Manufacturing process for cold-rolling roll

A manufacturing process and technology of cold rolling rolls, applied in the field of manufacturing process of cold rolling rolls, can solve the problems of short service life, frequent roll change, roll printing, etc., and achieve the effects of reducing equipment investment costs, prolonging service life, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

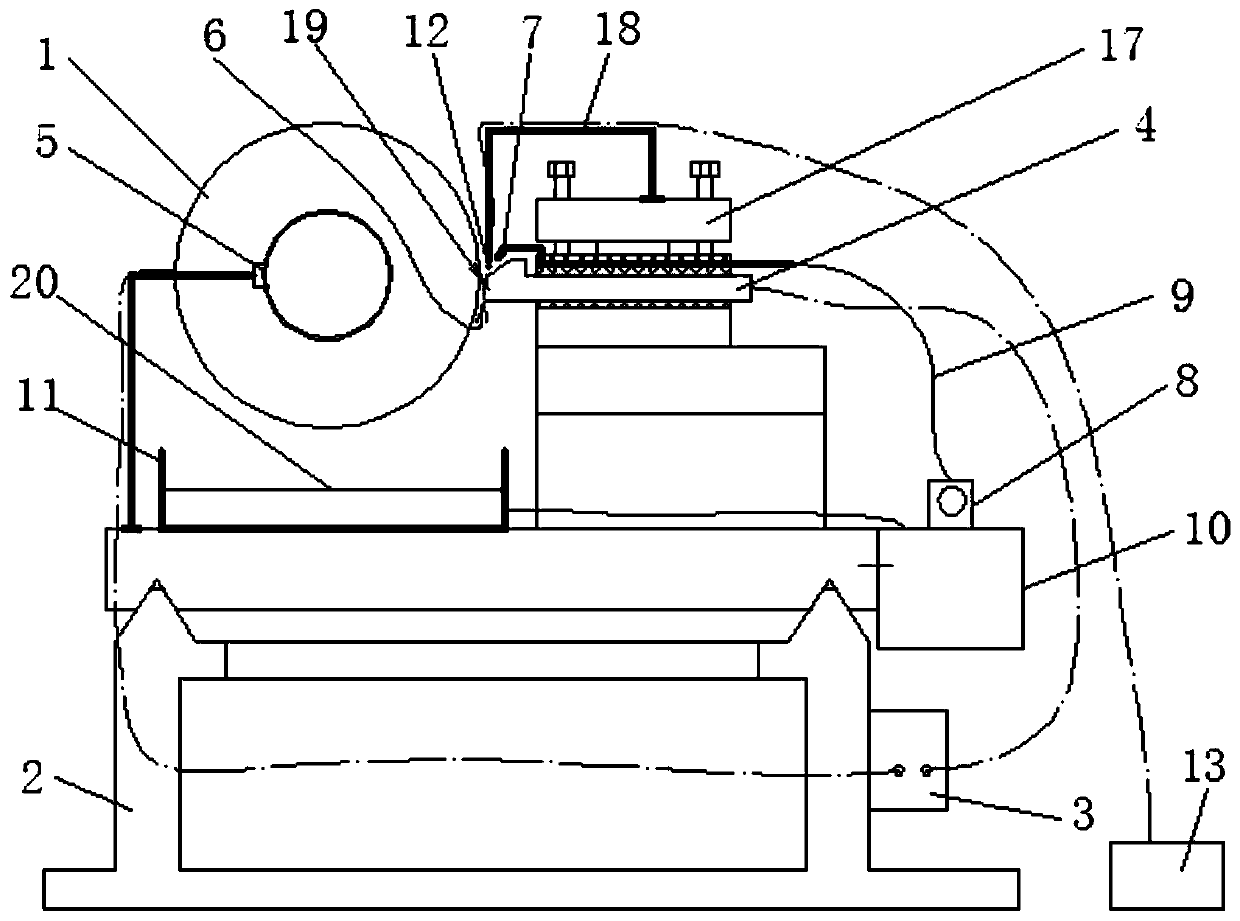

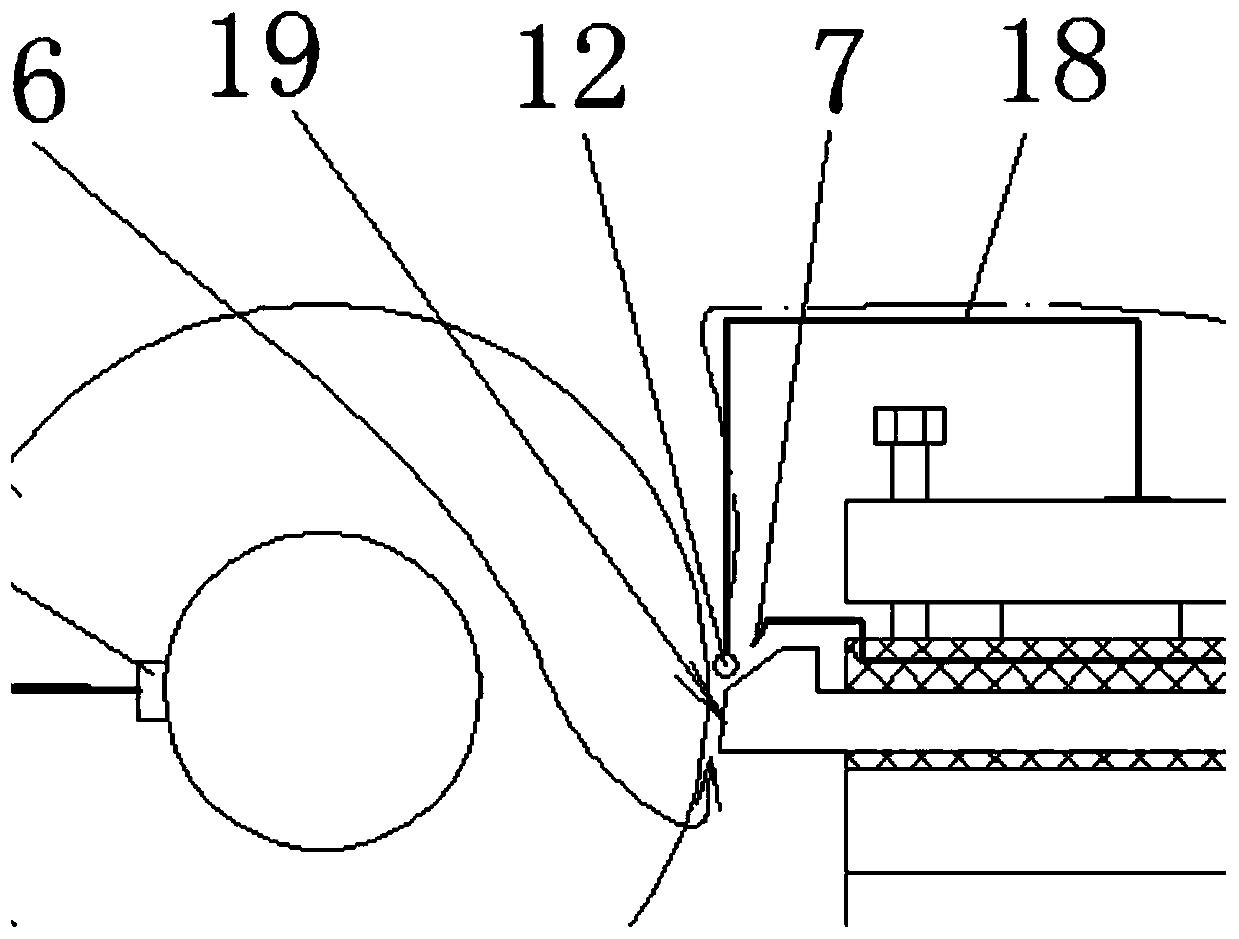

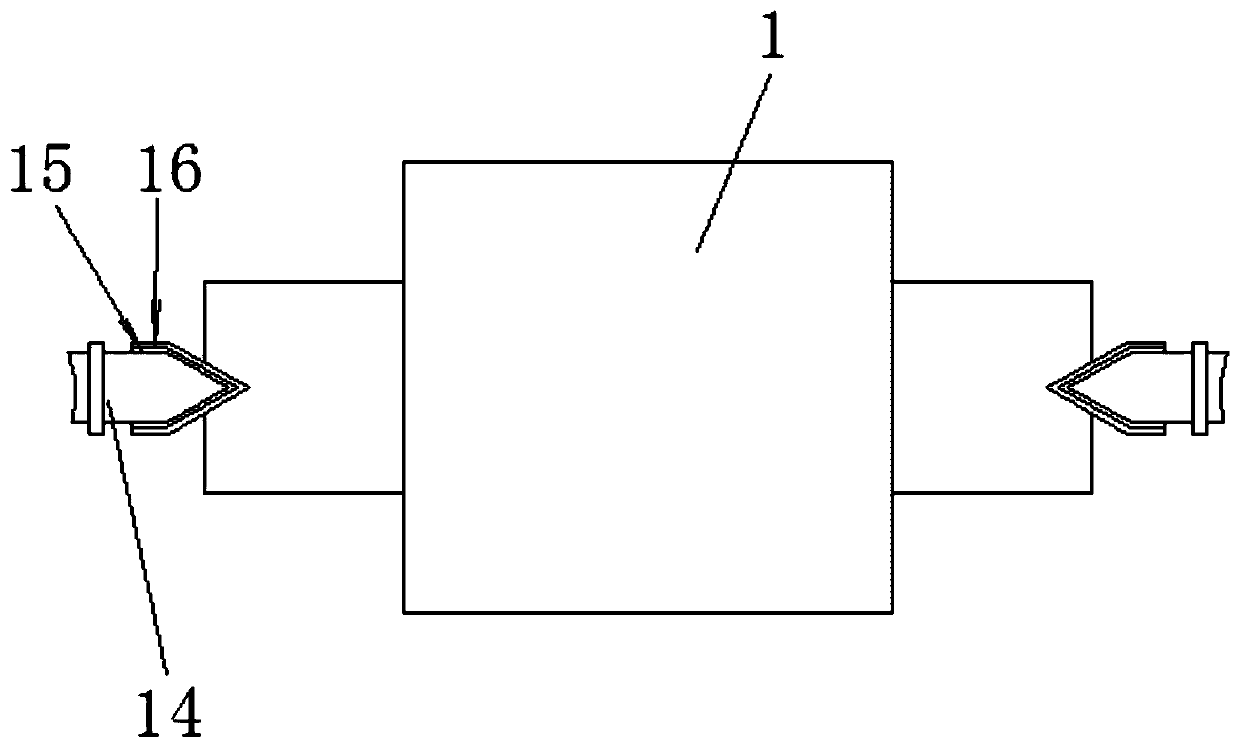

[0050] Such as Figures 1 to 4 Shown is an embodiment of a manufacturing process of a cold roll of the present invention, which sequentially includes ingot casting, forging, post-forging heat treatment, rough turning, quenching and tempering treatment, finishing turning, surface quenching, cold treatment, low temperature tempering, finishing Grinding, surface texturing, and electrochemical passivation processes; wherein, in the surface quenching process, a dual-frequency quenching machine tool is used to perform dual-frequency quenching treatment on the working surface of the cold roll; in the surface texturing process, the The EDT electric spark texturing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com