Patents

Literature

1744 results about "Maltitol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

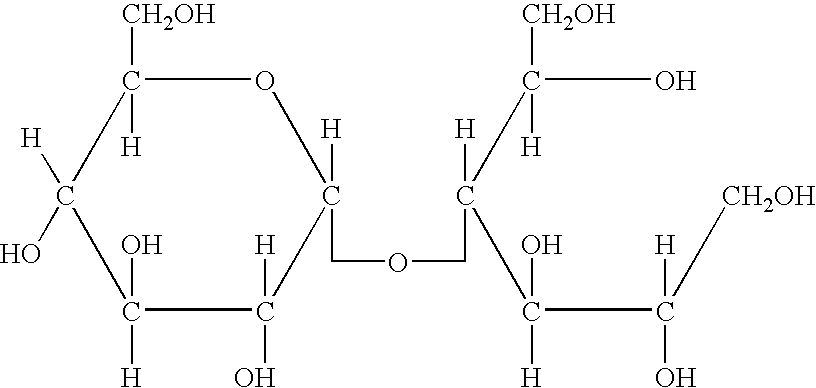

Maltitol is a sugar alcohol (a polyol) used as a sugar substitute. It has 75–90% of the sweetness of sucrose (table sugar) and nearly identical properties, except for browning. It is used to replace table sugar because it is half as caloric, does not promote tooth decay, and has a somewhat lesser effect on blood glucose. In chemical terms, maltitol is known as 4-O-α-glucopyranosyl-D-sorbitol. It is used in commercial products under trade names such as Lesys, Maltisweet and SweetPearl.

Yogurt

InactiveUS6025008AAvoid developmentSweetening the yogurt with the inherent sweetness thereofMilk preparationLactobacillusFish oilMaltitol

Yogurt containing lactic acid bacteria and Bifidobacteria, to which one or more kinds of sweet substances selected from a group consisting of palatinose, palatinite, maltose, maltitol, starch syrup, reducing starch syrup and trehalose as well as a refined fish oil containing highly unsaturated fatty acids such as DHA and EPA are added, is packed in an oxygen blocking hermetic package. The yogurt contains highly unsaturated fatty acids and has good flavor and taste, as well as excellent product quality stability, and does not generate a fishy odor during normal storage periods.

Owner:YAKULT HONSHA KK

Sweetener containing d-psicose and foods and drinks obtained by using the same

Providing a D-psicose-containing sweetener with the modification of the taste of D-psicose, comprising D-psicose, a sugar alcohol and / or a high intensity sweetener, preferably containing D-psicose as the main component, particularly a low-calorie sweetener and / or a sweetener giving refreshing feel in the oral cavity, as well as foods and drinks obtained by using the D-psicose-containing sweetener with the modification of the taste of D-psicose, and other products given with sweetness. The sugar alcohol is one or more sugar alcohols selected from the group consisting of sorbitol, mannitol, lactitol, maltitol, xylitol and erythritol, while the high intensity sweetener is one or more high intensity sweeteners as selected from aspartame, acesulfame K, sodium cyclamate, sodium saccharin, Sucralose (under trade name), stevia sweetener, dulcin, taumatin, neotame and monellin.

Owner:MATSUTANI CHEM INDS CO LTD +1

Weight losing and meal replacement protein type solid beverage

ActiveCN102687750AEnhance nutritional propertiesAdd flavorMilk preparationBiotechnologyPROTEIN S HEERLEN

The invention provides a weight losing and meal replacement protein type solid beverage, which comprises ingredients including concentrated whey protein powder, soy isolate protein powder, dried skim milk, soluble dietary fiber, maltitol or erythritol, maltodextrin, fructo-oligose or fructose, soya bean lecithin, nutrose, low-fat pectin and the like. The protein in the body is effectively supplemented, the satiety is effectively prolonged, the appetite and the caloric intake are more strictly controlled, and further, the goal of losing the weight is reached. The product has the advantages that the nutrition is balanced, the mouth feeling is smooth, savoury and mellow, the carrying is convenient, the process is simple and feasible, and the solid beverage is suitable for mass production.

Owner:浙江诺特健康科技股份有限公司

Method of preparing an improved low-calorie, low-fat food foodstuff

Owner:MITSUBISHI SHOJI FOODTECH CO LTD

Solid pharmaceutical preparation

InactiveUS6299904B1Good disintegrationPromote dissolutionOrganic active ingredientsBiocideLow-substituted hydroxypropylcelluloseMaltitol

A solid preparation which comprises (i) a pharmaceutically active ingredient, (ii) one or more water-soluble sugar alcohols selected from the group consisting of sorbitol, maltitol, reduced starch saccharide, xylitol, reduced palatinose and erythritol, and (iii) low-substituted hydroxypropylcellulose having hydroxypropoxyl group contents of 7.0 to 9.9 percent by weight; which exhibits excellent buccal disintegration and dissolution and also appropriate strength.

Owner:TAKEDA PHARMA CO LTD

Reduced-carbohydrate and nutritionally-enhanced frozen desserts and other food products

InactiveUS20060286248A1Mitigate laxation effectReduce impactFrozen sweetsConfectioneryTagatoseMaltitol

A reduced carbohydrate ice cream or other frozen dessert product that contains a low-digestible sweetener system and a fermentable fiber material. The a low-digestible sweetener system consists of one or more low-digestible sweeteners having a molecular weight of from about 90 to about 190; and is typically a low molecular weight saccharide or a polyol. Typical low-digestible sweeteners include mannitol, maltitol, sorbitol, lactitol, erythritol, xylitol, isomalt, glycerin, talitol, mannose, tagatose, fructose, arabinose, fucose, lycose, ribose, sorbose, talose, and xylose, and mixtures thereof. The low-digestible sweetener replaces the digestible sugars to provide the appropriate freezing point depression of the product. The level of fermentable fiber is sufficient to mitigate a Taxation effect that can be caused by ingestion of the amount of the low-digestive sweetener. The fermentable fiber can be an inulin, a maltodextrin resistant to human digestion, an oligofructose, a fructooligosaccharide, a high water binding fermentable fiber, and a mixture thereof.

Owner:TECHCOM GRP LLC

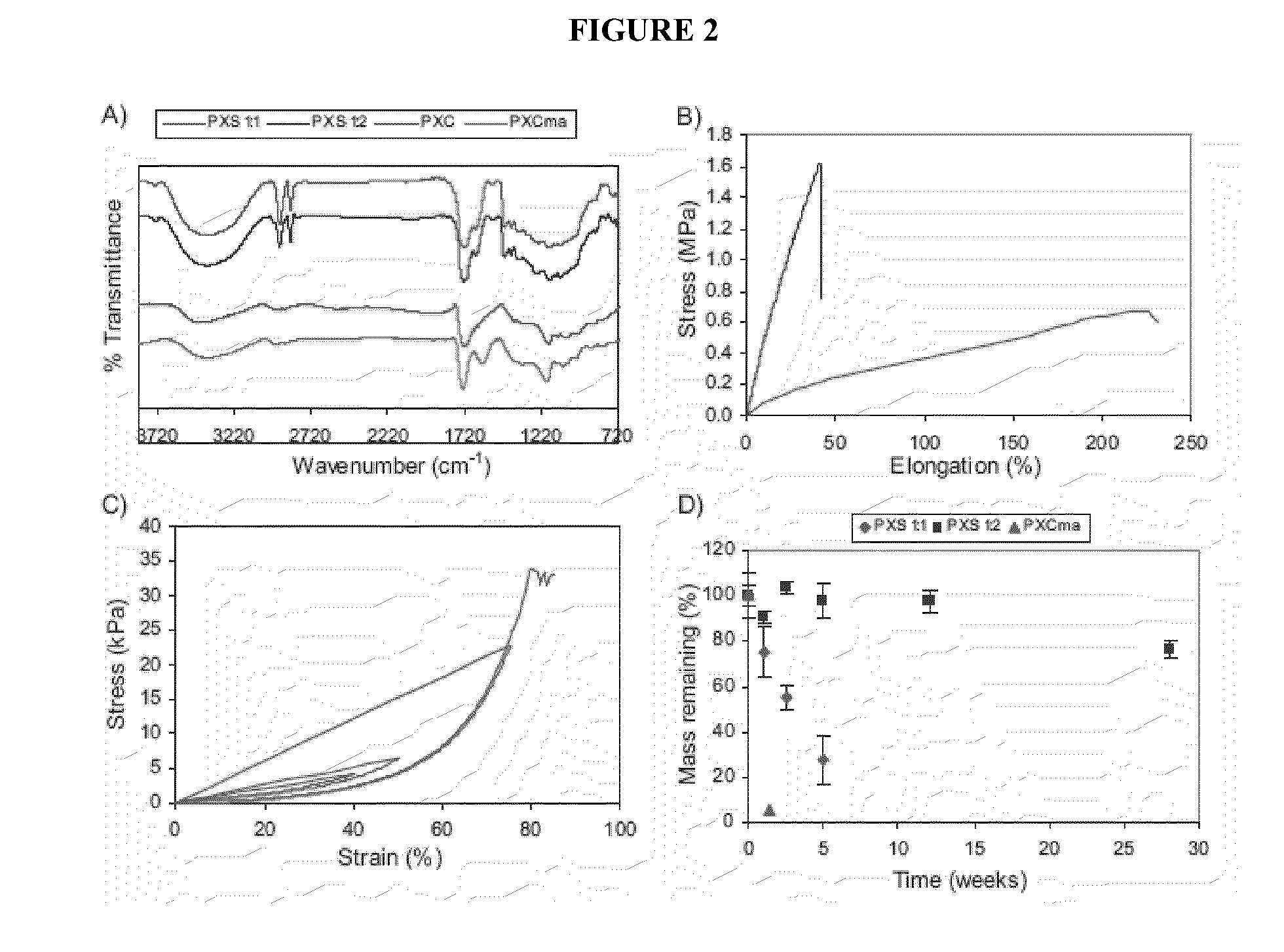

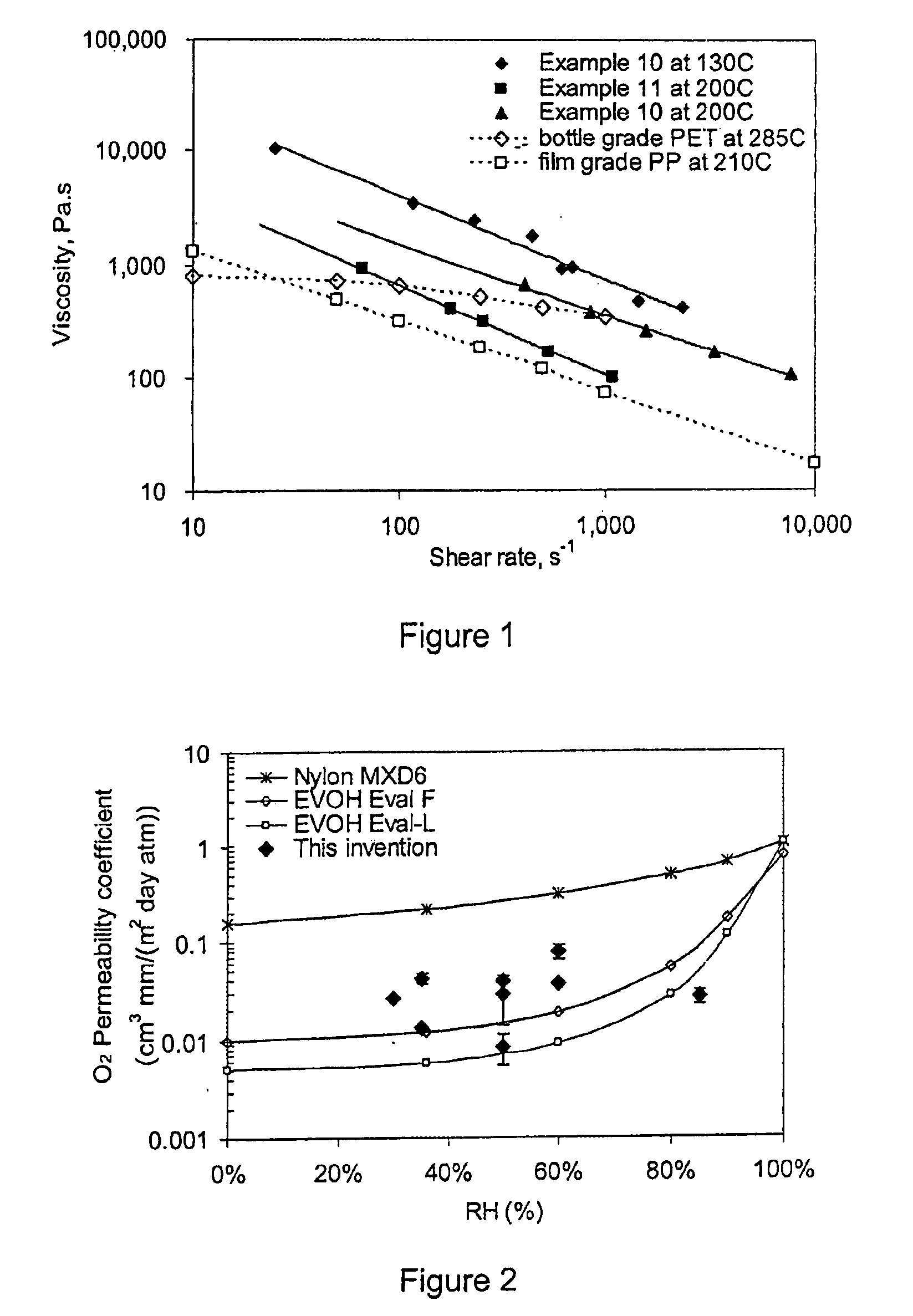

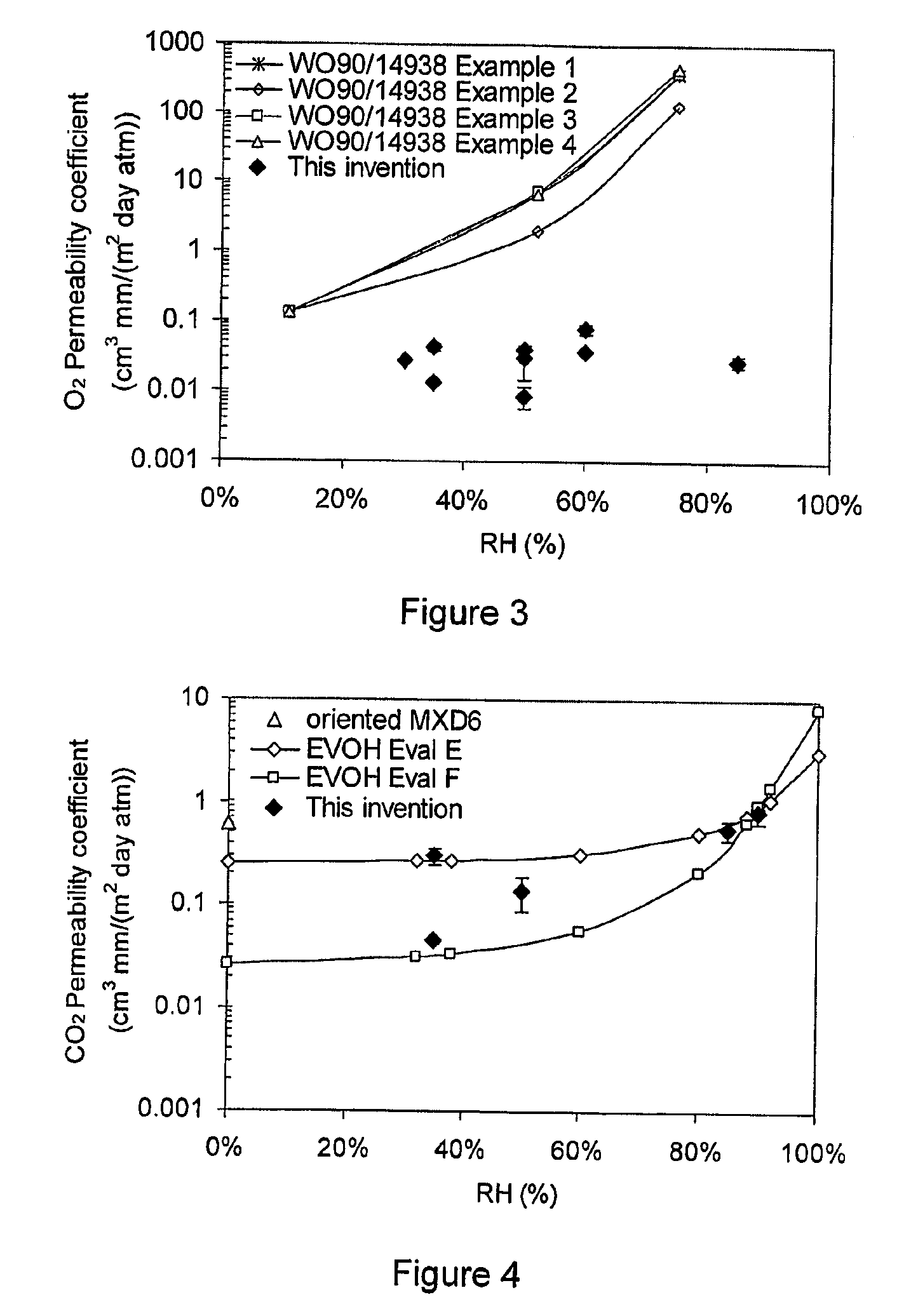

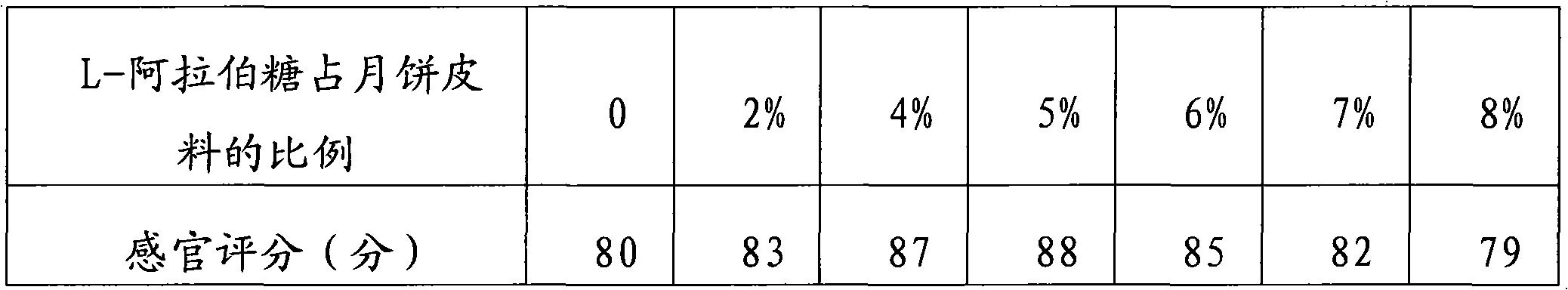

Polymeric films

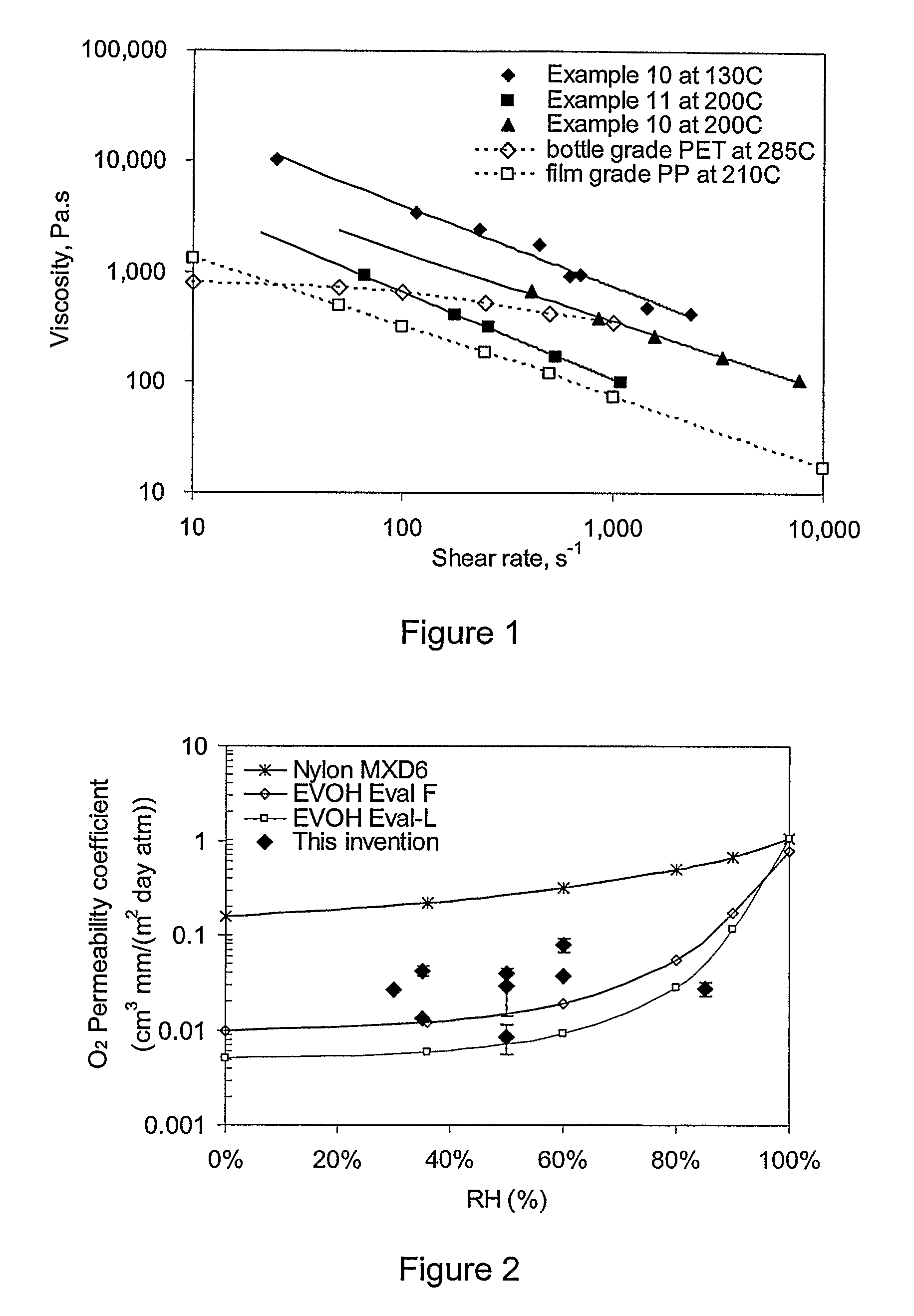

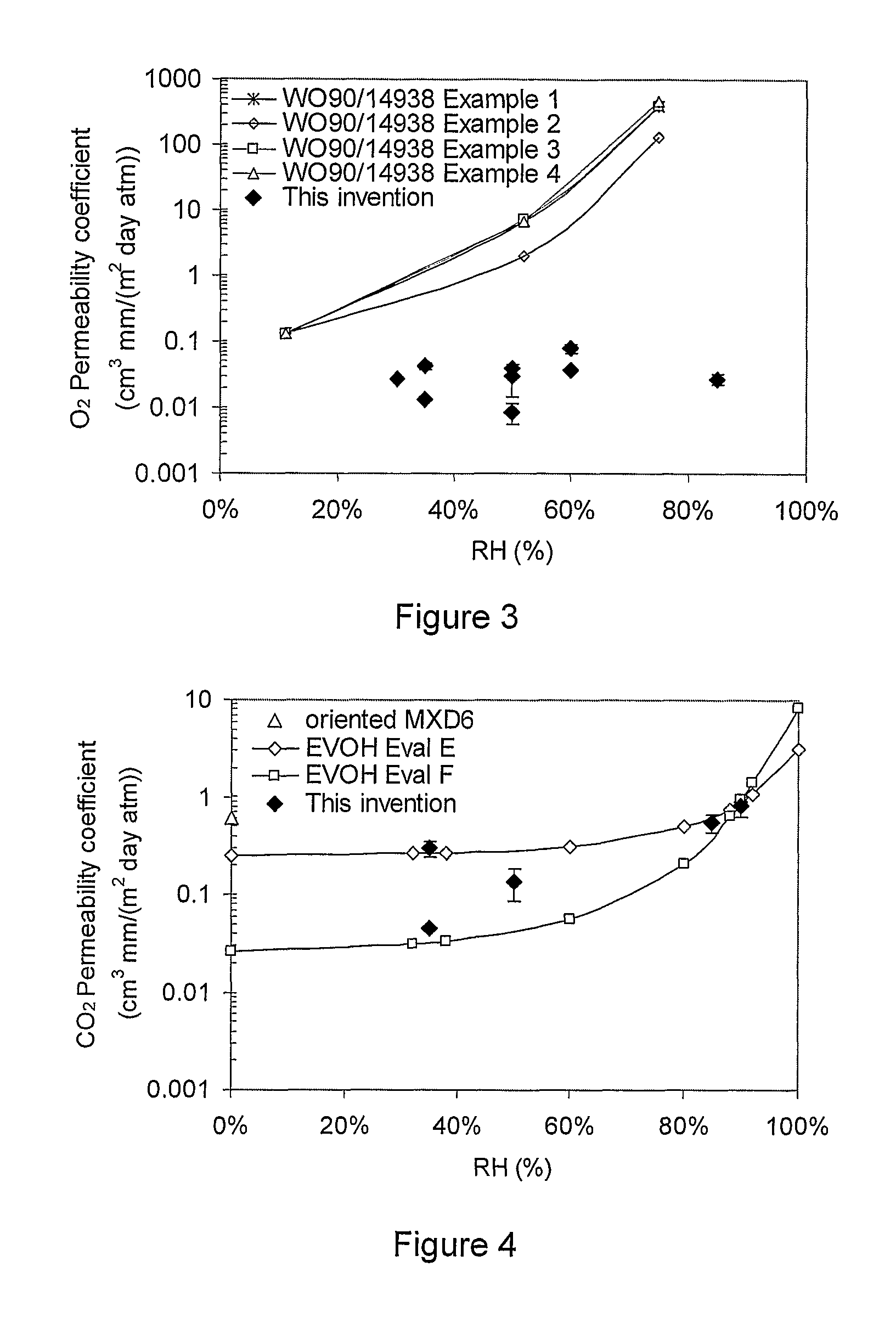

ActiveUS20090312462A1Excellent oxygen barrier propertiesSuitable for usePaper coatingDomestic articlesMolten statePolymer science

A polymer composition and its use for thin film packaging applications including on a dry basis: a) from 45 to 90% by weight of starch; b) from 0.1 to 15% by weight of a water soluble polymer selected from polyvinyl alcohol, polyvinylacetate, and copolymers of ethylene and vinyl alcohol which have a melting point compatible with the molten state of the starch component; and c) from 5 to 45% by weight of one or more plasticizers having a molecular weight in the range of 50-6000, more preferably 50-2500 and more preferably still 100-400 and desirably selected from the group consisting of sorbitol, glycerol, maltitol, xylitol, mannitol, erythritol, glycerol trioleate, tributyl citrate, acetyl tri-ethyl citrate, glyceryl triacetate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate, polyethylene oxide, ethylene glycol, diethylene glycol or polyethylene glycol.

Owner:PLANTIC TECH

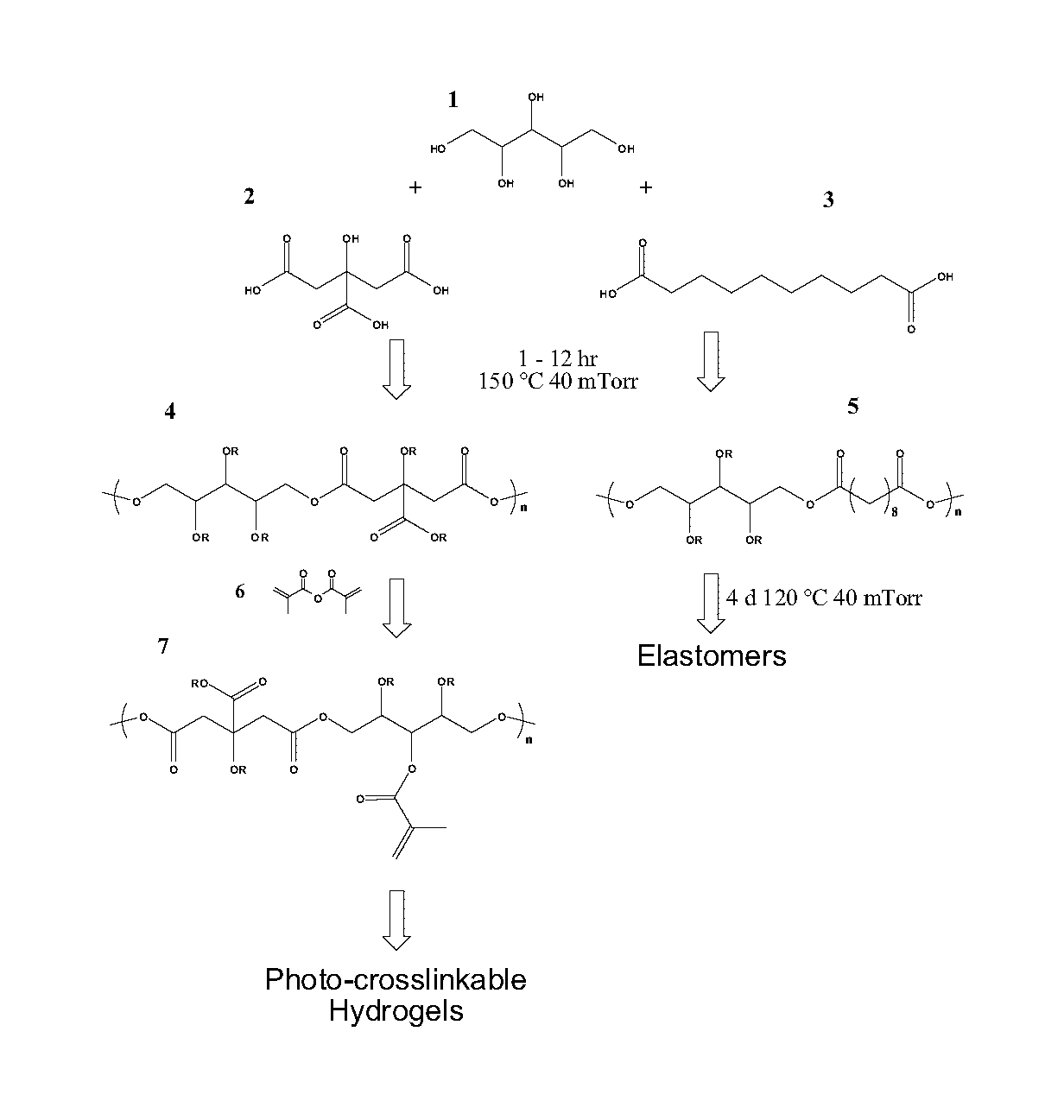

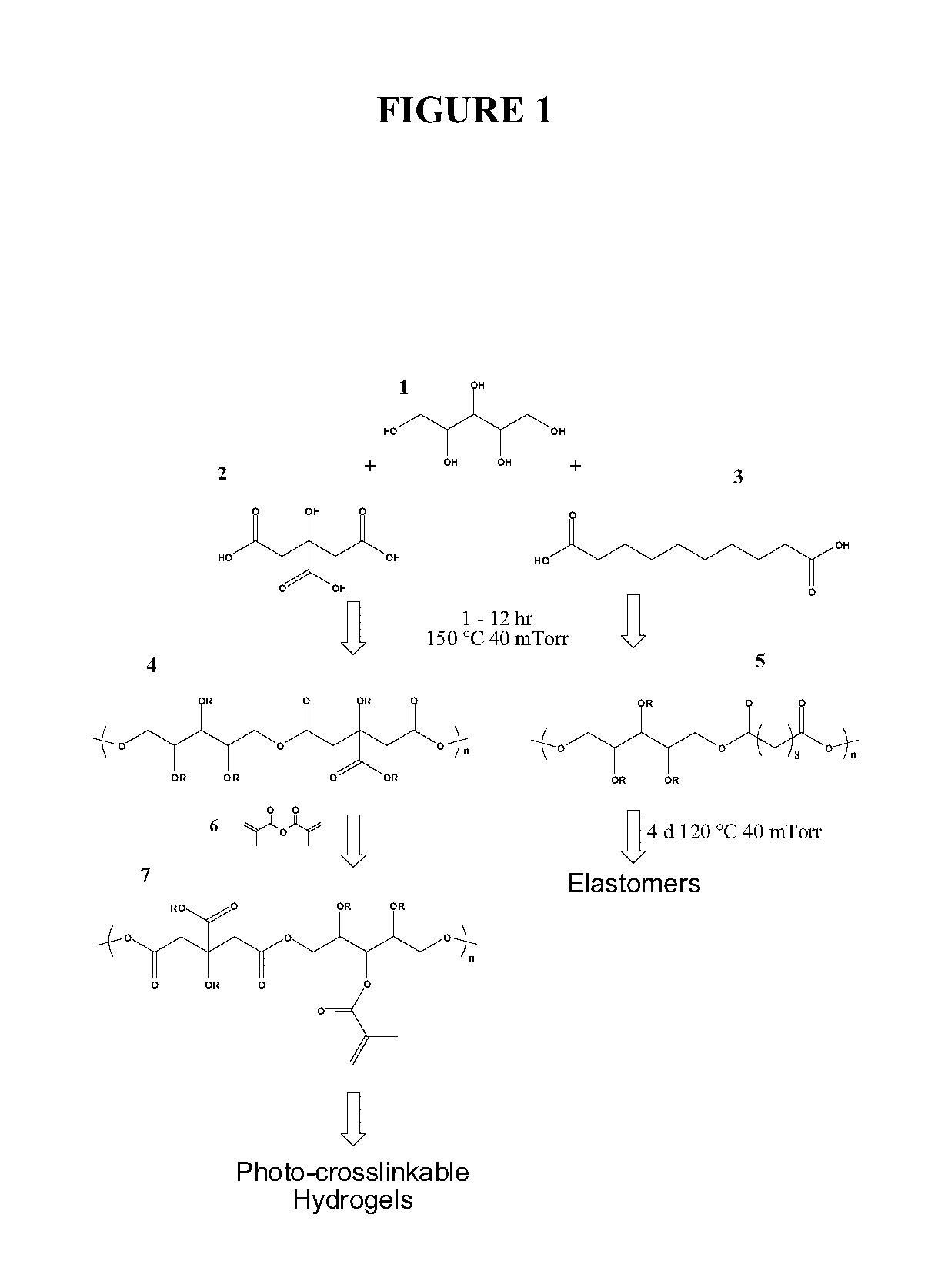

Polyol-based polymers

ActiveUS20110008277A1Cheap preparationOrganic active ingredientsProsthesisMethacrylatePolymer science

The present invention provides inventive polyol-based polymers, materials, pharmaceutical compositions, and methods of making and using the inventive polymers and materials. In certain aspects of the invention, an inventive polymer corresponds to a polymer depicted below. Exemplary inventive polymers includes those prepared using polyol units (e.g., xylitol, mannitol, sorbitol, or maltitol) condensed with polycarboxylic acid units (e.g., citric acid, glutaric acid, or sebacic acid). The inventive polymers may be further derivatized or modified. For example, the polymer may be made photocrosslinkable by adding methacrylate moieties to the polymer.

Owner:THE GENERAL HOSPITAL CORP +1

Tea jelly sweet

The invention discloses a tea jelly sweet which is prepared from raw material in the formula in parts by weight: 4-10 parts of functional composition, 30-60 parts of maltitol, 30-40 parts of starch syrup, 3.5-7 parts of plural gel, 0.1-10 parts of lecithin, 0.1-3 parts of hydrogenated vegetable oil, 1-3 parts of peppermint oil and 20-40 parts of water, wherein the functional composition comprises one or several of ultra-micropowder or extractions or original materials of pu-erh tea, black tea, green tea, Oolong tea, white tea, yellow tea and dark tea and other functional factors; and the plural gel comprises modified starch, gelatine, agar and carrageenan. The invention has the characteristics of defined functions, attractive appearance, natural aroma, good taste and the like, has no artificially-synthesized pigment and essence and sweetner causing decayed tooth and is suitable for groups to eat for a long term so as to improve the sub-health state.

Owner:云南龙润茶业集团有限公司

High-intensity sweetener-polyol compositions

InactiveUS20050196503A1Improve sweetness qualityImprove taste qualityConfectionerySweetmeatsCyclamatesMANNITOL/SORBITOL

The present invention provides a sweetener composition and methods for improving the taste of a sweetener composition. The sweetener composition includes a mixture of a high-intensity sweetener such as aspartame, encaspsulated aspartame, neotame, encapsulated neotame, cyclamate, sucralose, saccharin or Acesulfame-K, with polyols such as maltitol, sorbitol, mannitol, erythritol, xylitol, lactitol, or palatinit, wherein the high-intensity sweetener is present in the mixture in an amount from about 0.0001% to 15% by weight.

Owner:RICHMOND CHEM CORP

Barrier film

InactiveUS20090110942A1Stable mechanical propertiesImprove homogeneityFireproof paintsFibre treatmentMolten statePolyethylene oxide

A barrier composition which is injection mouldable and able to be made into a transparent film or incorporated (by co-extrusion and / or lamination) into multi-layer film products, the composition on dry basis: a) from 45 to 90% by weight of a starch and / or a modified starch selected from starches modified by reaction with a hydroxyl alkyl group, an acetate or a dicarboxylic acid anhydride or a grafting polymer; b) from 4 to 12% by weight of a water soluble polymer selected from polyvinyl alcohol, polyvinylacetate, and copolymers of ethylene and vinylalcohol which have a melting point compatible with the molten state of the starch components c) from 5 to 45% by weight of a non-crystallising mixture of sorbitol and at least one other plasticizer selected from glycerol, maltitol, xylitol, mannitol, glycerol trioleate, epoxidised linseed or soybean oil, tributyl citrate, acetyl tri-ethyl citrate, glyceryl triacetate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate; polyethylene oxide or polyethylene glycol; d) from 0.3 to 2.5 % by weight of a C12-22 fatty acid or salt; e) from 0.25% to 3% of an emulsifier system having a hydrophilic lipophilic balance value between 2 and 10. The barrier film may be co-injection moulded with polyethylene terephthalate (PET) or polylactic acid (PLA) for blow moulding into beverage bottles, with polyethylene (PE) or polypropylene (PP) or biodegradable polymers for high gas-barrier containers or closures, or may be co-extruded with polyethylene, polypropylene or polylactic acid for thin film packaging applications or for blow-moulded containers.

Owner:PLANTIC TECH

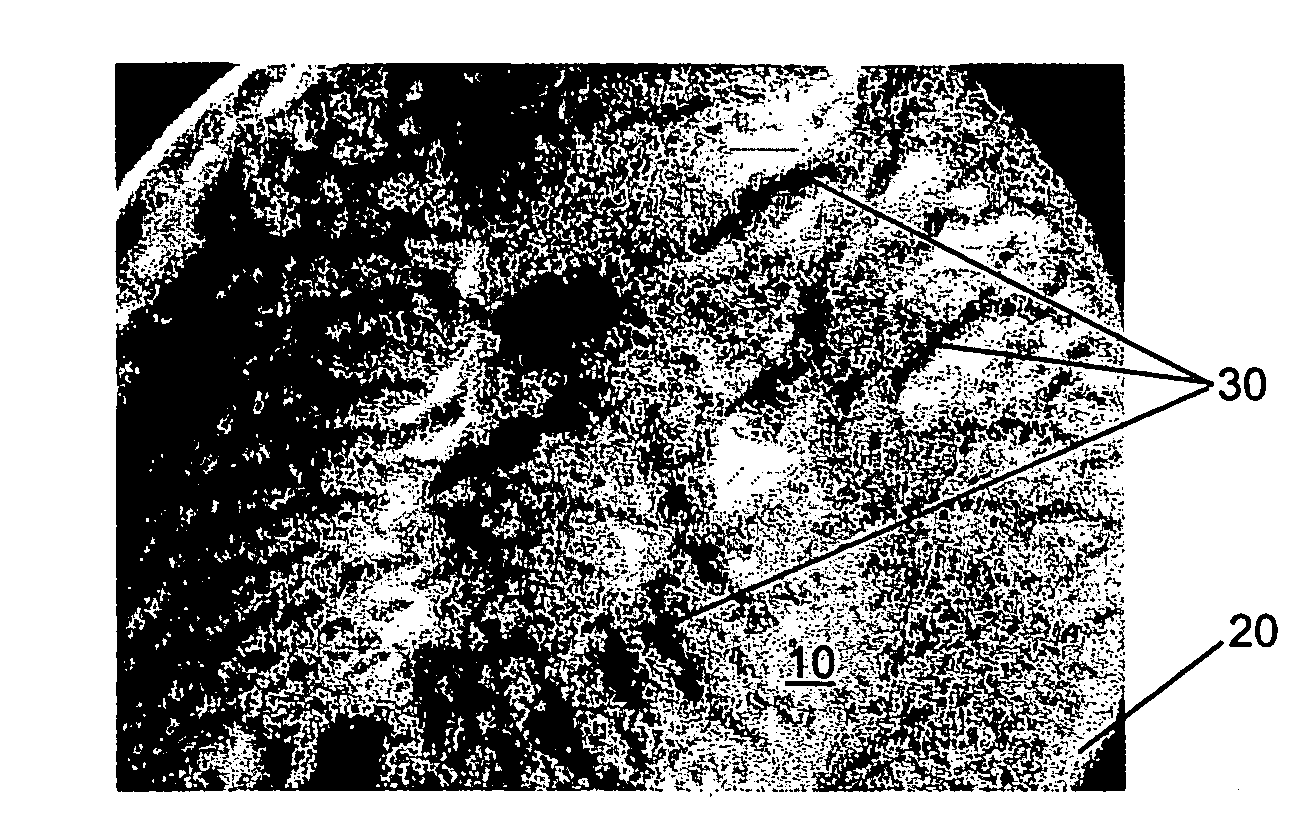

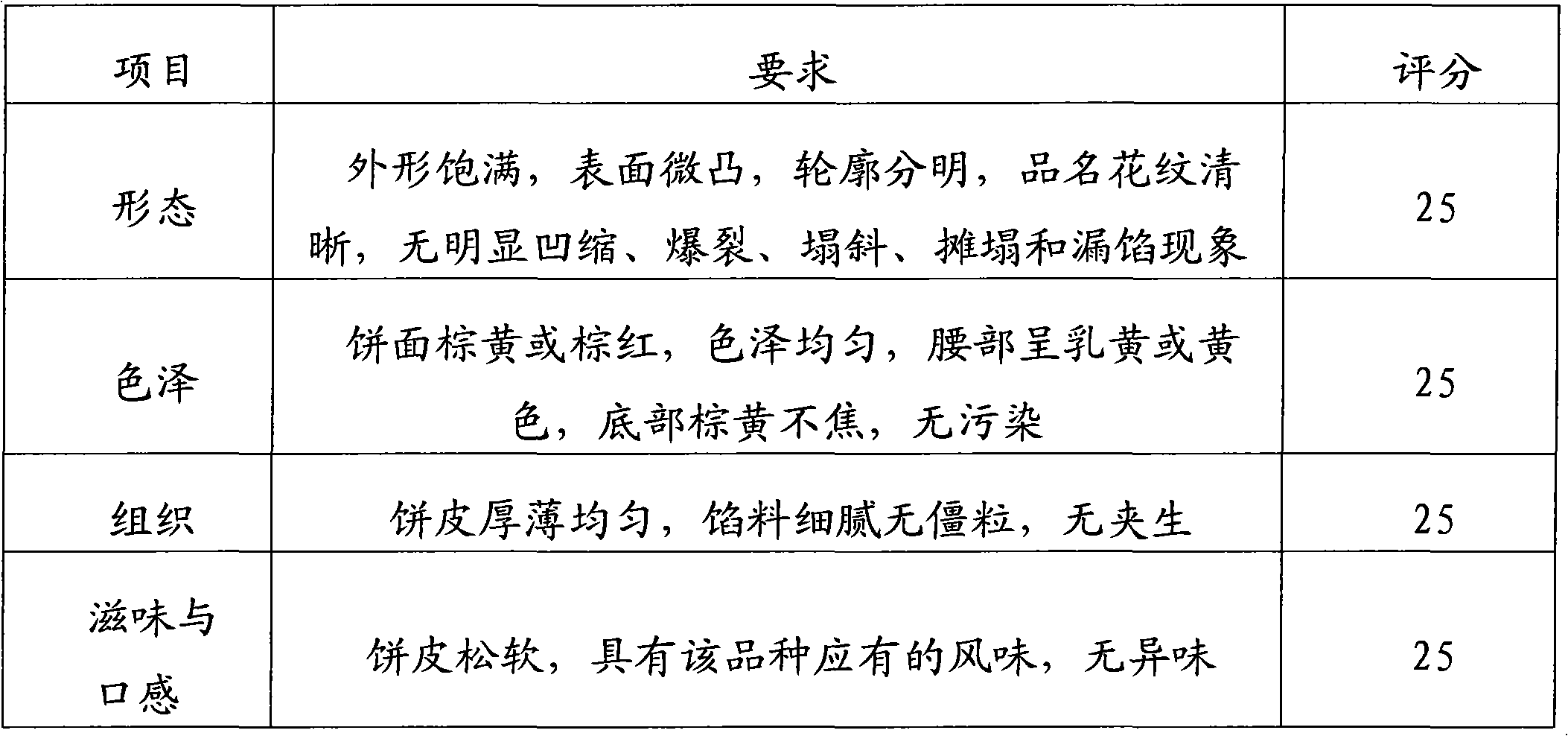

Moon cake

ActiveCN101889600AEasy to shapeImprove plasticityDough treatmentBakery productsAlkaline waterVegetable oil

The invention discloses a moon cake. The moon cake comprises a moon cake cladding and a moon cake filling, wherein the moon cake cladding comprises the following raw materials: 40 to 70 percent of wheat flour, 20 to 45 percent of sugar alcohol, 2 to 8 percent of L-arabinose, 5 to 20 percent of animal and vegetable oil or hydrogenated animal and vegetable oil and 0.2 to 2 percent of alkaline water. The technical problems of soft cladding and poor plasticity caused by the low viscosity of a sugar-free moon cake which takes maltitol solution as a cladding in the prior art are solved. Therefore, the moon cake has the characteristics of easily-shaped cladding, high plasticity and stable texture in baking process.

Owner:SHENGQUAN HEALTANG

Barrier film

InactiveUS7854994B2Improve the level ofImprove homogeneityFibre treatmentBottlesPolyethylene terephthalate glycolPolyethylene oxide

A barrier composition which is injection mouldable and able to be made into a transparent film or incorporated (by co-extrusion and / or lamination) into multi-layer film products, the composition on dry basis: a) from 45 to 90% by weight of a starch and / or a modified starch selected from starches modified by reaction with a hydroxyl alkyl group, an acetate or a dicarboxylic acid anhydride or a grafting polymer; b) from 4 to 12% by weight of a water soluble polymer selected from polyvinyl alcohol, polyvinylacetate, and copolymers of ethylene and vinylalcohol which have a melting point compatible with the molten state of the starch components c) from 5 to 45% by weight of a non-crystallising mixture of sorbitol and at least one other plasticizer selected from glycerol, maltitol, xylitol, mannitol, glycerol trioleate, epoxidised linseed or soybean oil, tributyl citrate, acetyl tri-ethyl citrate, glyceryl triacetate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate; polyethylene oxide or polyethylene glycol; d) from 0.3 to 2.5% by weight of a C12-22 fatty acid or salt; e) from 0.25% to 3% of an emulsifier system having a hydrophilic lipophilic balance value between 2 and 10. The barrier film may be co-injection moulded with polyethylene terephthalate (PET) or polylactic acid (PLA) for blow moulding into beverage bottles, with polyethylene (PE) or polypropylene (PP) or biodegradable polymers for high gas-barrier containers or closures, or may be co-extruded with polyethylene, polypropylene or polylactic acid for thin film packaging applications or for blow-moulded containers.

Owner:PLANTIC TECH

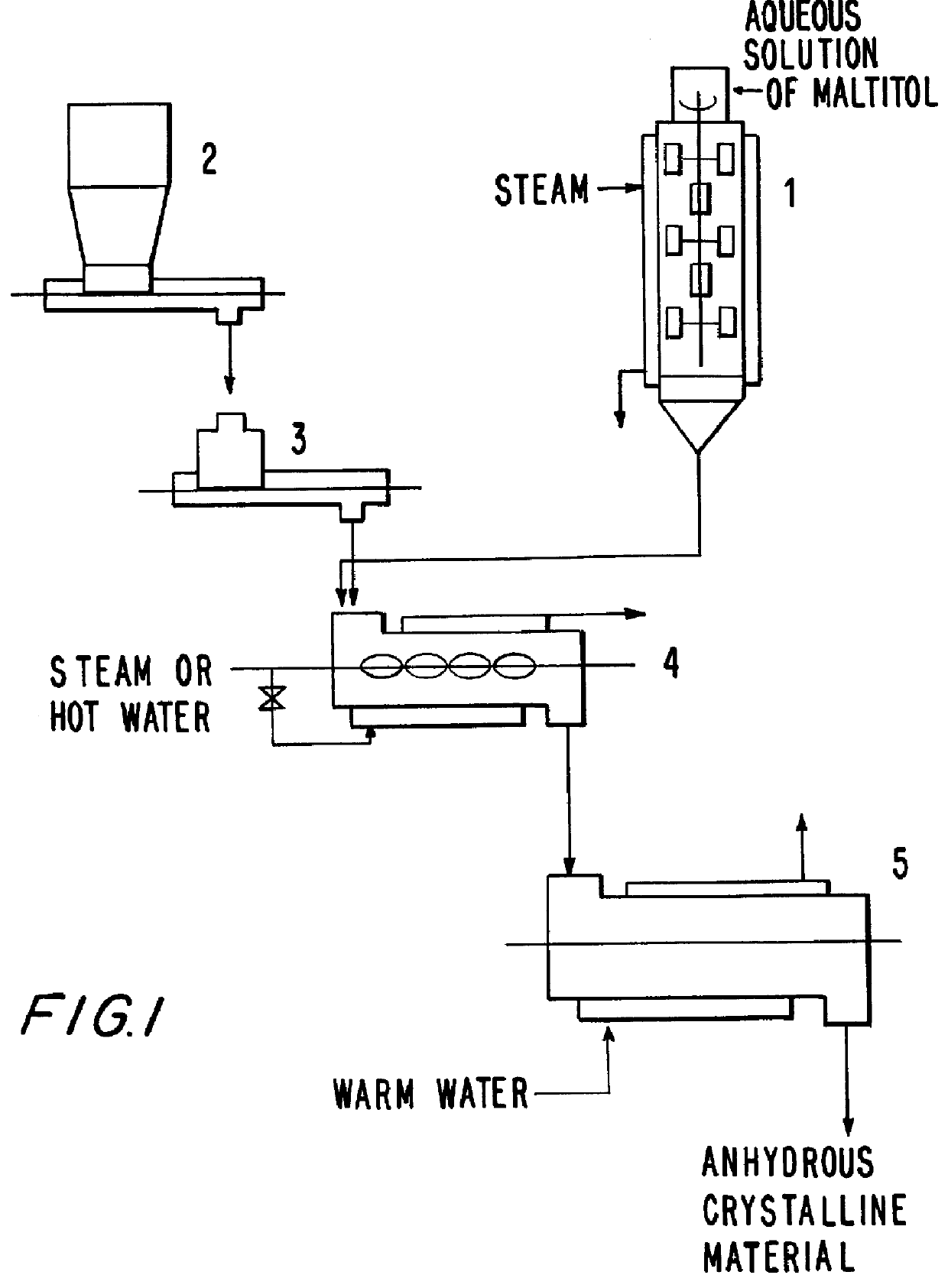

Method for the continuous manufacture of anhydrous crystalline maltitol and a manufacturing apparatus therefor

InactiveUS6120612ALow production costLabor expenseSugar derivativesSugar crystallisationHigh concentrationPolymer science

Disclosed herein is a continuous manufacturing method for anhydrous crystalline maltitol comprising the following steps: (i) a heating and concentrating step where an aqueous solution containing maltitol in which maltitol is a main ingredient is continuously heated and concentrated to give a concentrated solution having a high concentration; (ii) a seed crystal adding and mixing step where the seed crystals are added to and mixed with the above concentrated solution with heating to give a massceuite containing the seed crystals; and (iii) a crystal aging step where the massceuite is subjected to disintegration, mixing, stirring and transfer in an atmosphere in which temperature and moisture are adjusted to proceed the crystallization.

Owner:HAYASHIBARA BIOCHEMICAL LAB INC +1

Non-crystallizing syrups containing sorbitol and their use in chewing gum

ActiveUS20070196534A1Low costImproved chewing gum compositionContainers for annular articlesChewing gumMaltitolGlycerol

An aqueous syrup for use in chewing gum, particularly pellet gum, comprises, on a dry basis, greater than about 98% polyols, of which i) about 50% to about 90% is sorbitol, ii) about 3% to about 30% is maltitol, iii) about 2% to about 20% are polyols, other than sorbitol and maltitol, with a degree of polymerization (DP) of 1 or 2, and iv) less than about 20% (and perhaps less than about 12%) are polyols with a DP of 3 or greater. The syrup is made with less than about 1.0% plasticizing agent, such as glycerin or propylene glycol. The syrup contains less than 5% water. The syrup can be made by evaporating a mixture of a sorbitol solution, a maltitol syrup and one or more polyols selected from the group consisting of mannitol, xylitol, lactitol, erythritol, hydrogenated isomaltulose, and combinations thereof. Methods of using the syrup to make chewing gum, and chewing gum products containing the syrup are also provided.

Owner:WM WRIGLEY JR CO

Adhesive for casting mold, manufacturing core and method of manufacturing the same

InactiveCN101108407AReduce the amount addedHigh strengthFoundry mouldsFoundry coresPentaerythritolPolyethylene glycol

A cohesion agent for casting module and making core is provided, which is characterized in that: the mass per centage ration of the main chemical component of the cohesion agent is SiO2, 23 to 31, K2O 0.5 to 28, Na2O 1 to 21, modifying agent 0.5 to 21 and excess water. Wherein, the modifying agent chooses one or two in sorbierite, xylitol, mannite, maltitol, glycol, propanediol, glycerol, pentaerythritol, diglycol, propylene glycol, carbowax, PPG and polyglycerol, the adding volume is 0.5 to 21 per cent. When using the cohesion agent to prepare sand mole core, the dosage is little, the old sand can be recycled and the prepared core has good collapse performance.

Owner:SHENYANG HYATON FOUNDRY MATERIAL

Weight-losing nutrition bar and preparation method thereof

The invention provides a weight-losing food with balanced nutrition, containing the following components of: soybean isolate protein expanded grains, maltitol liquid, water-soluble dietary fiber, concentrated lactalbumin, glycerol, fish collagen protein, phytosterol, quick-freezing blueberry grains, Arabic gum, sodium caseinate and compound vitamin. The weight-losing bar has the advantages of good taste and high protein content; the weight-losing food bar can enhance the satiety and also can supplement the protein; and meanwhile, functional food raw materials including the fish collagen protein, the phytosterol and the like, the compound vitamin and the like are added, so as to achieve the aim of healthily losing the weight of a consumer.

Owner:浙江诺特健康科技股份有限公司

Functional health-care ice cream

ActiveCN101530152AAchieve melt resistanceReach the tasteFrozen sweetsFood preparationMonoglycerideIsomaltooligosaccharide

The invention relates to functional health-care ice cream of cold drink food, which is technically characterized in that the ice cream is prepared by the following raw materials according to a definite proportion: xylitol, maltitol, isomaltitol, sorbitol, isomaltitol oligosaccharide, skim milk powder, natural cream, maltodextrin, sodium pyrophosphate, gelatin, guar gum, locust bean gum, xanthan gum, sodium carboxymethyl cellulose, monoglyceride, monodiacylglycero, and the balance of drinking water. The functional health-care ice cream has the same production process as common ice cream. Taking functional sugar substitutes such as the xylitol and the like as the main materials, simultaneously non-fat solid, the natural cream, the maltodextrin, pyrophosphates, edible colloid, edible essence and natural pigments are prepared into the ice cream. Taking nutrition, health and safety as aims, the ice cream with low calorie and high nutrition is developed; and the ice cream has the functions of preventing decayed tooth, preventing yellow tooth, protecting liver, proliferating enteric beneficial strains, adjusting organism metabolism, losing weight and the like, does not increase blood sugar after eating, and is an ideal food for diabetes patients and fat people.

Owner:LIAONING TIANQI FOOD GROUP

Solid preparation

InactiveUS20010009678A1Good disintegrationPromote dissolutionBiocideMetabolism disorderLow-substituted hydroxypropylcelluloseMaltitol

A solid preparation which comprises (i) a pharmaceutically active ingredient, (ii) one or more water-soluble sugar alcohol selected from the group consisting of sorbitol, maltitol, reduced starch saccharide, xylitol, reduced palatinose and erythritol, and (iii) low-substituted hydroxypropylcellulose having hydroxypropoxyl group contents of 7.0 to 9.9 percent by weight; which exhibits excellent buccal disintegration and dissolution and also appropriate strength.

Owner:TAKEDA PHARMA CO LTD

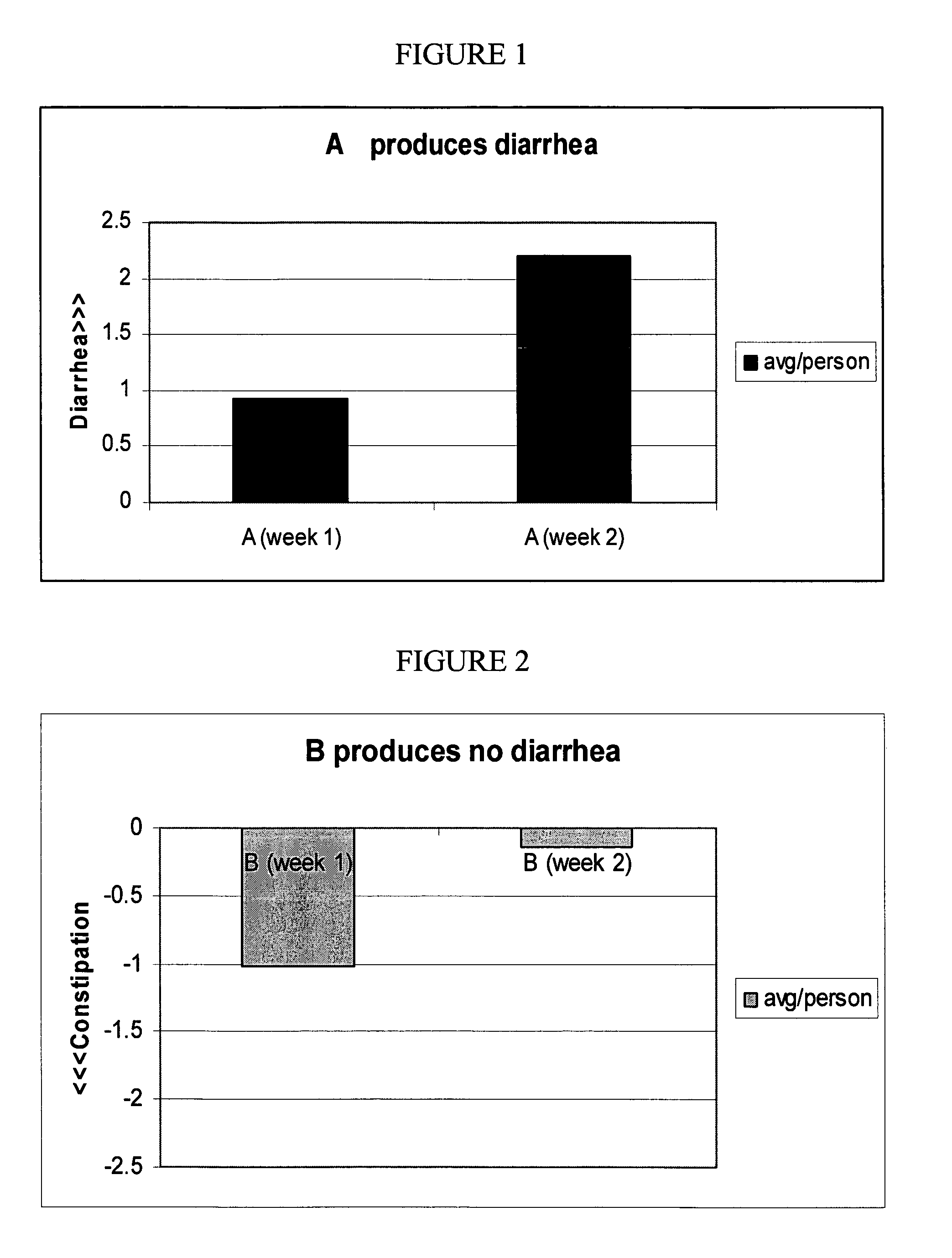

Compositions containing at least one polyol and inulin characterized by reduced tendencies of the at least one polyol to induce acute diarrhea

InactiveUS7147883B1Trend downUnpleasant TaxationSugar food ingredientsSugar derivativesGalactitolIsomalt

A composition containing at least one polyol and certain amounts of inulin relative to the at least one polyol, characterized by a reduced tendency of the at least one polyol to induce acute diarrhea. The at least one polyol may be, for example: xylitol, sorbitol, maltitol, mannitol, isomalt, isomaltitol, lactitol, hydrogenated starch hydrolysates (HSH), glycerol, propylene glycol, erythritol, galactitol and combinations thereof. The composition also contains inulin in amounts sufficient to at least partially reduce, or eliminate, the tendency of the polyol to induce acute diarrhea. Foodstuffs, including drinks and beverages, contain said compositions.

Owner:SILVER BARNARD S

Preserved fruits without sugar additives

The invention provides a preserved fruit without additive sugar which is prepared by the steps of selecting fruits, gum dipping, boiling in sugar, sugar dipping and baking, etc., and has the advantage that cane sugar and syrup in traditional technique are replaces by xylitol, sorbierite, maltitol or mannite, etc. Not only the sugar content of the product obtained by the invention is low and is lower than 30 percent but also the product has the advantages of abundant nourishment, unique flavor and good taste, which is suitable for wide crowd and especially for the special crowd of diabetics, etc.

Owner:SHANXI UNIV

Food compositions and related methods

ActiveUS20060008576A1Adverse disadvantageConfectionerySweetmeatsChocolate confectionerySugar substitute

An amorphous sugar-free sweetening composition acts as a sugar substitute in the production of a chocolate confection. Maltitol syrup may be employed in a chocolate confection mixture with a dry milk substitute composition to form a chocolate confection with improved taste and texture characteristics as compared to other sugar-free chocolate confection compositions. Other amorphous sweetening compositions may be used in the production of chocolate compositions. Methods of making chocolate compositions are also disclosed.

Owner:ARCHER DANIELS MIDLAND CO

Natural deodorant composition

The present invention relates to a natural deodorant system and a natural system for topical and systemic delivery of active ingredients, both systems being primarily free of, preferably substantially free of, more preferably essentially free of, and most preferably completely free of ethoxylates or other petrochemical derivatives, and comprising: (a) at least one of (1) glycerine (preferably of plant origin), (2) a polyol selected from the group consisting of galactitol, erythritol, inositol, ribitol, dithioerythritol, dithiothreitol, (3) a sugar alcohol, selected from the group consisting of mannitol, sorbitol, xylitol and maltitol, (4) a hydrogenated starch hydrosylates of at least one of berries, apples or plums, and (5) mixtures thereof; (b) water or a lower monohydric alcohol, selected from the group of methanol, ethanol, propanol and isoproponal, or mixtures thereof, present at a combined concentration of at least 20%; (c) one or more carrageenans (preferably of plant origin) or alginates, or mixtures thereof, present in combined concentrations of less than about 2%; and (d) optionally, one or more thickeners or gums selected from the group consisting of tara, guar, xanthan, Arabic, tragacanth, agar, locust bean gum, ghatti and microcrystalline celluloses.

Owner:TERRA FA NATUALS

Mouldable Biodegradable Polymer

InactiveUS20100297458A1Synthetic resin layered productsCellulosic plastic layered productsMolten statePolyethylene oxide

A biodegradable injection mouldable polymer composition including on a dry weight basis from 45-85% w / w by weight of a starch and / or a modified high amylose starch, from 2-15% w / w by weight of a water soluble polymer preferably selected from polyvinyl alcohol, polyvinyl acetate and copolymers of ethylene and vinyl alcohol which have a melting point compatible with the molten state of the starch components, and from 5-45% w / w by weight of one or more polyol plasticizers having a molecular weight in the range of 50-6000, more preferably 50-2500, and still more preferably 100-400 and preferably selected from the group consisting of sorbitol, glycerol, maltitol, xylitol, mannitol, erythritol, polyglycerol, glycerol trioleate, tributyl citrate, acetyl tri-ethyl citrate, glyceryl triacetate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate, polyethylene oxide, ethylene glycol, diethylene glycol or polyethylene glycol; more preferably glycerol, maltitol, sorbitol, erythritol and xylitol. The composition is preferably substantially soluble in water.

Owner:PLANTIC TECH

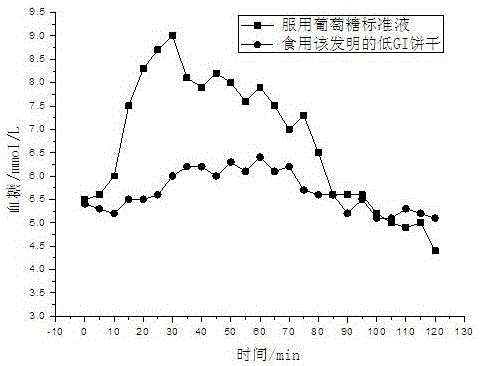

Low-glycemic-index biscuits and making method thereof

InactiveCN106614916AEnhanced GI valueLow GI valueDough treatmentModified nutritive productsFiberSodium bicarbonate

The invention relates to low- glycemic-index biscuits and a making method thereof. The making method comprises the following steps: taking raw materials in parts by weight, mixing table salt with konjaku flour and inulin, and adding water for stirring so as to obtain a mixture A; heating anhydrous butter until the anhydrous butter is melted, performing rapid stirring to get foam, adding eggs, and continuing to quickly get foam so as to obtain a mixture B; adding water to ammonium bicarbonate and sodium bicarbonate for stirring and dissolving so as to obtain a mixture C; uniformly mixing flour with maltitol, xylitol, defatted soy flour, tartarian buckwheat powder, wheat dietary fibers, green bean powder, scindapsus aureus, resistant dextrin, buckwheat, nonfat dry milk powder and celery powder, enabling the prepared mixture A, the mixture B and the mixture C to be concocted into dough by a dough mixer, and performing refrigeration standing; pressing the dough into sheets with a noodle press, so as to obtain shaped biscuit blanks; and putting the biscuit blanks in an oven, performing baking under 180 DEG C for 10min, then performing cooling, and performing packaging so as to obtain the low- glycemic-index biscuits. The GI value of the made biscuits made by the method disclosed by the invention is 41.8 or below, so that the made biscuits are really suitable for diabetics to eat.

Owner:上海融朋电子商务有限公司

Preparation method of xylitol liver-protecting tablet

InactiveCN101744865AEffective preventionEffective therapeuticAnthropod material medical ingredientsHydroxy compound active ingredientsCross-linkPropolis

The invention relates to a preparation method of a xylitol liver-protecting tablet, belonging to the technical field of medical health care. The formula of the xylitol liver-protecting tablet comprises the following raw materials in proportion: 15-45 parts of kudzu root extract, 2-20 parts of glycyrrhizic acid, 5-35 parts of propolis powder, 20-60 parts of xylitol, 1-10 parts of low-substituted hydroxypropyl cellulose, 1-10 parts of cross-linked sodium carboxymethyl cellulose and 0.5-5 parts of magnesium stearate; and a coating agent comprises 0.5-40 parts of hydroxypropyl methylcellulose, 1-30 parts of polyethylene glycol 6000, 0.5-40 parts of talcum powder, 0.5-30 parts of titanium pigment, 0.5-30 parts of iron oxide brown and 10-75 parts of maltitol. The finished product of the xylitol liver-protecting tablet is prepared by the processing steps of crushing, mixing, tabletting, coating and the like. In the invention, by using the xylitol as a main raw material and adding partial auxiliary materials, the xylitol liver-protecting tablet which is a health food and has auxiliary protection effect on chemical liver injury is prepared. The xylitol liver-protecting tablet can effectively prevent and treat fatty liver; and after patients suffering from the fatty liver take the xylitol liver-protecting tablet, severe fatty liver can be relieved into moderate fatty liver, and moderate fatty liver can be relieved into mild fatty liver. Thus, the xylitol liver-protecting tablet has obvious benefit to improve liver functions of human bodies and has wide market prospects.

Owner:FUTASTE PHARM CO LTD

Coated chewing gum

InactiveUS20070184149A1Increased crunchExtended shelf lifeContainers for annular articlesChewing gumPolyolMaltitol

A chewing gum product includes a center portion and a coating portion. The center portion includes a polyol component, gum base, an intense sweetener, a flavoring agent, and less than 1% glycerin. The polyol component includes a single polyol selected from the group consisting of isomalt, maltitol, and erythritol and is essentially free from any polyols other than the single polyol. The center portion is essentially free of hydrogenated oligosaccharides. The coating portion includes the single polyol and substantially covers the center portion. The coating portion is essentially free of any polyols other than the single polyol.

Owner:WM WRIGLEY JR CO

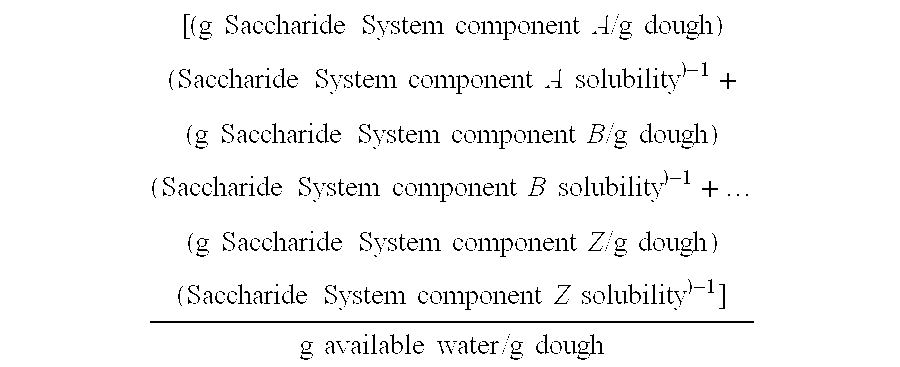

Reduced sucrose cookie dough

A reduced sucrose cookie dough is provided comprising a Saccharide System. The Saccharide System comprises a crystalline sugar alcohol comprising at least one member selected from the group consisting of crystalline maltitol, -crystalline lactitol, and crystalline isomalt and at least one member selected from the group consisting of a liquid sugar alcohol and a long chain sugar complex. The Saccharide System has a Collective Solubility that is within about 20% of the solubility of sucrose in the dough. The cookie dough has a sucrose content of less than 0.5 grams per serving size. Methods of making the cookie dough are also provided.

Owner:GENERAL MILLS INC

High-fiber biscuits processed from fresh bean dregs and processing method thereof

InactiveCN101816318AGood fiber tasteHigh Soy Fiber ContentDough treatmentBakery productsFiberMaltitol

The invention provides high-fiber biscuits processed from fresh bean dregs, which have high bean fiber content and good fiber mouthfeel, and a processing method which is simple, low in production cost and high in production efficiency. The high-fiber biscuits processed from the fresh bean dregs comprise the following components in part by weight: 17.48 to 21.48 parts of anhydrous ghee, 8.8 to 12.8 parts of egg, 0.35 to 0.95 part of cake oil, 21.1 to 25.1 parts of weak flour, 10.99 to 14.99 parts of maltitol, 21.8 to 25.8 parts of fresh bean dregs, 0.03 to 0.05 part of stevioside, 0.42 to 1.02 parts of soybean meal, 0.16 to 2.76 parts of baking powder, 0.16 to 0.56 part of soda, 0.06 to 0.16 part of salt, 1.56 to 2.76 parts of milk powder and 3.41 to 7.41 parts of salad oil. The method for processing the high-fiber biscuits from the fresh bean dregs comprises four steps of preparing slurry, forming the biscuits, baking the biscuits, and cooling and packaging.

Owner:WUXI CITY LINGSHAN FOODS

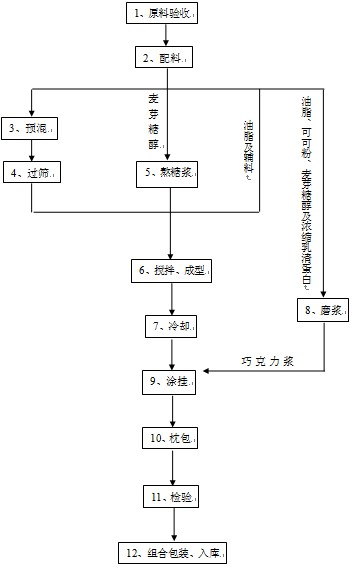

Minor cereal cake made from five black cereals and maltitol

The invention provides a minor cereal cake made from five black cereals and maltitol, which belongs to the technical field of food processing. The minor cereal cake is mainly characterized by being prepared from the raw materials of wheat powder, duck wheat powder, black rice powder, rye powder, black beam powder, black sesame powder, maltitol, eggs, palm oil, starch and the like through the processing steps of powder mixing, blank making, deep frying, syrup making, pulp application, forming, cutting forming and the like. The prepared cake not only is crisper and softer than the traditional cakes, but also presents the natural color of the five black cereals and has the unique and delicate taste. The cake also has the functions for preserving health and preventing various diseases, is an ideal leisure healthy food for both the old and the young, and is especially suitable for people with angiocardiopathy, diabetes, hyperlipemia, hypertension and obesity.

Owner:南阳谷香情食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com