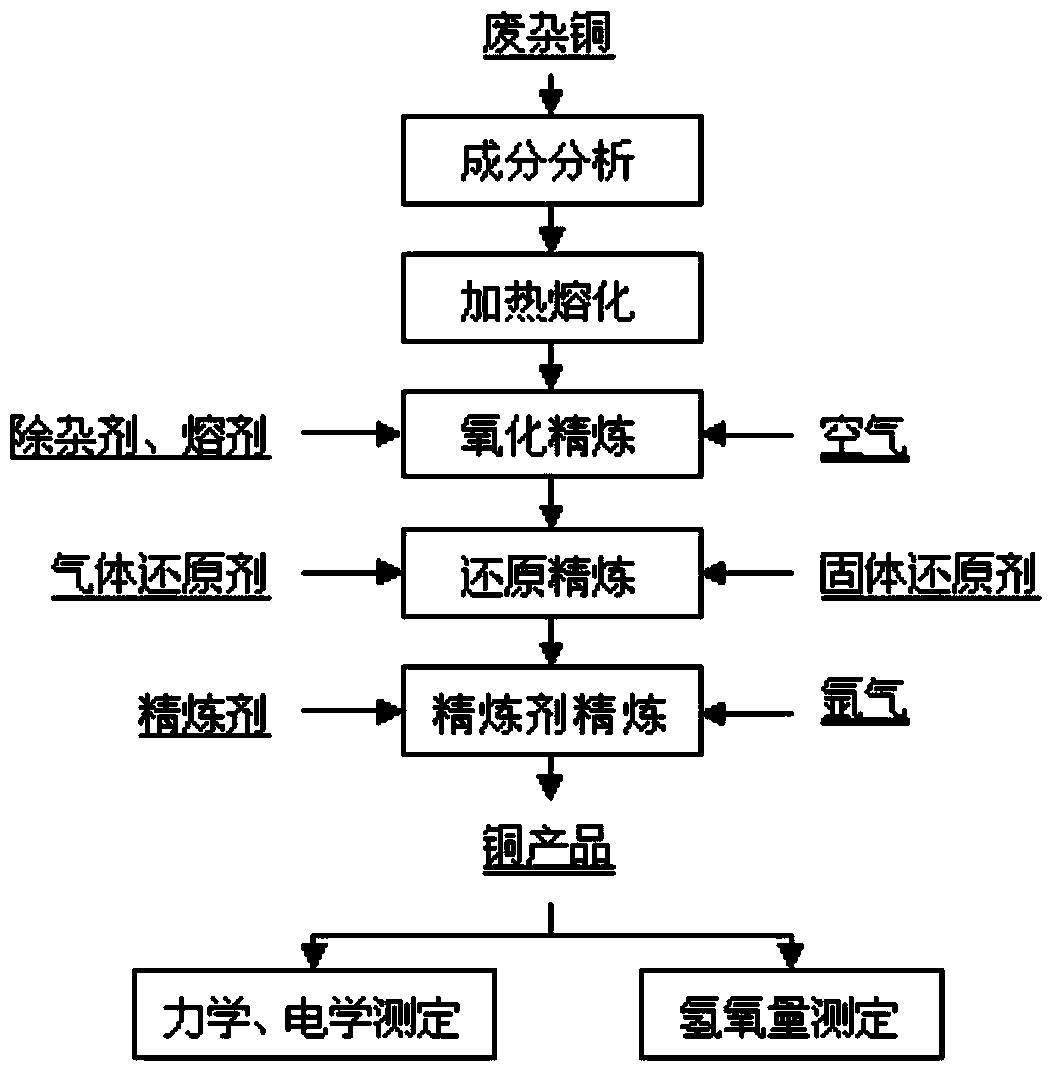

Method for directly producing high-purity oxygen-free copper by pyrogenic process continuous refining of scrap copper

A technology of scrap copper and oxygen-free copper, applied in the field of non-ferrous metal metallurgy, can solve the problems of high energy consumption, high oxygen content in products, long process and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

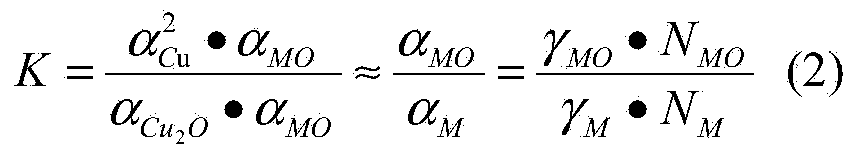

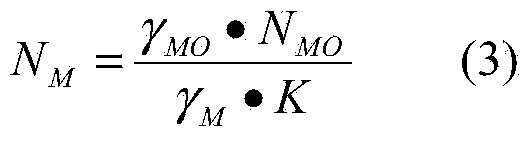

Method used

Image

Examples

Embodiment 1

[0062] Using scrap copper bought back on the market as raw material, carry out refining experiments, wash and dry, take samples for ICP full analysis, and make a mixture as shown in Table 1:

[0063] Table 1 Chemical composition / wt% of scrap copper mixture

[0064] the element

Cu

Pb

sn

Ni

Zn

Sb

S

Al

Fe

Au,Ag

non-metal

content

93.58

0.52

0.84

0.33

0.14

0.11

0.67

0.14

0.10

0.05

3.52

[0065] (1) oxidation refining

[0066] Take P 2 o 5 7.5g, Na 2 CO 3 After mixing 7.5g, boil it at low temperature to make a molten salt with uniform composition. After the molten salt is cooled and ground, mix it with 200g of the mixture evenly, and add it to a 500ml corundum crucible; put the crucible into a closed heating furnace and quickly heat up to 1200°C , start blowing compressed air, the flow rate of blowing air is 0.5L / min, the pressure is 0.4Mpa, stop the blowing after 60min,...

Embodiment 2

[0074] Mixture composition is identical with embodiment 1, gets NaPO 3 15g, Na 2 CO 3 Mix 15g and 200g of the mixture evenly and put it into a 500ml corundum crucible, put the crucible into a closed heating furnace, rapidly raise the temperature to 1220°C and blow in compressed air at a flow rate of 0.5L / min and a pressure of 0.4Mpa After reacting for 60 minutes, stop the blowing, keep the heat for 20 minutes, remove the slag, and then blow (10V%CO+90V%N 2 ) mixed gas, the flow rate of blowing the mixed gas is 0.3L / min, the pressure is 0.3Mpa, the ventilation is stopped after 30min, and after standing for 10min, at the temperature of 1200℃, add 0.1g calcium boride into the melt, and simultaneously blow High-purity argon gas is used to stir the melt, the flow rate of argon gas is 0.25L / min, and the pressure is 0.3Mpa. After 30min, the flow of argon gas is stopped, and the temperature is kept for 20min.

[0075] After the crucible was cooled, samples were taken to analyze the...

Embodiment 3

[0078] Mixture composition is identical with embodiment 1, gets NaPO 3 10g, Na 2 CO 3 Mix 20g and 200g of the mixture evenly and put it into a 500ml corundum crucible, put the crucible into a closed heating furnace, rapidly raise the temperature to 1150°C and blow in compressed air at a flow rate of 0.5L / min and a pressure of 0.4Mpa After reacting for 60 minutes, stop the blowing, keep the heat for 20 minutes, remove the slag, and then blow (10V%CO+90V%N 2 ) mixed gas, the flow rate of blowing the mixed gas is 0.3L / min, the pressure is 0.3Mpa, stop the ventilation after 30min, and after standing for 10min at a temperature of 1200°C, add 0.2g lanthanum-cerium-copper alloy (cerium 8 %, 12% lanthanum, 80% copper), and at the same time blow high-purity argon to stir the melt, the flow rate of blowing argon is 0.25L / min, the pressure is 0.3Mpa, stop argon after 30min, and keep warm for 20min. Sampling and analyzing the composition of product copper after the crucible is cooled, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Relative conductivity | aaaaa | aaaaa |

| Relative conductivity | aaaaa | aaaaa |

| Relative conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com