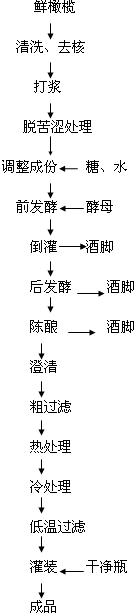

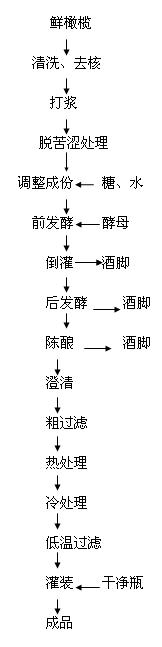

Production technology of fructus phyllanthi wine

A production process, olive wine technology, applied in the production process of Yunnan olive wine, can solve the problems of color, taste and physical and chemical hygiene indicators not up to standard, tannin and tannin cannot be effectively removed, and damage the active ingredients of Yunnan olives, etc., to achieve The production process is scientific and reasonable, the production cost is low, and the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Using fresh Yunnan olive fruit as raw material, after cleaning, pitting, crushing, sedimentation and filtration, and debittering treatment, add ingredients to the fruit juice to make a slurry. The slurry is composed of 40% Yunnan olive juice, 40% purified water, and white sugar. 20%; the dosage of active dry yeast EC118 is 0.3‰, stir evenly, pour into semi-sealed fermentation, control the room temperature at 22°C, after 12 days of fermentation, the alcohol content is about 11%vol, and the residual sugar is 7-10g / L , you can pour it into the post-fermentation, the room temperature of the post-fermentation is 18 ℃ ~ 20 ℃, after one month, the wine liquid is transparent yellowish brown or amber, with obvious wine and fruit aroma, the alcohol content is 11 ~ 12%vol, into aging. The longer the aging time, the better the quality of the wine. After aging, the wine body enters the following process. It is naturally clarified by the gelatin tannin method and then filtered; the f...

Embodiment 2

[0026] Using fresh Yunnan olive fruit as raw material, after cleaning, pitting, crushing, sedimentation and filtration, and debittering treatment, add ingredients to the fruit juice to make a slurry. The slurry is composed of 60% Yunnan olive juice, 20% purified water, and white sugar. 20%, the dosage of active dry yeast 71B is 0.4‰, stir evenly, pour into semi-sealed fermentation, control the temperature to ferment at 25°C until the alcohol content is about 4%vol, lower the fermentation temperature to 20°C, and ferment at two stages of temperature The wine is full-bodied and fruity. The alcohol content is about 11% vol, and the residual sugar is 7-10g / L, then the tank can be poured into and then fermented. The rest of the process is the same as that of Example 1.

Embodiment 3

[0028] Using fresh Yunnan olive fruit as raw material, after cleaning, pitting, crushing, sedimentation and filtration, and debittering treatment, add ingredients to the fruit juice to make a slurry. The slurry is composed of 60% Yunnan olive juice, 15% purified water, and concentrated apple juice 25%, the dosage of active dry yeast is 0.2‰ for 71B and 0.2‰ for EC118, stir evenly, pour into semi-sealed fermentation, control the temperature to ferment at 20°C, add concentrated fruit juice fermentation liquid is rich in nutrition, relatively low The fermentation temperature controls the fermentation speed. The alcohol content is about 11% vol, and the residual sugar is 7-10g / L, then the tank can be poured into and then fermented. The rest of the process is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com