Test system and test method for dynamic bending fatigue property of thin film material

A fatigue performance testing, thin-film material technology, applied in vibration testing, testing of machine/structural components, testing material strength using repetitive force/pulse force, etc. The preparation method is complex and other problems, so as to achieve the effects of low cost, wide application frequency range, and simple and fast sample clamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

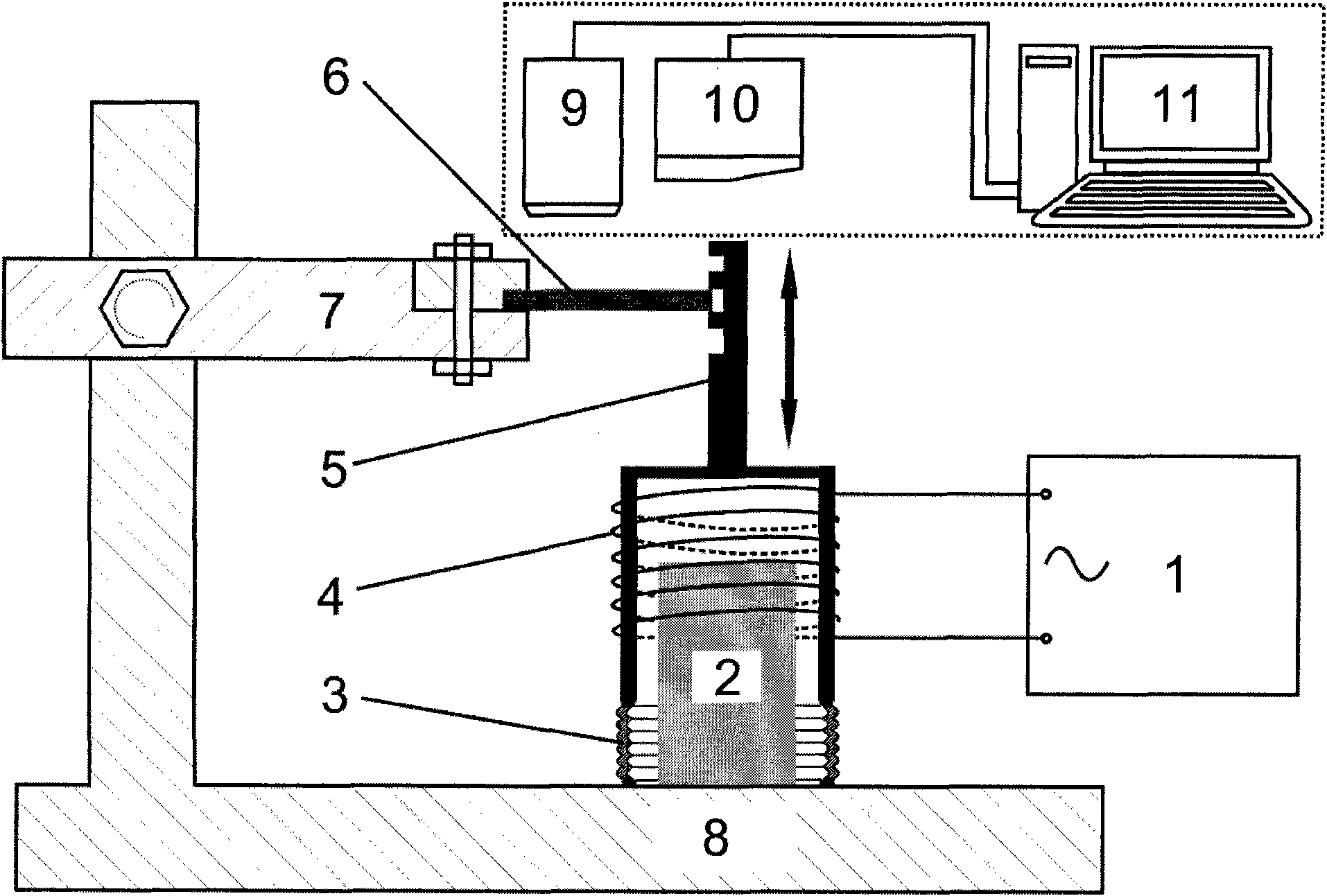

[0033] The principle diagram of the test system of the present invention is as follows figure 1 shown.

[0034] Cu-Ta bilayer films with a total thickness of 1 μm and a single layer thickness of 500 nm were prepared on a polyimide substrate with a thickness of 125 μm by magnetron sputtering. Cut the sample into a rectangular sample of 12mm×2mm as the sample to be tested. First adjust the clamp on the base frame so that it is on the same level as the groove on the driving rod corresponding to the thickness of the sample, then fix one end of the sample on the clamp, and the other end of the sample snaps into the groove of the driving rod. The power supply generates an alternating current signal with a frequency of 100Hz and inputs it into the coil, thereby driving the driving rod to perform periodic reciprocating motion, and driving the free end of the sample to vibrate. The amplitude of the free end of the sample measured by the laser displacement sensor is 760 μm. Warp 8.64...

Embodiment 2

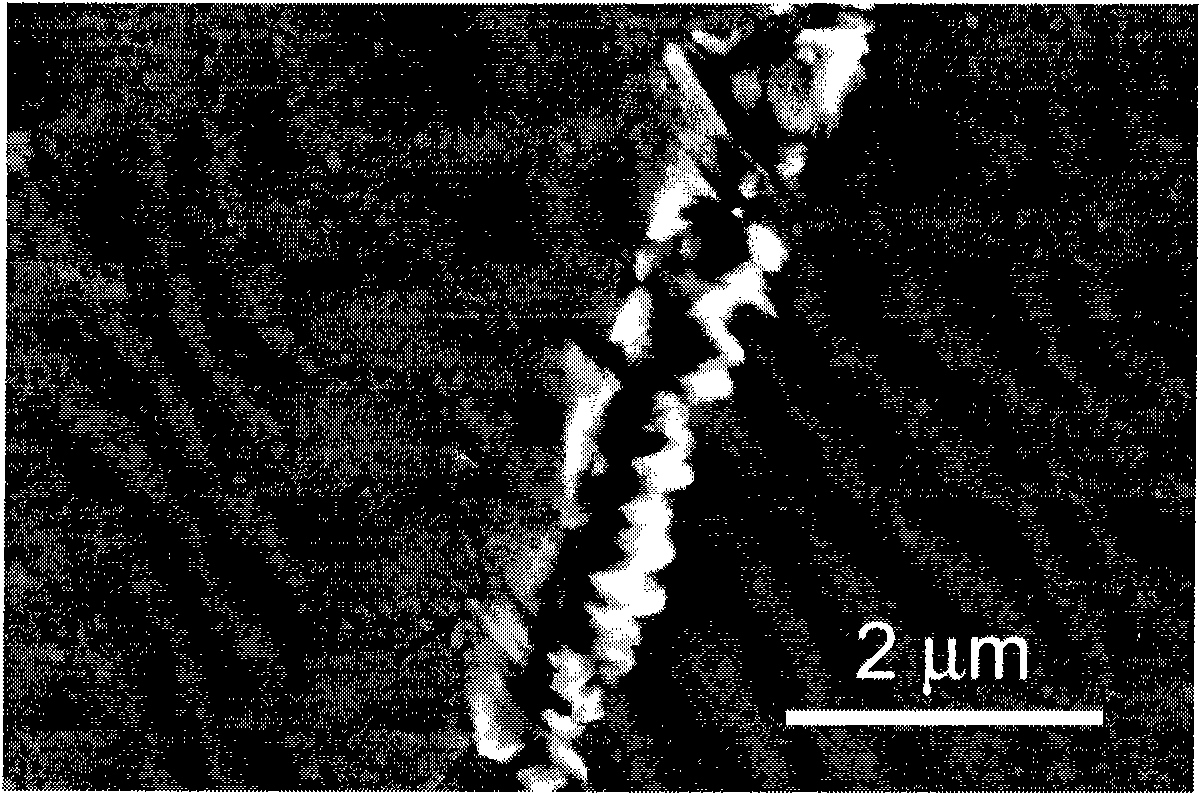

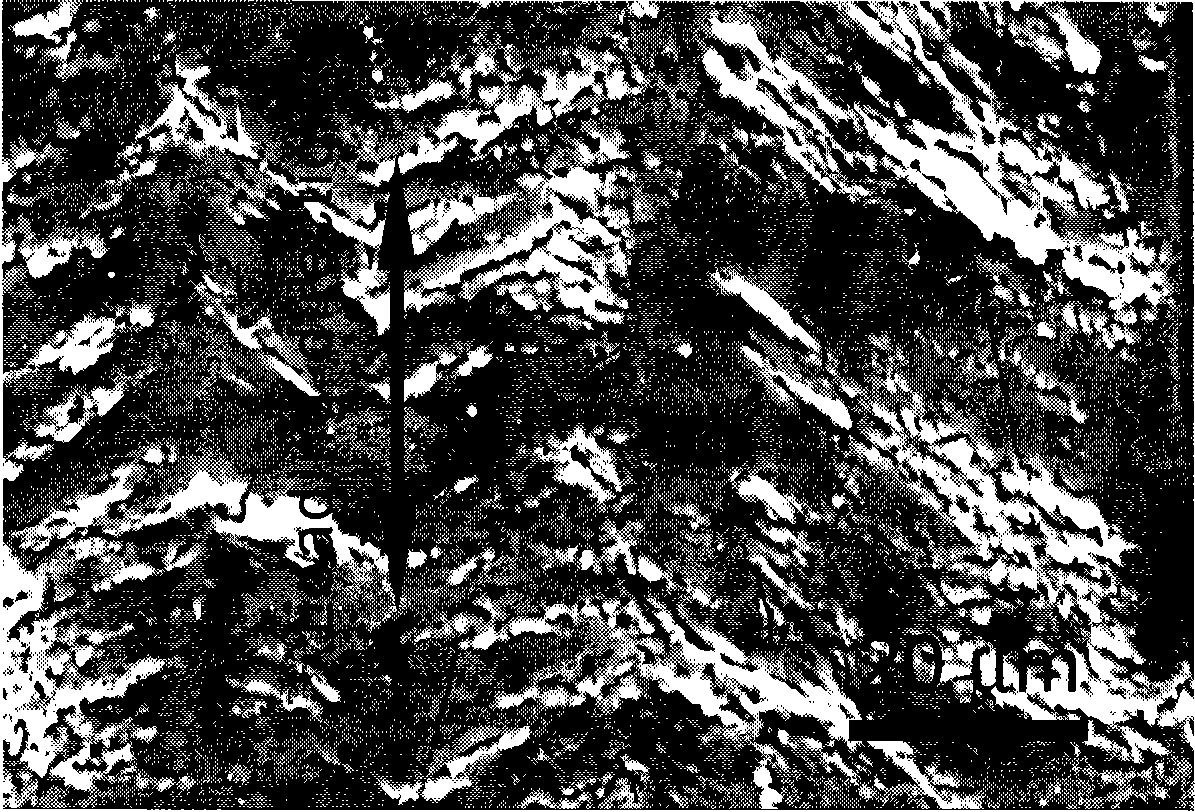

[0036] The rolled copper foil with a thickness of 180 μm was made into a rectangular sample of 8 mm×2 mm by wire cutting as the sample to be tested. Adjust the clamp on the base frame so that it is on the same level as the groove of the driving rod corresponding to the thickness of the sample, then fix one end of the sample with the clamp and snap the other end into the groove. The AC signal with a frequency of 50 Hz generated by the power supply is input to the coil, and the coil drives the driving rod to do periodic reciprocating motion in the magnetic field, thereby driving the free end of the sample to vibrate. Warp 2.57×10 6After cycles of fatigue loading, the specimen fractured. Scanning electron microscope observation shows that there is obvious fatigue extrusion on the surface of the sample, specifically as image 3 shown. The number of fatigue extruded strips per unit area decreases with increasing distance from the root of the cantilever beam. The angle between t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com