Patents

Literature

1783 results about "Gas diffusion layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

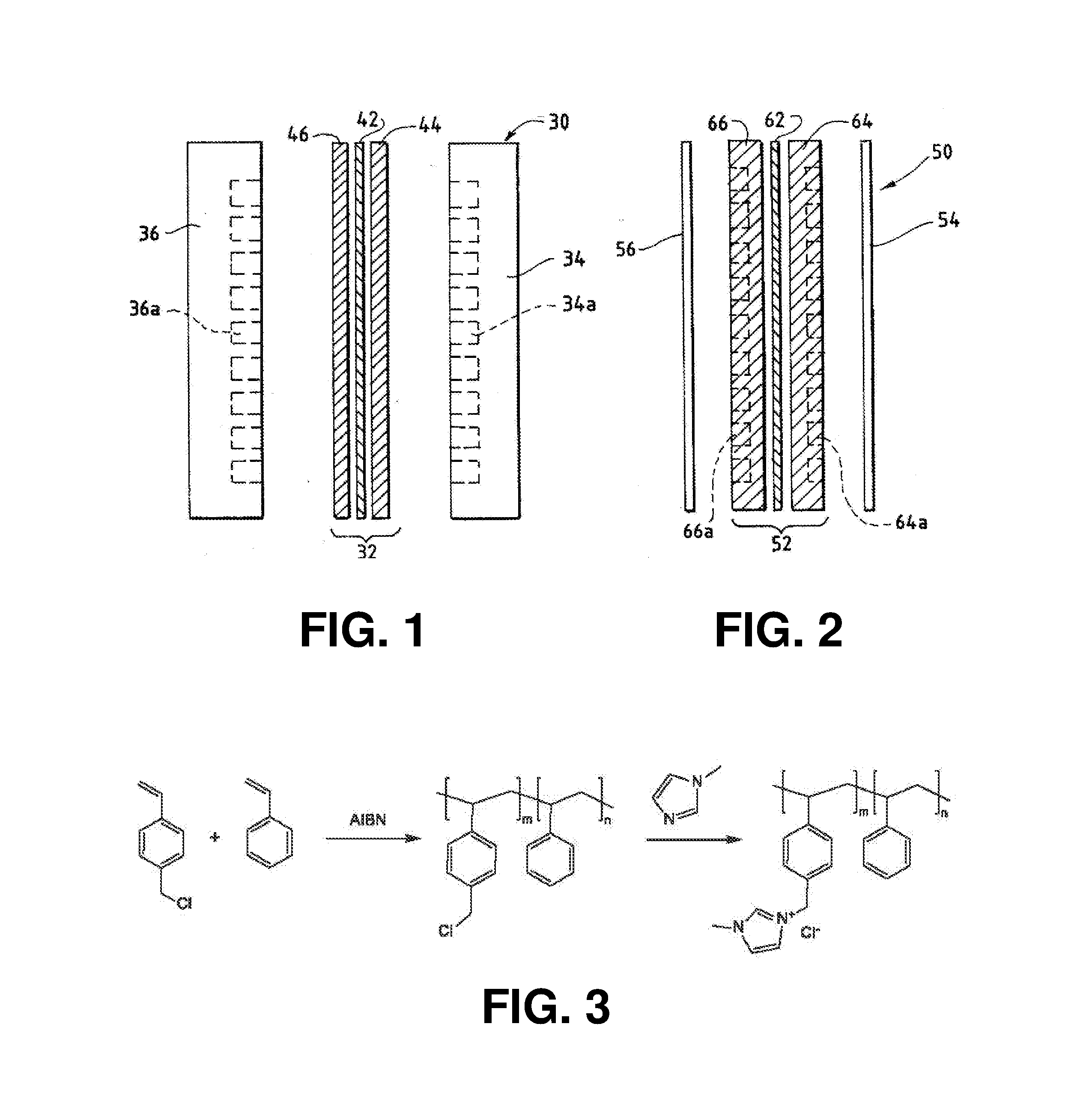

Method And System For Electrochemical Production Of Formic Acid From Carbon Dioxide

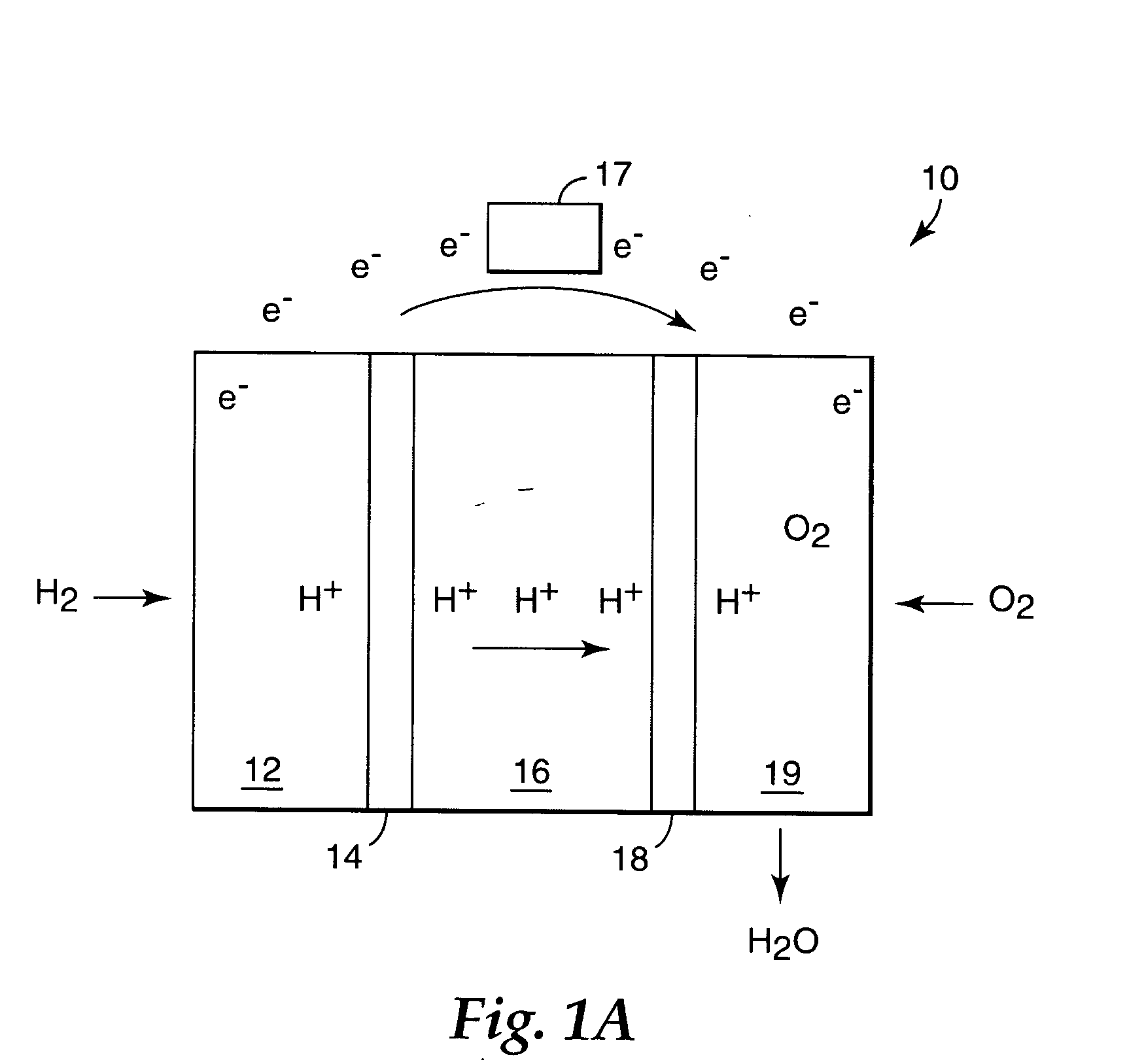

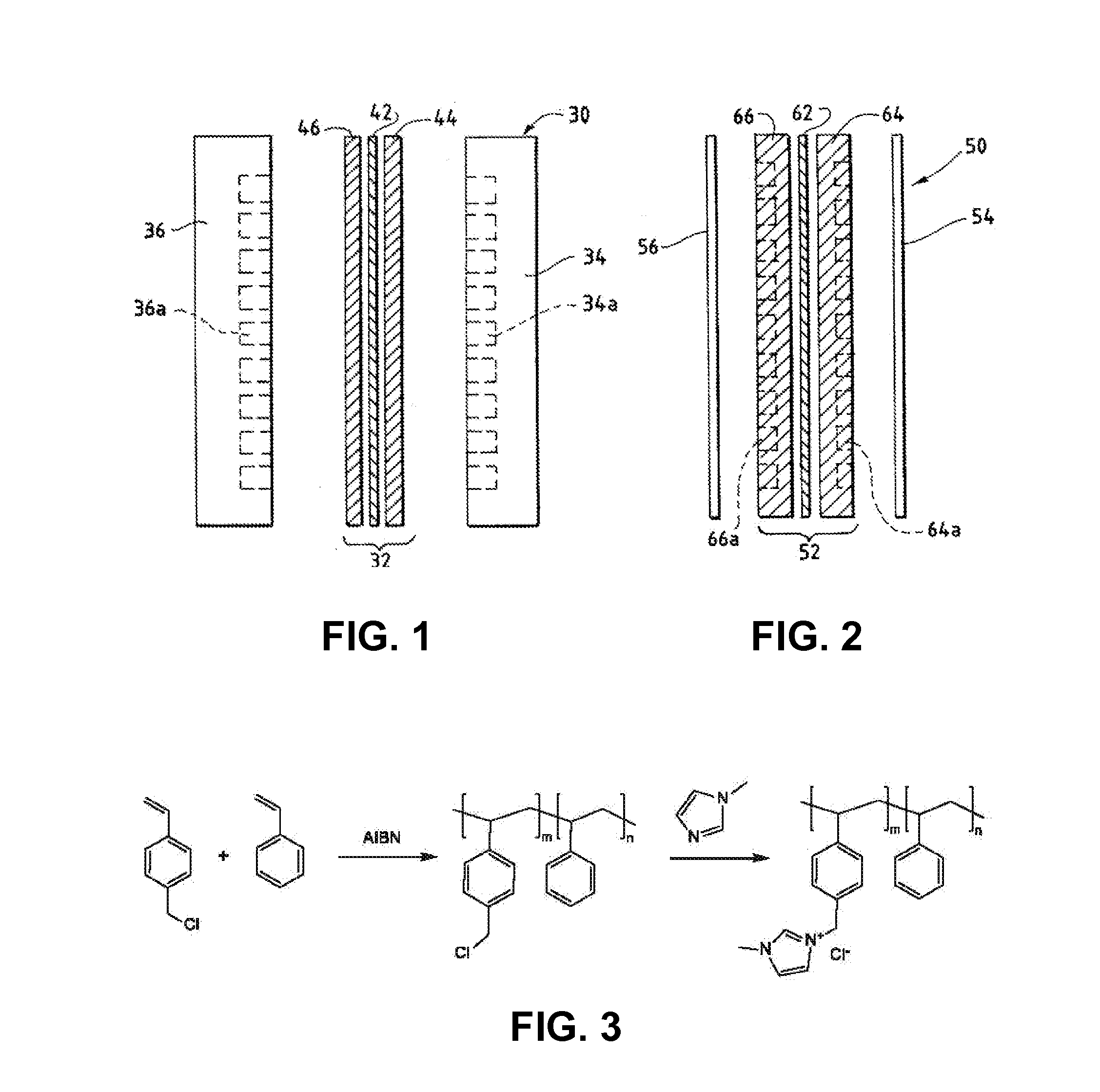

An electrochemical device converts carbon dioxide to a formic acid reaction product. The device includes an anode and a cathode, each comprising a quantity of catalyst. The anode and cathode each have reactant introduced thereto. Two membranes, a cation exchange polymer electrolyte membrane and an anion exchange polymer electrolyte membrane, are interposed between the anode and the cathode, forming a central flow compartment where a carbon dioxide reduction product, such as formic acid, can be recovered. At least a portion of the cathode catalyst is directly exposed to gaseous carbon dioxide during electrolysis. The average current density at the membrane is at least 20 mA / cm2, measured as the area of the cathode gas diffusion layer that is covered by catalyst, and formate ion selectivity is at least 50% at a cell potential difference of 3.0 V. In some embodiments, at least one polymer electrolyte membrane comprises a polymer in which a constituent monomer is (p-vinylbenzyl)-R, where R is selected from the group consisting of imidazoliums, pyridiniums and phosphoniums. In some embodiments, the polymer electrolyte membrane is a Helper Membrane comprising a polymer containing an imidazolium ligand, a pyridinium ligand, or a phosphonium ligand.

Owner:DIOXIDE MATERIALS

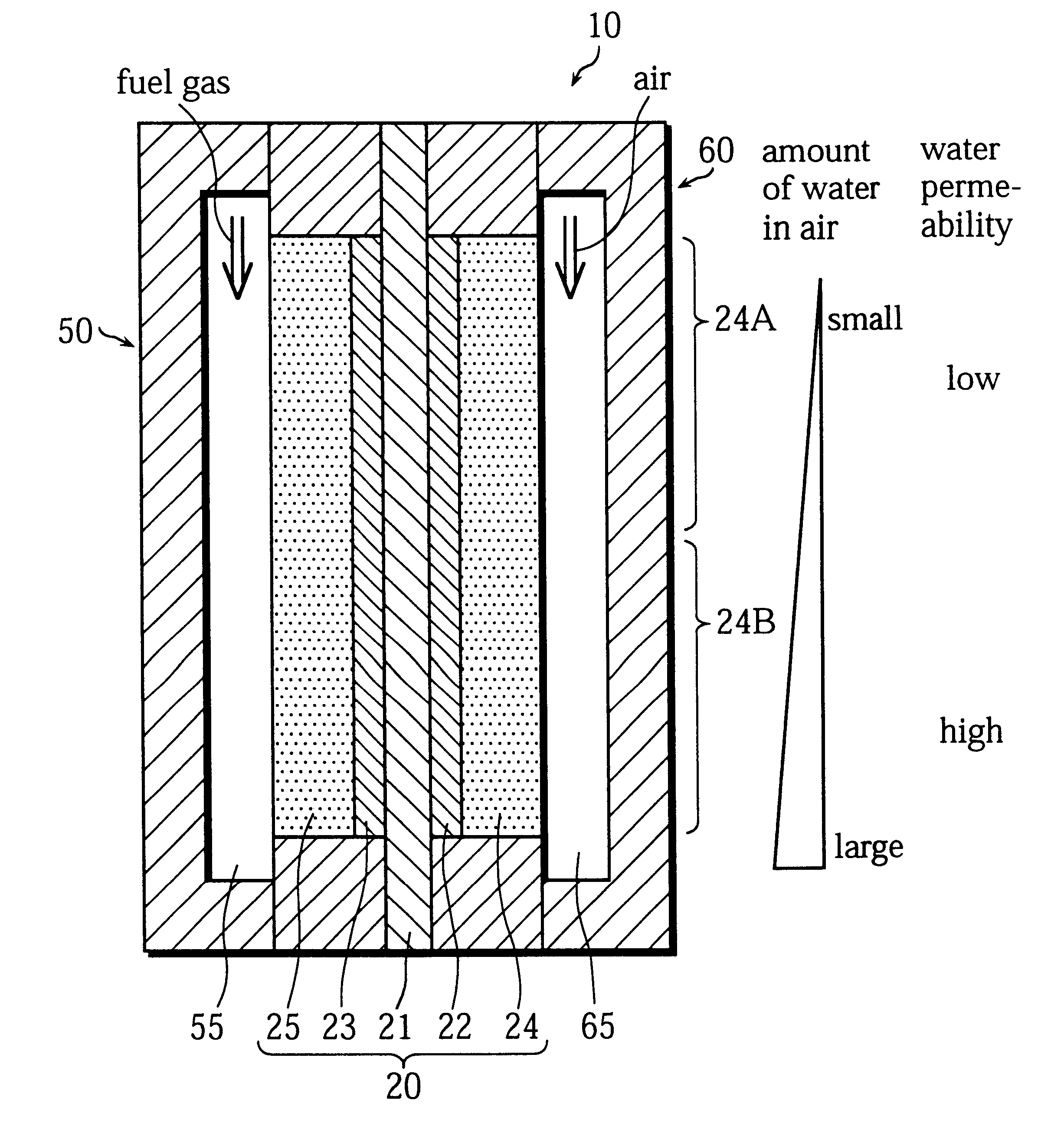

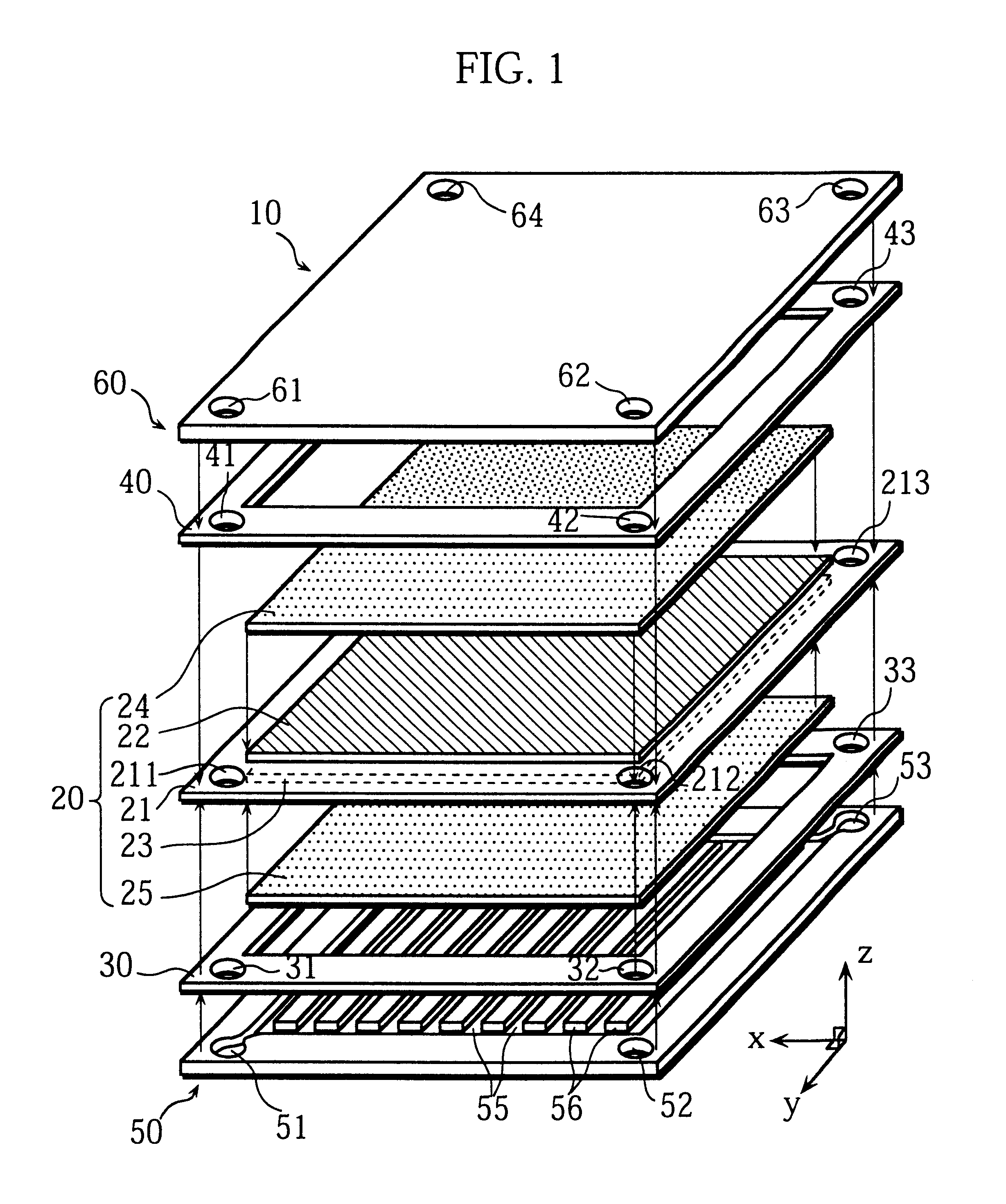

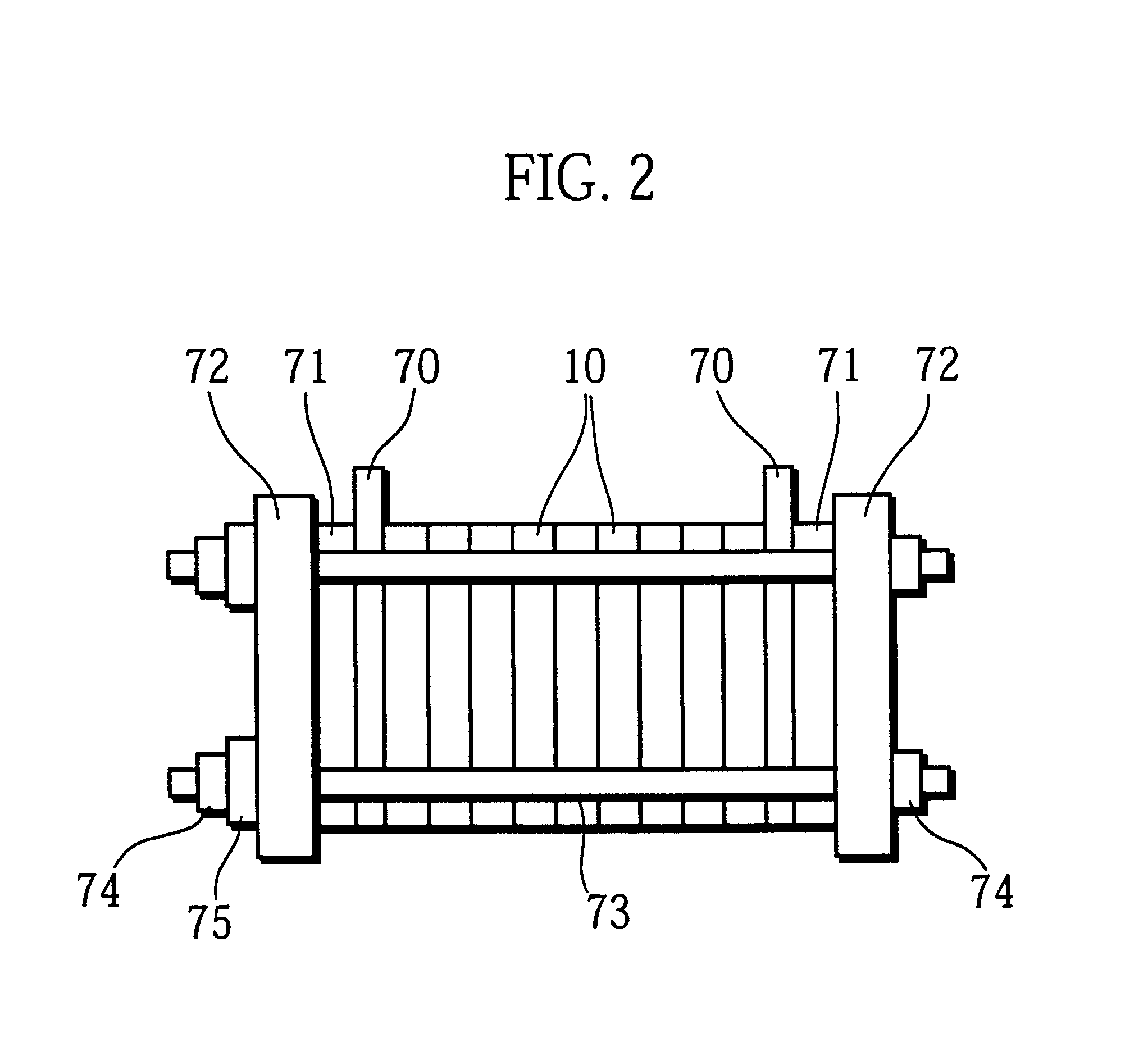

Fuel cell having water permeability adjustment capability

The object of the present invention is to provide fuel cell including a cell that is formed by sandwiching solid polymer membrane between an anode and a cathode that generates electricity with stability and high performance by evenly moistening the solid polymer membrane. For this purpose, in a gas diffusion layer 24, which is positioned adjacent to a cathode catalyst layer 22, the content of fluororesin in an area on the side of the entrance for the oxidizer is set to be higher than in another area on the side of the exit so that the water repellency in the entrance side area is higher than in the exit side area. As a result, a water permeation suppressing part 24A, where the water permeability is relatively low, is formed in the area on the entrance side, while a water permeable part 24B, where the water permeability is relatively high, is formed in the area on the exit side.

Owner:SANYO ELECTRIC CO LTD

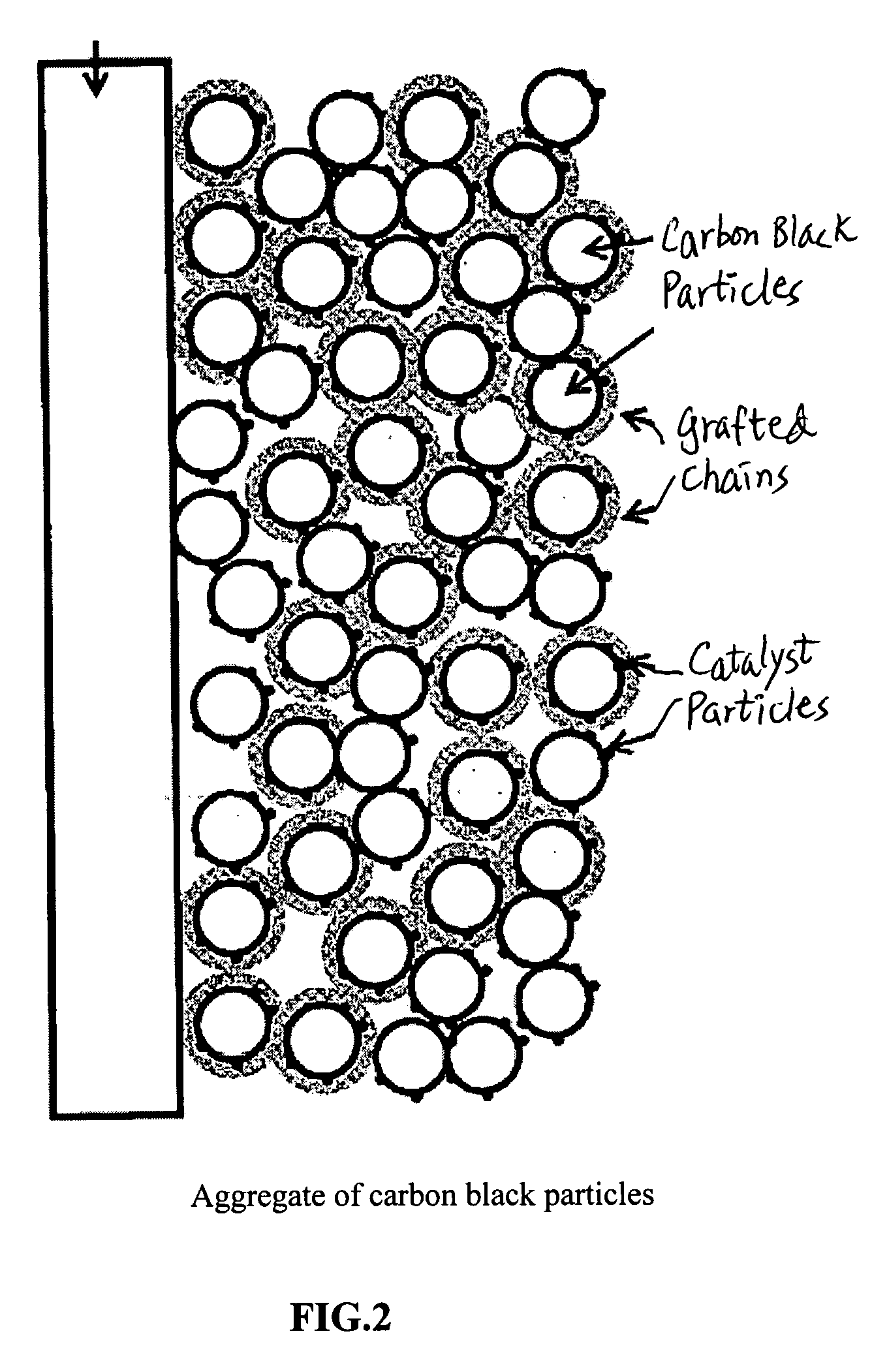

Modified carbon products, their use in fluid/gas diffusion layers and similar devices and methods relating to the same

Gas / Fluid diffusion layers incorporating modified carbon products. The modified carbon products advantageously enhance the properties of gas / fluid diffusion layers, leading to more efficiency within a fuel cell or similar device incorporating the gas / fluid diffusion layer.

Owner:CABOT CORP

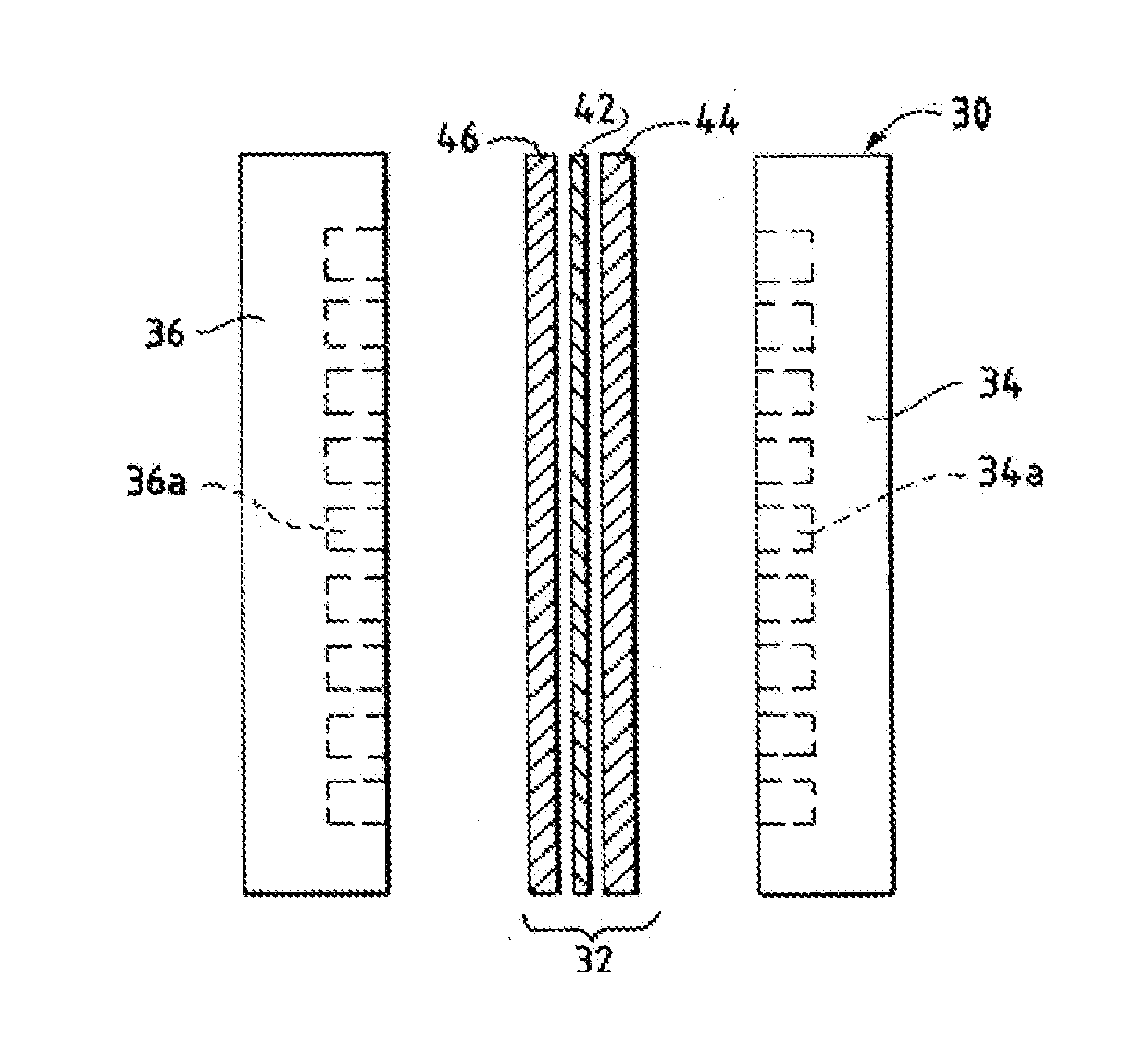

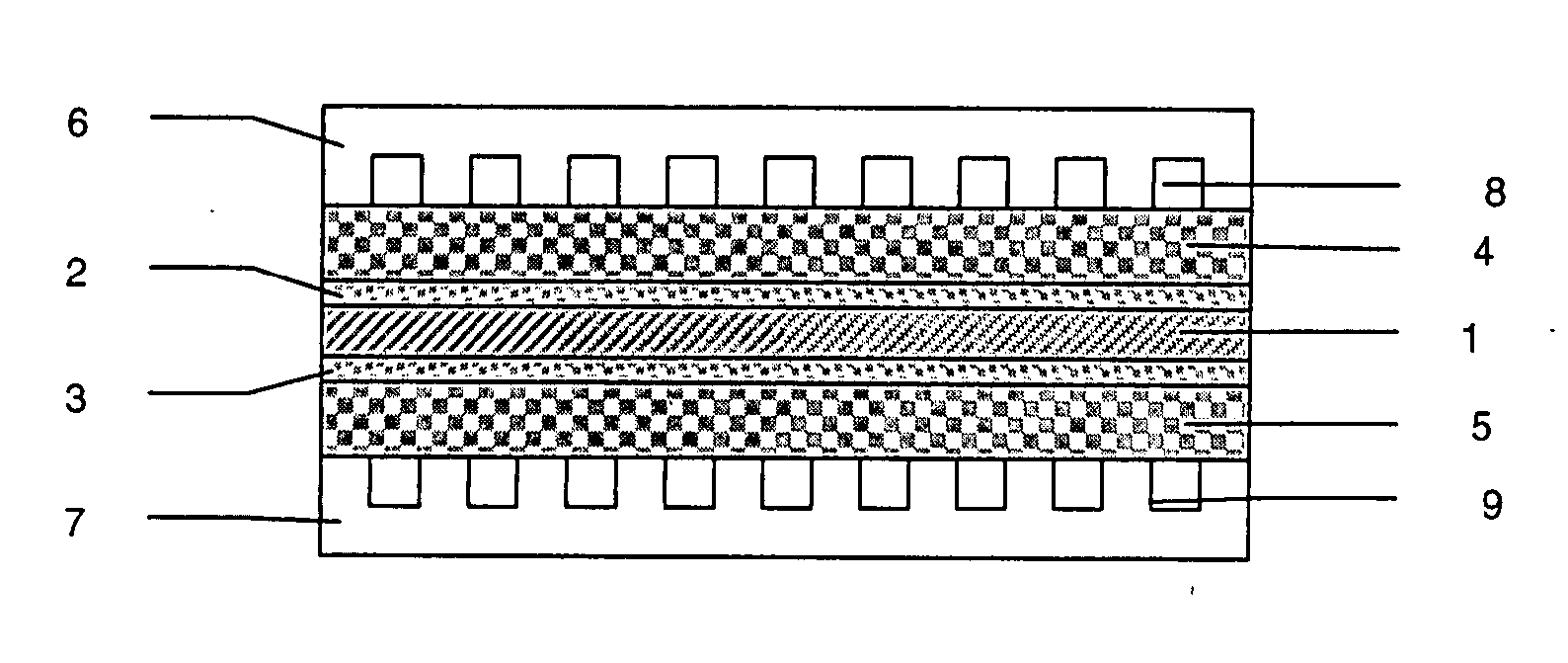

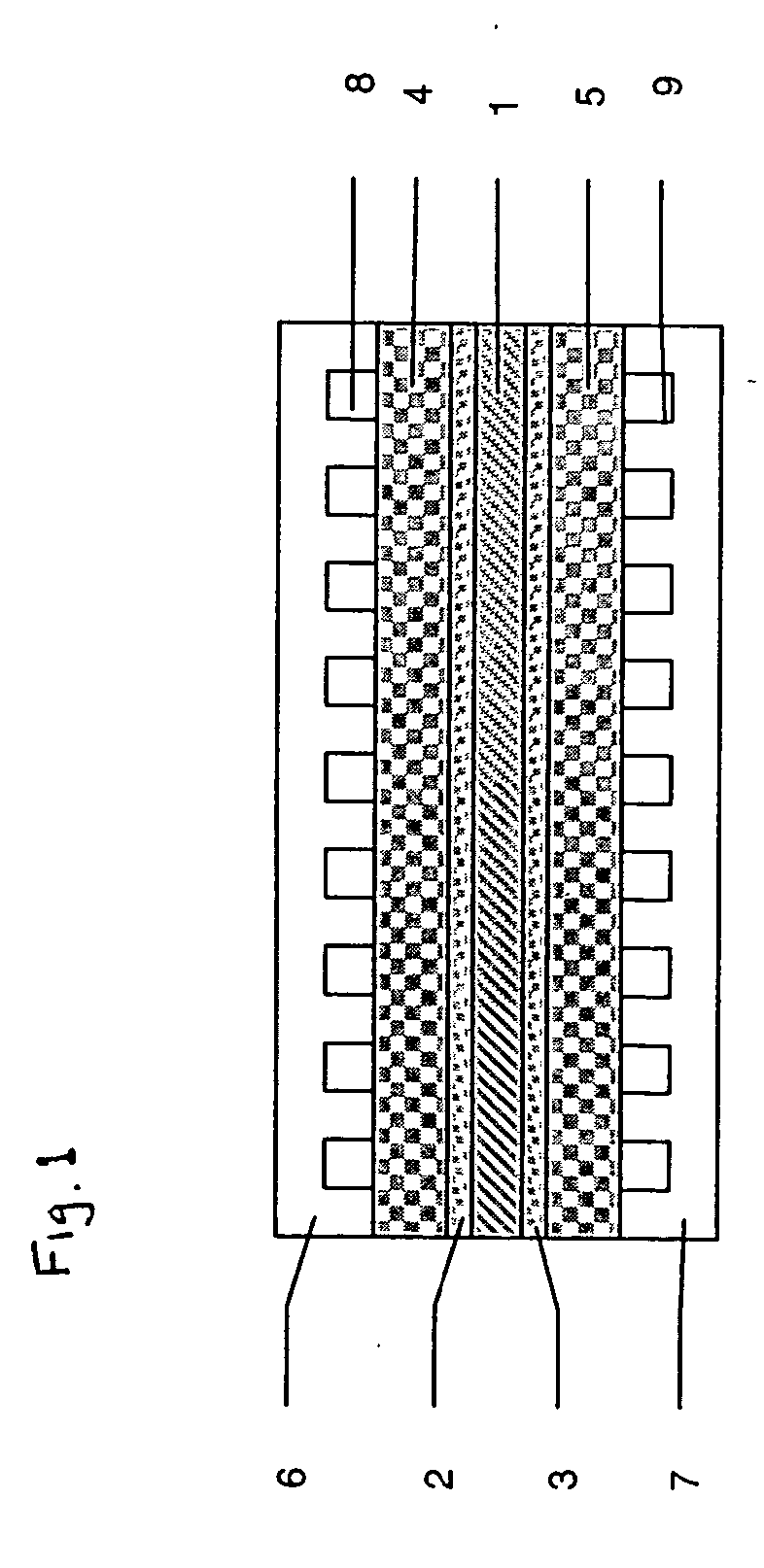

Membrane electrode assembly and fuel cell

InactiveUS20050142397A1Avoid damageDesired performanceFuel cells groupingFuel cell auxillariesPolymer electrolytesFuel cells

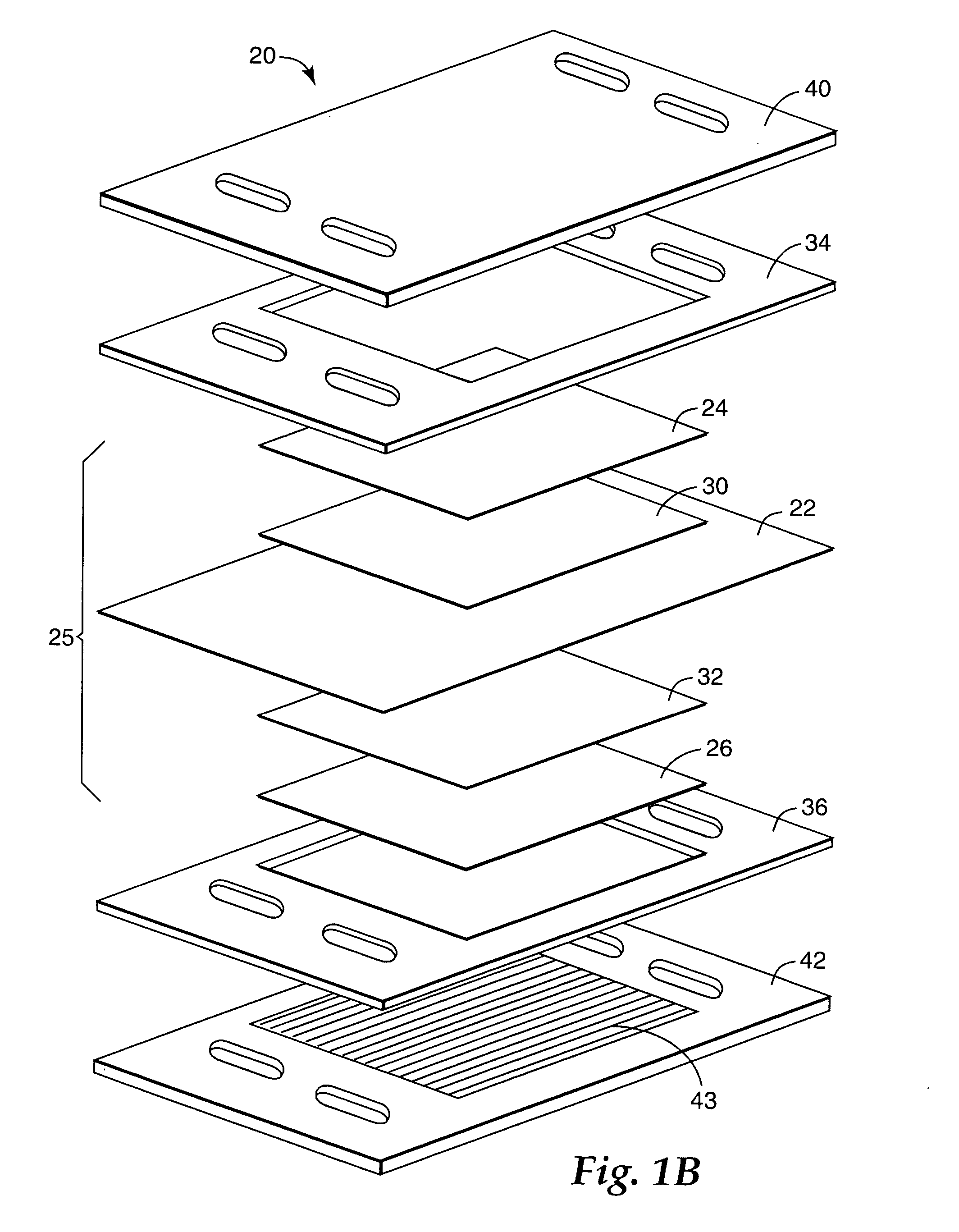

A membrane electrode assembly includes an anode, a cathode, and a solid polymer electrolyte membrane interposed between the anode and the cathode. The anode and the cathode include gas diffusion layers and electrode catalyst layers. Mixture layers are provided over predetermined areas H around surfaces of the electrode catalyst layers. The electrode catalyst layers and adhesive layers are mixed in the mixture layers, respectively.

Owner:HONDA MOTOR CO LTD

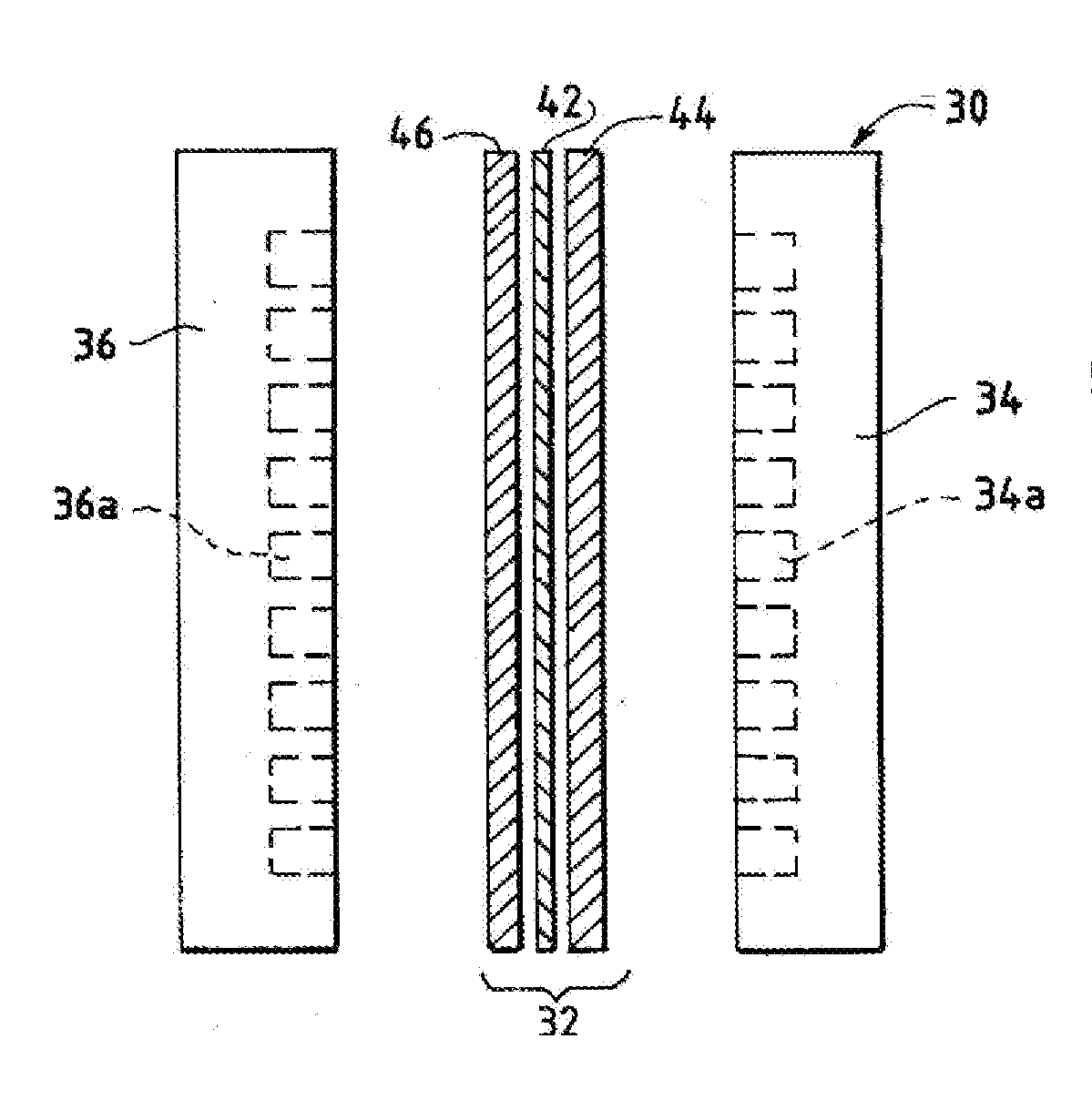

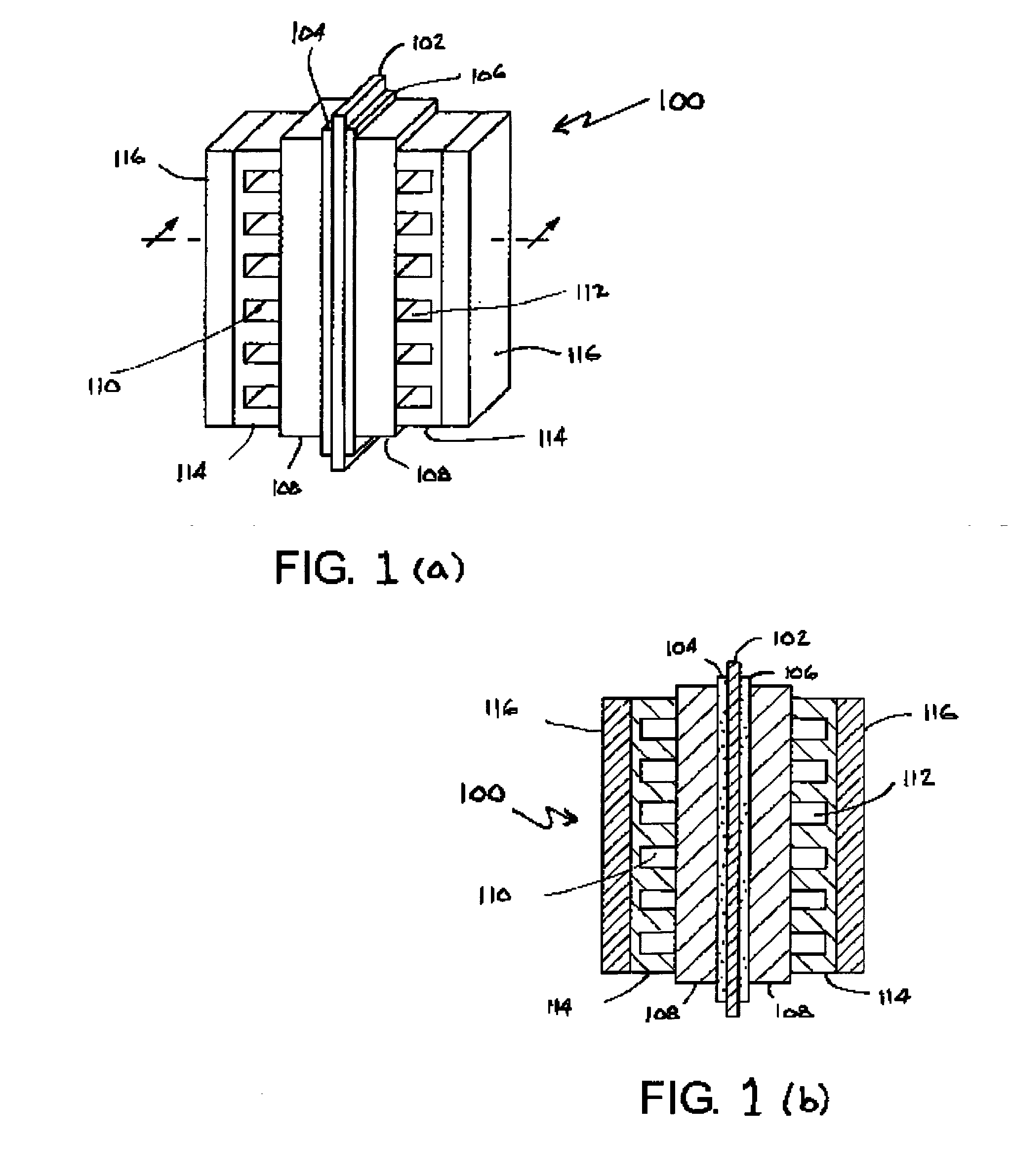

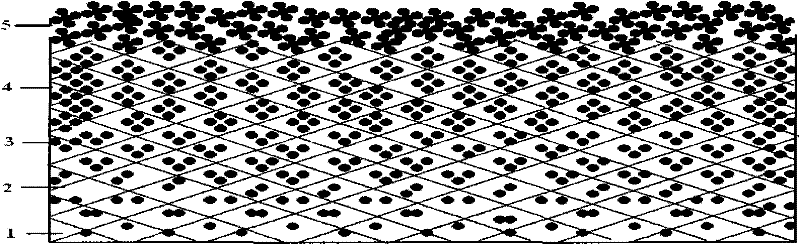

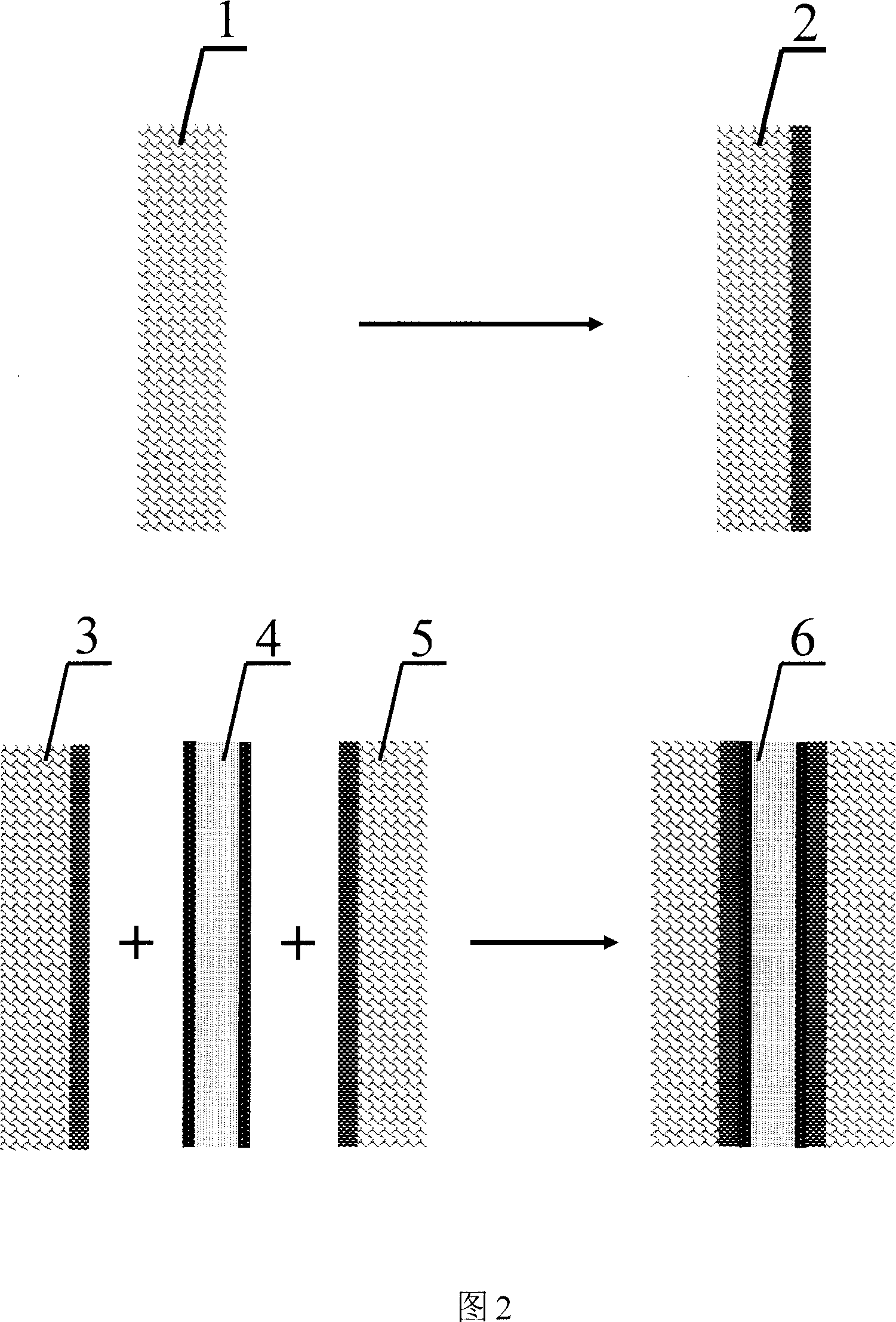

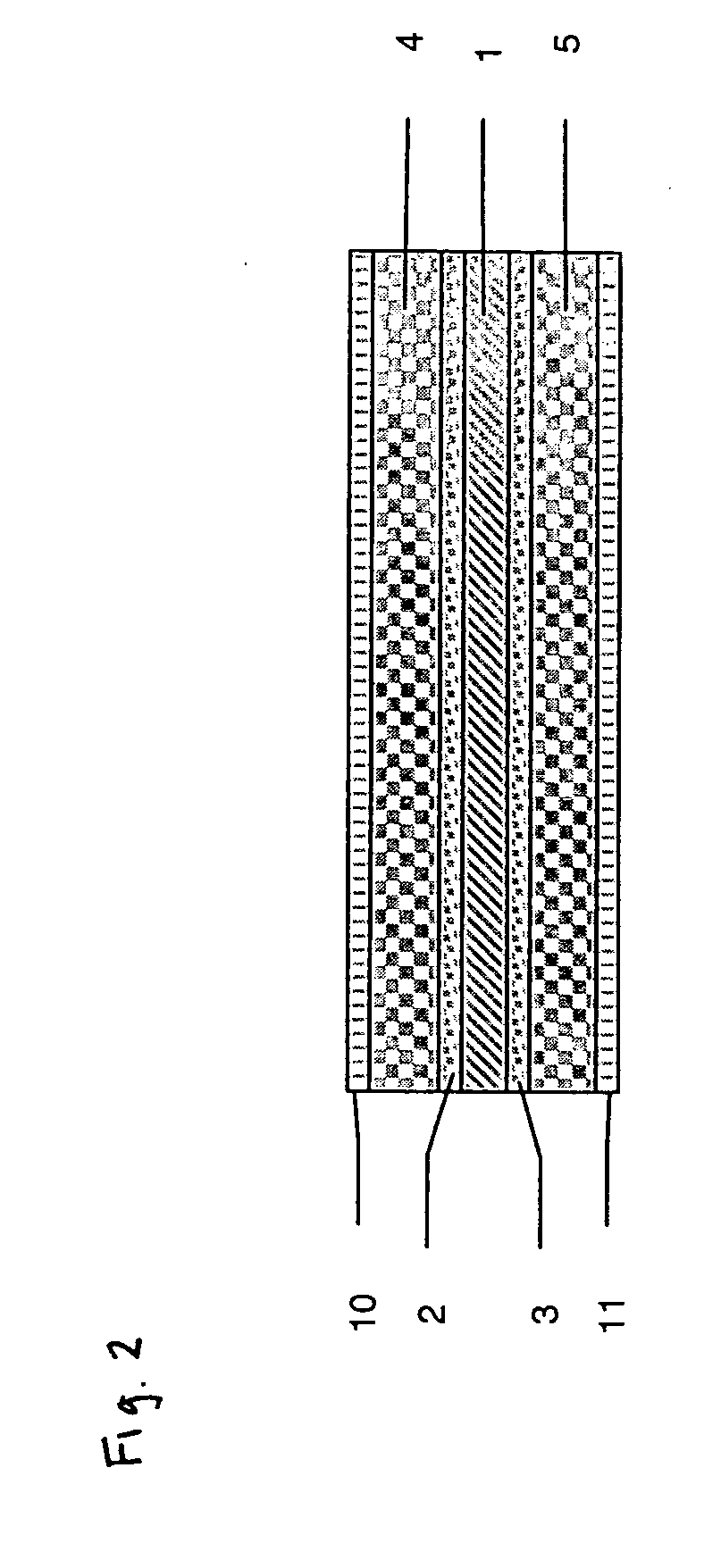

Novel membrane electrode assembly and its manufacturing process

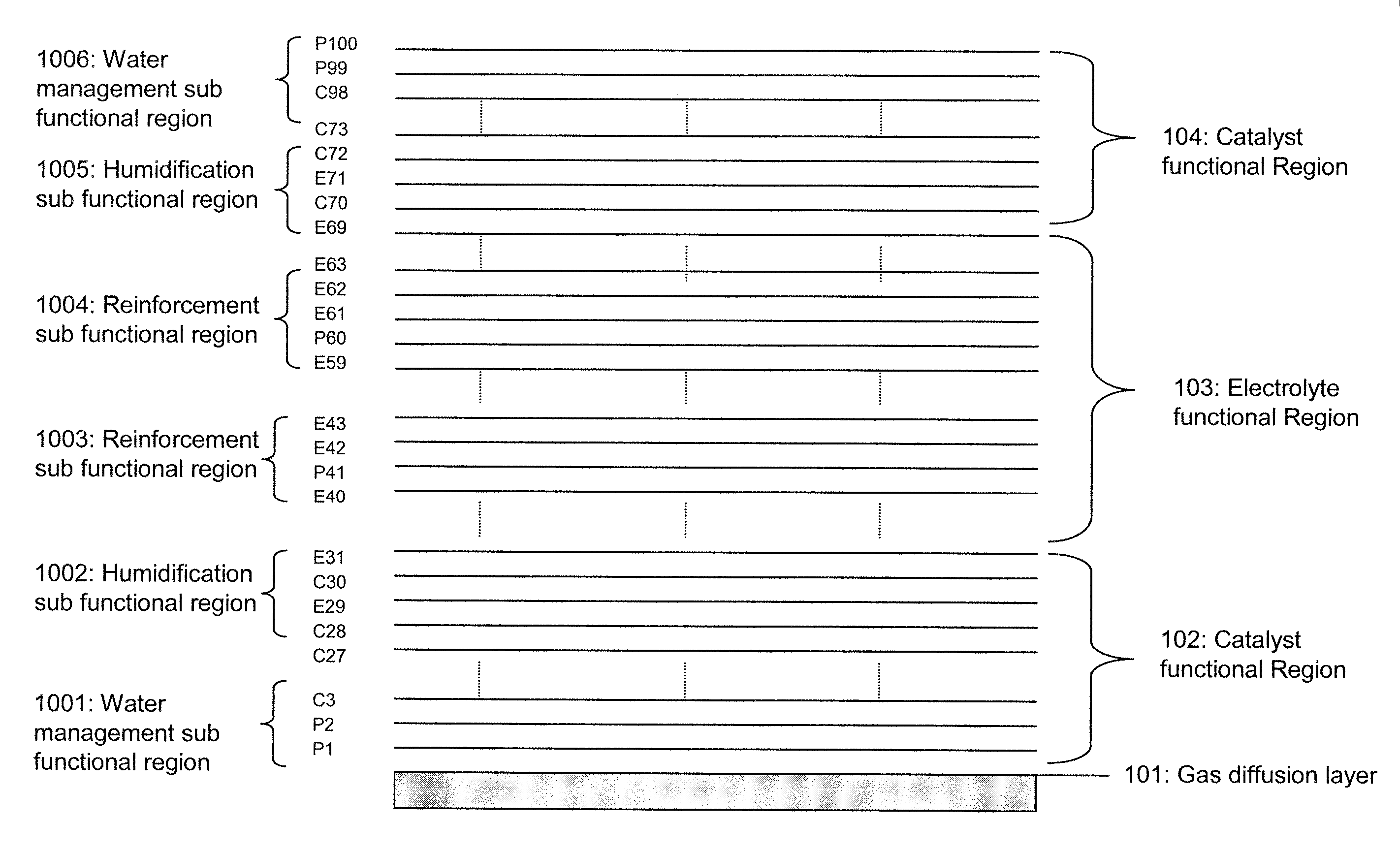

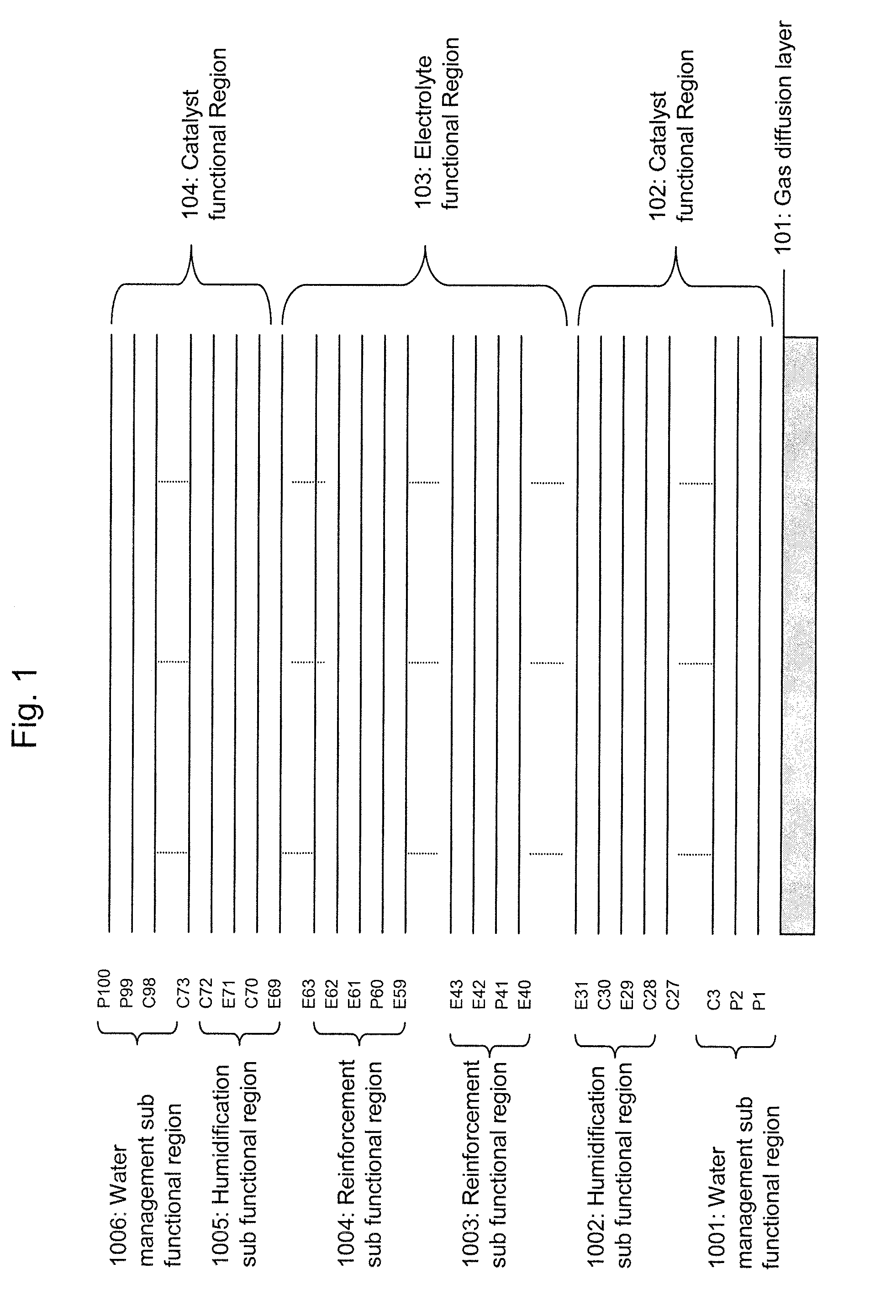

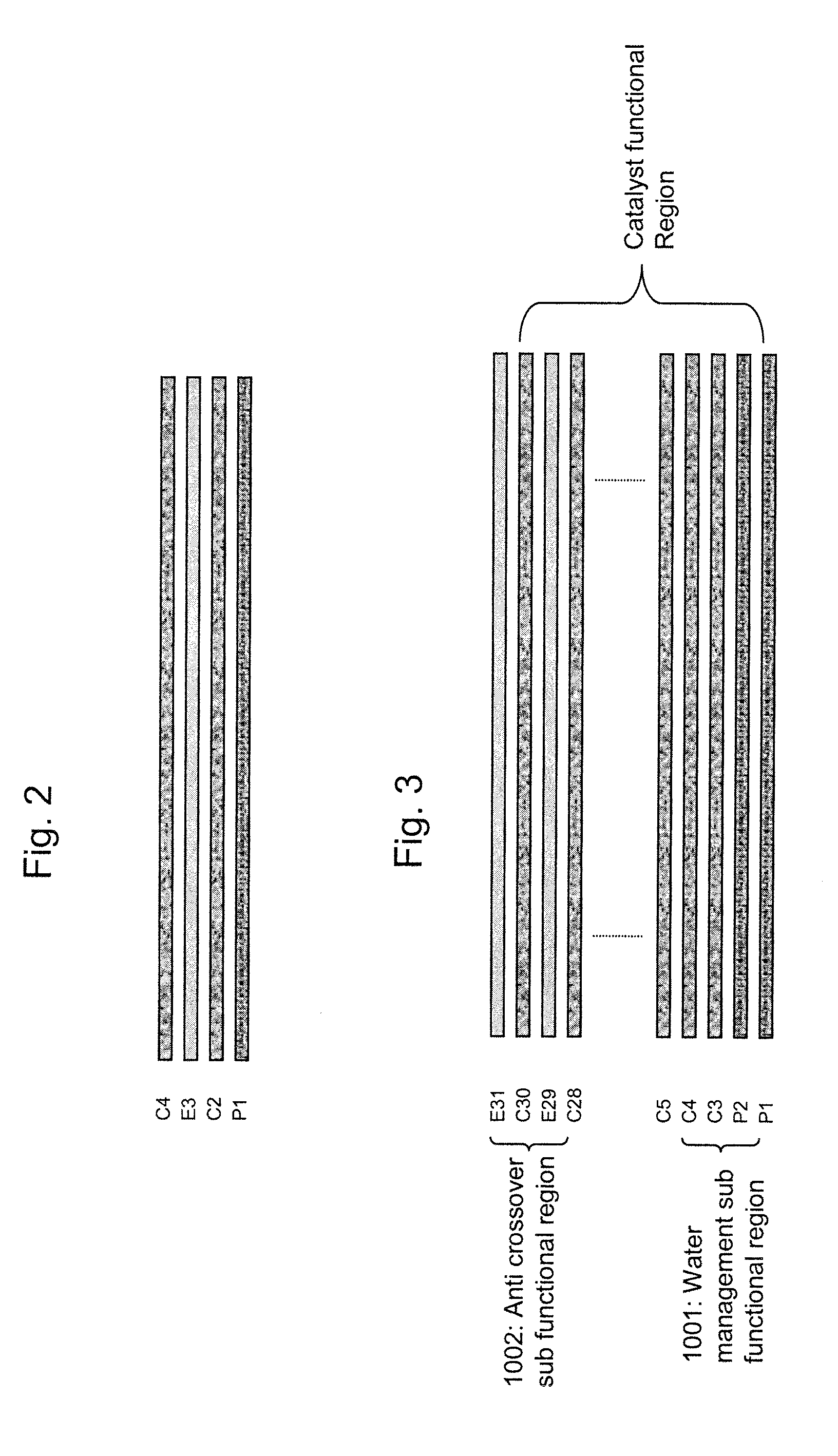

InactiveUS20070275291A1Reduce electric resistanceReduce resistance protonSolid electrolytesFinal product manufacturePtru catalystMembrane electrode assembly

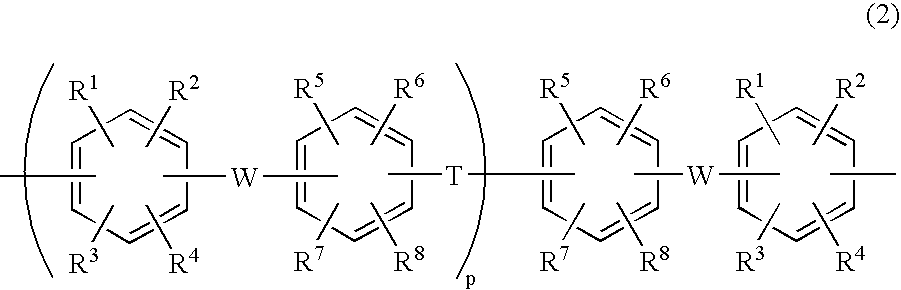

A membrane electrode assembly including a gas diffusion layer and a layered structure made up of from 4 to 1000 layers including layers of a first type and layers of a second type, wherein the layers of the first type are electrolyte layers and the layers of the second type are catalyst layers, the layered structure having one or more catalyst functional regions, each made up of layers of the first and second types, and one or more electrolyte functional regions, each made up of layers of the first and second types.

Owner:SHANGHAI HORIZON FUEL CELL TECH

Membrane-electrode assembly for fuel cell

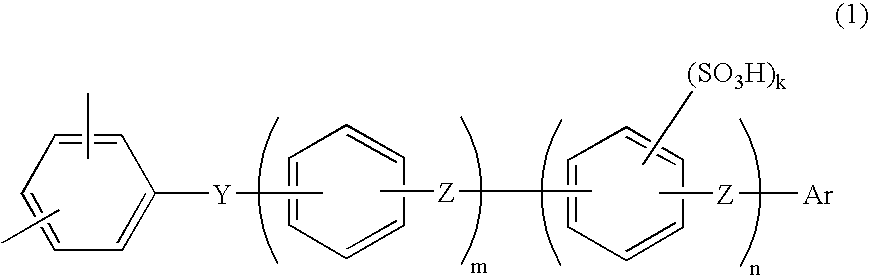

InactiveUS20060127728A1Improve creep resistanceIncreased durabilitySemi-permeable membranesActive material electrodesPolymer electrolytesPtru catalyst

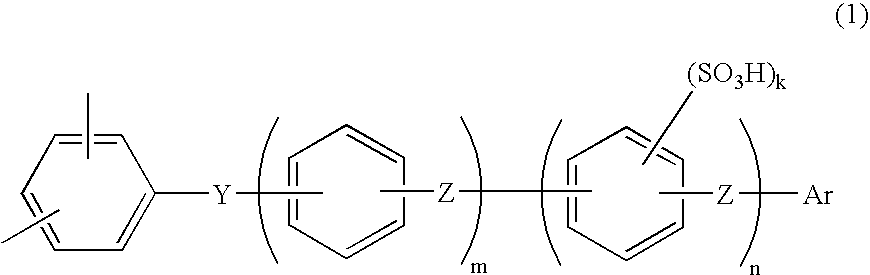

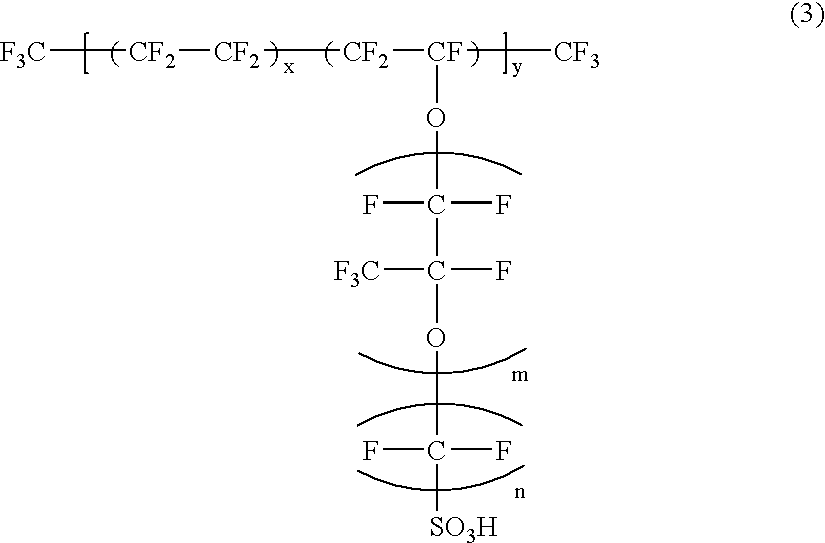

The present invention provides a membrane-electrode assembly for fuel cell which comprises a solid polymer electrolyte membrane comprising a specific polyarylene having a sulfonic acid group and has excellent creep resistance, power generation performance and durability against power generation under high-temperature environment. The membrane-electrode assembly is characterized in that a pair of electrodes each comprising a gas diffusing layer and a catalyst layer are joined to both sides of a solid polymer electrolyte membrane so that the catalyst layer side comes into contact with the membrane, said membrane comprises a sulfonated polyarylene comprising constituent unit represented by the following formula (1): wherein Y is a group represented by —C(CF3)2—, (CF2)i—, wherein i is an integer of 1 to 10, —SO— or —SO2—; Z is a divalent electron-donating group or a direct bond; Ar is an aromatic group having a substituent represented by —SO3H; m is an integer of 0 to 10; n is an integer of 0 to 10; and k is an integer of 1 to 4.

Owner:JSR CORPORATIOON +1

Mea-Gasket Assembly and Polymer Electrolyte Fuel Cell Using Same

InactiveUS20070264557A1Simple structureAvoid flowFuel cells groupingFuel cell auxillariesPolymer electrolytesFuel cells

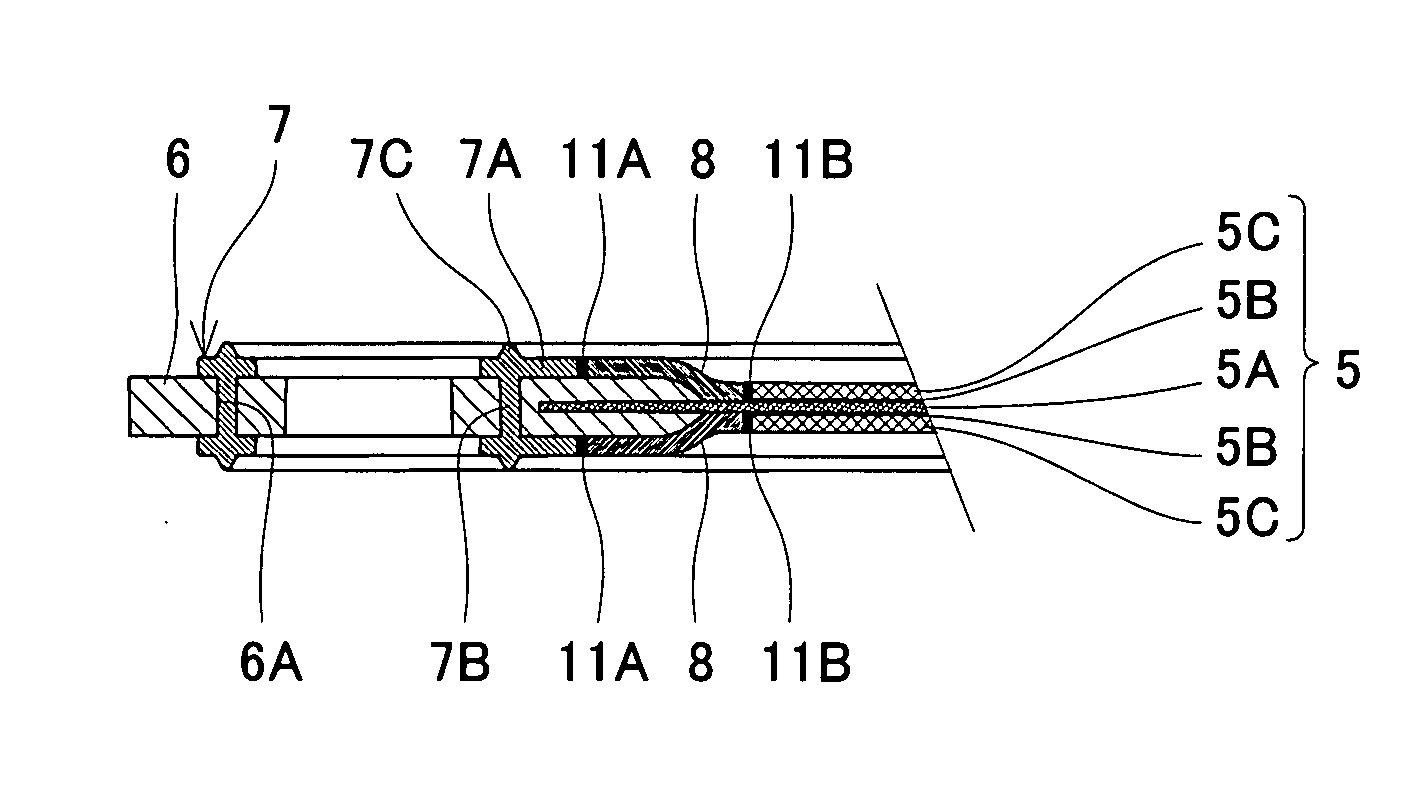

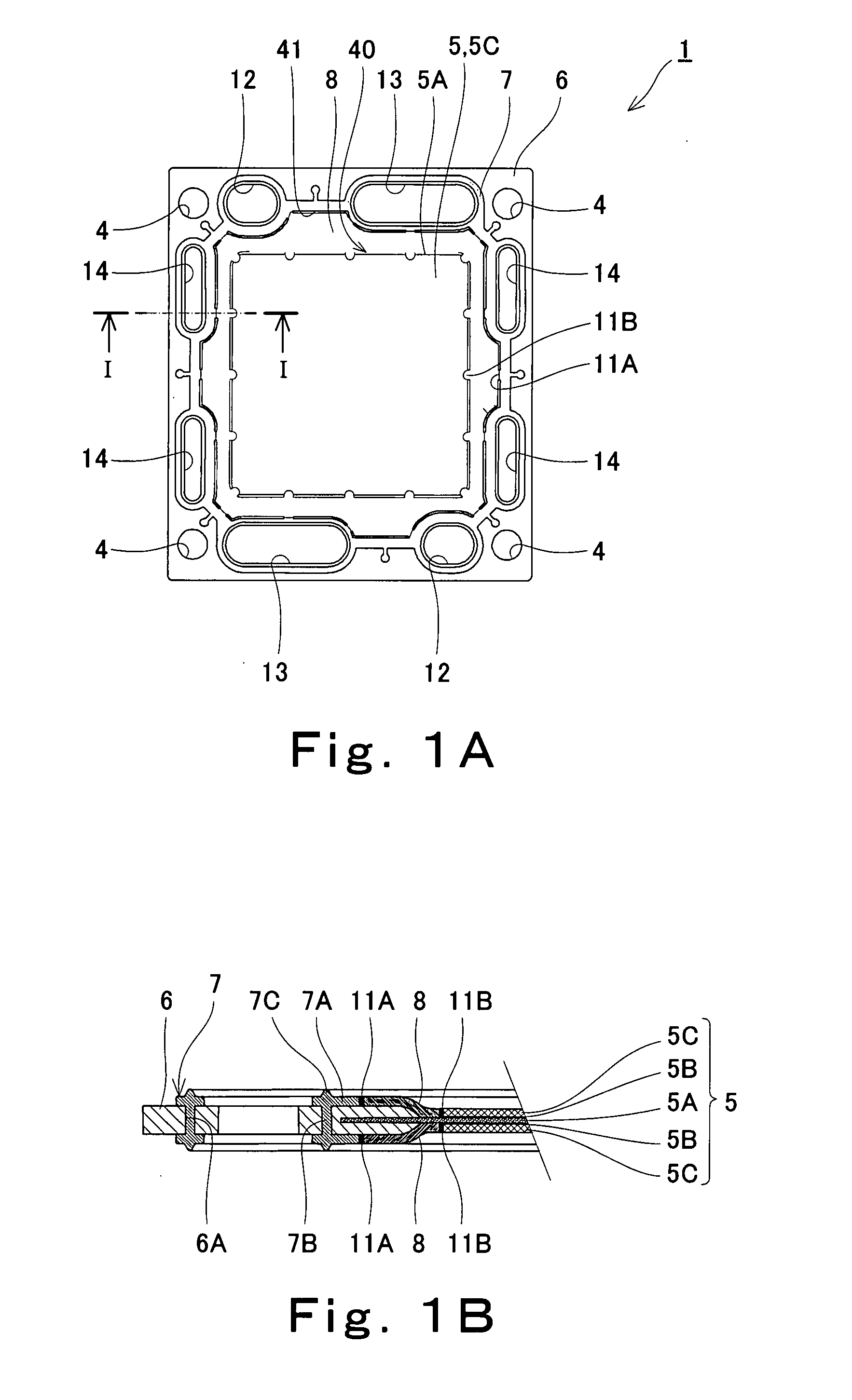

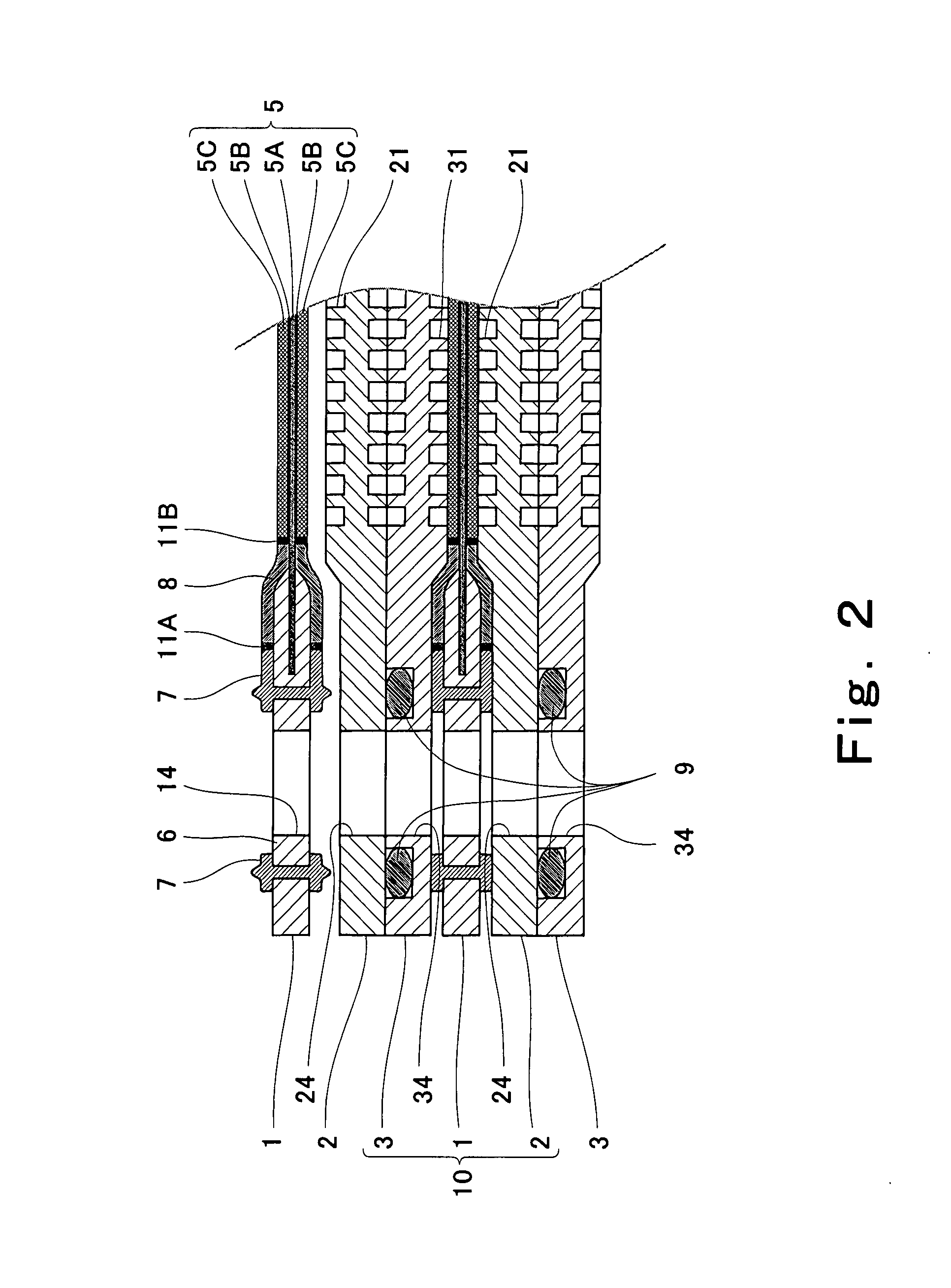

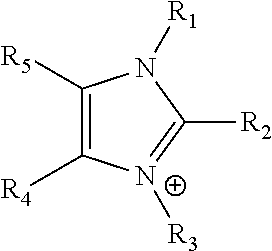

The invention provides an MEA-gasket assembly (1) comprising: an MEA (5) having a polymer electrolyte membrane (5A), catalyst layers and gas diffusing layers (5C); a plate-like frame (6) which is joined to a portion of the polymer electrolyte membrane (5A) so as to enclose the MEA (5), the portion being located in a peripheral region of the MEA (5) and which has a plurality of fluid manifold holes (12, 13, 14); and an annular gasket (7) formed on both faces of the frame (6), wherein an annular gap formed between the inner peripheral edge of the annular gasket (7) and the outer peripheral edges of the gas diffusing layers (5C) is at least partially closed.

Owner:PANASONIC CORP

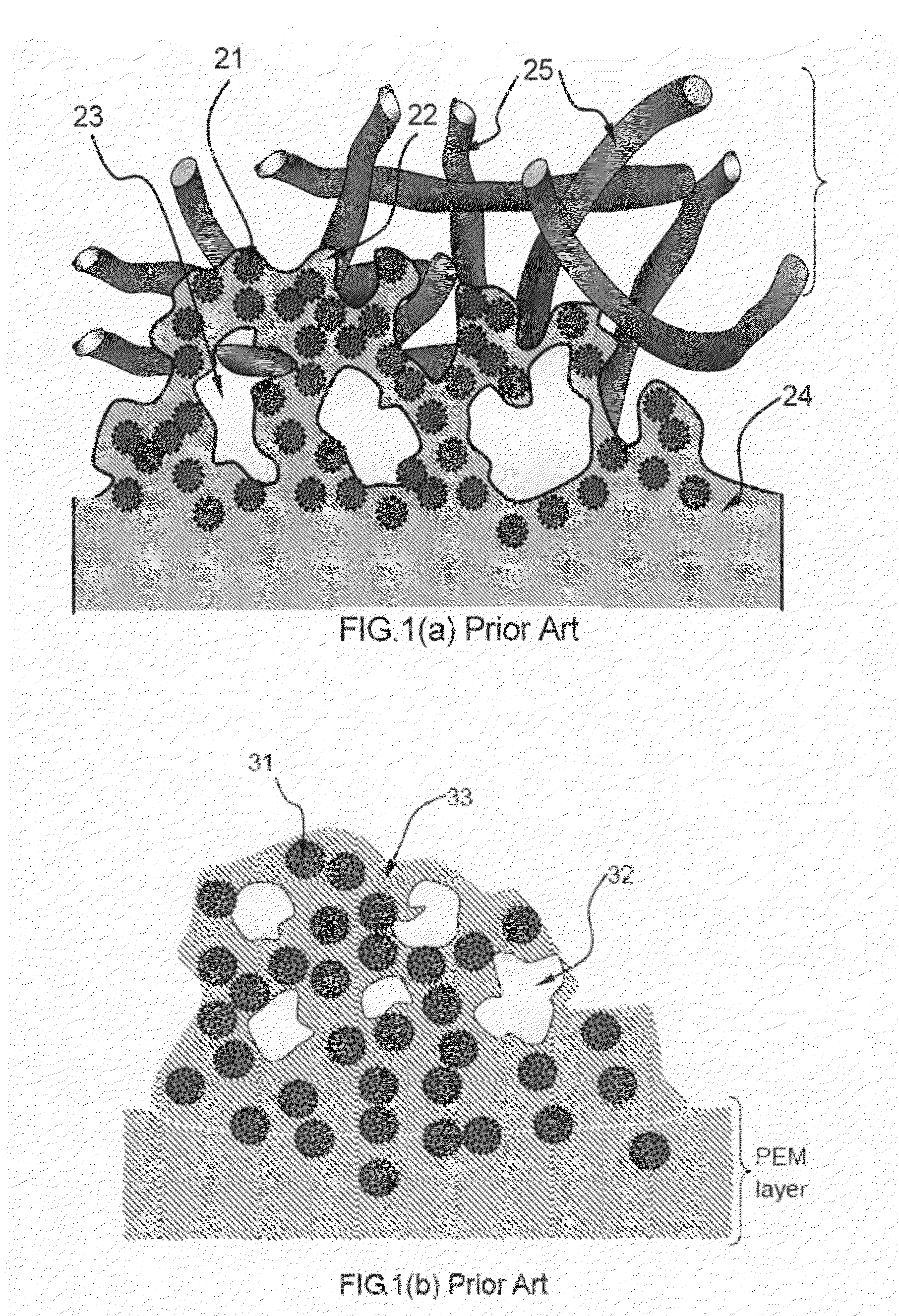

Polymer electrolyte fuel cell

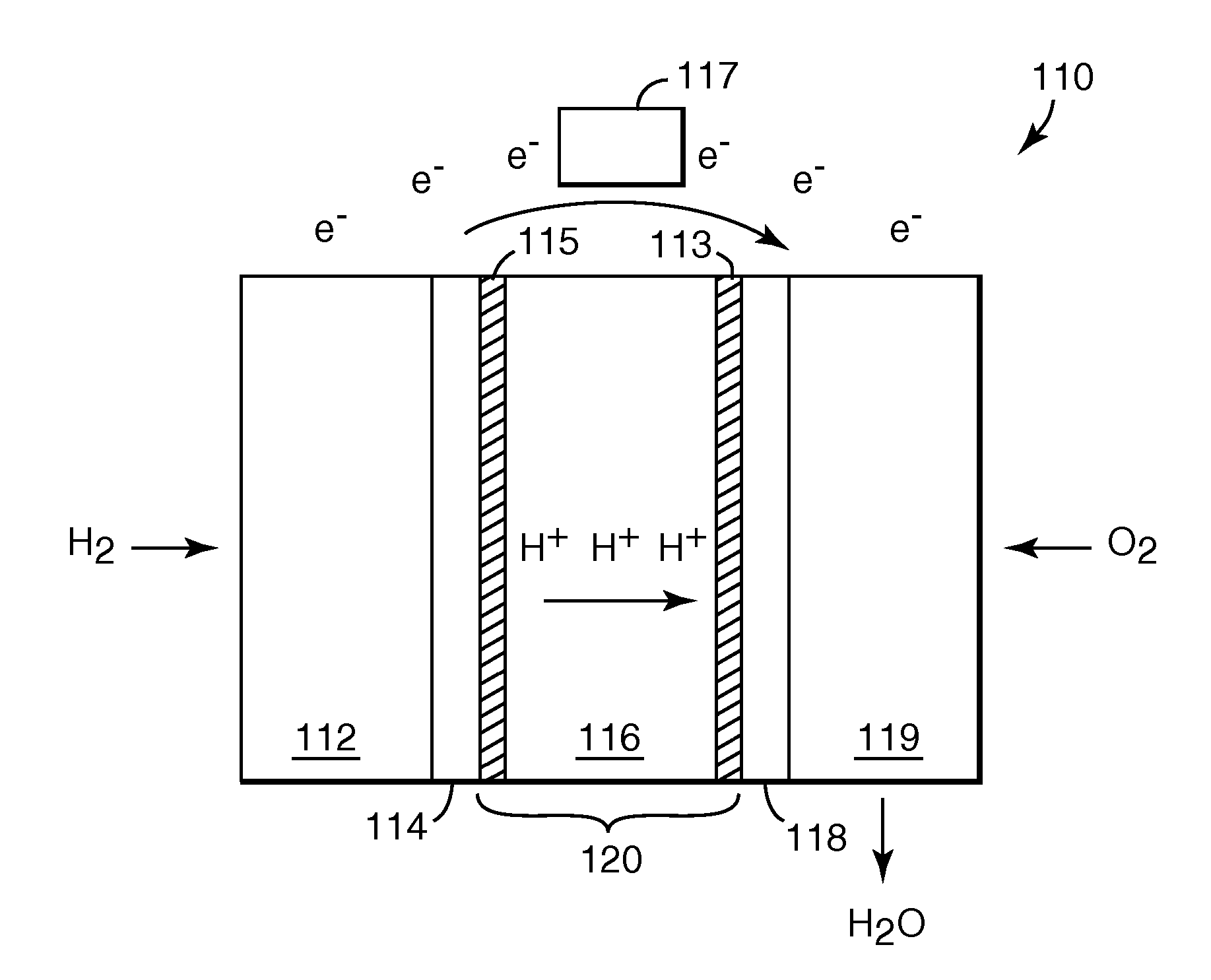

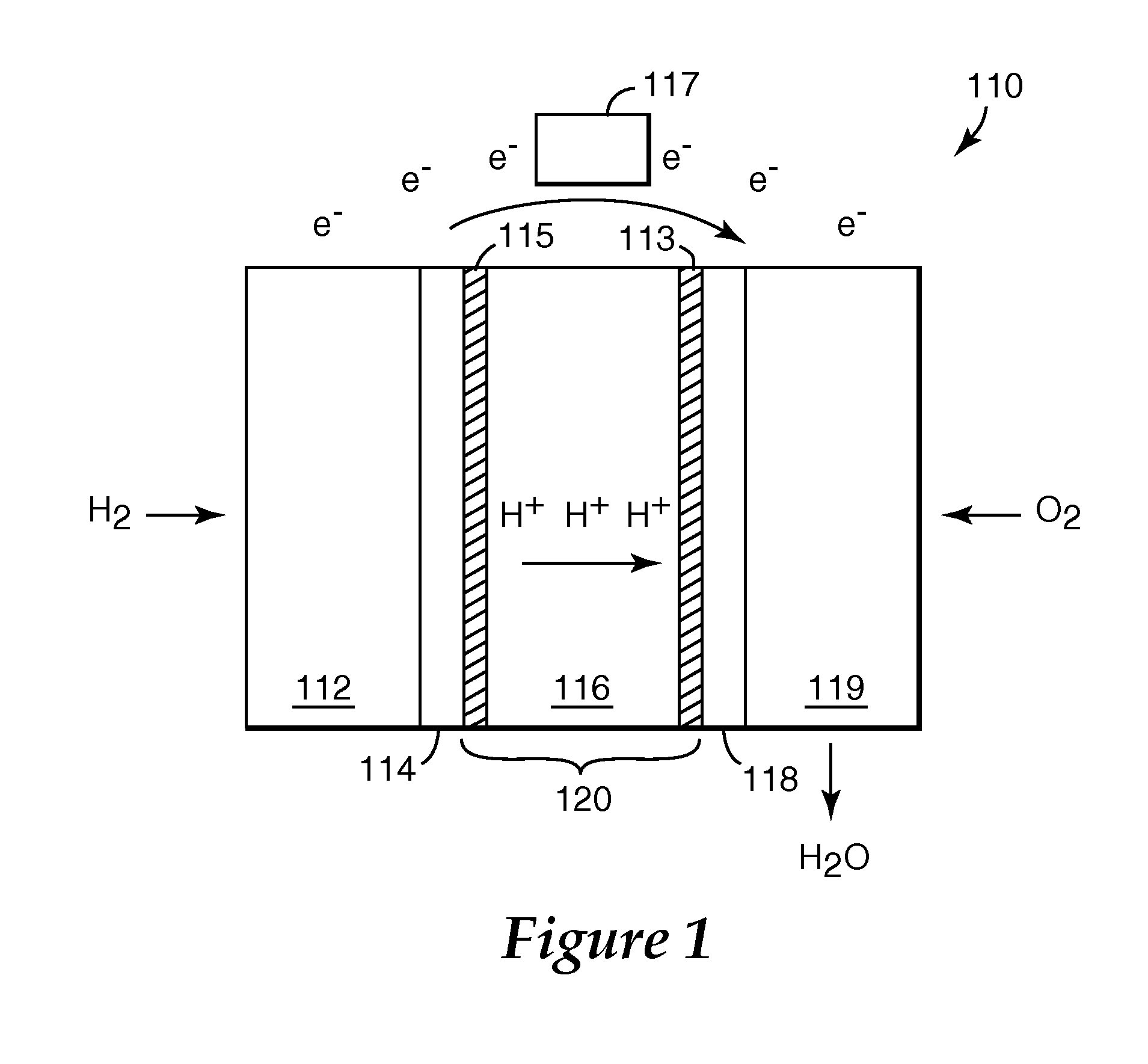

ActiveUS20040131919A1Reduce wasteCarry lotActive material electrodesSolid electrolyte fuel cellsPolymer electrolytesFuel cells

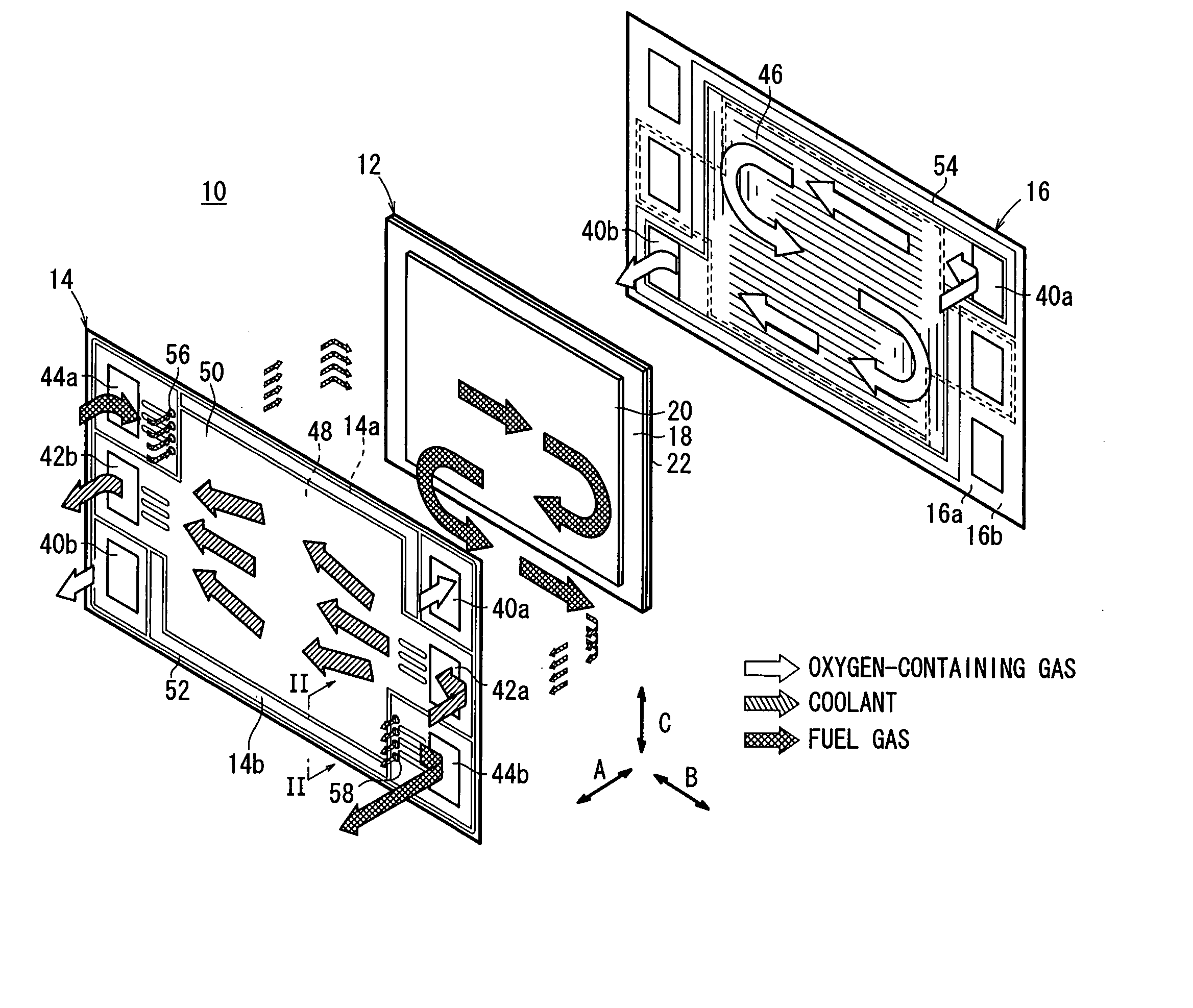

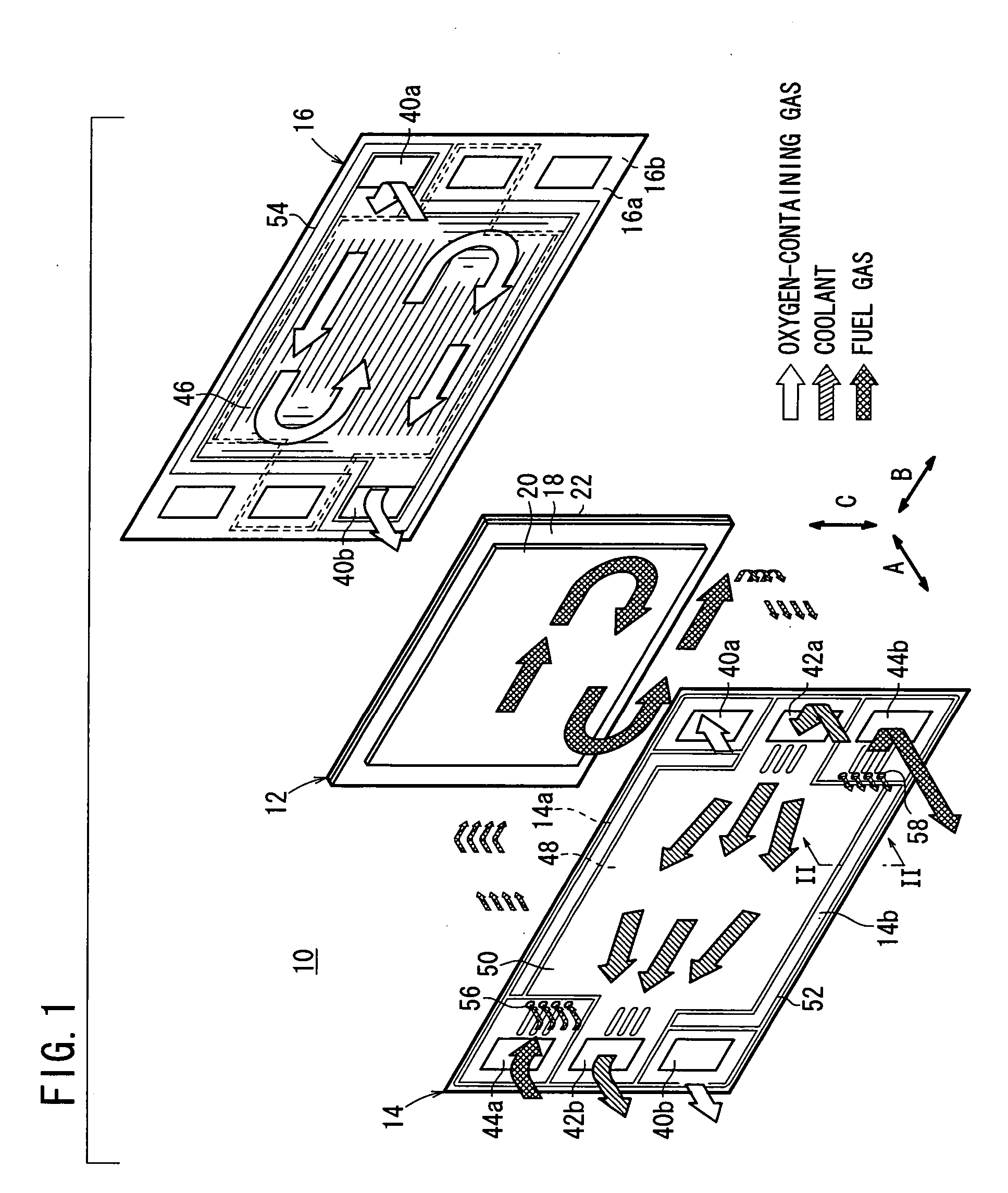

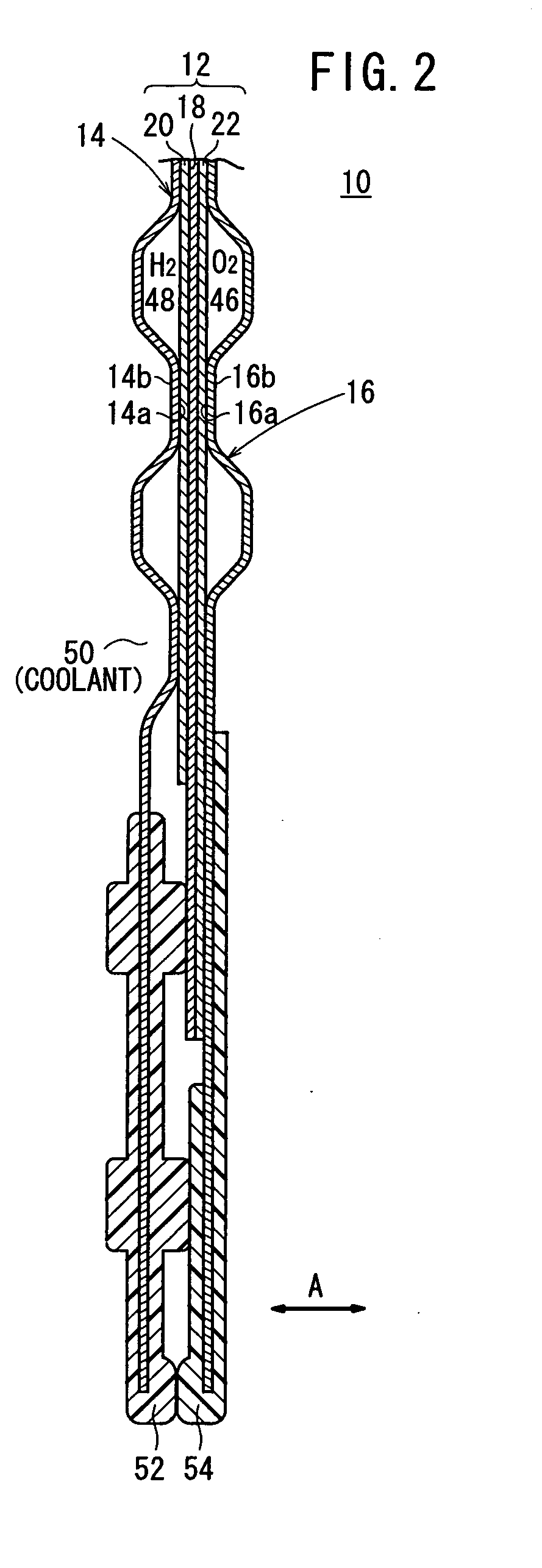

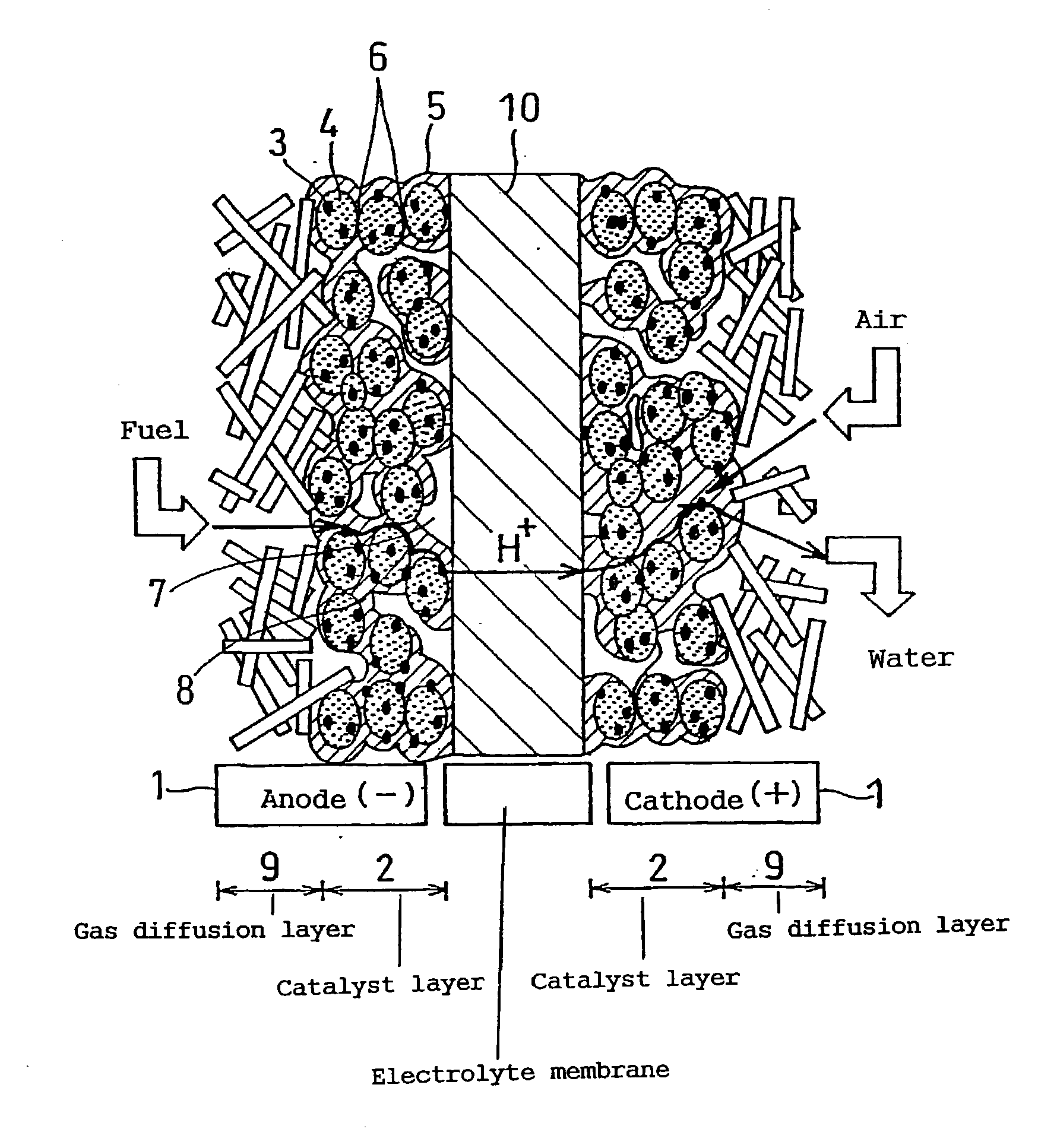

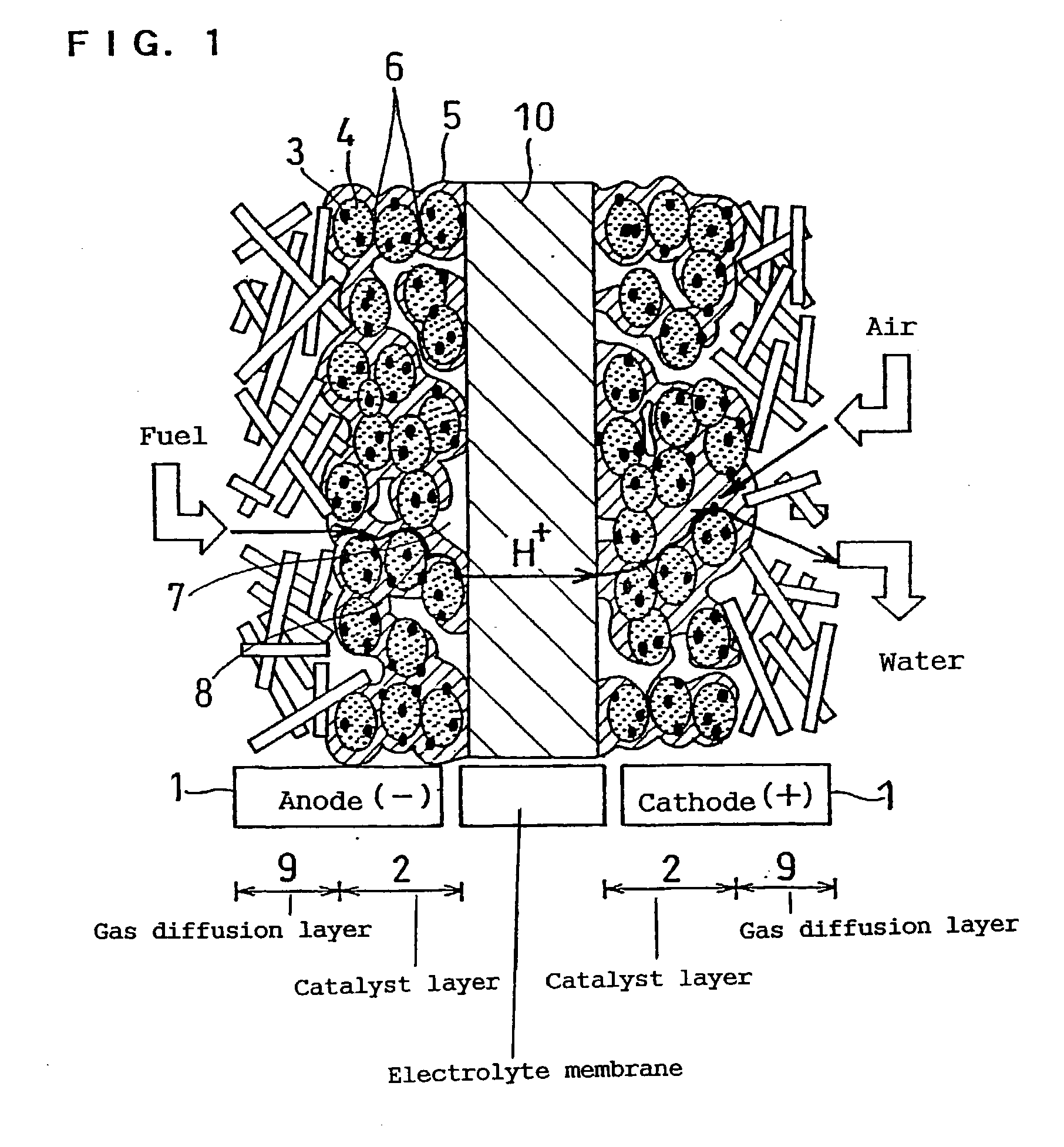

In a polymer electrolyte fuel cell including a hydrogen ion conductive polymer electrolyte membrane; a pair of electrodes composed of catalyst layers sandwiching the hydrogen ion conductive polymer electrolyte membrane between them and gas diffusion layers in contact with the catalyst layers; a conductive separator plate having a gas flow channel for supplying a fuel gas to one of the electrodes; and a conductive separator plate having a gas flow channel for supplying an oxidant gas to the other electrode, in order to bring a hydrogen ion conductive polymer electrolyte and a catalyst metal of the catalyst layers containing the hydrogen ion conductive polymer electrolyte and conductive carbon particles carrying the catalyst metal sufficiently and uniformly into contact with each other, the polymer electrolyte is provided in pores of an agglomerate structure of the conductive carbon particles. Consequently, the reaction area inside the electrodes is increased, and higher performance is exhibited.

Owner:PANASONIC CORP

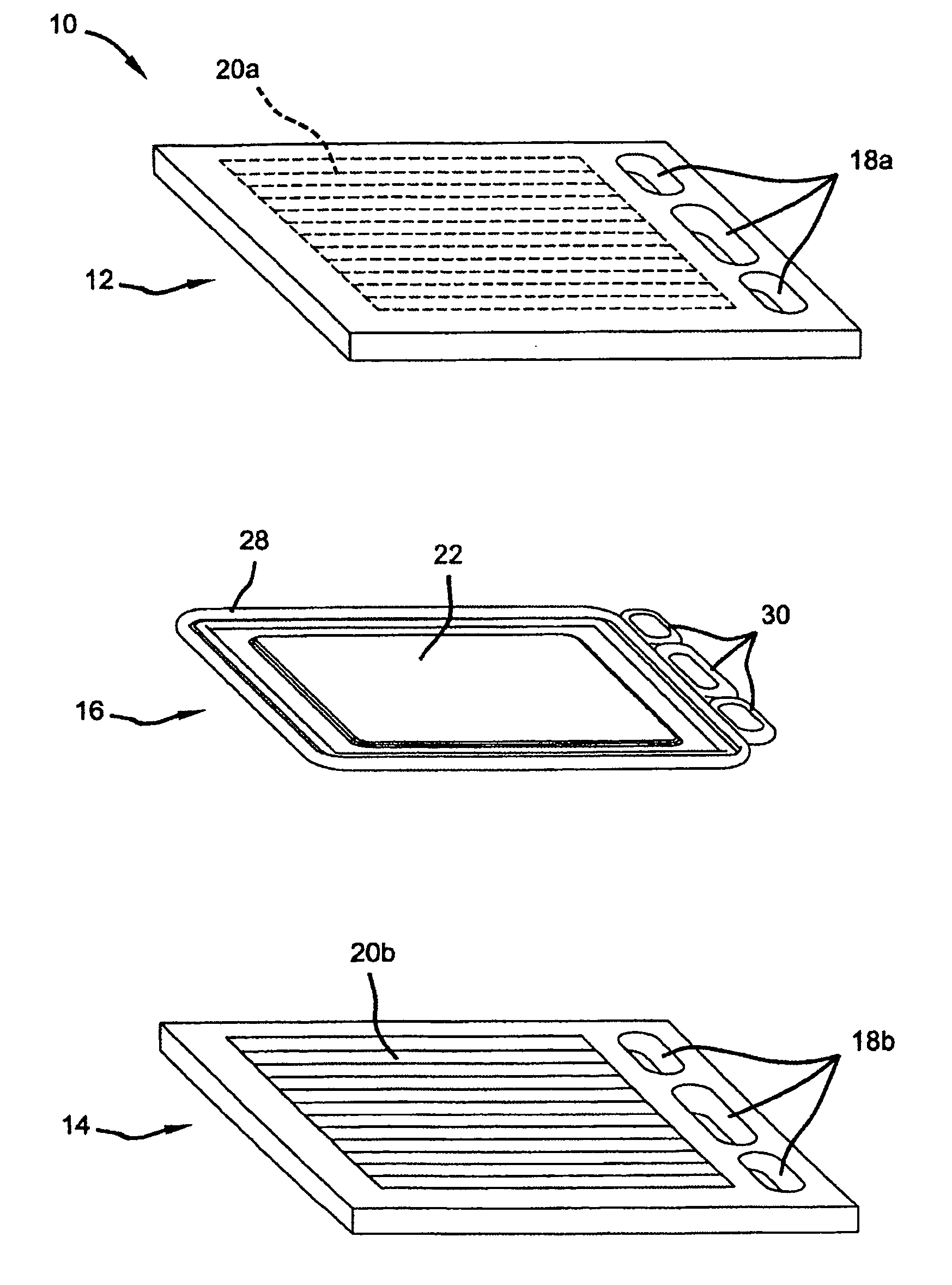

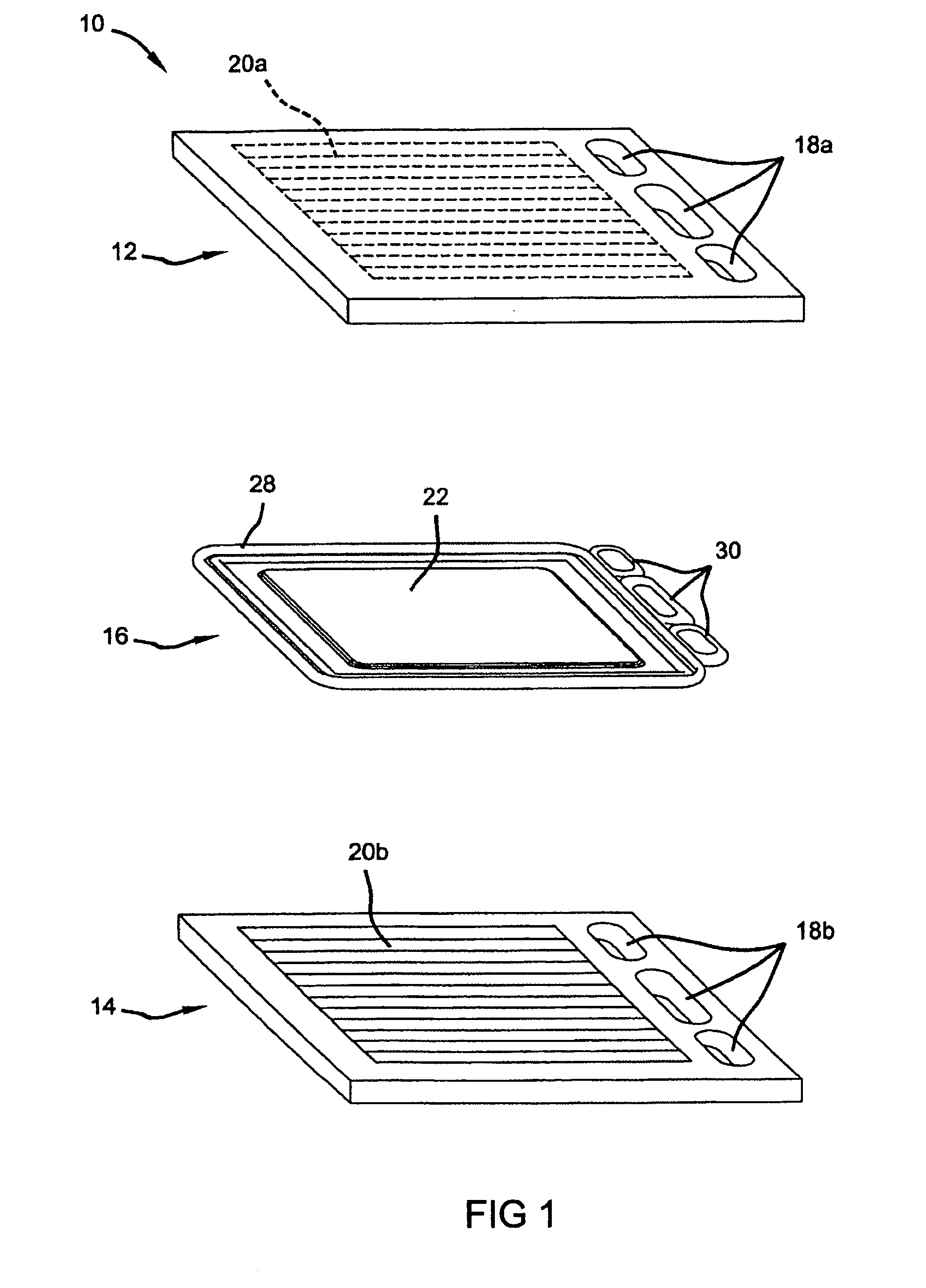

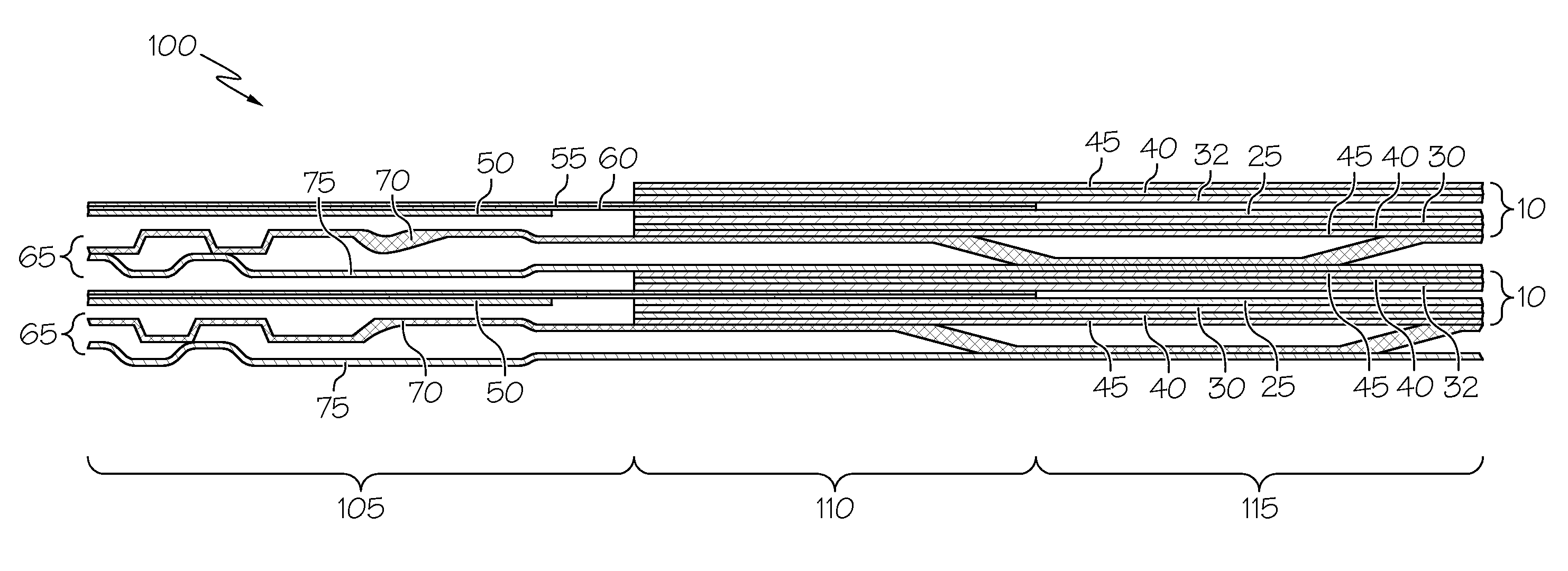

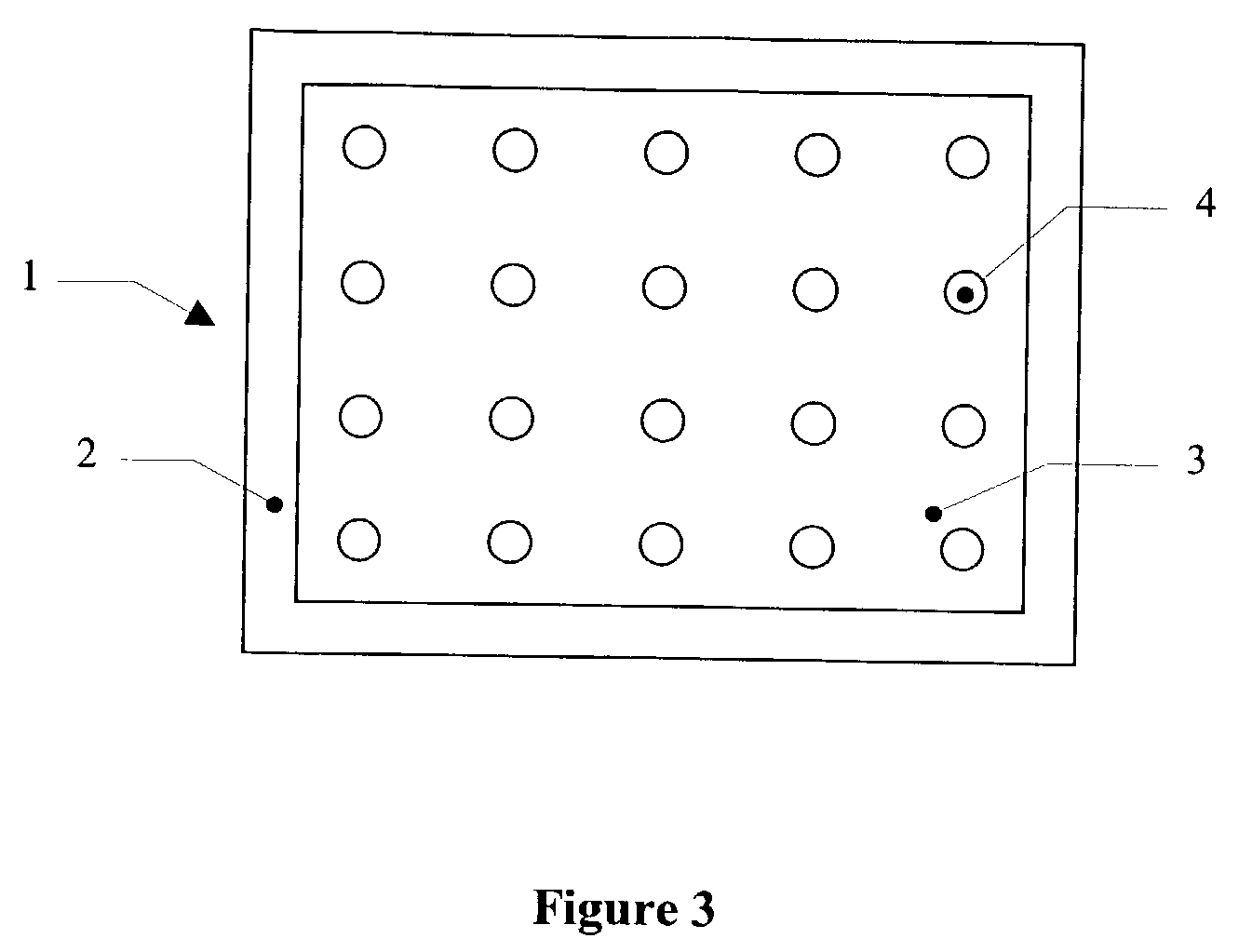

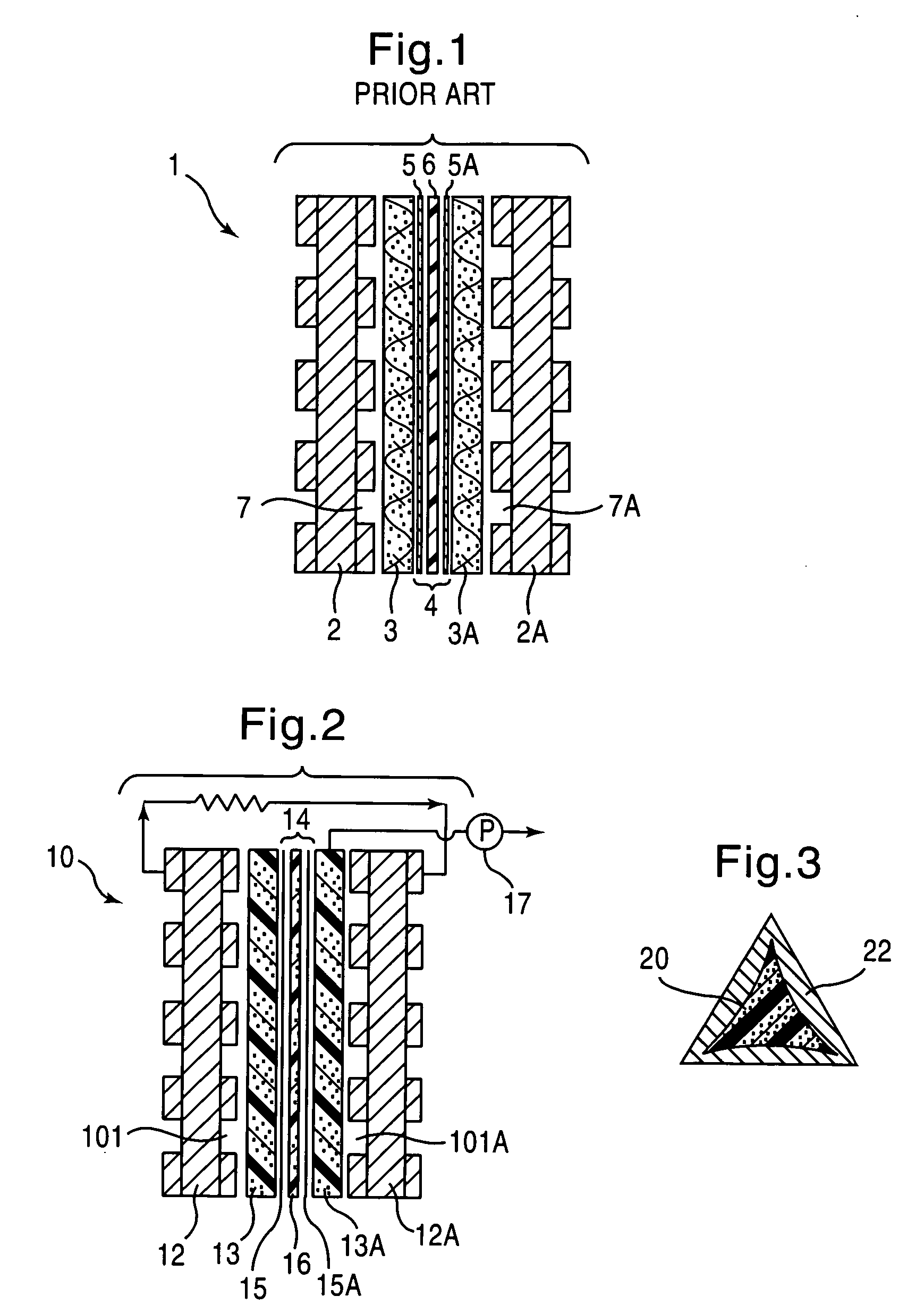

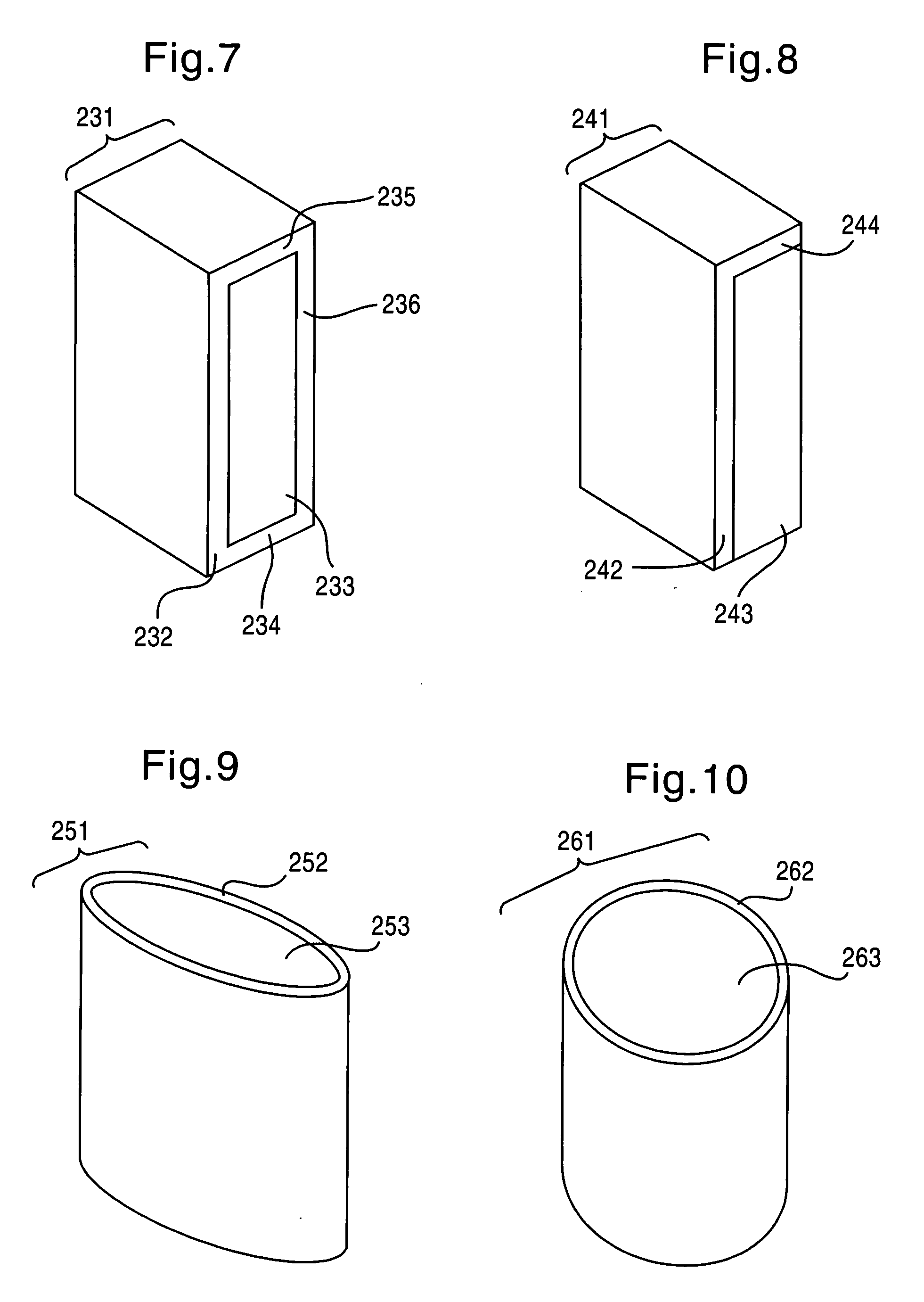

Gas diffusion layer incorporating a gasket

InactiveUS20080143061A1Facilitate achieving a predetermined thickness of the subassembly componentsEngine sealsFuel cells groupingMembrane electrode assemblyElectrical and Electronics engineering

A gas diffusion layer incorporating a gasket (GIG) is described along with assemblies incorporating the GIG subassembly. Processes for making the GIG and membrane electrode assemblies (MEAs) incorporating the GIG are also described. A GIG subassembly includes a gas diffusion layer (GDL) and a gasket bonded to the GDL. The gasket includes a first gasket layer and a second gasket layer. The second gasket layer is formed of a gasket material in contact with the first gasket layer and the GDL. The gasket material of the second gasket layer bonds the GDL to the first gasket layer. An adhesive layer, and optionally a removable adhesive liner, is disposed on a surface of the first gasket layer opposite the second gasket layer. In some MEA configurations, the GDL is disposed within an aperture in the first gasket layer.

Owner:3M INNOVATIVE PROPERTIES CO

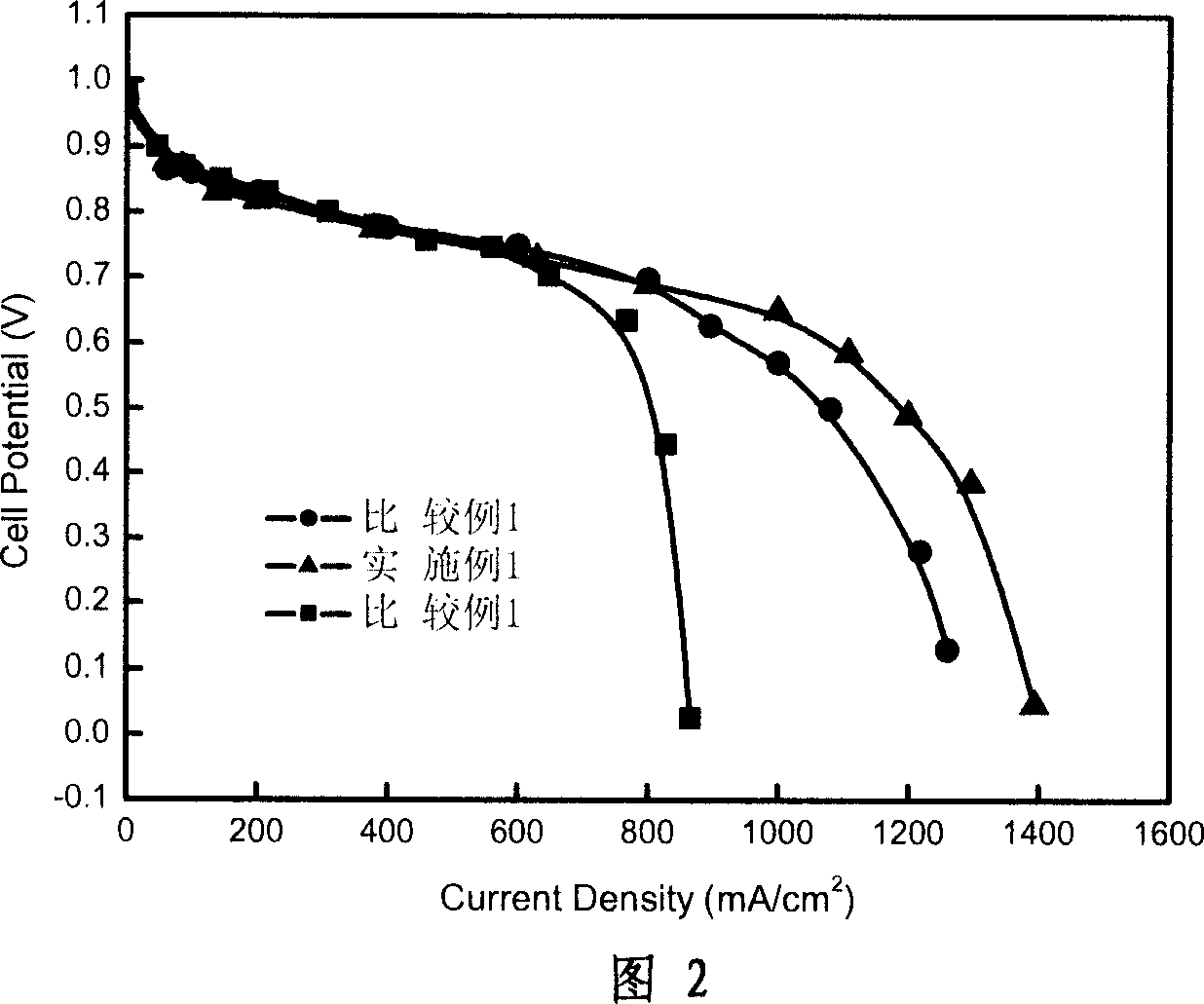

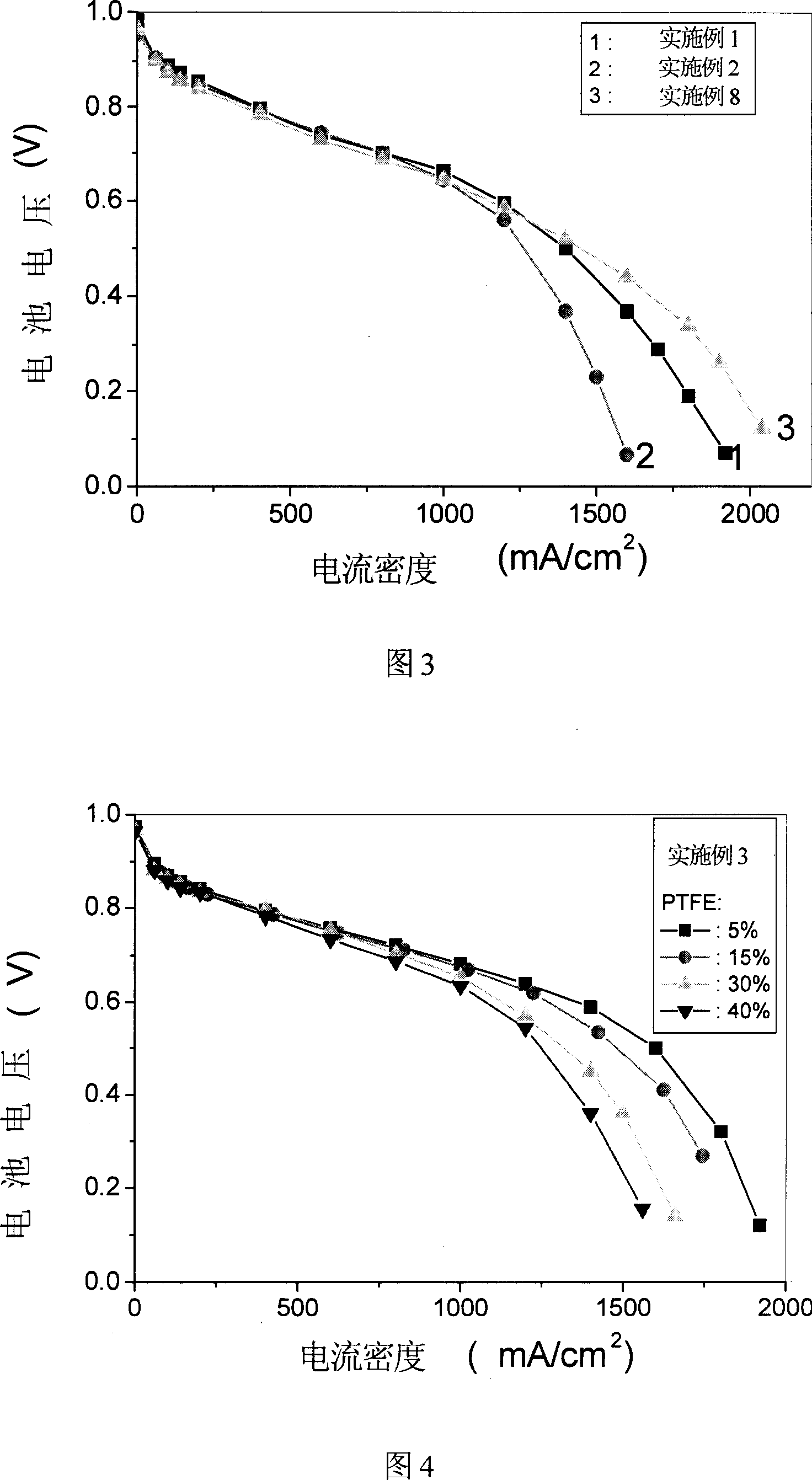

Gas diffusion layer for low temp fuel cell and preparing process thereof

ActiveCN1949570AImprove mass transfer effectNot easy to coagulateCell electrodesFuel cell detailsFuel cellsLiquid water

The invention relates to a low-temperature fuel cell, concretely a gas diffusion layer for low-temperature fuel cell and the preparing method thereof, where the gas diffusion layer is composed of substrate layer and microporous laye, and the microporous layer is mixed of two or more conductive carbon materials. And the preparing method: taking and mixing two or more conductive carbon materials in proportion into composite conductive material, uniformly diffusing the composite condutive material and hydrophobic agent in solvent to form plup; uniformly arranging the pulp on one or two sides of a hydrophobic processed porous conductive substrate; finally forming the gas diffusion layer by thermal treatment. Because of preparing microporous layer by compositive conductive material, it forms a double-function hole structure beneficial to reacting gas transmission and liquid water transmission, improving battery performances.

Owner:SUNRISE POWER CO LTD

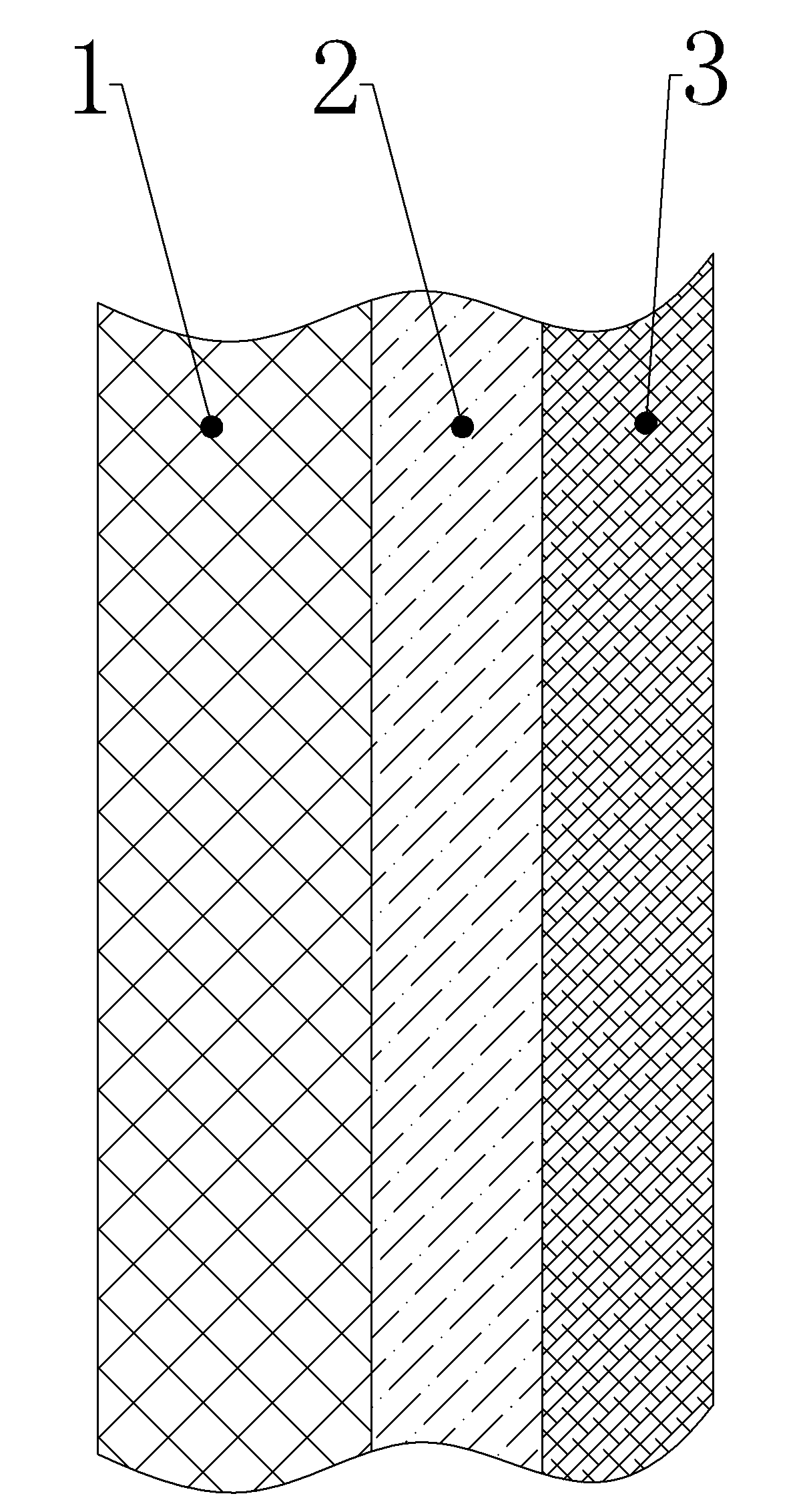

Gaseous diffusion layer of proton exchange membrane fuel cell and preparation method thereof

InactiveCN102024961AFacilitated DiffusionEasy dischargeFinal product manufactureFuel cell detailsPorositySurface layer

The invention discloses a gaseous diffusion layer of a proton exchange membrane fuel cell and a preparation method thereof. The diffusion layer comprises a basal layer and a micropore layer, and the micropore layer consists of a micropore lining layer and a micropore surface layer. The micropore lining layer is located between the basal layer and the micropore surface layer, the micropore lining layer is the micropore layer with larger porosity and stronger hydrophobicity, and the micropore surface layer the micropore layer with smaller porosity and weaker hydrophobicity in comparison with the micropore lining layer. The preparation method comprises the steps of: water-repellency treatment, slurry preparation, micropore layer coating and roasting at high temperature. Because gas diffuses from the basal layer to the micropore layers in the fuel cell reaction, by manufacturing the micropore layers in the gaseous diffusion layer step by step in the invention, gradient decrease is formed between the porosities from the basal layer to the two micropore layers in the gaseous diffusion layer, which is more beneficial to the diffusion of reaction gas and the discharge of water generated by the cell, and the power of the cell can be obviously improved.

Owner:SUNRISE POWER CO LTD

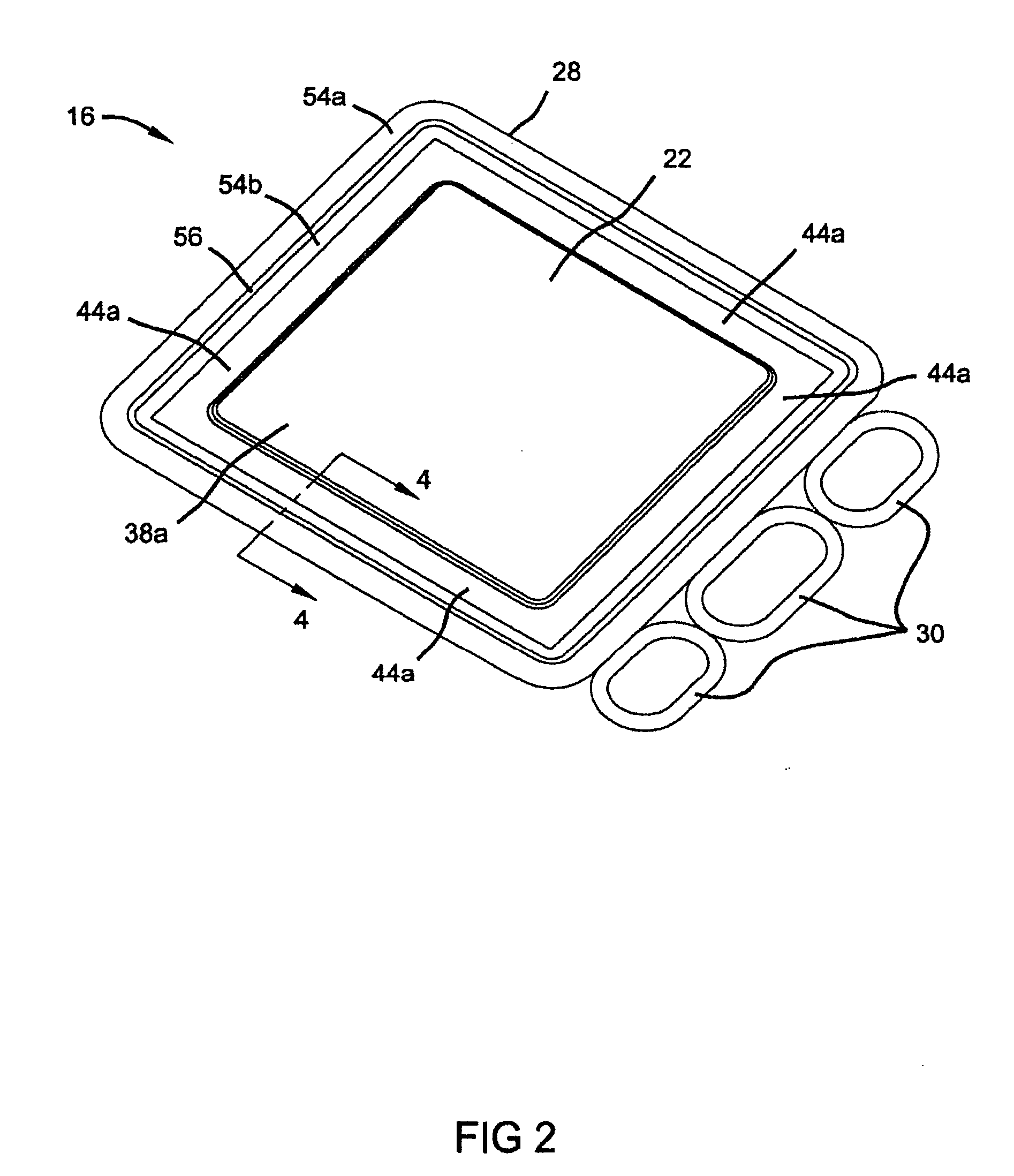

Integrally molded gasket for a fuel cell assembly

InactiveUS20070003821A1Damaging the MEAFuel cells groupingActive material electrodesFuel cellsHigh density

A fuel cell membrane electrode assembly (MEA) comprising first and second gas diffusion layers and an ion exchange membrane disposed between the diffusion layers. Each diffusion layer includes an inner surface facing the membrane, an outer surface opposite the inner surface, and a side surface defining a perimeter of the diffusion layers. An outboard region extends about the diffusion layers at the perimeter. The outboard region surrounds an inboard region. The outboard region has a low density region proximate to the side surface and a high density region between the low density region and the inboard portion. A seal is mounted at the low density region. The high density region prevents portions of the seal from entering the inboard region thereby damaging the MEA. The seal includes a first rim having a smaller radius than a second rim. The smaller radius allows the seal to fit between adjacent support plates and increases the durability of the seal.

Owner:FREUDENBERG NOK GEN PARTNERSHIP

Curable subgasket for a membrane electrode assembly

InactiveUS20060078781A1Cell electrodesCell component detailsPolymer electrolytesMembrane configuration

A subgasket for a membrane electrode assembly is deposited on a surface of a MEA component and cured in situ. A membrane electrode subassembly includes a polymer electrolyte membrane, a gas diffusion layer and a catalyst layer between the polymer electrolyte membrane and the gas diffusion layer. The membrane electrode subassembly includes a subgasket, disposed over one or more components of the membrane electrode subassembly. The subgasket is made of a layer of material that is depositable and curable in situ. A peripheral edge of the gas diffusion layer overlaps the subgasket.

Owner:3M INNOVATIVE PROPERTIES CO

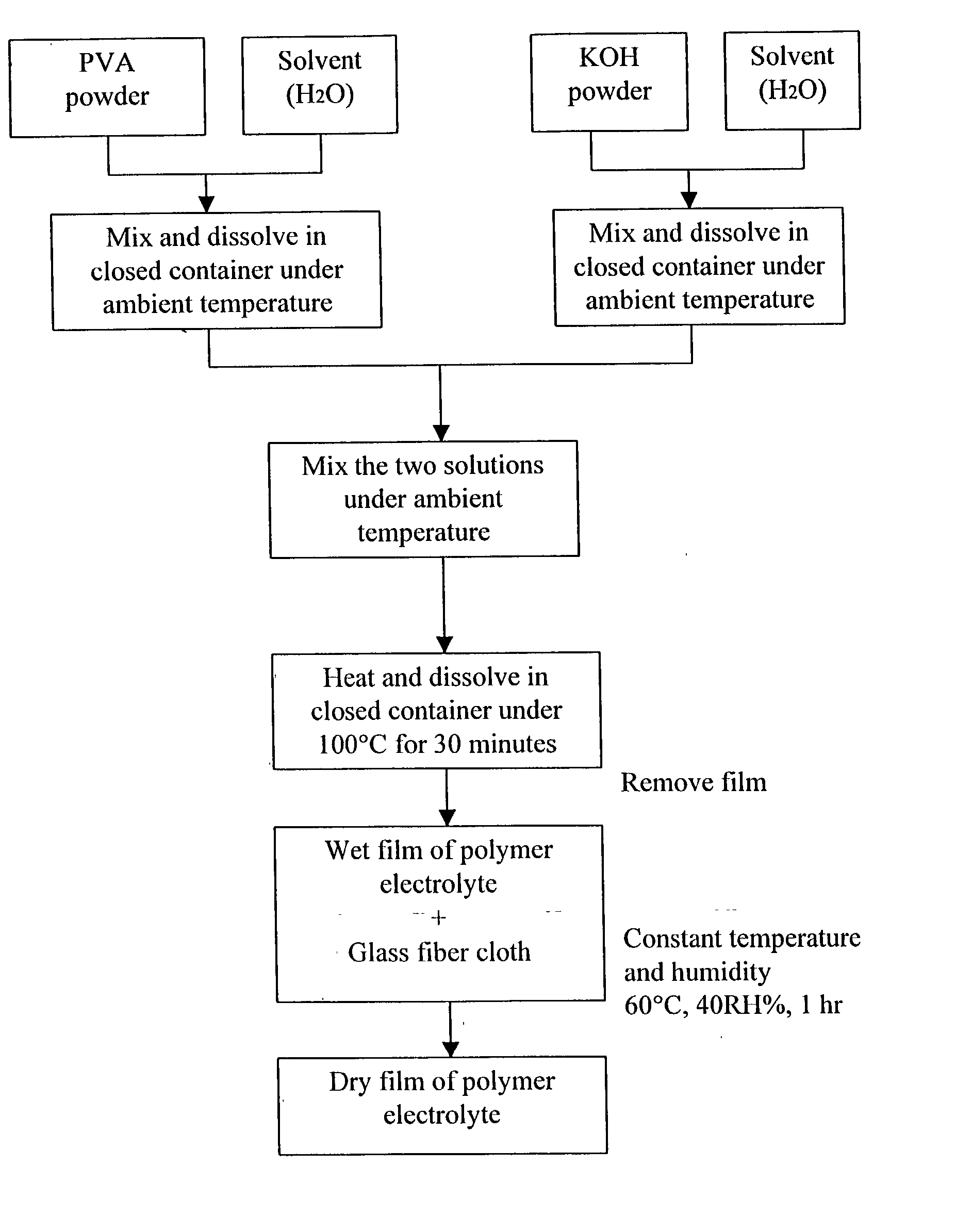

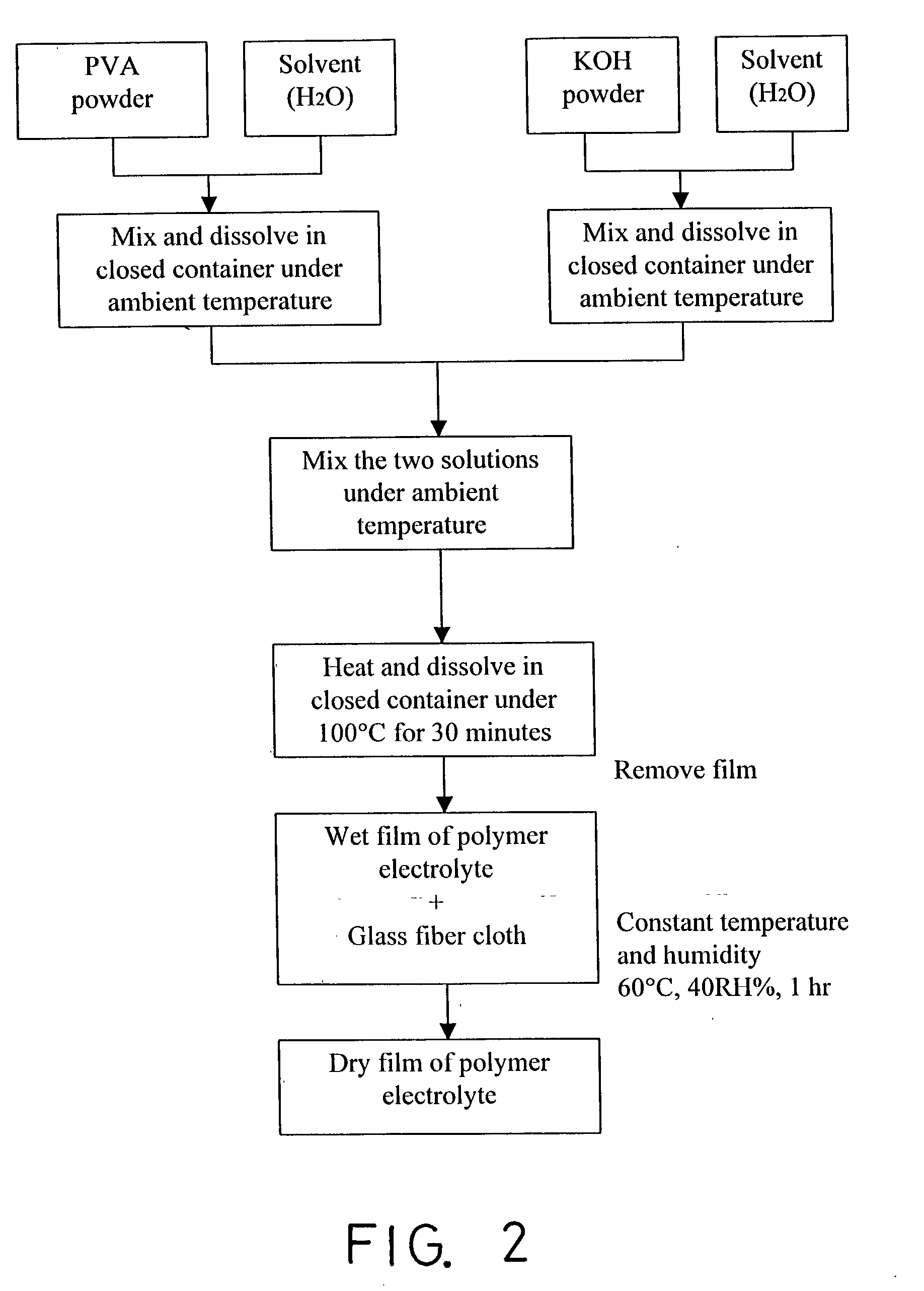

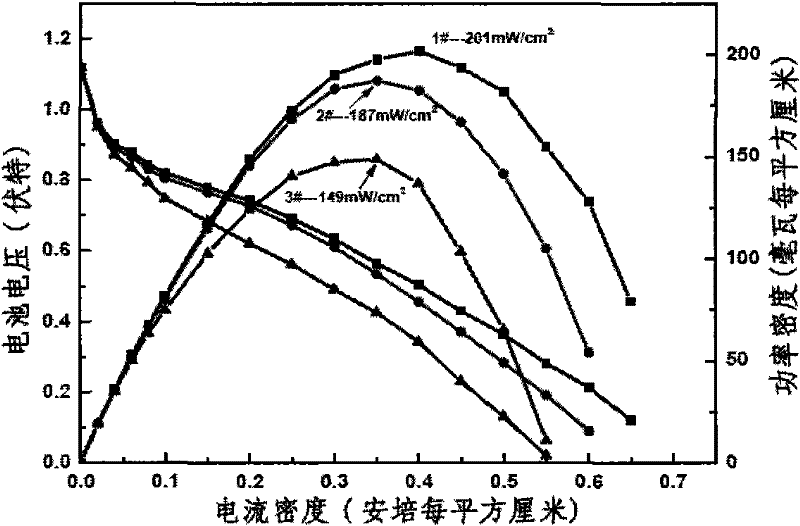

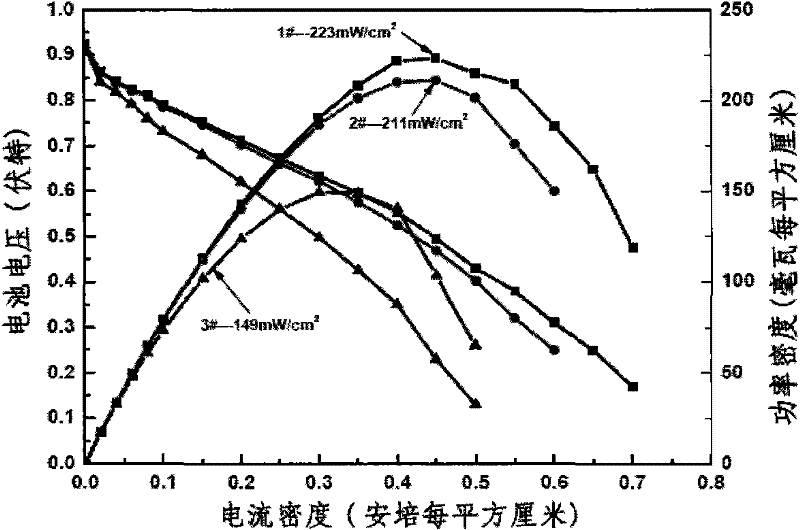

Method for preparing solid-state polymer zinc-air battery

InactiveUS20030228522A1Increase surface areaIncrease motivationFuel and primary cellsAlkaline accumulatorsZinc–air batteryAir cathode

This invention relates to a method for fabricating solid-state alkaline polymer Zn-air battery, which consists of a zinc-gel anode, an air cathode electrode, and alkaline polymer electrolyte. The formulation of said zinc gel anode is similar to that of alkaline Zn-MnO2 battery. The zinc gel anode contains a mixture of electrolytic dendritic zinc powders, KOH electrolyte, gelling agent and small amount of additives. The air cathode electrode is made by carbon gas diffusion electrode, which comprises two layers, namely gas diffusion layer and active layer. The active layer on the electrolyte side uses a high surface area carbon for oxygen reduction reaction and potassium permanganate and MnO2 as catalysts for oxygen reduction. The diffusion layer on the air side has high PTFE content to prevent KOH electrolyte from weeping or climbing. Due to adequate amount of fresh air and oxygen supply, the air cathode electrode can run continuously. Theoretically, the polymer zinc-air battery is an accumulator if the cell has sufficient zinc powder and electrolyte, and the air cathode plays the role of energy transfer.

Owner:MING CHI UNIVERSITY OF TECHNOLOGY

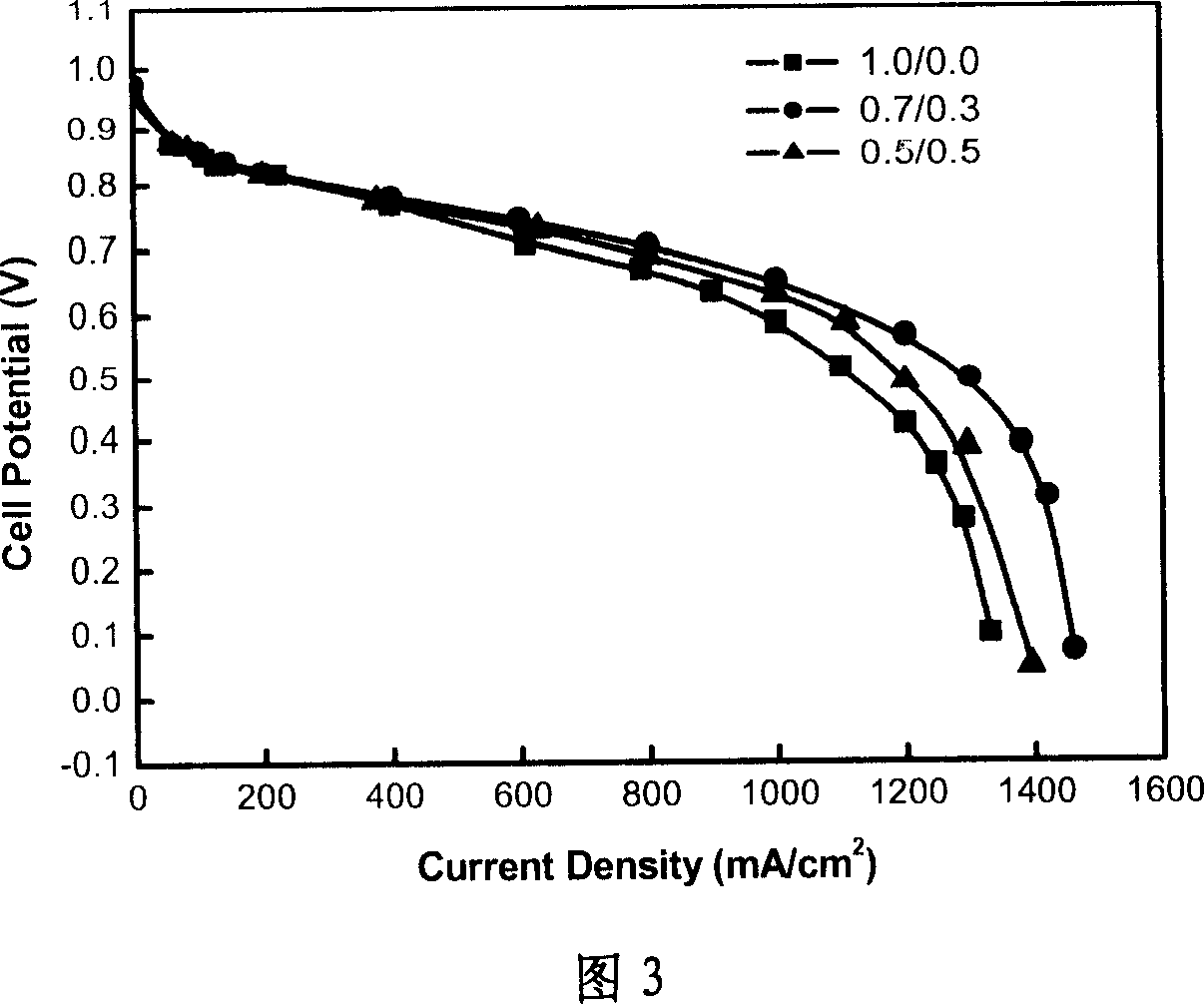

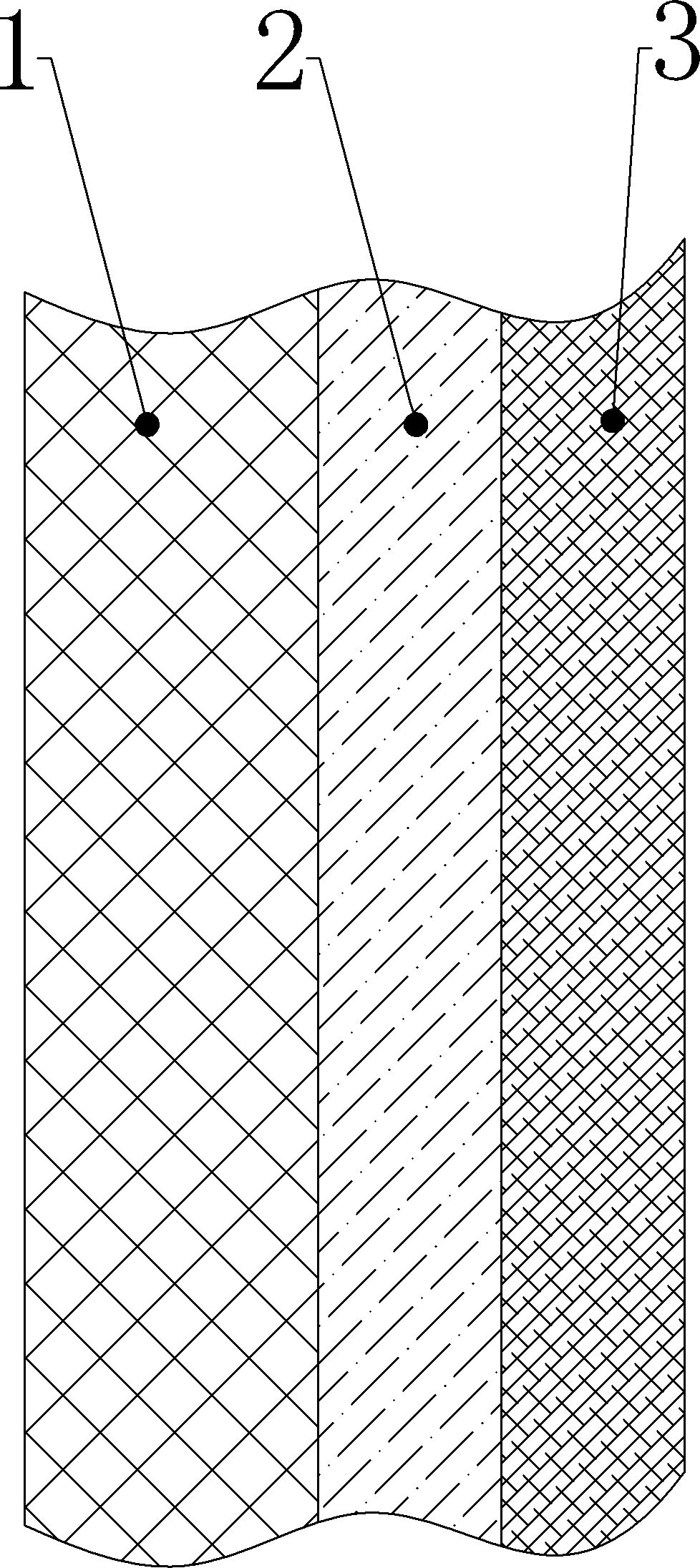

Gas diffusion layer with gradient hole structure and preparation and applications thereof

The invention relates to a gas diffusion layer with a gradient hole structure for fuel batteries and a preparation method and applications thereof. The gas diffusion layer consists of a macroporous carbon-based support body and a micro-porous layer which are overlapped, wherein the material of the micro-porous layer is embedded in the macroporous carbon-based support body from one side, far from the flow field of a battery, of the macroporous carbon-based support body to form a transitional hole layer; the transitional hole layer is composed of the material of the micro-porous layer and the fiber of the macroporous carbon-based support body and is obtained by embedding the material of the micro-porous layer in the side, far from the flow field of a battery, of the macroporous carbon-based support body; and the curvature of reaction gas transfer from the side next to the flow field to the side next to a catalyst layer in the gas diffusion layer increases gradiently and the air permeability gradually reduces from 4-10s / 100ml to 100-900s / 100ml. By adopting the gas diffusion layer with the structure, the mass transfer curvatures of water and the gas in the gas diffusion layer (GDL) can be effectively increased, the transfer path of the product-water can be prolonged and liquid water in the battery can be maintained; and the gas diffusion layer is particularly suitable for fuel batteries working under low humidity and the cathodes of alkaline fuel batteries.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for manufacturing fuel cell elecrolyte film-electrode bond

InactiveUS20030158273A1Sufficiently suppressReduce adhesionIon-exchanger regenerationFinal product manufactureFuel cellsConductive polymer

In order to obtain an electrolyte membrane-electrode assembly using a thin electrolyte membrane, the present invention provides a production method of an electrolyte membrane-electrode assembly comprising: a step of forming a hydrogen ion-conductive polymer electrolyte membrane on a base material; a treatment step of reducing adhesion force between the base material and the hydrogen ion-conductive polymer electrolyte membrane; a step of separating and removing the base material; and a step of bonding a catalyst layer and a gas diffusion layer onto the hydrogen ion-conductive polymer electrolyte membrane, and, in order to obtain an electrolyte membrane-electrode assembly which has a catalyst without clogging and is excellent in electrode characteristics, the present invention provides a production method of an electrolyte membrane-electrode assembly comprising: a step of bonding a hydrogen ion-conductive polymer electrolyte membrane and a catalyst layer via a coating layer; a step of removing the coating layer; and a step of obtaining an electrolyte membrane-electrode assembly by forming a gas diffusion layer on the catalyst layer.

Owner:PANASONIC CORP

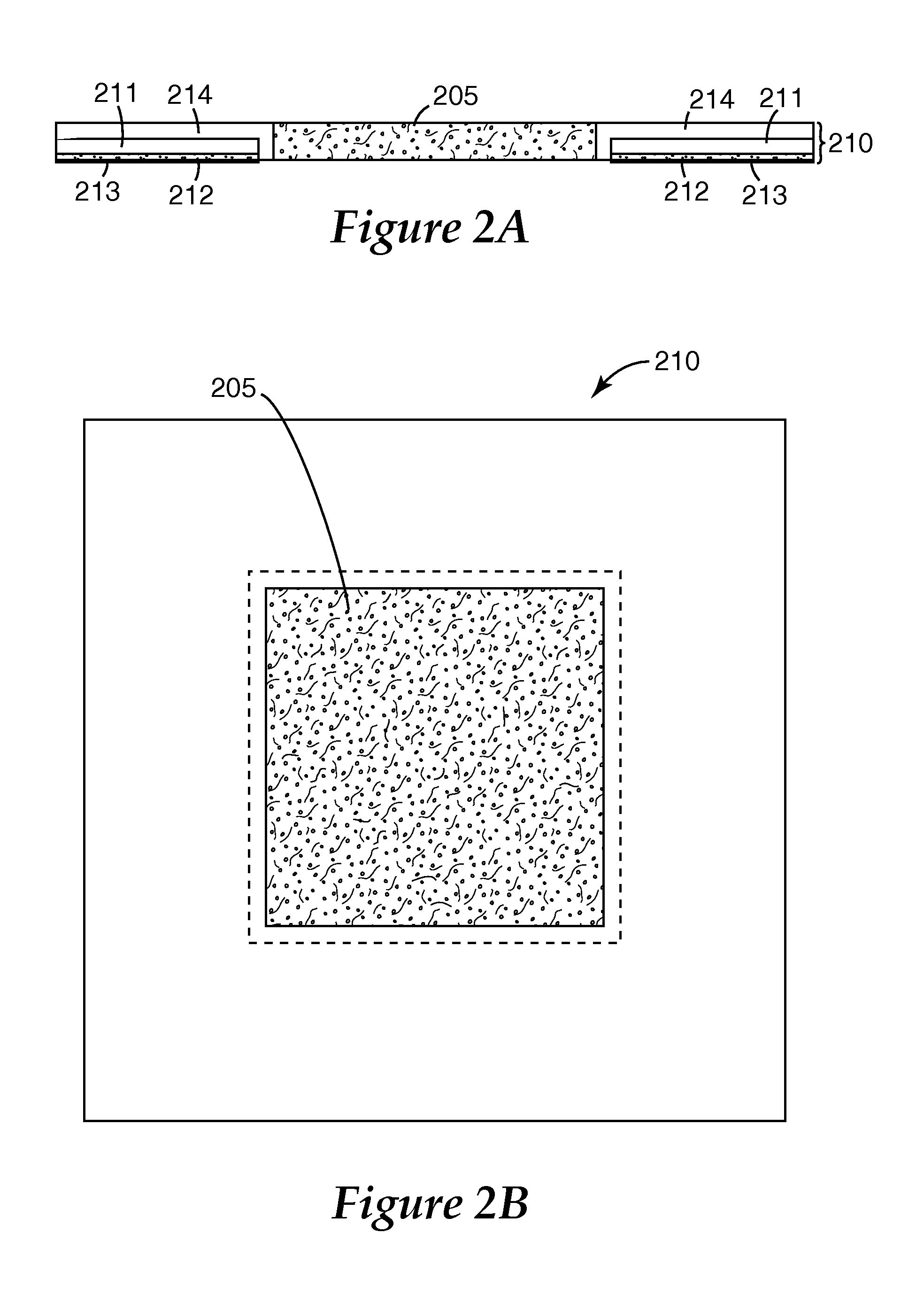

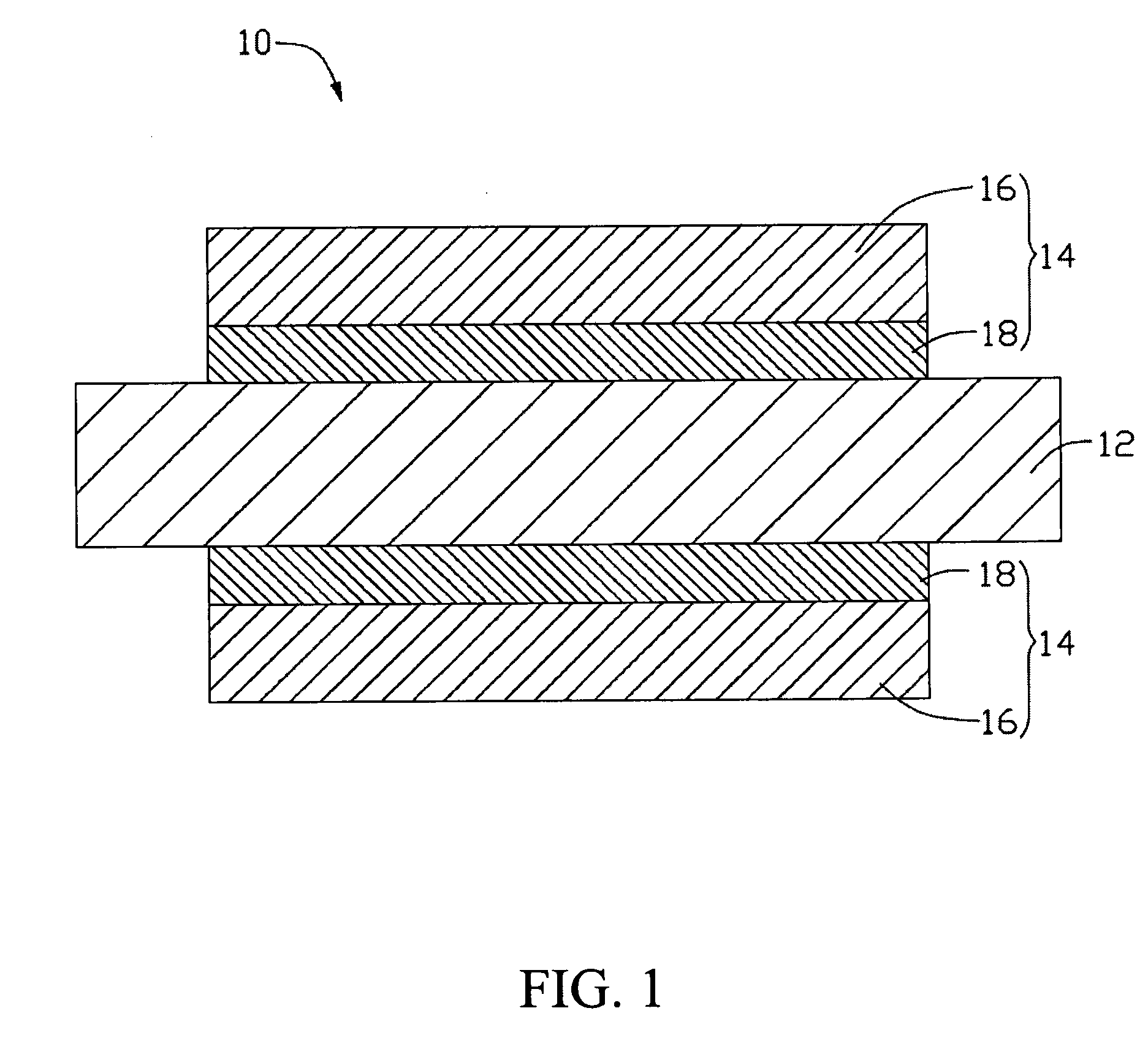

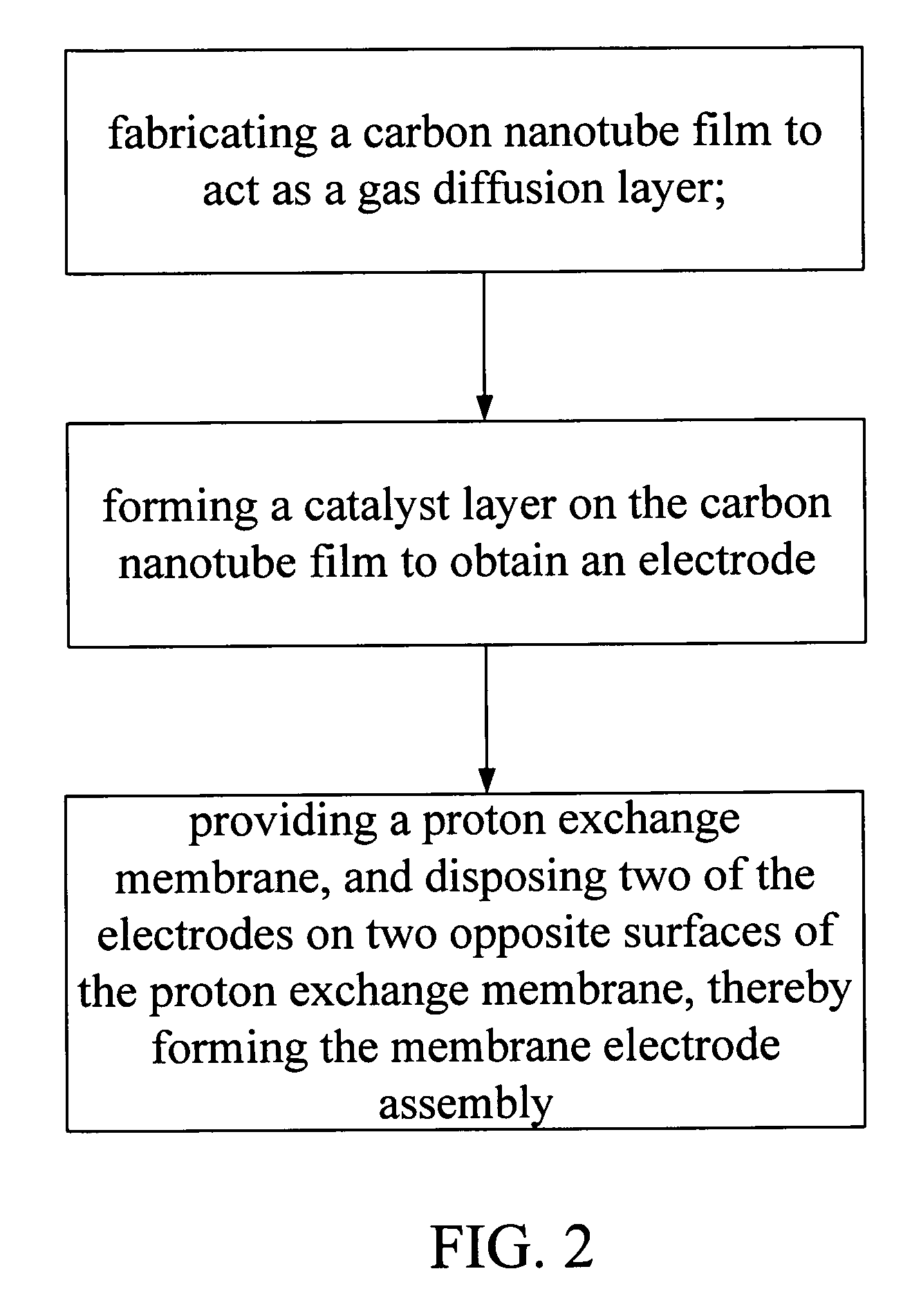

Membrane electrode assembly and method for making the same

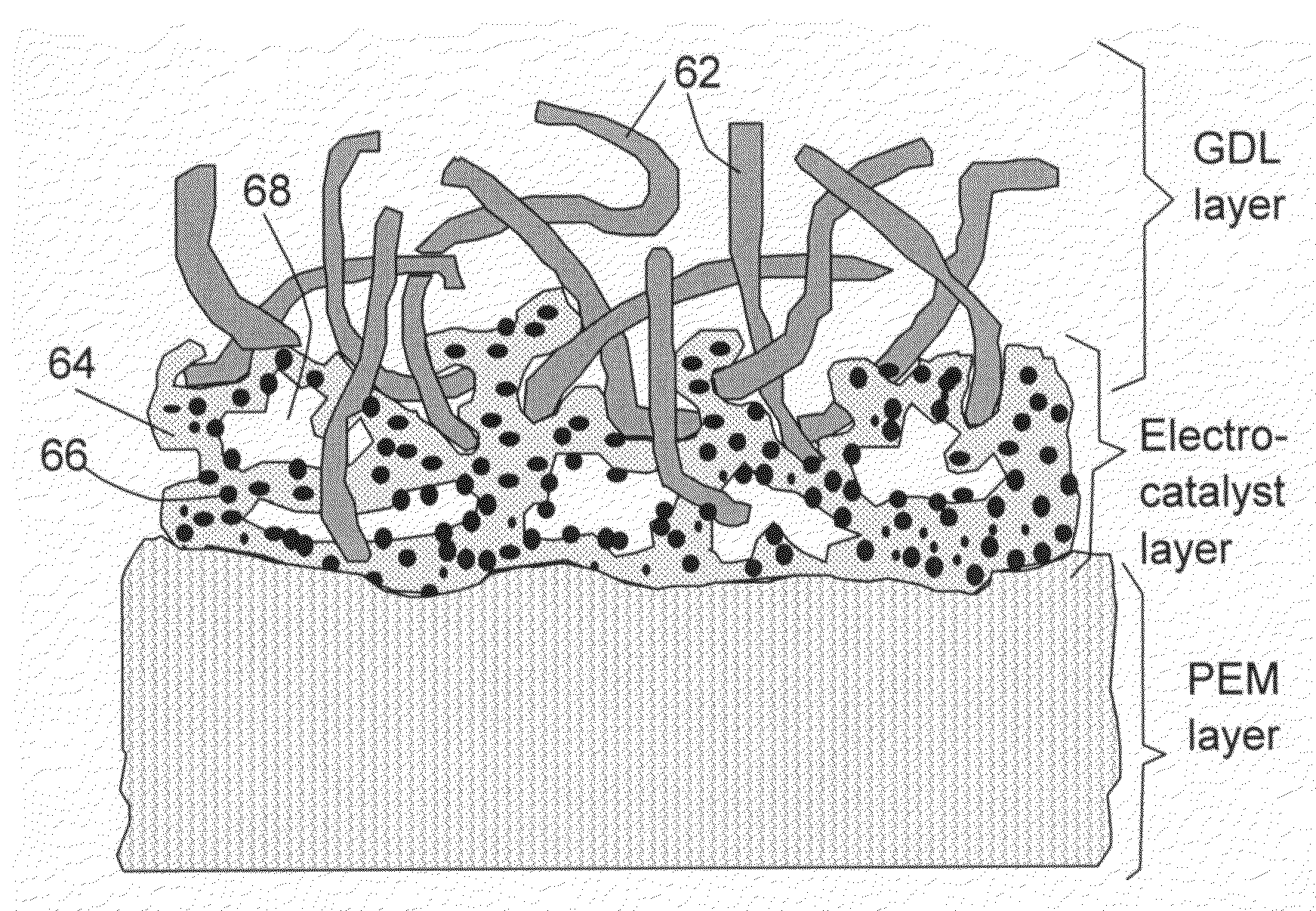

InactiveUS20090117434A1High tensile strengthFree-standing structureFinal product manufactureSolid electrolyte fuel cellsProtonCarbon nanotube

The present invention relates to a membrane electrode assembly. The proton exchange membrane includes two opposite surfaces. The two electrodes are separately disposed on the two opposite surfaces of the proton exchange membrane. The two electrodes are separately disposed on two opposite surfaces of the proton exchange membrane. Further, each electrode includes a catalyst layer and a gas diffusion layer. The catalyst layer is configured for being sandwiched between the gas diffusion layer and the proton exchange membrane. The gas diffusion layer includes a carbon nanotube film. The carbon nanotube film includes a plurality of carbon nanotubes, which are selected from the group consisting of the carbon nanotubes isotropically arranged, arranged along a fixed direction, or arranged along different directions. And a method for making the membrane electrode assembly is also included.

Owner:TSINGHUA UNIV +1

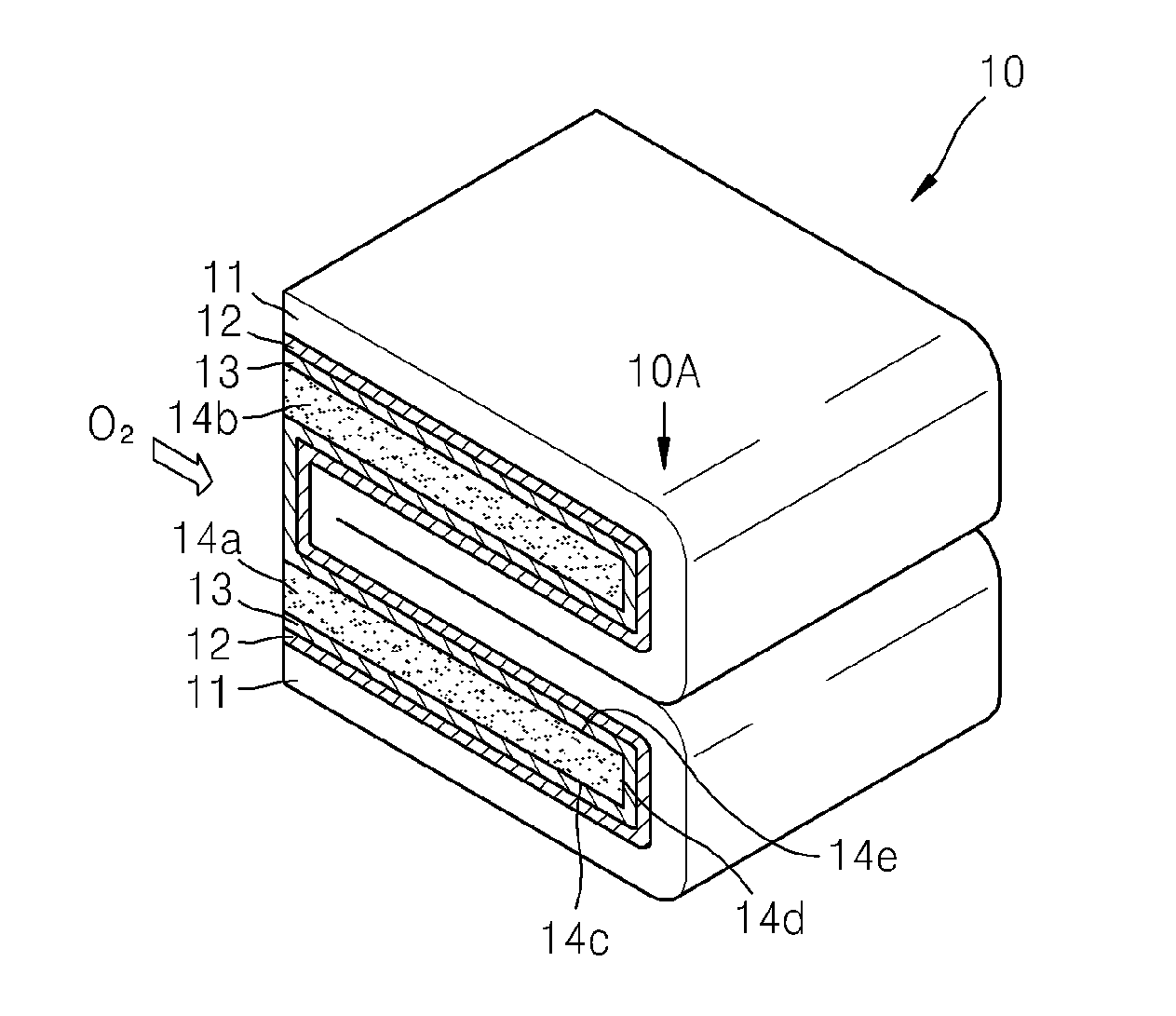

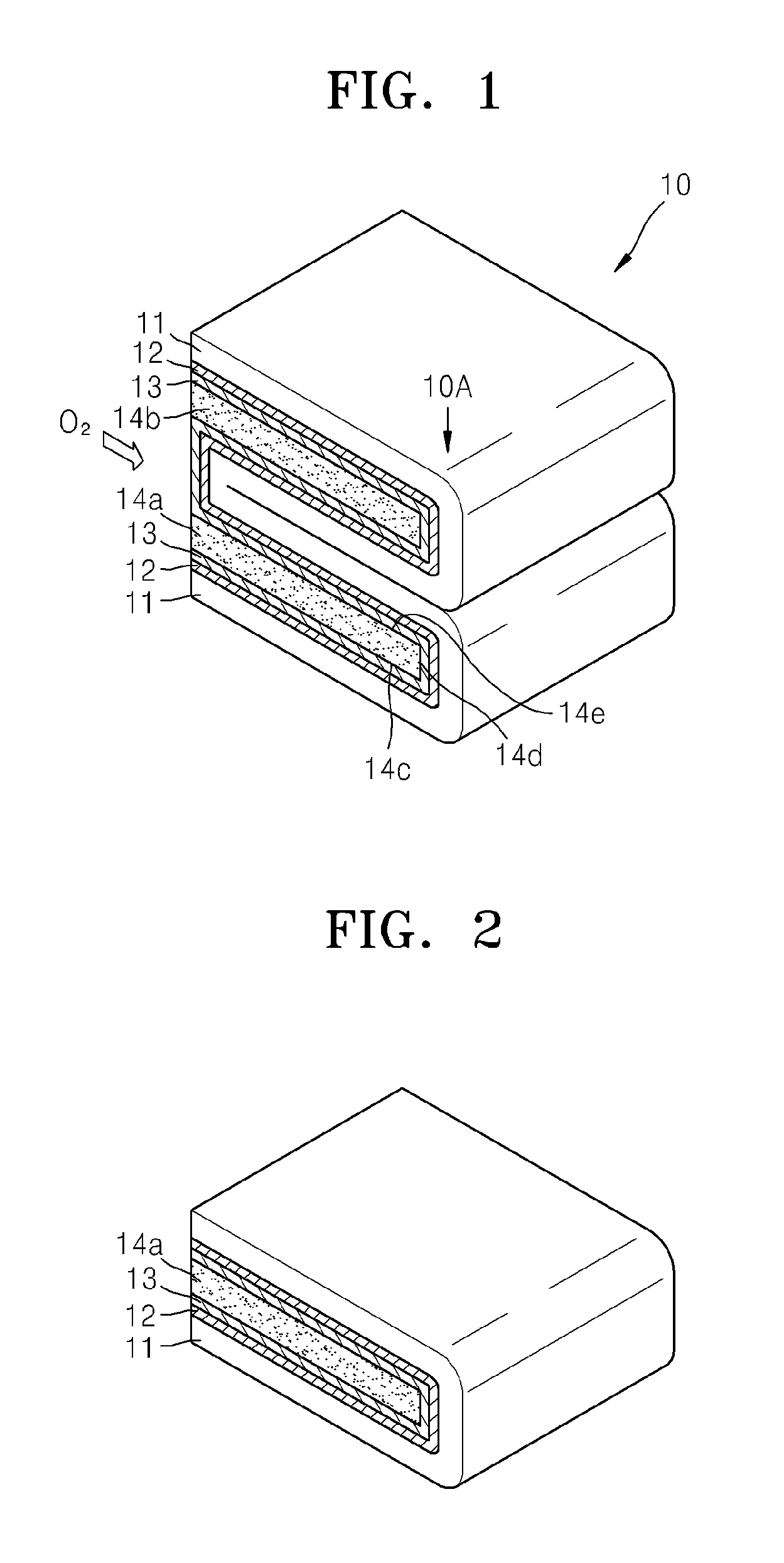

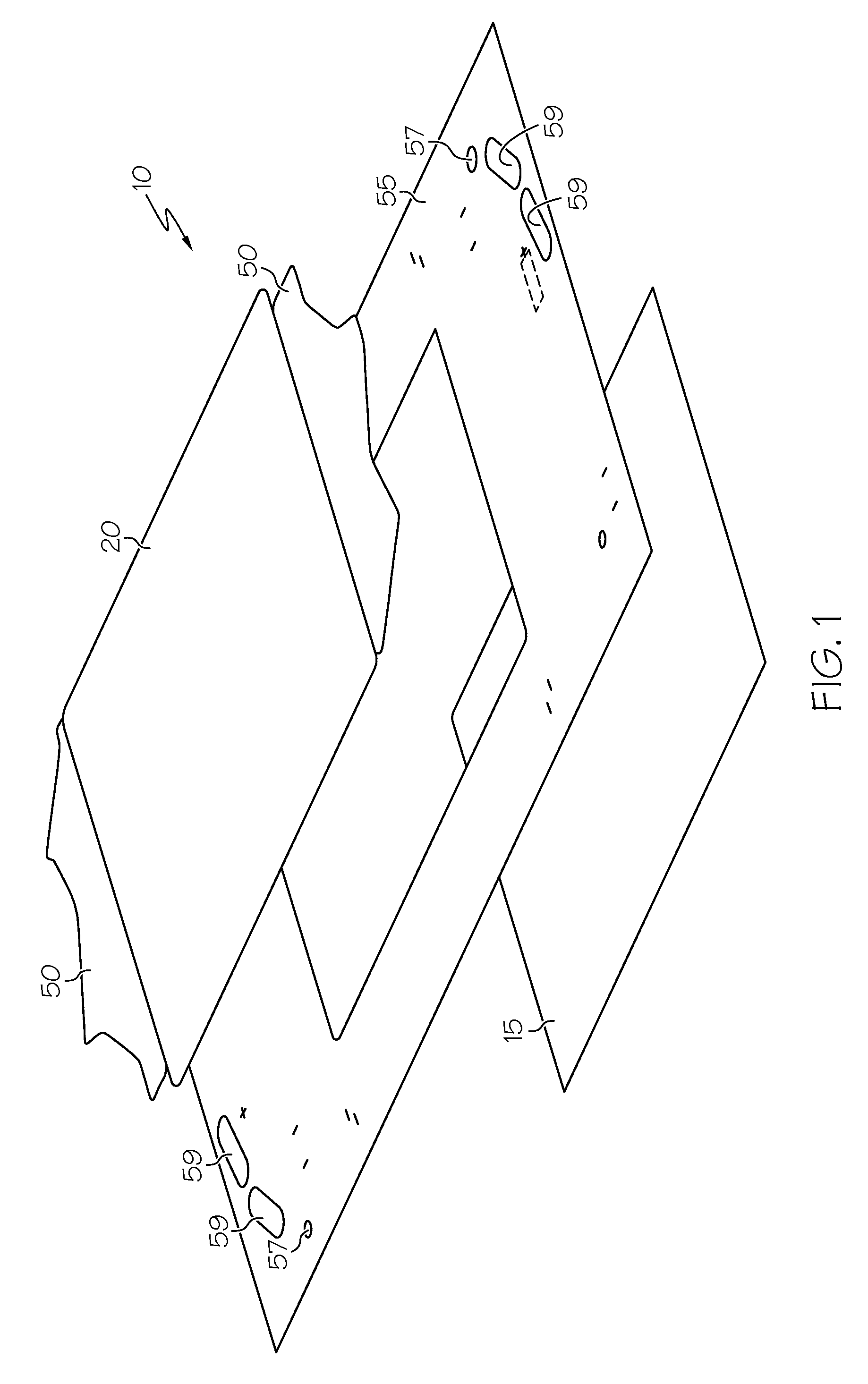

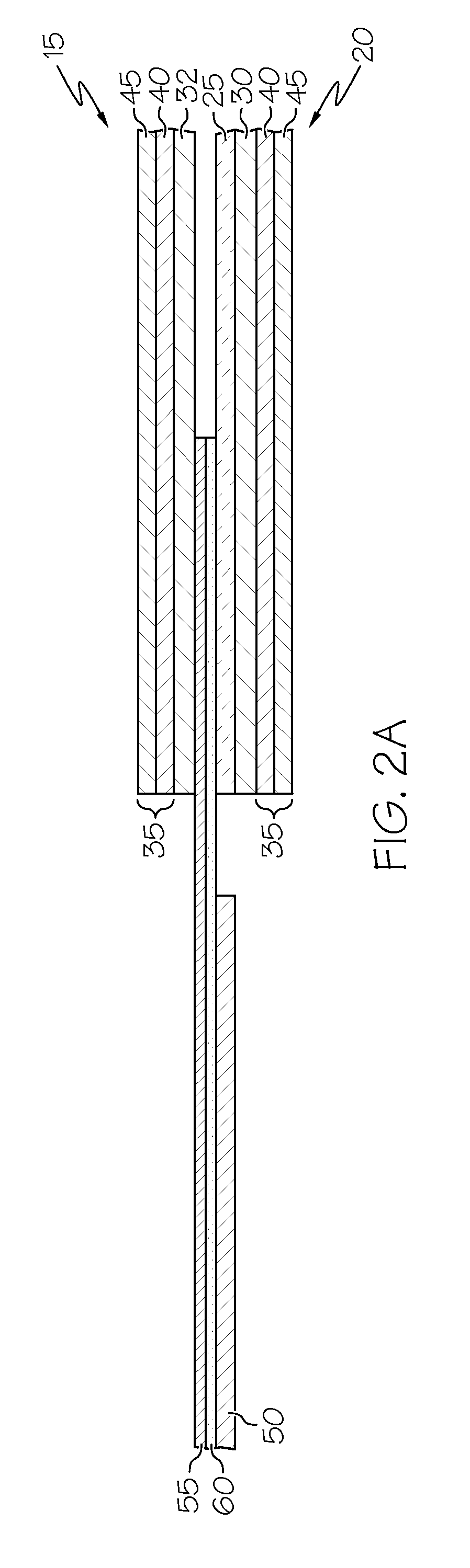

Metal-air battery having folded structure and method of manufacturing the same

A metal-air battery including: a negative electrode metal layer; a negative electrode electrolyte layer disposed on the negative electrode metal layer; a positive electrode layer disposed on the negative electrode electrolyte layer, the positive electrode layer comprising a positive electrode material which is capable of using oxygen as an active material; and a gas diffusion layer disposed on the positive electrode layer, wherein the negative electrode electrolyte layer is between the negative electrode metal layer and the positive electrode layer; wherein the negative electrode metal layer, the negative electrode electrolyte layer, and the positive electrode layer are disposed on the gas diffusion layer so that the positive electrode layer contacts a lower surface and an opposite upper surface of the gas diffusion layer, and wherein one side surface of the gas diffusion layer is exposed to an outside.

Owner:SAMSUNG ELECTRONICS CO LTD

Gas diffusion layer for proton exchanging film fuel cell and its preparing method

InactiveCN1988225ALight weightUniform surfaceFinal product manufactureCell electrodesFiberHydrophile

This invention relates to a gas diffusion layer used in proton exchange film fuel cells and its preparation method, in which, the gas diffusion layer includes a multihole supporting layer and a microhole layer, the multihole supporting layer is a net and porous structure, the microhole layer is composited on the surface of the porous supporting layer closing to the catalyzed layer and covers the surface of the large hole and fiber dense region of the supporting layer uniformly but not penerates into the inside of the supporting layer, which applies a drying method to prepare a gas diffusion layer used in proton exchange membrane fuel cells, and polymr 1 and 2 containing FI is either a same kind or different, and the hydrophile / hydrophobic degree of the two layers is adjustable, so the gas diffusion layer structure is matched with the running condition of the fuel cell and discharges water more easily.

Owner:SUNRISE POWER CO LTD

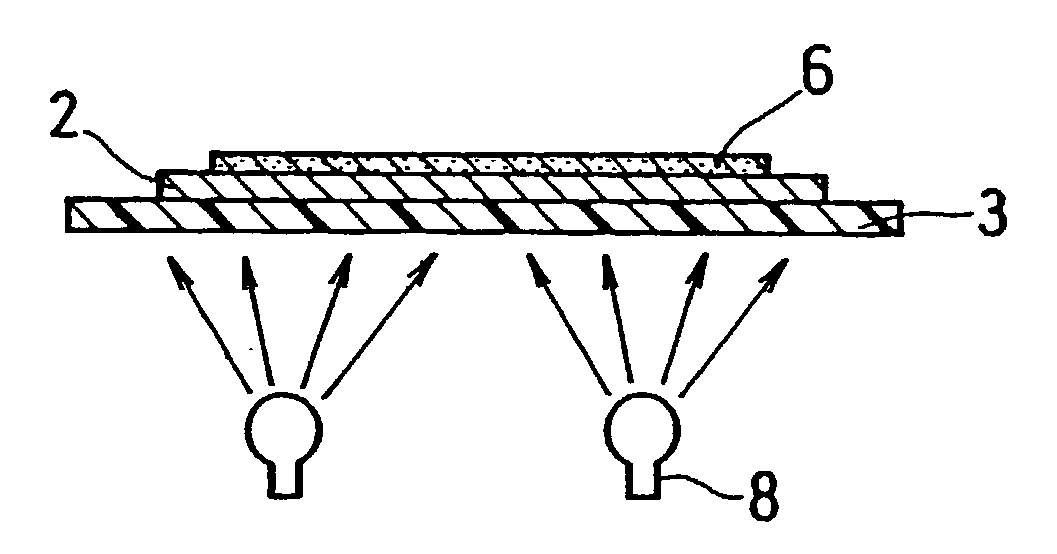

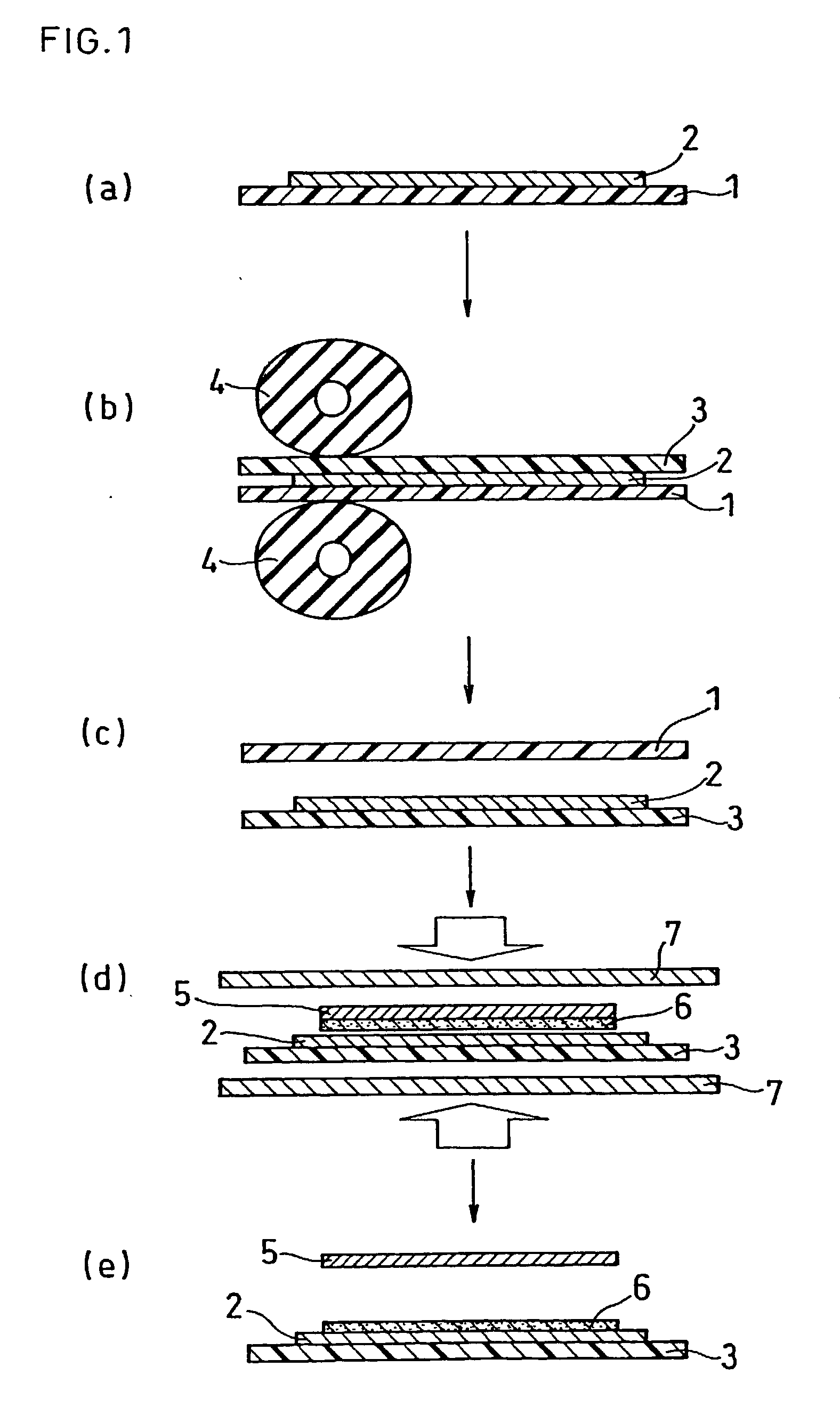

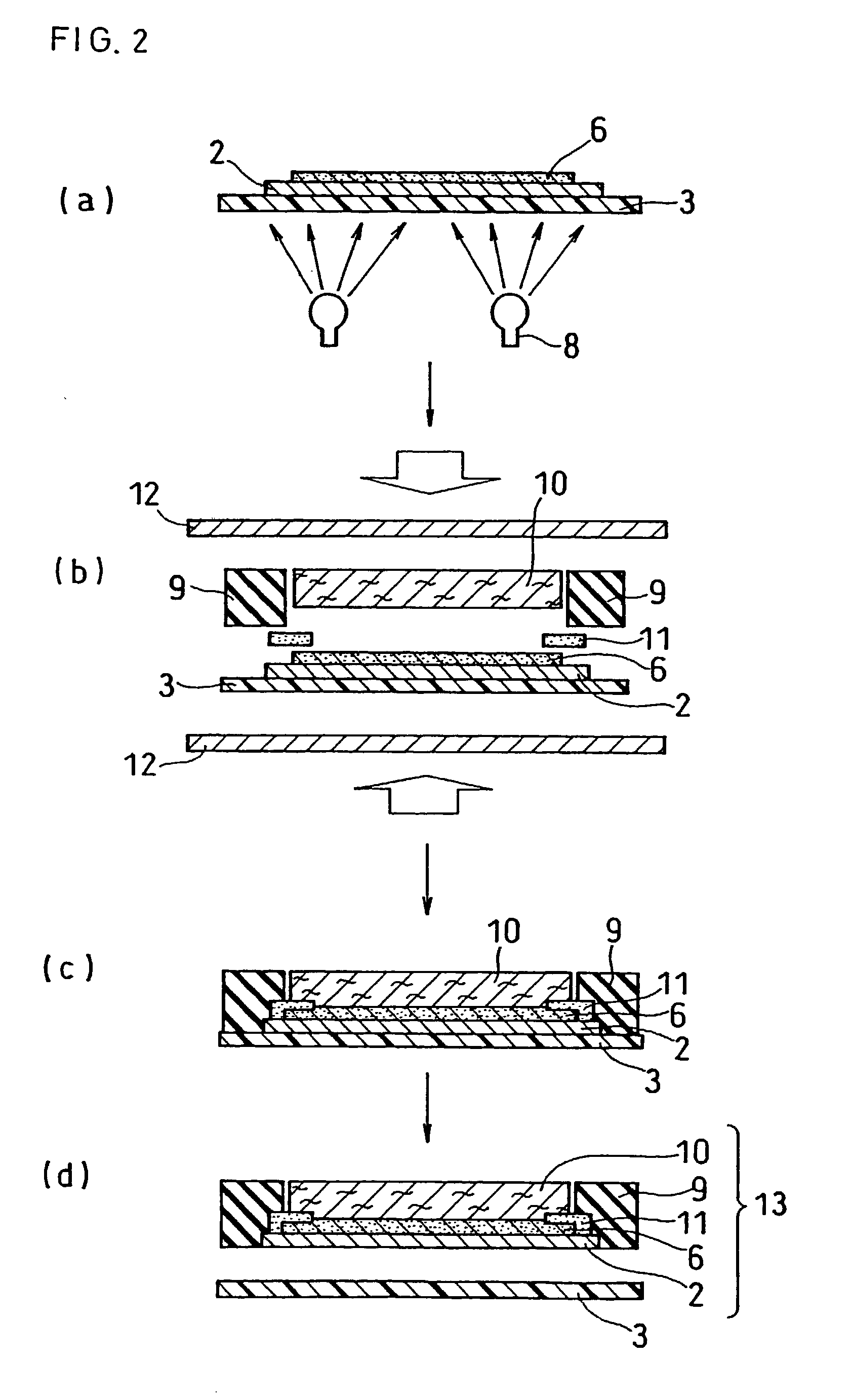

Core component having sealed frame and membrane electrode prepared thereby

ActiveCN101393989AStable supportDimensional stabilitySolid electrolyte fuel cellsSealing/support meansPhysical chemistryCore component

The invention relates to a core component with a sealed frame and a membrane electrode prepared by using the core component. A method for preparing the membrane electrode of the core component with the sealed frame is characterized in that a sealed frame material coated with a sticky glue layer on one surface thereof at the normal temperature is adopted, and a strengthened underlay is attached to the other surface thereof. The sealed frame is overlapped on two surfaces of an ion exchange membrane under the condition that one surface of the ion exchange film is supported. Then, an active area of the ion exchange membrane is coated with a catalyst, and the core component (CCM) with the sealed frame is prepared, and then carries out the hot pressing with a gas diffusion layer with a micropore layer and a gas diffusion layer (GDL), so as to prepare the membrane electrode (MEA).

Owner:武汉理工新能源有限公司

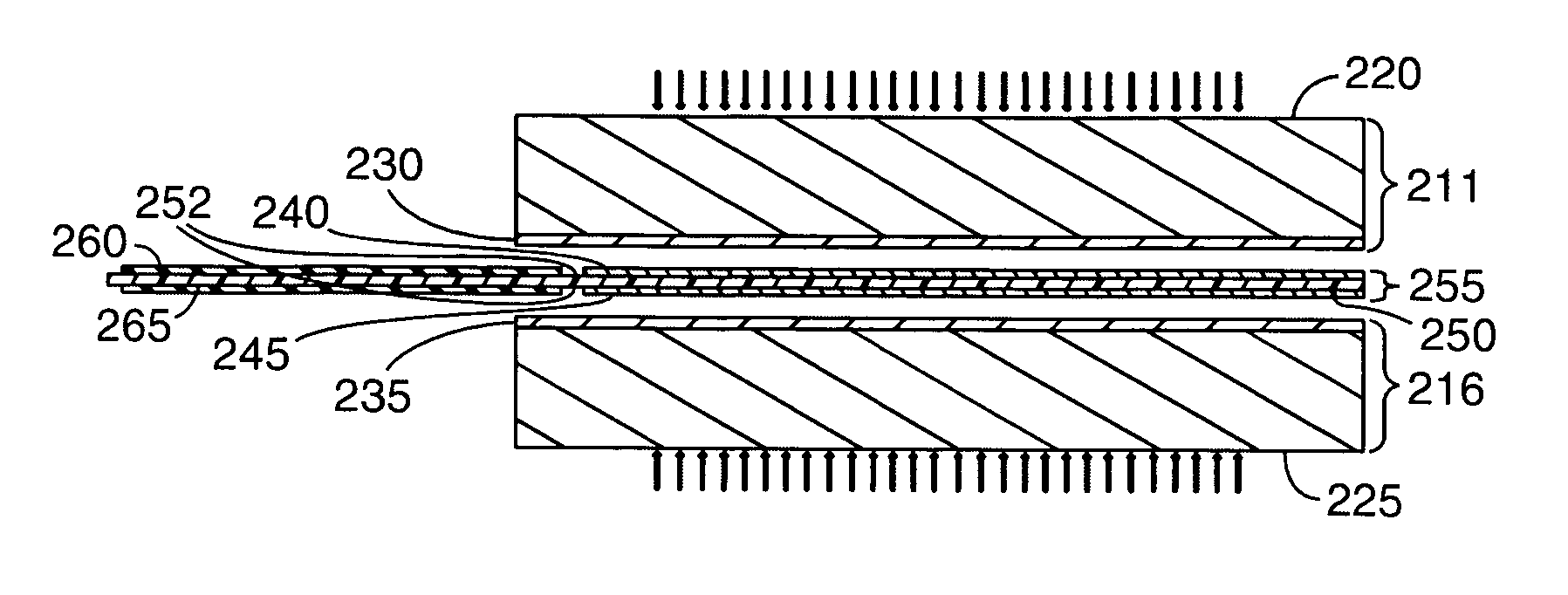

Integrated fuel cell assembly and method of making

An integrated fuel cell assembly is described. The integrated fuel cell assembly includes a polymer membrane; an anode electrode and a cathode electrode on opposite sides of the polymer membrane; a pair of gas diffusion media on opposite sides of the polymer membrane, the gas diffusion media comprising a microporous layer and a gas diffusion layer, the anode electrode and the cathode electrode positioned between the polymer membrane and the pair of gas diffusion media; a subgasket positioned around a perimeter of one of the gas diffusion media, the subgasket defining an active area inside the perimeter, the subgasket having a layer of thermally activated adhesive thereon; and a bipolar plate sealed to the subgasket by the layer of thermally activated adhesive. Methods of making the integrated fuel cell assembly and assembling fuel cell stacks are also described.

Owner:GM GLOBAL TECH OPERATIONS LLC

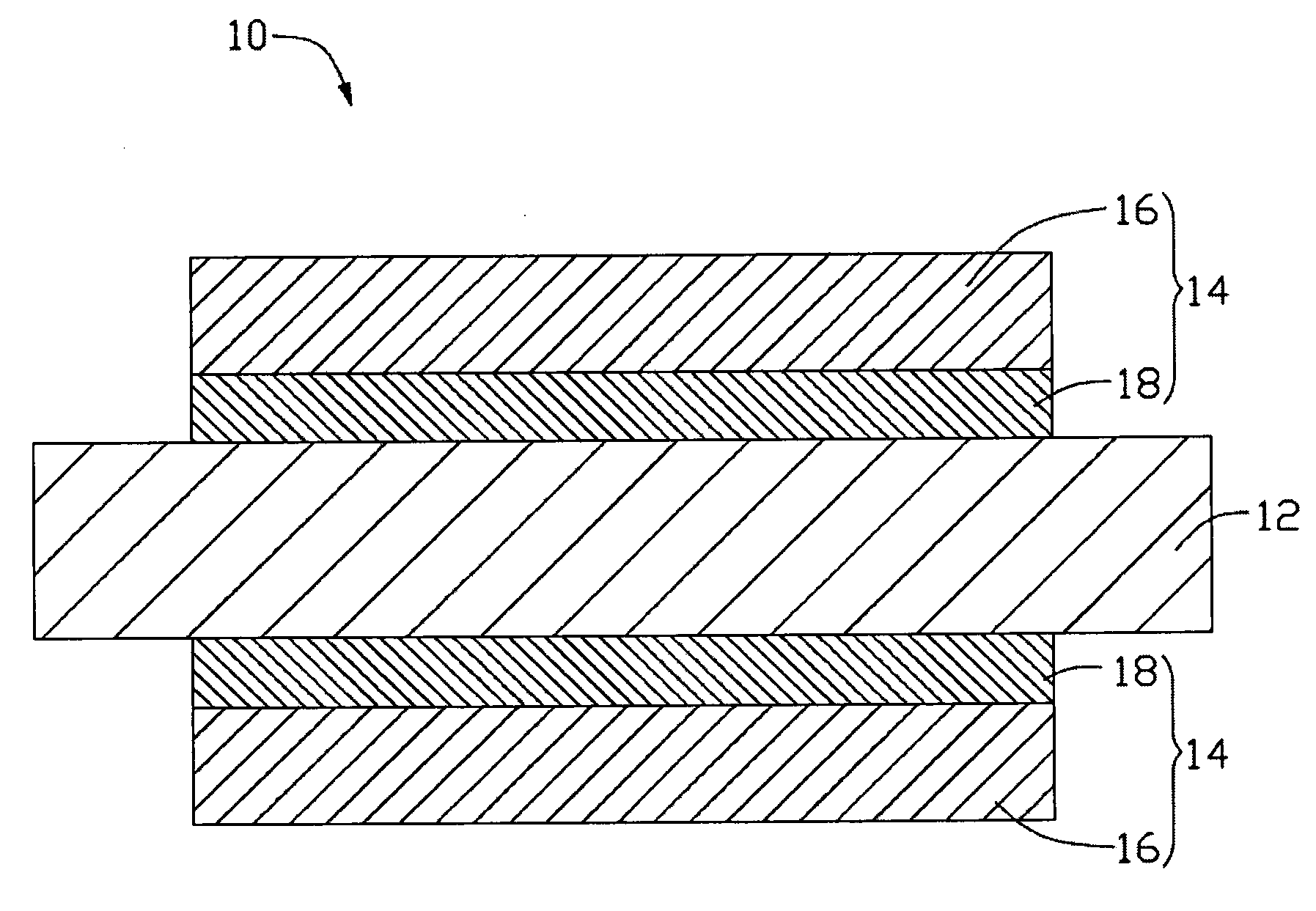

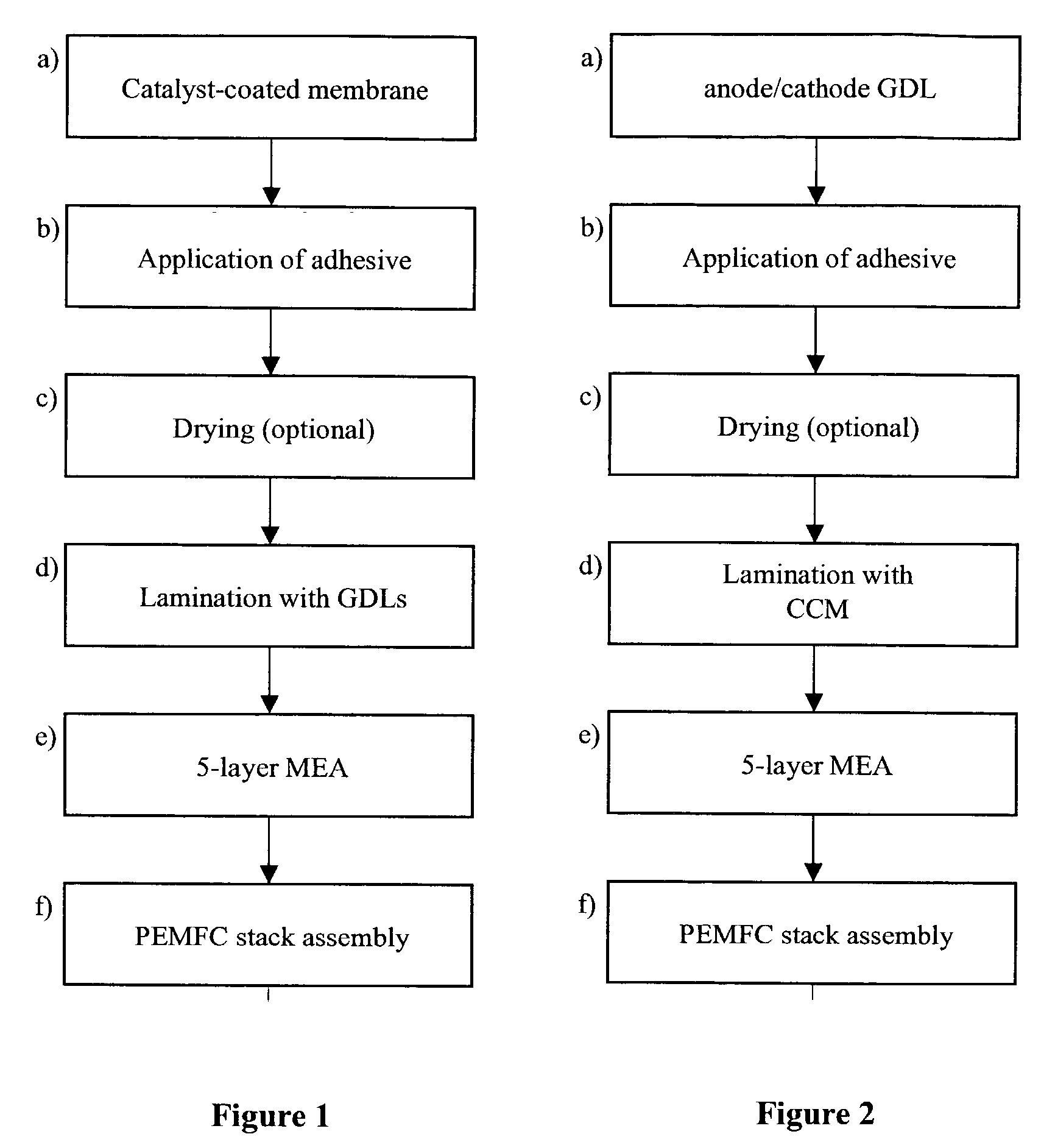

Process for the manufacture of membrane-electrode-assemblies using catalyst-coated membranes

ActiveUS20030224233A1Easy to assembleSimple handlingCellsSemi-permeable membranesCoated membranePolymer electrolytes

The present invention relates to the field of electrochemical cells and fuel cells, more specifically to polymer-electrolyte-membrane (PEM) fuel cells and describes a process for the manufacture of membrane-electrode-assemblies (MEAs) containing five layers. The five-layer MEA is assembled together by means of a lamination process involving an adhesive component. The anode gas diffusion layer, the catalyst-coated membrane and the cathode gas diffusion layer are combined together by a low temperature / low pressure lamination process. Handling of the MEAs and assembly of the products into PEMFC and DMFC stacks is simplified. Less damage and perforation of the catalyst-coated membrane occurs and thus the performance of the five-layer MEAs is significantly improved.

Owner:UMICORE AG & CO KG

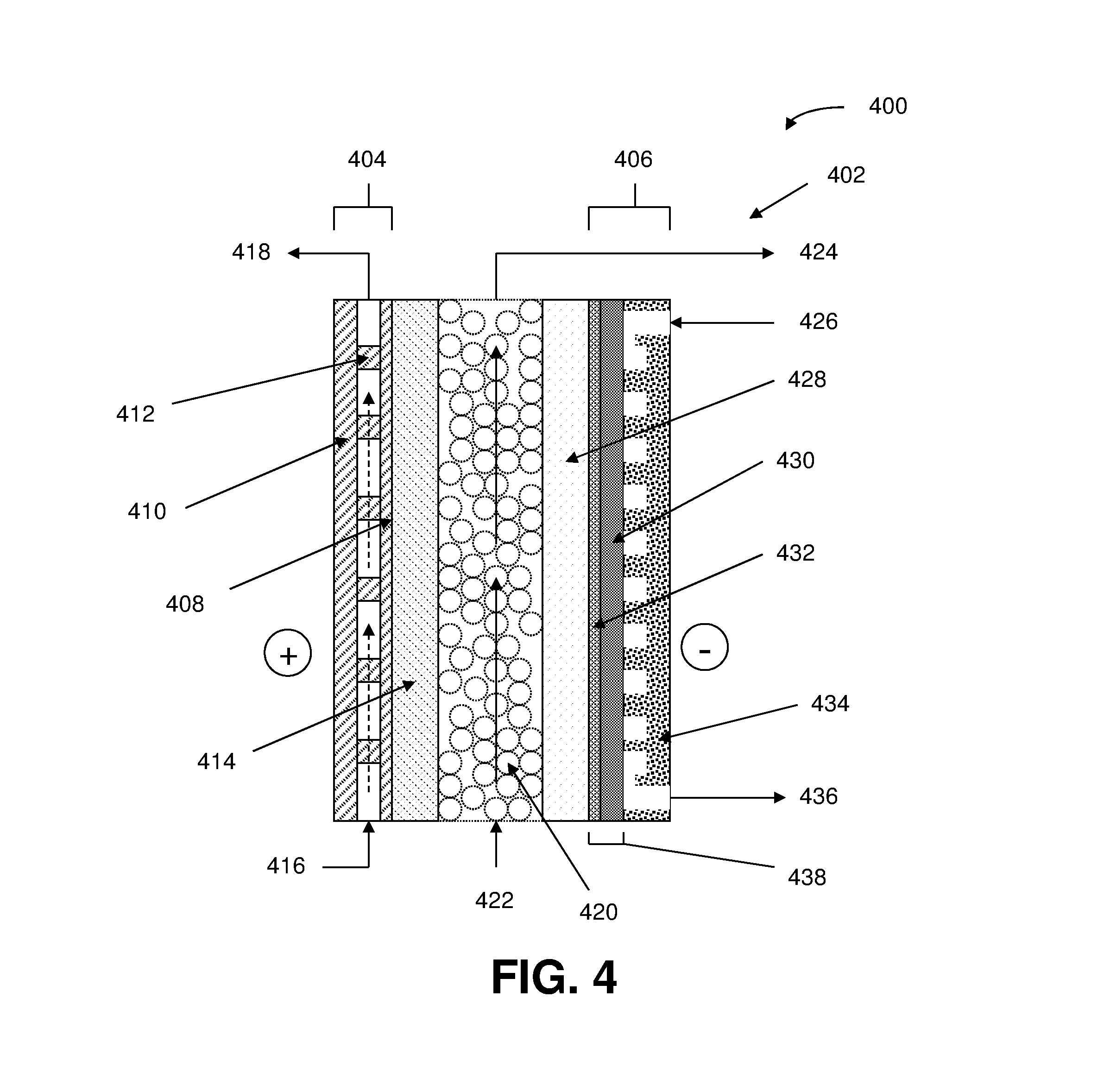

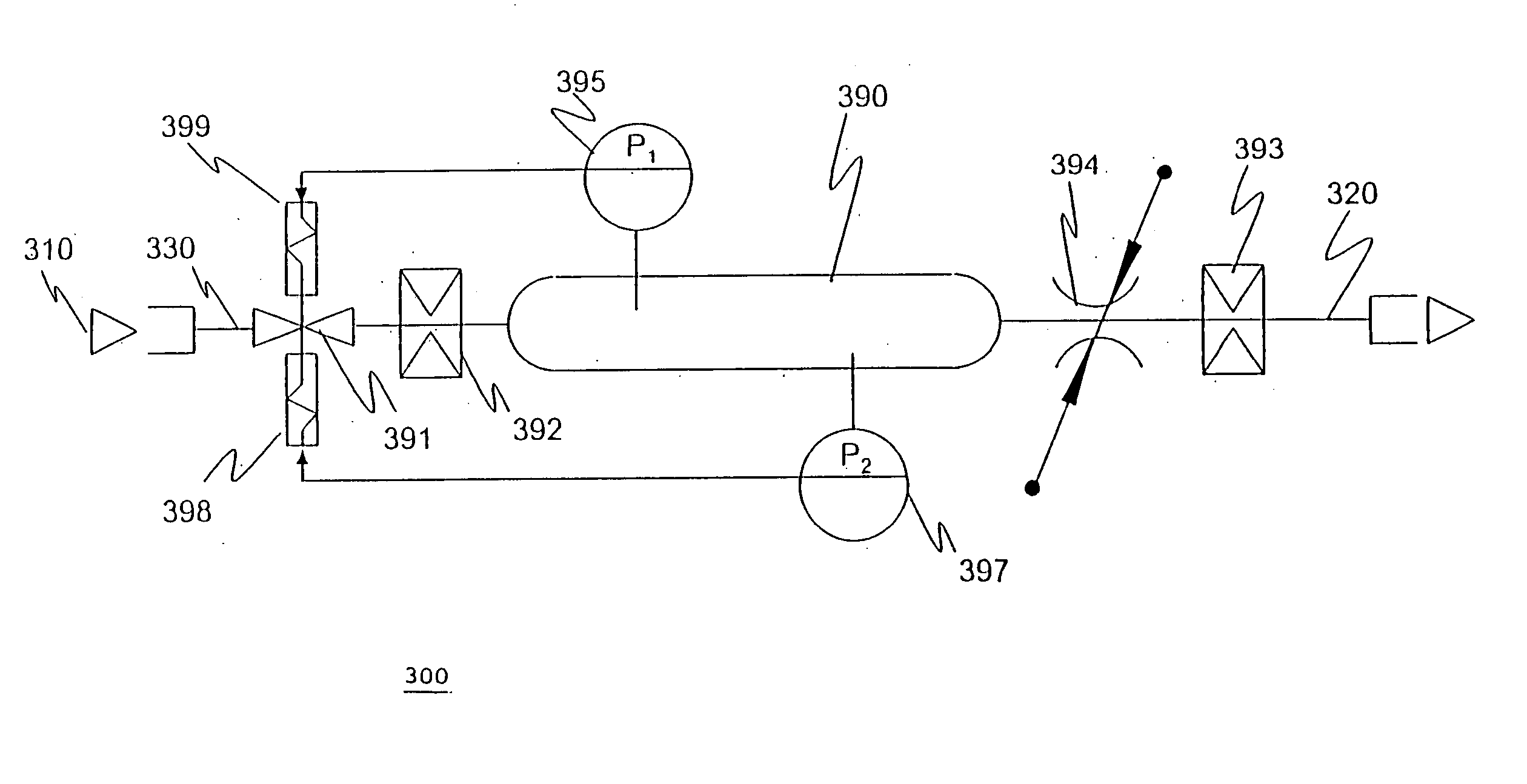

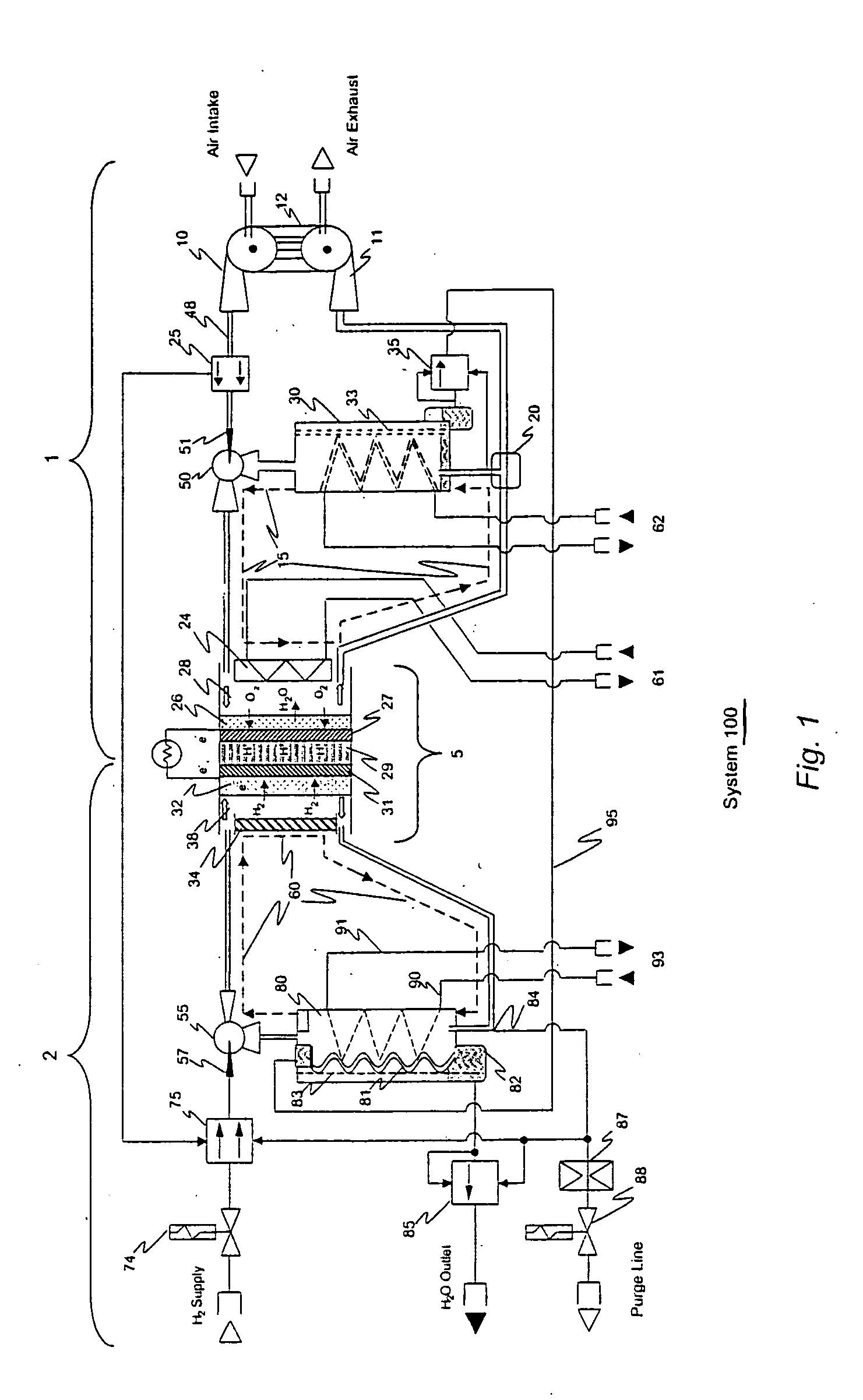

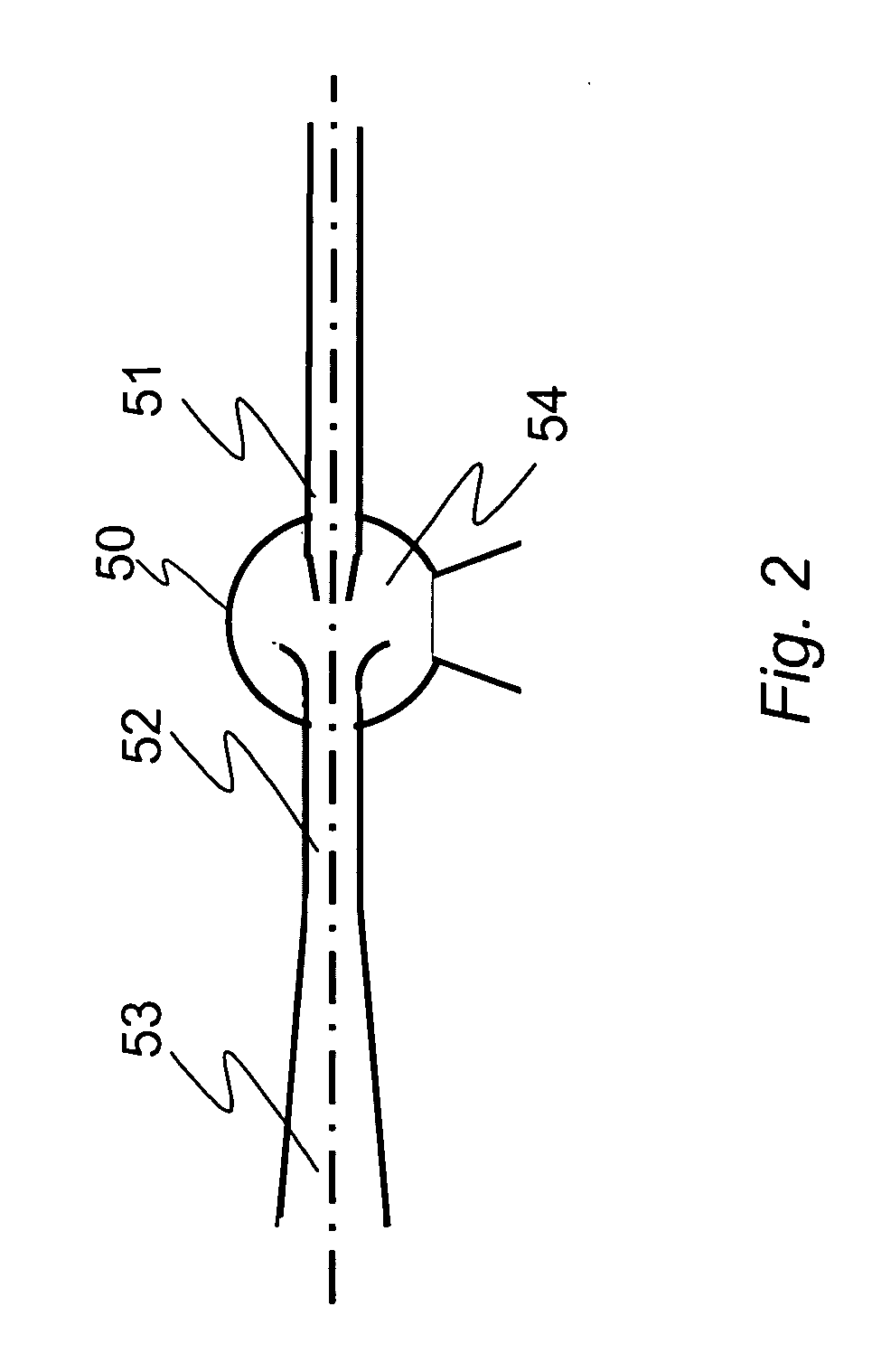

Fuel cell with integrated feedback control

InactiveUS20050100777A1Volume adjustableEasy loadingCell electrodesFuel cell auxillariesElectrochemical responsePartial oxidation

A recirculating reagent fuel-cell includes an ion-exchange membrane interposed between an anode and cathode anode to form a membrane / electrode assembly (MEA), the MEA interposed between a fuel gas diffusion layer and an oxidant gas diffusion layer. An oxidant and fuel flow network are provided having an input portion for supplying reagent and an output portion for removing reagent after electrochemical reaction. At least one of the oxidant flow network and fuel flow network includes a recirculation loop, the recirculation loop feeding back a portion of the fuel or oxidant after electrochemical reaction to their respective input portion. The fuel flow network can include a water vapor condenser to extract water from the cathodes in proportion to the external load on the fuel cell stack and the fuel flow network can include an evaporator, where water is fed to the evaporator in the fuel loop from the condenser in the oxidant feed loop.

Owner:ULTIMATE COMBUSTION

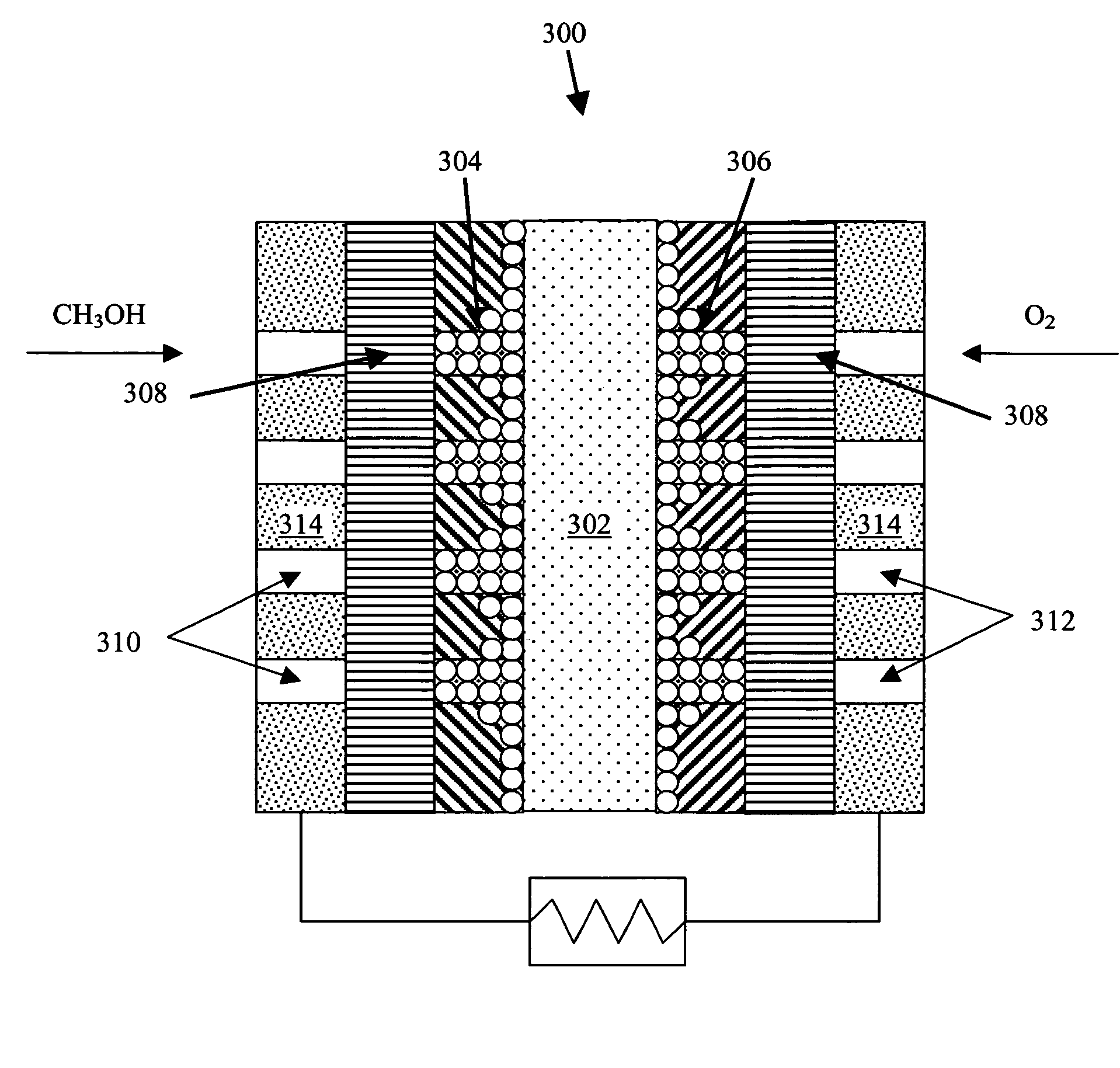

Electrochemical Device For Converting Carbon Dioxide To A Reaction Product

ActiveUS20160108530A1Low faradaic efficiencyLow conversion currentCellsSolid electrolytesElectrolysisPyridinium

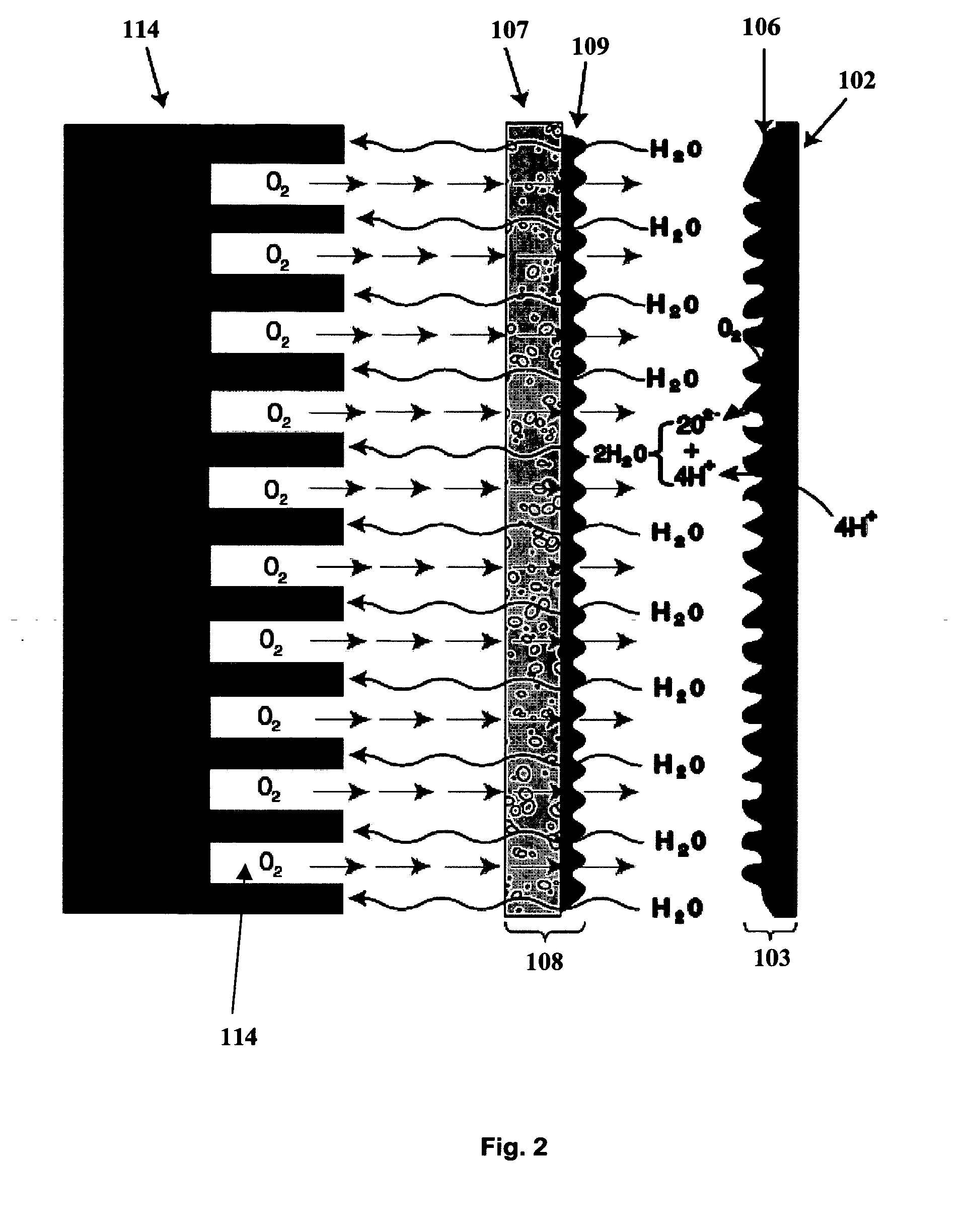

An electrochemical device converts carbon dioxide to a reaction product. The device includes an anode and a cathode, each comprising a quantity of catalyst. The anode and cathode each has reactant introduced thereto. A polymer electrolyte membrane is interposed between the anode and the cathode. At least a portion of the cathode catalyst is directly exposed to gaseous carbon dioxide during electrolysis. The average current density at the membrane is at least 20 mA / cm2, measured as the area of the cathode gas diffusion layer that is covered by catalyst, and CO selectivity is at least 50% at a cell potential of 3.0 V. In some embodiments, the polymer electrolyte membrane comprises a polymer in which a constituent monomer is (p-vinylbenzyl)-R, where R is selected from the group consisting of imidazoliums, pyridiniums and phosphoniums. In some embodiments, the polymer electrolyte membrane is a Helper Membrane comprising a polymer containing an imidazolium ligand, a pyridinium ligand, or a phosphonium ligand.

Owner:DIOXIDE MATERIALS

Gas diffusion layer having carbon particle mixture

InactiveUS20050130023A1Prevent floodingLong dimensionFuel cells groupingElectrode carriers/collectorsFuel cellsConductive materials

The invention relates to a gas diffusion layer, a device having the gas diffusion layer and a catalyst layer, a fuel cell containing the gas diffusion layer, and a gas diffusion electrode. The gas diffusion layer comprises a flexible, electrically non-conductive, porous material having a solid matrix, interconnected pores or interstices through the solid matrix, at least one external surface and internal surfaces, which internal surfaces are the surfaces of the walls of the pores or interstices, wherein at least a portion of the at least one external surface is coated with one or more layers of an electrically conductive material, the electrically conductive material comprising a mixture of at least two populations of electrically conductive carbon particles of different size, wherein the at least two populations of electrically conductive carbon particles are substantially uniformly mixed in the direction of a plane extending along the at least one external surface.

Owner:FOAMEX LP

Thin film fuel cell assembly

InactiveUS20070105008A1Reduce contact resistanceLight weightElectrode carriers/collectorsActive material electrodesPolymer electrolytesFuel cells

A fuel cell assembly including: a membrane electrode assembly and current collector sub-unit including (i) a polymer electrolyte membrane having a cathode side and an anode side; (ii) catalyst layers disposed, respectively, on both sides of the polymer electrolyte membrane; (iii) gas diffusion layers disposed, respectively, on sides of both catalyst layers, wherein the gas diffusion layers are laminated on the catalyst layers; and (iv) porous current collectors disposed, respectively, on sides of both gas diffusion layers, wherein the porous current collectors are laminated on the gas diffusion layers. The fuel cell assembly also includes a hydrogen supplier layer disposed on the anode side of the sub-unit, sealed to the edges of the sub-unit and forming an anode chamber; and a hydrogen inlet and a hydrogen outlet connected the anode chamber.

Owner:SHANGHAI HORIZON FUEL CELL TECH

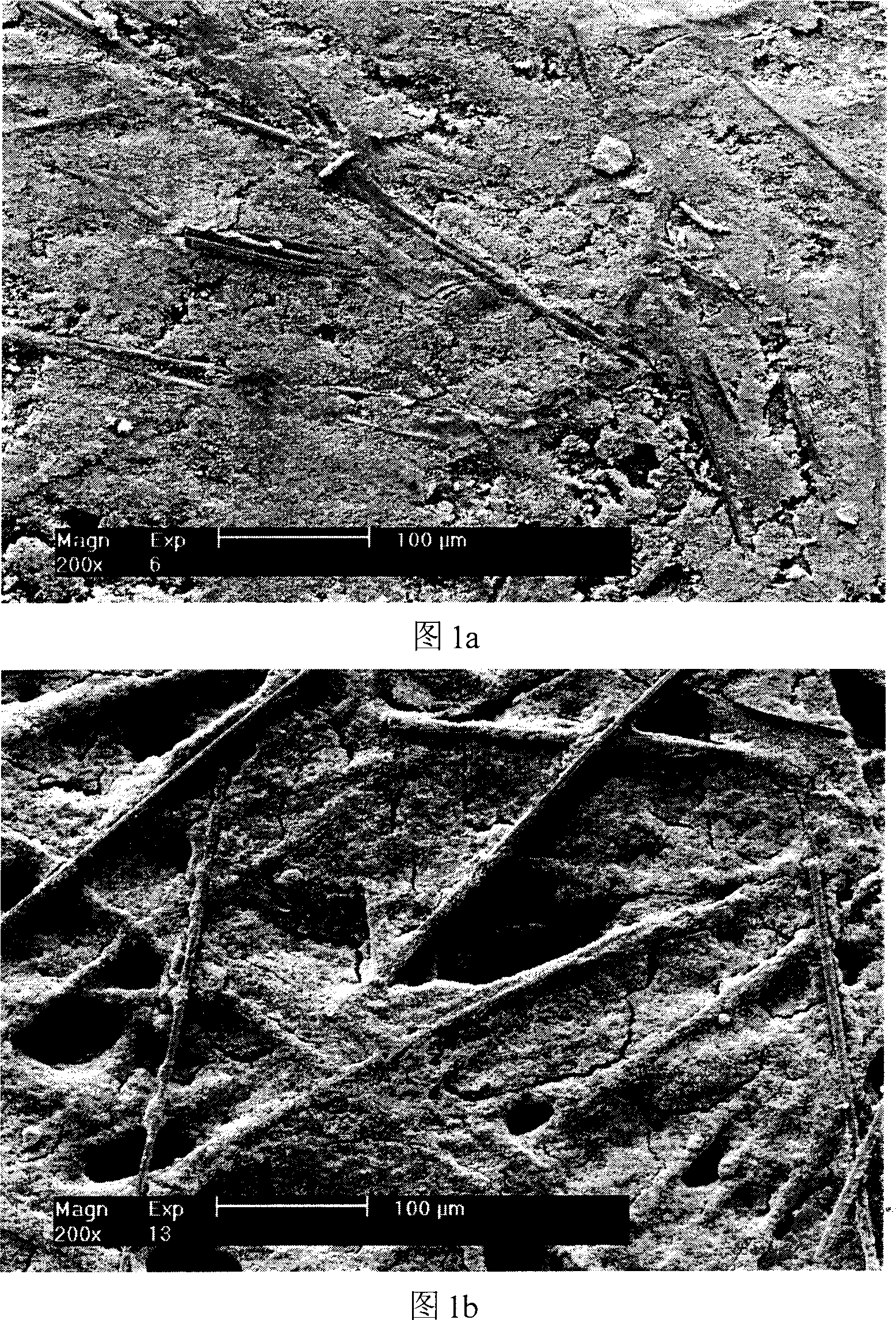

Carbon fiber paper and preparation method thereof

ActiveCN101798774AAffect mechanical propertiesLow structural stabilityFinal product manufactureCell electrodesFiberCarbon fibers

The invention relates to carbon fiber paper and a preparation method thereof, in particular to carbon fiber paper which has low cost and high structural stability and can be used for gas diffusion layers of proton exchange membrane fuel cells (PEMFC) and a preparation method thereof. The carbon fiber paper of the invention comprises PAN-based graphite fibers and resin carbon and is in a three-dimensional reticular structure formed by the PAN-based graphite fibers bonded by the resin carbon, the resin carbon is tightly lapped on the junction of every two PAN-based graphite fibers, and the mass percent of the resin carbon of the carbon fiber paper is 10-20%. The preparation method of the carbon fiber paper of the invention comprises the steps of activating, short cutting, paper making and molding by a wet process, resin spraying, drying, hot pressing, heat treating and the like. The invention solves the problems of time consumption and energy consumption of activating treatment of the carbon fiber paper in the prior art, overhigh cost of the carbon fiber paper, unsatisfactory bonding effect of the traditional phenolic resin and unstable structure of the carbon fiber paper after high-temperature heat treatment, and overcomes the defects of the prior art.

Owner:DONGHUA UNIV

Conducting polymer-transition metal electro-catalyst compositions for fuel cells

ActiveUS20080193827A1Improve fuel cell performanceReduced Ohmic lossCell electrodesConductive materialConductive polymerOxygen

An electro-catalyst composition for use as an electrode, gas diffusion layer-supported electrode, catalytic electrode-coated solid electrolyte layer, and / or membrane-electrode assembly in a proton exchange membrane (PEM) type fuel cell. The composition comprises: (a) a proton- and electron-conducting polymer having at least one heteroatom per backbone monomer unit thereof and a plurality of neutral transition metal atoms covalently bonded to at least a portion of the heteroatoms; wherein the polymer has an electronic conductivity no less than 10−4 S / cm and a proton conductivity no less than 10−5 S / cm. Preferably, the electro-catalyst composition further comprises (b) a plurality of catalytically active particles of a transition metal, nucleated around the covalently bonded transition metal atoms. Also preferably, additional catalytically active catalyst particles with an average dimension smaller than 2 nm (most preferably smaller than 1 nm) are physically dispersed in such a polymer and typically not chemically bonded thereto. A hydrogen-oxygen PEM fuel cell or a direct methanol fuel cell (DMFC) featuring such an electro-catalyst composition in a thin-film electrode exhibits a superior current-voltage response.

Owner:NANOTEK INSTR GRP LLC

Gas diffusion layer of PEMFC (Proton Exchange Membrane Fuel Cell) and preparation method thereof

ActiveCN103401003AWide variety of sourcesLow priceCell electrodesFuel cell detailsFiberCarbon fibers

The invention discloses a gas diffusion layer of a PEMFC (Proton Exchange Membrane Fuel Cell). The gas diffusion layer comprises a substrate and a micropore layer, wherein the substrate is a porous metal net of which the surface is provided with an electroplating layer; the pore diameter of the porous metal net is 0.076-0.4mm, and the thickness of the porous metal net is 0.01-0.4mm; the micropore layer is formed by coating carbon black slurry on the surface of a carbon fiber fabric, and the substrate and the micropore layer are overlapped and then laminated into a whole. The preparation method comprises the following steps of: overlapping the sintered micropore layer and one or more layers of treated porous metal nets, and then pressing, thereby obtaining the gas diffusion layer which utilizes the metal net as the substrate. The preparation method is simple process and convenient to operate.

Owner:KUSN INNOVATION INST OF NANJING UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com