Patents

Literature

320 results about "Metaphosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A metaphosphate ion is an oxyanion that has the empirical formula PO⁻₃. The structure of a metaphosphate ion can be described as being made up of PO₄ structural units in which each unit shares two corners with another unit. This can come about in two ways.

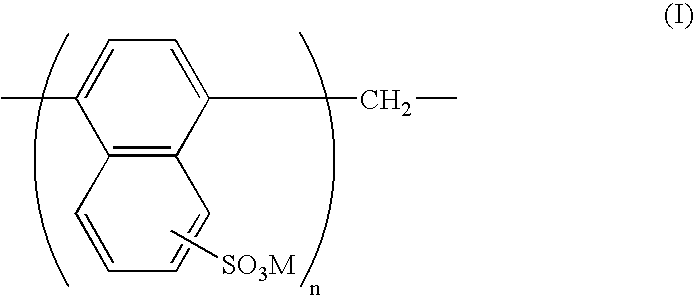

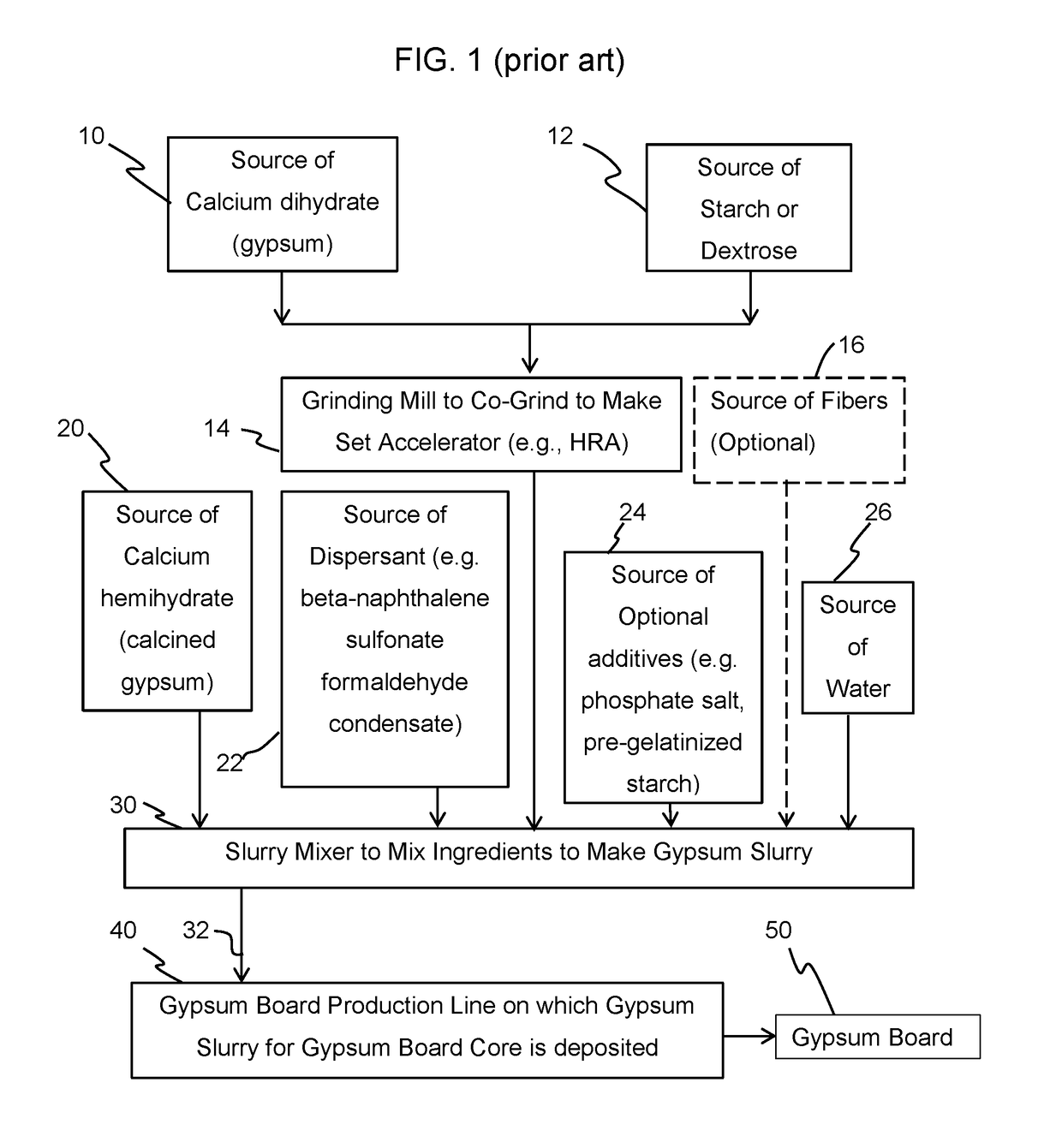

Method of improving dispersant efficacy in making gypsum products

The invention generally provides gypsum-containing slurries including stucco, trimetaphosphate salt, and naphthalenesulfonate dispersant, wherein the trimetaphosphate salt is present in an amount of at least about 0.12% by weight based on the weight of stucco. Other slurry additives can include accelerators, binders, starch, and paper fiber, glass fiber, and other known ingredients. The invention also comprises the gypsum-containing products made with such slurries, for example, gypsum wallboard, and a method of making gypsum wallboard.

Owner:UNITED STATES GYPSUM CO

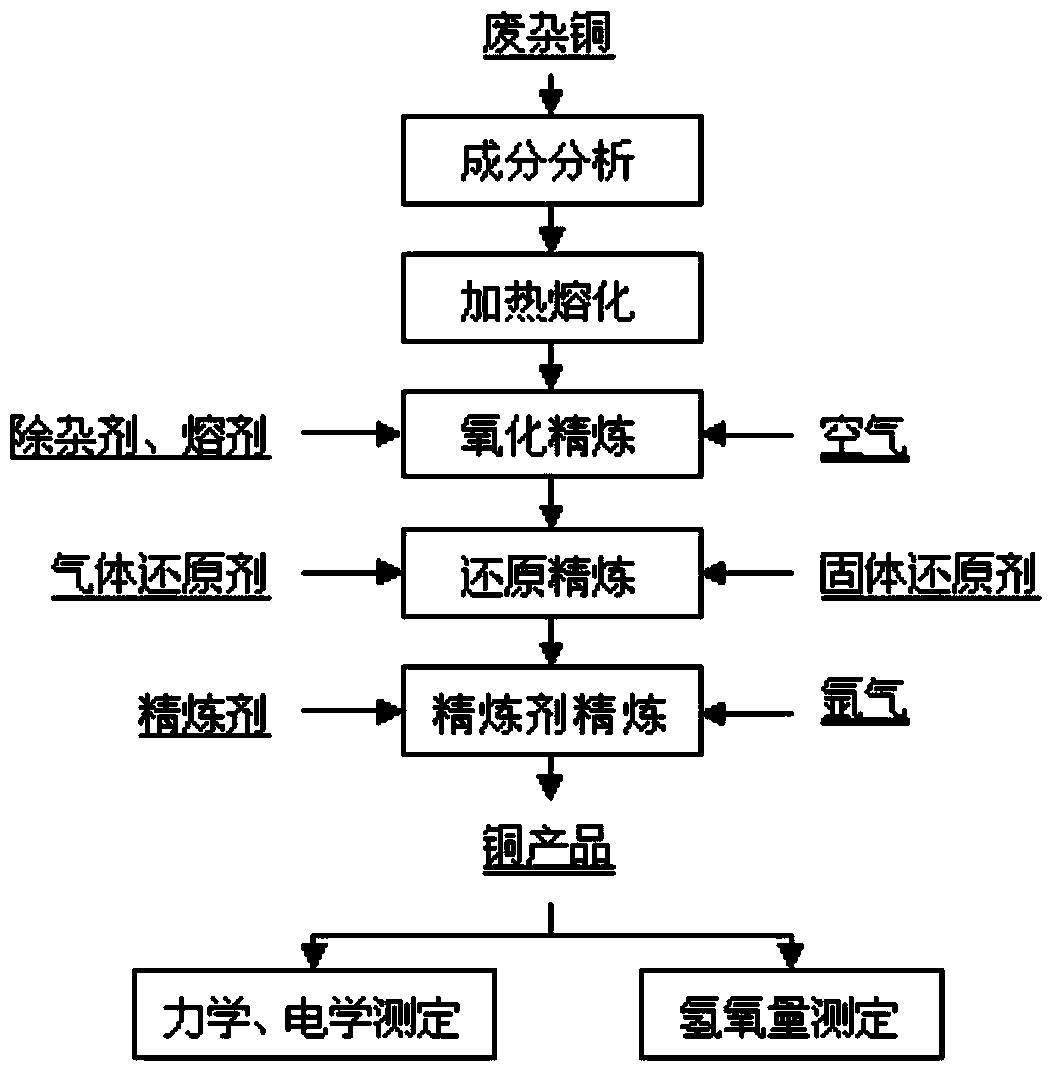

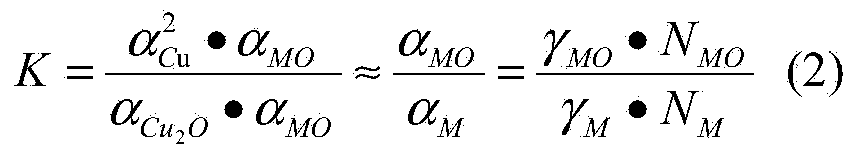

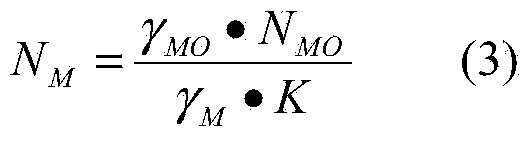

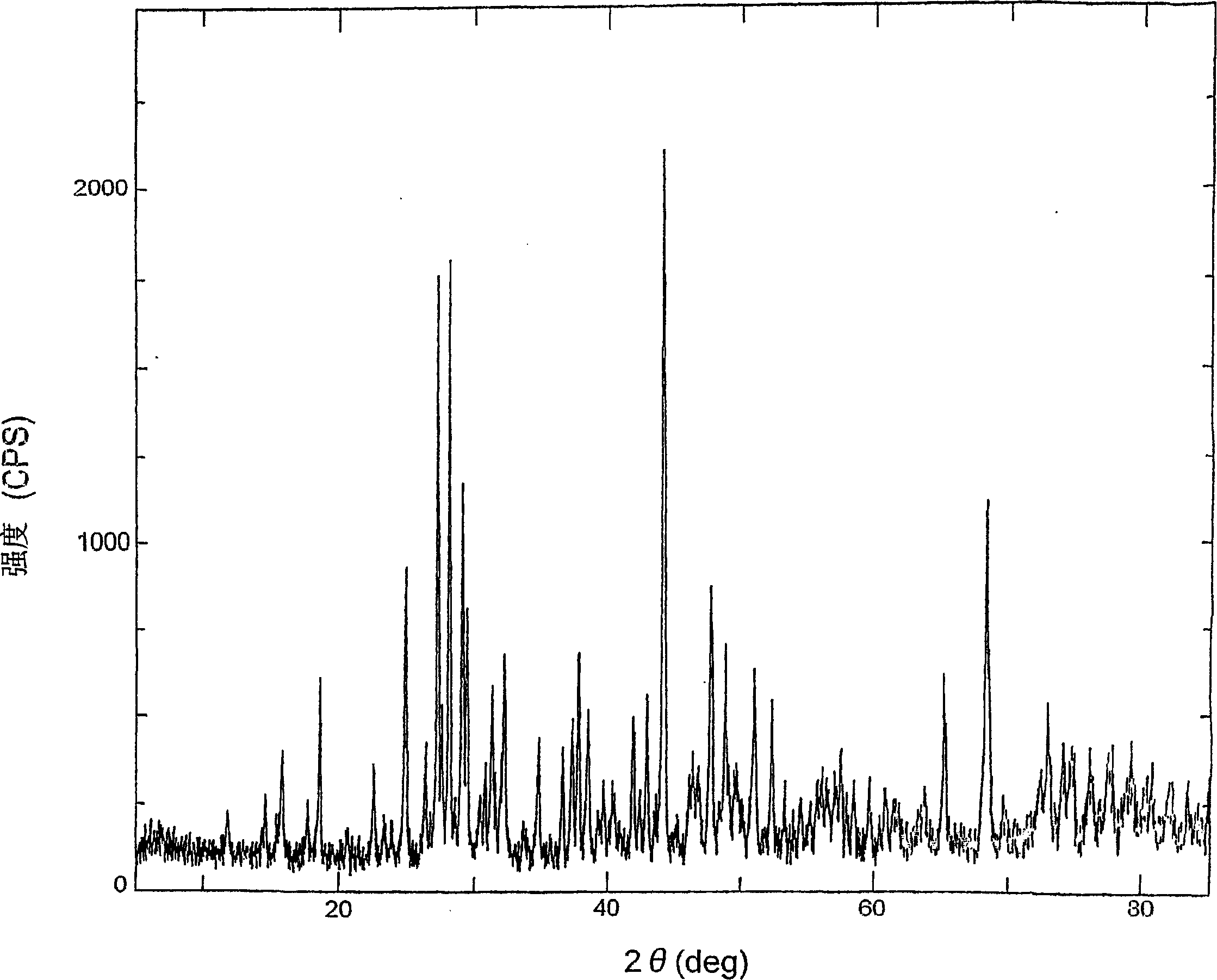

Method for directly producing high-purity oxygen-free copper by pyrogenic process continuous refining of scrap copper

ActiveCN103725897AOptimizing Process ParametersReduce manufacturing costProcess efficiency improvementElectrolysisCopper wire

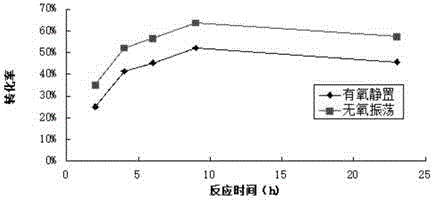

The invention relates to a method for directly producing high-purity oxygen-free copper by pyrogenic process continuous refining of scrap copper, and belongs to the technical field of non-ferrous metallurgy. The method comprises the following steps: by taking scrap copper as a raw material; analyzing the component characteristics of each batch of raw material, and then preparing into a mixture, wherein the mass percent of a copper element in the mixture is greater than or equal to 93%; adding metaphosphate or phosphorus pentoxide and flux to the mixture; refining by oxidation; stewing and drossing after oxidation is finished, and then orderly carrying out reduction refining and refining agent refining under an agitation state, so as to obtain the high-purity oxygen-free copper of which the copper content is greater than or equal to 99.95% and the oxygen content is smaller than 0.003%, wherein the electrical resistivity of the obtained copper wire after drawing is below 0.017241omega / (mm), and the relative electrical conductivity is over 100% of International annealed copper standard (IACS). The method is strong in flexibility, significant in refining effect, and applicable to different components of scrap copper materials; the scrap copper can be used for directly making a rod after being refined. Compared with the traditional pyrogenic process smelting-electrolytic refining-copper cathode purification process, the method disclosed by the invention has the beneficial effects that the flow is shortened, the cost is reduced, the energy is saved, and continuous operation is achieved.

Owner:CENT SOUTH UNIV

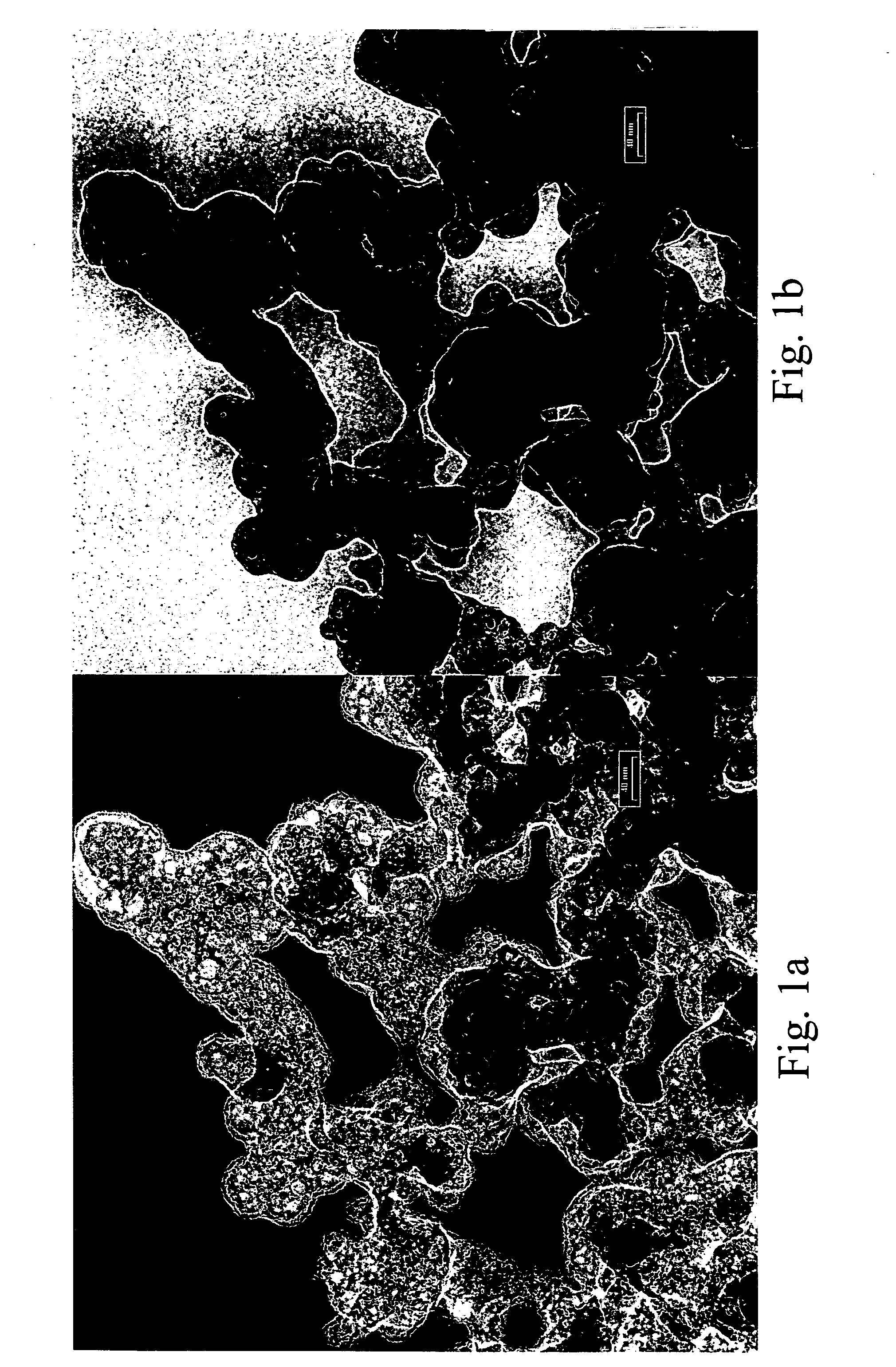

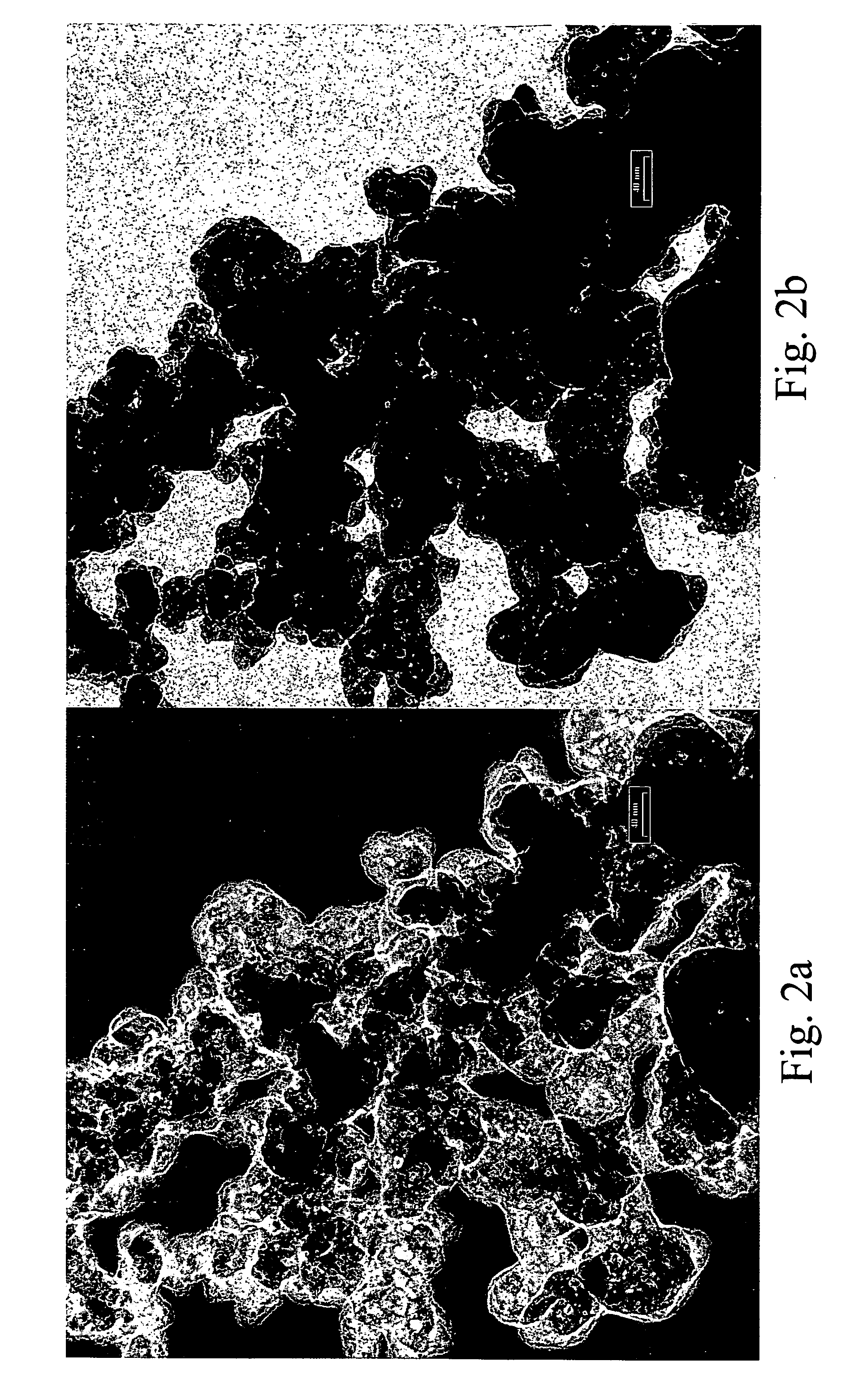

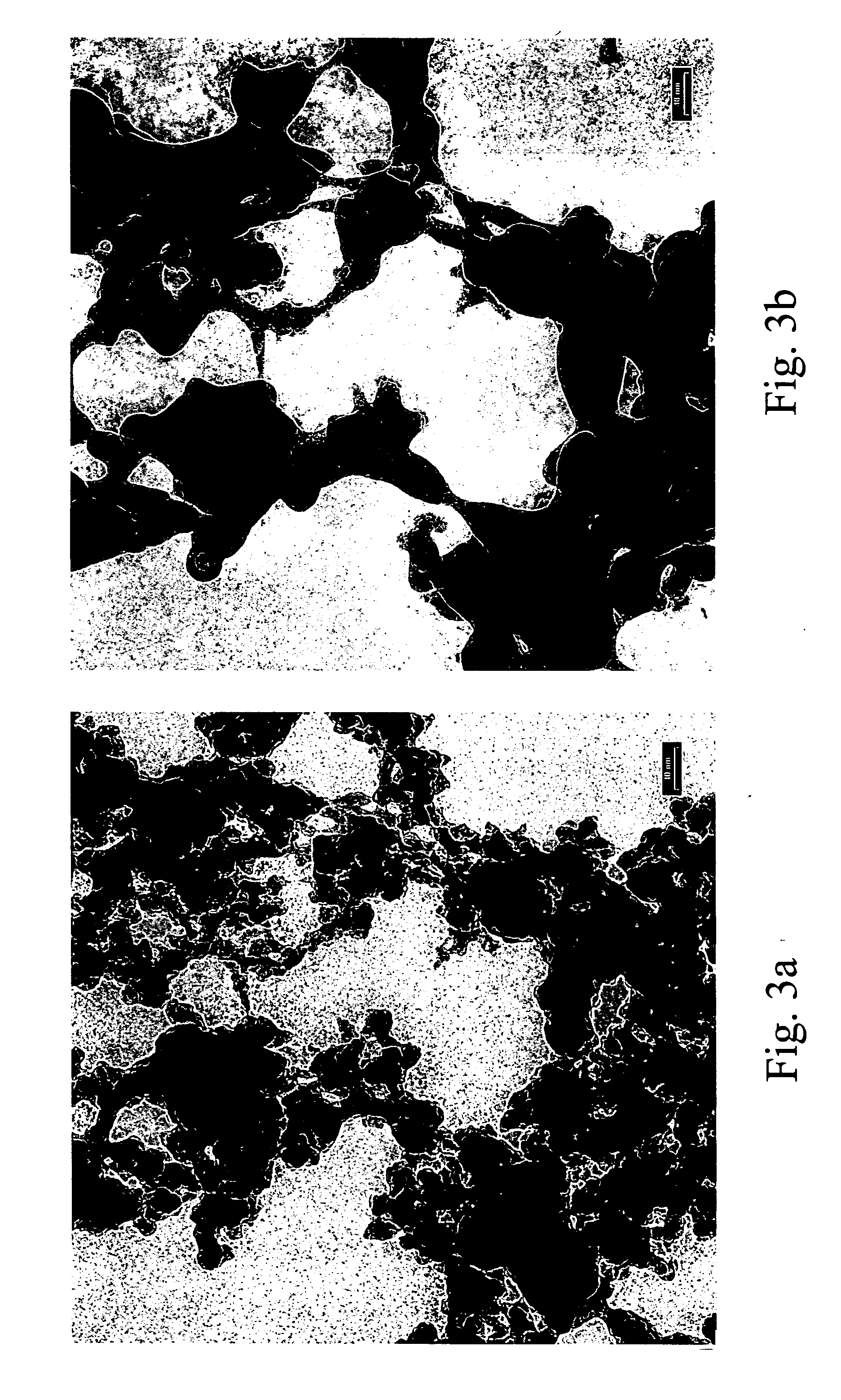

Aluminum phosphate, polyphosphate and metaphosphate particles and their use as pigments in paints and method of making same

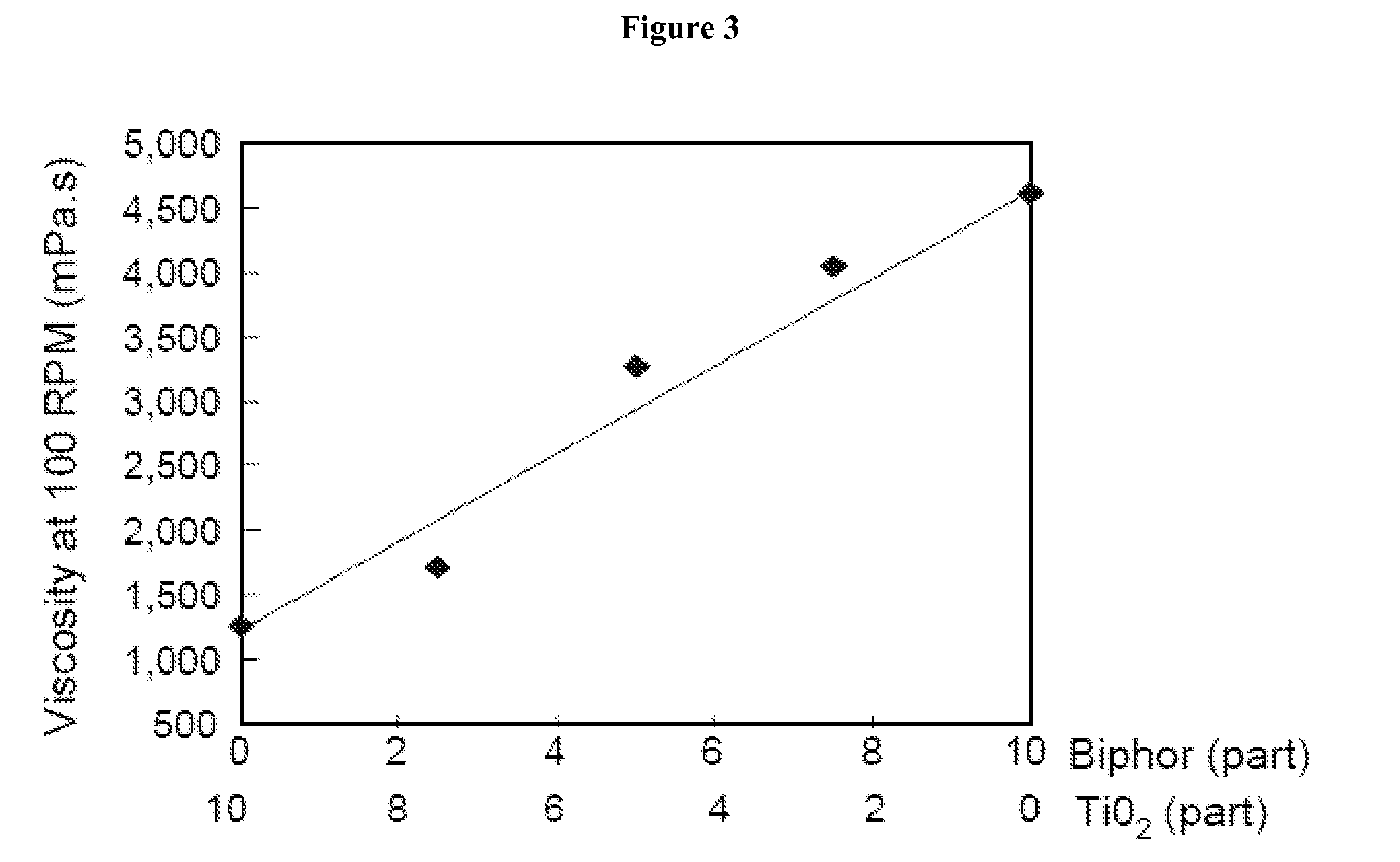

An aluminum phosphate composition comprising aluminum phosphate, aluminum polyphosphate, aluminum metaphosphate, or a mixture thereof. The composisition may be characterized by, when in powder form, having particles wherein some of the particles have at least one or more voids per particle. In addition, the composition is characterized by exhibiting two endothermic peaks in Differential Scanning Calorimetry between about 90 degrees to about 250 degrees Celsius. The composition is also characterized by, when in powder form, having a dispersibility of at least 0.025 grams per 1.0 gram of water. The composition is made by a process comprising contacting phosphoric acid with aluminum sulfate and an alkaline solution to produce an aluminum phosphate based product; and optionally calcining the aluminum phosphate, polyphosphate or metaphosphate based product at an elevated temperature. The composition is useful in paints and as a substitute for titanium dioxide.

Owner:BUNGE AMORPHIC SOLUTIONS +1

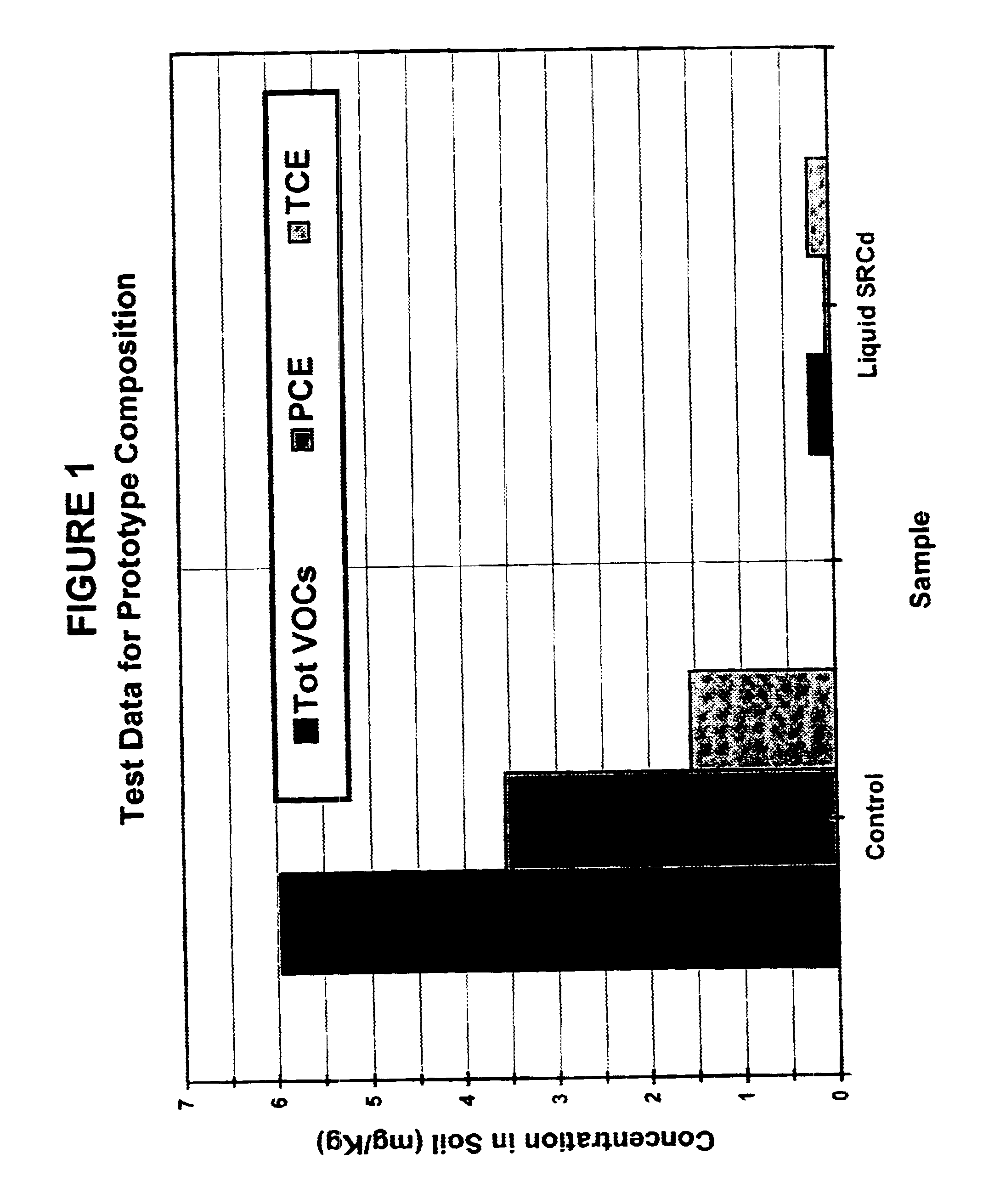

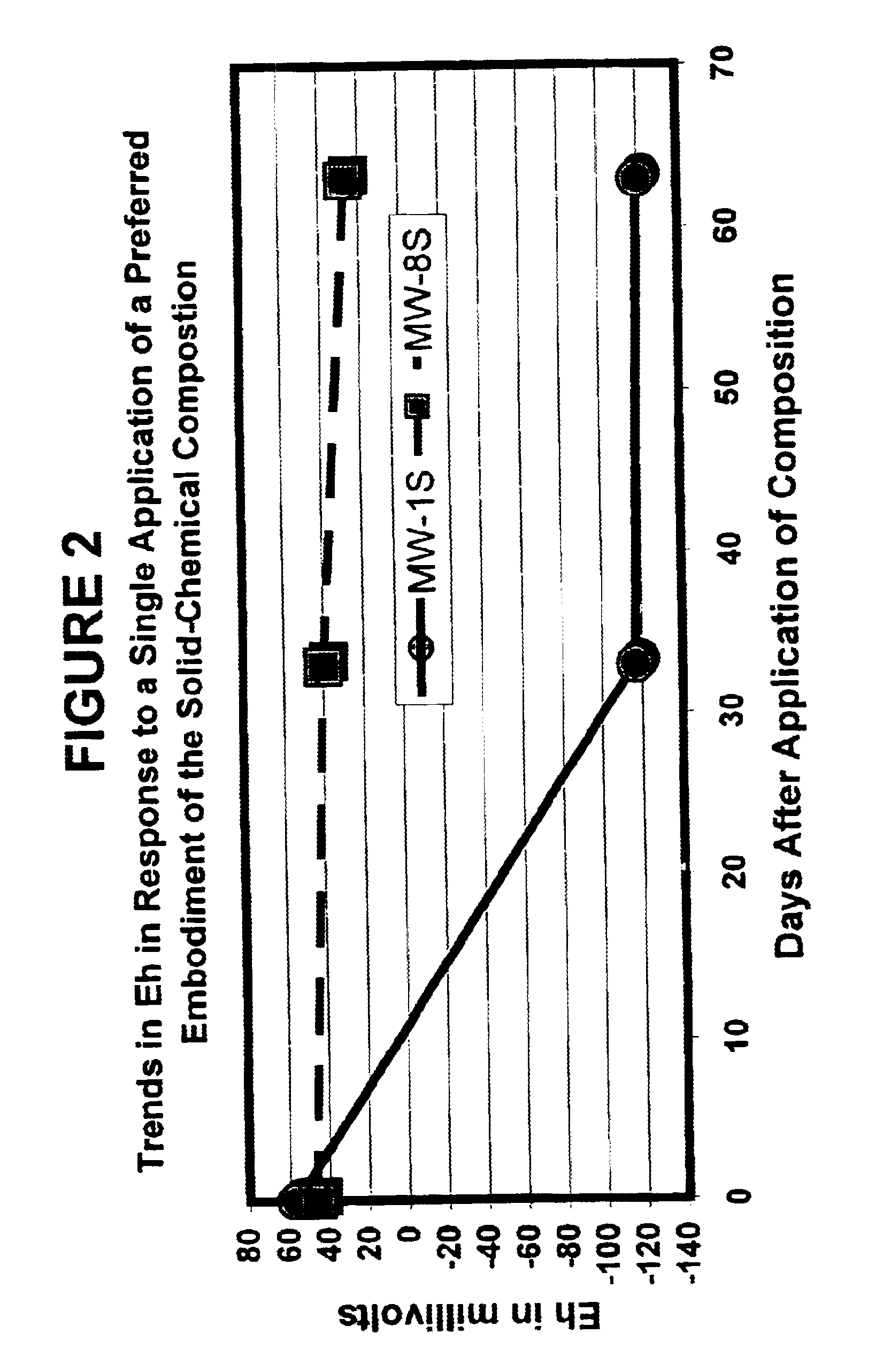

Solid-chemical composition for sustained release of organic substrates and complex inorganic phosphates for bioremediation

InactiveUS6620611B2Improve solubilityIncreasing speed and effectivenessBacteriaWater treatment compoundsPseudomonasTrichoderma spp

A slow-release solid chemical composition for environmental bioremediation is provided. The composition comprises a source of soluble organic substrates which include sugars, soluble organic polymers and mixtures of them in an amount of 7% to 90%, insoluble organic substrates an amount of 10% to 70%, complex inorganic phosphates in an amount of 0.5% to 7% and soluble organic salts in an amount of 2% to 70%. The insoluble organic substrates include fibrous plant materials, starches, cellulosic materials and mixtures of these substrates. The complex inorganic phosphates include ringed metaphosphates, linear polyphosphates and mixtures. The organic salts include lactates, formates, acetates, citrates, etc. Also the composition further comprises microorganisms which include Bacillus spp., Rhizobium spp., Bradyrhibzobium spp., Fibrobacter spp., Clostridium spp., Pseudomonas. spp., Geobacter spp., Arthrobacter spp., Nocardia, spp., aspergillus spp., Trichoderma spp., Candida spp., Yarrowia spp. and combinations of these microorganisms. The composition can be prepared in various forms, including granules, briquettes, pellets, tablets or capsules.

Owner:HINCE ERIC CHRISTIAN MR

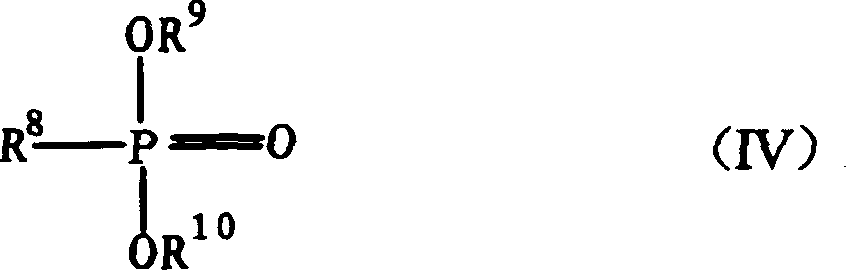

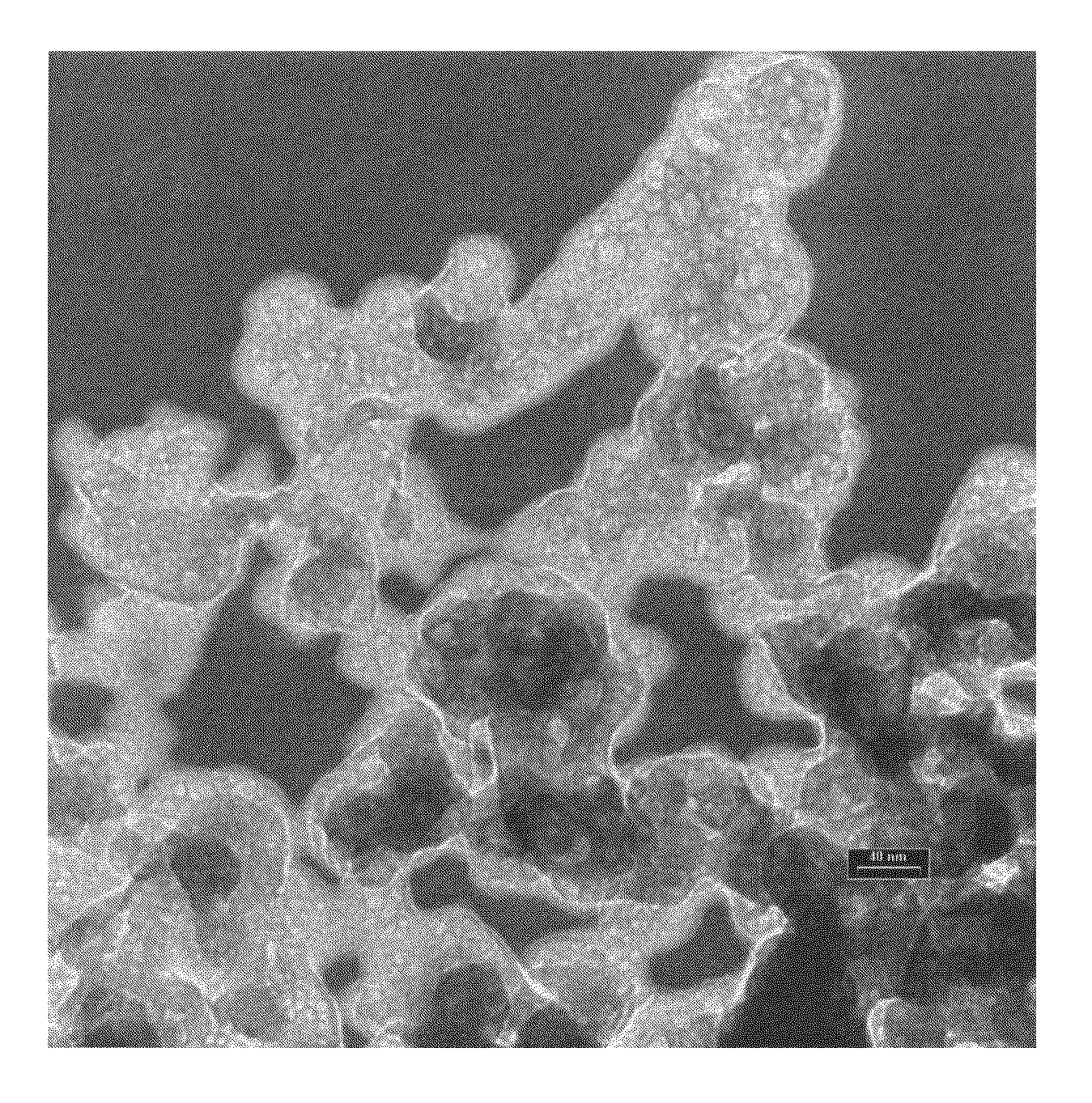

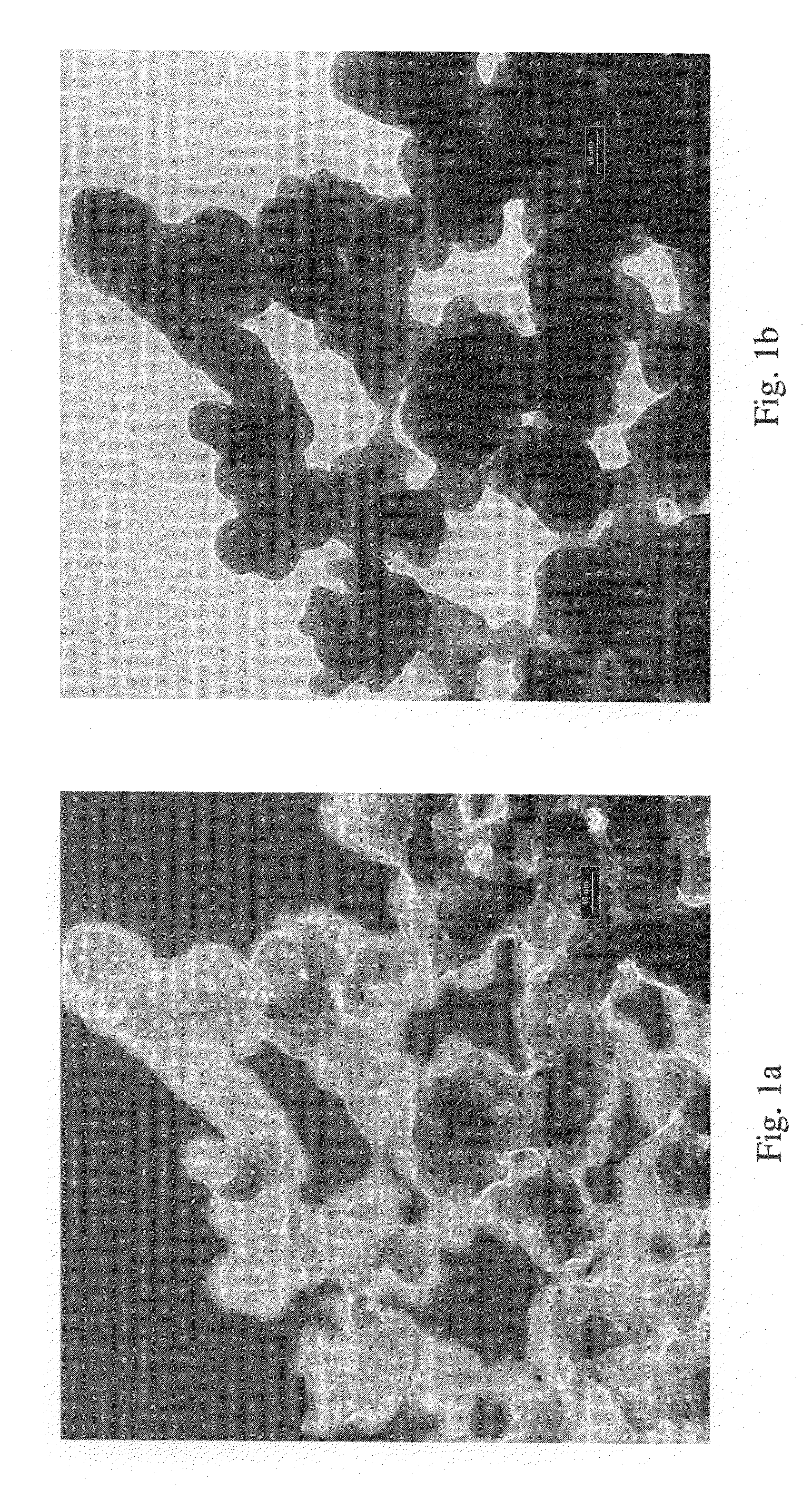

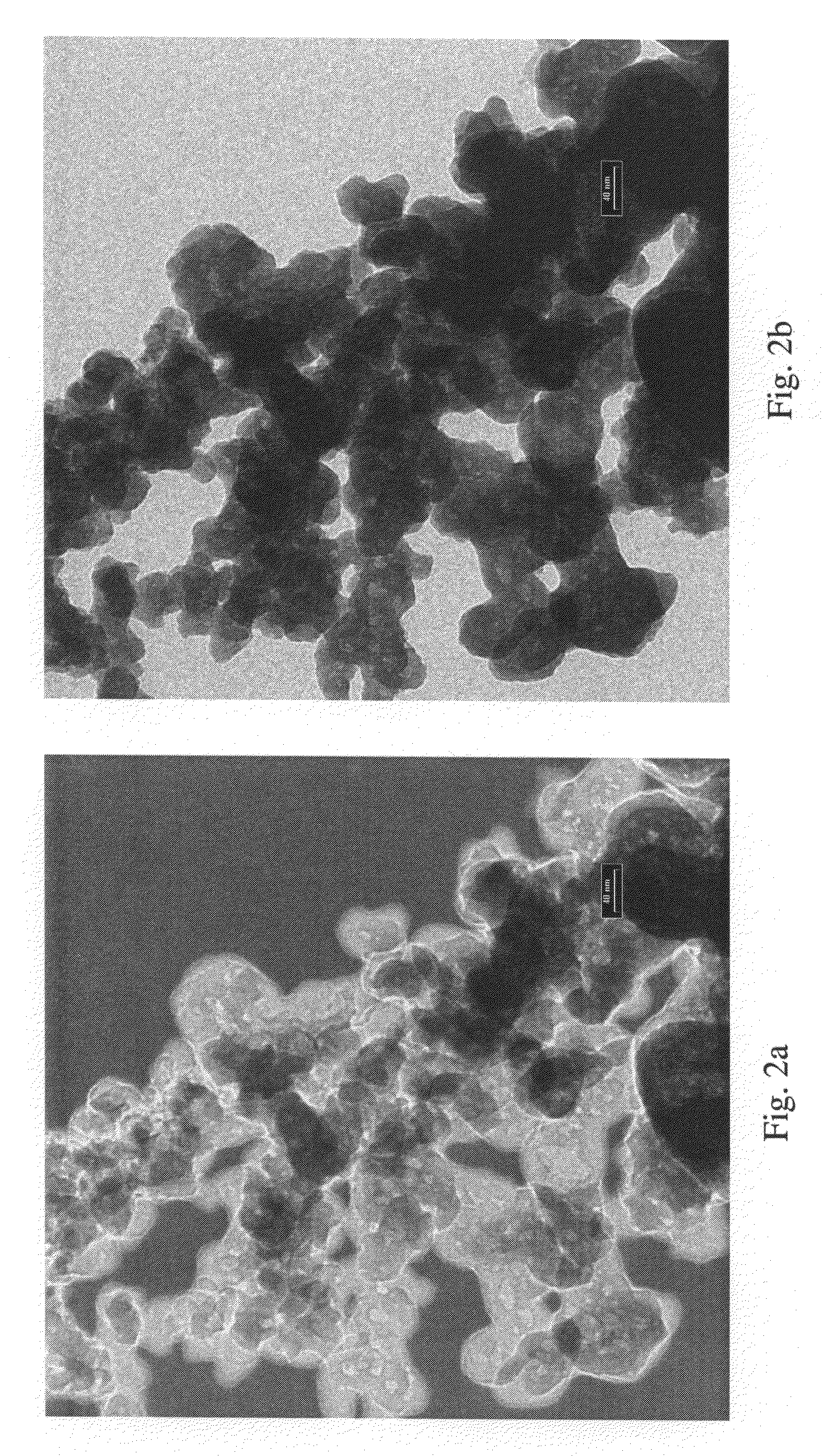

Preparation of organic additive-treated, pyrogenic silica-encapsulated titanium dioxide particles

One aspect of the invention is to provide a composition comprising a titanium dioxide particle having on the surface of said particle a substantially encapsulating layer comprising a pyrogenically-deposited metal oxide; said substantially encapsulating layer having on its surface at least one organic surface treatment material selected from an organo-silane, an organo-siloxane, a fluoro-silane, an organo-phosphonate, an organo-acid phosphate, an organo-pyrophosphate, an organo-polyphosphate, an organo-metaphosphate, an organo-phosphinate, an organo-sulfonic compound, a hydrocarbon-based carboxylic acid, an associated ester of a hydrocarbon-based carboxylic acid, a derivative of a hydrocarbon-based carboxylic acid, a hydrocarbon-based amide, a low molecular weight hydrocarbon wax, a low molecular weight polyolefin, a co-polymer of a low molecular weight polyolefin, a hydrocarbon-based polyol, a derivative of a hydrocarbon-based polyol, an alkanolamine, a derivative of an alkanolamine, an organic dispersing agent, or a mixture thereof. Another aspect of the invention is to provide processes for producing said composition.

Owner:EI DU PONT DE NEMOURS & CO

Method for rapid synthesis of aluminum orthophosphate salt polyalcohol

InactiveCN101172596AProduction Method AdvantagesShort synthesis timePhosphorus compoundsMicrowave ovenPhosphoric acid

The invention discloses a method for rapidly synthesizing aluminum phosphate salt polymeric compound. The method is characterized in that the mixture of phosphoric acid and aluminum hydroxide reacts and the mixture is synthesized under microwave condition. The method comprises the following steps: the phosphoric acid and the aluminum hydroxide are added with water to be mixed and stirred uniformly according to mol ratio; the mixture after being stirred uniformly is put into a microwave oven, and the defrosting and heating mode is selected to radiate the mixture; 750 W is selected to heat the mixture; white aluminum tripolyphosphate powder is gotten through hydrating, drying and grinding. The aluminum tripolyphosphate powder product is put into the microwave oven again to be radiated with 900 W power, and aluminum metaphosphate powder is gotten. The method integrates the reaction and polymerization of the prior art, reduces the composition time, saves the energy and the equipment, and improves the production efficiency. Because of the penetrating action of the microwave, the composition is not limited by the material quantity, and the synthetic ratio of the aluminum tripolyphosphate and the aluminum metaphosphate is improved. Related equipment can be adopted during the industrial production to realize continuous scale production.

Owner:GUANGXI UNIV FOR NATITIES

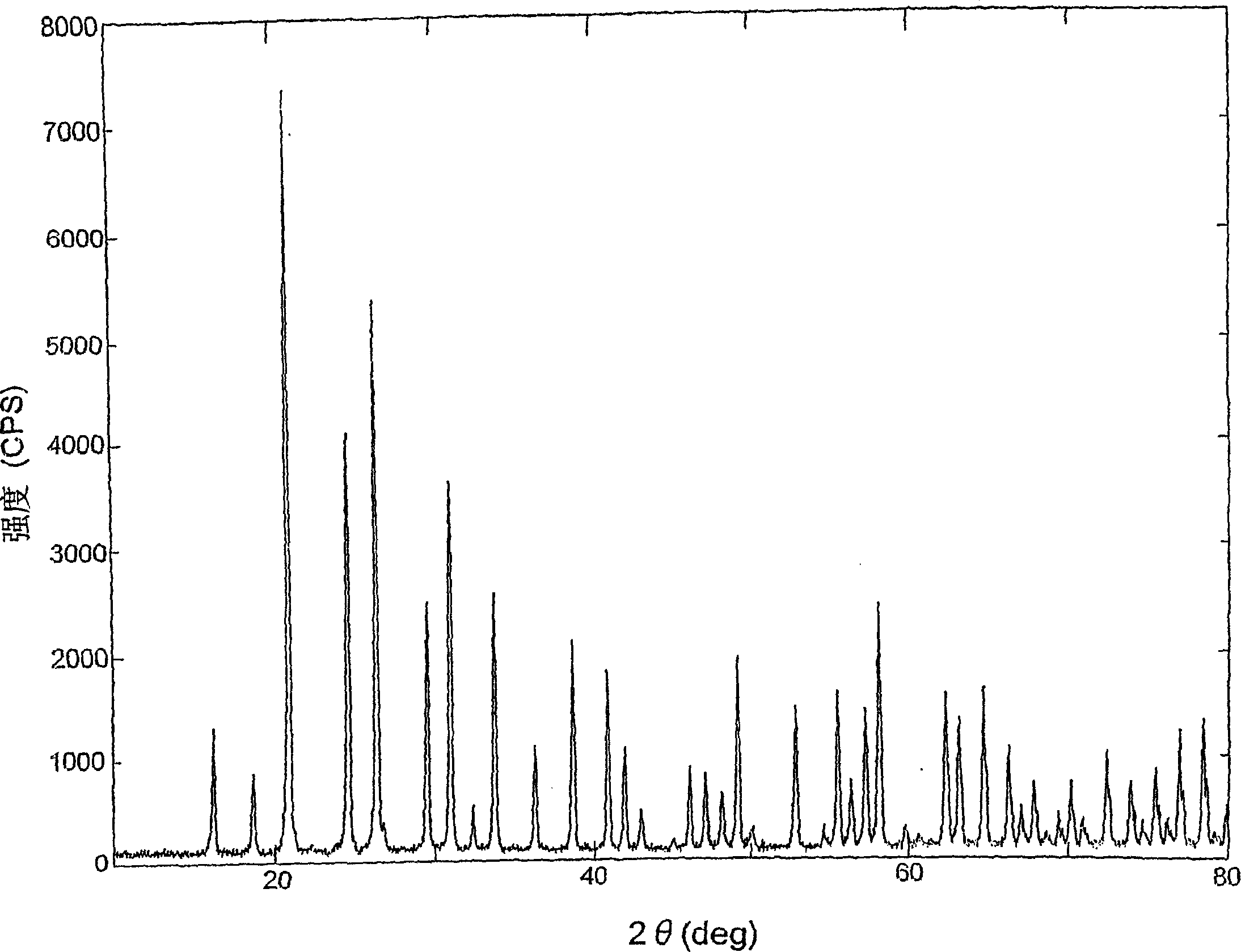

High purity metaphosphate and method for production thereof

A high purity metaphosphate, characterized in that it contains each coloring metal element in an amount of 5 ppm or less. Metaphosphates include an aluminum salt, a barium salt, a calcium salt, a magnesium salt and a strontium salt. Aluminum metaphosphate is suitably produced by a method comprising a first step of reacting an aluminum compound with phosphoric acid with heating to prepare a fluidized reaction mixture comprising aluminum biphosphate, a second step of spreading an aluminum metaphosphate powder in a vessel for firing, adding the fluidized reaction mixture comprising aluminum biphosphate from the first step on the powder and then firing them, and a third step of pulverizing the fired product from the second step.

Owner:NIPPON CHECMICAL IND CO LTD

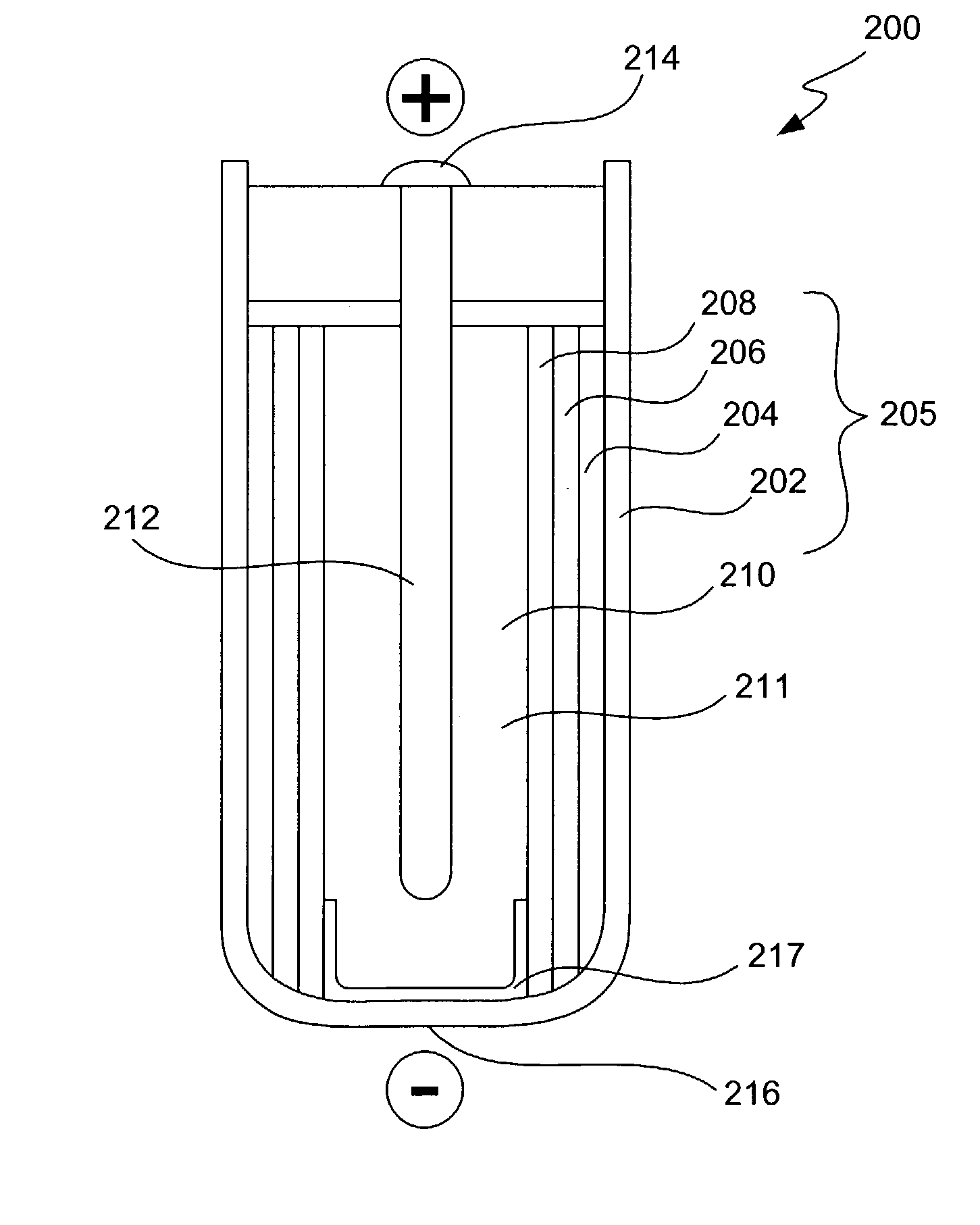

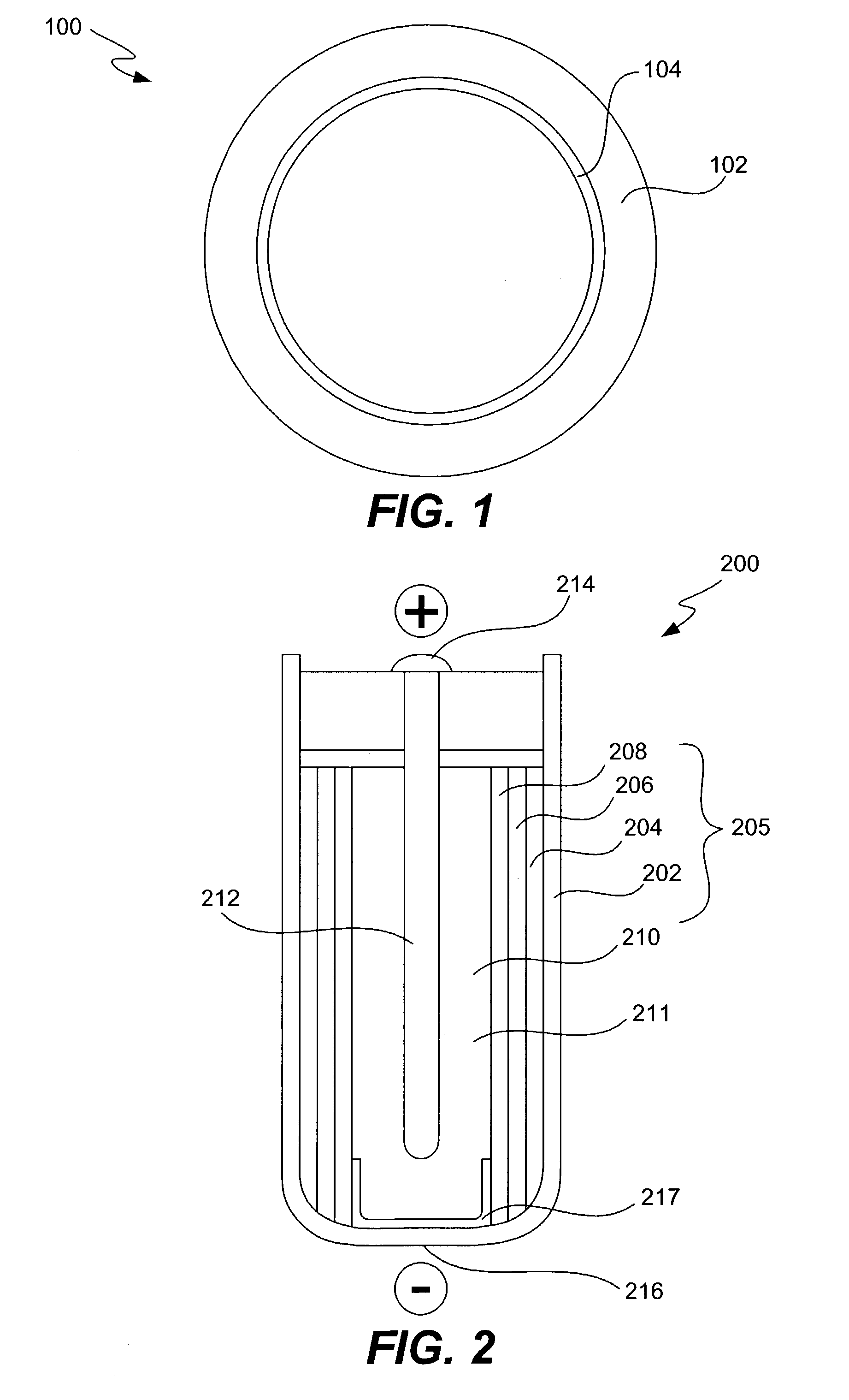

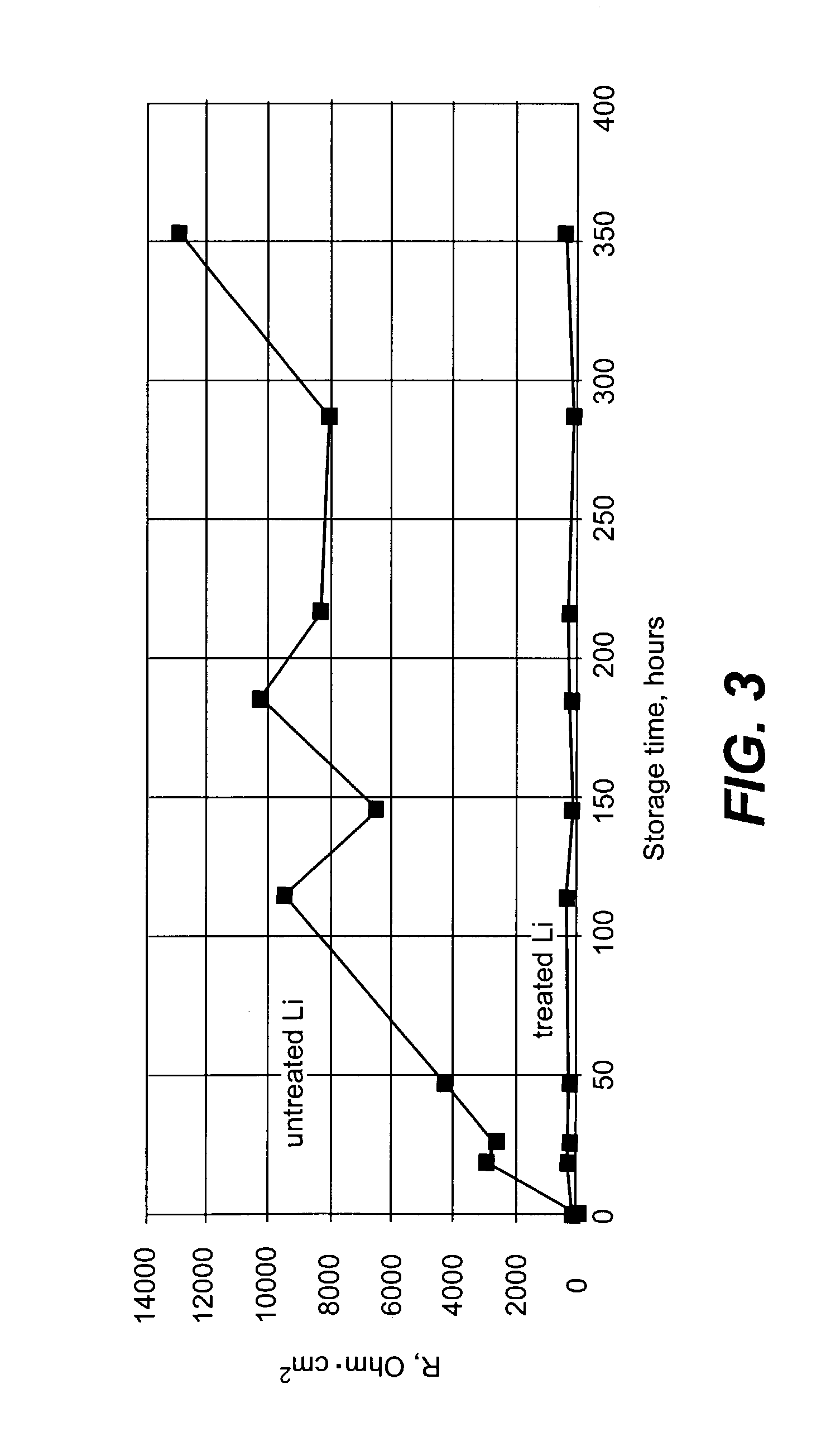

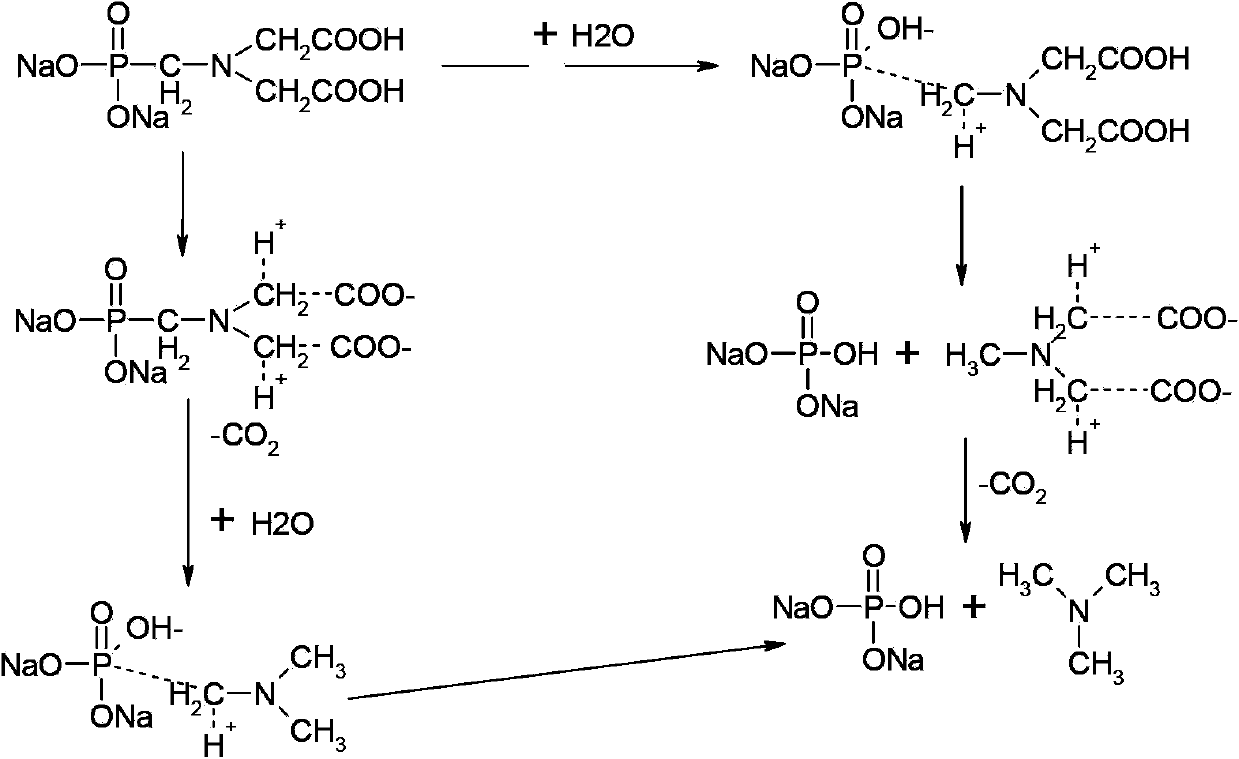

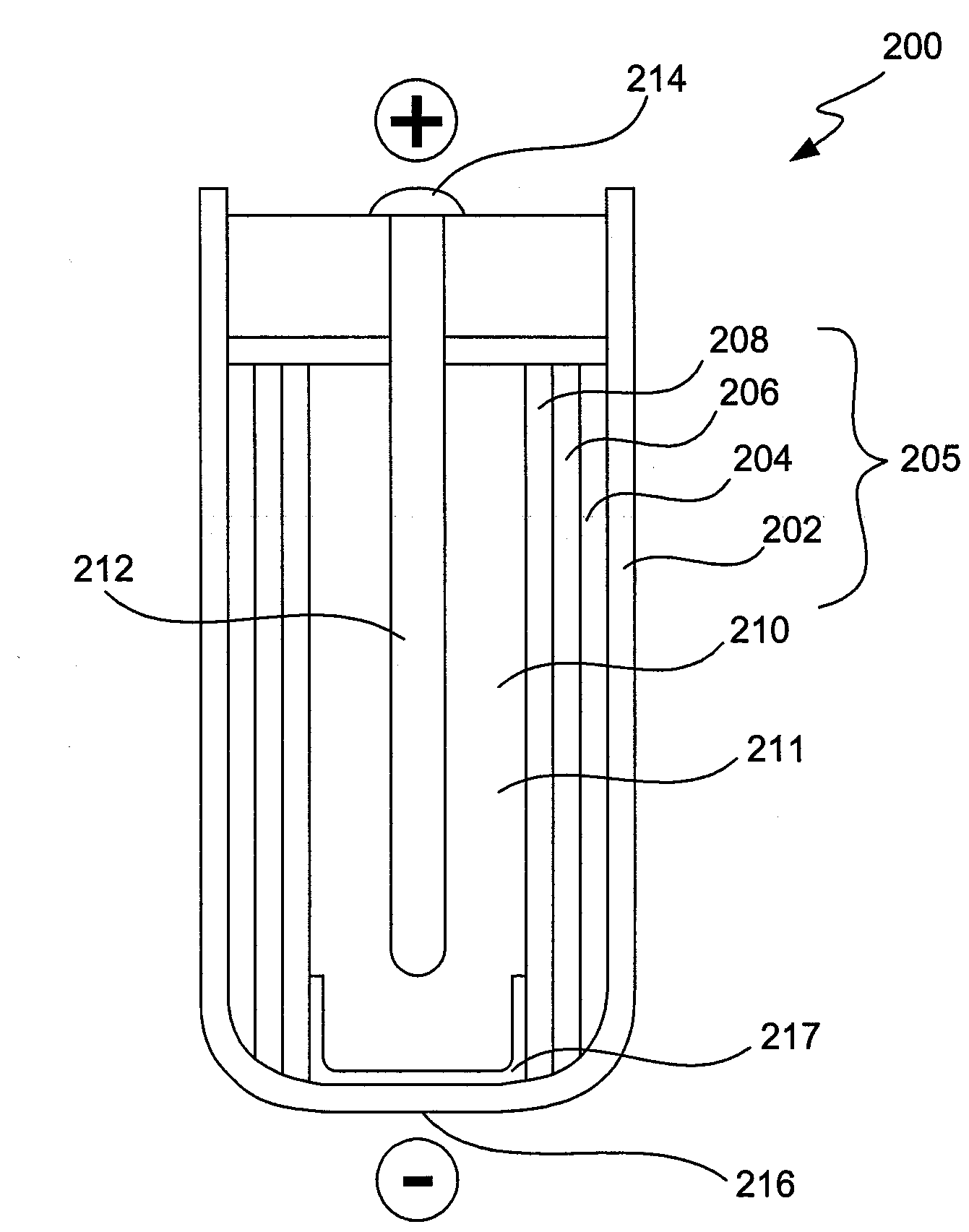

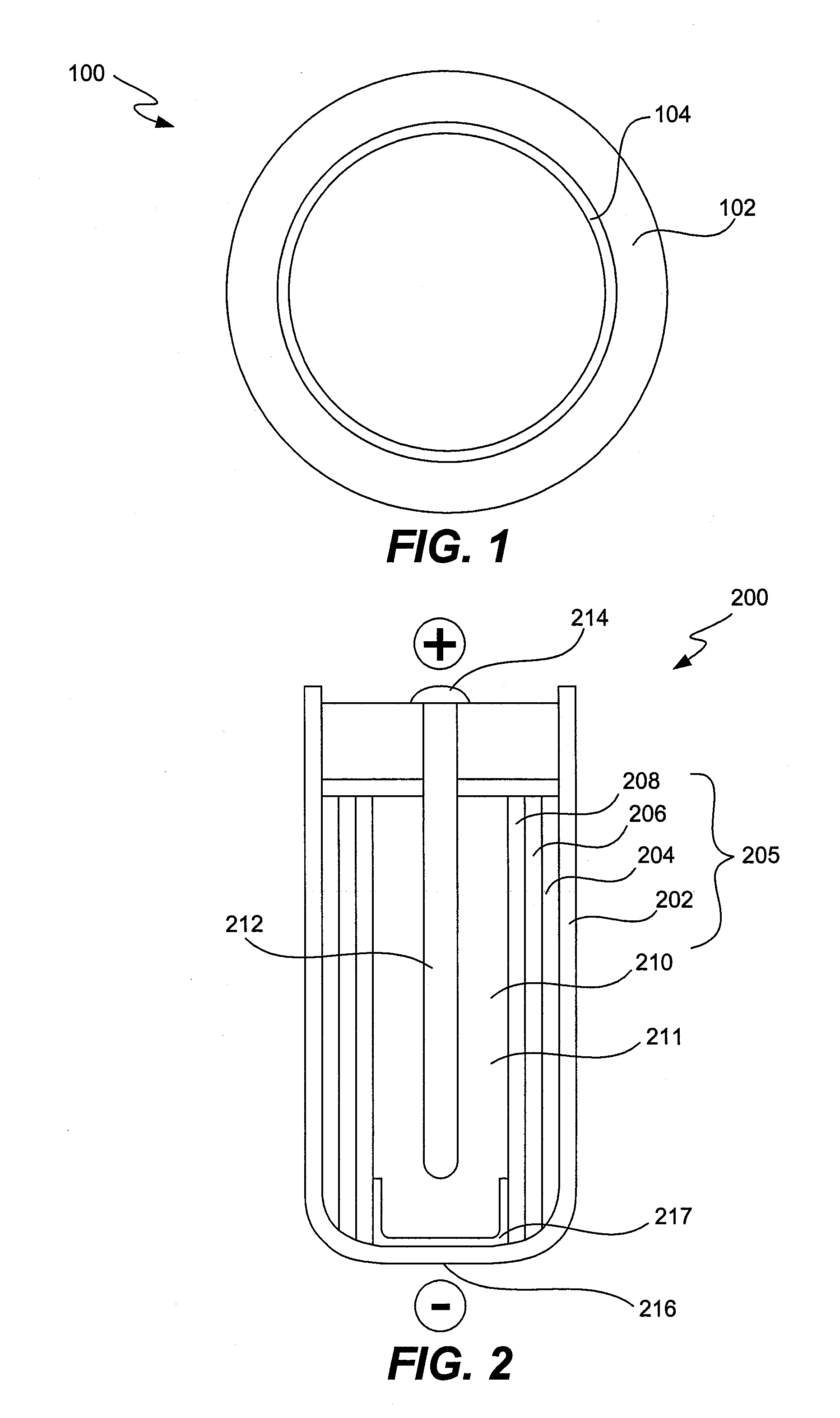

Alleviation of voltage delay in lithium-liquid depolarizer/electrolyte solvent battery cells

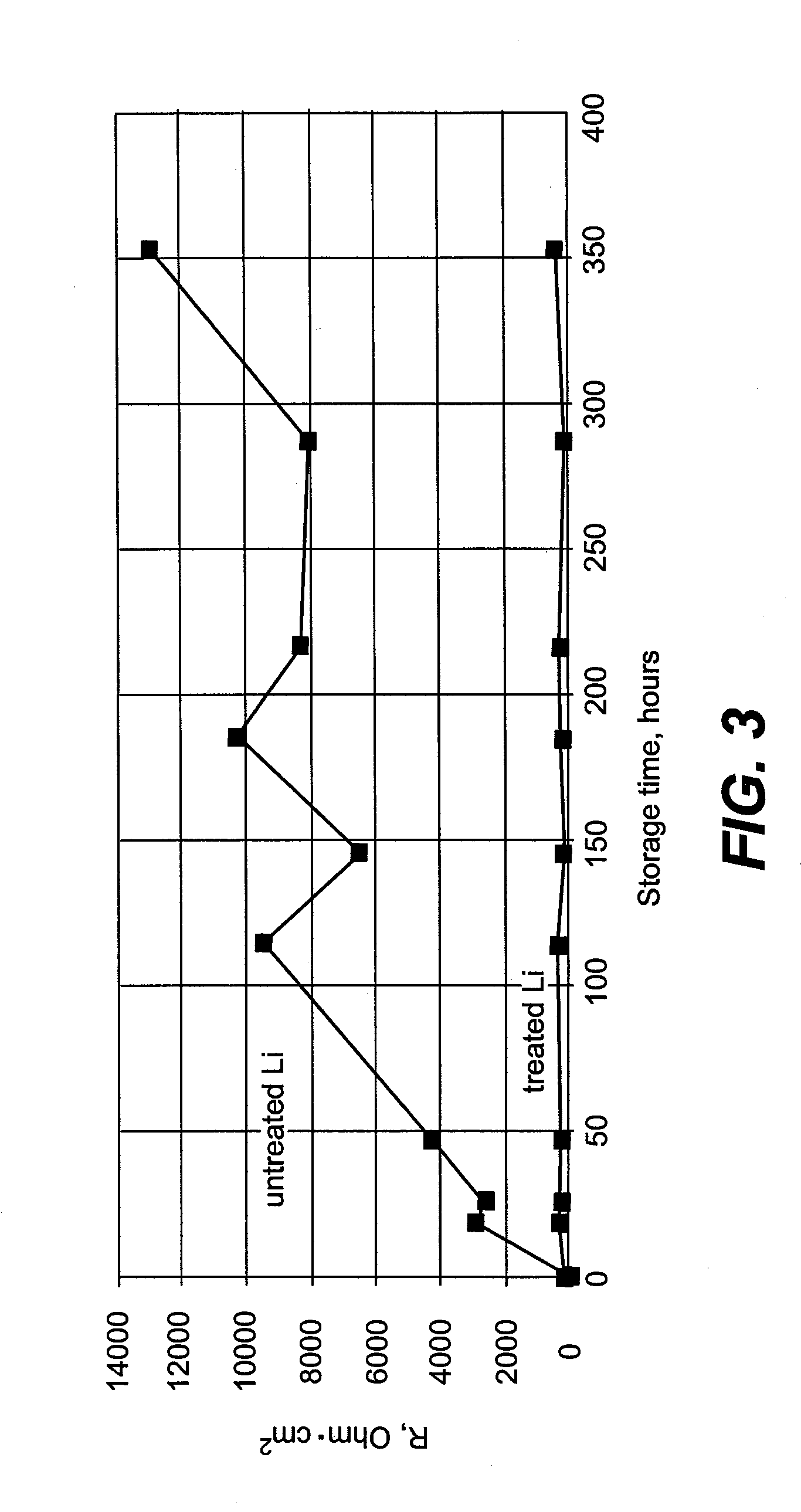

InactiveUS7482096B2Reduce degradationImprove stabilityElectrode manufacturing processesSolid electrolyte cellsChemical treatmentInorganic compound

Voltage delay in an active metal anode / liquid cathode battery cell can be significantly reduced or completely alleviated by coating the active metal anode (e.g., Li) surface with a thin layer of an inorganic compound with Li-ion conductivity using chemical treatment of Li surface. Particularly, preferred examples of such compounds include lithium phosphate, lithium metaphosphate, and / or their mixtures or solid solutions with lithium sulphate. These compounds can be formed on the Li surface by treatment with diluted solutions of the following individual acids: H3PO4, HPO3 and H2SO4, their acidic salts, or their binary or ternary mixtures in a dry organic solvent compatible with Li, for instance in 1,2-DME; by various deposition techniques. Such chemical protection of the Li or other active metal electrode significantly reduces the voltage delay due to protected anode's improved stability toward the electrolyte.

Owner:POLYPLUS BATTERY CO INC

Comprehensive treatment and resource utilization method for industrial organic phosphorus waste liquid

ActiveCN103964622AFully recycleReduce generationMultistage water/sewage treatmentWater/sewage treatment by neutralisationResource utilizationEvaporation

The invention discloses a comprehensive treatment and resource utilization method for an industrial organic phosphorus waste liquid. The technology includes firstly the industrial organic phosphorus waste liquid allows organic phosphorus to be oxidized into inorganic phosphorus by a catalytic wet oxidation method, then the inorganic phosphorus material is subjected to evaporation, concentration and desalination, small-molecule organic matters generated from oxidation are removed, the material after concentration is subjected to high temperature treatment, and a solid product is recycled. Through the method of the invention, the waste liquid can be avoided from being directly subjected to a high temperature contact oxidation process to possibly generate nitrogen oxides, dioxin, smoke dust and other air pollution factors difficult to deal with, and secondary pollution cannot be generated. The waste liquid after treatment is appropriately blended to be transformed into pyrophosphate, polyphosphate, metaphosphate, orthophosphate and other substances according to needs, so that recycling and reutilization of phosphorus is achieved.

Owner:JIANGSU YOUTH CHEM +1

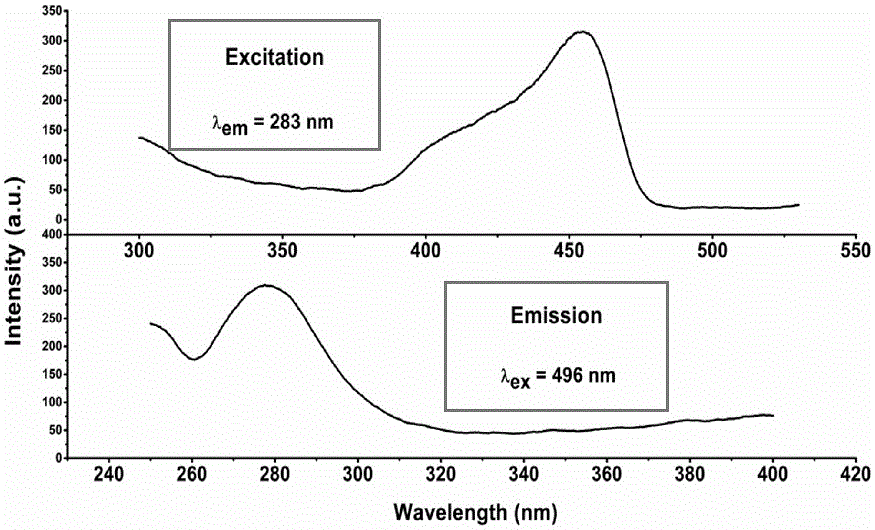

Phosphate or metaphosphate based visible-ultraviolet up-conversion luminescence material doped with rare earth ions, and preparation method and application thereof

InactiveCN105018089ASimple processEasy to operateFood preservationLuminescent compositionsUltraviolet lightsLED lamp

The present invention discloses a phosphate or metaphosphate based visible-ultraviolet up-conversion luminescence material doped with rare earth ions, wherein phosphate or metaphosphate serves as a substrate, and the substrate material is doped with Pr<3+>; a molar ratio of phosphate or metaphosphate to Pr<3+> is (0.9-3):(0.01-0.1). The present invention further provides a preparation process of the material, comprising: (a) according to the chemical formula, weighing oxide materials of corresponding elements and ammonium dihydrogen phosphate according to a stoichiometric ratio; and (b) grinding the weighed materials, burning the ground materials at the temperature of 850 to 950 DEG C for 2.5-4 h, cooling the materials to the room temperature, and grinding the materials to obtain a powder-like up-conversion luminescence material. It is experimentally proved that when excited by a common light source (such as an incandescent lamp, an xenon lamp, a fluorescent lamp and an LED lamp), especially by sunlight, the material can emit ultraviolet light UVC that can effectively kill bacteria; and the material has a broad application prospect in the fields of food safety and environmental protection.

Owner:HEBEI UNIVERSITY

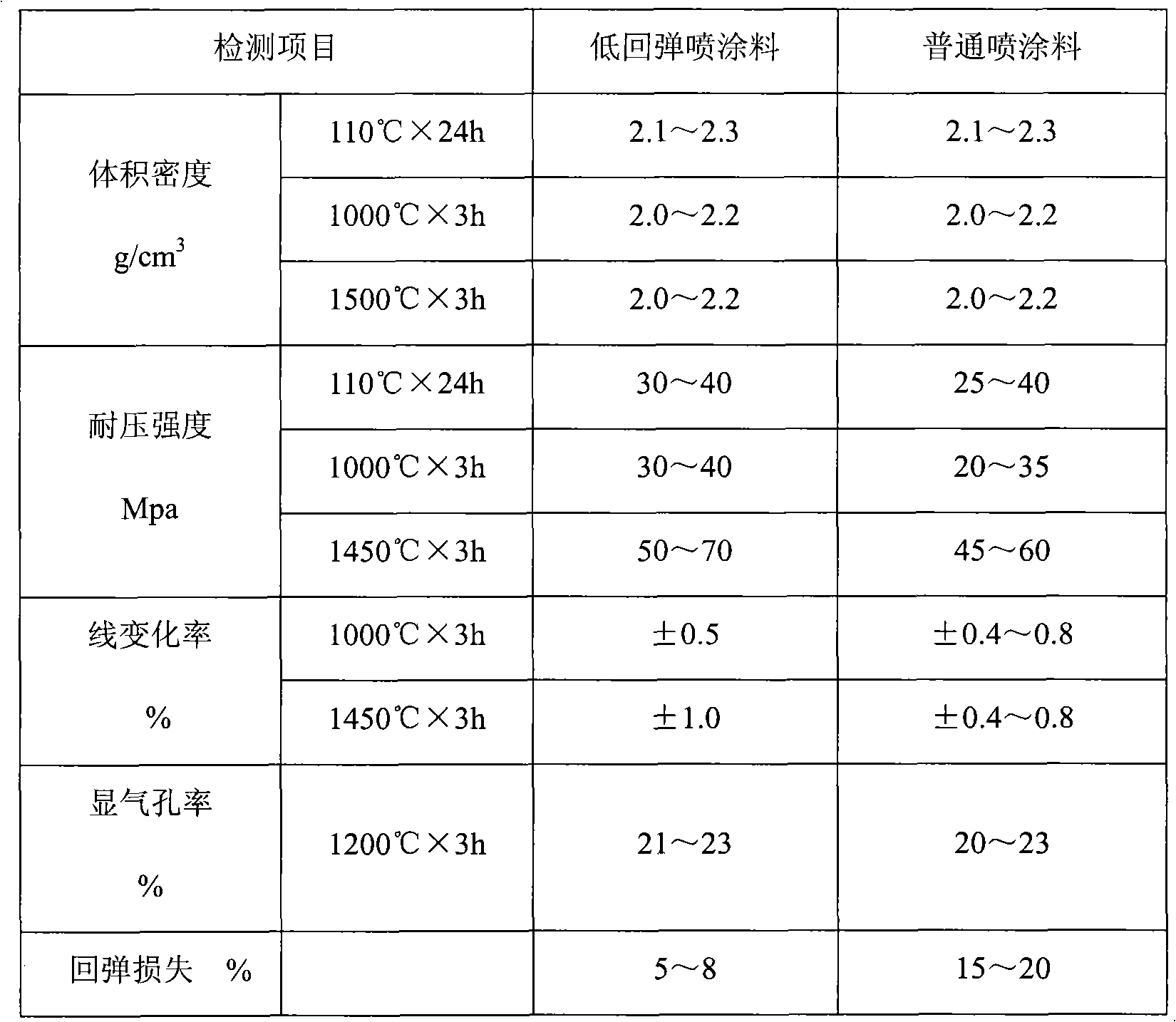

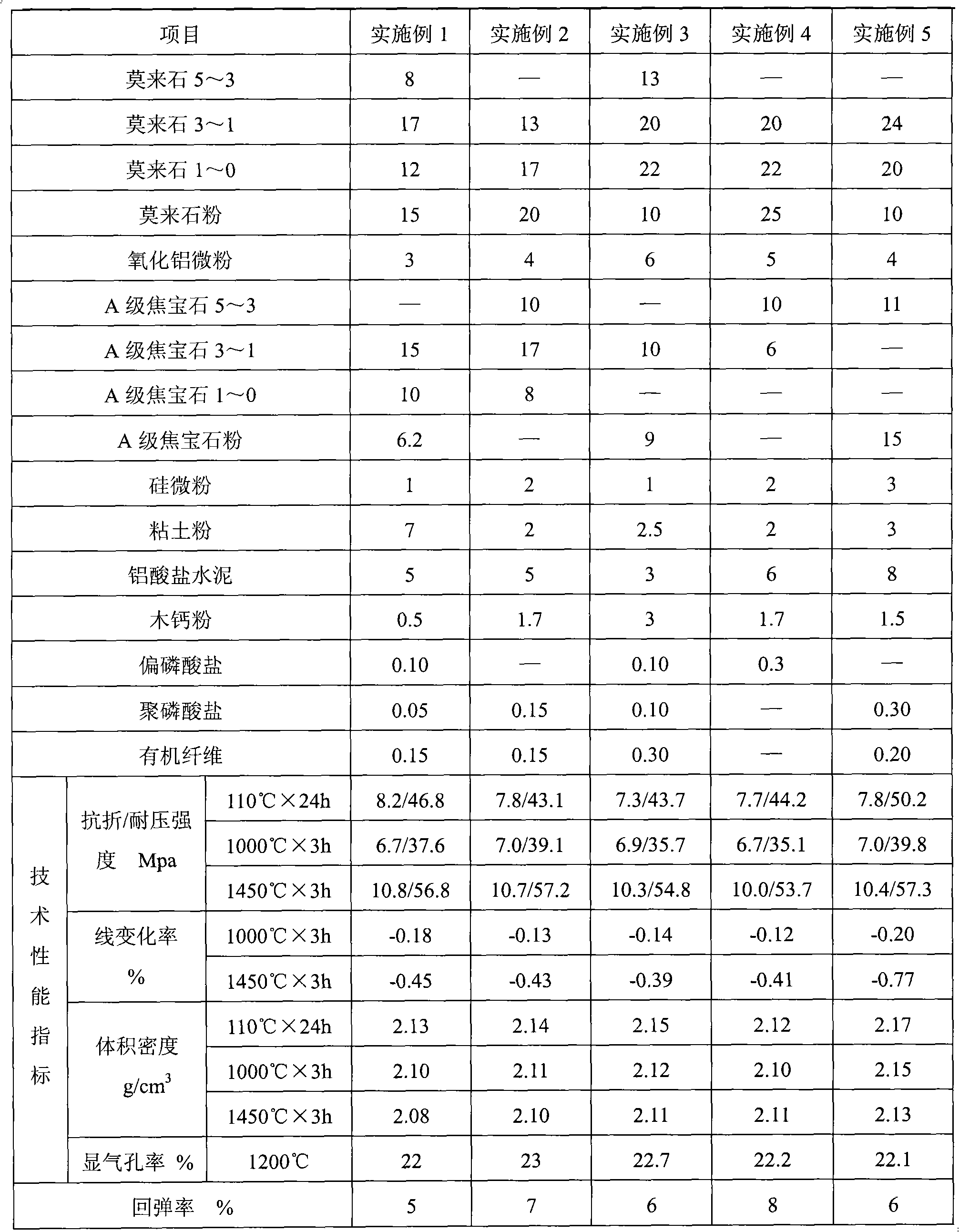

Low springback rate spraying and coating material for thermal-state blast furnace maintenance and preparation method thereof

The invention provides a low springback rate spraying and coating material for thermal-state blast furnace maintenance and a preparation method thereof. The spraying and coating material comprises the following raw materials in percentage by weight: 30-50% of synthetic mullite particles with the diameter of 5-0mm, 30-50% of A-level flint clay particles with the diameter of 5-0mm, 10-25% of synthetic mullite powder of 200-325 meshes, 0-15% of A-level flint clay powder of 200-325 meshes, 3-8% of aluminate cement, 2-7% of clay powder, 1-3% of silica micropowder of 2-5mu, 3-6% of aluminum oxide micropowder of 5mu, 0-0.3% of polyphosphate, 0-0.3% of metaphosphate, 0.5-3% of lignosulphonate calcium powder and 0-0.3% of organic fiber,The invention has the outstanding characteristics that the springback loss is small, waste of raw materials in the process of construction is reduced on one hand, and the start-up operation of the furnace is facilitated on the other hand; and the spraying and coating material provided by the invention meets the performance requirements on performances such as strength, scouring resistance, scouring and permeation resistance, rapid construction at 150-300 DEGC and the like, and is especially suitable for an unshaped refractory for thermal-state blast furnace lining maintenance. The invention has the outstanding characteristics that the springback loss issmall, waste of raw materials in the process of construction is reduced on one hand, and the start-up operation of the furnace is facilitated on the other hand; and the spraying and coating material provided by the invention meets the performance requirements on performances such as strength, scouring resistance, scouring and permeation resistance, rapid construction at 150-300 DEG C and the like, and is especially suitable for an unshaped refractory for thermal-state blast furnace lining maintenance.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

Active carbon catalyst, preparation method and application thereof in preparing acrylic acid by dehydrating lactic acid

InactiveCN101537362AGet rid of dependencyReduce energy consumptionOrganic chemistryCatalyst activation/preparationActivated carbonActive component

The invention discloses an active carbon catalyst, a preparation method thereof and application thereof in preparing acrylic acid by dehydrating lactic acid. The catalyst is obtained by taking active carbon (AC) or acidified and oxidized active carbon (HOAC) as the primary active component, introducing one or more than one of acid phosphate or metaphosphate or pyrophosphate with immersion method or direct grinding mixing method and drying. The catalyst is used for preparing acrylic acid by dehydrating lactic acid with high lactic acid conversion rate and acrylic acid selectivity, wherein the lactic acid conversion rate is 100% and the acrylic acid selectivity is up to 65%.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

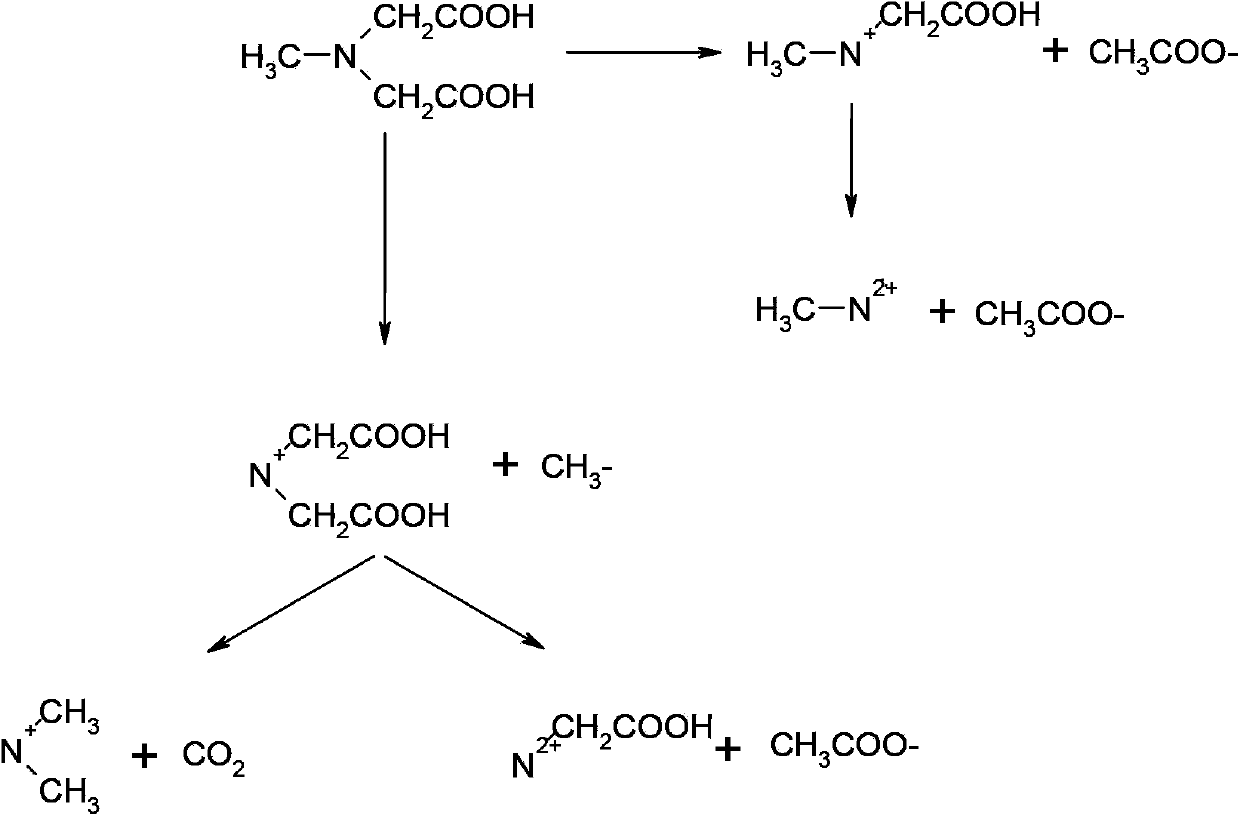

Method for producing glutathione based on enzymic method in vitro

The invention relates to a method for producing glutathione based on enzymic method in vitro. Through expression and catalysis of glutathione compound difunctional enzymes and polyphosphoric acid kinases, tetraphosphate and hexametaphosphate serve as phosphoric acid donors to regenerate ATP (adenosine triphosphate), and the glutathione is generated under the catalytic action of the glutathione compound difunctional enzymes by taking glutamic acid, glycine and cysteine as substrates. Compared with existing glutathione production methods, the method has the advantages that inhibition effect of the glutathione compound difunctional enzymes is low, and the content of the glutathione obtained from a reaction system is high; sodium and kali salt of phosphoric acid donors, such as the tetraphosphate and the hexametaphosphate, used in the reaction process is low in cost and easy to get; the phosphoric acid donors serve as substrates of the polyphosphoric acid to generate the ATP, and accordingly, production cost is reduced greatly; the amino acid ratio of Gly:Gys:Gly is lowered to 2:1:2, the content of amino acid in the system is low, and later product separation is facilitated.

Owner:BEIJING UNIV OF CHEM TECH

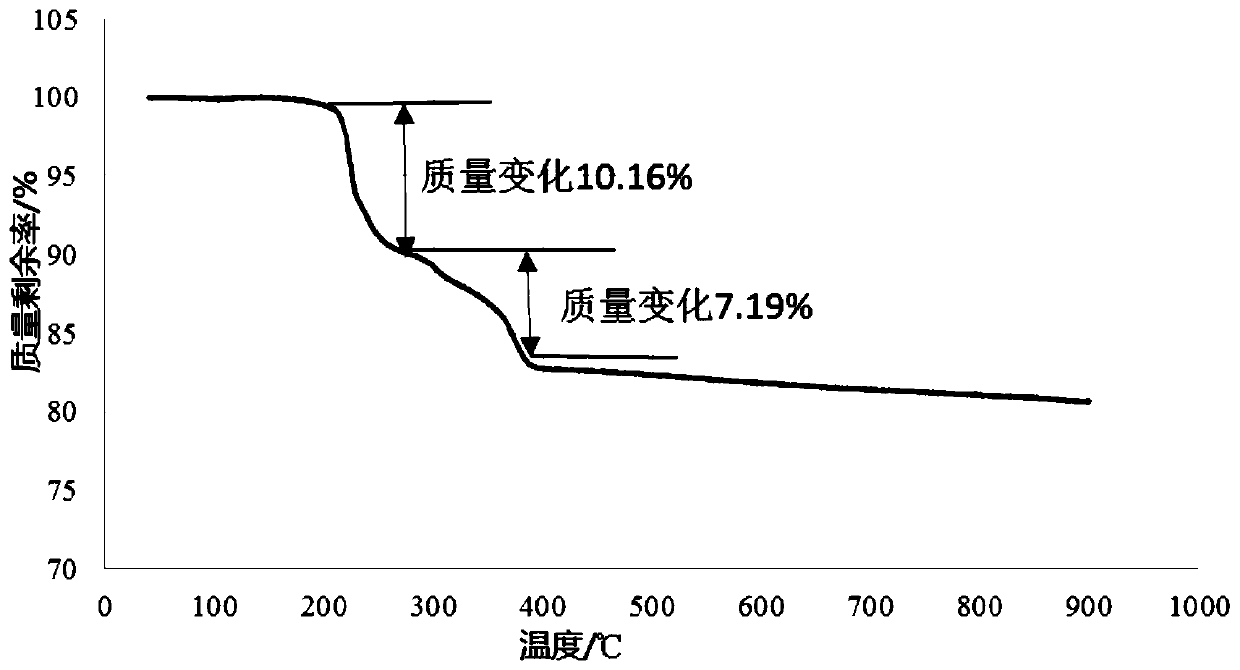

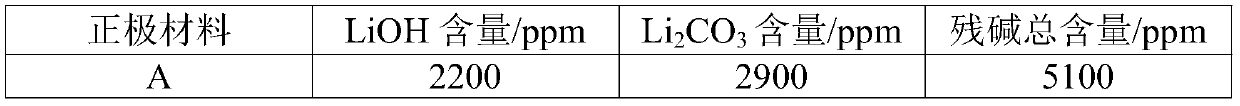

Lithium ion battery positive electrode material and preparation method thereof, and battery

ActiveCN109713284AImprove cycle performanceReduce residual alkaliCell electrodesSecondary cellsPhysical chemistryPyrophosphate

The invention relates to the technical field of lithium ion batteries, and discloses a lithium ion battery positive electrode material and a preparation method thereof, and a battery. The method includes the following steps: 1) a precursor of the lithium ion battery positive electrode material is mixed with phosphate, and then low temperature calcination is performed to obtain the precursor havingpyrophosphate or metaphosphate coating layers on the surface; and 2) the precursor is mixed with a lithium salt, and high temperature calcination is performed to obtain the positive electrode material, wherein the temperature of the low temperature calcination is 250-400 DEG C, and the time is 8-12 hours. The positive electrode material prepared by the method includes an active material having ageneral molecular formula of LiaNixCoyMnzO2, and a coating layer of lithium pyrophosphate or lithium metaphosphate, residual alkali of the positive electrode material can be reduced, and cycle stability of the positive electrode material is improved.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Antimicrobial moldproof agent for silk fabrics

ActiveCN103757893AWon't breakHas antibacterial and antifungal effectsAnimal fibresFiberPhosphoric acid

The invention discloses an antimicrobial moldproof agent for silk fabrics, which is prepared from the following components in parts by weight: 8-12 parts of citric acid, 7-11 parts of polyoxyethylene trimethyl ammonium chloride, 6-10 parts of vinyl siloxane, 5-9 parts of chitosan quaternary ammonium salt, 4-8 parts of tetrasodium metaphosphate, 3-7 parts of tin tetrachloride, 3-7 parts of potassium oxalate, 3-7 parts of sodium alginate, 5-9 parts of phenyl salicylate and 10-14 parts of amyl acetate. The antimicrobial moldproof agent has favorable antimicrobial and moldproof effects; the finished fabric has favorable washing fastness and soft feeling; and the preparation technique is simple, is nontoxic and harmless to the human body, and can not destroy the cocoon fibers in the silk fabric.

Owner:上海福晏精细化工有限公司

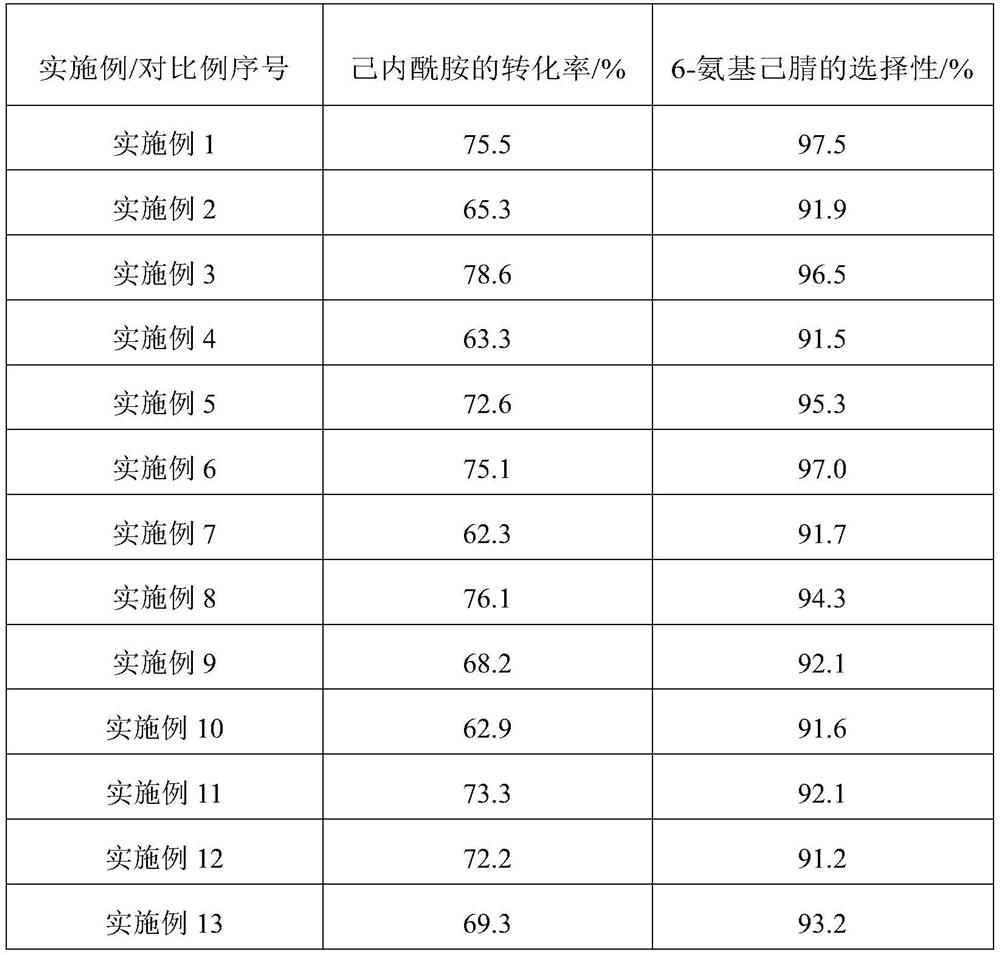

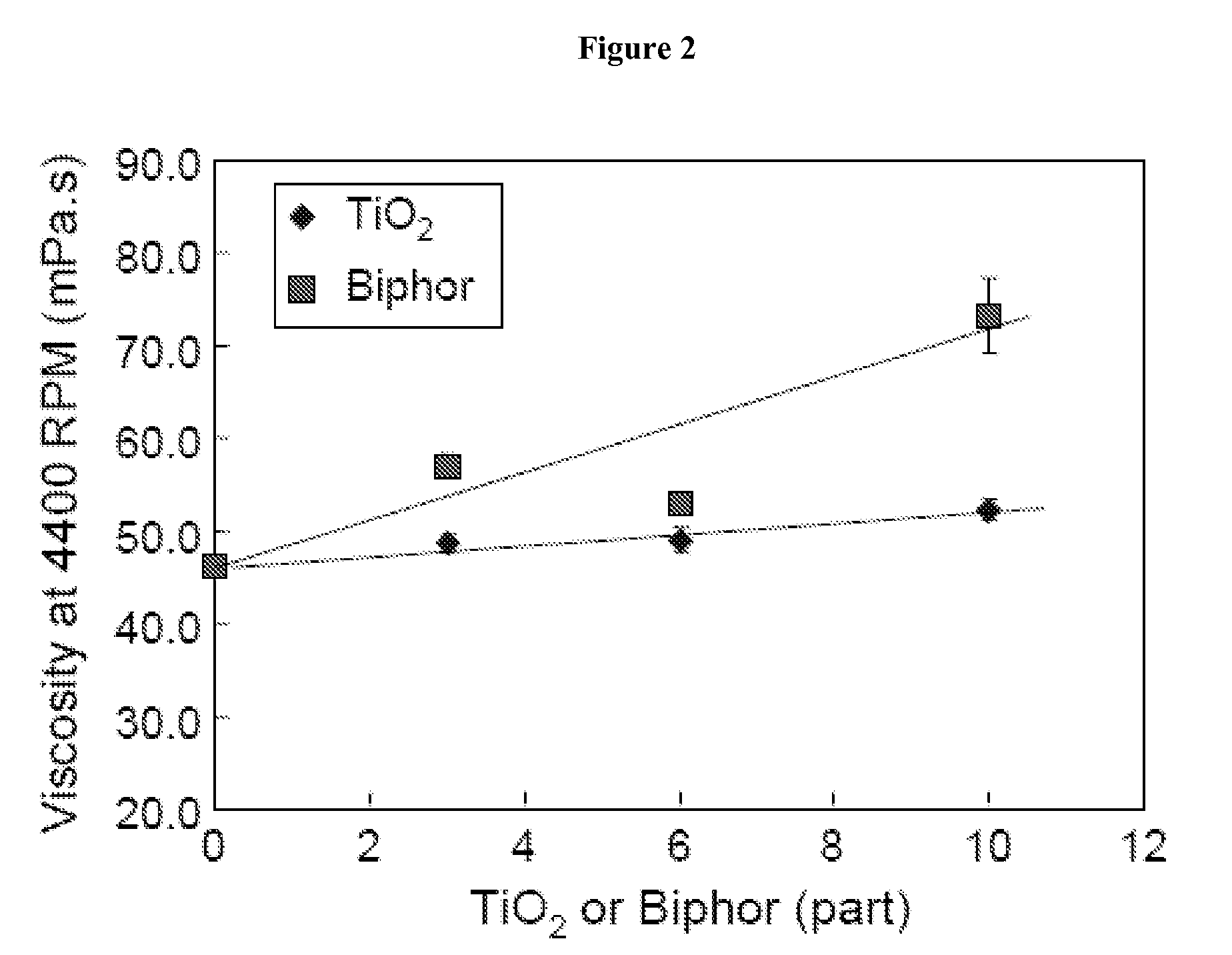

Preparation method of catalyst for synthesizing hexamethylenediamine intermediate 6-aminocapronitrile and synthesis method of 6-aminocapronitrile

ActiveCN111672526AHigh strengthHigh activityPhysical/chemical process catalystsCarboxylic acid nitrile preparationPhosphorous acidMagnesium phosphate

The invention provides a preparation method of a catalyst for synthesizing a hexamethylenediamine intermediate 6-aminocapronitrile and a synthesis method of the 6-aminocapronitrile. The preparation method comprises the following steps: S1, mixing a carrier, a binder, water and a peptizing agent to obtain a mixture; S2, molding the mixture to obtain a molded carrier; and S3, modifying the molded carrier in a modifier acidic solution to obtain the catalyst for synthesizing the hexamethylenediamine intermediate 6-aminocapronitrile, wherein the mass ratio of the modifier to the molded carrier is (0.1-1): 1, and the modifier is selected from one or more of calcium phosphate, magnesium phosphate, aluminum phosphate, calcium metaphosphate, magnesium metaphosphate, aluminum metaphosphate and aluminum phosphite. Therefore, the catalyst has better strength, activity and selectivity. The preparation method is simple, wide in raw material source and relatively low in cost.

Owner:JIANGSU YANGNONG CHEM GROUP +3

Use of Aluminum Phosphate, Polyphosphate and Metaphosphate Particles in Paper Coating Applications

InactiveUS20100203318A1Avoid smudgingSimple compositionDefoamers additionCoatings with pigmentsMetallurgyPolyphosphate

Provided herein are coating compositions for paper comprising aluminum phosphate, aluminum metaphosphate, aluminum orthophosphate and / or aluminum polyphosphate pigments. Methods of making and using the compositions are described.

Owner:BUNGE AMORPHIC SOLUTIONS +1

Preparation of pyrolized silicon oxide encapsulated titanium oxide powders treated with organic additives

InactiveCN1896148AIncreased mixing capacityPigment treatment with organosilicon compoundsSilanesSilicon oxide

A composition containing titanic oxide grain encapsulated by pyrolytic monox and its productionby organic additive treatment are disclosed. The material consists of organic silane, organic siloxane, fluoro-silane, organic phosphate, organic acid phosphate, organic pyrophosphate, organic poly-phosphate, organic metaphosphate, organic hypophosphite, organic sulfonic acid compound, sulfcarboxylic acid, hydrocarbyl carboxylic acid ester, hydrocarbyl carboxylic acid derivatives, hydrocarbyl amide, low-molecular-weight hydrocarbon wax, low-molecular-weight polyolefine, low-molecular-weight polyolefine multi-polymer, hydrocarbyl polyol, hydrocarbyl polyol derivative, alkanolamine, alkanolamine derivative, organic dispersant or their mixtures.

Owner:EI DU PONT DE NEMOURS & CO

Starch-based biodegradable material and production method of its disposable tableware

InactiveCN1354197AReduce areaNo pollution in the processPlatesLinear low-density polyethylenePersulfate

The present invention relates to a starch base bio-degradable material and its production method of disposable tableware. Its production raw material includes starch, persulfate, hexametaphosphate, dibasic alcohol, titanium dioxide, calcium carbonate, talcum powder, titanate, polyvinyl wax, polybasic acid, polypropylene, high-density polyethylene and linear low-density polyethylene. When it is prepared, firstly 50-70% of starch can be added into high-speed mixing and stirring machine. Then the auxiliary materials are added in turn, through the processes of stirring, starch modification and mixing, discharging to blending channel, the invented product can be obtained. Said invention starch base bio-degradable material and its tableware can be quickly degraded into friendly substance for soil in three months to one year under the condition of microbial environment, and do not result in "white pollution".

Owner:祝光富

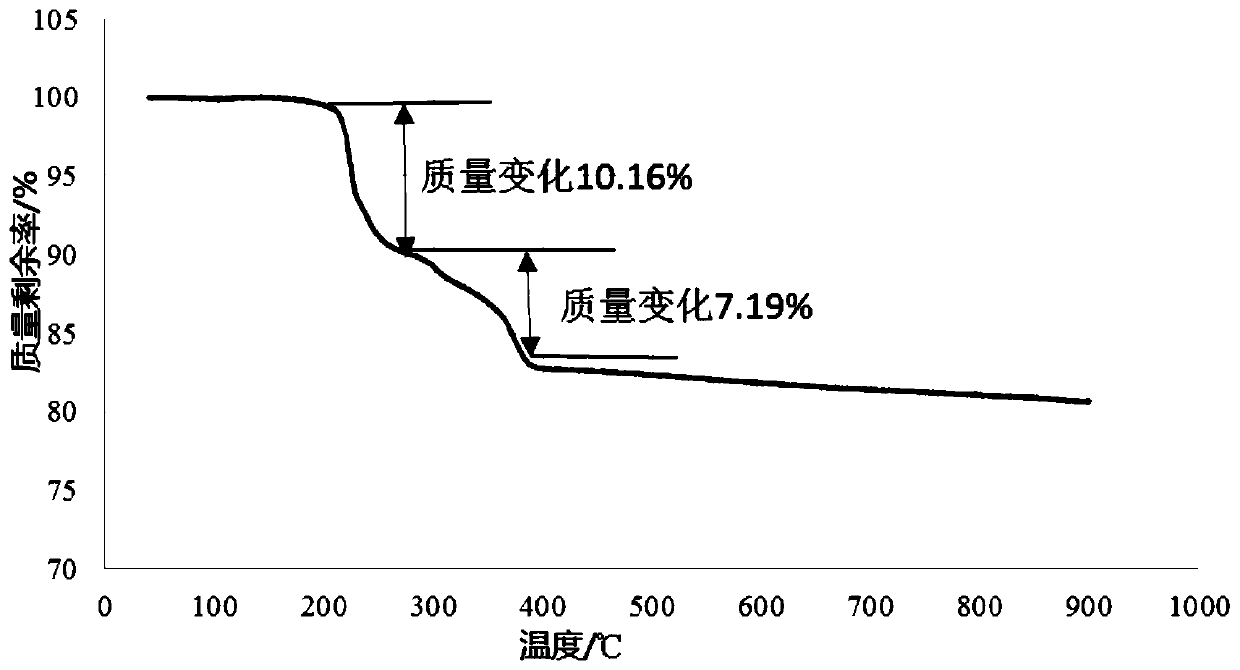

Rare earth composite metaphosphate coated lithium positive material and preparation method thereof

ActiveCN110061203AAvoid corrosionImprove cycle performanceSecondary cellsPositive electrodesLithiumRare-earth element

The invention provides a rare earth composite metaphosphate coated lithium positive material and a preparation method thereof. The rare earth composite metaphosphate coated lithium positive material comprises rare earth composite metaphosphate and a lithium positive material, wherein a chemical formula of the rare earth composite metaphosphate is xLiPO3.yM(PO3)m.zR (PO3)n; M is one or more of Na,K, Mg, Ni, Ca, Sr and Ba; R is one or more of a rare earth element, Al, Ti, Ni, Mn, Zr, Nb, Hf and Ta; m is equal to an average valence state of the element M; n is equal to an average valence state of the element R; x is greater than 0 and less than or equal to 0.50; y is greater than or equal to 0 and less than or equal to 0.50; z is greater than 0 and less than 1.0; and the sum of x, y and z isequal to 1. The rare earth composite metaphosphate is adopted as a coating material, so that the surface of the lithium positive material can be prevented from being corroded by an electrolyte, and the lithium positive material has better cycling performance and higher thermal stability under a voltage of 4.50V or even above. Meanwhile, the rare earth composite metaphosphate can generate a liquidglass phase, and is spread on the surface of the lithium positive material, so that the coating layer is more uniform.

Owner:BEIJING TAIFENG XIANXING NEW ENERGY TECH CO LTD +1

Aluminum phosphate, polyphosphate and metaphosphate particles and their use as pigments in paints and method of making same

Owner:BUNGE AMORPHIC SOLUTIONS +1

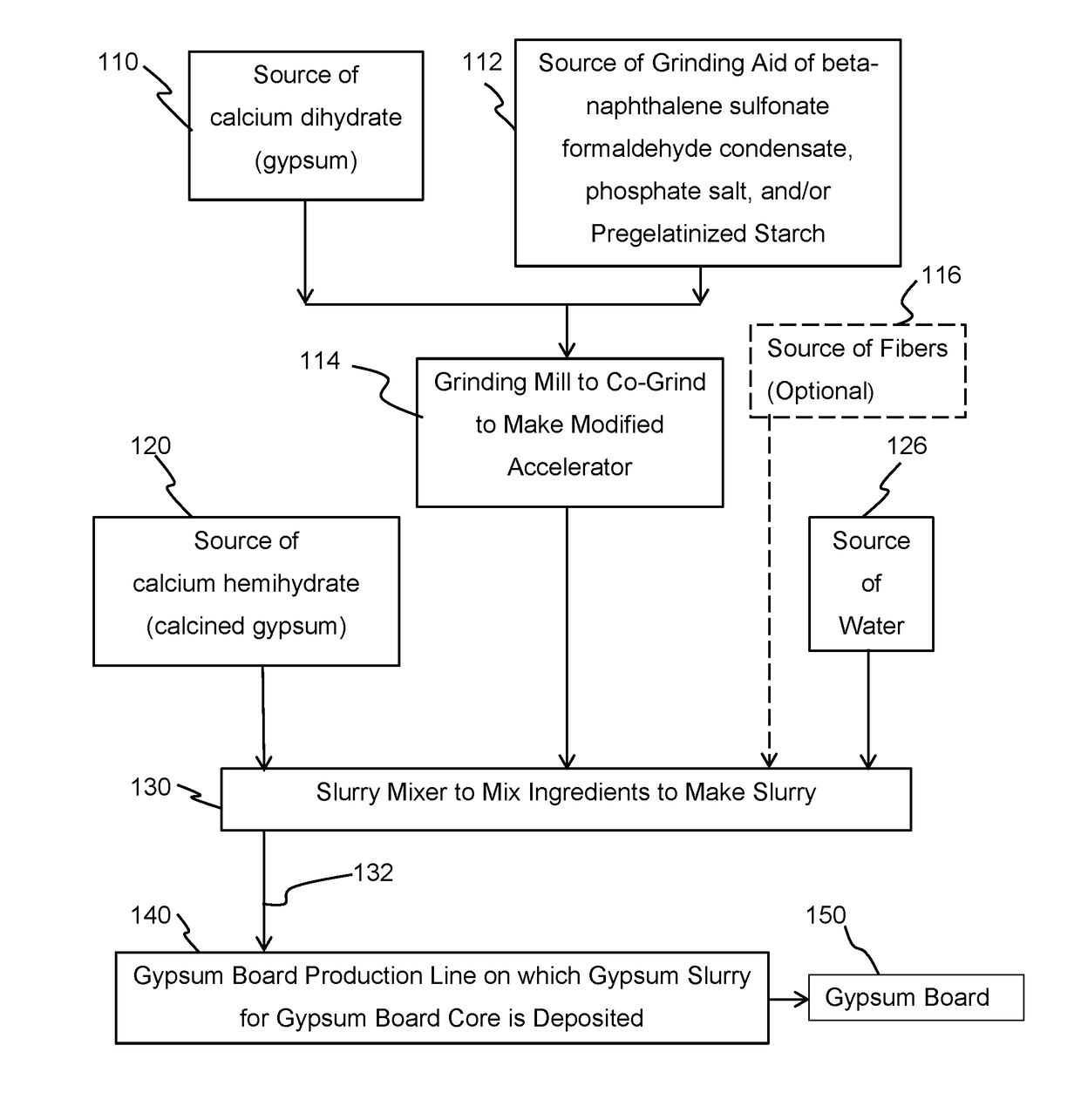

Gypsum set accelerator and method of preparing same

A modified gypsum set accelerator and a method of preparing the same is provided, which includes dry loose finely ground particles of a mixture of ground dry calcium sulfate dihydrate and a grinding aid selected from one or more of beta-naphthalene sulfonate formaldehyde condensate, trimetaphosphate phosphate salt, tripolyphosphate salt, tetra-pyrophosphate salt, and pregelatinized starch.

Owner:UNITED STATES GYPSUM CO

Alleviation of voltage delay in lithium-liquid depolarizer/electrolyte solvent battery cells

InactiveUS20090071835A1Reduce degradationImprove stabilityElectrode manufacturing processesVacuum evaporation coatingChemical treatmentInorganic compound

Voltage delay in an active metal anode / liquid cathode battery cell can be significantly reduced or completely alleviated by coating the active metal anode (e.g., Li) surface with a thin layer of an inorganic compound with Li-ion conductivity using chemical treatment of Li surface. Particularly, preferred examples of such compounds include lithium phosphate, lithium metaphosphate, and / or their mixtures or solid solutions with lithium sulphate. These compounds can be formed on the Li surface by treatment with diluted solutions of the following individual acids: H3PO4, HPO3 and H2SO4, their acidic salts, or their binary or ternary mixtures in a dry organic solvent compatible with Li, for instance in 1,2-DME; by various deposition techniques. Such chemical protection of the Li or other active metal electrode significantly reduces the voltage delay due to protected anode's improved stability toward the electrolyte.

Owner:POLYPLUS BATTERY CO INC

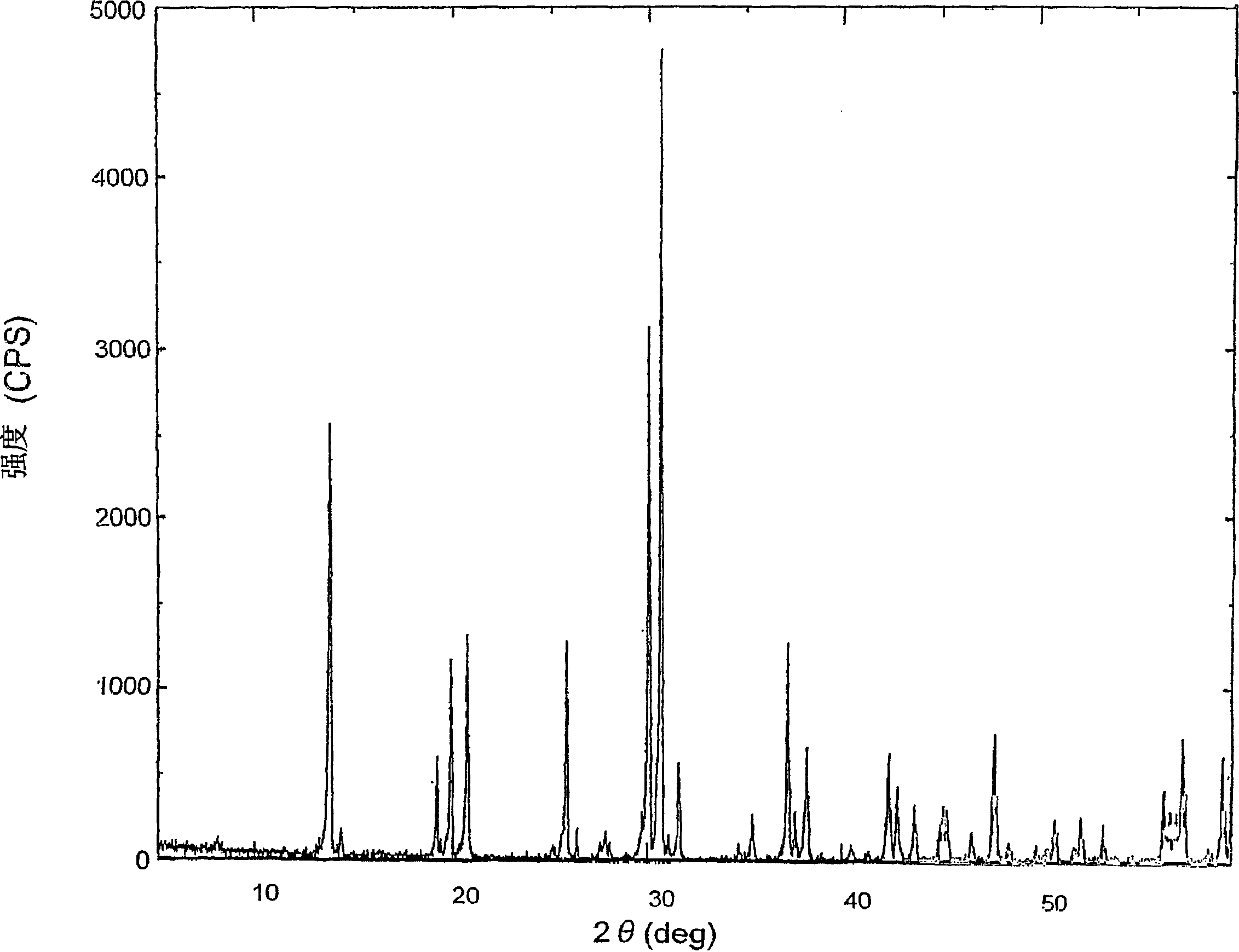

Temperature control stepwise conversion method of producing electronic grade aluminum metaphosphate

ActiveCN102408103AHigh purityReduce manufacturing costPhosphorus compoundsTemperature controlPhosphoric acid

The invention discloses a temperature control stepwise conversion method of producing electronic grade aluminum metaphosphate, which comprises the following steps of: adding water and phosphoric acid in the weight ratio of 1 : 1 to a reaction kettle; slowly adding aluminum hydroxide after reacting completely,, and controlling the weight ratio of the added aluminum oxide to the phosphoric acid to 1 : 2; placing the produced aluminum dihydrogen phosphate in a box, and placing in a heating furnace, then closing the heating furnace; increasing temperature of the heating furnace, and extracting air to result in negative pressure state in the heating furnace; and carrying out temperature control baking to the heating furnace by three steps to obtain high-purity aluminum metaphosphate, taking out and cooling at room temperature. Using the method of carrying out stepwise conversion to the aluminum dihydrogen phosphate by controlling different temperatures to obtain the high-purity electronic grade aluminum metaphosphate, the characteristics of simple and clear operation steps, high stability and safety of industrial flow operation, high purity of produced aluminum metaphosphate, low production cost and batch production and the like can be realized.

Owner:SICHUAN MINGJING PHOTOELECTRIC TECH

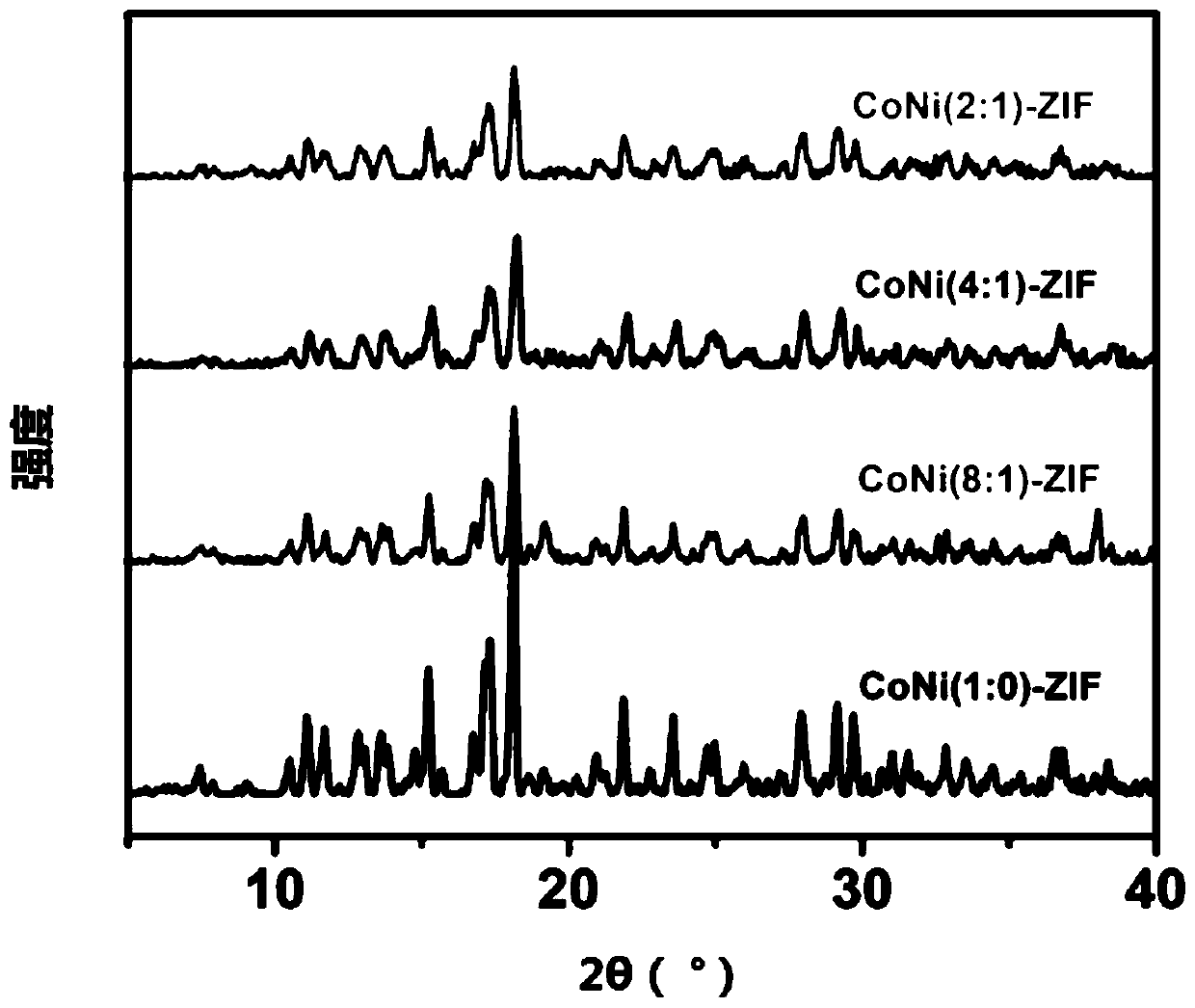

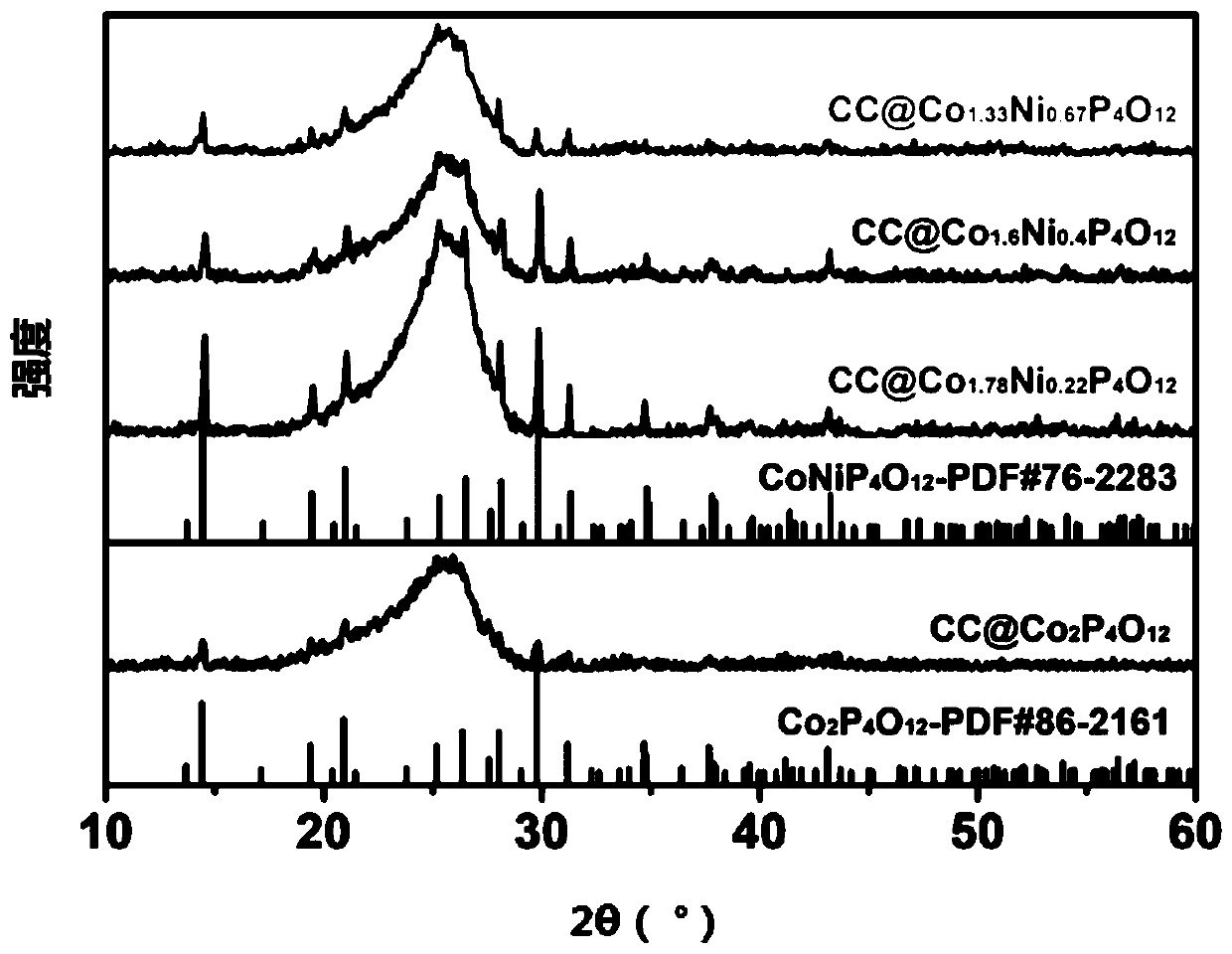

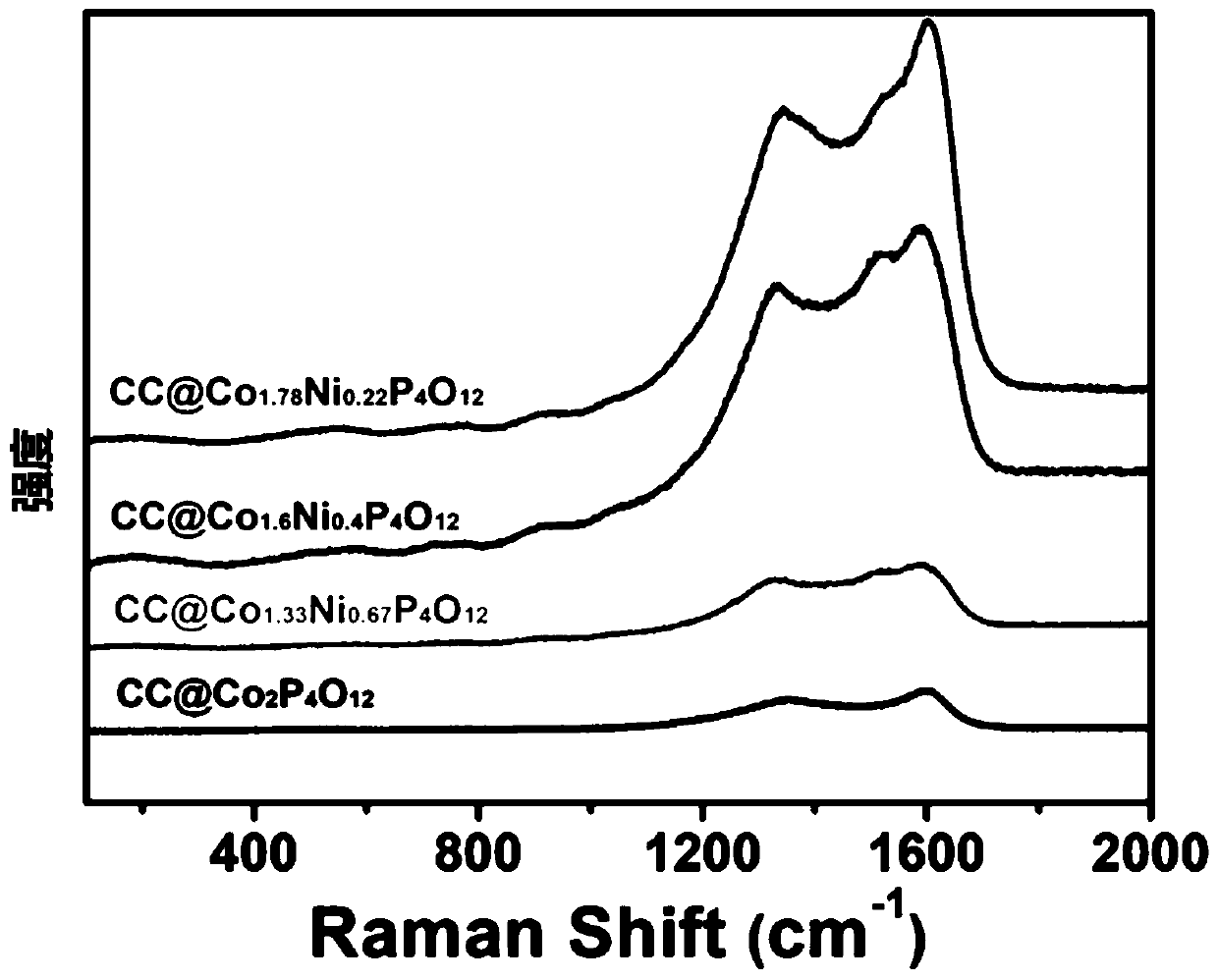

Preparation method for cobalt-nickel bimetal metaphosphate nanometer array loaded on carbon cloth substrate

ActiveCN110124704AImprove conductivityOptimize electronic structurePhysical/chemical process catalystsElectrodesElectrolysisModified carbon

The invention relates to a preparation method for a cobalt-nickel bimetal metaphosphate nanometer array loaded on a carbon cloth substrate, and relates to the field of preparation methods for bimetalmetaphosphate modified carbon nanometer composite materials. The invention is to solve the technical problems of low stability and catalytic activity for a conventional anode catalyst and high cost for noble metals and oxides of the noble metals. The preparation method comprises the following steps: allowing Co-based bimetallic MOFs to uniformly grow on a conductive carbon cloth through a co-precipitation method so as to obtain a CoNi(n)-ZIF nanometer array, and subjecting the CoNi(n)-ZIF nanometer array to a low-temperature solid-phase phosphorylation reaction so as to obtain a Co<2-x>NixP4O<12->C nanometer array catalyst. The catalyst provided by the invention is a non-noble metal catalyst, reduces the cost of a reaction and has good catalytic activity to oxygen evolution. The material prepared by using the method provided by the invention is used in an oxygen evolution reaction through water electrolysis.

Owner:HARBIN INST OF TECH

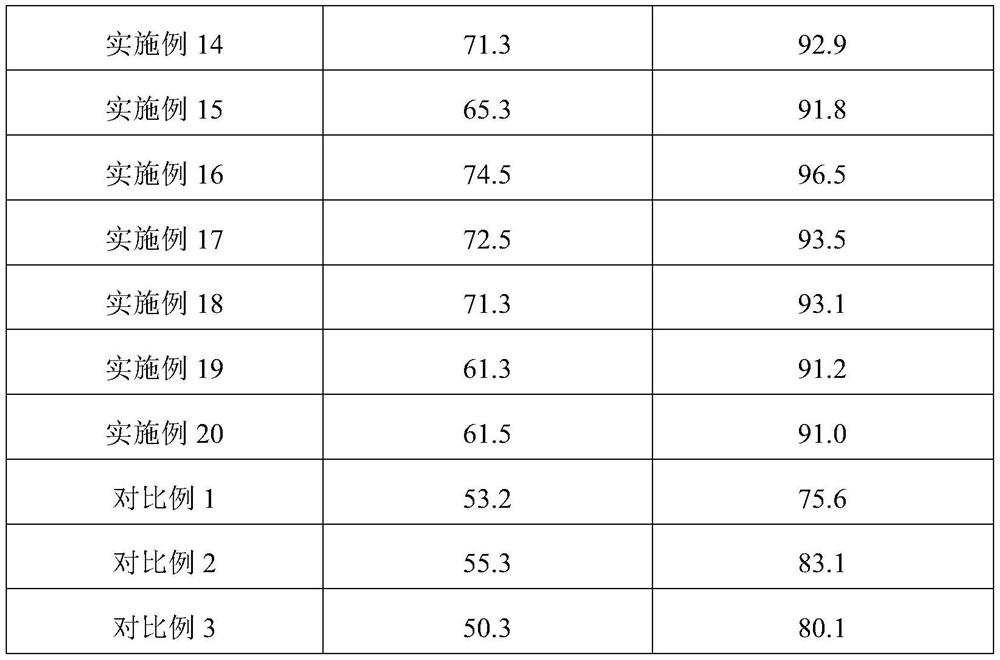

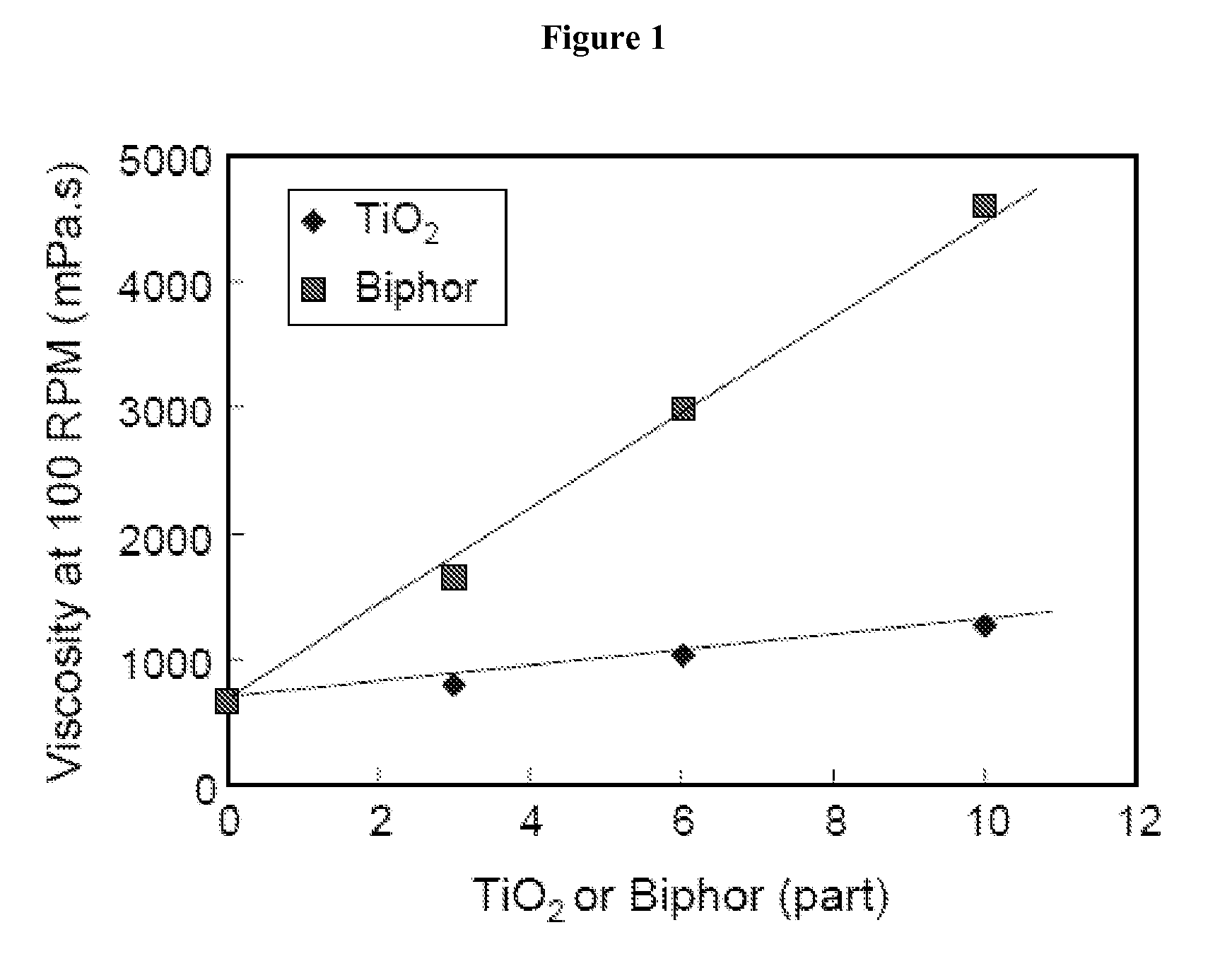

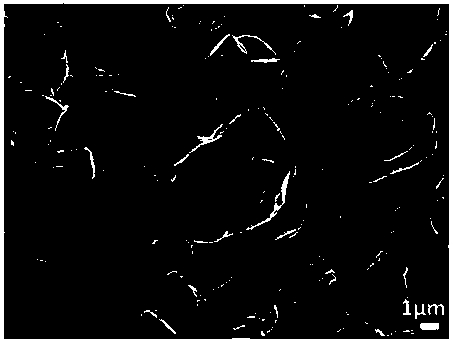

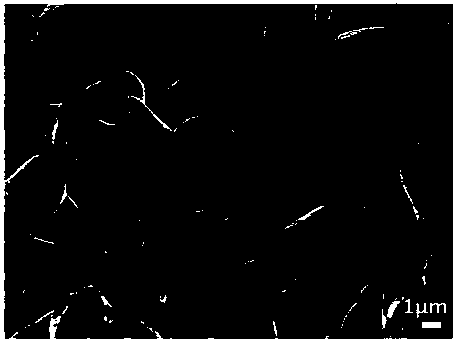

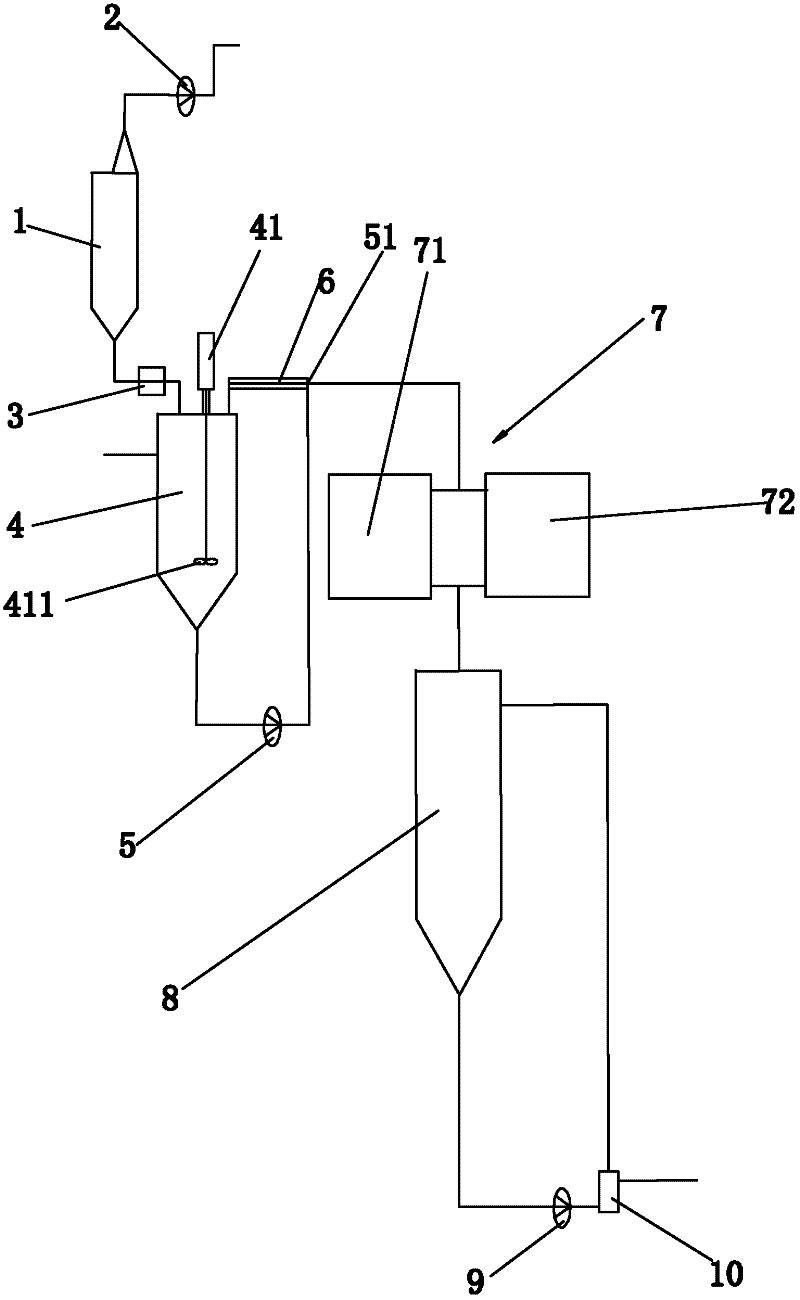

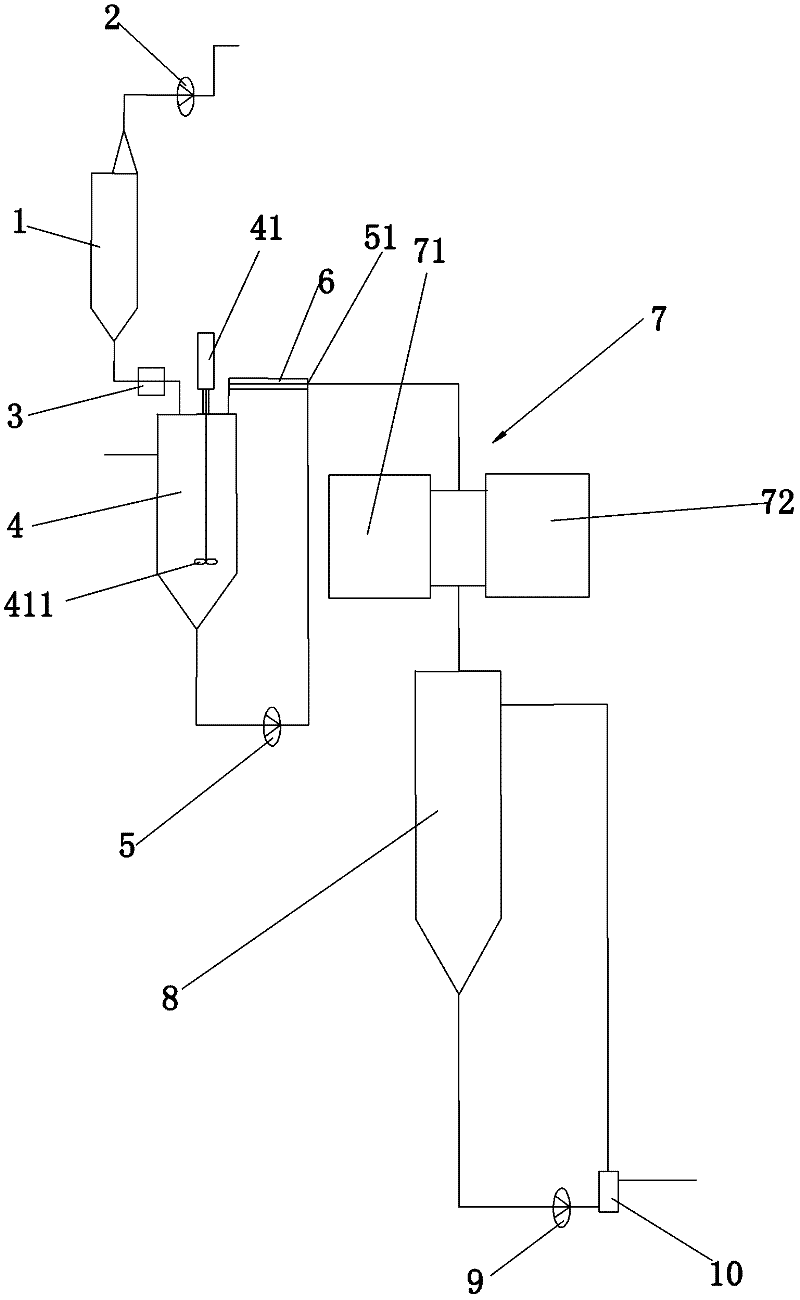

Process and equipment for preparing chinlon delustering agent

ActiveCN102352538AReduce preparation timeGood dispersionFilament-forming treatmentArtifical filament manufacturePhysical chemistrySalt solution

The invention discloses a process for preparing a chinlon delustering agent. The process comprises the following steps of: (1) adding deionized water into a preparation tank and adding a dispersing agent in an amount which is 0.1 to 0.3 percent of the mass of titanium dioxide, wherein the dispersing agent is 8 to 12 percent metaphosphate solution; (2) predispersing; (3) mixing the titanium dioxide, the deionized water and the metaphosphate solution uniformly; (4) dispersing the titanium dioxide to be below 1 mu m by using a dispersing pump and cooling titanium dioxide suspension to 20 to 35 DEG C by using a cooling device, wherein the dispersing pump and the cooling device are connected with the outlet at the bottom of the preparation tank; (5) conveying the titanium dioxide suspension into a settling tank to settle at the temperature of between 20 and 35 DEG C for 18 to 30 hours; and (6) conveying the titanium dioxide suspension subjected to settlement into a storage tank. The invention also discloses equipment for preparing the chinlon delustering agent. By the process and the equipment for preparing the chinlon delustering agent, the preparation time of the titanium dioxide is reduced; the dispersing ratio and the utilization ratio of the titanium dioxide are increased; and spinning broken ends are reduced.

Owner:浙江华建尼龙有限公司

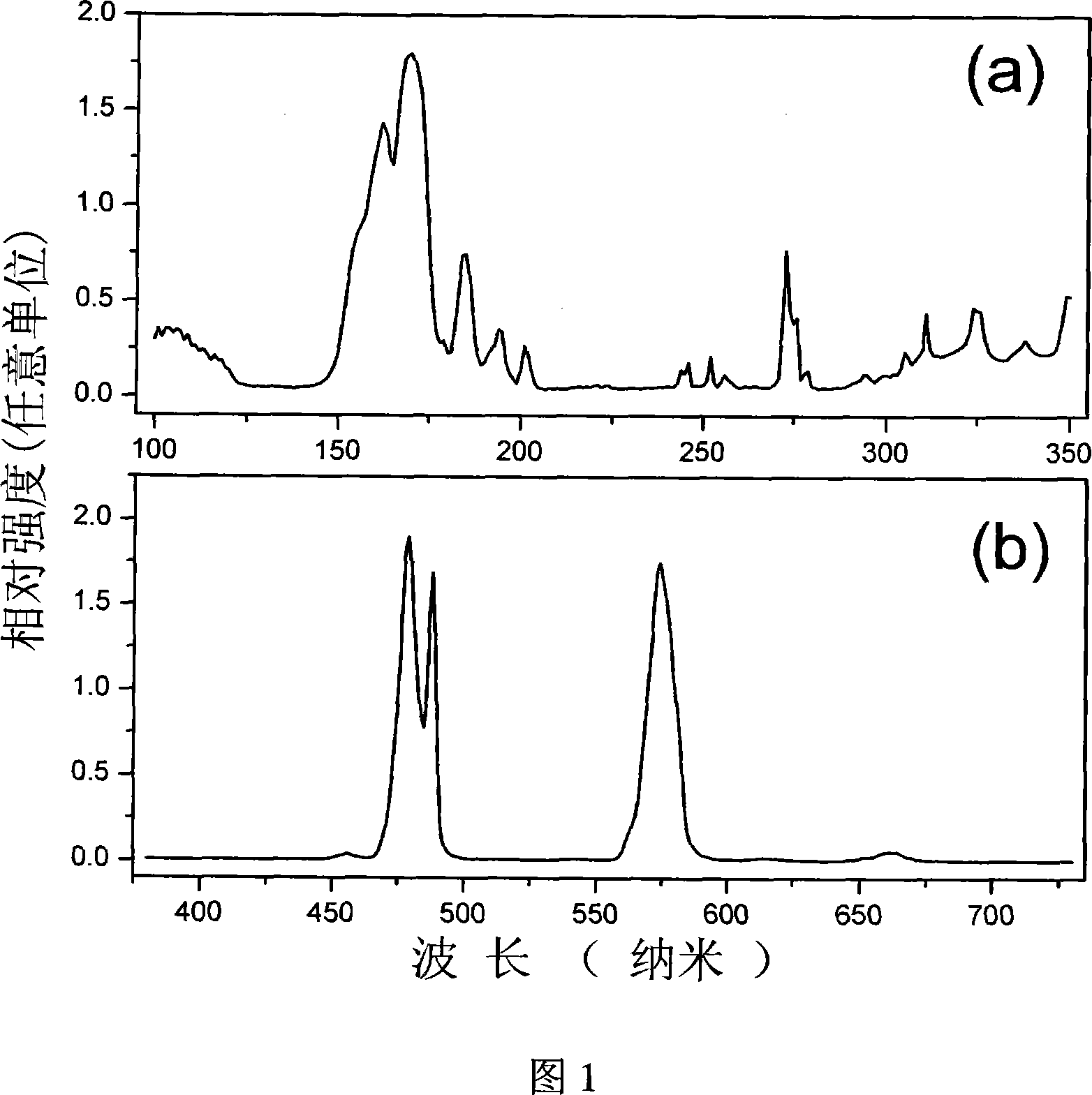

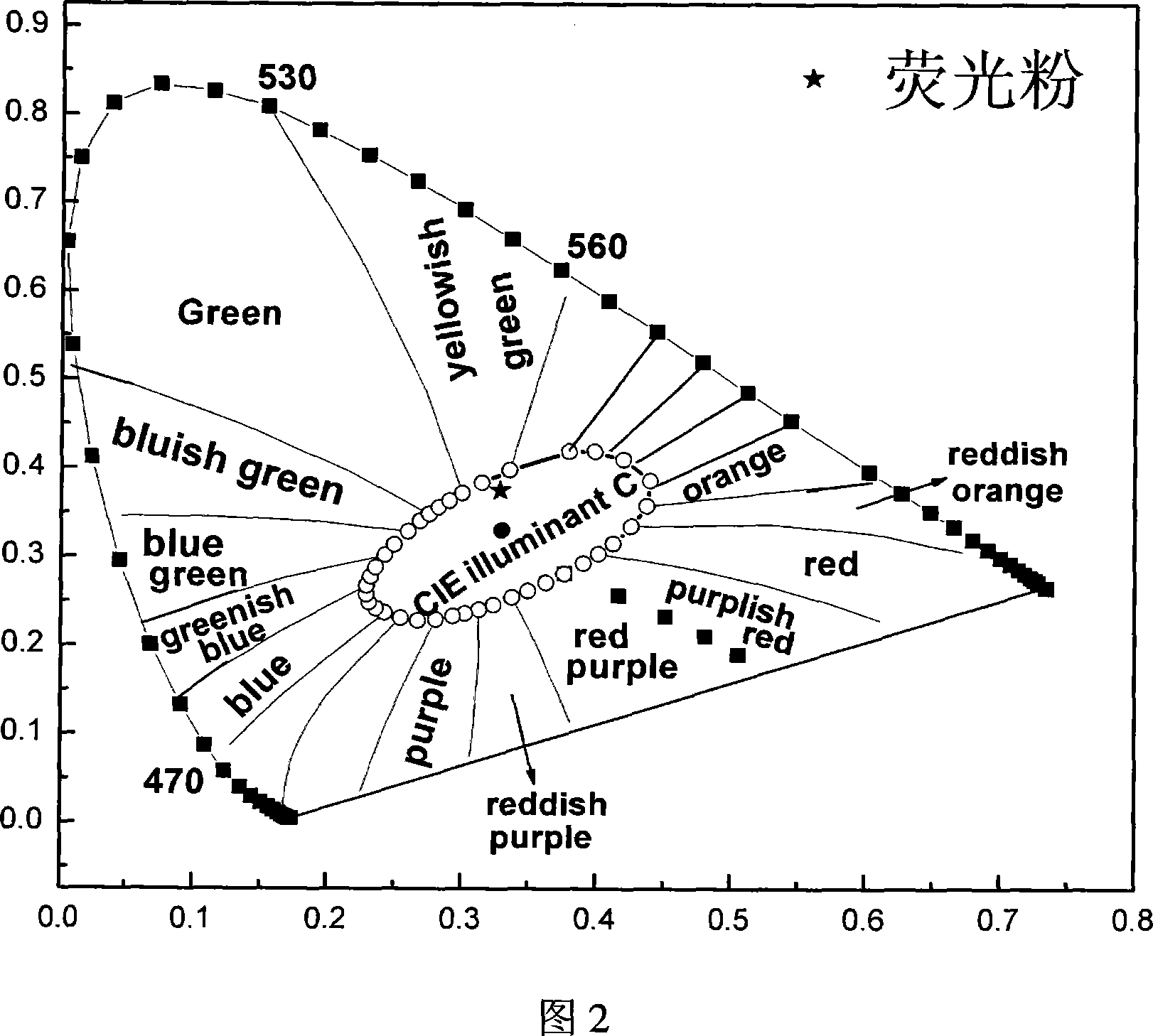

White light emitting base metal rare earth tetrametaphosphate luminous material for non-hg fluorescent lamp and preparing process thereof

InactiveCN101220274AEasy to prepareReduce manufacturing costGas discharge lamp usageLuminescent compositionsRare-earth elementBiological activation

The invention discloses a white light luminescent alkali metal rare earth tetrametaphosphate luminescent material used for non-mercury discharge fluorescent lamp, in which the chemical composition expression is M(RE1-xDyx)(PO3)4. M chosen from Li<+>, Na<+>, K<+>, Rb<+> and Cs<+> is the alkali metal ion. RE chosen from La, Gd, Y and Lu is the rare earth element. Dy<3+> (trivalent rare earth dysprosium ion) is the active ion and x in which the value range is that 0.005 is less than or equal to x and the x is less than or equal to 0.50 is the molar content of the active ion (dysprosium ion) corresponding to the rare earth mental ion. The luminescent material has the strong absorption within the vacuum ultraviolet band; meanwhile, the rare earth dysprosium ion emits the white light under the activation of the vacuum ultraviolet light. The invention also discloses a preparation method of the luminescent material with simple preparation procedure. The prepared luminescent material emits the white light of the best purity with proper color coordinate which is suitable for the non-mercury discharge fluorescent lamp.

Owner:SUN YAT SEN UNIV

Electrolyte, anodization method and anodized silicon-aluminum alloy

The invention provides an electrolyte, an anodization method and an anodized silicon-aluminum alloy. The electrolyte contains equivalent silicate ions and equivalent metaphosphate ions, wherein the equivalent silicate ions refer to silicate ions converted from all ions and particles containing a silicon element based on equal silicon element content, and the quivalent metaphosphate ions refer to metaphosphate ions converted from all ions and particles containing a phosphor element based on equal phosphor element content; and the electrolyte refers to an alkaline hydrosol. By adopting the electrolyte, an anodization film with good hardness, wear resistance and corrosion resistance can be formed on the surface of the silicon-aluminum alloy.

Owner:HANGZHOU WIN WIN TECH CO LTD

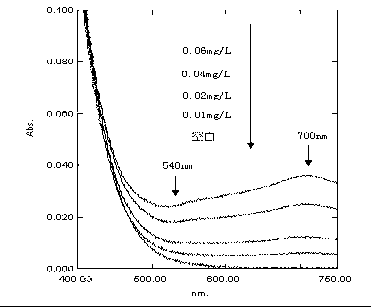

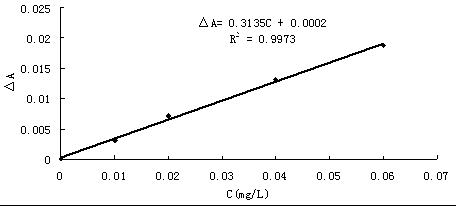

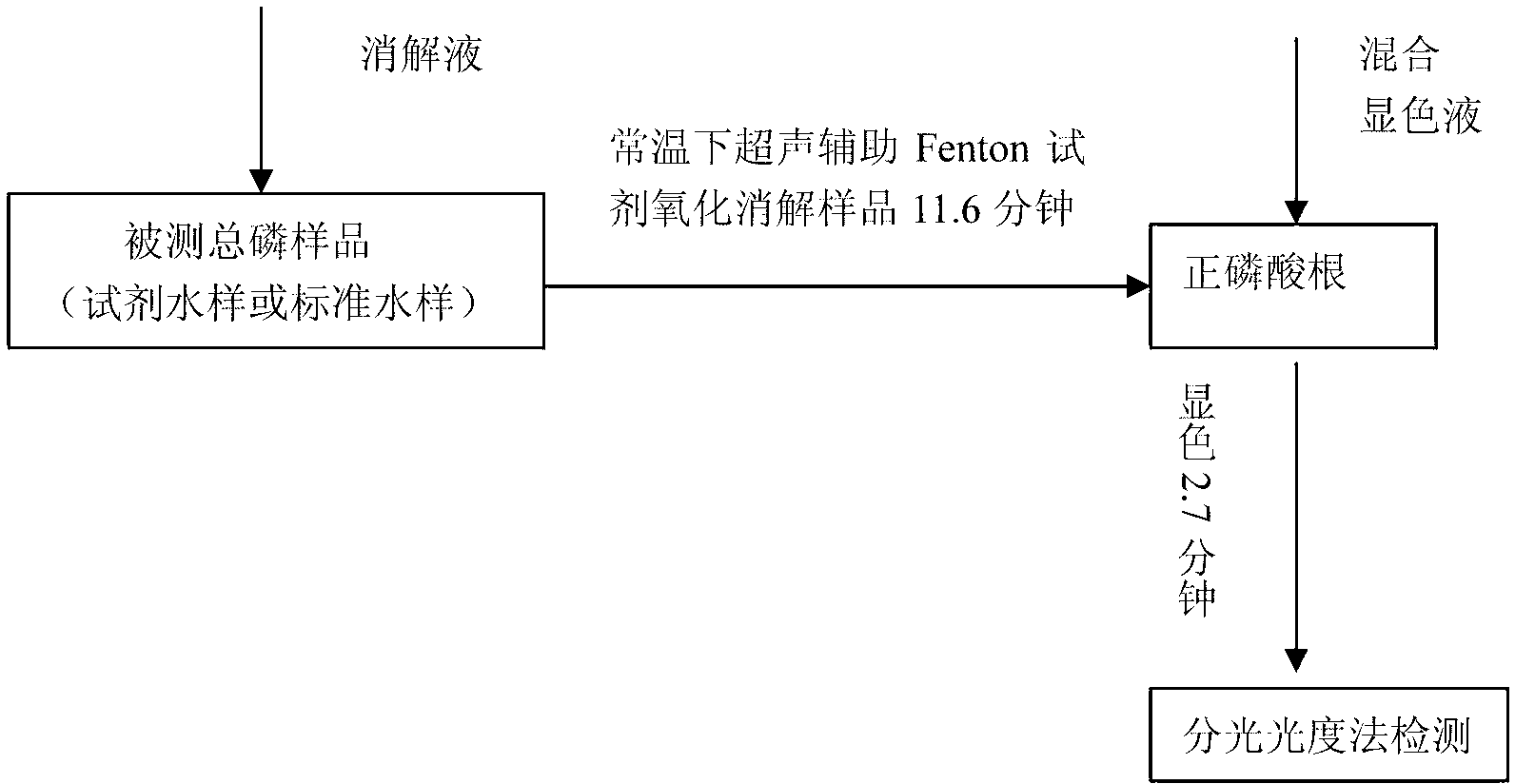

Water-quality total phosphor efficient digestion and rapid detection method

InactiveCN103267734APromotes fast digestionQuick checkPreparing sample for investigationColor/spectral properties measurementsUltrasonic cavitationFenton reagent

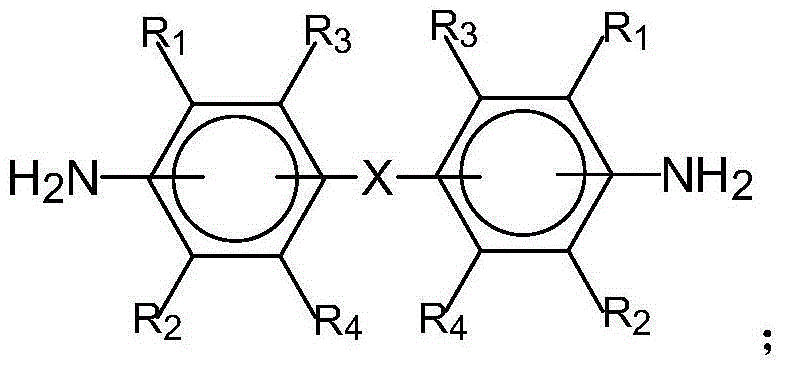

The invention relates to a water-quality total phosphor efficient digestion and rapid detection method under normal temperature and normal pressure; in acidic medium, Fenton reagent (FeSo4 and H2O2), Fe2+catalysis H2O2 generate hydroxyl radical (.OH) with very strong oxidizability to oxidize and digest a plurality of phosphorus containing compounds like organic phosphor in the water sample; meanwhile, under the effect of ultrasonic cavitation, oxidation and digestion reaction of phosphor of various valences like pyrophosphate, metaphosphate and polyphosphate etc. are prompted. The method of rapid detection of total phosphor by ultrasound-assisted Fenton reagent can solve the problems of complex process, time consuming and energy consuming, tedious steps and high temperature and high pressure for digestion of existing national standard method in prior art, and meet the requirement of on-site rapid detection of water-quality total phosphor.

Owner:CHINA THREE GORGES UNIV +1

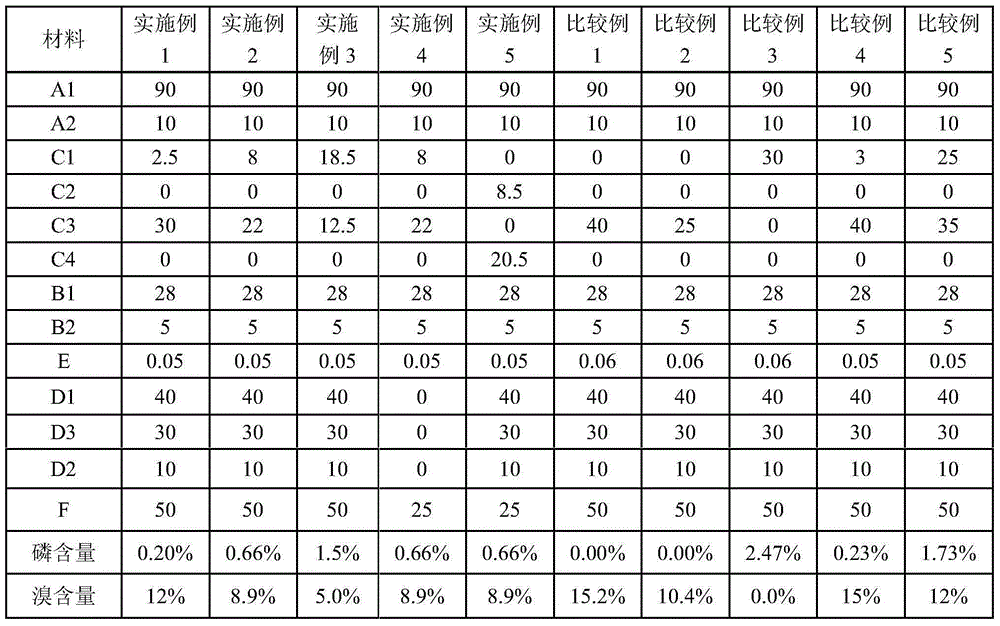

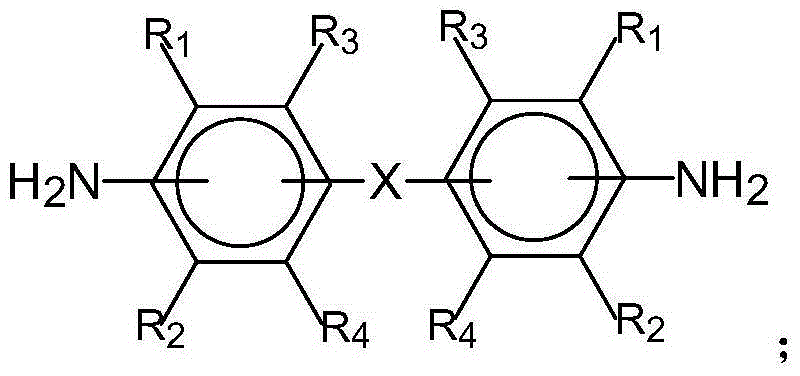

Epoxy resin composition for copper-clad board and application thereof

InactiveCN105086365AImproved tracking indexEffective cost controlPrinted circuit aspectsSynthetic resin layered productsEpoxyPolystyrene

The invention relates to an epoxy resin composition for a copper-clad board and an application thereof. The epoxy resin composition comprises flame retardant additives containing phosphorus and flame retardant additives containing bromine and can be used for preparing prepreg and copper-clad laminated boards. According to the epoxy resin composition for the copper-clad board and the application thereof, brominated polystyrene, decabromodiphenyl ethane and the like are adopted to serve as sources of the bromine, phosphazene, melamine polyphosphate, aluminum metaphosphate or melamine cyanurate and the like serve as sources of the phosphorus, the proportion of the flame retardant additives containing the phosphorus and the flame retardant additives containing the bromine of the composition is adjusted to make the bromine content controlled between 5% and 12% and make the phosphorus content controlled between 0.2% and 1.5%, and the flame retardancy of the composition can reach grade UL94 V-0; compared with a pure-bromine flame-retardant copper-clad board, the heat resistance is higher, and a higher CTI value can be reached; compared with a pure-phosphorus flame-retardant copper-clad board, the rate of moisture absorption is lower, and the adhesive property and the technological operability which are needed for printing circuit substrates can be provided; compared with a traditional board which has a high CTI and adopts a large amount of aluminum hydroxide, by means of the epoxy resin composition for the copper-clad board, the CTI can reach to be above 600 V by utilizing a small amount of the aluminum hydroxide or not utilizing the aluminum hydroxide at all.

Owner:GUANGDONG SHENGYI SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com