Patents

Literature

1128 results about "Fatigue cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

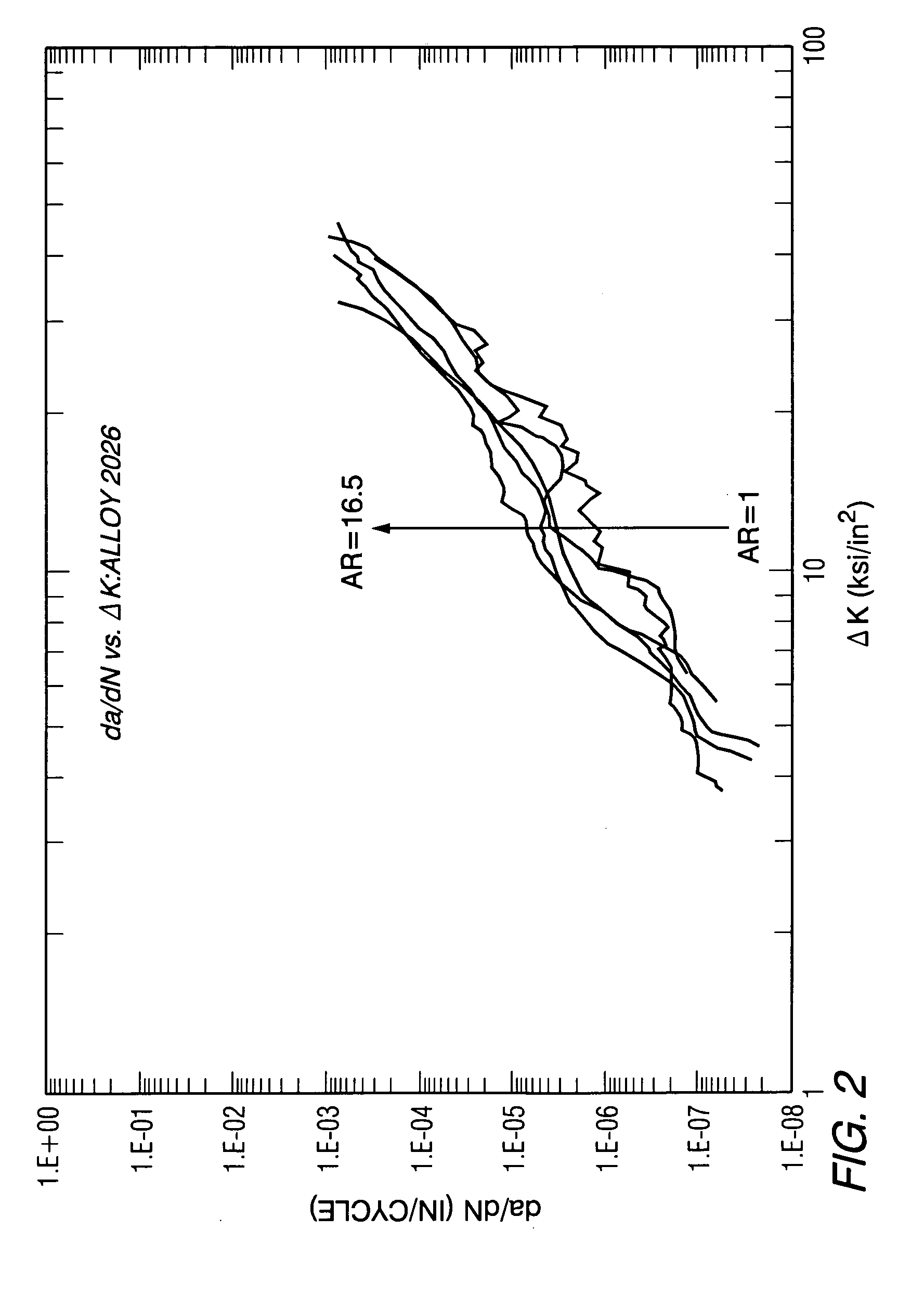

Aluminum-copper-magnesium alloys having ancillary additions of lithium

InactiveUS7438772B2Improve fracture toughnessEquivalent and improved fatigue crack growth resistanceSolubilityLithium

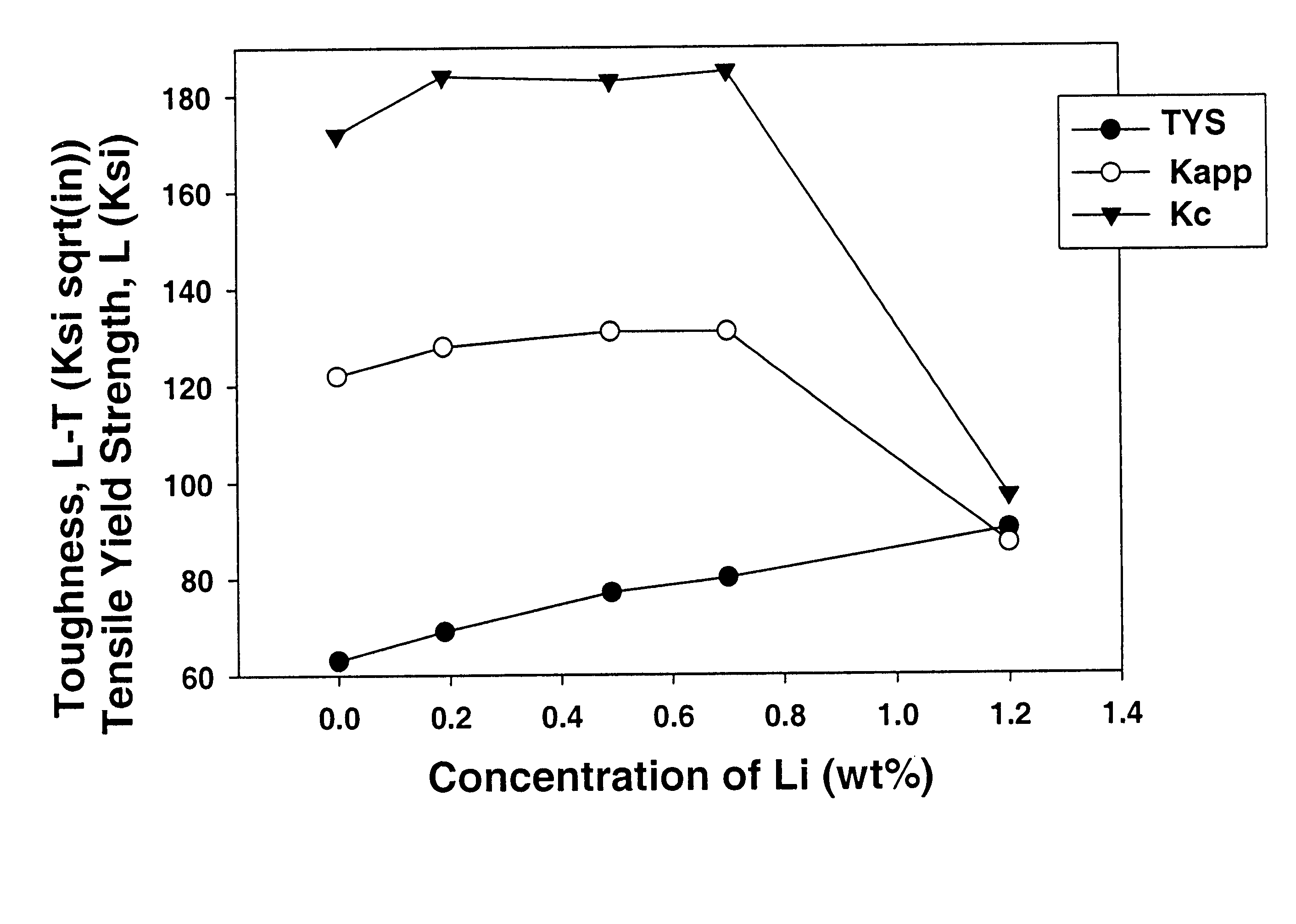

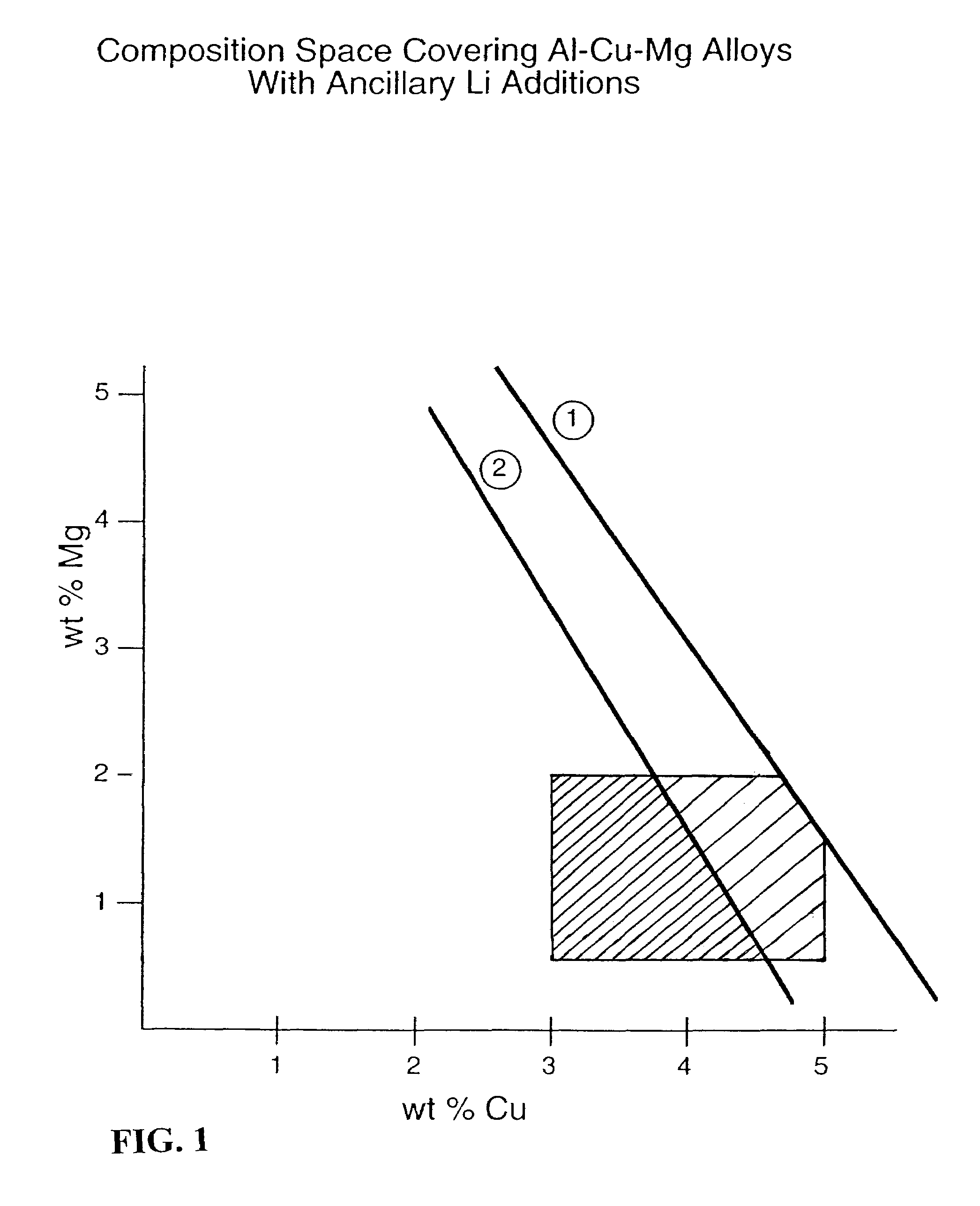

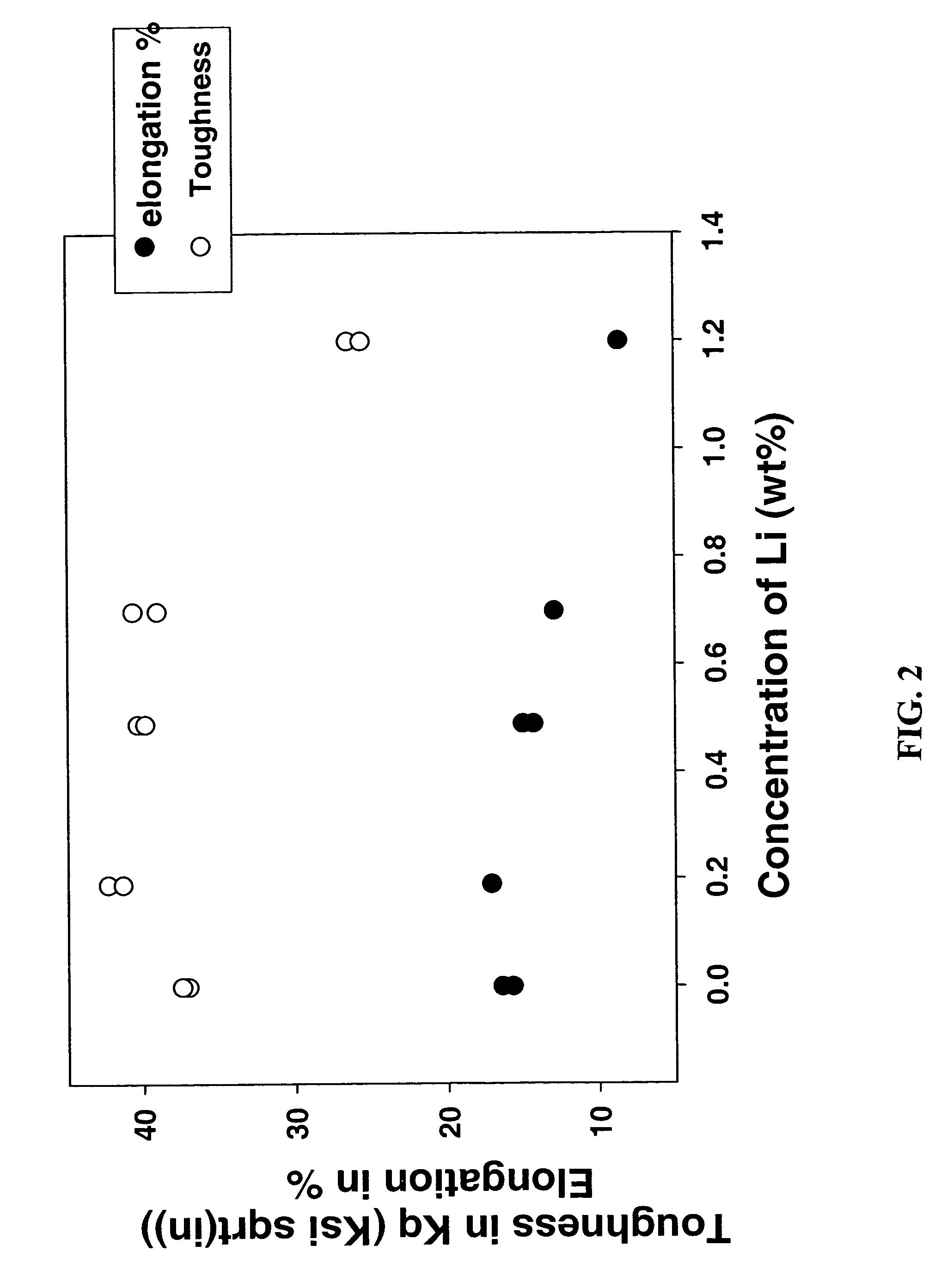

An aluminum-copper-magnesium alloy having ancillary additions of lithium. The alloy composition includes from about 3 to about 5 weight percent Cu, from about 0.5 to about 2 weight percent Mg, and from about 0.01 to about 0.9 weight percent Li. The combined amount of Cu and Mg is maintained below a solubility limit of the aluminum alloy. The alloys possess improved combinations of fracture toughness and strength, and also exhibit good fatigue crack growth resistance.

Owner:ARCONIC INC

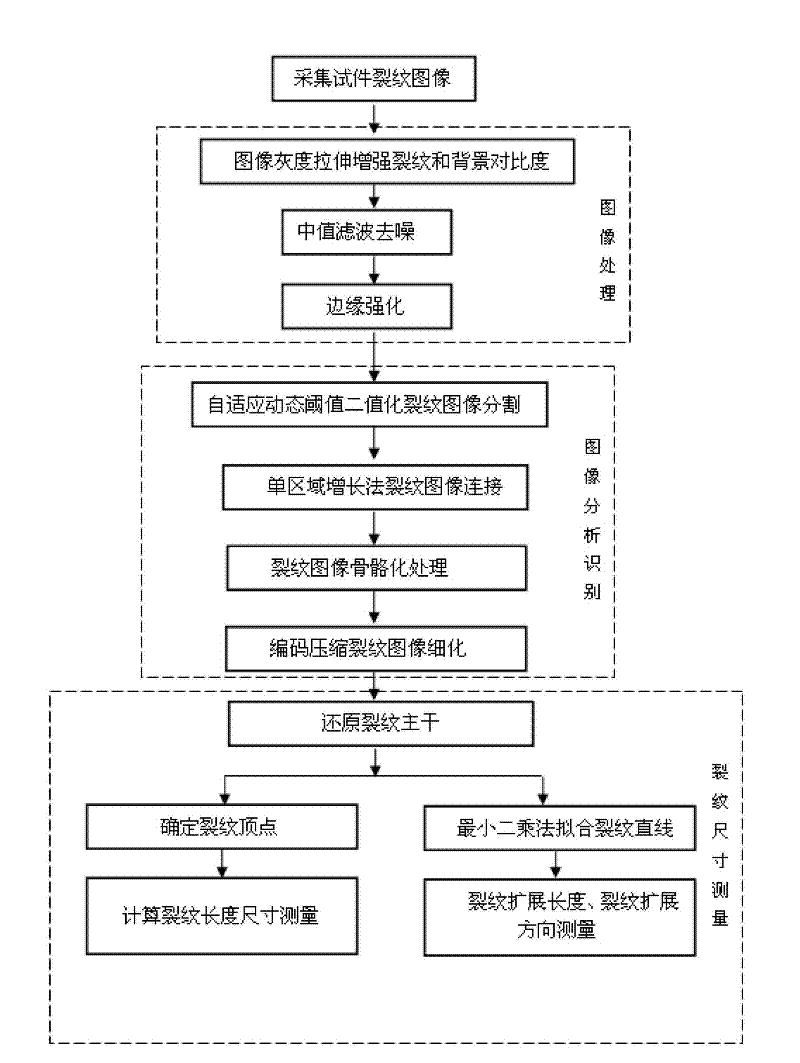

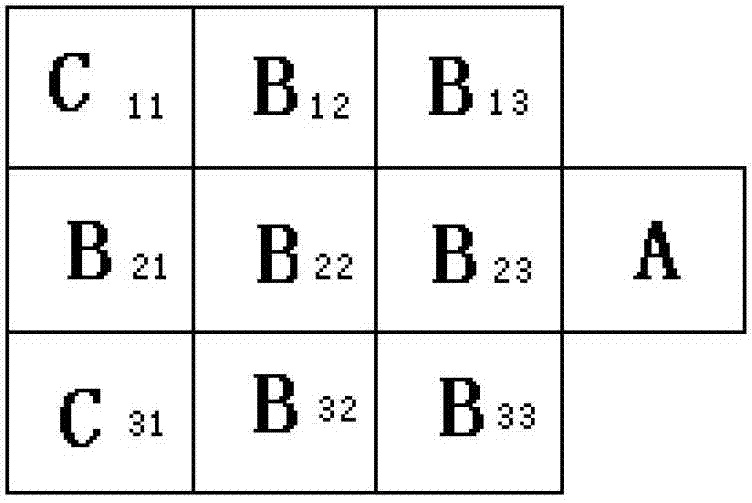

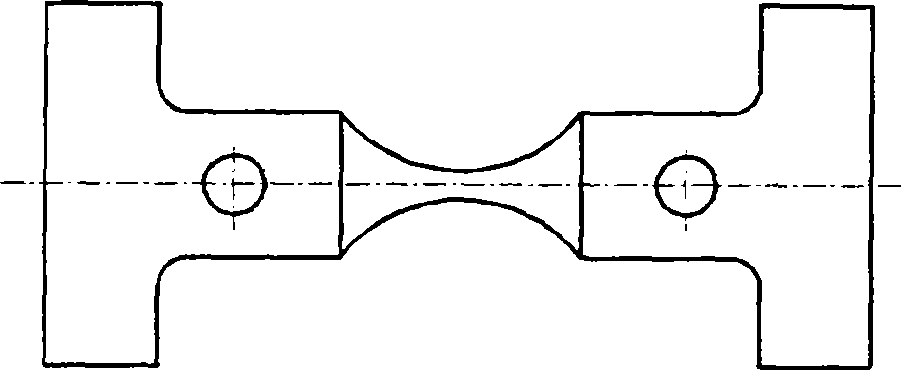

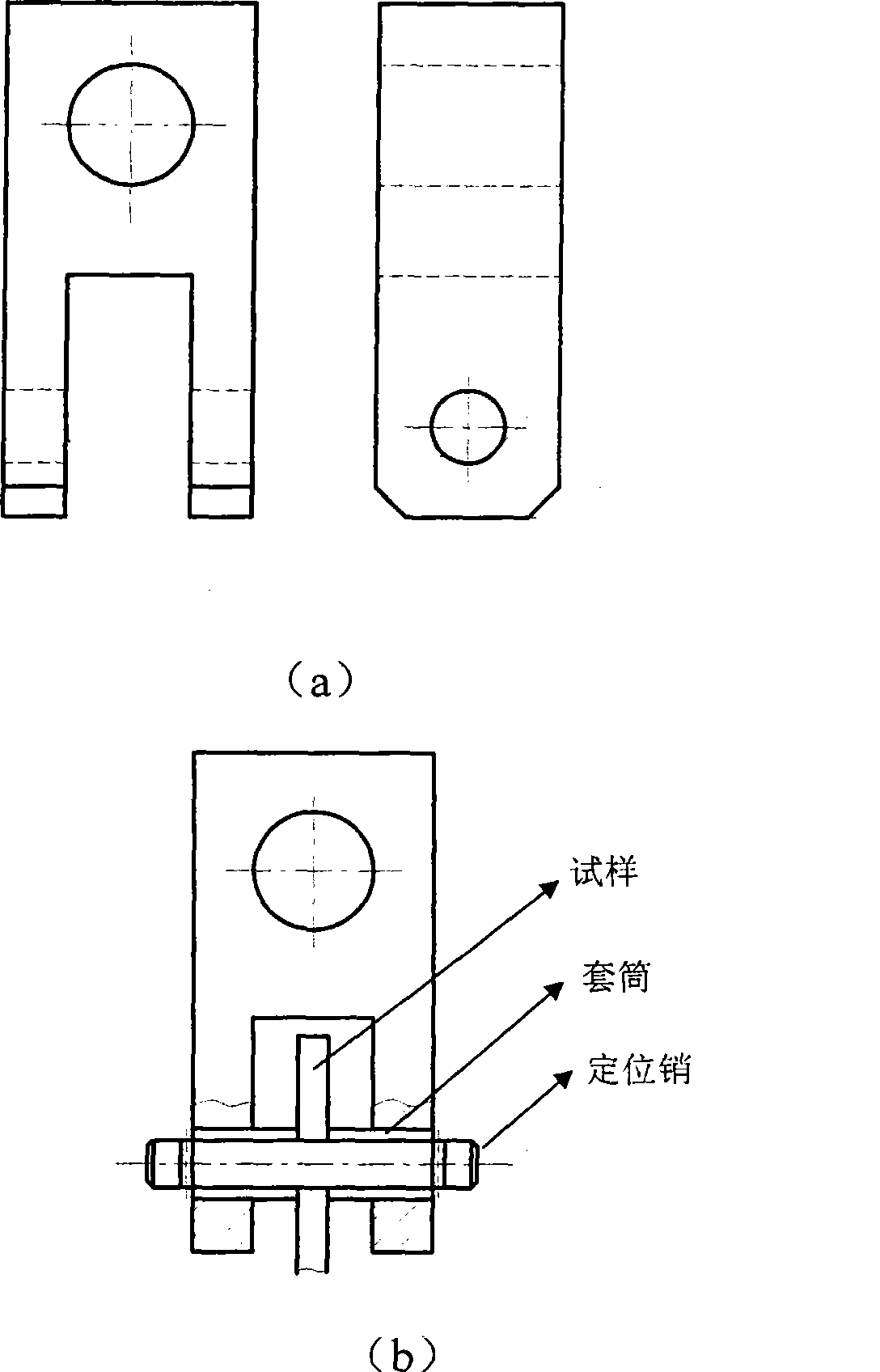

Dynamic crack length measurement method for machine vision fatigue crack propagation test

ActiveCN102692188AHigh measurement accuracyIntuitive visualization of the expansion processUsing optical meansMaterial strength using repeated/pulsating forcesAnti jammingInternational standard

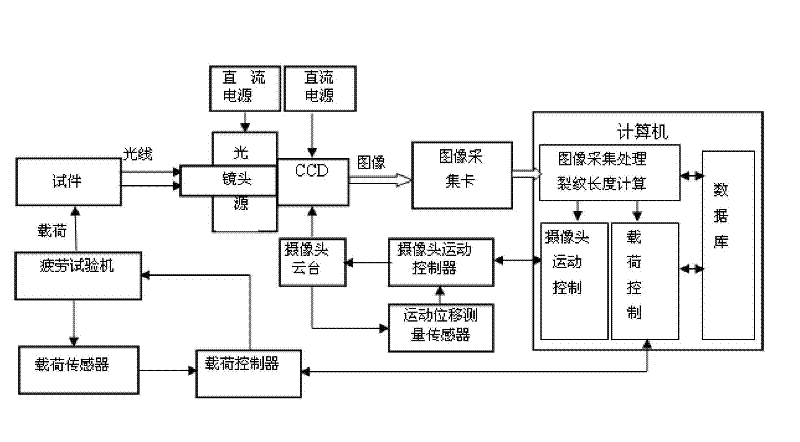

The invention provides a dynamic crack length measurement method for a fatigue crack propagation test based on the machine vision technology. The method comprises the following steps: 1, performing machine vision crack measurement system calibration; 2, performing fatigue test, wherein a test piece with precracks begins to generate fatigue cracks along the direction of the precracks, and the fatigue cracks extend; 3, collecting crack images, wherein a mode of collecting single-face images of the test piece and a mode of collecting two-side images of the test piece are used in the fatigue crack propagation test; 4, reinforcing the collected images; 5, identifying the position of the trunk of cracks, as well as peaks and identifying directions of cracks by using the method of image analysis and crack identification; and 6, calculating the actual crack identifying length and crack length. The method has the advantages of simplifying the process and reducing work load; and by the method, the crack identifying process can be visually and accurately observed and recorded, the calculated crack length specified by the international standard can be measured accurately. The method also has the advantages of high measurement accuracy and good system anti-jamming performance.

Owner:平邑经济开发区投资发展有限公司

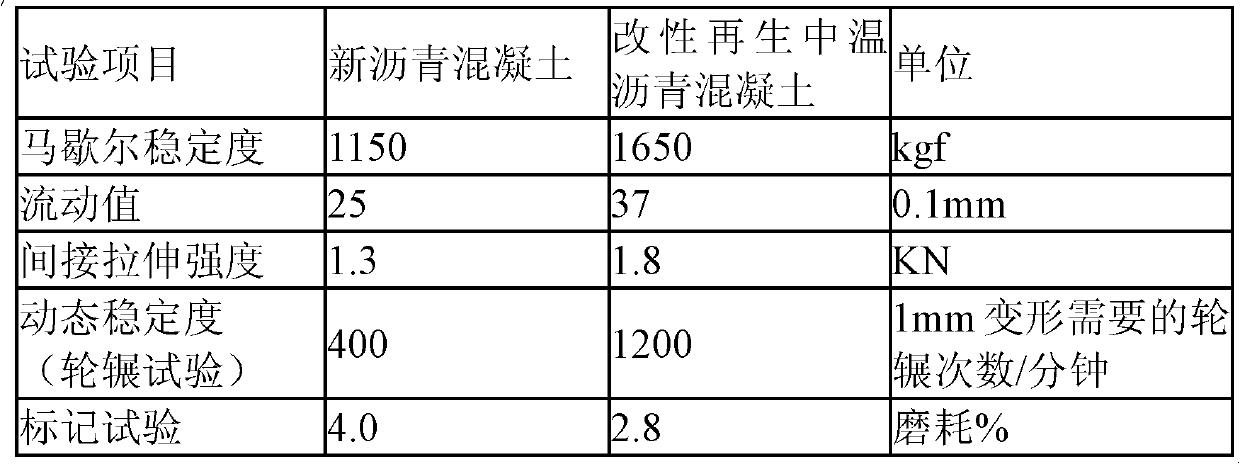

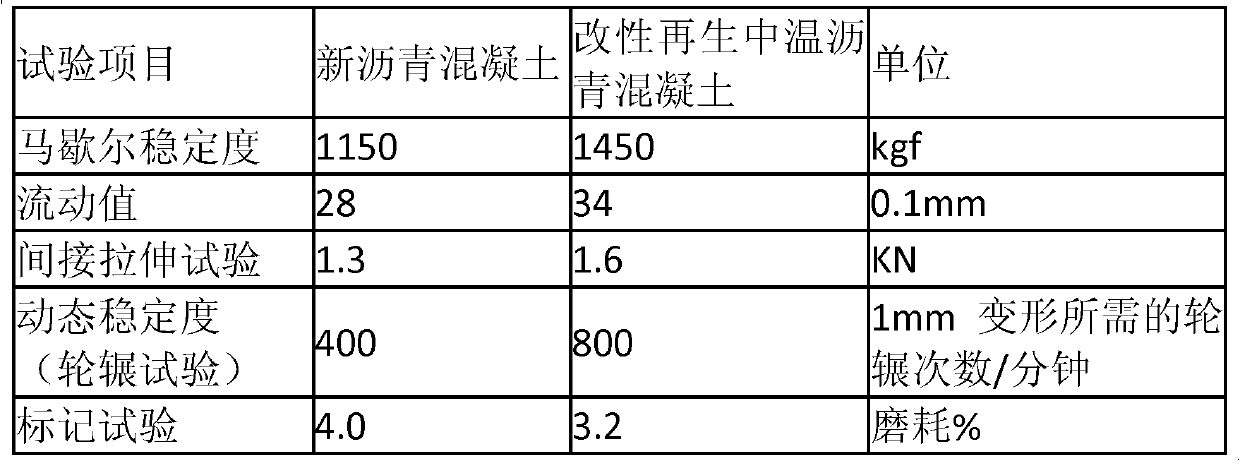

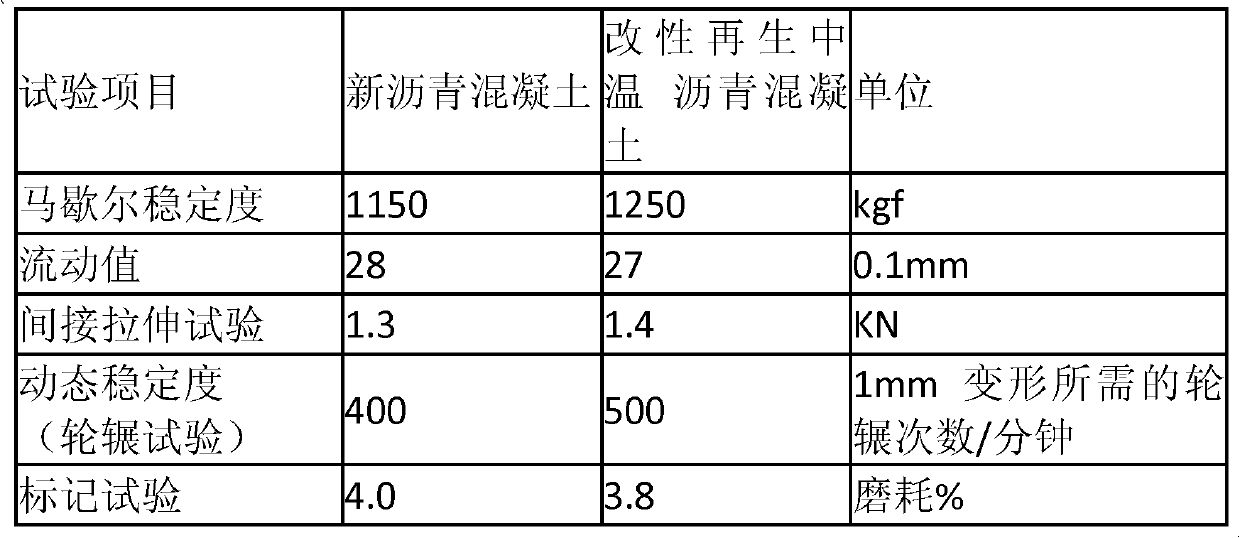

Temperature-adjusted and modified recycled ascon composition for reusing 100% of waste ascon for road pavement, and method for manufacturing same

InactiveCN102448907AImprove qualityLow production temperatureIn situ pavingsSolid waste managementCost savingsParticle-size distribution

Provided is a temperature-adjusted and modified recycled ASCON composition for reusing 100% of waste ASCON for road pavement, and a method for manufacturing same, wherein the composition is used in asphalt pavement as a material for the wearing course, surface course, binder course, and base course, and the method comprises: feeding 100 wt % of waste ASCON aggregate having up to a 53 mm particle size distribution into a mixer via a feeding inlet for new aggregate; adding 0.1 to 20 wt % of a recycling modifier and 0.1 to 20 wt % of a temperature-adjusting additive to the waste ASCON via the feeding via the inlet for new aggregate; and homogeneously mixing said materials at 5 to 180 DEG C for 0.5 to 3 minutes. The recycling modifier improves the physical properties of recycled ASCON, while the temperature-adjusting additive adjusts the temperatures for producing and constructing recycled ASCON. The present invention may provide economic, social and technological conveniences by improving the overall recycling technology of waste ASCON. The conveniences may be achieved by virtue of: cost-saving in production by using only waste ASCON without any new materials; saving waste disposal costs; preventing the destruction of nature to obtain aggregate; reducing the consumption of new asphalt; preventing environmental pollution through the reuse of waste products; preventing the early occurrence of plastic deformation and fatigue cracks due to improving the quality of the recycling modifier; economic benefits from the prolonged lifespan of road pavement; the possibility of being used as a material for the wearing course and surface course of major roadways; saving energy in the production and construction of recycled ASCON by adding the temperature-adjusting additive; and reducing greenhouse gas emissions.

Owner:许政道

Modified asphalt binder material using crosslinked crumb rubber and methods of manufacturing the modified asphalt binder

ActiveUS20060249049A1Increase elasticityAcceptable rotational viscosityIn situ pavingsCoatingsCross-linkPolymer science

Bituminous asphalt binder materials which are modified by the addition of crumb rubber or ground tire rubber and a cross-linking agent are described. In addition, methods are provided for producing a modified asphalt binder containing crumb rubber or ground tire rubber and a cross-linking agent. The modified asphalt binders comprise neat asphalt, crumb rubber, one or more acids and a cross-linking agent. Optionally, the modified asphalt binder may include one or more polymer additives. The crumb rubber may be obtained from recycled truck and / or automobile tires. The addition of crumb rubber in asphalt binders can improve the consistency and properties of the asphalt binders at high and low temperatures. In particular, the modified asphalt binders of the present invention exhibit improved elastic behavior, resulting in improved performance of roads or other surfaces paved using the modified asphalt binder. Road resistance to permanent deformation, fatigue cracking and thermal cracking is improved by use of the modified asphalt binder.

Owner:INNOPHOS INC

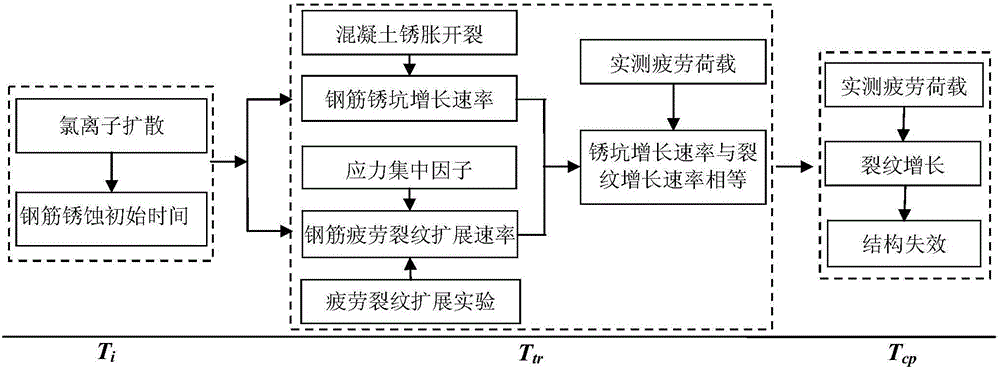

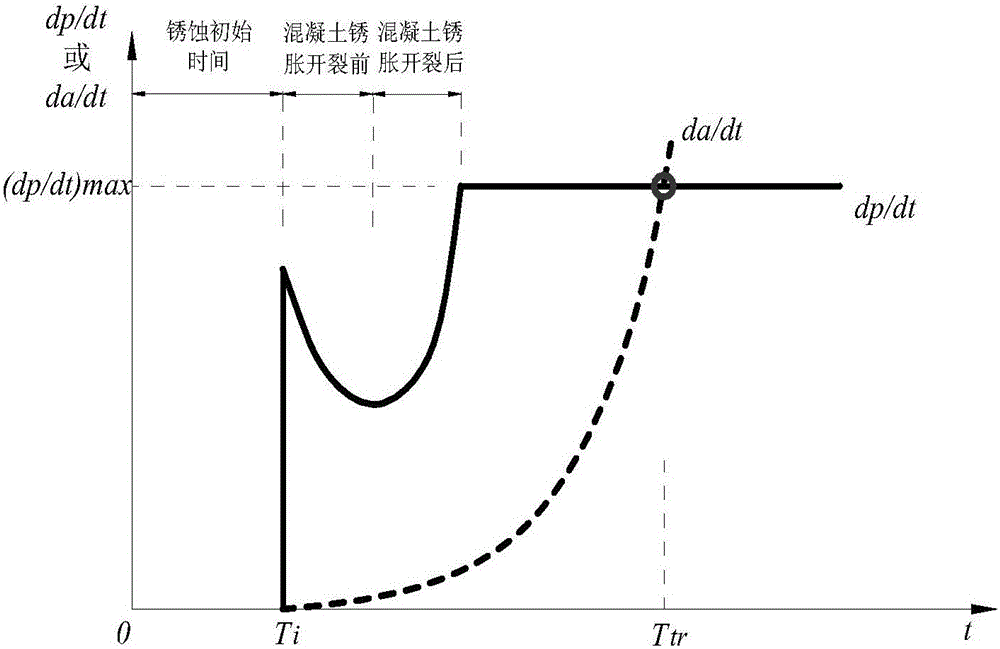

Method for evaluating fatigue life of aged reinforced concrete bridge

ActiveCN105825030AThe prediction method is reasonableGeometric CADForecastingStress concentrationCrazing

The invention discloses a method for evaluating the fatigue life of an aged reinforced concrete bridge. The method comprises the following steps of obtaining initial corrosion time of reinforcement in concrete based on the second diffusion law of Fick, and considering the influence of concrete cracking due to corrosion expansion in a corrosion rate model; adopting a small crack growth and near threshold growth analysis and determining relevant parameters of fatigue crack propagation rate of materials by developing a fatigue crack propagation test of reinforced concrete materials; performing a corrosion fatigue test or finite element analysis on corroded reinforcement to obtain stress concentration factors at different corrosion levels, and integrating into a stress intensity factor model to obtain the fatigue crack propagation rate of the reinforcement under the influence of corrosion; comparing the magnitude of a corrosion pit growth rate and the fatigue crack propagation rate and gradually converting into a single growth analysis on fatigue cracks of the reinforcement; meanwhile, combining with vehicle load observing information to realize life evaluation of a bridge at different service stages. The prediction method disclosed by the invention is reasonable and high in popularization, and can provide technical support for evaluating the life of the concrete bridges.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

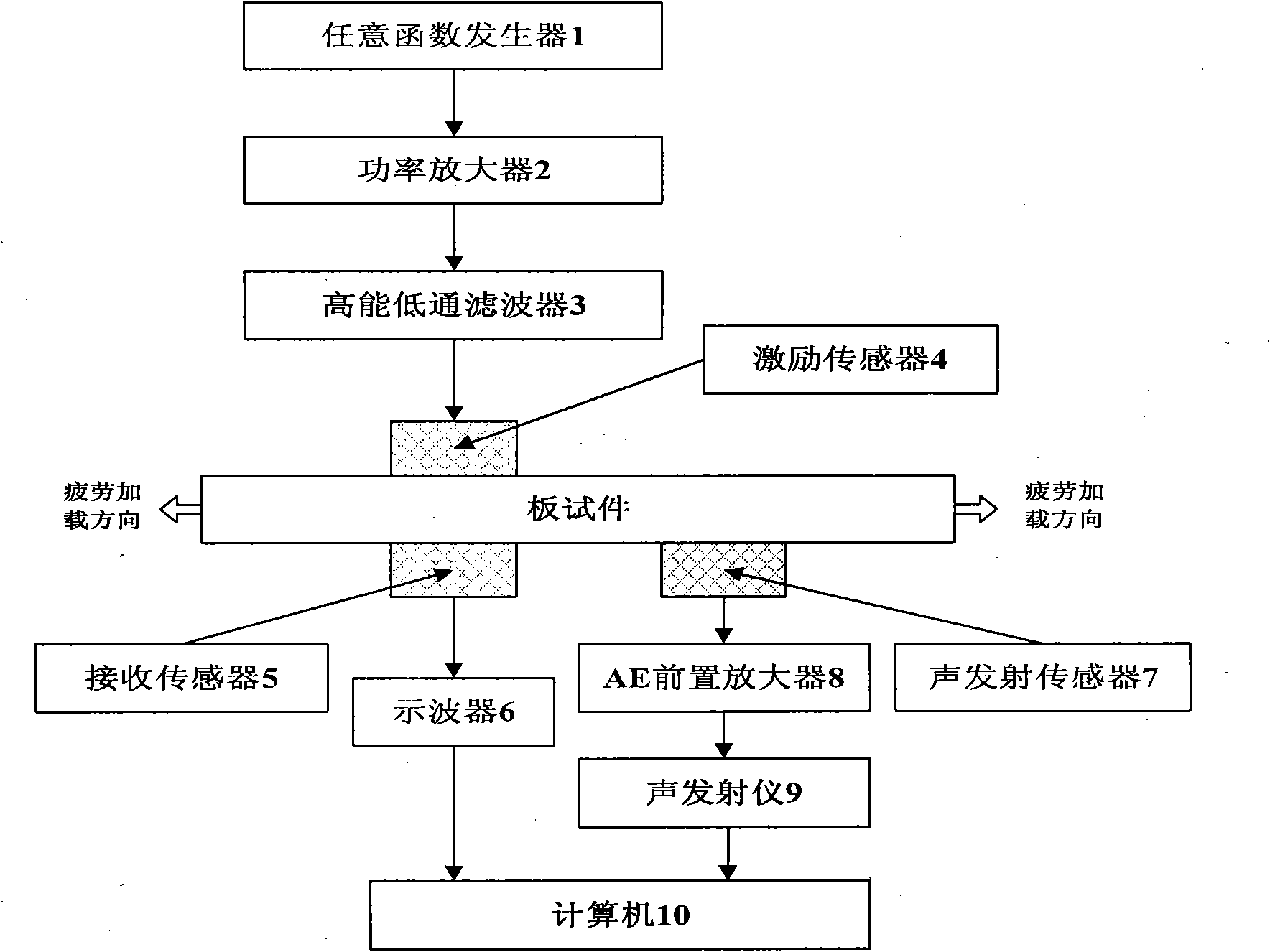

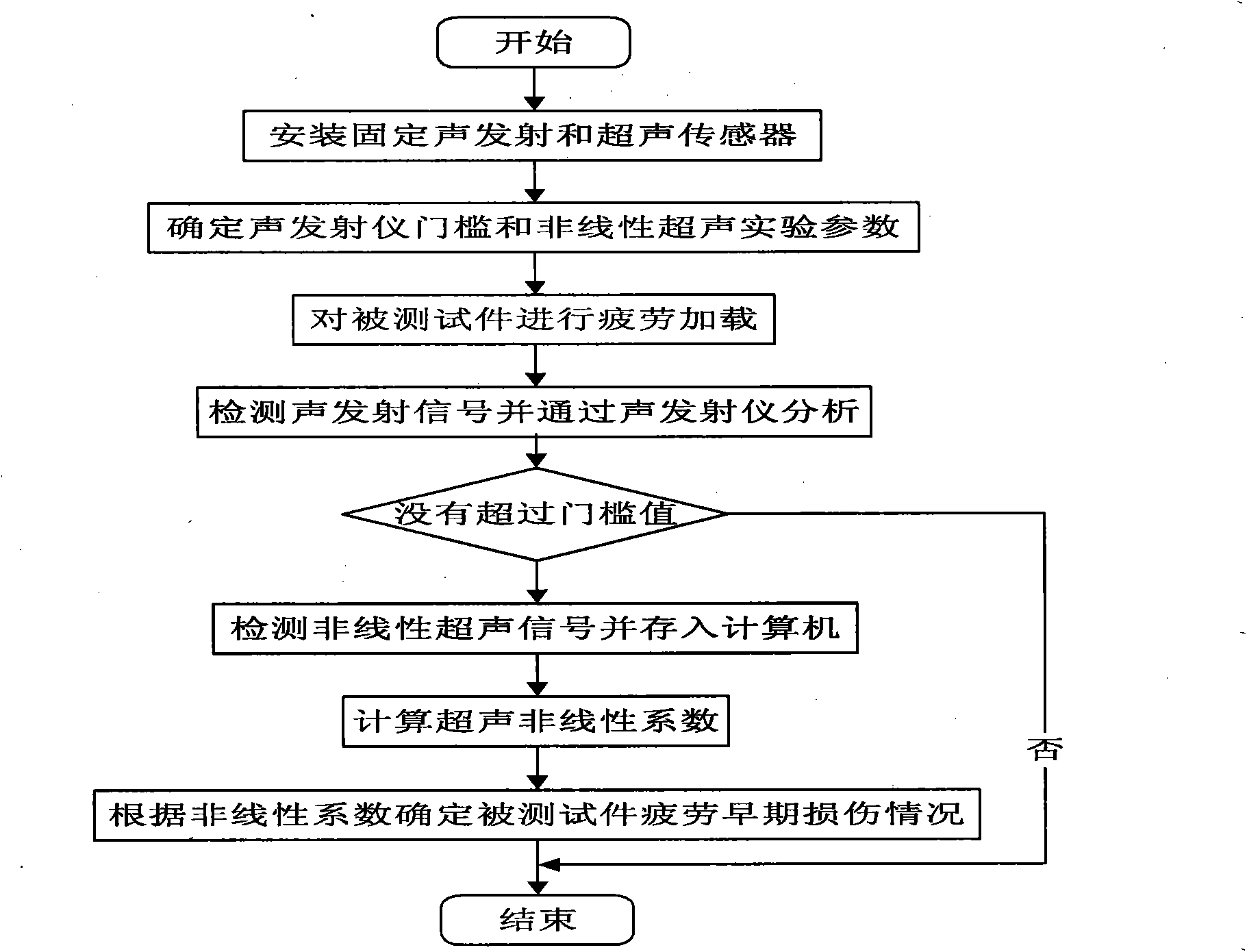

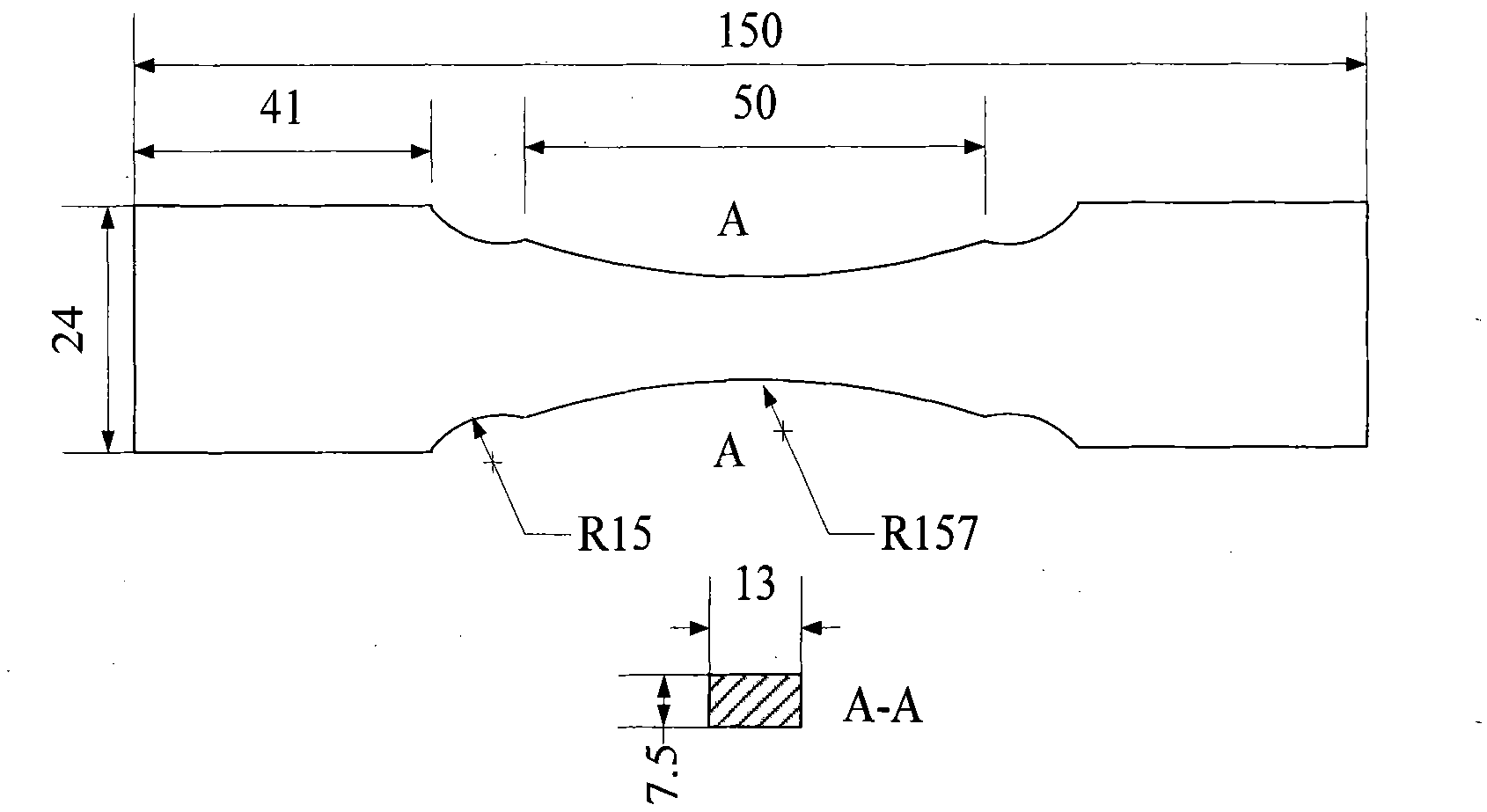

Method for non-linear ultrasonic online detection of early fatigue damage to metal material

InactiveCN101806778ARealize the whole process of fatigue detectionSolve misjudgmentMaterial analysis using acoustic emission techniquesFatigue damageSonification

A method for the non-linear ultrasonic online detection of early fatigue damage to a metal material belongs to the field of nondestructive detection. The method comprises the following steps: determining an excitation signal parameter according to the thickness of a tested piece and inputting the parameter to an arbitrary function generator to generate a sound signal; determining a threshold value of an acoustic emission instrument according to the amplitude of a no-load noise signal; performing fatigue loading on the tested piece, continuously detecting an acoustic emission signal in real time with an acoustic emission sensor, amplifying the acoustic emission signal, inputting the acoustic emission signal into the acoustic emission instrument, and judging ring with the acoustic emission instrument when the amplitude of the acoustic emission signal exceeds the preset the threshold value of the acoustic emission instrument; detecting a non-linear ultrasonic signal at equal time interval if the acoustic emission instrument does not display the ring or the times of the continuous ring is not more than an empirical value; and stopping detection if the displayed ring times is more than the empirical value, because fatigue cracks are generated and develop. On the basis of non-linear ultrasonic nondestructive detection, the method of the invention introduces acoustic emission technique, so the method does not make incorrect judgment when detecting the early fatigue damage to the metal material and realizes continuous online detection.

Owner:BEIJING UNIV OF TECH

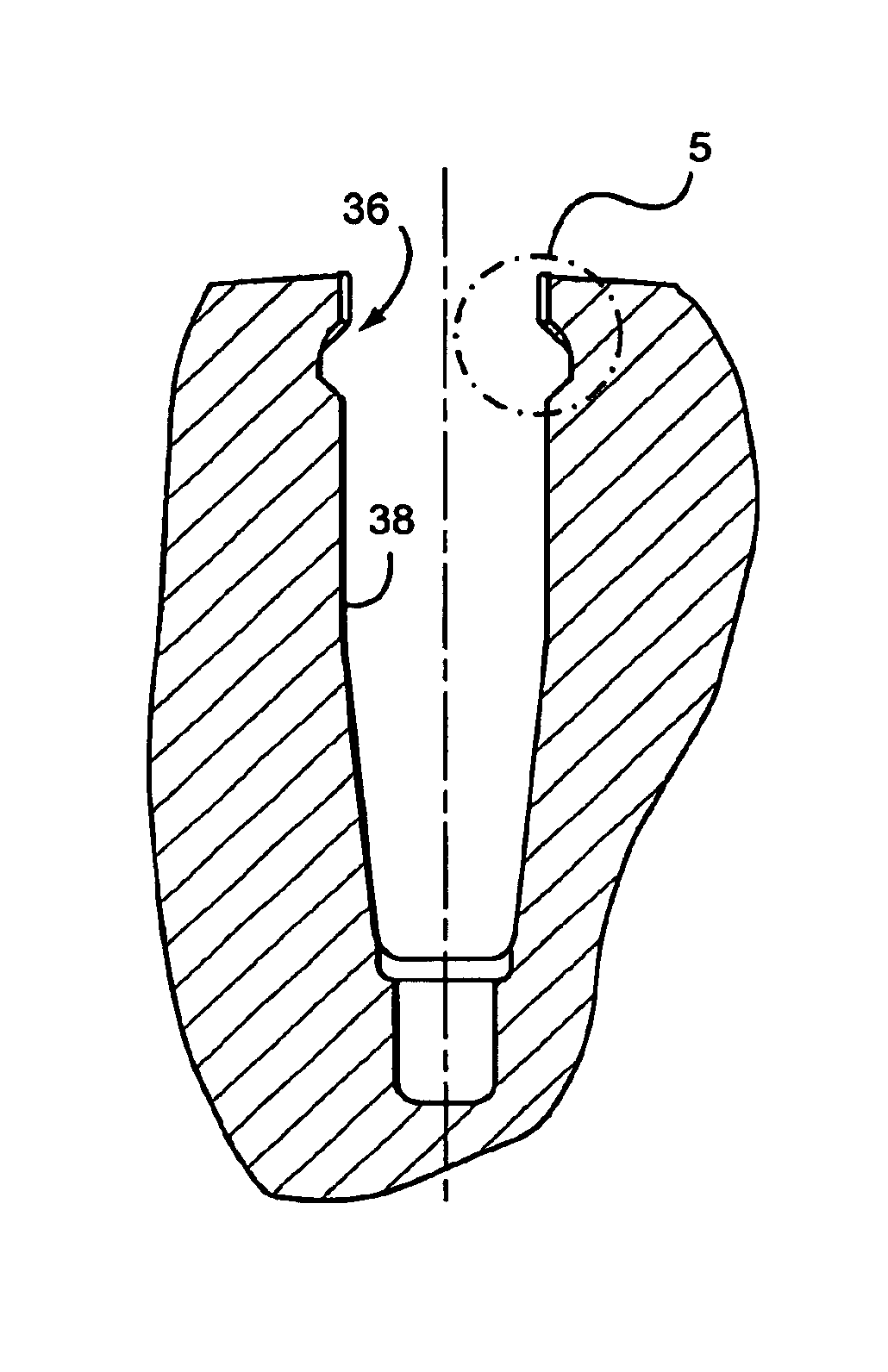

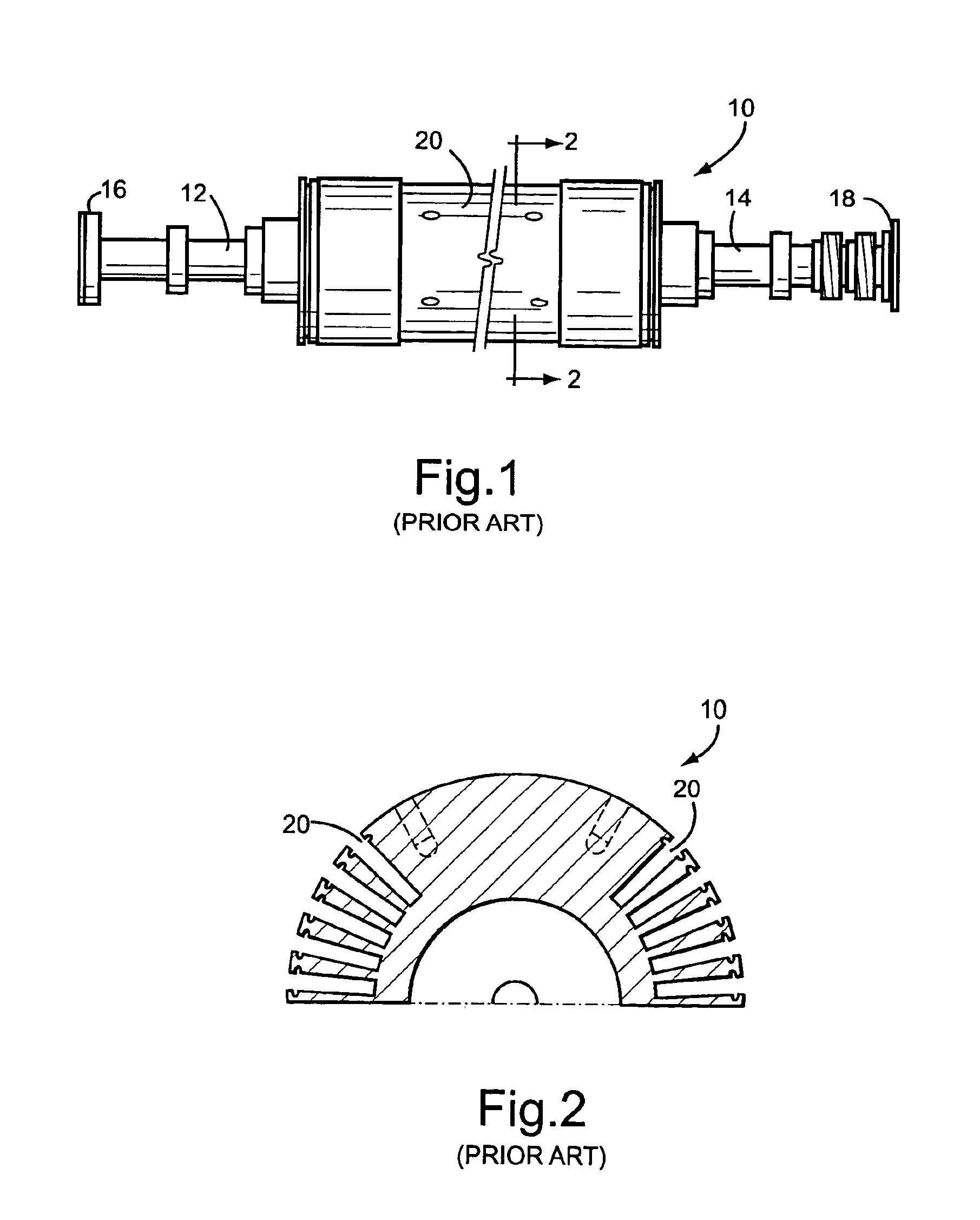

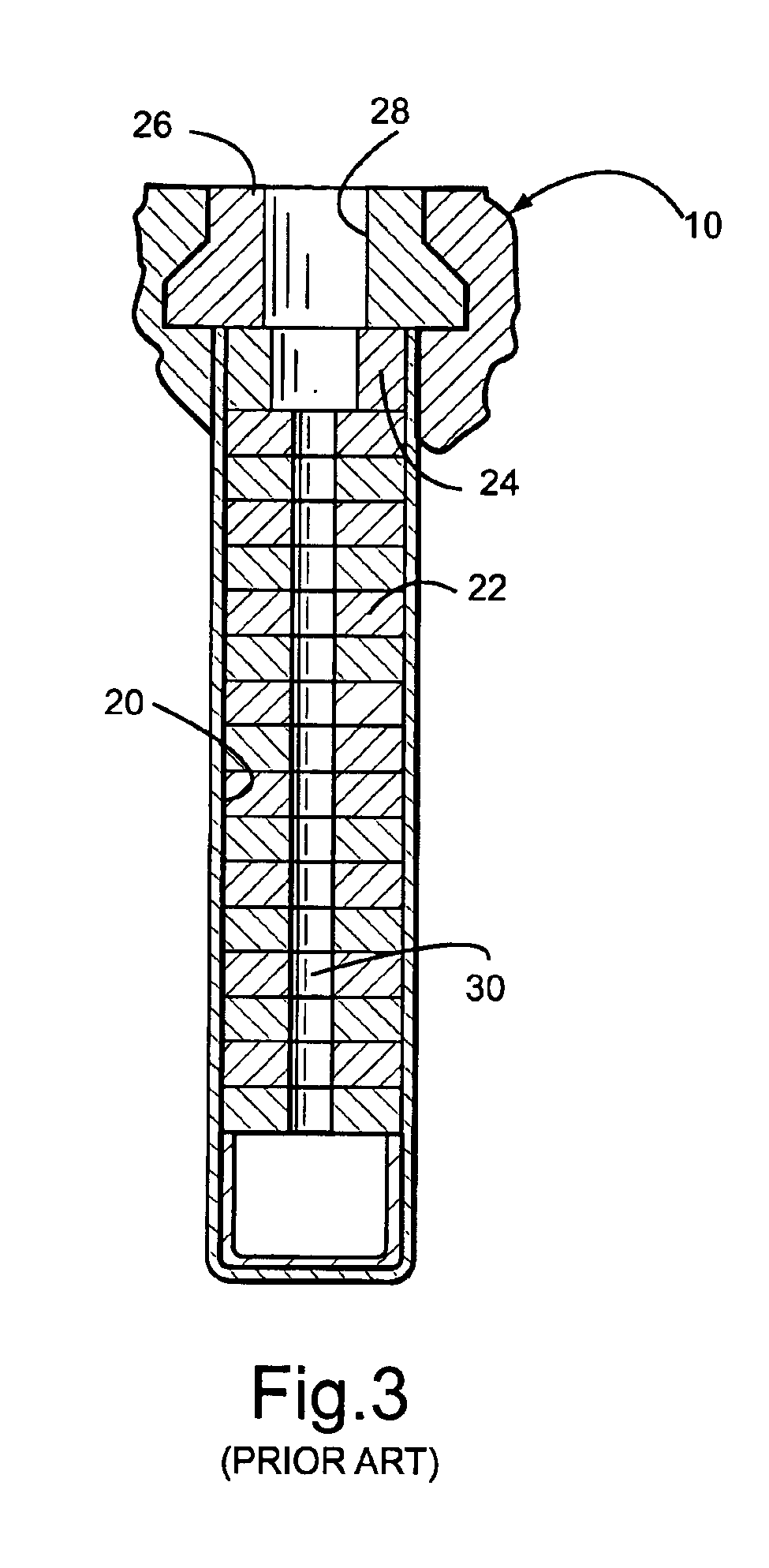

Generator rotor fretting fatigue crack repair

InactiveUS6849972B1Reduces the low and high cycle fatigue life of the rotorReduces low and high cycle fatigue lifeWindingsMagnetic circuit rotating partsFrettingClassical mechanics

A method of repairing a crack in at least one side of a dovetail portion of a generator rotor coil slot wall, the dovetail portion having received at least two axially adjacent steel wedges and including at least a radial entry surface, an inwardly tapered surface and an intermediate radial surface, the method comprising a) machining a groove at least partly along the inwardly tapered surface to remove damaged material from the coil slot wall; and b) replacing the at least two axially adjacent steel wedges.

Owner:GENERAL ELECTRIC CO

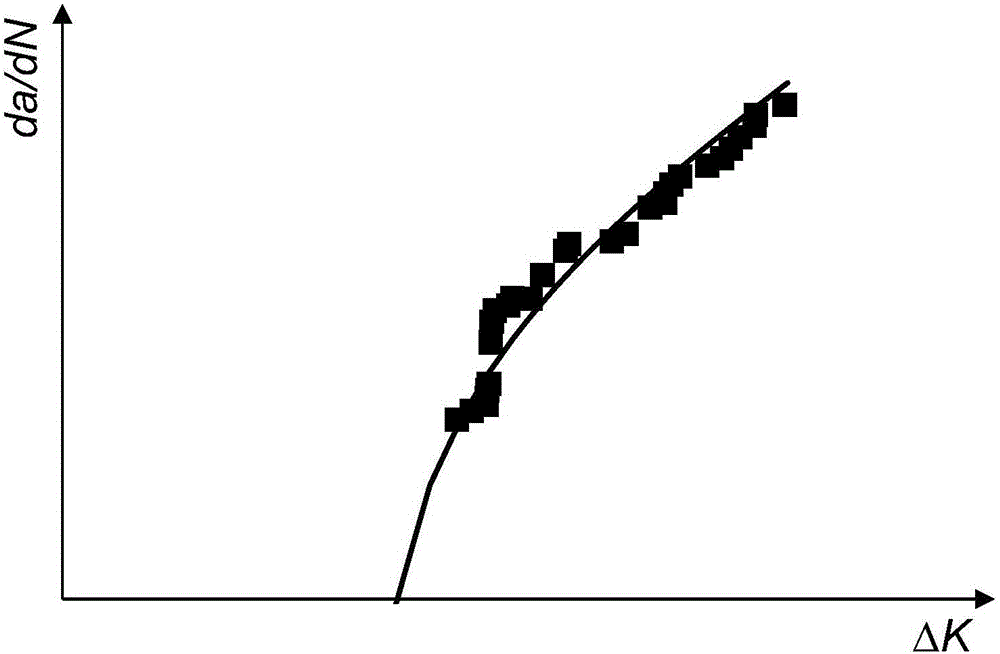

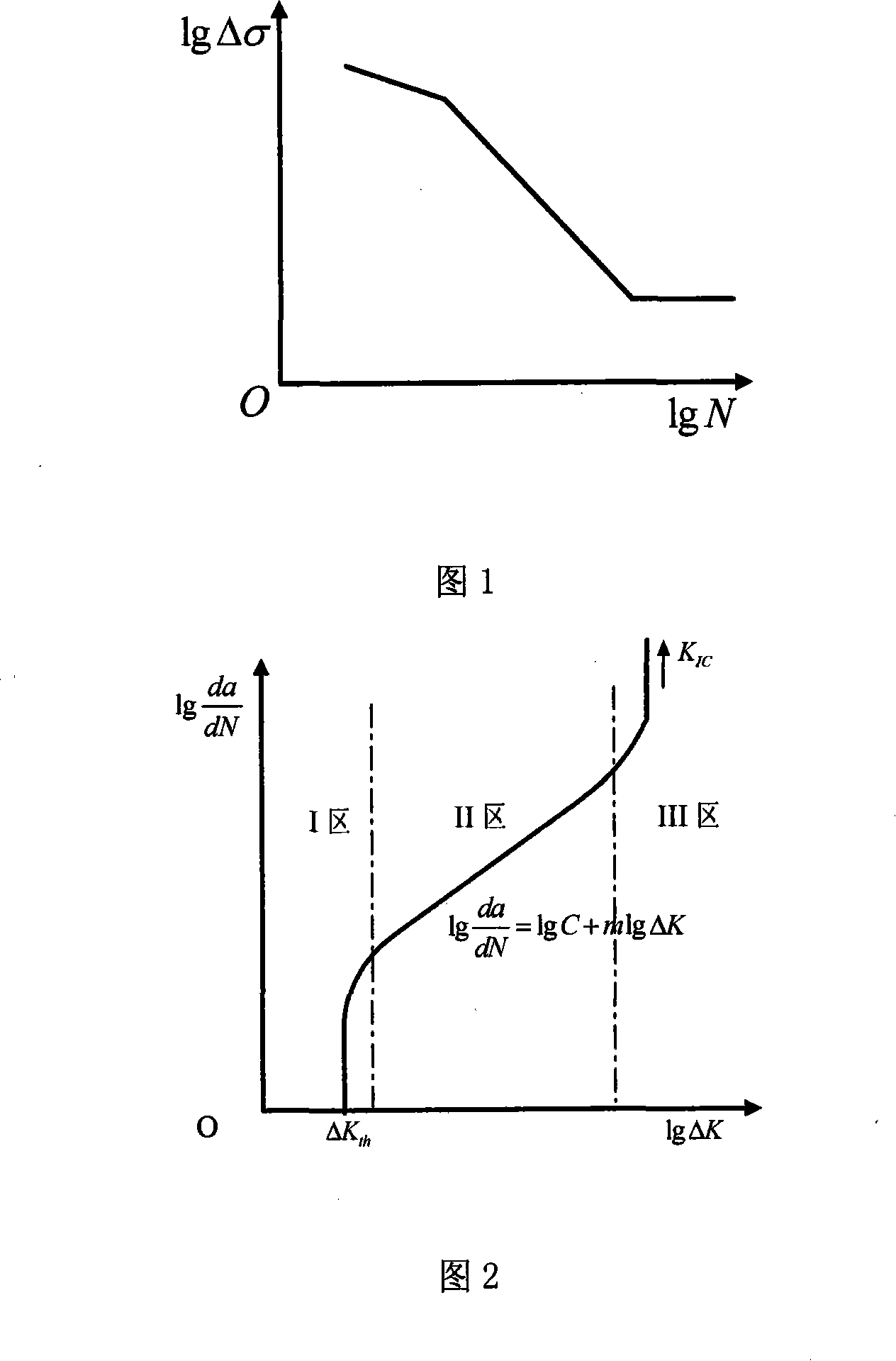

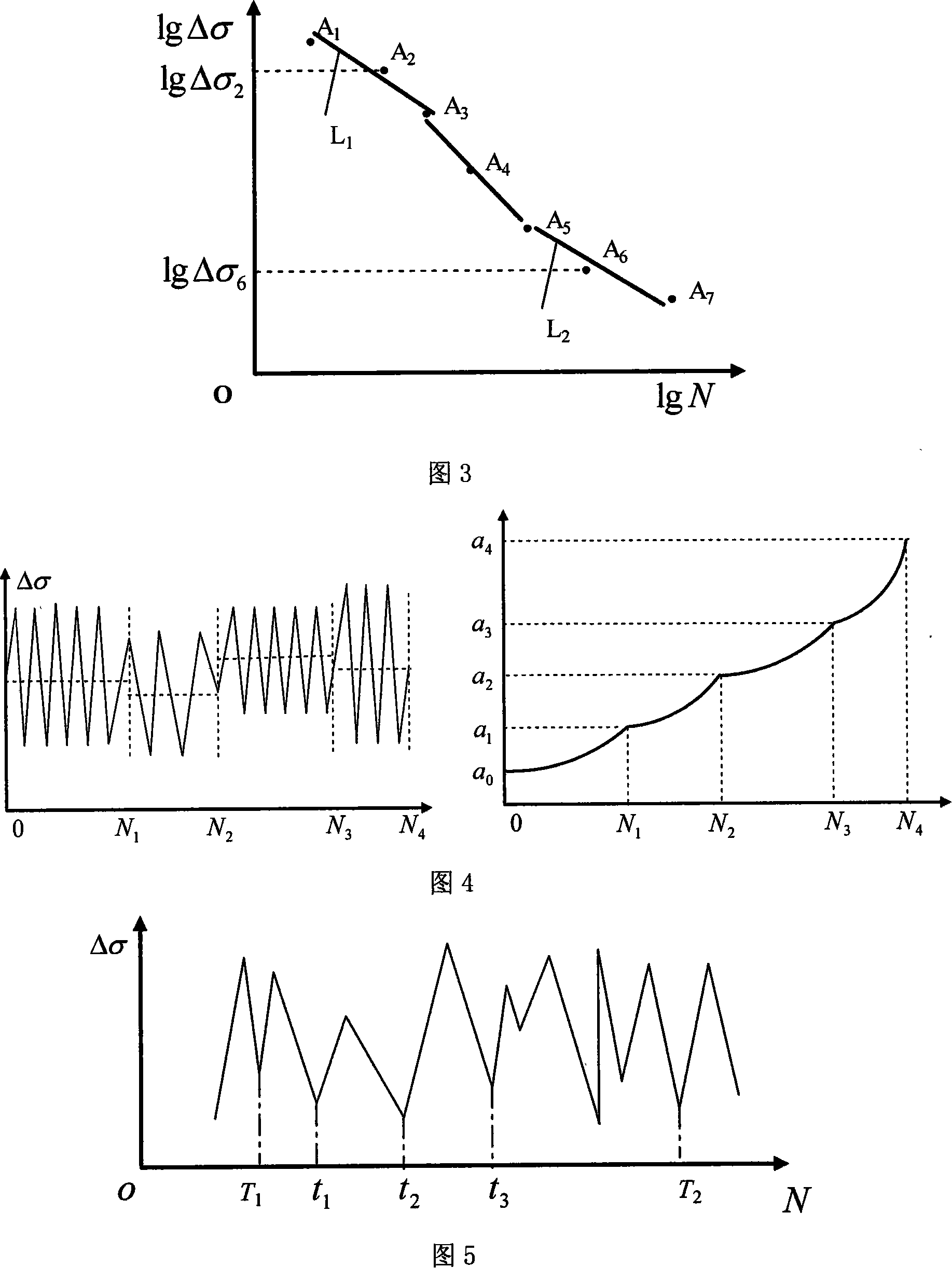

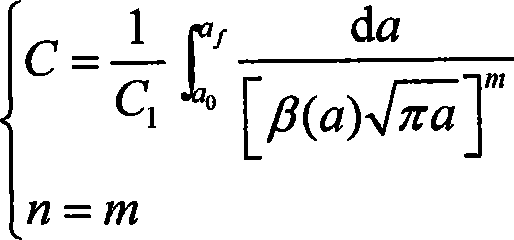

Mechanical structure crack expansion rate and crack expansion life span predication method

InactiveCN101122560ASave moneyShorten the development cycleUsing mechanical meansComplex mathematical operationsHysteresisCrazing

A crack growth rate and crack growth life prediction method for a mechanical structure belongs to a calculation method for fatigue crack growth rate and crack growth length of the mechanical structure. At first, a relationship between S-N and P-S-N curve expressions (power function form) and a crack growth rate curve expression (Paris formula) is built up in the method. A determination method of the crack growth rate under the conditions of block spectrum load, overload hysteresis load and random load is proposed. And a determination method of Paris curve parameters is provided when the S-N and P-S-N curves cannot be expressed in power function form. And a method for improving the prediction precision of the crack growth rate and the crack growth life is proposed. The S-N and P-S-N curves are used by the method to predict the crack growth rate and the crack growth life. Therefore, the method has the advantages of little dependence on tests and high precision and can shorten the product development period and save much manpower, material resources and financial resources.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

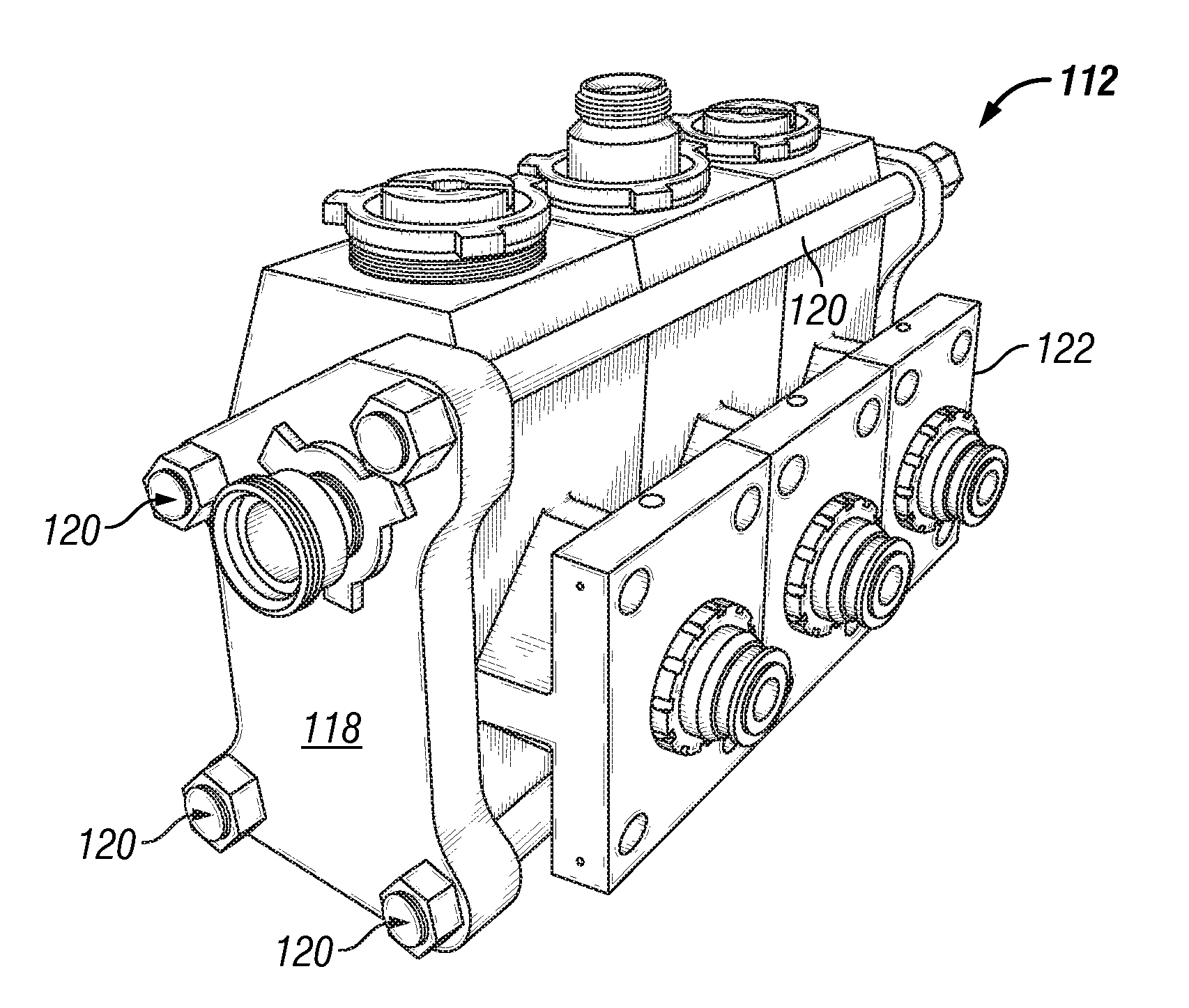

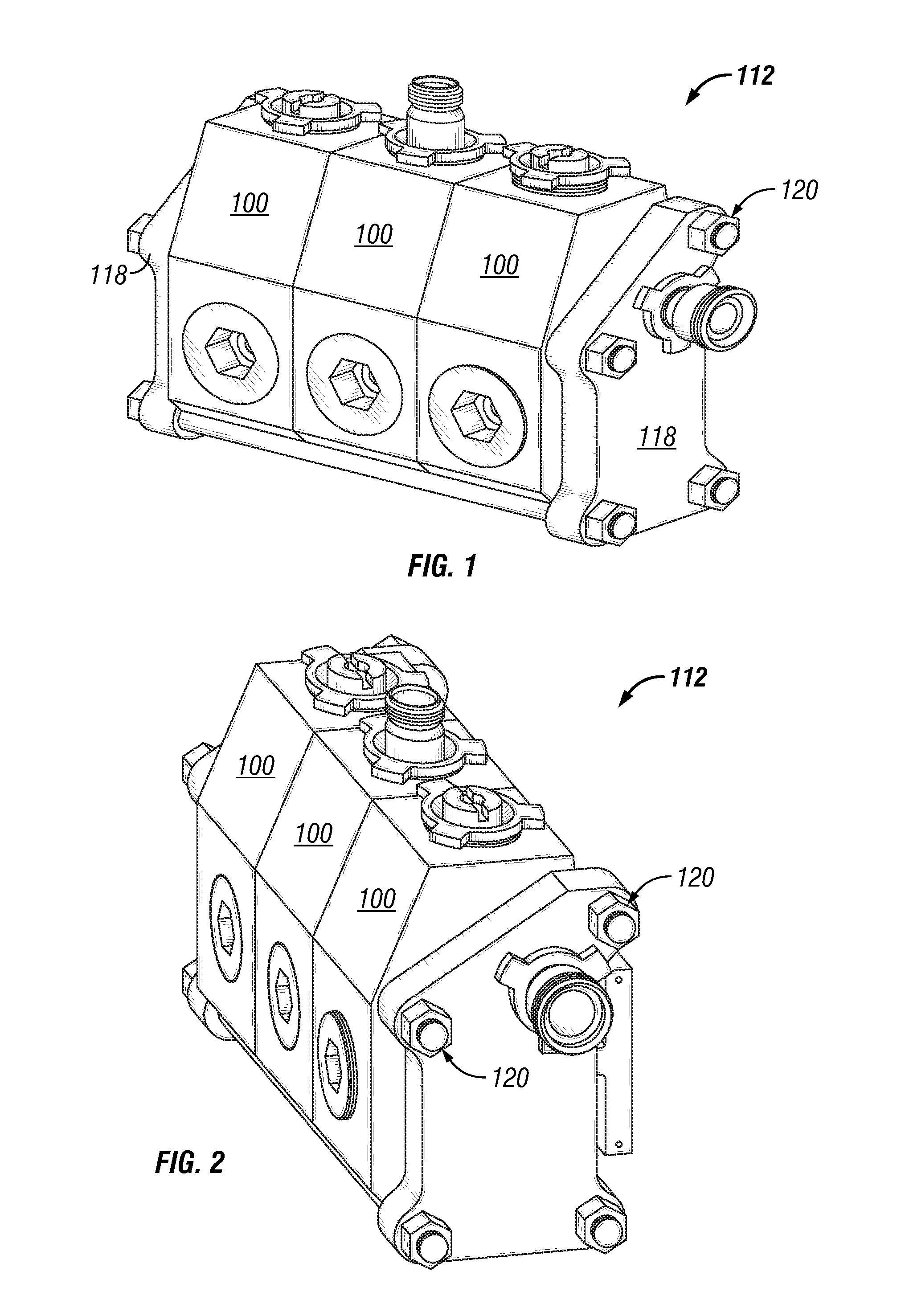

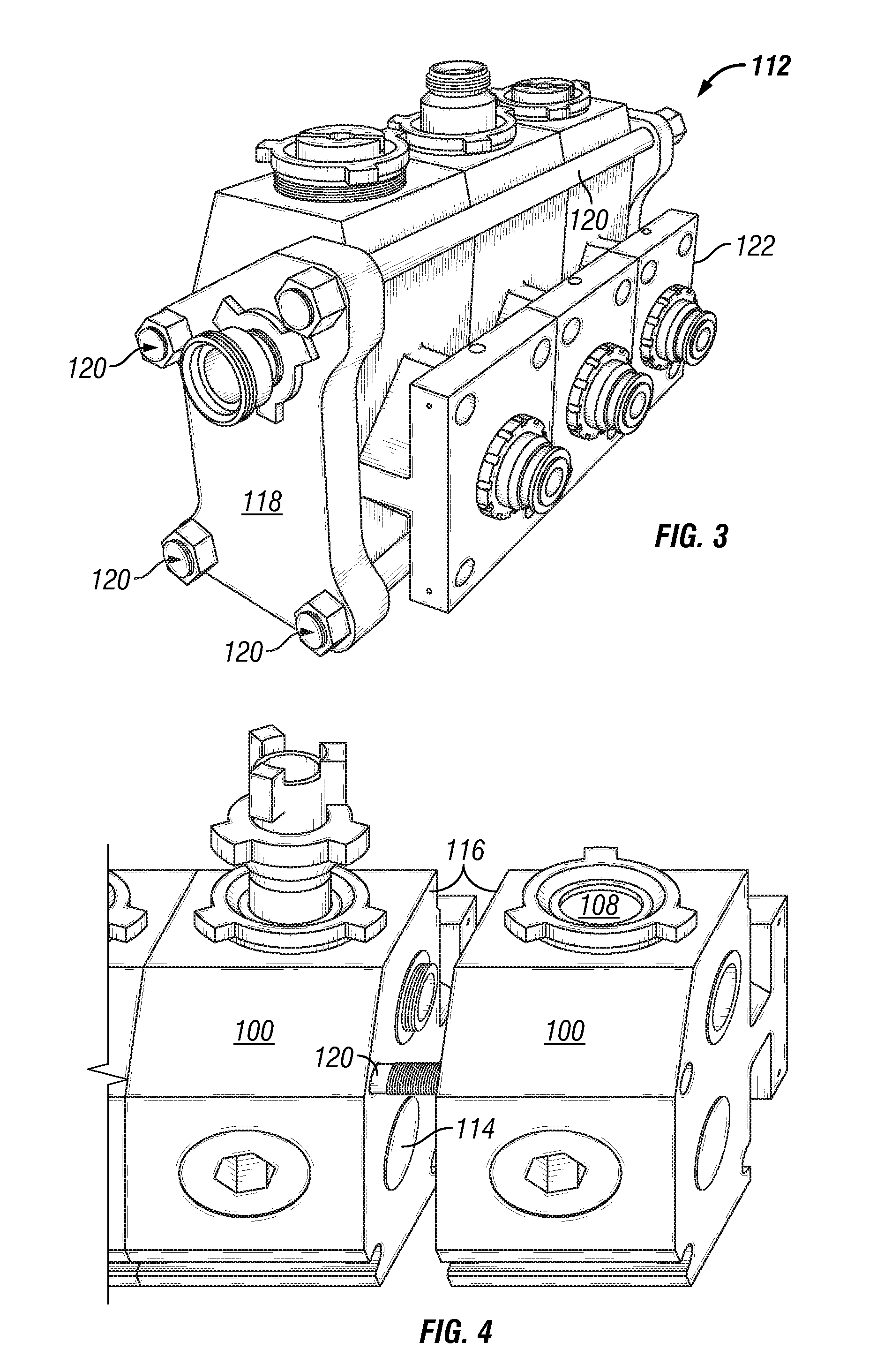

Pump body

ActiveUS20110081268A1Preventing initiationAvoid fatigue crackingPortable framesValve arrangementsEngineeringFatigue cracking

A multiplex fluid pump assembled from a plurality of pump bodies connected side by side between opposing end plates with a plurality of fasteners tightened to compress the pump bodies between the end plates. Raised surfaces on opposite exterior side surfaces of each pump body are engaged with an adjacent end plate or an adjacent pump body to apply a pre-compressive force at the raised surfaces and thereby inhibit the initiation of fatigue cracks.

Owner:LIBERTY OILFIELD SERVICES LLC

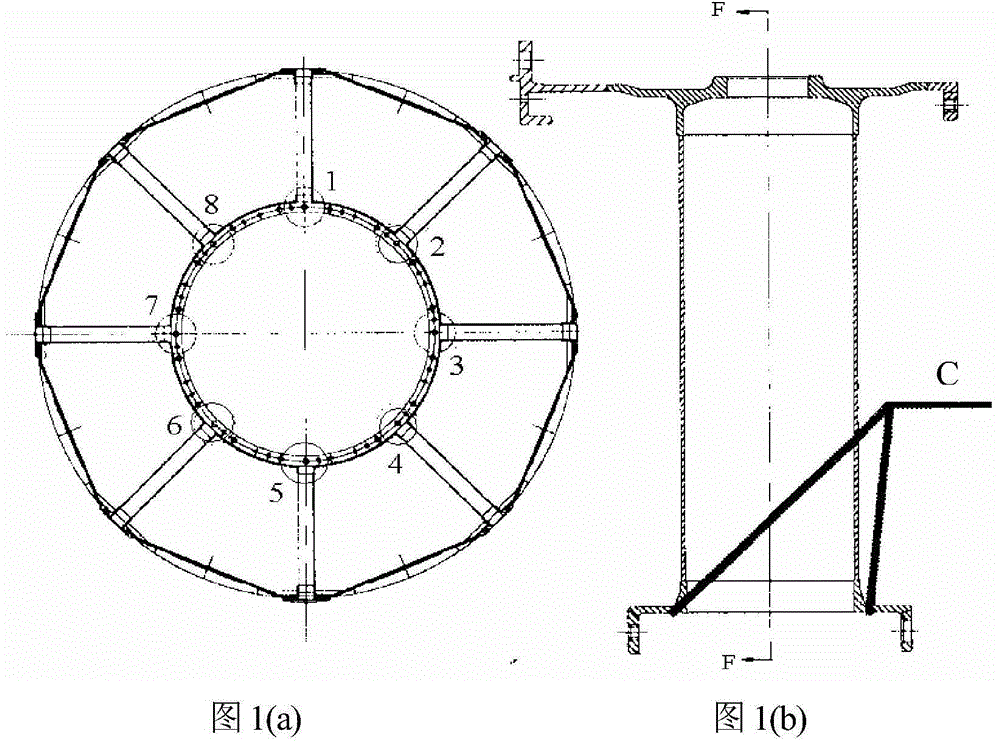

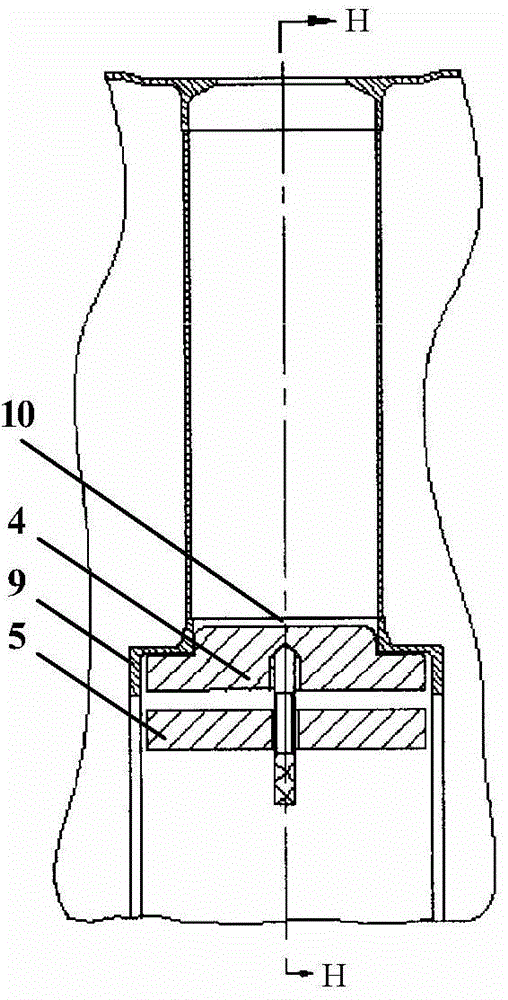

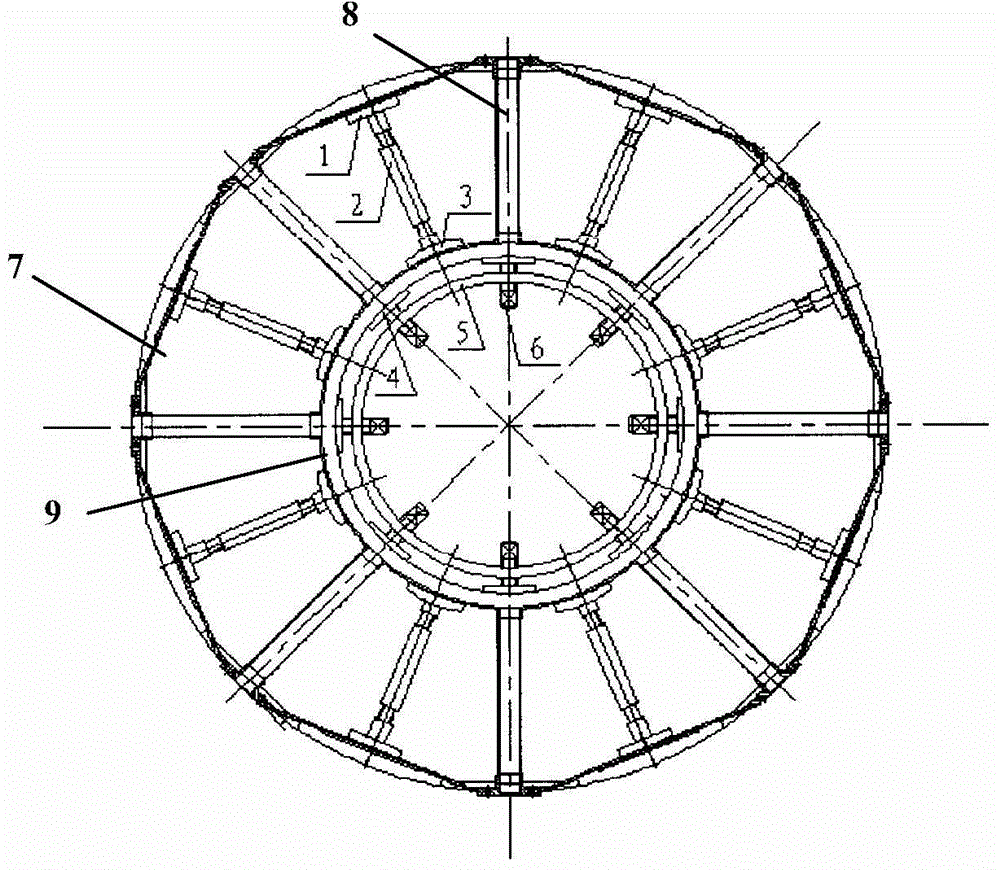

Method and tooling for controlling deformation of nickel-based ageing-strengthening high-temperature alloy casing welding assembly

ActiveCN103551770AAvoid fatigue crackingMeet reliabilityWelding/cutting auxillary devicesAuxillary welding devicesWelding residual stressElectron

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

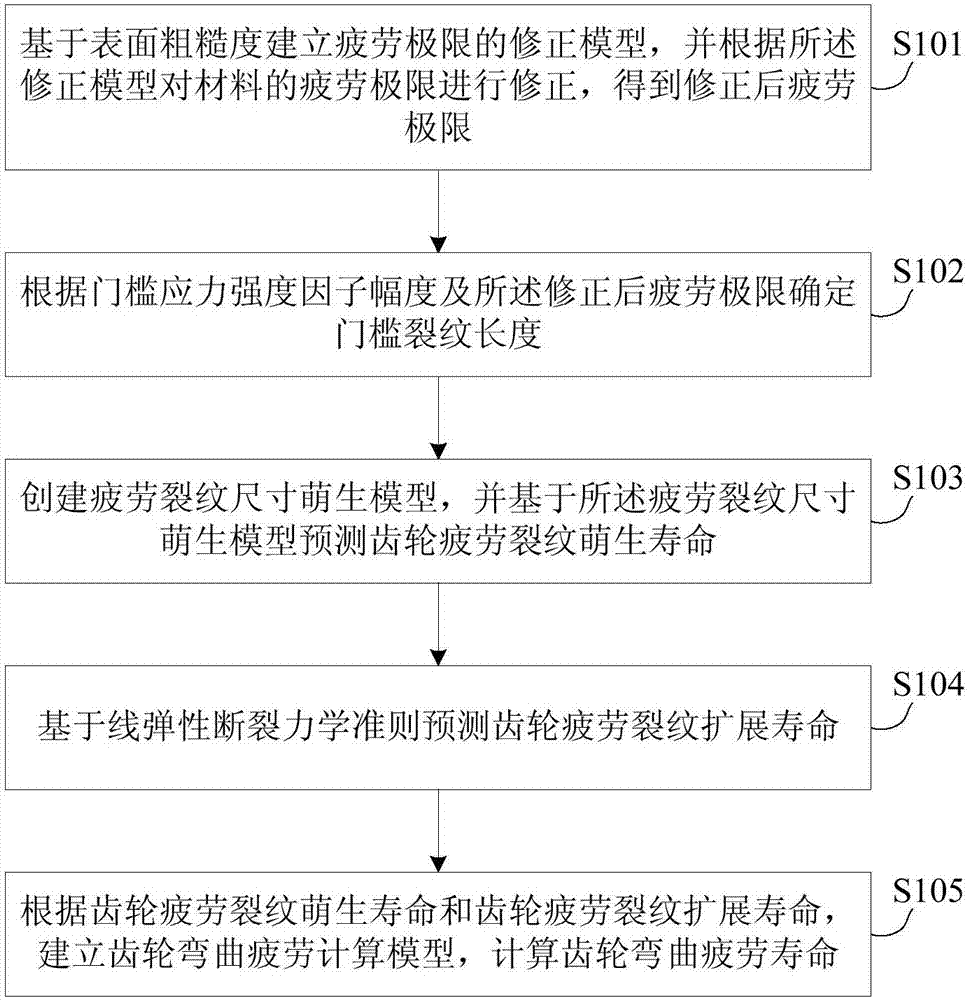

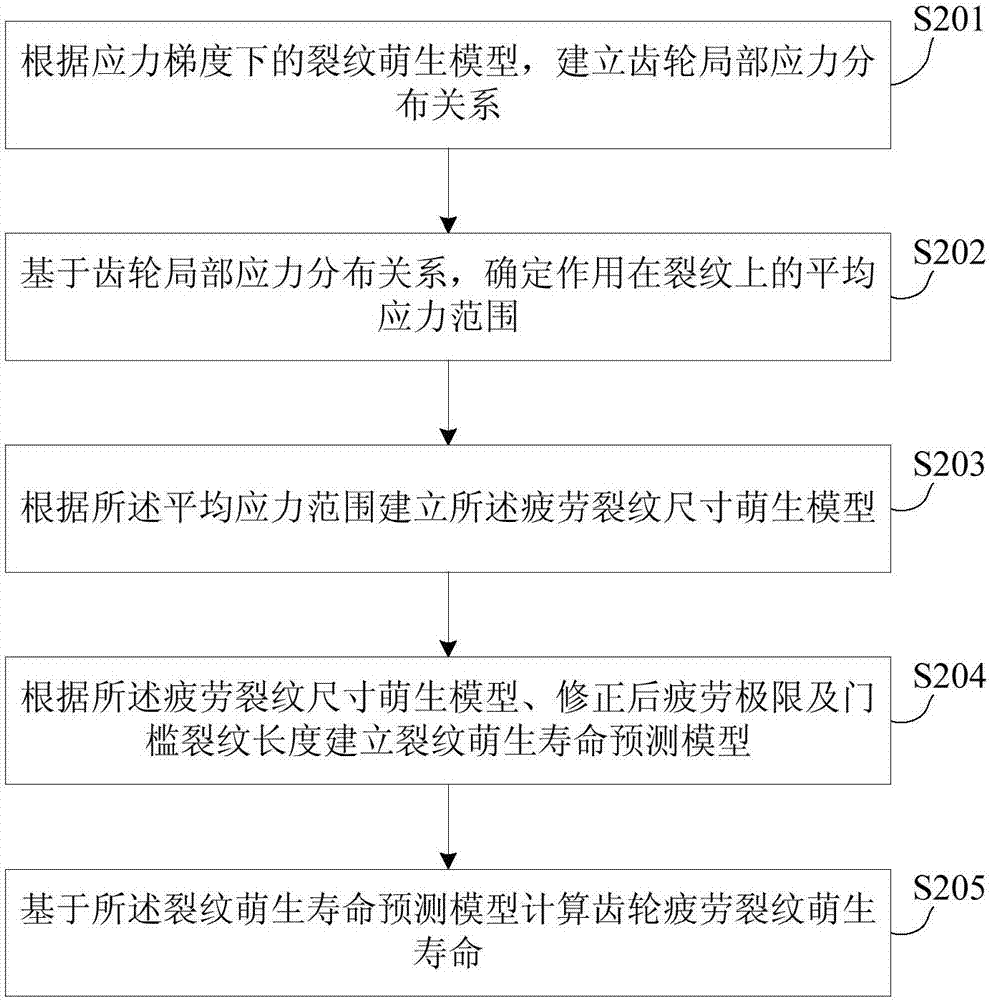

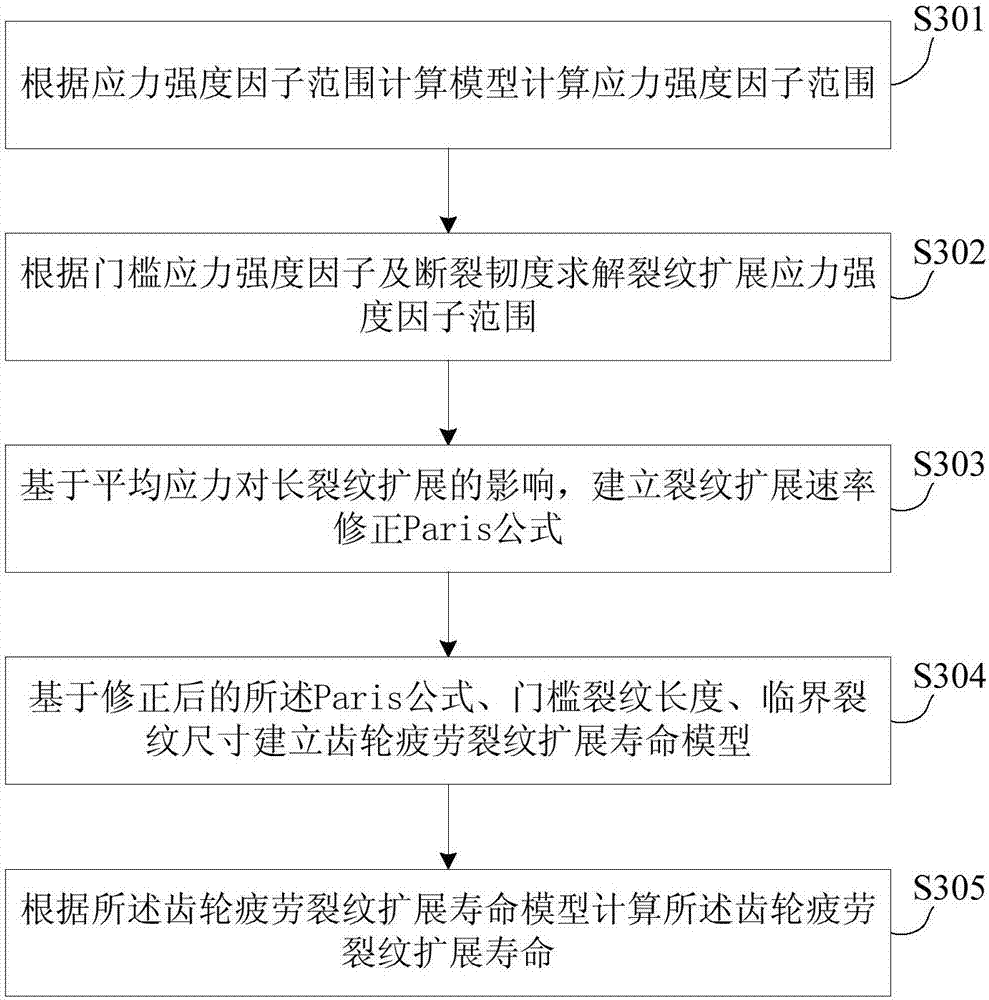

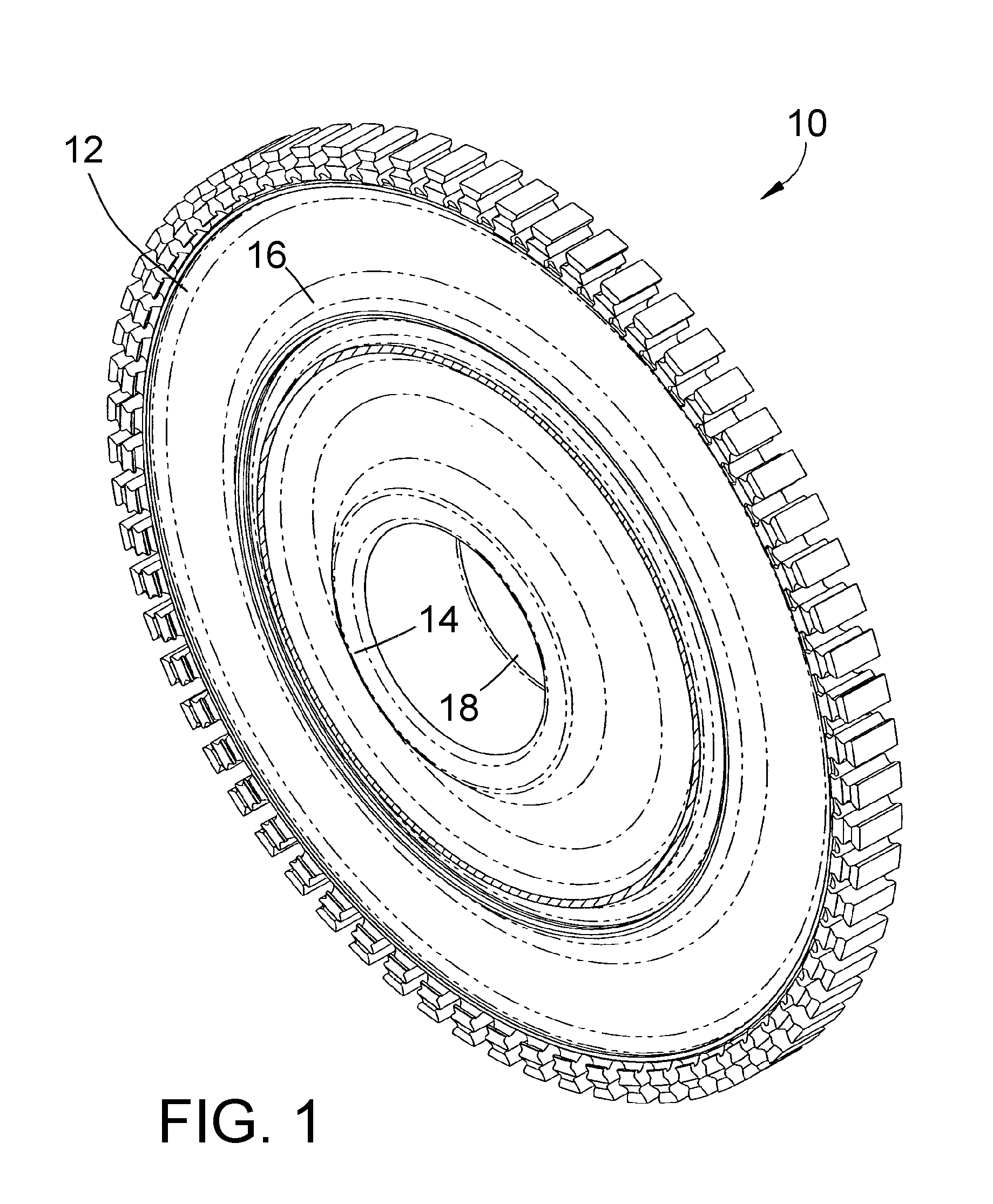

Gear bending fatigue life forecast method and apparatus

ActiveCN106886663ASimplify the operating life prediction processPredicting Flexural Fatigue LifeGeometric CADDesign optimisation/simulationGuidelineSurface roughness

The invention provides a gear bending fatigue life forecast method and a device. The gear bending fatigue life forecast method comprises the steps that a fatigue limit amendment model is built based on the surface roughness, and the fatigue limit of materials is amended according to the amendment model, the fatigue limit after the amendment is obtained; the threshold crack length is determined according to the threshold stress strength factor range and the amended fatigue limit; a fatigue crack size initiation model is created, and gear fatigue crack initiation life is forecasted based on the fatigue crack size initiation model; gear fatigue crack propagation life is forecasted based on the linear elastic fracture mechanics guidelines; according to the gear fatigue crack initiation life and gear fatigue crack propagation life, a gear bending fatigue calculation model is built, to calculate the gear bending fatigue life.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

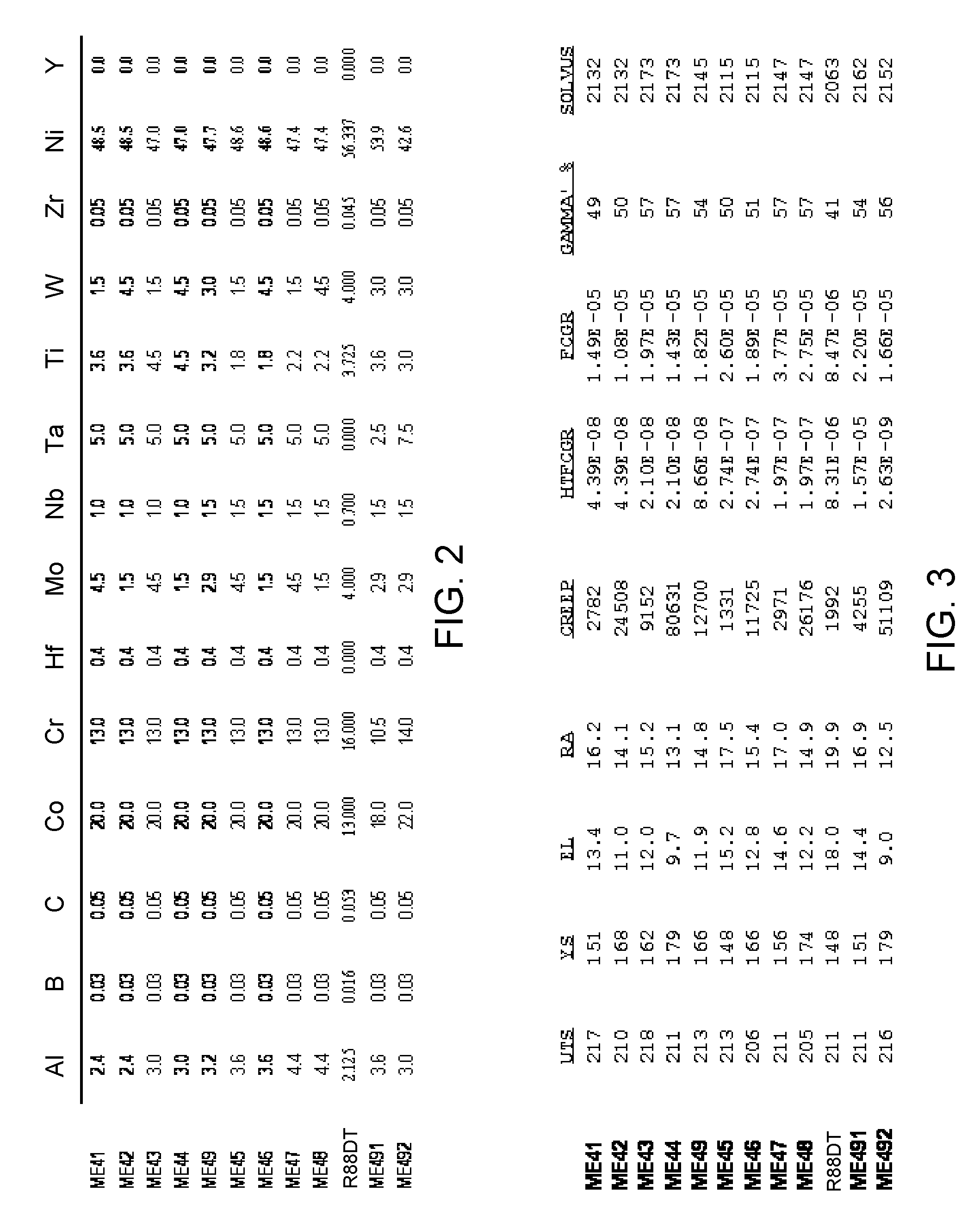

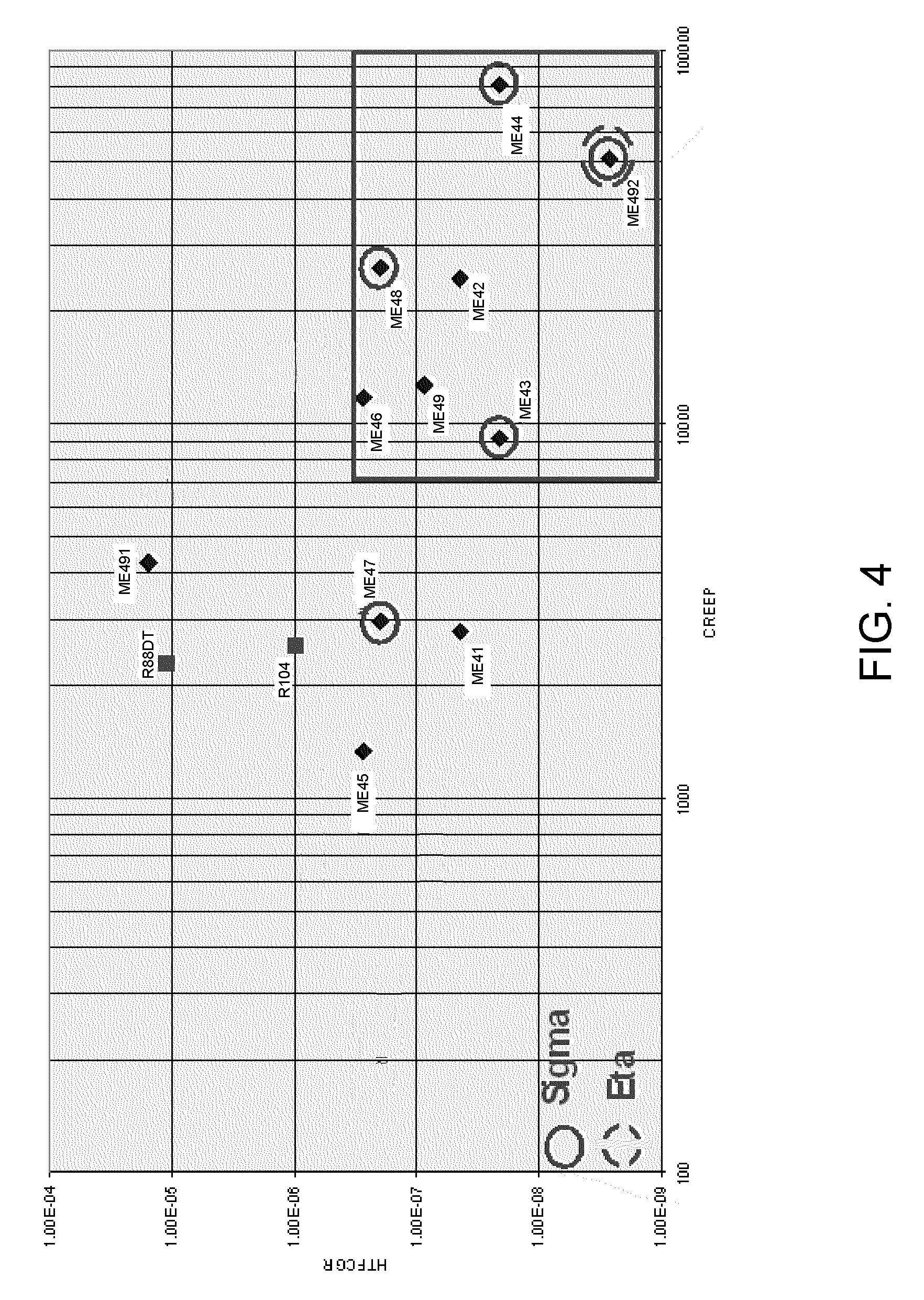

Nickel-base alloy, processing therefor, and components formed thereof

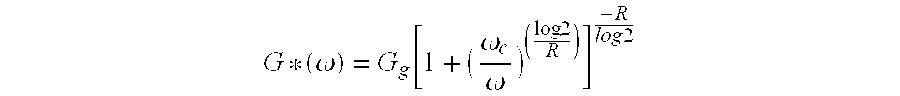

A gamma prime nickel-base superalloy and components formed therefrom that exhibit improved high-temperature dwell capabilities, including creep and dwell fatigue crack growth behavior. The superalloy contains, by weight, 10.00 to 22.0% cobalt, 10.0 to 14.0% chromium, 4.0 to 6.0% tantalum, 2.0 to 4.0% aluminum, 2.0 to 6.0% titanium, 1.5 to 5.0% tungsten, 1.5 to 5.0% molybdenum, 1.0 to 3.5% niobium, 0.05 to 0.6% hafnium, 0.02 to 0.10% carbon, 0.01 to 0.40% boron, 0.02 to 0.10% zirconium, the balance essentially nickel and impurities, wherein the titanium:aluminum weight ratio is 0.7 to 1.5. The superalloy is hot worked and heat treated to contain cellular gamma prime precipitates that distort grain boundaries, creating tortuous grain boundary fracture paths that are believed to promote the fatigue crack growth resistance of the superalloy.

Owner:GENERAL ELECTRIC CO

Rejuvenation of reclaimed asphalt

ActiveUS20140338565A1Low cloud and pour pointImprove thermal stabilityIn situ pavingsSolid waste managementCrack resistanceFatty acid

Asphalt compositions comprising reclaimed asphalt and a rejuvenating agent are disclosed. The reclaimed asphalt comprises aggregate and an aged binder. The rejuvenating agent, which has a cyclic content of at least 5 wt. %, comprises an ester or ester blend derived from an acid selected from aromatic acids, fatty acids, fatty acid monomers, fatty acid dimers, fatty acid trimers, rosin acids, rosin acid dimers, and mixtures thereof. The rejuvenating agent revitalizes the aged bitumen binder of reclaimed asphalt and restores its physical properties to those of the original performance-grade bitumen. Improvements include desirable softening, low-temperature cracking resistance, better fatigue cracking resistance, good elevated temperature performance, improved miscibility, and restored temperature sensitivity. The rejuvenating agents enable the use of higher levels of recovered asphalt, particularly RAP, in asphalt mixtures, reduce binder and aggregate costs, and help the road construction industry reduce its reliance on virgin, non-renewable materials.

Owner:KRATON CHEM LLC

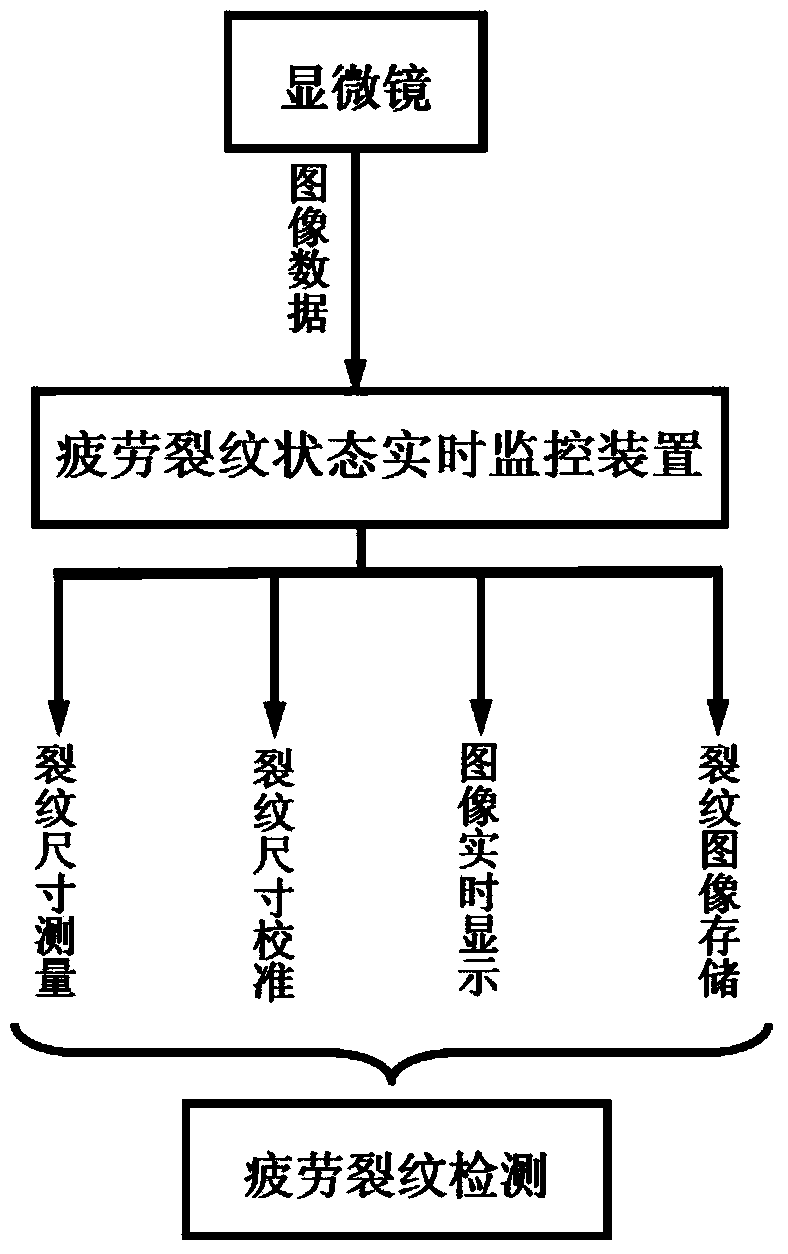

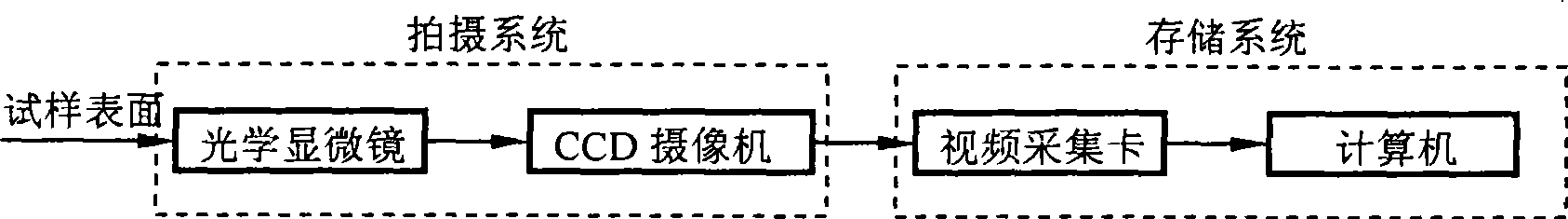

On-line fatigue crack detecting system and on-line fatigue crack detecting method

ActiveCN103529128ADetection of germination in real timeReal-time detection of scalabilityMaterial analysis using acoustic emission techniquesMaterial analysis by optical meansMicroscopic imageAcoustic emission

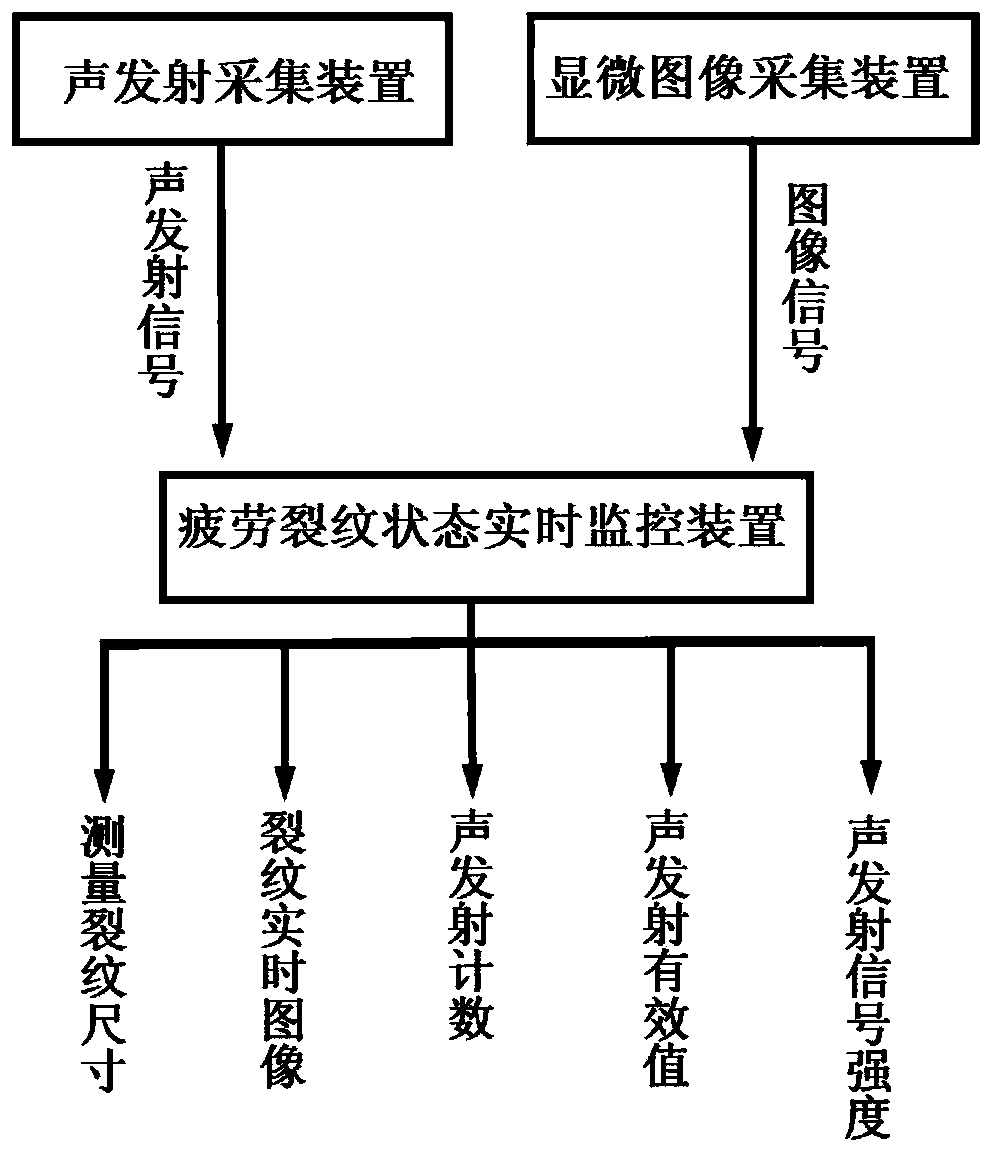

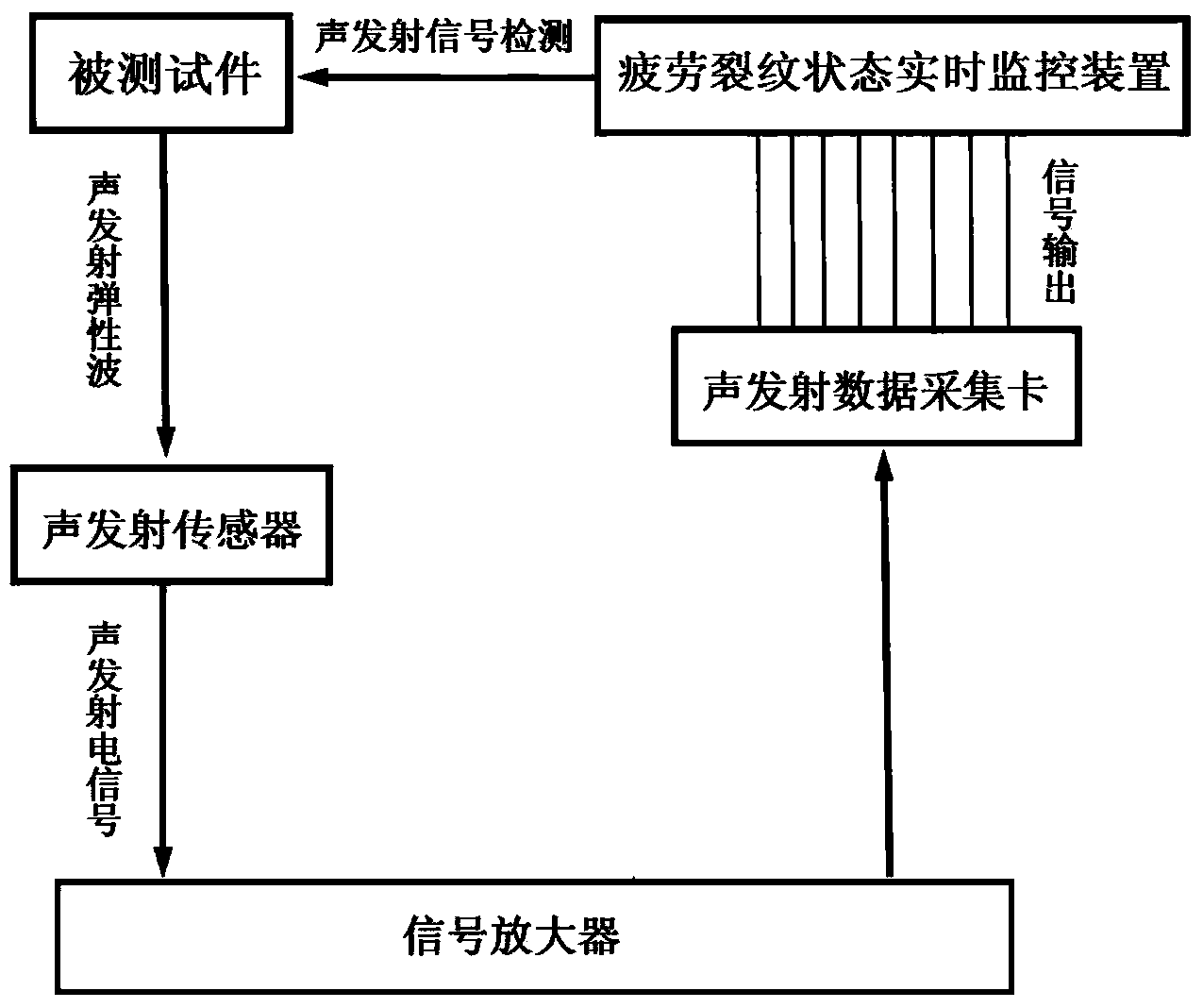

The invention discloses an on-line fatigue crack detecting system. The detecting system comprises an acoustic emission collecting device, a microscopic-image collecting device and a real-time fatigue crack state monitoring device. The acoustic emission collecting device collects acoustic emission signals of fatigue crack initiation and extension and release in real time. The microscopic-image collecting device collects image signals of fatigue crack states in real time. The real-time fatigue crack state monitoring device receives the signals from the acoustic emission collecting device and signals from the microscopic-image collecting device. A real-time fatigue crack state monitoring software, which is used to process the received signals and generates acoustic emission characteristic parameters, images and crack dimension data of a fatigue crack changing process, is disposed in the real-time fatigue crack state monitoring device. The invention also provides an on-line fatigue crack detecting method. The detecting system and the detecting method can achieve on-line dynamic real-time detection of fatigue crack initiation and extension.

Owner:TIANJIN ENG MACHINERY INST

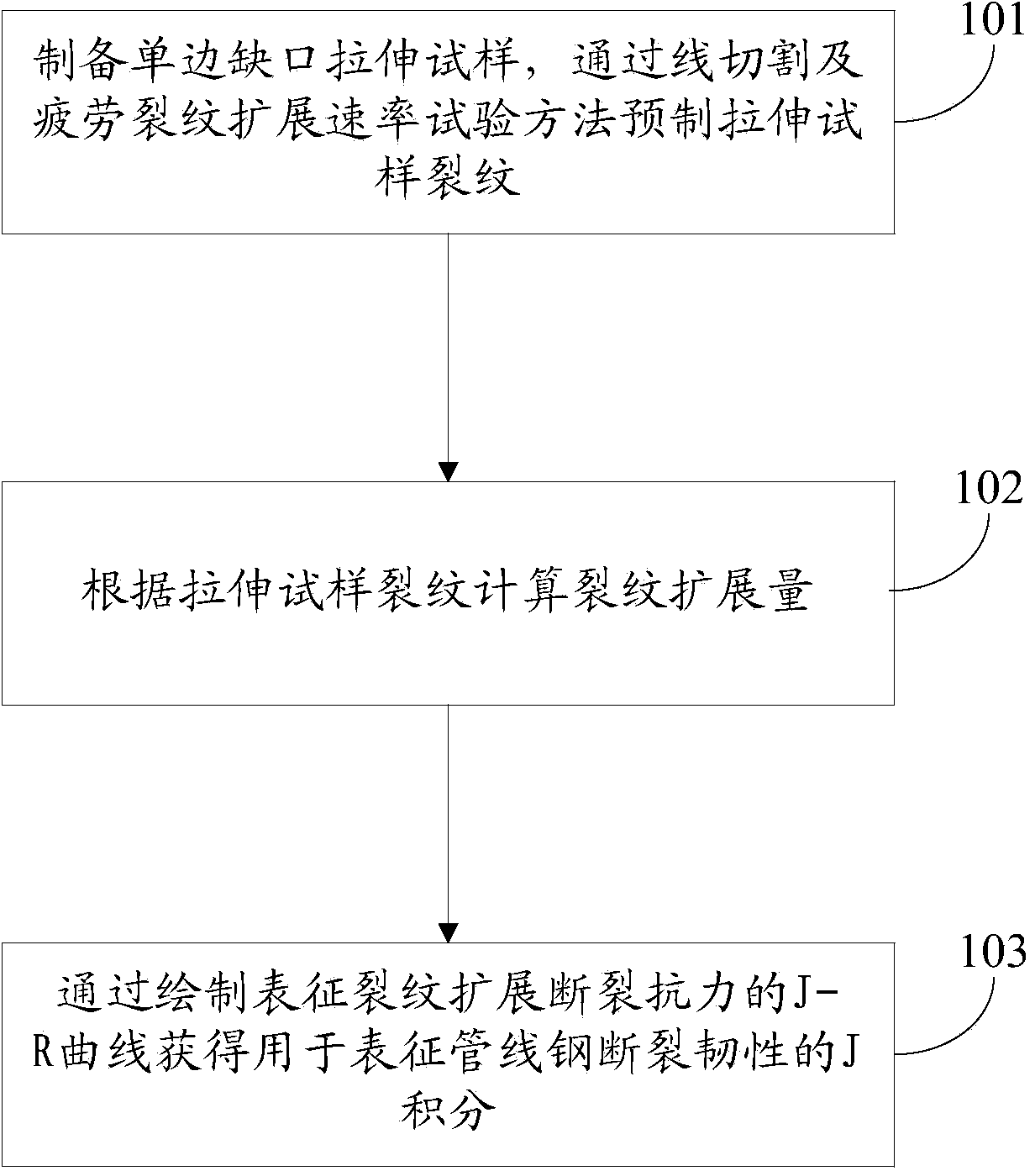

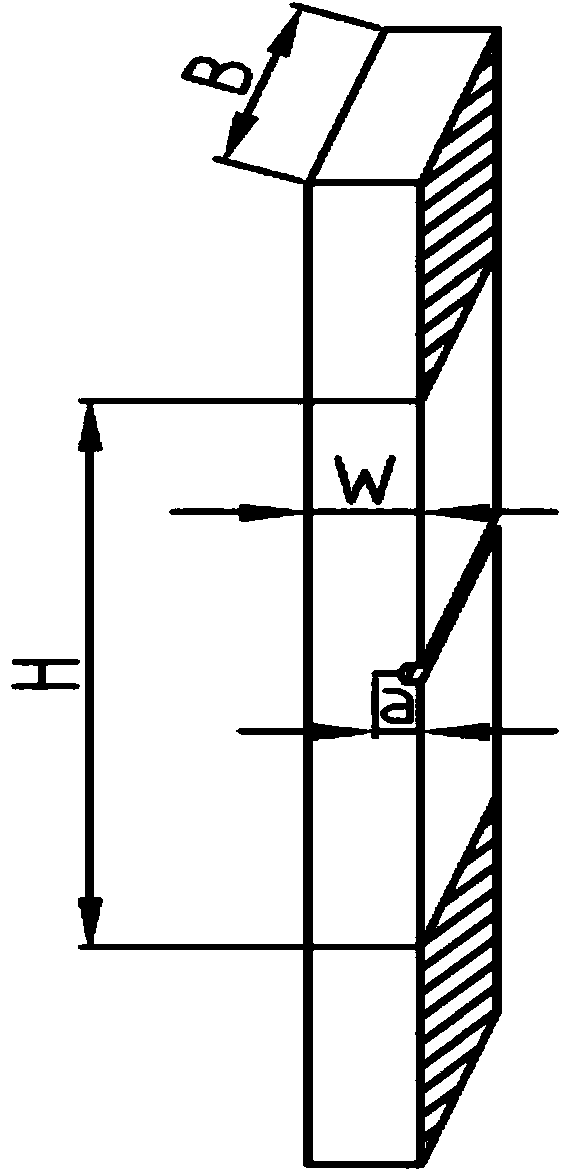

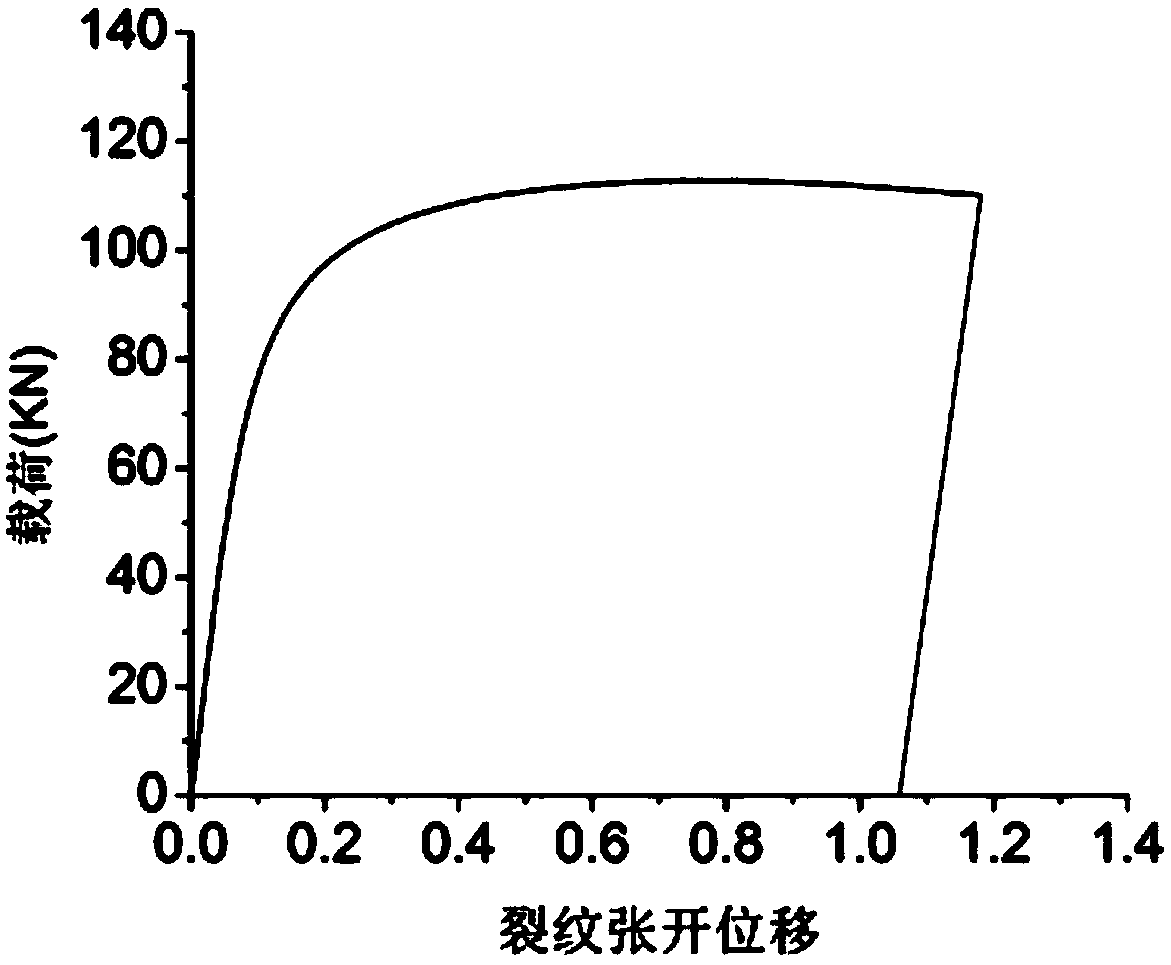

Method for measuring fracture toughness of pipeline steel by using unilateral notched tensile test

ActiveCN103604694AAvoid wastingReasonable fracture toughness valueMaterial strength using tensile/compressive forcesCrack resistanceStress intensity factor

The invention discloses a method for measuring fracture toughness of pipeline steel by using a unilateral notched tensile test. The method is characterized by comprising the steps of preparing a unilateral notched tensile test sample; prefabricating a tensile sample crack by wire-electrode cutting and fatigue crack growth rate test method; calculating crack growth amount according to the tensile sample cracks; and acquiring J integration and stress intensity factor K for characterizing the fracture toughness of the pipeline steel by drawing a J-R curve for characterizing crack resistance of the crack growth. The method measures the fracture toughness of the pipeline steel by using tensile samples (SENT samples), overcomes the defects that the scope of measurement results of tensile samples (SENT samples) by a conventional technology is so small that the fracture toughness of the pipeline steel can not be evaluated; the crack toughness value of the tensile samples (SENT samples) can be more reasonable; waste of test for pipeline steel materials can be prevented; and the method has the advantages of high measurement accuracy.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Nickel-base superalloys and components formed thereof

A gamma prime nickel-base superalloy and components formed therefrom that exhibit improved high-temperature dwell capabilities, including creep and hold time fatigue crack growth behavior. A particular example of a component is a powder metallurgy turbine disk of a gas turbine engine. The gamma-prime nickel-base superalloy contains, by weight, 16.0 to 30.0% cobalt, 11.5 to 15.0% chromium, 4.0 to 6.0% tantalum, 2.0 to 4.0% aluminum, 1.5 to 6.0% titanium, up to 5.0% tungsten, 1.0 to 7.0% molybdenum, up to 3.5% niobium, up to 1.0% hafnium, 0.02 to 0.20% carbon, 0.01 to 0.05% boron, 0.02 to 0.10% zirconium, the balance essentially nickel and impurities, wherein the titanium:aluminum weight ratio is 0.5 to 2.0.

Owner:GENERAL ELECTRIC CO

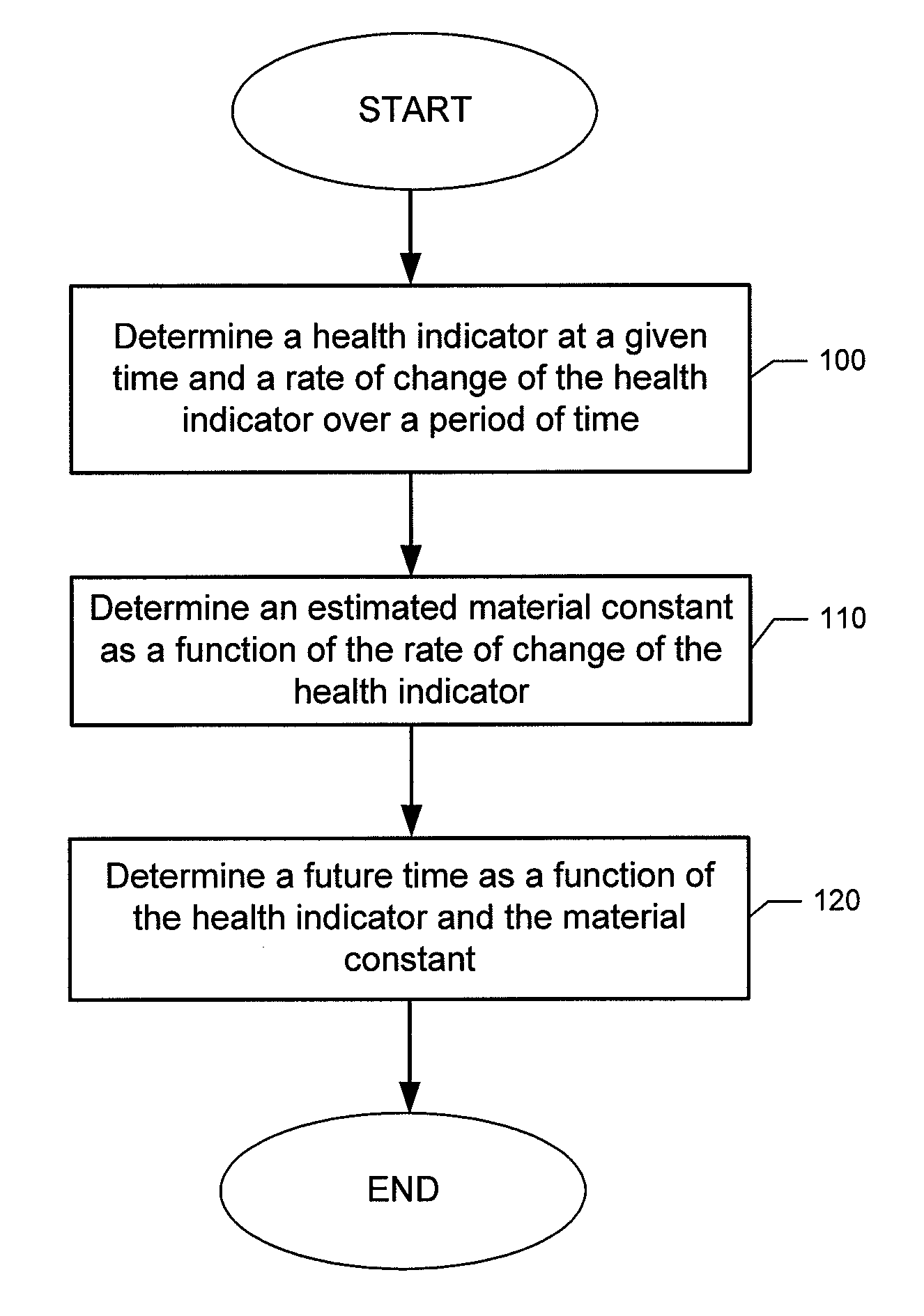

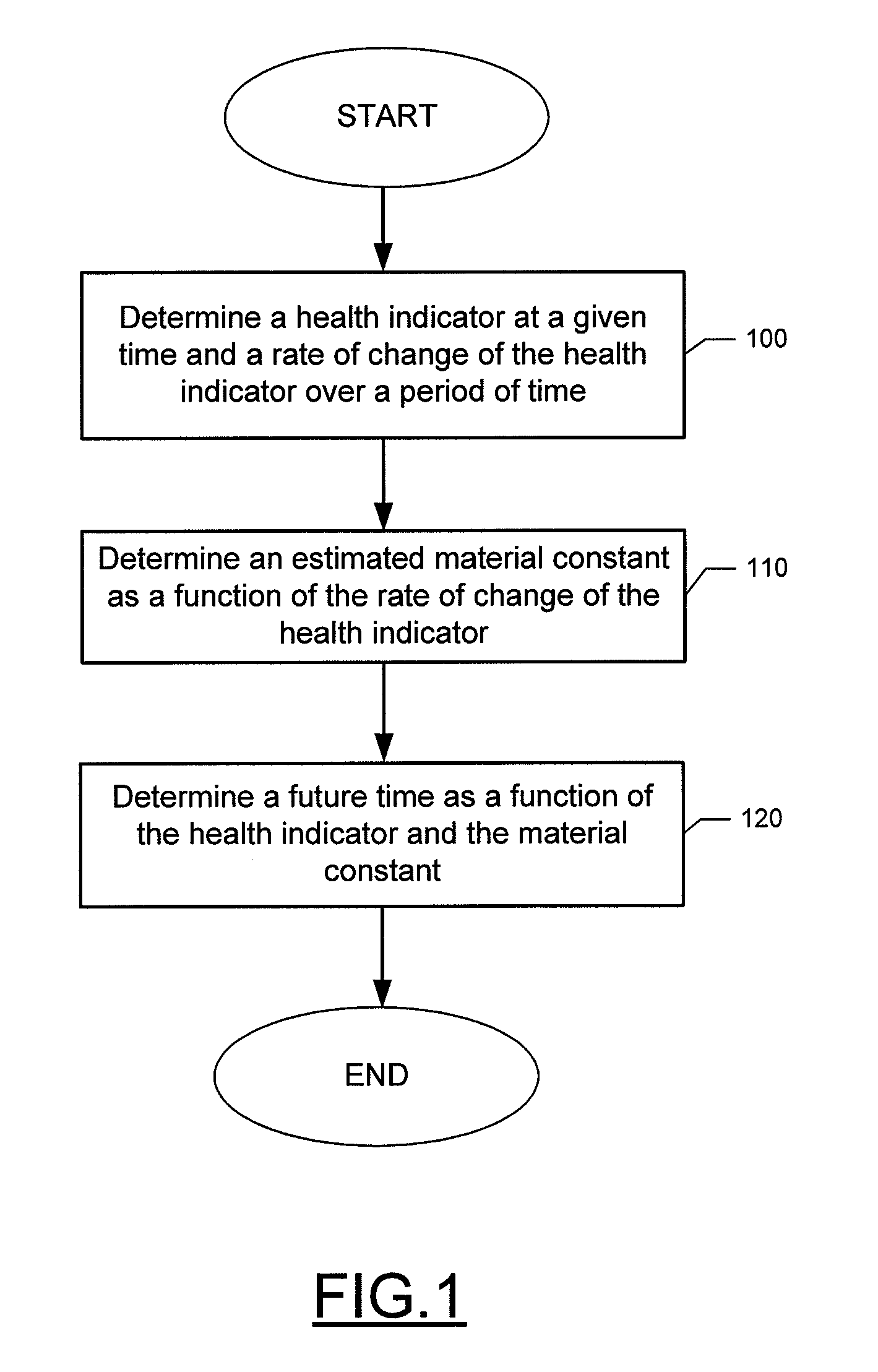

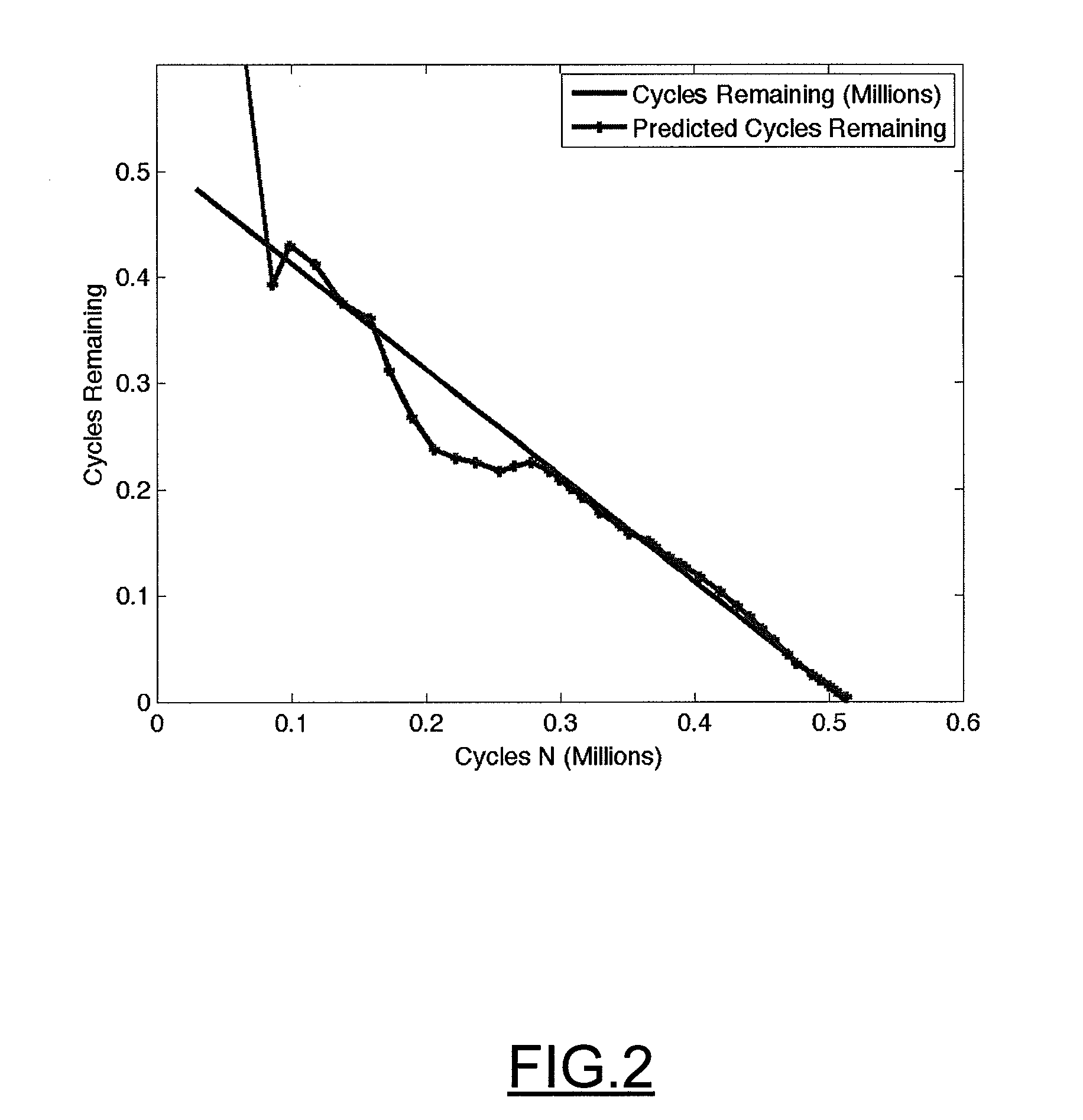

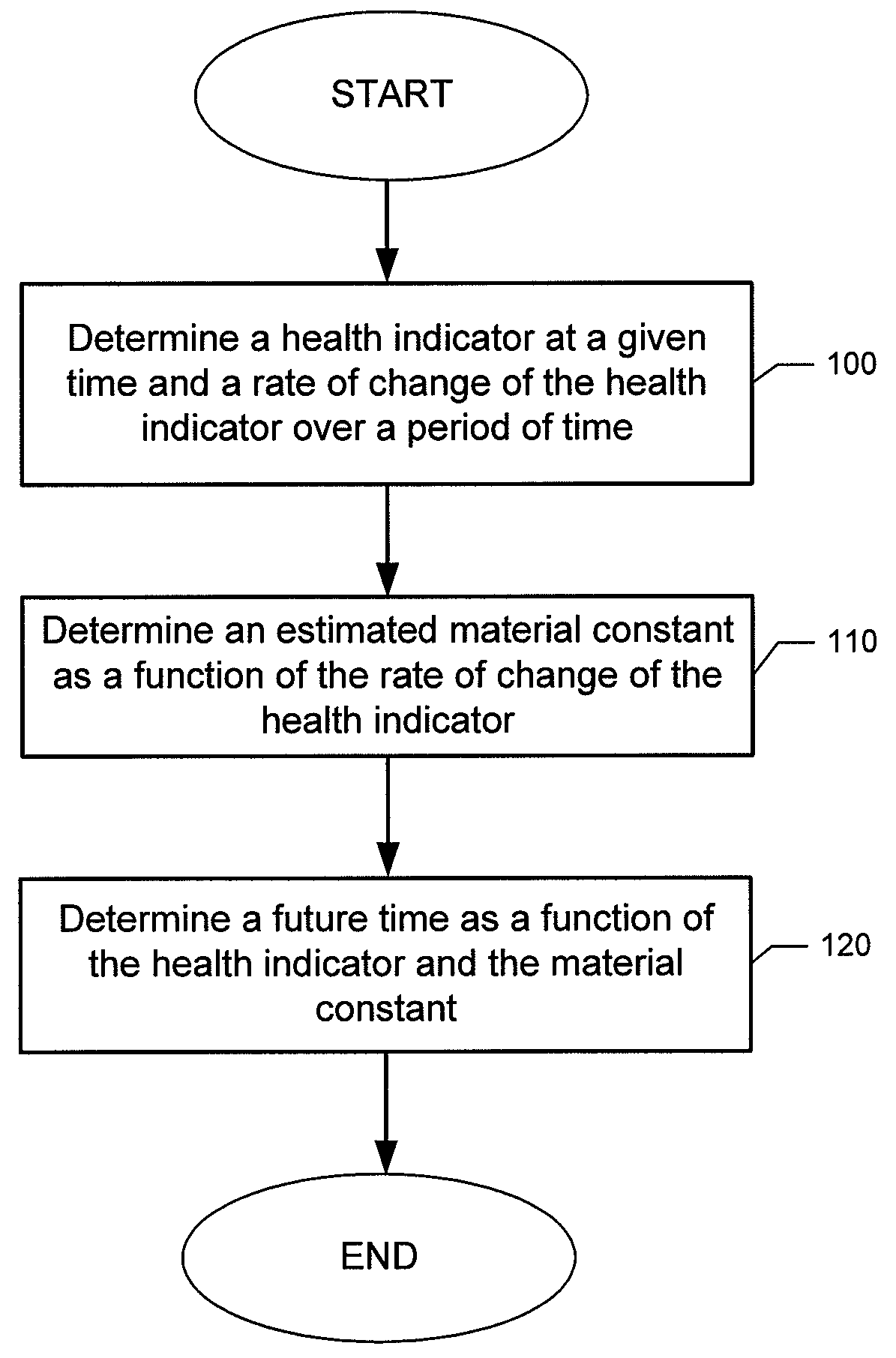

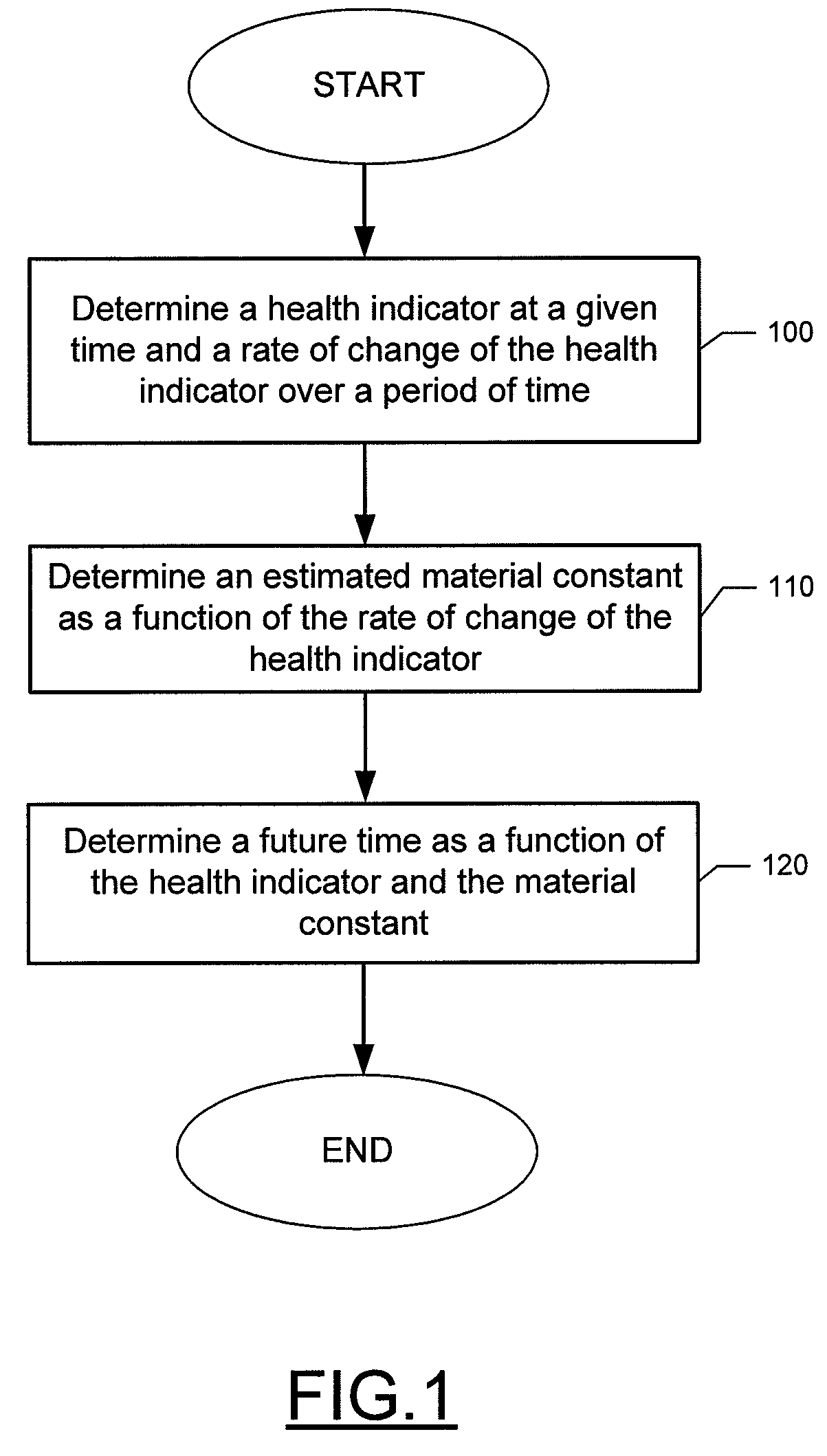

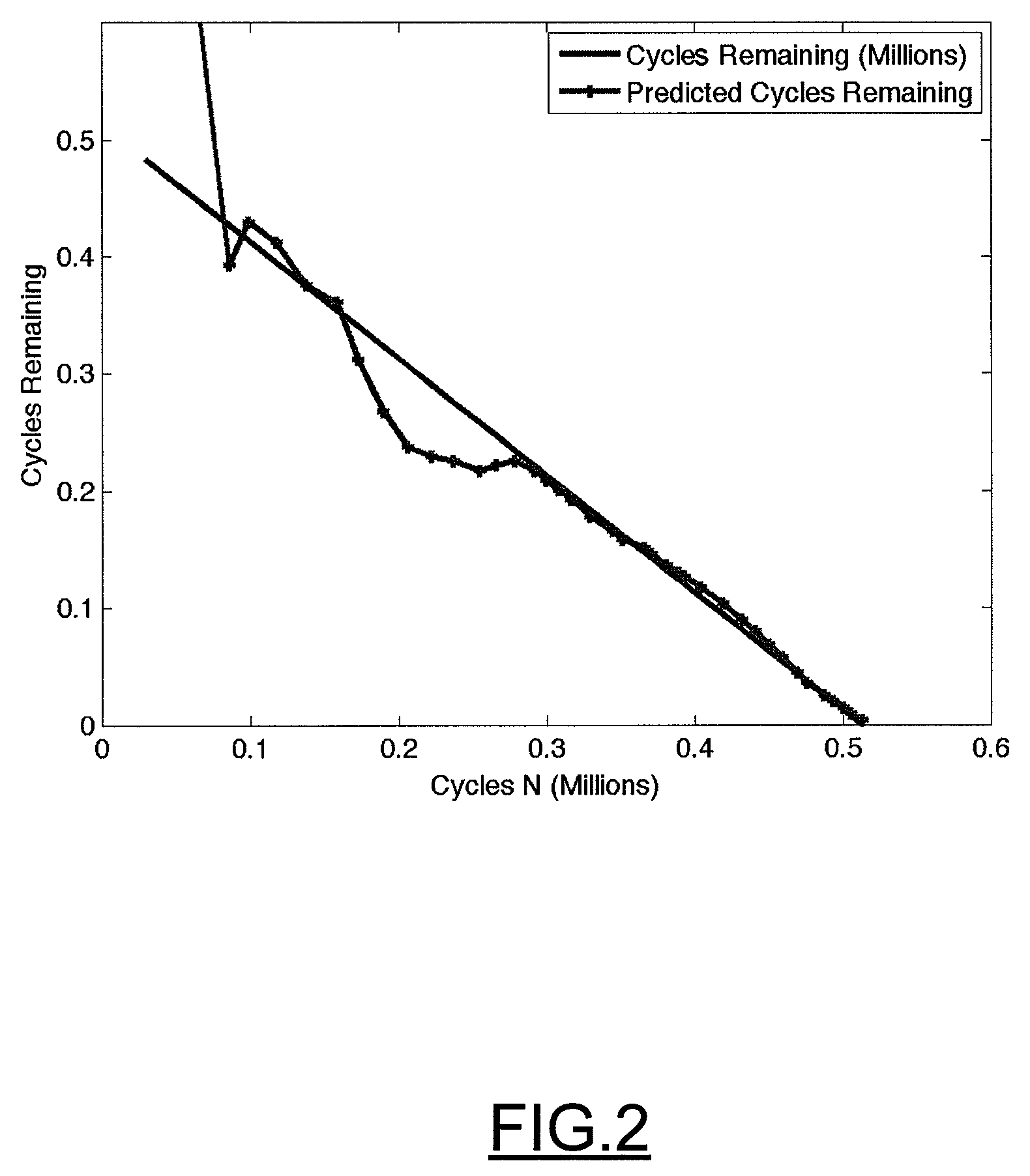

Method, apparatus and computer program product for determining a future time of a component

A method, apparatus and computer program product are provided for determining a future time associated with a component, where the future time can be indicative that some action can be taken with respect to the component. In some embodiments, future time can be indicative of a component's remaining useful life or time until maintenance is required. The future time can be determined as a function of a health indicator and a material constant. In some exemplary embodiments of the present invention, the functional relationship between the future time, the health indicator and the material constant can be based on the functional relationship of Paris' law for fatigue crack growth.

Owner:SIMMONDS PRECISION PRODS

Method for manufacturing surface crack sample for nondestructive testing sensitivity test

ActiveCN101710040ASimple and fast operationEasy to preparePreparing sample for investigationCrazingFatigue loading

The invention belongs to nondestructive testing technology, and relates to a method for manufacturing a surface crack sample for a nondestructive testing sensitivity test. The method adopts a fatigue loading mode to manufacture a crack defect, and the operation is simple; the manufactured fatigue crack defect has small dimensions and belongs to typical crack defect. Therefore, the manufactured fatigue crack defect has excellent representativeness for natural crack defects. The method can successfully acquire crack samples with dimensions of natural cracks; and dimensions and shapes of the samples and directions and positions of the crack defects can meet most test requirements. The manufacturing process is easily controlled, which is particularly applicable to adjustment and experimental verification for circumferential magnetization detection sensitivity in magnetic particle testing, and the method can be applied to testing research of detecting sensitivity of the surface cracks in three nondestructive testing specialities, namely ultrasound, vortex and penetration.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

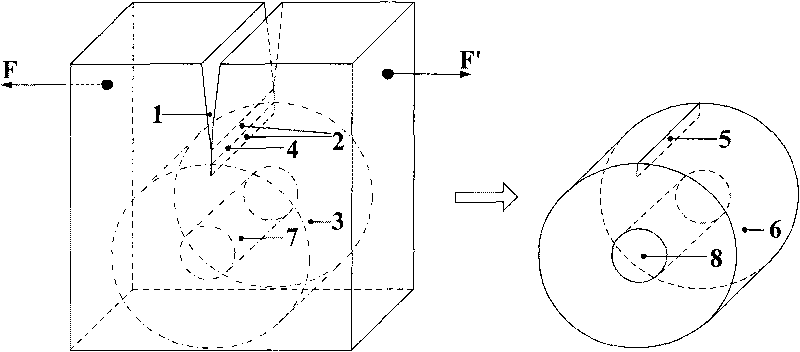

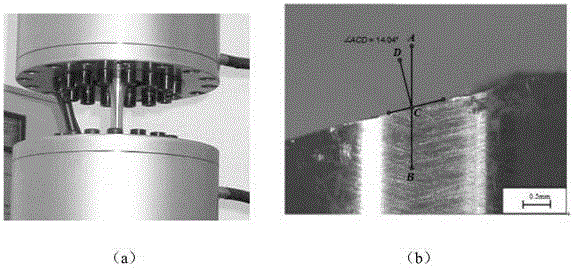

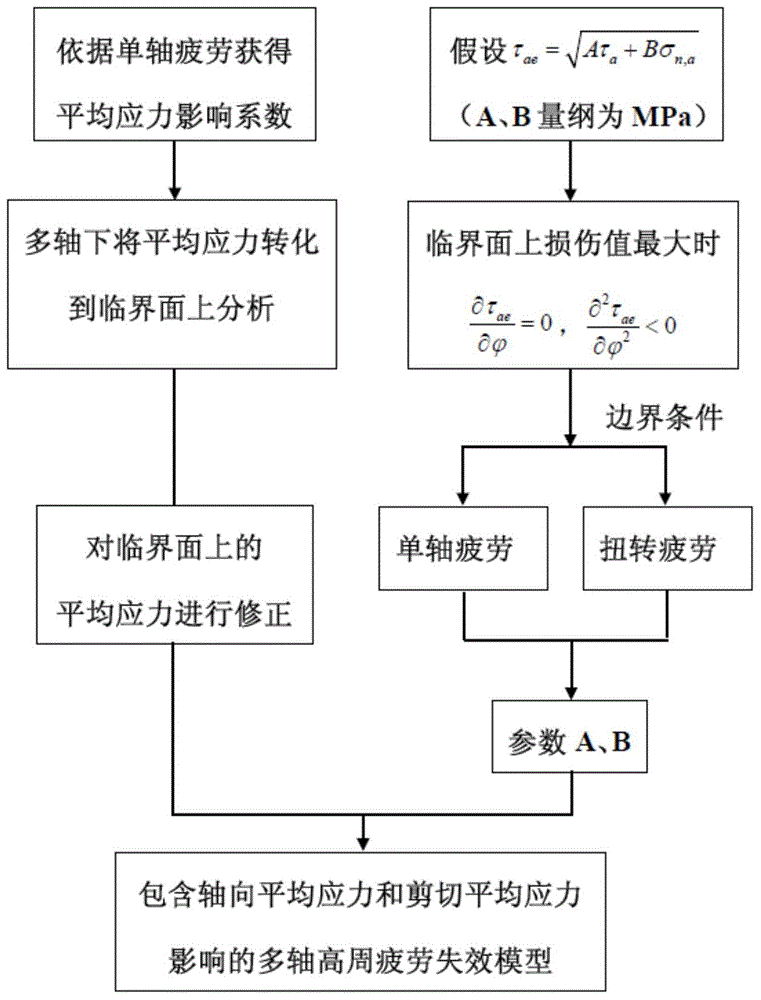

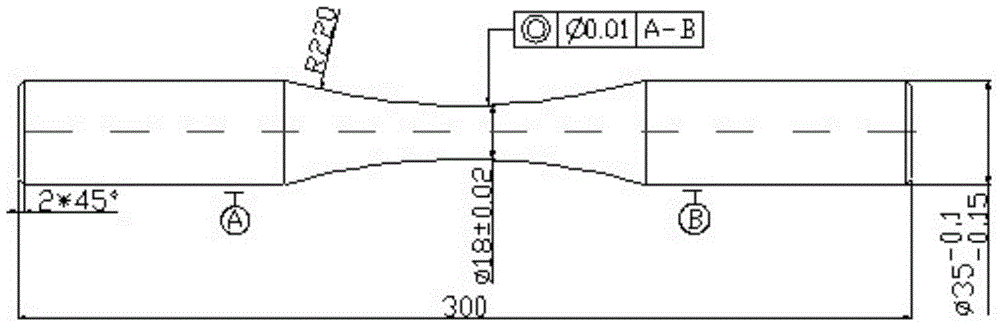

Prediction method of metal material multiaxial high cycle fatigue failure including mean stress effect

ActiveCN104699976APredict fatigue lifeAccurate predictionSpecial data processing applicationsStrength propertiesFatigue loadingShear stress

The invention discloses a prediction method of metal material multiaxial high cycle fatigue failure including mean stress effect; the prediction method of metal material multiaxial high cycle fatigue failure including mean stress effect comprises the following steps: using the uniaxial fatigue and the pure torsional fatigue as the boundary conditions for calculating the biggest damage surface born by the material during the fatigue loading process and taking the biggest damage surface as the boundary surface, selecting the positive stress and the shearing stress on the boundary surface as the damage parameter, using the mean stress effect parameter obtained by the uniaxial fatigue for correnting the stress on the boundary surface, and establishing the metal material multiaxial high cycle fatigue failure prediction model including axial direction mean stress and shearing stress influence; the prediction method of metal material multiaxial high cycle fatigue failure including mean stress effect is also applied to the situation without axial mean stress and shearing mean stress. The fatigue service life, the fatigue crack initiation and the initial extension direction of the material under multiaxial high cycle fatigue loading situation can be precisely forecasted while the axial mean stress and shearing mean stress are present.

Owner:XIANGSHAN WEIHUI MAGNET

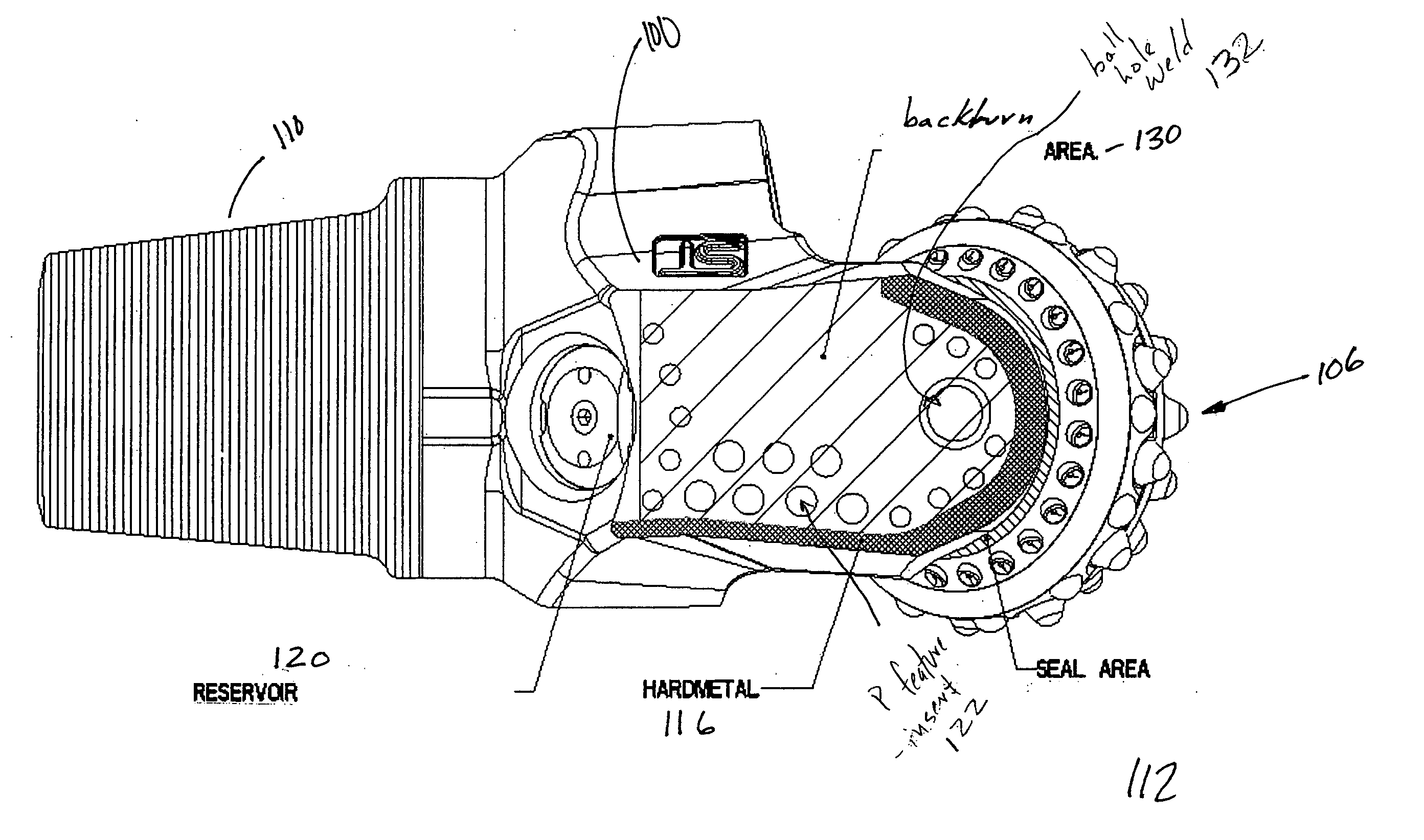

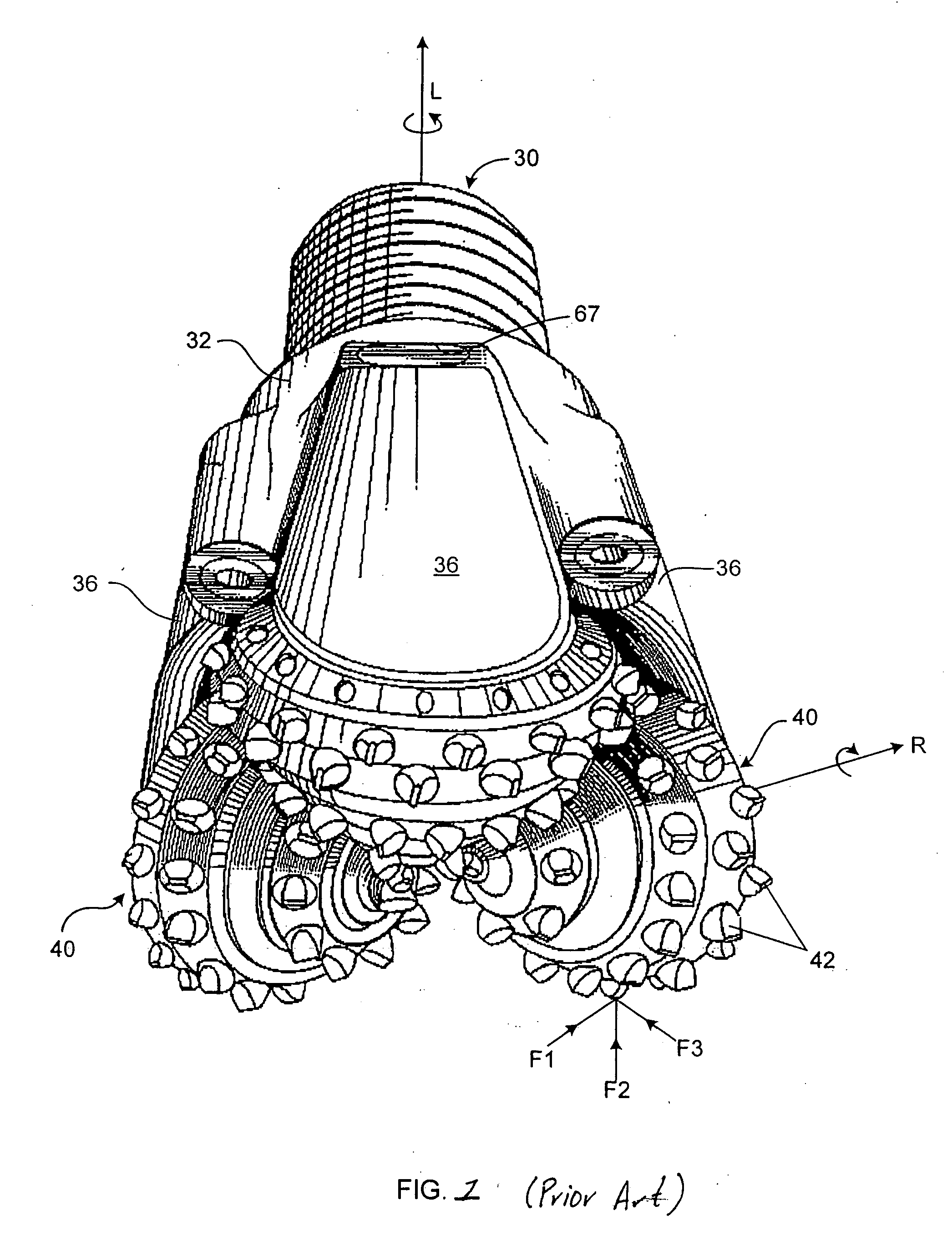

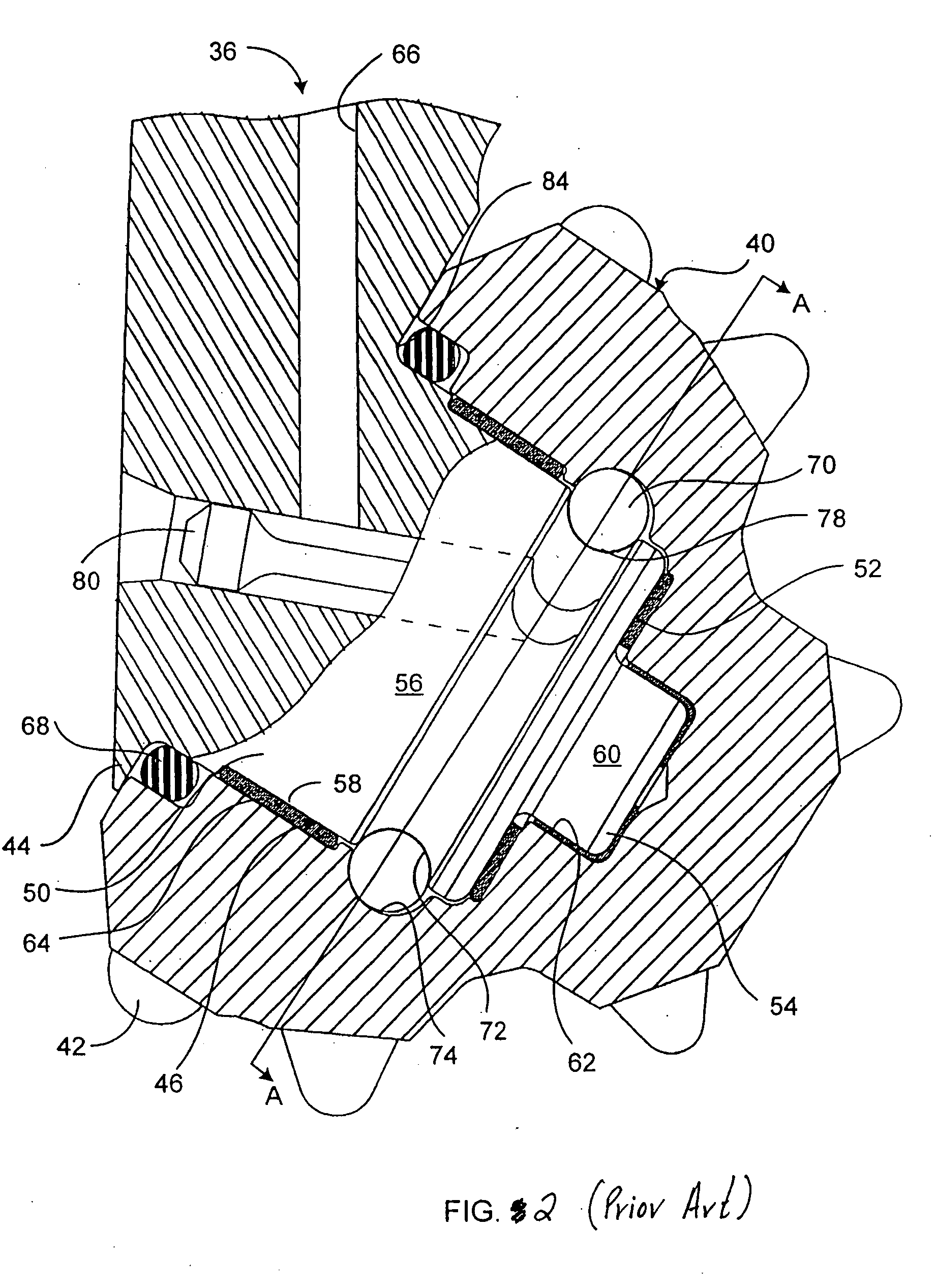

Drill bit having increased resistance to fatigue cracking and method of producing same

The present invention relates to a roller cone drill bit that includes a bit body adapted to be rotated about a longitudinal axis, where the bit body has at least one leg depending therefrom, wherein the leg comprises a treated portion that provides a residual compressive stress, and a roller cone rotatably mounted on a journal. The treated portion treatment may comprise one selected from shot peening, laser-shock peening, and hammer peening. Further, the present invention relates to a method of manufacturing a roller cone drill bit that includes inducing a compressive stress, through plastic deformation, in at least a portion of at least one leg depending from a bit body. The inducing a compressive stress may comprise one selected from shot peening, laser-shock peening, and hammer peening.

Owner:SMITH INT INC

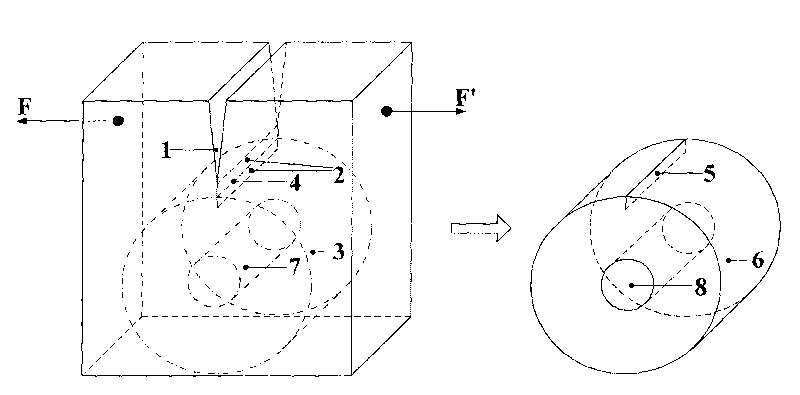

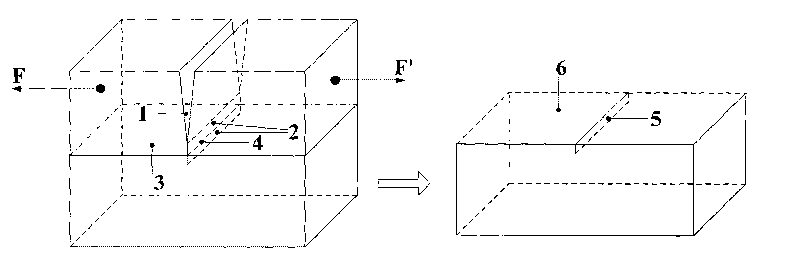

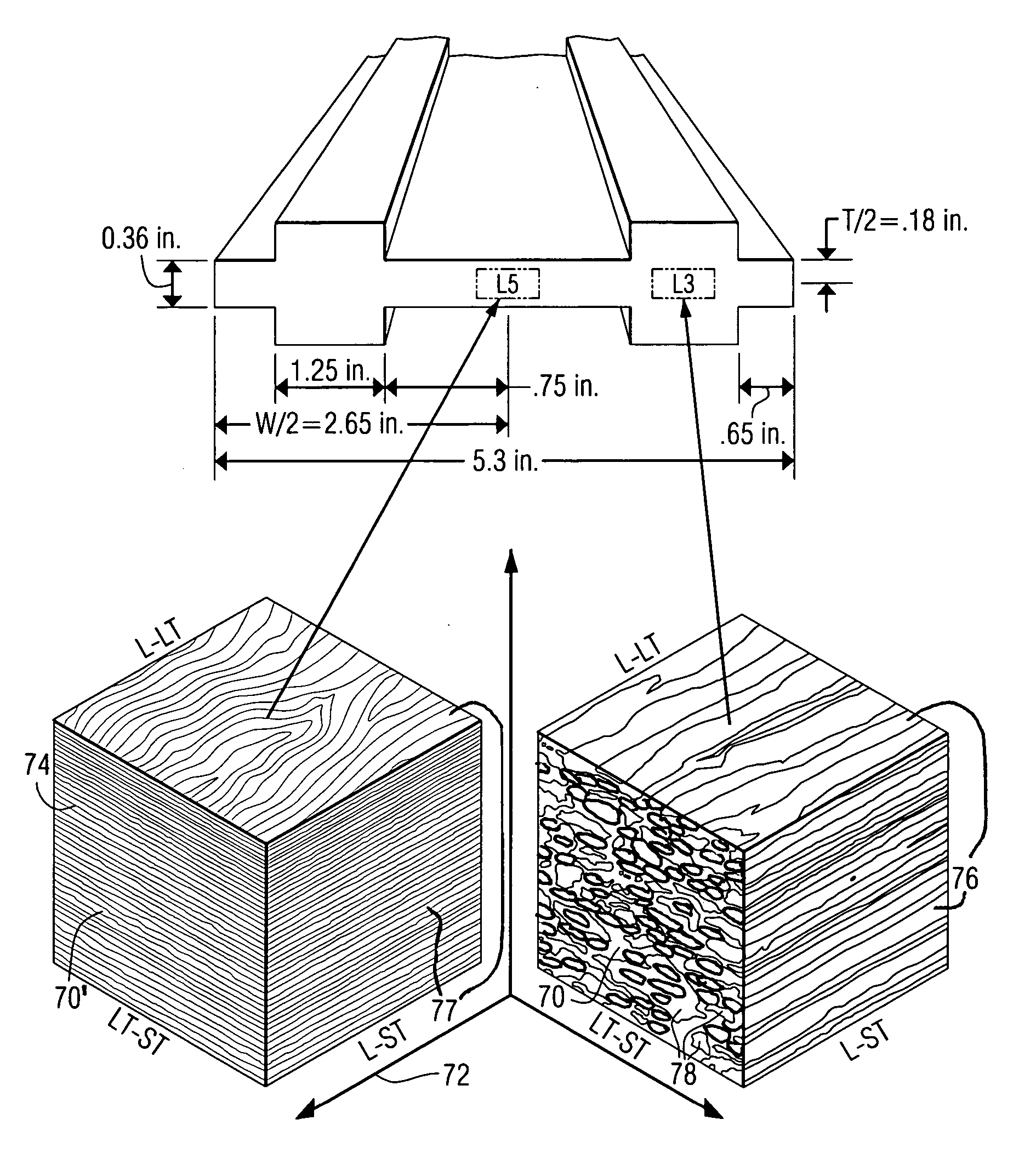

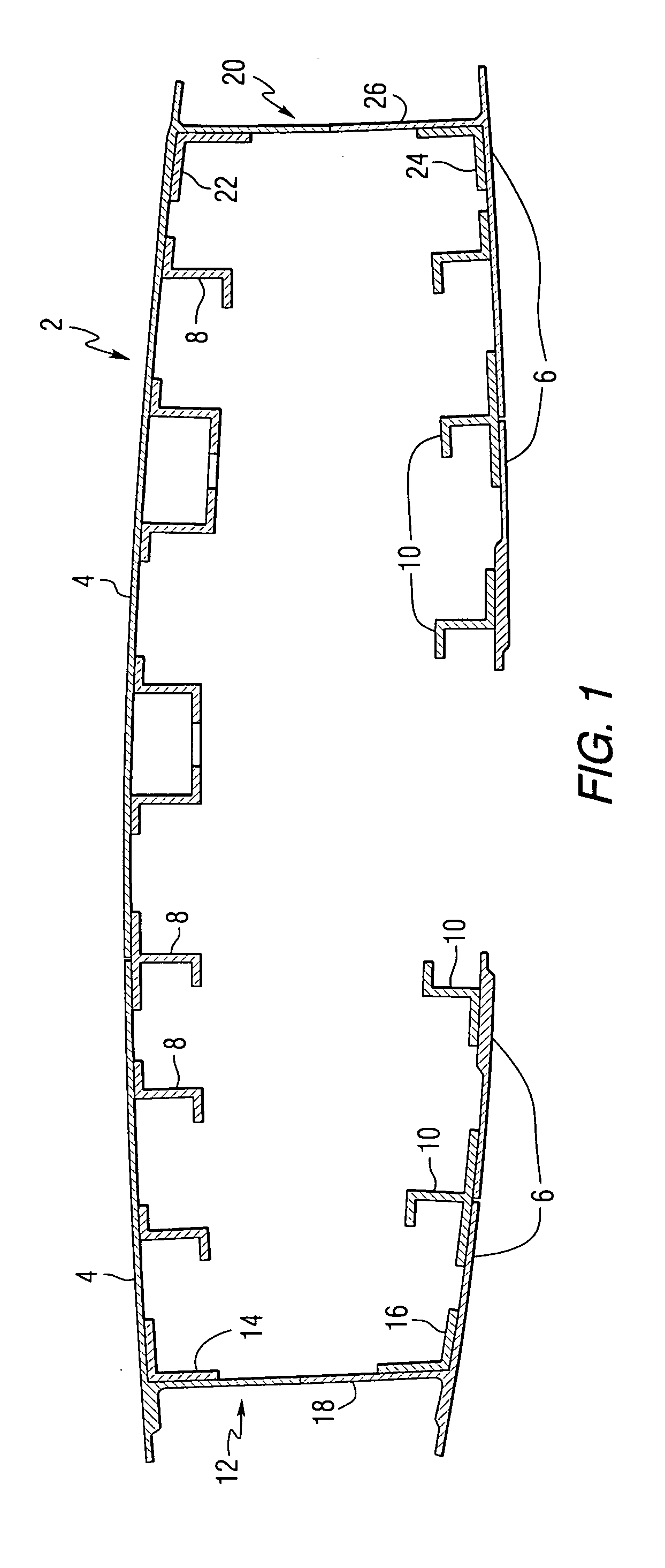

Structural members having improved resistance to fatigue crack growth

InactiveUS20050241735A1High damage toleranceReduce rate of fatigue crack growthLayered productsExtrusion containersFiberDamage tolerance

An extruded structural member having improved damage tolerance containing a base section (6); a stiffening section having at least one pair of structural stiffeners (10), the structural stiffeners integral with the base section (6) and projecting outwardly thereof; and at least one intra-stiffener (90) area positioned between the pair of structural stiffeners (10), the intra-stiffener area (90) having a microstructure with intentionally increased amounts of fiber texture to reduce the rate of fatigue crack growth in the extruded structural member.

Owner:ARCONIC INC

Method, apparatus and computer program product for determining a future time of a component

A method, apparatus and computer program product are provided for determining a future time associated with a component, where the future time can be indicative that some action can be taken with respect to the component. In some embodiments, the future time can be indicative of a component's remaining useful life or time until maintenance is required. The future time can be determined as a function of a health indicator and a material constant. In some embodiments, the functional relationship between the future time, the health indicator and the material constant can be based on the functional relationship of Paris' law for fatigue crack growth.

Owner:SIMMONDS PRECISION PRODS

Surface fatigue crack detecting method based on CCD image characteristic

InactiveCN101413901AImprove reliabilityLow costOptically investigating flaws/contaminationSurface fatigueImaging processing

The invention discloses a method used for detecting surface fatigue crack with CCD image characteristic, aiming at the defects that the existing fatigue crack detection method has low precision, needs the contact with the samples, needs expensive equipment and is troublesome to execute, and the like. The method utilizes the MATLAB image processing technology to research the characteristic parameters (length and width) used for characterizing the surface fatigue crack extension, compares two characterization methods, and validates the precision of the method used for detecting the surface fatigue crack images. The method has the advantages of high precision, non-contact type, simple equipment, easy execution, and the like, can realize the intellectualized malfunction diagnosis, and provides guiding suggestions for practical production.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

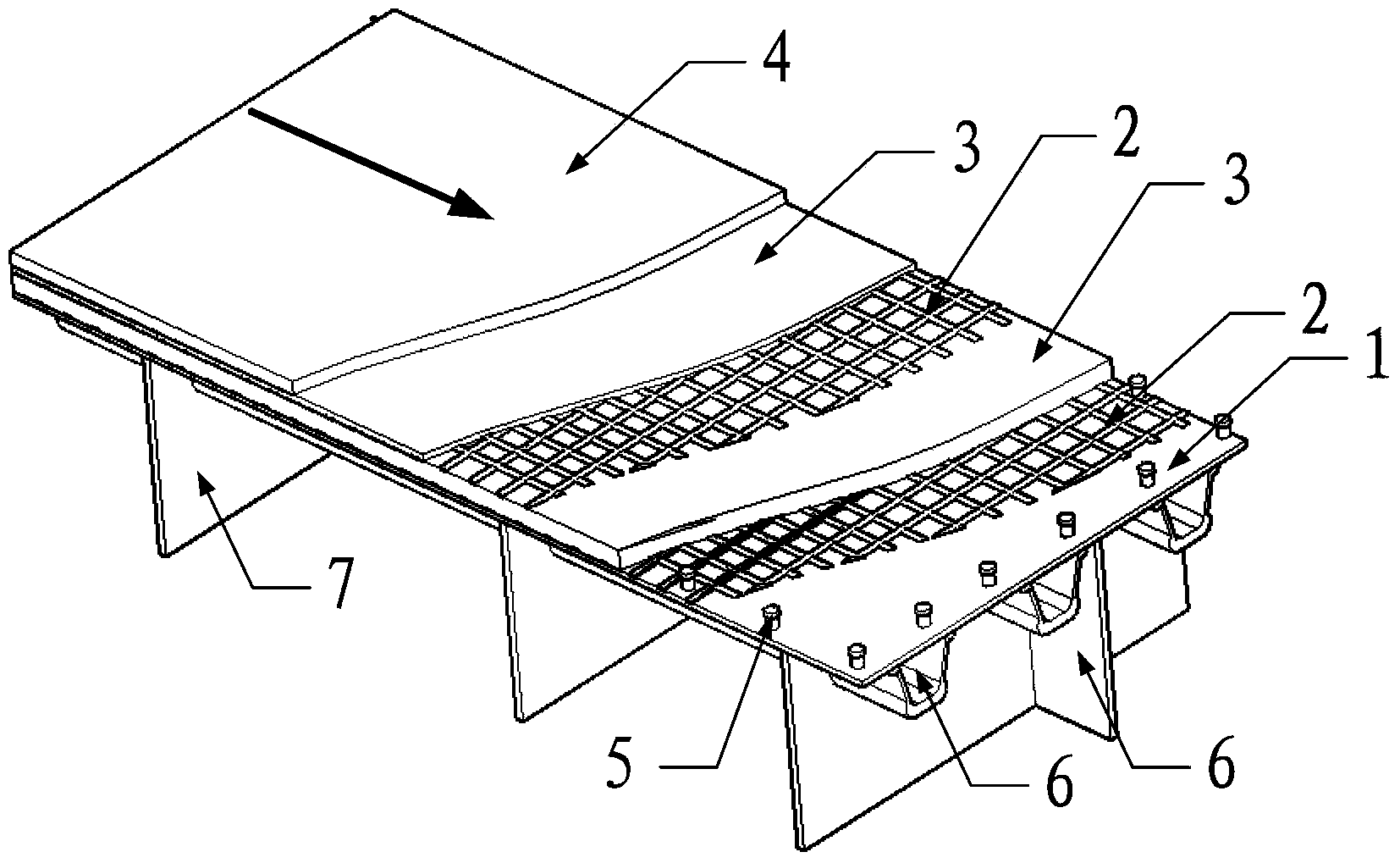

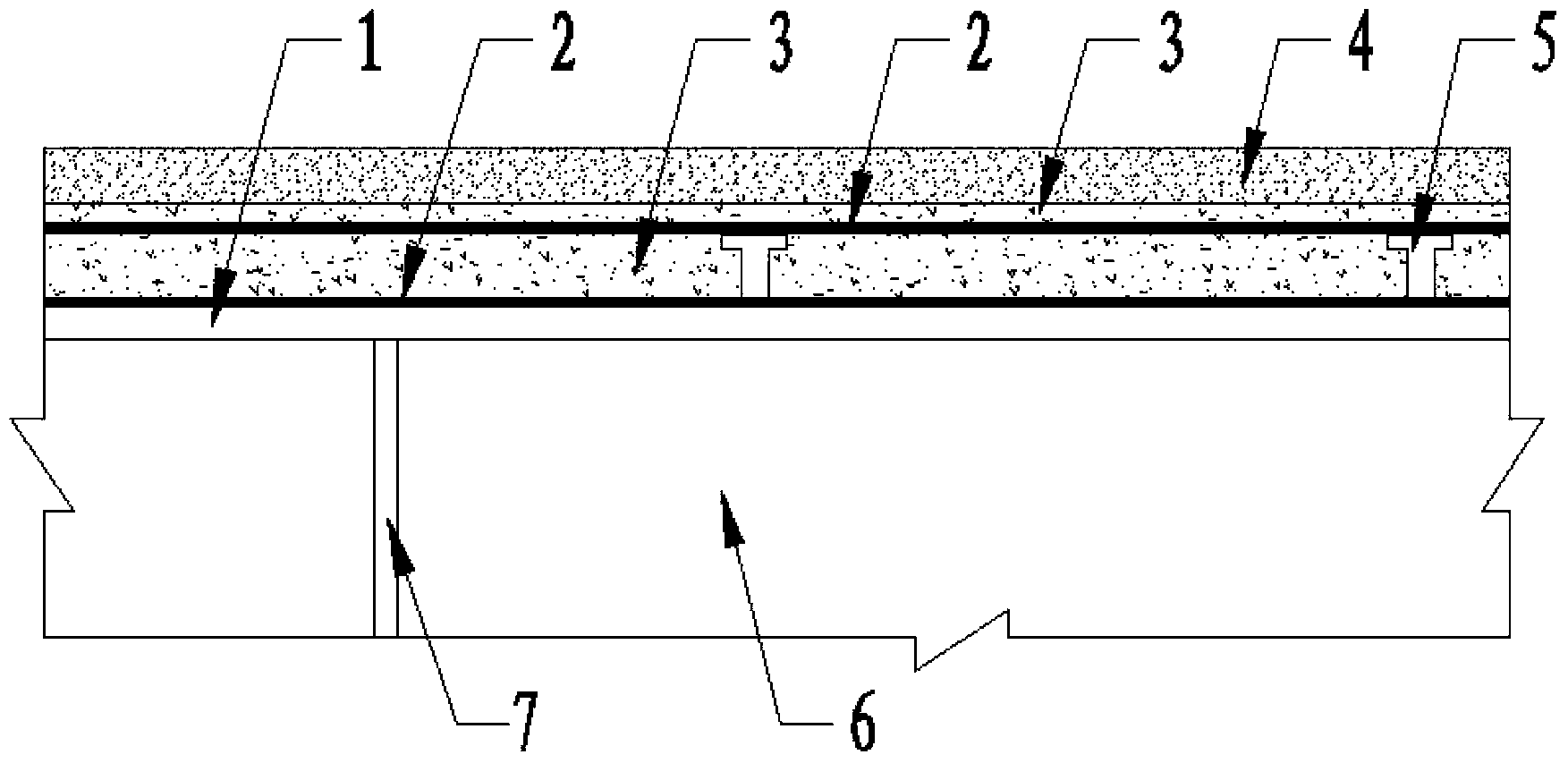

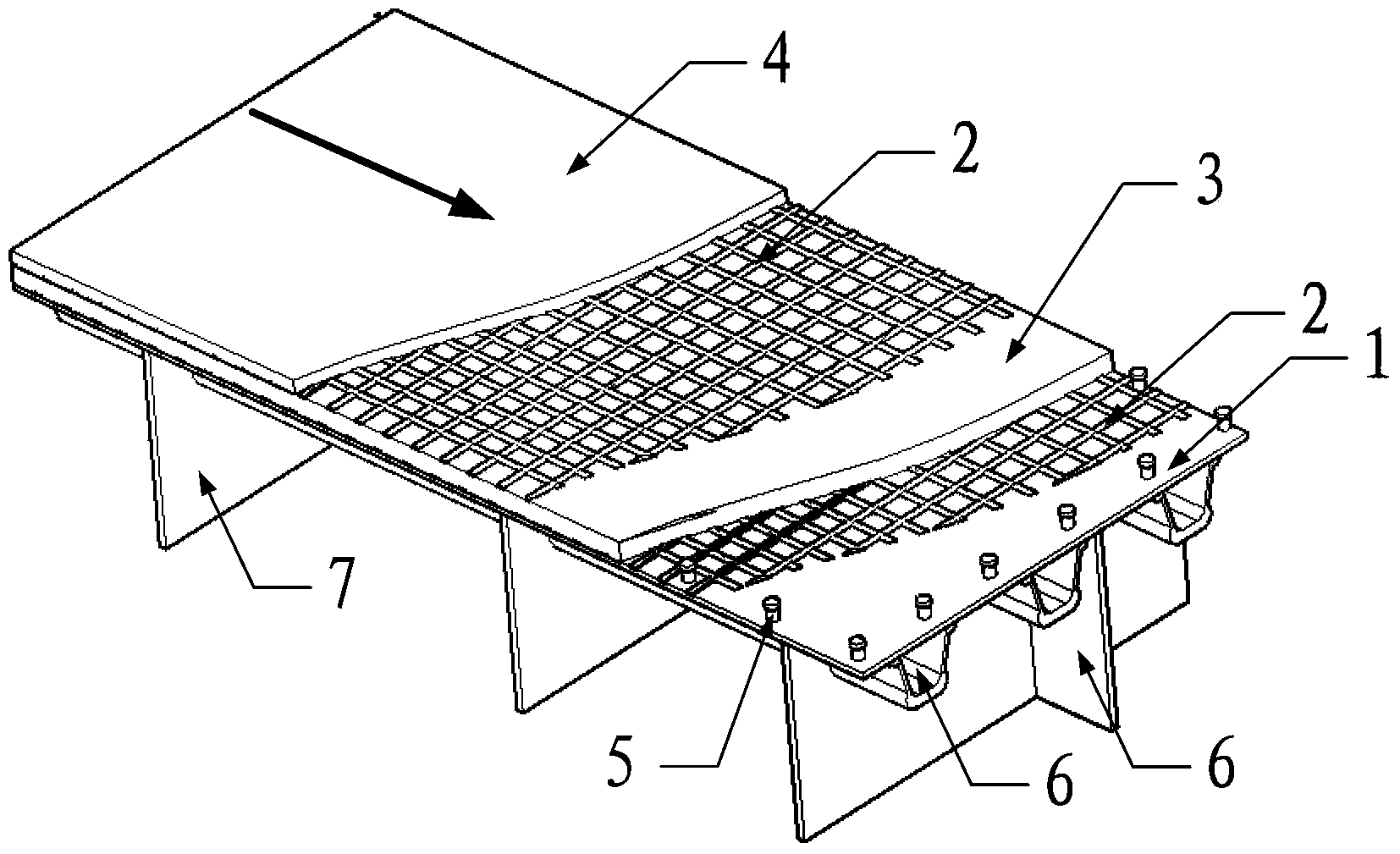

Orthotropic steel plate-fiber grating reinforced concrete combined deck structure

InactiveCN103410089AReduced risk of fatigue crackingHigh strengthPaving reinforcementsIn situ pavingsFiberEpoxy

The invention discloses an orthotropic steel plate-fiber grating reinforced concrete combined deck structure. The deck structure comprises an orthotropic steel plate, fiber gratings, concrete and a wearing layer. The fiber gratings, the concrete and the wearing layer are arranged on the upper side of the orthotropic steel plate successively. The fiber grating is connected with the orthotropic steel plate on the lower side of the fiber grating through a high-performance epoxy resin adhesive, and shear keys are arranged on the periphery of the orthotropic steel plate as required so as to increase the bonding strength. The deck structure has the advantages of being high in interlayer shear resistant capacity, anti-stripping, water-proof, high in rigidity and strength, and good in toughness, is provided with stable high-temperature stability and low-temperature crack resistance, is capable of effectively preventing interlayer cracking, reducing the fatigue cracking risk of the orthotropic steel plate and pavement layers and improving plus or minus bending moment resistance of the steel plate, and is applicable to building and repairing of various steel deck structures.

Owner:NANJING TECH UNIV

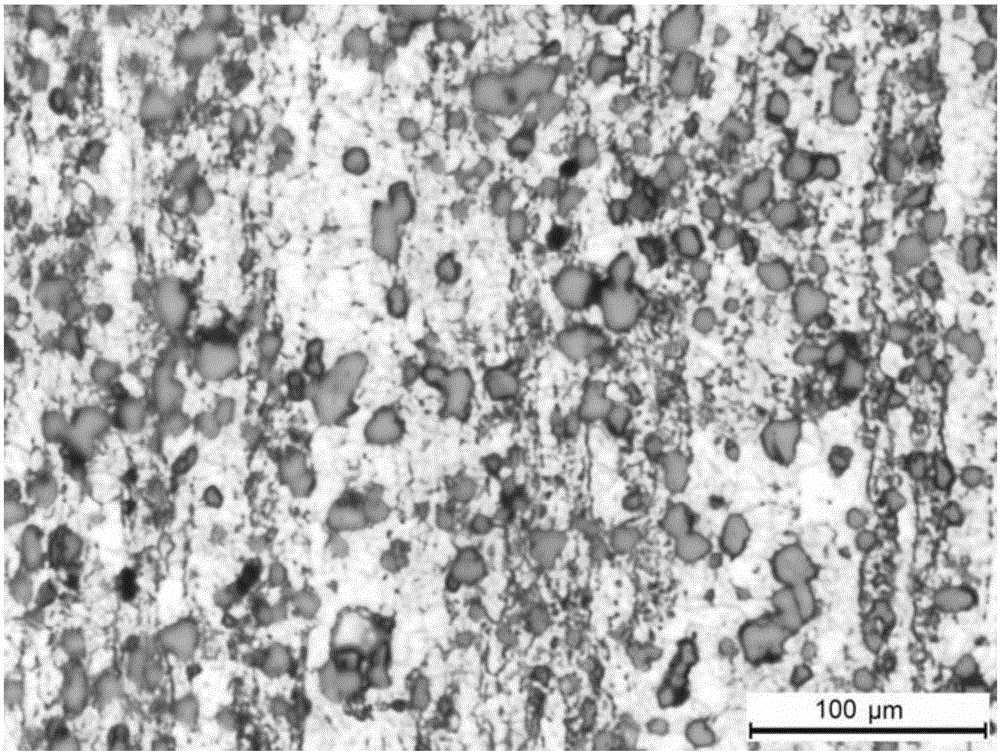

Silicon carbide particle reinforcement aluminum-based composite for train brake disc and preparation method

Disclosed are a silicon carbide particle reinforcement aluminum-based composite for a train brake disc and a preparation method. The composite includes the following components of, by mass percentage, 15-25% of SiC particles, 18-24% of Si, 0.6-3.5% of Mg, 0.15-0.35% of Zr, 0.12-0.45% of Sc, and the balance Al and unavoidable impurities. According to the preparation method, SiC, Mg, Si, Zr and Sc with the particle size being 10-15 [mu]m are added into molten aluminum in the form of intermediate alloy, SiC with the particle size being 15-25 [mu]m is added into the molten aluminum in the form of particles, and thus the silicon carbide particle reinforcement aluminum-based composite is obtained. The SiC thin particles are added in the form of Mg-SiC, so that the problems of uniform dispersing difficulty of silicon carbide particles in a matrix and poor interface bonding are effectively solved, the particle reinforcement effect is fully played, and the toughness of alloy is improved. Meanwhile, transitional element zirconium and rare earth element scandium are added to replace titanium fine grains, the roughness and heat resistance of the aluminum-based composite are remarkably improved, and occurrence of heat fatigue cracks is restrained. In addition, the added rare earth scandium has a good modification effect on the interfacial compatibility of the silicon carbide particles and aluminum alloy.

Owner:湖南中南智造新材料协同创新有限公司

Self-diagnosis system for wind-induced cumulative fatigue damage of pull lug node substructure of mast structure

InactiveCN101825522AEnsure safetyMaterial analysis using acoustic emission techniquesForce measurementFatigue damageReal time analysis

The invention discloses a self-diagnosis system for wind-induced cumulative fatigue damages of a pull lug node substructure of a mast structure. The system comprises a displacement measuring apparatus, a pull rope tension determination module, a welding residual stress determination module, a pull lug substructure wind-induced stress field determination module, a fatigue crack initiation degree real-time analysis module and a man-machine interaction interface, so that the system can timely inform a user of the degree of the cumulative fatigue at the danger point position of the pull lug node substructure of the mast structure and the time when the cumulative fatigue crack initiation occurs and make early warning on cumulative fatigue cracks when the pull lug node substructure of the mast structure is in a good condition. In addition, the system also comprises an acoustic emission sensor, a strain transducer, a fatigue crack growth determination module and an ultimate crack length and fracture analysis module, so that the system can timely inform the user of the degree of the cumulative fatigue crack growth and the time when the fracture occurs, timely repair the crack and ensure the safety of the mast structure when the cumulative fatigue cracks of pull lug node substructure of the mast structure occur.

Owner:WUHAN UNIV OF TECH

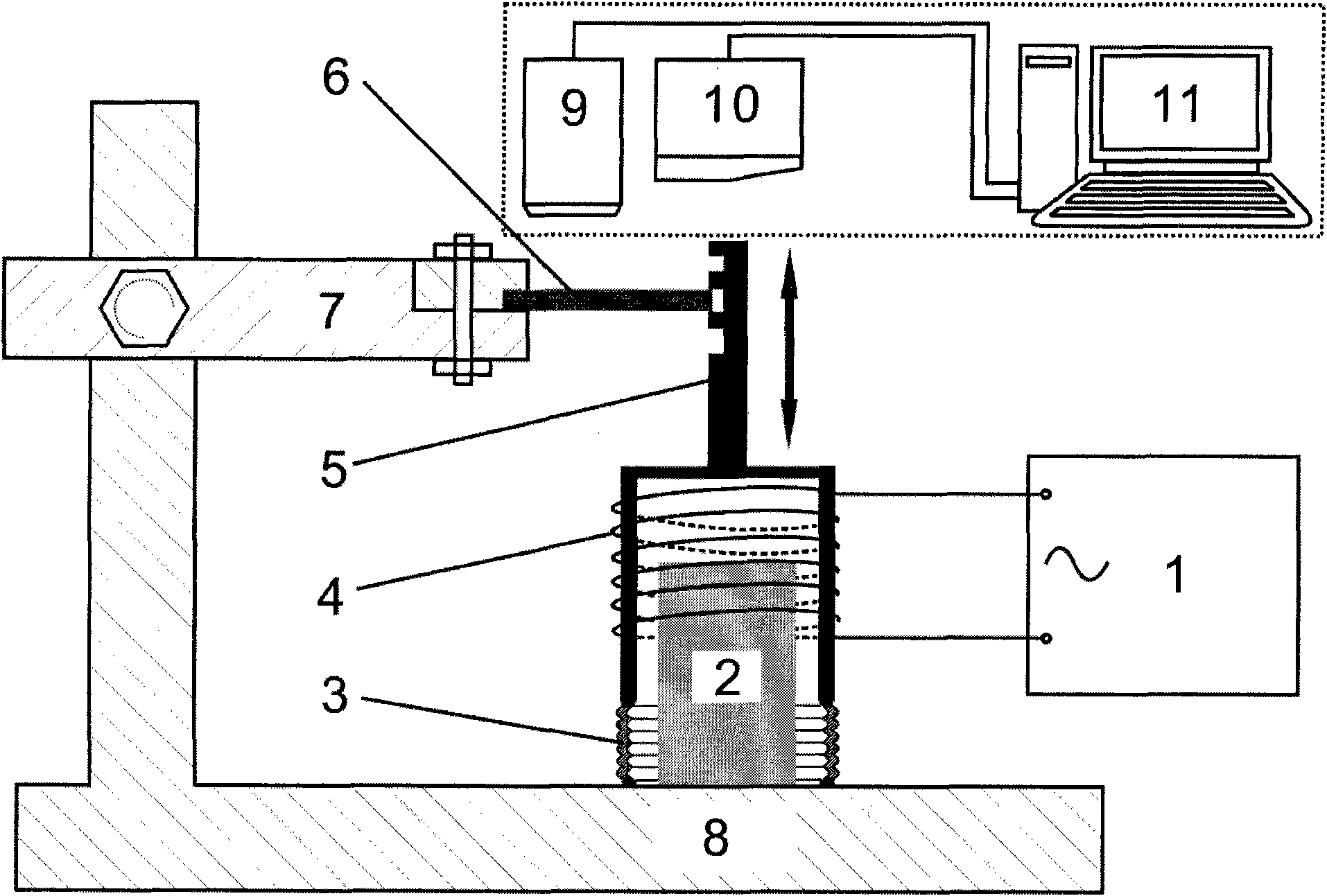

Test system and test method for dynamic bending fatigue property of thin film material

InactiveCN101571467AEasy and fast clampingWide range of loading frequencyMaterial strength using repeated/pulsating forcesVibration testingFatigue loadingEngineering

The invention relates to a test system and a test method for the dynamic bending fatigue property of a small-scale thin film material. The test system comprises an electromagnetic driving part, a sample holding part and a measuring and observing part, and the system provides functions and a test method for dynamic bending fatigue property test for the thin film materials used for various micro / nanoelectronic mechanical systems and supported with matrix or without matrix, the metalized interlinking body foil material used for an integrated circuit and various two-dimensional thin plate type materials and can record in-situ real-time monitoring and analysis to the appearance of the tested sample. The free end of the cantilever beam sample is driven under the electromagnetic force of the electrified coil in the stationary magnetic field to reciprocate relatively to the equilibrium position thereof, thus various types of cyclic fatigue loads can be applied to various material samples, and the precision of the applied fatigue loads can reach the millinewton magnitude. The invention can be used to evaluate the fatigue property and the fatigue crack growth behaviors of various thin film materials.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

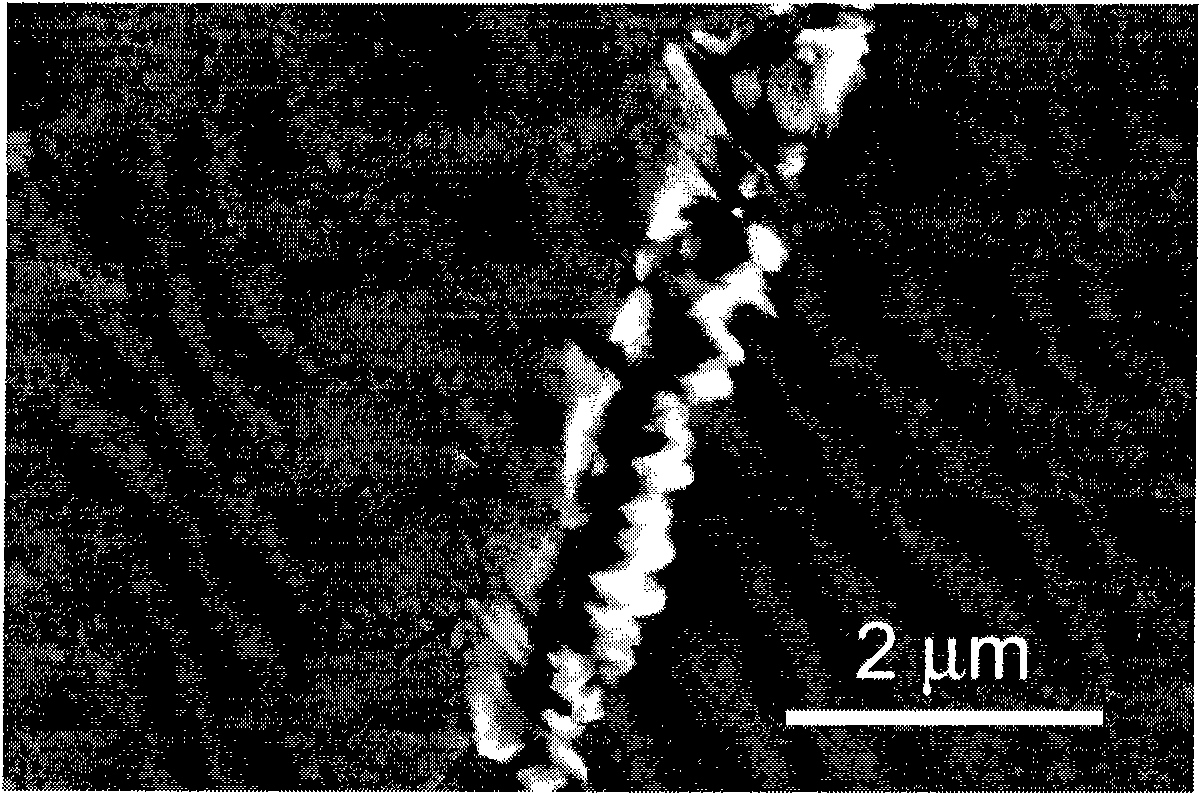

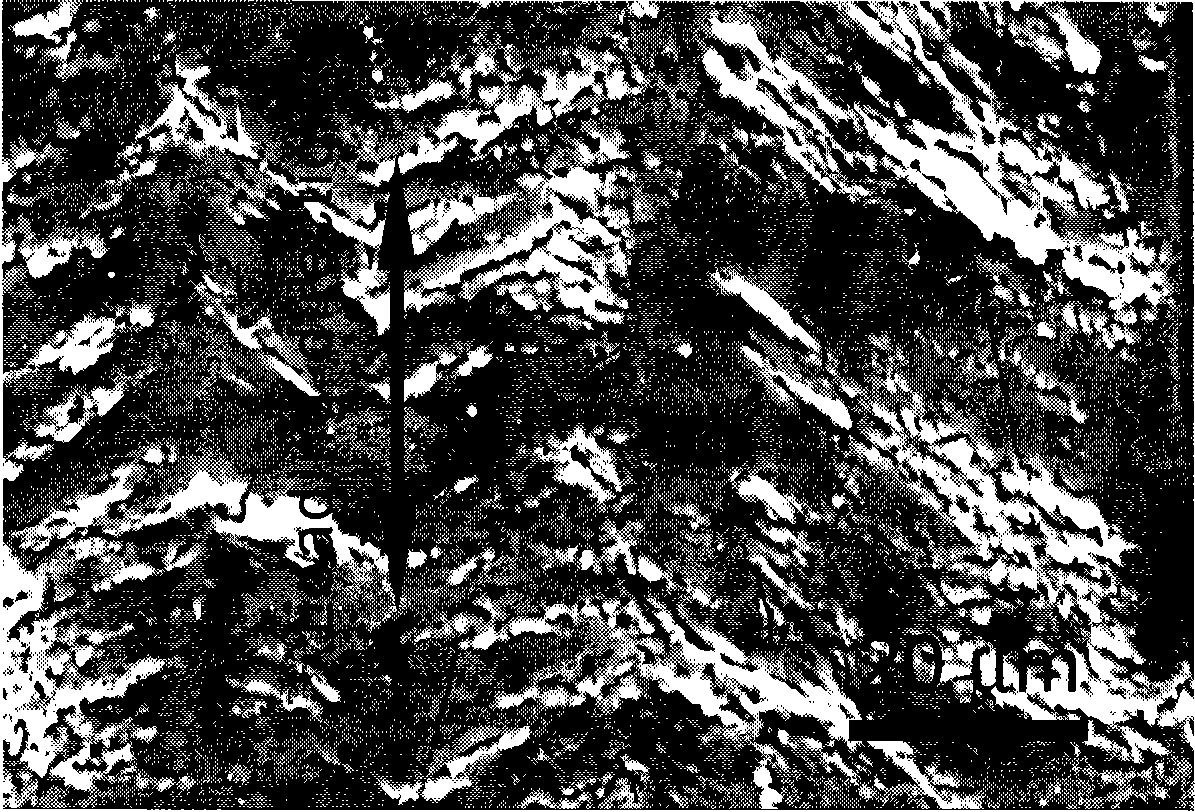

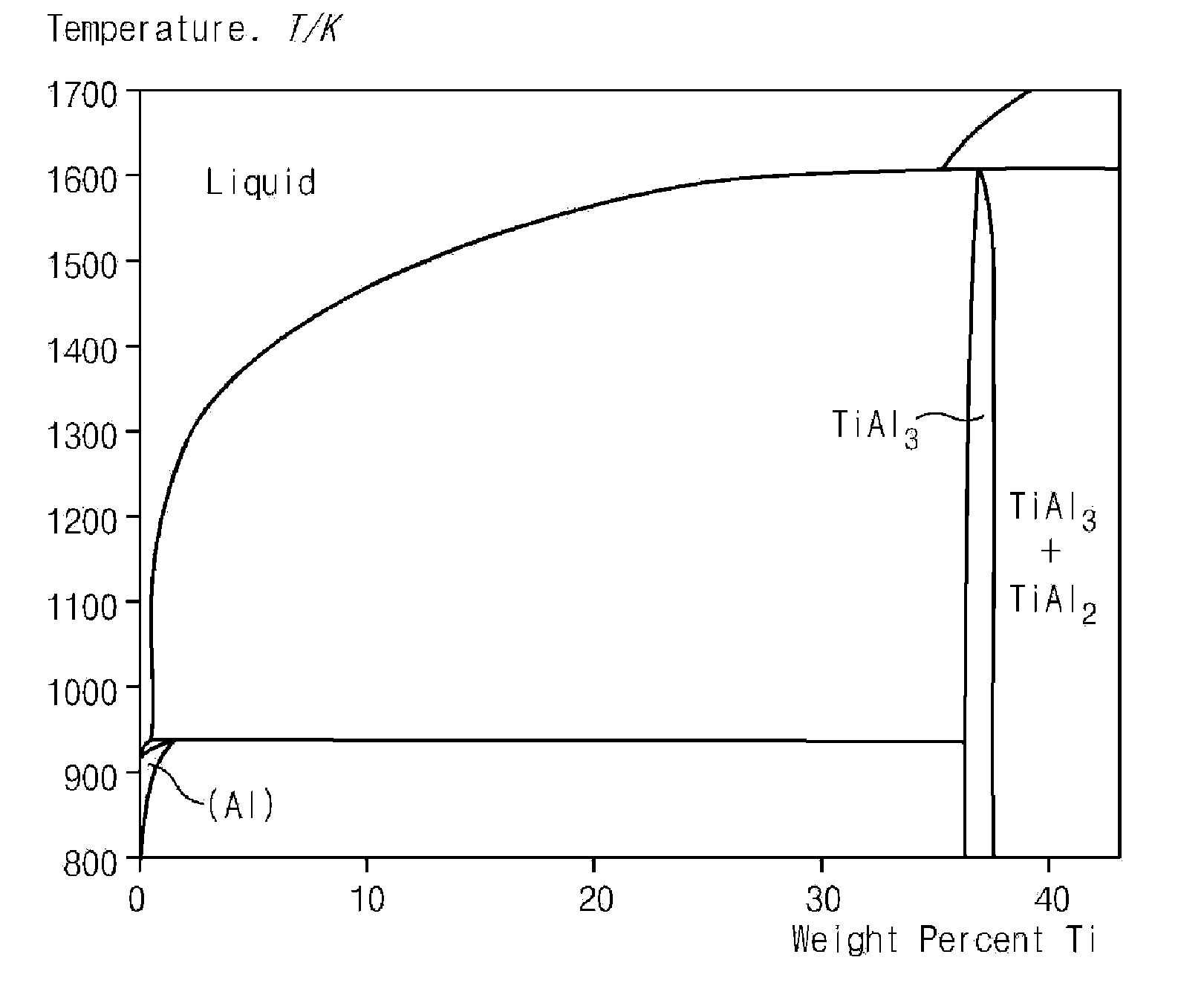

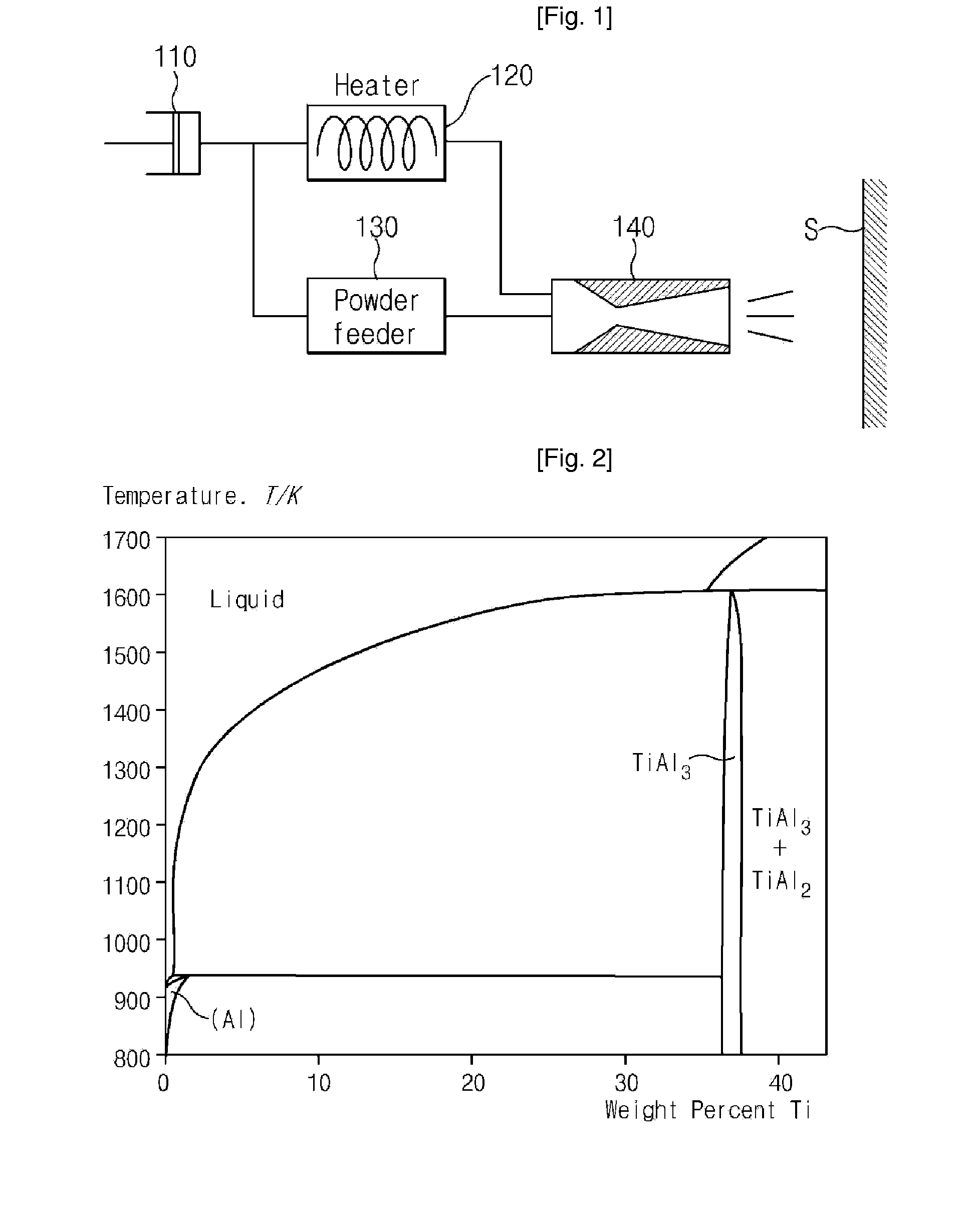

Method of Preparing Metal Matrix Composite and Coating Layer and Bulk Prepared Thereby

InactiveUS20090120539A1High temperature strengthAvoid heat buildupMolten spray coatingEfficient propulsion technologiesCrazingHeat treated

This invention provides a method of preparing a metal matrix composite, and a coating layer and bulk prepared by using the same and in particular, it provides a method of preparing a metal matrix composite, which comprises the steps of providing a substrate; preparing a mixed powder comprising i) a first metal powder comprising a metal, alloy or mixture particle thereof, ii) a second metal powder comprising an intermetallic compound forming metal particle which forms an intermetallic compound along with the metal or the alloy element of the alloy, and iii) a ceramic powder comprising a ceramic or mixture particle thereof; injecting the mixed powder prepared above into a spray nozzle for coating; coating the mixed powder on the surface of the substrate by accelerating the mixed powder in the state of non-fusion at a speed of 300 to 1,200 m / s by the flow of transportation gas flowing in the spray nozzle; and forming the intermetallic compound by the thermal treatment of the coated coating layer, and a coating layer and bulk prepared by using the same, whereby the coating layer and bulk material with high wear resistance and excellent resistance against fatigue crack on the surface without causing damages such as heat strain to the substrate during the preparation of the coating layer can be provided.

Owner:SKC SOLMICS

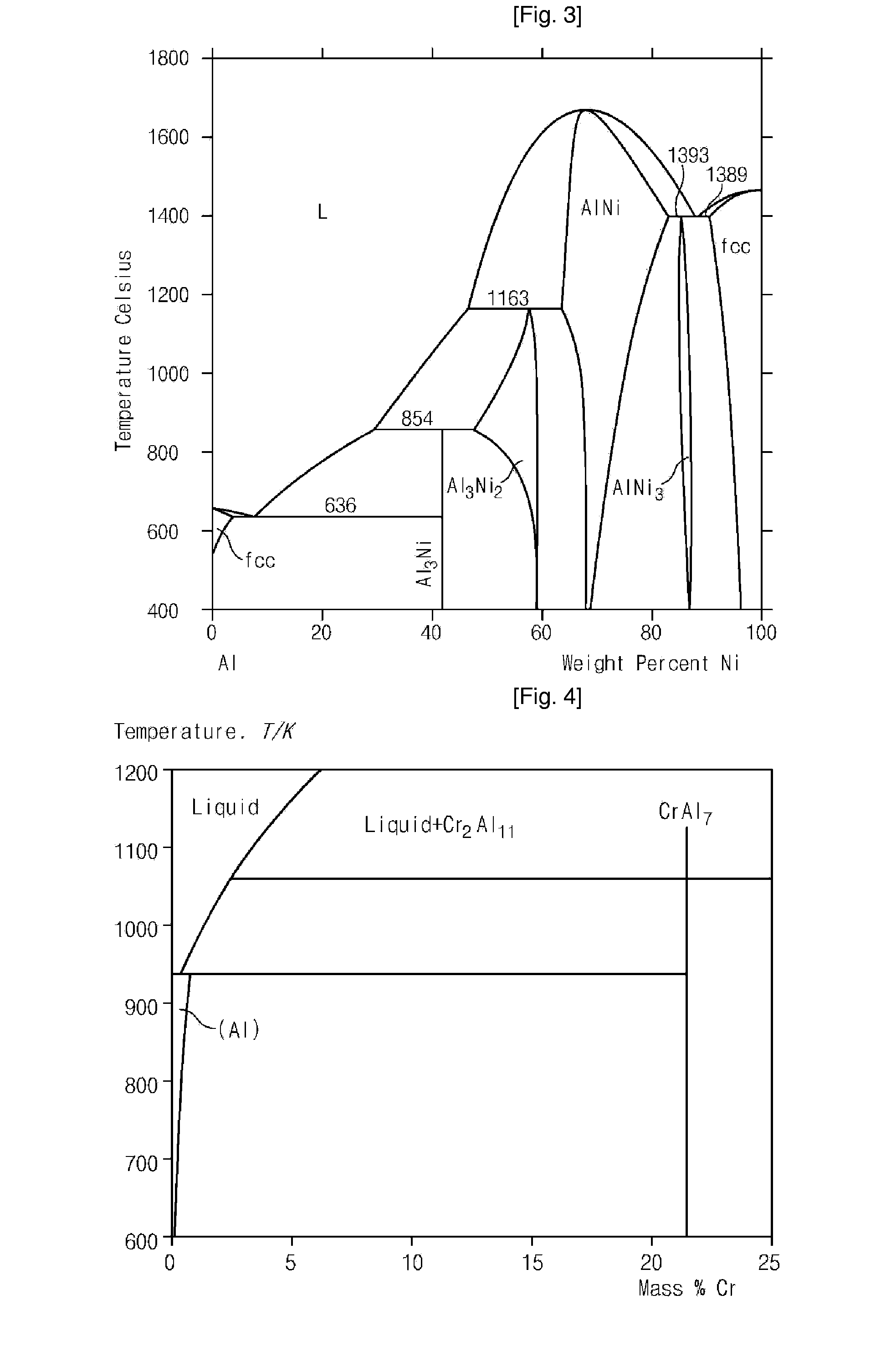

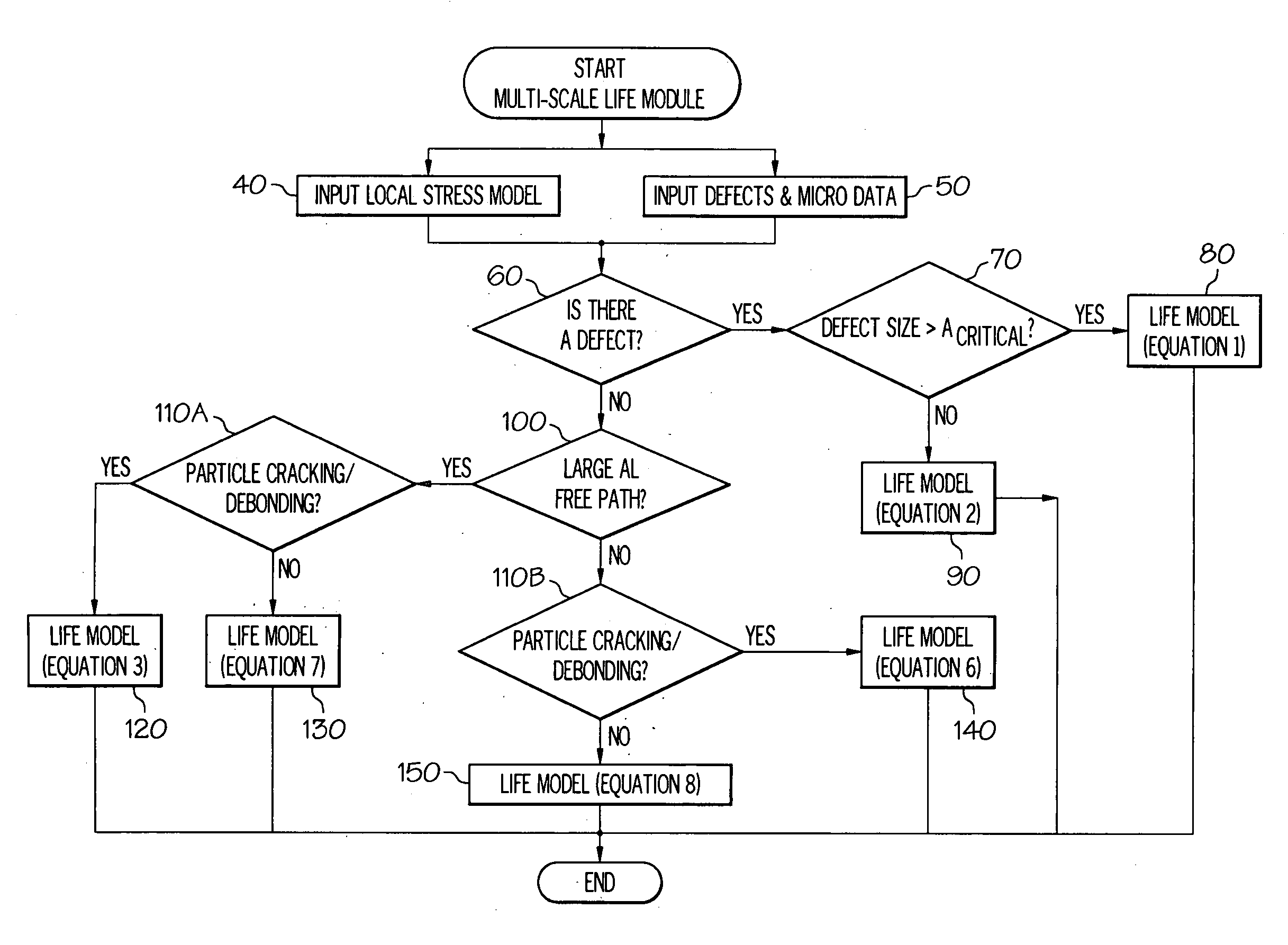

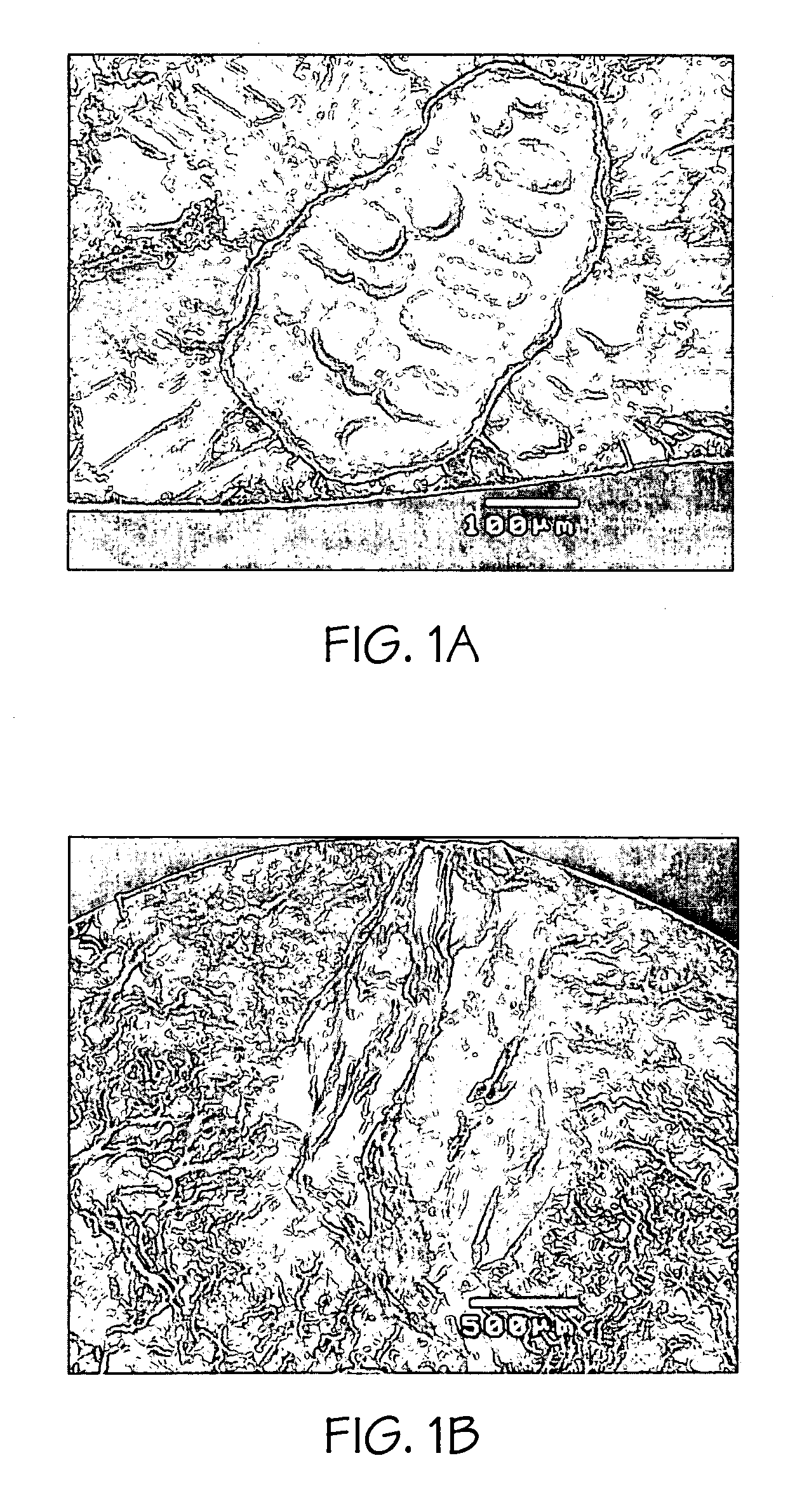

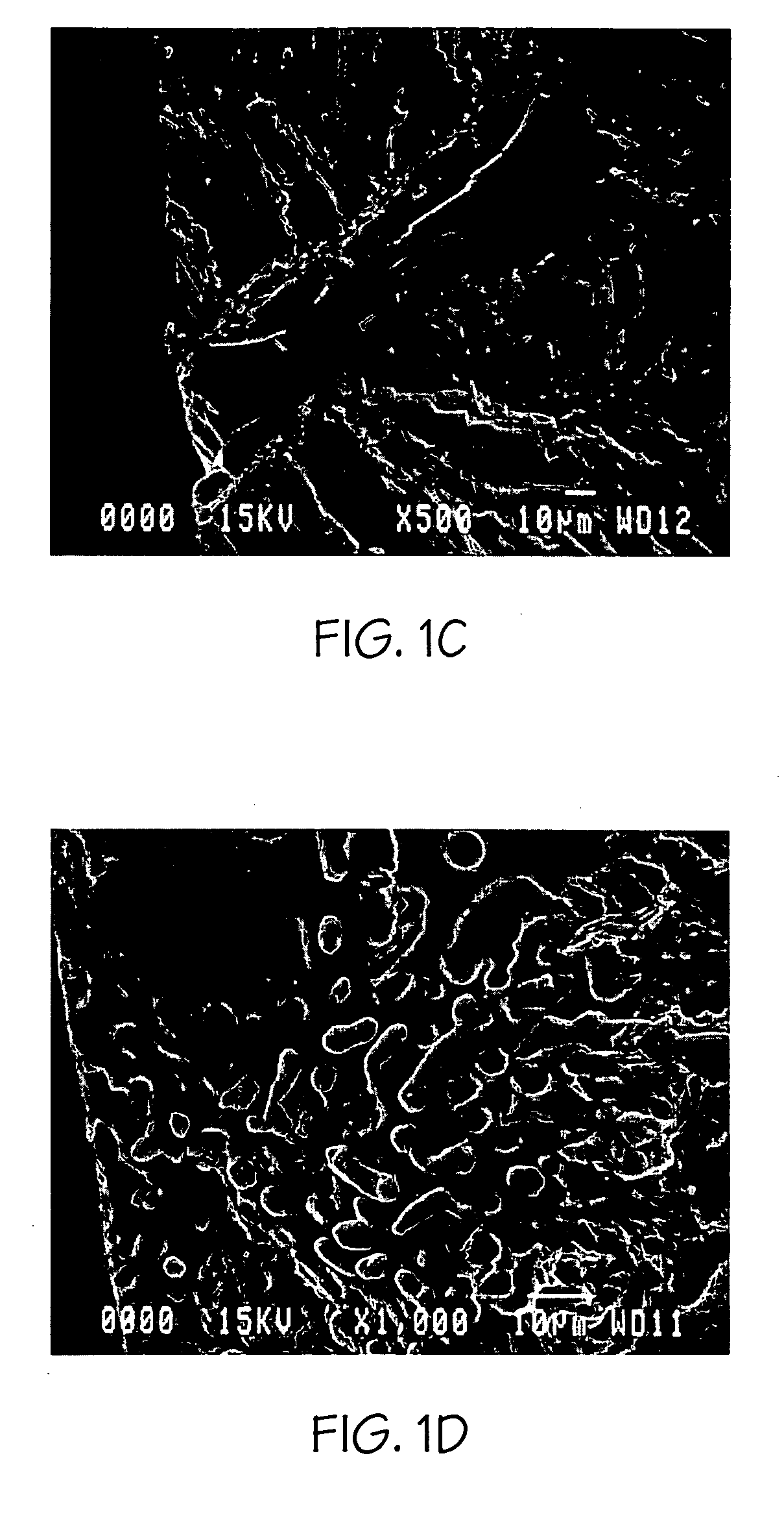

Methods and systems to predict fatigue life in aluminum castings

InactiveUS20090276166A1Accurately fatigue propertyAccurate of fatigue propertyPlug gaugesDigital computer detailsCrazingCasting defect

Methods and systems of predicting fatigue life in aluminum castings that combines extreme values of both casting flaws and microstructures with multiscale life models. The multiscale life models account for differing fatigue crack initiation based on the size scale of the defect and microstructure features, including provisions for generally millimeter scale casting flaws, generally micrometer scale second phase particles by cracking or debonding, or submicrometer scale dislocation interactions with precipitates which form persistent slip bands. In the presence of casting flaws, the fatigue initiation life is negligible and the total fatigue life is spent in propagation of a fatigue crack from such flaws. In the absence of casting flaws, however, the total fatigue life is spent in both crack initiation and propagation, except for the case where fatigue cracks initiate from large second phase particles in a coarse microstructure. The extreme values of casting flaws, second phase particles, mean free path through an aluminum matrix or grain sizes are obtained from extreme value statistics when two or three dimensional sizes of casting flaws and microstructure features are provided by either direct measurement or analytical prediction. The upper bound flaw or microstructure feature size is calculated by extreme value statistics.

Owner:GM GLOBAL TECH OPERATIONS LLC

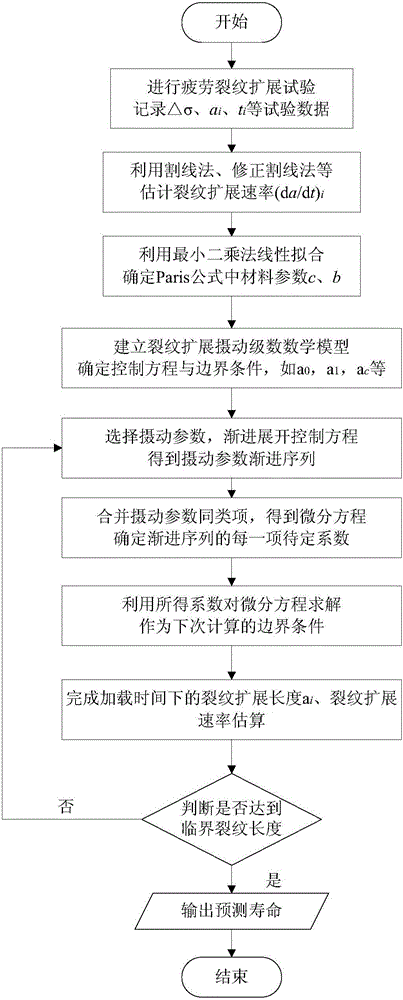

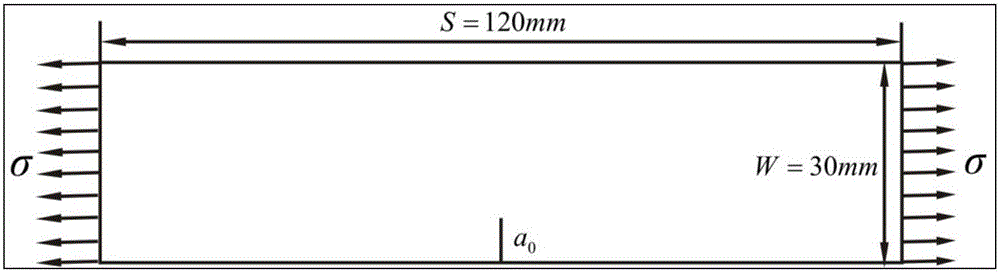

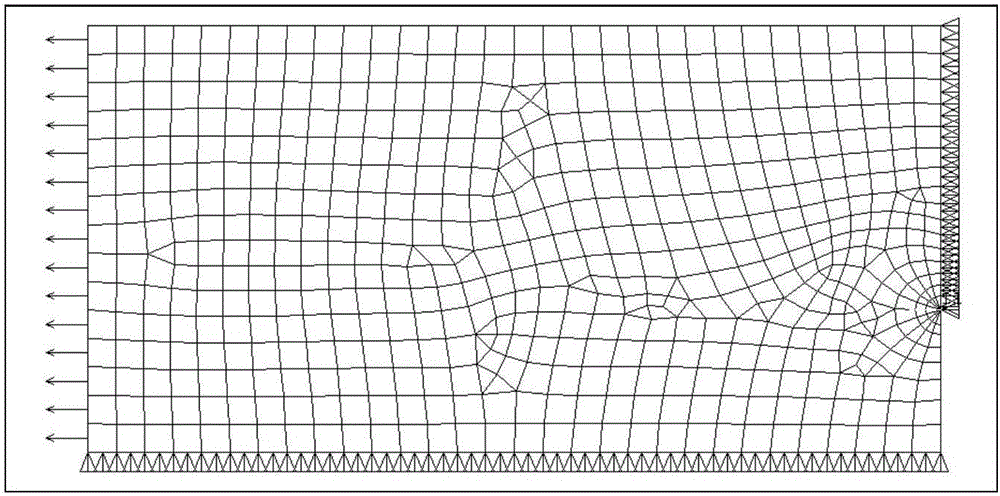

Method capable of carrying out fatigue crack propagation rate estimation and life prediction

InactiveCN105956315AEasy to understandEasy to acceptDesign optimisation/simulationSpecial data processing applicationsMetallic materialsLeast squares

The invention discloses a method capable of carrying out fatigue crack propagation rate estimation and life prediction. The method comprises the following steps: (1) carrying out a fatigue crack test, and recoding data including crack length, time and the like; (2) processing the data to estimate a propagation rate corresponding to the crack length; (3) taking a Paris formula as a least-squares fit line to determine metal material parameters; (4) establishing a crack propagation perturbation series model to obtain a control equation and a boundary condition; (5) selecting a perturbation parameter asymptotic expansion control equation to form a perturbation parameter asymptotic sequence; (6) combining like terms to obtain differential equations under different powers to determine a coefficient to be determined, and carrying out iterative solving on the differential equations to obtain boundary conditions during next calculation; and (7) utilizing a calculation result to finish crack propagation rate estimation, judging whether the crack length exceeds a critical crack or not, jumping to (5) if the crack length exceeds the critical crack, and finishing fatigue life prediction if the crack length exceeds the critical crack. The method can effectively estimate the crack propagation rate and predict the fatigue life, and improves calculation precision.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com