Alloy powder for repairing martensitic steel by laser additive manufacturing and its preparation and application

A technology of alloy powder and laser additive materials, which is applied in the direction of additive manufacturing, additive processing, and improvement of process efficiency. Cycle, the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

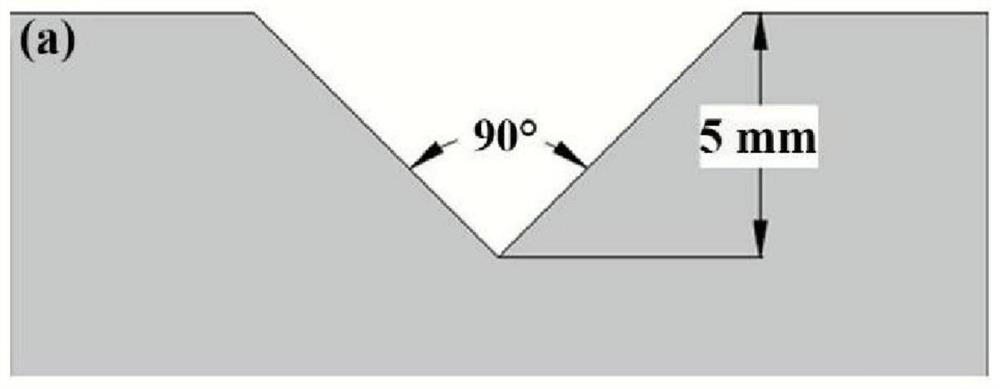

[0059] Select a piece of H13 hot work die steel, whose Ms point is about 350°C, simulate the wear or fatigue cracks, and then grind and groove the damaged area, such as figure 2 As shown, and then perform laser additive repair, which specifically includes the following steps:

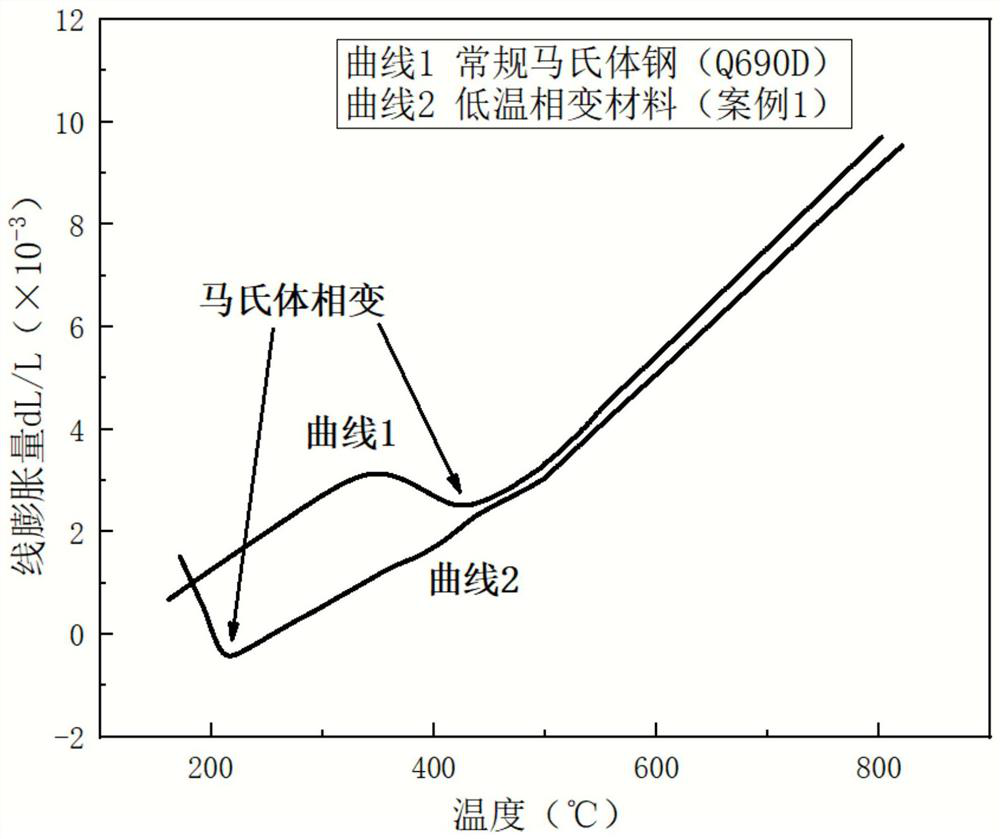

[0060] S1: The powder weight is weighed according to the ratio of H13 steel: 304 stainless steel: invar 36 = 50:9:9. After calculation, the chemical composition of the mixed alloy powder is: C: 0.32%; Cr: 6.1%; Ni: 6.1% ; Mn: 0.6%; Si: 0.8%; Mo: 0.9%; V: 0.7%; the balance is Fe and unavoidable impurities, and its Ms point is about 210 ° C. The thermal expansion curve is shown in figure 1 Curve 2.

[0061] S2: The mixing method is ball mill mixing. Put the weighed powder into a mixing bottle containing steel balls. The ratio of balls to materials is 1:10. Wrap insulating tape around the mixing bottle, and then put it in a ball mill roller for mixing for 6 hours. Machine speed is 350r / min.

[0062] S3...

Embodiment 2

[0066] A piece of Q690D steel is selected, its Ms point is about 410℃, and the thermal expansion curve is shown in figure 1 Curve 1, simulating the damage, and then grinding and grooving the damaged area, and performing laser additive repair, which specifically includes the following steps:

[0067] S1: The powder weight is weighed according to the ratio of H13 steel: 304 stainless steel: invar 36: pure iron powder = 32:28:7:16. After calculation, the chemical composition of the mixed alloy powder is: C: 0.2%; Cr: 8.0 %; Ni: 6.1%; Mn: 0.8%; Si: 0.7%; Mo: 0.5%; V: 0.4%; the balance is Fe and unavoidable impurities.

[0068] S2: The mixing method is ball mill mixing. Put the weighed powder into a mixing bottle containing steel balls. The ratio of balls to materials is 1:10. Wrap insulating tape around the mixing bottle, and then put it in a ball mill roller for mixing for 6 hours. Machine speed is 350r / min.

[0069] S3: Fully dry the mixed powder prepared in S2, put it in a dr...

Embodiment 3

[0073] Select a piece of QP980 steel, whose Ms point is about 390°C, simulate its damage, and then polish and groove the damaged area, and perform laser additive repair, which specifically includes the following steps:

[0074] Change the powder preparation ratio in the implementation case to H13 steel: 304 stainless steel: invar 36: pure iron powder = 8:20:6:15, and the chemical composition of the mixed alloy powder is: C: 0.11%; Cr: 8.2%; Ni: 8.1%; Mn: 0.9%; Si: 0.6%; Mo: 0.2%; V: 0.2%; the balance is Fe and unavoidable impurities.

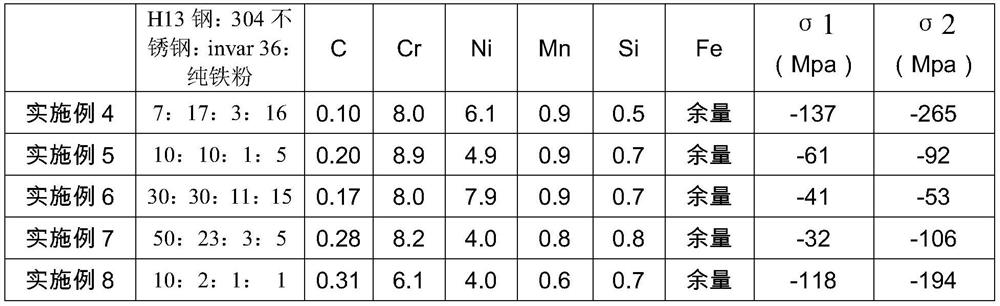

[0075] Then carry out mixing, drying, and laser additive repair according to S2, S3, and S4 in the implementation case 2. Finally, a dense and defect-free filling metal layer is obtained. The residual stress test results of the repaired area are σ1=-137Mpa, σ2=- 265Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com