Semiconductor device, adhesive, and adhesive film

An adhesive, semiconductor technology, applied in the direction of adhesive types, semiconductor devices, film/sheet adhesives, etc., can solve the problem of unusable, cracked, large thermal expansion coefficient difference between semiconductor chips and printed wiring boards And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

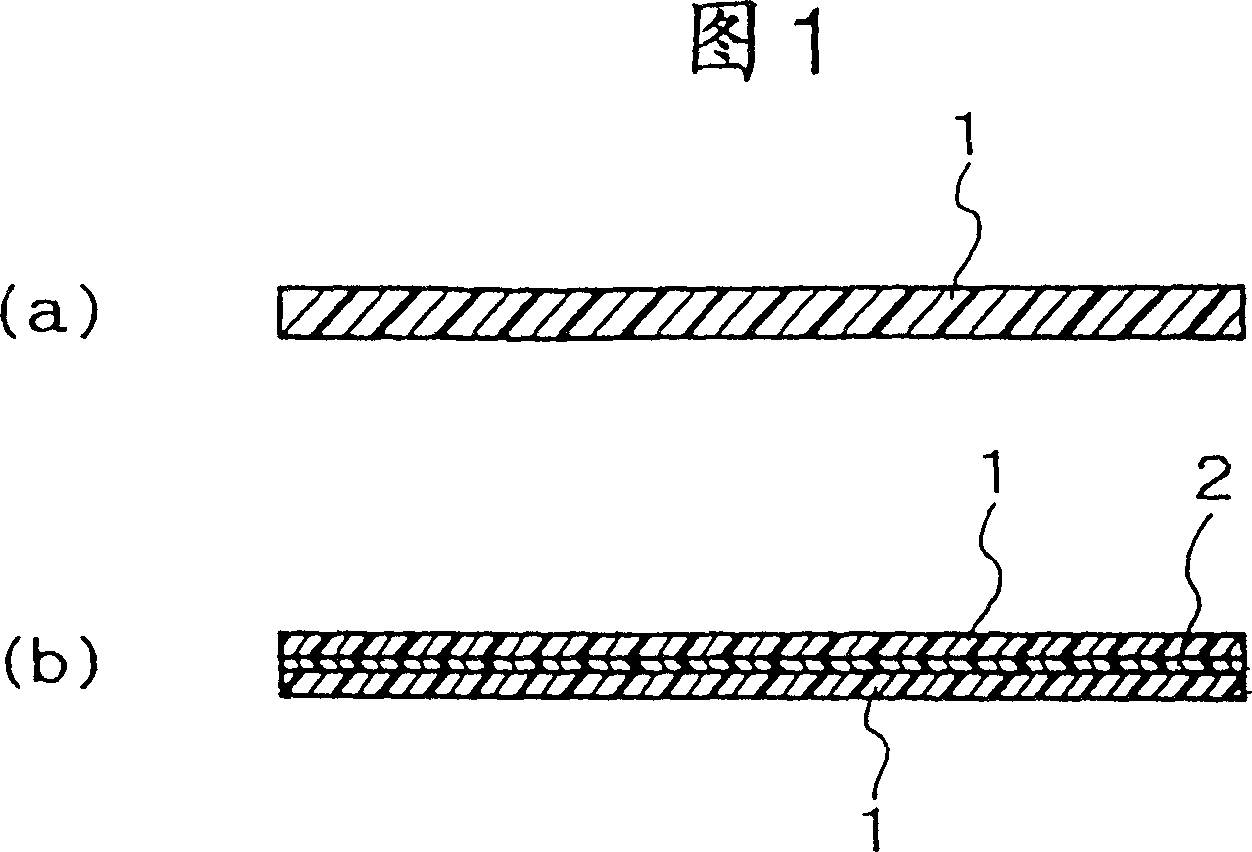

[0144] FIG. 1(a) is a cross-sectional view of a single-layer thermosetting adhesive film, which is composed of a thermosetting adhesive 1. As shown in FIG. The elastic modulus of the cured product measured with a dynamic viscoelasticity measuring device at 25°C is specified as 10-2000MPa, and the elastic modulus at 260°C is specified as 3-50MPa, which is in the range of exothermic heat. A semi-cured state at the level of 10 to 40% of the total curing calorific value when measured by DSC (differential calorimeter). An epoxy group-containing acrylic copolymer film in which the amount of solvent remaining in the thermosetting adhesive film is dried to 2% or less is used.

[0145] FIG. 1(b) shows a cross-sectional view of a three-layer adhesive film in which a thermosetting adhesive 1 is applied to both sides of a polyimide film 2. As shown in FIG. In this example, as the polyimide film, Ube Industries, Ltd. UPILEX (trade name) with a thickness of 50 micrometers was used.

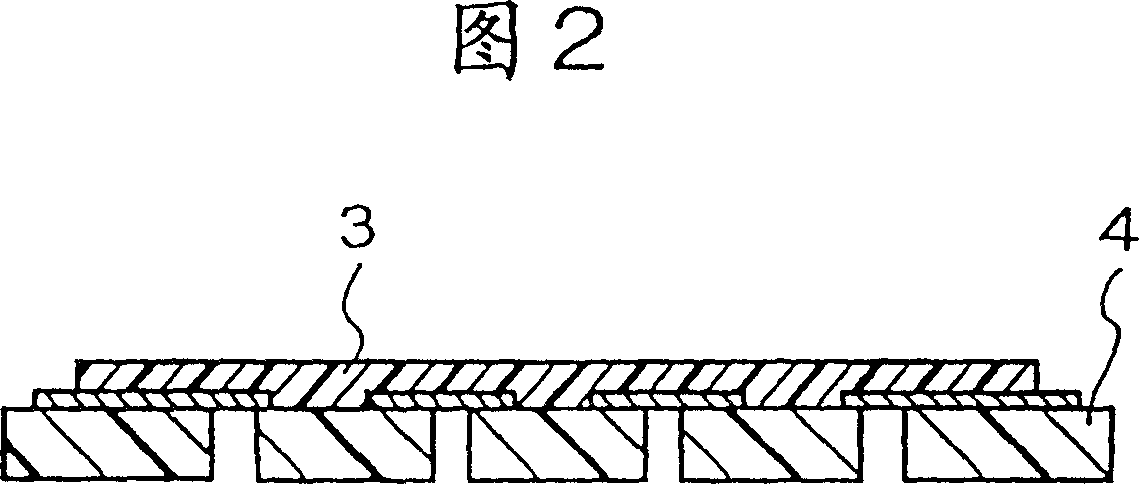

[014...

Embodiment 2

[0157] FIG. 7 shows a manufacturing process of a semiconductor mounting substrate and a semiconductor device.

[0158] The thermosetting adhesive tape (adhesive member) 3 made of the thermosetting adhesive 1 is cut into a predetermined size by a die cutter (FIG. 7(a)). The cured product of thermosetting adhesive 1 has an elastic modulus of 10-2000 MPa at 25°C measured with a dynamic viscoelasticity measuring device, and an elastic modulus of 3-50 MPa at 260°C. The semi-cured state is about 10 to 40% of the total curing heat generation.

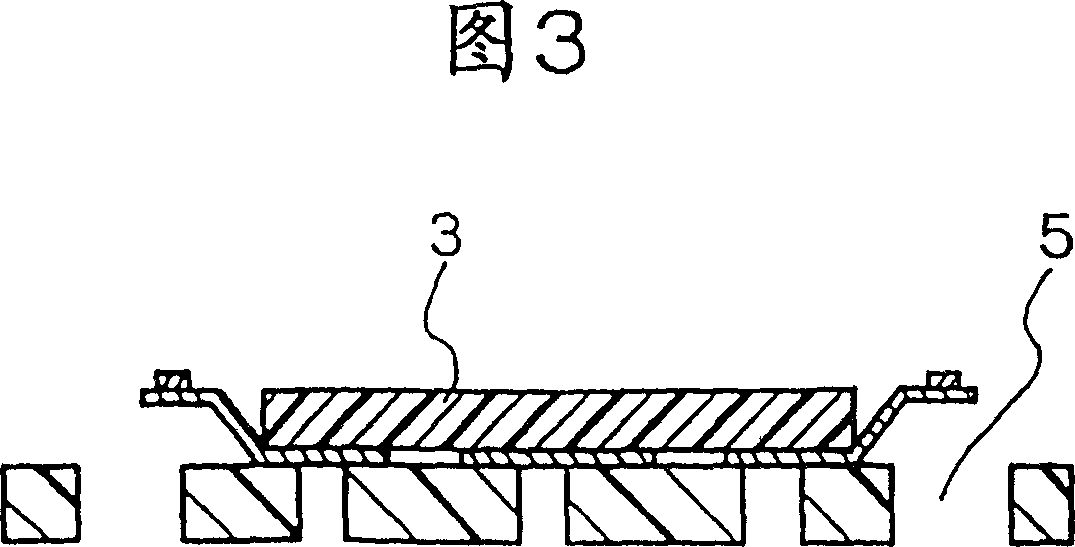

[0159] On the surface of the polyimide film substrate 5 on which one layer of Cu wiring is applied and the same inner lead portion and through-holes for external solder terminals as the TAB tape are formed, the cut thermosetting adhesive tape 3 is precisely aligned. , and hot-pressed with a hot press to obtain a semiconductor mounting substrate ( FIG. 7( b )).

[0160] In this example, a set of frame substrates for semiconductor mounting was...

Embodiment 3

[0180] As epoxy resin, use 45 parts by weight of bisphenol A type epoxy resin (epoxy equivalent 200, EPIKOTE 828 produced by YukaShell Epoxy Co., Ltd.); cresol novolak type epoxy resin (epoxy equivalent 220, Sumitomo Chemical Industry Co., Ltd. produces ESCN001) 15 weight parts; As epoxy curing agent, use 40 weight parts of novolac type epoxy resin (PLYOPHENLF2882 produced by Dainippon Ink Chemical Industry Co., Ltd.); Solubility and the high molecular weight resin of weight-average molecular weight more than 30,000, use 15 parts by weight of phenoxy resin (molecular weight 50,000, PHENOTOHTO YP-50 produced by Dongdu Chemical Co., Ltd.); as epoxy-containing acrylic rubber, use Epoxy acrylic rubber (molecular weight 1,000,000, the HTR-860-P3 that Imperial Chemical Industry Co., Ltd. produces) 150 weight parts; As curing accelerator, use curing accelerator 1-cyanoethyl-2-phenylimidazole (CUREZOLE 2PZ -CN) 0.5 parts by weight; as a silane coupling agent, use 0.7 parts by weight o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com