Semiconductor device, adhesive, and double-sided adhesive film

一种粘合剂、粘合膜的技术,应用在粘合剂类型、半导体器件、薄膜/薄片状的粘合剂等方向,能够解决耐湿性试验劣化大、产生裂缝、不能使用等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

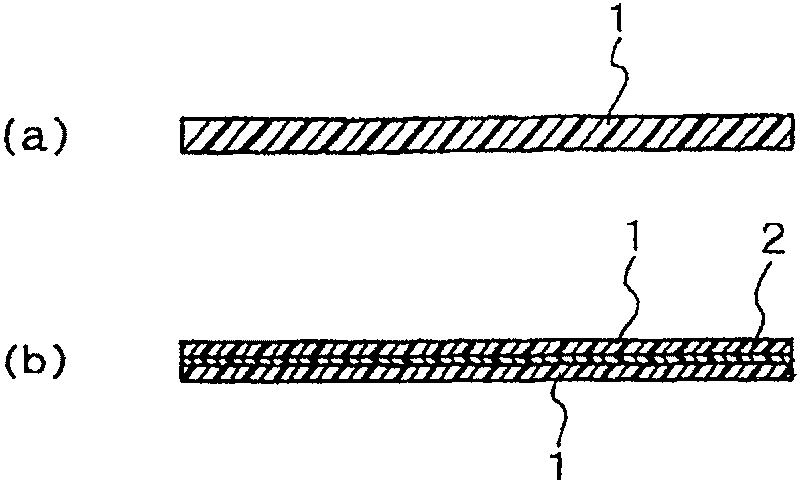

[0144] figure 1 (a) is a cross-sectional view of a single-layer thermosetting adhesive film, which is composed of a thermosetting adhesive 1 and its cured product is determined by a dynamic viscoelasticity measuring device at 25° C. The elastic modulus 10 is defined as the range of 2000 MPa, and , the modulus of elasticity at 260°C is specified in the range of 3-50MPa, and the semi-cured state is 10-40% of the total curing heat when measured by DSC (differential calorimeter). Use the thermosetting adhesive film inside Epoxy-containing acrylic copolymer films with residual solvent content dried to less than 2%.

[0145] figure 1 (b) shows a cross-sectional view of a three-layer adhesive film in which a thermosetting adhesive 1 is applied to both sides of a polyimide film 2 . In this example, as the polyimide film, a 50-micron-thick ユ-ピレ produced by Ube Industries was used. ツ クス (trade name).

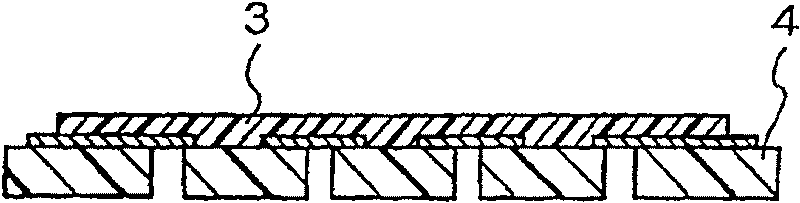

[0146] figure 2 It is a cross-sectional view of a substrate for mounting a semi...

Embodiment 2

[0157] Figure 7 The manufacturing steps of the semiconductor mounting substrate and the semiconductor device are shown.

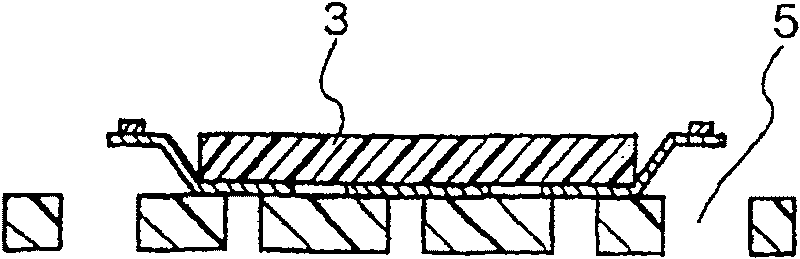

[0158] The thermosetting adhesive tape (adhesive member) 3 made of thermosetting adhesive 1 is cut into a prescribed size ( Figure 7 (a)). The cured product of thermosetting adhesive 1 has an elastic modulus of 10-2000 MPa at 25°C measured with a dynamic viscoelasticity measuring device, and an elastic modulus of 3-50 MPa at 260°C. The semi-cured state is about 10 to 40% of the total curing heat generation.

[0159] On the surface of the polyimide wax substrate 5 where one layer of Cu wiring is applied and the inner lead portion and the through hole for the external solder terminal are formed as in the TAB tape, the cut thermosetting adhesive tape 3 is precisely aligned. Afterwards, carry out hot pressing with hot press machine, obtain the substrate for semiconductor mounting ( Figure 7 (b)).

[0160] In this example, a multi-connected semiconductor...

Embodiment 3

[0189] As the epoxy resin, 45 parts by weight of bisphenol A type epoxy resin (epoxy equivalent 200, produced by Yuhua Shell Epoxy Co., Ltd.) 45 parts by weight; cresol novolak type epoxy resin (epoxy equivalent 220 , ESCN001 produced by Sumitomo Chemical Industry Co., Ltd.) 15 parts by weight; As the epoxy resin curing agent, use novolak type epoxy resin (プリイオ-フライリ-フリリ-フリオ-フ produced by Dainippon Ink Chemical Industry Co., Ltd. エ NF2882) 40 parts by weight; As a high molecular weight resin with compatibility with epoxy resin and weight average molecular weight more than 30,000, phenoxy resin (molecular weight 50,000, produced by Dongdu Chemical Co., Ltd. エ ノト-トYP-50) 15 parts by weight; As epoxy-containing acrylic rubber, use epoxy-containing acrylic rubber (molecular weight 1,000,000, the HTR-860-P3 that Imperial Chemical Industry Co., Ltd. produces) 150 parts by weight; As curing Accelerator, use curing accelerator 1-cyanoethyl-2-phenylimidazole (キ エ アゾ-ル 2PZ-CN) 0.5 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com