Patents

Literature

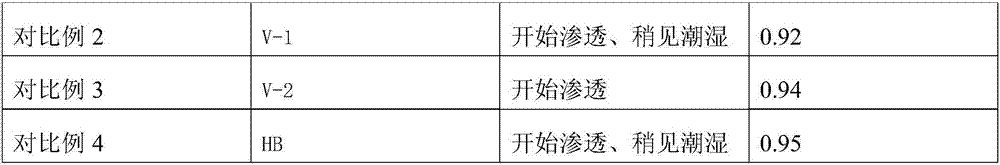

666 results about "Decabromodiphenyl ethane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-protection flame-proof electrostatic resistance polypropylene material and method for producing the same

The invention relates to an environmental-friendly polypropylene material with flame resistance and antistatic capacities, which comprises parts by weight of components that: 100pbw of pp resin, 30-50 portions of flame retardant, 10-20 portions of flame-retardant synergist, 40-60 portions of fillers and 10-30 portions of antistatic agent. The PP resin is high fluidity homopolymerization PP; the flame retardant is deca-diphenylethane; the flame-retardant synergist is antimony trioxide; the filler is 2000 meshes talcum powder; the antistatic agent is conductive carbon black; lubrication dispersing agent is aethylenum double fatty acid amide TAS-2A. The preparation method of the material is that: according to the part by weight, 100 portions of PP resin, 30-50 portions of flame retardant, 10-20 portions of flame-retardant synergist, 40-60 portions of fillers, 10-30 portions of antistatic agent and 1-10 portions of lubrication dispersant are weighted and mixed in a high-speed mixer for 3 to 5 minutes, and after mixing, the mixed raw materials are molten, squeezed and made into particles in a parallel twin-screw extruder. The polypropylene material of the invention has the advantages of good mechanical intensity, antistatic effect, flame resistance and being environment-friendly.

Owner:ANHUI KEJU NEW MATERIALS

Polymer material for ammeter case

The invention relates to a high molecular material for an ammeter shell, which consists of PC-based resin, glass fiber, main flame retardant, dripping resistant agent, toughening agent, compatilizer, lubricant, and hindered phenol and phosphate ester of antioxidant. The high molecular material is characterized in that the PC is a mixture of two or more than two different PC with 5 to 24 of melt index, the main flame retardant is decabromodiphenylethane, the compatilizer is maleic anhydride grafting ABS, the toughening agent is PTW, and the lubricant is PETS and OP wax; and each component has the following adding weight portion: 490 to 770 portions of the PC-based resin, 100 to 300 portions of the glass fiber, 50 to 70 portions of the main flame retardant, 50 to 100 portions of the compatilizer, 20 to 40 portions of the toughening agent, 5 to 10 portions of the dripping resistant agent, 5 to 10 portions of the lubricant, and 4 to 6 portions of the antioxidant.

Owner:CHONGQNG PRET NEW MATERIAL +2

High and low voltage power distribution cabinet housing material and preparation method thereof

ActiveCN104151745AImprove performanceImprove insulation performanceDiethylene glycol monobutyl etherIsobutanol

The invention relates to the field of power supply materials, and discloses a high and low voltage power distribution cabinet housing material. The material is prepared from the raw materials of, by weight, 30-40 parts of polyvinyl chloride, 20-25 parts of silicon carbide, 10-12 parts of borax, 8-10 parts of quartz sand, 8-10 parts of phenolic resin, 8-9 parts of glycerol monostearate, 7-8 parts of isobutanol, 7-8 parts of polycarbonate, 5-7 parts of diethylene glycol monobutyl ether, 5-7 parts of decabromodiphenyl ethane, 2-3 parts of graphite, 2-3 parts of aluminum tripolyphosphate, 2-3 parts of antimony trioxide, 1-2 parts of glass fiber, and 1-2 parts of silica gel powder. According to the housing material provided by the invention, good insulation performance can be effectively maintained. Mechanical performance, heat conduction performance, and flame retardant performance of the material are greatly improved.

Owner:SHANDONG MENGQI ELECTRIC CO LTD

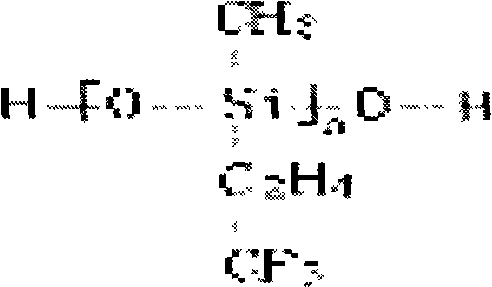

Nanometer enhanced type fluorosilicone rubber long-acting anti-fouling flashing coating

ActiveCN101338159AIncreased hydrophobic migration speedIncreased durability of hydrophobic migrationAntifouling/underwater paintsPaints with biocidesInsulation layerElectric power system

The invention provides a nanometer strengthening fluoride silicone rubber long-acting anti fouling and flashing coating material (nano PRTV coating material) which is used on an external insulation layer of a power system high pressure transmission and transformation device. The coating is composed of the following compositions (weight portion) of 20-40 percent of hydroxyl-fluoride containing polysiloxane, 2-5 percent of small molecular siloxane, 1-6 percent of cross linker, 0.02-1 percent of catalyst, 2-6 percent of nano silicon dioxide, 4-6 percent of decabromodiphenyl ethane, 1-2 percent of pigment and 30-50 percent of solvent. The coating provided by the invention is provided with perfect flame retardancy, solvent resistance, oil resistance, high and low temperature resistance and good self-cleaning performance. The surface of the coating material is smoother than dirt flash preventing coating material. Compared with the dirt flash preventing coating material, the coating material of the invention is greatly improved in aspects of hydrophobic migration speed, proportionality, sustainability, etc. Once filming can be realized. With the service life of more than 20 years, the coating material can be used permanently.

Owner:XIAN TAIPING ELECTRONICS TECH & DEVCO

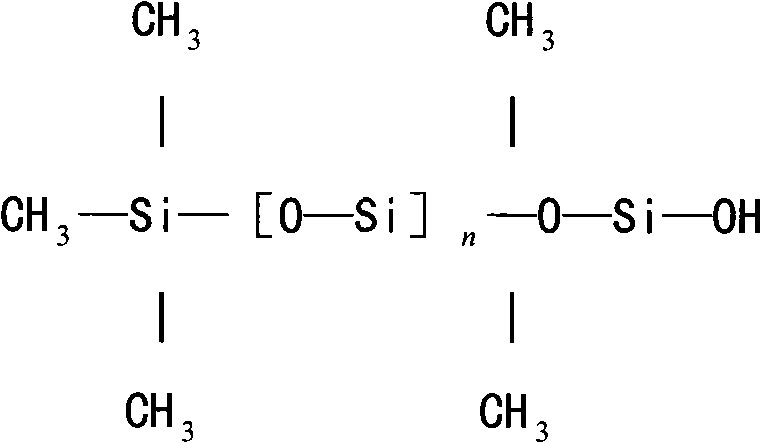

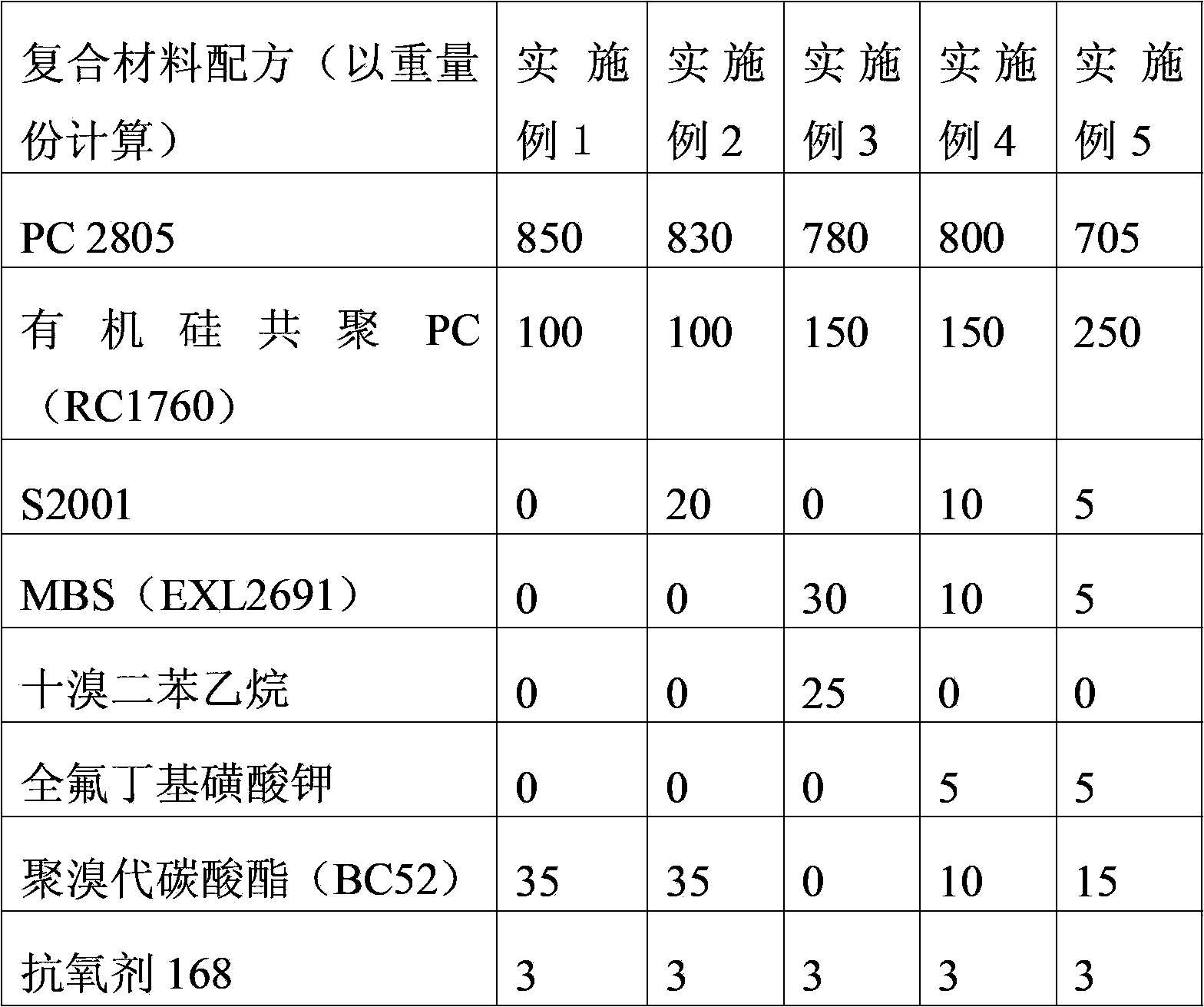

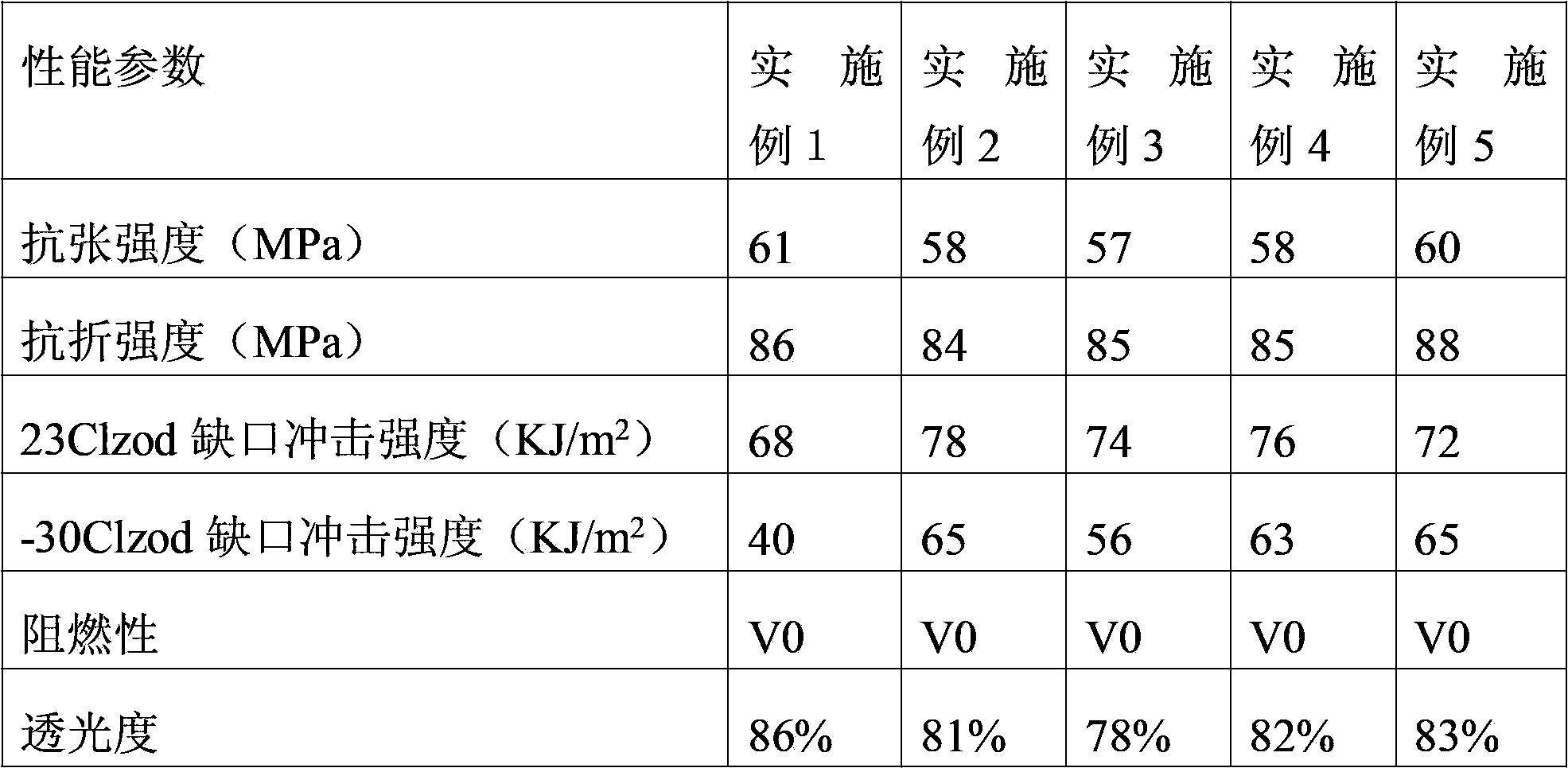

High-transparency low-temperature-impact-resistant flame-retardant polycarbonate composite material and preparation method thereof

ActiveCN103788610AImprove low temperature impact resistanceEnhance and improve low temperature impact resistanceMold fillingPotassium

The invention discloses a high-transparency low-temperature-impact-resistant flame-retardant polycarbonate composite material and a preparation method thereof. The composite material comprises following components by weight: 700-850 parts of polycarbonate resin, 100-250 parts of organosilicone co-polymer PC, 0-30 parts of a low-temperature-impact modifying agent and 10-14 parts of a flame retardant. The low-temperature-impact modifying agent is one of an organosilicone type flexibilizer and an acrylate type flexibilizer or a mixture of the organosilicone type flexibilizer and the acrylate type flexibilizer. The flame retardant is one of or a mixture of several compounds selected from decabromodiphenylethane, poly(bromocarbonate), potassium perfluorobutane sulfonate or diphenylsulfonesulfonate. The organosilicone co-polymer PC is polycarbonate resin obtained by copolymerization of bisphenol A and organosilicone and has a relative molecular weight of 20000-30000. The preparation method of the composite material is also provided. According to the composite material and the preparation method, the low-temperature-impact-resistant performance of the PC resin is largely enhanced, and the composite material has excellent flame retardance and can preserve the high transparency of the material itself. In addition, the material has advantages of easy mold filling, low processing temperature, short processing and forming period, and the like.

Owner:SHANGHAI CHANGWEI JINCI ENG PLASTIC

Glass fiber reinforced environment friendly flame-retardant nylon alloy for thin wall products and preparation thereof

The invention discloses a glass fiber reinforced environment-friendly flame retardation nylon alloy used for thinwalled articles. The glass fiber reinforced environment-friendly flame retardation nylon alloy mainly comprises the following components: 25 to 35 percent of nylon 66 resin, 8.85 to 16.55 percent of nylon 6 resin, 25 to 30 percent of glass fiber, 3 to 6 percent of glass micro-bead, 14 to 20 percent of TDE, 4 to 7 percent of antimony trioxide, 0.05 to 0.15 percent of antioxidant 1010, 0.1 to 0.3 percent of antioxidant 168, and 1 to 4 percent of compatilizer EPDM-g-MAH. The preparation method for the nylon alloy comprises the following steps: weighing the substances of the components by weight percentage; mixing the components evenly and adding the components into a twin screw extruder; then quantitatively and continuously adding the glass fibers for full fusion and compounding in the twin screw extruder; and finally packaging the product after machine head extrusion, bracing, cooling, granulation and drying. The invention aims to provide the glass fiber reinforced environment-friendly flame retardation nylon alloy with high flame retardant property and thinwalled performance.

Owner:昆山顺威工程塑料有限公司

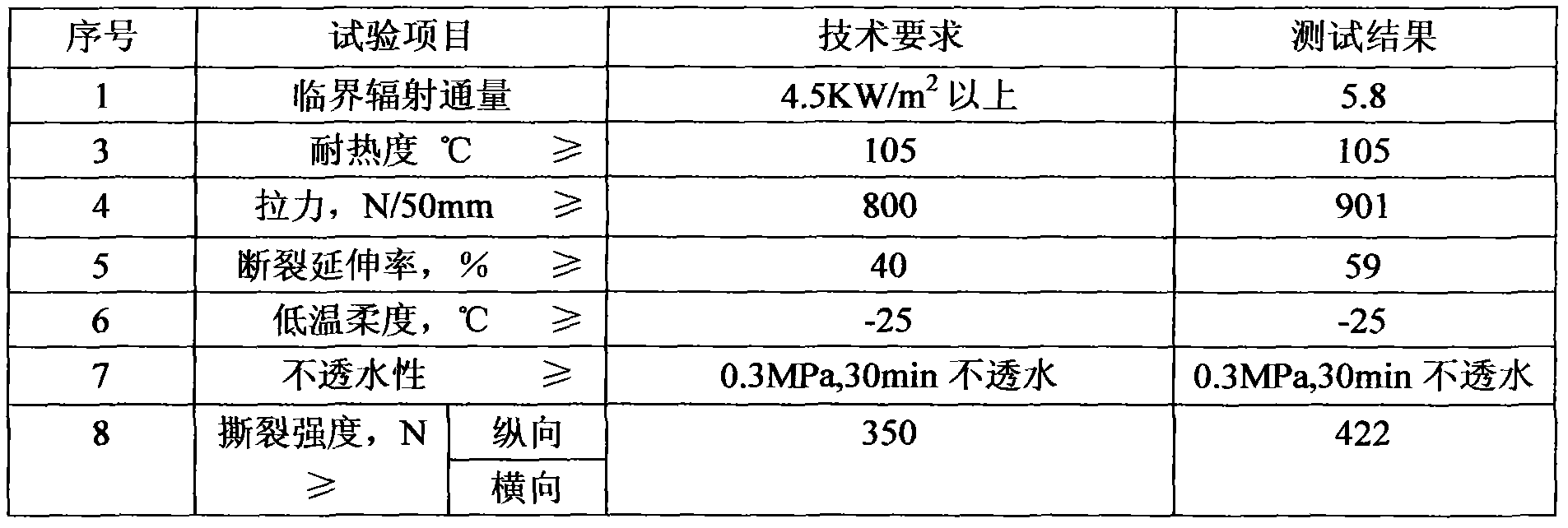

Burnthrough-resistant water-based fire retardant glue for spinning

The invention provides burnthrough-resistant water-based fire retardant glue for spinning. The burnthrough-resistant water-based fire retardant glue is prepared from the following components in parts by weight: 100 parts of a water-based adhesive, 10 to 100 parts of a halogen flame retardant, 3 to 100 parts of a synergistic flame retardant, 0 to 30 parts of an auxiliary and 0 to 100 parts of water, wherein the water-based adhesive is prepared from ethylene-vinyl acetate copolymer emulsion and an auxiliary adhesive; the solid content of the ethylene-vinyl acetate copolymer emulsion is 20 to 56 percent; the weight ratio of the water-based adhesive to the halogen flame retardant is (1 to 8) to 1; the halogen flame retardant is prepared from one or more of decabromodiphenyl ether, decabromodiphenyl ethane, tri(2,3-dibromo propyl) isocyanuric acid ester, tri(tribromophenyl) cyanurate, ethylene bis (tetrabromophthalimide), tetrabromo bisphenol A, hexabromocyclododecane, octo-bromo-ether, chlorine ester resin, ploy (vinylidene chloride) resin, brominated styrene, brominated epoxy resin, polyvinyl chloride, chlorinated paraffin and methyl chloride.

Owner:WUJIANG HONGYUAN SPRAY WEAVING CO LTD

Flame-proof polystyrene composition and its preparation method

The invention provides a fire-retardant polystyrene combination and its preparation method. involving flame-retardant resin modification field. The said combination contains (weight parts) polystyrene 100, halogen flame-retardant 8~25, and synergistic flame retardant 2~6. The halogen flame retardant is brominated polystyrene or a mixture of decabrominated dipheny ethane and hexabromocyclododecane with thermal decomposition temperature greater than or equal to 200degreeC, wherein the ratio of decabrominated dipheny ethane to hexabromocyclododecane is at 2 : 1 ~ 1 : 2. The synergistic flame retardant is antimony trioxide. The combination is prepared by mixing and melting the above materials with good fire-retardant properties, flame retardant level up to FV-0 level (GB / T4609-93) and the oxygen index up to 28, which can be applied to various adverse circumstances.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

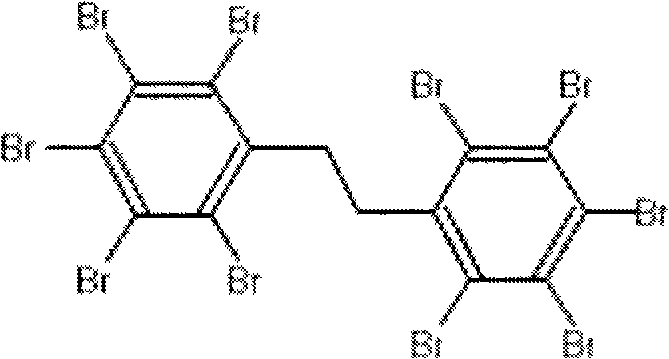

Brominated Diphenyl Ethane Mixtures and Resin Compositions Including the Same

ActiveUS20100029828A1Improve flame resistanceImproving flowabilityOrganic chemistryThermal stabilityChemistry

A brominated diphenyl ethane mixture of the present invention comprises about 0 to about 2% by weight of pentabromodiphenyl ethane, about 55 to about 85% by weight of hexabromodiphenyl ethane, about 1 to about 20% by weight of heptabromodiphenyl ethane, about 1 to about 25% by weight of octabromodiphenyl ethane, about 0 to about 10% by weight of nonabromodiphenyl ethane, and about 0 to about 5% by weight of decabromodephenyl ethane. The brominated diphenyl ethane mixture can be added to thermoplastic resin as a flame retardant, can exhibit excellent compatibility with thermoplastic resins, can minimize the generation of environmental problems, and can obtain excellent impact resistance, thermal stability, weatherability and flowability as well as improved flame resistance.

Owner:LOTTE ADVANCED MATERIALS CO LTD

Method for manufacturing agglomerate of decabromodiphenyl ethane and antimony trioxide

InactiveCN101003634AAvoid increasing powder flame retardant contentExacerbated lossAntimony trioxidePolyresin

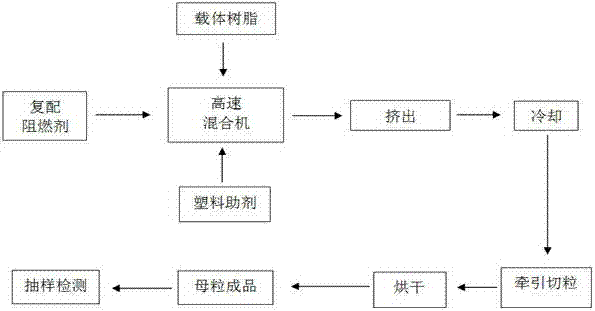

This invention relates to a method for producing decabromodiphenyl ethane and antimony trioxide master batches. The raw materials comprise: decabromodiphenyl ethane powder (particle sizes are 0.4-2.0 mum) 50-70 wt.%, antimony trioxide powder 20-40 wt.%, carrier 4-20 wt.%, dispersant 4-10 wt.%, and titanate or silane coupling agent 0.1-1 wt.%. The method comprises: heating and stirring the raw materials in a high-speed stirrer adequately, adding into a twin-screw extruder, granulating, screening by a vibrational screen, drying by a dryer, and packaging. The obtained master batches can be directly added into resin for extrusion or injection-molding, which can simplify the process, reduce dust amount, alleviate equipment abrasion, save raw materials, facilitate convenient mixing and uniform smelting quality, increase production efficiency, and improve product properties.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Anti-pollution flashover coating and preparation method thereof

ActiveCN101735727AWith flame retardant synergistic effectAdd lessFireproof paintsAntifouling/underwater paintsAluminium hydroxideSilicon dioxide

The invention discloses an anti-pollution flashover coating and a preparation method thereof. The anti-pollution flashover coating consists of the following compositions in part by weight: 20 to 40 parts of hydroxyl-terminated polyorganosiloxane, 4 to 8 parts of modified silicon fluorine resin, 1 to 3 parts of small molecular siloxane, 3 to 6 parts of nanometre silicon dioxide, 1 to 3 parts of decabromdiphenylethane (DBDPE), 1 to 3 parts of wollastonite, 4 to 8 parts of aluminium hydroxide, 1 to 2 parts of pigment, 1 to 6 parts of crosslinker, 0.02 to 1 part of catalyst and 30 to 60 parts of solvent, wherein the small molecular siloxane is trimethyl end-capped polydimethylsiloxane; the catalyst is dibutyltin dilaurate or stannous octoate; and the solvent is a mixed solvent of dimethylbenzene and butyl acetate in a weight ratio of 3:1-5:1. The prepared coating has the advantages of high flame retardant grade and good anti-pollution effect.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Production of high purity decabromodiphenylalkanes

Reaction-derived decabromodiphenylalkane product, especially decabromodiphenylethane product, of high purity is formed by (A) maintaining in a loop reactor a circulating inventory comprising at least Lewis acid bromination catalyst and excess liquid bromine; (B) introducing diphenylalkane and / or partially brominated diphenylalkane into the reactor so that bromination can occur; and (C) after a period of travel in the reactor during which solids of reaction-derived decabromodiphenylalkane product of high purity is formed, removing such solids from the reactor.

Owner:ALBEMARLE CORP

Method for producing polypropylene flame-retardant fibre

ActiveCN101476171AReduce surface temperatureImprove flame retardant performanceFlame-proof filament manufactureMonocomponent polypropylene artificial filamentFiberBoiling point

The invention relates to a method for producing polypropylene fire resistant fiber which includes steps as follows: A. self making fire resistant master batch that includes 30-50% decabromodiphenylethane, 10-30% diantimony trioxide, 0.3-0.5% calcium stearate; 1-3% chemical inhibitor, 10-20% dispersant, 0.03-0.5% ultraviolet absorbent; 0.03-0.05% cross linker, 20-40% PP slice; B. the raw material of step A is melt mixed granulation to obtain polypropylene fire resistant master batch by using a double screw extruder; C. the fire resistant master prepared by the step B mixes with polypropylene according with 2-8% rate that the material is mixed through a high speed mixing machine, is extrude and draft fibre, and is formed for preparing polypropylene fire resistant fiber. The method has advantages that the fire resistant agent decomposable produces incombustibility gas or liquid with high boiling point to cover the fabric surface in burning, and can isolate mutual diffusion of oxygen and combustible, has excellent fire resistance effect.

Owner:GUANGDONG MODERN HIGH TECH FIBER CO LTD

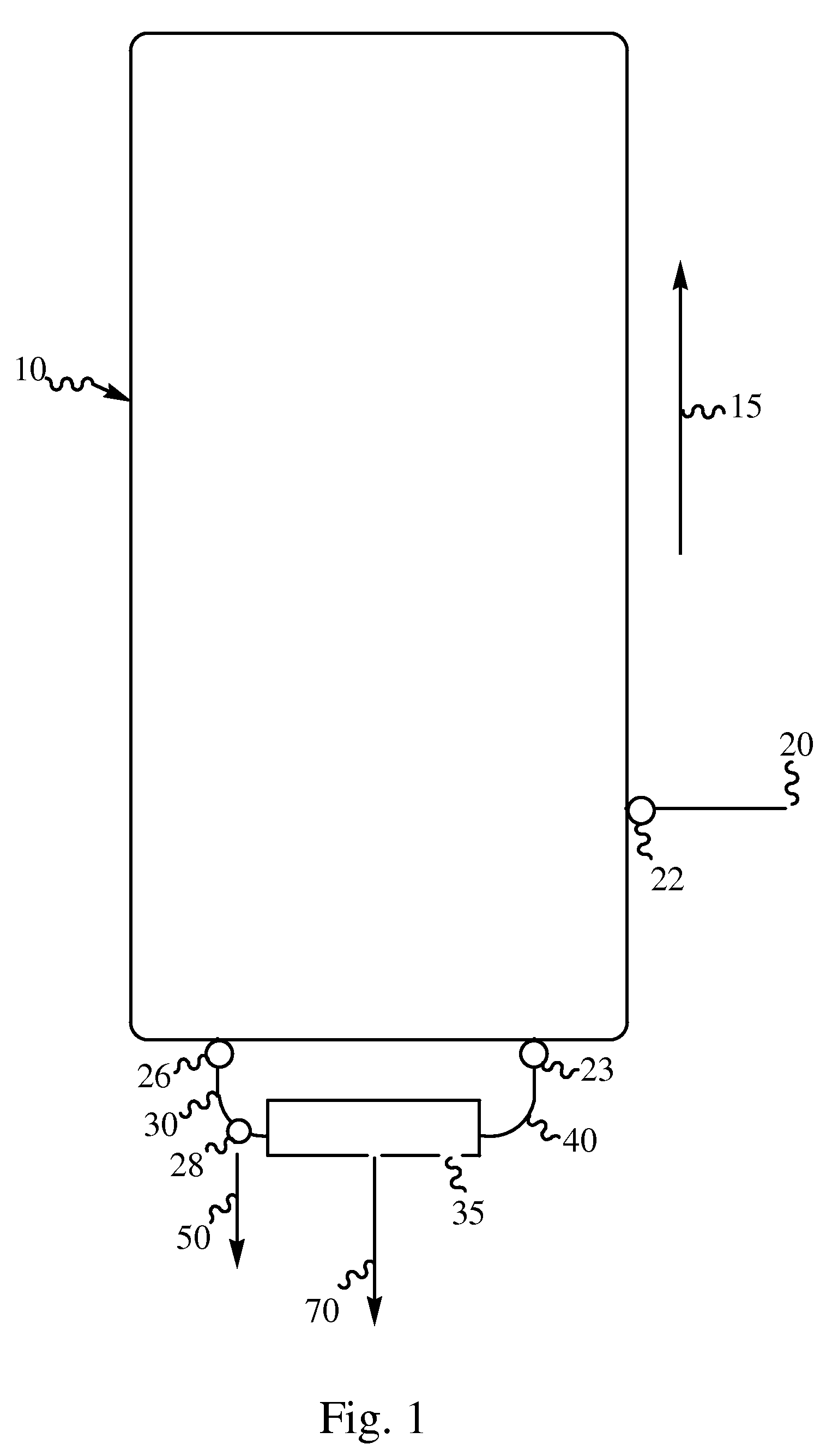

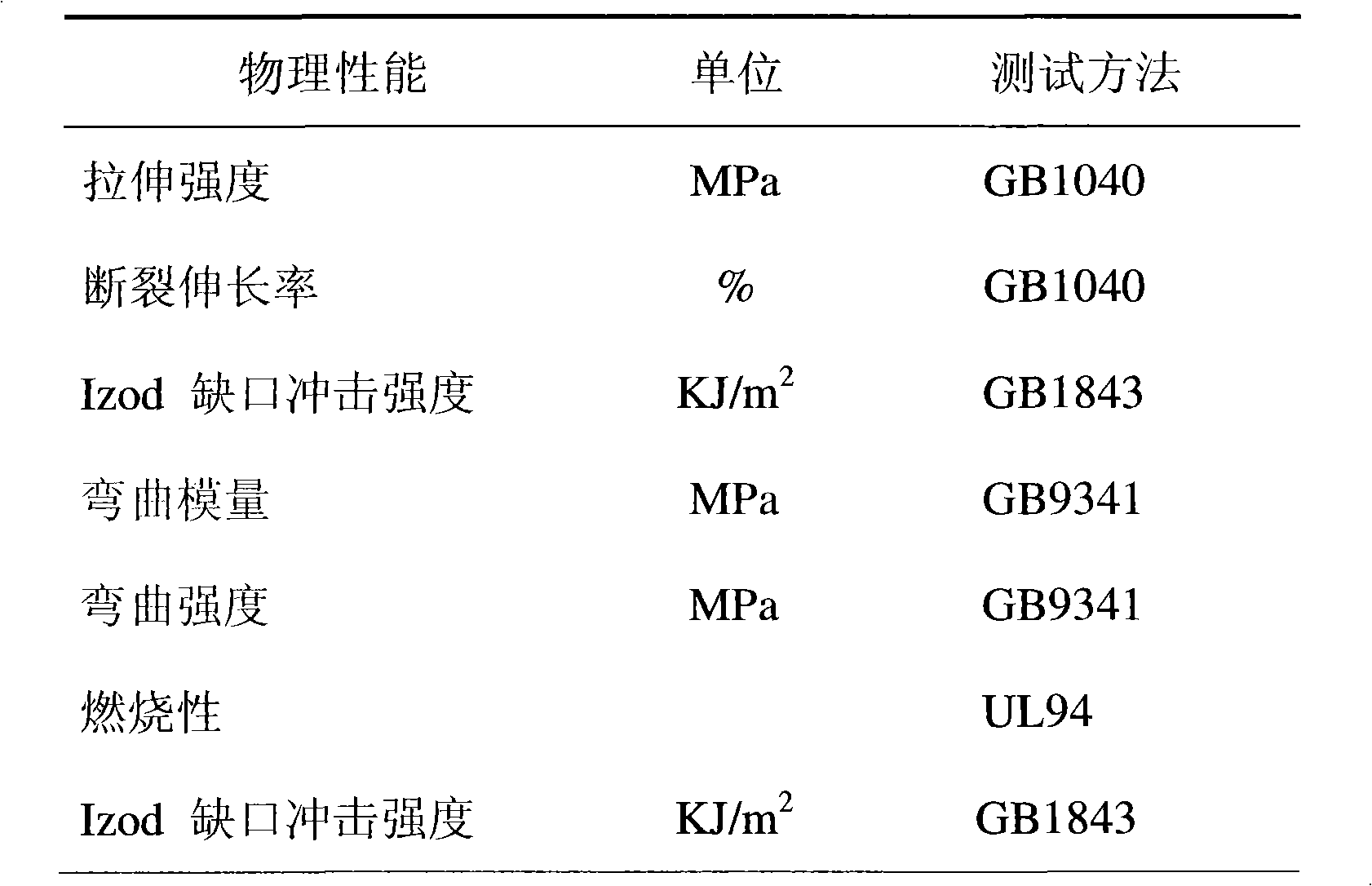

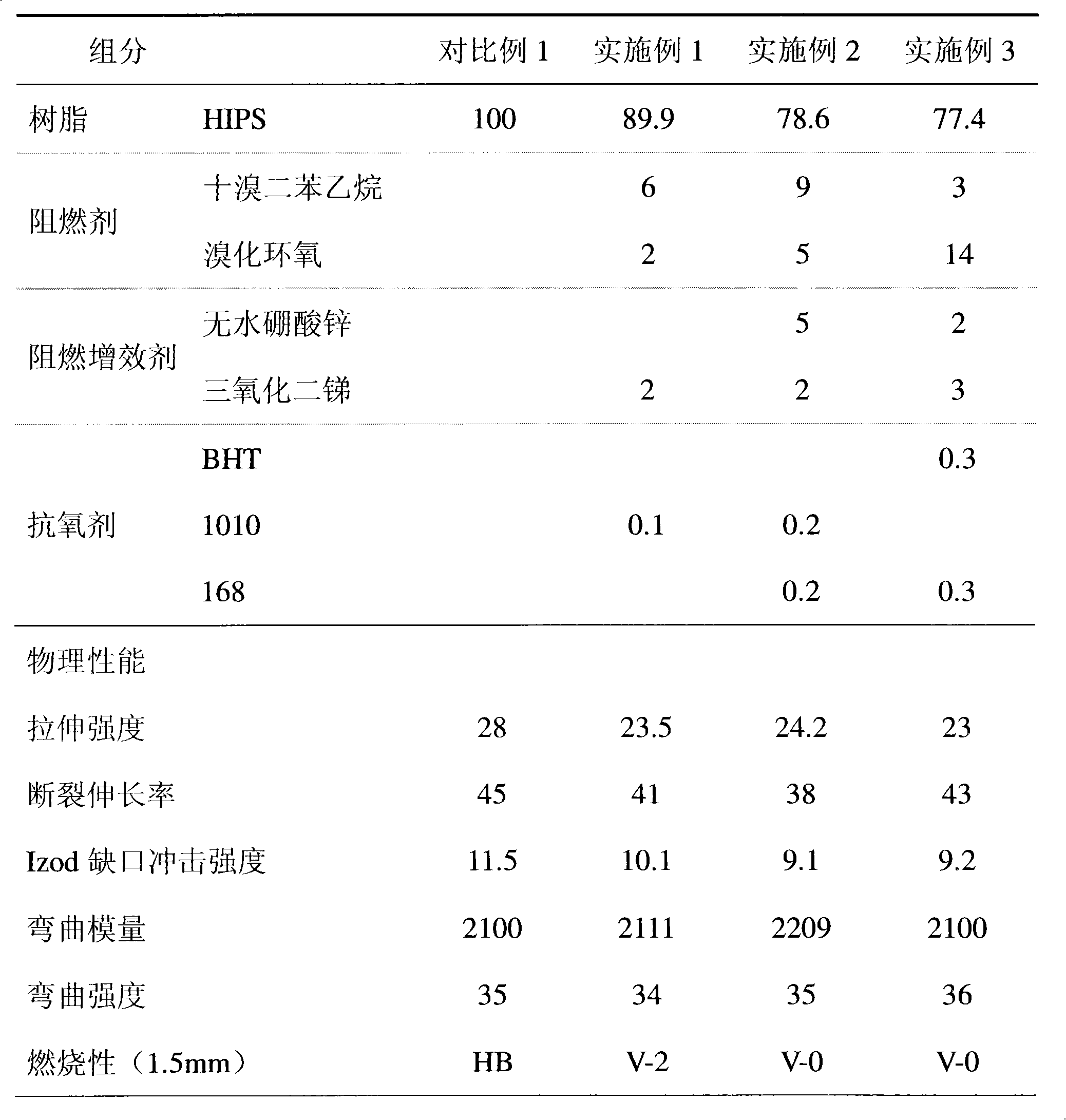

Flame-retardant highly impact resistant polystyrene complex containing decabromodiphenylethane and preparation thereof

The invention discloses a flame-retarding high impact-resistant polystyrene composite containing DBDPE and a preparation method thereof. The composite comprises the components with the following portions: 77 to 89.9 percent of high impact-resistant polystyrene resin, 3 to 10 percent of DBDPE flame retarding agent, 2 to 14 percent of brominated epoxy or tetrabromobisphenol A flame retarding agent, 2 to 7 percent of retardant synergist and 0.1 to 1 percent of antioxidant, which are one-time extruded and processed by a double screw extruder. The composite of the invention has good mechanical performance, unchanged processing performance, high flame retarding efficiency, high-grade flame retarding performance, small environmental pollution and small human harm, can meet the strict requirements for environment protection internationally at present, simultaneously has the advantages of easy forming and good surface glossiness, and is suitable for making shells of various electrical appliances.

Owner:SHANGHAI KINGFA SCI & TECH +1

Ultraviolet and aging resisting composite material for automotive upholstery and a preparing method composite material

The invention discloses an ultraviolet and aging resisting composite material for an automotive upholstery. The ultraviolet and aging resisting composite material is prepared from by weight, 100-103 parts of polylactic acid, 3.5-4 parts of nanometer antimonous oxide, 10-11 parts of decabromodiphenyl ethane, 25-27 parts of SEBS, 60-62 parts of hibiscus cannabinus fibers, 4-5 parts of cerium oxide, 7-8 parts of nano-zinc oxide, 0.8-1 part of benzotriazole, 0.6-0.7 part of silane coupling agent KH570, 1-1.3 parts of stearoyl-rac-glycerol, 5-6 parts of gelatin, a proper amount of water, 1-1.4 pars of ammonium polyphosphate and 6-7.4 parts of EVA emulsion. According to the ultraviolet and aging resisting composite material, the mixed fibers are steeped into a modified mixture of the cerium oxide, the nano-zinc oxide and the benzotriazole which are in synergistic effect and cover the surfaces and pores of the mixed fibers, and the ultraviolet resisting effect of the mixed fibers is improved; meanwhile, the lubricating ingredients such as the stearoyl-rac-glycerol are contained in the material, so that the a subsequent extrusion granulating process is smoother, and processability is improved.

Owner:WUHU HUANRUI AUTO INTERIOR DECORATION

Flame-resistant PC (Polycarbonate)/PBT (Polybutylene Terephathalate)/PET (Polyethylene Terephathalate) alloy and preparation method thereof

The invention relates to a flame-resistant PC (Polycarbonate) / PBT (Polybutylene Terephathalate) / PET (Polyethylene Terephathalate) alloy and a preparation method thereof. The alloy is prepared from the following components in percentage by weight: 30-50 percent of PC, 10-30 percent of PBT, 10-20 percent of PET, 3-8 percent of toughening compatibilizer, 9-15 percent of flame retardant, 4-8 percent of flame-resistant synergistic agent, 0.4-1 percent of antioxidant and 0.4-1 percent of processing aids, wherein the flame retardant is one of bromine brominated epoxy resin, brominated polystyrene and decabromodiphenylethane, the toughening compatibilizer is an ethane-methyl acrylate copolymer and (or) an ethane-methyl acrylate-methacrylic acid glycidyl ester copolymer. The preparation method of the flame-resistant PC / PBT / PET alloy comprises the following steps of: drying raw materials; fully mixing; stirring for 10-20min at a room temperature; and melting, blending and extruding. The alloy phase has excellent comprehensive performance and high performance price ratio, reaches the flame-resistant level of UL94-V0 and can meet the special use requirements of a certain places.

Owner:SHENZHEN FUHENG PLASTICS PIGMENT

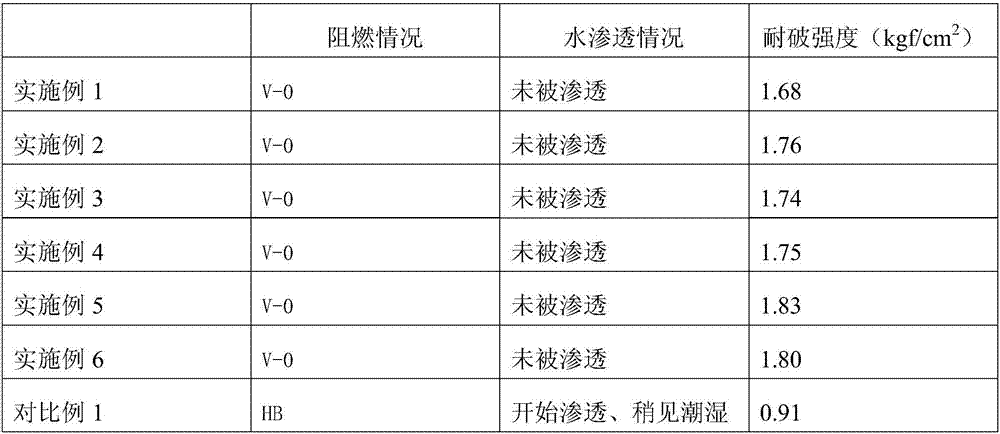

Waterproof and flame-retardant paper cone

ActiveCN106948211AHigh bromine contentImprove thermal stabilityWater-repelling agents additionReinforcing agents additionSodium metasilicateSodium Bentonite

The invention discloses a waterproof and flame-retardant paper cone, belonging to the technical field of electroacoustic products. The slurry of the paper cone is prepared by mixing and sitrring the following main raw materials in parts by weight: wood pulp, sisal hemp, cotton pulp, kapok, bulletproof fiber, wool, glass fiber, a dye, table salt, a hardening agent, a flexibilizer, a regulator, a waterproofing agent and a flame retardant, wherein the waterproofing agent is prepared through the following steps: adding acrylic rubber latex, hydroxyethyl cellulose, bentonite and sodium metasilicate according to a weight ratio of 1: (0.1-0.5): (0.2-0.5): (0.05-0.2) into water, carrying out mixing under stirring so as to form an emulsion, placing the emulsion in a stirring reflux device, and carrying out a reflux reaction for 3 to 4 hours; and the flame retardant is prepared by uniformly mixing kaolin with decabrominated dipheny ethane and antimonous oxide or magnesium hydroxide with a weight ratio of 1: (1-5) under stirring. The waterproof and flame-retardant paper cone provided by the invention has subdued sound effect and good dampproof and waterproof performances, flame retardance and mechanical performance, and is improved in use safety and prolonged in service life.

Owner:广西玉林市禹力音响配件有限公司

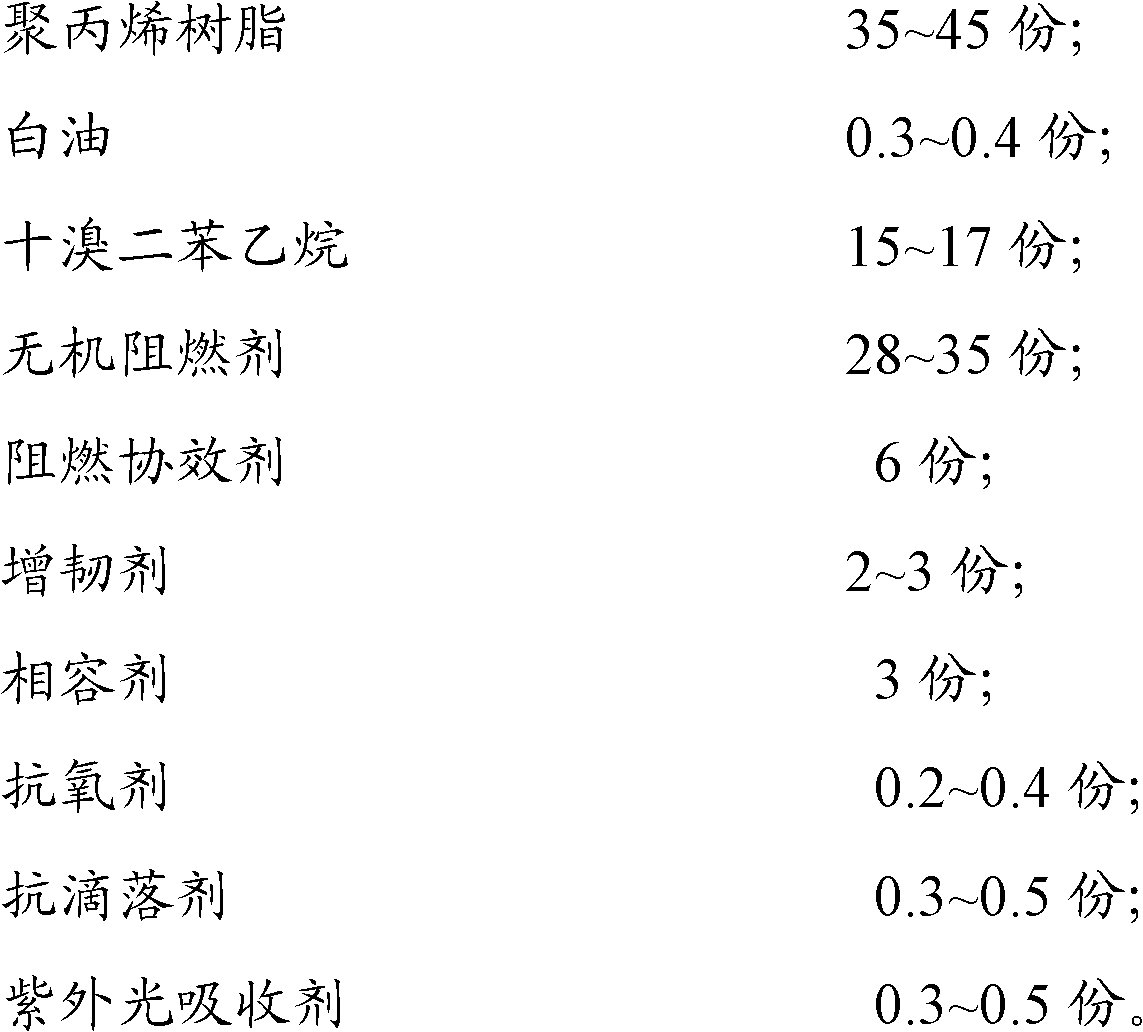

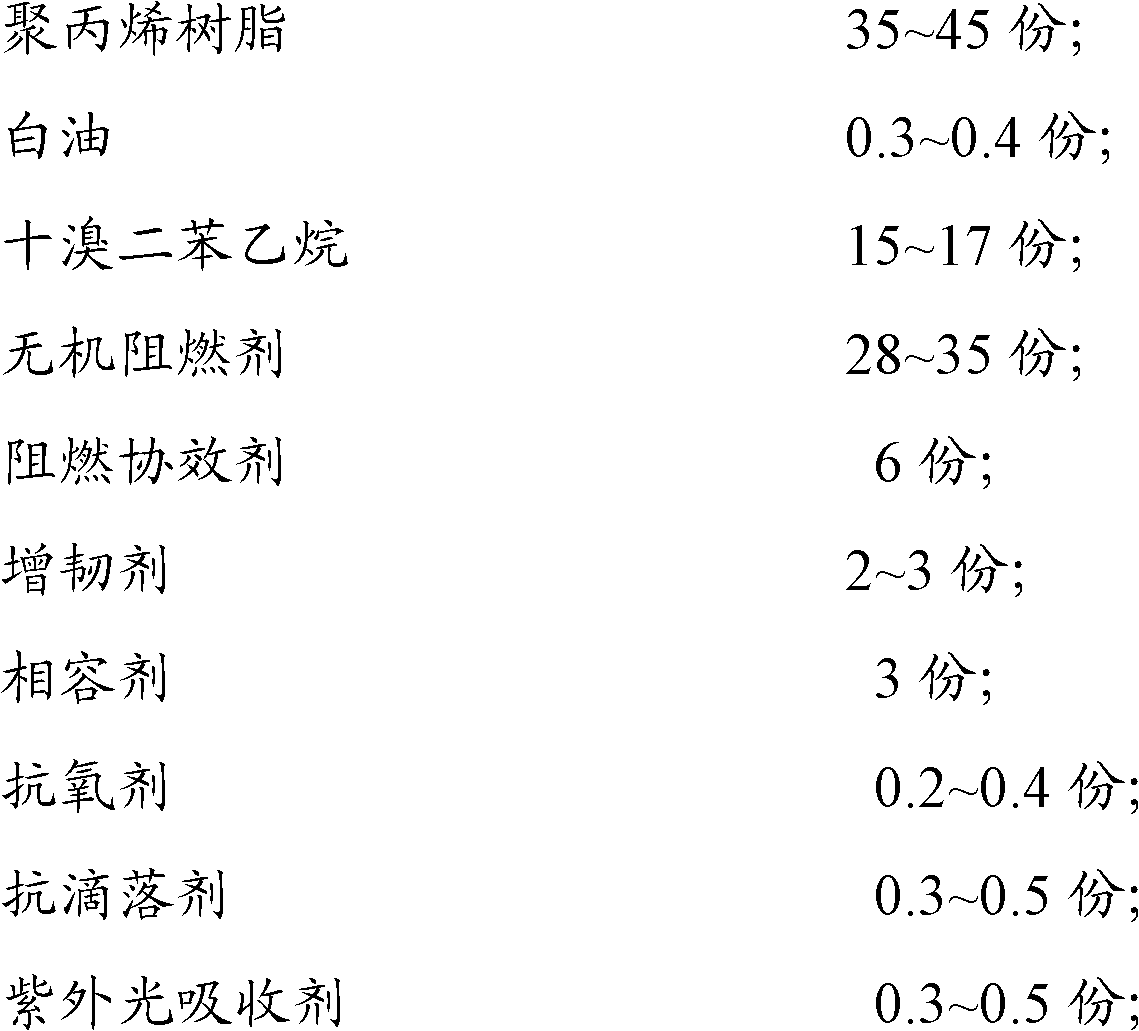

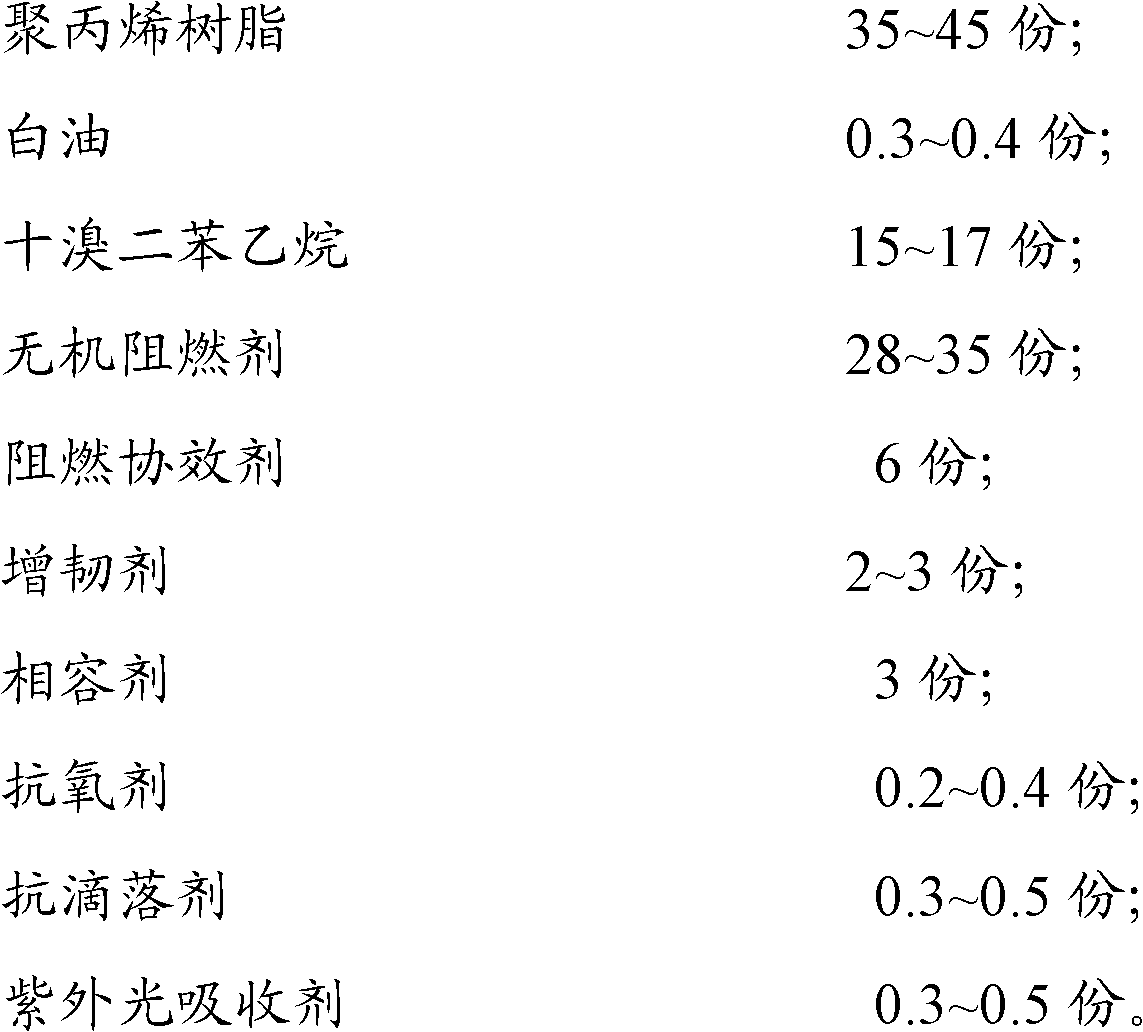

Flame retardant polypropylene composite material and its preparation method

The invention relates to a flame retardant polypropylene composite material and its preparation method. The retardant polypropylene composite material comprises the following components by weight: 35-45 parts of polypropylene resin, 15-17 parts of decabromodiphenylethane, 28-35 parts of inorganic fire retardant, 6 parts of flame retardant synergistic agent, 5-10 parts of flexibilizer and auxiliary agent. The flame retardant polypropylene composite material has excellent comprehensive properties, especially the flame retardant performance can reach a V-0 grade in UL-94 which accords with the flame retardant requirement, the material is environment-friendly and accords with the requirement of environmental protection, so that the flame retardant polypropylene composite material enables widepopularization and application. In addition, the invention also relates to a method for preparing the flame retardant polypropylene composite material.

Owner:古道尔工程塑胶(深圳)有限公司 +1

Electricity meter casing and preparation method thereof

InactiveCN103665688AImprove mechanical propertiesLow costTime integral measurementPolyvinyl alcoholPolyvinyl chloride

The invention belongs to the field of electronic materials, and discloses an electricity meter casing which is prepared by 100-110 parts of polyvinyl alcohol, 80-90 parts of polyvinyl chloride, 60-70 parts of starch ether, 45-50 parts of glass fiber, 35-40 parts of hydroxyethyl cellulose, 30-36 parts of polycarbonate, 25-28 parts of polylactic acid, 20-22 parts of decabromodiphenylethane, 18-20 parts of polydimethylsiloxane, 12-15 parts of chitin, 10-13 parts of silicon nitride powder, 78 parts of silica gel, 4-5 parts of sodium succinate, 2-4 parts of talcum powder and 2-3 parts of barium sulfate. The invention further discloses a preparation method of the electricity meter casing. The prepared electricity meter casing has better mechanical performance and excellent heat stability and flame retardant property.

Owner:STATE GRID CORP OF CHINA +1

Flame-retardant, environmentally-friendly and safe polyolefin sheath material and its preparation method

ActiveCN102977466AImprove flame retardant performanceExcellent non-flammabilityPlastic/resin/waxes insulatorsInsulated cablesPolymer scienceAntimony trioxide

The invention provides a flame-retardant, environmentally-friendly and safe polyolefin sheath material. The polyolefin sheath material is prepared from the following raw materials, by weight, 20-30 parts of ethylene propylene diene monomer, 60-80 parts of high-density polyethylene, 8-10 parts of acrylonitrile-butadiene rubber, 8-10 parts of a rubber smoked sheet, 0.5-1.0 part of bisphenol A, 1-3 parts of modified tree ash, 20-30 parts of triethyl citrate, 4-6 parts of magnesium oxide, 0.5-1.0 part of molybdenum trioxide, 30-50 parts of fumed silica, 10-13 parts of nanometer calcium carbonate, 0.5-1.0 part of capsaicin, 0.1-0.3 parts of an antioxidant AW, 0.5-1.0 part of a promoter MBTS, 0.2-0.5 parts of a promoter TMTD, 0.2-0.5 parts of sulfur, 8-10 parts of decabromodiphenylethane, 12-15 parts of antimony (III) oxide and 6-8 parts of zinc borate hydrate. The polyolefin sheath material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good low temperature resistance, good oil resistance, good abrasion resistance, and good prevention performance.

Owner:宝新高分子科技(广州)有限公司

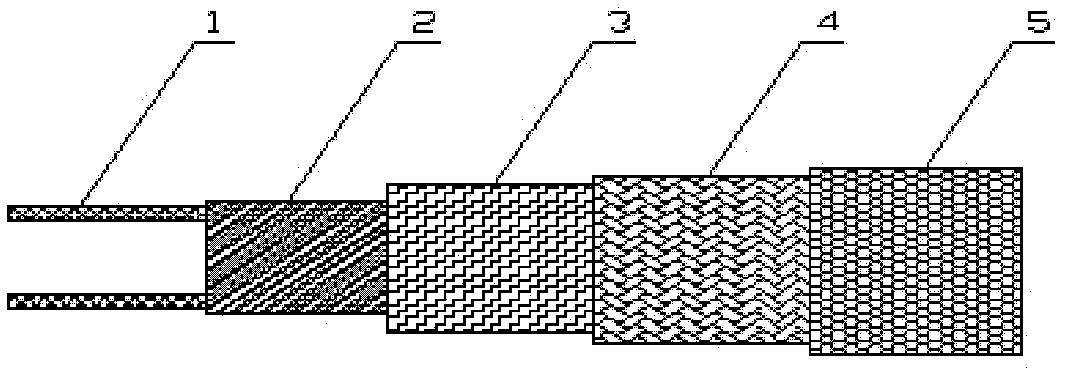

Fire-retarding thermal-shrinked indicated double pipe of radiant cross-linked and its preparation

ActiveCN1896128AGood weather resistanceExcellent wipe resistanceTubular articlesCross-linkCarvacryl acetate

A radiant cross-linking fire-retardant and heat-shrinkage indicating double pipe and its production are disclosed. The process is carried out by taking ethane-vinyl acetate multi-polymer, ethane-ethyl acrylate multi-polymer, ethylene-propylene rubber, fire-retardant decabromodiphenyl ethane, antimonous oxide, surface-activated superfine-magnesium hydrate and auxiliary as raw material, mill granulating, extrude forming, radiant cross-linking, expand sizing, and finish treating. It has better weather-resisting, high and low-temperature-resisting, anti-corrosive and antibacterial performances and long-period storage. It can be used for military industry, aviation and aerospace, civil high-terminal electronic equipment and cable.

Owner:广州凯恒科塑有限公司

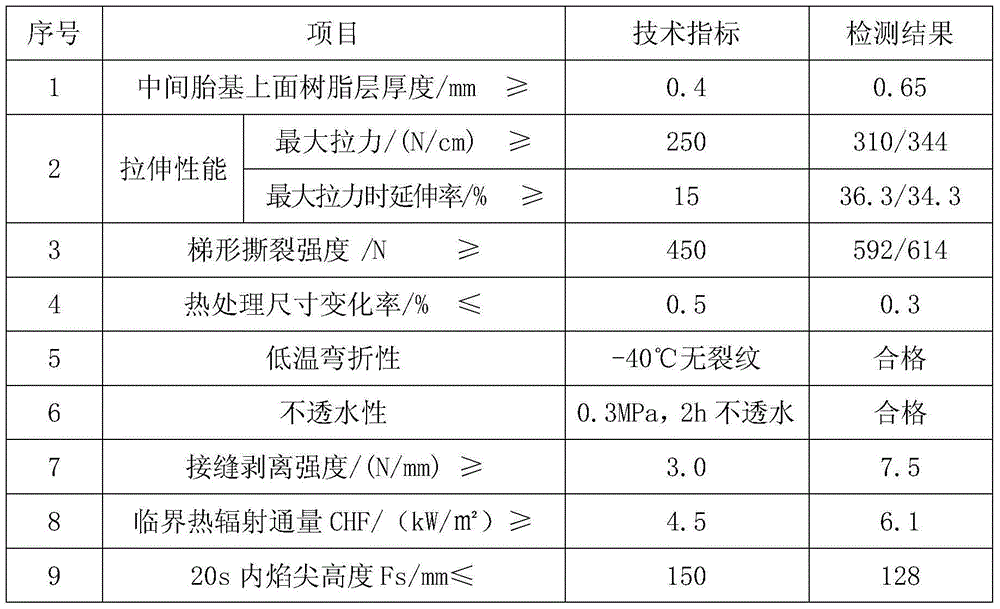

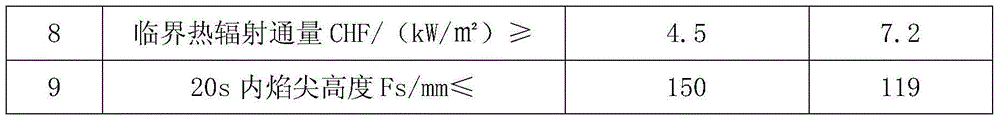

Fire-retardant thermoplastic polyolefin waterproof roll and preparation method thereof

InactiveCN104441887AImprove flame retardant performanceHave synergistic effectSynthetic resin layered productsGlass/slag layered productsFiberPolyolefin

The invention discloses a fire-retardant thermoplastic polyolefin waterproof roll, which is of a three-layer composite structure, wherein a middle layer is a fiber fabric layer; an upper surface layer and a lower surface layer are fire-retardant TPO roll layers; a fire-retardant TPO resin layer is prepared from TPO resin as a base material, a composite fire retardant as an assistant and other auxiliary materials; the composite fire retardant is composed of decabrominated dipheny ethane (DBDPE), magnesium hydrate, antimonous oxide and zinc borate; and the auxiliary materials are selected from one or a mixture of more than one of packing, titanium dioxide, a compatilizer, an antioxidant, an ultraviolet absorbent, a light stabilizer and black master batches. According to the waterproof roll disclosed by the invention, through use of the composite fire retardant, the defect that an existing TPO waterproof roll is inflammable is solved; the fire-retardant target is achieved under the premise of ensuring the welding construction and waterproof effect reliability of the product; and through use of the composite fire retardant, the combustion performance of the TPO roll belonging to inflammable materials can be up to A grade maximally, and reaches the non-inflammable grade.

Owner:YUEYANG ORIENTAL YUHONG WATERPROOF TECH

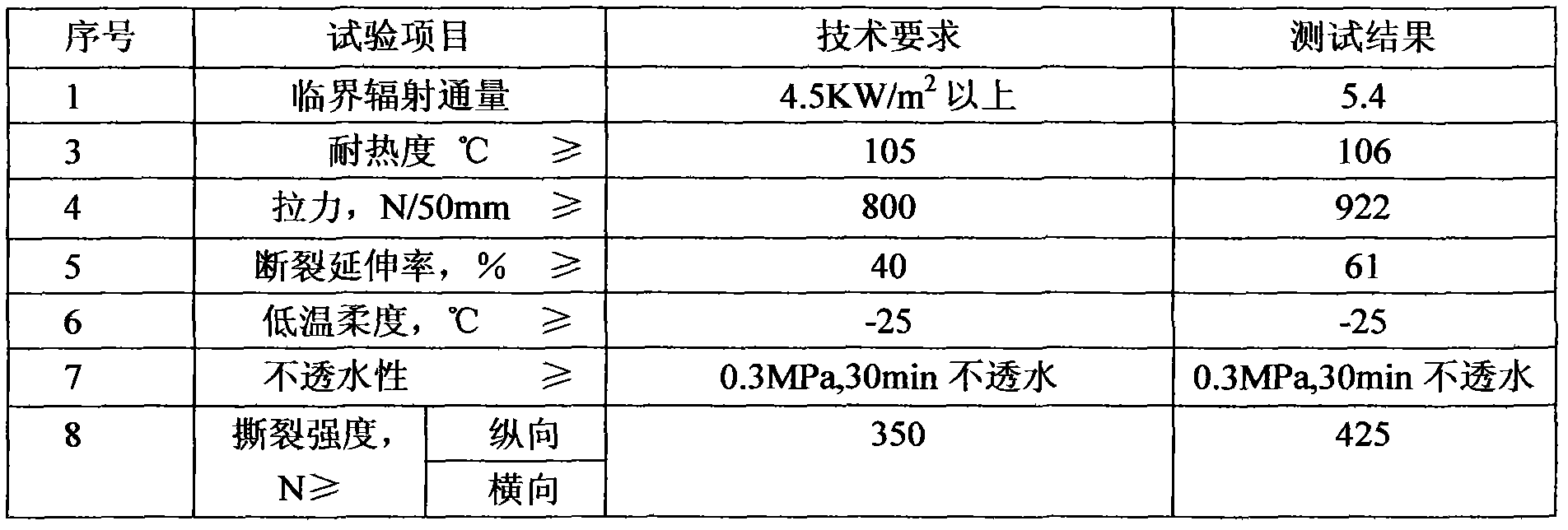

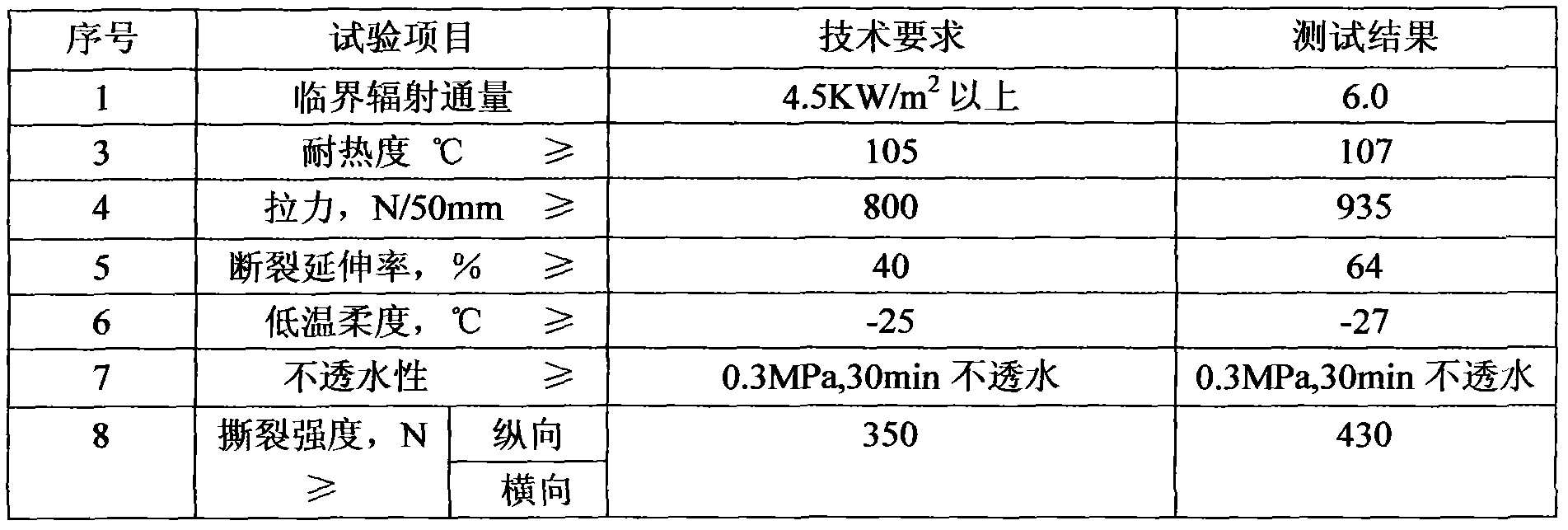

Flame-retardant polymer modified asphalt waterproof roll and preparation method thereof

ActiveCN102134810AImprove flame retardant performanceNo pollution in the processSynthetic resin layered productsTextiles and paperPolymer modifiedPolymer science

The invention provides a flame-retardant polymer modified asphalt waterproof roll, which is in a multi-layer composite structure, a middle layer is a non-woven fabric layer, and an upper surface layer and a lower surface layer are flame-retardant polymer modified asphalt coatings, wherein each flame-retardant polymer modified asphalt coating comprises the following components in parts by weight: 100 parts of heavy duty road petroleum asphalt, 15-30 parts of composite flame retardant which further comprises 3-7 parts of decabromodiphenylethane, 5-10 parts of diantimony trioxide, 3-5 parts of magnesium hydroxide, 3-5 parts of aluminum hydroxide and 1-3 parts of zinc borate, and 15-30 parts of polymer modifier which further comprises 10-20 parts of butadiene-styrene-butadiene copolymer, 2-5 parts of styrene-butadiene rubber and 2-5 parts of atactic polypropylene. The invention further provides a preparation method of the roll.

Owner:XUZHOU WONIUSHAN NEW WATERPROOF MATERIALS

Sound-absorbing and heat-preserving composite environment-friendly material for automotive upholstery and preparing method of sound-absorbing and heat-preserving composite environment-friendly material

InactiveCN105176023AHigh impact strengthHigh elongation at breakArtificial filament washing/dryingMelt spinning methodsEpoxyHibiscus

The invention discloses a sound-absorbing and heat-preserving composite environment-friendly material for an automotive upholstery. The sound-absorbing and heat-preserving composite environment-friendly material is prepared from, by weight, 100-103 parts of polylactic acid, 3.5-4 parts of nanometer antimonous oxide, 10-11 parts of decabromodiphenyl ethane, 25-27 parts of SEBS, 60-62 parts of hibiscus cannabinus fibers, 10-12 parts of banana fiber paste, 8-9.2 parts of cotton pulp, 2-2.5 parts of epoxy butyl oleate, 7-9 parts of expanded vermiculite, 5-6 parts of cork wood, 5-6 parts of arabic gum and a proper amount of water. According to the sound-absorbing and heat-preserving composite environment-friendly material, the banana fiber paste, the cork wood, the expanded vermiculite and other ingredients are adopted to be prepared into modified powder through a series of processes to be added into preparation of a steeping paste, treated mixed fibers maintain the good bending property, meanwhile, the heat-preserving, sound-insulating and vibration-reducing performance is further improved, and thus the sound-absorbing and heat-preserving composite environment-friendly material can meet the requirement of the functional automotive upholstery and is suitable for producing an instrument table top, a ceiling and the like of an automobile.

Owner:WUHU HUANRUI AUTO INTERIOR DECORATION

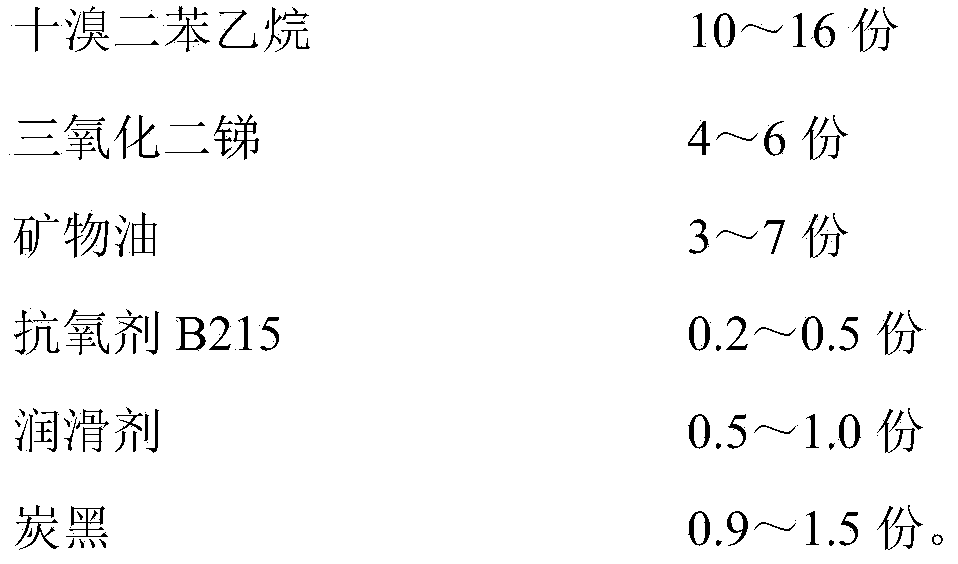

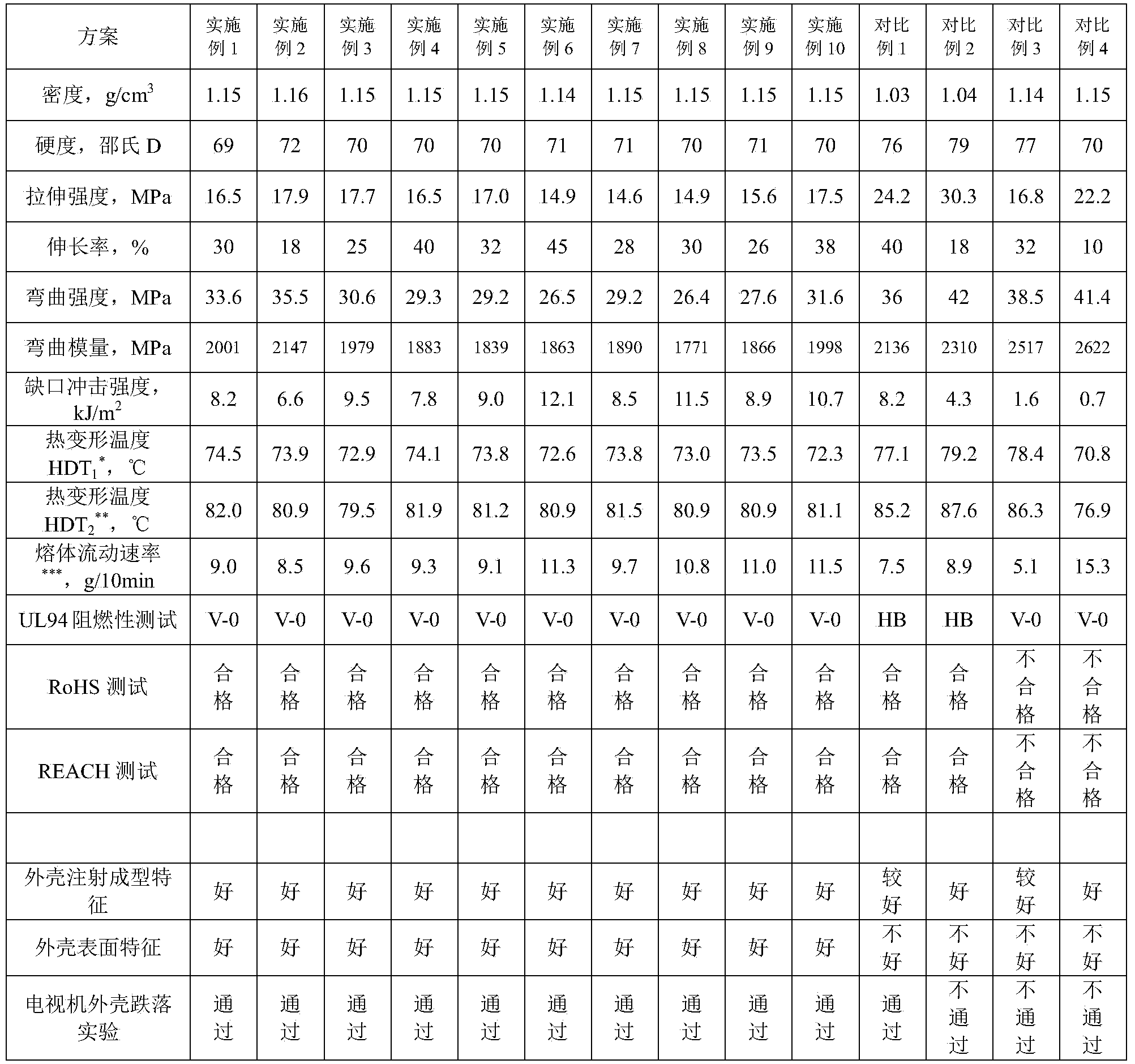

Environment-friendly flame-retardant modified HIPS (high impact polystyrene) LCDTV (liquid crystal display television) casing and preparation method thereof

ActiveCN103819865AImprove performanceBending strength balanceHazardous substanceButadiene-styrene rubber

The invention discloses an environment-friendly flame-retardant modified HIPS (high impact polystyrene) LCDTV (liquid crystal display television) casing and a preparation method thereof. The flame-retardant modified HIPS LCDTV casing contains no toxic and harmful substances such as polybrominated biphenyls, poly brominated diphenyl ethers and the like, the restriction of the use of certain hazardous substances in electrical and electronic equipment and REACH (registration, evaluation, authorization and restriction of chemicals) regulation requirements are met, and the flammability meets the UL-94V-0 grade. The environment-friendly flame-retardant modified HIPS LCDTV casing comprises raw materials by mass as follows: 45-70 parts of HIPS resin, 5-30 parts of GPPS (general purpose polystyrene) resin, 5-10 parts of thermoplastic styrene butadiene rubber SBS, 10-16 parts of decabromodiphenyl ethane, 4-6 parts of antimonous trioxide, 3-7 parts of mineral oil, 0.2-0.5 part of an antioxidant B215, 0.5-1.0 part of a lubricant and 0.9-1.5 parts of carbon black.

Owner:NANJING UNIV OF TECH +1

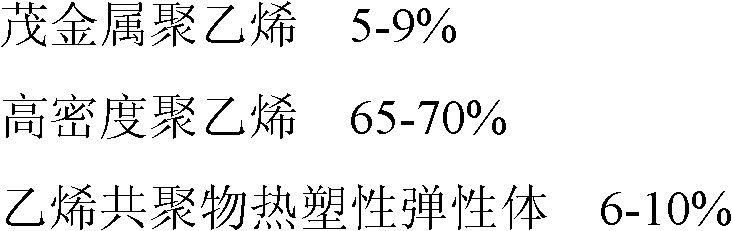

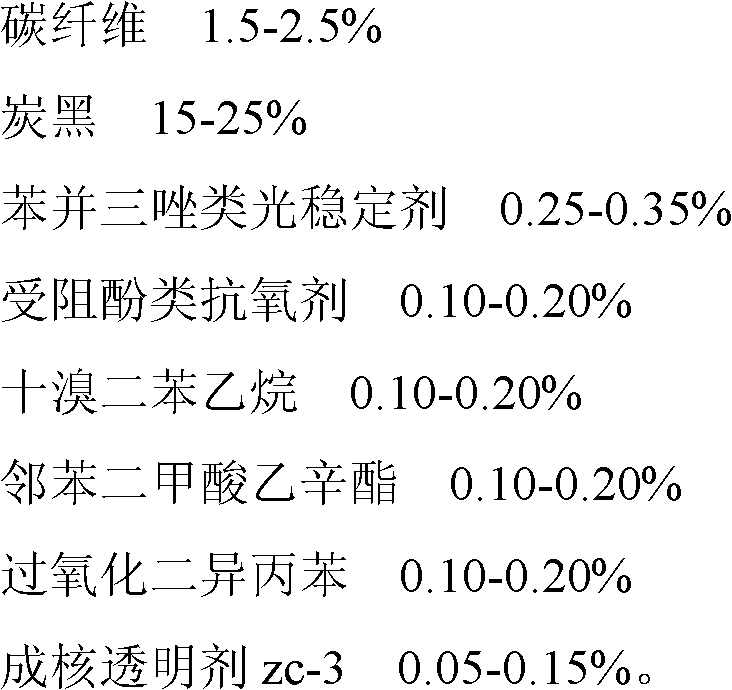

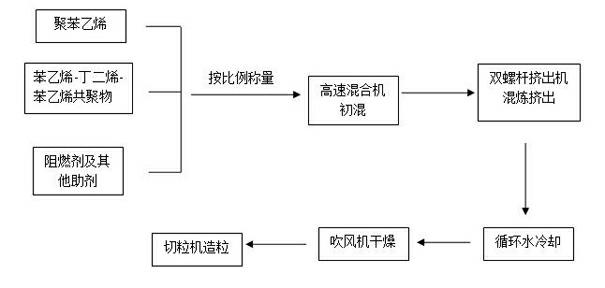

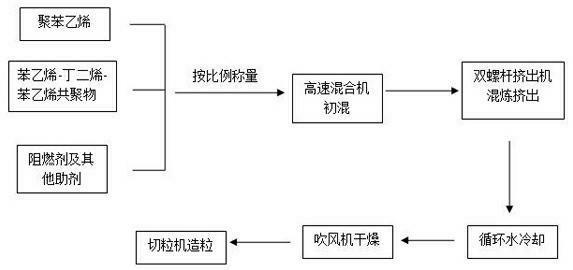

PTC (Positive Temperature Coefficient) high polymer heating material for self-limiting temperature electric tracing band

InactiveCN102604189AImprove PTC StrengthImprove tensile propertiesHeating element shapesPositive temperature coefficient thermistorsFiberCarbon fibers

The invention discloses a PTC (Positive Temperature Coefficient) high polymer heating material for a self-limiting temperature electric tracing band, which is prepared from the following raw materials in percentage by weight: 5 to 9 percent of metallocene polyethylene, 65 to 70 percent of high-density polyethylene, 6 to 10 percent of vinyl copolymer thermoplastic elastomer, 1.5 to 2.5 percent of carbon fibers, 15 to 25 percent of carbon black, 0.25 to 0.35 percent of benzotriazole light stabilizer, 0.10 to 0.20 percent of hindered phenol antioxygen, 0.10 to 0.20 percent of decabromodiphenylethane, 0.10 to 0.20 percent of diisooctyl ortho-phthalate, 0.10 to 0.20 percent of dicumyl peroxide and 0.05 to 0.15 percent of nucleating transparent agent zc-3. According to the invention, the elasticity modulus of the PTC material is improved, the maximum stress and the stress of a breaking point of the PTC material are increased, so that the PTC strength and the stretch resistance performance of the PTC heating material are improved.

Owner:WUHU XUHUI ELECTRIC NEW MATERIAL

High temperature resistant and flame retardant nitrile rubber cable material

InactiveCN103554572AImprove performanceWith high temperature resistanceRubber insulatorsLow-density polyethylenePolymer science

The invention relates to a cable material, and specifically relates to a high temperature resistant and flame retardant nitrile rubber cable material. The cable material comprises the following raw materials in parts by weight: 45-50 parts of nitrile rubber (3445), 14-17 parts of ethylene propylene terpolymer, 4-5 parts of polytetrafluoroethylene, 23-26 parts of low density polyethylene, 1-2 parts of sulphur, 4-6 parts of zinc stearate, 24-28 parts of N339 carbon black, 4-5 parts of soybean oil, 12-15 parts of sepiolite powder, 4-5 parts of antimonous oxide, 18-22 parts of vermiculite powder, 3-5 parts of zinc oxide by an indirect method, 3-5 parts of zinc stearate, 2-4 parts of potassium citrate, 1-2 parts of decabromodiphenylethane, 1-2 parts of acrylonitrile and 4-5 parts of an assistant. The cable material combines the advantages of nitrile rubber, ethylene propylene terpolymer, low density polyethylene and other assistant raw materials, and enhances performance of conventional nitrile rubber cable materials, so that the high temperature resistant and flame retardant nitrile rubber cable material has the advantages of high temperature resistance, flame retardance, aging resistance, storage resistance and the like, can satisfy the using demand of special occasions, and is harmless to the environment and human body and broad in application prospect.

Owner:安徽文峰电子科技集团有限公司

Flame-retardant nanometer master batch for polyester plastic

The invention discloses a flame-retardant nanometer master batch for a polyester plastic. The flame-retardant nanometer master batch comprises, by mass, 10-15% of a carrier, 40-60% of decabromodiphenylethane, 20-30% of diantimony trioxide, 6-10% of nano-sized magnesium hydroxide, 0.1-0.5% of a surface conditioning agent, 2-4% of a dispersant, 1-2% of a coupling agent and 0.1-1% of an antioxidant. The addition of the activated and modified nano-sized magnesium hydroxide makes the prepared flame-retardant master batch have an excellent dispersibility and an improved flame retardation property, and the flame-retardant master batch increases the flame retardation property of the polyester plastic and also guarantees the wear resistance, the rigidity, the toughness, the ageing resistance and the like of the polyester plastic. The flame-retardant master batch produced by adopting a production method in the invention can substitute a powdery flame retardant, can be directly added to the polyester plastic, can be used for wire drawing, extrusion, injection molding, blow molding or fiber granulation, and has the advantages of production operation simplification, production cost saving, material performance improvement, avoiding of the environmental pollution, benefiting for the clean production and the like.

Owner:QINGDAO XINZHAN PLASTIC

Flame-retarding toughening polystyrene master batch and preparation method thereof

The invention provides a flame-retarding toughening polystyrene master batch and a preparation method thereof, which can achieve the purposes of being high in flame resistance rate and free of dust in production environments. The technical scheme is that the master batch comprises the following components, by mass: 25-35 parts of polystyrene, 10-20 parts of styrene-butadiene- styrol copolymers, 15-25 parts of decahromopdipenyl ethane, 15-25 parts of brominated epoxy resin, 8-14 parts of antimonous oxide, 0.2-0.6 parts of lubricant zinc stearate, 0.3-0.8 parts of lubricant ethylene bis stearamide, 0.3-0.6 parts of calcium oxide, 0.1-0.3 parts of polytetrafluoroethylene and 0.2-0.4 parts of antioxygen. The flame-retarding toughening polystyrene master batch can be directly mixed with high impact polystyrene (HIPS) resin to produce plastic injection parts. The flame-retarding toughening polystyrene master batch with different contents can produce products with various flame-retarding grades, and is wide in application, convenient and fast.

Owner:QINGDAO GON TECHNOLOGY CO LTD

Compound inflaming retarding masterbatch and preparation method thereof

The invention provides a compound inflaming retarding masterbatch and a preparation method of the compound inflaming retarding masterbatch. The inflaming retarding masterbatch is formed by mixing carrier resin, a compound fire retardant, a lubrication dispersing agent and antioxygen. The method comprises the following steps of: mixing 1,2-Bis(2,3,4,5,6-pentabromophenyl)ethane, antimonous oxide, zinc borate, linear thermoplastic phenolic resin powder, adding a silane coupling agent for mixing to obtain the compound fire retardant; adding the dried carrier resin, the compound fire retardant, the lubrication dispersing agent and the antioxygen in a high-speed mixer for mixing, extruding, prilling and drying to prepare the compound inflaming retarding masterbatch. The diphenylethane decabromide serves as a main fire retardant which contains halogen and does not contain toxin, no poisonous polybrominated dibenzodioxins or polybrominated dibenzofurans are produced during burning, and simultaneously low-price zinc borate partially replaces expensive antimonous oxide, so that the compound inflaming retarding masterbatch has price superiorities, effectively reduces density of smoke obtained during burning simultaneously and restrains drop caused by burning and fusing. Synergistic effects of a compound inflaming retarding system greatly improve inflaming retarding efficiency of the compound inflaming retarding masterbatch.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com