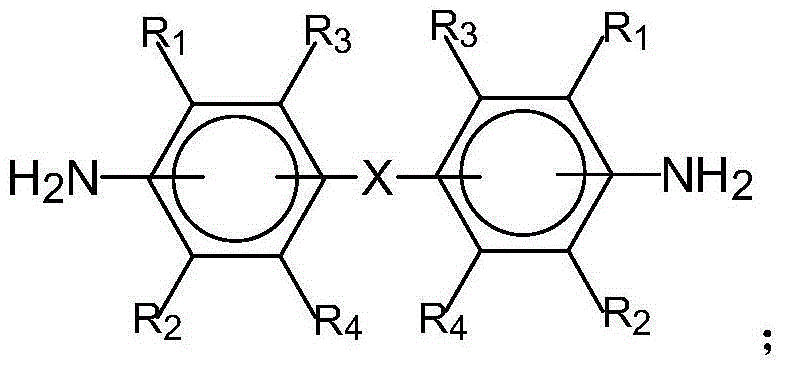

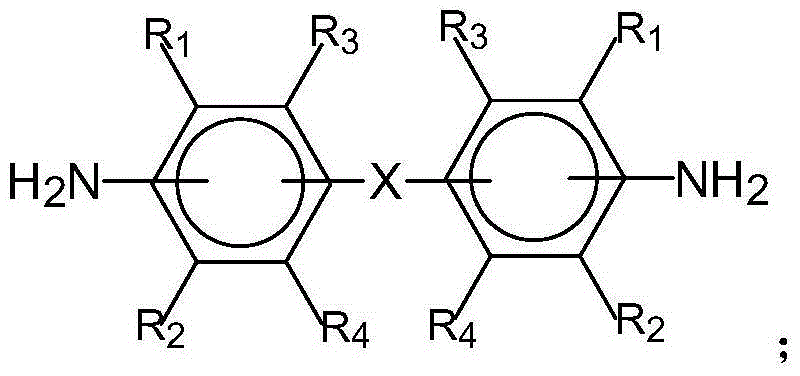

Epoxy resin composition for copper-clad board and application thereof

A technology of epoxy resin and composition, which is applied in the field of laminates, can solve the problems of easy moisture absorption of phosphorus elements, accelerated bromine decomposition, and decreased voltage resistance of composite substrates, and achieves improvement compared to tracking index and high glass Transformation temperature, excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

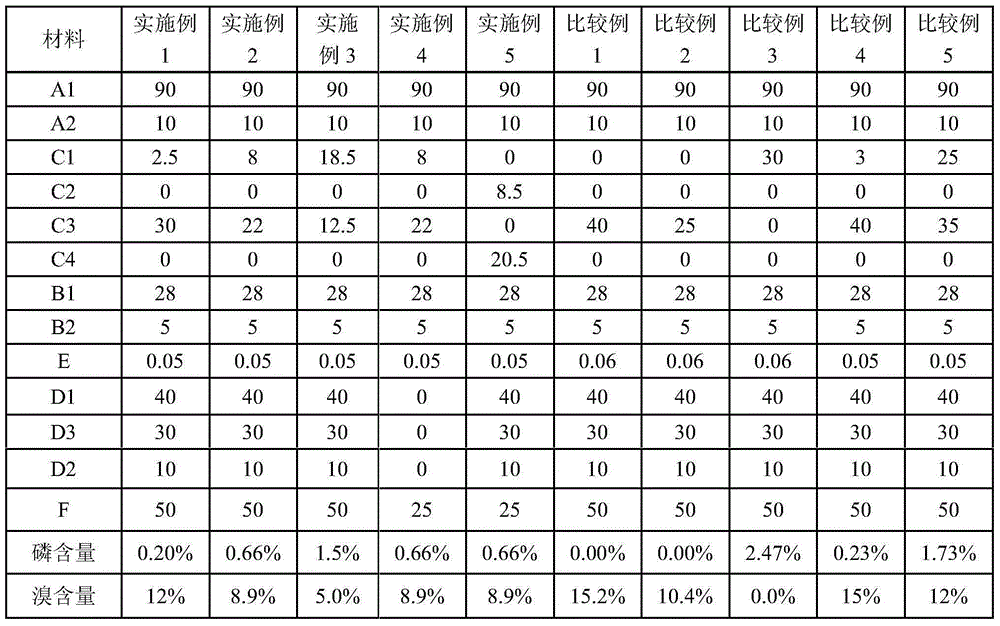

[0056] Example Preparation method of copper-clad laminate

[0057] Mix epoxy resin, phosphorus-containing and bromine-containing flame retardant additives, curing agent, filler and curing accelerator with an organic solvent, and use stirring and dispersing equipment to uniformly mix it, and pre-impregnate the epoxy resin composition in the Non-woven or woven glass fiber cloth, and dry in a gluing machine (120-180°C), to make a semi-cured prepreg for printed circuit boards.

[0058] Laminate several sheets of the above prepregs, laminate one or both sides of the laminate with copper foil, and then place it on a laminator at 120-200°C, heat-press and solidify, and make it for printed circuit board processing. Copper-clad laminate; the copper foil can also be replaced by aluminum foil, silver foil or stainless steel foil.

[0059] For the copper-clad laminate made in the above examples, test its glass transition temperature, comparative tracking index (CTI), flame retardancy, r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com