Patents

Literature

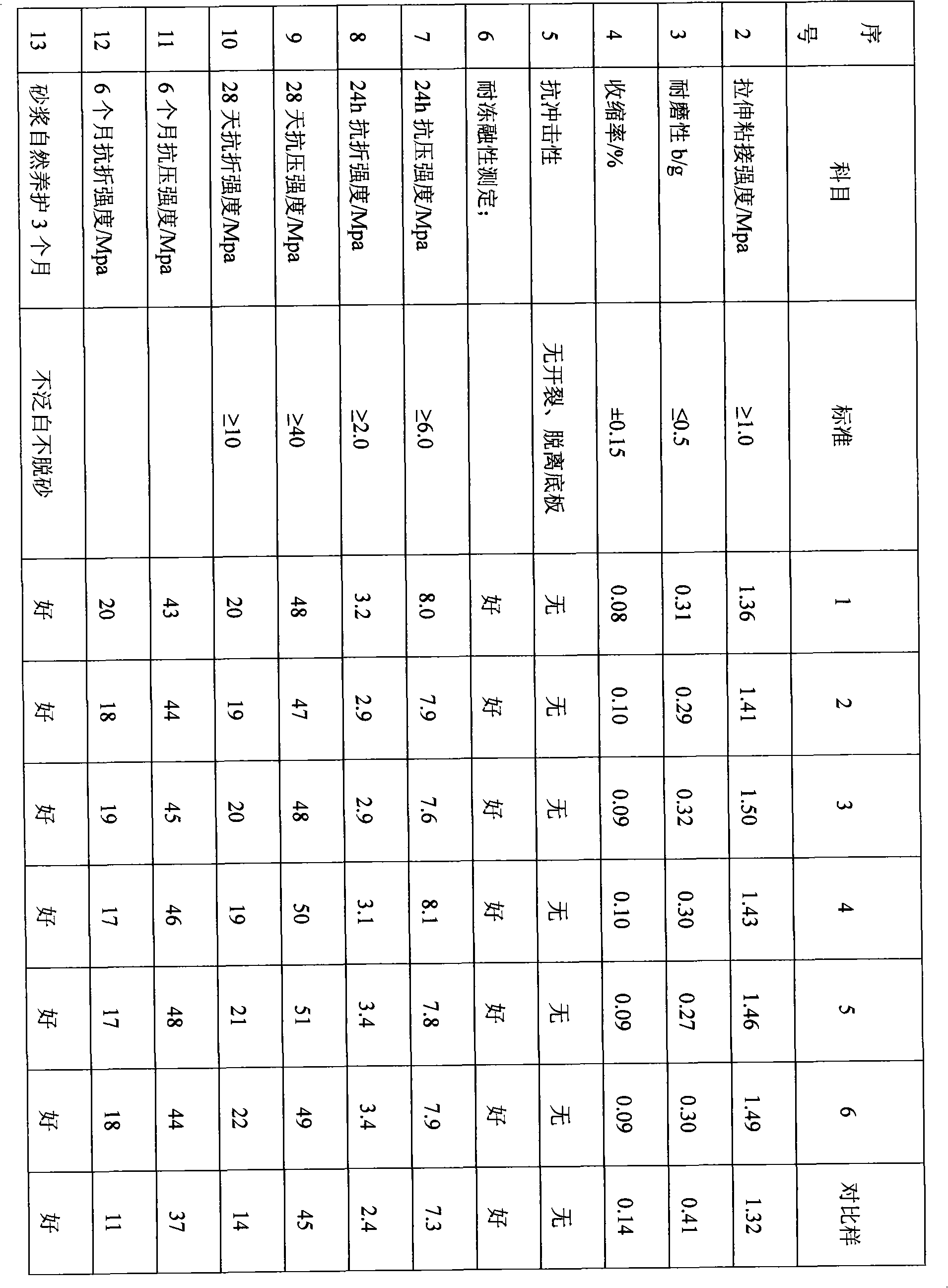

465results about How to "Improve water repellency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

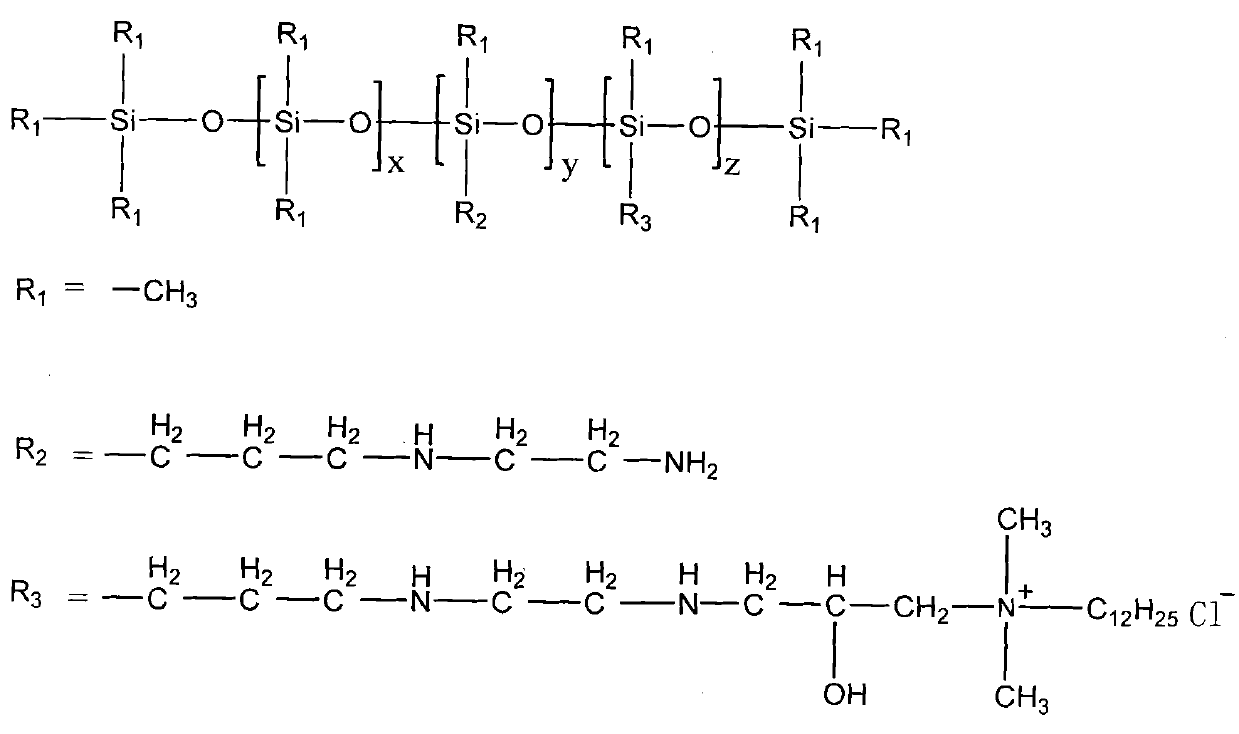

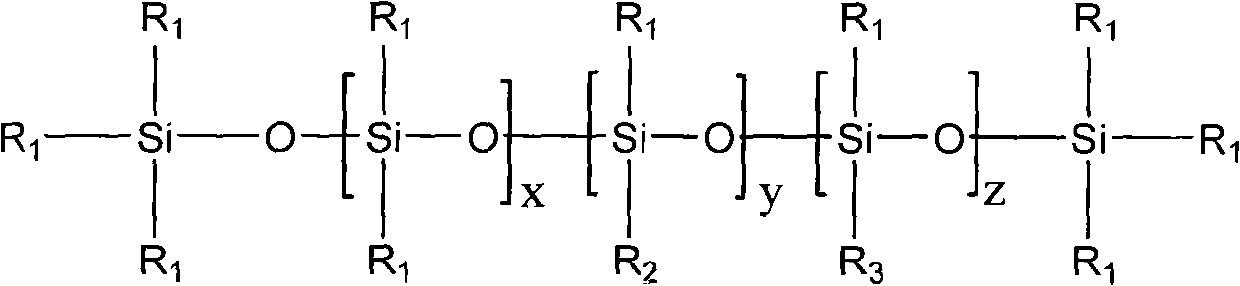

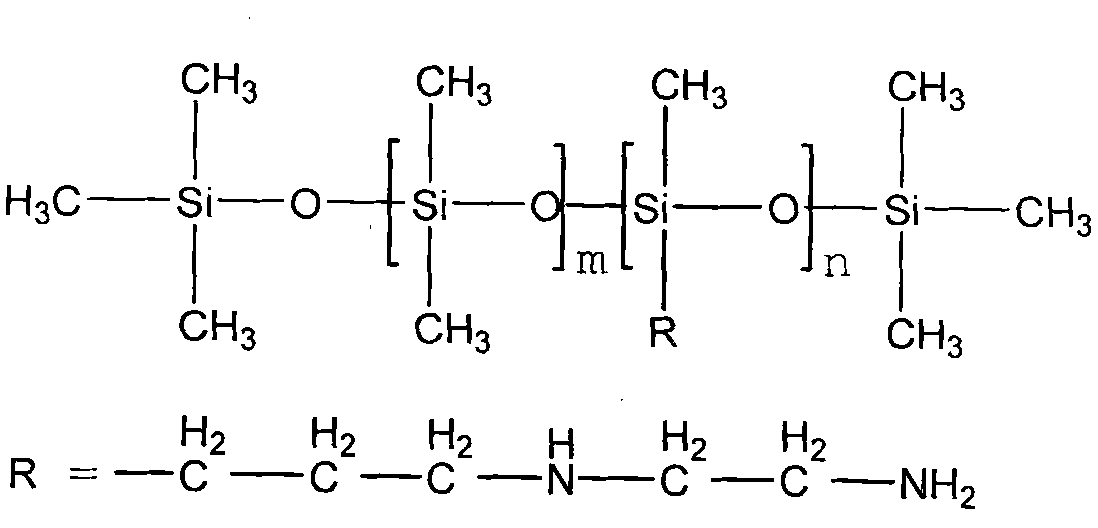

Quaternized modified amino silicone oil softener and preparation and application thereof

InactiveCN101914206AAvoid yellowingImprove hydrophilicityVegetal fibresTetramethylammonium hydroxideDisiloxane

The invention relates to a quaternized modified amino silicone oil softener and preparation and application thereof. The softener comprises the following general formula in the specification. The preparation comprises the following steps of: (1) adding octamethylcy-clotetrasiloxane into a container, adding a coupling agent N-beta-(aminoethyl)-gamma-aminopropyl methyl dimethoxysilane into the container dropwise, adding a tetramethyl ammonium hydroxide catalyst and subsequently a capping agent hexamethyl disiloxane into the container, and then performing reduced pressure distillation to obtain amino silicon oil; (2) dissolving the amino silicon oil into a solvent, adding the mixture into epichlorohydrin, stirring and heating to react under the protection of nitrogen, and removing the solvent by steaming to obtain an intermediate product; and (3) uniformly mixing N,N-dimethyl-decanamide and the solvent to obtain a mixture, stirring with heating, adding the intermediate product dropwise into the mixture under the protection of nitrogen, performing a thermostatic reaction, and removing the solvent by steaming to obtain the product. The softener of the invention has high hydrophilicity and high stability; fabric processed by the softener has excellent soft handfeel, high hydrophilicity, low yellowing, antibacterial property and the like; and the softener is simple to prepare and is suitable for industrial production.

Owner:DONGHUA UNIV

Formula of ceramic for insulator ceramic body and preparation method of the insulator ceramic body

InactiveCN102241506AHigh mechanical strengthImprove electrical performanceCeramicsPotassium dioxideMullite

The invention discloses a formula of a ceramic for an insulator ceramic body and a preparation method of the insulator ceramic body. Beneficial effects of a technical scheme of the invention comprise that the formula contains specific proportions of silicon oxide and alumina and the silicon oxide and the alumina are sintered into mullite to improve a mechanical strength and a hot and cold performance of a ceramic material, and silica can reduce a dry degree, a firing shrinkage degree and a bending deflection degree of a ceramic blank, play a supportive role in a ceramic blank and improve a mechanical strength of a ceramic blank; alumina can improve greatly a mechanical strength of ceramic blank; added potassium dioxide can reduce a sintering temperature, fill gaps of a ceramic blank and improve a compactness of a ceramic material, and a mechanical strength and an electrical performance of a ceramic blank; and through a cooperation with a preparation method, an insulator ceramic body obtains improved greatly hydrophobic properties, anti-fouling properties, insulating properties and mechanical properties.

Owner:SUZHOU AIJIAN ELECTRICAL PORCELAIN

Fluorinated silicone rubber anti-pollution flashover coating for extra-high voltage and preparation method thereof

ActiveCN101597463ALower surface energyReduce adhesionCoatingsDecabromobiphenyl etherAluminium hydroxide

The invention provides a fluorinated silicone rubber anti-pollution flashover coating for extra-high voltage and a preparation method thereof; the fluorinated silicone rubber anti-pollution flashover coating (short for FRTV) has the following compositions by mass percent: 5-30 percent of fluorinated silicone rubber, 10-30 percent of silicon rubber, 4-8 percent of nanometer grade gas-phase white carbon black, 0.5-8 percent of compound fire retardants, 0.2-0.5 percent of firming agent, 0.01-0.05 percent of catalyst, 0.02-0.08 percent of antioxidant, 2-8 percent of flatting agents, 0.2-0.4 percent of de-foaming agent, 0.1-0.5 percent of paint and 30-60 percent of solvent. The compound fire retardant is composed of inorganic aluminium hydroxide and organic decabromodiphenyl oxide, wherein comprising 1-6 percent of the inorganic aluminium hydroxide and 0.5-3 percent of the organic decabromodiphenyl oxide. The preparing process of the coating is simple, and the coating has good weather ability, oil resistance and longer service life.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST +1

Micron-nano-sized porous composite material and preparation method thereof

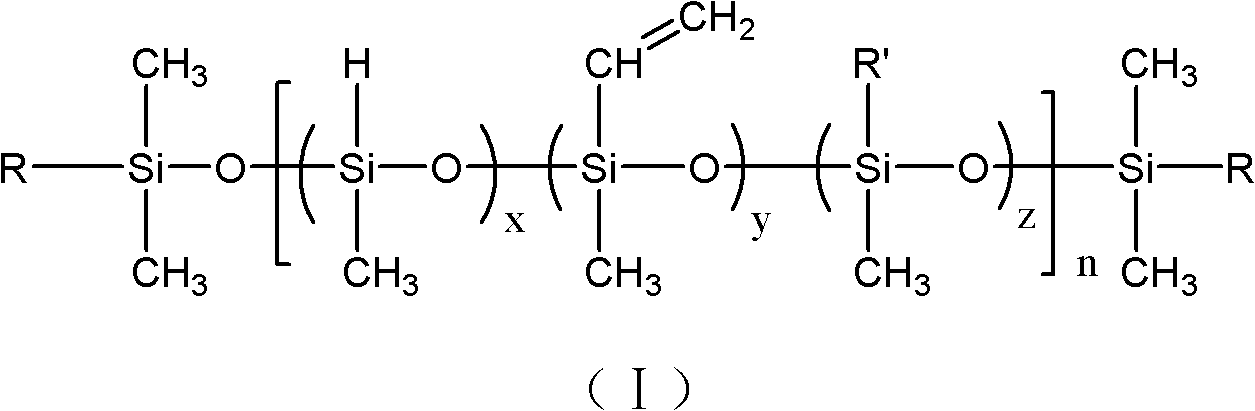

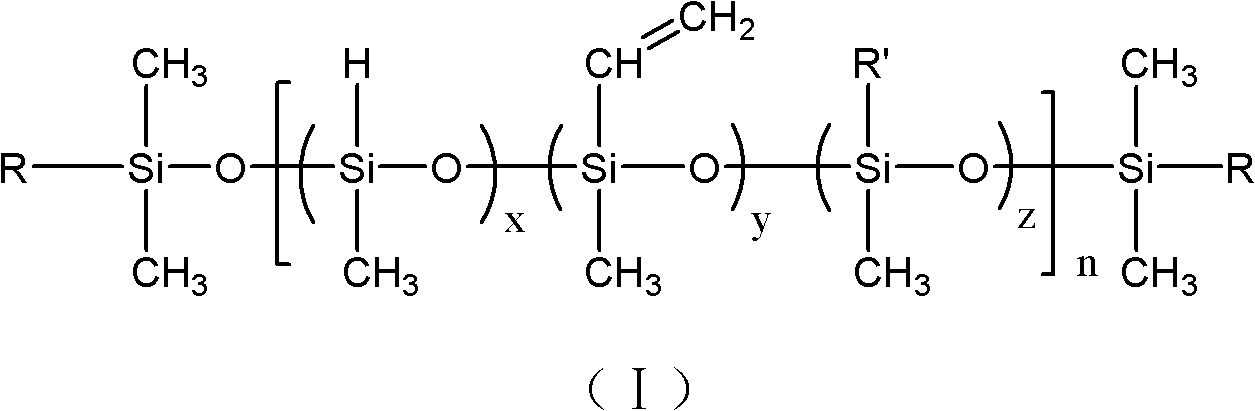

The invention provides a preparation method for a micron-nano-sized porous composite material, which comprises the following steps of: mixing an organic silicone polymer, a catalyst and a solvent to obtain a glue solution; mixing the glue solution with fibers or infiltrating the glue solution on the fibers to obtain a composition of the glue and the fibers; heating, solidifying and shaping the composition of the glue and the fibers to obtain a fiber-enhanced gel solid; heating the fiber-enhanced gel solid to 400-850 DEG C; and carrying out pyrolysis to obtain the micron-nano-sized porous composite material. The organosilicon polymer is at least one of polysiloxane and organic silicon resin disclosed in a formula (I). The method provided by the invention can be used for preparing a Si-C-O organic resin matrix and semi-organic semi-inorganic porous composite material from the nanoscale to the micron size.

Owner:INST OF CHEM CHINESE ACAD OF SCI

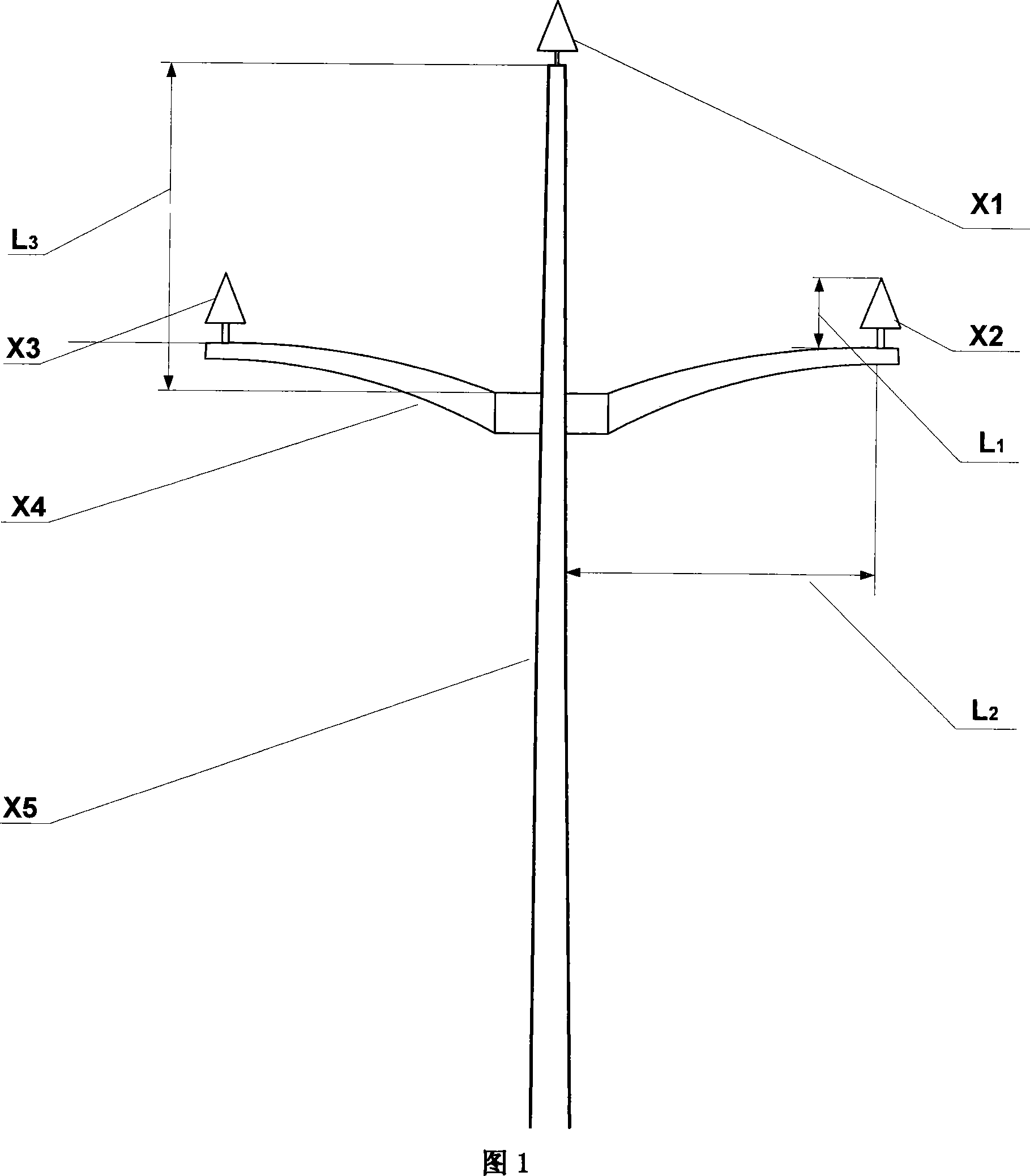

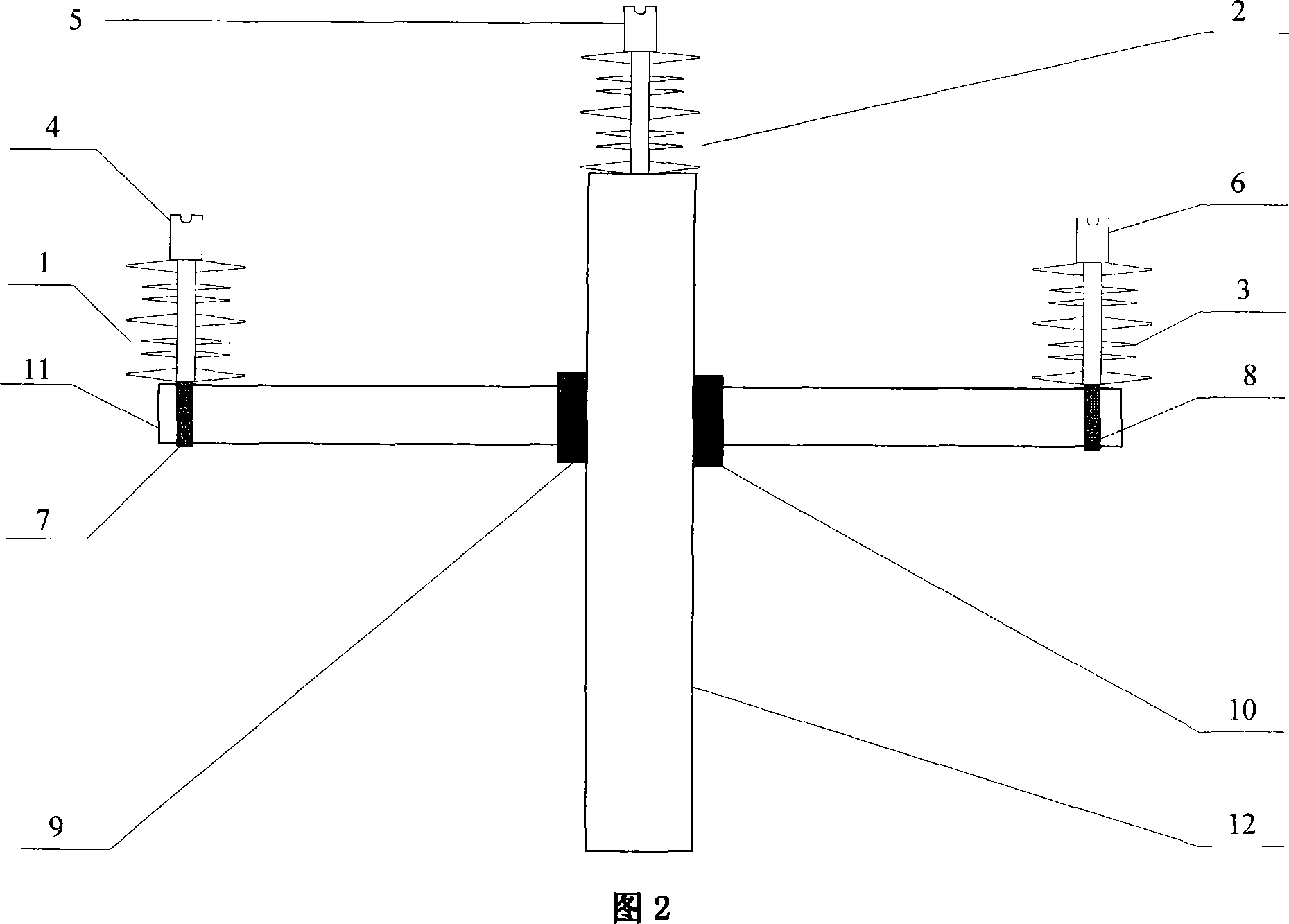

10 kV distribution line insulation tower head

ActiveCN101227071APreventing Lightning Disconnection AccidentsImprove the insulation levelOverhead installationInsulatorsEngineeringLine Break

A 10kV power distribution circuit insulation tower head is disclosed, which is characterized in that: adopting hydrophobic high-strength insulation bar to be assembled with needle-typed insulator by gold tool and form an insulation tower head entity, or adopting hydrophobic high-strength insulation bar to be assembled with gold tool directly and form an insulation tower head. By using the invention, the insulation level of the power distribution circuit can be greatly improved, the thunder discharge air gap can be obviously enlarged, the lightning stroke and line break accidents can be effectively prevented and the climbing distance can be expanded, further, the structure type is easy to improve self-cleaning ability and the occurrence of pollution flashover can be basically and completely precluded, which is beneficial in charged operation, simple in operation process and improves the operation security.

Owner:STATE GRID ELECTRIC POWER RES INST

Novel anti-pollution flashover coating for ultra and super high voltage insulator

ActiveCN105086820AReduce the temperaturePrevent escapeFireproof paintsAntifouling/underwater paintsSolventSurface-active agents

The invention belongs to the technical field of functional coatings and particularly relates to a novel anti-pollution flashover coating for an ultra and super high voltage insulator. The novel anti-pollution flashover coating comprises, by mass, 40%-50% of room temperature vulcanized silicone rubber, 5%-10% of titanate coupling agent, 2%-6% of composite fire retardant, 5%-12% of modified composite reinforcing agent, 2%-4% of nano TiO2, 0.5%-1% of surface active agent, 1%-5% ofhexamethyldisilazane, 0.2%-0.5% of antifoaming agent, 0.3%-0.6% of catalyst, 0.3%-0.6% of cross-linking agent and the balance solvent. The prepared anti-pollution flashover coating is sprayed on the surface of the cleaned ceramic insulator, and the coating can be used after being naturally cured for 96 hours under the condition of 25 DEG C+ / -2 DEG C and 40%-70% of RH. According to the anti-pollution flashover coating, after the sprayed anti-pollution flashover coating is completely cured, the contact angle is not smaller than 135 degrees.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Modification method for super-hydrophobic packing particle for anti-contamination flashover coating and application

InactiveCN107760065AElimination of hydroxylReduce clumpingCoatingsPigment treatment with organosilicon compoundsPolymer scienceContamination

The invention discloses a modification method for super-hydrophobic packing particles for an anti-contamination flashover coating and application. The modification method comprises the following steps: 1) preparing a packing particle dispersion; 2) preparing an ethanol dispersion of a fluorinated silane coupling agent, and adjusting the pH value of the ethanol dispersion of the fluorinated silanecoupling agent to 3-5; 3) adding the fluorinated silane coupling agent into the dispersion obtained in the step 2), performing ultrasonic treatment to sufficiently hydrate the fluorinated silane coupling agent so as to obtain a fluorinated silane coupling agent solution for later use; 4) adding the fluorinated silane coupling agent solution prepared in the step 3) into the dispersion with the packing particles prepared in the step 1), and performing a heating stirring reaction to modify the surfaces of the packing particles; 5) drying the modified material, and grinding, thereby obtaining themodified packing particles. According to the modification method, the surfaces of the packing particles for the anti-contamination flashover coating are modified by using the fluorinated silane coupling agent, then the surfaces of the packing particles are hydrophobic but oleophilic, furthermore the hydrophobicity of the coating is improved, and the hydrophobic angle can be up to 150 degrees or larger.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Preparation method of fluorine-containing polyacrylate soap-free emulsion

InactiveCN102585086AOvercome the defect of easy migrationImprove polymerization stabilityCoatingsEnd-groupSolvent

The invention relates to a preparation method of a fluorine-containing polyacrylate soap-free emulsion. According to the invention, the fluorine-containing polyacrylate soap-free emulsion is prepared by adopting an amphiphilic segmented copolymer polyacrylic acid-b-polyhexafluorobutyl acrylate (PAA-b-PHFBA) to substitute a routine emulsifier, and carrying out soap-free emulsion copolymerization on acrylate monomers, and can be applied to the leather field, the textile field, the coating field, the papermaking field, the adhesive field and the like. The compatibility of the hydrophobic segment of the used PAA-b-PHFBA and above prepolymerization monomers is good, so a problem of bad compatibility of fluorine-containing monomers is solved, thereby the stability of the emulsion polymerization process is substantially improved. Additionally, the PAA-b-PHFBA is anchored to emulsion particles in the emulsion polymerization, and the hydrophilic segment stretches into a water phase to stabilize the emulsion particles through an electrostatic effect and a steric hindrance effect, so the storage stability and the freeze-thaw resistance stability of the emulsion are improved, disadvantages of bad adhesion, bad water resistance and bad solvent resistance of films of common emulsions are overcome, and the mechanical properties, the adhesion and the abrasive resistance of the film of the emulsion are improved.

Owner:山西佳宇丰化工科技有限公司

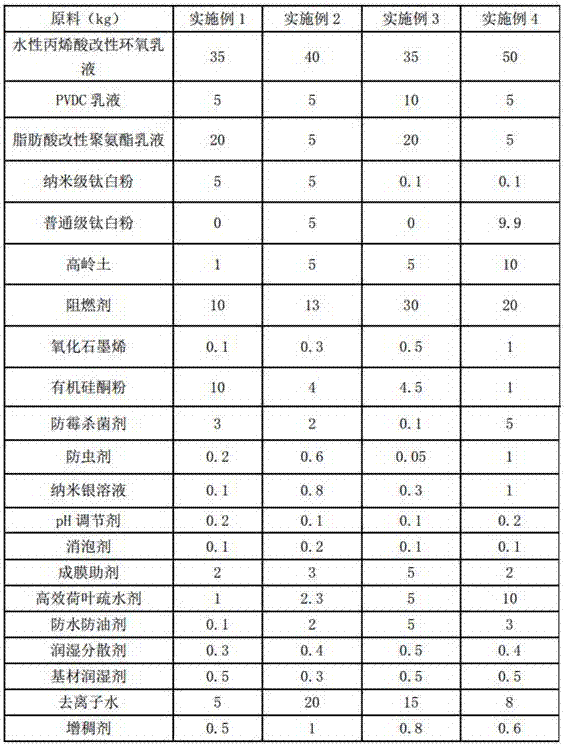

Multifunctional inner wall water paint

InactiveCN107141899ADeodorantWater resistantAntifouling/underwater paintsLuminescent paintsWater basedEmulsion

The invention relates to the technical field of water-based paint, and discloses multifunctional inner wall water paint. The water-based paint is prepared by forming a water-based acrylic acid emulsion and a fatty acid modified polyurethane emulsion into a water-based resin system, and compositely adding pigments, fillers and assistants such as water-based fluorescent powder, titanium dioxide, a nano silver solution, a waterproof and oilproof agent, an insect repellent agent and a mildewproof bactericide. The water-based paint has the characteristics of deodorization, water resistance, bacteriostasis and fluorescence, and is excellent in performance, nontoxic and environment-friendly.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

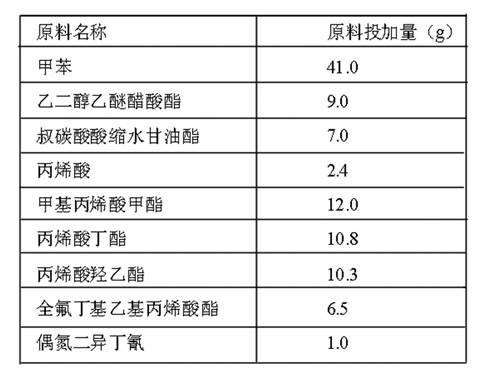

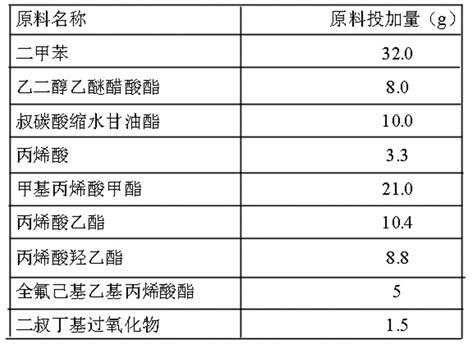

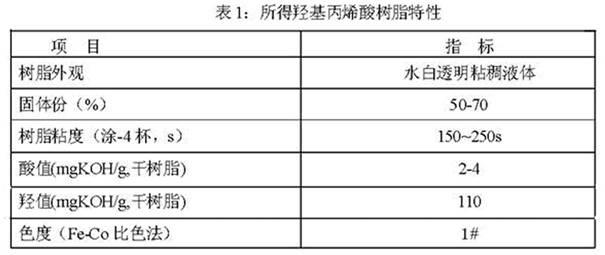

Hydroxylated acrylic resin as well as preparation method and application thereof

The invention relates to hydroxylated acrylic resin as well as preparation method and application thereof. The hydroxylated acrylic resin has a structural formula, wherein n is equal to 4, the sum of C number in 6, 8, R1 and R2 is 9, and the molecular weight is 10,000-20,000; the preparation method comprises the steps of: adding solvent and reactive solvent into a reaction vessel under protectionof nitrogen gas environment, and increasing temperature to 150-160 DEG C; evenly mixing acrylic acid, methyl methacrylate, ethyl acrylate, hydroxyethyl acrylate and perfluoroalkylethyl acrylate monomer with initiator, and carrying out dropwise addition for 3-4 hours; carrying out heat insulation for 1.5-2 hours; and reducing temperature to 40-70 DEG C for discharging, thus obtaining hydroxylated acrylic resin. A paint film formed by the hydroxylated acrylic resin and a curing agent has properties of both acrylic polyurethane and fluorocarbon coating. The prepared hydroxylated acrylic resin can carry out reaction smoothly at normal temperature and normal pressure, has low production cost, can be cured at normal temperature and be applied in the fields of ships, containers, drilling platforms, anticorrosion of steel structures, outer wall coating of high-rise buildings and the like.

Owner:JINZHOU DPF TH CHEM CO LTD

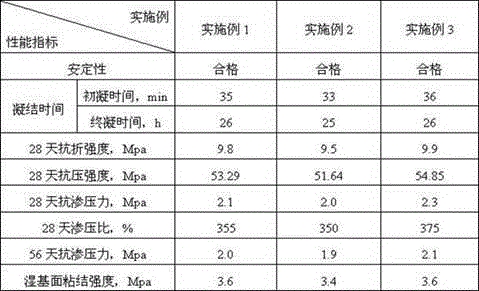

Cement base permeating crystallizing waterproof paint formed by reinforcing straw fibers

InactiveCN105060816AImprove impermeabilityHigh self-healing abilitySolid waste managementFiberPermeation

The invention discloses cement base permeating crystallizing waterproof paint formed by reinforcing straw fibers, and belongs to the technical field of building materials. The cement base permeating crystallizing waterproof paint is compounded from the following raw materials in percentage by weight: 30-60% of silicate cement, 10-25% of modified magnesite cement, 10-25% of fillings, 5-12% of quartz sand, 0.1-0.5% of expanded vermiculite powder, 0.05-0.2% of straw fibers, 0.8-1.5% of a chelating agent, 0.5-2% of a crystallizing precipitant, 1-5% of an ionic equilibrium agent, 0.1-0.3% of an antifoaming agent, 0.1-1% of redispersible latex powder and 0.3-0.6% of a water reducing agent. The cement base permeating crystallizing waterproof paint formed by reinforcing the straw fibers, disclosed by the invention, has double waterproof properties, good permeation resistance, good self-healing and repair capacity, good water pressure resistant capacity and rapid crack repairing capacity, is simple in production technology, low in cost and environment-friendly, and has the same life as that of concrete.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

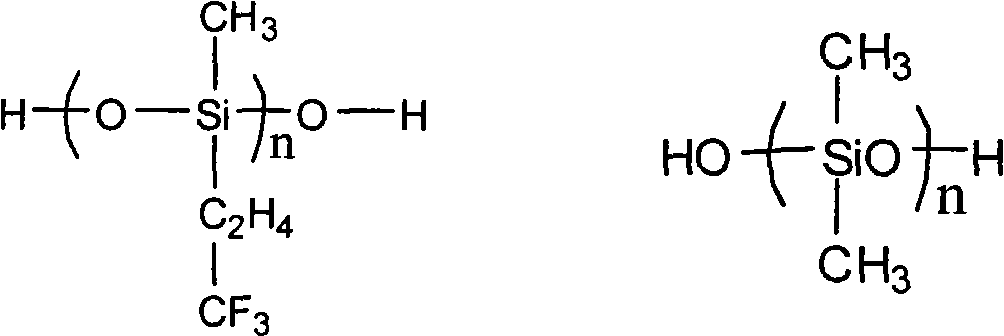

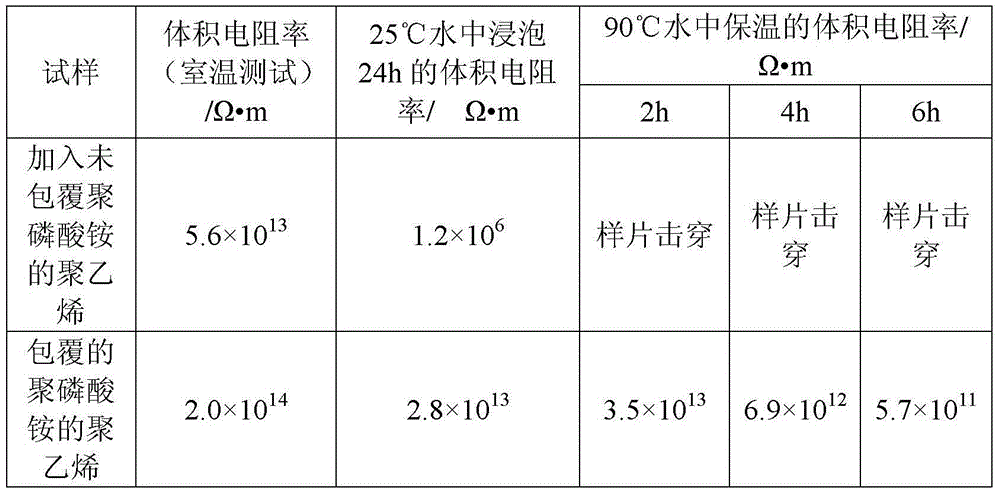

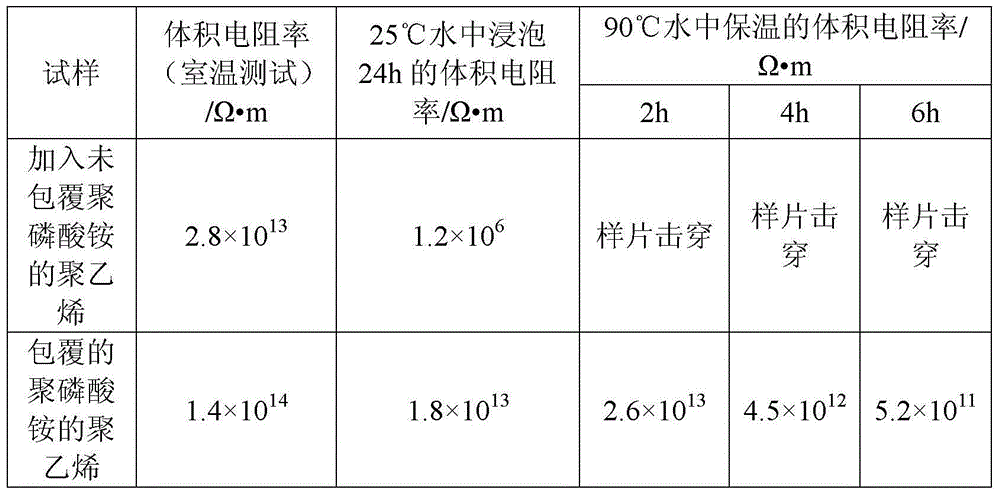

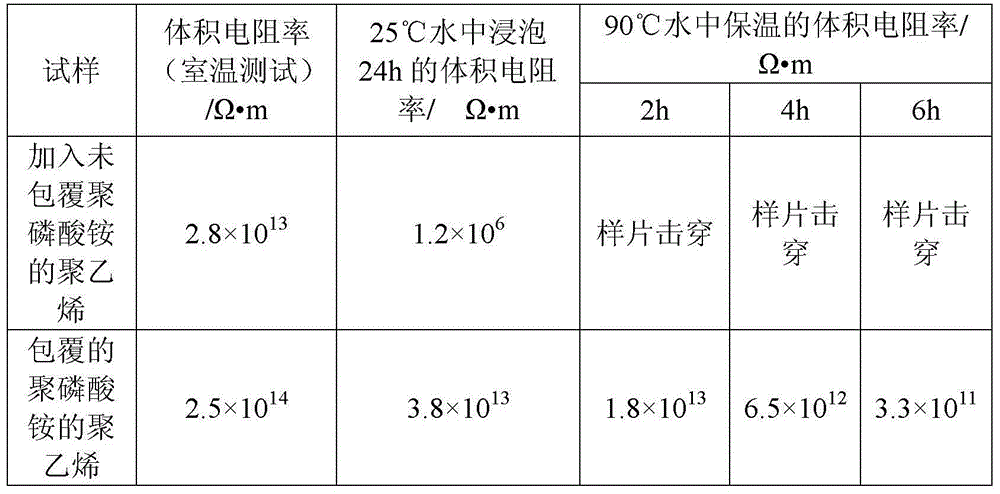

Preparation method of ammonium polyphosphate wrapped with fluorine-containing silicone oil on surface

ActiveCN104479172AReduce solubilityHigh volume resistivityPigment treatment with organosilicon compoundsSolubilityRoom temperature

The invention discloses a preparation method of ammonium polyphosphate wrapped with fluorine-containing silicone oil on the surface, relates to a preparation method of ammonium polyphosphate, and aims at solving the technical problems that existing modified ammonium polyphosphate as a fire retardant is easy to hydrolyze, so that the flame retardant property is reduced and the fire retardant in the material is easy to separate out. The method disclosed by the invention comprises the following steps: 1 heating ammonium polyphosphate; and 2 wrapping the surface of the ammonium polyphosphate with the fluorine-containing silicone oil. The method has the advantages that 1 the solubility of ammonium polyphosphate wrapped with the fluorine-containing silicone oil on the surface prepared by the method at a room temperature is greatly reduced in comparison with that of unwrapped ammonium polyphosphate at the room temperature; 2 the volume resistivity of a polyethylene material added with ammonium polyphosphate wrapped with the fluorine-containing silicone oil on the surface prepared by the method at the room temperature is greatly improved in compression with that of the polyethylene material added with the unwrapped ammonium polyphosphate; and 3 the hydrophobicity of ammonium polyphosphate wrapped with the fluorine-containing silicone oil on the surface prepared by the method is obviously improved, and the material compatibility and insulativity are also obviously improved.

Owner:HONGLONGJIANG ORIENT SCI & TECH

Waterproof phase-change heat storing plaster wallboard formed by reinforcing straw fibers

ActiveCN105060830AHigh strengthImprove waterproof performanceSolid waste managementCement boardPhase change

The invention discloses a waterproof type phase-change heat storing plaster wallboard formed by reinforcing straw fibers. The plaster wallboard is compounded from the following raw materials in percentage by weight: 20-60% of plaster gelate materials, 10-25% of phase-change heat storing microcapsules, 1-7% of a composite water repellent, 25-55% of mineral micro powder, 0.1-0.6% of straw fibers, 0.8-1.5% of a binder, 1-5% of an exciting agent and 0.2-1.5% of a water reducing agent. The preparation method comprises the following steps of: 1) firstly, adding the plaster gelate materials, the mineral micro powder, the straw fibers and the exciting agent into a reaction kettle, adding water, and uniformly stirring the plaster gelate materials, the mineral micro powder, the straw fibers, the exciting agent and the water so as to obtain a material A; 2) sequentially adding the phase-change heat storing microcapsules, the composite water repellent, the binder and the water reducing agent into the reaction kettle, and stirring the material A, the phase-change heat storing microcapsules, the composite water repellent, the binder and the water reducing agent once again so as to obtain a material B; and 3) directly pouring the material B in the reaction kettle into a mold through a grouting pump so as to obtain the phase-change heat storing plaster wallboard, wherein a fiber cement board is arranged on the inner surface of the mold. The waterproof type phase-change heat storing plaster wallboard disclosed by the invention has the advantages of being suitable for operation under humid environment, simple in production technology and environment-friendly.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

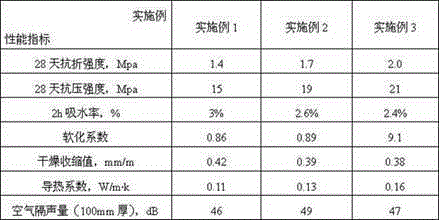

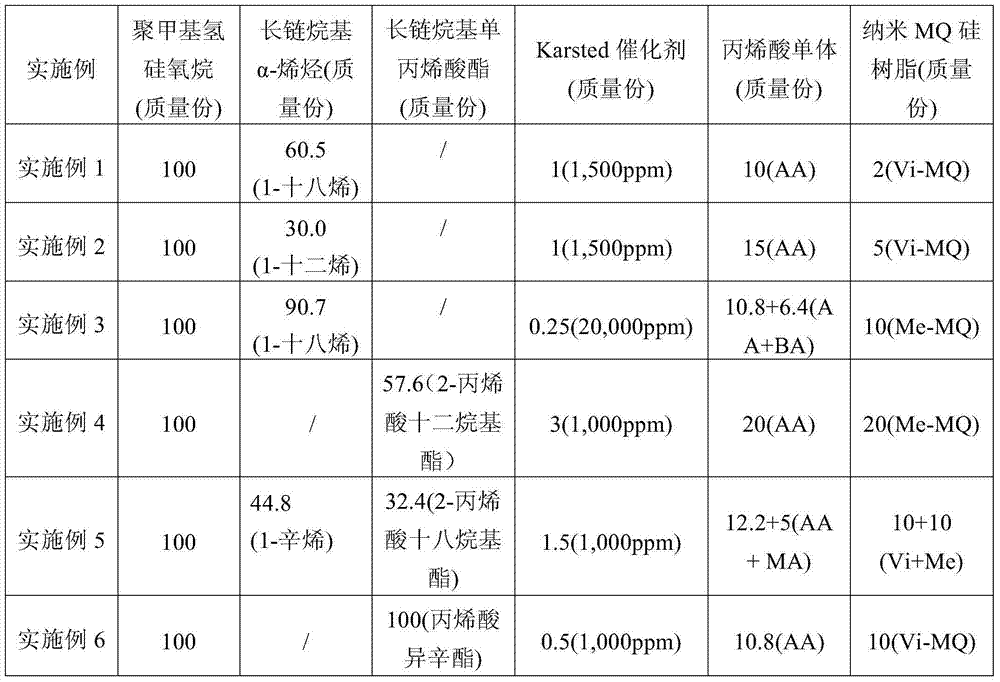

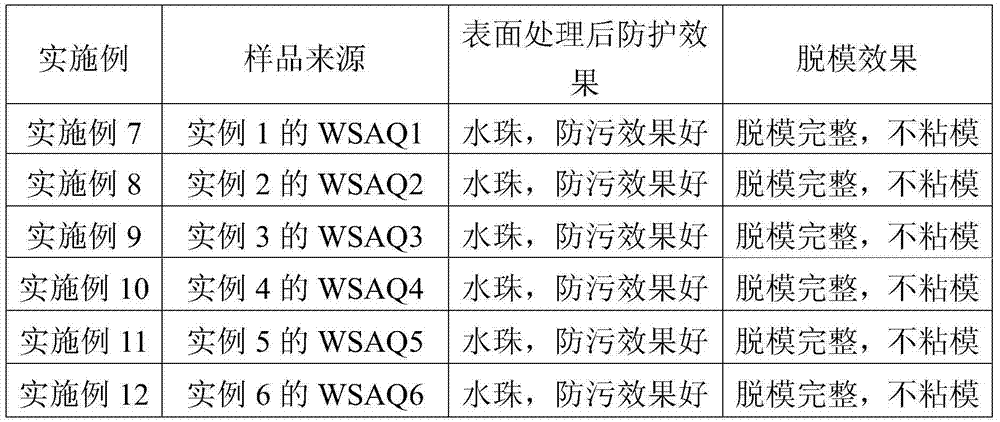

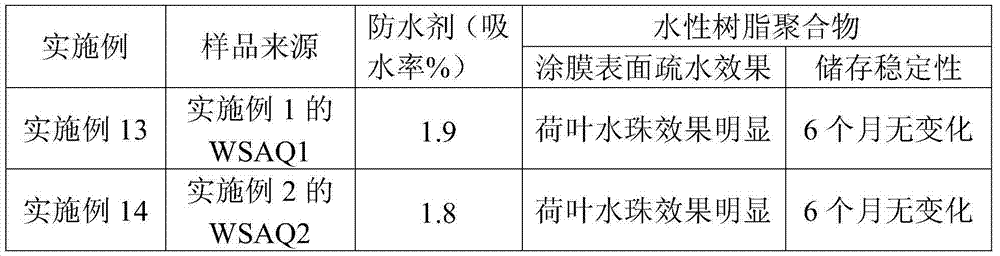

Self-emulsifying acrylic acid organic silicon wax protection material as well as preparation method and application thereof

InactiveCN103613717AImproves UV resistanceIncreased durabilityFibre treatmentCoatingsAlpha-olefinSelf emulsifying

The invention discloses a self-emulsifying acrylic acid organic silicon wax protection material as well as a preparation method and application thereof. The preparation method comprises the following steps: reacting 30 to 100 parts by mass of long-chain alkyl alpha-olefin or / and long-chain alkyl monoacrylate with 100 parts by mass of polymethylhydrosiloxane in the presence of a platinum complex catalyst, cooling, adding 10 to 20 parts by mass of acrylic monomer and 2 to 20 parts by mass of nanometer MQ silicon resin, and performing heat-preservation reaction, thereby preparing the acrylic acid organic silicon wax polymer; adding ammonium hydroxide for neutralizing the polymer, thereby preparing self-emulsifying acrylic acid organic silicon wax protection material. The self-emulsifying acrylic acid organic silicon wax protection material prepared through the method is good in stability, environment-friendly, good in dispersibility, excellent in waterproof hydrophobic property and remarkable in mold stripping effect; the self-emulsifying acrylic acid organic silicon wax protection material can be used as a nursing agent, a waterproof agent, a mold stripping agent, a waterborne polymer resin additive and the like in the fields of ceramics, natural stone, concrete, metal casting, cosmetics, paint and the like.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Photo-curing-based water and oil repellent finishing method for fabric

InactiveCN103526552AImprove water repellencyImprove the effect of oil repellent finishingFibre typesOrganic chemistryFluorine containing

The invention discloses a photo-curing-based water and oil repellent finishing method for a fabric, belonging to the technical field of fabric finishing, and aiming to overcome the shortcomings of high baking temperature, high production energy consumption and low processing efficiency in conventional after-finishing and achieve the water and oil repellent functional finishing of the fabric under a photo-curing condition. A process specifically comprises the following steps of (1) synthesizing a fluorine-containing urethane acrylate prepolymer, namely carrying out reaction on isocyanate and hydroxyethyl acrylate and carrying out reaction on a reaction product and a fluorine-containing polyether type diol long chain to obtain the prepolymer, or carrying out reaction on isocyanate and fluorine-containing polyether type diol and then adding the hydroxyethyl acrylate into a system; and (2) preparing a photo-curable resin system from the prepolymer, a reactive diluent, a photoinitiator, a solvent and the like, coating and rolling-compacting the photo-curable resin system on the surface of the fabric, and irradiating the fabric for a certain time by using ultraviolet light to finish curing of a resin with water and oil repellent effects on the surface of the fabric. According to the method, the water and oil repellent performance of the finished fabric is improved, and the strength of the fabric is slightly weakened; compared with a conventional thermal-baking-based chemical finishing method, the photo-curing-based water and oil repellent finishing method for the fabric has the advantages that the process flow is short, the energy consumption is low and the efficiency is high.

Owner:JIANGNAN UNIV

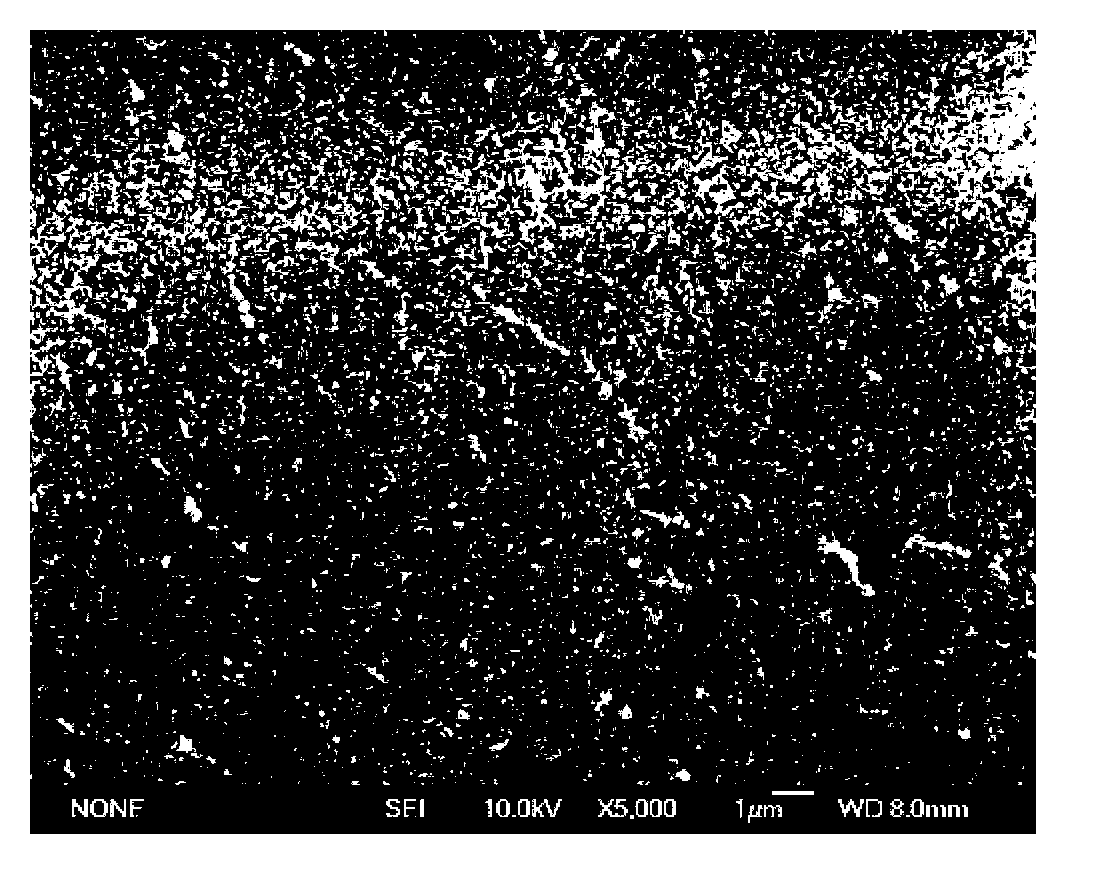

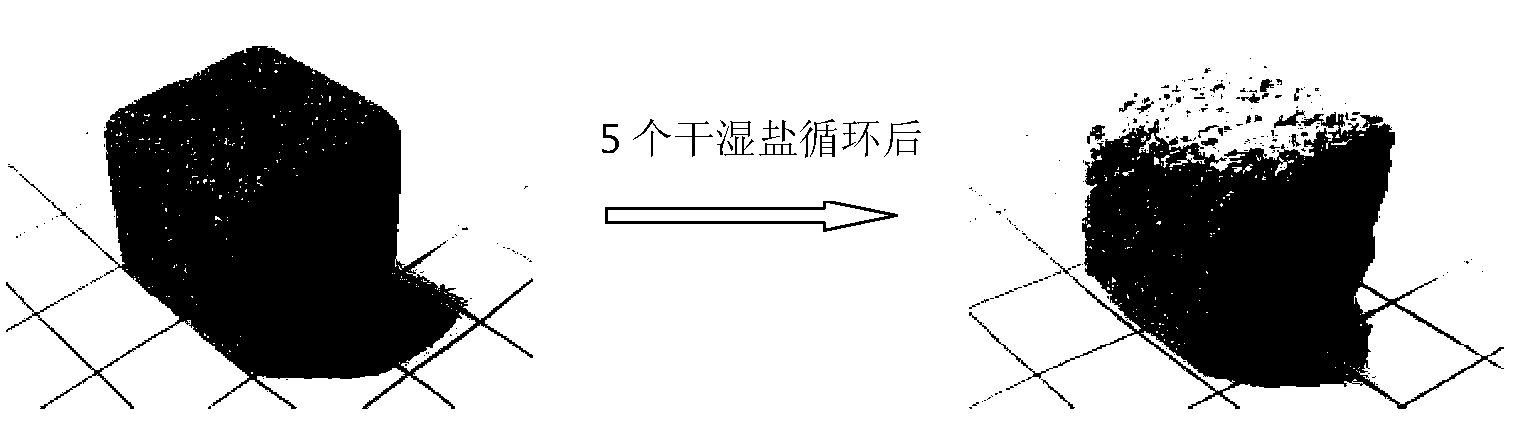

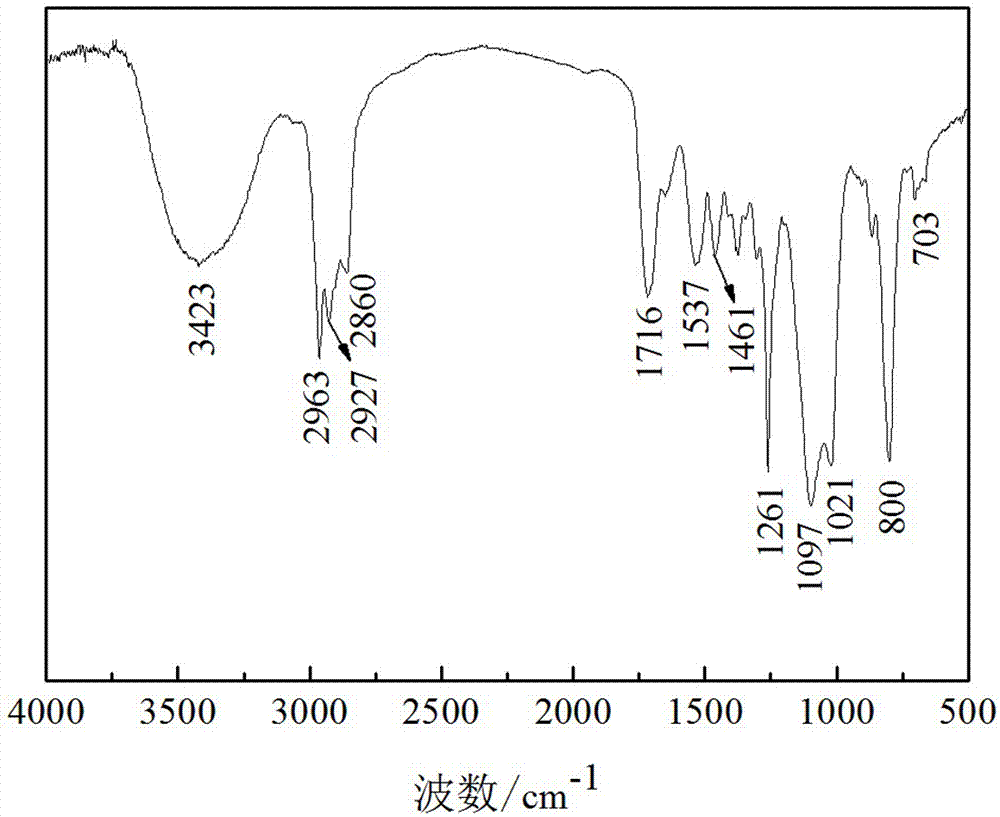

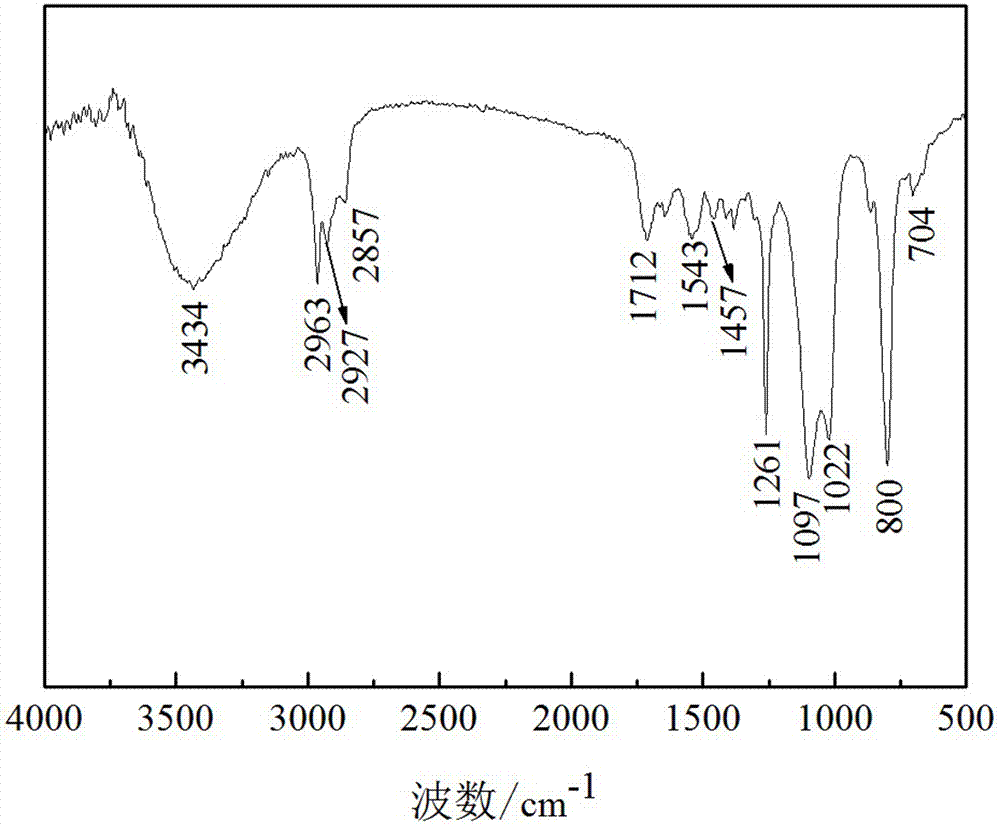

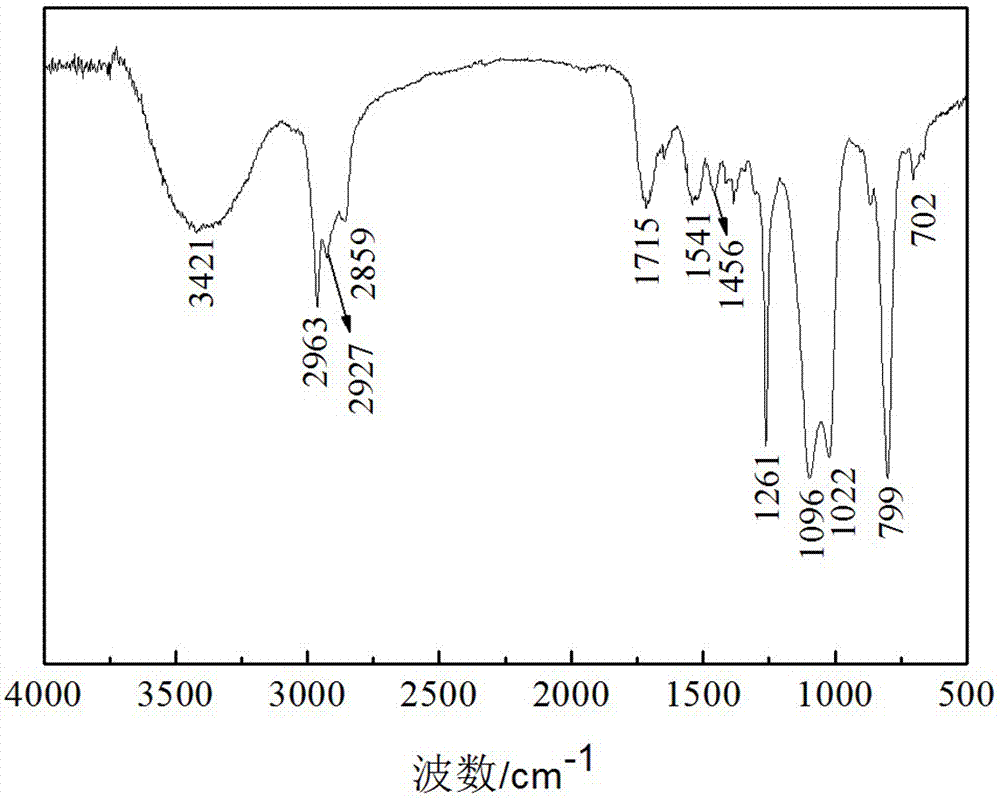

Reinforcement material for preservation of cultural relics, and preparation method and application thereof

The invention relates to a reinforcement material for preservation of cultural relics, and a preparation method and an application thereof. The reinforcement material for the preservation of the cultural relics is an organic silicon composite material prepared by a sol-gel reaction by using tetraethoxysilane as a matrix, silicon dioxide nanoparticles and terminal-hydroxyl polydimethylsiloxane as terminal-hydroxyl polydimethylsiloxane modifiers, wherein the mass ratio of the tetraethoxysilane to the nanosized silicon dioxide and to the polydimethylsiloxane is 100 : (0-25) : (0-6).

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Respirable high-flame-retardance outer-wall facing material

The invention discloses a respirable high-flame-retardance outer-wall facing material, which comprises redispersible latex powder, an organic-silicon water repellent, methylcellulose ether, a defoaming agent, an air-entraining agent, lignocellulose, a thixotropic lubricant, silicate cement, heavy calcium powder, fly ash, calcium hydroxide, starch ether, calcium formate and colored quartz sand. The respirable high-flame-retardance outer-wall facing material has the advantages of reasonable proportion, energy saving and environmental protection, and not only are the quality and the service lifeof an outer-wall heat-preserving system ensured, and heat-preserving heat-absorbing heat-storing performances are enhanced, but also the service life of a building wall body is greatly prolonged.

Owner:SHANDONG FENGYU ENERGY SAVING MATERIAL MFG

Polyurethane modified organic silicone water-repellency and antibiotic finishing agent, preparation method and application

InactiveCN107059405AImprove water repellencyIncrease self-emulsifying abilityBiochemical fibre treatmentLiquid repellent fibresPrepolymerCarbon chain

The invention discloses a polyurethane modified organic silicone water-repellency and antibiotic finishing agent, a preparation method and an application. The method comprises the following steps: adding isophorone diisocyanate into polypropylene glycol and glycerin monostearate dissolved in tetrahydrofuran and then reacting; adding N-methyl-N-benzyl-N,N-dihydroxyethyl chloride and hexahydro-1,3,5-tris-s-triazine and performing chain extension cross-linking reaction, thereby acquiring isocyanate group closed polyurethane prepolymer; reacting with double-ended hydroxypropyl polysiloxane; and removing solvents and emulsifying, thereby acquiring the polyurethane modified organic silicone water-repellency and antibiotic finishing agent used for finishing cotton and dacron / cotton textile. According to the invention, the process is simple; the introduction of long carbon chains in glycerin monostearate molecules can effectively promote the water-repellency property of the finished textile; and meanwhile, the antibacterial quaternary ammonium salt and triazine group introduced into finishing agent macromolecules can endow the finished textile with a long-lasting antimicrobial property.

Owner:SUZHOU YISITE NEW MATERIAL TECH

Ship corrosion preventing method

InactiveCN104525458ALower surface free energyReduce coefficient of frictionPretreated surfacesAnti-corrosive paintsSand blastingPre treatment

The invention discloses a ship corrosion preventing method. The ship corrosion preventing method comprises the following steps of steel plate surface pre-treatment, base material sanding treatment, weld joint and other structure defect repair sand blasting, priming paint coating, strengthening paint spraying, finishing paint spraying and follow-up maintenance. According to the ship corrosion preventing method, steel plate surface pre-treatment is performed before coating, an epoxy anticorrosive coating is sprayed on the position with high rust-proof requirement, and whole spraying is performed after spraying; during whole spraying, corrosion resistant polyurethane serves as film forming matter, a coating for a framework formed by sheet metal flakes does not contain precious metal and toxic components and is a novel environment-friendly coating, flakes are formed and distributed on the material surface, multiple layers of flakes are horizontally arranged in an overlapped mode, a path for a corrosive medium to permeate into a base material is prolonged, and the corrosion preventing performance of the coating is improved. The ship corrosion preventing method is short in technological process, and produced ships have excellent rust, corrosion and fouling preventing performance.

Owner:QINGDAO WUWEI THERMAL INSULATION MATERIAL

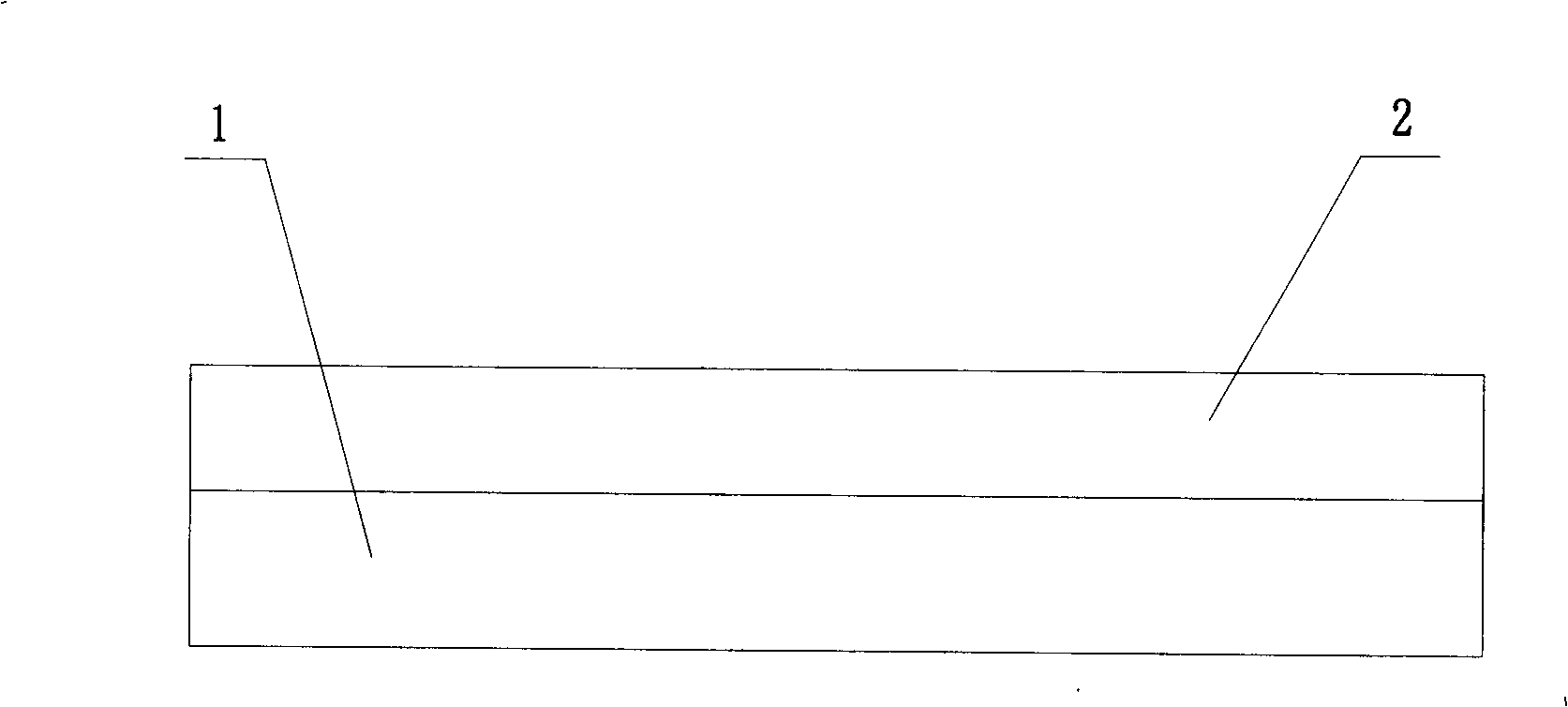

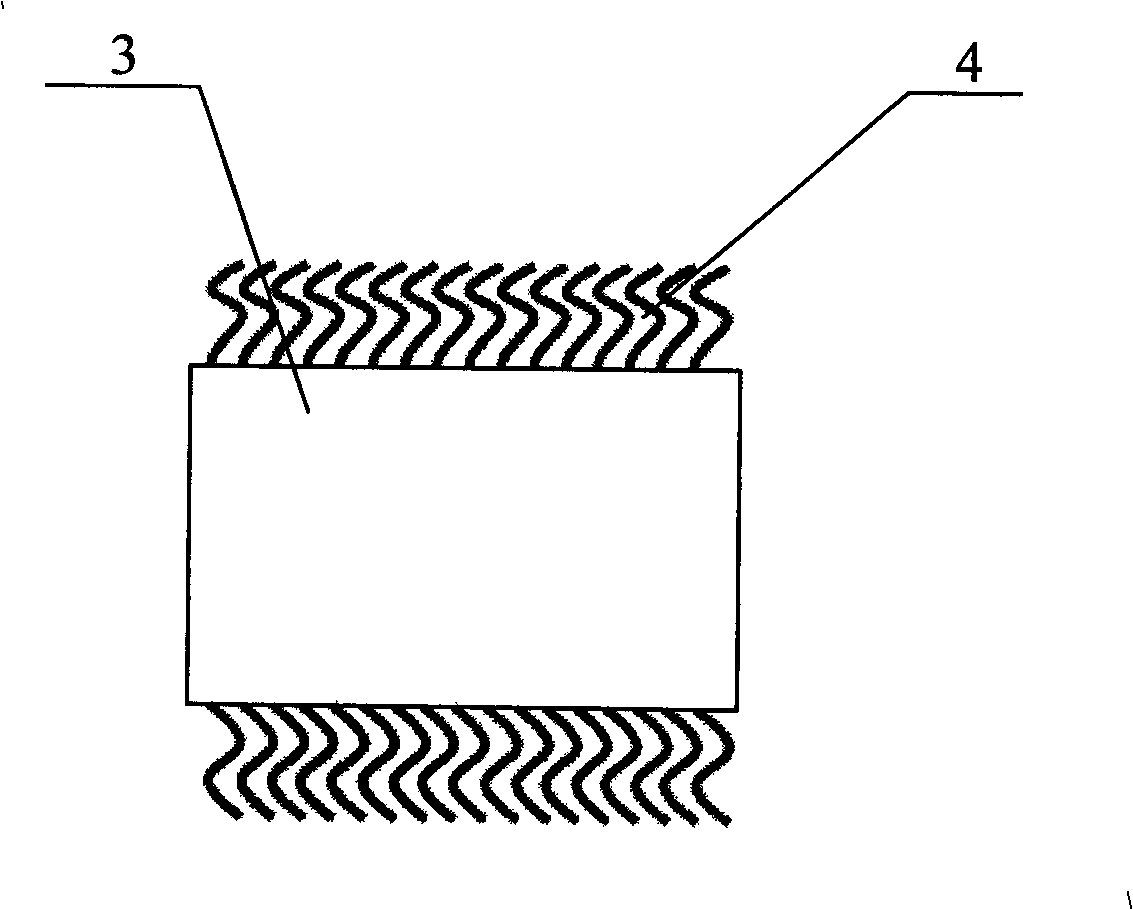

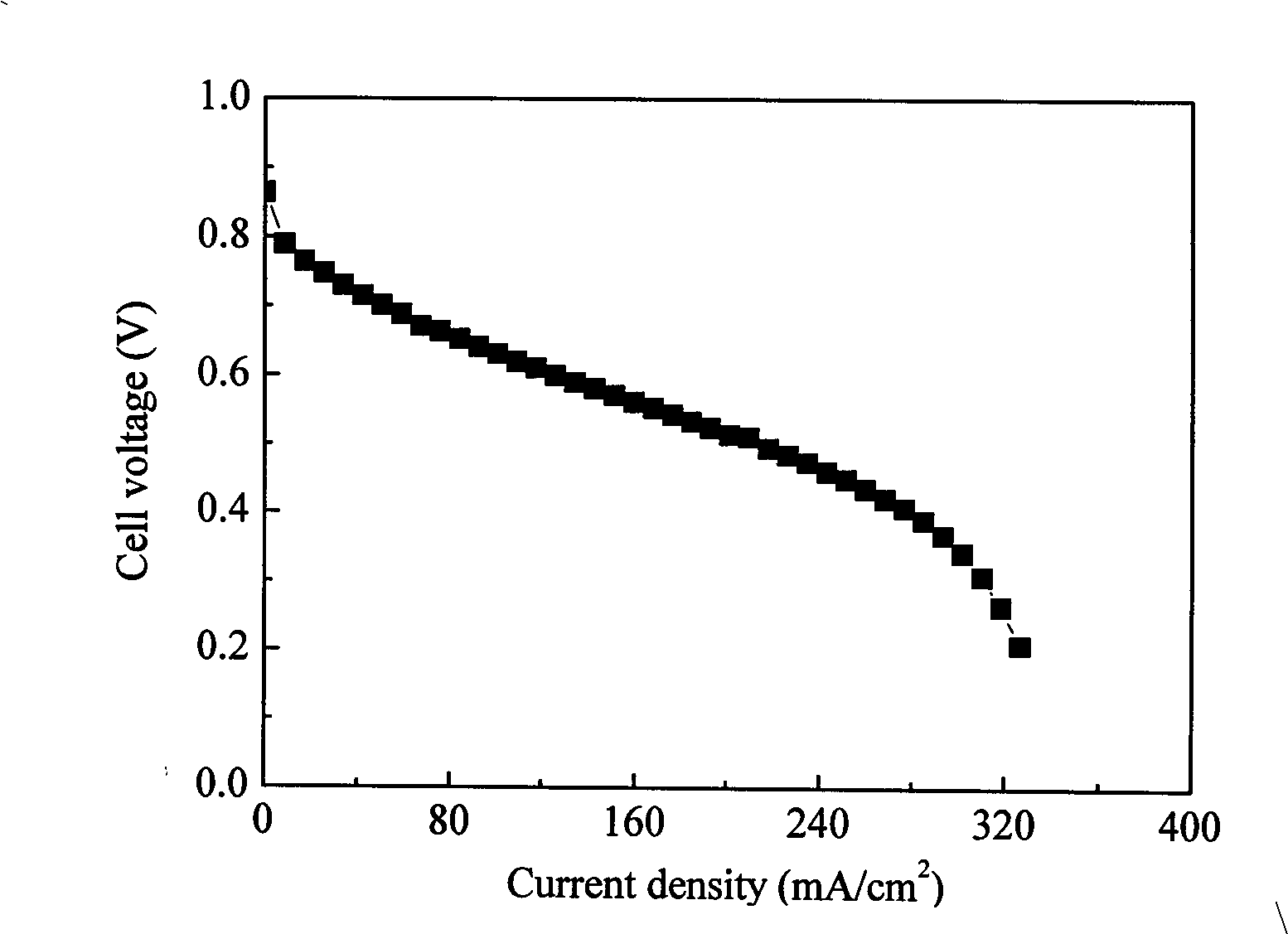

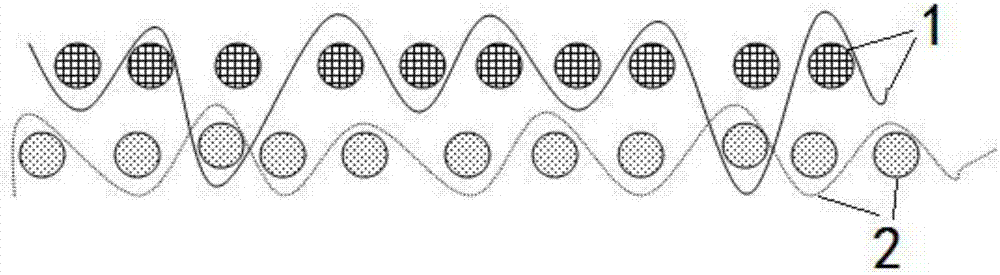

Gaseous diffusion layer for polymer electrolyte film fuel cell and preparation method thereof

InactiveCN101350412AEnhanced interactionAvoid accumulationCell electrodesFinal product manufactureConcentration polarizationSlurry

The invention relates to a gaseous diffusion layer for a polymer electrolyte membrane fuel battery and a preparation method thereof, relating to a gaseous diffusion layer for a fuel battery and a preparation method thereof. The invention is capable of settling the problem of uneven distribution of carbon paper or hydrophobic material in the existing gaseous diffusion layer which degrades the performance of the fuel battery due to relatively big concentration polarization and ohm polarization of the gaseous diffusion layer. The porous-material layer in the gaseous diffusion layer comprises a porous fiber layer and carbon nano-palp growing on the fibers of the porous fiber layer. The preparation method of the invention includes the procedures that the porous fiber layer is rinsed and dried; nano-particles of cobalt, nickel or cobalt-nickel alloy are loaded onto the fiber surface; hydrophobic treatment is conducted; and the slurry is coated on the surface of the supporting layer and sintered. The hydrophobic materials of the gaseous diffusion layer are distributed evenly, as a result, the concentration polarization and the ohm polarization of the gaseous diffusion layer are lowered and the performance of the fuel battery is improved. Besides, the equipments needed by the method are simple and are easy to realize.

Owner:HARBIN INST OF TECH

Underwater coating heavy corrosion protection coating and preparation method thereof

InactiveCN101781505AImprove water repellencySolving Dispersion ProblemsAntifouling/underwater paintsPaints with biocidesEpoxySeawater

The invention relates to the field of coating, in particular to an underwater coating heavy corrosion protection coating and a preparation method thereof. The coating is prepared by taking modified epoxy resin and complex curing agent as main film-forming materials and adding pigment and fillers. The coating has high underwater bonding strength and excellent underwater brushing performance. The coating is an environment-friendly product which has low surface treatment, does not float and is not decomposed when underwater construction, has good levelling property, good adhesive force and good drying performance. The product is applicable to the protection of surfaces of buildings, structures, bridges, drilling platforms, piles and columns and the like in seawater and fresh water, saves energy, shortens the construction period and improves the efficiency.

Owner:ZHONGKE CORROSION CONTROL ENG TECH CENT SHENYANG +1

Protecting mortar of express highway roadbed surface hard-face terrace

The invention provides a protecting mortar of the express highway roadbed surface hard-face terrace. The protecting mortar comprises the following components in parts by weight: 40-50 parts of ordinary silicate cement, 20-30 parts of quartz sand, 30-50 parts of carborundum, 2-4 parts of zeolite graft re-dispersible emulsion powder and 0.3-1 part of xanthan gum. The invention adopts zeolite graft re-dispersible emulsion powder; in the hydration process of silicate cement, the dense doping between anhydrite and crosslinked zeolite changes the lattice of cement so as to increase the wearability and antishrinking property of the express highway roadbed surface; the zeolite graft re-dispersible emulsion powder is crosslinked with xanthan gum to form composite polymer and the flexibility is increased to improve the anti-deforming force of the roadbed surface. The combined use of mortar and cement can increase the hardness, wear resistance, antishrinking property and anti-deforming force of the roadbed surface and prolong the service life of the highway.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Novel inorganic fireproof door and manufacturing method thereof

ActiveCN102900334AReduce erosionImprove earlyFireproof doorsDoor leavesAging resistanceCement slurry

The invention provides a novel inorganic fireproof door and a manufacturing method thereof, belonging to the technical field of magnesite products and solving the problems of poor structural stability and easiness of frost and halogenation return phenomena of the traditional inorganic fireproof doors. The novel inorganic fireproof door comprises an upper plate layer, a lower plate layer and a middle sandwich layer, wherein the middle sandwich layer comprises a wood frame and a filler filled in a gap of the wood frame. The fireproof door can be manufactured through the following steps of: (1) preparing a magnesium chloride aqueous solution; (2) preparing magnesium-chloride cement slurry; (3) preparing a modifying agent; (4) preparing mixed slurry; (5) preparing the filler; (6) manufacturing the lower plate layer; (7) placing the wood frame; (8) rolling rims; (9) filling; (10) manufacturing the upper plate layer; (11) closing molds; (12) pressing dies; and (13) curing and then demolding. The fireproof door and the manufacturing method thereof which are disclosed by the invention can be used for saving a large quantity of natural wood and are beneficial to protecting the natural environment, and the product has the advantages of aging resistance, high firmness and difficult deformation.

Owner:浙江杭海新城控股集团有限公司

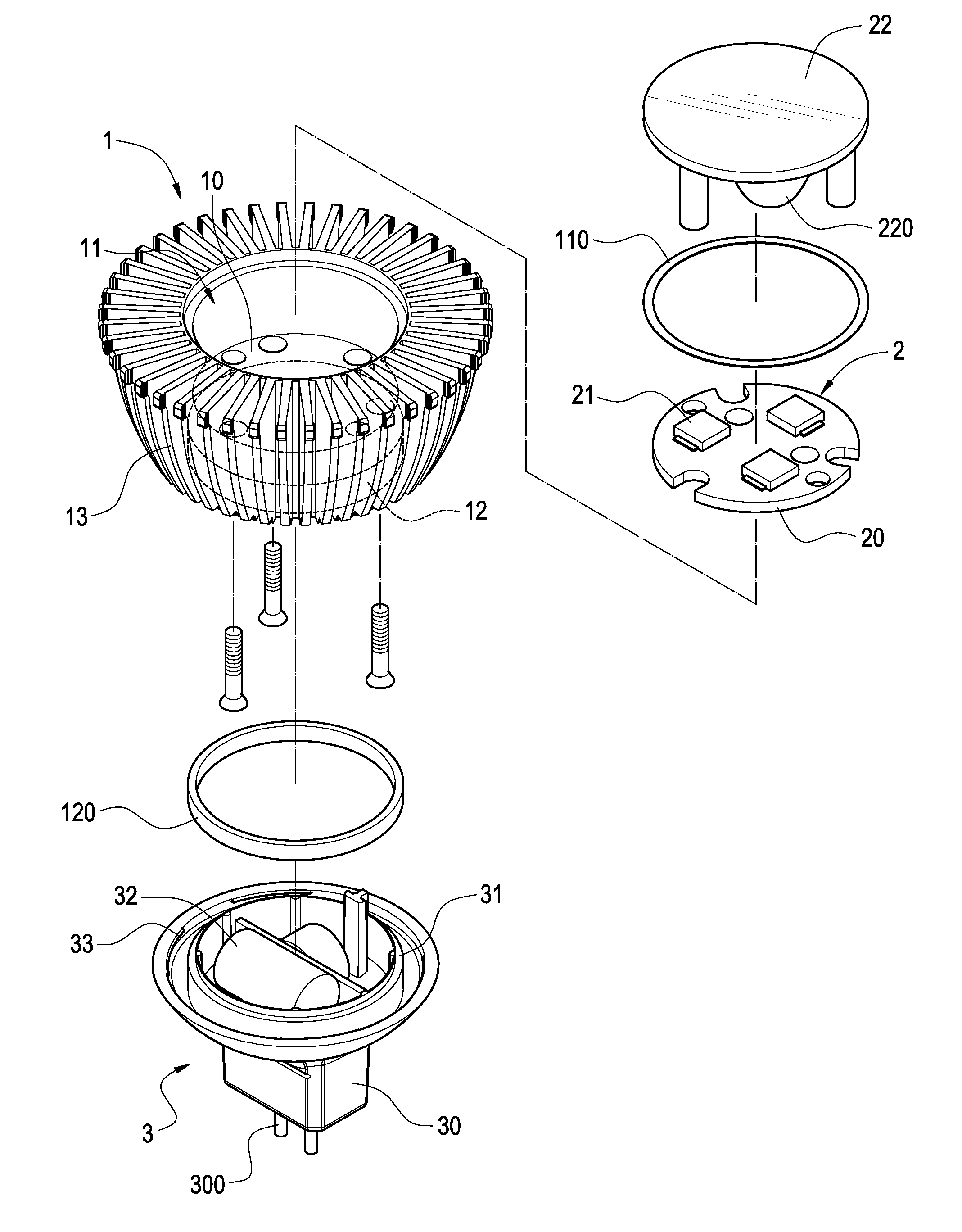

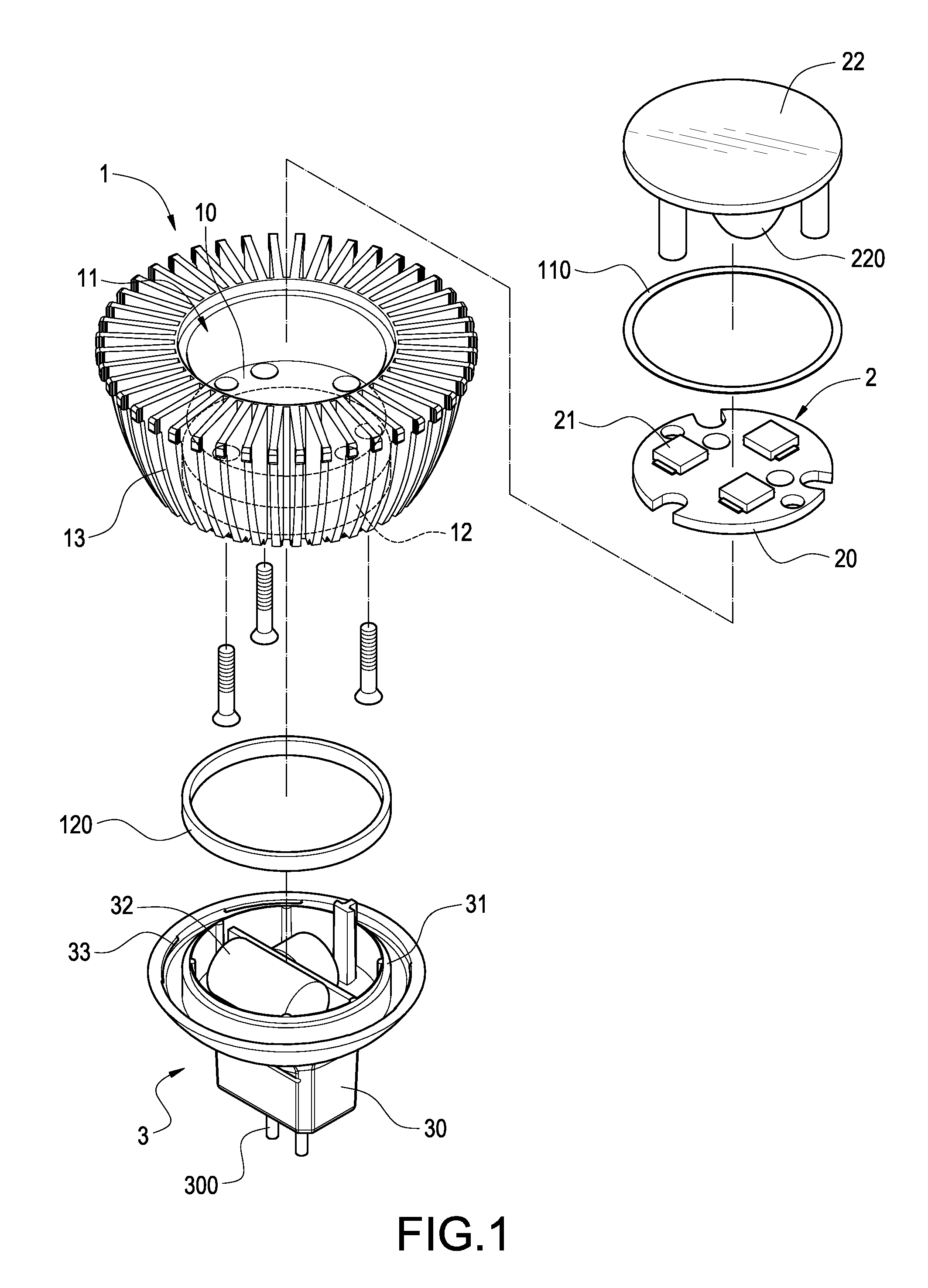

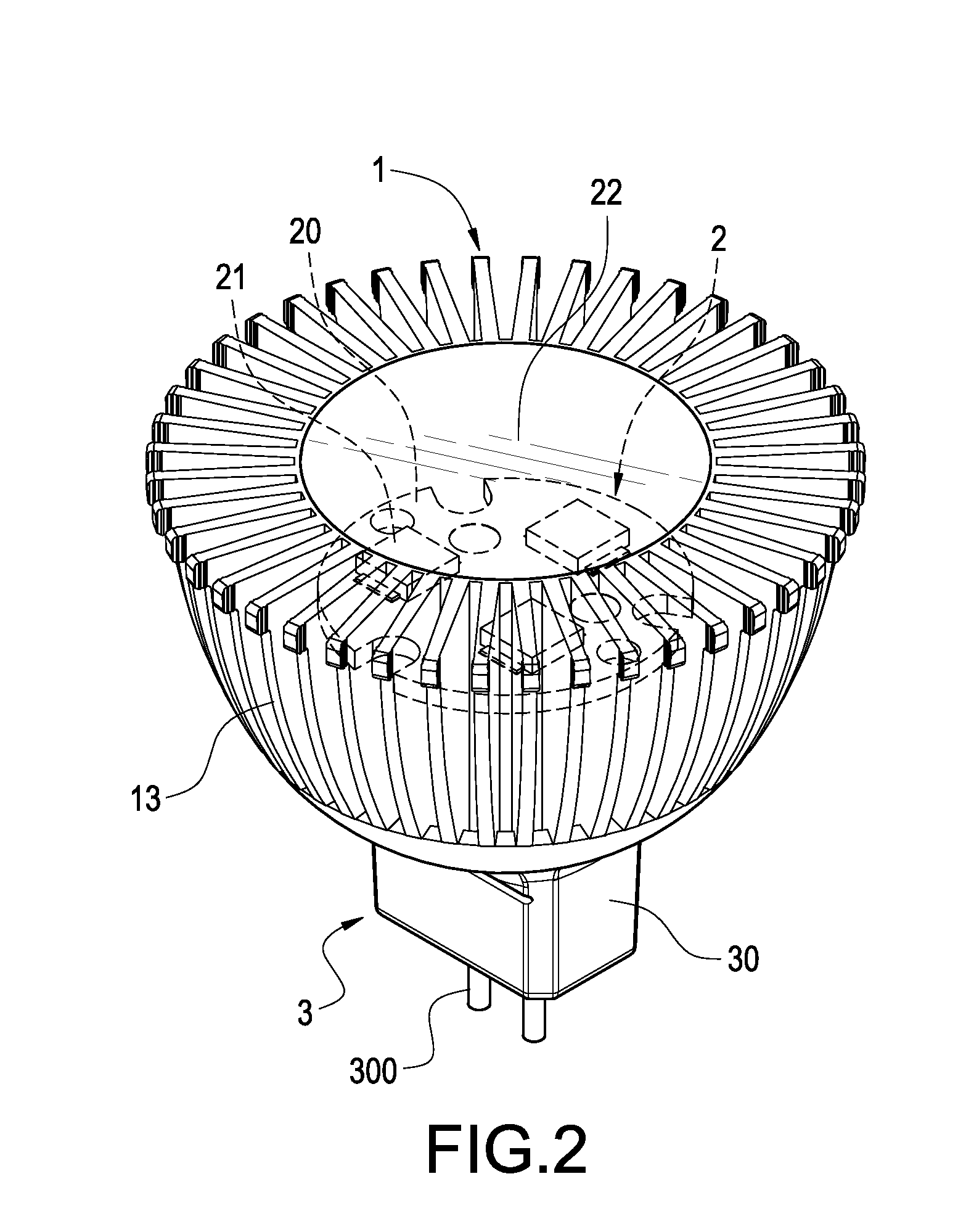

Lamp with double water resistance structure

InactiveUS20120106174A1Improve water repellencyIncreased durabilityPlanar light sourcesElectric circuit arrangementsEngineeringFastener

Owner:ECOLIGHTING

Double-layer flame-retardant fabric with water-repellent surface layer and hydrophil inner layer, and preparation technology thereof

InactiveCN106995965AHigh flame retardant and high temperature resistanceEasy to handleSynthetic resin layered productsHeating/cooling textile fabricsYarnSurface layer

The invention discloses double-layer flame-retardant fabric with a water-repellent surface layer and a hydrophil inner layer, and a preparation technology thereof. The double-layer flame-retardant fabric comprises the surface layer and the inner layer, wherein the surface layer is composed of at least one of aramid fibers, polyimide fibers, polysulfonamide fibers, flame-retardant viscose and ; the inner layer is formed by mixing flame-retardant modacrylic fibers with chloride, Tencel fibers and partner fibers, and the partner fiber is one selected from flame-retardant nylon fibers, aramid fibers and polysulfonamide fibers; water-repellency of the surface layer is implemented by the technology comprising the steps of preparing three proofing auxiliary size, soaking surface layer yarn into the three proofing auxiliary size, drying with high temperature, weaving and hot rolling with rollers; and water absorption of the inner layer is implemented by the technology comprising the steps of preparing hydrophil and sweat-releasing auxiliary size, soaking inner layer yarn into the size, drying, weaving and decating. The double-layer flame-retardant fabric with the water-repellent surface layer and the hydrophil inner layer has the characteristics of being soft, comfortable, air and moisture permeable and skin-friendly, has multifunctional protection performance, and meanwhile is high in comfort, so as to be applicable to special protection clothing in industries of firefighting, military police, electric power and smelting.

Owner:SHANGHAI IBENA TEXTILE PROD

Multifunctional water paint for woodware and preparation method of multifunctional water paint

InactiveCN107033748AHigh hardnessHigh glossFireproof paintsAntifouling/underwater paintsWater basedEmulsion

The invention relates to the technical field of water-based paint, and particularly discloses multifunctional water paint for woodware and a preparation method of the multifunctional water paint. Through compounding of various water-based resin emulsions, functional assistants and color fillers, the prepared water paint has ultralow VOC (volatile organic compound) content and has functions of fire, water, moth and bacteria resistance and self-cleaning.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

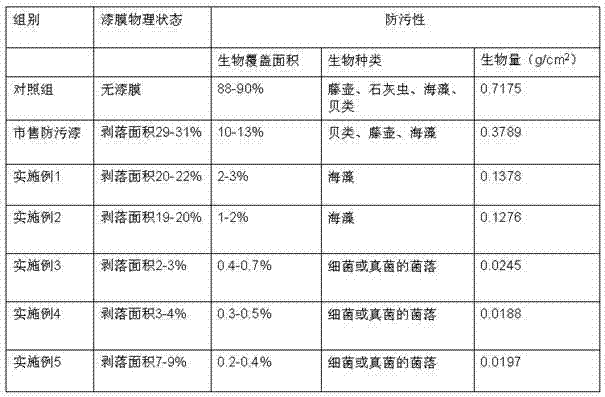

Bionic marine antifouling paint

ActiveCN103694754AStrong inhibition of adhesionPrevent adhesionAntifouling/underwater paintsPaints with biocidesSodium BentonitePolymer science

The invention discloses a bionic marine antifouling paint which comprises the following raw materials in parts by weight: 30-45 parts of fluorinated acrylic ester, 20-35 parts of silicone rubber, 2-10 parts of biological antifouling agent, 15-25 parts of filler, 0.5-1 part of organic bentonite, 0.5-1 part of polyethylene wax and 2-7 parts of propylene glycol. According to the bionic marine antifouling paint disclosed by the invention, P-cinnamate sulfate in the biological antifouling agent has a remarkably strong attachment inhibiting effect on marine bacteria and barnacle; homarine can prevent attachment of marine benthic diatom and barnacle; diterpene formamide has a function of inhibiting barnacle and shellfish larvae; the rubber silicon material and fluorinated acrylic ester material have extremely low surface free energy, low friction coefficient, high hydrophobicity and high contamination release performance, so that attachments are not easily attached or are insecurely attached.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

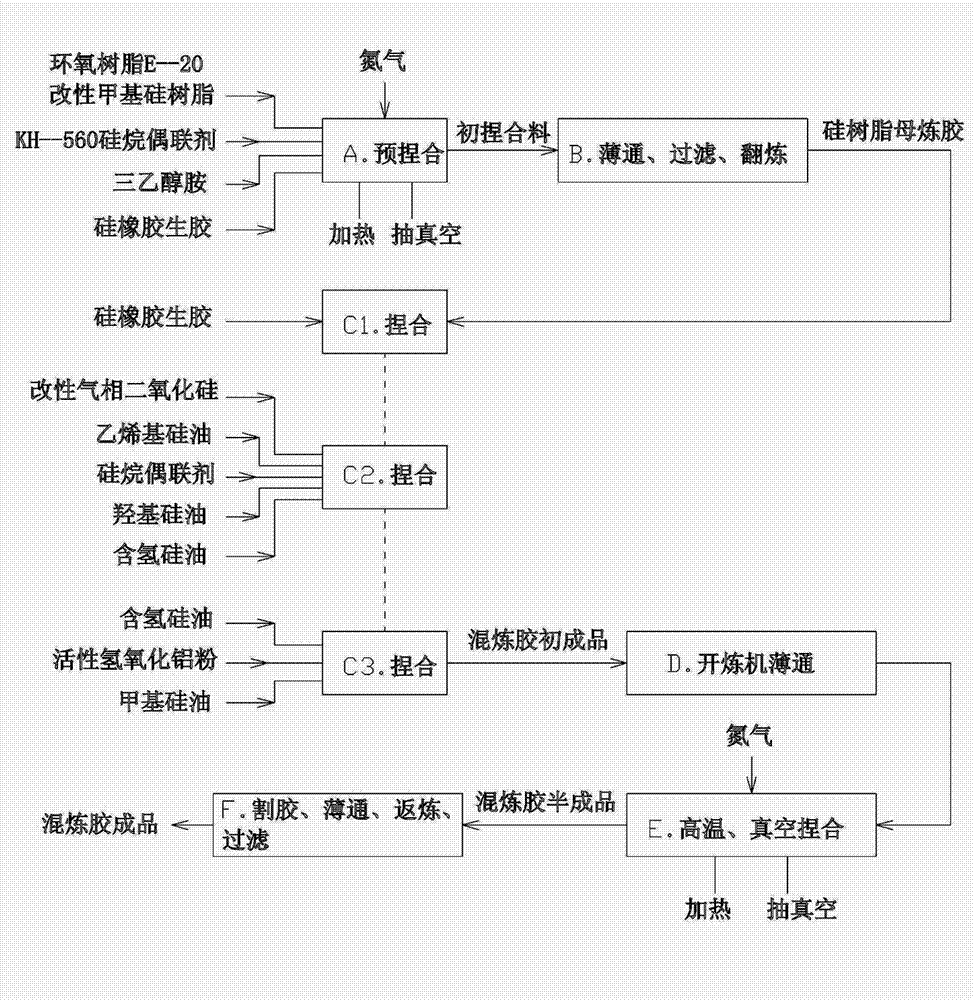

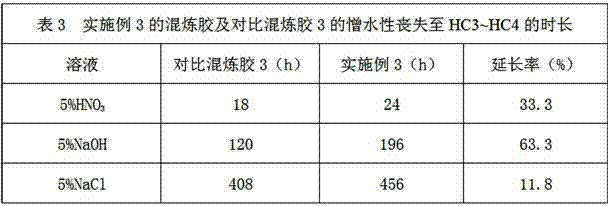

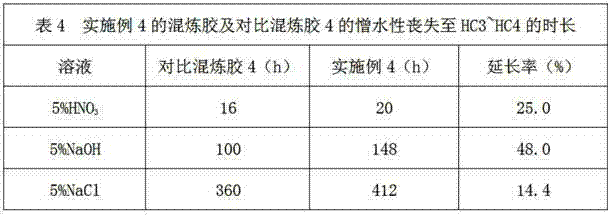

Compounded rubber for making chemical-corrosion-resistant composite insulator and preparation method thereof

The invention provides a compounded rubber for making a chemical-corrosion-resistant composite insulator, which is compounded from the following main raw materials in parts by weight: 100 parts of unvulcanized silicon rubber, 1-10 parts of epoxy resin E-20 modified methyl silicon resin, 18-40 parts of modified gas-phase silicon dioxide, 1-15 parts of silane coupling agent, 90-180 parts of active aluminum hydroxide powder and 0-1.2 parts of triethanolamine, wherein the silane coupling agent is one or mixture of A-151 silane coupling agent, A-171 silane coupling agent and KH-560 silane coupling agent; the unvulcanized silicon rubber is methylvinyl silicon rubber of which the vinyl content is 0.04-0.35%; and the content of epoxy resin in the epoxy resin E-20 modified methyl silicon resin is 40-75%. The invention also provides a preparation method of the compounded rubber. The test proves that the compounded rubber has favorable chemical corrosion resistance; and the composite insulator made from the compounded rubber is especially suitable for saline-alkali regions and chemical and dust pollution regions.

Owner:XUZHOU POWER SUPPLY OF JIANGSU ELECTRIC POWER +4

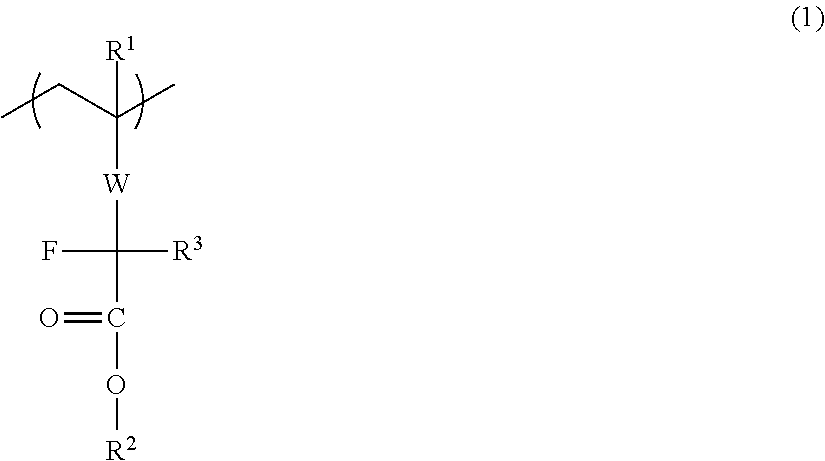

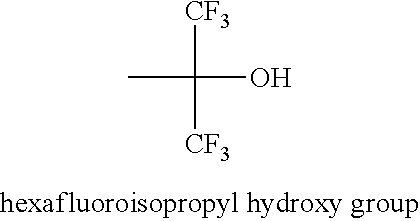

Top Coating Composition

InactiveUS20120040294A1Improve water repellency of top coatingHigh receding contact angleFibre treatmentSemiconductor/solid-state device manufacturingResistSolubility

Disclosed is a top coating composition formed on a resist film, for protecting the resist film, the top coating composition being a top coating composition for photoresist, characterized by containing a fluorine-containing polymer having a repeating unit represented by the following general formula (1). This composition is capable of controlling developing solution solubility and has a high water repellency.[In the formula, R1 represents a hydrogen atom, fluorine atom, methyl group or trifluoromethyl group, R2 represents a heat-labile protecting group, R3 represents a fluorine atom or fluorine-containing alkyl group, and W is a bivalent linking group.]

Owner:CENT GLASS CO LTD

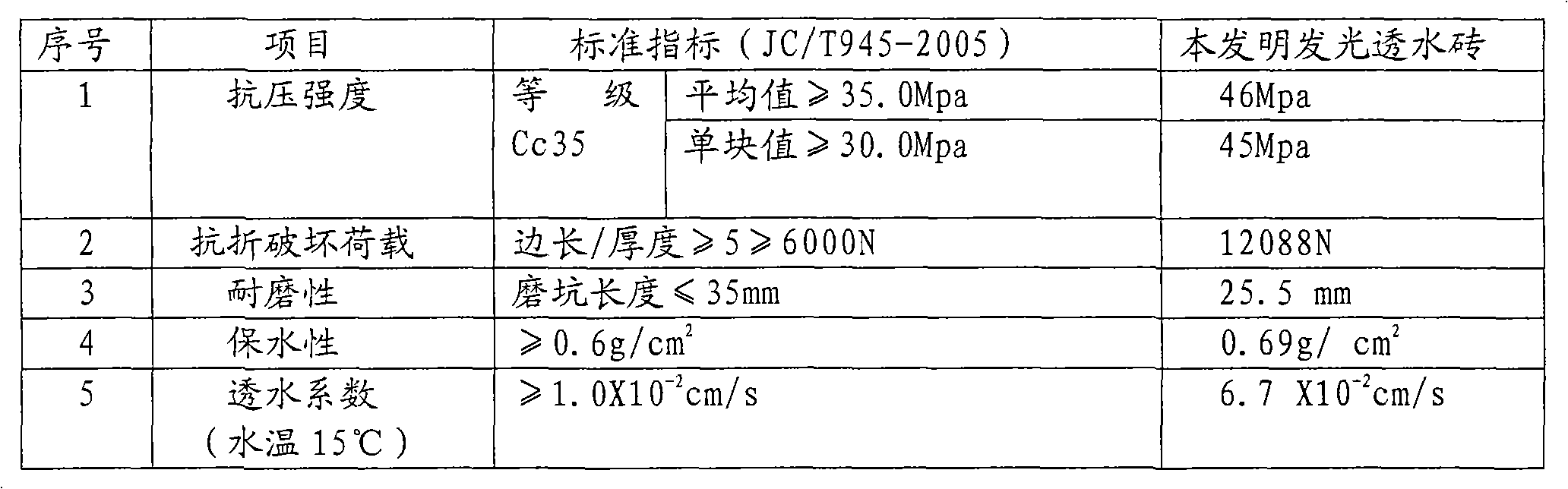

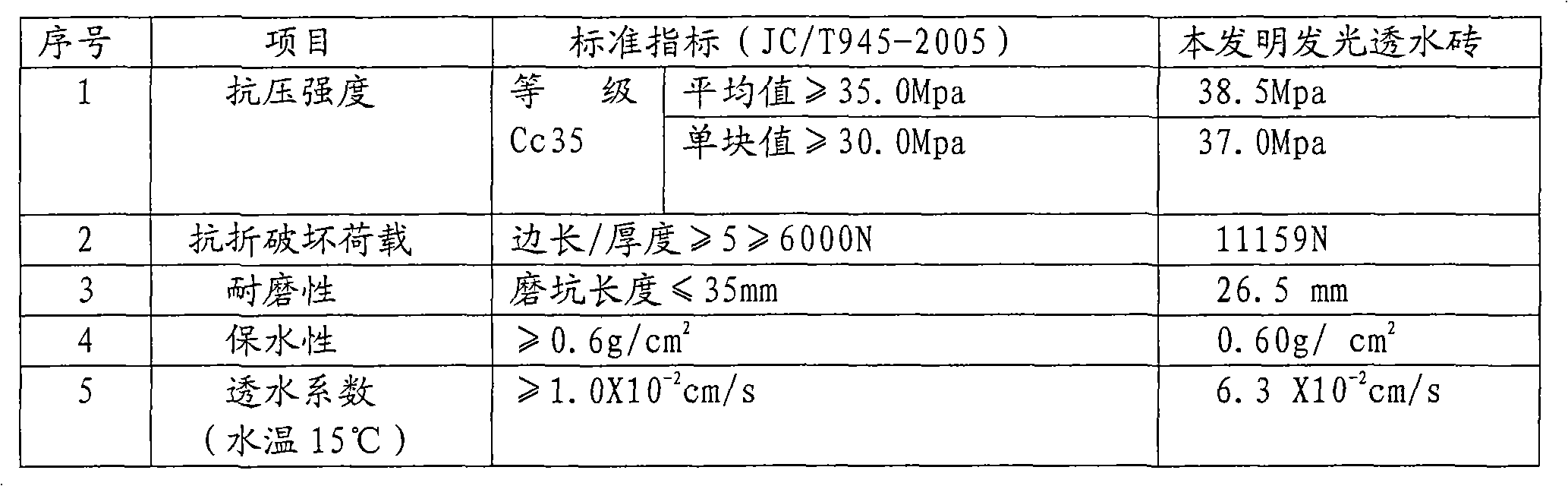

Method for preparing light-emitting materials

The invention relates to a method for preparing light-emitting materials, which comprises the following steps: carrying out pre-film coating treatment on aggregates, then adding bonding agents and light-emitting materials and / or reflective materials, and evenly stirring, thereby obtaining the light-emitting materials. The light-emitting materials can be used for manufacturing light-emitting bricks or be used for paving a pavement for forming the light-emitting pavement and the like. The light-emitting materials and products thereof have excellent abrasion resistance and light-emitting performance.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com