Ta and Co co-doped corrosion-resistant Fe-Mn-Si-Cr-Ni serial shape memory alloy

A fe-mn-si-cr-ni, memory alloy technology, applied in the field of corrosion-resistant Fe-Mn-Si-Cr-Ni series shape memory alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The Ta, Co co-doped corrosion-resistant Fe-Mn-Si-Cr-Ni series shape memory alloy of this embodiment case, the chemical composition of each element and its mass percent are: Fe-14Mn-6Si-9Cr-5Ni-6Co- 0.5 (TaC).

[0016] The alloy was aged at 700°C for 2 hours. The memory properties of alloys were measured by bending method. The sample is cut into 3mm×0.7mm×50mm sheet samples with a wire cutting machine to test the memory performance, and the shape memory effect is measured by the bending test method. The specific steps are: bend a flat sample after a certain process of heat treatment around a cylinder with a diameter of d for 180°, take out the sample after unloading, that is, the elastic partial recovery occurs, and measure the elastic recovery angle θe; then heat the sample to a certain The temperature was maintained for 5 minutes. At this time, due to the shape memory effect of the alloy, the shape of the sample obviously recovered. After cooling, the memory recovery...

Embodiment 2

[0021] The Ta, Co co-doped corrosion-resistant Fe-Mn-Si-Cr-Ni series shape memory alloy, the chemical composition and mass percentage of each element are: Fe-16Mn-5Si-9Cr-5Ni-9Co -1.0 (TaC).

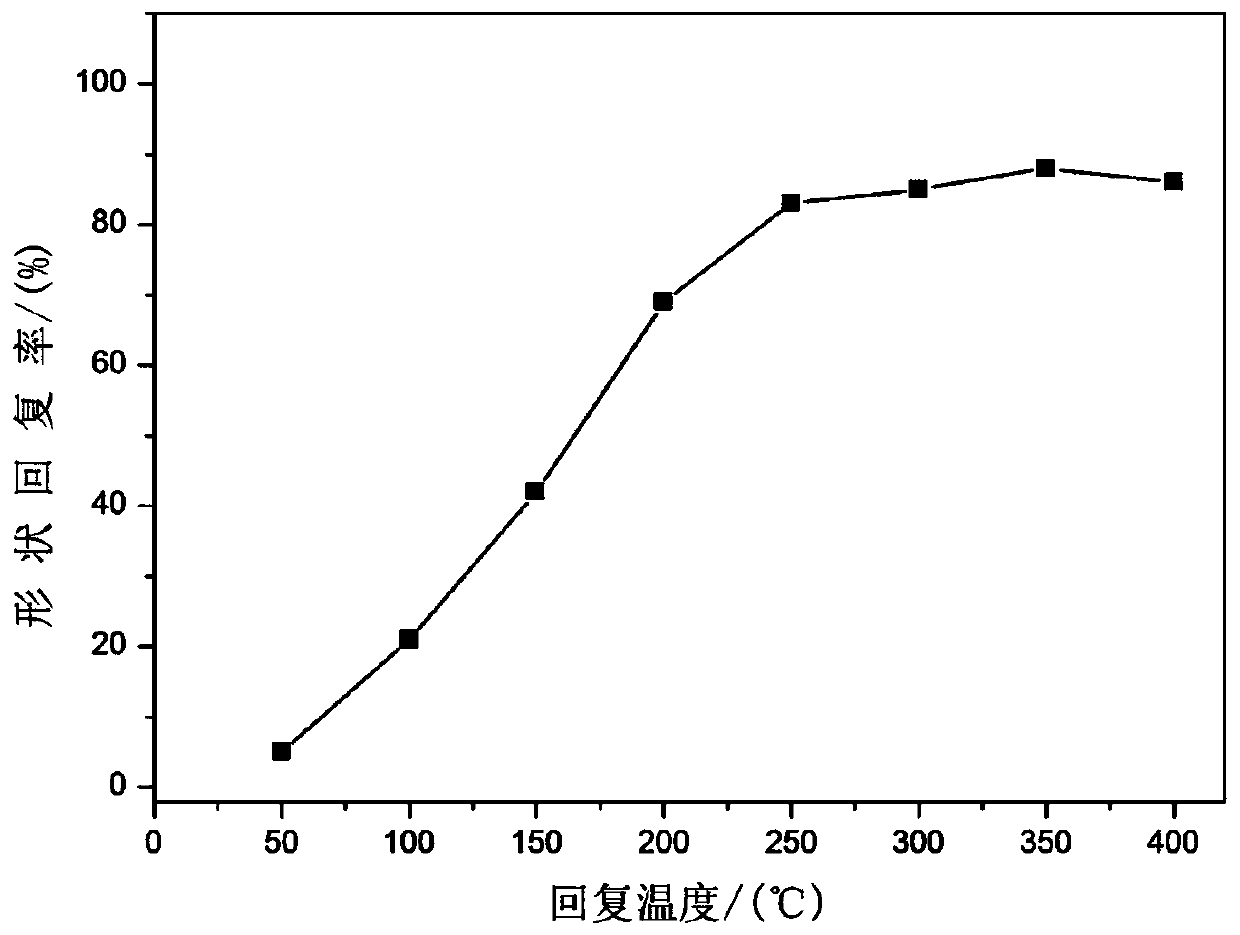

[0022] The shape memory performance test method is as described in Case 1. Tested by bending method, the shape recovery rate of the obtained memory alloy is as attached figure 1 shown.

[0023] In order to investigate the corrosion resistance of the alloy, the aging treated samples were cut into corrosion samples (4.5×60×120mm) of appropriate size and soaked in simulated seawater. The corrosion rate of the alloy was tested by weight loss method. The results show that the corrosion rate of Fe-16Mn-5Si-9Cr-5Ni-9Co-1.0 (TaC) (mass percent %) shape memory alloy is 0.0015g / m 2 h.

Embodiment 3

[0025] Ta, Co co-doped high corrosion resistance Fe-Mn-Si-Cr-Ni shape memory alloy of this embodiment, the chemical composition and mass percentage of each element are: Fe-17Mn-5Si-9Cr-5Ni- 11Co-1.5(TaC).

[0026] The shape memory performance test method is as described in Case 1.

[0027] In order to investigate the corrosion resistance of the alloy, the aging treated samples were cut into corrosion samples (4.5×60×120mm) of appropriate size and soaked in simulated seawater. The corrosion rate of the alloy was tested by weight loss method. The results show that the corrosion rate of Fe-17Mn-5Si-9Cr-5Ni-11Co-1.5 (TaC) (mass percent %) shape memory alloy is 0.0012g / m 2 h.

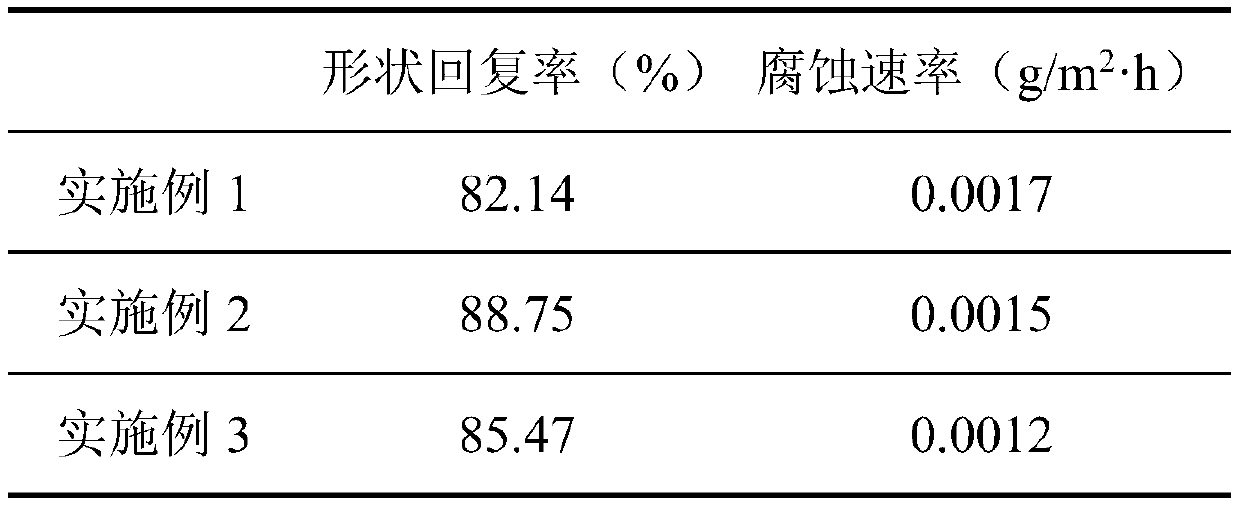

[0028] Table 1 is the shape recovery rate and corrosion rate of the Fe-Mn-Si-Cr-Ni series shape memory alloy of embodiment 1-3:

[0029] Table 1

[0030]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion rate | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com