End face driven gear hobbing clamp

A technology of gear fixture and driving roller, applied in the direction of gear tooth manufacturing device, belt/chain/gear, gear tooth, etc., can solve the difficulty of loading and unloading the workpiece gear, the poor consistency of the workpiece gear accuracy, and the easy pulling of the inner hole of the workpiece gear. damage and other problems, to meet the requirements of high-precision machining and mass production, high machining accuracy, easy and fast clamping and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings and embodiments.

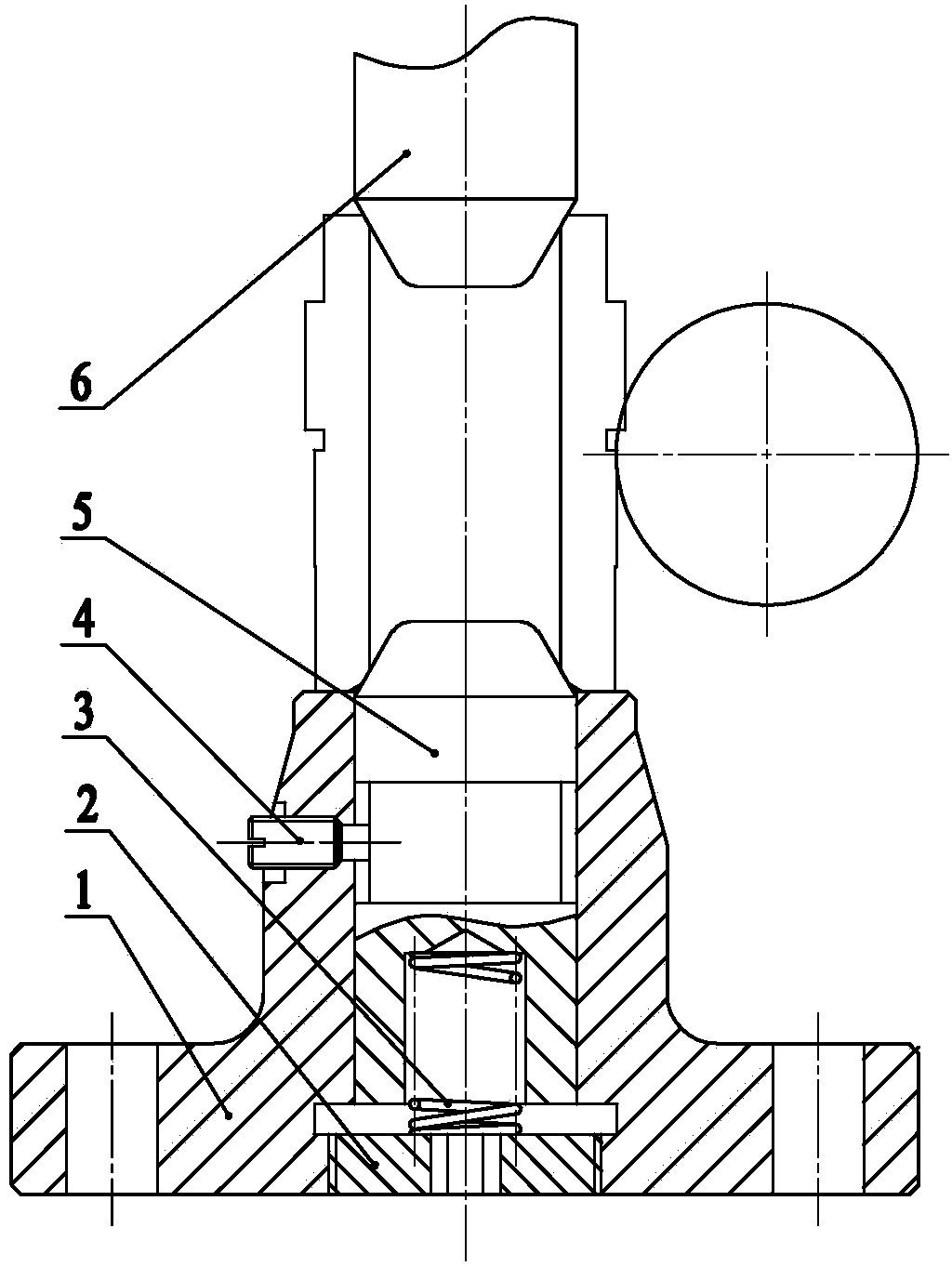

[0016] As shown in the figure: the end face driving roller gear fixture in the embodiment is mainly composed of a base 1, an adjusting nut 2, a strong spring 3, a top screw 4 and a floating center 5 and other components.

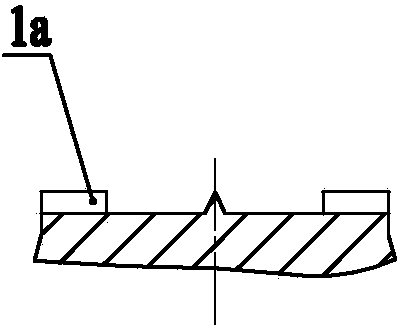

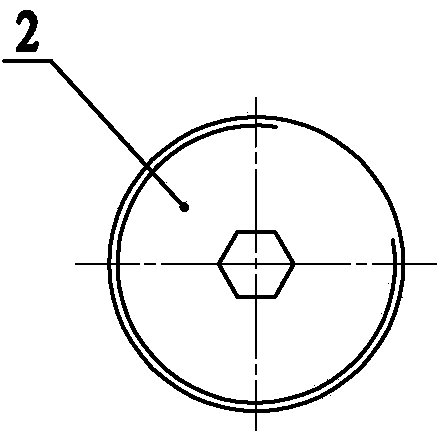

[0017] Such as figure 1 , the top of the base 1 is provided with circumferentially evenly distributed end pawls 1a, and the center of the base 1 is provided with a mounting hole, the strong spring 3 and the floating top 5 are installed in the mounting holes on the base 1, and the upper end of the strong spring 3 withstands the floating The top 5 and the lower end of the powerful spring 3 are supported on the adjustment nut 2, and the adjustment nut 2 is threaded in the installation hole; the top wire 4 radially penetrates the outer wall of the base 1, and the inner end of the top wire 4 is embedded in the shaft on the outer peripheral wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com