Patents

Literature

250results about How to "Excellent water repellency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorine-free superhydrophobic finishing agent containing modified nano silicon dioxide hydrosol and application thereof

ActiveCN102021819AExcellent water repellencyBasic physical and mechanical propertiesSilicon compoundsVegetal fibresOrganic solventHYDROSOL

The invention relates to a fluorine-free superhydrophobic finishing agent containing modified nano silicon dioxide hydrosol and application thereof. The finishing agent is prepared by the following steps of: (1) mixing a precursor, an anionic surfactant and water and stirring violently at the temperature of between 20 and 50 DEG C; and (2) slowly adding ammonia water serving as a catalyst dropwise, stirring, adding long-chain alkylsiloxane serving as a modifier and stirring continually so as to obtain modified SiO2 hydrosol. The finishing agent has a stable property, avoids the pollution of an organic solvent and has high water repellency when used for performing superhydrophobic finishing on textiles.

Owner:DONGHUA UNIV +1

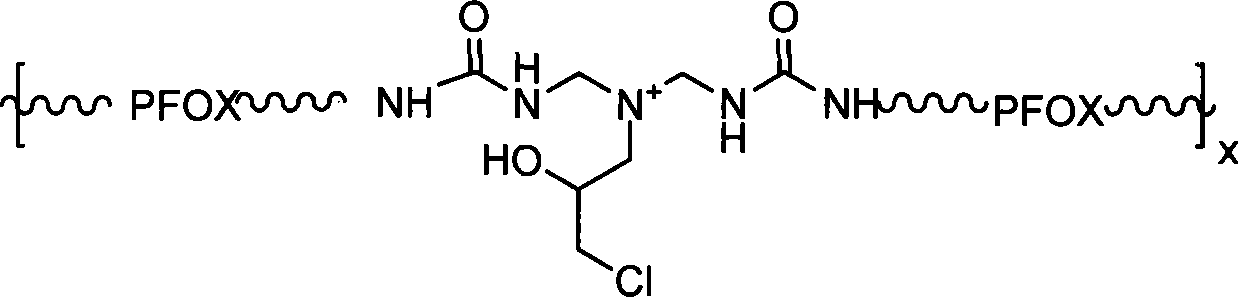

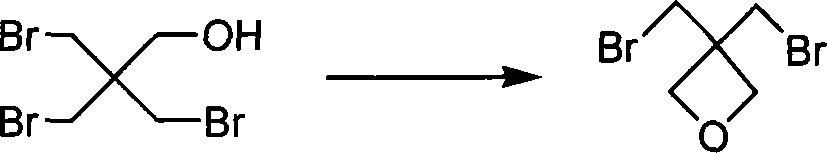

Fluorine-containing aqueous polyurethane and preparation method and application thereof

InactiveCN101041709AIncreased durabilityImprove waterproof performanceAntifouling/underwater paintsOther chemical processesGreen environmentFluorine containing

The invention discloses a making method and application of aqueous fluorine polyurethane, which contains cationic and anionic aqueous fluorine polyurethane with the making procedure comprises the following steps: (1) synthesizing bromoepoxybutane; (2) making fluoepoxybutane; (3) preparing fluorine polyether; (4) synthesizing aqueous polyurethane. The invention can be high-property green environment-protective water repellency, waterproof and stainproof paint, which possesses wide market prospect.

Owner:DONGHUA UNIV

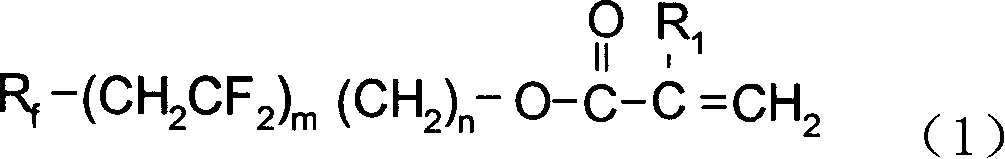

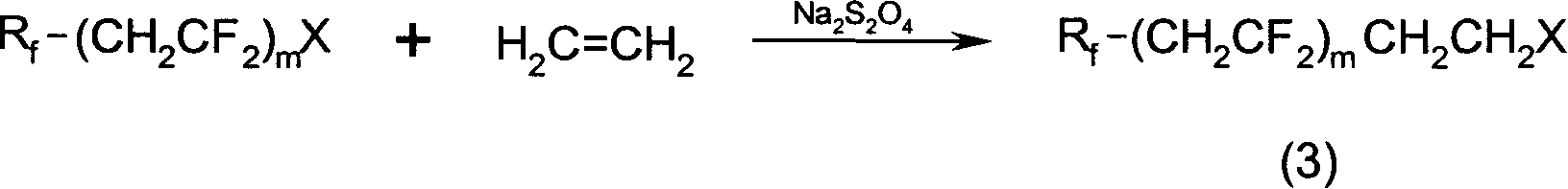

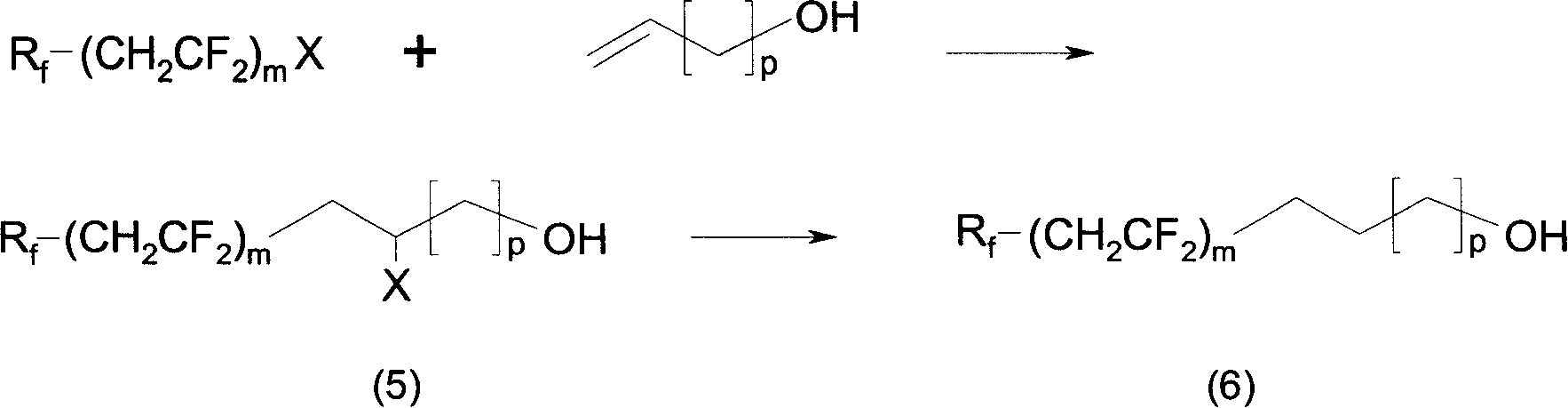

Fluorine-containing carbon chain acrylate, preparation method and application for copolymer thereof

InactiveCN1927894AExcellent water repellencyExcellent oil repellencyLiquid surface applicatorsFibre treatmentAlcoholCarbon chain

The present invention discloses the preparation process and application of fluorocarbon chain-containing acrylate and its copolymer. The preparation process of the fluorocarbon chain-containing acrylate includes the steps of: 1. synthesizing Rf(CH2CF2)mix; 2. synthesizing fluoric alcohol Rf-(CH2CF2)m(CH2)nOH; and 3. synthesizing fluorocarbon chain-containing acrylate. The present invention is used in surface water-repellent and oil-repellent treatment of fabric, metal, paper, glass, plastic, rubber, ceramic, etc. The present invention is one kind of high performance green water-repellent and oil-repellent agent with excellent water-repellent, oil-repellent and antifouling functions and degradability.

Owner:DONGHUA UNIV

Fluorine-free nano durable super hydrophobicity finishing method for cellulose fabric

InactiveCN101591853AEasy to prepareThe preparation method is safeVegetal fibresCelluloseOrganic acid

The invention relates to a fluorine-free nano durable super hydrophobicity finishing method for cellulose fabric, which comprises the following steps: (1) preparing hydrous medium solution containing tetra-alkyl ester silicate, polycarboxylic acid and a crosslinked catalyst, oscillating and stirring the hydrous medium solution to obtain SiO2 sol, soaking and rolling the cellulose fabric twice respectively, and curing the cellulose fabric; and (2) preparing non-aqueous solvent solution of alkyl siloxane catalyzed and hydrolyzed by using inorganic acid or organic acid water solution, soaking the cellulose fabric in the solution, and curing the cellulose fabric. The method is simple and safe, has low performance requirement on equipment, is easy for industrialization, and is particularly applicable to the hydrophobicity finishing of the cellulose fabric.

Owner:DONGHUA UNIV

Water-repellent, oil-repellent, sun-proof, anti-bend torsion and cold-resistant matt-leather-membrane aqueous coating adhesive for textiles and preparation method of matt-leather-membrane aqueous coating adhesive

ActiveCN104831540AAssociative functionCombined with styleFibre treatmentIsooctyl acrylatePolymer science

The invention relates to a water-repellent, oil-repellent, sun-proof, anti-bend torsion and cold-resistant matt-leather-membrane aqueous coating adhesive for textiles and a preparation method of the matt-leather-membrane aqueous coating adhesive. The preparation method comprises the steps of emulsifying isooctyl acrylate, isobornyl methacrylate, glycidyl methacrylate, trifluoroethyl methacrylate, vinyl trimethoxysilane, hydroxypropyl acrylate, fatty alcohol ethoxylate XL90 and dodecyl benzene sulfonate to trigger polymerization, and compounding a thickening agent, namely an associated polyurethane flatting rheological agent, a cross-linking agent, namely terminated isocyanate, a flatting agent, namely polymethyl urea resin and silicon dioxide with the particle size of 2-7 microns, so as to obtain the matt-leather-membrane aqueous coating adhesive.

Owner:DANDONG UNIK TEXTILE

Preparation method of waterproof moisture-permeable nanofiber composite membrane

InactiveCN110438659AImprove performanceSmall fiber diameterSilicaElectro-spinningWater vaporLiquid water

The invention relates to a preparation method of a waterproof moisture-permeable nanofiber composite membrane, and belongs to the technical field of textile materials. According to the preparation method, polyacrylonitrile is taken as a main raw material, polyvinylidene fluoride and polyurethane are added, the waterproof and moisture-permeable nanofiber composite membrane is prepared, and the waterproof and moisture-permeable membrane prepared from polyacrylonitrile nanofibers has the characteristics of high porosity, fine fiber diameter and small pore diameter. The waterproof and moisture-permeable effect of the fiber membrane is effectively improved, the hydrophobic microporous membrane is preliminarily obtained by blending polyacrylonitrile, polyvinylidene fluoride and polyurethane through a solution, the waterproof moisture-permeable membrane with a certain welding structure is obtained in combination with heat treatment, penetration of liquid water is effectively prevented, polyurethane is a block polymer, polar groups such as hydrophilic groups which exist on a macromolecular chain segment provide a carrier for water vapor transfer, meanwhile, the polyurethane has a certain hydrophobic property by the hydrophobic group on the chain segment, and by addition of the polyurethane, the nanofiber composite membrane has excellent comprehensive performance.

Owner:欧名龙

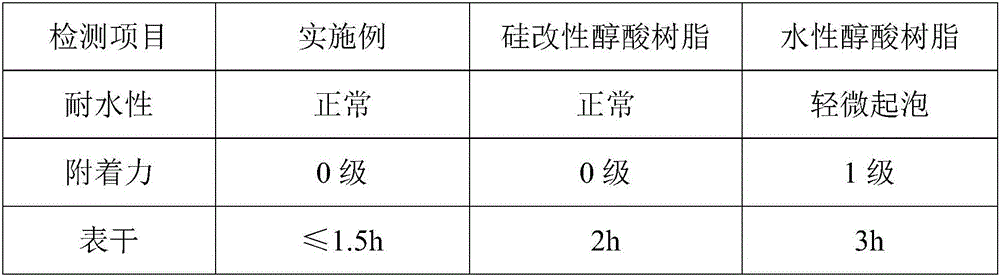

Fluorine-silicon modified waterborne alkyd resin and preparing method thereof

ActiveCN106117449AWith shielding protectionImprove thermal stabilityAntifouling/underwater paintsPaints with biocidesAcid anhydride formationStain

The invention relates to a fluorine-silicon modified waterborne alkyd resin and a preparing method thereof. The fluorine-silicon modified waterborne alkyd resin is prepared from vegetable oil fatty acid, organic acid anhydride, polyol, fluorinated allyl monomers, isocyanate, hydroxyl-terminated organic silicon, acrylic monomers and deionized water. Single-component waterborne paint, double-component waterborne paint and room-temperature curing paint can be blended with the fluorine-silicon modified waterborne alkyd resin prepared through the method. The prepared fluorine-silicon modified waterborne alkyd resin has the performance such as high adhesion, stain resistance, high hardness, water resistance, durability, hydrophobicity and self-cleaning performance, and can be widely applied to waterborne wood paint, waterborne industrial paint, waterborne anti-fouling paint, waterborne corrosion resistance paint, waterborne special engineering paint such as radar dome materials, wind power generation, nuclear power and vessel paint and the like.

Owner:湖南大禹防水建材科技有限公司

Method for preparing nylon-PEDOT (poly(3,4-ethylenedioxythiophene)) compound conductive fabric through in-situ polymerization

InactiveCN102808327AImprove conductivityLow costFibre typesIn situ polymerizationReaction temperature

The invention relates to a method for preparing nylon-PEDOT (poly(3,4-ethylenedioxythiophene)) compound conductive fabric through in-situ polymerization. The method comprises the following steps of: 1) pretreating a nylon fabric by using acidic solution, and padding the nylon fabric for times, wherein the dipping time is 5-15 minutes and the padding residual rate is 60-90 percent; and 2) dipping the nylon fabric in mixed solution containing ferric chloride, sodium polystyrenesulfonate and 3, 4-ethylenedioxythiophene (EDOT), keeping reaction temperature to be 30-90DEG C, keeping reaction time to be 1-20h, and after reaction is ended, taking out, washing and drying the fabric to obtain the nylon-PEDOT compound conductive fabric. By adopting the method, in combination with a padding technology which is commonly used for dyeing and finishing, the PEDOT can be enabled to rapidly enter the internal part of nylon fibers, the reaction time is shortened and the environmental pollution is small; and the nylon-PEDOT compound conductive fabric can be applied to the fields of textile chemical sensing and biological remediation materials, electromagnetic shielding materials and the like.

Owner:DONGHUA UNIV

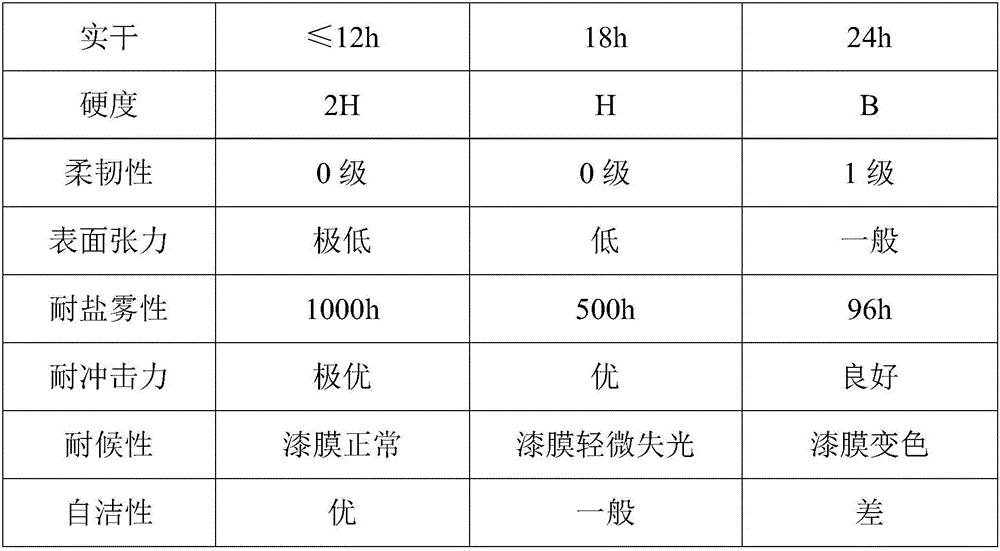

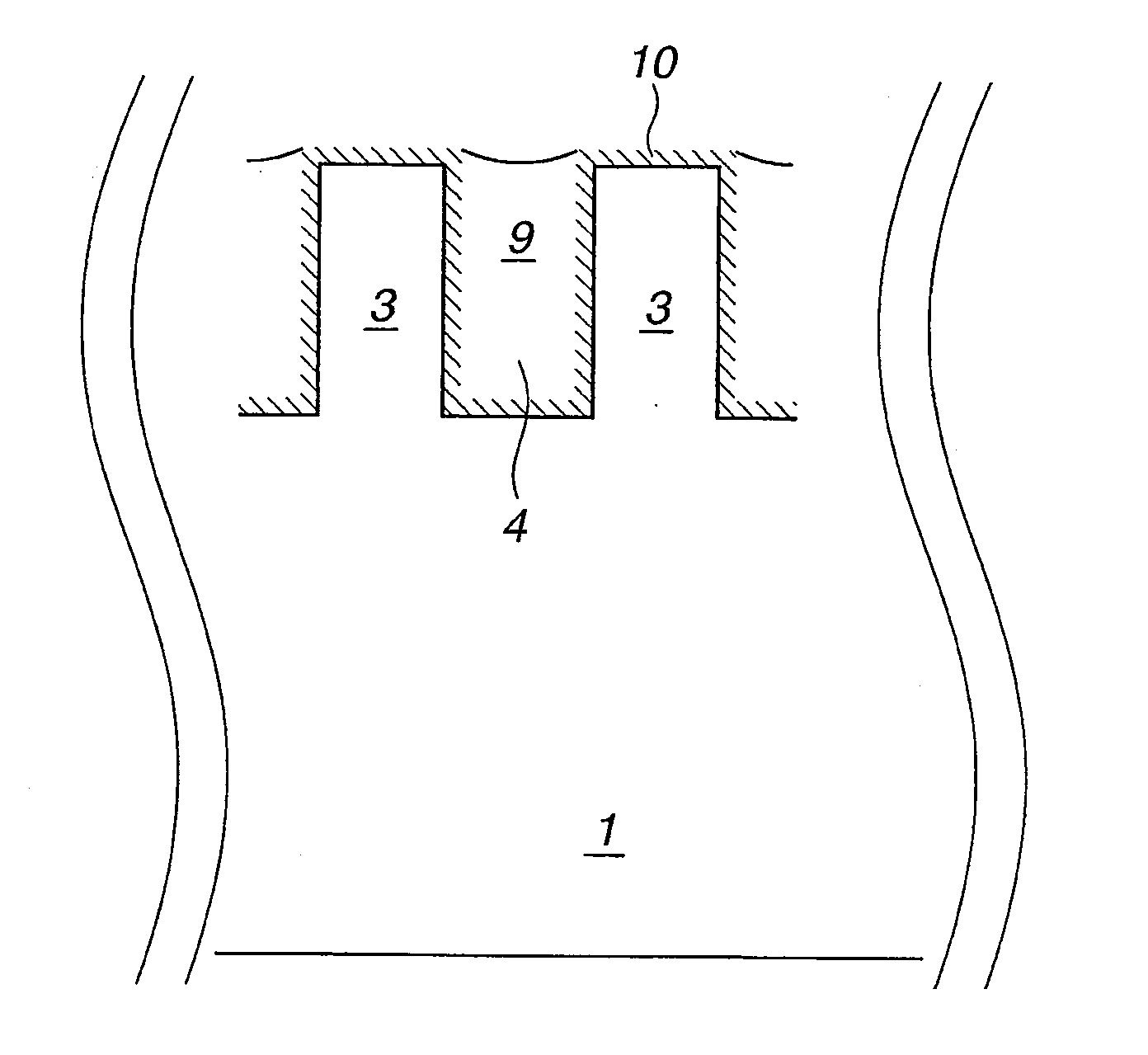

Chemical for Forming Protective Film

ActiveUS20130056023A1Excellent water-repellencyReduce wettabilityOther chemical processesSemiconductor/solid-state device manufacturingChemistryCompound (substance)

Disclosed is a liquid chemical for forming a water repellent protective film on a wafer that has at its surface a finely uneven pattern and contains silicon element at least at a part of the uneven pattern, the water repellent protective film being formed at least on surfaces of recessed portions of the uneven pattern at the time of cleaning the wafer. The liquid chemical contains: a silicon compound (A) represented by the general formula R1aSi(H)b(X)4−a−b and an acid; or a silicon compound (C) represented by the general formula R7gSi(H)h(CH3)w(Z)4−g−h−w and a base that contains no more than 35 mass % of water. The total amount of water in the liquid chemical is no greater than 1000 mass ppm relative to the total amount of the liquid chemical. The liquid chemical can improve a cleaning step that easily induces pattern collapse.

Owner:CENT GLASS CO LTD

Glass fibre reinforced plastic and anti-fouling corrosion resistant protecting agent for surface of high molecular products thereof

InactiveCN101338039AExcellent water repellencyExcellent weather resistance and durabilityCoatingsIonCorrosion resistant

The invention relates to a surface antifouling corrosion-resistant protectant for glass fiber reinforced plastic and other polymer products. The surface antifouling corrosion resistant protectant for glass fiber reinforced plastic and other polymer products, which is provided by the invention, is composed of fluoro-alkyl silane, long-chain alkyl silane, nanometer SiO2, alkyl silicate, alcohol, inorganic acid catalysts and de-ionized water or distilled water. The surface antifouling corrosion resistant protectant for glass fiber reinforced plastic and other polymer products, which is provided by the invention, can form a layer of low surface water-repellent, oil-proof, antifouling, anti-sticking, anti-ultraviolet and corrosion-resistant coat film on the surfaces of the glass fiber reinforced plastic and the other polymer products, the water contact angle can reach as high as 149 DEG, the purposes of effective reduction of rain accumulation as well as the attachment of atmospheric dust, guano, etc. on the surfaces of the glass fiber reinforced plastic and the other polymer products, acid rain corrosion damage resistance, salt mist corrosion damage resistance, ultraviolet corrosion damage resistance and reduction of use and maintenance cost are achieved.

Owner:SHANGHAI NALE MATERIAL TECH

Photo-curing-based water and oil repellent finishing method for fabric

InactiveCN103526552AImprove water repellencyImprove the effect of oil repellent finishingFibre typesOrganic chemistryFluorine containing

The invention discloses a photo-curing-based water and oil repellent finishing method for a fabric, belonging to the technical field of fabric finishing, and aiming to overcome the shortcomings of high baking temperature, high production energy consumption and low processing efficiency in conventional after-finishing and achieve the water and oil repellent functional finishing of the fabric under a photo-curing condition. A process specifically comprises the following steps of (1) synthesizing a fluorine-containing urethane acrylate prepolymer, namely carrying out reaction on isocyanate and hydroxyethyl acrylate and carrying out reaction on a reaction product and a fluorine-containing polyether type diol long chain to obtain the prepolymer, or carrying out reaction on isocyanate and fluorine-containing polyether type diol and then adding the hydroxyethyl acrylate into a system; and (2) preparing a photo-curable resin system from the prepolymer, a reactive diluent, a photoinitiator, a solvent and the like, coating and rolling-compacting the photo-curable resin system on the surface of the fabric, and irradiating the fabric for a certain time by using ultraviolet light to finish curing of a resin with water and oil repellent effects on the surface of the fabric. According to the method, the water and oil repellent performance of the finished fabric is improved, and the strength of the fabric is slightly weakened; compared with a conventional thermal-baking-based chemical finishing method, the photo-curing-based water and oil repellent finishing method for the fabric has the advantages that the process flow is short, the energy consumption is low and the efficiency is high.

Owner:JIANGNAN UNIV

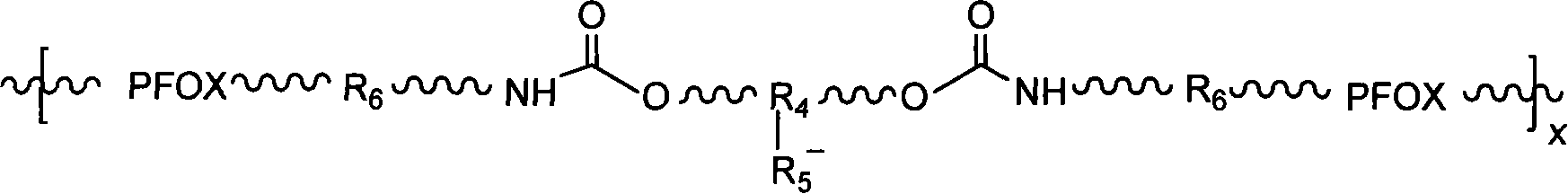

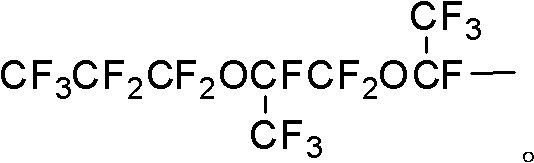

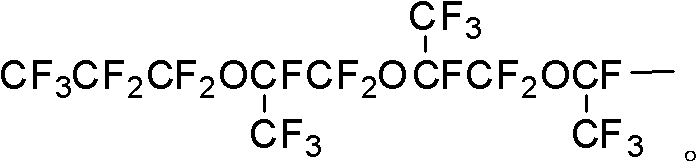

Fluorine-containing polyether acrylate polymer and preparation method thereof

InactiveCN102504136AGood water repellencyGood weather resistanceVegetal fibresFunctional monomerEmulsion

The invention relates to a fluorine-containing polyether acrylate polymer and a preparation method thereof. The structural formula of the polymer is shown in the specifications. The preparation method comprises the following steps of: (1) dissolving an emulsifier into a solvent, and stirring at the temperature of 20-200 DEG C for 2-24 hours to obtain an emulsion; (2) dropwise adding a functional monomer and fluorine-containing polyether acrylate into the emulsion respectively, stirring at the temperature of 20-200 DEG C for 2-24 hours, and performing ultrasonic treatment for 2-24 hours to obtain a pre-emulsion; and (3) under the protection of N2, heating to 20-200 DEG C, dropwise adding an initiator into the pre-emulsion, and reflowing for 2-24 hours. The fluorine-containing polyether acrylate polymer has the advantages of easiness for biodegrading, low environmental pollution and simple preparation method; and perfluoropolyether is adopted instead of long chain perfluoralkane, so that the defects of non-biodegradability of long chain perfluoralkane and harm of perfluoroctane sulphonated substance serving as a raw material of long chain perfluoralkane to human beings are overcome.

Owner:DONGHUA UNIV

Preparation method of water-repellent hybrid fluorine-containing resin coating

The invention discloses a preparation method of a water-repellent hybrid fluorine-containing resin coating. The preparation method comprises the following steps: first, under the action of an initiator, carrying out solution copolymerization on perfluoroalkyl acrylate, other acrylates, styrene and a reactive styrene epoxy compound to synthesize an epoxy fluorostyrene-acrylic resin intermediate; second, carrying out hydrolytic polycondensation on aminoalkyl trialkoxy silane in an alcohol solution to prepare an aminoalkyl silsesquioxane oligomer in a topological structure; and third, hybridizing and cross-linking the epoxy fluorostyrene-acrylic resin by the aminoalkyl silsesquioxane oligomer, co-mixing with a nano-paint to prepare a coating; and leveling, surface-drying, roasting and curing to obtain the resin coating with a good water-repellent effect.

Owner:德施普(辽宁)新材料技术有限公司

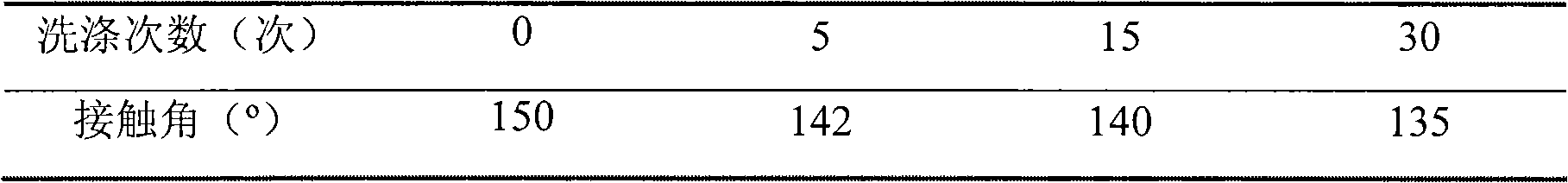

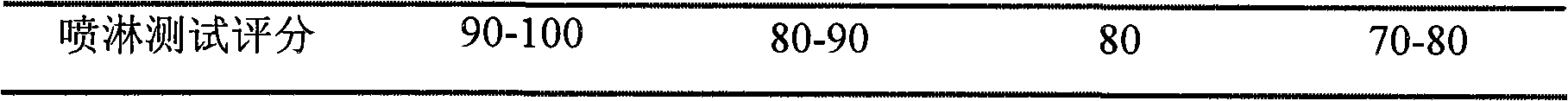

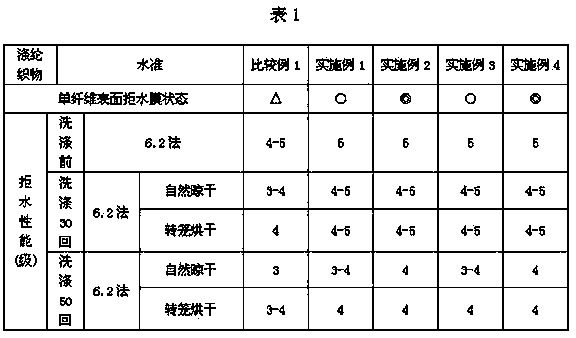

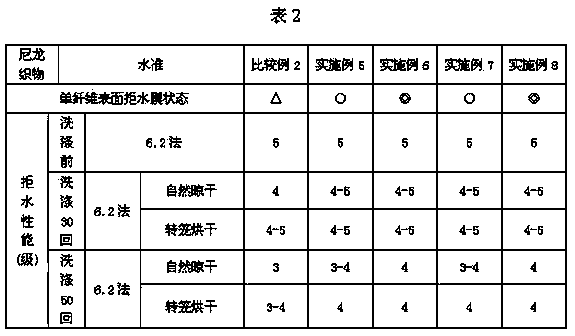

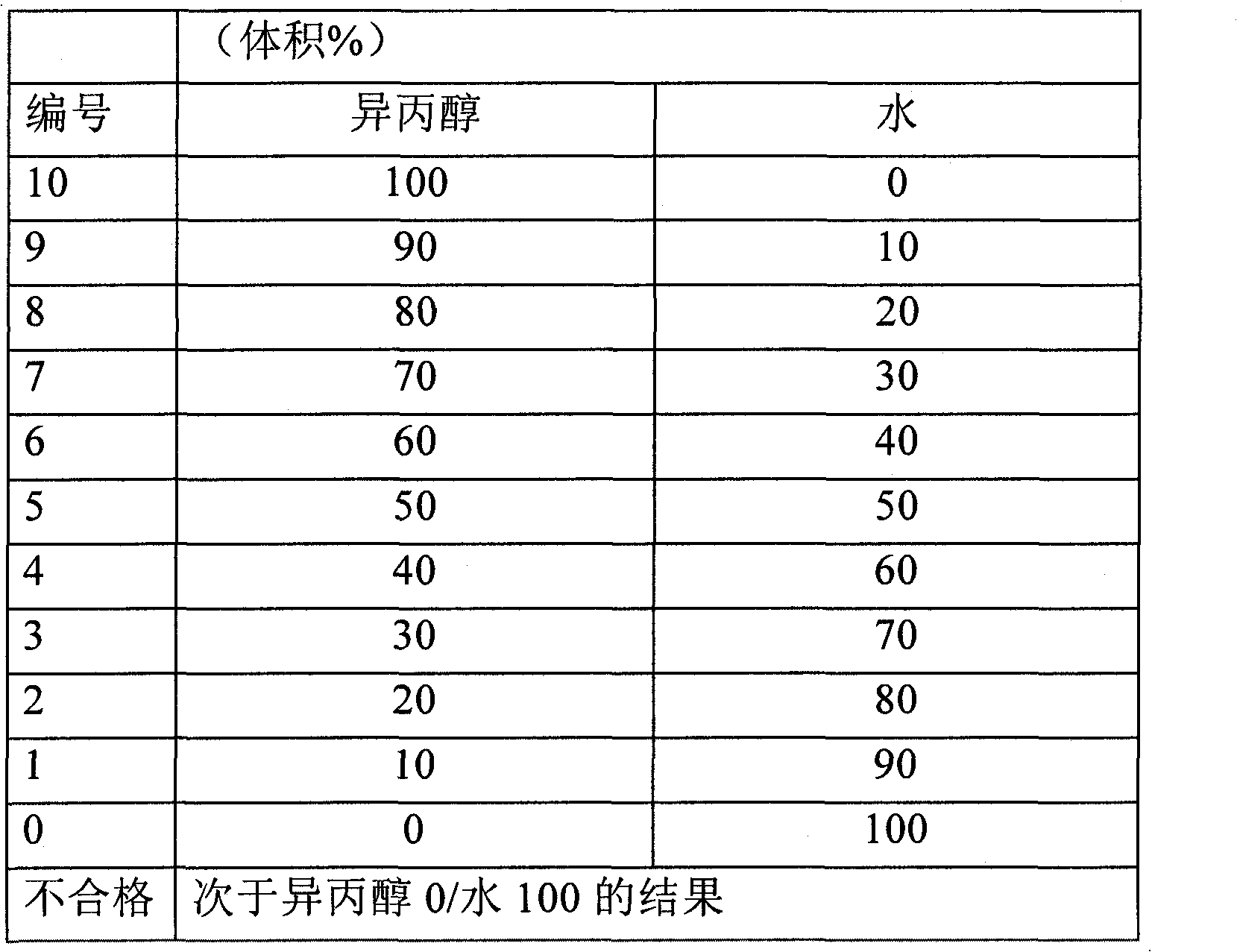

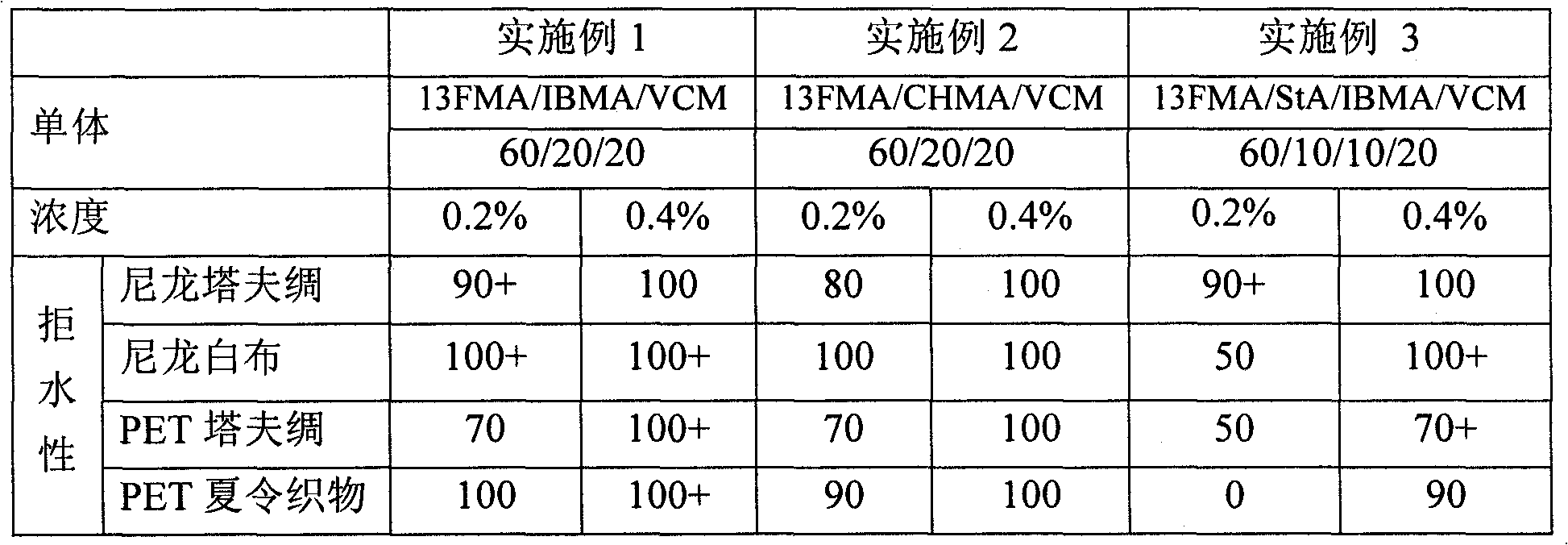

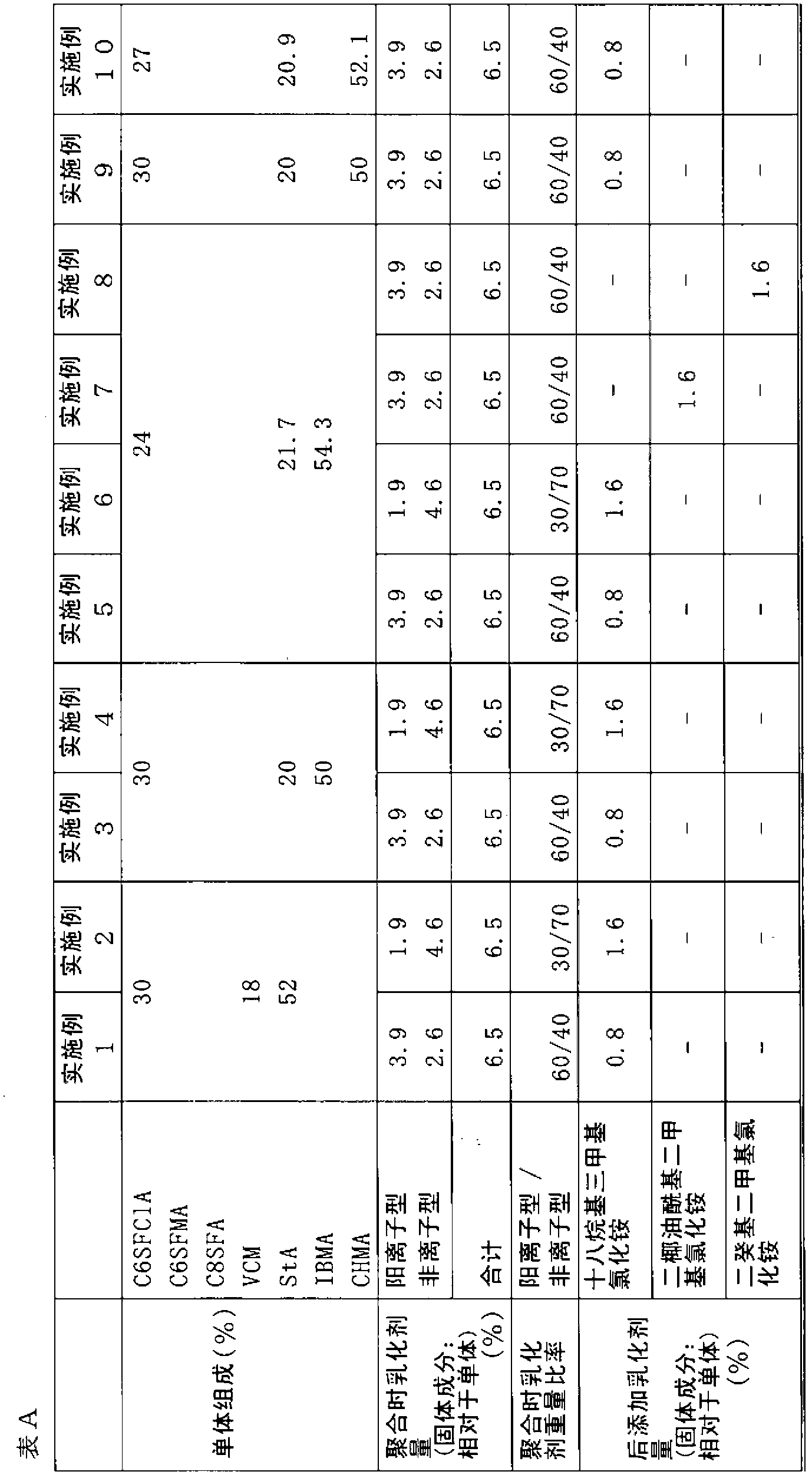

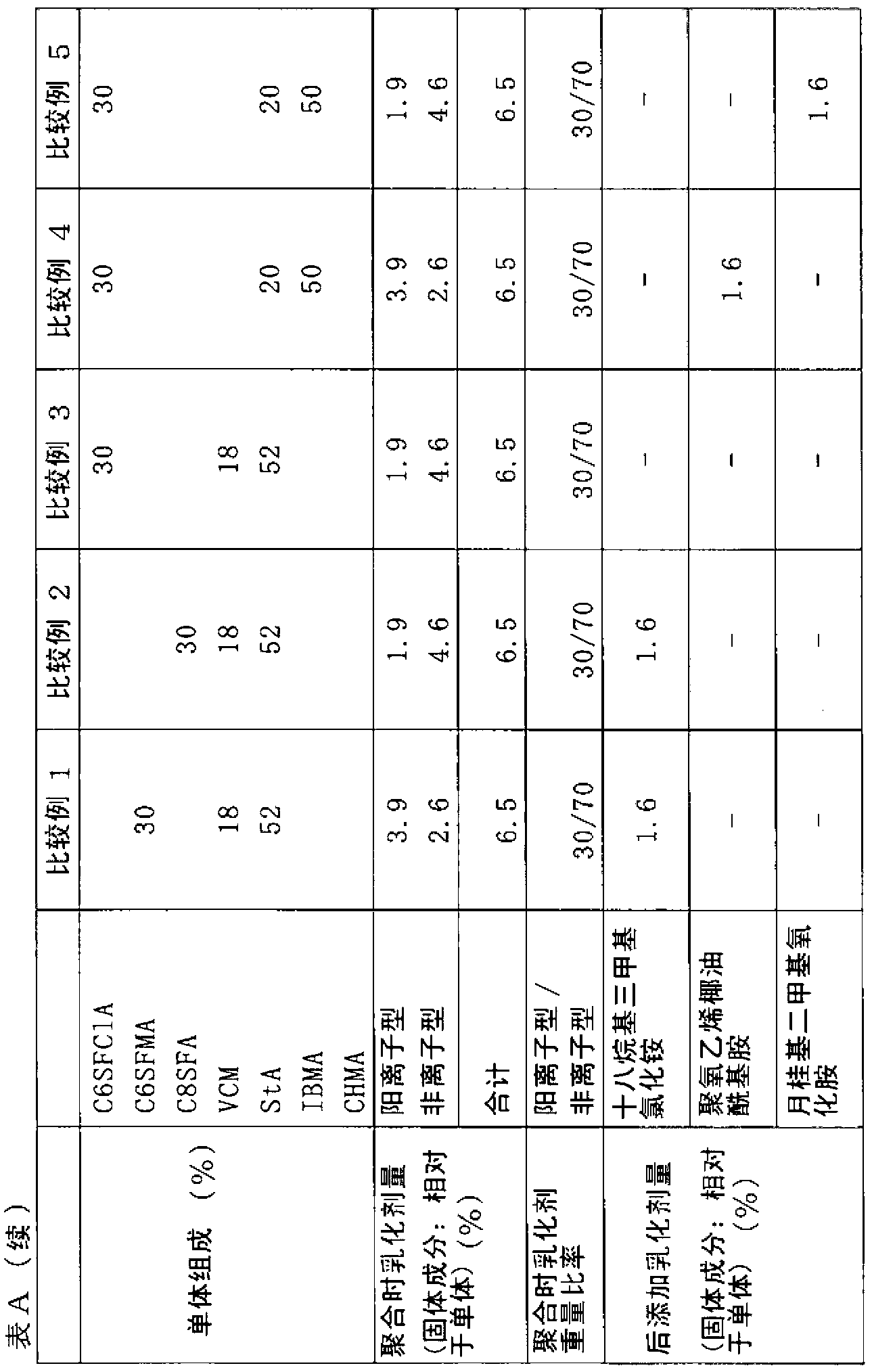

Textile subjected to water repellency treatment and production method for textile

The invention discloses a textile subjected to water repellency treatment and a production method for the textile. The textile mainly comprises cationic dye-dyeable modified polyester fibers and / or nylon fibers; the single fiber surface of the textile is at least covered with a resin film formed by water-repellent C6 fluororesin and water-repellent non-fluororesin; the surfaces of the cationic dye-dyeable modified polyester fibers and / or nylon fibers have anionic groups. The textile has durable washability and high water repellency.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

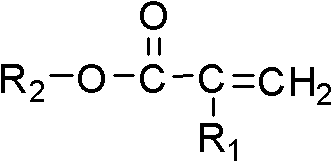

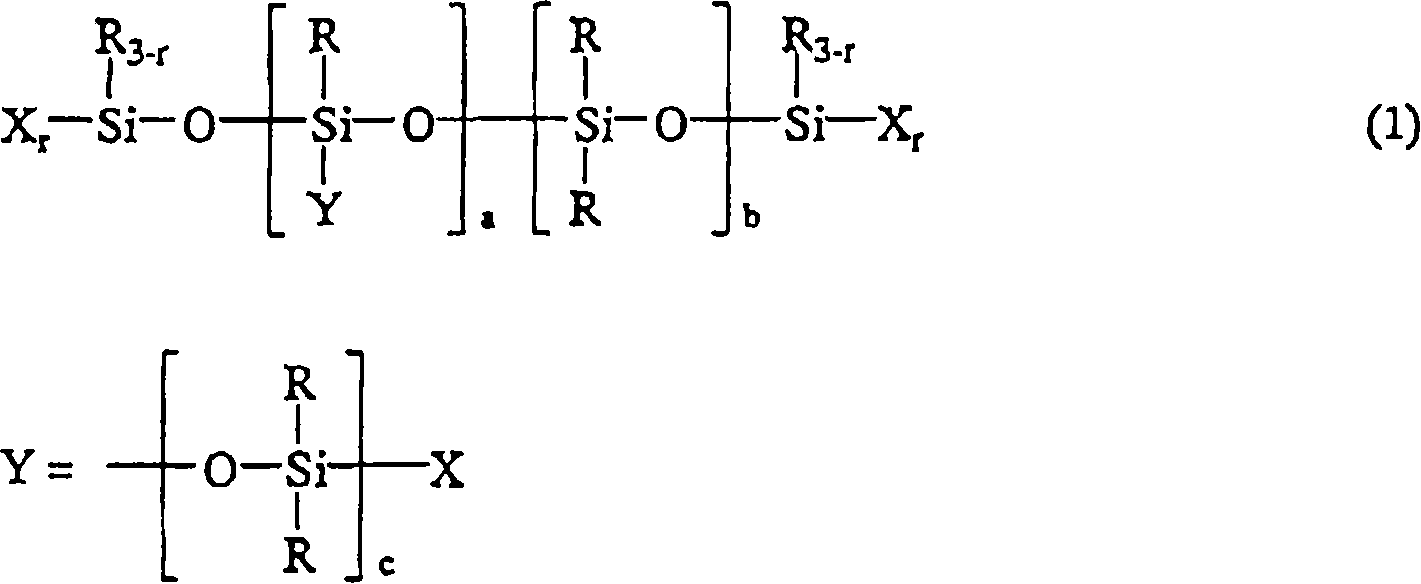

Water- and oil-repellent composition

ActiveCN102149738AExcellent water repellencyImprove antifouling performanceWater-repelling agents additionLiquid repellent fibresHalogenHydrogen atom

A fluorine-containing polymer comprising repeating units derived from: (A) a fluorine-containing monomer represented by the general formula: CH2=C(-X)-C(=O)-Y-Z-Rf wherein X is a hydrogen atom, a monovalent organic group or a halogen atom, Y is -O- or -NH-; Z is a direct bond or a divalent organic group; Rf is a fluoroalkyl group having 1 to 20 carbon atoms; and (B) a (meth)acrylate monomer having a cyclic hydrocarbon group provides a water- and oil-repellent agent which imparts excellent water repellency, oil repellency and stain-proofing properties to a substrate.

Owner:DAIKIN IND LTD

Polyurethane-compounded cement-based expanded-perlite heat preservation plate and preparing method thereof

InactiveCN106116328AIncrease productivityGood dimensional stabilityCeramicwarePolyurethane adhesiveWeather resistance

The invention discloses a polyurethane-compounded cement-based expanded-perlite heat preservation plate and a preparing method thereof. The polyurethane composite cement-based expanded-perlite heat preservation plate is prepared from 50-100 parts of expanded perlite, 40-90 parts of cement, 5-10 parts of two-component polyurethane adhesive, 0.1-0.5 part of coupling agent, 0.1-0.25 part of fiber, 0.1-0.5 part of reusable dispersion emulsion powder, 40-90 parts of water, 0.5-2 parts of early strength agent and 0.1-0.5 part of water reducing agent. According to the polyurethane-compounded cement-based expanded-perlite heat preservation plate and the preparing method thereof, cement mortar is modified through polyurethane, polyurethane resin and the cement are evenly dispersed into the expanded perlite, hydration of the cement and solidification of polyurethane are carried out at the same time, and the mutually-filled whole structure is formed; the expanded perlite and the polyurethane cement-based composite are combined, and the polyurethane composite cement-based expanded-perlite heat preservation plate is prepared in a compression-molding mode; the defects of the expanded perlite are effectively overcome, and meanwhile the advantages and the like of the water resistance and heat preservation performance of the polyurethane material, the low heat conductivity of the expanded perlite, the high weather resistance of concrete and the liker are used.

Owner:ANHUI MINGYUAN NEW BUILDING MATERIAL TECH CO LTD

Coating emulsion composition, and water/oil-repellent paper and making method

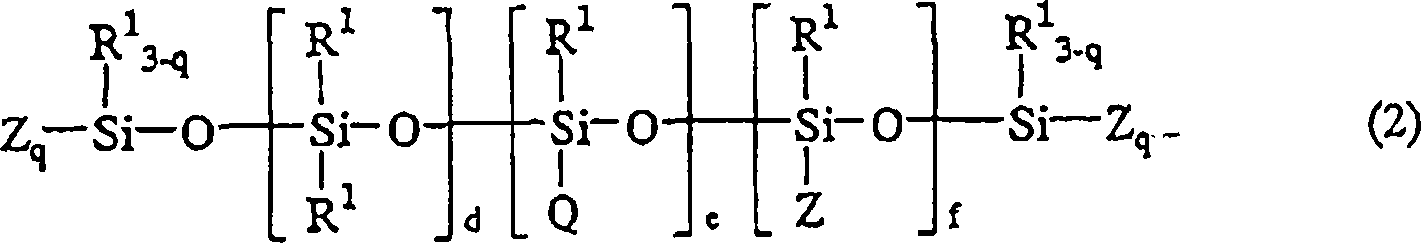

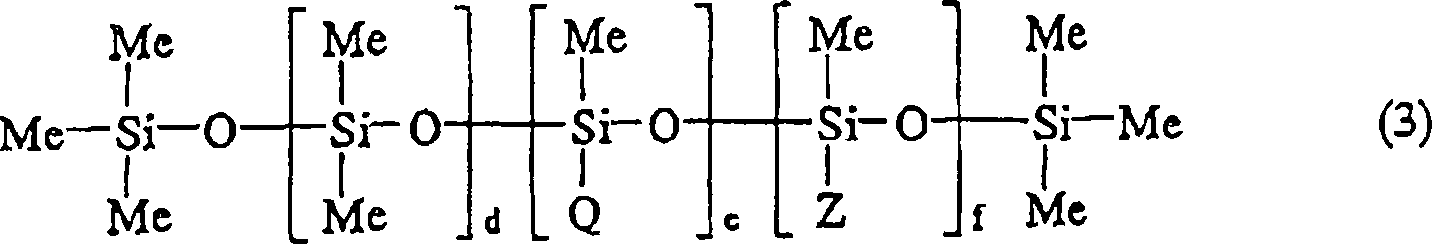

InactiveCN101195726ANo thickness differenceWater Repellent ImprovementWater-repelling agents additionCoatingsEmulsionAlkoxy group

The invention provides a paint latex composition, a water-resistance / oil-resistance paper sheet and a production method thereof. An organic polysiloxane comprising at least two silicon-bonded hydroxyl groups, the reaction product of an amino-containing organoalkoxysilanea dicarboxylic anhydride and an dicarboxylic acid ahhydride, an organic polysiloxane containing long-chain alkyl and alkoxy groups, but free of hydroxyl groups are emulsified and dispersed in water in the presence of a surfactant to form a coating emulsion composition.

Owner:SHIN ETSU CHEM IND CO LTD

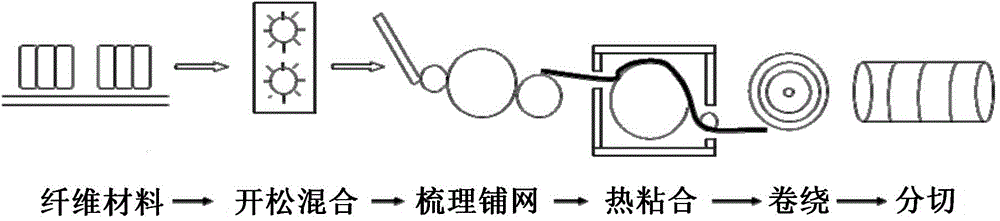

Production method for water-repellent non-woven fabric

InactiveCN104674456AFluffyExcellent water repellencyNon-woven fabricsBandagesEngineeringNonwoven fabric

The invention discloses a novel non-woven fabric and a production method thereof, particularly a production method for a water-repellent non-woven fabric, and the water-repellent non-woven fabric is mainly used as a surface material for personal hygiene care articles. The through-air nonwoven fabric is produced with fibers with water-repellent oil by the through-air method, and has good water-repellent property. The purpose of the design is to overcome the side leakage problem of conventional through-air nonwoven fabrics as the result of long penetration time or insufficient absorbing capacity, and moreover, the visual effect of thin and transparent side edges can be effectively improved. The production method is implemented by using hot air equipment to heat the sheath-core structure or eccentric core structure fibers with the water-repellent oil, and is a novel production method for through-air nonwoven fabrics.

Owner:北京大源非织造股份有限公司

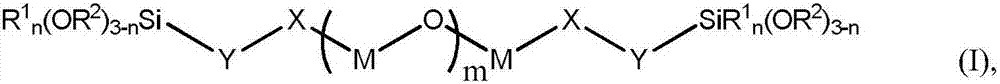

Elastomeric silicone emulsion for coating applications

ActiveCN107207899AGood flexibilityIncrease elasticityPolyether coatingsElastomerMoisture penetration

Emulsions of silicone terminated polyethers are used to modify paints and coatings over masonry, plaster, cellulous, and EIFS substrates to increase flexibility, water repellency, and elastomeric properties of the paints and coatings to protect the paint and coating substrates from cracking due to moisture penetration. The modified paints and coatings are also used as anti-graffiti paint.

Owner:WACKER CHEM GMBH

Preparation and application method for polyurethane modified acrylate water repellent

ActiveCN108978226AHigh bond strengthAvoid cold crispy hot stickyLiquid repellent fibresIsocyanateEmulsion

The invention discloses a preparation and application method for a polyurethane modified acrylate water repellent, and belongs to the technical field of macromolecules. According to the preparation and application method, an emulsion polymerization technology is adopted, diisocyanate, polymer dihydric alcohol and a hydrophilic chain extender are subjected to pre-polymerization and chain extension,an end-capping reagent is added for end-capping, then neutralization is carried out, water is added for emulsification, in the absence of an emulsifier, a product and an aliphatic acrylate monomer are subjected to copolymerization so as to prepare an anionic polyurethane modified acrylate composite emulsion, and the anionic polyurethane modified acrylate composite emulsion is used for textile finishing. The preparation and application method has the advantages that a long alkane chain endows fabric with the water repellent property, after the fabric is treated, a layer of water repellent filmis formed on the surface of the fabric, so that the water repellent capacity of the fabric is greatly improved, and polyurethane is added, the fabric can be endowed with the soft and full hand feeling; and in addition, the VOC emission amount is extremely low, and the method is suitable for environmental protection requirements.

Owner:高青如意纺织有限公司

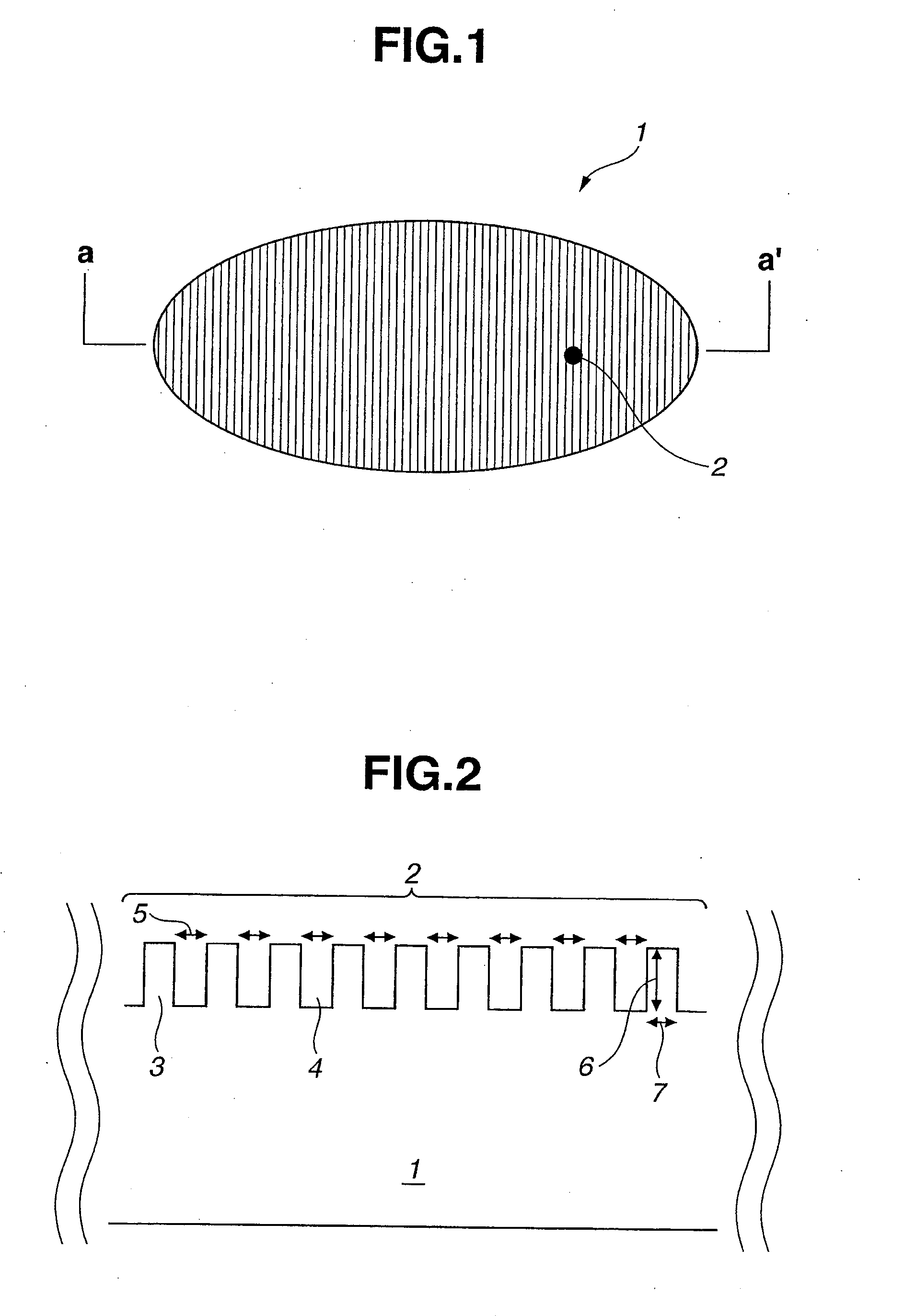

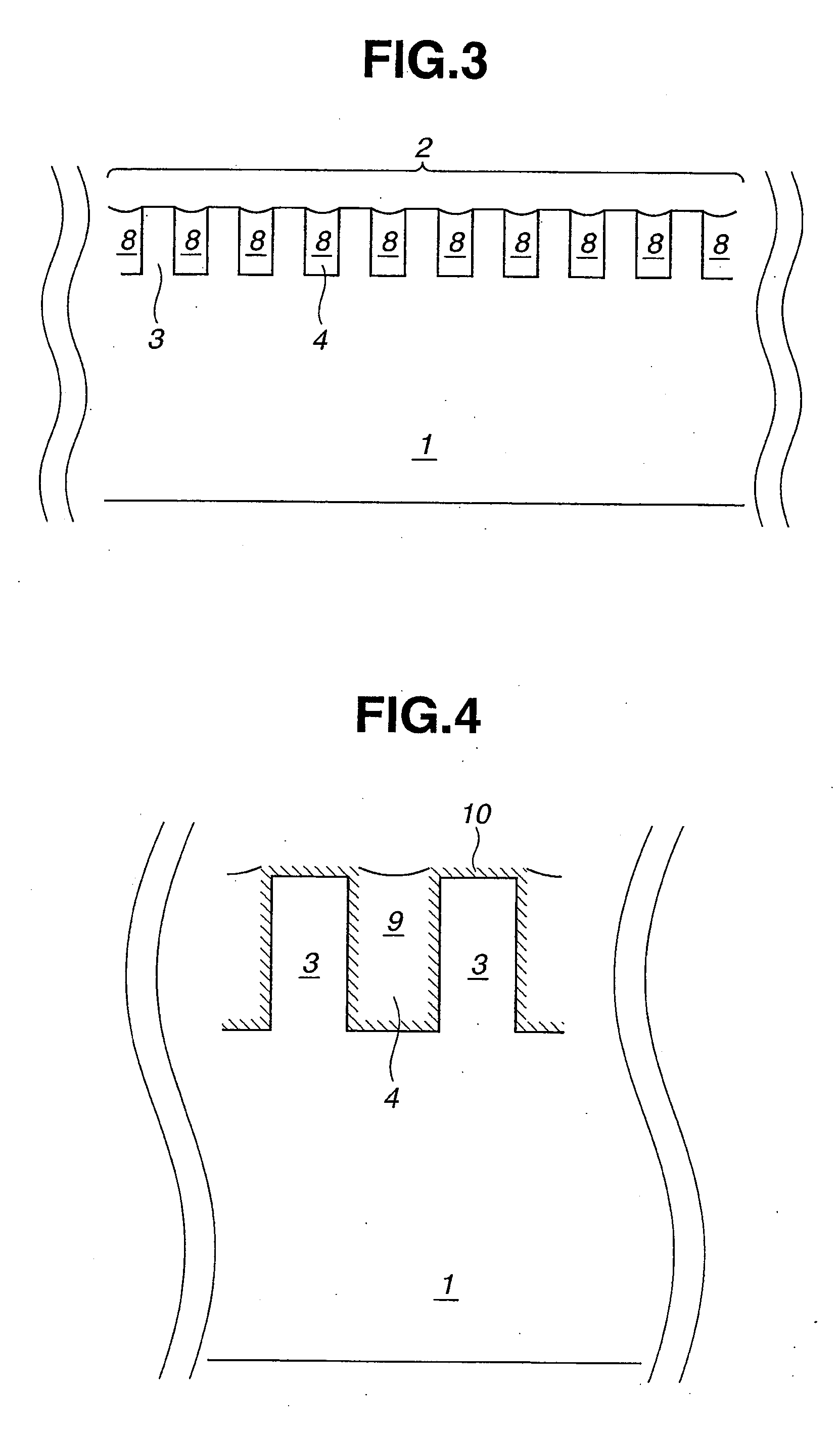

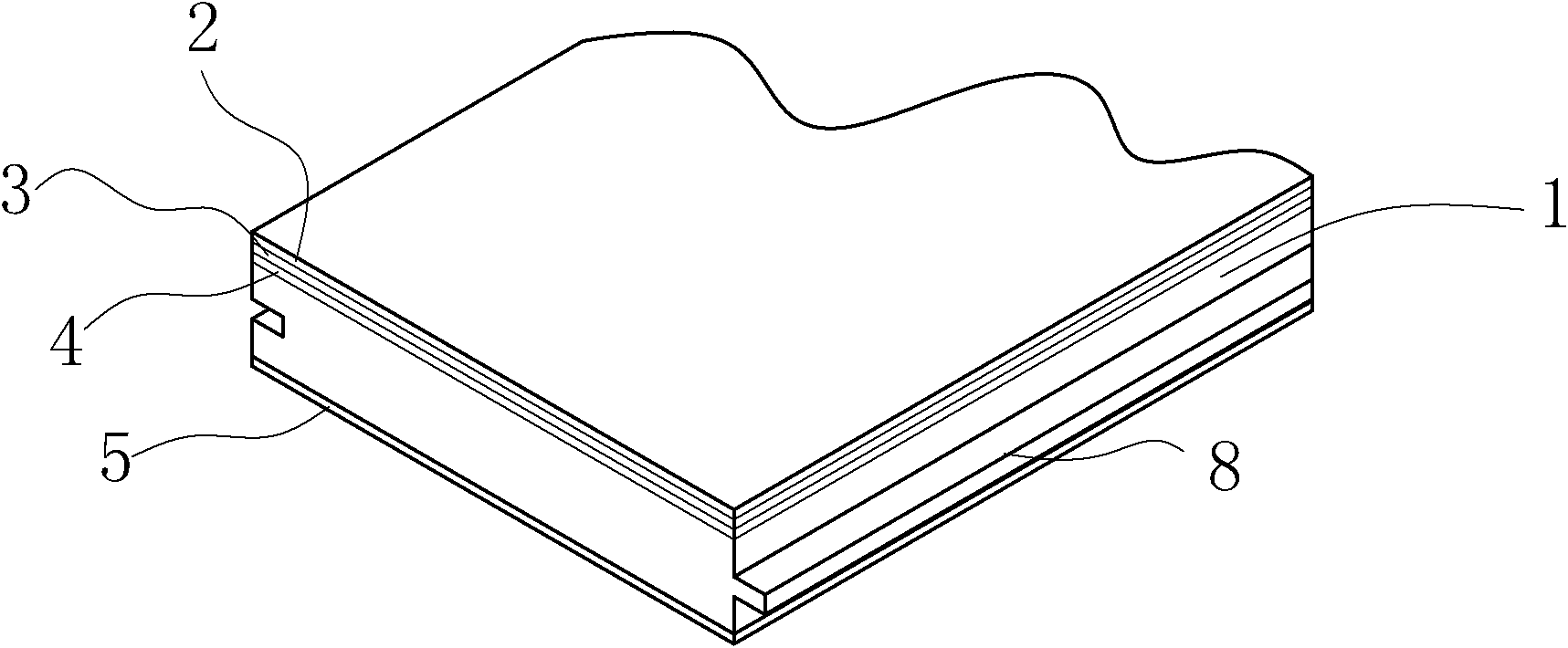

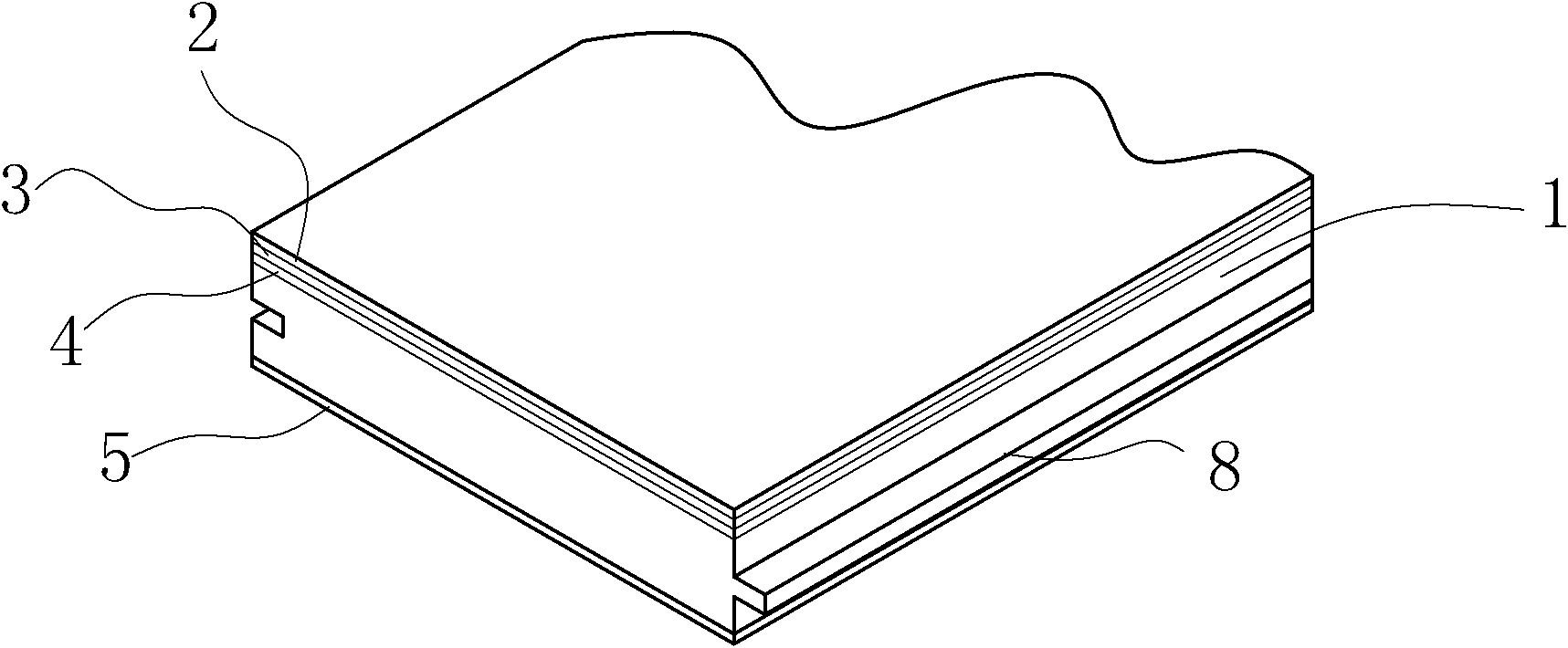

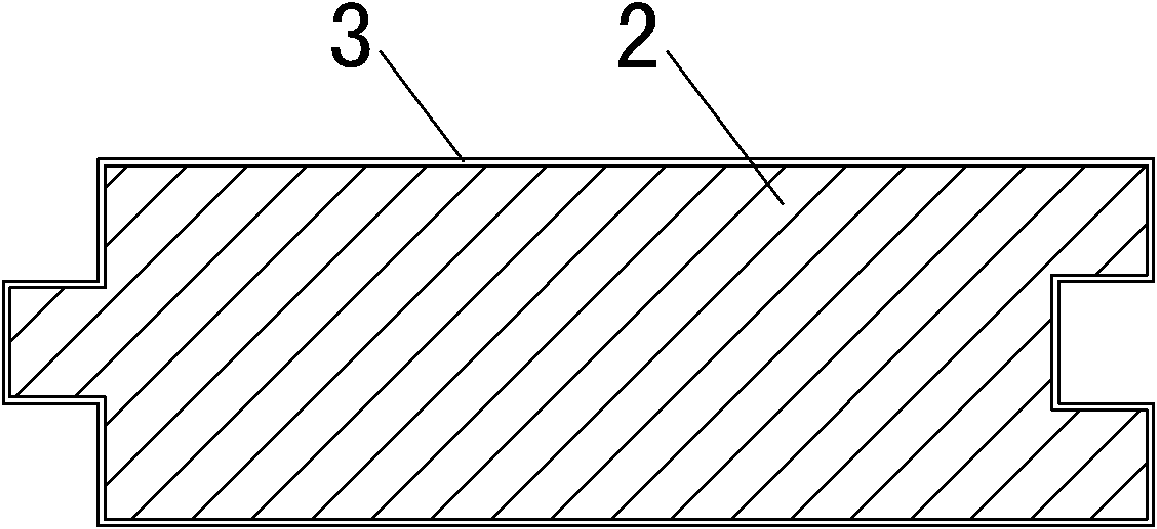

Anti-raise specialistic floor and production method thereof

The invention discloses an anti-raise specialistic floor and a production method thereof. The floor comprises a substrate (1), wherein a finish paint layer (2), a resin layer (3) and a primer layer (4) are sequentially laid above the substrate (1) from top to bottom; a back paint layer (5) is laid below the substrate (1); wood fiber conduits (6) of the substrate (1) are filled with resin (7); the substrate (1) is provided with a tongue-and-groove (8); and the surface of the tongue-and-groove (8) is laid with a wax layer (9). In the production process of the floor, a finished product is obtained through the production steps of: hacking, sanding, back paint coating, resin permeating, primer coating, resin retouching, finish paint coating, tongue-and-groove wax sealing, and the like. The product has excellent characteristics of preventing expansion, contraction and raising. The wood fiber conduits of various surfaces are effectively sealed, which can effectively prevent water from entering and draining to ensure that the floor per se has relatively stable internal environment so as to prevent the solid wood floor from raising, deforming and cracking.

Owner:ZHEJIANG JIAYE FLOORING CO LTD

Water-based lotus-leaf-structured hydrophobic over-printing varnish for wallpaper and preparation method of over-printing varnish

The invention specifically relates to water-based lotus-leaf-structured hydrophobic over-printing varnish for wallpaper and a preparation method of the over-printing varnish, and belongs to the technical field of ink. The technical problem to be solved is to provide an over-printing varnish by using which the surface of a wallpaper product can be smooth, bright and wear-proof and the lotus leaf type waterproof and moisture-roof effects can be realized, and a preparation method of the over-printing varnish. In order to solving the technical problem, the technical scheme adopted is as follows: the water-based lotus-leaf-structured hydrophobic over-printing varnish for the wallpaper is prepared from raw materials including a modified organic silicon polymer emulsion, a non-film-forming acrylate emulsion, an styrene-acrylic emulsion, neutralizing amine, propylene glycol, a water-based coalescing agent, a water-based leveling wetting agent, a mineral defoamer, a water-based nanoscale organosilicon waterproofing agent, a waterborne polyurethane thickening agent, deionized water and an organic silicon defoamer; the raw materials are stirred and mixed in a specific order to form the over-printing varnish.

Owner:山西金博雅油墨科技有限责任公司

Preparation and application of perfluoro-short-carbon-chain-containing water-repellent oil-repellent finishing agent

The invention relates to a preparation method of a perfluoro-short-carbon-chain-containing water-repellent oil-repellent finishing agent, which comprises the following steps: preparing N-propylperfluorohexylsulfamidoethylacrylate; dissolving fluorine-containing acrylic acid monomer, octadecyl acrylate and propylene-2-hydroxyethyl ester in a solvent to obtain a monomer mixed solution, adding half of emulsifier into the monomer mixed solution to carry out pre-emulsification, thereby obtaining a pre-emulsification monomer; carrying out pre-emulsification on water and the rest half of emulsifier, heating to 65-90 DEG C, adding half of initiator solution, adding half of pre-emulsification monomer after 4-5 minutes to react, adding the rest half of pre-emulsification monomer while slowly adding the rest of initiator, continuing the reaction for 4-8 hours after dropwise addition is finished, cooling to room temperature after the reaction is finished, and filtering to obtain the finishing agent. The finishing agent has high stability, and is free of restricted components which are harmful to the human body and environment; and the finished fabric has favorable water repellency, oil repellency and anti-fouling property.

Owner:DONGHUA UNIV

Urushiol organic silicon resin and preparing method thereof

The present invention discloses a urushiol organic silicon resin and a preparing method thereof. The urushiol organic silicon resin is prepared from the following raw materials of the percentages by weight: 20 to 30% of urushiol, 4 to 6% of aldehyde compound, 3 to 30% of organic silicon prepolymer, 0.5 to 1.5% of catalyst and 40 to 55% of diluent, based on the total weight of the raw materials. As an alternative, 5 to 20% of epoxy resin is added. The urushiol organic silicon resin has excellent properties on resisting heat, water, oxidation, cold, radiation, etc. The urushiol organic silicon resin can be broadly used in the fields of military affairs, aerospace, electronics, machinery, construction, chemical engineering, etc.

Owner:中华全国供销合作总社西安生漆涂料研究所

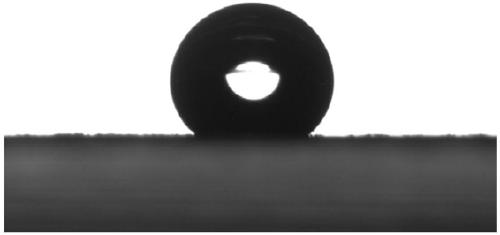

Fluoride-free and water-repellent fabric and fluoride-free and water-repellent finishing method of fabric

ActiveCN106592204AExcellent water repellencyLiquid repellent fibresVegetal fibresReduction treatmentRoom temperature

The invention provides fluoride-free and water-repellent fabric and a fluoride-free and water-repellent finishing method of the fabric and belongs to the technical field of after-finishing of textile products. The method comprises steps as follows: a sol solution A is prepared with a conventional method; graphene oxide with a single-layer structure is dispersed in water, and a solution B with the concentration of 0.1%-0.5% in percentage by mass is prepared; the solution B and the solution A in a volume ratio or a mass ratio being 1:10 are mixed, and a composite finishing solution is obtained; basic fabric is placed in the finishing solution C and is processed for 10-1000 min at the temperature in a range from room temperature to 90 DEG C, unnecessary solution is removed through rolling, and then the basic fabric is subjected to reduction treatment, washed with deionized water and prebaked for 3-30 min at the temperature of 50-90 DEG C; the basic fabric is post-baked for 10-100 min at the temperature of 95-130 DEG C. Based on the technological steps of the invention, the fluoride-free and water-repellent fabric with a surface contact angle being 110-152 degrees can be obtained.

Owner:JIANGXI CHANGSHUO OUTDOOR LEISURE PRODS

Preparation method for non-woven fabric for protective garment

InactiveCN109023923AExcellent water repellencyExcellent oil repellencyBiochemical fibre treatmentUltrasonic/sonic fibre treatmentChemistryGlycol methacrylate

The invention discloses a preparation method for a non-woven fabric for a protective garment. The preparation method comprises: cleaning and drying a polypropylene composite non-woven fabric, carryingout plasma treatment, placing the non-woven fabric in air to obtain a material A, uniformly mixing 10-hydroxy-cyclohexyl-phenyl ketone, a fluorine-containing acrylic resin, octadecyl methacrylate, glycidyl acrylate, borneol acrylate, fatty alcohol polyoxyethylene ether, ethylene glycol dimethacrylate and water to obtain a material B, adding the material A into the material B, carrying out ultraviolet light irradiation for a grafting reaction, carrying out washing and drying to obtain a material C, uniformly mixing p-aminobenzotrifluoride, n-octylamine, alkylaminoglucitol, 4-amino-1, 2, 4-triazole and dioxane, adding the material C into the mixture, carrying out a reaction process, carrying out washing and drying to obtain a material D, adding graphene oxide into water, adjusting pH to greater than 7, carrying out ultrasonic treatment, adding glucose into the reaction product for a reaction, mixing the product, hydroxylamine hydrochloride, allicin, a zinc complex, lentinan and a silk fibroin, adding the material D into the mixture, and carrying out padding and drying.

Owner:HEFEI JIENUO MEDICAL PROD CO LTD

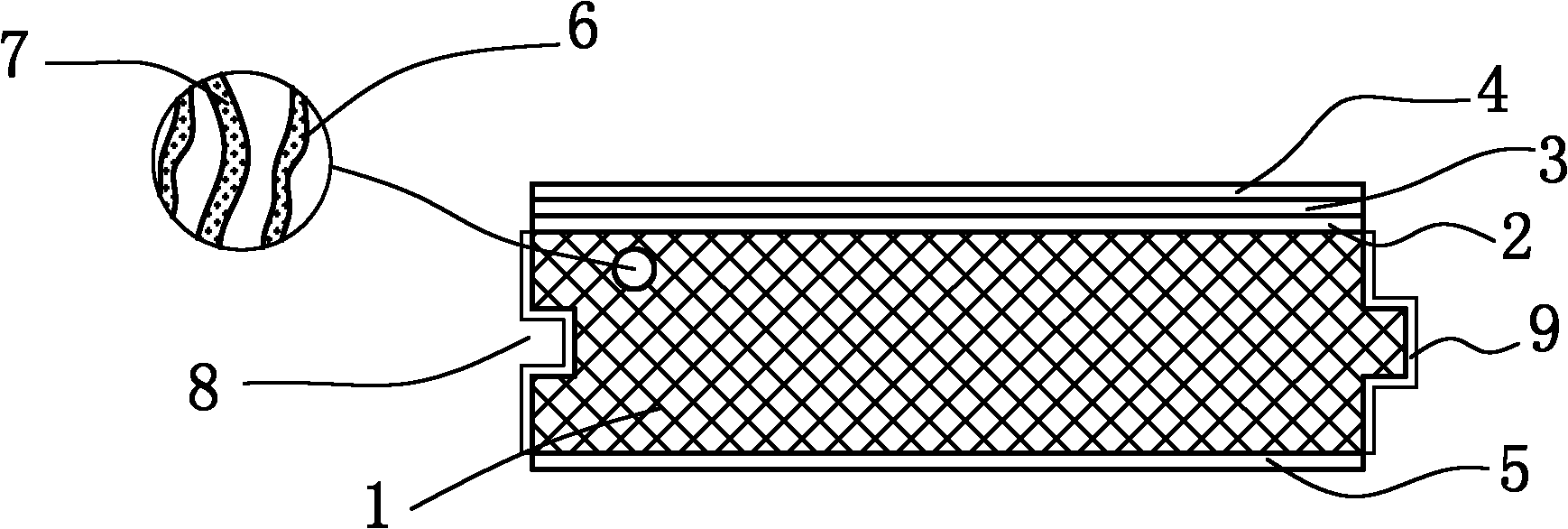

Waterproof wax-leakage environment-friendly wood floor and production method thereof

ActiveCN101581146ALong solution timeIncrease profitWood working apparatusFlooring insulationsFiberHazardous substance

The invention discloses a waterproof wax-leakage environment-friendly wood floor and a production method thereof. The wood floor (1) has two layers of structures from inside to outside, wherein the first layer is a base plate (2) and the second layer is a wax waterproof layer (3); and the inner part of the base plate (2) and fiber ducts of woods are filled with EM nano emulsifying wax. The production process of the wood floor comprises the following steps of: cracking of floor, dry processing, melting of wax, dipping, cooling, fine processing and the like, and then packaging and warehousing. The wood floor does not expands with heat and contracts with cold, meets the requirement of difference of areas with different latitudes of the world, has wide application range, and can be applied all over the word; in addition, the wood floor has very excellent water repellent property, water soaking resistance and water immersion resistance; as the paint coating procedure is removed from the production process, the invention saves paint cost and has good environmental protection property; and the wood floor does not contain any harmful substances of formaldehyde and the like, thus being a real raw type environment-friendly wood floor.

Owner:浙江方圆智能装配有限公司

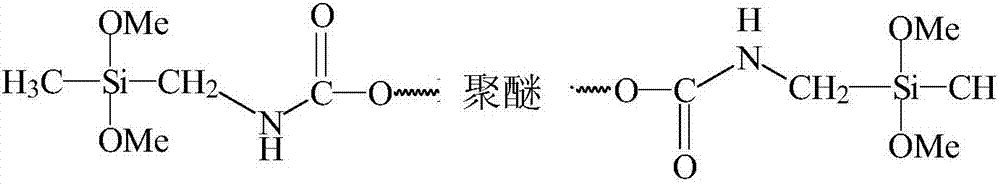

Production method of waterproof organosilicon modified solvent-free polyurethane synthetic leather

InactiveCN107268290AImprove controllabilityImprove waterproof performanceWaterborne vesselsTextiles and paperPolymer scienceIn situ polymerization

The invention discloses a production method of waterproof organosilicon modified solvent-free polyurethane synthetic leather. The production method comprises the following steps: firstly, adding a component A containing hydroxyl and a component B containing an isocyanate group into a reaction still, and reacting by stirring to obtain foaming slurry; secondly, adopting a dry process production line of the synthetic leather, blade coating the foaming slurry on release paper to form a coating, and then laminating the coating with a base fabric by a gap fitting mode through a laminating machine; thirdly, feeding a mixture into a drying oven for cooking to obtain the waterproof organosilicon modified solvent-free polyurethane synthetic leather. According to the production method disclosed by the invention, the waterproof organosilicon modified solvent-free polyurethane synthetic leather is produced by adopting a double foaming technology, a polyurethane in-situ polymerization waterproof technology, a heat-sensitive catalyst asynchronous catalysis technology and a single-pole constant temperature heating scrape coating technology; the production technology is environmentally friendly, simple, and stable; the quality of a product is good; a contact angle of water droplets on the surface of the synthetic leather is as high as 107 degrees, and static water seepage prevention can be kept for 15 days; the waterproof organosilicon modified solvent-free polyurethane synthetic leather can be used as a high-end functional yacht seat covering material.

Owner:SHAANXI UNIV OF SCI & TECH

Surface treating agent and manufacturing method thereof

InactiveCN103184690AImprove dispersion stabilityExcellent water repellencyLiquid repellent fibresCoatingsFiberFluorine containing

The utility model provides a surface treating agent. By using the surface treating agent, fiber substrate can have good waterproof performance. The surface treating agent includes (1) fluorine-containing polymer provided with (a) a repetitive unit sourced from a fluorine-containing monomer acting as Alpha-chlorin acrylate of perfluoroalkyl and (b) a repetitive unit sourced from a non-fluorine-containing monomer; and (2) cationic surfactant added after the polymerization of fluorine-containing polymer.

Owner:DAIKIN IND LTD

Energy saving fireproof paint and preparation method thereof

The invention provides energy saving fireproof paint and a preparation method thereof. The energy saving fireproof paint comprises the following components in parts by weight: 20-30 parts of a fire retardant, 7-12 parts of a carburization agent, 7-12 parts of a foaming agent, 9-15 parts of an inorganic hollow material, 10-22 parts of titanium dioxide, 31-43 parts of a cross-linking agent, 3-5 parts of an anti-aging agent, 2-5 parts of magnesium hydroxide, and 2-5 parts of diatomite. The energy saving fireproof paint has the advantages of solar heat reflection, heat insulation, water resistance, and corrosion resistance, and the advantages are identical to the advantages of energy saving paint; at the same time the energy saving fireproof paint has the advantages of self-extinguishing, flame retardation, formation of a compact heat insulating protective layer by expansion during fire hazard, and the like, and the advantages are identical to the advantages of fireproof paint.

Owner:广州市环康机电工程安装有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com