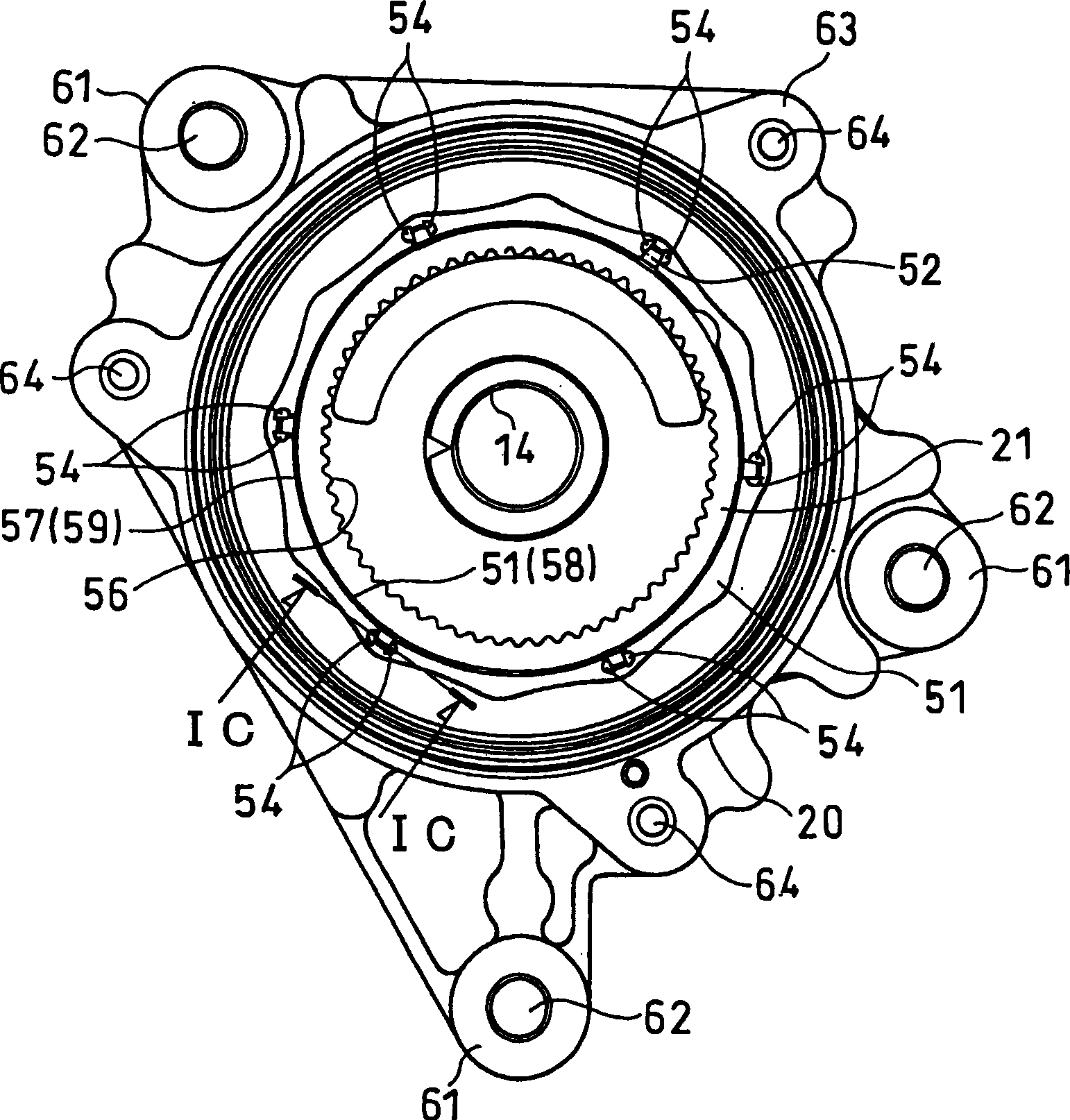

Valve timing control apparatus for internal combustion engine

InactiveCN103256084AInhibition of plastic deformationRolling contact bearingsMachines/enginesNeedle roller bearingExternal combustion engine

The invention provides a valve timing control apparatus for an internal combustion engine, and the valve timing control apparatus can integratlly conbine a motor output shaft and an eccentric cam by a bearing and prevent plastic deformation of of the eccentric cam. The valve timing control apparatus for the internal combustion engine comprises a retarding mechanism (8), and the retarding mechanism (8) is provided with a tube-shaped eccentric cam (39) whose outer periphery surface is eccentric relative to an axis, a plurality of rollers disposed between internal teeth and the eccentric cam, and a retainer maintaining comb state of each roller. The retainer rotates relative to the internal teeth through rotation of the eccentric cam. A tube-shaped motor shaft (13) which is fixed on inner periphery of an iron rotor is configured to connect in series with the eccentric cam. The whole eccentric cam and a major diameter (13a) of the motor shaft cross over in an axial direction and are pressed on an outer periphery surface of a retaining support (38a) of a needle bearing (38) which rotates on periphery of a cylinder portion (9b). The motor shaft and the eccentric cam are combined by the needle bearing.

Owner:HITACHI AUTOMOTIVE SYST LTD

Gear device

ActiveCN1779298ALow roundnessReduce concentricityToothed gearingsPortable liftingGear wheelEngineering

The invention provides a toothed gearing, in which the peripheral part of internal gear circular part is press-inserted to the internal peripheral part of the front casing built-in wall. After a plurality of clamping catches are inserted in lots of clamping slots on the internal peripheral part of the front casing built-in wall, the two ends of clamping catches are applied the outside force to make them plastically deform, so as to form a plurality of riveted fixing part.

Owner:DENSO CORP +1

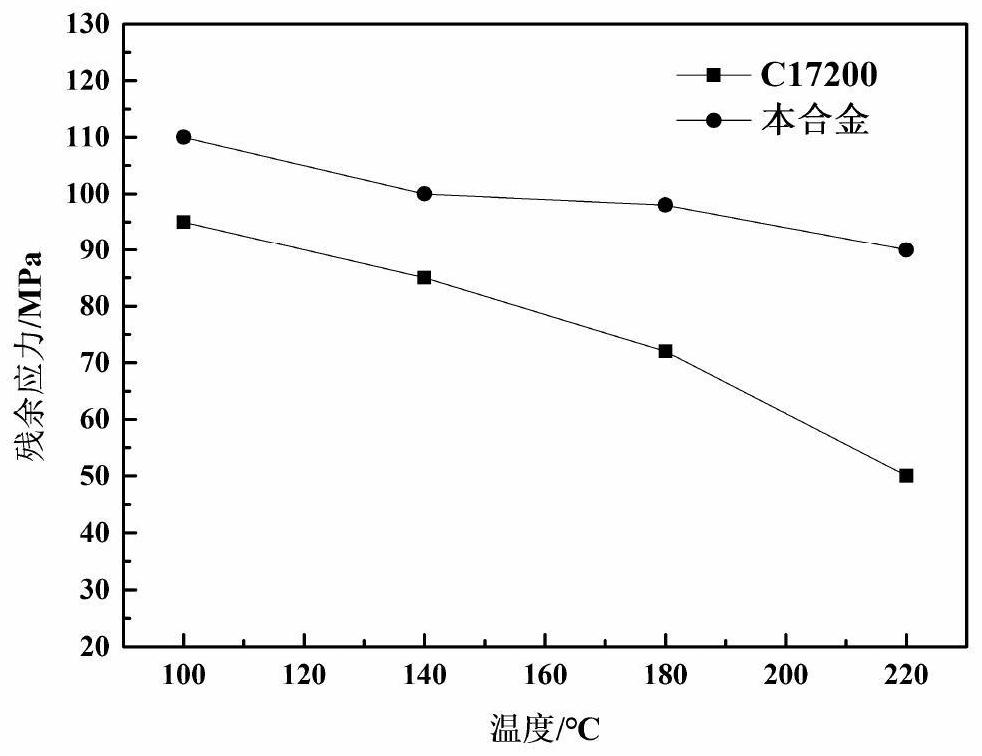

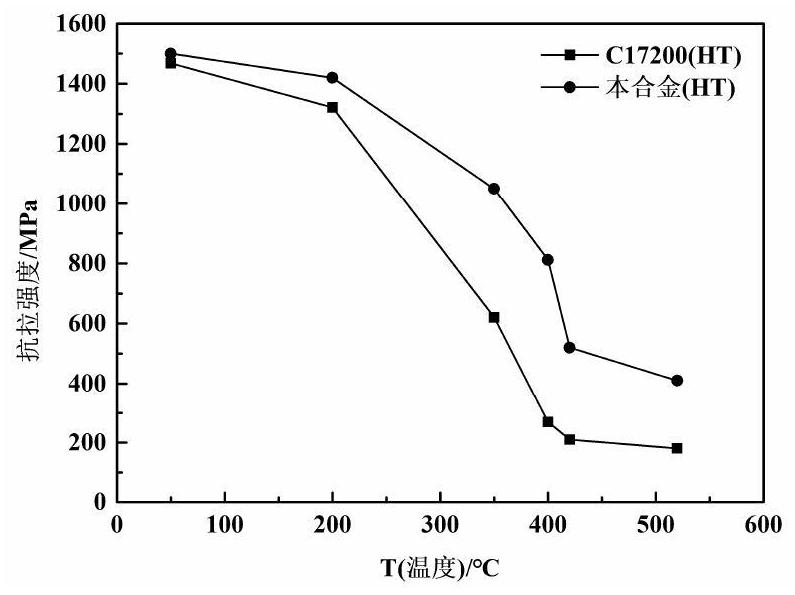

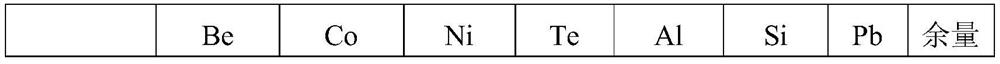

Preparation method of easy-for-turning Be-Cu alloy resistant to high-temperature softening and stress relaxation

The invention discloses a preparation method of an easy-for-turning Be-Cu alloy resistant to high-temperature softening and stress relaxation. The easy-for-turning Be-Cu alloy comprises 0.2-2.1 wt.% of Be, 0.1-0.7 wt.% of Te, more than 0.2 wt.% of Co and Ni, less than 0.7 wt.% of Co, Ni and Fe, no more than 4 wt.% of the sum of impurity elements, and the balance Cu. The preparation method comprises the following steps: a, carrying out blending, feeding, smelting and spray deposition according to the weight percentage, so as to obtain an ingot blank; and b, subjecting the ingot blank obtained in the step a to homogenizing heat treatment, hot machining technology, cold working technology as well as annealing, solid solution and aging heat treatment, so as to obtain the easy-turning Be-Cu alloy. Compared with that of a traditional high-Be Be-Cu alloy, the high-temperature softening temperature point of the the easy-for-turning Be-Cu alloy is improved by 75 DEG C + / - 10 DEG C; compared with that of a traditional low-Be Be-Cu alloy, the high-temperature softening temperature point of the the easy-for-turning Be-Cu alloy is improved by 90 DEG C + / - 10 DEG C; compared with that of a traditional Be-Cu alloy, the stress relaxation resistance of the easy-for-turning Be-Cu alloy is improved by 30%; and the Be-Cu material application working condition range is enlarged.

Owner:KINKOU SUZHOU COPPER IND CO LTD

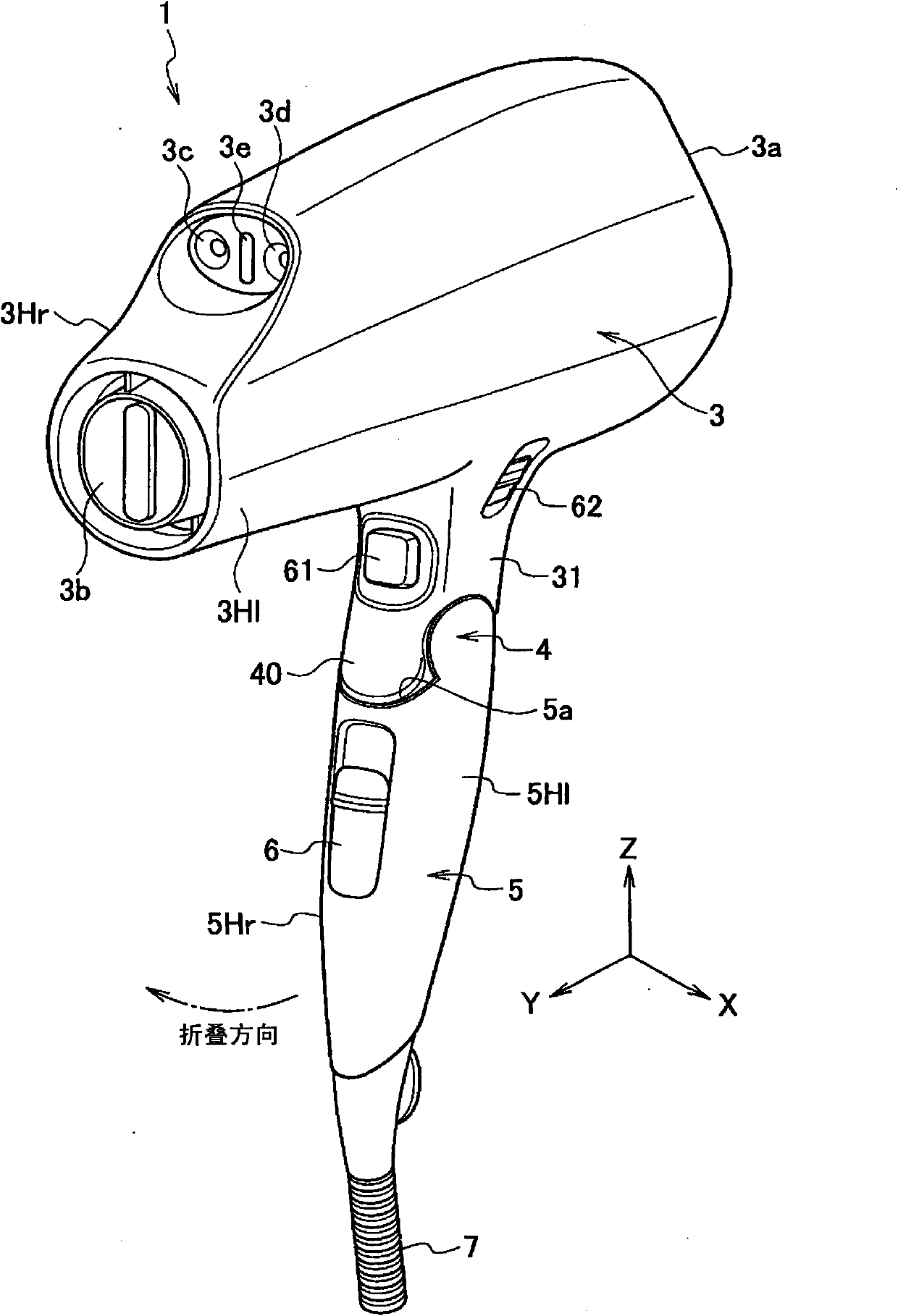

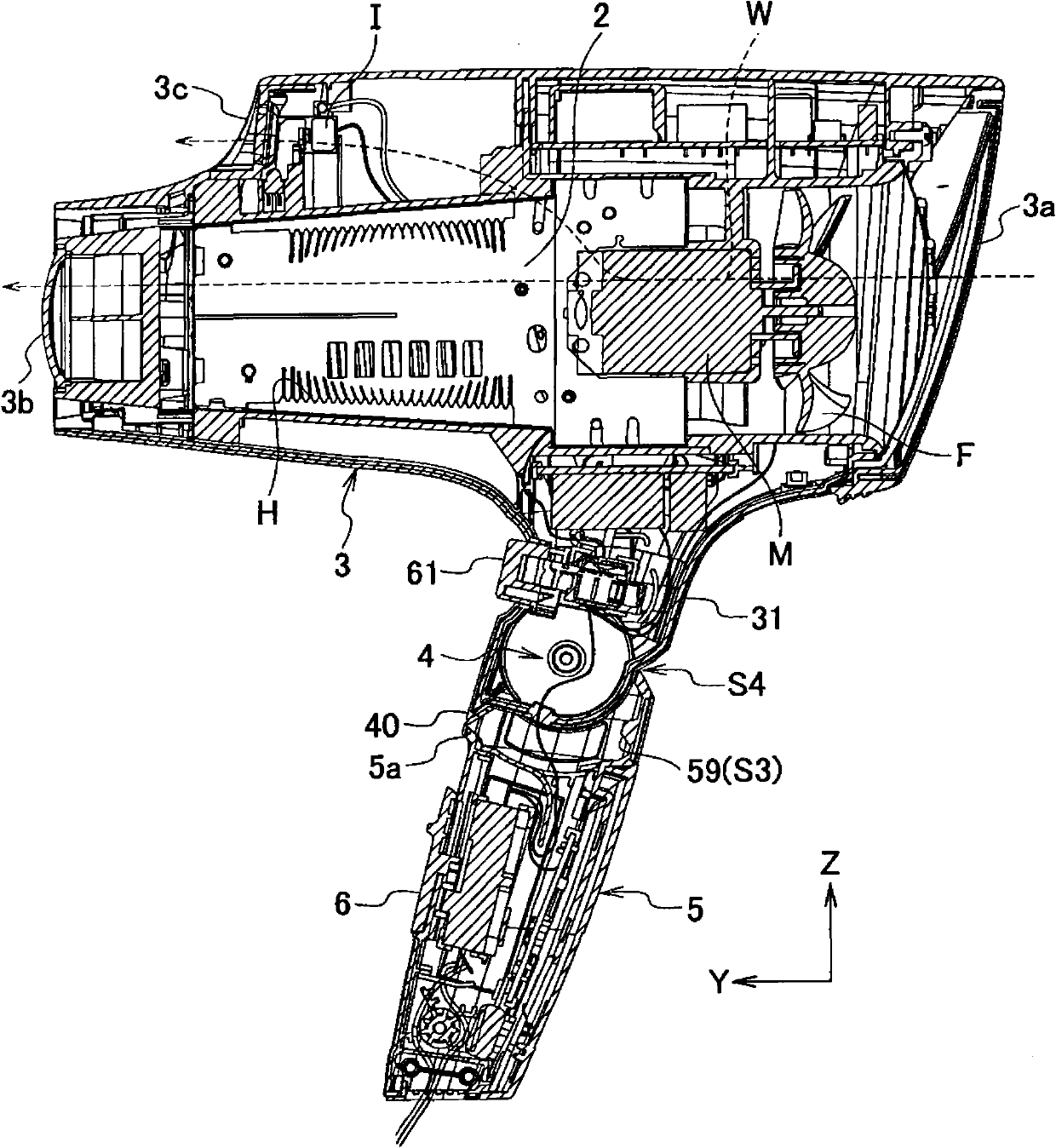

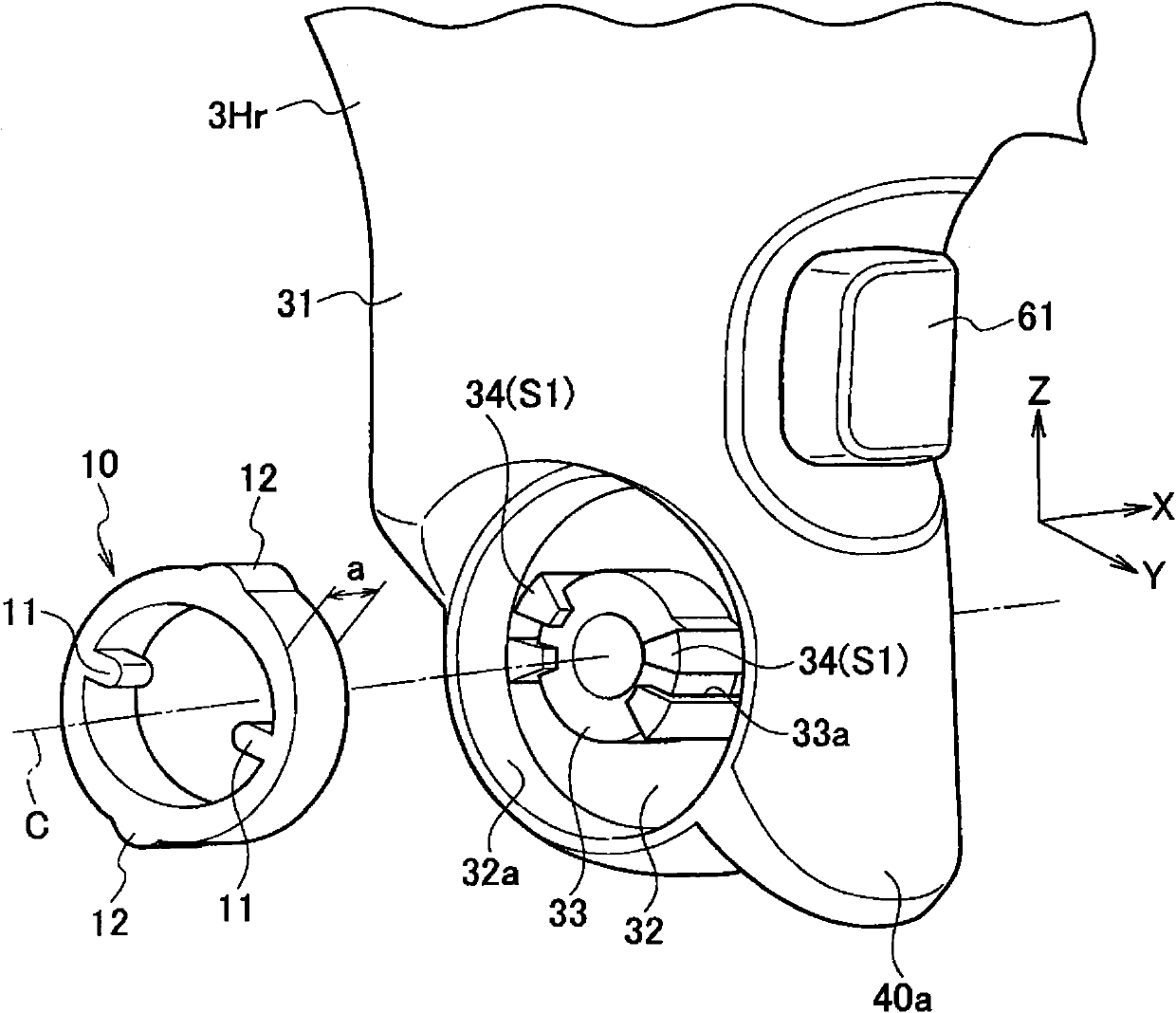

Hair care Device

InactiveCN102028348AIncrease repulsionInhibition of plastic deformationHair dryingEngineeringMechanical engineering

The invention provides a hair care device capable of inhibiting plastic deformation with regard to repetitive bending and deformation of a rotary ring without changing materials of a rotary ring. The hair care device is provided with a control mechanism (4) limiting rotation of a grab handle housing (5Hr) relative to a main body housing (3Hr) respectively at a use position and a folding position. The control structure is provided with a first fastening body (10) and a second fastening body (20), the first fastening body is disposed on a part (main body housing), and is provided with a first protruding part (12) protruding in a direction proportional to a rotary central shaft, the second fastening body can be relatively rotatably disposed on an other part (grab handle housing) relative to the first fastening body, and is provided with a second protruding part (22) freely performing crossover with the first protruding part with crimping of the first protruding part; radial wall thickness (tl) of the first protruding part (10K) disposed on the first fastening body is formed to be higher than radial wall thickness (t2) of other parts (10N).

Owner:PANASONIC CORP

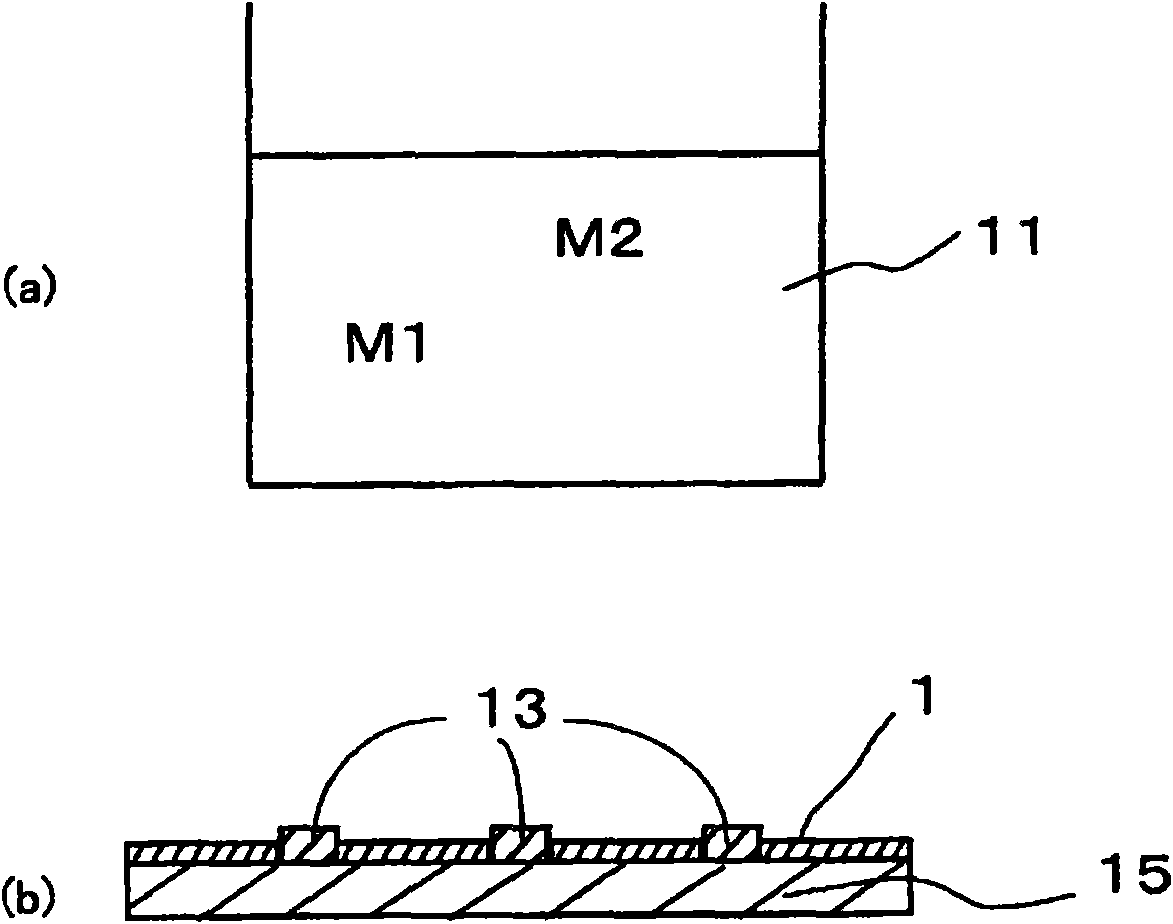

Metal films, methods for production thereof, methods for production of laminated electronic components, and laminated electronic components

InactiveCN101688321AHigh melting pointInhibition of contractionFixed capacitor electrodesFixed capacitor dielectricElectrical conductorElectronic component

A metal film containing Ni as a main component and Mn and at least one element selected from the group consisting of the elements of Groups 3A, to 6A of the periodic table includes a central part anda peripheral part in which Mn and the element selected from the group consisting of the elements of Groups 3A to 6A of the periodic table are present in a concentration higher in the peripheral part than that in the central part. The metal film used as a conductor layer can have an increased melting point at the peripheral part and thus can be prevented from shrinking during heating. The metal film used as a conductor layer in electronic components and the like can be prevented from plastically deforming or shrinking during heating so that the conductor layer can have a large effective area and high adhesion to ceramic layers.

Owner:KYOCERA CORP

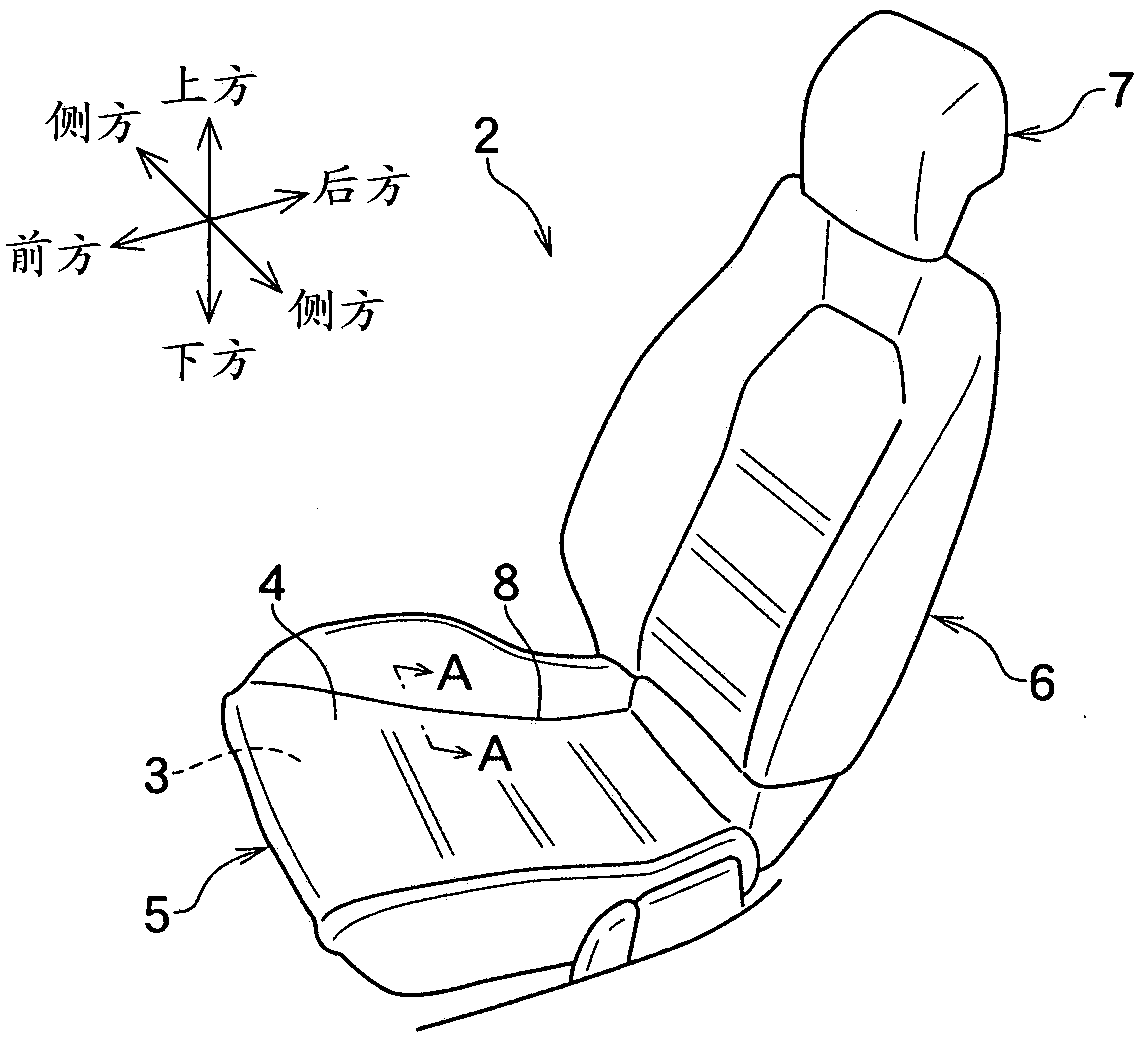

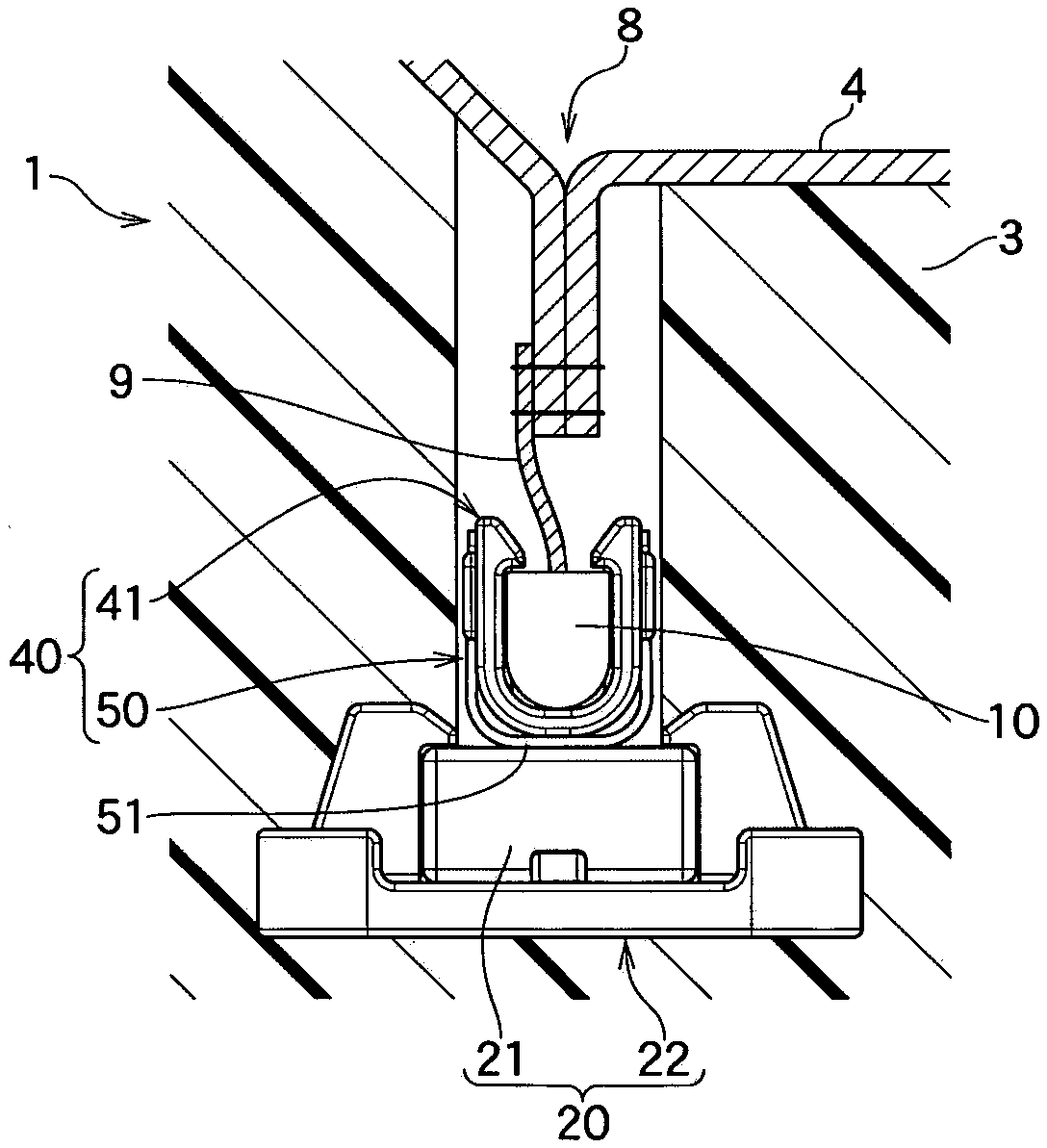

Seat-cover fitting structure

ActiveCN109955752APrevent accidental fall offInhibit sheddingSeat coveringsSeating furnitureCotton clothEngineering

Provided is a seat-cover fitting structure capable of preventing a seat cover from accidentally separating from a seat main body. In a seat-cover fitting structure 1, a resin clip 41 that is fitted toan end member 10 attached to the lower end of a hanging cotton-cloth member of a seat cover and a metal clip 50 that is fitted to the exterior of the resin clip 41 engage each other with gaps X1, X2,and X3 formed therebetween. In a state where the metal clip 50 is stuck to, by magnetic force, a main-body-side member that is embedded in the seat main body, the resin clip 41 moves with respect tothe metal clip 50 within the ranges of the gaps X1, X2, and X3.

Owner:NIFCO INC +1

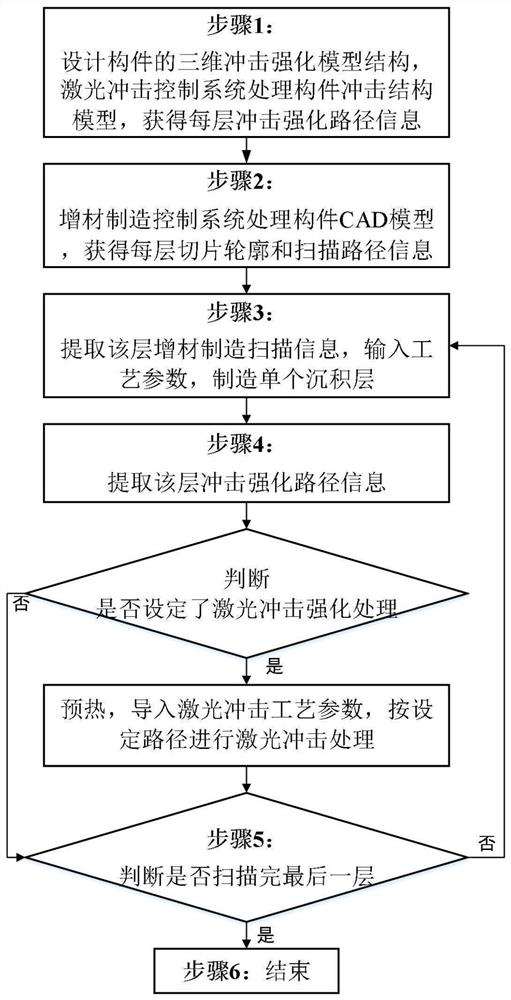

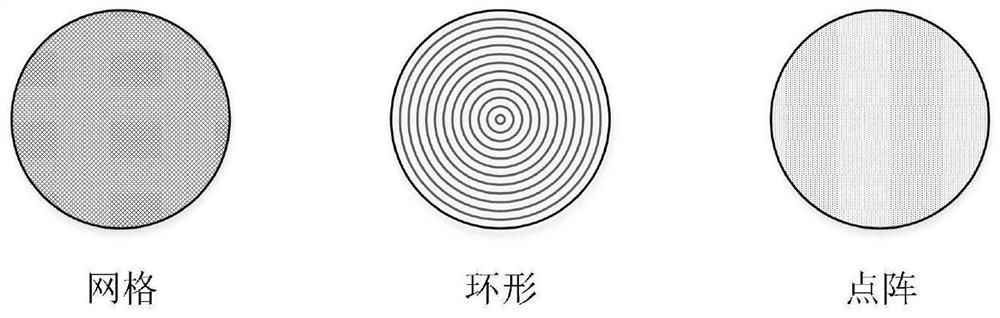

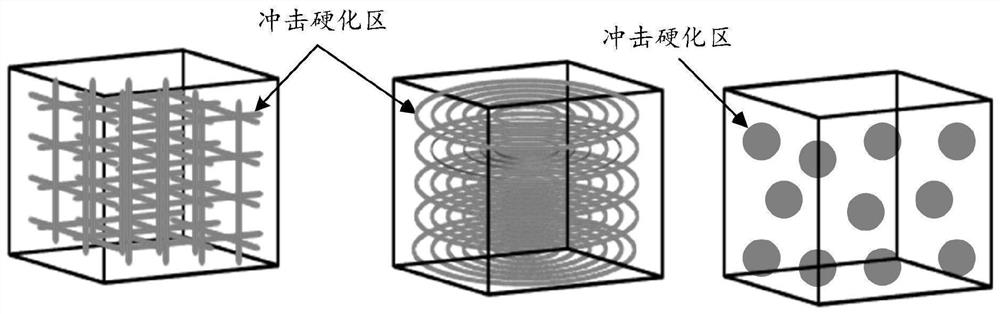

Laser Selective Shock-Additive Composite Manufacturing Method for Three-dimensionally Reinforced Shape Memory Alloys

ActiveCN113414408BIncrease the hardness valueRealize three-dimensional composite enhancementAdditive manufacturing apparatusIncreasing energy efficiencyGraphicsControl system

The invention discloses a laser selective area impact-additive composite manufacturing method for a three-dimensionally reinforced shape memory alloy, which comprises the following steps: designing a three-dimensional laser shock-strengthened structural model of a component, generating impact-strengthened path information for each layer; the additive manufacturing control system based on The alloy component model and process parameters are used to manufacture a single deposition layer; the laser shock strengthening control system extracts the impact strengthening path information of this layer, applies preheating to the deposited component as required, and performs laser shock treatment; and so on until the entire component forming and manufacture. By controlling the graphic structure and process parameters of the laser shock, the invention can accurately control the deformation state of austenite and martensite in the three-dimensional direction and the forward and reverse phase transformation of martensite in the shape memory alloy in situ, and realize the solid phase transformation of the alloy. , high-efficiency, high-quality integrated control and optimization of superelasticity and shape memory effects, providing new manufacturing methods and means for complex structures and high-performance shape memory alloys.

Owner:WUHAN UNIV

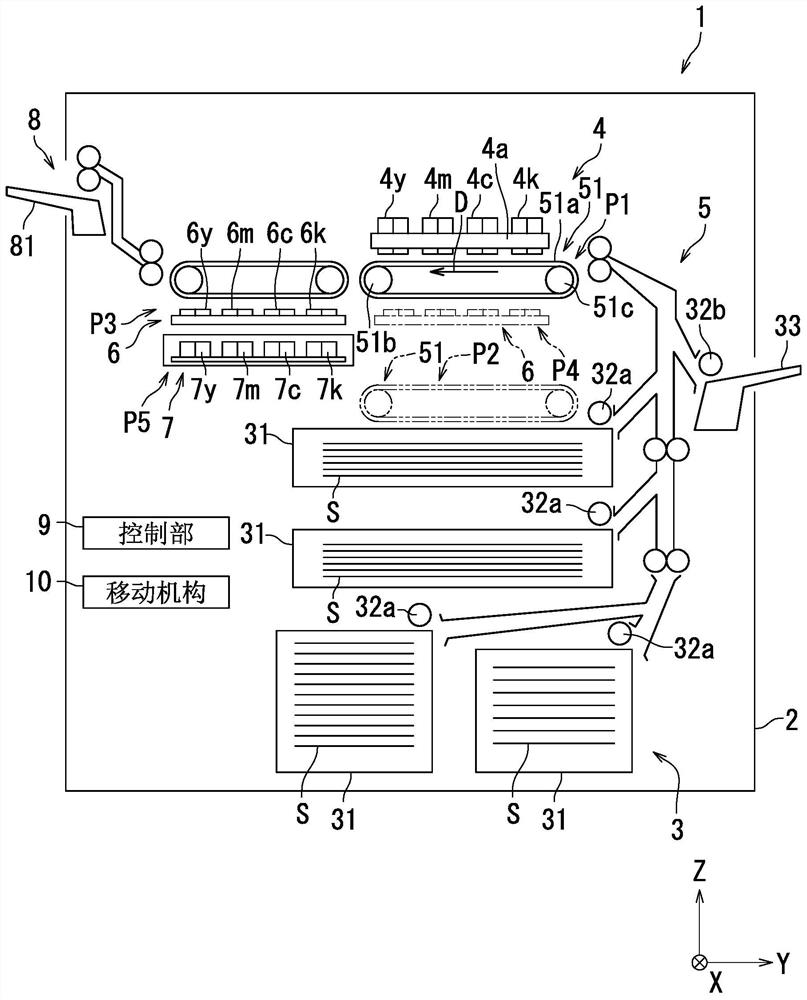

Fixing member and image forming device

Owner:KYOCERA DOCUMENT SOLUTIONS INC

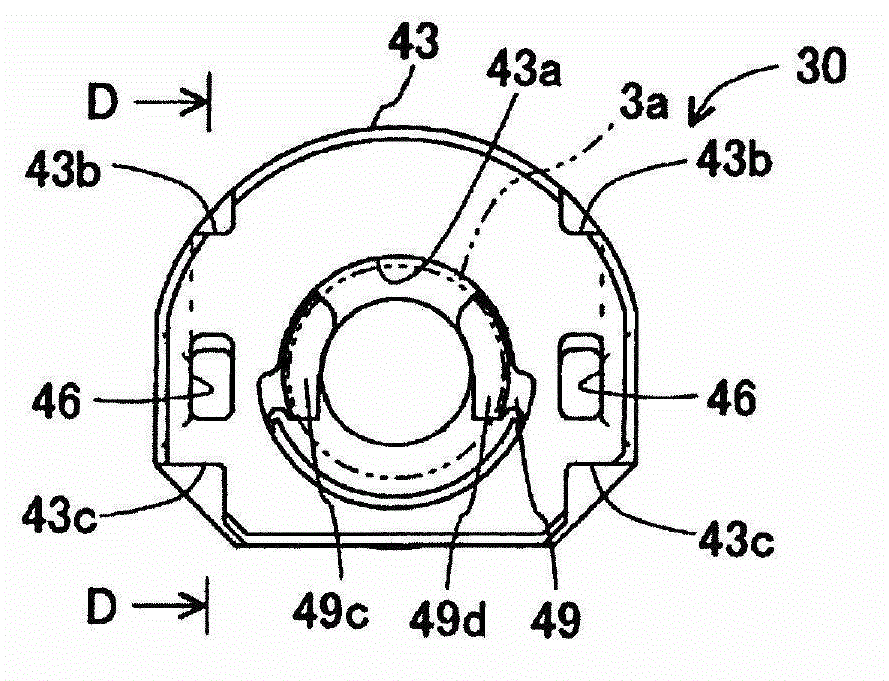

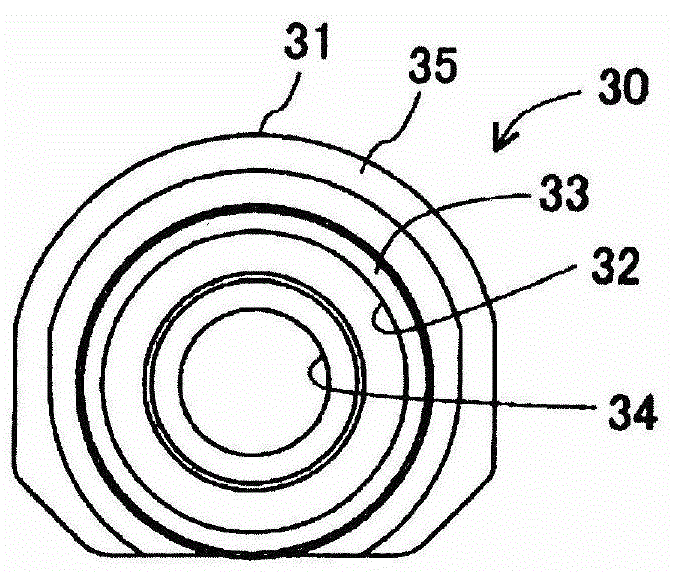

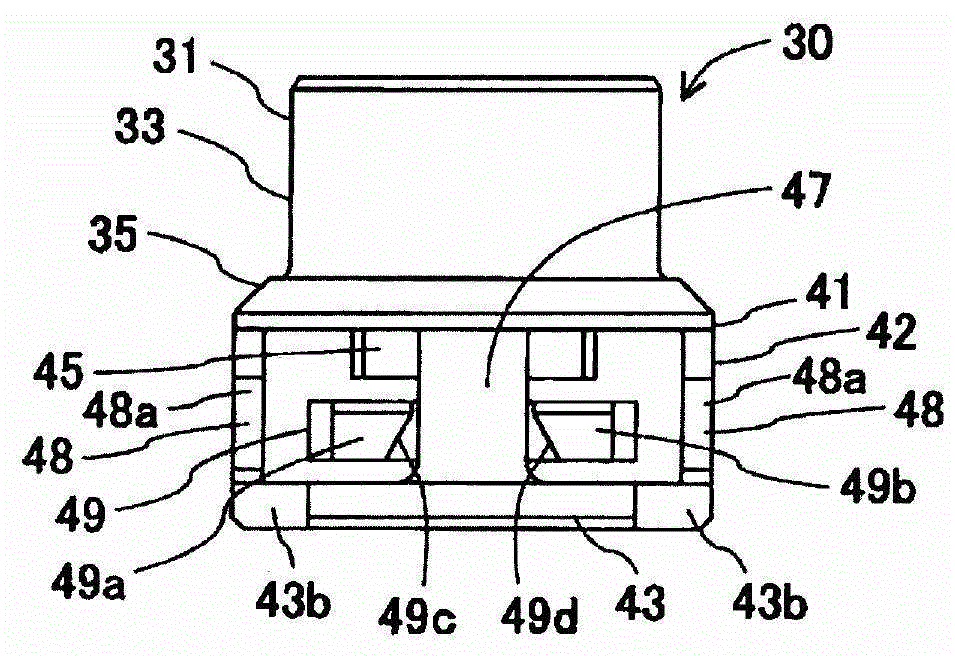

Quick connector

ActiveCN102918316BWell formedInhibition of plastic deformationPipe couplingsCouplingsEngineeringMechanical engineering

To provide a quick connector capable of surely confirming that a pipe body is engaged by a retainer when an elastically-deformable claw of the retainer and an elastically-deformable claw of a checker are adjacently arranged in an axial direction. Checker-axis direction elastically-deformable claws 52 and 52 have distal-end sides formed flexibly deformable in the axial direction, maintain a state of being engaged by a second engagement portion 46 of a retainer body 42 by having deflective deformation regulated by a retainer diameter-expanding elastically-deformable claw 49 in a state in which the retainer diameter-expanding elastically-deformable claw 49 is expanded diametrically, and regulate sliding from a first position with respect to the retainer body 42 toward a set radial direction by being engaged by the second engagement portion 46 of the retainer body 42. The checker-axis direction elastically-deformable claws 52 and 52 become releasable from engagement with the second engagement portion 46 of the retainer body 42 in a state in which the retainer diameter-expanding elastically-deformable claw 49 has restored its original shape, and thereby become slidable with respect to the retainer body 42 from the first position toward the second position in the set radial direction.

Owner:SUMITOMO RIKO CO LTD

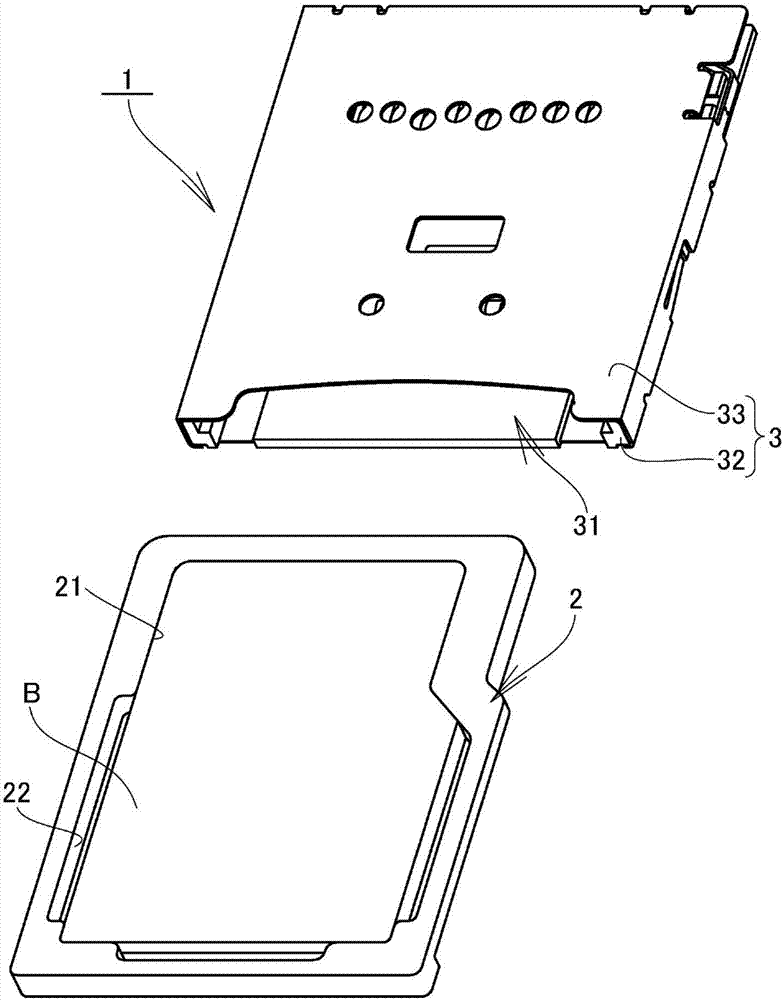

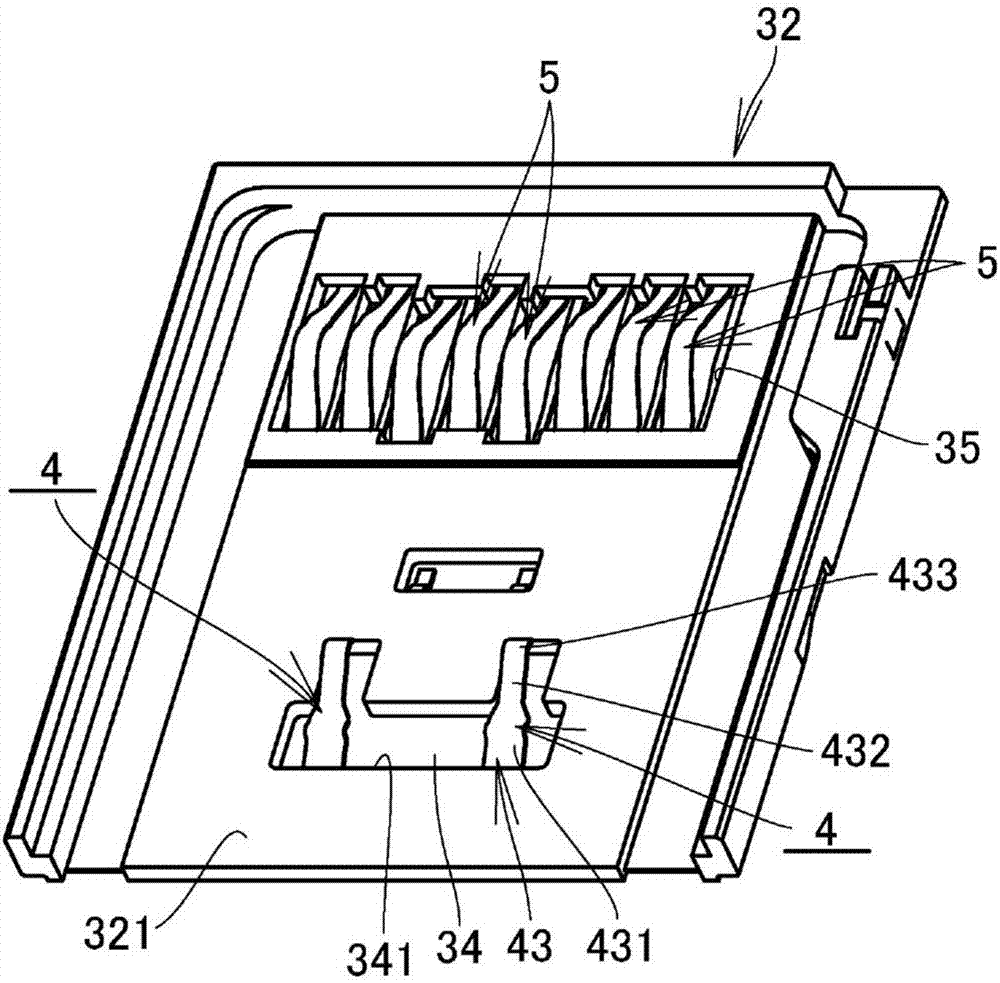

Card connector

InactiveCN106877021AConstant deflectionInhibition of plastic deformationElectrically conductive connectionsEngineering

The present invention provides a card connector capable of maintaining a stable contact state in accordance with a card having a different thickness and capable of suppressing excessive deflection of the elastic contact piece. The elastic contact piece (43) is provided with a resilient base portion (431) having one end supported on the housing (3), a main elastic piece portion (432) swingably supported on the elastic base portion (431), and a resilient contact piece (433), and the elastic base portion (431) is provided with a base portion (311) disposed at a distance from the support end (431a) supported by the housing (43) ) The abutment portion (6) is detected by the inner non-object card, and the spring constant is large and difficult to flex with the main elastic piece portion (432).

Owner:SMK CO LTD

A kind of substrate surface ultrasonic rolling textured alcrn coating and its preparation process

ActiveCN111235520BDimensional parameters are controllableControllable shapeVacuum evaporation coatingSputtering coatingUltimate tensile strengthBonding strength

The invention discloses an ultrasonic rolling textured AlCrN coating on a matrix surface and a preparation process. The preparation process includes the steps that ultrasonic rolling texturing is first carried out on the matrix metal surface, and then the AlCrN coating is prepared on the textured matrix metal surface. The ultrasonic rolling texturing process includes the steps that during continuous ultrasonic rolling, matrix metal is moved by a set distance in the -X direction, moved by a set distance in the +Y direction and then moved by a set distance in the +X direction to form an S-shapedfeeding path, the single S-shaped feeding path is repeated by at least one time, and thus the surface of the matrix metal is textured. The bonding strength of coating-substrate of the matrix metal can be enhanced remarkably, and the tribology performance of the matrix metal is improved significantly.

Owner:SHANDONG UNIV

Tool holder for grooving cutting blade

ActiveCN102601403BAvoid deformationReduced positioning contact areaTurning toolsTool holdersEngineeringFastener

The invention discloses a tool holder for grooving a cutting blade. The tool holder comprises a tool holder body and a fastener, a clamping portion of the tool holder body consists of an upper clamping portion and a lower supporting portion, an upper positioning surface of the upper clamping portion and a lower positioning surface of the lower supporting portion enclose a blade clamping groove, a rear supporting surface and an elastic extending section are arranged at the rear end of the blade clamping groove, the elastic extending section extends backwards to the neck of the tool holder body, the fastener penetrates through the upper portion and the lower portion of the elastic extending section, M discontinuous upper positioning tables are arranged on the upper positioning surface, and N discontinuous lower positioning tables are arranged on the lower positioning surface, wherein 2<=M<=6, and 2<=N<=6. The tool holder for grooving the cutting blade has the advantages that positioning positions and angles can be automatically adjusted, plastic deformation of the tool body can be effectively suppressed, and the tool holder is stable in structure and long in service life.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Semiconductor device, adhesive and adhesive film

InactiveCN1288731CInhibition of plastic deformationInhibition of mobilityFilm/foil adhesivesSemiconductor/solid-state device detailsDynamic viscoelasticityAdhesive

The present invention aims at an improvement in temperature-cycle resistance after packaging in semiconductor devices and also an improvement in moisture-absorbed reflow resistance, and provides an adhesive having a storage elastic modulus at 25°C of from 10 to 2,000 MPa and a storage elastic modulus at 260°C of from 3 to 50 MPa as measured with a dynamic viscoelastic spectrometer, and also a double-sided adhesive film, a semiconductor device and a semiconductor chip mounting substrate which make use of the adhesive, and their production process.

Owner:HITACHI CHEM CO LTD

Accumulator

ActiveCN104583606BReduce length dimensionReduce in quantityFluid-pressure actuator safetyAccumulator installationsElastomerEngineering

Provided is an accumulator, which: is capable of reducing the pressure difference that is generated by differences in coefficients of thermal expansion when liquid trapped in the liquid chamber and a sealed gas undergo thermal expansion during zero-down, thereby limiting the occurrence of plastic deformation in the bellows; and has a structure in which the parts are small and few in number. To achieve said purpose, the accumulator has a sealing member held on the port hole-side of the bellows cap via a seal holder. When operation of the machine is stopped and the pressure inside the pressure piping decreases, the sealing member contacts the sealing section and closes the liquid chamber. If liquid trapped in the liquid chamber when the liquid chamber is closed undergoes thermal expansion, the bellows cap moves in the direction away from the sealing section while the sealing member is still in contact with the sealing section. Since the sealing member is a rigid plate, the outer circumferential surface of which is covered by a flexible section obtained from a rubber-like elastic body, the flexible section allows relative movement of the bellows cap by undergoing shear deformation as a result of engagement with the seal holder.

Owner:EAGLE INDS

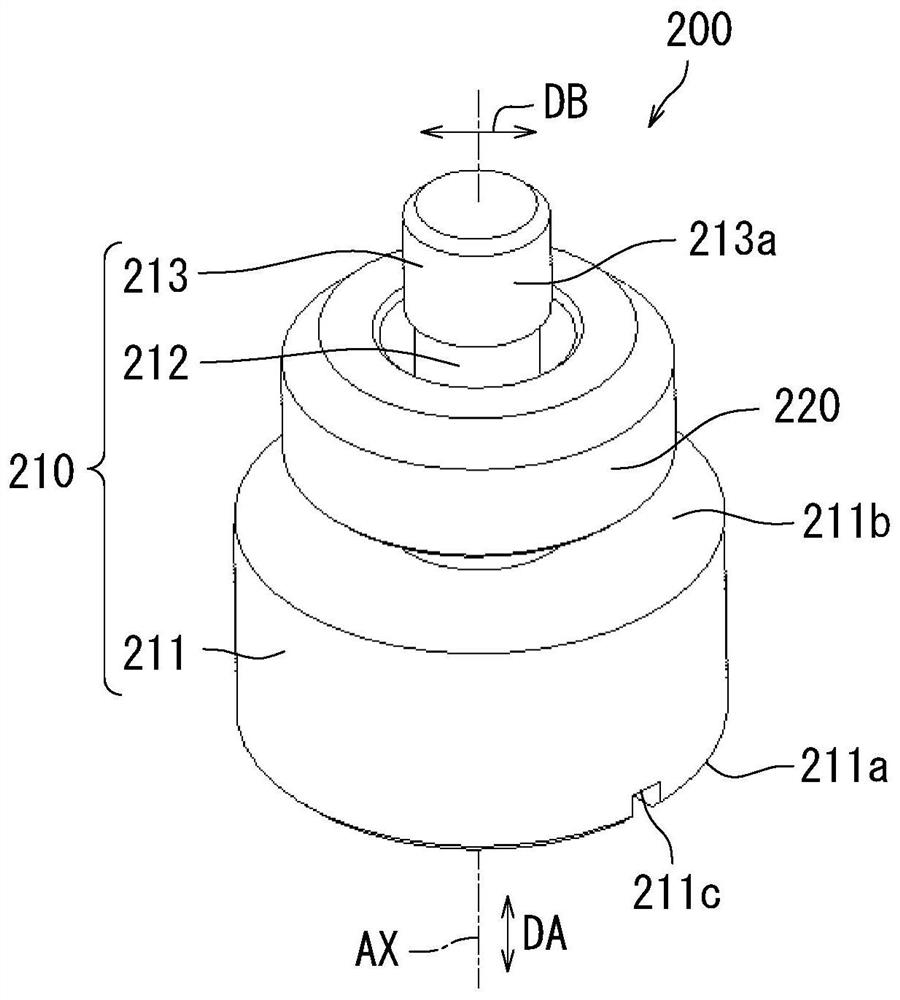

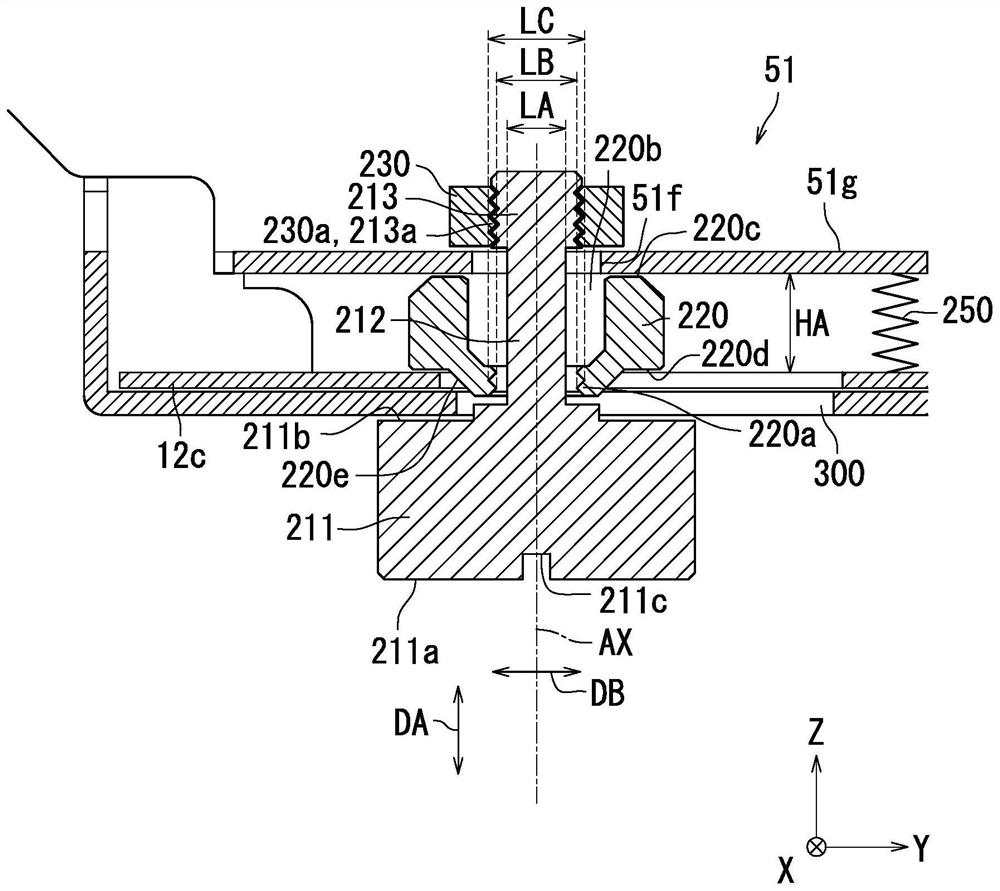

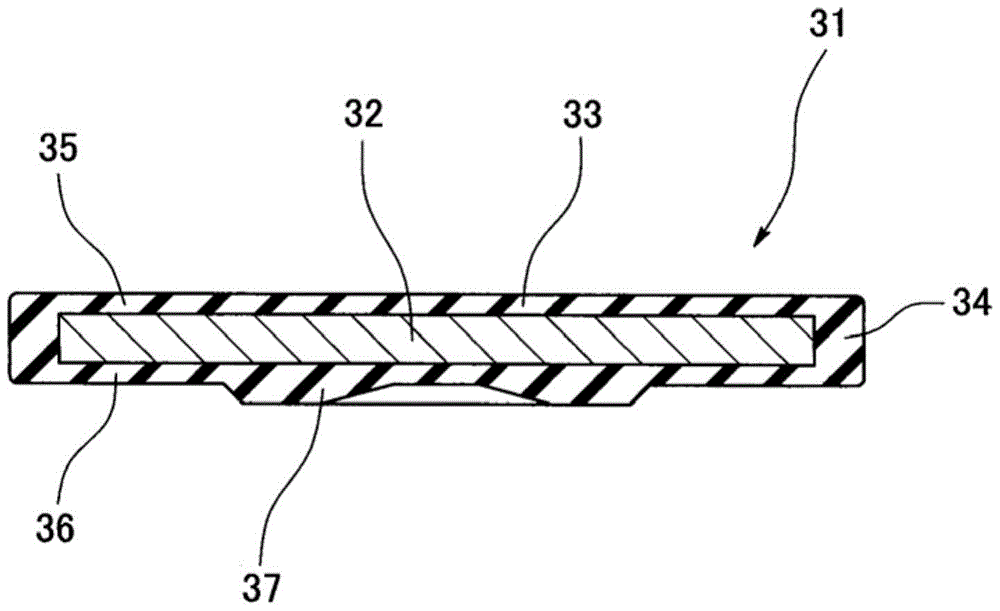

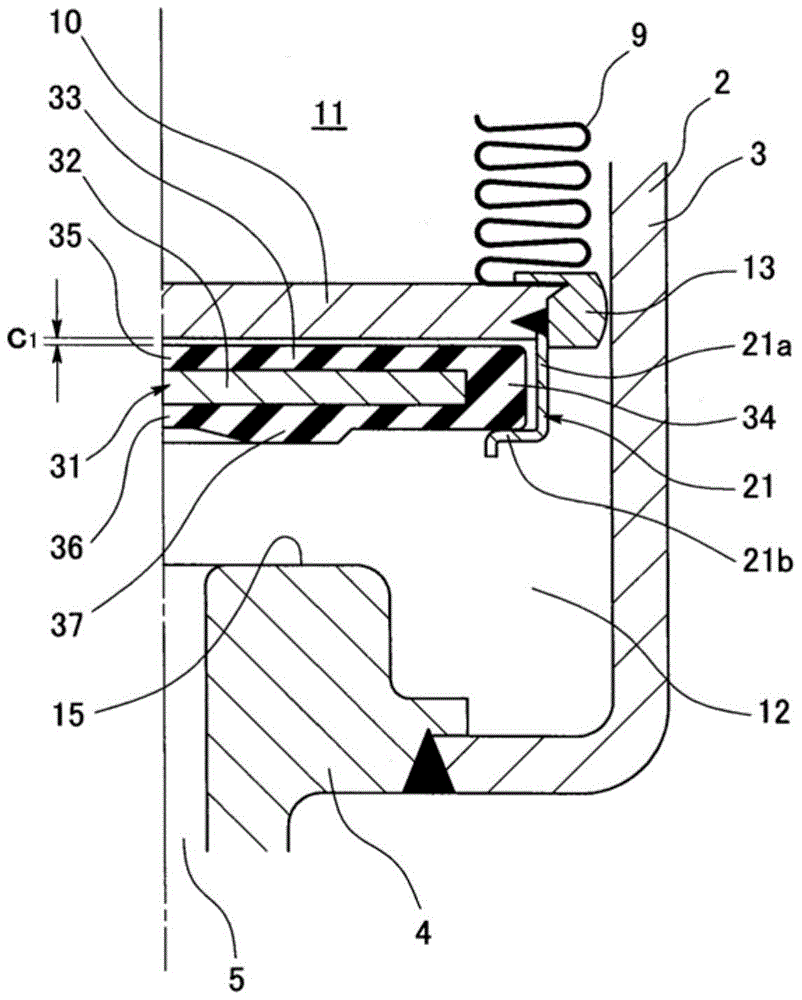

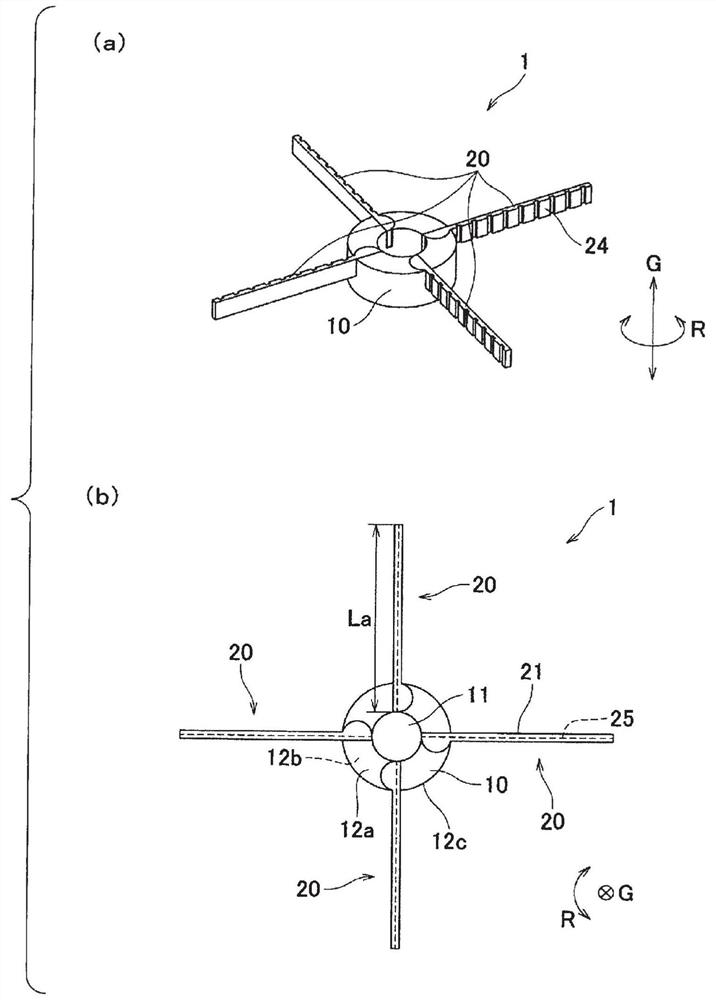

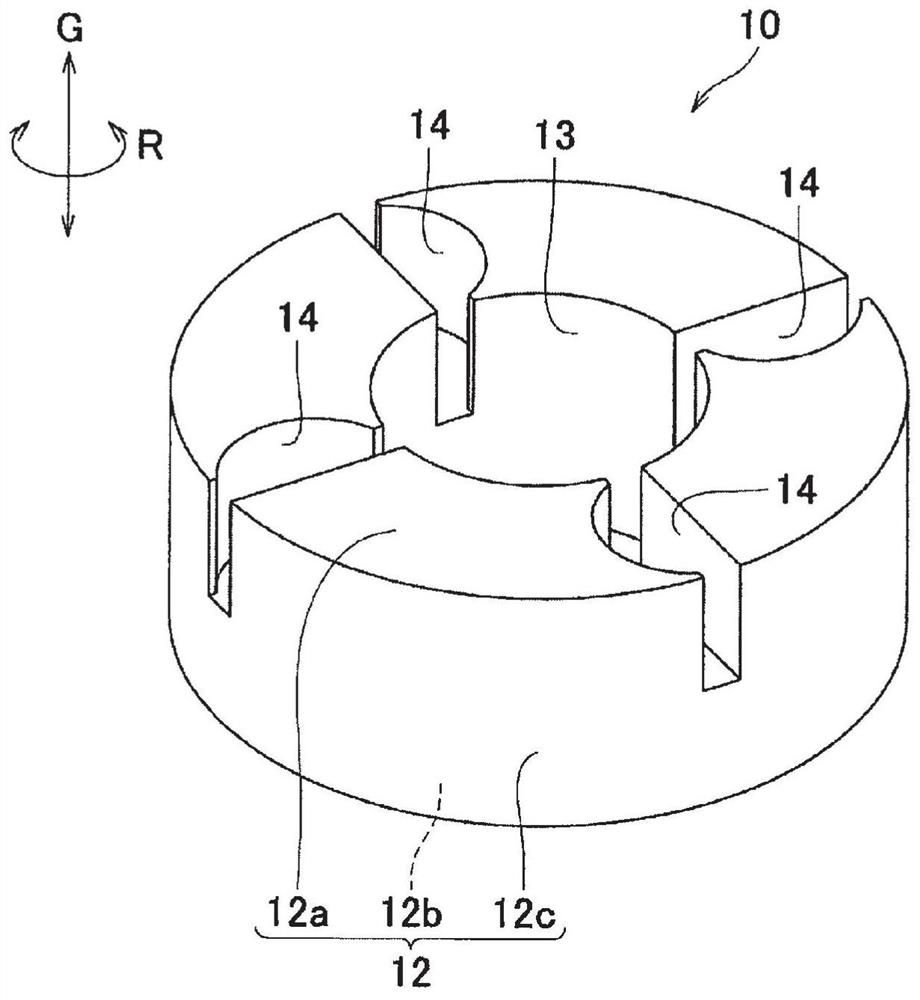

Blade member of impeller for paper conveying

ActiveCN110023216BIncreased durabilityEnhance resilienceCoin countersCoin/currency accepting devicesPolyesterFiber

The present invention relates to a blade member of an impeller for sheet conveyance, at least one of which is disposed so as to protrude from an outer peripheral surface of a rotatable cylindrical member, the blade member having a blade member main body made of a thermosetting polyurethane elastomer, and A plurality of core wires made of polyester fibers are arranged in parallel in the axial direction of the rotating shaft of the cylindrical member, and at least a part of the core wires is embedded in the blade member main body.

Owner:MITSUBOSHI BELTING LTD

Ta and Co co-doped corrosion-resistant Fe-Mn-Si-Cr-Ni serial shape memory alloy

InactiveCN110541127AImprove corrosion resistanceIncrease the stacking fault densityShape-memory alloyAustenite

The invention provides a Ta and Co co-doped corrosion-resistant Fe-Mn-Si-Cr-Ni serial memory alloy, and relates to the field of functional materials. The Ta and Co co-doped corrosion-resistant Fe-Mn-Si-Cr-Ni serial memory memorizing alloy comprises the following elements in weight percentage: 11 to 18% of Mn, 3-8% of Si, 5-13% of Cr, 3-10% of Ni, 1-11.0%of Co, 0.1-2.0% of Ta, 0.01-0.5% of C, and the balance Fe. According to the Ta and Co co-doped corrosion-resistant Fe-Mn-Si-Cr-Ni serial memory memorizing alloy, Ta and Co elements are added into the alloy, and TaC and other precipitated phasesare precipitated after aging treatment, so that an austenite matrix is strengthened, and the shape memory effect is improved; and the corrosion resistance is effectively improved by adding Co.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Semiconductor device, adhesive, and double-sided adhesive film

InactiveCN1837317BInhibition of plastic deformationInhibition of mobilityFilm/foil adhesivesSemiconductor/solid-state device detailsDynamic viscoelasticityAdhesive

The invention aims at improving the temperature resisting cycle characteristics after mounting and moisture absorption resiting reflow characteristics of a chip-mounted semiconductor, and provides anadhesive which functions as a bonding member to be used when a semiconductor chip is mounted on an organic supporting substrate and which has storage moduli at 25 DEG C and at 260 DEG C as measured with a dynamic visco-elasticity measuring instrument of 10-2000 MPa and 3-50 MPa, respectively, a double-coated adhesive film produced therewith, a semiconductor device, an semiconductor chip mounting substrate, and methods of manufacturing these products.

Owner:RESONAC CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com