Patents

Literature

1301 results about "Sebacic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sebacic acid is a naturally occurring dicarboxylic acid with the structure (HOOC)(CH₂)₈(COOH). In its pure state, it is a white flake or powdered crystal. The product is described as non-hazardous, though in its powdered form it can be prone to flash ignition (a typical risk in handling fine organic powders).

Elastomeric material compositions obtained from castor oil and epoxidized soybean oil

Elastomers are formed from castor oil and / or ricinoleic acid estolides and a polyester formed from an epoxidized vegetable oil such as ESO and a polycarboxylic acid such as sebacic acid, optionally in the presence of a peroxide initiator, or include crosslinked reaction products derived from ricinoleic acid or castor oil estolides, epoxy group-containing compounds such as epoxy resins and / or epoxidized vegetable oil, epoxy hardeners such as polyamine and polycarboxylic acid hardeners, thermally activated free radical initiators such as peroxides, and optionally but preferably include fillers such as limestone or wood flour. The elastomers can be prepared using a two-step, solvent-less procedure at elevated or ambient temperatures. These predominantly “all-natural” elastomers have physical properties comparable to conventional petroleum-based elastomers and composites and exhibit good flexibility, resiliency, abrasion resistance and inertness to hydrolysis. The resulting elastomers display good mechanical strength and resiliency, are resistant to abrasion and hydrolysis, and can be processed into sheet materials, which makes them attractive as floor covering components.

Owner:AFI LICENSING +1

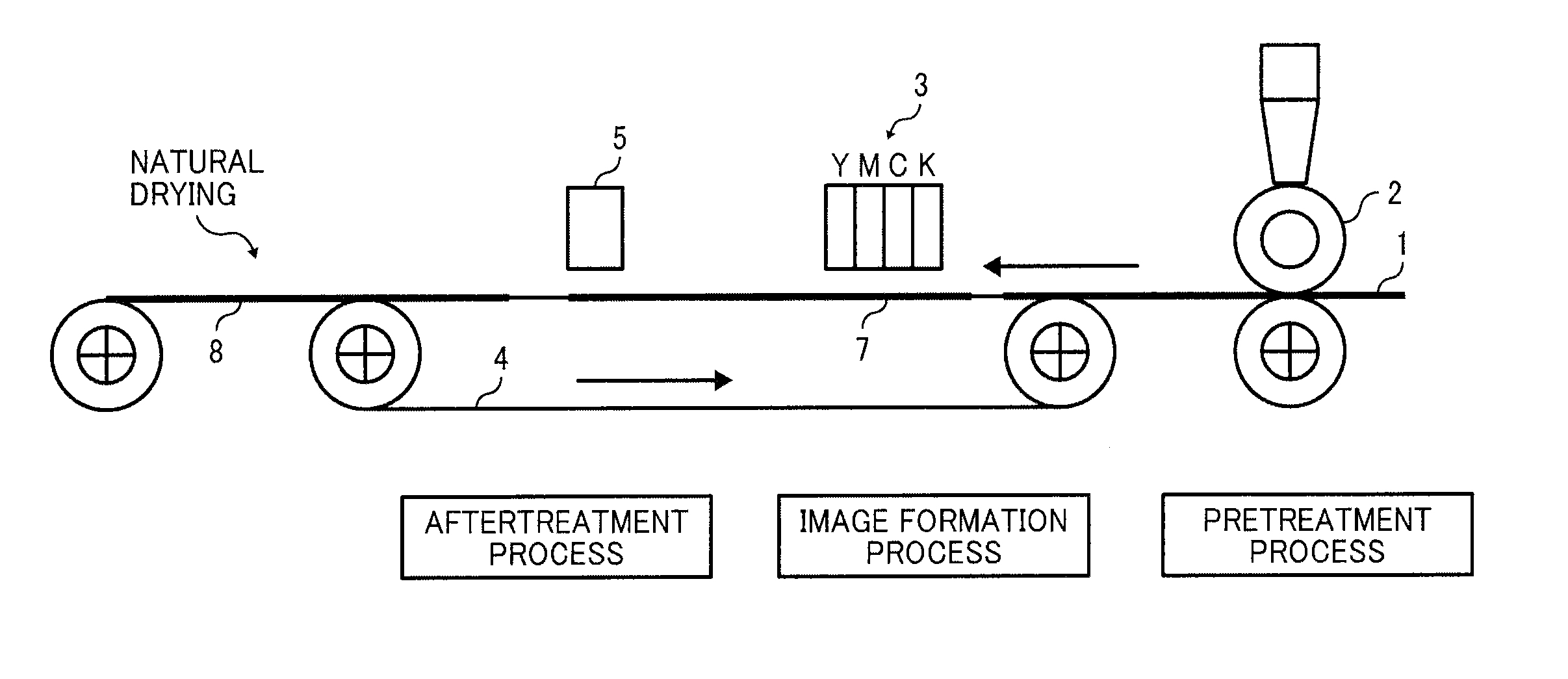

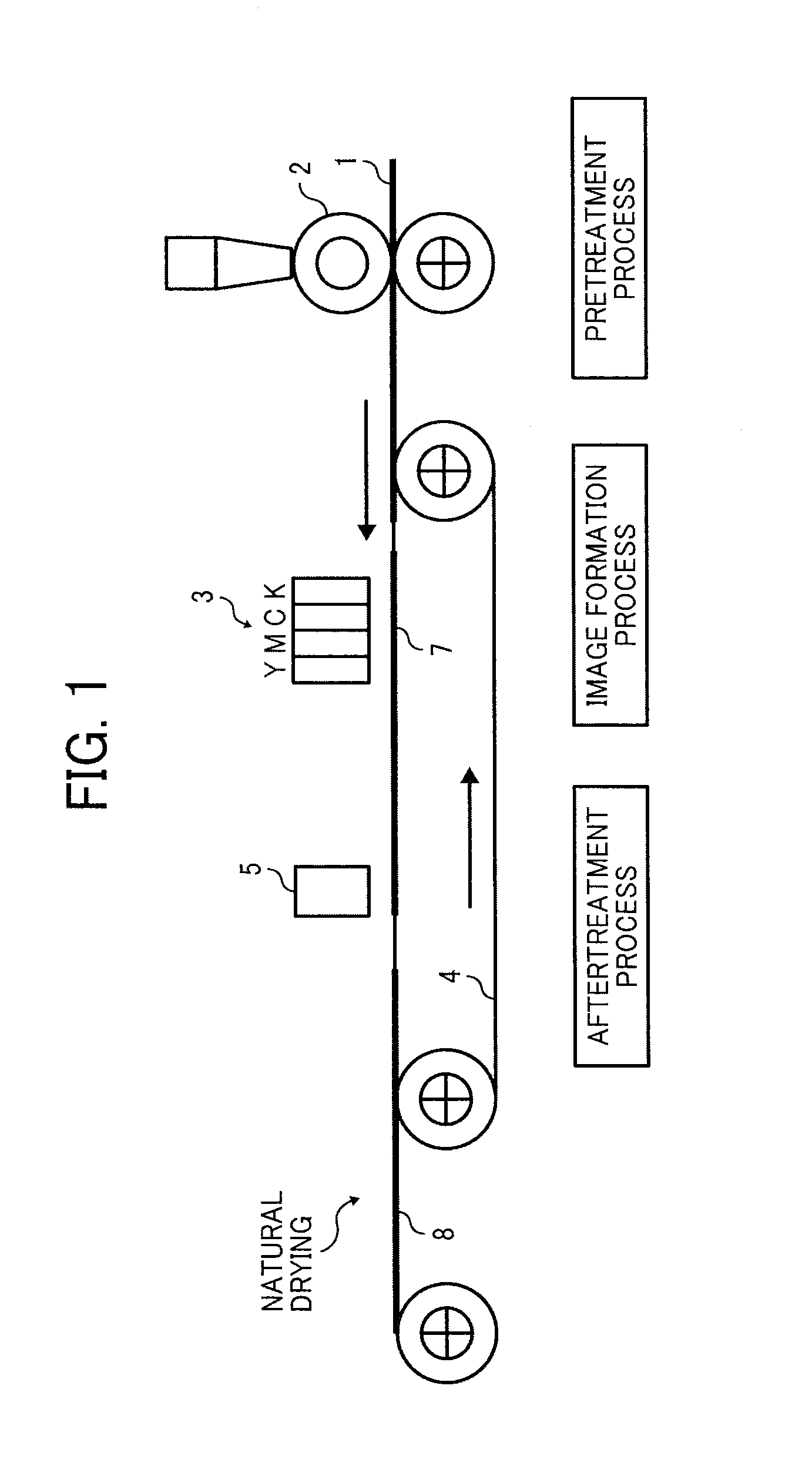

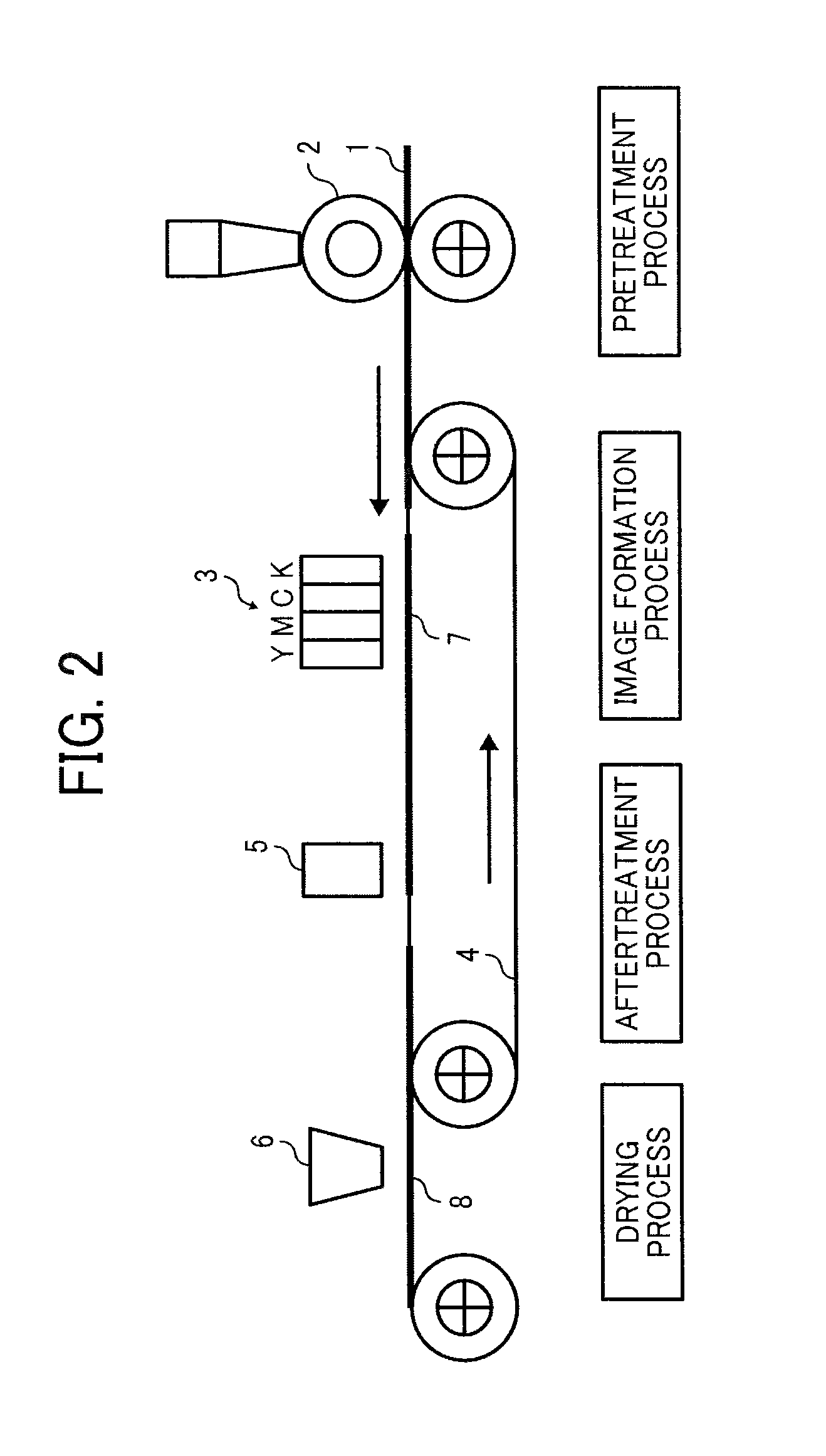

Image forming method

ActiveUS20130176369A1Measurement apparatus componentsDuplicating/marking methodsOrganic solventPolyol

An image forming method including adhering a pretreatment liquid to a surface of a recording medium bearing a coat layer thereon; adhering an ink including a colorant, an organic solvent, a surfactant and water to the surface of the recording medium to form an image of the ink; and adhering an aftertreatment liquid to the image-bearing surface of the recording medium to form a protective layer on at least the image on the recording medium. The organic solvent of the ink includes a polyalcohol having an equilibrium moisture content of not less than 30% by weight at 23° C. and 80% RH; a β-alkoxy-N,N-dimethylpropionamide compound, and at least one compound selected from 1,3-dioxane-4-methanol compounds, oxetane compounds, and sebacic acid dialkylester compounds.

Owner:RICOH KK

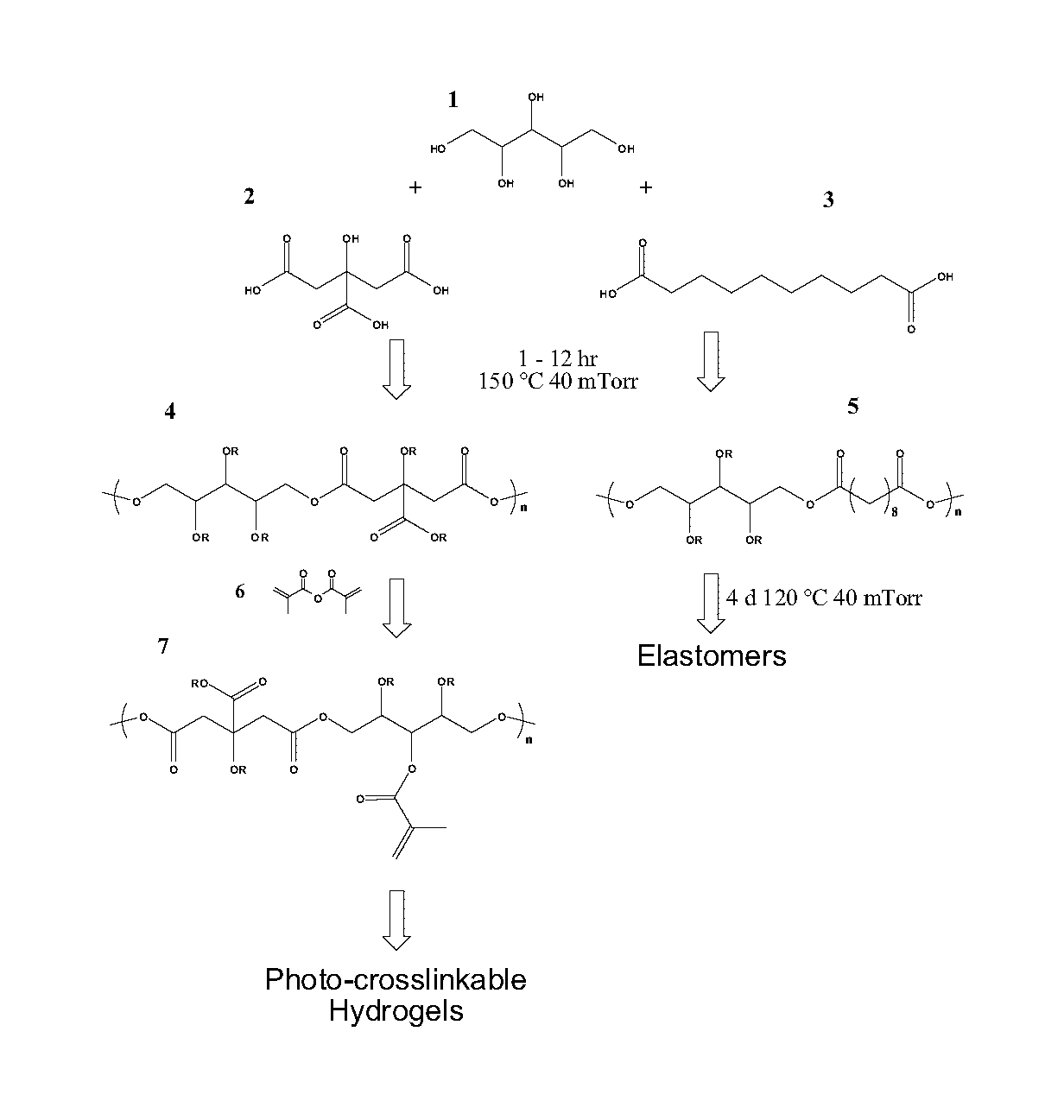

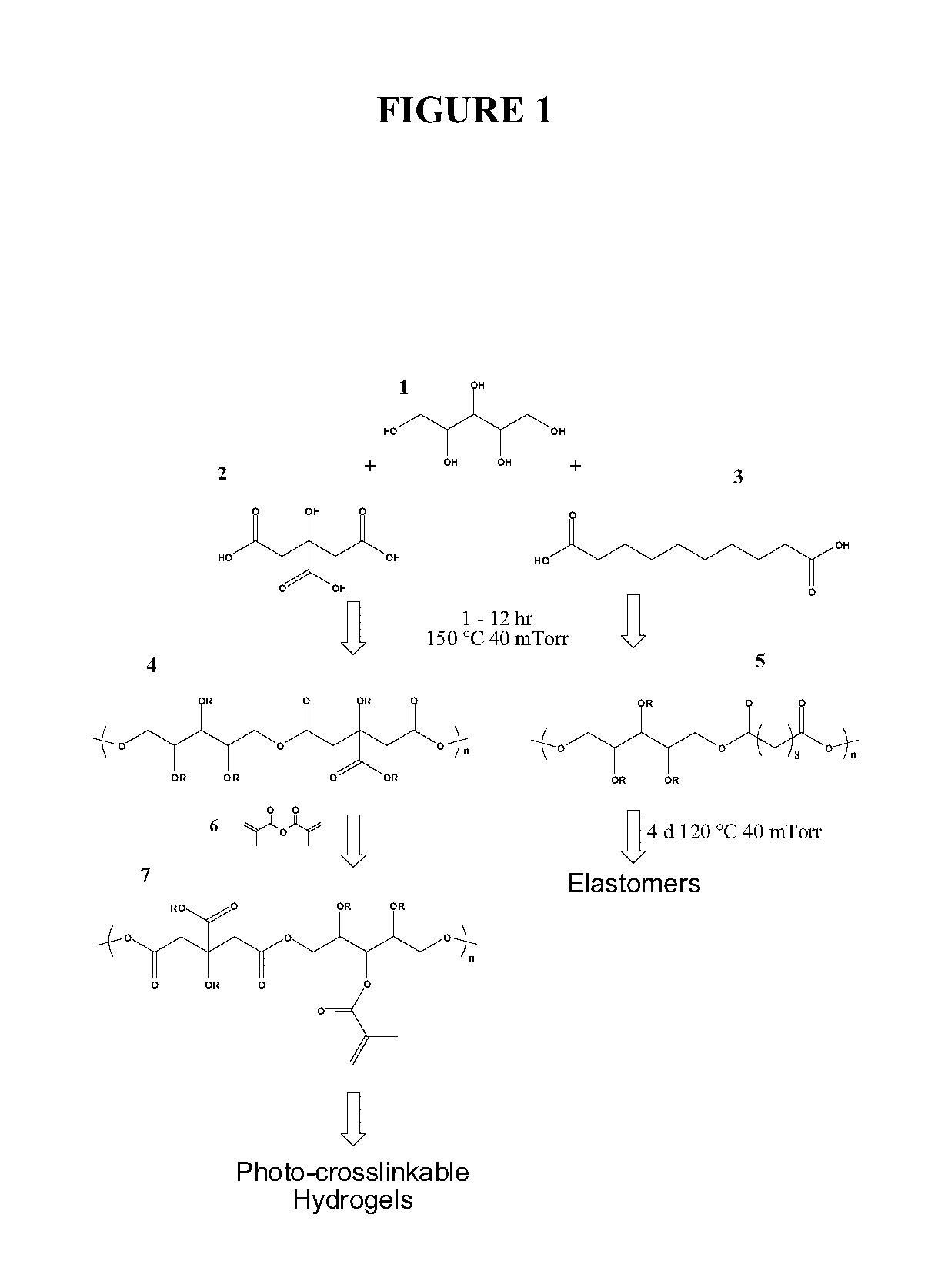

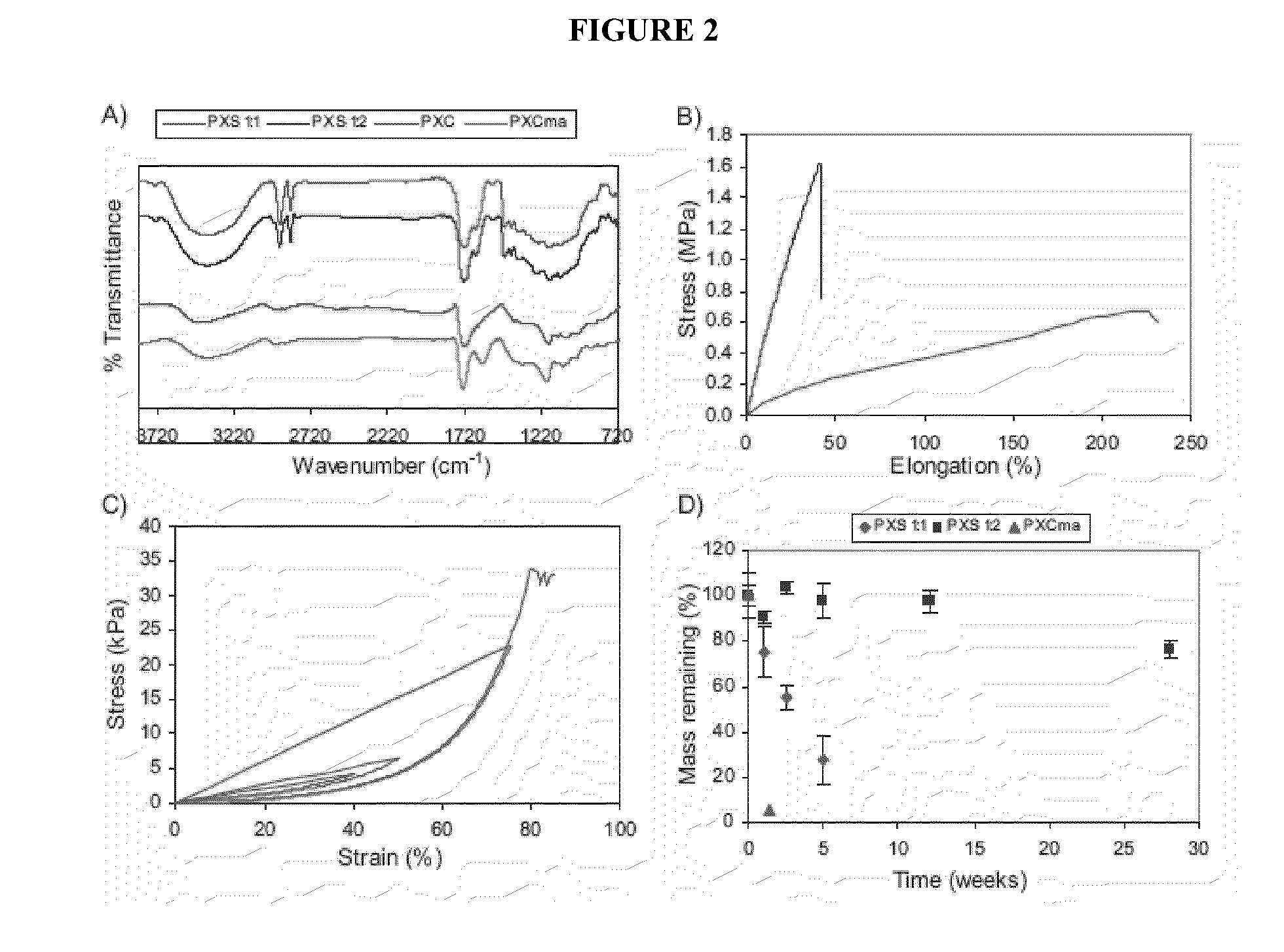

Polyol-based polymers

ActiveUS20110008277A1Cheap preparationOrganic active ingredientsProsthesisMethacrylatePolymer science

The present invention provides inventive polyol-based polymers, materials, pharmaceutical compositions, and methods of making and using the inventive polymers and materials. In certain aspects of the invention, an inventive polymer corresponds to a polymer depicted below. Exemplary inventive polymers includes those prepared using polyol units (e.g., xylitol, mannitol, sorbitol, or maltitol) condensed with polycarboxylic acid units (e.g., citric acid, glutaric acid, or sebacic acid). The inventive polymers may be further derivatized or modified. For example, the polymer may be made photocrosslinkable by adding methacrylate moieties to the polymer.

Owner:THE GENERAL HOSPITAL CORP +1

Elastomeric material compositions obtained from castor oil and epoxidized soybean oil

Elastomers are formed from castor oil and / or ricinoleic acid estolides and a polyester formed from an epoxidized vegetable oil such as ESO and a polycarboxylic acid such as sebacic acid, optionally in the presence of a peroxide initiator, or include crosslinked reaction products derived from ricinoleic acid or castor oil estolides, epoxy group-containing compounds such as epoxy resins and / or epoxidized vegetable oil, epoxy hardeners such as polyamine and polycarboxylic acid hardeners, thermally activated free radical initiators such as peroxides, and optionally but preferably include fillers such as limestone or wood flour. The elastomers can be prepared using a two-step, solvent-less procedure at elevated or ambient temperatures. These predominantly "all-natural" elastomers have physical properties comparable to conventional petroleum-based elastomers and composites and exhibit good flexibility, resiliency, abrasion resistance and inertness to hydrolysis. The resulting elastomers display good mechanical strength and resiliency, are resistant to abrasion and hydrolysis, and can be processed into sheet materials, which makes them attractive as floor covering components.

Owner:AFI LICENSING +1

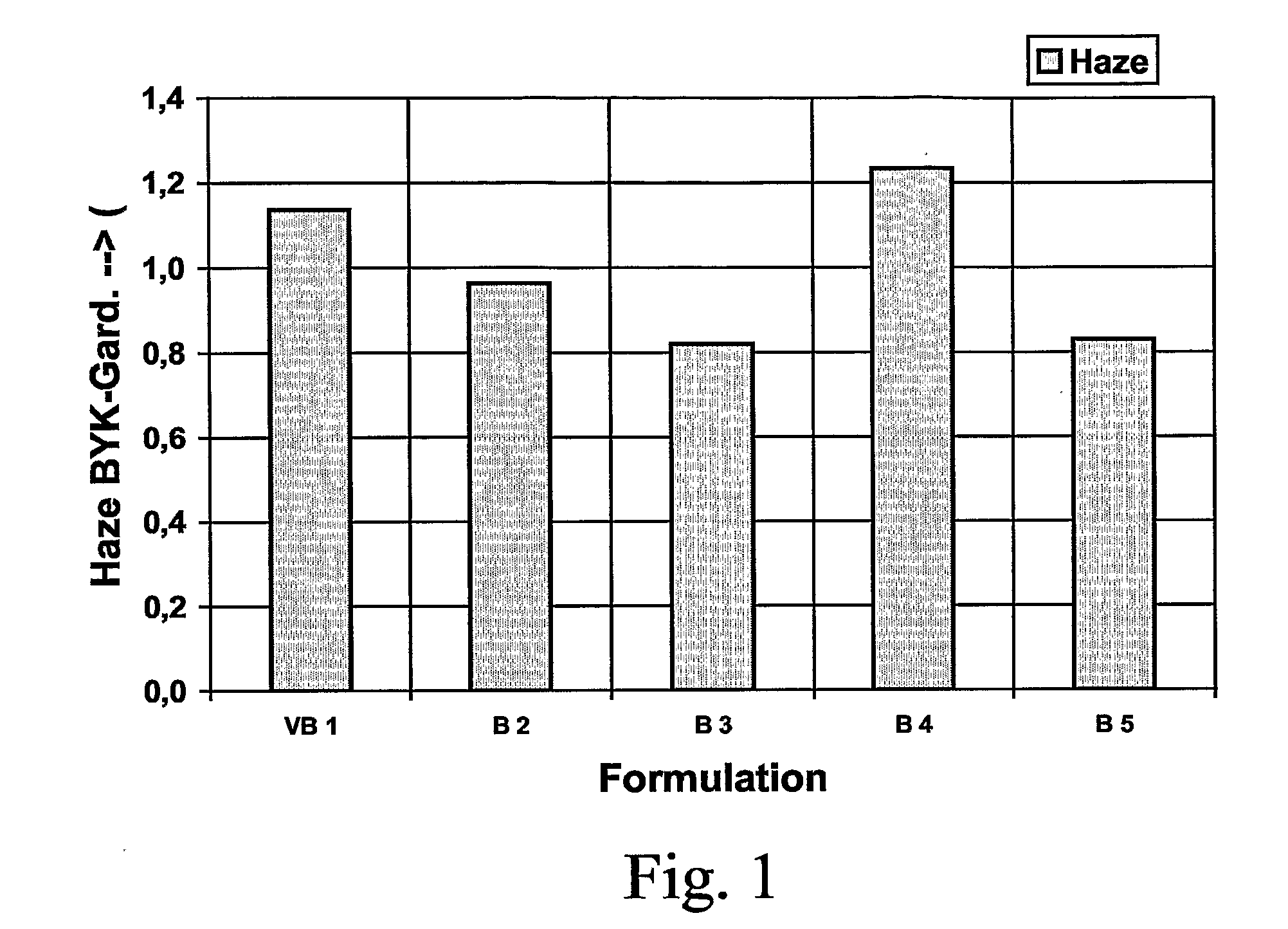

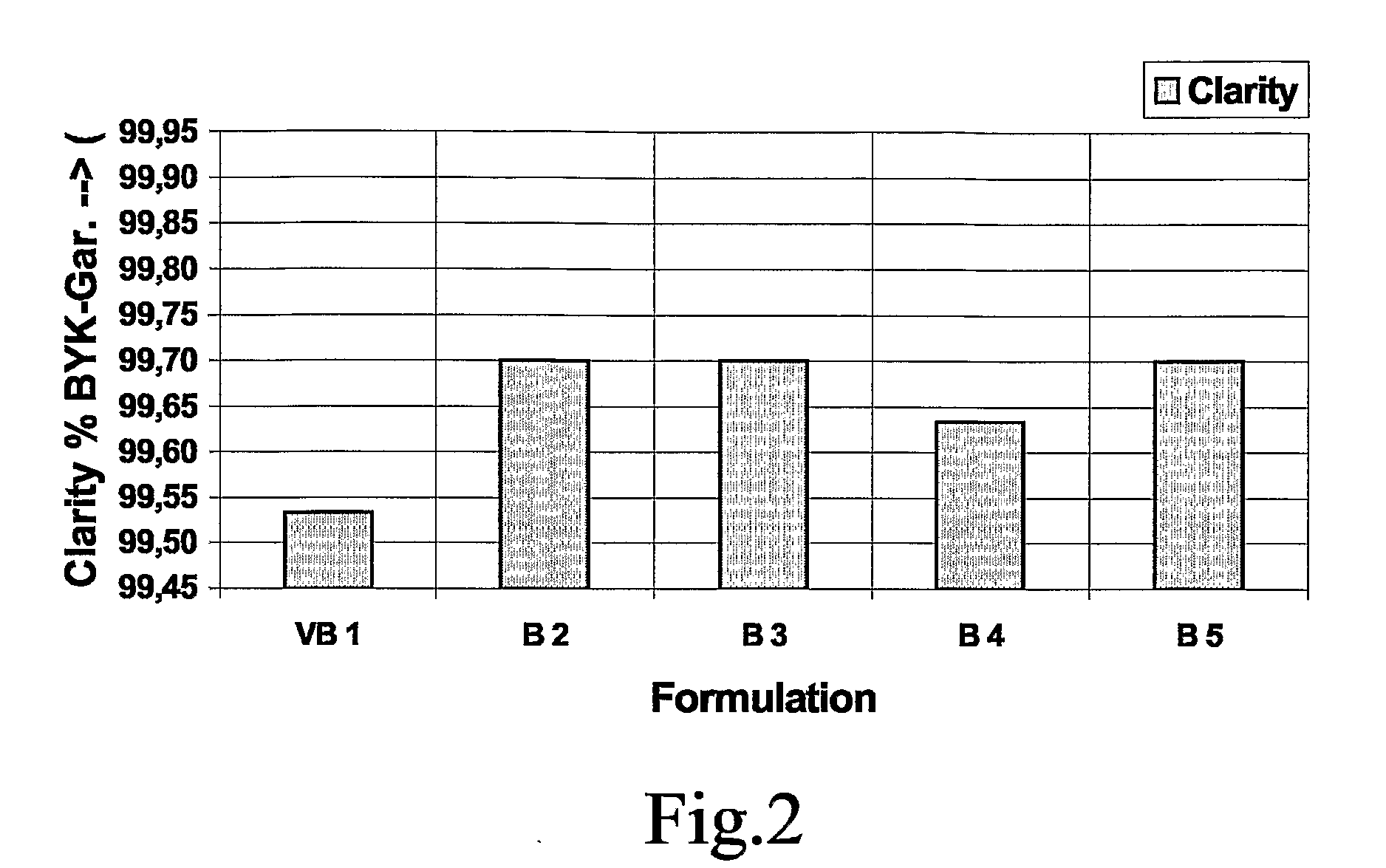

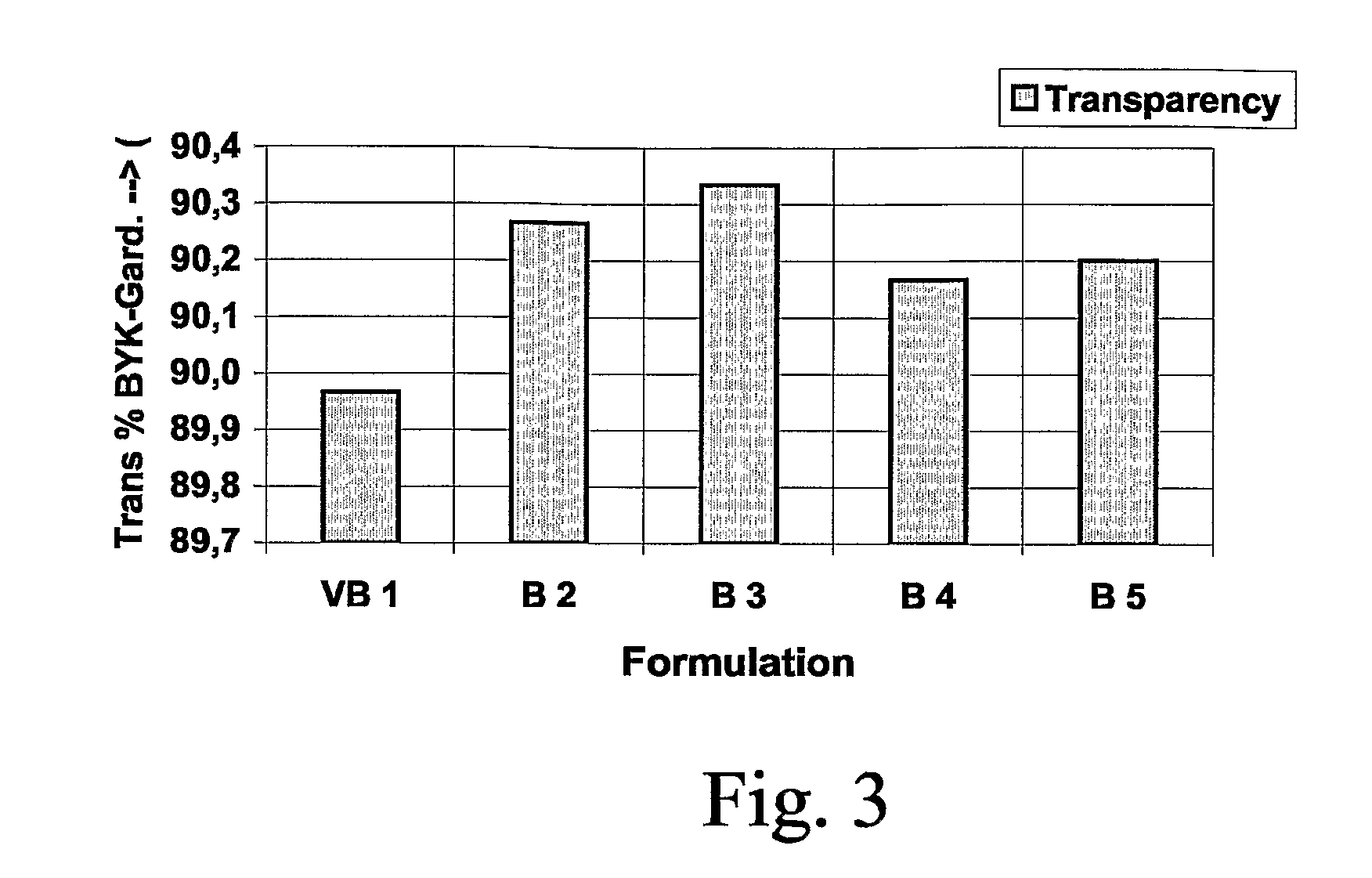

Materials composites of a moulded article of transparent or translucent dyeable plastics moulding compounds

InactiveUS20070128442A1Large flow lengthPerfect purityLayered productsThin material handlingPolymer scienceStearic acid

The present invention relates to materials composites of a moulded article of at least one transparent or translucent dyeable plastics moulding compound which moulded article is bonded to at least one transparent or translucent surface layer and / or to decorative films, functional films or coats or rubbers or other plastics, wherein the plastics moulding compound used for the manufacture of the moulded article, the surface layer or the other plastics contains in an amount of 0.01 to 5.0% by weight, preferably 0.01 to 2.0% by weight, each related to the total weight of the moulding compound, at least one lubricant selected from the group consisting of sorbitan esters, sebacic acid esters, dodecanedioic acid esters, docosanoic acid esters, glycerine, glycol, diethylene glycol, stearoyl amide, stearyl stearate, ethylene bissteroyl amide, octane pyrrolidone, and from the group consisting of non-polar paraffin oils and of tetracosanes, and wherein a permanent adhesion to the other plastics layers and / or sheets or coats or rubbers or other plastics is achieved.

Owner:EMS CHEM AG

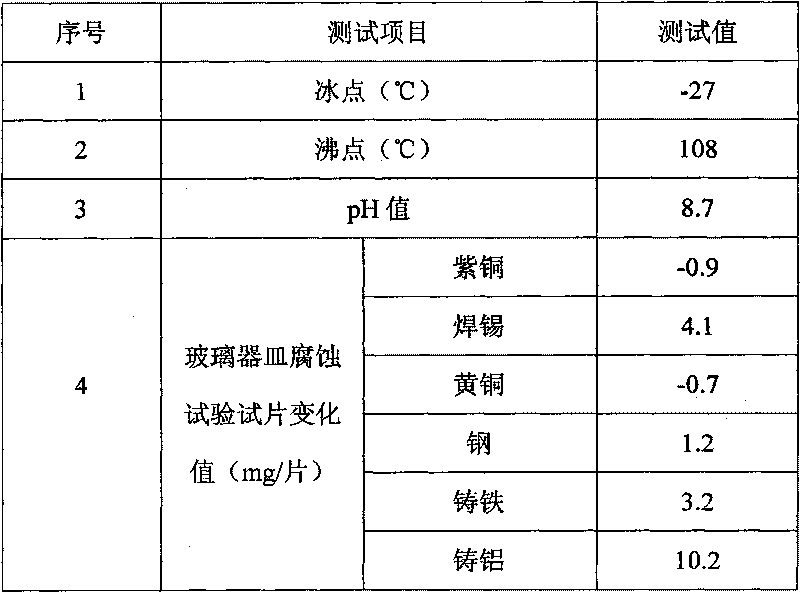

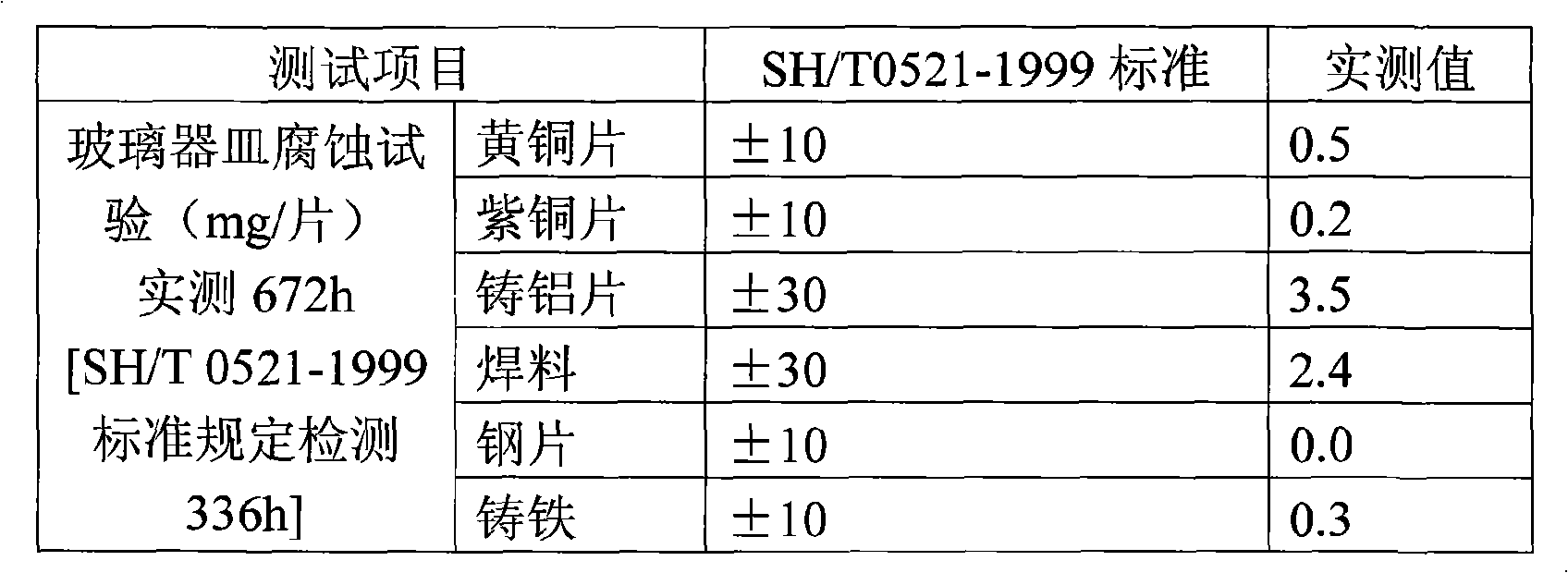

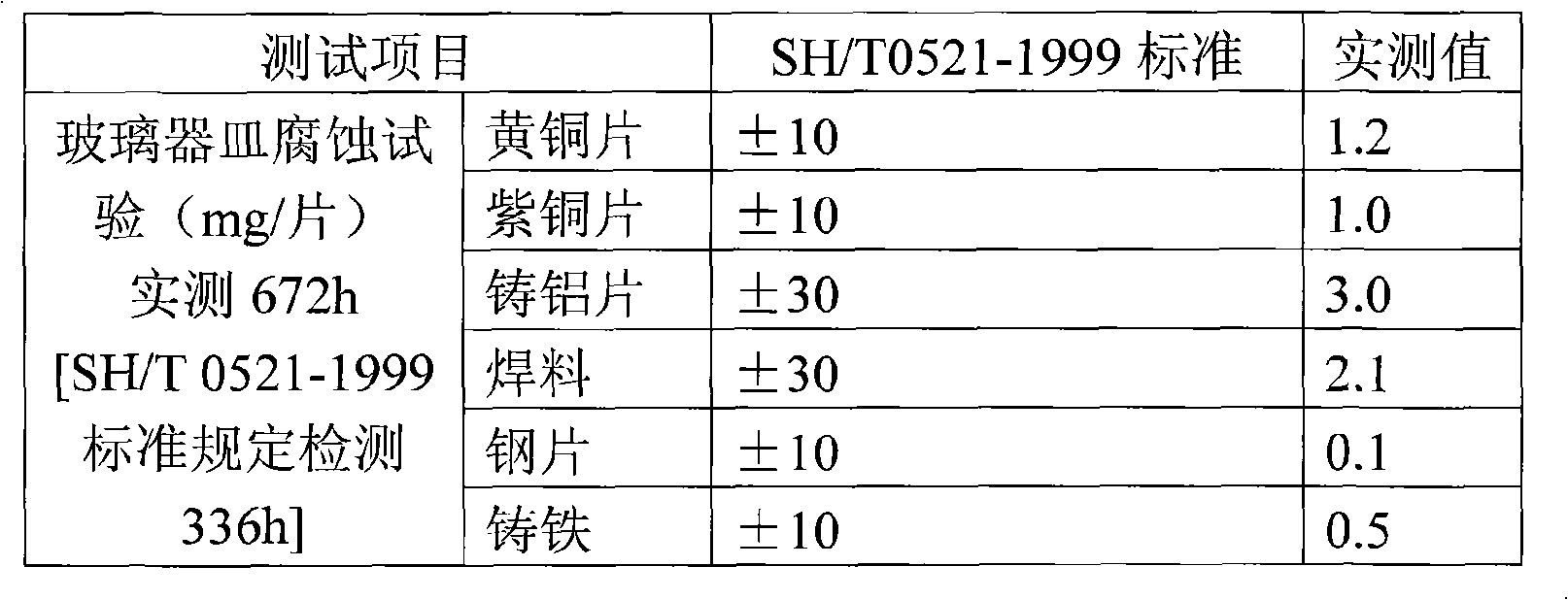

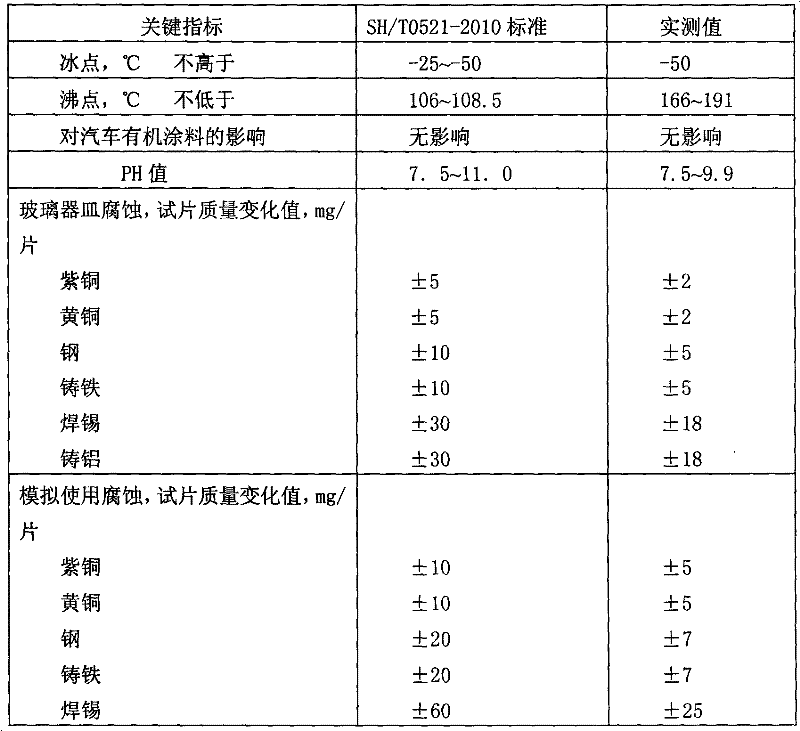

Engine antifreezing solution

ActiveCN101691484AAvoid the disadvantages of instabilityWith boiling suppressionHeat-exchange elementsCooperative interactionSebacic acid

The invention relates to an engine antifreezing solution which is prepared by mixing the following components to react: glycol, sodium molybdate, sodium hydroxide, isooctanoic acid, sebacic acid, sodium benzoate, benzotriazole, sodium 2-mercaptobenzothiazole, dye and deionized water. The invention adopts a new formula which uses organic matter as main component and inorganic matter as auxiliary component to reach the aim of controlled release on the basis of conventional inorganic and all-organic engine antifreezing solution technologies, wherein the organic acid uses the combination of monoacid and binary acid. The invention does not contain sodium borate and silicate so as to avoid the defect that precipitate is easy to generate due to the existence of sodium borate and silicate in glycol series antifreezing solution and the antifreezing solution is unstable; and the engine antifreezing solution of the invention does not contain amine, nitrate, phosphate and other substances which are harmful to the environment and human body. The researched antifreezing solution has good performances of stability, freeze-proofing, boil-proofing, corrosion-proofing and scale prevention through the cooperative interaction of components so as to perform multi-level anticorrosion protection for the cooling system of the vehicle.

Owner:SHAANXI DADI IND CO LTD OF CHINA NAT NUCLEAR

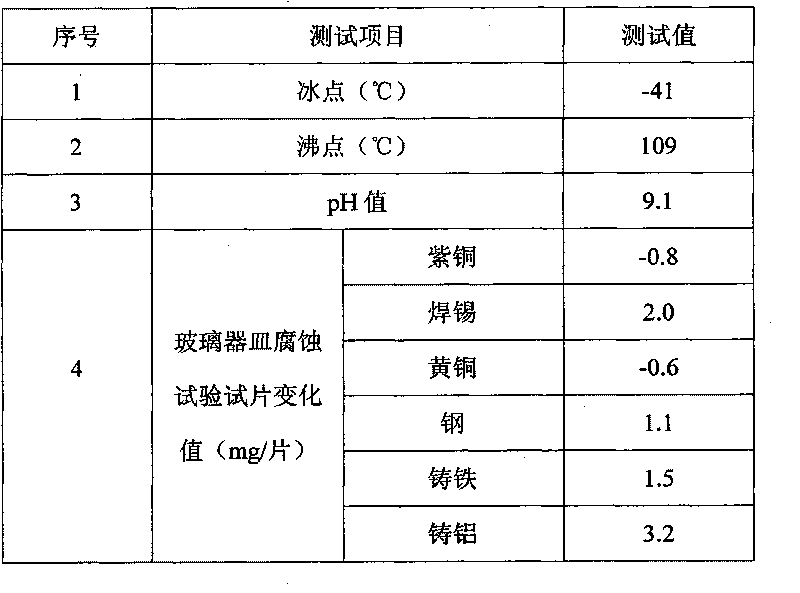

Organic engine cooling liquid

InactiveCN1336410AReduce corrosionImprove corrosion inhibitionHeat-exchange elementsSuccinic acidSebacic acid

The present invention relates to organic cooling liquid for engine, it is composed of ethylene glycol 1000 parts, sebacic acid 2-8 parts, terephthalic acid 2-5 parts, octytic acid 1-12 parts, methylbenezenetriazole 1-4 parts, p-tert-butylbenzoic acid 5-25 parts, succinic acid 1-4 parts, antifoaming agent 0.1-0.2 parts, the invented cooling liquid possesses the advantages of good metal corrosion resistance, good transportation stability, strong hard water resistance, small environmental pollution, no harmful component, small use level etc.

Owner:CHINA PETROLEUM & CHEM CORP

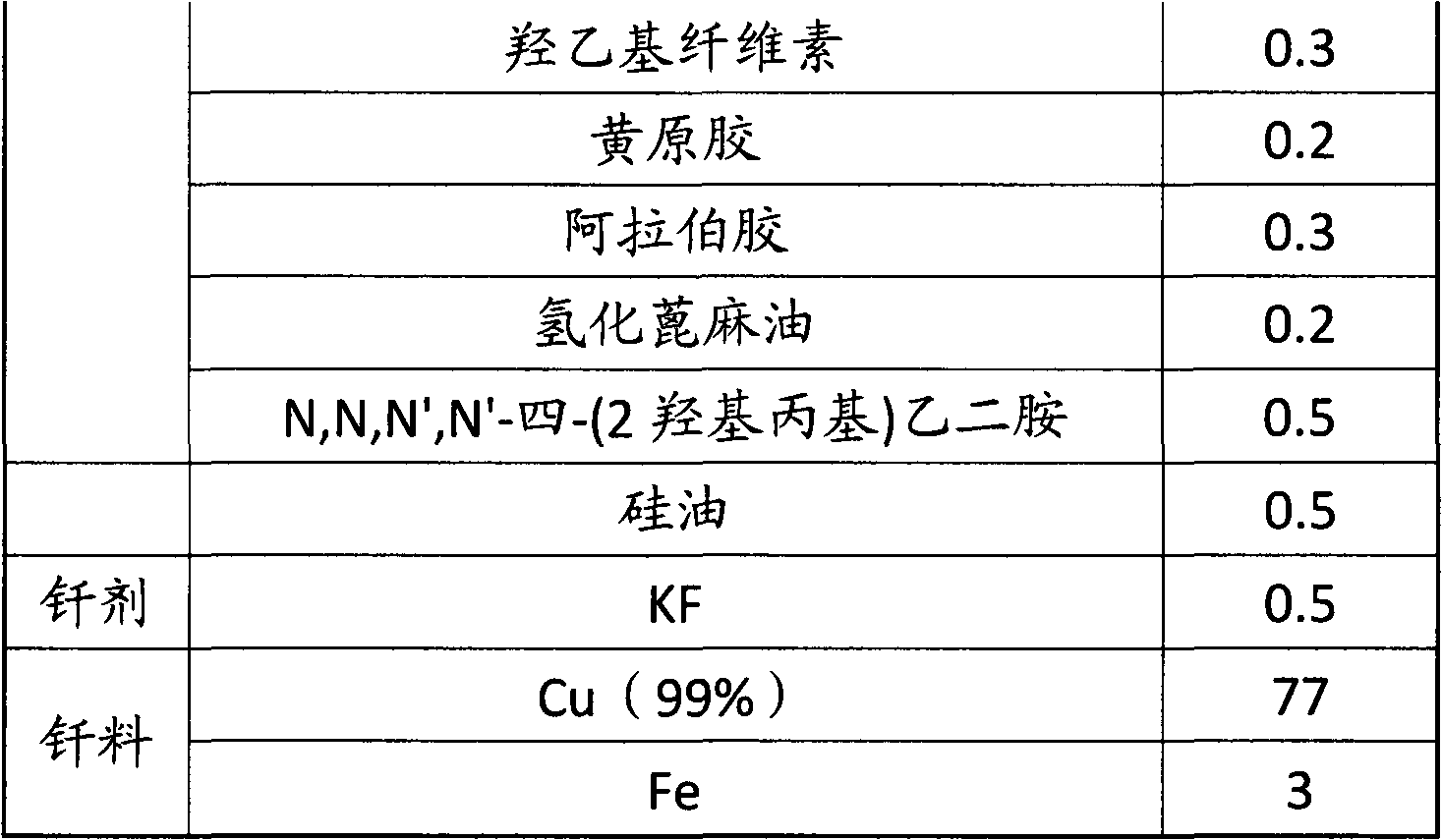

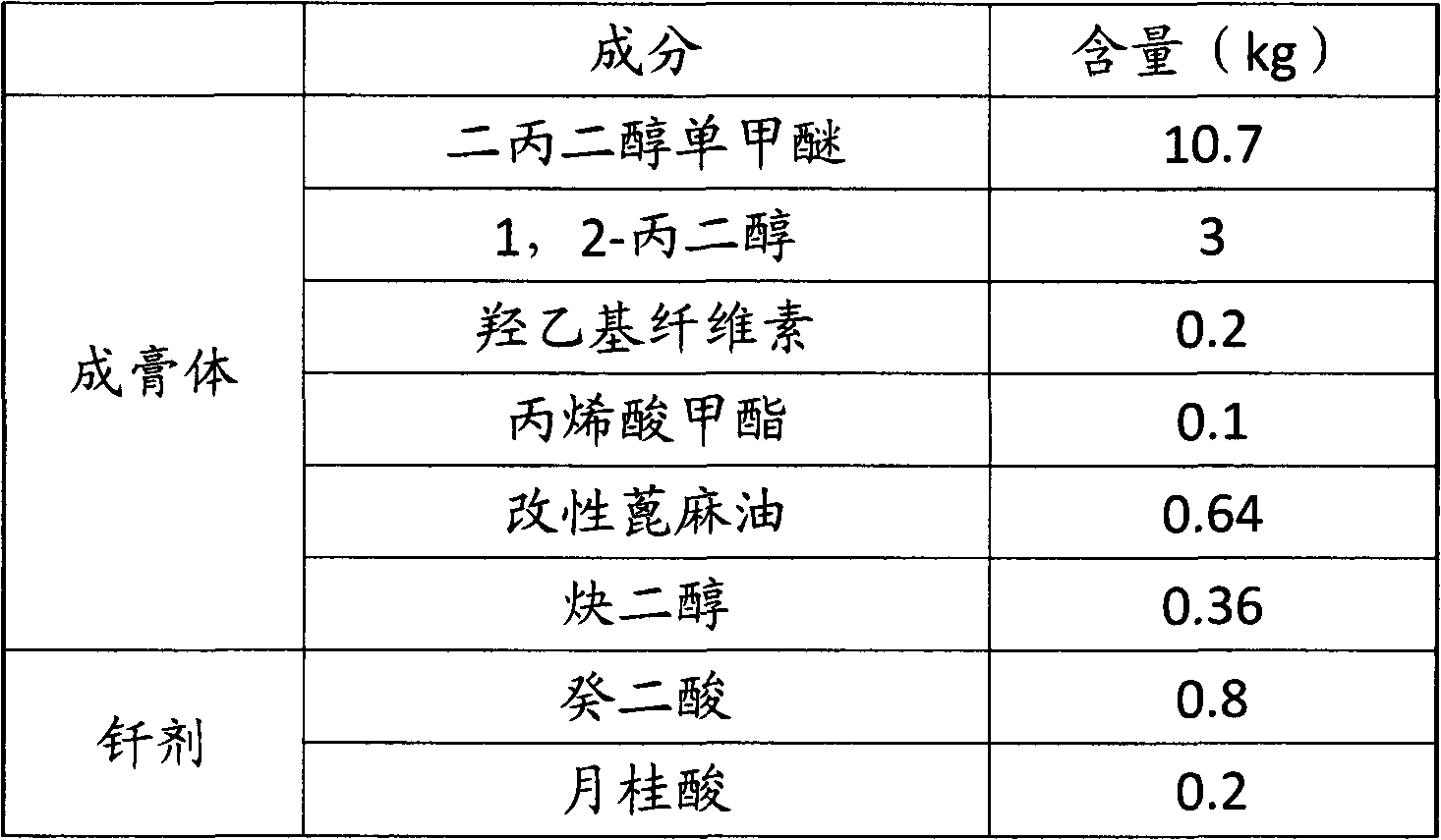

Copper welding paste for braze welding and preparation method thereof

ActiveCN103659053ALess corrosiveAvoid cleaningWelding/cutting media/materialsSoldering mediaPipe fittingSuccinic acid

The invention discloses copper welding paste for braze welding, a preparation method of the copper welding paste for braze welding and the application of the copper welding paste for braze welding. The copper welding paste for braze welding comprises 67wt%-92wt% of brazing filler metal, 8wt%-33wt% of pasty fluid and brazing flux of which the mass is 0-5% that of the brazing filler metal, wherein the brazing filler metal comprises Cu and / or one or more types of Cu alloy, the brazing flux comprises any one or more than two components of CaF2, KF, NaF, BaF2, sebacic acid, succinic acid, lauric acid and boric acid, and the pasty fluid comprises a solvent, a thickening agent, a rheological agent, an antifoaming agent and an activating agent. When the copper welding paste prepared through the method is applied before braze welding, the copper welding paste has good thixotropy, collapse resistance and fluidity; after braze welding, a part has high joint strength, a weld joint is plump and free of residues, and the part does not need cleaning; the copper welding paste can be widely applied to welding automobile pipe fittings, copper-based heat dissipation assemblies and stainless steel parts.

Owner:SUZHOU CUBRAZING MATERIALS CO LTD

PTC thermistor and substrate applied therein and manufacturing method thereof

InactiveCN102176360AUniform cross-linked structurePromote absorptionPositive temperature coefficient thermistorsHigh resistanceCross-link

A PCT thermistor comprises a substrate and two tinsel-shaped electrodes which are combined with two surfaces of the substrate. The substrate is made of the following components in weight percentage: 28-55% of high-polymer material; 22-32% of conductive filling material; 13-46% of auxiliary filling material; and 1-5% of auxiliary agent in processing. The high-polymer material is obtained through mixing one or multiple materials selected from: polyethylene, polypropylene, maleic anhydride grafted polyethylene, ethane-vinyl acetate copolymer, ethane-acrylic acid copolymer, polyvinylidene fluoride, polycaprolactam, polyhexamethylene adipamide, polydecamethylene sebacamide and polyundecylamide. The auxiliary agent in processing is one component or a mixture of multiple components selected from: an anti-oxidant, a coupling agent, a cross-linking agent and a sensitized cross-linking agent. The sensitized cross-linking agent is one component or multiple components selected from the unsaturated compounds of multiple functional groups with higher decomposition temperature. The PTC thermistor of the invention has the following advantages: high strength, and high resistance for multiple times of large current impact.

Owner:深圳市长园维安电子有限公司

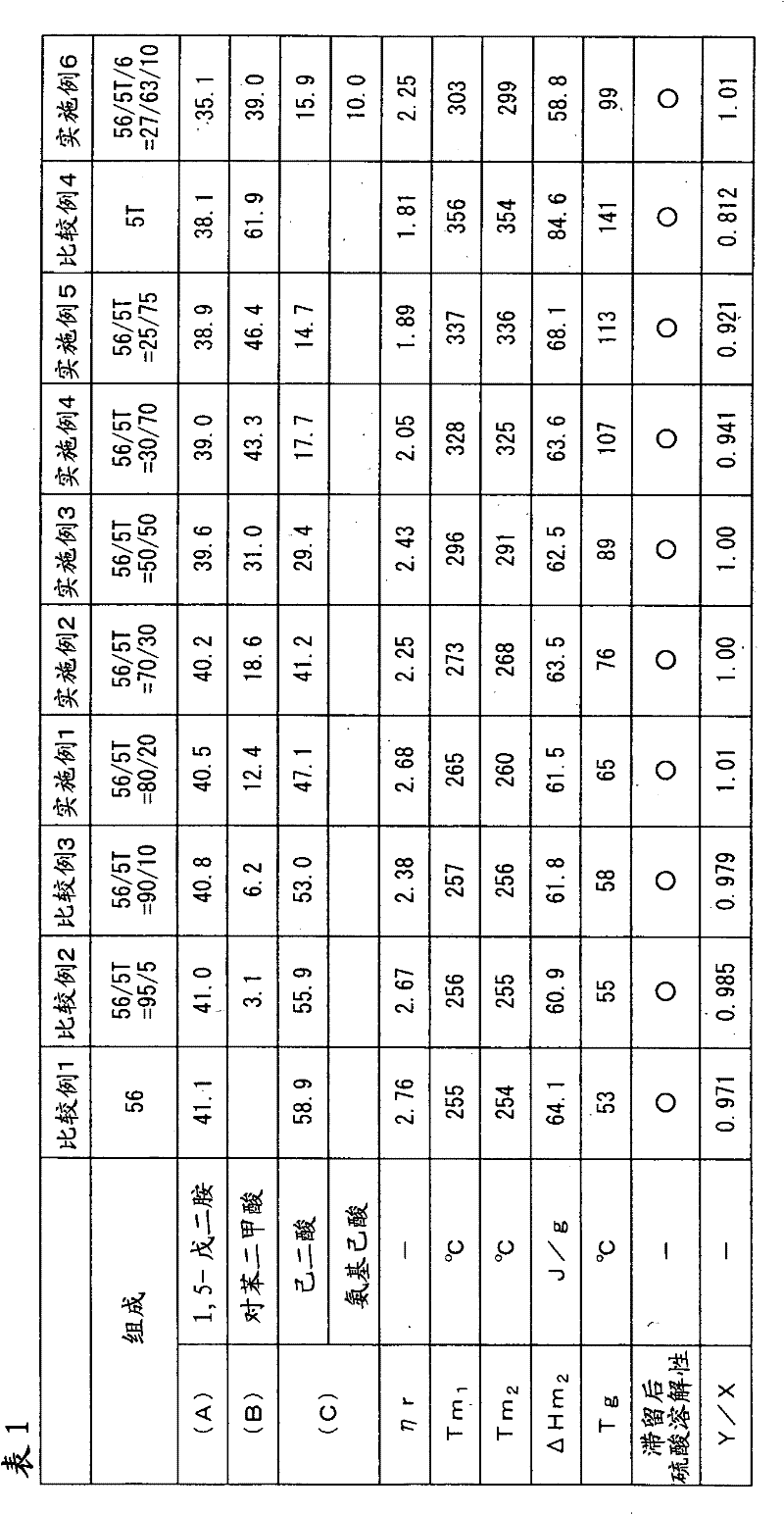

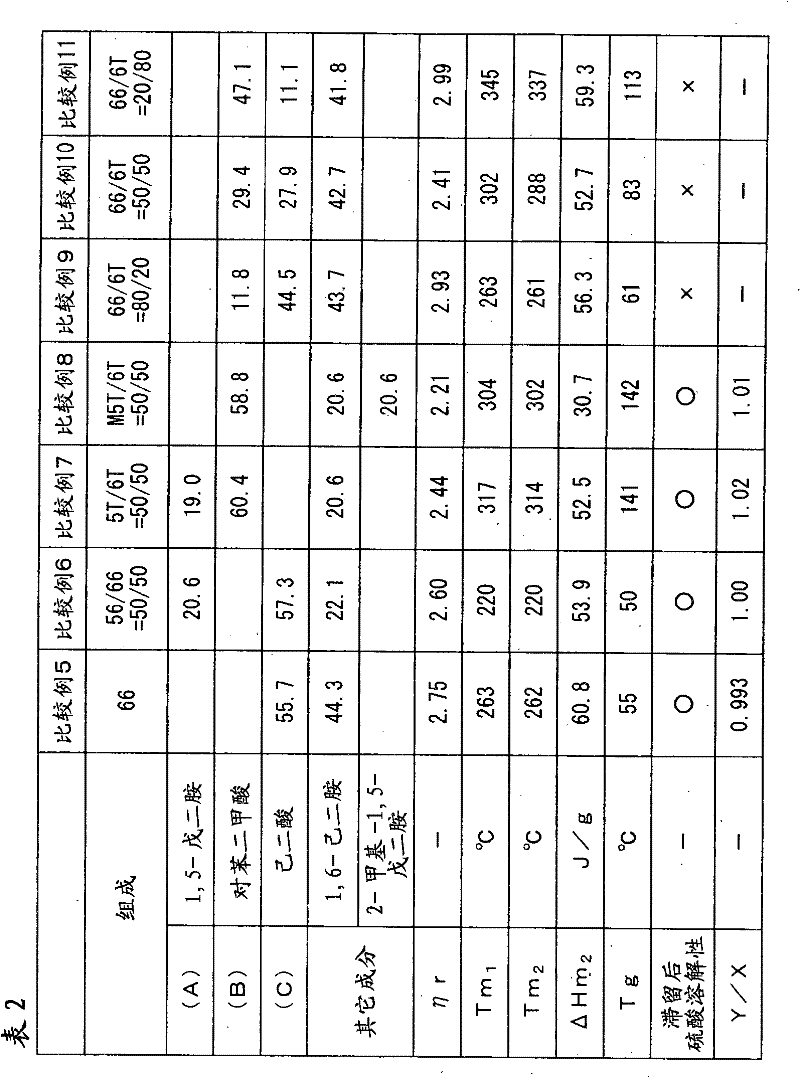

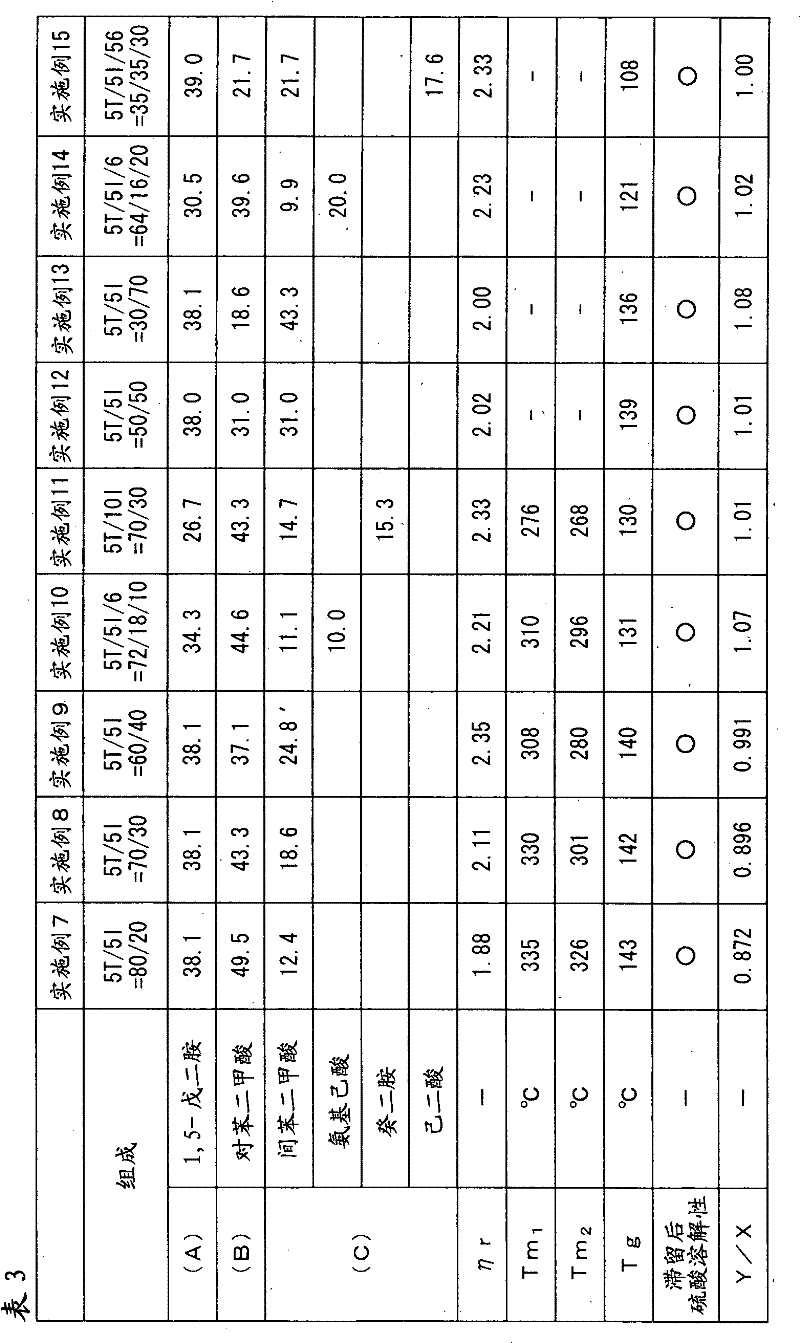

Polyamide resin, composition containing polyamide resin, and molded articles of polyamide resin and composition

InactiveCN102131845AImprove heat resistanceExcellent melt retention stabilityLaurolactamPolymer science

Disclosed is a polyamide resin which is produced by the polycondensation of (A) pentamethylenediamine, (B) terephthalic acid and / or a derivative thereof, and (C) at least one compound selected from adipic acid, azelaic acid, sebacic acid, undecanedioic acid, dodecanedioic acid, isophthalic acid, 1,9-diaminononane, 1,10-diaminodecane, 1,11-diaminoundecane, 1,12-diaminododecane, caprolactam, undecalactam, laurolactam, aminocaproic acid, 11-aminoundecanoic acid, 12-aminododecanoic acid, and derivatives of these compounds. In the polyamide resin, the ratio of a repeating unit derived from the component (C) is 10 to 50 wt% (inclusive) relative to the total weight of the polymer. A solution of the polyamide resin in 98% sulfuric acid, which contains the polyamide resin at a concentration of 0.01 g / ml, has a relative viscosity of 1.5 to 4.5 at 25 DEG C.

Owner:TORAY IND INC

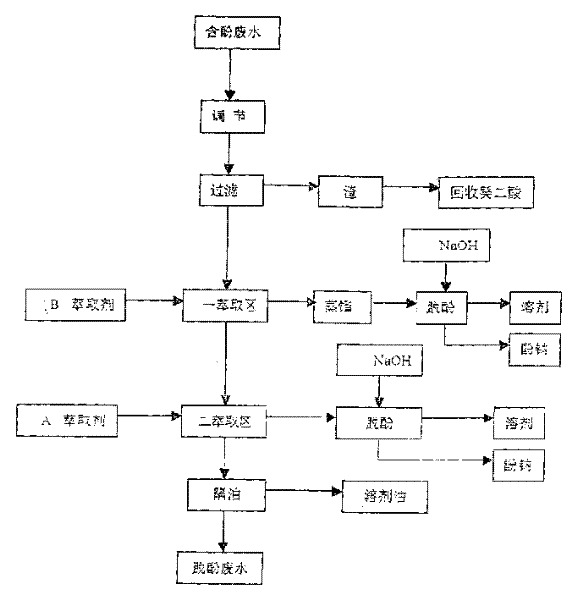

Treatment method of phenol-containing liquid waste in sebacic acid production

ActiveCN102503034AHigh partition coefficientPromote regenerationMultistage water/sewage treatmentNature of treatment waterLiquid wasteEvaporation

The invention discloses a treatment method of phenol-containing liquid waste in sebacic acid production, specifically comprising the steps of extraction, back extraction, evaporation, regulation, anoxic biochemical reaction and aerobic biochemical reaction, and the like. The phenol-containing liquid waste is filtered to remove the insoluble substance, the phenol substance in the liquid waste is extracted by a specially selected extracting agent, the extract phase is back extracted by alkaline liquor and is regenerated to be recycled, and the back extraction solution is returned to a sebacic acid production system. The raffinate is transferred into an evaporation system to be evaporated and separated to obtain a sodium sulfate by-product, the evaporation condensed water is homogenized and equalized after being cooled, the pH value is regulated, and the evaporation condensed water is performed with anoxic biochemical reaction by acclimated and cultured microorganisms in a biochemical reaction system in the presence of nutrient elements. The method provided by the invention is a method combining materialization and biochemical reaction, and the method has the advantages of reasonabledesign and strong maneuverability; furthermore, the treated liquid waste can satisfy the discharge standard to be discharged or recycled.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Anti-freezing fluid

ActiveCN101302424ATo achieve long-term goalsTo achieve the characteristics of green environmental protectionHeat-exchange elementsSodium molybdateAnti freezing

The invention discloses anti-freeze fluid. The compositions by weight percentage of the anti-freeze fluid are: 35 to 85 percent of glycol, 0.25 to 0.06 percent of sodium molybdate, 0.4 to 0.1 percent of sodium nitrate, 3.5 to 0.8 percent of potassium hydroxide, 1.2 to 0.2 percent of 85 percent phosphoric acid, 0.3 to 0.02 percent of metyl benzotriazole, 0.5 to 0.05 percent of benzotriazole, 3.5 to 0.8 percent of sebacic acid, 1.0 to 0.25 percent of undecanedioic acid, 1.0 to 0.2 percent of octanoic acid, 3.0 to 0.8 percent of sodium benzoate, 0.2 to 0.05 percent of hydrolytic-polymeric maleic anhydride, 0.003 to 0.01 percent of antifoaming agent, the balance being deionized water. The anti-freeze fluid is characterized by long effect and environmental protection, and can perform all-around multi-layer protection on an automobile cooling system.

Owner:张家港迪克汽车化学品有限公司

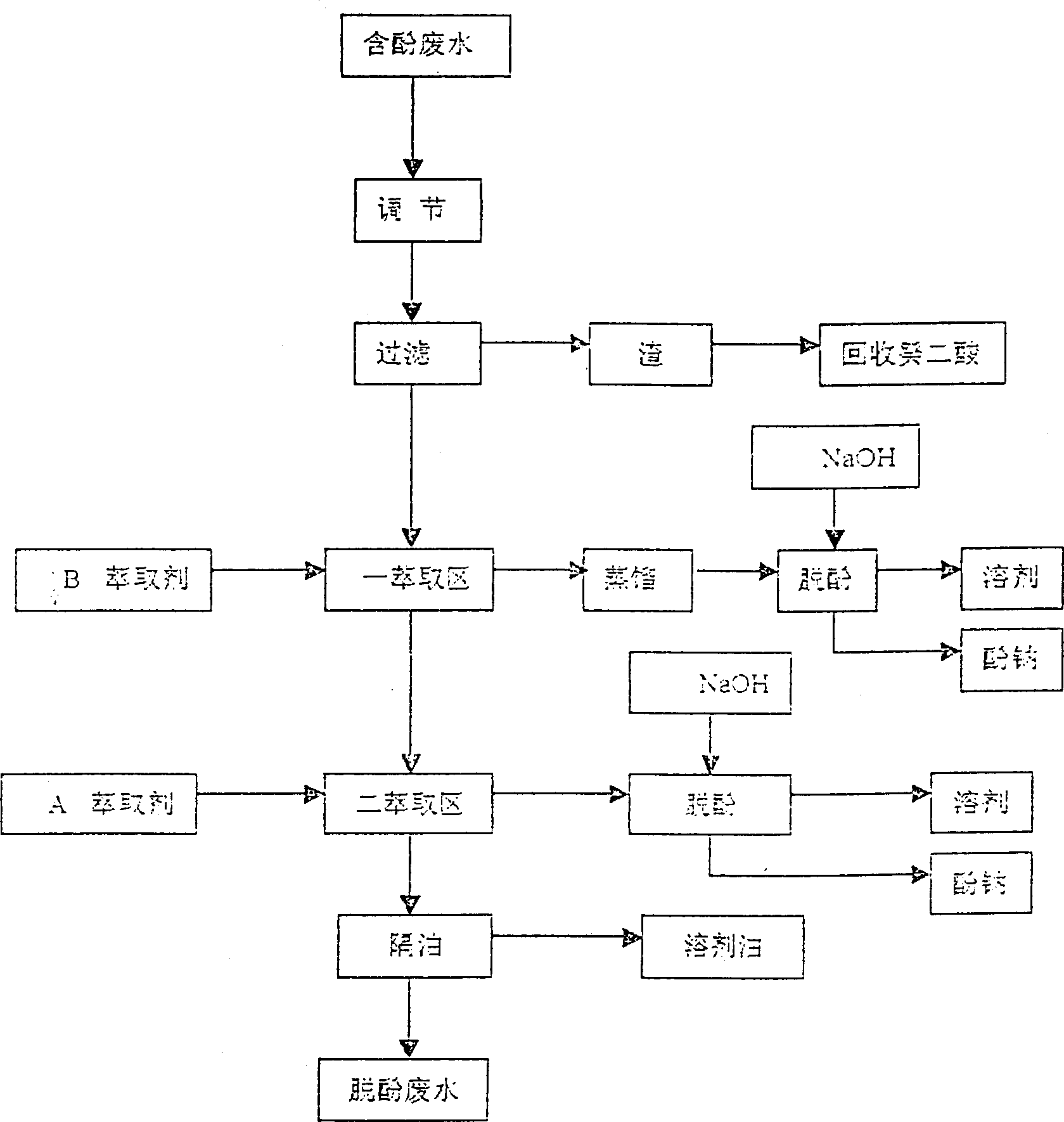

Treatment of phenol containing decanedioic acid waste water by extractive distillation

InactiveCN1450006AAvoid SaponificationLow processing and running costsMultistage water/sewage treatmentPhosphoric Acid EstersPhosphate

The method for treating waste water containing phenol which is produced in the course of producing sebacic acid includes five steps: regulation, filtration, extraction, removing phenol and isolating oil. After the phenol-containing waste water is filtered and its insoluble material is removed, in first extraction zone the high carbon alcohol is used as extraction agent to remove the organic material from waste water and effectively reduce content of phenol, the load extraction agent is fed into distillation procedure, the distilled high carbon alcohol can be reextracted and can be circularly used, and the organic material being in the waste water can be recovered in the form of high-boiling material, and the second extraction zone the mixture of phosphate and kerosene is used as extraction agent to make counter-current extraction with the phenol-containing waster water.

Owner:HAIHUA TIANHE ORGANIC CHEM SHANDONG

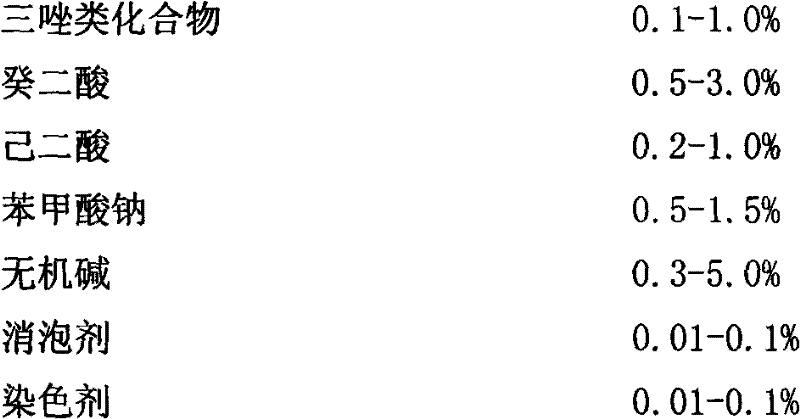

Life-cycle water-free cooling solution

The invention relates to a life-cycle water-free cooling solution which is characterized by comprising the following components in percent by weight: 10-50 percent of propylene glycol, 50-80 percent of ethylene glycol, 0.1-10 percent of triazole compounds, 0.5-3.0 percent of sebacic acid, 0.2-1.0 percent of adipic acid, 0.5-1.5 percent of sodium benzoate, 0.3-5 percent of inorganic base, 0.01-0.1 percent of antifoaming agent and 0.01-0.1 percent of colouring agent. The cooling solution has a freezing point of below -50 DEG C and a boiling point of 166-191 DEG C; and because the cooling solution does not contain water, problems of boiling, gas etching, evaporating, scaling, rusting and the like caused by water existing in the cooling solution are thoroughly eliminated, a steam air resistance layer seriously influencing heat radiation is avoided from generating, power of an engine can be effectively improved and fuel is saved. Because the cooling solution does not contain water and has a reasonable corrosion inhibition system, the problem of corrosion is thoroughly solved; and the cooling solution has a service life of reaching up to 8 hundred thousand kilometers, is added once without replacement, is a life-cycle cooling solution, is especially suitable for military vehicles, high-end vehicles and high-power heavy-loading trucks and passenger cars, and can ensure that the vehicles safely run under extremely hot weather, severe cold weather, and severe environments such as desert, plateau, snowfield and the like.

Owner:JIANGXI CHEPU IND CO LTD

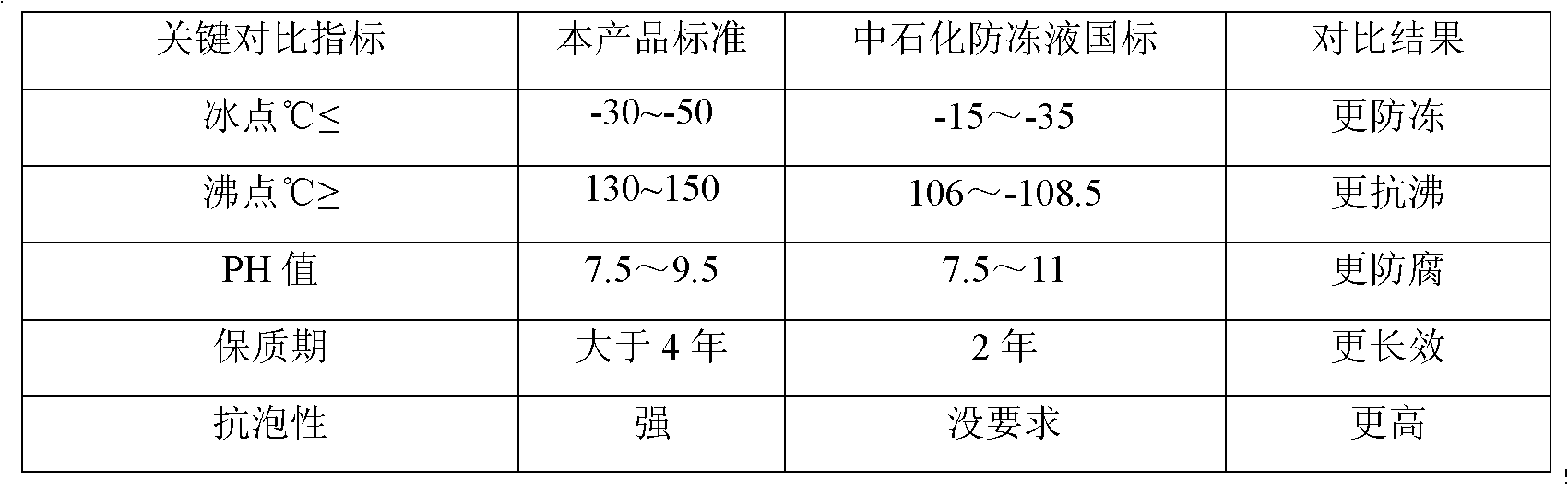

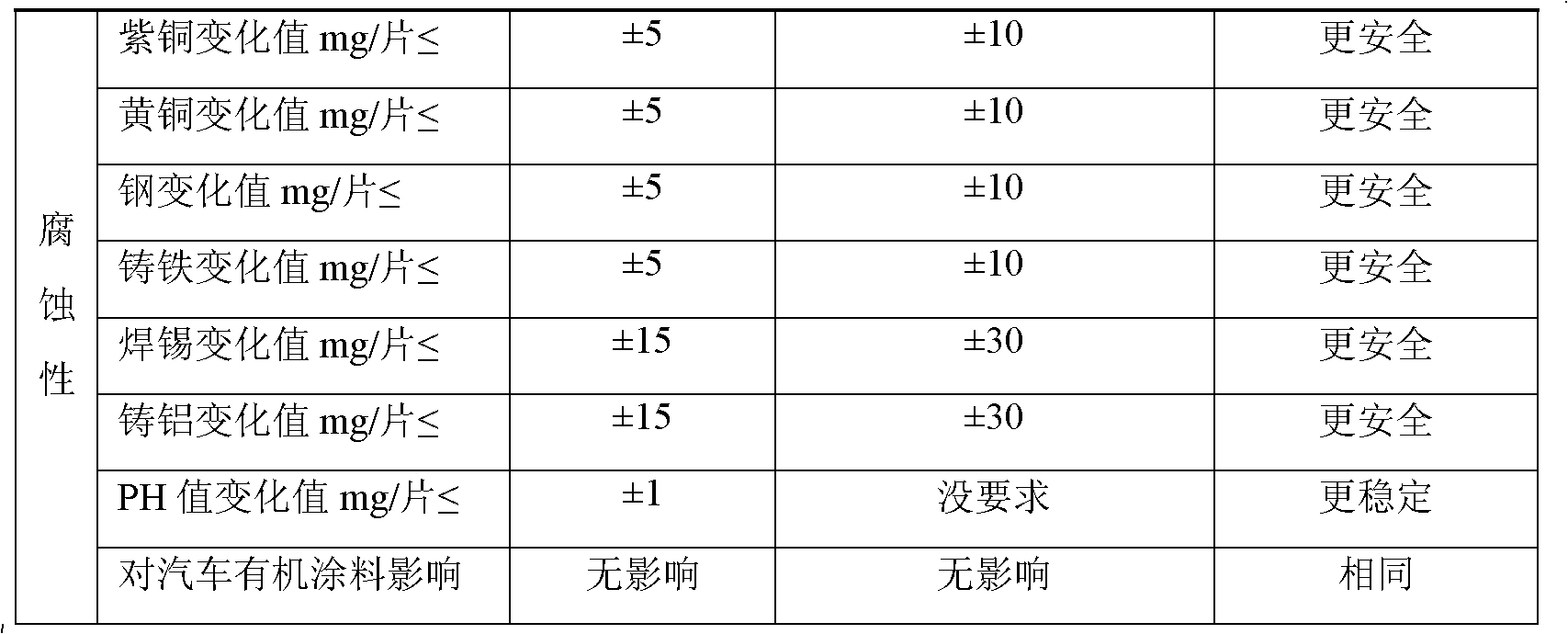

Non-aqueous coolant for engine

ActiveCN102002347AStable pHImprove antifreeze effectHeat-exchange elementsOctanoic AcidsPhosphoric acid

The invention relates to a non-aqueous coolant for an engine, which is characterized by comprising the following components in percent by weight: 10-80 percent of ethylene glycol, 10-80 percent of propylene glycol, 5-20 percent of polyol, 0.1-0.8 percent of phosphate-molybdate, 0.2-0.9 percent of silicate ester, 0.1-1 percent of 4-methyl 1H-benzotriazole, 0.2-0.8 percent of citric acid, 0.2-1 percent of sebacic acid, 0.1-1 percent of octanoic acid, 0.4-1.2 percent of citrate and 0.01-0.2 percent of cosolvent. The non-aqueous coolant has freezing point of -30--50 DEG C and boiling point of 130-150 DEG C, and ensures that the cold start of the engine is realized in cold weather; meanwhile, the working temperature of the engine is improved to 95-150 DEG C from the original 85-95 DEG C. The non-aqueous coolant belongs to a non-aqueous system, avoids electrochemical corrosion, and is a buffer system with pH of 7.5-9.5; and the added relevant auxiliaries have active corrosion resistance on aluminum and aluminum alloy and copper.

Owner:HEFEI UNIV OF TECH

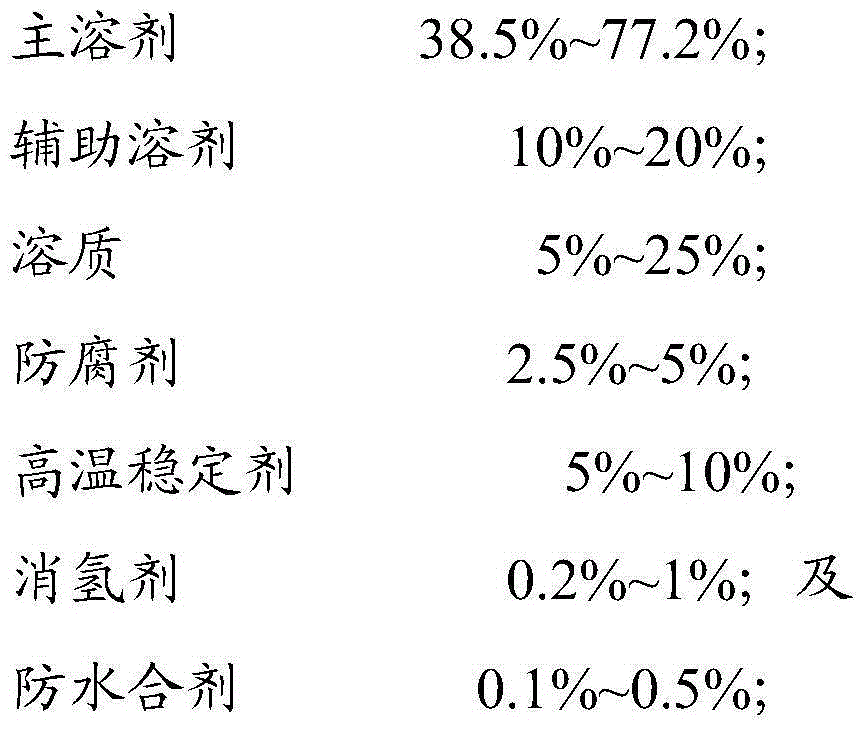

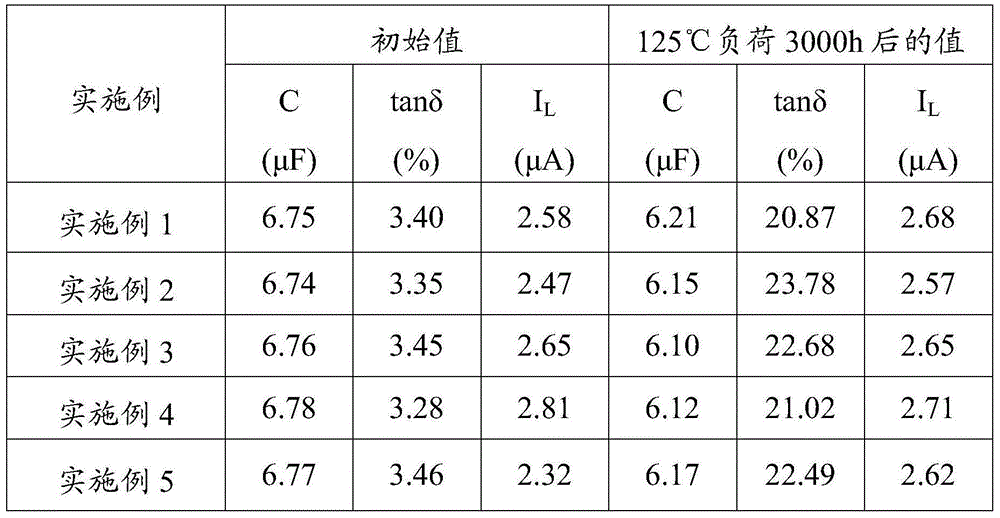

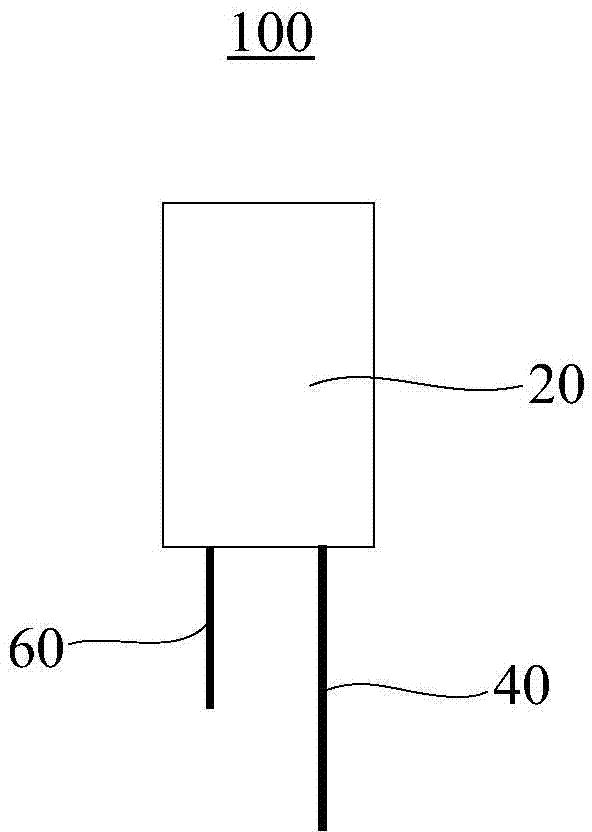

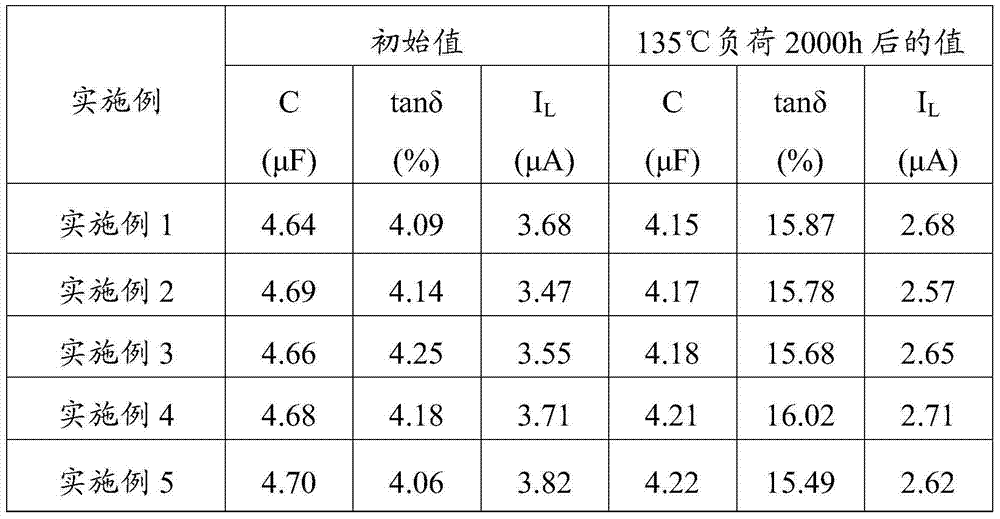

Chip type high-voltage aluminum electrolytic capacitor, electrolyte thereof and preparation method of electrolyte

The invention relates to a chip type high-voltage aluminum electrolytic capacitor, an electrolyte thereof and a preparation method of the electrolyte. The electrolyte comprises the following components of 38.5-77.2% of a main solvent, 10-20% of an auxiliary solvent, 5-25% of a solute, 2.5-5% of an antiseptic, 5-10% of a high-temperature stabilizing agent, 0.2-1% of a hydrogen removal agent and 0.1-0.5% of a hydration-proof agent by weight. The solute is at least one selected from ammonium 2-n-hexyl adipate, ammonium octaned icarboxylate acid, butly octanedioic acid, ammonium 2-n-hexyl adipate oxalate, ammonium sebacate, sebacic acid, ammonium hydrogen azelate, ammonium azelate and ammonium pentaborate. The high-temperature stabilizing agent is at least one selected from polyvinyl alcohol, polyvinyl acetaldehyde, polyvinylpyrrolidone, polyvinyl alcohol succinate and sulfanilic acid. The high temperature resistance is high.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

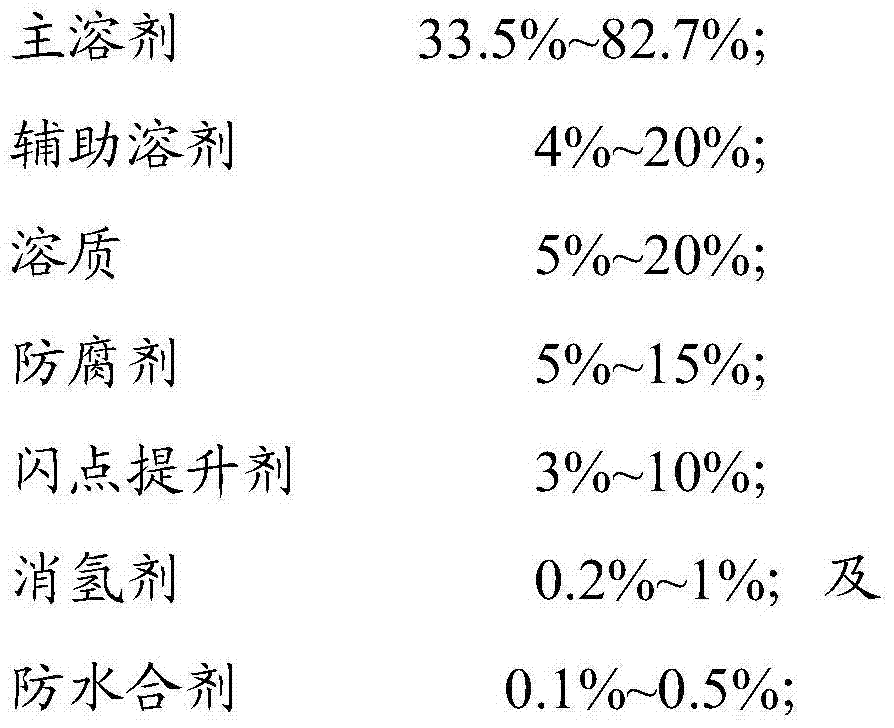

Electrolyte of aluminum electrolytic capacitor, preparation method thereof and aluminum electrolytic capacitor

The invention relates to electrolyte of an aluminum electrolytic capacitor, a preparation method thereof and the aluminum electrolytic capacitor. The electrolyte of the aluminum electrolytic capacitor includes the following components by mass: 33.5-82.7% of a main solvent, 4%-20% of an auxiliary solvent, 5%-20% of a solute, 5%-15% of a corrosion remover, 3%-10% of flash point promotion agent, 0.2%-1% of hydrogen elimination agent and 0.1%-0.5% of water-mixture-proof agent, wherein the solute is at least one of isodecyl ammonium sebate, 2-butyl-cork-acid-ammonium, 2- ethyl ammonium oxalate, 5, 6-ammonium sebate, potassium sebate, sebacic acid, azelaic acid, ammonium azelate, ammonium pentaborate and potassium carboxylate with chains with the number of carbon chains as 24-35. Experiments show that the aluminum electrolytic capacitor using the electrolyte has good high temperature resistance, the service life can be 2000 hours under the environment with the temperature high as 135 DEG C, and the service life is longer.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

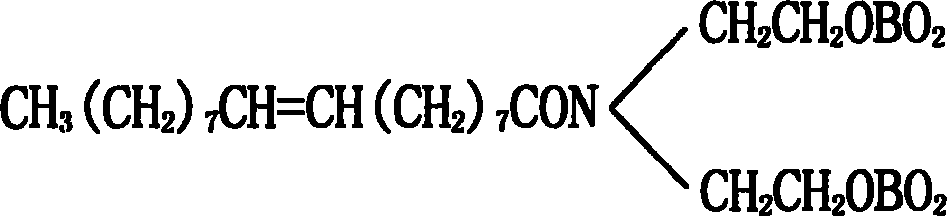

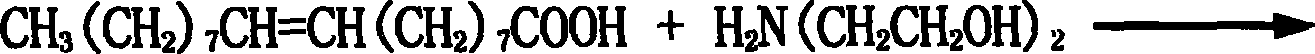

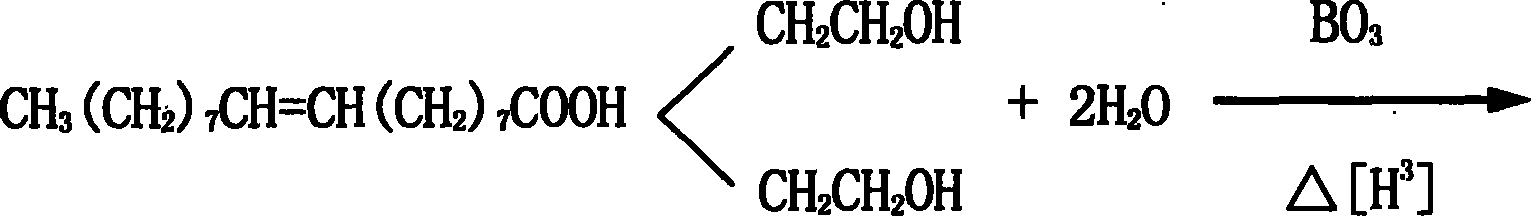

Oil soluble compound highly effective antirust additive and preparation method thereof

The invention discloses an oil soluble built high effective antirust additive and preparing method, which comprises the following steps: allocating 12-30 wt polyhydroxy carboxylic acids, 40-60 wt oleic acid acetal amide boric acid ester, 3-6 wt bromide triethyl cetyl ammonium, 2-6 wt alkyl group bromine generation ammonium salt, 10-30 wt dioctyl regular sebacate, 20-30 wt trolamine, 0. 7-1. 3 wt wool alcohol; getting the product. This product possesses good oil solubility, which can be used as antirust agent for ferrous metal and non-ferrous metals.

Owner:BEIJING TIANBAO TONGHUI MATERIAL PROTECTION TECH

No-cleaning leadless solder and preparation method thereof

InactiveCN101391350AAffect physical propertiesImprove liquidityWelding/cutting media/materialsSoldering mediaBenzyl benzoatActive agent

The invention relates to a no-clean lead-free tin welding wire and a preparation method thereof, wherein the lead-free welding wire is composed of 2 to 3 percent of flux and 97 to 98 percent of lead-free solder. The lead-free solder is composed of 0.5 to 0.7 percent of Cu, 0.03 to 0.05 percent of Ni, 0.01 to 0.02 percent of P, 0.005 to 0.01 percent of Ga and the remnant amount of Sn. The No-clean flux is composed of 1.0 to 4.0 percent of organic acid active agent, 0.5 to 5.0 percent of halogenated derivative active solvent, 2.0 to 5.0 percent of heat-resistant resin , 1.0 to 4.0 percent of cosolvent, 2.0 to 5.0 percent of high boiling point solvent and the remnant amount of modified rosin. The cosolvent belongs to ester compound and the high boiling point solvent is the mixed solvent of one or more of the SAF-25, dioctyl sebacate, benzyl benzoate, dioctyl adipate. In the preparation of the welding wire, the key point is first to form the alloys of Sn with other metals, and then the alloys can be added to the tin for melting. The lead-free welding wire of the invention has good heat resistance without halogen, low flux spattering, low odor, non-corrosive flux residue, strong practical feature, good electrical insulation after being welded, crack-free flux residue and high reliability.

Owner:太仓市首创锡业有限公司

Tech. for synthesizing high toughness epoxy vinyl ester resin

The invention relates to a high tenacity epoxy vinyl ester resin and the compounding method that takes open loop esterification reaction by using organic monad unsaturation carboxylic acid on the technology base, induces organic saturation dyadic carboxylic acid and end carboxy liquid nitrile butadiene rubber soft radical to improve the tenacity of the resin. The broken specific elongation 8-16%, impact intension is 20-30KJ / m2. It could satisfy the special need in fiberglass-reinforced plastics industry. The invention is simple structure, no tree wastes, and has good stability.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

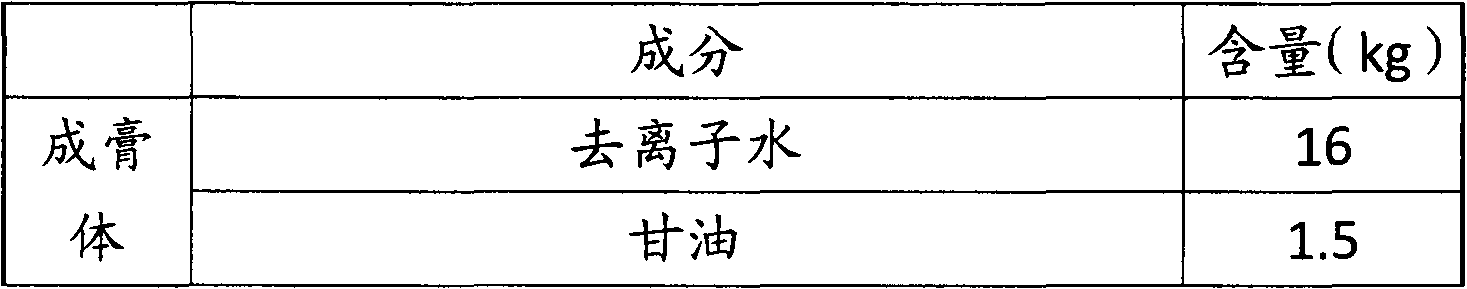

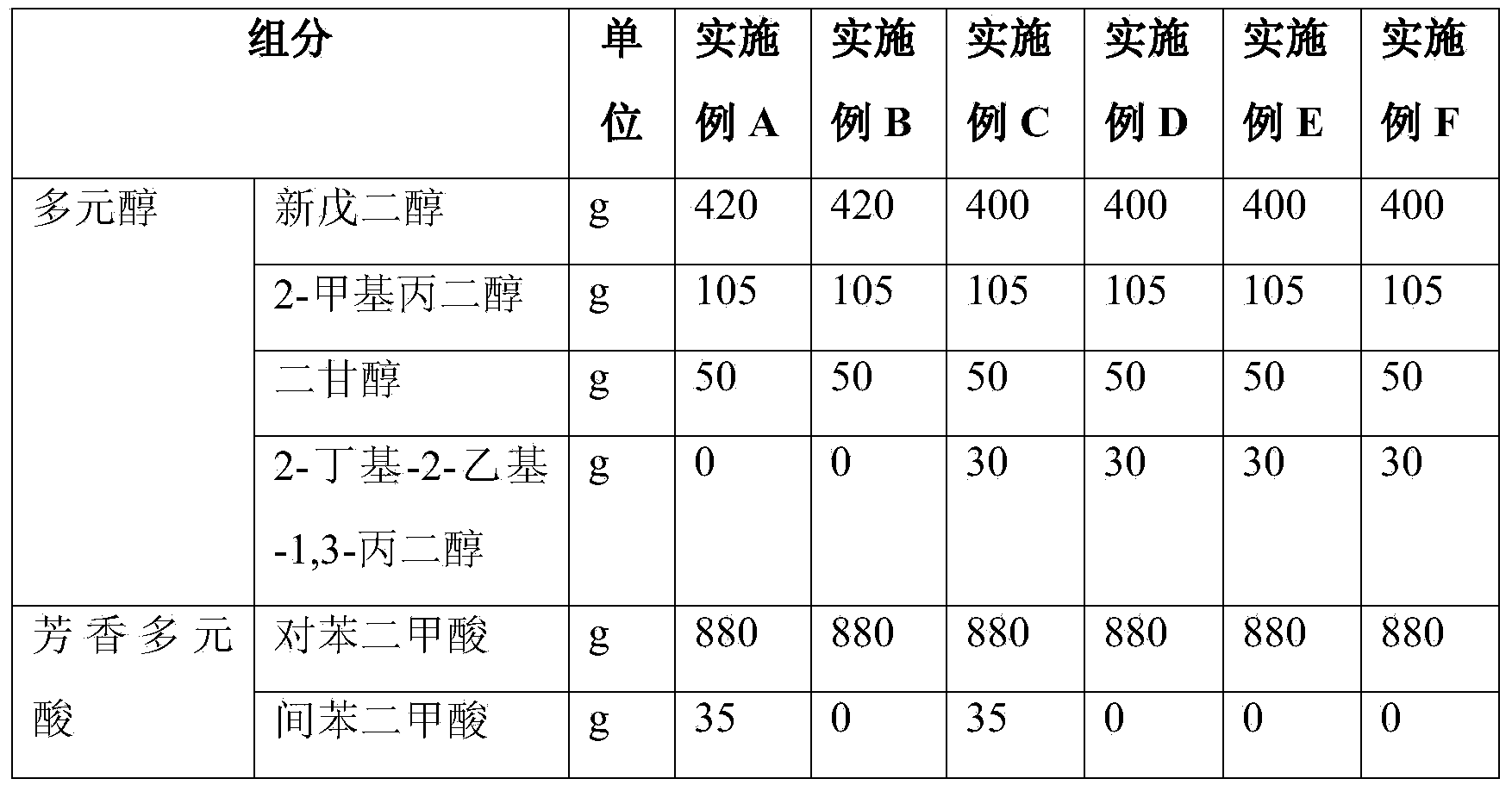

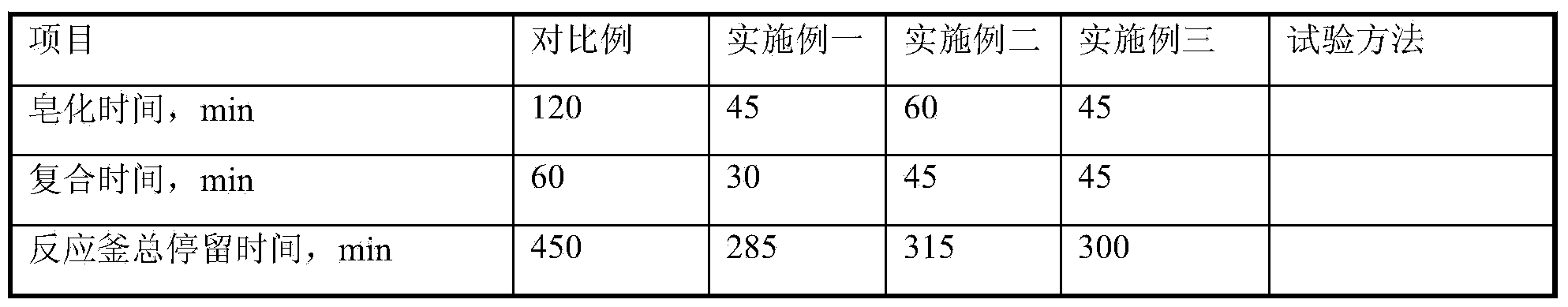

Preparation method for non-crystalline low-melting point polyester hot melt adhesive

The present invention discloses a preparation method for a non-crystalline low-melting point polyester hot melt adhesive. The method comprises the following steps: (1) adopting neopentyl glycol, diethylene glycol, ethylene glycol, adipic acid, sebacic acid and m-phthalic acid as raw materials, and carrying out an esterification reaction under an effect of a catalyst; and (2) adding a stabilizer, a condensation polymerization catalyst and an antioxidant to the product from the step (1), and carrying out a reduced pressure condensation polymerization reaction to obtain a copolyester with a melting point less than 120 DEG C. The polyester hot melt adhesive of the present invention shows a transparent state at the high temperature and the room temperature, does not crystallize, has a good fluidity in low temperature use, and has excellent wettability.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +2

Water soluble anti-rust agent

InactiveCN101712817AShort film forming timeImprove quick-drying performanceAnti-corrosive paintsHazardous substanceSebacic acid

The invention relates to a water soluble anti-rust agent on the surface of ferrous metal, which comprises the following components: 2 to 10 weight percent of barium petroleum sulfonate and / or barium dinonyl decyl sulfonate, 1 to 6 weight percent of sodium molybdate and / or amine molybdate, 0 to 10 weight percent of sebacic acid, 2 to 10 weight percent of polyacrylic ester, 3 to 20 weight percent of triethanolamine oleic soap and / or 2 to 6 weight percent of polyoxyethylenesorbitan monooleate, 0 to 15 weight percent of sodium alkylsulfonate, 0 to 8 weight percent of glycerin and the balance of water or machine oil. Compared with the conventional water soluble anti-rust agent, the water soluble anti-rust agent of the invention has the advantages of short film forming time, firm film forming adsorption and good anti-rust effect; the actual anti-rust period can reach 3 to 6 months; the formed film is thin and only 3 to 5 microns; common workpieces do not need film removal and can be directly assembled and coated; the film removal is convenient, and the film is only soaked and rinsed in mild water over 50DEG C and then can be removed quickly; and the anti-rust agent has no component containing toxic and harmful substances, does not contain phosphorus, has the advantages of good environmental protection and no pollution to the environment, and is the environment-friendly water soluble anti-rust agent.

Owner:无锡市弘育化工有限公司

Slow-release preparation containing beta-lactamase inhibitor and cephalosporin and its use

The present invention relates to a slow-released preparation containing beta-lactamase inhibitor and cephalosporin. Said slow-released preparation can be made into antibiotic slow-released injection or slow-released implant preparation. Said injection is formed from slow-released microsphere and solvent, the slow-released microsphere contains slow-released auxiliary material and beta-lactamase inhibitor with antibacterial effective dose and cephalosporin, the solvent is special one containing suspension adjuvant of carboxymethyl cellulose sodium, etc. and its viscosity is 100 cp-3000 cp (20 deg.C-30 deg.C). The slow-released auxiliary material is selected from EVAc, polylactic acid copolymer, sebacic acid copolymer, albumin glue and gelatin, etc. The slow-released implant preparation is prepared by using slow-released microsphere or adopting melting process. Said invention also provides its application method. and can obtain obvious therapeutic effect for curing various infective diseases.

Owner:JINAN SHUAIHUA PHARMA TECH

Polyesters, methods of their preparation and use

Crosslinked polycondensation products of: (a) polyols selected from the group consisting of: (1) polyols with three or more hydroxyl groups, (2) acetal forms of (1), and (3) mixtures thereof, and (b) polyacids selected from the group consisting of: (1) polyacids with two or more carboxylic groups, (2) anhydrides of (1), (3) esters of (1), and (4) mixtures thereof are disclosed. The resulting polyesters have a molar ratio of polyol to polyacid from about 1:3 to about 3:1 and are highly-crosslinked. Preferred monomers are sustainable monomers such as glycerol, citric acid, fumaric acid, and sebacic acid. Two-step heating processes for preparing the high molecular weight polyesters are also provided.

Owner:POLYMER PHASES +1

Anticancer sustained release agent containing epothilone

InactiveCN1969816AEasy injectionIncrease drug concentrationOrganic active ingredientsPharmaceutical delivery mechanismPolyethylene glycolDepressant

Disclosed is an anti-cancer drugs slow release agent containing Epothilone which comprises slow release microspheres and dissolvent, wherein the slow release microballoons comprise anti-cancer active constituents and slow release auxiliary materials, the dissolvent being specific dissolvent containing suspension adjuvant. The anticancer active constituents include Epothilone, Epothilone derivatives, Epothilone B, Epothilone D and combination of anti-cancer drugs selected from phosphoinositide-3-kinase inhibitor, of pyrimidine analogues and / or DNA restoring enzyme inhibitor, the slow release auxiliary materials include polylactic acid and its copolymer, polyethylene glycol, PLA-COOH copolymer, di-aliphatic acid and sebacylic acid copolymer, poly(erucic aciddipolymer-sebacylic acid), poly(fumaric acid-sebacylic acid), Polifeprosan, polylactic acid and other biocompatible high polymers, the viscosity of the suspension adjuvant is 100-3000cp (at 20-30 deg C), and is selected from sodium carboxymethylcellulose. The anticancer active constituents and the slow release microspheres can also be prepared into slow release implanting agent for intra-tumor or around-tumor injection or placement for the effective suppression of tumor growth and for the appreciable enhancement for curative effects of non-operative treatments such as chemotherapy.

Owner:JINAN SHUAIHUA PHARMA TECH

Polyester resin for epoxy-cured powder coating with high glossiness and high leveling property and preparation method thereof

ActiveCN103642014AControl surface tensionControl Melt ViscosityPowdery paintsEpoxy resin coatingsEpoxy1,3-Propanediol

The invention relates to a polyester resin for an epoxy-cured powder coating with high glossiness and high leveling property and a preparation method thereof. The polyester resin has relatively high glass-transition temperature. The technical scheme is as follows: the polyester resin for the epoxy-cured powder coating with high glossiness and high leveling property orderly comprises the following components: neopentyl glycol, 2-methylpropanediol, diglycol, 2-butyl-2-ethyl-1, 3-propylene glycol, terephthalic acid, isophthalic acid, sebacic acid and trimellitic anhydride. The preparation method of the polyester resin for the epoxy-cured powder coating with high glossiness and high leveling property comprises the following steps: 1) adding a proportioning amount of polyhydric alcohol to a reaction kettle, heating at normal temperature, and then feeding a proportioning amount of polyatomic acid and esterification catalyst; 2) carrying out thermal reaction until the water yield of the esterified water can be up to 95% or more of theoretical water yield; 3) adding trimellitic anhydride and isophthalic acid, and carrying out thermal reaction; 4) gradually vacuumizing, and reacting; 5) discharging.

Owner:ZHEJIANG CHUANHUA TIANSONG NEW MATERIAL CO LTD

Working electrolyte for wide temperature high voltage aluminium electrolytic capacitor and method for making same thereof

InactiveCN101114544AGuaranteed oxidation efficiencyImprove high temperature performanceElectrolytic capacitorsWorking temperaturePolyethylene glycol

The invention discloses working electrolyte for the aluminum electrolytic capacitor with wide working temperature range and high voltage and the manufacturing method. The invention includes the following materials (calculating with weight percent): 60 percent to 80 percent glycol, 5 percent to 20 percent Gamma butyrolactone, 0 percent to 5 percent water, 2 percent to 5 percent ammonium sebacate, 5 percent to 10 percent isosebacic acid ammonium, 0 percent to 5 percent sebacic acid, 0.1 percent to 2 percent ammonium dihydrogen phosphate, 0.1 percent to 1 percent citric acid, 0.1 percent to 2 percent p-nitrobenzoic acid and 5 percent to 20 percent polyethylene glycol. The manufacturing method is as follows: (1) well-mixing the glycol, Gamma butyrolactone and water and heating to 60 DEG C through 90 DEG C; (2) adding the ammonium sebacate, sebacic acid, ammonium dihydrogen phosphate, citric acid, p-nitrobenzoic acid, polyethylene glycol to the mixed solvent and well-mixing; (3) after ample dissolution of the materials, keeping the temperature in the step (3) for five through thirty minutes; (4) adding the isosebacic acid ammonium to the mixture and keeping the temperature in the step (3) for five through thirty minutes, and stopping heating and natural cooling in the air, and obtaining the aluminum electrolytic capacitor with wide working temperature range and high voltage. The product increases the conductivity and the sparking voltage of the working electrolyte and reduces the production cost.

Owner:GUANGXI NORMAL UNIV

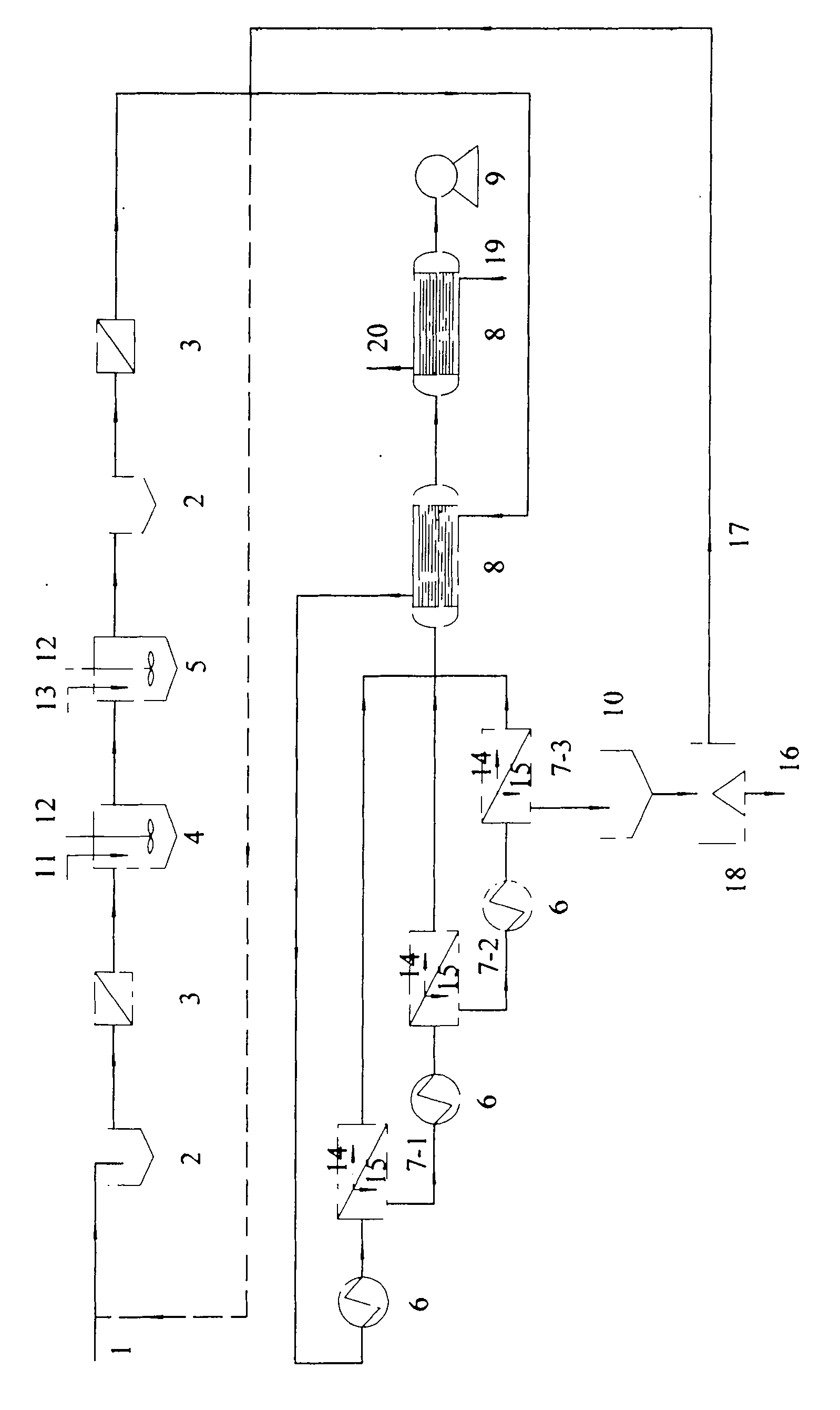

Lubricating grease for hub bearing of heavy load truck and preparation method thereof

InactiveCN103450978AEliminates tendency to overflowSlow dehydration stepThickenersThiocarbamateChemical industry

The invention relates to a lubricating grease and a preparation method thereof, particularly relates to a lubricating grease for a hub bearing of a heavy load truck and a preparation method thereof, and belongs to the technical field of a chemical industry. The lubricating grease is prepared from the following raw materials: (A) base oil which accounts for 60-85% of total weight of the lubricating grease, (B) a thickening agent, which is C12-C22 unitary organic acid which accounts for 7-12% of total weight of the lubricating grease, 0.5-3% of sebacic acid, 0.2-1% of boric acid, and 3-5% of lithium hydroxide oil solution, (C) an additive, which is thiocarbamate which accounts for 0.5-3% of total weight of the lubricating grease, 2-5% of sulfide olefin cottonseed oil, 2-4% of dialkyl dithiocarbamate salt, 0.5-2.5% of molybdenum dialkyl dithiophosphate, 0.3-2% of antirust agent and 0.3-1% of antioxidant. The lubricating grease has the beneficial effects that the production time is shortened; the lubricating grease is more controllable in process, stable in product quality, less in seepage loss of a high-temperature bearing, and prominent in extreme pressure property; lubricating protection can be better provided for hubs of the heavy load truck; the lubricating requirements of the hub bearing of the heavy load truck under various working conditions can be met; the grease exchange period of the hub bearing is prolonged.

Owner:JIANGSU LOPALTECH

Method for treating wastewater in production of sebacic acid

InactiveCN102030441AMultistage water/sewage treatmentNature of treatment waterFlocculationMembrane distillation

The invention discloses a method for treating wastewater in the production of high-salt sebacic acid by membrane distillation under reduced pressure, which comprises the following steps of: pretreating the wastewater such as performing static precipitation and flocculation precipitation, filtering, regulating pH value and the like, adding into a multistage membrane distillation system to highly concentrate the wastewater in the membrane distillation system so as to obtain desalted water, cooling concentrated solution, crystallizing in a crystallizer, and separating to obtain solid salt. The process is simple and the method is high-efficiency and economical.

Owner:TIANJIN MOKELI TECH

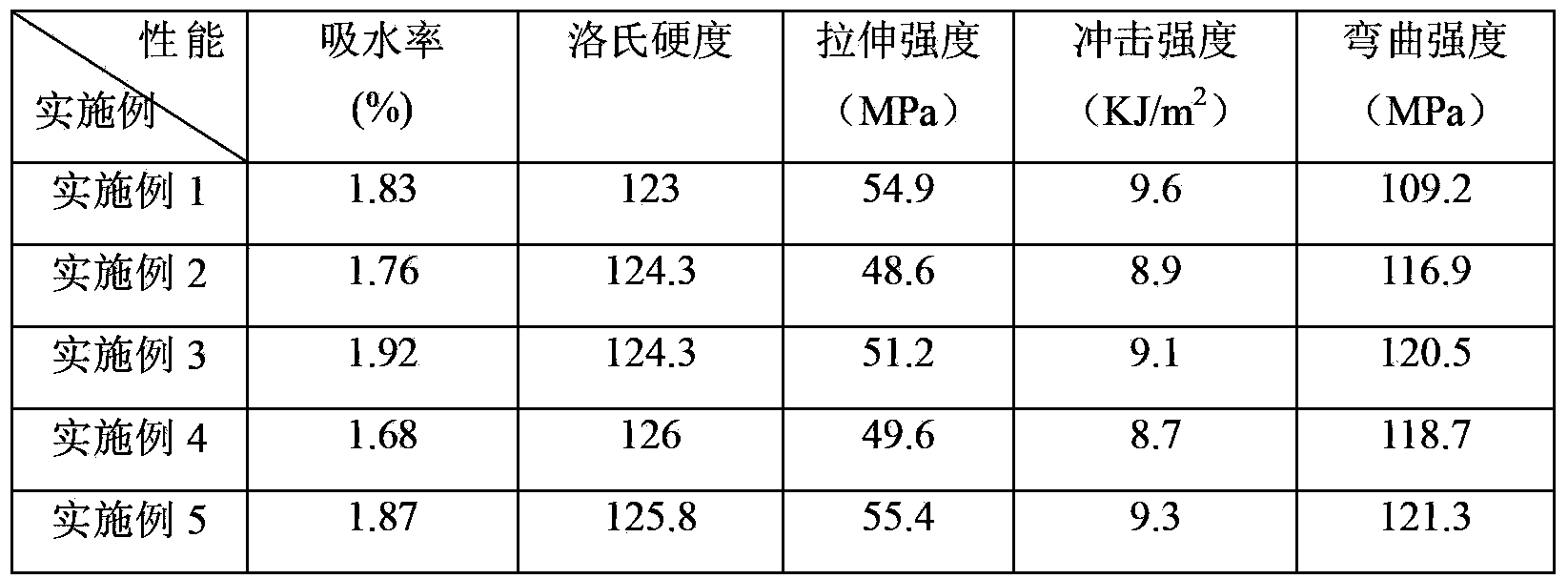

Low-water absorption biological nylon material PA610T and preparation method thereof

The invention belongs to the field of polymer nylon synthesis and relates to a low-water absorption biological nylon material PA610T and a preparation method thereof. The low-water absorption biological nylon material PA610T is prepared from 28-30 parts by weight of aromatic diacid, 32-34 parts by weight of sebacic acid, 38-38.5 parts by weight of hexanediamine, 0.1-0.3 parts by weight of a nucleating agent, 0.0003-0.0005 parts by weight of a catalyst and 30-50 parts by weight of deionized water. The low-water absorption biological nylon material PA610T has good fluidity and more ideal mechanical properties. Nylon prepared from the low-water absorption biological nylon material PA610T has water absorbency far lower than that of common nylon. The low-water absorption biological nylon material PA610T greatly widens a nylon application field.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com