Patents

Literature

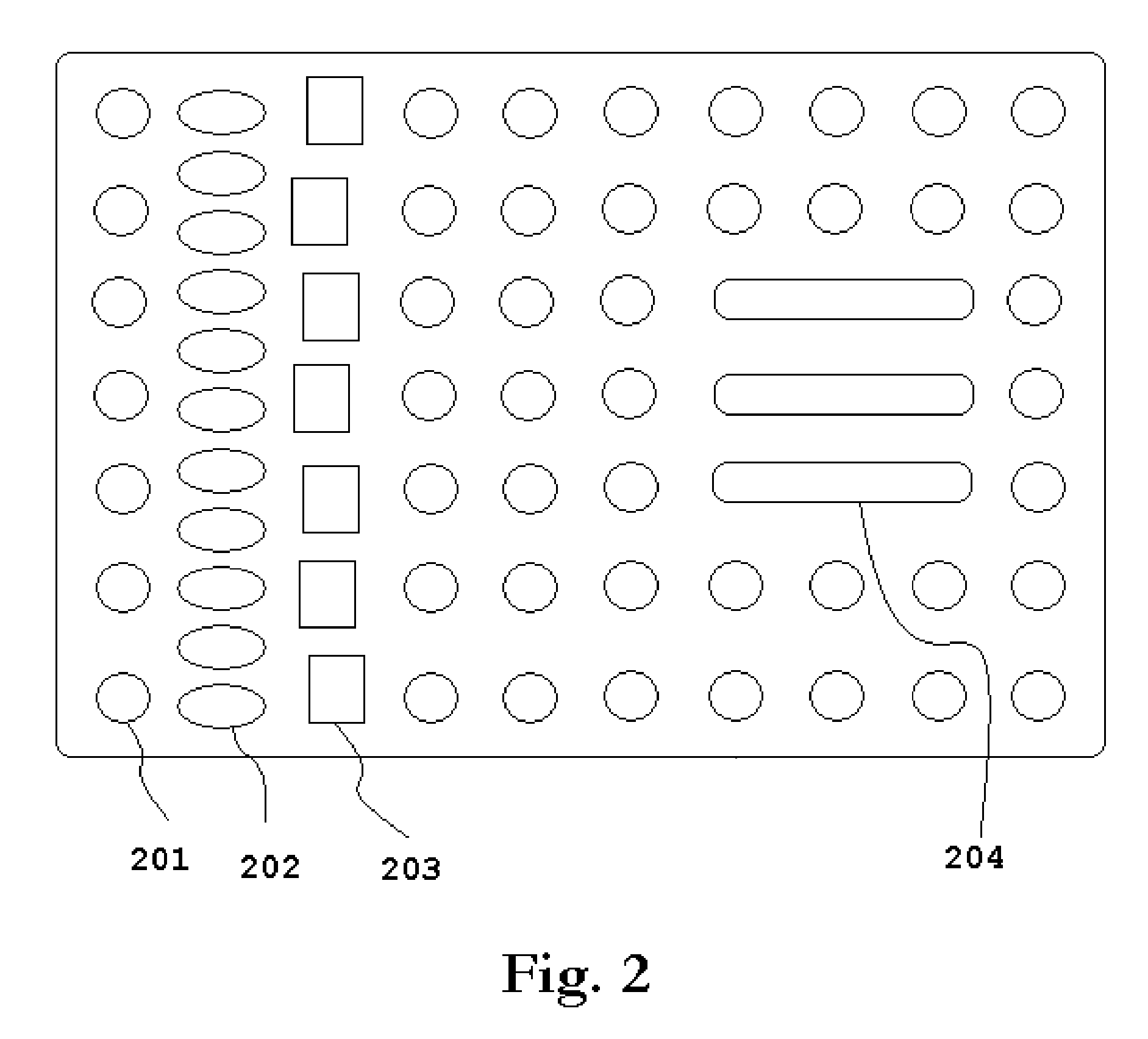

678 results about "Cold treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatments for Common cold: Treatment of the common cold starts with prevention. Preventive measures include covering the mouth and nose with an elbow or a tissue when coughing or sneezing and washing hands frequently with soap and water for at least 15 seconds. Antibacterial cleaners can also be effectively used to clean hands and surfaces.

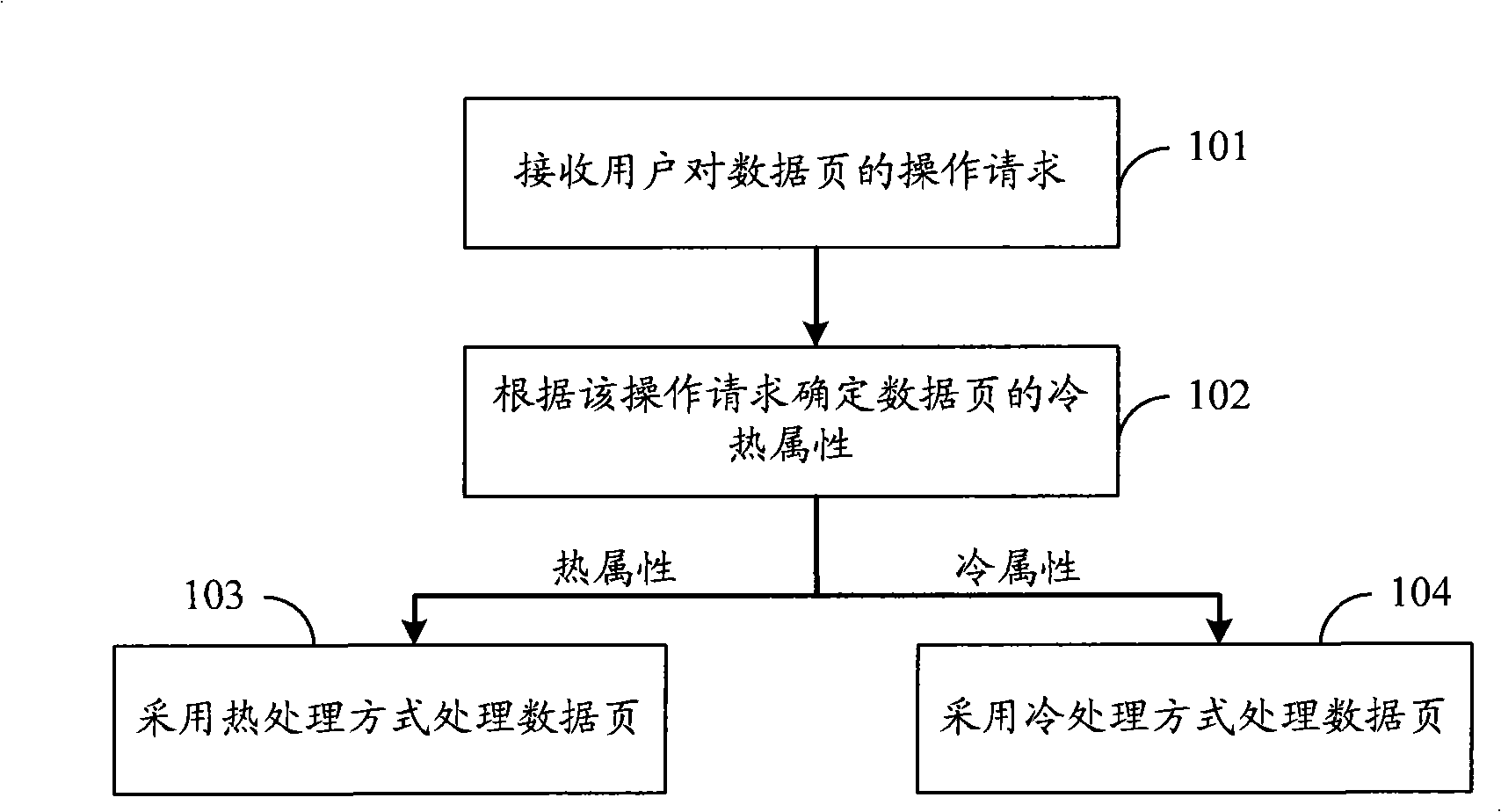

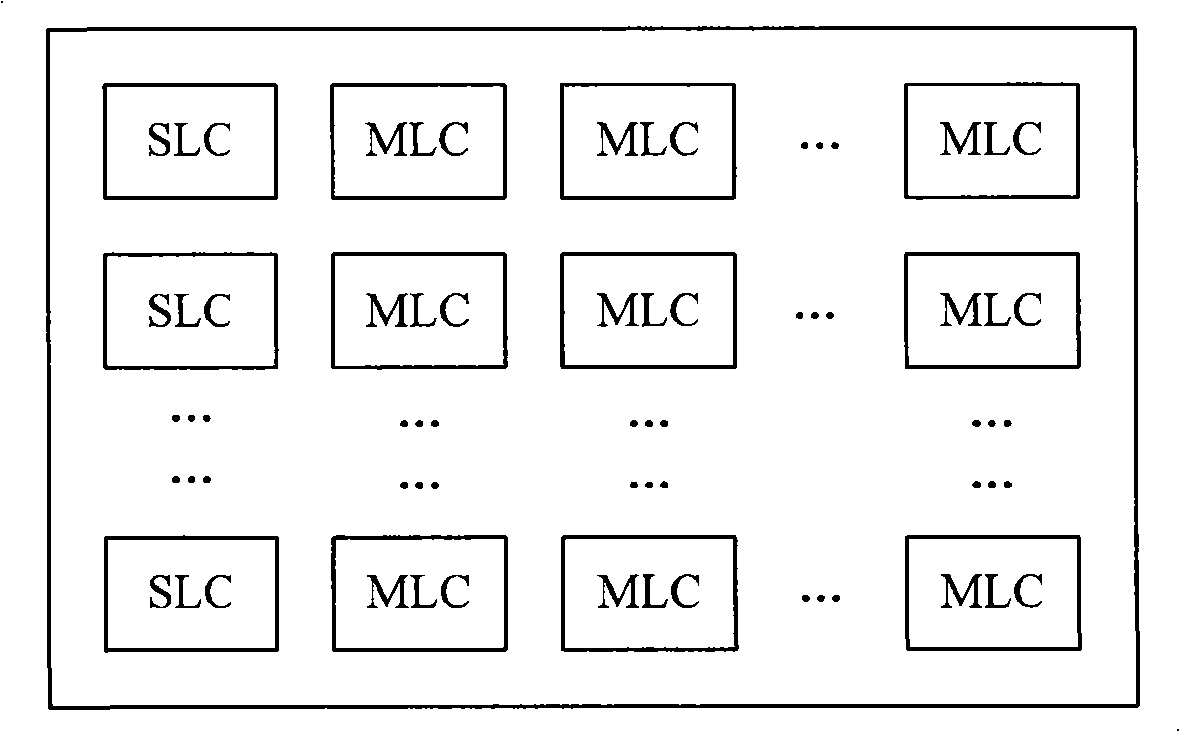

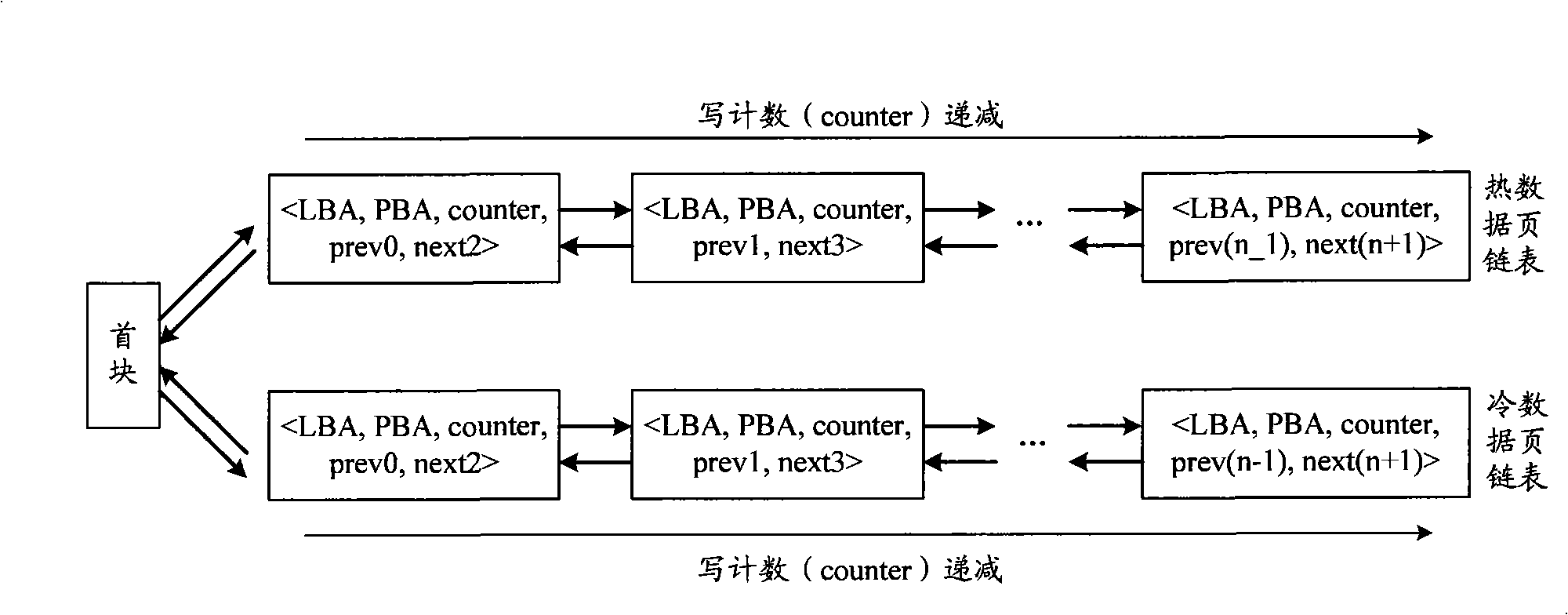

Data processing method, device thereof and flash-memory storage system

ActiveCN101526923AImprove space utilizationImprove data access performanceMemory adressing/allocation/relocationCold treatmentData access

The embodiment of the invention discloses a data processing method, a device thereof and a flash-memory storage system. The data processing method comprises the steps as follows: an operation request towards a data page of the user is received; whether the writing count of the data page is larger than a preset threshold value is judged according to the operation request; if the data page is larger than a preset threshold value, the data page is confirmed as thermal property, and the data page is processed in a way of heat treatment; if the data page is not larger than a preset threshold value, the data page is confirmed as cold property, and the data page is processed in a way of cold treatment, wherein, the cold property and the thermal property indicate the accessing frequency towards the data page of the user. The data processing device comprises a receiving unit and a processing unit. A flash memory comprises the receiving unit and a memory unit. A flash-memory storage system comprises the data processing device and the flash memory. The proposal provided by the embodiment of the invention can realize the high space utilization rate of the flash memory and also has high data accessing performance.

Owner:CHENGDU HUAWEI TECH

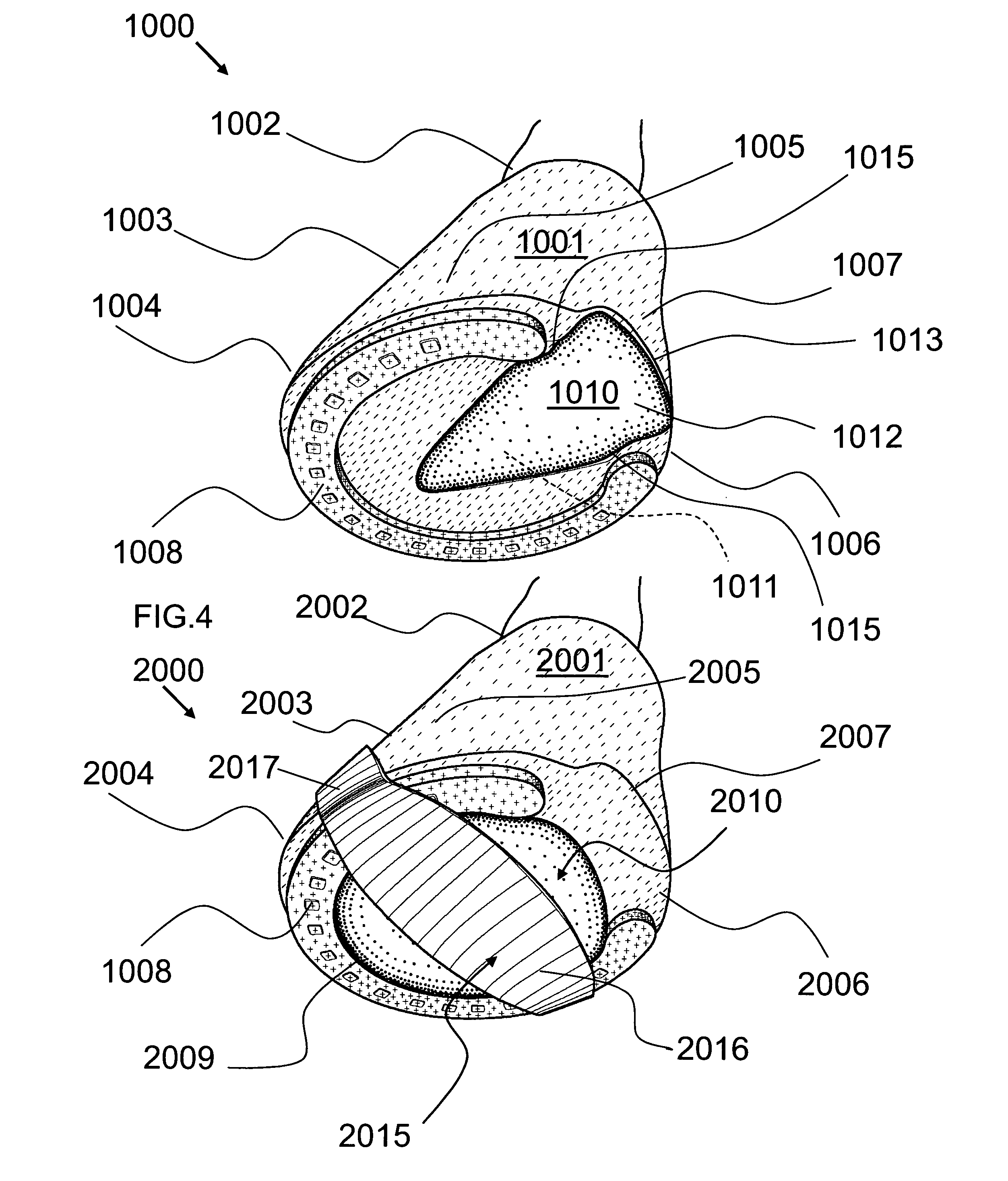

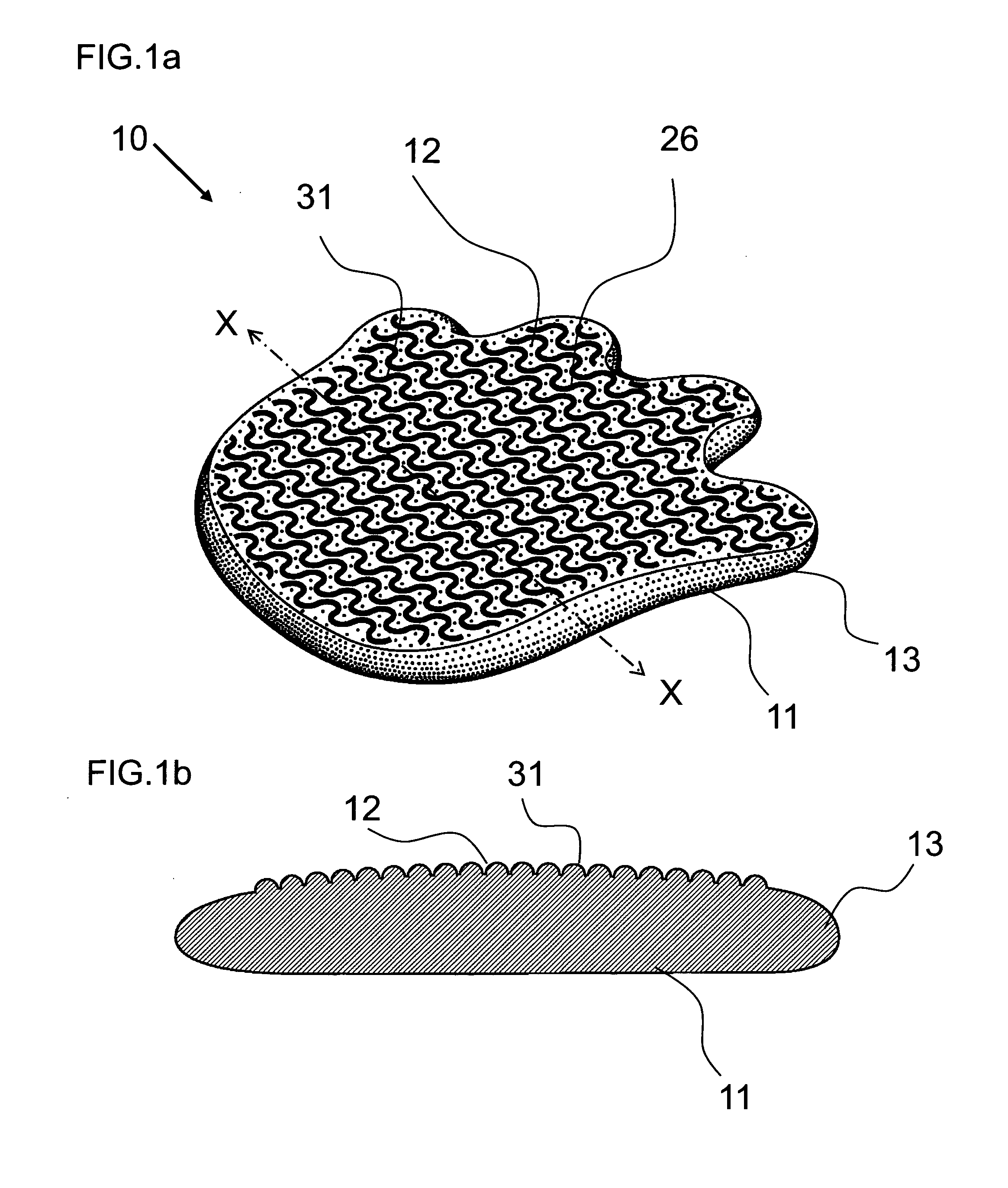

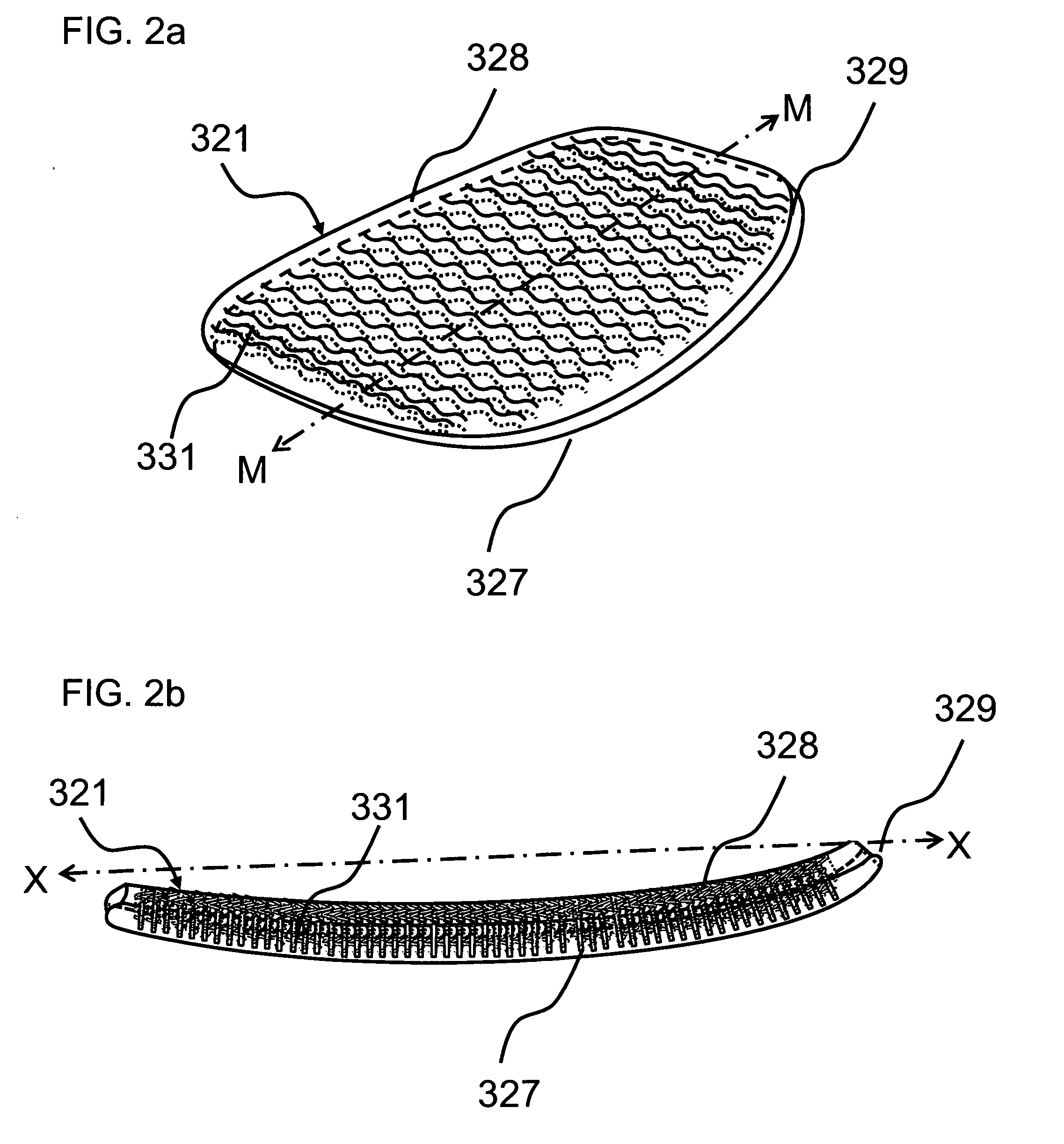

Thermal compressive aerating bandage and methods of use relating to same

InactiveUS20050124925A1Increase elasticityEffective coverageFinger bandagesFeet bandagesElastomerCold treatment

A lightweight, flexible, aerating, compressive, thermal bandage. Perforations allow the treatment area to aerate. Thermal capacity of the invention allows for hot or cold treatment in a manner that compressively supports the object undergoing thermal treatment while maintaining maximum mobility. The bandage is made from an elastomer such as polyeurathane with the addition of silicon and vegetable oil. Resin is used to color the product.

Owner:THEROGEL

Thermal compressive aerating bandage and methods of use relating to same

InactiveUS7351217B2Increase elasticityEffective coverageFinger bandagesFeet bandagesElastomerCold treatment

Owner:THEROGEL

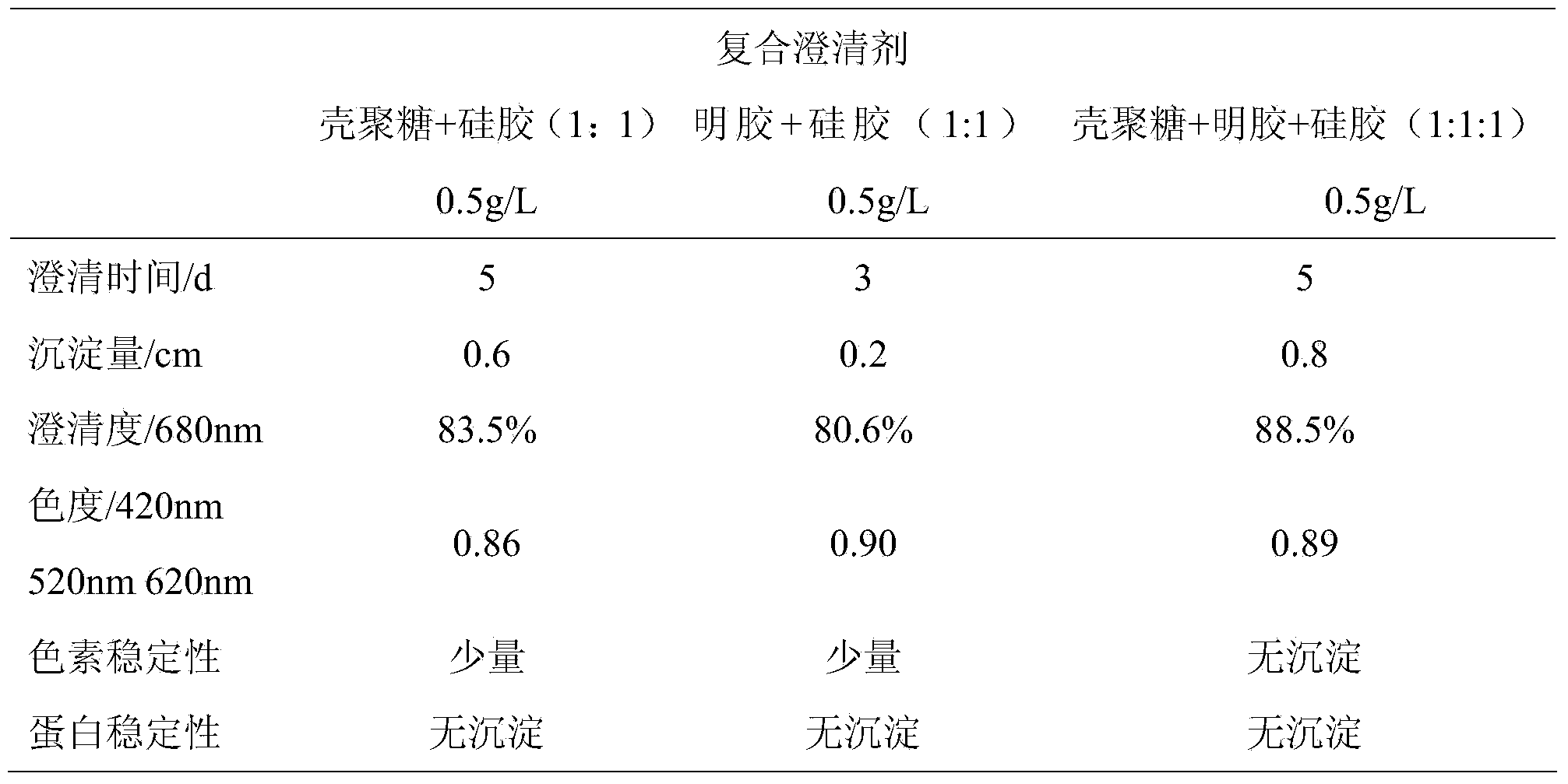

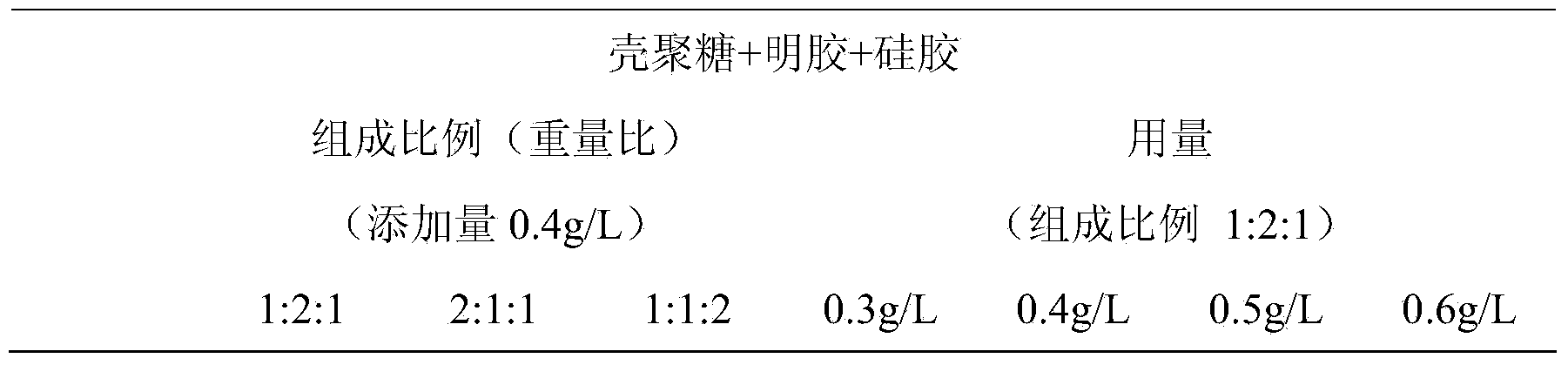

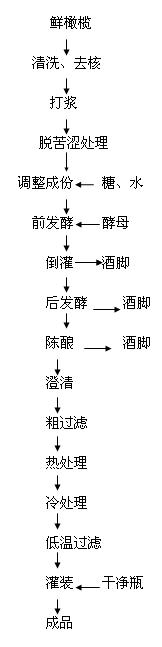

Brewing method for a fruit wine

The invention discloses a method for brewing a fruit wine. The raw materials of the fruit wine comprise the following components by weight percentage: 71wt%-86wt% of fruit crude juice, 9wt%-21wt% of white sand sugar, 4wt%-6wt% of yeast strain amplification culture solution and 1wt%-2wt% of lactobacillus strain amplification culture solution. The technological process of the method comprises the steps as follows: (1) juicing fruits, filtering and adding sulfur dioxide (SO2); (2) clarifying the fruit juice; (3) carrying out the primary fermentation; (4) carrying out the secondary fermentation; (5) clarifying the crude wine; (6) blending; (7) carrying out the cold treatment; and (8) sterilizing and canning. The method has the advantages that the strain amplification culture solution is subjected to the primary fermentation and the secondary fermentation, therefore, the fermentation speed is high, the fermentation time is short, and the fruit wine has good original taste and good stability; and the bentonite-loaded chitosan is adopted to carry out the clarifying treatment and a diatomite filter is used for filtering, thereby the fruit wine has pure original taste; and the 6-second flash sterilization at the high temperature of 105 DEG C is carried out to prolong the shelf life of the fruit wine.

Owner:海南省工业研究所

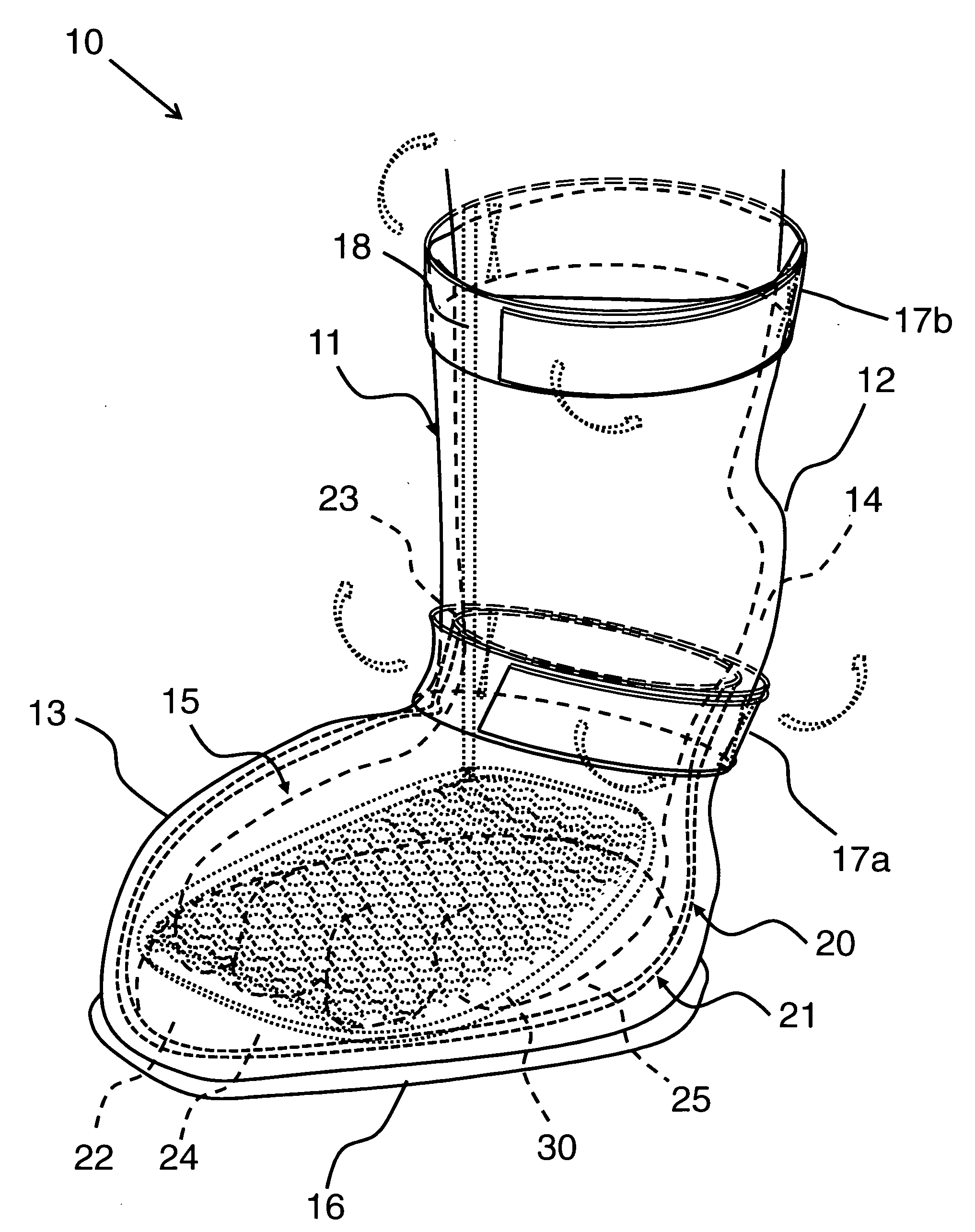

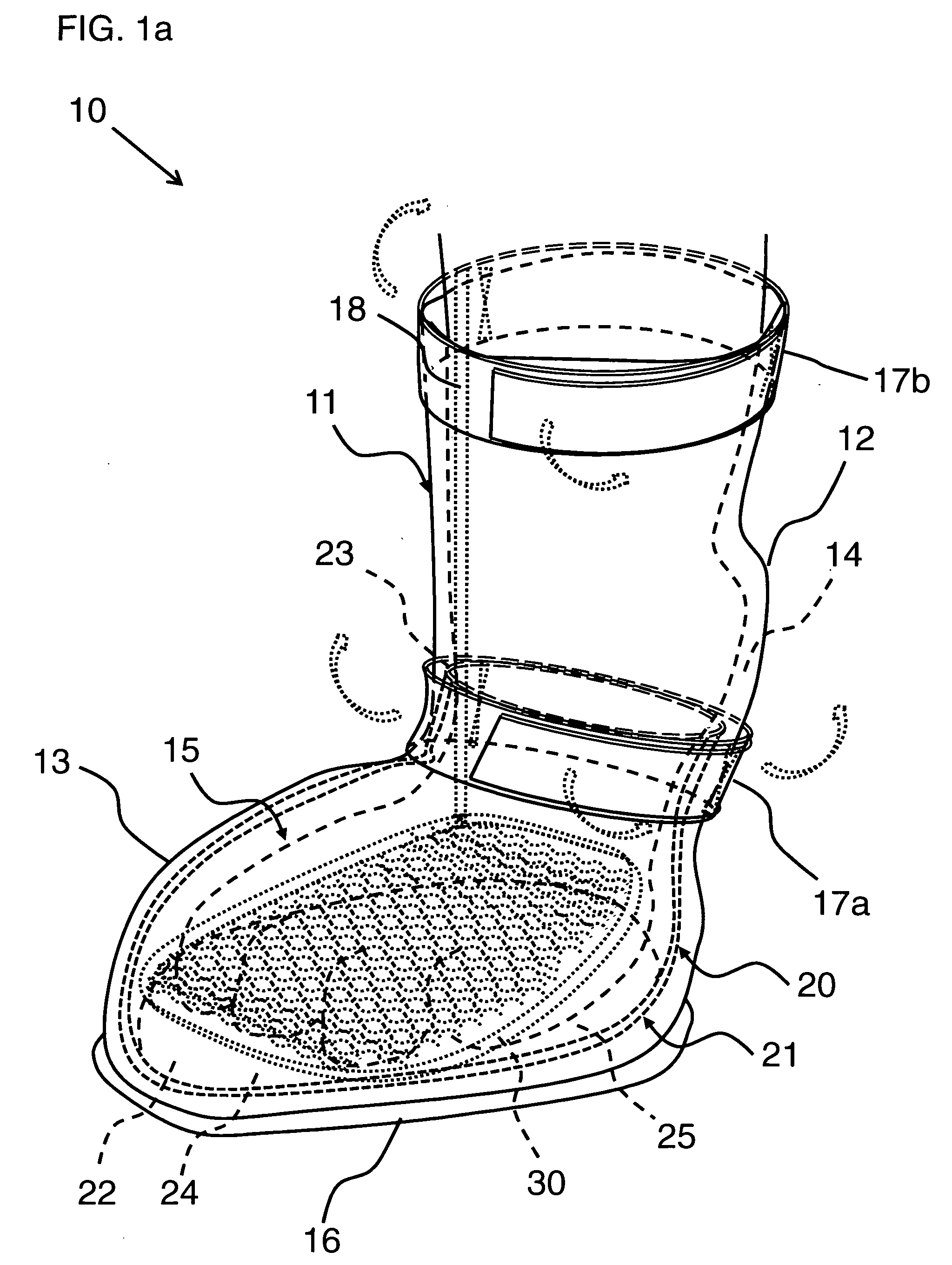

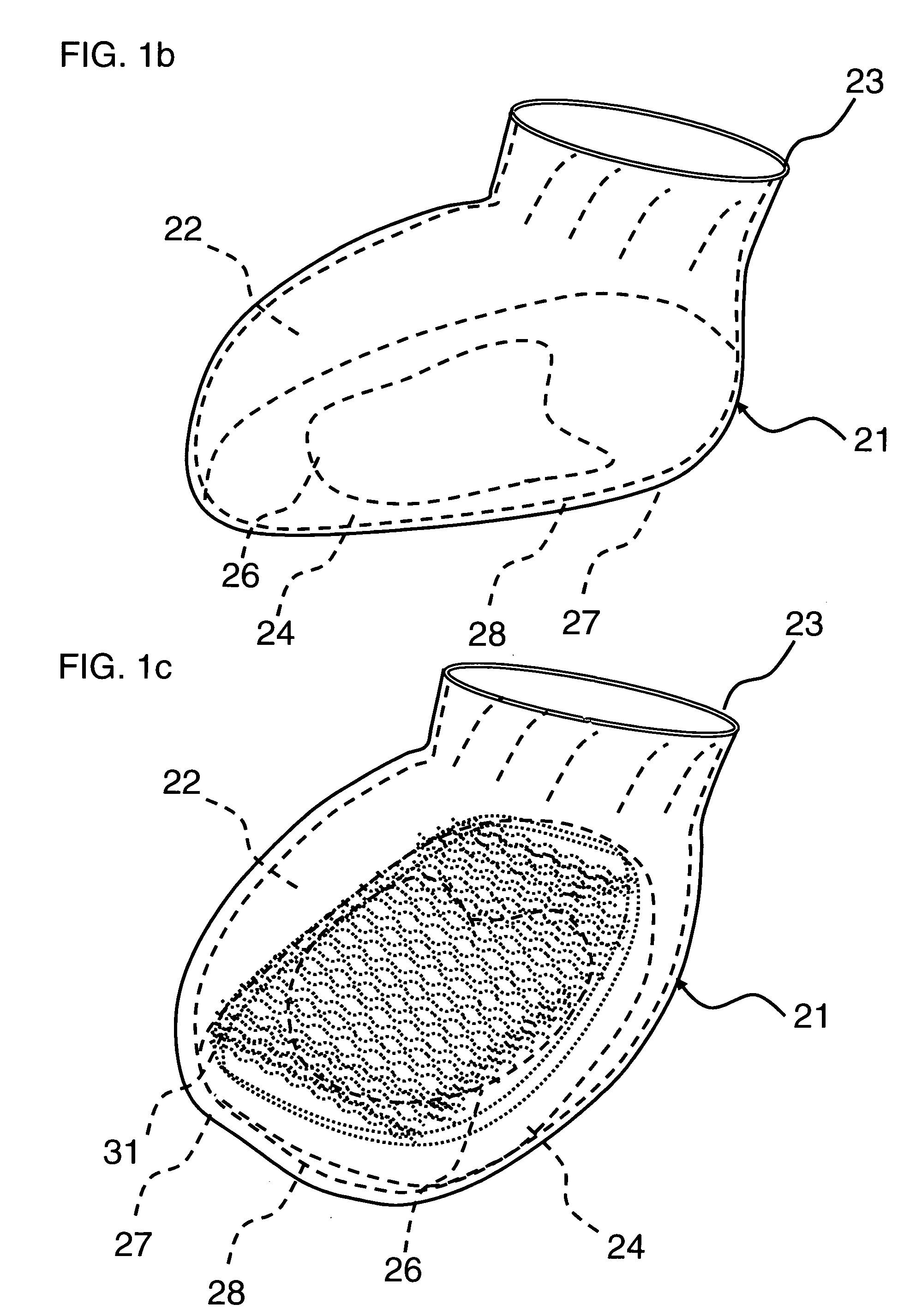

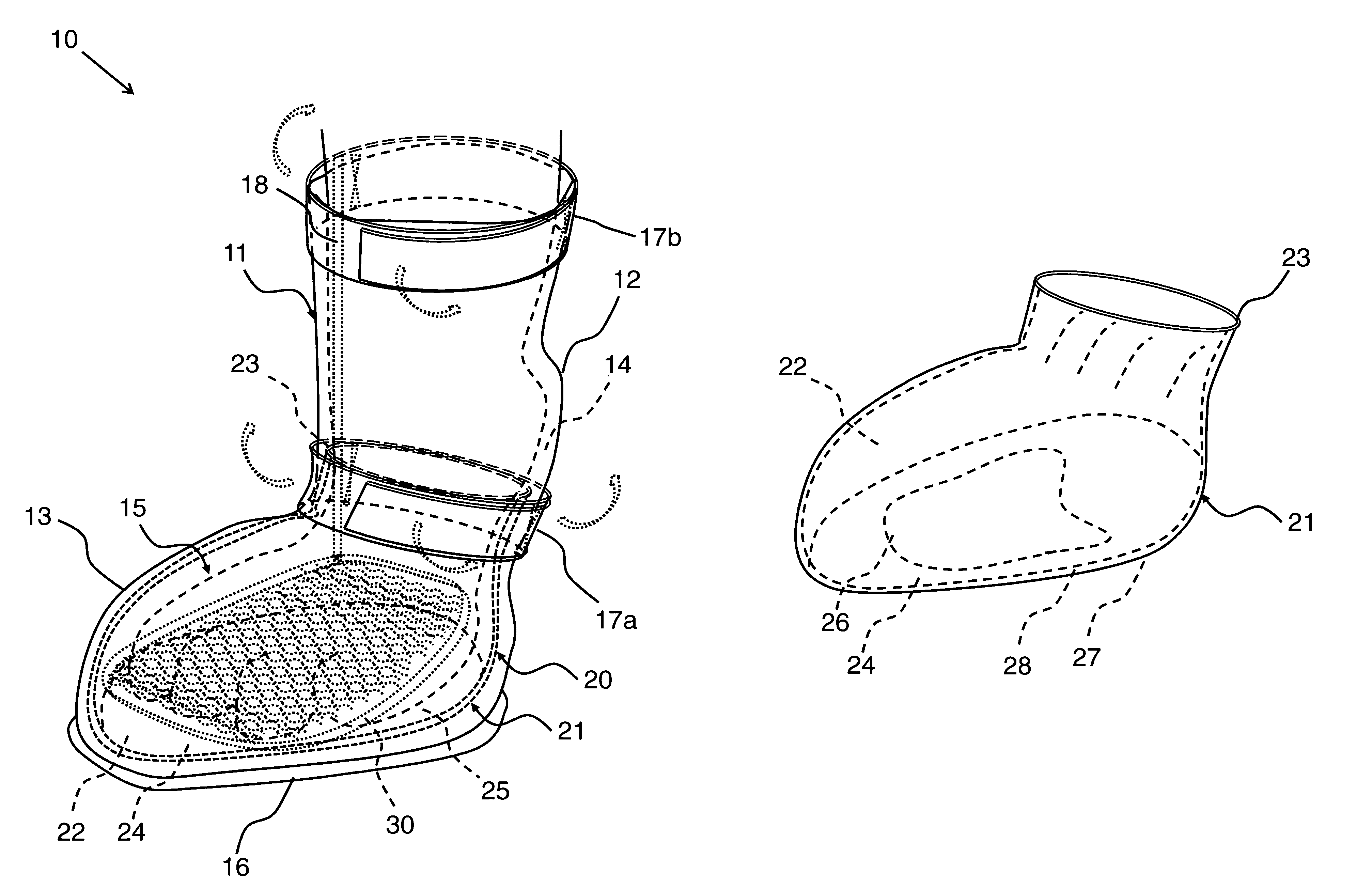

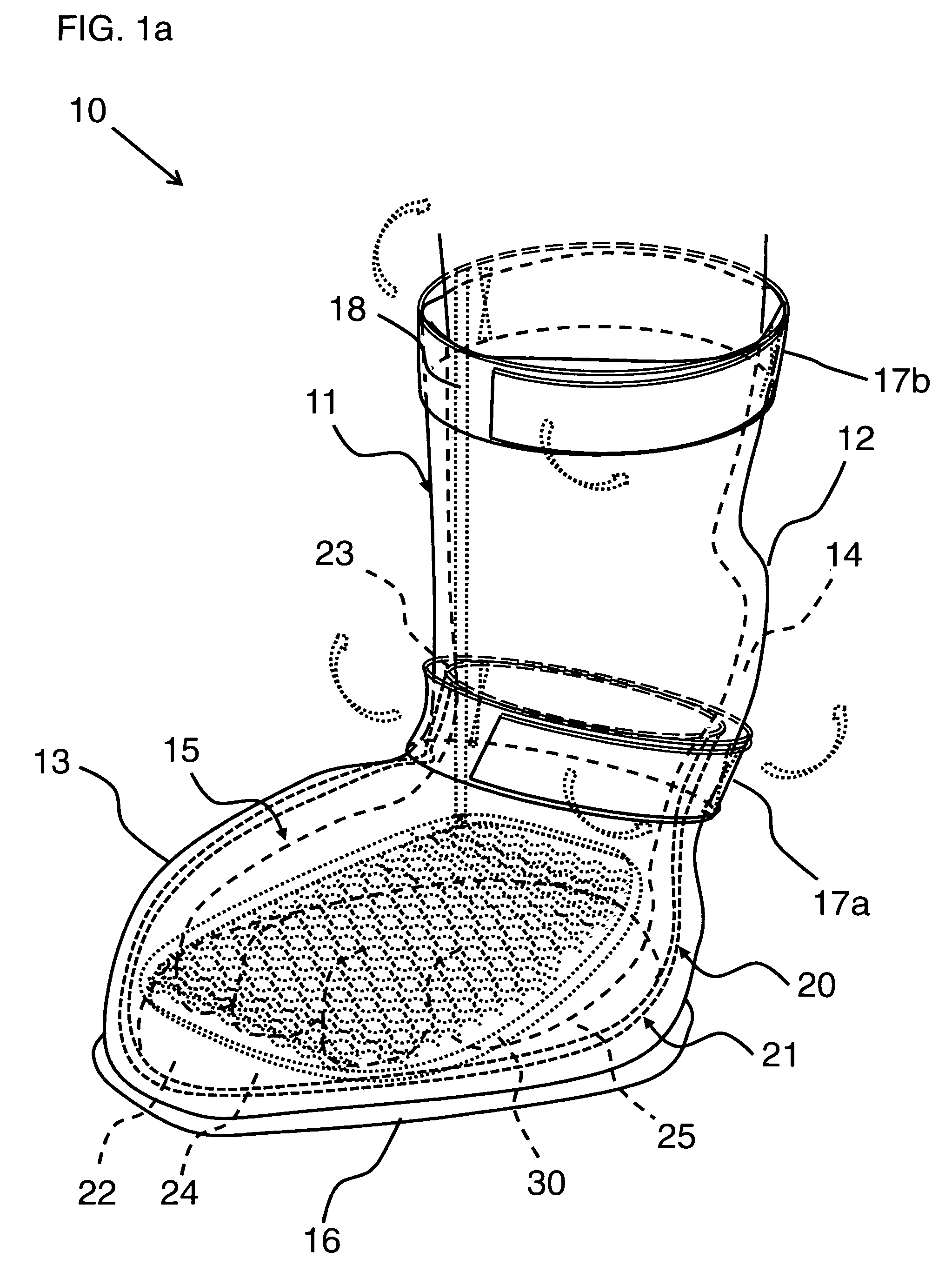

Therapeutic pet boot

InactiveUS20110041779A1Promote healingHealing of the paw is facilitatedSolesVeterinary bandagesCushioningCold treatment

A pet boot having therapeutic properties is worn on a pet's injured or sensitive paw to facilitate healing and or provide protection. The therapeutic pet boot includes an external boot member having a shaft and a paw portion constructed to form a cavity integrated therein appointed to receive an injured paw of a pet. The therapeutic pet boot further includes an internal therapeutic member appointed to be received within the cavity of the external boot member and is appointed to intimately contact the injured paw. The therapeutic pet boot is appointed to be worn on the injured paw of the pet to facilitate healing. The internal therapeutic member may comprise a gel bootee having a massaging gel sole or may comprise a gel inner layer or gel insole. Advantageously, the internal therapeutic member may directly deliver medicament to the paw and / or provide cold treatment or hot treatment therapies to the paw, while providing cushioning, shock absorption and protection from dirt and debris.

Owner:I DID IT

Therapeutic gel pad

A therapeutic gel pad for household pets and farm animals is worn on a pet's injured or sensitive body part to facilitate healing and provide protection or treatment. The therapeutic gel pad includes a base gel layer and an upper gel layer appointed to intimately contact a body region of the household animal and / or farm animal. The therapeutic gel pad may comprise a massaging gel sole or may comprise a gel inner layer or gel pad and may be provided with a securing member for securing the pad to the animal's body. Advantageously, the therapeutic gel pad may directly deliver medicament to the injury. It may also provide cold treatment or hot treatment therapies, while providing cushioning, shock absorption and protection from dirt and debris.

Owner:I DID IT

Method for brewing blueberry wine

ActiveCN103666922AMicroorganism based processesAlcoholic beverage preparationBiotechnologyOenococcus oeni

The invention discloses a method for brewing a blueberry wine. The method comprises the steps of selecting raw materials, selecting strains, fermenting with ethanol, carrying out malo-lactic fermentation, ageing, clarifying, stabilizing and the like. According to the method, optimized blueberries Huangshan 1# serve as the raw materials; high-temperature enzymolysis, high-temperature start-up and low-temperature long-time fermentation are carried out by using saccharomycetes RC212 as the fermentation strains; the malo-lactic fermentation is carried out by using oenococcus oeni SD-2 with high glucosidase activity; micro-aerobic ageing is utilized, so as to accelerate wine ageing and improve the quality of the wine; the blueberry wine can keep a clarified and stable state in long term by the technical means of natural clarification, cellaring, cold treatment, heat treatment, stabilizer adding, microfiltration and the like. In accordance with the method, a high-quality blueberry wine with good color, smell and taste can be obtained, and the obtained product meets the requirements of the national wine product quality standard GB2758-81.

Owner:JURONG WANSHANHONGBIAN BIOTECH

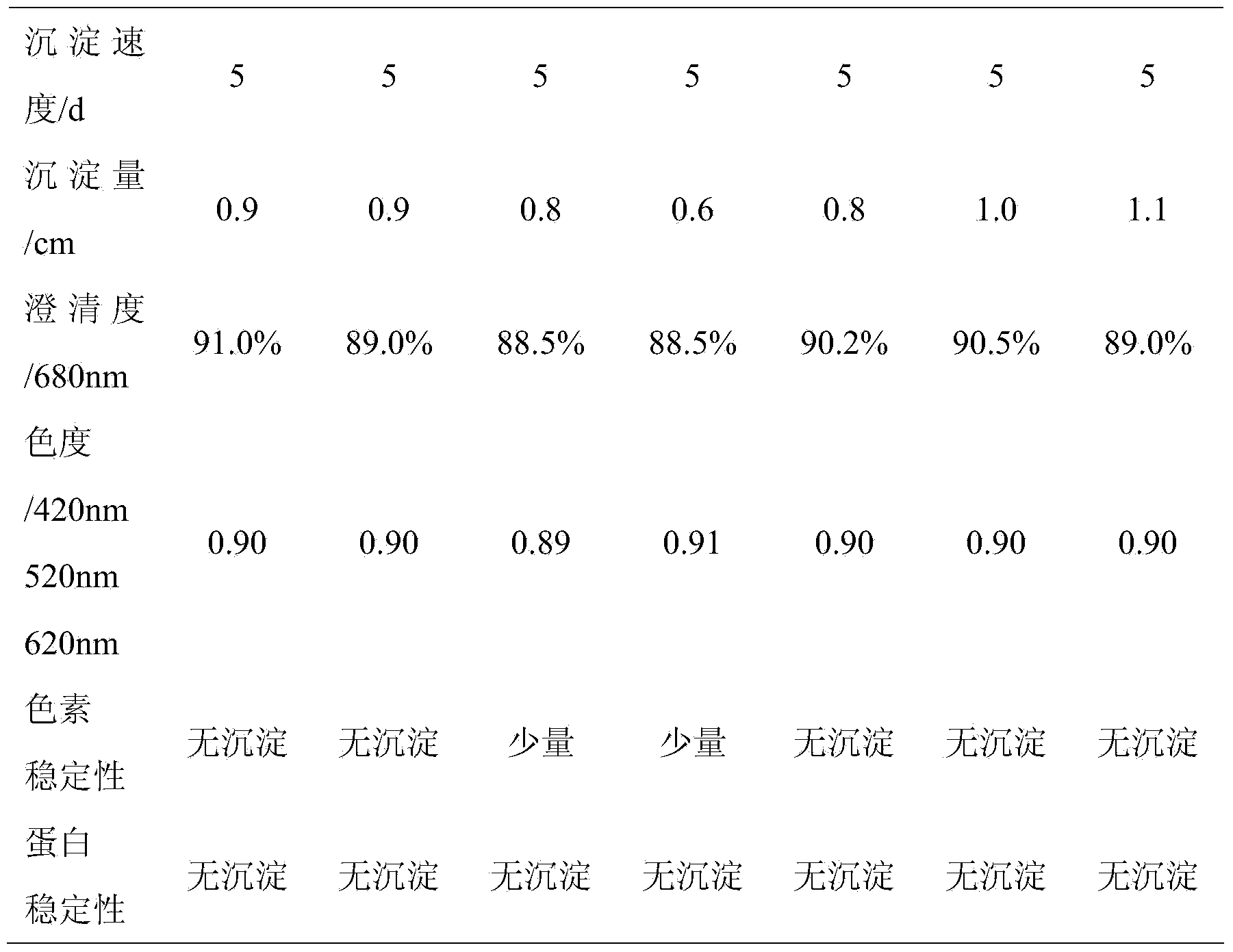

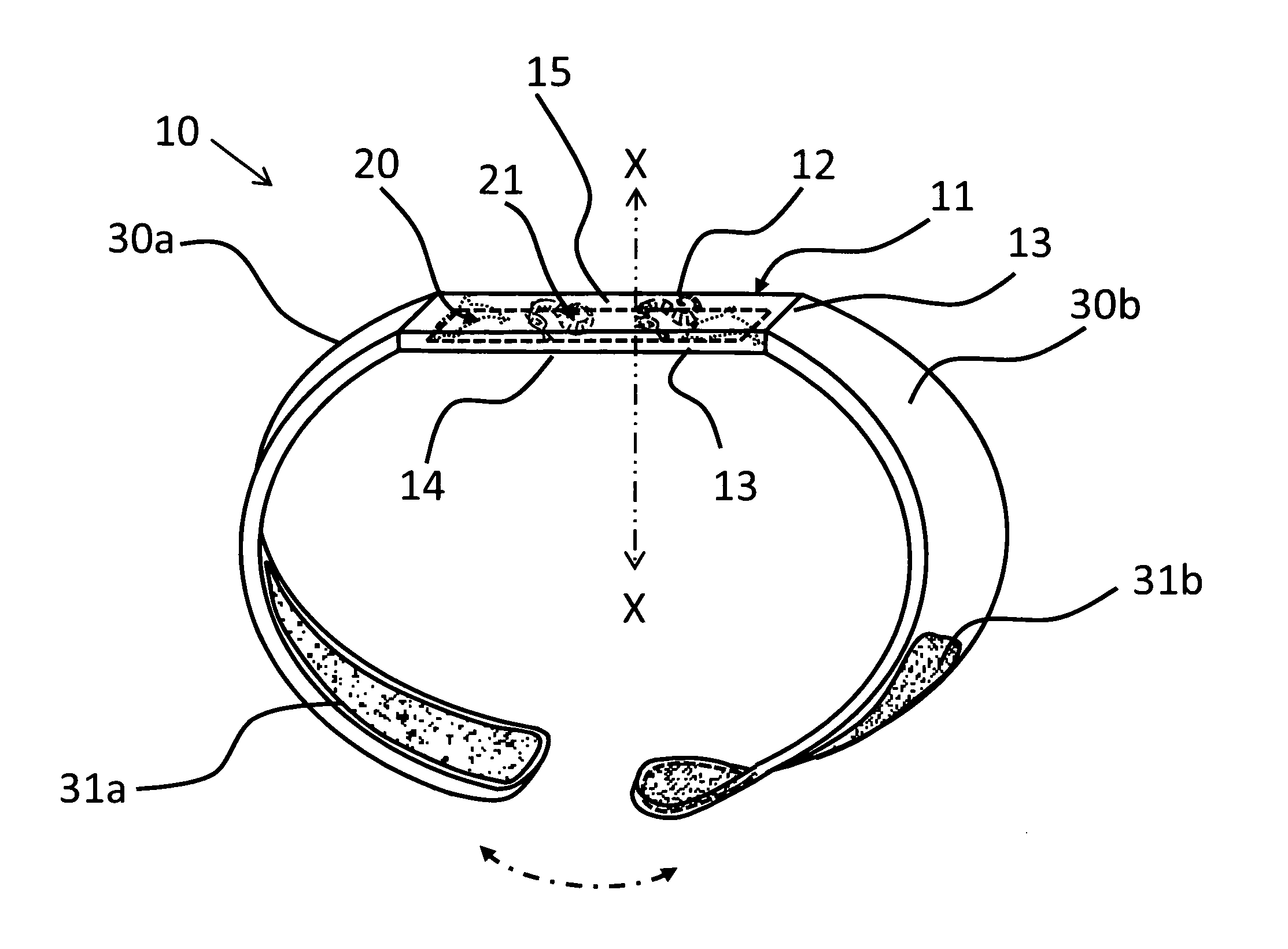

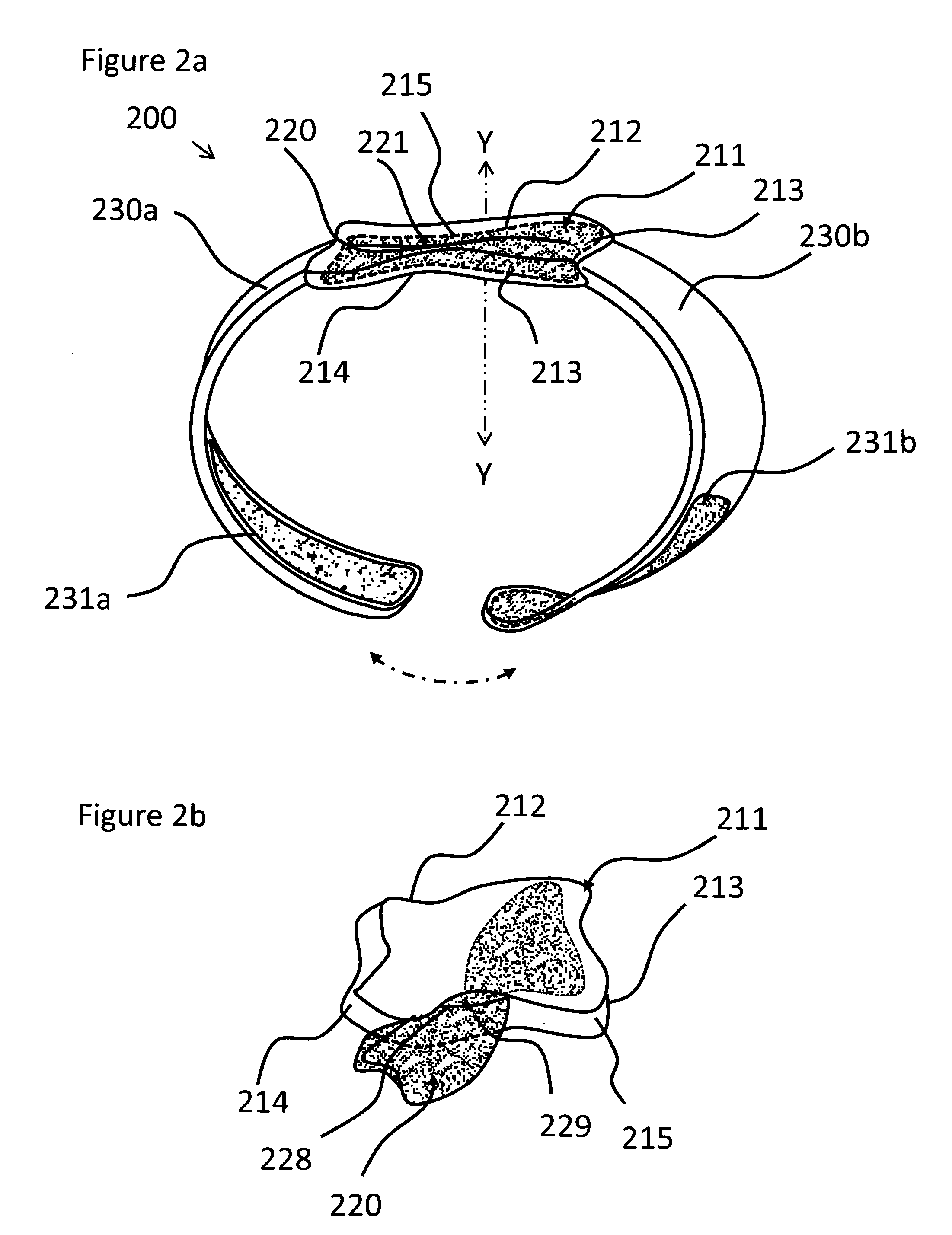

Therapeutic braceletand wrap

InactiveUS20110106227A1Healing experienceTherapeutic coolingTherapeutic heatingDistractionCold treatment

A bracelet and wrap having therapeutic properties is worn on a child's injured or sensitive wrist to facilitate healing and / or provide cold / warm treatment. The therapeutic bracelet and warp include a central portion having an internal chamber for receiving and housing a treatment pack. The therapeutic bracelet and warp further include first and second straps including mating fastener means attached to said central portion for securing the bracelet on the child's wrist. The therapeutic pack is appointed to either be a cold treatment pack or a hot treatment pack, depending on the type of treatment needed. Preferably, the treatment pack includes a transparent top wall and a liquid having a plurality of shapes suspended therein. In turn, the central portion's top side is constructed of a transparent material so that the shapes are visible. The therapeutic bracelet and wrap is appointed to be worn on an injury to facilitate healing while providing style, entertainment and distraction to the wearer.

Owner:DESIDERIO MARCELA N +1

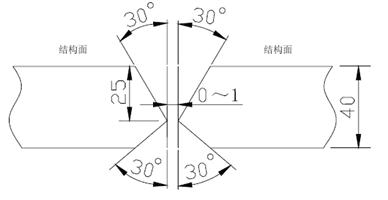

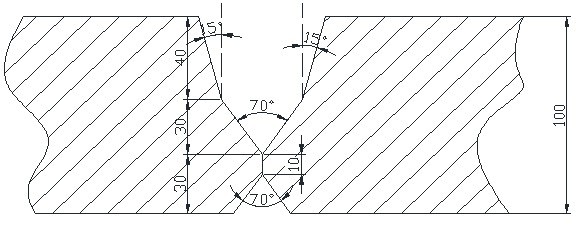

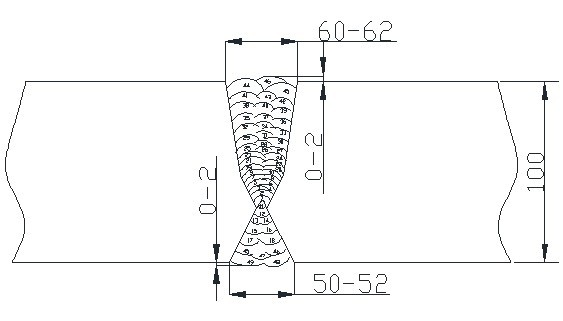

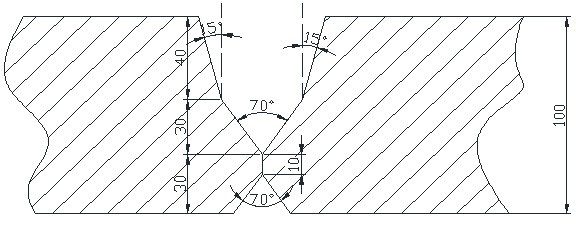

Plain butt welding process for high-strength hull structural steel

ActiveCN102019481AShorten the construction periodImprove labor efficiencyArc welding apparatusWorkpiece edge portionsHull structureCold treatment

The invention relates to a process for welding a high-strength hull structure steel, in particular to a plain butt welding process for a high strength hull structural steel plate (CCSE69040mm). The butt welding process is characterized in that effective specifications for bevel for welding, weld preheating, welding temperature, welding sequence, welding variables and after-welding cold treatment are provided. The plain butt welding process has the advantages of enabling the process of welding a super-thin high strength steel plate to be implemented smoothly, improving the operating efficiency, saving the raw materials, reducing the production cost, reducing the shipbuilding period, and filling a domestic technical blank on the welding of a high strength thick hull structural steel (CCSE69040mm).

Owner:WUCHANG SHIPBUILDING IND

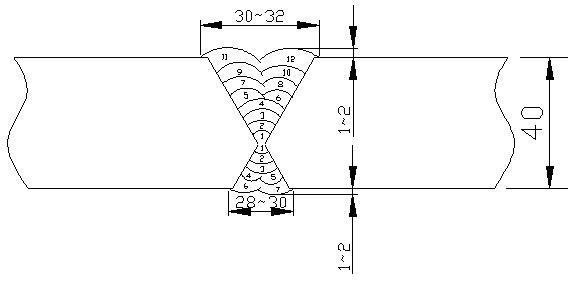

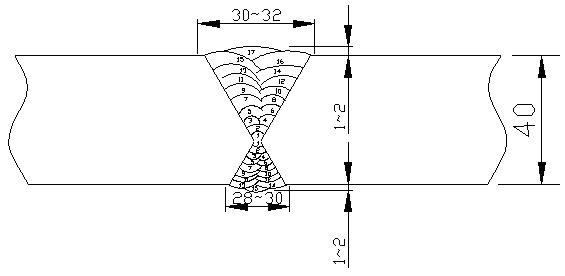

Downward and butt welding process for high strength steel for ship structure

ActiveCN102009256AShorten the construction periodImprove labor efficiencyArc welding apparatusCold treatmentButt welding

The invention in particular relates to a welding process for super thick high strength steel plates for ships and provides a downward and butt welding process aiming at downward and butt welding of EH36Z 100mm-thick high strength steel plates for a ship structure. By putting forward effective specifications for welding grooves, weld preheating, welding temperature, welding sequence, welding variables and cold treatment after welding, the welding process of the high strength steel for super thick plates can be smoothly implemented; and by using the welding process, the labor efficiency is improved, the raw materials is saved, the production cost is reduced, the ship building period is shortened, large scale practical application of the steel to the engineering is successfully implemented for the first time and the gap in the technical specifications in welding of the EH36Z 100mm-thick high strength steel for thick plates for the ship structure at home is filled in.

Owner:WUCHANG SHIPBUILDING IND

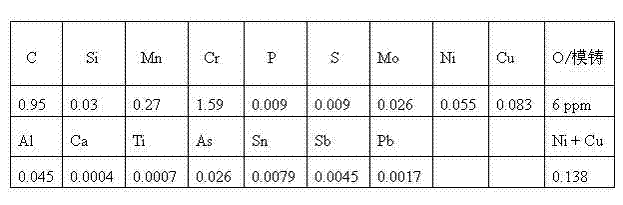

Cold roll for rolling lithium battery guard plate and manufacturing method thereof

ActiveCN103397267AHigh strengthImprove wear resistanceRollsMetal rolling arrangementsInduction hardeningService condition

The invention discloses a cold roll for rolling a lithium battery guard plate and a manufacturing method thereof. The cold roll contains the following chemical components in percentage by mass: 0.7-1.0% of C, 0.2-1.0% of Si, 0.2-0.6% of Mn, no more than 0.02% of P, no more than 0.02% of S, 2.0-4.0% of Cr, 0.2-0.6% of Ni, 0.2-0.8% of Mo, 0.1-0.5% of V and the balance of Fe and inevitable impurities. The manufacturing method of the cold roll comprises the processing steps of electroslag steel ingot fusion casting, roll blank forging, quenching and tempering treatment, induction hardening treatment, cold treatment, final heat treatment, machining and the like. The cold roll disclosed by the invention has high hardness and wear resistance; and under the service condition of the same strength, the service life of the cold roll is prolonged by 45-55% in comparison with the service life of the original common chrome steel cold roll, and the roll body case hardness of the cold roll can be up to 97-105 HSD.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Processing technique of 9Cr18 stainless steel capable of being improved to G3 level

InactiveCN101186005AOptimize processing parametersSpherical surface grinding machinesMetal working apparatusCold treatmentProcess quality

The invention relates to a 9Cr18 stainless steel ball processing technique which can be raised to G3 grade. The processing technique sequentially includes raw material inspection, ball-forging, stress-relief and anneal, hot-acid pickling, polishing, quenching plus cold treatment plus backfire, hard milling, a first-time stabilizing treatment, fine milling, a second-time stabilizing treatment, fine grinding, washing, fine appearance-forming and lubricating and packing. On a basis of making a full use of the existing steel ball processing technology, machine-tool equipments and testing equipments, the technique of the invention adopts a reinforced steel ball manufacturing equipment, industrial preparations, and a novel abrasive to optimize various machining process parameters in the steel ball processing technique and to strengthen a process quality testing and has a proper washing, packing and conserving proposals, etc. process technology. The invention can raise the precision grade of the stainless steel ball to G3 grade and solves the processing technology, testing control and finished-product washing of the 9Cr18 stainless steel ball, and then a batch manufacture is realized finally.

Owner:LUOYANG BEARING SCI & TECH CO LTD

Therapeutic pet boot

InactiveUS8176880B2Healing of the paw is facilitatedProvide supportSolesVeterinary bandagesCushioningCold treatment

A pet boot having therapeutic properties is worn on a pet's injured or sensitive paw to facilitate healing and or provide protection. The therapeutic pet boot includes an external boot member having a shaft and a paw portion constructed to form a cavity integrated therein appointed to receive an injured paw of a pet. The therapeutic pet boot further includes an internal therapeutic member appointed to be received within the cavity of the external boot member and is appointed to intimately contact the injured paw. The therapeutic pet boot is appointed to be worn on the injured paw of the pet to facilitate healing. The internal therapeutic member may comprise a gel bootee having a massaging gel sole or may comprise a gel inner layer or gel insole. Advantageously, the internal therapeutic member may directly deliver medicament to the paw and / or provide cold treatment or hot treatment therapies to the paw, while providing cushioning, shock absorption and protection from dirt and debris.

Owner:I DID IT

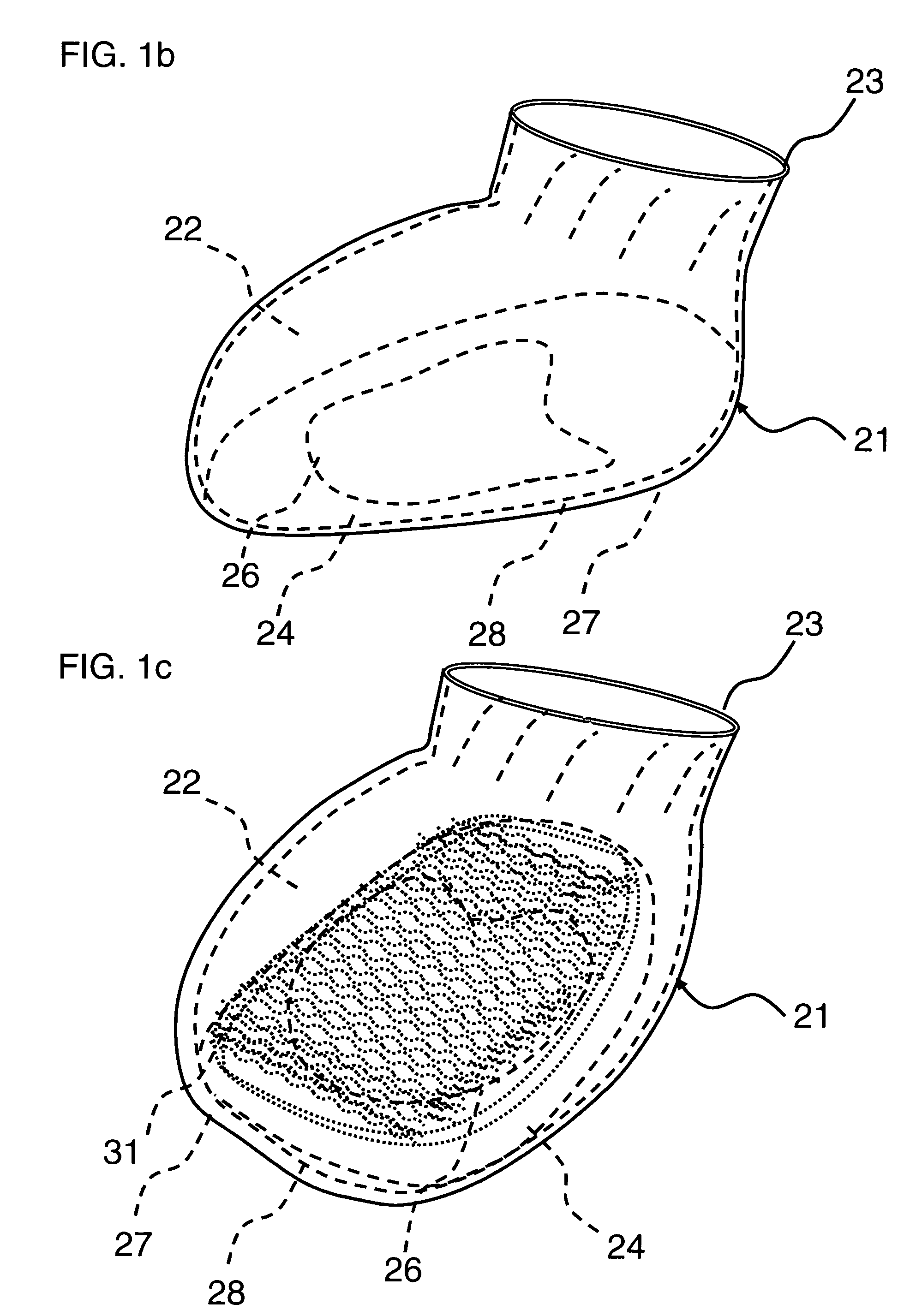

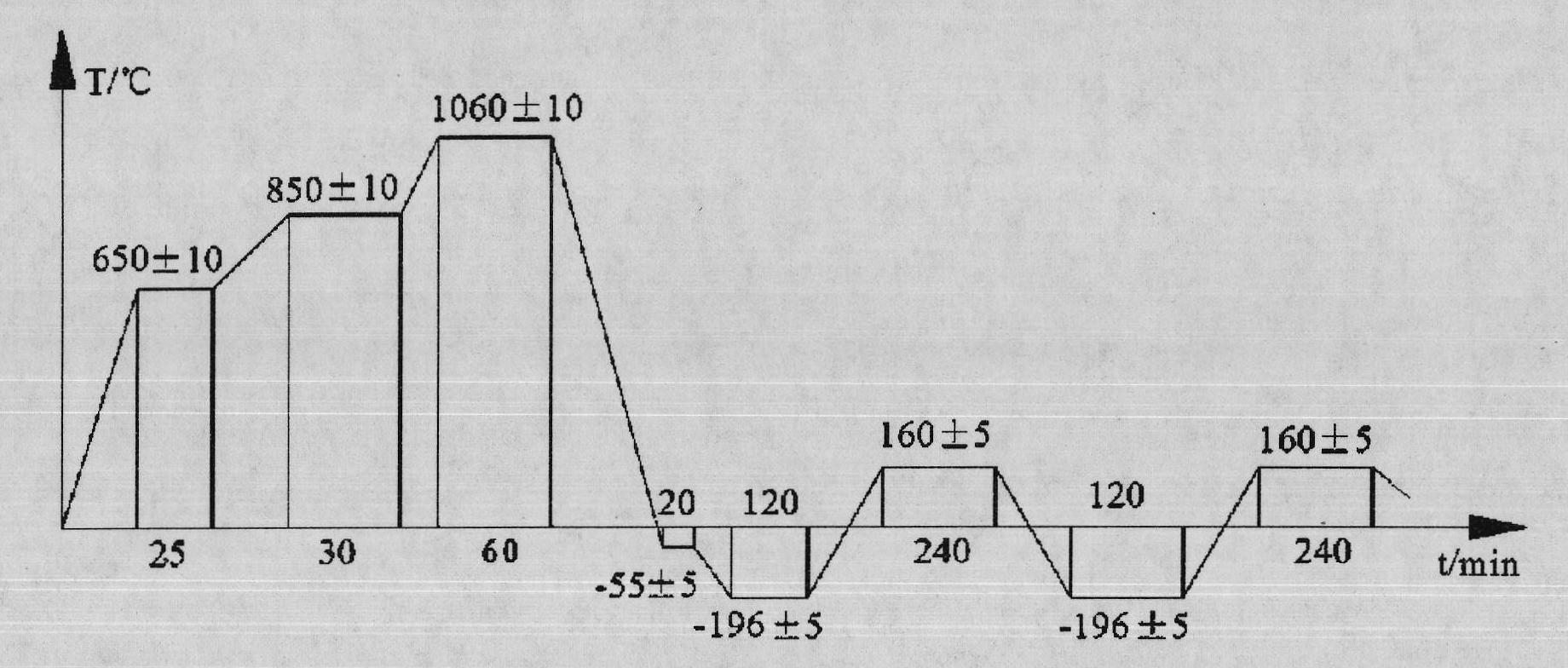

Thermal treatment technology of high-nitrogen stainless bearing steel

InactiveCN101935752AControl contentGuaranteed dimensional stabilityHeat treatment process controlCold treatmentRoom temperature

The invention discloses a thermal treatment technology of high-nitrogen stainless bearing steel, comprising the following steps of: primarily preheating at a temperature of 650+ / -10 DEG C and preserving the temperature for 25-35 min; secondarily preheating at a temperature of 850+ / -10 DEG C and preserving the temperature for 20-45 min; quenching at a temperature of 1060+ / -10 DEG C and preserving the temperature for 50-60 min; cooling to the room temperature after the quenching and performing cold treatment in half an hour at a temperature of -196+ / -5 DEG C for 2-3 h for twice; and warming to the room temperature after the cold treatment and performing tempering immediately at a temperature of 160+ / -5 DEG C for 4-4.5 h for twice. The best thermal treatment technology of 40Crl5Mo2VN high-nitrogen stainless bearing steel of the invention, which is finally determined on the basis of numerous experiments, not only effectively controls the content of the remained austenite to guarantee the size stability problem of the 40Crl5Mo2VN steel workpiece, but also solves the deformation problem and crack problem of the thermal treatment.

Owner:LUOYANG LYC BEARING

Production method for dedicated steel ball for bearing of high-speed high-precision numerical control machine tool

InactiveCN103008994AImprove manufacturing precisionExtend your lifeSpherical surface grinding machinesFurnace typesNumerical controlCarbon potential

The invention discloses a production method for a dedicated steel ball for a bearing of a high-speed high-precision numerical control machine tool. The method comprises the following steps of steel ball cold heading, namely machining blank by sleeve cutting, shaping, cold heading multi-station and high-speed cold heading ways; rough machining by adopting a macrocyclic light bulb technology; performing controllable atmosphere quenching, cold treatment and tapering treatment by adopting a continuous drum furnace, automatically controlling carbon potential; surface strengthening by adopting a frequency conversion speed adjusting multi-beating-plate structure; hard grinding by adopting a ceramic sand wheel to perform macrocyclic process to machine; after primary grinding, adopting double-roller sorting; after fine grinding, performing photoelectric eddy current test; performing ultra-fine grinding machining after aging treatment; and performing photoelectric detection after ultra-fine grinding. The diameter variation of the steel ball which is machined and produced by the method provided by the invention is less than 0.07 micron, the roundness is less than 0.05 micron, the spherical error is less than 0.05 micron, the surface roughness Ra is less than 0.07 micron, the variation of the diameter of the ball lot is less than 0.09 micron, and the bearing dmn value of the steel ball after being sleeved is more than 2.5*10<6> mm*r / min.

Owner:SHANDONG DONGE STEEL BALL GRP

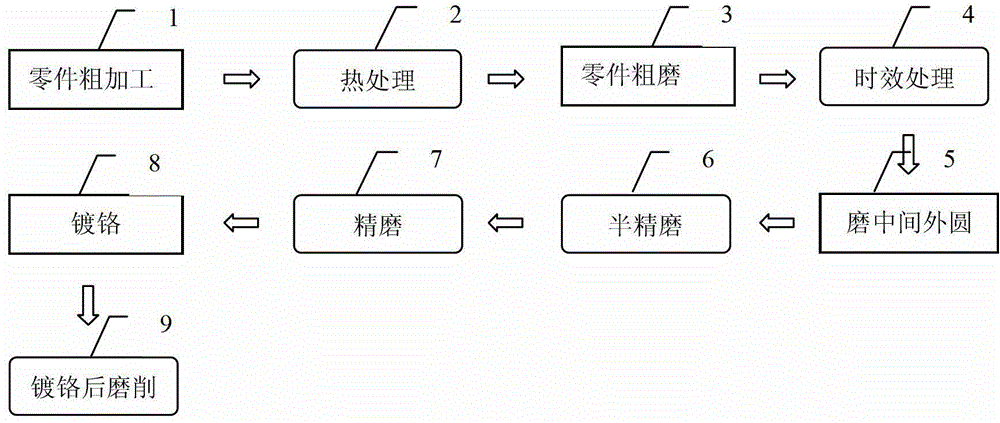

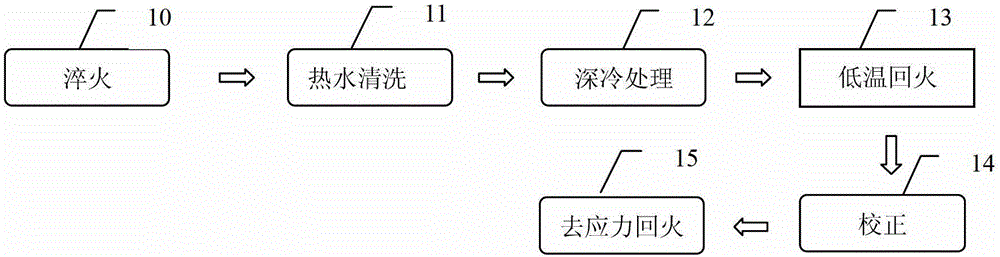

Technology treatment method of machining deformation of long and thin hole shaft type thin-wall part

InactiveCN103331651AImprove rigidityReduce unstable retained austeniteFurnace typesHeat treatment furnacesCold treatmentTempering

The invention provides a technology treatment method of machining deformation of a long and thin hole shaft type thin-wall part, and aims at providing a technology treatment method of the machining deformation, which is simple in flow, and high in machining precision and yield. The method adopts the following technical scheme that the method comprises the steps that the long and thin hole shaft type thin-wall part after mechanical rough machining and carburizing treatment is subjected to quenching heat treatment, subzero treatment and low temperature tempering treatment. During the quenching heat treatment, the quenching cooling time is 8-11S / mm; when a surface temperature of the part falls to 30-50 DEG C, the part is lifted up from oil; the surface temperature of the part rebounds in air after some time; and when the part is cooled to 30-50 DEG C again, residual oil is rinsed cleanly by hot water greater than or equal to 60 DEG C. During the subzero treatment, the part is transferred to a -70 DEG C to -80 DEG C refrigerator box to be refrigerated for 2-2.5h within 1h after quenching, and then subjected to air cooling for 60-90min till the part reaches a room temperature. During the low temperature tempering treatment, the part is subjected to heat preservation for 3-4h at 160-180 DEG C and the air cooling. The method solves the problem of the machining deformation of the long and thin hole shaft type thin-wall part due to heat treatment stress, grinding stress and the like, and the yield reaches 100%.

Owner:SICHUAN LINGFENG AVIATION HYDRAULIC MACHINERY

Production method of grape seed oil

InactiveCN101779705ASolve easy to produce turbiditySolve precipitationEdible oils/fats production/working-upForeign matterSolubility

The invention discloses a production method of grape seed oil, which belongs to the technical field of the food processing. Grape seeds are cleaned and broken, the moisture content of the grape seeds is adjusted, and the refined grape seed oil is produced through the procedures such as pre-heat treatment, enzymolysis, microwave treatment, post heat treatment, drying, squeezing, alkali refining, hydration, heat-cold treatment, decoloration and filtering. With the production method, the oil yield reaches 95 percent or more, procyanidin extraction rate can reach 60 percent or more, the destroy degree of other ingredients such as oilmeal protein after the oil pressing is small, the quality of the produced grape seed oil is good, and the nutrient components of the grape seed oil is maximally reserved; and particularly, the refining processes such as alkali refining, hydration, heat-cold treatment, decoloration and the like effectively removes different water-solubility and fat-soluble harmful foreign matters in the crude oil, so the quality of the grape seed oil is improved, and the quality guarantee period is prolonged.

Owner:河北龙王帽食品有限公司

Method for producing mulberry fruit wine and products thereof

InactiveCN101260355AKeep the flavorReduce moisture contentMicroorganism based processesAlcoholic beverage preparationYeastTemperature control

The invention discloses a method for producing mulberry fruit wine and a product, and is characterized in that the method comprises the following steps: mulberries are picked, sorted, washed, dried and crushed; the mulberries are made an initial fermentation by adding active dry yeast, pectase and sulfur dioxide; the post-fermentation is performed: clear juice of the mixture is sent into a post-fermentation tank, is fermented through temperature control, and is switched to another tank after the fermentation is finished, the lees are removed, thick paste of the initial fermentation is filtered through a diatomite filter, then supernatant fluid enters into the post-fermentation tank to ferment; during the aging period, the clear juice made a post-fermentation is transferred into an aging tank; the clear juice is clarified, filtered, sterilized, and made cold treatment and bottle filling. The product does not need to add white sugar, edible alcohol or other wines during the production, thereby assuring the flavor of the mulberry fruit wine, also ensuring that the mulberry fruit wine is the green health care fruit wine beverage without adding other ingredients, and fully achieving the invention objective of the invention.

Owner:南充市千年绸都第一坊酒业有限公司

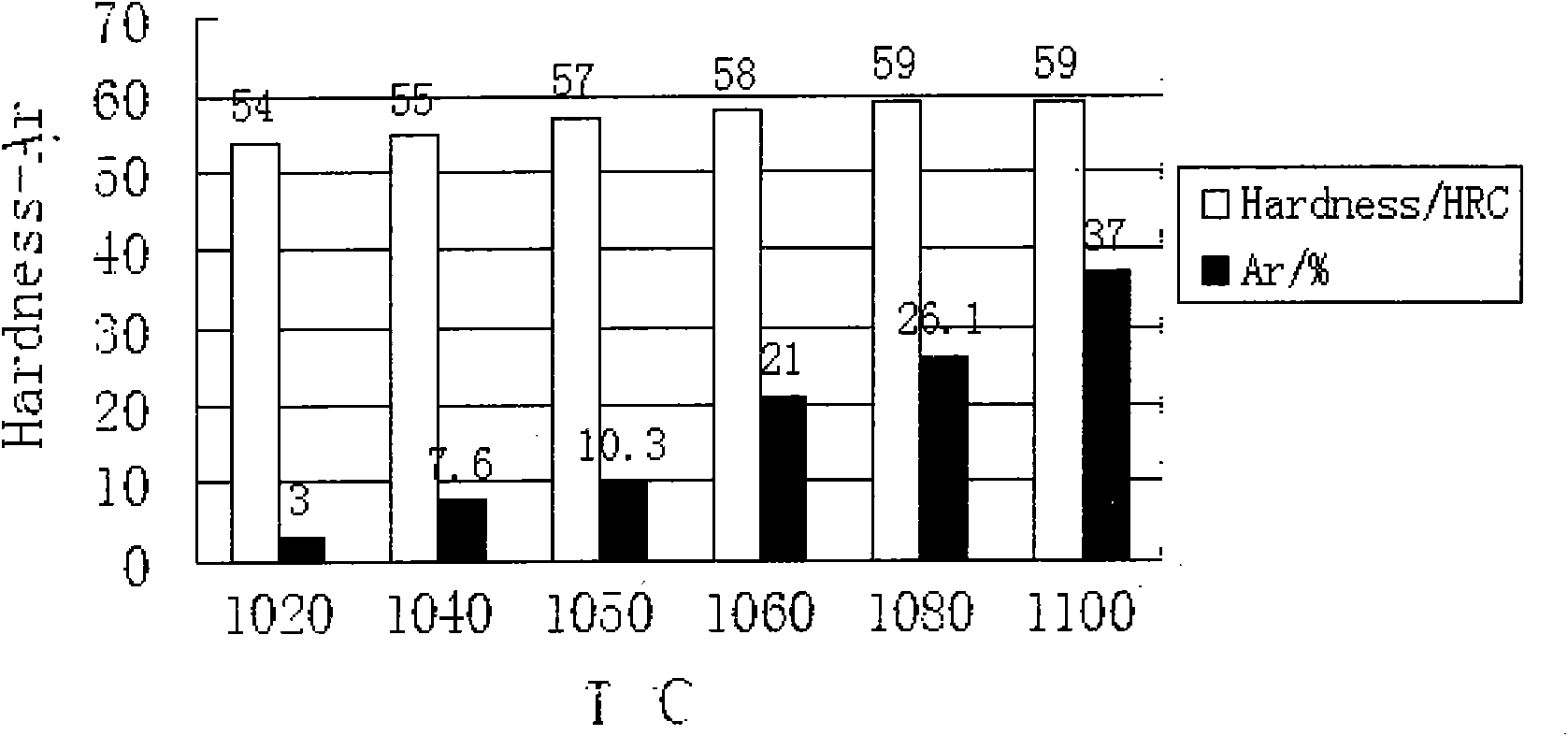

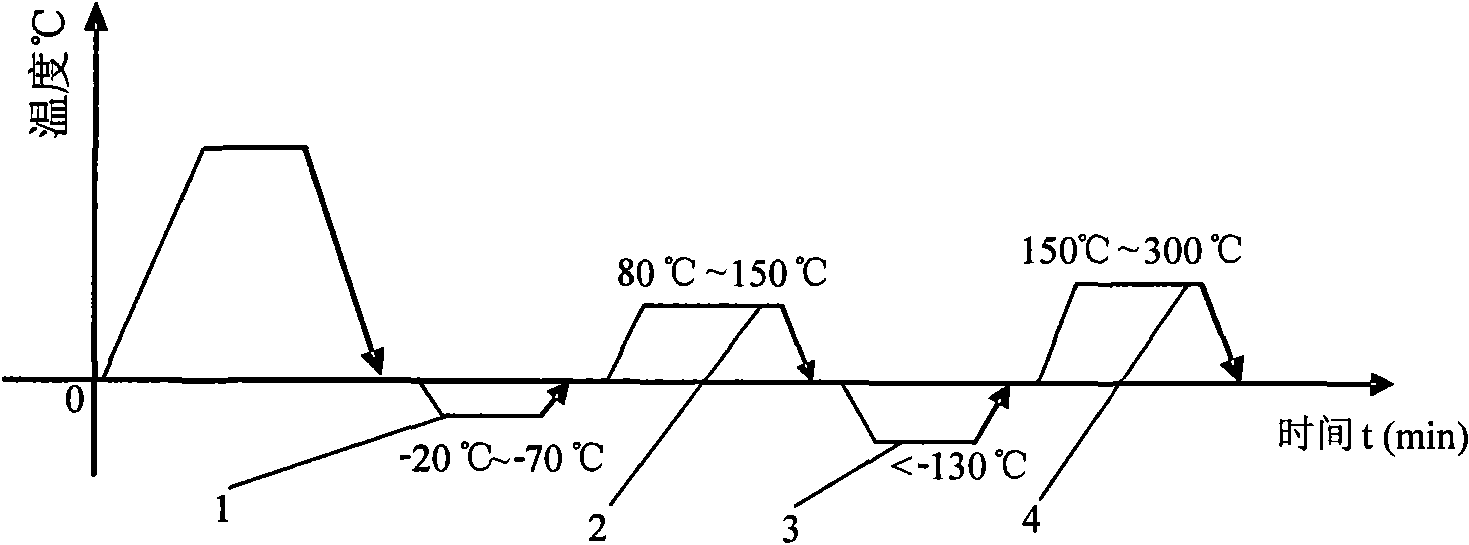

Composite temperature cold treatment process

The invention discloses a composite temperature cold treatment process, which comprises quenching and subsequent cold treatment. The process comprises the following steps: (1) performing quenching treatment on a steel part first; (2) performing the cold treatment immediately after the quenching at a temperature of between 20 DEG C below zero and 70 DEG C below zero until the center of the steel part is stone-cold; (3) performing lonneal for the first time at a temperature of between 80 and 150 DEG C; (4) performing sub-zero treatment at a temperature of less than 130 DEG C below zero until thecenter of the steel part is stone-cold; and (5) performing the lonneal for the second time. The composite temperature cold treatment process performs composite temperature cold treatment after the quenching, thus the process not only reduces retained austenite, stabilizes the size, increases the hardness, separates out superfine micro carbide and improves the wear resistance, but also effectivelycontrols the second type and the third type residual stresses of workpieces, greatly improves the impact toughness and avoids defects of macrocracks and the like because one time of the cold treatment and the lonneal are performed before the sub-zero treatment.

Owner:上海市机械制造工艺研究所有限公司

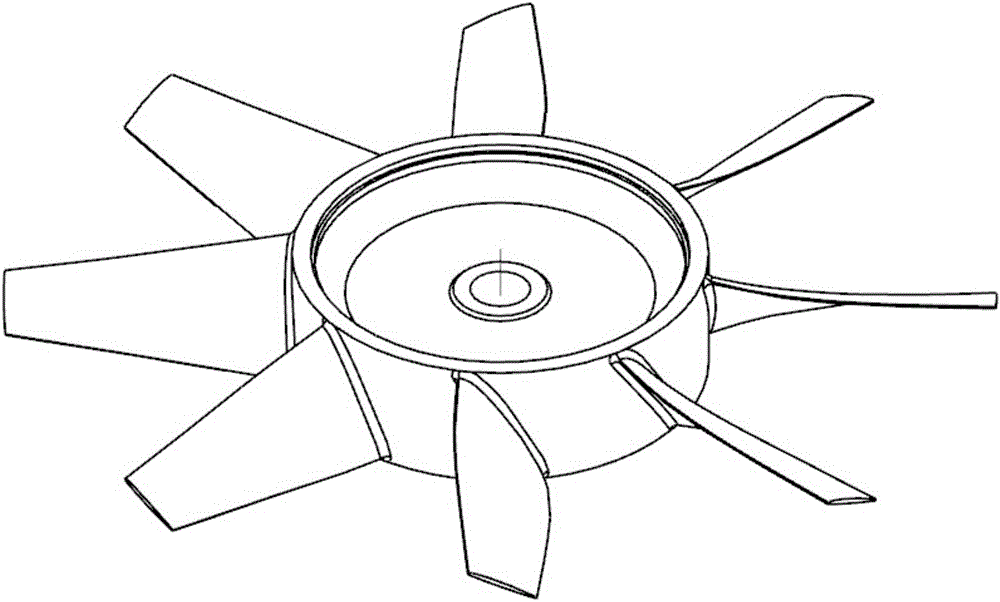

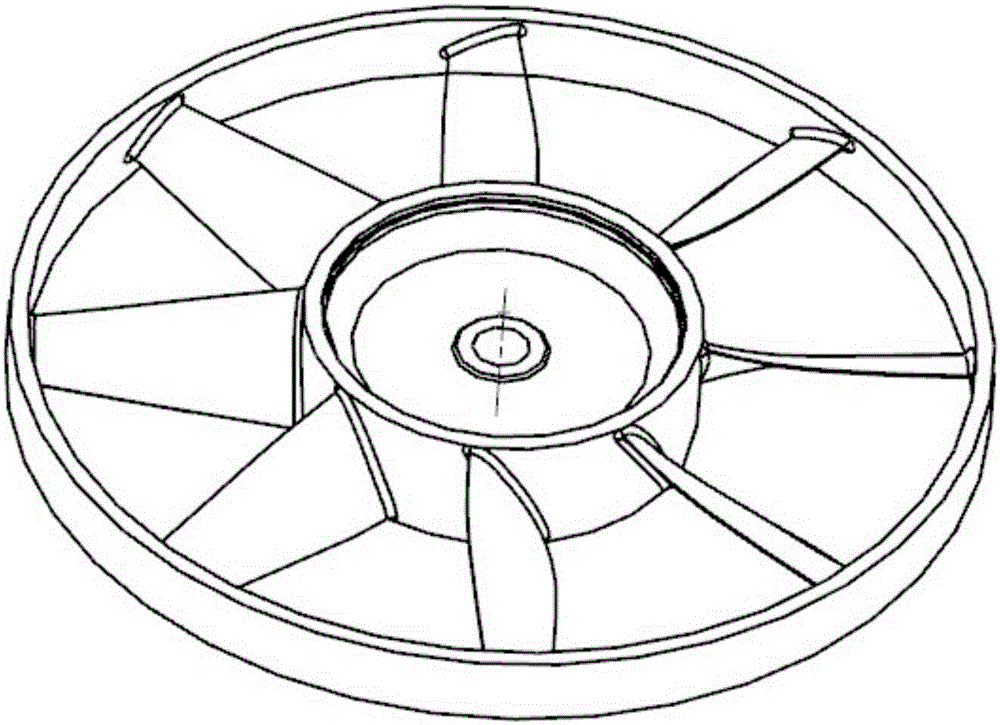

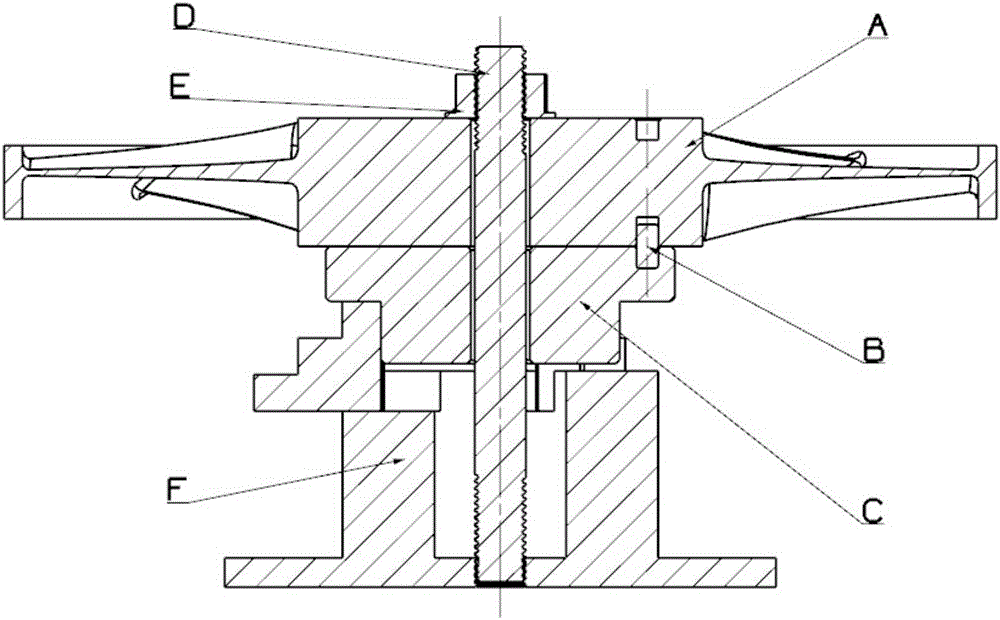

Manufacturing process of ultra-long blade complex curved surface integral impeller made of aluminum alloy material

InactiveCN105904169AManufacturing process improvements and enhancementsComplete shapeOther manufacturing equipments/toolsNumerical controlCold treatment

The invention relates to a manufacturing process of an ultra-long blade complex curved surface integral impeller made of an aluminum alloy material. The manufacturing process includes the specific steps of preparing materials, conducting rough machining on the profile of an impeller workblank, conducting heat treatment, conducting artificial aging, conducting semifinishing on the profile of the impeller, conducting ice-cold treatment, drilling a positioning hole, conducting five-axis linkage rough machining, conducting natural aging, conducting five-axis linkage finish machining, conducting clamp treatment, conducting numerical control turning, conducting linear cutting, conducting clamp treatment and conducting dynamic balancing. By the adoption of the process technology method, the ultra-long blade complex curved surface integral impeller made of the aluminum alloy material is manufactured, the blade shape of the ultra-long blade complex curved surface integral impeller made of the aluminum alloy material is complete, deformation is small, the blade lines of the blade faces of blades are smooth, mass reduction in dynamic balancing is small, and the yield is high; and process improvement in the integral impeller part of the structure is achieved, product quality is guaranteed effectively, the design requirement is met effectively, the stability of production quality is improved, and the reliability of products is guaranteed.

Owner:SHANGHAI INST OF TECH

Method for preparing graphene by inorganic membrane reactor

The invention relates to a method for preparing graphene by an inorganic membrane reactor. The method comprises the following concrete steps of: in a reaction kettle of the inorganic membrane reactor, carrying out water-bath heating for oxidation reaction after cold treatment on graphite powder, strong acid and strong oxidizer serving as raw materials; adding a hydrogen peroxide water solution; conveying the mixture by a pump to a membrane component for membrane filtration; washing the mixture with deionized water; carrying out concentration to obtain graphite oxide suspension; adding a reducing agent for reduction, thus obtaining graphene suspension; conveying the graphene suspension into the membrane component for continuous membrane filtration by the membrane component; carrying out washing by deionized water; carrying out concentration to obtain graphene suspension in the reaction kettle; and drying the graphene suspension to obtain graphene. By use of the method, the integration of preparation and separation of graphene is effectively realized, the waste rate of a product is lowered, the utilization rate of the raw material is improved, the production processes are simple and production in large batches is easy.

Owner:NANJING UNIV OF TECH

Processing method of blueberry and honeysuckle fruit wine

InactiveCN102965241AIncrease the juice yieldPure tasteMicroorganism based processesAlcoholic beverage preparationFruit wineCold treatment

The invention discloses a processing method of blueberry and honeysuckle fruit wine. The blueberry and honeysuckle fruit wine is prepared by steps of pre-treating, mixing, clarifying, grafting, fermenting, ultra-filtering, ageing, inspecting, packaging and sterilizing and the like by using blueberry, honeysuckle and folium mori as main materials. The juice yield of blueberry is improved by mixing the blueberry with bran when the blueberry is pulped; nutritional matters in blueberry can be decomposed completely by mixing various enzymes in the enzymolysis step; during fermentation, taste of a fermentation broth is ensured to be pure by using screened and largely cultivated saccharomycetes; during ultra-filtration, the deficiency that current filtering effect is poor is overcome by using a method of combining chitosan and fish gelatin; during ageing, a microwave assisted cold treatment method is adopted, so that the ageing time is short, saccharomycetes are pure, and the enzymolysis effect is good. The fruit wine is rich in nutrition of product, strong in taste, and mellow in fruity fragrance. The blueberry and honeysuckle fruit wine provides a novel path for getting rid of poverty of farmers in mountain areas while becoming a new member of the fruit wine family.

Owner:彭常安

Steel ball special for third-age hub bearing for luxury cars

ActiveCN102252024ALarge replacement frequencyHigh hardness dropBearing componentsProcess efficiency improvementCold treatmentThird age

The invention discloses a steel ball special for a third-age hub bearing for luxury cars, which is characterized by having the roundness of 0.13mum, the hardness of 64-64.5HRC, the single-grain hardness grain difference of 0.5HRC, the group hardness difference of 0.8HRC, the residual austenite of 8-12%, the stress of 800-1200Mpa, the half amplitude of 75-200Mpa, the strengthening layer thickness of 0.8-1.2mm and the metallographic structure of 2-3 level; the steel ball of the bearing is quenched by using an incomplete quenching process, 99.5% N2 is necessarily used as the protective atmosphere of a quenching and tempering technology during controllable atmosphere heat quenching treatment, the cold treatment is carried out immediately after quenching: after the steel ball restores room temperature after cold treatment, immediately performing a first tempering phase; and additionally providing a second tempering process after a grinding process. The invention has the advantages that: steel balls made of new material is adopted to prolong the service life of the steel balls; and in the ball blank forming process, the material consumption and the production cost are reduced.

Owner:JIANGSU LIXING GENERAL STEEL BALL

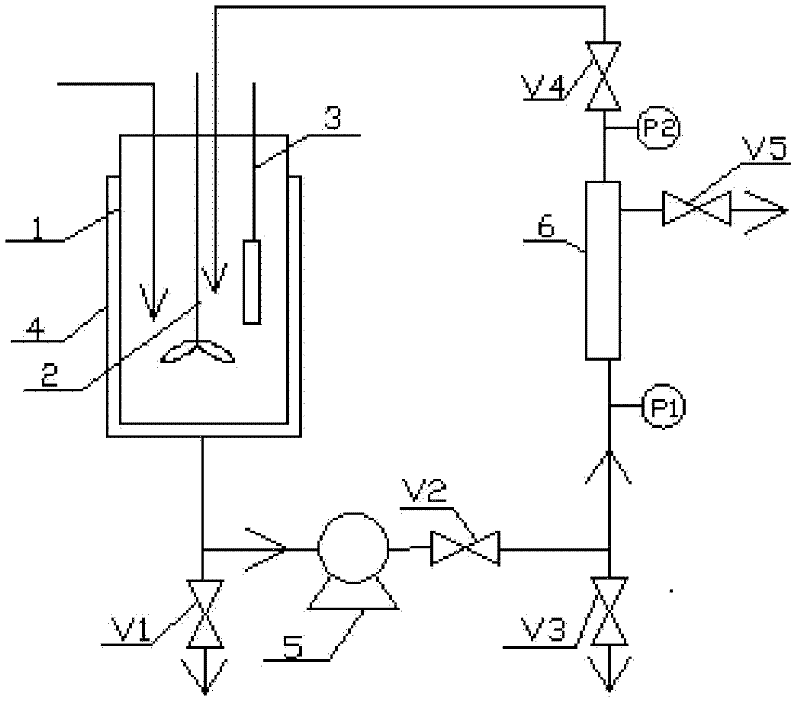

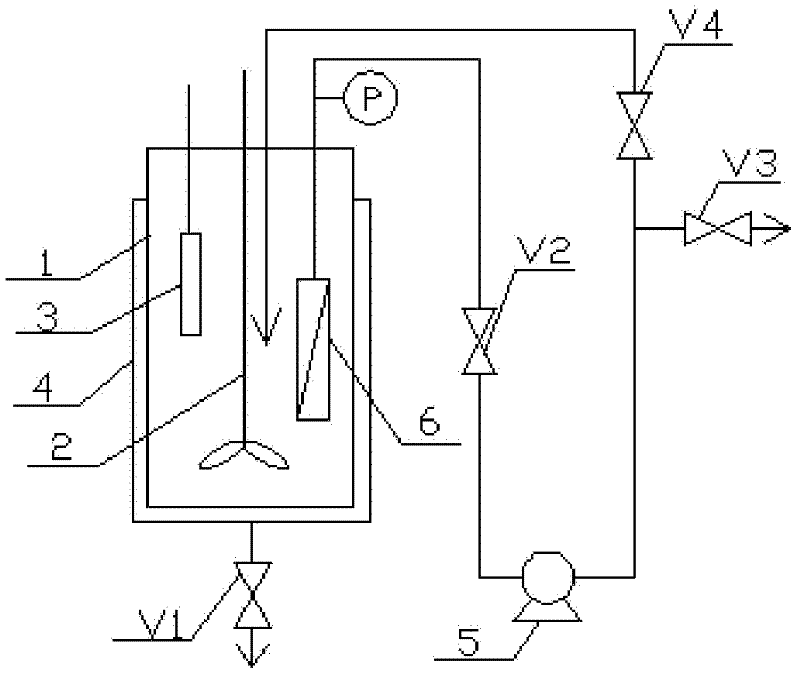

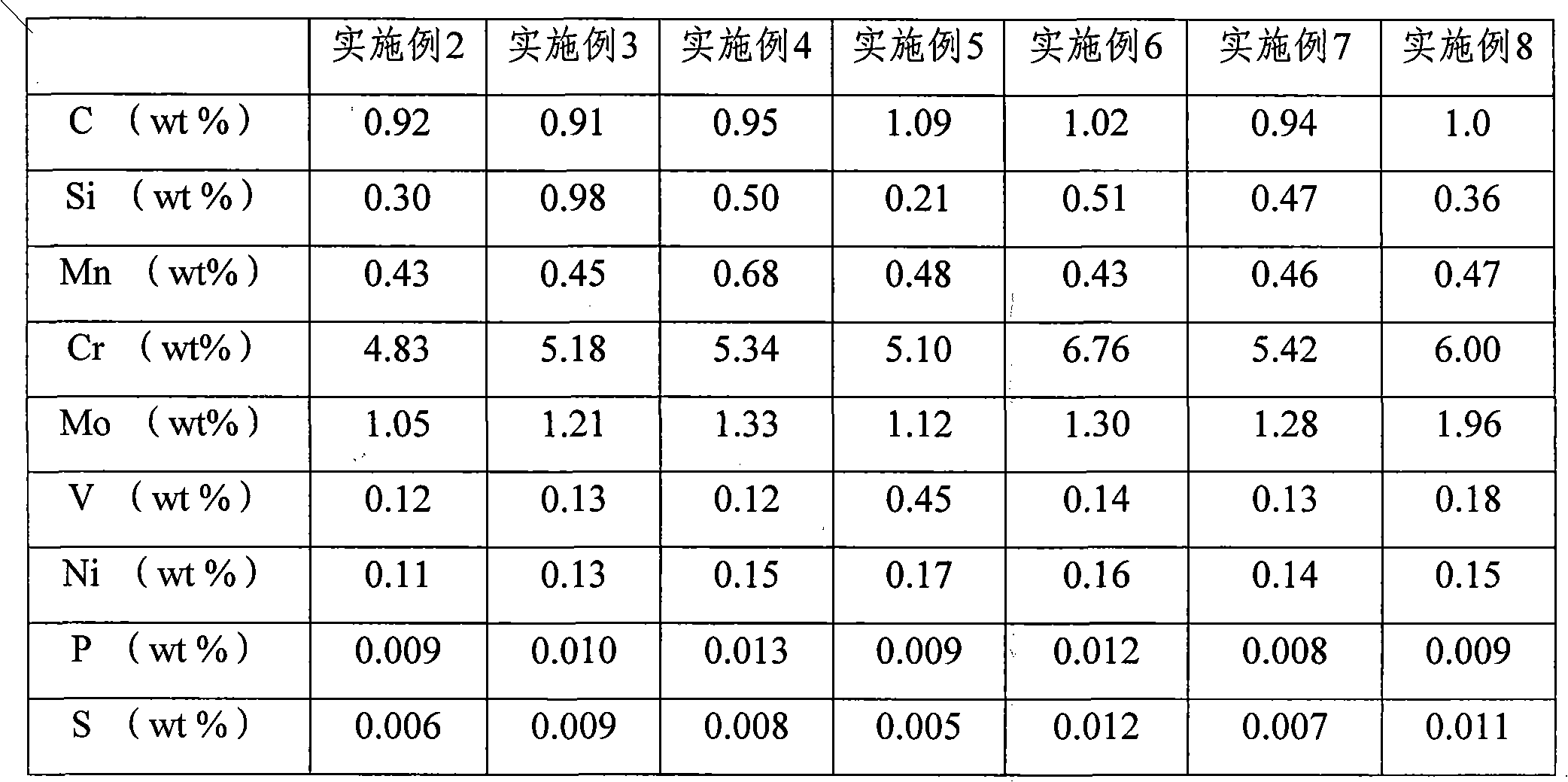

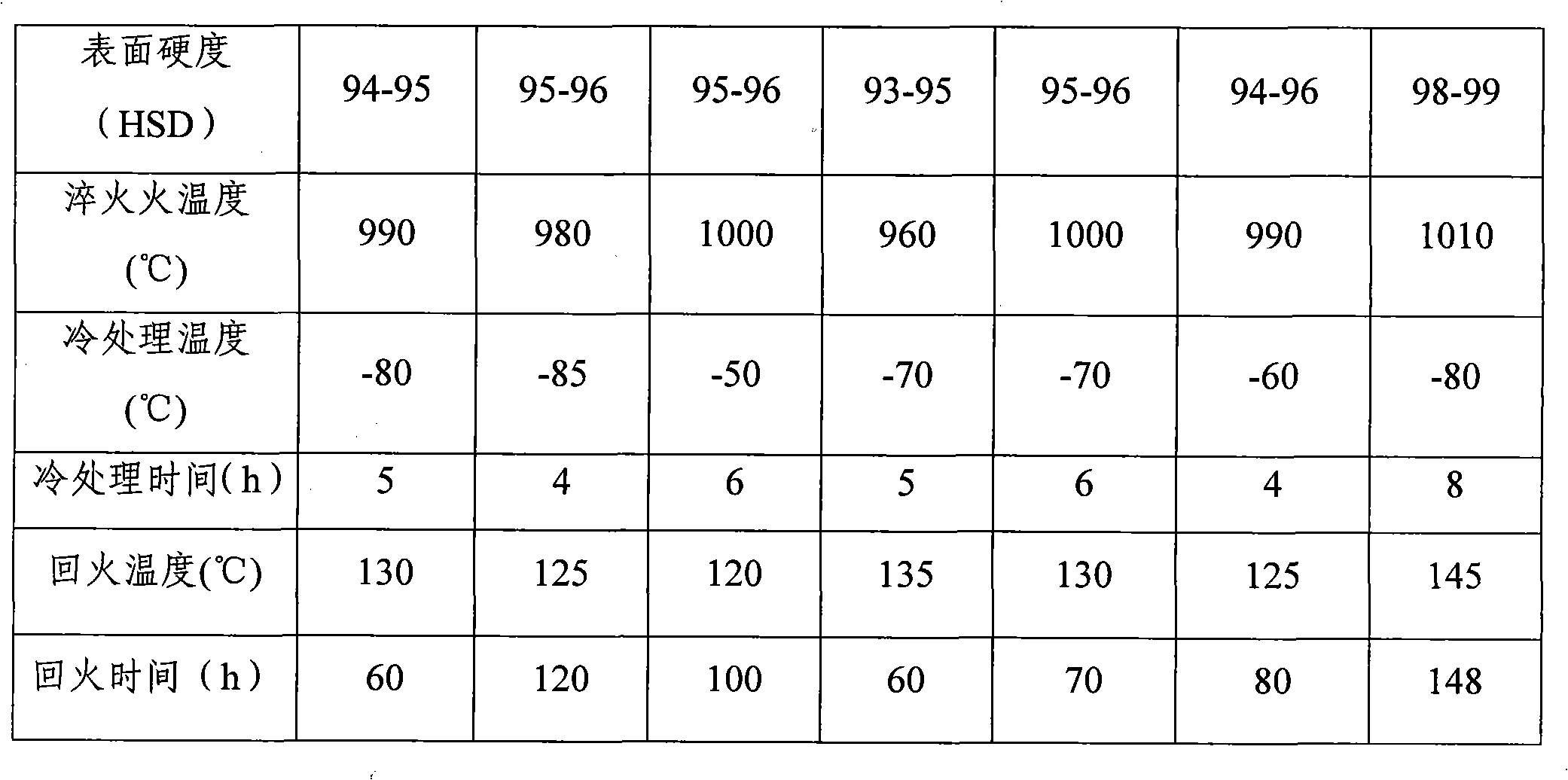

Cold roll with high abrasive resistance and high roughness retaining capability and manufacturing method thereof

ActiveCN101880834AHigh Roughness Retention CapabilityImprove wear resistanceFurnace typesRollsCold treatmentHardness

The invention discloses a cold roll with high abrasive resistance and high roughness retaining capability, which comprises the following chemical components in parts by weight: 0.90-1.10 parts of C, 0.2-1.00 part of Si, 0.40-0.70 part of Mn, 4.80-6.80 parts of Cr, 1.00-2.00 parts of Mo, 0.10-0.50 part of V, not more than 0.40 part of Ni, not more than 0.02 part of S, not more than 0.02 part of P and the balance of Fe. The surface hardness of the cold roll is 92HSD-100HSD; the quenching heating temperature for heat treatment is 960-1020 DEG C; the cold treatment temperature is minus 90 to minus 50 DEG C; the treatment time is 2-8h; the temper holding temperature is 120-145 DEG C; and the holding time is 60-150h. The cold-rolling working roll prepared by the materials and the performances of the invention has high roughness retaining capability and high abrasive resistance; and under the same service conditions, the service life of the cold roll of the invention is improved by 50% compared with the cold roll made of the previous common chromium steel material.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

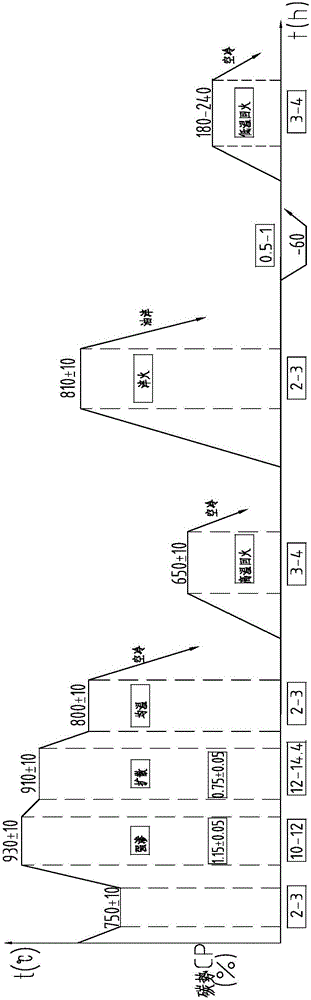

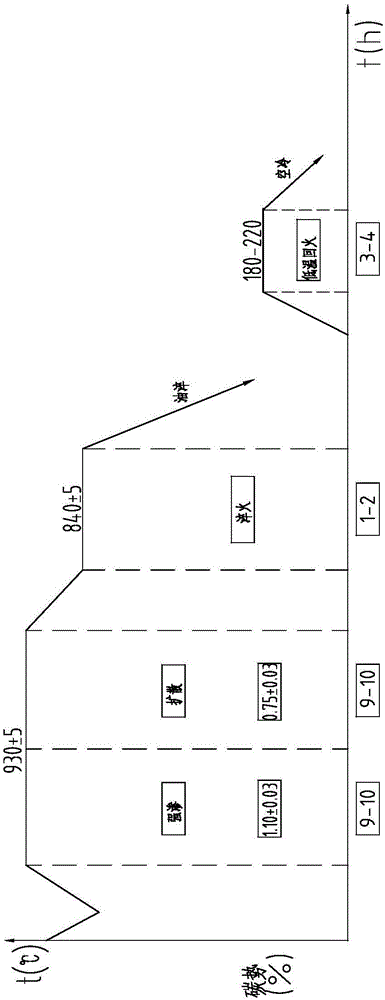

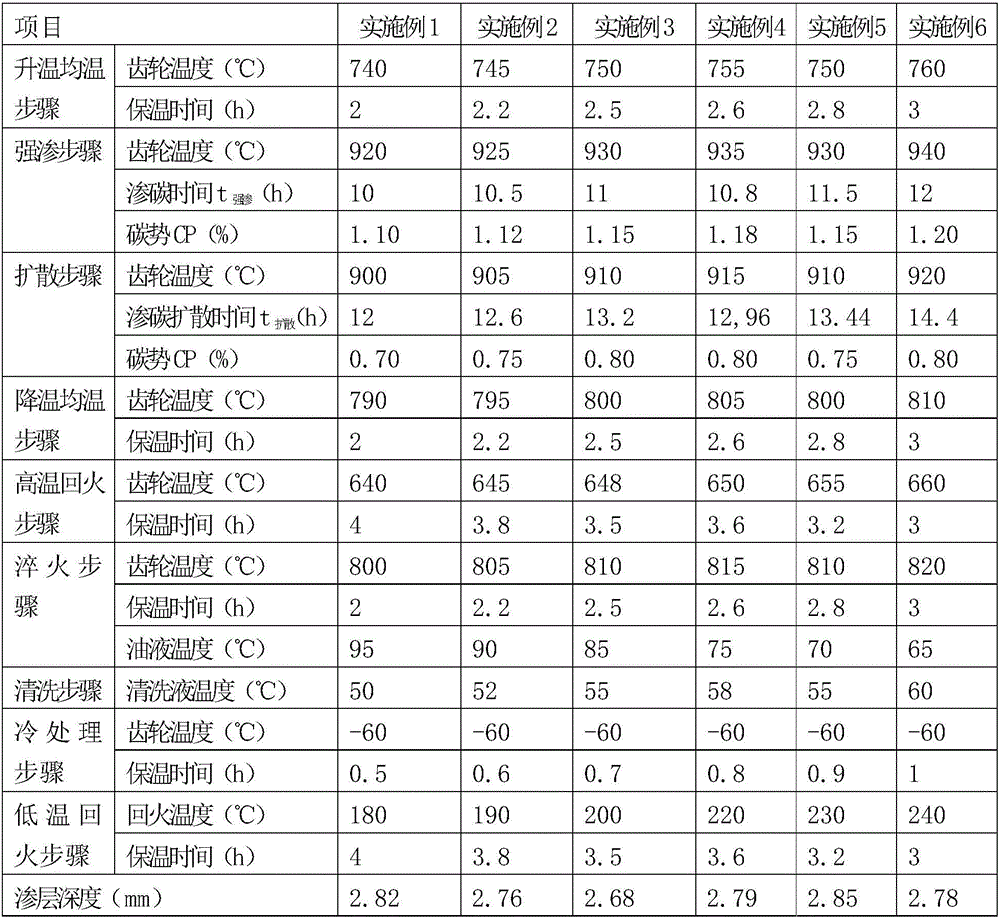

Carburizing and quenching method of low-speed heavy-duty gear

ActiveCN106756753AReduce carbon contentReduce carburizing potentialSolid state diffusion coatingFurnace typesCold treatmentLow speed

The invention relates to a carburizing and quenching method of a low-speed heavy-duty gear. The carburizing and quenching method comprises the steps of (1) temperature increase and temperature uniformization; (2) strong carburizing; (3) diffusion; (4) temperature decrease; (5) high-temperature tempering; (6) quenching; (7) cold treatment; and (8) low temperature tempering. According to the carburizing and quenching method of the low-speed heavy-duty gear, harmful carbide of a gear carburized layer can be effectively removed, dispersively distributed fine granular carbide can be obtained, the content of retained austenite on the surface is greatly decreased, a metallographic structure of the gear surface is improved, the surface hardness and abrasion resistance of the gear are improved, and the heat treatment property of a product is improved.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

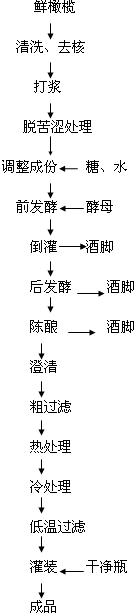

Production technology of fructus phyllanthi wine

ActiveCN102604789AKeep the tasteKeep the aromaAlcoholic beverage preparationCold treatmentFruit wine

The invention discloses a production technology of fructus phyllanthi wine. The production technology comprises the following steps of: preprocessing an olive raw material to obtain the olive pulp; crushing the olive pulp, and filtering to obtain olive juice; adding sodium hydroxide and sodium sulfite to remove bitter taste; adding water and white granulated sugar; and performing twice fermentation and ageing and the steps of cold treatment, heat treatment and the like to obtain olive fruit wine which can effectively maintain the specific taste and aroma of olive and is rich in multiple aminoacids and trace elements necessary to a human body. The production technology disclosed by the invention can be used for shortening the production period, and is simple and easy to implement and low in production cost.

Owner:云南顺宁府酒业有限责任公司

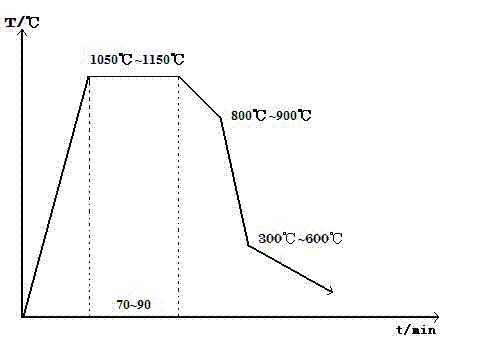

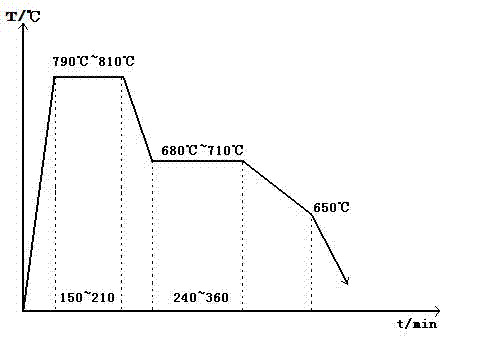

Heat treatment method of bearing

ActiveCN102758073AExtended service lifeControl of retained austenite contentFurnace typesHeat treatment furnacesAusteniteQuenching

The invention relates to a heat treatment method of a bearing. The heat treatment method comprises the following six steps of: heating, insulating, quenching, cleaning, cold treatment and tempering. The heat treatment method is characterized in that before the heating step, a fining treatment step of carbide is arranged; the fining treatment step comprises two steps of forging and spheroids annealing; the temperature of initial forging in the forging steps is 1050-1150 DEG C; the insulating time is 70-90 minutes; the temperature of the final forging and forming is 800-900 DEG C; then the stirring and cooling are carried out in boiling water till the temperature is 300-600 DEG C; the bearing is taken out of water and air-cooled till room temperature; and the spheroids annealing step comprises specific steps of: heating to 790-810 DEG C, insulating for 150-210 minutes under the temperature, air cooling to 680-710 DEG C, insulating for 4-6 hours, cooling till 650 DEG C along with a furnace, taking out of the furnace and carrying out air cooling. The cold-treatment step is carried out in 2 hours after the cleaning steps is finished after quenching, liquid nitrogen is adopted as cooling medium, cooling is carried out till the temperature is minus 70-minus 80 DEG C, insulation is carried out for 1.5-2 hours under the temperature, and returning the temperature naturally till the room temperature. The heat treatment method has the advantage that the service life of the bearing is prolonged by fining carbide particles, improving the hardness and controlling the content of the retained austenite in the metallographic structure.

Owner:汇洲智能技术集团股份有限公司 +1

Preparation method of sinomenine

The invention provides a preparation method of sinomenine, comprising the process for preparing and refining a sinomenine crude product. The preparation method provided by the invention comprises the following steps of: wetting and percolating caulis sinomenii coarse powder with HCL (hydrochloric acid), and extracting and crystallizing the percolation liquid to obtain a sinomenine crude product; and adding ethanol or purified water in the sinomenine crude product and heating and refluxing till the sinomenine crude product is dissolved, adding active carbon for filtering, then cooling, crystallizing, filtering and cleaning a filter cake with ethanol till the filtrate is colorless, and thus obtaining the sinomenine. The preparation method is simple to operate, belongs to cold treatment completely without the need of needs heating in the extraction process; the yield is high, and mother liquid is treated simply; moreover, the preparation method is safe and reliable, causes low pollution and plays a positive effect on environmental protection because only inorganic acid and alkali and a mall amount of level-two toxicity solvent are used.

Owner:HUNAN ZHENGQING PHARM GRP CO LTD +1

Production method of flower fermented wine

InactiveCN102304448AImproving the color of infused wineImprove aroma and tasteAlcoholic beverage preparationCold treatmentFruit wine

The invention relates to a production method of a flower fermented wine, belonging to the technical field of fruit wine production. The invention aims to solve the following technical problems: the traditional flower wine is not suitable for women and old people to drink due to overhigh alcohol content; nutritional ingredients in the flowers can not be completely released; and the traditional flower wine does not have the original color, fragrance, mouthfeel and the like of the flowers. The method comprises the following steps: preparing a mixed solution of flower petals, sucrose, honey and water, and adding Angel fruit wine yeast; carrying out primary fermentation; separating to obtain the wine; carrying out secondary fermentation; filtering and clarifying; carrying out cold treatment; sterilizing; and filling to obtain the finished product.

Owner:李易兴

Method for cryogenic treatment of galvanized steel sheet resistance spot welding electrode

InactiveCN1435505AExtend working lifeLow cryogenic processing costsElectrode featuresWelding/cutting media/materialsOperating lifeMaterials science

A process for deep cold treatment of the spot-welding electrode for the galvanized steel plate in order to elongate its service life includes putting the Cu-alloy electrodes in a container full of deep cold medium in a deep cold treater layer by layer, setting parameters, deep cold treating, and naturally raising their temp to ordinary temp. Its advantages are long service life elongated by 4 times, no splash on welding, and high welding quality.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com