Compound inflaming retarding masterbatch and preparation method thereof

A technology of flame retardant masterbatch and compound flame retardant, which is applied in the field of polymer materials, can solve the problems of restricting the use of polybrominated diphenyl ethers and polybrominated biphenyls (PBB), environmental protection and market recognition, and the concentration of toxic smoke is high. Manpower, significant flame retardant effect, high flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

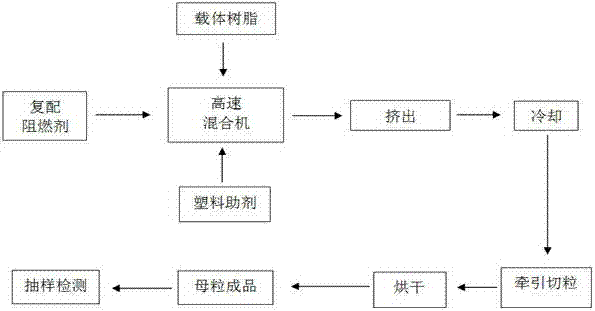

[0020] Such as figure 1 As mentioned above, the preparation method of a compound flame retardant masterbatch of the present invention is carried out based on a compound flame retardant masterbatch of the present invention, and the composition and content of the compound flame retardant masterbatch are as follows in parts by mass: 100 parts of carrier resin; 100 to 200 parts of compound flame retardant; 3 to 5 parts of lubricating dispersant; 2 to 3 parts of antioxidant, the preparation method of which is as follows: figure 1 , the specific method steps are as follows:

[0021] Implement the preparation method of a kind of composite flame retardant masterbatch of the present invention to carry out according to the following steps:

[0022] Step 1. Dry the carrier resin at 80-120° C. for 2 h to control the water content below 0.03% (mass percentage), and obtain the dried carrier resin for future use.

[0023] Step 2: Composite and surface treatment the compound flame retarda...

Embodiment 1

[0034] According to the above preparation method: the composition and content of the raw materials of the composite flame retardant masterbatch used in the present invention are: 100g low density polyethylene resin; 200g composite flame retardant; 5g polyethylene wax 420P; 2g antioxidant 1010 . Among them, the composition and content of the compound flame retardant masterbatch are: 120g of decabromodiphenylethane; 20g of antimony trioxide; 40g of zinc borate; 20g of linear thermoplastic phenolic resin powder; use 3g of silane coupling agent KH-570, The prepared compound flame retardant masterbatch.

[0035] The flame retardant masterbatch is used for flame retardant modification of polyethylene, adding 50%, passed the horizontal and vertical combustion test, has outstanding flame retardant effect, and reached the V-0 level requirement of UL-94 standard.

Embodiment 2

[0037] The difference between this example and Example 1 is that the carrier resin in the proportion of the compound flame retardant raw material masterbatch is 100 g of polypropylene resin, and the rest are the same to prepare the compound flame retardant raw material masterbatch.

[0038] The masterbatch is used for flame retardant modification of polypropylene, adding 45%, it has passed the horizontal and vertical combustion test, and has a significant flame retardant effect, and can also meet the V-0 requirements of the UL-94 standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com