Patents

Literature

203 results about "Plastics industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The plastics industry manufactures polymer materials — commonly called plastics — and offers services in plastics important to a range of industries, including packaging, building and construction, electronics, aerospace, and transportation.

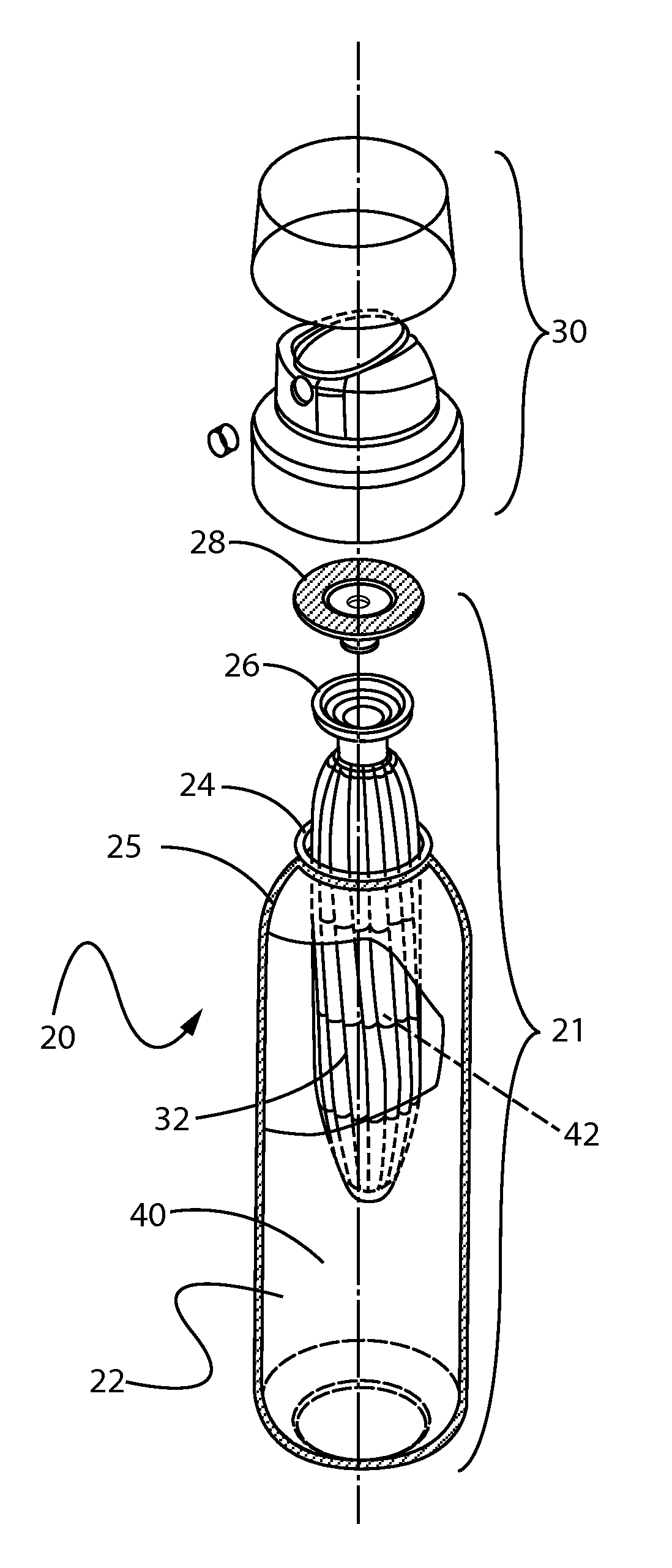

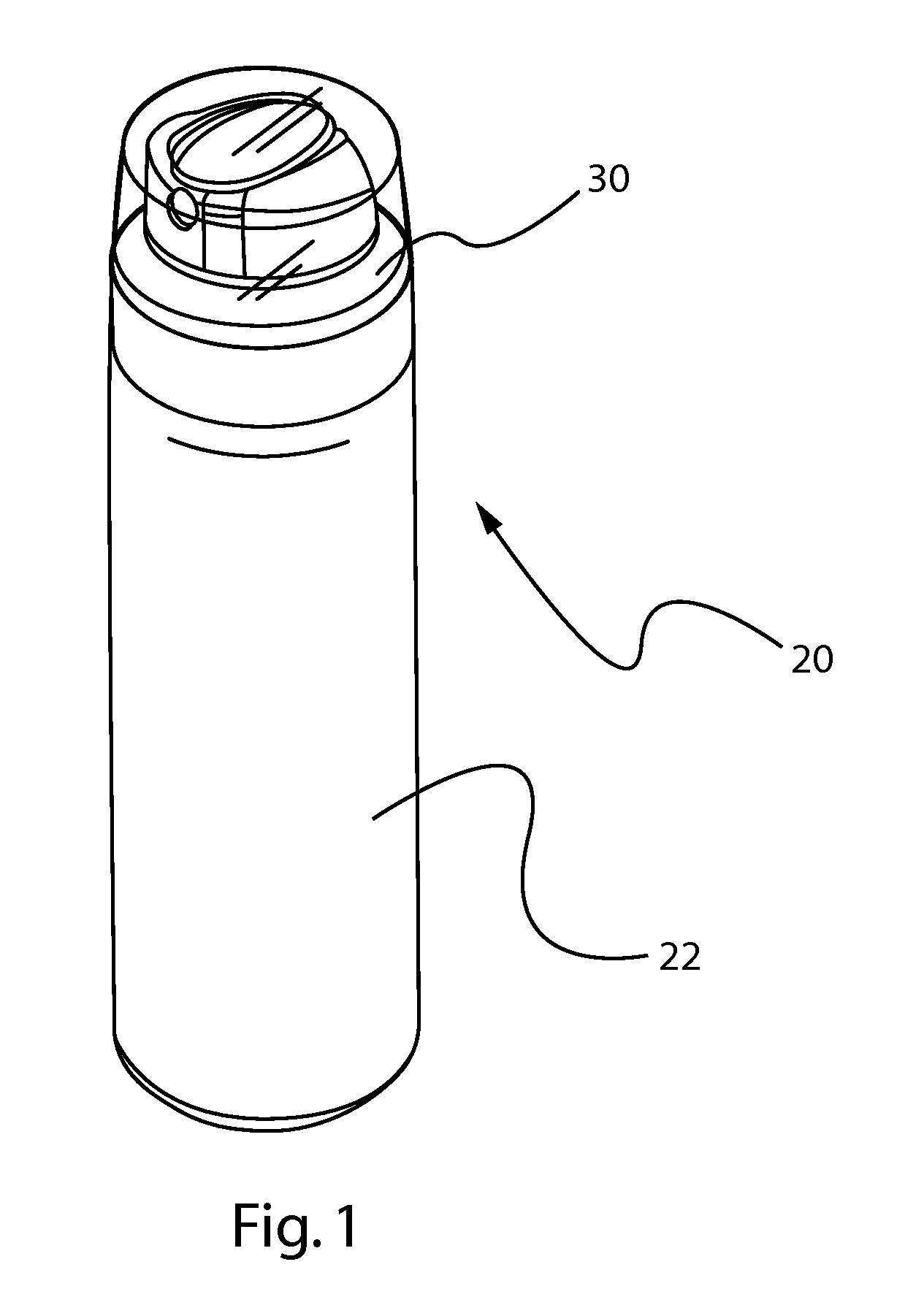

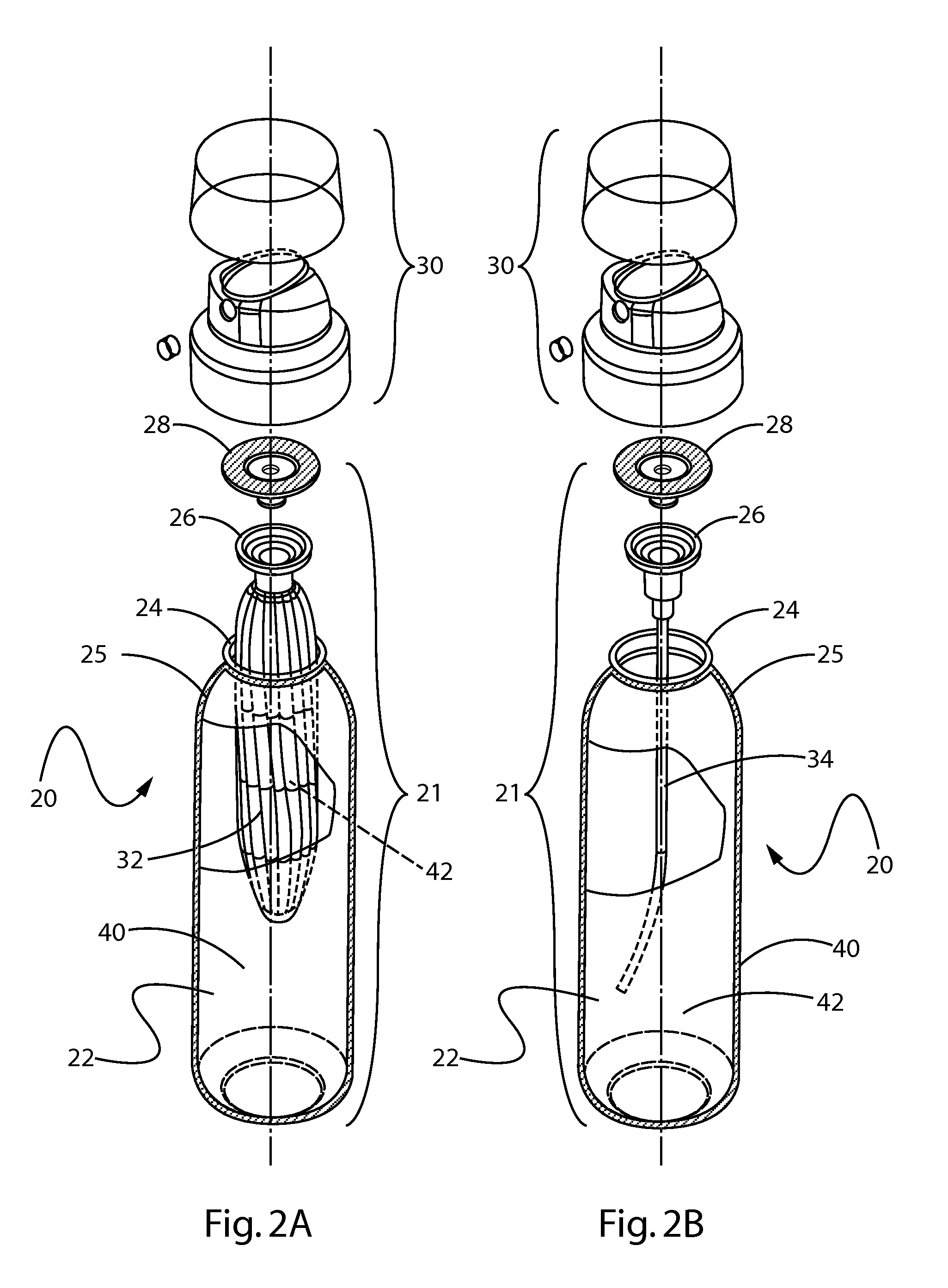

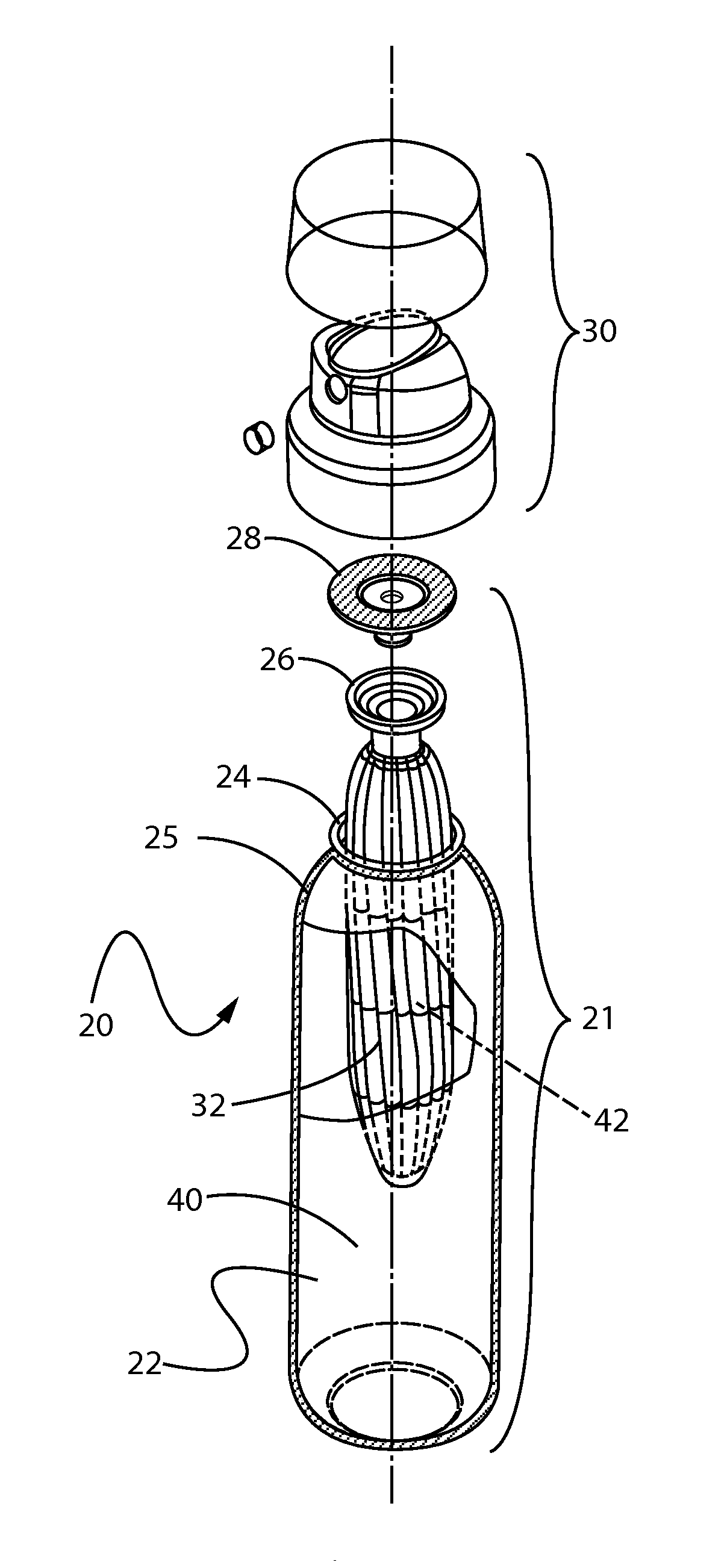

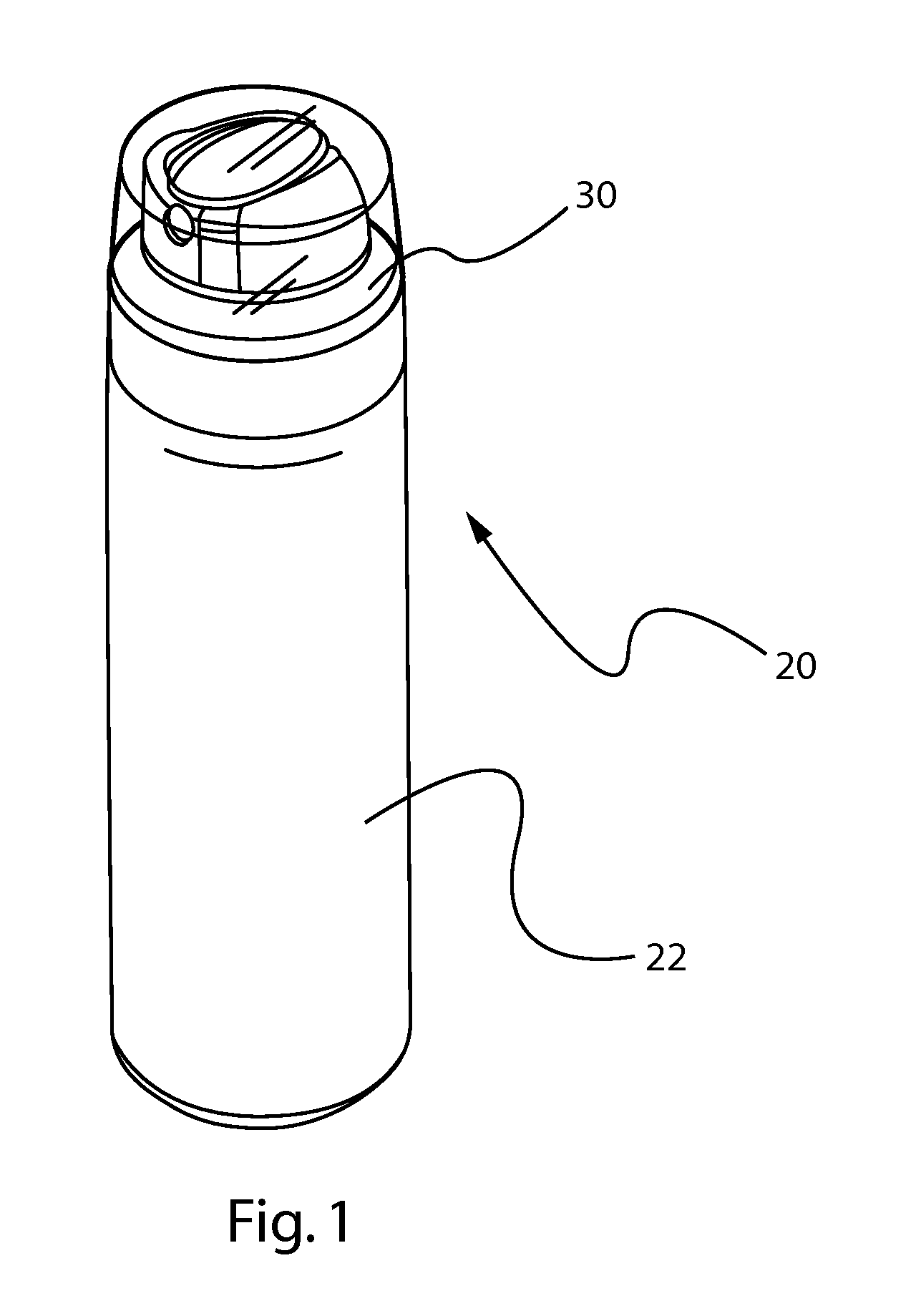

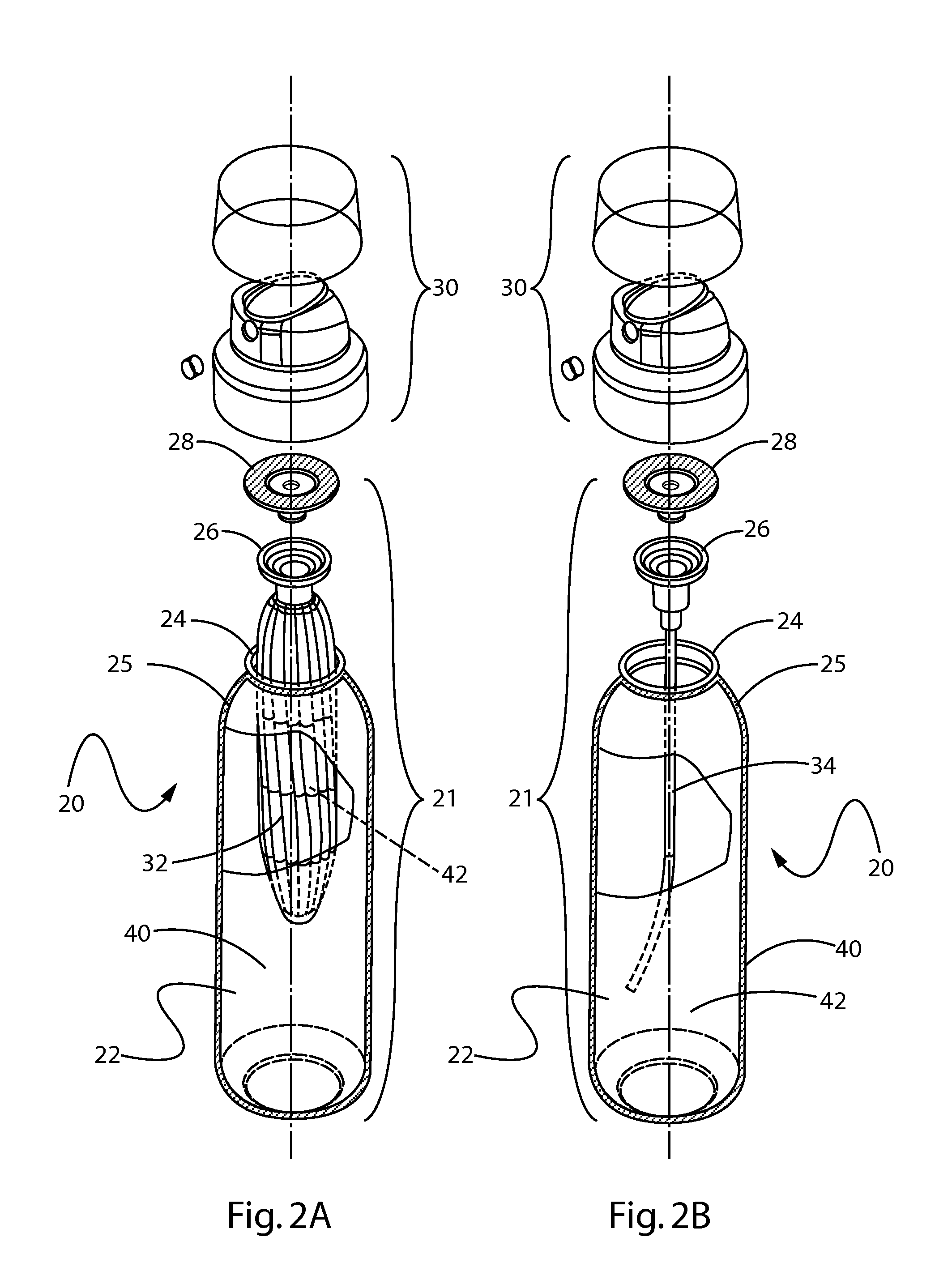

Recyclable plastic aerosol dispenser

An aerosol dispenser. The aerosol dispenser is made from materials which can go into a single recycling stream having a single class of materials, as defined by the Society of the Plastics Industry, and particularly may exclusively comprise Class 1 materials with no flammable product / propellant present.

Owner:THE PROCTER & GAMBLE COMPANY

Composite core material vacuum insulation panel and preparation method thereof

ActiveCN101691899AHigh material utilizationReduce processing costsThermal insulationPipe protection by thermal insulationPlastics industryVacuum insulated panel

The invention discloses a composite core material vacuum insulation panel and a preparation method thereof and relates to a vacuum insulation panel. The invention provides the composite core material vacuum insulation panel which utilizes a large number of scraps of rigid foam plastics in the existing rigid phenolic foam plastic industry, the rigid polyurethane foam plastic industry and the like and can significantly improve the comprehensive utilization rate of the rigid foam plastics, improve the environment and promote the recycling of materials, and the preparation method thereof. The composite core material vacuum insulation panel comprises a composite core material, a getter and a closed packaging bag. The composite core material vacuum insulation panel can be prepared by adopting the wet method or the dry method.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

Recyclable plastic aerosol dispenser

An aerosol dispenser. The aerosol dispenser is made from materials which can go into a single recycling stream having a single class of materials, as defined by the Society of the Plastics Industry, and particularly may exclusively comprise Class 1 materials with no flammable product / propellant present.

Owner:THE PROCTER & GAMBLE COMPANY

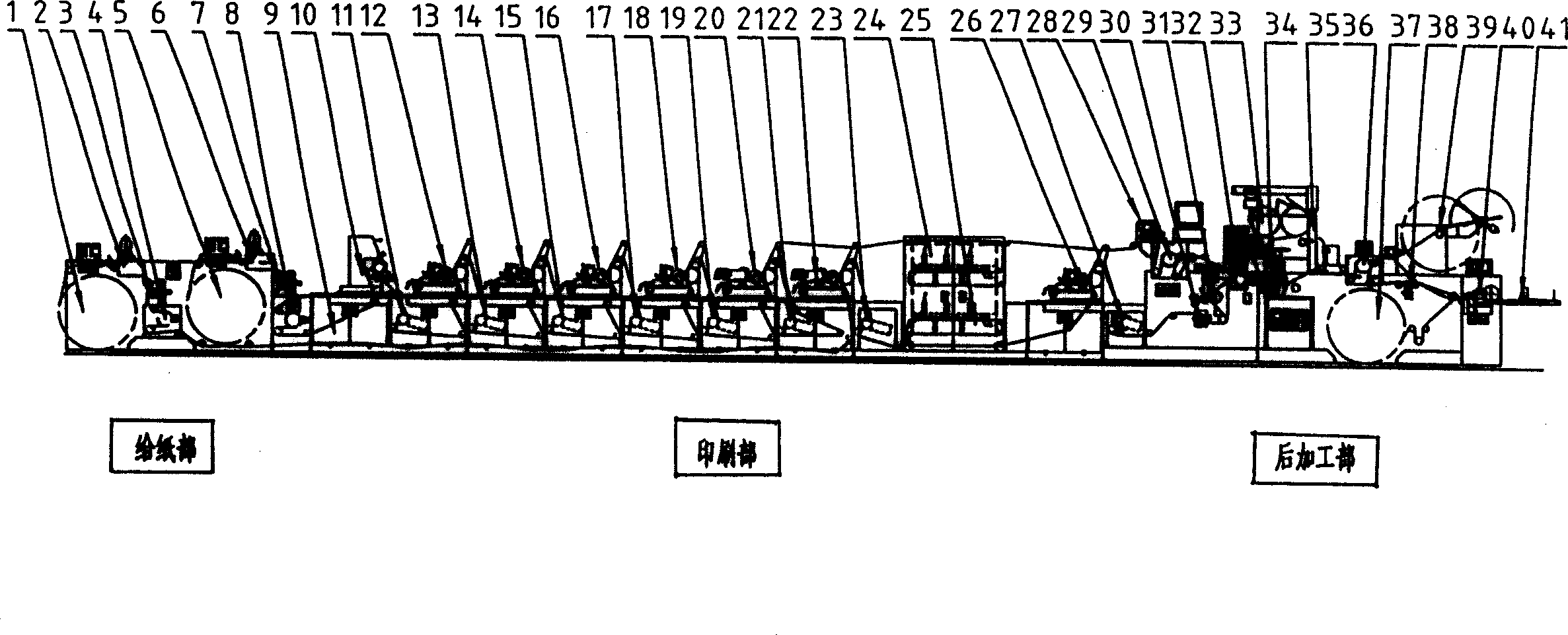

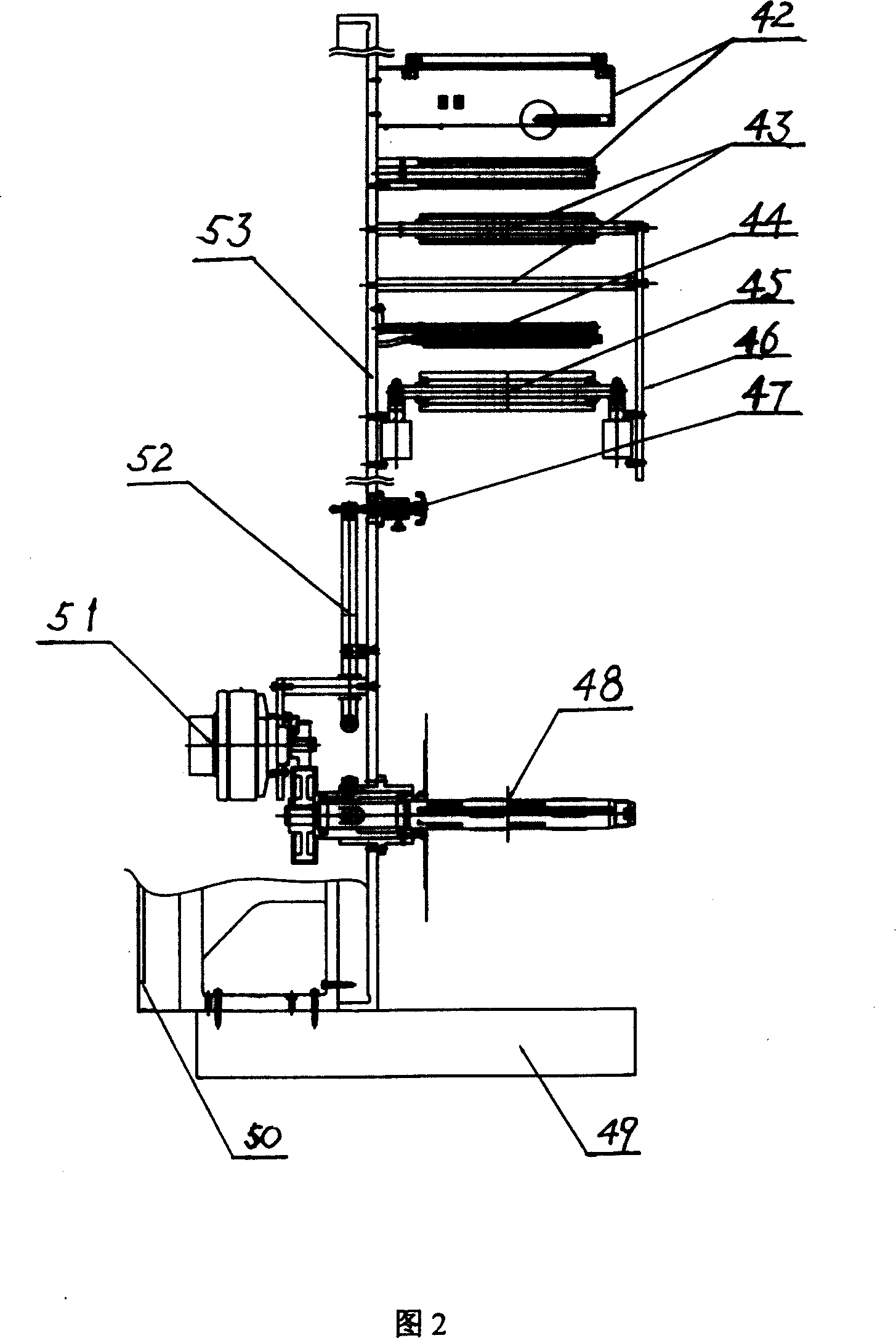

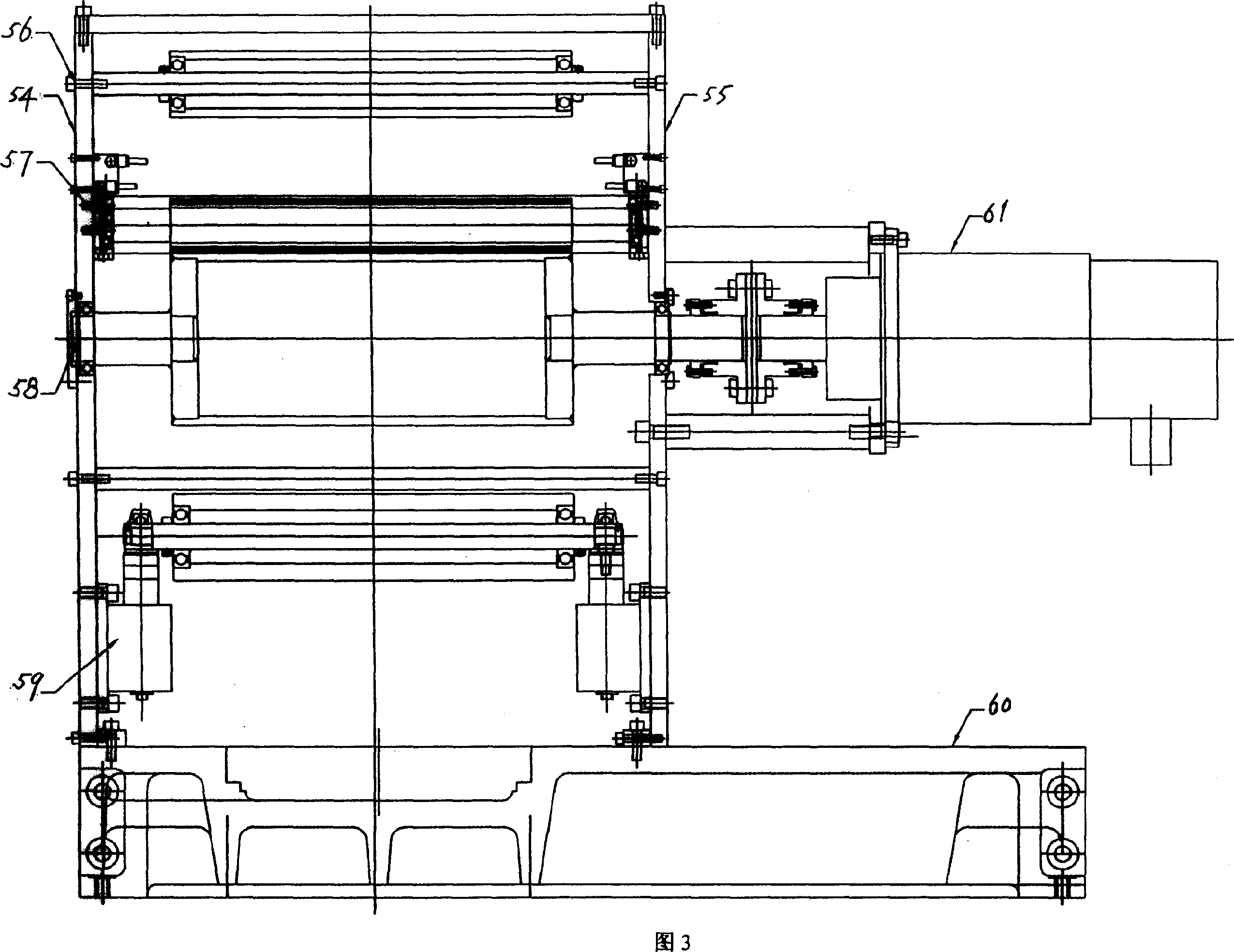

Label wheel rotary printing machine

InactiveCN101054011AImprove matchDry in timeLamination plant layoutStampsPlastics industryEngineering

The invention relates to a label rotary printing which is characterized by that: it is mainly comprised by paper feeding device, printing section, post-process portion, and can be linked with relief printing, flexographic printing, offset printing, and can be further linked with code spray, silicon oil coating, hot melting glue coating to make multi-layer anti-counterfeiting label, and two paper feeding portions can simultaneously print two rolls of stocks, and coats hot melting glue between the two rolls of stocks, and compounds them to obtain the non-drying glue label, and the invention is applicable in plastic industry for plastic film printing, and can be also used in printing commercial table and printing non-carbon impact paper; because the invention has five flexo printing color classes, it can be regarded as a pure five-color rotary flexo printing used in commercial packing printing field. The advantage of the invention is that: the invention can print single roll of stock as well as two rolls of stocks and can compound the two rolls of stocks, multi-layer non-drying glue label can be processed by multiple printings and ink jet printing on same device.

Owner:SHANGHAI XINMIN TAIYO KIKAI

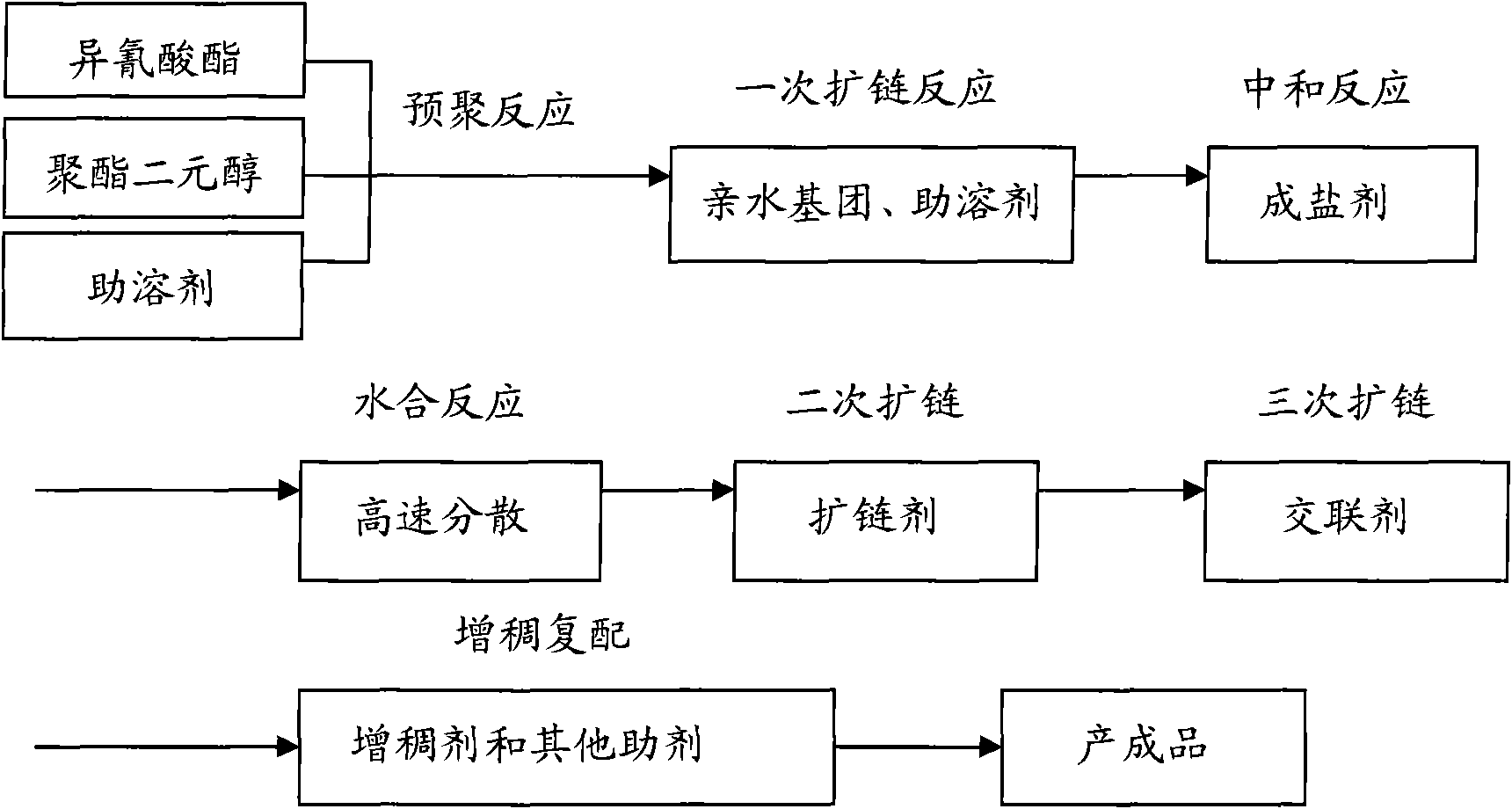

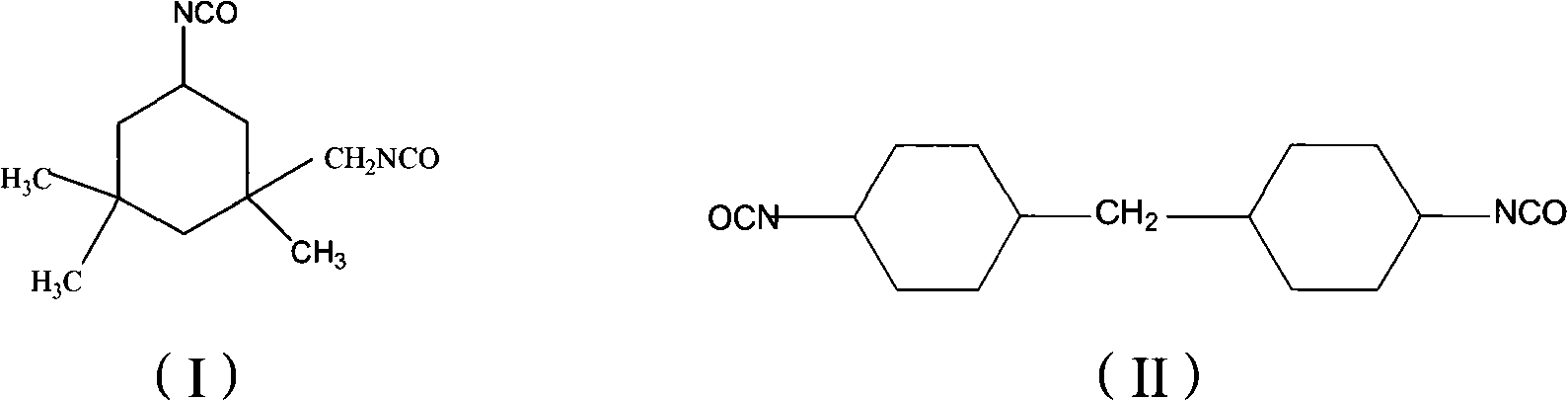

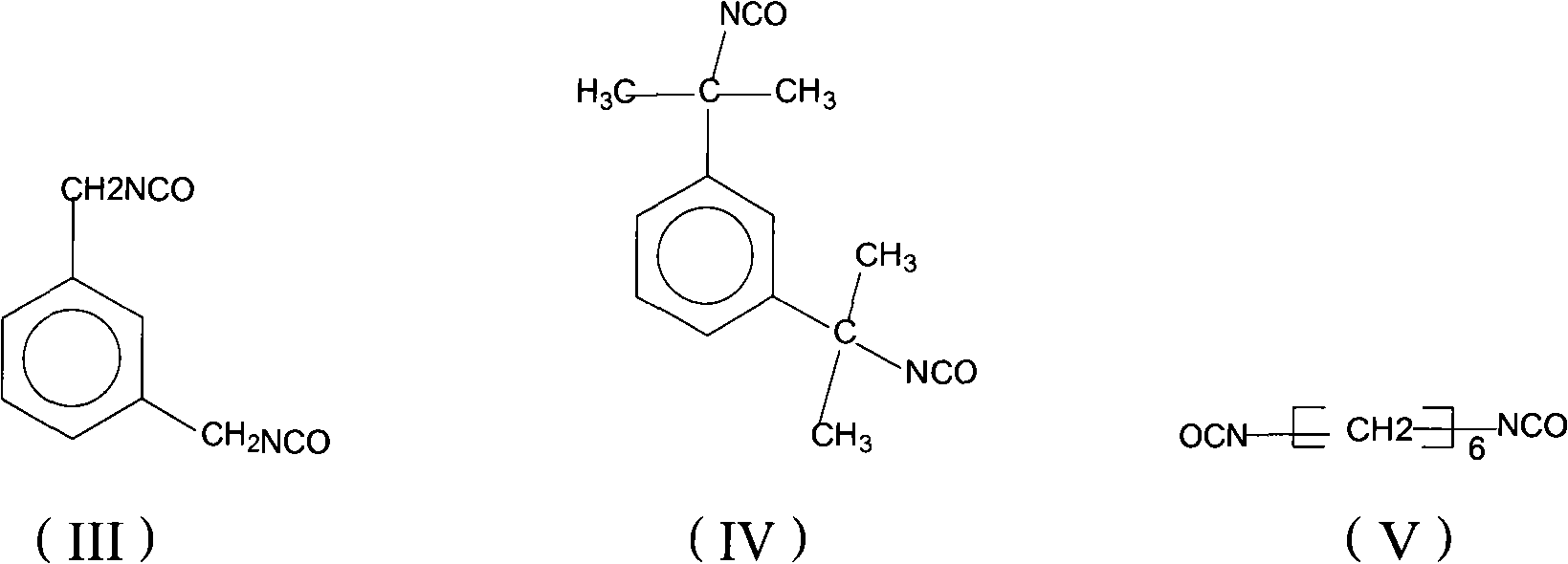

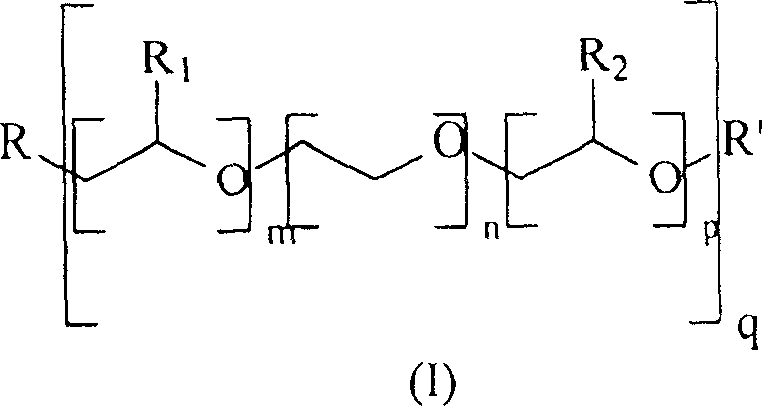

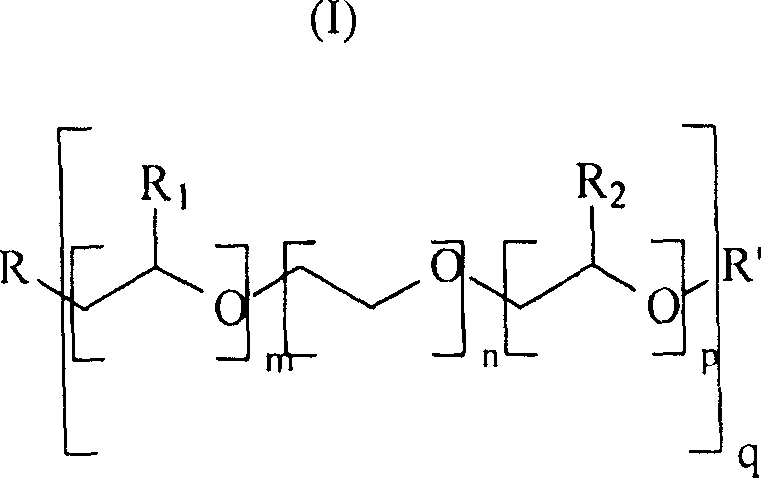

Water-borne polyurethane and preparation method thereof

The invention provides a water-borne polyurethane resin and preparation method thereof, which is formed by polymerization of aliphatic and / or alicyclic diisocyanate and polyester diol, wherein the polyester diol is polymerized by adipic acid and diol. The invention prepares a water-borne polyurethane dispersion solution through reaction between polyisocyanate and oligo-polyol, and adds some functional auxiliary agents to prepare a product with high mechanical strength, soften property and non-adhesion, thereby overcoming the shortcomings of low modulus, adhesion, low mechanical wetness, difficult adhesion regulation of conventional water-borne polyurethane, and meeting the physicality requirement of various industrial fields, in particular the synthetic leather based on physical and chemical properties thereof. Meanwhile, through the post-thickening combination technology, the water-borne polyurethane dispersion liquid is prepared into slurry to meet the requirements in chemicals, textile and plastics, in particular the synthetic leather and achieve the industrial applicability.

Owner:丽水市优耐克水性树脂科技有限公司

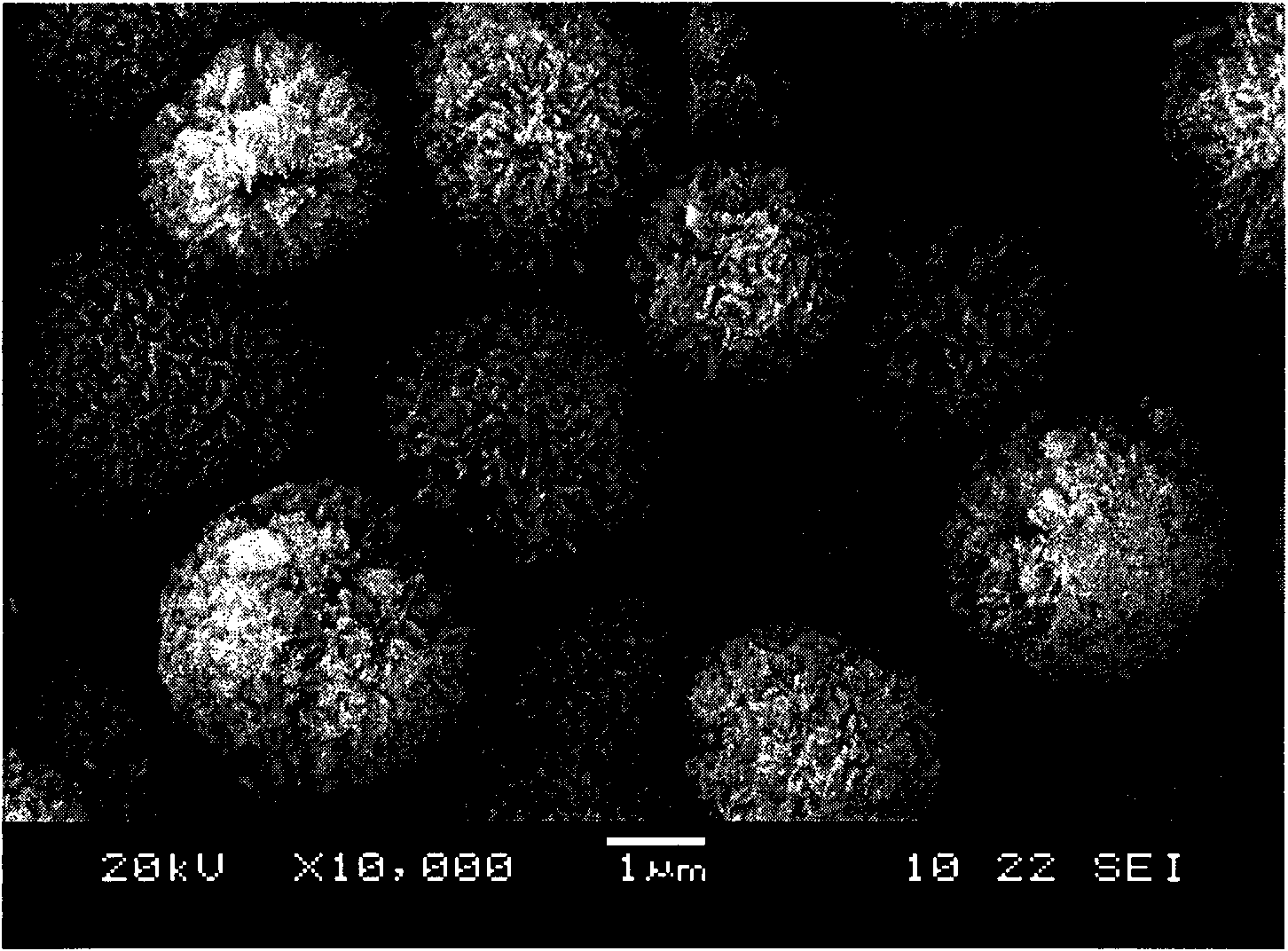

Production technique of nano calcium carbonate by normal temperature method

ActiveCN102674425APassivation sensitivityLess investmentCalcium/strontium/barium carbonatesNanotechnologyPlastics industryFilling materials

The invention discloses a production technique of nano calcium carbonate by a normal temperature method, belonging to the technical field of fine chemical engineering. The production technique comprises the following steps: proportioning, carbonizing, treating, dehydrating, primary drying, secondary drying and depolymerizing. The invention has the characteristics of low equipment investment, low energy consumption, low production cost and the like, can implement production under normal temperature conditions, and can control the particle size and crystal form. The nano calcium carbonate produced by the technique disclosed by the invention can be used as a filling material in plastics industry, rubber industry, paint industry, paper manufacturing industry, ink industry, adhesive industry and other industries.

Owner:HUNAN JINJIAN NEW MATERIAL TECH

Tech. for synthesizing high toughness epoxy vinyl ester resin

The invention relates to a high tenacity epoxy vinyl ester resin and the compounding method that takes open loop esterification reaction by using organic monad unsaturation carboxylic acid on the technology base, induces organic saturation dyadic carboxylic acid and end carboxy liquid nitrile butadiene rubber soft radical to improve the tenacity of the resin. The broken specific elongation 8-16%, impact intension is 20-30KJ / m2. It could satisfy the special need in fiberglass-reinforced plastics industry. The invention is simple structure, no tree wastes, and has good stability.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

Method for preparing functional polymer material

ActiveCN106283275AIncrease profitImprove efficacyMelt spinning methodsCellulose/protein filament chemical after-treatmentFiberPolymer science

The invention discloses a method for preparing a functional polymer material, and belongs to the field of fiber material and plastic processing. The invention aims at solving the shortcomings of low efficiency and high cost of carrying out functionalization on traditional polymer materials by blending and surface chemical grafting. The method disclosed by the invention comprises the following steps: acting an alternating electric field on functional material particles to be physically embedded on the surface of an extruded base material of the polymer material, carrying out chemical crosslinking and physical blending on a crosslinking group and the surface of the base material of the polymer material, and blowing cold air to the base material of the polymer material for curing or blowing cold air to the base material of the polymer material for curing after stretching to obtain the functional polymer material. The selection range of functional substances in the method disclosed by the invention is very wide, the utilization rate is high, the effect is good, the dosage is small, the preparation procedure of the material is short, and the efficiency is high, so that the method can be widely used in the fields of the textile and garment industry, plastic industry, environmental management, drug extraction and the like.

Owner:WUYI UNIV +1

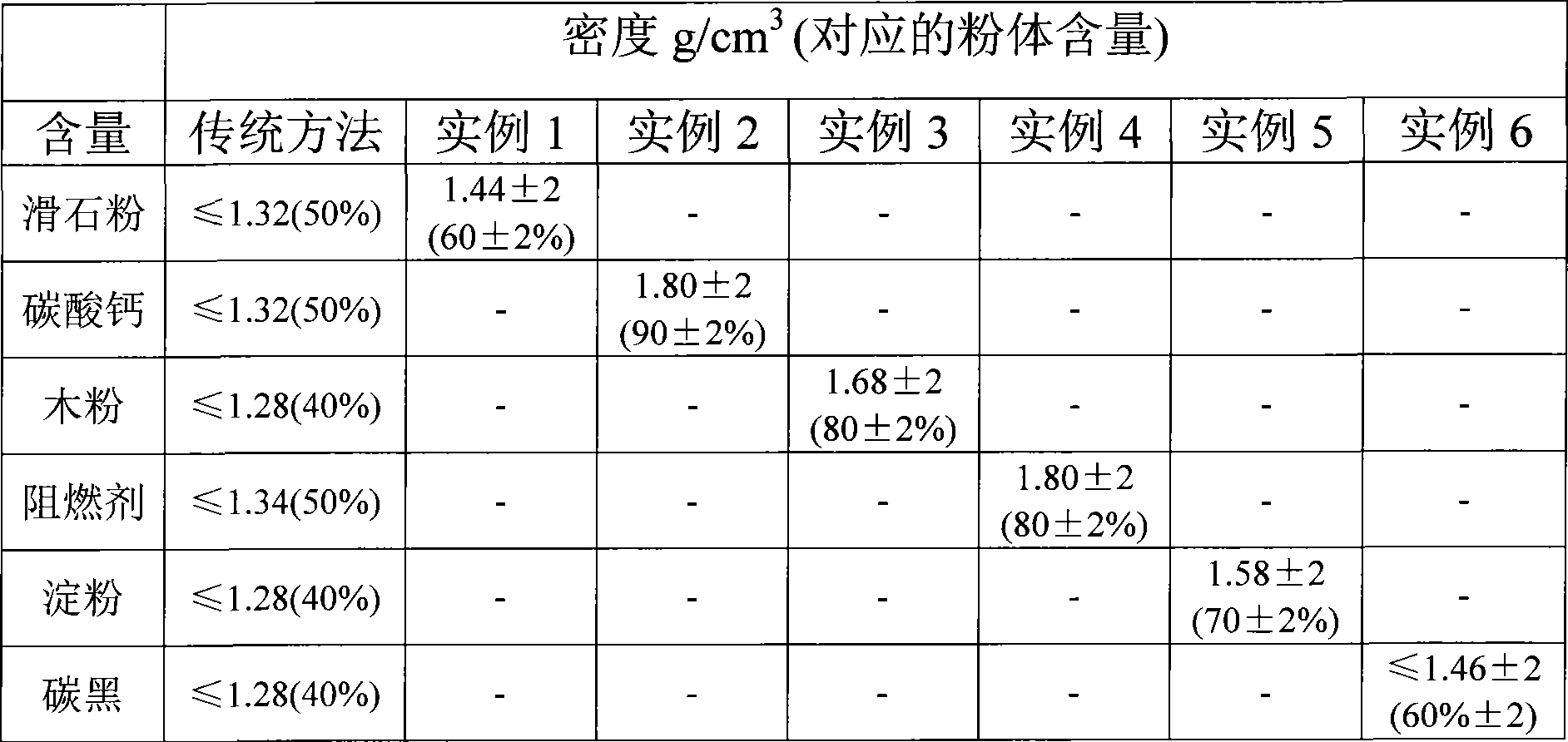

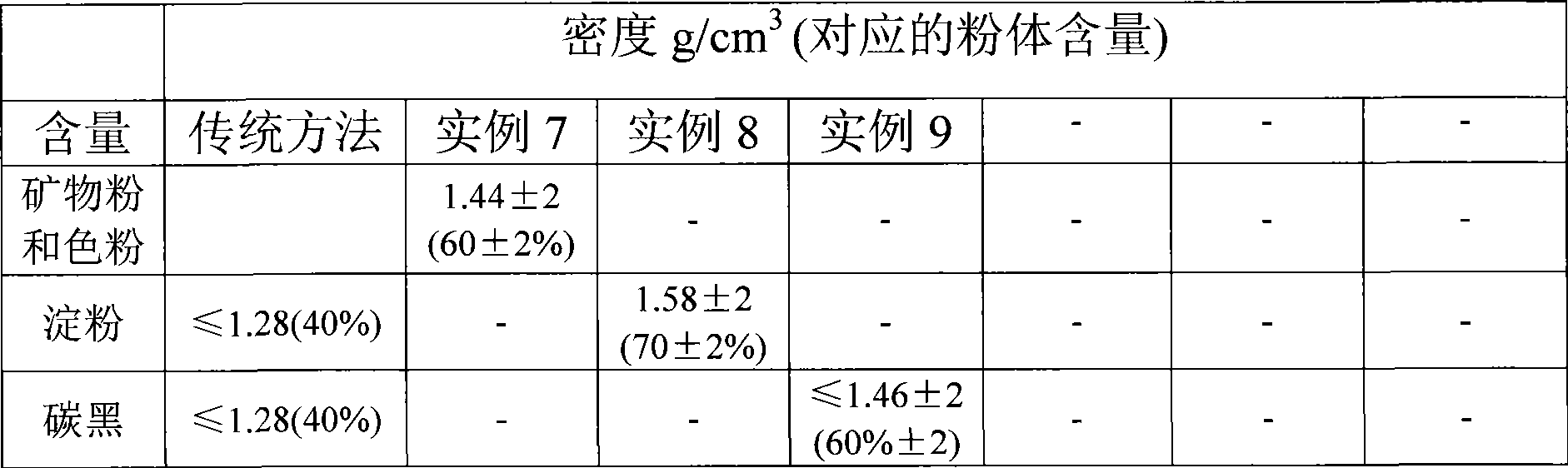

Method for preparing master batch with high-powder content

The invention provides a method for preparing masterbatch with high powder content. The method comprises the following steps: various raw materials are prepared, a Banbury mixer is kept at constant temperature, all the carriers and 50-80 percent of or all powder components, lubricant, dispersing agent and coupling agent are placed in the Banbury mixer for kneading; after the remained functional components are placed in the Banbury mixer for kneading, the Banbury mixer barn is turned over; the materials are decanted into the feeding hopper of a single screw extruder through a transporting receptacle; by the forced feeding of the feeding hopper, the single screw extruder is used to obtain functional masterbatch with high powder content. The method is capable of solving the problem that feeding is difficult during direct production of high powder when blending modified plastics system is filled, and the problem of difficult processing in the modified plastics industry; the masterbatch with high powder content can also meet the requirements of downstream products, and used to produce injection-moulded or extruded products.

Owner:GUANGDONG KINGFA TECH CO LTD

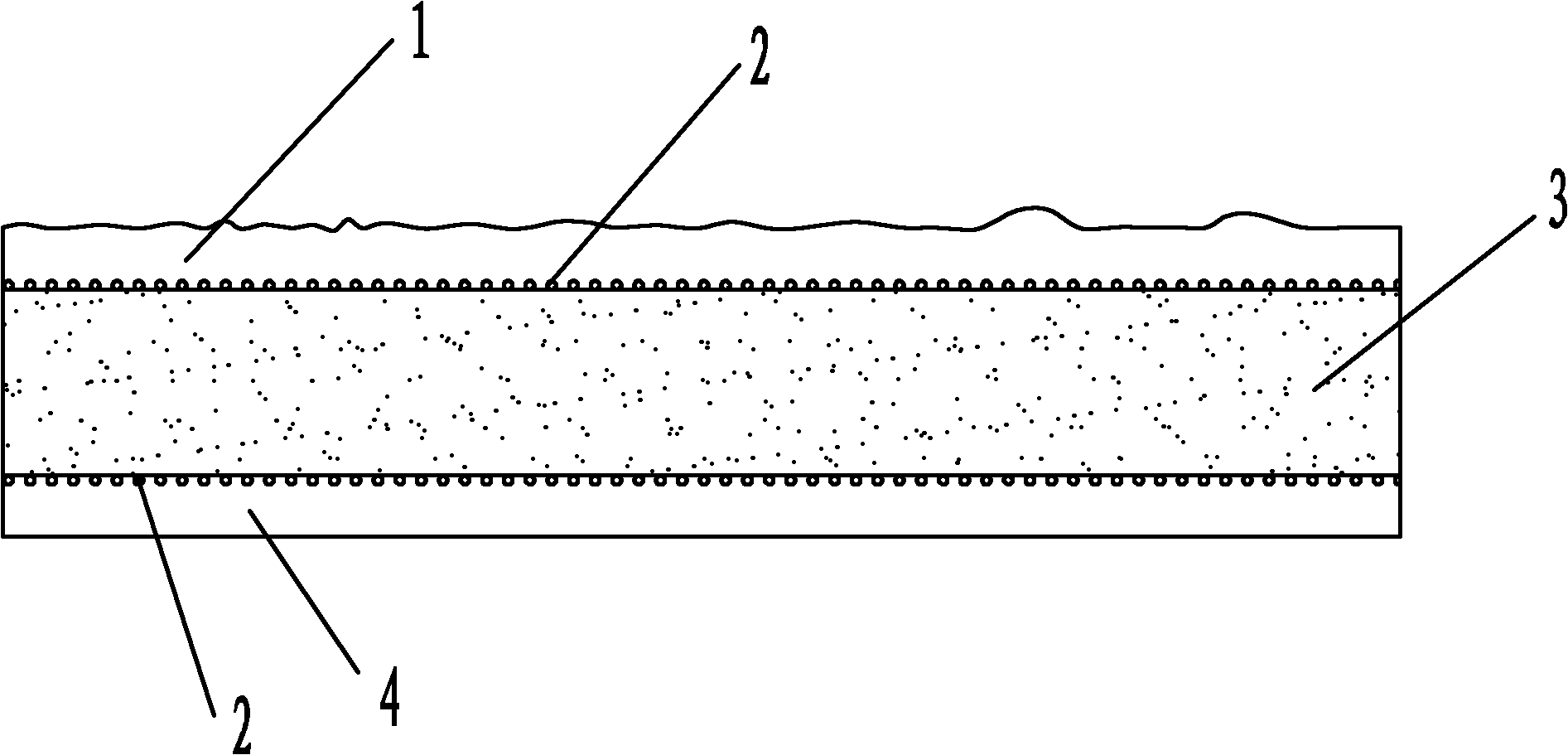

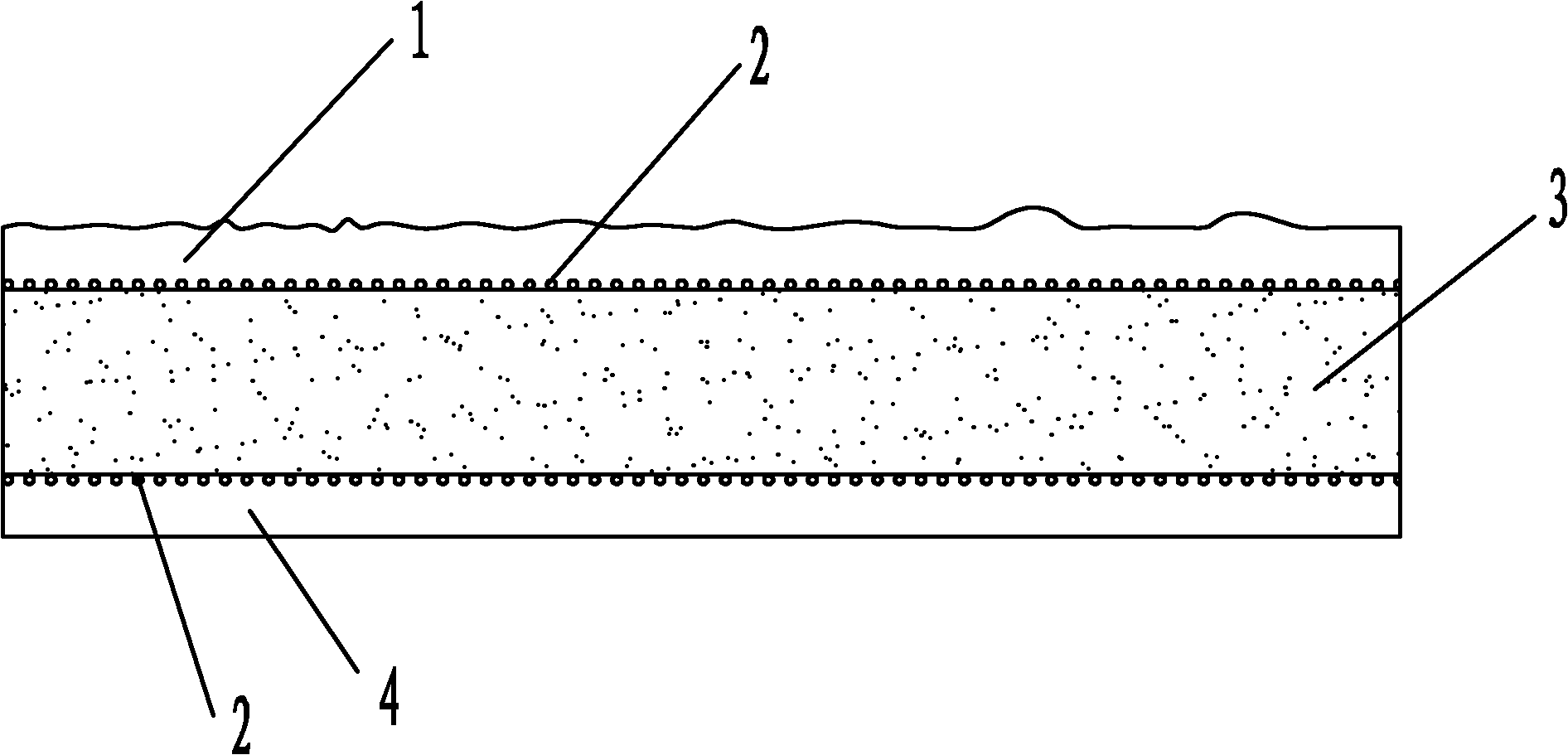

Baseplate of integral heat-preservation and energy-saving plate and preparation method thereof

InactiveCN102152501AImprove performance qualityAchieve heat preservation and energy saving functionCovering/liningsWallsFiberPlastics industry

The invention relates to a baseplate of an integral heat-preservation and energy-saving plate and a preparation method thereof, and the baseplate is characterized by mainly comprising a surface layer, a structure reinforced fibermesh, a middle layer, a structure reinforced fibermesh and a bottom layer which are sequentially connected, wherein the surface layer mainly comprises the following materials in parts by weight:. The preparation method comprises the following steps: preparing liquid raw materials and dry powder; respectively uniformly blending the dry powder, reinforcing glass fibers,poly-propylene fibers and pulps by using a uniform agitator so as to form a spare base stock; paving the surface layer, the middle layer and the bottom layer; paving the structure reinforced fibermesh between every two layers; and carrying out rolling and maintenance forming. The baseplate and preparation method thereof provided by the invention have the advantages that the natural raw materials such as tailings in the mining industry and the stone processing industry and the like and the debris puffed particles in the plastics industry are fully used, and various inorganic modified materialsare added, by carrying out low-temperature mould pressing on the materials in a certain proportion and utilizing the condensation reaction of the materials and the natural texture performance of a special mould, the baseplate of an ecological light-weight and low-carbon integral heat-preservation and energy-saving plate with natural stone or other material mechanisms can be processed by using a specially-designed processing device.

Owner:易科美德(天津)环保建材有限公司

Magnetic bio-carrier for treating sewage water and preparation method thereof

InactiveCN101254976AEasy to handleLow costSustainable biological treatmentBiological water/sewage treatmentTreatment effectPolystyrene

The invention belongs to the environment protective field, which relates to a magnetic biological carrier used for processing wastewater. The invention comprises 7 to 21 wt percent magnetic particle and 79 to 93 wt percent high molecular polymer; the magnetic particle comprises ferroferric oxide, metallic iron powder, and magnetite; and the high molecular polymer comprises polyethylene, polypropylene, polystyrene and powder rubber. After being stirred and fully mixed, the high molecular polymer particle and the magnetic particle are delivered into an extruder, and the high molecular polymer particle and the magnetic particle are fully mixed, extruded and sheared through fusing under the effect of the extruder, to form the high molecular polymer particle containing the magnetic particle. Then the high molecular polymer particle is ground and screened, finally a magnetic carrier is immersed into a surface active agent, and therefore the magnetic biological carrier is obtained. When the magnetic biological carrier provided by the invention is used to the water treatment, the treatment effect is good, the preparation method is simple, the required reagents and materials are easy to be found, the magnetic biological carrier can be reused, the principles of the extrusion molding and the mixing in the plastic industry are used for reference, and the magnetic biological carrier has the advantages that the controllability is high, the production cycle is short, and the industrialized production is easy to be realized. In addition, the production cost is reduced while the used product resource is circularly utilized by using the used high molecular polymer.

Owner:UNIV OF SCI & TECH BEIJING

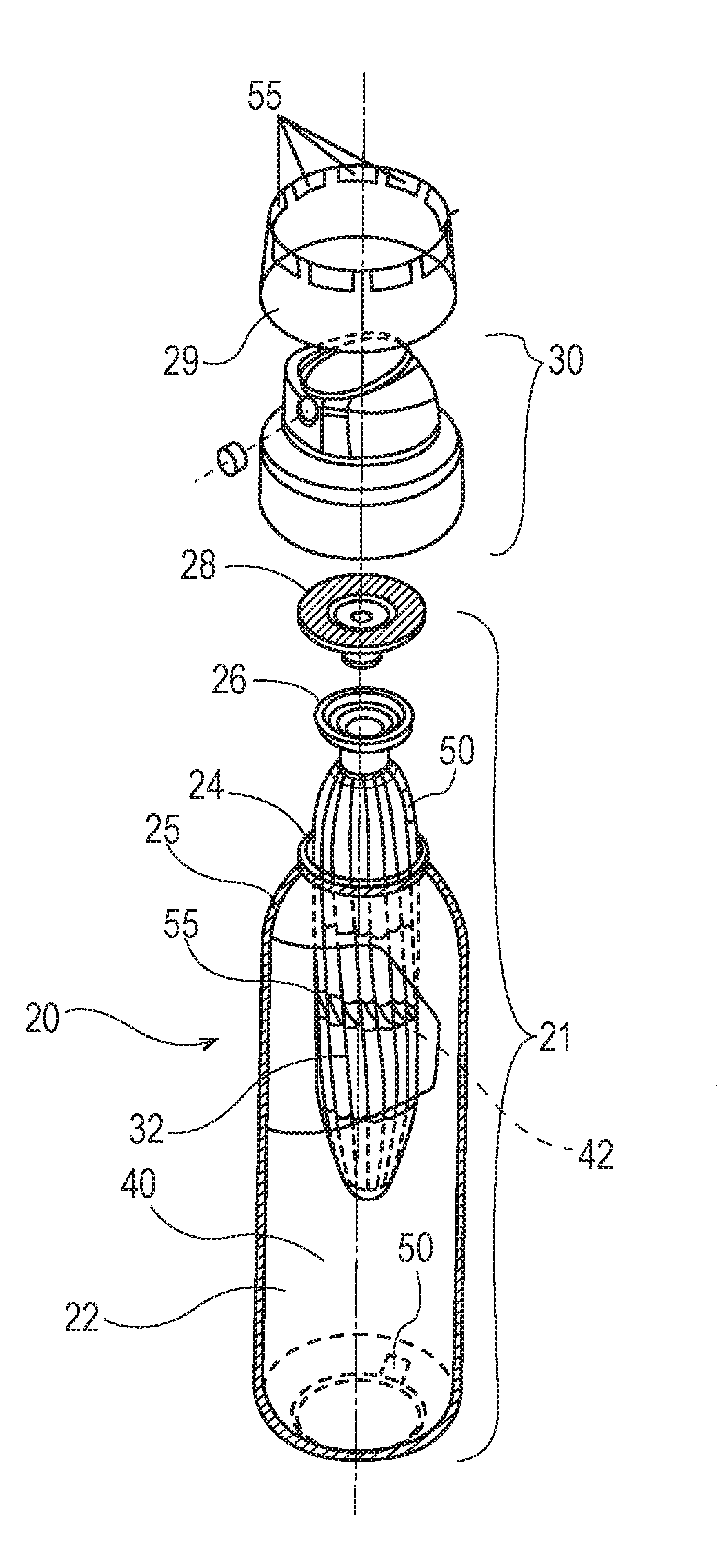

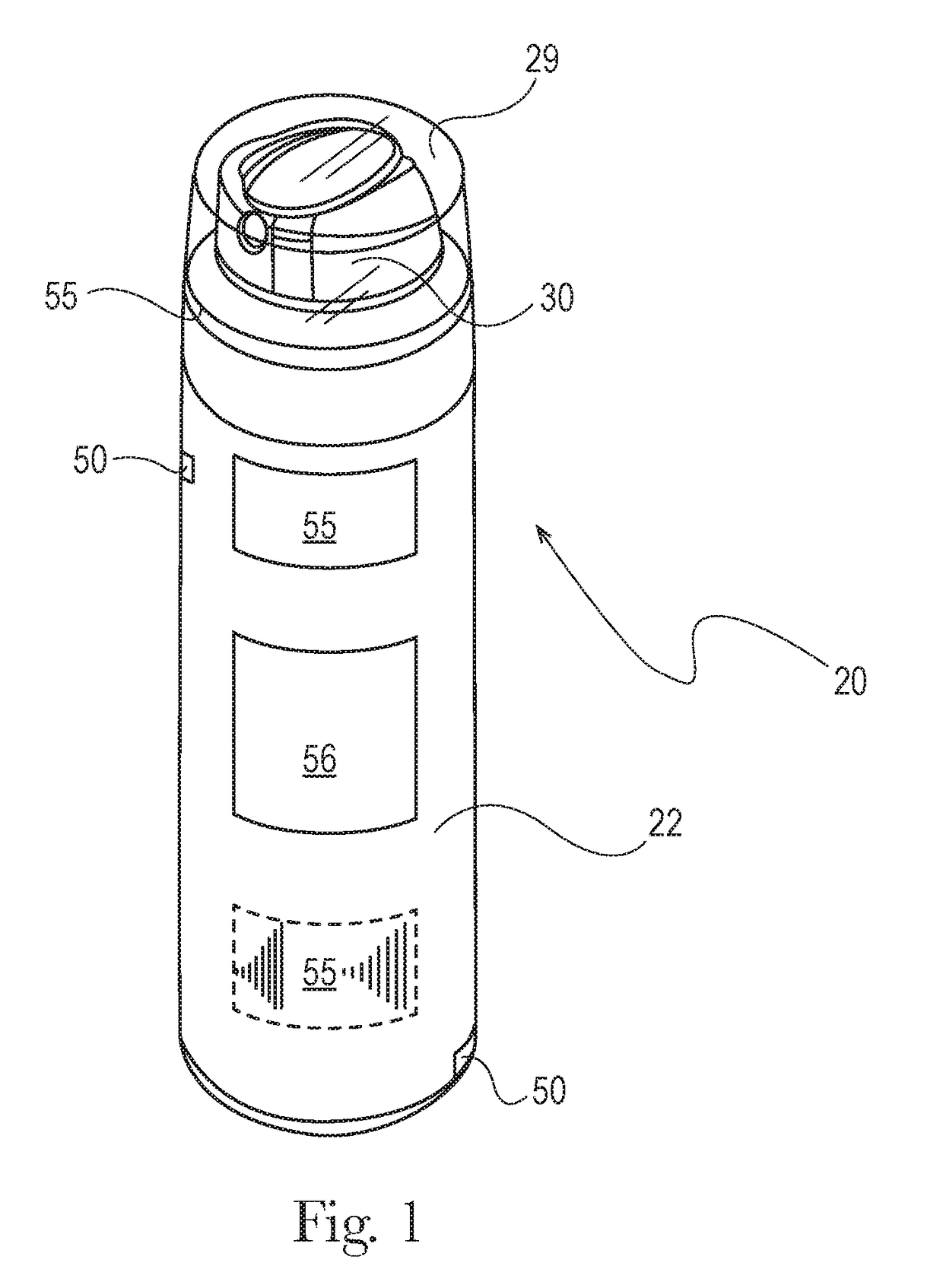

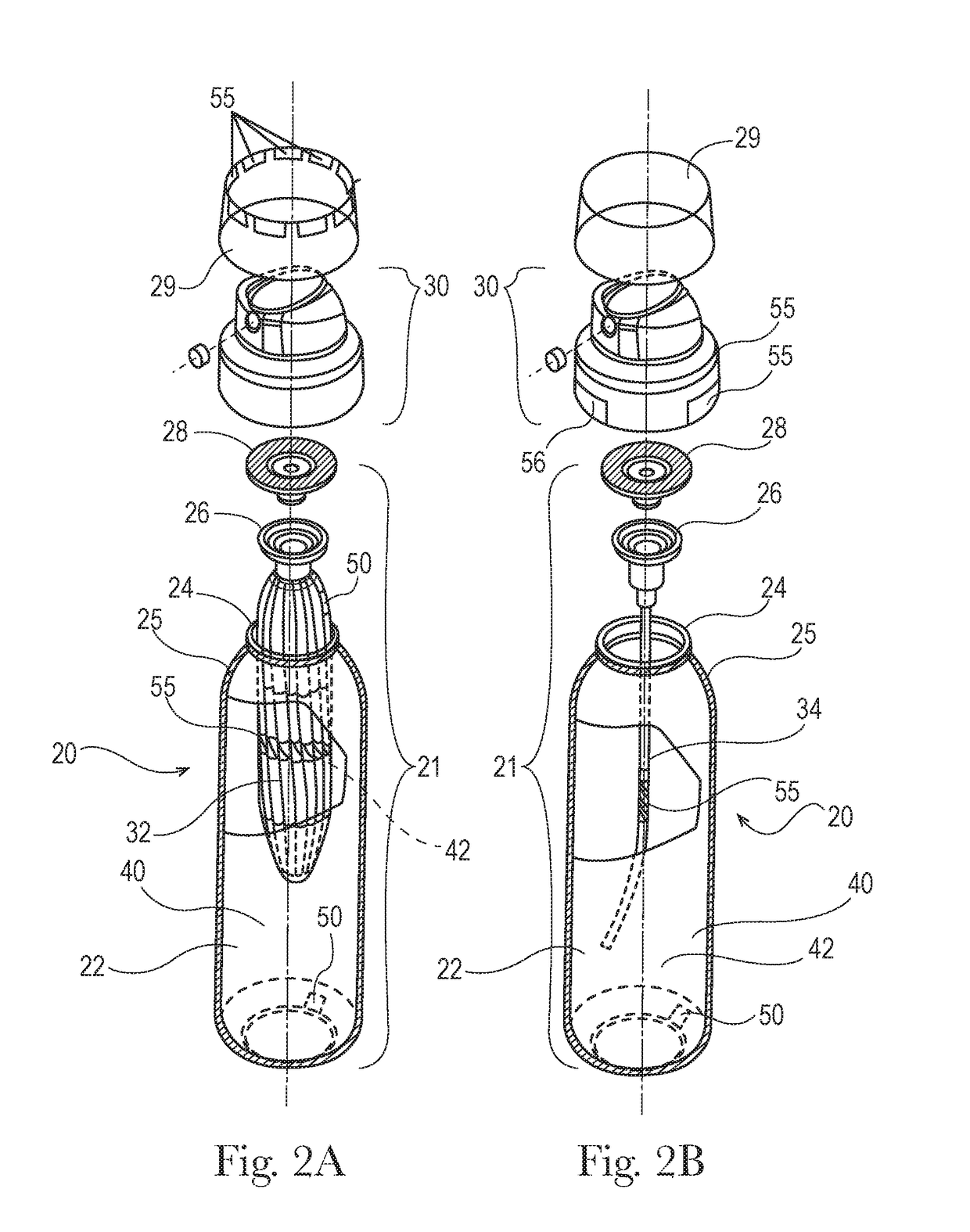

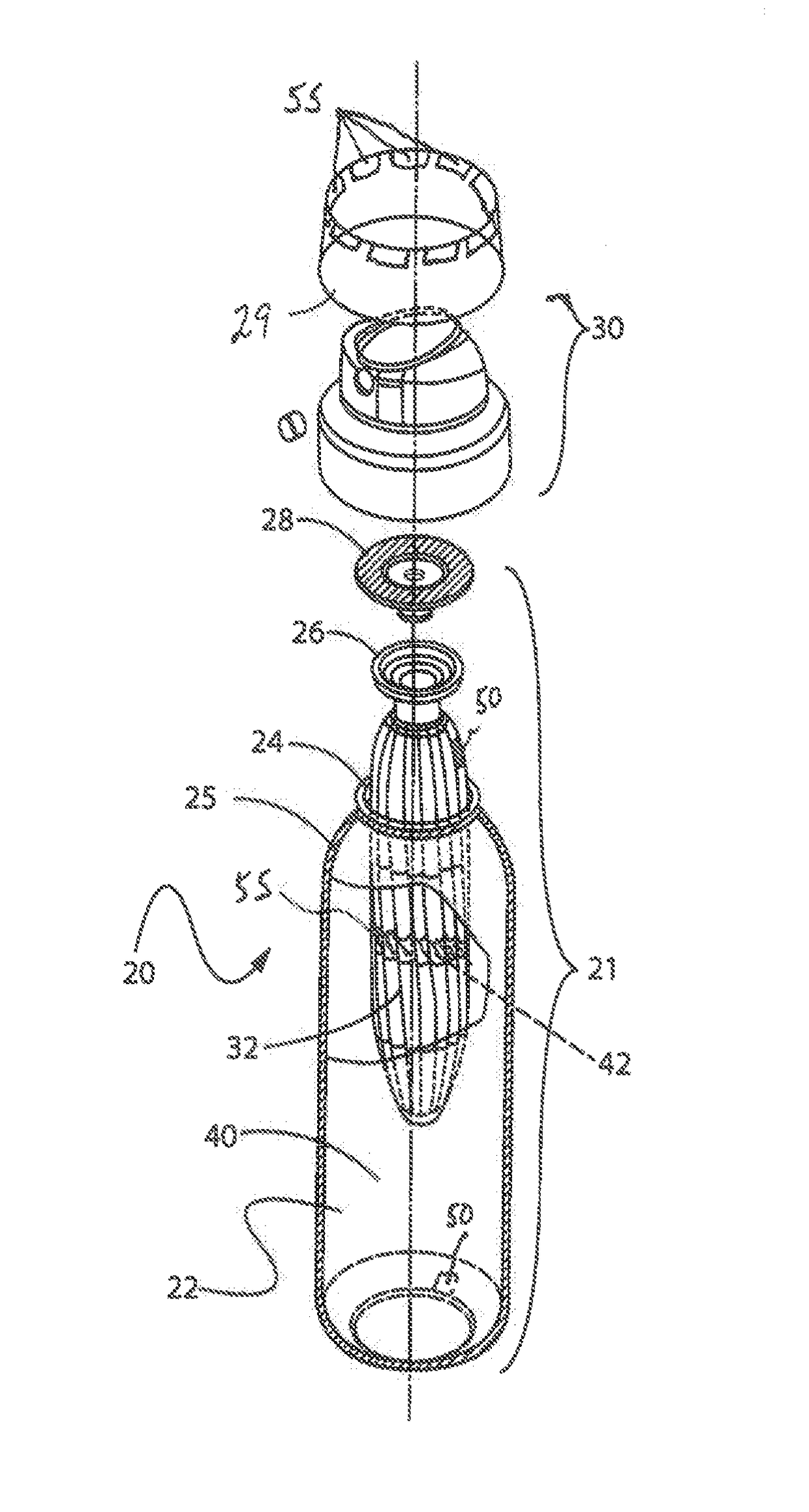

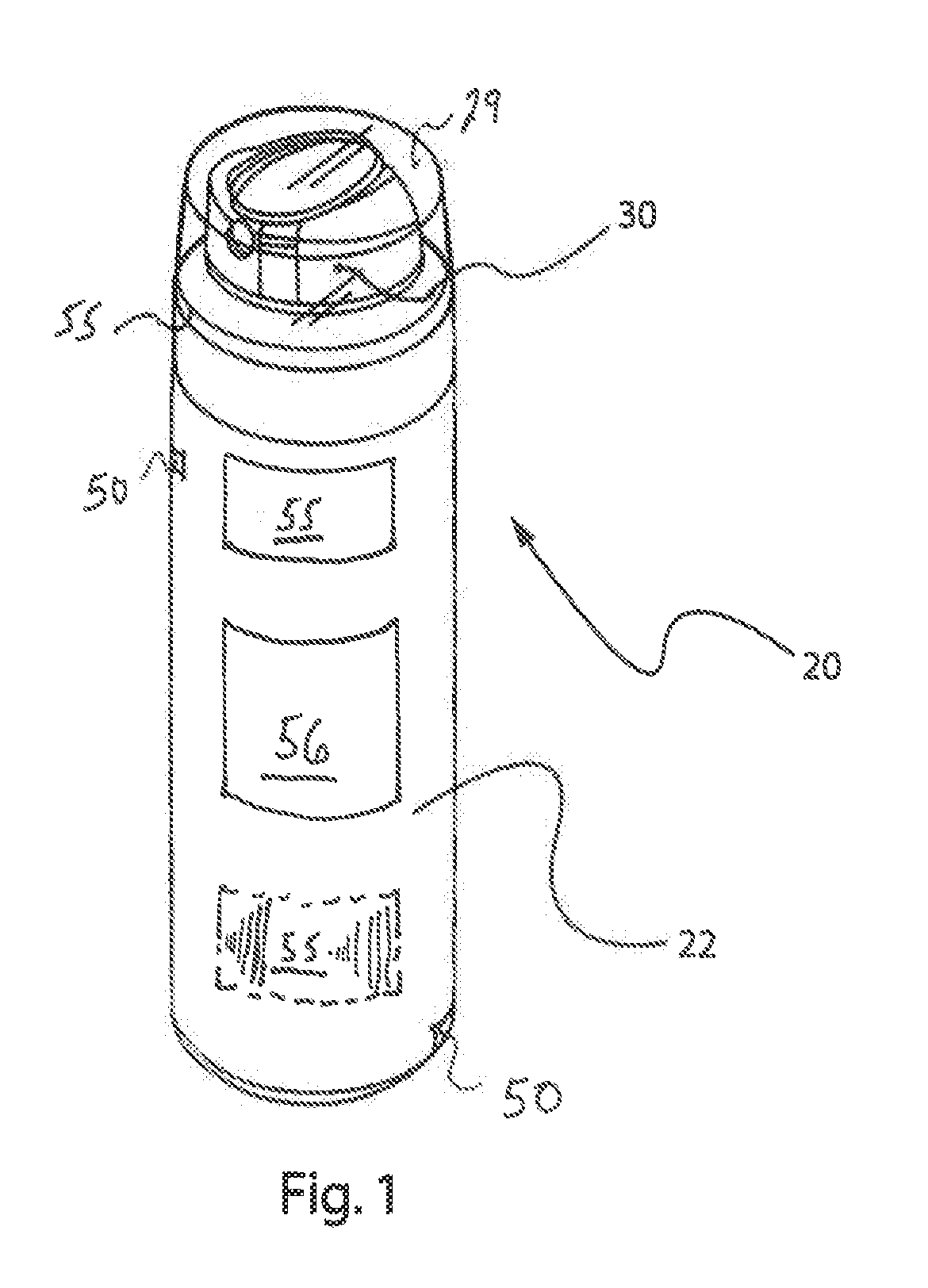

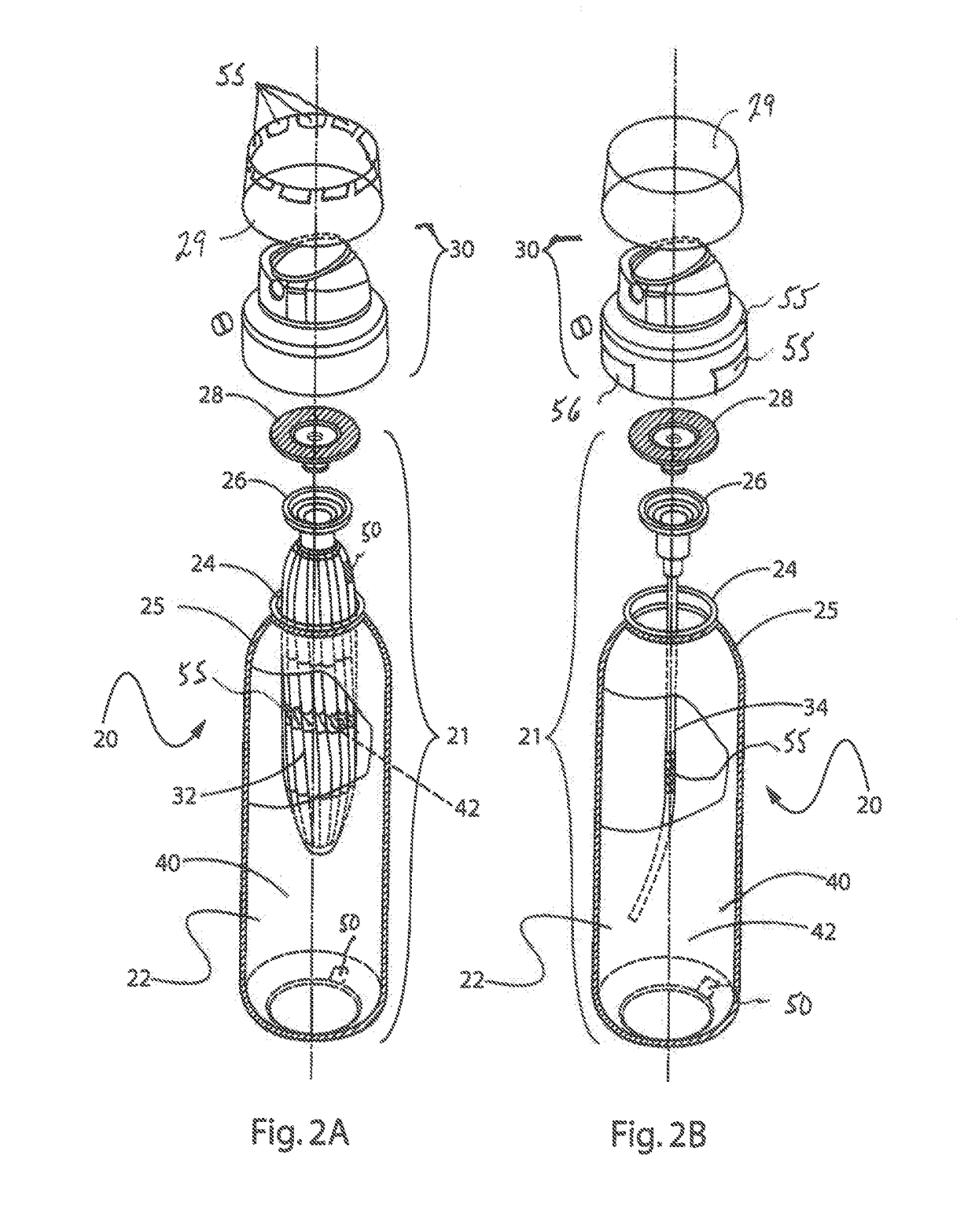

Aerosol dispenser having a safety valve

ActiveUS20180244460A1Catastrophic explosionPackage recyclingSpraying apparatusPlastics industryMicrowave oven

A method of warming food dispensable from an aerosol dispenser. The aerosol dispenser is made from materials which can go into a single recycling stream having a single class of materials, as defined by the Society of the Plastics Industry, and particularly may exclusively comprise Class 1 materials suitable for eating in a microwave oven. Consumer products, such as food, contained in the aerosol dispenser may be heated in a microwave oven prior to dispensing. Upon dispensing, food retains residual heat, and is suitable for eating or further cooking. Other heated products in the aerosol dispenser may be comfortably applied to the skin, used as air freshener, used for cleaning, etc. The aerosol dispenser may have indicia indicating the aerosol dispenser is suitable for microwave heating. The aerosol dispenser can have indicia indicating the aerosol dispenser is suitable for heating in a microwave oven. The indicia may be thermochromic, indiciating when a desired temperature has been reached. The aerosol dispenser can have a safety valve, to safely relieve product and / or propellant pressure upon overpressurization in a microwave oven. The safety valve may be single use or reusable.

Owner:THE PROCTER & GAMBLE COMPANY

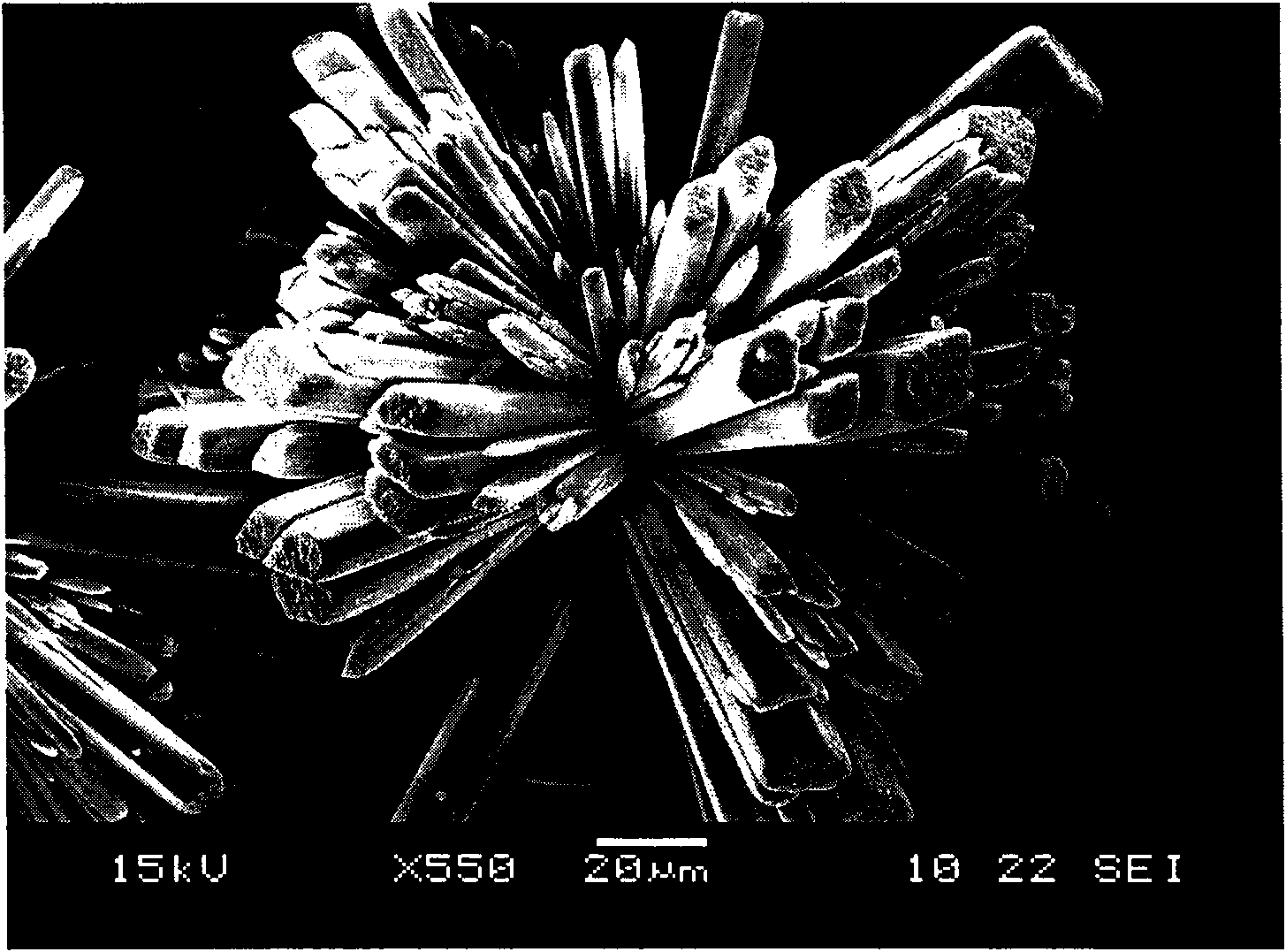

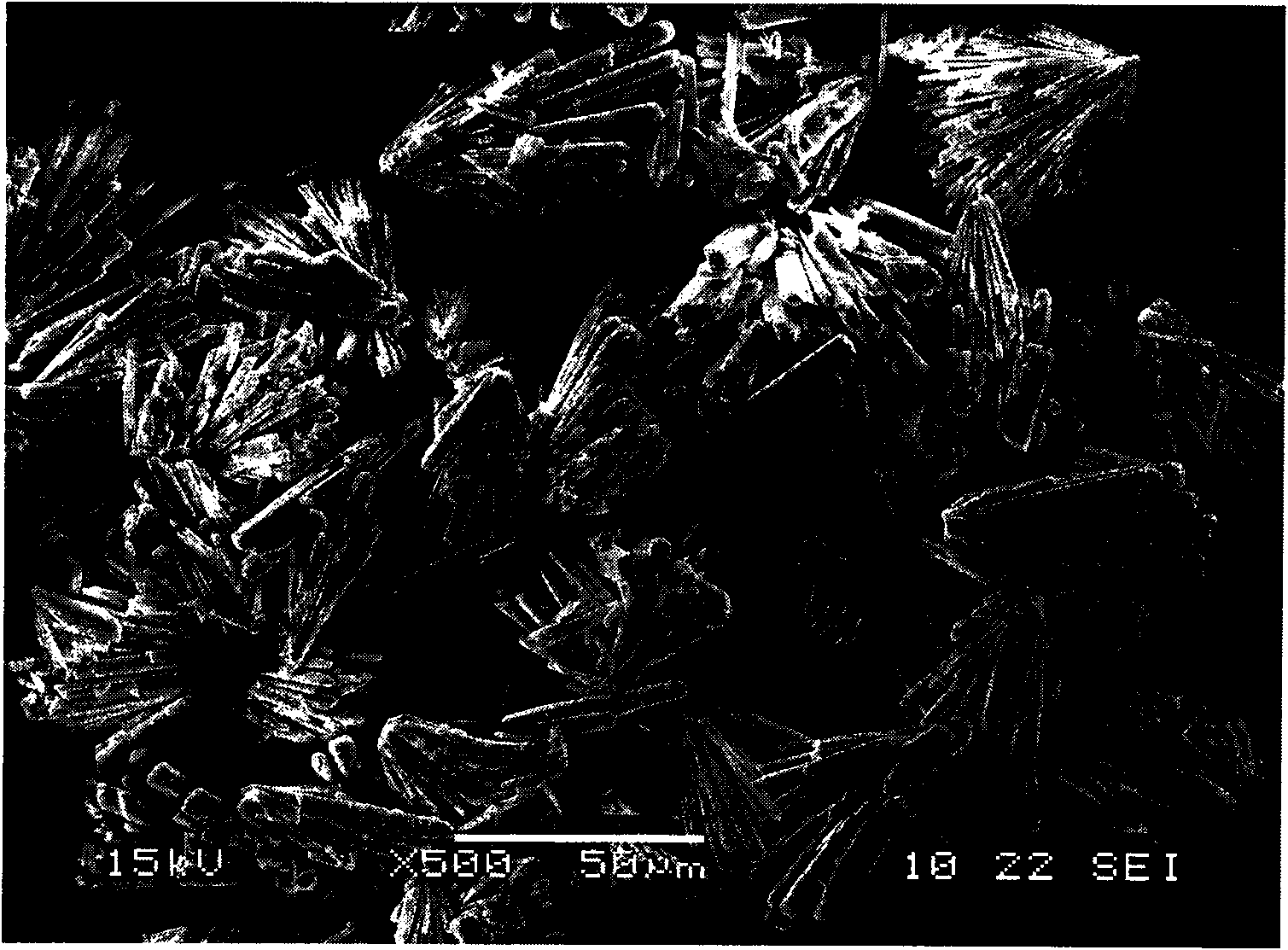

Spherical and radial magnesium carbonate and preparation method thereof

InactiveCN101613120AImprove filtering effectImprove the problem of slow filteringMagnesium carbonatesPlastics industryMagnesium salt

The invention provides a spherical and radial magnesium carbonate and a preparation method thereof. The method comprises the following steps: taking soluble magnesium salts and soluble carbonate as raw materials, taking surface active substances as additives, controlling reaction temperature at 15-75 DEG C in an aqueous solution system, keeping reaction for 2-20min; letting precipitate after the reaction stand for 1-6 days, washing and drying to obtain the spherical and radial magnesium carbonate product with intact crystal, little impurity in the crystal and high purity. The method is characterized by adding the surface active substances in preparation, which obviously improves shape and performance of the magnesium carbonate product, thus the magnesium carbonate product is easily filtered, better dispersed, and not easily conglobed. The magnesium carbonate product can be taken as an additive in industries such as plastics industry and rubber industry, and also can be taken as a raw material for preparing high-purity magnesia and other magnesium salts.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

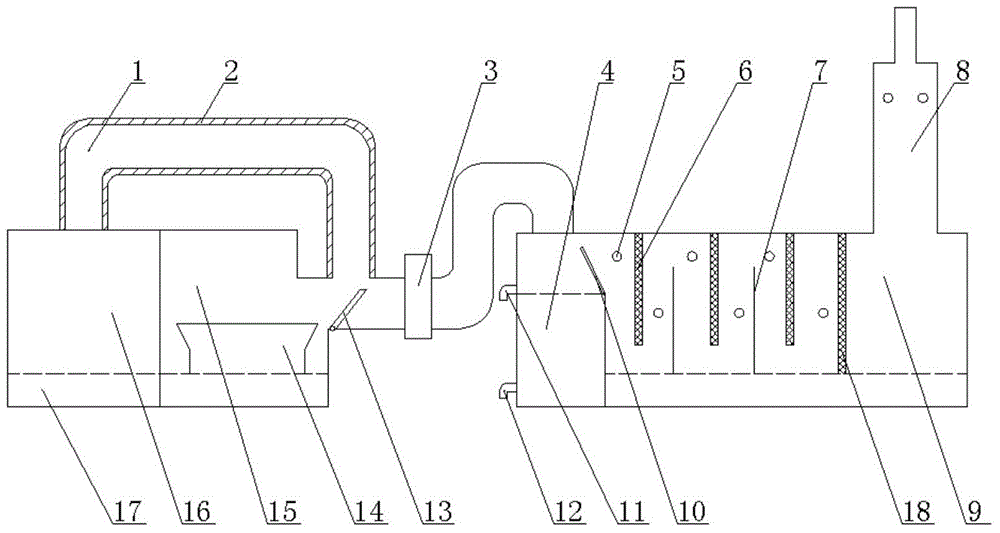

Purification equipment capable of effectively treating dense smoke and dust

InactiveCN103599673AAvoid damageFully filteredCombination devicesIncinerator apparatusPlastics industryCombustion chamber

The present invention relates to purification equipment capable of effectively treating dense smoke and dust. The purification equipment comprises a combustion chamber, a large particle dust removing chamber, water grooves, a flue, an induced fan and a purification chamber, wherein the bottoms of the combustion chamber, the large particle dust removing chamber and the purification chamber are provided with the water grooves, a funnel-shaped dry dust removing tank is arranged inside the large particle dust removing chamber, a water tank is arranged on the one purification chamber side corresponding to the flue, the top of the purification chamber is provided with a plurality of filtration screens, separation plates are arranged between the adjacent filtration screens and on the bottom of the purification chamber, both sides of the filtration screen are provided with a mist-like spraying port, and the purification chamber position on the far end of the flue is provided with a gas discharge channel. According to the present invention, the technical difficult problem that a lot of flue dust produced during filtration screen combustion can not be treated so as to cause adverse effects to the surrounding environment and produce heavy interference for normal production in the conventional plastic industry is overcome, and the dry dust removing and wet dust removing combined manner is adopted to completely filter the produced flue dust, wherein the purification rate can be more than 95%.

Owner:TIANJIN HUAQING BAISHENG PLASTIC INDAL

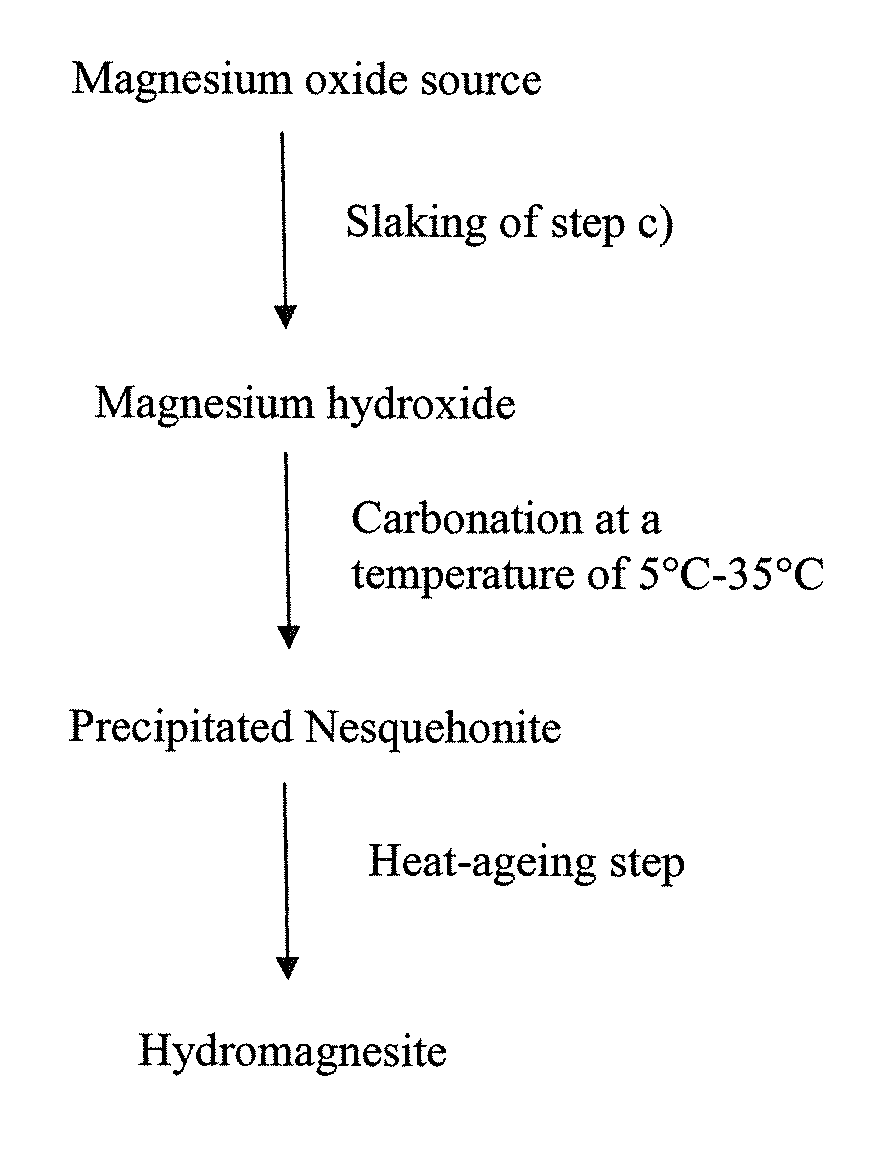

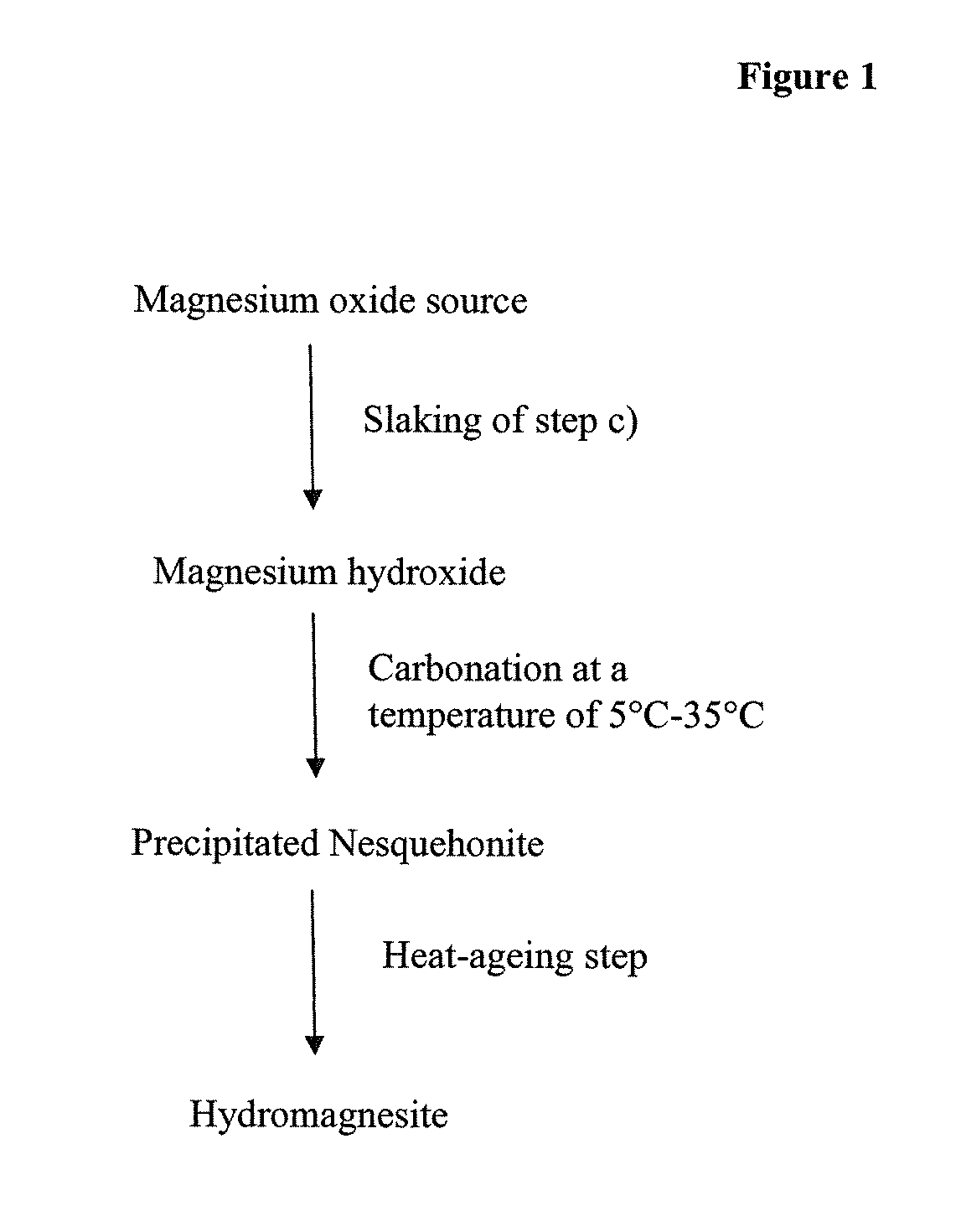

Precipitated magnesium carbonate

ActiveUS20140004347A1Small particle sizeHigh absolute densityCalcium/strontium/barium carbonatesPigmenting treatmentPlastics industryPolymer science

The present invention relates to a process for preparing hydromagnesite in an aqueous environment. The invention further relates to such hydromagnesite having a specific platy-like morphology in combination with a specific average particle size and to their use as minerals, fillers and pigments in the paper, paint, rubber and plastics industries and to the use as flame-retardant.

Owner:OMYA INT AG

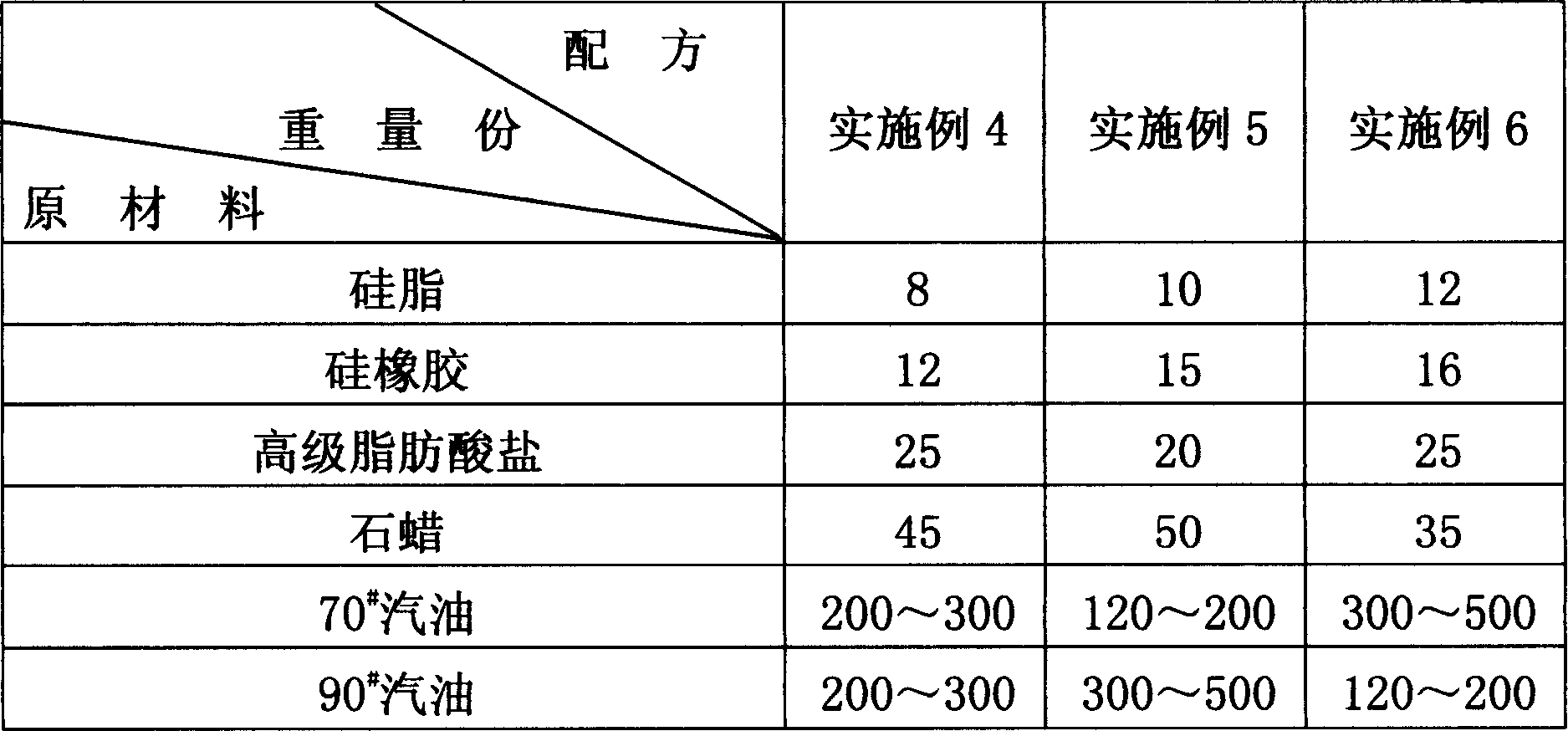

Method for preparing demolding agent for roducing epoxy glass fibre reinforced plastic composite material

The demolding agent is prepared with silicone grease 5-20 weight portions, silica rubber 10-60 weight portions, higher fatty acid salt 20-120 weight portions and paraffin 30-90 weight portions and through dissolving in gasoline solvent inside a reaction container, heating at 50-120 deg.c, and reflux stirring to form homogeneous demolding agent solution. The demolding agent may be sued in producing glass fiber reinforced epoxy plastic composite material in electronic industry, plastic industry, rubber industry, etc. and has the features of good demolding effect, no corrosion, no toxicity, high heat resistance and long shelf life.

Owner:高金技术产业集团有限公司

Molecular sieve based nano composite anti-ultraviolet material, its preparation method and use

The present invention provides one new kind of uvioresistant material. The host material of X, Y, A, STI, ZSM-5, MCM-41 series, SBA-15 series or other microporous and mesoporous molecular sieve and the guest material of nanometer cluster compound TiO2, ZnO, CeO2 or Fe2O3 are synthesized into the nanometer composite host-guest material. The synthetic material exhibits powerful absorption in UVA-UVB bands and thus may be used as ultraresistant agent for cosmetics, paints, rubber and plastic industry.

Owner:SHANGHAI JAHWA UNITED +1

Special polyethylene coloring masterbatch for white thin film and preparation method of masterbatch

The invention discloses a special polyethylene coloring masterbatch for a white thin film. The special polyethylene coloring masterbatch is prepared from the following raw materials in parts by weight: 20-38 parts of resin, 5-10 parts of polyethylene wax, 0.5-1.5 parts of white oil, 0.5-1.5 parts of zinc stearate, 10-35 parts of titanium dioxide and 25-40 parts of ground calcium carbonate; the resin is a mixture of low-density high pressure polyethylene and linear low-density polyethylene in the ratio of (5-8):3. A preparation method of the special polyethylene coloring masterbatch comprises the steps of weighing the raw materials, namely the mixed resin, titanium dioxide, ground calcium carbonate, polyethylene wax, zinc stearate and white oil, orderly adding the raw materials to a high-speed mixer and mixing thoroughly; after finishing mixing, transferring the mixture to a twin-screw extruder for melt extrusion, and then cooling, drying and pelleting, and finally, packaging. The special polyethylene coloring masterbatch is applied to the plastic industry, and is good in dispersity, high in heat resistance and low in production cost, and meanwhile, capable of improving the mechanical properties and the printing performance of the thin film products, and has outstanding price and quality advantages.

Owner:BLUESTAR CHENGDU NEW MATERIALS

Novel dry mineral pigment containing calcium carbonate, aqueous suspension containing said pigment, and the uses thereof

The invention relates to a method for producing a dry mineral pigment containing a product formed in situ by the multiple reaction of a calcium carbonate with the reaction product or products of said carbonate with at least one medium-strength to high-strength H3O<+> ion donor; with the reaction product or products of said carbonate with gaseous CO<2> formed in situ and / or from an external supply; and with at least one compound of formula R-X. The invention also relates to the mineral pigment obtained by said method, and to the applications thereof in the paint and / or plastics industries.

Owner:OMYA INT AG

Heat transfer release agent, preparation method thereof and use method thereof

InactiveCN102504676AStrong adhesionHigh hardnessDuplicating/marking methodsPolyester coatingsPlastics industryPolymer science

The invention provides a heat transfer release agent, a preparation method thereof and an oil injection operation-free use method thereof. The formula of the heat transfer release agent comprises a curing agent and a component which comprises a polyester resin, silicone oil, a defoamer, a leveling agent and a diluent according to certain weight percentages. The preparation method comprises the following steps: 1, stirring and uniformly mixing the diluent and the polyester resin; 2, stirring and uniformly mixing the defoamer, the silicone oil and the leveling agent; 2, and blending and uniformly mixing the component obtained in step 1 and the component obtained in step 2 to obtain the heat transfer release agent. In the use method, the thickness of the coating release layer is not less than 6mum, and the transferred release layer can be used as a protection layer; and by testing, the hardness can reach 2-3H, so a vanish baking effect is reached, and the oil injection operation is omitted, thereby the heat transfer release agent can be widely applied to the plastic industry.

Owner:XIAMEN HOWER MATERIAL

Coating applied to thread forming tap

InactiveCN103215544AExtended service lifeImprove adhesionExtrusion diesVacuum evaporation coatingPlastics industryCarbide

The invention discloses a coating applied to a thread forming tap. The coating comprises a transition layer, a functional layer and a self-lubricating layer which are arranged on a substrate of the tap from inside to outside, wherein the transition layer is a ceramic-phase nanocrystal structure of at least one simple substance, nitride, carbide or nitrogen carbide in transition metal Ti, Cr and Zr with the thickness of 200-250nm; the main functional layer is a ceramic-phase nanocrystal structure compound layer formed by alternating TiAlCrN and CrN coatings with the thicknesses of 2-3 micrometers; and the self-lubricating layer is WC (wolfram carbide) / C with the thickness of 2 micrometers. The coating applied to the thread forming tap can allow the tap to have better wear resistance, adhesiveness resistance, high-temperature oxidation resistance and self-lubricating exclusiveness, so that the service life of the tap for titanium alloy processing is prolonged, the production cost is lowered, and the coating can be applied to various taps widely used in electronic and plastic industries.

Owner:李固加

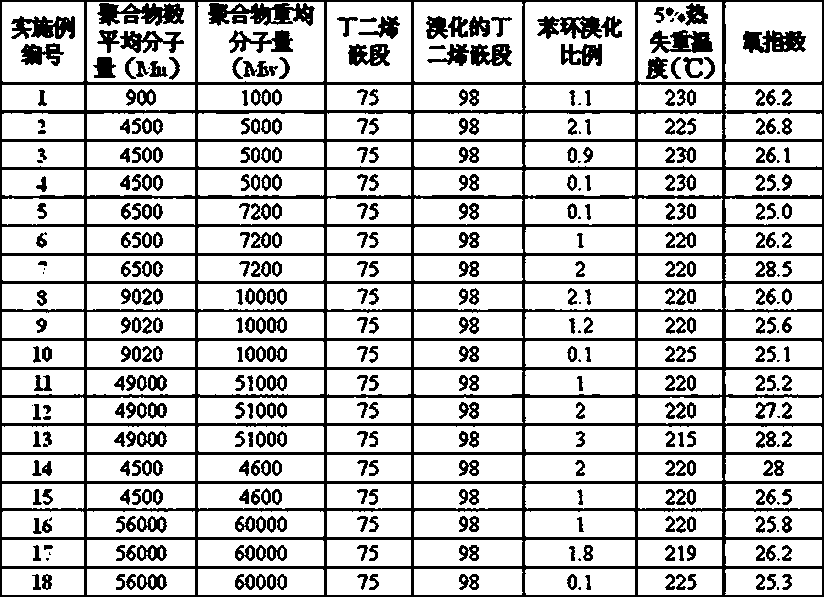

Bromized aliphatic olefin/vinyl aromatic copolymer flame retardant and preparation method thereof

InactiveCN104177516AIncrease bromination rateImprove flame retardant performancePlastics industryPolymer science

The invention provides a bromized aliphatic olefin / vinyl aromatic copolymer flame retardant which serves as a common flame retardant which substitutes HBCD and is used in the plastic industry. The bromized aliphatic olefin component of the bromized aliphatic olefin / vinyl aromatic copolymer flame retardant at least contains a bromized olefin monomer; the bromized vinyl aromatic component comprises 2-bromostyryl, 4-bromostyryl, 2,4-dibromostyryl, 6-bromostyryl and 2,4,6-tribromostyryl. Meanwhile, the invention further relates to a preparation method of the bromized aliphatic olefin / vinyl aromatic copolymer flame retardant.

Owner:QINGDAO FUNDCHEM +2

Heating of products in an aerosol dispenser and aerosol dispenser containing such heated products

PendingUS20170166391A1Avoid explosionPackage recyclingLiquid dispensingPlastics industryMicrowave oven

A method of warming food dispensable from an aerosol dispenser. The aerosol dispenser is made from materials which can go into a single recycling stream having a single class of materials, as defined by the Society of the Plastics Industry, and particularly may exclusively comprise Class 1 materials suitable for eating in a microwave oven. Consumer products, such as food, contained in the aerosol dispenser may be heated in a microwave oven prior to dispensing. Upon dispensing, food retains residual heat, and is suitable for eating or further cooking. Other heated products in the aerosol dispenser may be comfortably applied to the skin, used as air freshener, used for cleaning, etc. The aerosol dispenser may have indicia indicating the aerosol dispenser is suitable for microwave heating. The aerosol dispenser can have indicia indicating the aerosol dispenser is suitable for heating in a microwave oven. The indicia may be thermochromic, indicating when a desired temperature has been reached. The aerosol dispenser can have a safety valve, to safely relieve product and / or propellant pressure upon overpressurization in a microwave oven. The safety valve may be single use or reusable.

Owner:THE PROCTER & GAMBLE COMPANY

Composite titanium dioxide and preparation method thereof

ActiveCN103740139AHigh surface active substancesPigment treatment with non-polymer organic compoundsPolyvinyl chlorideCarbonization

The invention discloses a high-whiteness and high-performance composite titanium dioxide and a preparation method thereof, and particularly relates to a high brightness composite titanium dioxide preparation method capable of significantly enhancing the hiding power of the composite titanium dioxide. The specific process is realized by the following steps: grinding, carbonization reaction coating, ball milling, modification and the like. The invention provides the composite titanium dioxide with the surface covered with a long carbon chain anionic surfactant, the composite titanium dioxide powder surface is provided with (-C15-20 H30-40) long chain groups and alcohol groups possible to produce by coupling agent hydrolysis, auto-polymerization groups are formed by condensation reaction, so that a high surface activity material is grafted on the composite titanium dioxide surface. The active ultrafine composite titanium dioxide prepared by the invention can be used in plastics industry, especially in PVC (polyvinyl chloride) profiles, PVC pinch plate s and the plastics of the like.

Owner:丹东亿龙高科技材料有限公司

Preparation method of dicarboxylic dihydric alcohol ester plasticizer

InactiveCN106146300AHigh yieldEasy to separateOrganic compound preparationCarboxylic acid esters preparationPlastics industryAlcohol

A preparation method of dicarboxylic dihydric alcohol ester plasticizer includes the steps of conducting esterification reaction for 0.5-48 h with monobasic acid and dihydric alcohol as the raw materials under the catalysis effect at a temperature of 100-250 DEG C, and conducting reduced pressure distillation to obtain the dicarboxylic dihydric alcohol ester product. Dicarboxylic dihydric alcohol ester is non-toxic plasticizer and can replace phthalic acid ester to be used for the field of plastic industry, rubber industry and the like. The product prepared through the method is high in yield, easy to separate and friendly to the environment and has good application prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

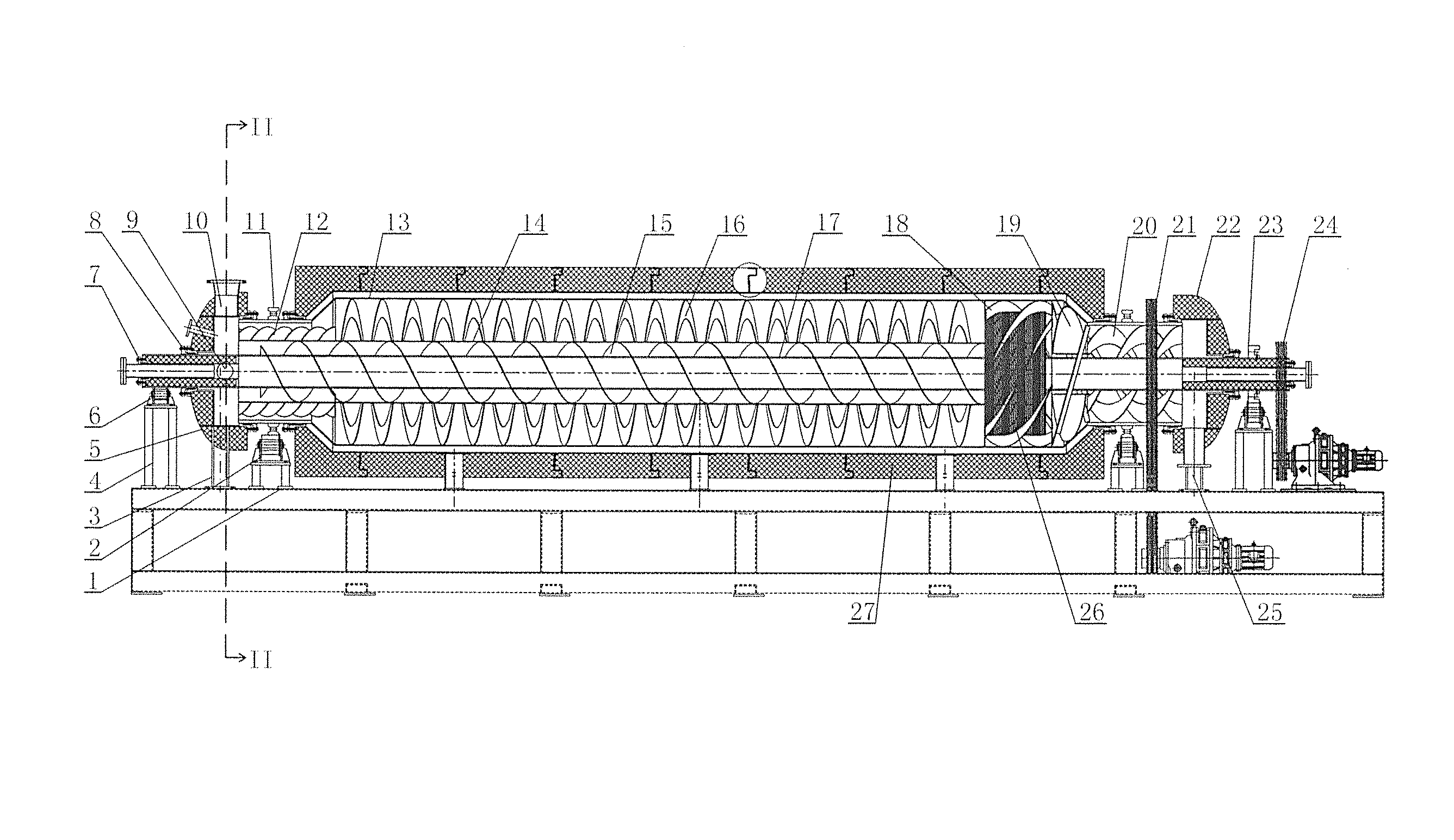

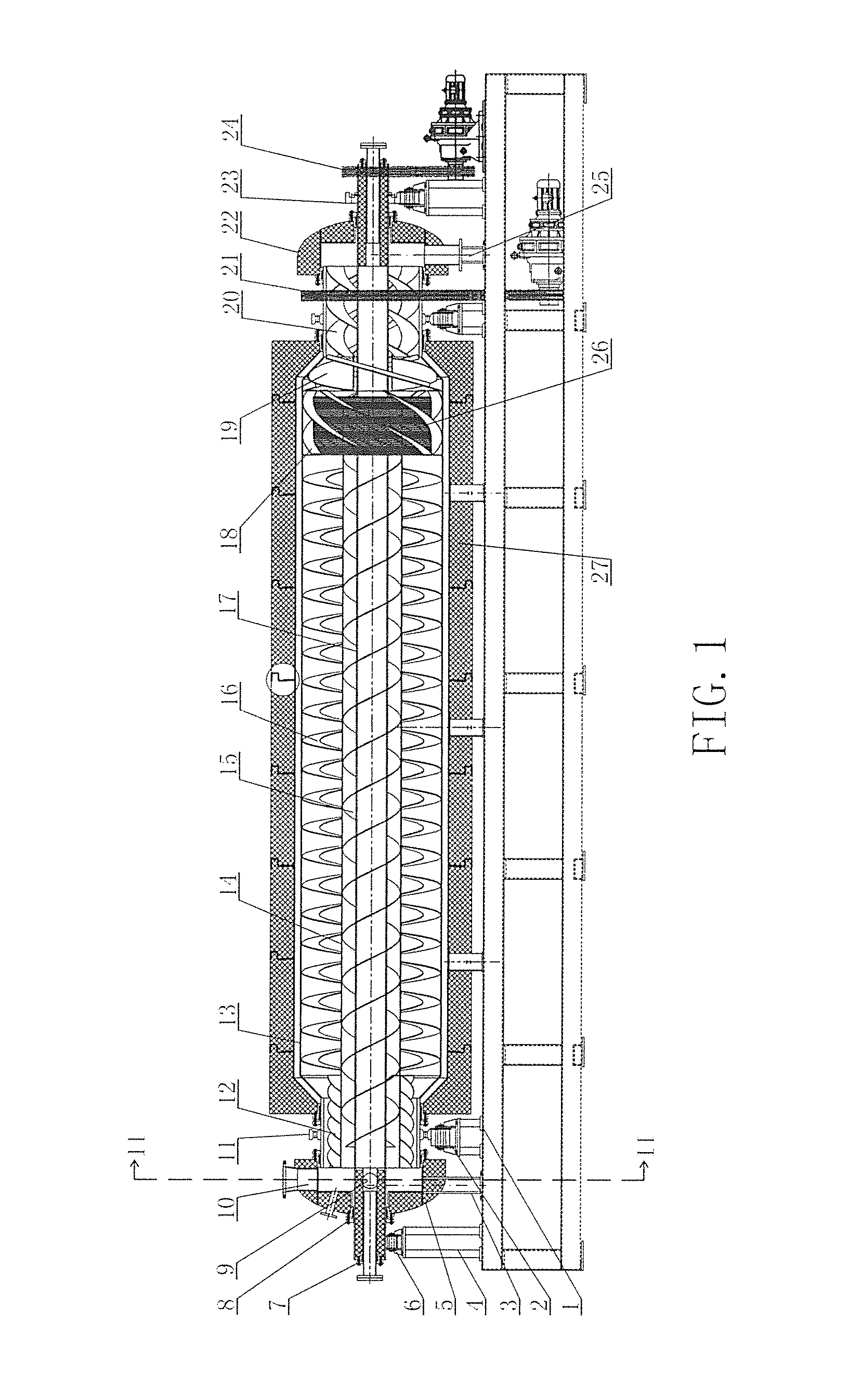

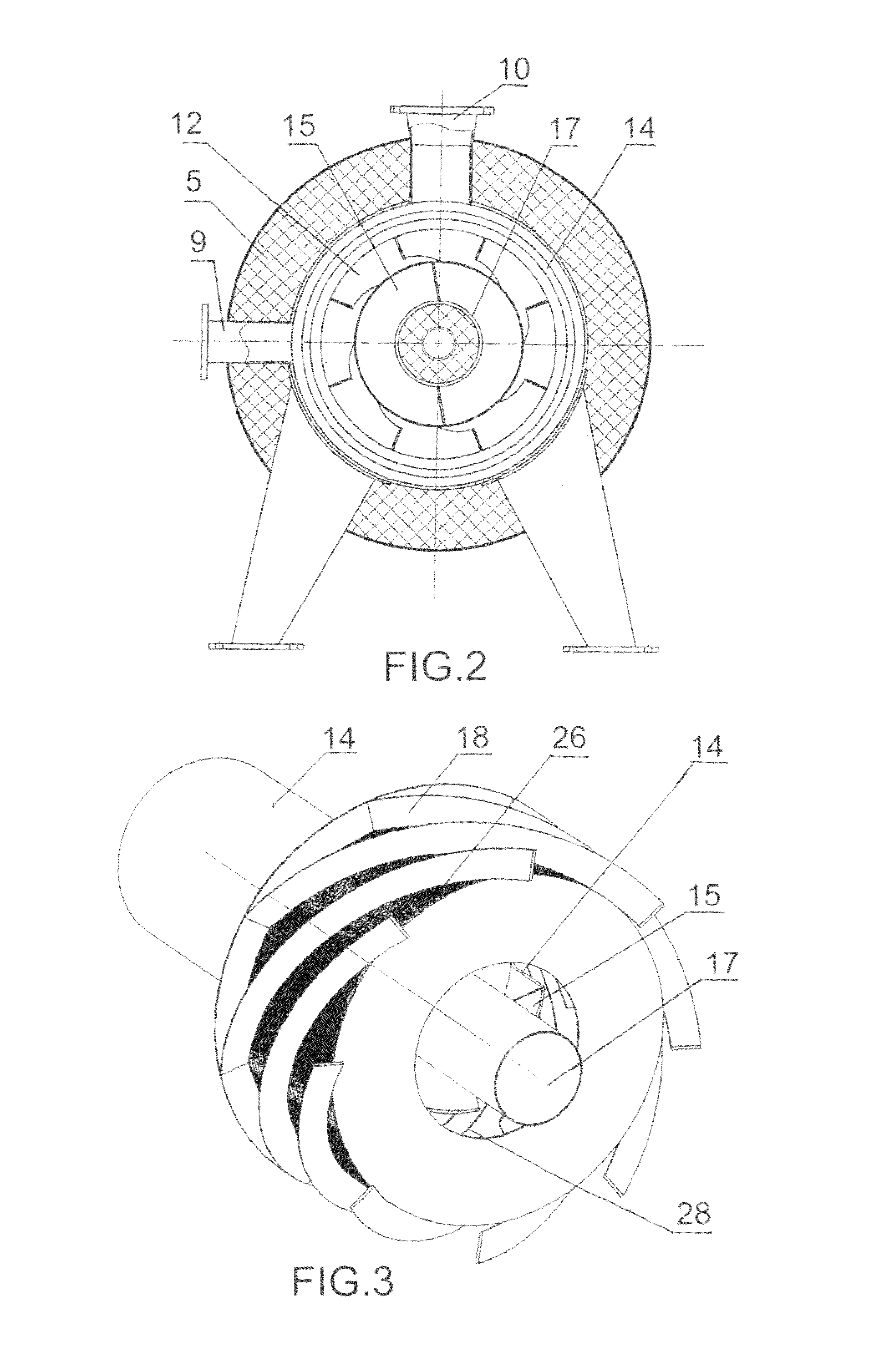

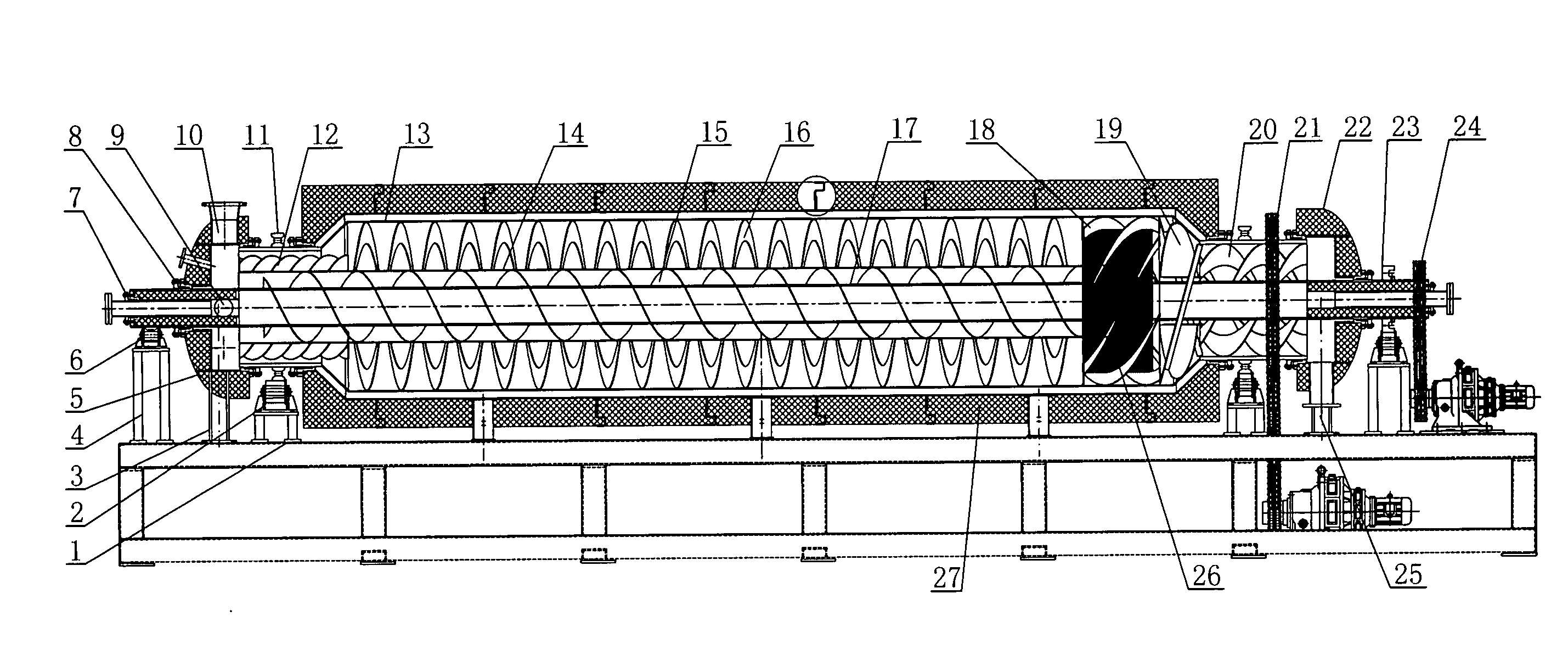

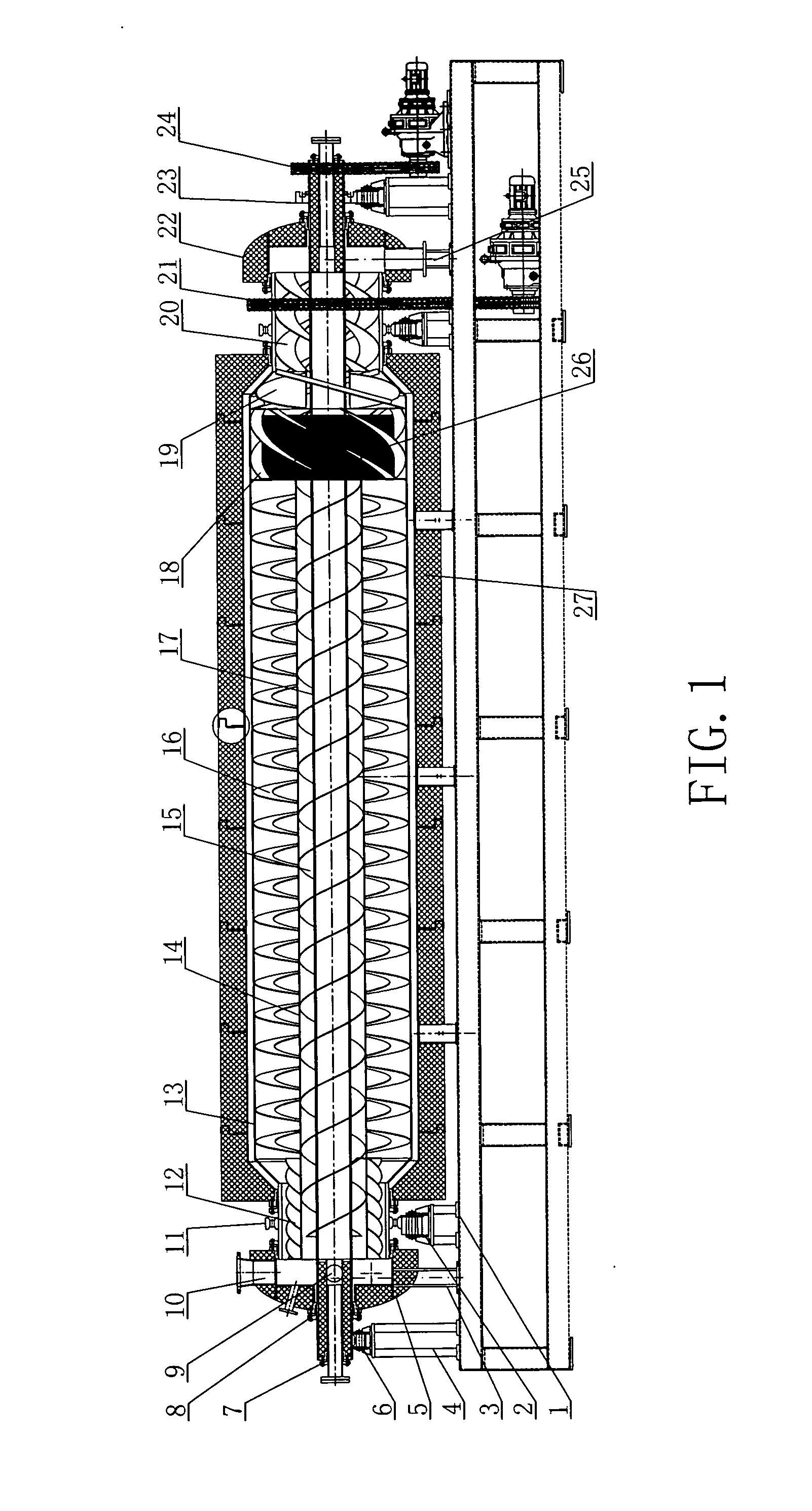

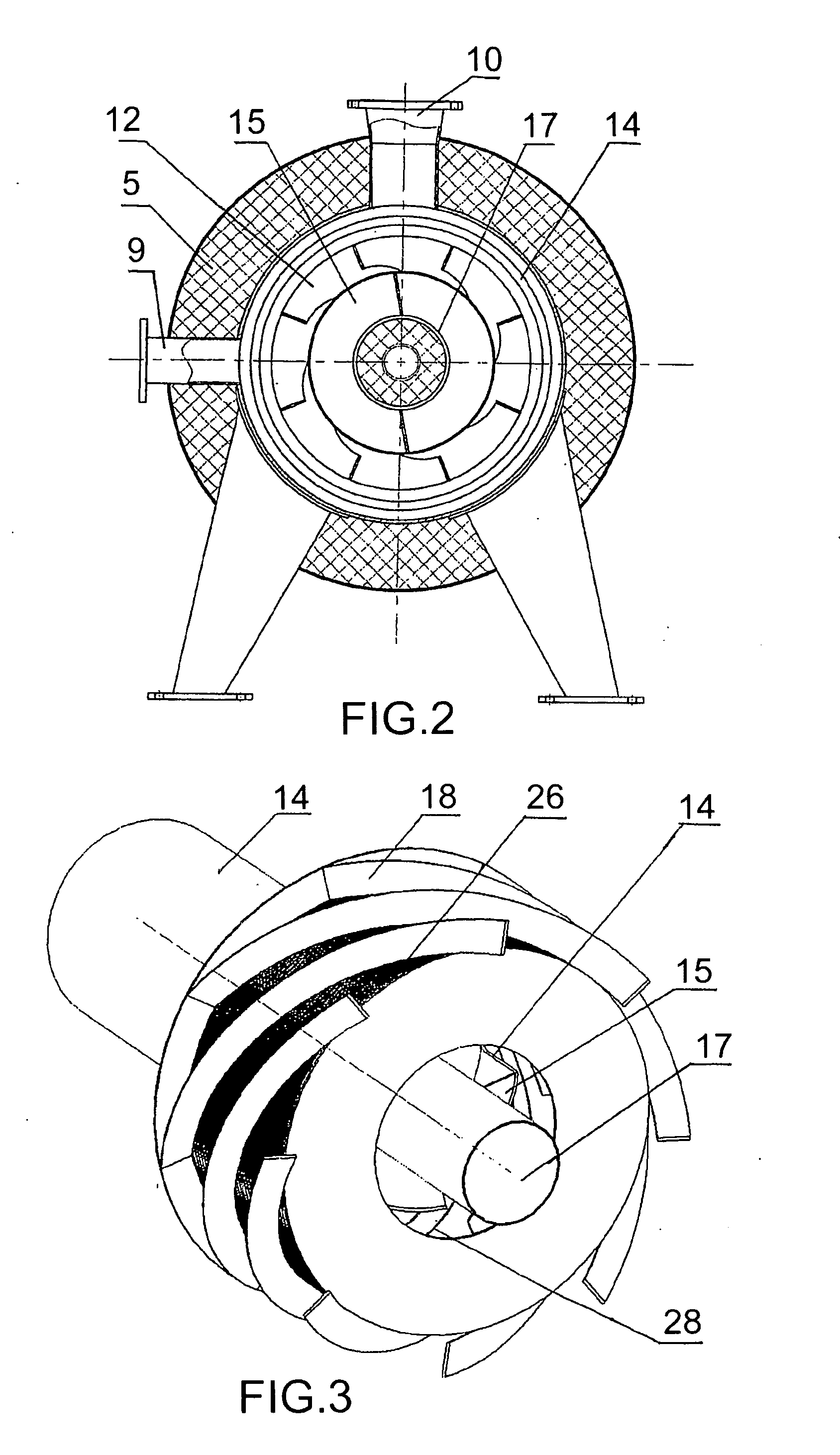

Industrial continuous cracking device of plastics

ActiveUS8728282B2Simple configurationSmall volumeCombustible gas coke oven heatingDirect heating destructive distillationPlastics industryHeat carrier

This invention is about an industrial continuous cracking device of plastics. The technical program of this invention is as following: it includes the outer cylinder and the internal cylinder, and the two sides of the internal cylinder are connected with the outer cylinder; at least one of the outer cylinder and the internal cylinder is set with heating mechanism, and the helical ribbon is fixed in the inside of the outer cylinder wall; the transport mechanism is fixed in the internal cylinder, with its direction contrary to the outer cylinder's the feeding direction. The structures of this invention are simple, and it can reduce the possessive space. Furthermore, when cycling in the cylinder, the solid heat carrier has no heat energy loss, and that can substantially reduce the operation cost of the equipment.

Owner:NIUTECH ENVIRONMENT TECHNOLOGY CORPORATION

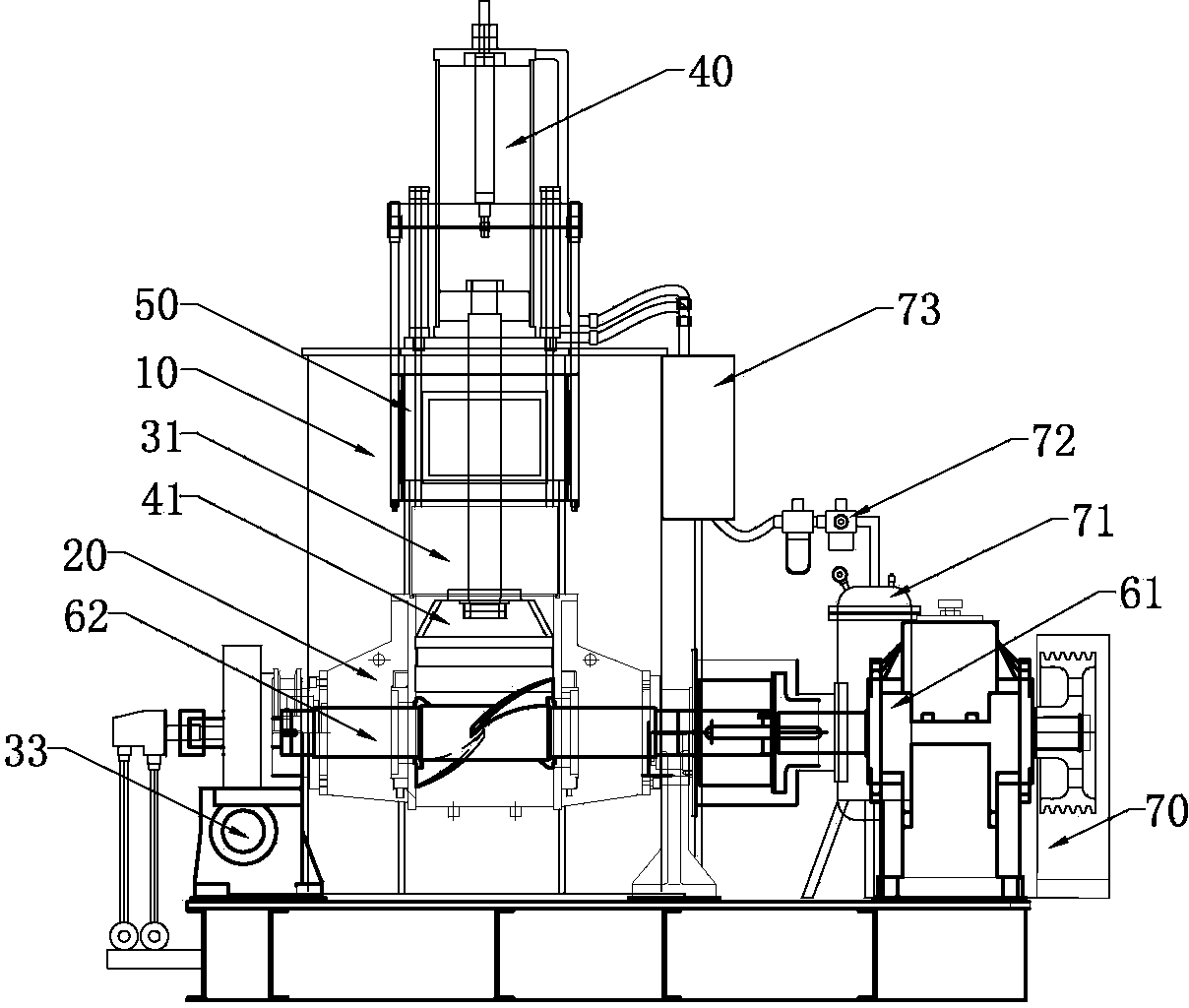

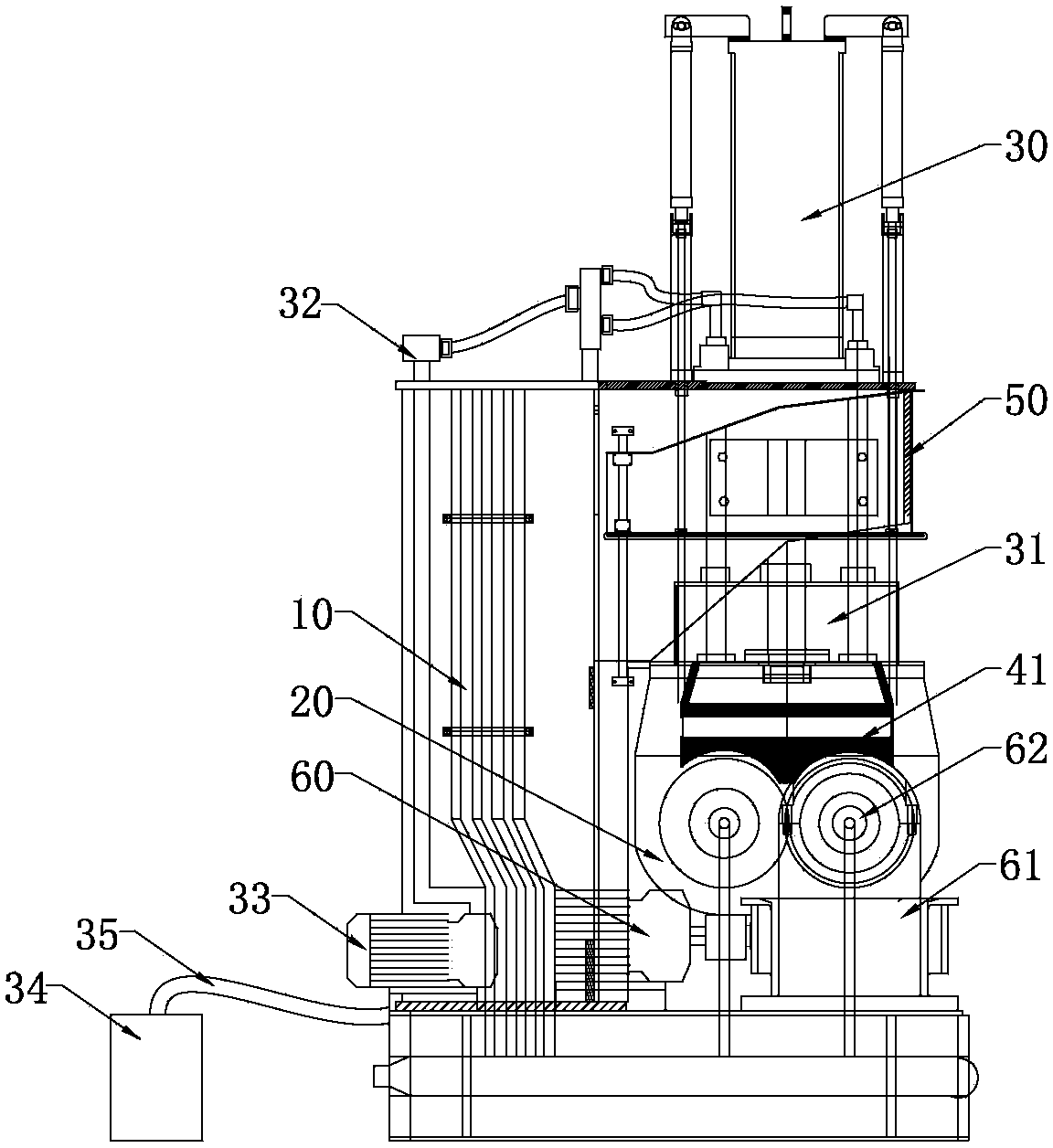

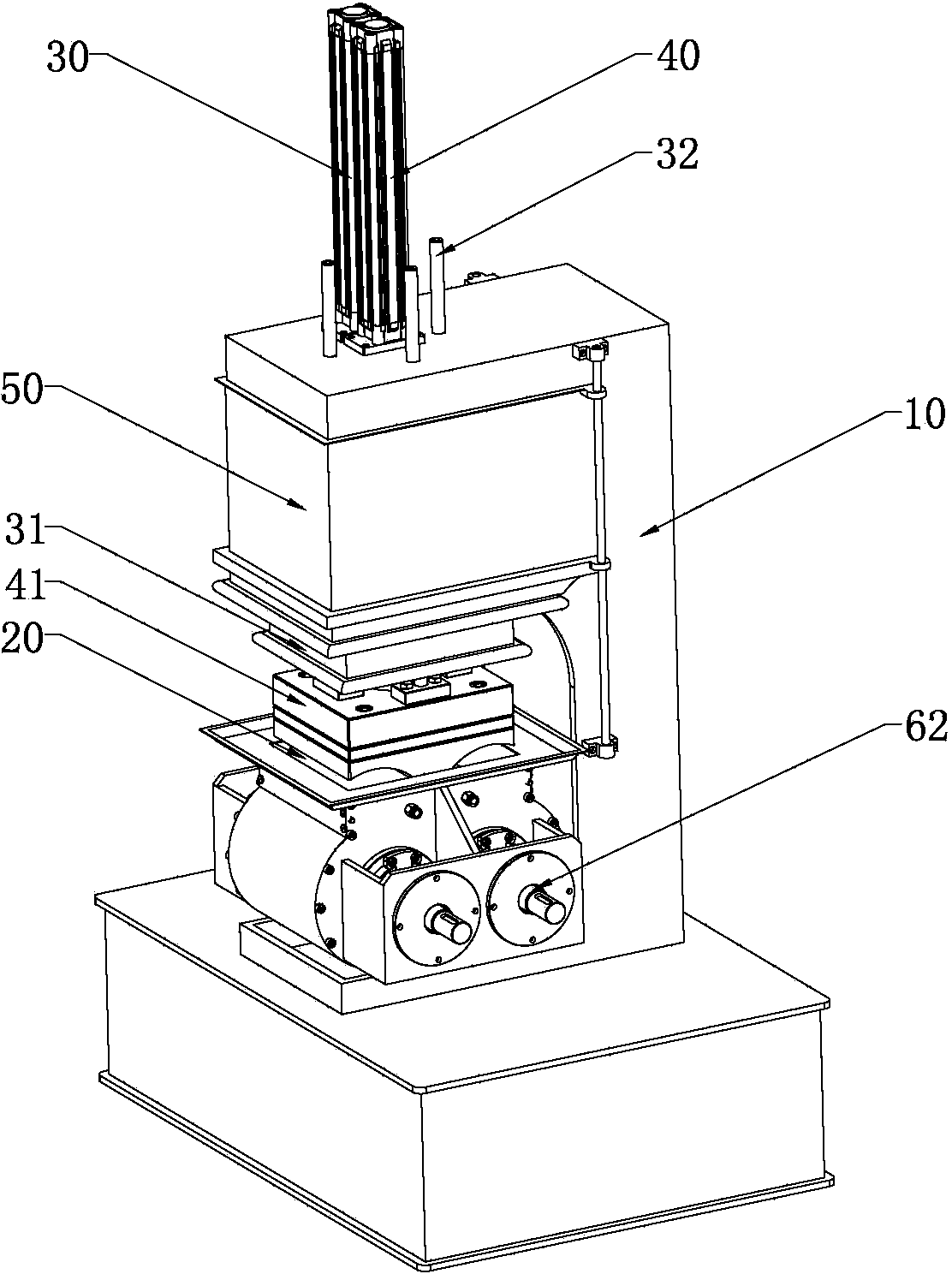

Vacuumizing mixing machine

The invention relates to the technical field of chemical-material mixing equipment and particularly relates to a vacuumizing mixing machine. The vacuumizing mixing machine comprises a rack, wherein the lower part of the rack is provided with a mixing chamber; the upper part of the rack is provided with a pressing device; the mixing chamber is connected with a mixing device; a vacuumizing device for vacuumizing the mixing chamber is arranged above the mixing chamber. The vacuumizing mixing machine has the advantages that the mixing chamber can be automatically vacuumized in a working process, so that harmful gases in the mixing chamber are prevented from being exhausted to the outside and further causing pollution, chemical materials in the mixing chamber are prevented from being oxidized by outside air, and high-quality products can be produced; the vacuumizing mixing machine is of great significance in low-carbon development of the rubber and plastic industry and reduction of the energy consumption; the production efficiency and the quality of rubber products are guaranteed, and the vacuumizing mixing machine has an important strategic interest in building the modern high-quality, high-efficiency, energy-saving and emission-reducing type enterprises and establishing the environment-friendly society.

Owner:GUANGDONG LINA IND CO LTD

Industrial continuous cracking device of plastics

ActiveUS20100282590A1Simple configurationSmall volumeMechanical conveying coke ovensProductsPlastics industryHeat carrier

This invention is about an industrial continuous cracking device of plastics. The technical program of this invention is as following: it includes the outer cylinder and the internal cylinder, and the two sides of the internal cylinder are connected with the outer cylinder; at least one of the outer cylinder and the internal cylinder is set with heating mechanism, and the helical ribbon is fixed in the inside of the outer cylinder wall; the transport mechanism is fixed in the internal cylinder, with its direction contrary to the outer cylinder's the feeding direction. The structures of this invention are simple, and it can reduce the possessive space. Furthermore, when cycling in the cylinder, the solid heat carrier has no heat energy loss, and that can substantially reduce the operation cost of the equipment.

Owner:NIUTECH ENVIRONMENT TECHNOLOGY CORPORATION

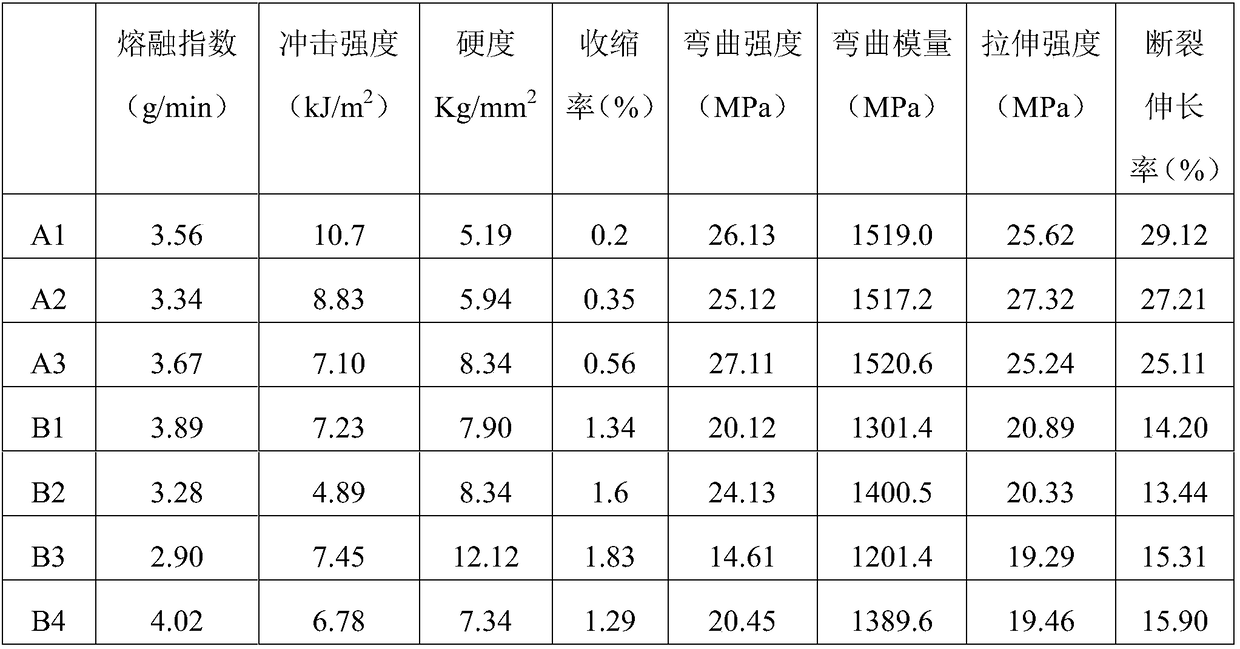

High-strength high-toughness polypropylene regenerated particles and preparation method thereof

The invention provides high-strength high-toughness polypropylene regenerated particles, prepared from the following materials by weight percent: 40-60 percent of waste polypropylene, 5-15 percent ofpolyolefin resin, 5-10 percent of elastomer, 10-20 percent of inorganic rigid particle and coupling agent, 5-20 percent of enhancer, 1-10 percent of bulking agent, 0.1-1 percent of nucleating agent and 0.5-1 percent of other aids. The invention also provides specific production process parameters and a preparation method of the polypropylene regenerated particles; the preparation method comprisesthe steps of firstly adopting a high-speed mixer to evenly mix the proportioned materials, and then preparing the polypropylene regenerated particles by the shear plasticizing action of a twin-screw extruder. The waste polypropylene is taken as a main raw material to prepare high-performance recycled polypropylene, the technological content of the waste polypropylene is effectively improved, the waste polypropylene is recycled, both the resource shortage problem and the environment problem are solved, and certain guiding significance is achieved for the development of recycled plastics industry.

Owner:中华全国供销合作总社天津再生资源研究所

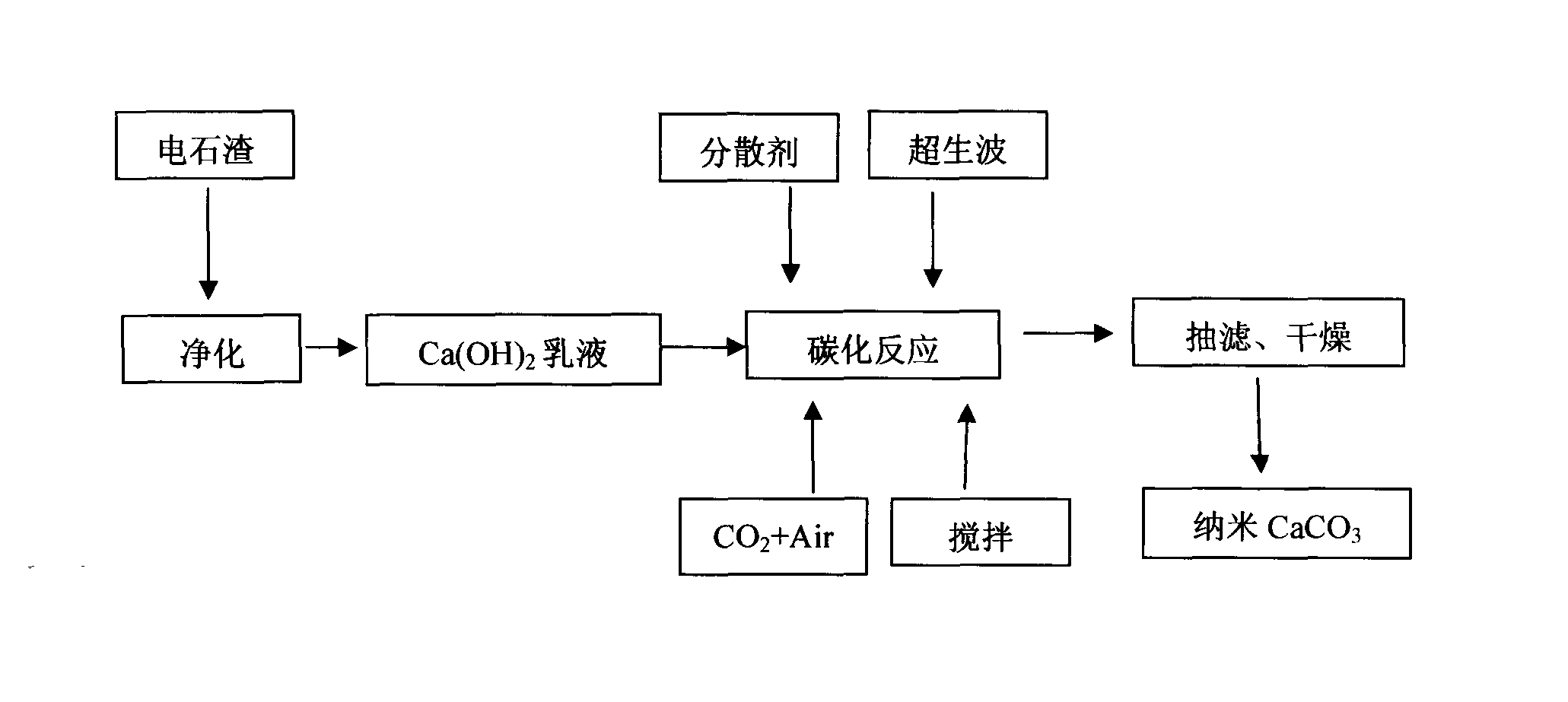

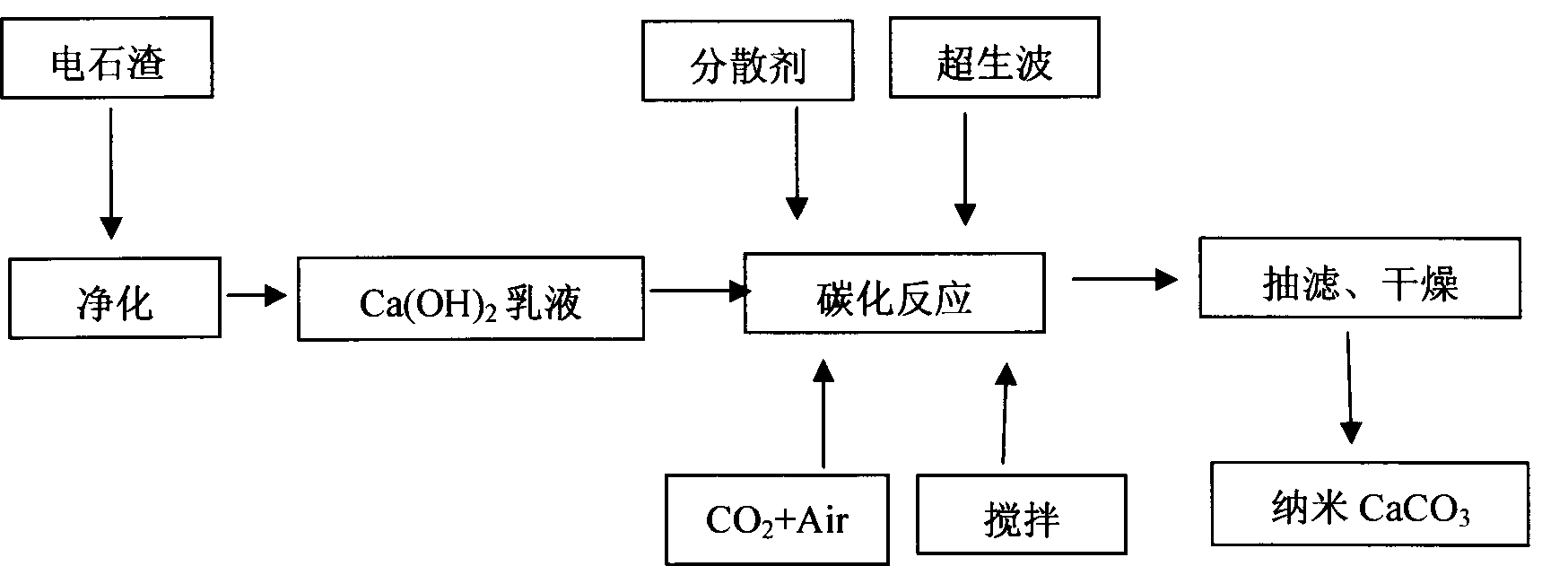

Method for preparing nanometer CaCO3 from calcium carbide slag through ultrasonic process

InactiveCN102515237AMass transfer speedReduce consumptionCalcium/strontium/barium carbonatesNanotechnologySlagToxic industrial waste

The invention relates to a method for preparing nanometer CaCO3 from calcium carbide slag through an ultrasonic process. The calcium carbide slag is purified to generate a Ca(OH)2 emulsion, the Ca(OH)2 emulsion which is added with a dispersant, CO2 and air is irradiated by ultrasonic waves, uniformly stirred, suck-filtered and dried to generate the nanometer CaCO3. The method for preparing the nanometer CaCO3 through adopting the ultrasonic process has the advantages of simple operation, no need of designing a new device, high product added value, gas-liquid-solid mass transfer speed improvement benefiting, realization of the resource comprehensive utilization of the industrial waste slag calcium carbide slag, limestone resource consumption reduction, production cost reduction, natural environment improvement, novel technology, operation benefiting, good product stability, substantial shortening of the preparation time, environment improvement, particle size of 30-200nm, and purity of above 99.2%. Production requirements of the rubber industry, the plastic industry and the coating industry are completely met.

Owner:XINJIANG TIANSHAN CEMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com