Patents

Literature

34results about How to "Ms points lowered" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Series flux cord welding rod used for pile-up welding reparing and remanufacturing large type medium high carbon steel parts

InactiveCN100999041AImprove crack resistanceHigh carbon contentArc welding apparatusWelding/cutting media/materialsHigh carbonRare earth

The present invention discloses a series flux-cored wire for reparation and refabrication of large-size medium-high carbon steel components and parts. Its chemical composition includes (wt%) 5-10 of fluorite, 25-45% of high-carbon ferrochrome, 2-10% of high-carbon manganese iron, 5-8% of tantiron, 10-15% of ferro-molybdenum, 8-14% of rare earth oxide, 5-15% of metal nickel, 2-5% of ferrovanadium, 0.5-2% of graphite, 2-4% of chloride and 1-2.5% of aluminium-magnesium alloy. Its external covering adopts low-carbon steel tape.

Owner:QINHUANGDAO WEIERDE SPECIAL WELDING IND

High strength low yield ratio welding structure steel and production method thereof

The invention belongs to welded structural steel with high strength and low yield ratio and a production method thereof, aiming at solving the defects that a steel plate or a steel coil with the specification smaller than 25mm can only be produced, the process is long, and the like. The invention adopts the measures that the welded structural steel contains chemical components by weight that: 0.04-0.10 percent of C, 0.60-2.00 percent of Si, 1.50-2.50 percent of Mn, less than or equal to 0.030 percent of P, less than or equal to 0.010 percent of S, 0.20-0.50 percent of Cu, 0.40-0.80 percent of Cr, 0.35-0.80 percent of Ni, 0.0008-0.0030 percent of B, and at least three of the following components: less than or equal to 0.60 percent of Mo, 0.015-0.060 percent of Nb, 0.030-0.120 percent of V, less than or equal to 0.030 percent of Ti, less than or equal to 0.040 percent of Als and less than or equal to 0.010 percent of Zr, and the rest is Fe and unavoidable impurities; and meanwhile, Mn and Cr also need to satisfy the condition that Mn and Cr are equal to 2.20-2.80 percent, and the welding cold crack sensitivity coefficient Pcm is equal to C plus Si / 30 plus (Mn plus Cu plus Cr) / 20 plus Mo / 15 plus Ni / 60 plus V / 10 plus 5B and is less than or equal to 0.30 percent; the production method comprises the following steps of heating a steel billet, rough rolling, finishing rolling, relaxing and laminar cooling, and the laminar cooling comprises the following steps of slow cooling, quick cooling and natural cooling to room temperature.

Owner:武钢集团有限公司

1180 MPa-grade ultrahigh-strength low-cost cold-rolled quenched partition steel and manufacturing method thereof

InactiveCN110093564AIncrease contentOrganizational stabilityUltimate tensile strengthMechanical property

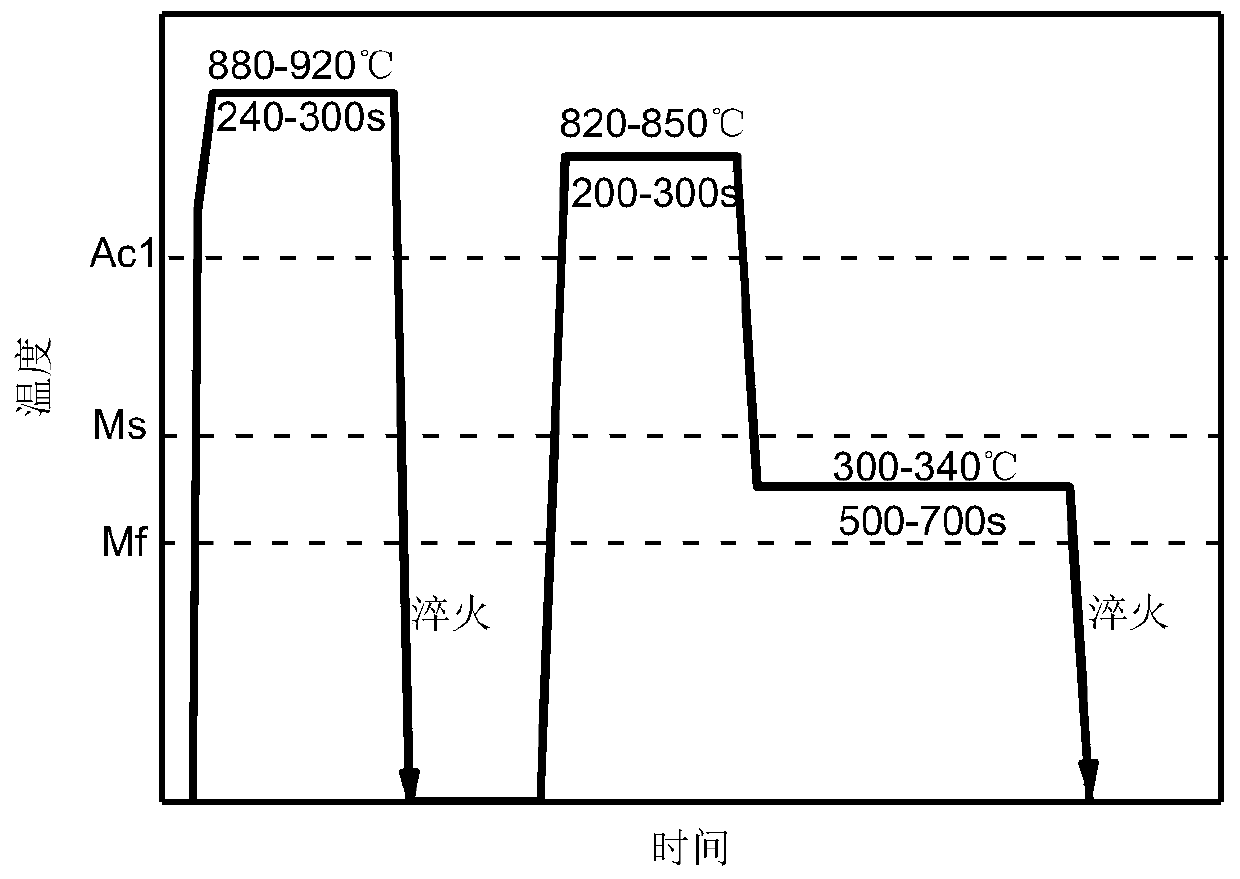

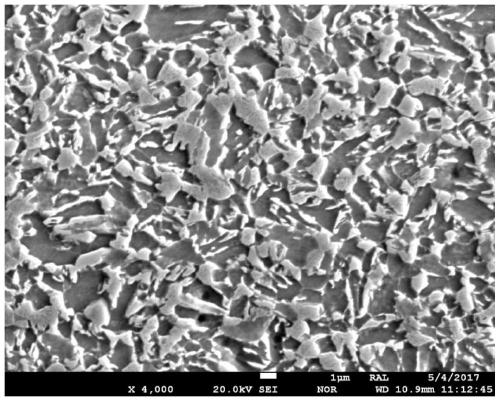

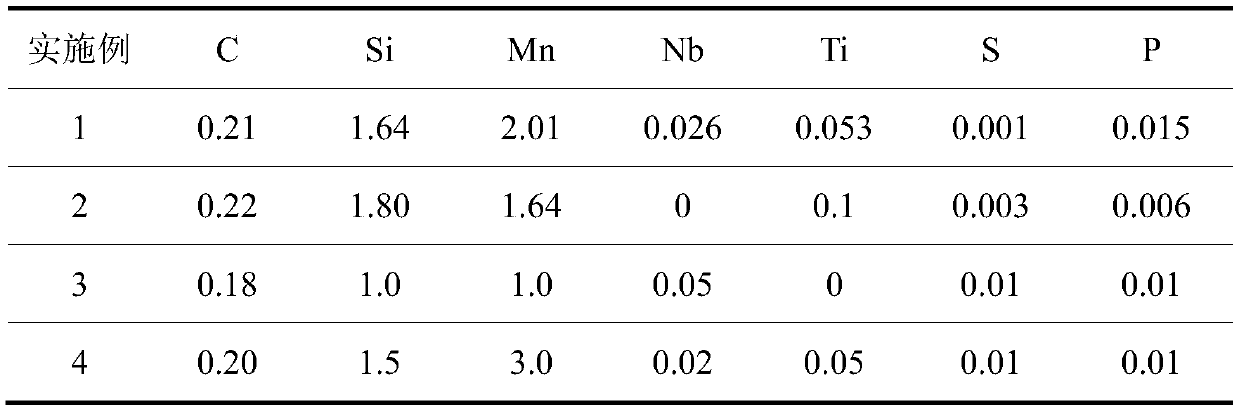

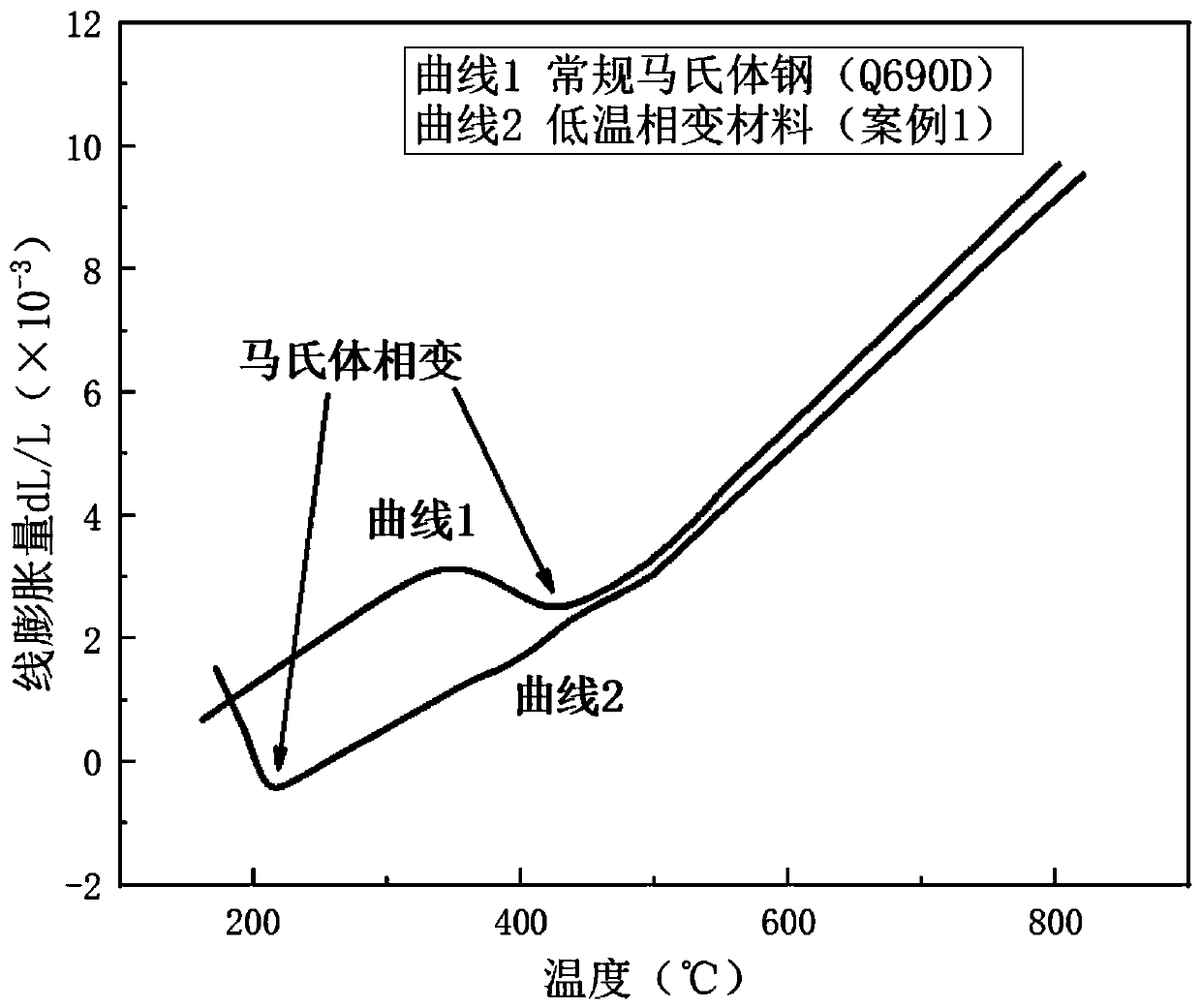

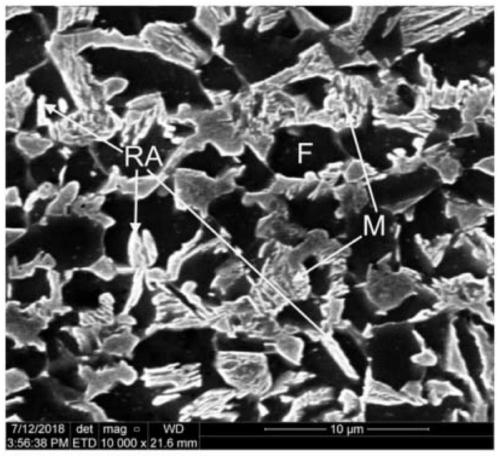

The invention relates to the field of third-generation advanced high-strength steel used for automobiles and discloses 1180 MPa-grade ultrahigh-strength low-cost cold-rolled quenched partition steel and a manufacturing method thereof. A steel plate comprises the chemical components including, by mass percent, 0.18-0.22% of C, 1.0-3.0% of Mn, 1.0-2.0% of Si, not greater than 0.05% of P, not greaterthan 0.02% of S, 0-0.05% of Nb, 0-0.2% of Ti and the balance iron and inevitable impurities. The steel plate manufacturing method relates to the process of steel smelting, hot rolling, cold rolling,pre-quenching and heat treatment, and finally, a ferrite-bainite-martensite-retained austenite mixed structure is obtained. According to the 1180 MPa-grade ultrahigh-strength low-cost cold-rolled quenched partition steel and the manufacturing method thereof, on the basis of traditional C-Mn-Si series quenched partition steel, Nb and Ti elements are added for refining the structure, pre-quenching treatment and a one-step partition process are adopted, finally the ultrahigh-strength quenched partition steel with the yield strength being 500-800 MPa, the tensile strength not smaller than 1180 MPa, the elongation after fracture not smaller than 20% and the product of strength and elongation not smaller than 24GPa.% is obtained, and the mechanical property is quite excellent.

Owner:NORTHEASTERN UNIV

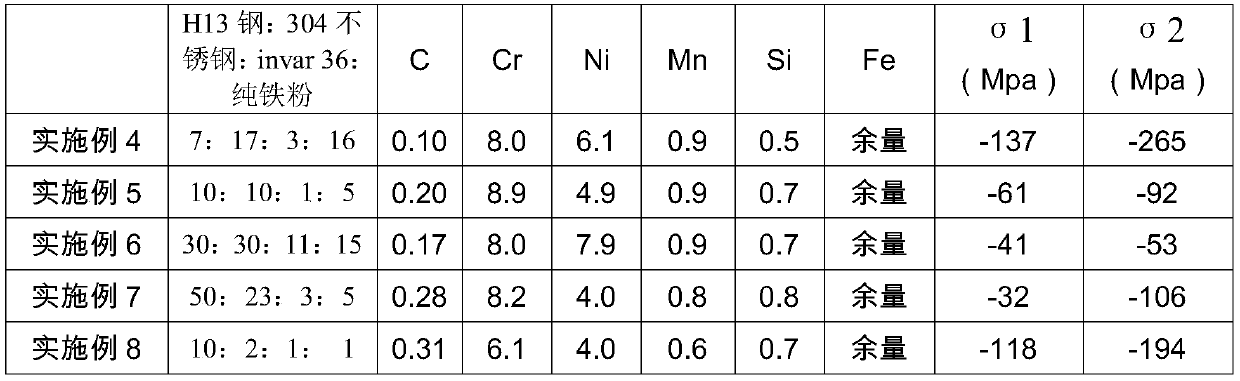

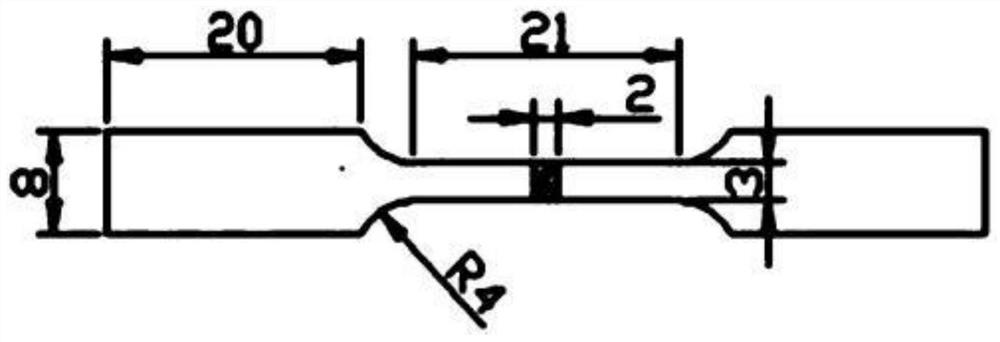

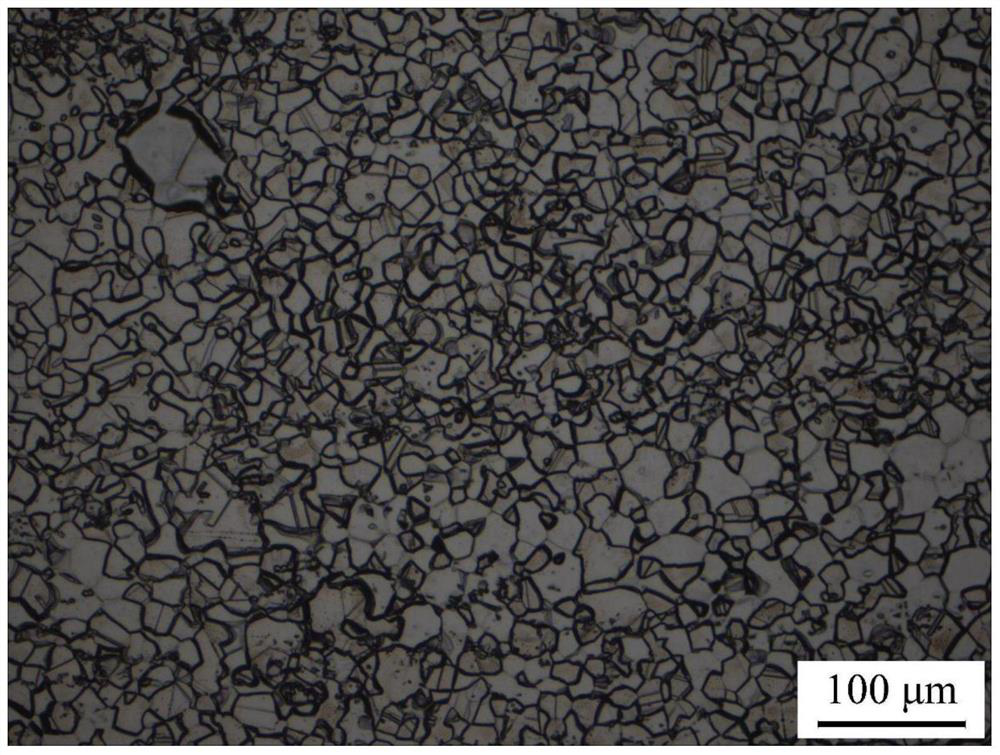

Alloy powder for repairing martensitic steel through laser additive manufacturing and preparation and application of alloy powder

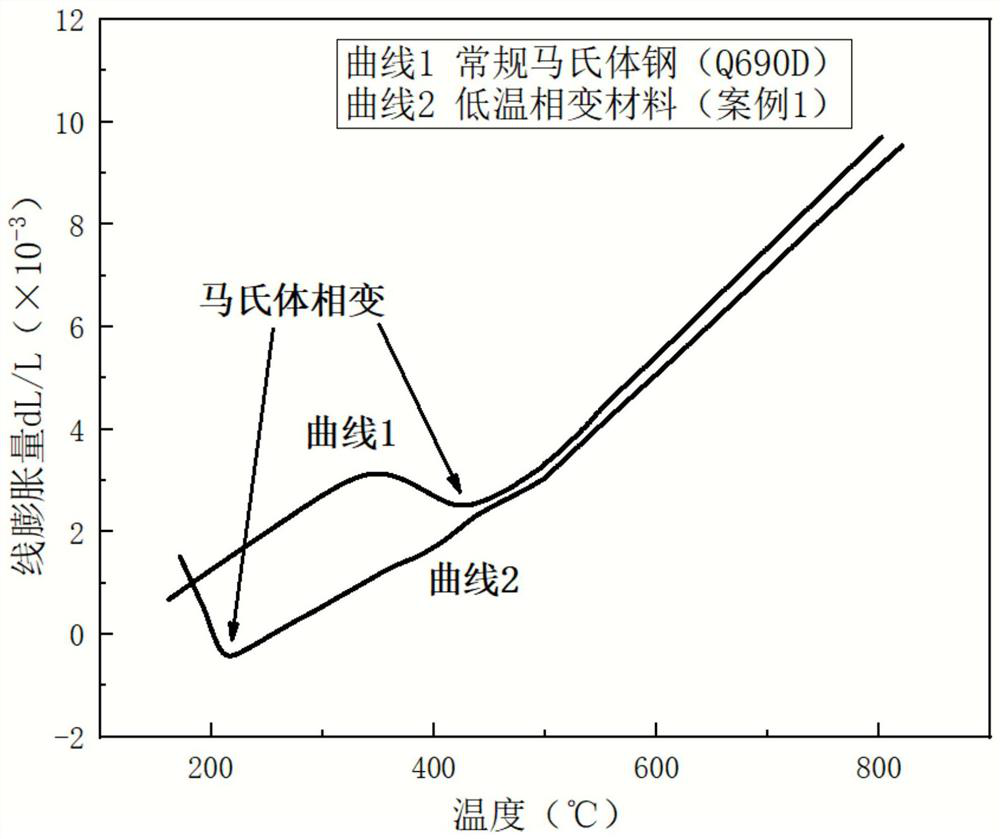

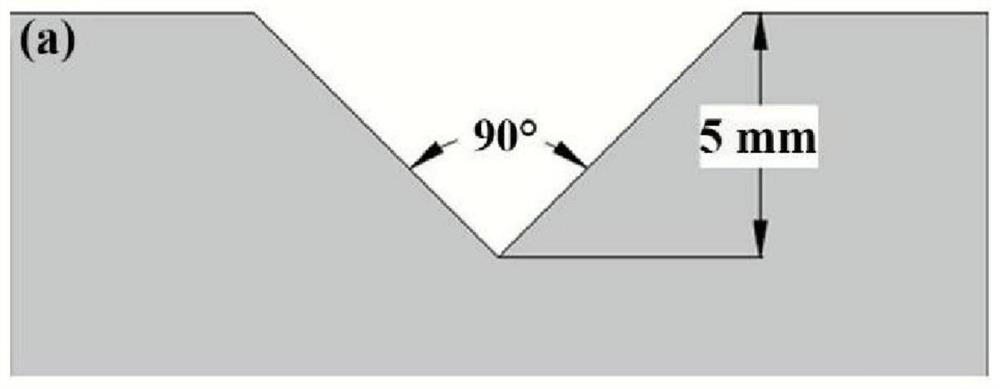

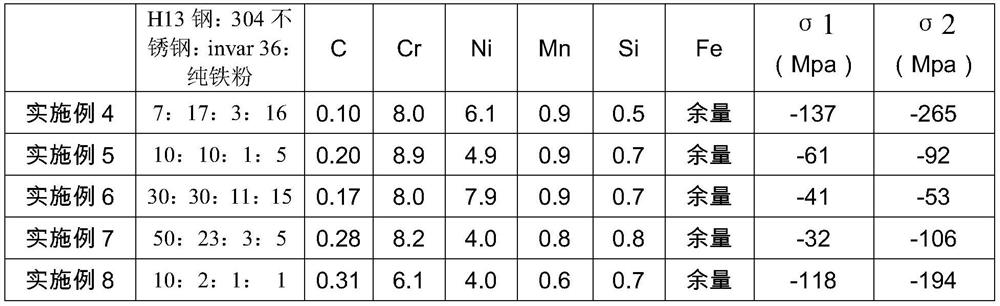

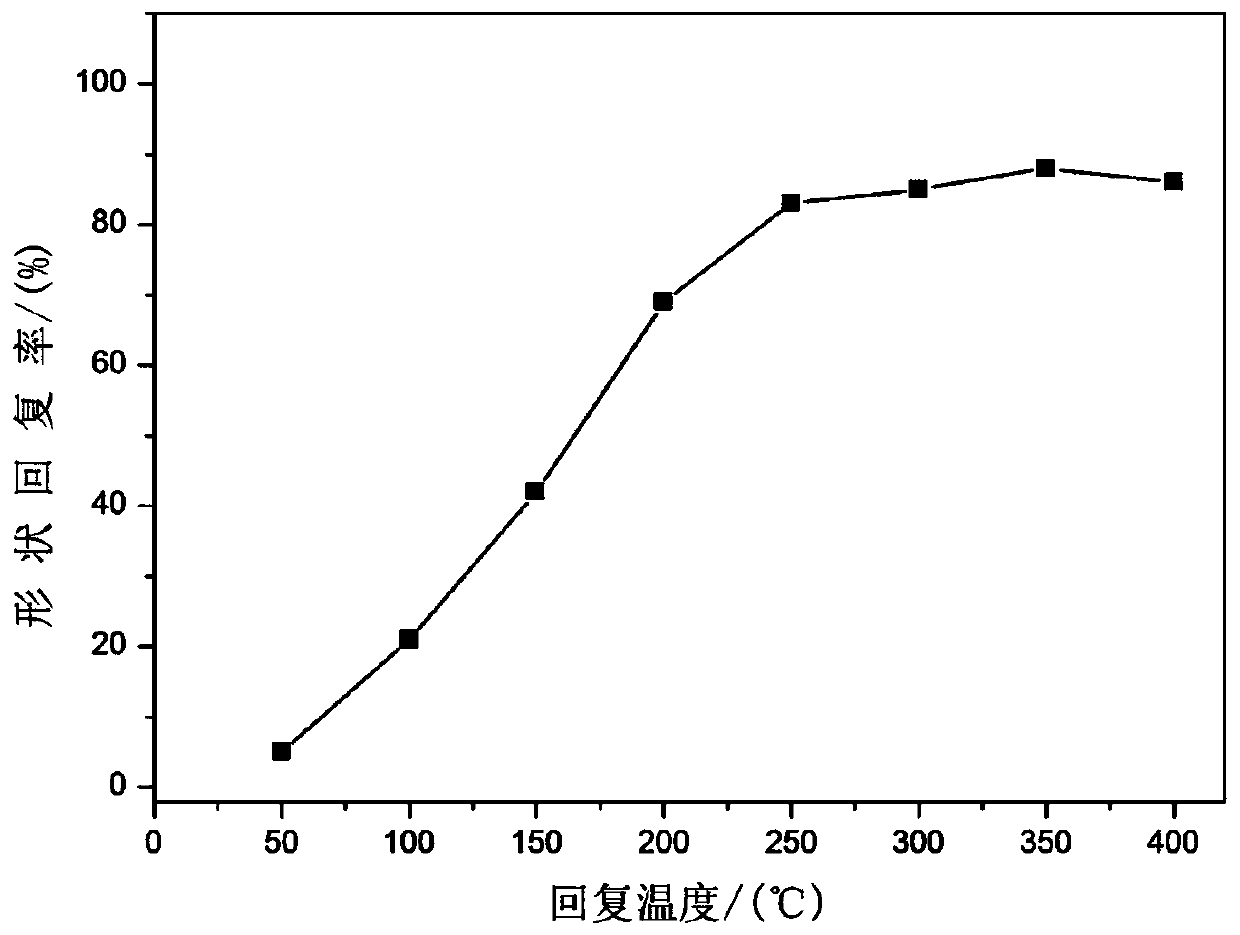

ActiveCN111390159AMs points loweredTensile stress is obtainedAdditive manufacturing apparatusIncreasing energy efficiencyMartensite transformationAlloy

The invention belongs to the field of laser additive manufacturing repair, and particularly relates to alloy powder for repairing martensitic steel through laser additive manufacturing and preparationand application of the alloy powder. The alloy powder contains the following components of, in percentage by mass, 0.03%-0.4% of C, 6%-10% of Cr, 4%-8% of Ni, 0.5%-1.5% of Mn, 0.6%-1.2% of Si and thebalance Fe and inevitable impurities, so that the alloy powder has a relatively low martensite phase transformation point. The alloy powder is used for repairing the martensitic steel through laser additive manufacturing, a martensitic structure is formed in a repaired area, the volume expansion effect of martensitic phase transformation is used for counteracting heat shrinkage generated by cooling of the repaired area, residual compressive stress is generated in the repaired area, the defects of deformation, fatigue cracks and the like of repaired parts are avoided, timeliness and reliability of part repairing are improved, and the damaged part can be used immediately after being repaired.

Owner:HUAZHONG UNIV OF SCI & TECH

High-manganese austenitic steel and preparation method thereof

PendingCN111850419ALower average molar massHigh densityFurnace typesHeat treatment furnacesAustenite grainManganese

The invention provides high-manganese austenitic steel and a preparation method thereof, and belongs to the technical field of metal materials. The high-manganese austenitic steel provided by the invention is prepared from the following components in percentage, by mass, 25 to 27 percent of Mn, 8 to 12 percent of Al, 1.2 to 1.4 percent of C, 0.05 to 0.1 percent of Nb and the balance of Fe. By adjusting the using amounts of Al, C and Mn, the density of the steel can be reduced, the stability and restoring force of austenite are improved, meanwhile, the solid solution strengthening effect is achieved, and the strength and abrasion resistance of the steel are improved; and the Nb element reduces network carbide in an as-cast structure, austenite grains are refined, and the yield strength is improved; and the result of the embodiment shows that the density of the high-manganese austenitic steel is about 6.62 g / cm < 3 > and is reduced by 15.13% compared with that of pure iron, the elastic modulus is larger than or equal to 142 GPa, the yield strength is larger than 1020 MPa, and the tensile strength is larger than 1150 MPa.

Owner:YANSHAN UNIV

Preparation method of alloy powder and coating layer for preparing iron-base cladding layer

The invention relates to a preparation method of alloy powder and a coating layer for preparing an iron-base cladding layer, and belongs to the technical field of coating layers. The alloy powder comprises the following components in percentage by weight: 12-18% of Cr, 20-28% of Mo, 1-1.8% of C, 2.5-4.5% of B, 0.3-1.2% of Si, 0.5-1.2% of Mn and the balance of Fe. The coating layer is prepared through the following step of: firstly pretreating a base body, wherein process parameters are as follows: a transferred arc voltage is 29-32 V, a transferred arc current is 70-80 A, a spraying distance is 12-14 mm, an ion gas is 4-4.5 L / h, a power delivery gas is 4-4.5 L / h, a protective gas is 6.5-7 L / h, and a power delivery voltage is 6.0-6.5 V. The cladding layer prepared by the method disclosed by the invention has the advantages of high rigidity, good abrasion resistance and less tendency of crack generation and other cladding defect generation.

Owner:BEIJING UNIV OF TECH

High-chromium cast steel roller for rolling of hot rolled plate strip

ActiveCN108060365AImprove stabilityShorten the production cycleFurnace typesRollsPearliteWear resistance

The invention discloses a high-chromium cast steel roller for rolling of a hot rolled plate strip. The high-chromium cast steel roller comprises a roller core and a roller body working layer. The roller body working layer comprises, by mass, 1.60-2.00% of C, 0.60-1.00% of Si, 0.80-1.50% of Mn, 12.00-15.00% of Cr, 1.00-2.00% of Ni, 1.00-2.50% of Mo, greater than or equal to 0.10% of V, less than orequal to 0.03% of S, less than or equal to 0.05% of P and the balance Fe and inevitable impurities. By improving the chemical components of the roller body working layer and adjusting the heat treatment process, the carbon content is increased, generation of pearlite in a cast structure is suppressed, thus, the mechanical strength and abrasion resistance of the roller are improved, high temperature quenching does not need to be conducted in the rolling process, equipment can be saved, the production period is shortened, the production cost is reduced, and the roller performance stability is improved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Bismuth-containing free-cutting pre-hardened plastic die steel and preparation method thereof

ActiveCN112030073AShorten the production cycleReduce processing costsMetal-working apparatusChemical compositionIngot

The invention discloses bismuth-containing free-cutting pre-hardened plastic die steel and a preparation method thereof. The die steel comprises the following chemical components of, in percentage bymass, 0.32%-0.40% of C, 0.15%-0.30% of Si, 1.50%-1.70% of Mn, 1.70%-2.00% of Cr, 0.85%-1.15% of Ni, 0.25%-0.40% of Mo, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.05%-0.10%of V, 0.05%-0.15% of Bi, and the balance Fe. The preparation method comprises the following steps that smelting and casting are performed into a cast ingot according to set chemical components, the cast ingot is subjected to high-temperature homogenization treatment into a forging stock, normalizing treatment is performed offline after forging to refine grains, and finally, quenched-tempered heattreatment is performed to obtain a uniform structure with the hardness of 32-48HRC. According to the bismuth-containing free-cutting pre-hardened plastic die steel, through reasonable chemical component design, the bismuth element is added to replace traditional free-cutting elements including sulfur and lead, and due to the fact that a sulfur content is controlled, reasonable forging and heat treatment processes are matched, the hot brittleness phenomenon and anisotropy caused by the sulfur element are avoided, meanwhile, the problems that the lead is harmful to human bodies and pollutes anenvironment are solved.

Owner:NORTHEASTERN UNIV

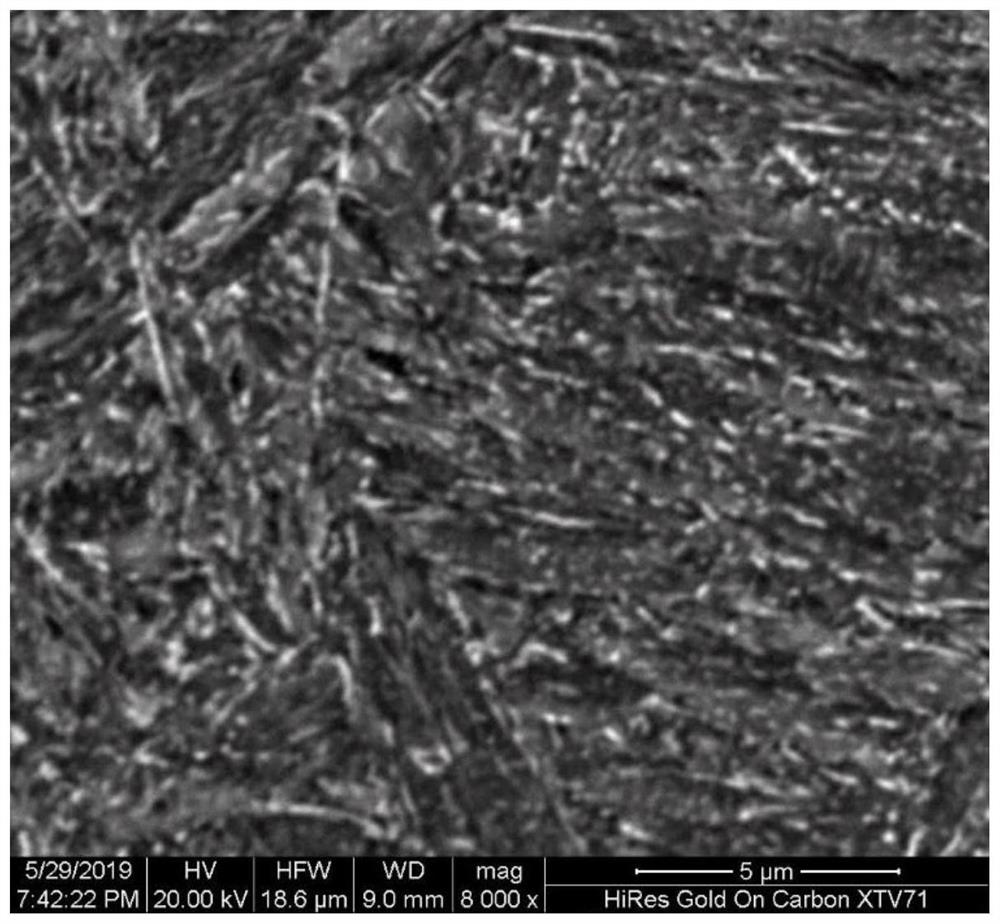

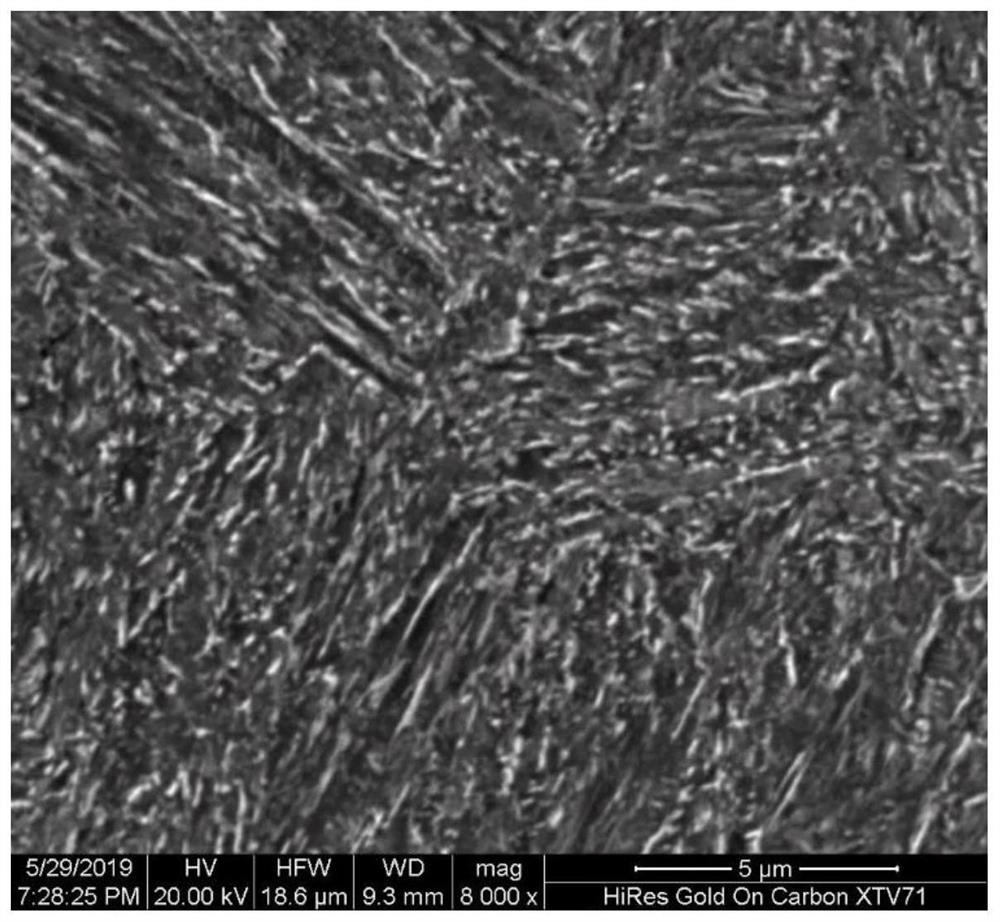

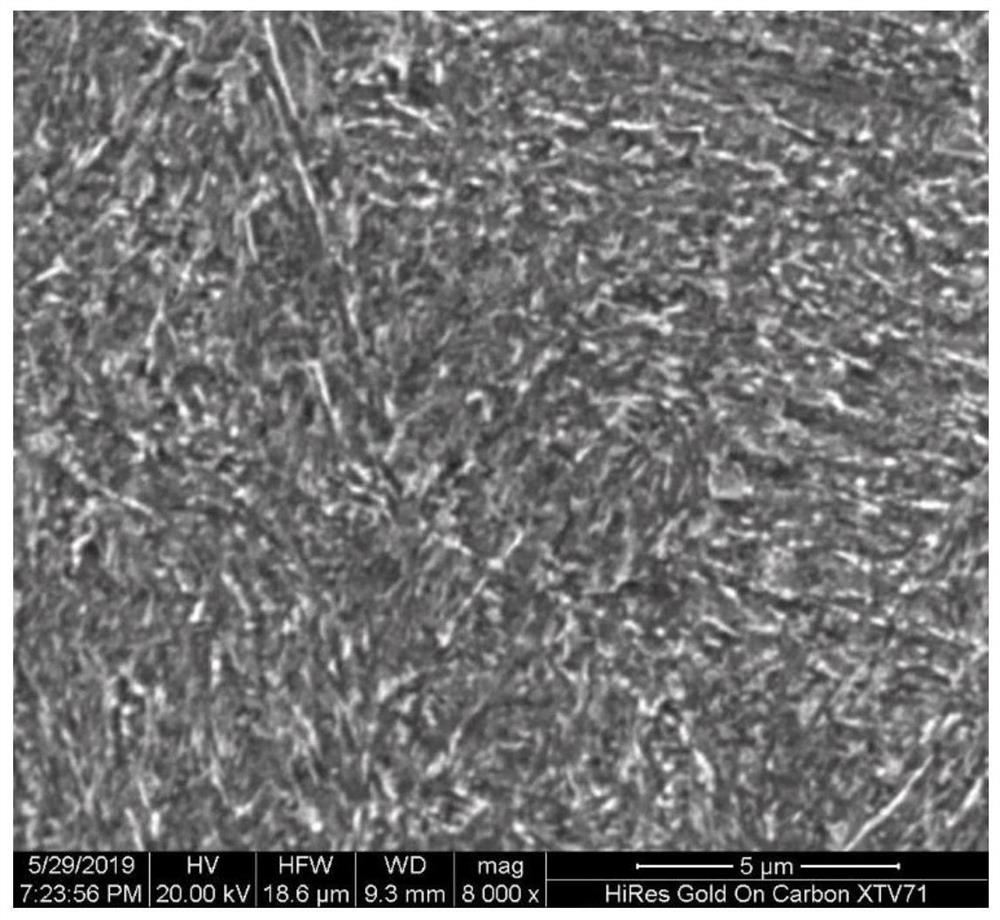

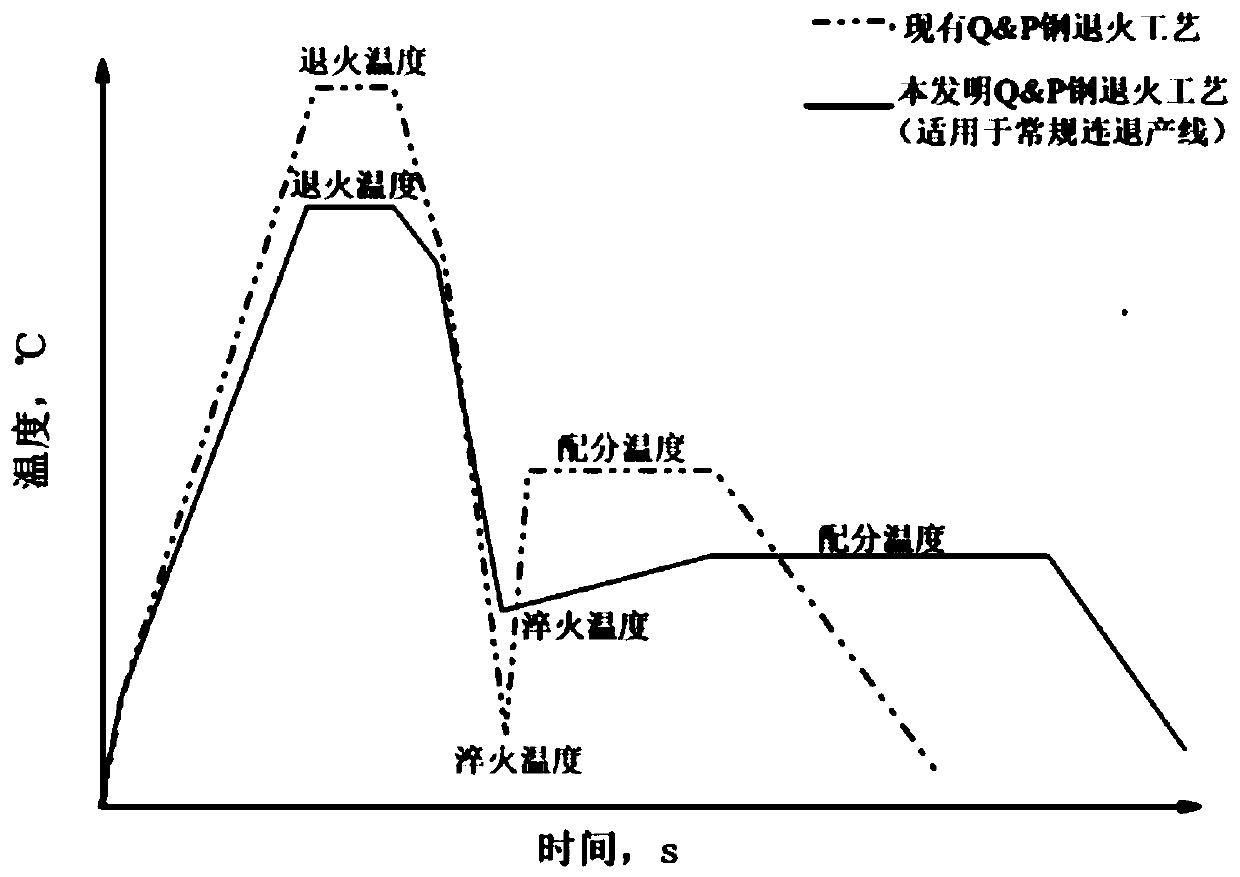

980 MPa-grade cold-rolled Q&P steel suitable for conventional continuous annealing production line and manufacturing method thereof

The invention provides 980 MPa-grade cold-rolled Q&P steel suitable for a conventional continuous annealing production line and a manufacturing method thereof. The 980 MPa-grade cold-rolled Q&P steelcomprises the following components including 0.16%-0.20% of C, 0.6%-1.0% of Si, 1.8%-2.0% of Mn, 0.05%-0.07% of Nb, 0.02%-0.03% of Ti, 0.40%-0.60% of Al, less than or equal to 0.02% of P, less than orequal to 0.01% of S and the balance Fe. Two-phase zone annealing is adopted, heating is performed to 810-850 DEG C, two-phase zone annealing is performed, slow cooling is performed to 720-760 DEG C,then cooling is performed to 260-300 DEG C at the cooling rate larger than or equal to 25 DEG C / s, quenching is performed, then heating is performed to 340-380 DEG C, partitioning is performed, finally cooling is performed to the room temperature, the annealing temperature is low, and the 980 MPa-grade cold-rolled Q&P steel can be implemented on the existing conventional continuous annealing production line. The steel meets the requirements for high strength and plasticity, good cold forming performance, resource saving, cost reduction and the like of automobile steel.

Owner:MAANSHAN IRON & STEEL CO LTD

Steel for high strength fastener for marine environment

The invention relates to steel for a high strength fastener for a marine environment. The steel is prepared from the following raw materials in percent by weight: 0.08-0.20% of C, 0.10-1.0% of Si, 0.3-1.0% of Mn, less than or equal to 0.005% of S, less than or equal to 0.005% of P, 0.2-1.2% of Cr, 4.5-9.5% of Ni, 0.3-1.0% of Mo, less than or equal to 0.15% of V and the balance Fe and other inevitable impurities. The hydrogen diffusion coefficient D of the steel is smaller than or equal to 10<-8>mm<2> / s. A hydrogen trap type of the steel is a reversible hydrogen trap, and the hydrogen escape activation energy Ea is smaller than 30 kJ / mol. Starting from an essential attribute design of a material, the average hydrogen content in the steel is reduced, and process and influence of hydrogen atoms taking part in hydrogen induced delayed fracture in an irreversible hydrogen trap are eliminated, so that the hydrogen induced delayed fracture problem of the high strength fastener for the marineenvironment is controlled effectively.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

Medium-manganese, high-hardness and high-tenacity wear-resisting ball and preparation method thereof

InactiveCN106811675AHigh hardnessHigh hardness and high toughnessGrain treatmentsManganeseRare earth

The invention discloses a medium-manganese, high-hardness and high-tenacity wear-resisting ball. The medium-manganese, high-hardness and high-tenacity wear-resisting ball comprises, by weight, 3.3%-3.7% of C, 5.5%-6.5% of Mn, less than 0.04% of S, less than 0.1% of P, 3.6%-4.6% of Si, 14.83%-16.83% of Cr, 0.012%-0.018% of Mo, 0.05%-0.09% of V, 0.01%-0.02% of W, 0.02%-0.06% of Ti, 0.01%-0.03% of Bi, 0.02%-0.045% of rare earth, 0.04%-0.055% of Mg, and the balance Fe and inevitable impurities. The invention further provides a preparation method of the medium-manganese, high-hardness and high-tenacity wear-resisting ball. According to the medium-manganese wear-resisting ball prepared through the method, by reasonably selecting the components, the wear resistance and corrosion resistance of the wear-resisting ball are improved, and the service life of the wear-resisting ball is prolonged.

Owner:WUHU BEISI SCI & TECH PARK

High-carbon, low-chromium and low-tungsten grinding ball high in hardness and resistant to impact and preparation method thereof

InactiveCN106868412AImprove wear resistanceAccelerated corrosionGrain treatmentsHigh carbonRare earth

The invention discloses a high-carbon, low-chromium and low-tungsten grinding ball high in hardness and resistant to impact. The high-carbon, low-chromium and low-tungsten grinding ball high in hardness and resistant to impact comprises the components of C, Cr, Si, Mn, Mo, Ni, rare earth, V, B, Ti, W, Nb, Ta, Al, Cu, S, P, Fe and inevitable impurities. The invention further discloses a preparation method of the high-carbon, low-chromium and low-tungsten grinding ball high in hardness and resistant to impact. According to the high-carbon, low-chromium and low-tungsten grinding ball high in hardness and resistant to impact and the preparation method of the high-carbon, low-chromium and low-tungsten grinding ball high in hardness and resistant to impact, by means of reasonable selection of the components, the hardness and the impact resistance of the grinding ball are improved, and the service life of the grinding ball is prolonged.

Owner:WUHU BEISI SCI & TECH PARK

Softening method of carburizing area obtained after CSS-42L gear steel is carburized

ActiveCN106755773AMs points loweredHardness RecoveryFurnace typesHeat treatment furnacesQuenchingStress relieving

The invention relates to a softening method of a carburizing area obtained after CSS-42L gear steel is carburized. After high-temperature austenitizing, oil quenching and stress removal treatment are performed, the Ms point of a carburized layer tissue is made to be greatly lowered, hardness of a material may be lowered to be HRC 28-35, and gear shaping, and gear hobbing or finish turning machining can be performed. After the material is softened, a grinding process can be replaced, grinding burn is effectively avoided, and production efficiency is improved.

Owner:HARBIN DONGAN ENGINE GRP

Series flux cord welding rod used for pile-up welding reparing and remanufacturing large type medium high carbon steel parts

InactiveCN100999041BImprove crack resistanceHigh carbon contentArc welding apparatusWelding/cutting media/materialsHigh carbonRare earth

The present invention discloses a series flux-cored wire for reparation and refabrication of large-size medium-high carbon steel components and parts. Its chemical composition includes (wt%) 5-10 of fluorite, 25-45% of high-carbon ferrochrome, 2-10% of high-carbon manganese iron, 5-8% of tantiron, 10-15% of ferro-molybdenum, 8-14% of rare earth oxide, 5-15% of metal nickel, 2-5% of ferrovanadium,0.5-2% of graphite, 2-4% of chloride and 1-2.5% of aluminium-magnesium alloy. Its external covering adopts low-carbon steel tape.

Owner:QINHUANGDAO WEIERDE SPECIAL WELDING IND

Heat treatment method of high-hardness and high-impact-toughness alloy material

The invention discloses a heat treatment method of a high-hardness and high-impact-toughness alloy material. The method comprises steps of austenitizing the material, and then putting the austenitizedmaterial into quenching oil for quenching treatment; after quenching treatment, putting the material into an isothermal molten salt bath medium for heat preservation and carrying out partition treatment; and putting the material into room-temperature water or oil for cooling treatment after distribution treatment to obtain the product. The impact toughness of the material can be improved while the hardness of the material is improved, and the service life of rolling can be effectively prolonged when the material is used for manufacturing the hobbing cutter of the shield tunneling machine.

Owner:GUIZHOU UNIV

High-chromium, high-hardness and high-tenacity wear-resisting ball and preparation method thereof

The invention discloses a high-chromium, high-hardness and high-tenacity wear-resisting ball. The high-chromium, high-hardness and high-tenacity wear-resisting ball comprises, by weight, 2.74%-2.94% of C, 1.24%-1.28% of Mn, 0.046%-0.050% of S, 0.051%-0.055% of P, 0.71%-0.91% of Si, 14.83%-16.83% of Cr, 0.14%-0.18% of Mo, 0.05%-0.09% of V, 0.01%-0.02% of W, 0.02%-0.06% of Ti, 0.01%-0.03% of Bi, 0.005%-0.015% of rare earth, 0.24%-0.28% of Nb, and the balance Fe and inevitable impurities. The invention further provides a preparation method of the high-chromium, high-hardness and high-tenacity wear-resisting ball. The wear-resisting ball prepared through the method is high in hardness and good in tenacity.

Owner:WUHU BEISI SCI & TECH PARK

High-strength impact-resistant wear-resistant material

The invention discloses a high-strength impact-resistant wear-resistant material. The high-strength impact-resistant wear-resistant material is prepared from the following components: greater than 0.64 mass percent and less than 0.71 mass percent of C, greater than 0.20 mass percent and less than 0.40 mass percent of Si, greater than 1.90 mass percent and less than 2.05 mass percent of Mn, greater than 0.90 mass percent and less than 1.05 mass percent of Cr, greater than 0.02 mass percent and less than 0.05 mass percent of Al, greater than 0.01 mass percent and less than 0.02 mass percent of P, greater than 0.001 mass percent and less than 0.015 mass percent of S, and the balance of Fe and unavoidable impurities. The wear-resistant material disclosed by the invention is high in strength, and good in impact resistance and wear resistance.

Owner:蚌埠市光辉金属加工厂

High rigidity low thermal expansion casting and manufacturing method thereof

Owner:신호코쿠머티리얼가부시키가이샤

High-chromium high-strength impact resistant alloy used for water pump motor

The invention discloses a high-chromium high-strength impact resistant alloy used for a water pump motor. The high-chromium high-strength impact resistant alloy used for the water pump motor is composed of, by mass, 1.3-1.6% of C, 1.8-2.5% of Si, 0.2-0.6% of Mn, 10-15% of Cr, 0.3-1.6% of Cu, 0.2-0.5% of Mo, 0.02-0.05% of P, 0.01-0.04% of S, 0.025-0.14% of Re and the balance Fe and inevitable impurities. By reasonably selecting components of the high-chromium alloy, the abrasion resistance and the corrosion resistance of an abrasion resisting part are improved, and the service life is prolonged.

Owner:宁国井田机电有限公司

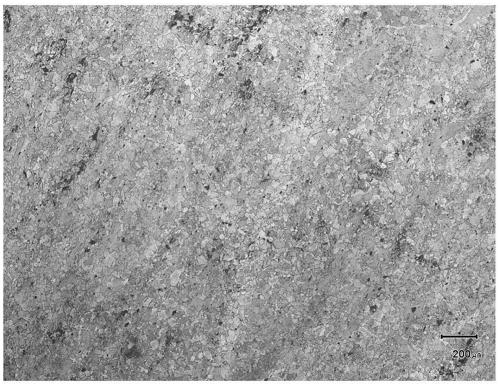

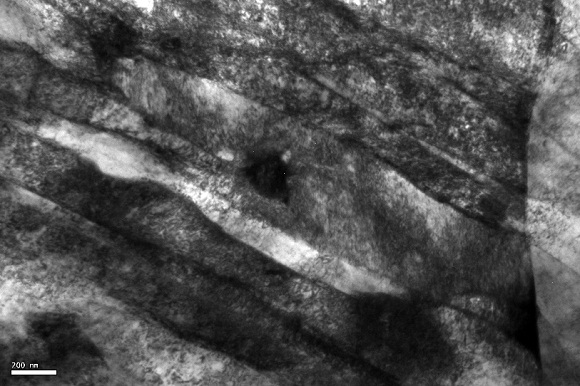

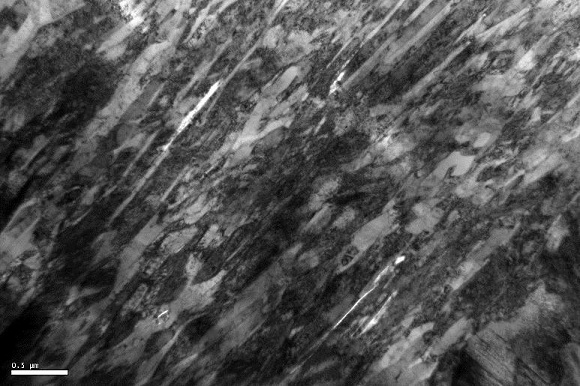

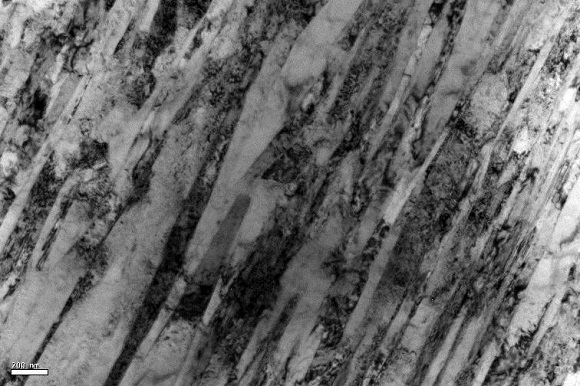

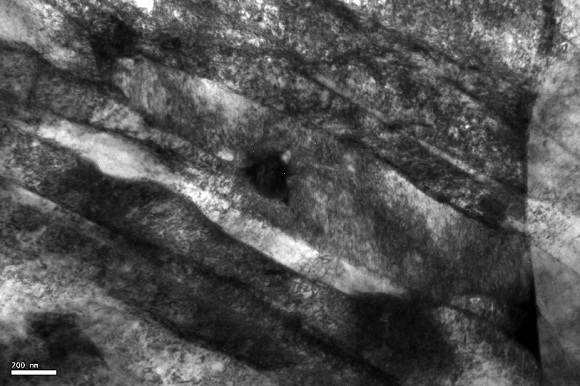

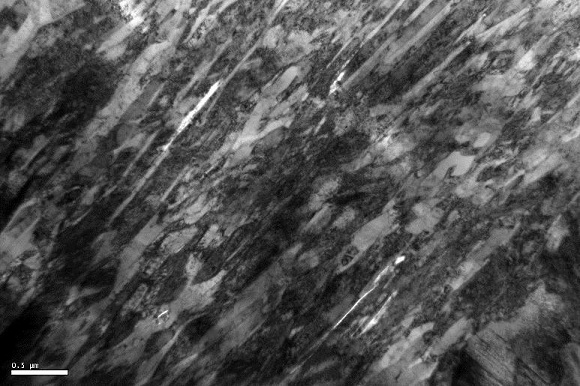

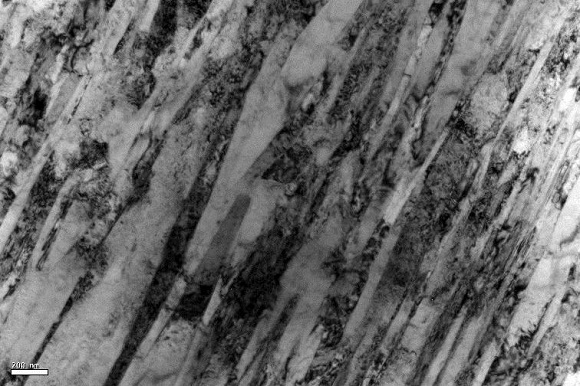

High-strength steel with nanometer, layered and metastable skeletal structure and preparing method thereof

The invention relates to high-strength steel with a nanometer, layered and metastable skeletal structure. The steel is prepared from the alloy components in percentage by weight: C: 0.01 to 0.1%, Mn:7.0 to 11.0%, Cu: 1.5 to 4.0%, Ni: 1.0 to 3.0%, Al: 1.0 to 2.0%, and the balance of Fe. The invention further relates to a method for preparing the high-strength steel with the nanometer, layered andmetastable skeletal structure. The method comprises the steps of weighing alloy components, smelting, casting, forging, hot rolling, cold rolling and heat treating process. The purpose of the invention is to provide the high-strength steel with the nanometer, layered and metastable skeletal structure and a preparation method thereof. The material has excellent mechanical properties, low productioncost, wide process window, and has a huge application prospect.

Owner:DONGGUAN UNIV OF TECH

Softening method for CSS-42l gear steel forging stock

ActiveCN106755771AReduce hardnessMs points loweredFurnace typesHeat treatment furnacesAusteniteQuenching

The invention relates to a softening method for a CSS-42l gear steel forging stock. According to the softening method, a material is entirely in an under-cooled austenite state by treatments of high-temperature austenization, oil quenching and stress elimination; the under-cooled austenite belongs to a soft structure which is relatively low in hardness, so the hardness of CSS-42L gear steel can be greatly reduced to HRC 28-35, and the requirements of machining are satisfied.

Owner:HARBIN DONGAN ENGINE GRP

High-hardness high-hardenability wear-resisting ball and preparing method thereof

The invention discloses a high-hardness high-hardenability wear-resisting ball. The high-hardness high-hardenability wear-resisting ball comprises, by weight percent, 0.35%-0.45% of C, 0.4%-0.8% of Mn, 0.001%-0.004% of S, 0.001%-0.004% of P, 0.5%-0.8% of Si, 1.4%-5.3% of Cr, 0.7%-0.8% of Mo, 0.03%-0.08% of V, 0.7%-1.1% of W, 0.02%-0.06% of Ti, 0.01%-0.03% of Bi, 2.5%-4.5% of Ni, 0.05%-0.3% of rare earth, 0.05%-0.15% of Sn, 0.04%-0.06% of Al and the balance Fe and inevitable impurities. The invention further provides a preparing method of the above high-hardness high-hardenability wear-resisting ball. The wear-resisting ball prepared through the preparing method is high in hardness and good in hardenability.

Owner:WUHU BEISI SCI & TECH PARK

Alloy powder for repairing martensitic steel by laser additive manufacturing and its preparation and application

ActiveCN111390159BMs points loweredTensile stress is obtainedAdditive manufacturing apparatusIncreasing energy efficiencyMartensite transformationAlloy

The invention belongs to the field of laser additive manufacturing and repairing, and more specifically relates to an alloy powder for laser additive manufacturing and repairing martensitic steel and its preparation and application. In terms of mass percentage, the alloy powder contains 0.03%-0.4% of C, 6%-10% of Cr, 4%-8% of Ni, 0.5%-1.5% of Mn, 0.6%-1.2% of Si, and the rest The amount is Fe and unavoidable impurities, so that it has a lower martensitic transformation point. Use this alloy powder to repair martensitic steel with laser additives, form martensite structure in the repaired area, and use the volume expansion effect of martensitic phase transformation to offset the thermal contraction caused by cooling the repaired area, resulting in residuals in the repaired area Compressive stress, avoid defects such as deformation and fatigue cracks in repaired parts, improve the timeliness and reliability of repaired parts, and realize "instant repair and use" of damaged parts.

Owner:HUAZHONG UNIV OF SCI & TECH

High-strength low-hardness low-chromium medium-manganese alloy for motor rotor

The invention discloses a high-strength low-hardness low-chromium medium-manganese alloy for a motor rotor. The high-strength low-hardness low-chromium medium-manganese alloy for the motor rotor comprises, by mass, no less than 3.3% and no more than 3.8% of C, no less than 3.3% and no more than 4.3% of Si, no less than 5.7% and no more than 7.0% of Mn, no less than 0.01% and no more than 0.15% of P, no less than 0.01% and no more than 0.02% of S, and no less than 0.025% and no more than 0.05% of Re, with the balance being Fe and unavoidable impurities. The alloy provided by the invention has excellent hardness and rigidity, low chromium content, medium manganese content and low cost, and the strength of rigidity of the alloy can meet demands of actual production.

Owner:宁国井田机电有限公司

Method for forging 316LN stainless steel forge piece

InactiveCN106048157AHigh mechanical strengthMs points loweredProcess efficiency improvementSS - Stainless steelForge

The invention discloses a method for forging a 316LN stainless steel forge piece. The method comprises the following steps of: enabling chemical components of 316LN stainless steel to satisfy the conditions that C is not greater than 0.03, Si is not greater than 0.75, Mn is not greater than 2.0, S is not greater than 0.03, P is not greater than 0.045, Cr is 16.0-18.0, Mo is 2.0-3.0, Hi is 10.0-14.0 and N is not greater than 0.25; placing the 316LN stainless steel into a smelting furnace, wherein an initial forging preheating temperature control melting point is 200-300 DEG C, the liquid phase change begins to occur when the initial forging melting point temperature of the 316LN stainless steel is at 1,000-1,300 DEG C, a gamma bulk phase region is narrower than a low-carbon steel phase region, the 316LN stainless steel begins to convert to austenite stainless steel at the temperature of 850-900 DEG C to be made into bar steel; after forging, air cooling the steel at 550 DEG C, annealing in a hot charging furnace, preserving heat at 770-790 DEG C, then slowly cooling below 550 DEG C along with the furnace, discharging and air cooling, eliminating the forged residual internal stress, obtaining fine granular pearlite structures, and providing structure preparation for final heat-treatment.

Owner:ANHUI RUIJIE FORGING

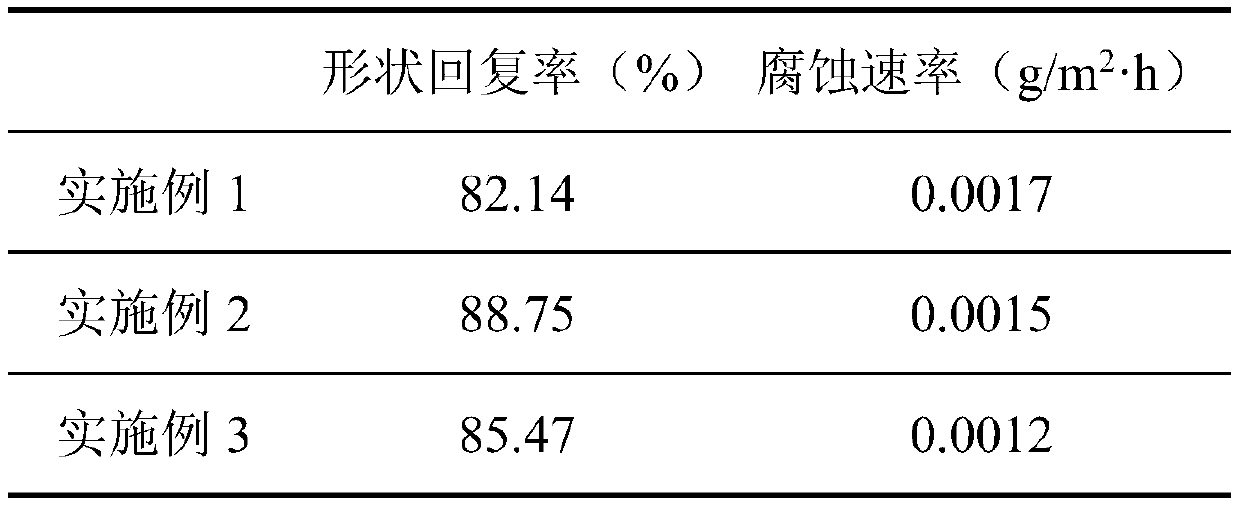

Ta and Co co-doped corrosion-resistant Fe-Mn-Si-Cr-Ni serial shape memory alloy

InactiveCN110541127AImprove corrosion resistanceIncrease the stacking fault densityShape-memory alloyAustenite

The invention provides a Ta and Co co-doped corrosion-resistant Fe-Mn-Si-Cr-Ni serial memory alloy, and relates to the field of functional materials. The Ta and Co co-doped corrosion-resistant Fe-Mn-Si-Cr-Ni serial memory memorizing alloy comprises the following elements in weight percentage: 11 to 18% of Mn, 3-8% of Si, 5-13% of Cr, 3-10% of Ni, 1-11.0%of Co, 0.1-2.0% of Ta, 0.01-0.5% of C, and the balance Fe. According to the Ta and Co co-doped corrosion-resistant Fe-Mn-Si-Cr-Ni serial memory memorizing alloy, Ta and Co elements are added into the alloy, and TaC and other precipitated phasesare precipitated after aging treatment, so that an austenite matrix is strengthened, and the shape memory effect is improved; and the corrosion resistance is effectively improved by adding Co.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

A method for softening the carburized area of css-42l gear steel after carburizing

ActiveCN106755773BMs points loweredHardness RecoveryFurnace typesHeat treatment furnacesGear wheelStress relieving

Owner:HARBIN DONGAN ENGINE GRP

A kind of high-strength steel with nano, layered and metastable skeletal tissue and its preparation method

The invention relates to a high-strength steel with nanometer, layered and metastable skeletal tissue, the weight percent of the alloy composition is: C: 0.01-0.1wt.%, Mn: 7.0-11.0wt.%, Cu: 1.5-4.0wt. .%, Ni: 1.0-3.0wt.%, Al: 1.0-2.0wt.%, and the balance is Fe; the present invention also relates to a preparation method of high-strength steel with nanometer, layered and metastable skeletal tissue, Including the processes of weighing alloy components, smelting, casting, forging, hot rolling, cold rolling and heat treatment, the purpose of the present invention is to provide a high-strength steel with nano, layered and metastable skeletal tissue and its preparation method. It has excellent mechanical properties, low production cost and wide process window, and has great application prospects.

Owner:DONGGUAN UNIV OF TECH

A kind of bismuth-containing free-cutting pre-hardened plastic mold steel and its preparation method

ActiveCN112030073BDoes not affect isotropyReduce wearMetal-working apparatusChemical compositionTempering

The invention discloses a bismuth-containing free-cutting pre-hardened plastic mold steel and a preparation method thereof. The chemical composition of the mold steel is as follows according to mass percentage: C: 0.32-0.40%, Si: 0.15-0.30%, Mn: 1.50-1.70 %, Cr: 1.70~2.00%, Ni: 0.85~1.15%, Mo: 0.25~0.40%, P≤0.015%, S≤0.005%, V: 0.05~0.10%, Bi: 0.05~0.15%, and the balance is Fe; its preparation method includes: smelting and casting into ingots according to the set chemical composition, forging the ingots into forging billets after high-temperature homogenization treatment, performing offline normalizing treatment to refine grains after forging, and finally undergoing quenching and tempering heat treatment, A uniform structure with a hardness of 32-48HRC is obtained. The bismuth-containing easy-cutting pre-hardened plastic mold steel of the present invention, through reasonable chemical composition design, adds bismuth element to replace the traditional easy-cutting elements sulfur and lead. It solves the thermal embrittlement phenomenon and the anisotropy caused by sulfur, and at the same time solves the problem that lead is harmful to the human body and pollutes the environment.

Owner:NORTHEASTERN UNIV LIAONING

A high chromium cast steel roll for hot strip rolling

ActiveCN108060365BImprove stabilityShorten the production cycleFurnace typesRollsPearliteUltimate tensile strength

The invention discloses a high-chromium cast steel roller for rolling of a hot rolled plate strip. The high-chromium cast steel roller comprises a roller core and a roller body working layer. The roller body working layer comprises, by mass, 1.60-2.00% of C, 0.60-1.00% of Si, 0.80-1.50% of Mn, 12.00-15.00% of Cr, 1.00-2.00% of Ni, 1.00-2.50% of Mo, greater than or equal to 0.10% of V, less than orequal to 0.03% of S, less than or equal to 0.05% of P and the balance Fe and inevitable impurities. By improving the chemical components of the roller body working layer and adjusting the heat treatment process, the carbon content is increased, generation of pearlite in a cast structure is suppressed, thus, the mechanical strength and abrasion resistance of the roller are improved, high temperature quenching does not need to be conducted in the rolling process, equipment can be saved, the production period is shortened, the production cost is reduced, and the roller performance stability is improved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com