Gas diffusion layer for proton exchanging film fuel cell and its preparing method

A technology of gas diffusion layer and proton exchange membrane, which is applied to the components of fuel cells, solid electrolyte fuel cells, fuel cells, etc. Problems such as carbon powder morphology and structure, to achieve reasonable water and gas distribution, easier discharge, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

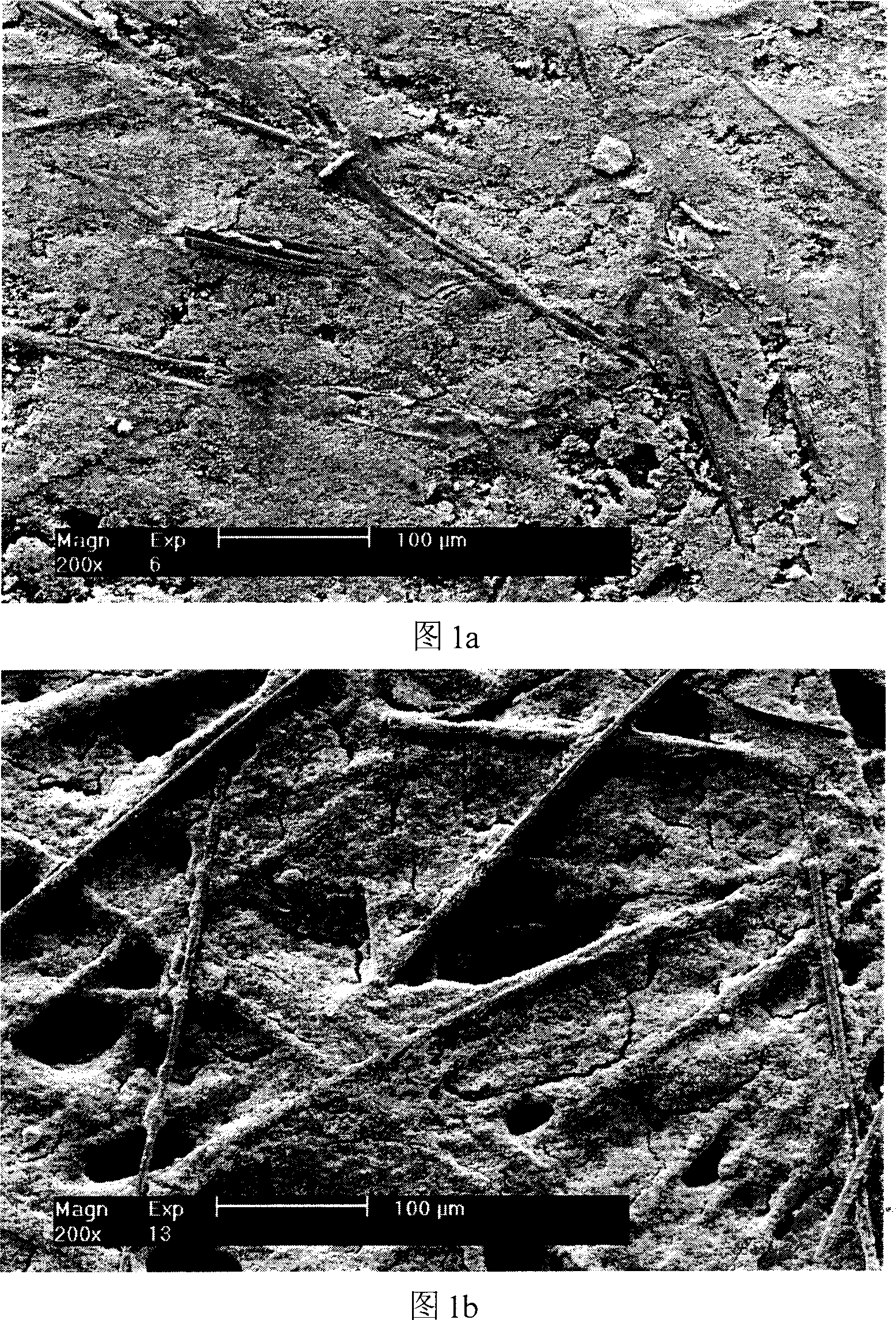

[0047] The gas diffusion layer includes a porous support layer and a microporous layer, the porous support layer is a mesh and porous structure, the microporous layer is compounded on the surface of the porous support layer near the catalyst layer, and the microporous layer has micropores; The microporous layer evenly covers the macropore and fiber dense area of the porous support layer, and does not go deep into the interior of the porous support layer.

[0048] PTFE emulsion (Daikin Industries Co., Ltd., concentration 60%) was diluted to 5%, then carbon paper (Toray TGPH-060) was put into the prepared PTFE emulsion and soaked for 5 minutes, and dried in the air. Repeat 5 times until the content of PTFE reaches 20%, and put it into a 60°C oven for 1 hour to dry. Then put it in a furnace at 360°C for 60 minutes.

[0049] Weigh 0.7g conductive carbon black (Vulcan XC-72, Cabot Co. particle size 30nm) and 0.3g PTFE powder (Daikin Industries Co., Ltd.) respectively, put them i...

Embodiment 2

[0053] The PVDF emulsion (Daikin Industry Co., Ltd.) was diluted to 10%, and then carbon paper (Toray TGPH-060) was put into the prepared PVDF emulsion to soak for 5 minutes, and then air-dried. Repeat 5 times until the content of PVDF is 30%, put it into a 60°C oven for 1 hour to dry. Then put it in an oven at 190°C for 55 minutes.

[0054] Weigh 1g of conductive carbon black (Acetylene Black, Henan, particle size 40nm) and 0.1g of PVDF powder (Daikin Industry Co., Ltd.) respectively, put them into a grinder, and grind for 1 minute (25000 rpm).

[0055] Scrape-coat the treated carbon powder + PVDF dry powder onto the surface of the hydrophobically treated carbon paper, the load of carbon powder is 0.8mgcm -2 . After rolling, put the treated carbon paper into the furnace, N 2 Protection, 170 ° C treatment for 55 minutes.

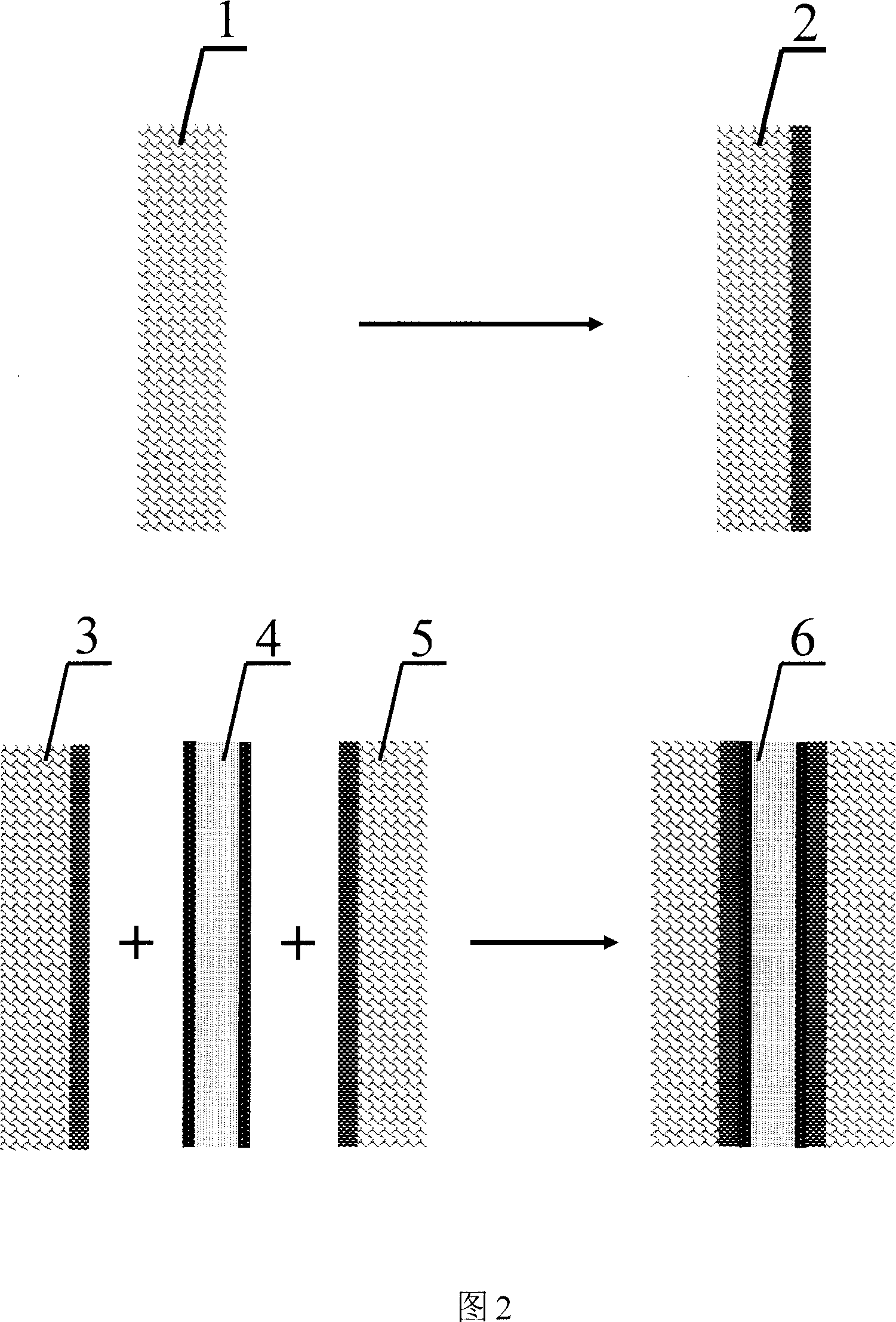

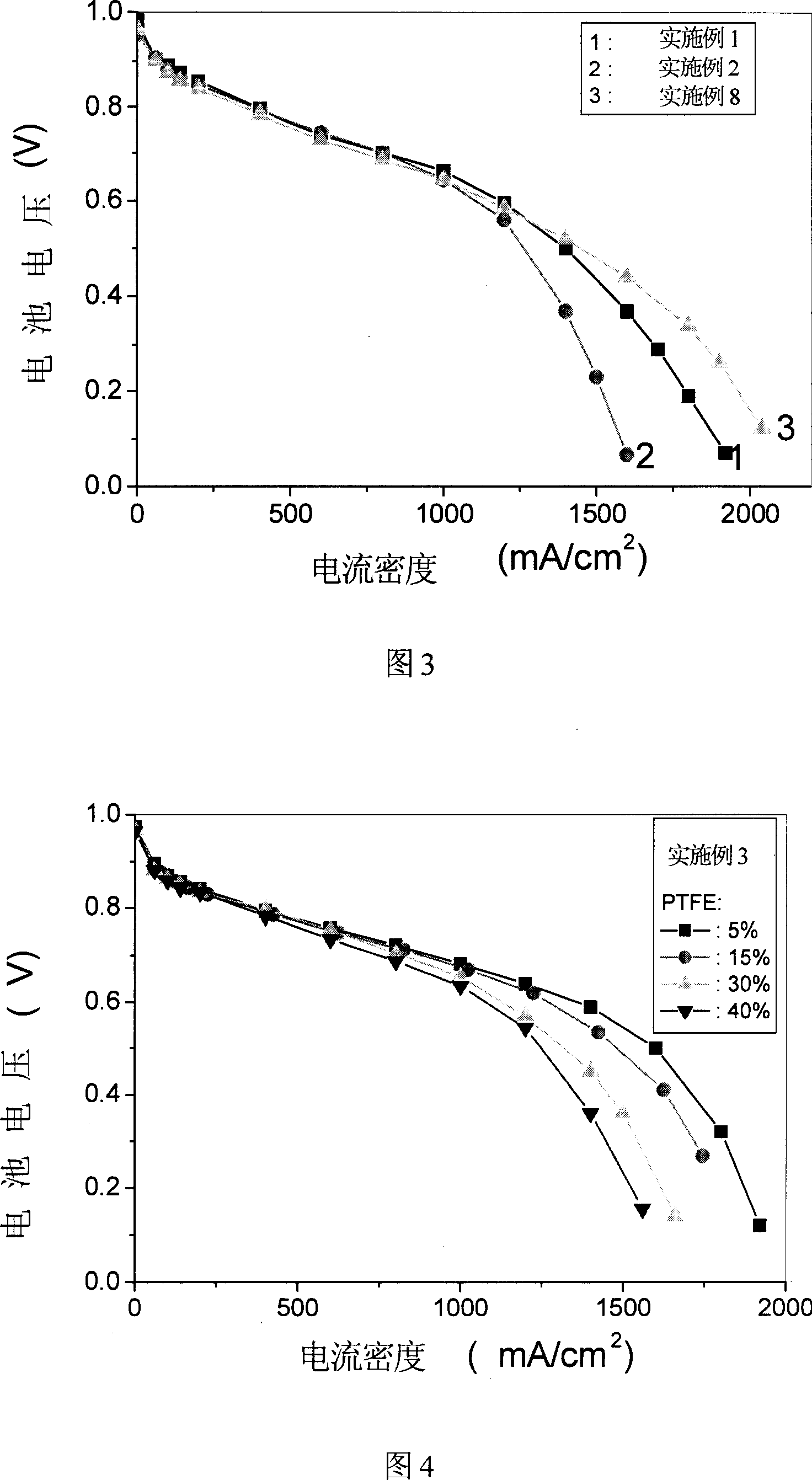

[0056] The prepared gas diffusion layer and membrane electrode CCM (self-made) assembled cells were tested, and the assembled MEA is shown in Figure 2. ...

Embodiment 3

[0058] Polytetrafluoroethylene (PTFE) emulsion (Daikin Industry Co., Ltd., concentration 60%) was diluted to 10%, then carbon paper (Toray TGPH-060) was put into the prepared PTFE emulsion and soaked for 5 minutes, and air-dried Dry. Repeat several times until the content of PTFE is 5%, 15%, 30% and 40% respectively. Dry the carbon paper in an oven at 60°C for 1 hour, and then put it in an oven at 340°C for 50 minutes.

[0059] Weigh 1g conductive carbon black (Vulcan XC-72, Cabot Co. particle size 30nm) and 0.01g polytetrafluoroethylene (PTFE) powder (Daikin Industry Co., Ltd.) / minute).

[0060] Squeegee-coat the treated carbon powder + PTFE dry powder onto the surface of the hydrophobically treated carbon paper, the amount of carbon powder is 1.0mgcm -2 . After rolling, put the treated carbon paper into the furnace, N 2 protection, 330°C for 50 minutes.

[0061] The prepared gas diffusion layer and membrane electrode CCM (self-made) assembled cells were tested, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com