Patents

Literature

2497results about How to "Remove completely" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stainless steel cleaner and stainless steel cleaning method

The invention belongs to the field of surface treatment, and relates to a stainless steel cleaner. The cleaner comprises a nonionic surfactant, an anionic surfactant, a complexing agent, a degreasing agent and deionized water, wherein the degreasing agent is one of amide, and a mixture of amide and hydramine. An environmentally-friendly cleaner comprising the amide or the hydramine, a composite surfactant and the like removes grease under the alkalescent condition, and has good cleaning effect due to the permeation effect of the composite surfactant on the grease and an oxide layer. The invention also relates to a stainless steel cleaning method. The stainless steel cleaner and the stainless steel cleaning method are widely applied to the treatment of various stainless steel surfaces.

Owner:BYD CO LTD

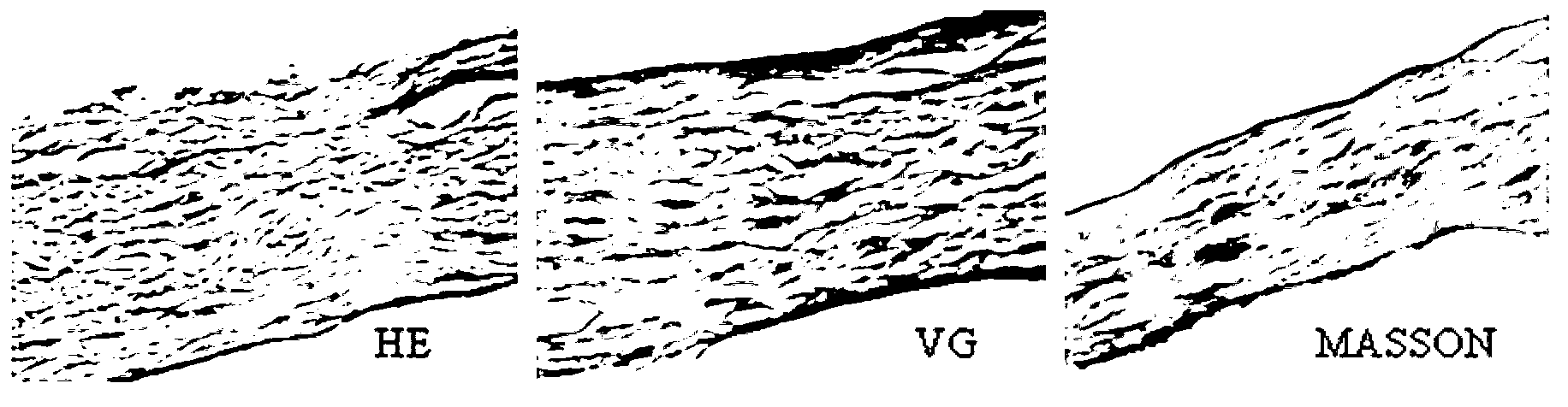

Acellular matrix repairing gel and new method for preparing the same

ActiveCN104971380ARetain biological activityImprove securityProsthesisCell-Extracellular MatrixClinical value

The invention relates to the field of bio-materials, and especially relates to an acellular matrix repairing gel and a new method for preparing the same. The invention discloses the acellular matrix repairing gel and the method for preparing the same, wherein the method includes steps of acellular treatment and gelatinization treatment on tissue and organs from mammal animals to prepare the acellular matrix repairing gel. The acellular matrix repairing gel is eliminated in immunogenicity of heterologous and foreign tissue, so that activity of extracellular matrix components of the tissue is maintained as more as possible. The gel can specially repair damaged tissue and organs of human body, is strong in applicability, is suitable for requirements of various irregular-shaped repair zones and different position environments in body and has a huge clinical value.

Owner:山东隽秀生物科技股份有限公司

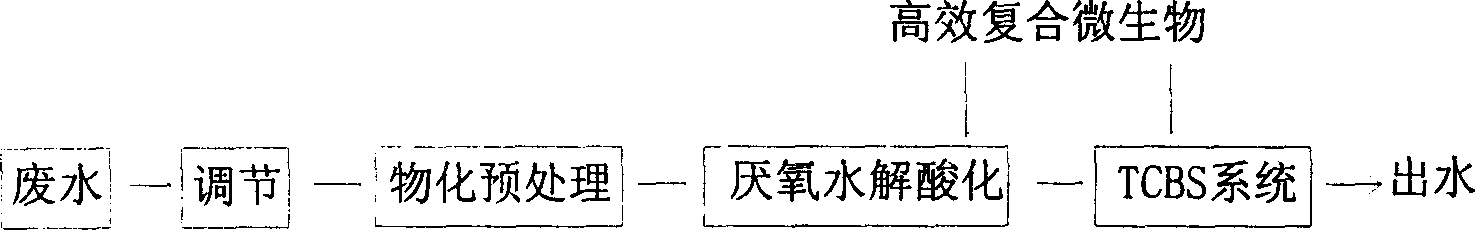

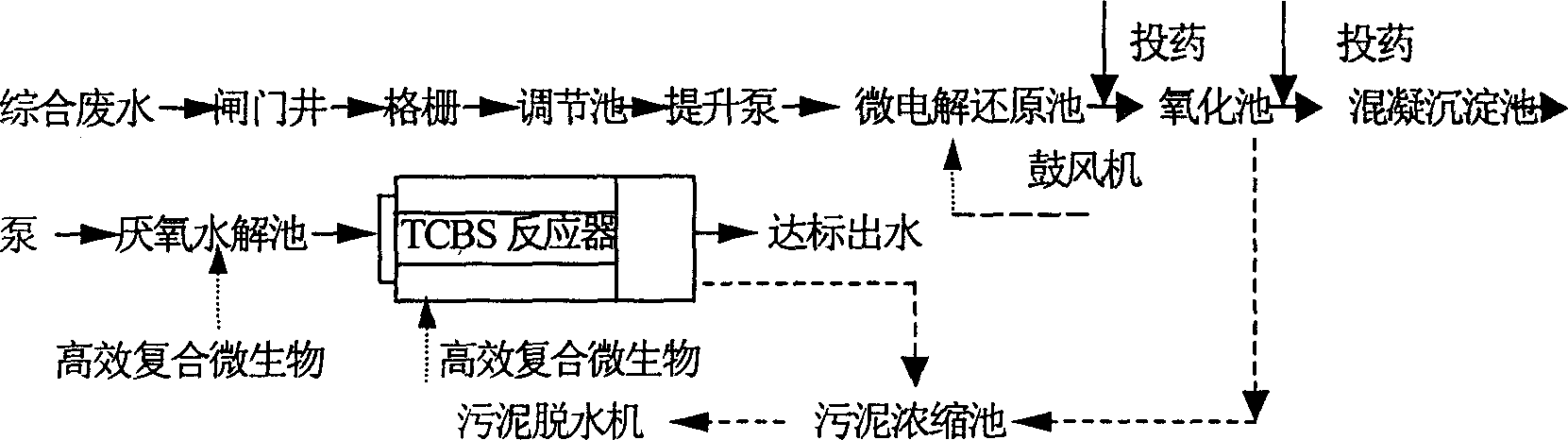

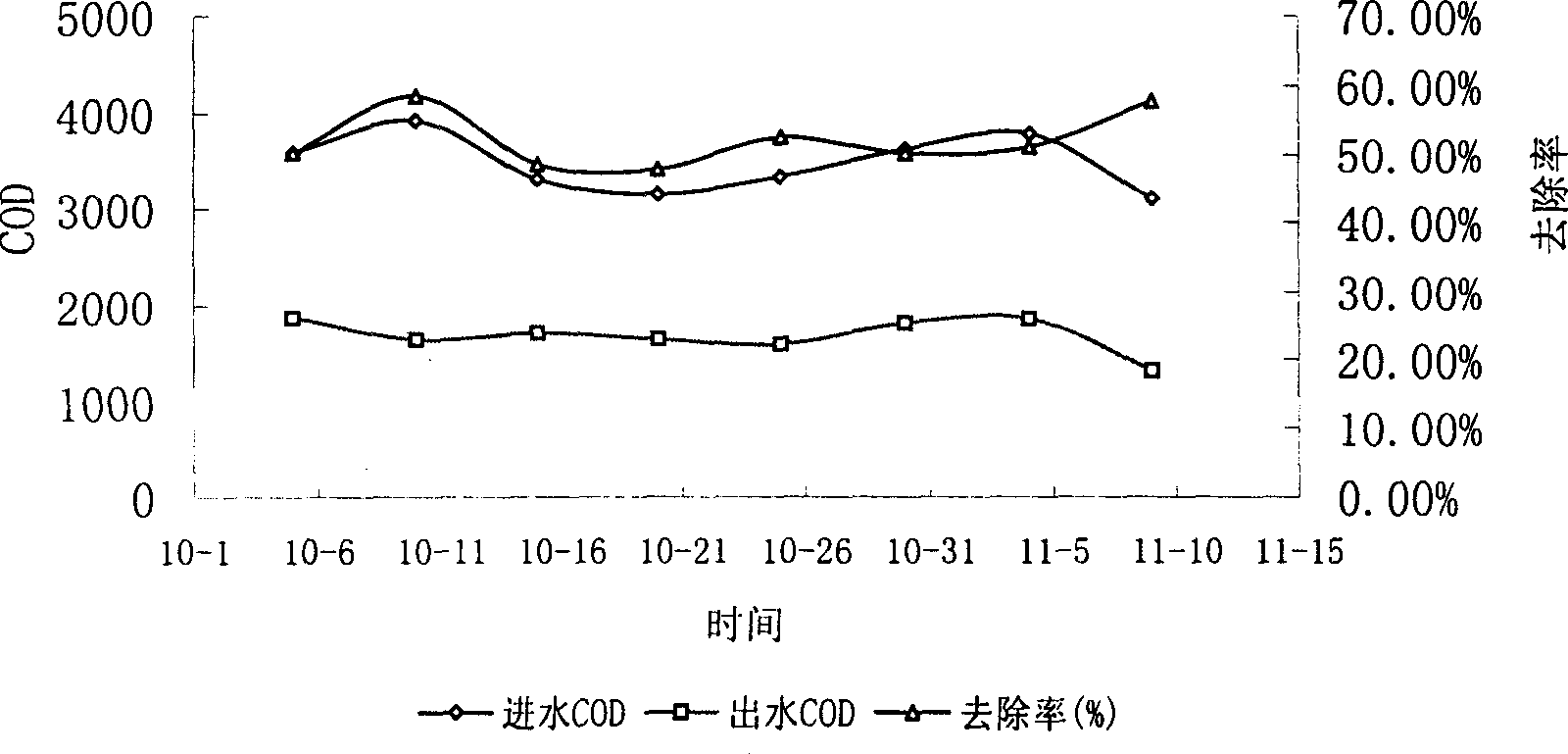

Organic waste water treatment process

InactiveCN1631818AAvoid toxicityHigh removal rateMultistage water/sewage treatmentHigh densityElectrolysis

Disclosed is a technique for processing organic waste water, including the following steps: (a) preprocession: pour the waste water into the micro electrolytic reducing pool where the iron-carbon micro electrolytic reaction occurs under the agtatering effect, add hydrogen peroxide into it to have. Fento oxidation, then the water enters into coagulation pool into which add NaOH and PAM; (b) anaerobe hydrolysis oxidation procession: power the organic waste water preprocessed into high effective anaerobe hydrolysis oxidation pool in which add into the TCBS reactor in which add into high effective compound microbe, making the water mix with the flowing-back mud with high density after denitrification. The invention can increase the biochemical of organic waste water, strengthen its resistance to poison and impact as well as the biological denitrification funcation, and making the waste water reach the national environment protection requirement by reducing the polluting load by steps.

Owner:何义亮 +1

Production method of biodiesel oil using high acid ralue animal and vegetable grease

InactiveCN1556174AAchieve cycleAchieve recyclingBiofuelsLiquid hydrocarbon mixture productionOil and greaseAlcohol

A process for preparing the biological diesel oil from the animal fat or vegetative oil with high acid number includes esterifying by glycerine under existance of strong acid catalyst, distilling in azeotropic solvent for removing water, mixing with methanol, transesterifying reacting to remove glycerine, water washing, and low-temp treating for removing high-smelting-point substances to obtain methyl ester of fatty acid, which is just the biological diesel oil.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

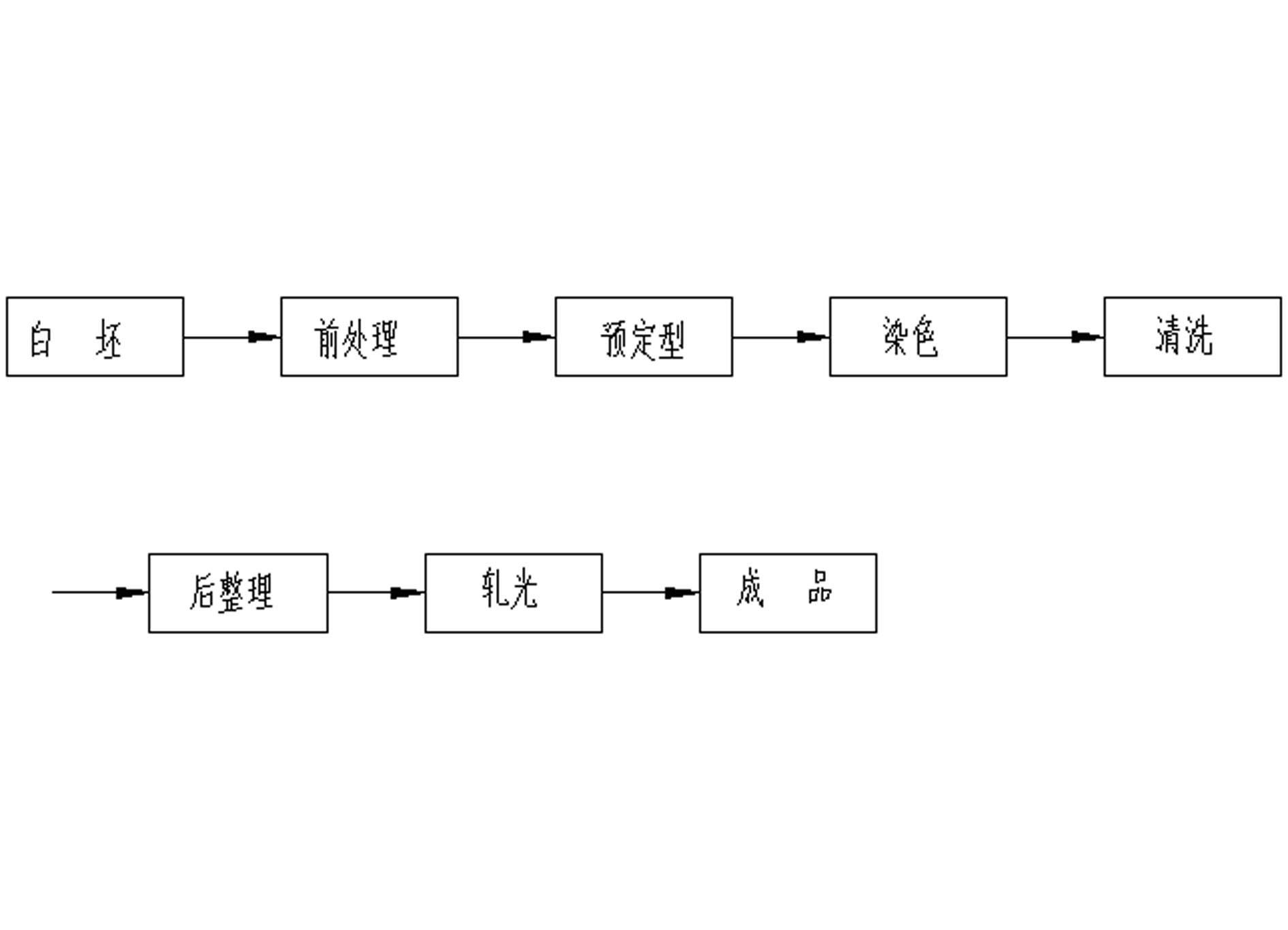

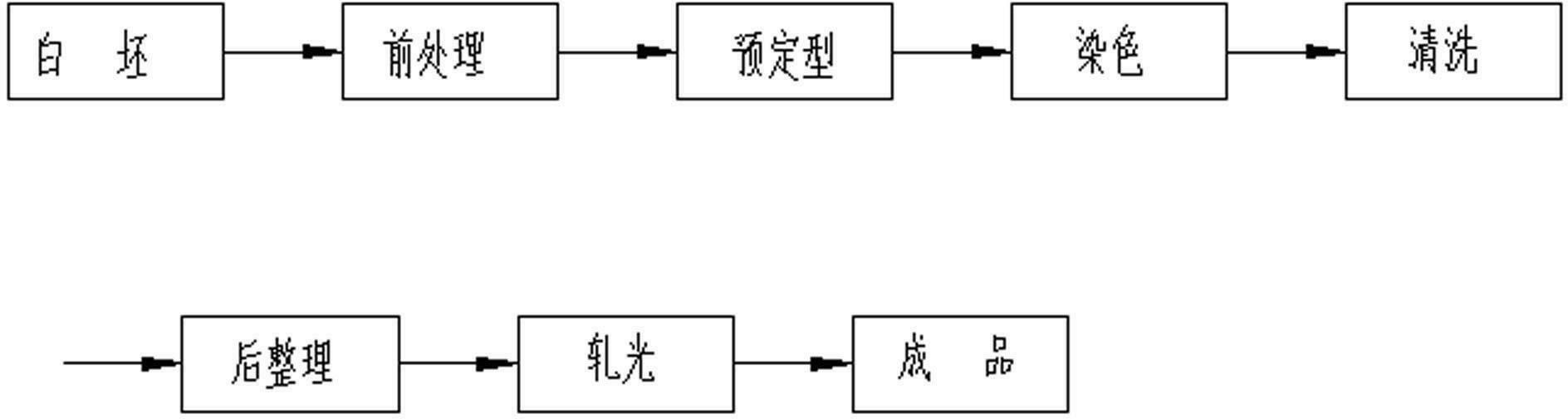

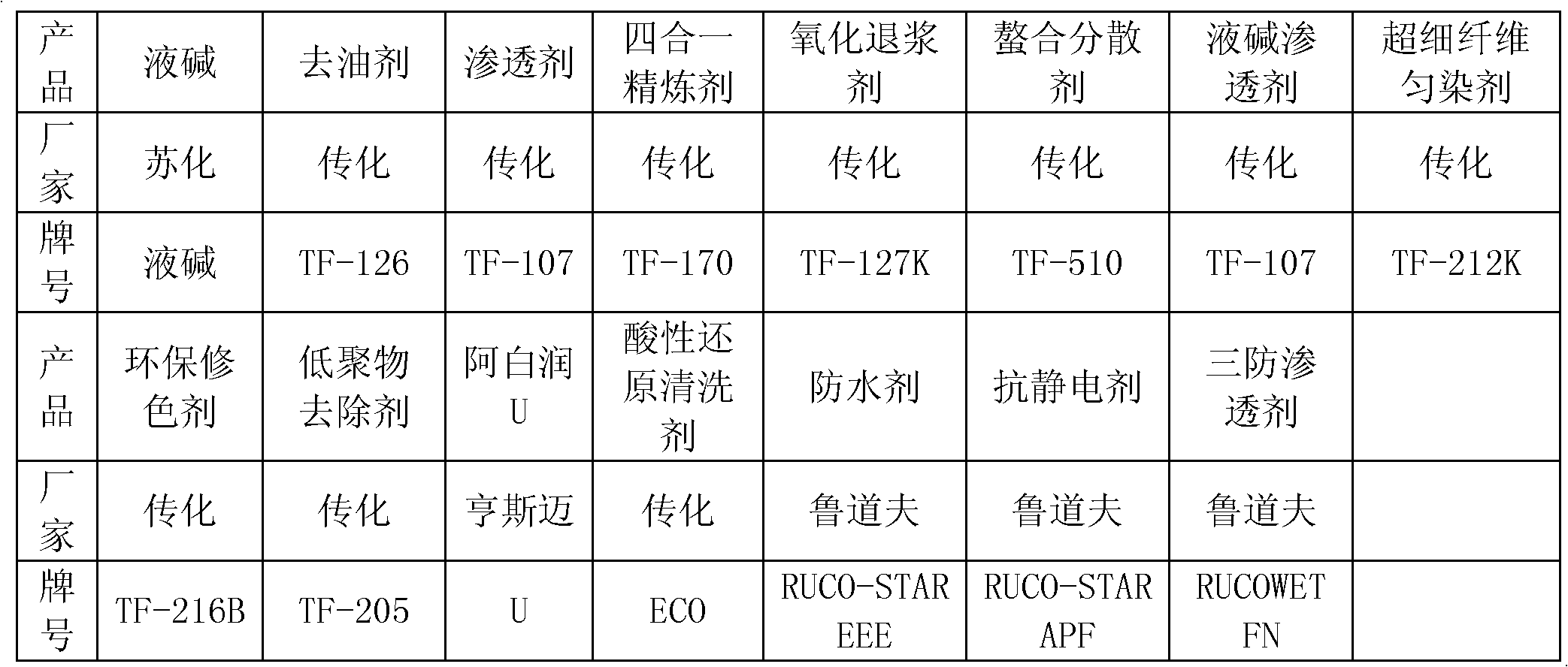

Novel dyeing and finishing processing technology of micro polyester fabric

ActiveCN102628211AReduce wrinklesReduce staining and chafingHeating/cooling textile fabricsDry-cleaning apparatus for textilesEnvironmental resistanceDisperse dye

The invention relates to a novel dyeing and finishing processing technology of a micro polyester fabric. The novel dyeing and finishing process disclosed by the invention is characterized by comprising the following steps of: (1) pretreatment, namely carrying out cold rolling and stacking processing comprising three stages, namely cold stacking, hot alkali treatment and high efficiency washing, on polyester gray fabric; (2) presetting, namely carrying out high temperature tentering and presetting on a pretreated fabric white body by utilizing a setting machine; (3) dyeing, namely dyeing the preset fabric white body by adopting superfine fiber leveling agent; and (4) cleaning, namely carrying out cleaning post-processing on the dyed fabric to remove disperse dyes which are not set after fibres are dyed. According to the novel dyeing and finishing processing technology disclosed by the invention, an environment-friendly and low-energy-consumption cold rolling and stacking pretreatment technology is used for carrying out pretreatment on the micro polyester fabric, on one hand, desizing effect is good and good dyeing and finishing processing conditions are provided for dyeing, and on the other hand, crease mark of the fabric can be effectively reduced; meanwhile, a formula of a dyeing process additive can be adjusted, albafluid U is added to reduce fabric dyeing scratch, and dyeing defects can be prevented from being caused.

Owner:SHENGHONG GRP CO LTD

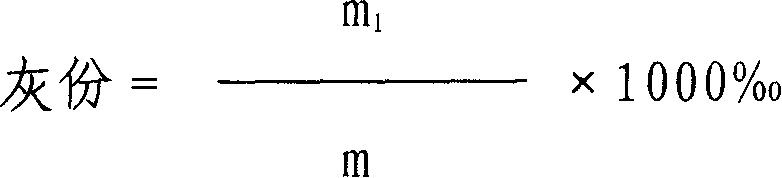

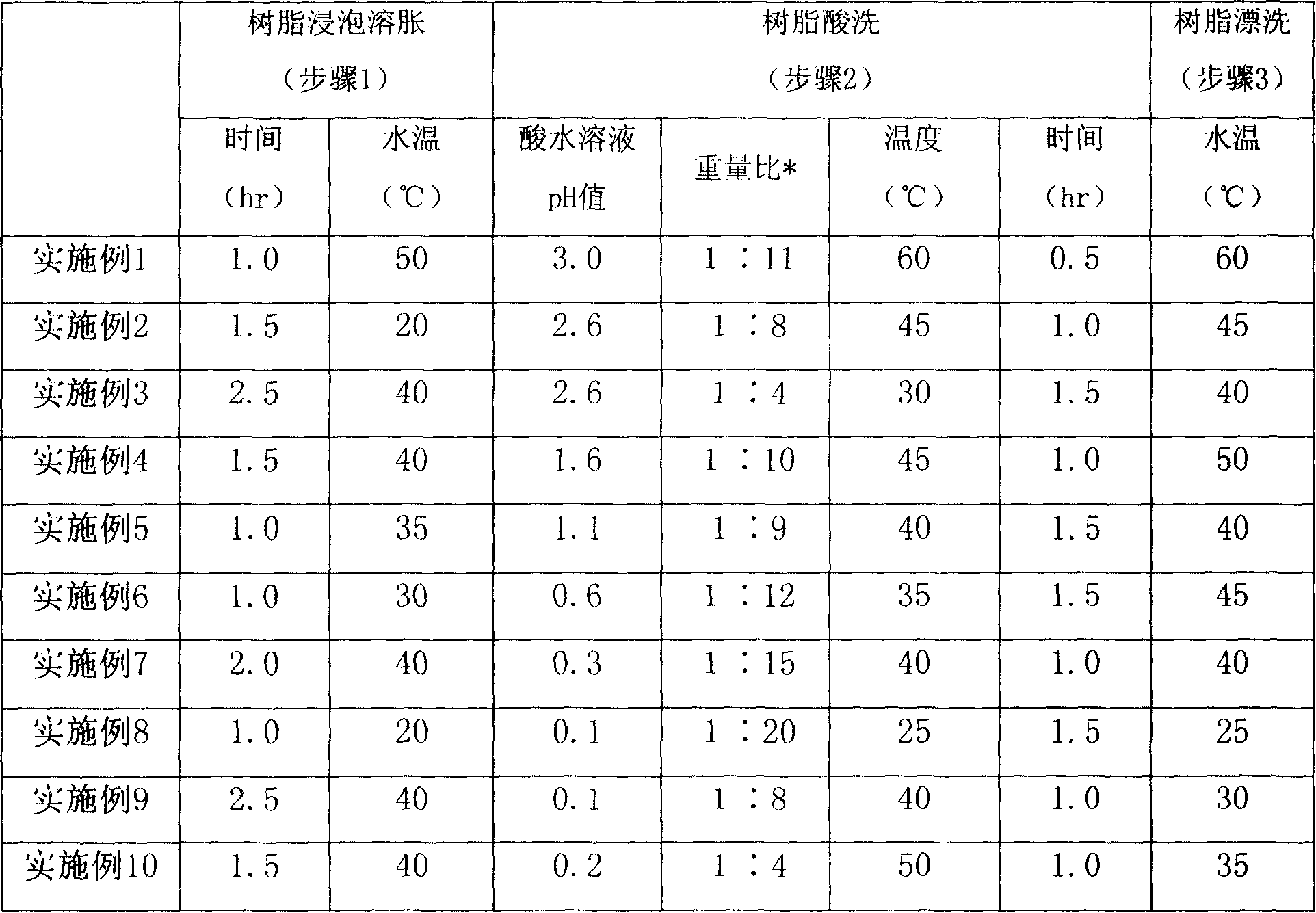

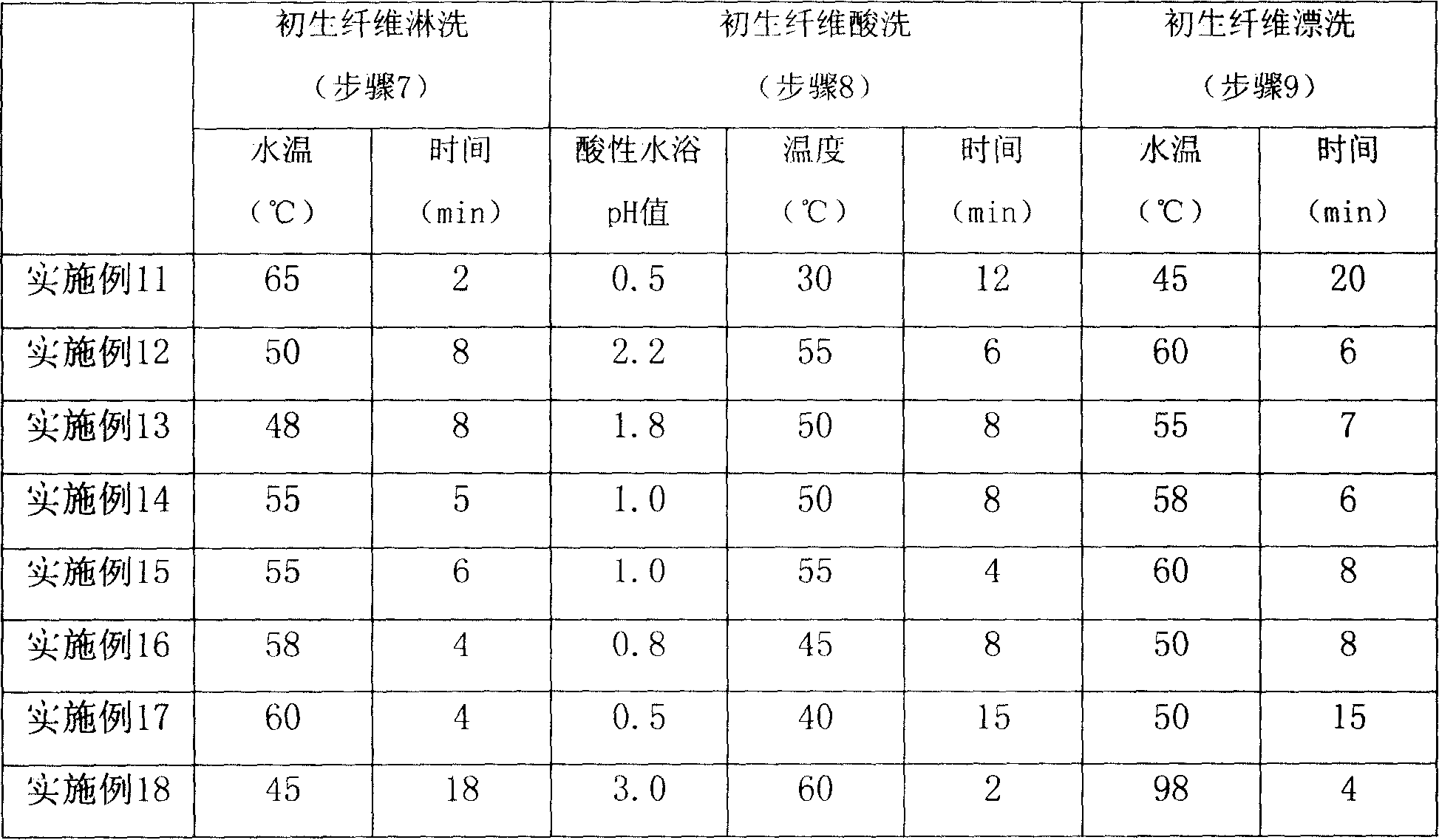

Method for preparing polyacrylonitrile-based carbon fiber protofilament

ActiveCN101165237AEfficient removalGood removal effectArtificial filament washing/dryingMonocomponent synthetic polymer artificial filamentPolymer scienceCarbon fibers

The process of preparing polyacrylonitrile fiber for carbon fiber includes the following steps: soaking resin in deionized water at 20-50 deg.c to swell for 1-2.5 hr; pickling in water solution of nitric acid or hydrochloric acid in pH 0.1-3.0 at 25-60 deg.c for 0.5-1.5 hr; rinsing with deionized water to neutral; dewatering and drying to water content lower than 3 %; dissolving in 35-58 wt% concentration NaSCN aqua to form spinning fluid in resin content of 8-16 wt%; debubbling and spinning to form initial fiber; washing with deionized water, acid aqua and hot water successively; drafting, oiling, drying, densifying, etc to produce polyacrylonitrile fiber for carbon fiber. The polyacrylonitrile fiber product has ash content not higher than 0.01% and alkali metal ion content not higher than 0.005%.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Extraction and separation method of cannabidiol

ActiveCN108314608AGood removal effectRemove completelyOrganic chemistryOrganic compound preparationSolubilityOrganic solvent

The invention discloses an extraction and separation method of cannabidiol. According to the method disclosed by the invention, the water solubility of the cannabidiol is enhanced through adopting analkaline solution and the cannabidiol is extracted and enriched by utilizing an organic solvent; then the cannabidiol is purified and enriched through a polyamide resin column, neutral aluminum oxideand a bonded silica gel column; then the cannabidiol is crystallized to obtain high-purity cannabidiol. The method disclosed by the invention is easy to operate, strong in practicability and suitablefor industrial popularization and application.

Owner:FIRST AFFILIATED HOSPITAL OF KUNMING MEDICAL UNIV +1

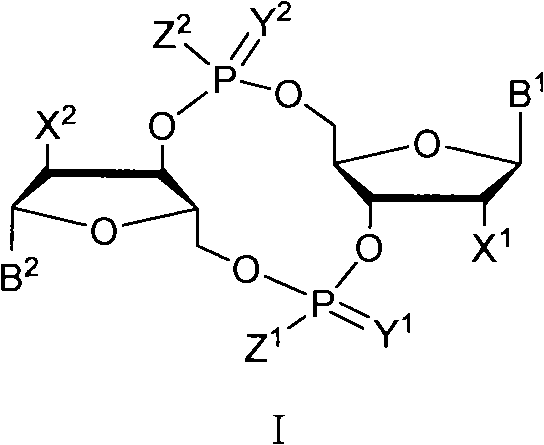

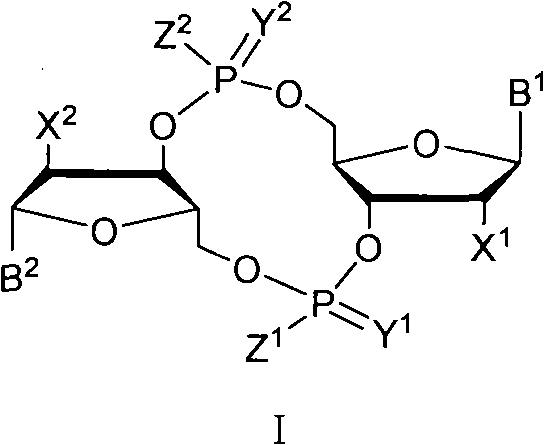

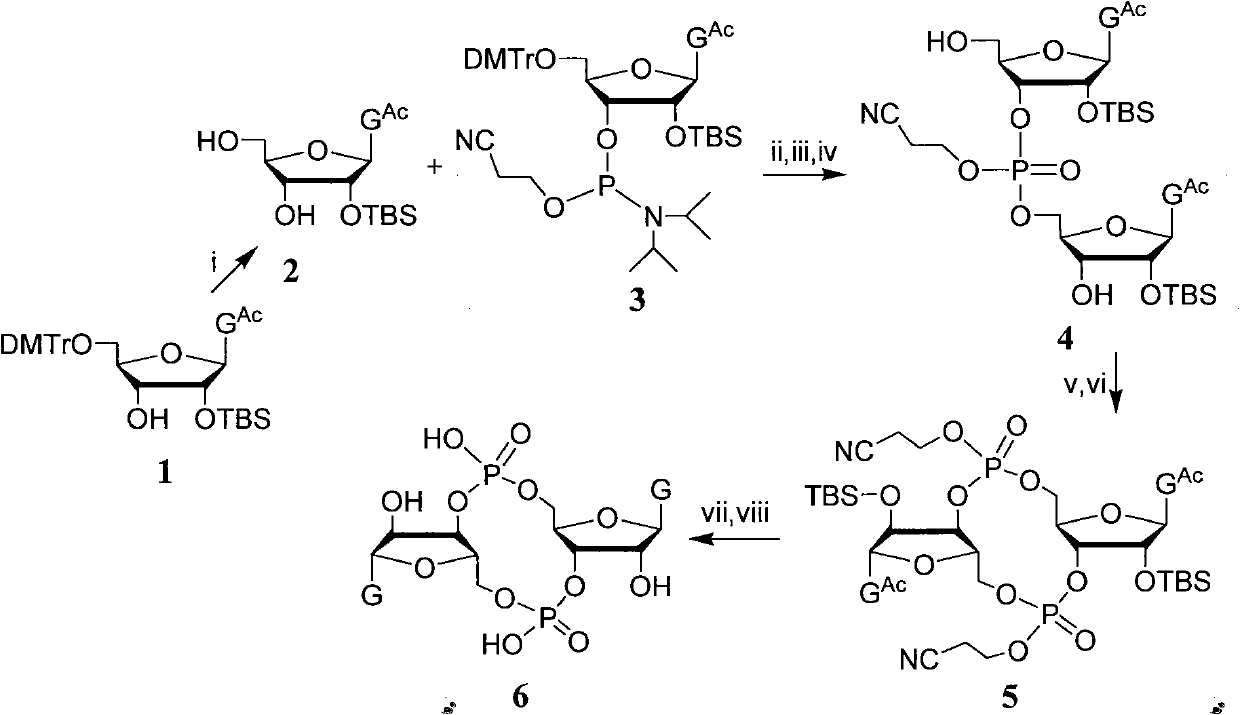

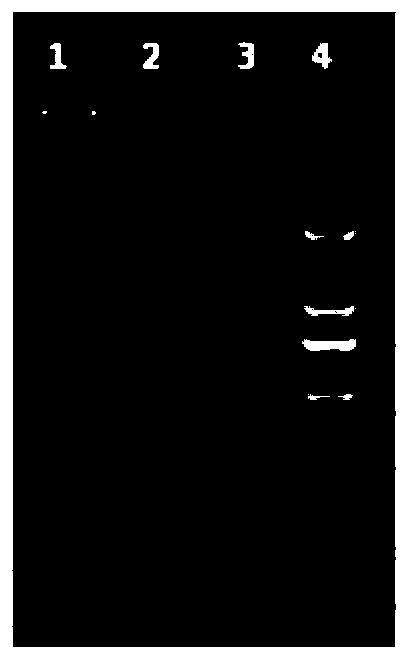

C-di-GMP, analogues thereof and preparation method thereof

ActiveCN102199183AInhibition formationPrevent proliferationSugar derivativesSugar derivatives preparationDrug developmentBiological membrane

The invention discloses a c-di-GMP and analogues thereof which have structures of a general formula I. The invention also discloses a novel preparation method-a kettle phosphoramidite method which can be used for rapidly, simply and conveniently preparing c-di-GMP compounds with high yield and low cost on a large scale and at mild conditions. The c-di-GMP is prevalent in bacteria and is a novel second messenger molecular which takes part in regulating multiple physiological functions. The research shows that the c-di-GMP and the analogues thereof can inhibit the formation of bacterium biological membranes and the multiplication of eukaryotic cells; and thereof the c-di-GMP and the analogues thereof have good medicine development prospect.

Owner:PEKING UNIV

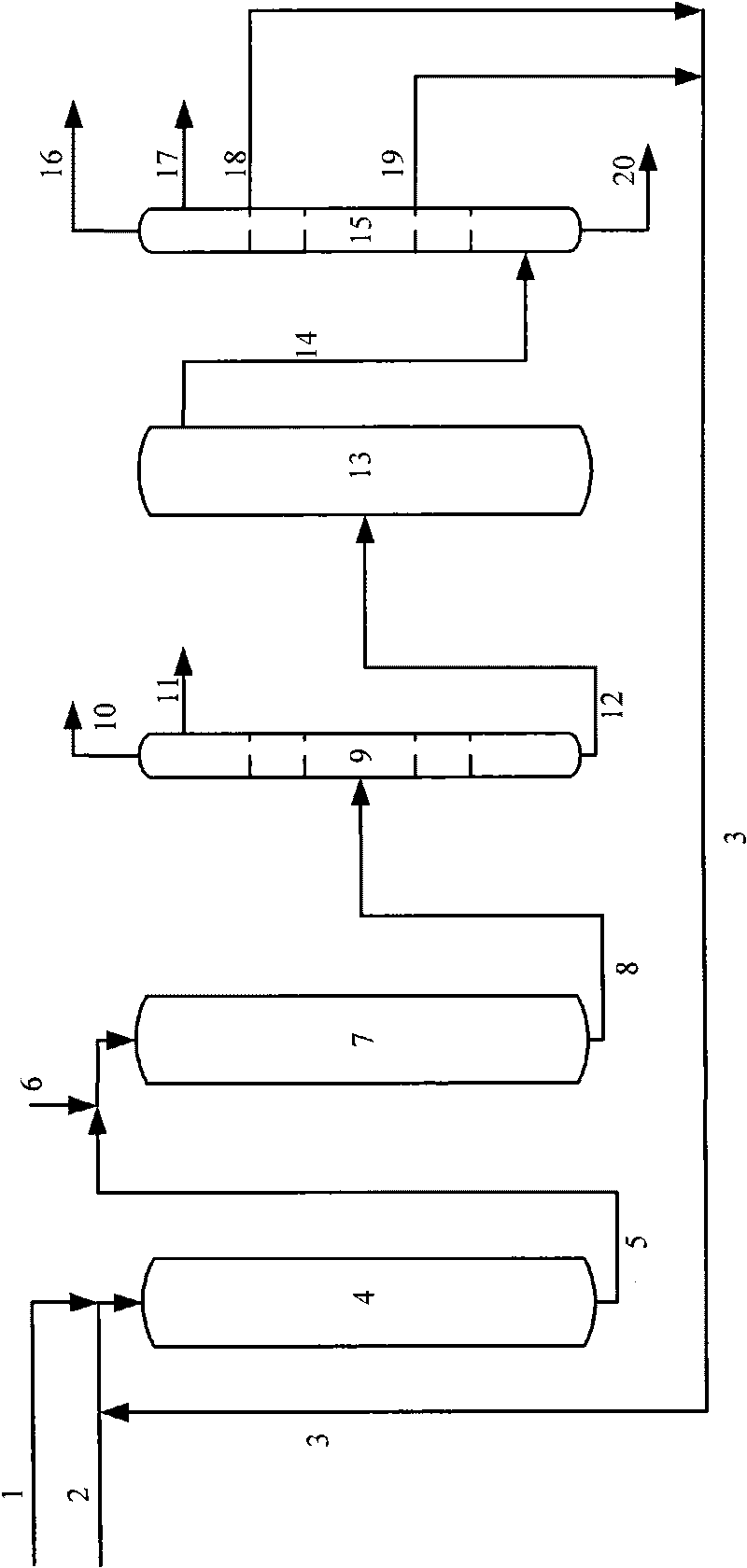

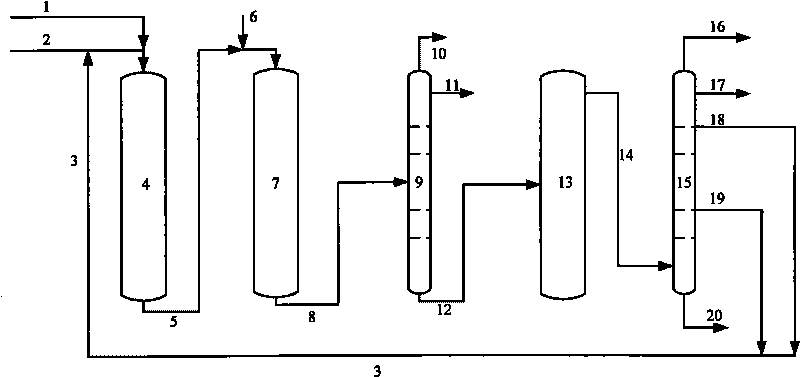

Method for producing light olefins and monocyclic aromatic hydrocarbons from heavy hydrocarbons

ActiveCN101747935AImprove propertiesDoes not affect activityTreatment with hydrotreatment processesWaxResidual oil

The invention provides a method for producing light olefins and monocyclic aromatic hydrocarbons from heavy hydrocarbons. The method produces qualified catalytic cracking raw materials through hydrogenation by taking wax oil and residual oil as raw materials, returns light cycle oil and heavy cycle oil which are catalytic cracking by-products to a hydrogenation unit for the catalytic cracking rawmaterials at the same time, hydrogenates the catalytic cracking by-products together with the catalytic cracking raw materials, and then takes the obtained product as the catalytic cracking raw materials to produce light olefins and monocyclic aromatic hydrocarbons. By introducing the residual oil before a second reaction zone of hydrogenation, the method widens the sources of the catalytic cracking raw materials, increases the processing amount of low-value residual oil, and solves the problem of the heat balance of catalytic cracking units. The light and heavy cycle oil of catalytic cracking is introduced into the hydrogenation unit, hydrogenated and then taken as the catalytic cracking raw materials, so that the yield of high-value products of the catalytic cracking units can be increased, and the deactivation of hydrogenation catalysts is delayed.

Owner:CHINA PETROLEUM & CHEM CORP +1

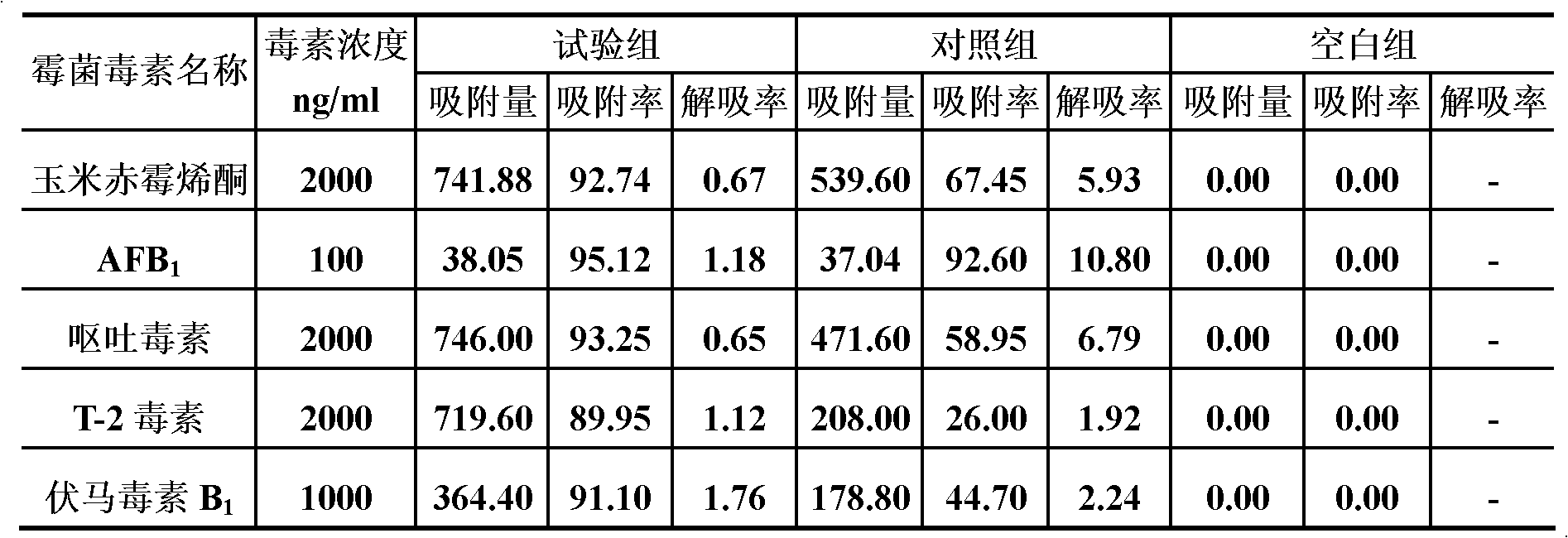

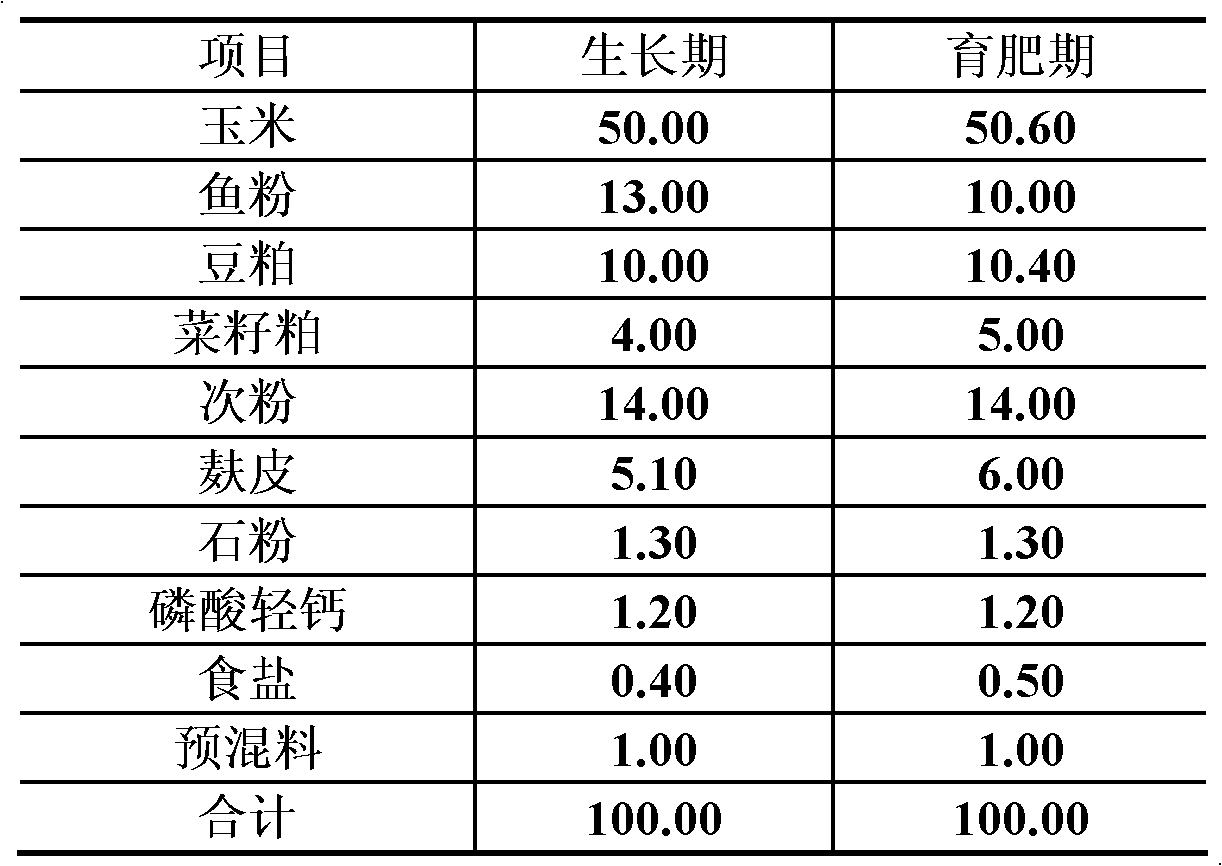

Novel mycotoxin detoxification agent for feed and preparation method and feed additive thereof

ActiveCN102028129APrevent diseaseEfficient removalAnimal feeding stuffAccessory food factorsFood additiveCell wall

The invention discloses a mycotoxin detoxification agent for feed and a preparation method and a feed additive thereof, and belongs to the field of feed additives. The mycotoxin detoxification agent can be used for detoxification of feed raw materials and compound feed of mycotoxin polluted corn, grains and the like. The mycotoxin detoxification agent consists of modified montmorillonite, yeast cell wall, chitosan and the like; and the preparation method has simple process. The novel mycotoxin detoxification agent for feed can effectively remove pollution of multiple mycotoxins such as aflatoxin, zearalenone, T2 toxin, vomitoxin and the like in the feed raw materials and the feed of the corn, the grains and the like, and prevent various diseases of livestock and poultry because of eating the mycotoxin polluted feed. The mycotoxin detoxification agent has simple preparation process, stable and controllable quality, convenience in use and low price, meanwhile has the advantages of supplementing nutrients, improving the disease resistance of cultured animal bodies and avoiding adsorbing nutrient elements in the feed, and guarantees the health and safety of the cultured animals.

Owner:BEIJING DABEINONG TECH GRP CO LTD +2

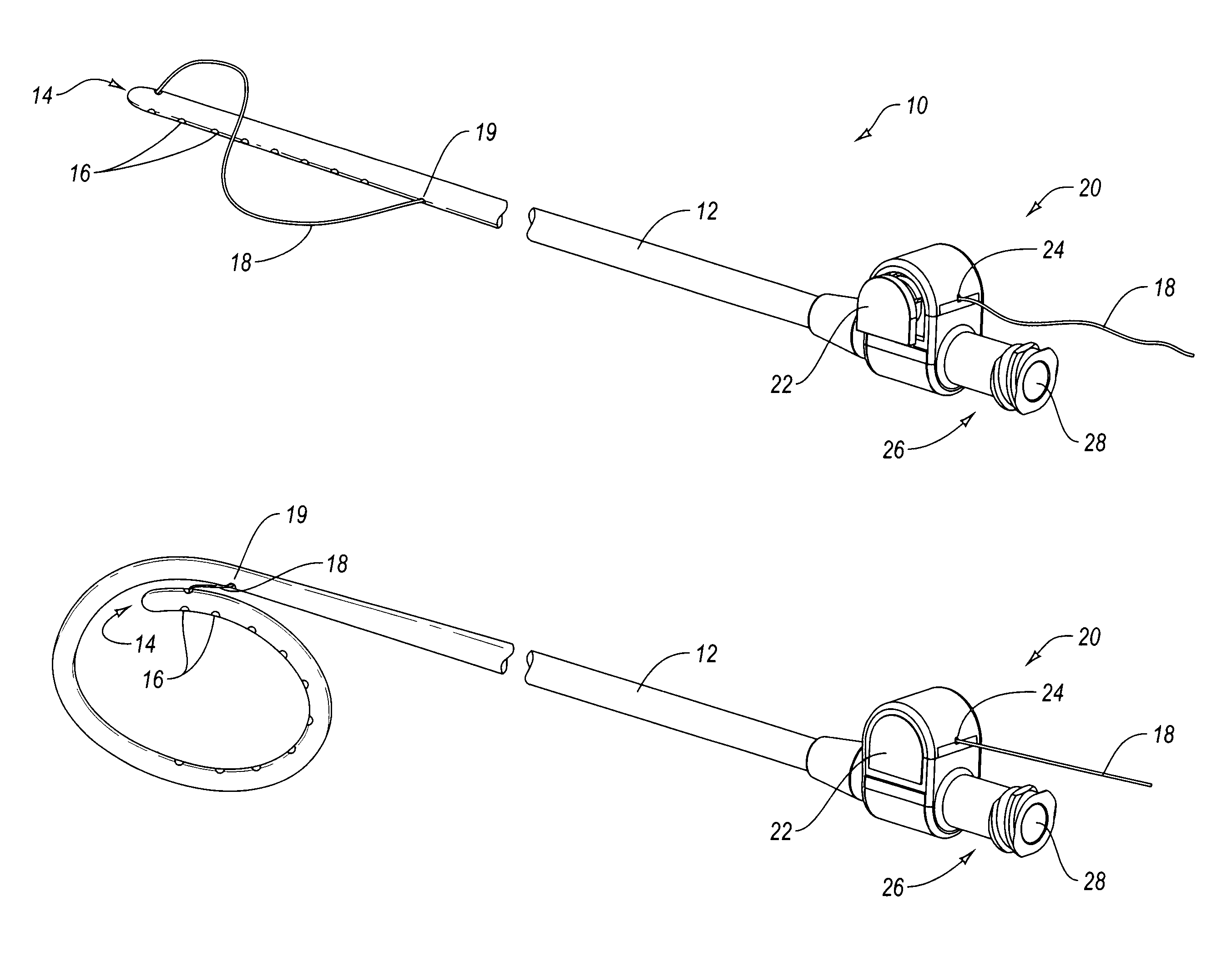

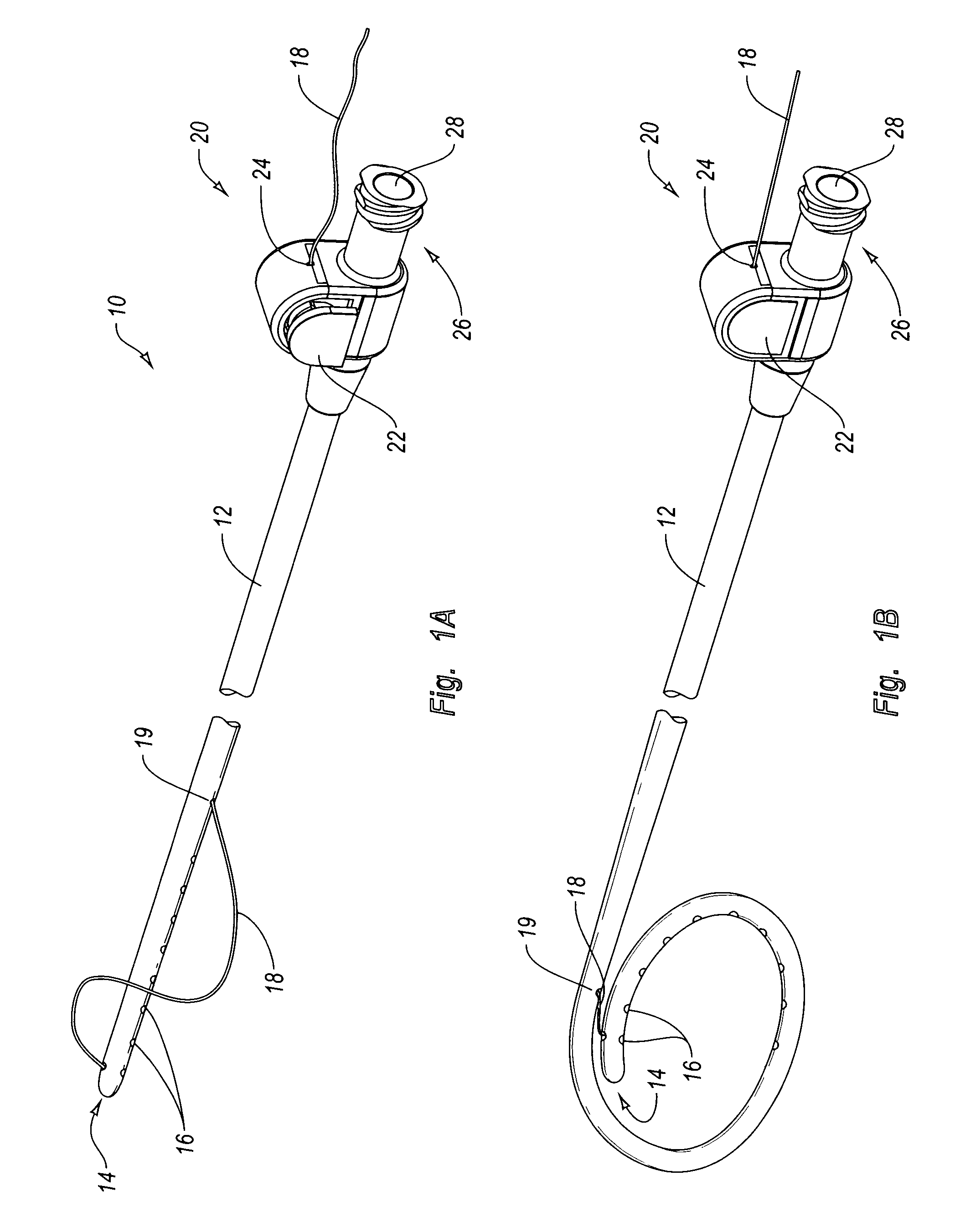

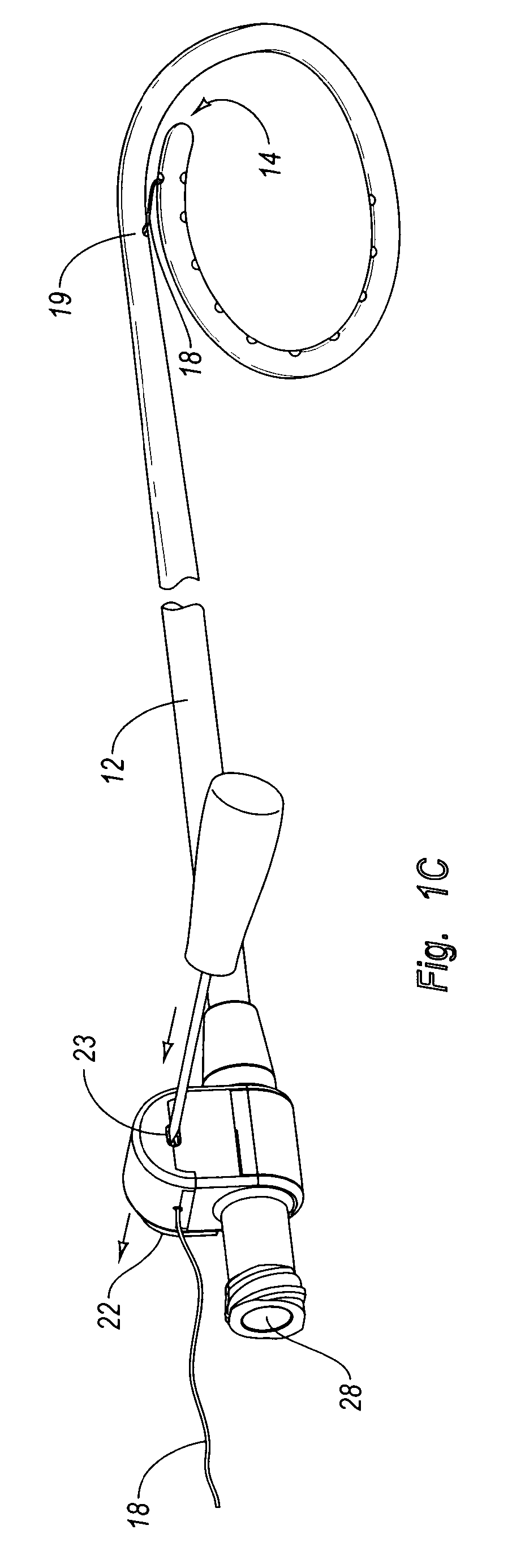

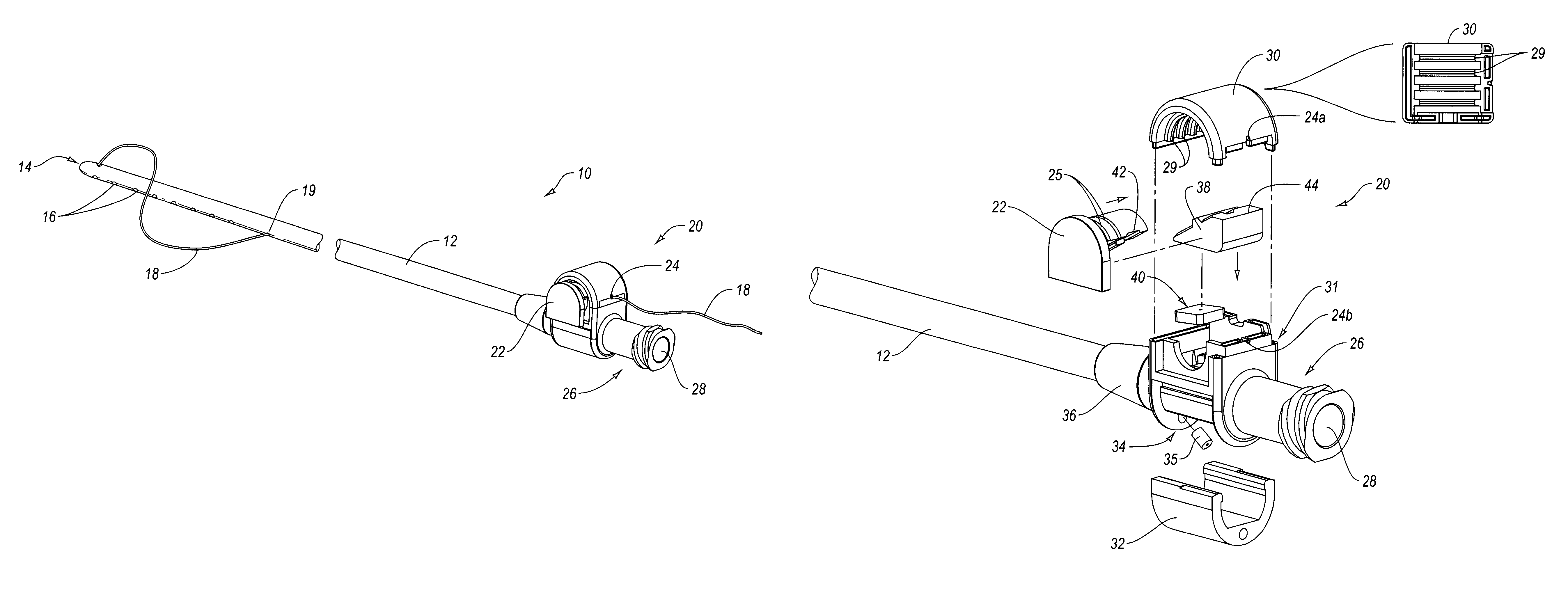

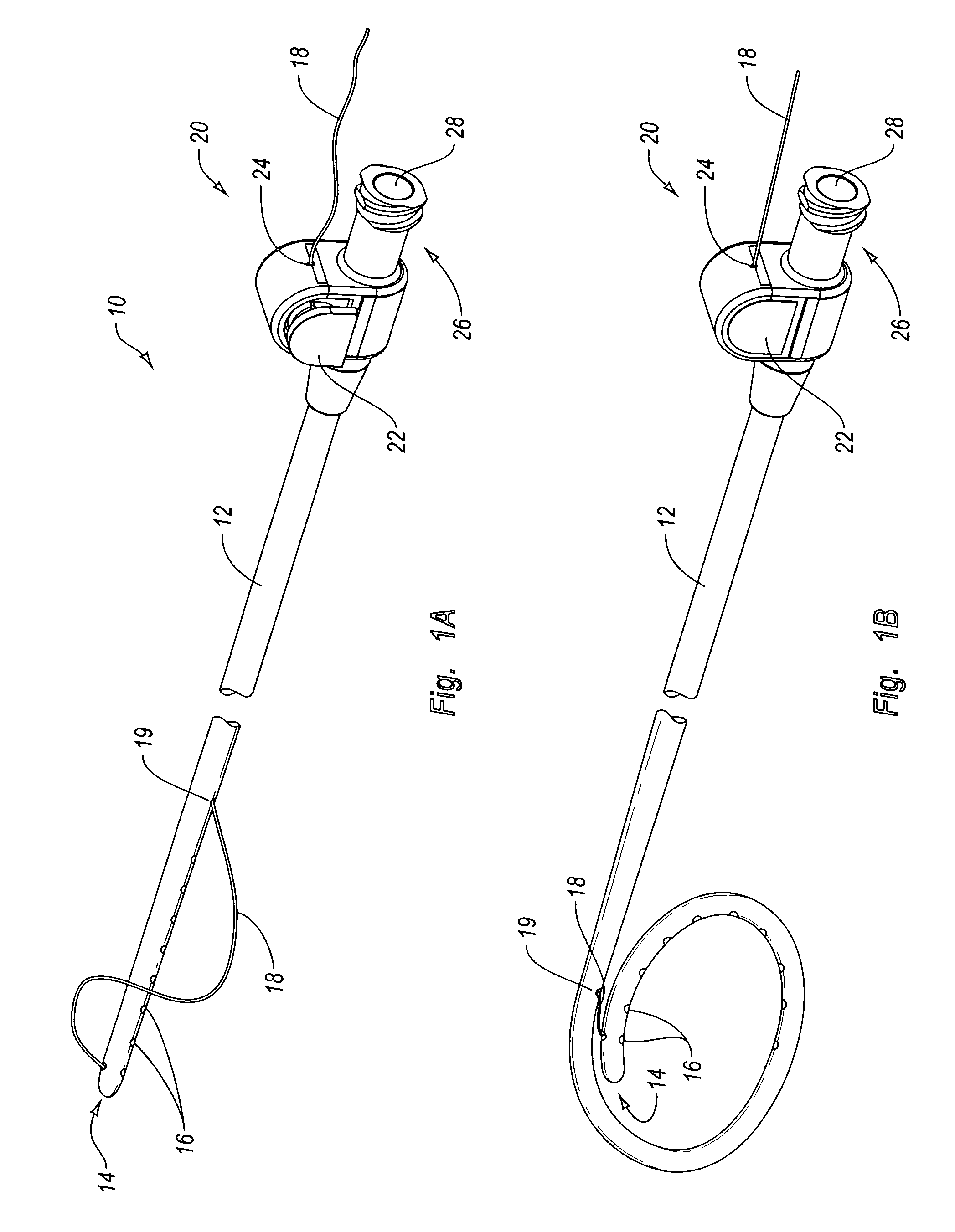

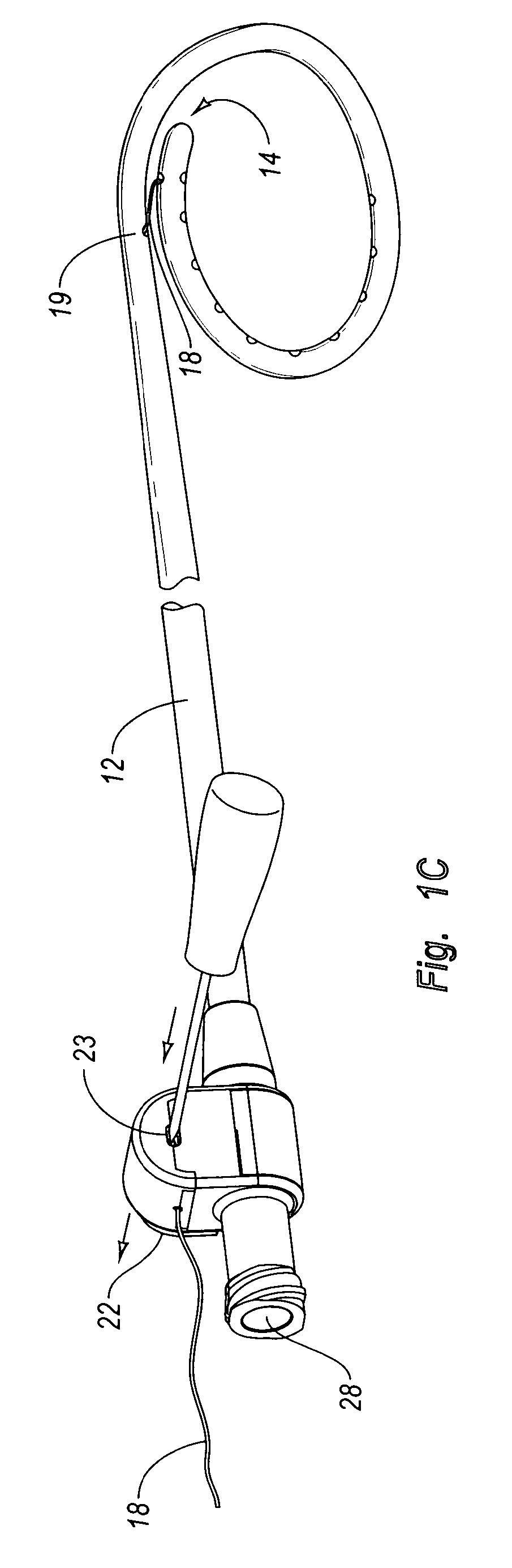

Drainage catheter with lockable hub

ActiveUS20070032779A1Reliable releaseRemove completelyWound drainsCatheterDrainage cathetersBody fluid

A reversible lockable drainage catheter for use in draining excess bodily fluid in a tissue having a catheter tube with a proximal end and a distal end, and a lockable hub positioned about the catheter tube. A suture of the drainage catheter can be reversibly tensioned, and locked in the tensioned conformation by depressing one or more surfaces of the lockable hub. The suture can then be released also by depressing one or more surface of the lockable hub, or by implementing one or more additional safety release mechanisms. For example, a safety release can be pulled in a proximal direction to release a tensioned suture. Similarly, the suture can be tensioned to a point that stretches an attachment point of the drainage catheter tube, and also causes the suture and safety release mechanism to disengage.

Owner:MERIT MEDICAL SYST INC

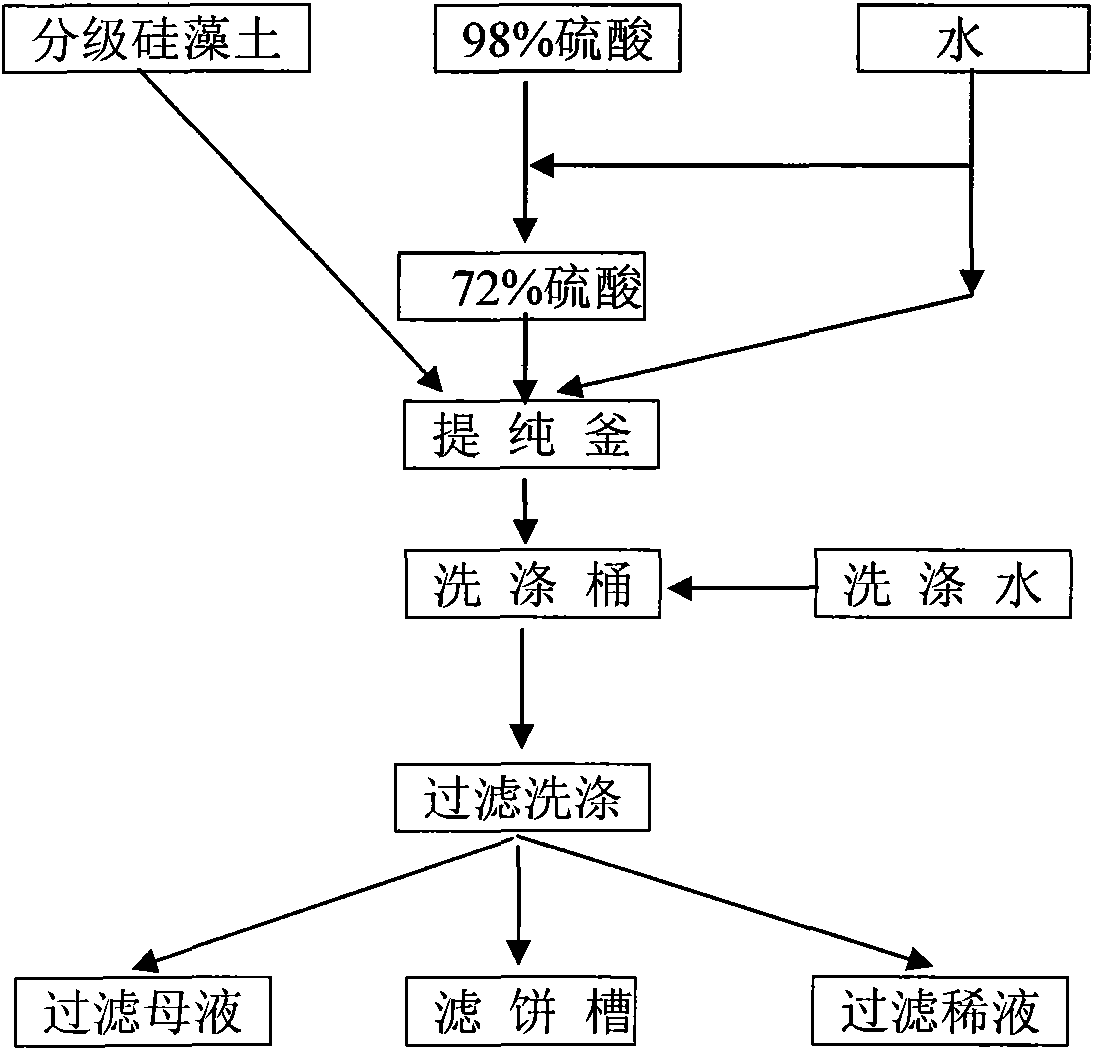

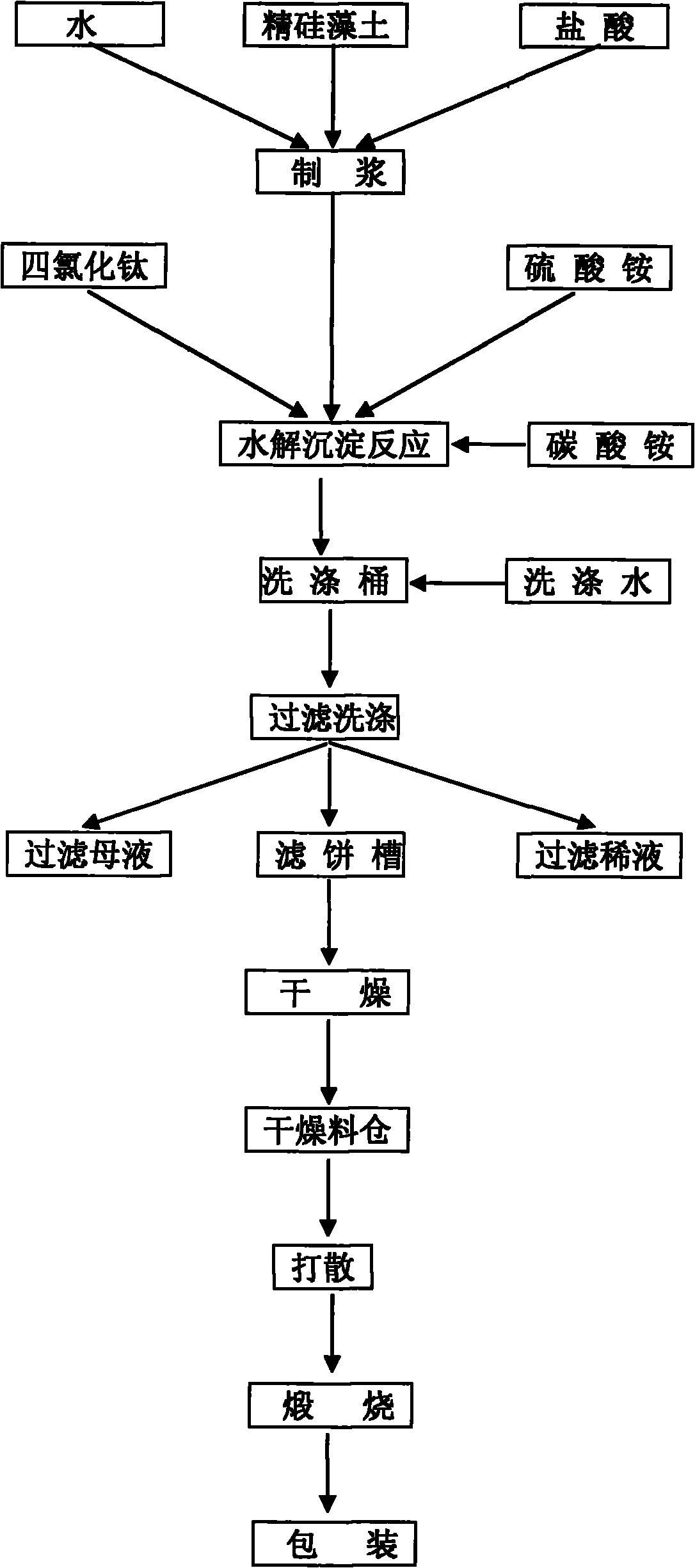

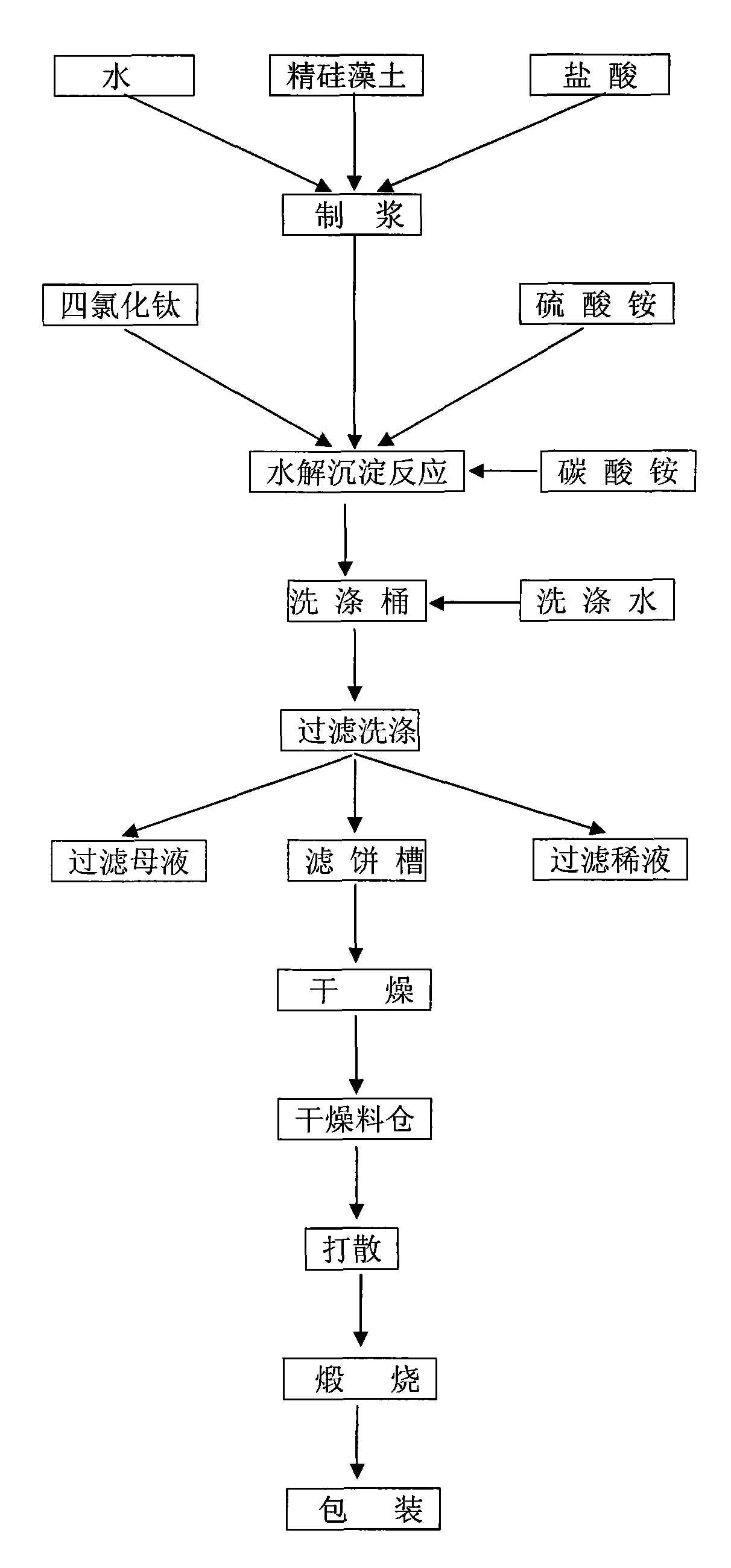

Process for producing nano titanium dioxide/diatomite composite photocatalytic material

ActiveCN101804338AThe preparation process is simpleGood effectOther chemical processesCatalyst activation/preparationAmmonium sulfateTitanium tetrachloride

The invention relates to a process for producing a nano titanium dioxide / diatomite composite photocatalytic material. The process comprises the following steps: purifying a diatomite raw material by using grading and acid-washing processes; synthesizing nano titanium dioxide / diatomite composite particles by adopting a hydrolysis-precipitation method through the purified diatomite serving as a carrier, titanium tetrachloride serving as a precursor and hydrochloric acid, ammonium sulfate and ammonium carbonate serving as aids; and filtering, washing, drying and burning the composite particles to form a finished product. The process can thoroughly remove harmful substances, has quite ideal effect on deep treatment of waste gas, lowers the cost and improves the photocatalytic performance.

Owner:临江市宝健纳米复合材料科技有限公司

Acellular biological patch, preparation method and apparatus thereof

The invention relates to an acellular biological patch, a preparation method and an apparatus thereof. In the invention, small intestines of pigs are taken as raw materials, which are subjected to a series of decellularization treatment by means of an acid, hydrogen peroxide, a mixed solution of high salt and alkali so as to obtain the acellular biological patch. According to the preparation method, after treatment by the hydrogen peroxide, the mixed solution of high salt and alkali can be employed to conduct twice recycling treatment, thus reaching the effects of thorough decellularization and antigen removal. The employment of a transverse and longitudinal alternating laying way maintains uniformity of the patch's mechanical properties, the tensile strength, suture tear force, tear strength and other mechanical indexes can well meet clinical demands, thus facilitating surgical suture operation. The employed drying mode has no need of any adhesive and suture line for fixation, so that a natural three-dimensional support structure of the product is maintained, and after implantation into the human body, no strong inflammatory response and immunological rejection response can occur. The patch has no toxicity on cells, so that infection and adhesion cannot occur in a repair process. The acellular biological patch provided in the invention is suitable for repair of body tissue defects and soft tissue injuries, and also can be used in the bioengineering field to serve as the tissue for reinforcing repair of membranous defects and infected wounds and serve as a biological scaffold material, etc.

Owner:SHAANXI BIO REGENERATIVE MEDICINE CO LTD

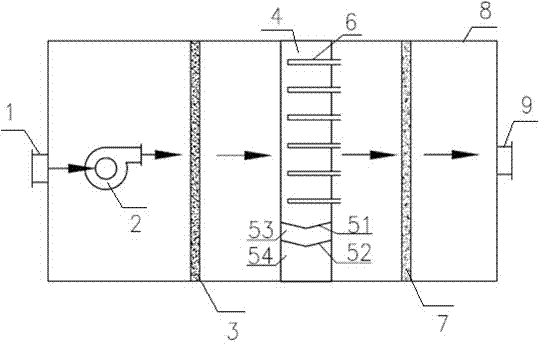

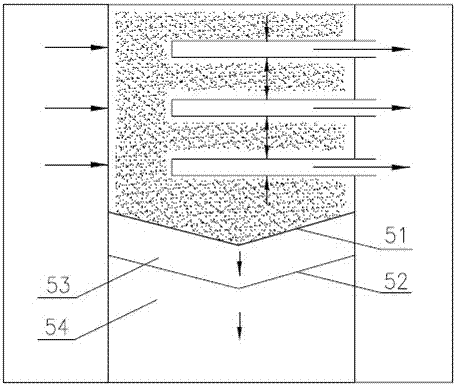

Air purifier for membrane separation

ActiveCN102824822AAvoid inactivationSuperior performance in removing volatile organic compoundsDispersed particle filtrationAir quality improvementRoom air cleanersCatalytic function

The invention relates to an air purifier for membrane separation. The purifier is an indoor air purifier integrated with the membrane filtering technology, the nanometer catalysis technology and the active carbon absorption technology. The air purifier comprises a shell, an air inlet and an air outlet arranged at the two ends of the shell. The air purifier is characterized in that the shell comprises a fan, a pre-filter net, a purifying chamber containing a separating membrane component, a dust collecting chamber and an active carbon net which are sequentially arranged; the dust collecting chamber is arranged at the bottom of the separating membrane component; the separated membrane for the air purifier has a catalytic function and removes volatile organic compound such as indoor benzene and formaldehyde when PM2.5 and germ are removed. The air purifier for membrane separation integrates a plurality of functions, is simple in structure, can continuously run and can be used for indoor air purification of families, hospitals and pharmaceutical factories.

Owner:NANJING UNIV OF TECH

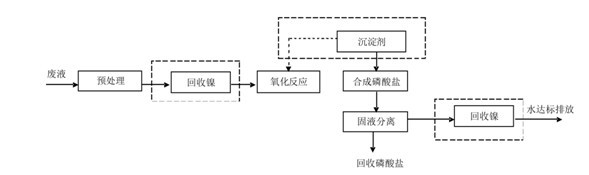

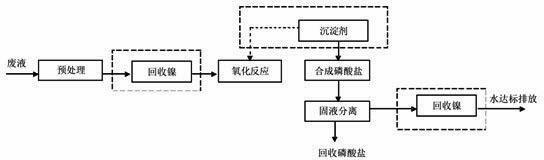

Method for degrading organic pollutant and recycling phosphate in chemical nickel-plating waste liquid

InactiveCN102616961AReduce phosphorus contentRemove completelyPhosphatesWaste water treatment from metallurgical processPhosphorous acidLiquid waste

The invention discloses a method for degrading organic pollutant and recycling phosphate in chemical nickel-plating waste liquid, which belongs to the technical field of environment-friendly waste water treatment and resource recycle. The method conducts oxidation degradation of organic pollutant in waste water through the oxidation technology, simultaneously oxidizes hypophosphorous acid radical and phosphorous acid radical in waste water into orthophosphate radical and recycles phosphate and nickel by enabling the orthophosphate radical and nonmetal or metal ions to be precipitated. The method achieves resource recycle while treating waste water and has good environment benefits and economical benefits and wide application prospect.

Owner:李朝林

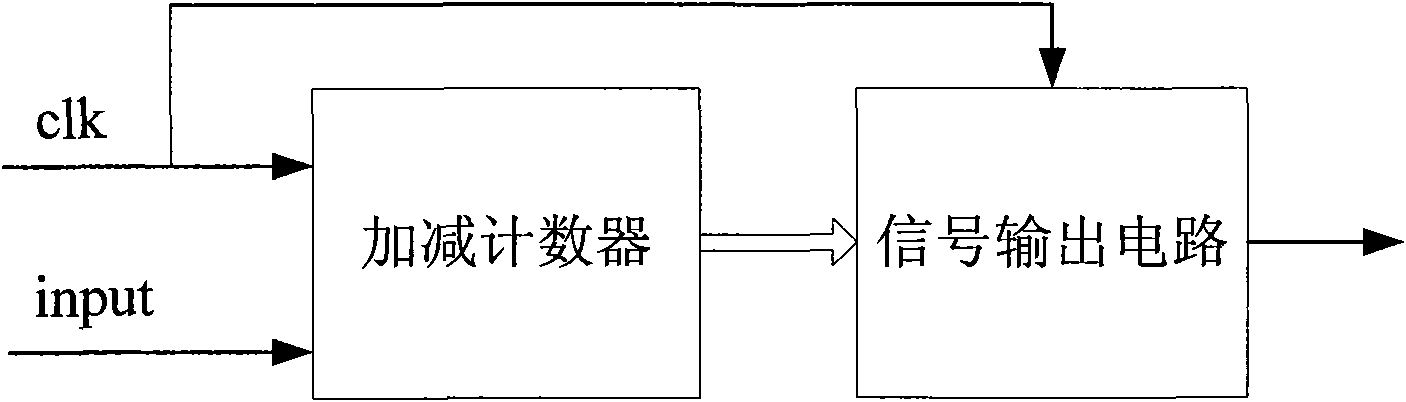

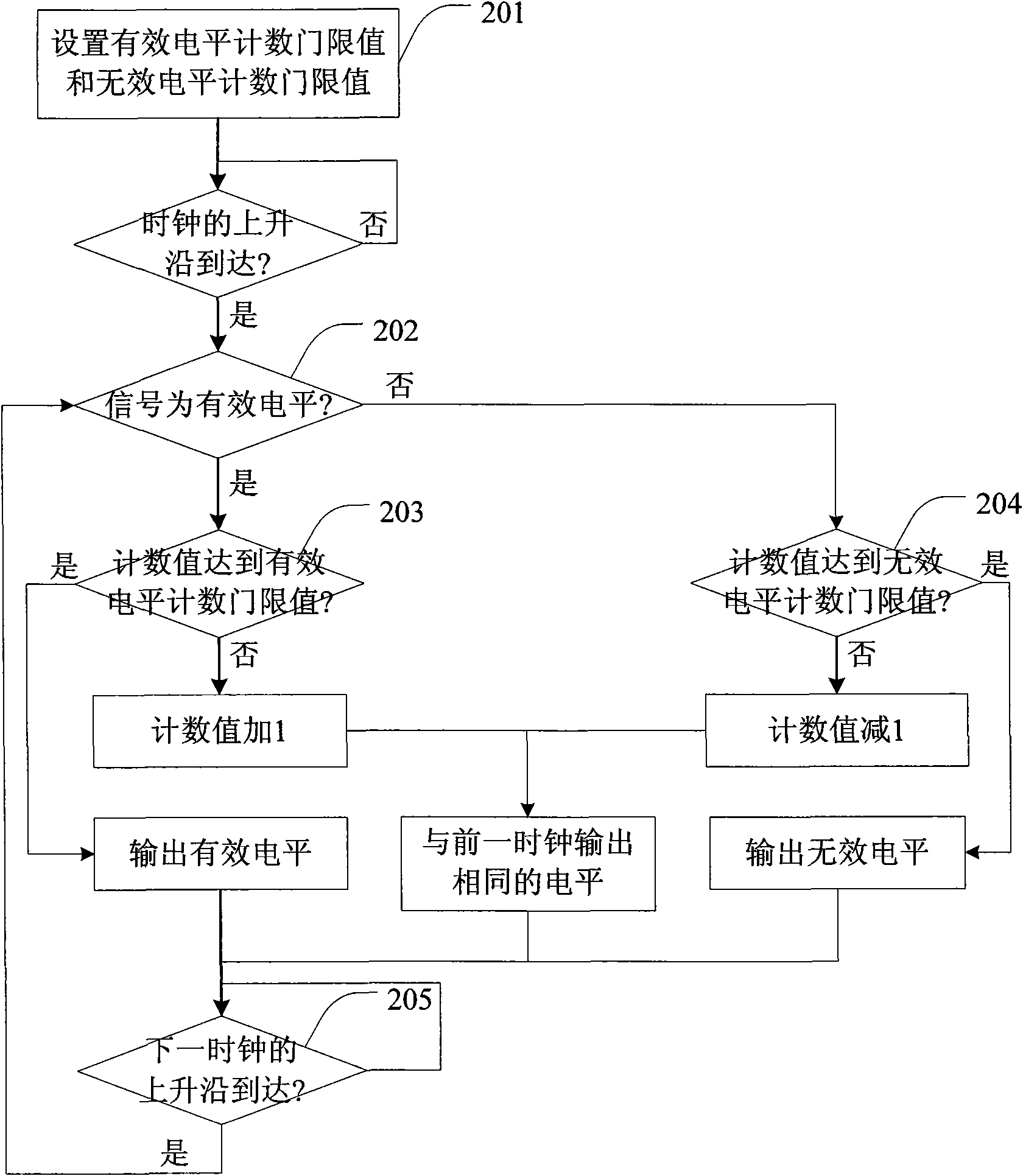

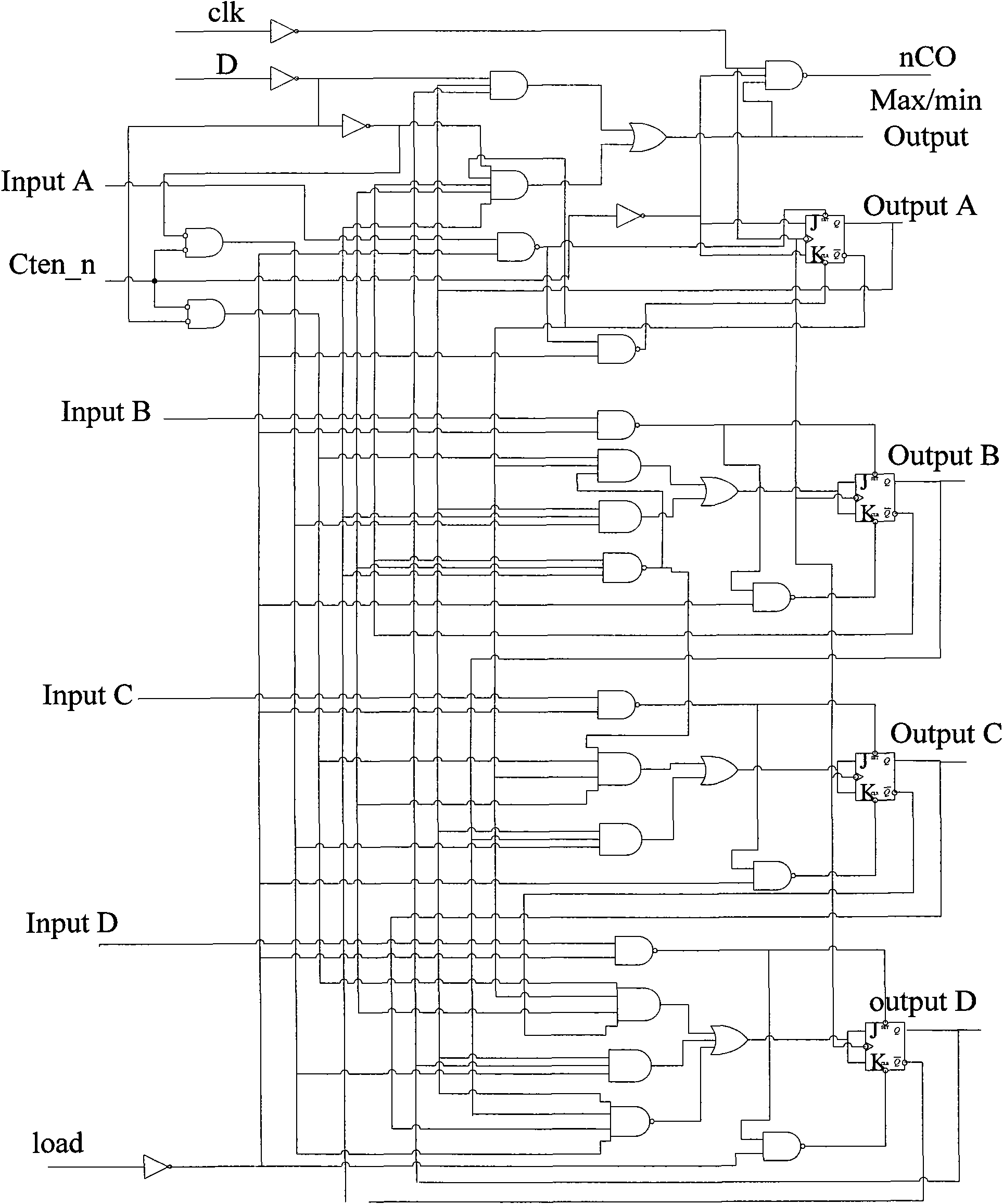

Method and device for eliminating signal noise

ActiveCN101568237ARemove completelyReduce difficultyPulse descriminationLogic circuit coupling/interface arrangementsComputer scienceGlitch removal

The invention discloses a method and device for eliminating signal noise, the device includes a backward-forward counter and a signal output circuit; the method for eliminating signal noise has the following steps: 1) setting valid and invalid level counting thresholds; 2) receiving the signal with signal noise needed to be eliminated by the backward-forward counter and beginning to count; when the rising edge of each clock arrives, if the signal is an valid electrical level, adding one on the current counting value, otherwise subtracting one; and the counting value does not increase / decrease until it reaches to a valid / invalid level counting threshold; meanwhile, the signal output circuit outputs signal without noise according to the counting value: when the rising edge of each clock arrives, if the counting value is a valid / invalid level counting threshold, then outputting valid / invalid level; if the counting value is between the valid and invalid level counting threshold, keeping the output equal to the output of the previous clock. The device provided by the invention can thoroughly eliminate wide noise, stably output signal without noise, and which is simple to be realized, thereby improving reliability of the system.

Owner:ZTE CORP

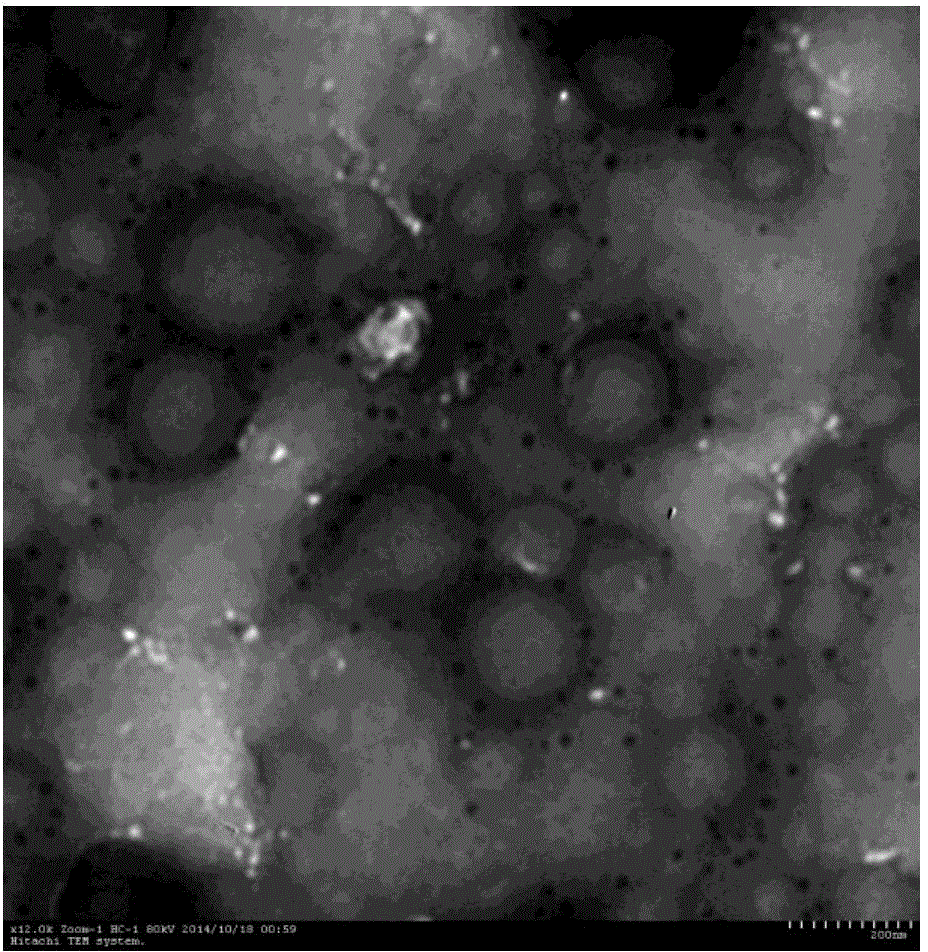

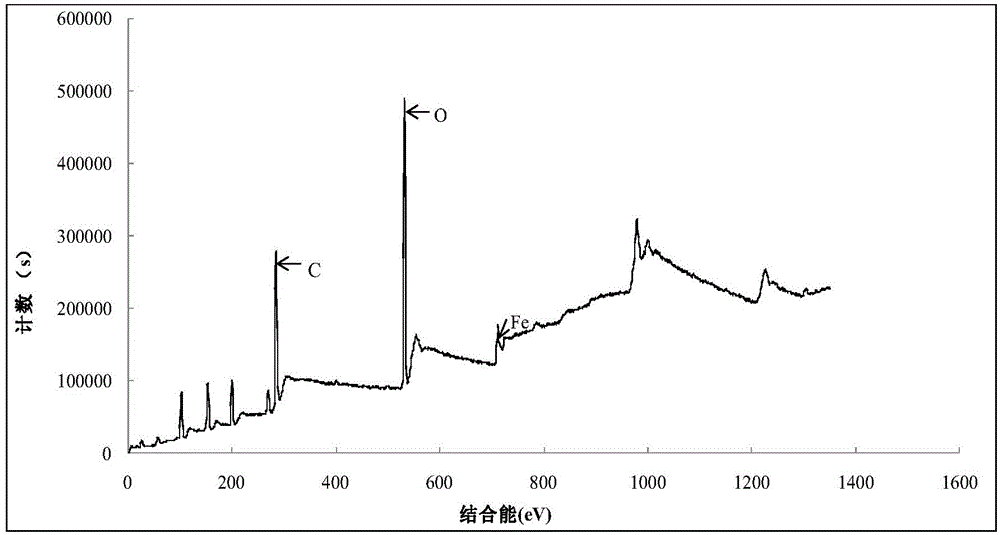

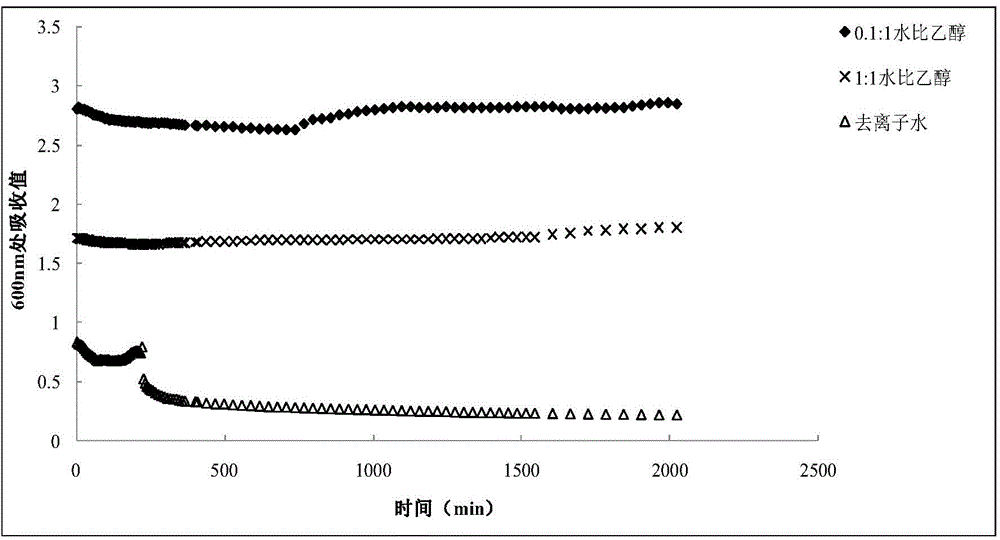

Method for preparing NZVI (nano-scale zero-valent iron) suspension from green tea as well as application of suspension

InactiveCN104857934ALarge specific surface areaImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionDissolutionSewage

The invention discloses a method for preparing NZVI (nano-scale zero-valent iron) from green tea as well as an application of a suspension of the NZVI. The method comprises technological steps as follows: A, preparing a green tea dissolution solution; B, preparing a ferric trichloride solution; C, preparing the GT-NZVI (green tea-NZVI) suspension. The prepared GT-NZVI has the advantages of good suspension stability, simple preparation technology, low cost, environment-friendliness, good stability, high penetrability in an aquifer and capability of quickly and thoroughly removing hexavalent chromium in sewage and underground water.

Owner:INST OF HYDROGEOLOGY & ENVIRONMENTAL GEOLOGY CHINESE ACAD OF GEOLOGICAL SCI

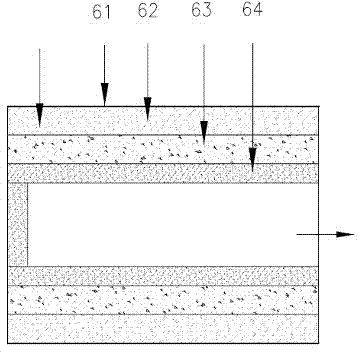

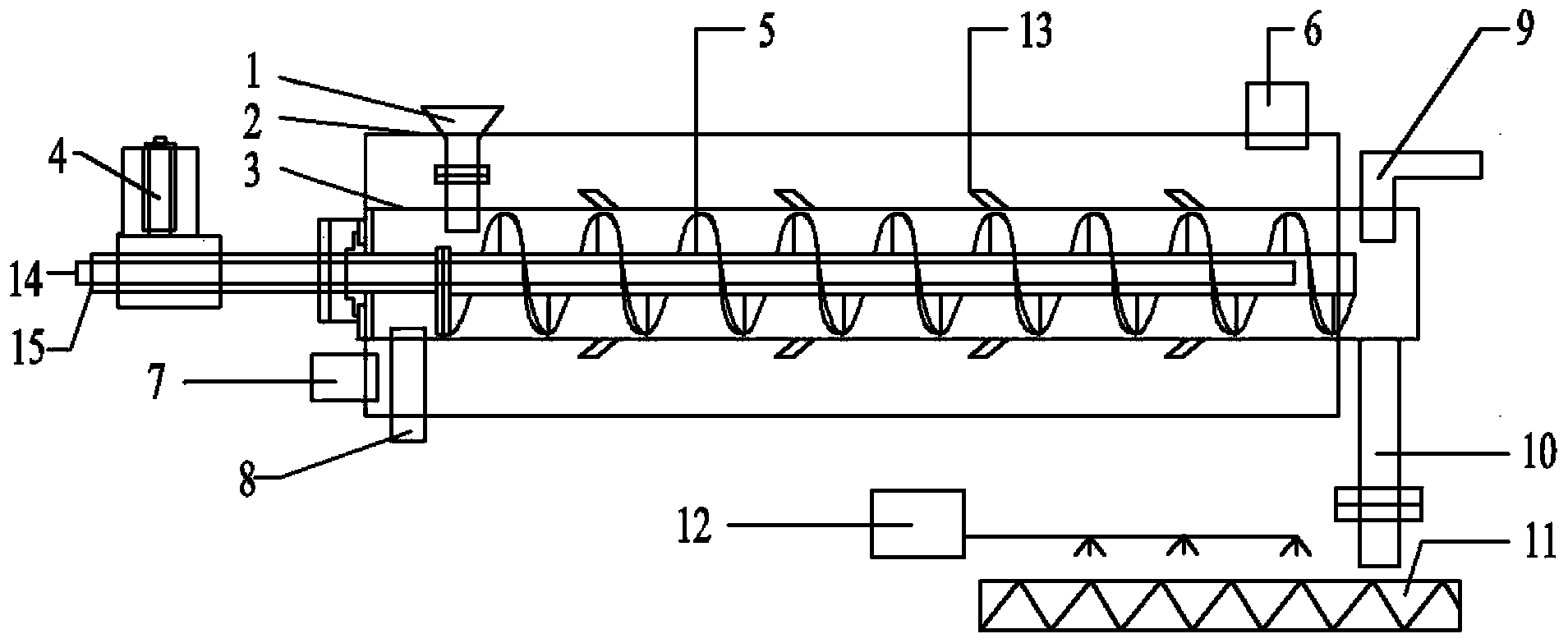

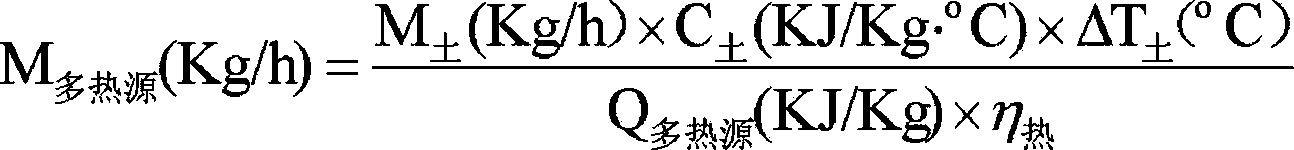

Multi-heat source and shaft intervallic heating type thermal desorption device for organic pollutant contaminated soil repair

ActiveCN103506378AEconomical and efficient processingRemove completelyContaminated soil reclamationHigh concentrationEngineering

The invention relates to the field of environmental protection, and aims to provide a multi-heat source and shaft intervallic heating type thermal desorption device for repairing organic pollutant contaminated soil. An intervallic heating type thermal desorption machine of the device is a jacket type heating furnace; a soil feeding port, an unearthing machine, a first multi-heat source inlet and a first multi-heat source outlet are formed in the outer cylinder; a carrier gas inlet and a carrier gas outlet are formed in the inner cylinder; and a hollow shaft type revolving shaft adopting a jacket structure is formed by an outer shaft sleeve and a hollow inner shaft sleeve; a second multi-heat source inlet and a second multi-heat source outlet respectively connected with the outer shaft sleeve or the inner shaft sleeve are formed in the hollow shaft type revolving shaft. The device can effectively treat the organic pollutant contaminated soil, is particularly suitable for repairing high-concentration and multi-component organic pollutant contaminated soil fields, has excellent adaptability to various heat sources, improves the synthetic utilization efficiency of the heat sources, has great soil processing capacity in unit time, and is particularly suitable for sandy contaminated soil. For the organic pollutant contaminated soil, the device can achieve the organic pollutant removing efficiency above 99.9%.

Owner:ZHEJIANG UNIV

Drainage catheter with lockable hub

ActiveUS7578814B2Reliable releaseSafe and convenient mannerWound drainsCatheterDrainage cathetersBody fluid

A reversible lockable drainage catheter for use in draining excess bodily fluid in a tissue having a catheter tube with a proximal end and a distal end, and a lockable hub positioned about the catheter tube. A suture of the drainage catheter can be reversibly tensioned, and locked in the tensioned conformation by depressing one or more surfaces of the lockable hub. The suture can then be released also by depressing one or more surface of the lockable hub, or by implementing one or more additional safety release mechanisms. For example, a safety release can be pulled in a proximal direction to release a tensioned suture. Similarly, the suture can be tensioned to a point that stretches an attachment point of the drainage catheter tube, and also causes the suture and safety release mechanism to disengage.

Owner:MERIT MEDICAL SYST INC

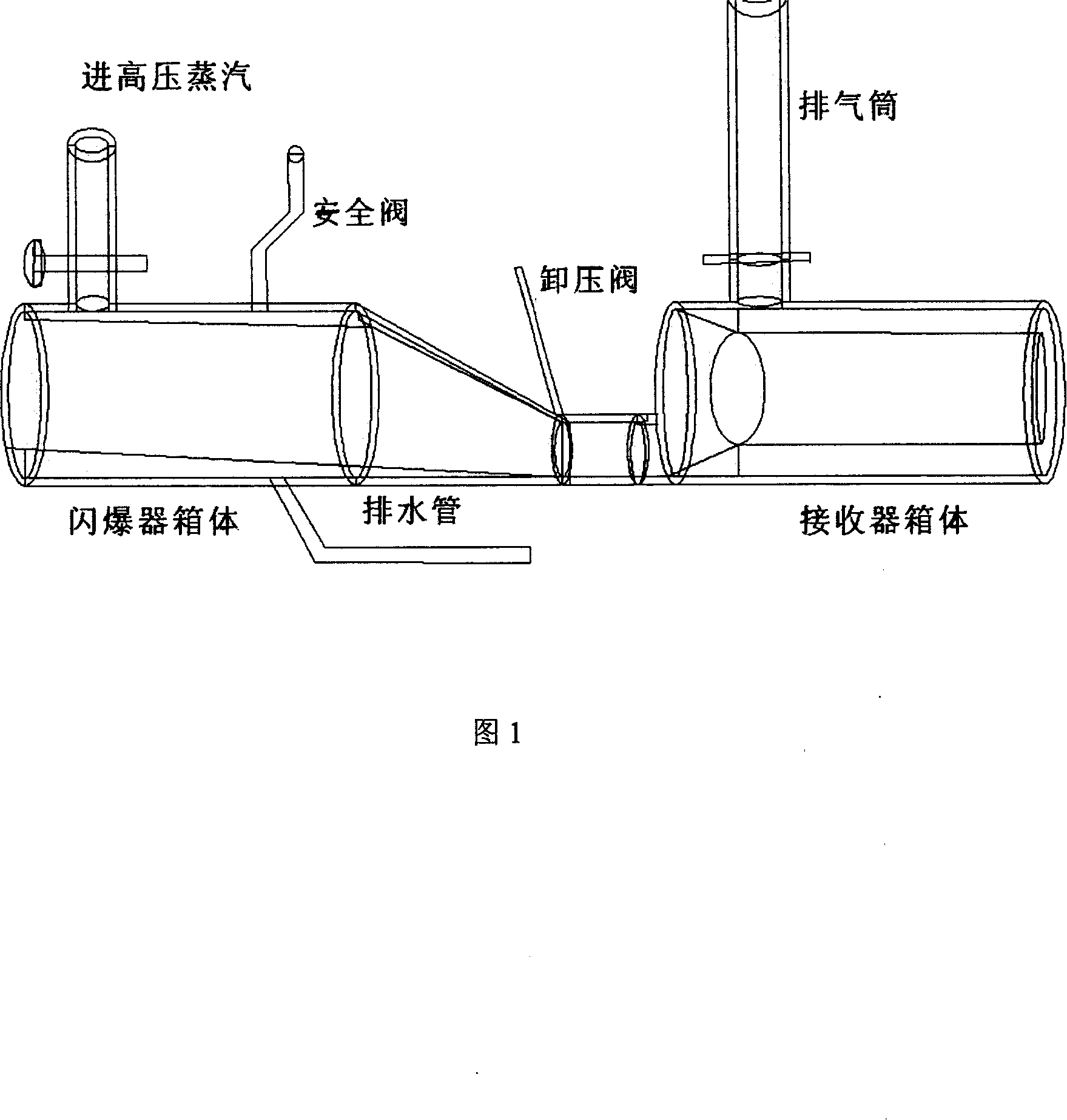

Hemp-like bast fibre flash explosion-high temperature boiling combination degumming technique

The flash bursting and high temperature digesting process for degumming hemp bast fiber includes pre-treatment, flash bursting and high temperature digesting to eliminate residual pectin, hemicellulose and lignin from hemp bast fiber, and raise the fiber fracturing degree and softness. The flash bursting and high temperature digesting process has ideal degumming effect, obvious non-fiber component eliminating effect and less pollution, and the degummed hemp bast fiber has high cellulose rate, high fiber fracturing degree and high fiber flexibility.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

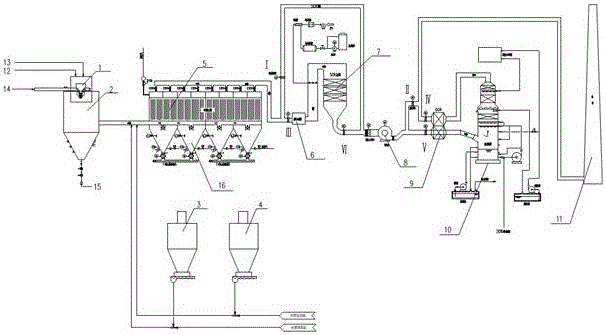

Garbage incineration fume ultralow emission purifying system

PendingCN106621754AImprove removal efficiencyAchieve cleanupCombination devicesGas treatmentActivated carbonPlate heat exchanger

The invention discloses a garbage incineration fume ultralow emission system. A garbage incineration fume purifying treatment device comprises an SNCR (selective non-catalytic reduction) device, a semi-dry type reaction tower, a slaked lime spraying device, an activated carbon spraying device, a bag type deduster, a steam heater, an SCR (selective catalytic reduction) reaction tower, a fume / fume heat exchanger, a wet type scrubbing tower, an induced draft fan and a chimney. The low-temperature fume after washing is performed with heat exchange in the fume / fume heat exchanger, heated, and exhausted out of the chimney. The garbage incineration fume purifying treatment device has the advantage that the emission of the fume is superior to the European Union 2000 standard.

Owner:SHANGHAI SUS ENVIRONMENT

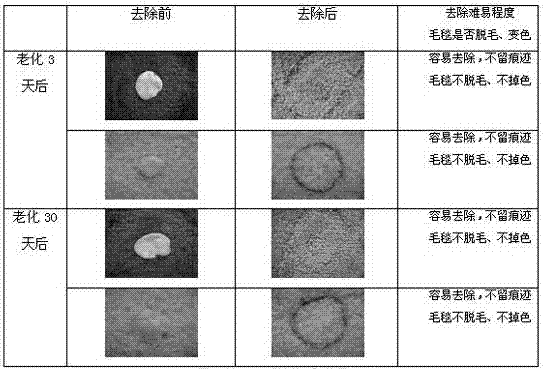

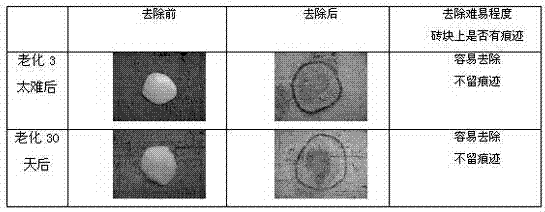

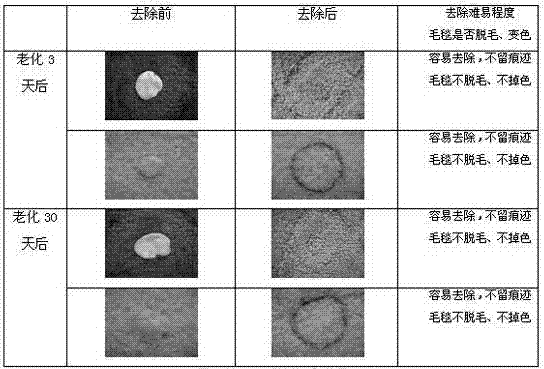

Environmentally friendly adhesive remover

ActiveCN102260599AGood value for moneyQuick removalOrganic detergent compounding agentsSurface-active detergent compositionsShoe polishEngineering

The invention relates to an environment-friendly degumming agent. The product can clear away residual chewing gums on clothes and waste chewing gums on the ground, also has good effects on label illegal advertisements, oil pen illegal advertisements, lipsticks, shoe polish, adhesive tape remaining trace and complex mixed oil blackspots, has a neutral formula, is safe and poisonless to the environment and human bodies, and is easy to use; and through experiments of comparing effects with those of the traditional degumming products which are prepared from tetrachloroethylene, acetic ether, dichloromethane, methylbenzene, dimethylbenzene and the like, the using amount is small under the condition that the same removal effect is achieved, and the environment-friendly degumming agent also has no pungent peculiar smell. The environment-friendly degumming agent comprises the following raw materials in part by weight: 20 to 60 parts of solvent, 5 to 20 parts of mixture containing cocamide, 1 to 10 parts of lauryl alcohol alkoxylate, 0.1 to 1.0 part of alkyl amine oxide, 10 to 30 parts of cosolvent, and the balance of water.

Owner:于文 +1

Preparation method of highly pure quartz sands

The invention discloses a preparation method of highly pure quartz sands. The method comprises the following steps: 1, roughing: cleaning a raw material, and crushing the cleaned raw material; 2, carrying out calcining and water quenching: calcining the crushed raw material, taking out particles, and quenching the particles in an ice-water mixture; 3, carrying out electric separation and magnetic separation: milling the quenched particles, carrying out electric separation and magnetic separation twice, and carrying out pulse magnetic field treatment; 4, pickling: immersing a material obtained in step 3 in a hydrochloric acid solution, filtering the immersed material, dialyzing the obtained first filtrate to recover hydrochloric acid, preparing a first mixed acid by using the recovered hydrochloric acid and a sulfuric acid solution, immersing quartz sands in the first mixed acid, filtering the immersed quartz sands, dialyzing the obtained second filtrate to obtain recovered mixed acid, preparing a second mixed acid by using the recovered mixed acid and a nitric acid solution, immersing the quartz sands in the second mixed acid, adding the immersed quartz sands to a sodium carbonate solution, and flushing the quartz ands; 5, floating the flushed quartz sands; and 6, drying the floated quartz sands. The preparation method allows highly pure quartz sands with the SiO2 content to be not lower than 99.995% to be produced, and takes a greatly lower acid amount than traditional methods.

Owner:江苏凯达石英股份有限公司

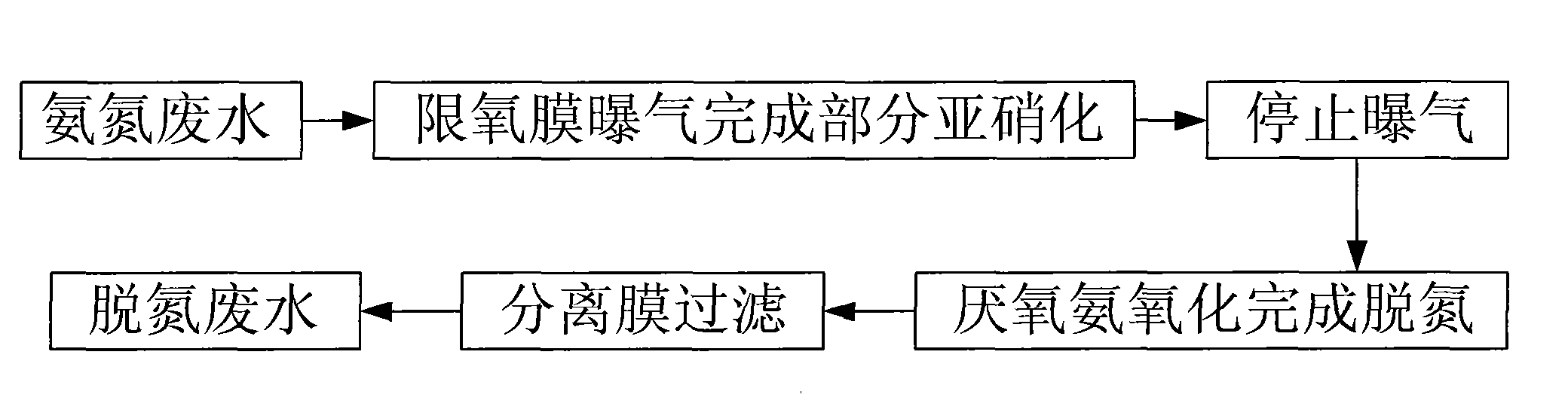

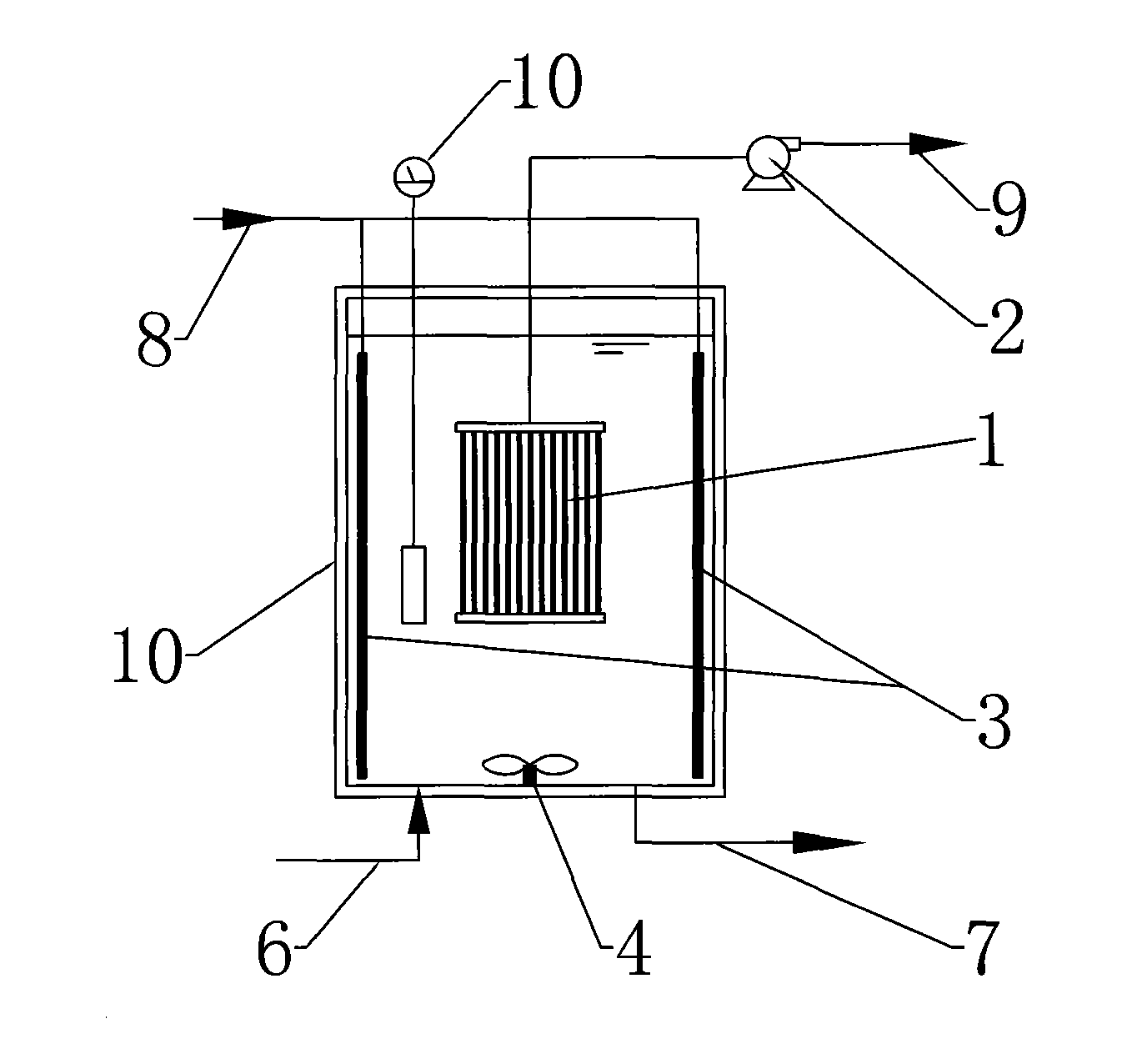

Single-stage whole process autotrophic denitrification sewage treatment device and technique thereof

InactiveCN101671094AAchieve enrichmentAchieve short-cut nitrificationWater/sewage treatment bu osmosis/dialysisTreatment with aerobic and anaerobic processesSingle stageAmmonia-oxidizing bacteria

The invention discloses a single-stage whole process autotrophic denitrification sewage treatment device and a technique thereof. The device comprises a reactor, a water outlet pump, a stirrer, a separation membrane component and an aeration membrane component, wherein the separation membrane component is arranged at the central part inside the reactor; the aeration membrane component consists ofa membrane tube which is wound on the inner wall of the reactor; and an air inlet pipe is connected with the aeration membrane component, and a water inlet of a water outlet pump is connected with theseparation membrane component by a pipeline. The method mainly comprises: the dissolved oxygen is controlled to be about 0.5-1.0mg / L, and partial short-cut nitrification is carried out on ammonia nitrogen under the action of ammonia-oxidizing bacteria; and then, aeration is stopped, denitrification is completed by anaerobic ammonium oxidation, and clean outlet water can be obtained by membrane separation. The invention leads the aeration membrane and the separation membrane to be arranged inside the same reactor to form a membrane aeration separating reactor, thus coupling bubble-free aeration, membrane separation and biological degradation. By utilizing the characteristics of high efficiency and easy control of membrane aeration, the good short-cut nitrification of nitrogenous effluent can be realized.

Owner:DALIAN JIAOTONG UNIVERSITY

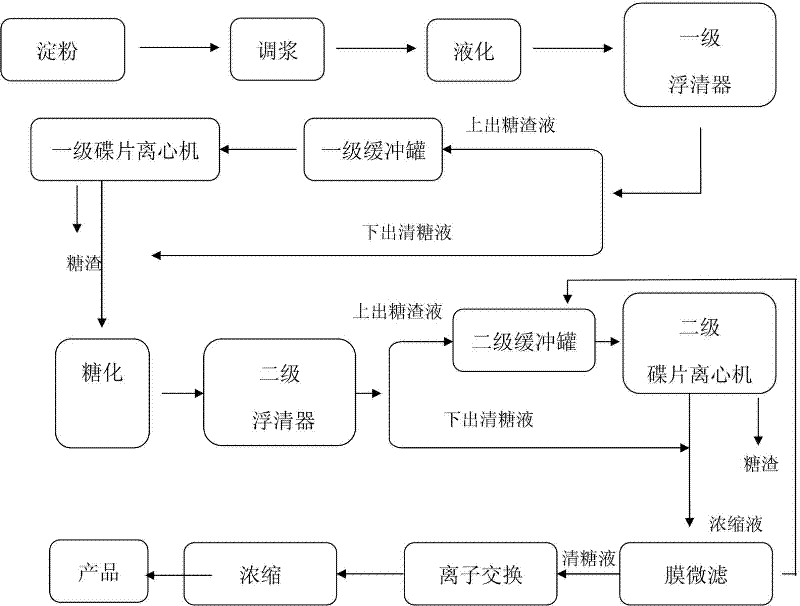

Process for producing starch sugar

ActiveCN102337316AQuality improvementImprove function and effectAnimal feeding stuffAccessory food factorsActivated carbonChaptalization

The invention discloses a process for producing starch sugar. The process comprises the following steps of: pulp-conditioning edible starch; liquefying; passing liquefied starch through a primary floating clarifier, guiding an upper floating sugar dreg liquid into a primary buffer tank, and then entering a primary disc-type centrifuge to be centrifugated and separated so as to extract sugar dregs; combining a clear sugar liquid flowing out of the primary disc-type centrifuge and a clear sugar liquid flowing out of the primary floating clarifier and flowing into a saccharifying tank to be saccharified into a saccharified liquid; passing the saccharified liquid through a secondary floating clarifier, guiding an upper floating sugar dreg liquid into a secondary buffer tank, and then enteringa secondary disc-type centrifuge to be separated so as to extract sugar dregs; combining a clear sugar liquid flowing out of the secondary disc-type centrifuge and a clear sugar liquid flowing out ofthe secondary floating scum clearing device and filtering by passing through a membrane micro-filtration system; and flowing a micro-filtered concentrated liquid containing dregs back to the secondary buffer tank, entering a micro-filtered clear sugar liquid into an ion exchange system to be decolorized and desalted, and then finally concentrating into a product. According to the process for producing the starch sugar disclosed by the invention, filter aids and activated carbon are not required in the clarification and the filtration processes, and high-purity sugar liquid can be obtained through the efficient operation of solid-liquid separation equipment; and meanwhile, sugar dregs without the filter aids and the activated carbon are extracted and can be used as a feedstuff raw materialfor animals, thereby changing waste into valuable, and no discharge of filtered solid wastes during the whole process exists.

Owner:双桥(厦门)有限公司

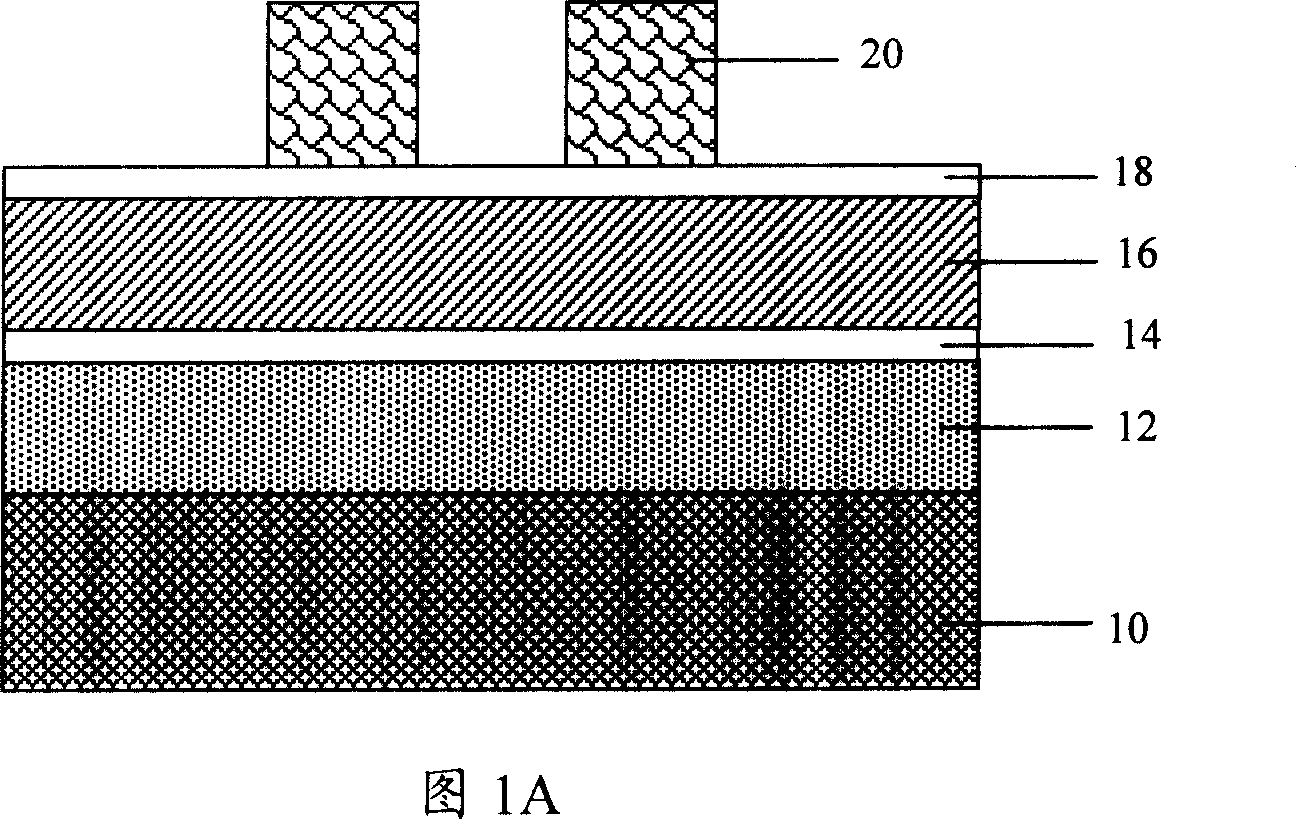

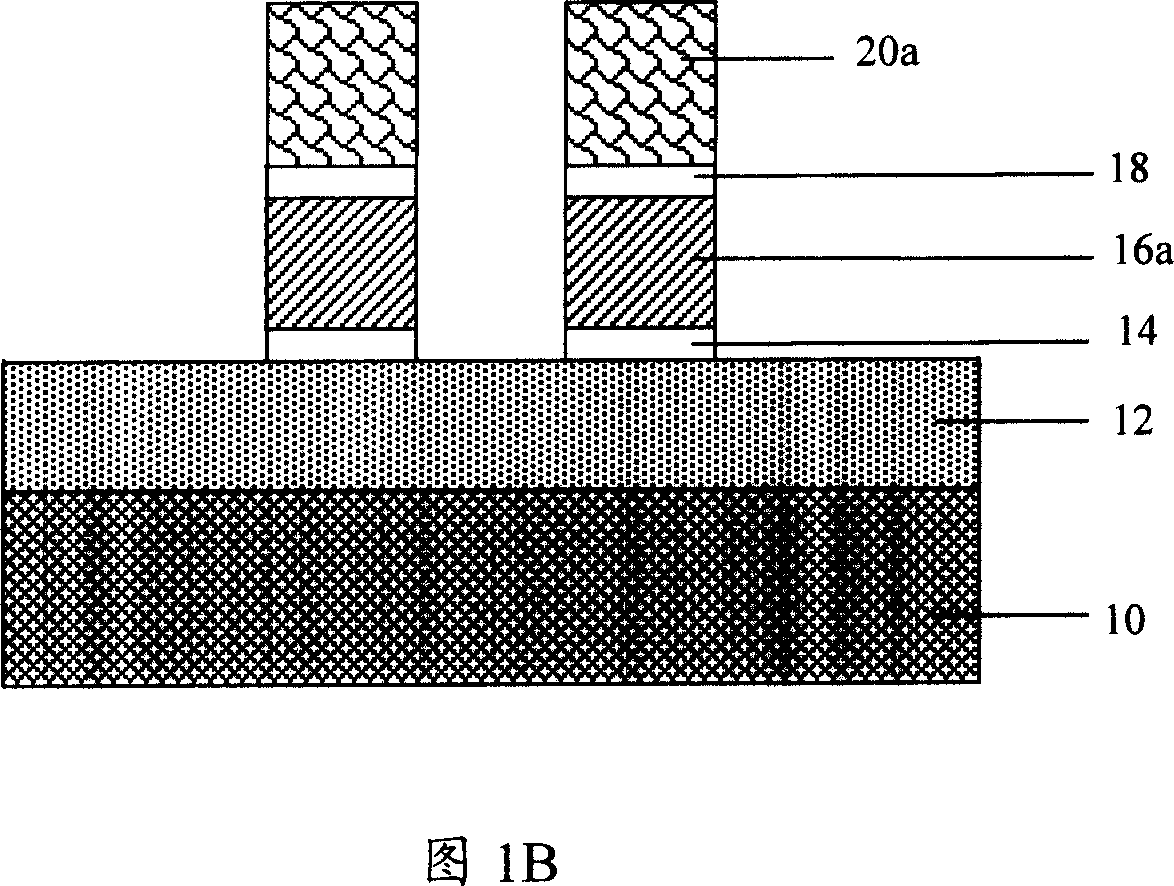

Method for removing etching residue

InactiveCN101063821ARemove completelyWon't change cdSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusElectrical conductorPhotoresist

This invention discloses one method to remove etch resides, which comprises the following steps: providing one semiconductor underlay; forming function layer on underlay and forming mask film layer on function layer; patterning the mask film layer; etching the said function layer to form needed image and to adopt gas spray to remove etch resides; removing etch resides. This invention method is to etch function layer to form needed image and then to remove etch resides and then adopts grey method to remove etch resides for final clear.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

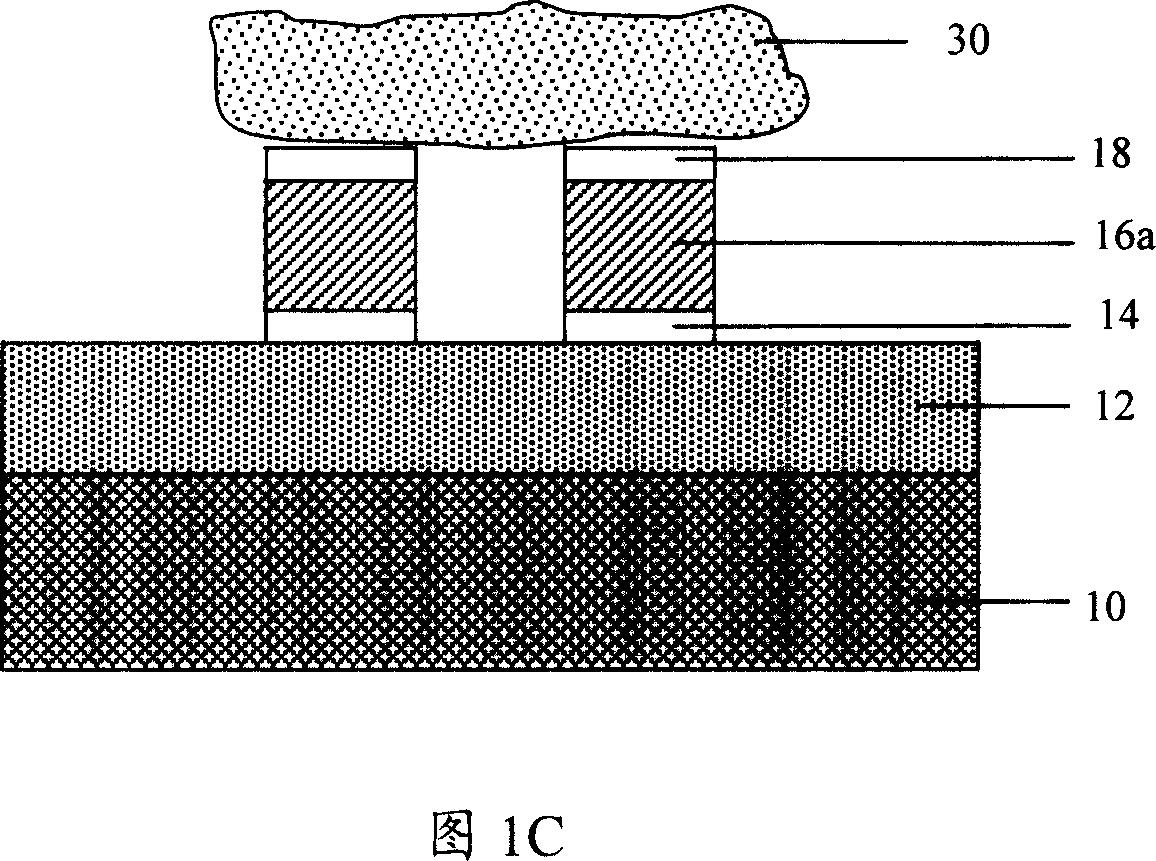

Water treatment method of zero-valent iron-copper bi-metal activated persulfate

InactiveCN105253983ASolve the problem of low production volumeRemove completelyWater contaminantsContaminated groundwater/leachate treatmentSulfate radicalsPolychlorinated biphenyl

The invention discloses a water treatment method of zero-valent iron-copper bi-metal activated persulfate. The water treatment method specifically comprises the steps that bi-metals including zero-valent iron and copper are added into water containing micro-pollutants, then persulfate is added, full mixing is performed, the bi-metals including the zero-valent iron and the copper are utilized to activate the persulfate so as to remove the micro-pollutants in the water. The water treatment method utilizes the bi-metals including the zero-valent iron and the copper to efficiently activate the persulfate so as to produce free sulfate radicals having strong oxidizing property, can achieve the purpose of quickly and thoroughly removing micro-pollutants, including multiple types of poisonous and harmful micro-pollutants in water, such as polychlorinated biphenyl, brominated flame retardants, drugs and personal care products (PPCPs) and algal toxin, and has the advantages of high activation efficiency, high oxidation and degradation efficiency of pollutants, wide pH using range, convenient operation and the like. The water treatment method can be applied to underground water remediation, treatment of industrial water (including electroplating wastewater, hospital wastewater, printing and dyeing wastewater and the like), drinking water treatment, wastewater treatment and the like.

Owner:SUN YAT SEN UNIV

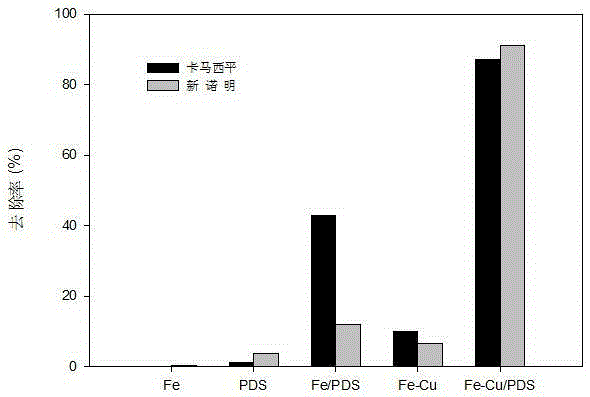

Method for deleting list items in sliding manner

ActiveCN103019589ASimplify user operationsImprove operational efficiencyInput/output processes for data processingMechanical engineeringDatabase

A method for deleting list items in a sliding manner comprises the following steps: judging whether the touch action received by screen touch equipment is the sliding aiming to the displayed items; if the touch action is taken as the predefined sliding aiming to the items, the items are deleted; and the predefined sliding is the sliding in the length direction of the items, the sliding distance and speed rate are not lower than preset threshold values. The method disclosed by the invention can simply, quickly and conveniently deletes the list items in a sliding manner.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

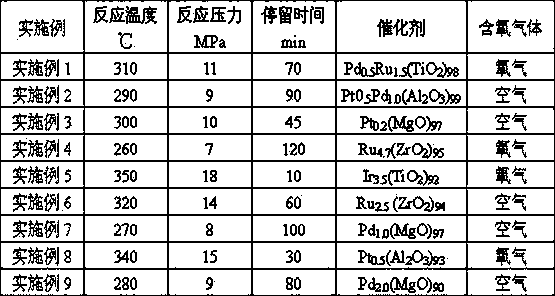

Processing method of wastewater of acrylonitrile production refining process

ActiveCN103420473ASimple processRemove completelyNature of treatment waterWater/sewage treatment by oxidationOxygenOrganic matter

The invention relates to a processing method of wastewater of an acrylonitrile production refining process. The processing of the wastewater of an acrylonitrile production refining system has the problems of complex processing technology and high operation cost. Through use of a technical scheme of the processing method of the wastewater of the acrylonitrile production refining process, the problems are well solved, and the processing method can be used for processing of the wastewater of the acrylonitrile production refining process. The technical scheme is shown as follows: the wastewater produced in the acrylonitrile refining process of the acrylonitrile production by ammoxidation of propylene and propane is mixed with an element-oxygen-containing gas to pass through a wet oxidation reactor to remove organic matters in the wastewater to enable the COD value of the wastewater to be less than 500 mg / L.

Owner:CHINA PETROLEUM & CHEM CORP +1

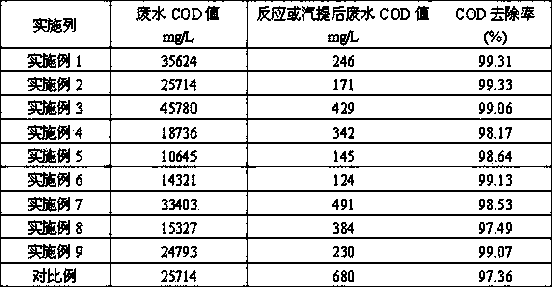

Method for transferring graphene with atomic cleanness

InactiveCN103449418APromote degradationImprove solubilityCarbon compoundsPolymethyl methacrylateSolvent

The invention discloses a method for efficiently transferring CVD (Chemical Vapor Deposition) graphene and acquiring atomically clean surfaces. The method comprises the following steps: spin-coating a layer of PMMA (polymethyl methacrylate) solution on the surface of a graphene / metal substrate, removing the metal substrate through corrosion of an (NH4)2S2O8 solution after being cured, cleaning graphene / PMMA, fishing out through a target substrate and then drying, then dissolving the PMMA layer through an organic acid solvent, and finally further removing the residual PMMA on the surface of the graphene through a high-temperature annealing manner, thus acquiring the atomically clean graphene surfaces. The graphene surface is large in area, complete in structure and little in defects and residual PMMA. According to the method, the residual PMMA is little, and the atomically clean surfaces can be more easily acquired. The graphene acquired through adopting the method is applicable to constructing electronic devices such as a field effect transistor, a light-emitting diode and a transparent electrode, and also can be used for theoretical research of surface interfaces.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com