Patents

Literature

103results about How to "Easy and fast clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

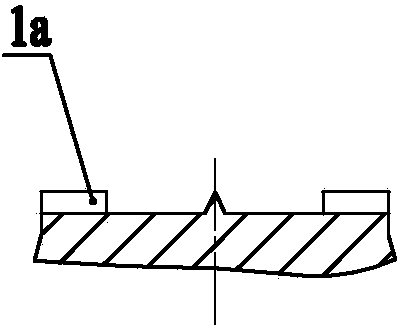

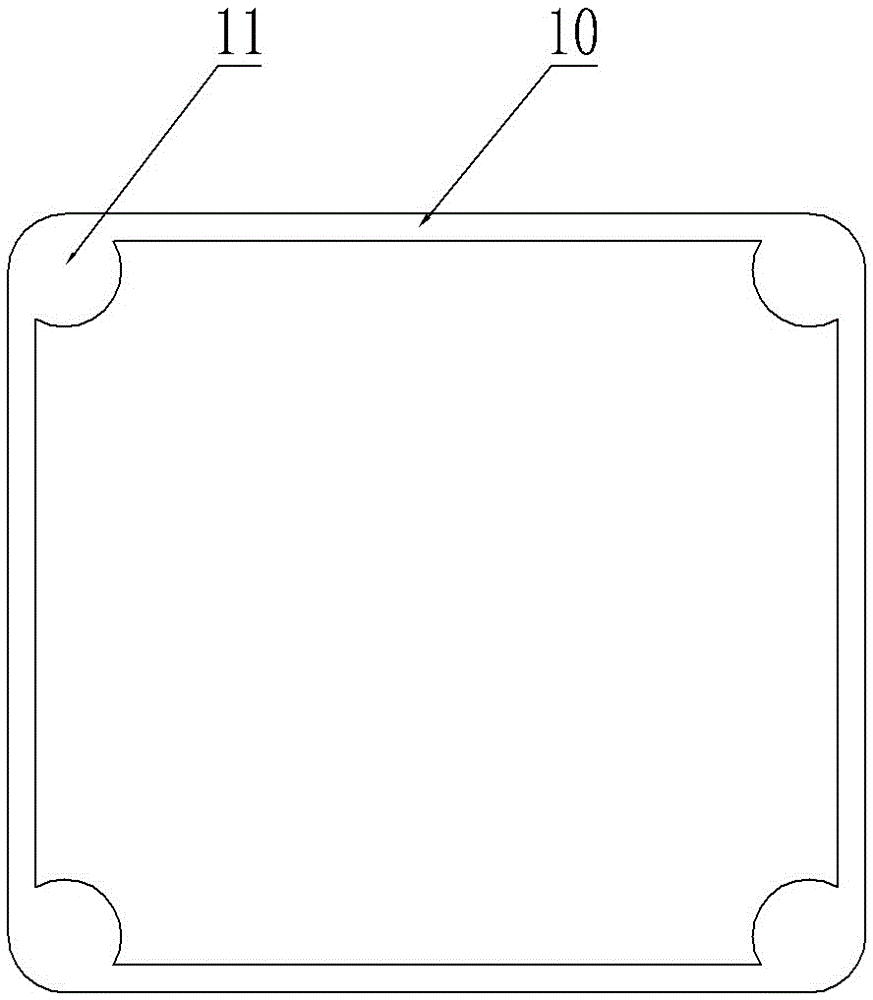

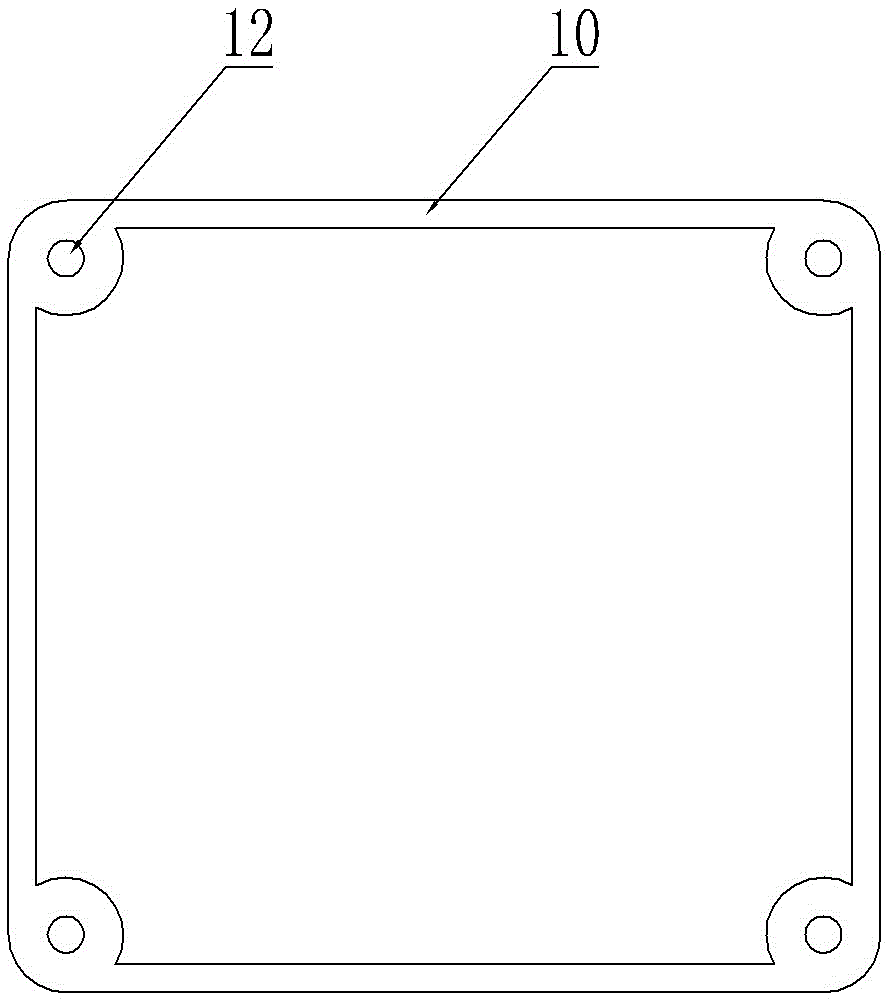

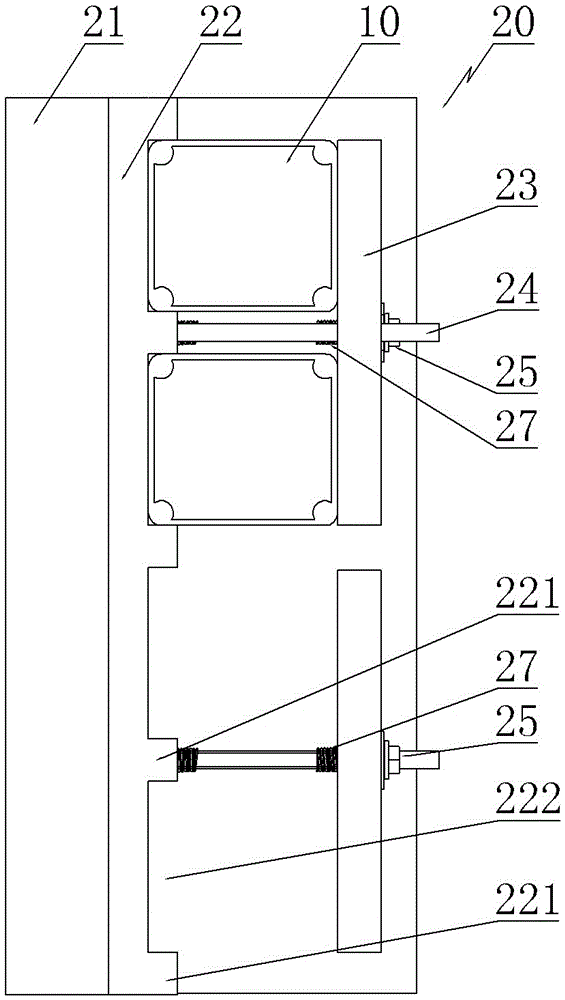

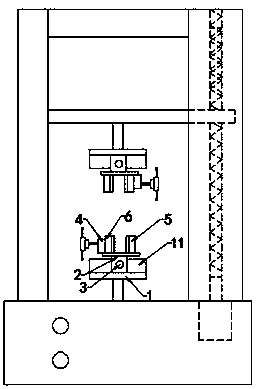

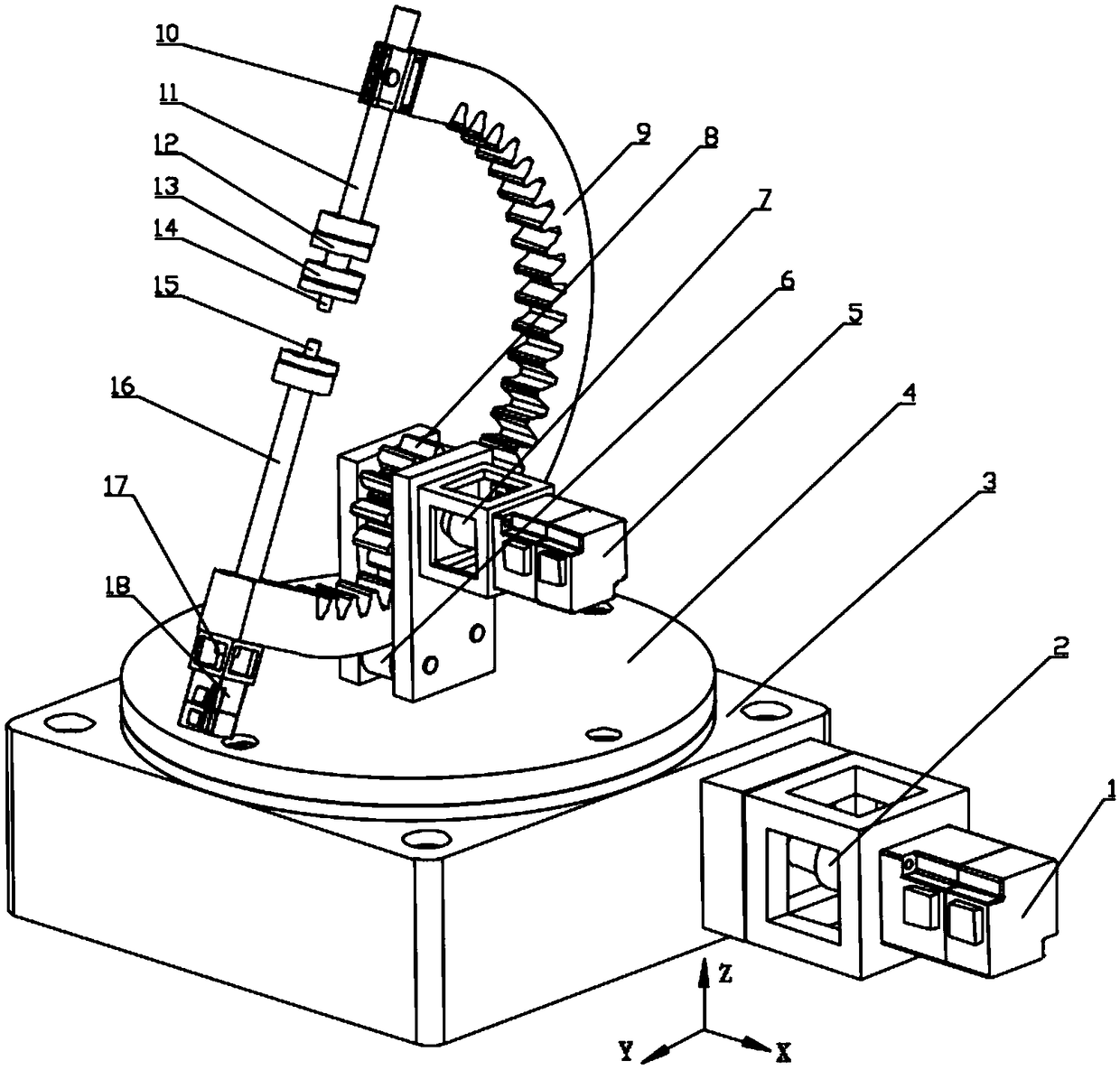

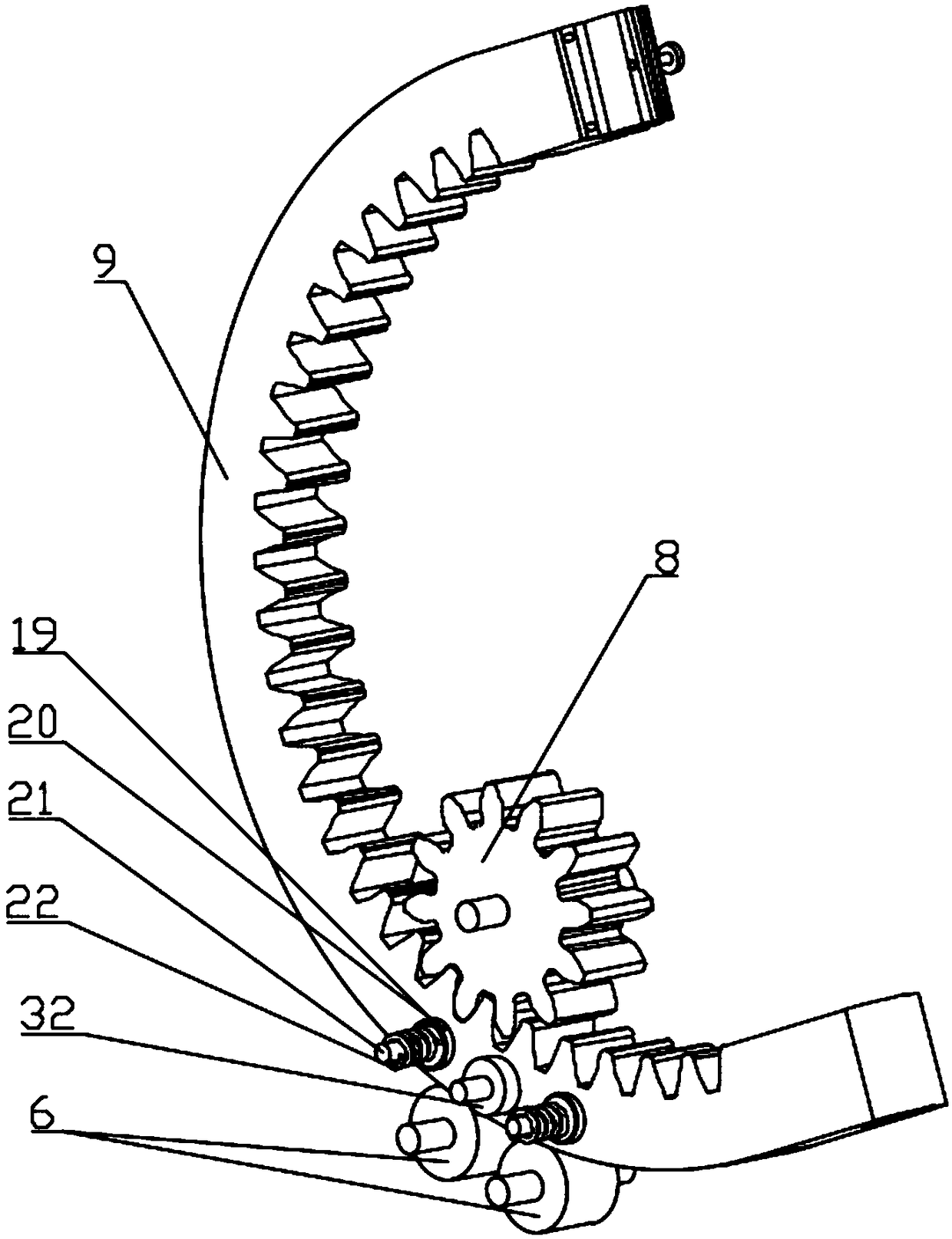

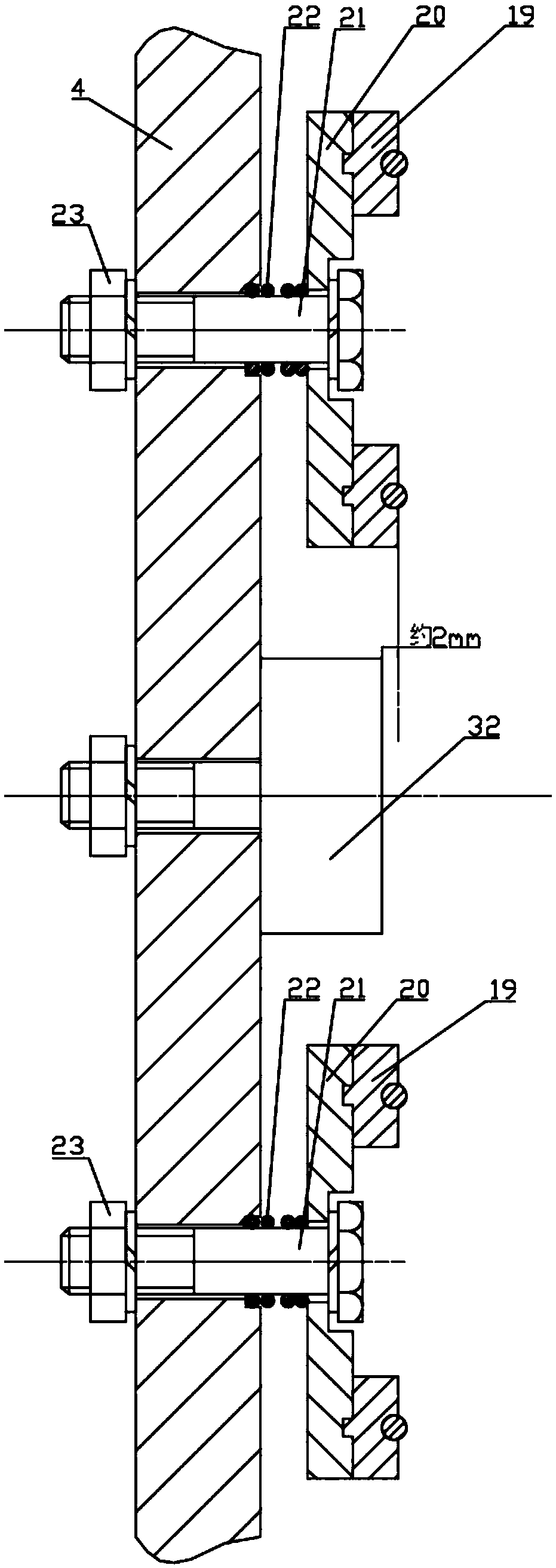

Test system and test method for dynamic bending fatigue property of thin film material

InactiveCN101571467AEasy and fast clampingWide range of loading frequencyMaterial strength using repeated/pulsating forcesVibration testingFatigue loadingEngineering

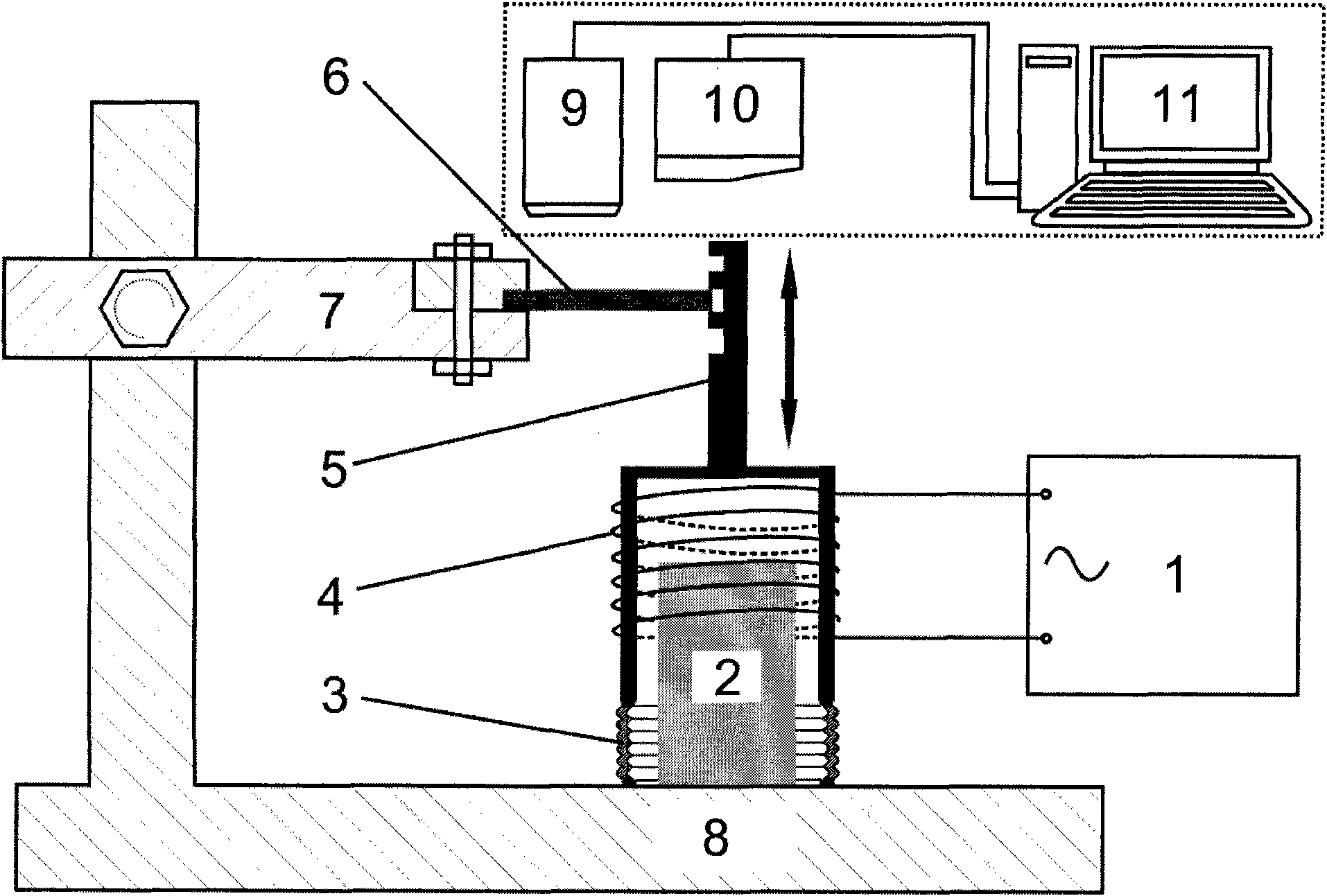

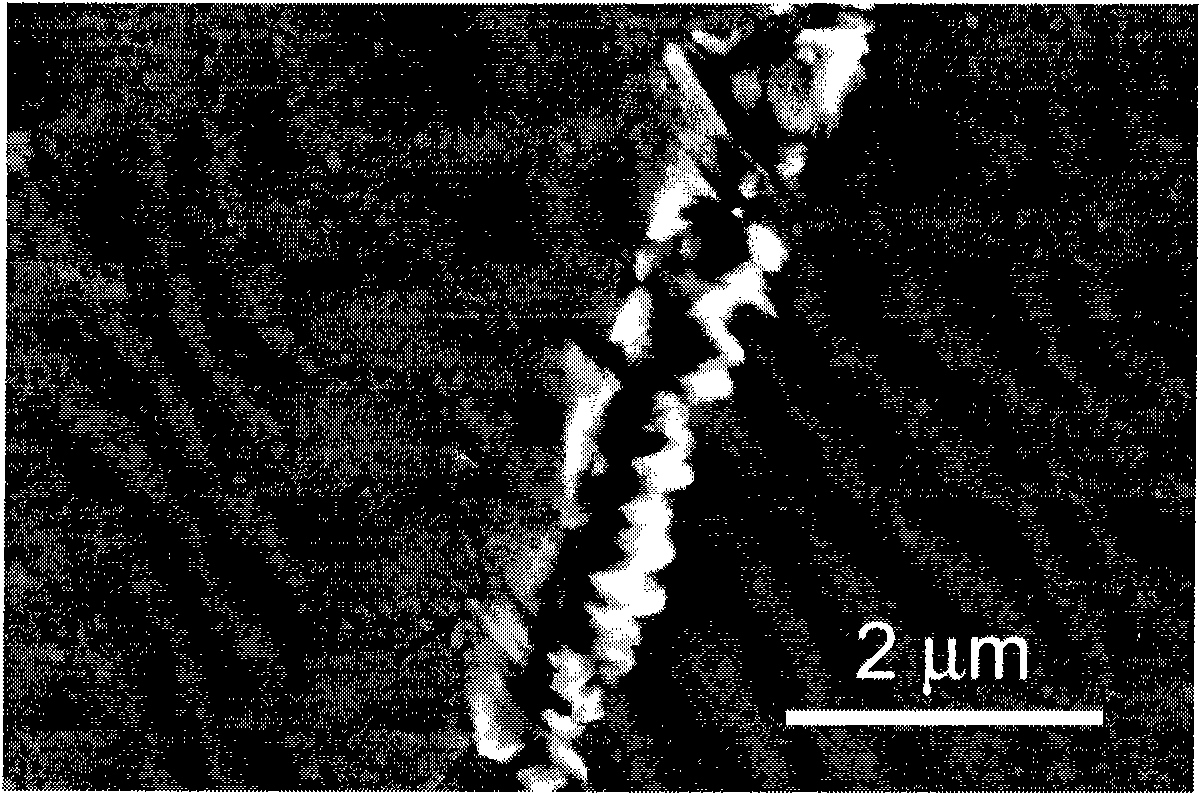

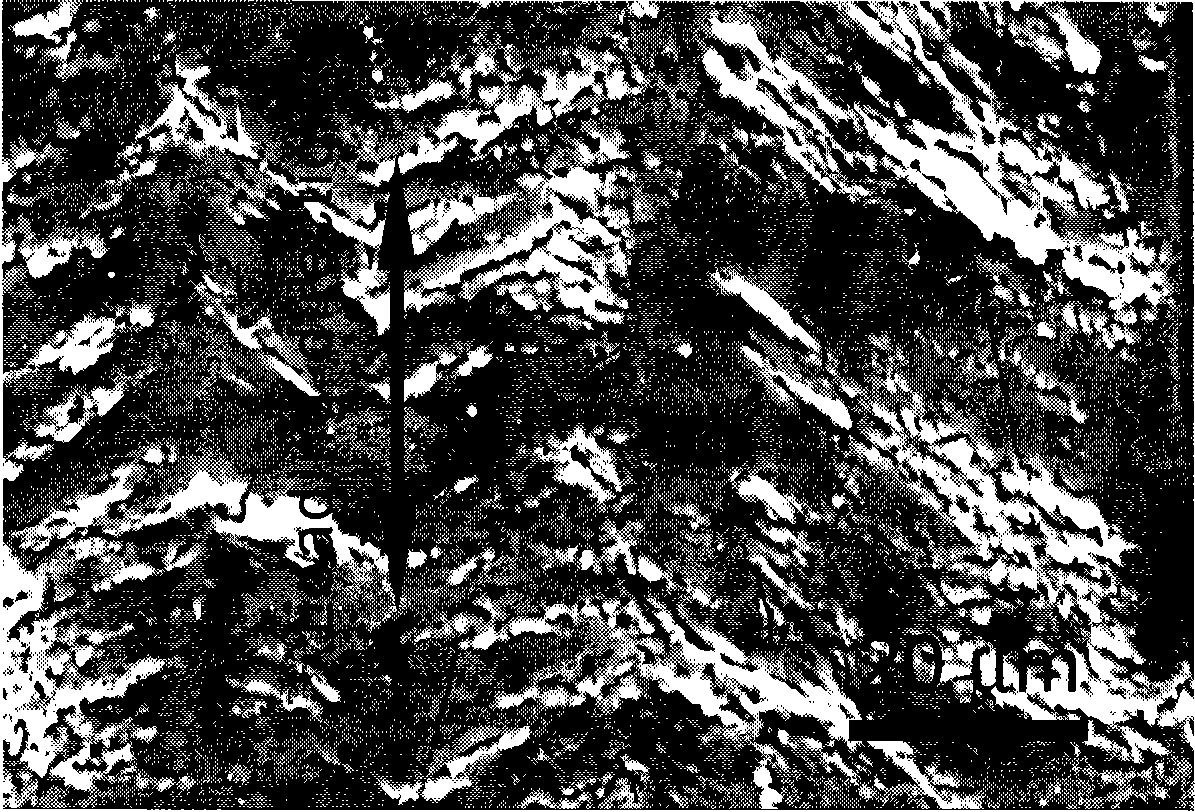

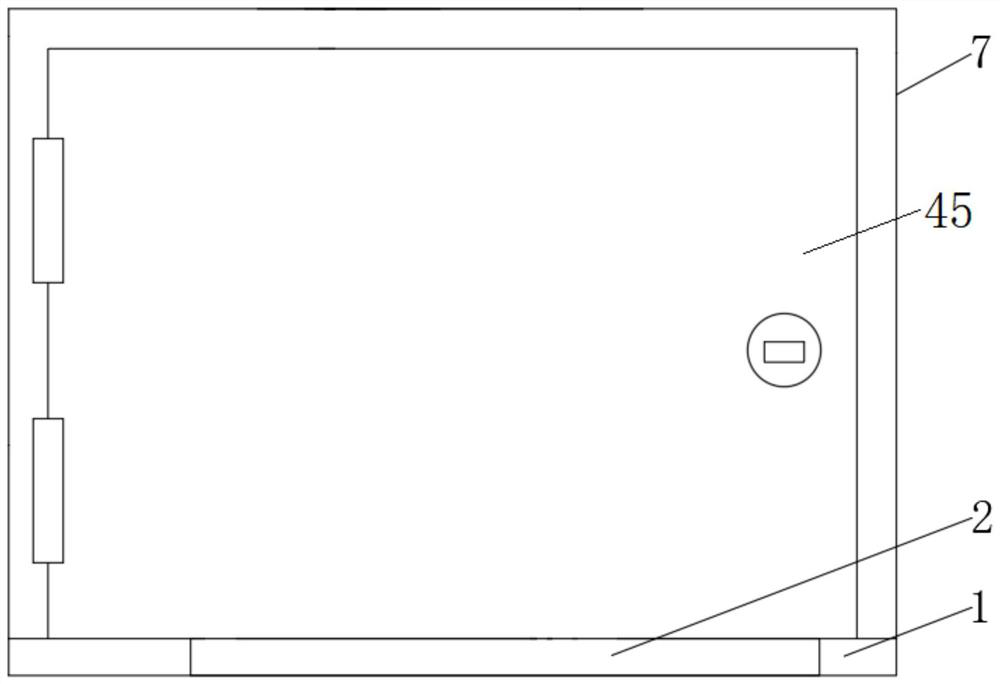

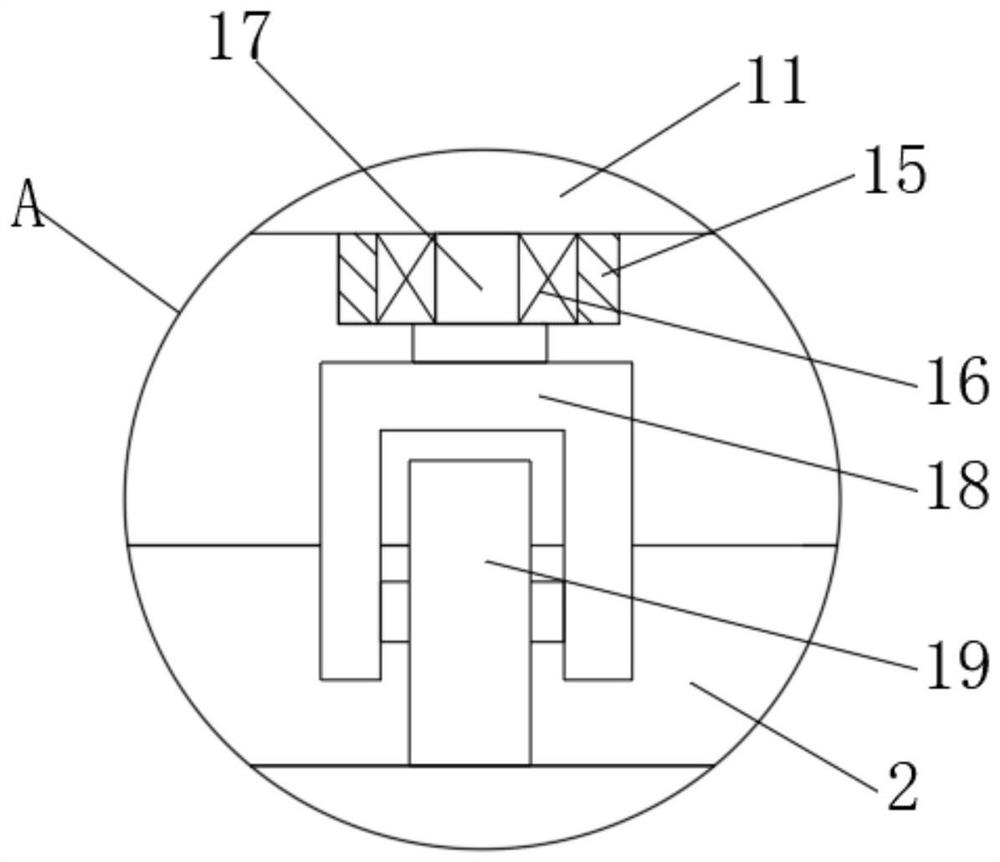

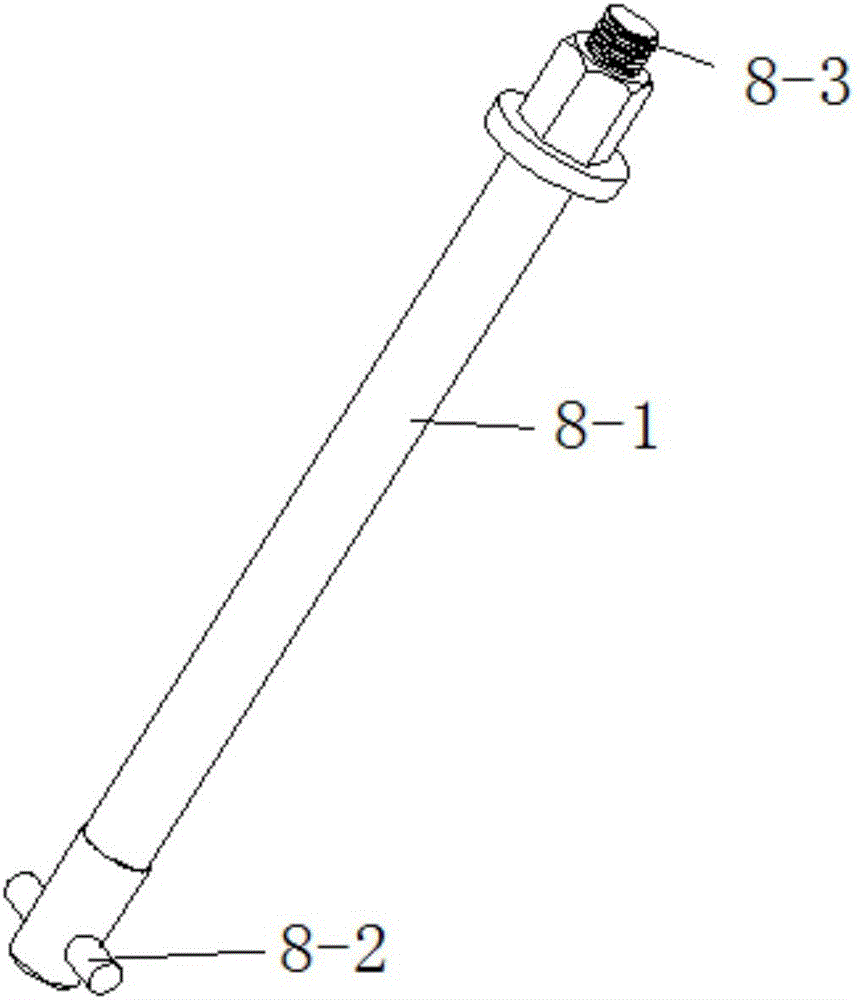

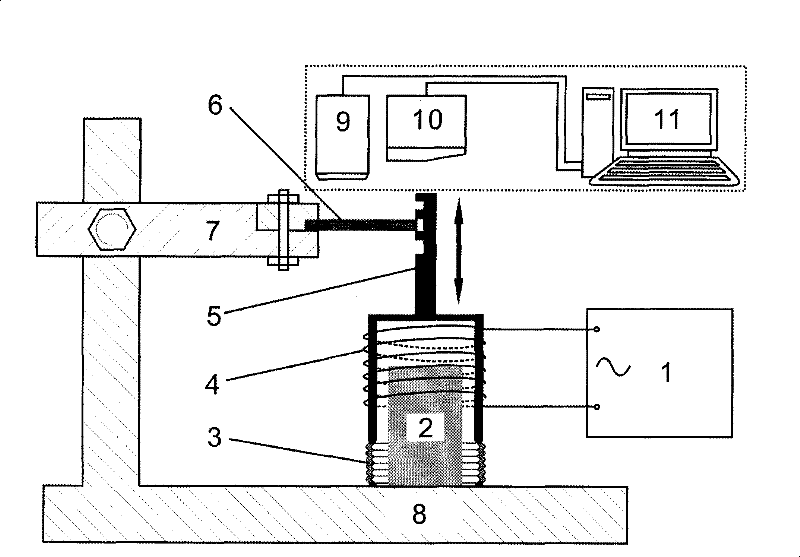

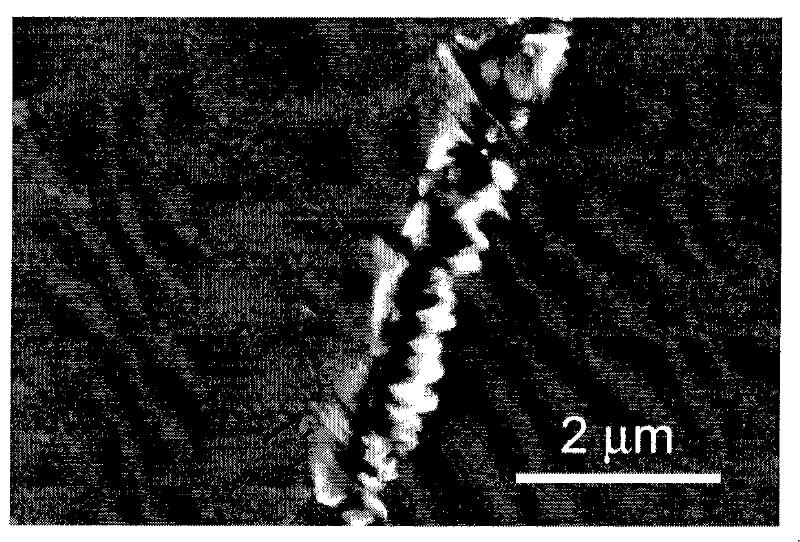

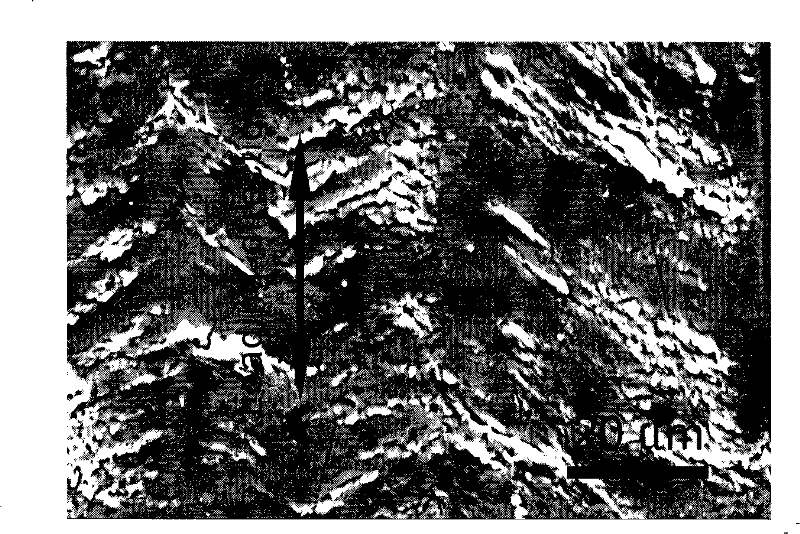

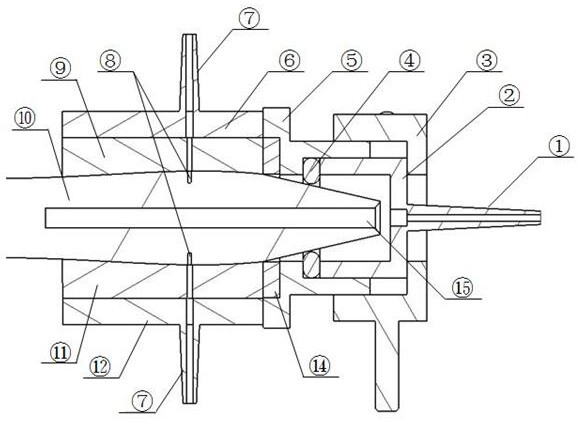

The invention relates to a test system and a test method for the dynamic bending fatigue property of a small-scale thin film material. The test system comprises an electromagnetic driving part, a sample holding part and a measuring and observing part, and the system provides functions and a test method for dynamic bending fatigue property test for the thin film materials used for various micro / nanoelectronic mechanical systems and supported with matrix or without matrix, the metalized interlinking body foil material used for an integrated circuit and various two-dimensional thin plate type materials and can record in-situ real-time monitoring and analysis to the appearance of the tested sample. The free end of the cantilever beam sample is driven under the electromagnetic force of the electrified coil in the stationary magnetic field to reciprocate relatively to the equilibrium position thereof, thus various types of cyclic fatigue loads can be applied to various material samples, and the precision of the applied fatigue loads can reach the millinewton magnitude. The invention can be used to evaluate the fatigue property and the fatigue crack growth behaviors of various thin film materials.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

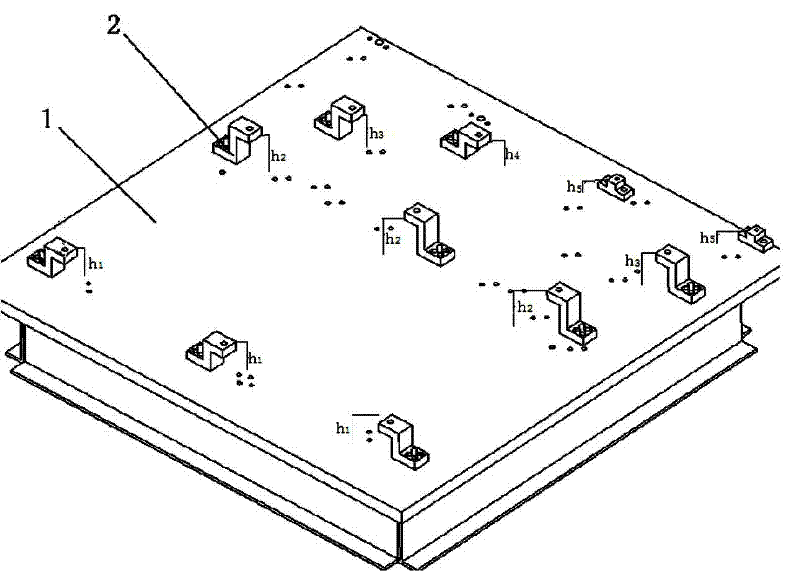

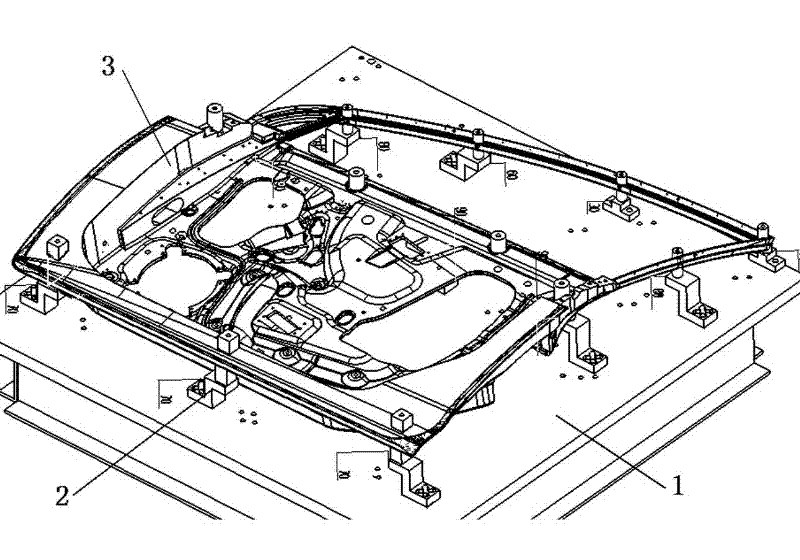

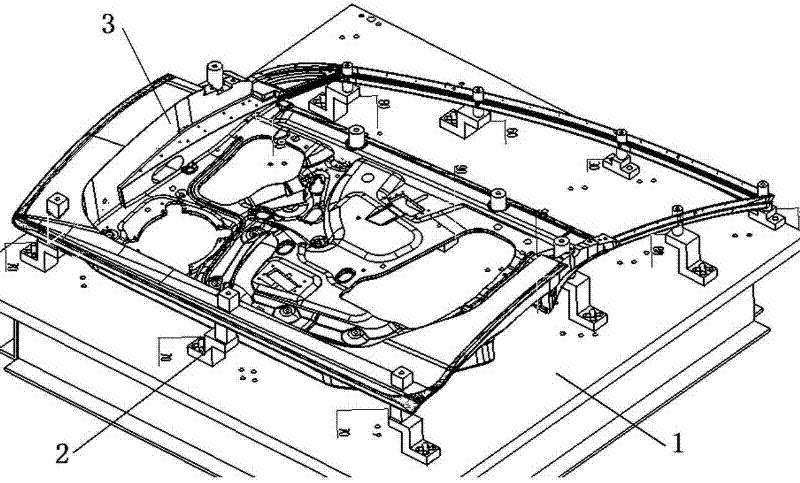

Thin-wall part processing clamping device and clamping detection method

InactiveCN102189421AReduce setup timeReduce distortionMechanical clearance measurementsPositioning apparatusComputer moduleIndustrial engineering

The invention discloses a thin-wall part processing clamping device which comprises a bottom plate and a positioning bracket. The thin-wall part processing clamping device is characterized in that the positioning bracket is Z-shaped; the bottom end of the positioning bracket is fixed on the bottom plate through a bolt; and the upper end of the positioning bracket is provided with a positioning hole for fixing a thin-wall part processing module. The invention also discloses a thin-wall part processing clamping detection method for the device, which shortens the workpiece clamping time, realizes the simple and quick clamping, improves the thin-wall part processing stability, reduces the workpiece deformation and improves the processing precision.

Owner:ROYAL GAUGE IND

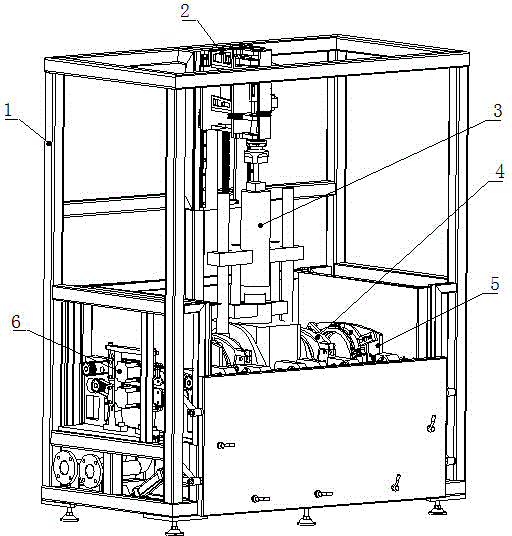

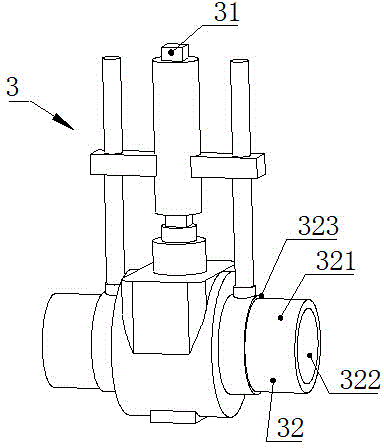

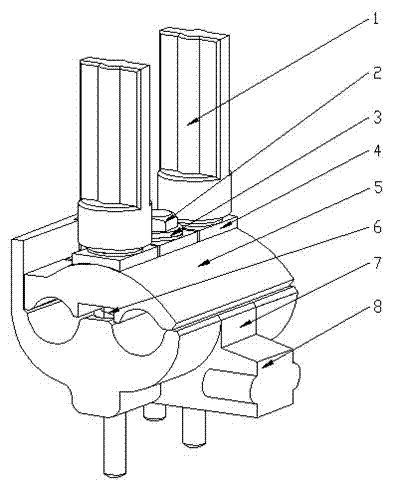

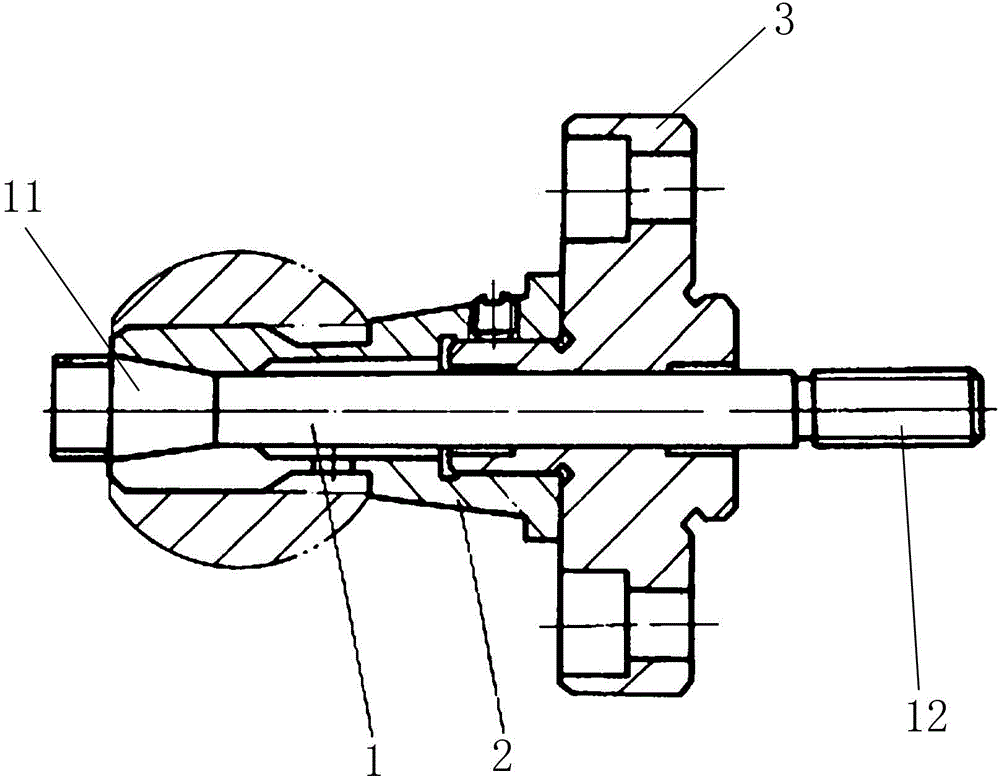

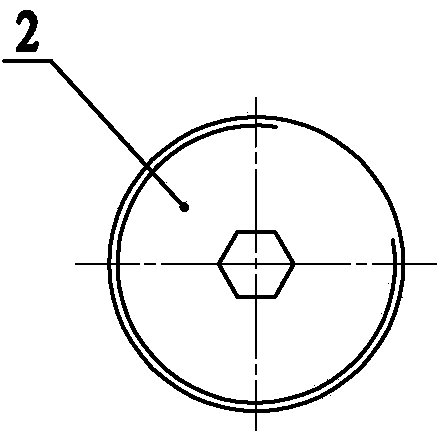

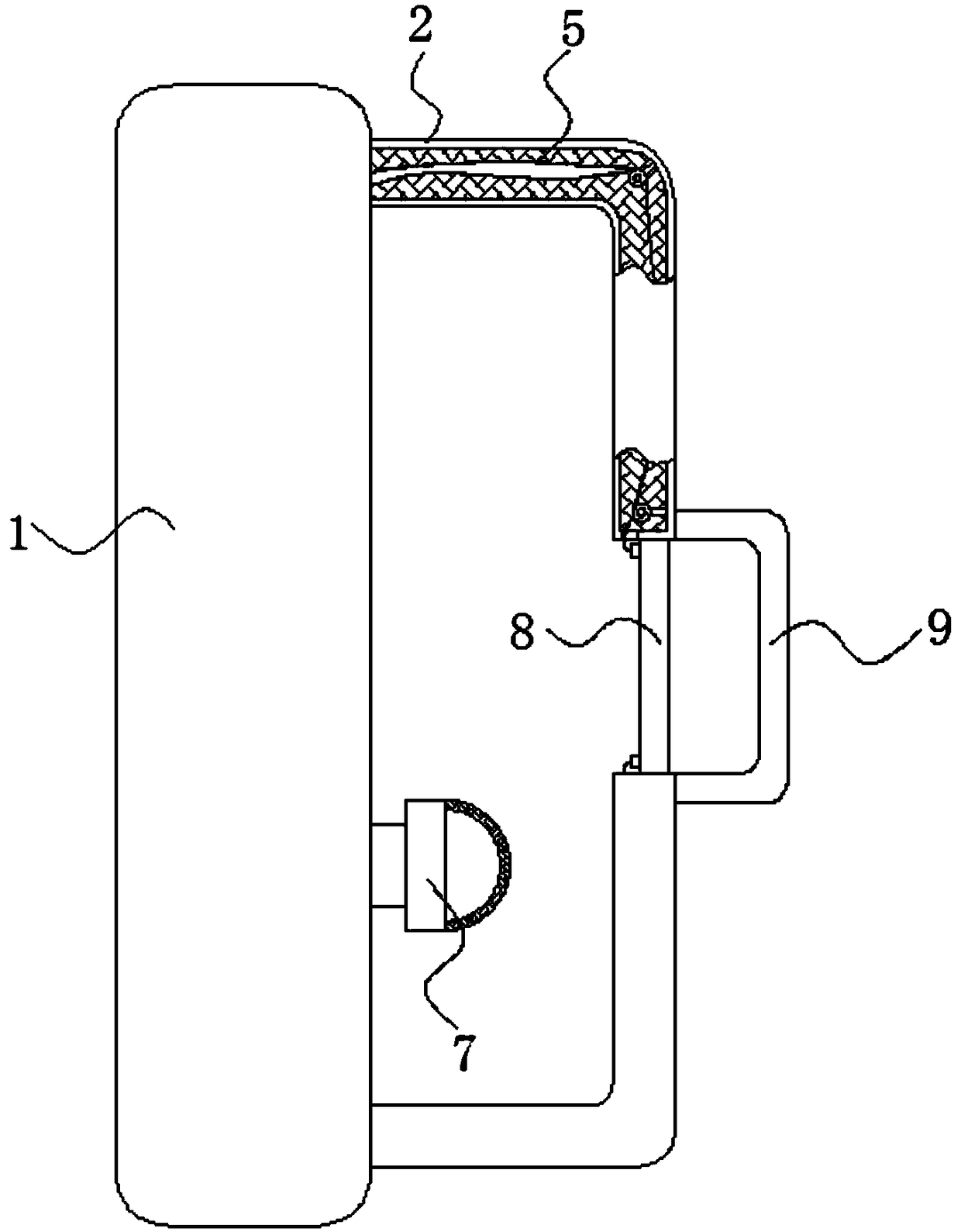

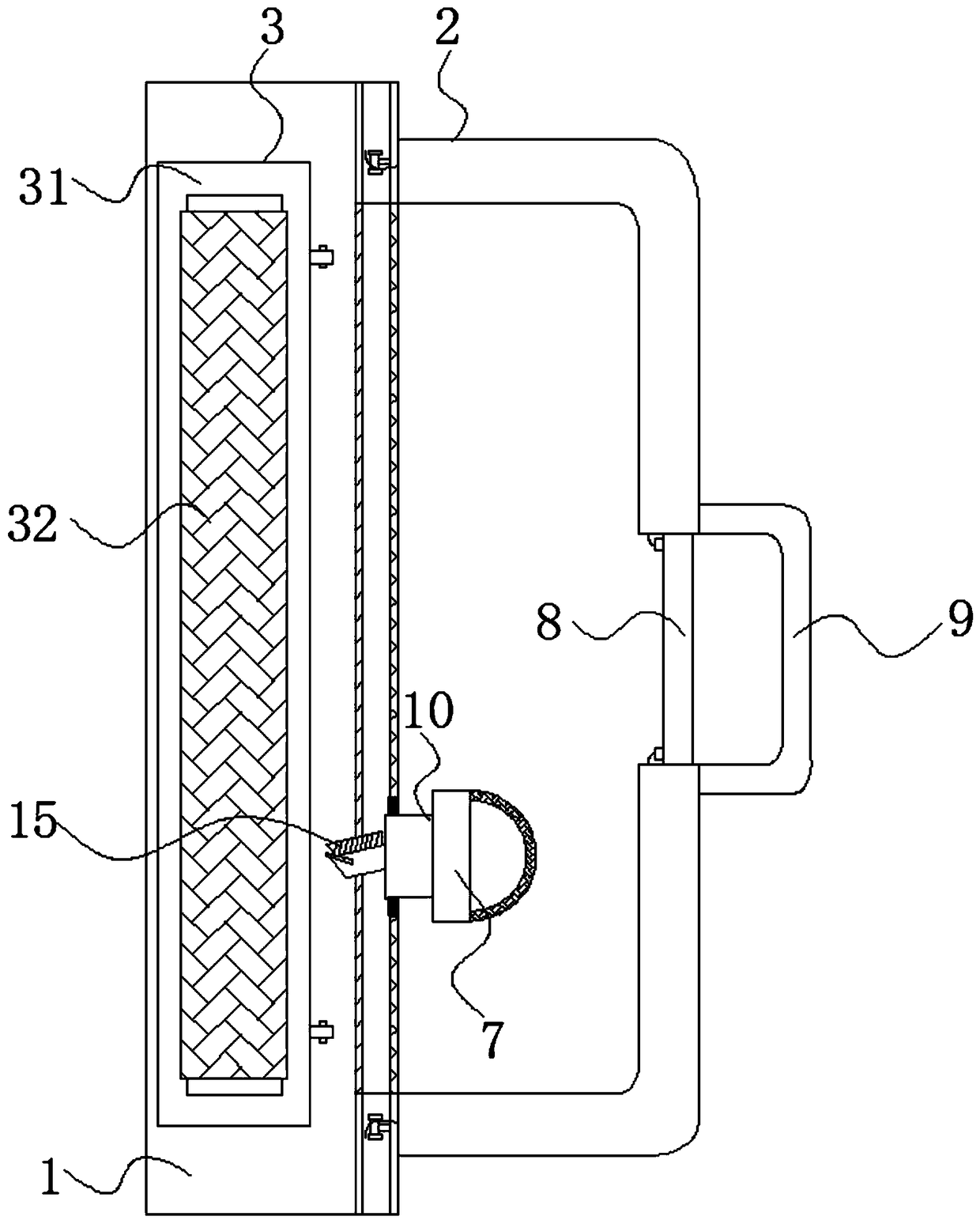

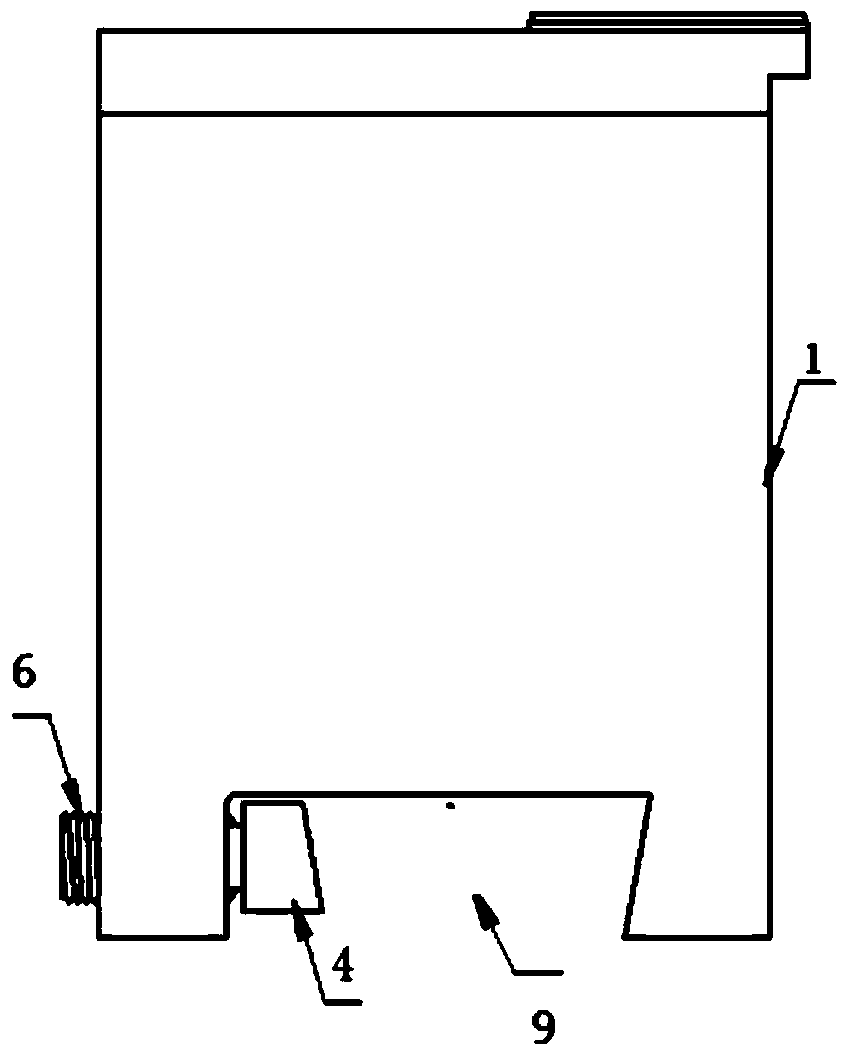

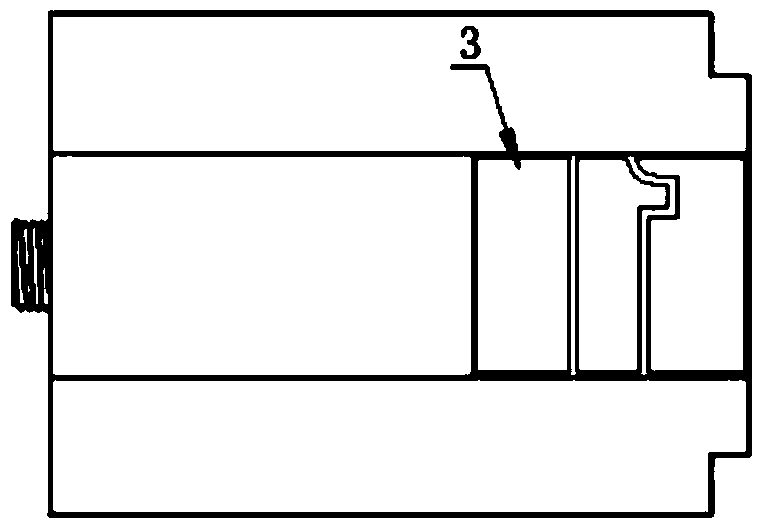

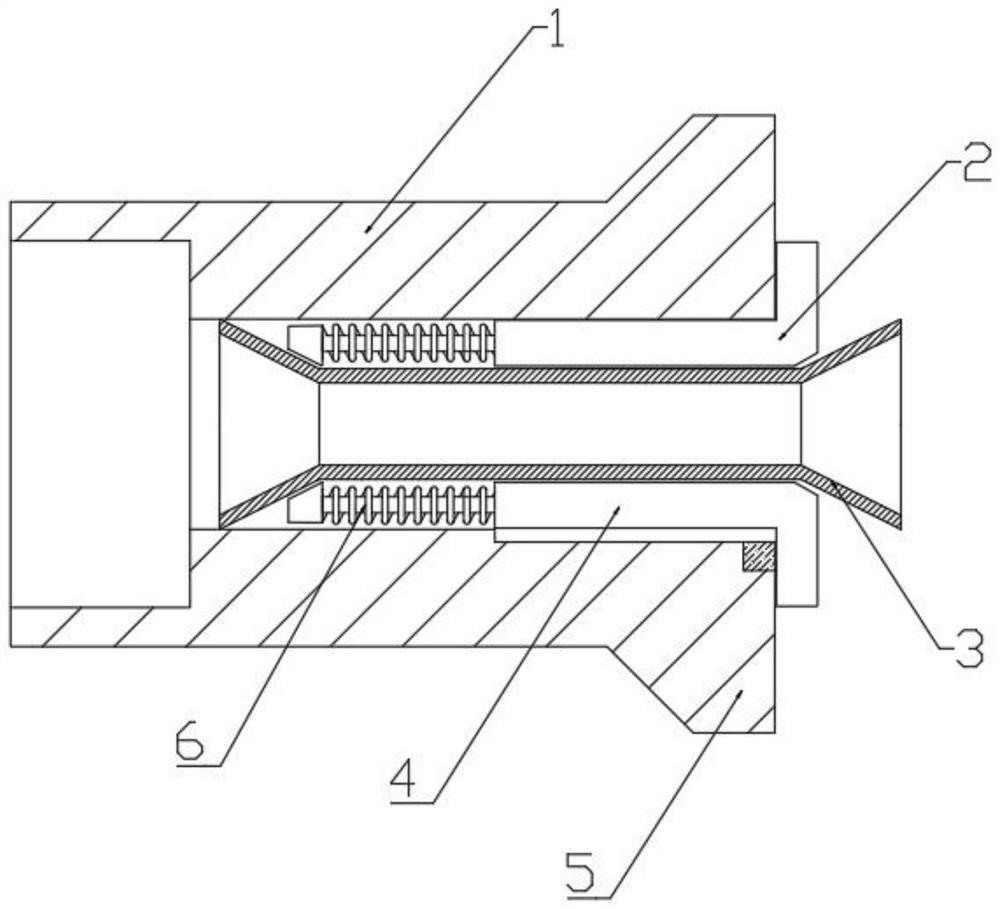

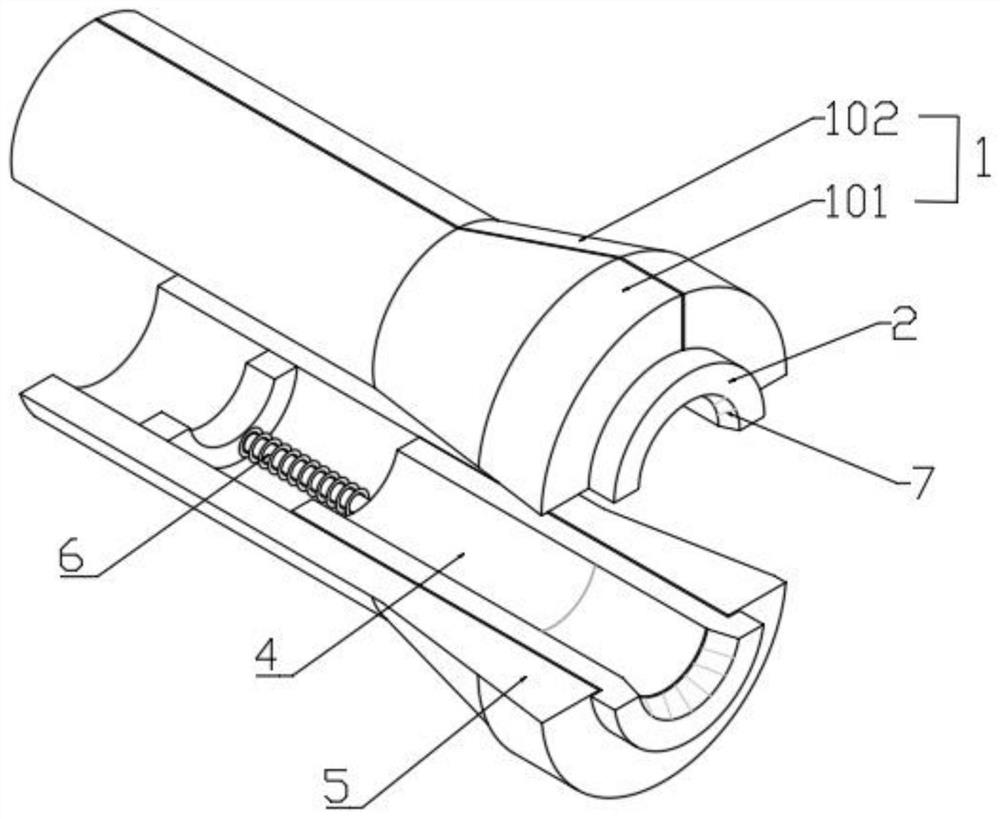

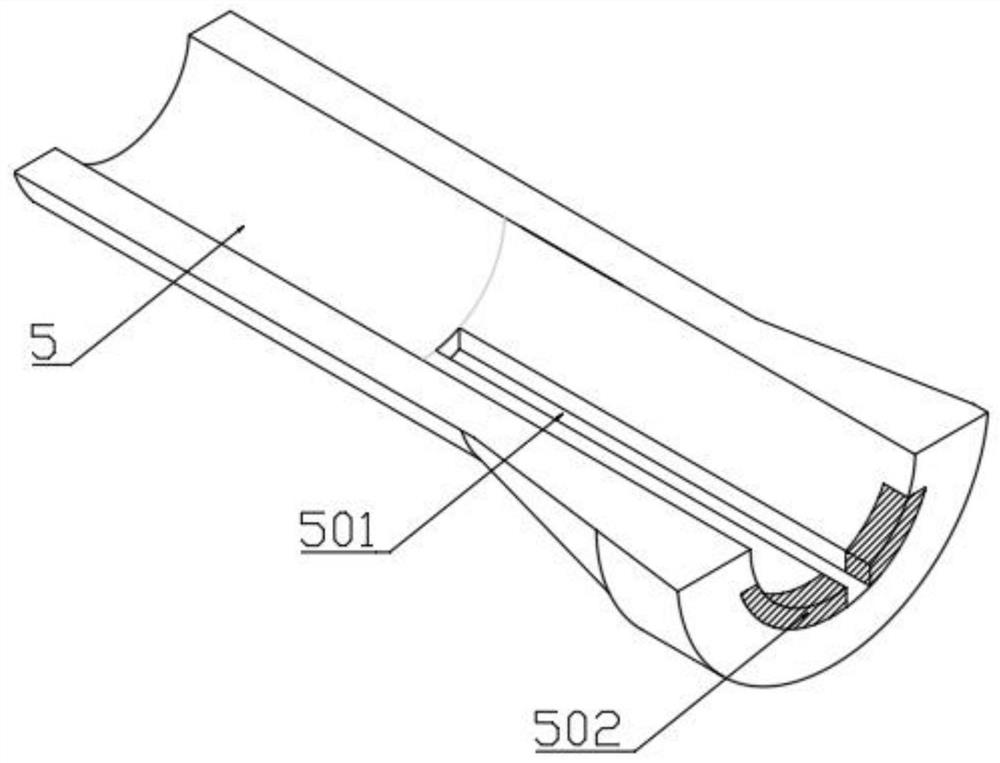

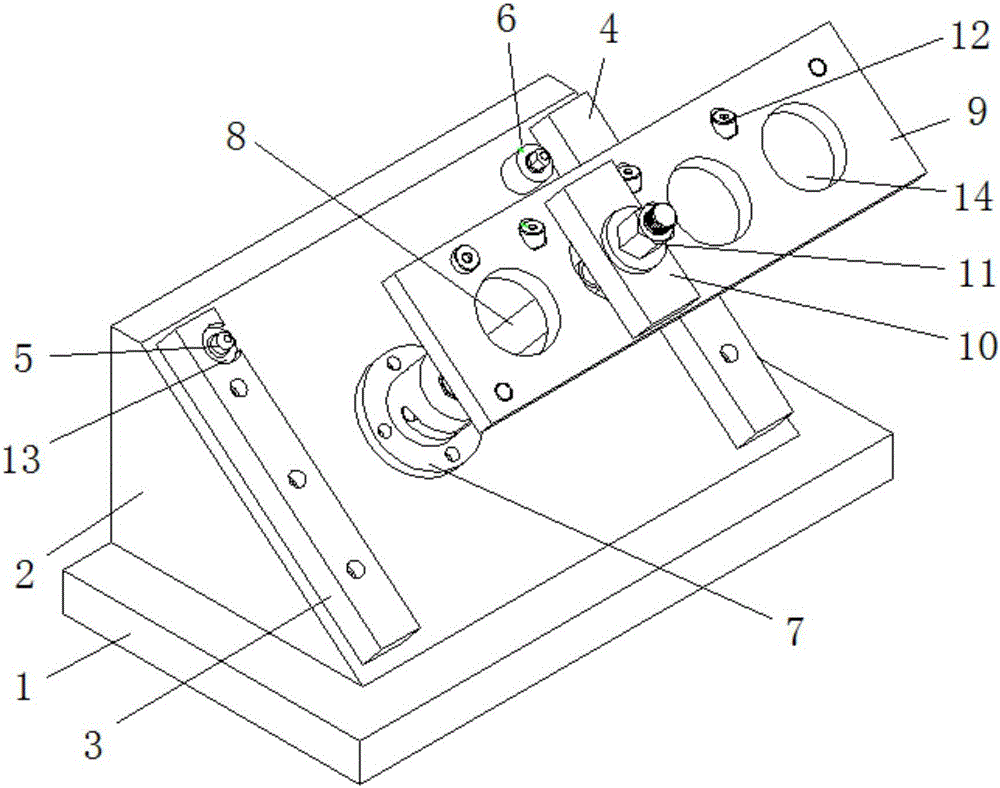

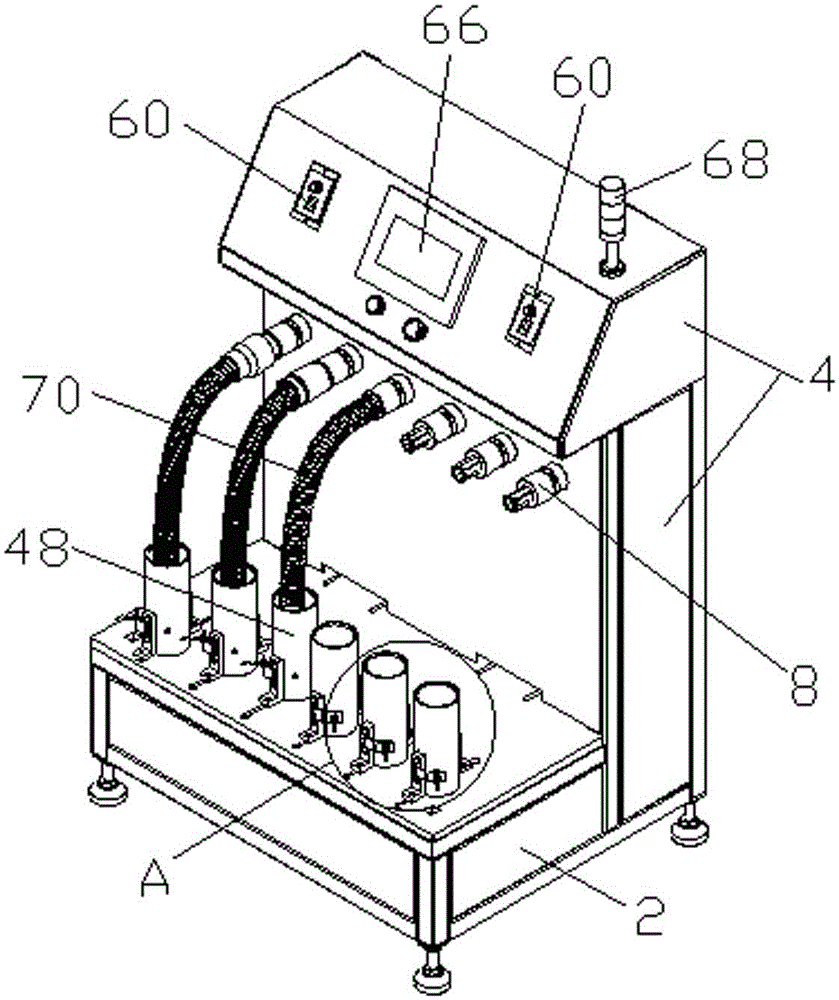

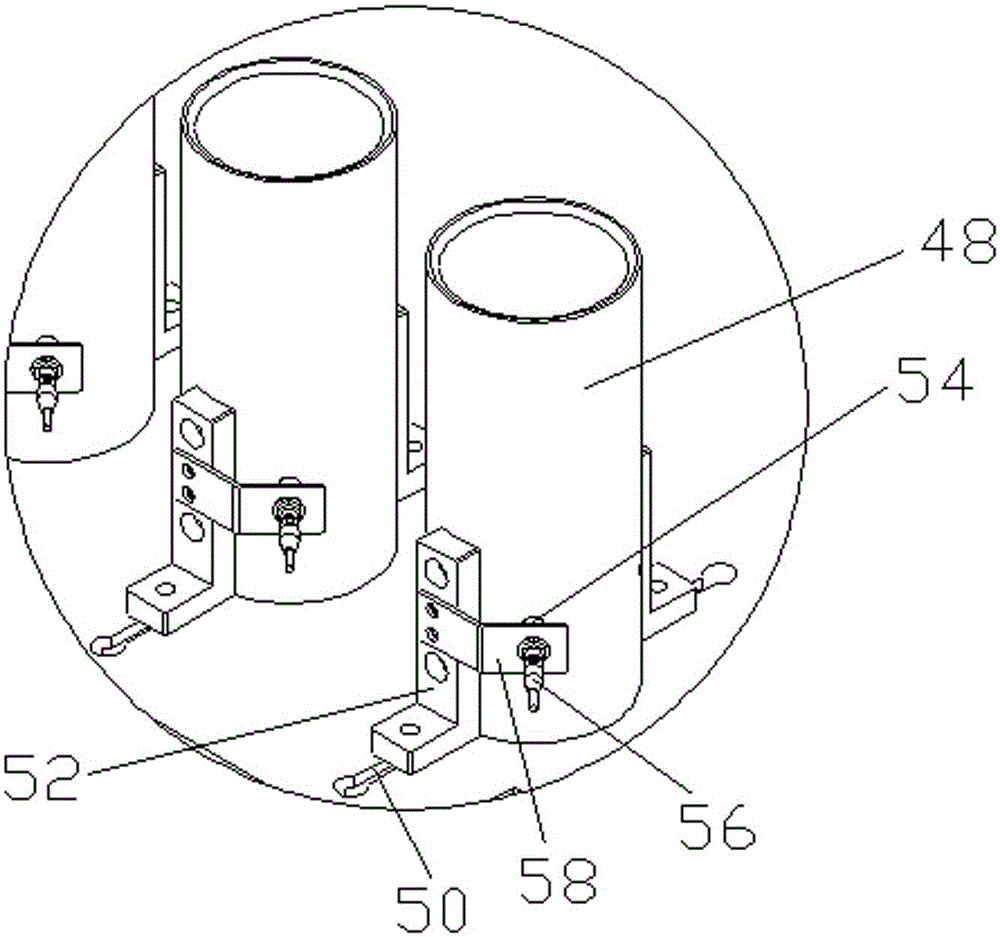

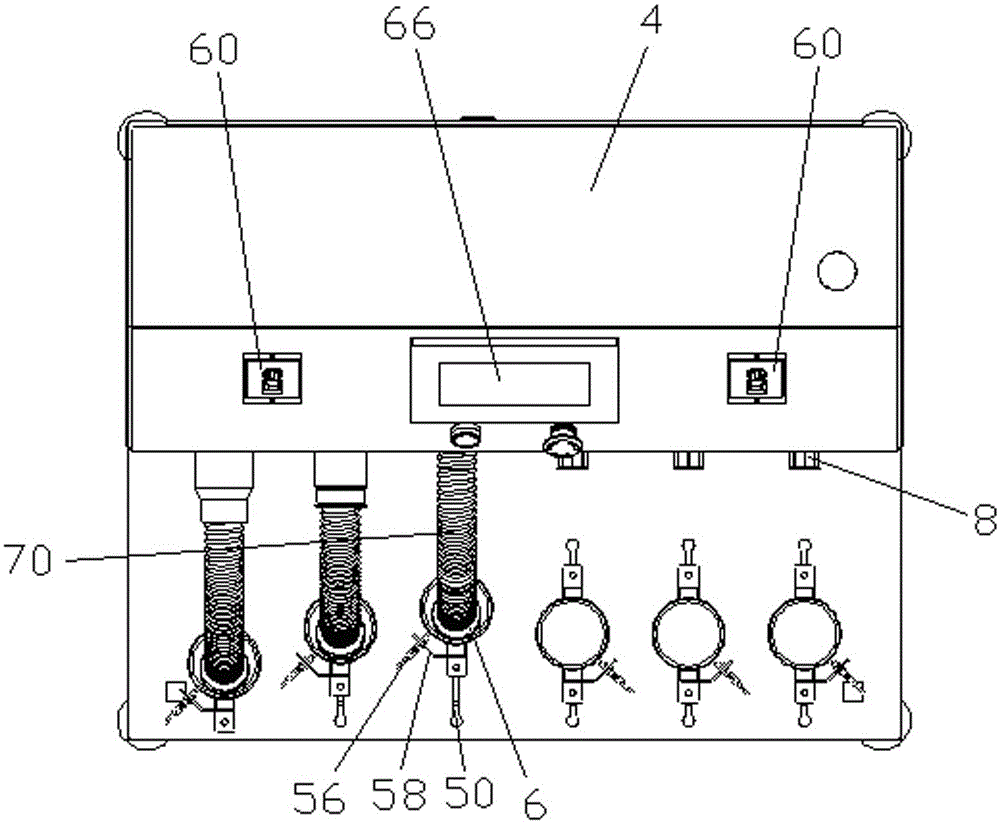

Polyethylene gas valve detection device

InactiveCN105588688AEasy and fast clampingReaction physicsDetection of fluid at leakage pointMachine part testingEngineeringTest requirements

The invention relates to a polyethylene (PE) gas valve detection device which is used for detecting the air-tightness and torque of finished products after PE gas ball valve assembly, and belongs to the field of PE gas valve production and quality inspection. According to the test requirements, a valve sealing mechanism cannot produce axial force, and the test torque is increased gradually. Most current detection devices cannot meet the requirements. In order to solve the technical defects of the existing detection devices, the invention discloses a novel PE valve air-tightness and operation torque detection device. The device has the following advantages: a clamp produces no axial force after valve clamping, and no damage is caused to the body of a valve after the completion of test; the torque applied to a valve is increased flexibly and can be controlled linearly; and no water tank is designed, the size of the device is reduced drastically, and the efficiency of test valve clamping is improved. Compared with similar devices, the PE gas valve detection device has obvious technological advancement and economic practicability, has obvious advantage in the production of valves, and has a very good economic effect.

Owner:广东万锦科技股份有限公司

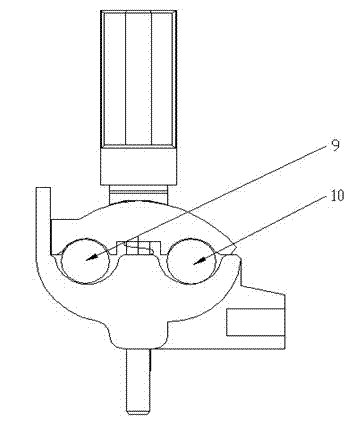

Manipulator clamping linking wire clamp special for high voltage electriferous work

ActiveCN102227071AAvoid direct contactIncrease job securityProgramme-controlled manipulatorGripping headsFixed bearingEngineering

The invention relates to a manipulator clamping linking wire clamp special for high voltage electriferous work. The manipulator clamping linking wire clamp comprises a lower fixed bearing block which is provided with a manipulator clamping position. The lower fixed bearing block has two alternate semicircle surfaces in parallel arrangement. A side surface of the lower fixed bearing block is provided with a fixed bearing side surface locating plate which is provided with a positioner. The manipulator clamping linking wire clamp also comprises a drainage wire prefixation crimping apparatus which is a drainage wire prefixation briquetting. The drainage wire prefixation briquetting fixedly connects the lower fixed bearing block and matches the positioner. The manipulator clamping linking wireclamp also comprises a main traverse line fixed crimping apparatus which is an overhead briquetting. The overhead briquetting connects the lower fixed bearing block through a fastener. The overhead briquetting also is provided with two parallel semicircle surfaces which match the two semicircle surfaces of the lower fixed bearing block. Also the middle part of the overhead briquetting is providedwith a groove where the drainage wire prefixation briquetting is installed.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

Welding clamp of water pump impeller

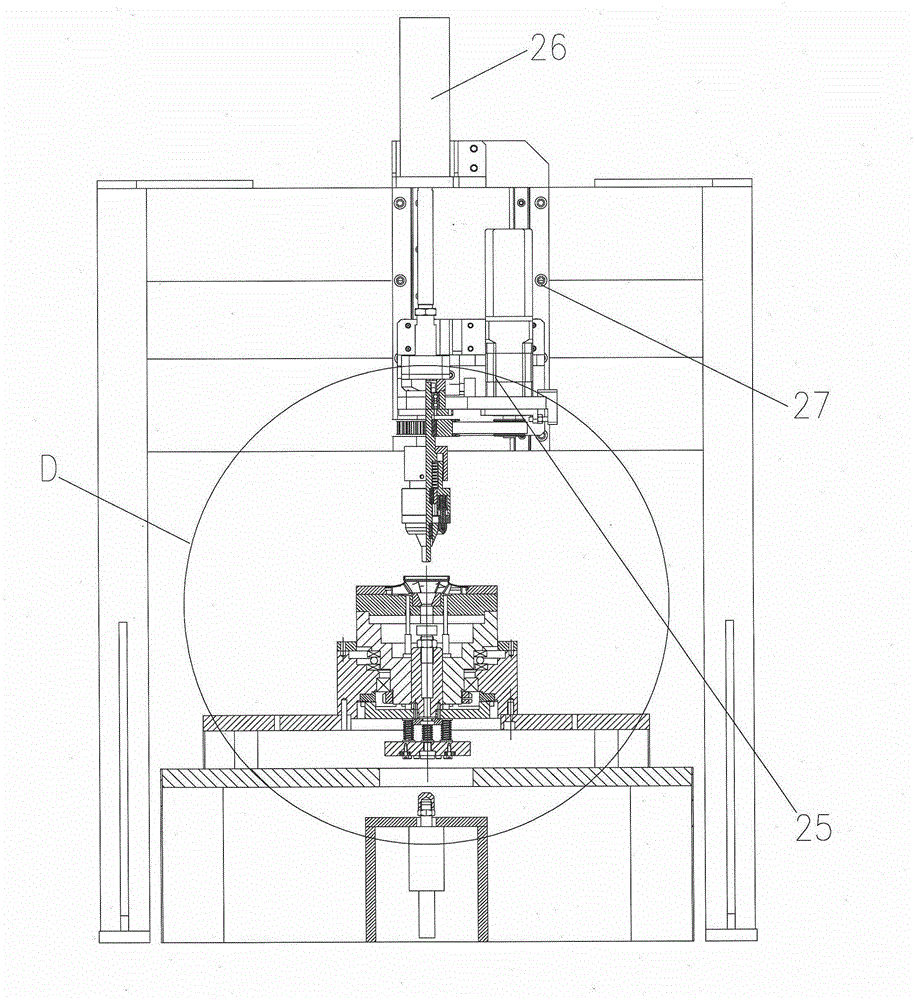

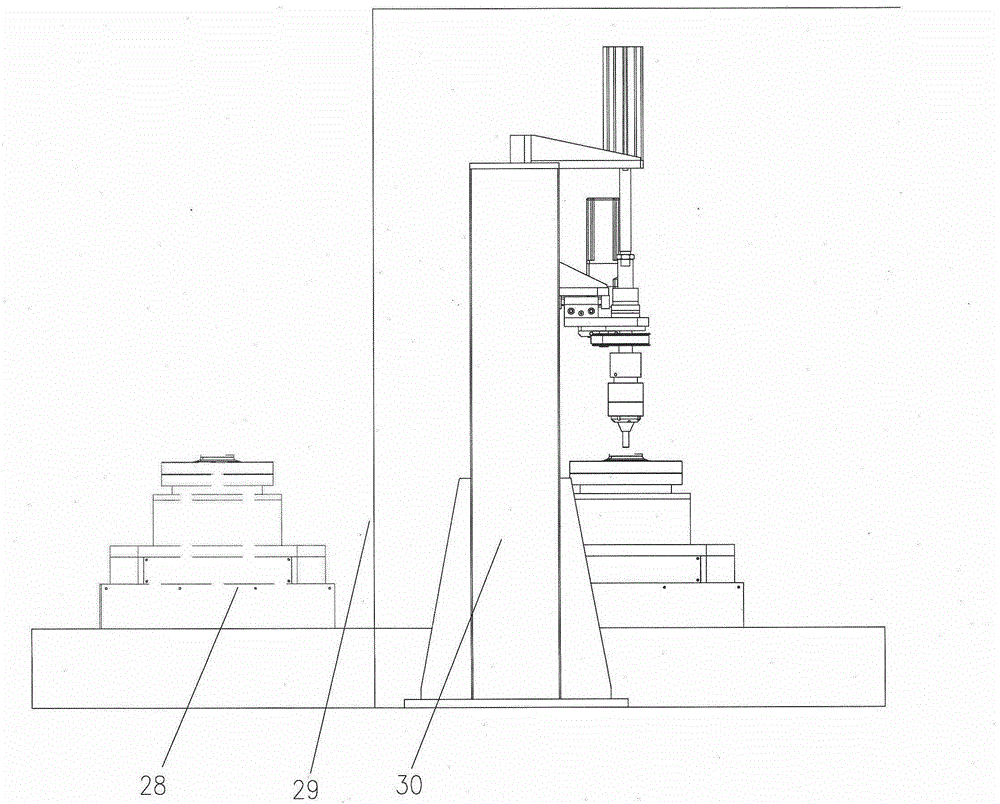

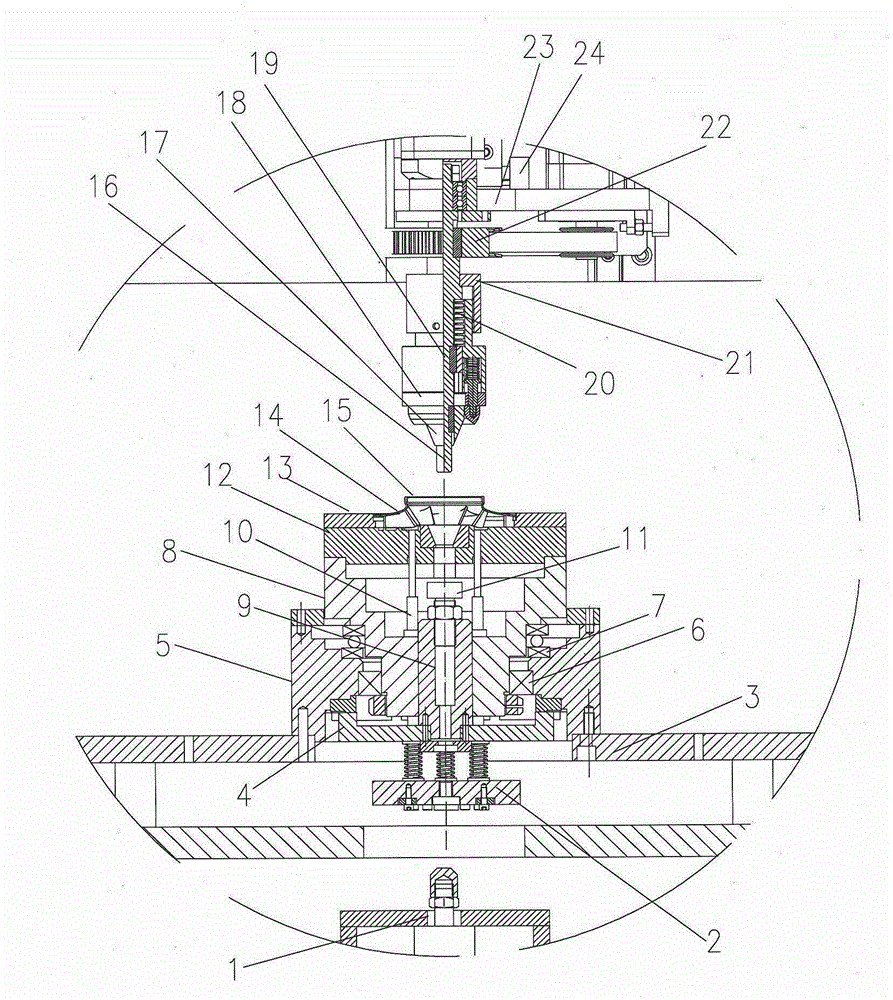

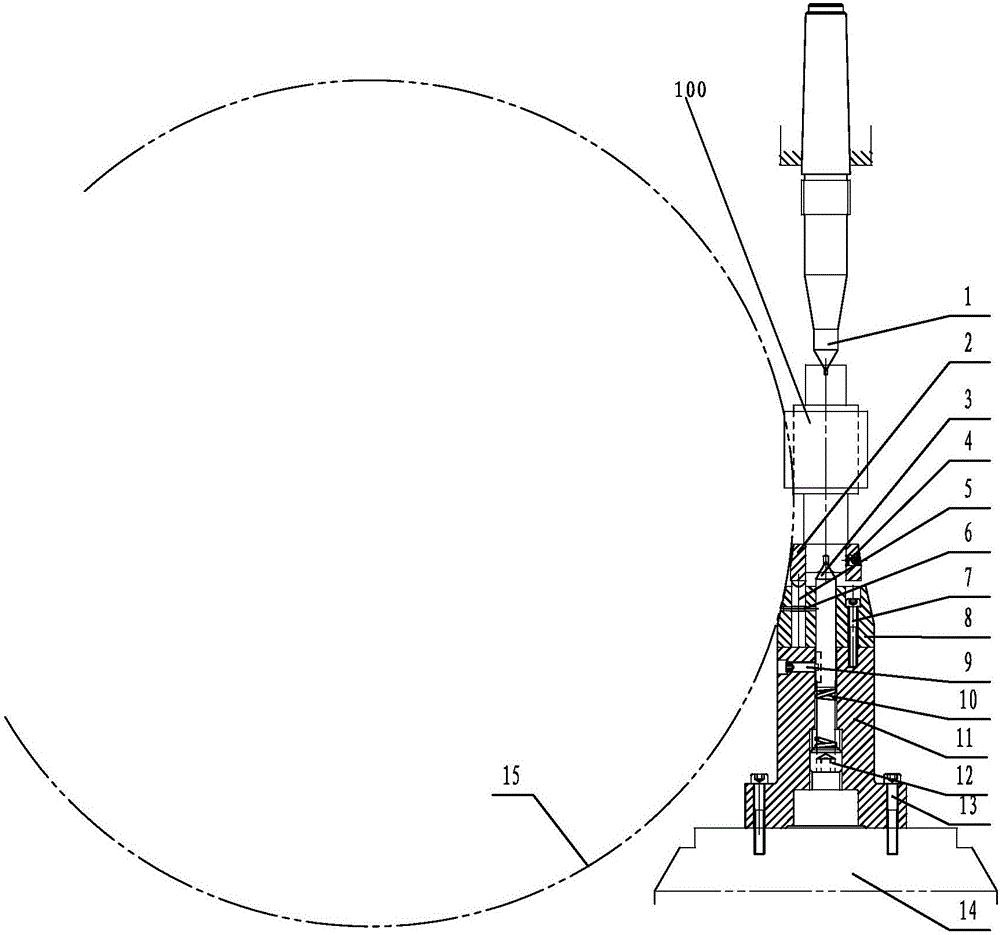

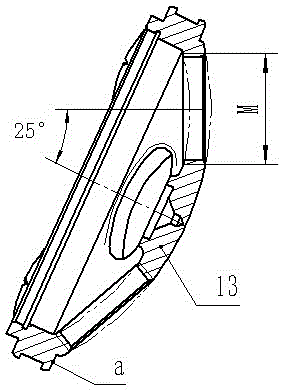

ActiveCN106312338AEasy and fast clampingPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlImpeller

The invention relates to a welding clamp of a water pump impeller. The welding clamp comprises a rotating base, a mold seat, a pressing and rotating device, a friction transmission pair, a portal frame, a discharging device and a one-dimensional numerical control workbench. The mold seat is mounted on the rotating base and is coaxial with the rotating base, and the rotating base is mounted on the one-dimensional numerical control workbench. The pressing and rotating device is mounted on the portal frame. One end of the friction transmission pair is mounted on the pressing and rotating device, and the other end of the friction transmission pair is mounted on the mold seat. The discharging device is mounted on the lower portion of the rotating base. The portal frame is mounted above the rotating base in a stretching-over manner. It can be guaranteed that a rotating shaft of the pressing and rotating device and the rotating base are coaxial by adjusting the portal frame and the pressing and rotating device. Compared with a traditional welding device, the welding clamp is simple and fast in clamping and accurate in locating; through combination with the modern laser welding process, fast welding can be achieved; the welding quality is reliable; the zero rejection rate is achieved; the production efficiency is high; and the labor intensity is low.

Owner:WUHAN CHUTIAN IND LASER EQUIP

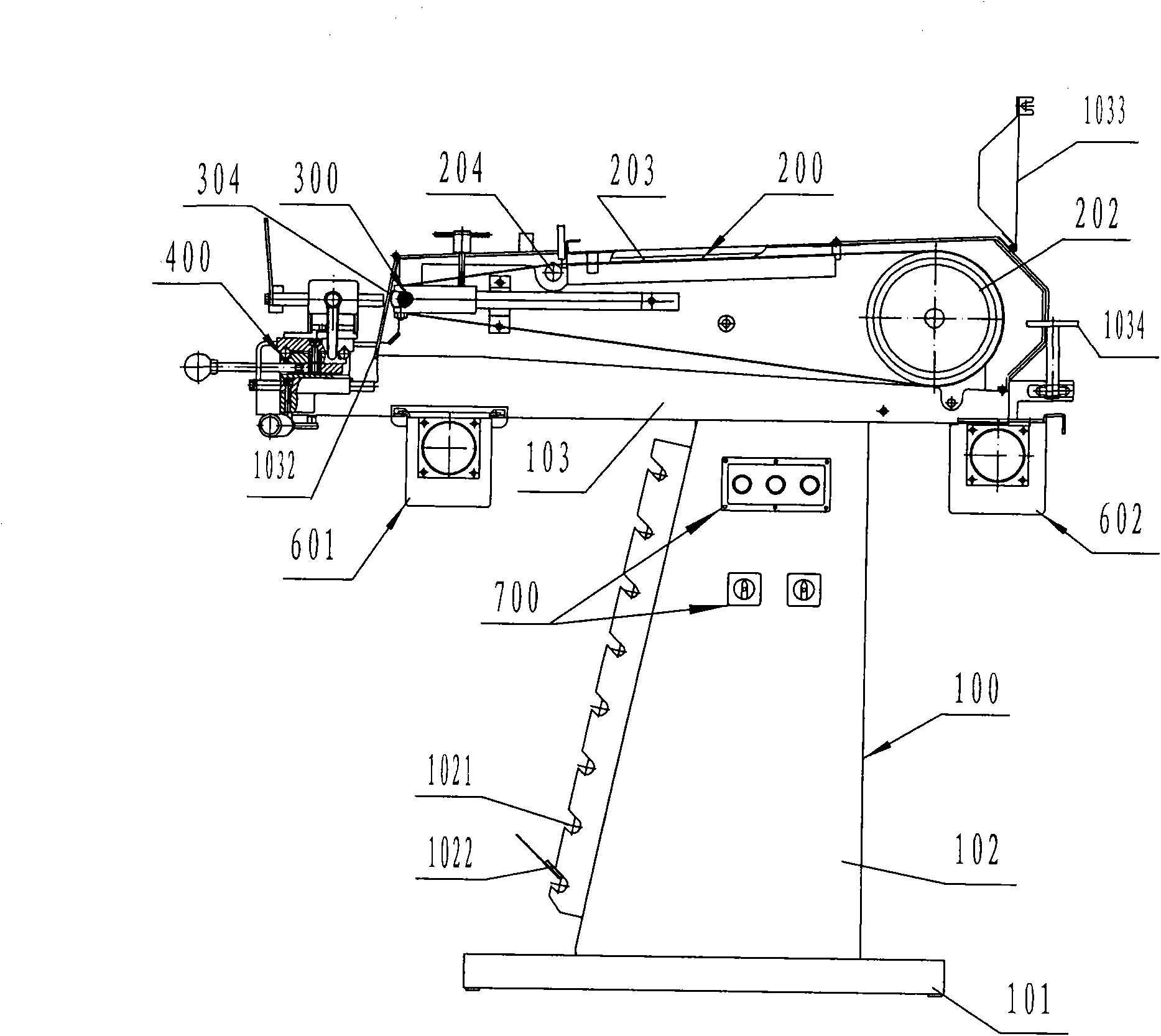

Small multifunction belt sander

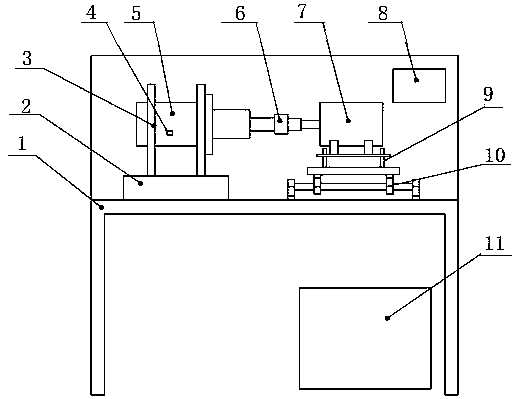

The invention discloses a small multifunction belt sander which comprises a sander body portion, a power portion, a roll shaft adjusting mechanism, a workpiece clamping mechanism, a sanding belt tensioning mechanism, a dedusting device and an electrical control system. A roll shaft in the roll shaft adjusting mechanism is arranged at one end of a roll shaft frame through a pair of bearings and a pair of adjusting screw assemblies, and the other end of the roll shaft frame is in a floating connection with a box; an adjusting bolt is arranged at the outer end of the inner side of the roll shaft frame, and the outer end is close to the roll shaft; two locking handles are vertically arranged at intervals, and inner ends of the two locking handles and a semicircle shaft fixed on the inner side of the middle of the roll shaft frame form a thread connection; and a zero line is marked on one side surface of the roll shaft frame to be matched with a vertical ruler on the box to be adjusted for using. According to the small multifunction belt sander, arc-shaped surfaces with various radians and angles can be ground at the end of a round metal tube or a rod in a molding mode, plate type metal workpiece plane can be ground, metal workpiece chamfering deburring processing is performed, the operation is convenient, fast, safe and environment-friendly, the positioning adjustment and grinding accuracies are high, labor intensity is low, working efficiencies are high, and the service life is long.

Owner:莱州鑫岳机械股份有限公司

Device for clamping eccentric parts

InactiveCN102107367AGuaranteed clamping accuracyEasy and fast clampingAuxillary equipmentPositioning apparatusHigh volume manufacturingCoupling

The invention discloses a device for clamping eccentric parts, which relates to the field of machinery. In the existing mechanical working, when eccentric parts are processed, the operation of clamping the eccentric parts is difficult, the working accuracy is not easy to guarantee, and the qualification rate of finished products is low, therefore, the existing eccentric-part clamp device is not suitable for batch production. The device disclosed by the invention comprises a coupling disk, a mandrel, a clamp bolt, a stop pin, a counter-weight block, an open washer and a nut, wherein the mandrel is embedded in a hollow cavity of the coupling disk, the clamp bolt is in threaded connection with the mandrel, the open washer is used for adjusting the position of the mandrel relative to the coupling disk, the nut is used for fixing the coupling disk, the counter-weight block is used for balancing workpieces, and the stop pin is used for positioning. The device disclosed by the invention is an eccentric-part clamp device with a simple structure and easily-guaranteed working accuracy, and has the advantages of wide application scope, high operating efficiency, simplicity in installation, capability of being applied in batch production, and the like.

Owner:杨元昌

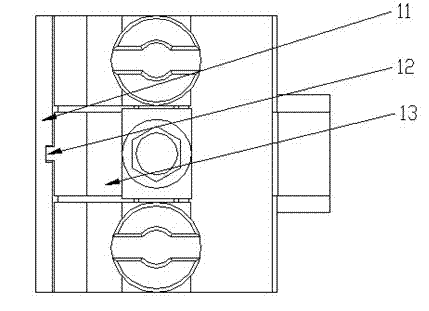

Fitting clamp for fine-pitch tube bundle

ActiveCN102390009ACompact structureEasy to install and disassembleWelding/cutting auxillary devicesAuxillary welding devicesManufacturing qualityEngineering

The invention relates to a fitting clamp for a fine-pitch tube bundle, which comprises two fitting clamp assemblies concentrically connected through a connecting plate; each fitting clamp assembly comprises two insertion plates, a tray and a fastening device, wherein the tray is arranged between the bottom ends of the two insertion plates; the fastening device is arranged between the top ends of the two insertion plates; the thickness of each insertion plate is less than a gap between two adjacent pipes; and the spacing width between the two insertion plates and the pitch of the adjacent pipes are correspondingly arranged. The fitting clamp for the fine-pitch tube bundle can be suitable for the concentric fitting operation on the end part of the fine-pitch tube bundle in an integrated gasification combined cycle (IGCC) gasification furnace or a large-capacity circulating fluid bed (CFB) boiler, is convenient for welding and is capable of effectively ensuring the product manufacturing quality and cycle.

Owner:SHANGHAI BOILER WORKS

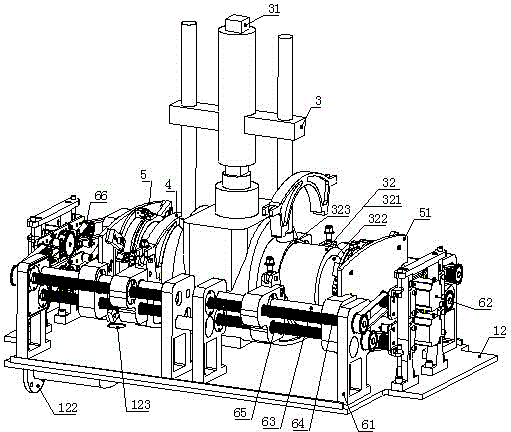

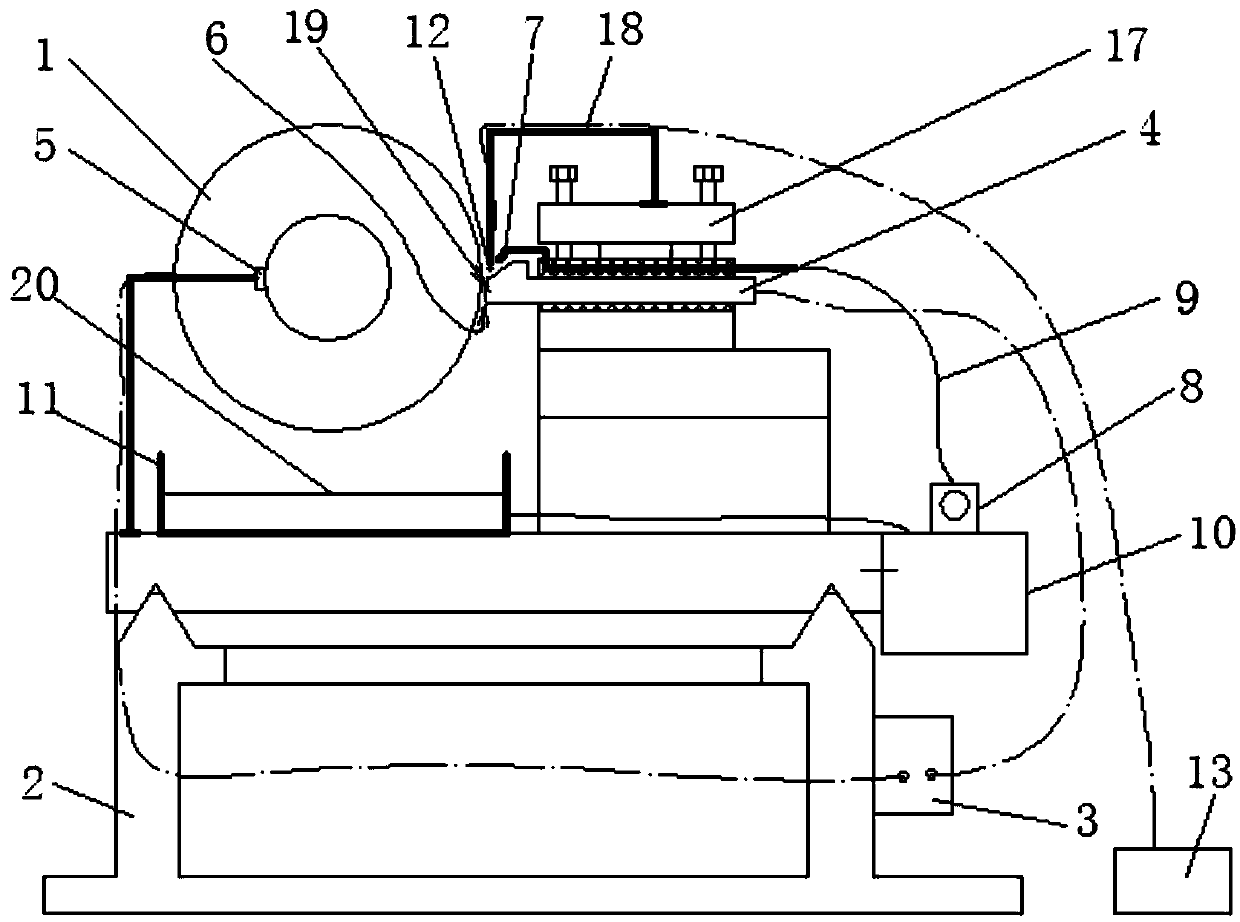

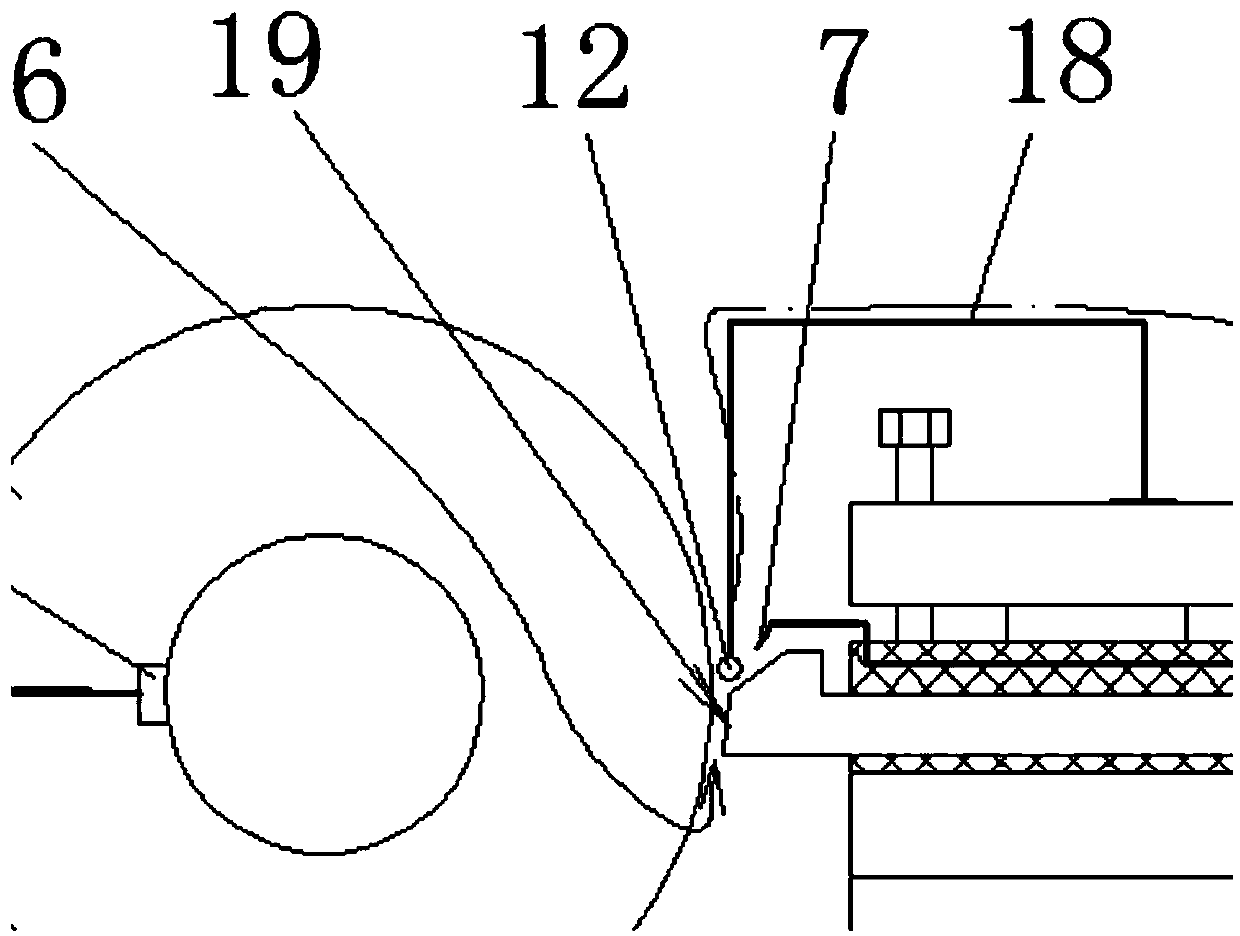

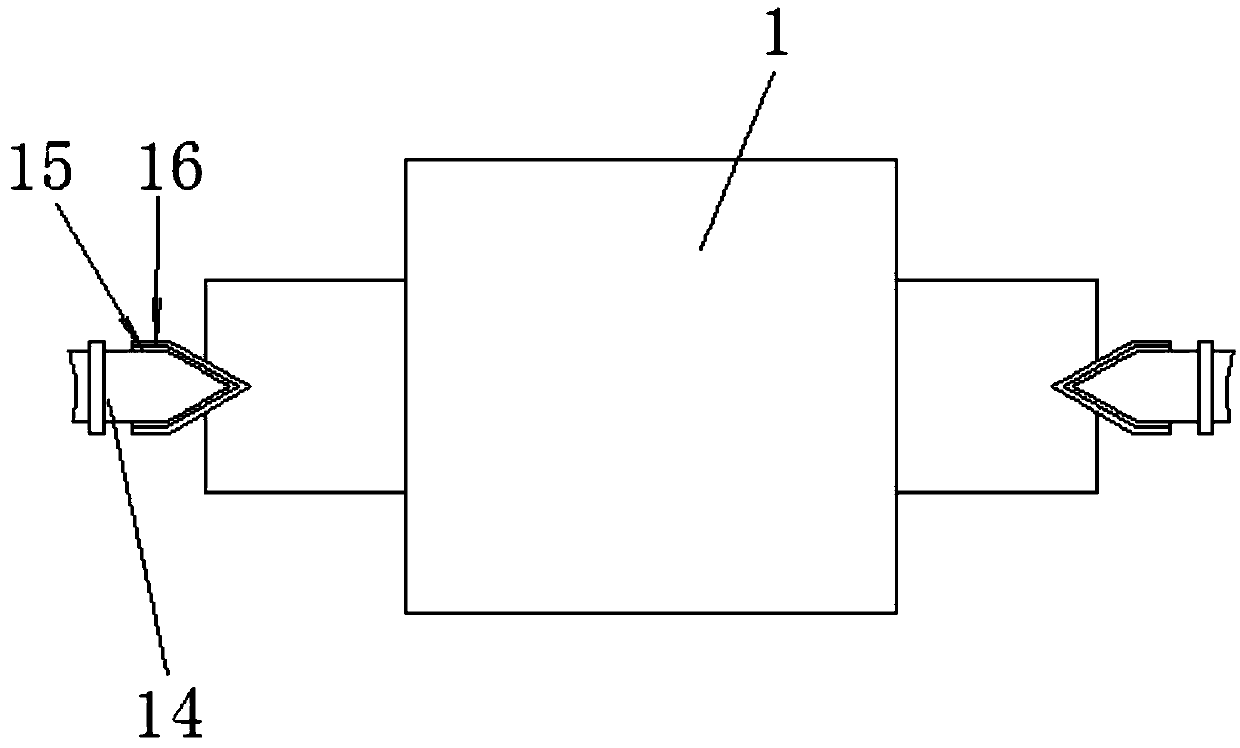

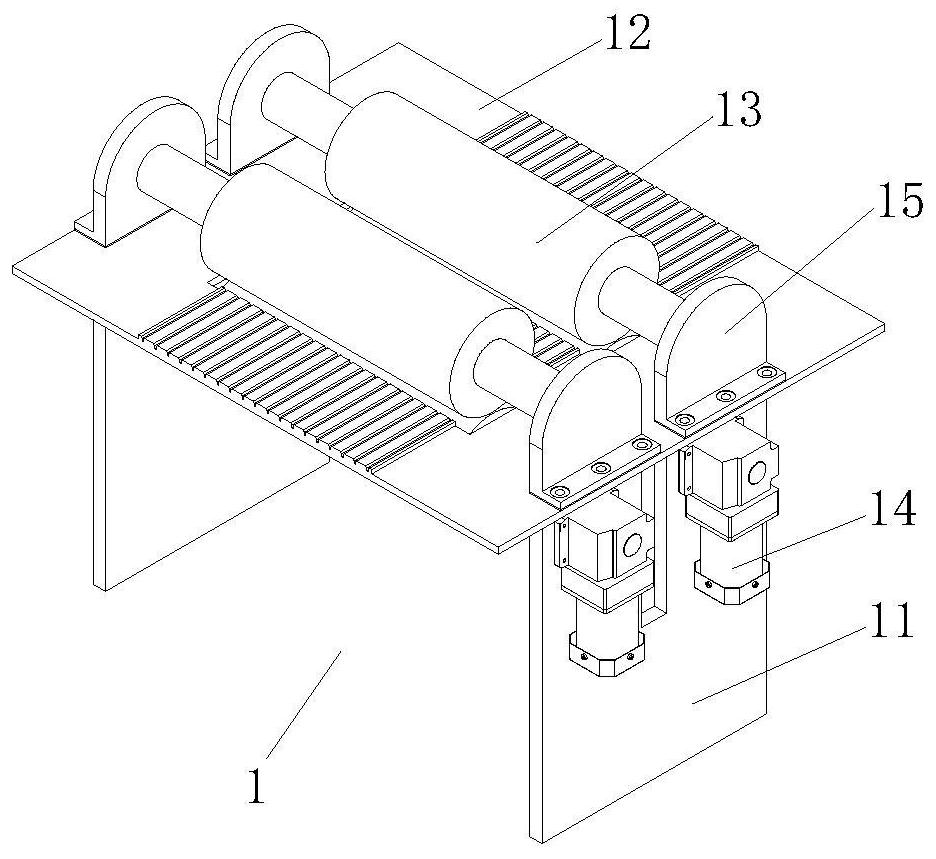

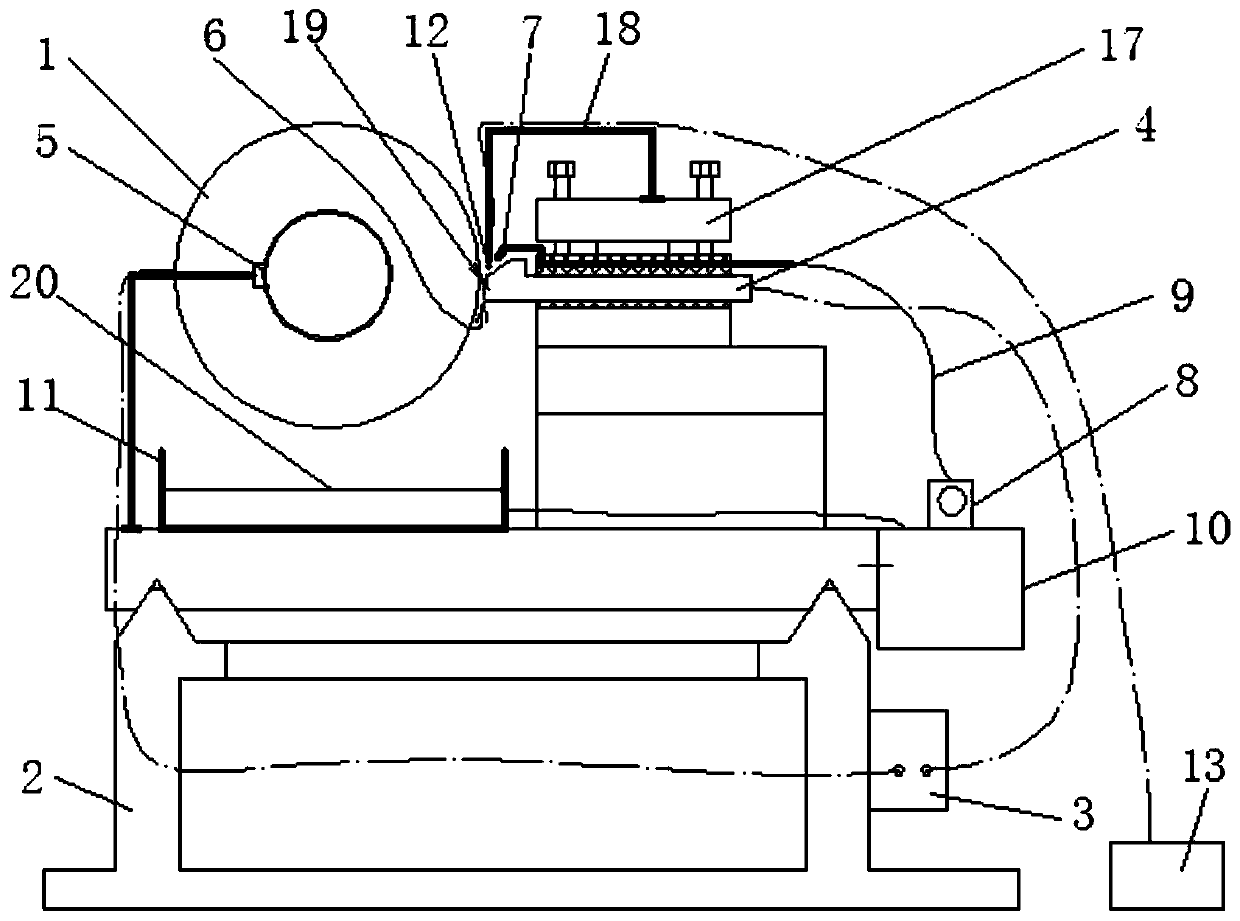

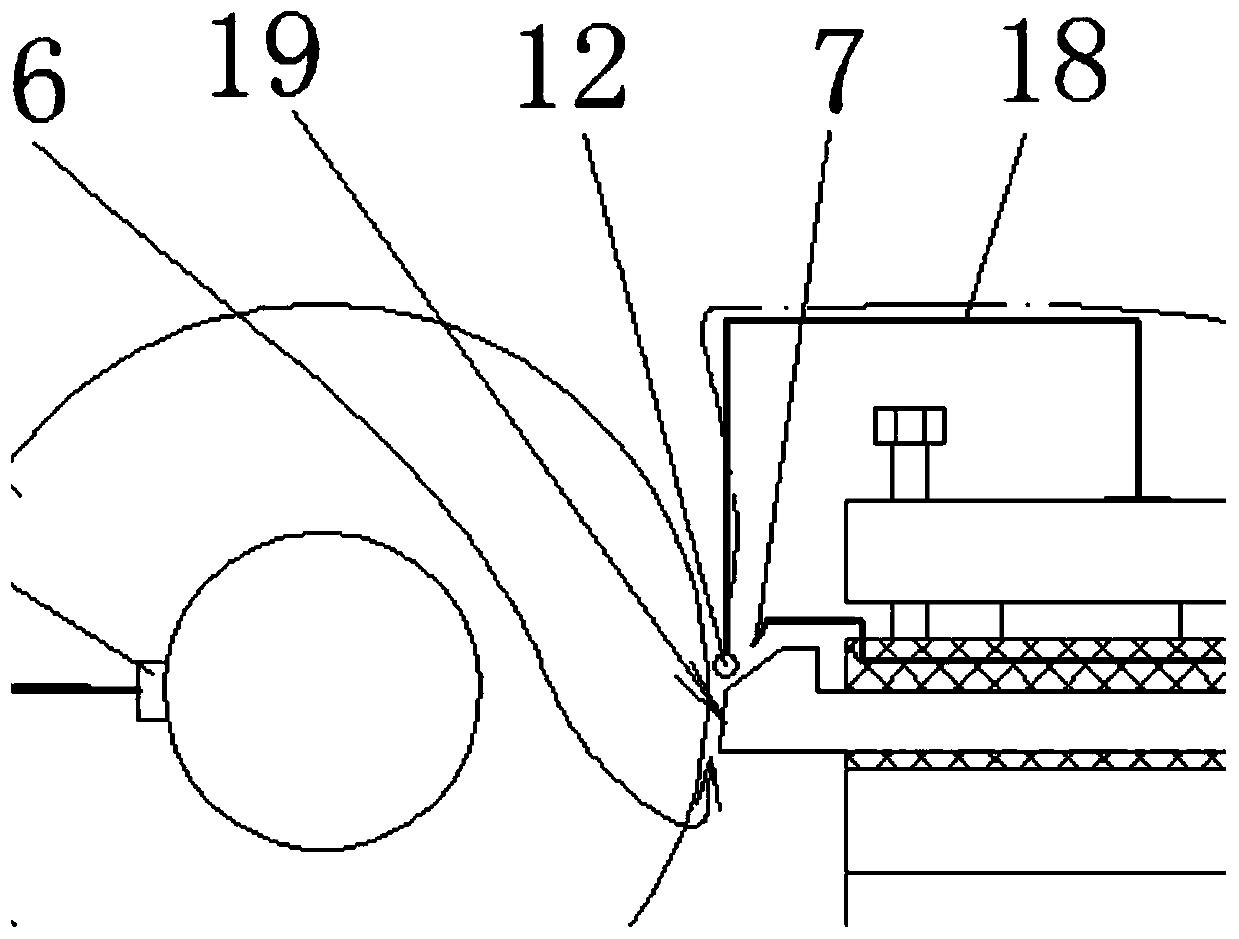

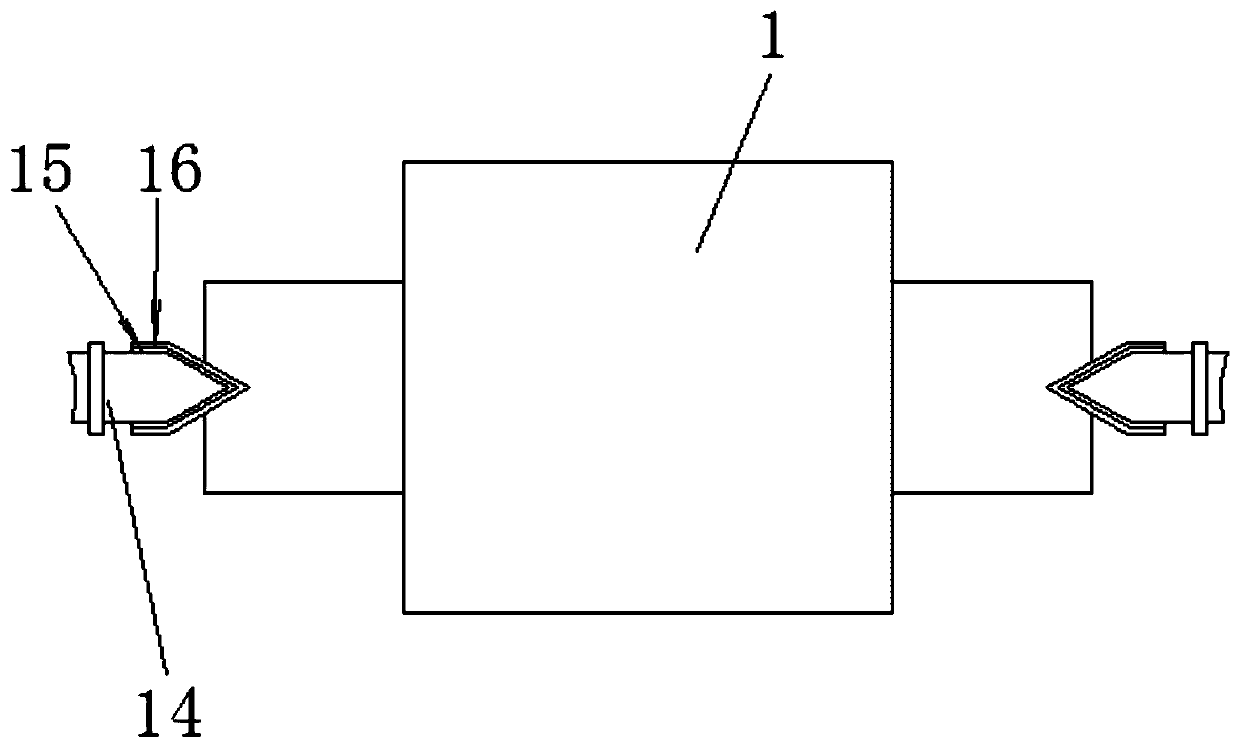

Surface passivation system for prolonging service life of EDT roughened cold rollers

ActiveCN109514012AExtended service lifeAchieve passivation effectMachining electrodesMachining working media supply/regenerationElectrolysisManufacturing technology

The invention relates to the technical field of cold roller manufacturing, and discloses a surface passivation system for prolonging service life of EDT roughened cold rollers. The system comprises rotary driving equipment and a pulse electrochemical burr removing device; the pulse electrochemical burr removing device comprises a pulse power supply, a tool electrode and an electric brush; the electric brush is contacted with outer circle surfaces of cold rollers; the head part of the tool electrode is near roughened outer circle surfaces of the cold rollers; a gap for enabling electrolyte to pass through is formed between the head part of the tool electrode and the roughened outer circle surfaces of the cold rollers; an electrolyte nozzle with a spout aligned to the gap is arranged above the gap; the electrolyte nozzle is connected to an electrolyte box through a pump and a pipeline; an electrolyte collecting tank for collecting electrolyte is arranged under the roughened outer circlesof the cold rollers; and the electrolyte collecting tank is connected with the electrolyte box. The system prolongs the service life of the EDT roughened cold rollers, improves the quality of rolledparts, and reduces the roller change efficiency.

Owner:JIANGYIN RUNYUAN MACHINERY

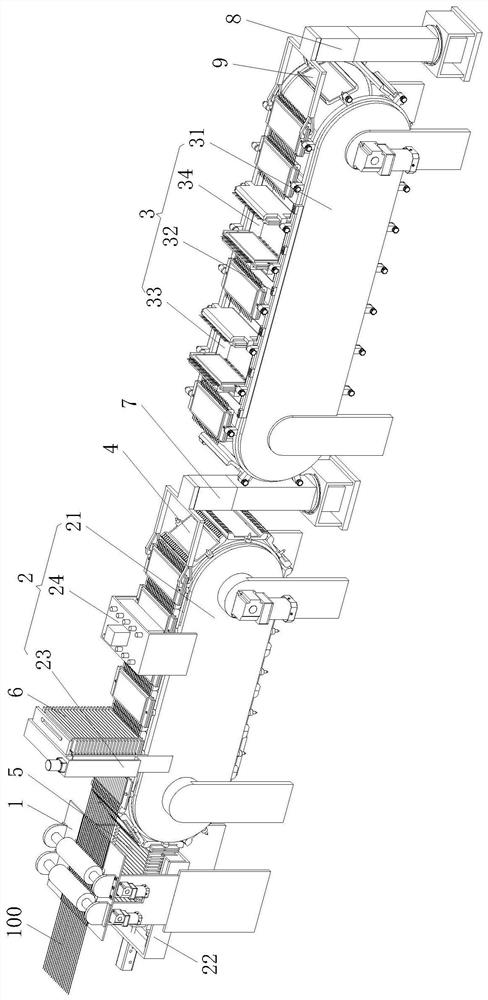

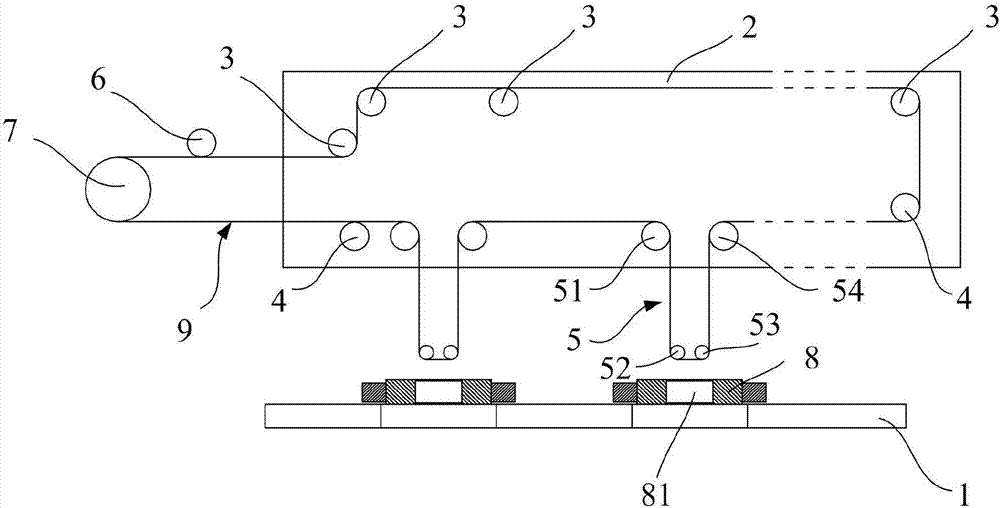

Varnished wire depainting and tinning automatic production equipment

ActiveCN112186472AFully automatedIncrease productivityLine/current collector detailsTinningMechanical engineering

The invention discloses varnished wire depainting and tinning automatic production equipment which comprises a varnished wire conveying unit, a varnished wire clamping and cutting unit, a first manipulator device, a varnished wire depainting and tinning unit and a second manipulator device which are sequentially arranged. The varnished wire clamping and cutting unit comprises a first conveying device, a clamping lower die automatic feeding device, a clamping upper die automatic feeding device and an automatic cutting device, a first clamping die containing groove is formed in the first conveying device, and the varnished wire depainting and tinning unit comprises a second conveying device, a pose switching mechanism, a depainting groove and a tinning groove. A second clamping die placing groove is formed in the second conveying device. According to the invention, the automation of the whole production process of varnished wire conveying, clamping, cutting, paint removing and tin coating can be realized, the clamping process is simple and rapid, the clamping die can be recycled, the varnished wires have the same paint removing length and consistent tin coating effect, the productionefficiency and the product quality are greatly improved, and the production cost is reduced.

Owner:安徽交通职业技术学院

Tooling for processing lamp spherical holder

The invention discloses a tooling for processing a lamp spherical holder. The tooling comprises a base, a pull rod, an elastic mandrel and a press head, wherein the base is of a hollow structure, and is detachably connected with a main shaft of a machine tool, a positioning boss is arranged at the right end of the base, a mounting boss is arranged at the left end of the base, a slide passage is arranged in the center of the base, the elastic mandrel comprises a plurality of fins and a seat body, the fins are arranged along the circumference of the left end, the seat body is arranged at the right end and is used for fixing the fins, an inner hole is formed in the seat body, and is in clearance fit with the positioning boss, an expansion joint is formed among the fins, a rubber sealing ring is arranged in each expansion joint, the middle part of the pull rod is glidingly connected with the interior of the slide passage, the left end of the pull rod penetrates through the inner hole of the seat body, extends to the fins of the elastic mandrel and is connected with the press head, the press head is in a cone shape, the diameter of the press head is gradually reduced from left to right, and the inner side of each fin is provided with a conical surface which is matched with the press head. By adopting the scheme, the tooling has the advantages that the clamping is convenient and rapid, the operation is easy, the lamp spherical holder can be quickly fixed, and the production efficiency is greatly improved.

Owner:重庆博钻太阳能灯具有限公司

Headstand type threading-free wire cut electrical discharge machining device

ActiveCN107186301AEasy and fast clampingAvoid collisionElectrical-based machining electrodesClosed loopElectrical discharge machining

The invention discloses a headstand type threading-free wire cut electrical discharge machining device comprising a workpiece clamping platform, a guide wheel support fixing plate, a wire coiling cylinder, an electrode wire, first guide wheels, second guide wheels and a plurality of electric spark guide wheel machining mechanisms. The electrode wire is wound around the wire coiling cylinder, the first guide wheels, the second guide wheels and the electric spark guide wheel machining mechanisms to form a closed loop. Meanwhile, the electrode wire is sequentially wound around the upper left circumferential face of an upper right guide wheel, the lower right circumferential face of a lower right guide wheel, the lower left circumferential face of the lower left guide wheel and the upper right circumferential face of an upper left guide wheel of each electric spark guide wheel machining mechanism to achieve 180-degree reversing. Compared with the prior art, the headstand type threading-free wire cut electrical discharge machining device has the advantages of being easy, convenient and rapid to install, reliable in use, capable of effectively improving the production efficiency and the like.

Owner:GUANGDONG UNIV OF TECH

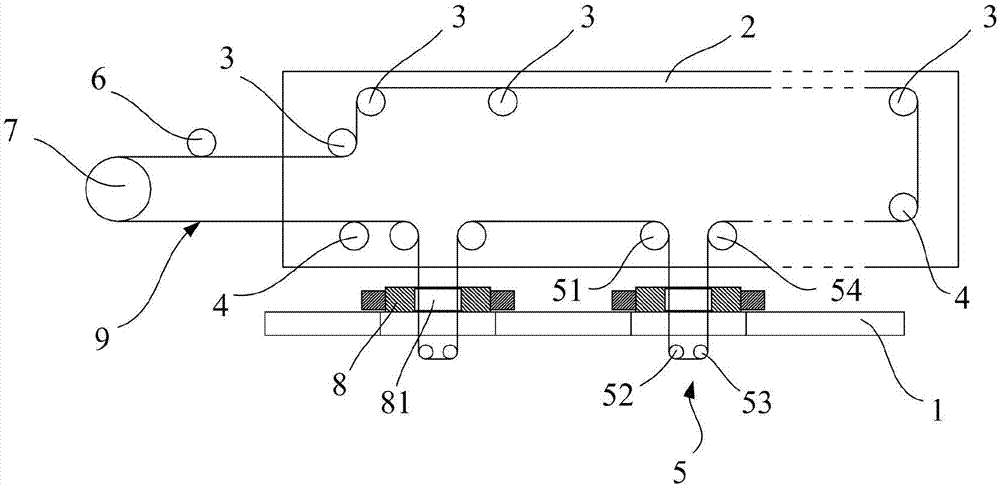

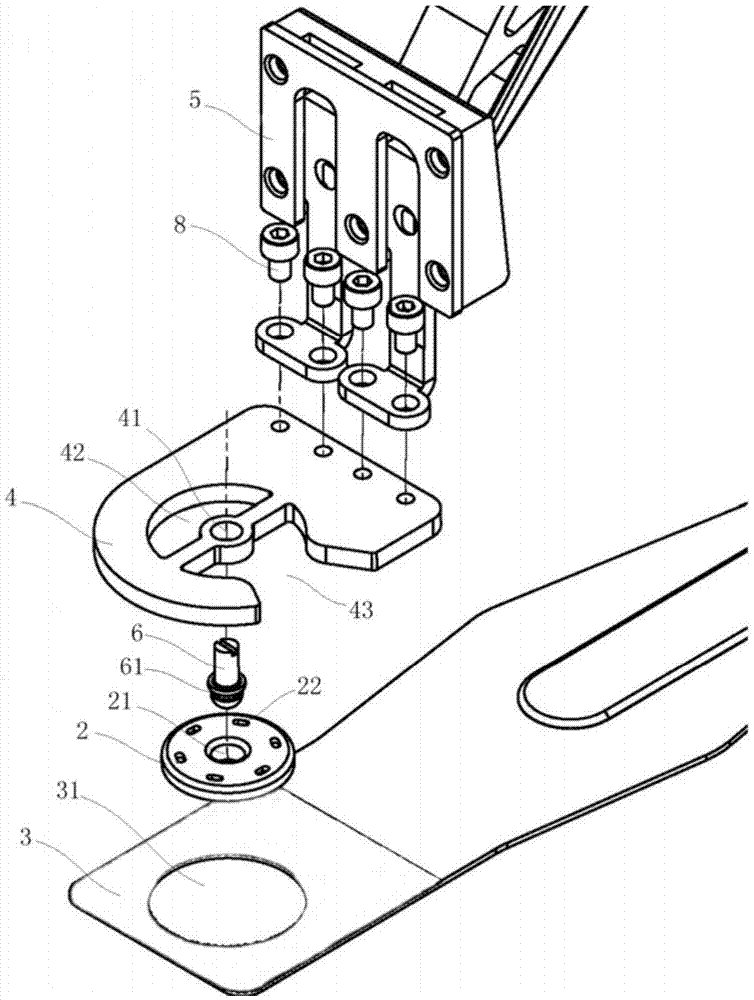

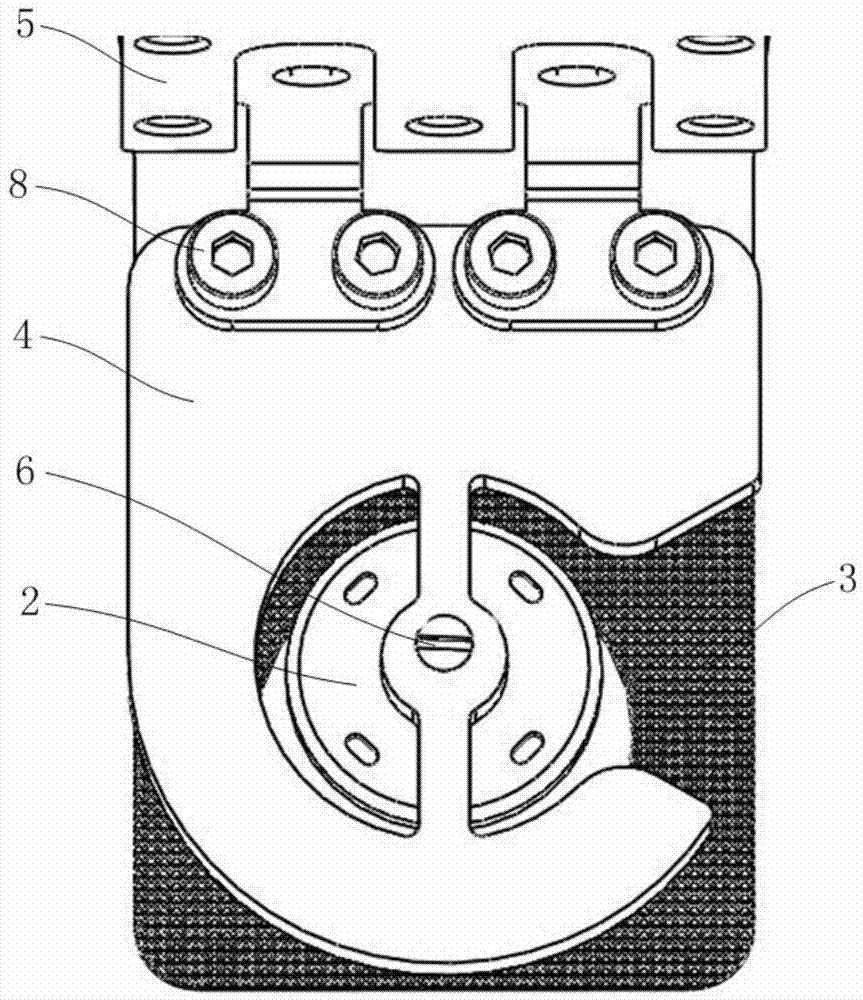

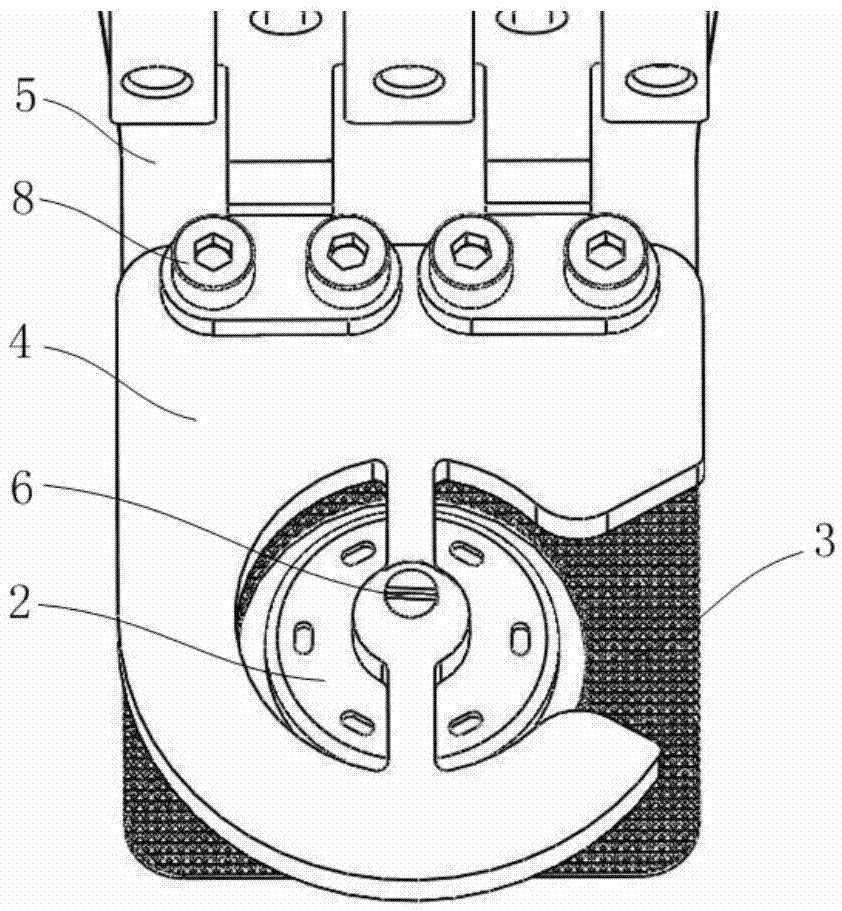

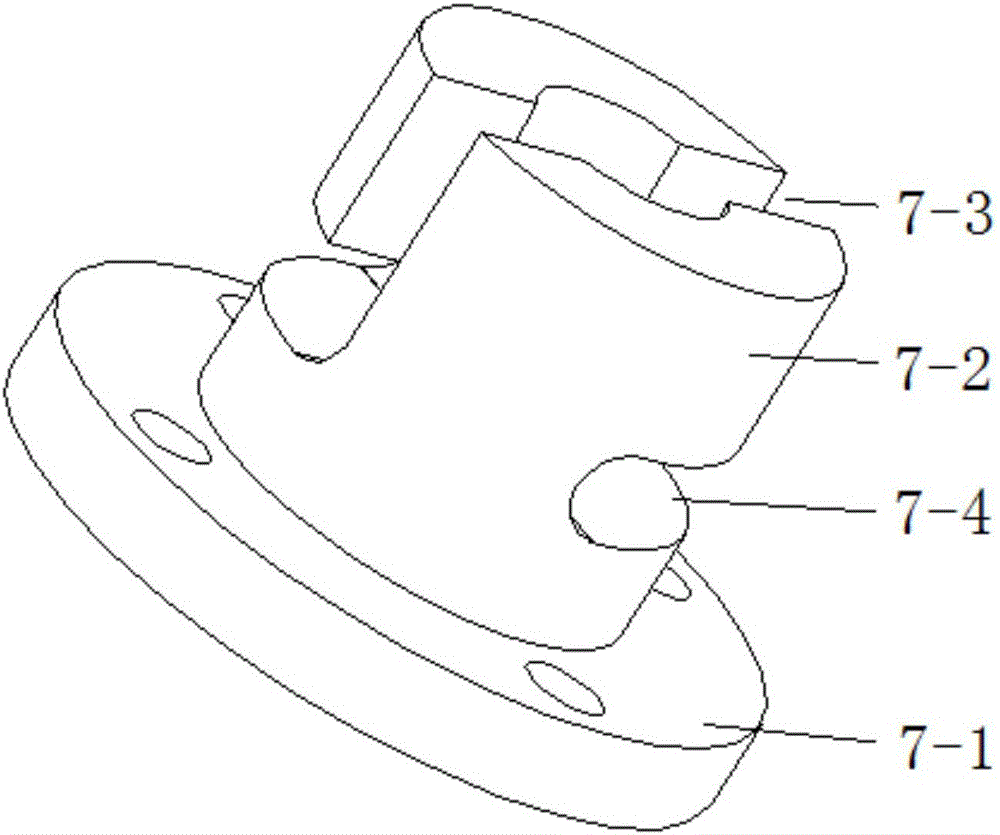

Special presser foot for sewing snap fastener and snap fastener sewing method

ActiveCN105442196ASimple and fast clamping and adjustmentQuick and easy clipping and adjustment processPressersSewing needleFastener

The invention provides a special presser foot for sewing a snap fastener and a snap fastener sewing method. The special presser foot comprises a feeding plate located above a needle plate. The feeding plate is proved with a positioning hole matched with the snap fastener in shape, a presser foot piece is arranged above the feeding plate and fixedly connected with a feeding frame assembly, a central hole is formed in the middle of the presser foot piece, an annular space for a sewing needle to penetrate through is formed in the pressure foot piece in the circumferential direction of the central hole, and a connecting piece connected with the snap fastener is inserted in the central hole and extends towards the feeding plate. By means of the special presser foot for sewing the snap fastener and the snap fastener sewing method, frequently-applied snap fasteners with different dimensions on the market can be easily and quickly clamped and adjusted, and the problem that wrench tongs of an existing button sewing machine can not achieve universality on diversified snap fasteners is solved; in addition, the snap fastener clamping and adjusting process is easy and fast each time, the sewing efficiency is greatly improved, the labor intensity is lowered, and the demand of mass production garment factories for production efficiency is met.

Owner:BULLMER ELECTROMECHANICAL TECH

Manufacturing process for cold-rolling roll

ActiveCN109807554AAchieve passivation effectExtended service lifeIncreasing energy efficiencyFurnace typesCold treatmentManufacturing technology

The invention relates to the technical field of rolling roll manufacturing, and discloses a manufacturing process for a cold-rolling roll. The manufacturing process for the cold-rolling roll sequentially comprises the procedures of ingot casting, forging, heat treatment after forging, rough turning machining, quenching and tempering treatment, finish turning machining, surface quenching, cold treatment, low-temperature tempering, accurate grinding machining, surface texturing, and electrochemical passivation, wherein in the procedure of surface quenching, double-frequency quenching treatment is carried out on the working surface of the cold-rolling roll through a double-frequency quenching machine tool; in the procedure of surface texturing, texturing treatment is carried out on the working surface of the cold-rolling roll through an EDT electric spark texturing machine tool; and in the procedure of electrochemical passivation, deburring passivation treatment is carried out on microcosmic tip parts on the working surface of the cold-rolling roll through pulse electrochemical deburring equipment. According to the manufacturing process for the cold-rolling roll, the service life of the EDT textured cold-rolling roll is prolonged, the quality of a rolled part is improved, and the roll changing frequency is reduced.

Owner:JIANGYIN RUNYUAN MACHINERY

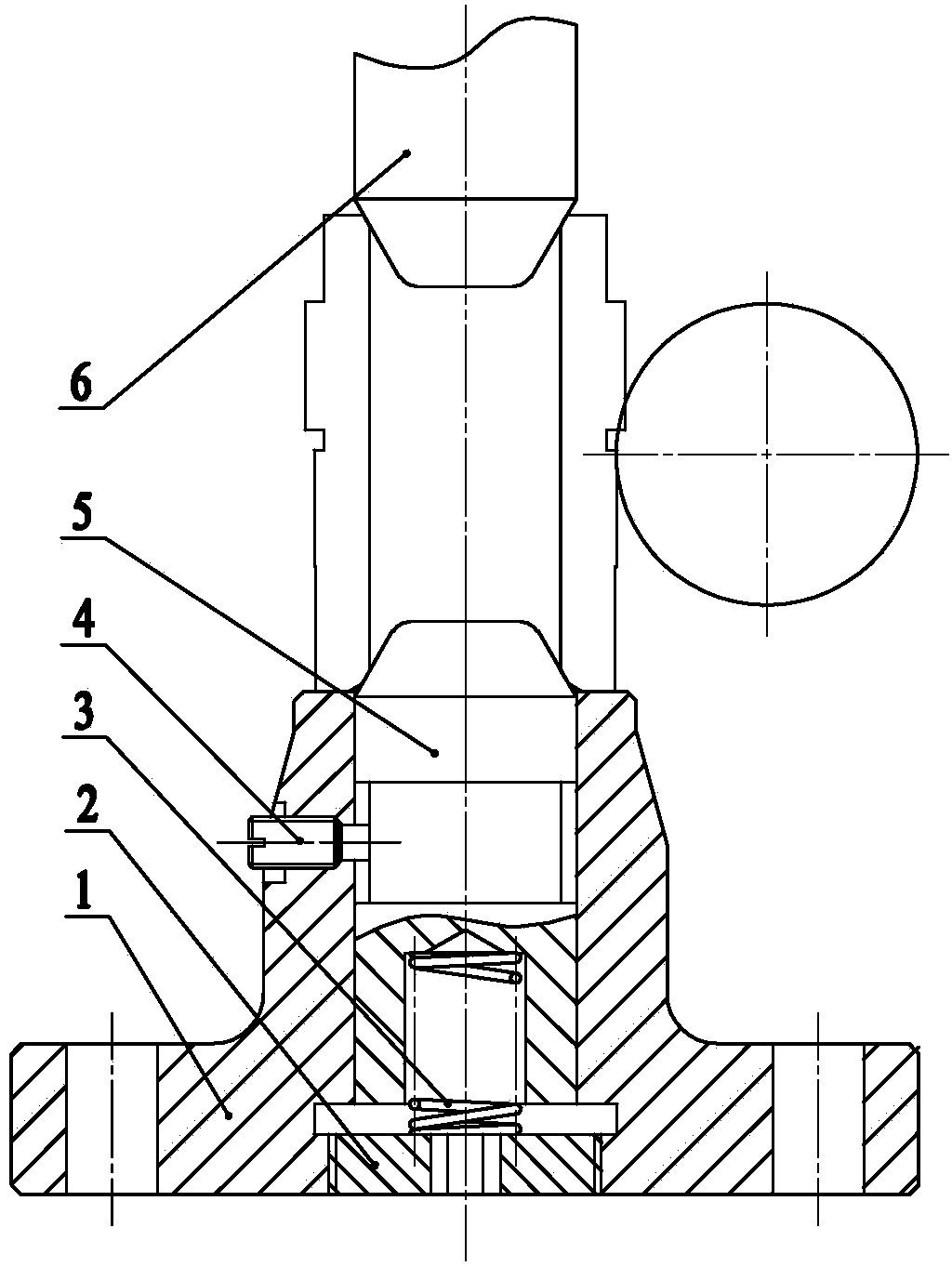

End face driven gear hobbing clamp

InactiveCN103639538AHigh positioning accuracyImprove machining accuracyGear-cutting machinesGear teethHobbingGear wheel

The invention relates to an end face driven gear hobbing clamp. The end face driven gear hobbing clamp is characterized by comprising a base, an adjusting nut, a powerful spring, a jackscrew and a floating tip, wherein end face pawls evenly distributed circumferentially are arranged at the top of the base, an installing hole is formed in the center of the base, the powerful spring and the floating tip are installed in the installing hole in the base, the upper end of the powerful spring abuts against the floating tip, the lower end of the powerful spring is supported on the adjusting nut, and the adjusting nut is connected in the installing hole in a threaded mode. The jackscrew radially penetrates the outer wall of the base, the inner end of the jackscrew is embedded into an axial long groove in the peripheral wall of the floating tip, and the jackscrew can prevent the floating tip from bouncing out or falling and limit rotation of the floating tip. The end face driven gear hobbing clamp is simple in structure, simple and convenient to operate, quick, efficient, good in reliability and capable of achieving quick and accurate gear centering and meeting high-accuracy gear machining and batch production requirements.

Owner:WUXI WEIFU CHINA ITAL GEAR

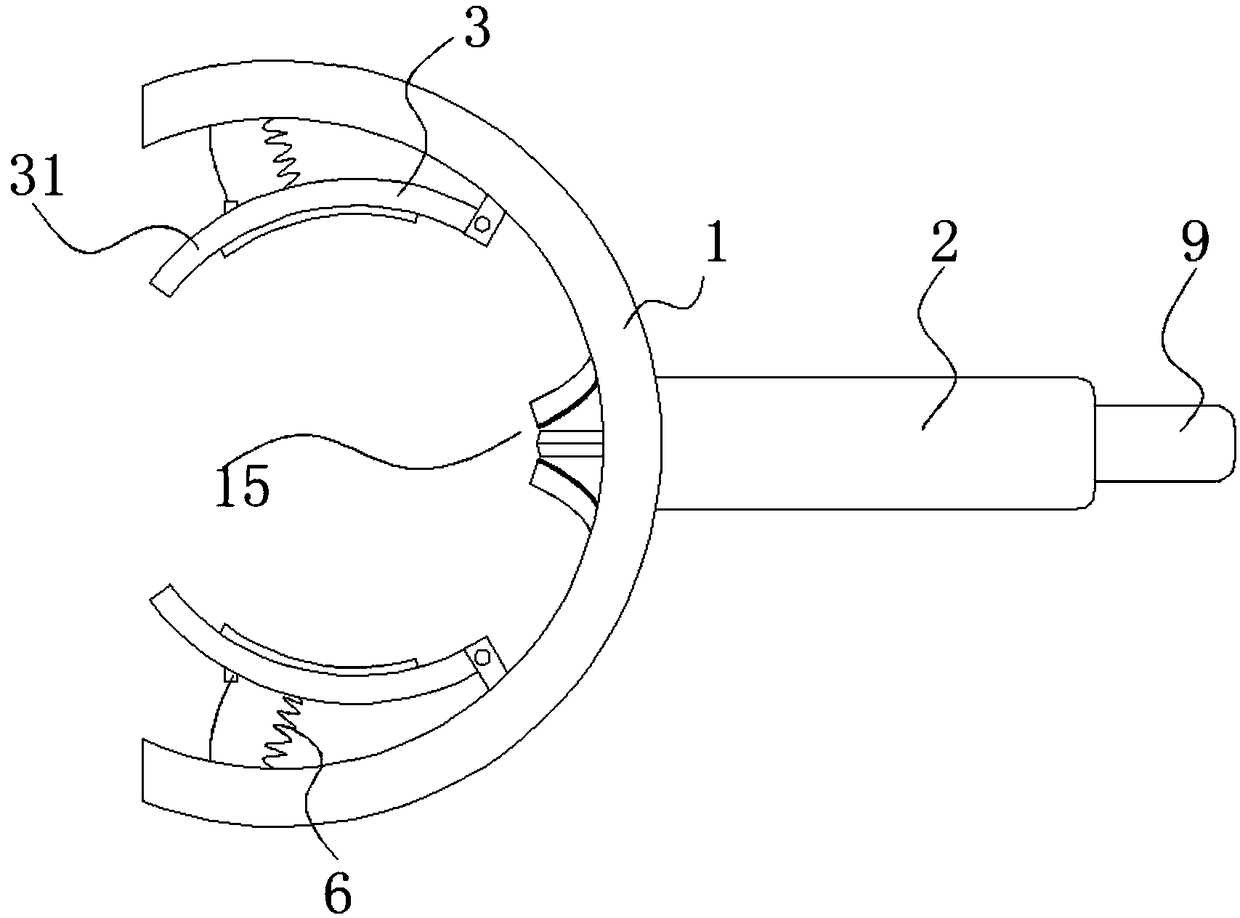

Handheld peony root system skin core-pulling device

ActiveCN109465860AComplete core pullCore pulling safetyMetal working apparatusPlant ingredientsCuticleEngineering

The invention provides a handheld peony root system skin core-pulling device, and relates to the field of peony processing and manufacturing devices. The handheld peony root system skin core-pulling device comprises an open circular placement seat and a handle frame arranged on one side of the open circular placement seat, and an arc clamping mechanism is hinged to the inner side of the open typecircular placement seat through a middle shaft. Compared with the prior art, the arc clamping mechanism is arranged inside the open circular placement seat, and a blade placing frame is arranged on anopening type blade, so that the following beneficial effects that when peony roots are subjected to traditional manual core pulling, firstly, the peony roots can be kept very stably and do not move,the roots are more stable when the opening type blade is used for cutting the peony roots in the axial direction so as to perform core pulling, then cores can be more completely exposed outside, corepulling is facilitated, moreover, the peony roots are more complete and safer when the peony roots are cut under the combination of the blade placing frame, and an operator cannot be hurt by the opening type blade are achieved.

Owner:凤阳大明旅游发展(集团)有限公司

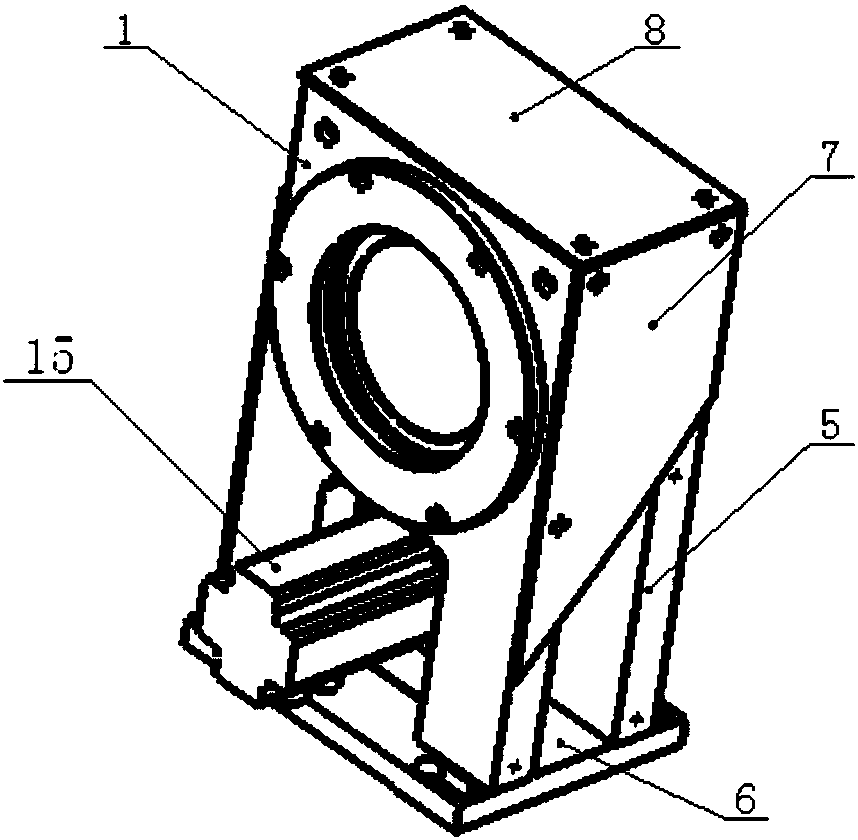

Circular oil distributing pipe welding clamping device

InactiveCN108422113AEasy and fast clampingPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPipe welding

The invention relates to a circular oil distributing pipe welding clamping device including a self-made synchronous belt rotating assembly, an external chuck assembly and a mounting bracket assembly.The external chuck assembly is arranged on the self-made synchronous belt rotating assembly. The self-made synchronous belt rotating assembly is arranged on the mounting bracket assembly. The self-made synchronous belt rotating assembly, the external chuck assembly and the mounting bracket assembly are arranged on a device working table. A photoelectric sensor is arranged on the self-made synchronous belt rotating assembly. As an initiator of a signal, the photoelectric sensor ensures the consistency and the stability of welding in welding process of a workpiece. The circular oil distributingpipe welding clamping device of the invention has accurate positioning, reliable welding and high efficiency.

Owner:WUHAN CHUTIAN IND LASER EQUIP

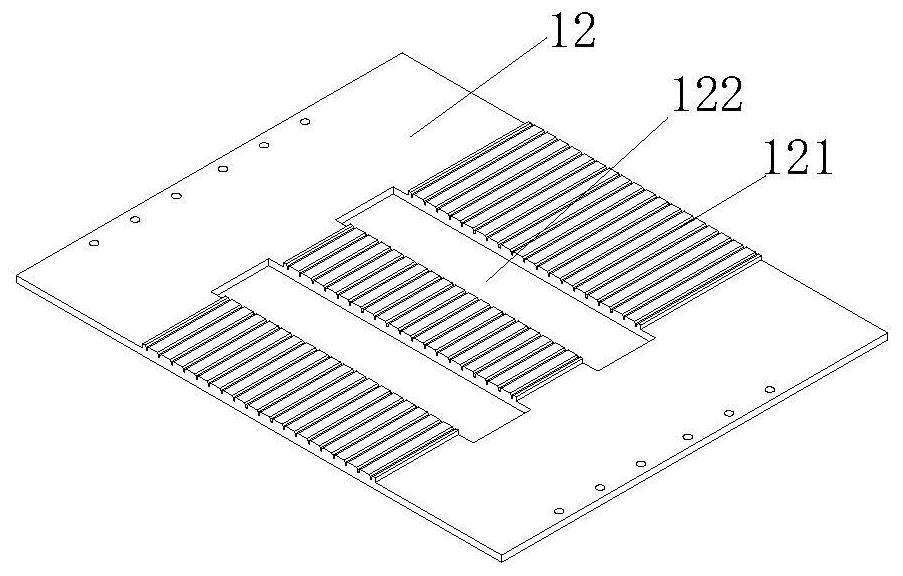

Multi-connection tool clamp of motor housing

InactiveCN106514340ARealization of press-fitting and fixingImprove processing efficiencyPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention provides a multi-connection tool clamp of a motor housing, and aims at solving the technical problems of an existing tool clamp which is only applied to clamping and processing of single housing, and is low in processing efficiency, complex in structure, and cumbersome to clamp. The multi-connection tool clamp for the motor housing comprises a bottom plate. The multi-connection tool clamp for the motor housing is characterized by further comprising a supporting plate, pressing plates and bolts, wherein the supporting plate is vertically fixed to the bottom plate; a plurality of convex edges are arranged at intervals on the end surface of one side of the supporting plate along the length direction; a positioning groove in which the motor housing can be clamped is formed between every two adjacent convex edges; every two positioning grooves are correspondingly provided with one pressing plate; the bolts passing through the pressing plates are in thread connection with the corresponding convex edges.

Owner:WUXI KAIHAN TECH

Automobile front bumper tensile strength test device

InactiveCN109708962APracticalEasy and fast clampingVehicle testingMaterial strength using tensile/compressive forcesSlide plateUltimate tensile strength

Owner:丹阳市亚美车辆部件有限公司

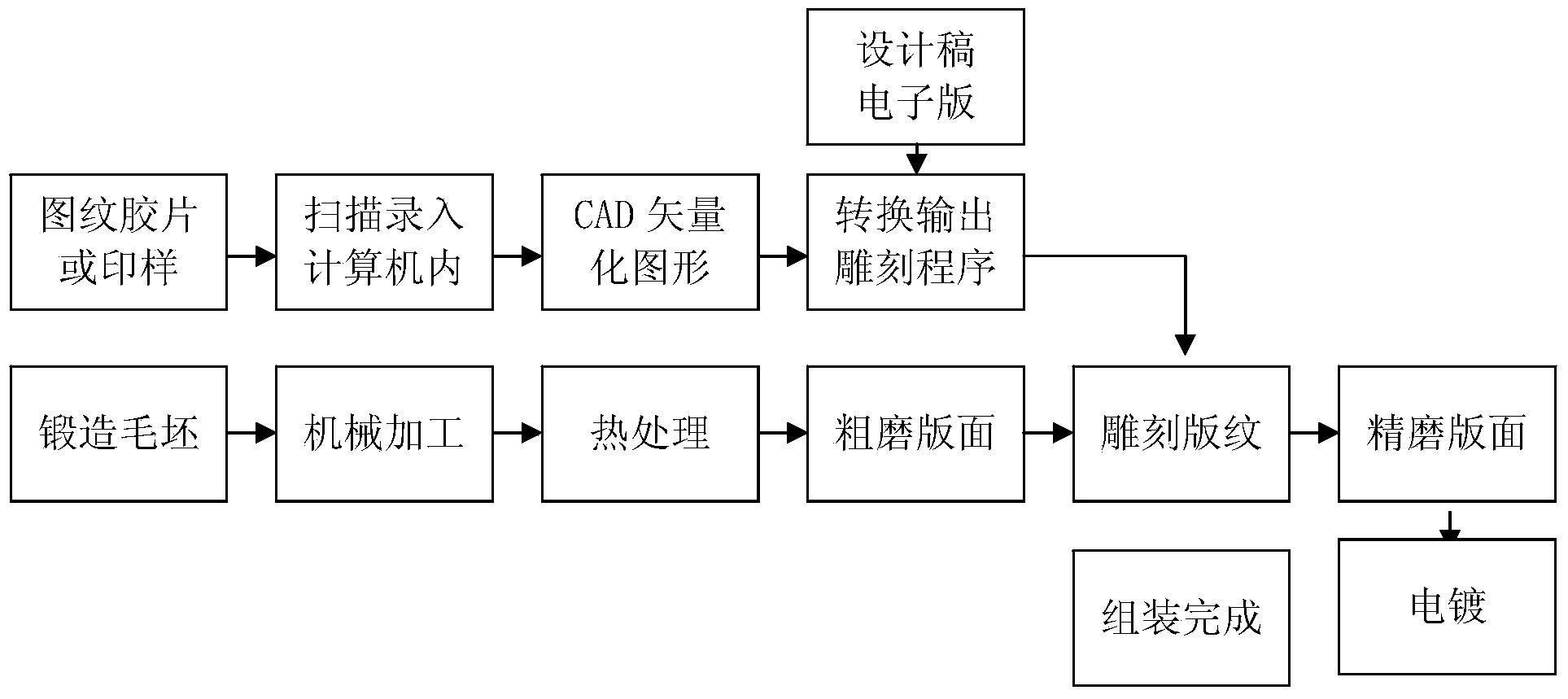

Embossing printing plate for code printer and processing method thereof

ActiveCN104260575AAvoid lossOvercoming the disadvantages of being thin and brittlePlate printingFoil printingEngineeringHardness

The invention discloses an embossing printing plate for a code printer and a processing method thereof. The embossing printing plate for the code printer comprises a plate surface and a bottom seat which bears the plate surface, wherein the plate surface is arranged an optional position on the bottom seat according to positions of printing patterns, the plate surface is composed of a plurality of independent embossing printing plate blocks or 2-6 squares of plate wheels, a forked tail clamp groove is formed in the lower portion of the bottom seat, a clamping block is arranged on one side of the forked tail clamp groove, the clamping block is adjusted by a clamping screw which transversely passes through the lower portion of the bottom seat, the plate surface is made of 40Cr steel and / or high carbon steel and / or alloy tool steel material, and hardness of the plate surface is improved by performing heat treatment on the plate surface during the manufacture process. The embossing printing plate for the code printer is high in production efficiency and durable. Simultaneously, the processing method of the embossing printing plate for the code printer is provided. The embossing printing plate for the code printer, produced by using the processing method, is resistant to wear and long in use life.

Owner:北京中融安全印务有限公司

Specially-shaped part clamping equipment of numerically-controlled lathe

InactiveCN111673492AClamping is firmGuarantee the quality of productionWork clamping meansPositioning apparatusBell mouthStructural engineering

The invention provides specially-shaped part clamping equipment of a numerically-controlled lathe, belongs to the technical field of tool fixtures, and aims to solve the problems that existing tool fixtures of numerically-controlled lathes are single in function, specially-shaped parts cannot be clamped directly, the production precision is difficult to guarantee and the production quality is reduced. The equipment comprises an upper clamping plate; each of the upper clamping plate and a lower clamping plate adopts the half-cylindrical-pipe-shaped structure; the front end of the upper clampingplate and the front end of the lower clamping plate are distributed in the half-horn shapes. According to the equipment, an upper cushion block and a lower cushion block are added to the outside of aspecially-shaped casing pipe part, a first arc-shaped surface is formed at the front end of the upper cushion block, a second arc-shaped surface is formed at the front end of the lower cushion block,the arc-shaped surfaces are matched with the horn mouth part of the specially-shaped casing pipe part in diameter, the specially-shaped casing pipe part is clamped between the cushion blocks during clamping, the middle section of the part can be thickened, the horn mouth can be avoided, the specially-shaped casing pipe part can be clamped firmly, the specially-shaped part can be clamped easily and quickly, the influence of the specially-shaped part on production and machining can be eliminated, and the production quality is guaranteed.

Owner:湖北豪凯汽车零部件有限公司

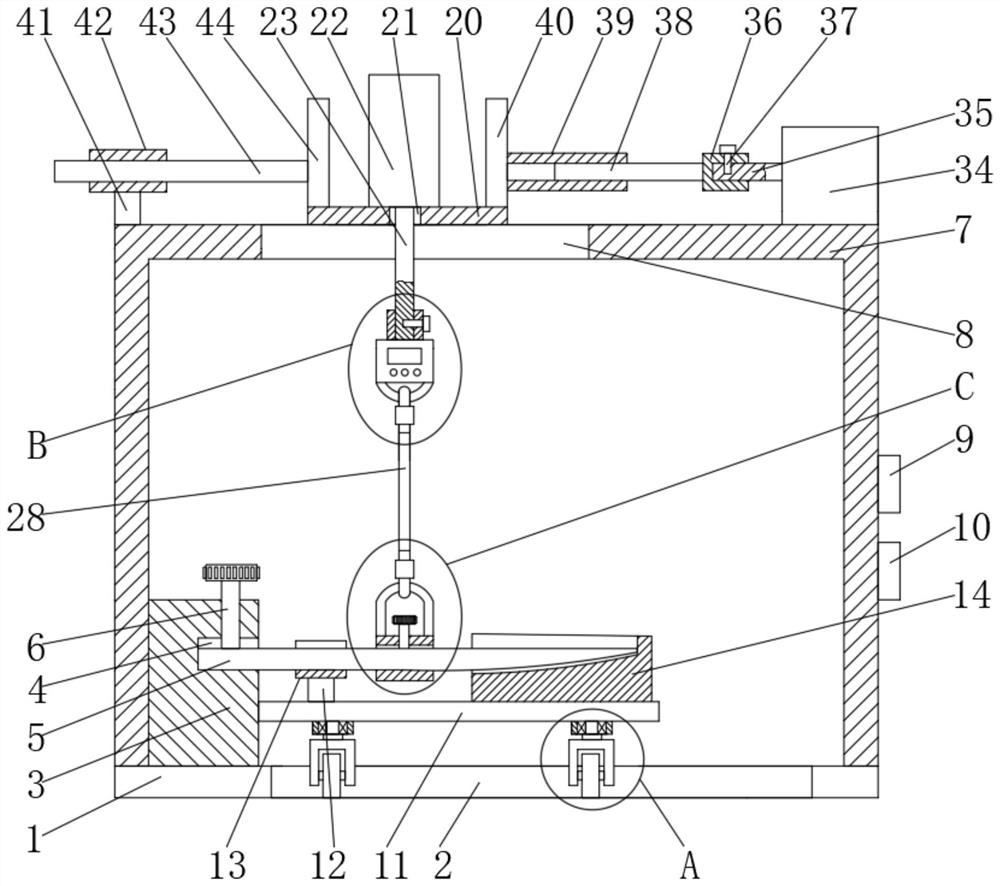

Strength detection device for wind wheel blade of fan generator set

InactiveCN112798410AEasy transferEasy and fast clampingMachine part testingMaterial strength using tensile/compressive forcesHydraulic cylinderElectric machinery

The invention discloses a strength detection device for a wind wheel blade of a fan generator set. The strength detection device comprises a bottom plate, a box body, a hydraulic cylinder and a forward and reverse rotation motor, a notch is formed in the inner side of the bottom plate, a fixing base is fixedly connected to the upper end of the bottom plate, a fixing groove is formed in the fixing base, a blade is inserted into the fixing groove, a fixing rod is connected in the fixing base through threads, the lower end of the fixing rod is in close contact with the surface of the blade, the box body is fixedly connected to the upper end of the bottom plate, the inner side of the box body is fixedly connected with the fixing base, and a first switch and a second switch are fixedly installed at the right end of the box body; the first switch and the hydraulic cylinder are connected with an external power source in series through wires, and the second switch and the forward and reverse rotation motor are connected with the external power source in series through wires. According to the strength detection device for the wind wheel blade of the fan generator set, the strength detection device has the characteristics of convenience in transferring and clamping, capability of realizing multi-point detection and safety protection.

Owner:吴怡潼

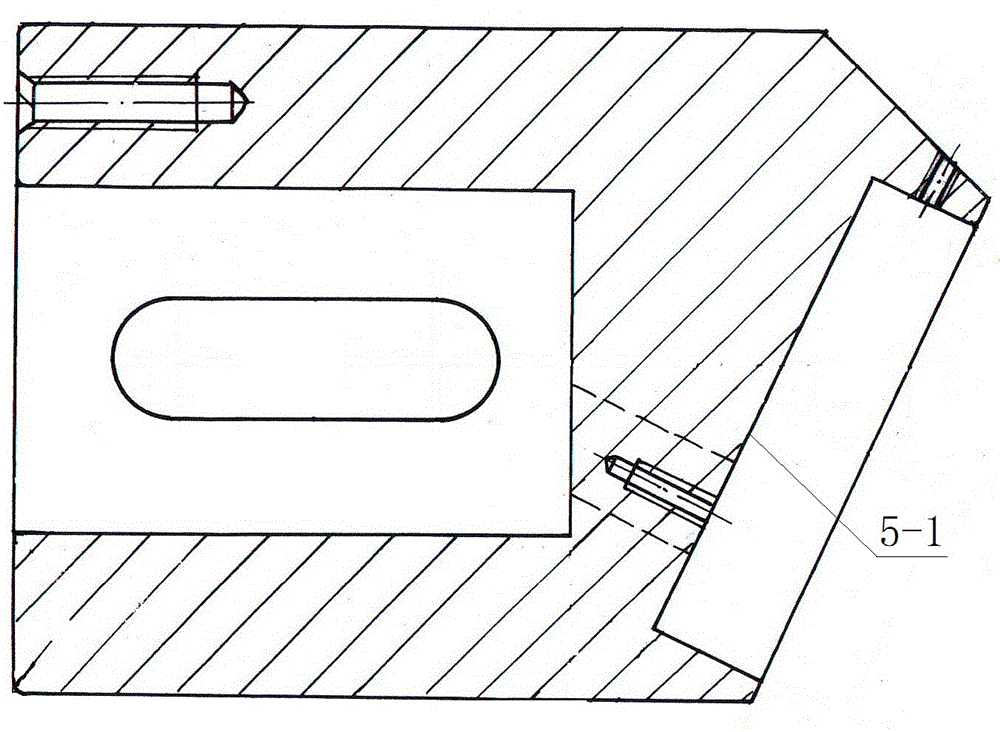

Engine cylinder body top surface inclined hole drilling fixture

InactiveCN106141730AEasy and fast clampingImprove stabilityPositioning apparatusDrill jigsEngineeringCylinder block

The invention discloses an engine cylinder body top surface inclined hole drilling fixture. The engine cylinder body top surface inclined hole drilling fixture comprises a base; the upper end surface of the base is provided with a trapezoidal supporting body; a left supporting block and a right supporting block are symmetrically arranged on the two sides of an inclined surface at the front end of the supporting body; a first positioning pin and a second positioning pin are arranged in the positions, between the upper end of the left supporting block and the upper end of the right supporting block, of the inclined surface of the supporting body; a detachable installation seat is arranged in the middle of the inclined surface of the supporting body, and a connection rod penetrating through a cylinder sleeve hole of an engine cylinder body during working is installed on the detachable installation seat; the upper end of the connection rod is sleeved with a drill sleeve installation plate and a pressing plate in sequence, and a lock nut for locking the pressing plate is installed at the top of the connection rod in a screwing mode; and the drill sleeve installation plate is provided with a plurality of drill sleeves distributed at intervals. According to the structure of the engine cylinder body top surface inclined hole drilling fixture, the supporting body, the positioning pins, the detachable installation seat, the connection rod and other components are used in a matched mode, and positioning and clamping of the engine cylinder body can be conducted conveniently and quickly, so that the firmness and stability of drilling machining of inclined holes in the top surface of the clamped engine cylinder body are improved.

Owner:芜湖火龙动力科技有限公司

Test system and test method for dynamic bending fatigue property of thin film material

InactiveCN101571467BEasy and fast clampingWide range of loading frequencyMaterial strength using repeated/pulsating forcesVibration testingReciprocating motionTest sample

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

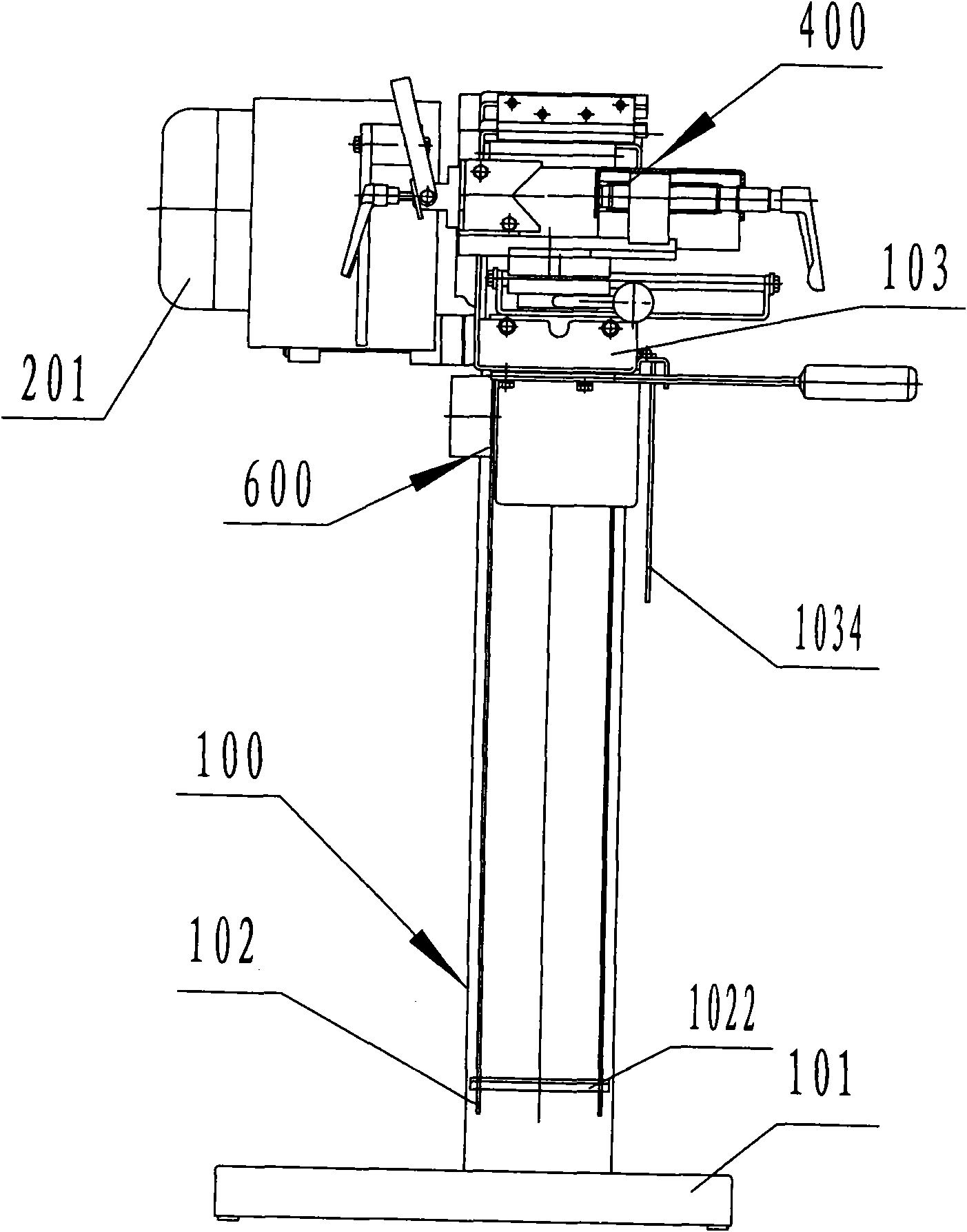

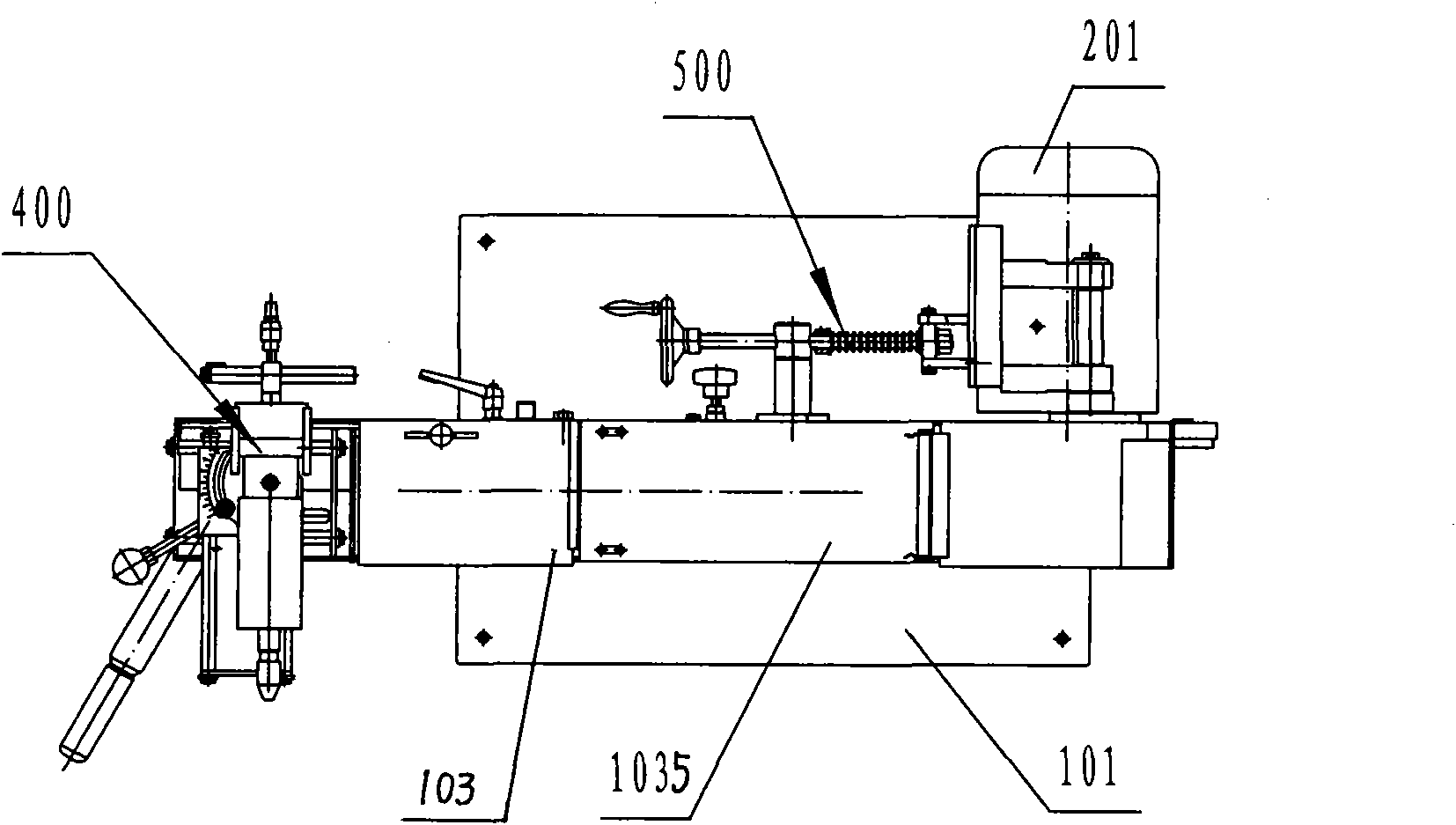

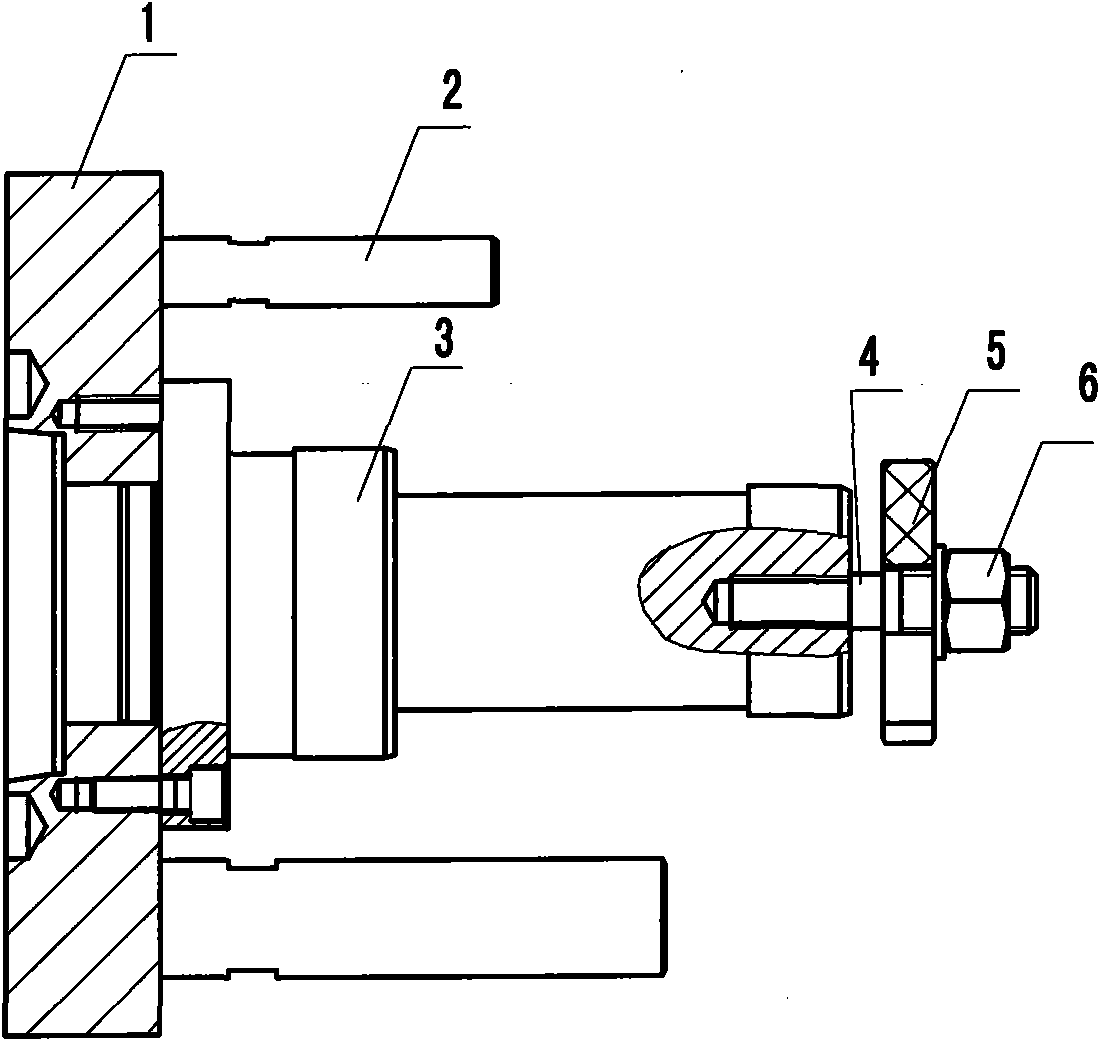

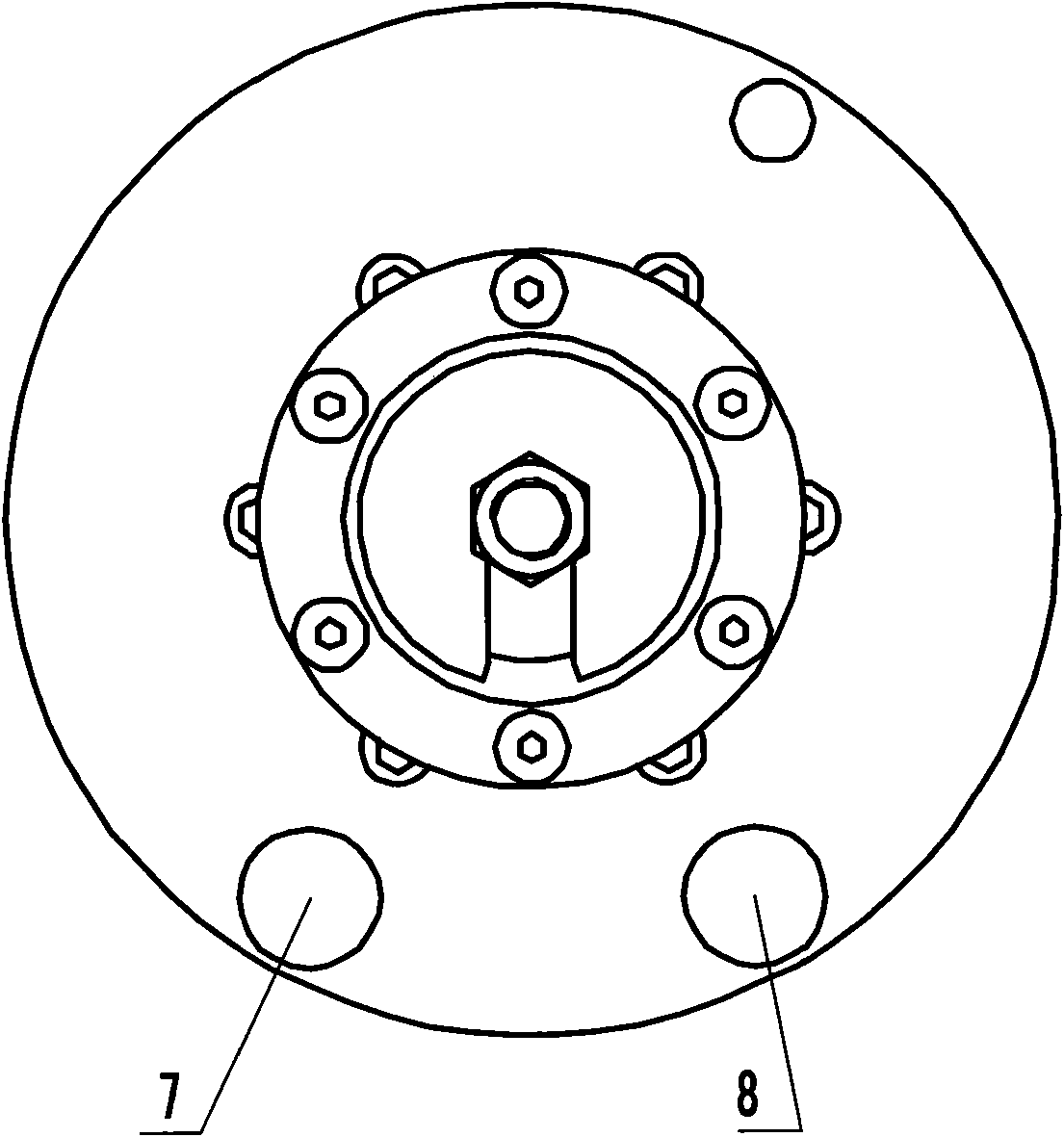

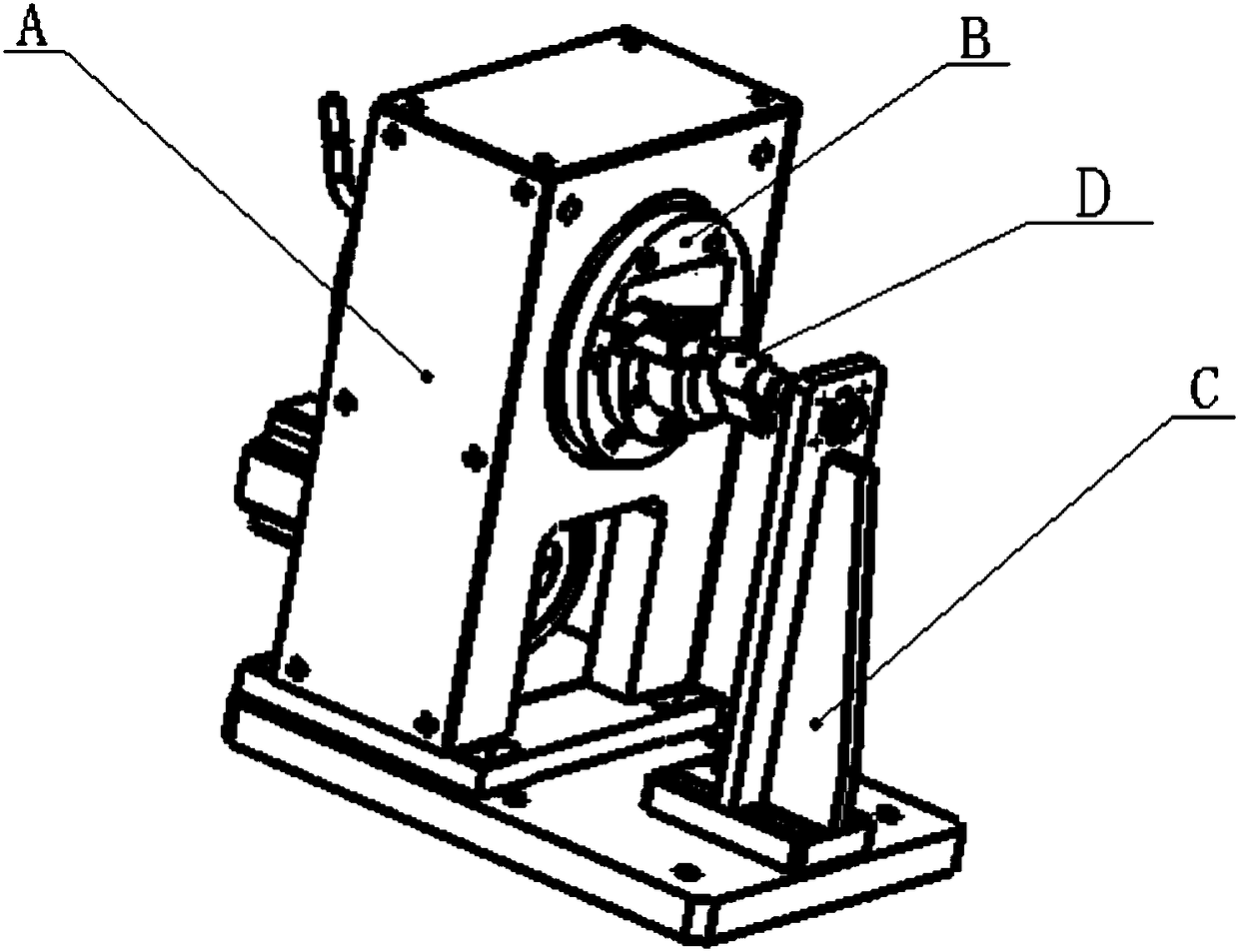

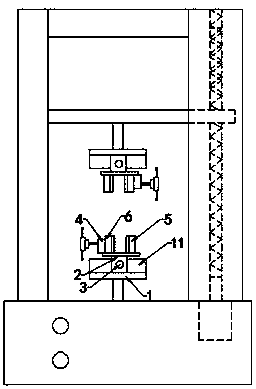

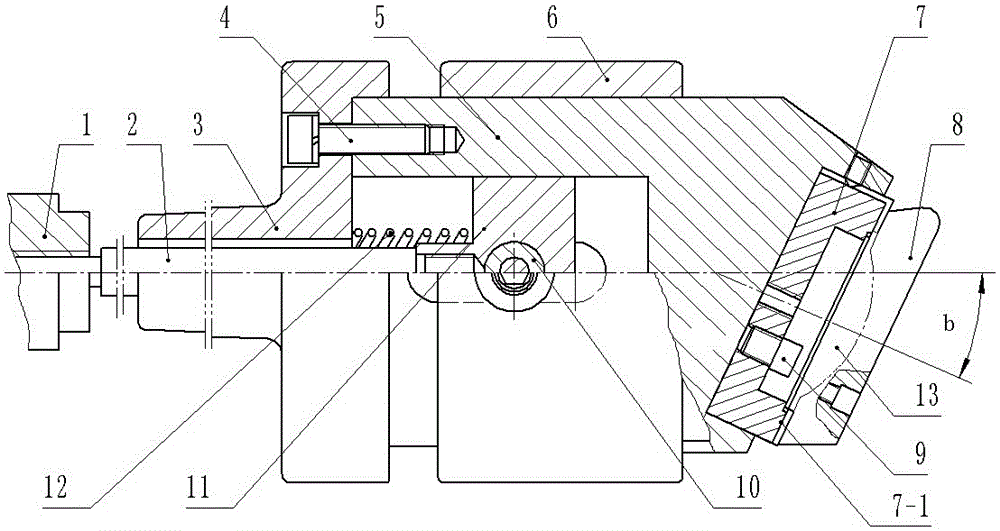

Straight-joint type spindle running-in testbed

InactiveCN109596341AEasy and fast clampingQuick and easy adjustabilityMachine gearing/transmission testingCouplingDrive motor

A straight-joint type spindle running-in testbed is disclosed. A support seat is fixed on a platform by bolts, a straight-joint spindle is mounted to the support seat, the straight-joint spindle is precisely positioned through a clamping block by using bolts, fastening bolts perform clamping fixation, a vibration sensor is installed at the bearing position of the straight-joint spindle, vibrationmonitoring is implemented on a running bearing, a drive motor lifting adjustment device is installed on a drive motor front-rear adjustment device through bolts, one end of a coupling is linked and fixed to the output shaft end of the drive motor, and the drive motor and the coupling are installed on the drive motor lifting adjustment device to carry out the running-in test on the straight-joint spindle, and the vibration frequencies at different rotational speeds are monitored by the vibration sensor. The straight-joint type spindle running-in testbed is suitable for running in various straight-joint spindles with different external dimensions, quickly and simply carries out clamping and adjustment of the straight-joint spindle, prolongs the service life of the spindle, and is applied tothe technical field of manufacturing in the modern metal part processing industry and the equipment manufacturing industry.

Owner:SHENYANG AEROSPACE MITSUBISHI AUTOMOBILE ENGINE MFG CO LTD

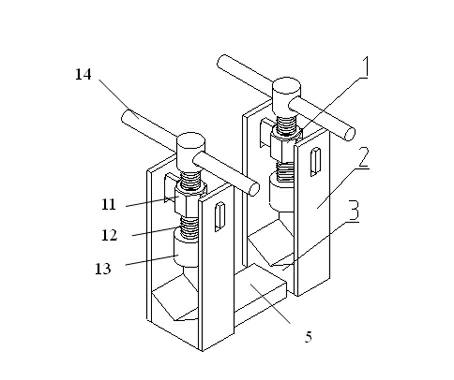

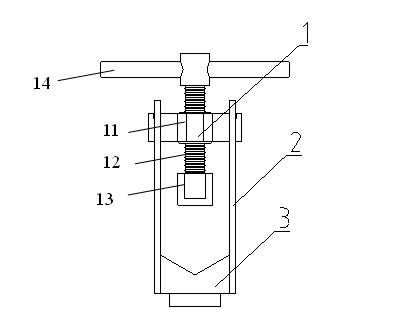

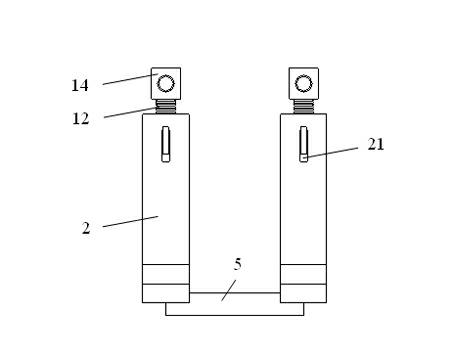

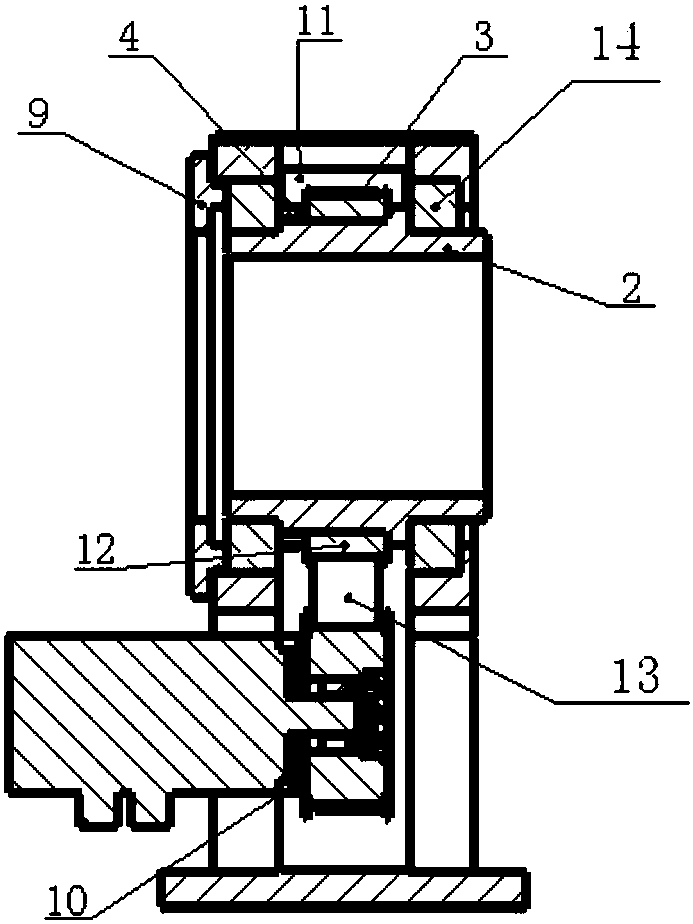

Dust collector bellows rotation fatigue strength test machine

InactiveCN105157977AImprove test efficiencyEasy and fast clampingMachine part testingMaterial strength using repeated/pulsating forcesScrew threadUltimate tensile strength

The invention discloses a dust collector bellows rotation fatigue strength test machine, comprising a pedestal, an electric cabinet arranged on one side of the pedestal and at least one group of counter weights arranged above the pedestal; the electric cabinet is provided with at least one group of clamps which are identical with the counter weights in structures; the clamp comprises a tension mandrel, a tension sleeve in cooperation with a tension mandrel screw thread pair; and the tension mandrel is connected to a transmission assembly. The invention has double motors and 6 working stations, and can perform multiple groups of tests; a ball head plunger is installed inside the clamp and can be installed on or disassembled from a rotation shaft, which is easy for the operation staff to clamp the product off-line; the clamps and the counter weights adopt identical structures and a principle and are easy to clamp; the free end of the tension sleeve is provided with a boss, which prevents the bellows from following up and slipping during the rotation; each working station has a limiting cylinder, which guarantees the test process to be stable; the transmission structure is simple and easy to maintain; the motor is equipped with an independent speed regulator, which is easy to regulate the speed; and the invention adopts the photo electric device, and stable and reliable in working.

Owner:JIANGSU BVM INTELLIGENT TECH

Novel L-shaped pressure sensor clamp

InactiveCN111720671AEasy and fast clampingEasy to alignStands/trestlesAviationStructural engineering

The invention belongs to the related field of aviation manufacturing and particularly relates to a novel L-shaped pressure sensor clamp. The novel L-shaped pressure sensor clamp is used for connectingground testing equipment with a left L-shaped pressure sensor and a right L-shaped pressure sensor on a machine through testing pipelines when used for an atmospheric data system air-tight test, a ventilation test and a pressure sensor performance test. The novel L-shaped pressure sensor clamp comprises an upper shell and a lower shell which are used for fixing the L-shaped pressure sensors. Oneend of the upper shell and one end of the lower shell are connected with a main body at the same time. A sealing ring is arranged in the main body. A tightening hand wheel and a pressing sleeve are arranged outside the main body. A main pressure pipe joint nozzle is arranged at one end of the main body. A static-pressure part of the L-shaped pressure sensor special clamp adopts an up-down clampingmounting mode, so that a sealing pad is deformed to ensure reliable sealing; meanwhile the up-down mounting mode facilitates aligned communication of a vent hole in the clamp and upper static pressure holes and lower static pressure holes in the L-shaped pressure sensors, and the mounting time is saved; and the clamping operation of the clamp is more convenient and faster, the test success rate is increased, and the working efficiency is improved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Gear grinding fixture adopting end surface drive for small gear shaft

InactiveCN106513869AHigh positioning accuracyImprove consistencyGear-cutting machinesGear teethGear grindingSet screw

The invention provides a gear grinding fixture adopting end surface drive for a small gear shaft. The gear grinding fixture comprises an upper centre, a clamping sleeve, a floating centre, a first set screw, end surface pawls, pins, a centre seat, a second set screw, a spring, a connection seat and an adjustment nut, wherein the upper centre is installed in a tailstock sleeve of a machine tool, and axial movement of the upper centre is realized by virtue of the pressure of a tailstock; the lower end of the upper centre is abutted against a central hole in the upper end of the gear shaft; the clamping sleeve sleeves the excircle of the lower end of the gear shaft, and is fixed to or released from the gear shaft through the first set screw arranged on the side surface of the clamping sleeve; the centre seat is fixed to the top end of the connection seat; the end surface pawls which are peripherally distributed are arranged on the centre seat, and the pins are embedded in radial holes of the centre seat and the end surface pawls; the end surface pawls are indented in the end surface of the clamping sleeve, which is located above the centre seat; central holes are arranged in the centres of the centre seat and the connection seat, and the floating centre is installed in the central holes; and the upper end of the floating centre is abutted against a central hole in the lower end of the gear shaft due to the elasticity of the spring. The fixture is capable of meeting the requirements of high accuracy and batch machining of gear grinding for the gear shaft.

Owner:WUXI WEIFU CHINA ITAL GEAR

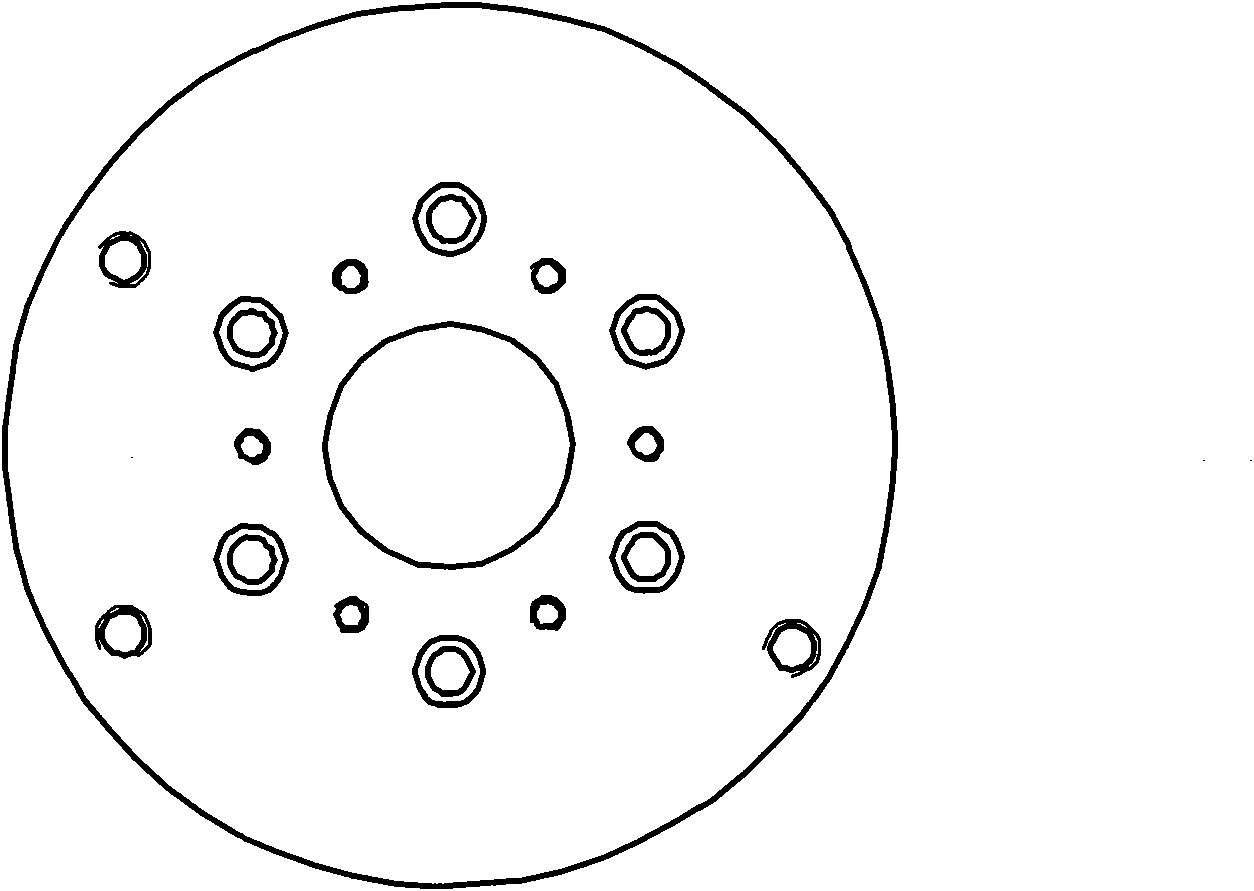

Machining method for threaded holes in fixed disc

ActiveCN104999140AEasy clamping of fixed plateQuick and easy clampingThread cutting machinesPositioning apparatusEngineeringMachining

The invention discloses a machining method for threaded holes in a fixed disc. A fixed-disc turning clamp is used. Parts are arranged, i.e., a spherical shell of the fixed disc is placed in a counter bore of a fixed-disc locating block, so that a locating pin extends into a blank hole of one threaded hole, and the axis of the threaded hole to be machined coincides with the axis of a barrel portion; and then a hand wheel is tightened so as to make a pulling rod pull a supporting sleeve backwards, and thus two fixed-disc pressing plates are in compression connection with a locating surface of the fixed disc and the fixed disc is fixed on the fixed-disc locating block. A lathe is started, and a turning tool is adopted to machine one threaded hole in the spherical shell of the fixed disc. The hand wheel is loosened, and the fixed disc with the three machined threaded holes is taken down. Compared with the prior art, the machining method is advantageous in that the problems that threaded holes in a spherical shell of a fixed disc are difficult to machine and clamping and producing efficiency is low at present can be solved.

Owner:WUZHOU OKA OPTICAL INSTR

Automated three-degree-of-freedom fixture for blisk polishing and grinding

ActiveCN108705448AIncrease productivityReduce resistanceGrinding machinesGrinding work supportsThree degrees of freedomEngineering

The invention provides an automated three-degree-of-freedom fixture for blisk polishing and grinding, and belongs to the technical field of blisk robot polishing and grinding machining. The automatedthree-degree-of-freedom fixture comprises a rotating platform, a first rotating assembly and a second rotating assembly, the first rotating assembly is installed on the rotating platform, and the second rotating assembly is installed on the first rotating assembly and used for clamping a blisk. According to the automated three-degree-of-freedom fixture for blisk polishing and grinding, three-rotational degree-of-freedom adjustment is conducted on the blisk through the rotating platform, the first rotating assembly and the second rotating assembly, the purpose that the blisk posture is automatically adjusted to adapt to the machining modes of different portions of the blisk in the blisk robot polishing and grinding machining process is achieved, the fixture is simple in structure and convenient to use, and the automated polishing and grinding efficiency and positioning precision of the blisk are greatly improved.

Owner:HUST WUXI RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com