Patents

Literature

613 results about "Brominated flame retardant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

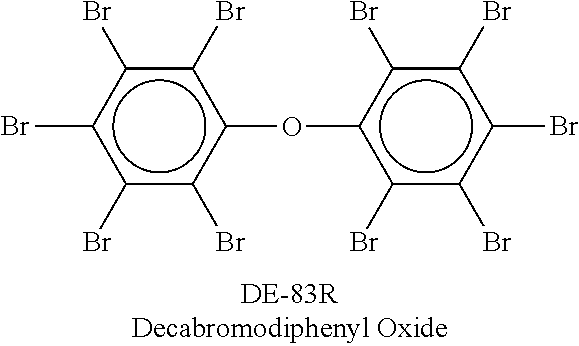

Brominated flame retardants (BFRs) are organobromine compounds that have an inhibitory effect on combustion chemistry and tend to reduce the flammability of products containing them. The brominated variety of commercialized chemical flame retardants comprise approximately 19.7% of the market. They are effective in plastics and textile applications like electronics, clothes and furniture.

Stabilized extruded alkenyl aromatic polymer foams and processes for extruding stabilized alkenyl aromatic polymer foams

Prepare an extruded thermoplastic polymer foam having a thermoplastic polymer composition having defined therein multiple cells, the thermoplastic polymer foam containing at least one thermoplastic polymer, a brominated flame retardant, an epoxy containing organic compound and 180 weight parts or less of water extractable cations using a brominated flame retardant, an innocuous stabilizer and a blowing agent containing water.

Owner:DOW GLOBAL TECH LLC

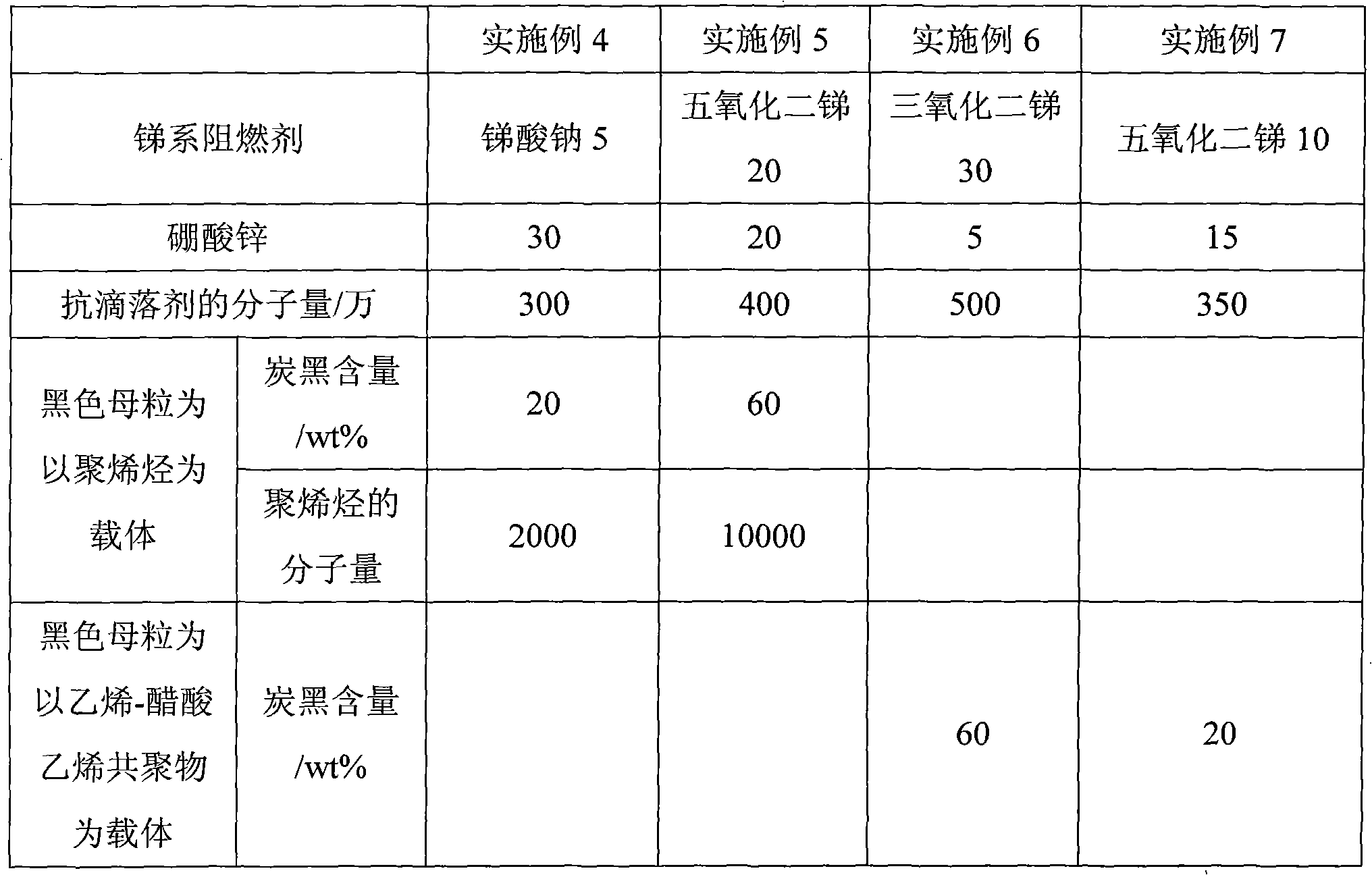

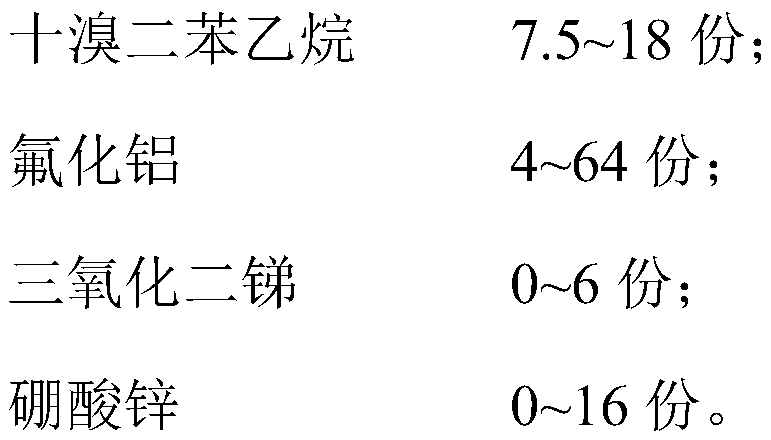

Polyamide composition with flame retardance and thermoplasticity

The invention discloses a polyamide composition with flame retardance and thermoplasticity. The polyamide composition with flame retardance and thermoplasticity comprises the following components in percentage by weight: 30-90% of thermoplastic polyamide resin, 5-40% of a brominated flame retardant, 0.5-15% of a flame-retardant synergist and 0-50% of a reinforcing material. According to the polyamide composition, the brominated flame retardant, the high-efficiency flame-retardant synergist (namely zinc borate) and organic silicon are added in polyamide resin, on the one hand, the polyamide composition can replace antimony trioxide which is a rare material and is limited to be exploited by the nation at present, limited strategic resources of the nation can be saved, and the cost is lowered; and on the other hand, the flame retardance, a CTI (comparative tracking index) value and GWIT (glow wire ignition temperature) of the polyamide composition can be improved greatly, and the safety guarantee is provided for the use of the flame-retardant polyamide product on electronic appliances with high requirements.

Owner:KINGFA SCI & TECH CO LTD +1

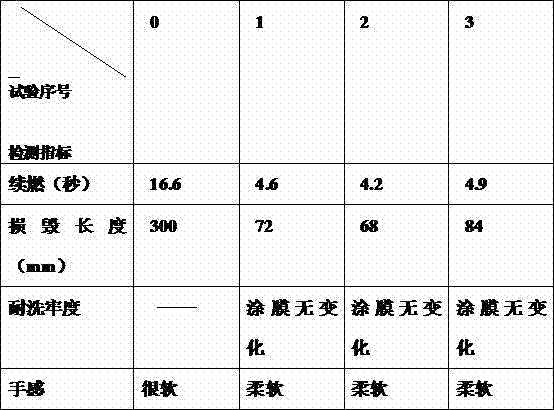

Aqueous foaming flame-retardant coating glue for textile and preparation thereof

ActiveCN101498105AMeet the new demands of finishingMeet the technical requirements of foam finishingVegetal fibresPolymer scienceEmulsion

The invention discloses an aqueous foaming flame-retardant coating gum for textiles and a preparation method thereof. The existing flame-retardant coating gum can not meet requirements of a foaming finishing process. The aqueous foaming flame-retardant coating gum is prepared from the following components: aqueous substrate emulsion comprising aqueous polyurethane emulsion and aqueous acrylic ester emulsion, brominated flame retardant additive, phosphate based flame retardant additive, a flame retardant synergistic agent, a thickening agent, a foaming agent, a foaming stabilizer, an anti-settling agent and a feeling agent. The coating gum can meet the requirements of a foaming finishing technique, finishes coatings of fabrics after directly being physically foamed by a mechanical foaming machine and meets new requirements of textiles for coating finishing.

Owner:传化智联股份有限公司 +2

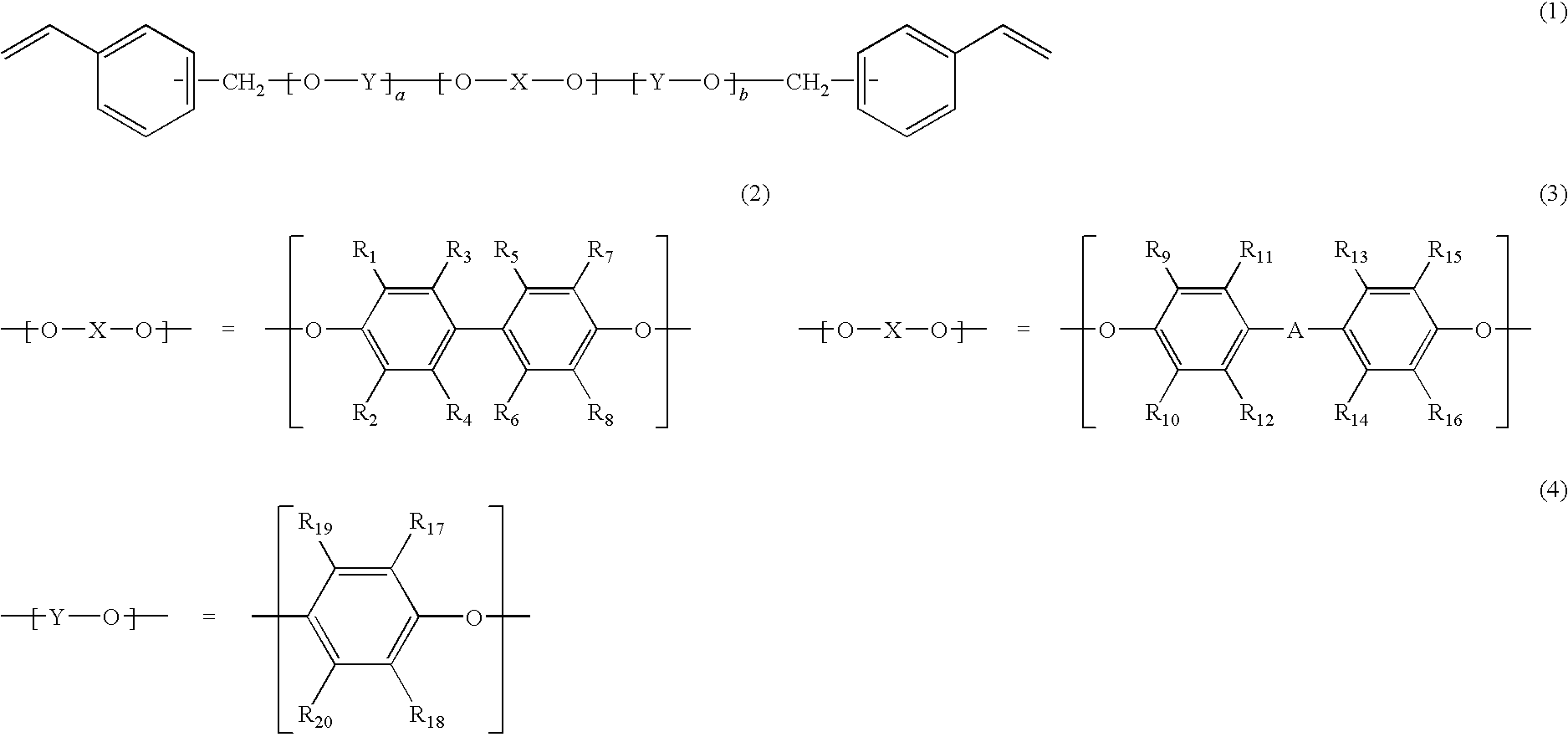

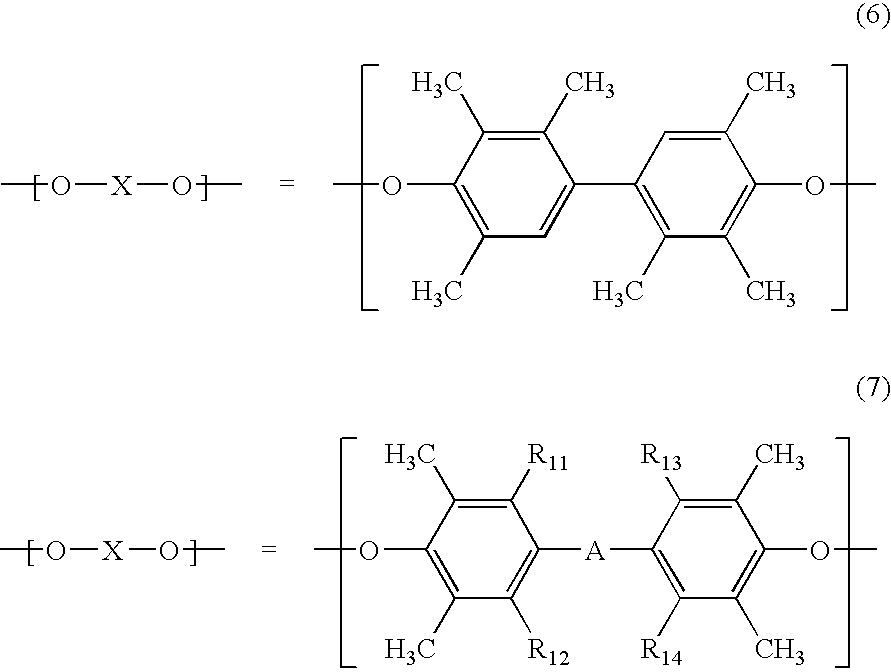

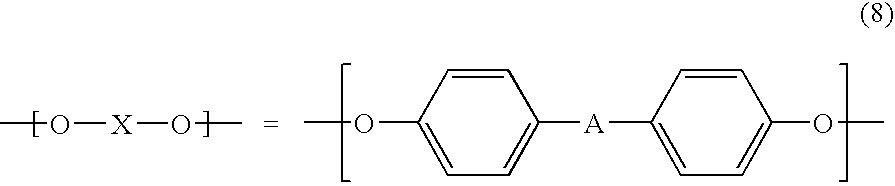

Resin composition, prepreg and metal-foil-clad laminate

ActiveUS20090247032A1Improve suppression propertiesHigh multilayerPrinted circuit aspectsSynthetic resin layered productsMetal foilCopper foil

A vinyl-compound-based resin composition containing a terminal vinyl compound (a) of a bifunctional phenylene ether oligomer having a polyphenylene ether structure, a naphthol aralkyl type cyanate ester resin (b), a bisphenol A cyanate ester resin (c), a brominated flame retardant (d) and an inorganic filler (e), which resin composition is for use in a printed wiring board for high multilayer and high frequency and is improved in moldability and copper foil peel strength, which are conventional problems, without any decrease in electric characteristics and heat resistance after moisture absorption while keeping flame retardancy, a prepreg comprising the above resin composition and a glass woven fabric, a metal-foil-clad laminate obtained by disposing a metal foil on one side or both sides of a stack of at least one prepreg and laminate-molding the resultant set, and a resin sheet obtained by applying a solution of the above resin composition to a surface of a metal foil or a film.

Owner:MITSUBISHI GAS CHEM CO INC

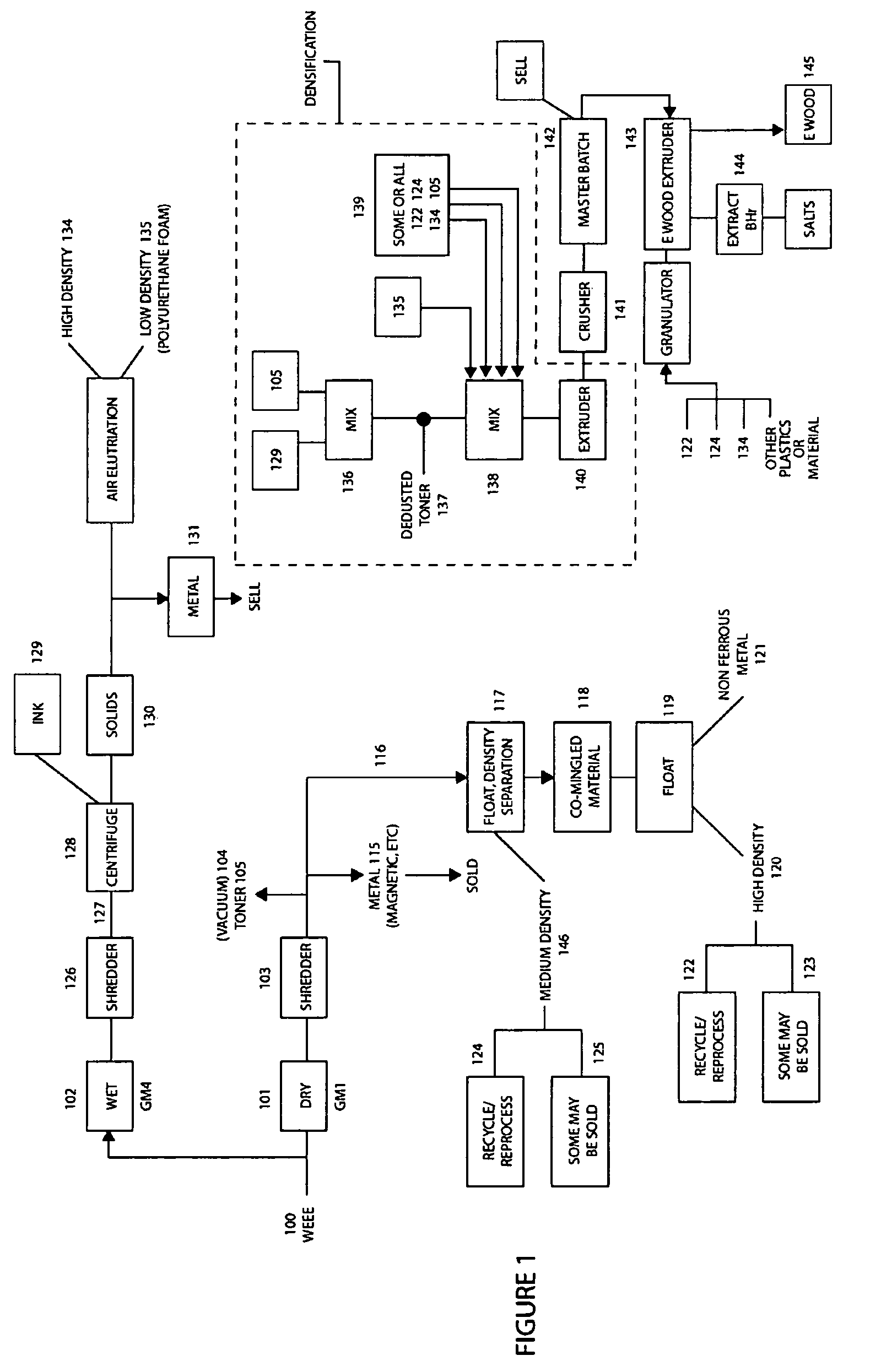

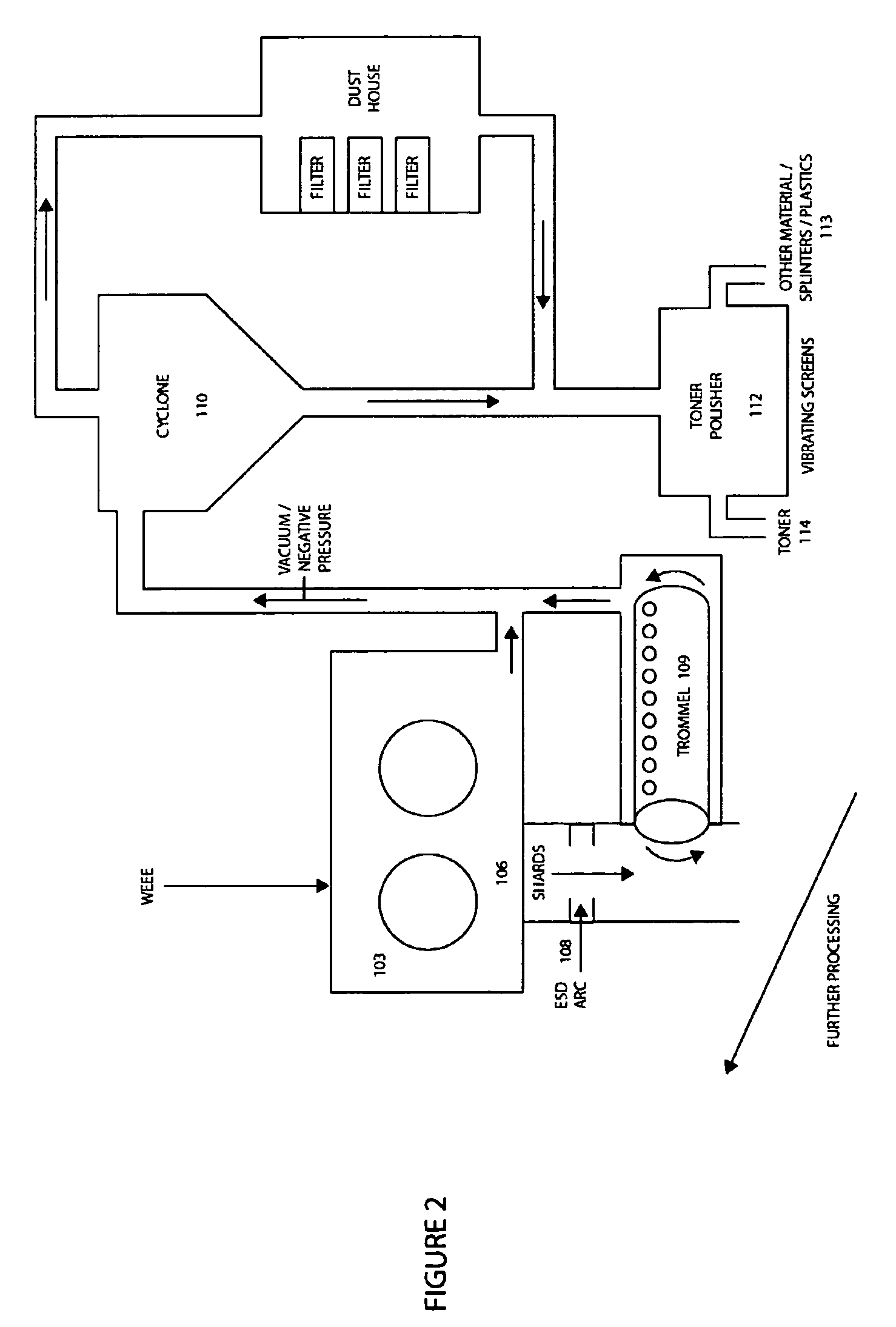

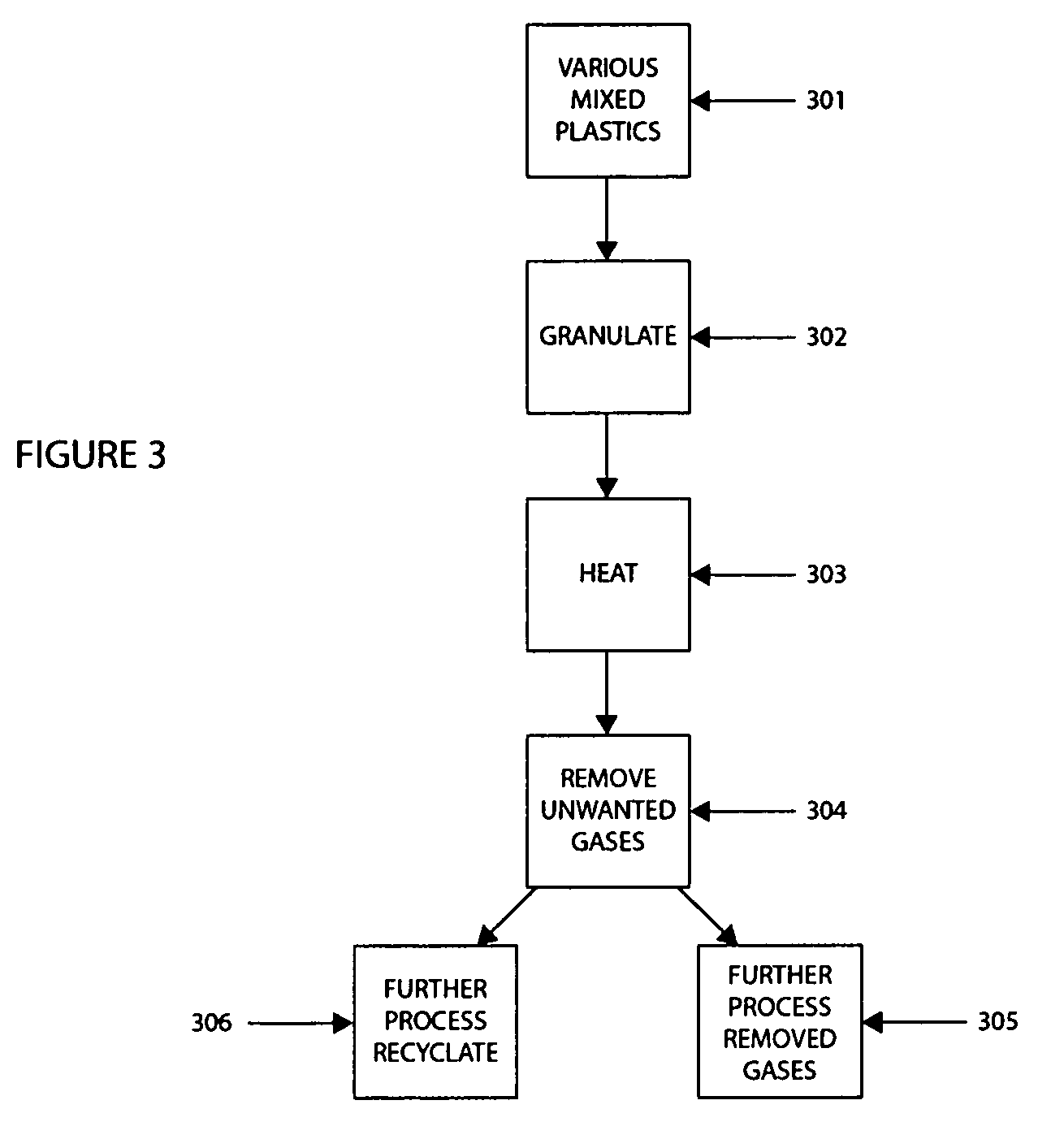

Method of recycling mixed streams of ewaste (WEEE)

The present invention relates to the recycling of waste electrical and electronic equipment (WEEE). Preferably, the present invention relates to the substantial recycling of all material forming the WEEE, thus providing substantially zero landfill. In yet another form, the invention relates to an additive and / or method of providing an additive. In still another form, the invention relates to recycling ink, toner, and / or PU foam from imaging consumables, forming part of the WEEE. In another form, the invention relates to the recycling of plastic materials containing flame retardants, including the recycling of plastics materials, such as plastics materials containing brominated flame retardants generally based on styrenics (e.g. PS, HIPS, ABS, PPO / PS, PPE / PS, ABS / PC) and polyamides (Nylon 6, nylon 6,6, nylon 12) and other engineering plastics such as polyacetal, polycarbonate, PET, PBT, liquid crystal polymers.

Owner:CLOSE THE LOOP TECH

Water-based flame-retardant coating adhesive and preparation method thereof

ActiveCN104404769AImprove flame retardant performanceIncrease hydrostatic pressureFibre treatmentWater basedCarbon layer

The invention discloses a water-based flame-retardant coating adhesive and a preparation method thereof. The conventional flame-retardant coating adhesive adopts a gas-phase fire retardant as a main component, and fabrics cannot reach the BS-5852:2006 flame retardant test standard after being subjected to coating finishing by the conventional flame-retardant coating adhesive. The water-based flame-retardant coating adhesive comprises the following components in part by weight: 100 parts of waterborne base emulsion consisting of 30-60 parts of waterborne polyurethane emulsion and 40-70 parts of waterborne polyacrylate emulsion, 30-60 parts of a brominated flame retardant, 10-40 parts of polyhydroxylated compound, 5-10 parts of a phosphorus flame retardant, 5-20 parts of a flame retardant synergist, 5-10 parts of a thickening agent, 0.5 part of waterborne blocked isocyanate, and 0.3-0.5 part of a feeling agent. When the water-based flame-retardant coating adhesive performs coating finishing on fabrics, a continuous compact carbon layer is formed on the surface of the fabrics after flame occurs, so that the flame is effectively isolated, and the fabrics can reach the BS-5852:2006 flame retardant test standard.

Owner:传化智联股份有限公司 +1

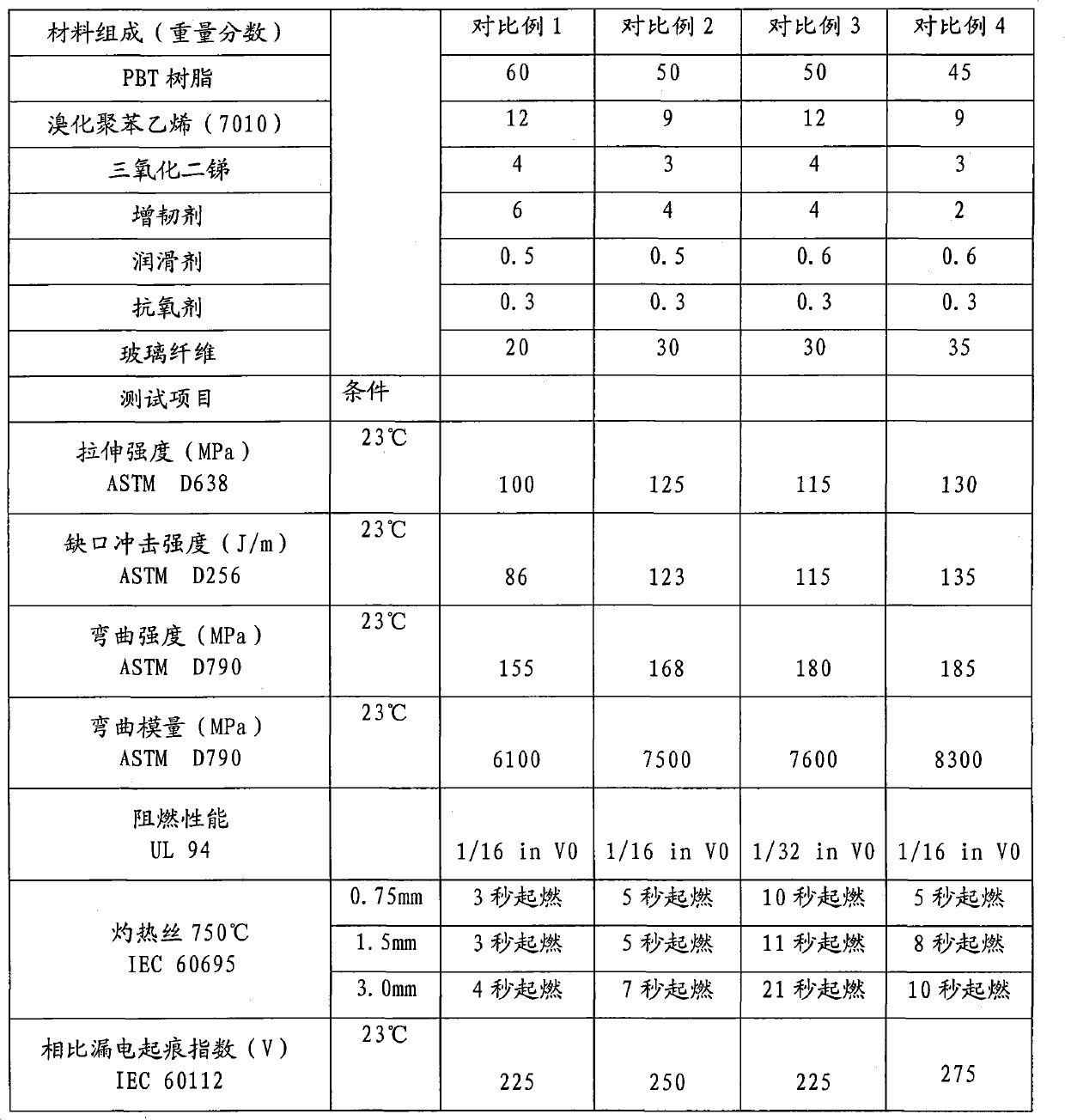

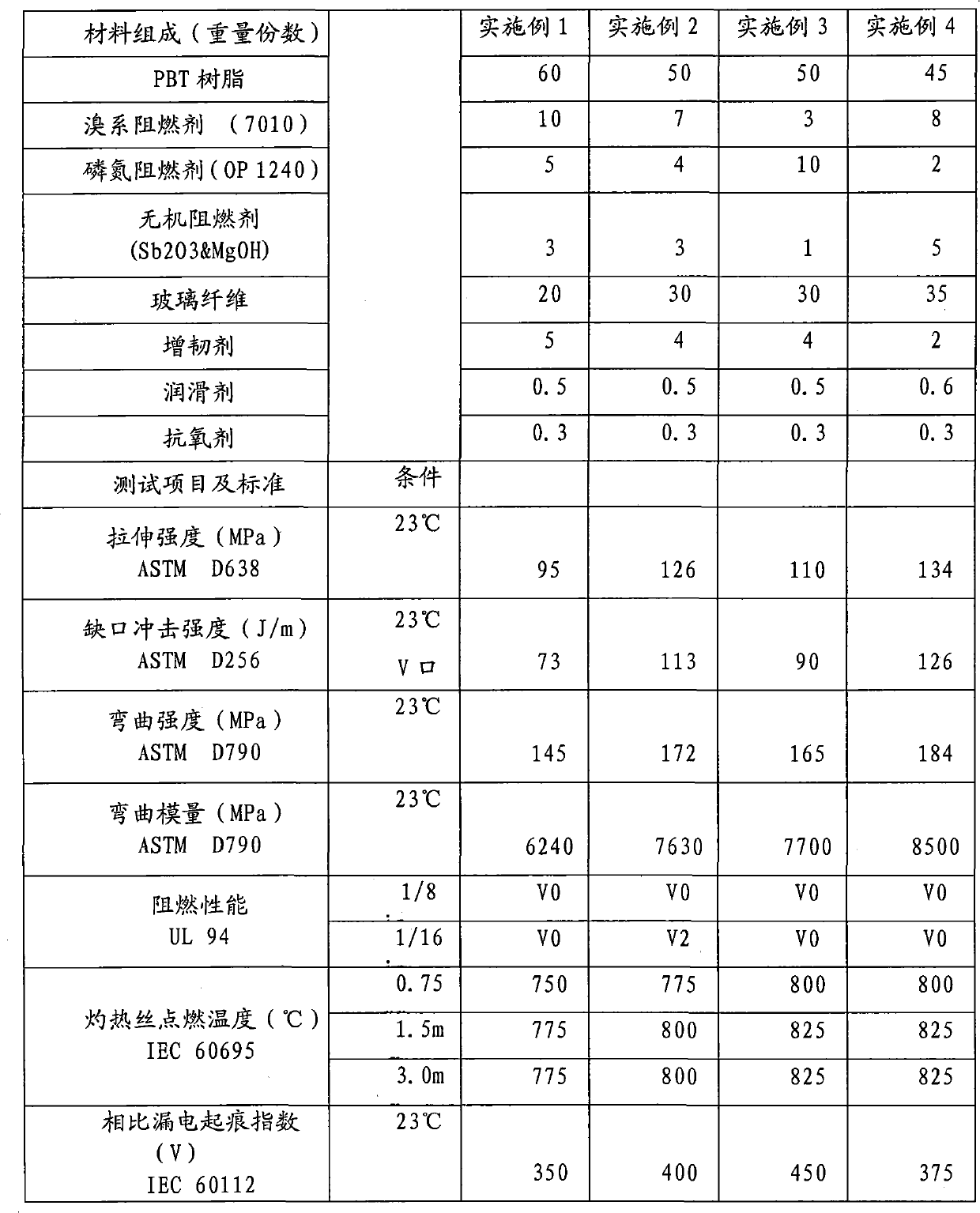

Flame-retardant enhanced PBT material and preparation method thereof

InactiveCN101817972ARaise the ignition temperatureHigh tracking indexComparative Tracking IndexAntioxidant

The invention discloses a flame-retardant enhanced PBT material and a preparation method thereof. The flame-retardant enhanced PBT material comprises the following components in percentage by weight: 45 to 60 percent of PBT resin, 3 to 10 percent of brominated flame retardant, 1 to 10 percent of phosphorus-nitrogen flame retardant, 1 to 5 percent of inorganic flame retardant, 2 to 5 percent of toughening agent, 20 to 35 percent of glass fiber, 0.3 to 1 percent of lubricating agent, and 0.1 to 0.6 percent of antioxidant. The flame-retardant enhanced PBT material has high ignition temperature of glowing filament, high comparative tracking index, and better mechanical property, and can be widely applied to the field of unattended electronic and electric products.

Owner:SHENZHEN KEJU NEW MATERIAL

Flame Resistance Natural Fiber-Filled Thermoplastics with Improved Properties

Flame retardant systems containing brominated flame retardants and chlorinated flame retardants with synergists and char formers are incorporated into wood-filled resins in combination with compatibilizers to enhance physical properties and to increase water extraction resistance and long term durability. Desirable embodiments of the invention relate to brominated and chlorinated flame retardant additives, synergists, and char formers for use in resins, including polyolefins, fillers, wood-filled polyolefins, in particular wood-filled polyolefins comprising over 20% wood flour, in combination with compatibilizers and methods of use of the flame retardants and fillers. The invention includes methods of making and using the composition.

Owner:CHEMTURA CORP

Flame retardant compositions for flammable plastics and flame retarded plastic compositions containing the same

A flame retardant composition for rendering flammable plastics flame retardant is provided. The composition comprises a brominated flame retardant, a free-radical generator selected from 2,3-dimethyl-2,3-diphenyl-butane or its homologs, and a phthalocyanine or naphthalocyanine complex with a metal of groups 7 to group 10 of the IUPAC periodic chart. The quantity of the brominated flame retardant may be saved when incorporating into flammable plastic materials in conjunct with the free-radical generator and the phathalocyanine or naphthalocyanine complex of the above type.

Owner:DAI ICHI KOGYO SEIYAKU CO LTD

Low-L value inflaming retarding ABS modified resin and preparation method thereof

The invention relates to a low-L value (less than 27) inflaming retarding ABS modified resin and a preparation method thereof. The resin comprises the components with the content (based on parts by weight): 100 parts of ABS resin, 10-25 parts of brominated flame retardant, 20-40 parts of inorganic inflaming retarding master batch, 0.1-0.5 part of anti-dripping agent, 0.2-1 part of antioxidant, 0.1-0.5 part of light stabilizer, 1-3 parts of lubricating agent and 1-4 parts of black master batch. Compared with the prior art, the invention has reasonable technique, overcomes the defect of high L value (namely, low degree of blackness) of the existing inflaming retarding ABS resin, and adopts the novel high-efficiency inflaming retarding synergistic effect technology. The invention leads the resin has higher degree of blackness by reasonably selecting the grain diameter of antimony trioxide, a carbon black lubricating dispersion system and the processing technique of a master batch method on the basis of maintaining the excellent performance of the inflaming retarding ABS resin, and has wide application prospect in the field of the requirement of high degree of blackness.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Stabilized extruded alkenyl aromatic polymer foams and processes for extruding stabilized alkenyl aromatic polymer foams

Prepare an extruded thermoplastic polymer foam having less 1000 parts per million, based on total polymer weight, of cations from water soluble salts that exist or form into a solid or glassy state that is less malleable than the thermoplastic polymer as the foamable composition exits an extrusion die during foam manufacturing using a brominated flame retardant, an innocuous stabilizer and a blowing agent containing water.

Owner:STOBBY WILLIAM G

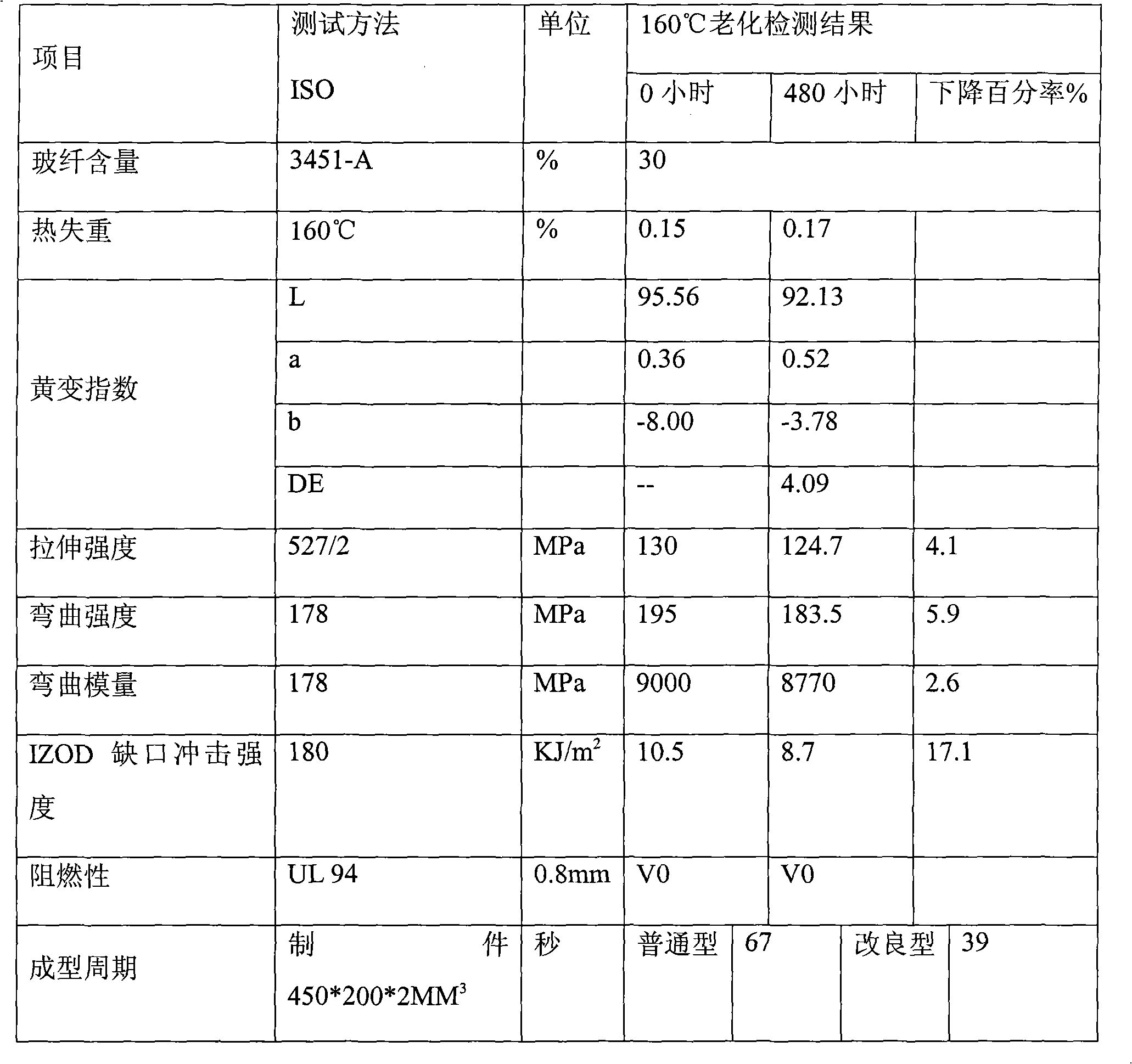

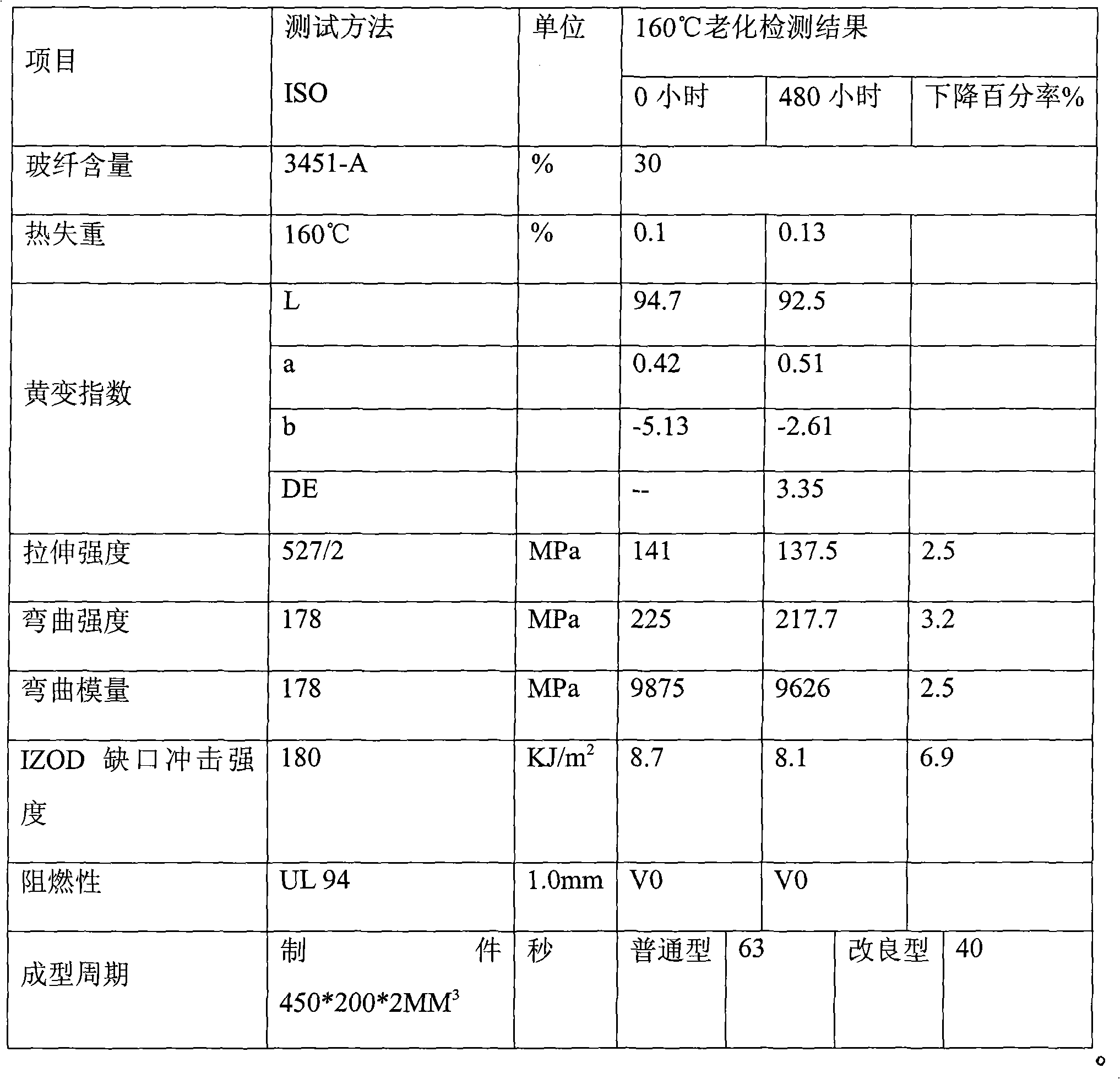

Flame-proof reinforced Valox compound and preparation thereof

InactiveCN101275010ANot easy to change colorGood thermal and oxygen aging stabilityPolytetramethylene terephthalateGlass fiber

The invention discloses a flame retardant intensified polybutylene terephthalate composite and a preparation method thereof; weight portions of the compositions for preparing the flame retardant intensified polybutylene terephthalate composite are: 100 portions of medium viscosity PBT resin, 15 to 30 portions of brominated flame retardants, 10 to 30 portions of composite mother particles, and 15 to 150 portions of fiber glass. The product of the invention has good stability of heat resistance and oxygen aging in the treatment process and good stability of heat resistance and oxygen aging in long-term use at high temperature, so light color and bright color products are difficult to change color during the processing period, and difficult to turn yellow or black under long-term use at high temperature, which can satisfy the application in long-term use at high temperature for electronic and electrical components and appearance parts and large power energy-saving light.

Owner:SHANGHAI KINGFA SCI & TECH +1

Flame-retardant polypropylene composition with high glow-wire ignition temperature

The invention discloses a flame-retardant polypropylene composition with high glow-wire ignition temperature (GWIT). The composition is characterized by comprising the following components in percentage by weight: 35.0 to 66.5 percent of polypropylene, 15.0 to 20.0 percent of brominated flame retardants, 3.0 to 8.0 percent of flame-retardant synergist, 15.0 to 35.0 percent of high-efficiency composite flame retardant, 0.1 to 0.5 percent of primary antioxidant, 0.1 to 0.5 percent of auxiliary antioxidant and 0.3 to 1.0 percent of processing aid. The composition has the advantages that: a) the composite flame retardant can achieve a microcapsule coating effect around the composite flame retardant, and the heat is taken away and the heat conduction is reduced by isolating oxygen; b) ultrafine magnesium hydroxide can generate metal oxide to reduce heat conduction in the heating process of a glow wire, and produce steam which can take away the heat, and the surface treatment of the precipitated ultrafine magnesium hydroxide slightly affects the mechanical properties of the flame-retardant modified polypropylene composition; and c) an organosiloxane polymer with high polymerization degree can form a silicon carbide gel isolation layer to isolate oxygen and achieve a flame-retardant effect, the GWIT is higher than required 750 DEG C, and the composition is widely applied to the fields of machinery, industry and the like.

Owner:KINGFA SCI & TECH CO LTD +2

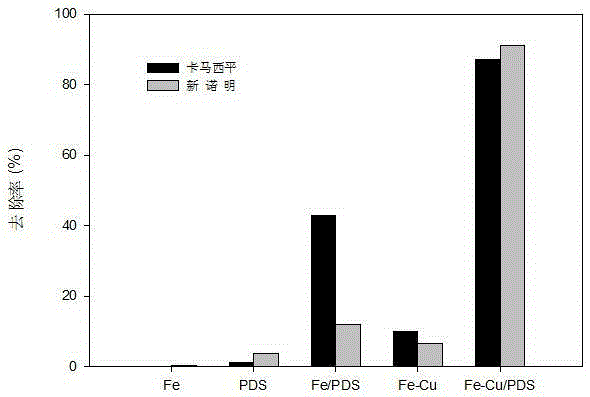

Water treatment method of zero-valent iron-copper bi-metal activated persulfate

InactiveCN105253983ASolve the problem of low production volumeRemove completelyWater contaminantsContaminated groundwater/leachate treatmentSulfate radicalsPolychlorinated biphenyl

The invention discloses a water treatment method of zero-valent iron-copper bi-metal activated persulfate. The water treatment method specifically comprises the steps that bi-metals including zero-valent iron and copper are added into water containing micro-pollutants, then persulfate is added, full mixing is performed, the bi-metals including the zero-valent iron and the copper are utilized to activate the persulfate so as to remove the micro-pollutants in the water. The water treatment method utilizes the bi-metals including the zero-valent iron and the copper to efficiently activate the persulfate so as to produce free sulfate radicals having strong oxidizing property, can achieve the purpose of quickly and thoroughly removing micro-pollutants, including multiple types of poisonous and harmful micro-pollutants in water, such as polychlorinated biphenyl, brominated flame retardants, drugs and personal care products (PPCPs) and algal toxin, and has the advantages of high activation efficiency, high oxidation and degradation efficiency of pollutants, wide pH using range, convenient operation and the like. The water treatment method can be applied to underground water remediation, treatment of industrial water (including electroplating wastewater, hospital wastewater, printing and dyeing wastewater and the like), drinking water treatment, wastewater treatment and the like.

Owner:SUN YAT SEN UNIV

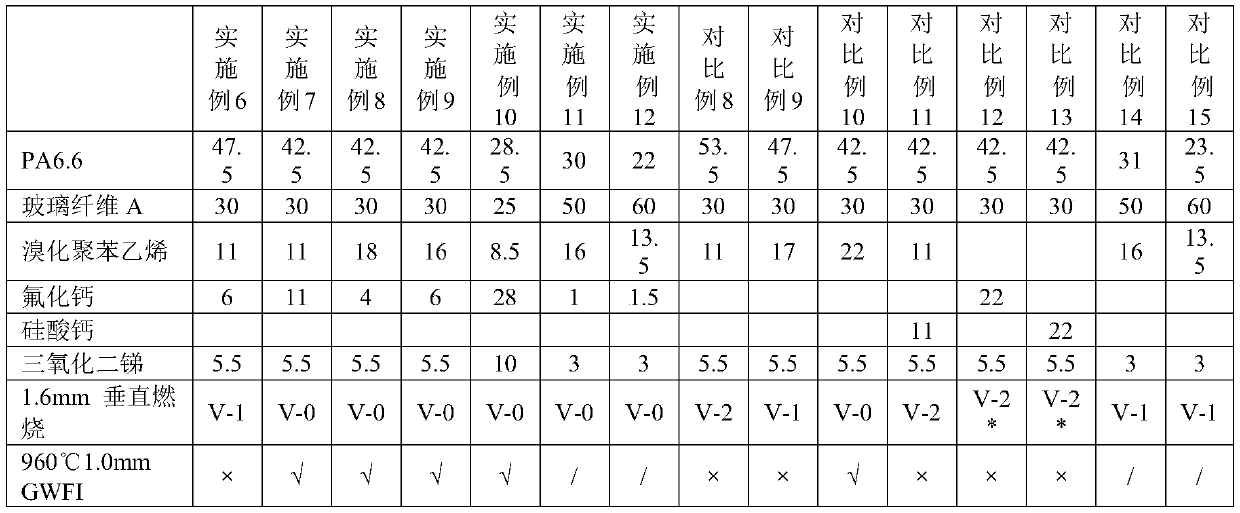

Flame retardant reinforced nylon material with high glow wire ignition temperature and preparation method thereof

The invention relates to the technical field of high-molecular material, and more specifically relates to a flame retardant reinforced nylon material with a high glow wire ignition temperature and a preparation method thereof. The flame retardant reinforced nylon material with a high glow wire ignition temperature of the invention comprises nylon 6 resin, brominated flame retardant system, anti-oxidant alkali-free glass fibre and processing auxiliary agent. The material of the invention has an increased glow wire ignition temperature of 850 DEG C compared with 750 DEG C specified in European Union IEC60695 standard, so as to expand usage scope of an unwatched electric appliance; the flame retardant reinforced nylon material has advantages of high strength, high toughness, rapid moulding and good cost performance, and can satisfy requirements of electron electric appliances and household electrical appliances, such as microswitch, socket connector and fuse.

Owner:GUANGDONG WAYLAM ENG PLASTICS

Halogen-flame retardant and application thereof

ActiveCN109836817AReduce the difficulty of productionReduce dosageCost ControlsInorganic fluorine compounds

The invention belongs to the field of flame retardant technology and provides a halogen-frame retardant. The halogen-flame retardant comprises a first component and a second component. The first component is composed of a main flame retardant and an auxiliary flame retardant. The main flame retardant is selected from a brominated flame retardant and a chlorinated flame retardant; and the auxiliaryflame retardant is a fluorine compound. The second component is a flame-retardant synergistic compound, selected from metal oxides of the group IIIA, IVA, VA metals in the periodic table of the elements or salt thereof, transition metal oxide, a silicon-based flame retardant, a phosphorus-based flame retardant and a nitrogen-based flame retardant. The invention also provides a resin composite material, an elastomer composite material and a relative formed body containing the halogen-frame retardant, a coating medium and related part or structural body, and an impregnated material. The invention has the following beneficial effects: the technical bias that fluoride cannot effectively perform the flame-retardant effectiveness and then cannot be used or is hard to be used as a flame retardant is corrected; the actual usage of the brominated flame retardant and / or the chlorinated flame retardant is reduced, and then the production difficulty of the flame retardant and the environmental pollution are reduced, and the color matching and cost control difficulty is reduced.

Owner:BENSONG ENG PLASTICS HANGZHOU

Flame resistance natural fiber-filled thermoplastics with improved properties

InactiveUS20080073627A1Good physical propertiesIncrease water extraction resistanceFireproof paintsThermoplasticPolyolefin

The invention relates to flame retardant systems including the brominated flame retardants and chlorinated flame retardants with synergists and char formers for use in wood-filled resins in combination with compatibilizers to enhance physical properties and to increase water extraction resistance and long term durability. Desirable embodiments of the invention relate to brominated and chlorinated flame retardant additives, synergists, and char formers for use in resins, including polyolefins, fillers, wood-filled polyolefins, in combination with compatibilizers and methods of use of the flame retardants and fillers. The invention includes methods of making and using the composition.

Owner:CHEMTURA CORP

Antistatic modified polyester and method for preparing same

The invention discloses antistatic modified polyester and a method for preparing the same. The antistatic modified polyester comprises the following components by weight percent: 30-70 percent of polyester resin, 0-50 percent of alkali-free glass fibre, 8-20 percent of brominated flame retardant, 1-5 percent of antimony trioxide, 1-8 percent of antistatic agent, 0-10 percent of toughening agent, 0.1-0.5 percent of antioxidant, 0-5 percent of coloring agent and 0.5-1 percent of processing auxiliary. The antistatic modified polyester has good thermal stability, excellent mechanical performance, can be made into a variety of colors and has broad application prospect.

Owner:KINGFA SCI & TECH CO LTD +1

Efficient flame retardant polyolefin composition

Owner:ZHONGSHAN COMPLORD NEW MATERIALS CO LTD

Low-precipitate flame-retarded polyamide composition and preparation method thereof

The invention relates to the technical field of a high polymer material and especially relates to a low-temperature flame-retarded polyamide composition, and the composition includes the raw materials based on the following mass percentage: 20-70% of nylon resin, 10-30% of main flame retardant, 0-15% of synergistic agent, 10-40% of alkali-free glass fiber, 0-1% of antioxidant, and 0-2% of lubricant, wherein the nylon resin is one of nylon 66 and nylon 6 or their mixture; the main flame retardant is a brominated flame retardant; the synergistic agent is selected from one of compounds of antimonous oxide master batch, zinc borate, silicon dioxide and metallic oxide or the mixture prepared by more than one compound; the lubricant is a lubricant with high molecular weight and dispersion and includes one of polyethylene wax, modified PE wax, OP wax and lignite wax. The polyamide composition isn't easily migrated or precipitated at high-temperature moisture conditions and low in material cost, the preparation method is simple and beneficial to popularization and application.

Owner:江苏晋伦塑料科技有限公司

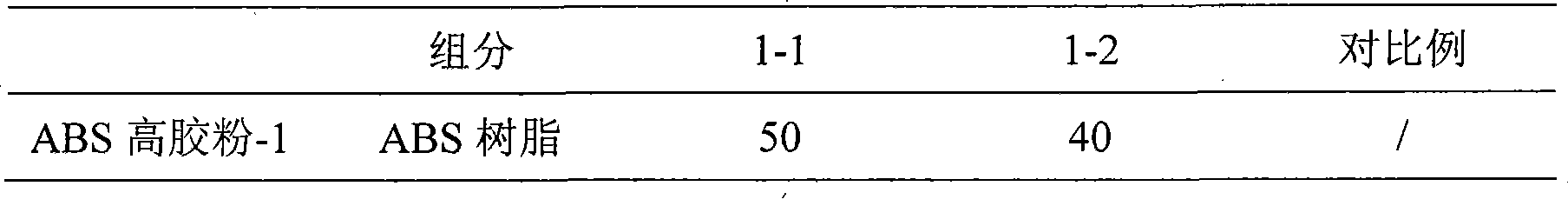

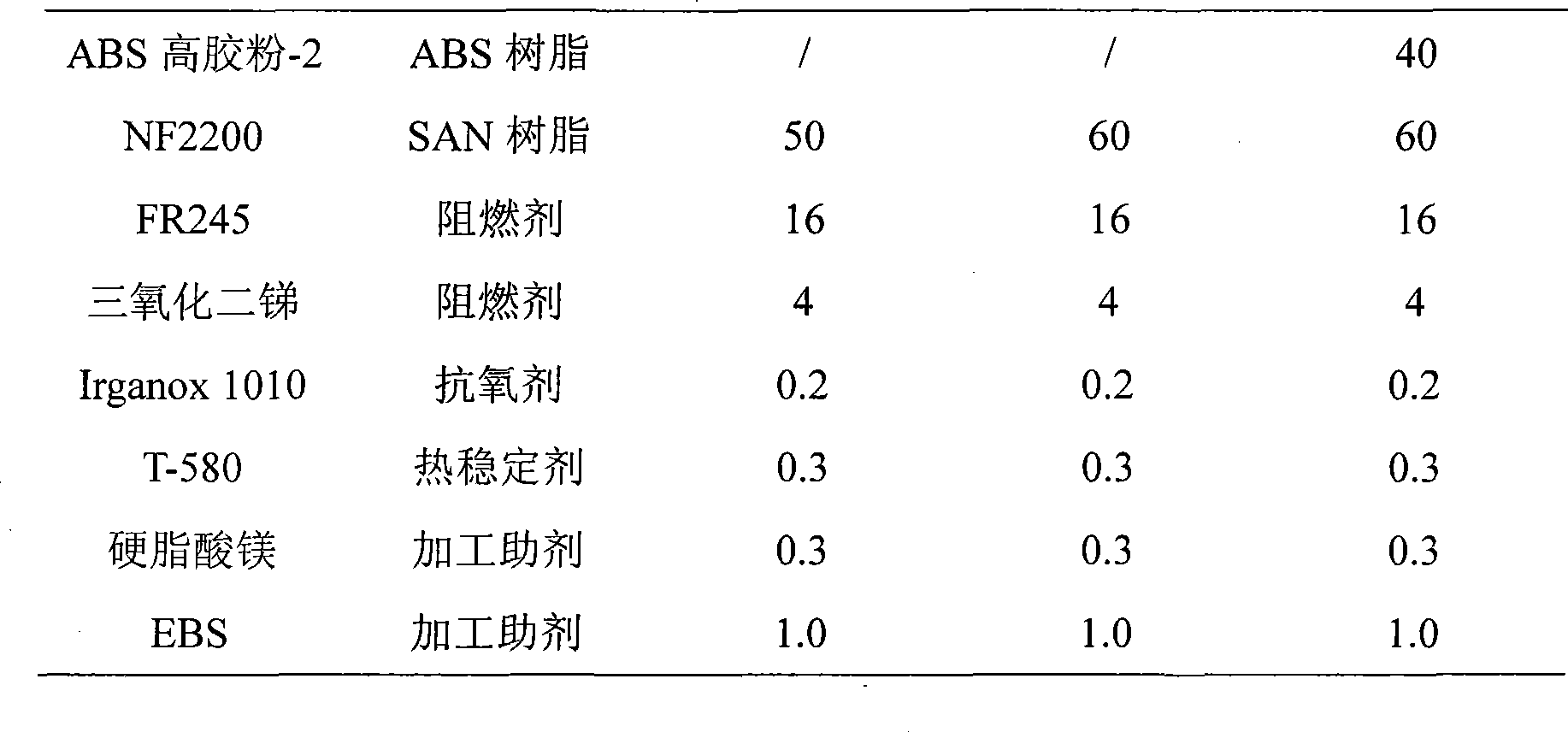

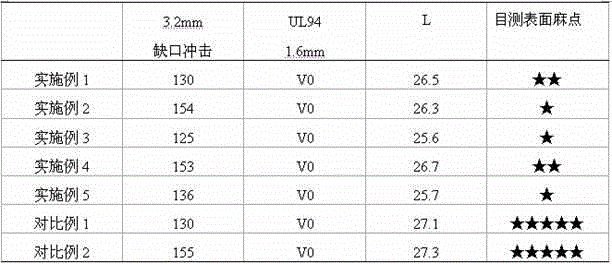

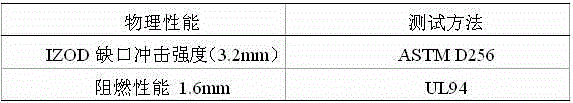

High gloss flame-retardant ABS modified resin and preparation thereof

The invention relates to the technical field of polymer material, in particular to a flame-retardant ABS modified resin having high glaze and a manufacturing method thereof. The invention provides the flame-retardant ABS modified resin having high glaze, which comprises ABS high glue powder, SAN resin, brominated flame retardant, antimonic flame retardant, antioxidizer, heat stabilizer and processing aid. The flame-retardant ABS modified resin is characterized in that the ABS has the rubber-particle size being less than 1mum. Based on maintaining excellent physical property of the original ABS resin, the flame-retardant ABS modified resin having high glaze has good flame retardant property and the high glaze of the surface. The flame-retardant ABS modified resin having high glaze can be prepared by traditional twin-screw extrusion process equipment, has the advantages of simple and continuous production flow, high production efficiency and stable product quality, and can be widely applied to the industries such as household electrical appliances having high glaze and flame-retardant requirements, automobile industry, etc.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

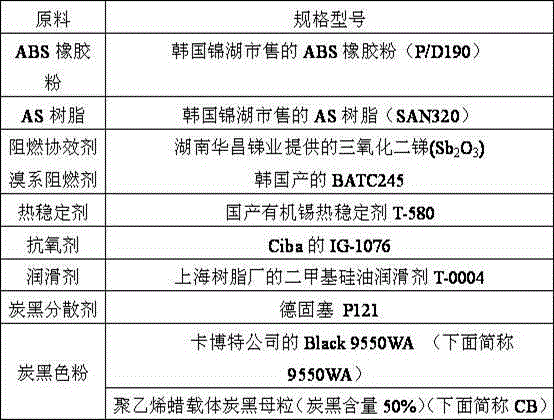

Flame-retardant acrylonitrile butadiene styrene (ABS) resin with excellent surface glossiness and high blackness and preparation method of ABS resin

The invention relates to a flame-retardant acrylonitrile butadiene styrene (ABS) resin with excellent surface glossiness and high blackness. The ABS resin comprises the following components in parts by weight: 20-60 parts of ABS rubber powder, 40-80 parts of AS (Acrylonitrile-Styrene) resin, 2-6 parts of flame-retardant synergist, 5-25 parts of brominated flame retardant, 0.1-1 part of heat stabilizer, 0.1-1 part of antioxidant, 0.1-1 part of lubricating agent, 0.1-2 parts of carbon black dispersing agent and 0.1-5 parts of carbon black powder, wherein the carbon black dispersing agent is a block polymerization amphipathic siloxane compound of which one end is provided with a lipophilic group and of which the other end is provided with a hydrophilic group; the carbon black powder is pure carbon black or carbon black master-batches with polyolefin or ethylene vinyl acetate copolymer as a carrier. The invention also provides a method for preparing the flame-retardant ABS resin. The flame-retardant ABS resin has extremely high surface glossiness and balanced toughness and fluidity and is particularly suitable for household appliance industry with the requirements of high glossiness and flame retardant property.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Flame retardant compositions for flammable plastics and flame retarded plastic compositions containing the same

A flame retardant composition for rendering flammable plastics flame retardant is provided. The composition comprises a brominated flame retardant, a free-radical generator selected from 2,3-dimethyl-2,3-diphenylbutane or its homologs, and a phthalocyanine or naphthalocyanine complex with a metal of groups 7 to group 10 of the IUPAC periodic chart. The quantity of the brominated flame retardant may be saved when incorporating into flammable plastic materials in conjunct with the free-radical generator and the phathalocyanine or naphthalocyanine complex of the above type.

Owner:DAI ICHI KOGYO SEIYAKU CO LTD

Surface covering rubber for high-temperature-resisting and flame-retardant conveyer belt and preparation method thereof

The invention relates to surface covering rubber for a high-temperature-resisting and flame-retardant conveyer belt and a preparation method thereof, and belongs to the technical field of the surface covering rubber. The method comprises the following steps of: plasticating ethylene propylene rubber on an open mill, and then sequentially adding the ethylene propylene rubber, reinforcing carbon black and high abrasion-resistant carbon black for mixing; then adding zinc oxide, magnesium oxide, an aging inhibitor, stearic acid, an oil softener, magnesium hydroxide, chlorinated paraffin, ammonium polyphosphate, an organic brominated flame retardant, zinc borate and diantimony trioxide for refining, after the materials are discharged from an internal mixer, performing rolling refining on the materials in the open mill, after the open mill is stopped, placing the materials into the internal mixer, and adding dicumyl peroxide, a vulcanizing agent and a cross-linking aid; and finally producing films, and sending the films into a water pool for water cooling, heat bodying and tabletting. The rolled rubber films have cloth liners and are coiled for shaping the conveyer belt. The surface covering rubber for the high-temperature-resisting and flame-retardant conveyer belt and the preparation method thereof have the advantages of keeping the original heat-resisting property of the high-temperature-resisting conveyer belt, and having the excellent flame retardant property of the flame-retardant conveyer belt.

Owner:WUXI BOTON TECH CO LTD

High-fluidity high-fire resistance polyvinyl chloride composite material and method for preparing same

The invention discloses a high-fluidity high-fire resistance polyvinyl chloride composite material and a method for preparing the same. The composite material mainly comprises the following components in part by weight: 100 parts of polyvinyl chloride, 3 to 6 parts of stabilizer, 40 to 50 parts of plasticizer, 6 to 10 parts of brominated flame retardant, 6 to 10 parts of zinc borate, 4 to 8 parts of antimony trioxide and 15 to 25 parts of flow modifier. The preparation method comprises the following steps of A: mixing raw materials in a ratio; and B: performing extrusion and granulation. The polyvinyl chloride composite material has quite high fluidity and fire resistance, has excellent heat resistance, weathering resistance and ultraviolet resistance, does not contain phthalic acid and heavy metal and is an environment-friendly polyvinyl chloride composite material.

Owner:NINGBO XIANFENG NEW MATERIAL

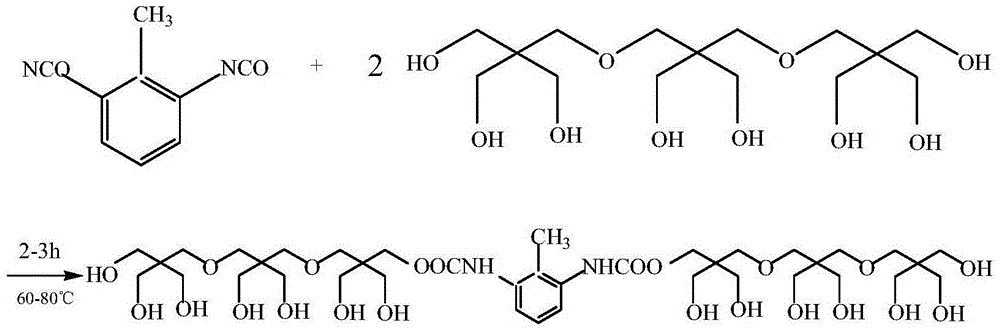

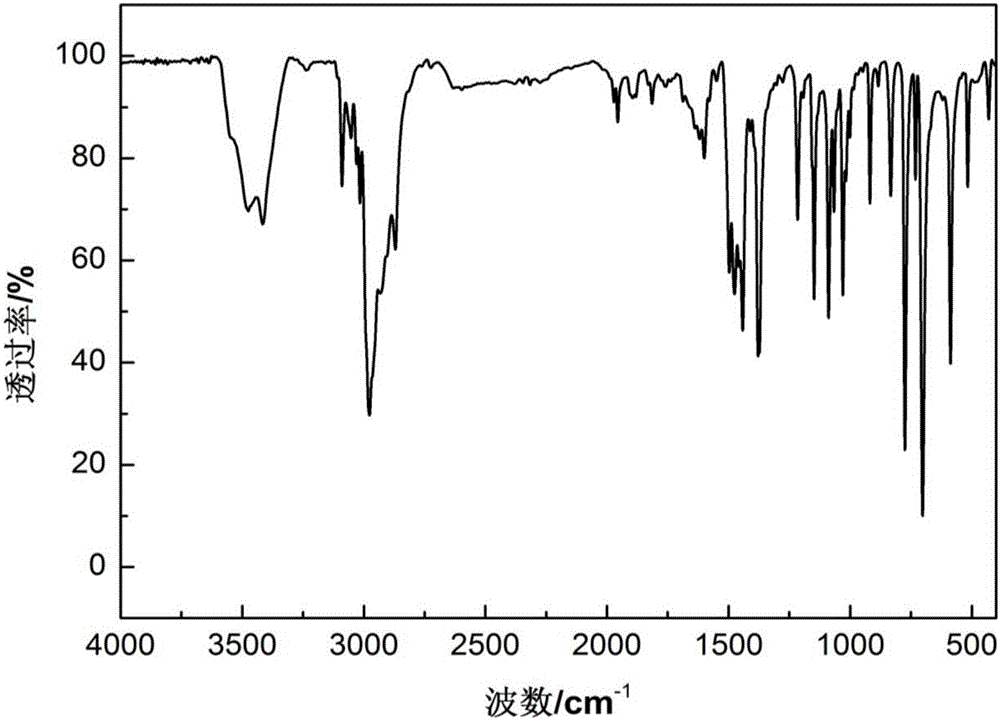

Waterborne flame-retardant polyurethane resin and preparation method thereof

InactiveCN102212181APolyether contains a lot of bromineImprove flame retardant performanceFibre treatmentPolyurea/polyurethane coatingsEmulsionPolymer science

The invention discloses waterborne flame-retardant polyurethane resin and a preparation method thereof. The waterborne flame-retardant polyurethane resin is waterborne flame-retardant polyurethane resin of brominated flame-retardant polyether, which has the solid content ranging from 20% to 40%. The preparation method comprises the step that: a polyurethane prepolymer A for preparing the brominated polyether and polyurethane B for preparing blocked isocyanate of the brominated polyether are subjected to emulsion and chain extending reaction to prepare the waterborne flame-retardant polyurethane resin. The waterborne flame-retardant polyurethane resin has excellent flame retardant property and washing fastness, and can be used directly as a flame-retardant coating adhesive and flame-retardant paint for fabrics, and the like.

Owner:山东建荣教学设备有限公司

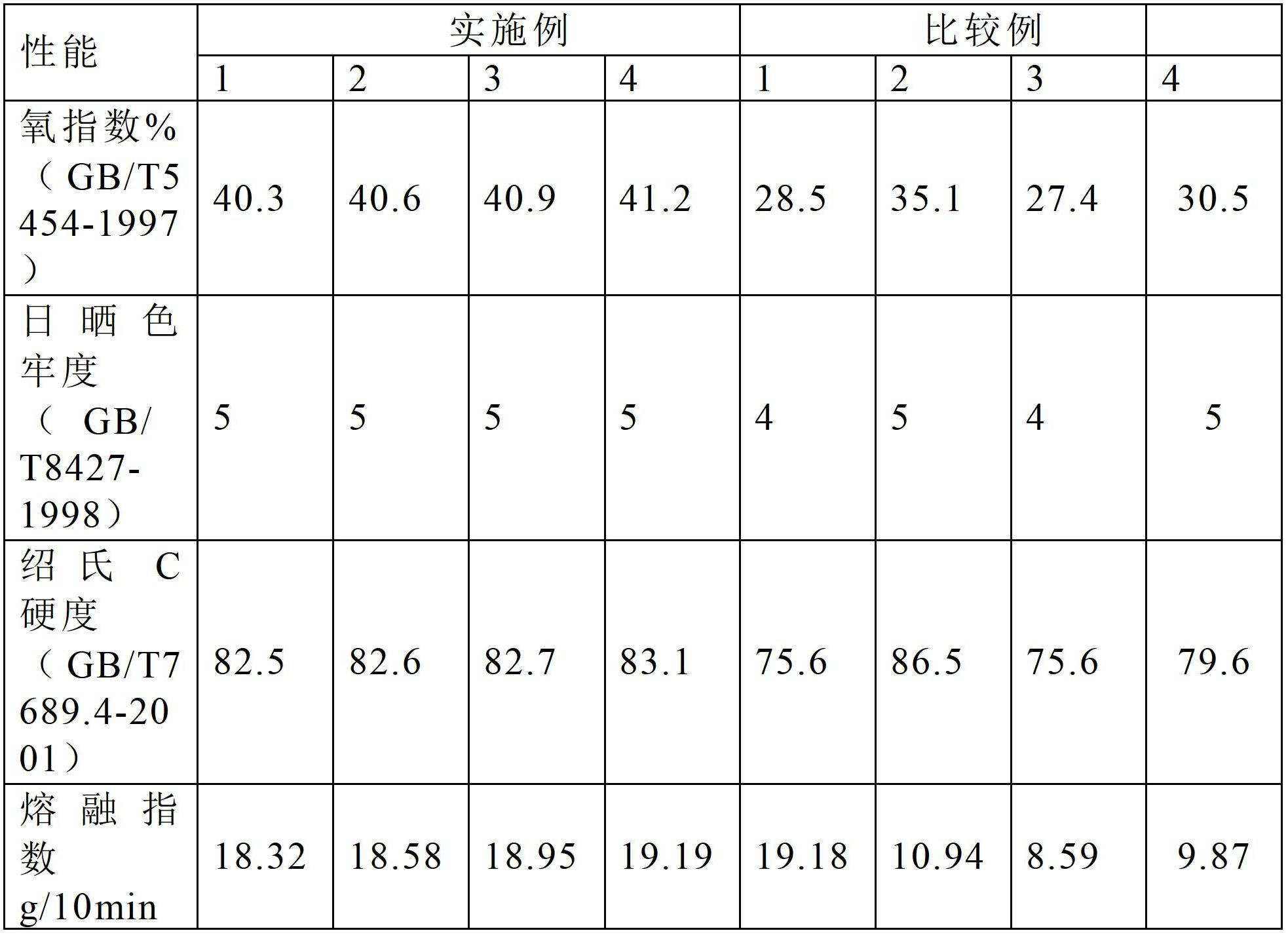

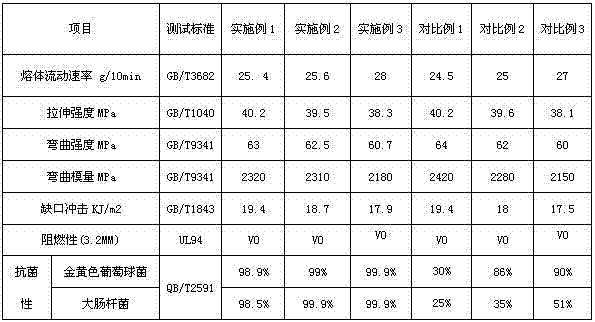

High antibacterial flame-retardant acrylonitrile-butadiene-styrene (ABS) material and preparation method thereof

The invention provides a high antibacterial flame-retardant acrylonitrile-butadiene-styrene (ABS) material and a preparation method thereof. The high antibacterial flame-retardant ABS material is prepared from ABS resin, a flexibilizer, a brominated flame retardant, an auxiliary fire retardant, polytetrafluoroethylene, a heat stabilizer, an antioxidant, a lubricating agent, glycerol monostearate and a zinc ion antibacterial agent in parts by weight. By adopting the high antibacterial flame-retardant ABS material, the zinc ion antibacterial agent, the brominated flame retardant and the auxiliary fire retardant are adopted; meanwhile, an efficient dispersant glycerol monostearate is adopted to pre-disperse the antibacterial agent; the antibacterial material can be evenly dispersed in the composition; birdnesting of the antibacterial agent is prevented; meanwhile, gathering of the antibacterial agent at the surface of the flame-retardant ABS material is facilitated by the lubricating effect of the dispersant; the antibacterial effect of the material is greatly improved; the antibacterial effect of the antibacterial agent is improved; the antibacterial property, the fire resistance and excellent mechanical property of the ABS material are improved.

Owner:ORINKO NEW MATERIAL CO LTD

Halogen-free flame-retardant ABS/PET alloy and preparation method thereof

The invention discloses a halogen-free flame-retardant ABS / PET alloy and a preparation method thereof. The alloy consists of the following components in percentage by weight: 15 to 50 percent of PET resin, 30 to 60 percent of ABS resin, 5 to 15 percent of phosphorus flame retardants, 5 to 10 percent of nitrogenated flame retardants, 0 to 6 percent of compatilizer, 0 to 5 percent of flexibilizer and 0 to 0.5 percent of antioxidant. The alloy avoids releasing harmful substances to human body in a combustion process of brominated flame retardants by combining a flame-retardant system by adopting phosphorus and nitrogen compounds, has environmental-friendly significance, simultaneously improves combination properties of a composite material and is easy to mold and process.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

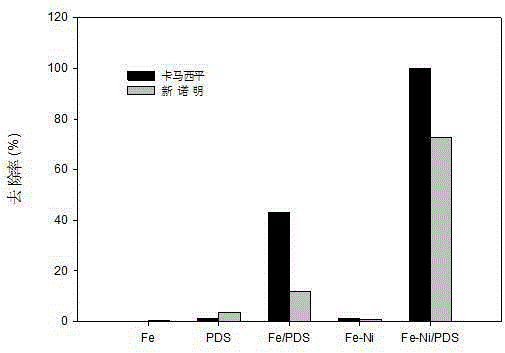

Method for treating water by using zero-valent iron-nickel bi-metal activated persulfate

InactiveCN105198067ASolve the problem of low production volumeRemove completelyWater/sewage treatment by oxidationSulfate radicalsPolychlorinated biphenyl

The invention discloses a method for treating water by using zero-valent iron-nickel bi-metal activated persulfate. According to the method, the zero-valent iron-nickel bi-metal activated persulfate is used, and micropollutants in the water are removed. The zero-valent iron-nickel bi-metal activated persulfate is used for efficiently generating high-oxidizing-property sulphate radical and high-oxidizing-property hydroxyl radical to attack the micropollutants, the micropollutants are degraded, and the purpose of quickly and thoroughly removing various poisonous and harmful micropollutants such as polychlorinated biphenyl, brominated flame retardants, medicines, personal care products (PPCPs) and algal toxin can be achieved. Compared with the existing the method for treating water by using zero-valent iron activated persulfate, the method has the advantages of high activating efficiency, high yield of the sulphate radical, high micropollutants removing efficiency and the like, is convenient and easy to operate, obvious in effect and wide in pH (potential of hydrogen) using range, and can be used for ground water remediation, treatment of industrial water comprising electroplating wastewater, wastewater of hospitals, printing and dyeing wastewater, treatment of drinking water, treatment of sewage and the like.

Owner:SUN YAT SEN UNIV

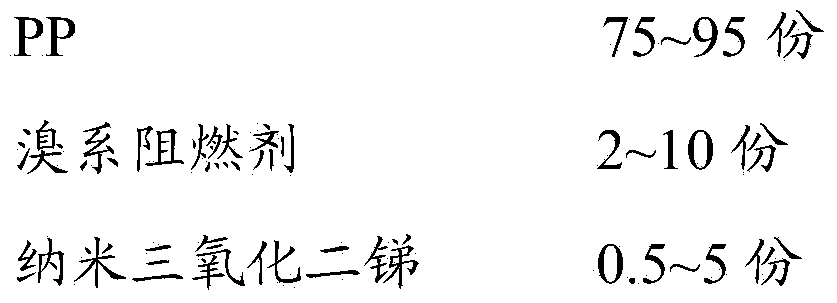

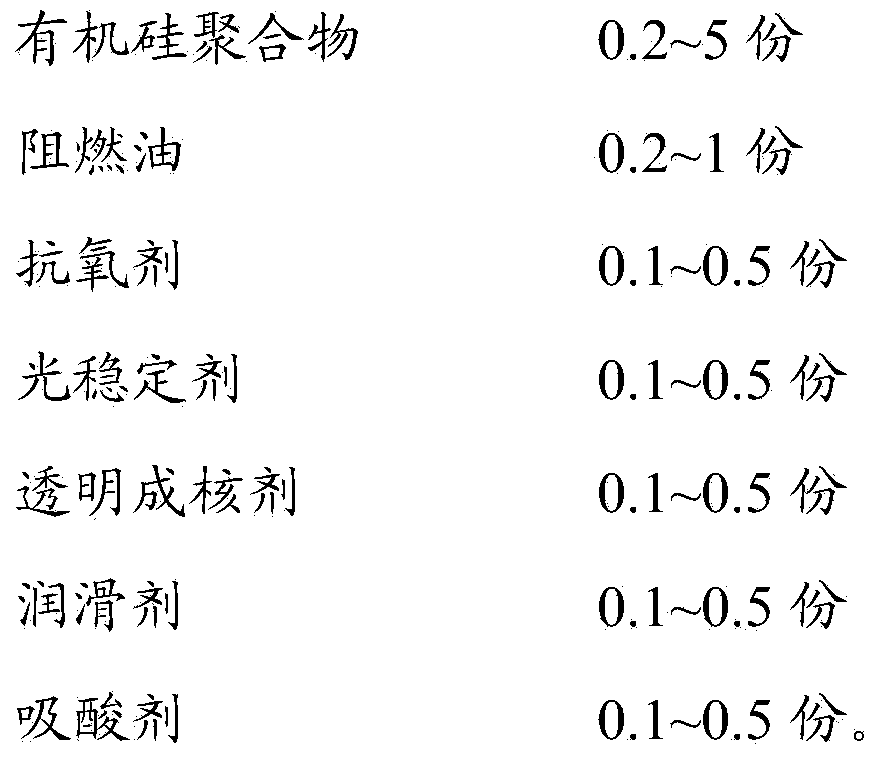

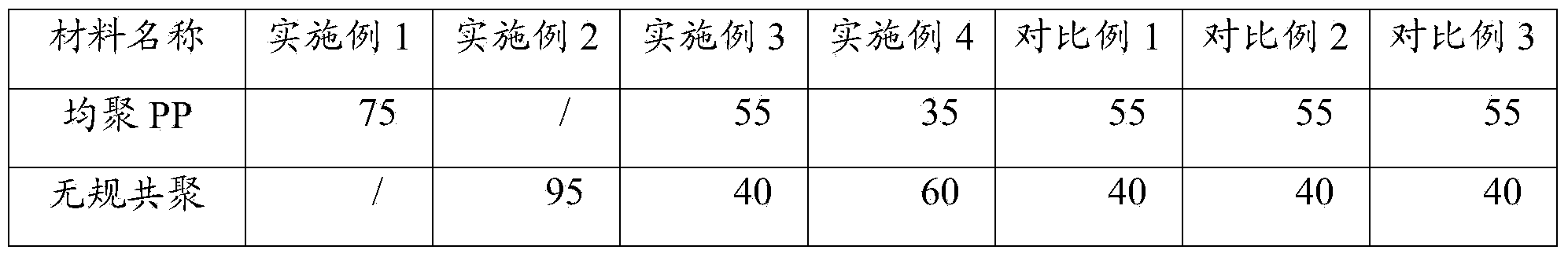

Flame-retardant scraping-resistant photodiffusion PP material and preparation method thereof

The invention provides a flame-retardant scraping-resistant photodiffusion PP material and a preparation method thereof. The flame-retardant scraping-resistant photodiffusion PP material comprises the following components in parts by weight: 75-95 parts of PP, 2-10 parts of a brominated flame retardant, 0.5-5 parts of nano antimonous oxide, 0.2-5 parts of an organosilicon polymer, 0.2-1 part of flame-retardant oil, 0.1-0.5 part of an antioxidant, 0.1-0.5 part of a photostabilizer, 0.1-0.5 part of a transparent nucleating agent, 0.1-0.5 part of a lubricant, and 0.1-0.5 part of an acid absorbent. By selecting specific type of functional additives and under synergistic mechanism of all raw materials, the PP material finally has the advantages of high transparency and haze, flame retardance, scraping resistance, low cost, excellent toughness, light density, excellent yellowing resistance, high thermal deformation temperature, no toxicity and the like and is recyclable, and the usage performance of the PP material can be greatly promoted.

Owner:江苏沃特新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com