Hemp-like bast fibre flash explosion-high temperature boiling combination degumming technique

A technology of bast fiber and process method, which is applied in the directions of fiber treatment, chemical post-treatment of fibers, textiles and papermaking, etc., can solve the problems of difficulty in large-scale promotion of biological degumming, low enzyme activity, and lack of ligninase. Satisfy safety and ease of operation, improved spinnability, and complete removal of pectin and lignin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] a. Prepreg treatment

[0048] The hemp husk is soaked in a sulfuric acid solution, the sulfuric acid concentration is 0.05% (o.w.f), the time is 0.1-2h, and the temperature is 20°C. After pretreatment, by extrusion, the liquid rate of hemp belt is controlled at 20%;

[0049] b. flash explosion

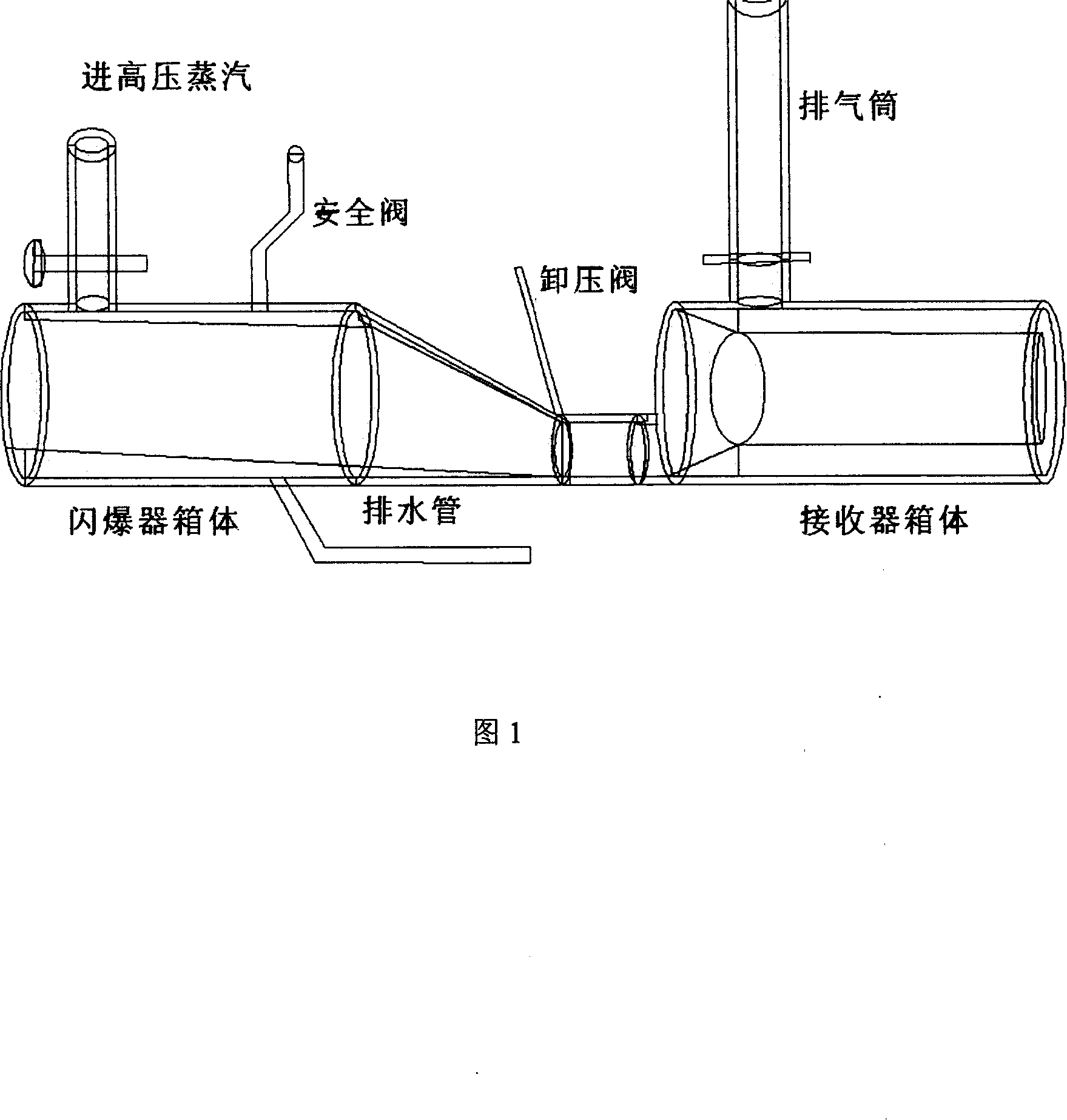

[0050] Put the above-mentioned pre-soaked hemp husk into a flash explosion device consisting of three parts: a steam generator, a flash explosion device and a receiver, pass in hot steam to pressurize to 0.5Mpa, and then keep the pressure in the flash explosion device box For 10 minutes, the momentary release of pressure through the relief valve exploded into the receiver box, partially degumming and splitting the fibers.

[0051] c. High temperature cooking

[0052] After the flash-exploded hemp husk is washed, it is steamed at high temperature to further remove impurities on the fiber. The high-temperature cooking treatment adopts the lye cooking method, the high-temperatu...

Embodiment 2

[0054] a. Prepreg treatment

[0055] Soak ramie hemp skin in sulfuric acid solution, the concentration of sulfuric acid is 0.2% (o.w.f), the time is 2h, and the temperature is 50°C. After the pretreatment, the liquid rate of the ramie belt is controlled at 100% by drying;

[0056] b. flash explosion

[0057] Put the above-mentioned pre-soaked ramie husks into a flash explosion device consisting of three parts: a steam generator, a flash explosion device and a receiver, pass in hot steam to pressurize to 2.0Mpa, and then maintain the pressure in the flash explosion device box 90 minutes, momentary release of pressure through the relief valve to blast into the receiver box, partially degumming and splitting the fibers.

[0058] c. High temperature cooking

[0059] After the flash-exploded hemp husk is washed, it is steamed at high temperature to further remove impurities on the fiber. The high-temperature cooking process adopts the lye cooking method, the high-temperature co...

Embodiment 3

[0061] a. Prepreg treatment

[0062] Soak the hemp husk in NaOH solution, the NaOH concentration is 0.1% (o.w.f), the time is 0.2h, and the temperature is 20°C. After pretreatment, by drying, the liquid rate of hemp belt is controlled at 50%;

[0063] b. flash explosion

[0064] Put the above-mentioned pre-soaked hemp husk into a flash explosion device consisting of three parts: a steam generator, a flash explosion device and a receiver, pressurize it to 2.0Mpa with hot steam, and then keep the pressure in the flash explosion device box 90 minutes, momentary release of pressure through the relief valve to blast into the receiver box, partially degumming and splitting the fibers.

[0065] c. High temperature cooking

[0066] After the flash-exploded hemp husk is washed, it is steamed at high temperature to further remove impurities on the fiber. The high-temperature cooking treatment adopts the lye cooking method, the high-temperature cooking temperature is 180°C, the treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com