Multi-connection tool clamp of motor housing

A technology of motor housings and tooling fixtures, which is applied in the direction of manufacturing tools, clamping, positioning devices, etc., can solve the problems of cumbersome clamping, low processing efficiency, and complex structure, and achieve simple structure, improved processing efficiency, and clamping Easy and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

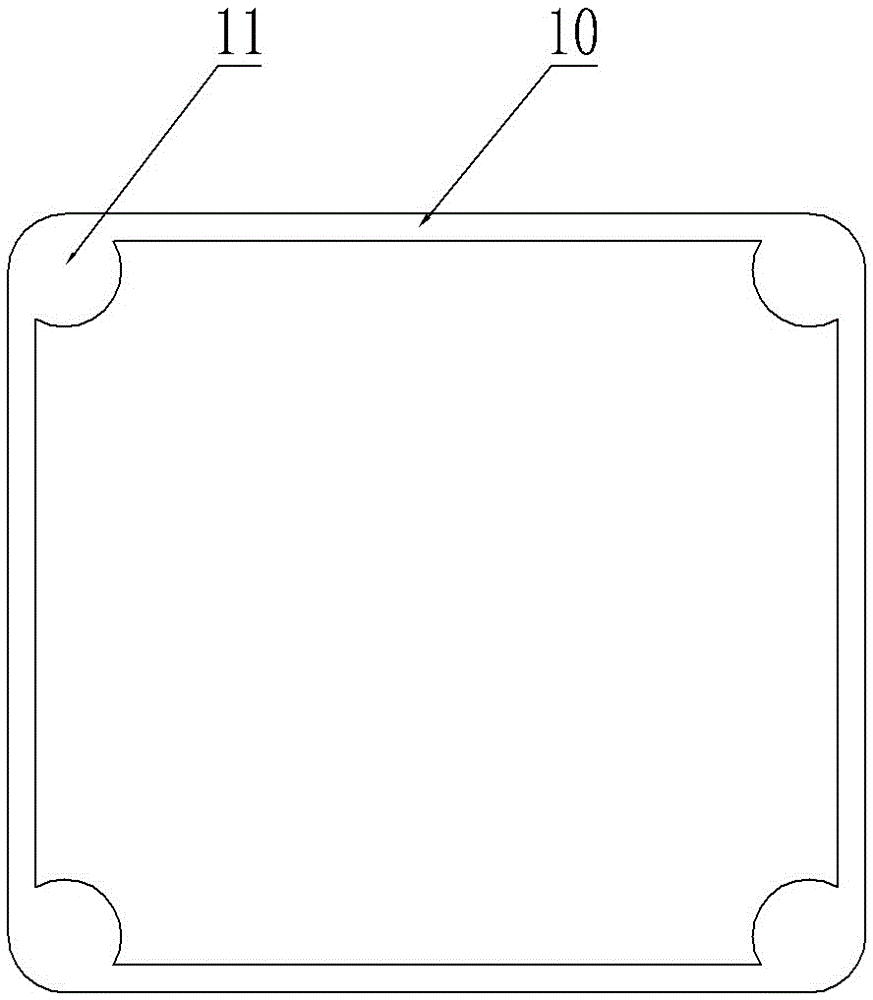

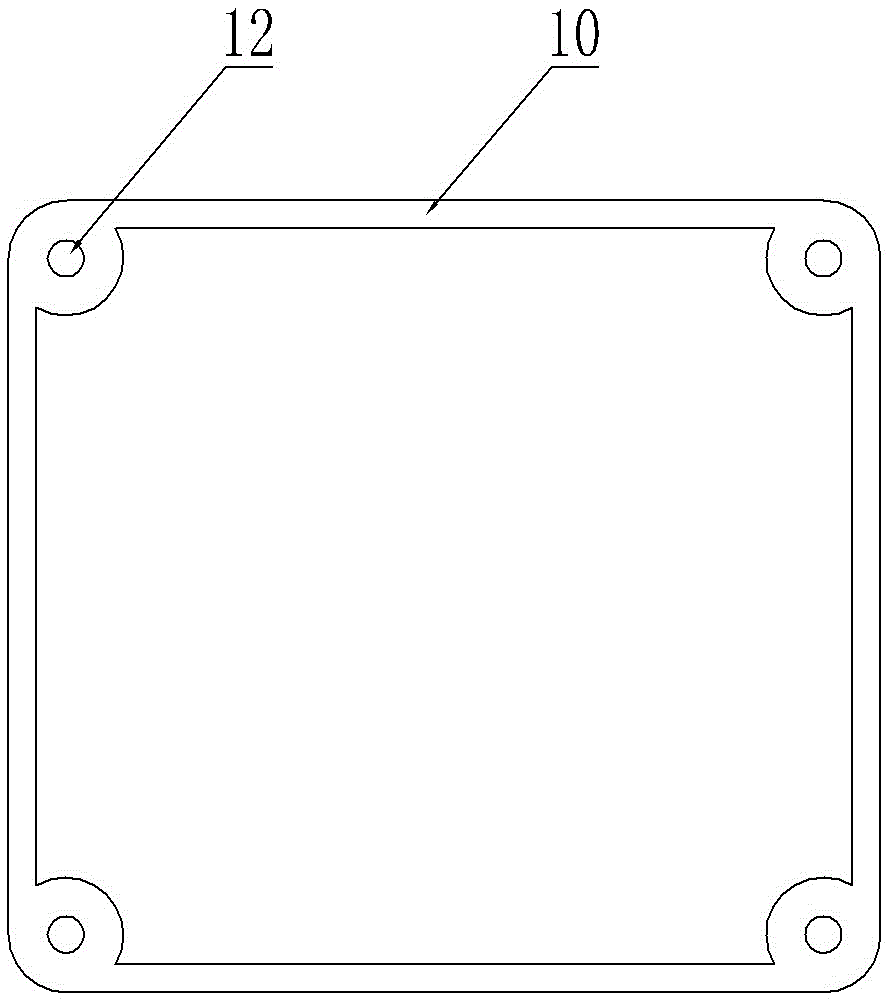

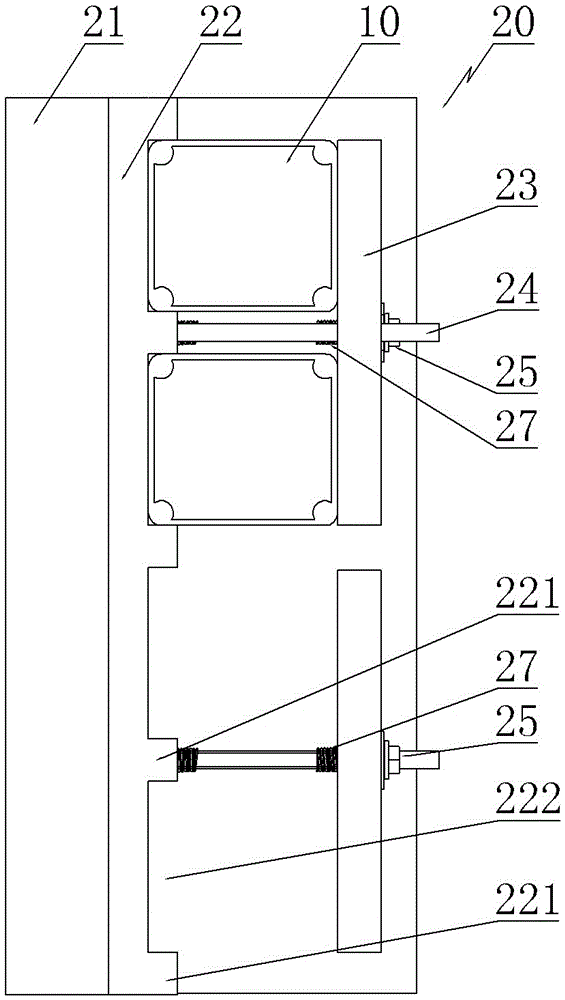

[0017] Such as Figure 1~Figure 5 As shown, the multi-unit fixture 20 of the motor housing includes a base plate 21, a support plate 22, a pressure plate 23 and bolts 25, the support plate 22 is vertically fixed on the base plate 21, and one end surface of the support plate is spaced along the length direction. A plurality of ribs 221 are provided, and positioning slots 222 engaged with the motor housing are formed between adjacent ribs 221, and a pressure plate 23 is provided corresponding to each two positioning slots, and bolts 25 penetrate through the pressure plate 23 and are screwed to the ribs 221 ; Rib 221 is located on the position on both sides of bolt 25 and is symmetrically provided with guide post 24, and pressure plate 23 is provided with guide sleeve 28 corresponding to guide post, and guide post 24 runs through guide sleeve 28;

[0018] A spring 27 is sheathed on the bolt, and the two ends of the spring 27 abut against the rib 221 and the pressure plate 23 resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com