Patents

Literature

844 results about "Direct production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Direct production is a term that is used to describe a situation where a company, a group of individuals, or a person produces what he or she needs without having to rely on any other person or organization. The concept of direct production also entails that the item produced in this form must only be due to the talents and efforts of the producer.

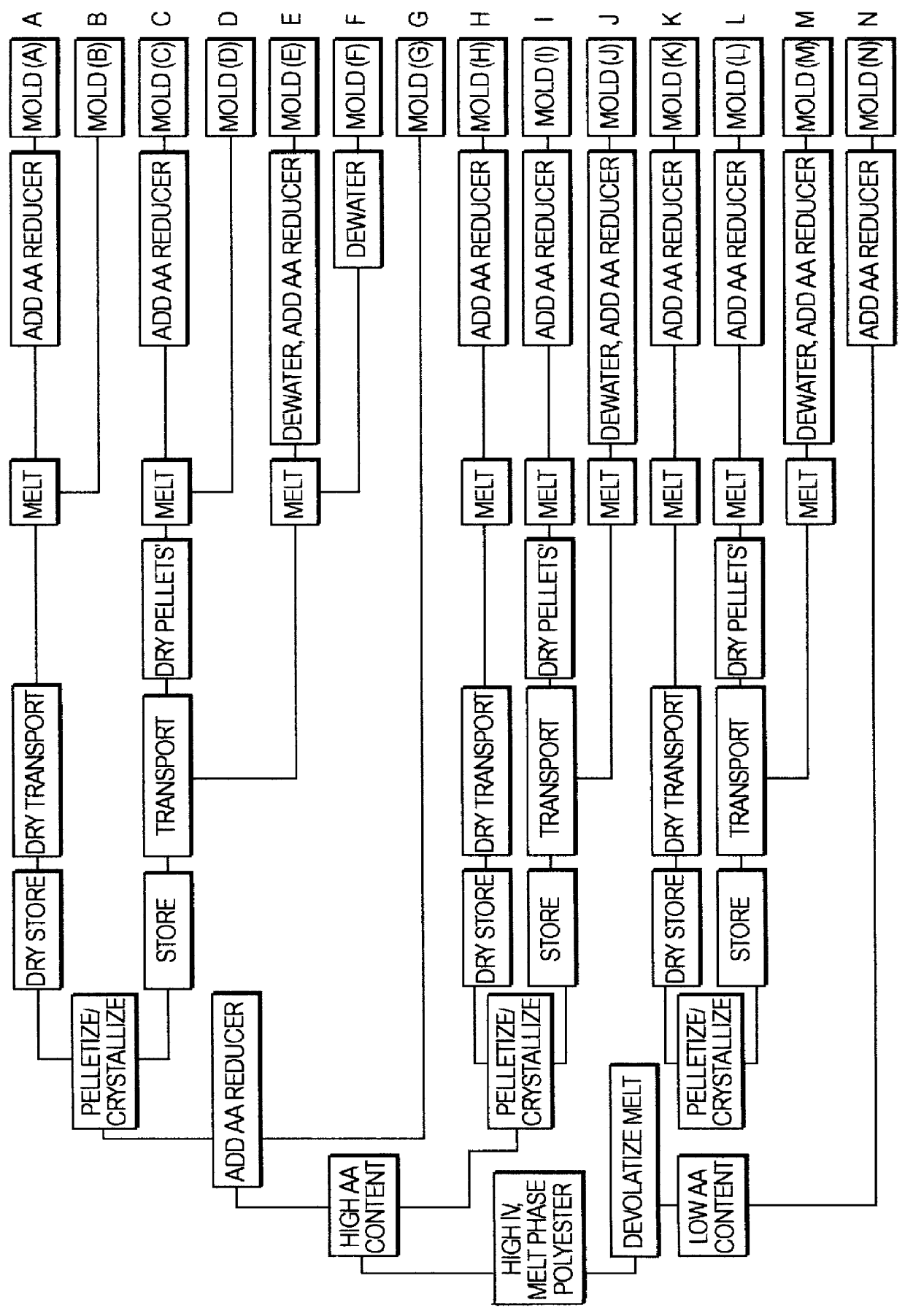

Process for producing pet articles with low acetaldehyde

The present invention discloses a process for producing molded, shaped or extruded articles comprising the steps of: a) melt reacting, in the presence of a catalyst which is substantially free of Co compounds, at least one glycol and at least one dicarboxylic acid to form a polyester having an I.V. of at least about 0.5 dL / g, wherein said at least one glycol is selected from the group consisting of glycols having up to 10 carbon atoms and mixtures thereof and said dicarboxylic is selected from the group consisting of alkyl dicarboxylic acids having 2 to 16 carbon atoms, aryl dicarboxylic acids having 8 to 16 carbon atoms and mixtures thereof; b) adding an acetaldehyde reducing additive to said polyester to form a reduced acetaldehyde polyester; and c) forming said reduced acetaldehyde polyester into articles directly from step b. Thus, the present invention provides a process for directly producing from the melt article having extremely low acetaldehyde content.

Owner:GRUPO PETROTEMEX DE C V

Method for selection of transformed cells

ActiveUS20080120739A1Growth inhibitionClimate change adaptationOther foreign material introduction processesSelect agentDirect production

The invention provides methods for the selection of transgenic cells. The invention relates to the unexpected finding that cells expressing a gene conferring tolerance to auxin-like herbicides such as dicamba may be directly selected from non-transgenic cells using auxin-like herbicides as a selective agent. In this manner, plants exhibiting tolerance to auxin-like herbicides can be directly produced without the need for separate selectable markers.

Owner:MONSANTO TECH LLC

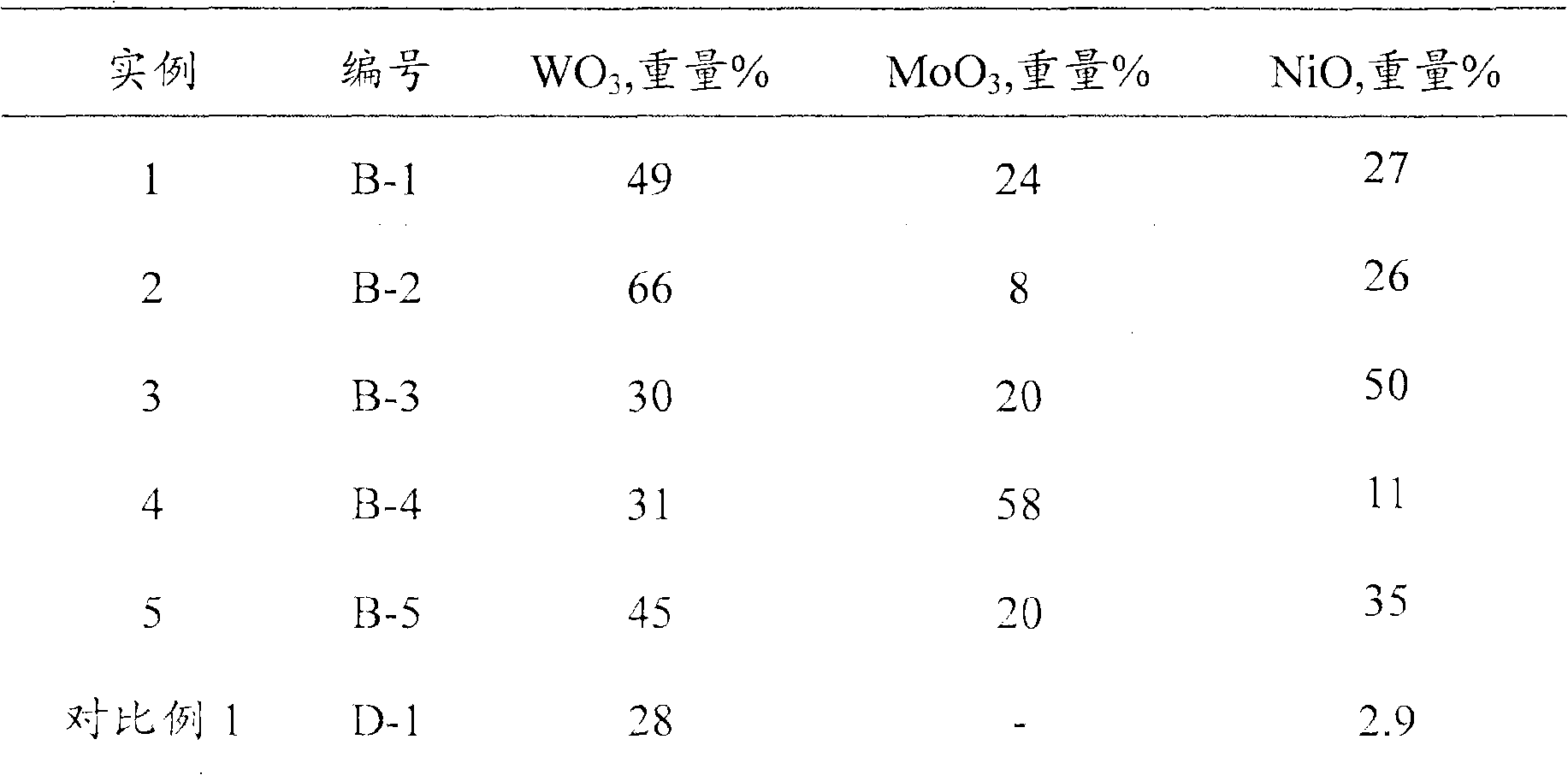

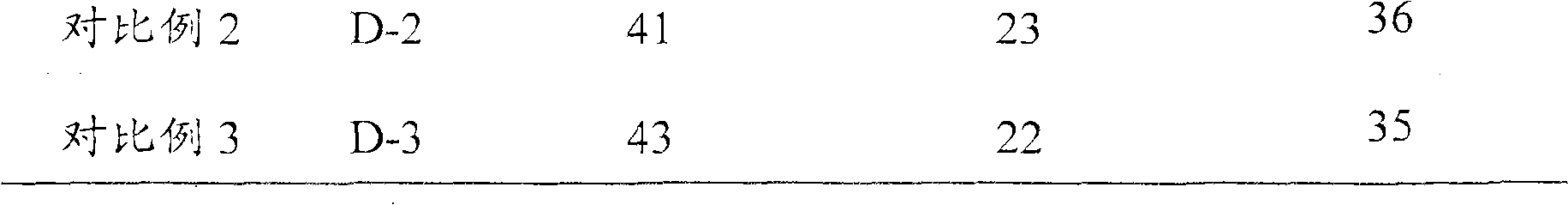

Hydrogenation catalyst composition, preparation method and use thereof

ActiveCN101306374AHigh activityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsGramSulfur

The invention discloses a hydrogenation catalyst combination, as well as the preparation and the application thereof. The catalyst comprises a catalytic agent containing at least one VIII group metal component, at least two VIB group metal components and an organic addition agent, X-ray is used for diffracting the characterization, and the catalyst has diffraction peaks when d is equal to 9.8 A-12.8 A, d is equal to 3.65 A-4.65 A, d is equal to 2.1 A-3.1 A and d is equal to 1.03 A- 2.03 A. Compared with the prior art, the catalyst of the invention has higher hydrogenation activity. When the invention is used for hydro-treating hydrocarbon oil, the reaction can be carried out under milder reaction conditions. If the hydrocarbon oil hydro-treating method provided by the invention is adopted, clean diesel oil which has sulfur of lower than 10 microgram / gram and accords with the European No. V discharge standard can be directly produced under the pressure of 6.4 MPa and the temperature of 340 DEG C.

Owner:CHINA PETROLEUM & CHEM CORP +1

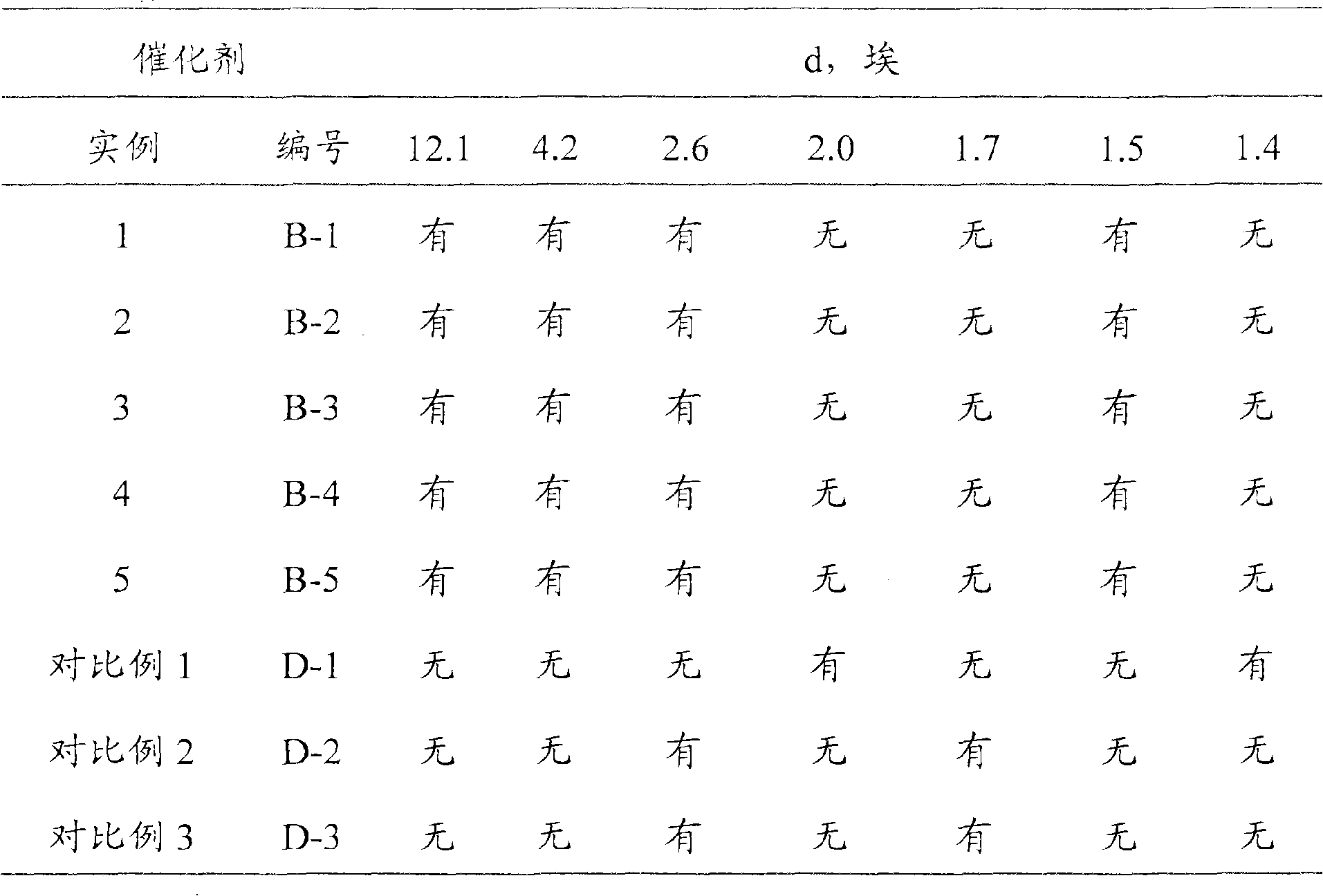

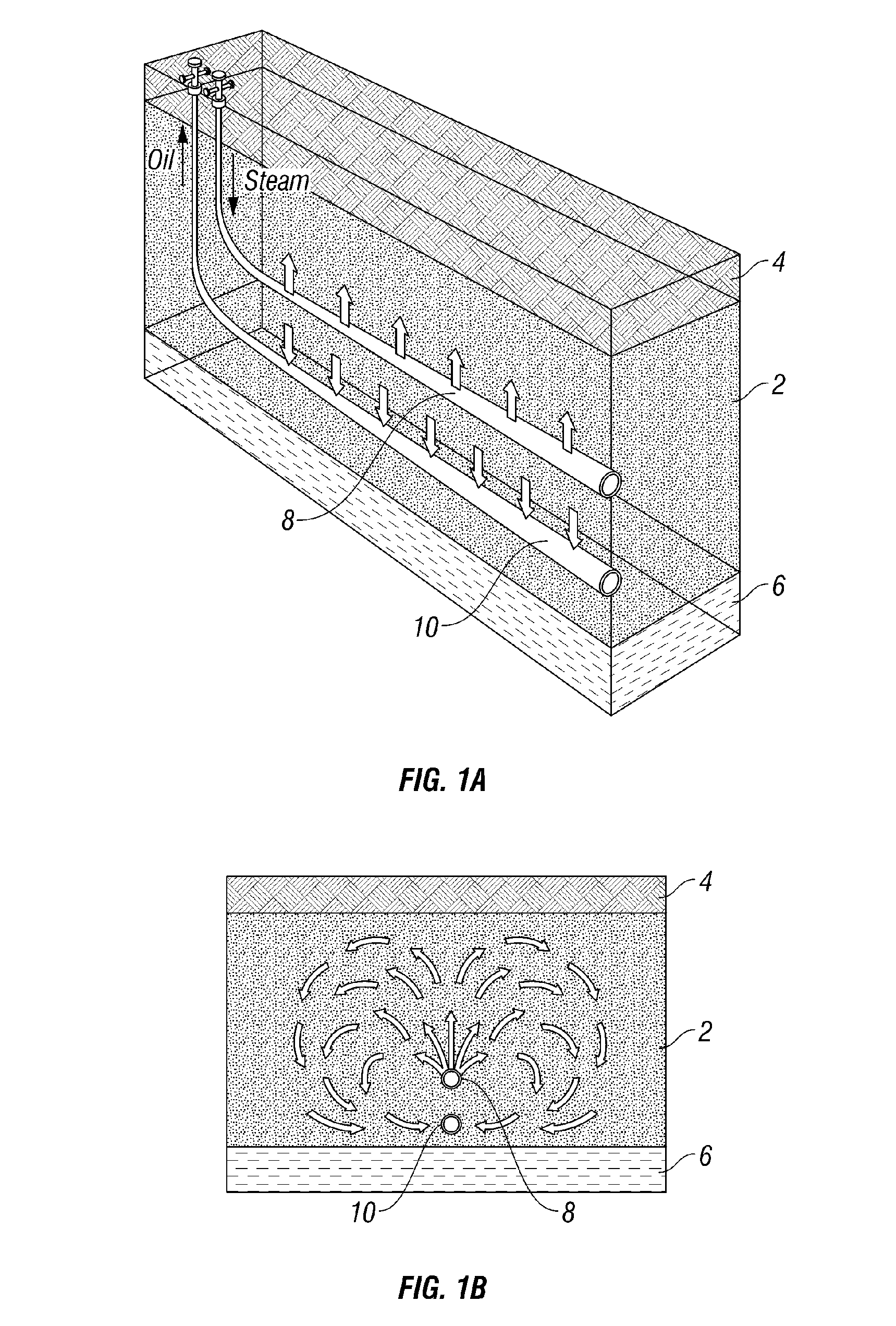

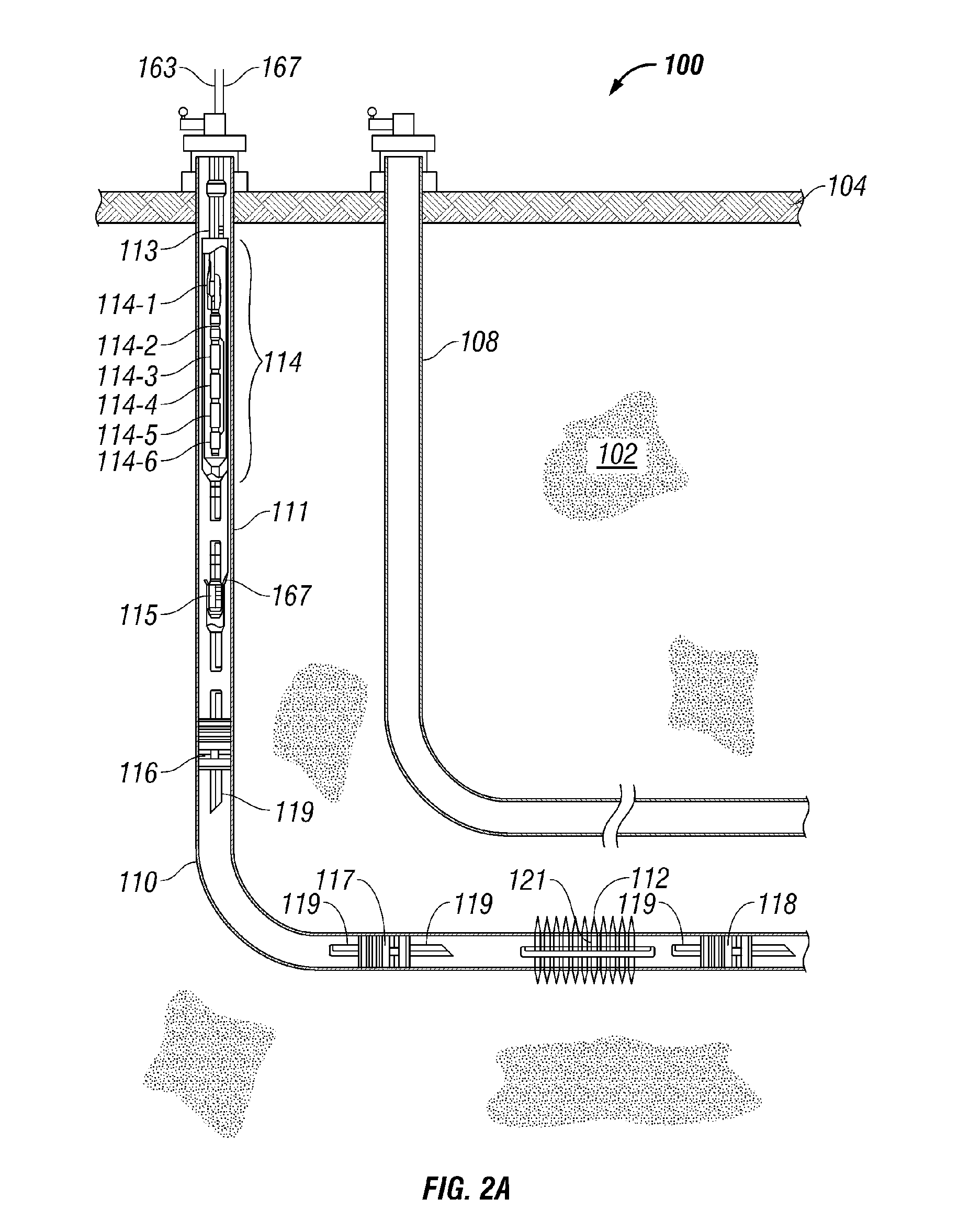

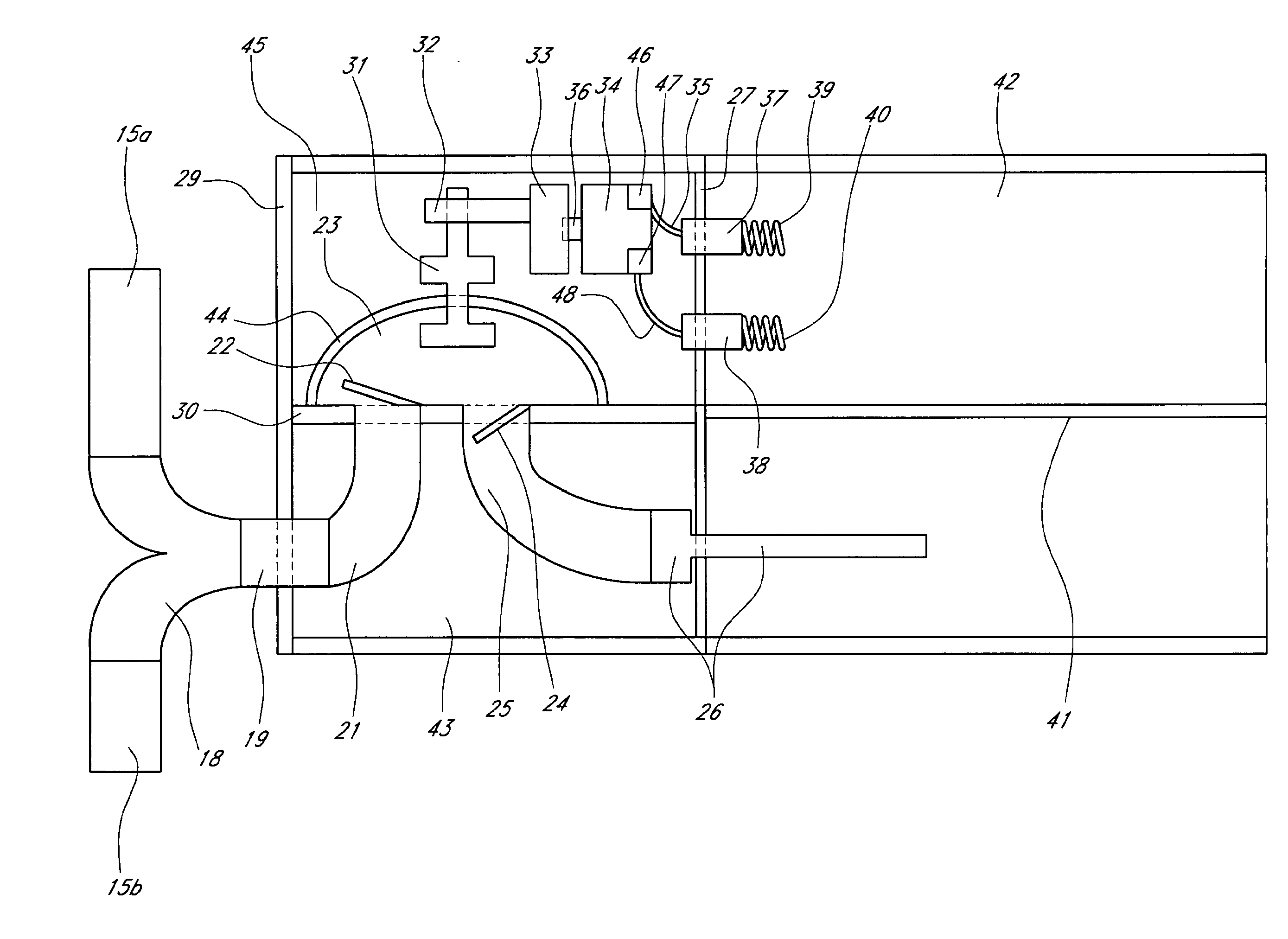

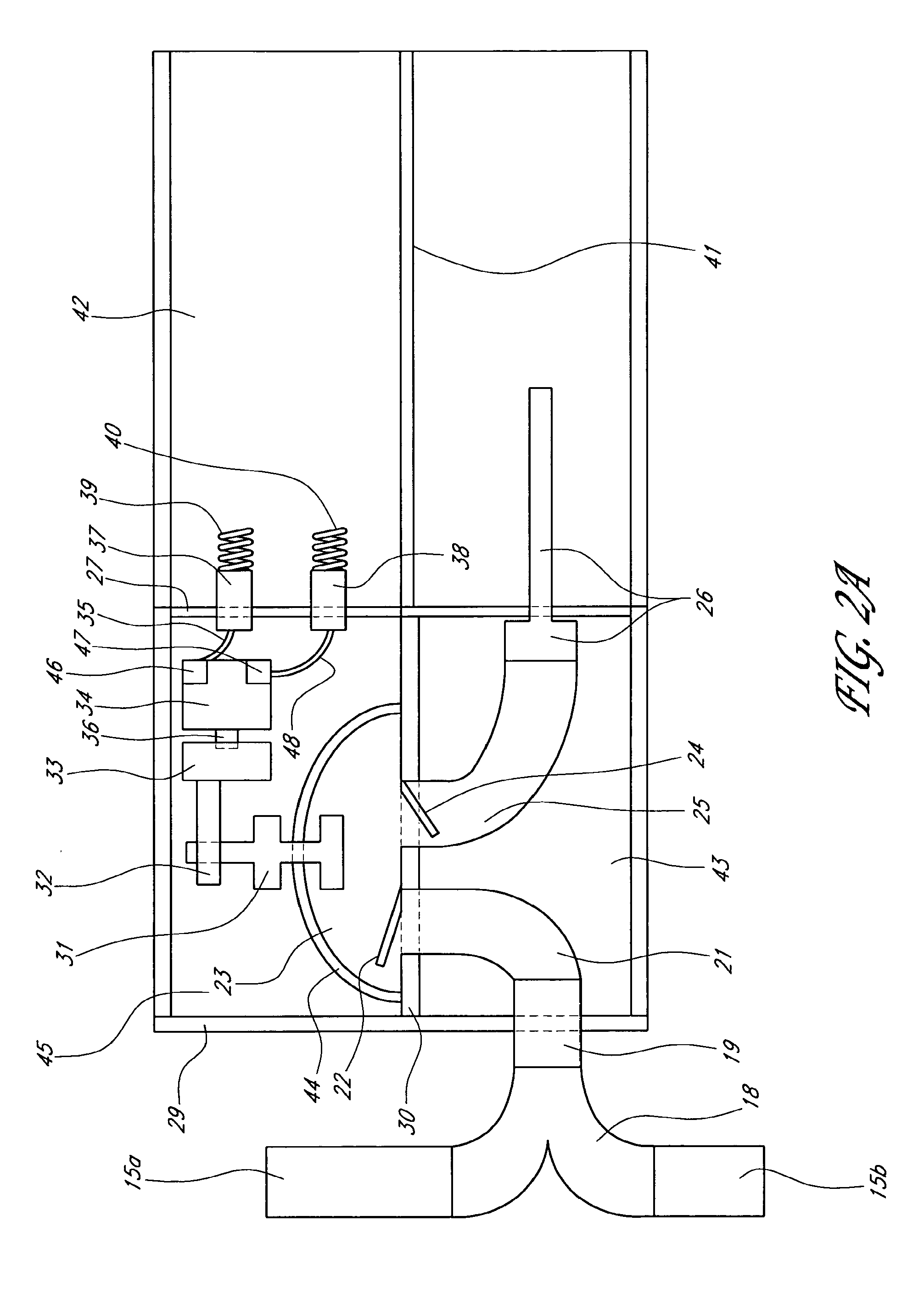

Real-Time Production-Side Monitoring and Control for Heat Assisted Fluid Recovery Applications

An automatic control system that protects downhole equipment and surface equipment from high temperatures resulting from the breakthrough of injection vapor. The system operates to derive an estimate of the temperature of production fluid at a location upstream from the downhole equipment. An alarm signal is generated in the event that this temperature exceeds a threshold temperature characteristic of injection vapor breakthrough. Electric power to the downhole equipment is automatically shut off in response to receiving the alarm signal. A bypass valve selectively directs production fluid to a bypass path. The system operates to derive an estimate of the temperature of the production fluid at a location upstream from the surface equipment. An alarm signal is generated when this temperature exceeds a threshold temperature characteristic of injection vapor breakthrough. The bypass valve is automatically controlled to direct production fluid to the bypass path in response to receiving the alarm signal.

Owner:SCHLUMBERGER TECH CORP

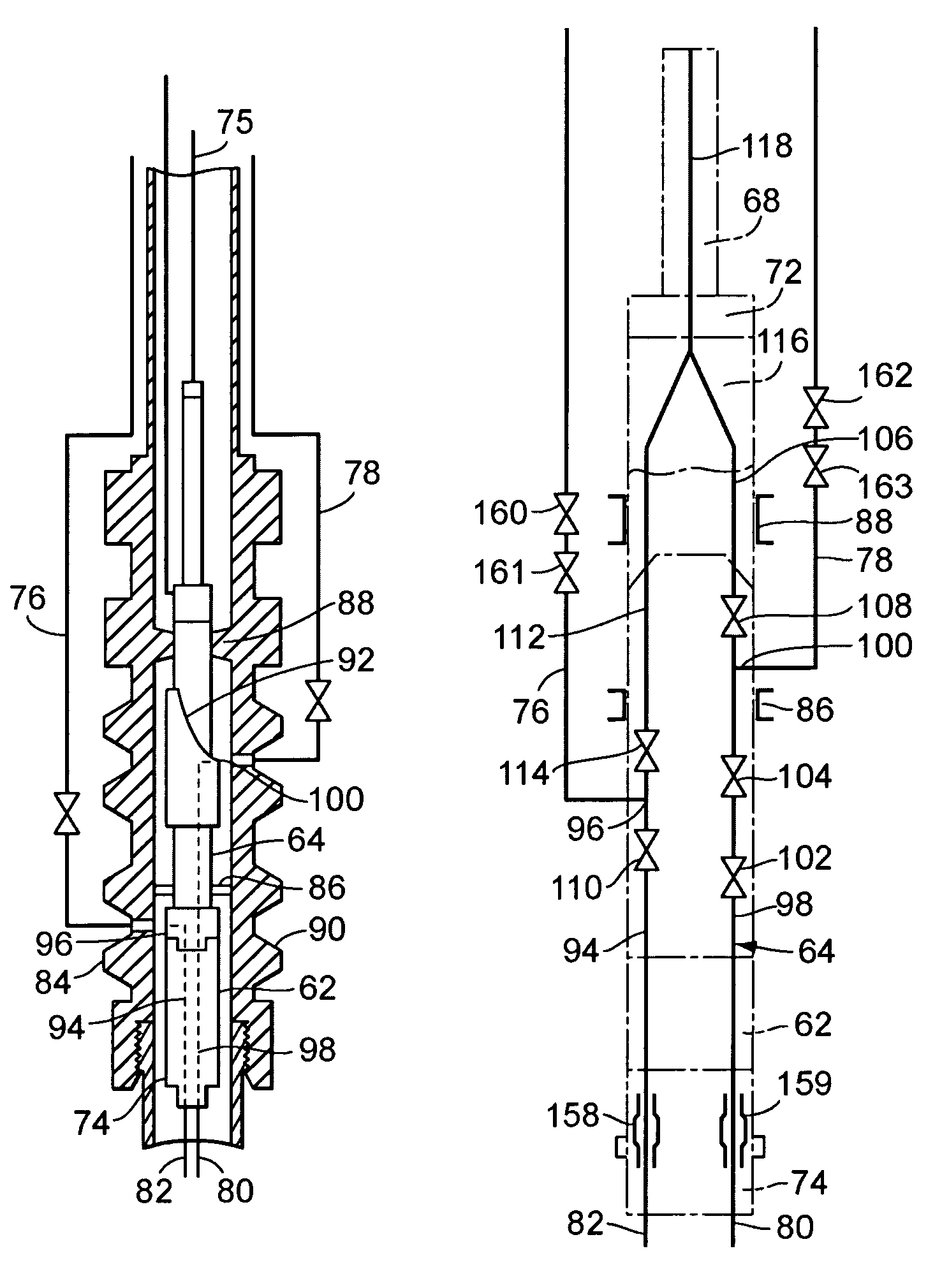

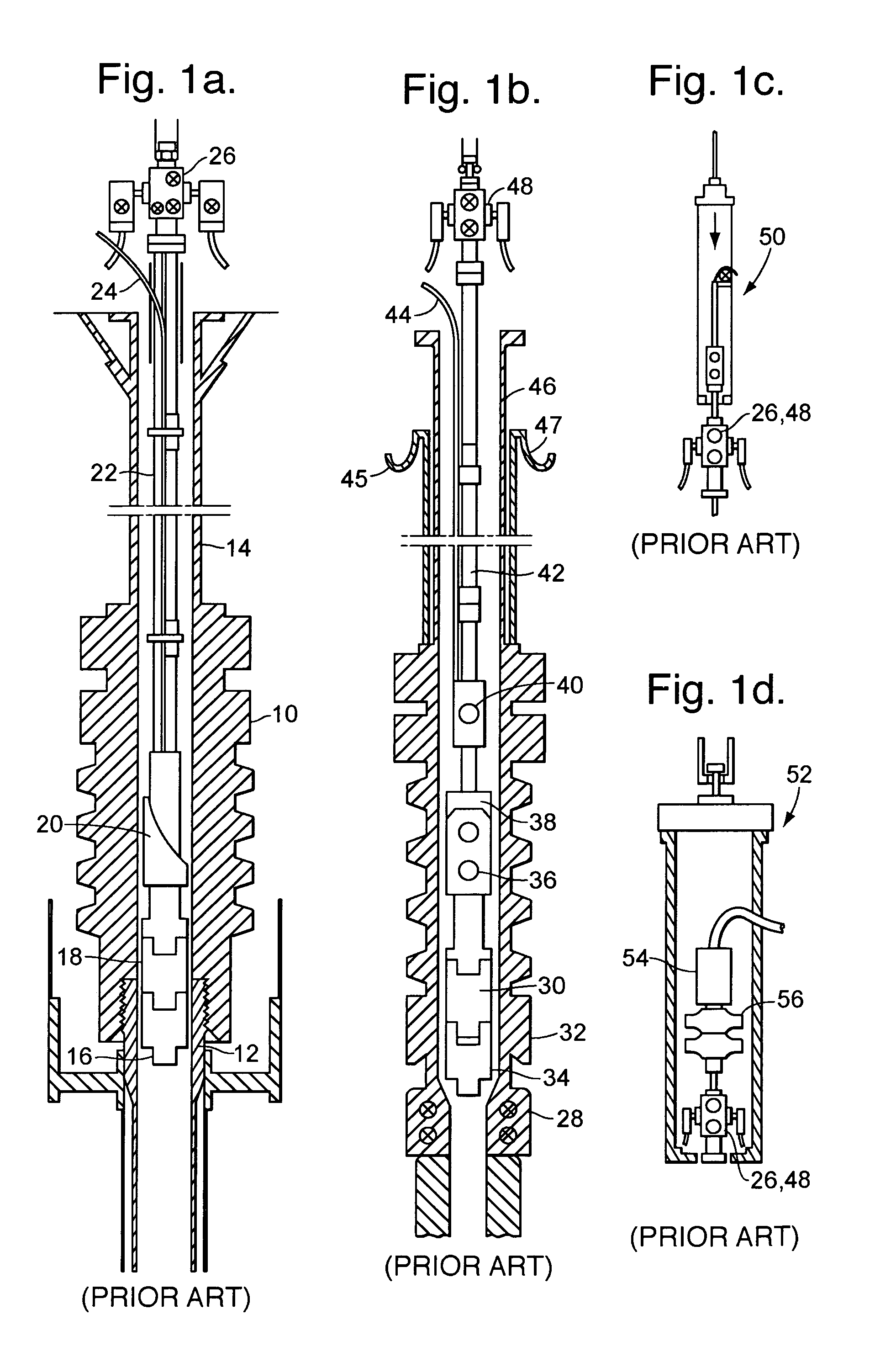

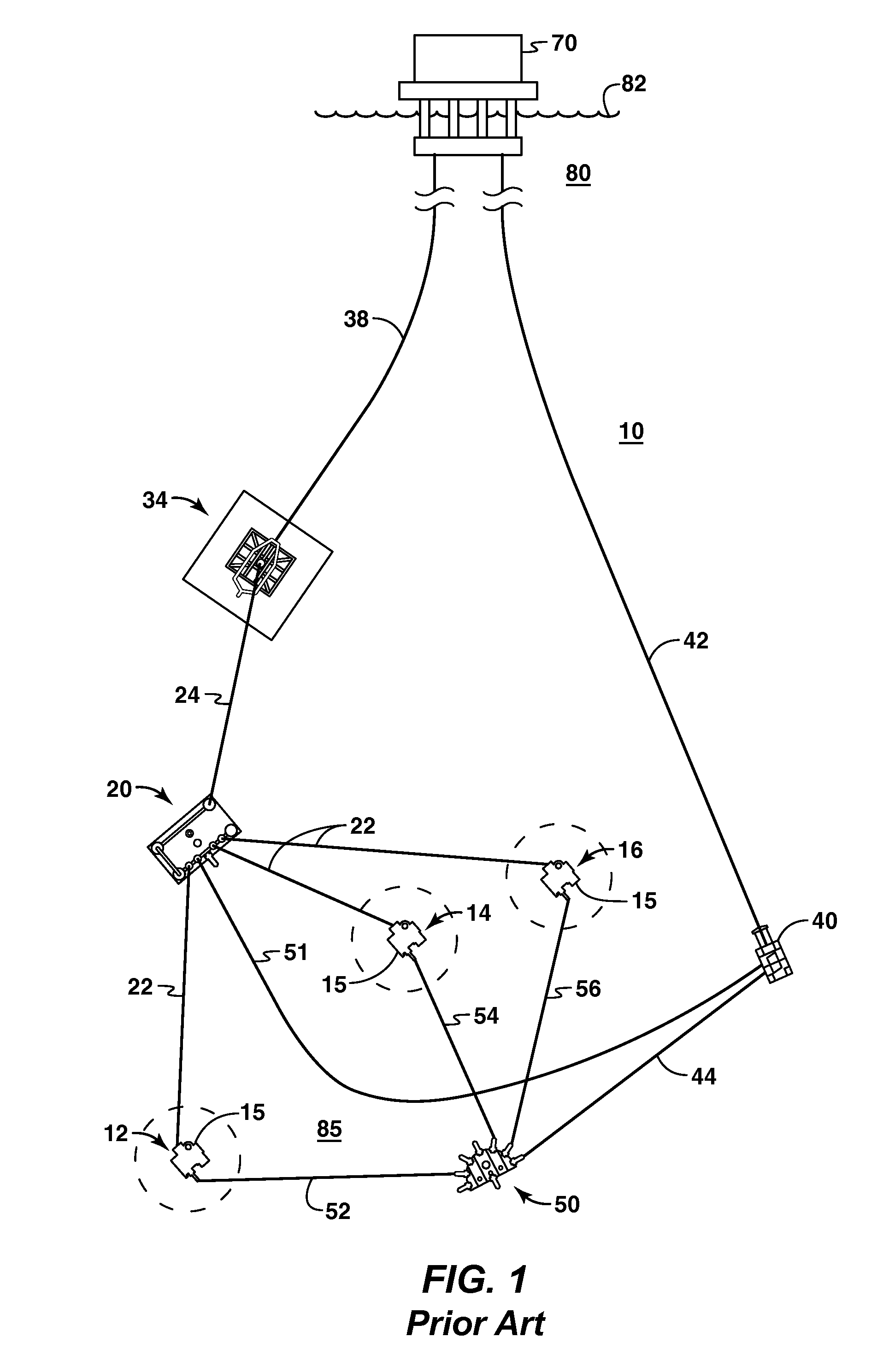

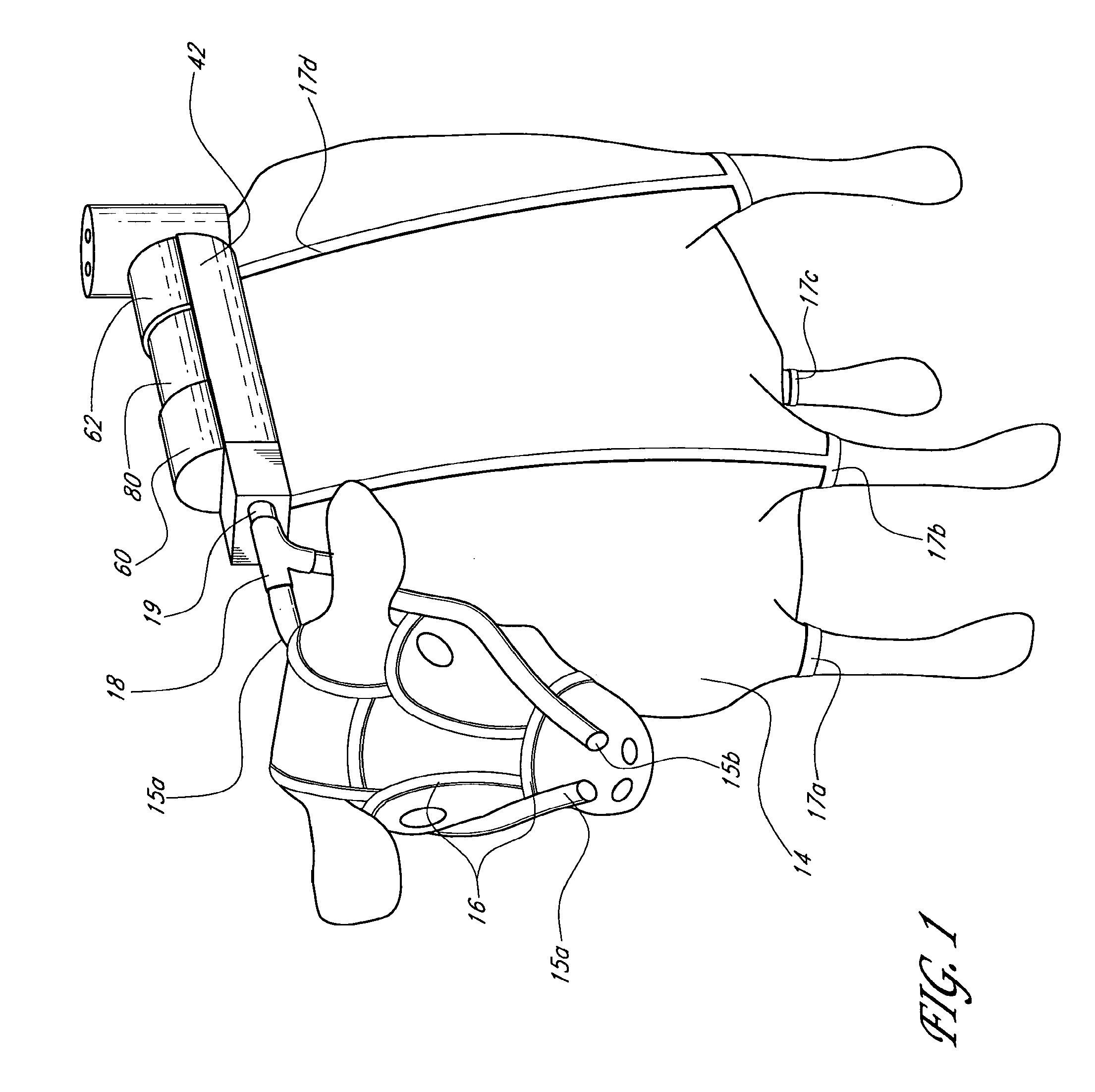

Device for installation and flow test of subsea completions

InactiveUS7114571B2Simpler and reliable and rapid disconnectionDrilling rodsFluid removalLine tubingTubing hanger

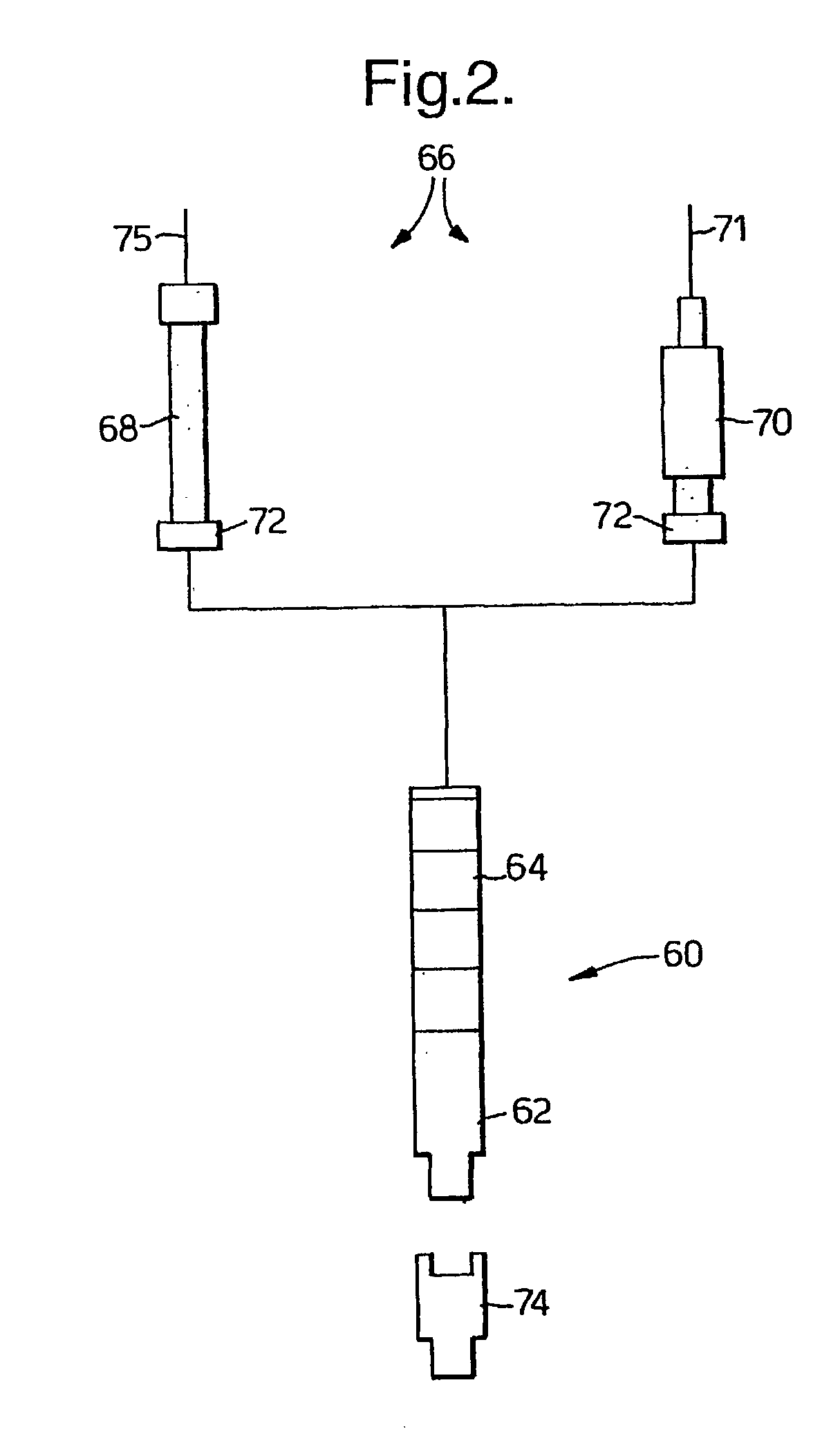

A running string for a subsea completion comprises an upper section (70) which may be a coiled tubing (CT) injector unit as shown, or a wireline lubricator (FIG. 8). A lower section (60) provides wireline / CT access to production / annulus bores of a tubing hanger (not shown) attached to tubing hanger running tool (62). A flow package (64) in the lower section (60), together with BOP pipe rams (86) and annular seal (88), directs production and annulus fluid flows / pressures to the BOP choke / kill lines (78 / 76). The upper and lower sections allow installation and pressure / circulation testing of, and wireline / CT access to, a subsea completion, without the use of a high pressure riser.

Owner:FMC TECH INC

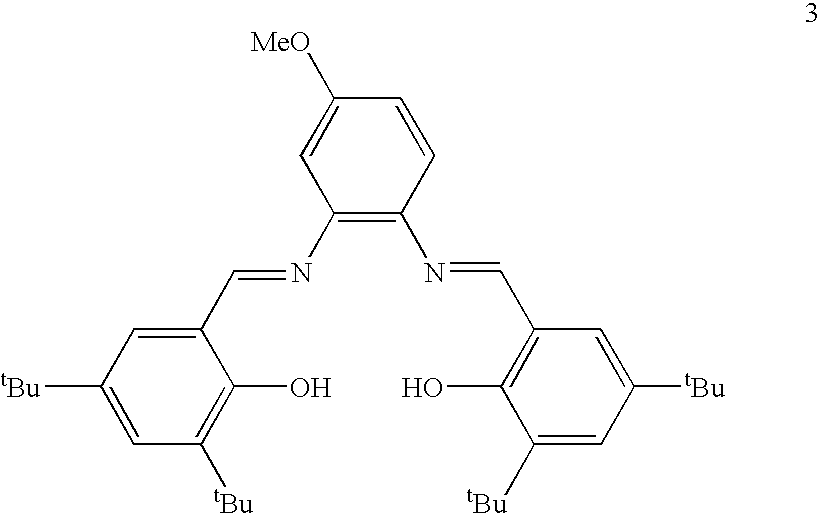

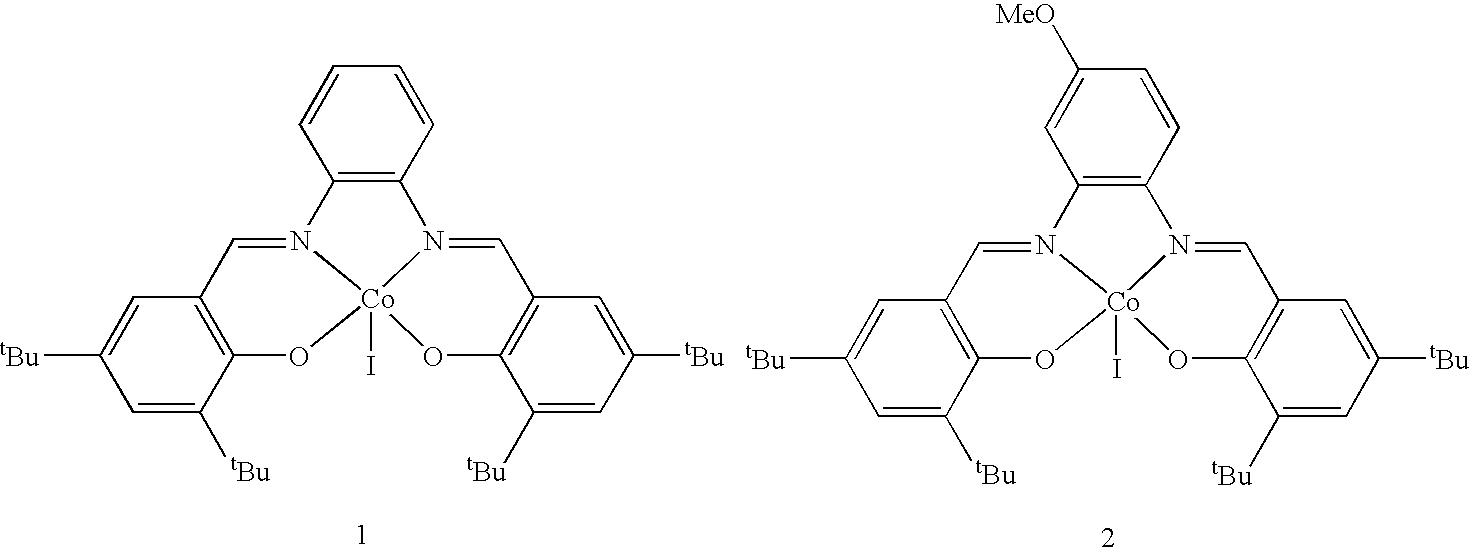

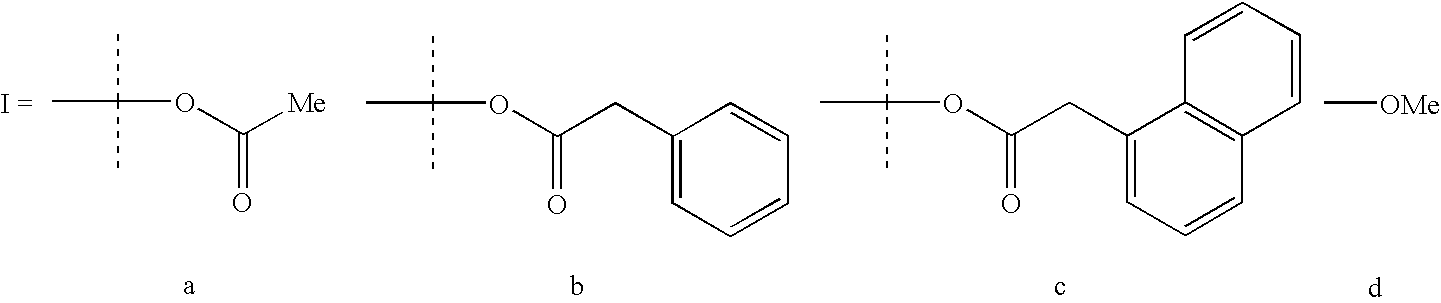

Isotactic specific catalyst for direct production of highly isotactic poly (propylene oxide) or highly isotactic poly (butylene oxide)

InactiveUS7399822B2Molecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsDirect productionPropylene oxide

Owner:CORNELL RES FOUNDATION INC

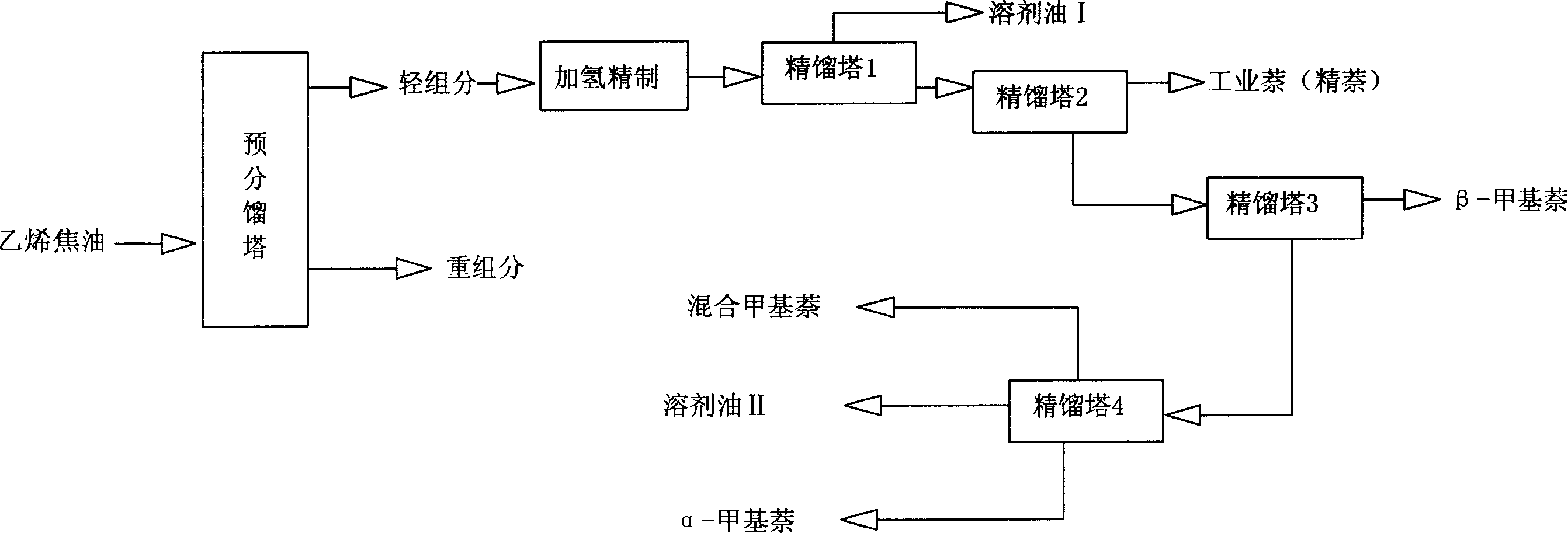

Ethylene bottom oil complex processing technology

ActiveCN1970688AHigh purityEasy to operateHydrocarbon purification/separationHydrocarbonsTarBeta-methylnaphthalene

The invention discloses an extracting method of industrial refined naphthalene, alpha-methylnaphthalene, beta-methylnaphthalene from ethylene tar, which is characterized by the following: prefractionating ethylene tar under 260-280 deg.c; hydrogenating light fractionated component under 160-300 deg.c at 3.0-4.0Mpa to remove insaturated hydrocarbons; rectifying to separate refined naphthalene with crystallizing point at 79.6 deg.c; obtaining alpha-methylnaphthalene and beta-methylnaphthalene with each purity over 95%.

Owner:浙江美阳国际工程设计有限公司

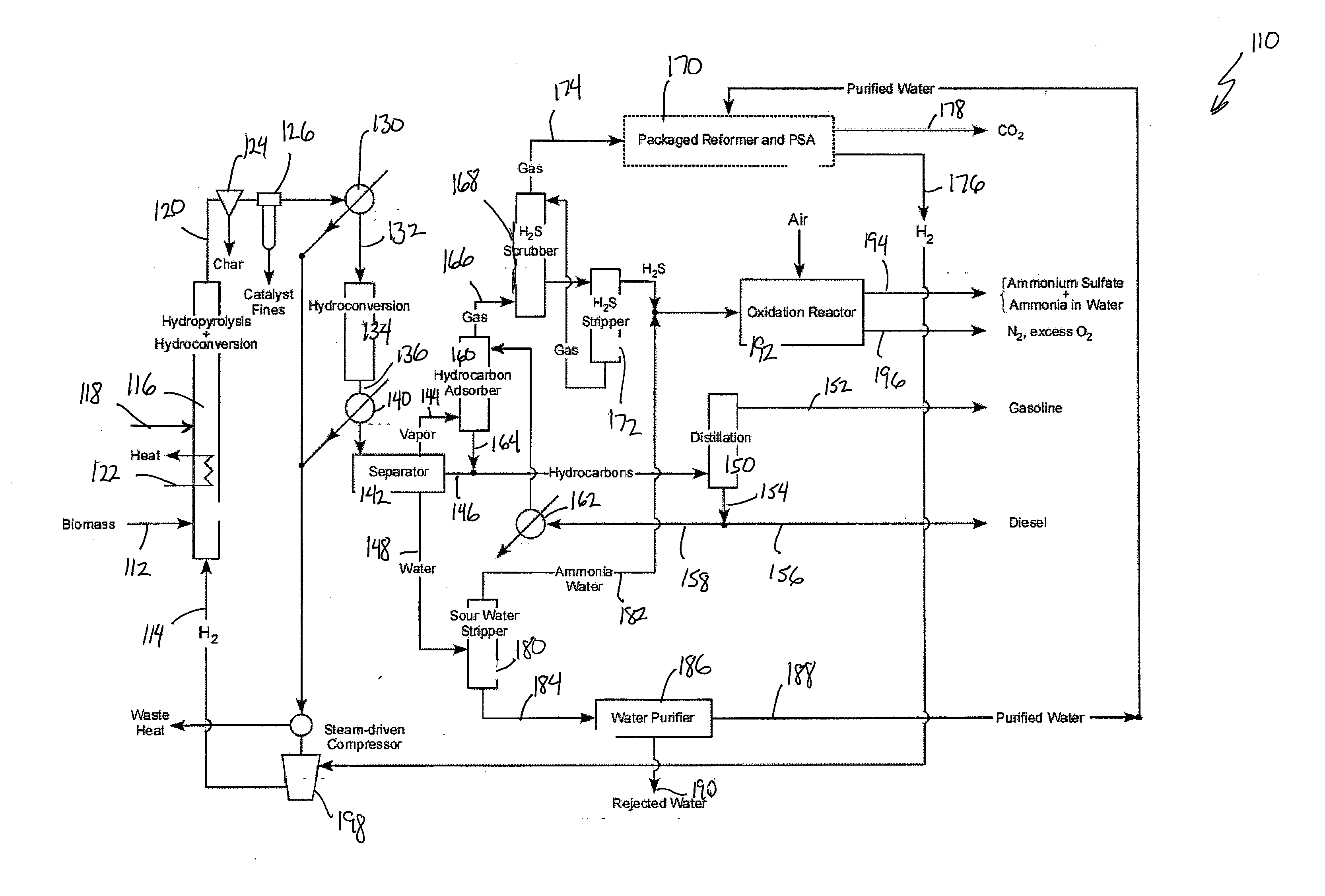

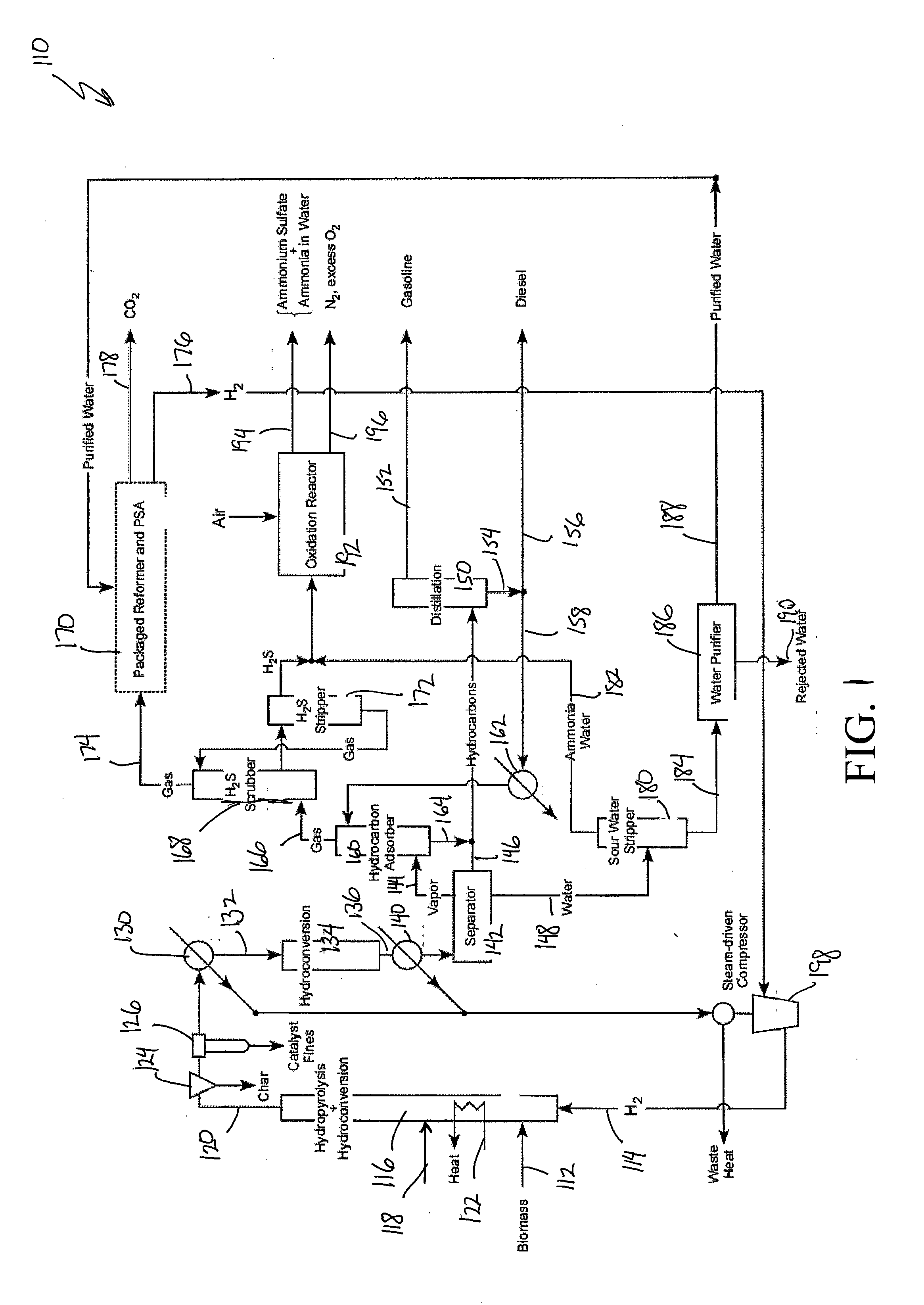

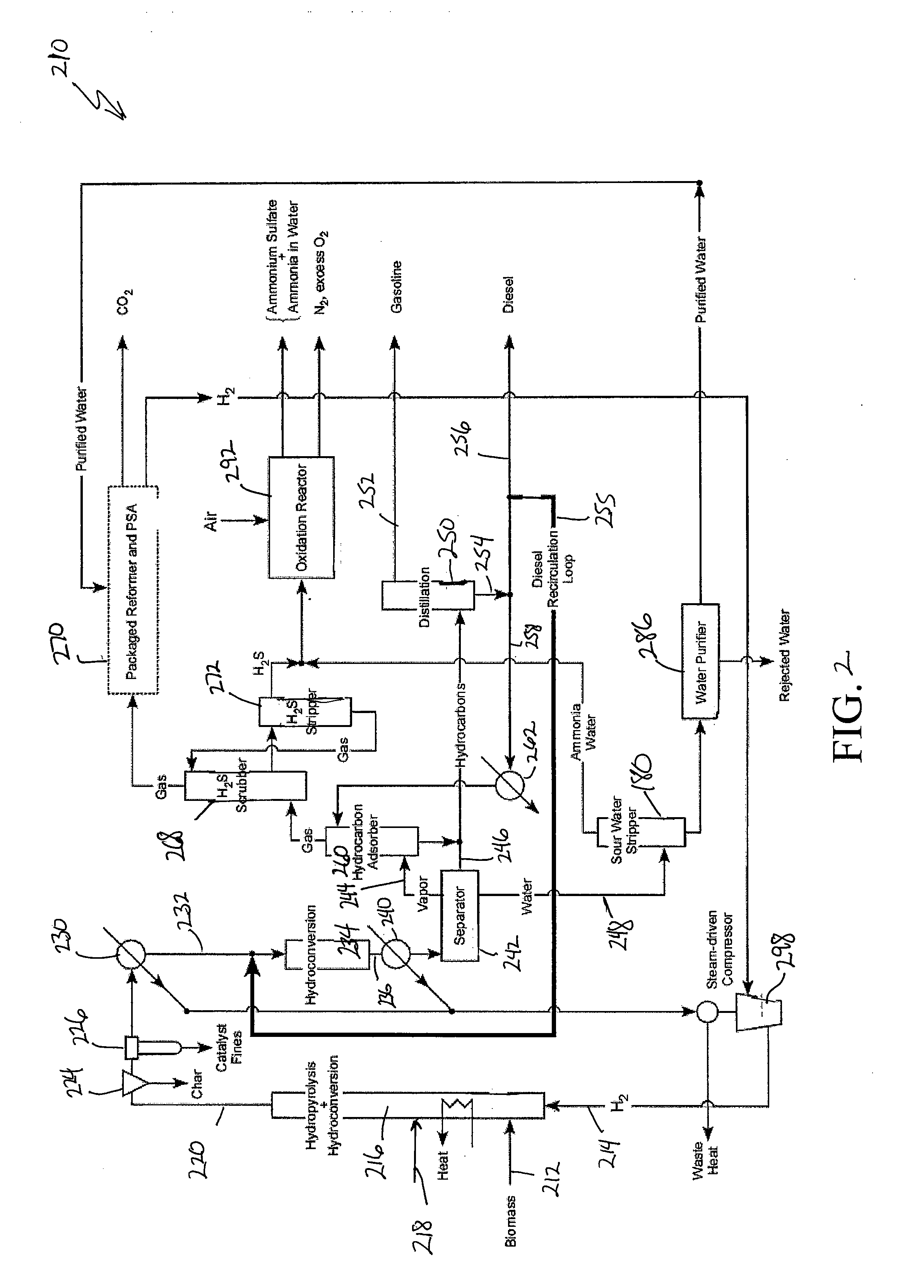

Direct production of fractionated and upgraded hydrocarbon fuels from biomass

Multistage processing of biomass to produce at least two separate fungible fuel streams, one dominated by gasoline boiling-point range liquids and the other by diesel boiling-point range liquids. The processing involves hydrotreating the biomass to produce a hydrotreatment product including a deoxygenated hydrocarbon product of gasoline and diesel boiling materials, followed by separating each of the gasoline and diesel boiling materials from the hydrotreatment product and each other.

Owner:GAS TECH INST

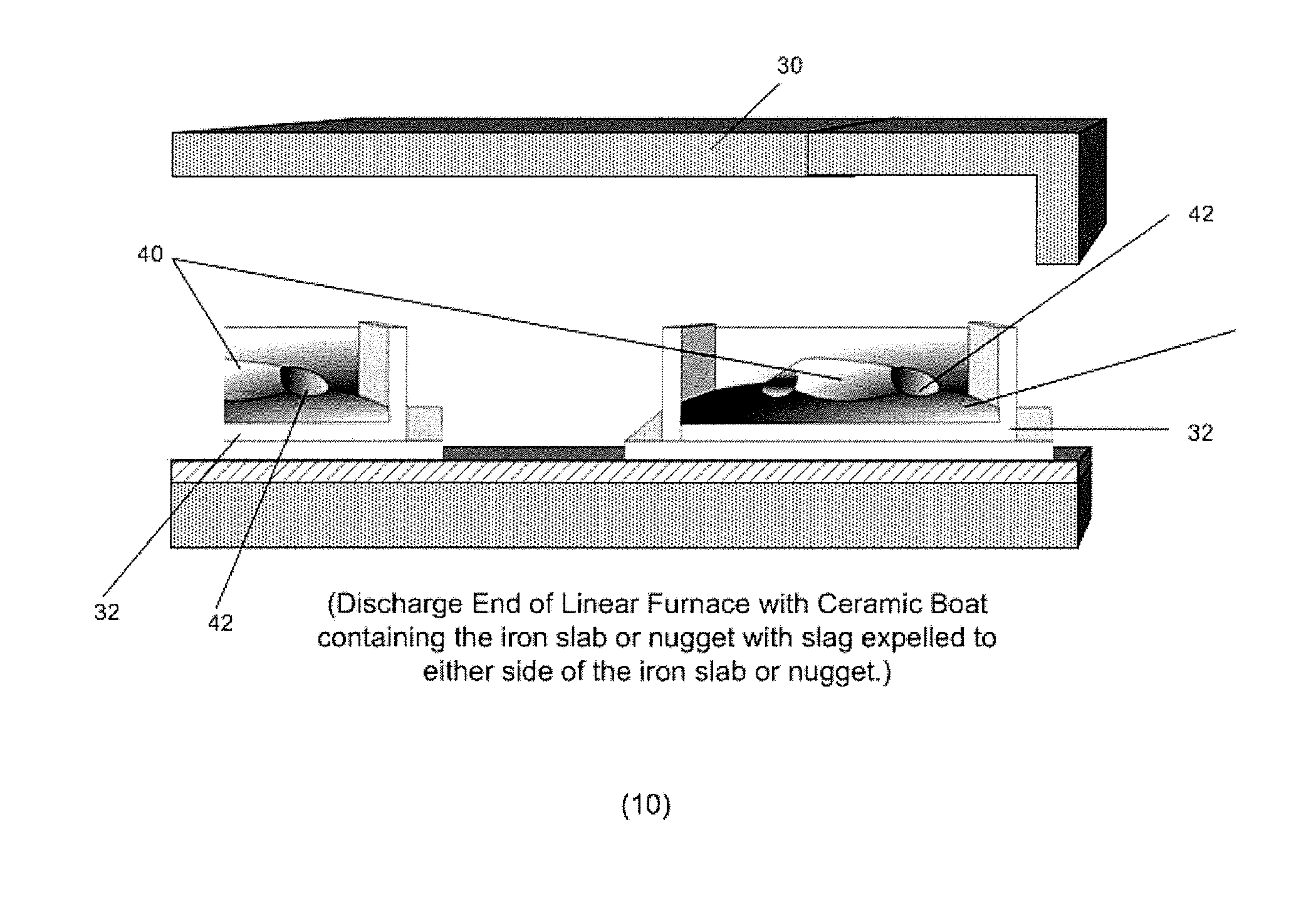

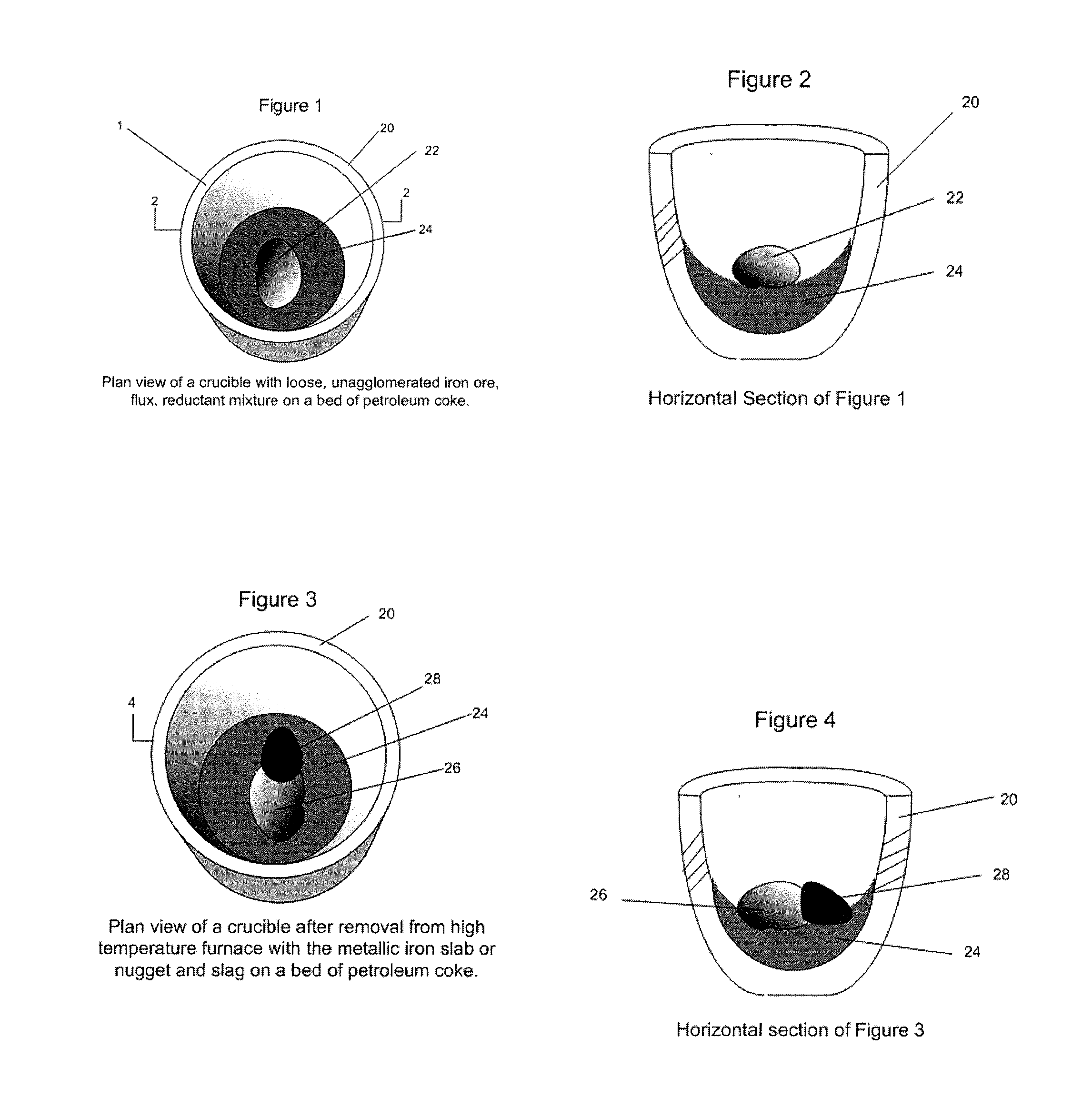

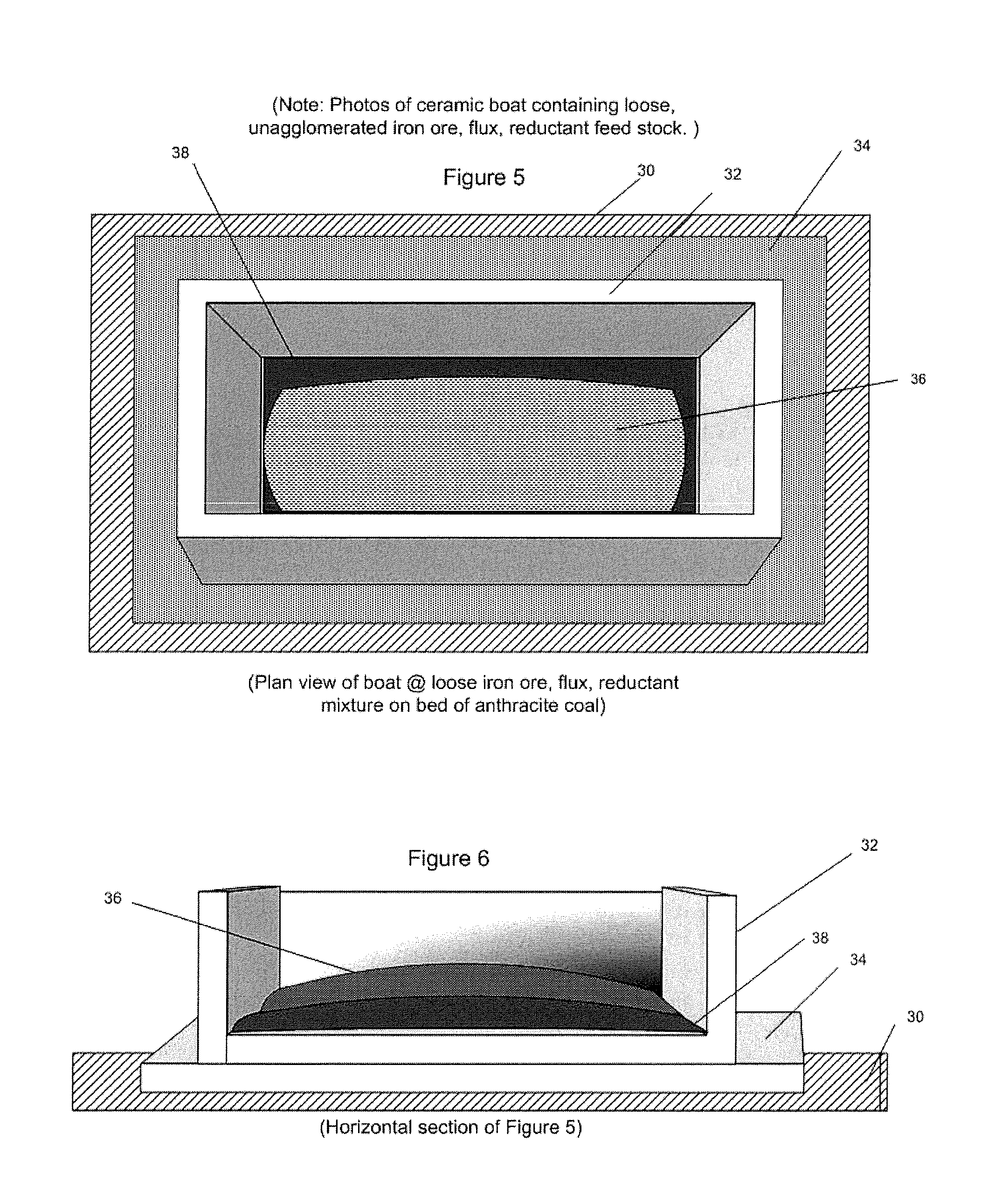

Direct Production of Iron Slabs and Nuggets From Ore Without Pelletizing or Briquetting

ActiveUS20130081516A1Lower cost of capitalReduce operating costsExhaust gas handlingGas emission reductionParticulatesIronstone

Metallic iron is produced from a composition formed from a mixture of iron ore particles and particles of a reductant made of a biomass material, a coal or coke in a particulate form together with a flux and is processed in a loose, un-agglomerated non-pelletized, non-briquetted form in a reducing furnace to produce metallic iron directly from the ore. An excess of biomass or coal or coke reductant can be used to provide CO and H that can be recovered as a synthetic gas and converted to electrical or other energy. Metallic iron nuggets or slabs can be produced from manganiferous ores or concentrates. Manganese can be caused to enter the nugget or slab or the slag by adjusting the furnace temperature. Titaniferous ores or concentrates can be used to produce metallic iron slabs or nuggets and a titanium-rich slag.

Owner:SIMMONS JOHN J

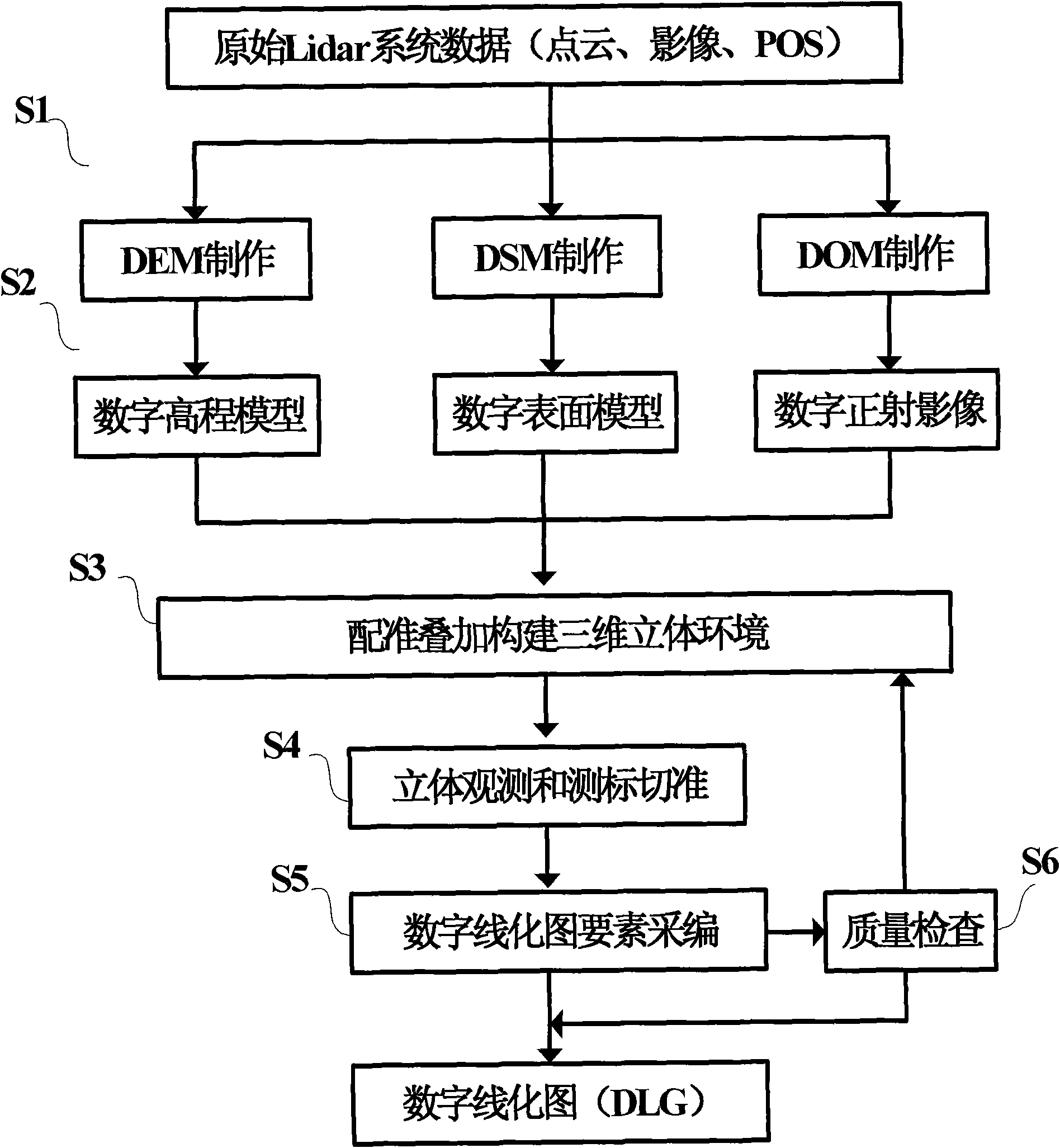

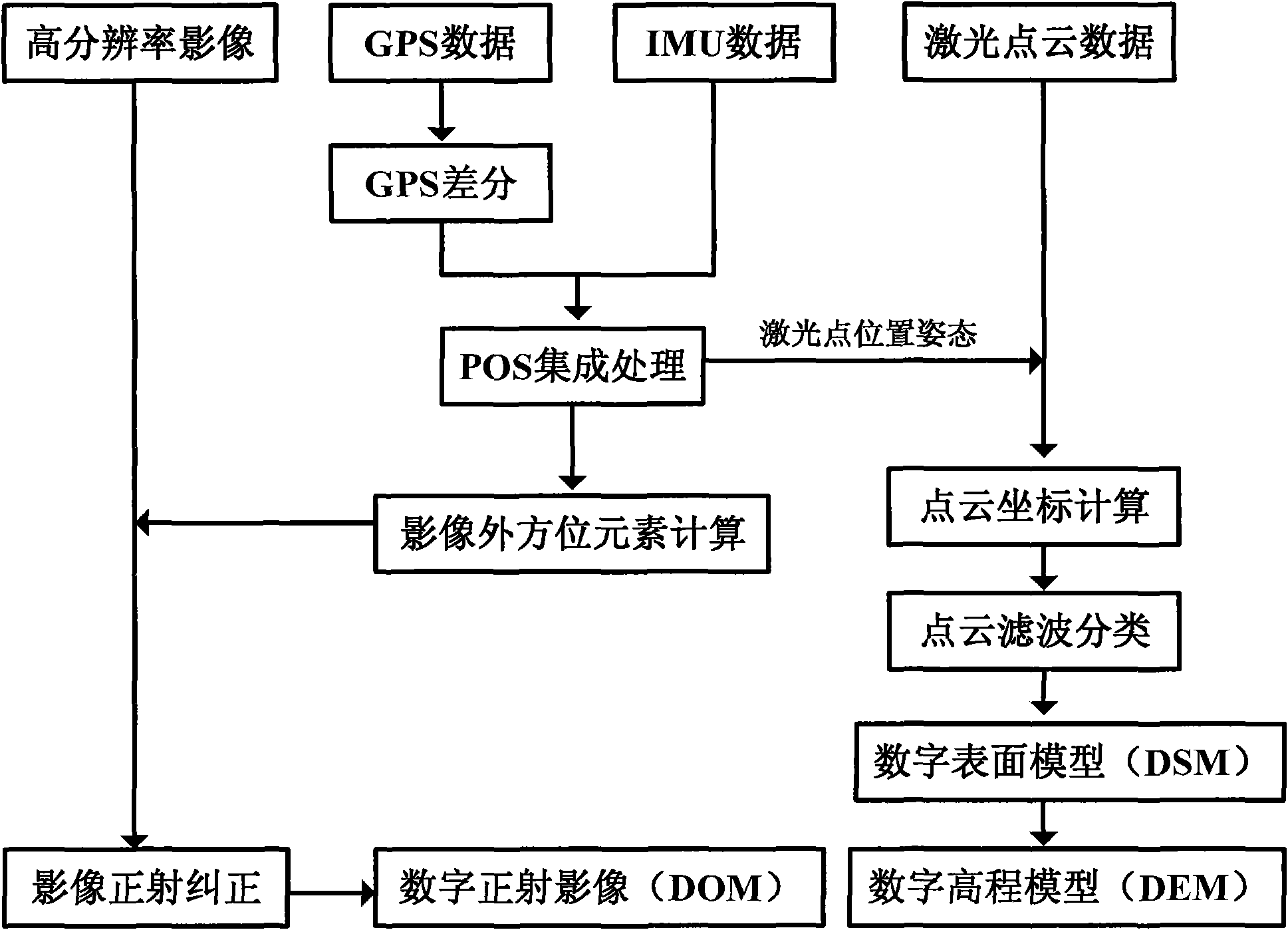

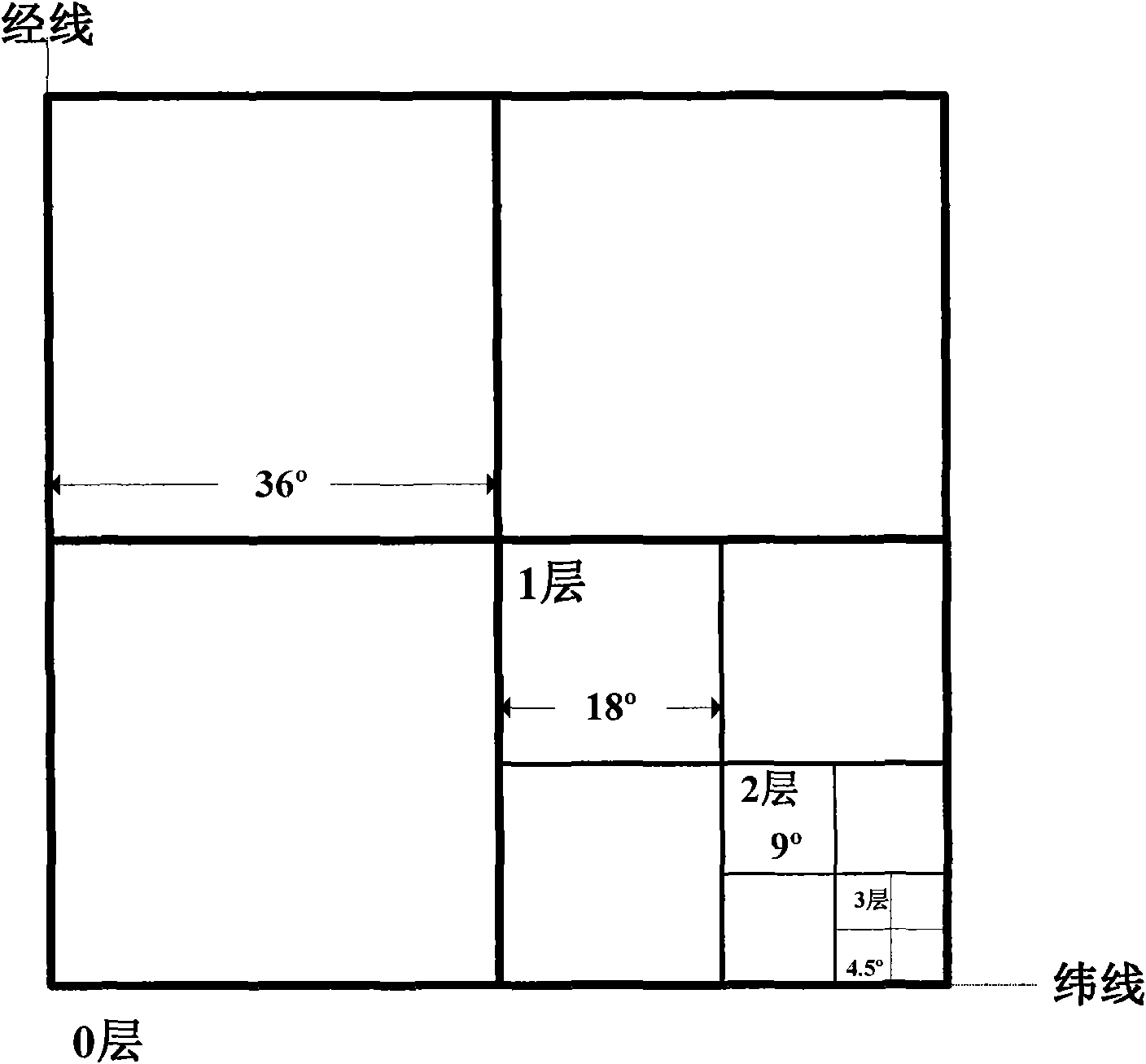

Method for measuring image and inspecting quantity under light detection and ranging (LiDAR) three-dimensional environment

InactiveCN101777189ASolve the problem of direct production of digital linear graph (DLG) productsImprove practicalityImage analysisPicture interpretationMultiple sensorSoftware

The invention relates to the technical field of mapping, in particular to a method for measuring image and inspecting quantity under the light detection and ranging (LiDAR) three-dimensional environment, comprising the following steps of: respectively manufacturing a digital surface model (DSM), a digital evaluation model (DEM) and a digital ortho image (DOM) according to multiple sensor data obtained by the LiDAR system, respectively layering and partitioning the DSM, the DEM and the DOM in advance, laminating the DSM, the DEM and the DOM to construct a three-dimensional environment, three-dimensionally measuring mark and intersecting, acquiring and cataloging digital line graphic (DLG) elements, and inspecting quality of the DLG. The invention breaks through the limitation that photogrammetric survey needs complex flow chart of data processing and professional photogrammetric survey equipment and software to construct stereopair by two photos, solves the problem that the LiDAR system directly generates the DLG products, shortens the period of DLG production by the LiDAR system, largely improves the practicability and the use value of the LiDAR system, and provides the base for the large-scale application of the LiDAR system in mapping, electricity, city planning, geology and design of road and railway.

Owner:WUHAN UNIV

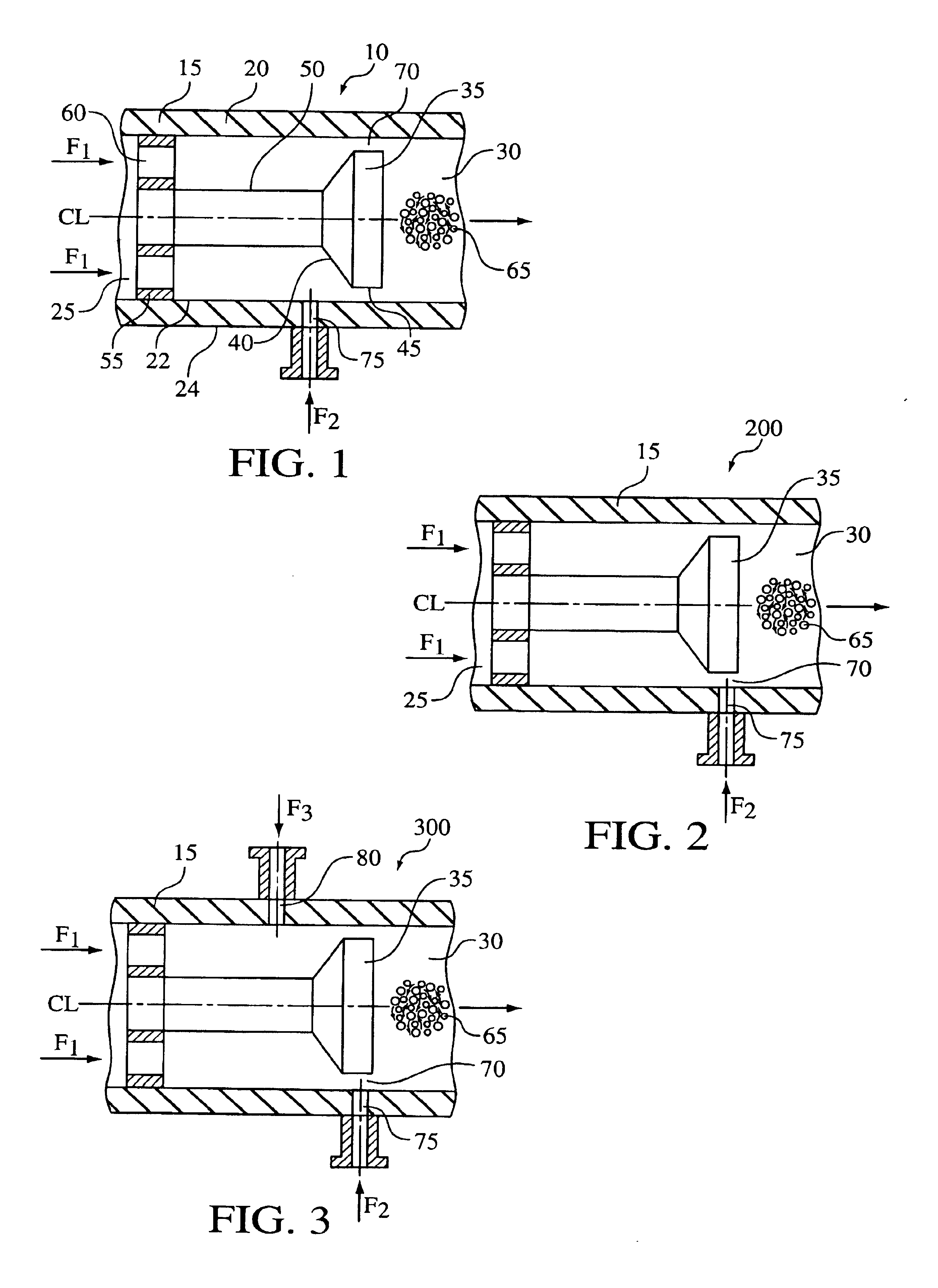

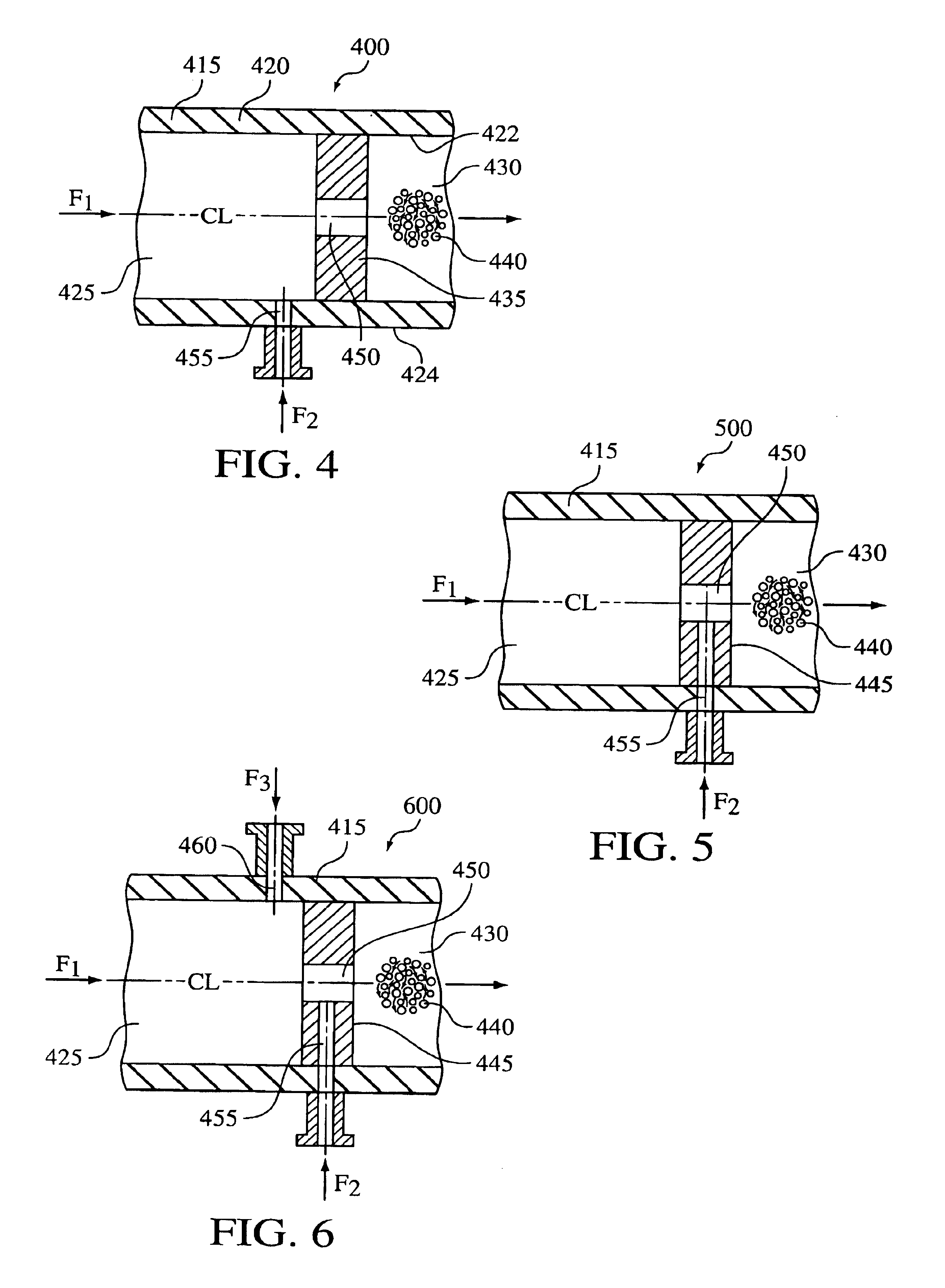

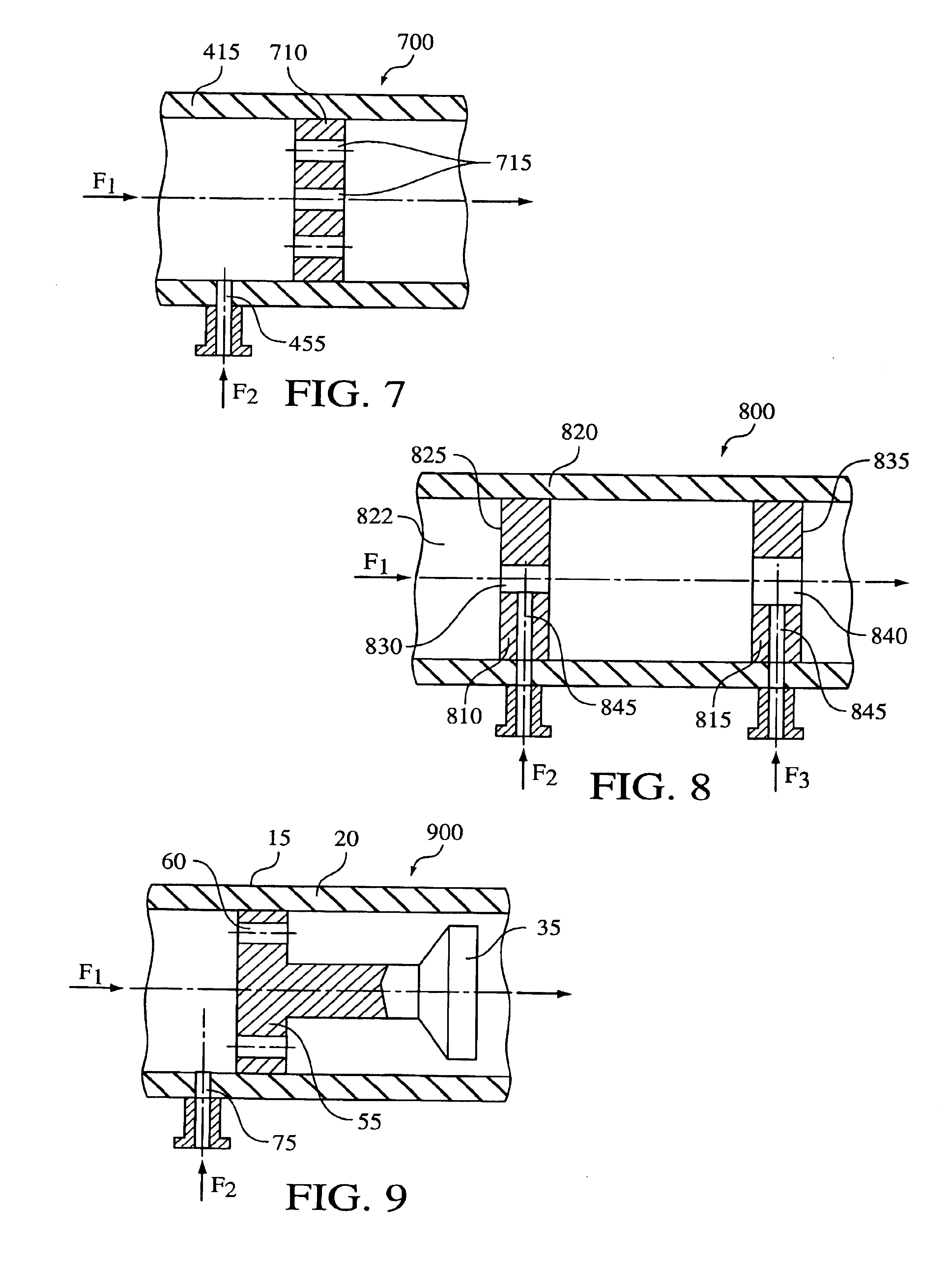

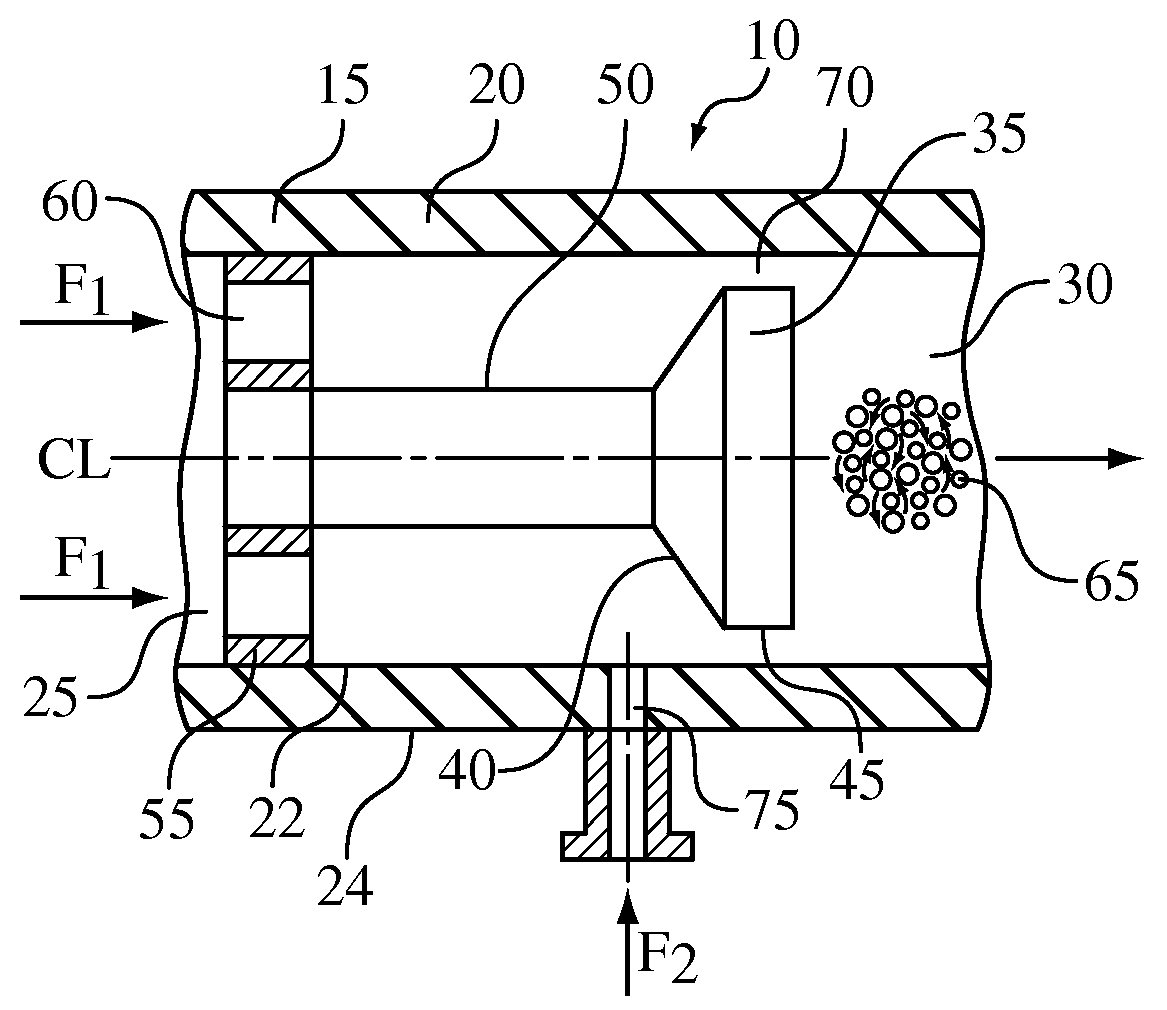

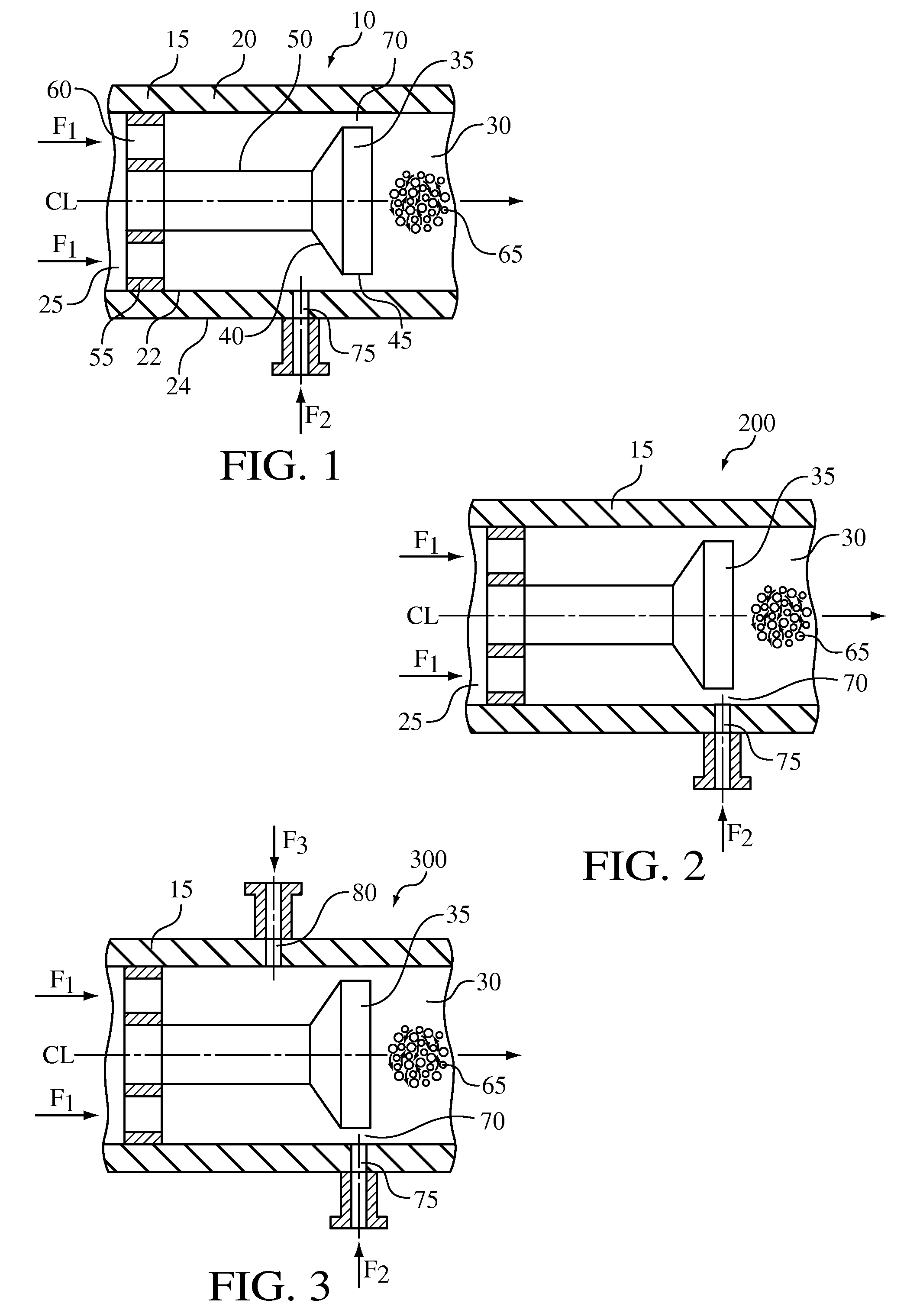

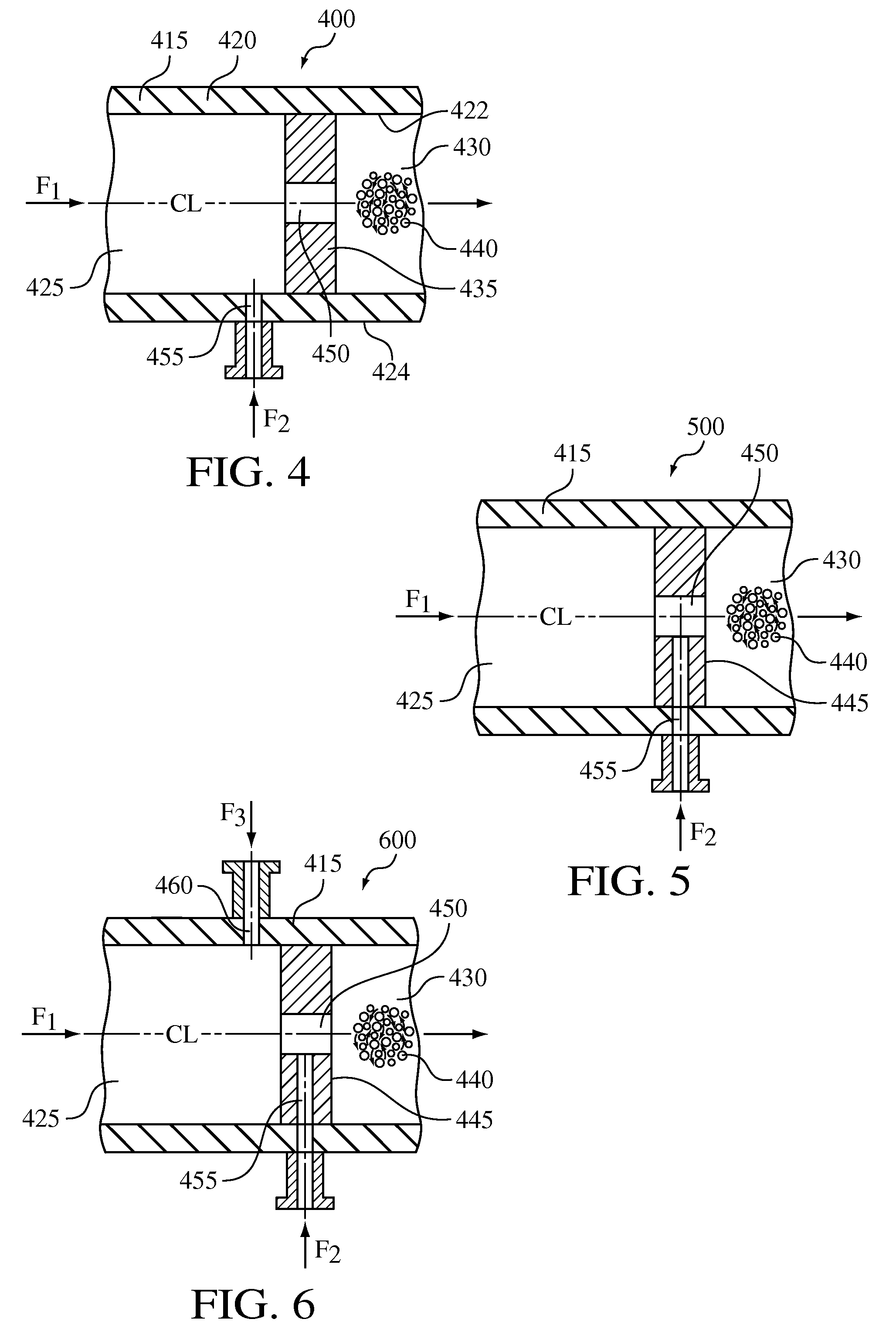

Hydrodynamic cavitation crystallization process

A device and process for crystallizing a compound using hydrodynamic cavitation comprising the steps of mixing at least one stream of a solution of such compound to be crystallized with at least one stream of an anti-solvent and passing the mixed streams at an elevated pressure through a local constriction of flow to create hydrodynamic cavitation thereby causing nucleation and the direct production of crystals.

Owner:ARISDYNE STSTEMS INC

Hydrodynamic cavitation crystallization device and process

InactiveUS20080194868A1Polycrystalline material growthFrom normal temperature solutionsAnti solventCavitation

A device and process for crystallizing a compound using hydrodynamic cavitation comprising the steps of mixing at least one stream of a solution of such compound to be crystallized with at least one stream of an anti-solvent and passing the mixed streams at an elevated pressure through a local constriction of flow to create hydrodynamic cavitation thereby causing nucleation and the direct production of crystals. The compound to be crystallized can be, for example, an active pharmaceutical ingredient.

Owner:CAVITECH HLDG

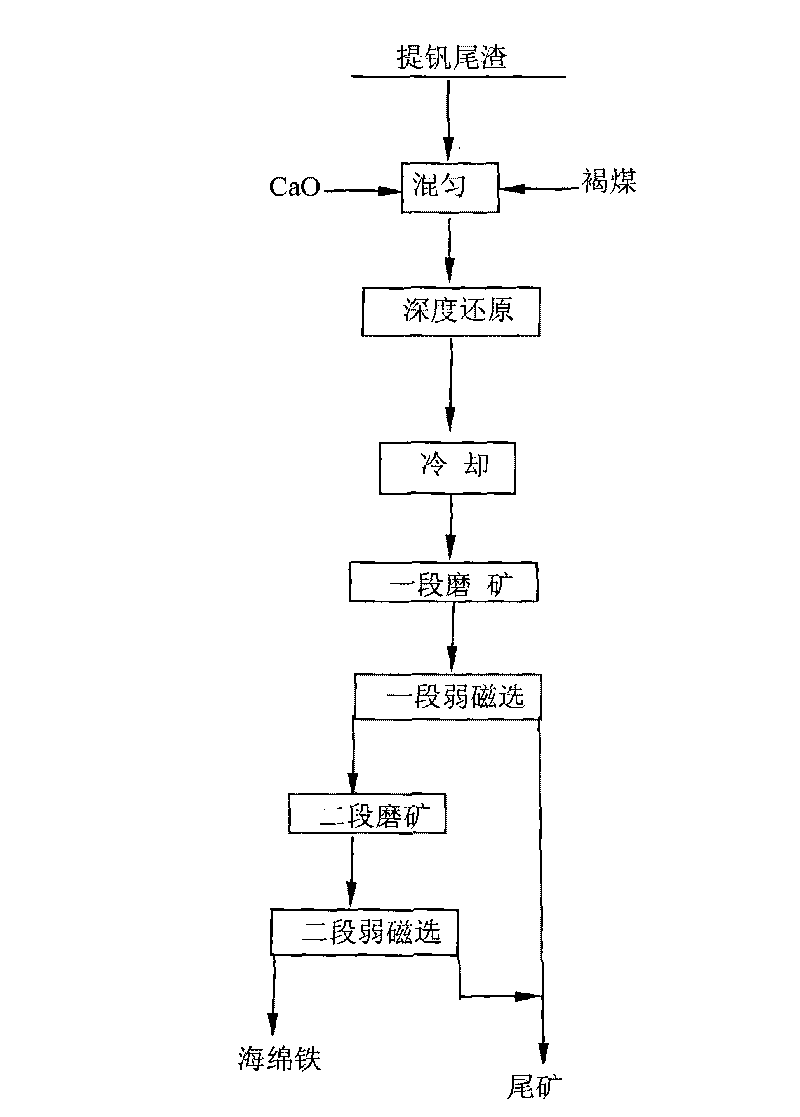

Technique method for directly producing sponge iron by carrying out deep reduction on extracted vanadium tailings

The invention relates to a technique method for directly producing sponge iron by carrying out deep reduction on extracted vanadium tailings, belonging to the field of iron making. The method adopts brown coal as the reducing agent, and simultaneously CaO is added as slag former and used for increasing alkalinity to synergize with Na2O and K2O in the tailings to react with SiO2 and Al2O3 to generate zeolite-like stable mineral so as to boost extraction and separation of sponge iron in products of deep reduction. The products of deep reduction are subject to two-section ore grinding-two-section low intensity magnetic separation technique to obtain sponge iron with iron grade larger than 90% and TiO2 smaller than 0.20%. The invention is simple in technique and easy to control, and has large reserves of raw materials and low price; the product can be used as raw material for steel making; other impurities meet steel making requirements, the technique flow of processing iron ore into rolled steel is shortened, the environment pollution caused by sintering, pelletizing and blast furnace iron making of iron ore concentrate obtained by other methods can be avoided, and the invention has obvious environment benefit and energy conservation and consumption reduction effects.

Owner:UNIV OF SCI & TECH BEIJING

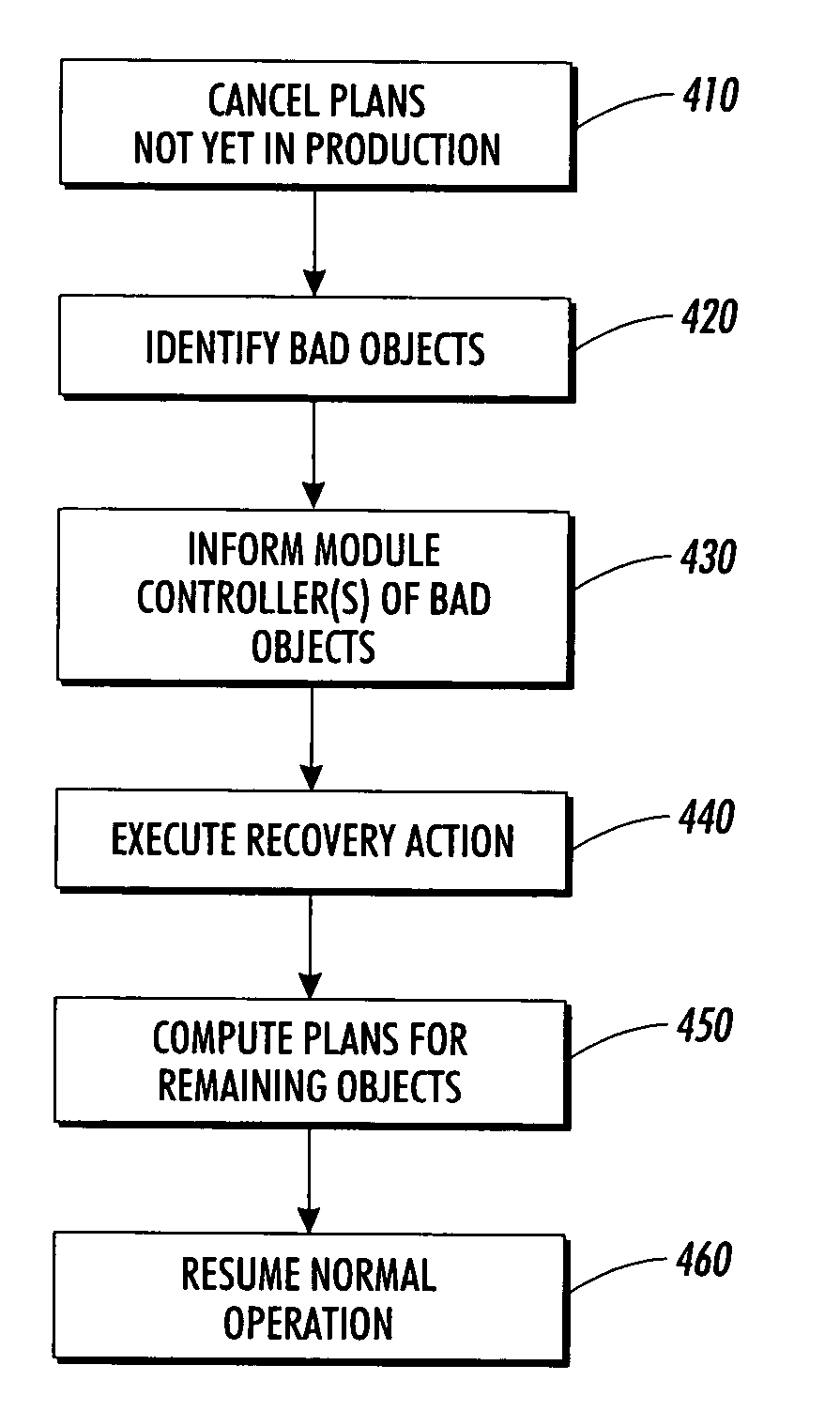

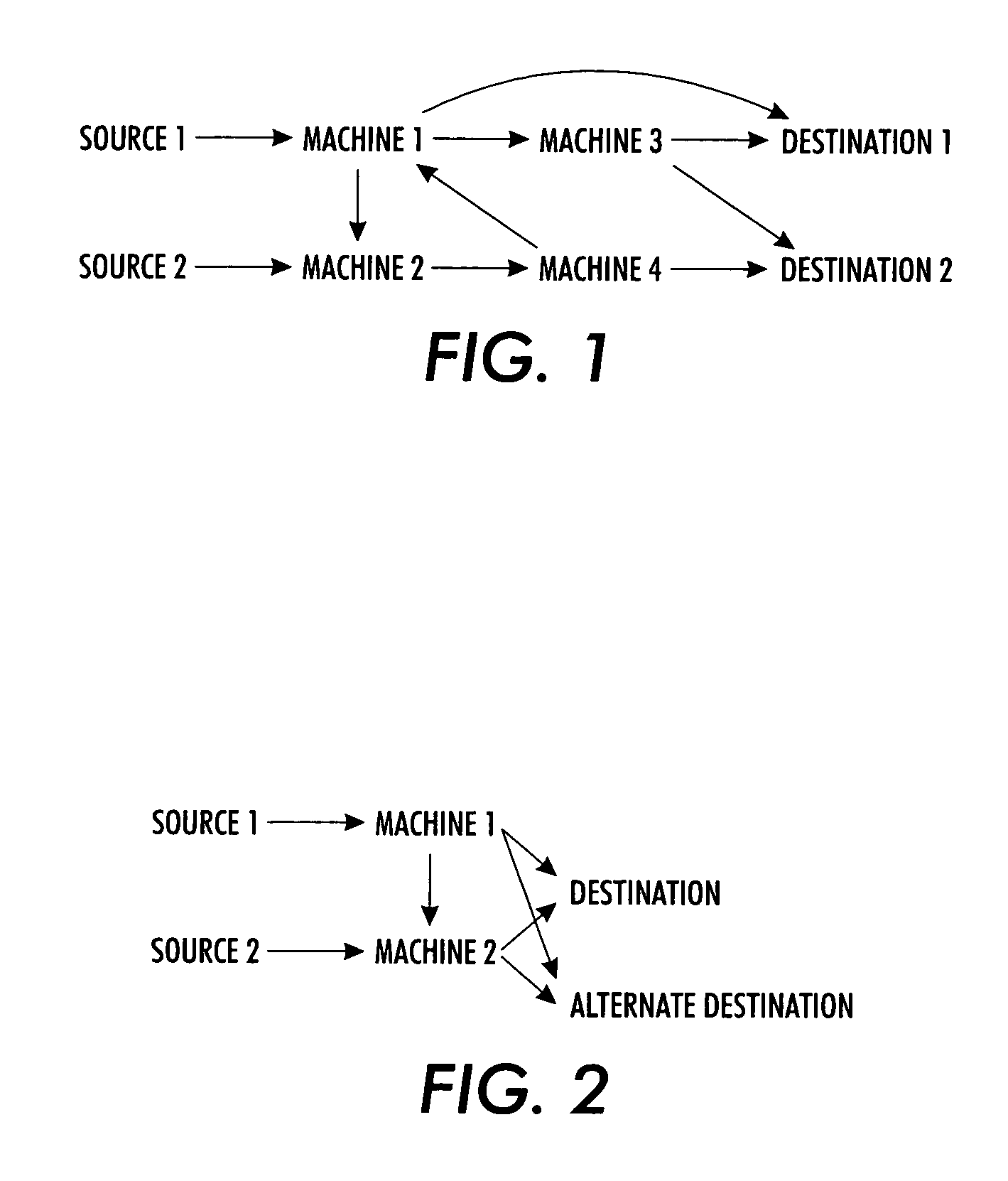

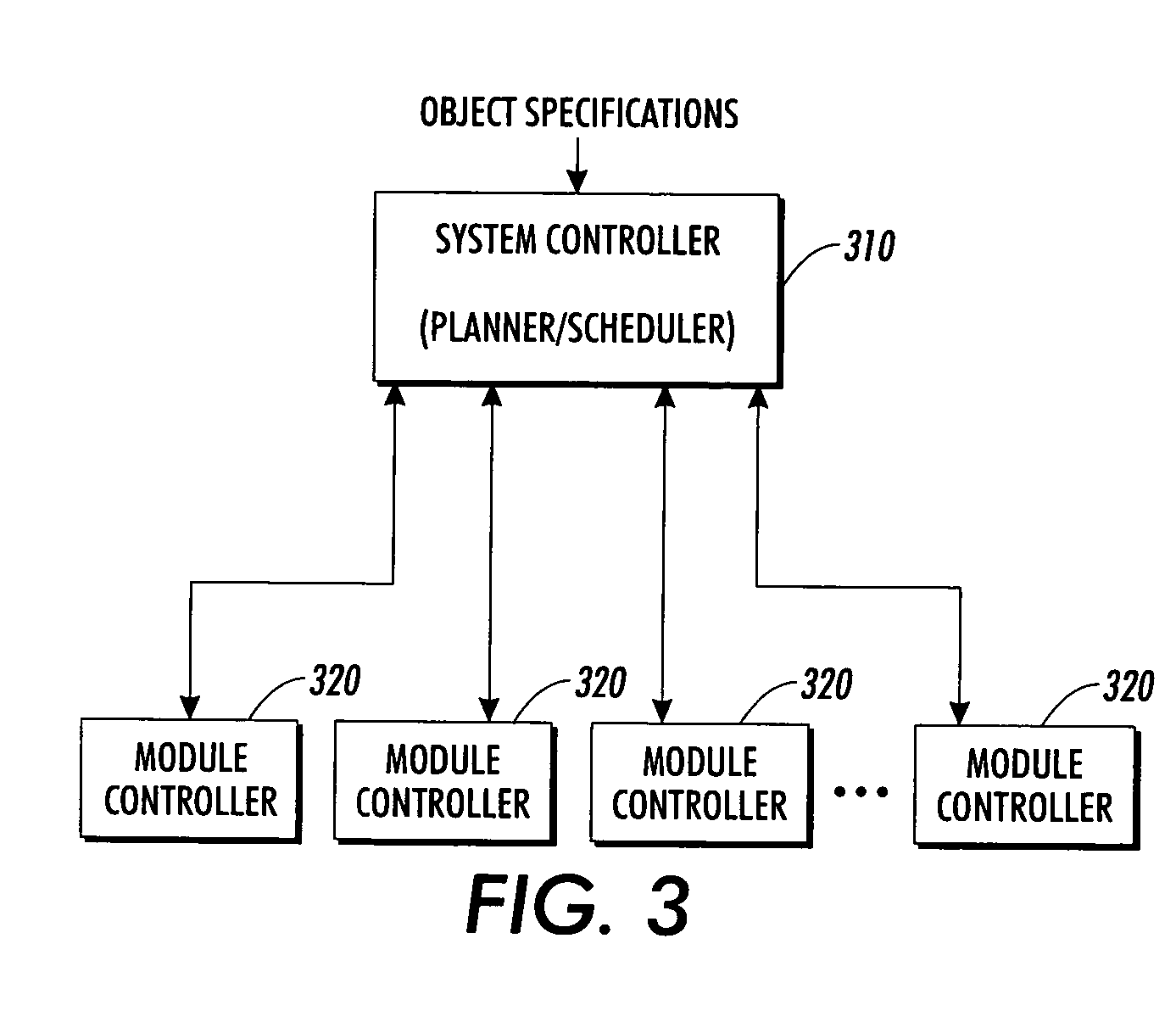

Exception handling in manufacturing systems combining on-line planning and predetermined rules

A method for performing exception handling operates within a computer controlled multi-step production system for producing objects. The system includes a system controller, within which reside a planner / scheduler and module controller(s). The system controller receives a stream of object specifications for objects to be produced including the jobs to which they belong. The planner / scheduler plans and schedules the jobs incrementally, and the system controller sends commands to the module controller(s) directing production of the planned and scheduled objects by production system modules. The method includes receiving notice in the system controller of a problem situation present within the multi-step production system and halting planning for the production of subsequent objects. Plans are canceled plans for all objects that have not begun production, and all objects affected by the problem situation are marked as bad objects. The system controller planned exception handling / recovery or module controller directed exception handling / recovery is applied and normal operation is resumed.

Owner:XEROX CORP

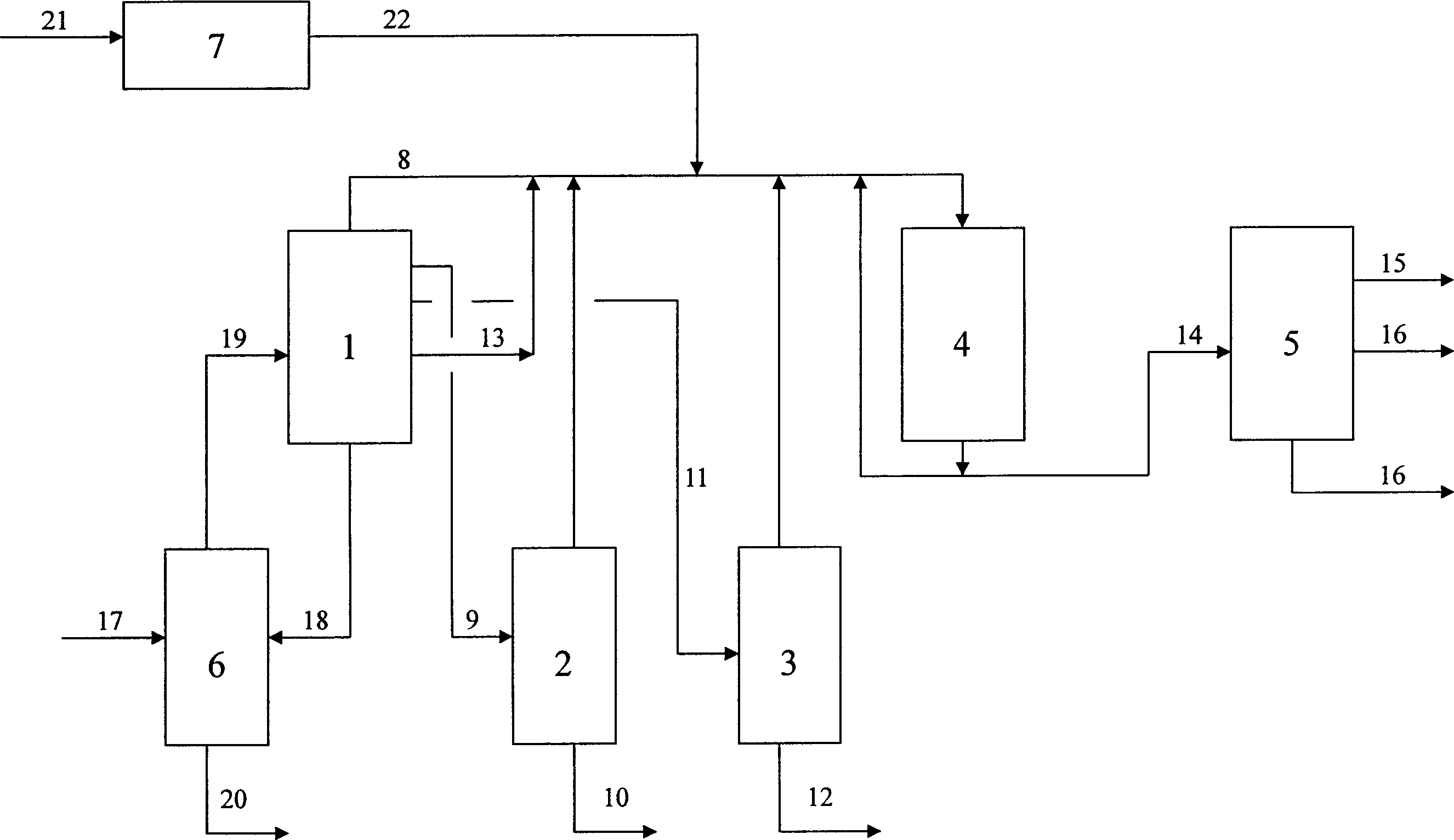

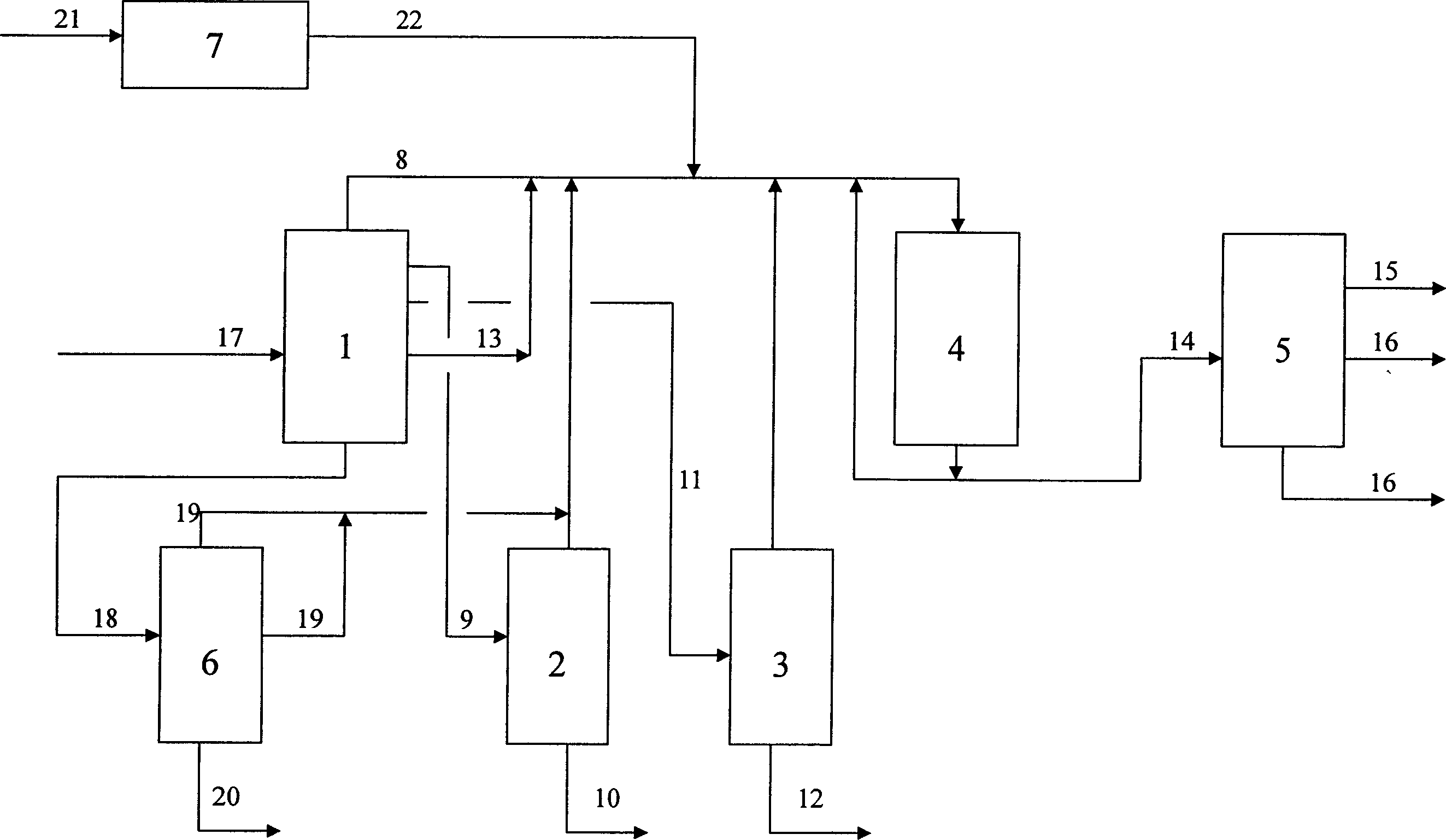

Process for producing chemical industry products and fuel oil from coal tar

InactiveCN1597866ATreatment with hydrotreatment processesTar working-up by distillationChemical industryLighter fuel

The invention is a method of producing chemical products and fuel oil by coal tar, relating to a method of producing chemical products and fuel oil by coal car, including vehicle fuel oil. And its characteristic: separating the coal tar into light and heavy fractions, where the light fraction includes light coal tar and tar pitch. The light fraction is used to produce light products by hydrofining or modifying. The processing of the tar pitch combines with coke furnace or delay coking, thus not only producing more chemical products such as phenol, naphthalene and gasoline, diesel oil / light fuel, etc, but also improving the coke quality of the coke furnace or directly producing low-ash content coke. Simultaneously, it adds an inhibitor to inhibit or slow down the coking in the furnace pipe or reactor, thus assuring long-term operation of the device.

Owner:山西东辉能源集团有限公司 +11

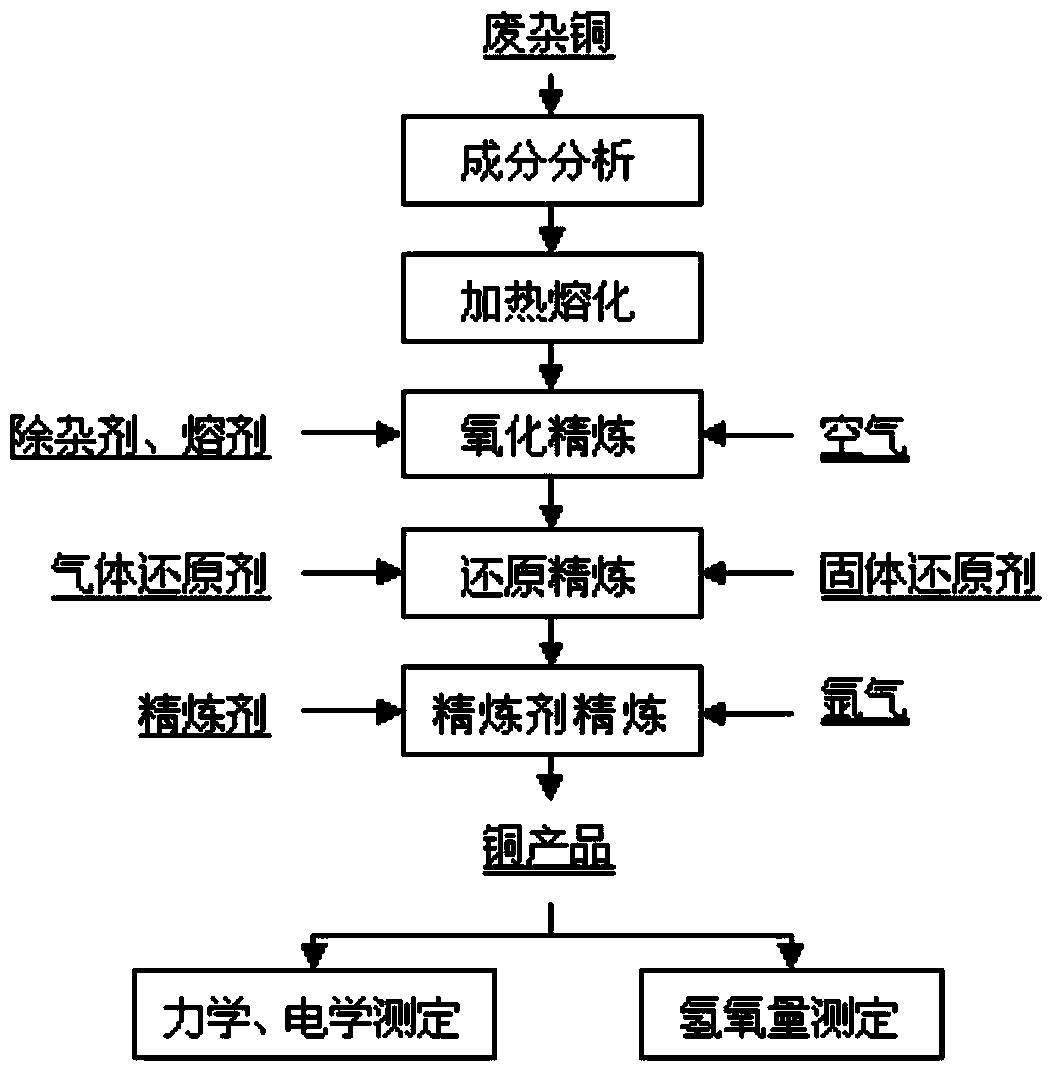

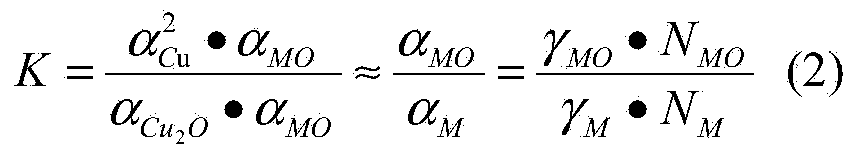

Method for directly producing high-purity oxygen-free copper by pyrogenic process continuous refining of scrap copper

ActiveCN103725897AOptimizing Process ParametersReduce manufacturing costProcess efficiency improvementElectrolysisCopper wire

The invention relates to a method for directly producing high-purity oxygen-free copper by pyrogenic process continuous refining of scrap copper, and belongs to the technical field of non-ferrous metallurgy. The method comprises the following steps: by taking scrap copper as a raw material; analyzing the component characteristics of each batch of raw material, and then preparing into a mixture, wherein the mass percent of a copper element in the mixture is greater than or equal to 93%; adding metaphosphate or phosphorus pentoxide and flux to the mixture; refining by oxidation; stewing and drossing after oxidation is finished, and then orderly carrying out reduction refining and refining agent refining under an agitation state, so as to obtain the high-purity oxygen-free copper of which the copper content is greater than or equal to 99.95% and the oxygen content is smaller than 0.003%, wherein the electrical resistivity of the obtained copper wire after drawing is below 0.017241omega / (mm), and the relative electrical conductivity is over 100% of International annealed copper standard (IACS). The method is strong in flexibility, significant in refining effect, and applicable to different components of scrap copper materials; the scrap copper can be used for directly making a rod after being refined. Compared with the traditional pyrogenic process smelting-electrolytic refining-copper cathode purification process, the method disclosed by the invention has the beneficial effects that the flow is shortened, the cost is reduced, the energy is saved, and continuous operation is achieved.

Owner:CENT SOUTH UNIV

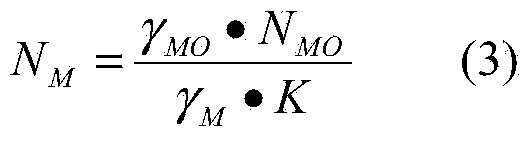

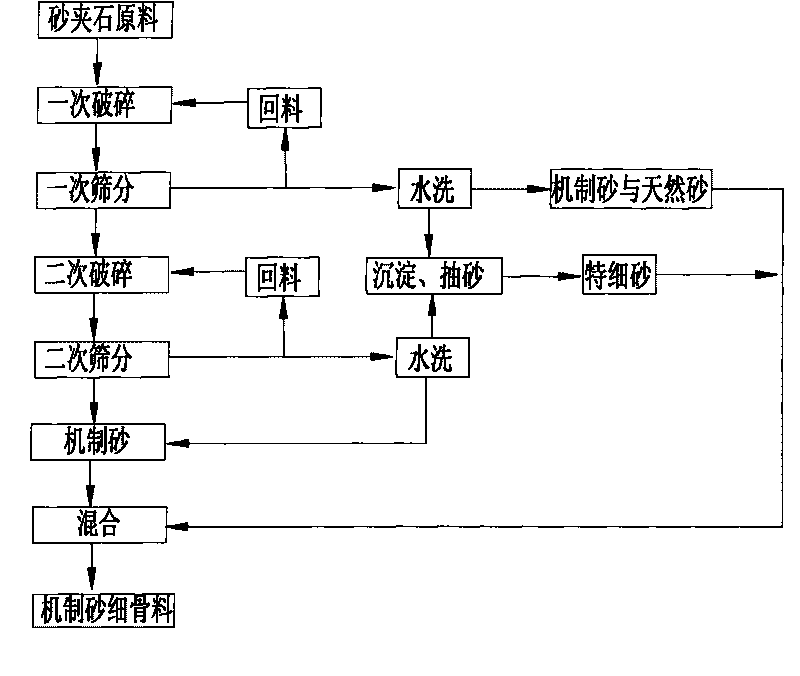

Preparation method of machine-made sand fine aggregate

ActiveCN101708968AMeet pumping requirementsEasy constructionGrain treatmentsFineness modulusDirect production

The invention discloses a preparation method of fine aggregate in concrete, specially relating to a preparation method of machine-made sand fine aggregate. The method adopts sand preparing technology; when preparing machine-made sand fine aggregate, the machine-made sand is combined with special fine sand with smallest grain diameter to produce the machine-made sand fine aggregate with certain fineness modulus. The method overcomes the deficiency that in traditional technology, the fineness modulus of the machine-made sand fine aggregate can not be accurately regulated and controlled, and the method of the invention can directly produce the machine-made sand fine aggregate satisfying premixed concrete pumping as well as construction and easy performance requirements.

Owner:CHONGQING NO 3 CONSTR

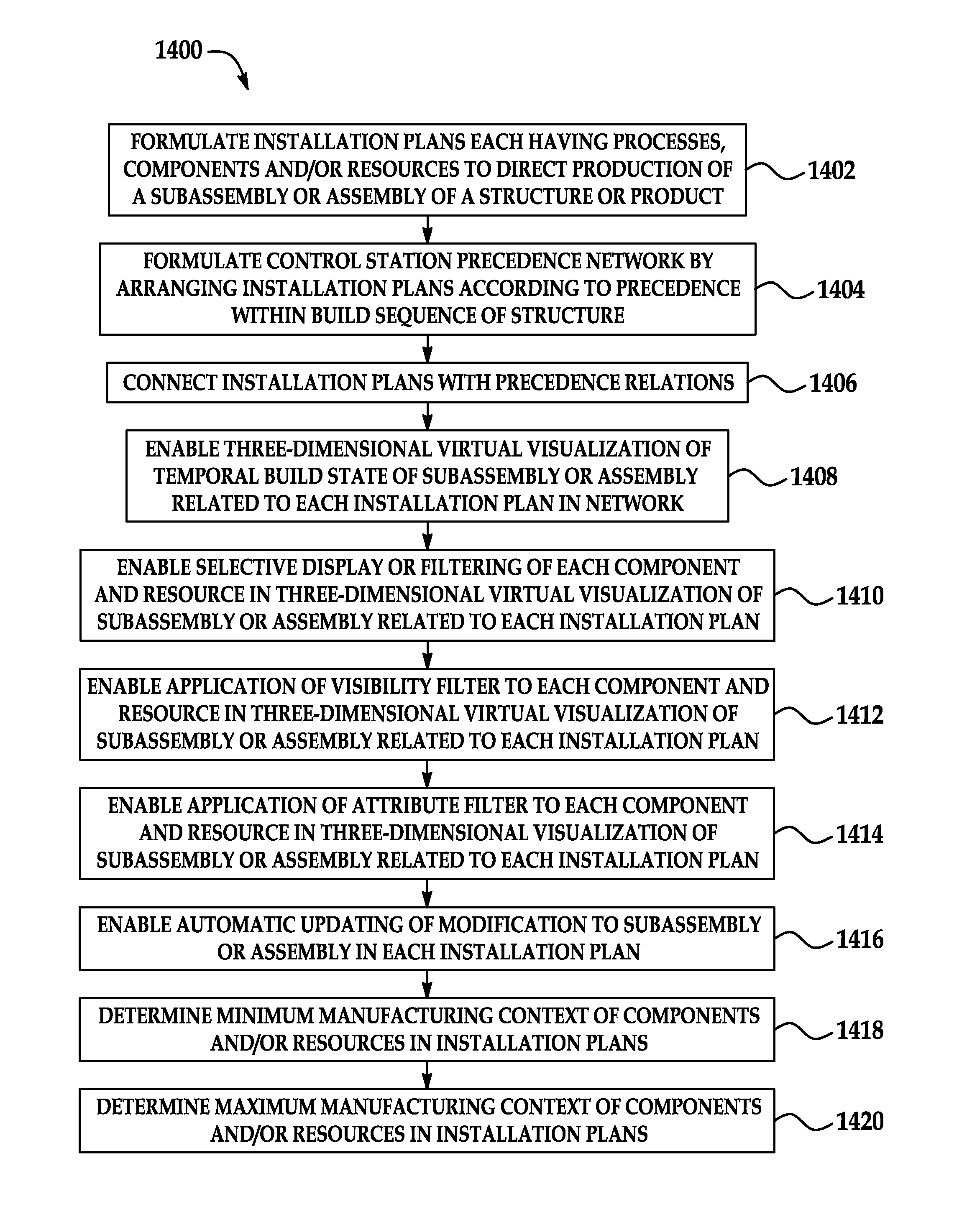

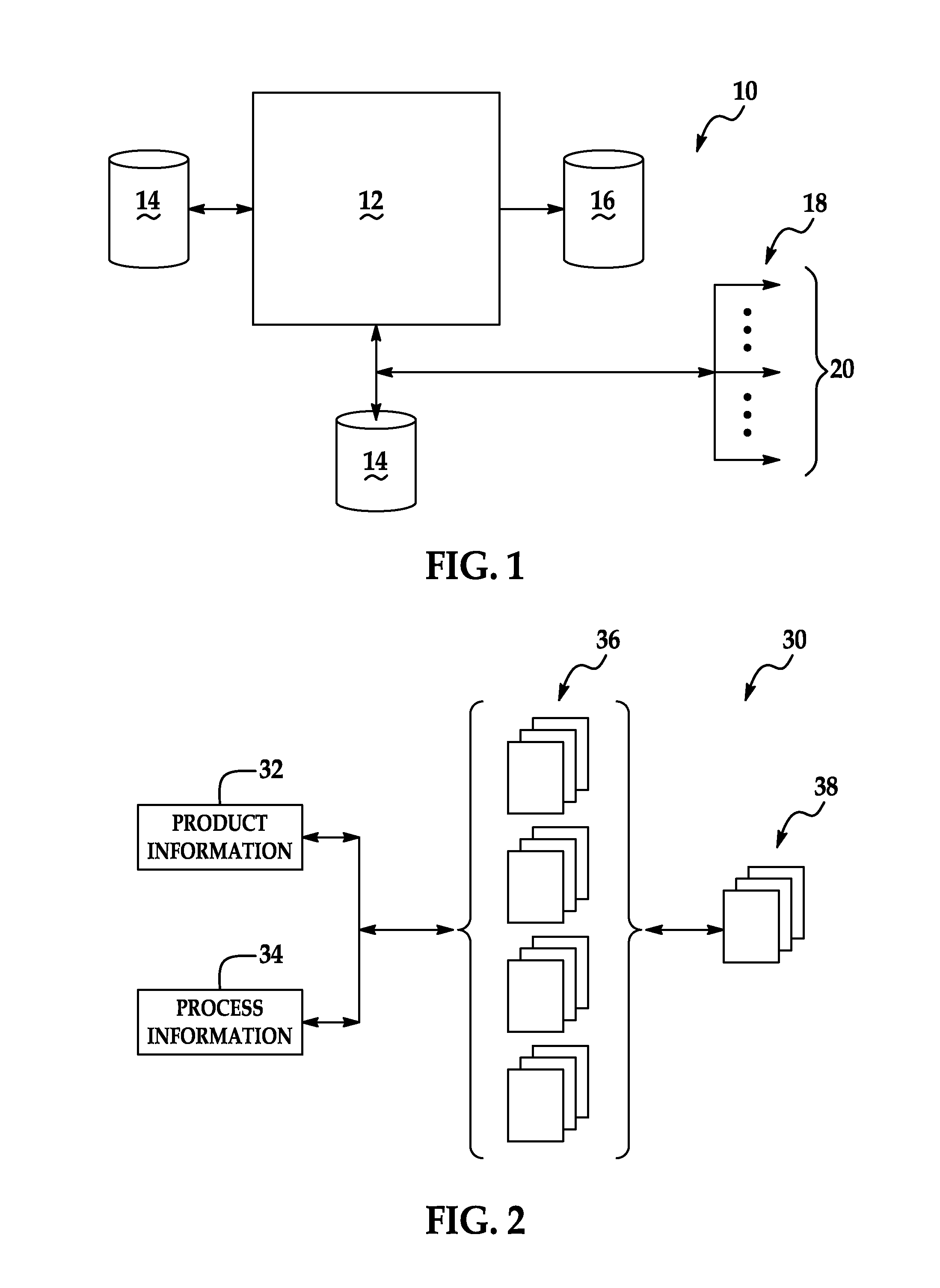

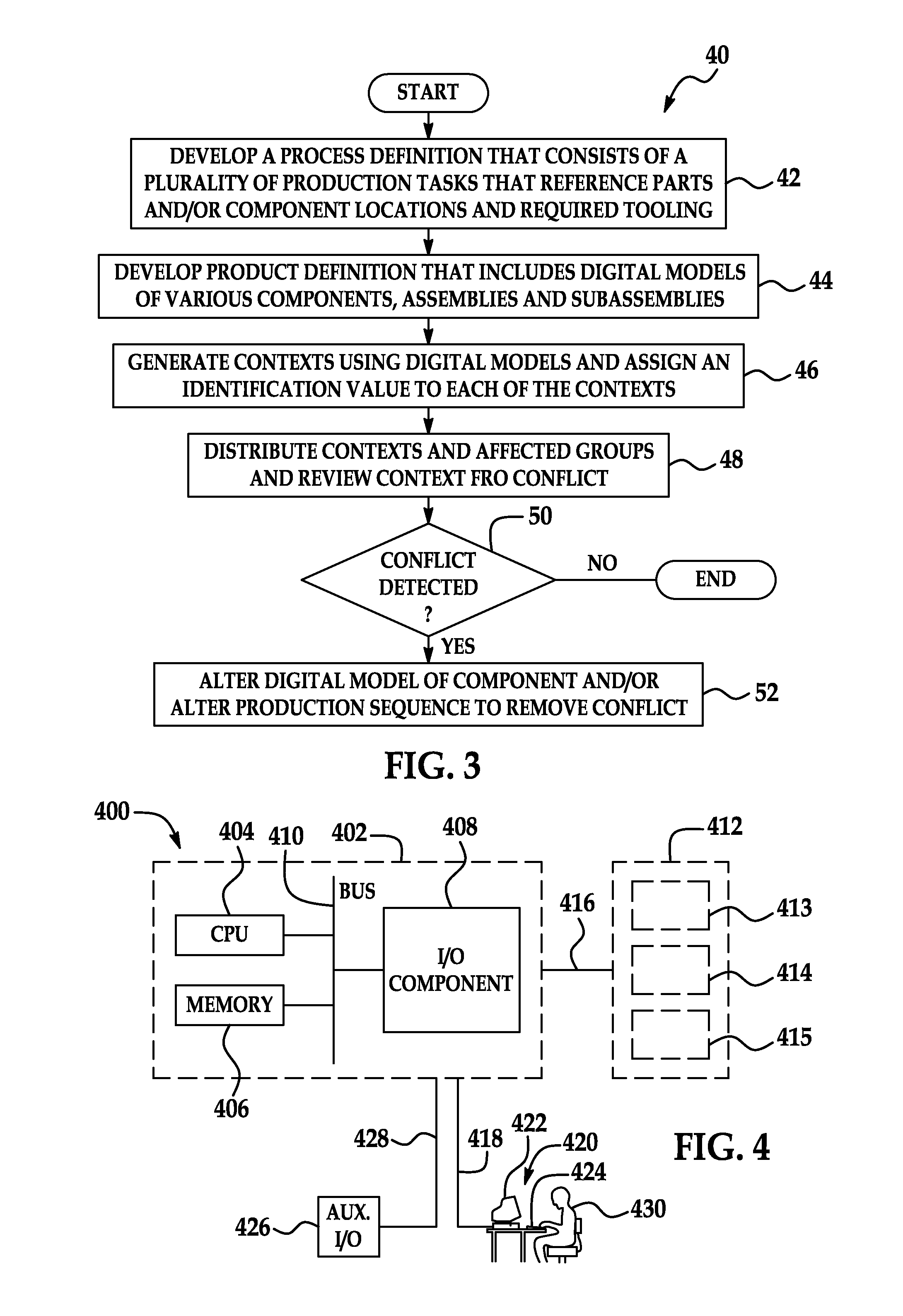

Visualization of product build using precedence transversal method

A method for visualization of product build which includes compilation of a virtual temporal configuration of an in-process assembly and visualization of the results using three-dimensional representations of the affected products and associated resources. An illustrative embodiment of the method includes formulating a plurality of installation plans each adapted to direct production of a portion of a product within a build sequence of the product and enabling three-dimensional virtual visualization of a temporal build state of the portion of a product for each of the installation plans.

Owner:THE BOEING CO

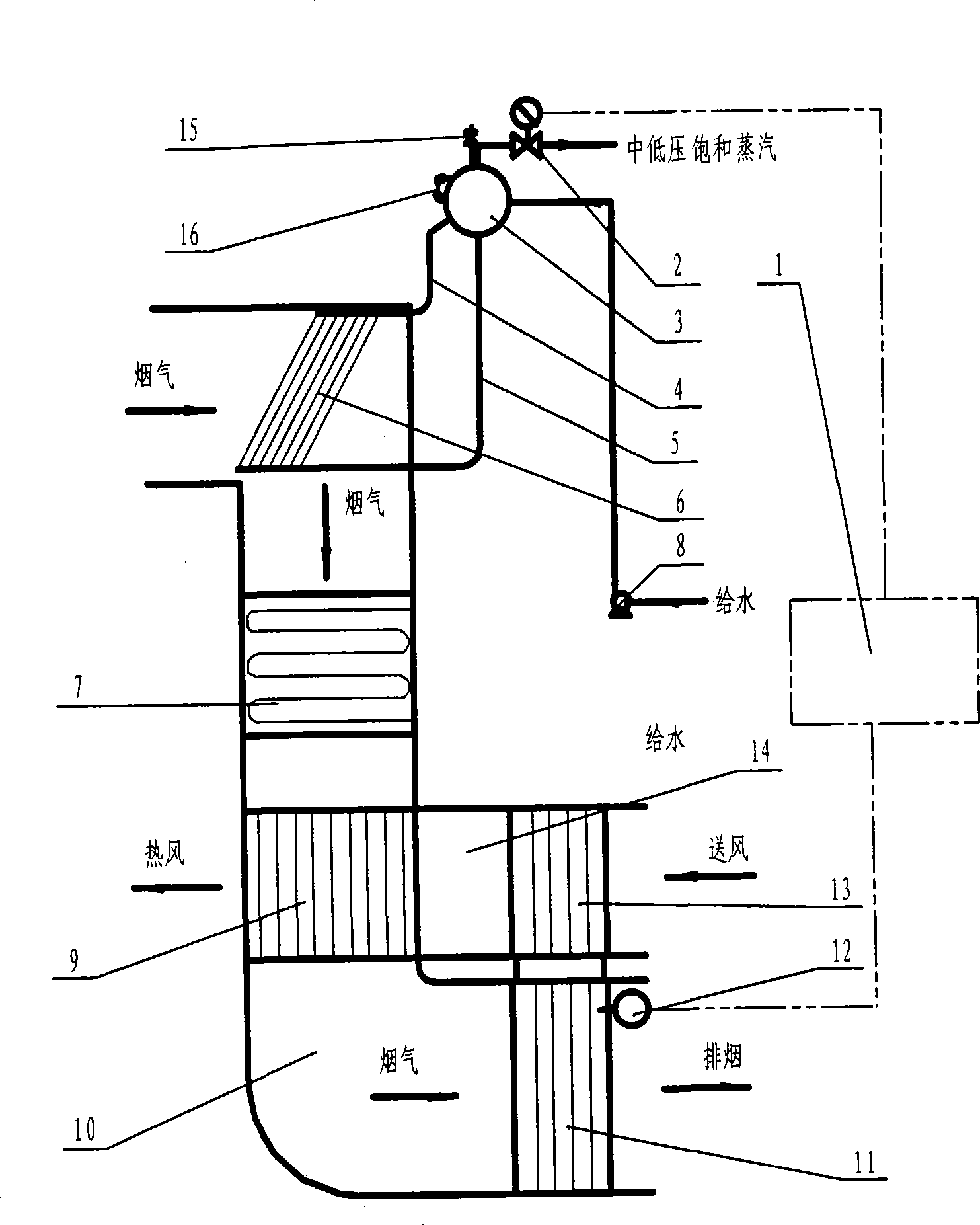

Composite phase change heat exchanger with medium and low pressure

InactiveCN101398265AAvoid condensationIndirect heat exchangersHeat exchange apparatusAir preheaterAutomatic control

The invention discloses a composite phase change heat exchanger with a medium-pressure and low-pressure evaporator, which comprises the medium-pressure and low-pressure evaporator and a steam header which are communicated by an ascending pipe and a descending pipe, a water feeding pipe and a steam outputting pipe are arranged on the steam header, an upper section of the composite phase change heat exchanger is positioned in a wind channel of an original air preheater, and a lower section of the composite phase change heat exchanger is positioned in a back flue channel of the air preheater; an automatic control device of the composite phase change heat exchanger adjusts and controls the heat exchange volume of the evaporator and the wall temperature of the lower section of the composite phase change heat exchanger. The composite phase change heat exchanger not only directly produces low-pressure or medium-pressure steam by using the recycled heat through a steam generating device and provides heat usage as a heat supply, but also controls the thermal equilibrium among the heat exchange volumes of the flue gas, the medium-pressure and low-pressure evaporator, a coal economizer and the wall of the air preheater by adjusting the steam flow of the steam outputting pipe of the steam header through the automatic control device, and consequently leads the flue gas temperature at the outlet to be higher than a flue gas acid dew point on the lower section wall surface of the composite phase change heat exchanger, avoids moisture condensation and achieves the purpose of utilizing waste heat of the flue gas to the utmost degree.

Owner:杨本洛 +1

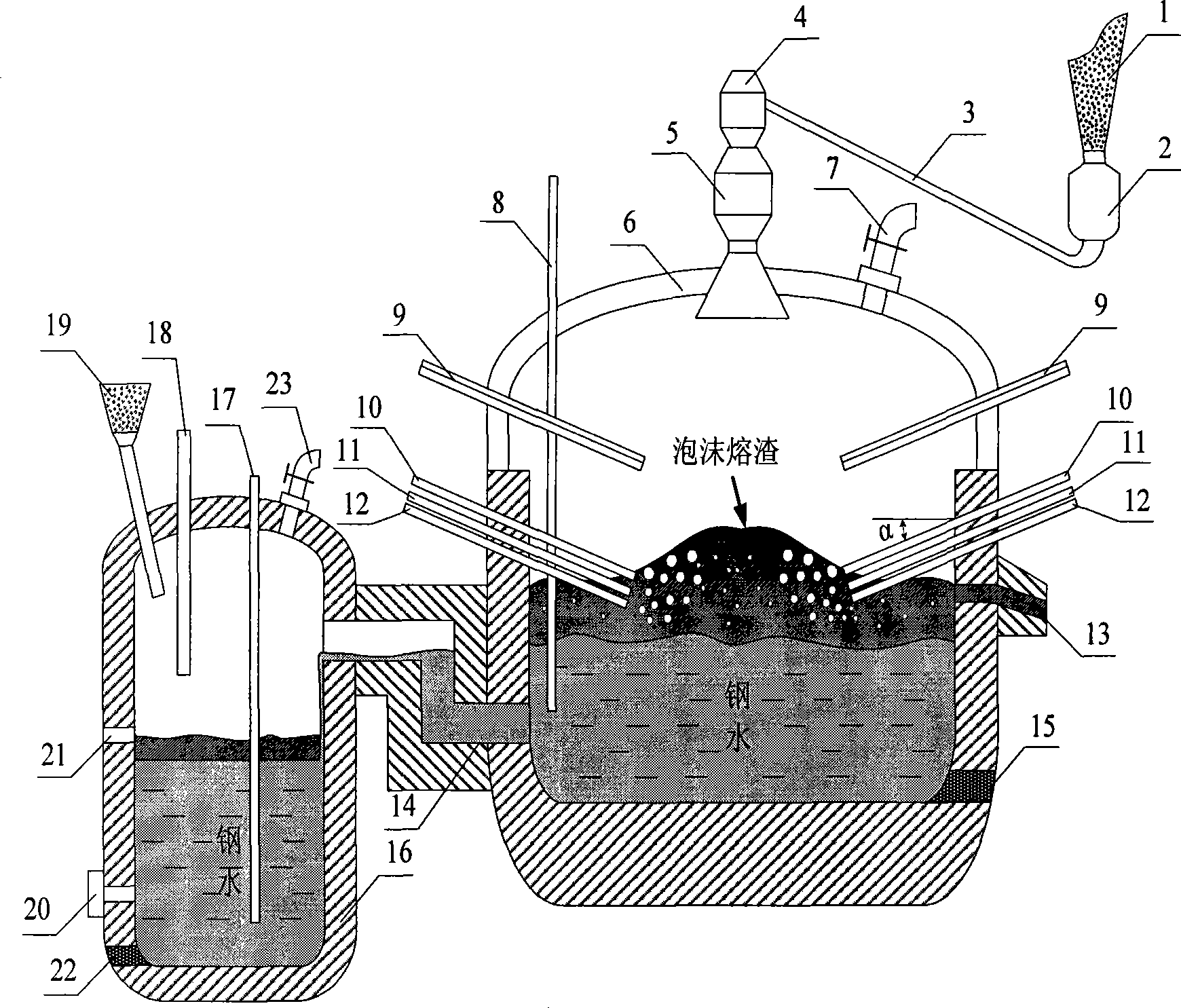

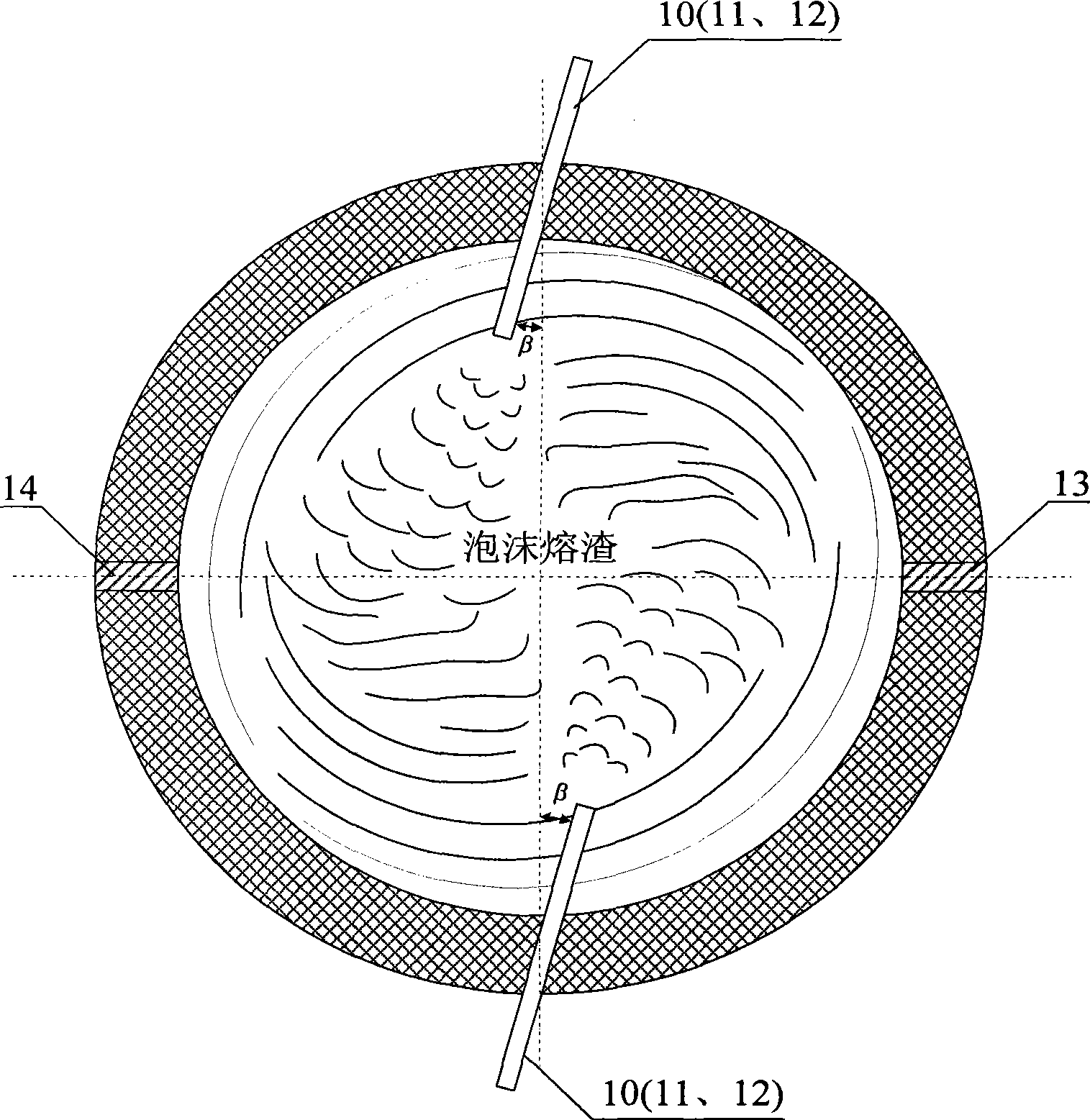

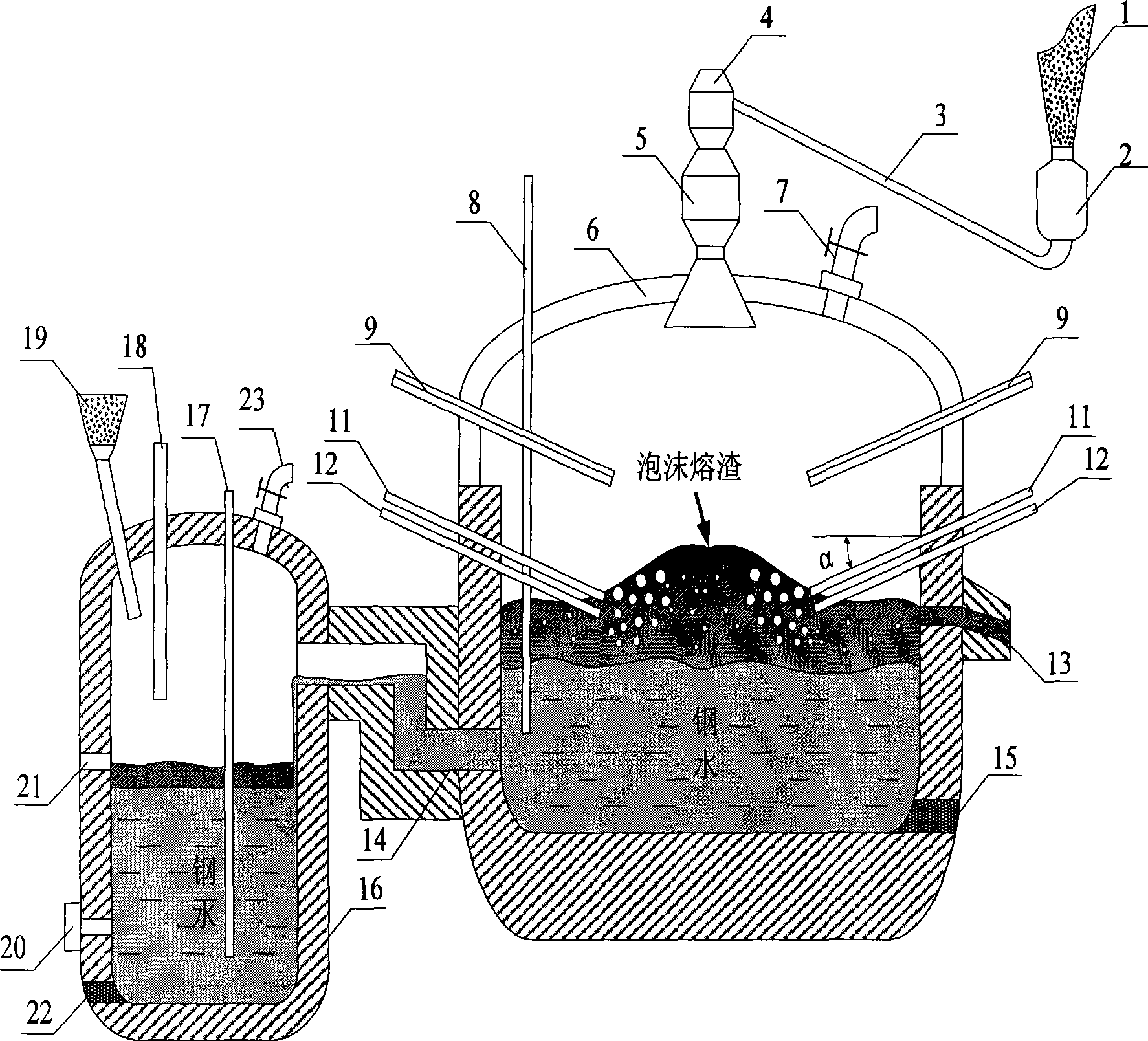

Process and device for continuous steelmaking from ferriferous material

ActiveCN101445848AReduce carbon contentIncrease temperatureFurnace typesProcess efficiency improvementSteelmakingMelting tank

The invention relates to a process for continuous steelmaking from a ferriferous material. A molten pool is formed in a steel-smelting furnace at first, and carbonic material and oxygen are insufflated to form foaming slag; the ferriferous material and a fluxing agent are added into the smelting furnace to be molten and reduced, oxygen is insufflated into the molten steel so as to reduce the carbon content in the molten steel, the temperature of the molten steel is risen, and the molten steel is stirred with the generated CO gas; high temperature oxygen or oxygen-enriched air is insufflated and burns with CO gas generated in the smelting furnace; and the molten steel continuously flows into an oxygen blowing furnace through a siphon nozzle, and a small quantity of the fluxing agent is added into the oxygen blowing furnace so that slag formation, desulfurization and dephosphorization are performed, the C content and the temperature in the molten steel are further adjusted through blowing oxygen by an insertion oxygen lance, therefore, the obtained molten steel is directly supplied for an LF refining furnace or an RH refining furnace. The invention has the advantages that the productivity equipment including a suspended pre-reduction furnace, the smelting furnace and the oxygen blowing furnace, the investment for devices and capital construction is saved, the land is saved, the physical distribution is simplified, and the continuous production and the automatic control are facilitated.

Owner:LAIWU IRON & STEEL GRP

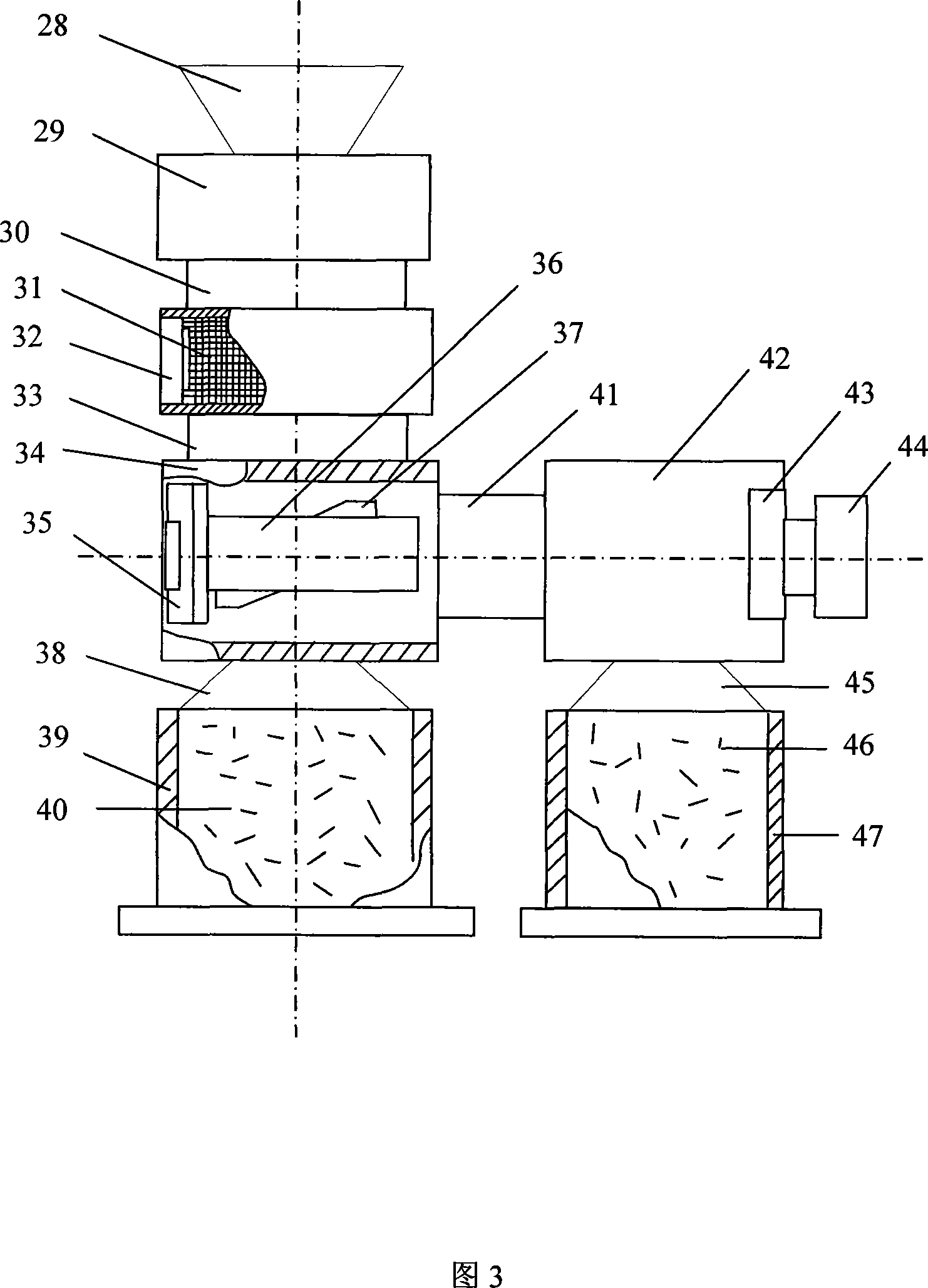

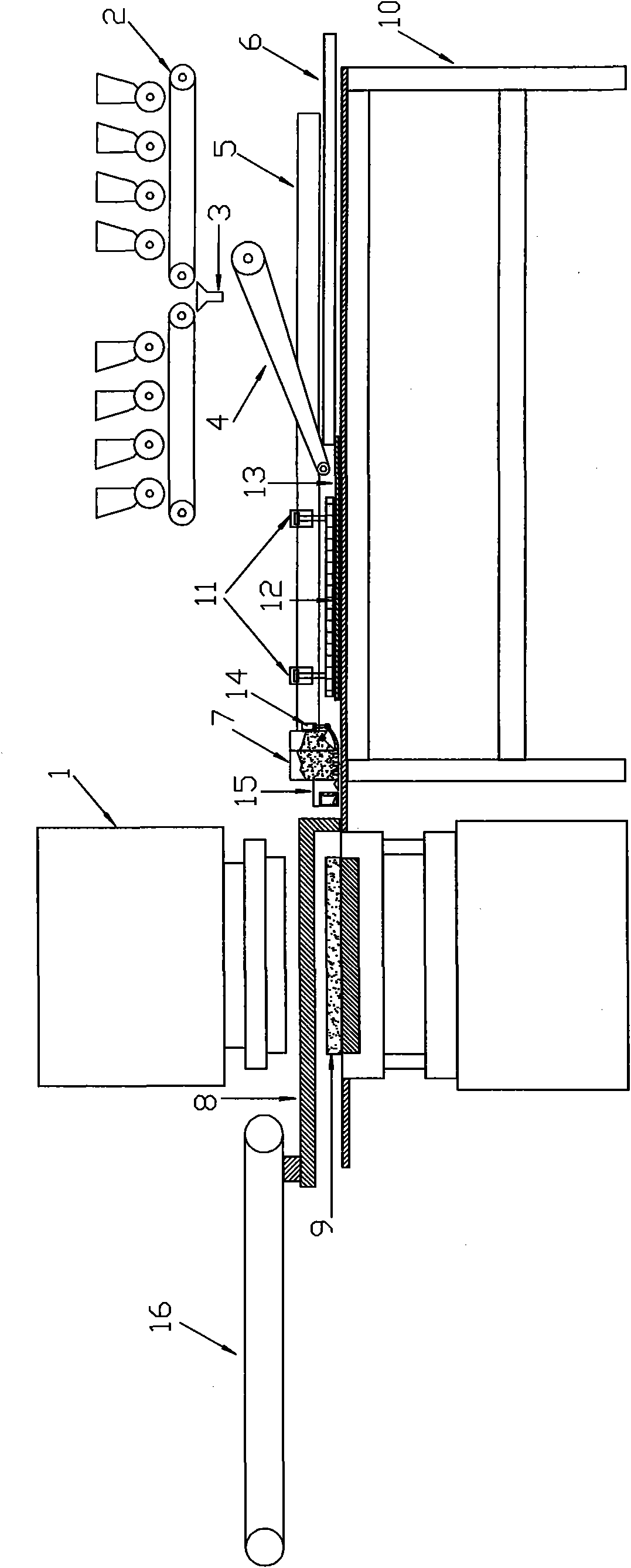

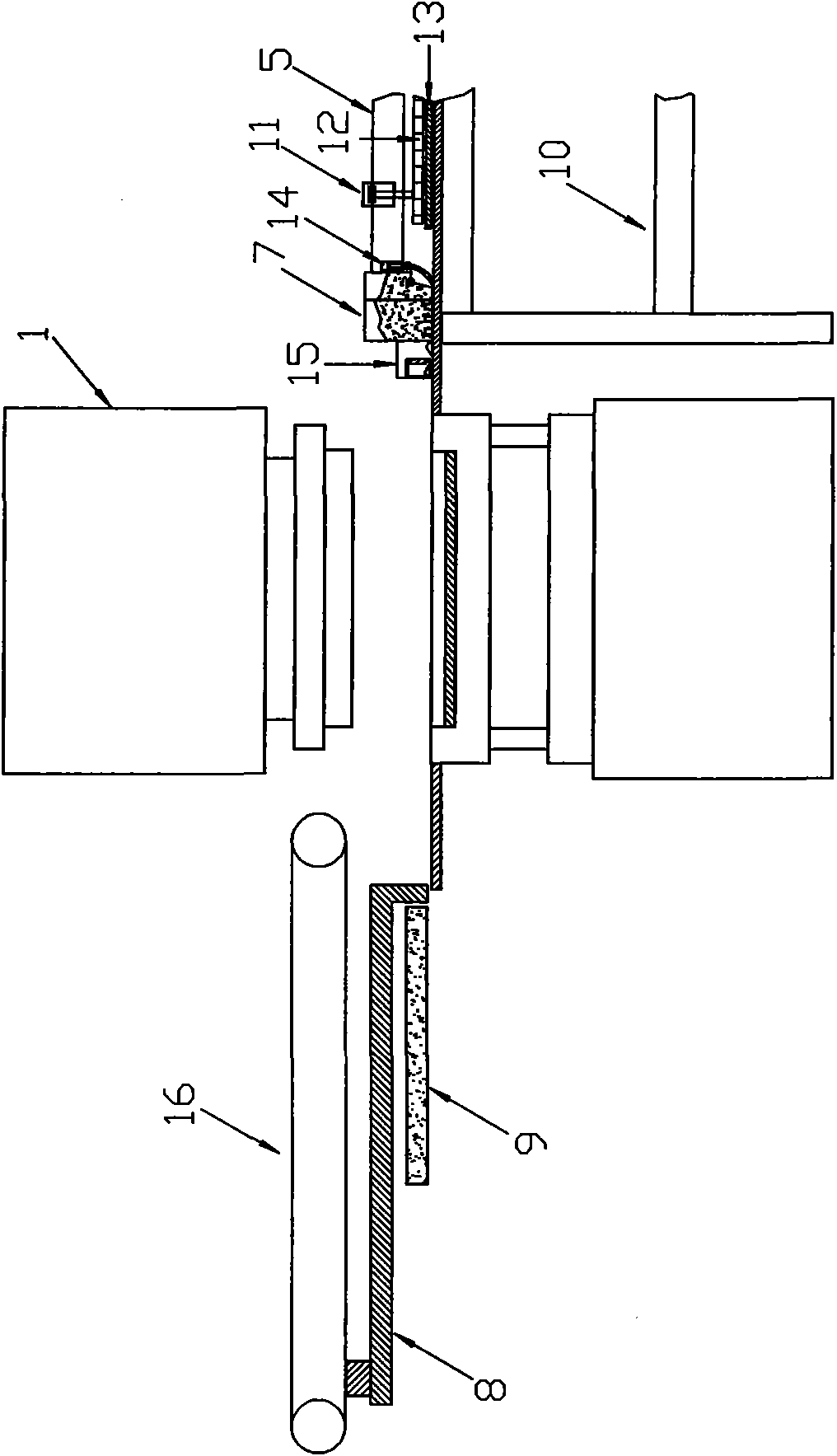

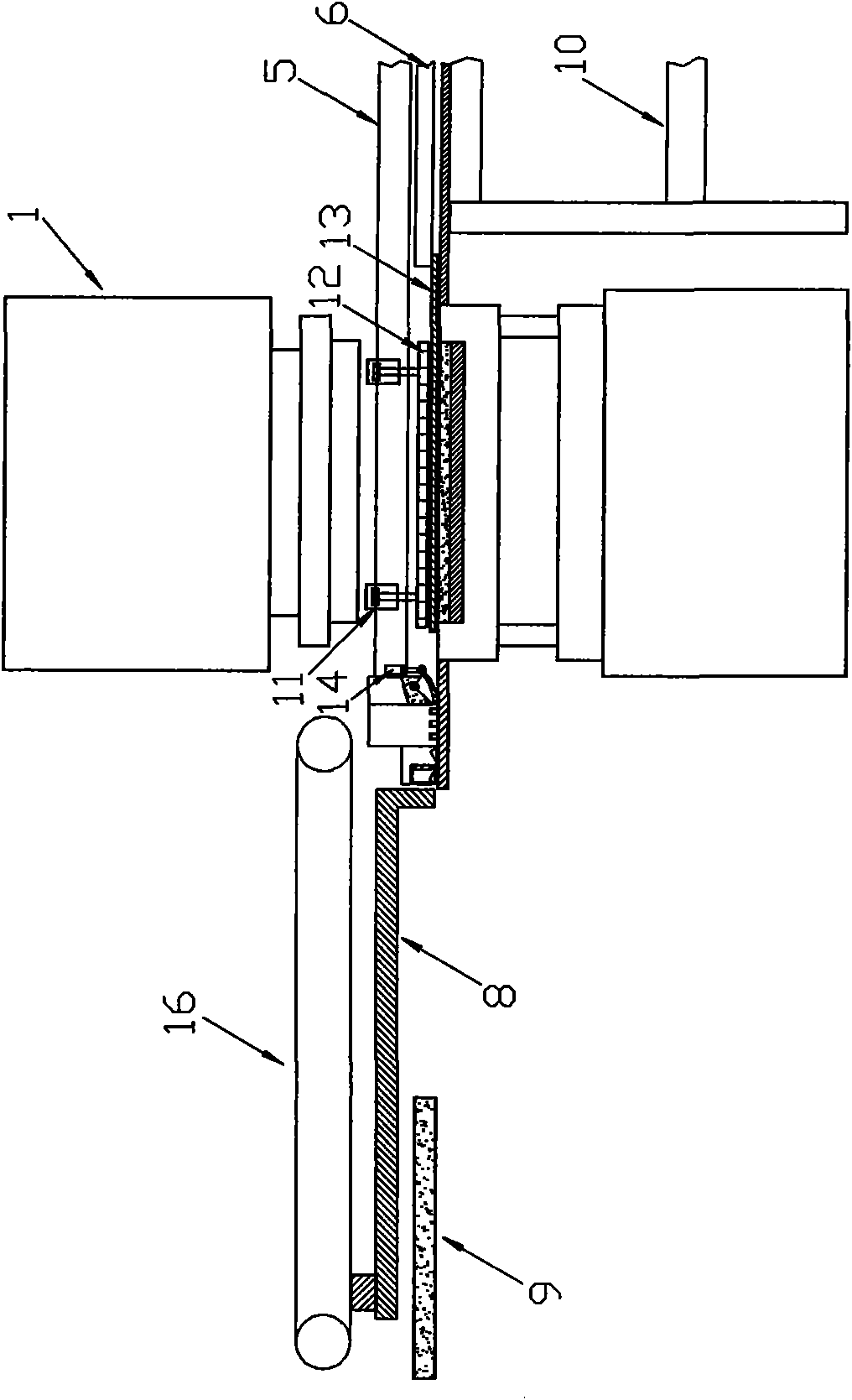

Method for selective laser sintering for quick and direct production of injection die

InactiveCN1970202AImprove sinterabilityHigh strengthIncreasing energy efficiencyTotal factory controlEpoxySelective laser sintering

A selective laser sintering quick manufacturing of the mold comprises CAD three dimension model design, storing STL files after treatment by the section software, sending the STL data to SLS quick forming machine. Spreading a composite powder of polyamide and copper on the power bed of selective laser sintering machine, with copper powder grain side 200--400, their weight ratio ranging 2:1-7:1, scanning and sintering in the selected zone of the laser harness, laser speckle 10-250 mum, scanning distance 0.04-0.1mm, scanning speed 1000- 3000mm / s, single layer thickness 70-150 mum, repeating till the formation of the complete mold inlaid, coating the surface with epoxide resin or acrylic acid series solidification system, polishing the surface thereafter. It is simple in process, short in processing period, low in cost, suitable for small volume plastic parts pilot run, testing and production.

Owner:HUAZHONG UNIV OF SCI & TECH

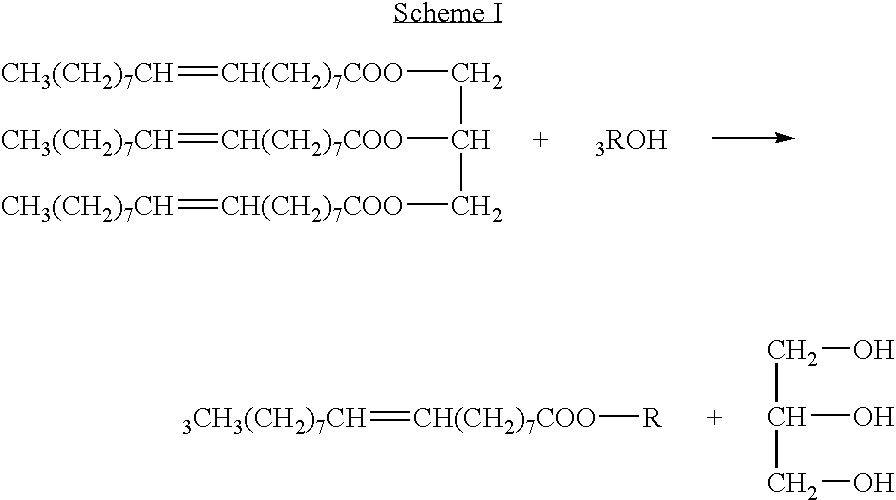

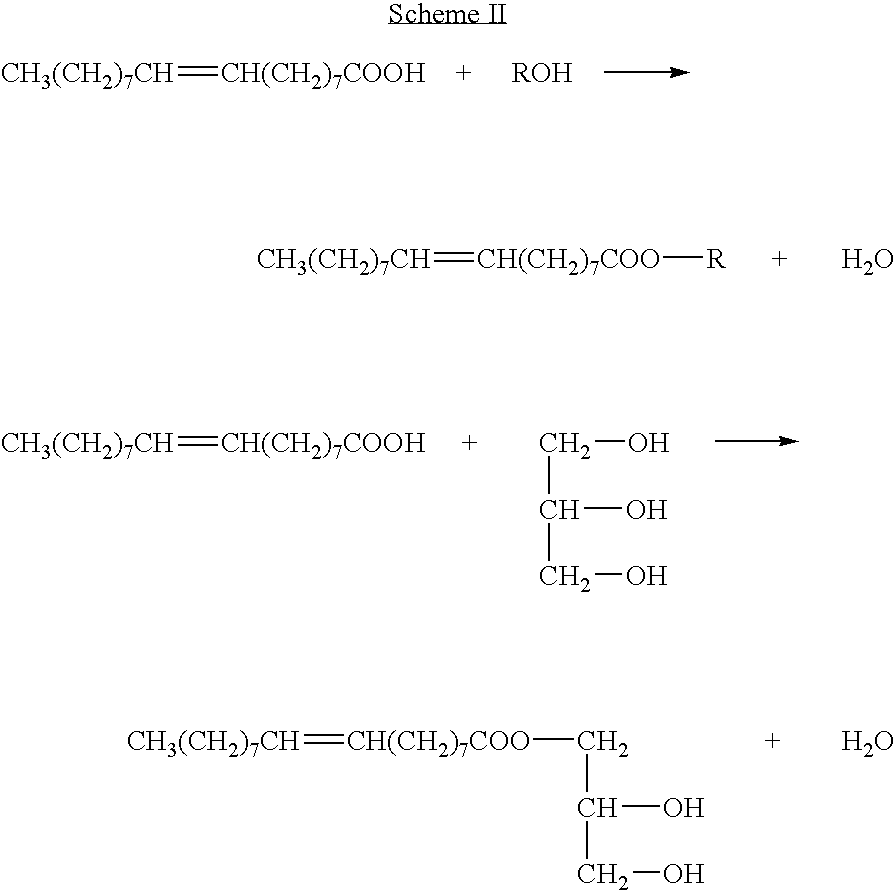

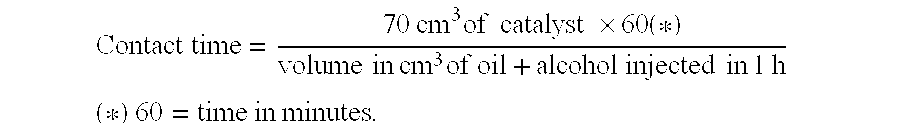

Process for transesterification of vegetable or animal oils using heterogeneous catalysts based on titanium, zirconium or antimony and aluminium

InactiveUS20050266139A1Possible formFatty acid esterificationPreparation by ester-hydroxy reactionHomogeneous catalysisTitanium oxide

A novel process is described for producing esters of linear monocarboxylic acids containing 6 to 26 carbon atoms, by reacting vegetable or animal oils, neutral or otherwise, with monoalcohols containing 1 to 18 carbon atoms in the presence of a catalyst selected from: mixtures of titanium oxide and alumina having formula: (TiOx)y(Al2O3)1-y where x has the value 1.5 to 2.2 and y, representing the weight ratio of the two oxides, has a value of 0.005 to 0.995; mixtures of zirconium oxide and alumina having formula: (ZrOx)y(Al2O3)1-y where x has the value 1.5 to 2.2 and y has a value of 0.005 to 0.995; and mixtures of antimony oxide and alumina having formula: (SbOx)y(Al2O3)1-y where x has the value 1.2 to 2.6 and y has a value of 0.005 to 0.995, in order to directly produce, in one or more steps, an ester for use as a fuel and a pure glycerin.

Owner:INST FR DU PETROLE

Super plastic forming method for plate type heat converter special titanium plate

InactiveCN101121178AHigh yield strengthEasy to processRoll mill control devicesFurnace typesPlate heat exchangerTitanium

The present invention relates to a superplastic forming method for the titanium plate specially used for the plate type heat exchanger, which belongs to the field of mechanical processing technology. The present invention comprises the following steps that spongy titanium is chosen to be the melted raw material; the spongy titanium is placed in a vacuum plasma smelting furnace to be directly cast into plate base; the plate base forms a plate of a thickness of 2.0 to 2.4 mm after the process of heating, hot rolling, acid and alkali washing; second heating, hot rolling and acid and alkali washing and annealing; the plate of a thickness of 2.0 to 2.4 mm after the annealing in the vacuum smelting furnace forms a titanium plate of a thickness of 0.5 to 0.6 mm after the process of cold rolling, cleaning, second annealing and cold rolling, acid and alkali washing and third annealing. The present invention adopts the process that the spongy titanium which contains oxygen, iron and nitrogen of comparatively high content is directly processed into the titanium plate base in the plasma smelting furnace and directly rolled into the plate without forging and pressing.

Owner:上海桦厦实业有限公司

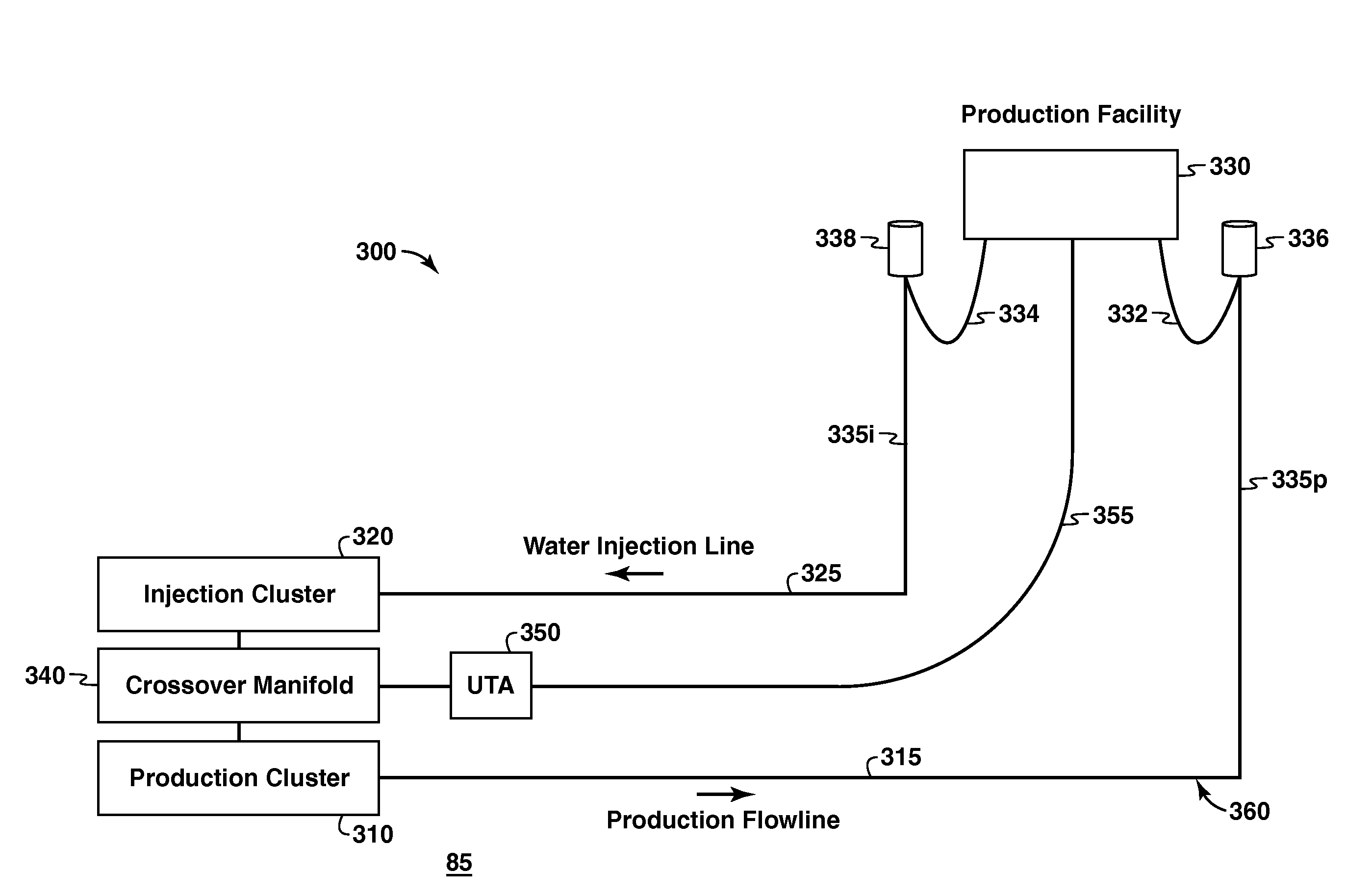

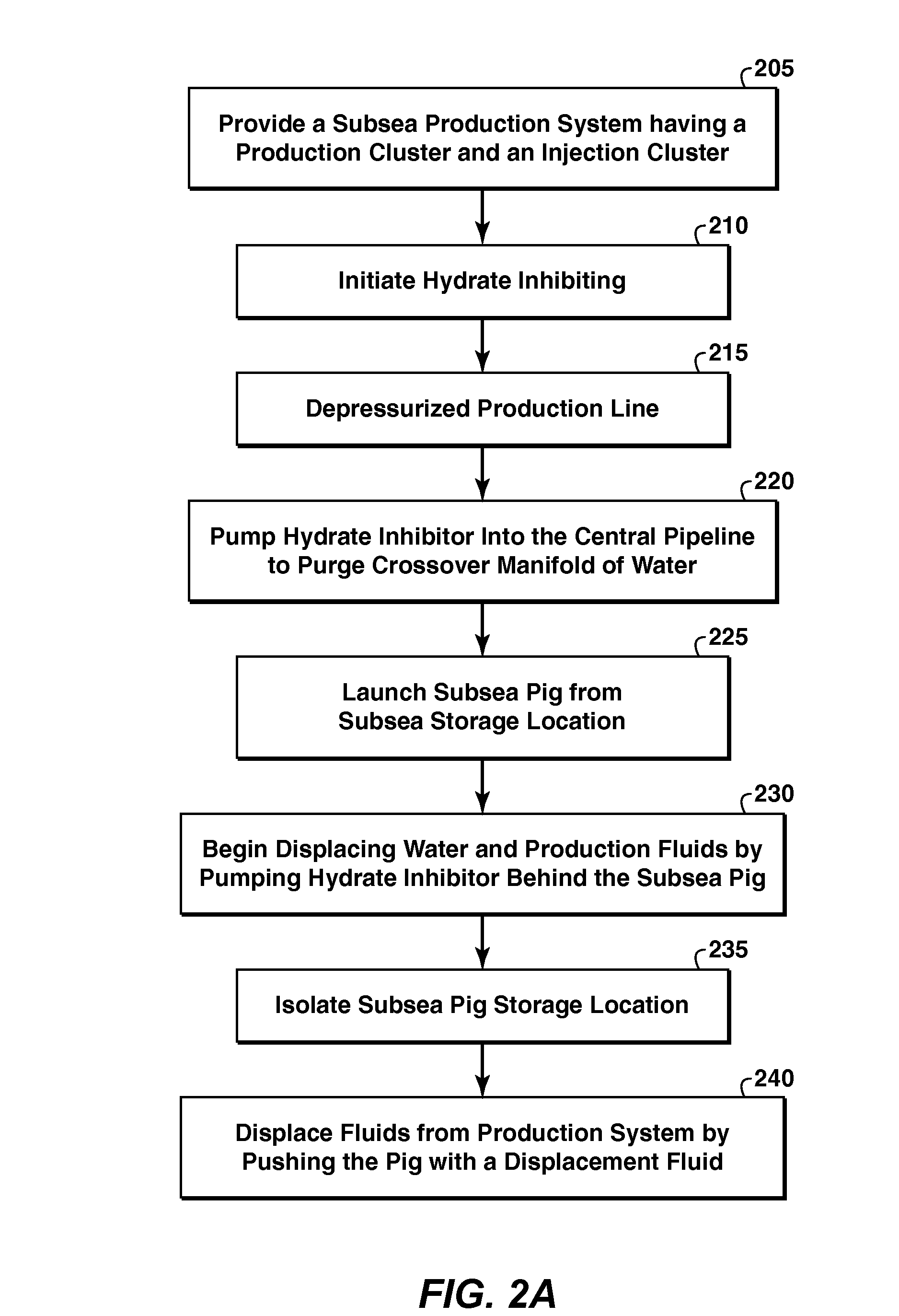

Method and Apparatus For Flow Assurance Management In Subsea Single Production Flowline

Managing hydrates in a subsea includes a host production facility, a production cluster comprising one or more producers, a water injection cluster comprising one or more water injectors, a water injection line, and a single production line for directing production fluid from the one or more producers to the host production facility. The methods comprise placing a pig in the subsea production system, shutting in production from the producers, and injecting a displacement fluid into the subsea production system in order to displace the hydrate inhibitor and any remaining production fluids in the production flowline and to further move the pig through the production flowline. The method may also include further injecting displacement fluid into the subsea production system in order to displace the hydrate inhibitor and pig through the single production line and to the host production facility.

Owner:EXXONMOBIL UPSTREAM RES CO

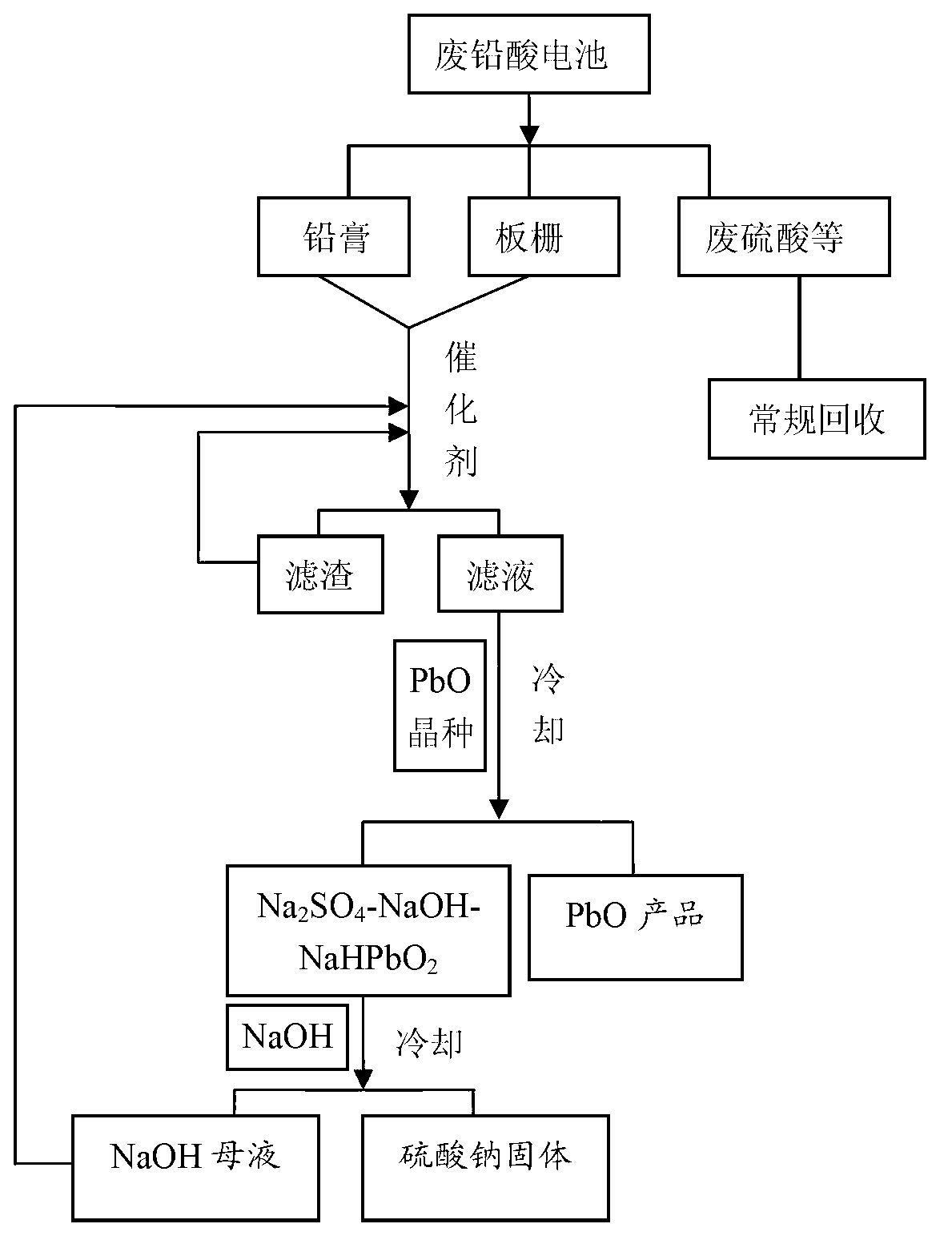

Method for recycling waste lead-acid cells to directly produce lead oxide

ActiveCN103014347AImprove recycling efficiencyMeet the needs of high-purity PbOLead oxidesProcess efficiency improvementLead oxideEngineering

The invention discloses a method for recycling waste lead-acid cells to directly produce lead oxide, belonging to the wet-process metallurgical field of recycling lead from lead-containing materials and waste lead-acid cells. The method for recycling waste lead-acid cells to directly produce lead oxide comprises the following steps of: carrying out a reaction on diachylum, lead powder and sodium hydroxide solution in the presence of catalyst to obtain a mixed solution containing NaHPbO2, sodium sulfate and sodium hydroxide, and un-reacted lead powder and impurities, and separating the mixed solution; cooling and filtering the mixed solution to obtain PbO crystals, and an alkaline solution containing Na2SO4 and the residual NaHPbO2; adding the NaOH to the solution, re-cooling the mixture to separate out sodium sulfate solid and obtain the NaOH solution containing the residual NaHPbO2; and carrying out re-dissolving-filtering-re-crystallizing to the PbO in the NaOH solution with mass concentration of 15-50% to obtain the pure lead oxide solid. The lead recovery ratio is generally between 98.5% and 99.2%, and the purity of the lead oxide is as high as 99.99% or higher.

Owner:BEIJING UNIV OF CHEM TECH

Coal gangue biomass solid forming fuel and preparation method thereof

InactiveCN101805651ACalorific value of combustion is stableGood benefitBiofuelsSolid fuelsSocial benefitsAdhesive

The invention discloses a coal gangue biomass solid briquettes fuel, which comprises the following components in percentage by weight: 40 to 85 percent of coal gangue with the combustion heat value higher than 2,000 kilocalories, 10 to 50 percent of agricultural organic waste, 1 to 5 percent of combustion improver, and 1 to 5 percent of adhesive. The method for preparing the coal gangue biomass solid fuel comprises the following steps: crushing the coal gangue with the combustion heat value higher than 2,000 kilocalories; and adding the agricultural organic waste, the combustion improver, and the adhesive in a certain proportion to directly produce the coal gangue biomass solid forming fuel with a stable combustion value by adopting forming machinery. The solid forming fuel is prepared by reasonably using a large quantity of agricultural organic waste and the coal gangue in a certain proportion; and the combustion heat value is stable. The biomass solid forming fuel can be used as the fuel of boilers, stoves and other combustion devices, and has good social benefits, environmental protection benefits, and economic benefits.

Owner:童风

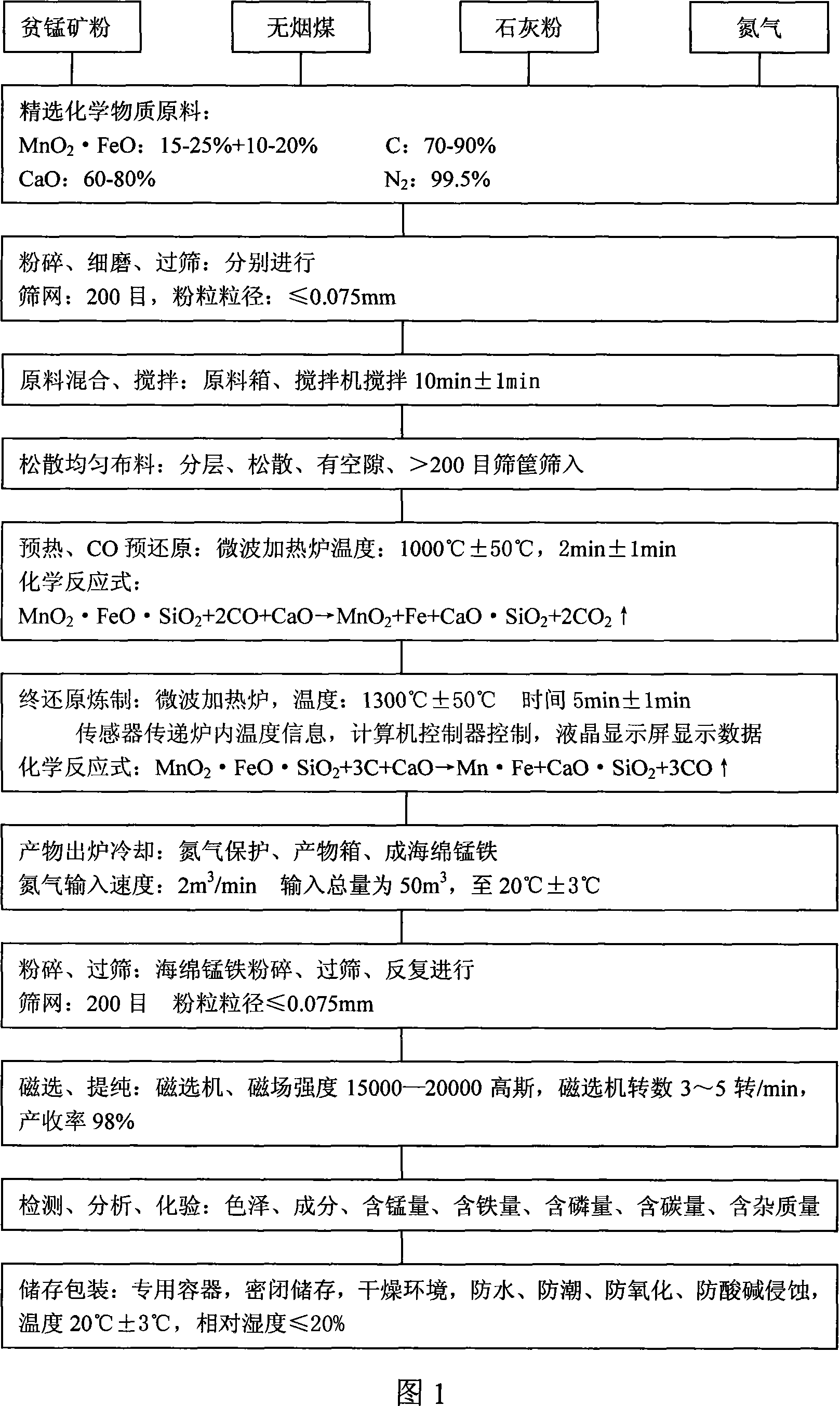

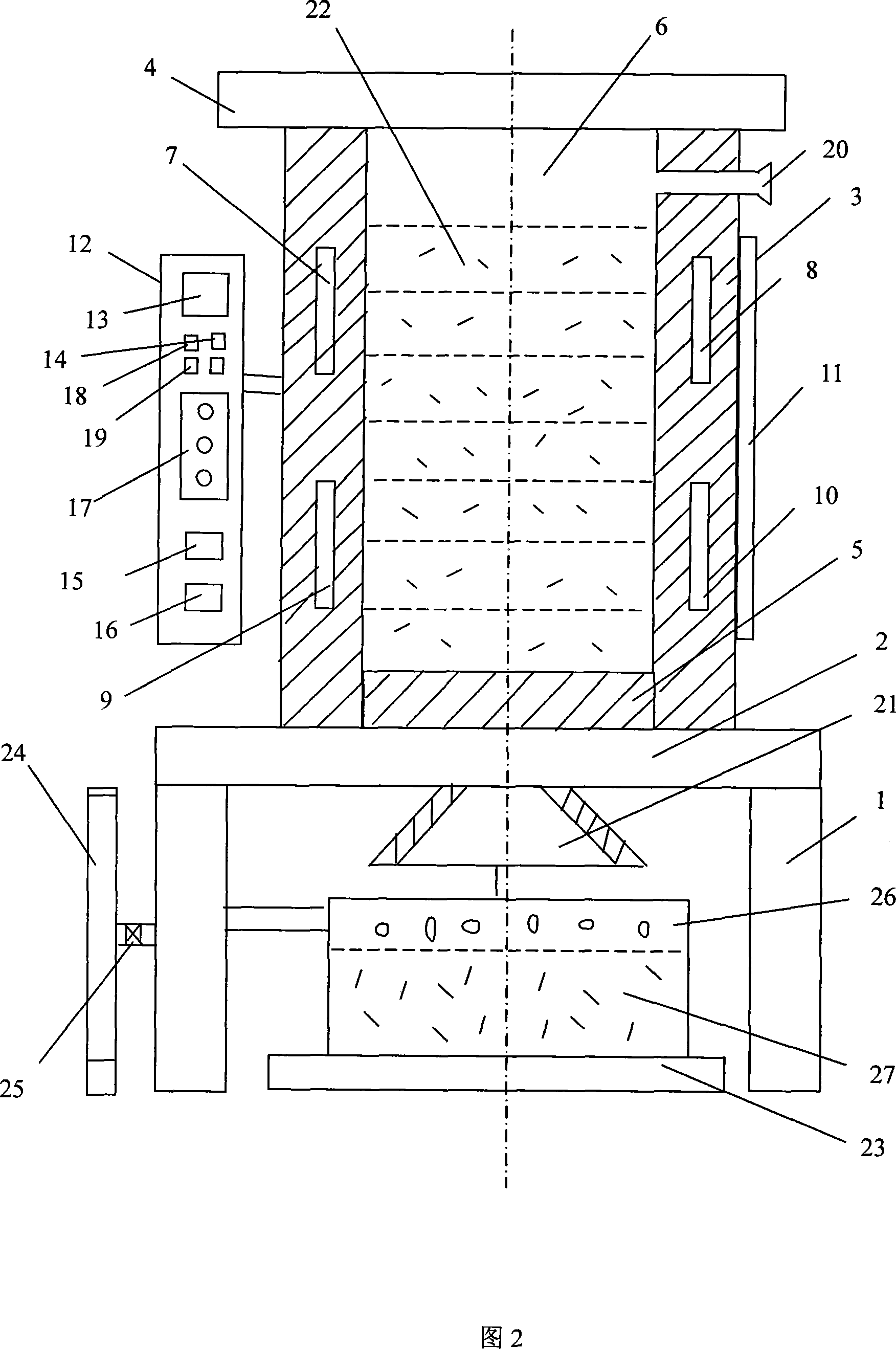

Method for preparing low-carbon metal manganese iron by using manganese-poor powdered ore

The invention relates to a low-carbon ferromanganese production method using low-grade manganese mineral powder. The low-grade manganese mineral powder which has rich reserves is heated by a micro-wave oven, reduced by carbon, smelted at high temperature, purified by magnetic separation to directly prepare low-carbon ferromanganese. And the production method saves sintered agglomeration process with large energy consumption and serious pollution. The low-carbon ferromanganese with high purity is made through the steps that: the material is carefully chosen, crushed, fine- grinded, sieved, mixed, stirred, preheated by the micro-wave oven, pre-reduced through carbon monoxide, finally reduced, smelted at high temperature, cooled under the protection of nitrogen and purified by magnetic separation. The preparation method has the advantages of short technological process, less using equipment, being suitable for large- scale industrialization production, the yield rate can reach 98 percent, wherein manganese content is 75 percent and iron content is 20 percent, and the content of carbon is less than 0.5 percent; the content of harmful material sulfur is also less than 0.5 percent; the content of phosphor is less than 0.2 percent. The products have the advantages of low carbon, low phosphor and sulfur containing, no agglomeration, no pollution to environment. The method is the ideal ferromanganese direct production method using low-grade manganese mineral powder and fills up a scientific research blank in the field in China.

Owner:TAIYUAN UNIV OF TECH

Method for directly producing high-purity electronic level cobaltous sulfate by using cobalt-containing waste

ActiveCN102061390AMeet high purity requirementsImprove overall recoveryProcess efficiency improvementTotal recoveryGoethite

The invention provides a method for directly producing high-purity electronic level cobaltous sulfate by using cobalt-containing waste, in particular a process for producing cobaltous sulfate by using cobalt-containing waste. The method comprises the steps of: checking and classifying raw materials, wet-milling and size-mixing, acid-decomposing, filtering, washing, separating, and extracting copper sponge. The method is characterized by also comprising the steps of: removing iron with a goethite process, extracting P2O4 and removing impurities, separating nickel from cobalt, extracting N235, purifying, concentrating and crystallizing. The high purity electron level cobaltous sulfate is directly regenerated by using various kinds of cobalt wastes, the requirement of the modern high-technology industry on high purity of the cobaltous sulfate is met; the total recovery of the cobalt is higher than or equal to 98 percent; various usable elements can be comprehensively recycled, and coppersponge, tungsten carbide, iron hydroxide and nickel carbonate can be regenerated while the electronic level cobaltous sulfate as a main product is regenerated. The invention has the advantages of comprehensively utilizing waste cobalt resources, recycling the wastes, improving the enterprise benefit, and being beneficial to the development of energy conservation, emission reduction, environment protection and circular economy.

Owner:HUNAN JINYUAN NEW MATERIALS CO LTD

Equipment and method for producing imitation stone-texture ceramic tile

The invention relates to equipment and a method for producing an imitation stone-texture ceramic tile. The equipment comprises a hydraulic machine, a tile pulling rod, a material pushing frame of a secondary material spreader and a composite base material hopper, wherein the tile pulling rod is arranged at the front end of the composite base material hopper on the material pushing frame of a secondary material spreader and consists of two tile pulling arms and a transverse rod. The equipment is characterized by also comprising a tile pulling mechanism driving the tile pulling rod and a powder removing mechanism which is used for removing powder and arranged between the hydraulic machine and the composite material hopper. The invention also provides a secondary material spreading device and a method thereof, which not only can solve the problem of directly producing a ceramic tile with a clear texture effect pattern imitating a natural stone without a polishing working procedure difficult to be realized in a counter steer mode, particularly a rough surface or dull surface micro powder ceramic tile with the texture effect pattern imitating the natural stone, but also can ensure that the texture effect pattern imitating the natural stone in a micro powder material can be kept more complete.

Owner:GUANGDONG NEWPEARL CERAMIC GRP CO LTD

Process for the utilization of ruminant animal methane emissions

InactiveUS20100279180A1Reduce materialReduce decreaseBioreactor/fermenter combinationsTurbine/propulsion fuel supply systemsRuminant animalEnteric fermentation

Owner:NEWLIGHT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com