Gaseous diffusion layer for polymer electrolyte film fuel cell and preparation method thereof

A technology of gas diffusion layer and electrolyte membrane, which is applied to fuel cell parts, fuel cells, electrical components, etc., can solve the problems of ohmic polarization reduction, large concentration polarization of gas diffusion layer, etc., and achieve uniform distribution, Effect of improving mass transfer ability and conductivity, enhancing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

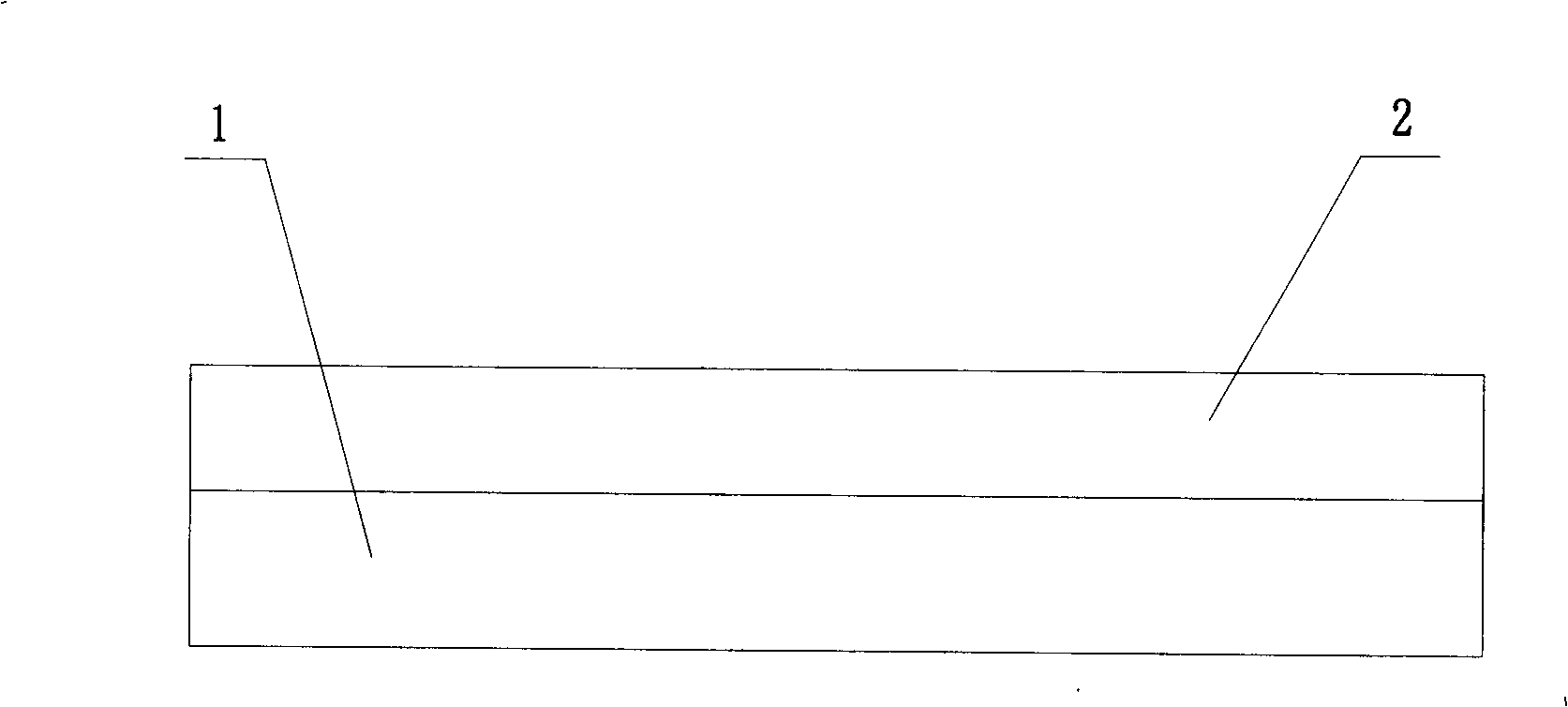

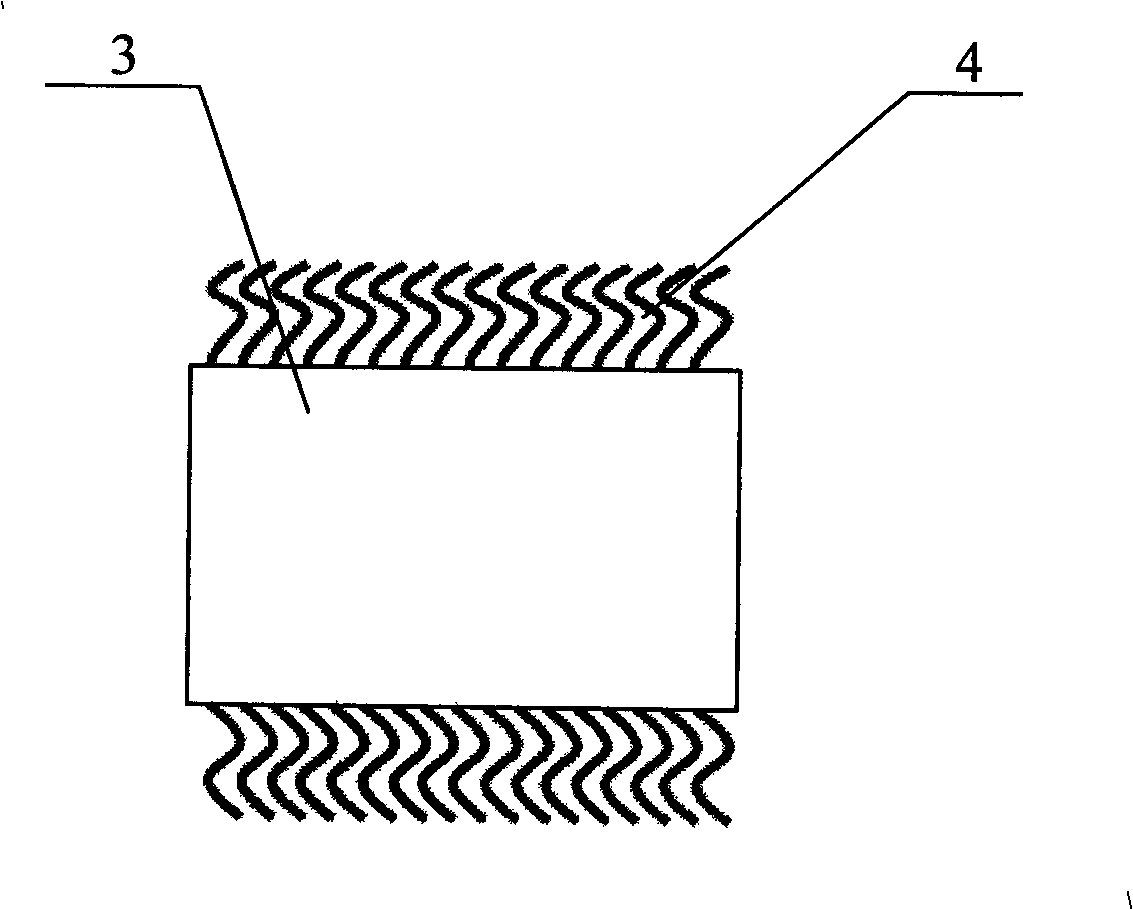

[0009] Specific implementation mode 1: Combination figure 1 with figure 2 To illustrate this embodiment, the gas diffusion layer used in the polymer electrolyte membrane fuel cell of this embodiment is composed of a support layer 1 and a microporous layer 2. The microporous layer 2 covers the surface of the support layer 1, and the support The layer 1 is made of a hydrophobically treated porous material layer composed of a porous fiber layer and carbon nanowhiskers 4 grown on the fibers 3 of the porous fiber layer.

specific Embodiment approach 2

[0010] Specific implementation manner two: combination figure 2 To describe this embodiment, the difference between this embodiment and the first embodiment is that the porous fiber layer of this embodiment is made of carbon paper, carbon cloth or metal fiber mesh. With this arrangement, the hydrophobic material is more evenly distributed in the gas diffusion layer.

specific Embodiment approach 3

[0011] Specific implementation mode three: combination figure 2 To describe this embodiment, the difference between this embodiment and the first embodiment is: the porosity of the porous fibrous layer of this embodiment is 20%-95%, and the average pore diameter is greater than 1um. With this arrangement, the hydrophobic material is more evenly distributed in the gas diffusion layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com